Patents

Literature

4899results about How to "High adjustment accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

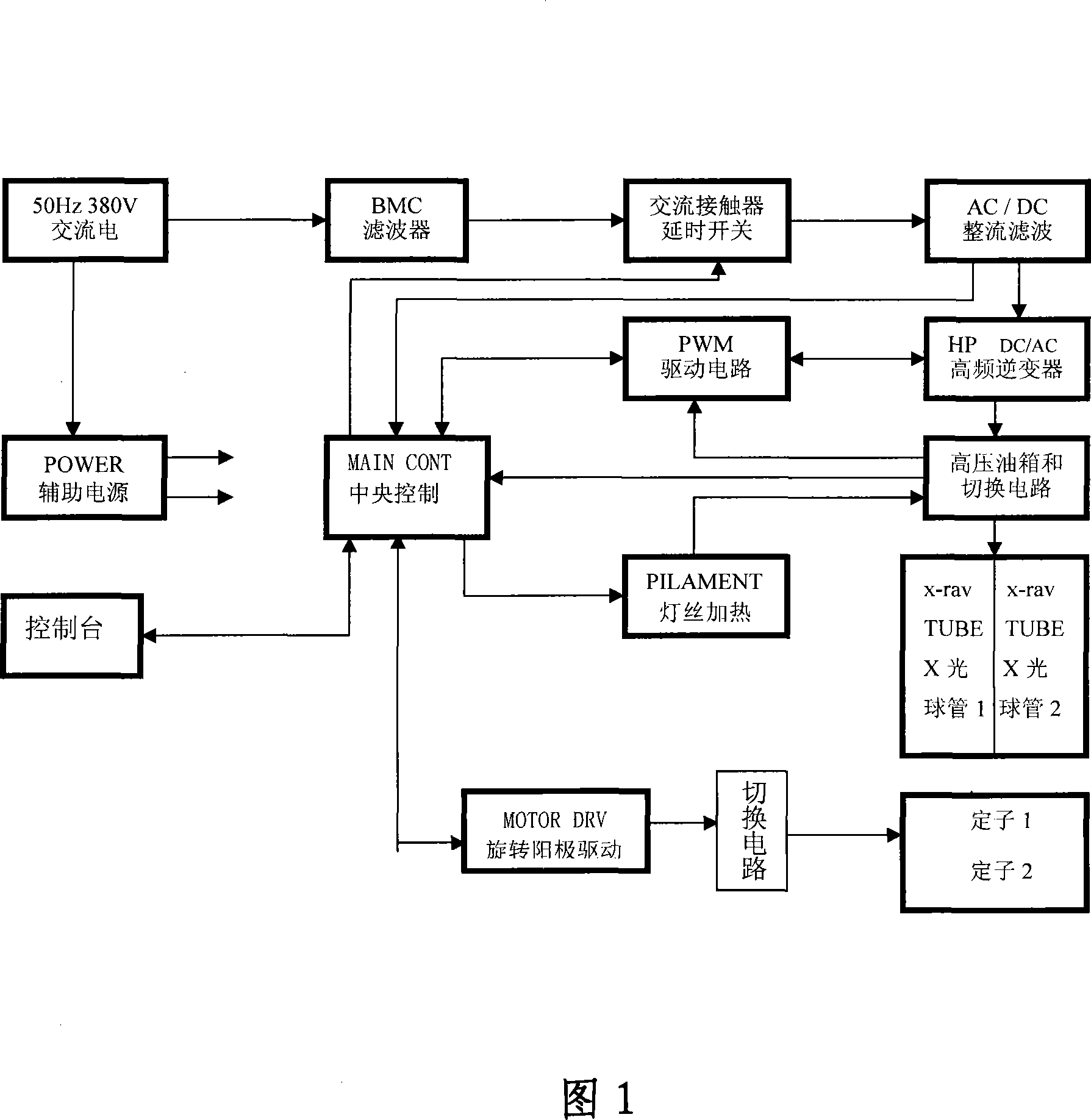

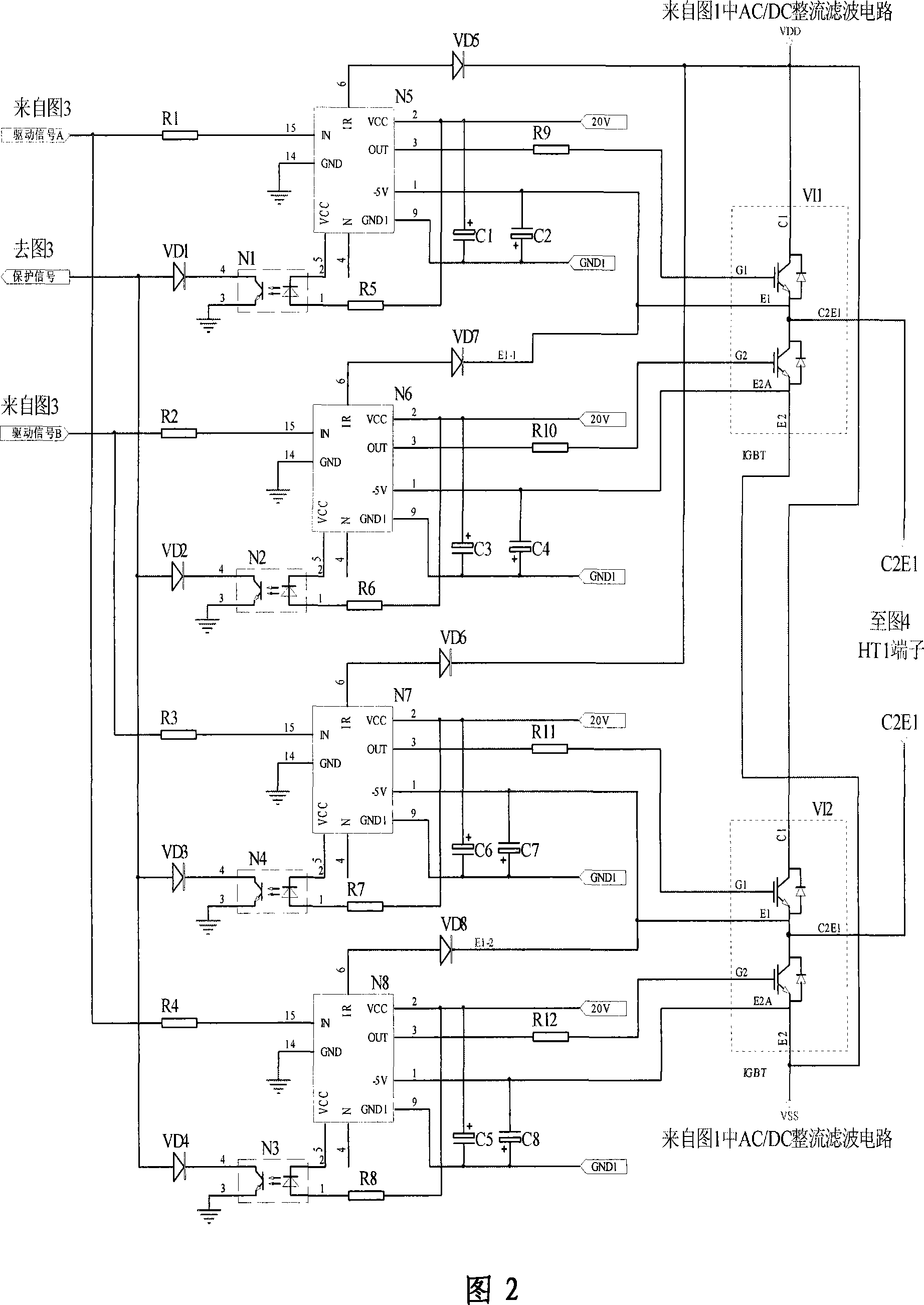

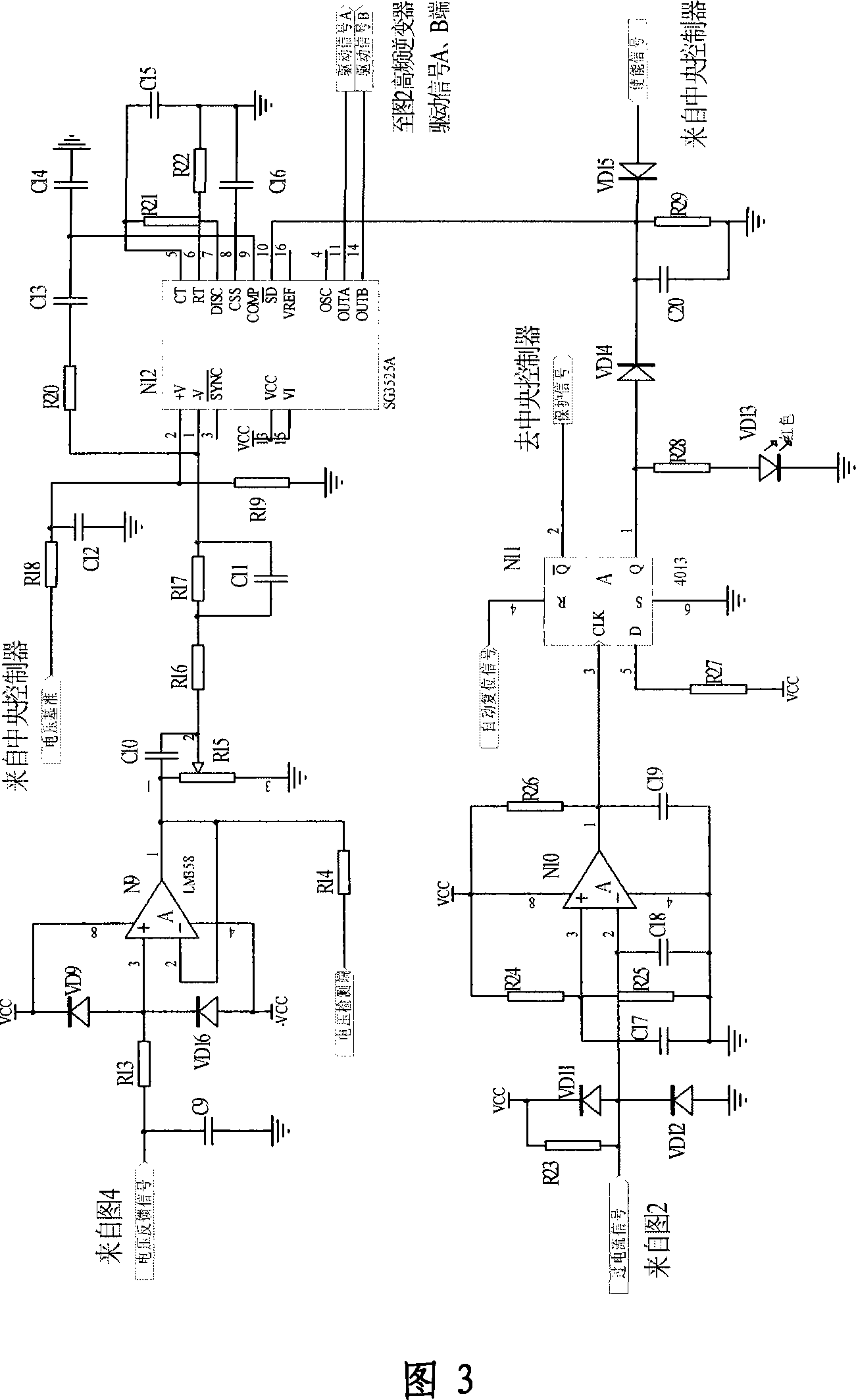

Medical diagnosis X radial high-frequency and high-voltage generator based on dual-bed and dual-tube

ActiveCN101188900ASolve the problem of shift workImprove clarityAc-dc conversionX-ray apparatusX-rayEngineering

The invention discloses a two-bed duplex tube medical diagnosis X-ray high frequency high voltage generator, which comprises a power supply and a central control unit, and also comprises a high frequency inverter circuit, a pulse-width modulation drive circuit and a high voltage commutation circuit. The generator converts the industrial power supply into two way high frequency high voltage, and then obtains positive end DC high voltage and negative end DC high voltage after the rectification and the filter to supply an X-ray pipet for working. Because the frequency is high and the high voltage ripple after the rectification and the filter is minimum, causing the X-ray pipet of a radiographic table and the X-ray pipet of an electric perspective table to work in turn under the condition of arranging only one set of high voltage supply. The equipment investment is saved, and the work of using the X-ray diagnosis for the medical staff is convenient. Being served as the high voltage supply, the invention is also suitable for the safety detection fields such as the industrial fault detection, the civil aviation, the station, the custom, etc., and supplies the stable high quality high voltage for the equipment.

Owner:广西道纪医疗设备有限公司

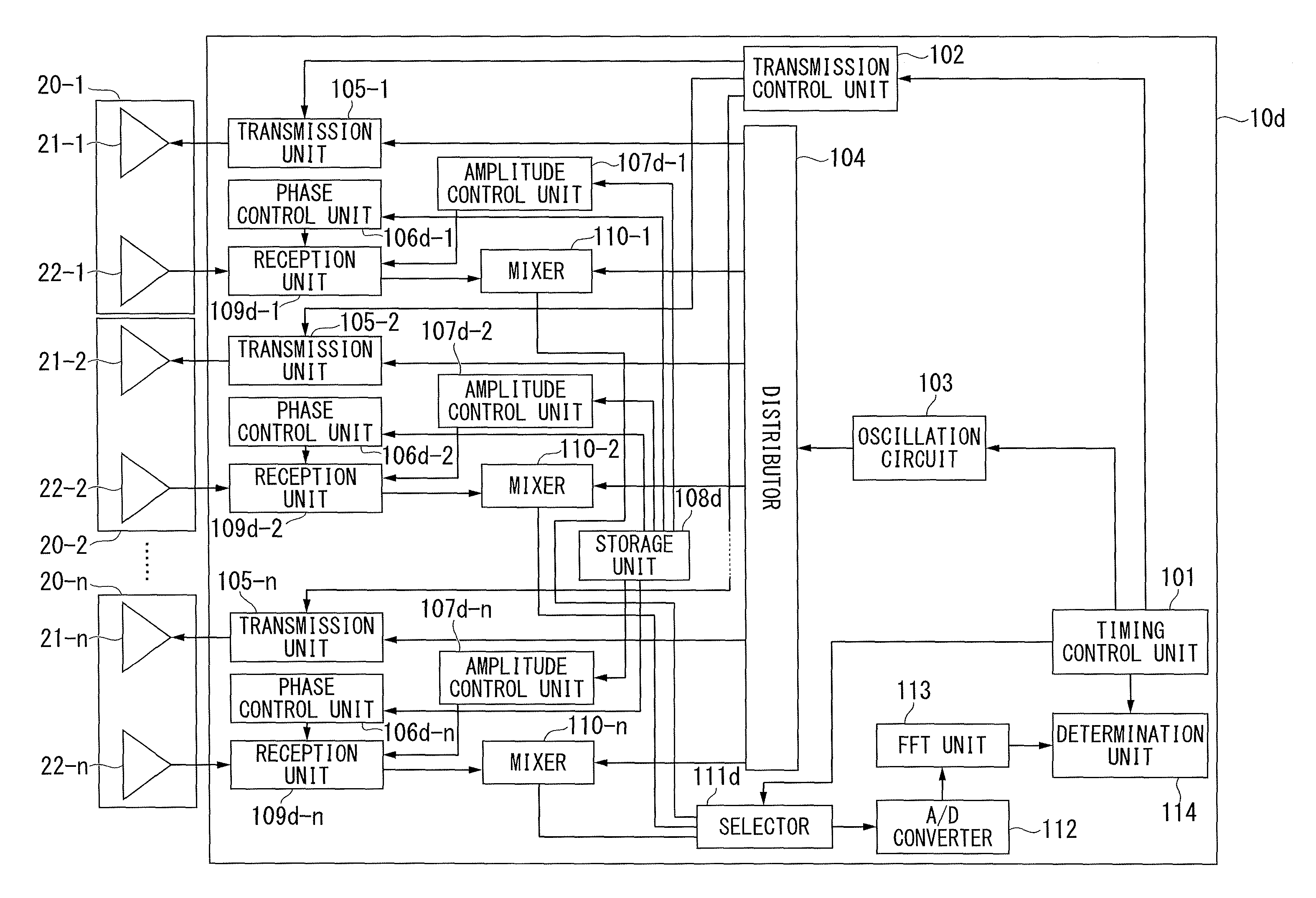

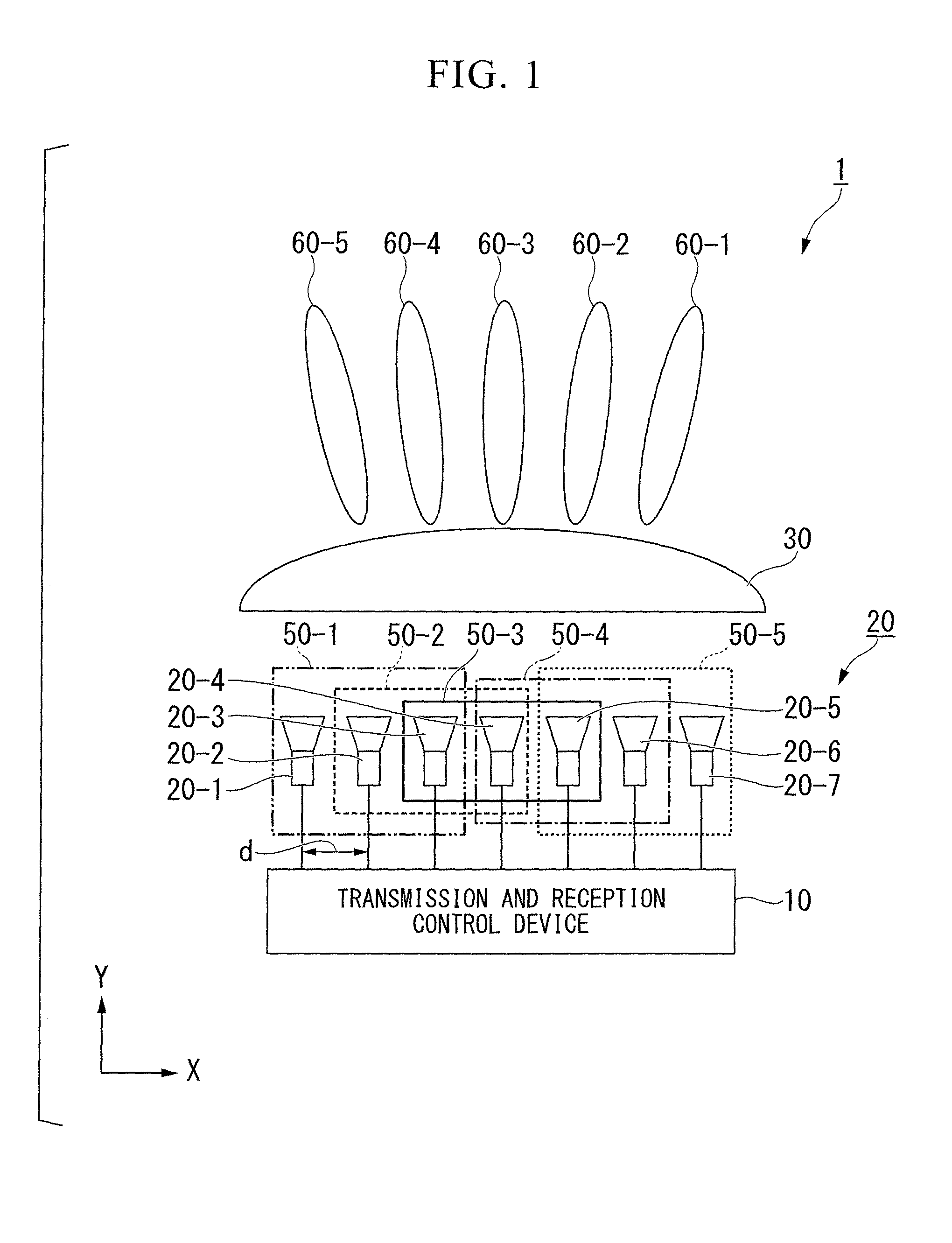

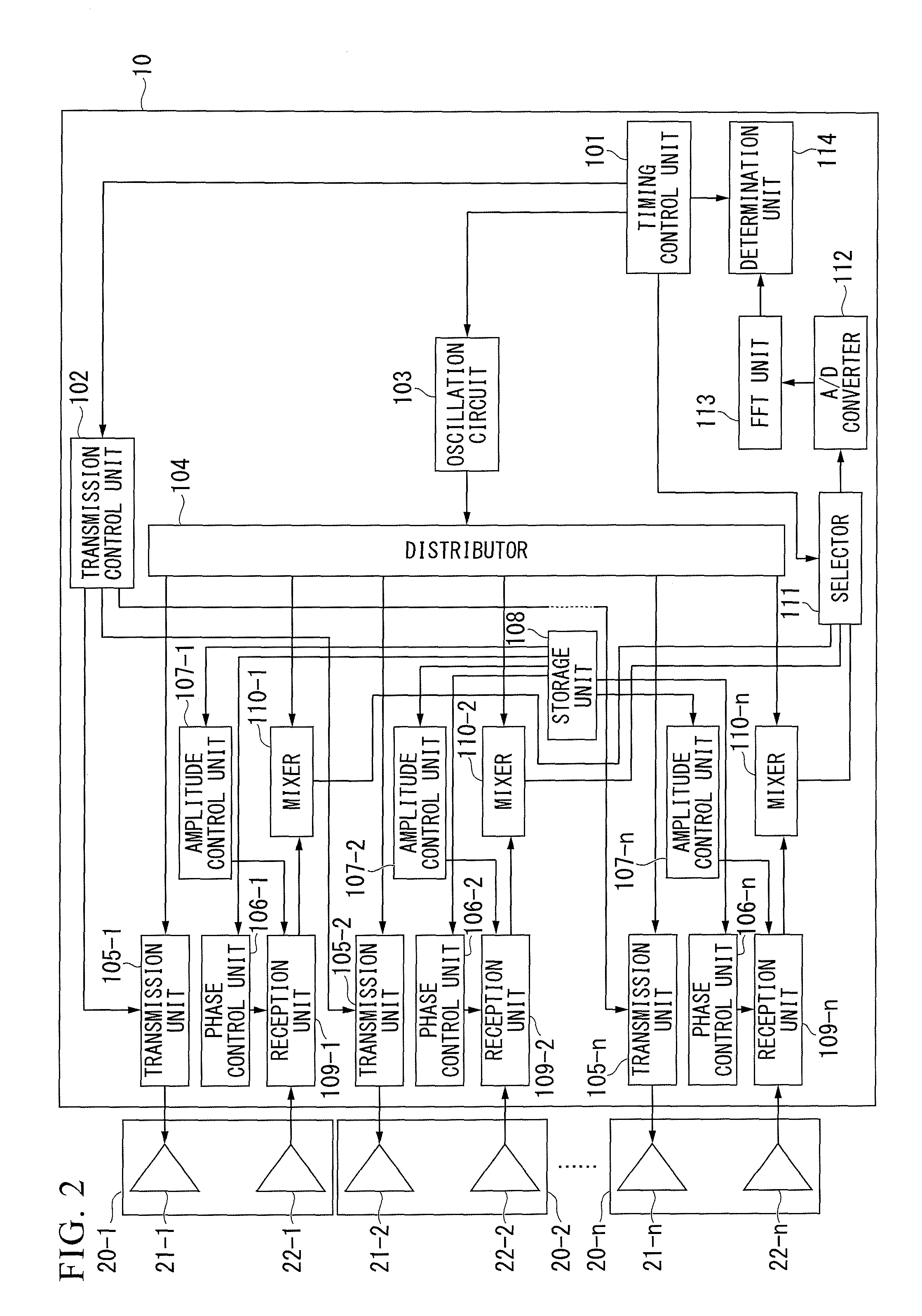

On-board radar apparatus

InactiveUS20140285373A1Increase costIncrease in sizeWaveguide hornsIndividually energised antenna arraysObject basedRadar

An on-board radar apparatus includes an antenna unit configured by combining one of a lens and a reflector, and a plurality of antenna elements, a transmission and reception unit configured to emit a radio wave using, for at least one of transmission or reception, a partial antenna of a plurality of patterns configured by the antenna elements that are part of the plurality of antenna elements, and to receive a reflection wave obtained by reflection of the radio wave from an object, and a detection unit configured to detect the object based on the reflection wave received by the transmission and reception unit.

Owner:NAT UNIV CORP SHIZUOKA UNIV +1

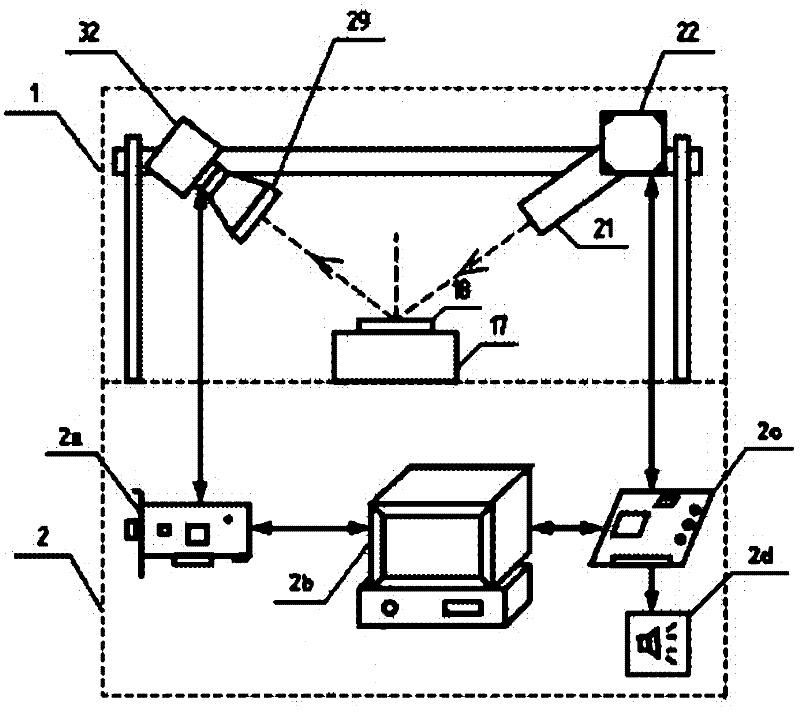

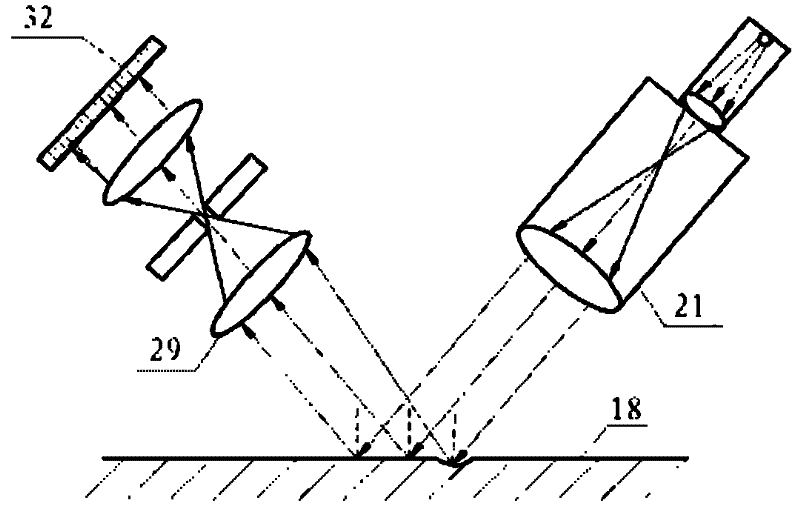

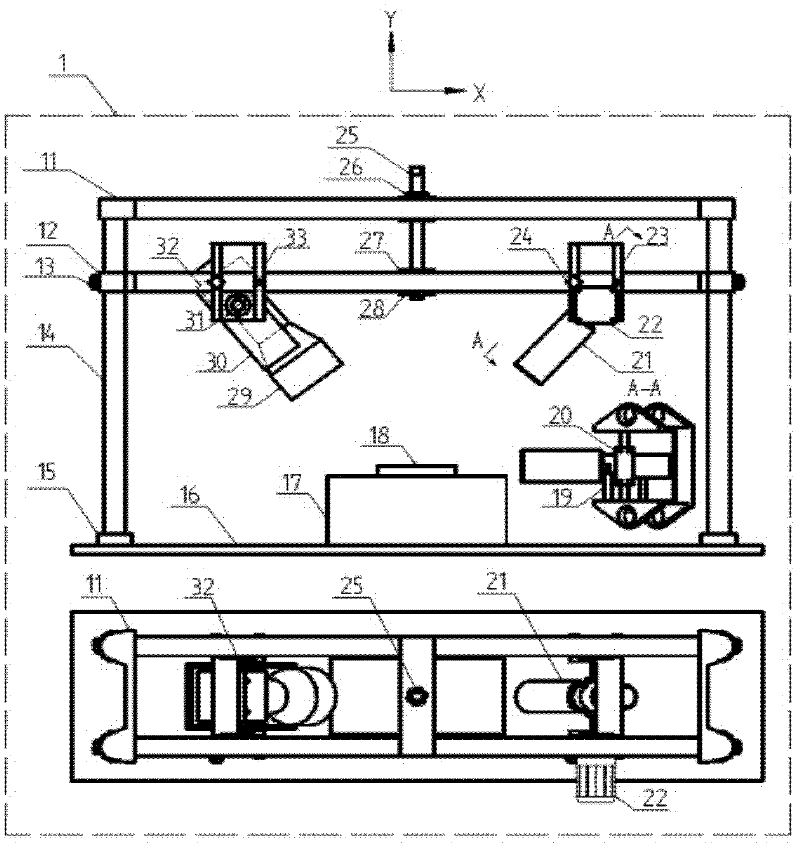

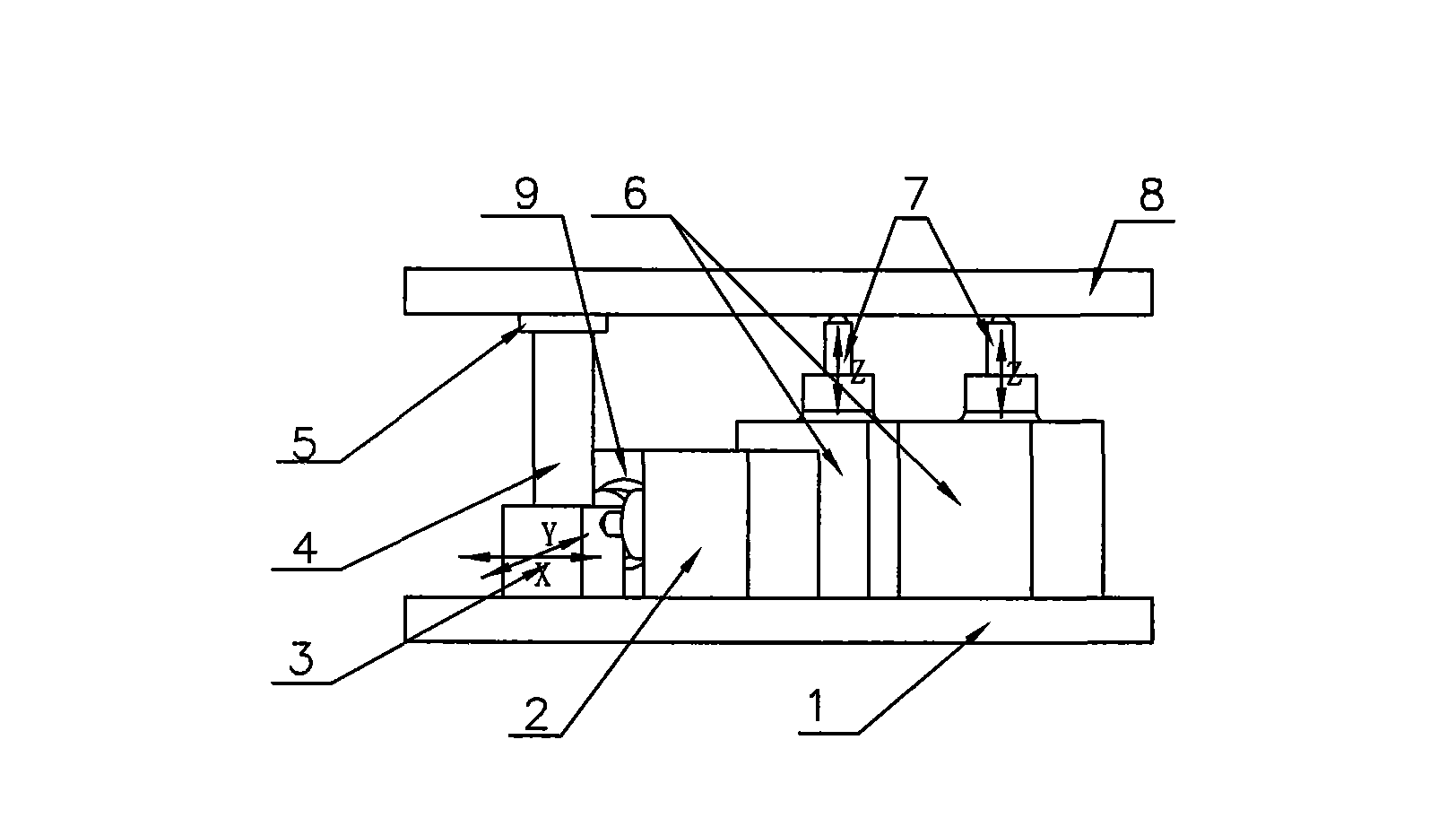

Device and method for detecting micro defects on bright and clean surface of metal part based on machine vision

ActiveCN102590218ARealize installation positioningEasy to operateOptically investigating flaws/contaminationEffect lightCcd camera

The invention relates to a device and method for detecting micro defects on the bright and clean surface of a metal part based on machine vision. The device comprises an imaging, positioning and adjusting mechanism and a processing unit, wherein the imaging, positioning and adjusting mechanism comprises a base plate, a guide rod, a fixed support, a sliding support, a stepping motor, a CCD (Charge Coupled Device) camera, a telecentric lens and parallel light sources, wherein the imaging and coaxial lighting of the CCD camera are primarily adjusted; an image collection card, an industrial personal computer, an equipment control card and an alarm are electrically connected in the processing unit and are used for collecting, transmitting, storing, processing, displaying and alarming image. The method comprises coaxial lighting adjustment and image processing, wherein coaxial lighting adjustment comprises the steps of triggering the equipment control card via software of the industrial personal computer to drive the stepping motor, and adjusting the rotating angles of the parallel light sources until the coaxial lighting condition is satisfied; and image processing comprises the steps of detecting defects on the internal surface of the detected part, respectively detecting large and small defects on the outer edge on the surface of the detected part, displaying the processing images in real time and judging the results.

