Scraping coater

A technology of scraper coating machine and frame, which is applied in the direction of coating and coating liquid on the surface, etc., which can solve the problems of poor coating quality, uneven coating, uneven coating, etc., and achieve good coating quality, The effect of avoiding outflow and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

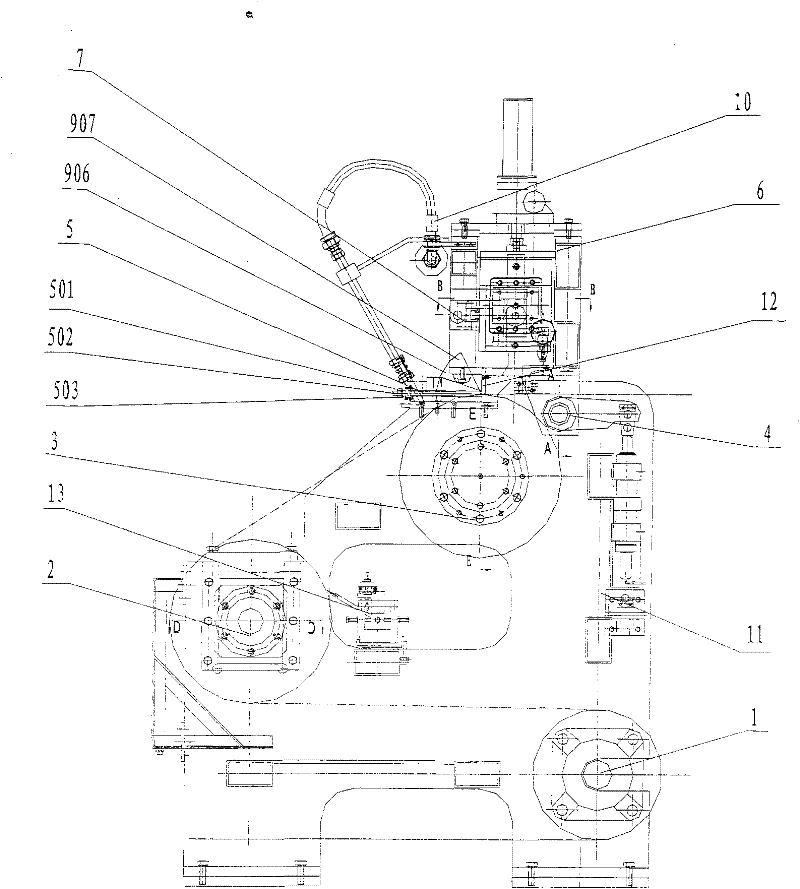

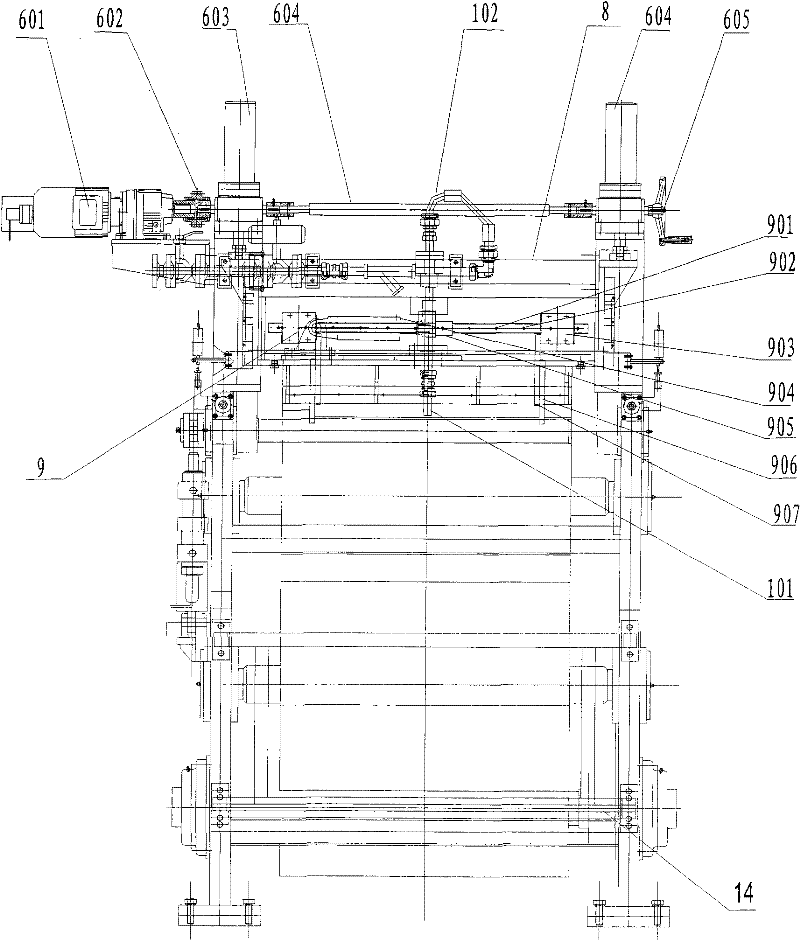

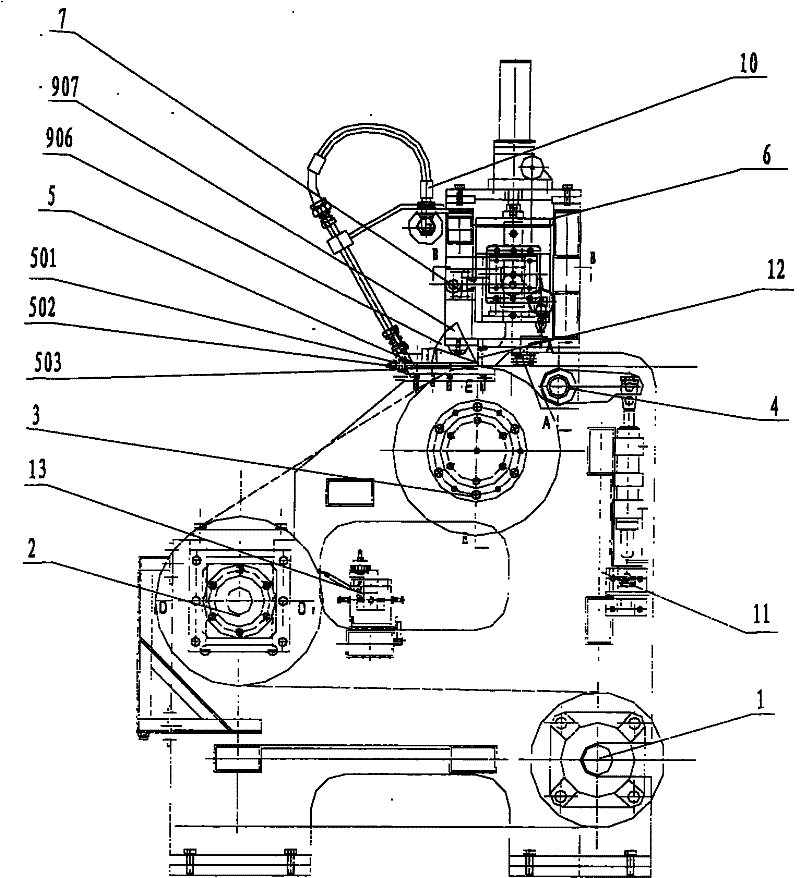

[0017] Combine below figure 1 , figure 2 The specific embodiment of the invention will be described in detail.

[0018] Such as figure 1 with figure 2 Shown, the present invention is a kind of scraper coater, is mainly applicable to the scraper coater of plate coating viscosity bigger coating, is made up of frame 11, support roller 3, scraper device 12, feeding device 10, pendulum frame 7 , edge guide centering device 9, rotating shaft 4 constitute, pendulum frame 7 connects frame 11 through rotating shaft 4, feeding device 10 is installed on pendulum frame 7, support roller 3 is installed on frame 11, and edge guide device pair Middle device 9, scraper device 12 pass movable crossbeam 8, and movable crossbeam 8 and digital display device 15 are all installed on the swing frame 7.

[0019] The frame 11 is connected with the swing frame 7 by the rotating shaft 4, and the connecting rod driven by the hydraulic cylinder to rotate around the rotating shaft 4 drives the swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com