Patents

Literature

59 results about "Guiding center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In physics, the motion of an electrically charged particle such as an electron or ion in a plasma in a magnetic field can be treated as the superposition of a relatively fast circular motion around a point called the guiding center and a relatively slow drift of this point. The drift speeds may differ for various species depending on their charge states, masses, or temperatures, possibly resulting in electric currents or chemical separation.

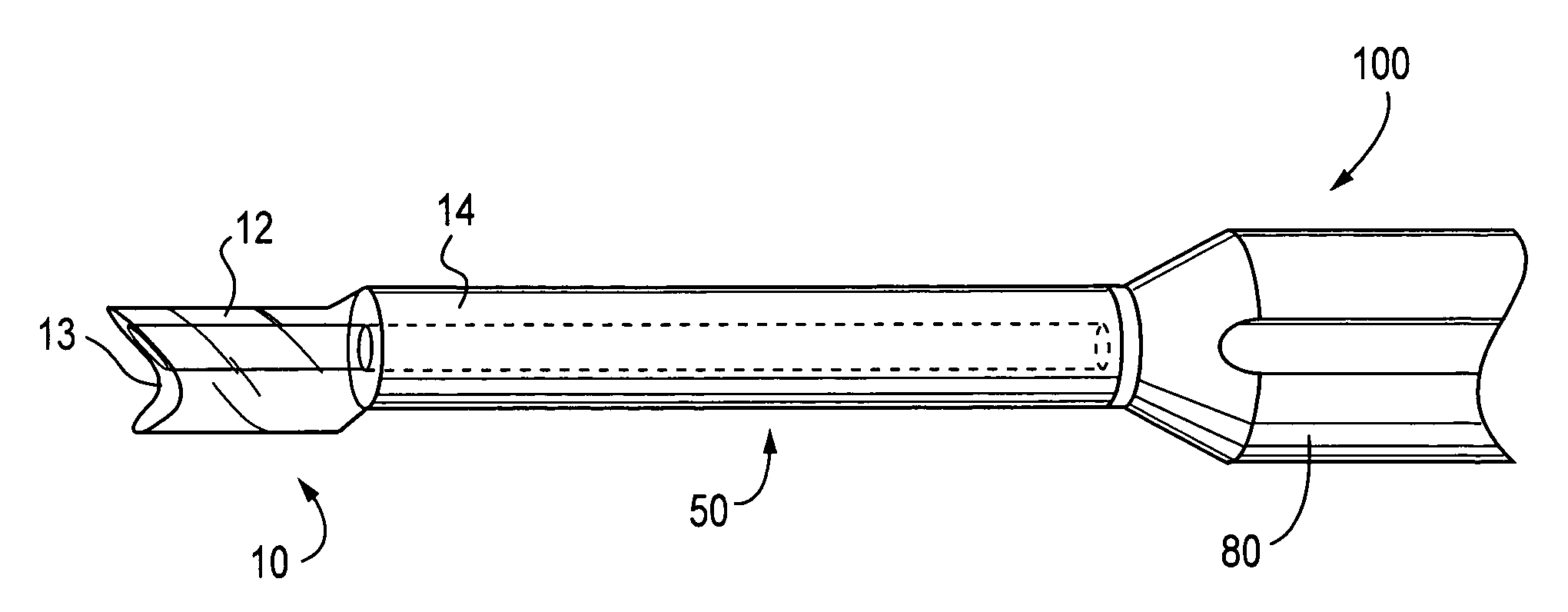

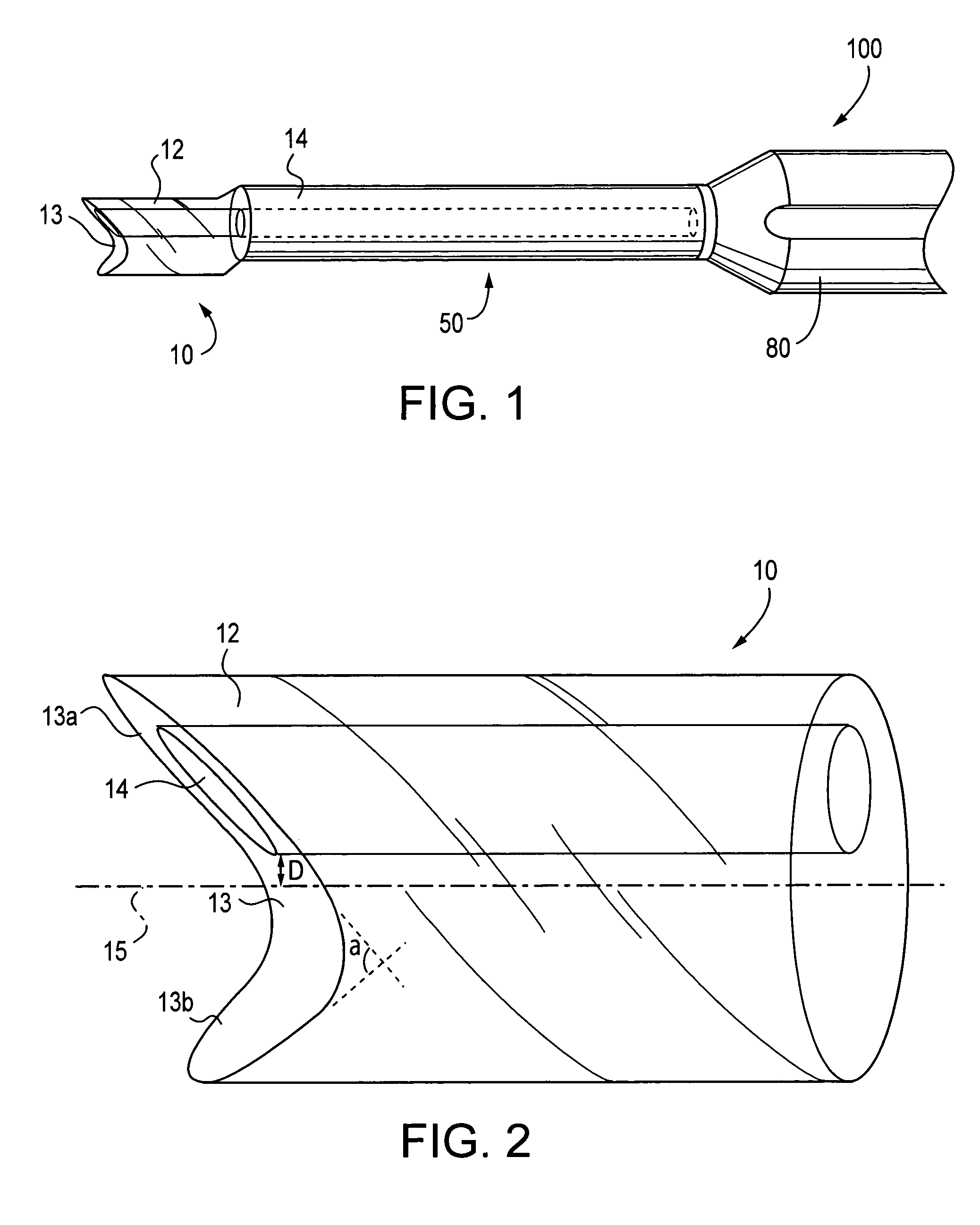

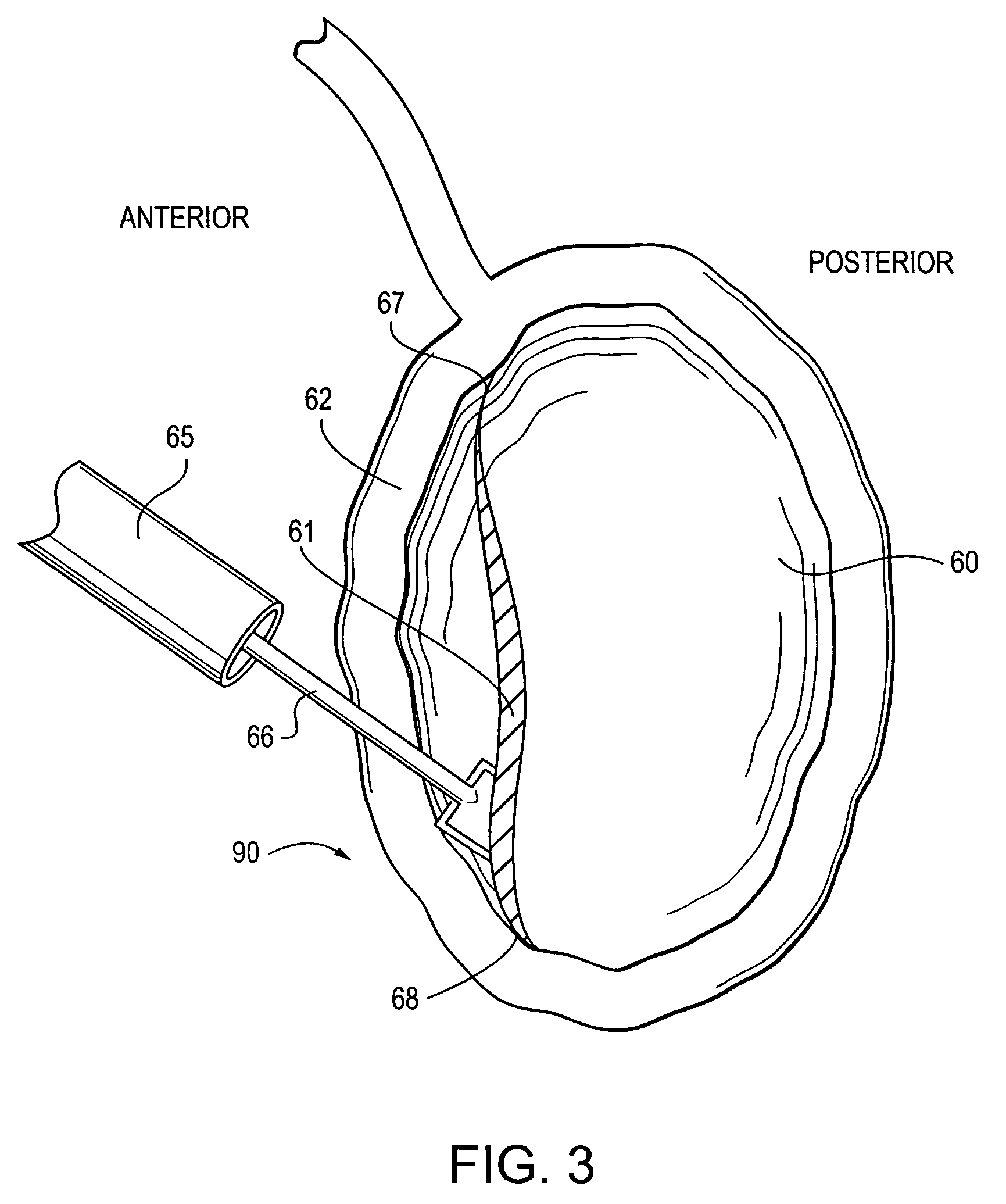

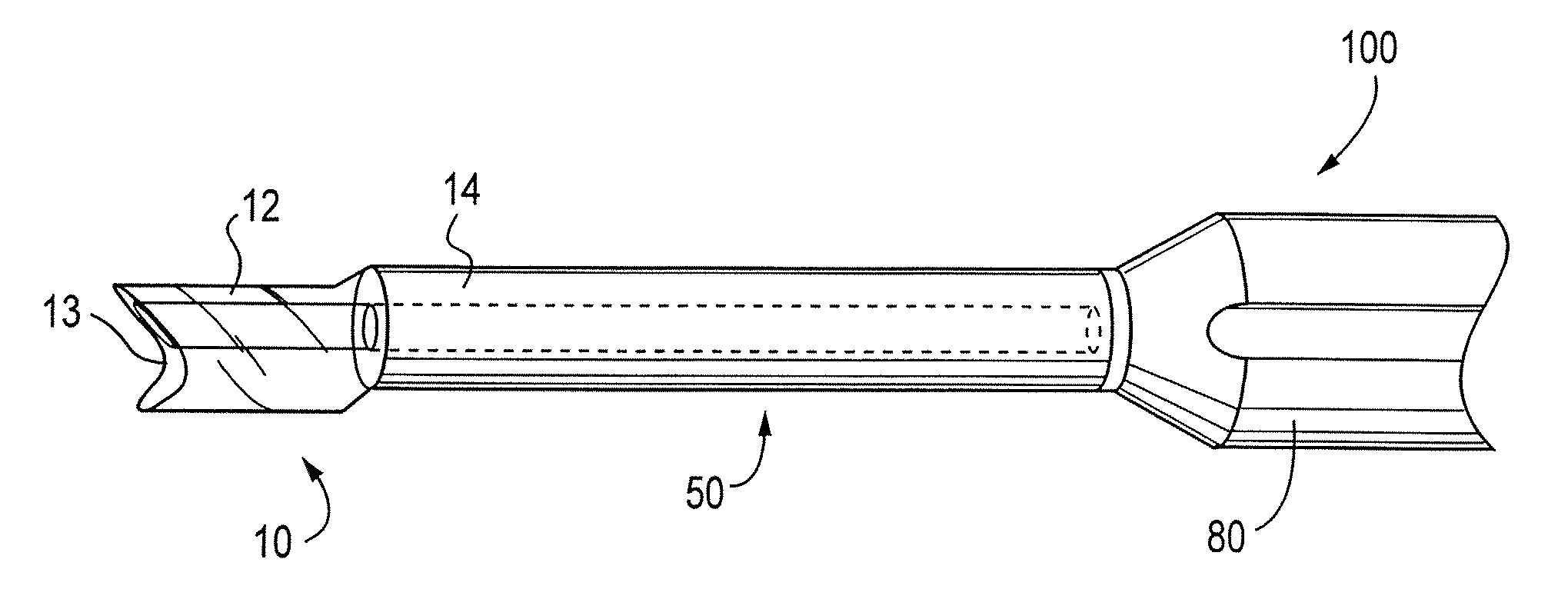

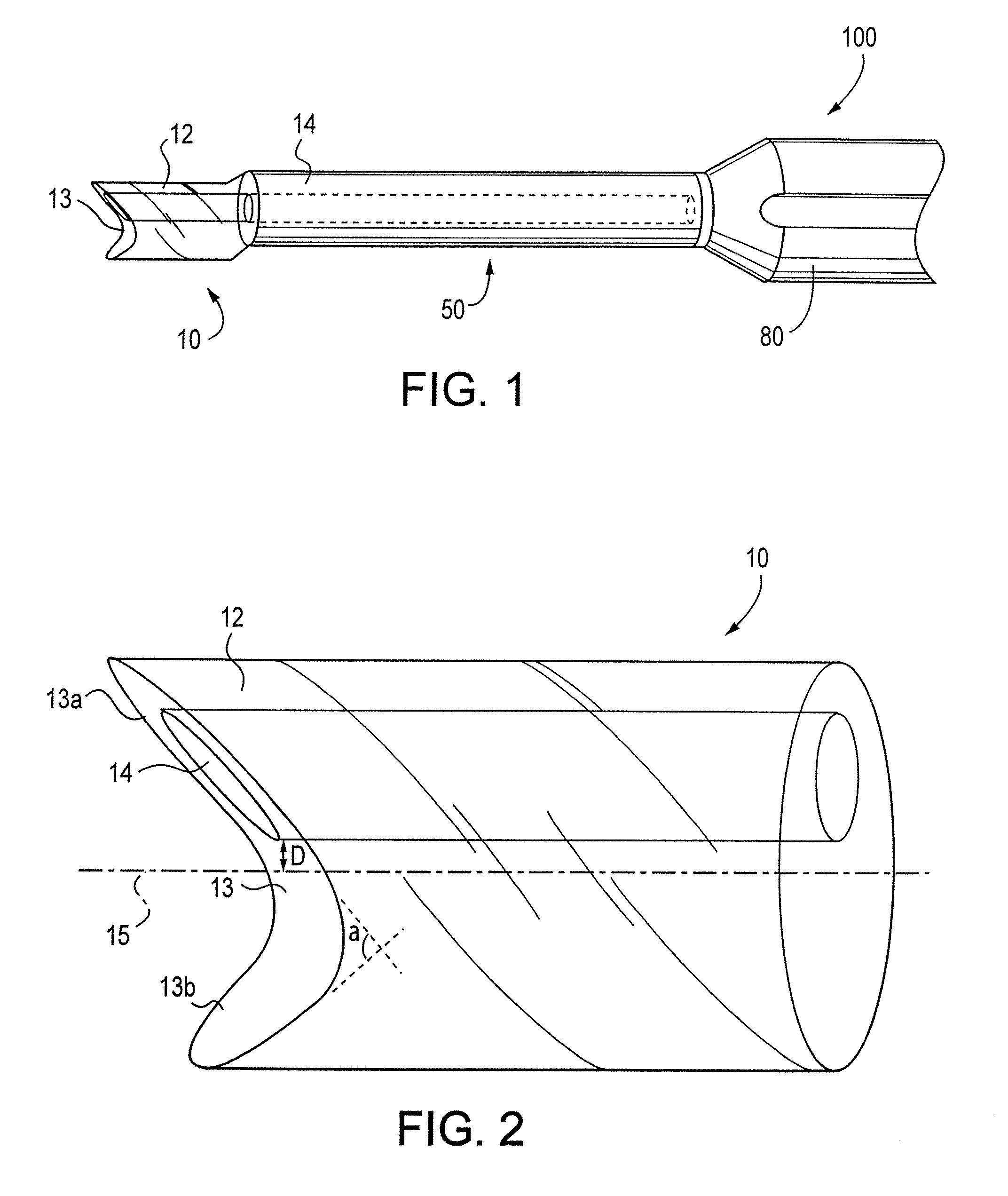

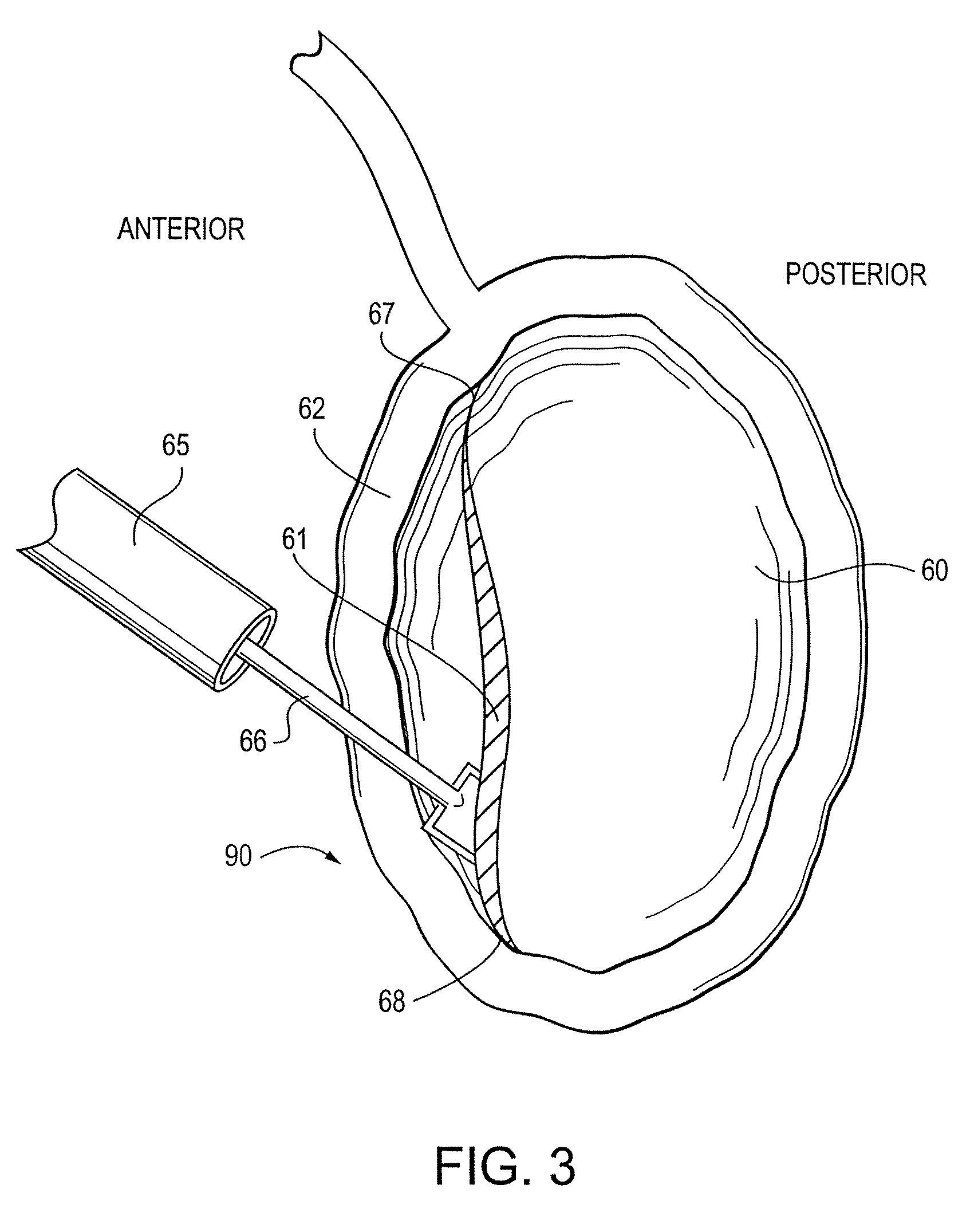

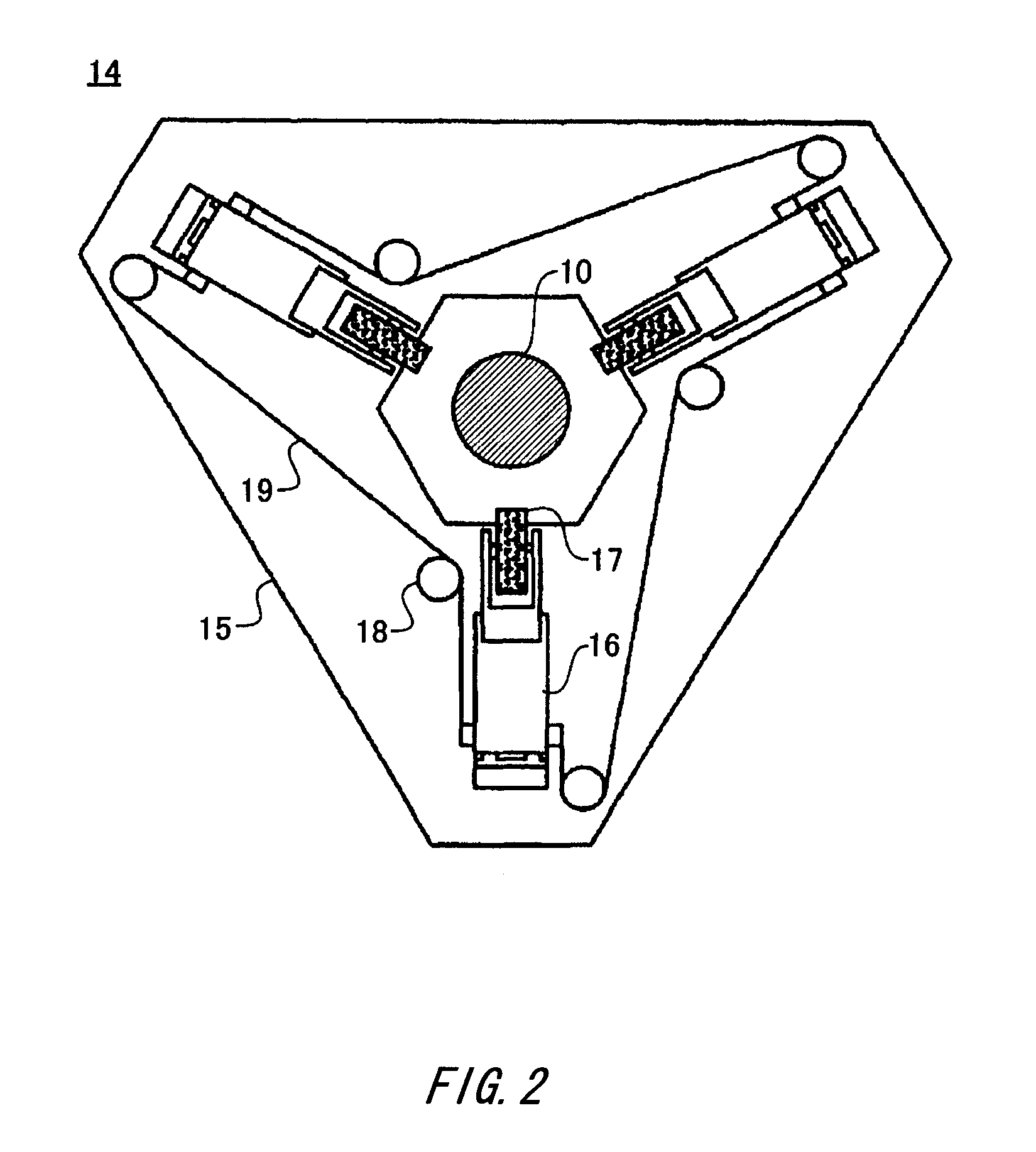

Method of using offset drill guide in arthroscopic surgery

ActiveUS7204839B2Avoid damageMinimal amountProsthesisOsteosynthesis devicesArthroscopic procedureSuture anchors

A cannulated offset drill guide and surgical methods for repairing Bankart lesions. The cannulated offset drill guide comprising a shaft which is offset from the guide center line by about 1 to 3 mm, more preferably of about 1.5 mm. The cannulated offset drill guide is provided at its proximal end with a concave clear tip which allows a surgeon to visualize the drill and the insertion of an anchoring device, for example a suture anchor. The concave clear tip has beveled, smooth edges to prevent damage to adjacent bone and tissue, and to avoid damage to the rubber dam of the cannula through which the offset drill guide is inserted. The configuration of the concave clear tip is designed to engage and match the generally convex-curve articulating face of the glenoid, and to precisely aligning the offset drill guide with the glenoid face. The clear tip may also be employed in a standard drill guide having a shaft which is not offset from the center line of the guide.

Owner:ARTHREX

Offset drill guide and arthroscopic method

ActiveUS20070288031A1Avoid damageMinimal amountProsthesisOsteosynthesis devicesSuture anchorsGuiding center

Owner:ARTHREX

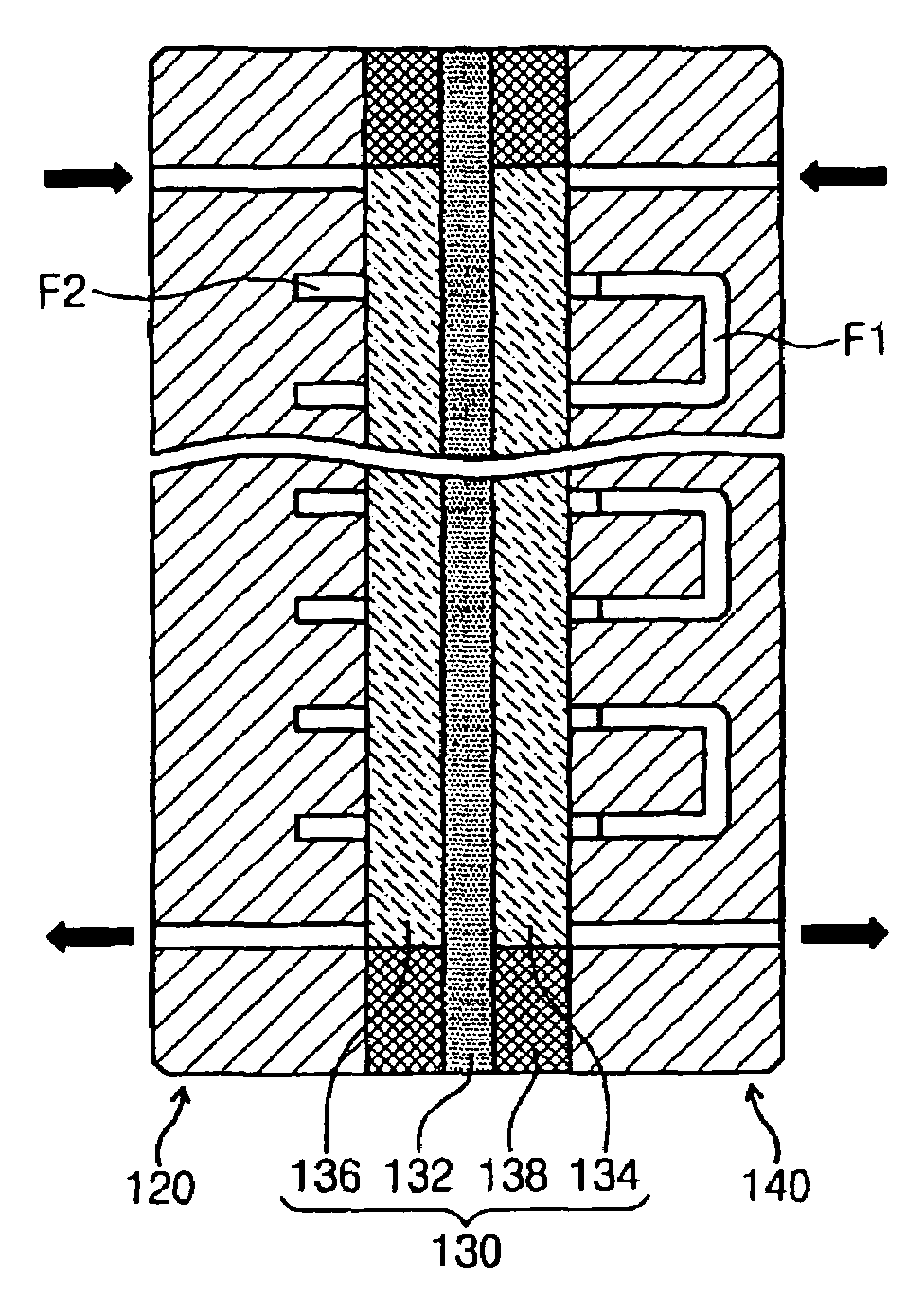

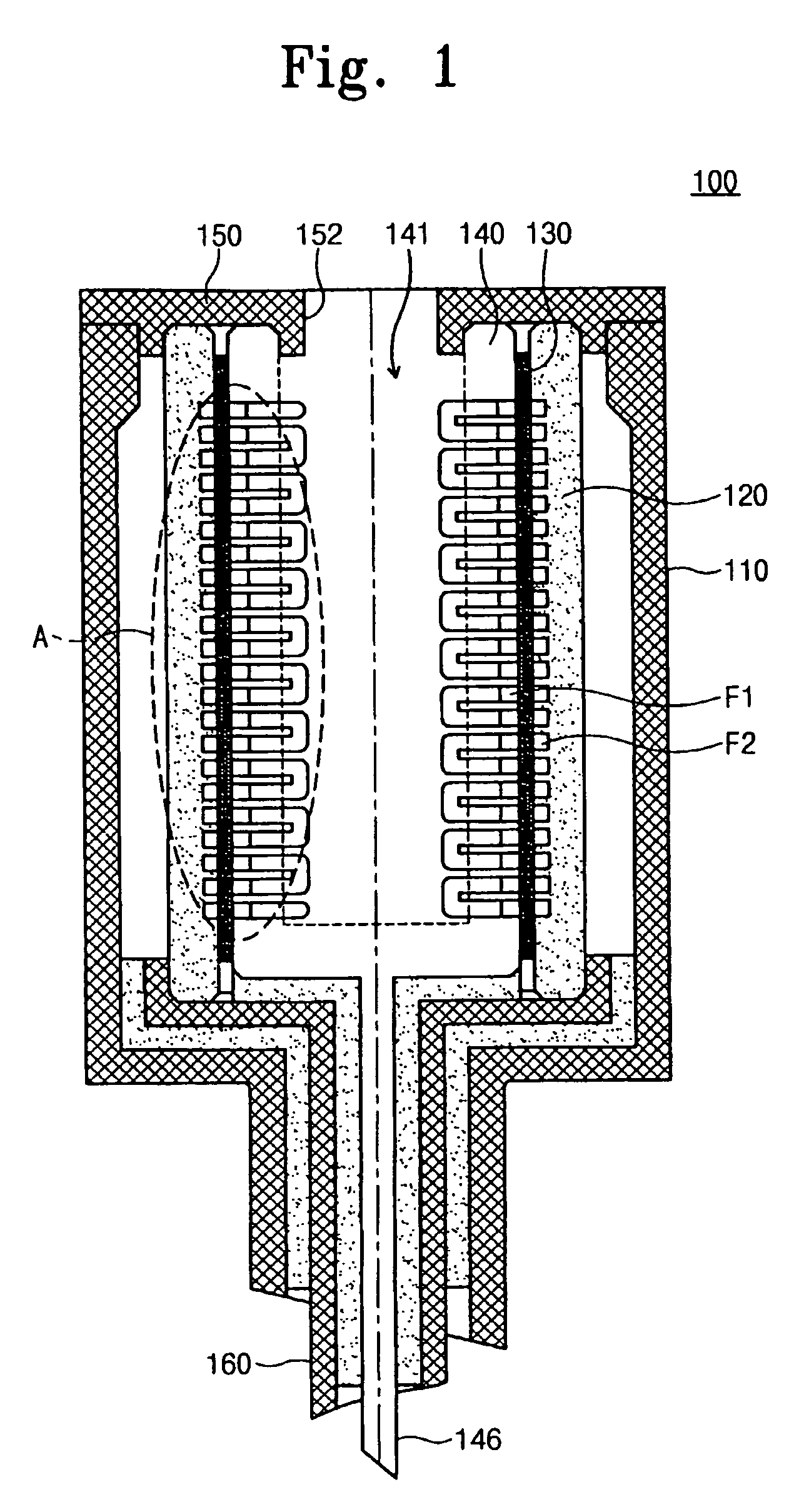

Toroidal probe unit for nuclear magnetic resonance

InactiveUS7339378B2Electrical apparatusTents/canopiesNMR - Nuclear magnetic resonanceElectrical conductor

Disclosed is a probe unit for nuclear magnetic resonance. The probe unit includes a cylindrical outer conductor, a cylindrical central conductor concentrically disposed in the outer conductor, a membrane assembly and fluid paths guiding the flow of fluid in the space between the central and outer conductors. By applying a RF current between the outer and central conductors, a sensing magnetic field is generated in a radial direction. Accordingly, it is possible to detect in real time and in situ, variations of characteristics as well as spatial distribution changes, of a fluid under reaction and / or passing through the fluid paths in the space between the central and outer conductors.

