Patents

Literature

8325 results about "Soldering gun" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A soldering gun is an approximately pistol-shaped, electrically powered tool for soldering metals using tin-based solder to achieve a strong mechanical bond with good electrical contact. The tool has a trigger-style switch so it can be easily operated with one hand. The body of the tool contains a transformer with a primary winding connected to mains electricity when the trigger is pressed, and a single-turn secondary winding of thick copper with very low resistance. A soldering tip, made of a loop of thinner copper wire, is secured to the end of the transformer secondary by screws, completing the secondary circuit. When the primary of the transformer is energized, several hundred amperes of current flow through the secondary and very rapidly heat the copper tip. Since the tip has a much higher resistance than the rest of the tubular copper winding, the tip gets very hot while the remainder of the secondary warms much less. A tap on the primary winding is often used to power a pilot lamp which illuminates the workpiece.

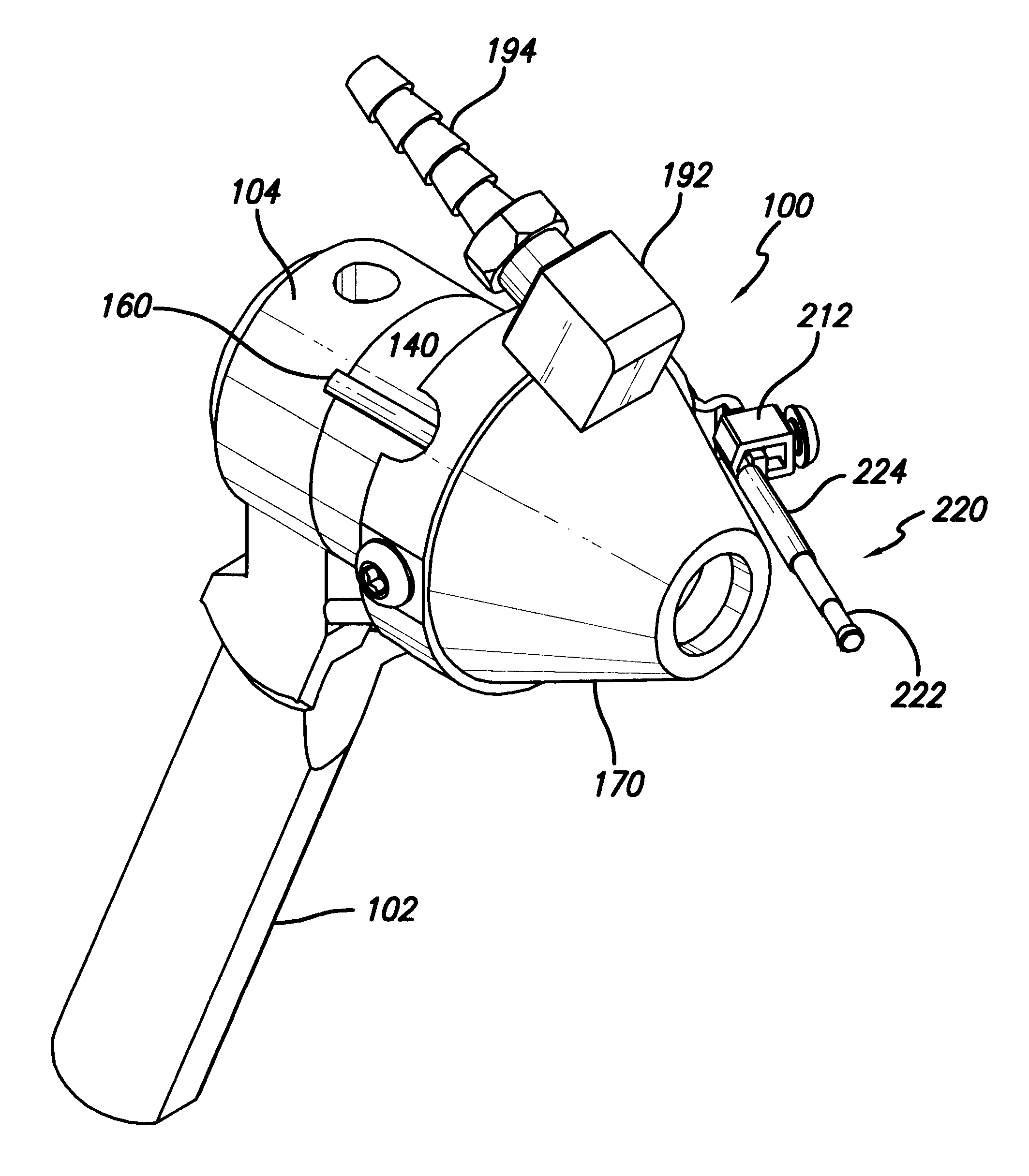

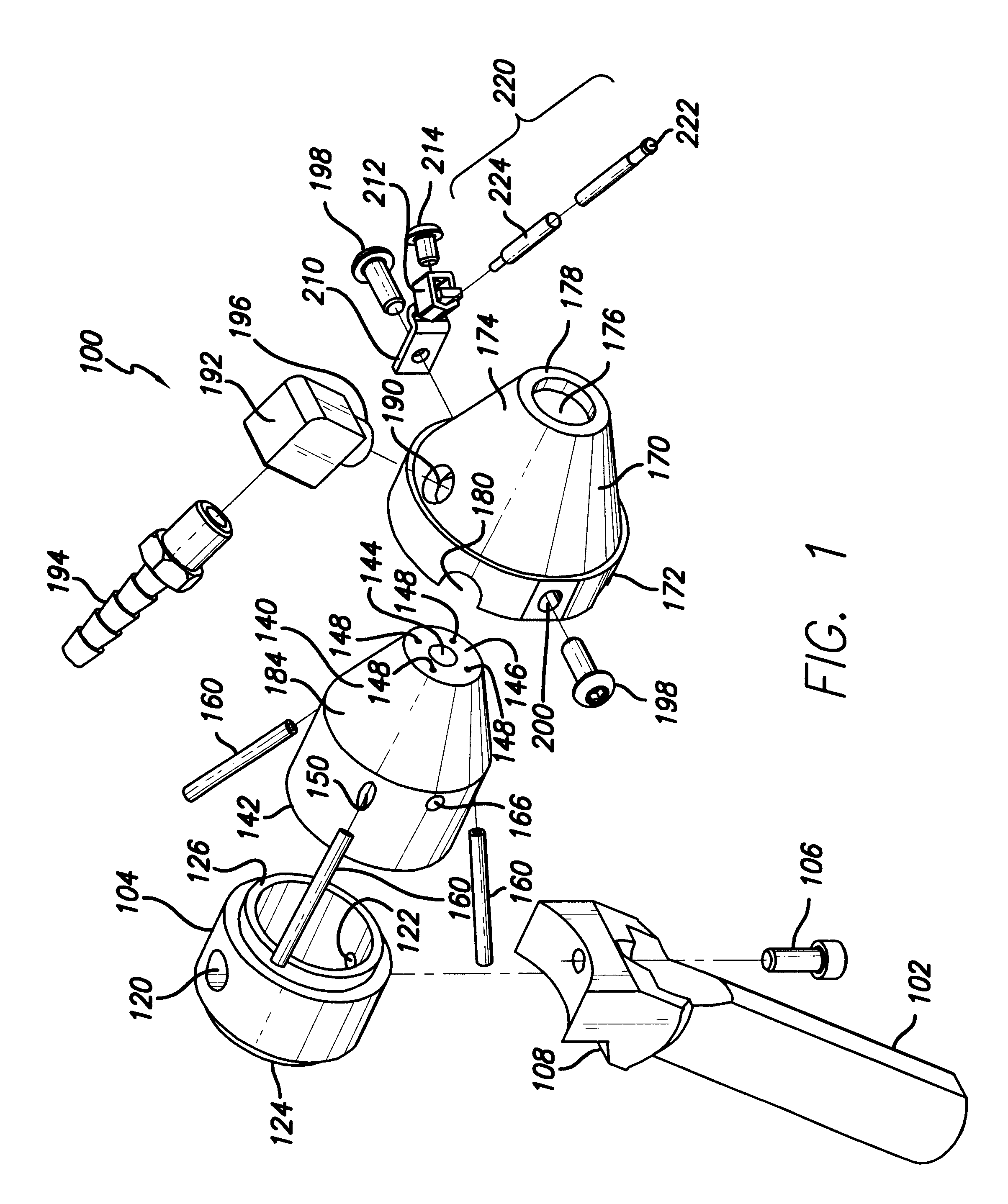

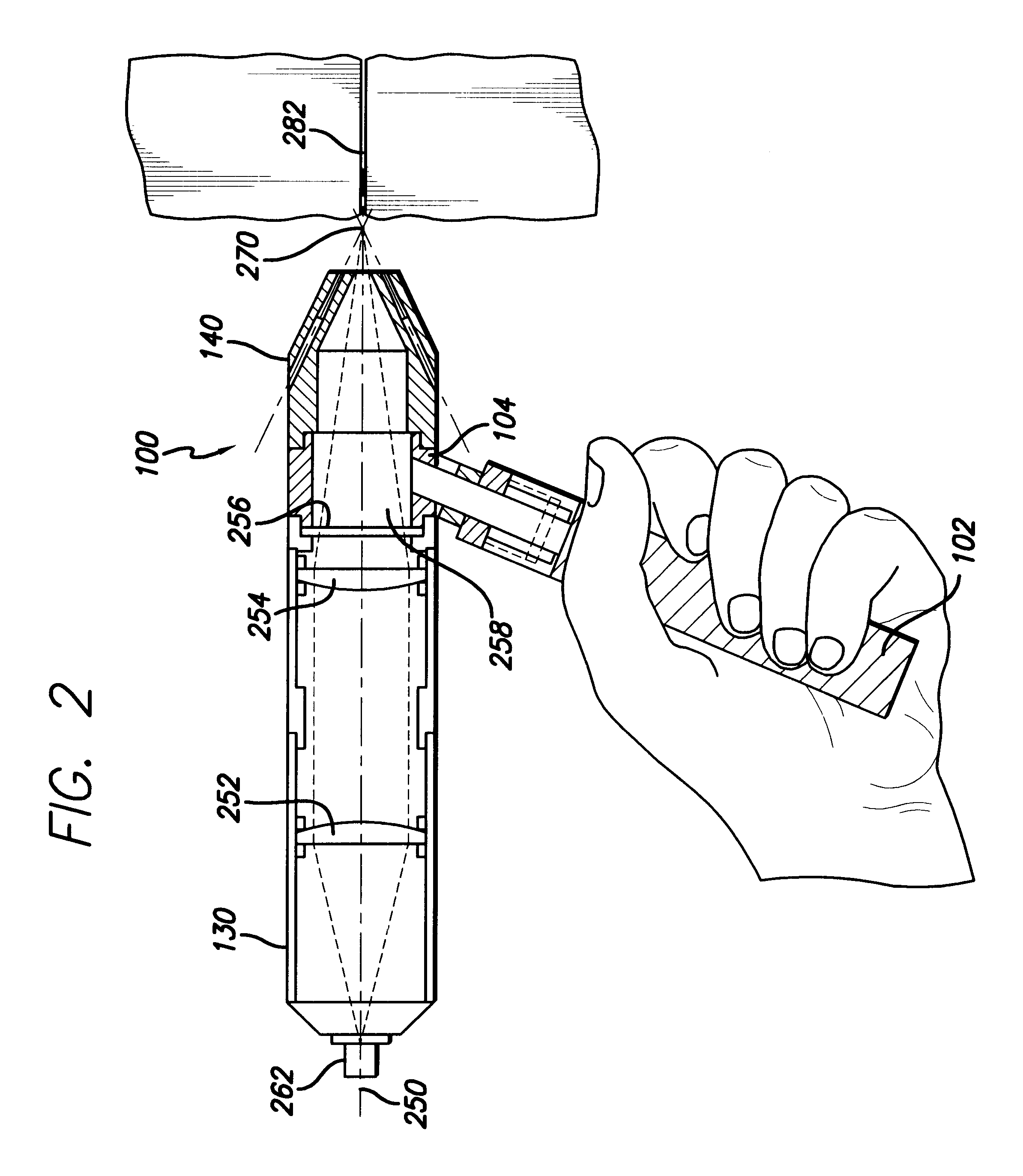

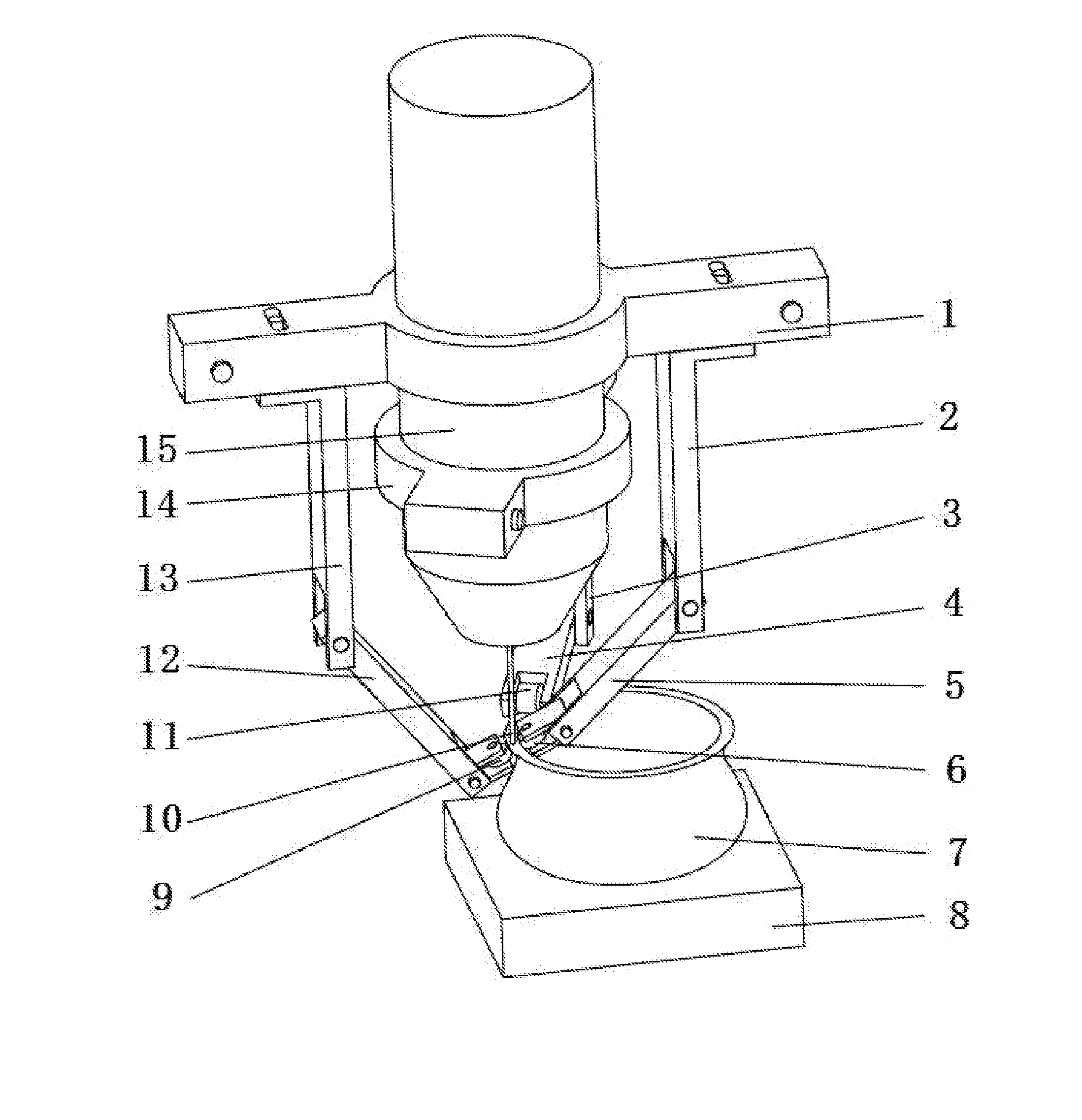

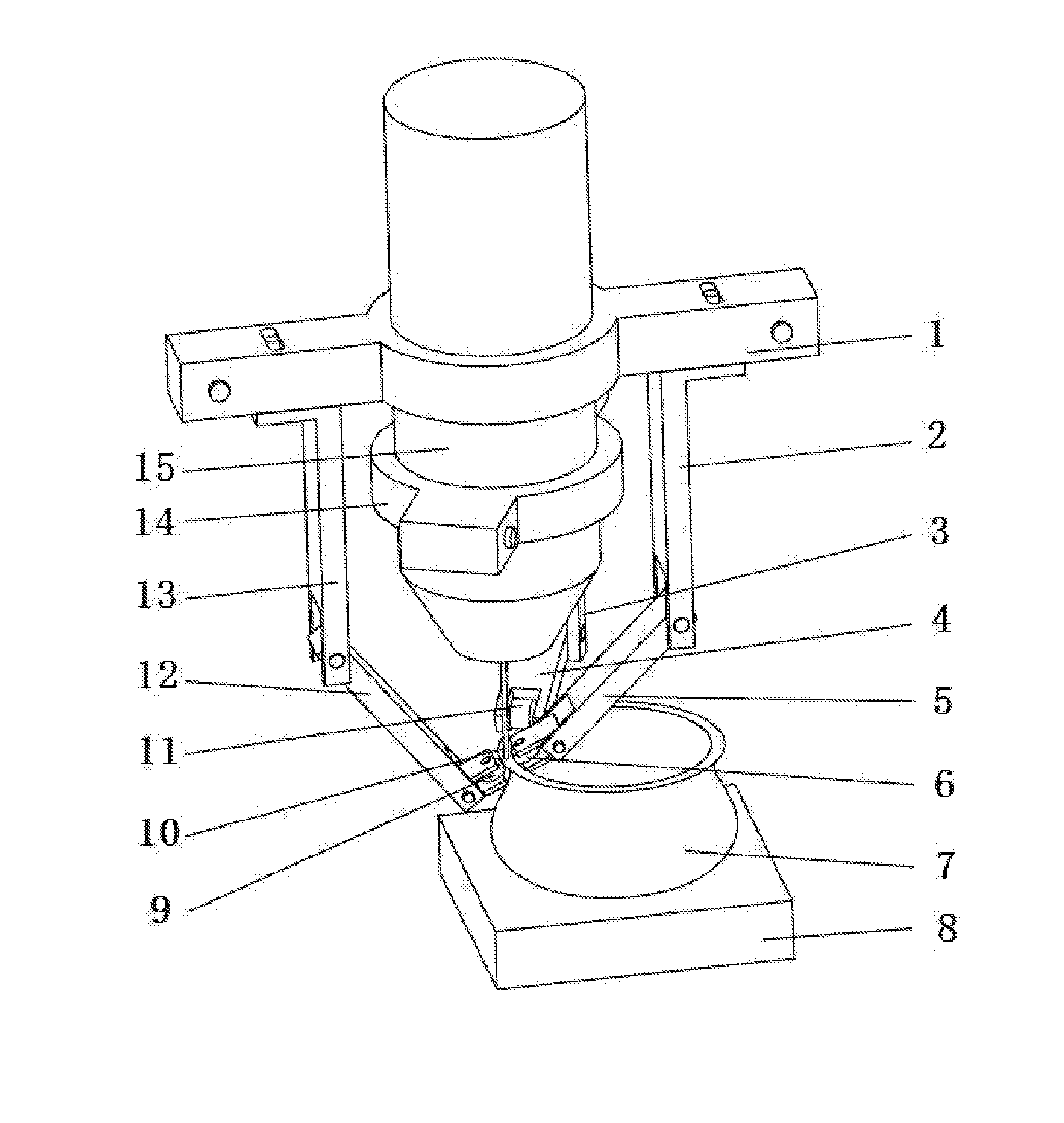

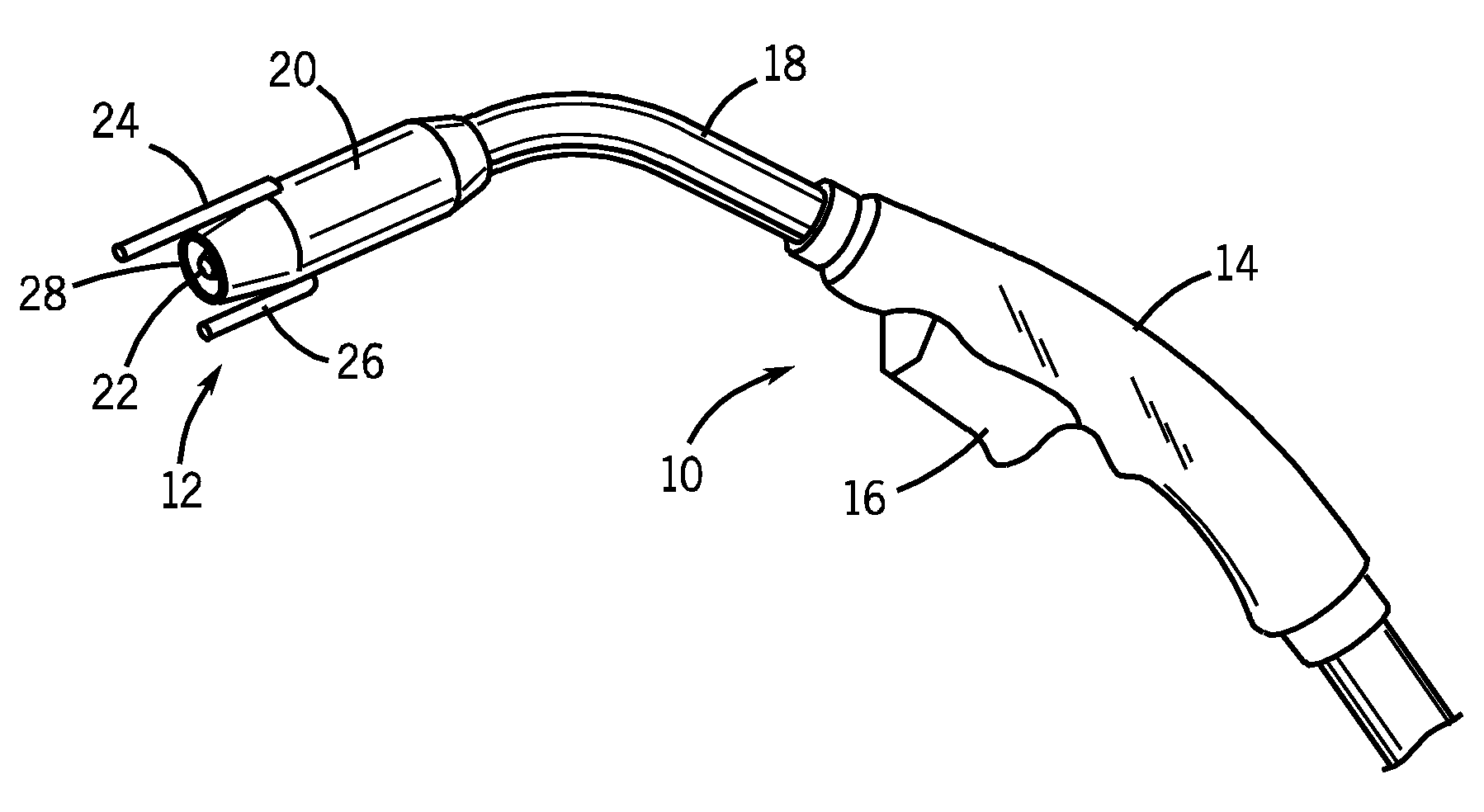

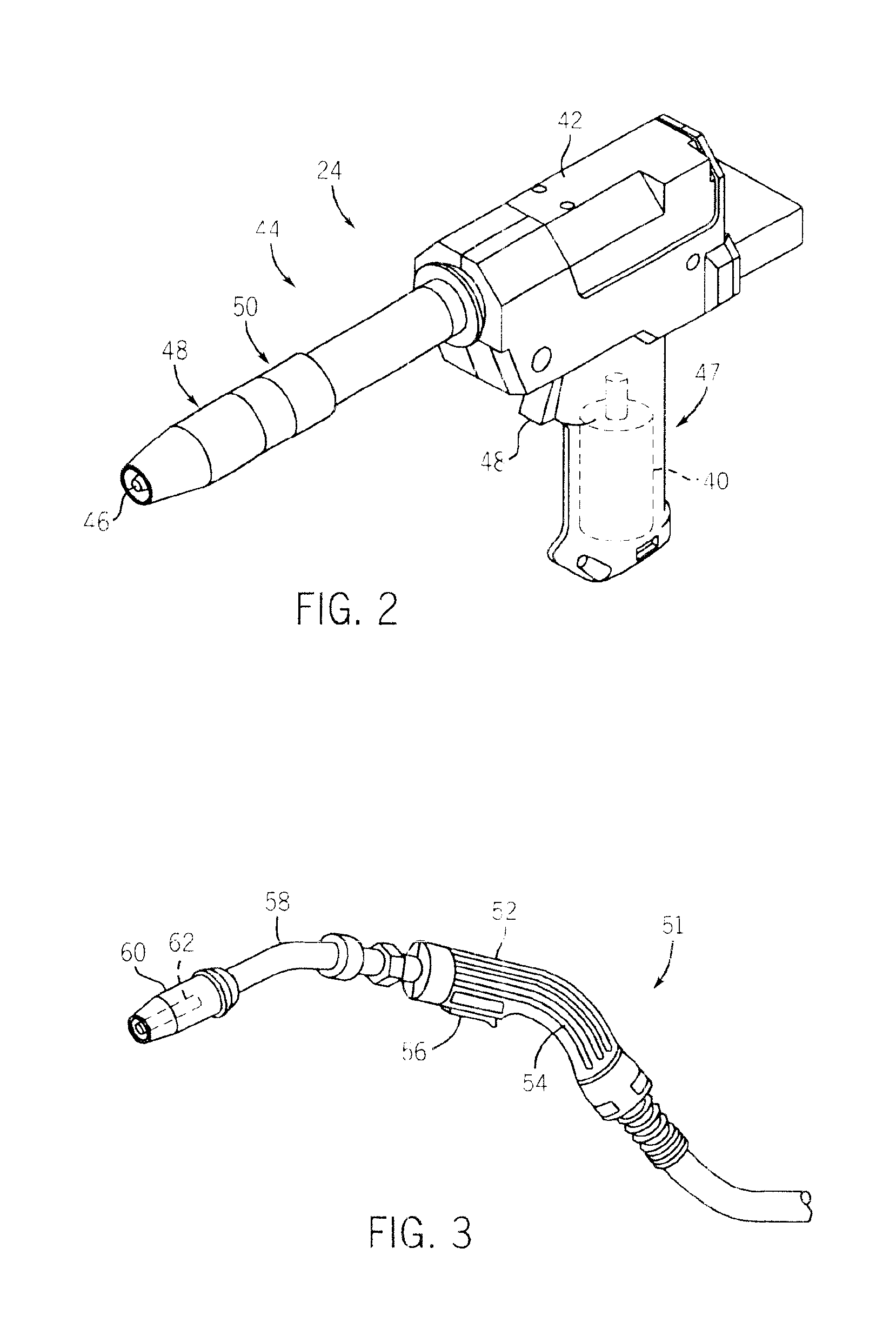

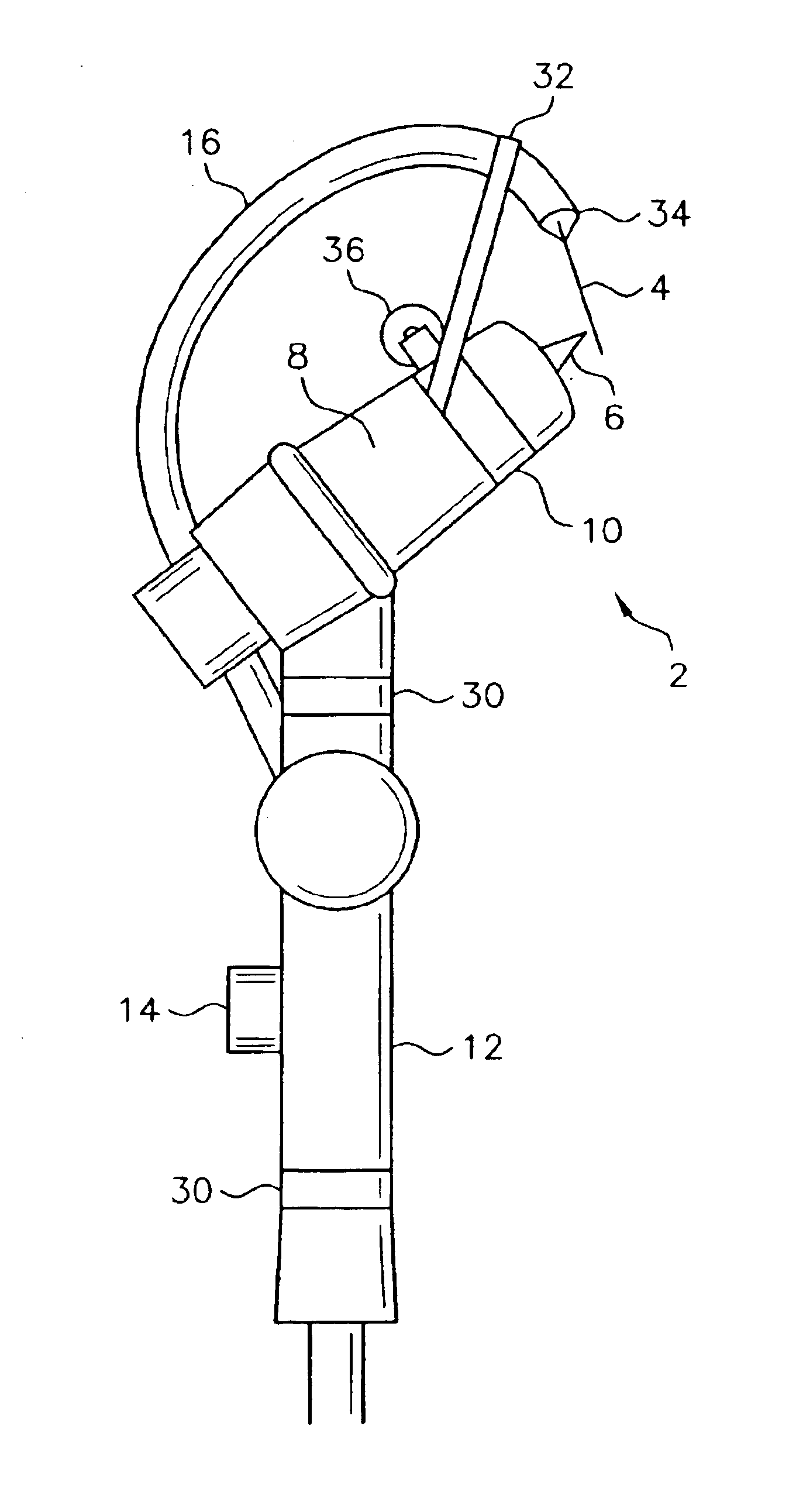

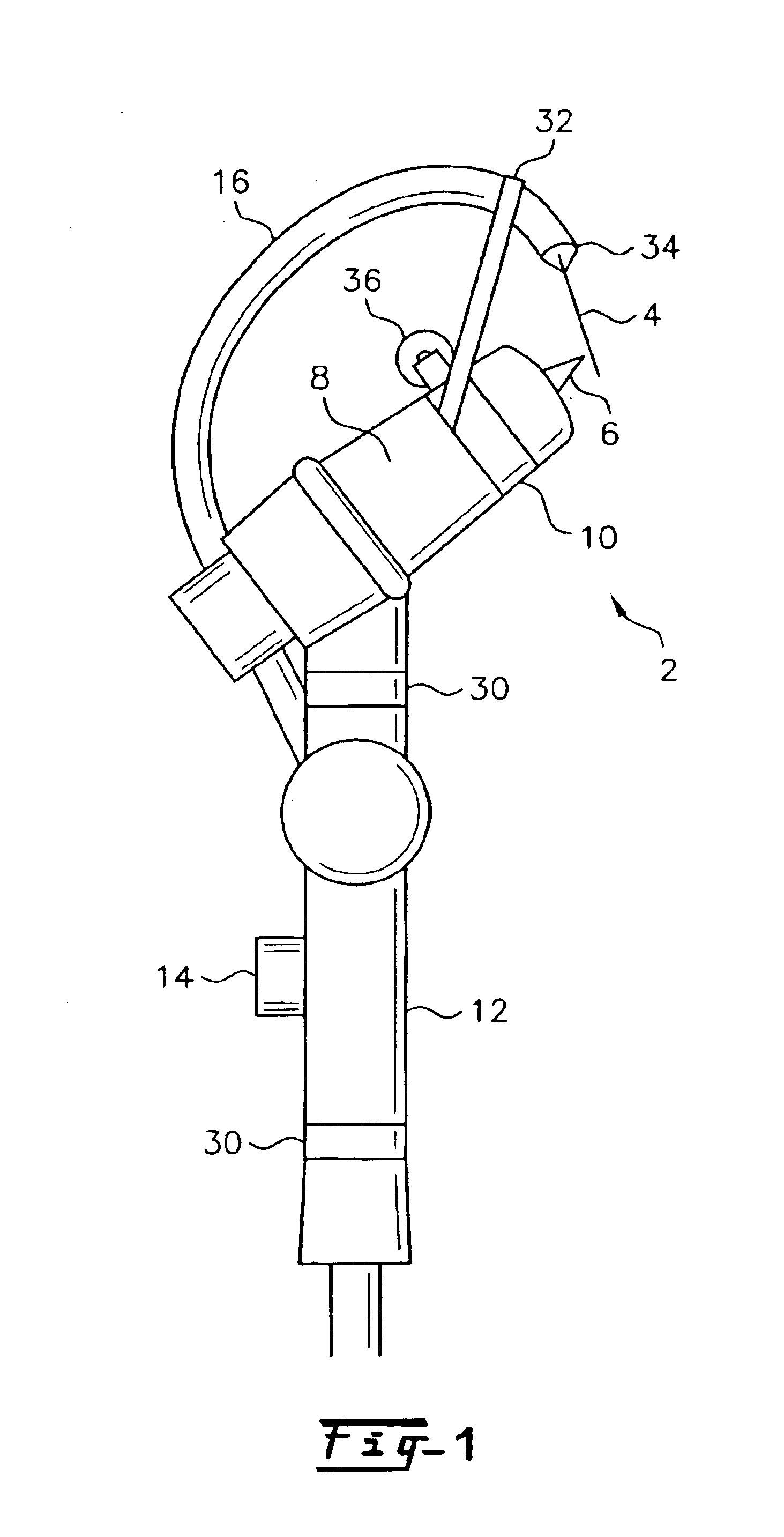

Hand held powder-fed laser fusion welding torch

A novel and inventive hand held powder-fed laser fusion welding torch providing manual flexibility for laser welding with powder-fed material. The hand held laser includes a body, handle, and nozzle assembly. The nozzle may be shrouded by a cover that is slightly spaced apart from the nozzle. The gap between the two may provide space through which inert gas may flow. Laser light from a remote source shines through the nozzle's central aperture. The nozzle aperture may be circumscribed by powder channel outlets aligned upon a working focal point coincident with the laser beam to treat a workpiece. A proximity sensor may enable selective welding torch operation according to the presence of a workpiece.

