Patents

Literature

331 results about "Current divider" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In electronics, a current divider is a simple linear circuit that produces an output current (IX) that is a fraction of its input current (IT). Current division refers to the splitting of current between the branches of the divider. The currents in the various branches of such a circuit will always divide in such a way as to minimize the total energy expended.

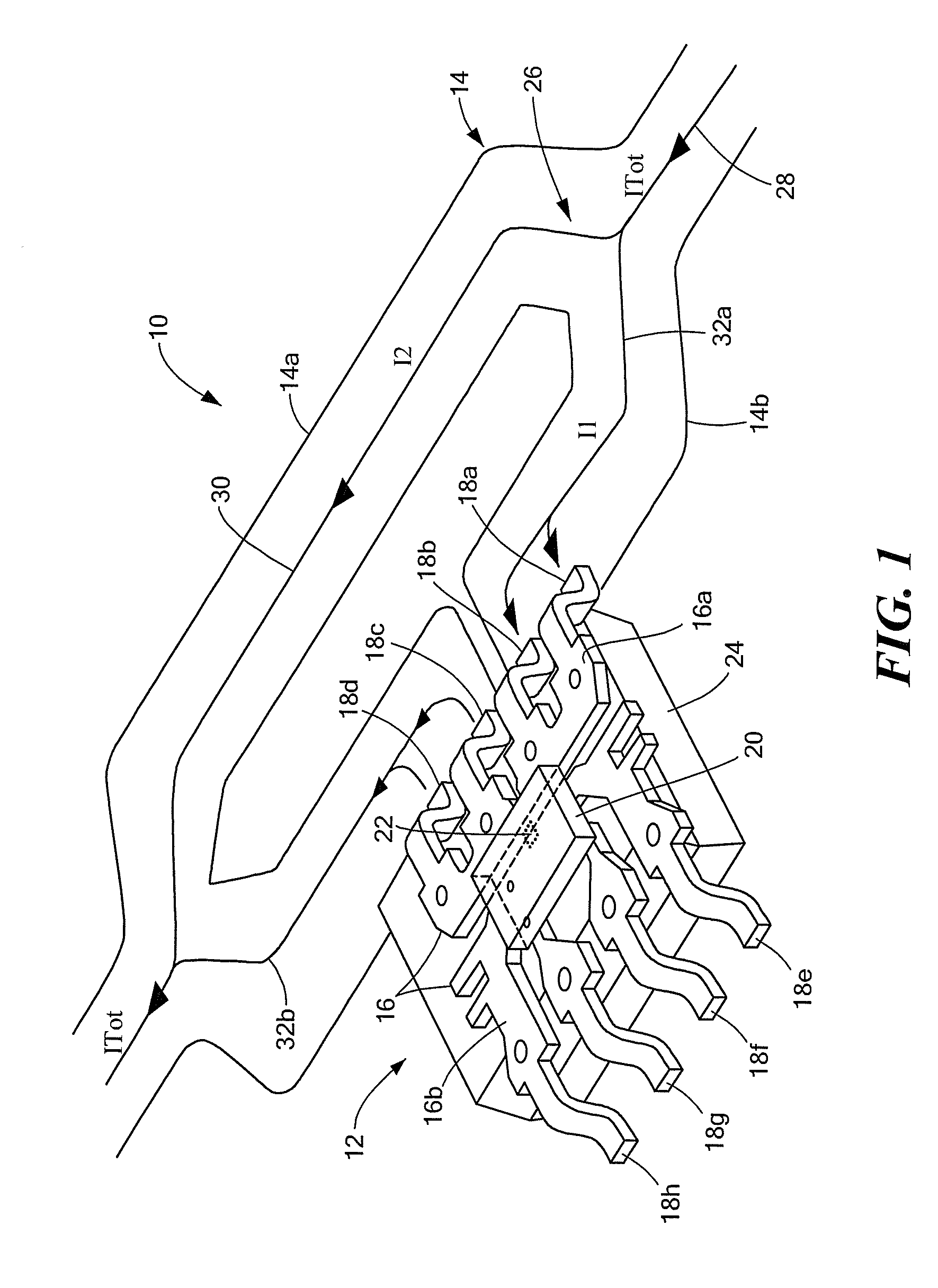

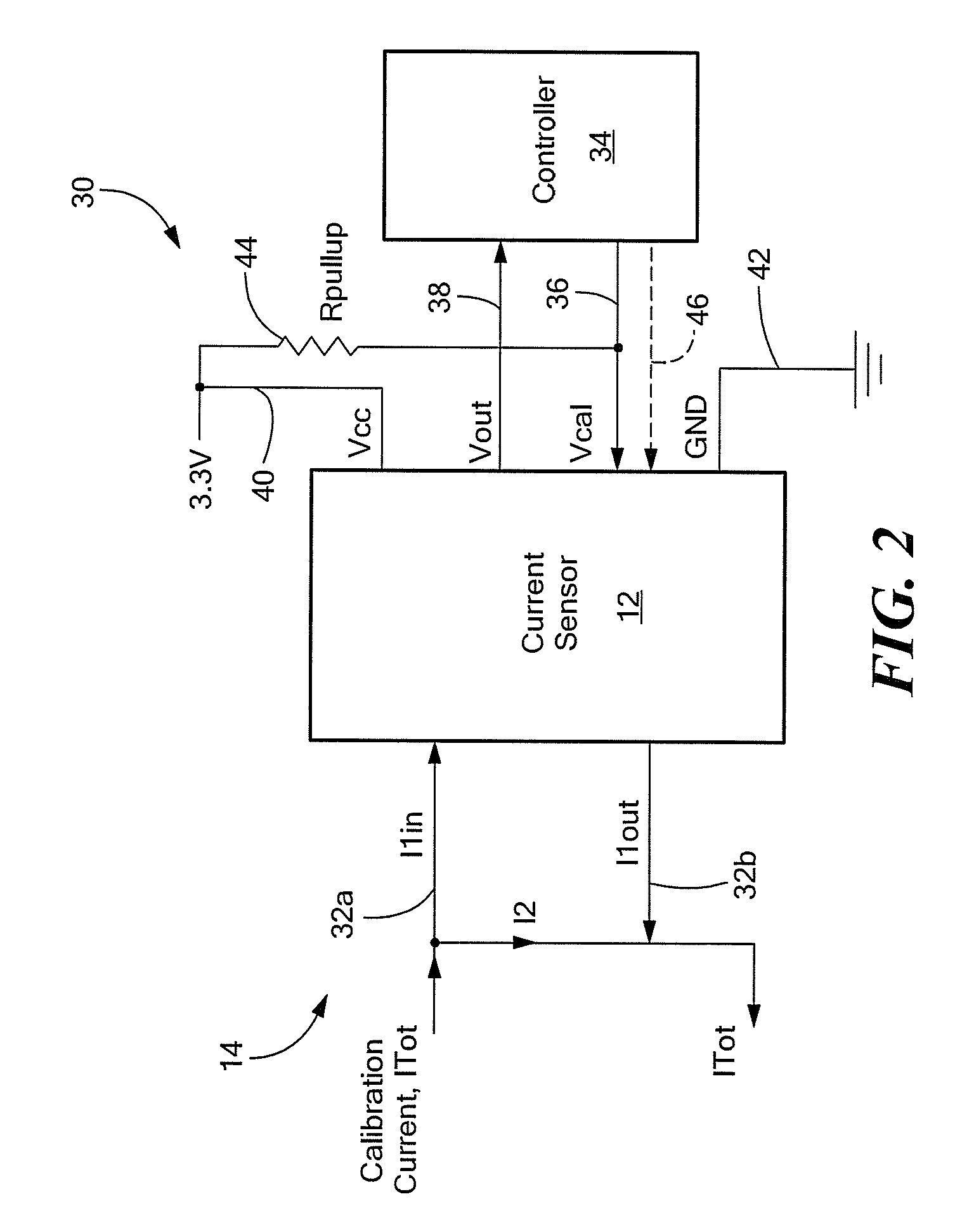

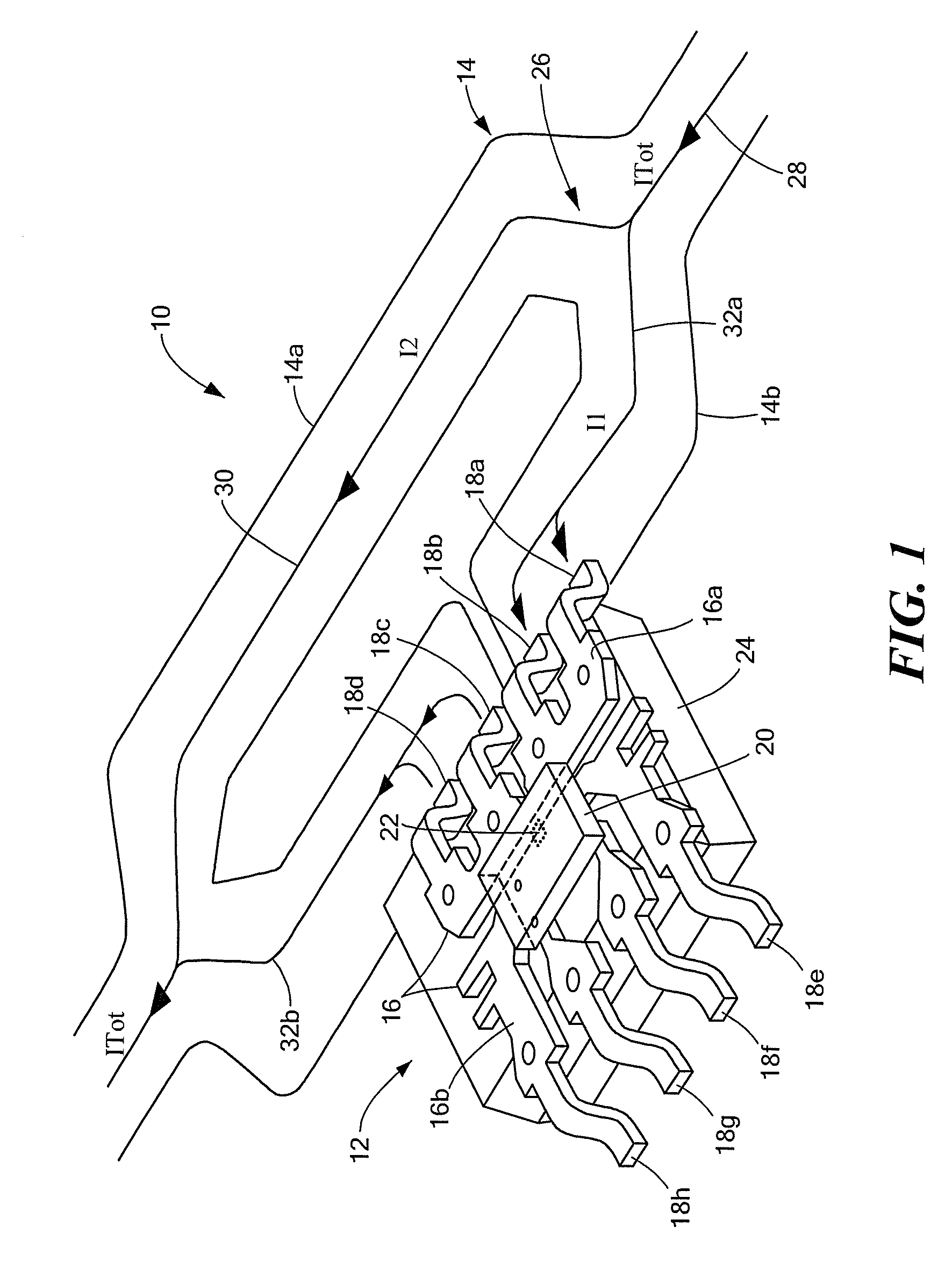

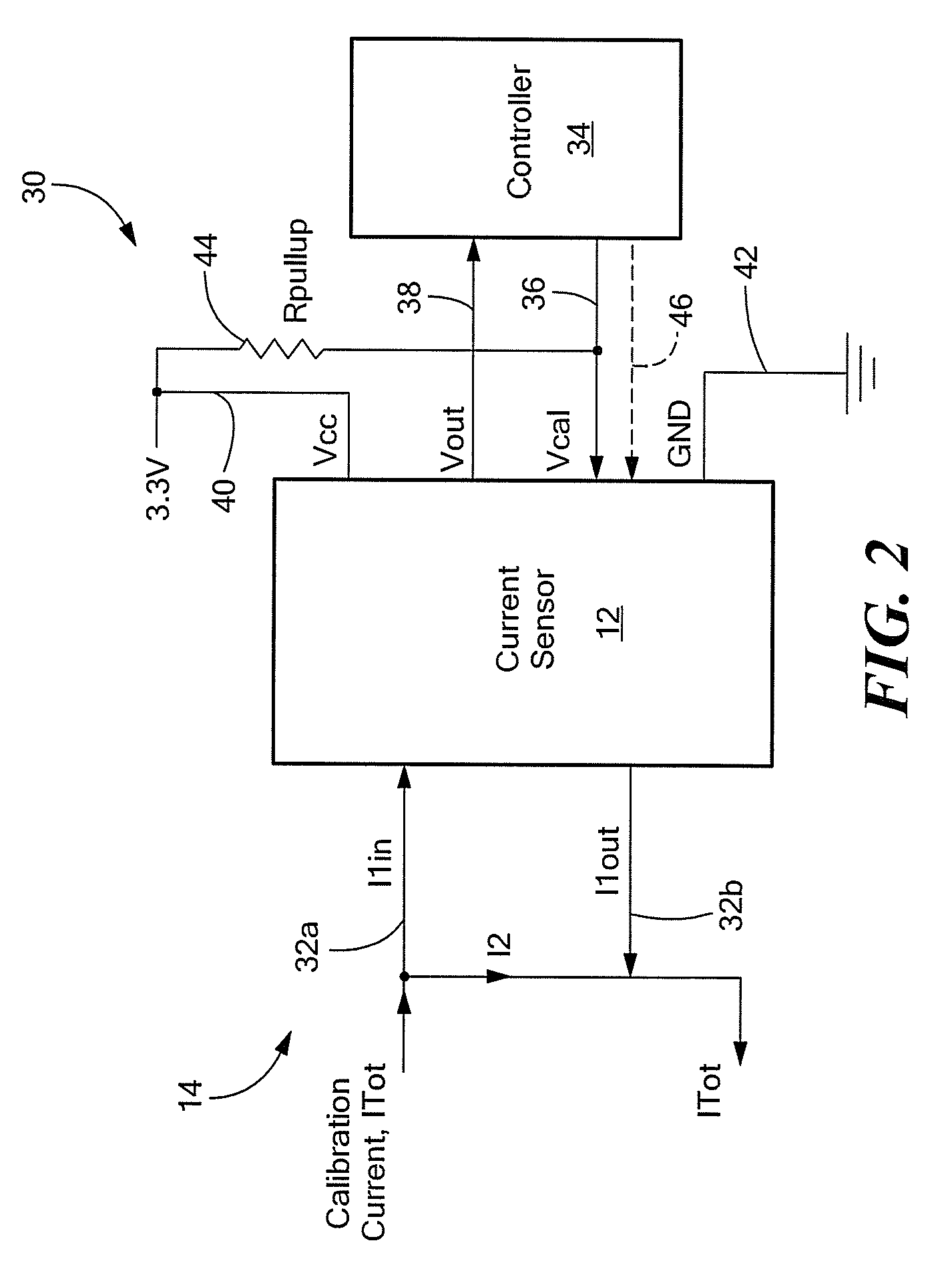

Current sensor with calibration for a current divider configuration

ActiveUS20130015843A1Acceleration measurement using interia forcesBase element modificationsShunt DeviceElectrical conductor