Owner:KOREA BASIC SCI INST

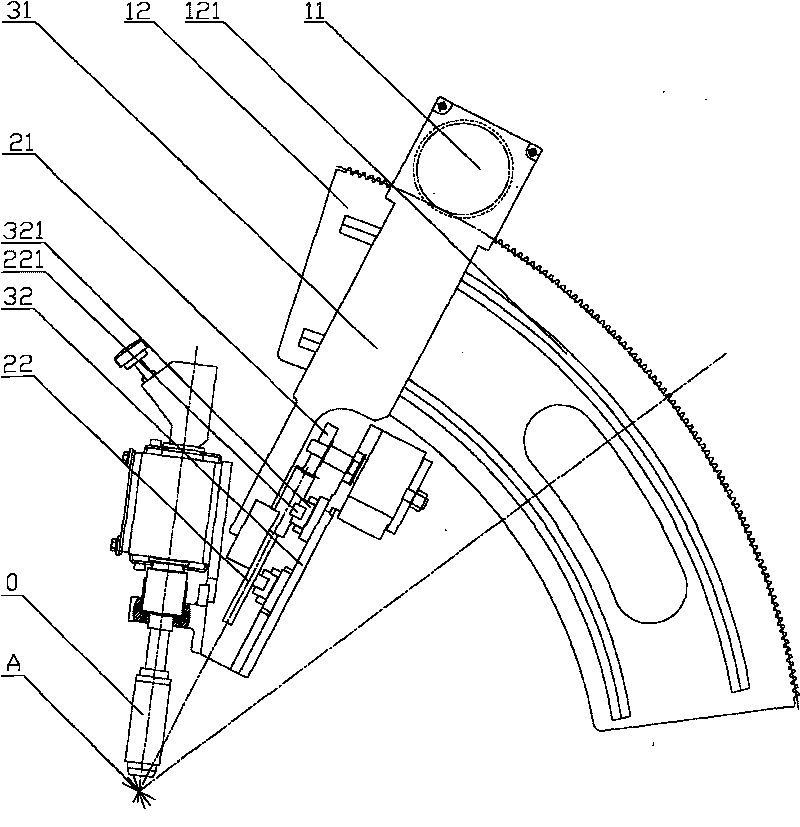

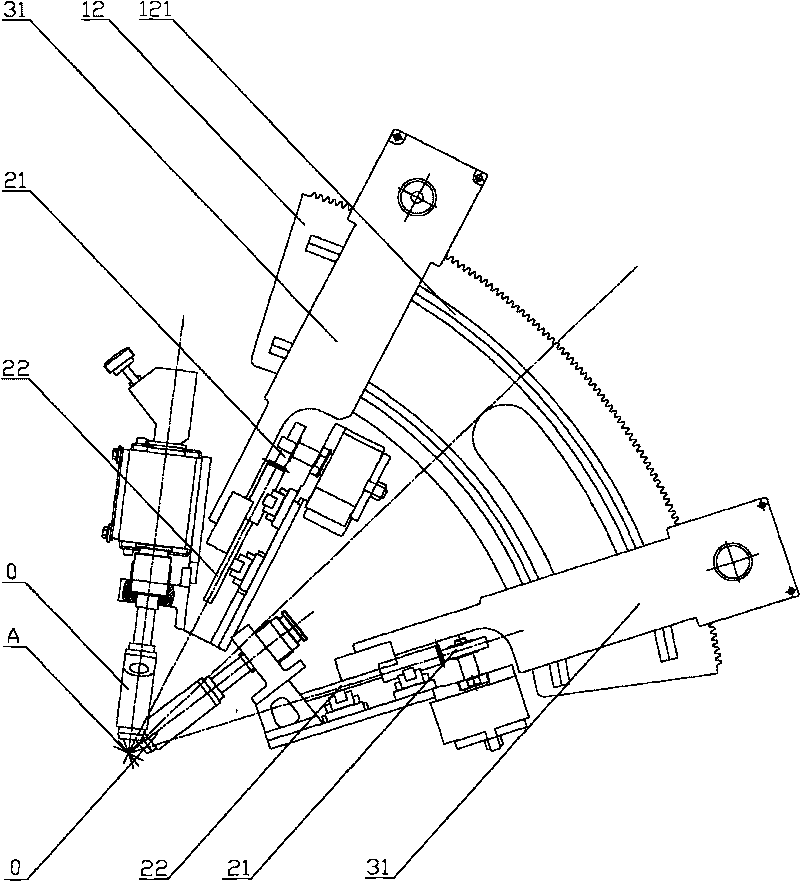

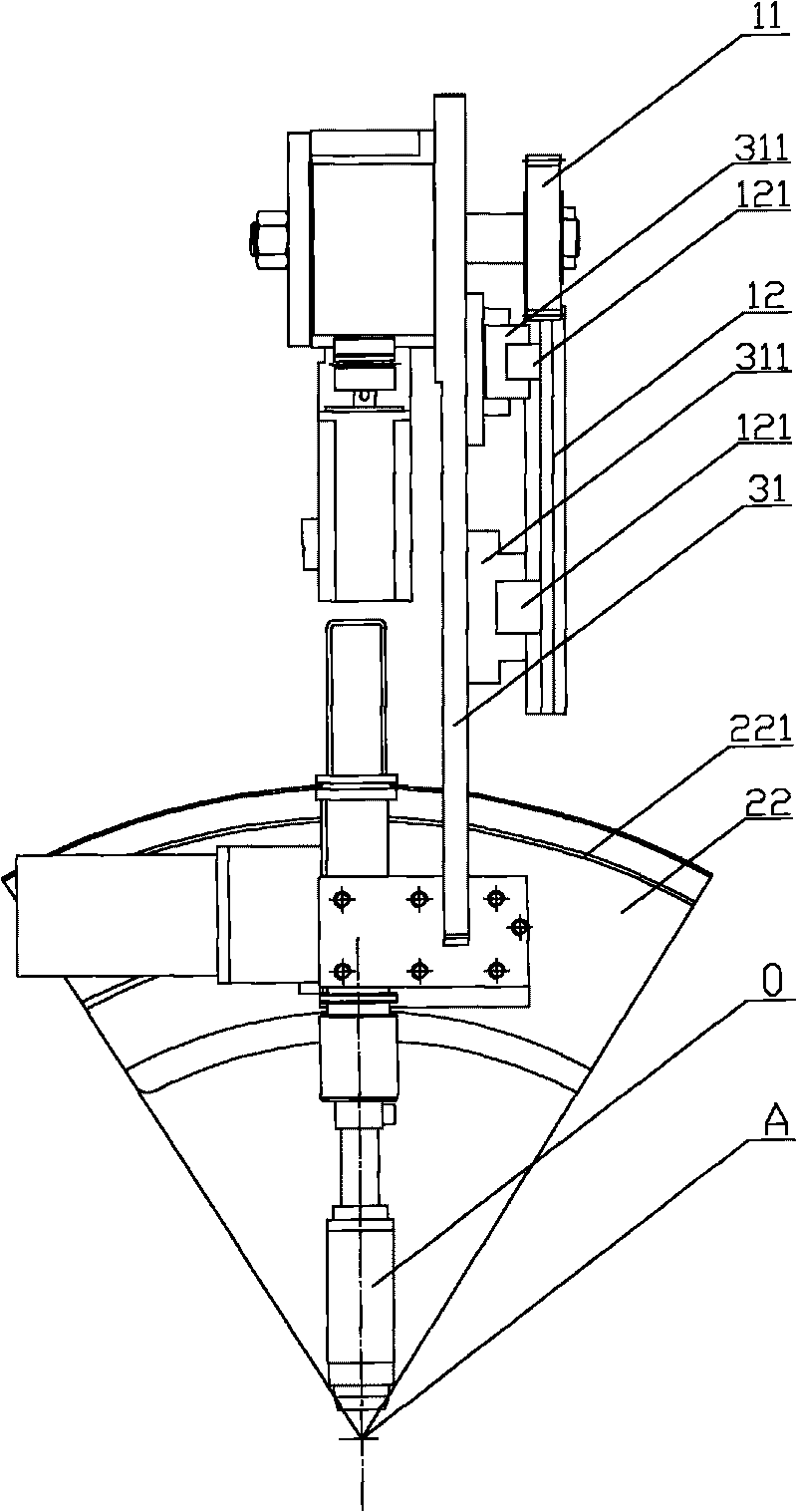

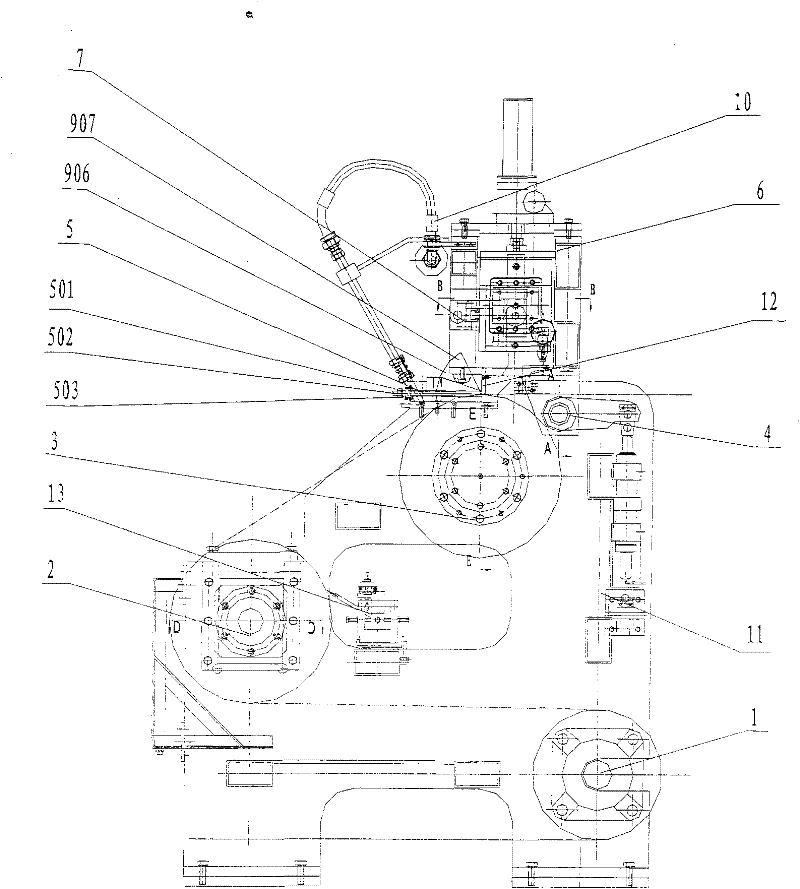

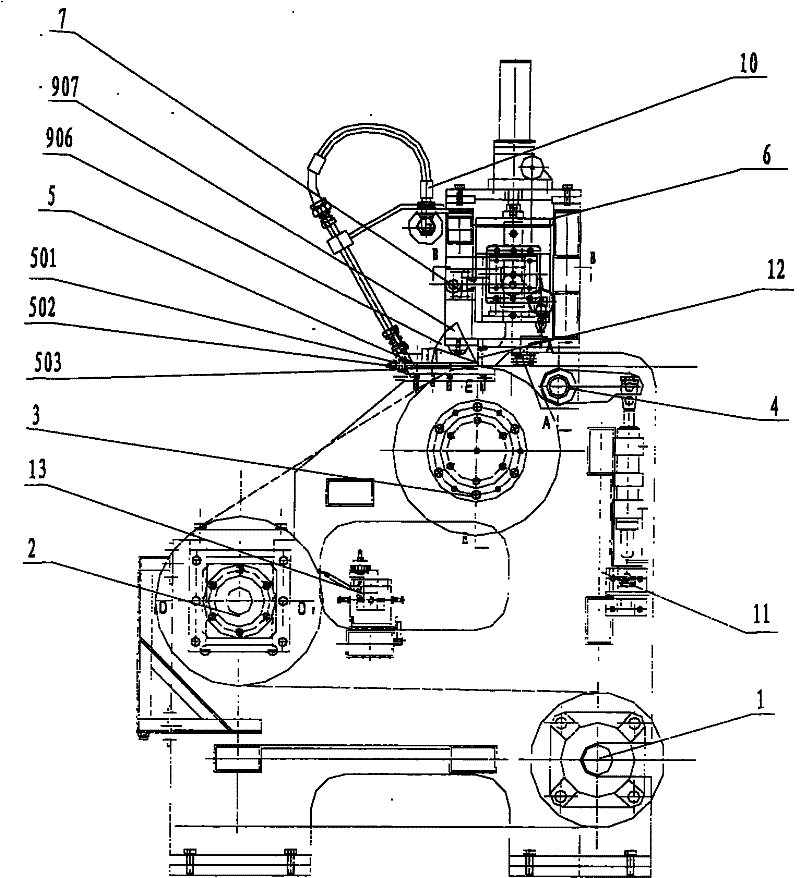

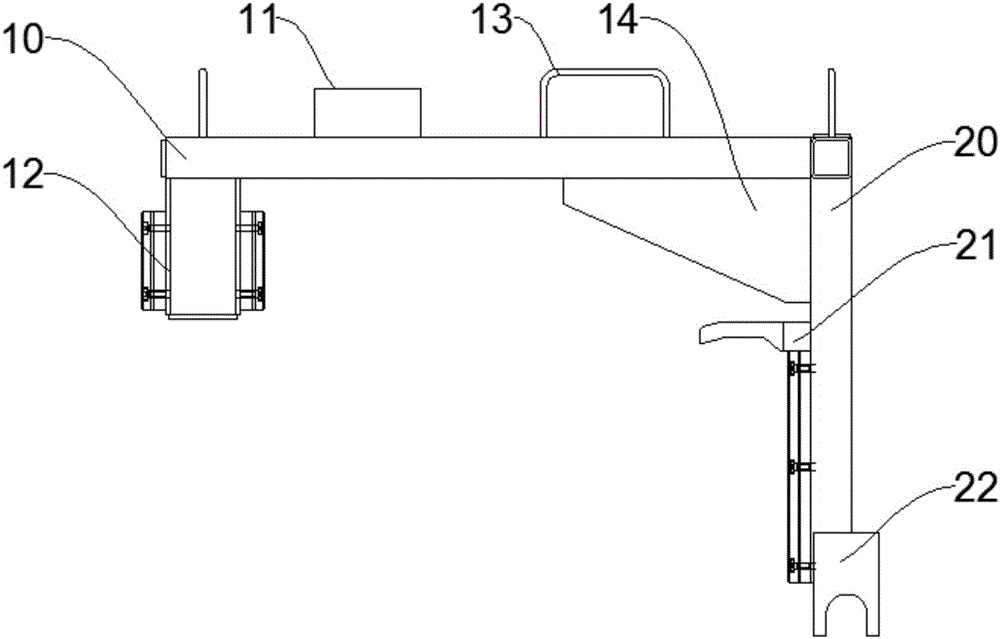

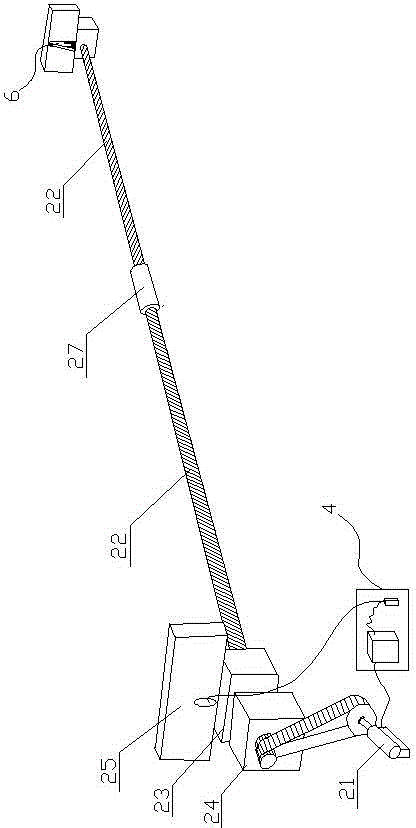

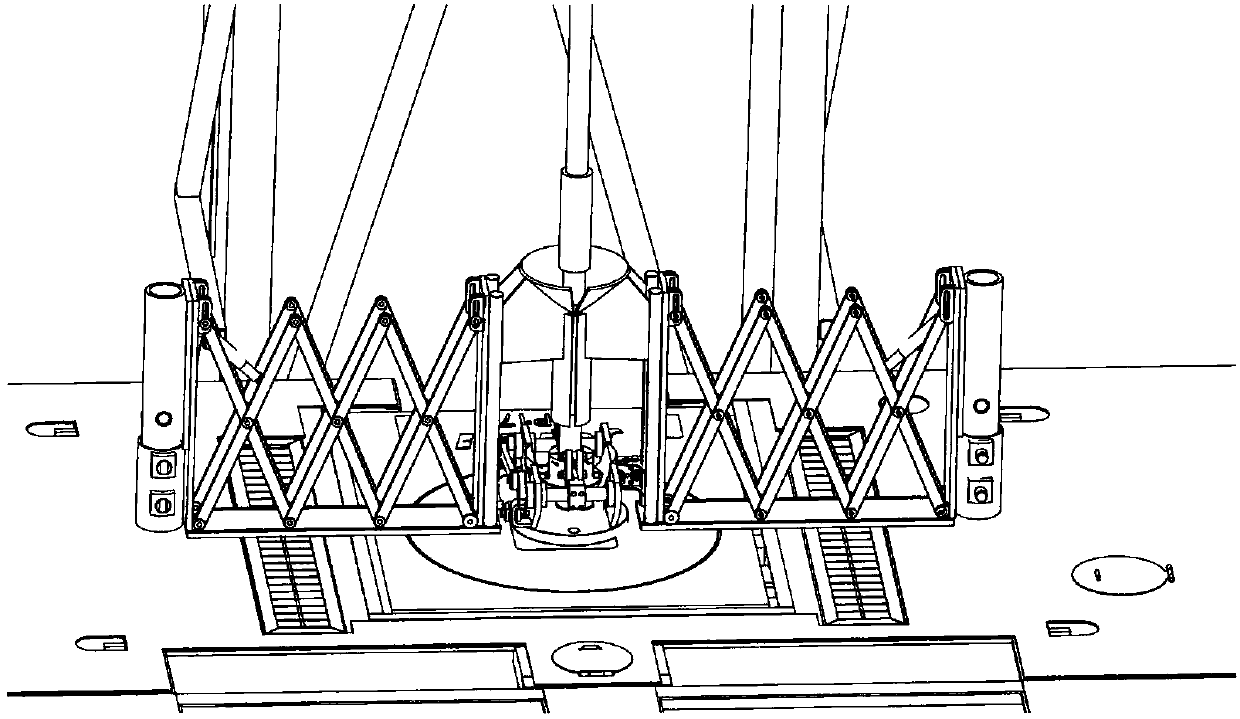

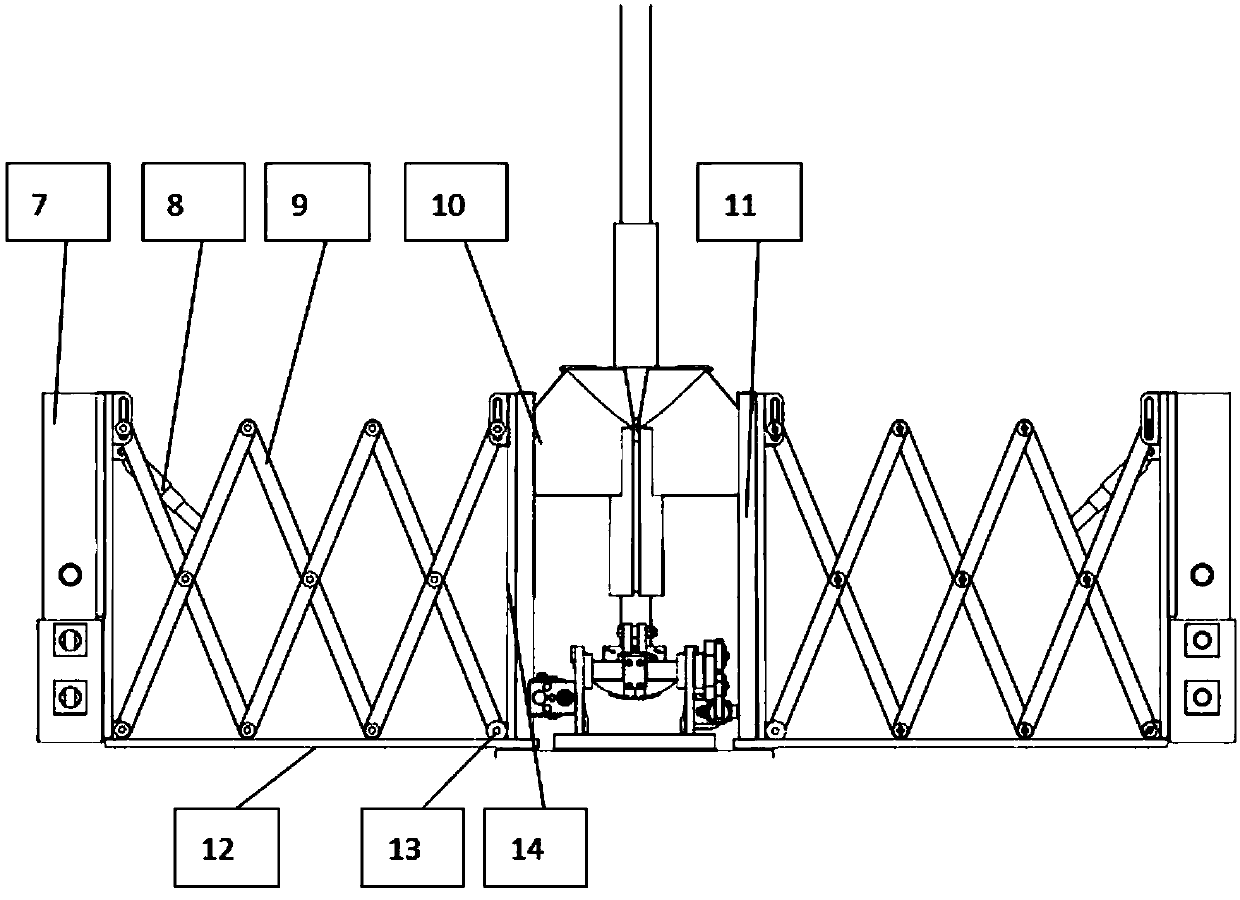

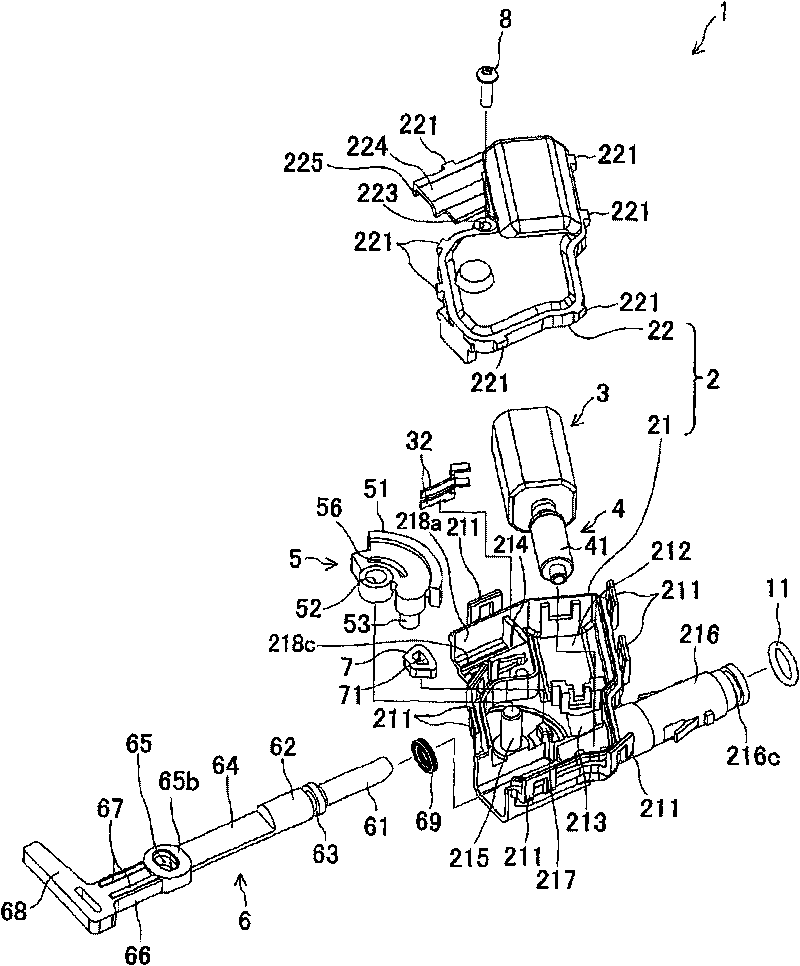

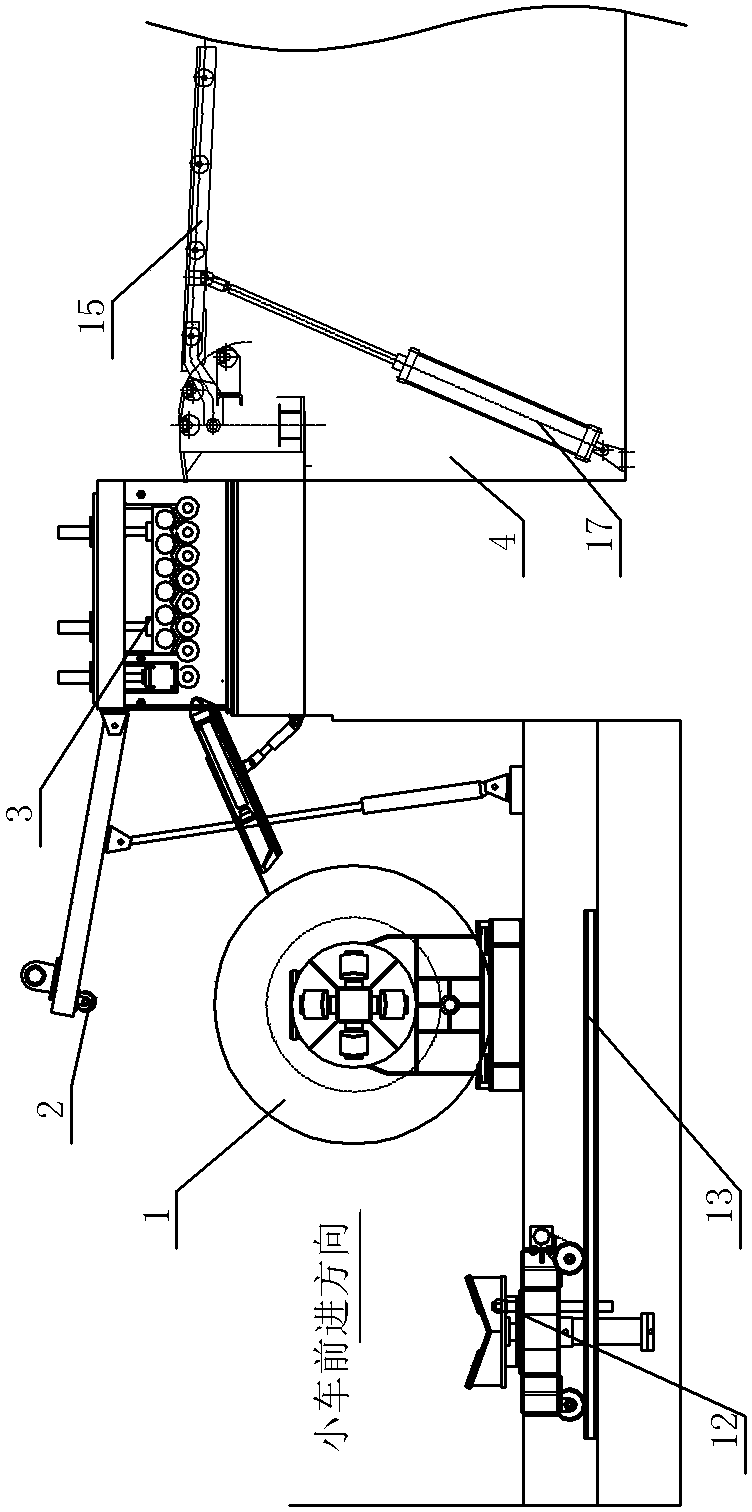

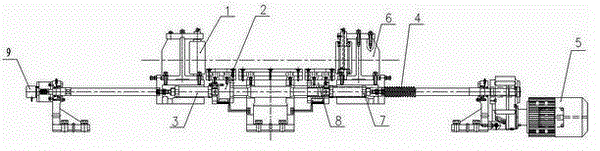

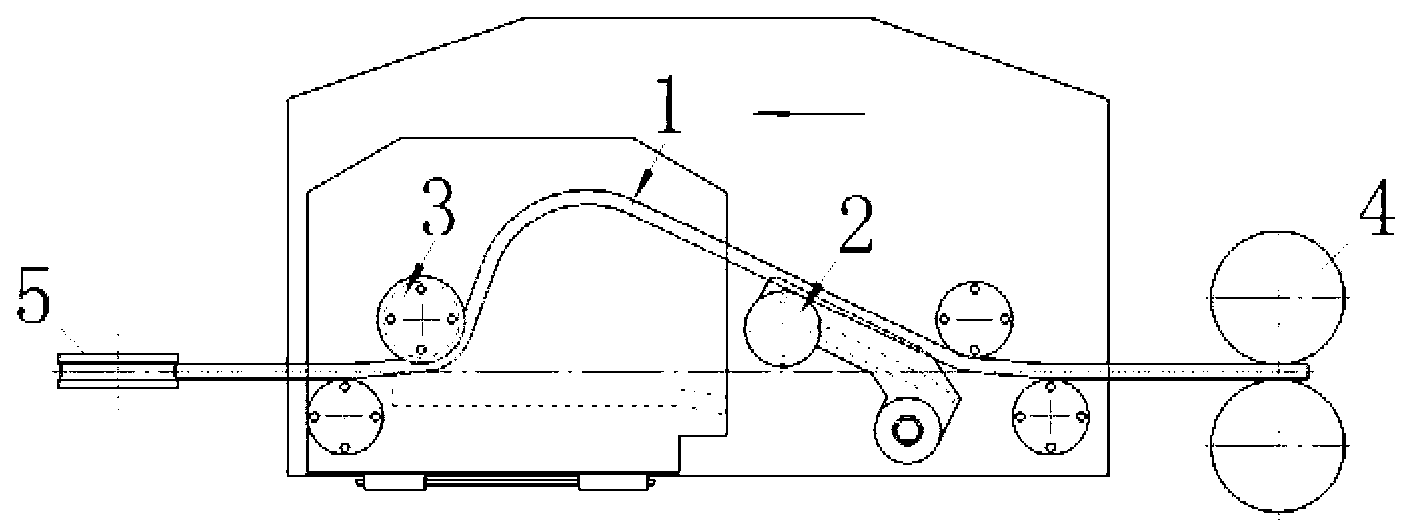

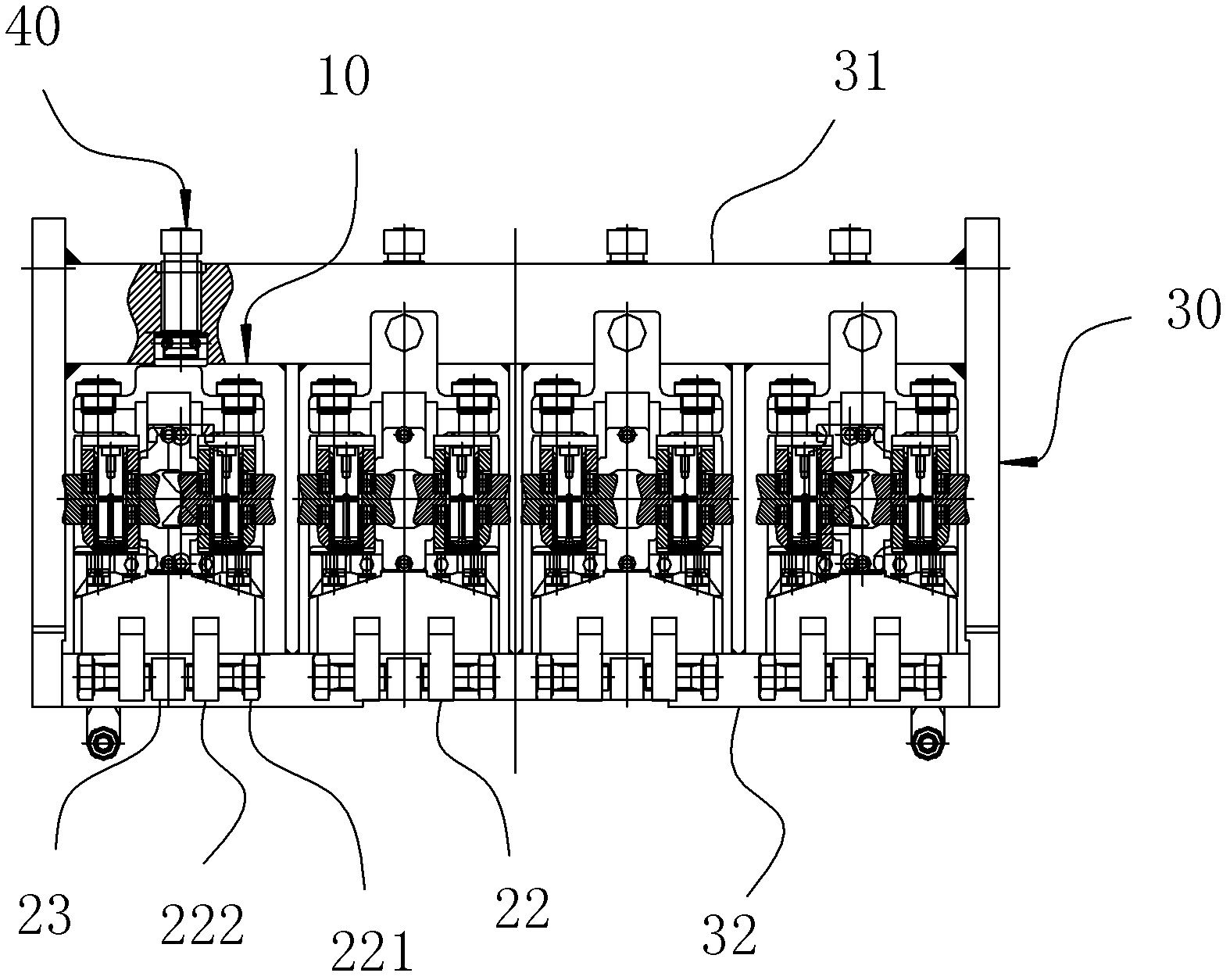

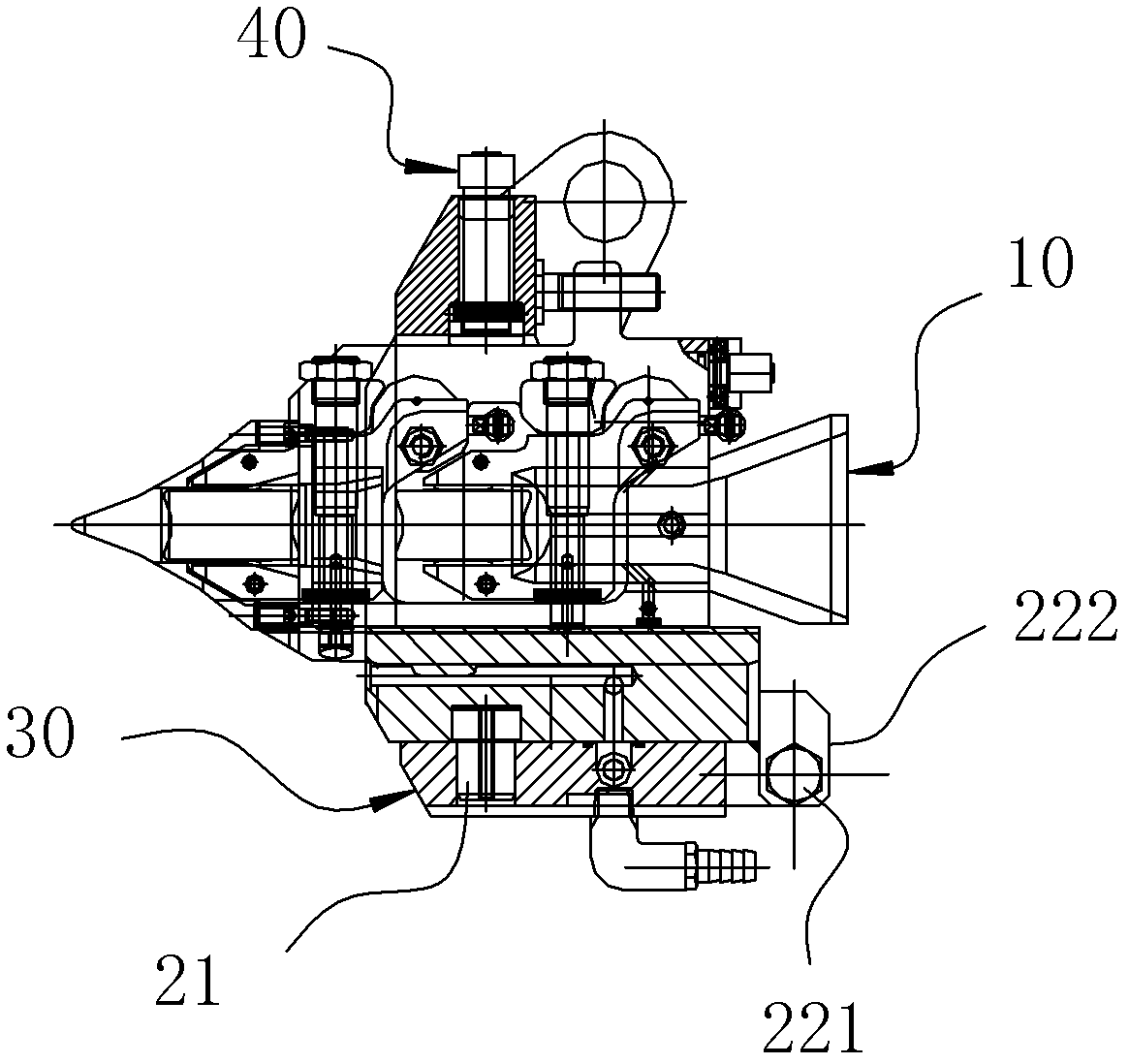

Welding robot and device for adjusting posture of welding gun of welding robot

InactiveCN101712157AChange postureAvoid influenceWelding/cutting auxillary devicesAuxillary welding devicesFistWeld seam

The invention discloses a device for adjusting the posture of a welding gun, which is used for a welding robot. The device comprises a first guide device arranged on the welding robot and a first driving device arranged on the upper part of the welding gun (0), wherein the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0). In the working process of the welding gun, the first driving device drives the upper part of the welding gun (0) to sway along the first guide device, and because the guiding center of the first guide device coincides with the endpoint at the tail end of the welding gun (0), when the upper part of the welding gun (0) sways along the fist guide device, the position of the endpoint at the tail end of the welding gun (0) is not changed, and the posture of the welding gun (0) in the welding process is changed, so the welding stability and the welding seam quality can be stably ensured for a long time.