Owner:HONEYWELL INT INC

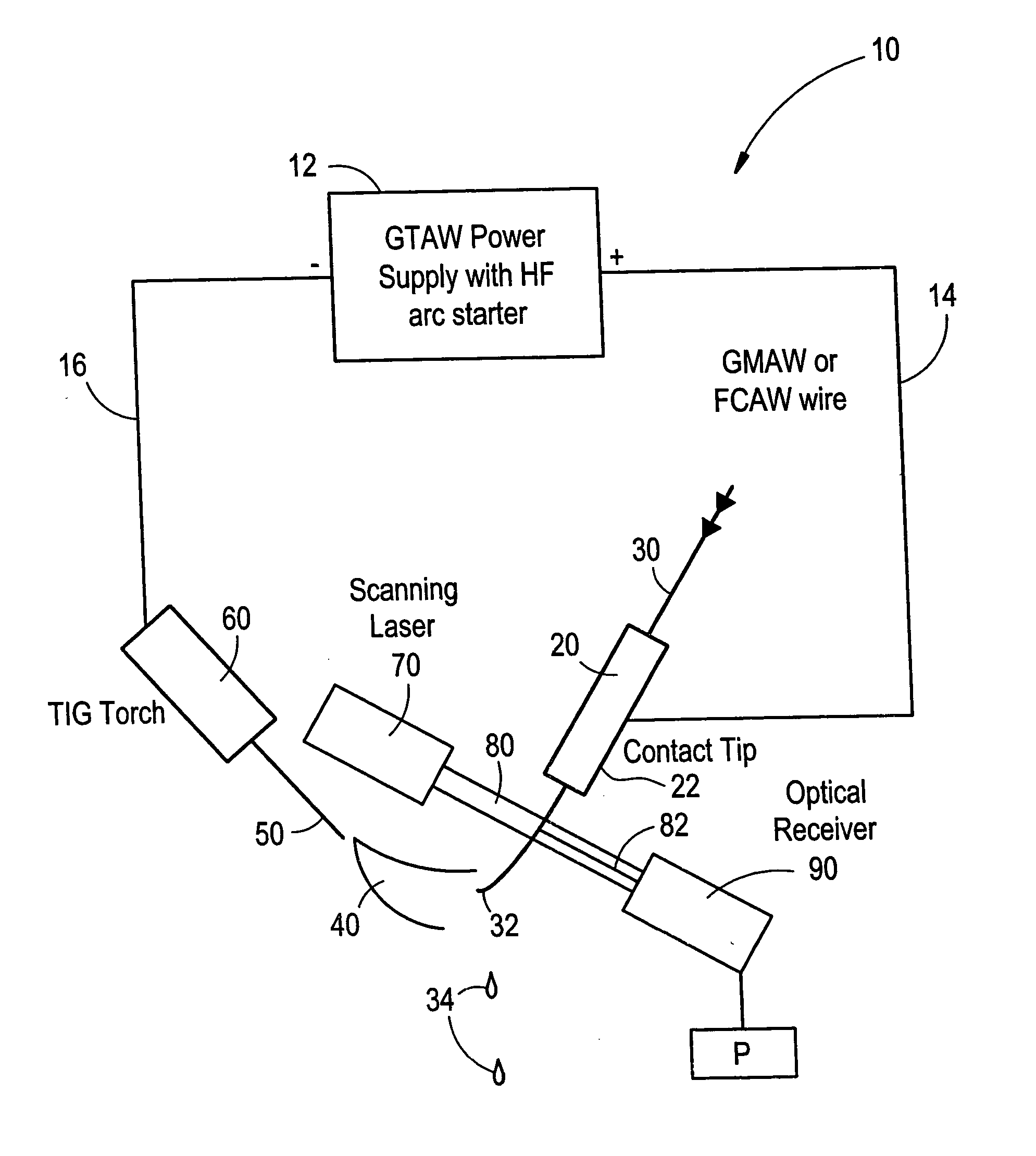

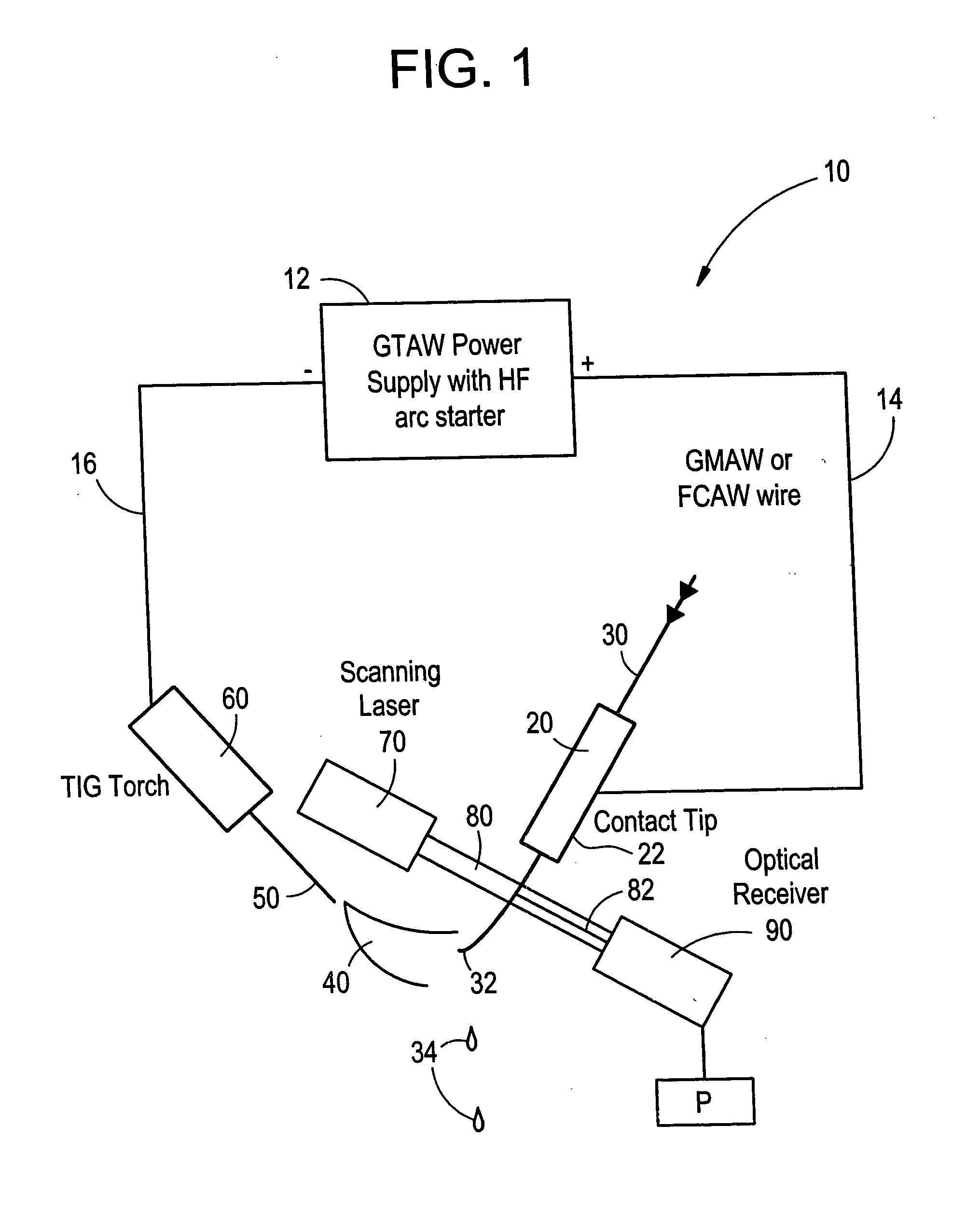

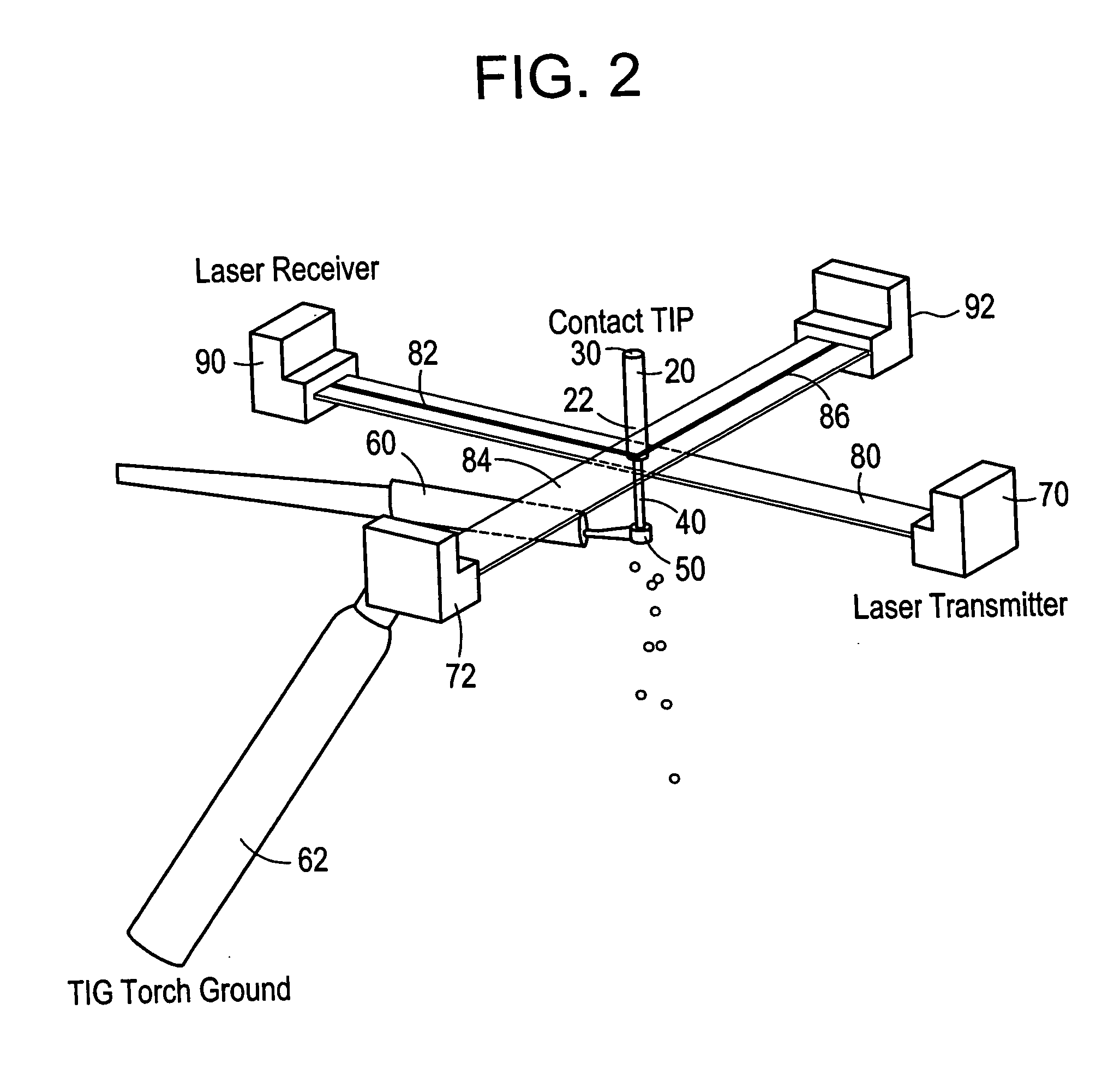

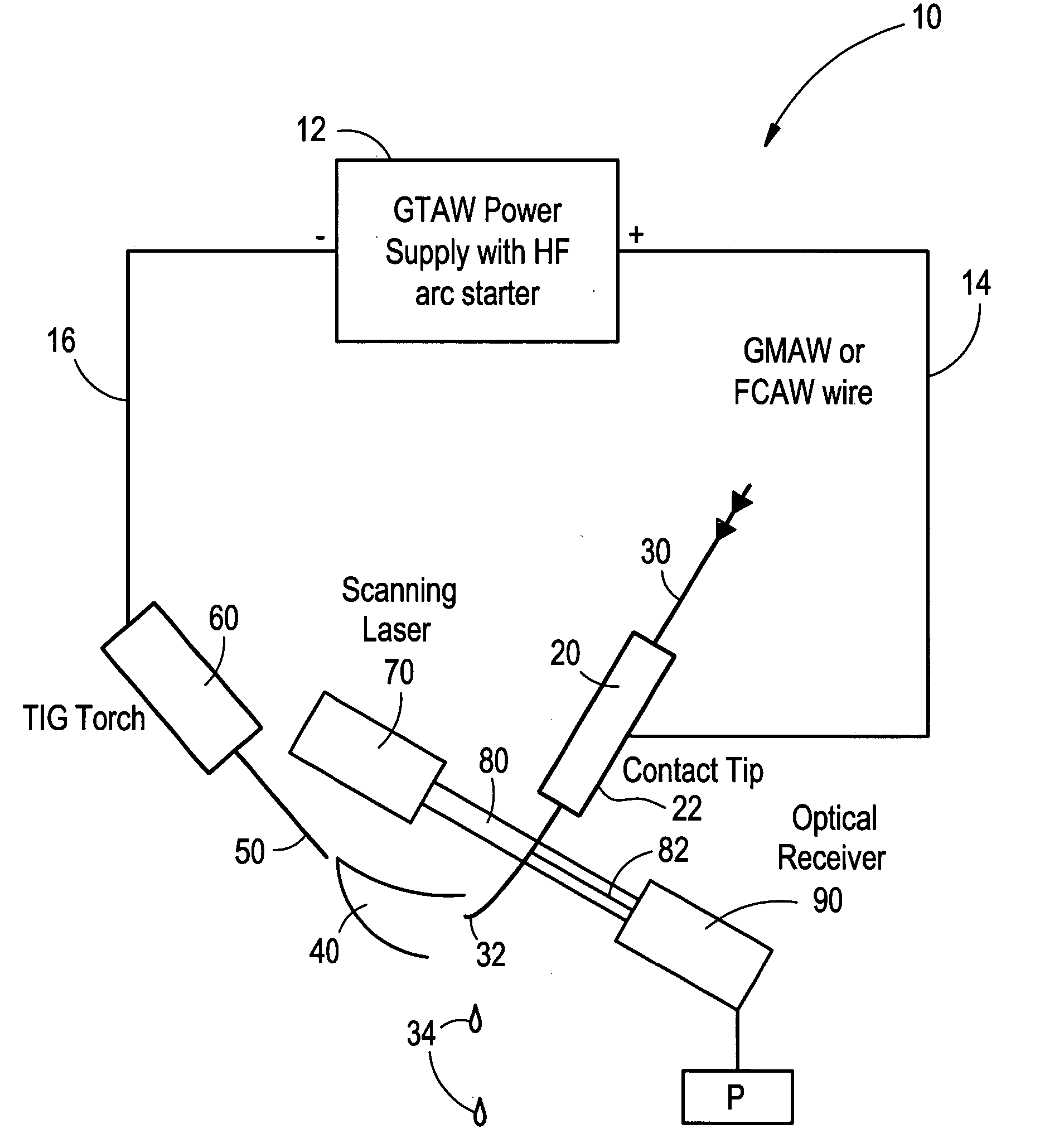

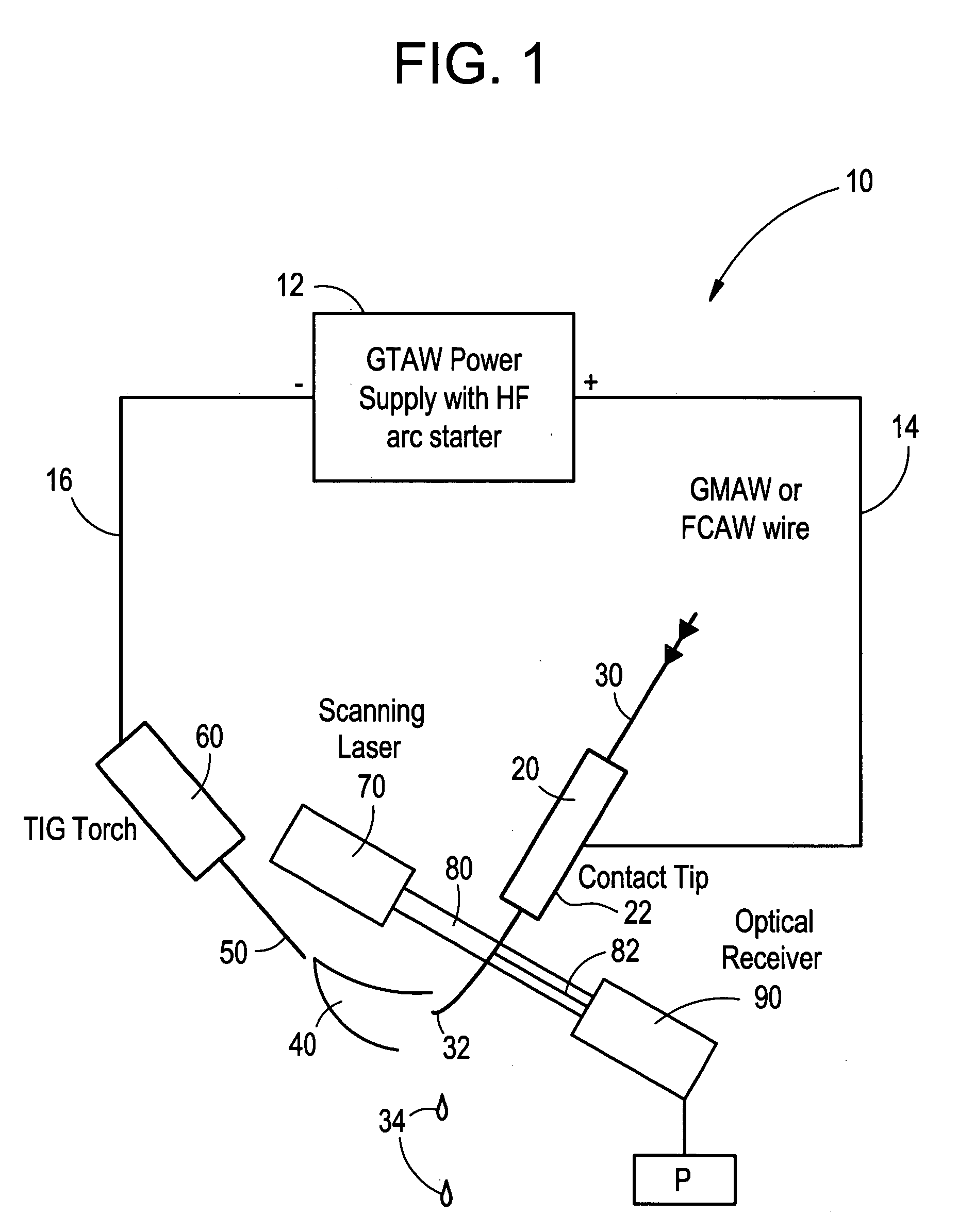

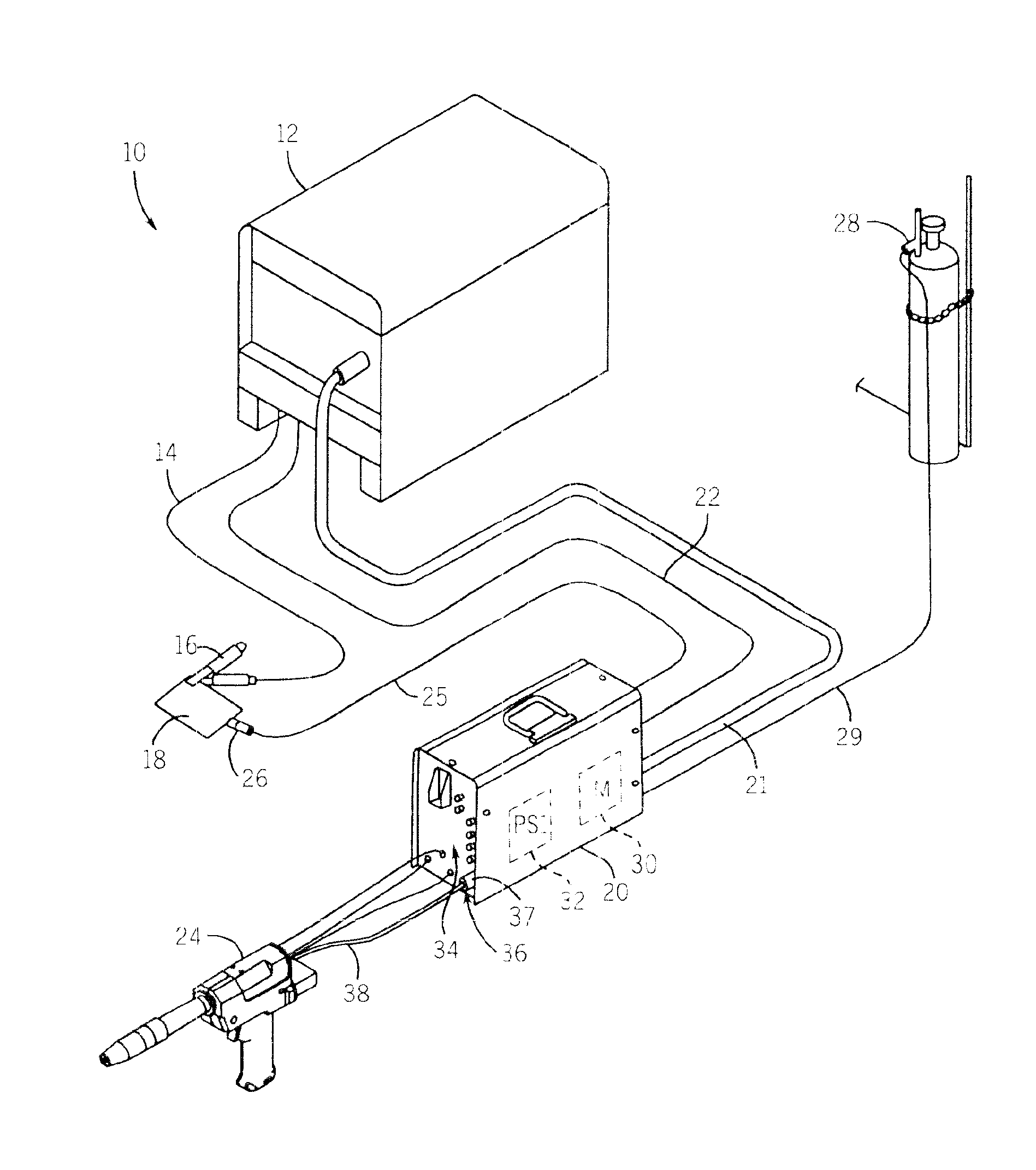

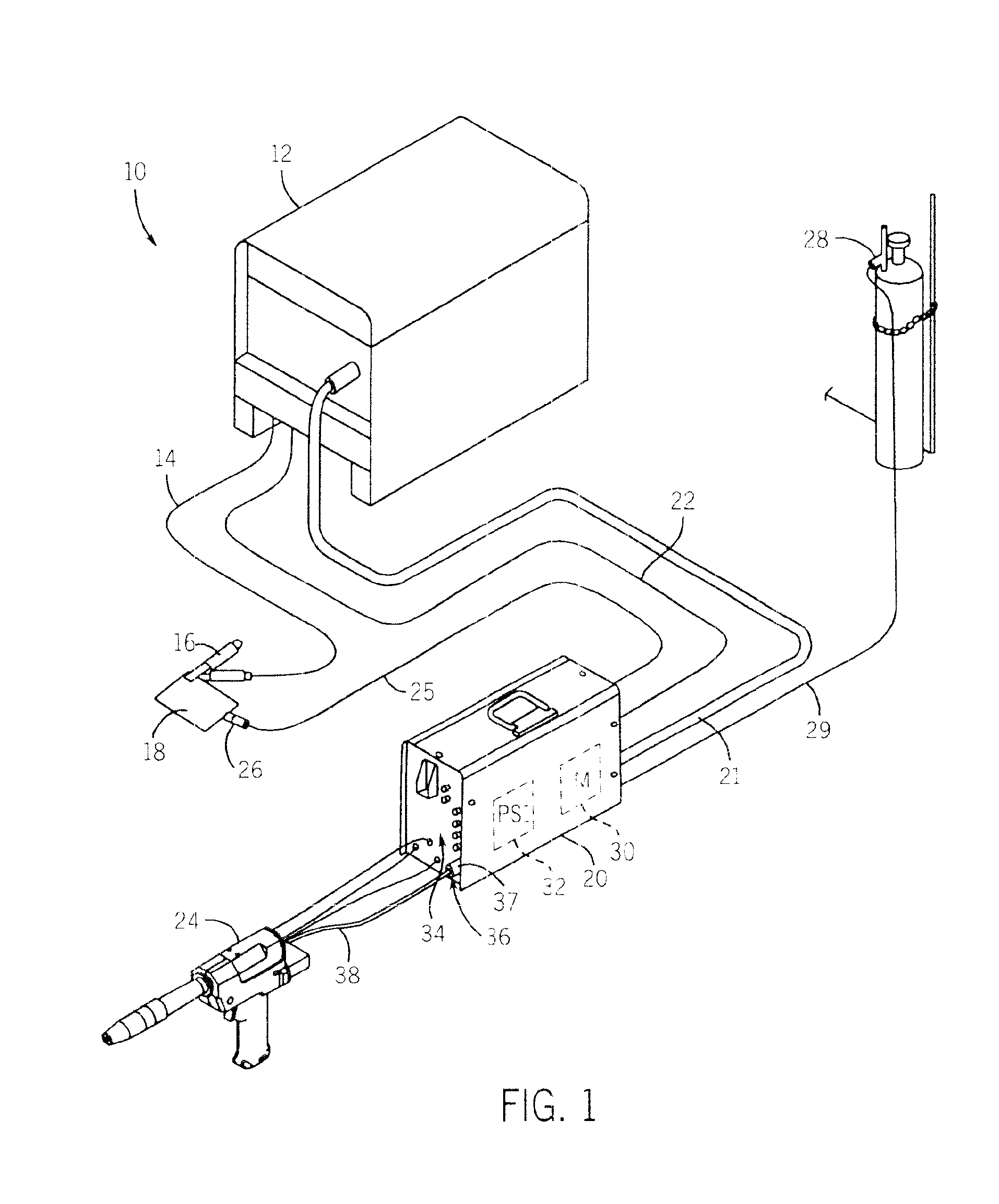

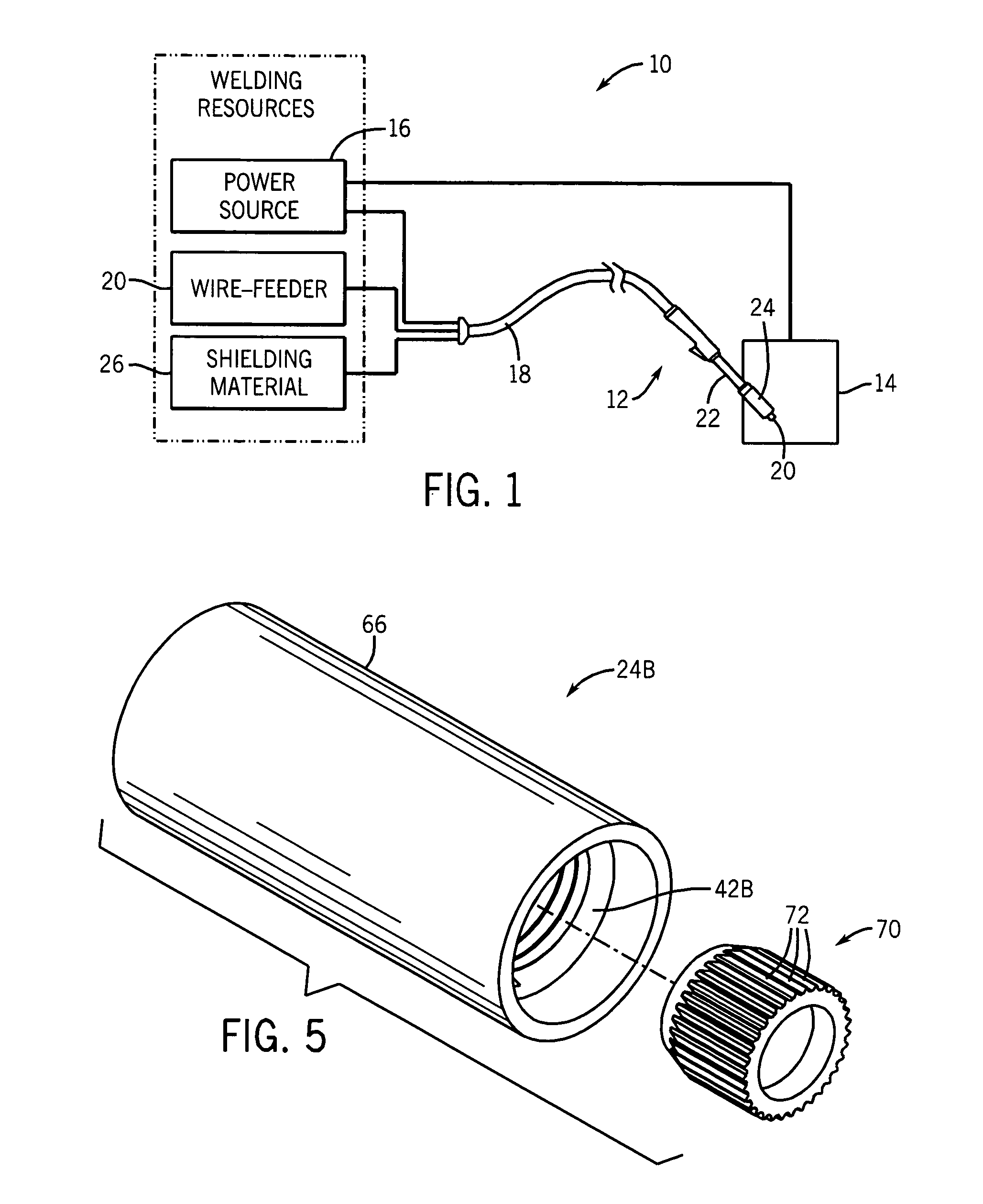

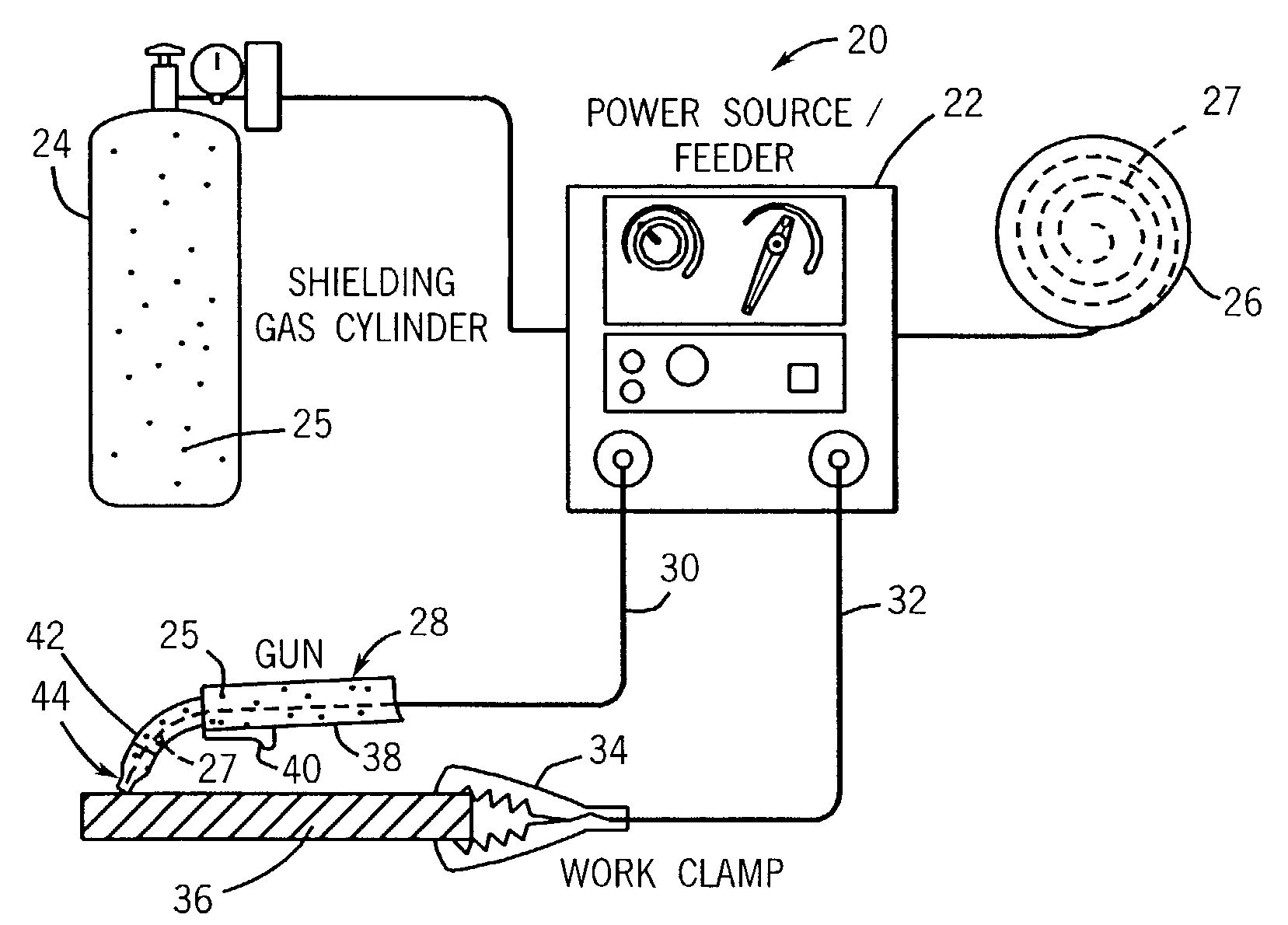

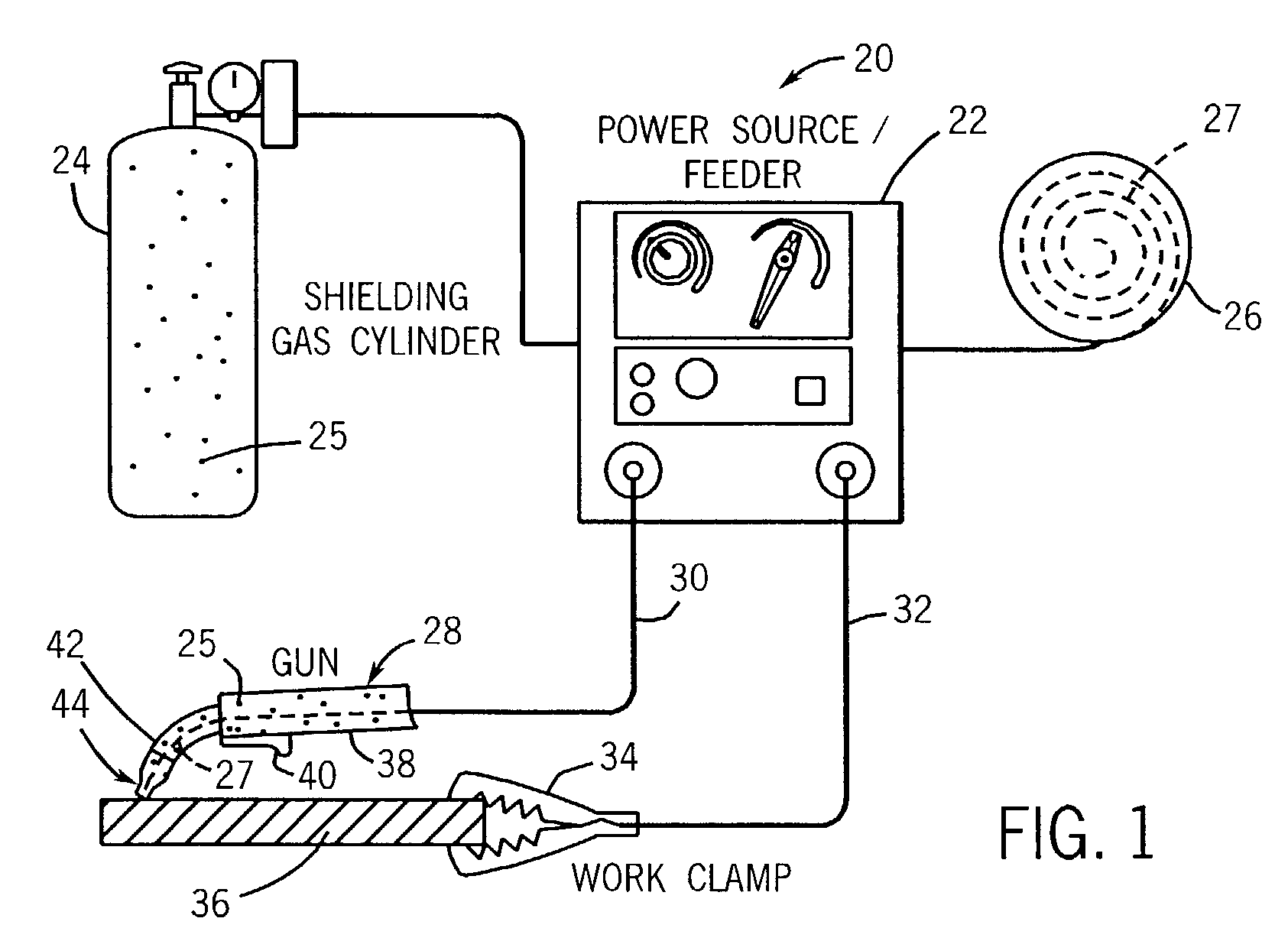

Welding wire positioning system

Owner:LINCOLN GLOBAL INC

Welding wire positioning system

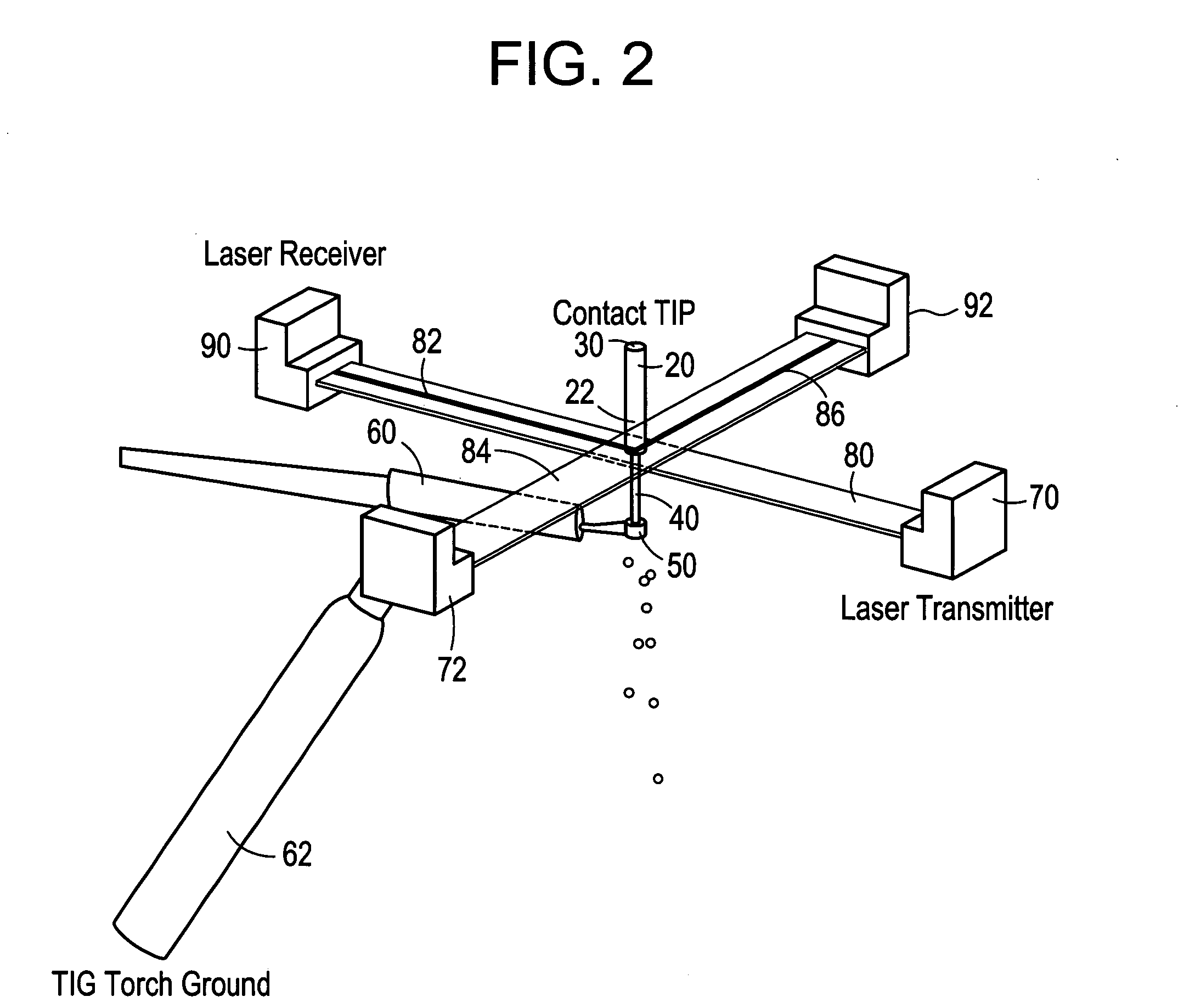

InactiveUS20050006363A1Minimize wire movementMinimize impactConveyorsArc welding apparatusTransverse planeEngineering

An electrode position detection system for a welder having a laser that is projected in a lateral plane to laterally cross a welding wire at a location below a contact tip of a welding gun and a receiver that receive the laser bean after crossing the welding wire, and a measuring device that determines one or more parameter of the welding wire based on the received laser beam. Arc voltage measurements can also be used to determine one or more parameter of the welding wire.

Owner:LINCOLN GLOBAL INC

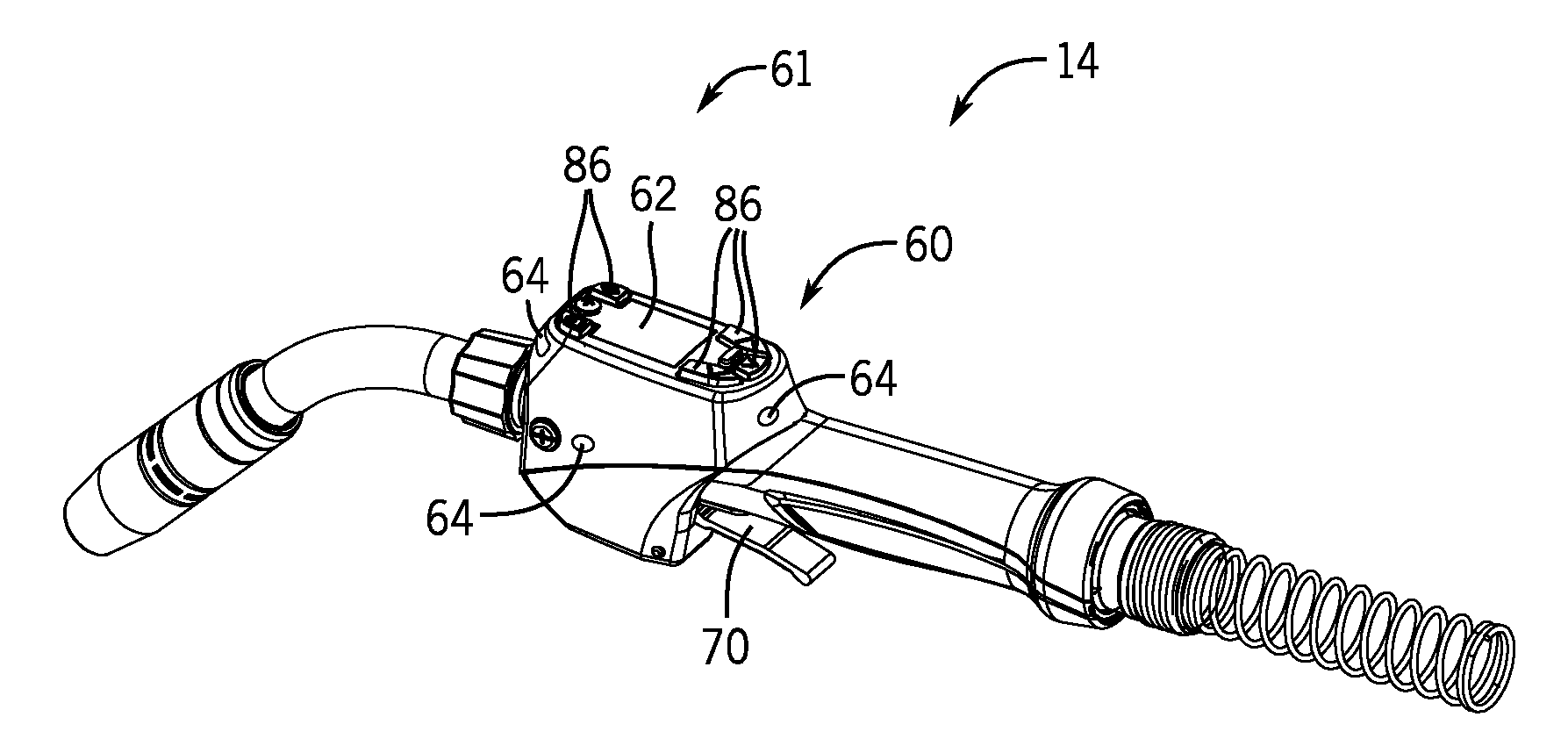

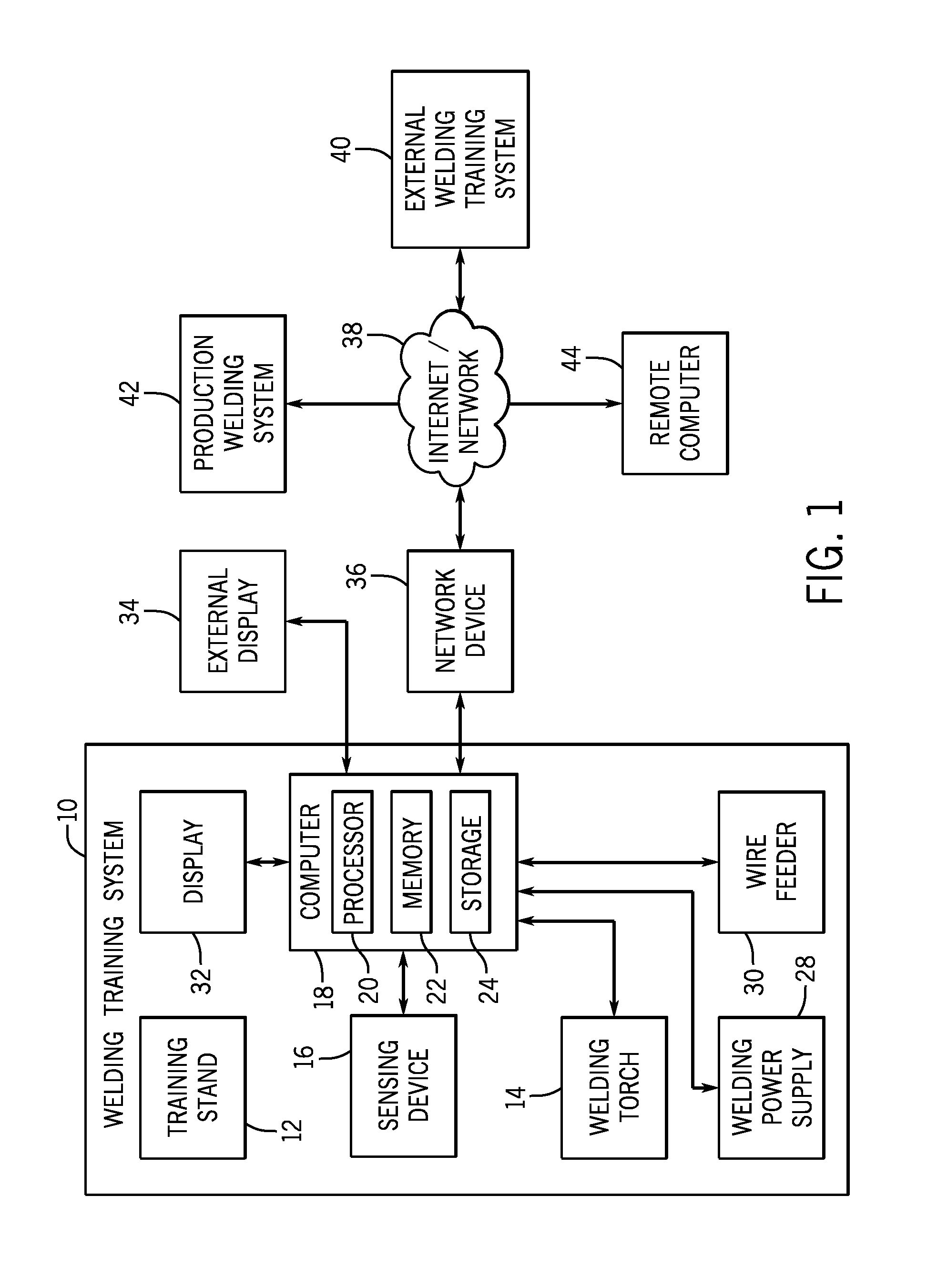

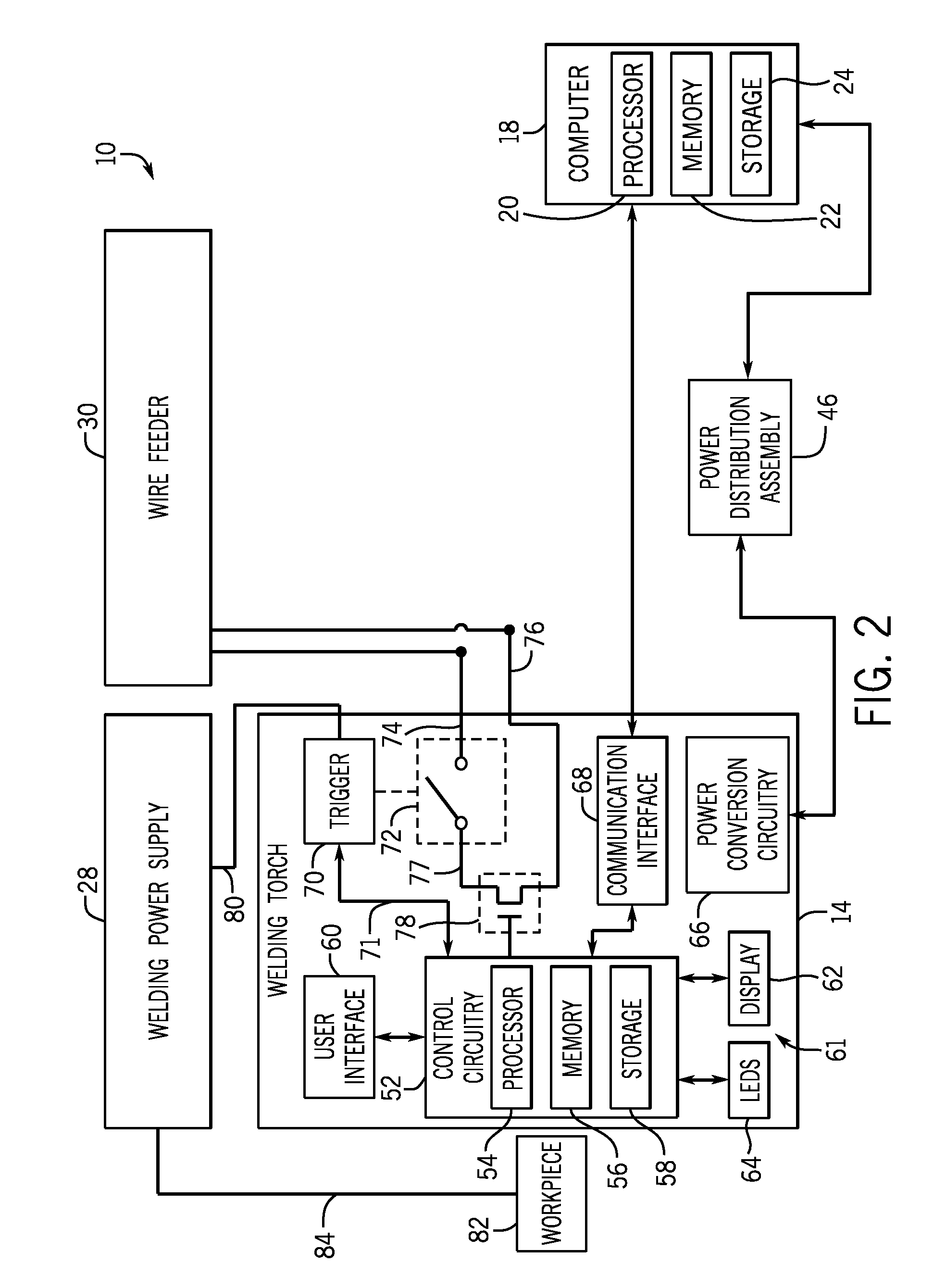

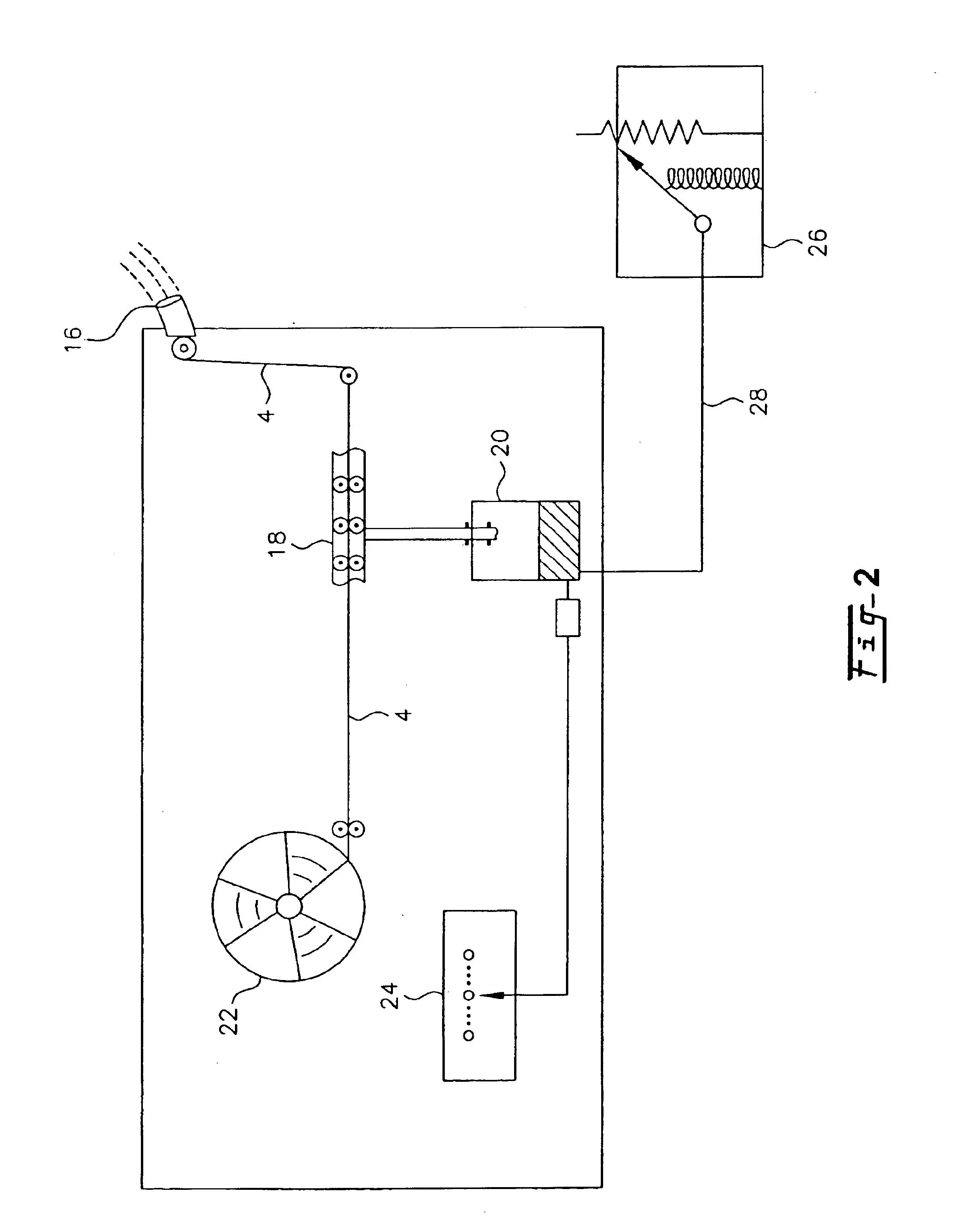

Feedback from a welding torch of a welding system

ActiveUS20150194072A1Electrode vibration holdersCosmonautic condition simulationsDisplay deviceEngineering

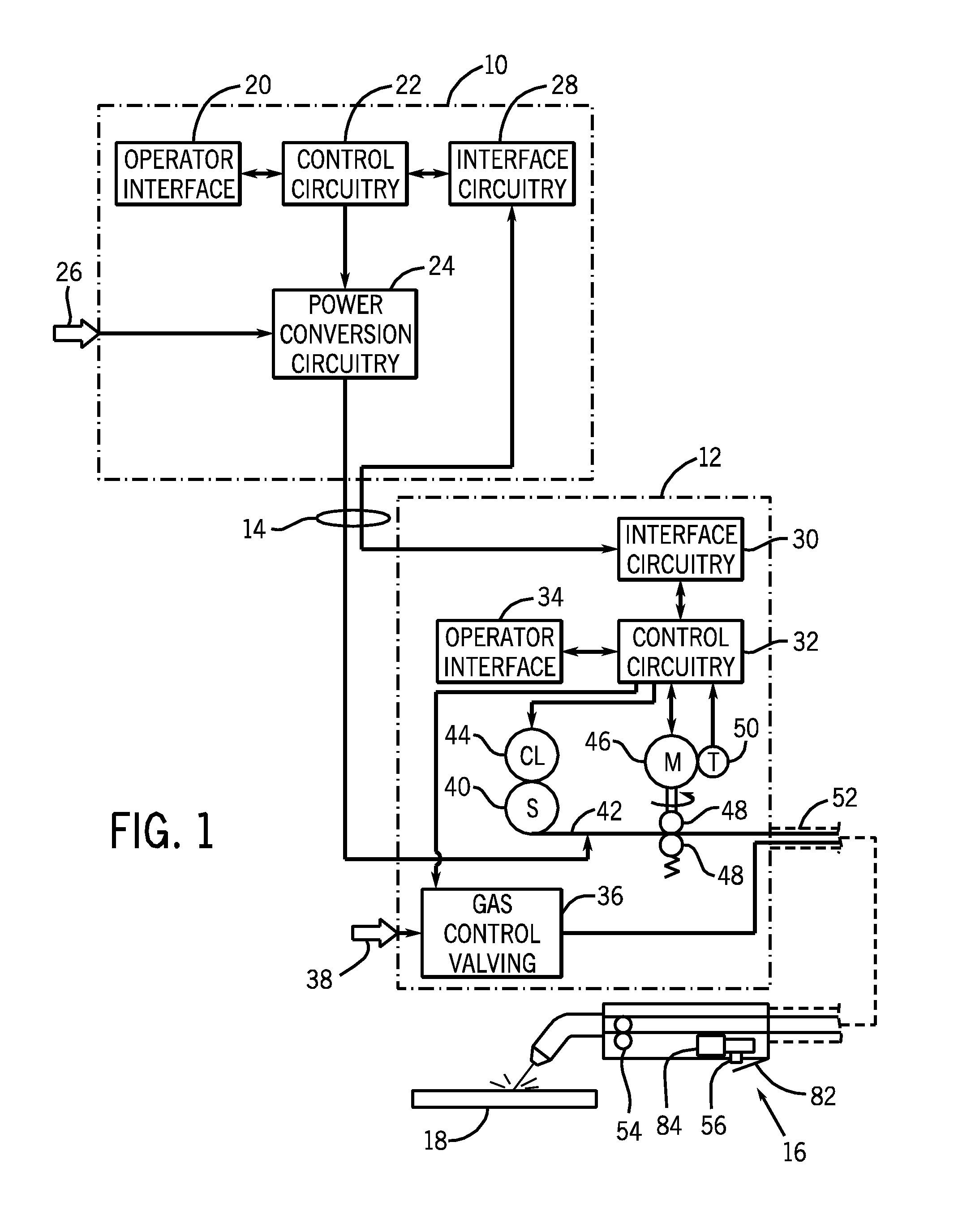

