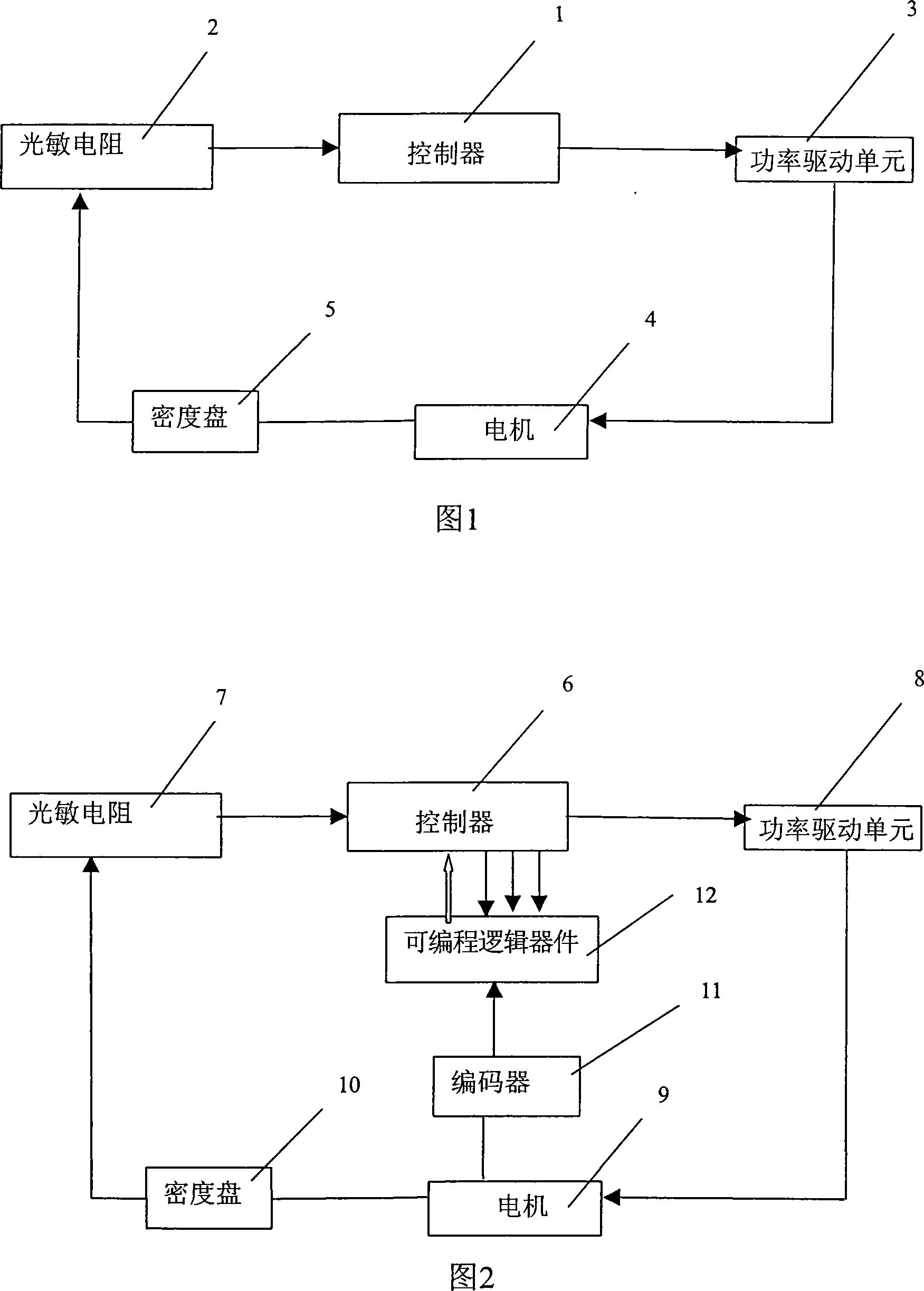

Density disc drive device of automatic light modulation system

A disk drive device and automatic dimming technology, which is applied in control/regulation systems, light control, non-electric variable control, etc., can solve problems such as low adjustment accuracy, inability to control motor speed, and poor anti-disturbance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