Owner:BEIHANG UNIV +1

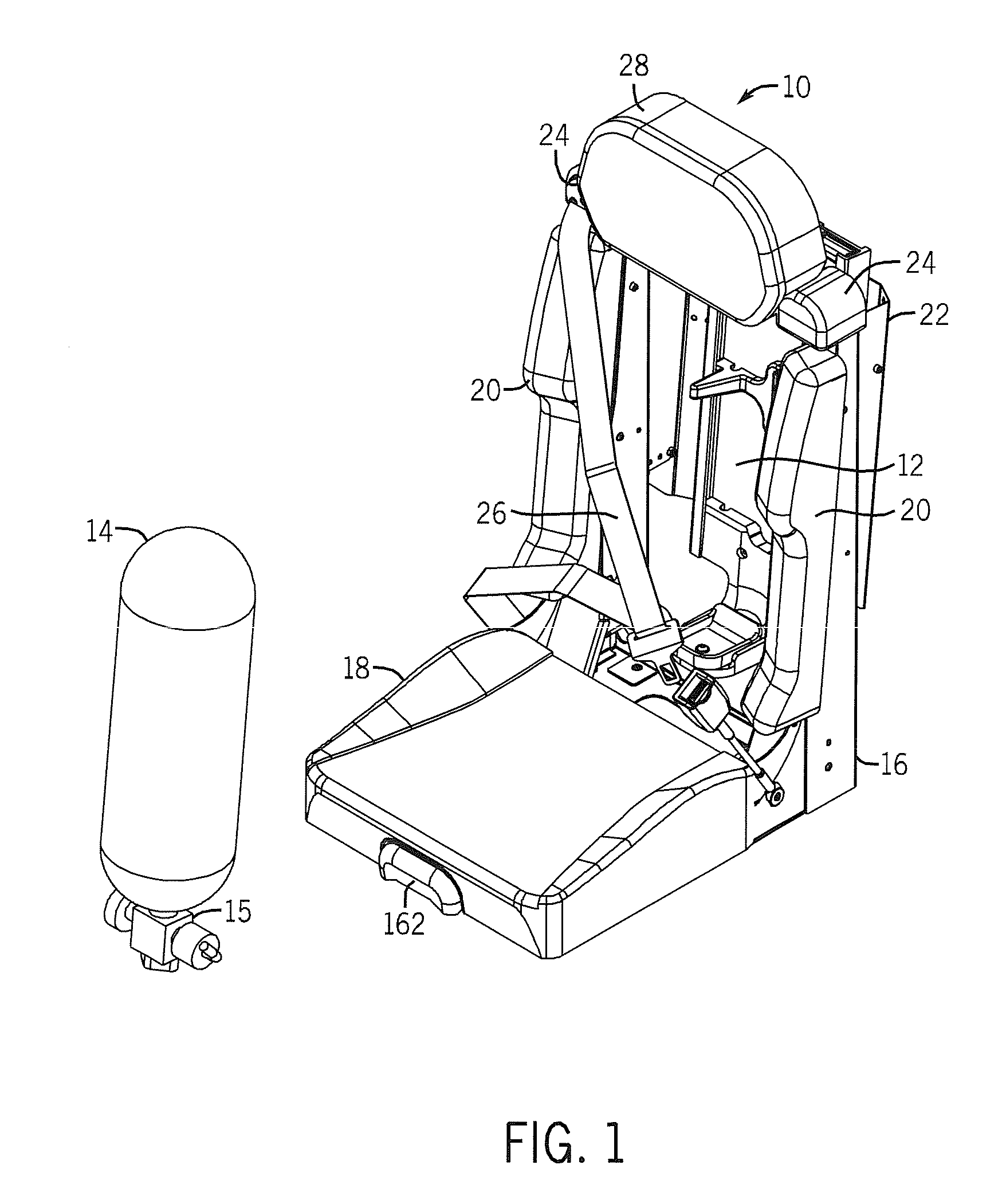

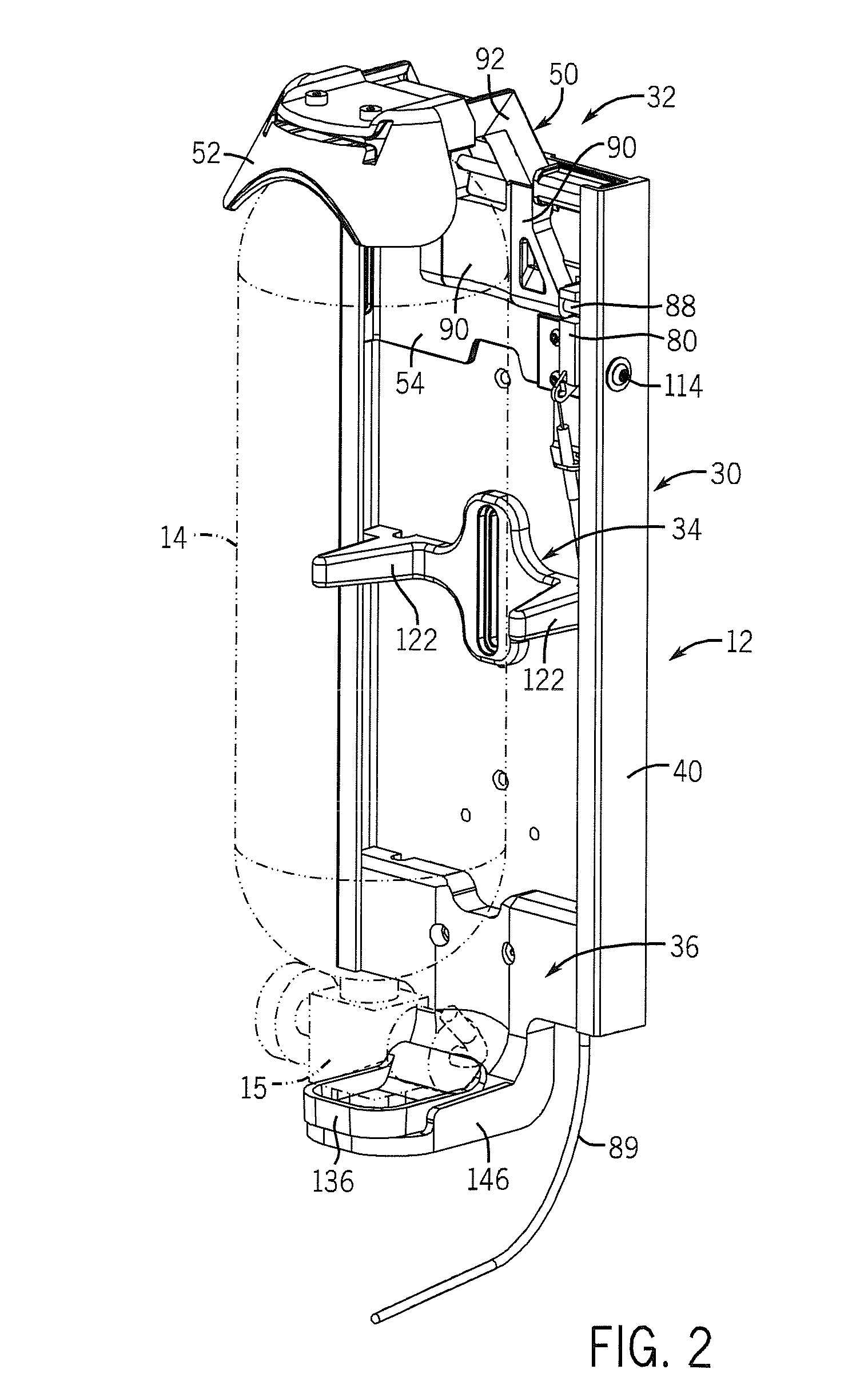

Automatic Locking SCBA Mounting Bracket Assembly

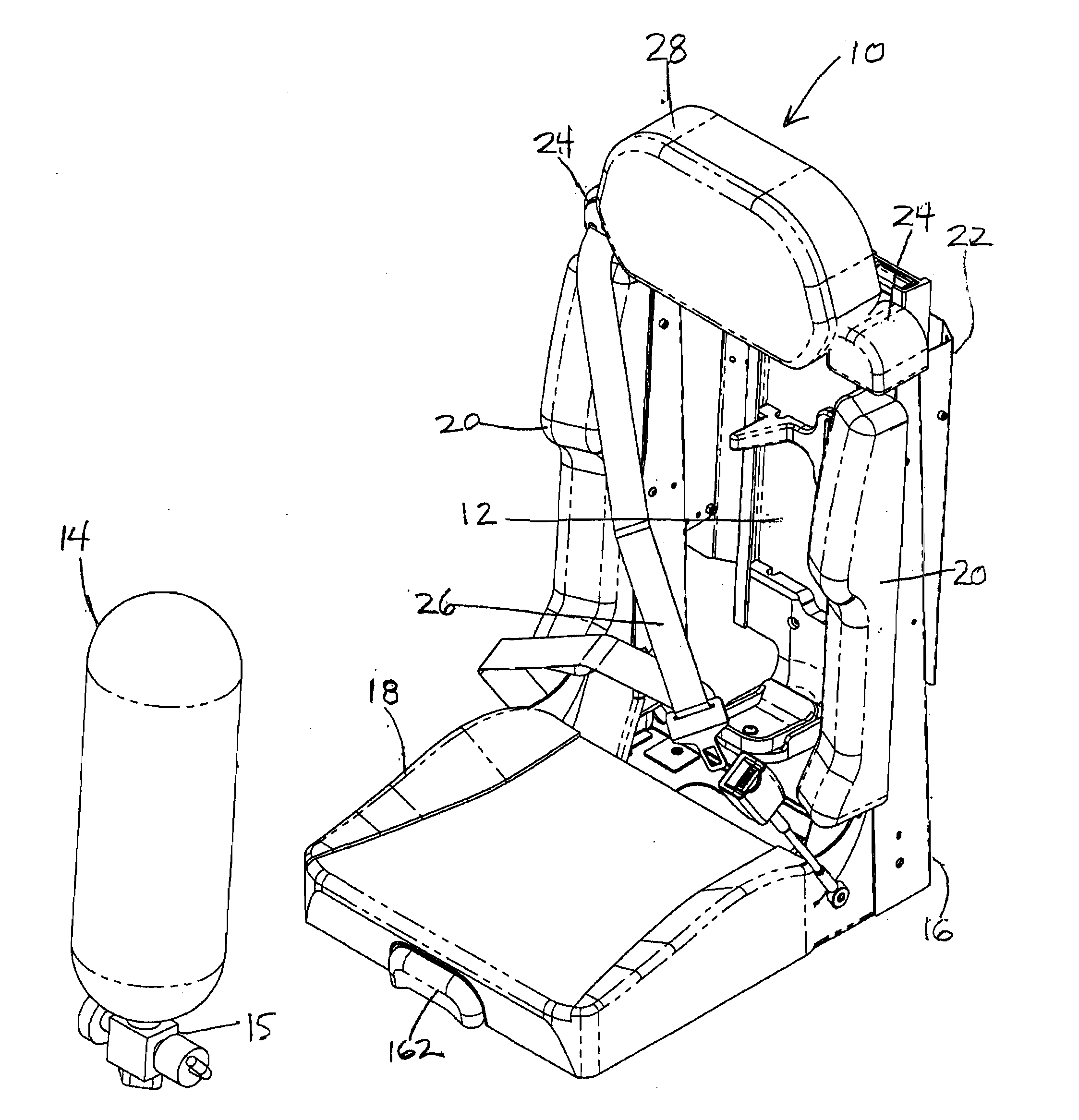

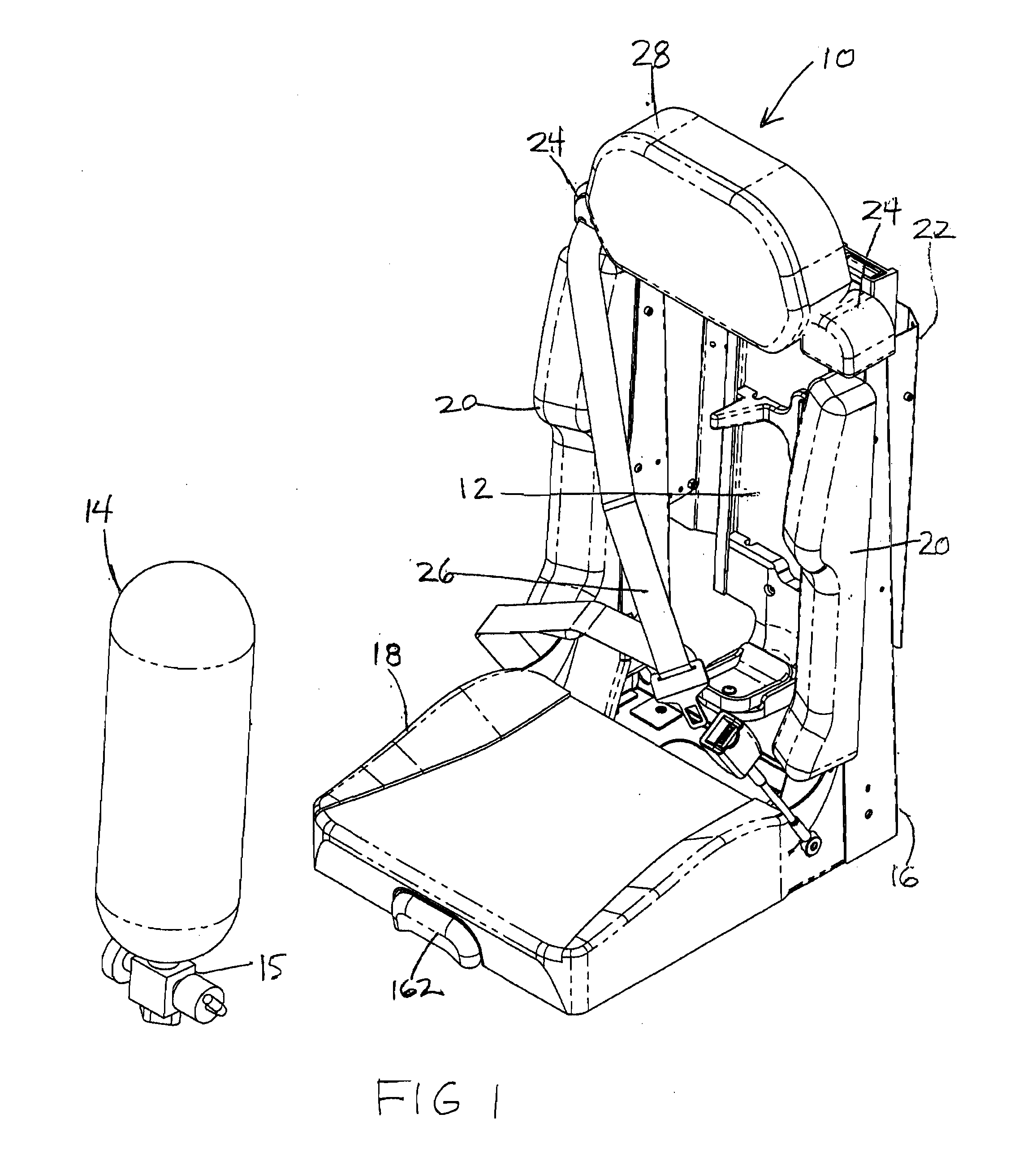

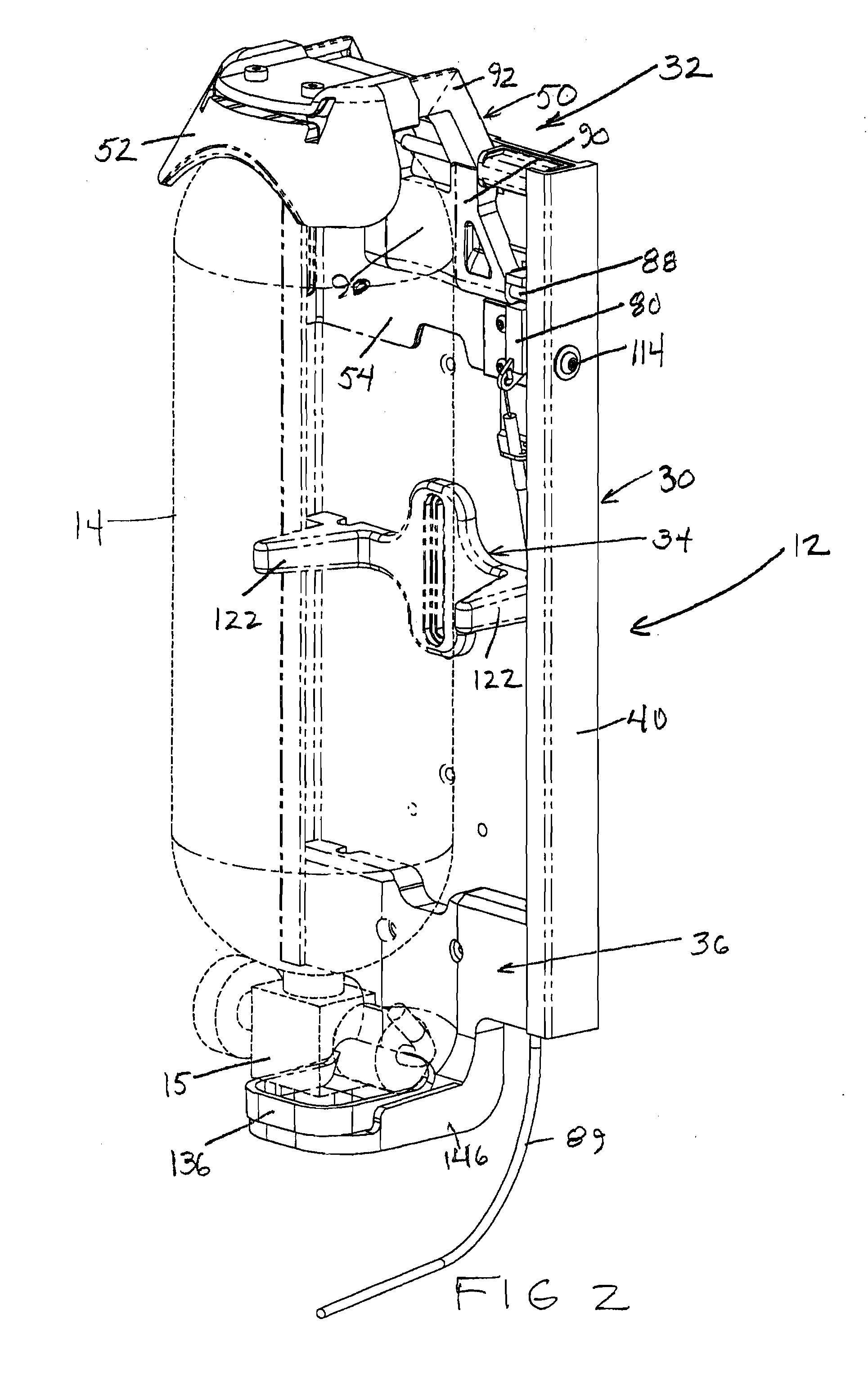

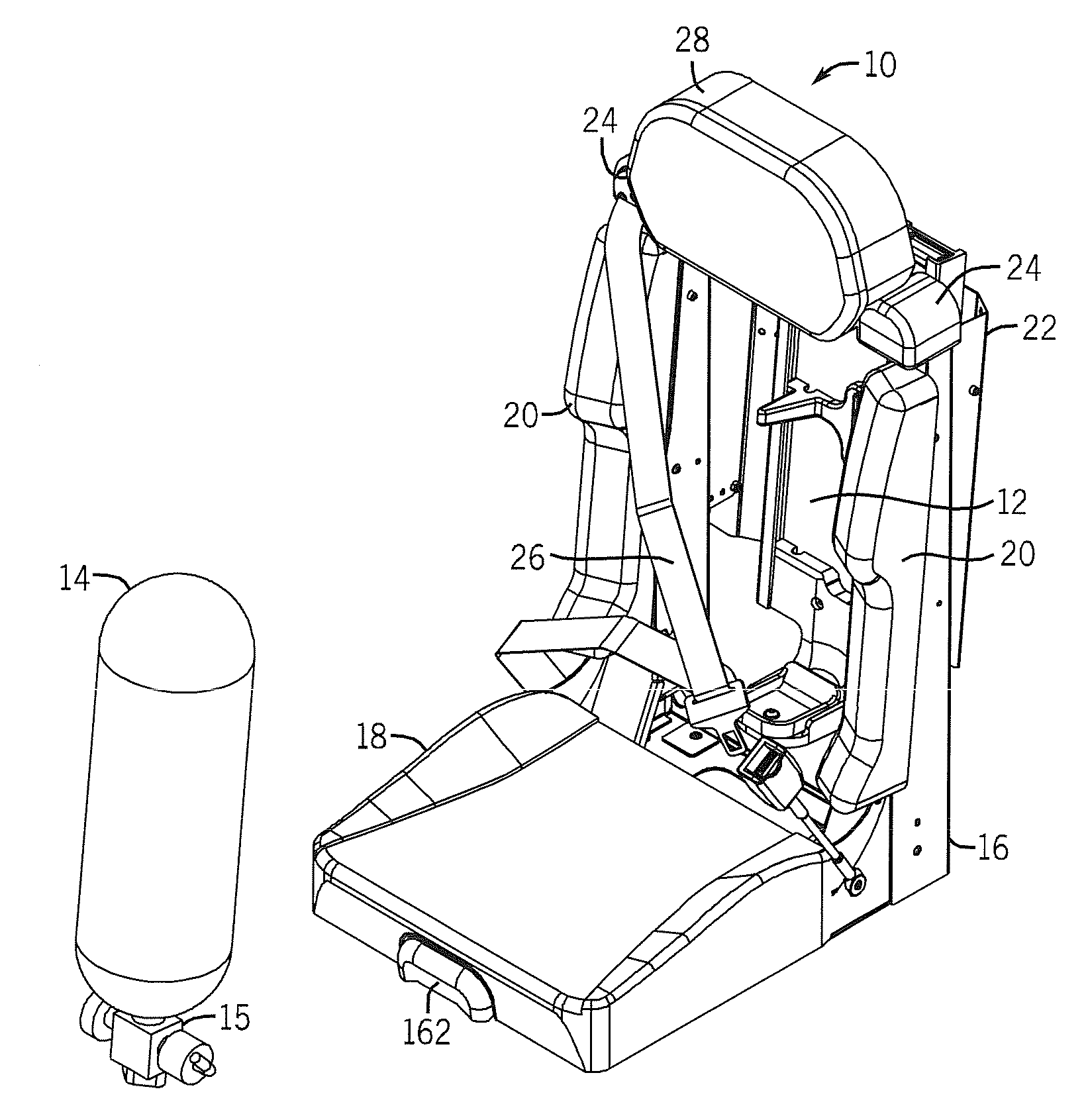

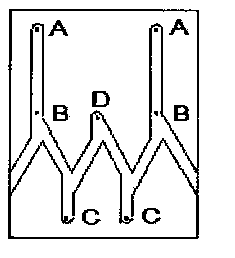

A mounting bracket assembly is provided for releasably holding a self-contained breathing apparatus. The assembly includes a mounting plate, a clamping arrangement secured on an upper portion of the mounting plate and movable between an unlatched position and a latched position relative to the self-contained breathing apparatus, a guide connected on an intermediate portion of the mounting plate and a support structure mounted on a lower portion of the mounting plate. The clamping arrangement includes a pivot arm having an actuator plate biased forwardly of the mounting plate in the unlatched position, and a self-contained breathing apparatus engaging clamp swung upwardly above the mounting plate in the unlatched position. The clamping arrangement further includes a latching mechanism engageable and disengageable with the pivot arm for providing latched and unlatched positions. Movement of the self-contained breathing apparatus against the actuator plate automatically swings and locks the clamp downwardly on an upper end of the self-contained breathing apparatus, and causes the pivot arm to engage the latching mechanism in the latched position with the guide centering and retaining an intermediate portion of the self-contained breathing apparatus and the support structure supporting a lower portion of the self-contained breathing apparatus.

Owner:H O BOSSTREETCAR

Automatic locking SCBA mounting bracket assembly

A mounting bracket assembly is provided for releasably holding a self-contained breathing apparatus. The assembly includes a mounting plate, a clamping arrangement secured on an upper portion of the mounting plate and movable between an unlatched position and a latched position relative to the self-contained breathing apparatus, a guide connected on an intermediate portion of the mounting plate and a support structure mounted on a lower portion of the mounting plate. The clamping arrangement includes a pivot arm having an actuator plate biased forwardly of the mounting plate in the unlatched position, and a self-contained breathing apparatus engaging clamp swung upwardly above the mounting plate in the unlatched position. The clamping arrangement further includes a latching mechanism engageable and disengageable with the pivot arm for providing latched and unlatched positions. Movement of the self-contained breathing apparatus against the actuator plate automatically swings and locks the clamp downwardly on an upper end of the self-contained breathing apparatus, and causes the pivot arm to engage the latching mechanism in the latched position with the guide centering and retaining an intermediate portion of the self-contained breathing apparatus and the support structure supporting a lower portion of the self-contained breathing apparatus.

Owner:H O BOSSTREETCAR

Automatic locking scba mounting bracket assembly

A mounting bracket assembly is provided for releasably holding a self-contained breathing apparatus. The assembly includes a mounting plate, a clamping arrangement secured on an upper portion of the mounting plate and movable between an unlatched position and a latched position relative to the self-contained breathing apparatus, a guide connected on an intermediate portion of the mounting plate and a support structure mounted on a lower portion of the mounting plate. The clamping arrangement includes a pivot arm having an actuator plate biased forwardly of the mounting plate in the unlatched position, and a self-contained breathing apparatus engaging clamp swung upwardly above the mounting plate in the unlatched position. The clamping arrangement further includes a latching mechanism engageable and disengageable with the pivot arm for providing latched and unlatched positions. Movement of the self-contained breathing apparatus against the actuator plate automatically swings and locks the clamp downwardly on an upper end of the self- contained breathing apparatus, and causes the pivot arm to engage the latching mechanism in the latched position with the guide centering and retaining an intermediate portion of the self-contained breathing apparatus and the support structure supporting a lower portion of the self-contained breathing apparatus.

Owner:H O BOSSTREETCAR

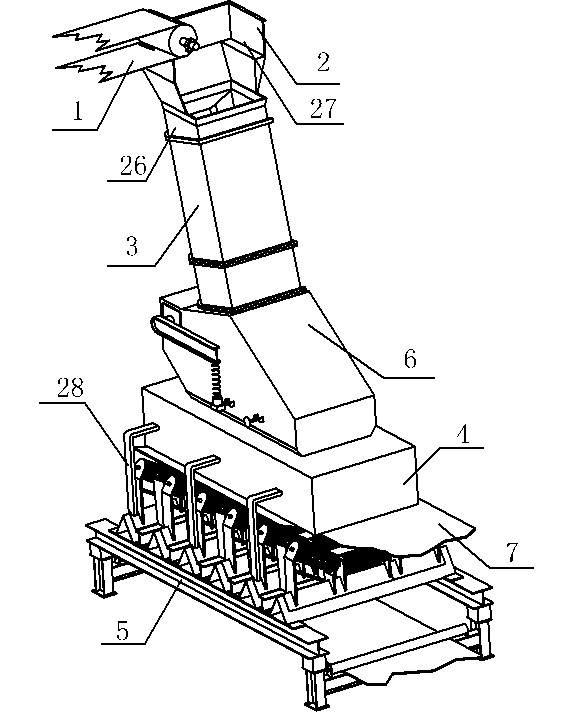

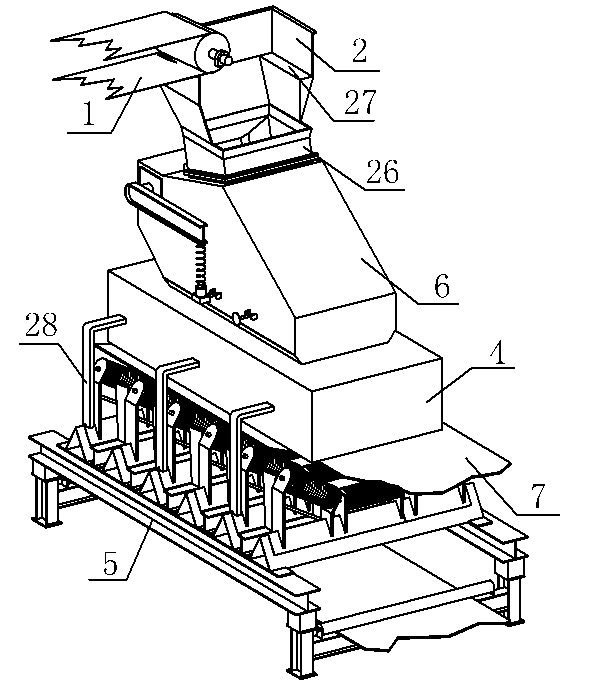

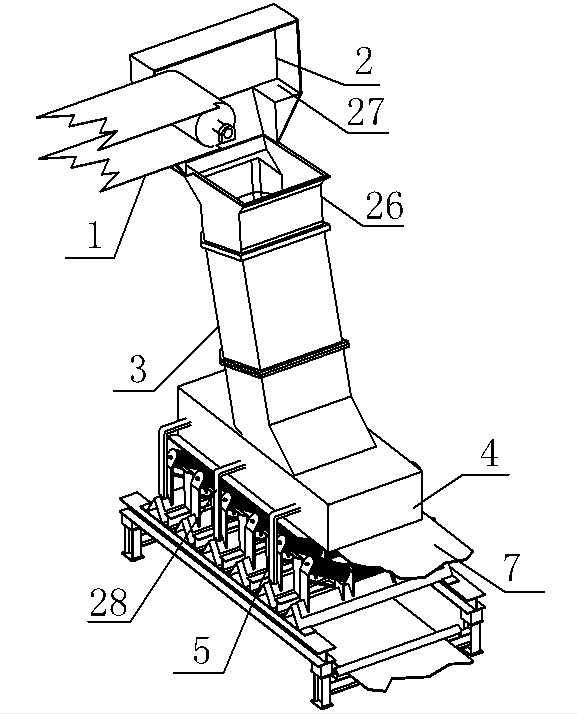

Material transfer method and transfer device

The invention discloses a material transfer method and a used material transfer device. Materials are accumulated on a discharge hopper to form a material storage area; when the materials are accumulated fully, the materials overflow and slide downwards into a material guide centering chute, enter a buffer fork through the material guide centering chute, and are accumulated on a fork plate to form a storage area; and then the materials are continuously conveyed to a material guide groove, and finally conveyed to a receiving adhesive tape on a receiving buffer device with a support plate. Because the discharge hopper with the material storage area, the buffer fork and the material guide centering chute with a groove-shaped receiving bearing surface are used, the materials are accumulated on the discharge hopper and the buffer fork to a material accumulation layer, and the subsequent materials are well buffered and centralized on the middle part of the adhesive tape so as to effectivelyreduce the abrasion of equipment caused by the materials and prevent the adhesive tape from deflecting and scattering the materials; and meanwhile, the receiving buffer device with the support plate is used below the receiving adhesive tape so that the materials are supported by the anti-tearing support plate when falling from the upside and the adhesive tape is prevented from being torn.