A welding system includes a welding torch. The welding torch includes a sensor configured to detect a motion associated with the welding torch, a temperature associated with the welding torch, or some combination thereof. A display of the welding torch is activated, a determination is made that the welding torch has been involved in a high impact event, live welding using the welding torch is disabled, a software selection is made, or some combination thereof, based on the motion, the temperature, or some combination thereof.

Owner:ILLINOIS TOOL WORKS INC

Method for manufacturing metal parts and molds and micro-roller used therefor

ActiveUS20130197683A1Formability of complexImprove accuracyArc welding apparatusAdditive manufacturing with liquidsNumerical controlWire rod

A method for manufacturing parts and molds by: 1) slicing a three-dimensional CAD model of a part or mold; 2) planning a modeling path according to slicing data of the three-dimensional CAD model, whereby generating numerical control codes for modeling processing; and 3) performing fused deposition modeling of powders or wire material of metal, intermetallic compounds, ceramic and composite functional gradient materials by layer using a welding gun on a substrate layer via a numerical control gas shielded welding beam or laser beam according to a track specified by the numerical control code for each layer. A micro-roller or a micro-extrusion unit is installed at a contact area between melted and softened areas. The micro-roller or the micro-extrusion unit synchronously moves along with fused deposition area, which results in compressing and processing of the fused deposition area during the fused deposition modeling.