Owner:安徽中科智能高技术有限责任公司

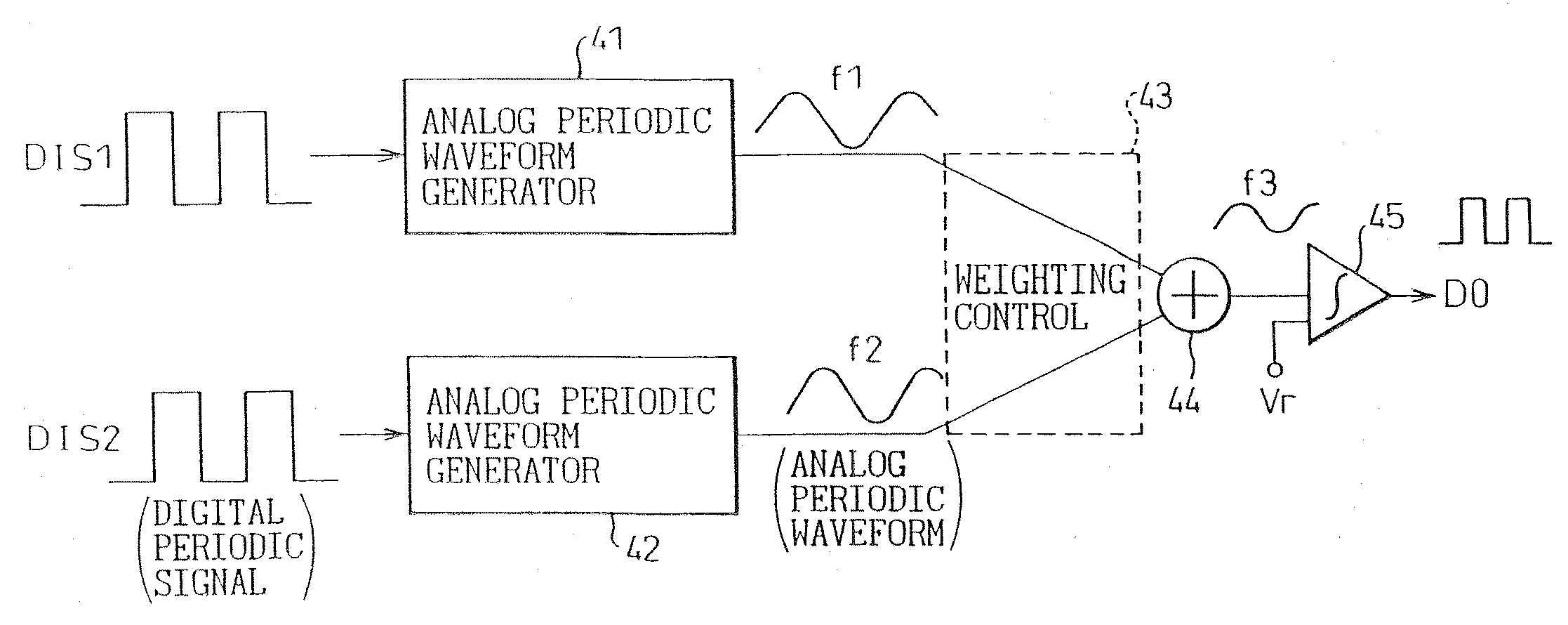

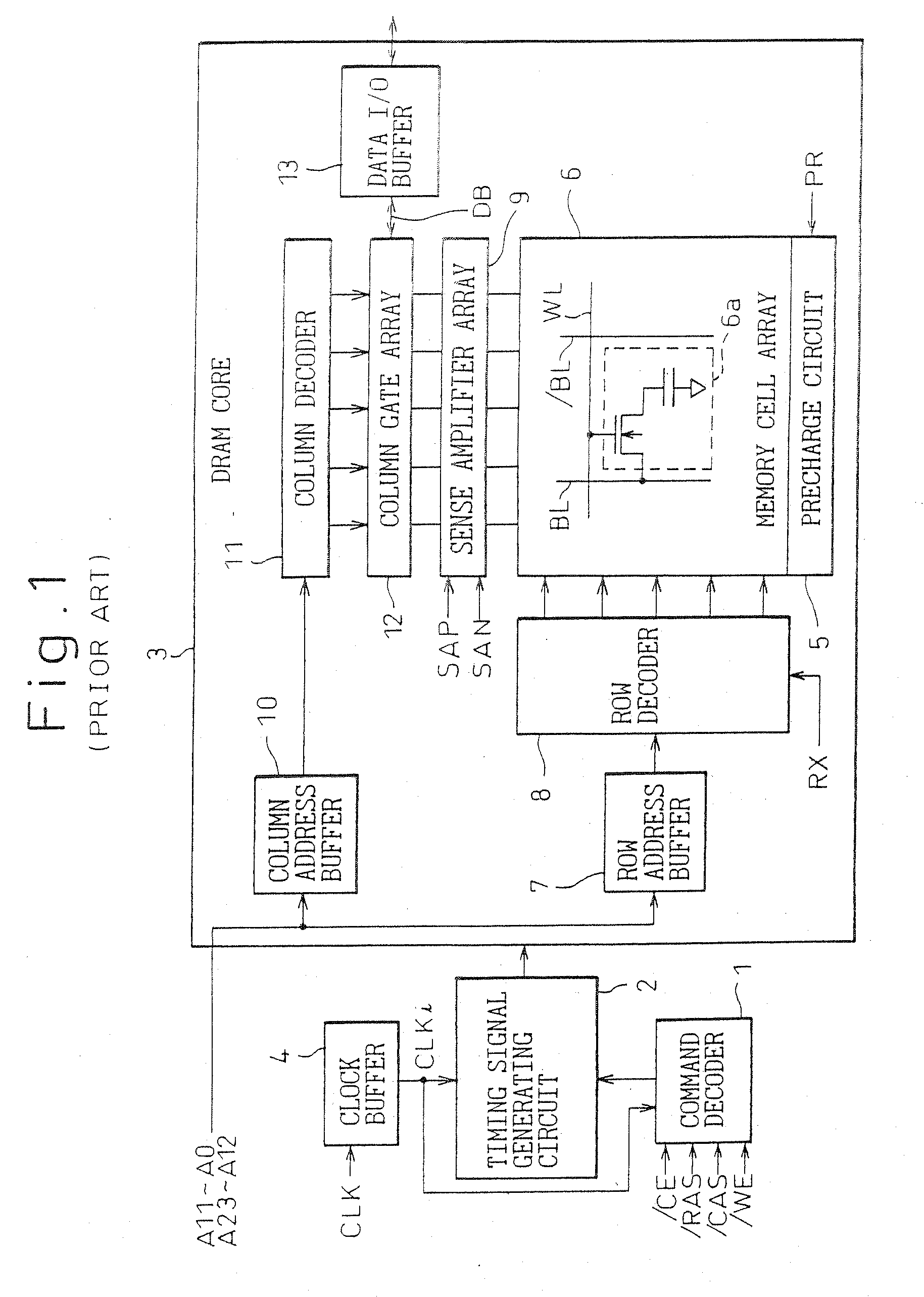

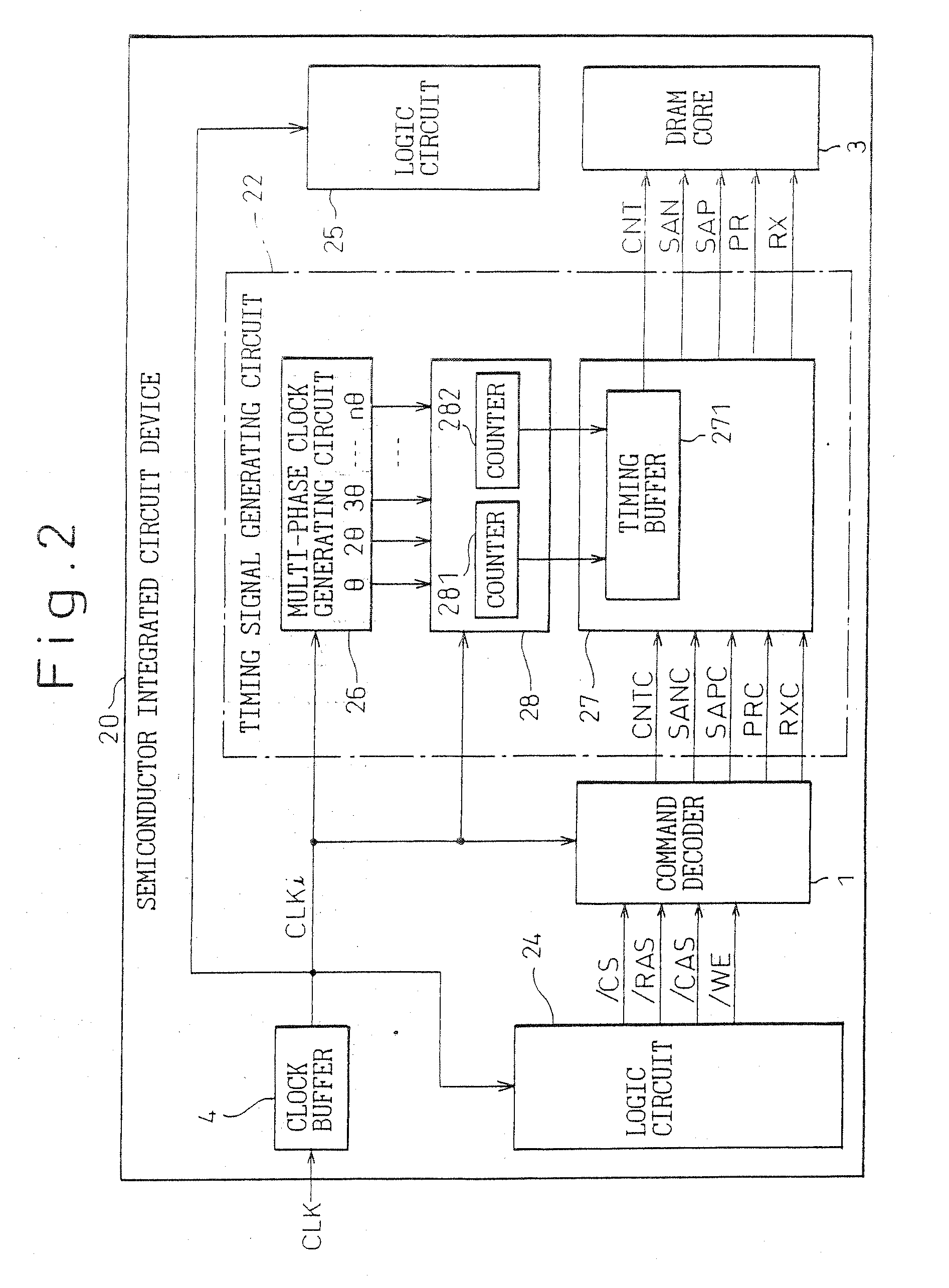

Timing Signal Generating Circuit, Semiconductor Integrated Circuit Device and Semiconductor Integrated Circuit System to which the Timing Signal Generating Circuit is Applied, and Signal Transmission System

InactiveUS20090195281A1High adjustment accuracySimple circuitPulse automatic controlError detection/correctionControl signalEngineering

Owner:FUJITSU LTD

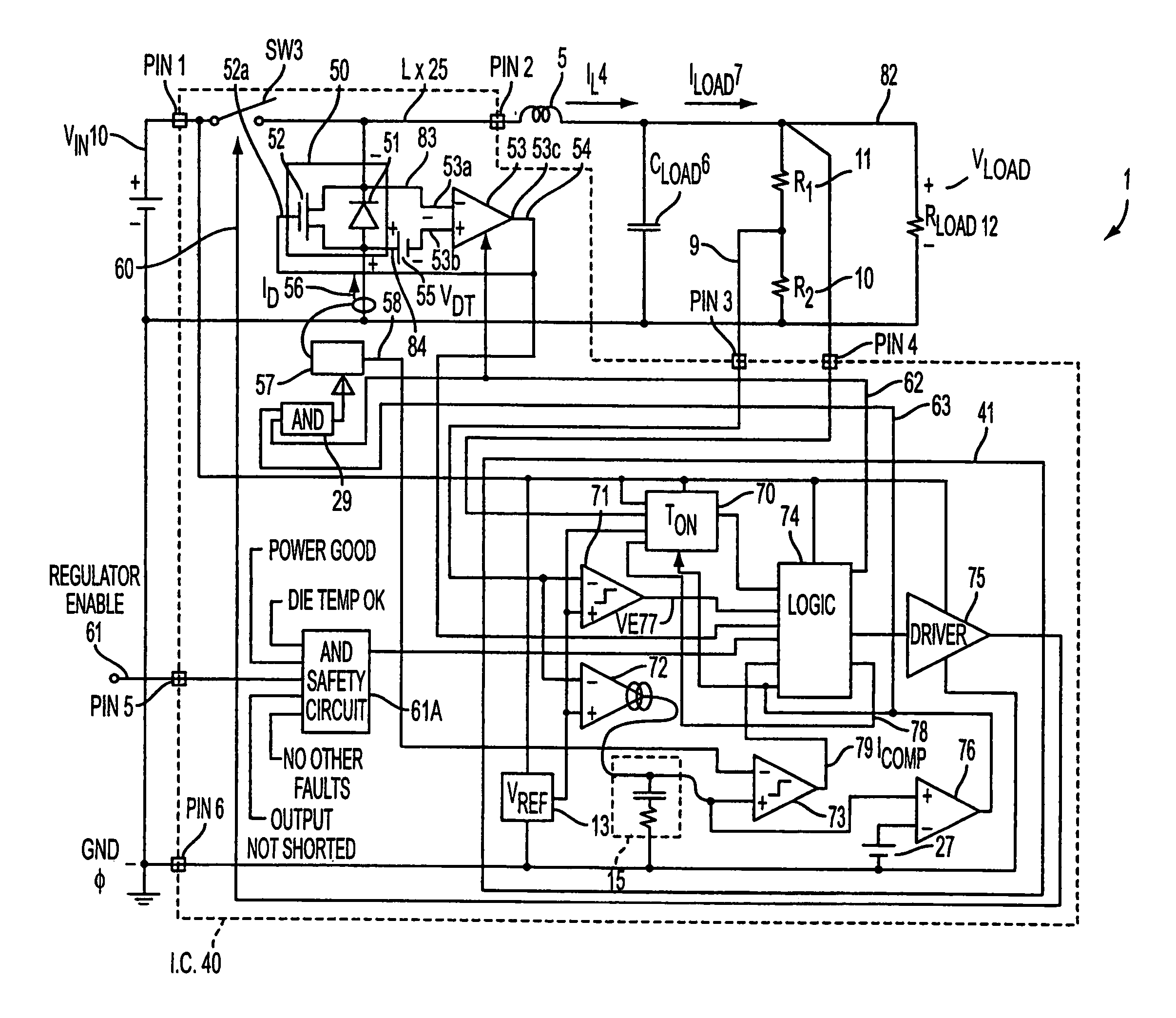

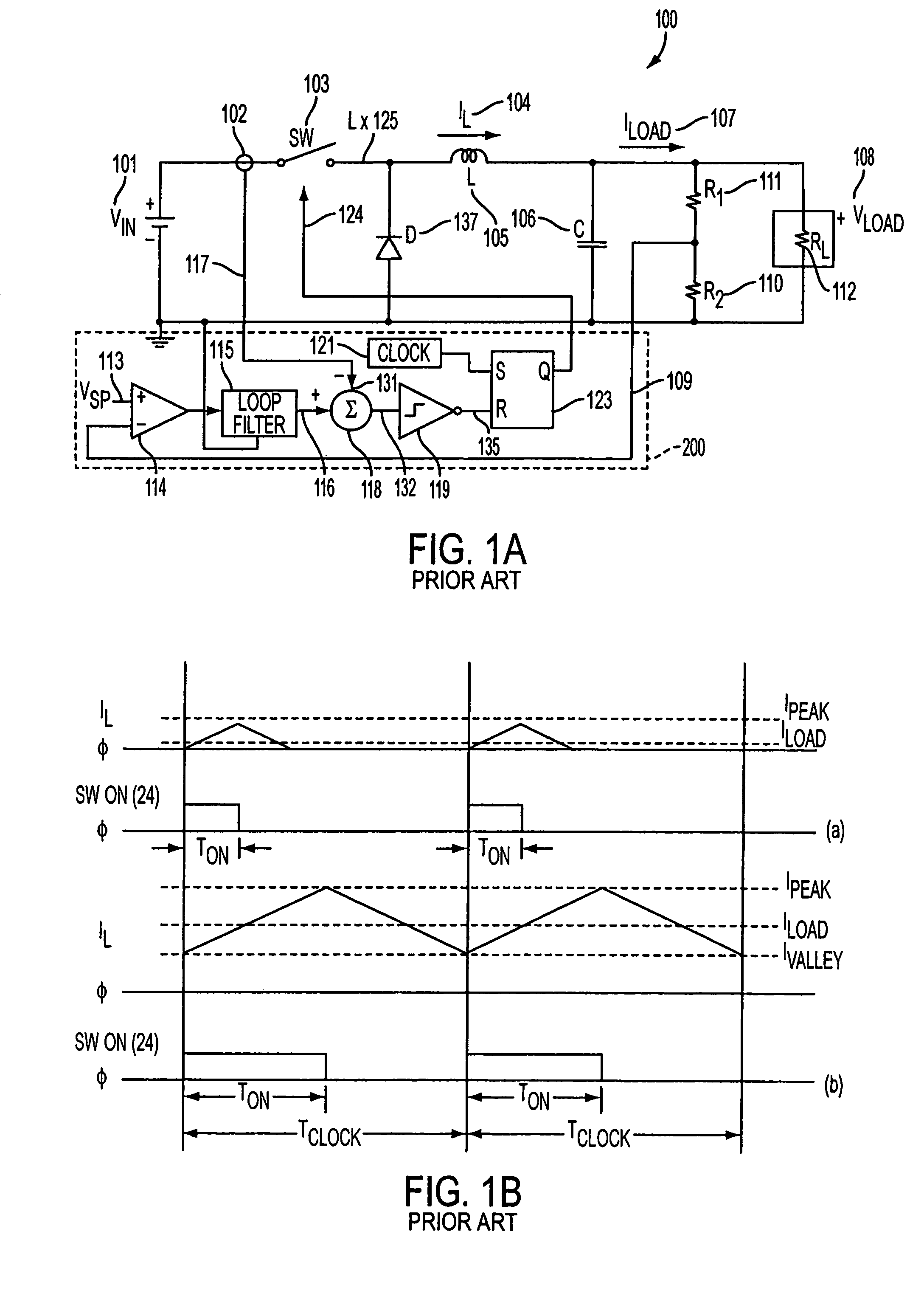

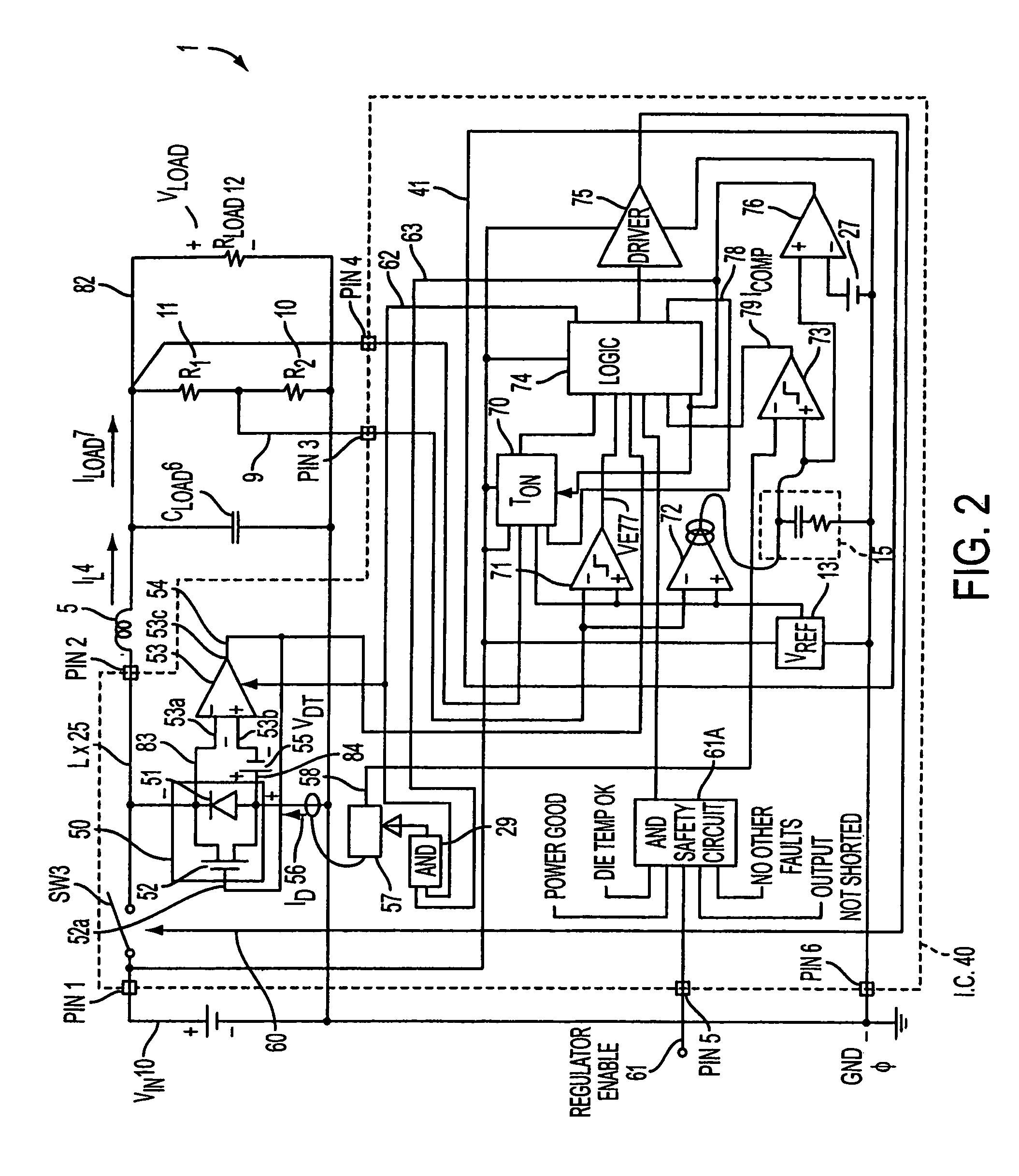

Current mode switching regulator with predetermined on time

InactiveUS7250746B2High adjustment accuracyDc-dc conversionElectric variable regulationPower switchingEngineering