Owner:HUADIAN HEAVY IND CO LTD

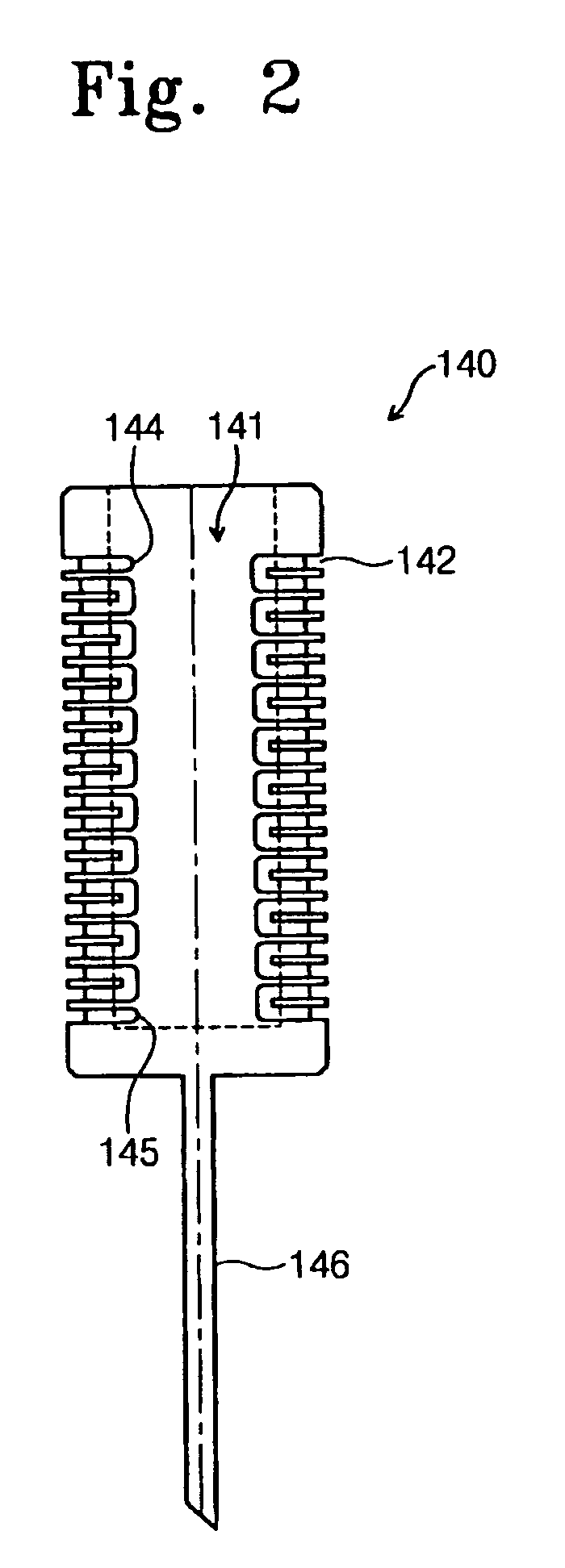

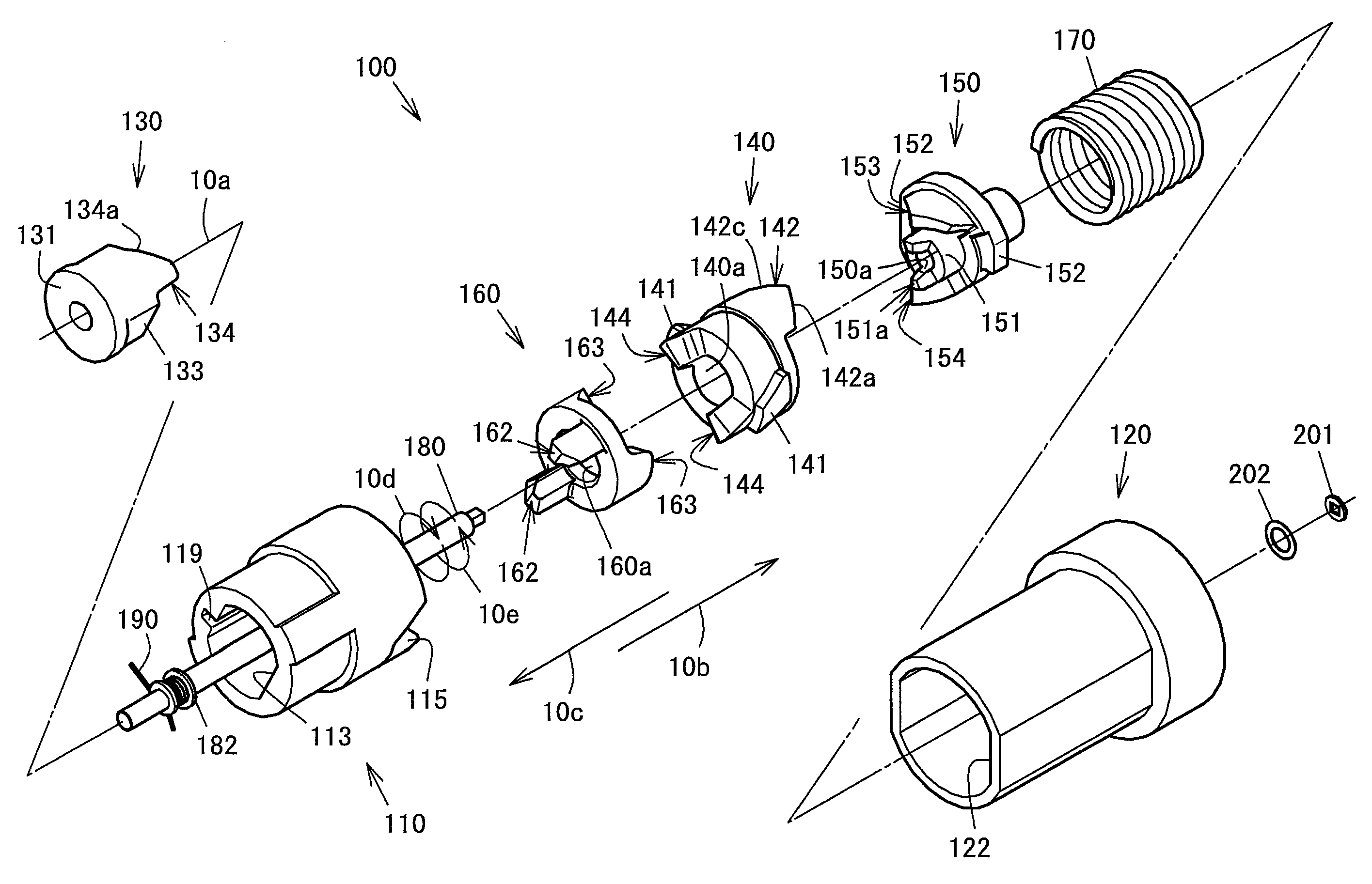

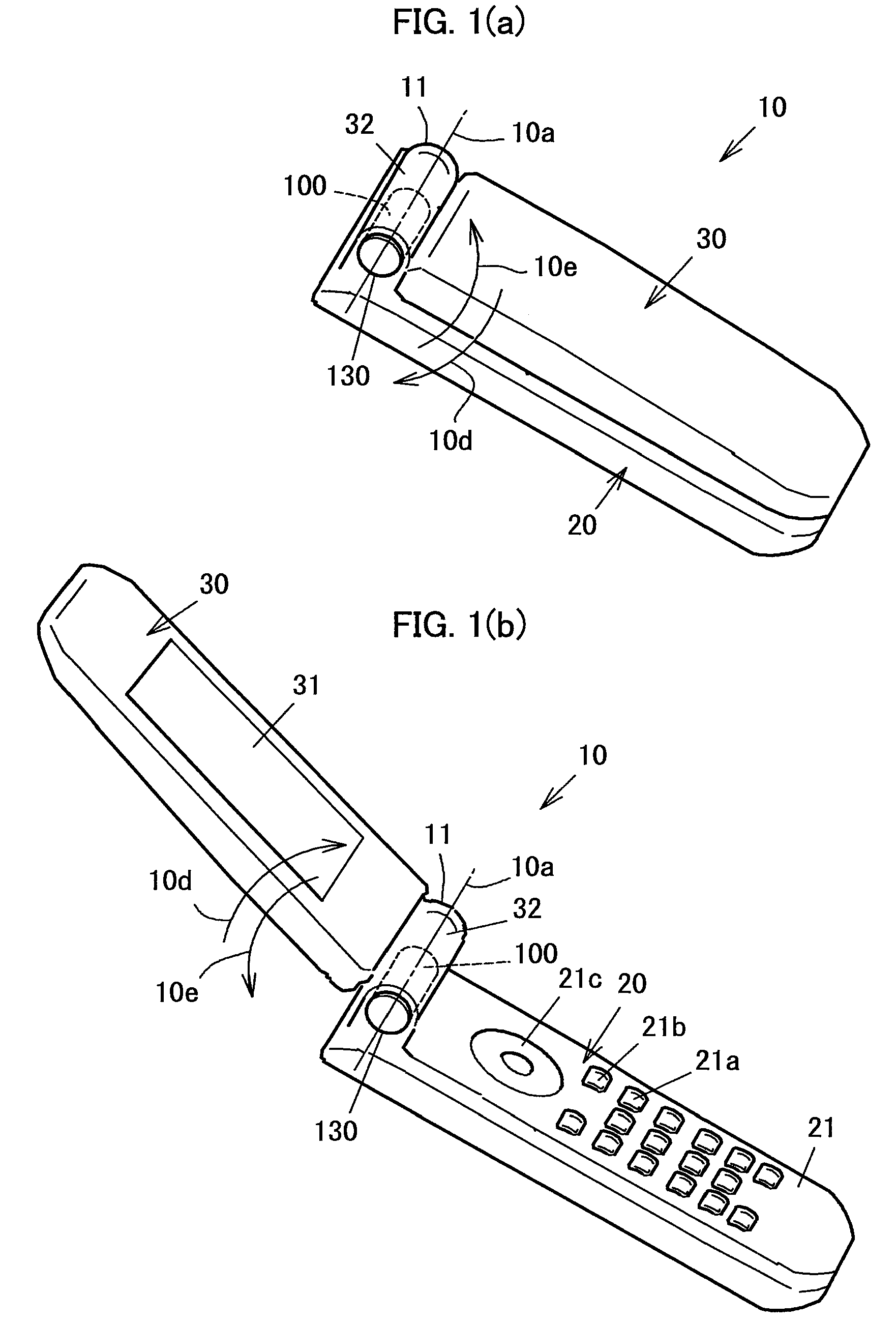

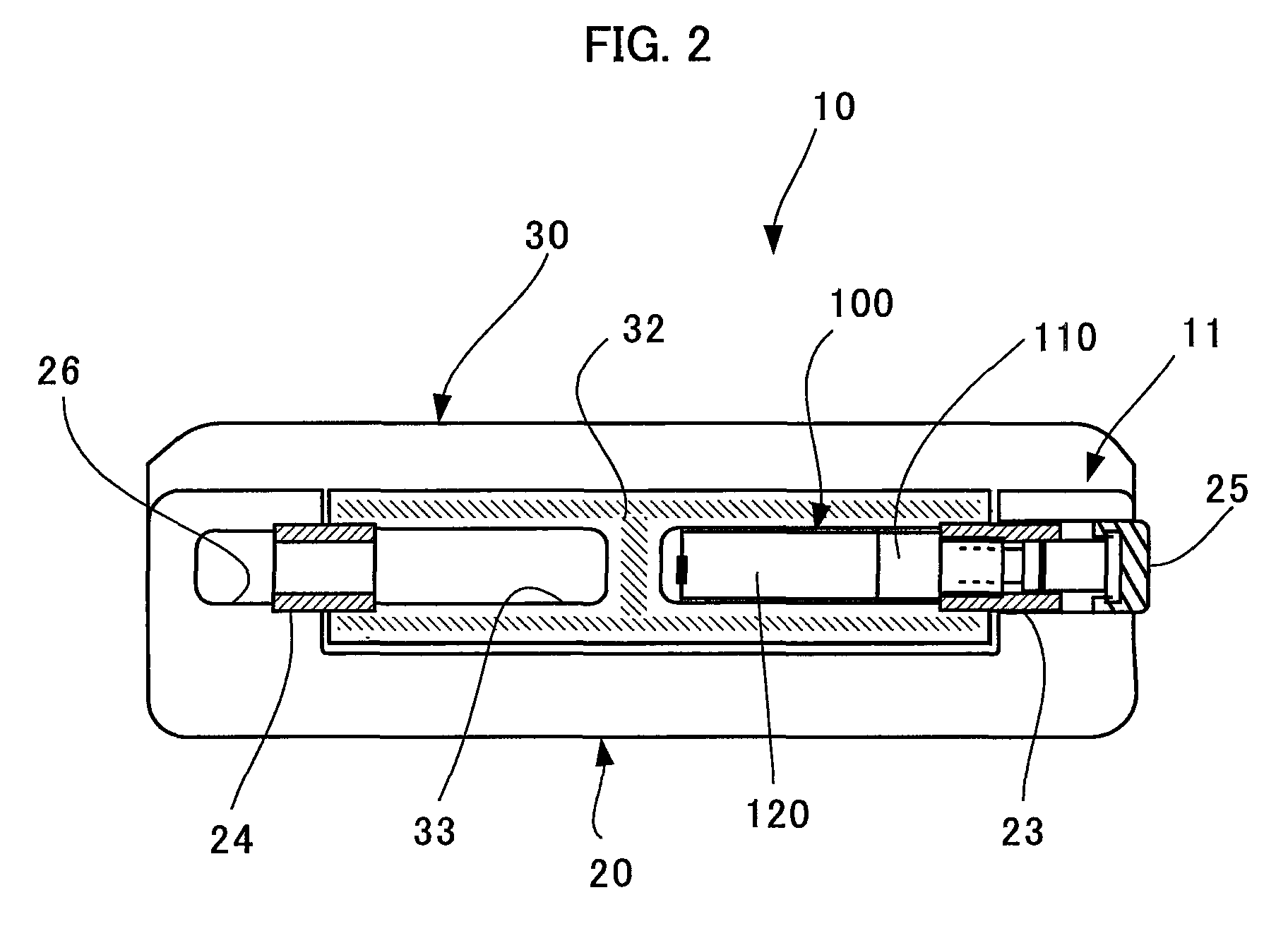

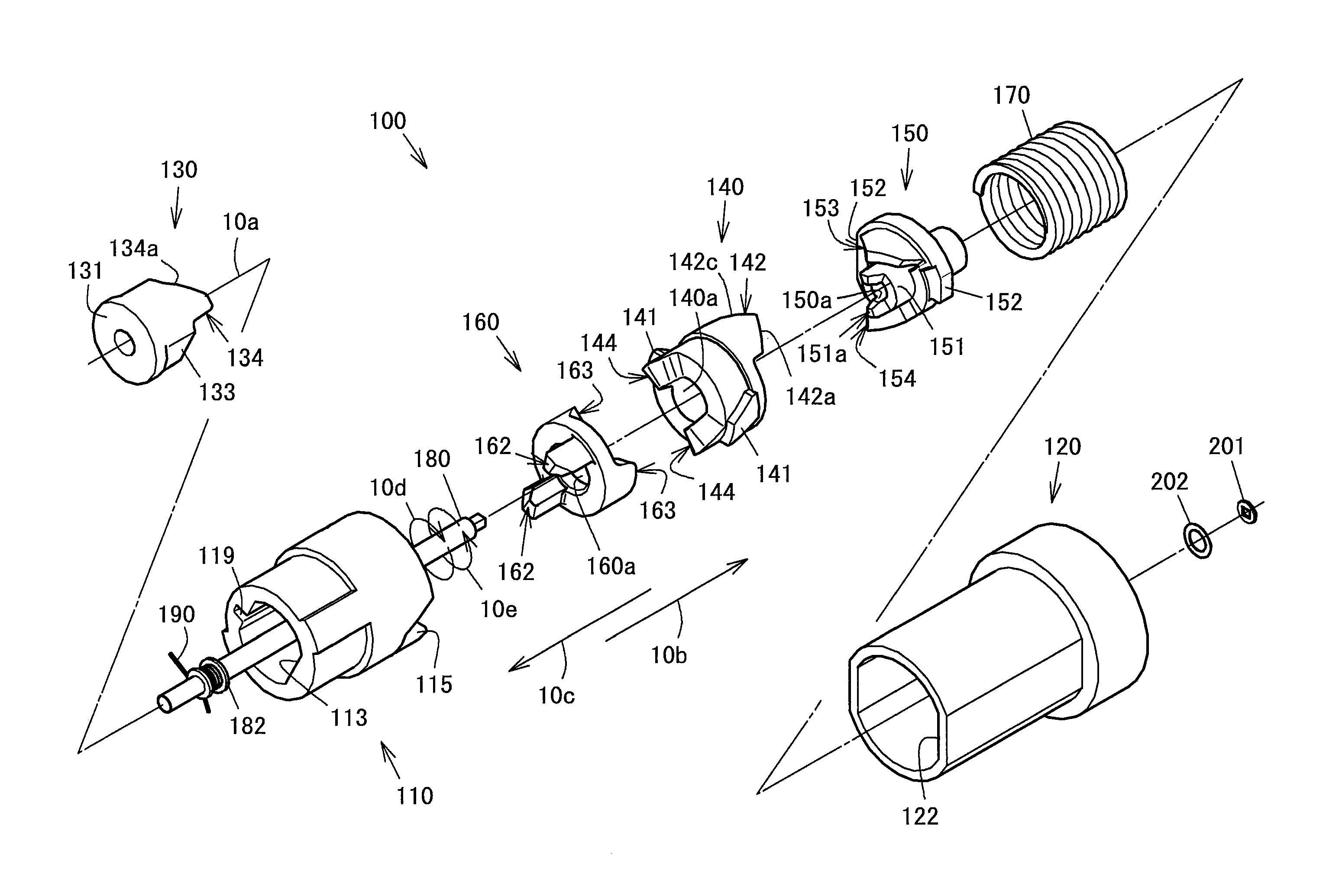

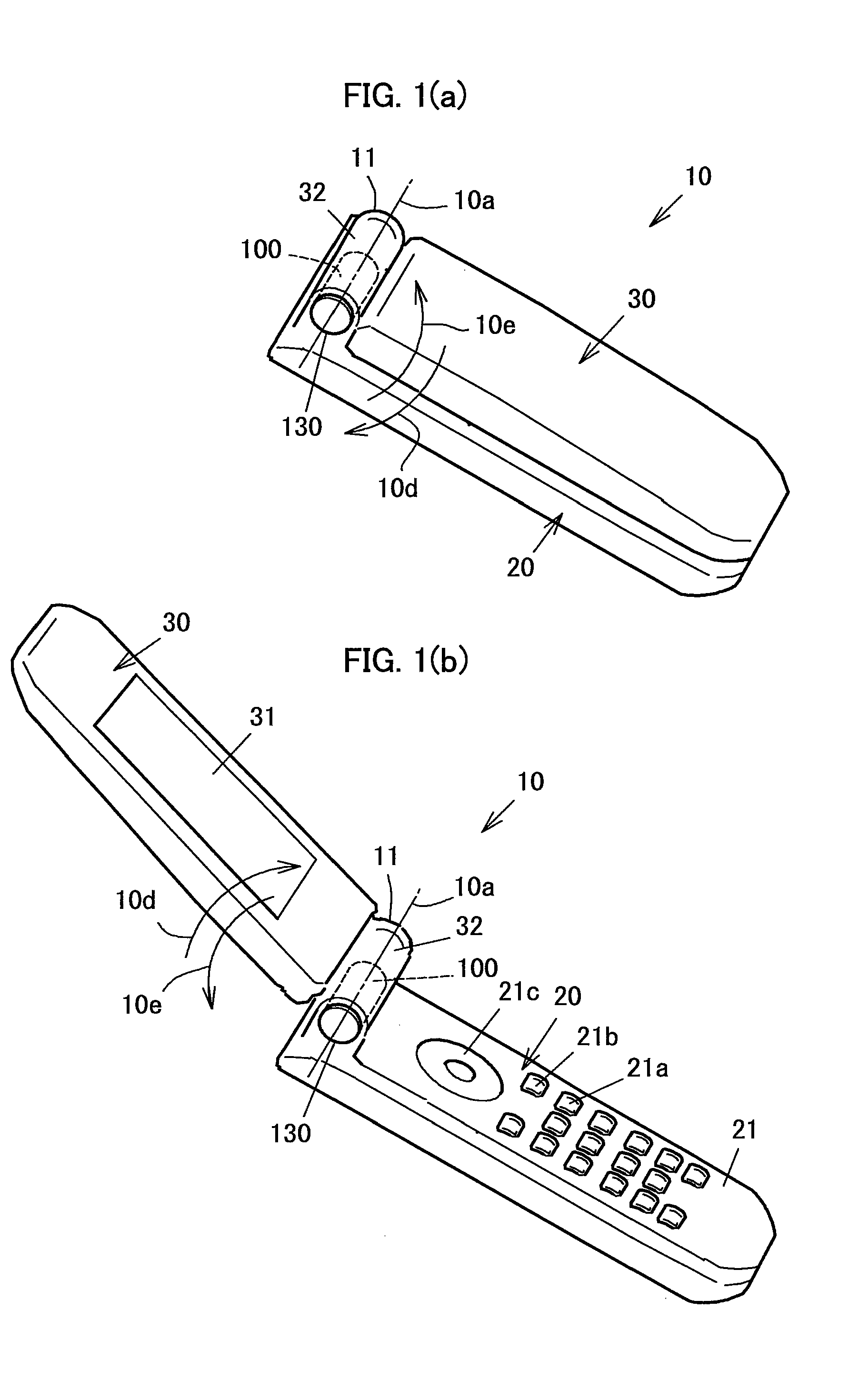

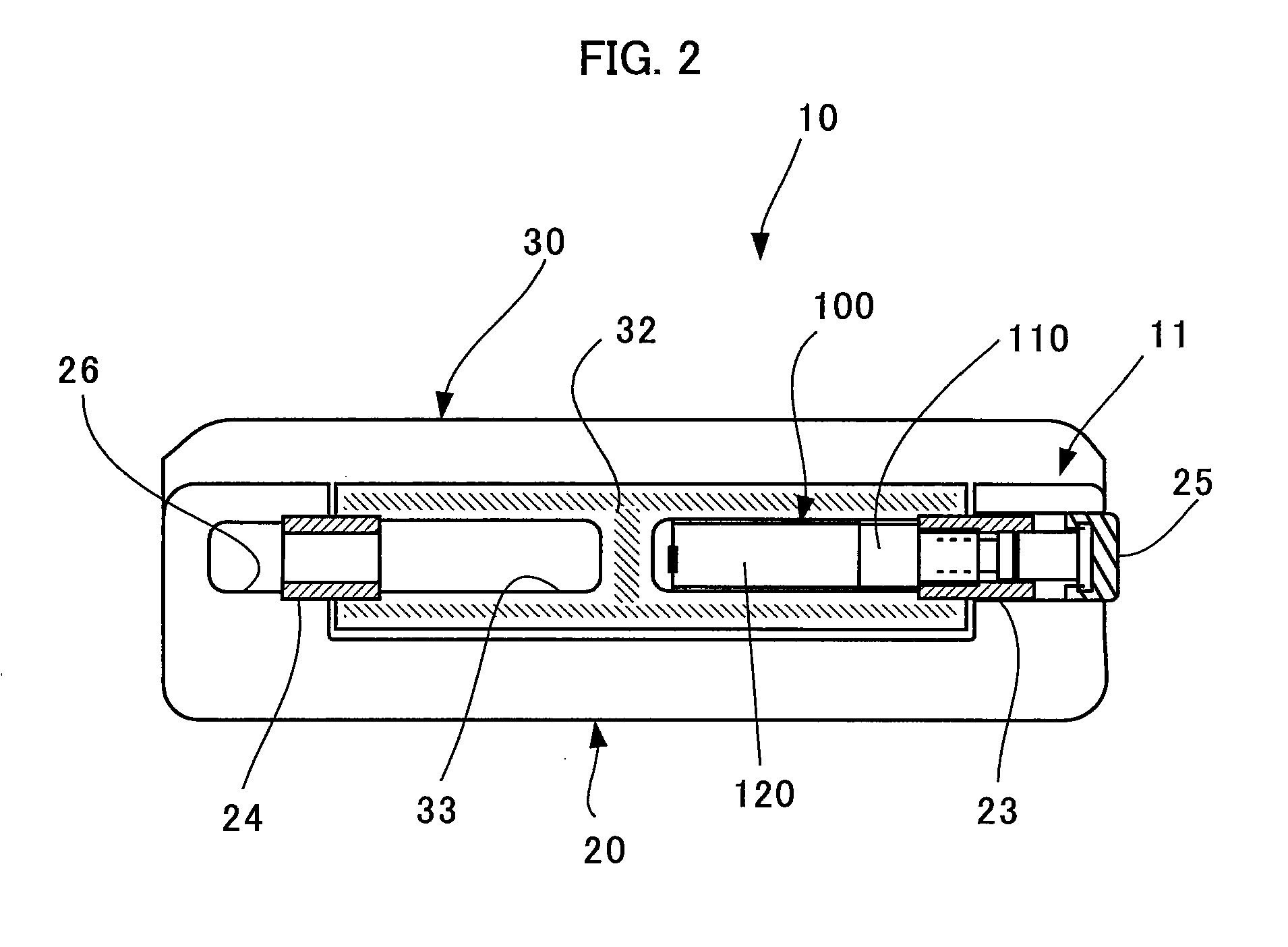

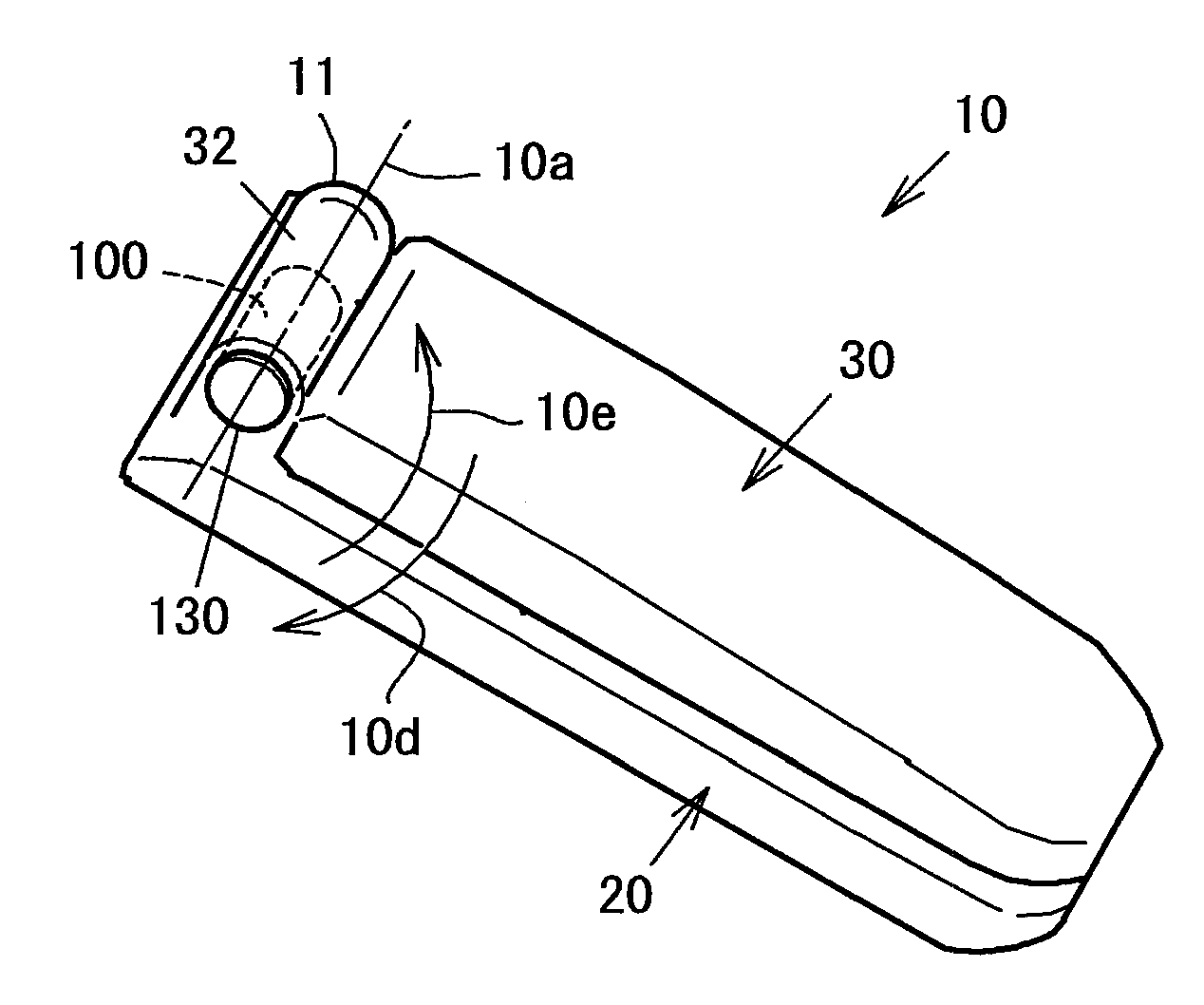

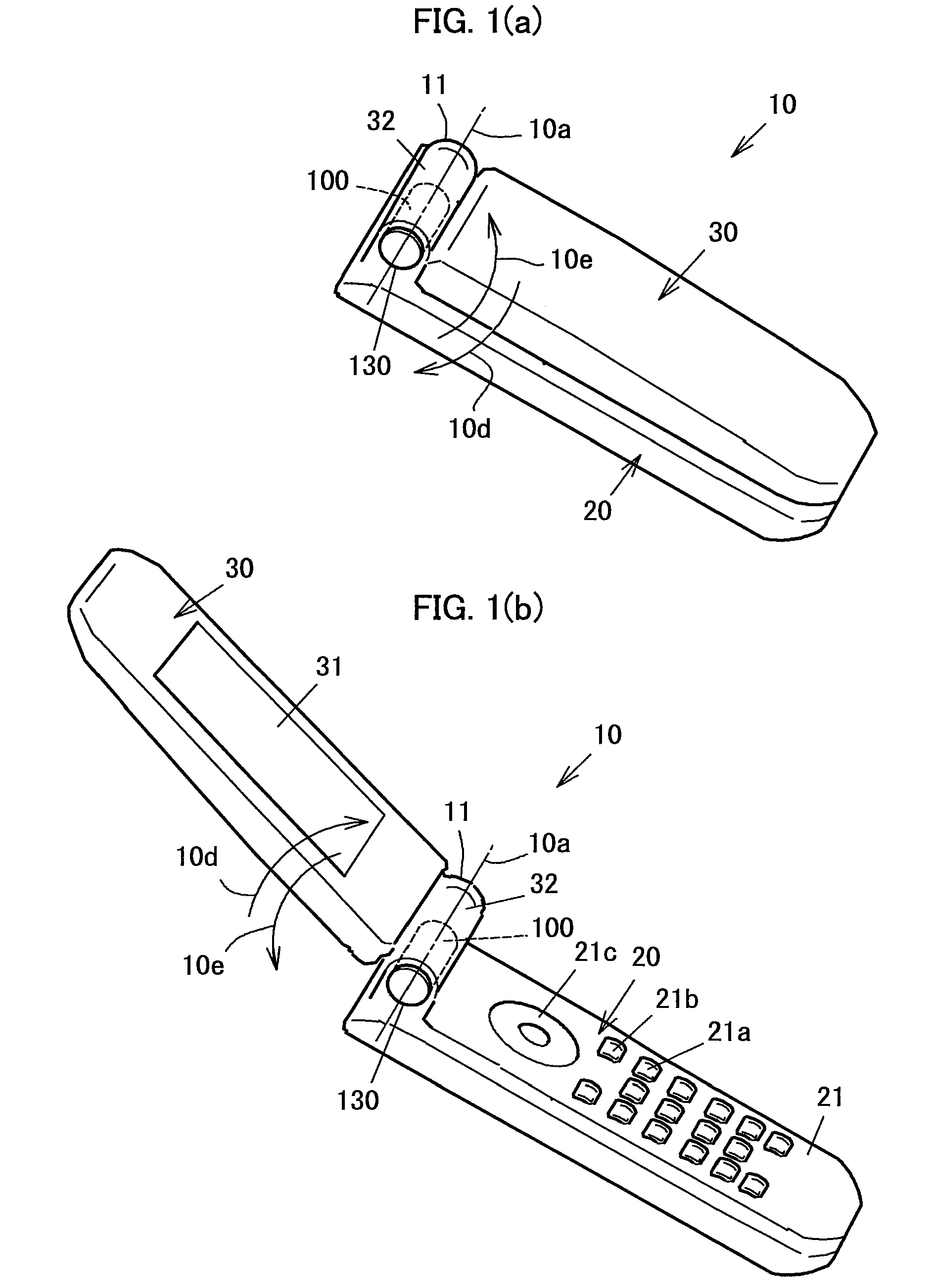

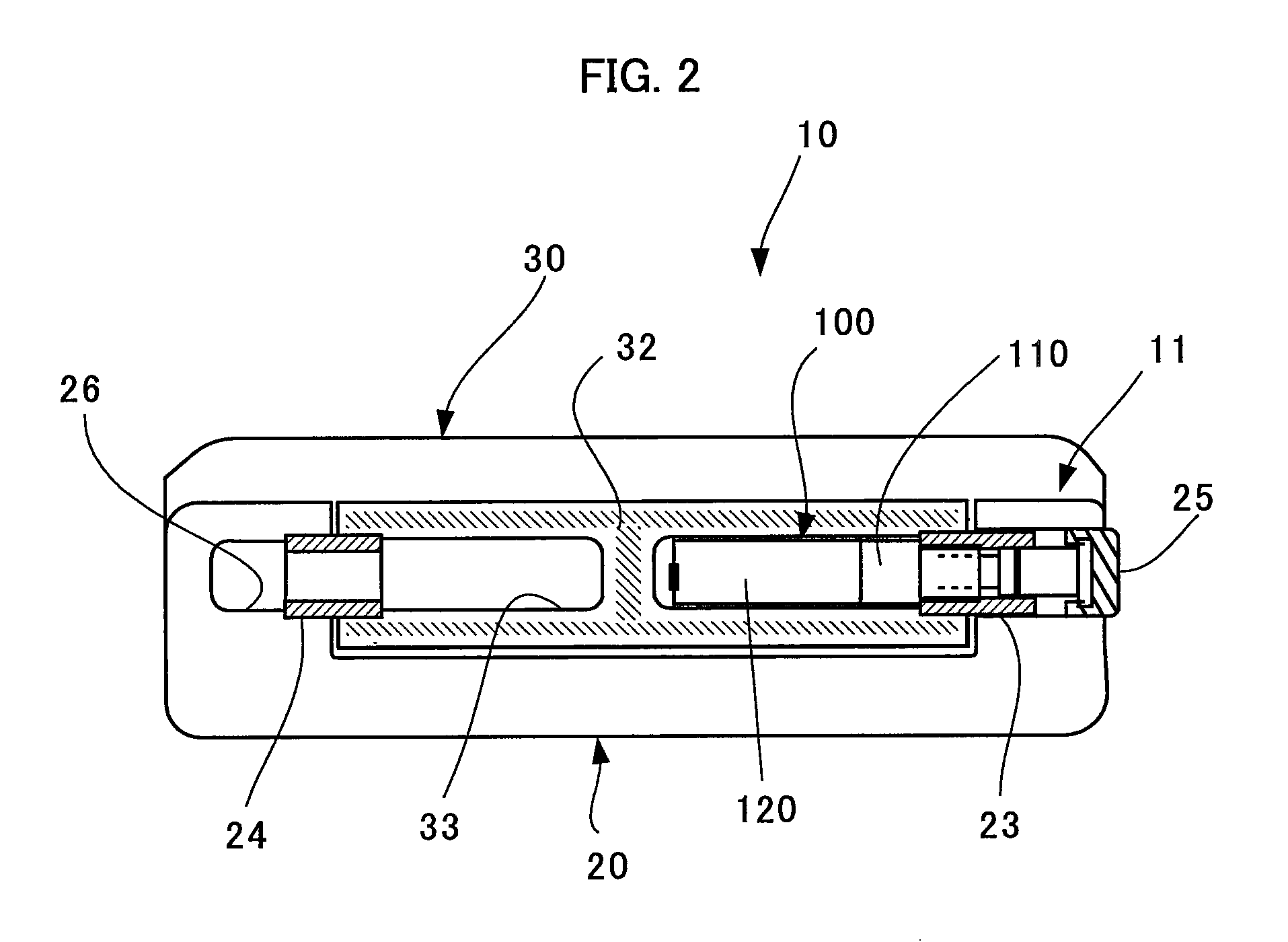

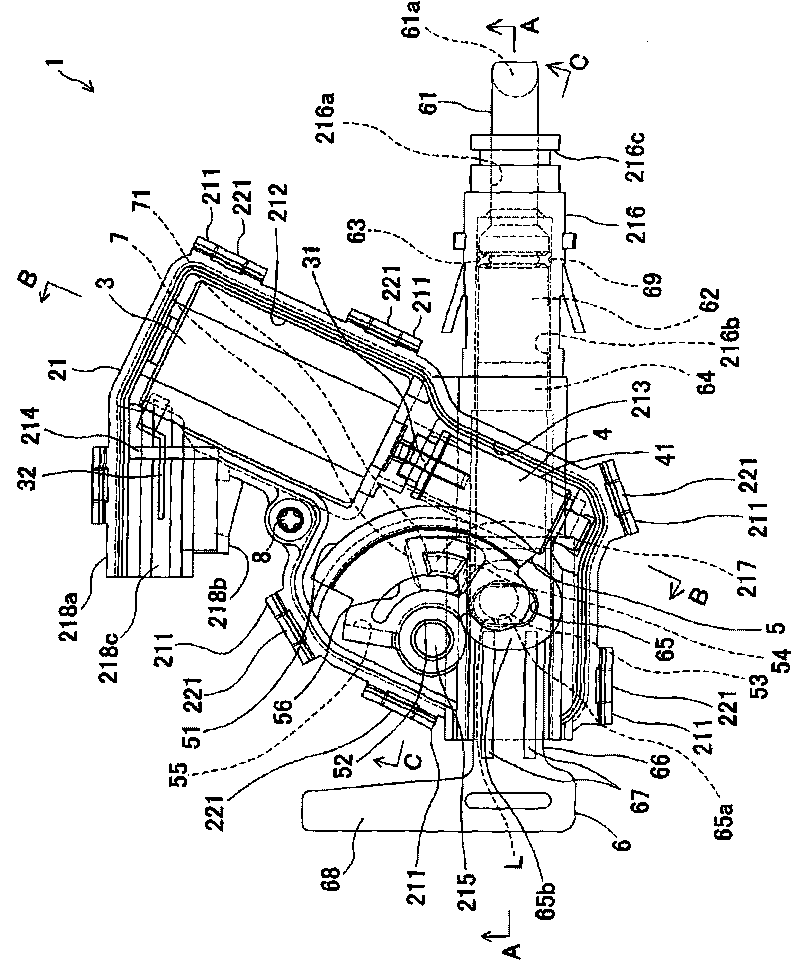

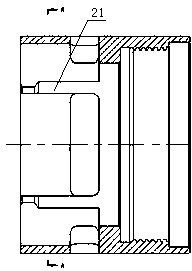

Opening/closing device and mobile device using the same

InactiveUS7974666B2Low costSmall sizeInterconnection arrangementsSubstation equipmentEngineeringGuiding center

It is an object of the present invention to provide an opening / closing hinge device which can be produced simple in construction and inexpensive in production by reducing the number of the parts forming part of the mobile device and to provide a mobile device small in size, reduced in cost and sufficiently reliable in the hinged members. The second member is rotated with respect to the first member toward the opening operation direction through the movable cam (150) by the urging force of the urging means (170) when the operation cam (130) is displaced in the predetermined operation direction by the external operation force. The fixed guide member (110) has inclined guide portions (115) each inclined at an advance angle in a predetermined inclination direction with respect to the surface perpendicular to the guide center axis to have the second rotation cam (140) rotated around the guide center axis in response to the displacement of the second rotation cam (140) along the guide center axis. The second rotation cam (140) being driven to rotate by the inclined guide portions (115) under a pressing force from the movable cam (150) to have its engagement state with the movable cam (150) changed and to have the urging direction of the second member by the urging means (170) changed when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the operation starting position.

Owner:PANASONIC CORP

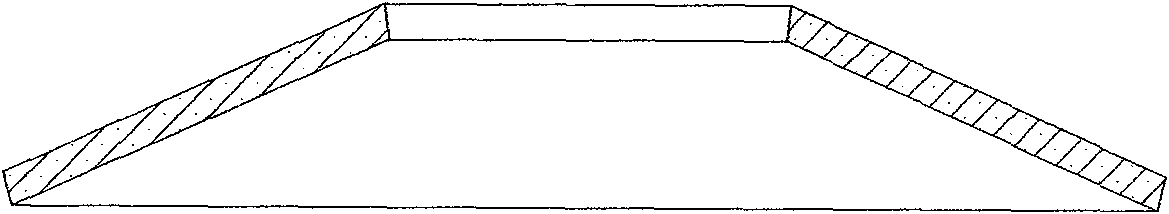

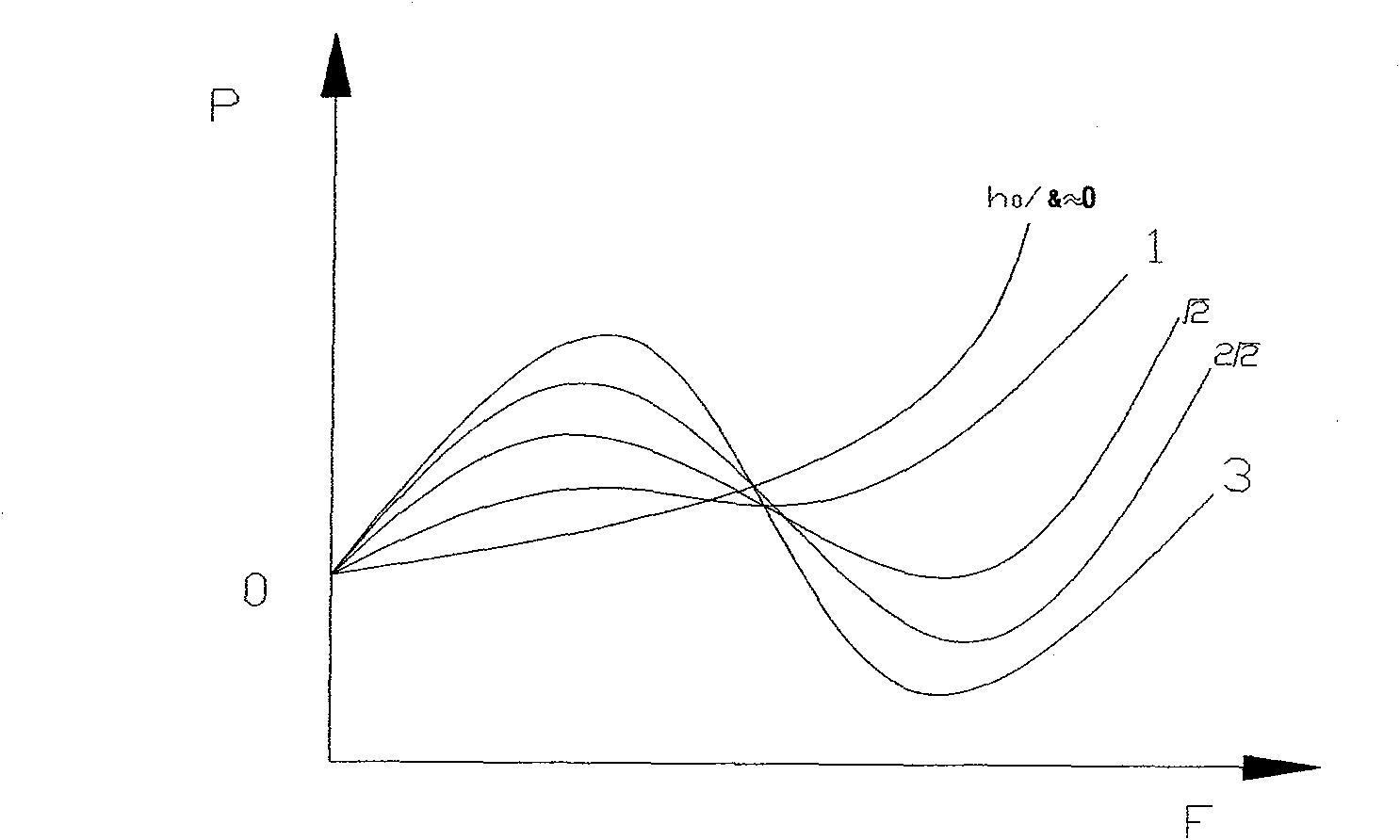

Opening/Closing Device and Mobile Device Using the Same

InactiveUS20100024165A1Smooth transferring operationReliable engagementSubstation equipmentHingesSurface pressureEngineering

It is an object of the present invention to provide an opening / closing device which can be produced simple in construction and reduce the surface pressure of its cam portions, and a mobile phone which can be reduced in cost and sufficiently reliable in the hinged members by using the opening / closing device. In the opening / closing device operable to rotate the second member (30) with respect to the first member (20) hingedly connected the second member (30) in an opening operation direction by operating first and second rotation cams (160, 140), and a movable cam (150) held in engagement with the second rotation cam (140) in response to the displacement of the operation cam (130), the second rotation cam (140) and the movable cam (150) have a plurality of kinds of end cam portions ((142, 153), (143, 154)) formed thereon at different radiuses (r1, r2) from the guide center axis (110c) in opposing relationship with each other, the urging direction of the urging means (170) to the second member (30) is changed by the end cam portions ((142, 153), (143, 154)) when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the predetermined operation starting position.

Owner:PANASONIC CORP