Owner:HUAZHONG UNIV OF SCI & TECH

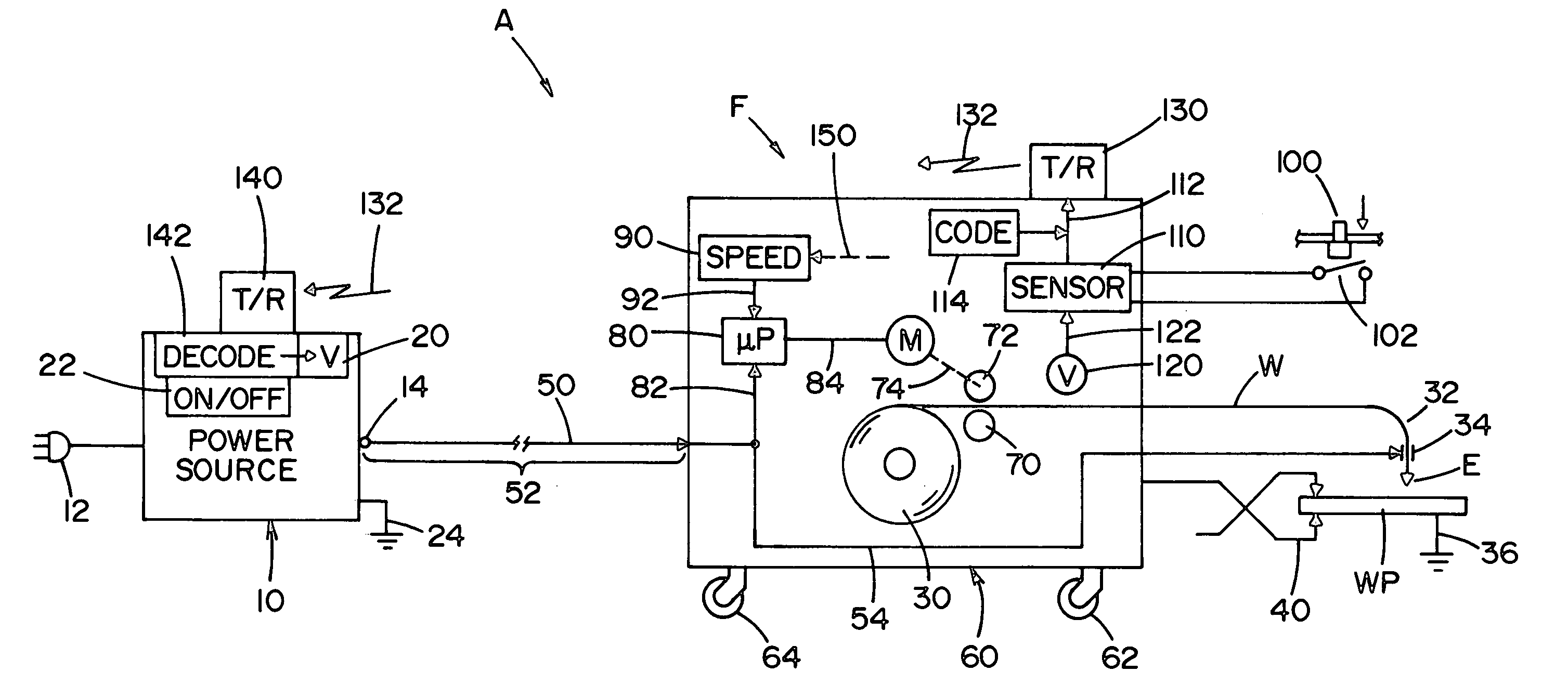

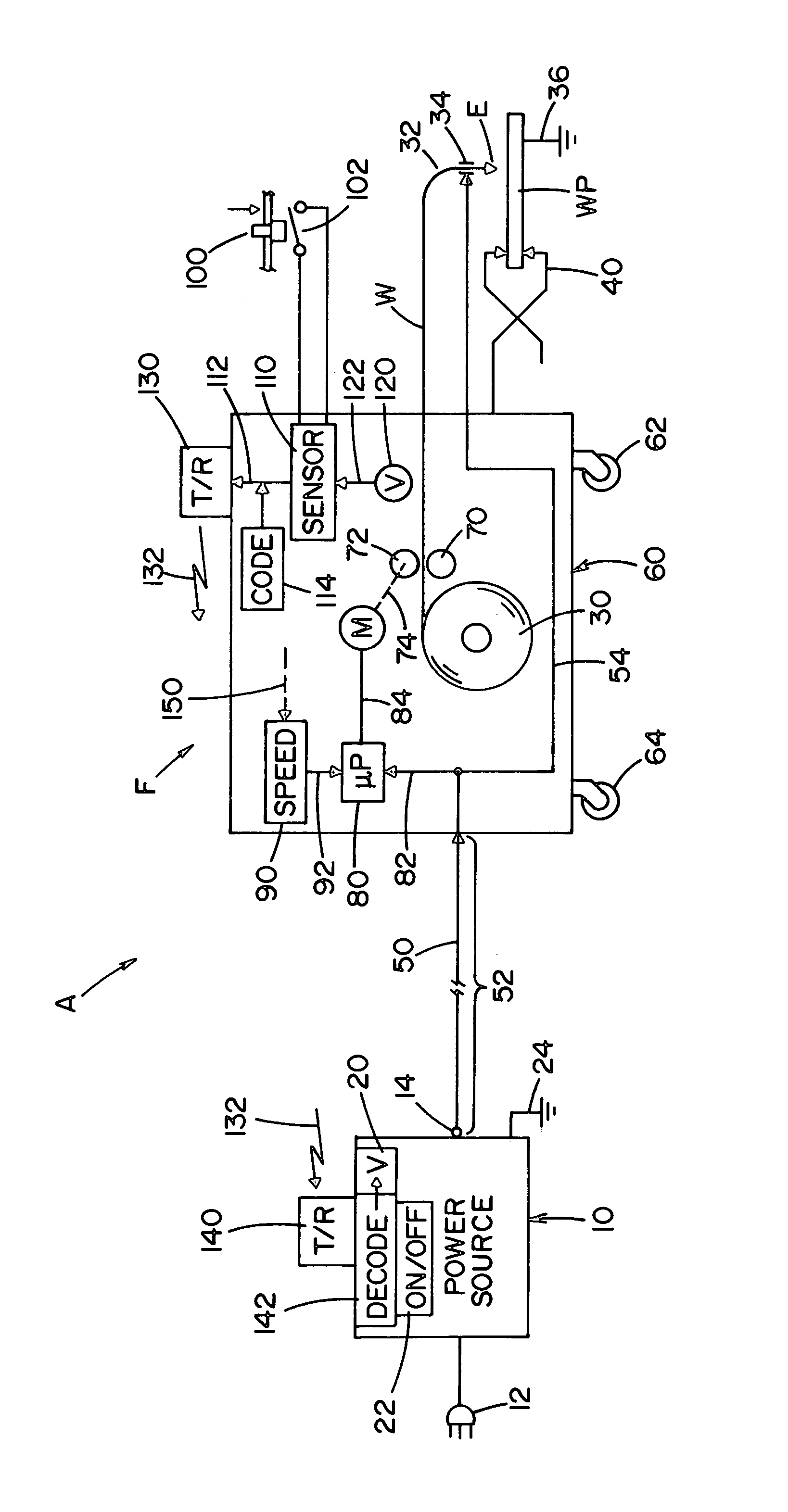

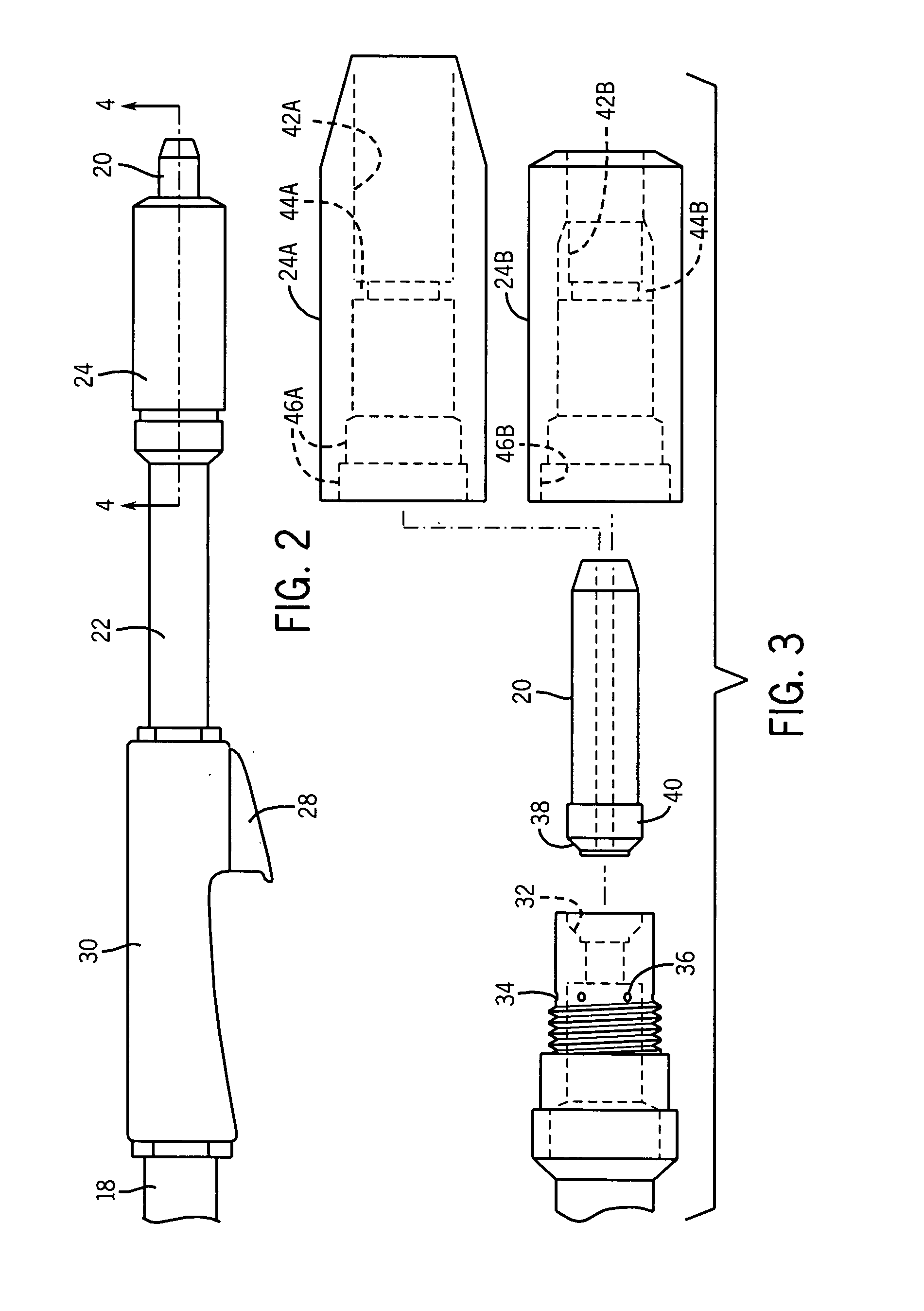

Remote wire feeder

Owner:LINCOLN GLOBAL INC

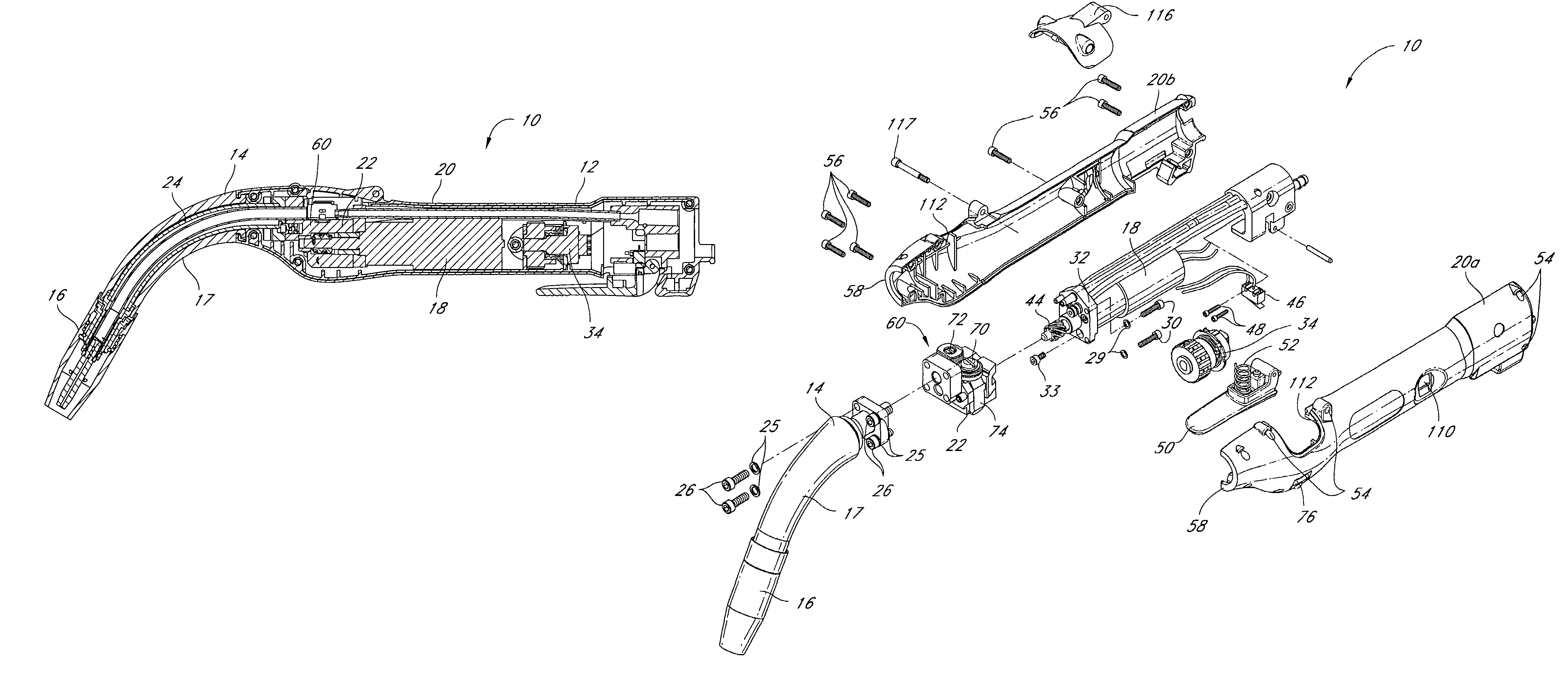

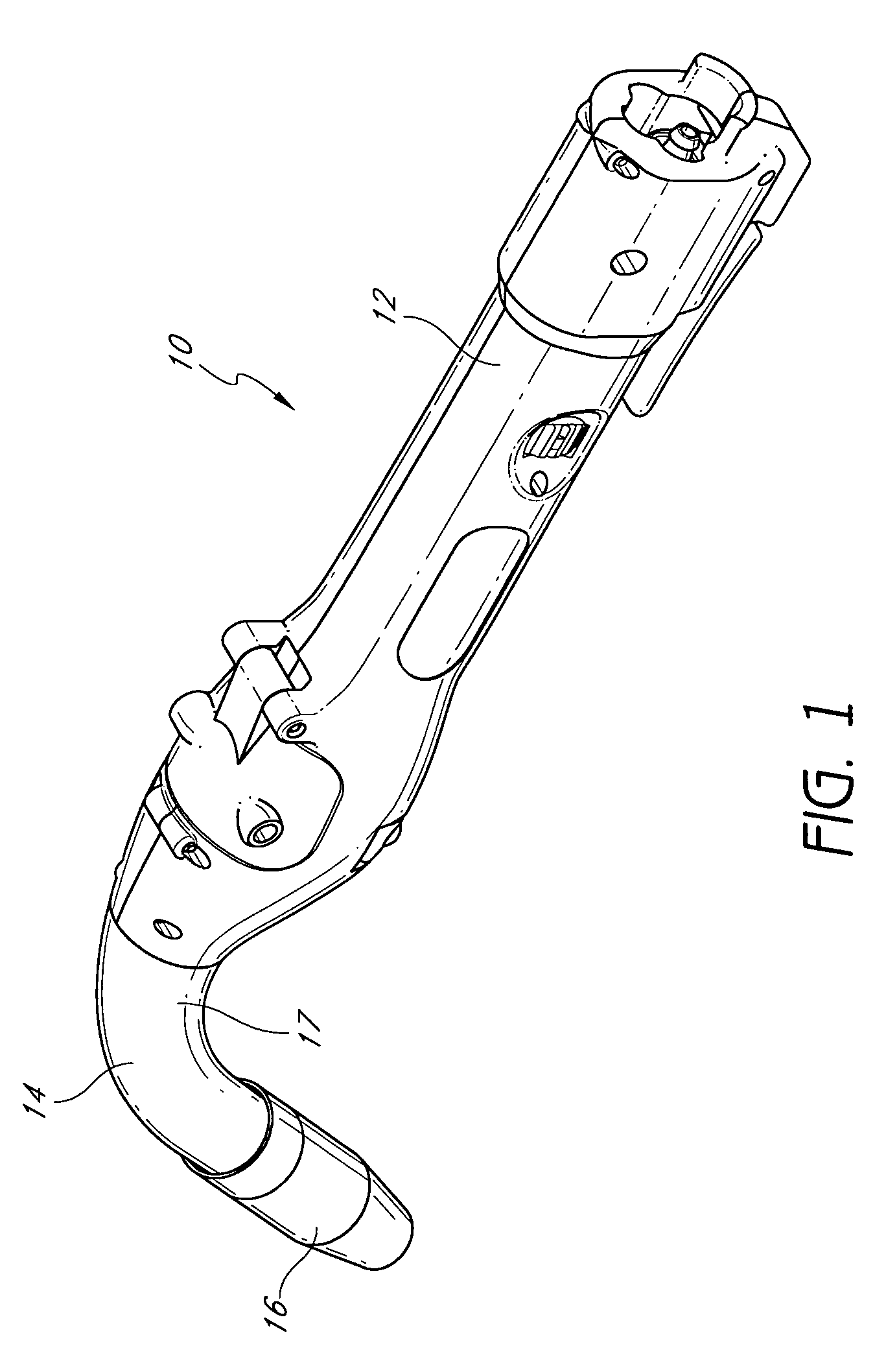

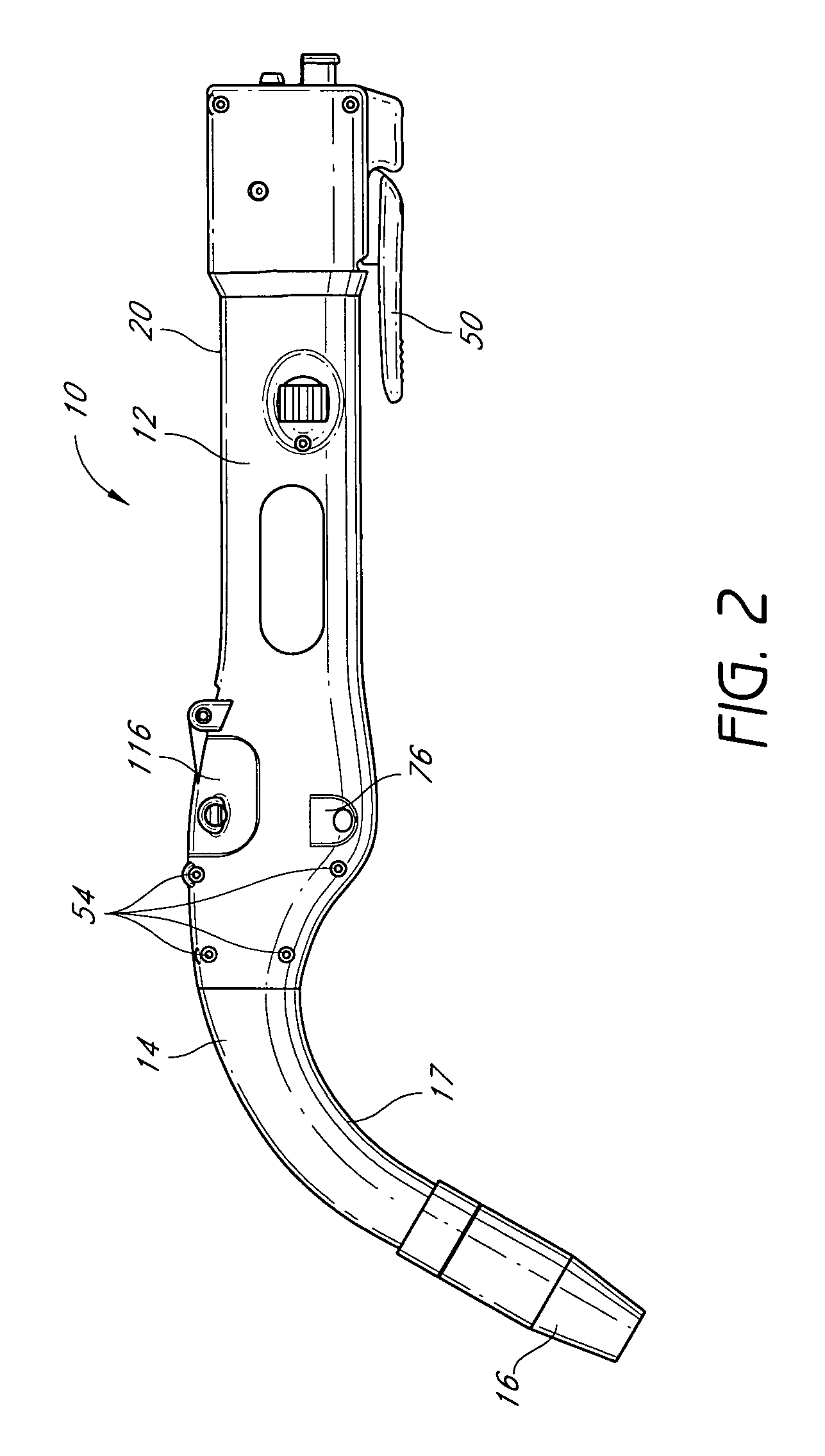

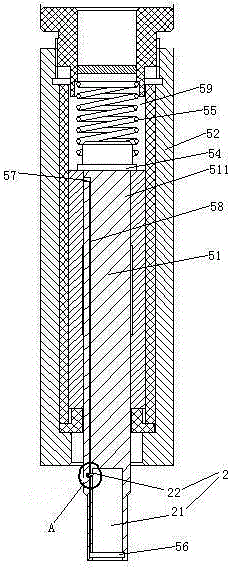

Welding torch with wire feed speed control

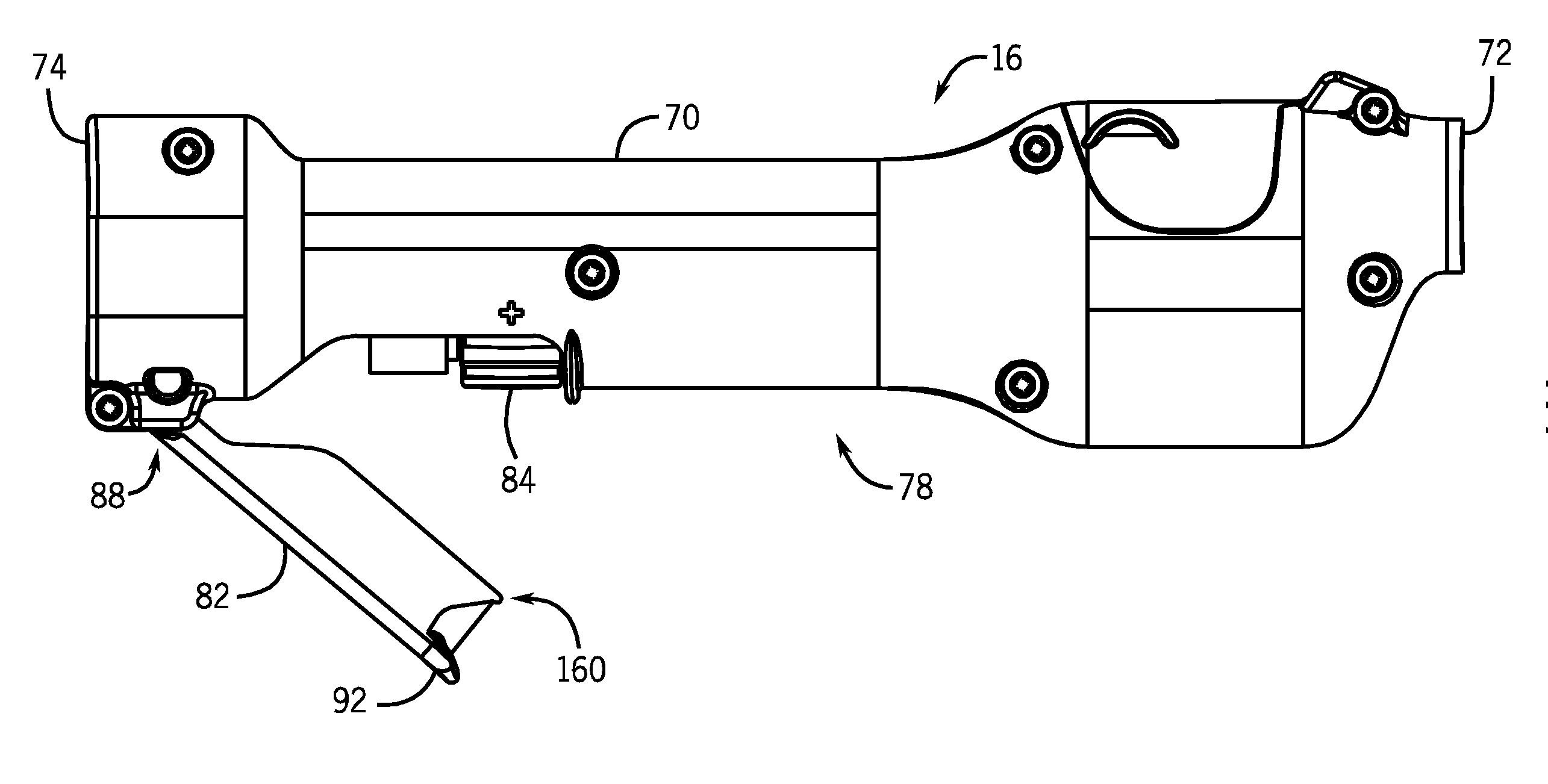

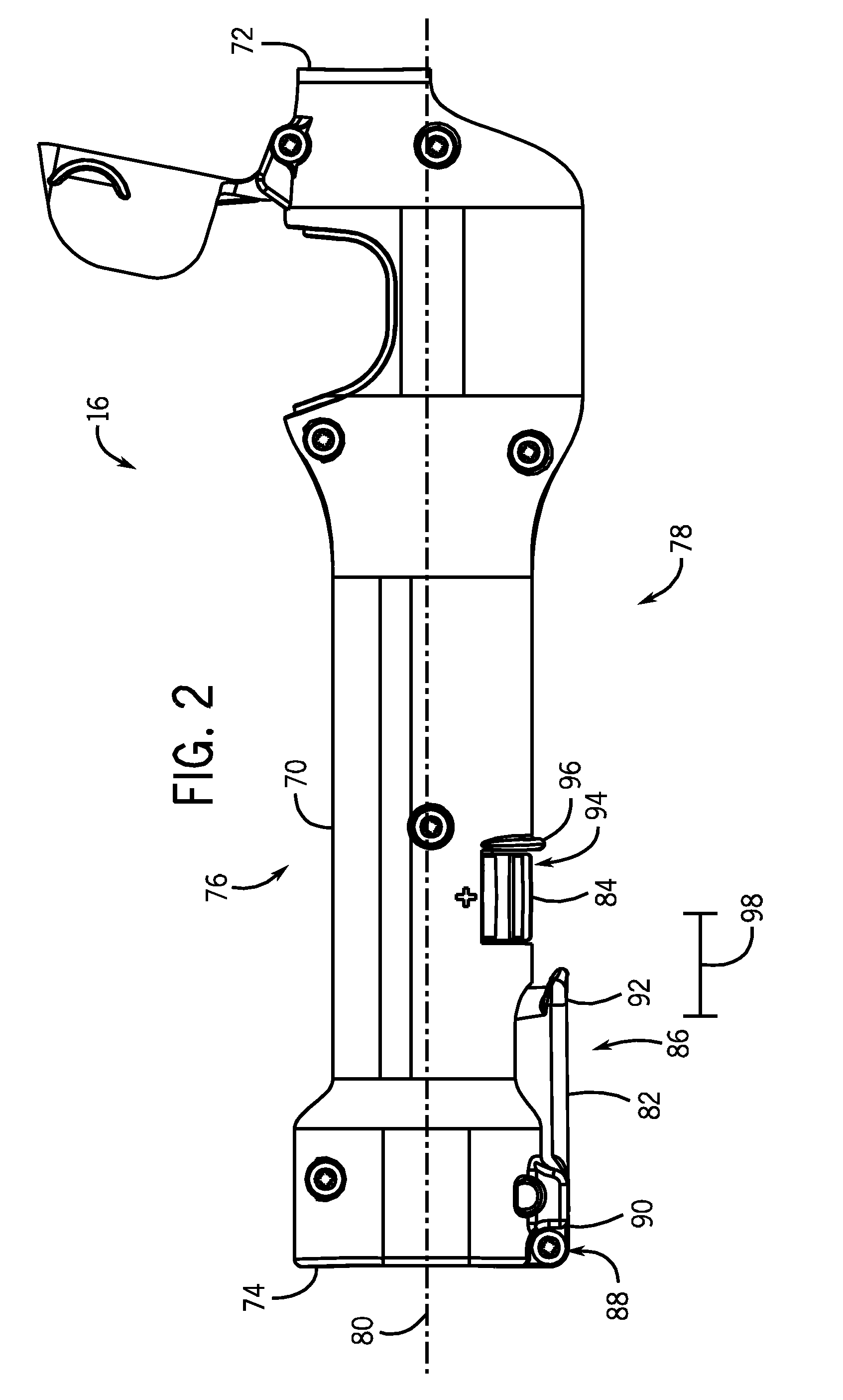

A welding torch has a torch handle. A wire drive assembly is disposed in the torch handle and includes a drive motor and a drive roller. The wire drive assembly contacts the welding wire and is configured to drive the welding wire from a wire feeder to a welding operation. In addition, the welding torch has a trigger and a wire feed speed adjustment assembly. The trigger is disposed near a rear end of the torch handle and is configured to be depressed by an operator for initiating feed of the welding wire. The adjustment assembly is positioned near the rear end of the handle adjacent to the trigger and on the same side of the handle as the trigger. The adjustment assembly allows operator adjustment of a feed speed of the welding wire.

Owner:ILLINOIS TOOL WORKS INC

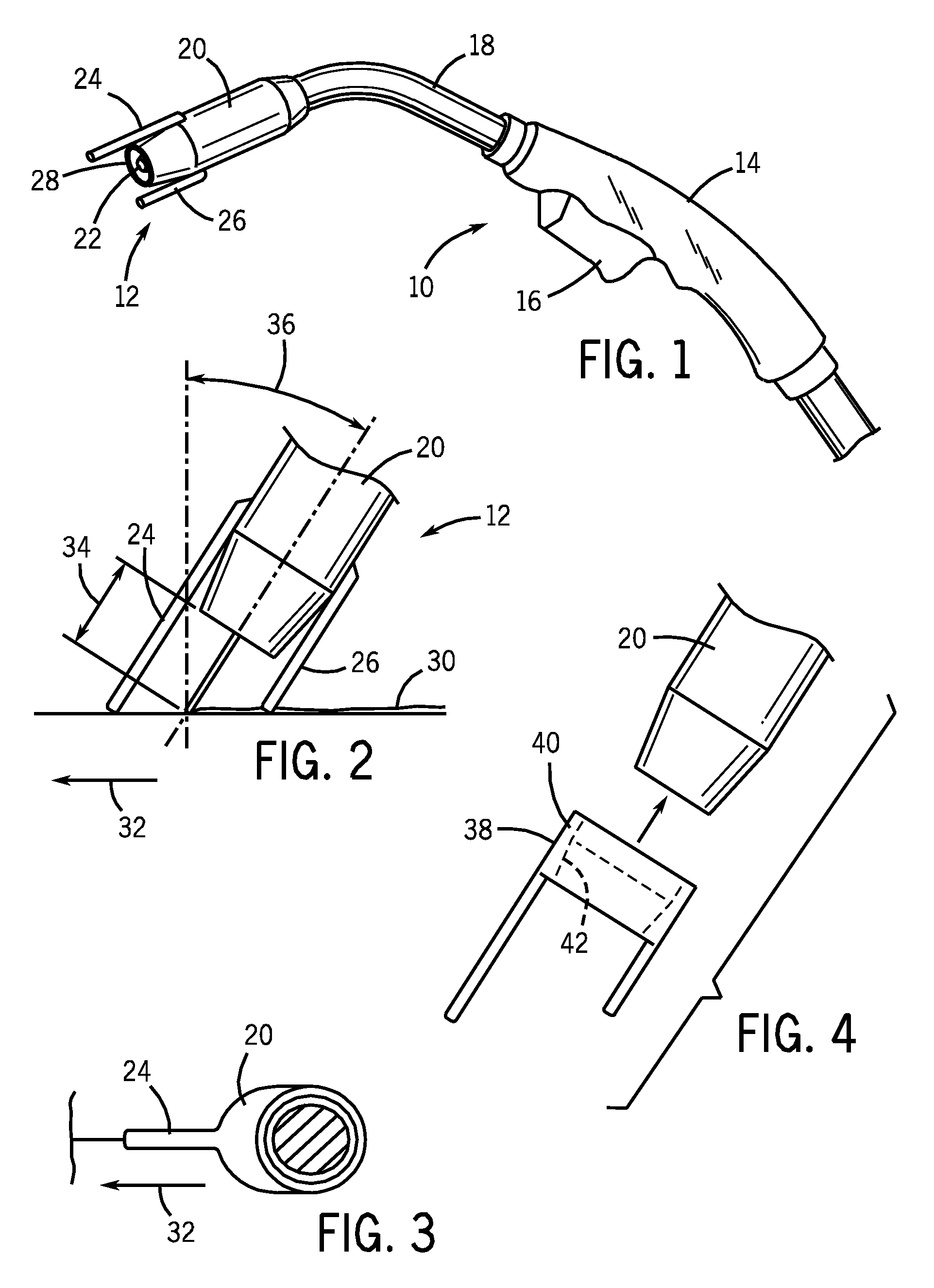

Positioning attachment for a welding torch

InactiveUS20090230107A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A positioning attachment for definition of torch angle and torch to workpiece distance during welding and / or training is provided. The positioning attachment includes one or more legs of equal or varied lengths capped with a tip, which contacts the workpiece, and a body, which may be permanently attached or removably secured to the welding torch nozzle. Certain embodiments may be made of heat resistant metals or ceramic to withstand high temperatures during welding. The positioning attachment may be mounted on the welding torch nozzle or provided as an extension of the contact tip.

