Optimized operation control method and system of distributed energy system

A technology of distributed energy and operation optimization, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of reduced economy, larger deviation of load optimization distribution, optimized management, etc., to achieve energy utilization efficiency improvement, The effect of smooth regulation of load supply and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

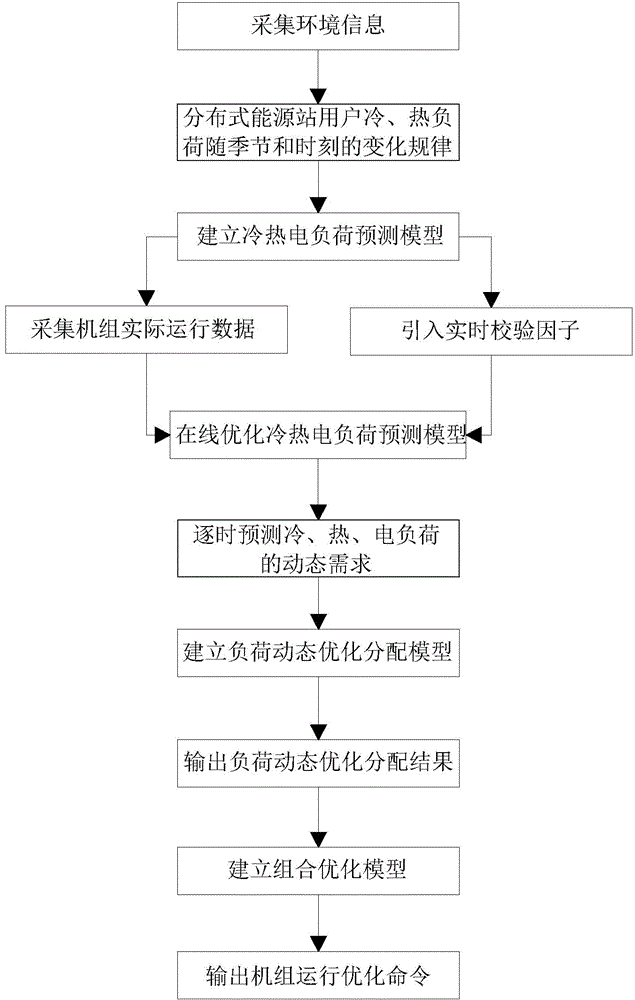

[0049] Embodiment 1 of the present invention: an operation optimization control method of a distributed energy system, such as figure 1 shown, including the following steps:

[0050] 1. Data collection

[0051] Collect environmental information and actual operating data of the unit; the environmental information includes local ambient temperature and humidity information; the actual operating data of the unit includes the load rate and working efficiency of the unit.

[0052] 2. Establishment of cooling, heating and power load forecasting model

[0053] The general power plant aims at the amount of power generation, and the others are incidental products; while the distributed energy station based on combined cooling, heating and power technology operates in a "cooling (heating) constant power" mode. That is to say, the main purpose of the energy station is to generate cooling load or heating load, and power generation becomes a supplementary product. In the design stage of ...

Embodiment 2

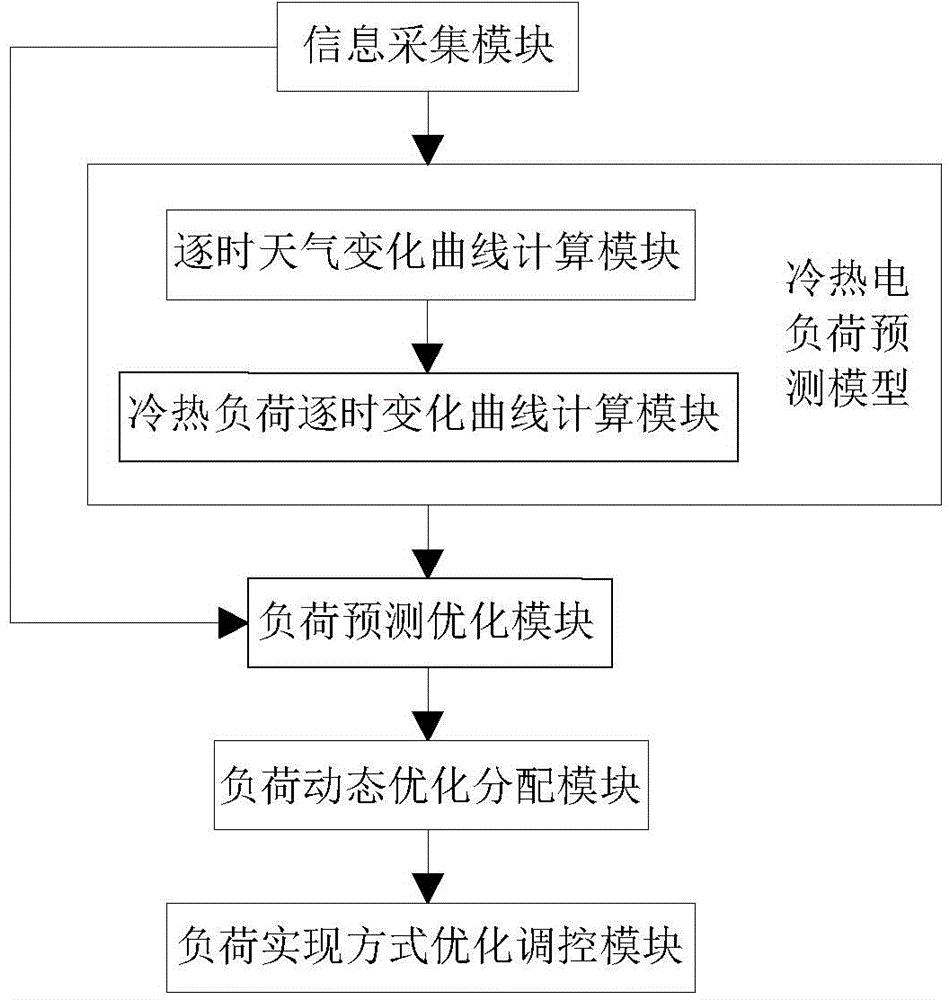

[0074] Embodiment 2 of the present invention: an operation optimization control system of a distributed energy system implementing the method described in Embodiment 1, such as figure 2 shown, including:

[0075] Information collection module, used to collect environmental information and unit actual operation data;

[0076] The cooling, heating and power load forecasting model is used to obtain the changing law of cooling and heating loads of distributed energy station users with seasons and time according to the data collected by the information collection module, and then establish the cooling and heating load according to the changing law and the user's steam demand plan. Electric load forecasting model;

[0077] The load forecasting optimization module is used to optimize the cooling, heating and power load forecasting model online by introducing real-time verification factors and actual unit operation data, and predict the dynamic demand of cooling, heating and electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com