Opening/closing device and mobile device using the same

InactiveUS20090280874A1Smooth transferring operationEasy to participateSubstation equipmentHingesRotational axisGuiding center

It is an object of the present invention to provide an opening / closing hinge device which can be produced simple in construction and inexpensive in production by reducing the number of the parts forming part of the mobile device and to provide a mobile device small in size, reduced in cost and sufficiently reliable in the hinged members. The second member is rotated with respect to the first member toward the opening operation direction through the movable cam (150) by the urging force of the urging means (170) when the operation cam (130) is displaced in the predetermined operation direction by the external operation force. The fixed guide member (110) has inclined guide portions (115) each inclined at an advance angle in a predetermined inclination direction with respect to the surface perpendicular to the guide center axis to have the second rotation cam (140) rotated around the guide center axis in response to the displacement of the second rotation cam (140) along the guide center axis. The second rotation cam (140) being driven to rotate by the inclined guide portions (115) under a pressing force from the movable cam (150) to have its engagement state with the movable cam (150) changed and to have the urging direction of the second member by the urging means (170) changed when the operation cam (130) is operated to cause the first rotation cam (160) to be rotated from the operation starting position.

Owner:PANASONIC CORP

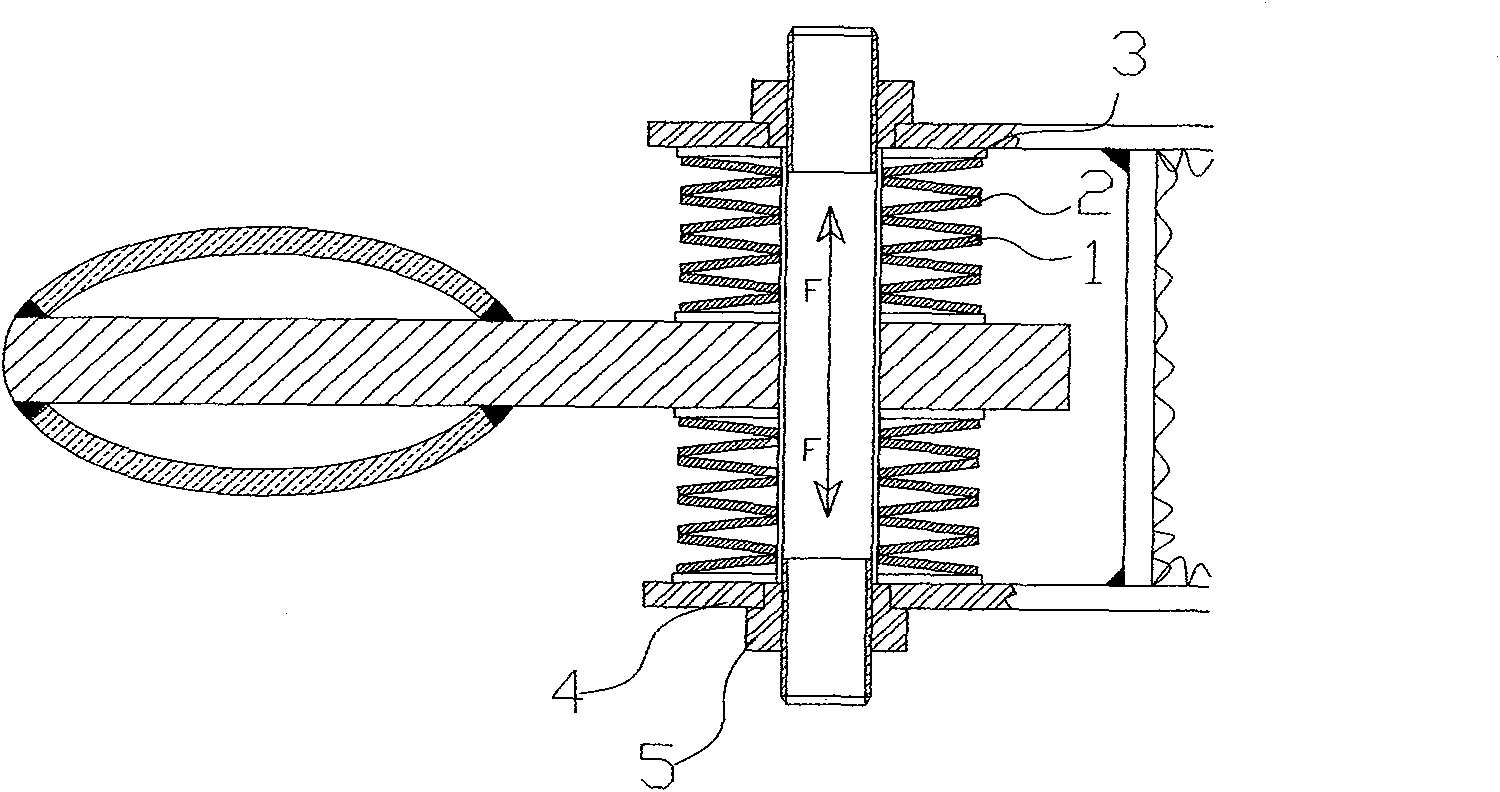

Damping device with disk spring assembly structure

ActiveCN101929517ACan control the maximumMinimal compression set can be controlledHigh internal friction springsViscoelastic dampingEngineering

The invention provides a damping device with a disk spring assembly structure, relating to building shock absorption and damping device. The device comprises a disk spring assembly, a spacer, an inner guide connected with the disk spring assembly, screw stems and nut caps connected with the disk spring assembly, and a moveable block connected with the disk spring assembly. An interlayer steel plate rubber blanket and a bottom plate fixedly connected with the lower part of the interlayer steel plate rubber blanket form a horizontal shock isolator; the horizontal shock isolator is characterizedin that the upper part of the shock isolator is fixedly connected with a connecting plate, the upper part of the connecting plate is provided with a vertical shock isolator; the vertical shock isolator comprises a sleeve with the lower end thereof connected with the connecting plate, the sleeve is internally provided with a main disk spring assembly, an auxiliary disk spring assembly and a viscoelastic damper; the main disk spring assembly is arranged at a guiding center, the auxiliary disk spring assembly and the viscoelastic damper are arrayed in a stagger manner on a large circle with the main disk spring assembly as the circle center, the main disk spring assembly and each auxiliary disk spring assembly are both internally provided with a guide cylinder fixed with the connecting plate, the upper end and lower end of the guide cylinder are both provided with fixed screws and nut caps, the lower part of the core column of each viscoelastic damper is fixed with the connecting plate, and the top plate and the bottom part of the viscoelastic damper are respectively arranged at the upper end and the lower end of the vertical shock isolator.