Owner:COLLABO INNOVATIONS INC

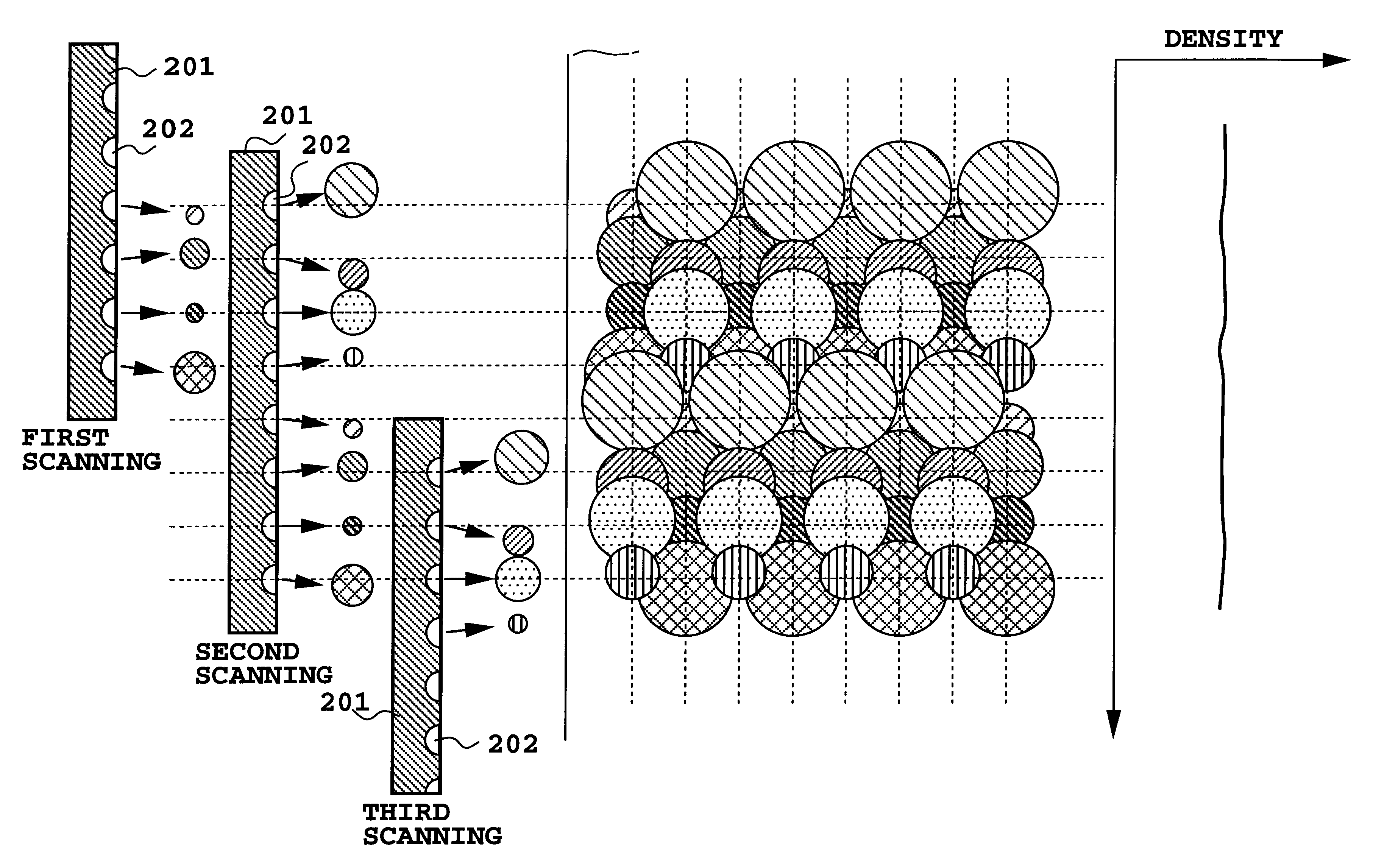

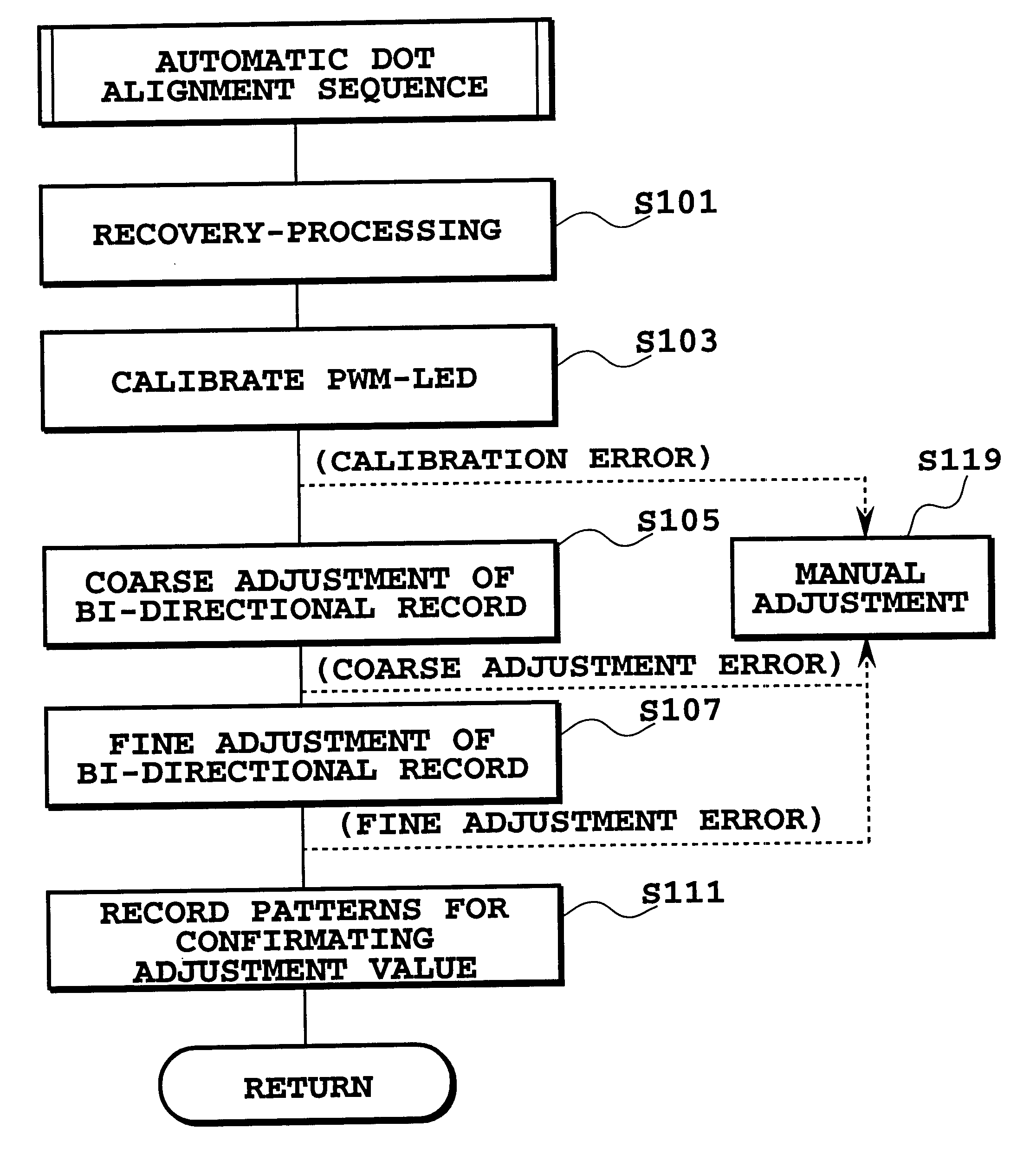

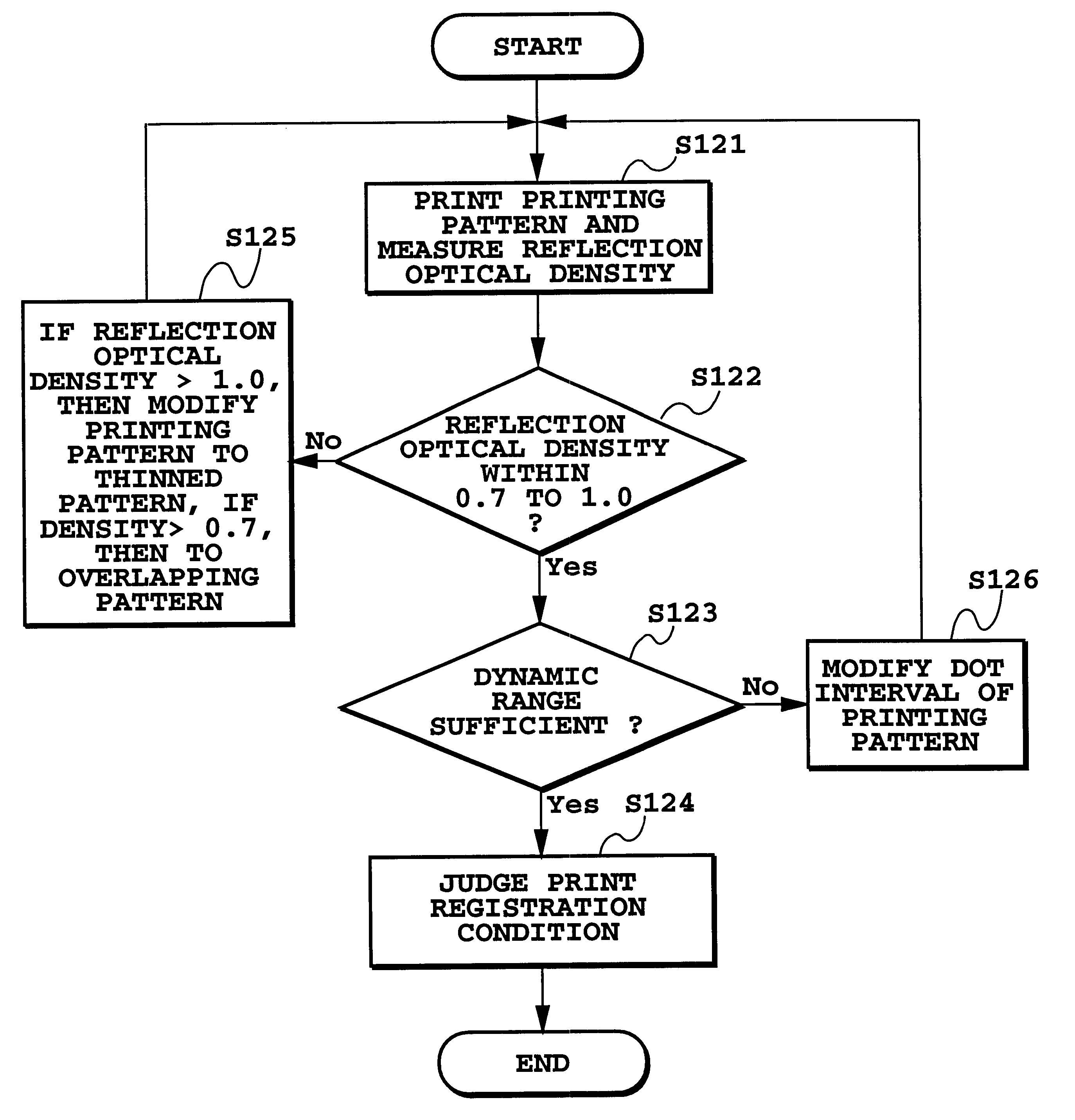

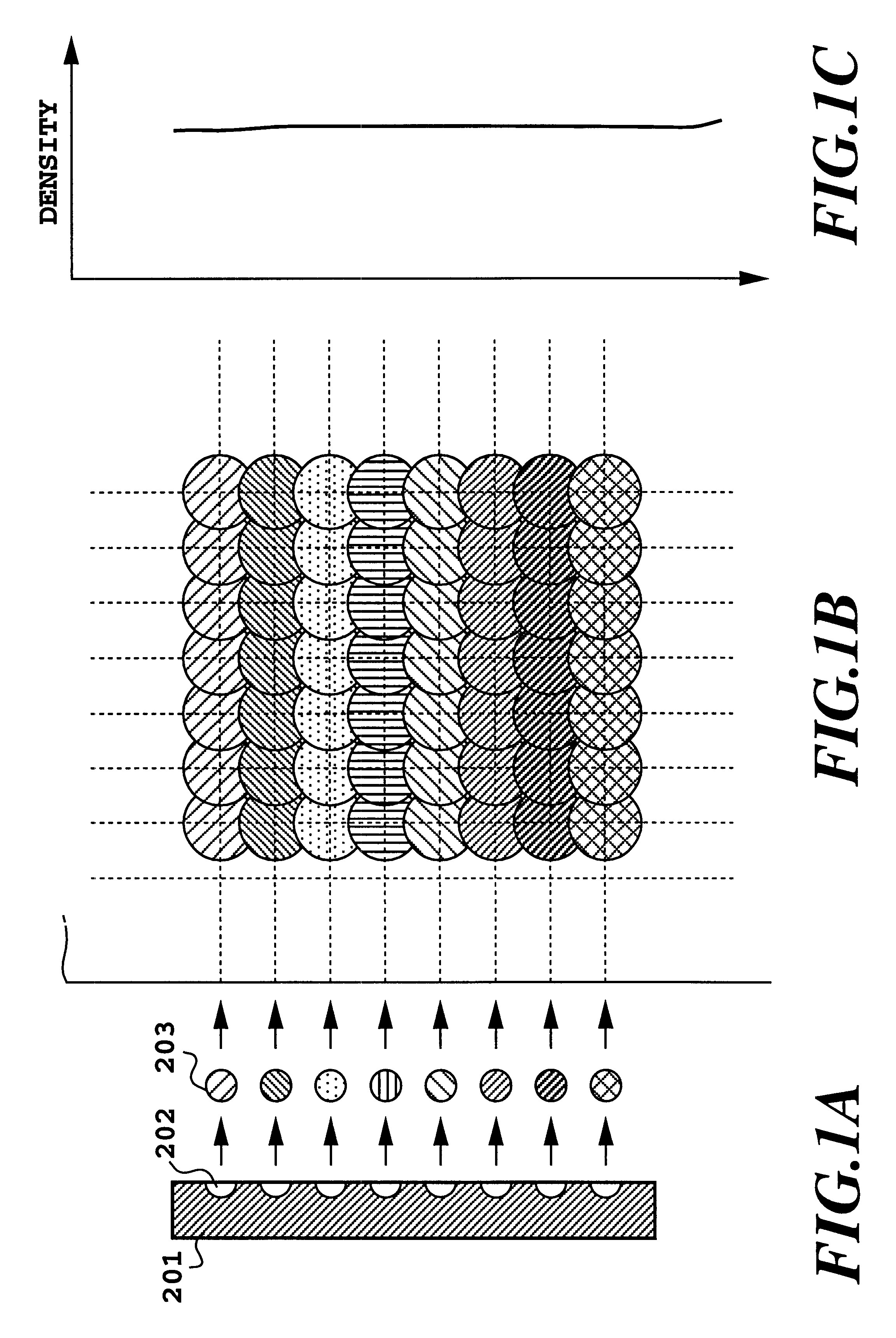

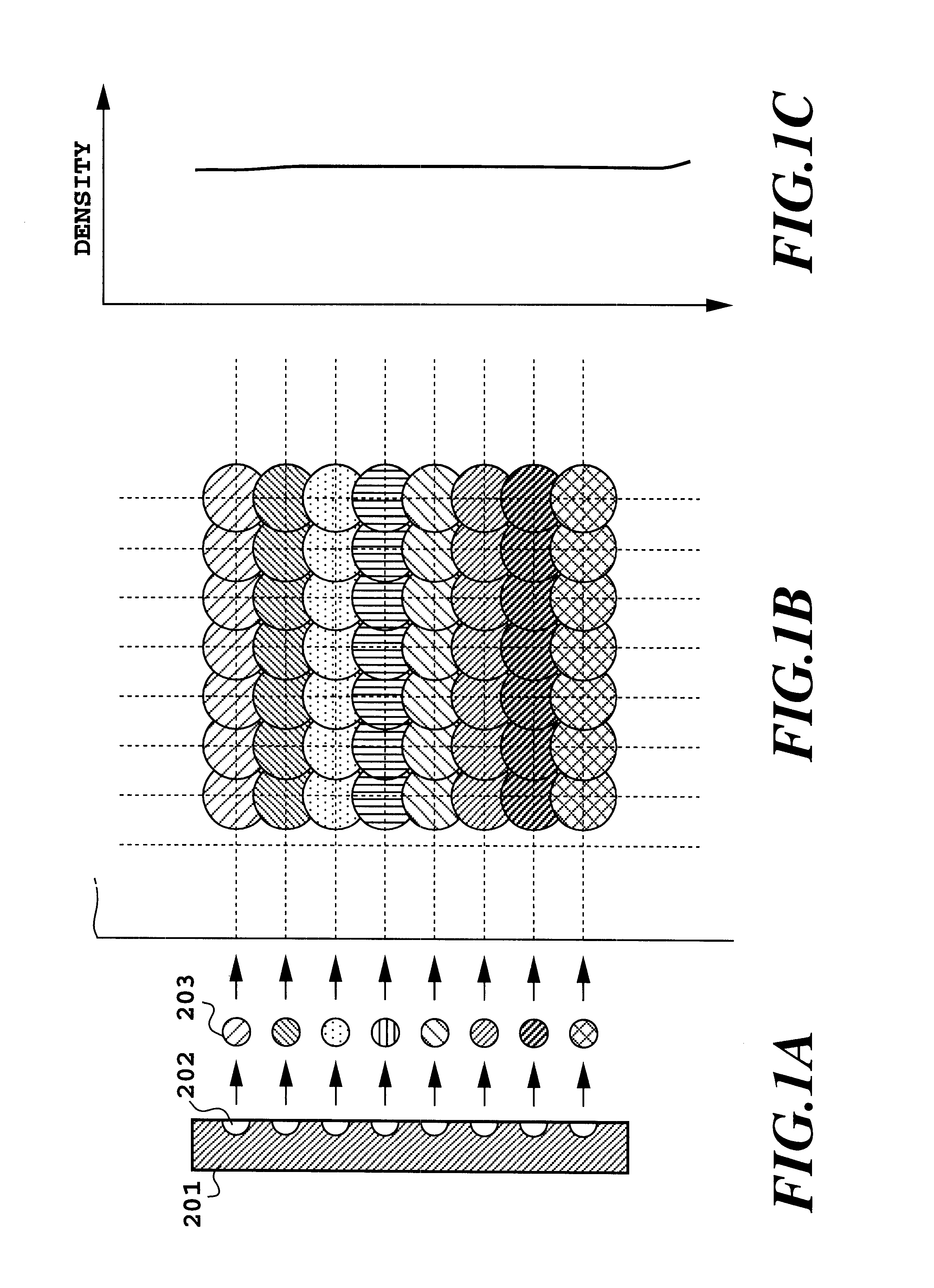

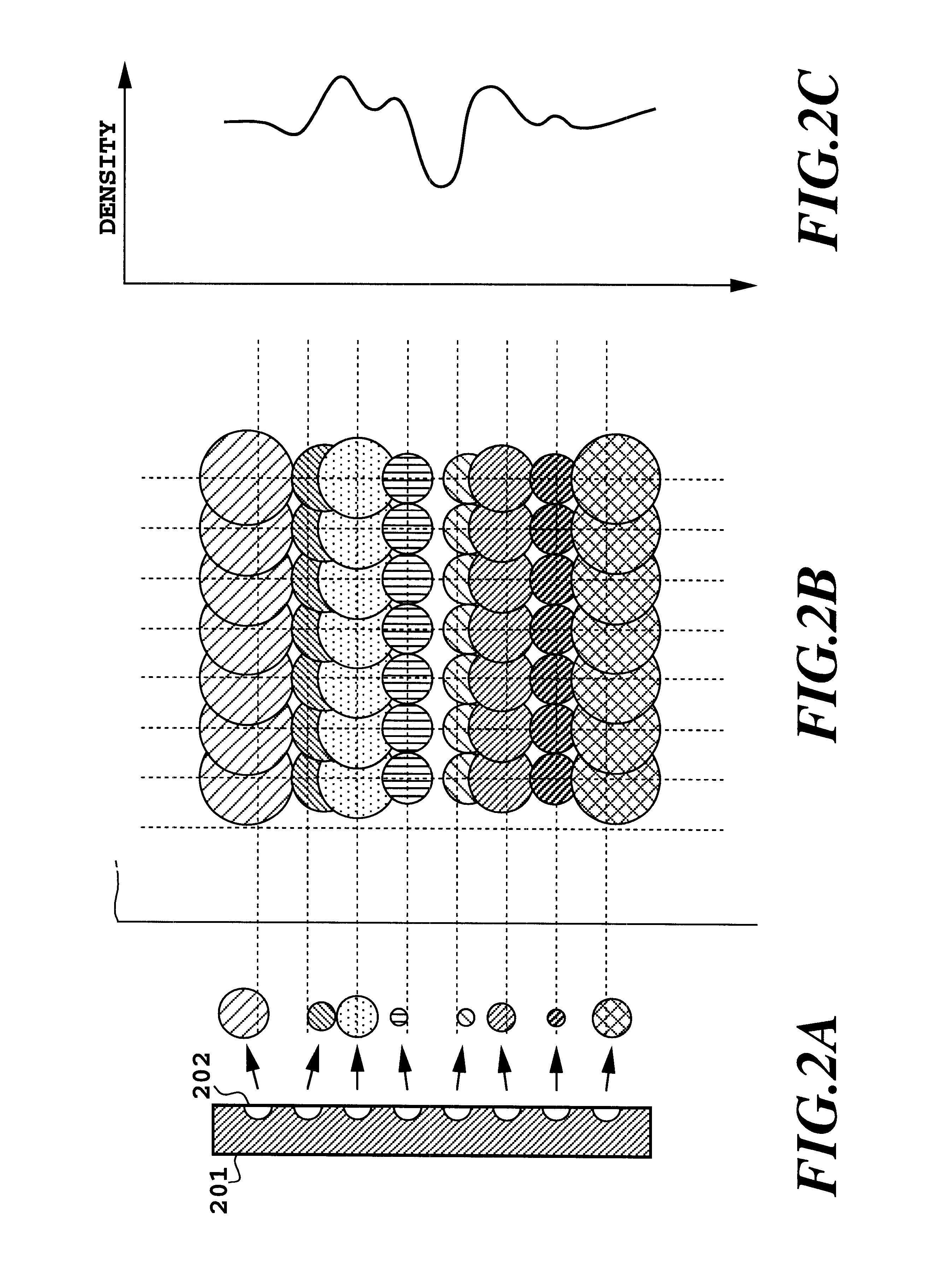

Adjustment method of dot printing positions and a printing apparatus

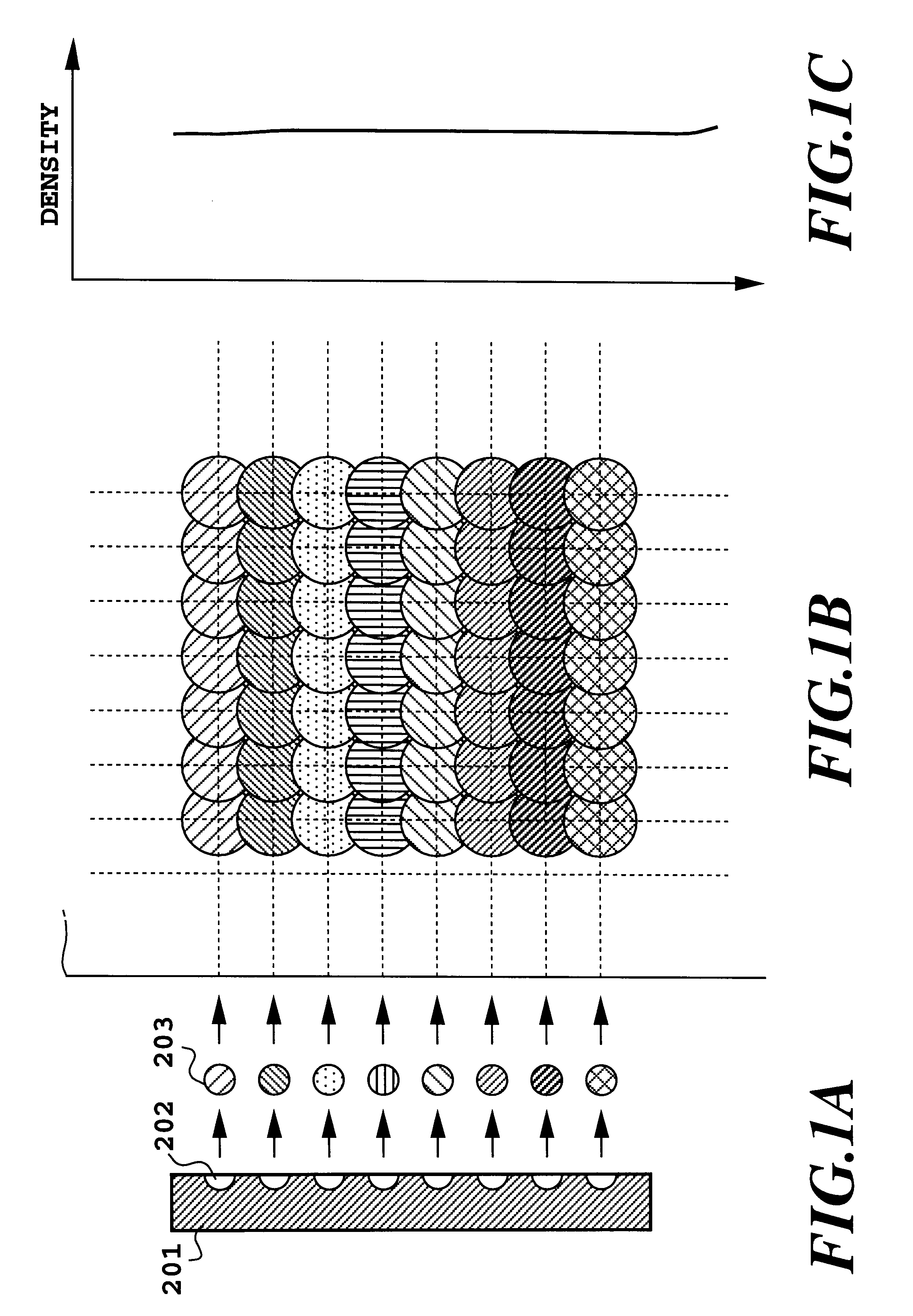

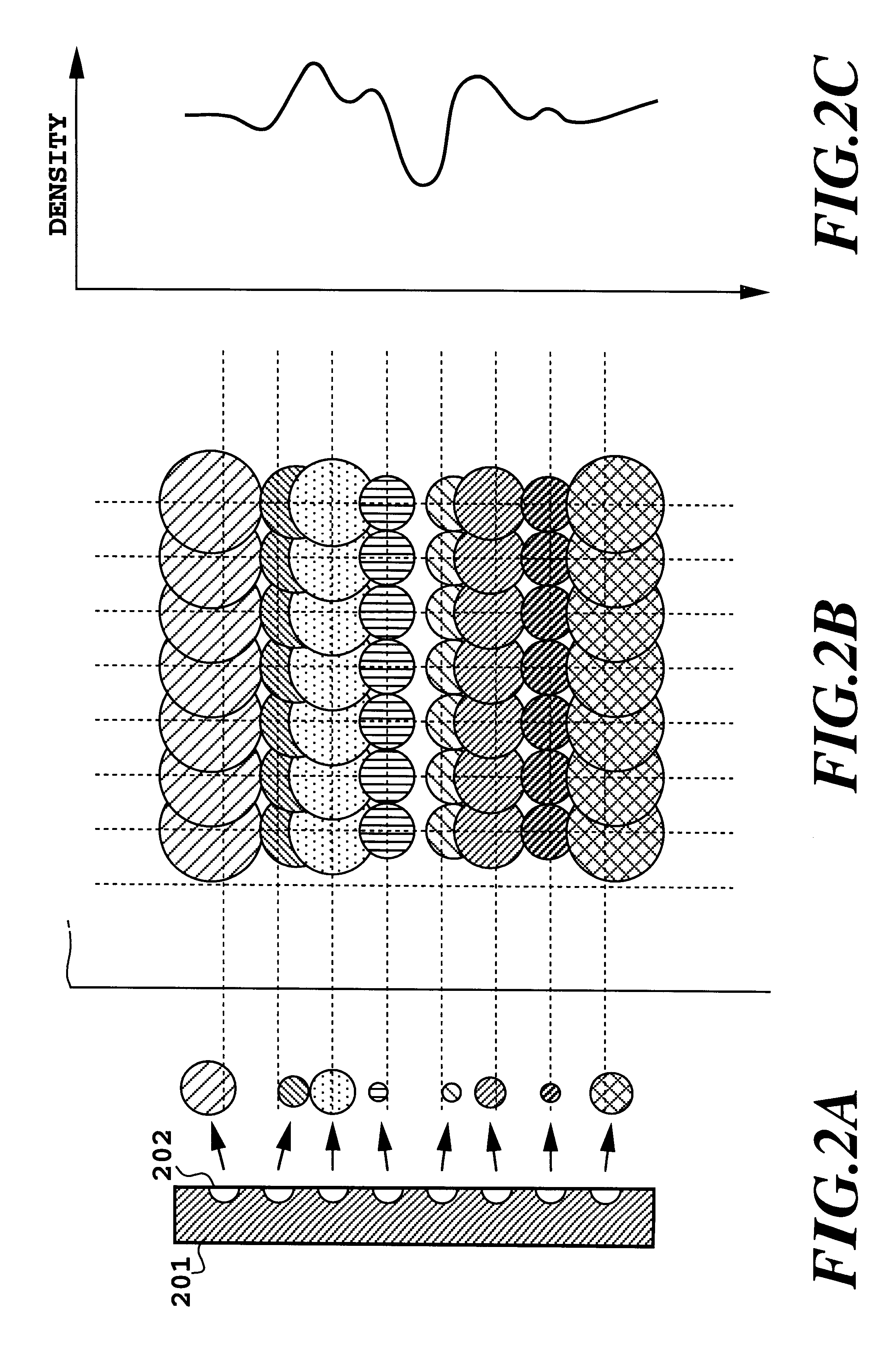

InactiveUS6257143B1Guaranteed uptimeLow costCylinder pressesPlaten pressesEngineeringPrinting registration

A plurality of patterns respectively having different area factor of dot formation area are formed by forward and reverse scanning printing of a print head, and then optical characteristics of the plurality of formed patterns are measured. A function representing the relationship between the printing position offset between the forward and reverse printings is determined from the optical characteristics. Then, respective pattern having a predetermined area factor of dot formation area is formed by means of forward and reverse scanning where the speed is differentiated according to the mode of a printing apparatus, and then the optical characteristics of this pattern is measured. By applying this measured optical characteristics to the function, an adjustment value of the dot formation position conditions between the forward and reverse scans is obtained for each mode. This makes it easy to perform printing registration in a printing apparatus in the case of printing by a forward and reverse scan of a printing head or in the case of printing by means of a plurality of printing heads. In this case, operations by a user etc. are also unnecessary and are easily performed.

Owner:CANON KK

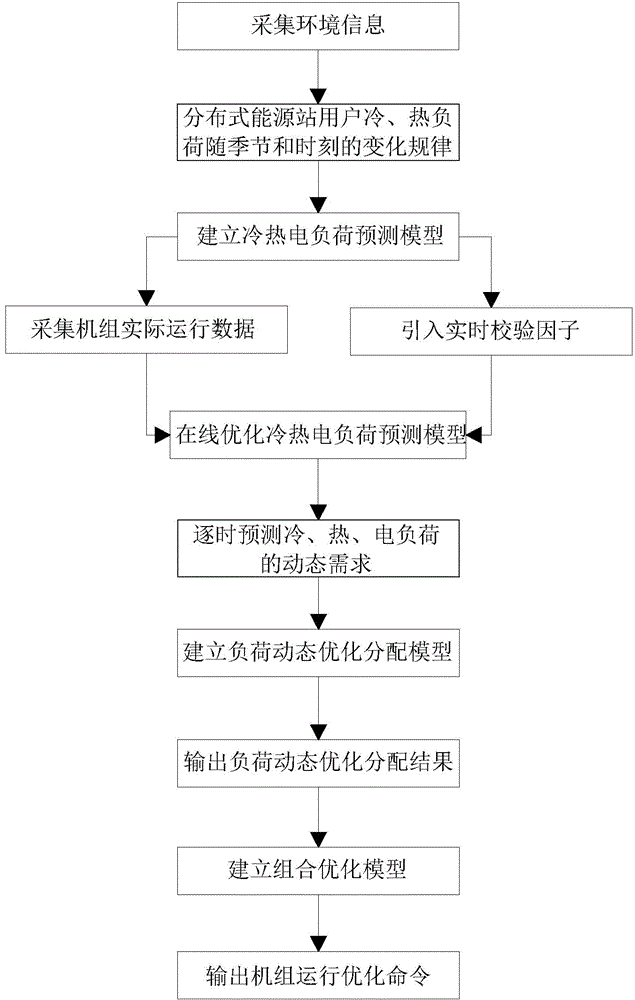

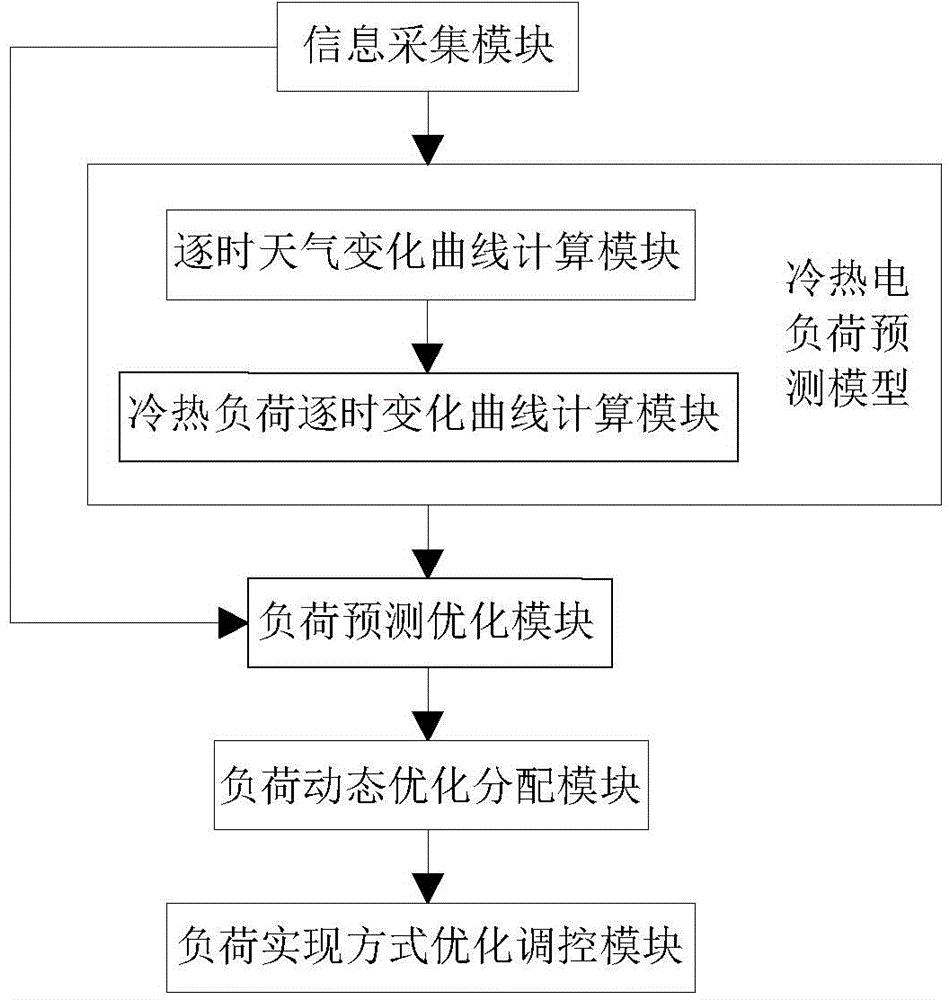

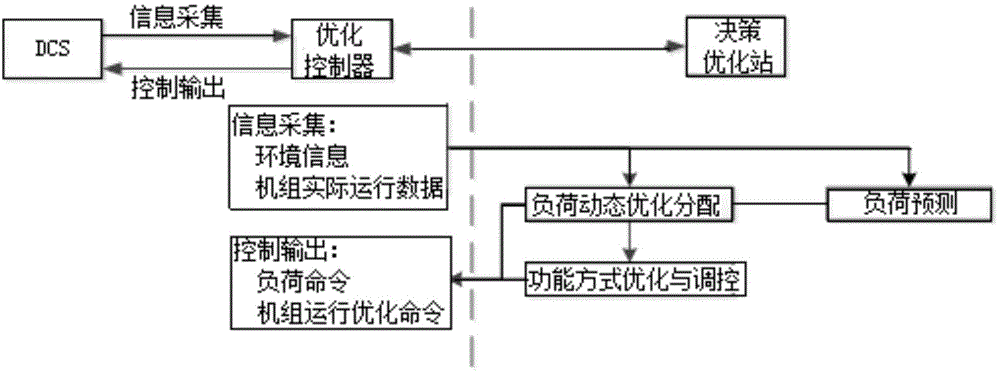

Optimized operation control method and system of distributed energy system

ActiveCN104571068AAchieve optimal allocationIncrease speedTotal factory controlProgramme total factory controlElectricityLoad forecasting

The invention discloses an optimized operation control method and system of a distributed energy system. The method include: S1, collecting environmental information and actual operation data of a unit so as to acquire a change rule of cold and hot load of a distributed energy station user with season and moment, and establishing a cold, hot and electric load prediction model; S2, optimizing the cold, hot and electric load prediction model on line by introducing real-time calibration factors and the actual operation data of the unit; S3, on the premise that the energy utilization efficiency is met, establishing a dynamic optimized load distribution model according to the dynamic requirements of the predicated cold, hot and electric load by taking a whole-plant economic benefit optimization as an objective, and outputting dynamic optimized load distribution results; S4, based on the whole-plant economic benefit optimization, establishing an optimal combination model according to the dynamic optimized load distribution results, and outputting a unit operation optimization command. High-precision load prediction information can be acquired, a corresponding optimization command is formed, and online optimization control is performed on the load dynamics and unit operation.

Owner:CHINA HUADIAN SCI & TECH INST

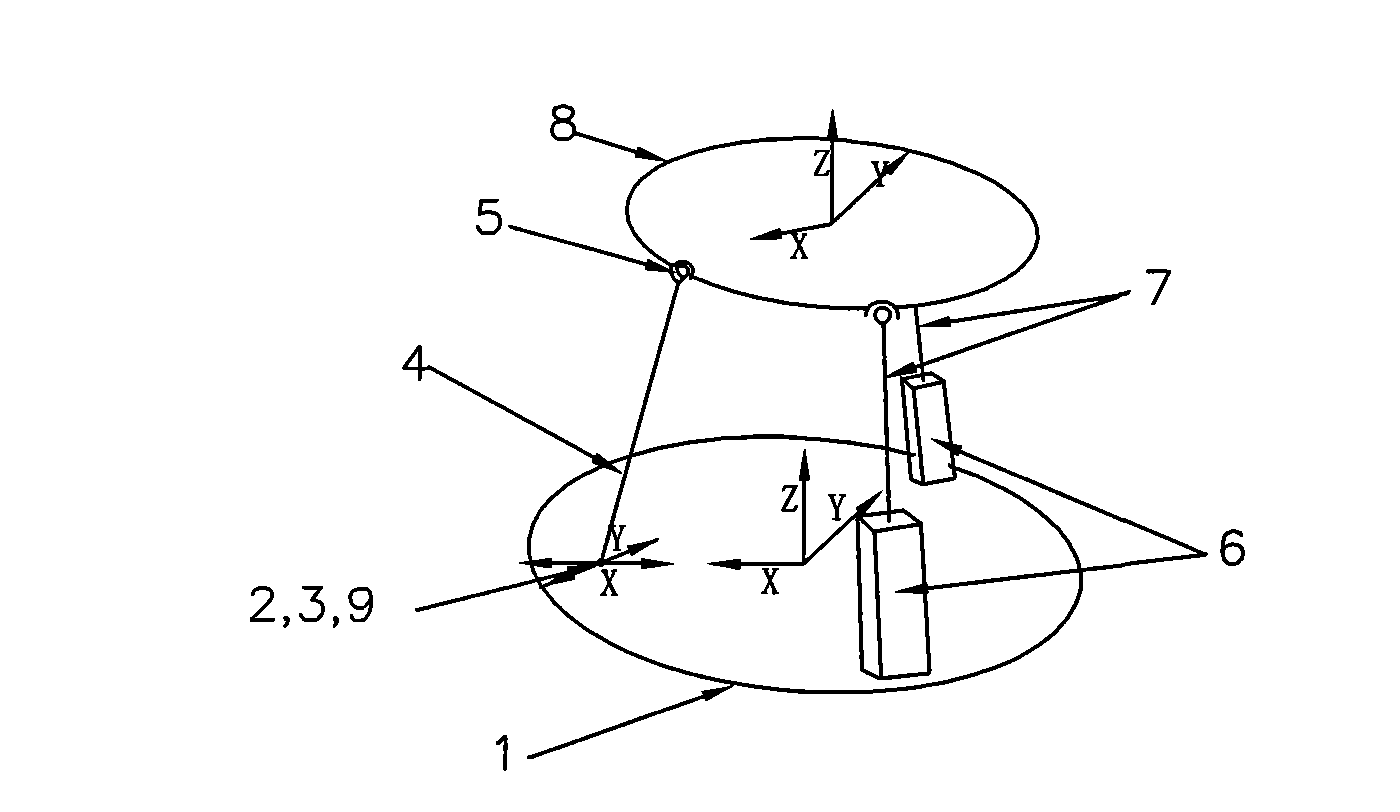

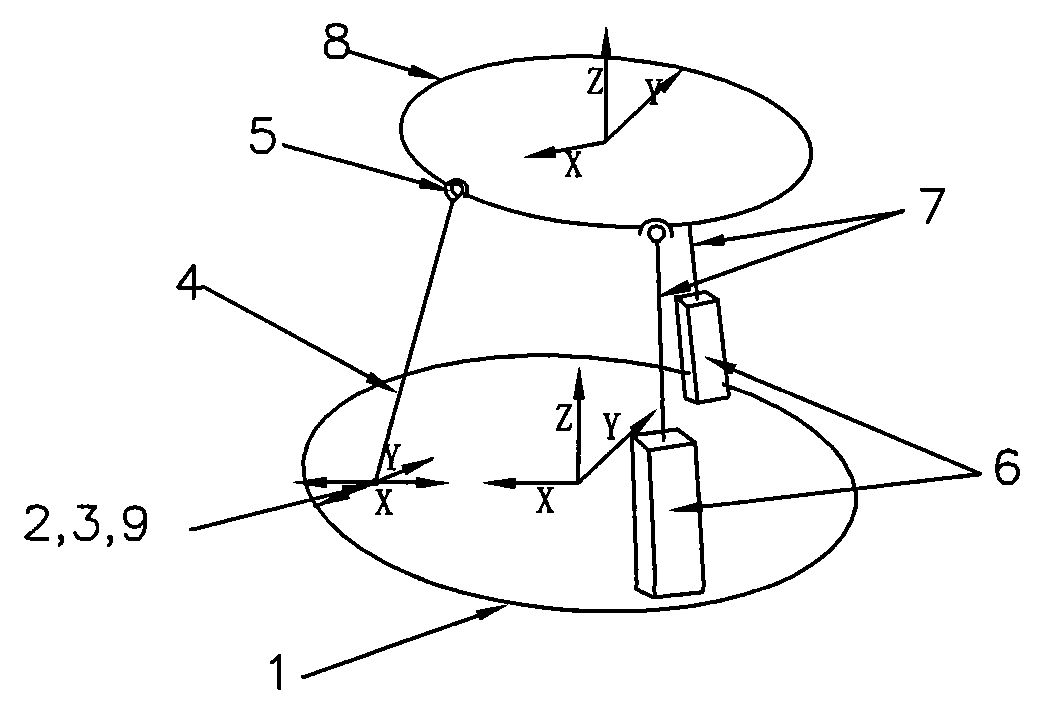

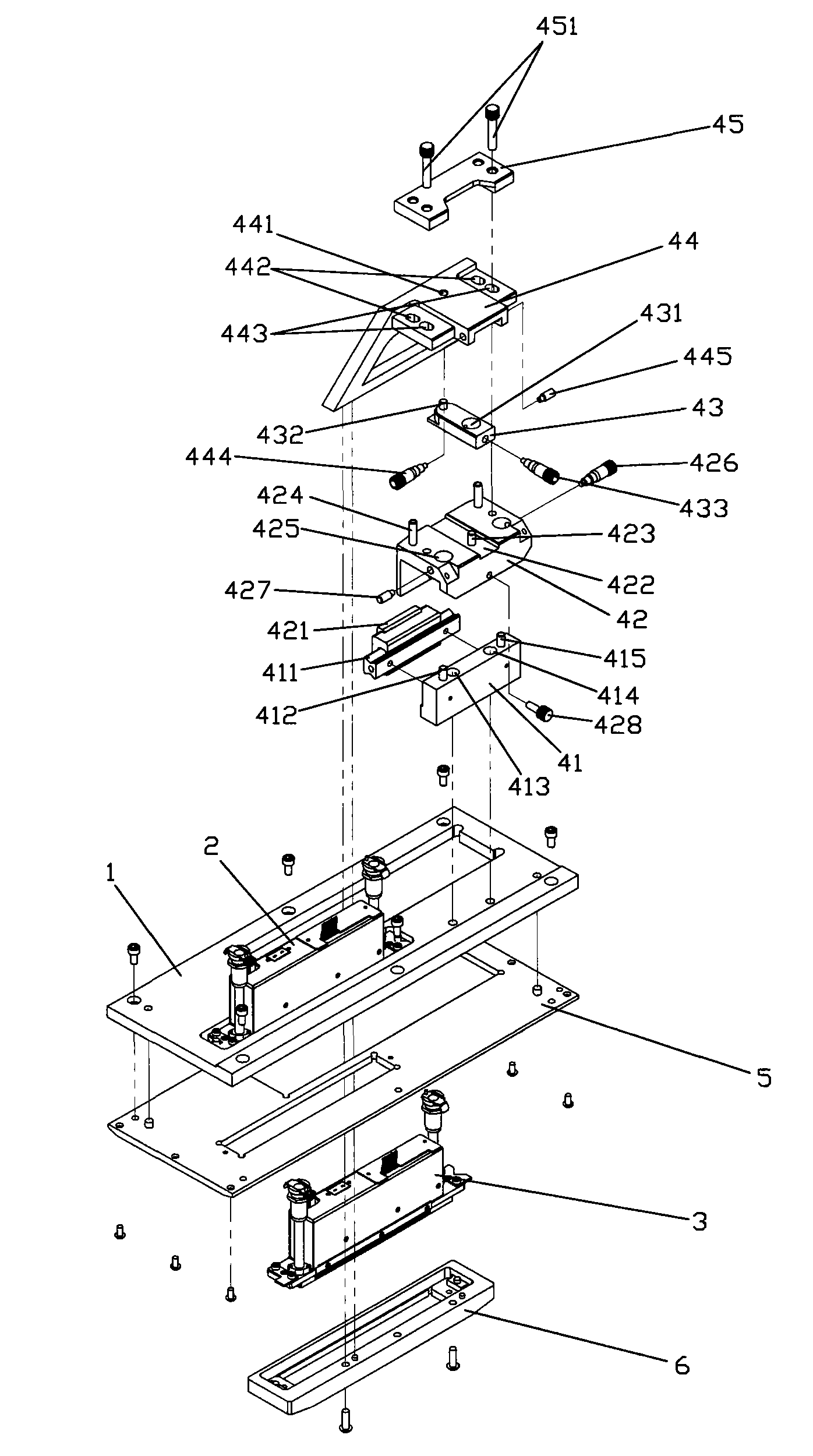

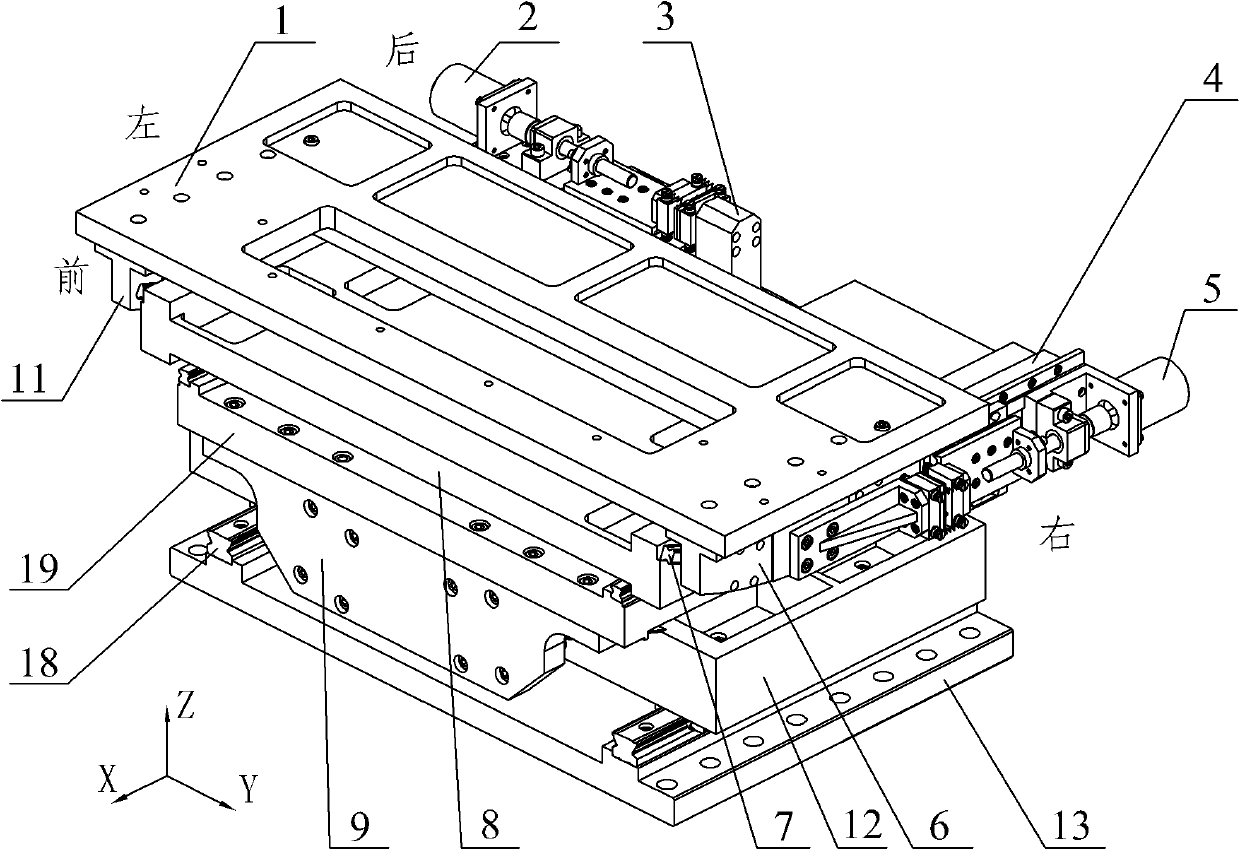

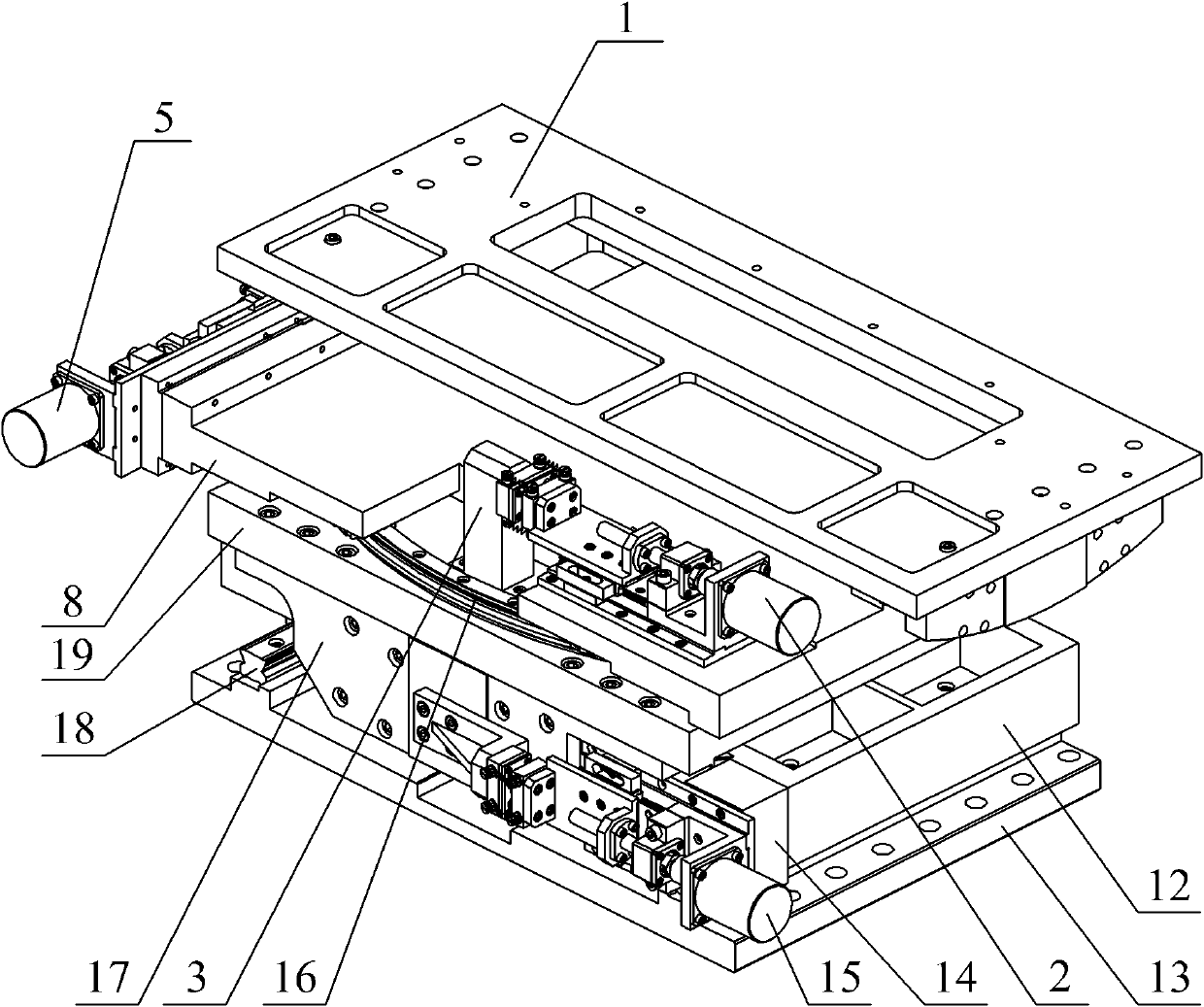

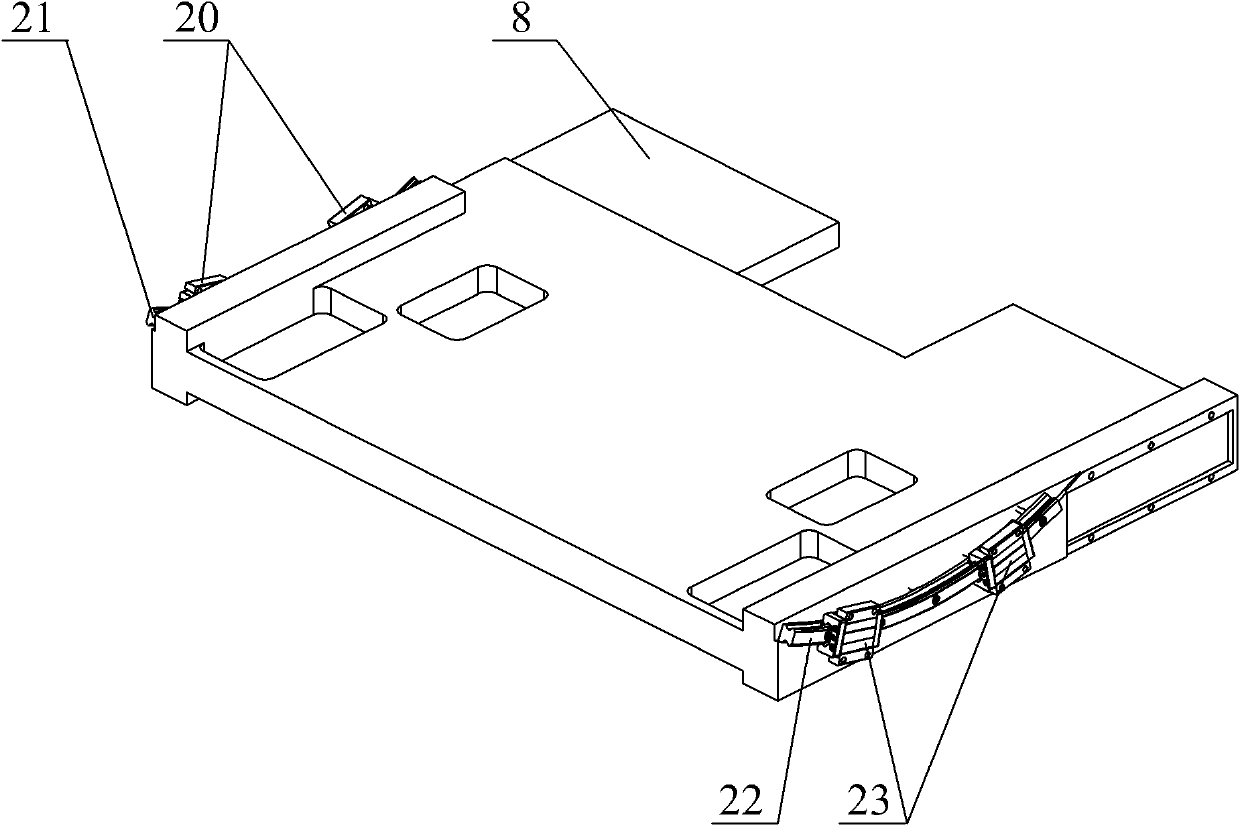

Roundness/cylindricality measurement workbench capable of automatically regulating center and inclination

