Patents

Literature

37results about How to "Implement servo control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

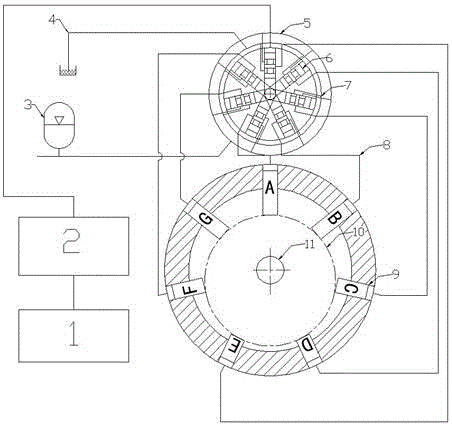

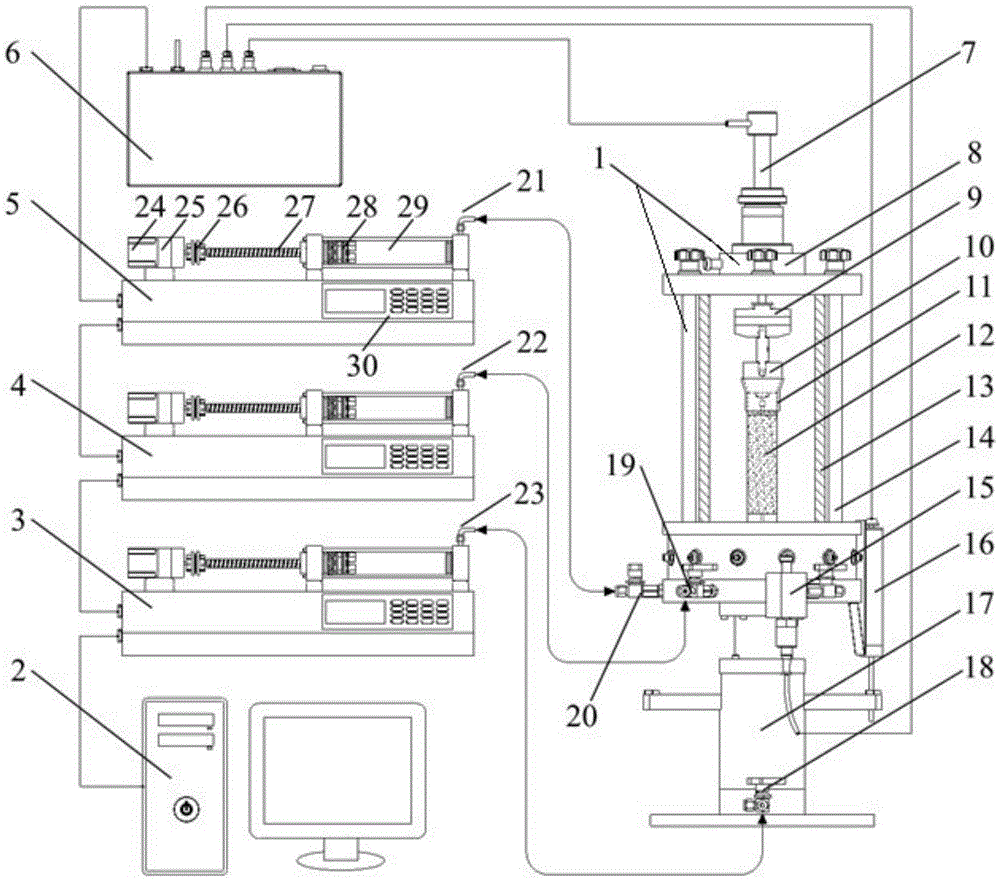

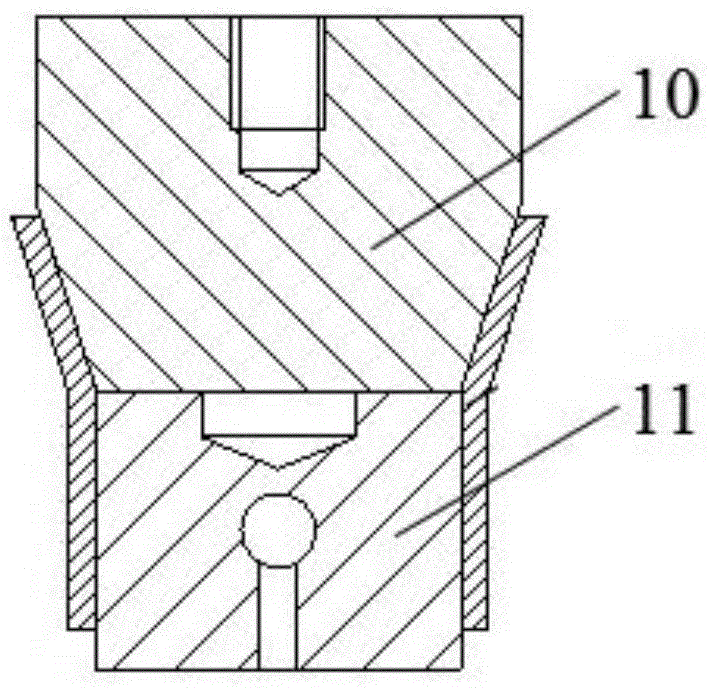

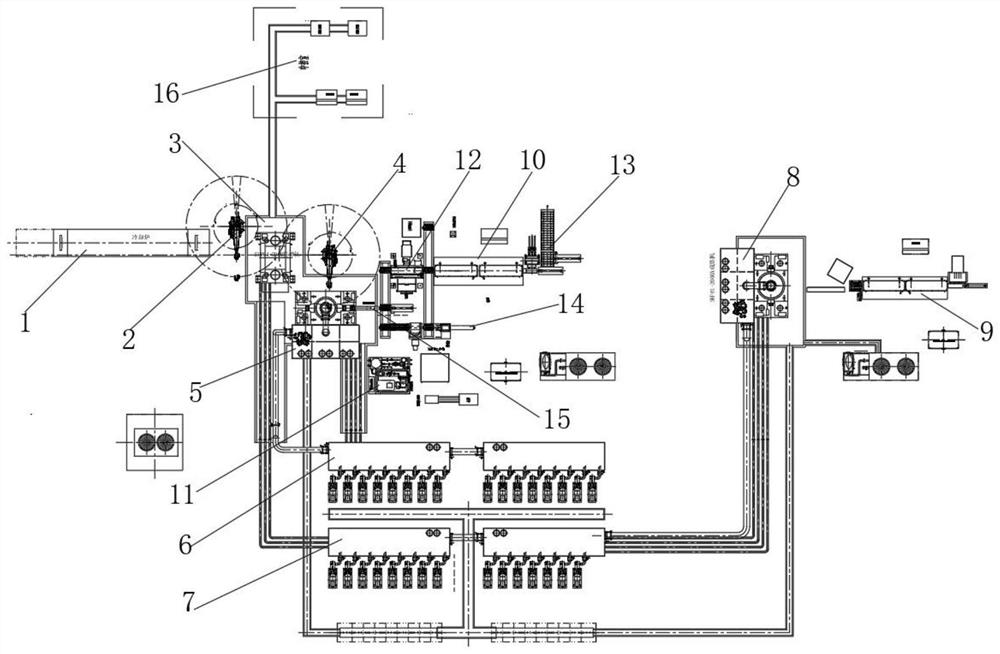

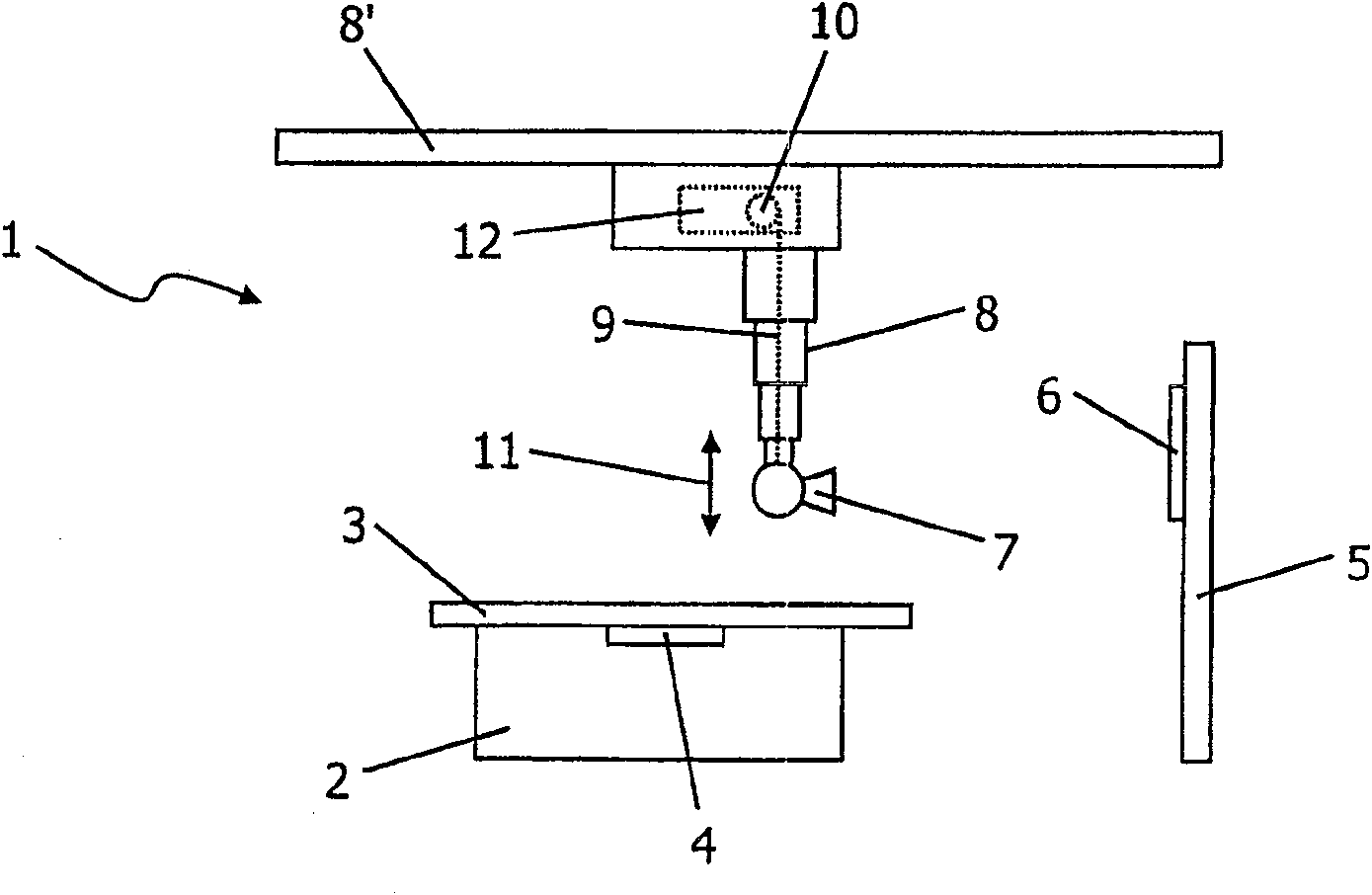

Full-automatic three-axis testing system for saturated soil stress path

ActiveCN104048879APrecise axial pressure controlHigh accuracy of data acquisition and controlMaterial strength using tensile/compressive forcesStress pathEngineering

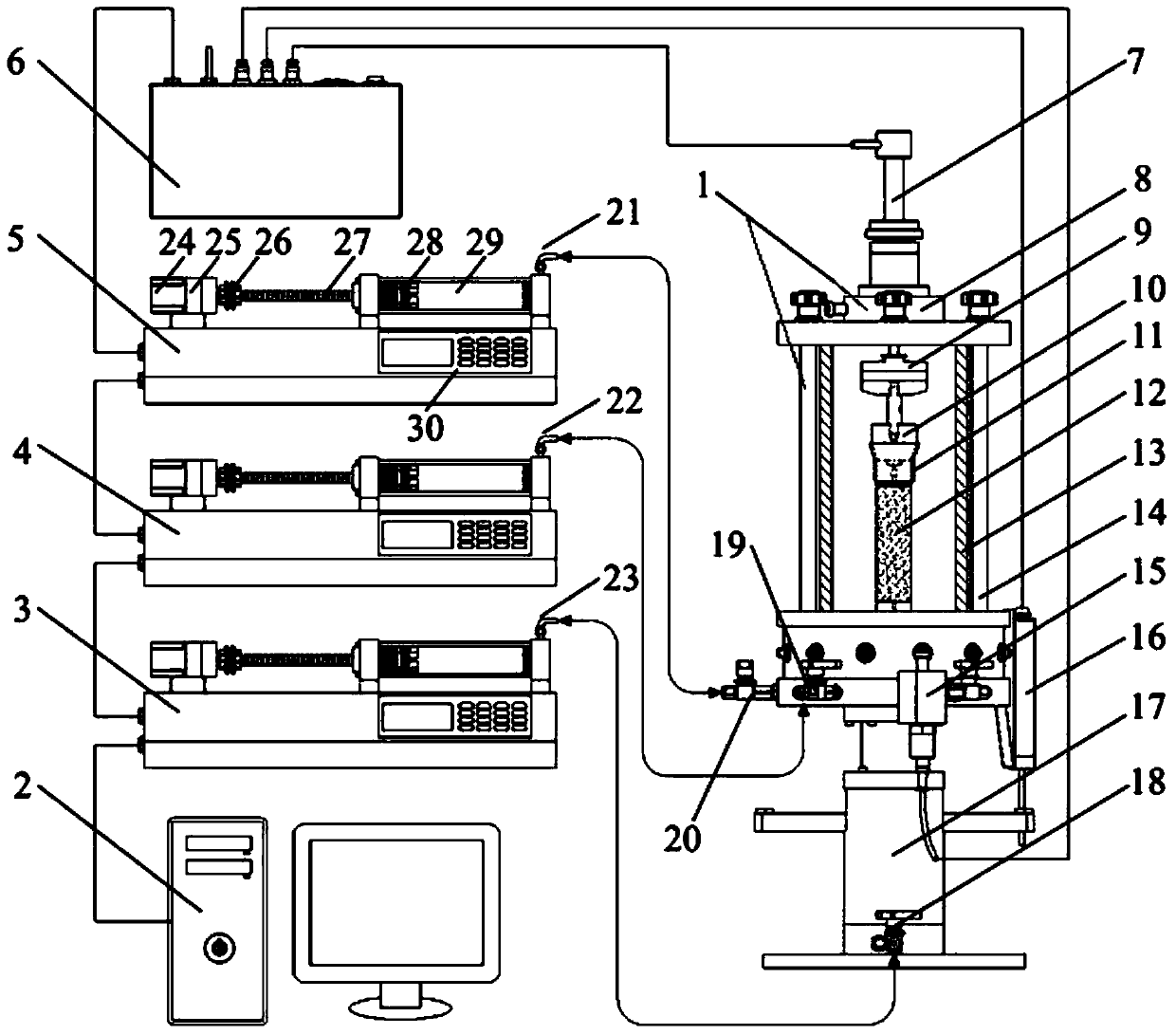

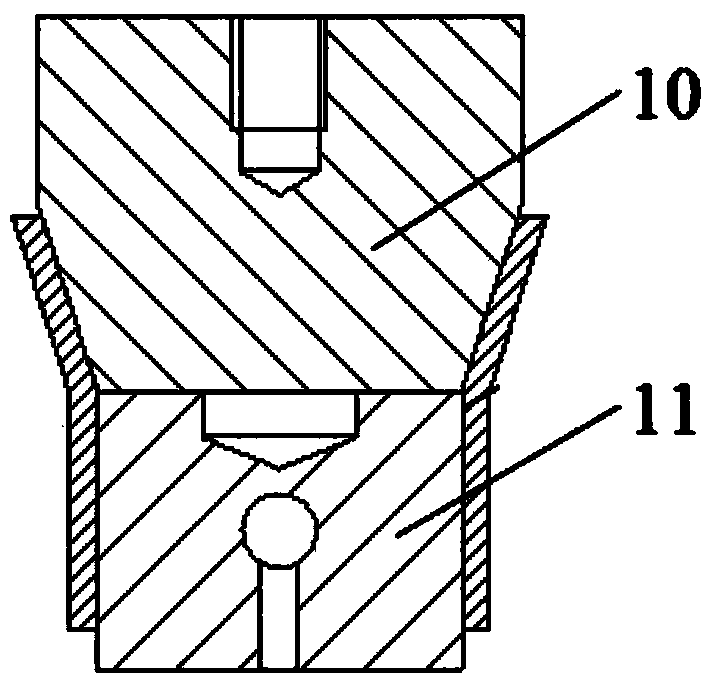

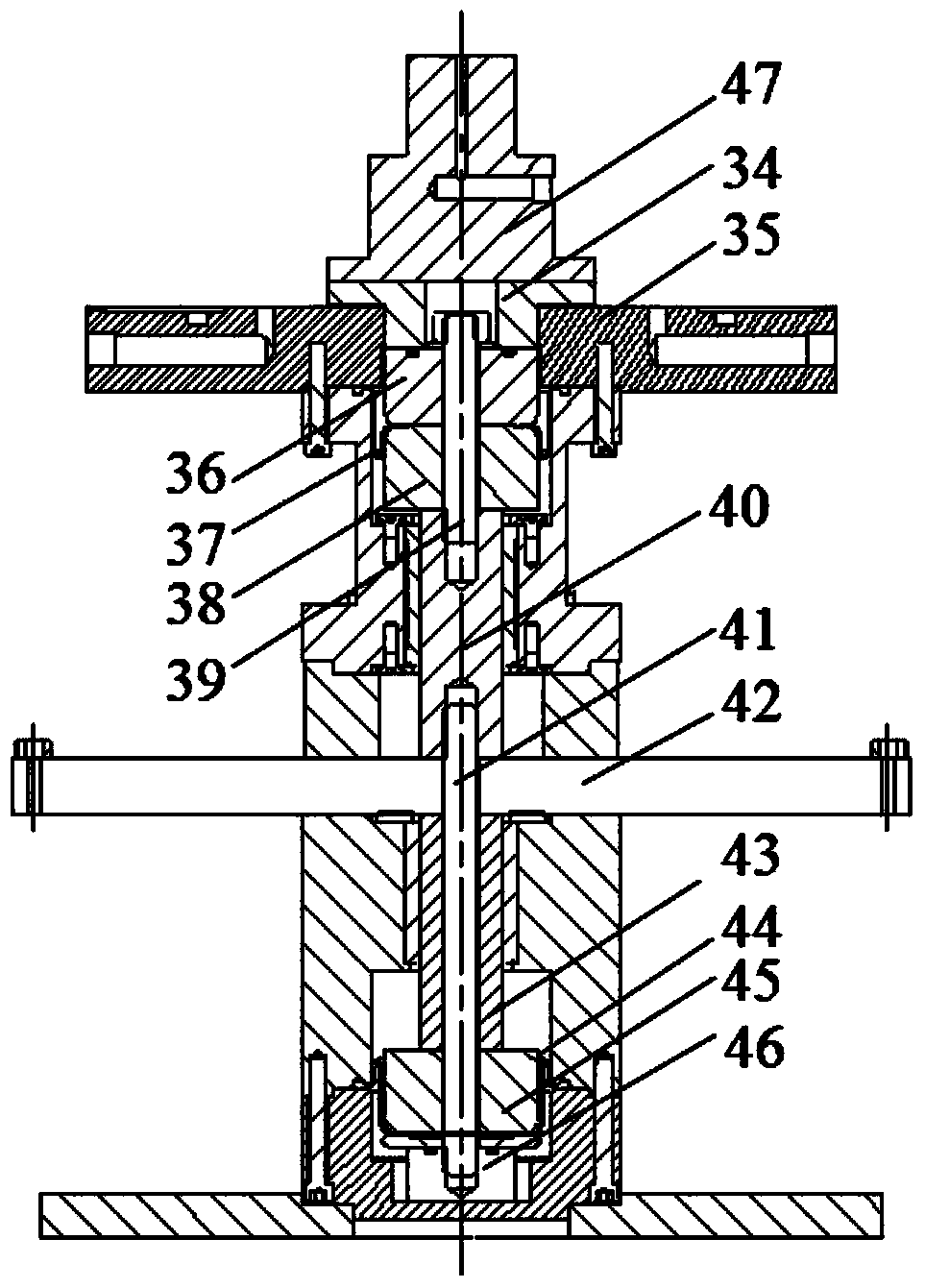

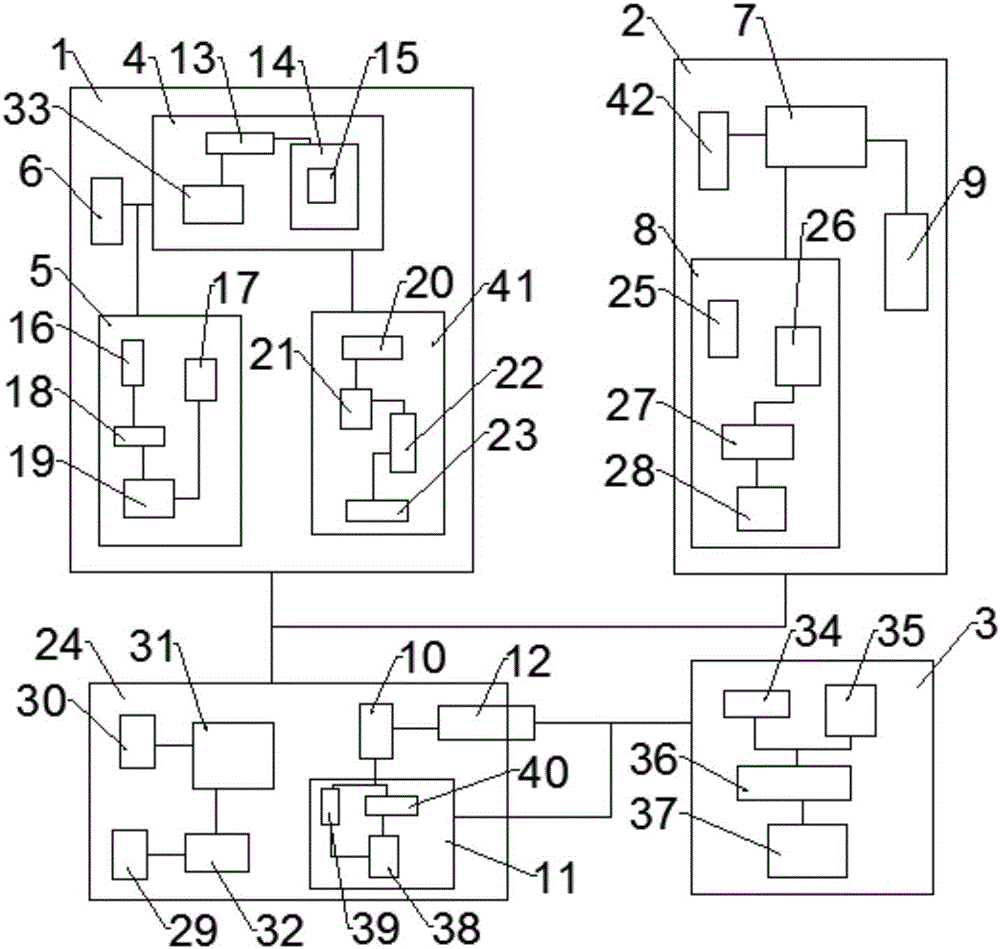

The invention discloses a full-automatic three-axis testing system for a saturated soil stress path. The full-automatic three-axis testing system comprises a pressure chamber (1), a computer (2), an axial force volume controller (3), a confining pressure volume controller (4), a back pressure volume controller (5), a data acquisition box (6) and a pressure volume control system connected with the computer (2). The full-automatic three-axis testing system for the saturated soil stress path is reasonable in structural design, convenient to operate, high in automation degree and good in stability and can be used for accurately controlling a complicated stress path of a soil body.

Owner:南京泰克奥科技有限公司

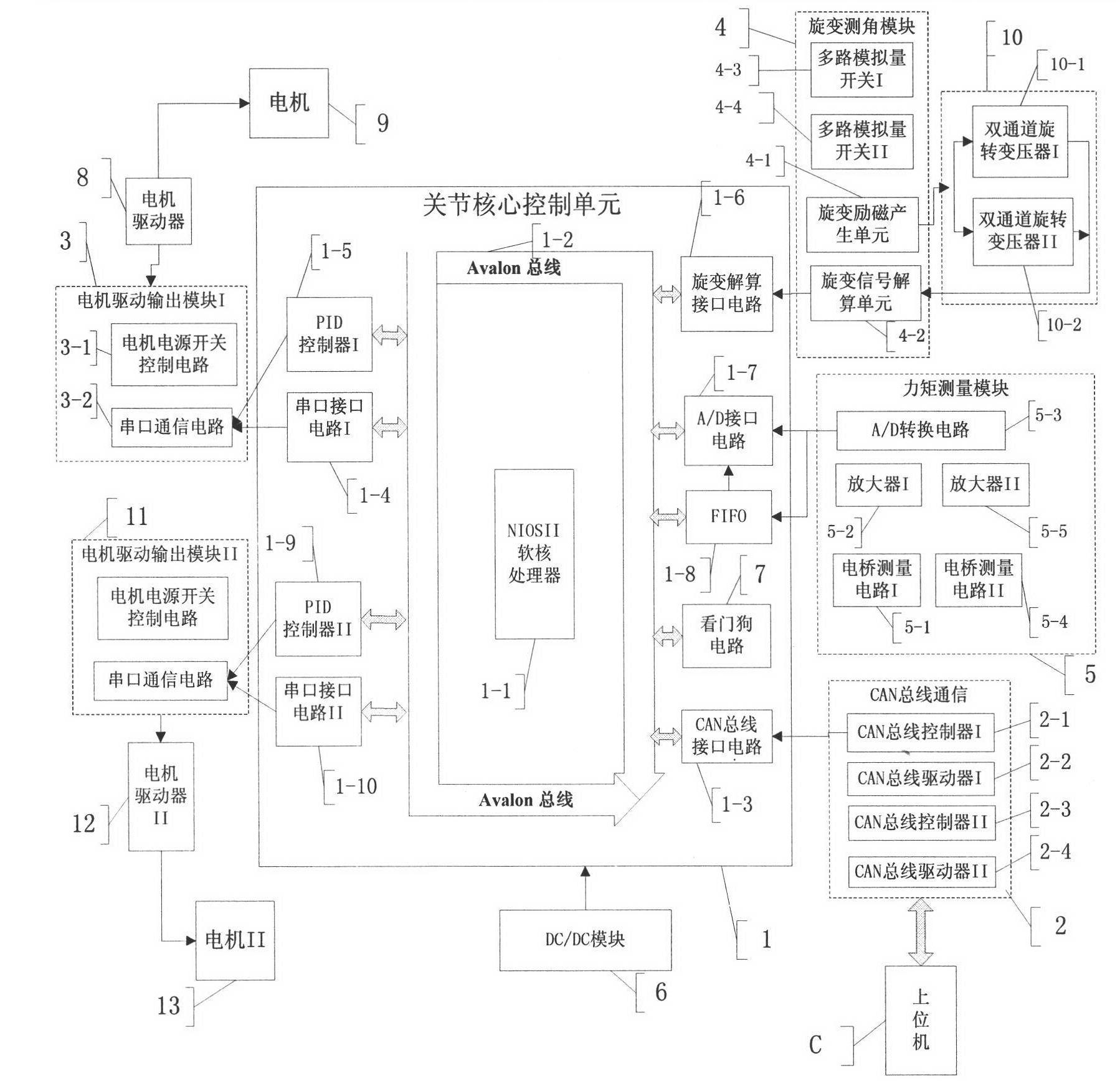

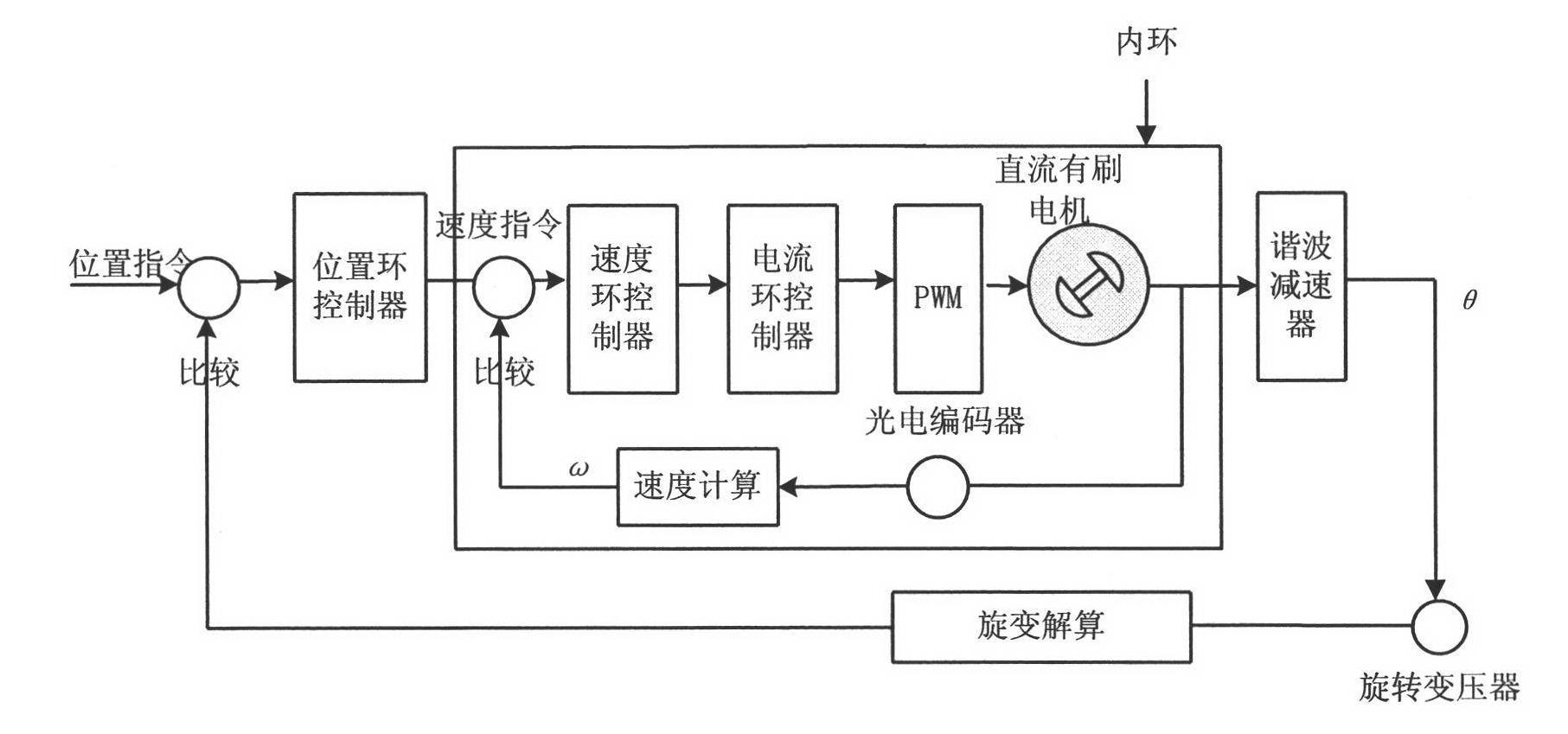

FPGA-based modularization double-joint servo control system

InactiveCN102354134AImprove reliabilityMiniaturization and ReliabilityProgramme control in sequence/logic controllersModularityInterface circuits

The invention discloses an FPGA-based modularization double-joint servo control system which comprises a joint core control unit, a CAN bus communication module, a motor drive output module, a rotating transformer angle measuring module, a torque measuring module and a DC / DC module, wherein the joint core control unit comprises an NIOSII soft core processor, an Avalon bus, a CAN bus interface circuit, a serial interface circuit I, a PID (Proportion Integration Differentiation) controller I, a rotating transformer resolution interface circuit, an A / D interface circuit, an FIFO (First In First Out) and a watch dog circuit; the CAN bus communication module comprises a CAN bus controller I and a bus driver I, the motor drive module comprises a motor power supply switch control circuit and a serial communication circuit; the rotating transformer angle measuring module comprises a rotating transformer excitation generating unit and a rotating transformer signal resolution unit; and the torque measuring module comprises a bridge measurement circuit, an amplifier and an A / D conversion circuit. The upper computer is communicated with the joint core control unit through a CAN bus, the joint core control unit sends a command to the motor driver through a serial interface of the motor drive module, and the motor driver controls the motor and feeds back position information of the motor.