Owner:上海核工碟形弹簧制造有限公司

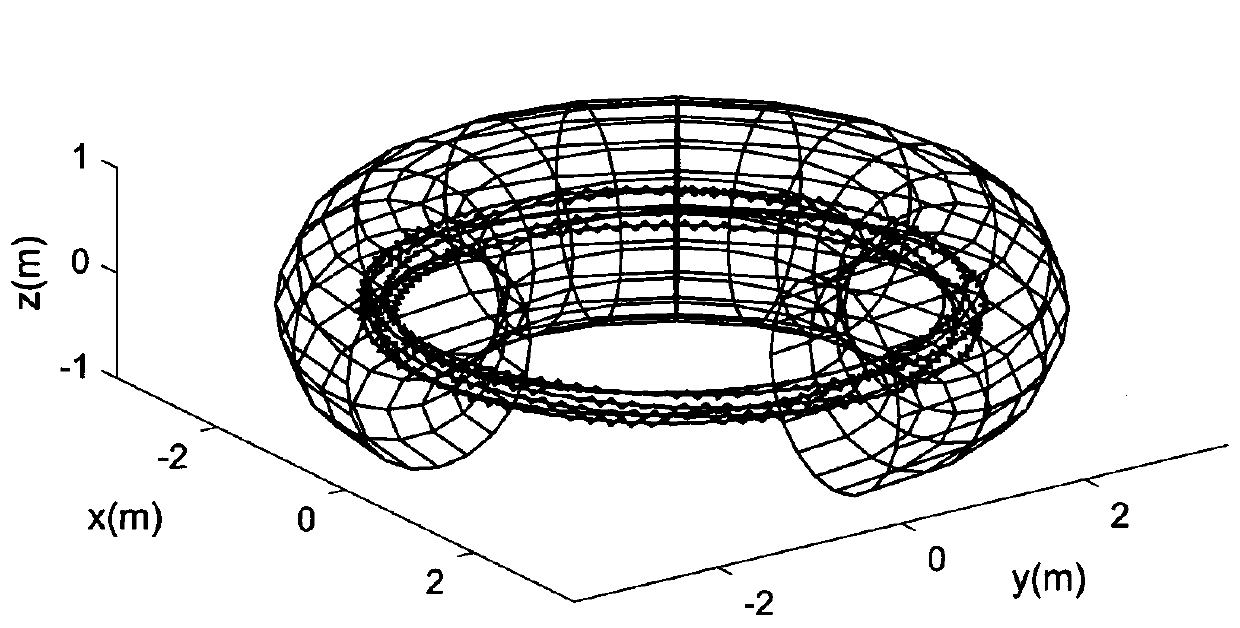

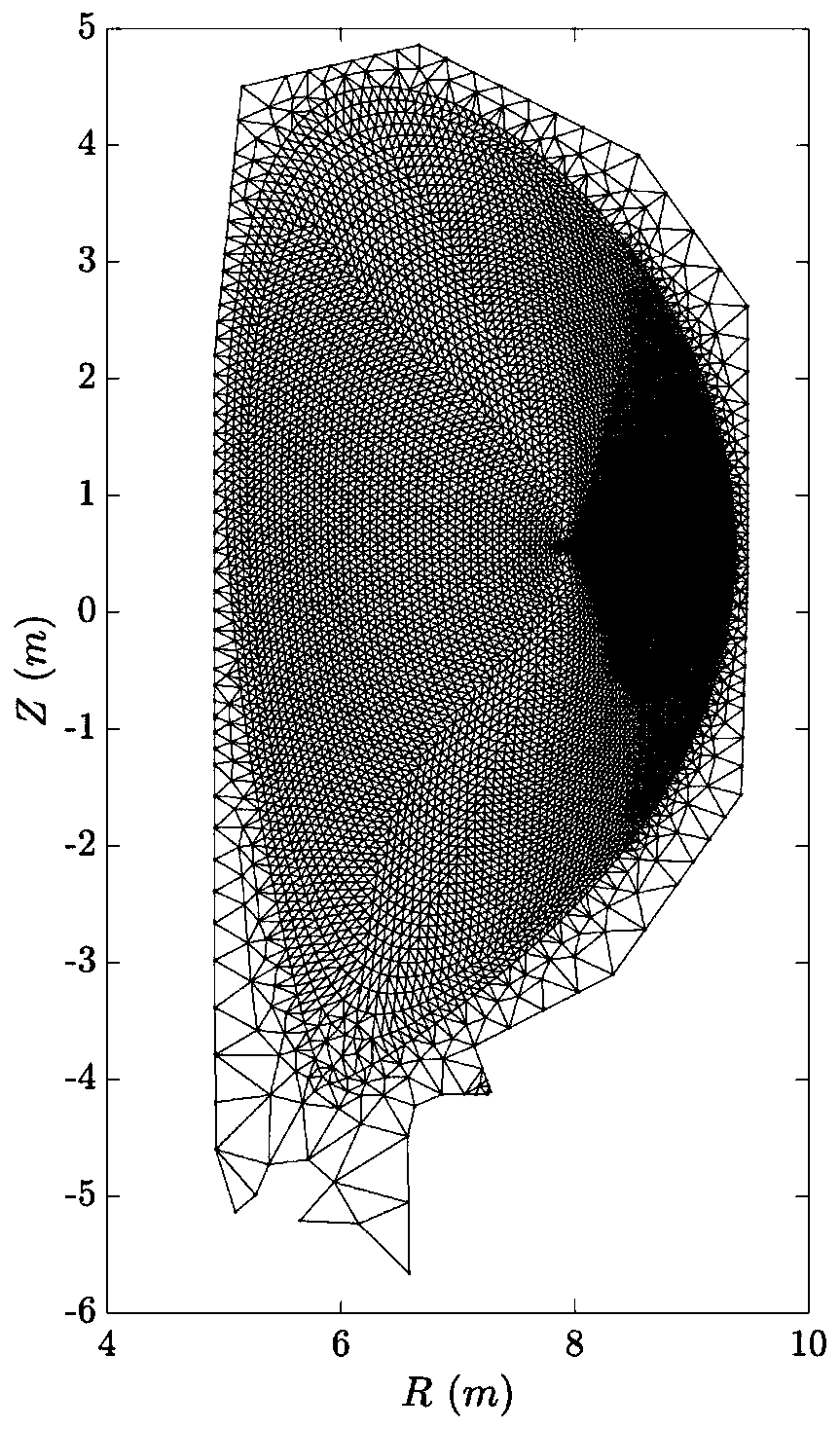

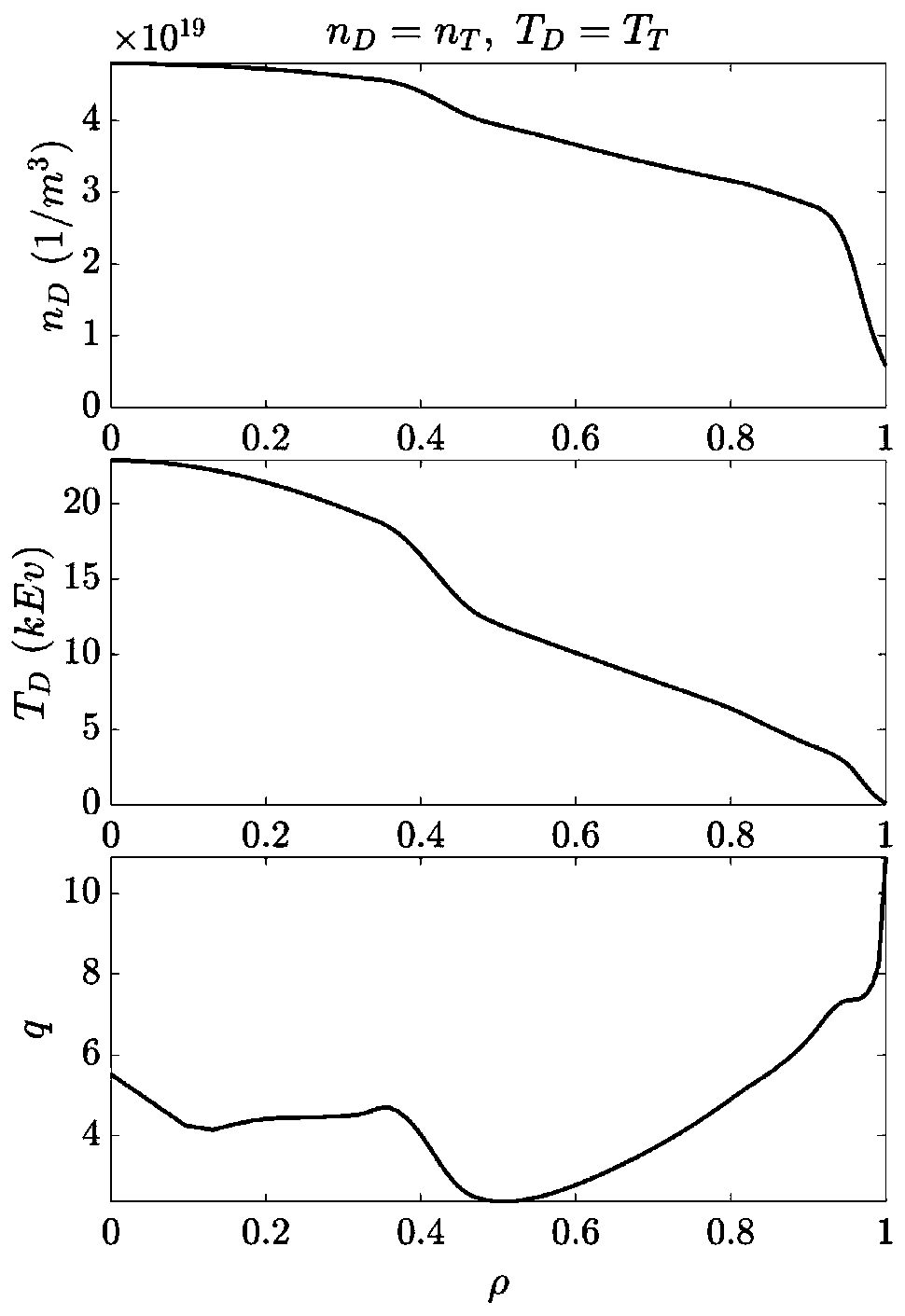

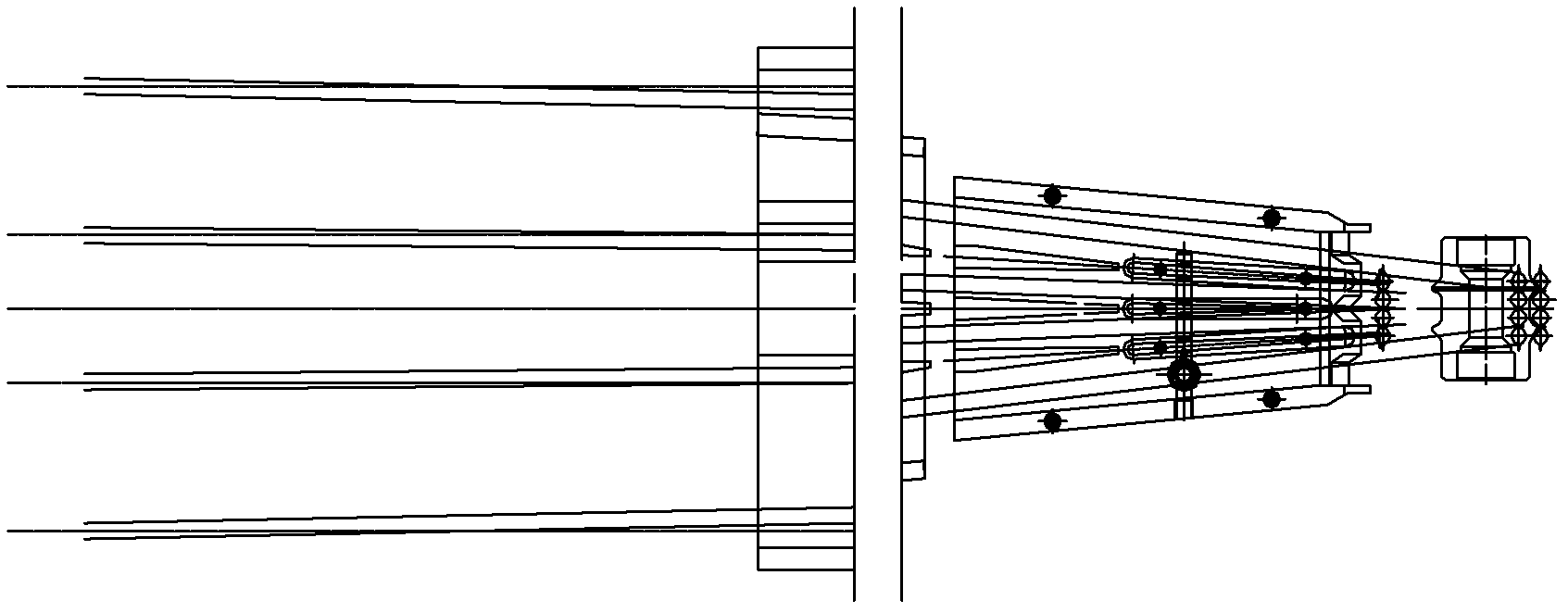

Test particle simulation method for analyzing constraint performance of high-energy particles in Tokamak

ActiveCN111259599AQuick analysisQuick descriptionDesign optimisation/simulationNumerical stabilityEnergy particle

The invention discloses a test particle simulation method for analyzing the confinement performance of high-energy particles in Tokamak, and belongs to the field of magnetic confinement controlled nuclear fusion. The method comprises the following steps: firstly, dividing a two-dimensional triangular mesh according to input parameters such as a balanced magnetic field and a plasma profile; secondly, loading high-energy particle information, which comprises information such as position and speed, into a phase space; then, according to the full-orbit equation and the guide center orbit equation,the evolution of the particles along with time is solved, and a Monte Carlo method is adopted in the collision module; and finally, outputting information of all particles, and outputting informationsuch as particle distribution, energy flow and current after the information is processed by the post-processing module. According to the method, physical processes such as transportation and loss ofhigh-energy particles can be simulated, the calculation efficiency is high, the numerical stability is high, and the method is a stable and efficient numerical simulation method.

Owner:DALIAN UNIV OF TECH

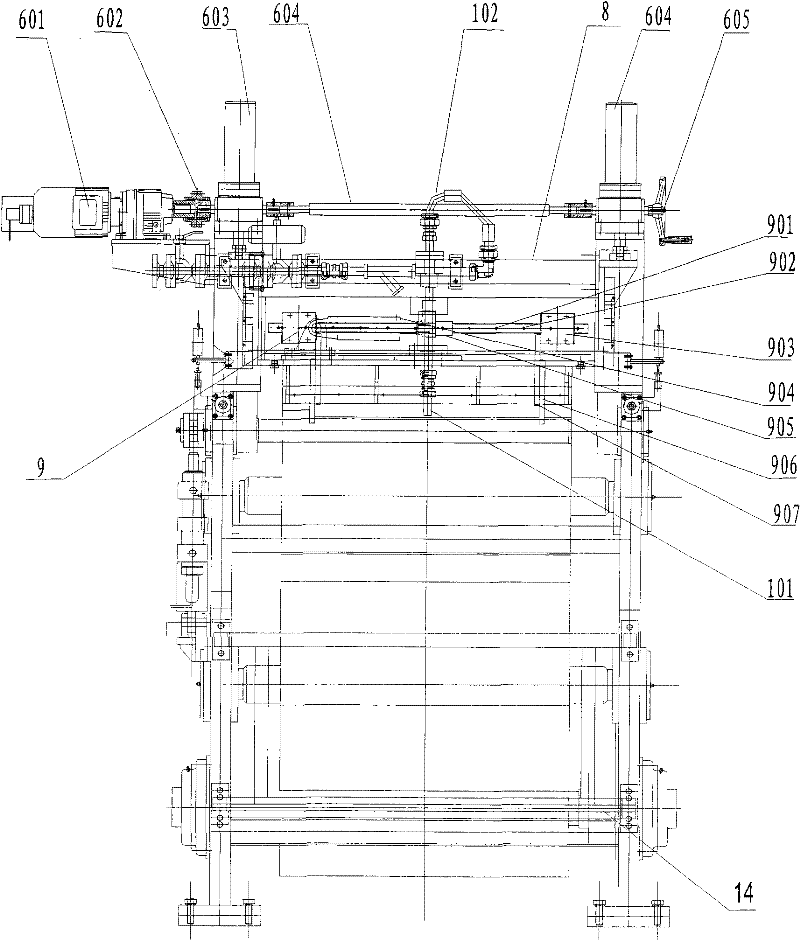

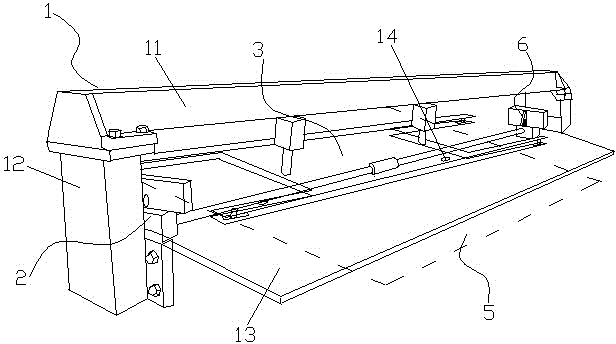

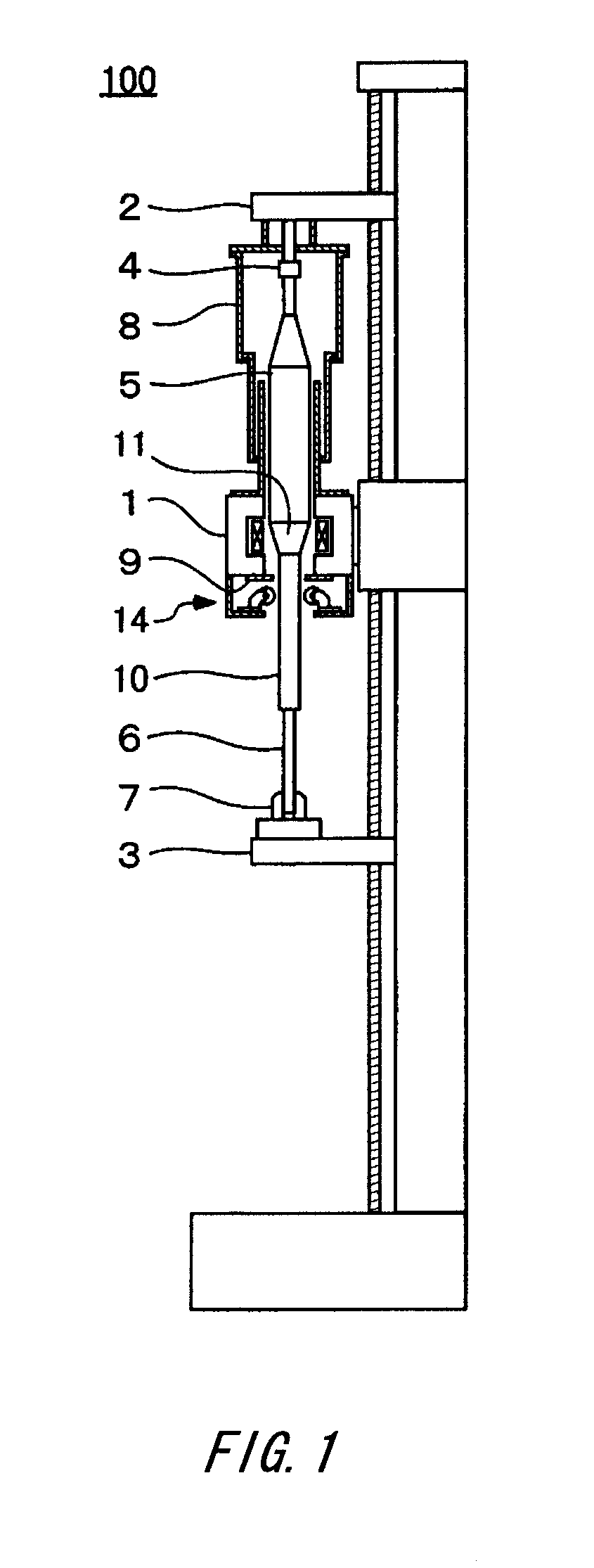

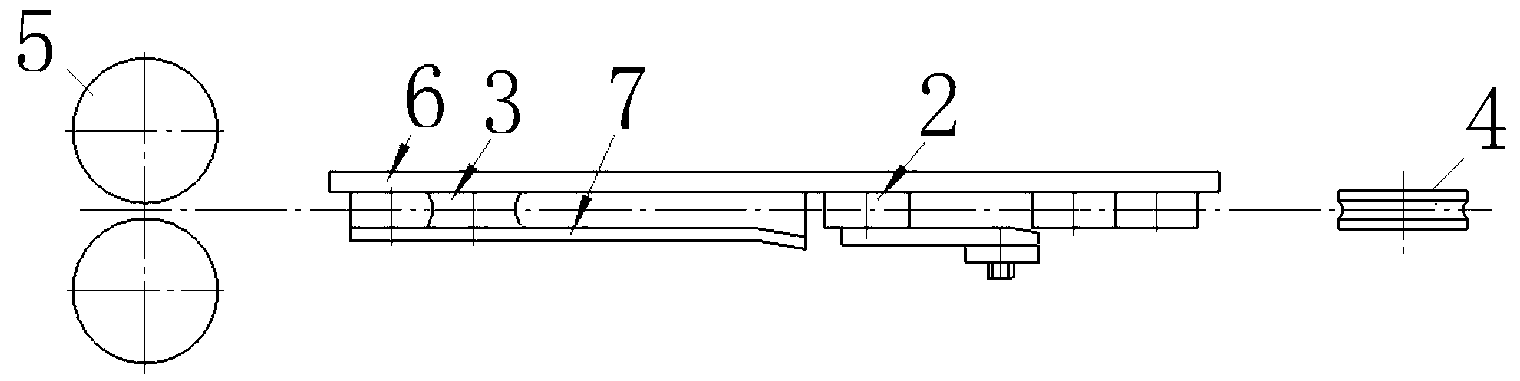

Scraping coater

InactiveCN102451809AHigh precisionImprove coating qualityLiquid surface applicatorsCoatingsDisplay deviceEngineering

The invention provides a scraping coater which is used for overcoming phenomena of paint waste, non-uniform coating, and difficulty to ensure coating thickness caused by roller coating and spraying of a sheet material when the viscosity of paint is high; the adopted technical scheme is that: the scraping coater comprises a frame 11, a supporting roller 3, a scraper device 12, a material-charging device 10, a swing frame 7, an edge guide centering device 9, and a rotating shaft 4; the swing frame 7 is connected with the frame 11 through a rotating shaft 4; the material-charging device 10 is mounted on the swing frame 7; the supporting roller 3 is mounted on the frame 11; the edge guide centering device 9 and the scraper device 12 are mounted on the swing frame 7 through a mobile crossbeam 8; with the technology, the coating effect is good; with the position of the scraper device 12 controlled by an encoder disposed on a pressing device 6 and a digital display device 15, the gap between the scraper and a steel band on the supporting roller 3 is controlled; the invention has the characteristics of high precision of coating thickness control, uniform coating, and high paint utilization rate.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

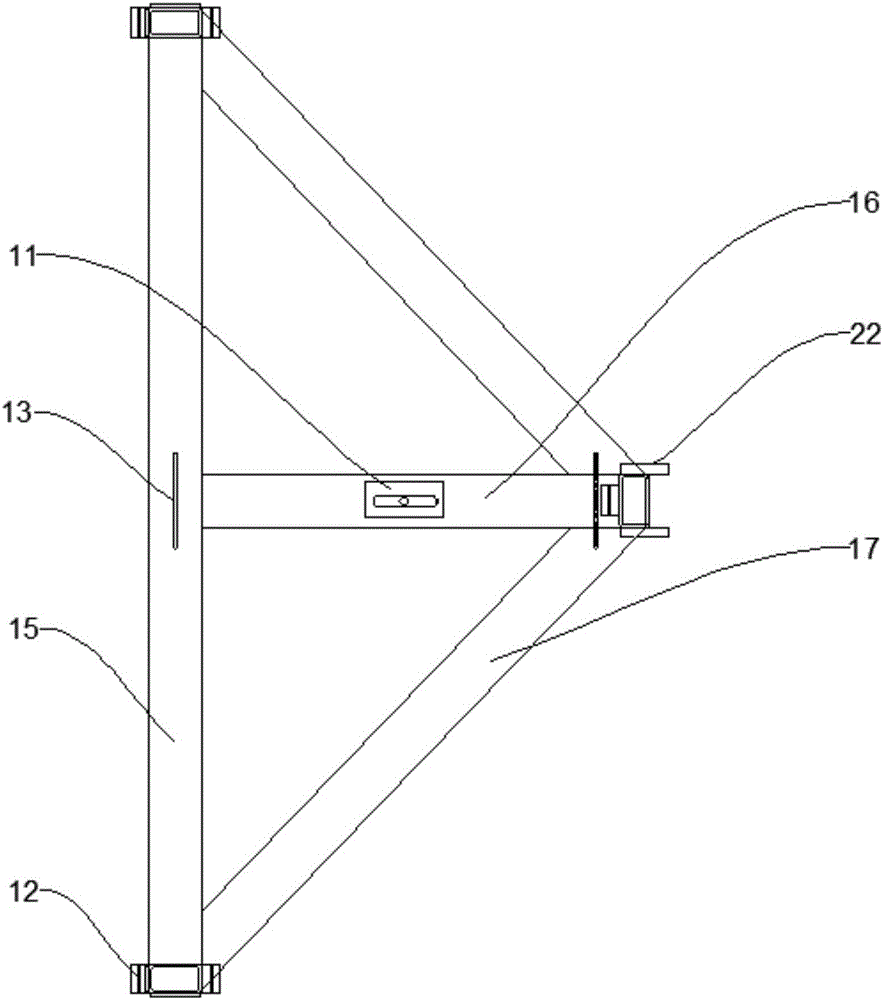

Arc alignment device for mold and arc alignment method

The invention provides an arc alignment device for a mold and an arc alignment method. The arc alignment device for the mold comprises a supporting frame. The supporting frame is provided with oscillation guide centering devices, an arc alignment reference block and an offline arc alignment sample plate locating piece, wherein the oscillation guide centering devices are used for simulating a mold oscillation guide device, the arc alignment reference block is used for simulating the position of an outer arc reference surface of the mold, and the offline arc alignment sample plate locating piece is used for simulating the centering and fixing positions of an offline arc alignment sample plate of a mold centering platform. By the adoption of the arc alignment device for the mold and the arc alignment method, during arc alignment, the offline centering platform can be adjusted and fixed offline, and then a copper plate and a foot roll of the mold are centered uniformly and offline; an outer arc roller of a supporting and guiding section can be detected online, and mold oscillation guide wheels of the supporting and guiding section can be uniformly adjusted offline; and hence, automatic arc joint is achieved after the mold is in position, and exchange of the molds of all the strands of a multi-strand casting machine is achieved.