InactiveCN102102986AImprove adjustment efficiencyRealize the function of automatic centering and tiltingMeasurement devicesEngineeringLinear motor

The invention relates to a roundness / cylindricality measurement workbench capable of automatically regulating center and inclination, which comprises a pedestal fixedly connected with a power shaft, an operating platform for placing a measured workpiece, three support frames, a sensor for measuring the eccentricity of the measured workpiece, and a control computer for receiving an output signal of the sensor and regulating the space position of the operating platform. The output signal of the sensor is transmitted to the control computer; the support frames comprise two telescopic support frames and a fixed support frame, the upper ends of the telescopic support frames are in spherical contact with the operating platform, the lower parts of the telescopic support frames are connected with a Z-axis linear motor, the Z-axis linear motor is fixed on the pedestal, the upper end of the fixed support frame is connected with the operating platform through a Hooke hinge assembly, and the lower part of the fixed support frame is connected with a sliding block assembly; the sliding block assembly is connected with an X-axis linear motor and a Y-axis linear motor respectively; and the X-axis linear motor and the Y-axis linear motor are fixed on the pedestal. The workbench has high regulating efficiency.

Owner:西安威而信精密仪器有限公司

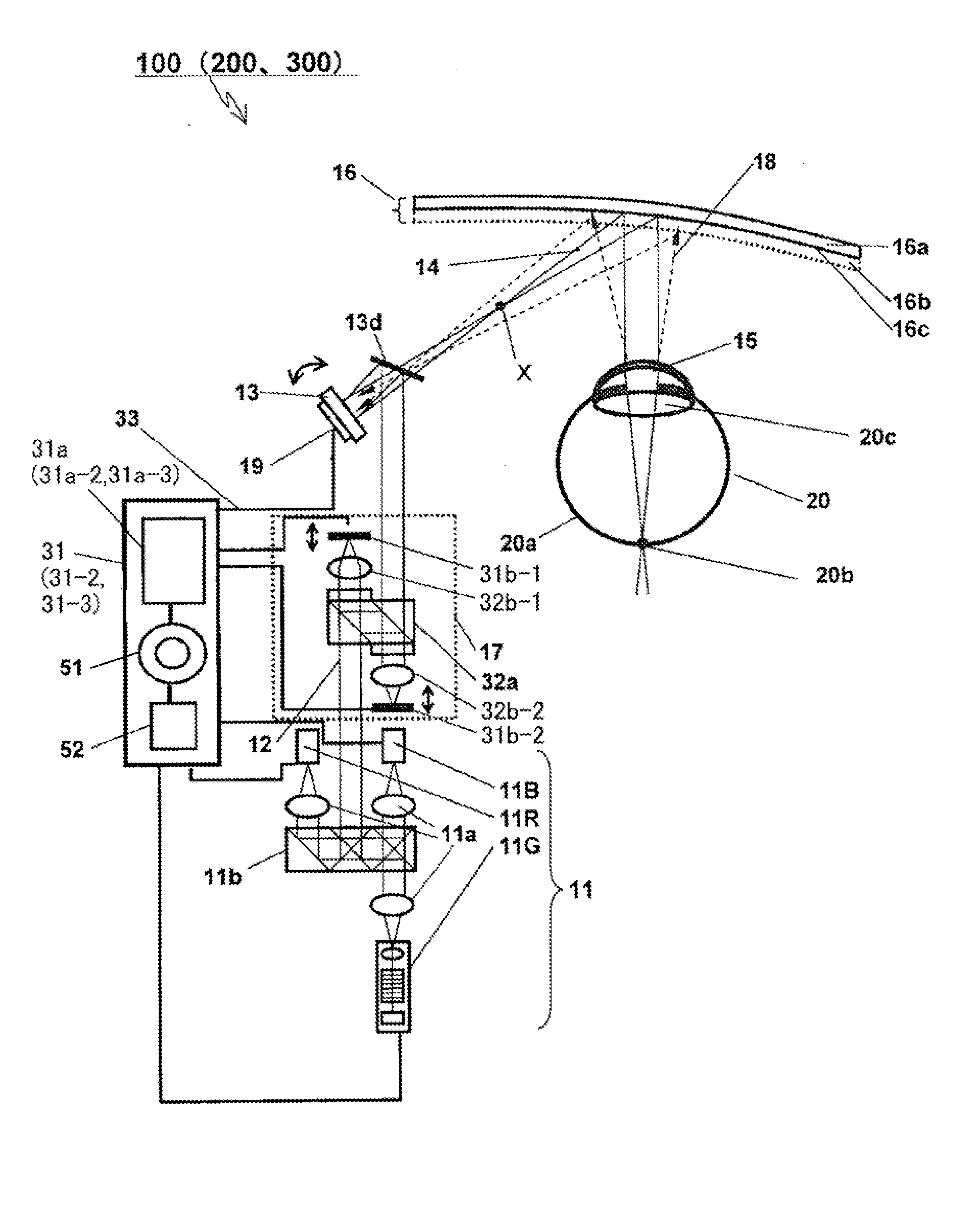

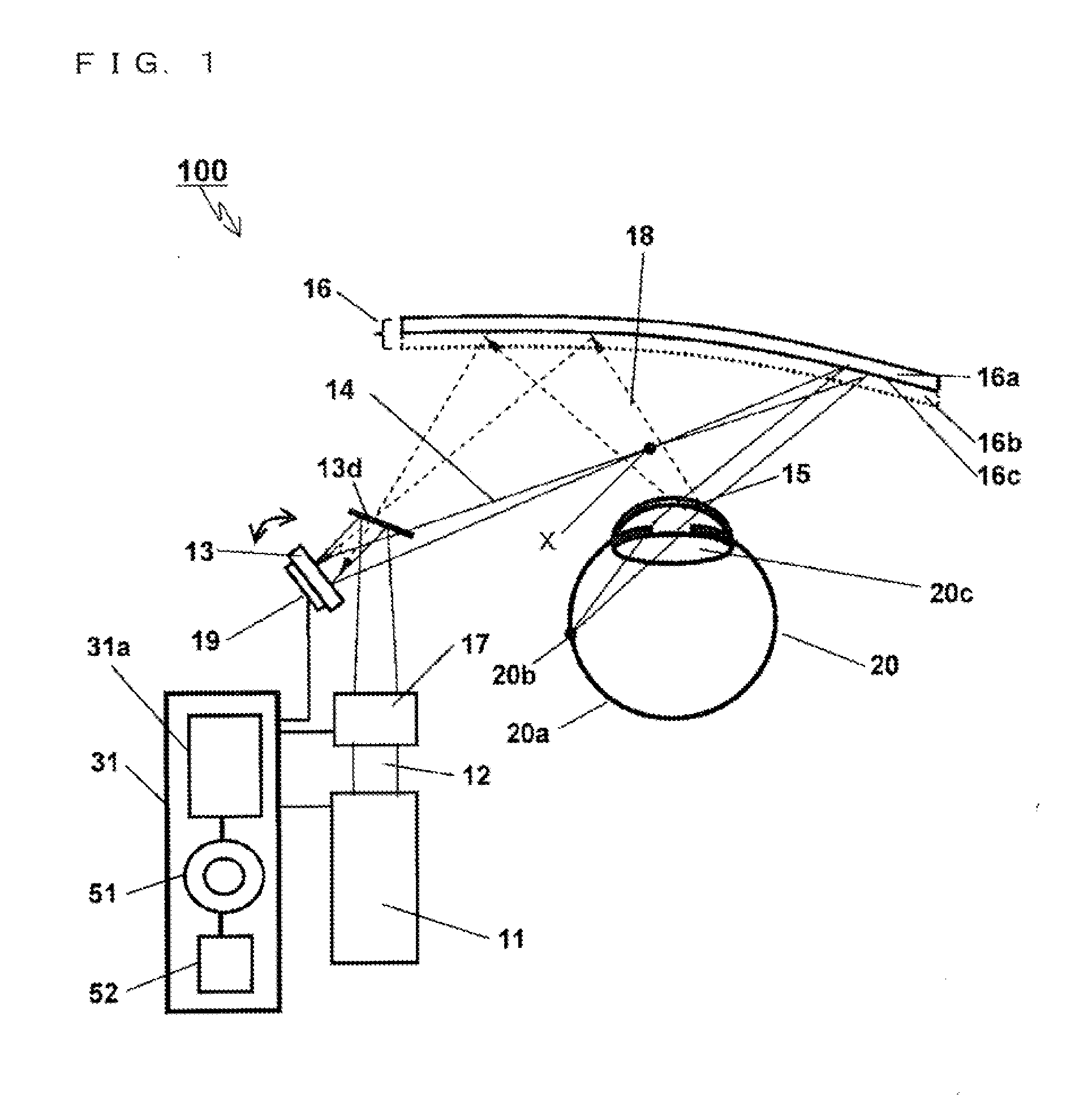

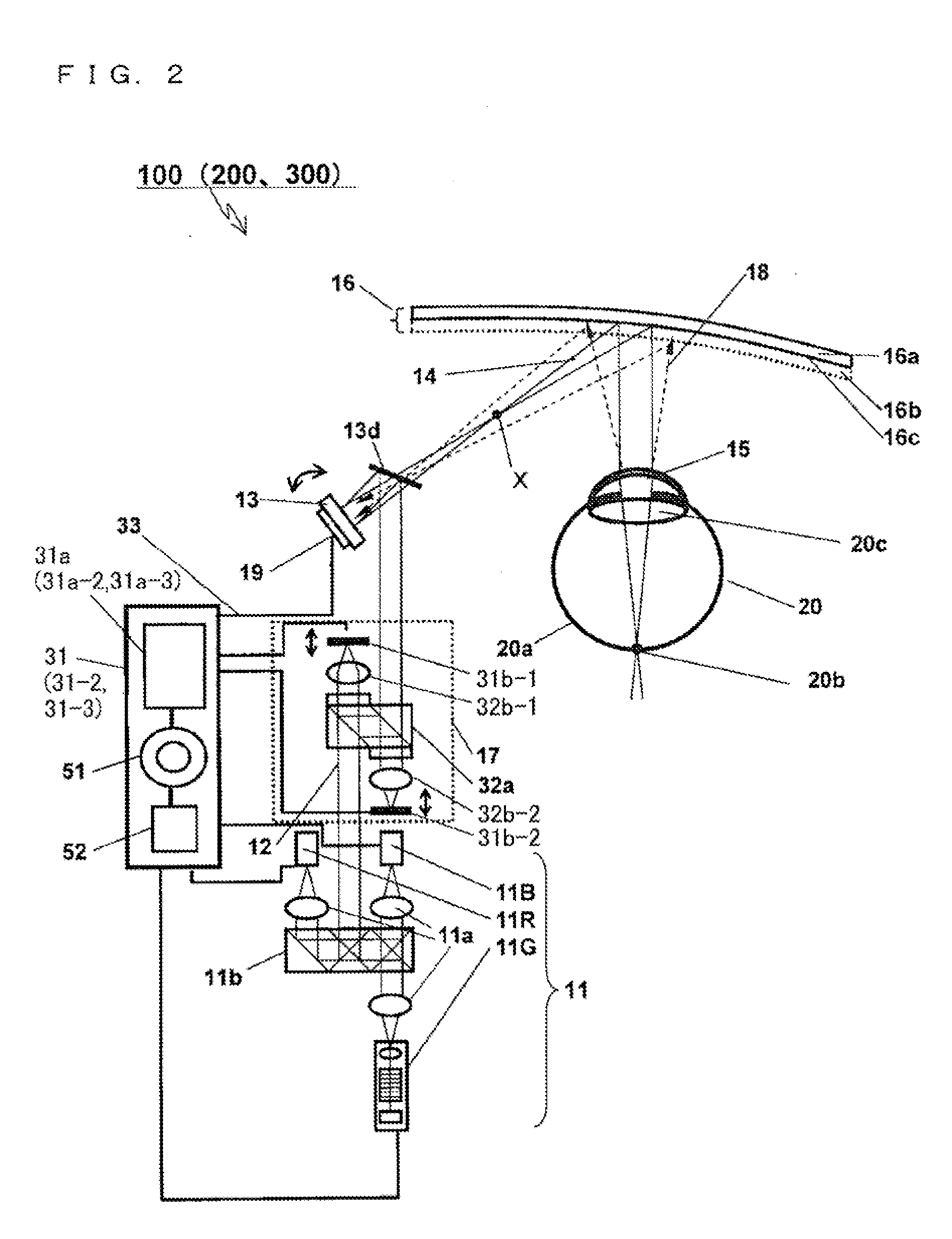

Image display apparatus and image display method

InactiveUS20090316115A1Accurate focus adjustmentEasy to adjustProjector focusing arrangementCamera focusing arrangementImage formationLaser light

An image display apparatus and an image display method, by which a desired image formation state on a retina can be constantly maintained, are provided. Thus, the image display apparatus of the present invention includes a laser light source for emitting laser light; a focus position adjustment section for adjusting a focus position, of the laser light by adjusting a spread angle of the laser light emitted by the laser light source; a scanning section for scanning a predetermined to-be-scanned area by using the laser light adjusted by the focus position adjustment section as scanning light; a light deflection section disposed at the predetermined to-be-scanned area for leading the scanning light to a cornea of the user; a light detection section disposed at a position where the light detection section has an optically conjugate relation with a surface of the cornea through the light deflection section, for detecting a part the scanning light reflected on the surface of the cornea and generating a detection signal; and a control section for controlling the laser light source, the focus position adjustment section, and the scanning section, The control section controls the focus position adjustment section to adjust the focus position of the laser light such that the detection signal generated by the light detection section agrees with an initial setting signal that is set in advance by the light detection section during an initial setting operation.

Owner:PANASONIC CORP

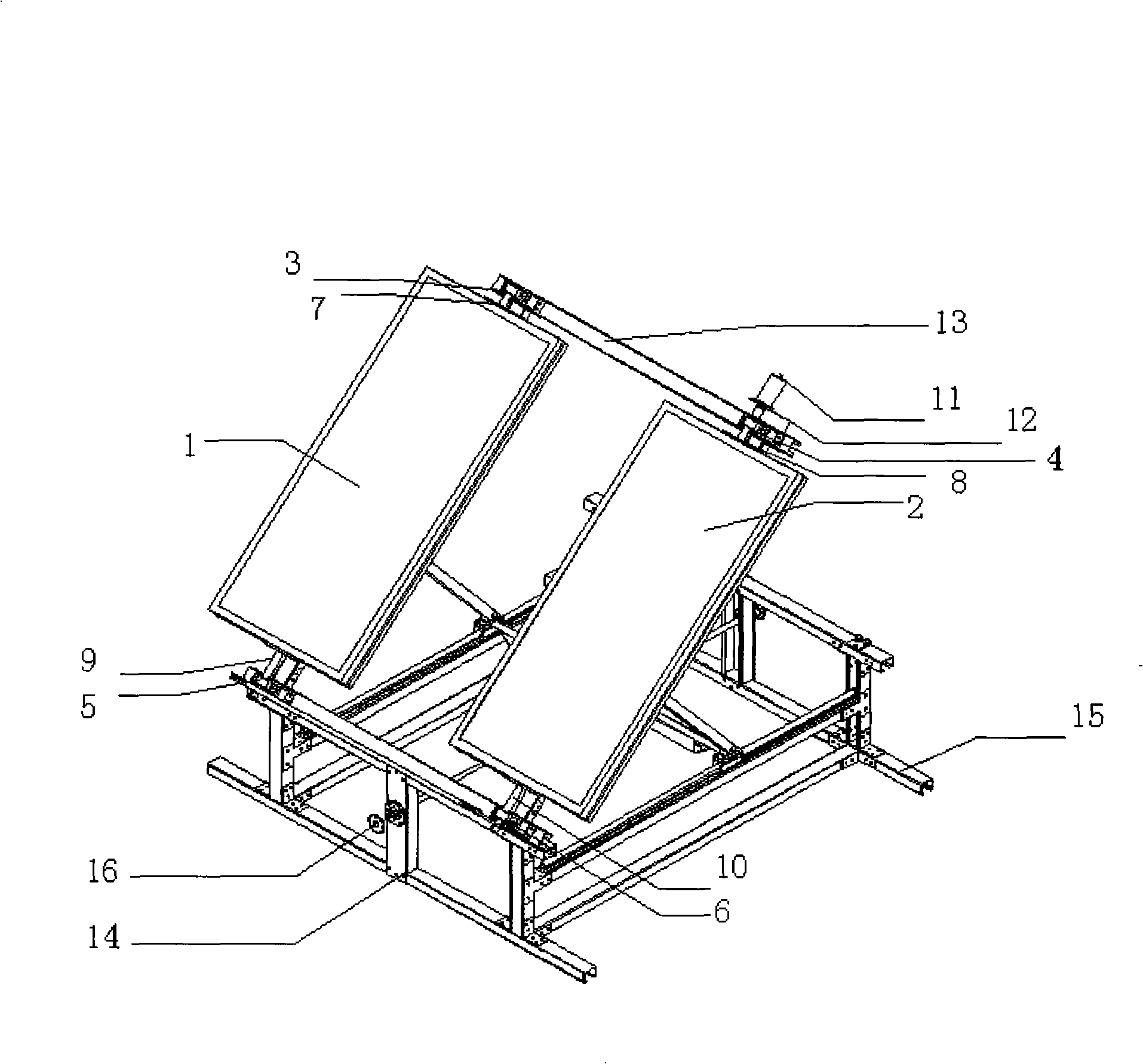

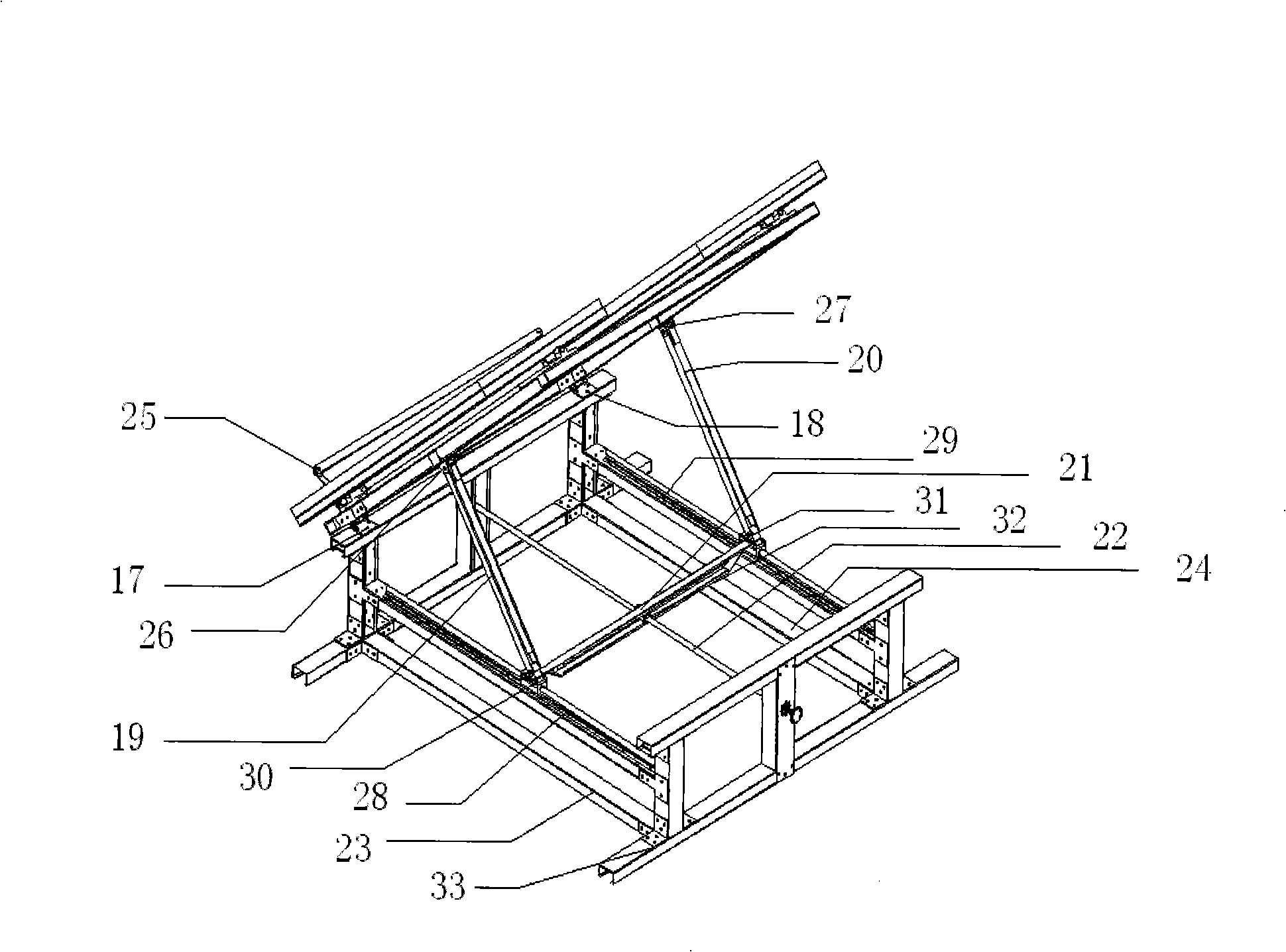

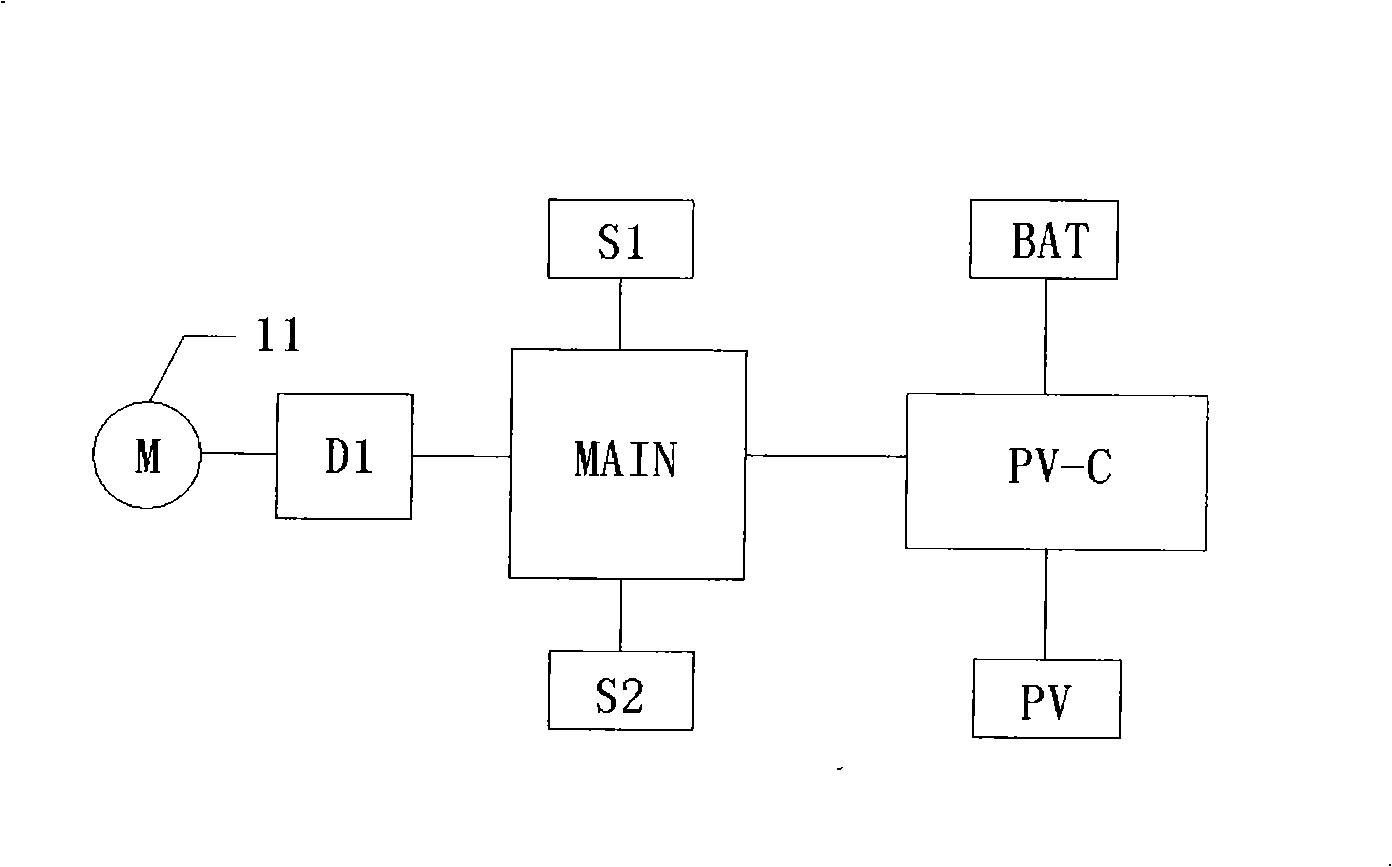

Photovoltaic power generation apparatus capable of automatically tracking sun direction

InactiveCN101345501AEasy accessImprove scalabilityPhotovoltaic supportsPhotovoltaic energy generationEngineeringMotive power

The invention discloses a photovoltaic generation device capable of automatic tracking sun position comprising a sun time-angle tracking unit, an array inclination angle regulating unit, a photovoltaic cell fixedly connected to the upper frame and bearings with holders on the bottom front frame and a motor arranged on a connector on top of the photovoltaic cell, wherein the motor brings along the connector and the photovoltaic cell rotating coaxially under the signal drive, at the same time the left and right sides of the photovoltaic cell are supported by two side frames with a linkage beam connecting to the lower end, a lead screw is crossed between the bottom front frame and the bottom back frame of the bottom frame, when the lead screw rotates under the external motive power action, the linkage beam connected to the lead screw shifts along the sliding guideway, the frames stands or lay down thereupon and the inclination angle of the photovoltaic cell changes correspondingly. The device of the invention can real-timely regulates the rotation angle and inclination angle, has advantages of low cost, easy to expand, simple structure and high control precision.

Owner:CHINA AGRI UNIV

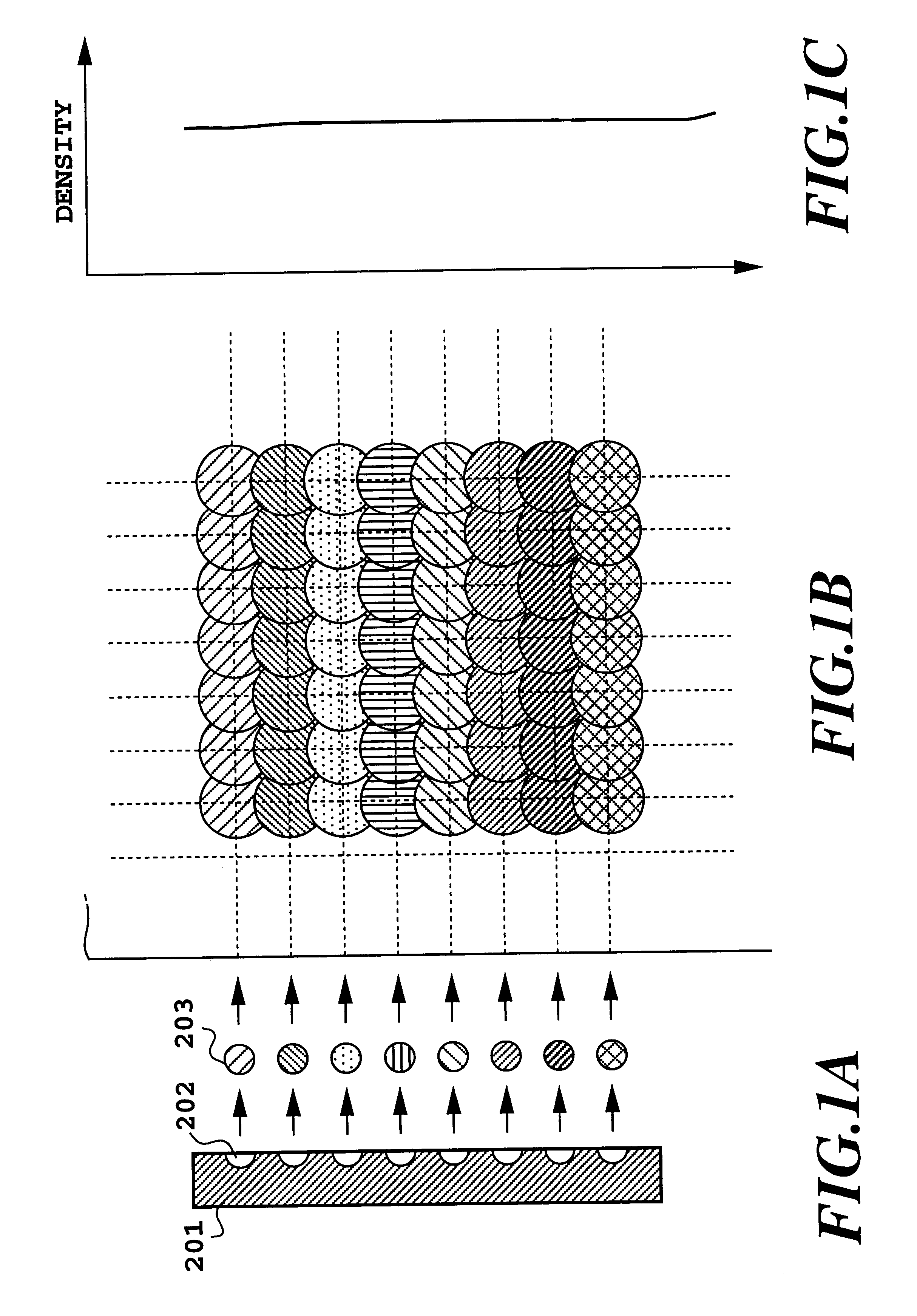

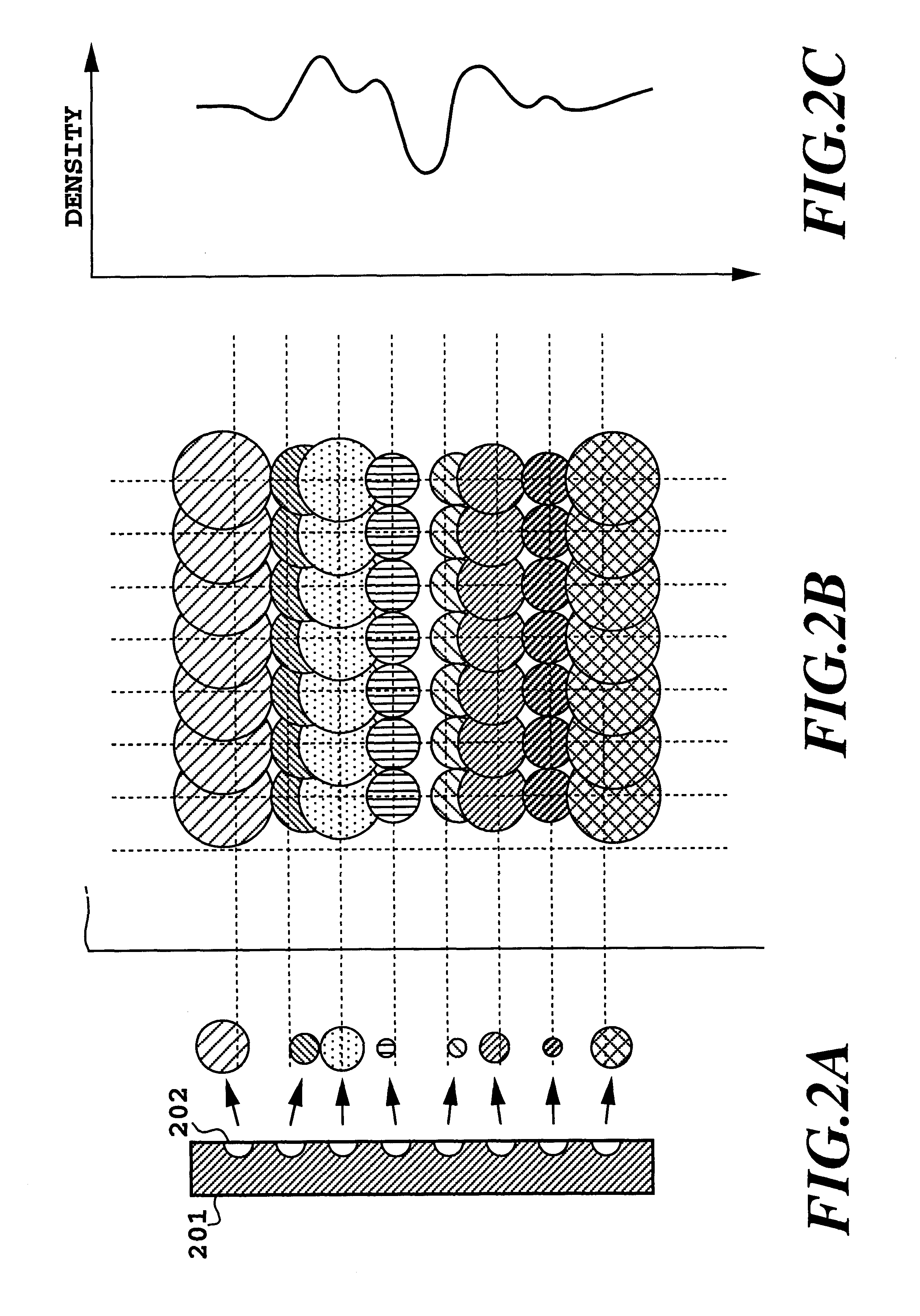

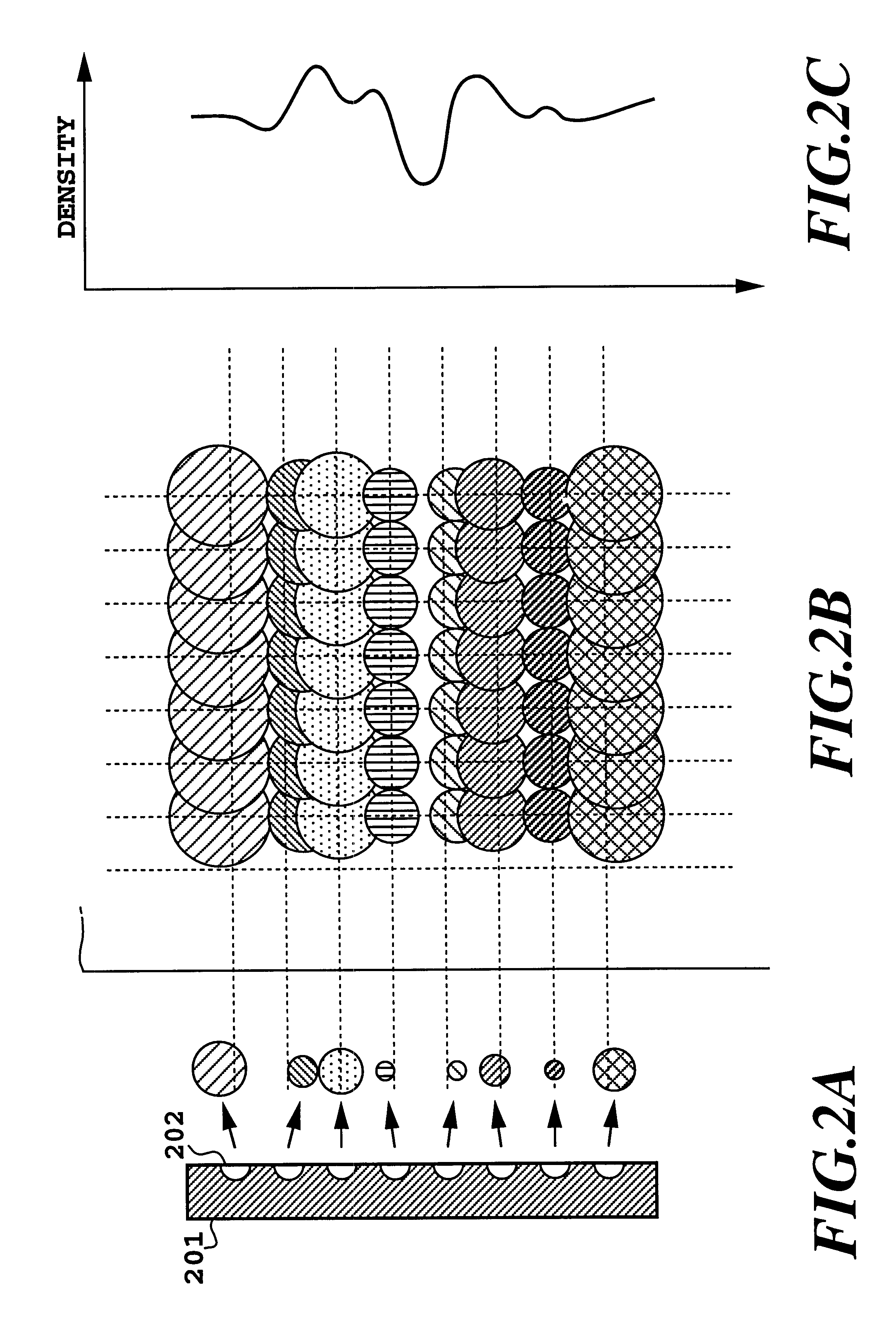

Calibration method for an optical sensor, an adjustment method of dot printing positions using the calibration method, and a printing apparatus