Owner:BEIJING UNIV OF POSTS & TELECOMM

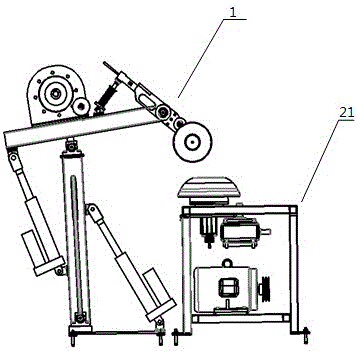

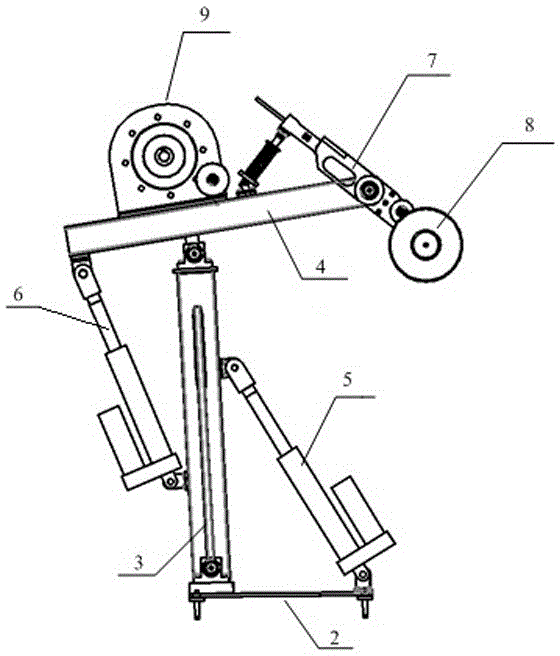

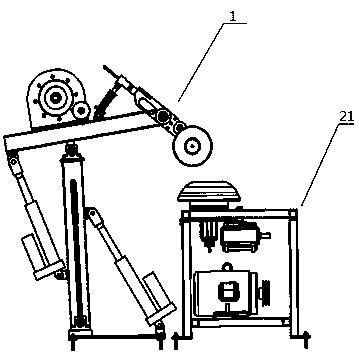

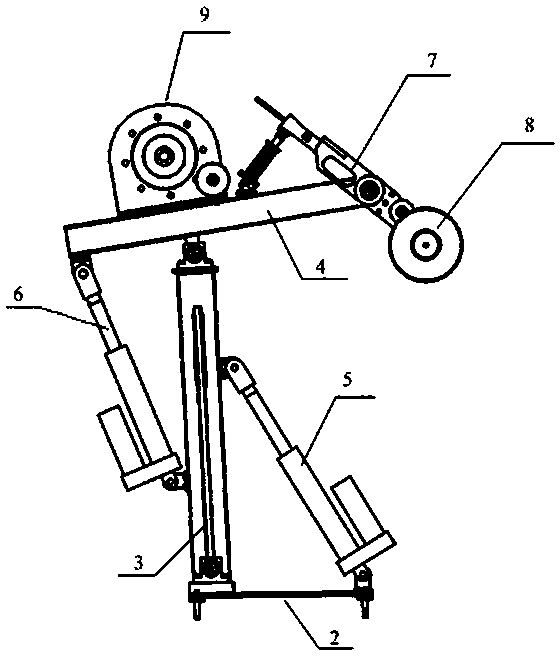

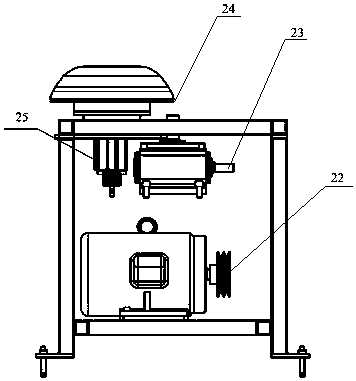

Grinding equipment and grinding method

ActiveCN105666280AAchieve grindingImplement servo controlSpherical surface grinding machinesGrinding feed controlControl systemEngineering

The invention discloses grinding equipment and a grinding method. The grinding equipment and the grinding method aim at solving the problems that at present, manpower is mainly adopted to grind a pot billet, consequently, operation efficiency is low, the requirement of an existing grinding device for the position of the pot billet is low, and certain limitation exists. The grinding equipment comprises a grinding mechanism and a control system; and the grinding mechanism comprises a grinding support, a first supporting rod, a second supporting rod, a first telescopic arm, a second telescopic arm, a third supporting rod, a grinding wheel and a grinding wheel driving device. One end of the first supporting rod is movably connected with the grinding support, and the first supporting rod can rotate relative to the grinding support; and the other end of the first supporting rod is movably connected with the second supporting rod. According to the grinding equipment, the automatic grinding requirement for workpieces with different sizes can be met, the extremely-high adaption is achieved, the grinding quality is good, efficiency is high, the production period is short, the cost is low, the good application prospect is achieved, and the equipment is worth applying and popularizing in a large-scale manner.

Owner:SICHUAN FUDE ROBOT

Standard of angle measurer

ActiveCN102620703AImplement servo controlHigh precisionVehicle wheel testingAutomatic controlProgrammable logic controller

The invention discloses a standard of an angle measurer. The standard comprises a rotating device and a control system, and is characterized in that: the rotating device is a double-shaft mechanical rotating device and comprises a direction and position rotary axis system and a pitch rotary axis system which are interconnected and vertical, wherein each rotary axis system is provided with an electromagnetic locking device, an angular contact bearing, a permanent-magnetic direct-current torque motor and an angle measuring element; the direction and position rotary axis system is connected with a worktable top used for placing an apparatus to be detected; and the angle measuring element of each rotary axis system forms an angle measuring system. The standard adopts the technology of combining low-speed large-torque driving technology, automatic control technology, precise measuring technology, touch screen artificial intelligent technology and programmable logic controller (PLC), so standard angle technology with high precision and high load, which can output at any angle, is realized, and a plurality of types of angle measurers, such as various wheel positioning apparatuses, are subjected to metrological verification / calibration.

Owner:佛山市质量计量监督检测中心

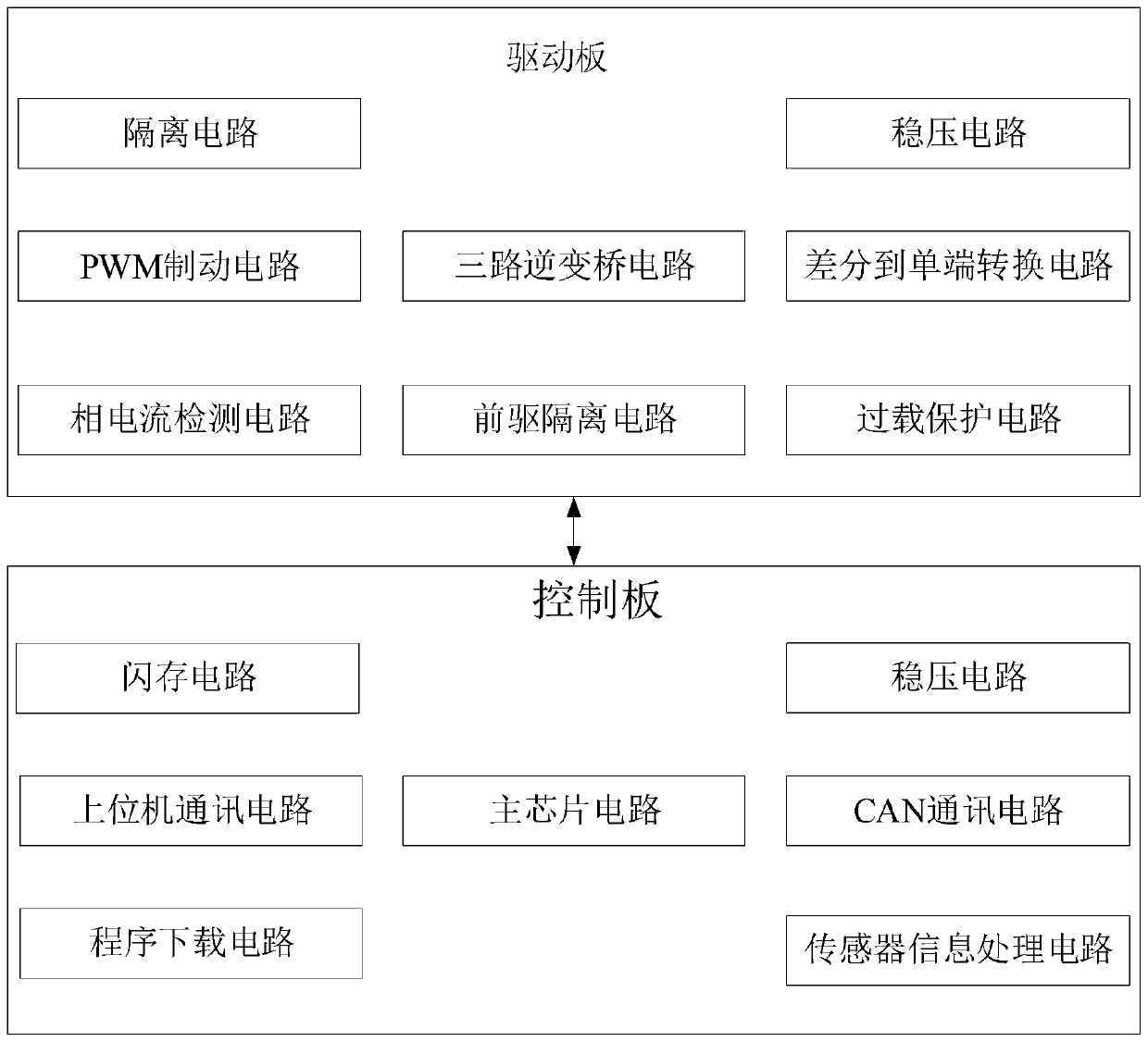

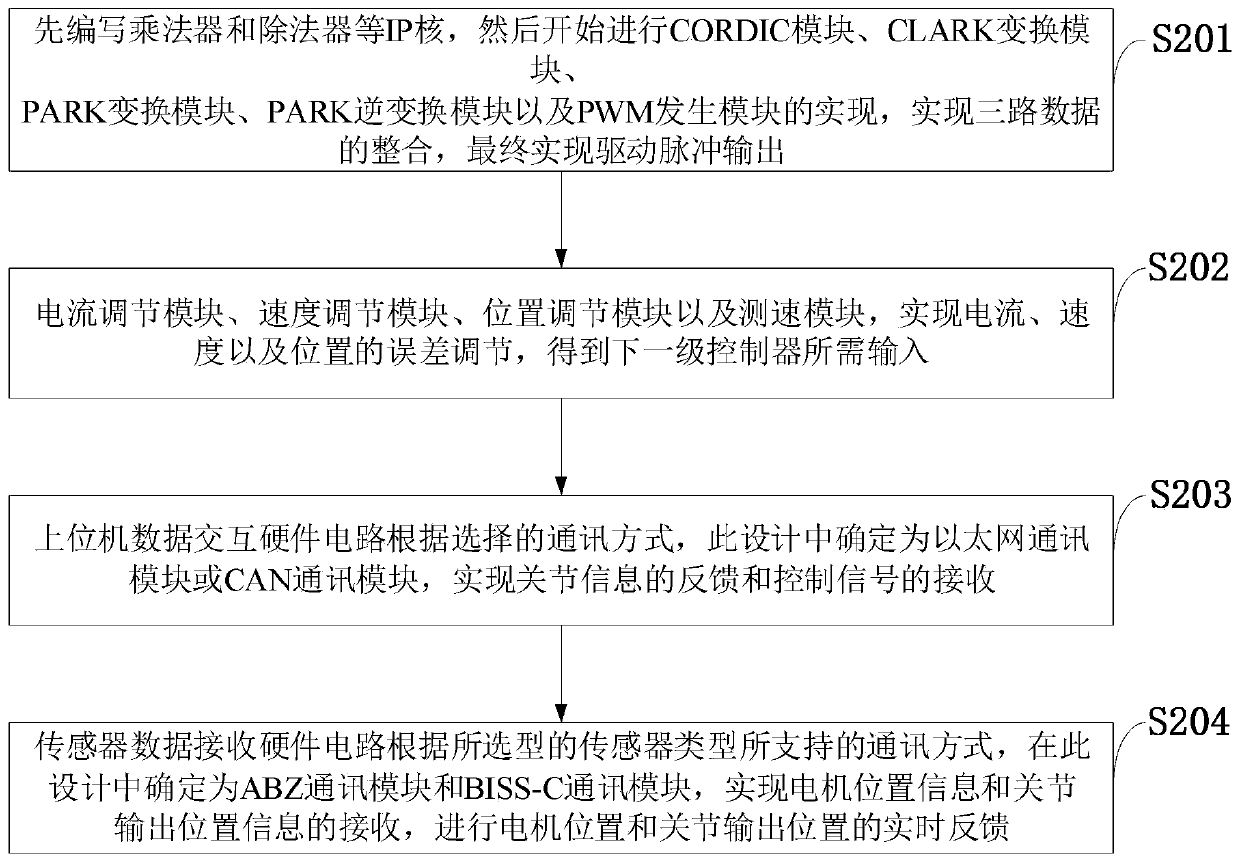

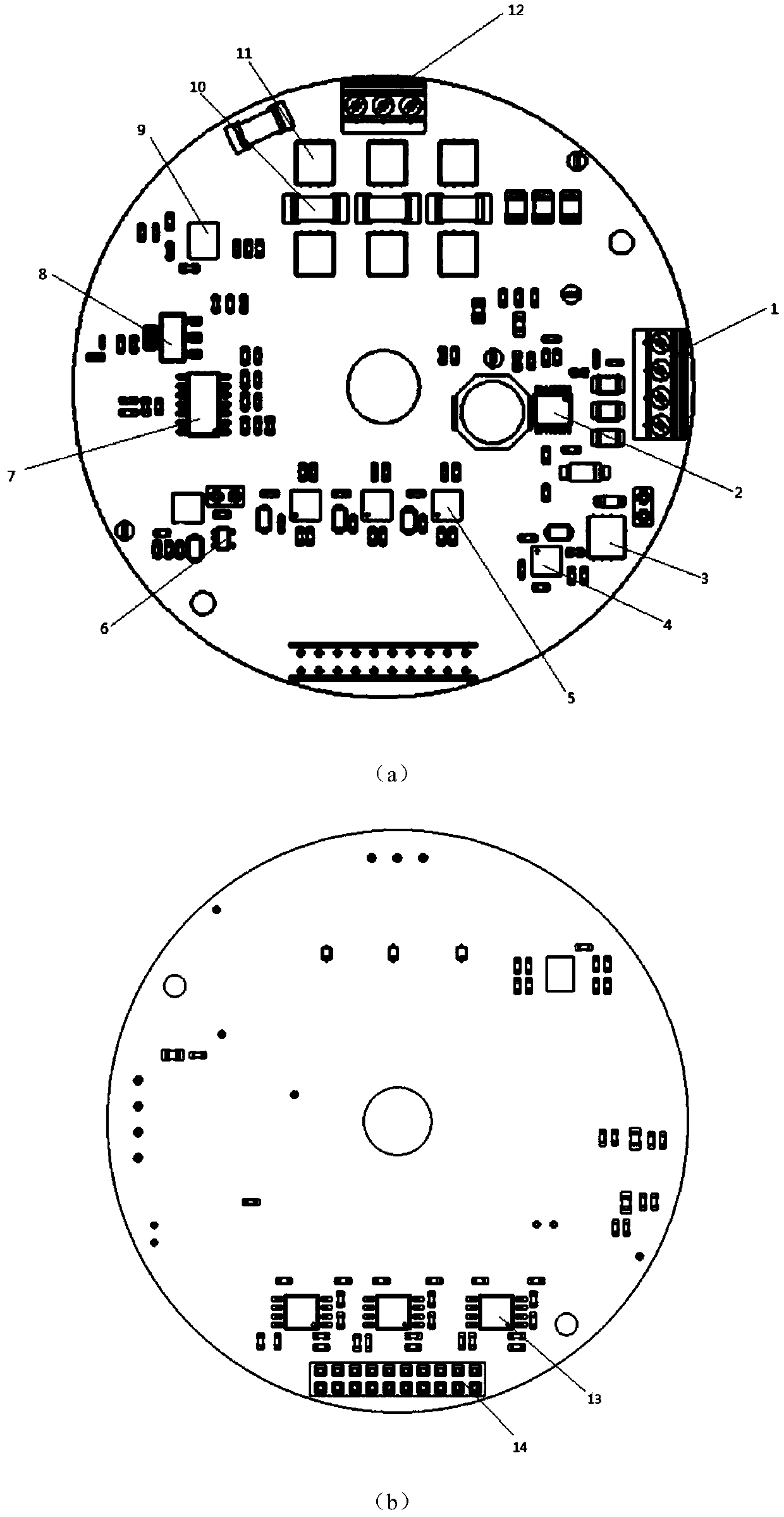

Restructuring collaborative robot joint integrated drive control system, method and application

ActiveCN111070208ARealize joint real-time monitoring functionReduce integration complexityProgramme-controlled manipulatorJointsLoop controlControl signal

The invention belongs to the technical field of power electronics and servo control, and discloses a restructuring collaborative robot joint integrated drive control system, method and application. The restructuring collaborative robot joint integrated drive control system comprises a driving panel and a control panel, wherein a driving panel is used for driving a servo motor, controlling a main inverter circuit to drive the servo motor after isolation of a control signal is realized as well as realizing phase current detection and overcurrent protection functions; and a control panel is usedfor realizing driving of the motor and information acquisition of an internal sensor in a restructuring robot joint and controlling a permanent magnet synchronous motor in the joint through adopting vector control so as to achieve three-closed-loop control of motor driving current, motor rotating speed and an output end position. According to the restructuring collaborative robot joint integrateddrive control system, method and application, comprehensive coverage of joint requirements of the collaborative robot is achieved, a continuous peak phase current output expectation reaches 19.0 A, and the maximum efficiency expectation reaches 99%; meanwhile, an efficient vector control algorithm is realized to carry out motor control, and six paths of drive board control signals are output; andfinally, accurate control of the motor position is realized.

Owner:XIDIAN UNIV

Digital servo hydraulic motor

InactiveCN106089863AGreat power to weight ratioIncrease output powerServometer circuitsFluid-pressure actuator componentsHydraulic motorLow speed

The invention provides a digital servo hydraulic motor. A stepping motor is adopted in the digital servo hydraulic motor to drive a cam mechanism to control a set of flow distributing sliding valves to act in sequence, pressure oil is sequentially distributed to different plunger cavities of a radial plunger motor according to a certain rule, and meanwhile hydraulic oil in other plunger cavities is sequentially led to an oil returning path (an oil tank). The output end is integrated with a cycloidal-pin wheel speed reduction mechanism to achieve low-speed output, the rotating speed is further reduced, and the stepping angle of the digital servo hydraulic motor is reduced. According to the basic principle, the stepping motor is utilized for driving the cam mechanism to rotate, an oil distributing valve element located at the specific angle is pushed, the reversing operation is conducted, and therefore the pressure oil entering the plunger cavities of the radial plunger motor is controlled. Switching control is conducted on the movement of each plunger, stepping output is achieved, low-speed output is achieved through the cycloidal-pin wheel speed reduction mechanism, and a servo control function is achieved.

Owner:王林翔

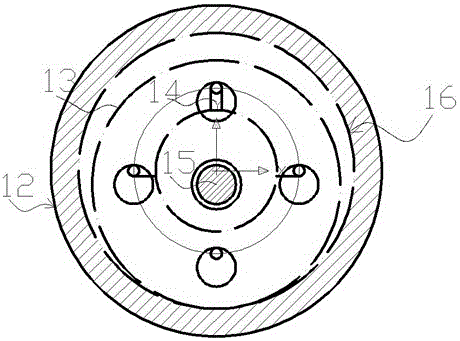

Slurry injection servo control device for indoor slurry injection simulation test and operation method

ActiveCN107632652AWell mixedRealize limitSimultaneous control of multiple variablesInjection pressureInlet channel

The invention discloses a slurry injection servo control device for an indoor slurry injection simulation test and an operation method. The device comprises a pressure supply unit, a slurry storage stirring unit and a measurement and control unit, wherein the slurry storage stirring unit comprises a chamber having an accommodation space, the chamber is internally provided with a multi-stage stirring mechanism, the chamber is provided with a slurry inlet channel and a slurry outlet channel, the pressure supply unit is used for providing servo control pressure for slurry accommodated in the slurry storage stirring unit, the measurement and control unit is connected with the pressure supply unit and the slurry storage stirring unit, and slurry injection servo closed loop control is realized through controlling the applying pressure and the flow velocity or the flow of the slurry inlet channel and the slurry outlet channel. The is advantaged in that measurement and control for slurry injection pressure are carried out through a servo control loading disc, the slurry injection flow and the slurry injection amount are measured and controlled through adjusting the volume of the slurry, and random switching servo control on the slurry injection pressure, the slurry injection flow and the slurry injection amount can be carried out.