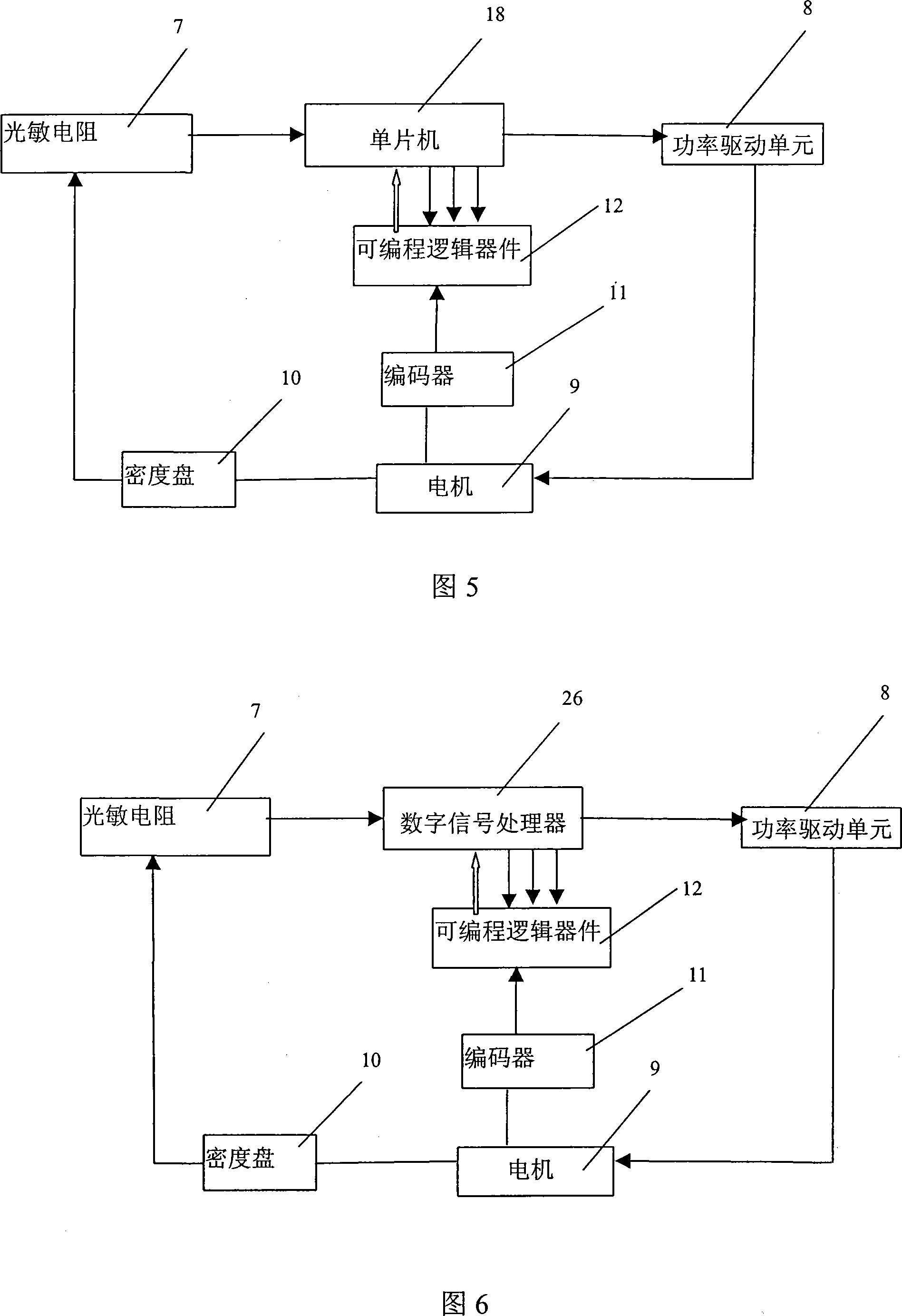

[0016] Embodiment 1 (as shown in Figure 5)

[0017] The present invention comprises a controller 6, a photoresistor 7, a power drive unit 8, a motor 9, an encoder 11, and a programmable logic device 12; Connect the voltage divider circuit, and the other end connects the A / D input of the single-chip microcomputer 18; Input terminal; two output terminals of the power drive unit 8 are respectively connected with the positive and negative ends of the motor 9 power supply; When the value is equal to the standard value, the single-chip microcomputer 18 enables the output to be 0, and the power drive unit 8 has no drive signal output; The power drive unit 8 outputs a drive signal according to the width adjustment wave and direction signal output by the single-chip microcomputer 18, so that the motor 9 rotates forward or reversely, drives the density disc 10 to rotate to adjust the luminous flux, and changes the illuminance value received by the photoresistor 7, thereby reducing the ...

Embodiment 2

[0020] Embodiment 2 (as shown in Figure 5)

[0021] The present invention includes a controller 6, a photoresistor 7, a power drive unit 8, a motor 9, an encoder 11, and a programmable logic device 12; , one end of which is connected to the voltage divider circuit, and the other end is connected to the A / D input of the digital signal processor 26; the I / O port of the enabling of the digital signal processor 26, the width modulation wave output PWM and the output direction signal are connected to the power drive unit 8 The enabling and input terminals of the power drive unit 8 are respectively connected to the positive and negative terminals of the motor 9 power supply; the digital signal processor 26 reads the divided voltage value on the photoresistor 7 and compares it with the standard value. When the divided voltage value on the photoresistor 7 is equal to the standard value, the digital signal processor 26 enables the output to be 0, and the power drive unit 8 has no drive...

