Laser hybrid welding equipment

A hybrid welding and equipment technology, which is applied in the field of laser hybrid welding equipment, can solve problems such as the inability to adjust the angle, and achieve the effects of improving efficiency, suitable for promotion, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with specific embodiments.

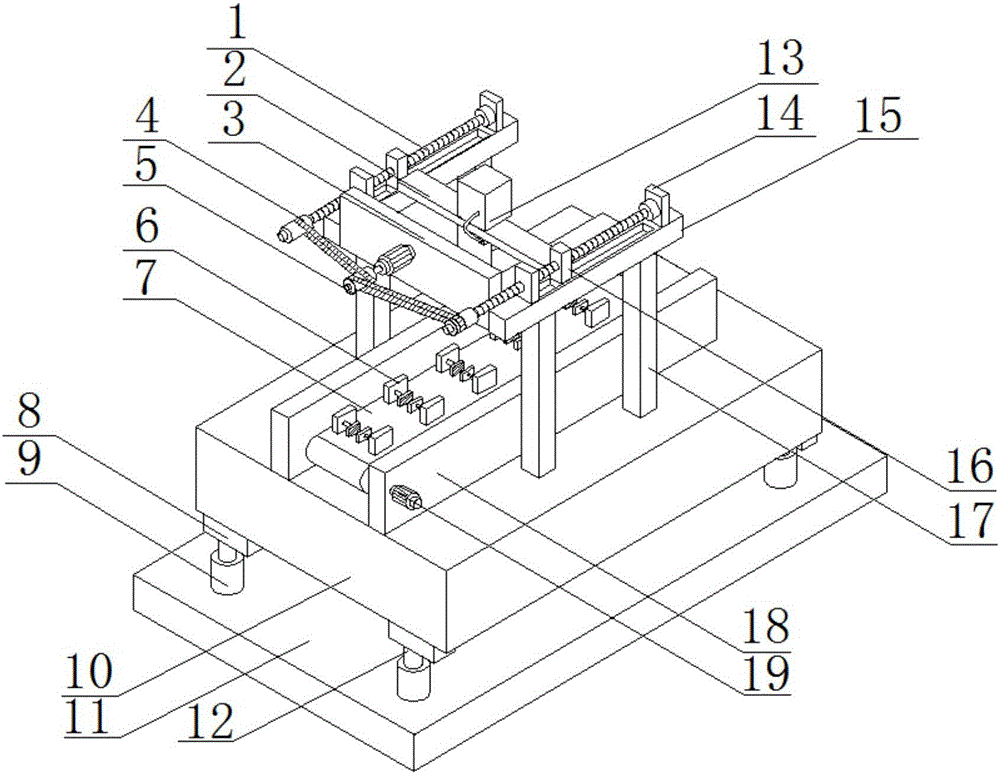

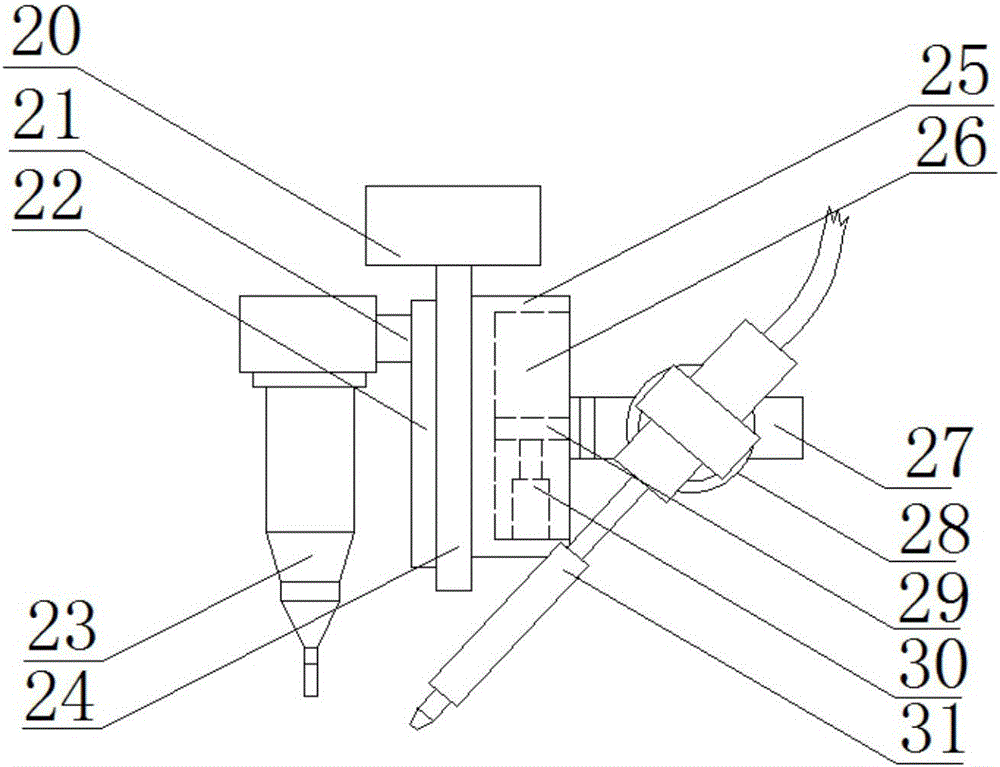

[0017] refer to Figure 1-2 , a kind of laser hybrid welding equipment, comprises the operating platform 10 that is used for welding, and the lower end of operating platform 10 is provided with shock-absorbing device, and the middle part of the upper end of operating platform 10 is provided with the conveying device that is used to transmit the workpiece to be welded, and is provided with on the conveying device A plurality of workpiece clamping mechanisms, both sides of the transmission device are provided with two parallel support rods 17, the upper end of the support rods 17 is fixed with a connecting block 15, two connecting blocks 15 are provided with a moving mechanism, and the moving mechanism is provided with There is a fixing device, and welding equipment is arranged on the fixing device, and the welding equipment is composed of a laser welding device and an arc we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com