Owner:ILLINOIS TOOL WORKS INC

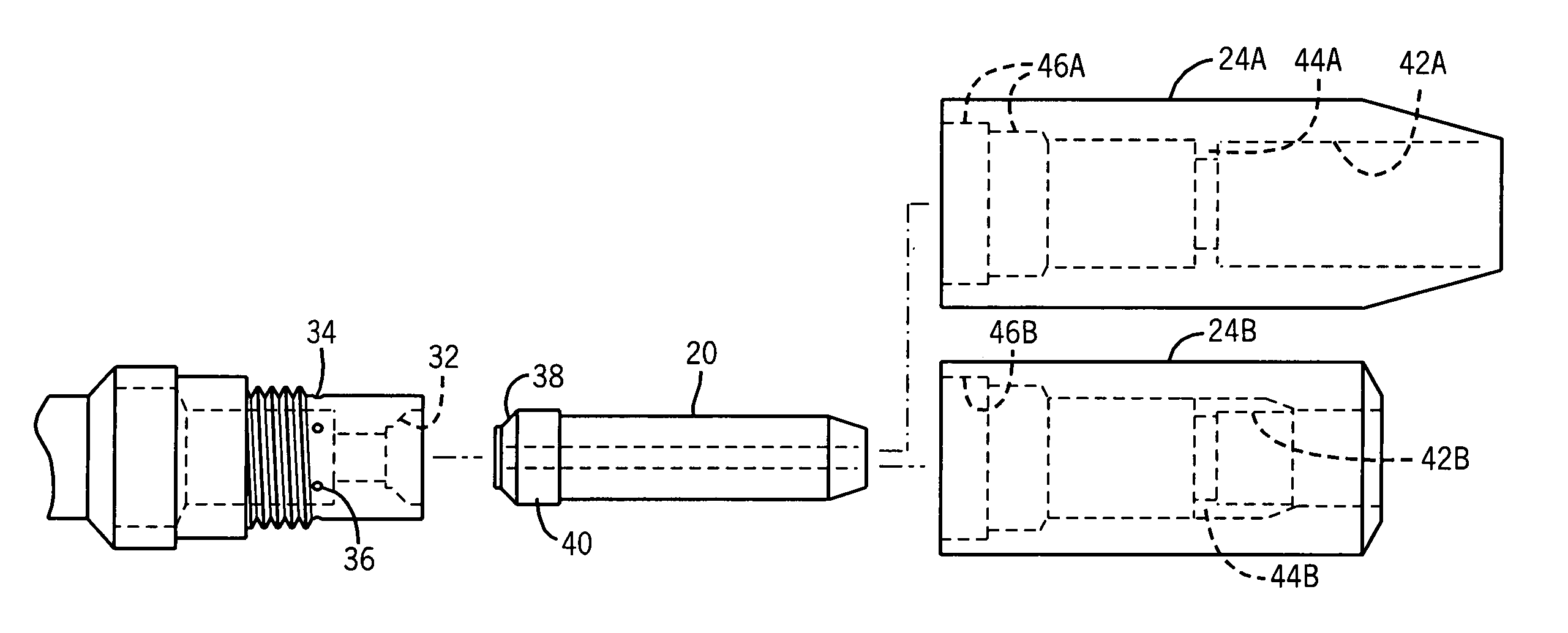

Method and apparatus to automatically determine type of gun connected to a wire feeder

Owner:ILLINOIS TOOL WORKS INC

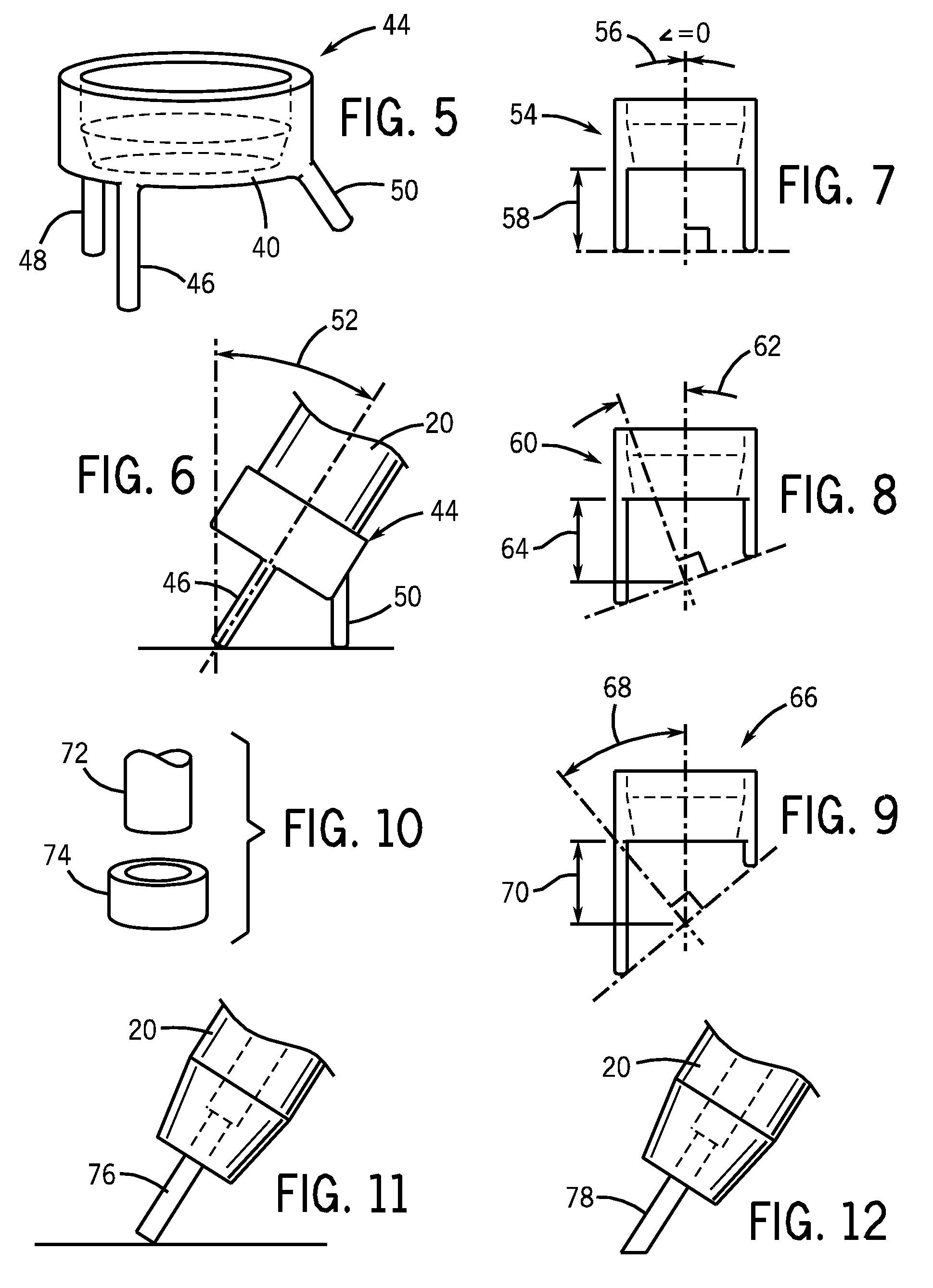

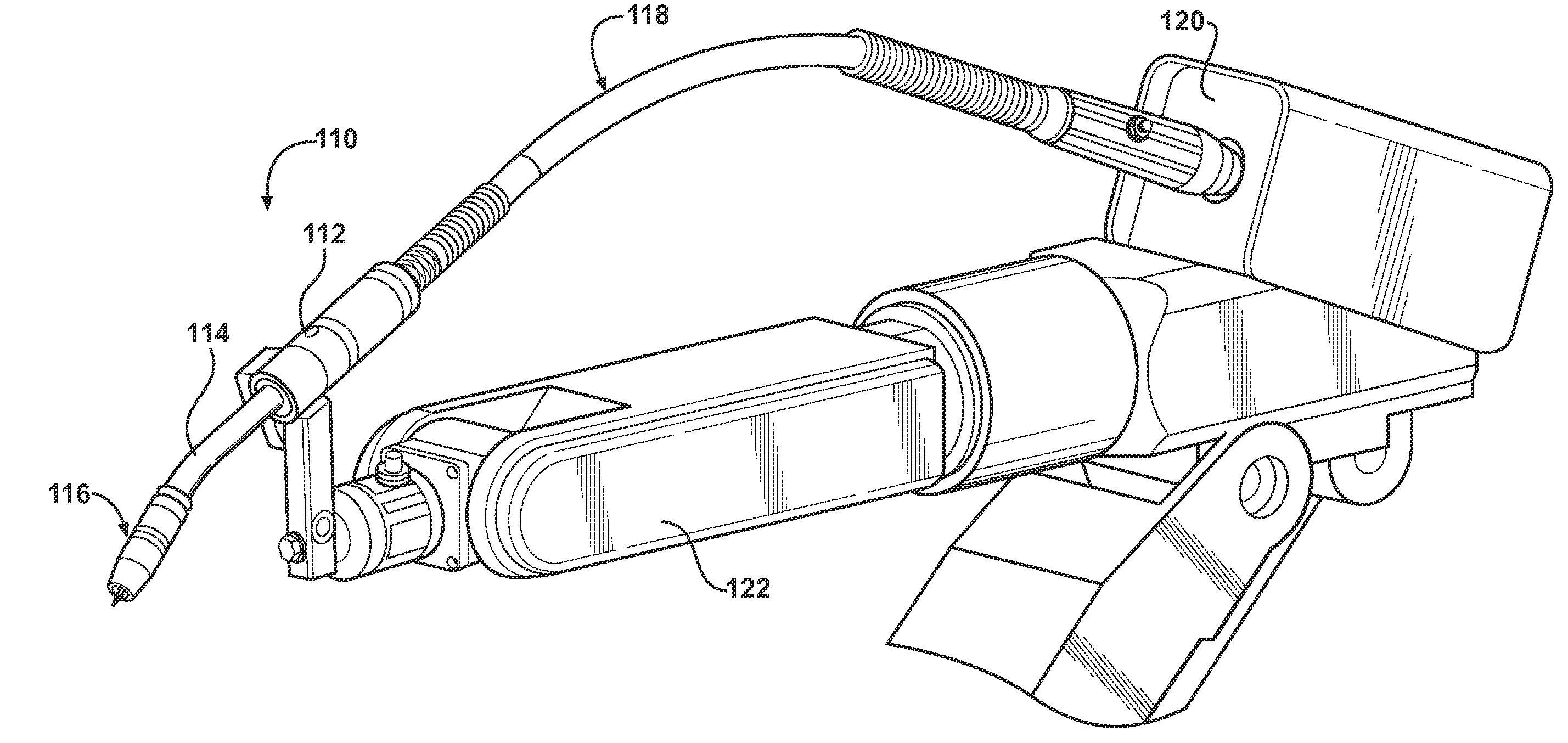

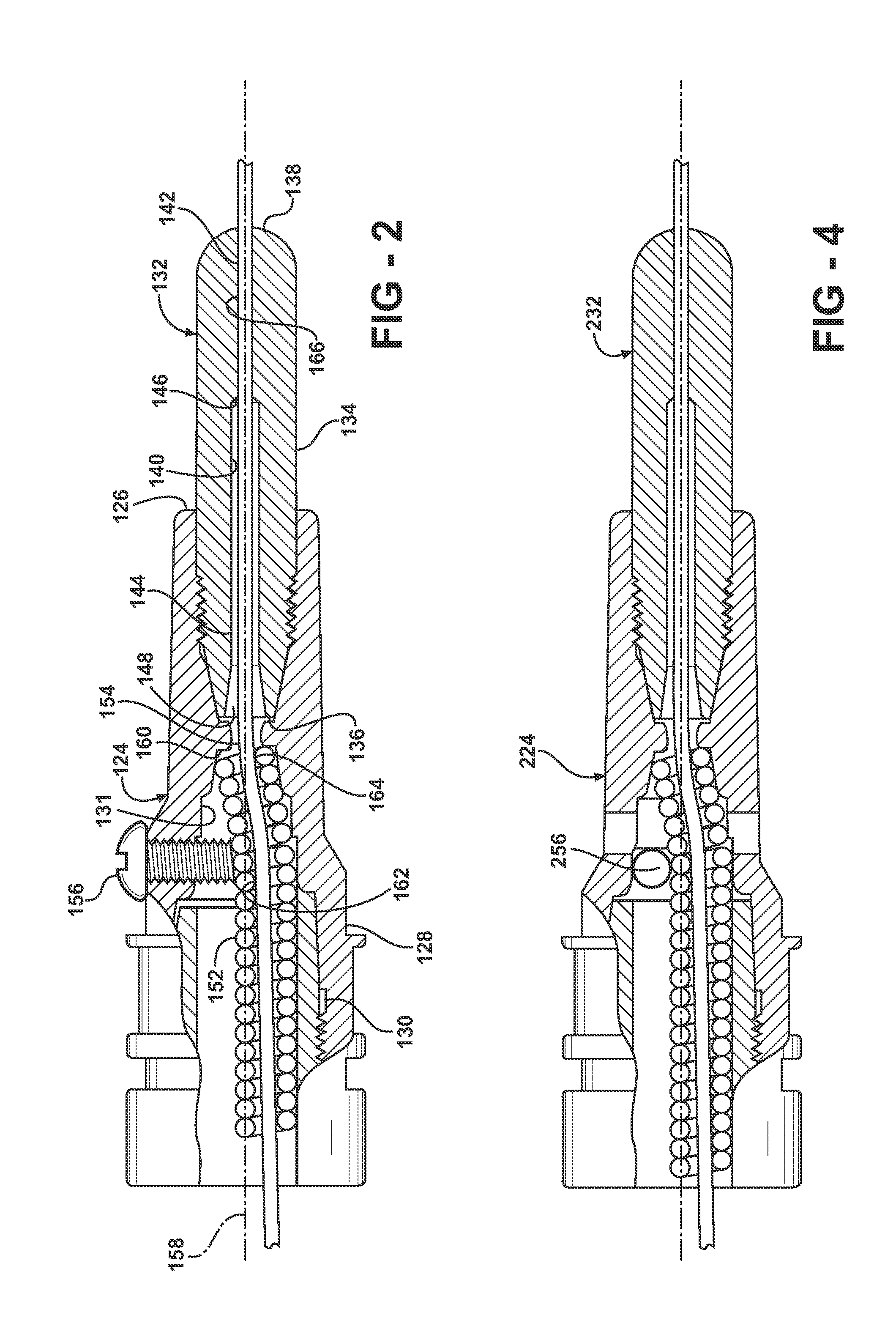

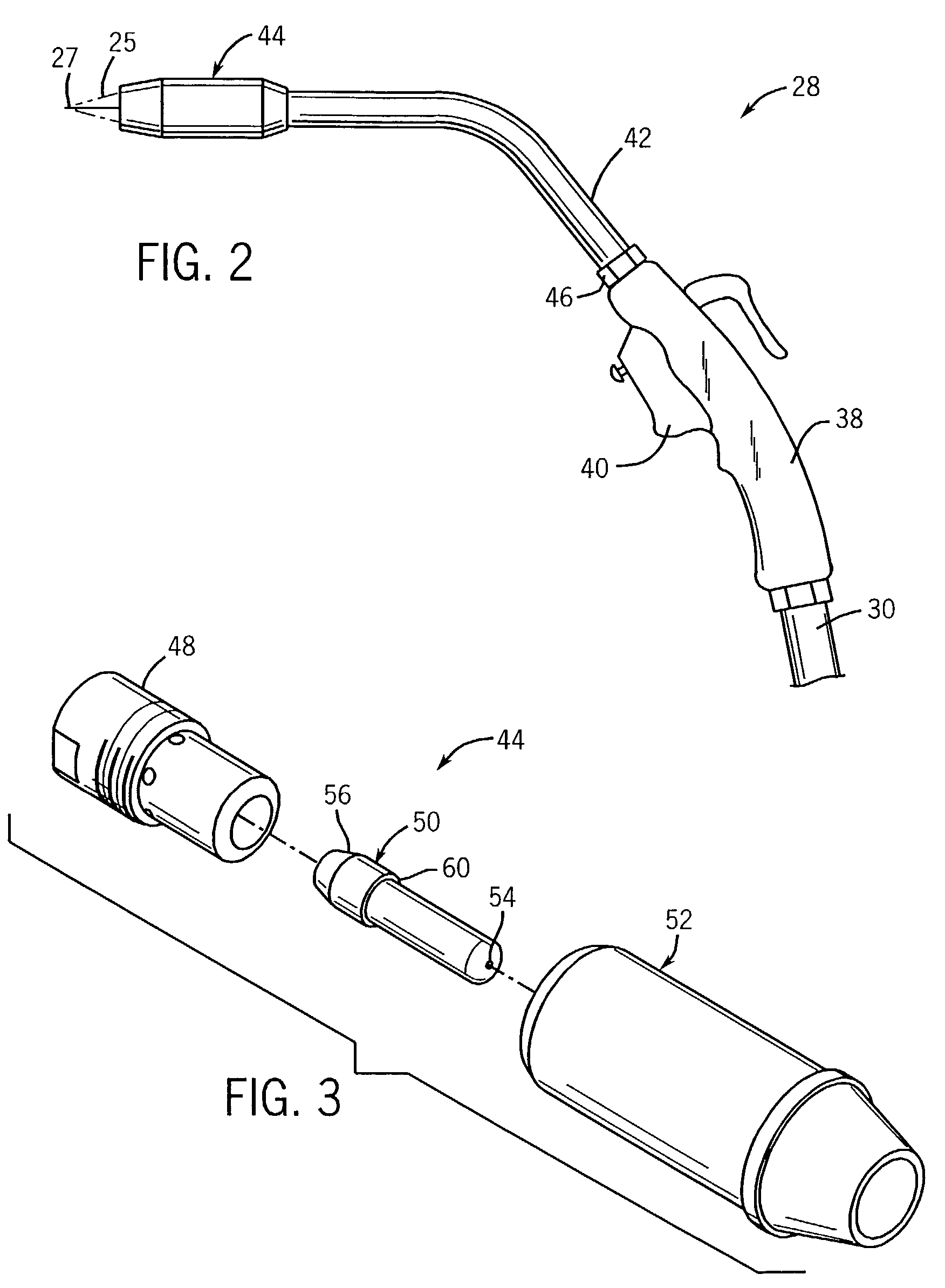

Retaining head and contact tip for controlling wire contour and contacting point for gmaw torches

ActiveUS20090152255A1Straight welding wire contourMinimize impactElectrode supporting devicesContact forceWelding torch

A retaining head for a MIG welding device includes a contact tip mounting end, an opposite retaining head mounting end, and a throughbore extending from one of the ends to the other end. A deflector is disposed along the throughbore and is adjustable for imparting a bend in welding wire passing through the throughbore. The deflector provides a straight wire contour for the welding wire that is fed out of the welding torch, while maintaining sufficient contact force between the welding wire and the contact tip. The deflector also reduces the effect of wire twist on the contact point between the welding wire and the contact tip.

Owner:ILLINOIS TOOL WORKS INC

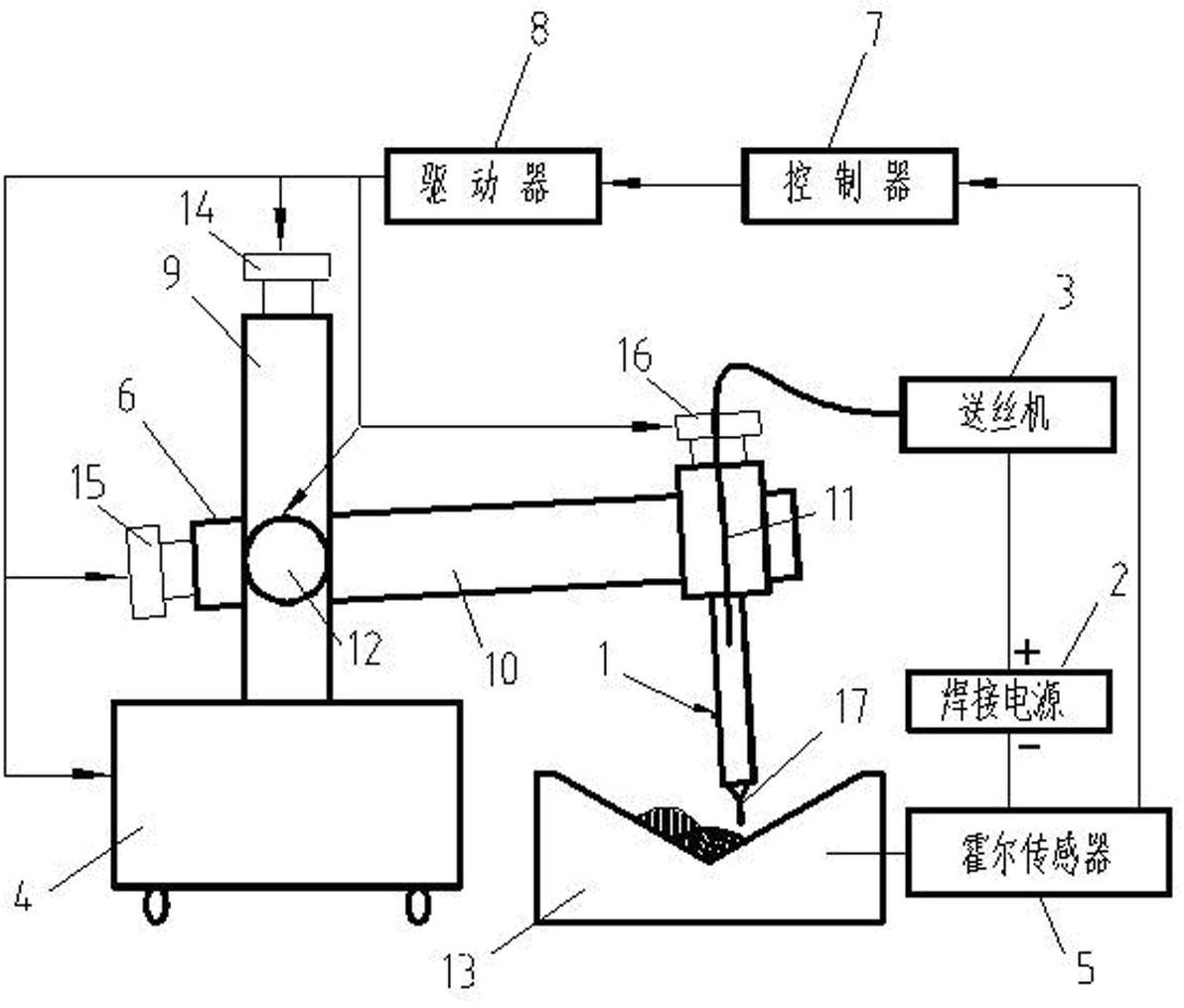

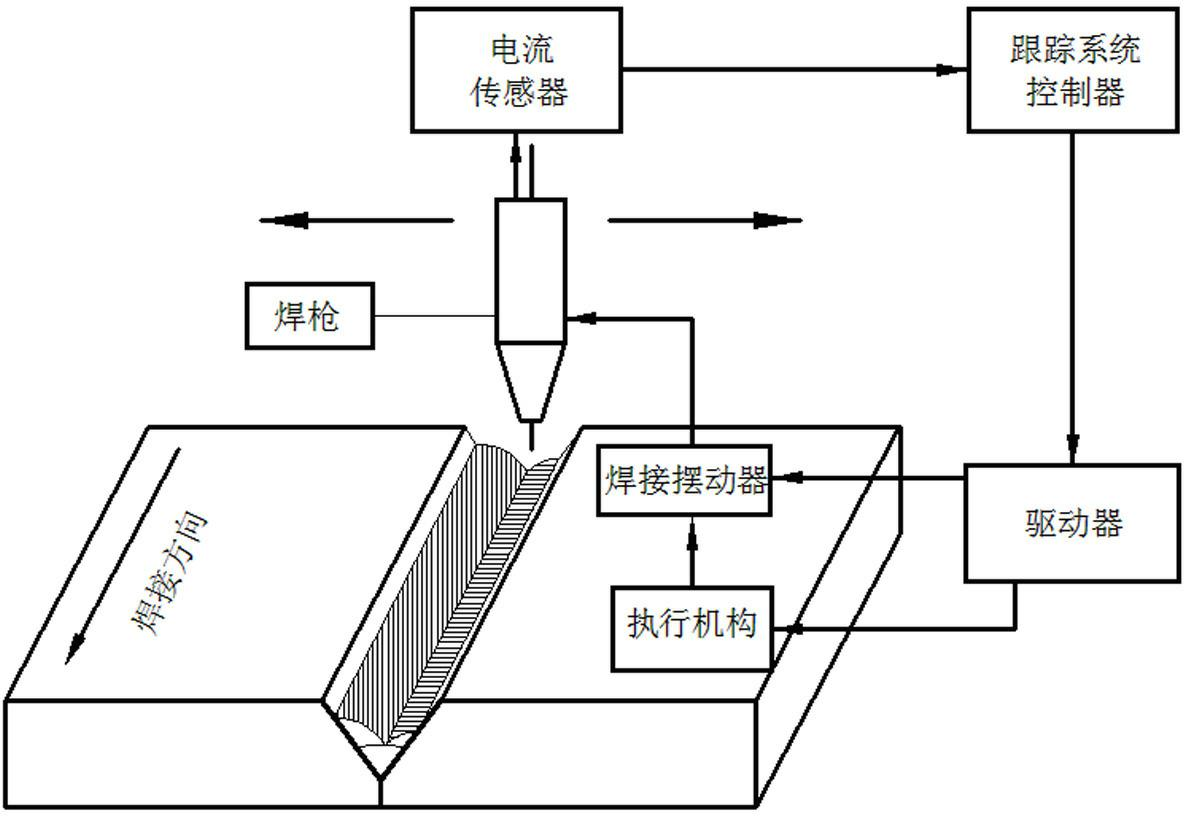

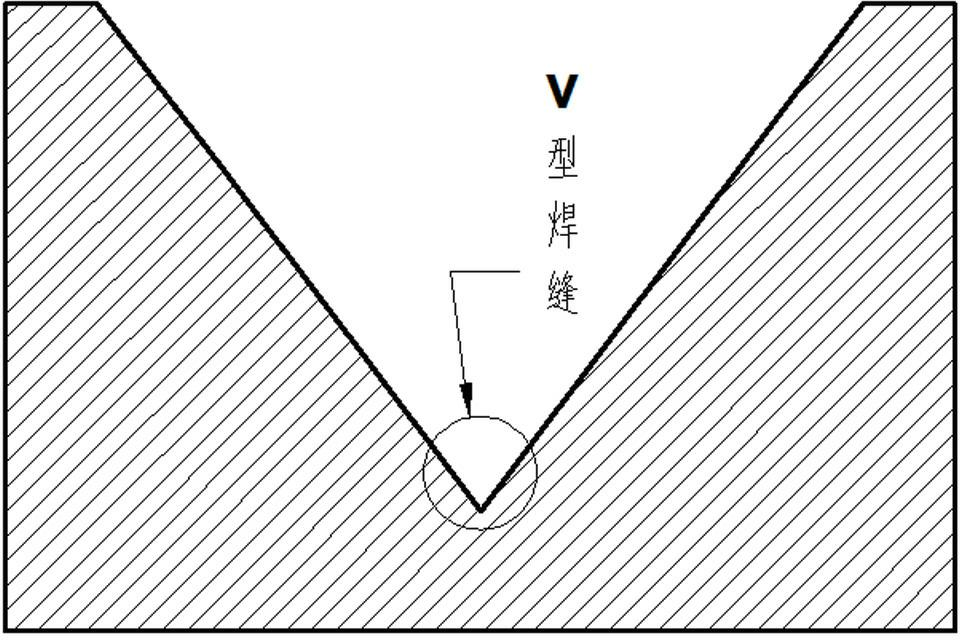

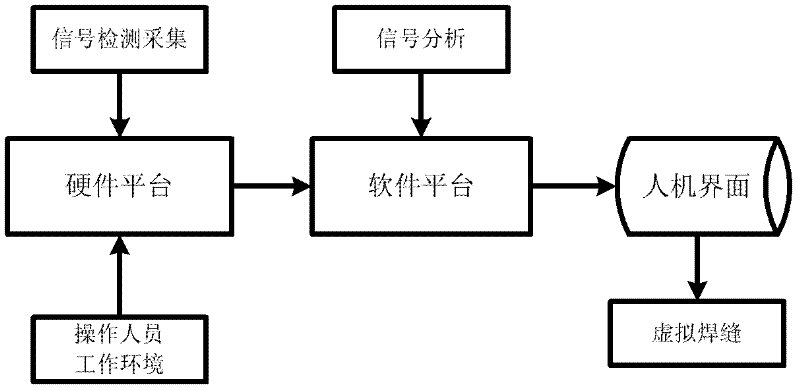

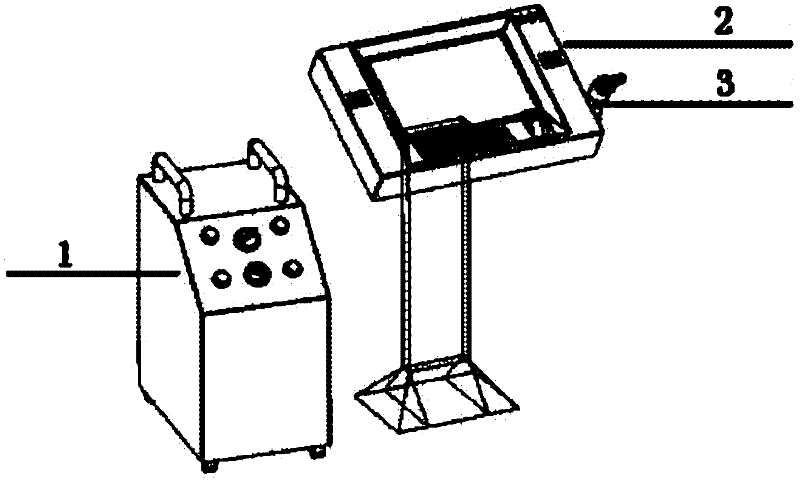

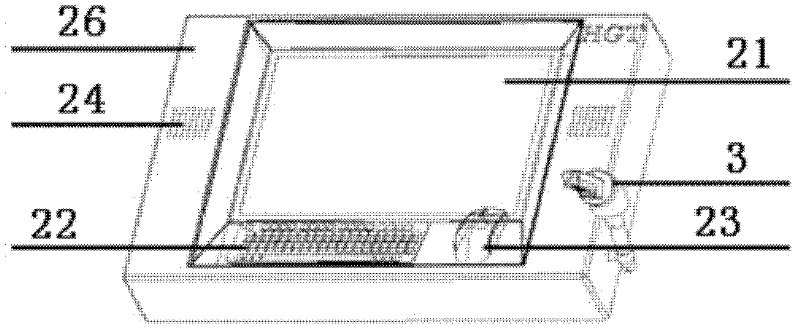

Swing arc-based multi-layer and multi-channel weld tracking system and identification method thereof

InactiveCN102615390AHigh precisionGuaranteed uptimeArc welding apparatusWelding power supplyCurrent sensor

