Dynamic and static load synchronous servo control system for three-axis six-direction Hopkinson pressure bar

A Hopkinson pressure bar and servo control system technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as multi-directional simultaneous or delayed impact loading of materials that cannot be truly reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

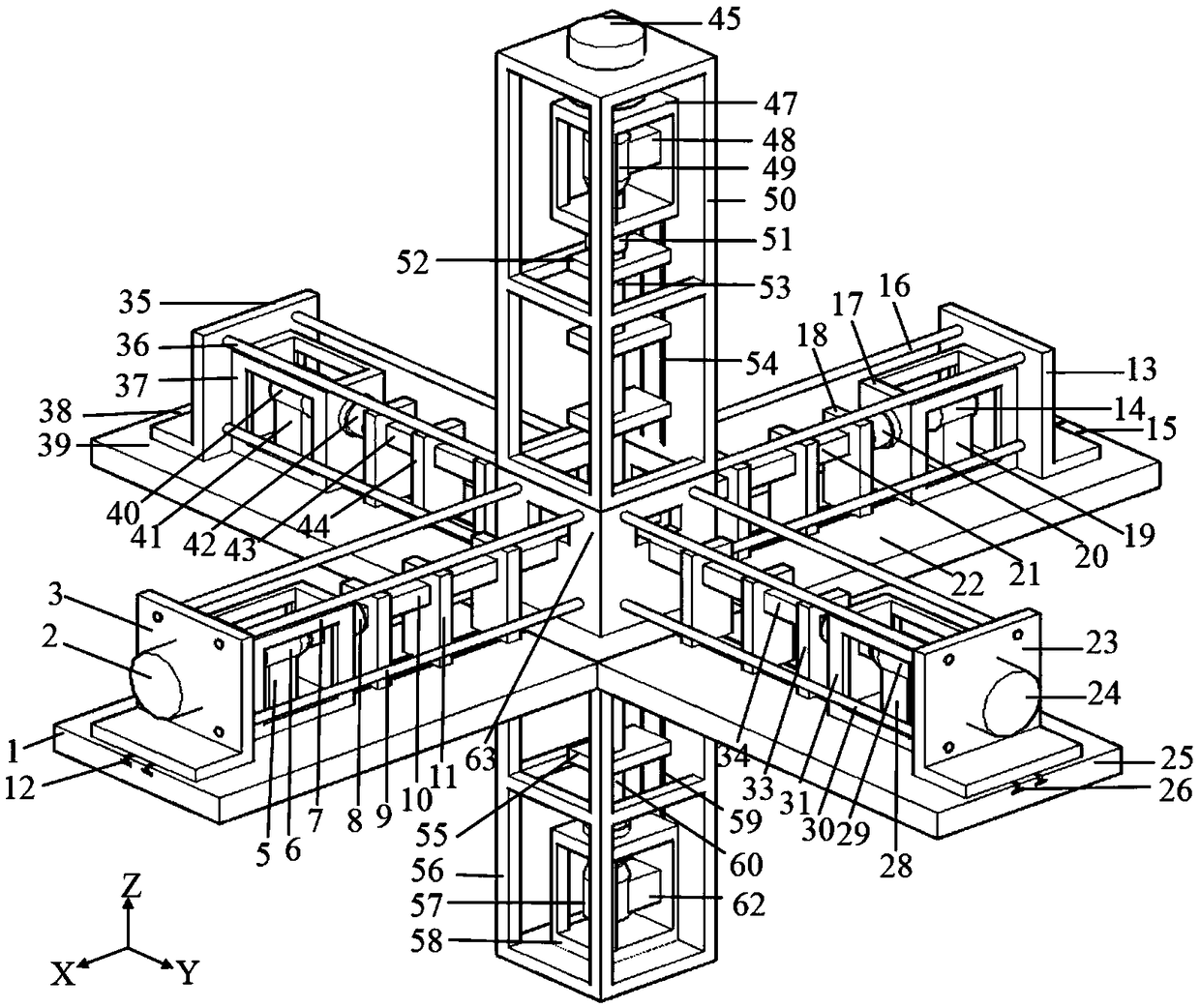

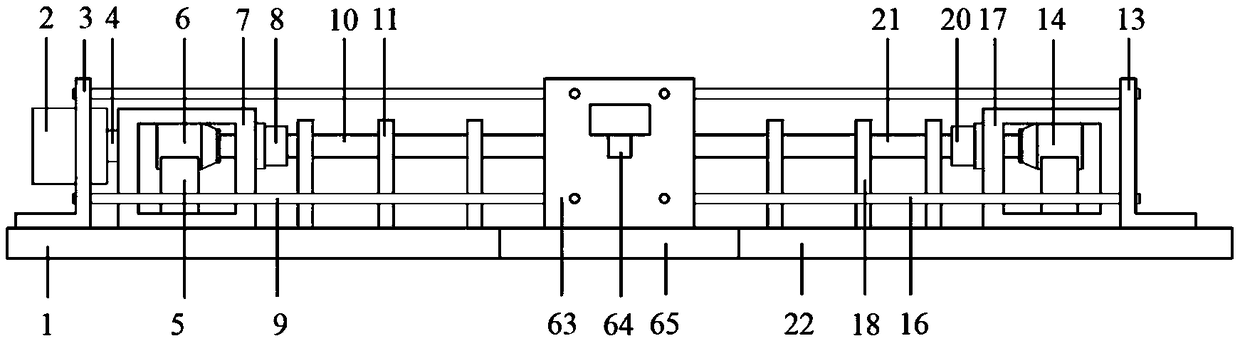

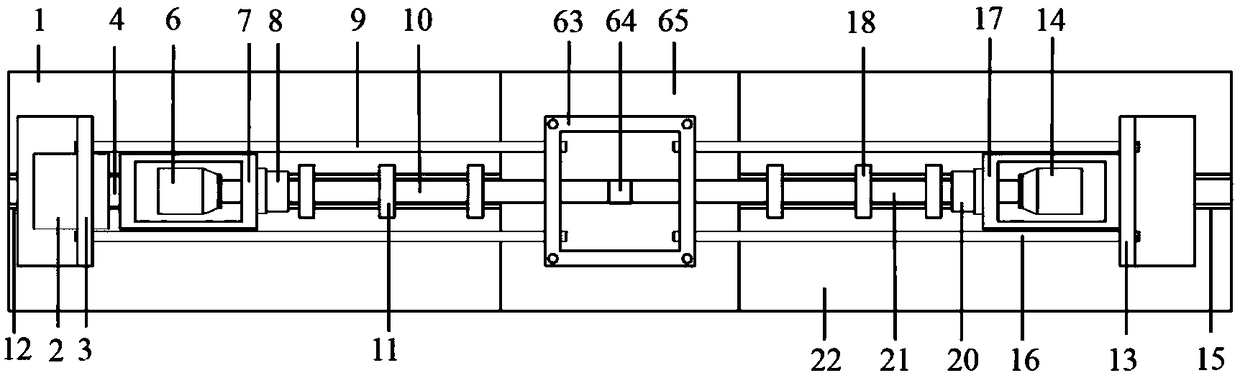

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] figure 1 Three-dimensional diagram of the electromagnetically loaded Hopkinson rod system for the three-axis six-direction synchronous coordinated control. The test device is placed on a horizontal cross support platform, which includes X + To support platform 1, X - To support platform 22, Y + to support platform 25 and Y - To support platform 39 and center support platform 65. Center cube square box 63 upper surfaces (along Z + To) fully open, along the X + to, X - to, Y + to, Y - direction, and Z - A square opening is set in the middle of the central cube square box, and the size of the square opening is the same as the size of the square bar; the central cube square box 63 is placed in the center of the upper surface of the central support platform 65, and forms an orthogonal cross with the horizontal cross support platform. The coordinate system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com