InactiveUS6474767B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusPrinting registrationElectrical and Electronics engineering

In a complimentary printing by bi-directional scanning of a head or by a plurality of heads, a plurality of patterns in which a print start timing is shifted by a predetermined amount are printed with respect to a reference dot formed by the forward scan of the bi-directional scanning or by one of the plurality heads. In these patterns, an area factor by the dots formed by printing of the patterns is designed to be varied depending upon shifting amount. An average density is read from each of the plurality of patterns, optically. The timing at which the maximum one among average densities read from the patterns is obtained, can be set as the printing registration condition. Further, before the above reading operation, an optical sensor used for this operation is calibrated, for improving accuracies of the reading and the registrating. By these processings, printing registration between a forward and a reverse scan of a print head or printing registration between a plurality of print heads in a printing apparatus can be performed simply and with high accuracy.

Owner:CANON KK

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6454390B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusVolumetric Mass DensityEngineering

In a complimentary printing by bi-directional scanning of a head or by a plurality of heads, a plurality of patterns in which a print start timing is shifted by a predetermined amount are printed with respect to a reference dot, e.g. formed by the forward scan of the bi-directional scanning or by one of the plurality heads. In these patterns, an area factor by the dots formed by printing of the patterns is designed to be varied depending upon shifting amount. An average density is read from each of the plurality of patterns, optically. The timing at which the maximum one among average densities read from the patterns is obtained, can be set as the printing registration condition. Further, a processing including a coarse adjustment to a fine adjustment is performed in a series of algorithm. By these processings, printing registration between a forward and a reverse scan of a print head or printing registration between a plurality of print heads in a printing apparatus can be performed simply and with high accuracy, without operating by a user.

Owner:CANON KK

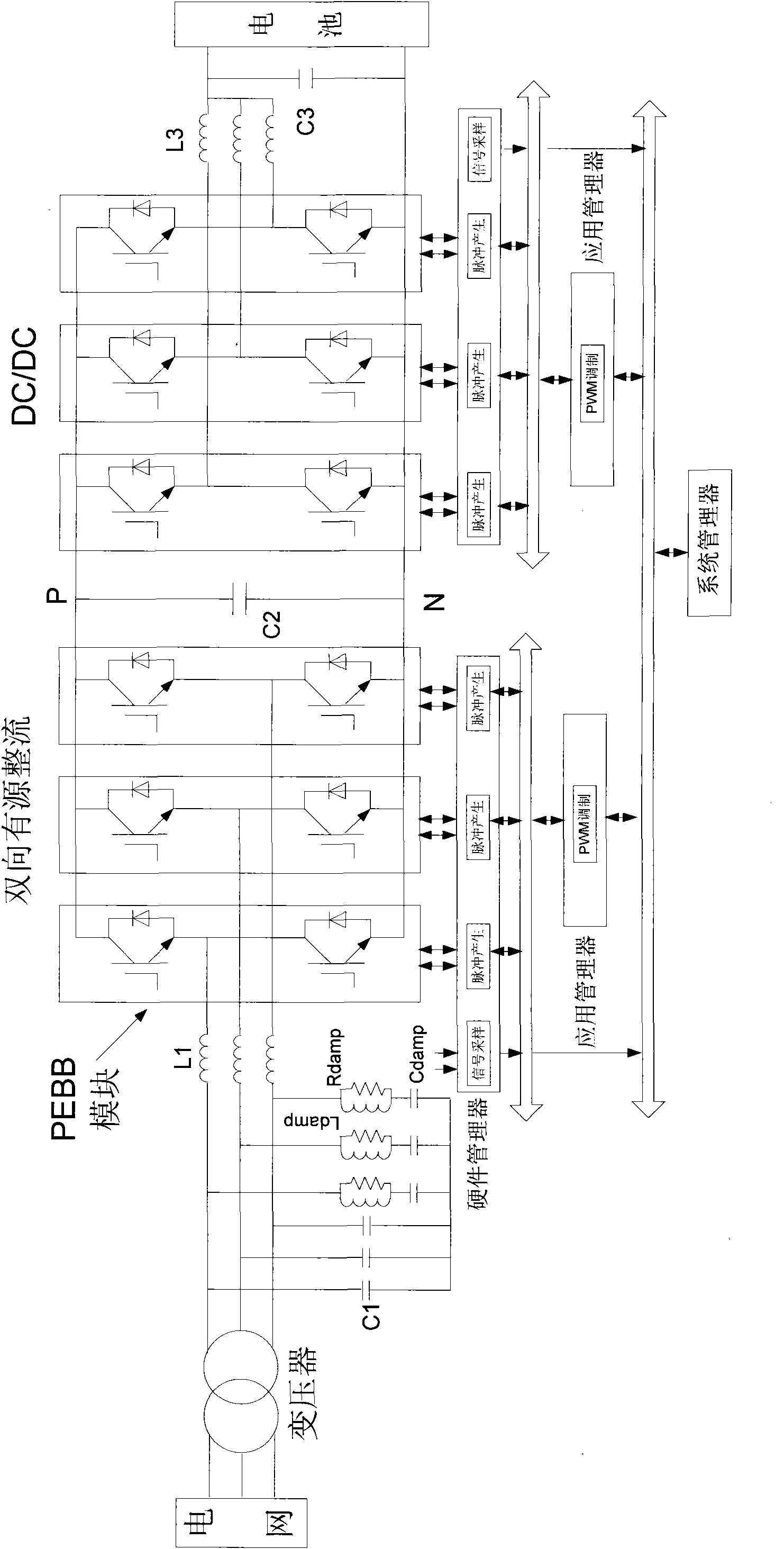

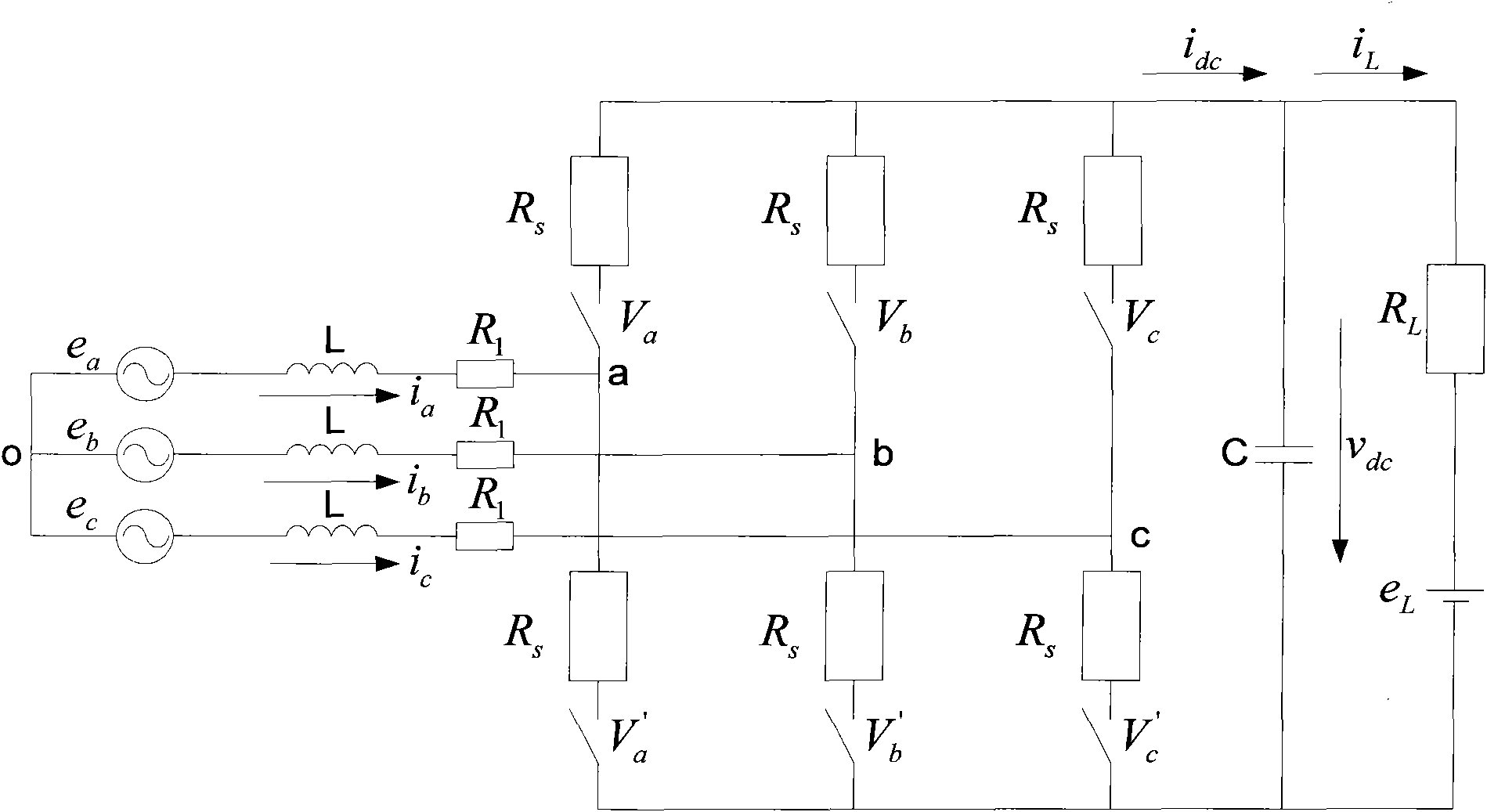

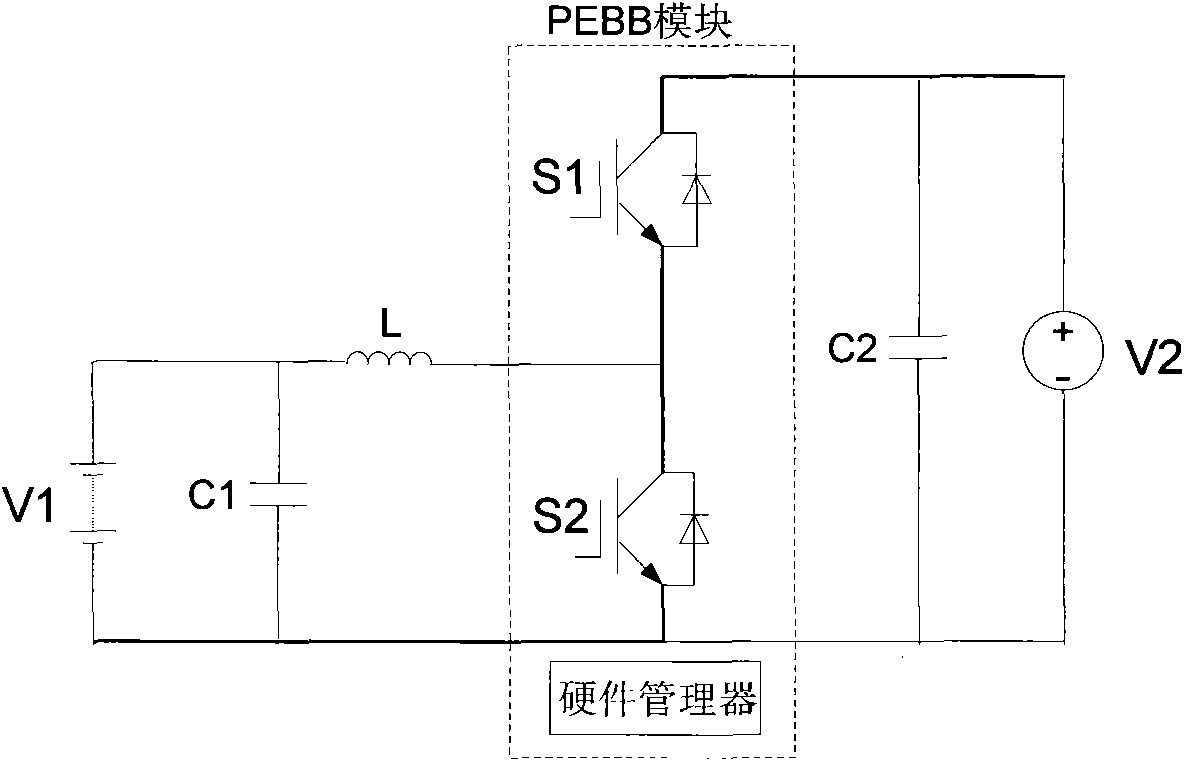

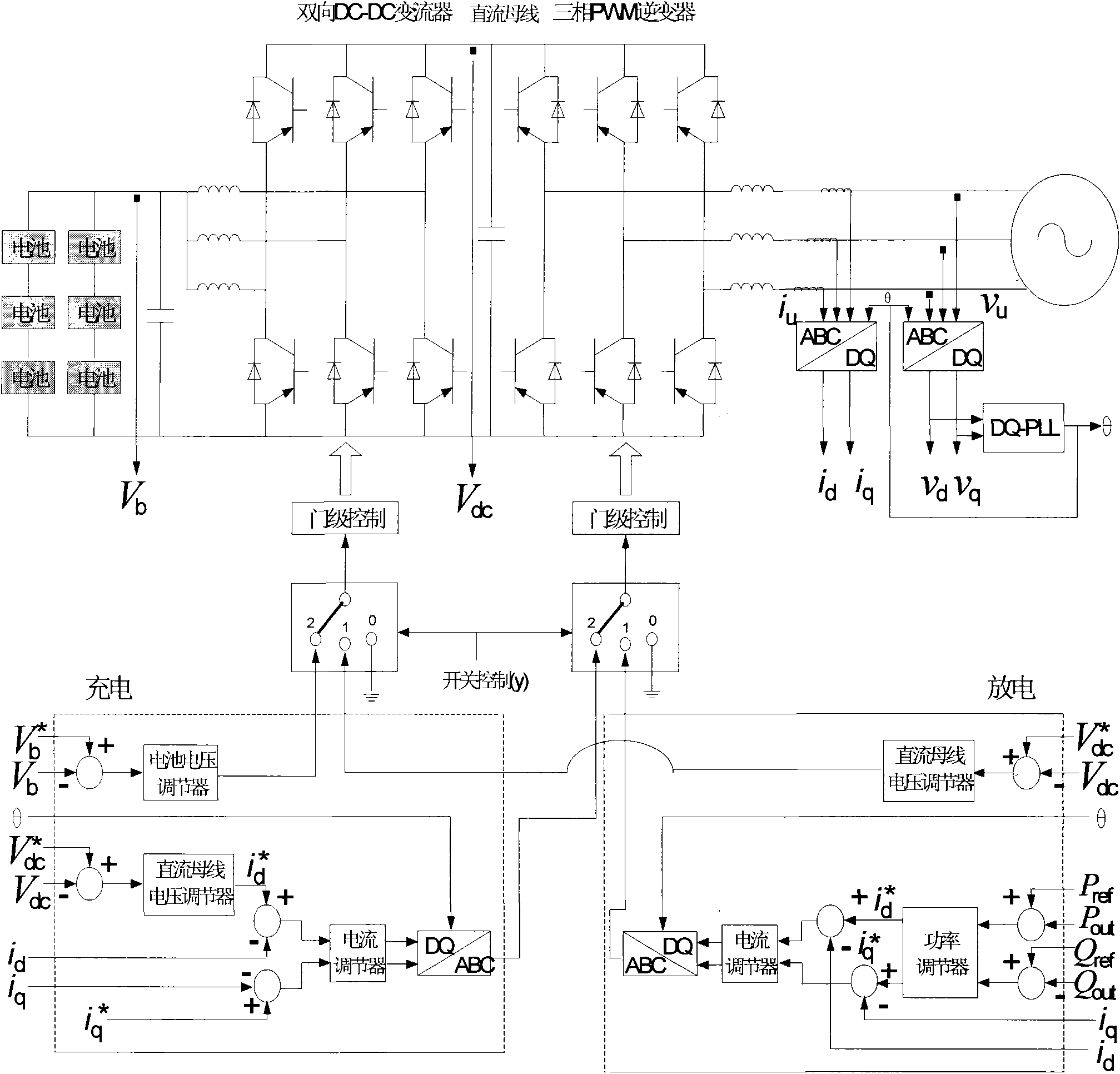

Power supply topology structure of electric automobile bidirectional charger

InactiveCN101814766ASimple designHigh response speed and adjustment accuracyBatteries circuit arrangementsAc-dc conversionModularityDc converter

The invention relates to a main circuit topology structure of an electric automobile bidirectional charger converter based on a power electronic module, which comprises a bidirectional four-quadrant AC / DC converter module, a bidirectional DC / DC converter module and a control system. The control system comprises two identical general controllers for respectively controlling the converter process of the AC / DC converter module and the DC / DC converter module. The invention enables the converter to have compact hardware structure and greatly improved universality, reliability and modularity degree.

Owner:CHINA ELECTRIC POWER RES INST +1

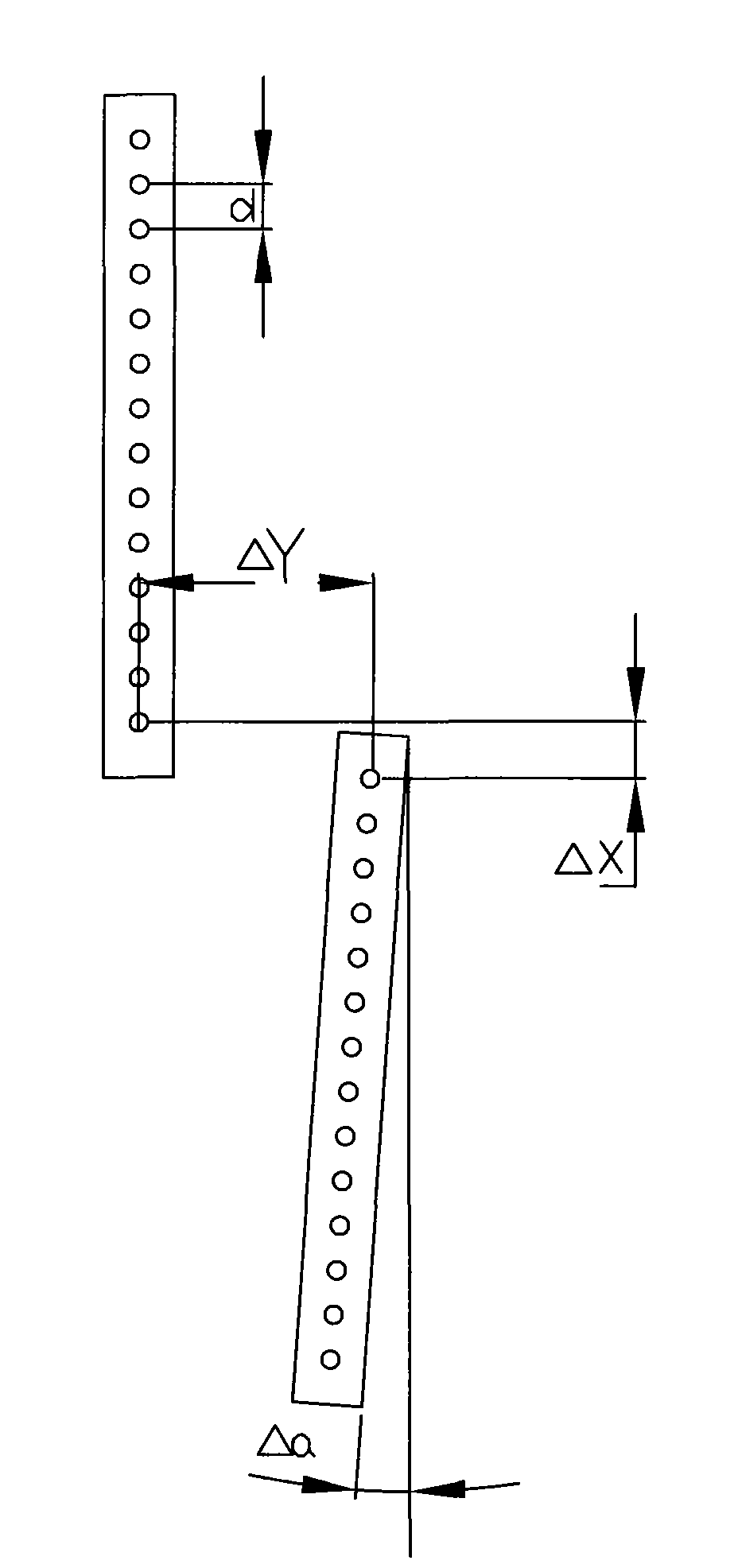

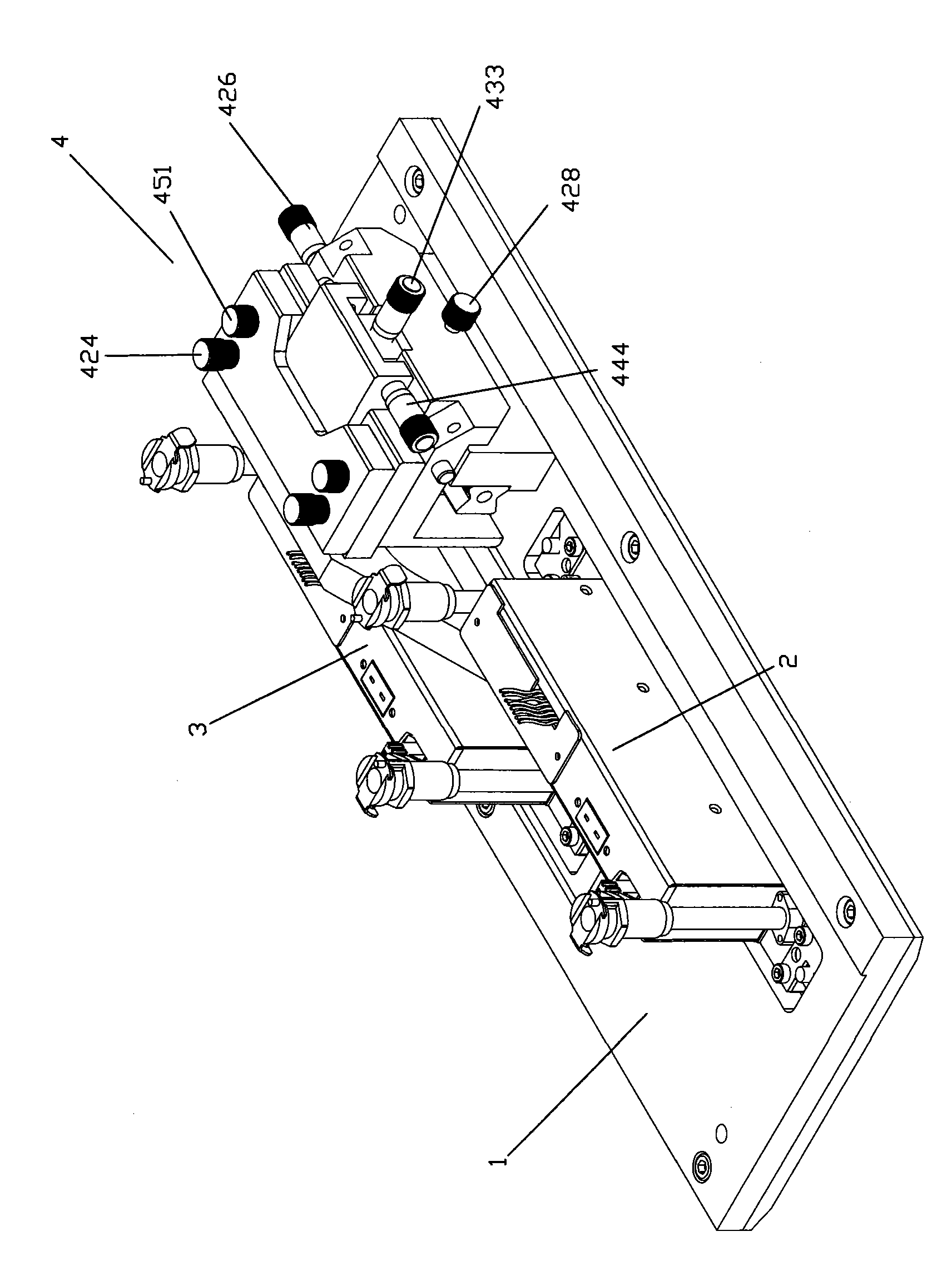

Mechanism for mounting and adjusting spray heads of inkjet printer

InactiveCN101863165AGuaranteed accuracyHigh adjustment accuracyPower drive mechanismsEngineeringMechanical engineering

The invention discloses a mechanism for mounting and adjusting spray heads of an inkjet printer. The mechanism comprises a base plate and an adjusting mechanism, wherein the base plate is provided with at least two spray head mounting positions; each spray head mounting position is provided with a fixed spray head or a movable spray head; the fixed spray head is fixedly arranged on the spray head mounting position; the movable spray head is connected with the adjusting mechanism; and the adjusting mechanism adjusts the transverse and longitudinal relative positions between the spray heads and adjusts the angle between the spray heads by controlling the movement of the movable spray head. The mechanism for mounting and adjusting the spray heads of the inkjet printer has a simple structure and high adjustment accuracy, can adjust the spray heads in a plurality of directions, and is convenient to mount and maintain.

Owner:BEIJING MEIKEYI

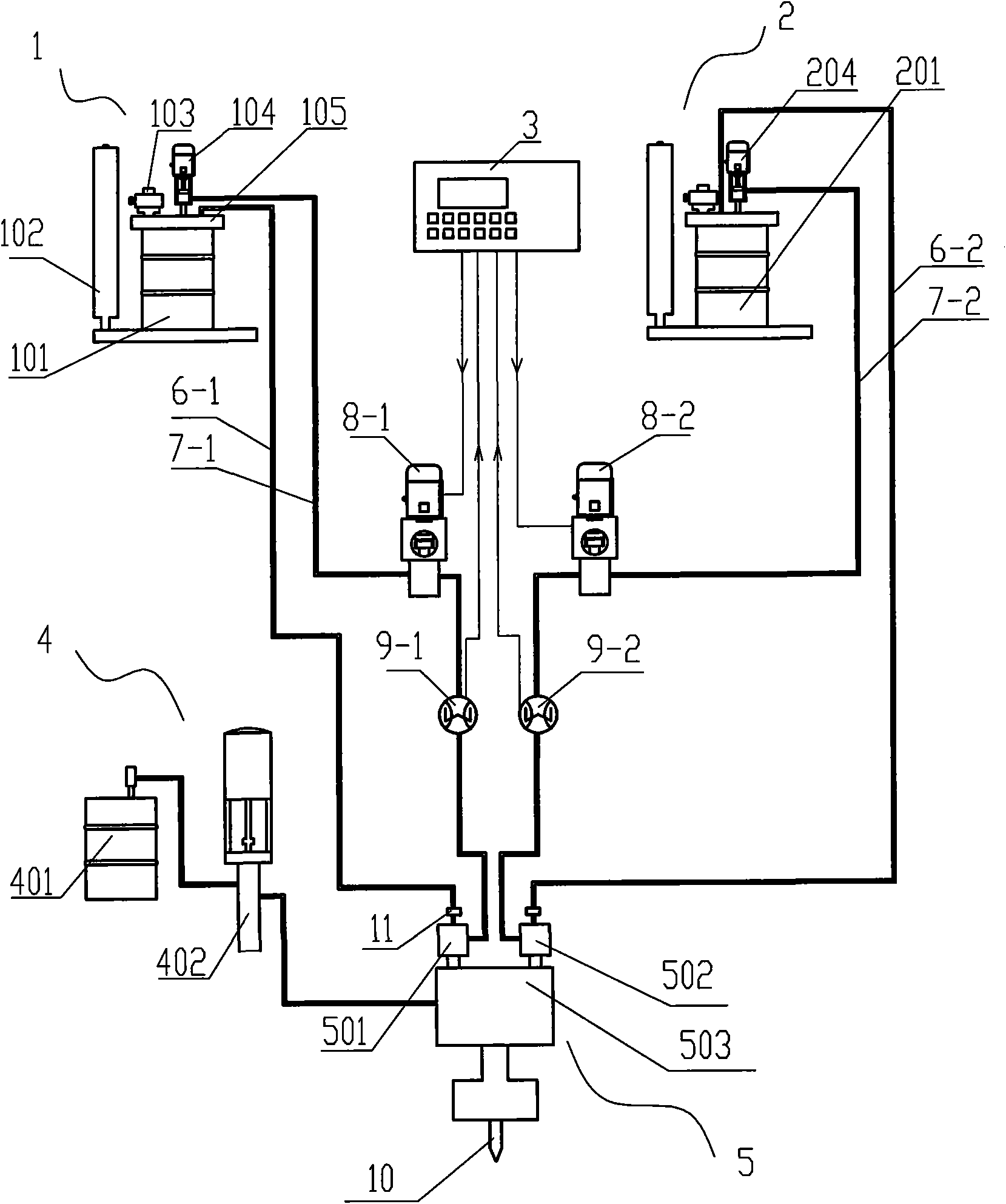

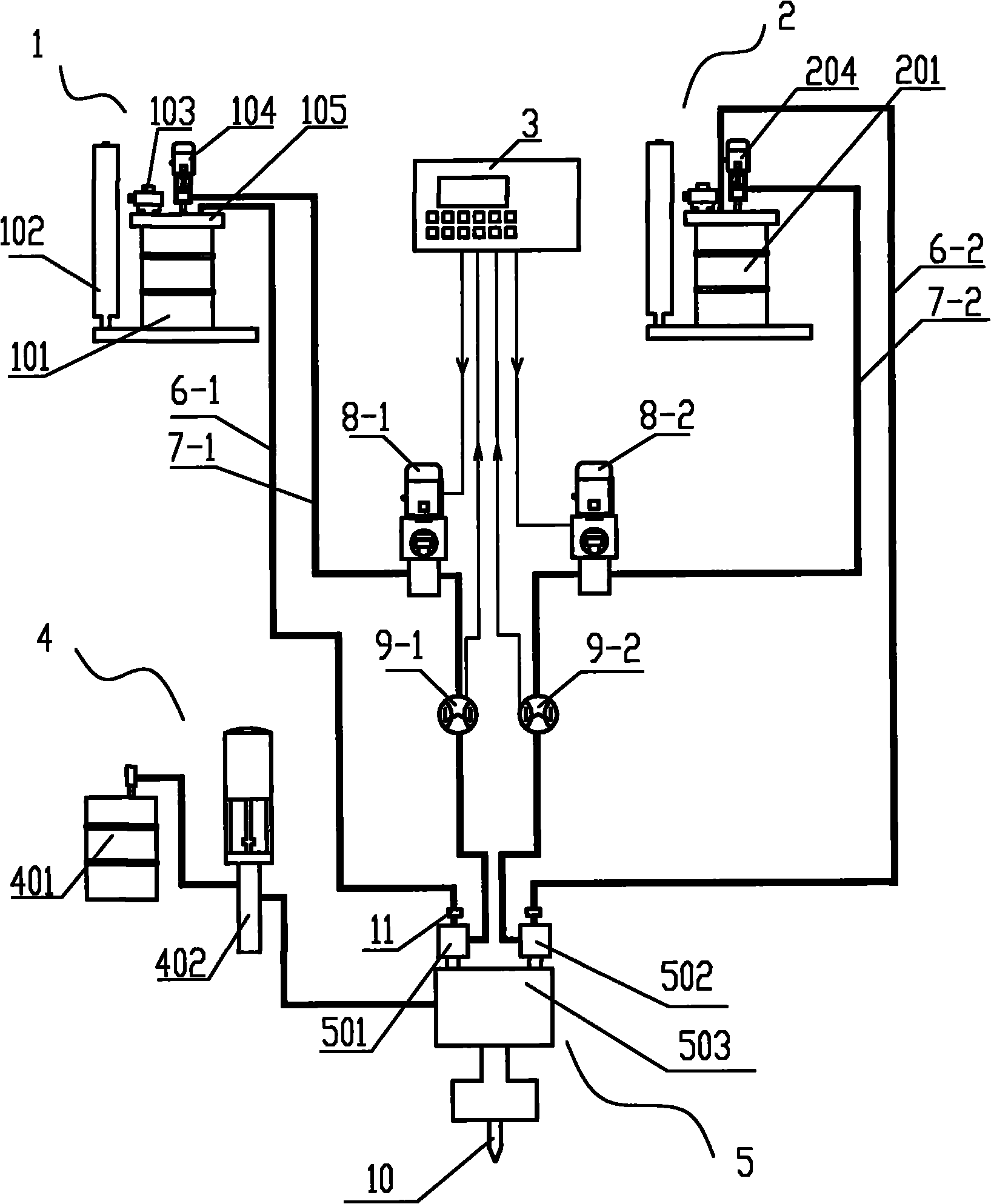

Two-component spraying system

InactiveCN101850312AHigh trafficWide range of proportional adjustmentLiquid spraying apparatusProgrammable logic controllerEngineering

The invention discloses a two-component spraying system which comprises a first material conveying system, a second material conveying system and a spray gun, wherein the structure of the first material conveying system is identical to that of the second material conveying system; a discharge port of a first material conveying pump of the first material conveying system is communicated with a mixing device through a first material conveying pipe; a first gear pump and a first flow meter are sequentially arranged on the first material conveying pipe; the output end of the mixing device is connected with the spray gun; the output end of a programmable logic controller (PLC) is respectively connected with the control ends of the first gear pump and a second gear pump; and the output ends of the first flow meter and a second flow meter are respectively connected with the input end of the PLC. In the invention, the PLC and the flow meters are used for accurately controlling the flow and the ratio of two-component coatings, and the flow and the ratio are automatically regulated by utilizing programs; and the ratio regulation range of two components is wider.