Owner:SHANDONG UNIV

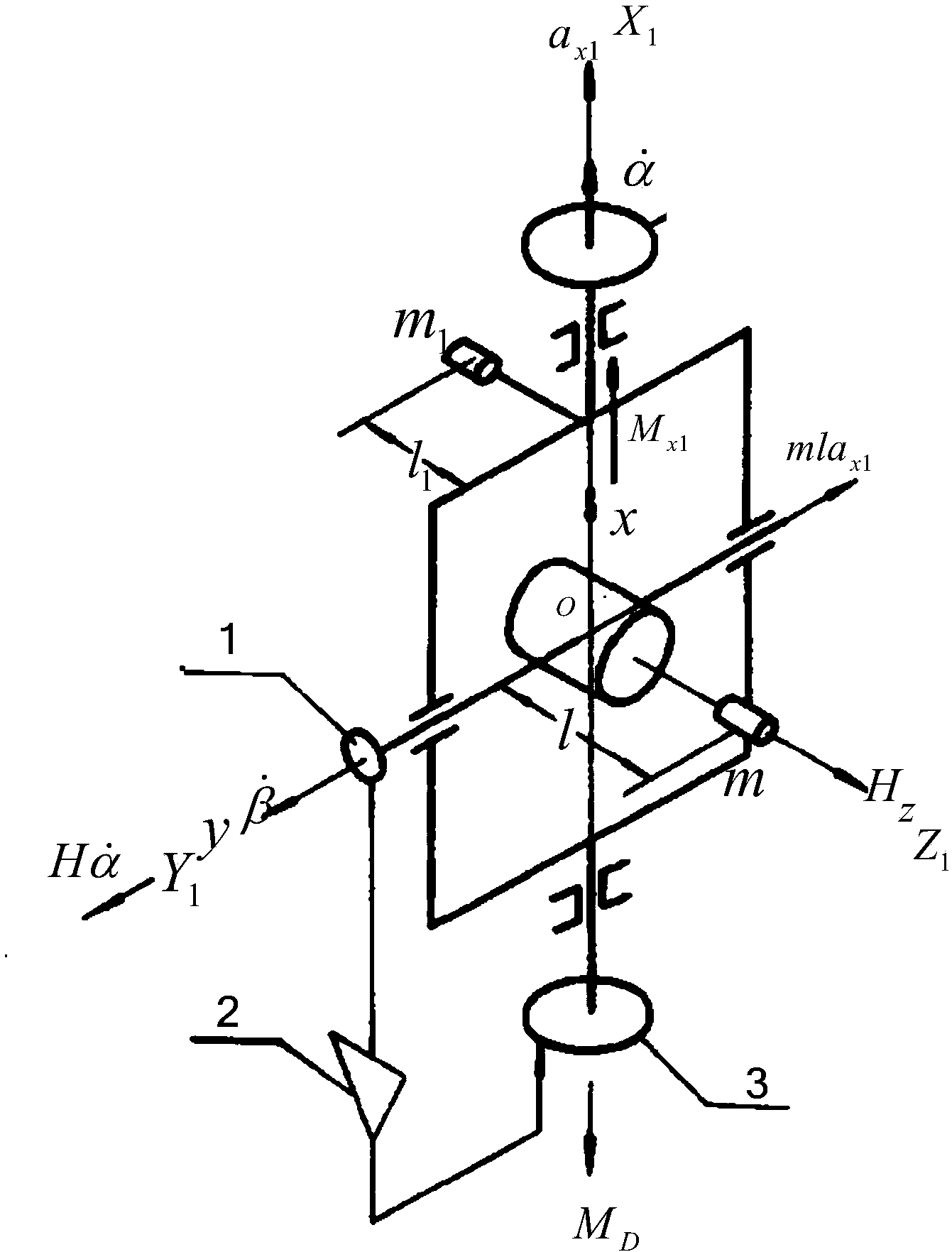

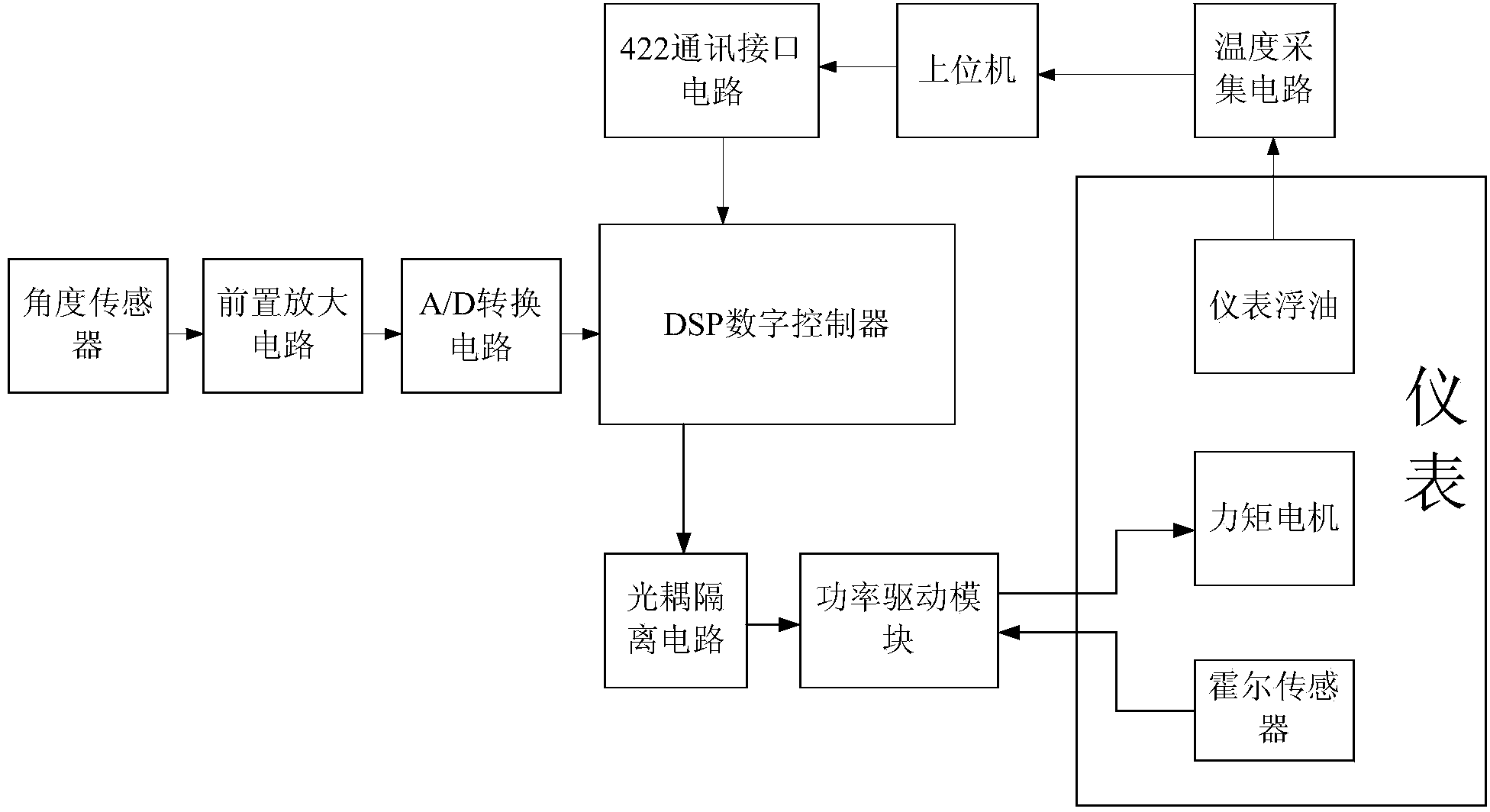

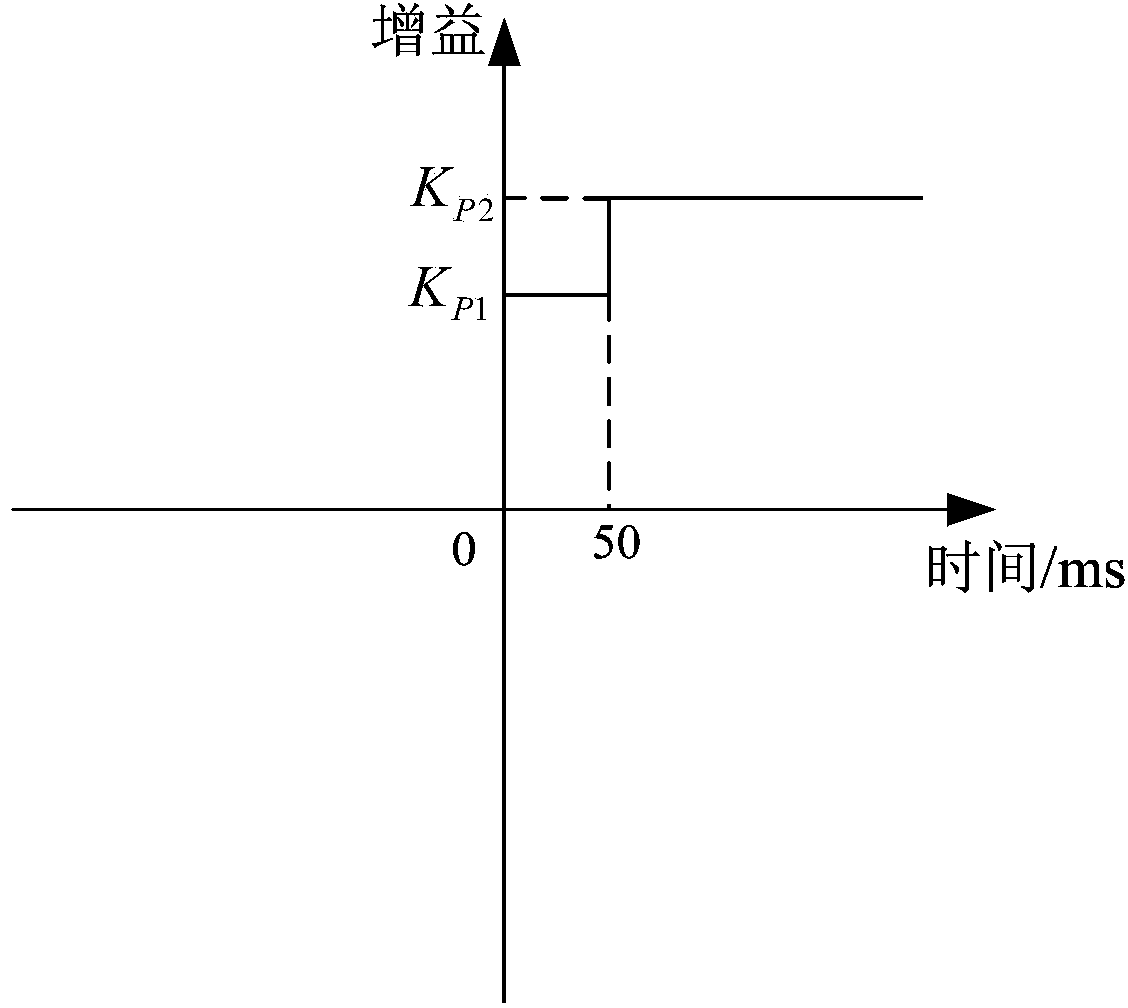

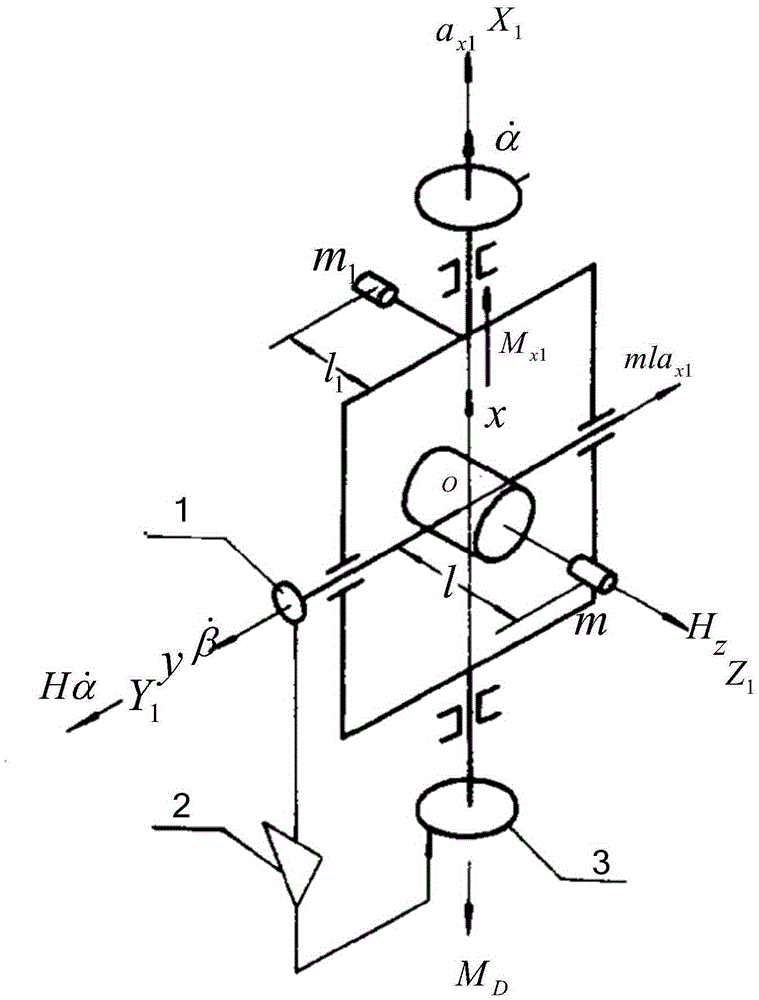

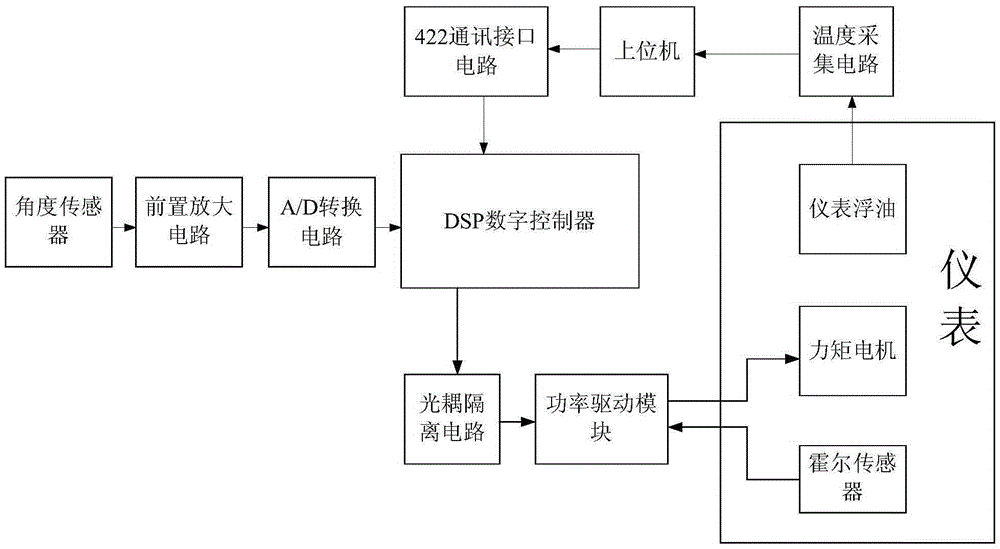

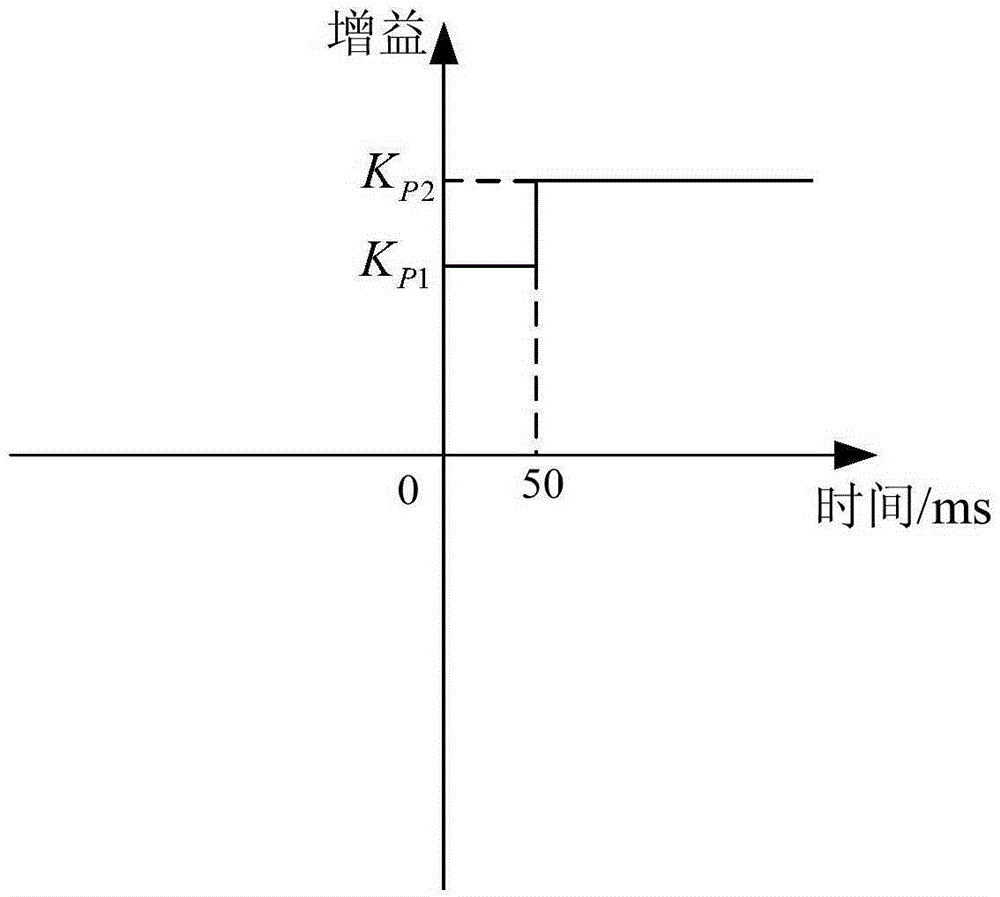

Servo loop control system and control method for floating oil support inertia instrument

ActiveCN103872965AImplement servo controlHighly integratedAC motor controlNavigation by speed/acceleration measurementsLinear controlLoop control

The invention discloses a servo loop control system and control method for a floating oil support inertia instrument. The control system mainly comprises an angle sensor, a front positioned amplification circuit, an A / D (analog / digital) conversion circuit, a DSP (digital signal processor) digital controller, a photocoupling isolation circuit, a power driving module, a moment motor, a hall sensor, a 422 communication interface circuit, a temperature collection circuit and an upper computer. The nonlinear control in the starting stage of the control system and the temperature gradient precise control of an instrument servo loop are respectively realized by introducing a variable parameter correction network DSP digital controller. The upper computer collects the floating oil temperature information in the instrument by the temperature collection circuit and sends the information to the DSP digital controller by the 422 communication interface circuit. The DSP digital controller compares the temperature with a given temperature threshold value and calls corresponding control parameters, so the variable parameter servo control for different temperatures of the instrument is realized. The control system is high in integration degree, high in control precision, high in automation degree, safe and reliable.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

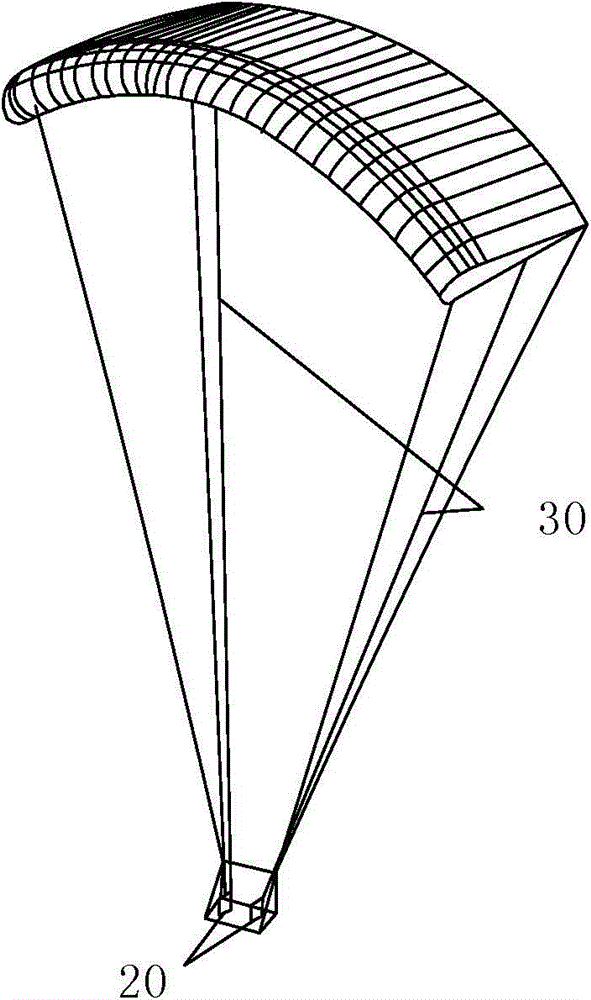

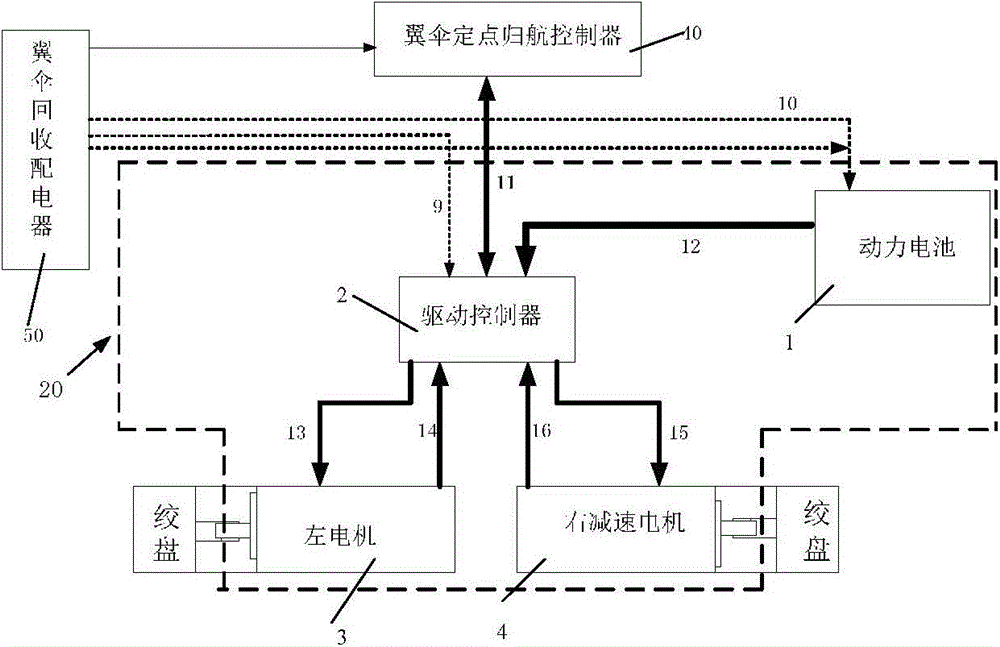

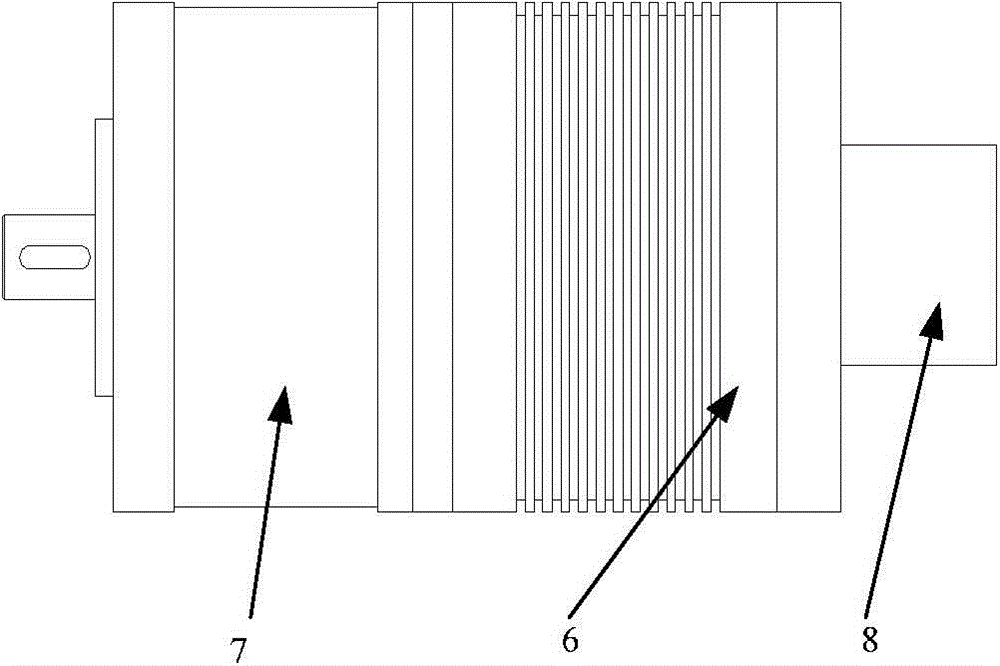

Parafoil fixed-point homing servo control device and control method

InactiveCN104699109AImplement servo controlHigh control precisionPosition/course control in three dimensionsPower batteryControl signal

The invention provides a parafoil fixed-point homing servo control device and a control method. The parafoil fixed-point homing servo control device comprises a power battery, a driving controller and an operation rope control device. The power battery supplies power to the driving controller and the operation rope control device, and the driving controller receives control signals and drives and controls the operation rope control device. The parafoil fixed-point homing servo control device and the control method have the advantages that by adoption of the driving controller for receiving the control signals and driving and controlling the operation rope control device, servo control of an operation rope can be realized, and control precision improvement, size reduction and weight reduction can be realized effectively.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

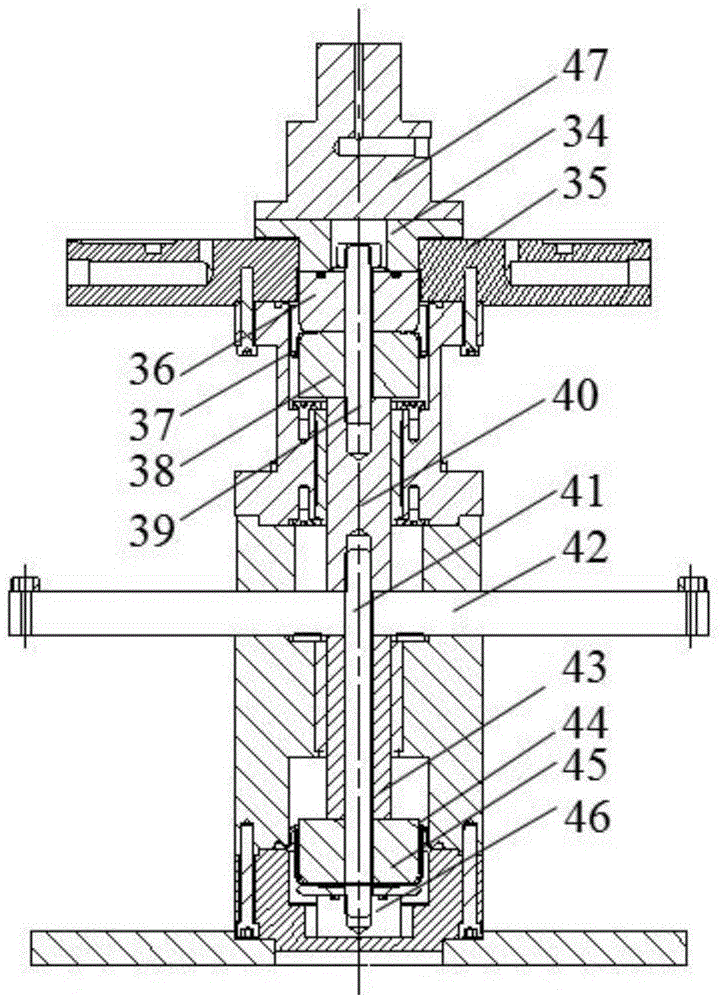

Dynamic and static load synchronous servo control system for three-axis six-direction Hopkinson pressure bar

InactiveCN109406310ASolving problems in a free stateImplement servo controlStrength propertiesHydraulic cylinderTest sample

The invention provides a dynamic and static load synchronous servo control system for a three-axis six-direction Hopkinson pressure bar. A square bar is fixed by a self-lubricating square bar and fixed by a support frame, and the square bar and a central cube square box are in centering connection in a square opening. A confining pressure loading hydraulic cylinder and a confining pressure loadingactuator are combined with a confining pressure loading frame in series, an electromagnetic pulse excitation chamber is placed in the confining pressure loading frame and freely and tightly fitted with the incident end of the square bar, the confining pressure loading frame and a boss are connected in series, and the boss is placed at the incident end of the square bar. The setting of the boss can ensure that the incident end of the Hopkinson pressure bar is a free end after a test sample is subjected to static confining pressure, the problem that the free state of the ends of a Hopkinson incident bar and a transmission bar cannot be ensured after the static prestress is applied in the traditional dynamic and static combination Hopkinson bar system is solved, and test conditions are provided for subsequent application of electromagnetic excitation stress pulses and ultrasonic testing under in-situ pressure maintenance conditions.

Owner:SHENZHEN UNIV

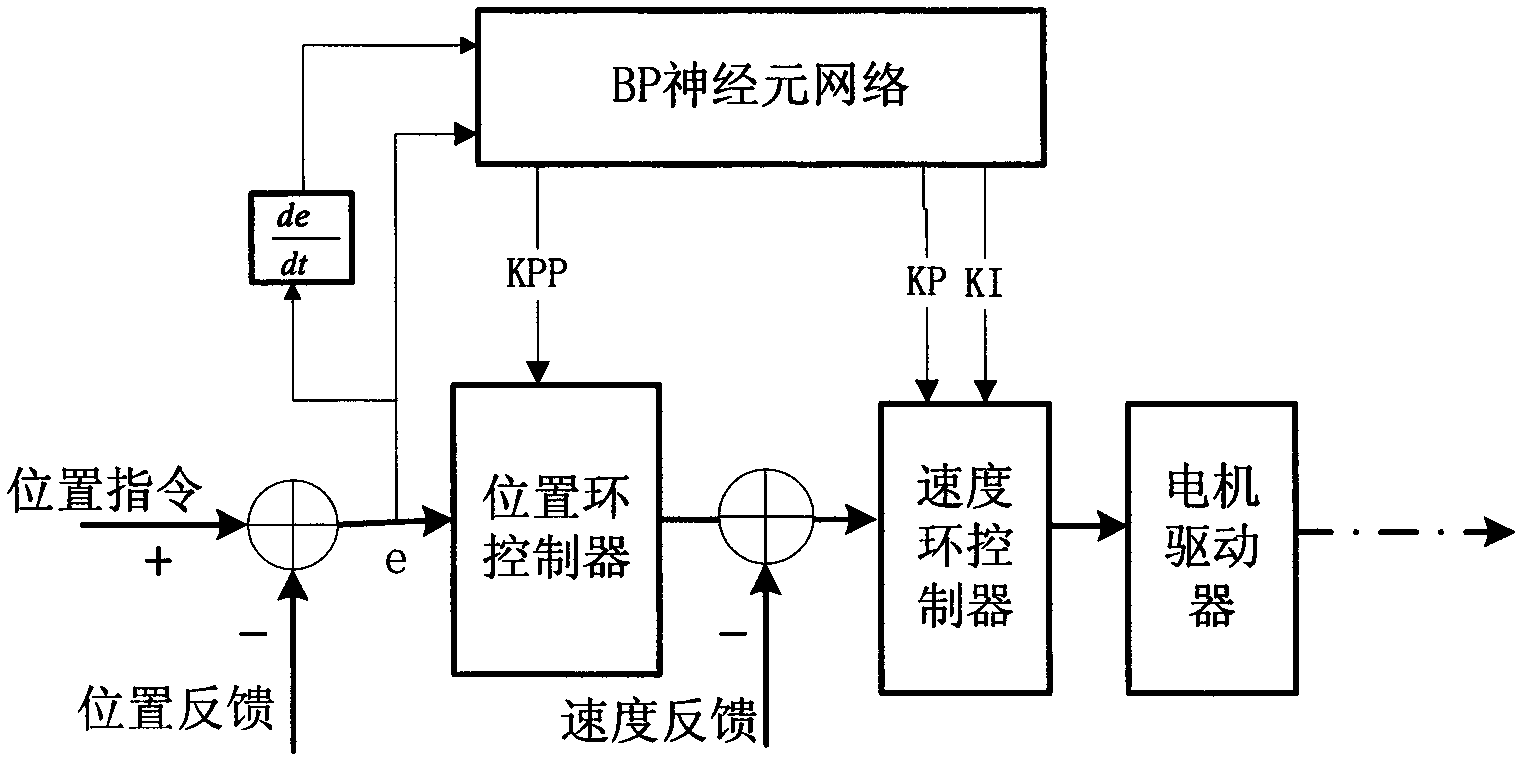

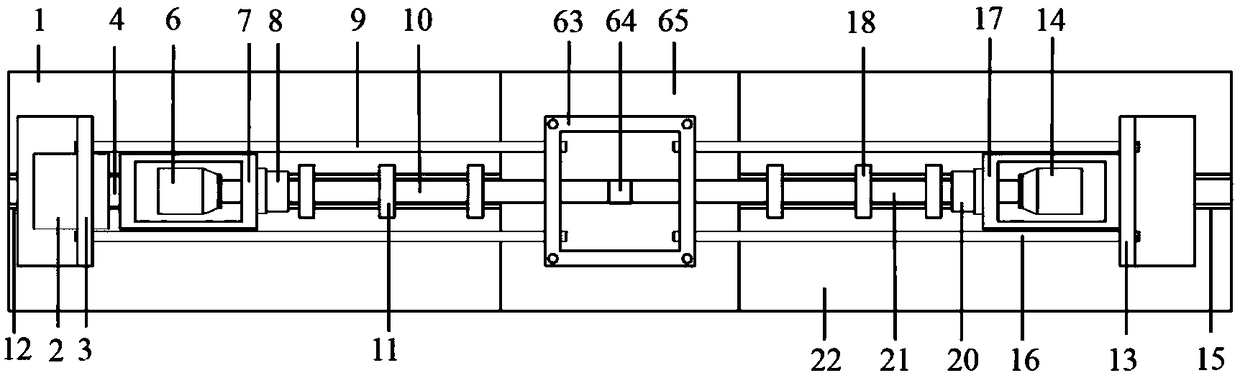

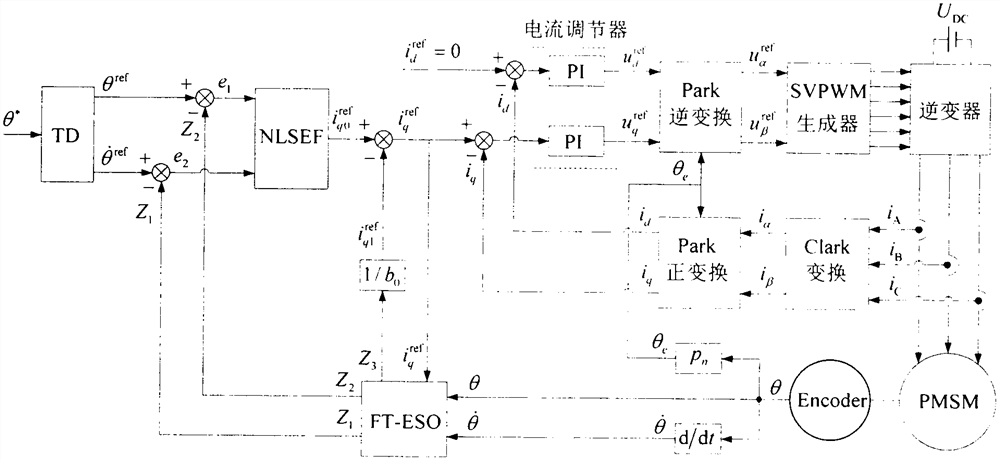

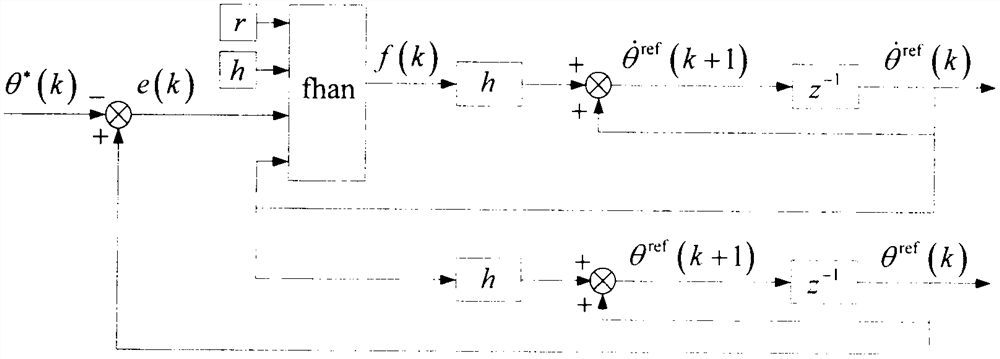

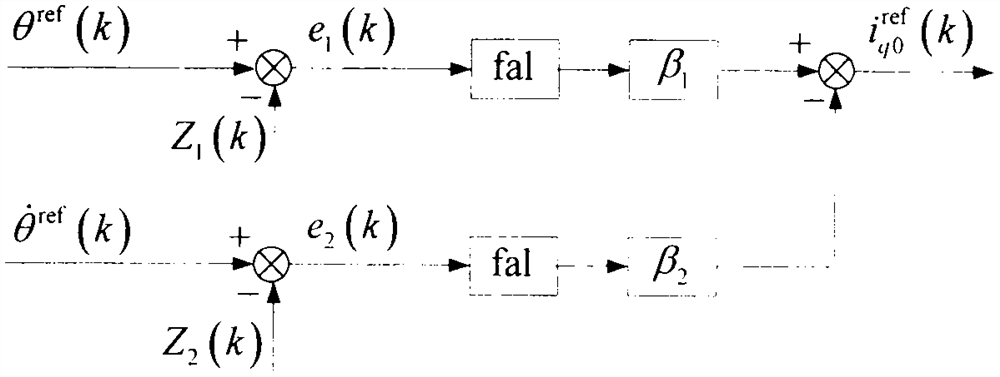

Active-disturbance-rejection position servo control method for permanent magnet synchronous motor

ActiveCN113364377AMovement trend changeImplement servo controlElectronic commutation motor controlAC motor controlLoop controlInterference resistance

The invention discloses an active-disturbance-rejection control method based on an improved extended state observer, and aims to overcome the defects of large tracking error, poor anti-interference capability, poor robustness, low response speed and the like in a traditional permanent magnet synchronous motor position servo system. The method comprises the steps of firstly, introducing speed into the extended state observer as an input quantity, and obtaining a better observation effect on the second-order state variable; and secondly, by introducing a finite time state observer, enabling the state observer not only to have the characteristic that a traditional extended state observer can observe disturbance, but also have the advantage that the finite time state observer can converge in finite time. Compared with a traditional position-speed-current three-closed-loop control method, the method has the advantages of being small in tracking error, high in anti-interference capacity and capable of following position signals with higher frequency, and the performance of a position servo system of the permanent magnet synchronous motor is improved.

Owner:TIANJIN UNIV

Autonomous mobile robot communication system based on CAN bus

InactiveCN106444491AAchieve positioningImplement servo controlProgramme controlComputer controlWireless dataTransceiver

The invention discloses an autonomous mobile robot communication system based on a CAN bus. The system comprises a human-computer interaction unit and a CAN bus control unit. A DSP control system is connected between the data links of the human-computer interaction unit and the CAN bus control unit through an FPGA controller. The human-computer interaction unit includes a wireless local area network interface, and the output end of the wireless local area network interface is connected with a CAN bus adapter card. The CAN bus control unit includes a network server, and the network server is connected with a wireless data transceiver. The FPGA controller includes a GPS positioning module and a servo system, and the output end of the servo system is connected with the DSP control system. Frequency conversion is performed between a clock detection module and the DSP control system. A controller local network structure based on a CAN bus is adopted, and reliable, real-time and flexible data communication is realized between the DSP system and an upper control computer independent of each other.