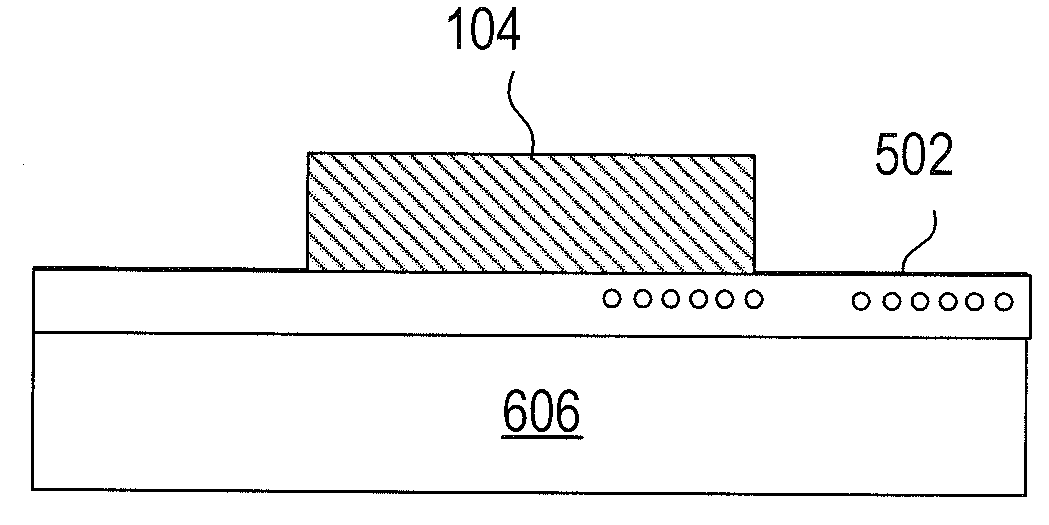

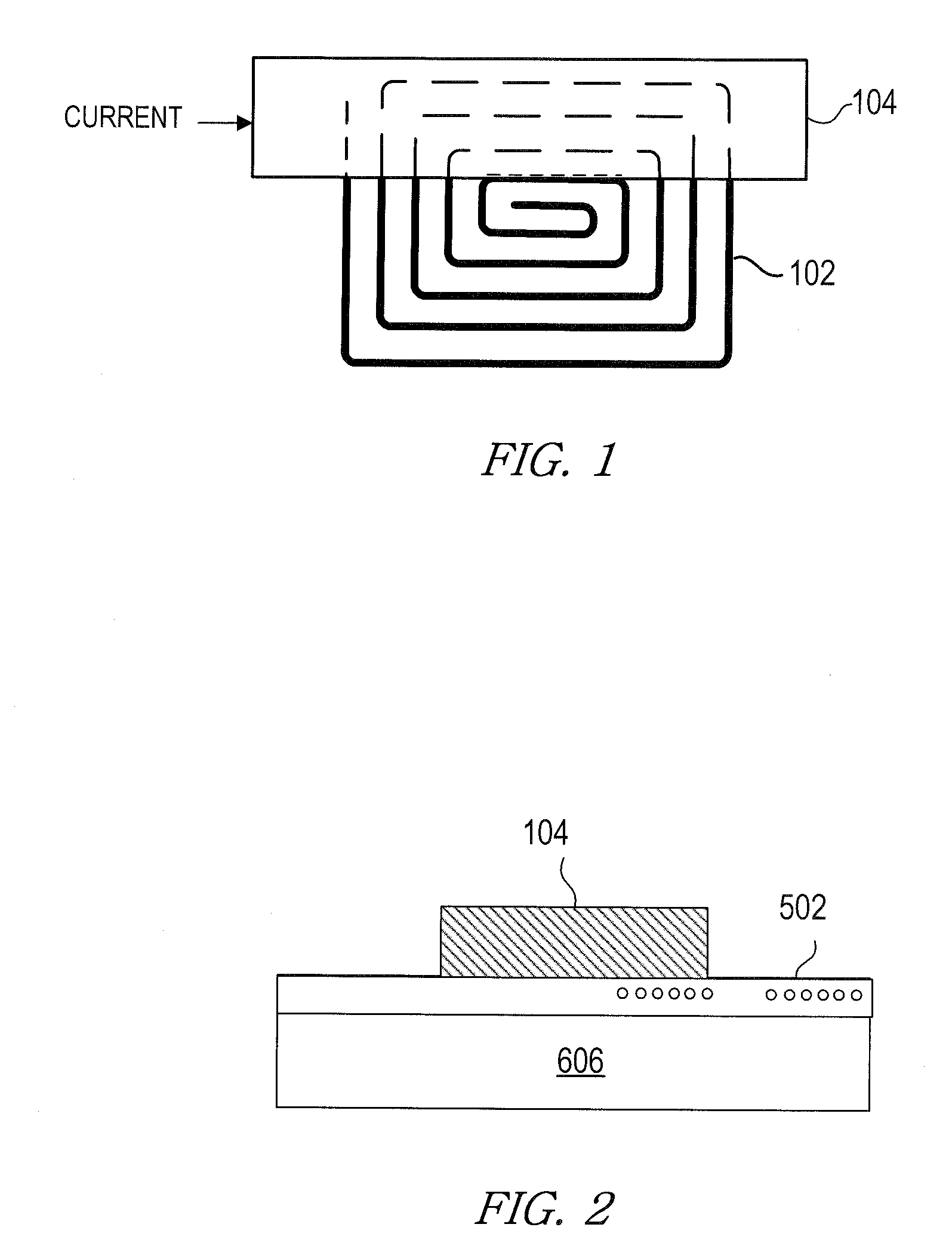