Owner:XIANGTAN UNIV

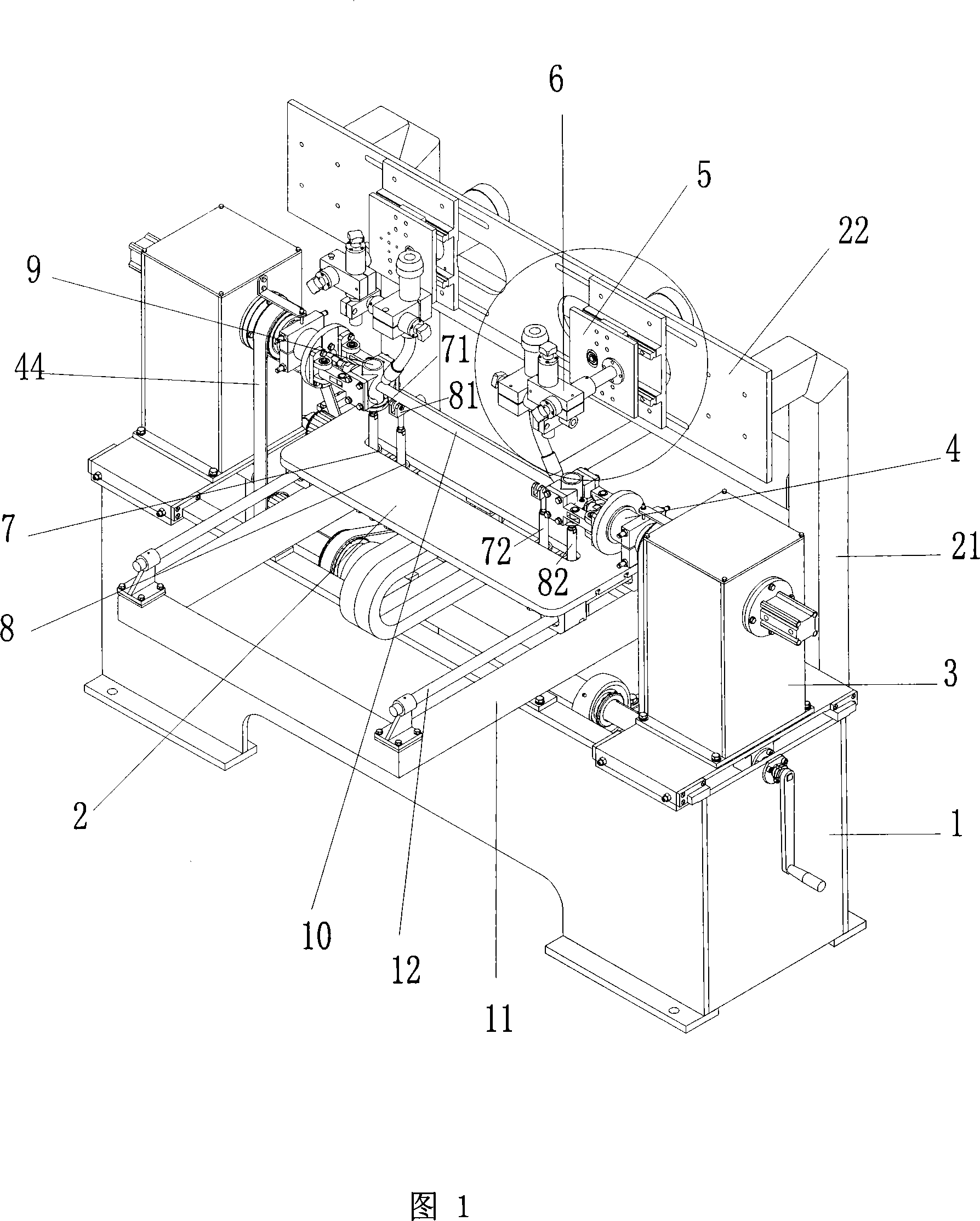

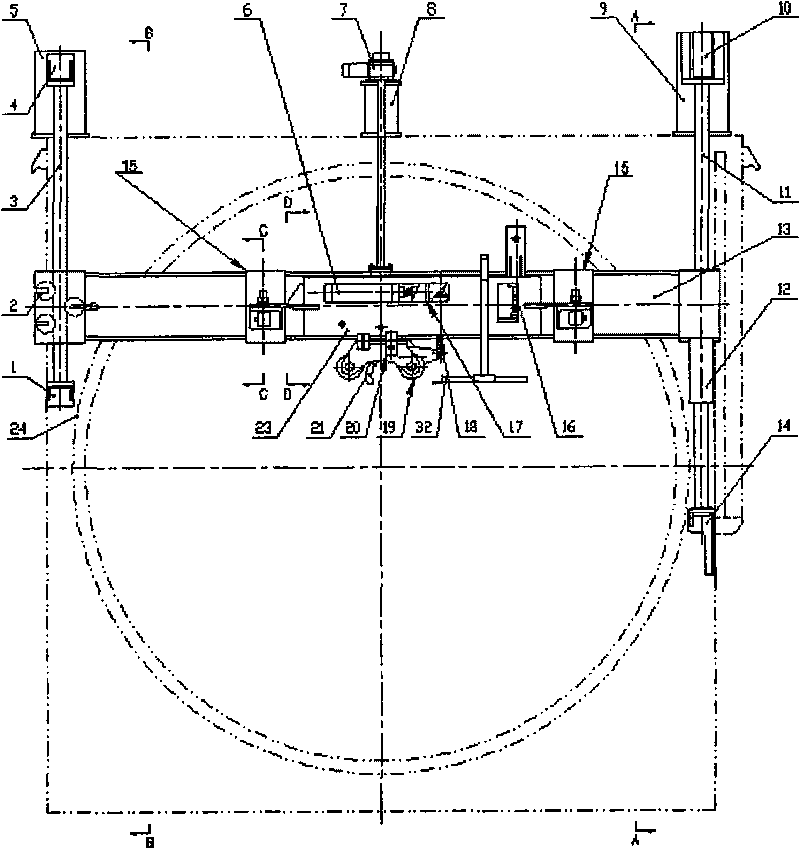

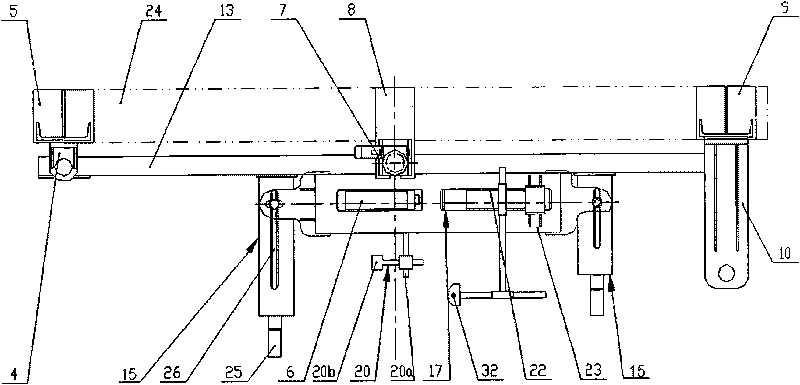

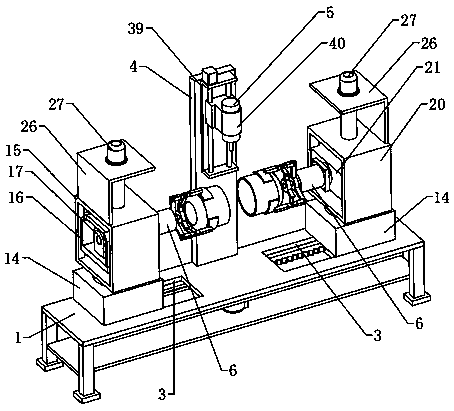

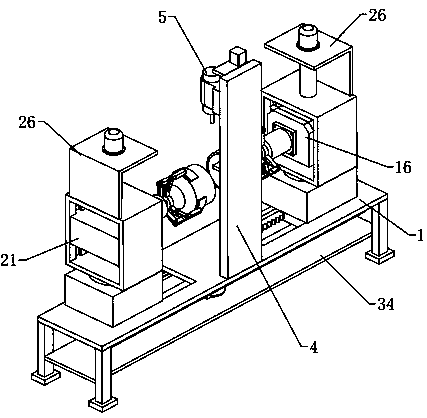

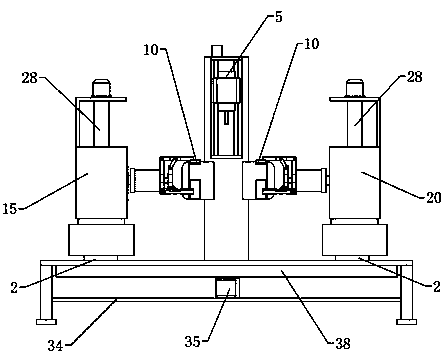

Intersecting line dual-annular seam automatic welding machine

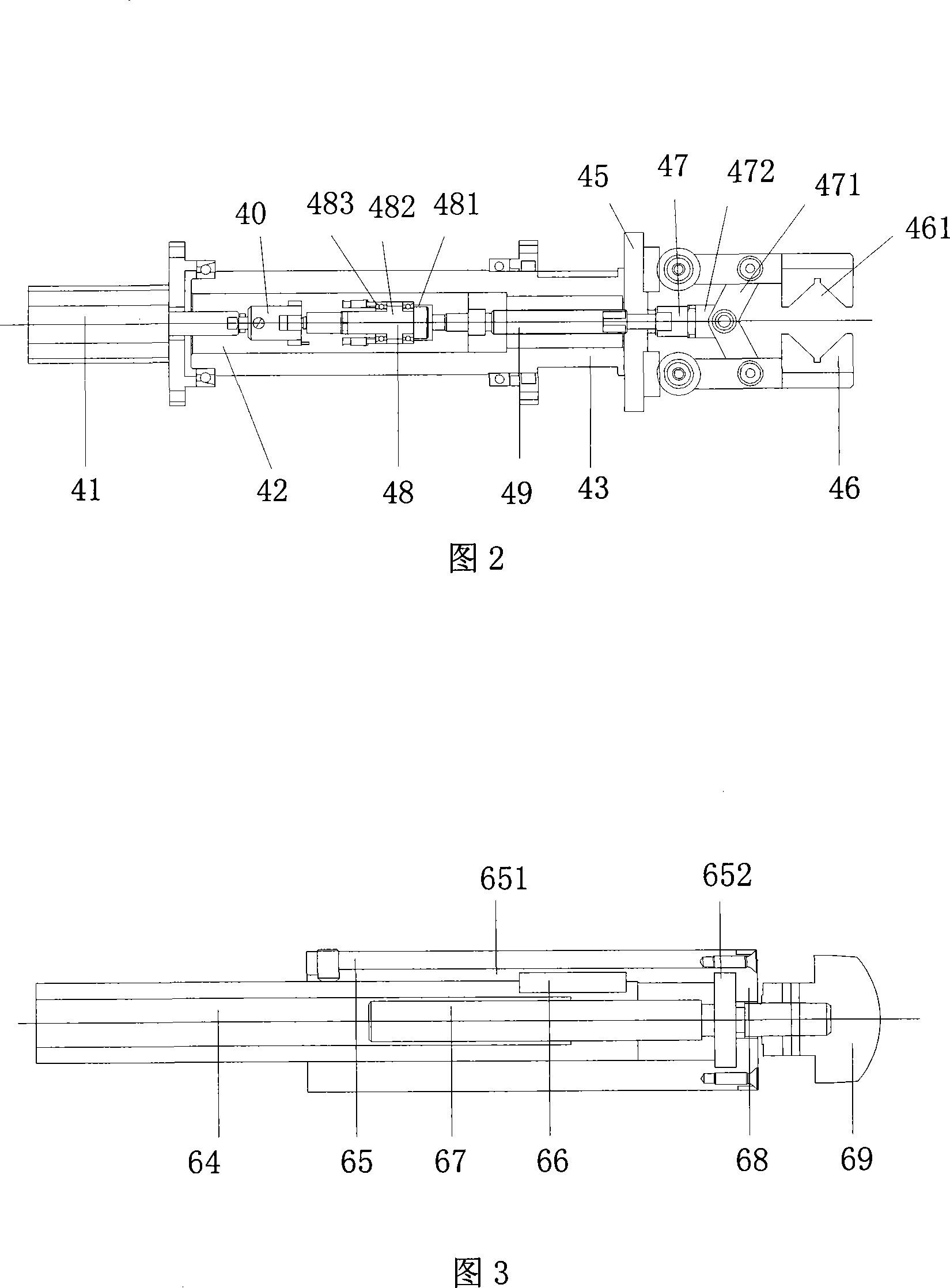

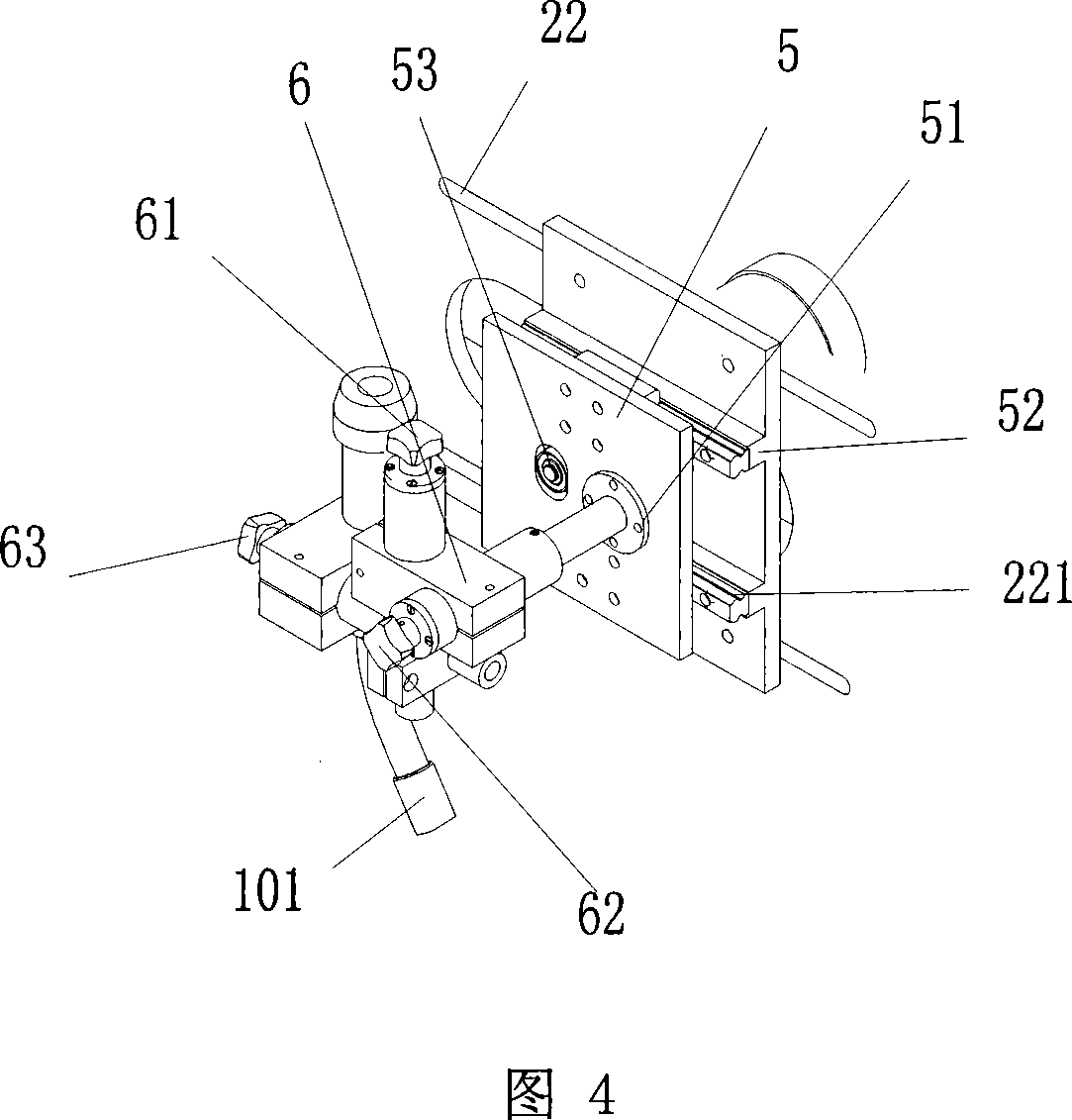

InactiveCN101234462AImprove comfortGuaranteed accuracyWelding/cutting auxillary devicesArc welding apparatusInsertion stentReciprocating motion

An intersecting line double annular gaps automatic welding machine relates to a pipe annular gap welding device, comprising a machine tool body component, a dynamic device which is arranged on the machine tool body component, a workpiece platform which is movably arranged on the machine tool body component and operates reciprocating horizontal movements driven by the dynamic device, a primacy workpiece and a secondary workpiece lifting mechanism which are arranged on the workpiece platform and move horizontally with the workpiece platform, a fixture box which is arranged on the machine tool body component, a rotary fixture which is arranged on the fixture box and is driven by the dynamic device to clamp and carry the primacy workpiepce and the secondary workpiece to do rotary movements, a welding torch stent assembly which is arranged on the machine tool body component, an eccentric slide block mechanism which is arranged on the welding torch stent assembly, a welding torch component which is arranged on the slide block of the welding torch stent assembly and is driven by the slide block to realize the horizontal reciprocating movements. The welding torch component is provided with a welding torch which can realize the welding of the intersecting line between the primacy workpiece and the secondary workpiece. The pipe annular gap welding device has the advantages that the whole machine is controlled by a PLC and is welded by a way of rotating workpieces, and the workpiece rotation which is driven by adopting a stepping motor is correct in transmission.

Owner:上海气焊机厂有限公司

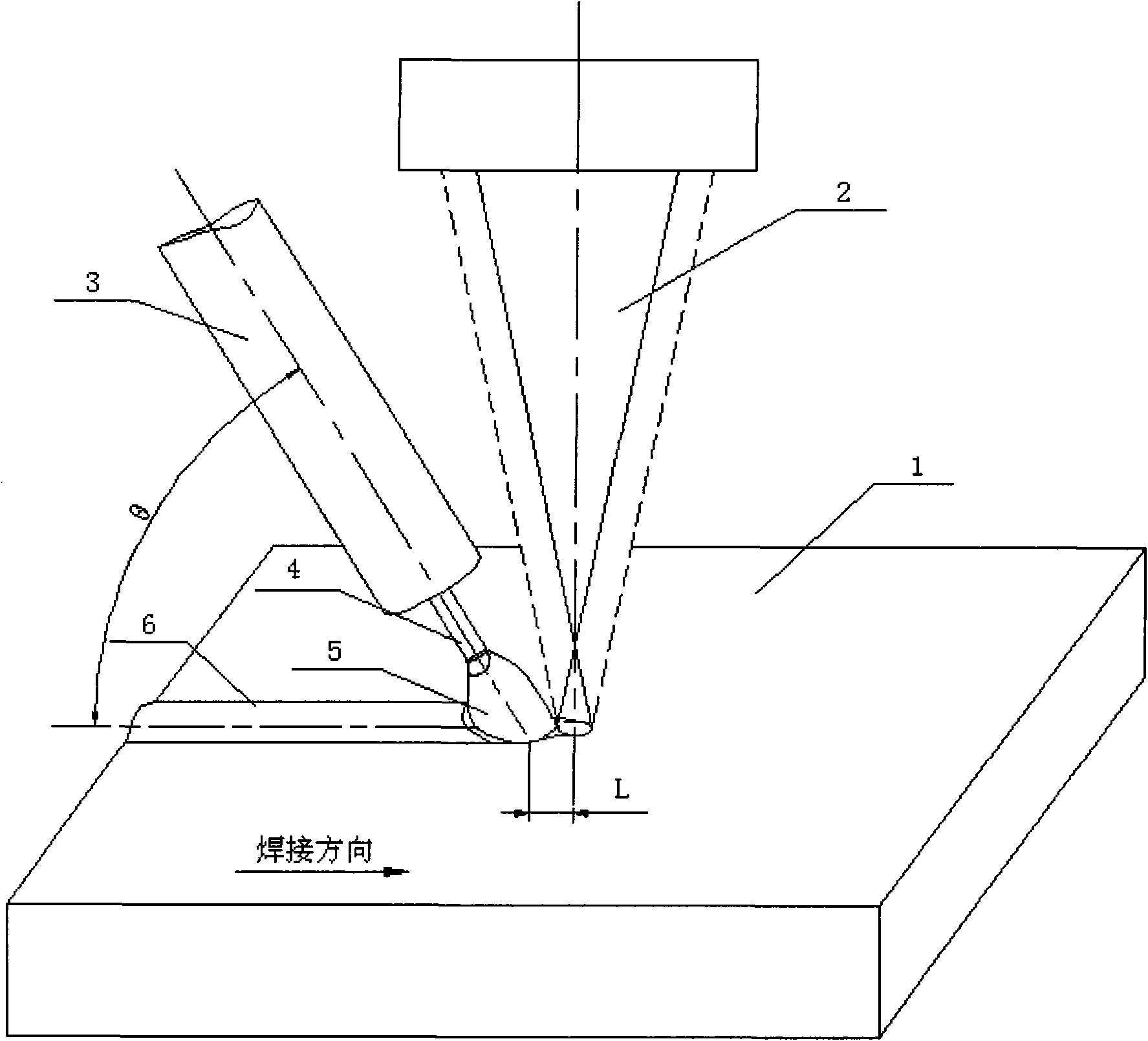

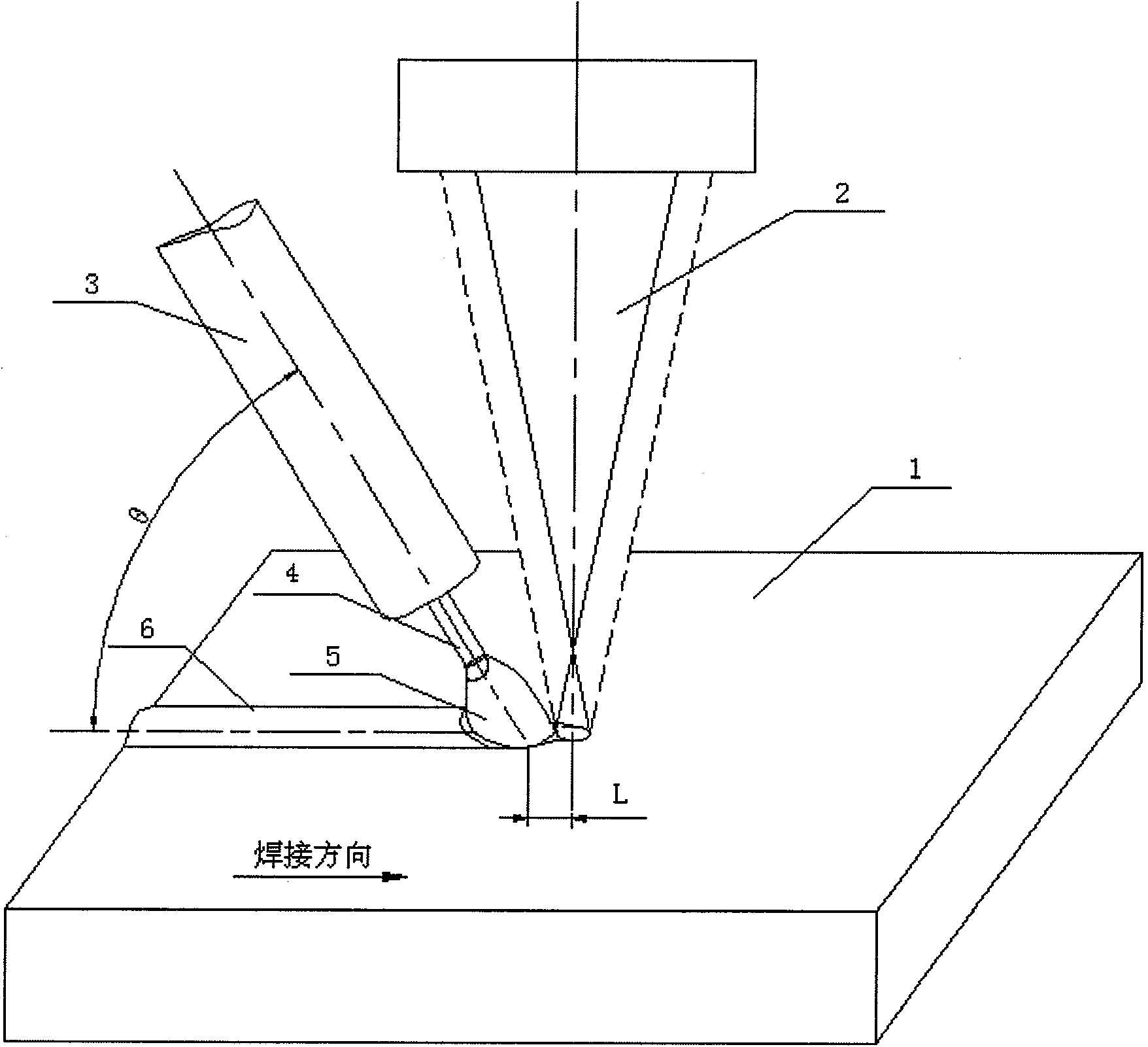

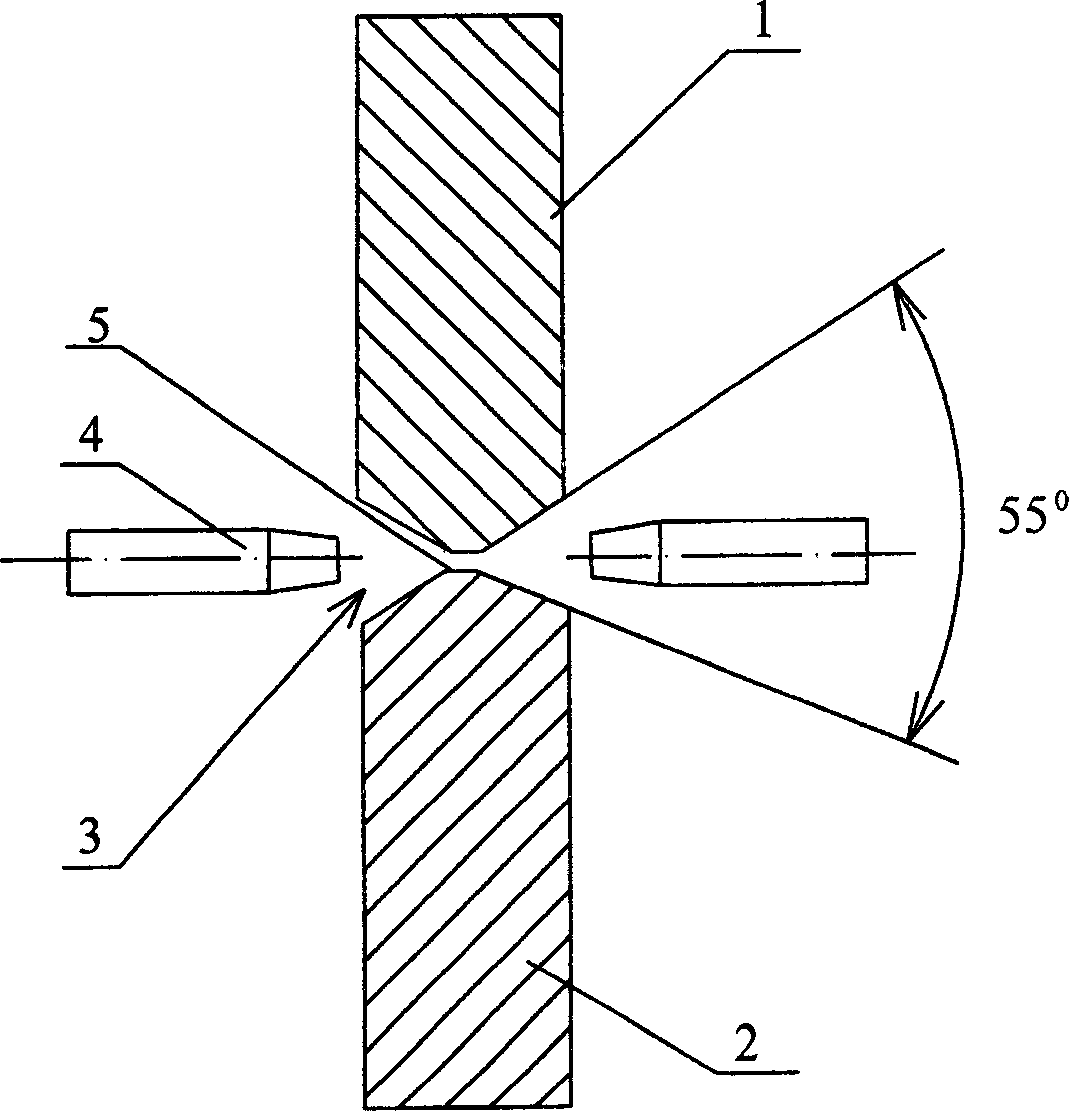

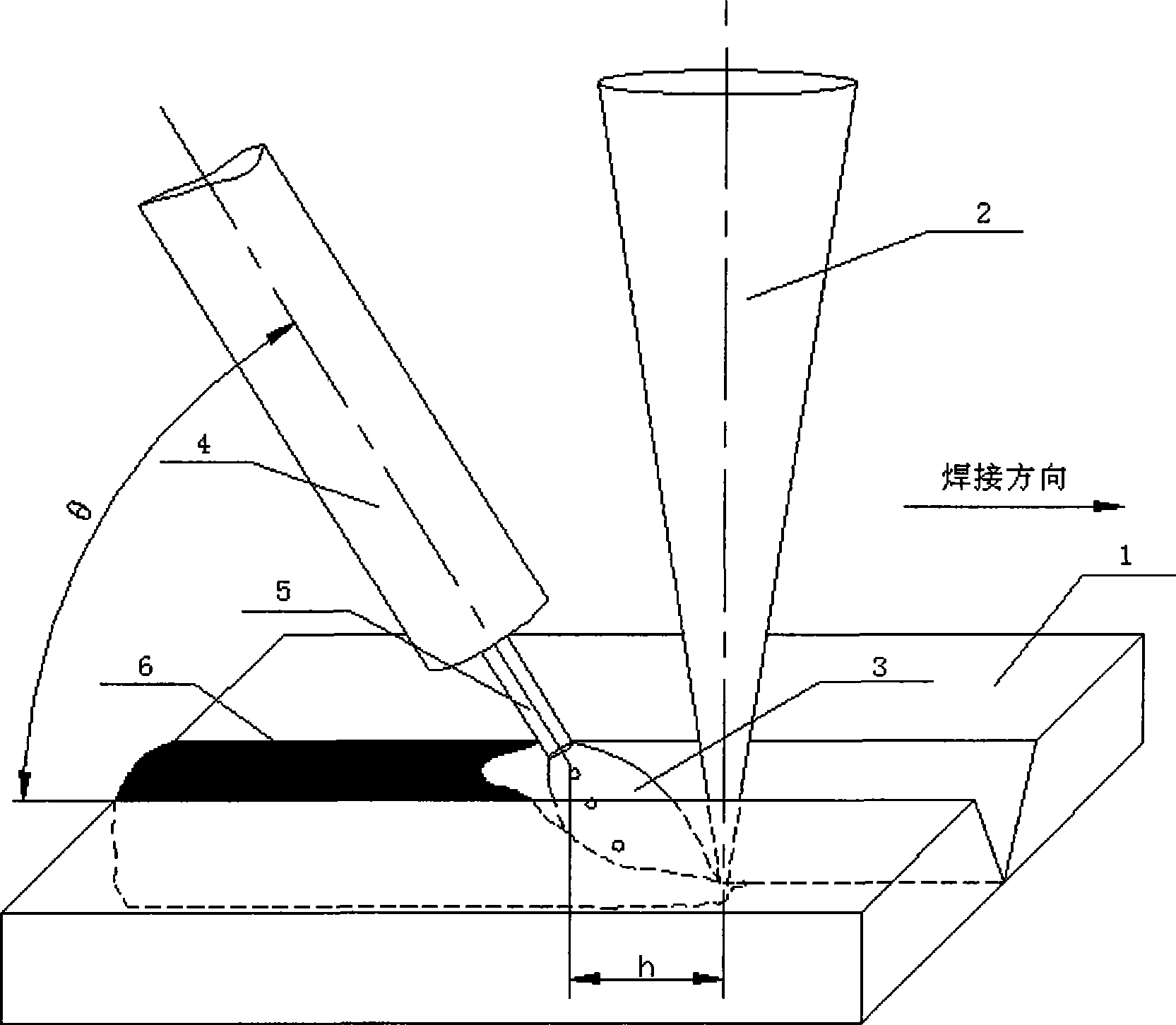

Method for welding with laser-cold metal transferred arc composite heat source

ActiveCN101811231ASolve the problem of poor spreadabilityImprove stabilityLaser beam welding apparatusArc stabilityAlloy

The invention provides a method for welding with a laser-cold metal transferred arc composite heat source, and belongs to the technical field of composite heat sources. The welding method solves the technical problems of low-quality welding lines and low arc stability of the pure Ar-protected cold metal transferred arc welding. The method comprises the following steps of: using pure Ar gas for protection during welding, and forming a novel composite heat source by using the cold metal transferred arc(5) and a laser beam (2) of which the power is more than or equal to 800, wherein the laser beam (2) is defocused, the diameter of a laser spot formed by the laser beam (2) on the surface of a workpiece (1) to be welded is 1 to 4mm, a spot of the cold metal transferred arc (5) can be arranged in front of or behind the spot of the laser beam (2), the central distance of the two spots is 0 to 8mm, and an included angle between a welding torch(3) of the cold metal transferred arc(5) and the horizontal plane is 45 and 75 degrees. The composite heat source is mainly used for welding plates and tubes made of stainless steel, high-strength steel and nickel-based alloy.

Owner:HARBIN WELDING INST LTD

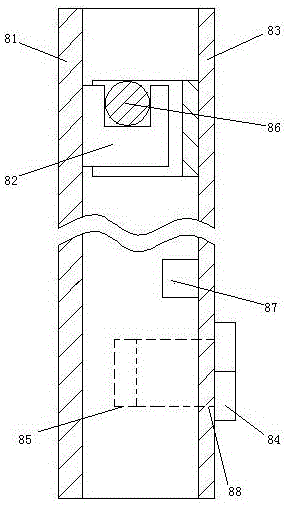

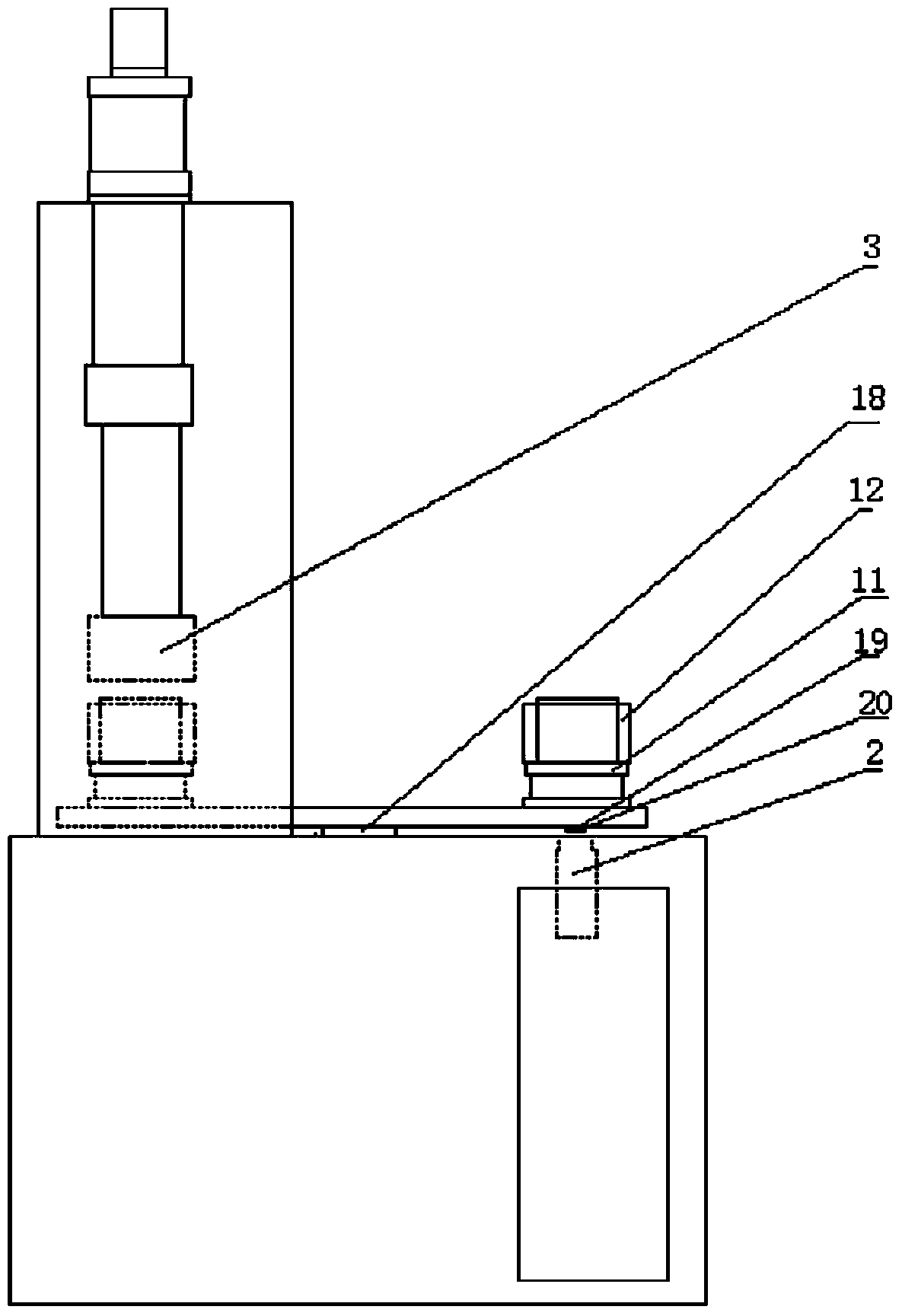

Co2 gas shielded welding welding operation simulator

InactiveCN102298858AMaster the welding feelImprove welding skillsCosmonautic condition simulationsSimulatorsElectricitySpray nozzle

The invention provides a welding operation simulator for CO2 gas shield arc welding. The simulator comprises a control cabinet, an operation console, and a simulation welding gun. The simulation welding gun includes a welding gun rod, a handle, an arc plastic housing, an electric touch pen, a spring, a mobile copper sheet, an inductive proximity switch, an inclination angle sensor, and a nozzle. One end of the electric touch pen is fixedly connected with the mobile copper sheet and the electric touch pen passes through a center of the nozzle that is connected with the mobile copper by the spring. The inductive proximity switch is installed at one end of the welding gun rod and the double-shaft inclination angle sensor is installed at the other end of the welding gun rod. One end of an insulating cylinder is sleeved around the periphery of the nozzle and the other end of the insulating cylinder is sleeved around the periphery of the welding gun rod, wherein the inductive proximity switch is installed at the welding gun rod. One end of the arc plastic housing is connected with the welding gun rod and the other end of the arc plastic housing is connected with the handle. The inductive proximity switch and the double-shaft inclination angle sensor are connected with a computer in the control cabinet; besides, the operation console comprises a touch screen that is used as a welding test panel, wherein the touch screen is connected with the computer in the control cabinet. According to the invention, a training cost is substantially reduced; meanwhile, the training can be carried out safely and efficiently.

Owner:XI AN JIAOTONG UNIV

Double sides double arc welding method

ActiveCN1603045AReduce stressGuarantee welding qualityArc welding apparatusWorkpiece edge portionsJoint stressWelding deformation

The invention relates to a double side dual-arc welding method. It includes the following steps that the work-piece connection part waited for welding is made both sides welding groove; the both sides welding groove and its both sides surface is ground and cleaned out before the welding; the two independent electric arcs elicited by two welding guns of the two welding machines are conducted both sides dual-arc symmetry bottoming welding respectively at the both sides welding groove; after the bottoming welding, the two independent electric arcs are conducted both sides dual-arc filling welding respectively at the both sides welding groove. The invention avoids the carbon arc-air gouging back gouging process, simplifies the welding process, so that the automation welding can be realized. It avails to practice gas shielded welding, ensure the welding quality, reduce the welding deformation, and decrease joint stress. The method can apply to important metal structural parts welding.