Owner:河北新兴铸管有限公司

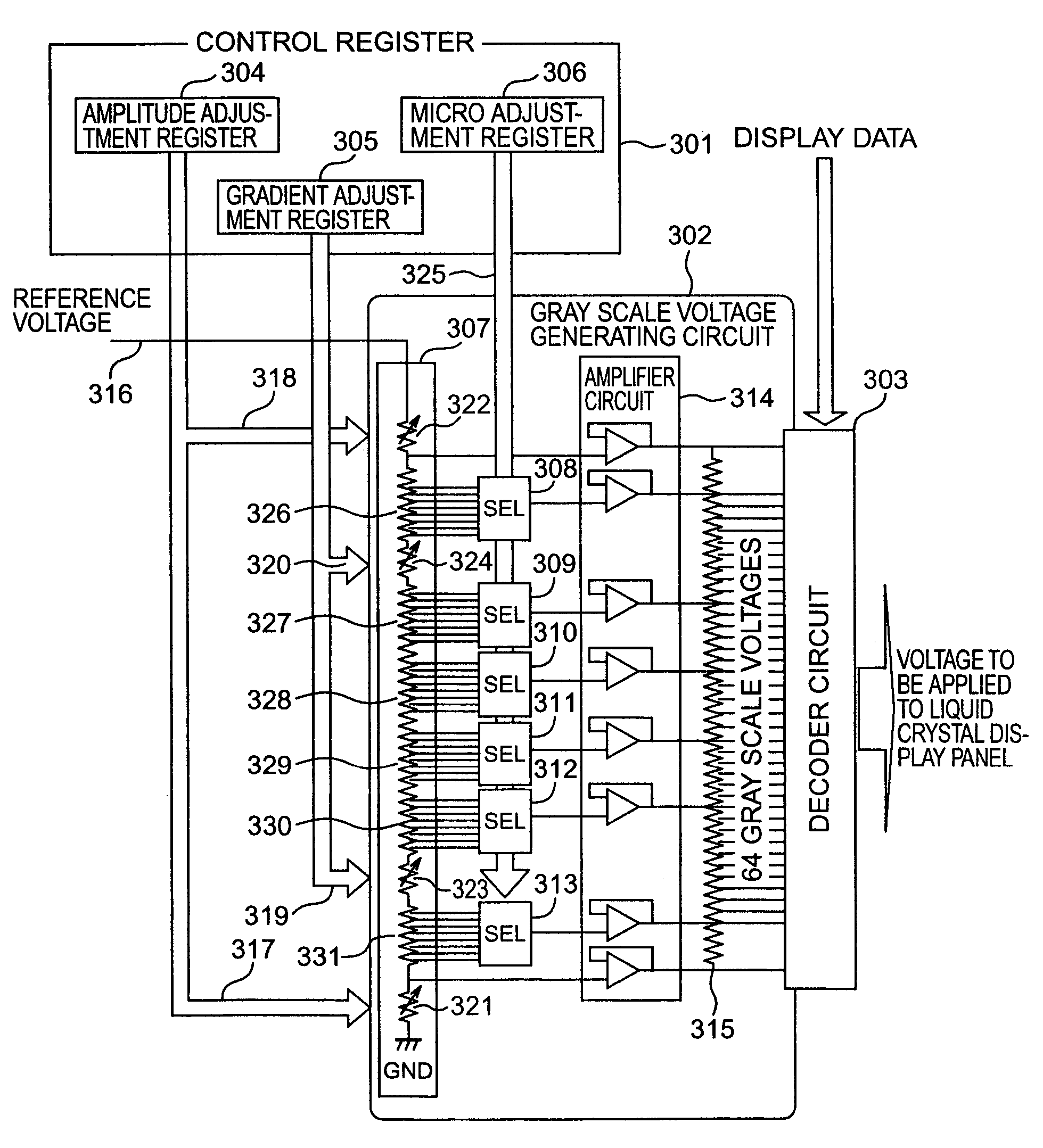

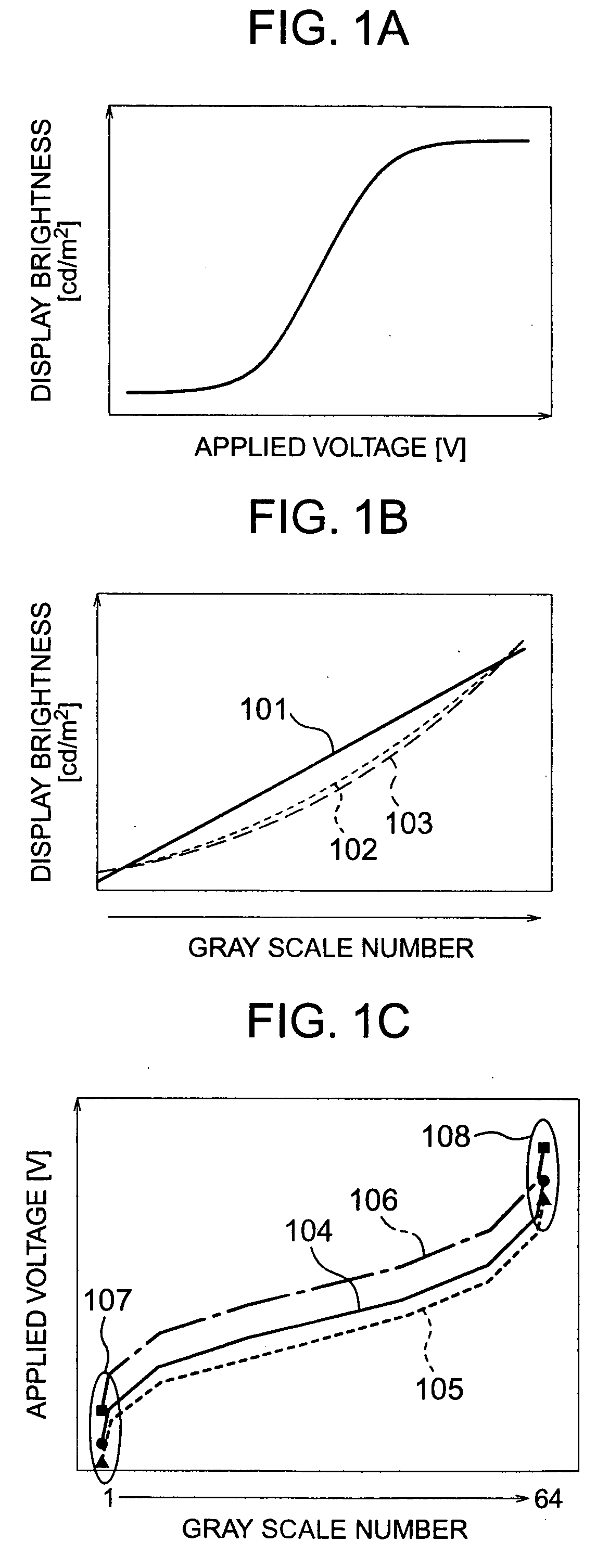

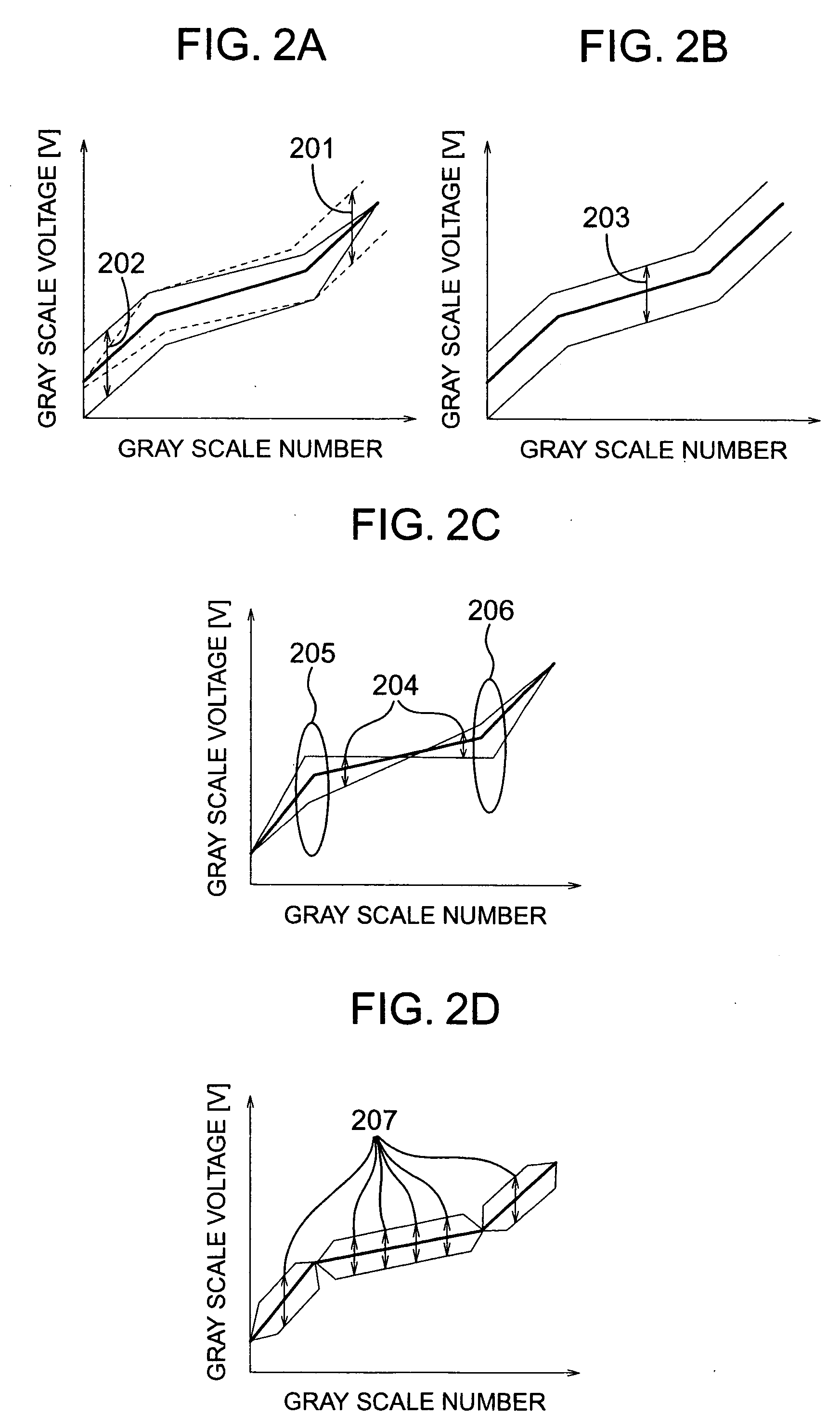

Display apparatus and driving device for displaying

InactiveUS20050200584A1High adjustment accuracyImprove image qualityTelevision system detailsCathode-ray tube indicatorsDisplay deviceVoltage reference

A driving display device includes a gray scale voltage generating circuit for generating a plurality of levels of gray scale voltages from a reference voltage, an amplitude adjustment register capable of setting the amplitude of a characteristic curve of a plurality of levels of the gray scale voltages with respect to gray scale numbers, and a gradient adjustment register capable of setting the gradient of the characteristic curve. With this arrangement, the gradient and amplitude of the gray scale number-gray scale voltage characteristic are adjusted.

Owner:RENESAS ELECTRONICS CORP

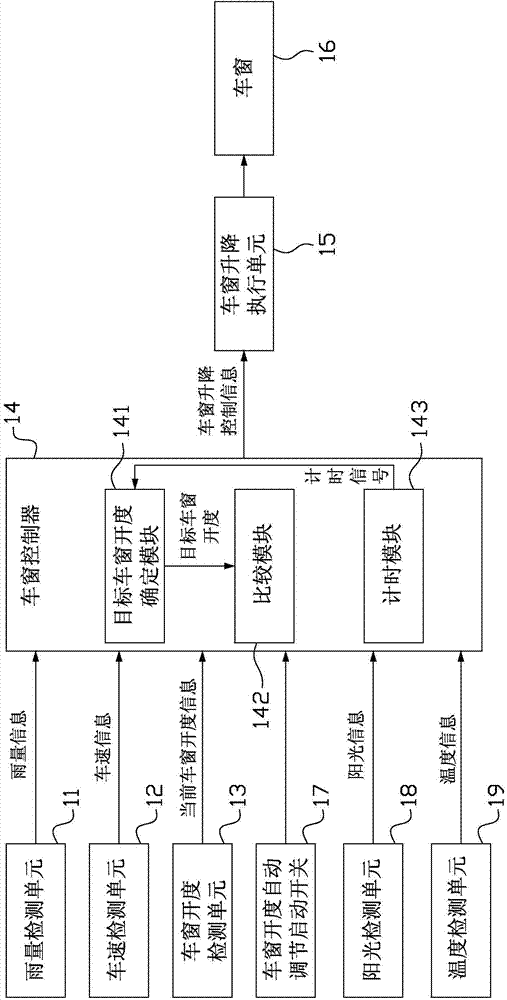

System for automatically controlling opening degree of automobile window

ActiveCN103786667AHigh adjustment accuracyImprove comfort experienceElectric/fluid circuitControl systemExecution unit

A system for automatically controlling the opening degree of an automobile window is used or automatically regulating the opening degree of the automobile window so as to control wind dryness when an automobile runs with the automobile window opened. The control system comprises a rainfall detection unit, an automobile speed detection unit, a unit for detecting the opening degree of the automobile window, an automobile window controller, an automobile window lifting executing unit and the automobile window, wherein the rainfall detection unit is used for detecting information of rainfall outside the automobile, the automobile speed detection unit is used for detecting the speed information of the automobile, the unit for detecting the opening degree of the automobile window is used for detecting the current opening degree information of the automobile window, the automobile window controller is used for receiving the rainfall information, the automobile speed information and the current opening degree information of the automobile window, the target opening degree of the automobile window is obtained according to the rainfall information and the automobile speed information, and the lifting control information of the automobile window is output to the automobile window lifting executing unit after the target opening degree of the automobile window is compared with the current opening degree information of the automobile window; the automobile window lifting executing unit automatically lifts the automobile window up and down according to the lifting control information of the automobile window, and the automobile window can be lifted to the target opening degree of the automobile window.

Owner:山西吉利汽车部件有限公司

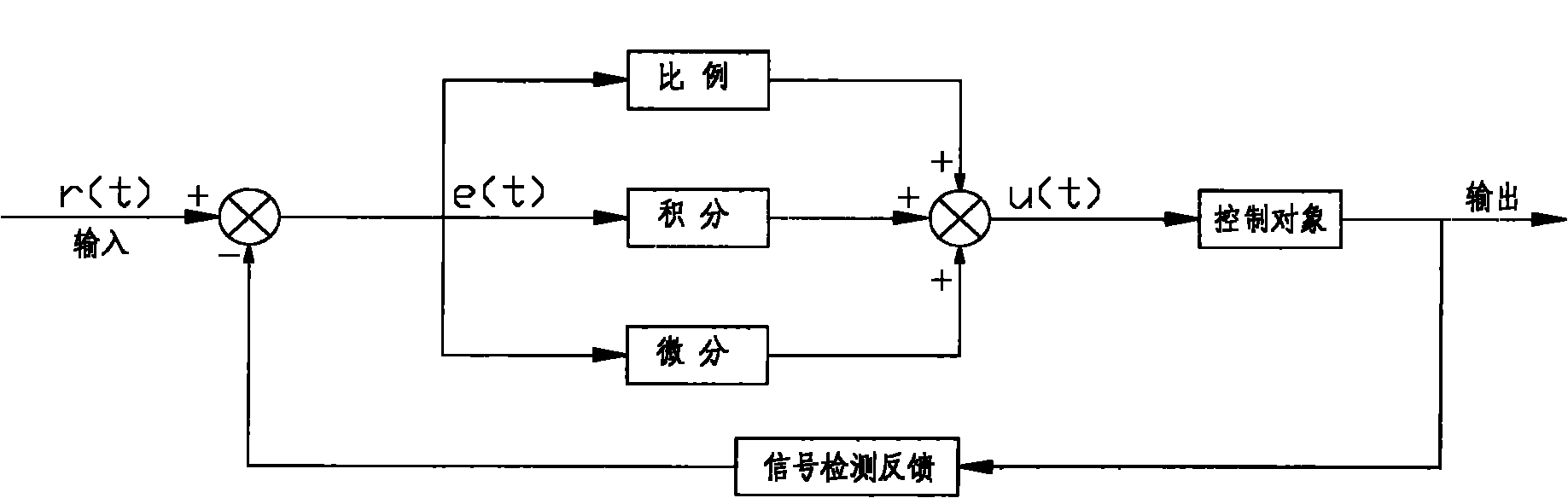

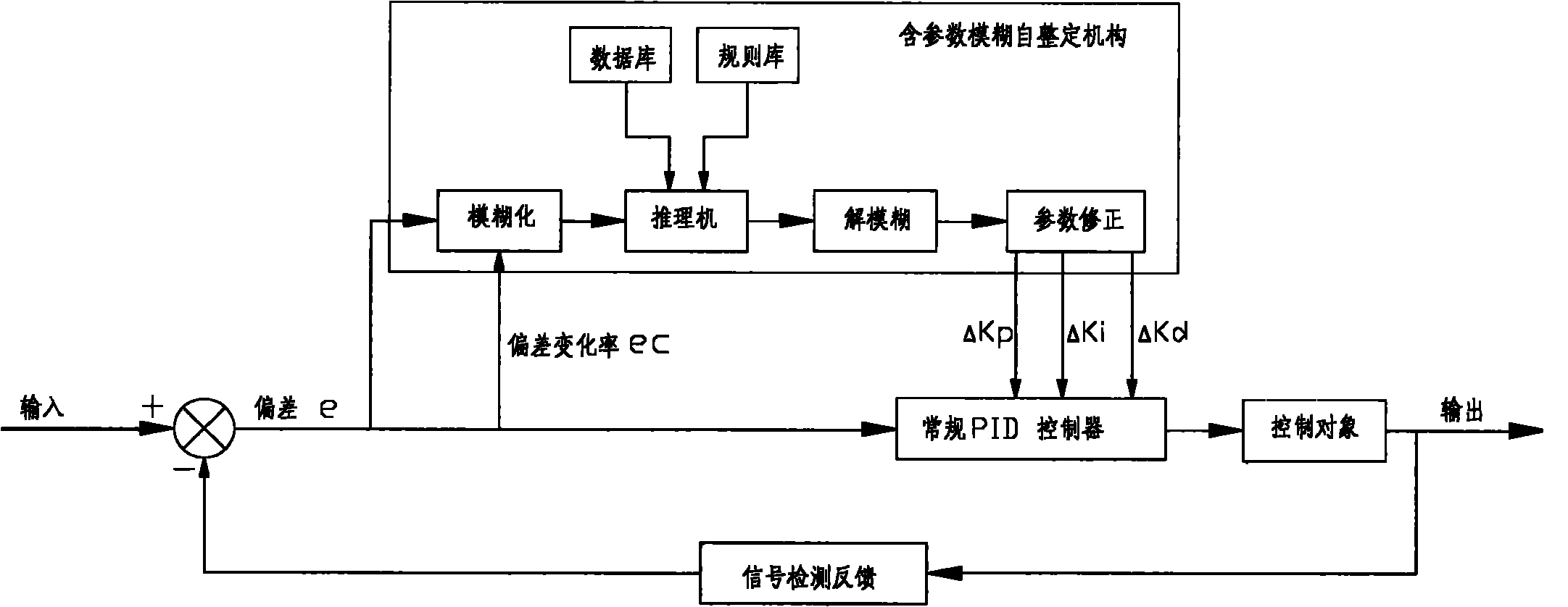

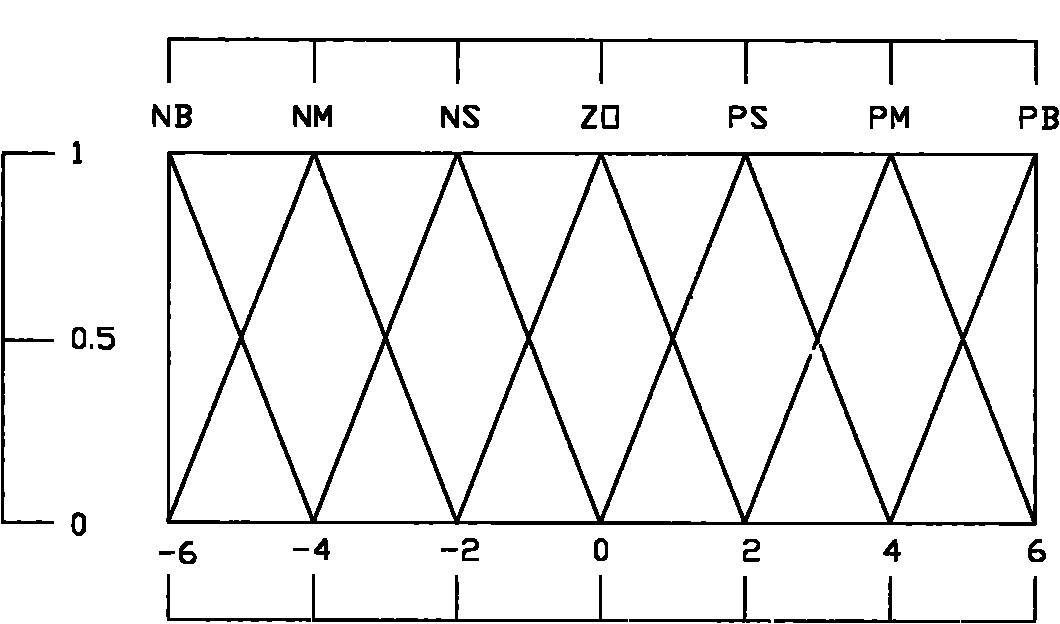

Fuzzy proportion integration differentiation (PID) control method and device for industrial environment high-precision air conditioner

InactiveCN102032640AHigh adjustment accuracyHigh precisionSpace heating and ventilation safety systemsLighting and heating apparatusIndustrial settingControl circuit

The invention discloses a fuzzy proportion integration differentiation (PID) control method and a fuzzy PID control method device for an industrial environment high-precision air conditioner. The method comprises the following steps of: selecting an input quantity of a fuzzy PID controller as a deviation e between an expected value and an actual output and a deviation change rate ec, and establishing a bivariate continuous function relation between parameters Kp, Ki and Kd and the absolute value of the deviation and the absolute value of the deviation change, wherein output quantities are the correction quantities delta Kp, delta Ki and delta Kd of the PID parameters; and determining a fuzzy relation between the three PID parameters and the deviation e and the deviation change rate ec, continuously detecting e and ec in operation, adjusting the three parameters on line according to a fuzzy control theory to obtain adjusted Kp, Ki and Kd, and inputting Kp, Ki and Kd into the PID controller. The control device comprises a fuzzy control circuit on a circuit board, wherein a self-setting mechanism circuit for setting the parameters on line is also arranged on the fuzzy control circuit. The precision of the temperature, humidity and pressure difference control of the industrial environment high-precision air conditioner is improved by introducing the fuzzy control into the conventional PID controller and comprehensively using the characteristics of the conventional PID controller and the fuzzy controller.

Owner:XIAN XIYI INTELLIGENT TECH

Adjustment method of dot printing positions and a printing apparatus

InactiveUS6464319B1Low costGuaranteed uptimeSpacing mechanismsOther printing apparatusSmall dropletPrinting registration

In the case where an image is formed with a mixture of large and small droplets by bi-directional printing in an ink jet printing apparatus in which ink is ejected in the form of, e.g., a droplet for printing operation while scanning by a print head, misalignment caused by a difference in ejection speed between the large and small droplets is prevented. For this purpose, there is provided a printing registration method according to the present invention comprises the steps of forming reference dots with the large and small droplets in forward scan printing, forming shifted dots in reverse scan printing on changed registration conditions, acquiring a adjustment value of the condition of dot forming positions on the basis of optical characteristics according to a plurality of shifting amounts of the relative printing positions between forward scanning and reverse scanning, controlling the order of formation of the large and small dots in the forward scanning and the reverse scanning, and correcting the adjustment value according to the offset amount of the small dot forming positions on the basis of the difference in ejection speed or the like.

Owner:CANON KK

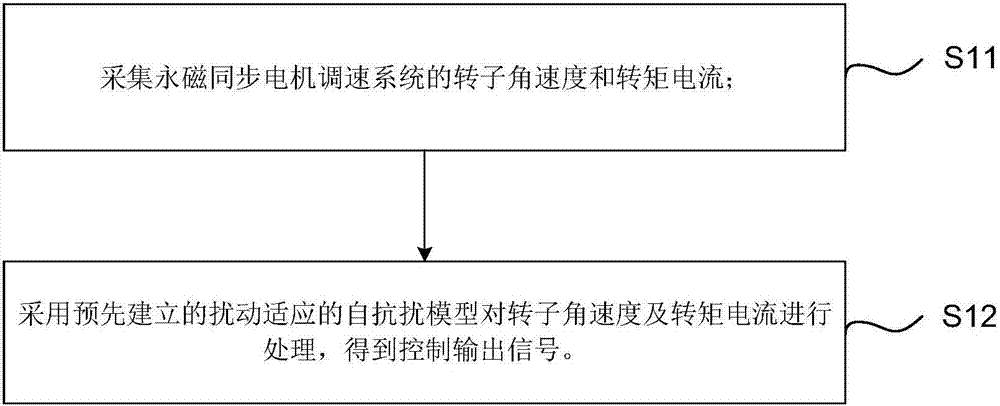

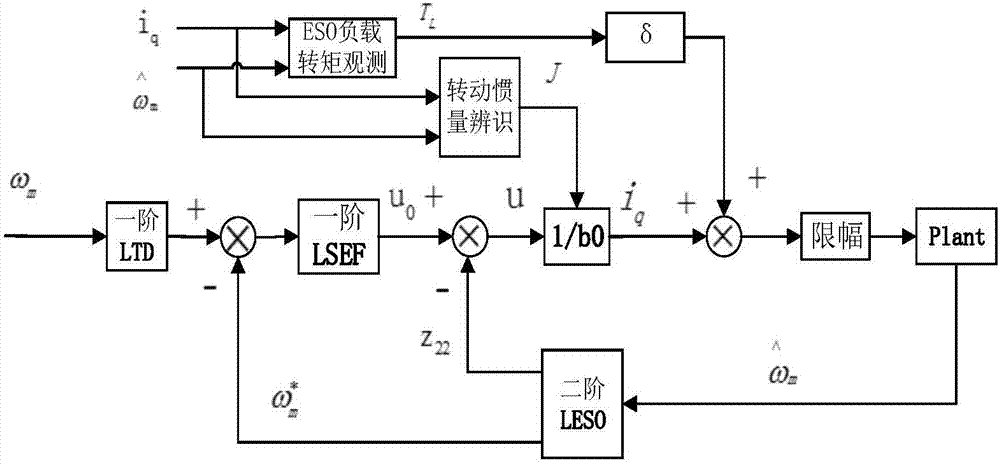

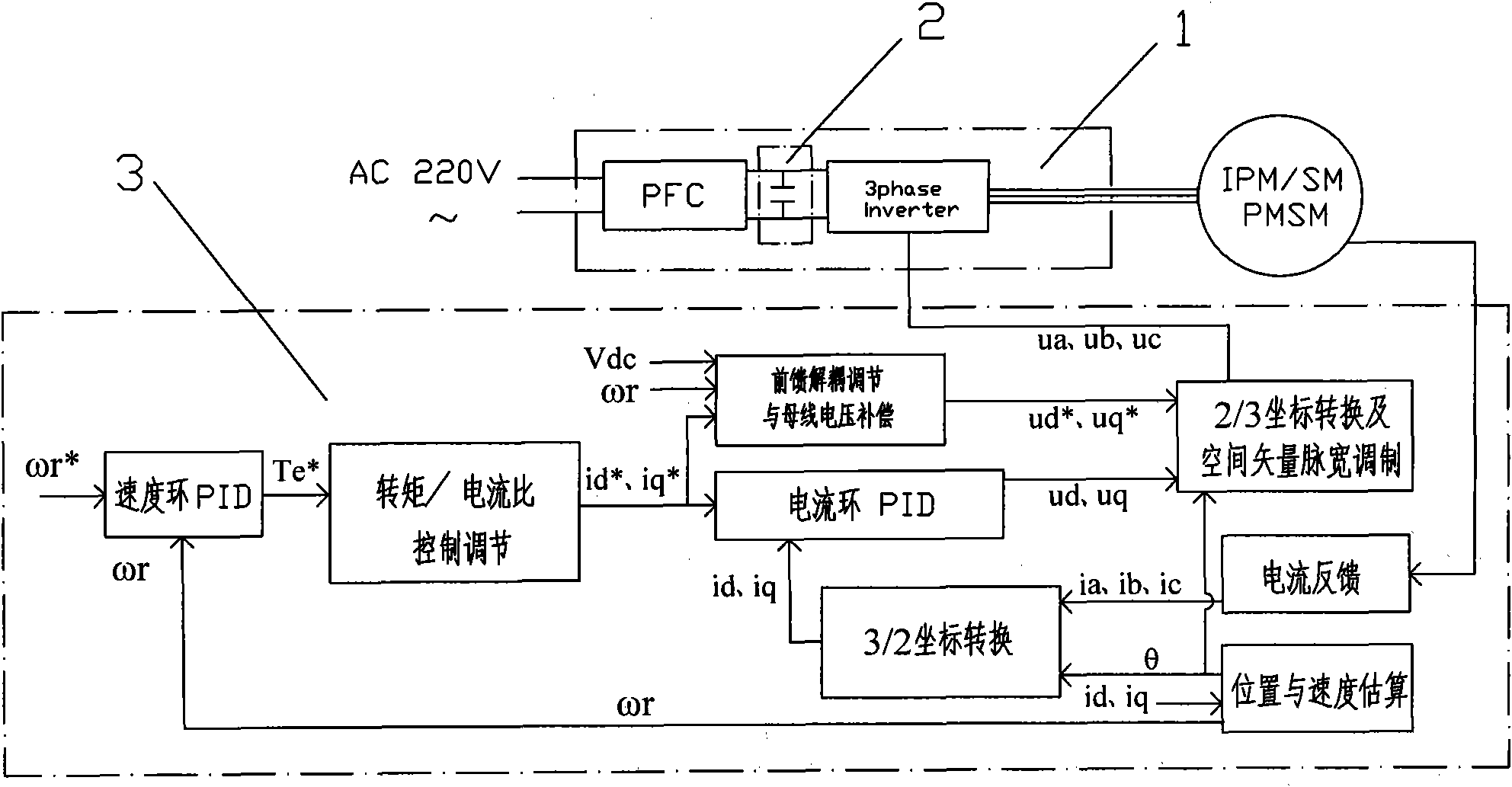

Active-disturbance-rejection control method and system for speed regulation system of permanent-magnet synchronous motor

InactiveCN107425769AImprove anti-interference abilityHigh adjustment accuracyElectronic commutation motor controlVector control systemsInterference resistanceSynchronous motor

The embodiment of the invention discloses an active-disturbance-rejection control method and system for a speed regulation system of a permanent-magnet synchronous motor. The active-disturbance-rejection control method comprises the steps of acquiring a rotor angular speed and a torque current of the speed regulation system of the permanent-magnet synchronous motor; processing the rotor angular speed and the torque current by employing an active-disturbance-rejection model which is built in advance and is adaptive to disturbance to obtain a control output signal; performing rotational speed control on the speed regulation system of the permanent-magnet synchronous motor according to the control output signal, wherein the active-disturbance-rejection model is built according to a first-order linear active-disturbance-rejection control sub-model, a rotational inertia identification sub-model and a load torque observation sub-model, the rotational inertia identification sub-model is built according to a Landau identification algorithm, and the load torque observation sub-model is built according to an expansion state observer; and adjusting control gain b0 of the system according to the identified rotational inertia and a calculation relation b0=Kt / J. According to the active-disturbance-rejection control method disclosed by the embodiment of the invention, the adjustment accuracy of the control grain b0 is improved during the application process, and the anti-interference capability of the speed regulation system of the permanent-magnet synchronous motor is improved.