Owner:WUHU YANGZHAN NEW MATERIAL TECH SERVICE CO LTD

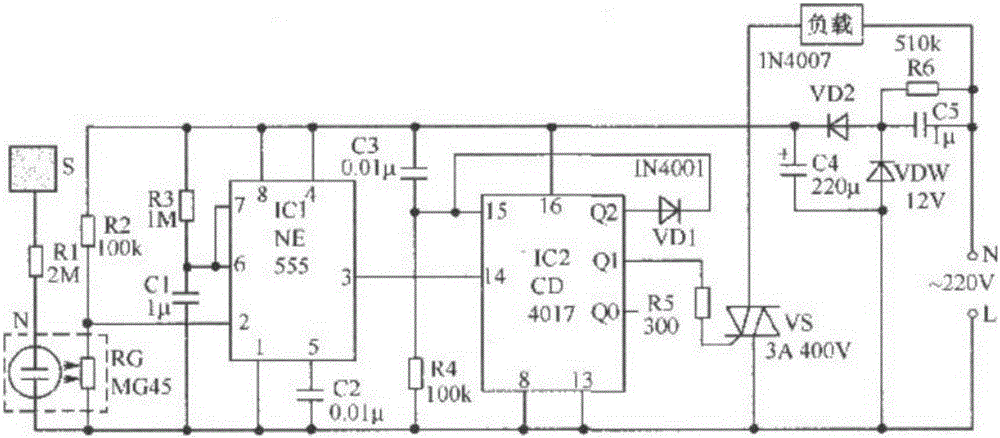

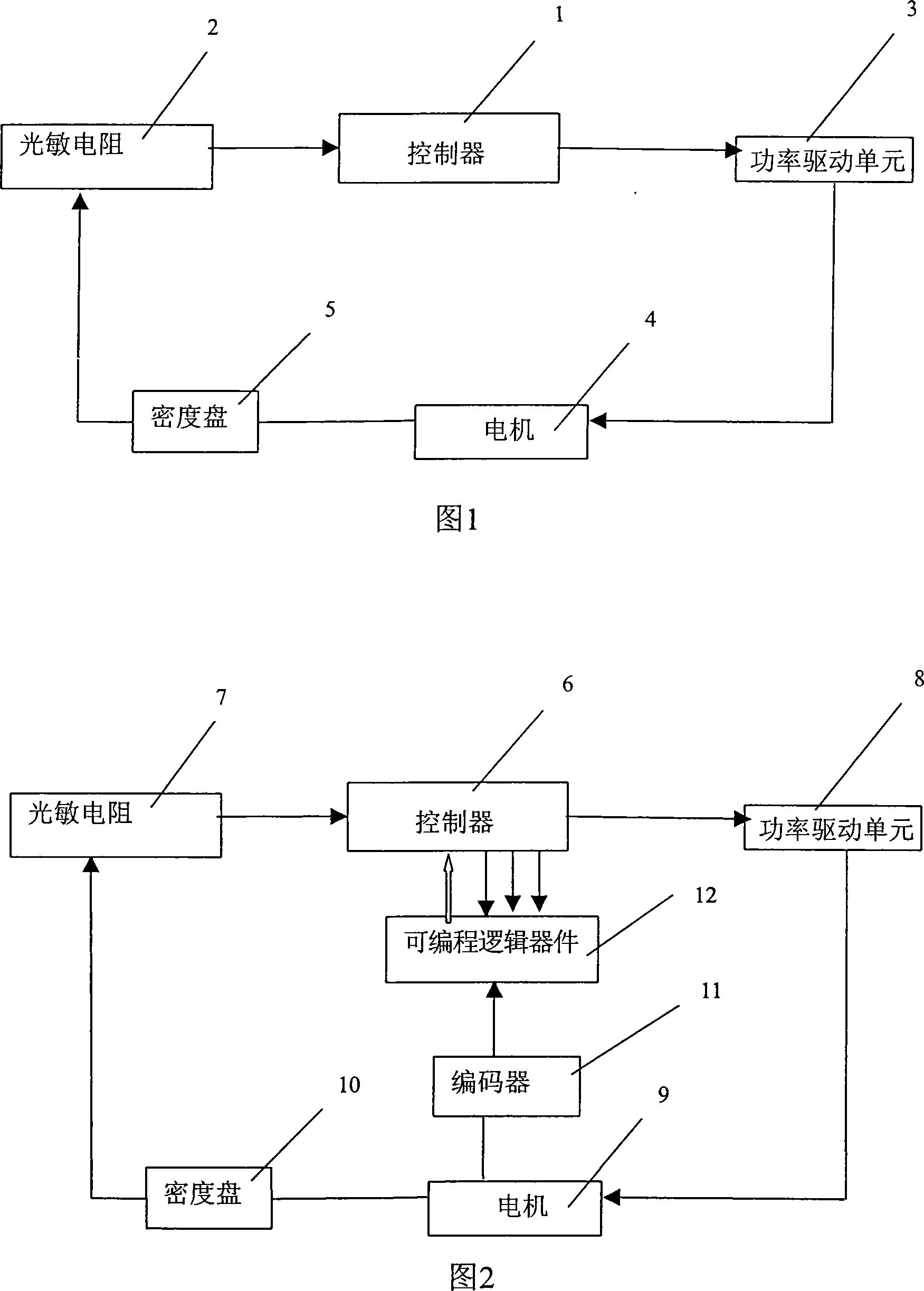

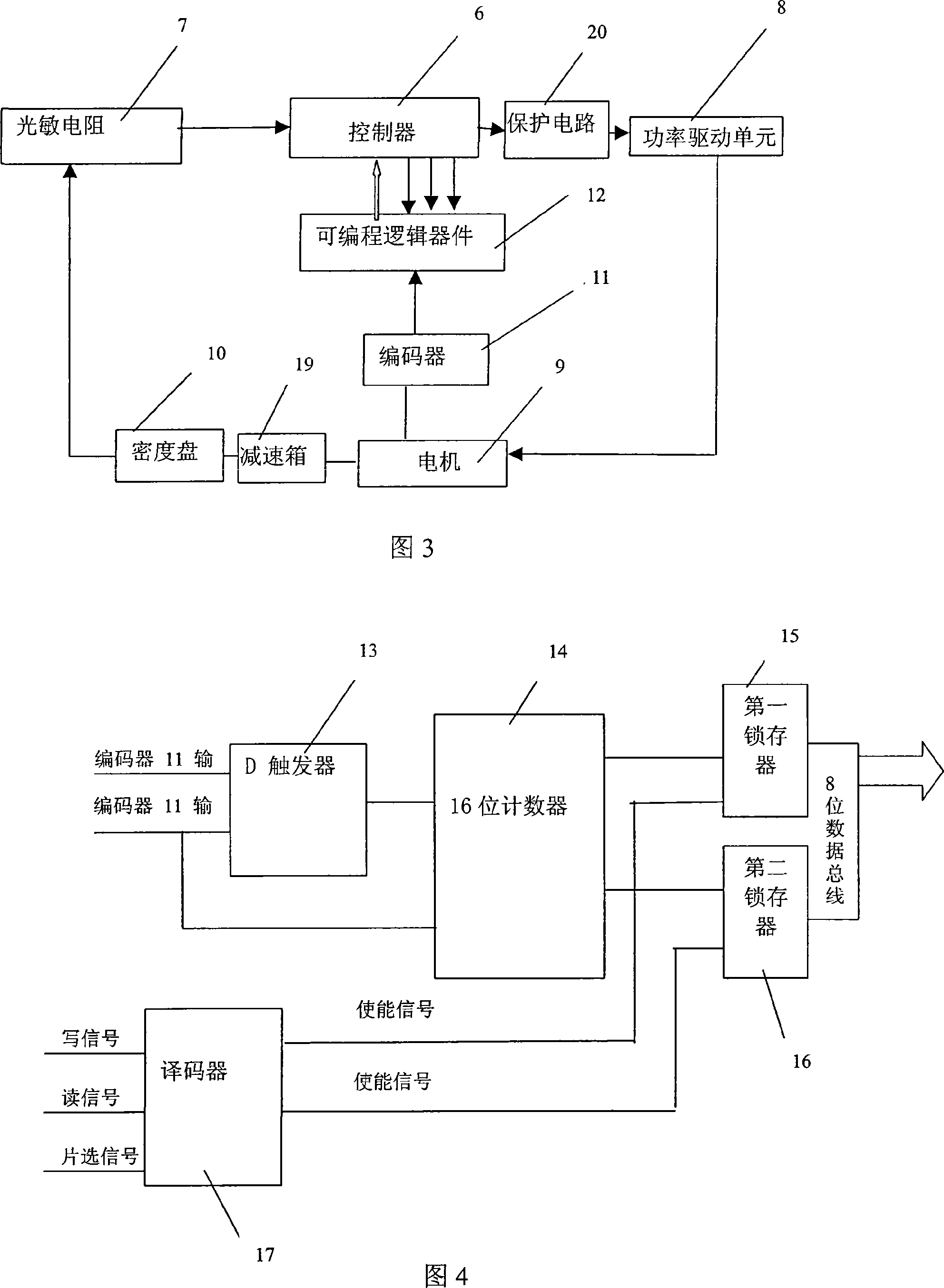

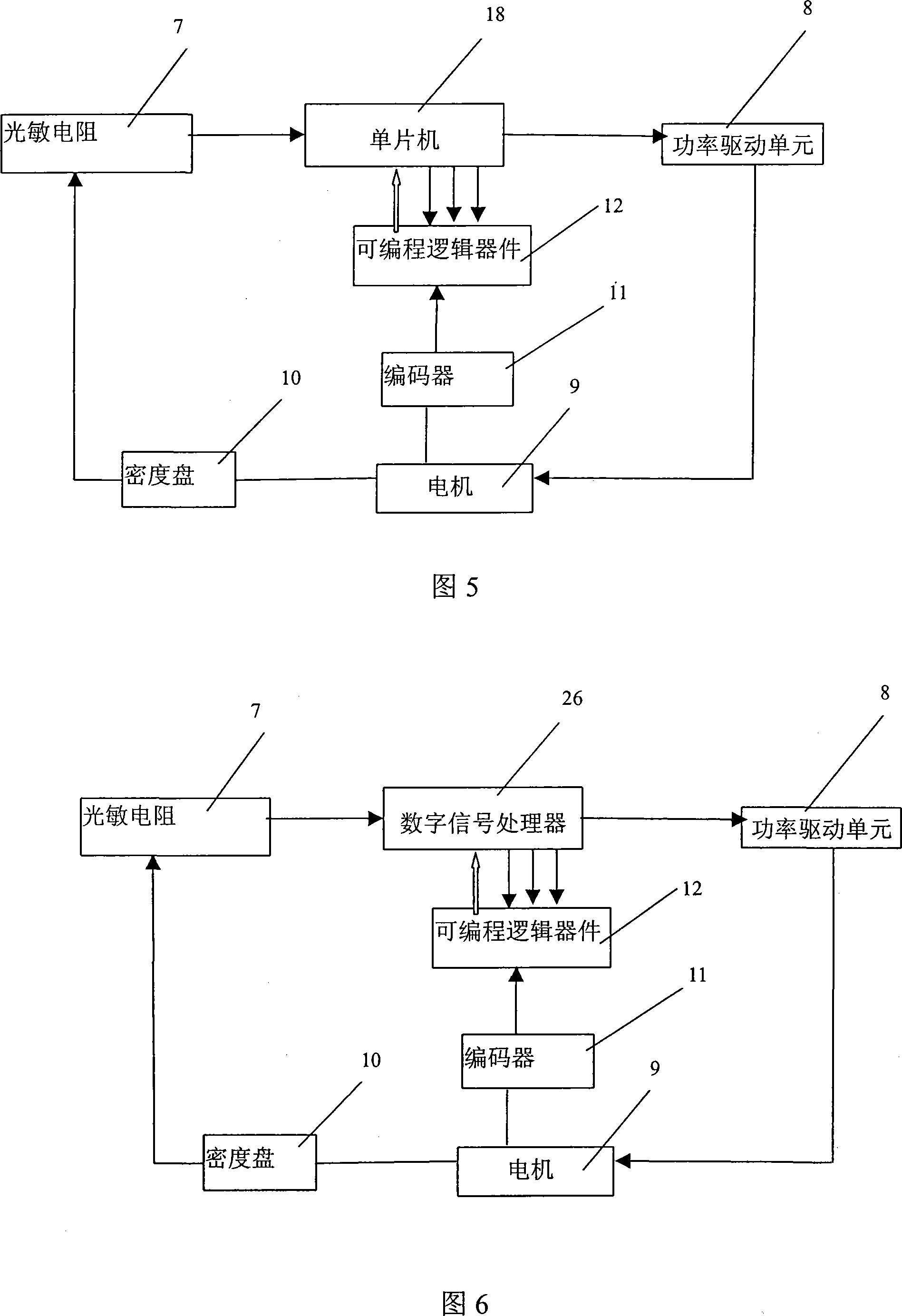

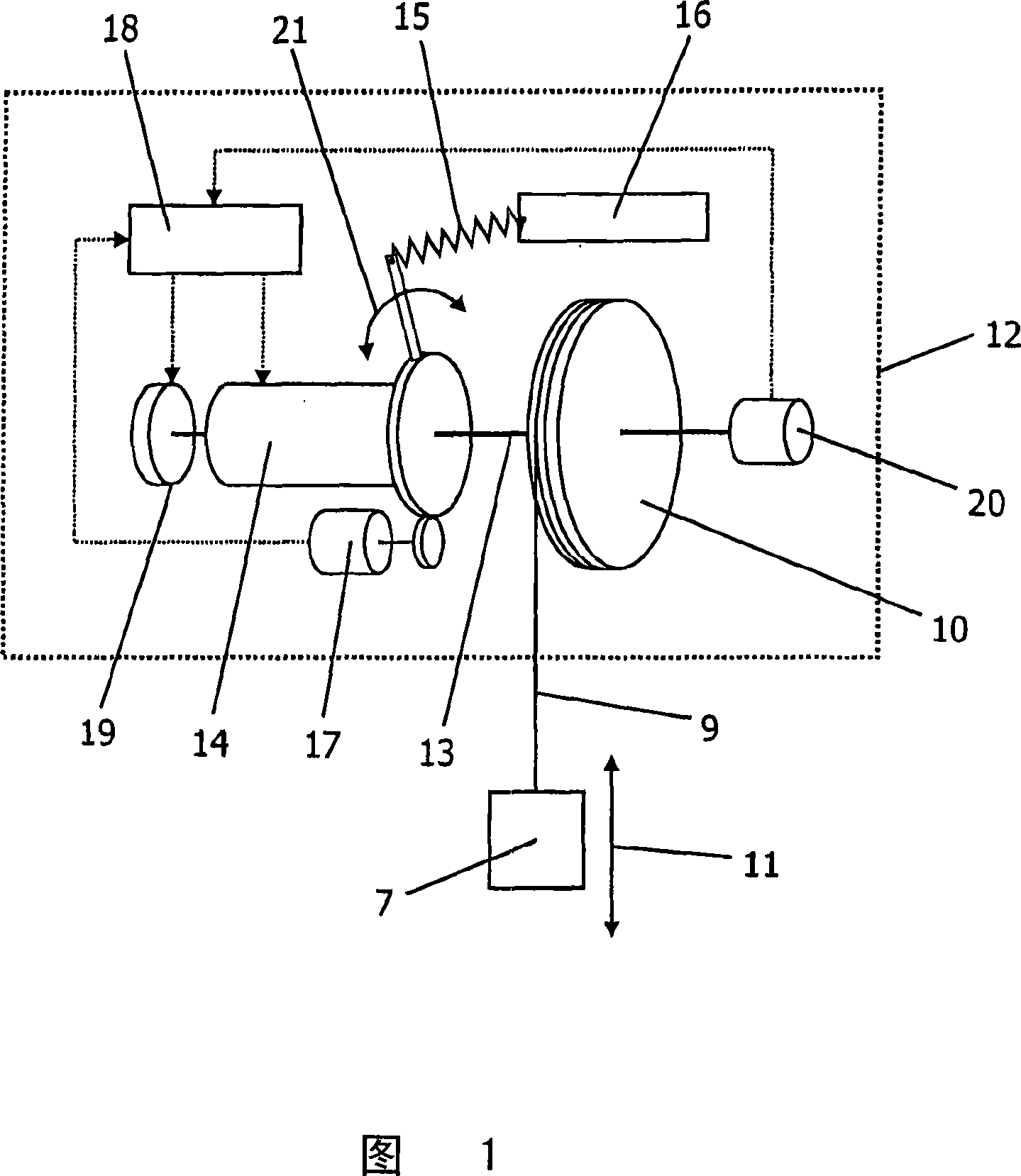

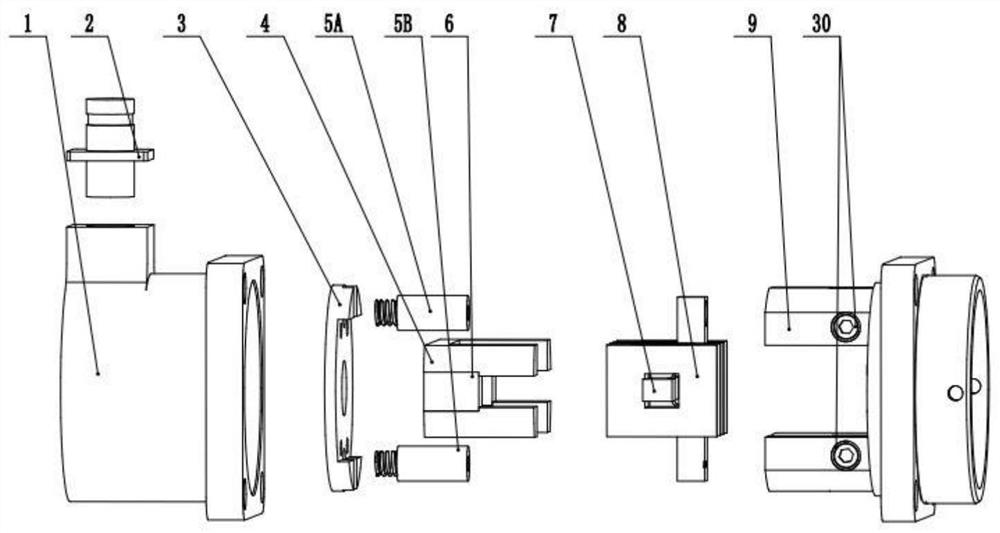

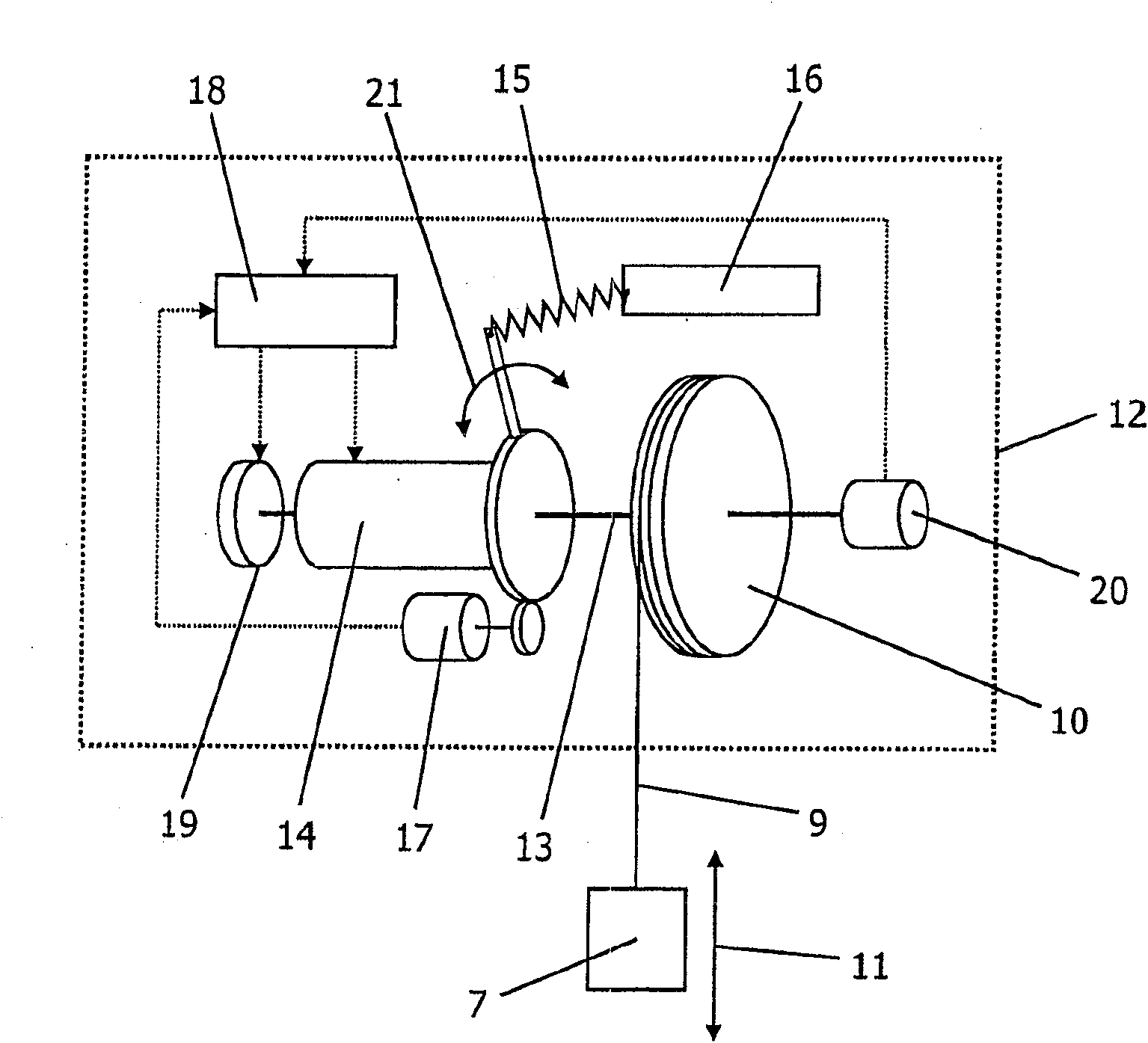

Density disc drive device of automatic light modulation system

InactiveCN101145061AImplement servo controlQuick responseLight controlElectrical resistance and conductanceElectric machine

The present invention relates to a density-disk driving device used in a double-loop-controlled automatic lighting system, the device takes a encoder and a counter as speed feedback elements, takes a photosensitive resistor as a position feedback element, and forms a speed-position double-loop system; when the illumination value received by the photosensitive resistor is quite different from the standard value, the dutyfactor of the width wave output by a controller is bigger, the rotating speed of a motor is increased, which rotates the density disk fast; while the illumination value received by the photosensitive resistor is mostly equal to the standard value, the dutyfactor of the width wave output by the controller is smaller, the rotating speed of the motor is reduced, which reduces the speed of the density disk; in this way, on one hand, the illumination flux can reach the standard value in short time; on the other hand, the density disk can be stopped at the correct position to gain the required standard illumination flux, so that the film can get the best contrast. The present invention has fast response and high precision of adjustment.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

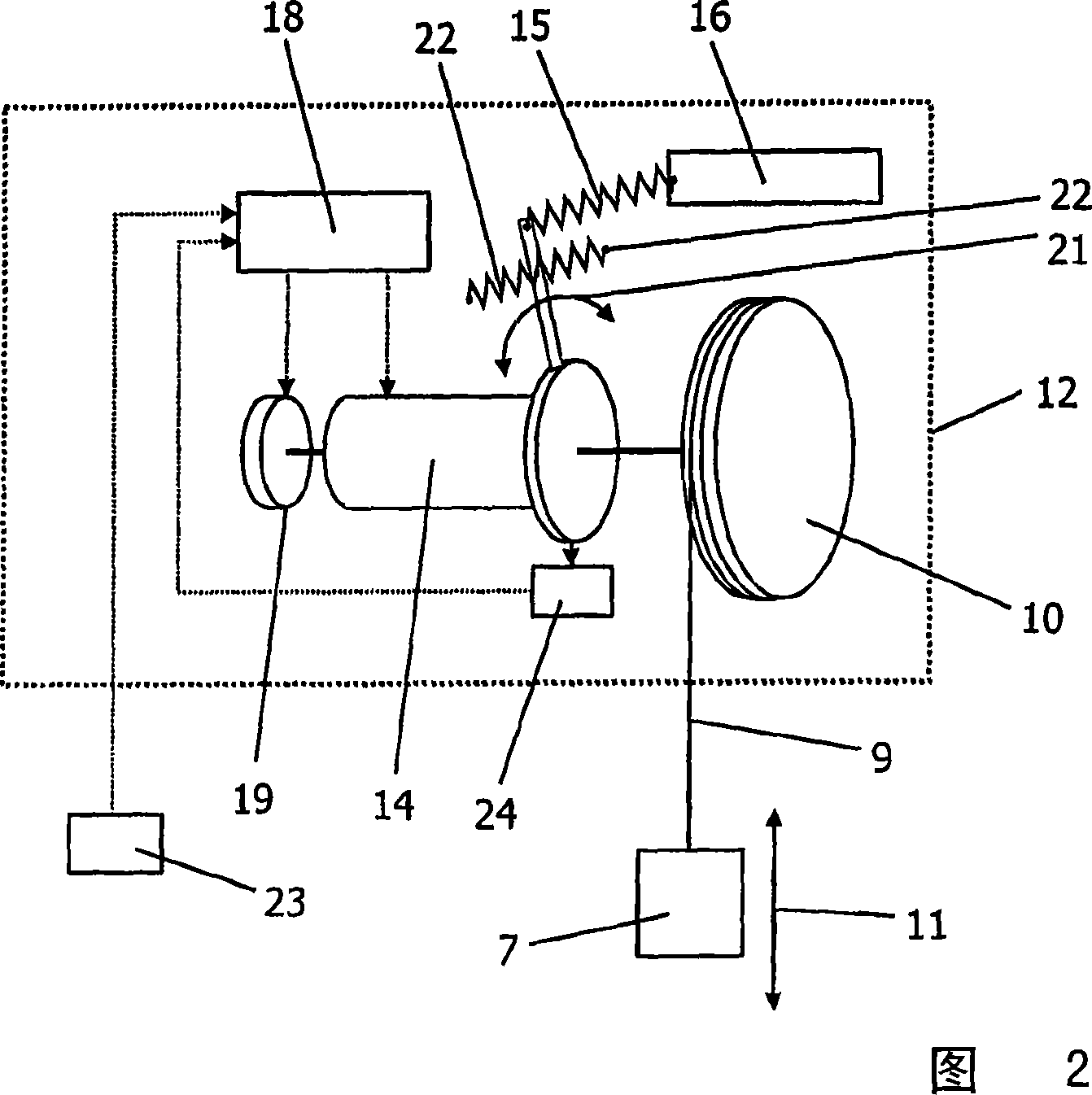

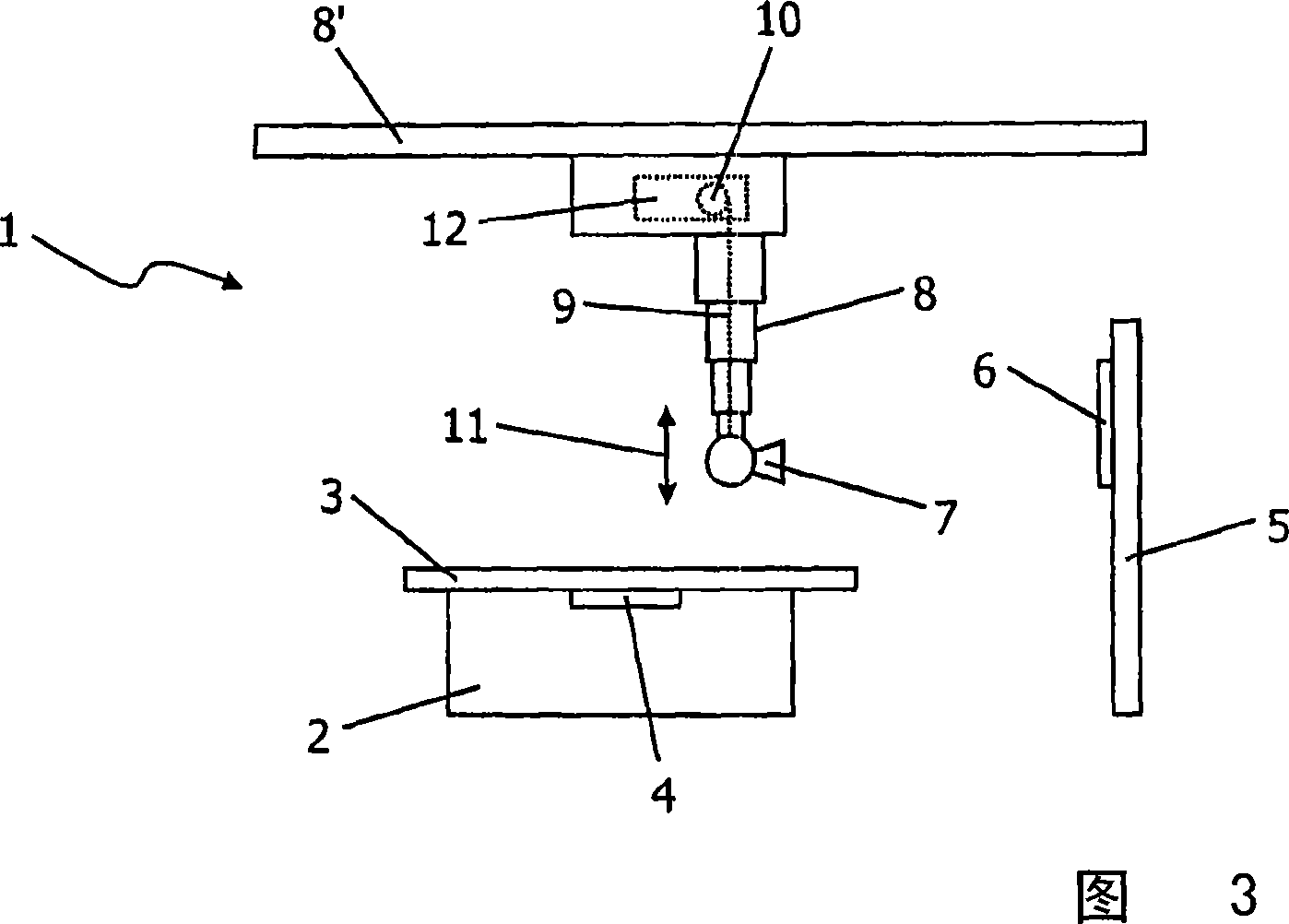

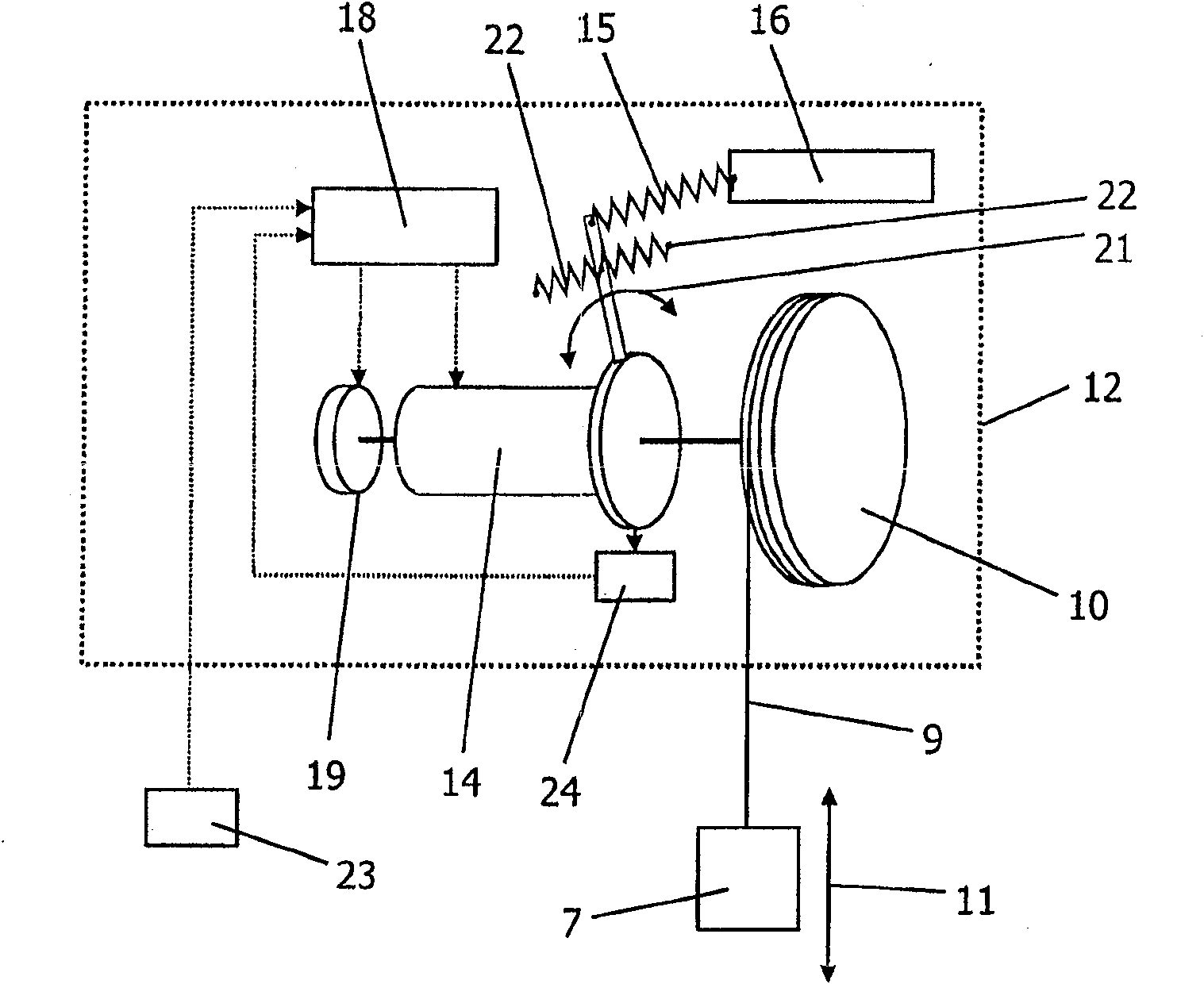

Drive unit for X-ray system

ActiveCN101065063APrecise and Direct Movement ControlEfficient feedbackEngineering emergency devicesStands/trestlesCollision detectionDrive shaft