Owner:渤海造船厂集团有限公司

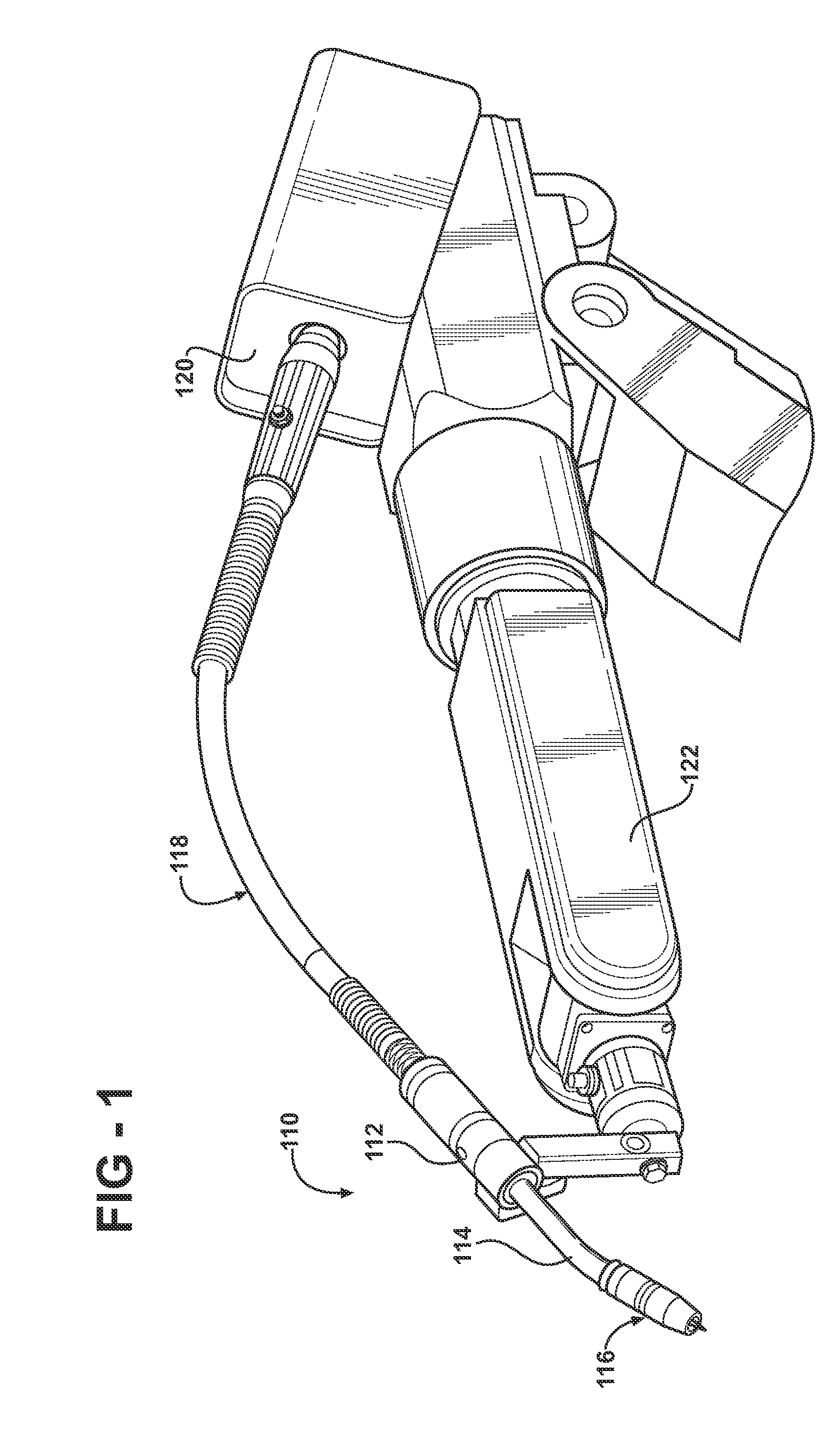

Welding gun

ActiveUS7244909B2Good speed controlPrevent unintentional adjustmentSoldering apparatusElectrode supporting devicesMotor driveTorch

Several aspects of an in-line welding gun are disclosed. In one aspect, the welding gun has a variable profile insulating boot disposed over the torch barrel of the gun. The variable profile insulating boot may include a molded material having varying thickness to provide the desired insulating properties. In another aspect of the welding gun, a speed control mechanism for the motor driving the wire feed assembly is positioned in a recess in the housing such that it reduces the risk of being unintentionally adjusted during operation of the welding gun. In another aspect of the welding gun, the wire feed mechanism features a feeder roller and an idler roller that may be separated without opening the housing of the welding gun. To separate the rollers, the user may depress a portion on the exterior of the housing to press on a pivotable lever on which the idler roller is disposed.

Owner:M K PRODS

Hand held powder-fed laser fusion welding torch

A novel and inventive hand held powder-fed laser fusion welding torch providing manual flexibility for laser welding with powder-fed material. The hand held laser includes a body, handle, and nozzle assembly. The nozzle may be shrouded by a cover that is slightly spaced apart from the nozzle. The gap between the two may provide space through which inert gas may flow. Laser light from a remote source shines through the nozzle's central aperture. The nozzle aperture may be circumscribed by powder channel outlets aligned upon a working focal point coincident with the laser beam to treat a workpiece. A proximity sensor may enable selective welding torch operation according to the presence of a workpiece.

Owner:HONEYWELL INTERNATIONAL INC

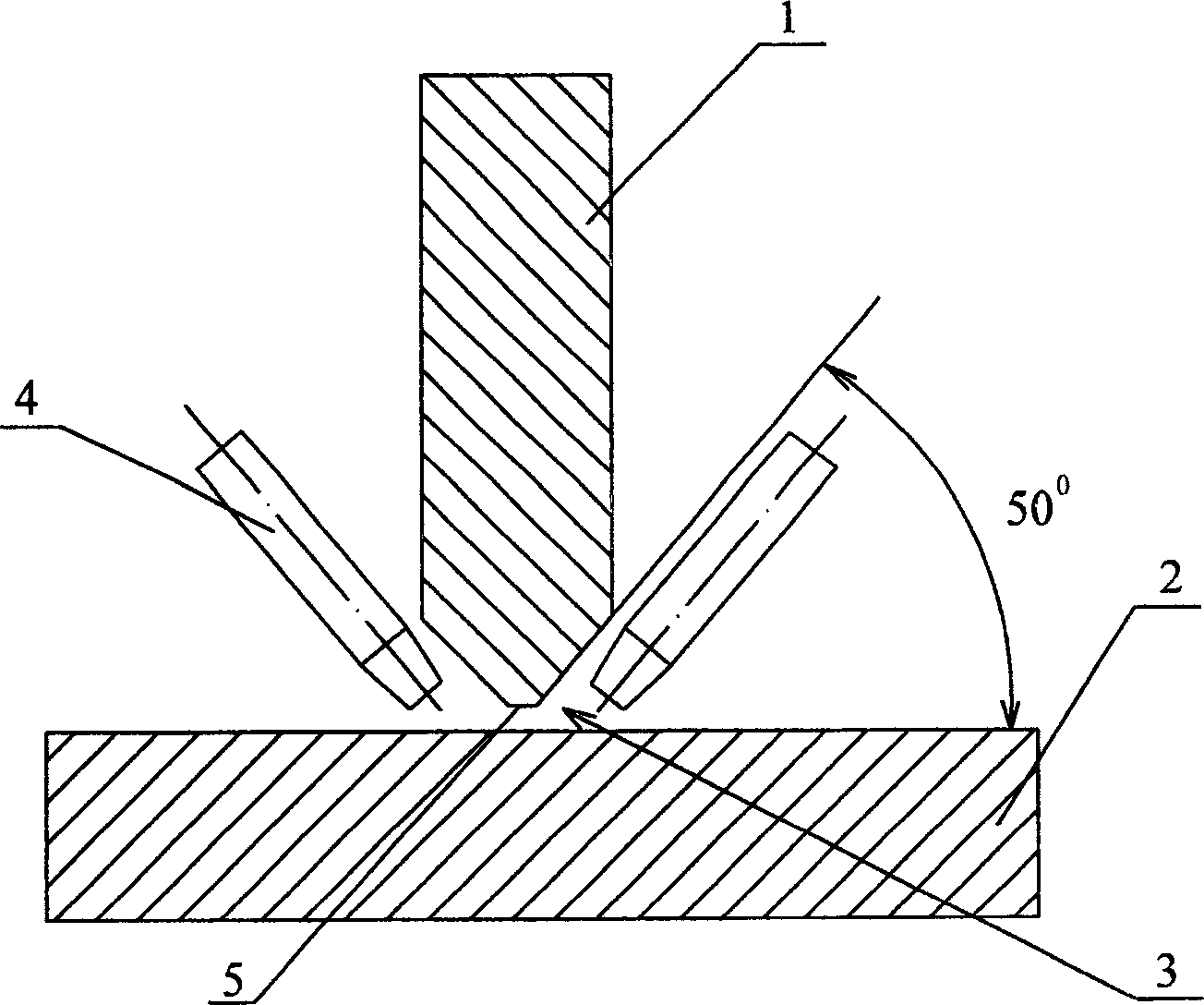

High-strength or ultra-high strong steel laser-electrical arc composite heat source welding method

InactiveCN101367157AImprove performanceLow preheat weldingLaser beam welding apparatusMetalSoldering process

The invention provides a novel high-strength or ultrahigh-strength steel laser-arc composite heat source welding method, which belongs to the technical field of the welding of high-strength or ultrahigh-strength steel. The method aims to solve the technical problem that the higher temperature needs to be adopted for preheating in order to prevent cold cracks during the welding of the high-strength or ultrahigh-strength steel. The welding method mainly comprises the following steps: the laser power is higher than 800 watts, a composite form that laser (2) is ahead and electric arc (3) follows is adopted along the welding direction, the filament spacing h is controlled to between 3 and 7 millimeters, and an included angle theta between an electric arc welding gun (4) and the horizontal plane is between 45 and 60 DEG. When the method is used to weld, a composite heat source welding pool is elongated and the oscillation of the pool is sharpened, so that the solidification rate of pool metal is reduced and grains are refined, thereby reducing the cold crack sensitivity during the welding process of the high-strength or ultrahigh-strength steel. The welding method can reduce the preheating temperature of the welding of the high-strength or ultrahigh-strength steel, and even can realize high-strength non-preheating welding.

Owner:HARBIN WELDING INST LTD

Welding device for side sealing plate barb of switch cabinet

InactiveCN105057865AImprove connection strengthImprove quality consistencyResistance electrode holdersWelding/cutting auxillary devicesRubber ringElectricity

The invention relates to the technical field of manufacturing of low-voltage drawer-type switch cabinets and discloses a welding device for a side sealing plate barb of a switch cabinet. The welding device comprises an electric welding machine, a spot welding gun, supporting pillars, a lower base, an electric conduction block, a suspending plate and an upper seat. The electric welding machine is provided with two electrodes, and the spot welding gun is connected with one of the electrodes. Clamps are arranged on the lower seat, and the suspending plate is connected with the upper seat through an air cylinder. The electric conduction block is connected to the suspending plate. The electric conduction block is electrically connected with the other electrode. The spot welding gun is connected to the suspending plate and is provided with a barb fixing structure. The supporting pillars comprise damper springs, upper sections and lower sections, wherein the upper sections and the lower sections are sleeved together. The upper ends of the upper sections are provided with connecting rings, inner rings are arranged in the connecting rings in a penetrating mode, the inner rings and the connecting rings are connected together through rubber rings, and connecting pins connected to the lower seat are arranged in the inner rings in a penetrating mode. The welding device has the advantages that a welded part does not need to be fixed manually, and the vibration isolation effect is good; the problems that much effort is cost in welding and the welding quality is poor due to welding by manually fixing the welded part are solved.

Owner:张进

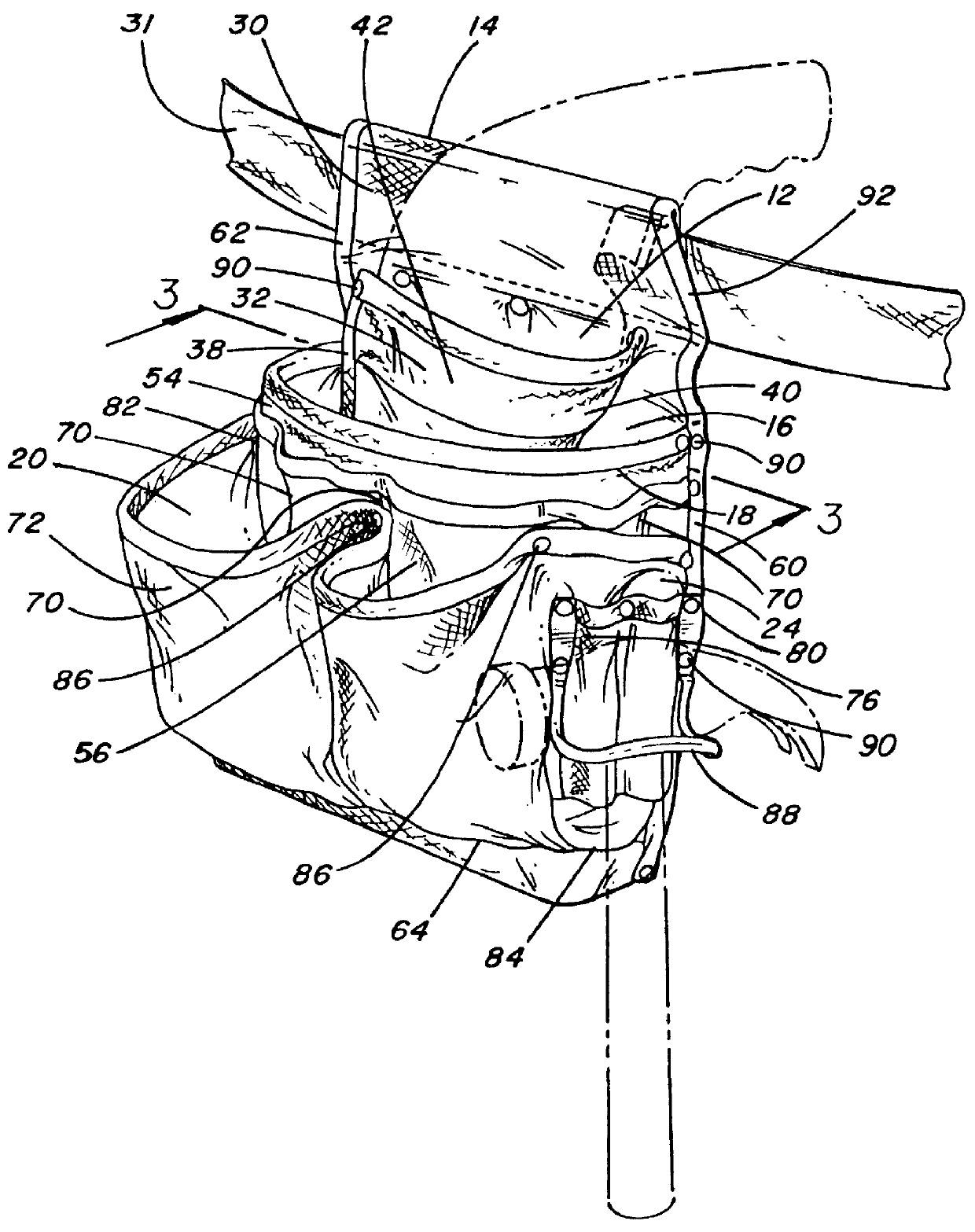

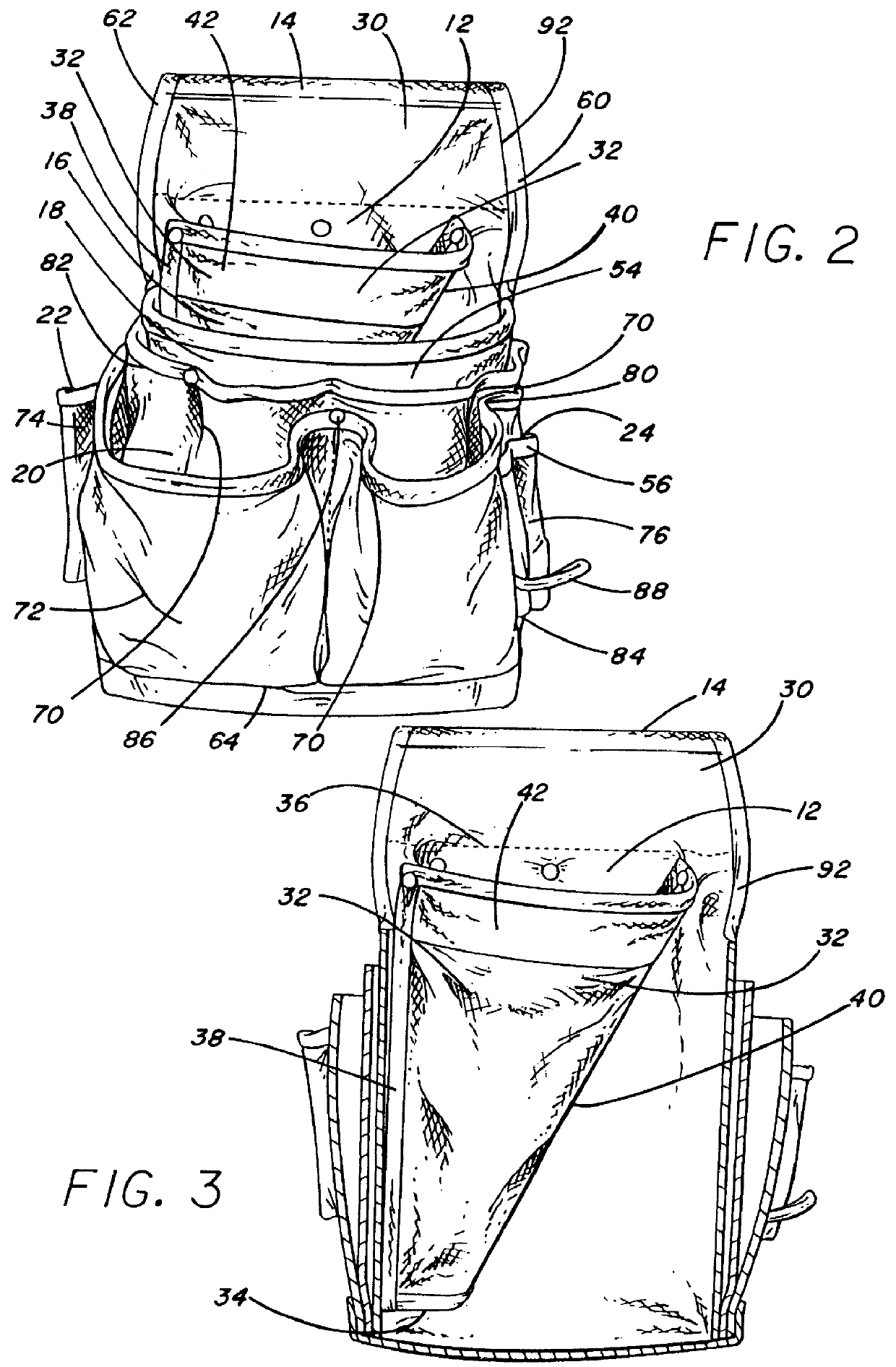

Specially configured tool holder

InactiveUS6119909AEasy and safe transportationEasy accessTravelling sacksTravelling carriersEngineeringPower tool

The tool holder of the present invention has one or more pockets which are specially configured to hold a variety of portable tools and other objects. Specifically, the present invention comprises a tool holder or bag that has at least one pocket configured so that it can carry a relatively heavy power tool such as a power drill, or a lighter tool having an angular portion such as a soldering gun, caulking gun and the like. In the preferred embodiment, the specially configured pocket is placed in the area closest to the user to provide additional structural support for the tool to be placed therein. Pockets can also be specially configured to contain other tools.

Owner:CUSTOM LEATHERCRAFT MFG

Contact tip assembly for a welding torch

InactiveUS20070210049A1Easy transitionEasy to assembleElectrode supporting devicesWelding torchSoldering gun

Owner:ILLINOIS TOOL WORKS INC

Wire feed speed adjustable welding torch

InactiveUS6841752B2Adjustable speedWelding/cutting media/materialsWelding electrode featuresWire rodEngineering

Owner:WARD JOSEPH J

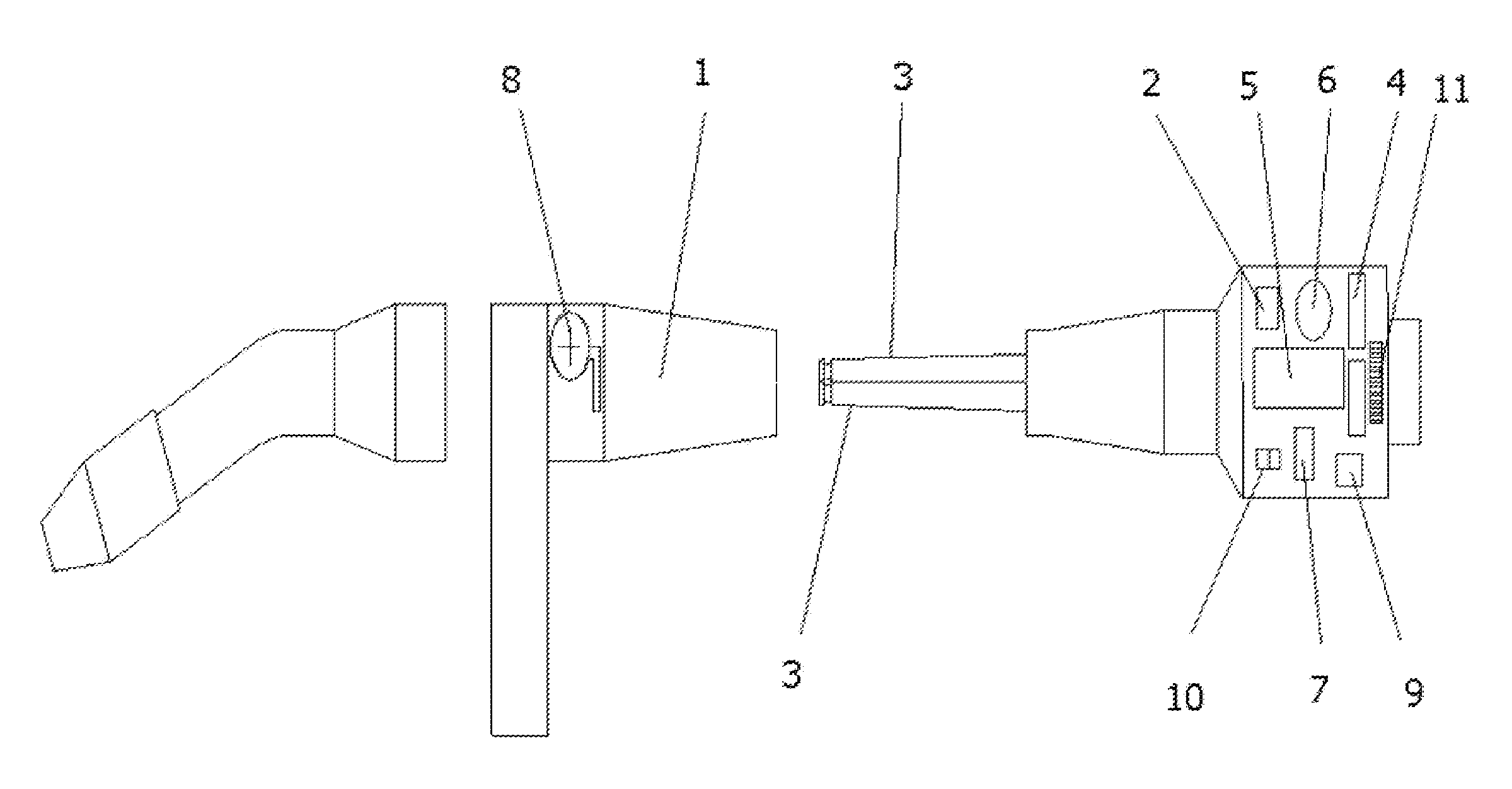

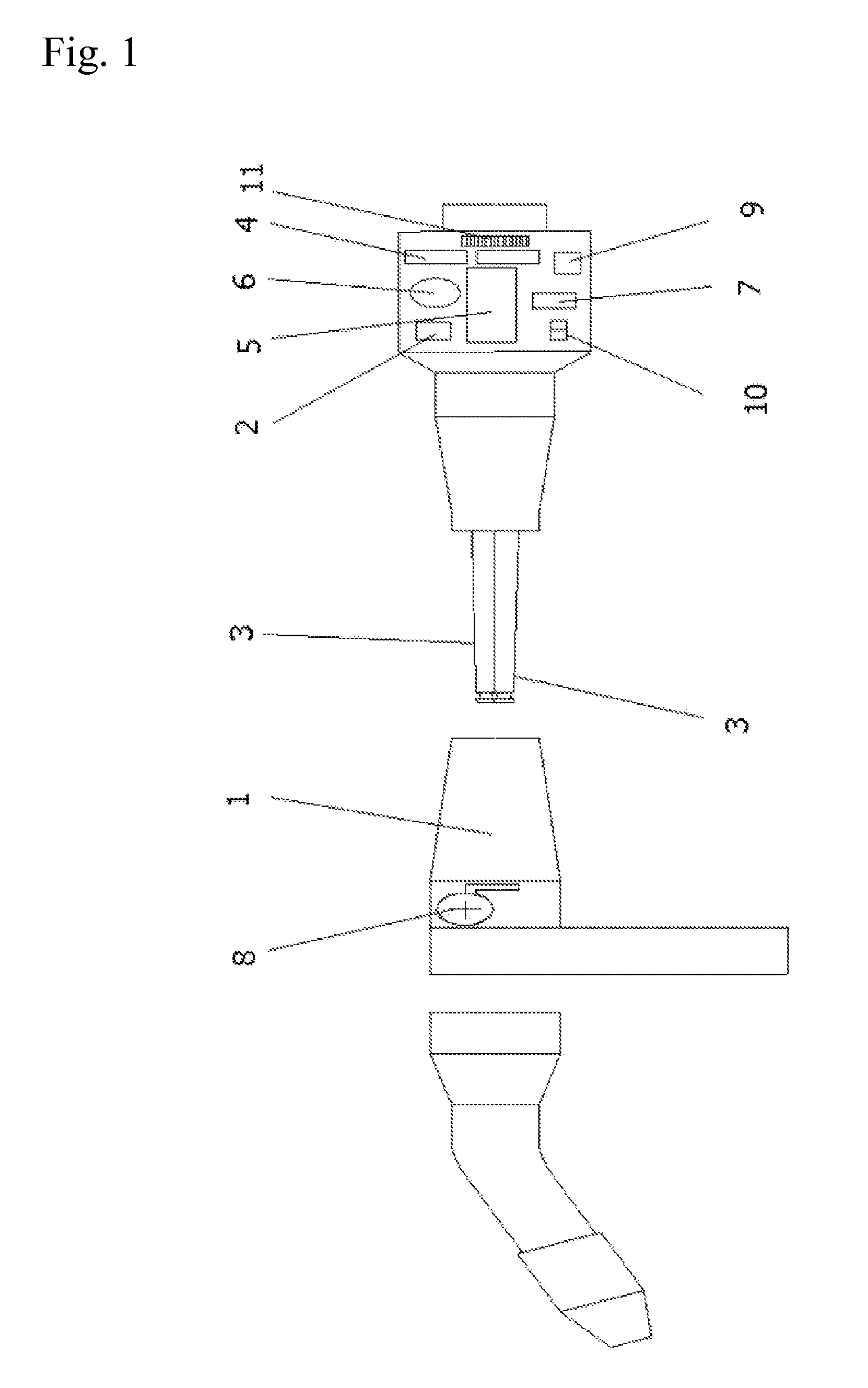

Dual-conductor welding gun

InactiveUS20090236325A1Reduce demandReduce the total massElectric discharge heatingWelding/cutting auxillary devicesMicrocontrollerElectrical conductor

Welding gun with double conductor composed by a torch body (1) and electronic scales (2) to measure the intensity of the sensors (6) located in each conductor (3) and with mechanisms to trigger an alarm when there is an imbalance of the intensities circulating through both conductors. To this end, a microcontroller (5) connected to intensity (6) and temperature (8) sensors in the conductors is used, with indicators of failure or anomaly. The microcontroller (5) program calculates the difference between the magnitudes of both intensity signals and determines which of the two is higher, and, based on predefined parameters, triggers the corresponding alarm signal.

Owner:MORENO GOZALBO JOSE CARLOS

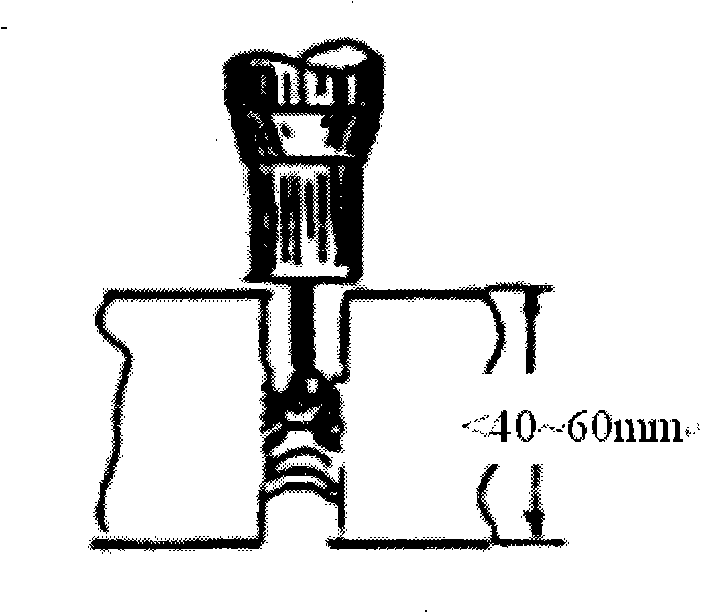

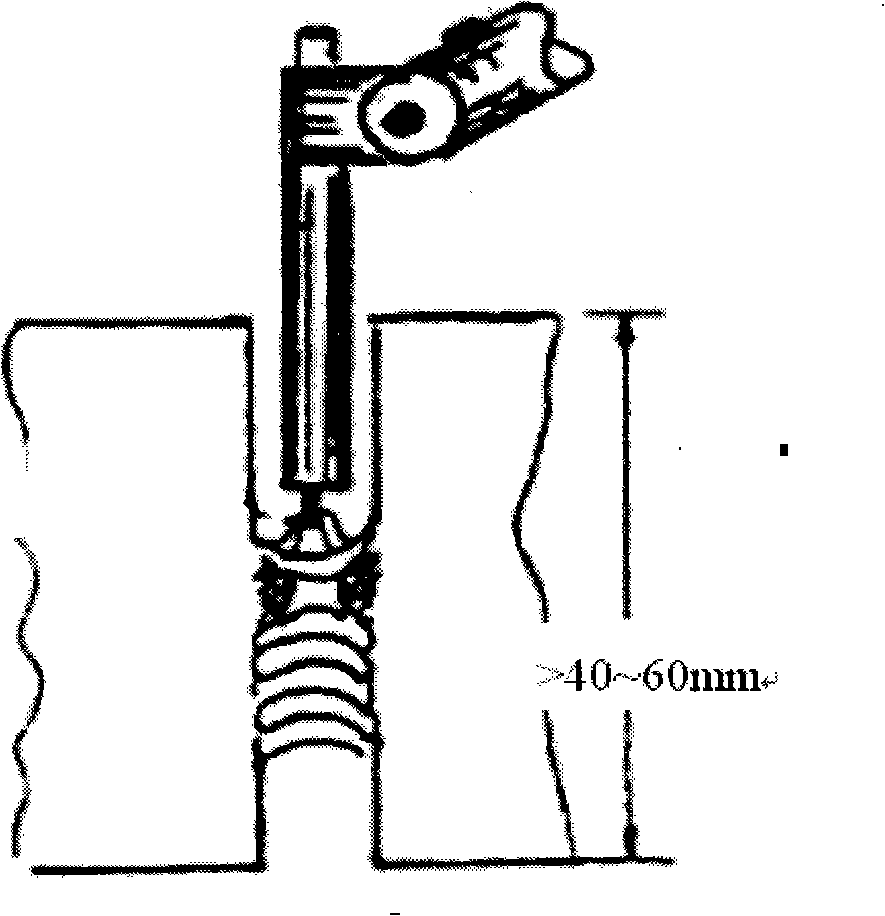

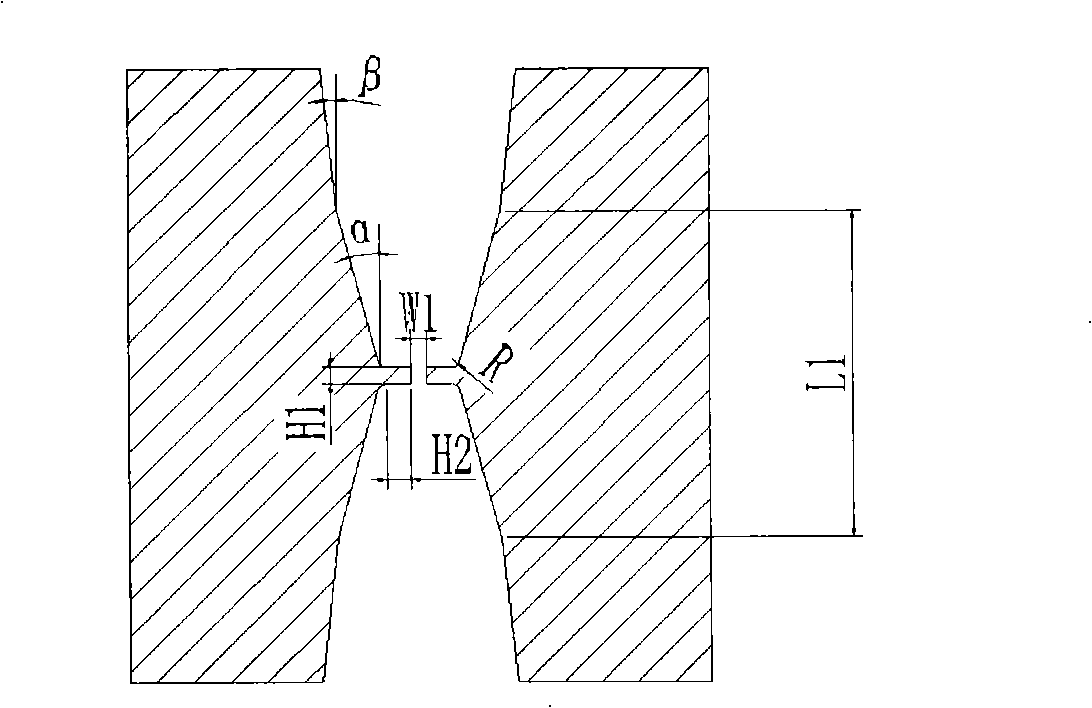

TIG automatic welding technique for titanium alloy thick plate narrow interstice

InactiveCN101293303AEnables narrow gap weldingWeld firmlyElectrode supporting devicesWorkpiece edge portionsEngineeringTitanium alloy

The invention discloses a narrow clearance TIC automatic welding technique for a thick plate of titanium alloy. The welding technique comprises six items of a welding torch form, a welding line spreading form, a bevel for welding form, selecting the parameters of the welding process, selecting the protection atmosphere of the welding process and eliminating a welding stress adopted by welding process. The welding technique of the invention realizes the narrow clearance welding for the large thick plate of the titanium alloy, has stable welding process, can obtain the welding lines which have no defects, qualified properties and 10mm to 16mm of widths of the welding lines on a cover surface layer, thus solving the key technical problems of the narrow clearance TIC automatic welding for the large thick plate of the titanium alloy, realizing the narrow clearance TIC automatic welding for the thick plate of the titanium alloy and having the advantages of high manufacture efficiency, low manufacture cost, small residual stress and residual deformation of joints, relatively thin and small welding line tissues and good mechanical property of the joints.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