Owner:GUANGDONG UNIV OF TECH

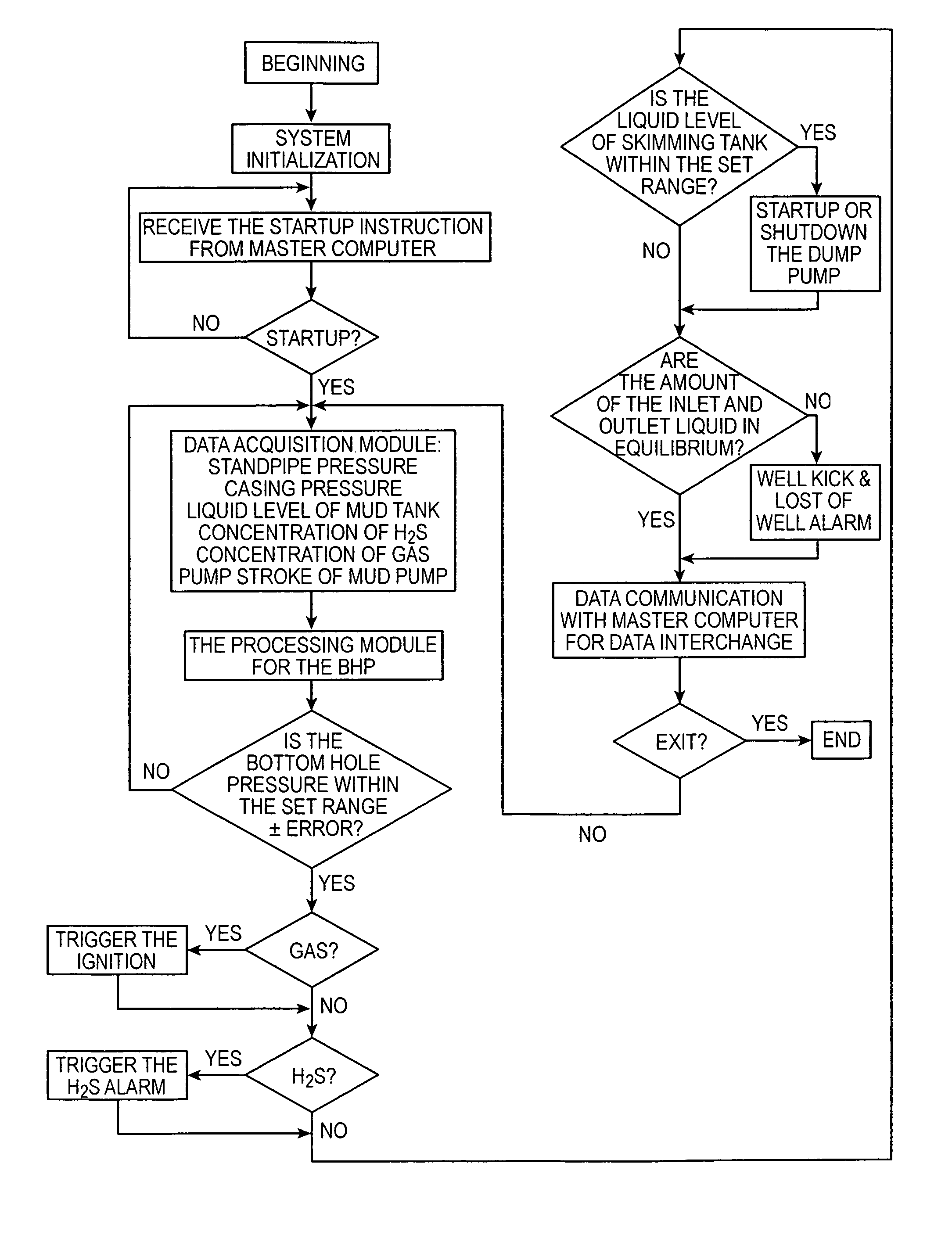

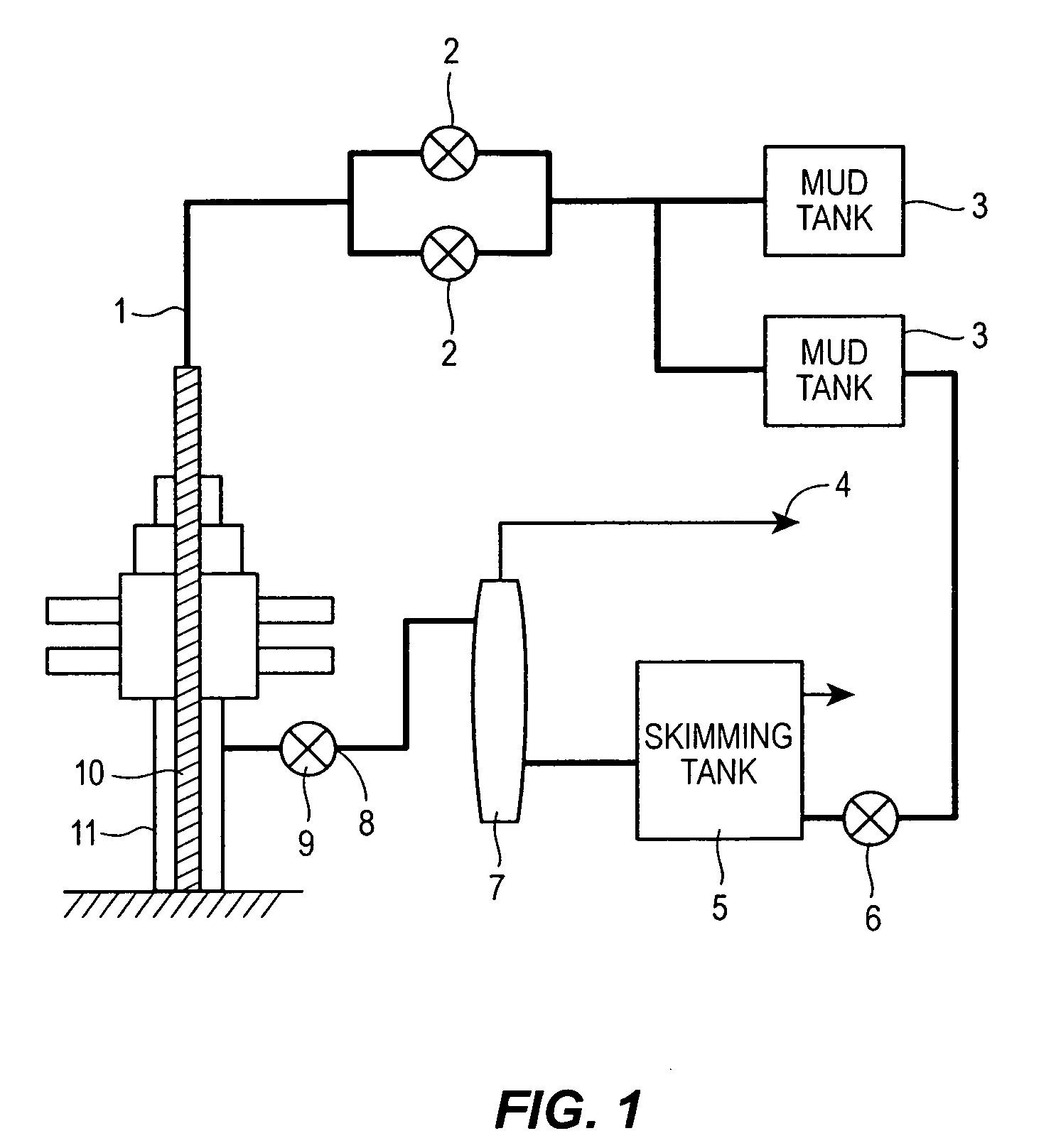

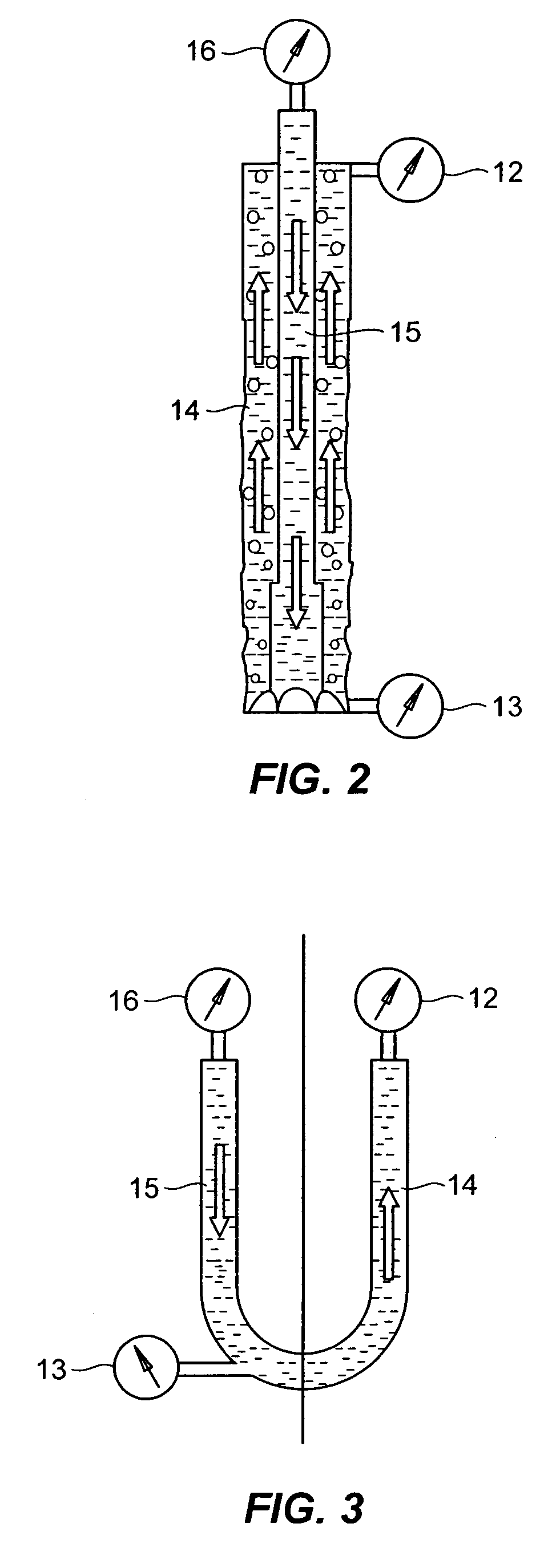

Automatic control system and method for bottom hole pressure in the underbalance drilling

ActiveUS7158886B2Accurate calculationRelatively small errorElectric/magnetic detection for well-loggingConstructionsAutomatic controlAutomated control system

This invention provides an automatic control system and method for bottom hole pressure (BHP) in the underbalanced drilling. It relates to a computer automatic control technology. The automatic control system according to the invention includes a processing module for the BHP based on the mechanisms of hydraulics. The BHP in the underbalanced drilling is calculated from the acquired standpipe pressure (SPP), the calculated circulating pressure loss in the drilling tools, drill bit pressure drop and the fluid colunm pressure in the drill string. The resulting BHP is then compared with the set pressure value of the system. In case that the BHP is higher or lower than the set pressure, an instruction to regulate throttle valve opening will be issued in order to bring the BHP back to the set pressure range and complete BHP monitoring and control.

Owner:CHINA PETROCHEMICAL CORP +1

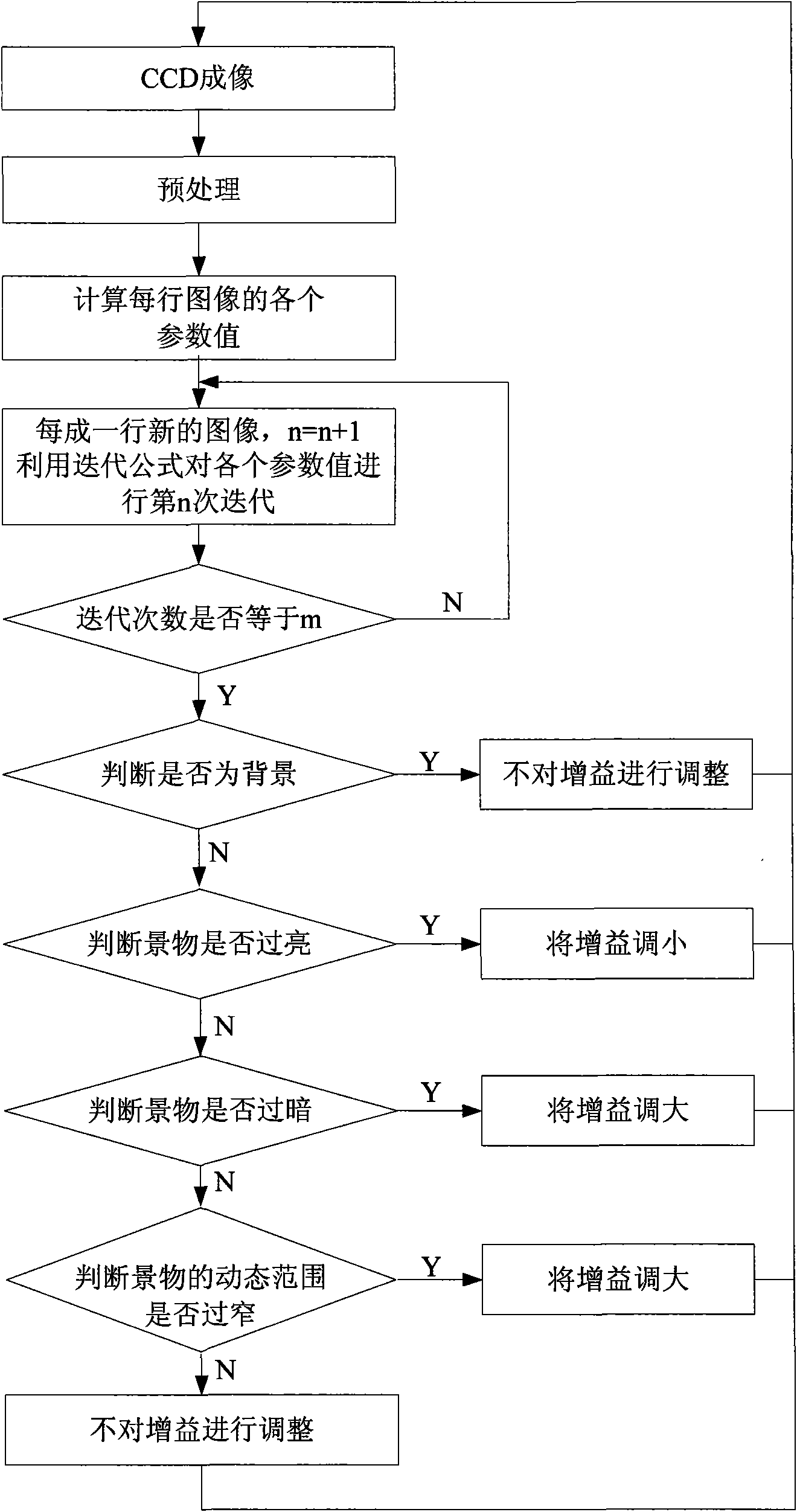

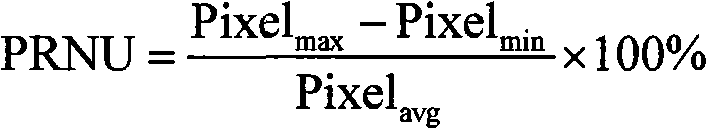

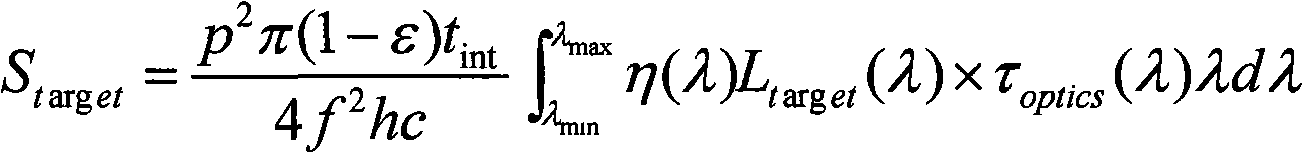

Self-adapting real-time regulating method for linear array remote sensing CCD camera dynamic range

ActiveCN101588515ASolve difficult problems that cannot be predicted from the entire imageIncrease or decrease exposure timeTelevision system detailsColor television detailsProperty valueLimit value

A self-adapting real-time regulating method for the linear array remote sensing CCD camera dynamic range, includes the steps: (1)setting the statistical property values of the image data; (2)receiving the image data line by line and removing the noise spot; (3)predicting for the next line of image data by utilizing a attenuation factor; (4)calculating each statistical property value of the predicted image data; (5) if the calculated variance being smaller than the variance threshold value, keeping the linear array CCD integral time constant, otherwise, (6)if the calculated average value being more than the average value upper limit value, decreasing the linear array CCD integral time; if the average value being smaller than the average value lower limit value, increasing the linear array CCD integral time; if the average value being between the average value upper limit value and the average value lower limit value, transferring the step (7), (7) if the difference of the calculated grey scale maximum value to the calculated grey scale minimal value being smaller than the grey scale threshold value, increasing the linear array CCD integral time, otherwise keeping the linear array integral time constant. The method of the invention has high modulation accuracy and good real time, and is beneficial for the realization on the present remote sensing linear array CCD camera.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Control device and control method of air conditioner compressor and variable-frequency air conditioner

InactiveCN102400899AImproved high-frequency operating characteristicsHigh adjustment accuracySpace heating and ventilation safety systemsLighting and heating apparatusPower factorData information

The invention provides a control device of an air conditioner compressor. The control device comprises a main circuit unit and a weak-magnetic closed-loop regulating circuit, wherein the weak-magnetic closed-loop regulating circuit acquires working data information of the compressor from the main circuit unit, performs analysis and computation according to the acquired information, and supplies a control signal to a contravariant circuit of the main circuit unit so as to control the working voltage and working frequency of the compressor. The invention also provides a variable-frequency air conditioner with the control device of the air conditioner compressor. The invention further provides a control method of the air conditioner compressor. The control method comprises the following steps of: supplying power to the compressor by the main circuit unit; acquiring the working data information of the compressor from the main circuit unit by using the weak-magnetic closed-loop regulating circuit; performing analysis and computation according to the acquired information; and supplying the control signal to the contravariant circuit so as to control the working voltage and working frequency of the compressor. A power factor correction (PFC) circuit is matched with the weak-magnetic closed-loop regulating circuit to realize the high-efficiency and stable running of the compressor in a high-frequency area and a low-frequency area.

Owner:HAIER GRP CORP +1

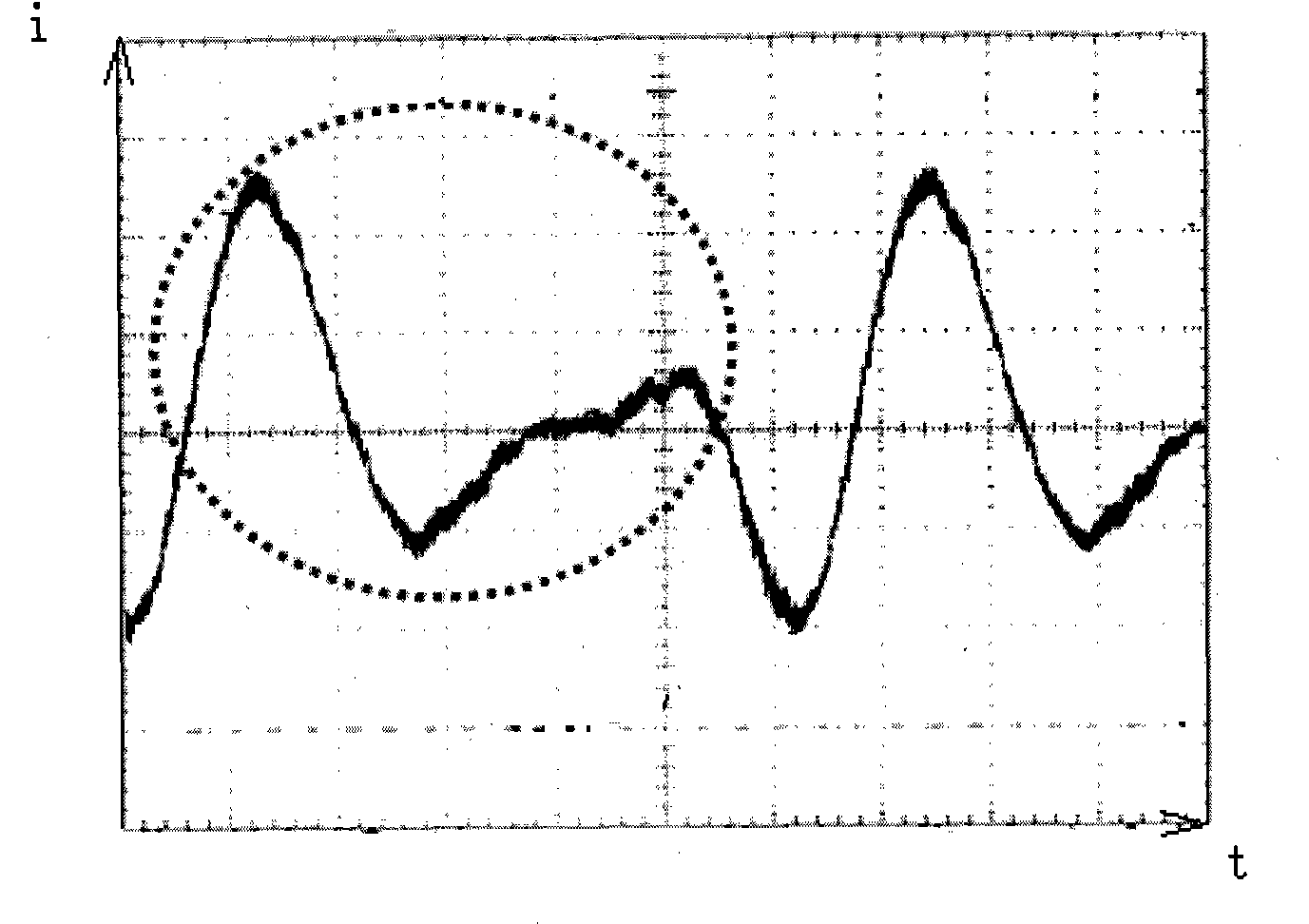

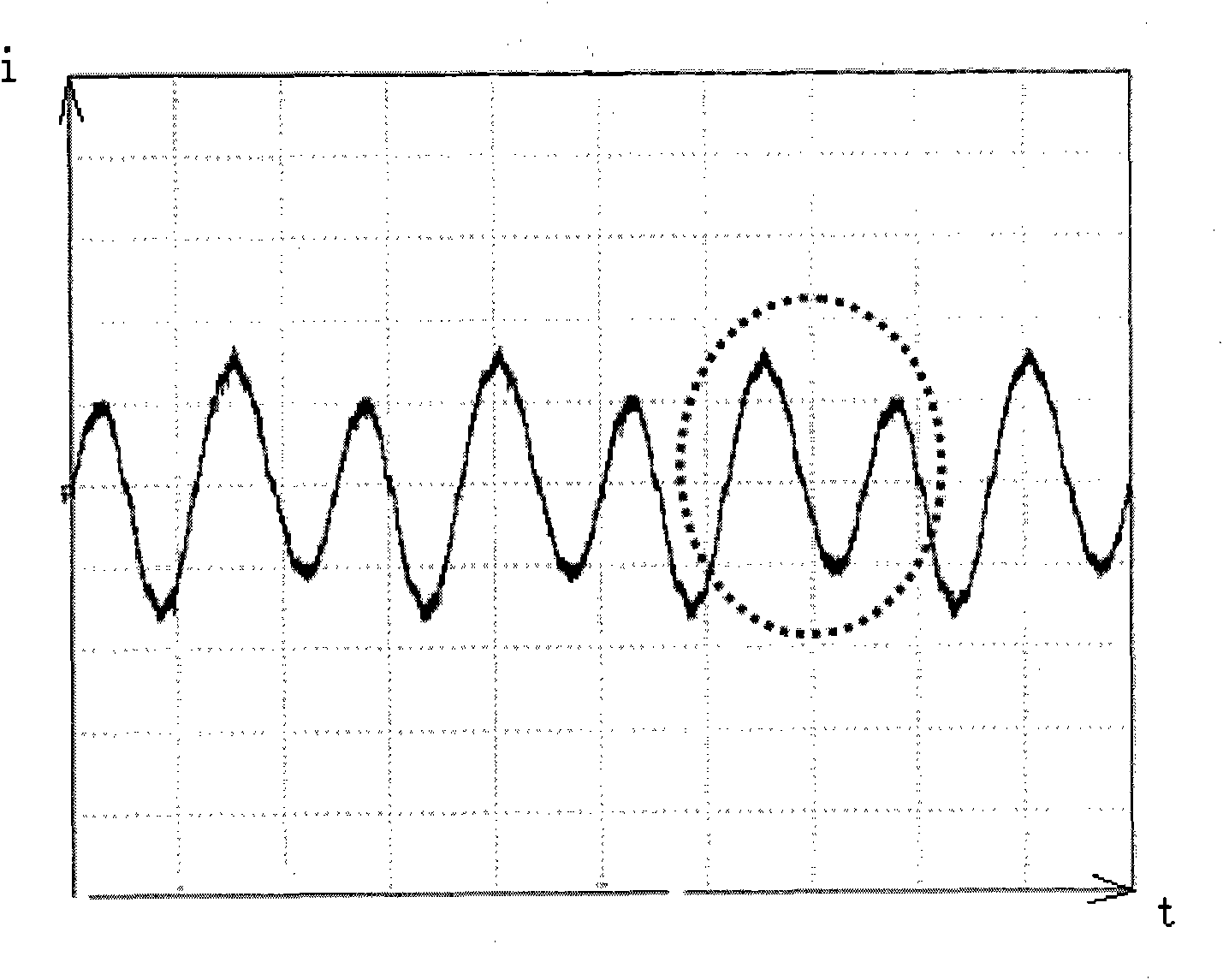

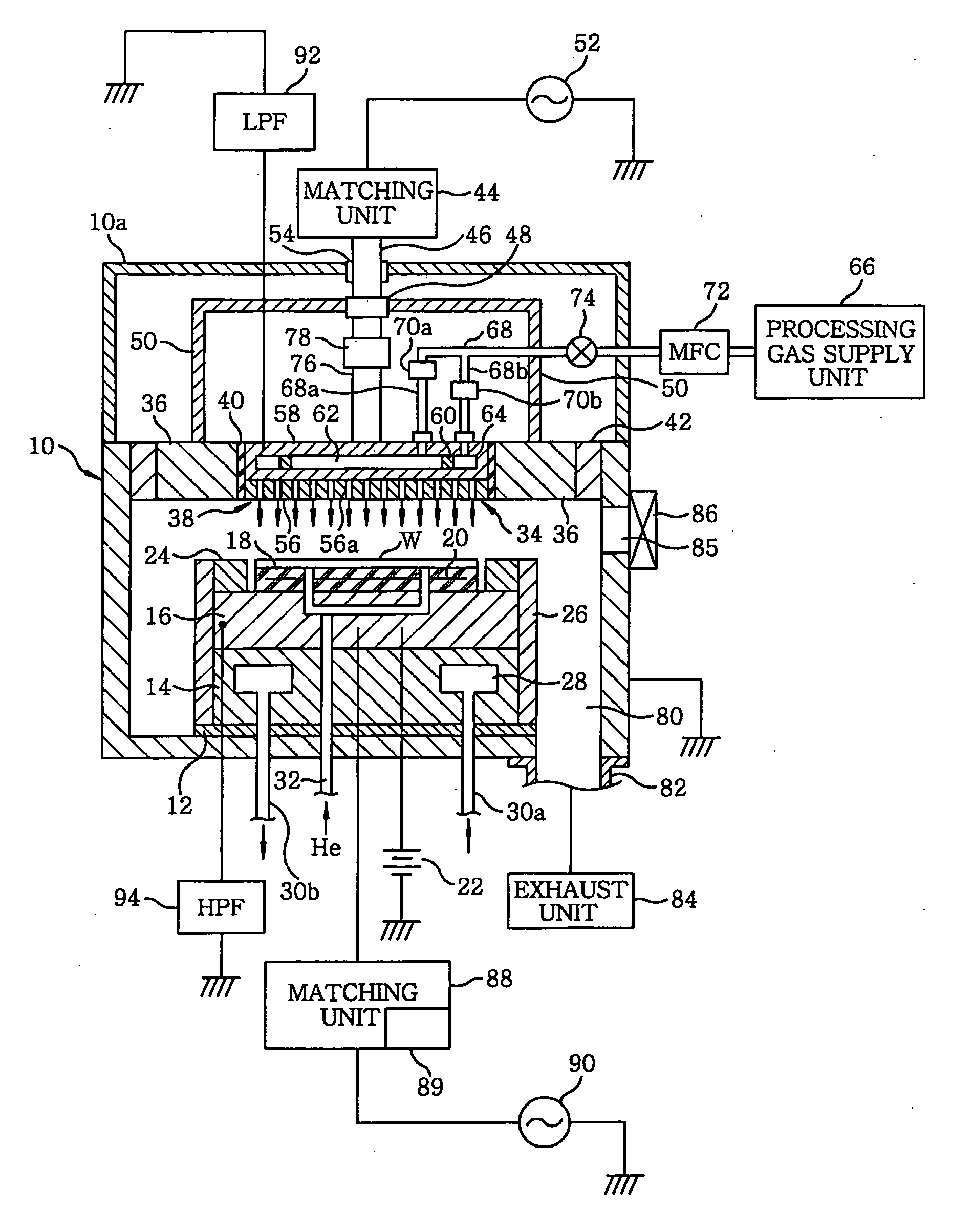

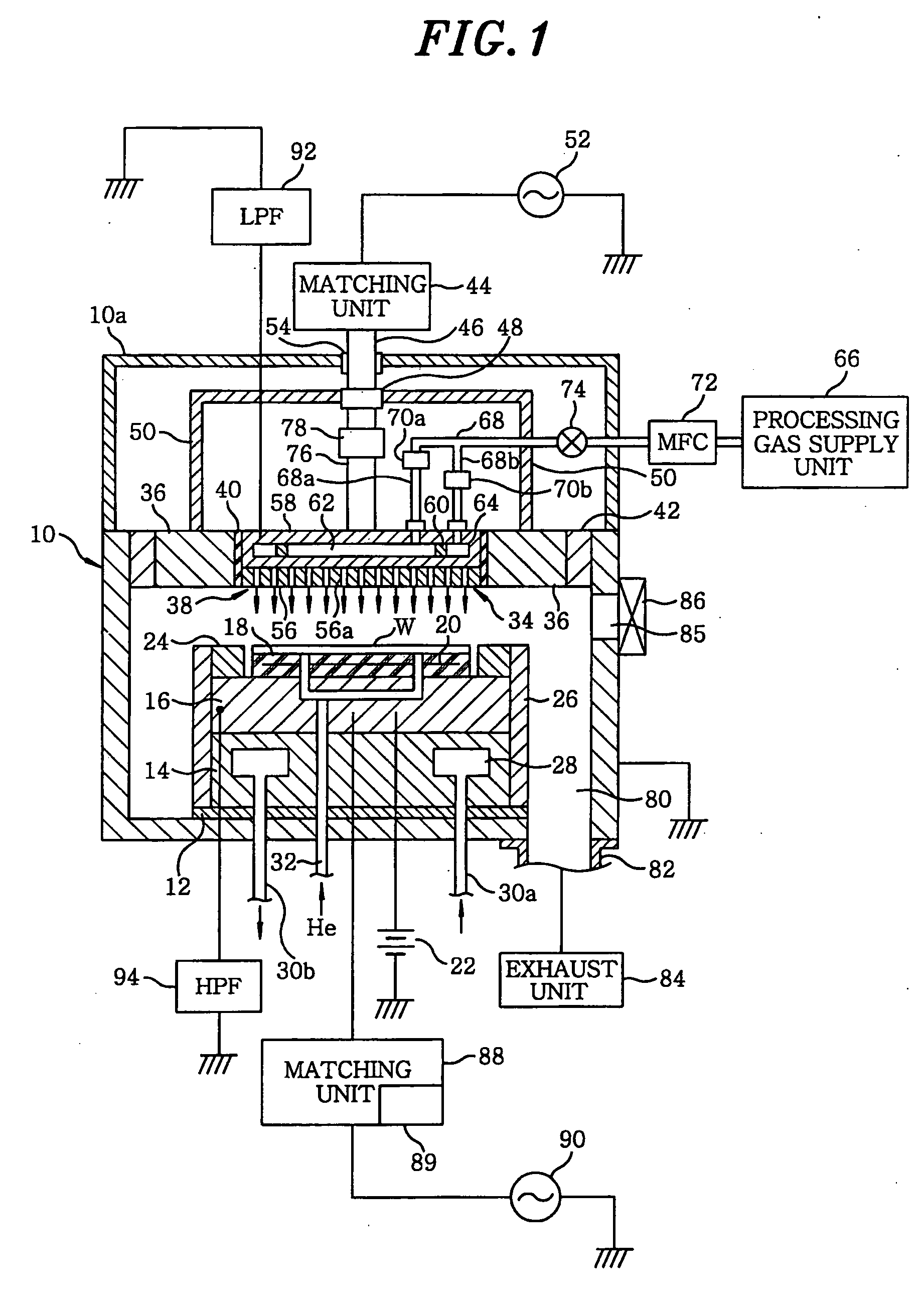

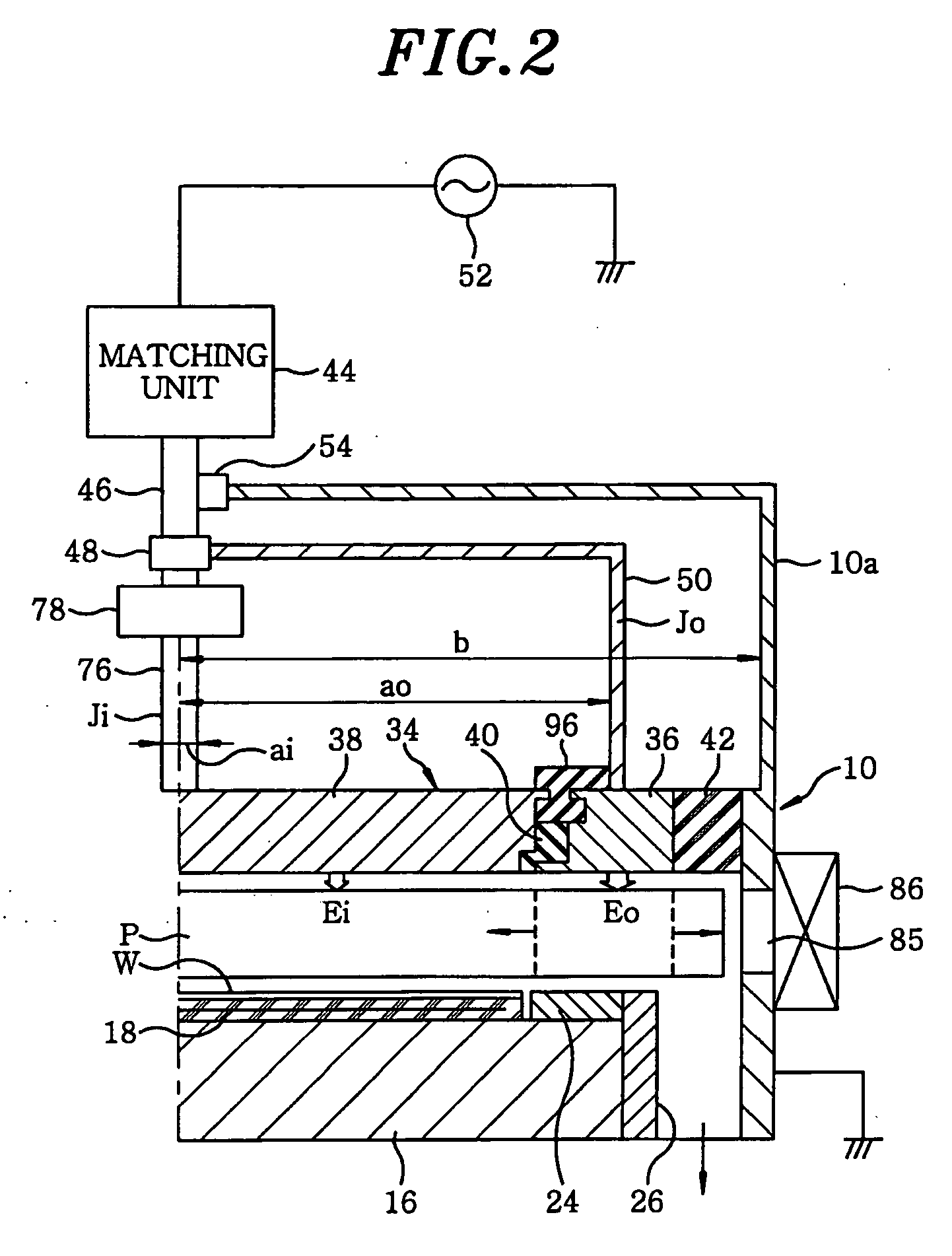

Plasma processing apparatus and impedance adjustment method

InactiveUS20060021580A1Minimize impedance differenceHigh impedance adjusting accuracyElectric discharge tubesChemical vapor deposition coatingEngineeringRadio frequency

A plasma processing apparatus, for performing a plasma processing on a substrate to be processed by generating a plasma of the processing gas in an evacuable processing chamber, includes an impedance adjusting mechanism. The impedance adjusting mechanism is provided with a resonance circuit formed to allow a radio frequency current to flow into the first electrode; a variable impedance unit installed on a power feed line to the first electrode; a detector for detecting an apparatus state to be used to search a resonance point of the resonance circuit; and a controller for searching a resonance point of the resonance circuit by detecting a signal of the apparatus state of the detector while varying a value of the variable impedance unit in a state where the plasma is formed and then adjusting the value of the variable impedance unit at the resonance point to a reference value.

Owner:TOKYO ELECTRON LTD

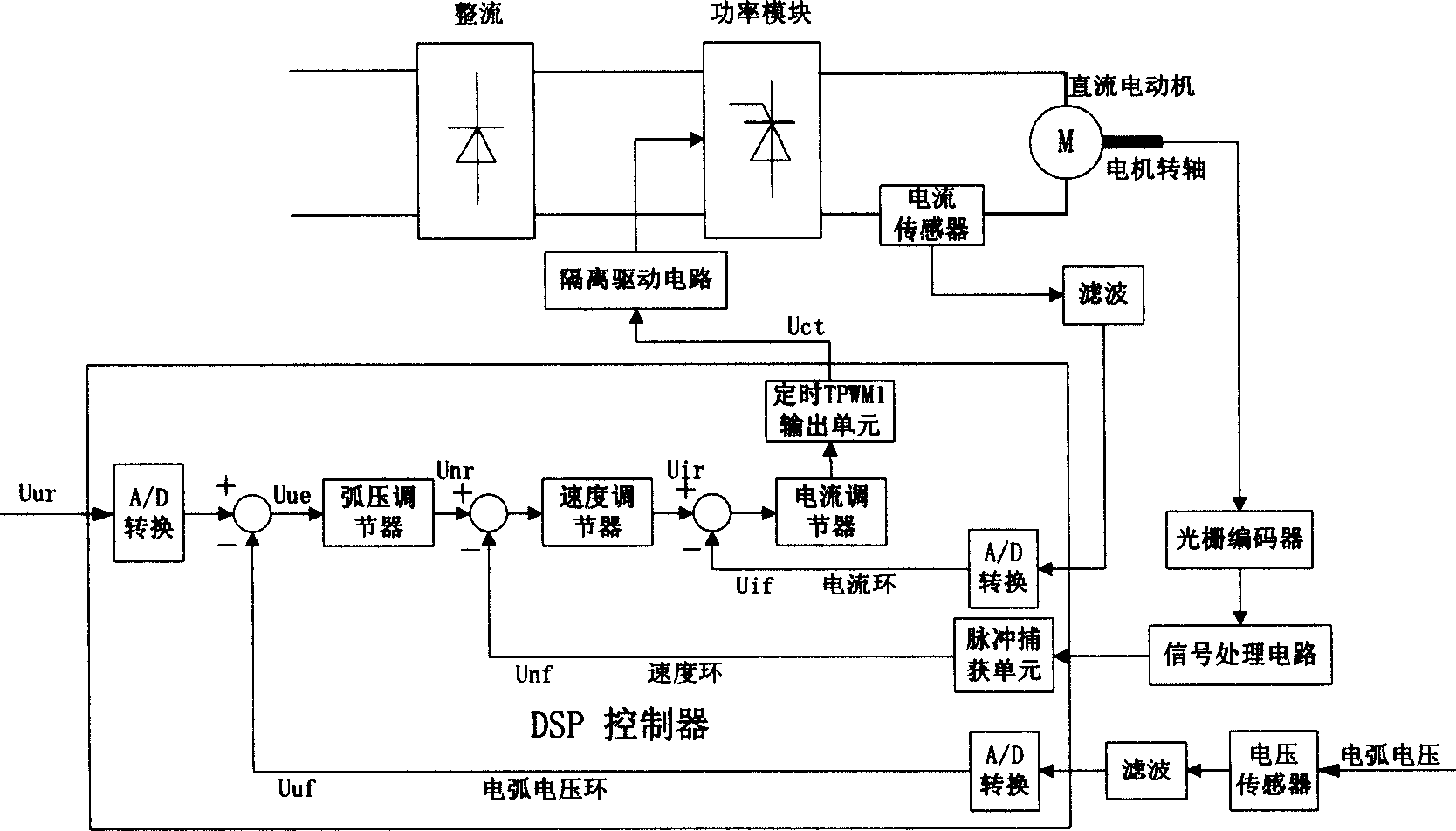

Full-digital speed change control method for wire feeding for submerged arc welding

InactiveCN1634676ARealize full digital controlFlexible adjustmentArc welding apparatusLoop controlControl signal

This invention relates to whole digital buried arc welding varying wire feed control method, which adopts series three-loop control structure with inner one as current ring, second ring as rotary speed ring and outer ring as arc voltage ring with one adjustor in each ring for arc voltage, rotation speed and current. It adopts high speed digit signals processor as central control part to form whole digital DC servo motor control system whose all control strategies area realized by software and the hardware completes digital trigger function and signal process function.