The invention relates to a drive unit (12) for vertical or horizontal movement of a component (7) of a diagnostic X-ray device (1), comprising a motor and gear unit (14), a pulley (10) mounted on a drive shaft (13) of the motor and gear unit (14), and traction means (9), e.g. a rope or a drive belt, wound around the pulley (10), the component (7) to be moved being either attached to the traction means (9) or connected with the drive unit (12). In order to provide a drive unit (12) enabling collision detection, emergency stop functionality, and improved handling with regard to control of the motion of the component (7) by an operator of the X-ray device (1), the invention proposes that the motor and gear unit (14) is rotatable about the axis of the drive shaft (13) against the elastic force of a balancing spring (15), wherein provision is made for a rotation sensor (17,24), which rotation sensor (17,24) is adapted for detecting a rotation of the motor and gear unit (14) and for generating a corresponding rotation detection signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

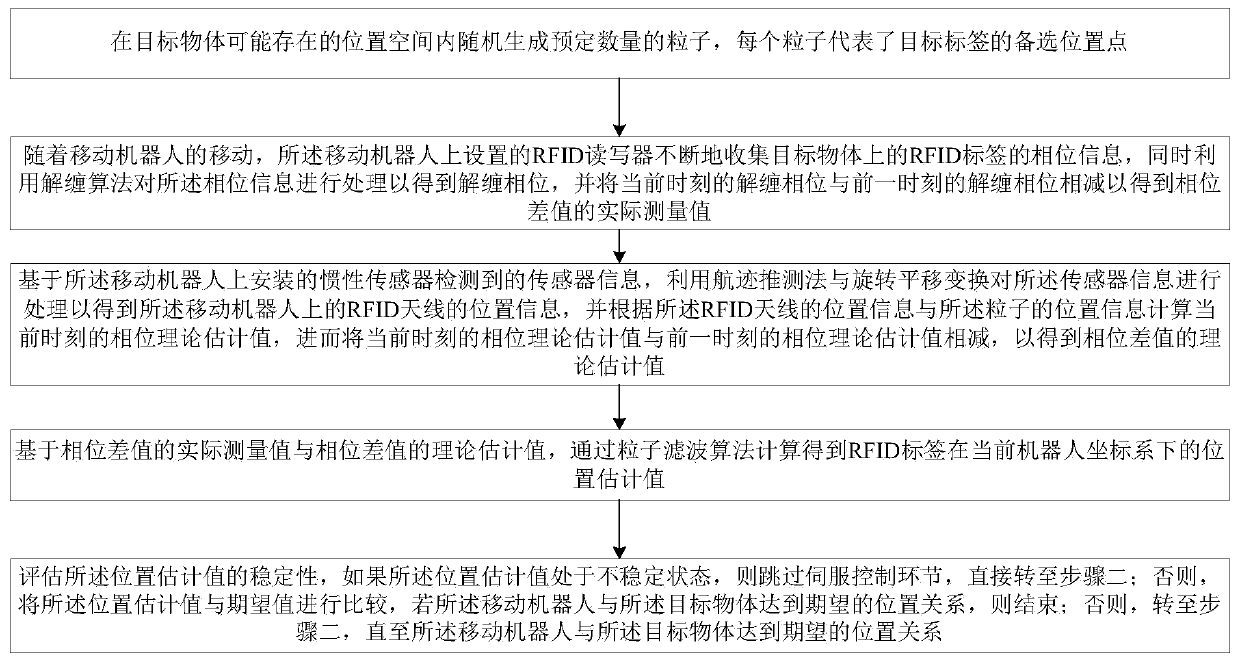

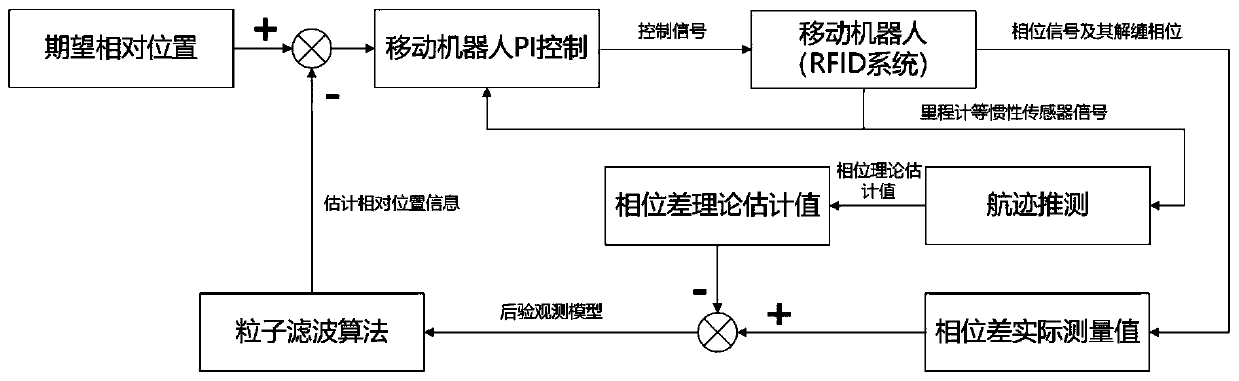

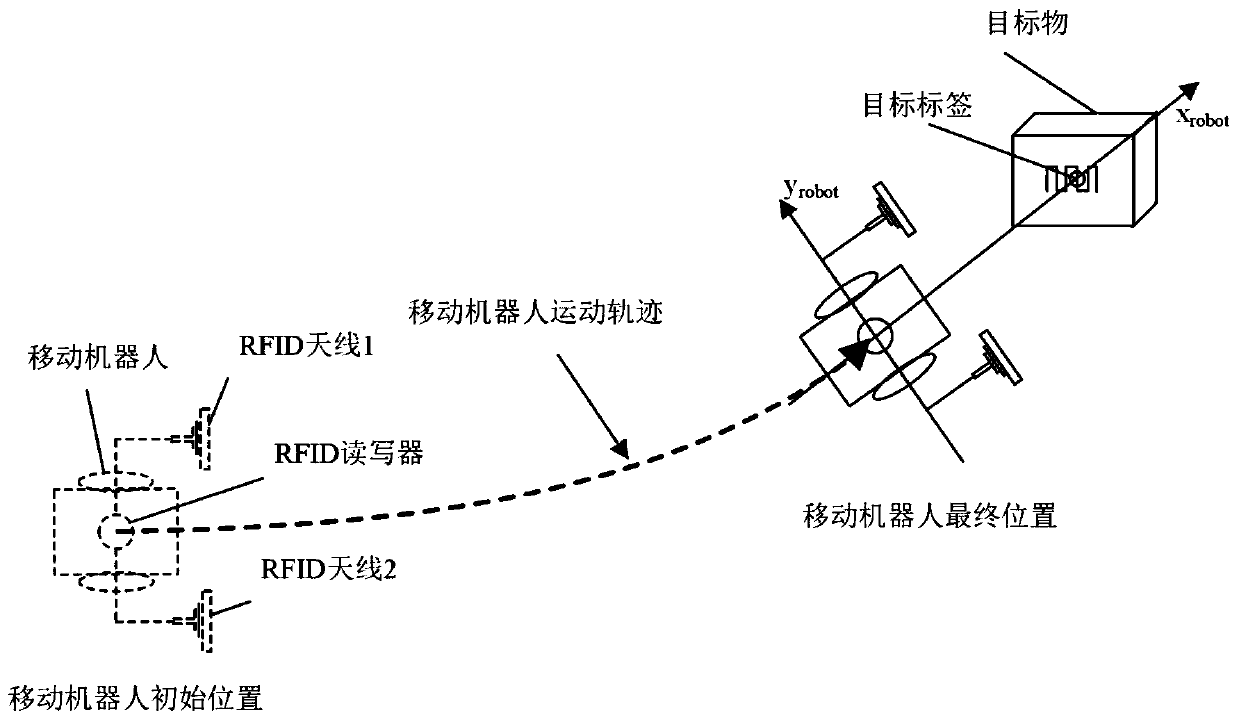

Mobile robot RFID servo method based on positions

ActiveCN110442014AEasy to implementGood applicabilityCo-operative working arrangementsControllers with particular characteristicsMobile robotReader writer

The invention belongs to the technical field relevant to mobile robot servo, and discloses a mobile robot RFID servo method based on positions. The method comprises the following steps of (1) randomlygenerating the preset quantity of particles in an existence position space of a target object; (2) continually collecting phase information of an RFID label on the target object by a RFID reader-writer arranged on a mobile robot, and further obtaining a practical measured value of a phase difference value; (3) processing sensor information so as to obtain the position information of a RFID antennae arranged on the mobile robot, and further obtaining a theoretical estimated value of the phase difference value; (4) performing calculation by a particle filter algorithm to obtain the position estimated value of the RFID label in the coordinate system of the current mobile robot; and (5) evaluating the stability of the position estimated value; and performing corresponding processing accordingto the evaluation result until the mobile robot and the target object reach the expected position relationship. The method has the advantages that the implementation is easy; and the applicability ishigh.

Owner:HUAZHONG UNIV OF SCI & TECH

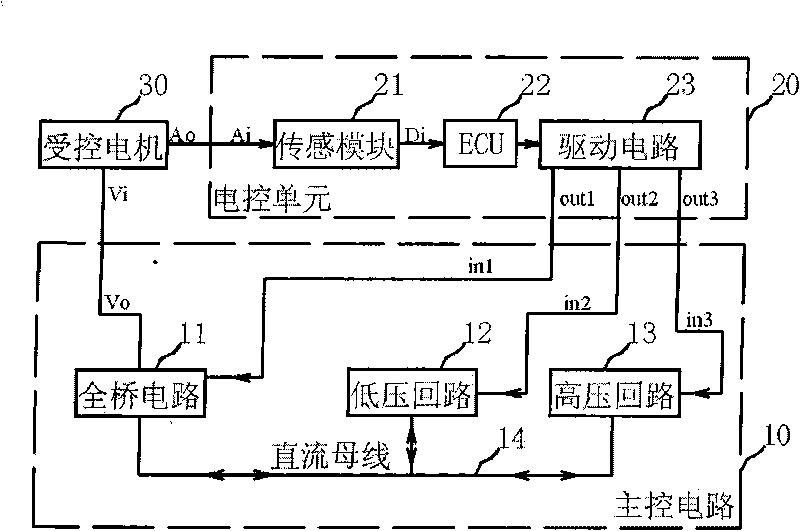

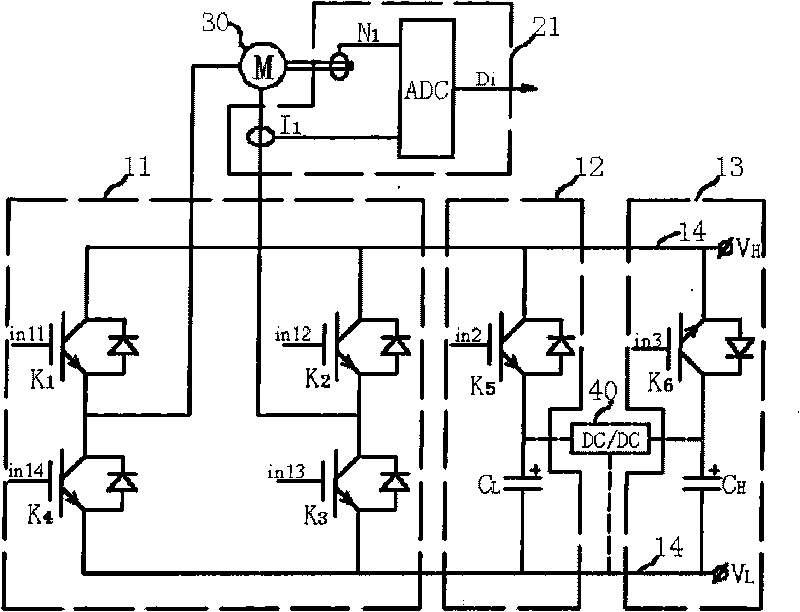

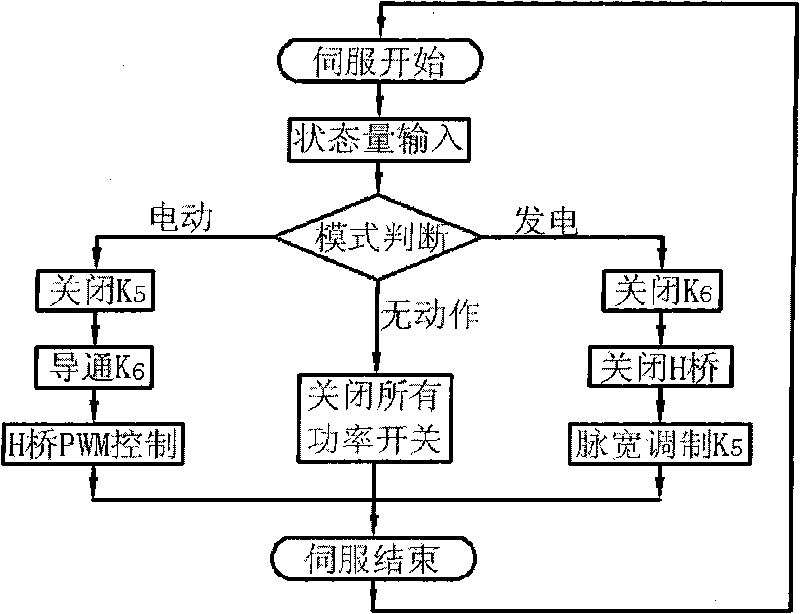

Motor control system capable of realizing high-efficiency recovery of kinetic energy and control method thereof

InactiveCN101741292AImplement servo controlImprove efficiencyMotor/generator/converter stoppersElectrodynamic brake systemsFull bridgeLow voltage

The invention discloses a motor control system capable of realizing the high-efficiency recovery of kinetic energy, which comprises a electric control unit, a main control circuit, and a controlled motor; wherein the main control circuit comprises an H type full bridge circuit, a lower voltage loop, and a high voltage loop which are mutually connected in parallel through a direct current bus, and three input ends of the main control circuit are respective a first input end of the full bridge circuit, a second input end of the lower voltage loop, and a third input end of the high voltage loop; an analog signal input end of the electric control unit is connected to an analog signal output end of the controlled motor; the first output end of the electric unit is connected with the first input end of the full bridge circuit, the second output end of the electric control unit is connected with the second input end of the lower voltage loop, and the third output end of the electric control unit is connected with the third input end of the high voltage loop; and the voltage end of the full bridge circuit is the output end of the main control circuit. Without using large power direct current converter, the invention can improve the range and the efficiency of the kinetic energy with the help of the afterflow effect of per se inductance of the motor.

Owner:NANJING UNIV OF SCI & TECH

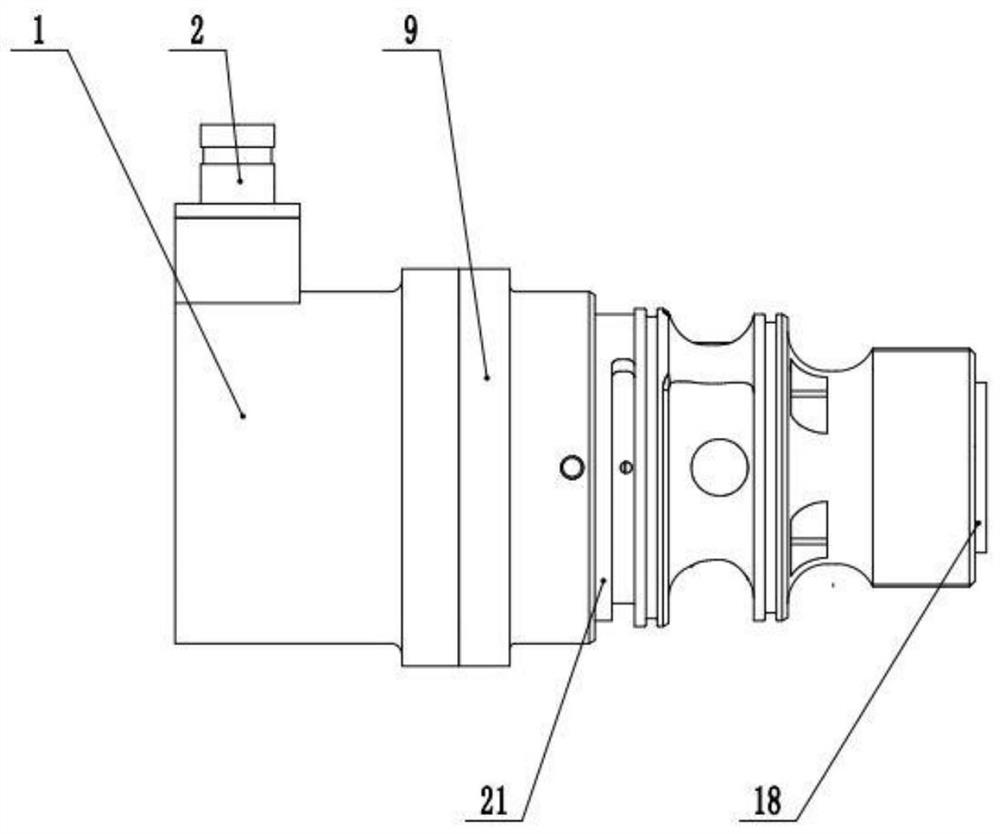

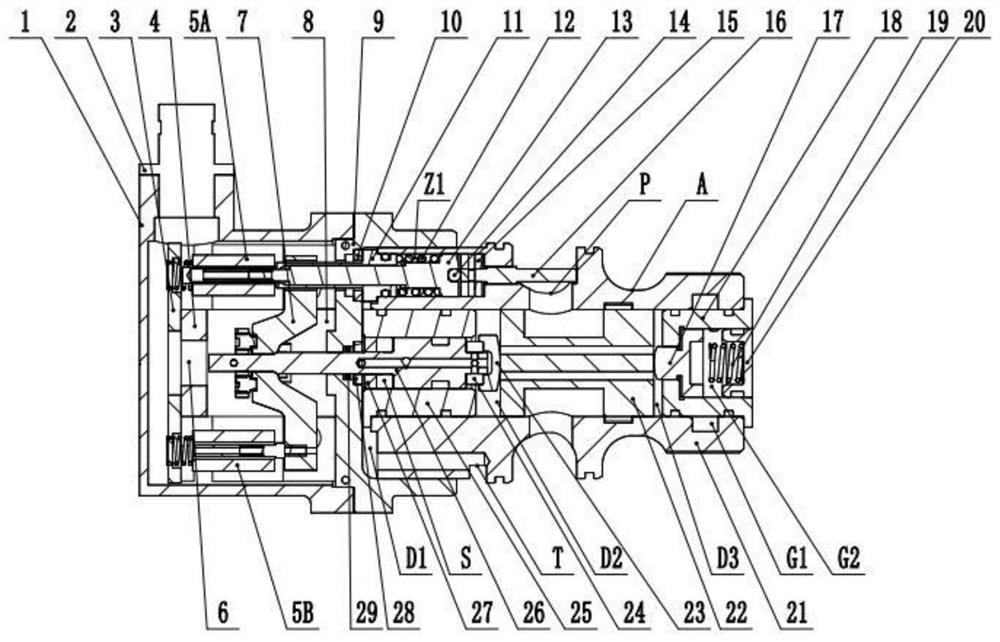

Two-dimensional plug-in type load sensitive valve

InactiveCN112983916ALess input signalLarge hydraulic driving forceOperating means/releasing devices for valvesServomotor componentsTorque motorEngineering

A two-dimensional plug-in type load sensitive valve comprises an electric-mechanical converter and a valve body which are coaxially connected in sequence, the electric-mechanical converter is a torque motor, the valve body comprises a valve sleeve and a valve element, and the valve element is installed in the valve sleeve in an axial sliding mode. A rear plug sleeve is installed at the right end of the valve element, a high-pressure piston capable of axially sliding is arranged in the rear plug sleeve, and the left end of the high-pressure piston extends out of the rear plug sleeve to abut against the right end of the valve element. A high-pressure sealing head is mounted at the right end of the rear plug sleeve, a high-pressure spring is arranged between the high-pressure piston and the high-pressure sealing head, and the rear plug sleeve, the high-pressure piston and the high-pressure sealing head are matched to form a high-pressure spring cavity. The output end of the torque motor is connected with the valve element through a two-dimensional piston. According to the two-dimensional plug-in type load sensitive valve, input signals are small, hydraulic driving force is large, and normal work under the high-pressure working condition is easy to achieve. The structure is simple and compact, system heating is reduced, and system efficiency is improved; A pilot valve is accurately controlled through a digital controller, the opening degree of a main valve port is pushed to achieve the purpose that the flow of an outlet is not changed, that is, the flow is irrelevant to loads.

Owner:ZHEJIANG UNIV OF TECH

A grouting servo control device and operation method for indoor grouting simulation test

ActiveCN107632652BWell mixedRealize limitSimultaneous control of multiple variablesInjection pressureLoop control

The invention discloses a slurry injection servo control device for an indoor slurry injection simulation test and an operation method. The device comprises a pressure supply unit, a slurry storage stirring unit and a measurement and control unit, wherein the slurry storage stirring unit comprises a chamber having an accommodation space, the chamber is internally provided with a multi-stage stirring mechanism, the chamber is provided with a slurry inlet channel and a slurry outlet channel, the pressure supply unit is used for providing servo control pressure for slurry accommodated in the slurry storage stirring unit, the measurement and control unit is connected with the pressure supply unit and the slurry storage stirring unit, and slurry injection servo closed loop control is realized through controlling the applying pressure and the flow velocity or the flow of the slurry inlet channel and the slurry outlet channel. The is advantaged in that measurement and control for slurry injection pressure are carried out through a servo control loading disc, the slurry injection flow and the slurry injection amount are measured and controlled through adjusting the volume of the slurry, and random switching servo control on the slurry injection pressure, the slurry injection flow and the slurry injection amount can be carried out.

Owner:SHANDONG UNIV

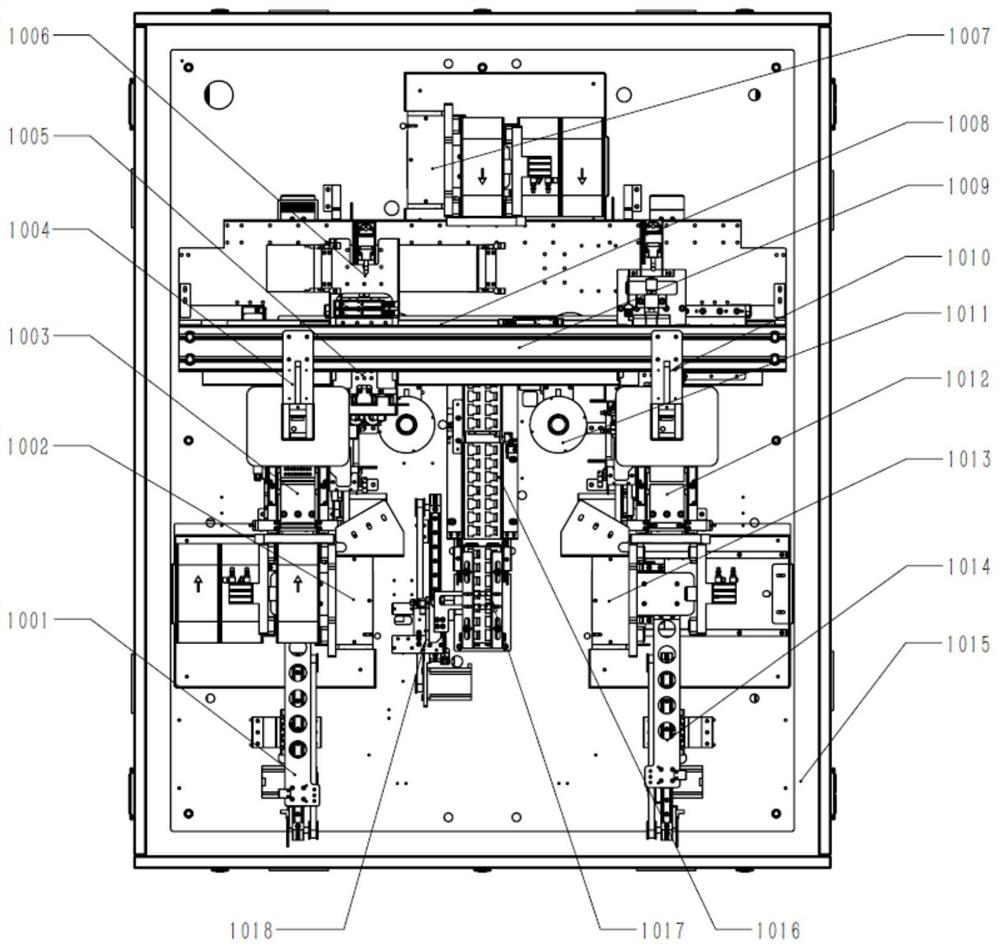

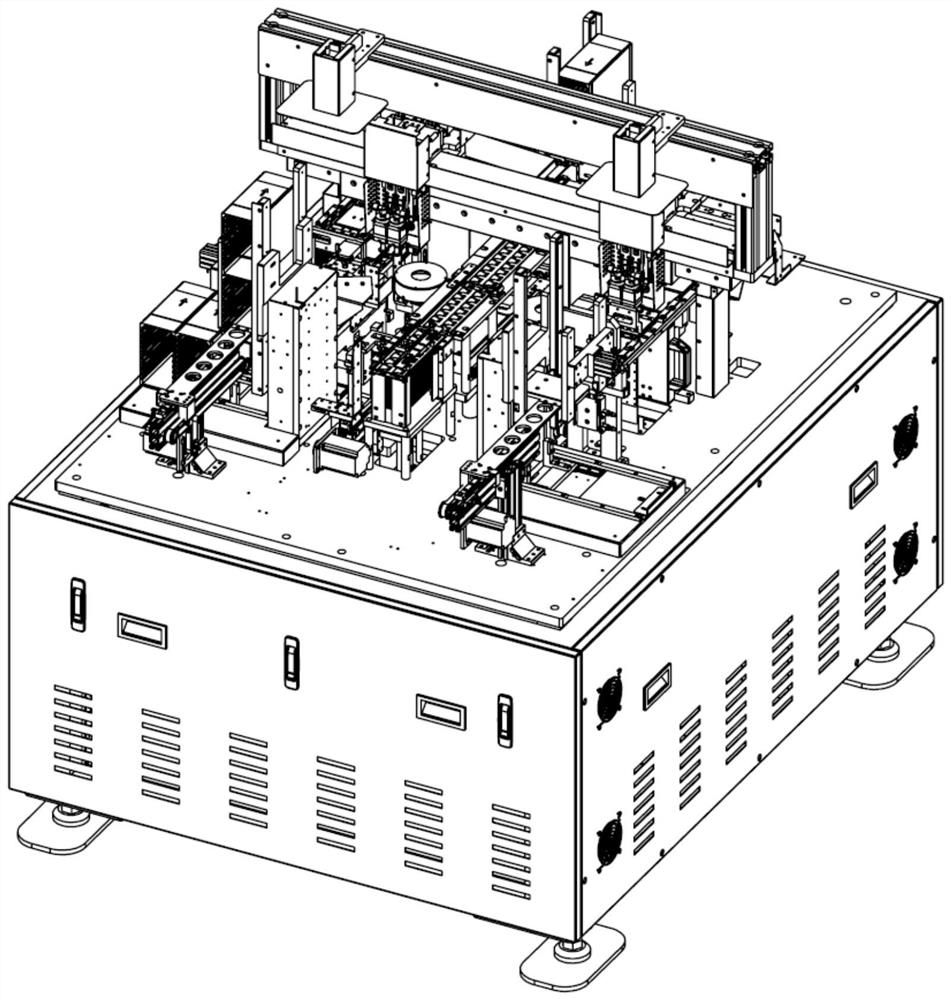

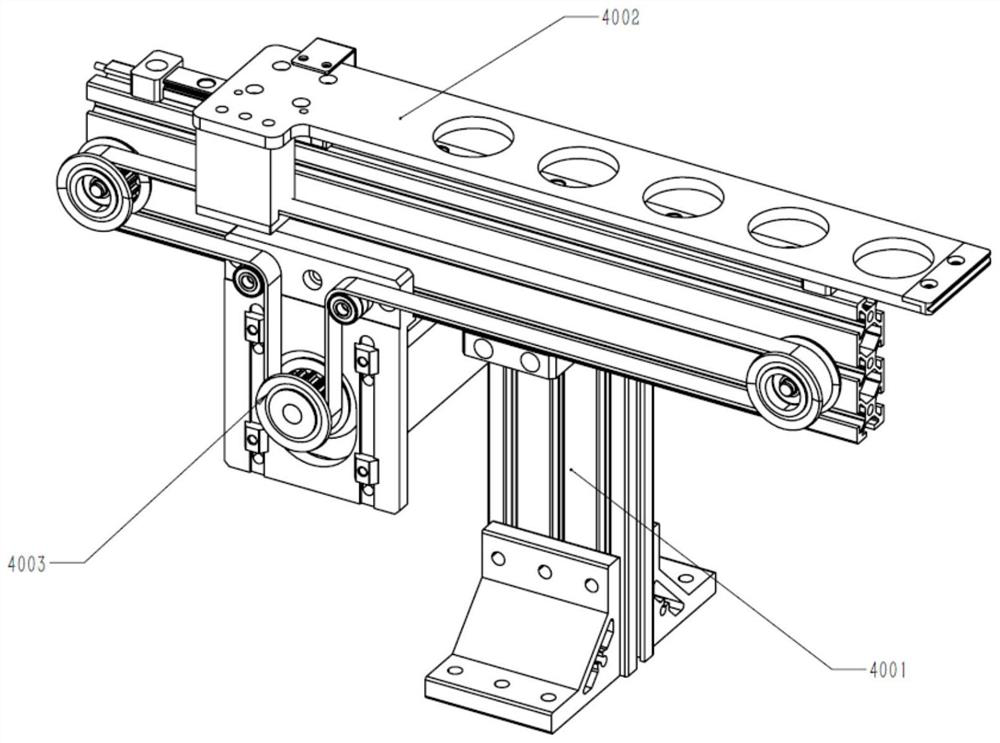

Full-automatic mobile phone camera module stripping machine

PendingCN111843482AAchieve pickupImplement servo controlAssembly machinesMetal working apparatusControl engineeringVisual positioning

The invention discloses a full-automatic mobile phone camera module stripping machine. The full-automatic mobile phone camera module stripping machine comprises a rack mechanism, wherein a left pushing plate mechanism is arranged on the rack mechanism, a left feeding magazine mechanism is arranged on one side of the left pushing plate mechanism, a left film tearing and stripping closing mechanismis arranged on one side of the left feeding magazine mechanism, an upper left visual acquisition unit is arranged on one side of the left film tearing and stripping closing mechanism, and a carrier plate supply mechanism is arranged on one side of a storage carrier plate jacking mechanism. According to the precise matching between the mechanisms, the functions of visual accurate positioning, manipulator accurate picking, high-speed load transfer, precise placement, finished product storage and the like can be smoothly achieved, all the requirements of the above processes can be stably achieved, according to the full-automatic mobile phone camera module stripping machine, the load transfer precision is high, the precision of a feeding and receiving module is high, the servo control is accurate, the placement of products by visual positioning is stable, the yield rate is high, and thus the production efficiency and reliability of the whole equipment are extremely high.