Owner:CISDI ENG CO LTD

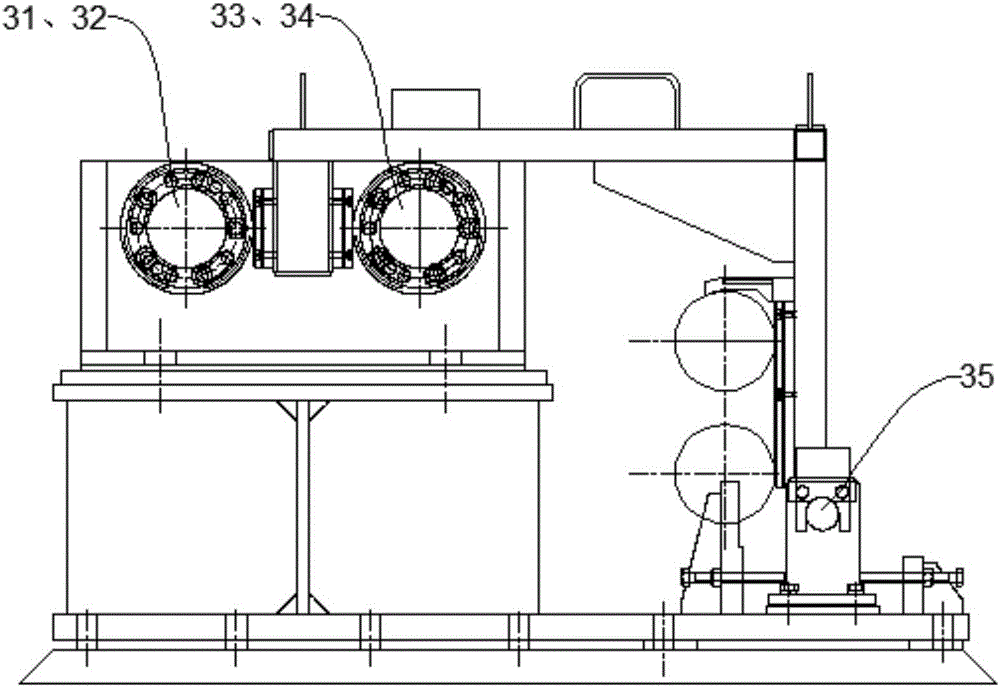

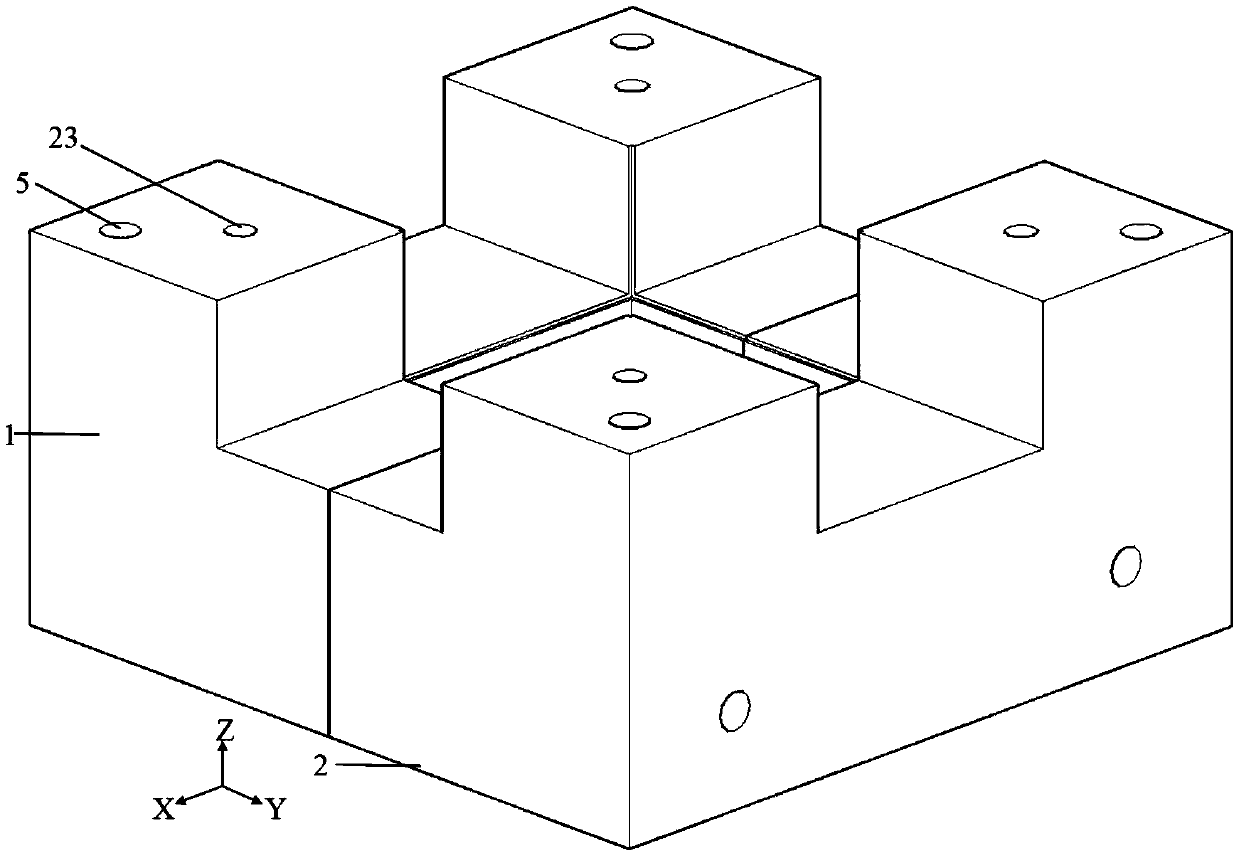

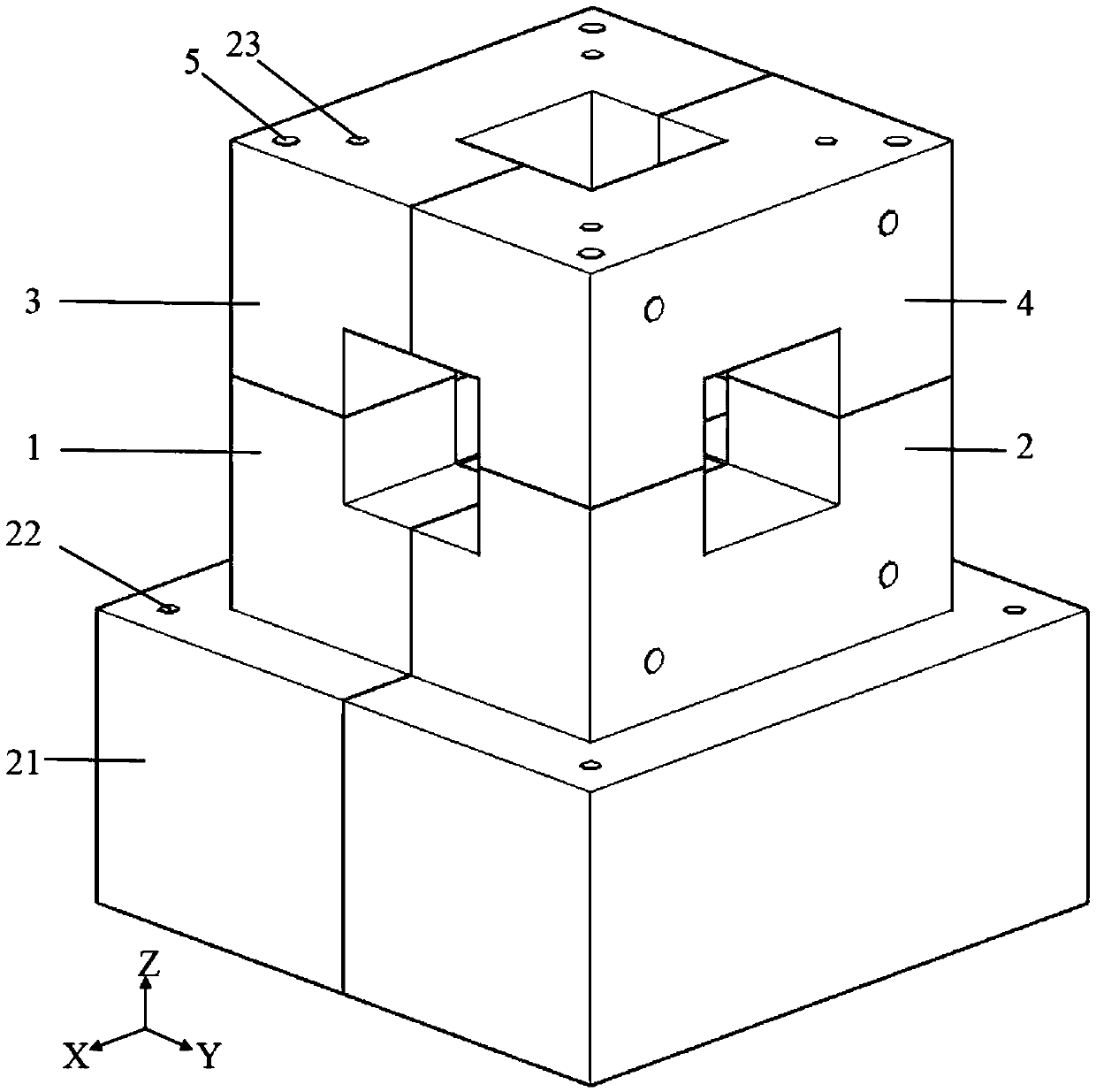

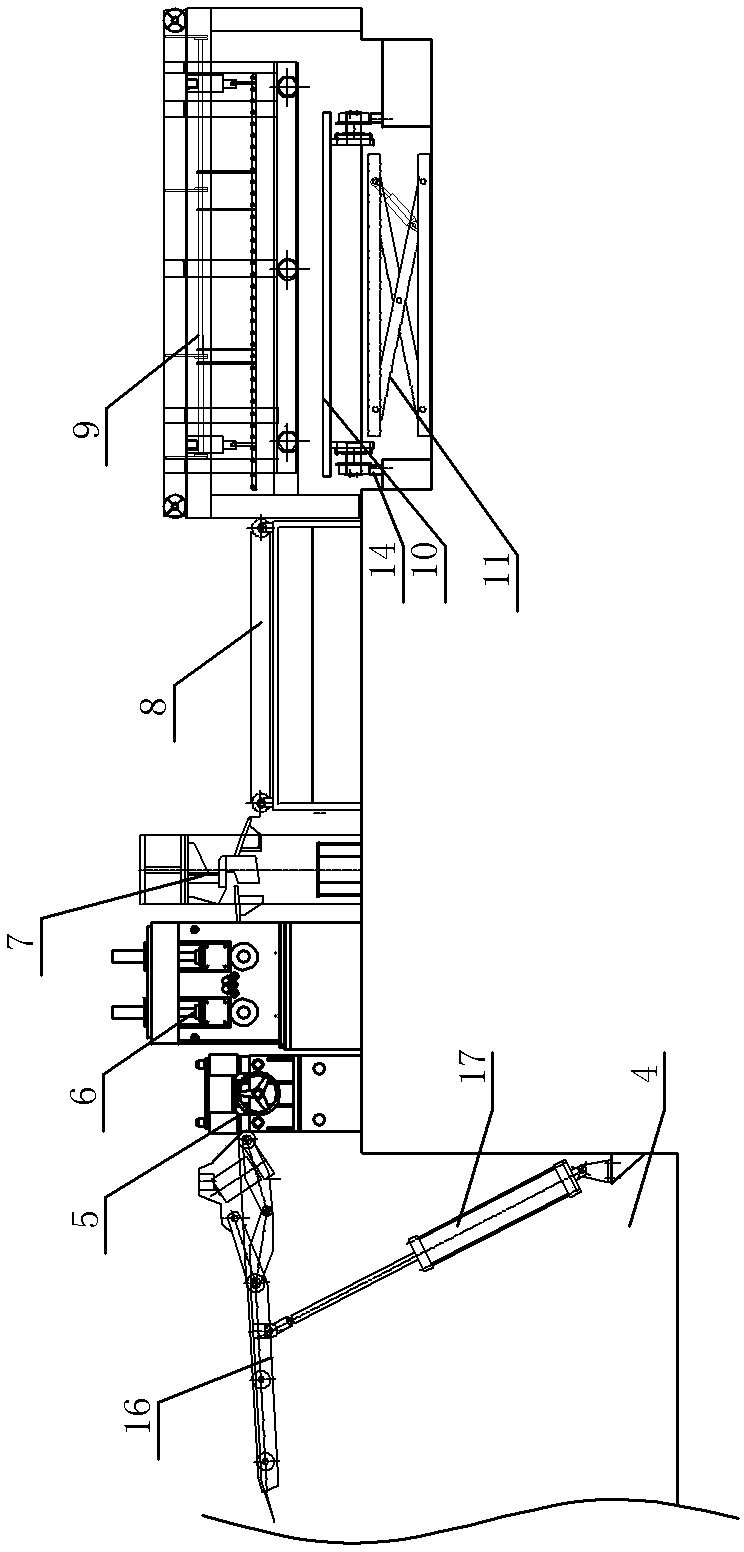

Positioning centering system and method for true three-axis Hopkinson pressure bar and positioning method

ActiveCN109668775APrecise positioningQuick alignmentMaterial strength using single impulsive forceMeasuring instrumentEngineering

The invention provides a positioning centering system and method for a true three-axis Hopkinson pressure bar. A positioning guiding centering box is a cube, and square holes are reserved on the six surfaces of the positioning guiding centering box, and the sizes of the square holes in the six surfaces are the same as the size of a square rod of a Hopkinson rod; the size of an inner cavity of thepositioning guiding centering box is the same as the size of a cubic sample, and the positioning guiding centering box is designed to be symmetrical four parts. The method comprises the steps that step 1, the positioning guiding centering box is assembled, step 2, the positioning guiding centering box is immediately placed in the center position of a central cube square box, and step 3, the three-axis six-direction pressure bar is quickly and precisely aligned with assisting of an infrared laser measuring instrument. Through structural design of the positioning guiding device box and the tubesquare box, the quick and precise positioning centering mounting of test materials such as rock and concrete can be ensured. According to the positioning centering method for the true three-axis Hopkinson pressure bar, quick alignment of the three-axis six-direction pressure bar can be ensured through an infrared laser measuring instrument auxiliary mounting system.

Owner:SHENZHEN UNIV

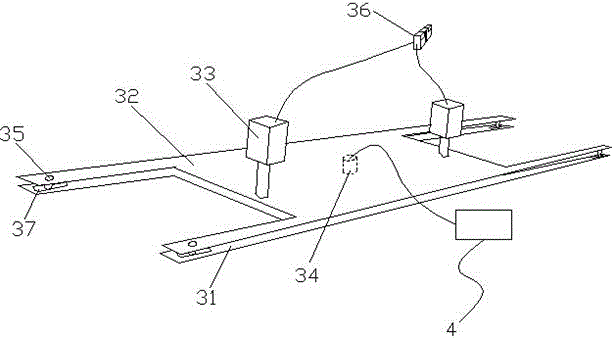

Pressing plate type side guide centering device

ActiveCN105290654APrevent arching deformationOvercome vulnerabilityWelding/cutting auxillary devicesAuxillary welding devicesStrip steelGuiding center

The invention relates to the field of centering mechanisms of cold rolling finished product machine set welding machines, in particular to a side guide centering device. According to the pressing plate type side guide centering device, a movable pressing plate mechanism comprises a lower layer pressing plate, an upper layer support plate and a drive device. The edges of the lower layer pressing plate and the upper layer support plate are supported and connected through connection rods. The parts where the connection rods make contact with the lower layer pressing plate and / or the upper layer support plate are provided with slide grooves. The connection rods slide in the slide grooves freely. A deformation sensor is arranged in the middle between the lower layer pressing plate and the upper layer support plate. The lower layer pressing plate and the upper layer support plate are driven by the drive device to move synchronously to press strip steel. A controller controls and is connected with a stepping motor and the deformation sensor which are in a centering drive mechanism. According to the pressing plate type side guide centering device, the strip steel is prevented from humping deformation, and when the strip steel humps, a side guide plate can be controlled to stop running through a signal of the deformation sensor, so that the centering accuracy and effectiveness in the process in which thin strip steel is centered through the centering device are effectively improved, and the welding efficiency of the welding machines is improved and stabilized.

Owner:BAOSHAN IRON & STEEL CO LTD

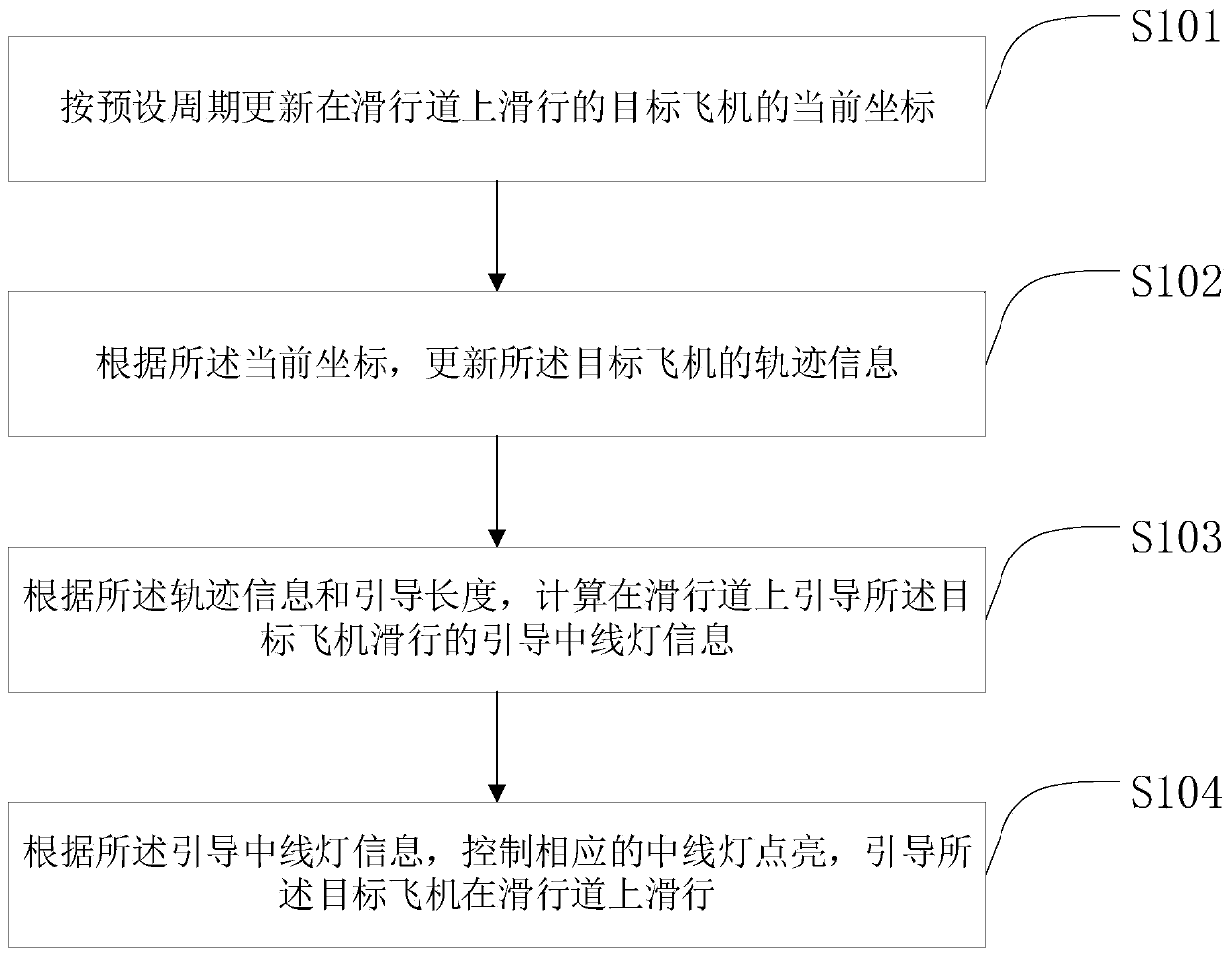

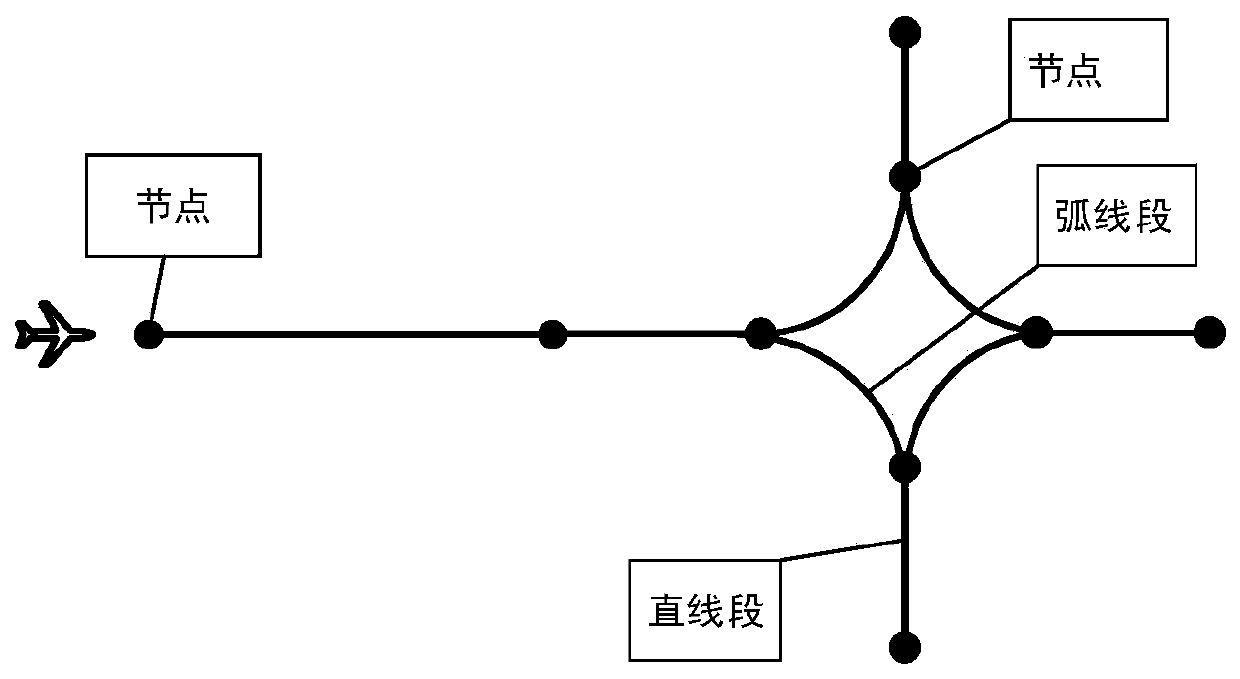

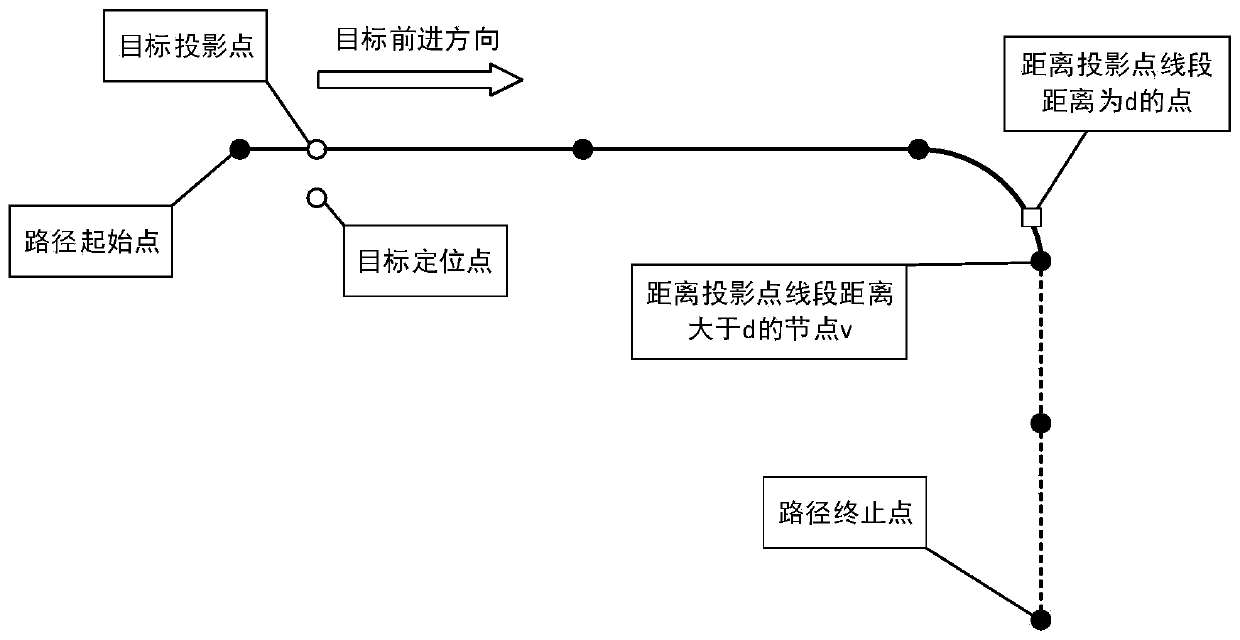

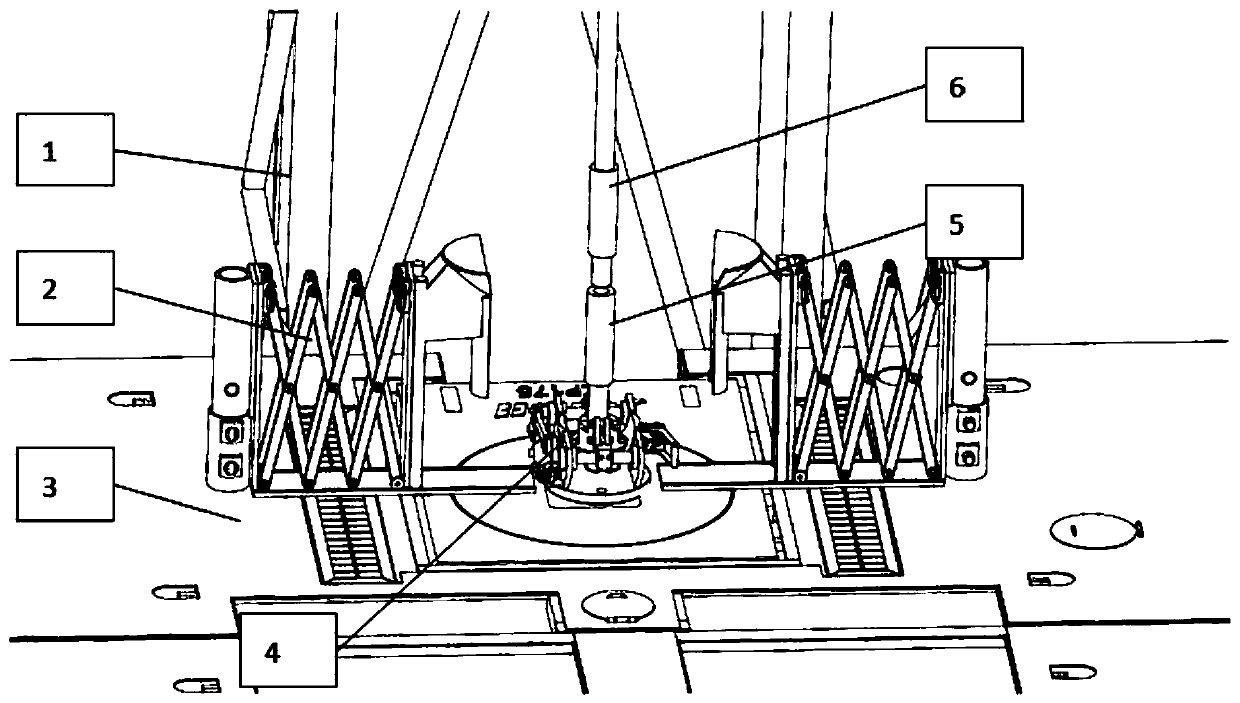

Light control method, device and system for guiding aircraft to slide on ground, and medium

ActiveCN109788618AIncrease profitImprove securityElectric light circuit arrangementEnergy saving control techniquesMiddle lineGuiding center

The invention provides a light control method for guiding an aircraft to slide on the ground. The method comprises the following steps: updating current coordinates of a target aircraft gliding on a taxiway according to a preset period; updating trajectory information of the target aircraft according to the current coordinates; calculating guiding center line lamp information for guiding the aircraft to slide on the taxiway according to the trajectory information and a guiding length; and controlling to turn on a corresponding guiding center line lamp according to the guiding center line lampinformation to guide the target aircraft to slide on the taxiway. The aircraft can be guided to slide by the center line lamp on the taxiway, thereby avoiding sliding errors and greatly improving thesafety level and the operation efficiency of the airport ground traffic.