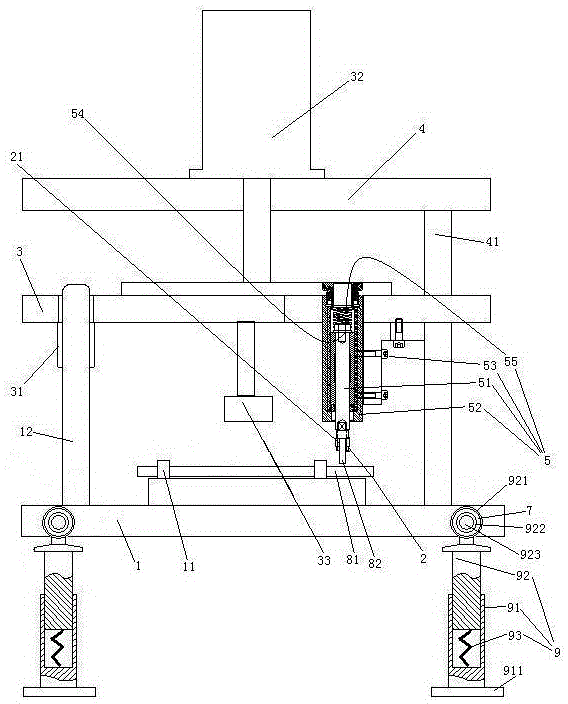

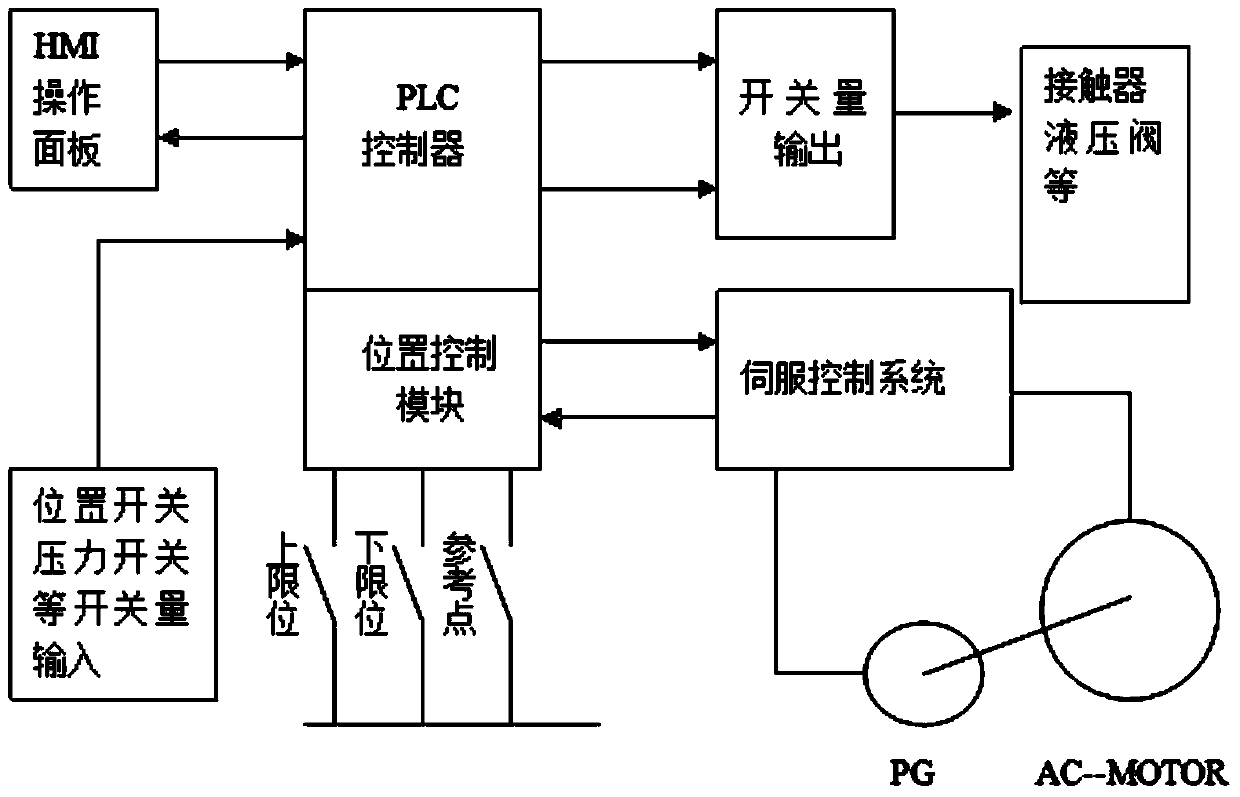

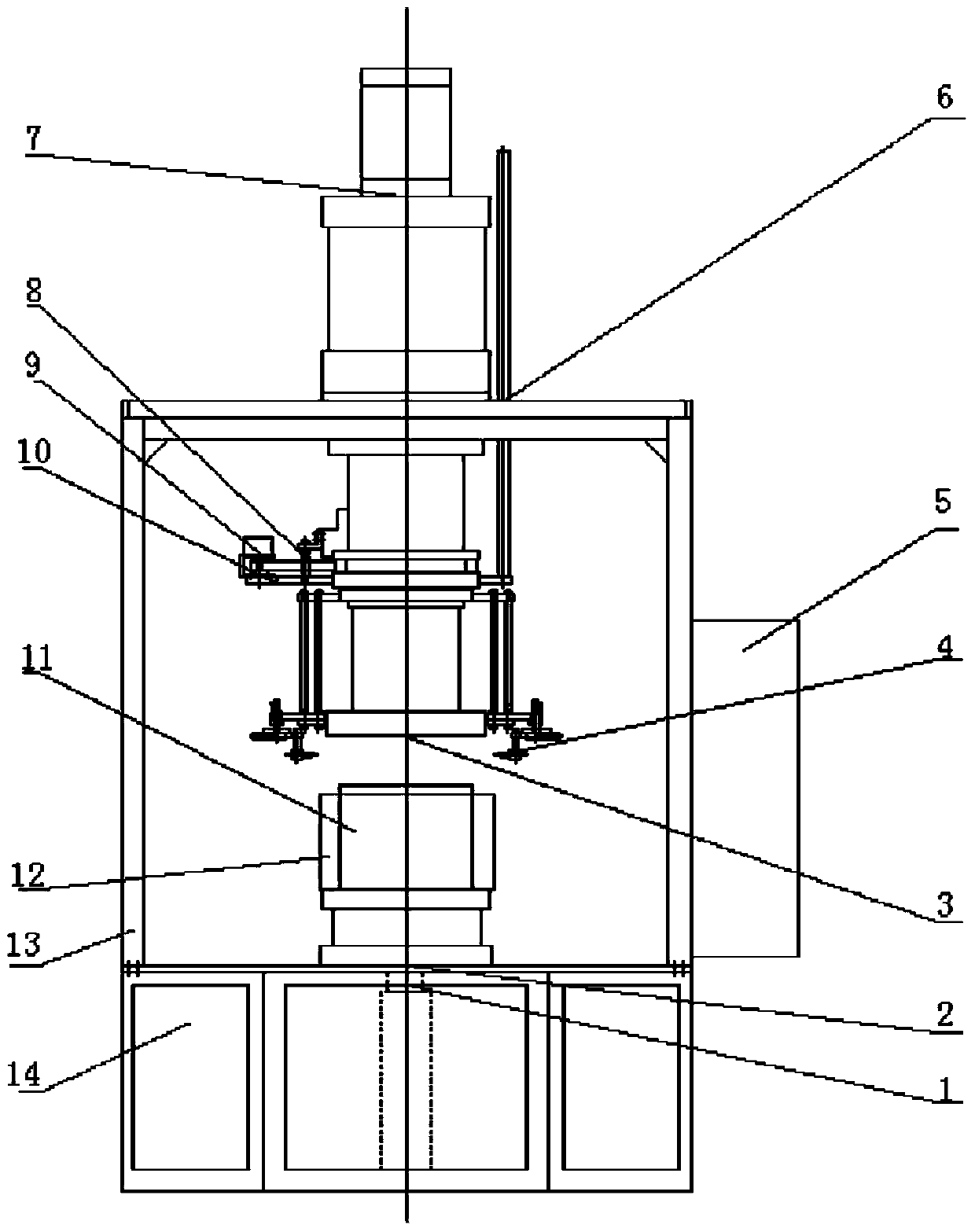

Automatic welding device and welding method for stators

InactiveCN103433637AHigh yieldWith station rotation functionWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderRotation function

The invention discloses an automatic welding device and welding method for stators. The automatic welding device comprises a shell body, a base, a rotary table, a lifting mechanism, a compressing device, welding guns, an electrical cabinet, a guide rod, a hydraulic cylinder, a lead screw, a servo motor, dabber fixtures and a servo control system, wherein the rotary table is installed on the base through a rotary shaft, the lifting mechanism is installed in a rectangular tank of the base, the two dabber fixtures which are the same in structure are installed on the horizontal plane of the rotary table, and the welding guns are evenly distributed on the outer circumference of the compressing device. The rotary table is provided with the two dabber fixtures and has the work station rotating function, and two stators can be installed at the same time and then are welded and machined through rotation of the rotary table; meanwhile, the welding guns are installed at the same time, welding of multiple passes of welding lines can be conducted, and accordingly working efficiency is improved. A servo motor of the automatic welding device is controlled by the servo control system, and machining speed and position are accurate.

Owner:DALIAN JIAOTONG UNIVERSITY

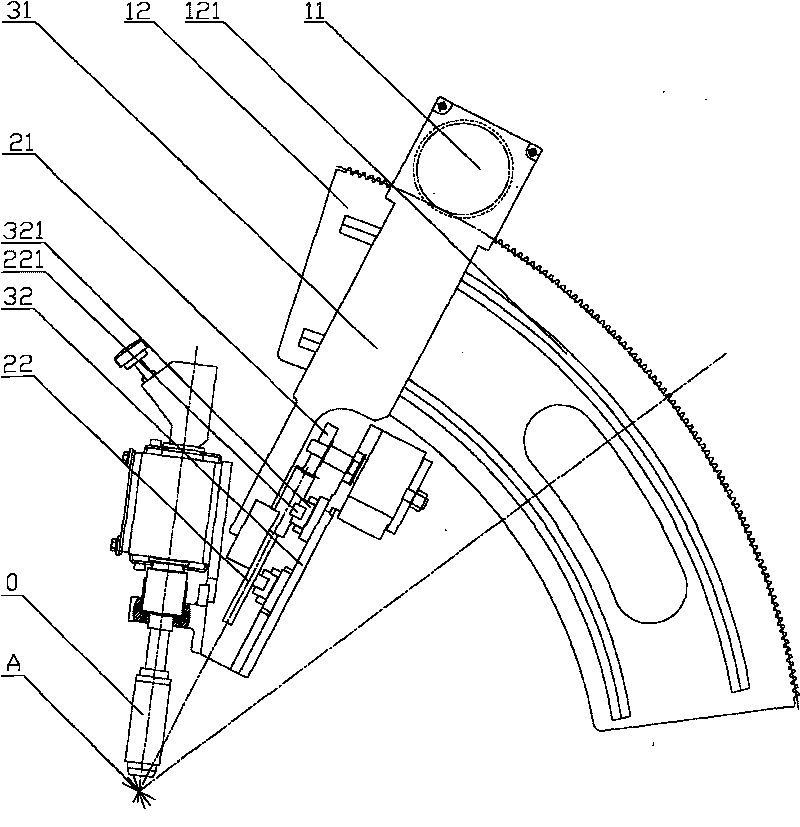

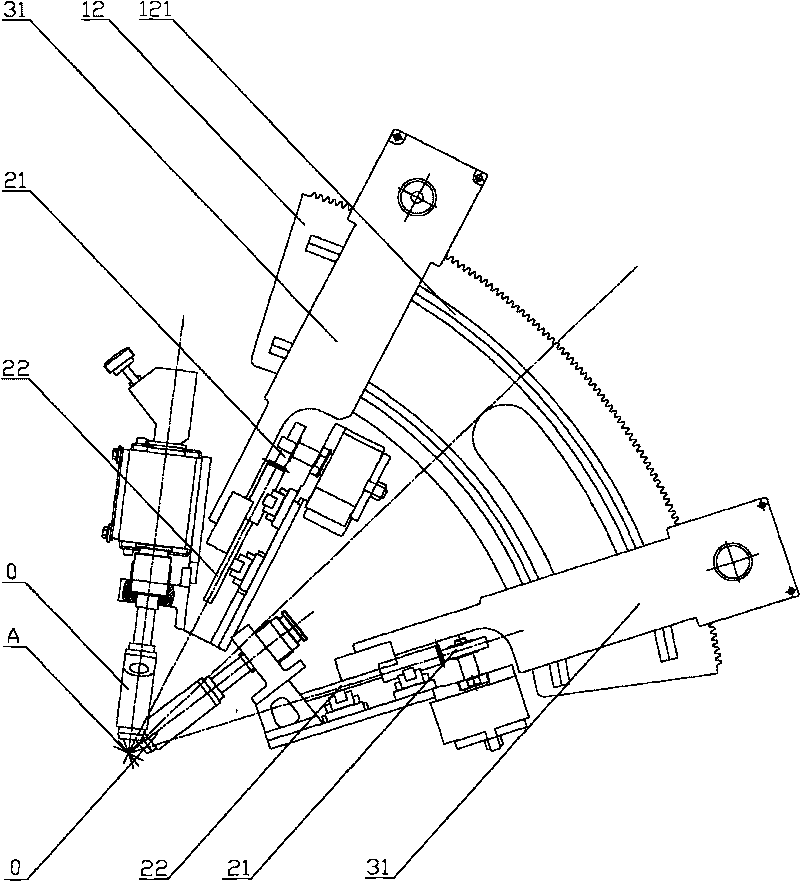

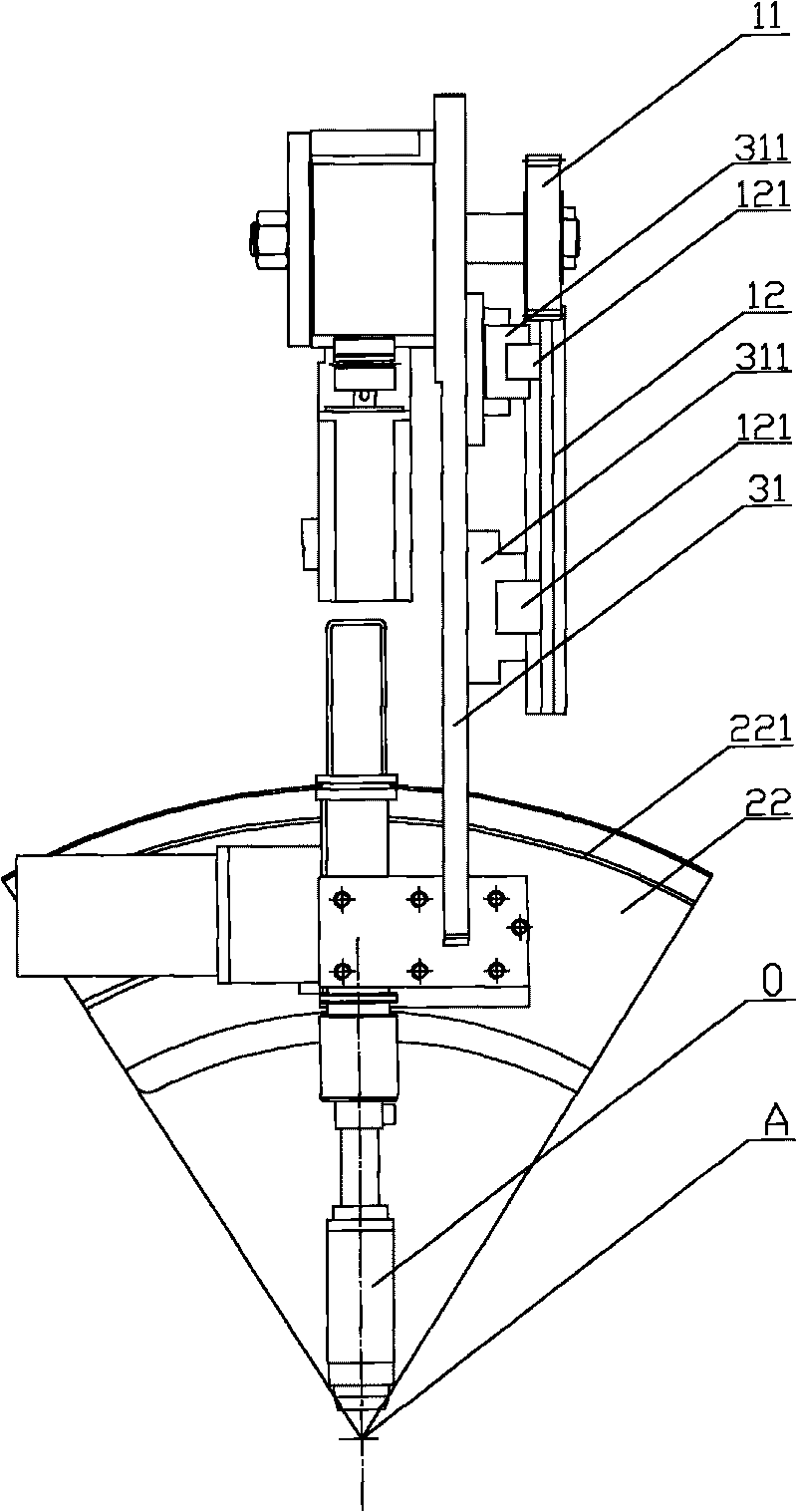

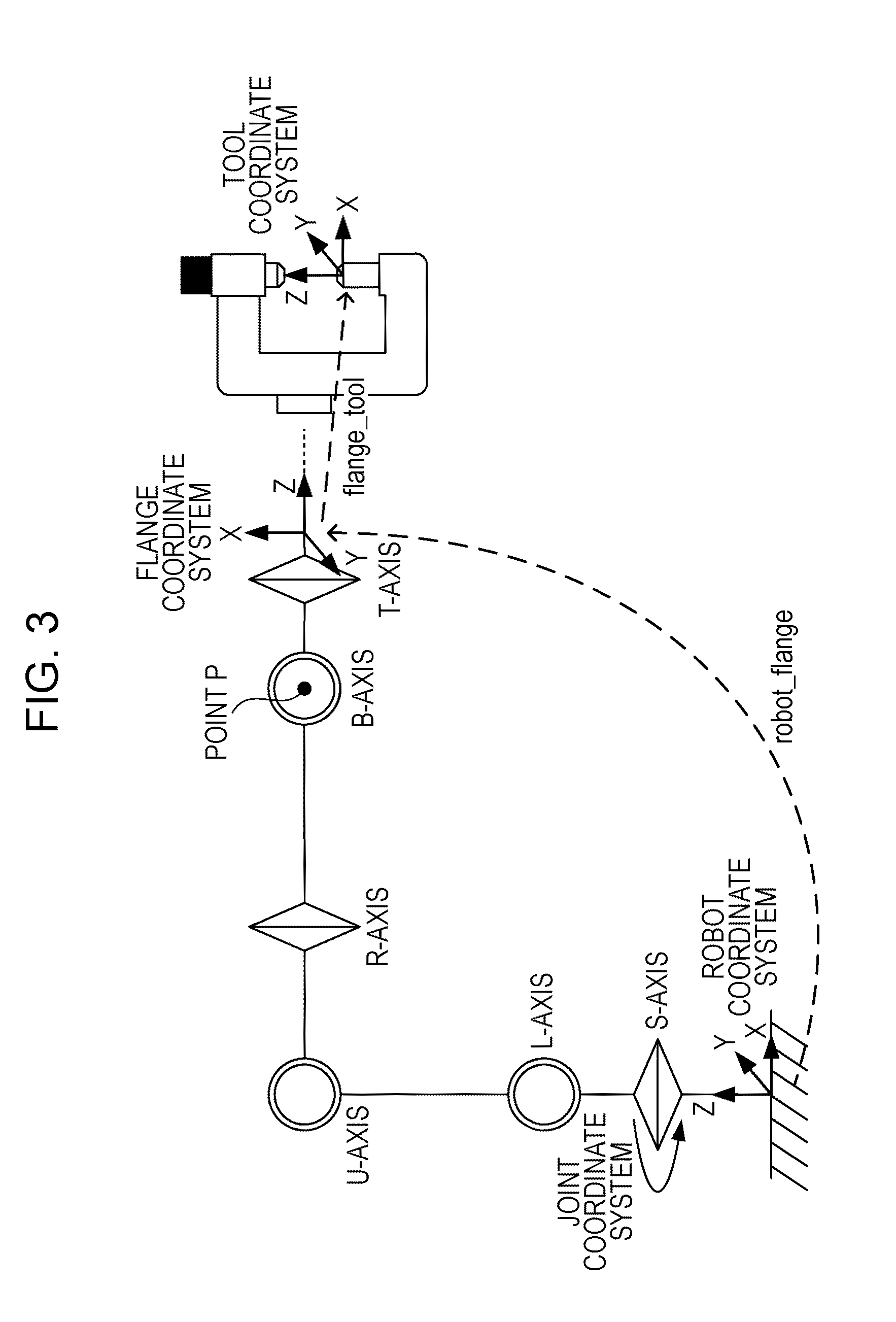

Welding robot and device for adjusting posture of welding gun of welding robot

InactiveCN101712157AChange postureAvoid influenceWelding/cutting auxillary devicesAuxillary welding devicesFistWeld seam

The invention discloses a device for adjusting the posture of a welding gun, which is used for a welding robot. The device comprises a first guide device arranged on the welding robot and a first driving device arranged on the upper part of the welding gun (0), wherein the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0). In the working process of the welding gun, the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and because the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0), when the upper part of the welding gun (0) sways along the fist guide device, the position of the endpoint at the tail end of the welding gun (0) is not changed, and the posture of the welding gun (0) in the welding process is changed, so the welding stability and the welding seam quality can be stably ensured for a long time.

Owner:BEIHANG UNIV +1

Automatic wielding mechanical device for forming machine of numerical control reinforcing cage

ActiveCN101700555AReduce labor intensityLow costMeshed-ring wire networkWelding/cutting auxillary devicesNumerical controlHooping

The invention discloses an automatic wielding mechanical device for a forming machine of a numerical control reinforcing cage. The structure thereof comprises a turnplate rack, a first guide post, a second guide post, a movable bracket, a hoist, a case shell, a hook, a rolling mechanism, a welding-gun supporting mechanism and a screw pitch regulating mechanism; the left side and right side of the movable bracket are mounted on the first guide post and the second guide post in a sliding way; the top of the movable bracket is provided with the hoist driving the movable bracket to move up and down; the case shell is arranged at one side of the movable bracket and provided with the hook, the rolling mechanism, the welding-gun supporting mechanism and the screw pitch regulating mechanism; and the screw pitch regulating mechanism is used for regulating the position and angle of the case shell. The invention has the beneficial effects that: the automatic wielding mechanical device can automatically and coordinately complete welding operation of the reinforcing cage under the control of a control system, the regulation of different positions and angles of the case shell can be realized; with the rotation of the reinforcing cage, the hook can automatically hook the longitudinal steel bars, the welding-gun supporting mechanism and the reinforcing cage rotate synchronously and are always aligned with the intersection point of the hooping and the main reinforcement of the reinforcing cage, so as to perform automatic wielding in replacement of man power; the labor intensity is lowered, man power is saved, production efficiency is improved, and welding quality is bettered.

Owner:TJK MACHINERY TIANJIN

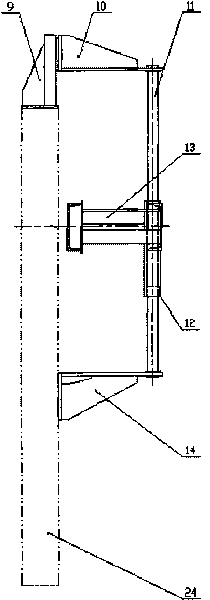

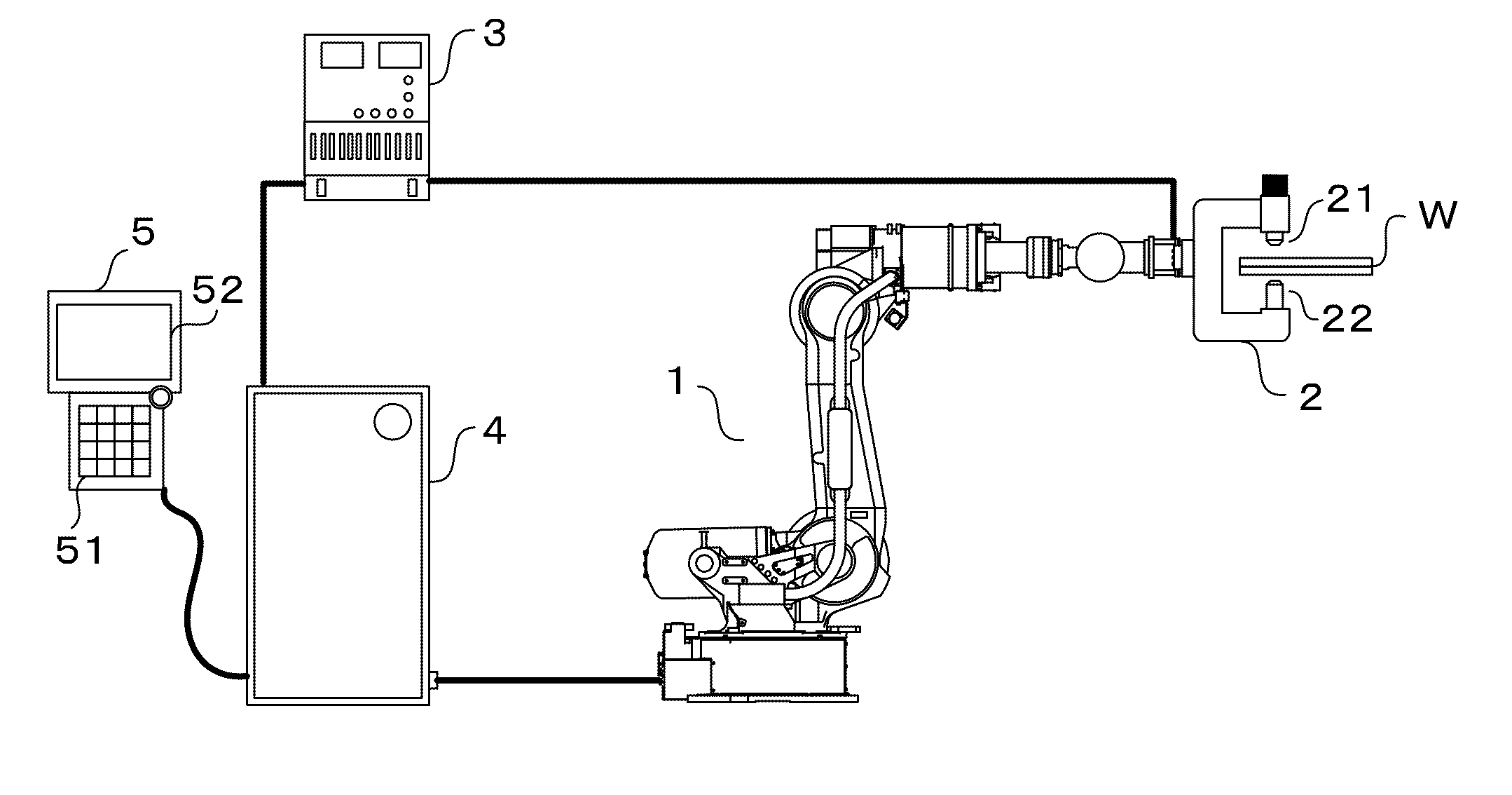

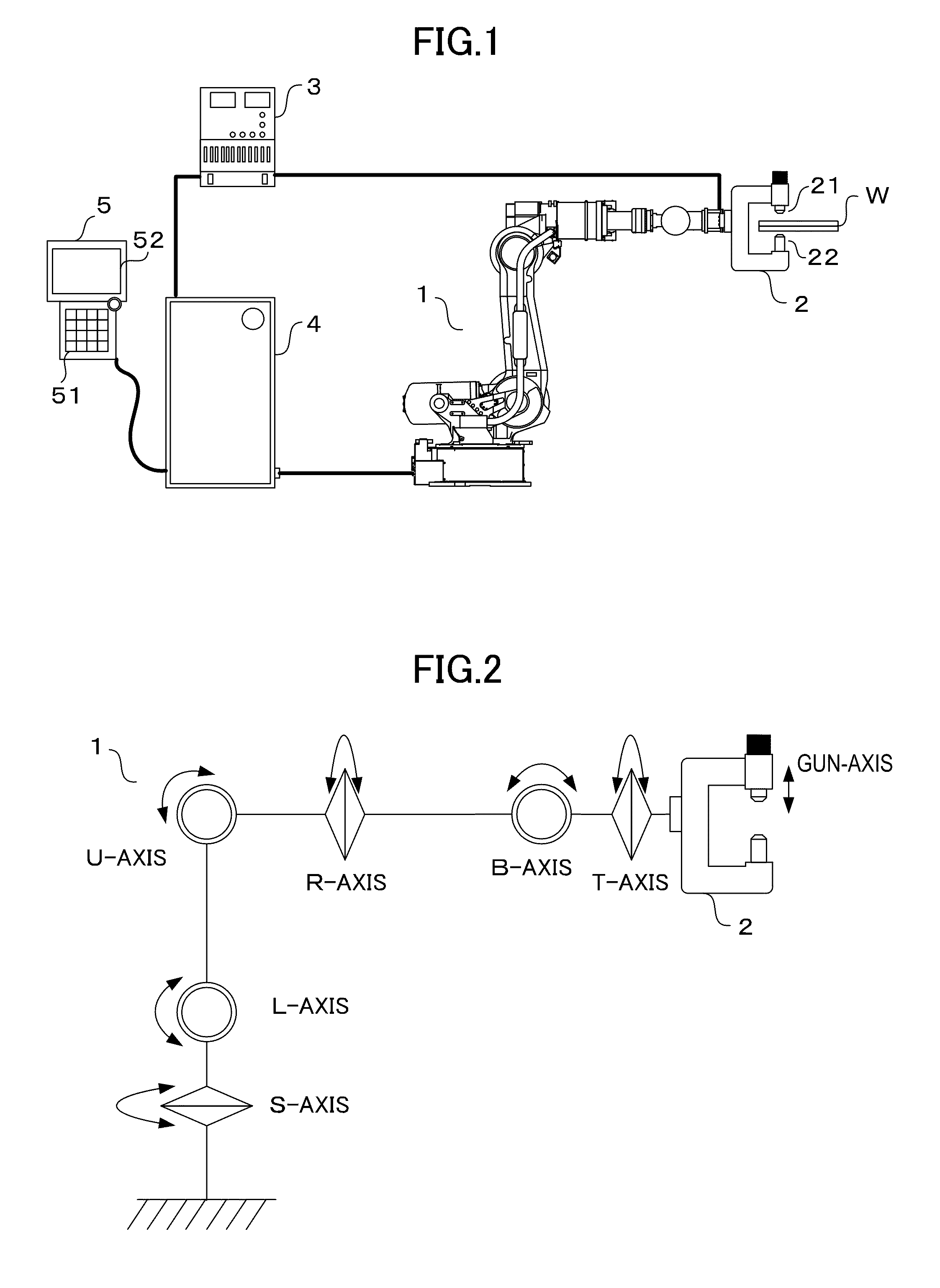

Robot system

InactiveUS20120000891A1Easy to correctBending amountWelding/cutting auxillary devicesAuxillary welding devicesRobotic systemsSpot welding

For teaching a welding-point position for a robot, processing of a robot system includes first processing for moving a spot welding gun to a position at which movable and fixed electrodes pinch the welding point; second processing for extending the movable electrode toward a member to be welded by driving of a motor, detecting contact between the movable electrode and the member based on a torque command to the motor, and stopping the movable electrode after the contact is detected; and third processing for operating the robot toward the movable electrode to move the fixed electrode toward the member while maintaining the contact between the movable electrode and the member by the driving of the motor, detecting contact between the fixed electrode and the member based on a disturbance torque acting on a joint of the robot, and stopping the operation of the robot after the contact is detected.

Owner:YASKAWA DENKI KK

Welding gun having contact tip and method of operating same

InactiveUS7105775B2Support devices with shieldingNon-shielding electrode holdersAbutmentBiomedical engineering

A welding gun adapted to secure a contact tip within the welding gun without threading the contact tip and without the use of tools. The contact tip may be adapted to abut a surface of a first member disposed within the welding gun. The surface may be a surface of a gas diffuser. The surface may be adapted to abut the contact tip. The contact tip also may be adapted for abutment with a second member to urge the contact tip toward the first member. The second member may be a portion of a nozzle adapted to abut the contact tip to urge the contact tip toward the surface of the first member. A method of assembling a welding gun also is provided. The method may comprise disposing a contact tip between a first and a second member and capturing the contact tip between the first and second members.

Owner:ILLINOIS TOOL WORKS INC

Automatic steel cylinder girth welding device

InactiveCN110666385AAutomatic height adjustmentImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesButt jointSteel cylinder

The invention relates to the technical field of steel cylinder girth welding, and specifically relates to an automatic steel cylinder girth welding device. The automatic steel cylinder girth welding device comprises an operation table, wherein an opposite driving assembly is arranged at the bottom of the operation table; the opposite driving assembly comprises two movable bottom plates; a movablenotch used for allowing each movable bottom plate to move is formed in the operation table; a rotary table is arranged at the top of each movable bottom plate; a left side rotating assembly and a right side auxiliary rotating assembly are arranged on the two rotary tables correspondingly; clamping jaw assemblies are arranged at the adjacent ends of the left side positioning rotating assembly and the right side rotating assembly correspondingly; lifting adjusting assemblies are arranged above the left side rotating assembly and the right side auxiliary rotating assembly correspondingly; a vertical support is arranged between the two clamping jaw assemblies; and a welding gun capable of lifting is arranged on the vertical support. According to the device, the height of each steel cylinder needing to be welded can be adjusted correspondingly, butt joint is automatically carried out, the height of the welding gun can be automatically adjusted, and the welding precision is improved.

Owner:温金建

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com