Owner:天津伍嘉联创科技发展股份有限公司

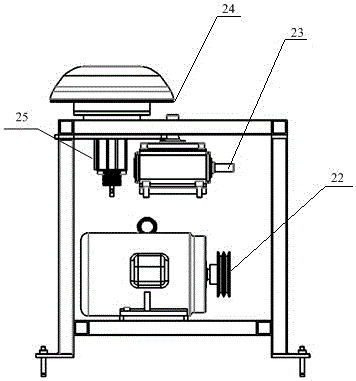

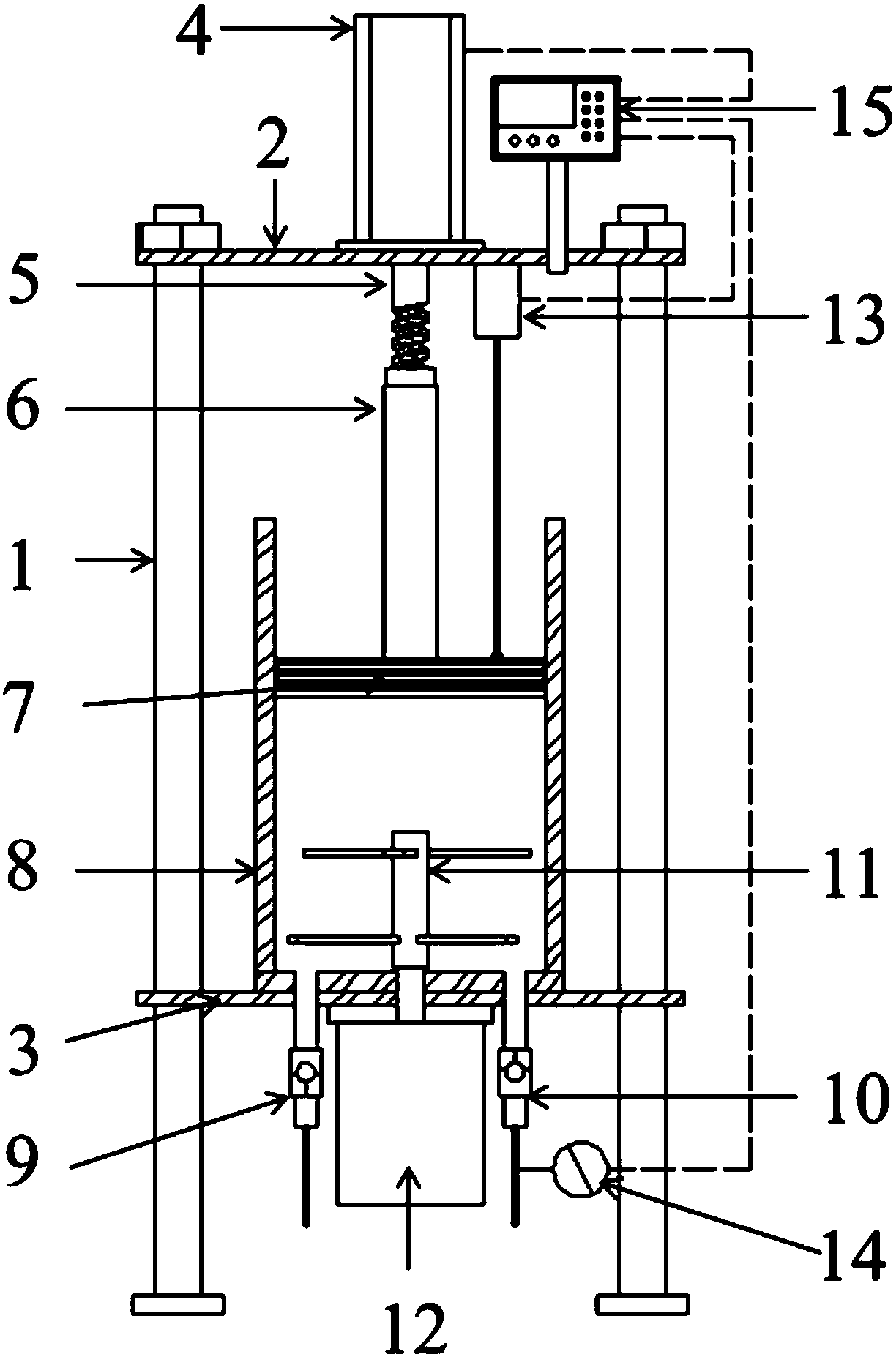

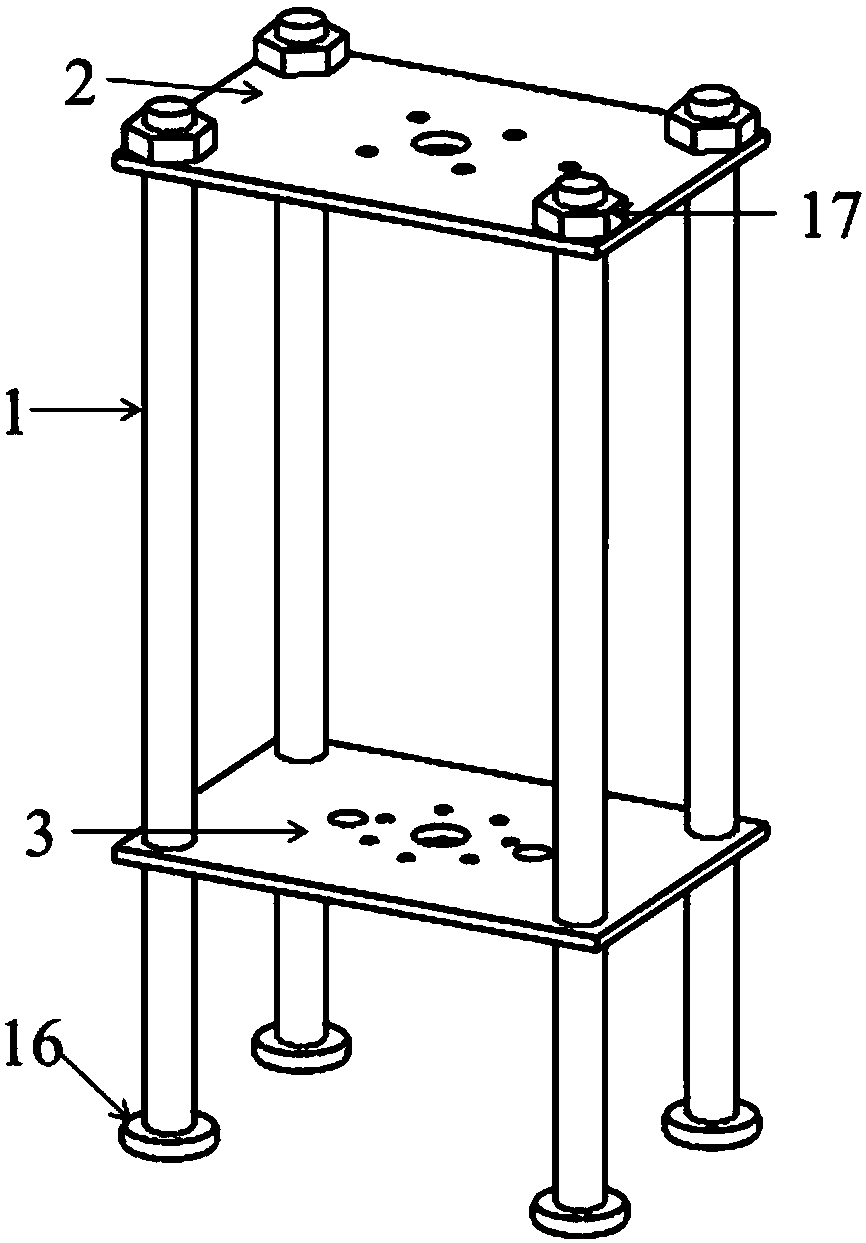

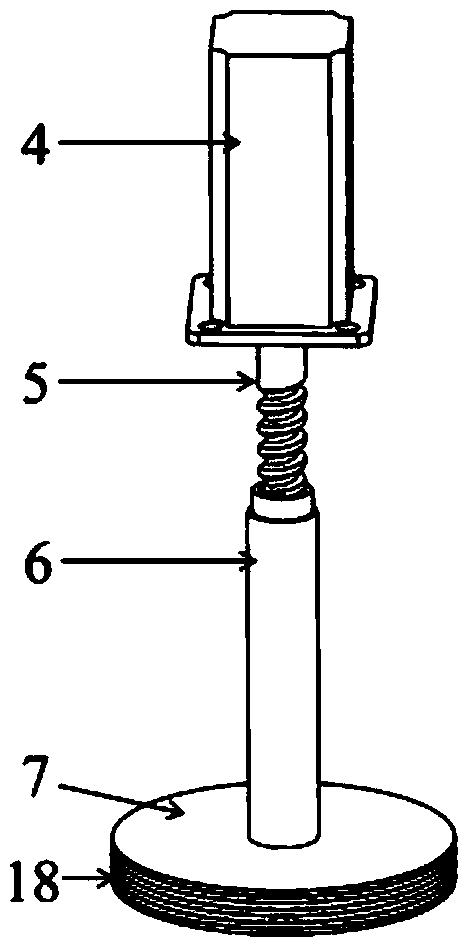

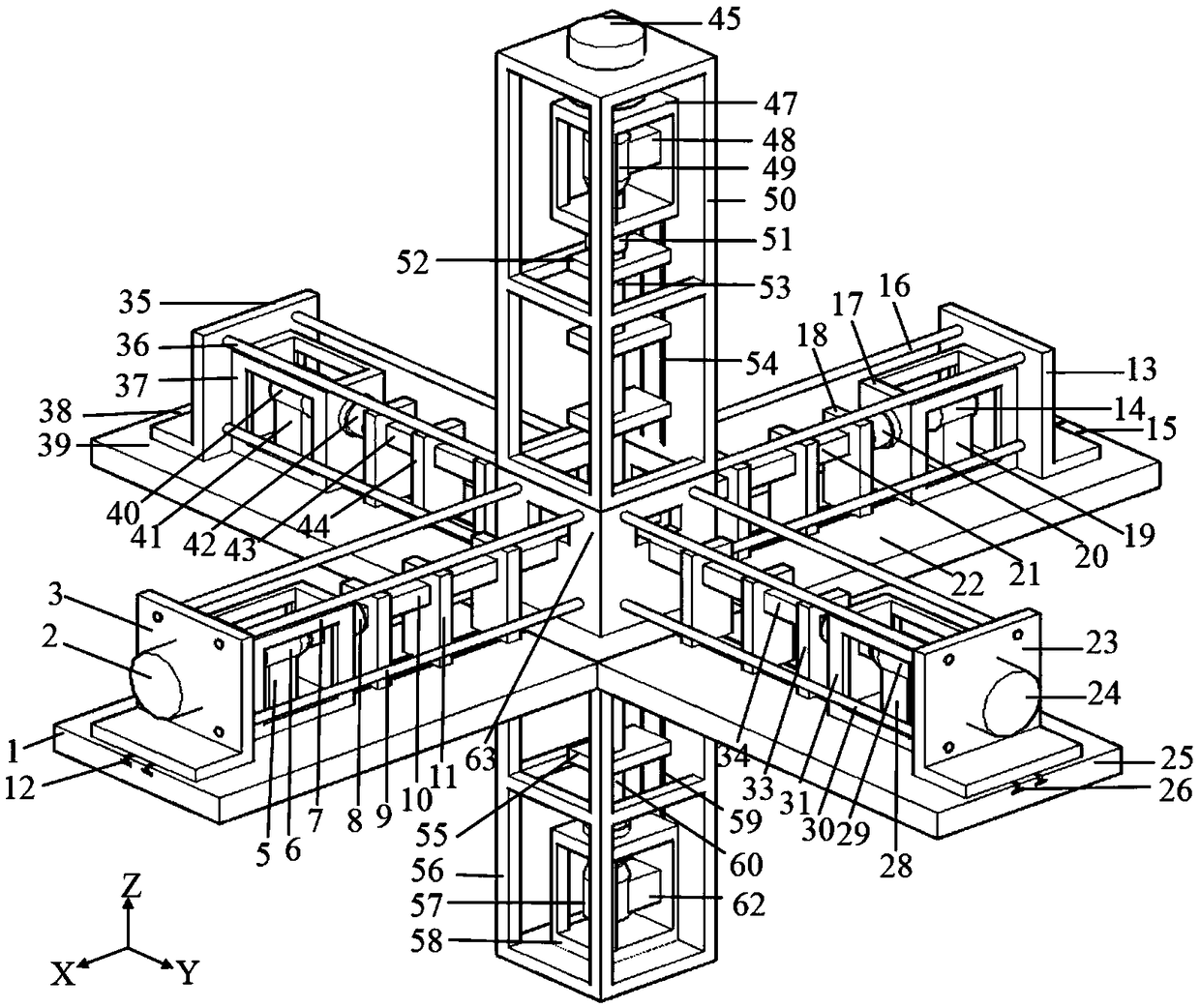

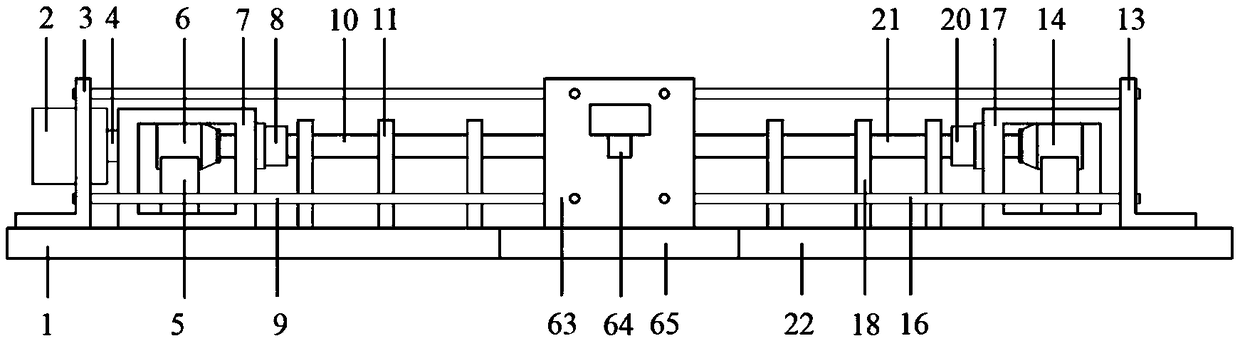

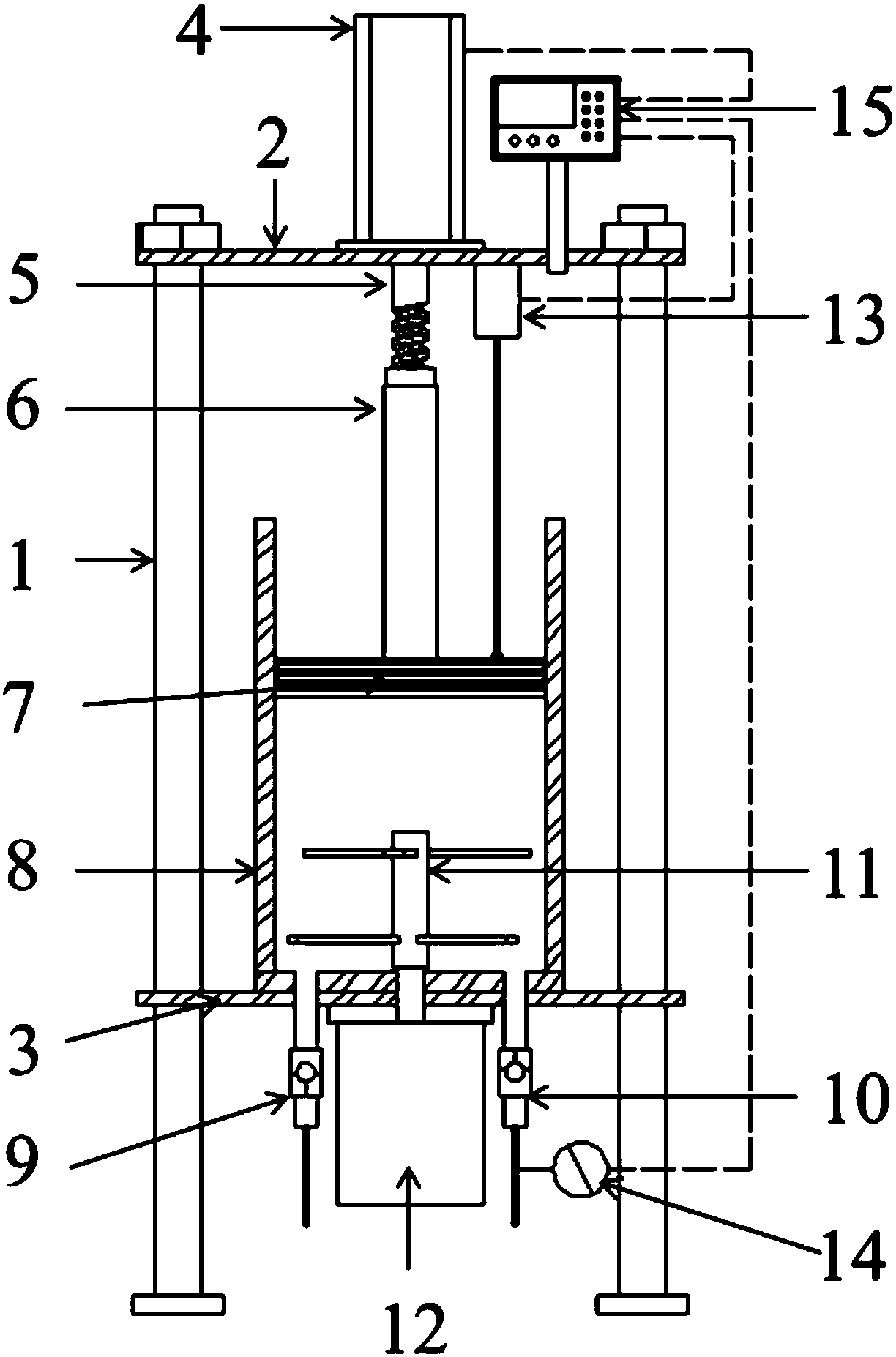

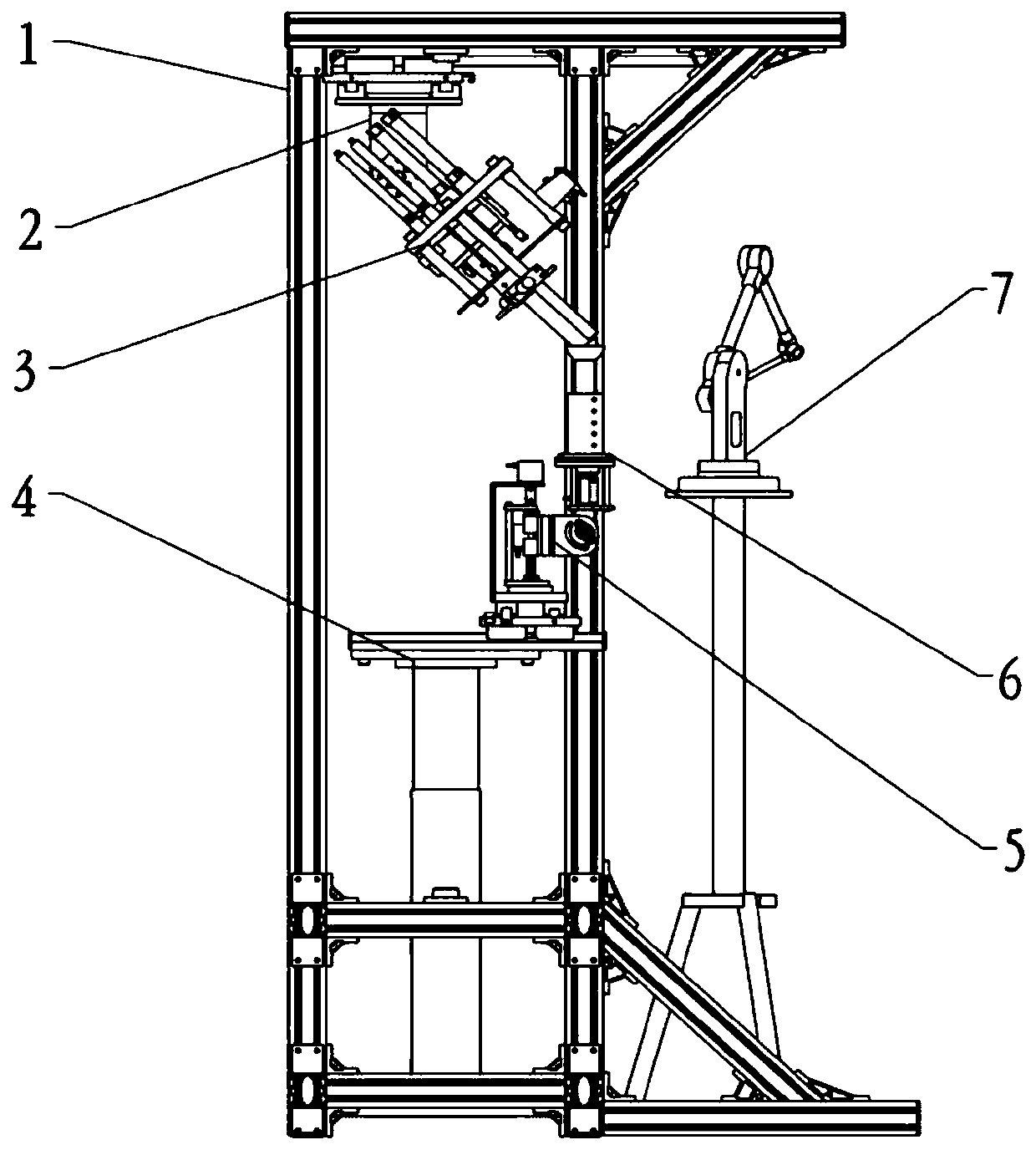

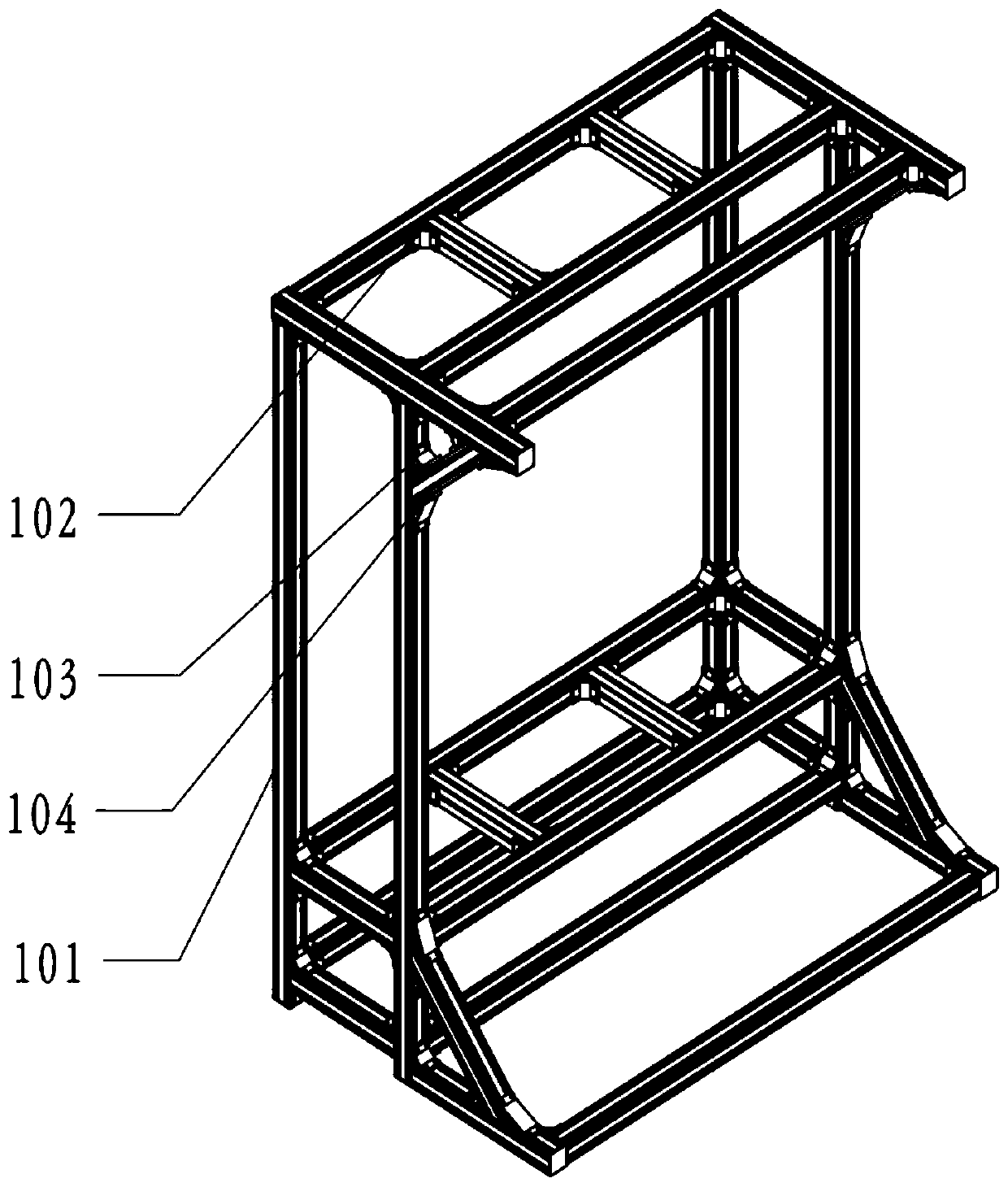

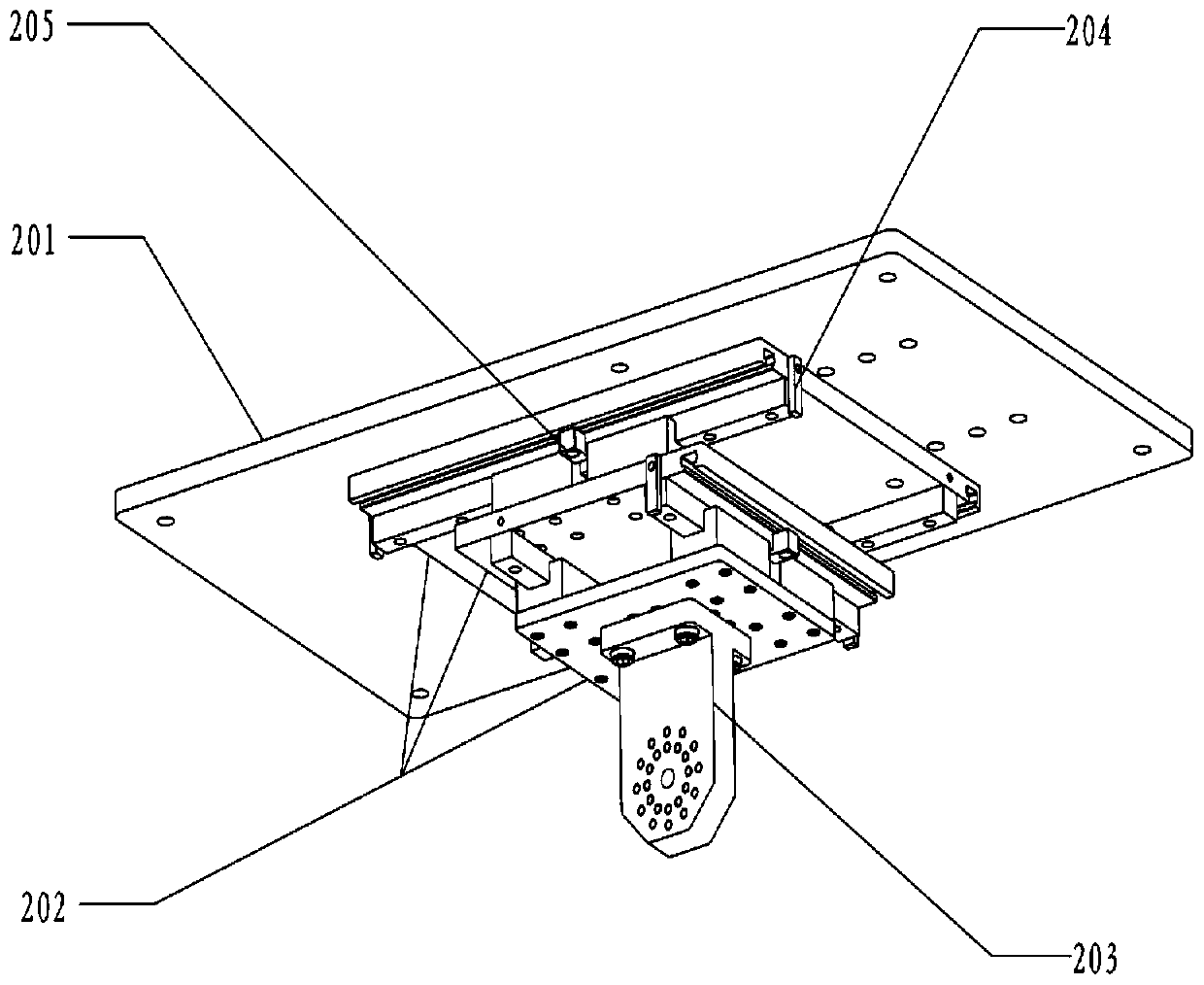

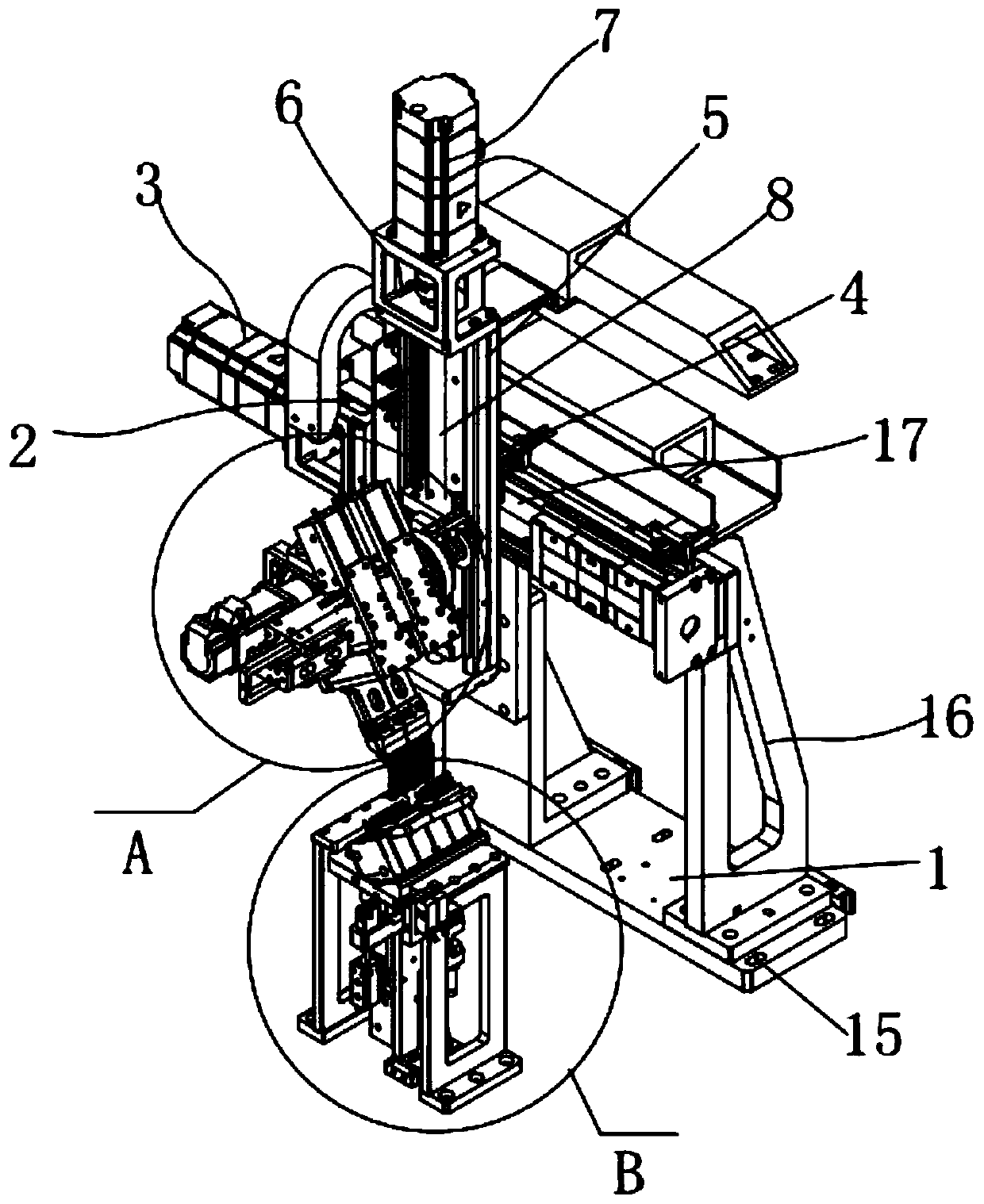

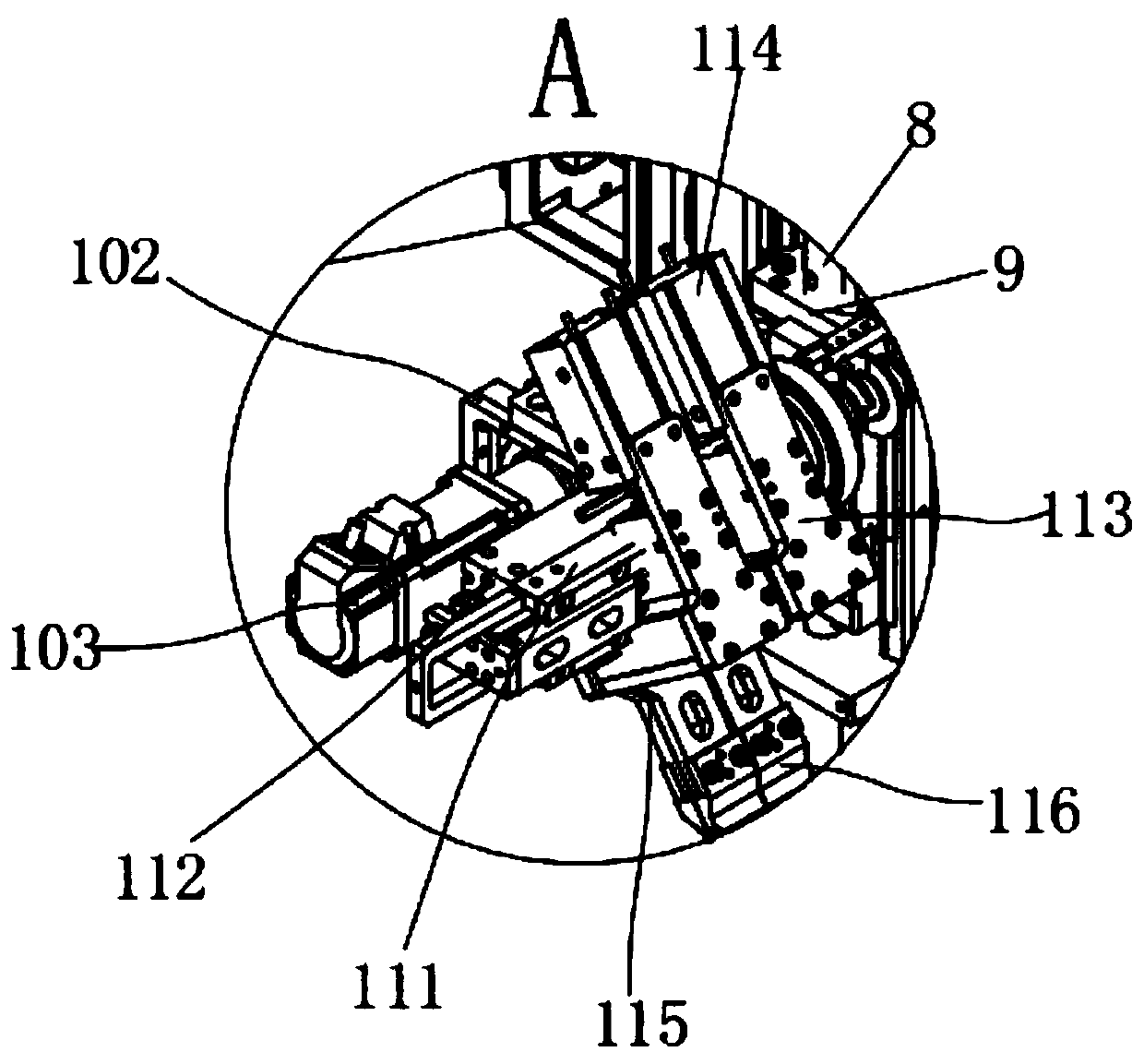

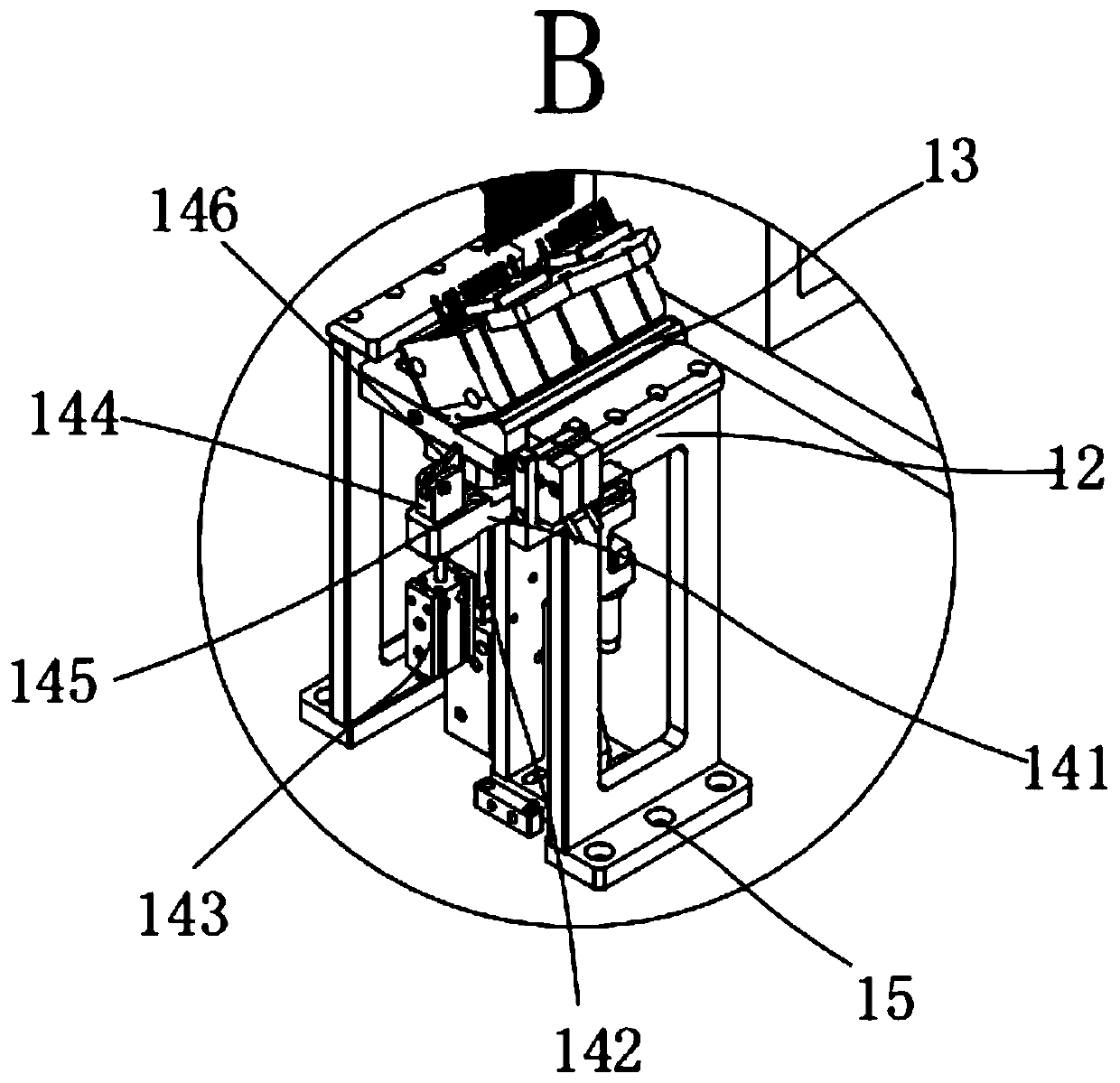

Knee joint force loading and biomechanical characteristics detection experimental platform

ActiveCN108766169BImplement servo controlQuick and easy muscle loading methodEducational modelsTotal knee replacement surgeryArticularis genus

The invention provides an experimental platform for knee joint force loading and biomechanical detection. The experimental platform is mainly composed of seven parts including a frame unit, a femoralpose adjustment unit, a femoral reactivity and ligament strain measurement and force loading unit, a knee joint flexion driving unit, a tibia pose driven unit, a tibia internal and external rotationmeasurement unit, and a patella pose detection unit. The device compares the biomechanical characteristics of the in-vitro knee joint under different surgical techniques by detecting the biomechanicalcharacteristics of the knee joint after surgeries such as total knee replacement, anterior cruciate ligament reconstruction, and posterior cruciate ligament reconstruction.

Owner:SHANGHAI INNOMOTION

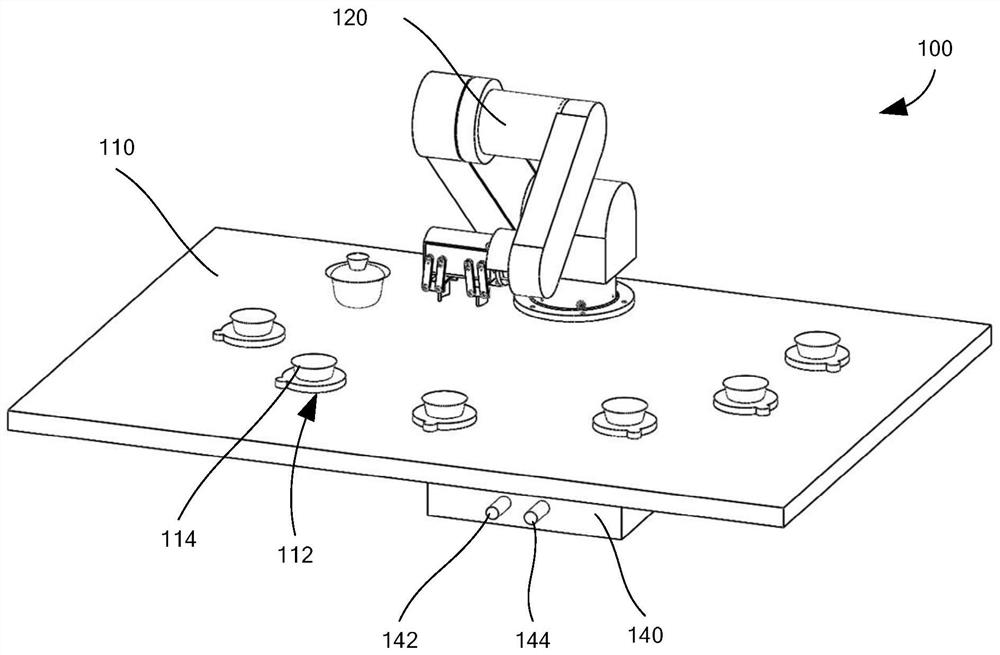

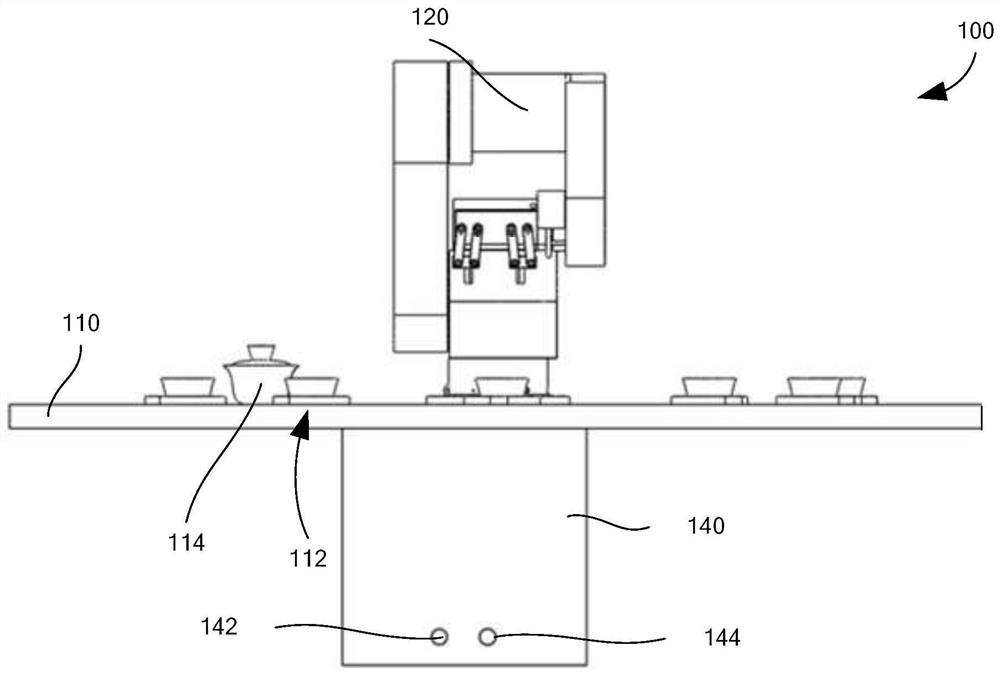

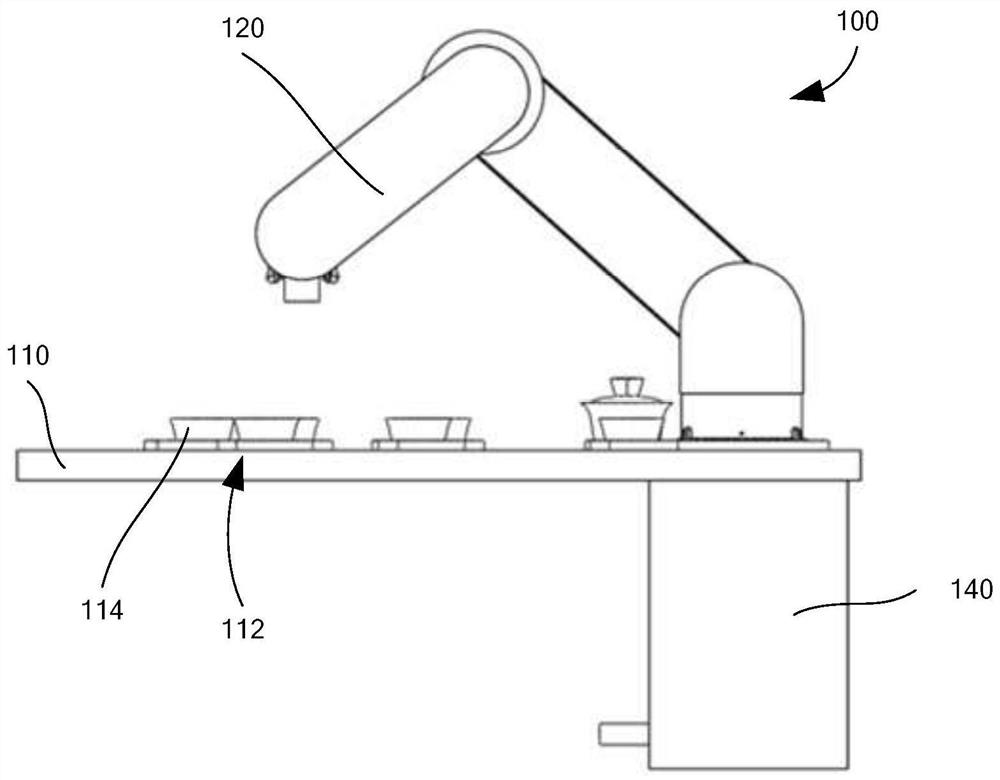

Tea making robot

PendingCN113616076AImplement servo controlLow costBeverage vesselsManipulatorReduction driveDrive shaft

The invention provides a tea making robot. The tea making robot comprises a carrier; a mechanical arm arranged on the carrier, wherein the mechanical arm comprises a plurality of driving shafts which are rotatably connected; a main control box which is connected with the carrier, wherein a motor assembly for driving the mechanical arm is arranged in the main control box; and a transmission assembly which is connected with the motor assembly and the driving shaft of the mechanical arm so as to drive the driving shaft of the mechanical arm. According to the tea making robot, the multiple motor assemblies for driving the mechanical