Owner:SHANGHAI JIAO TONG UNIV

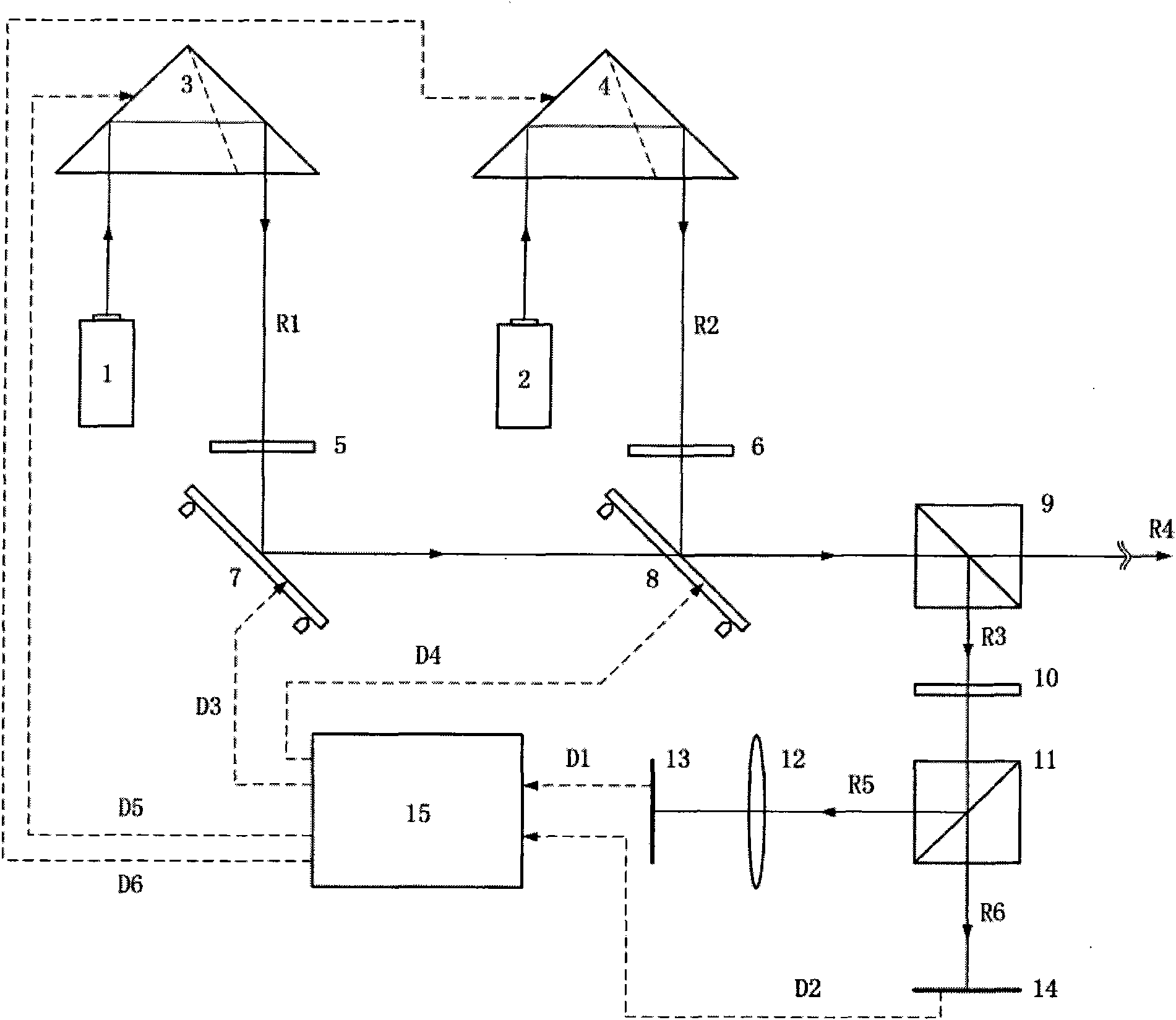

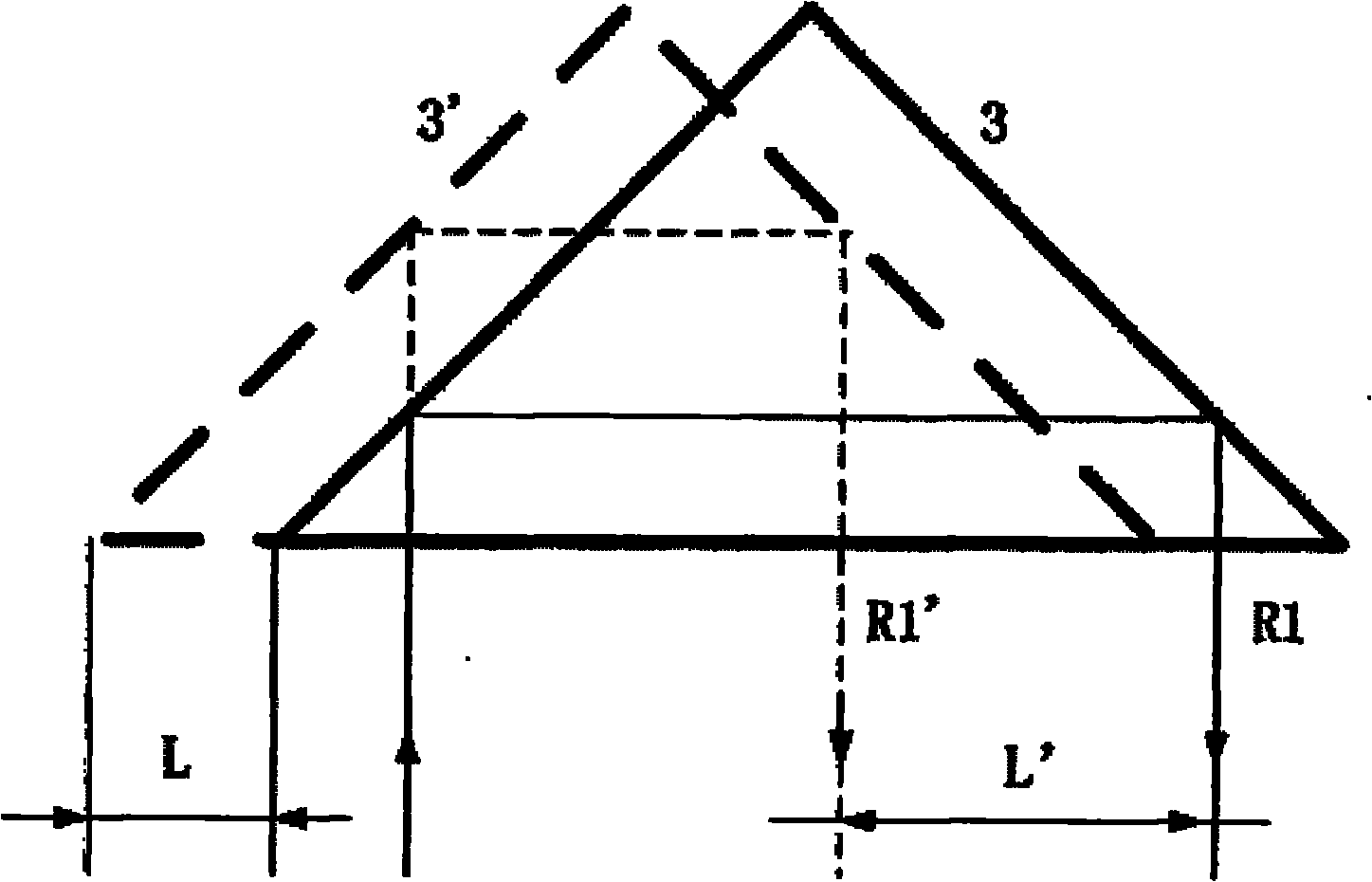

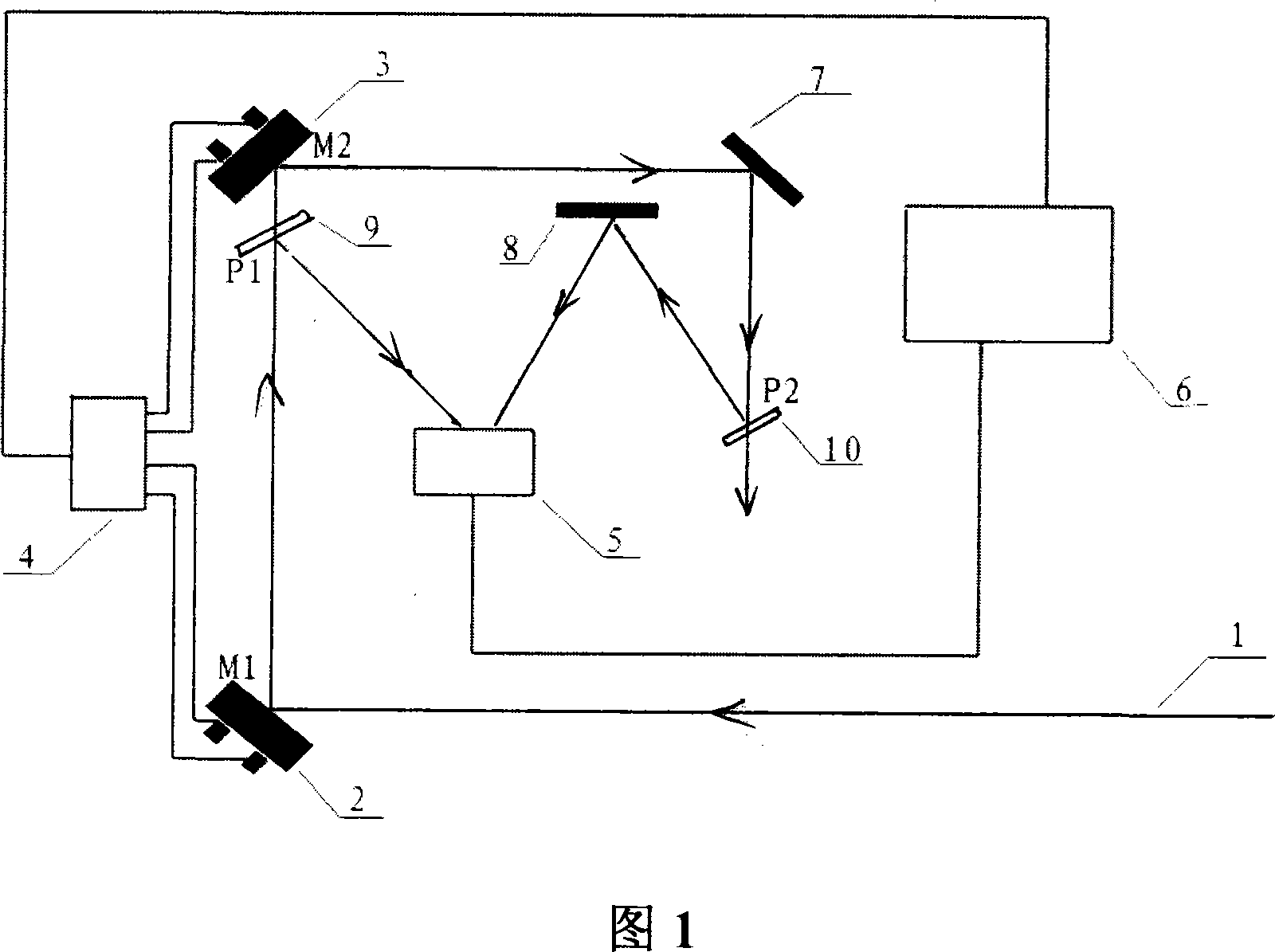

Device and method for coaxially adjusting double beams in real time

InactiveCN101859030AEasy to useGuaranteed continuityUsing optical meansNon-linear opticsLight beamEngineering

The invention provides a device and a method for coaxially adjusting double beams in real time. The device and the method realize coaxial convergence of the double beams by modulating the double beams and turning back rays, and meanwhile realize detection and real-time adjustment of the double beams by taking coaxial light split parts of the double beams as detected beams and performing light splitting treatment on the detected beams; and alternated adjustment of the double beams ensures high-precision coaxial collimation of emergent beams and overcomes the defect of the prior art on the aspect of coaxial real-time adjustment of double laser beams. The device and the method have high adjustment speed and precision, do not affect normal use of equipment during adjustment, ensure continuity and accuracy of observation and measurement, can be applied to the double beams with different wavelengths, and can detect the double beams at the same time by using a set of detection module so as to save devices with low cost.

Owner:ZHEJIANG UNIV

Method and arrangement for real time monitoring laser luminous spot and light path automatically collimating

InactiveCN101063751ASimple structureHigh precisionProgramme controlComputer controlElectricityDevice Monitor

This invention relates to one laser spot real time monitor and light path automatic calibration method and device, which uses single CCD camera head to collect laser spot, piezoelectricity electrical lens rack automatic calibration path by use of computer for spot process and real time monitor, wherein the device monitor spot frequency is about 10Hz and feedback control frequency is of 1Hz to eliminate and lower shake circle for float more than one second with stability less than 0. 5 micro arc degree in calibration laser space.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

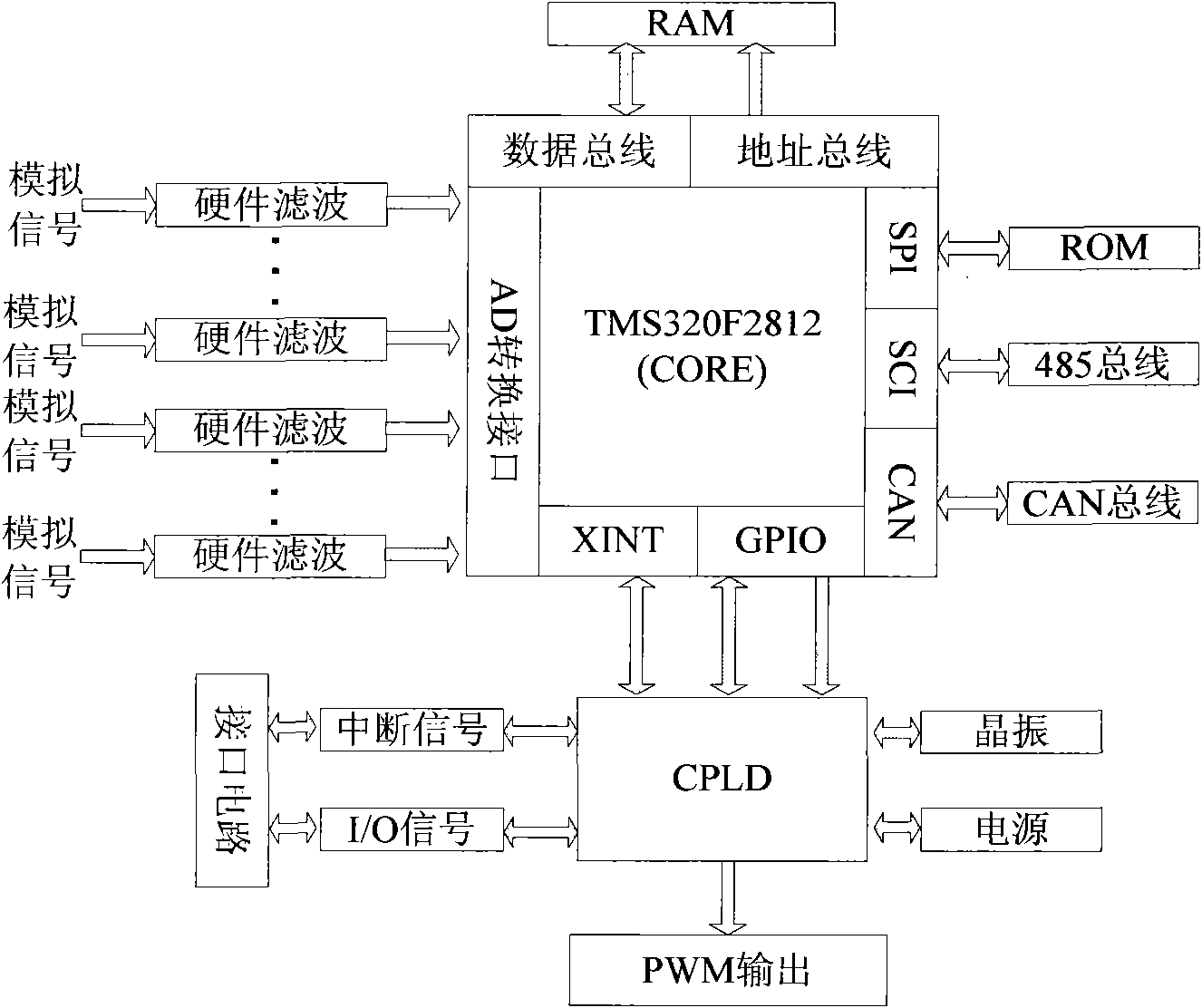

Power supply control system of bidirectional electric automobile charger

InactiveCN101814765APowerful digital signal processing functionRealize the communication functionBatteries circuit arrangementsAc-dc conversionControl systemPower control system

The invention provides a digital control system of a great-power bidirectional electric automobile charger system converter, belonging to the technical field of electric automobile chargers. The control system adopts a structure of matching a DSP (Digital Signal Processor) with a PLD (Programmable Logic Device) and combines the stronger data operational capability of the DSP, the high integration of the PLD and the repeated programming property of hardware, thereby making the structure of the controller hardware compact and greatly improving versatility, reliability and real-time property. The controller charger proposed by the invention can charge various batteries to reach a fully charged state at a higher speed without influencing the service life of the batteries and is convenient to adopt various intelligent charging strategies.

Owner:CHINA ELECTRIC POWER RES INST +1

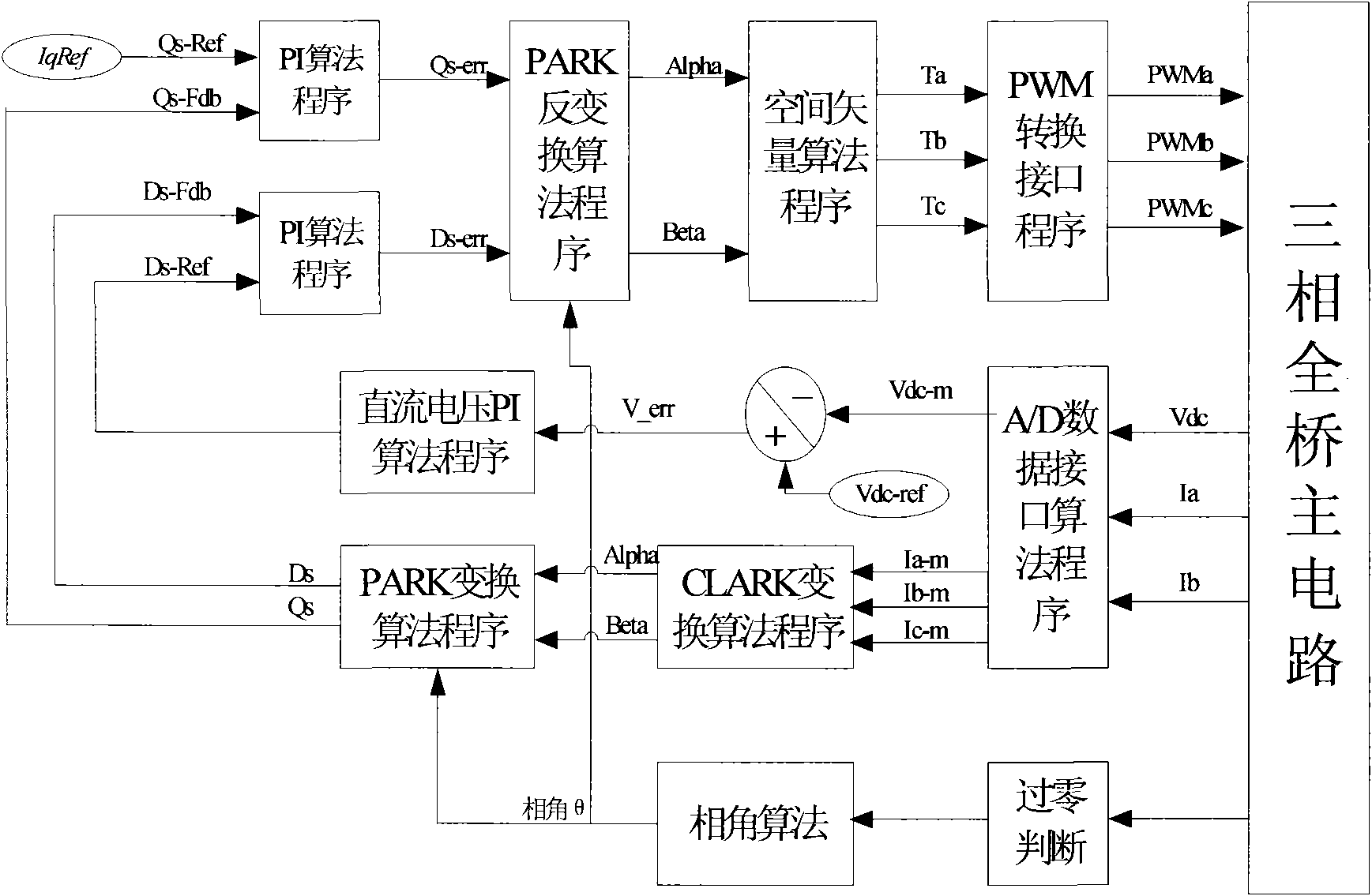

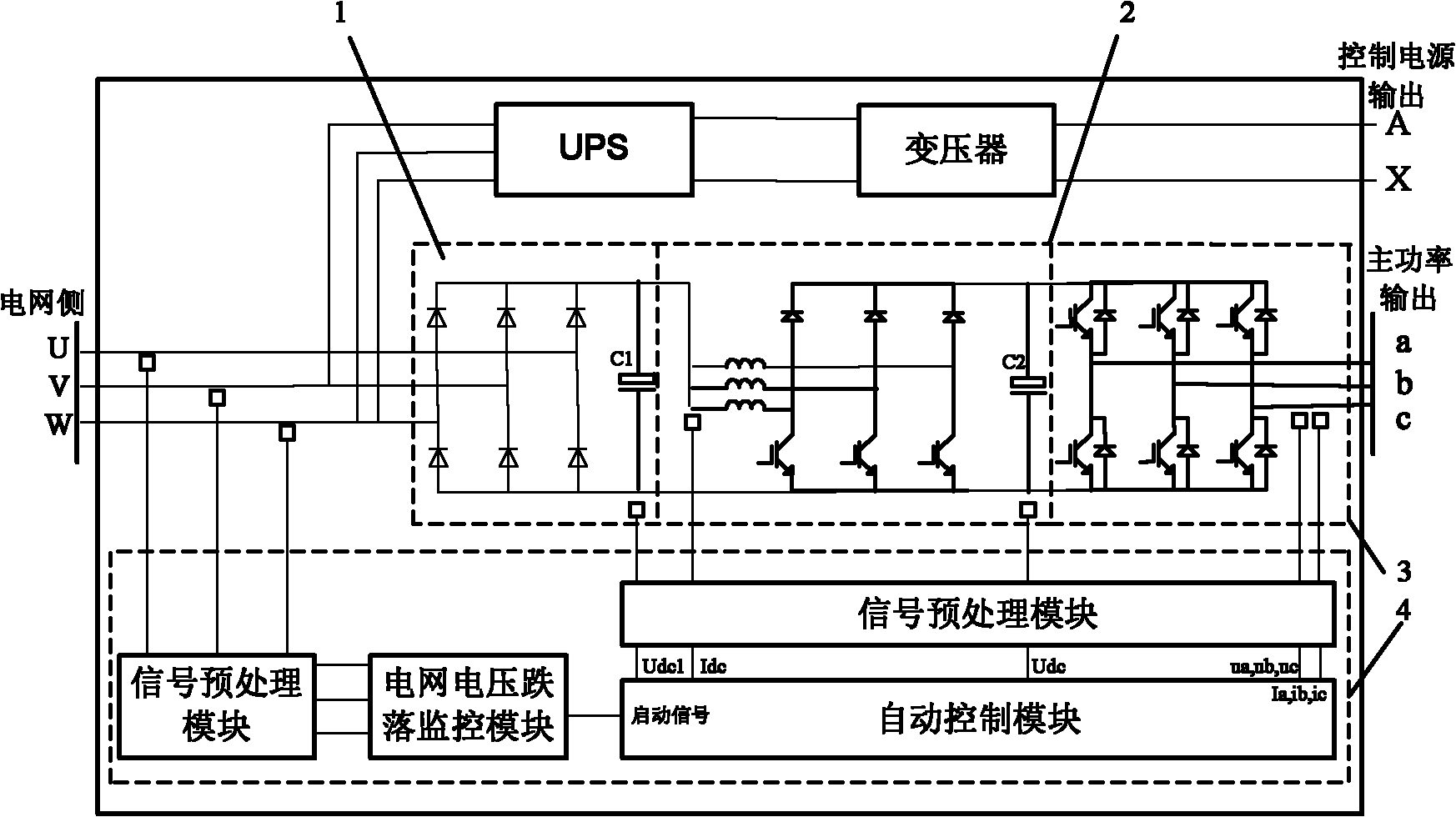

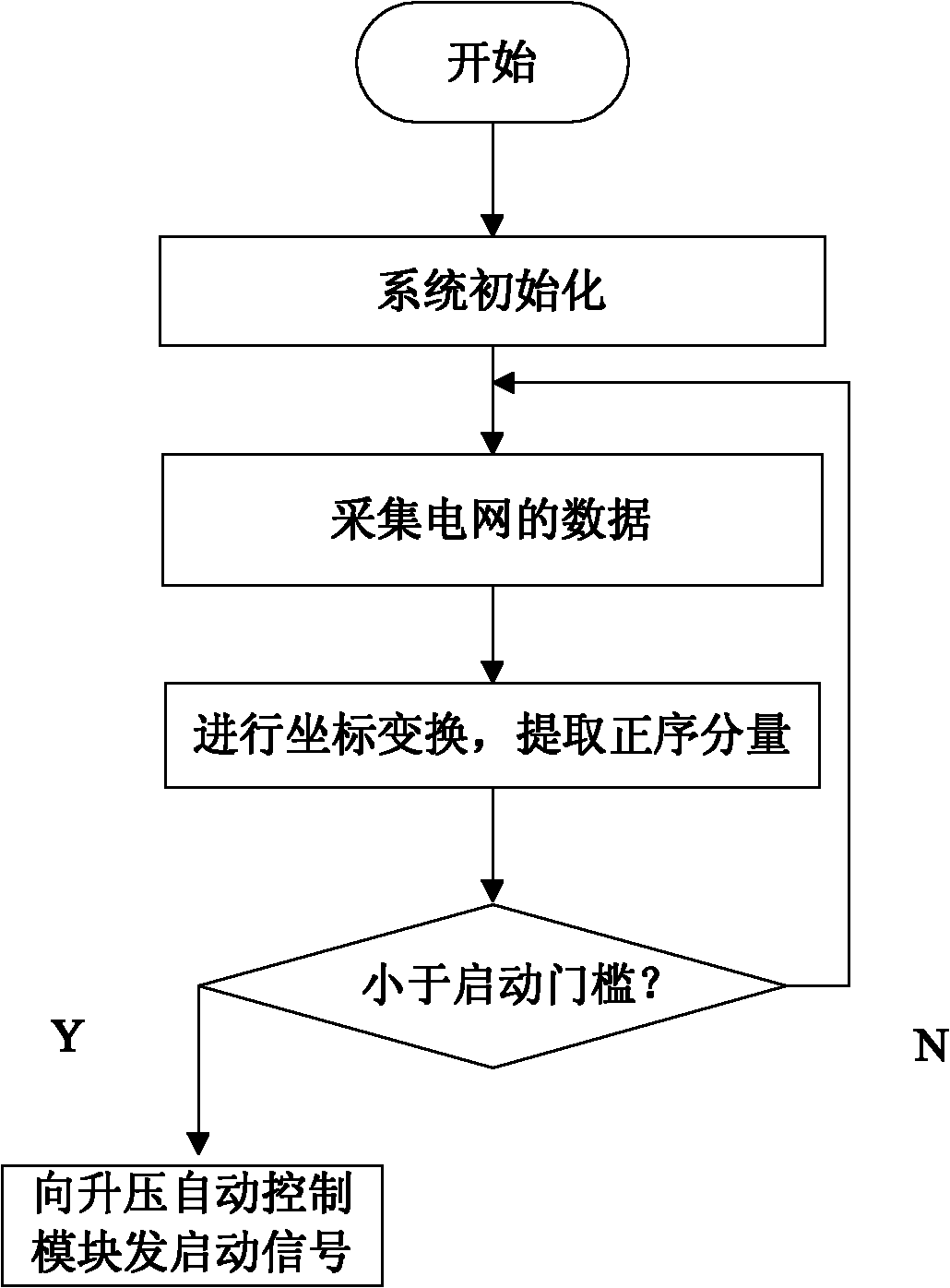

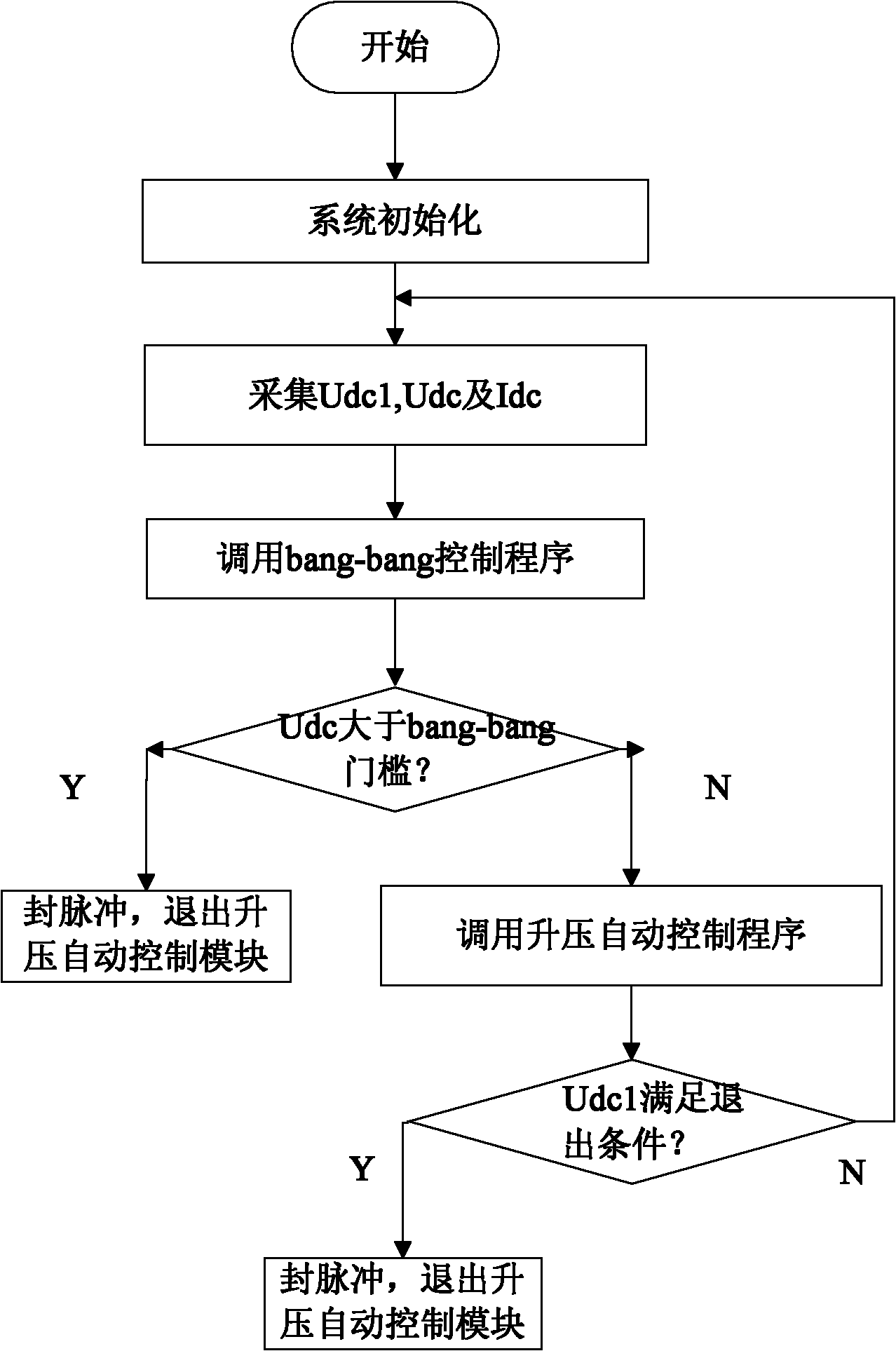

Inverter device for asynchronous motor with low voltage ride-through capability

ActiveCN102291085AGuaranteed reliable operationHigh adjustment accuracyAC motor controlLow voltage ride throughPower grid

The invention discloses an asynchronous motor frequency converter device with low-voltage ride through capability. An alternating-direct-alternating mode is adopted for a frequency converter, namely, firstly converting a working frequency alternating power supply into a direct current power supply by a rectifier; and then converting the direct current power supply into an alternating power supplywith controllable voltage and frequency through an inversion link and providing the alternating power supply to an asynchronous motor. A diode rectification module in the inner part is switched in after the working frequency alternating power supply is switched in the frequency converter; the alternating current is converted into direct current; the output of a rectifier bridge is switched into aBOOST module; the output of the BOOST module is switched into the input of a DC / AC (direct current / alternating current) inverter module; and the output of the inverter module, serving as an alternating current supply, is directly supplied to the asynchronous motor. Under the normal condition, the BOOST module is not started, when the drop of the power grid voltage is detected, the BOOST module starts automatically, sufficient direct current voltage sources for the inversion link are ensured, and the stable operation of the asynchronous motor is ensured.

Owner:NORTHEAST CHINA GRID +5

High-precision pose adjusting device for spliced grating

The invention discloses a high-precision pose adjusting device for a spliced grating, and relates to a high-precision pose adjusting device for a grating set. The device solves the problem that the high-precision grating pose adjusting device cannot realize precise grating adjustment of multiple degrees of freedom. A pitch adjusting unit is driven by a pitch adjusting micro driver to drive a pitch adjusting right guide rail sliding block to slide on a corresponding guide rail so as to realize directional independent grating adjustment; a deflection adjusting unit is driven by a deflection adjusting micro driver to drive a deflection adjusting framework and front and rear deflection guide rail sliding blocks to slide on the corresponding guide rails so as to realize directional independent grating adjustment; an in-plane adjusting unit is driven by an in-plane adjusting micro driver to drive an in-plane adjusting front and rear guide rail sliding blocks to slide on the corresponding guide rails so as to realize independent grating adjustment; and a linear adjusting unit is driven by a linear adjusting micro driver to drive a linear adjusting framework and left and right linear guide rail sliding blocks to slide on the corresponding guide rails so as to realize directional independent grating adjustment. The device is used for high-precision pose adjustment of the spliced grating set.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com