Owner:THE SECOND RES INST OF CIVIL AVIATION ADMINISTRATION OF CHINA

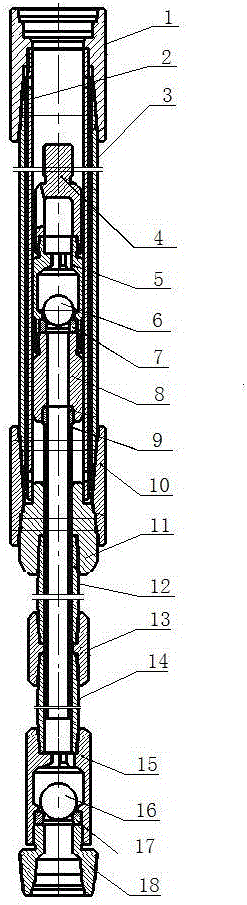

Novel drill pipe shackle assembling and centering device

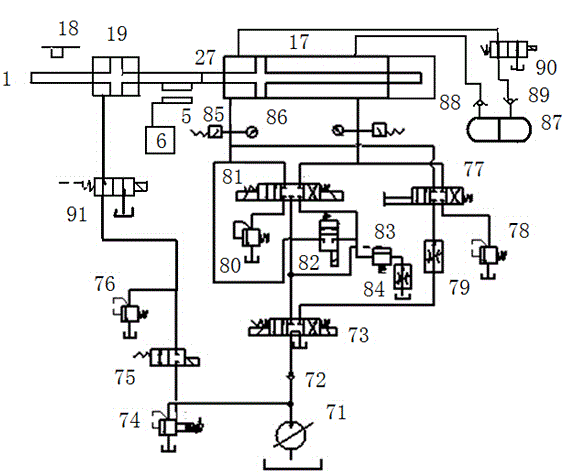

InactiveCN107869317AEliminate manual operationSimple structureDrilling rodsDrilling casingsHydraulic cylinderGuiding center

The invention belongs to the field of petroleum equipment, and particularly relates to a novel drill pipe shackle assembling and centering device. The device is characterized in that hydraulic cylinders of two centering device bodies push a connecting rod to move, and drive a centering tank to clamp and fix drill pipes; the centers of the to-be-connected drill pipes are aligned by guiding of a centering tank horn mouth, then the centering tank is retracted, and hydraulic power tongs are used for assembling shackle. The centering tank clamps and fixes the drill pipes, the centering tank horn mouth is used for guiding centering, and the device can be of an integrated structure or a split structure. The height of the centering tank can be adjusted through springs so that various adjustment modes of the springs, air cylinders, the hydraulic cylinders, lead screws and the like can be used. In order to guarantee the clamping accuracy and the movement stability of the centering tank, a guiderail is arranged on the movement track of the centering tank, and wheels are arranged on the lower side of the centering tank to move along the guide rail. The device is convenient, stable and reliable to use, high in working efficiency, and capable of reducing the labor intensity of workers and greatly improving the safety of operators.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

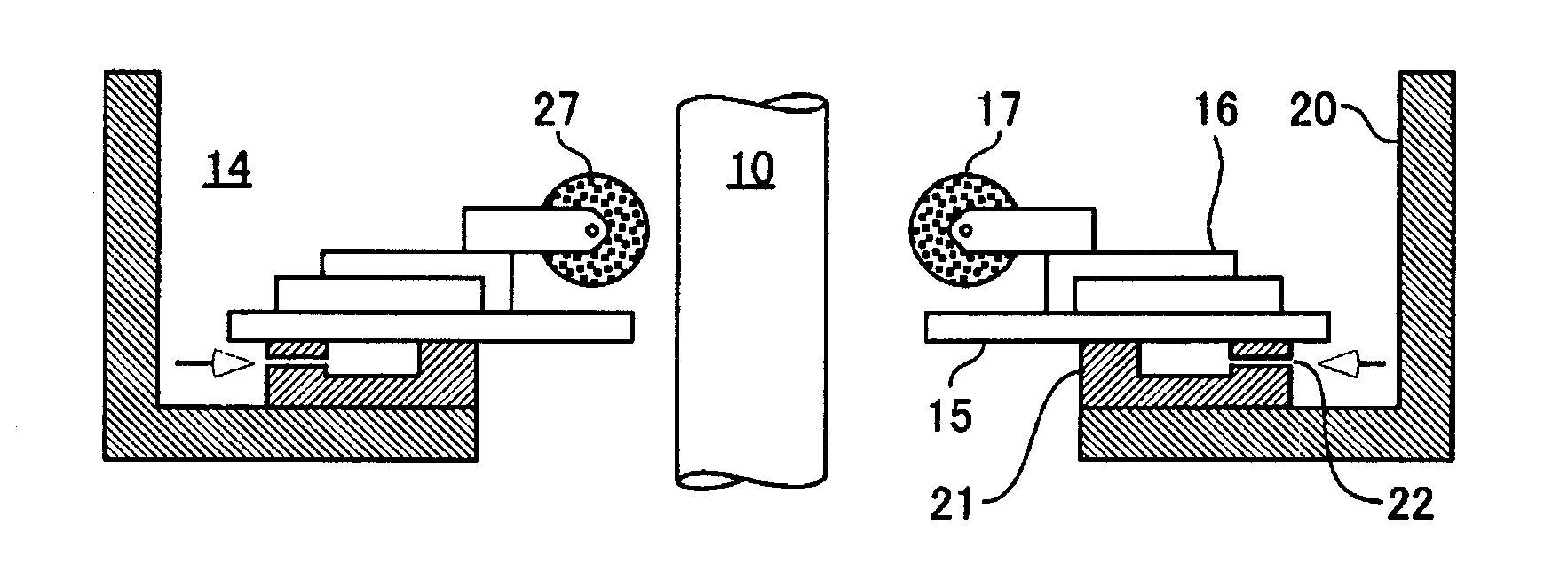

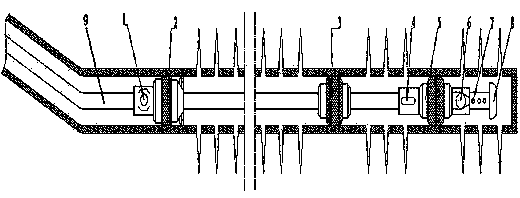

Glass base material elongating method and glass base material elongating apparatus

ActiveUS20130291601A1Glass fibre drawing apparatusMaterial analysis by optical meansEngineeringGuiding center

A glass base material elongating method of sequentially feeding rod-like glass base materials hung by a glass base material feeding mechanism into a heating furnace, and pulling a glass rod with a smaller diameter by a pulling chuck at a lower part of the heating furnace, includes: aligning, by an alignment guiding device that guides the glass rod, a guiding center of the alignment guiding device with an axis of the glass rod, the alignment guiding device guiding the glass rod between the heating furnace and the pulling chuck.

Owner:SHIN ETSU CHEM IND CO LTD

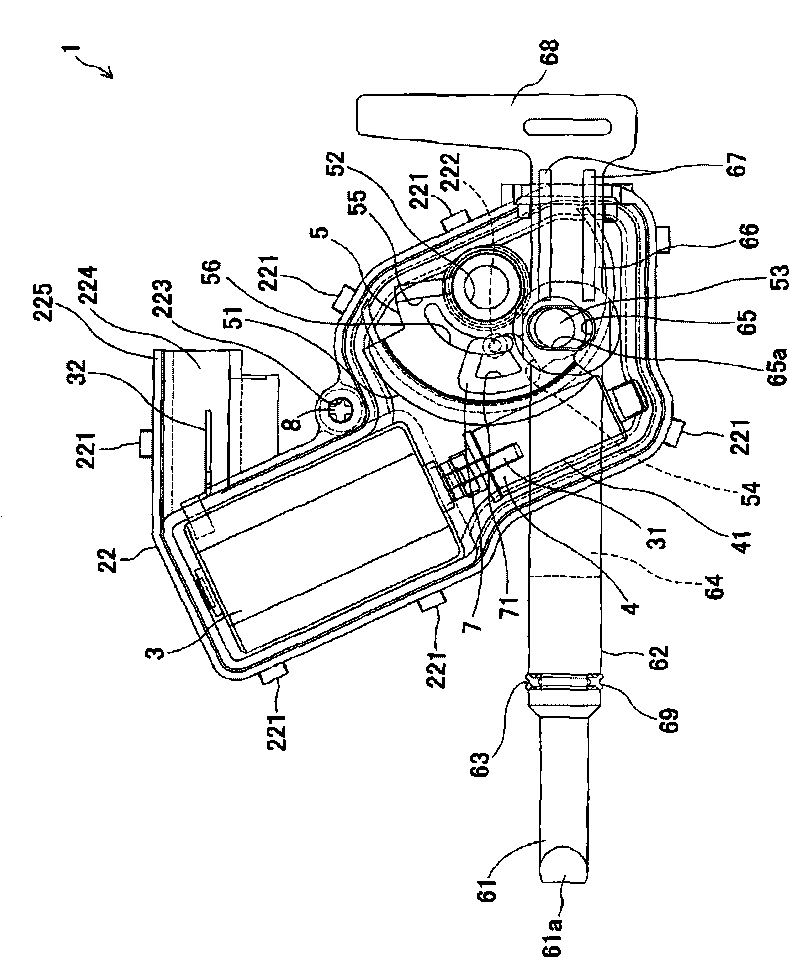

Lid lock apparatus for vehicle

InactiveCN101725290AEasy to shapeEasy to demouldPower transmission/actuator featuresElectrical locking actuatorsEngineeringGuiding center

The invention provides a lid lock apparatus for a vehicle which is smoothly operated. An electric motor (3) provided within the lid lock apparatus (1) is operated to rotate a worm wheel (5) via a worm (4) so that a lock shaft (6) advances and retreats relatively to a housing (2) and makes the lid engage and disengage from the vehicle main body. An engagement pole (53) engaged with the lock shaft (6) is formed on the worm wheel (5). The lock shaft (6) includes a support portion (62) driven by the housing in the thickness direction, a relief portion (64) biased to a support portion (62) for arranging the worm wheel (5), and a relief portion (64) provided with an interlock bore (65) for allowing the engagement pole (53) to insert in the thickness direction. The inner peripheral surface of the interlock bore (65) is projected inwards in the guide center so that the engagement pole (53) and the interlock bore (65) are engaged near the guide center in the thickness direction of the support portion (62).

Owner:AISIN SEIKI KK

Steel flattening unit production line structure

InactiveCN103659271AImprove cutting efficiencyReduce labor intensityMetal-working feeding devicesOther manufacturing equipments/toolsProduction lineStrip steel

The invention provides a steel flattening unit production line structure with the effects of increasing flattening efficiency of large hot-rolled strip steel and reducing labor intensity of workers. The steel flatting unit production line structure comprises an uncoiling machine, a guide mechanism is arranged above the uncoiling machine, a flattening machine is arranged behind the uncoiling machine, a union storage chamber is arranged behind the flattening, a guide centering roll is arranged behind an output shaft of the union storage cavity, a servo shear gauge is arranged behind the guide centering roll, a high-speed shearing machine is arranged at the output end of the servo shear gauge, the back of the high-speed shearing machine leads to the inlet side of a conveyor, the outlet side of the conveyor leads to a collection rack, and a discharge flatcar is arranged at the lower outlet of the collection rack, and is supported in rails.

Owner:WUXI XINJIAYUAN METALLURGY MACHINERY MFG

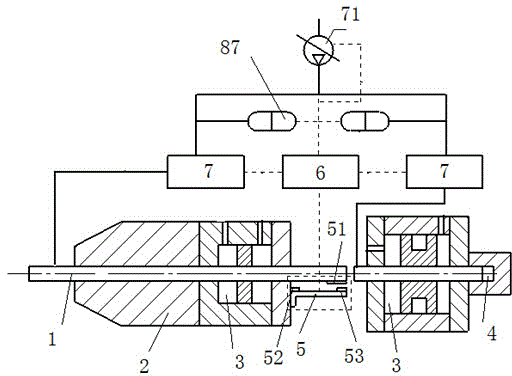

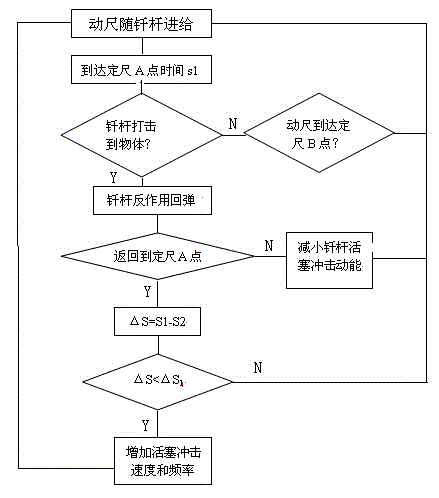

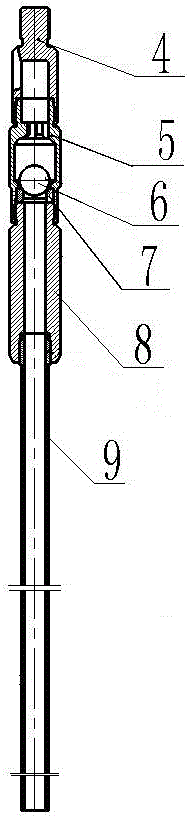

Self-adaptive intelligent hydraulic and pneumatic impact breaking hammer

The invention discloses a self-adaptive intelligent hydraulic and pneumatic impact breaking hammer. The self-adaptive intelligent hydraulic and pneumatic impact breaking hammer comprises a drill rod, a drill rod reciprocating guiding centering mechanism, a piston reciprocating mechanism, an airtight nitrogen volume changing mechanism, an optical grating position sensor, an optical grating signal processing device and a servo driving system. The optical grating position sensor is composed of a movable ruler and two fixed rulers, the movable ruler is installed on the drill rod and reciprocates synchronously along with the drill rod, the two fixed rulers are fixed to a guiding sleeve of the drill rod reciprocating guiding centering mechanism in the feeding direction of the drill rod, the fixed ruler A is located above the fixed ruler B, the fixed ruler A is used for detecting the time of passing through a detecting point of the fixed ruler A of the movable ruler in feeding and bouncing, and controlling the hitting speed and frequency of the drill rod, and a detecting point of the fixed ruler B is used for detecting the feeding limit position of the drill rod. The optical grating position sensor is connected with the optical grating signal processing device. The optical grating signal processing device is connected with the servo driving system which enables the drill rod to change the frequency and speed of hitting an object in a self-adaptive mode according to the hardness of the hit object. According to the self-adaptive intelligent hydraulic and pneumatic impact breaking hammer, the tool use efficiency is improved.

Owner:滁州国登管业科技有限公司

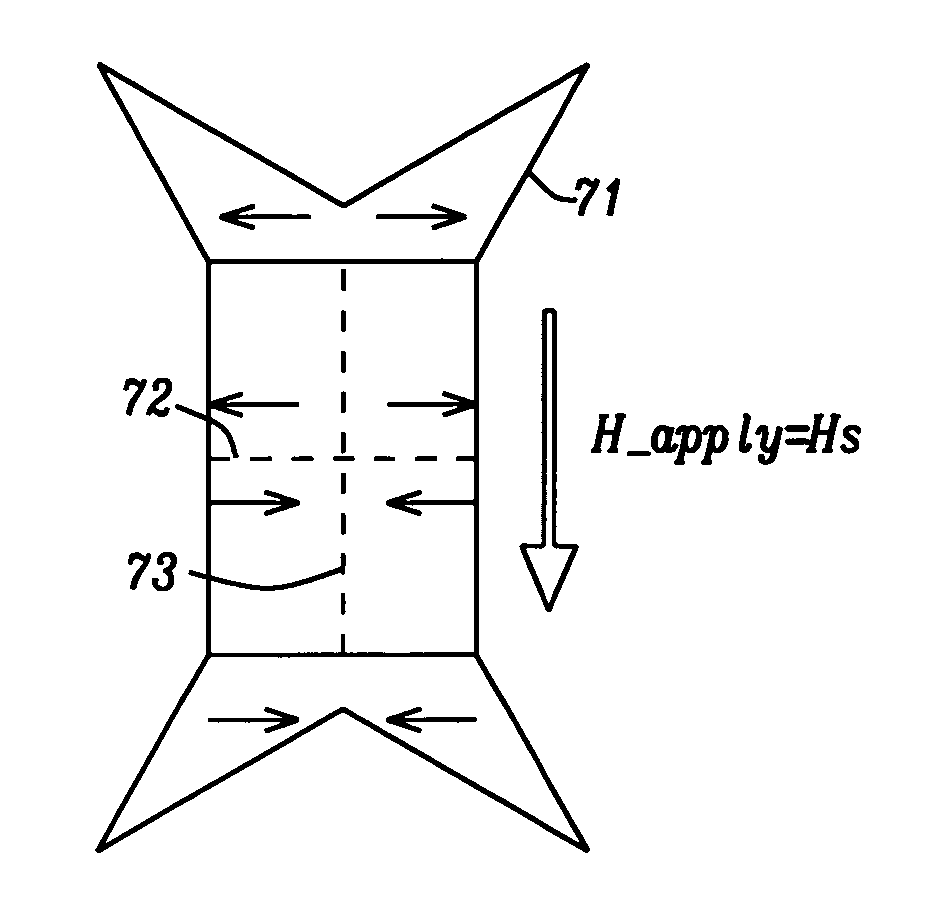

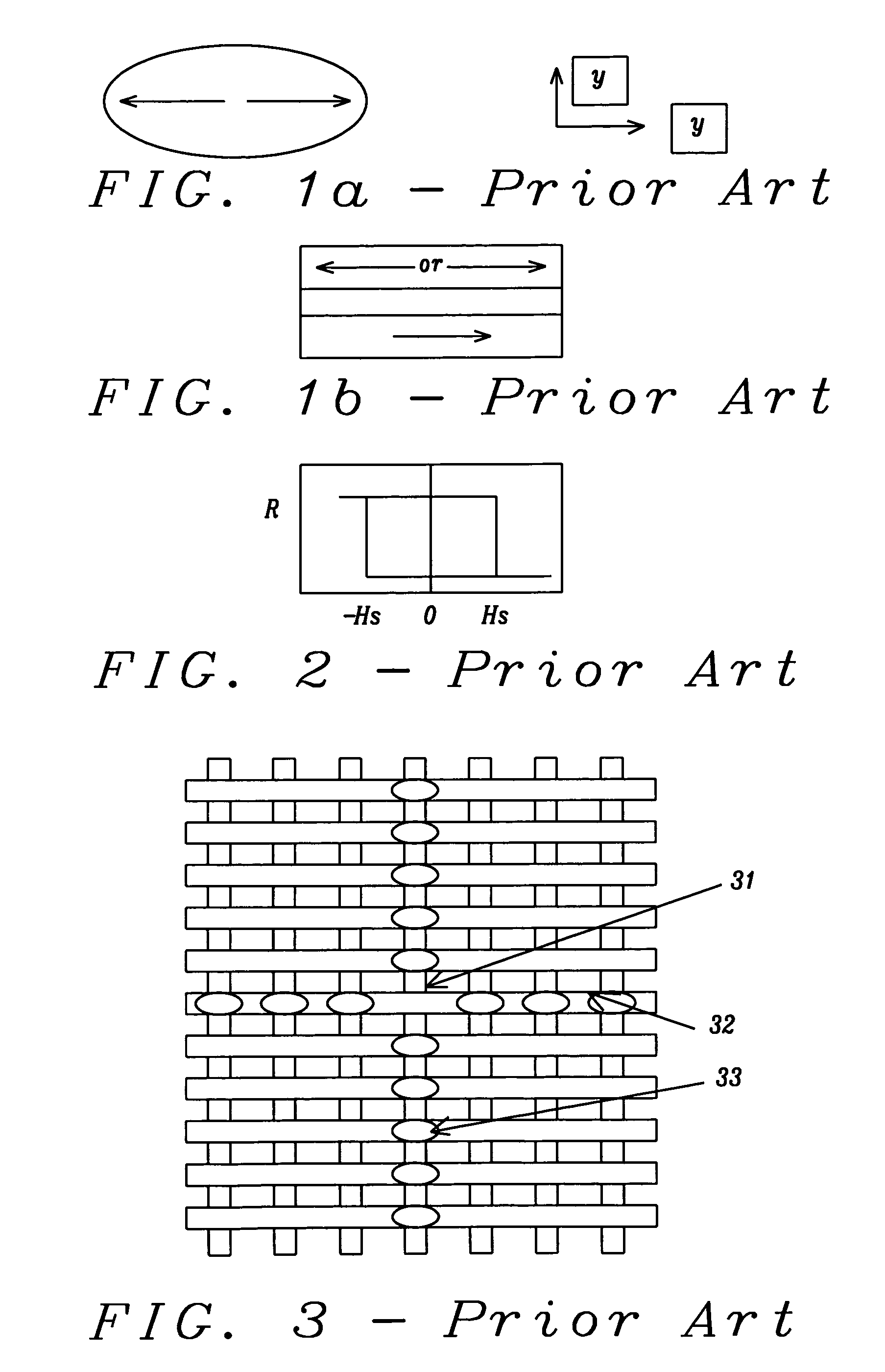

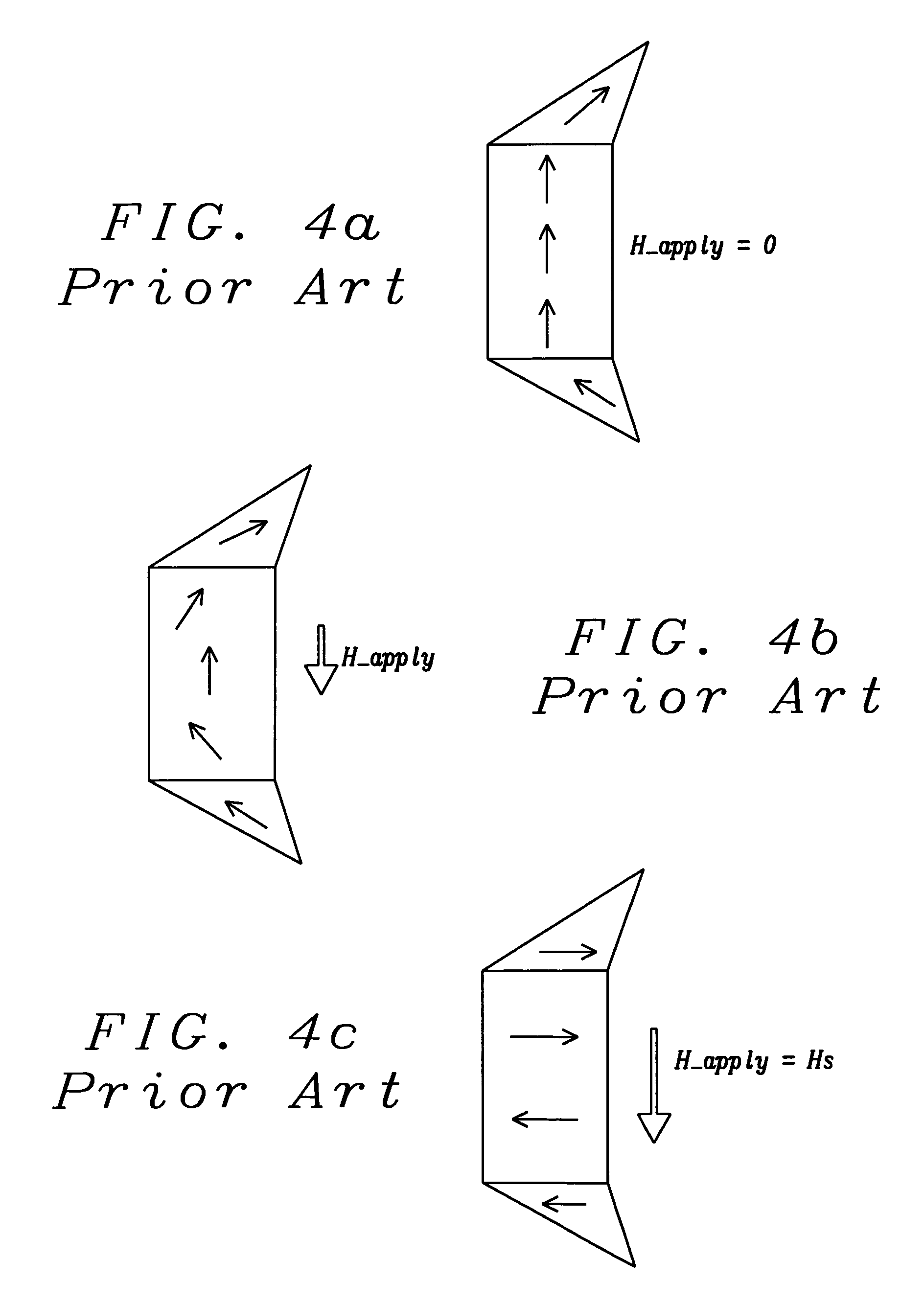

MRAM with cross-tie magnetization configuration

Owner:TAIWAN SEMICON MFG CO LTD

Mechanical side guide centering device

InactiveCN104826876ASnap openFast and accurate centering with mechanical side guidesGuiding/positioning/aligning arrangementsStopped workMotor drive

Disclosed is a mechanical side guide centering device. The device is used for mechanical centering during belt penetrating of a metal plate belt in a unit. A left vertical guide roller seat is connected with a left lead screw nut seat through a left air cylinder, and a right vertical guide roller seat is connected with a right lead screw nut seat through a right air cylinder; and the left lead screw nut seat and the right lead screw nut seat are each connected with a lead screw. Threads at the connecting position of the lead screw and the left lead screw nut seat and threads at the connecting position of the lead screw and the right lead screw nut seat are opposite in rotating direction, and the lead screw is connected with a motor; the motor drives the left lead screw nut seat and the right lead screw nut seat to oppositely move through the lead screw, and therefore the left vertical guide roller seat and the right vertical guide roller seat are moved oppositely to the stroke position; the motor stops working, a left air cylinder and a right air cylinder connected to the left lead screw nut seat and the right lead screw nut seat push the left vertical guide roller seat and the right vertical guide roller seat respectively to be rapidly opened; and an absolute value encoder is arranged at one end of the lead screw. A hand wheel does not need to be manually driven, and the lead screw can be directly driven by the motor to carry out mechanical centering; according to the width of a material incoming plate, the moving stroke can be arranged; and after the moving stroke is in place, the air cylinders control the vertical guide roller seats to be automatically bounced off. The mechanical side guide centering device is simple in structure, high in efficiency, small in manual intervention and stable and reliable in belt penetrating.

Owner:XIANGYANG ZHENBEN TRANSMISSION EQUIP

Self-washing type sand setting prevention small-displacement oil pump

ActiveCN105715523AReduce gritMaintain self-cleaning functionPositive displacement pump componentsFlexible member pumpsCouplingThick wall

The invention relates to a self-washing type sand setting prevention small-displacement oil pump. The self-washing type sand setting prevention small-displacement oil pump comprises a guide turbulent tube assembly, a plunger assembly and a pump barrel assembly. The guide turbulent tube assembly is mainly composed of a pump barrel coupling, a centering guide rail and a guide barrel. The plunger assembly comprises a plunger open valve cover, a plunger closed valve cover, a traveling valve ball, a traveling valve seat, a guide centering device and a hollow plunger assembly, wherein the plunger open valve cover is arranged in the centering guide rail; the lower portion of the plunger open valve cover is connected with the plunger closed valve cover; the traveling valve ball and the traveling valve seat are arranged inside the plunger closed valve cover and fixed with the guide centering device; the lower portion of the guide centering device is connected with a hollow plunger; and the guide centering device is located in the centering guide rail and in close fit with the centering guide rail. The internal diameter of the thick-wall pump barrel is slightly smaller than that of a lengthened pump barrel. The disturbance function is realized in the oil pump so that set sand can be reduced and the self-washing function can be kept; and besides, eccentric wear to the plunger is avoided.

Owner:NORTHEAST GASOLINEEUM UNIV

Vertical loop device for high-speed wire rod rolling mill

InactiveCN103182395AAvoid scratchesImprove work efficiencyFlexible work arrangmentsMetal rolling arrangementsWire rodEngineering

The invention discloses a vertical loop device for a high-speed wire rod rolling mill. The device is arranged between an upstream rolling mill and a downstream rolling mill, and comprises a loop rising roller, a guide roller, and loop side plates arranged on two sides of the guide roller, wherein a guide slot with a guide centering function is formed in the roller surface of the guide roller. A rolled piece can always operate at the middle position of a loop rolling channel by the guide slot, the rolled piece is prevented from being scratched by the loop side plates, and the product quality is improved; the wire scratching phenomenon is eliminated, the rolling fault time is greatly reduced, and the working efficiency of the rolling mill is improved; and the wear of the loop side plates and a downstream rolling mill inlet guide and protection part is reduced, the service life is prolonged, and the rolling cost is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

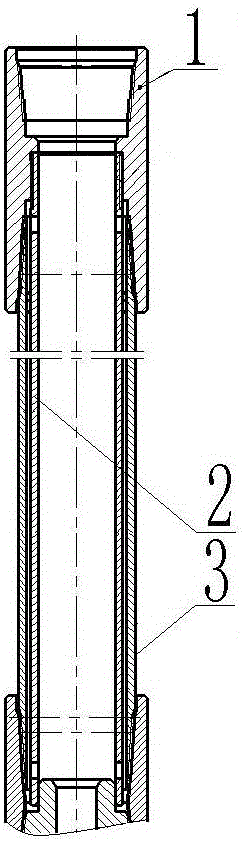

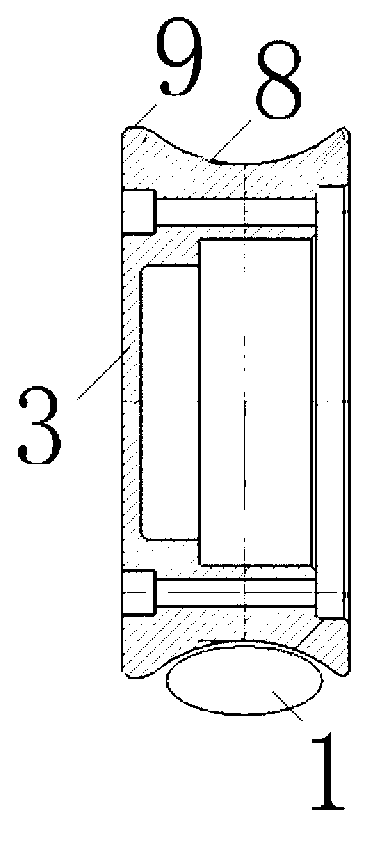

Compressing type subsealing packer

ActiveCN104314511AUp and down pressure balanceEasy to unpackFluid removalSealing/packingGuiding centerMechanical engineering

The invention belongs to the technical field of gas production of oilfields, and specifically provides a compressing type subsealing packer. The compressing type subsealing packer comprises a reversing centralizing mechanism, an anchoring mechanism and a sealing mechanism which are connected from bottom to top in sequence; the reversing centralizing mechanism comprises a lower connector, a guide center pipe, a guide pin, a guide pin carrier, a centralizing block, a centralizing block carrier and a spring; the anchoring mechanism comprises a slip box, a slip, a slip spring and a cone body; the sealing mechanism comprises a lower side ring, an outer rubber barrel, a center pipe, an inner rubber pipe, an inner center rod and a pressing cap. Compared with the general cracking packer, the compressing type subsealing packer has the advantages that the construction efficiency is high, the requirement for dragging and cracking a plurality of sections by feeding at a time can be met, and the problem that the working cost and risk are increased due to frequent putting out and feeding can be solved at the same time.

Owner:PETROCHINA CO LTD

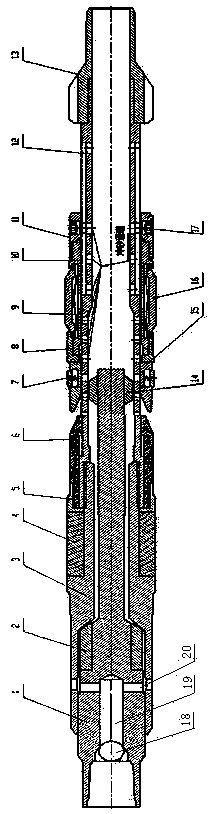

Oil well horizontal well oil jacket simultaneous injection type double-sealing single-clamping volume fracturing tubular column and fracturing method thereof

The invention belongs to the technical field of oil and gas field reservoir reformation, and particularly relates to an oil well horizontal well oil jacket simultaneous injection type double-sealing single-clamping volume fracturing tubular column and a fracturing method thereof. The tubular column comprises an oil tube, and the tail end of the oil tube is sequentially connected with a packer, a check valve, a perforated tube and a guide centering device. A pressure transmitting ejector is connected between the packer and the oil tube. A second packer, a third packer and an annular injection valve are connected in series to the oil tube. The second packer is placed above the pressure transmitting ejector, the third packer is placed above the second packer, and the annular injection valve is placed above the third packer and is connected to the oil tube in series next to the third packer. The problems that a common double-sealing single-clamping staged fracturing technology is only suitable for oil tube injection fracturing construction in the prior art, fluid friction is large, and construction displacement cannot be improved easily can be solved, liquid flow is injected into the oil tube and a casing pipe at the same time, and layer-by-layer layered volume fracturing construction of an oil well horizontal well can be achieved from bottom to top.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Guide centering adjustment device

ActiveCN102357538AReduce consumptionSolve the actual travel pathGuiding/positioning/aligning arrangementsEngineeringGuiding center

The invention belongs to the field of steel rolling machinery, and particularly relates to a guide centering adjustment device at an entrance of a multi-line splitting rolling product rack. The device comprises a guide body and a base for fixing the guide body, wherein the guide body and the base are in surface contact and fit; the guide centering adjustment device also comprises a regulation mechanism for driving the guide body to swing along the fitting surface of the base; and the swing axle center of the regulation mechanism is located on the traveling path of the rolling piece. The equipment provided by the invention has a simple structure, and realizes accurate positioning; and through the equipment, the problem in the deflection angle between the actual traveling path of the rolling piece and the guiding path of the guide is solved, thus the steel adhesion in the splitting rolling process is effectively reduced, the product quality is improved, the production efficiency is improved, the guide consumption is reduced, and the equipment is suitable for practical splitting rolling production.

Owner:HEFEI BAISHENG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com