arm are arranged in the main control box, and the multiple motor assemblies are connected with the multiple driving shafts in a one-to-one correspondence mode and used for controlling the multiple driving shafts correspondingly; furthermore, the motor assemblies and the driving shaft of the mechanical arm are connected through the transmission assemblies, the motor assemblies indirectly control the mechanical arm to move through the transmission assemblies, the motor assemblies do not need to be arranged in the mechanical arm, and the weight and the size of the mechanical arm are effectively reduced by arranging the multiple motor assemblies in the main control box in a centralized mode; and therefore, the performance requirements on the motor and the speed reducer are reduced.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD

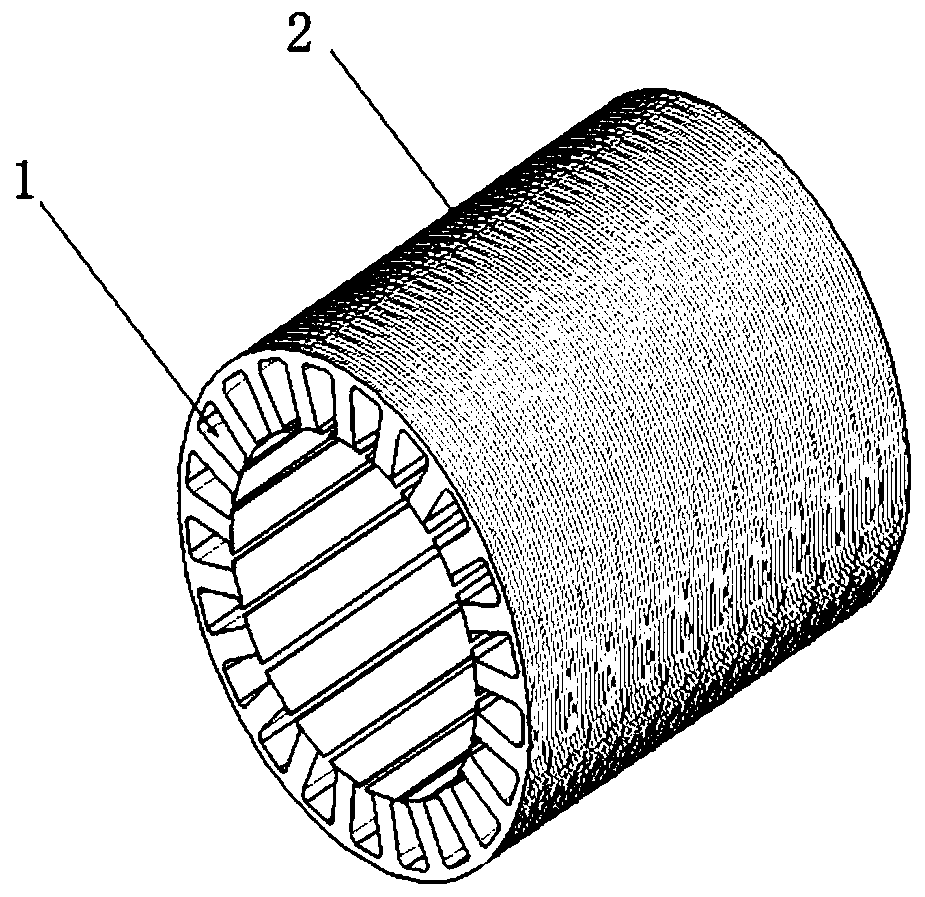

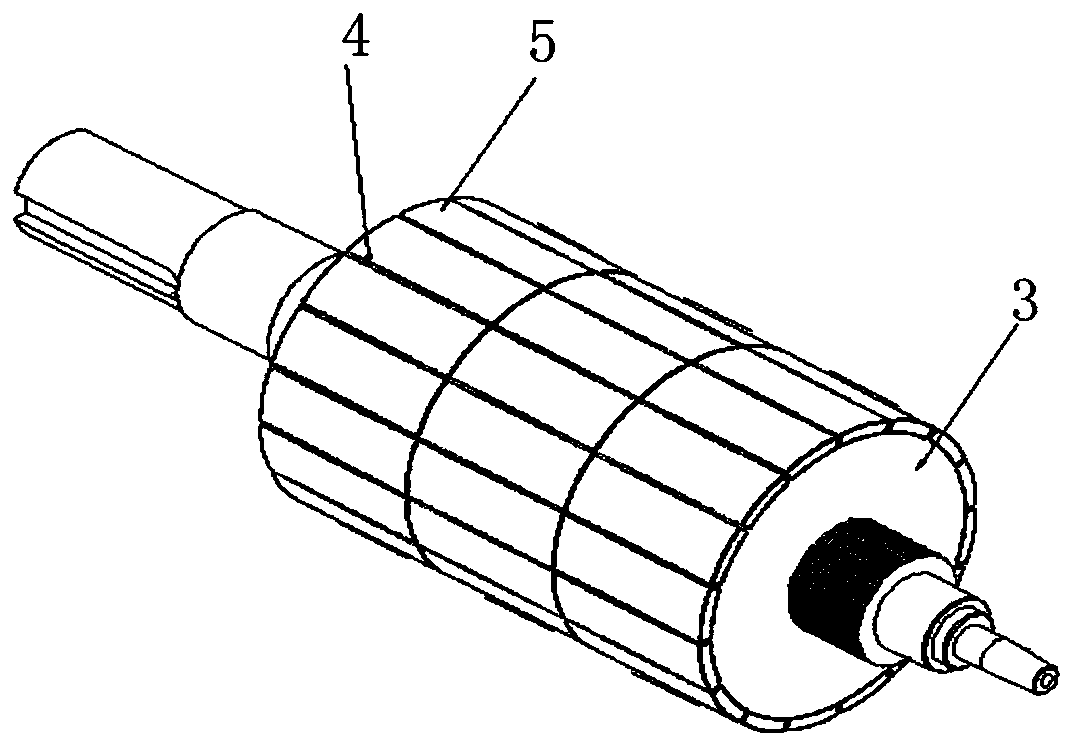

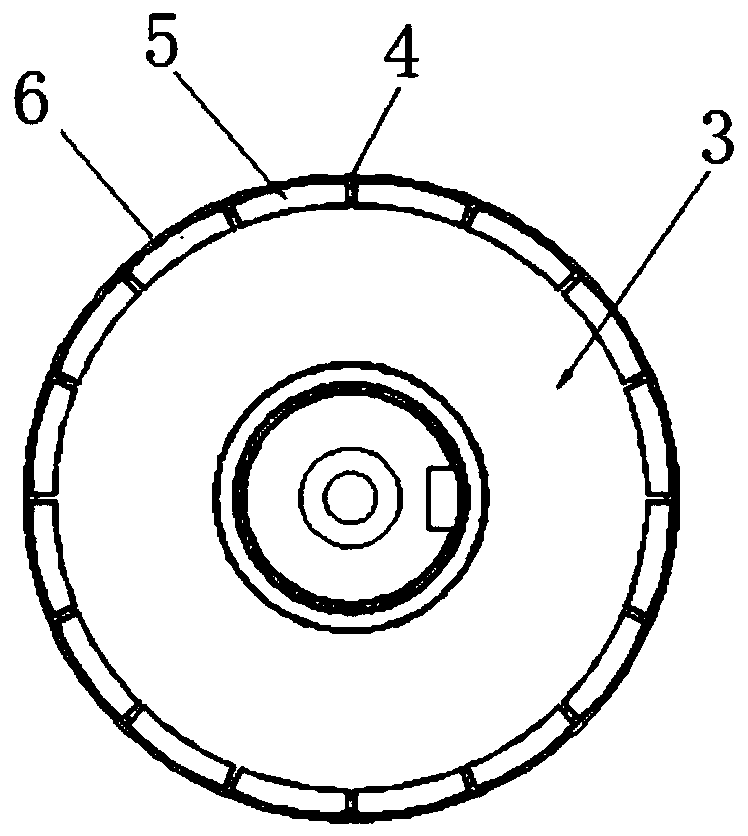

Brushless servo motor

PendingCN110707848AEasy to fixReduce torqueMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic isolation

The invention discloses a brushless servo motor. The outer wall of an rotor iron core is uniformly provided with a plurality of magnetic isolation strips parallel to the axis of the iron core, the arc-surface magnetic steels fixedly connected with the outer wall of the iron core are arranged between the adjacent magnetic isolation strips, and then fixing sleeves sleeve the magnetic isolation strips and the magnetic steels, so that the problem in the prior art that the fixing effect of a motor rotor on the magnetic steels is worse, is effectively solved, and the installation is convenient. Because of the magnetic bias design of the magnetic steel, the magnetic flux leakage can be reduced, the sine wave servo control is achieved, and the defects of low-speed noise and small torque are overcome. The brushless servo motor has very small low-speed sound, large torque and high efficiency, does not generate the environmental noise, is energy saving, and reduces the consumption.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

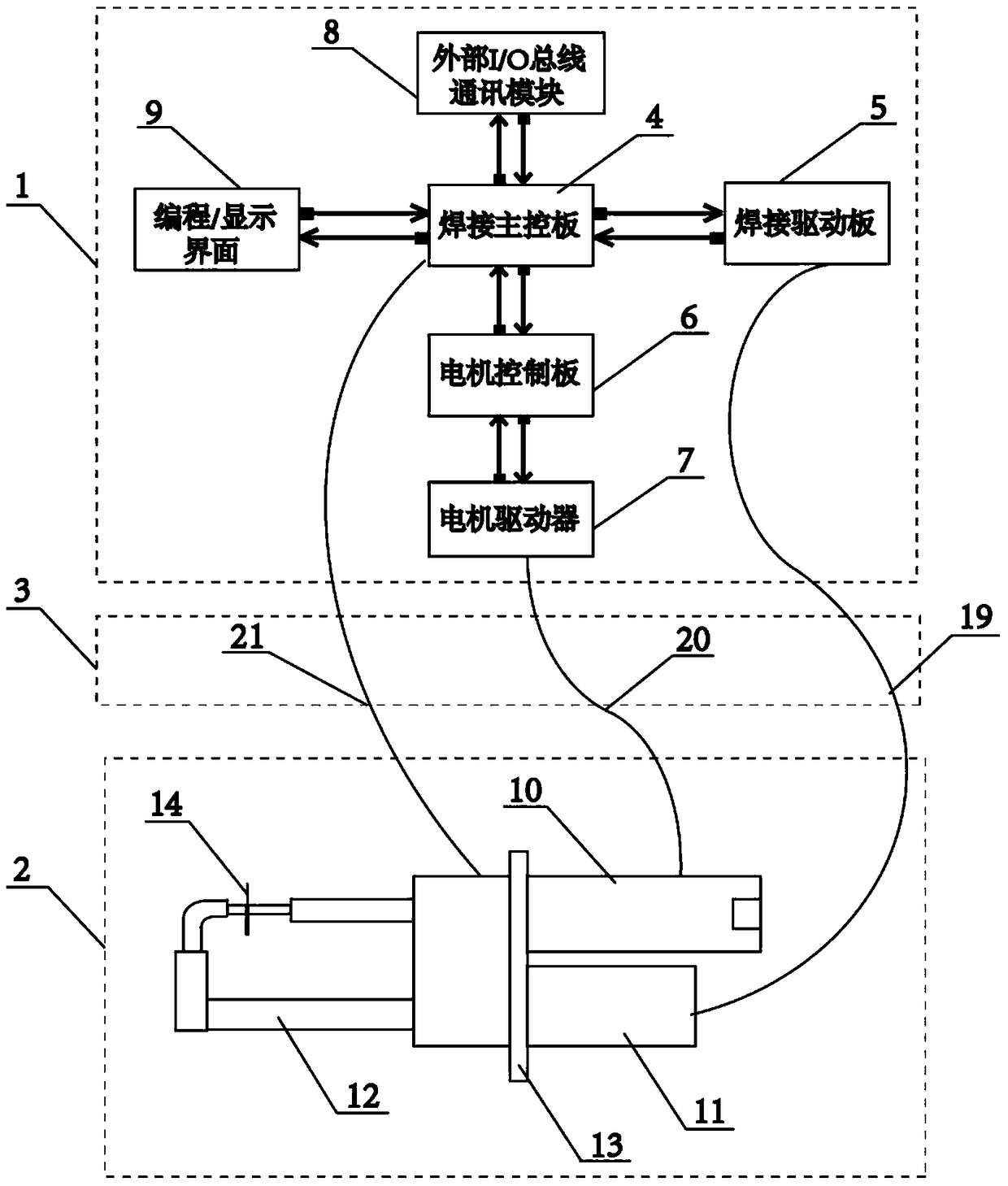

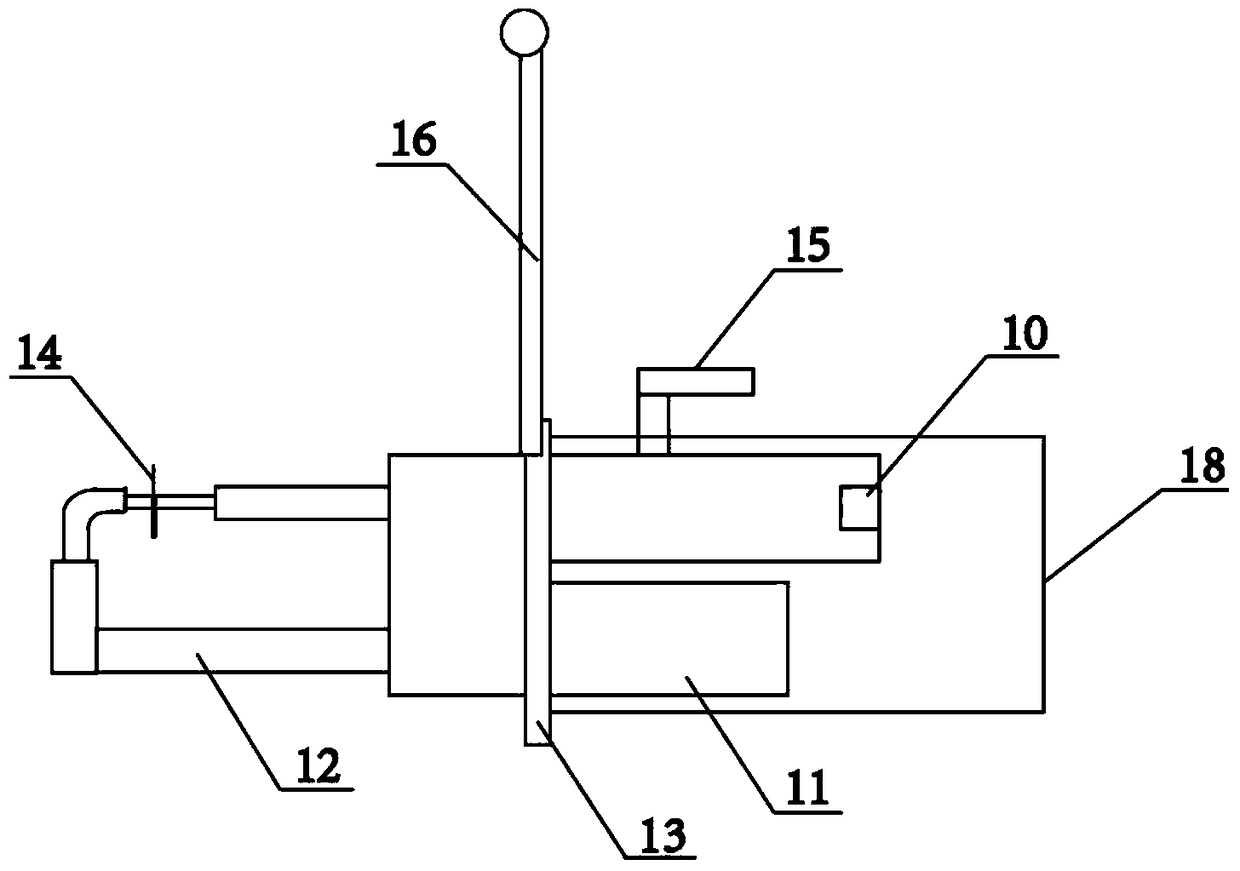

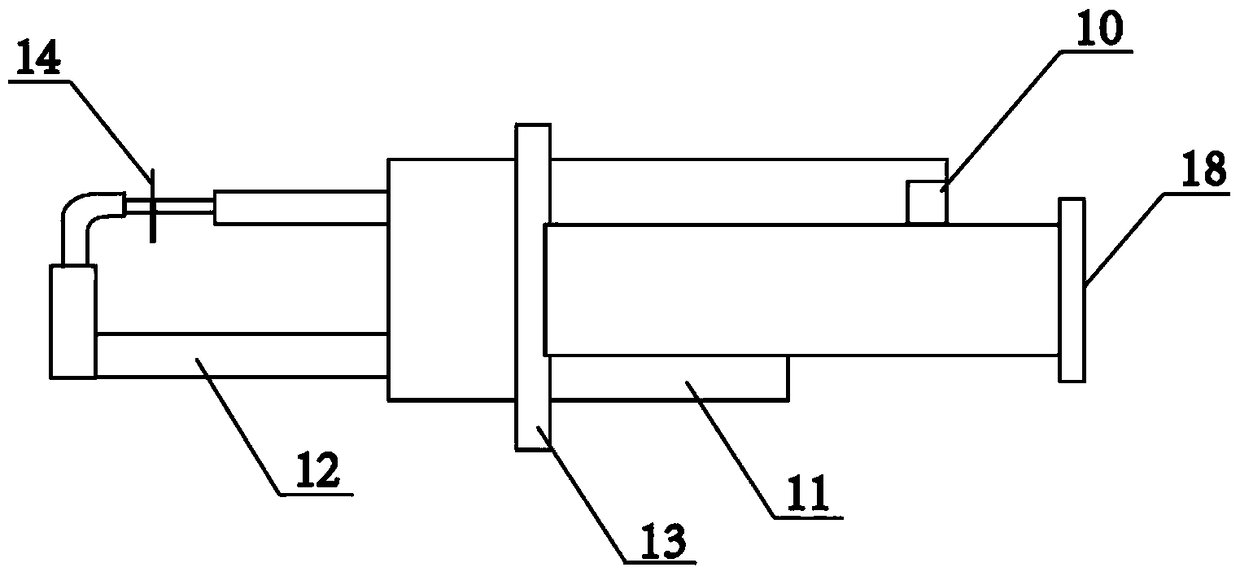

Servo pressure spot welding system

ActiveCN105522302BWelding time synchronization controlWelding current synchronous controlWelding/cutting auxillary devicesAuxillary welding devicesTransformerWelding power supply