Embodiment 3

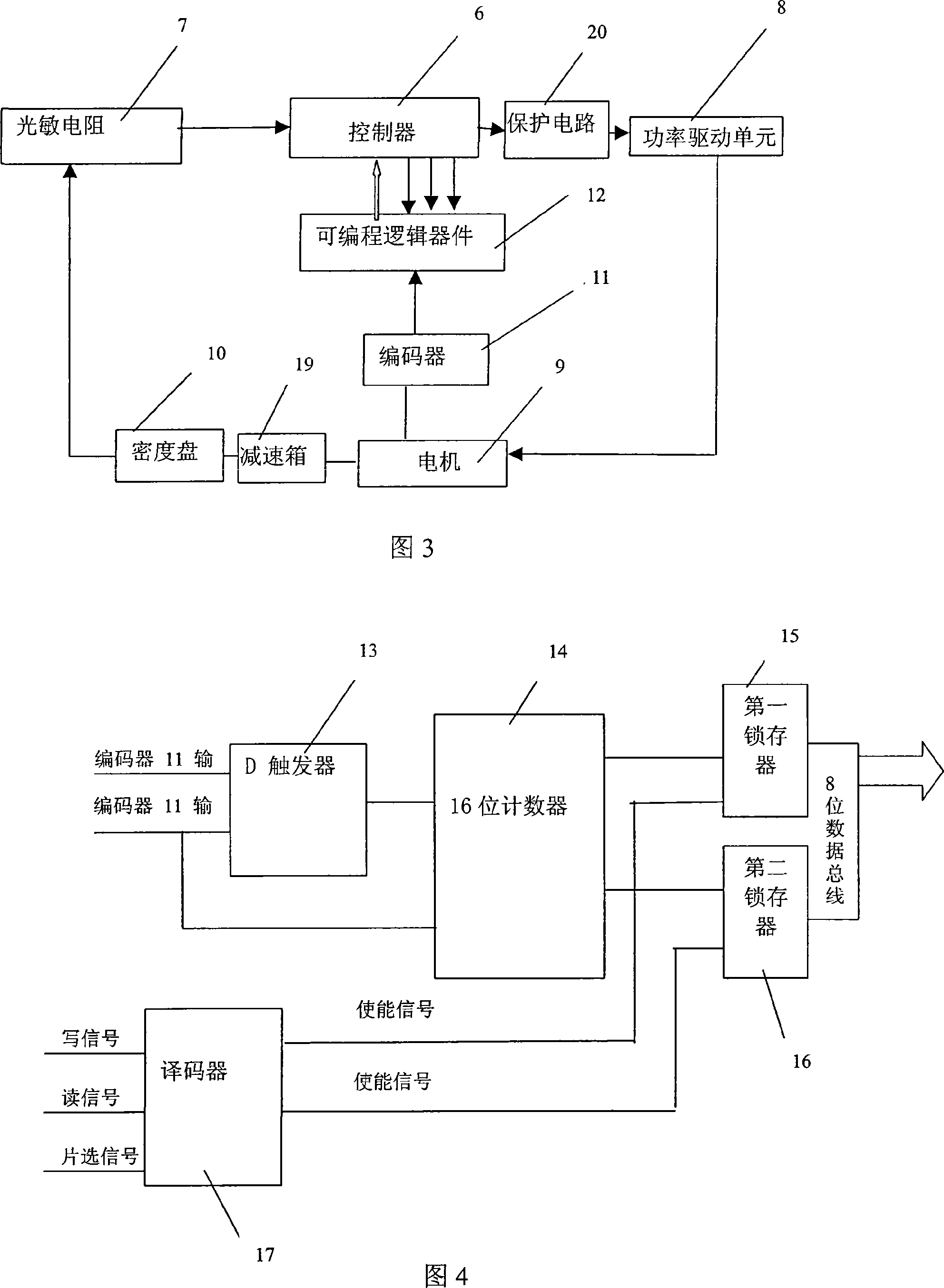

[0024] Embodiment 3 (as shown in Figure 6)

[0025] The present invention includes a controller 6 , a photoresistor 7 , a power drive unit 8 , a motor 9 , a reduction box 19 , an encoder 11 , a programmable logic device 12 and a protection circuit 20 .

[0026] The controller 6 adopts a single-chip microcomputer 18 , and the photoresistor 7 is placed on one side of the density disk 10 , one end of which is connected with a voltage divider circuit, and the other end is connected with the A / D input of the single-chip microcomputer 18 .

[0027] The protection circuit 20 includes a first NOT gate 21, a second NOT gate 22, a third NOT gate 23, a first three-terminal input AND gate 24, and a second three-terminal input AND gate 25; the enabling EN of the microcontroller 18 is directly connected to the power drive An enable input of the unit 8; the width-adjustable wave output HSO.0 of the single-chip microcomputer 18 is simultaneously connected to an input end of the first three-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com