A wide and high-efficiency area hybrid linear concentrated winding permanent magnet motor system and control method

A permanent magnet motor and concentrated winding technology, which is applied in the direction of motor control, motor generator control, AC motor control, etc., can solve the problems of reduced power density, narrow high-efficiency area, and low efficiency, so as to improve slot fullness and broaden high-efficiency area, reducing the effect of eddy current loss and circulation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

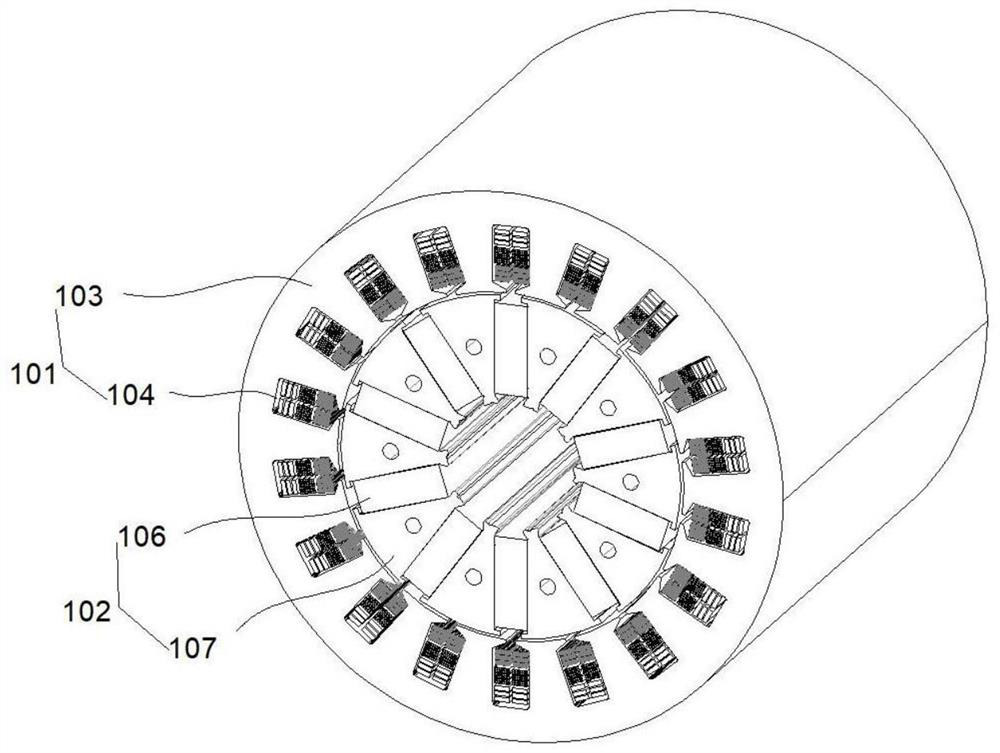

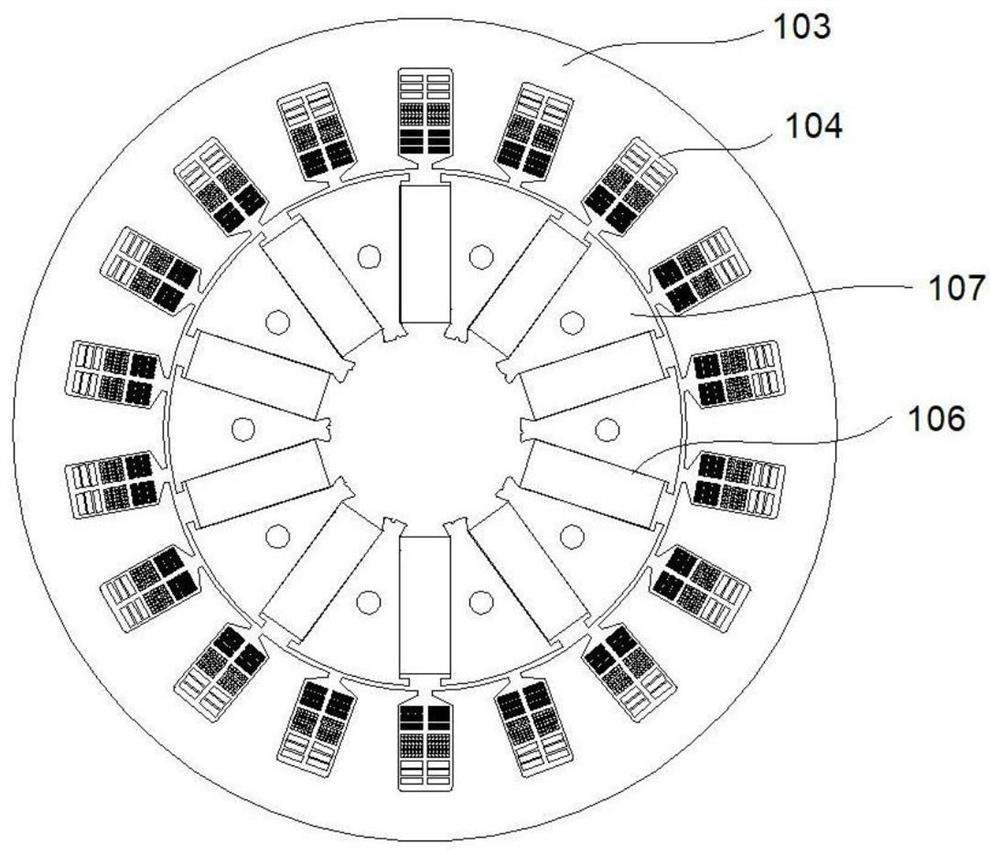

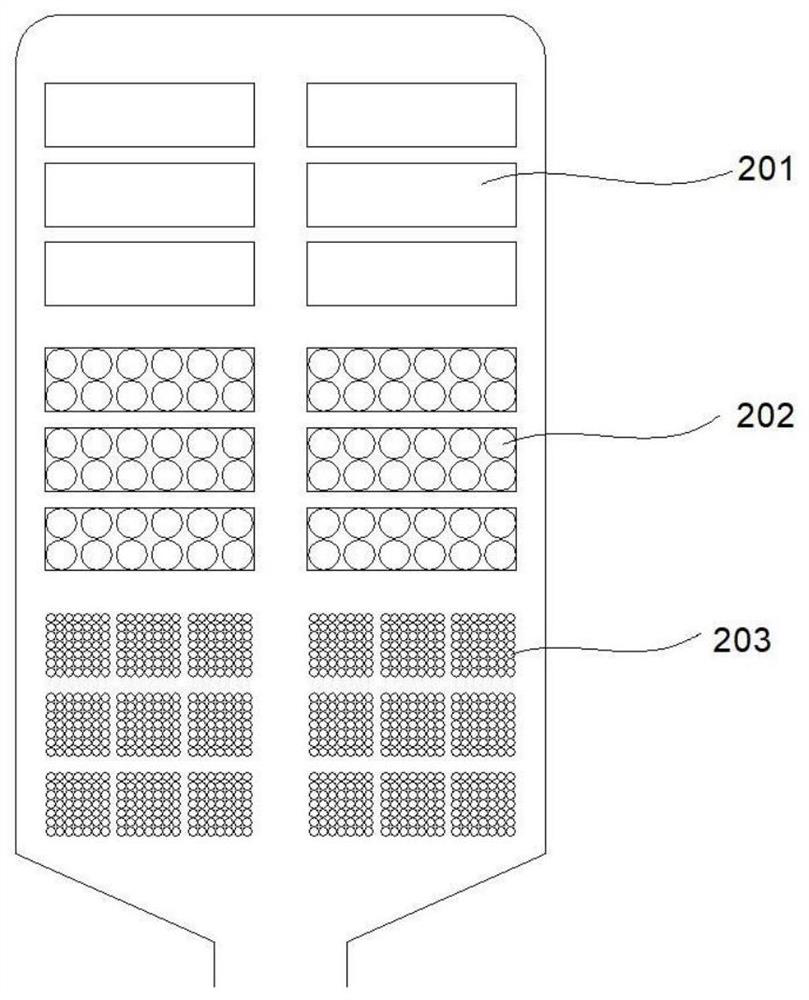

[0035] refer to Figures 1 to 7 , a hybrid linear concentrated winding permanent magnet motor system of the present invention includes a device body 100, the device body 100 includes a stator part 101 and a rotor part 102, the stator part 101 and the rotor part 102 are connected to each other, and there is an air gap in the middle ; Integrated module 200, the integrated module 200 integrates a flat copper wire 201, a round copper wire 202, a Litz wire 203 mixed-line multi-phase concentrated winding permanent magnet motor and a current distribution type all-in-one controller 204; and, The winding module 300, the winding module 300 current distribution type all-in-one controller 204 is composed of a combination of a current distributor 301 and multiple sets of inverter modules 302, and each inverter module 302 is connected to a set of three-phase windings 303 .

[0036] The stator component 101 includes a stator iron core 103 and a stator winding 104. The stator iron core 103 i...

Embodiment 2

[0044] refer to Figures 4 to 5 , this embodiment is different from the first embodiment in that: this embodiment discloses a control method for a wide-efficiency region hybrid linear concentrated winding permanent magnet motor, wherein the current divider is based on the input bus voltage, torque, rotational speed The speed and torque look-up table is carried out through the signal; the current state working area is determined through the speed and torque table; the multi-phase current distribution mode is selected according to the working area to realize wide and high-efficiency control. The speed and torque table is determined according to the optimal distribution mode of efficiency of multi-phase with different ratios in the whole working state of the system, and the multi-phase current distribution mode corresponding to the table lookup table is the optimal current distribution state of efficiency under the corresponding working area.

[0045] Determining the distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com