Owner:天津七所高科技有限公司

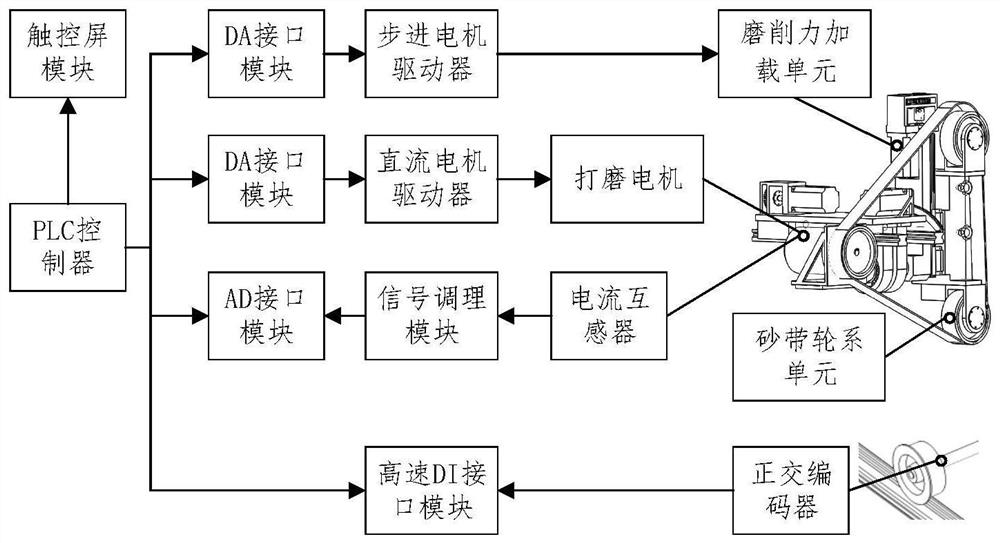

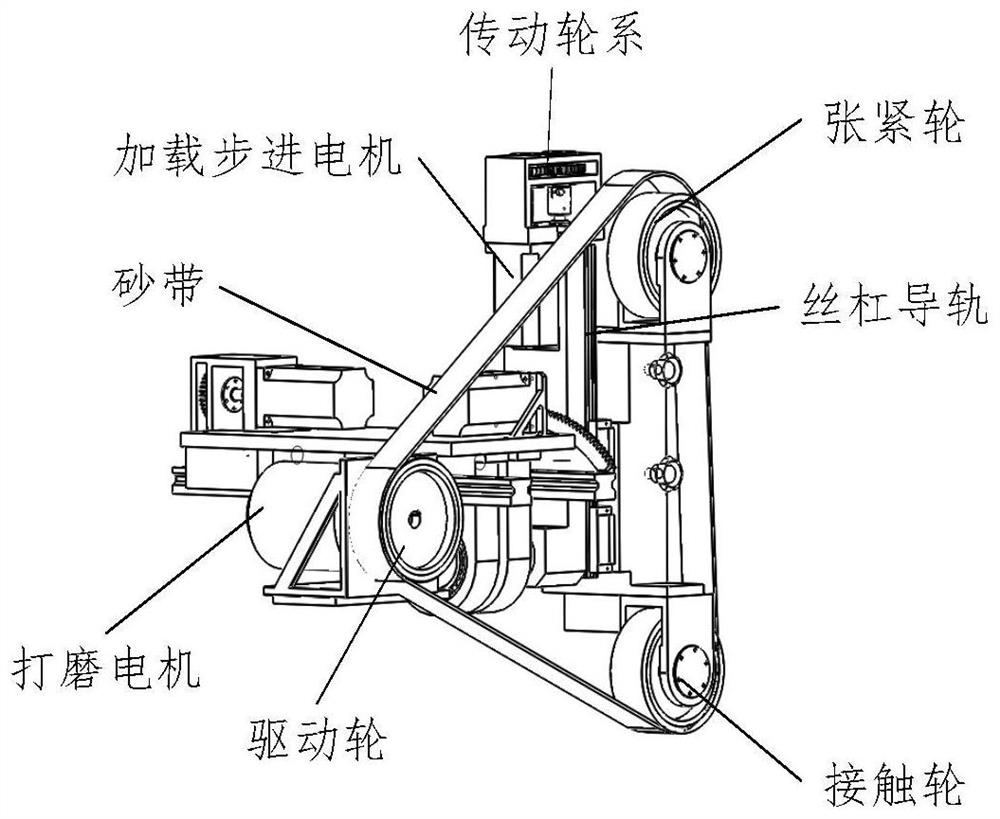

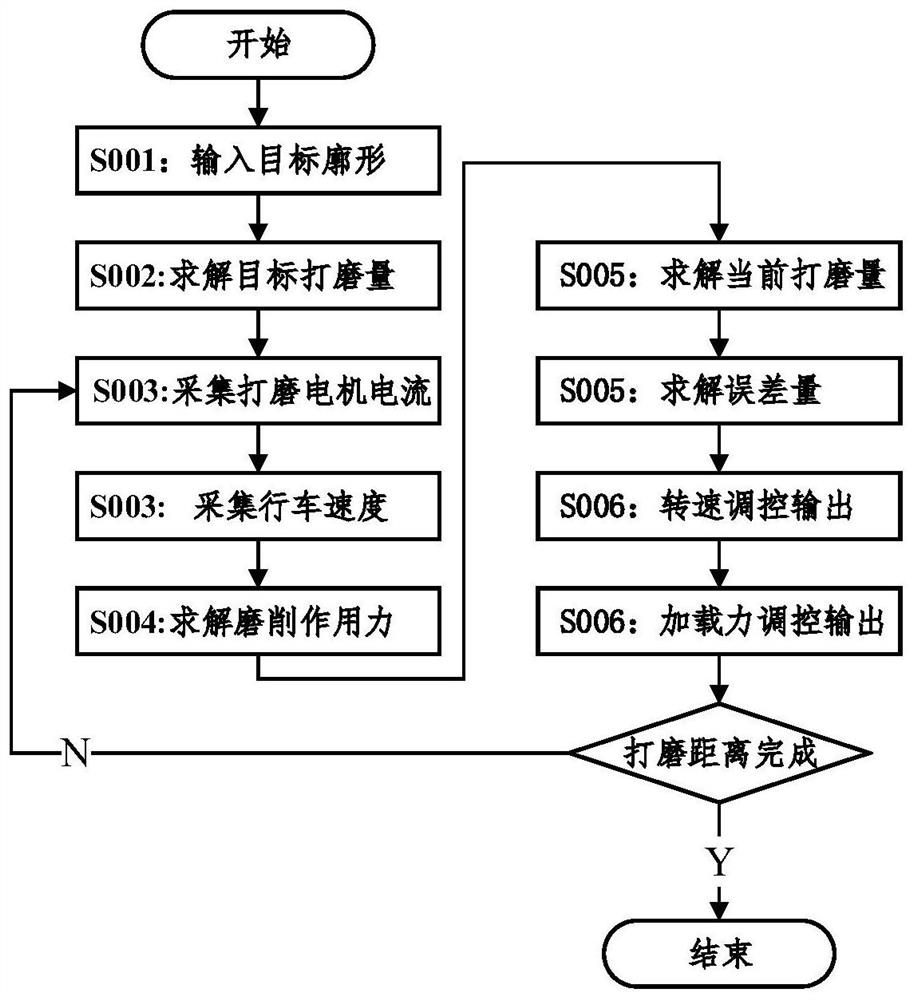

Abrasive Belt Rail Grinding Operation Control System and Grinding Control Method

The invention provides an abrasive belt type rail grinding operation control system and a grinding control method thereof. The system includes: an interconnected grinding control device and a grinding implementation mechanism; the grinding control device collects the rotational speed of the abrasive belt, the current signal of the grinding motor and the travel speed of the grinding vehicle, and generates a grinding motor control signal and The grinding force control signal is transmitted to the grinding implementation mechanism; the grinding implementation mechanism regulates the rotation speed of the grinding motor according to the grinding motor control signal, regulates the rotation speed of the abrasive belt, and regulates the grinding effect of the abrasive belt on the rail according to the grinding force control signal Force to achieve material removal on the rail surface. The system and method of the embodiment of the present invention grasp the grinding operation state in real time according to the operation signal feedback, and form a high-precision control closed loop by adjusting the rotation speed of the grinding motor and the combined action of the grinding force to realize the grinding operation of the abrasive belt type rail. The whole process is under servo control.

Owner:BEIJING JIAOTONG UNIV

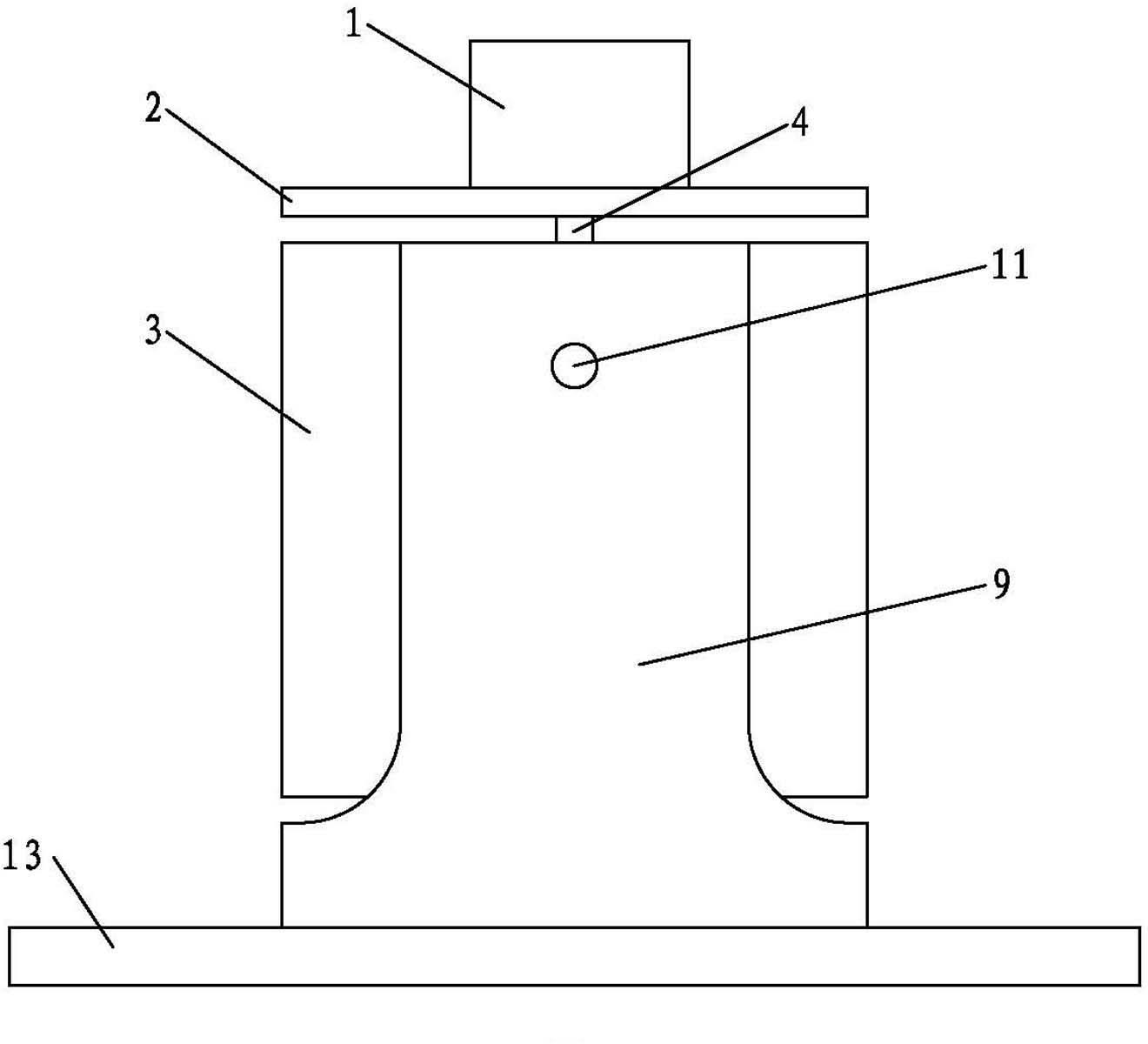

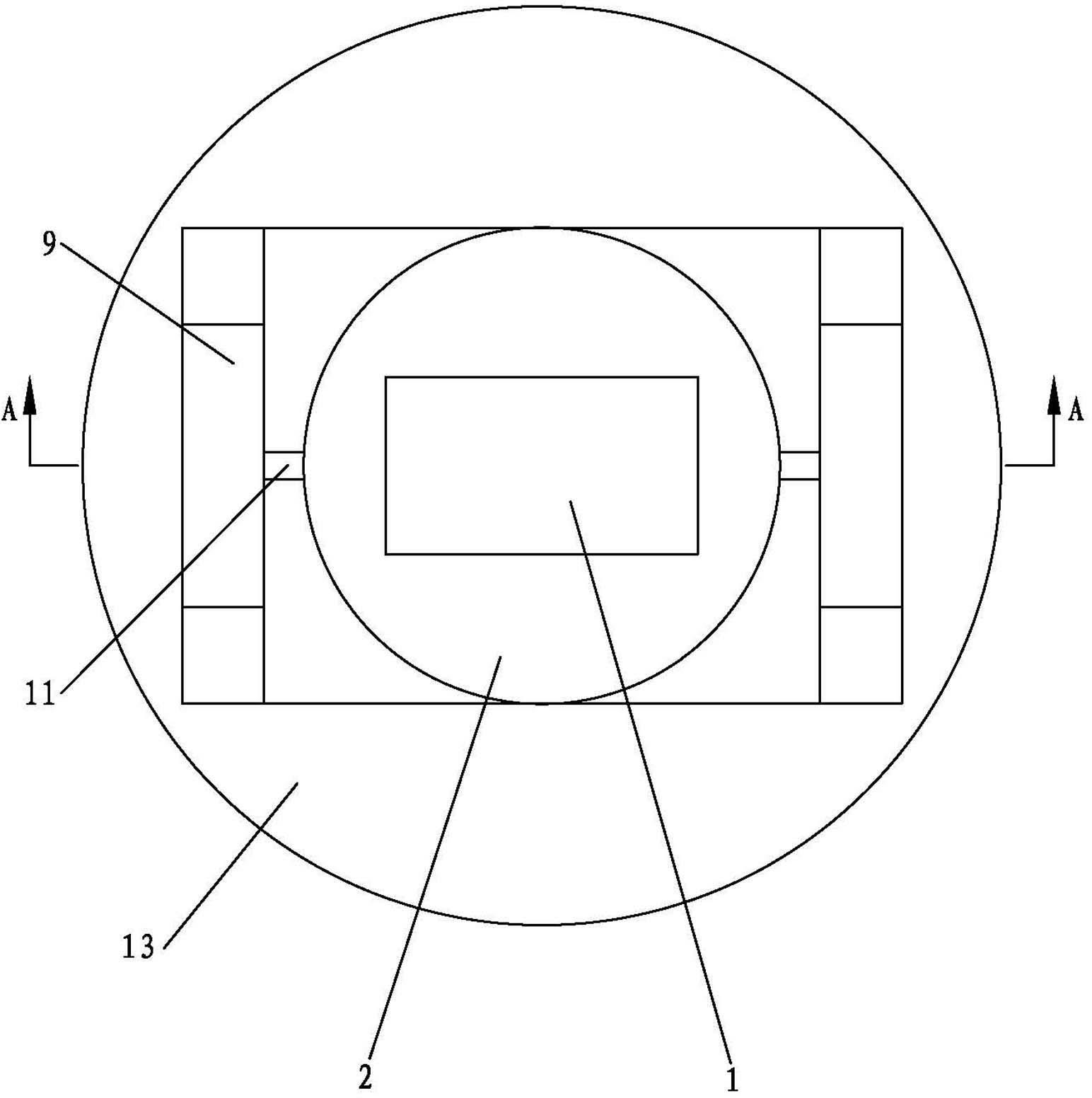

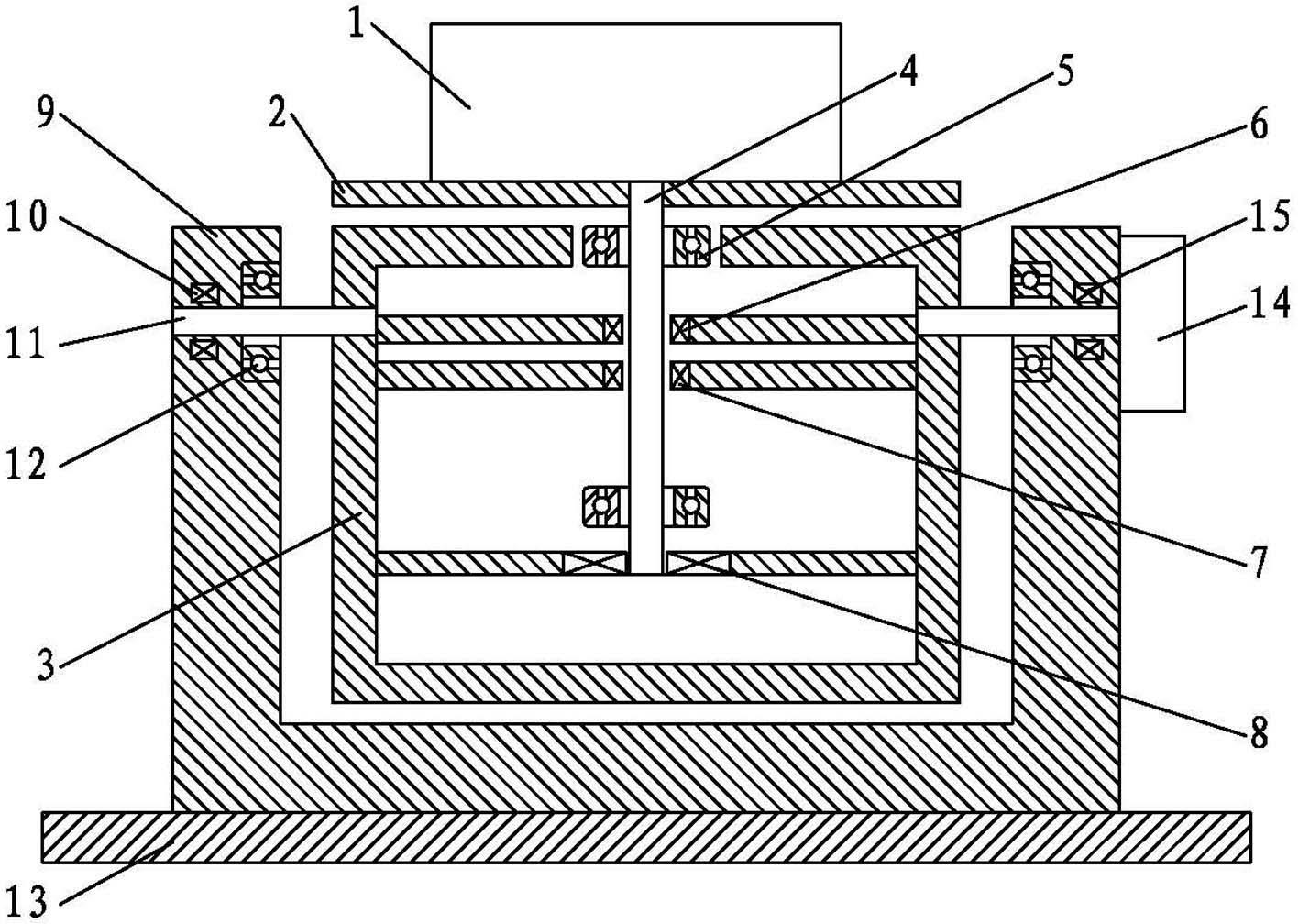

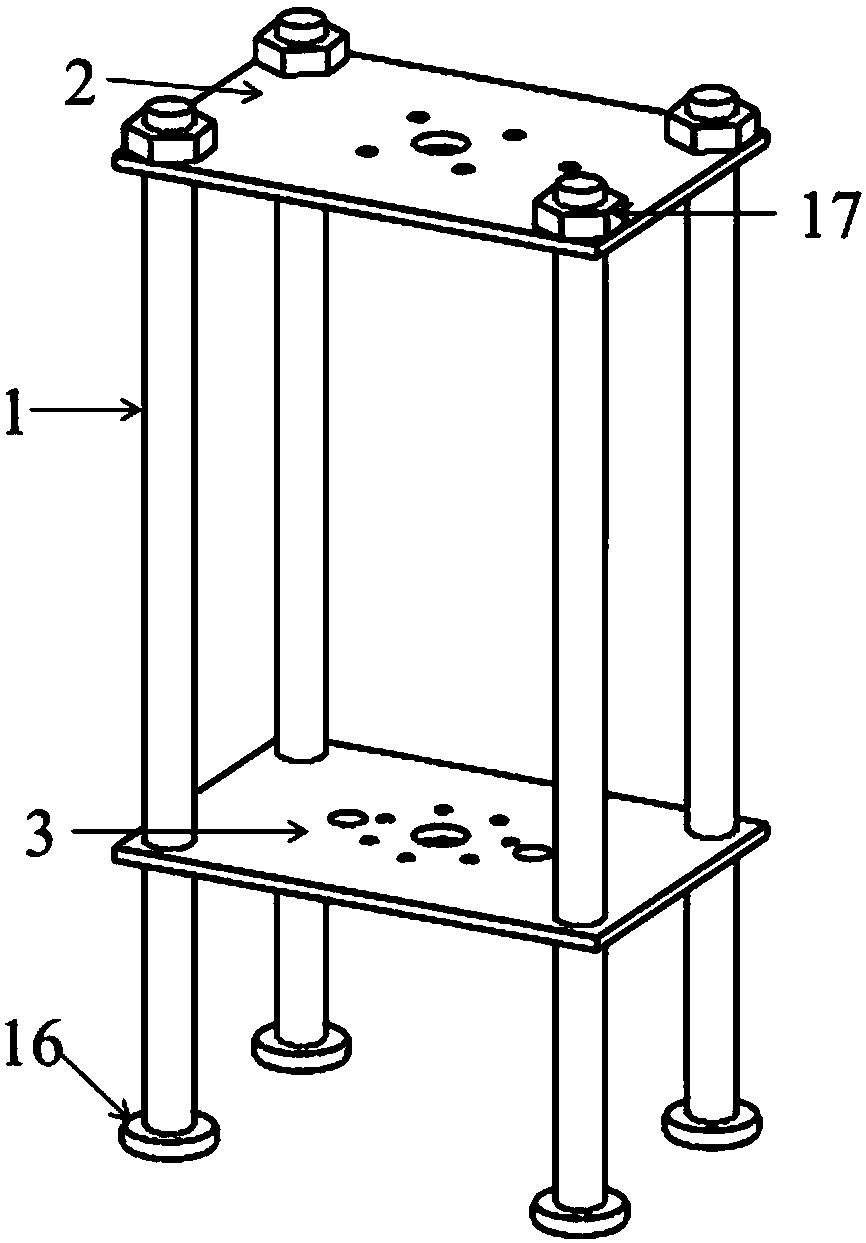

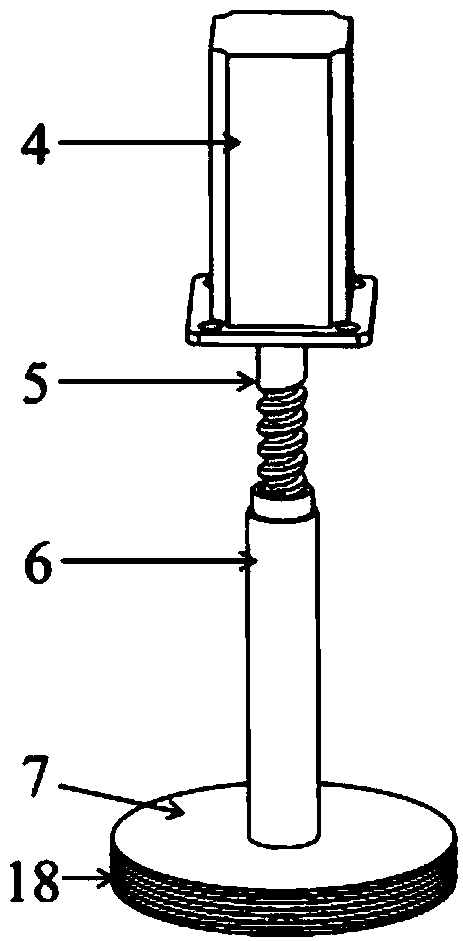

A fully automatic triaxial test system for saturated soil stress path

ActiveCN104048879BImplement servo controlImplement servo-controlled loadingMaterial strength using tensile/compressive forcesTriaxial shear testControl system

The invention discloses a full-automatic three-axis testing system for a saturated soil stress path. The full-automatic three-axis testing system comprises a pressure chamber (1), a computer (2), an axial force volume controller (3), a confining pressure volume controller (4), a back pressure volume controller (5), a data acquisition box (6) and a pressure volume control system connected with the computer (2). The full-automatic three-axis testing system for the saturated soil stress path is reasonable in structural design, convenient to operate, high in automation degree and good in stability and can be used for accurately controlling a complicated stress path of a soil body.

Owner:南京泰克奥科技有限公司

A kind of polishing equipment and polishing method

ActiveCN105666280BAchieve grindingImplement servo controlSpherical surface grinding machinesGrinding feed controlControl systemEngineering

The invention discloses grinding equipment and a grinding method. The grinding equipment and the grinding method aim at solving the problems that at present, manpower is mainly adopted to grind a pot billet, consequently, operation efficiency is low, the requirement of an existing grinding device for the position of the pot billet is low, and certain limitation exists. The grinding equipment comprises a grinding mechanism and a control system; and the grinding mechanism comprises a grinding support, a first supporting rod, a second supporting rod, a first telescopic arm, a second telescopic arm, a third supporting rod, a grinding wheel and a grinding wheel driving device. One end of the first supporting rod is movably connected with the grinding support, and the first supporting rod can rotate relative to the grinding support; and the other end of the first supporting rod is movably connected with the second supporting rod. According to the grinding equipment, the automatic grinding requirement for workpieces with different sizes can be met, the extremely-high adaption is achieved, the grinding quality is good, efficiency is high, the production period is short, the cost is low, the good application prospect is achieved, and the equipment is worth applying and popularizing in a large-scale manner.

Owner:SICHUAN FUDE ROBOT

A Servo Loop Control System and Control Method for Oil Slick Supporting Inertial Instrument

ActiveCN103872965BImplement servo controlHighly integratedAC motor controlNavigation by speed/acceleration measurementsLoop controlLinear control

The invention discloses a servo loop control system and control method for a floating oil support inertia instrument. The control system mainly comprises an angle sensor, a front positioned amplification circuit, an A / D (analog / digital) conversion circuit, a DSP (digital signal processor) digital controller, a photocoupling isolation circuit, a power driving module, a moment motor, a hall sensor, a 422 communication interface circuit, a temperature collection circuit and an upper computer. The nonlinear control in the starting stage of the control system and the temperature gradient precise control of an instrument servo loop are respectively realized by introducing a variable parameter correction network DSP digital controller. The upper computer collects the floating oil temperature information in the instrument by the temperature collection circuit and sends the information to the DSP digital controller by the 422 communication interface circuit. The DSP digital controller compares the temperature with a given temperature threshold value and calls corresponding control parameters, so the variable parameter servo control for different temperatures of the instrument is realized. The control system is high in integration degree, high in control precision, high in automation degree, safe and reliable.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Hot stamping automatic production line with drawing, stretching and punching functions

PendingCN114713712AImprove efficiencyImprove processing qualityShaping toolsMetal-working feeding devicesHot stampingProduction line

The invention discloses a hot stamping automatic production line with a drawing and punching function. The hot stamping automatic production line comprises a cooling furnace used for cooling semi-finished products. The first pump station and the second pump station are used for providing hydraulic power; the hydraulic drawing machine, the hydraulic profiling punching flanging machine and the hydraulic secondary profiling punching machine are respectively used for drawing, profiling punching flanging and secondary profiling punching operation on the workpiece; the hydraulic drawing machine is arranged on one side of the cooling furnace, and a transfer manipulator is arranged between the hydraulic drawing machine and the cooling furnace; the hydraulic type profiling punching flanging machine is arranged on one side of the hydraulic type drawing machine and located in the feeding direction of the hydraulic type drawing machine, and a feeding mechanical arm is arranged between the hydraulic type profiling punching flanging machine and the hydraulic type drawing machine. The hot stamping automatic production line with the stretching and punching functions is reasonable in layout, and the projectile body forming machining efficiency and machining quality can be greatly improved.

Owner:HEFEI HAIDE HYDRAULIC PRESS

Drive unit for X-ray system

ActiveCN100563565CImplement servo controlPrecise and Direct Movement ControlEngineering emergency devicesStands/trestlesCollision detectionDrive shaft

The invention relates to a drive unit (12) for driving vertical or horizontal movement of a device (7) of an X-ray diagnostic apparatus (1), the drive unit (12) comprising a motor and The transmission unit (14), the pulley (10) mounted on the drive shaft (13) of the electric motor and the transmission unit (14) and the traction device (9), such as a rope or drive belt, wound around the pulley (10), will Said device (7) to be moved is attached to a traction device (9) or connected to a drive unit (12). In order to provide the ability to perform collision detection and emergency stop functions and to enable the operator operating the X-ray device (1) to improve the movement control of the device (7), the present invention proposes that the motor and transmission unit (14) can be wound around The axis of the drive shaft (13) rotates, wherein a rotation sensor (17, 24) is provided, the rotation sensor (17, 24) is adapted to detect the rotation of the motor and the transmission unit (14) and is used to generate a corresponding rotation detection signal.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Servo rotary pin inserting device

PendingCN110311285AAchieve angle adjustmentImplement servo controlContact member assembly/disassemblyEngineeringSupport plane

The invention discloses a servo rotary pin inserting device, which comprises a first support frame, wherein the first support frame is provided with a first servo motor, an output shaft of the first servo motor is fixed with a first lead screw, the first lead screw is in transmission connection with a first mounting block, the first mounting block is fixed with a second support frame, the second support frame is provided with a second servo motor, an output shaft of the second servo motor is fixed with a second lead screw, the second lead screw is in transmission connection with a second mounting block, the second mounting block is provided with an angle rotating mechanism, the angle rotating mechanism is provided with a pin inserting and moving mechanism, the lower side of the pin inserting and moving mechanism is provided with a third support frame, the upper end of the third support frame is provided with a placement table, and one side of the placement table is provided with a positioning mechanism. According to the structure, the PIN can be taken and inserted in the horizontal direction, the vertical direction and any angle direction, pin insertion can be carried out on different products, and the application range is wide.

Owner:江苏倚信自动化设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com