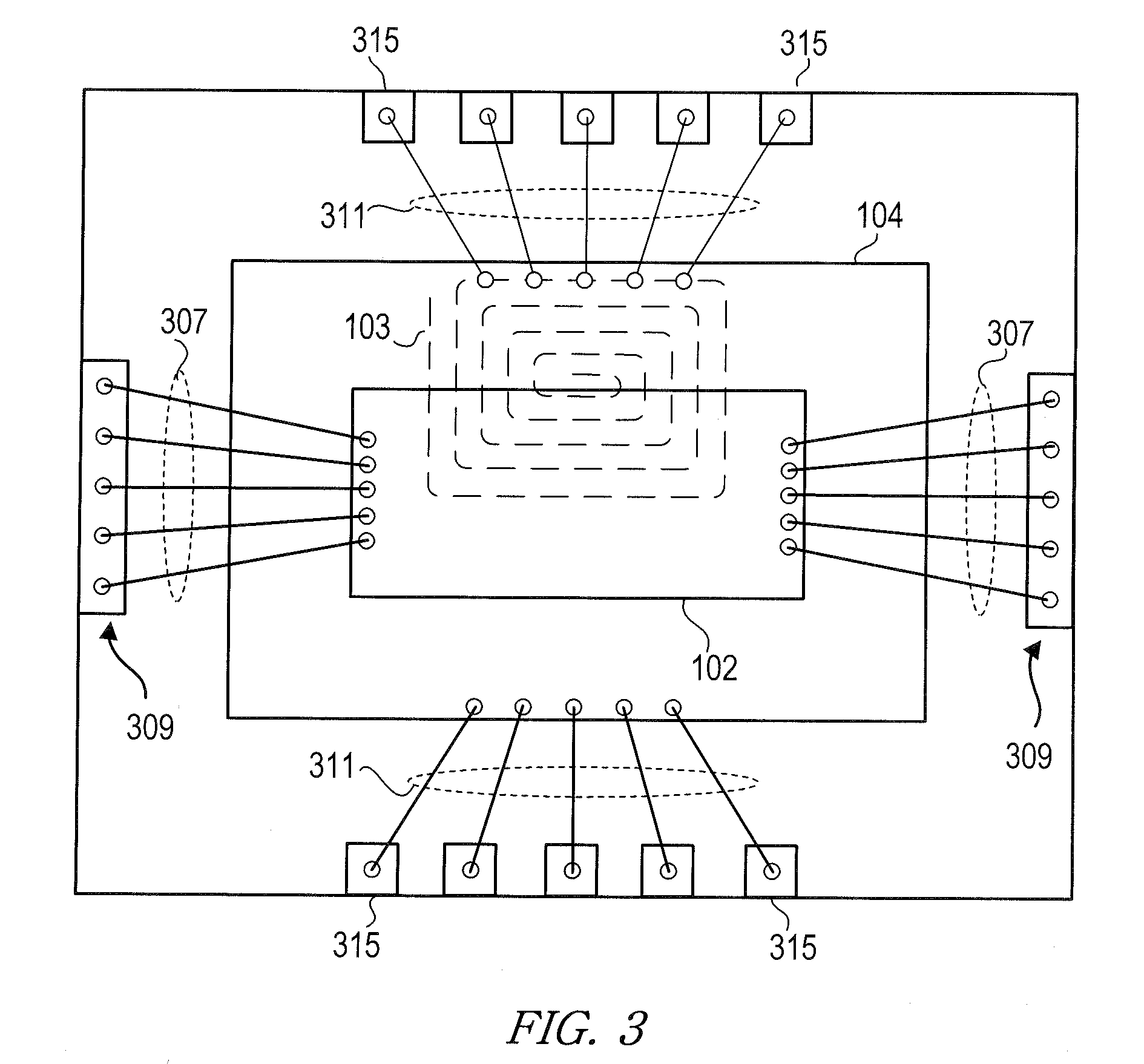

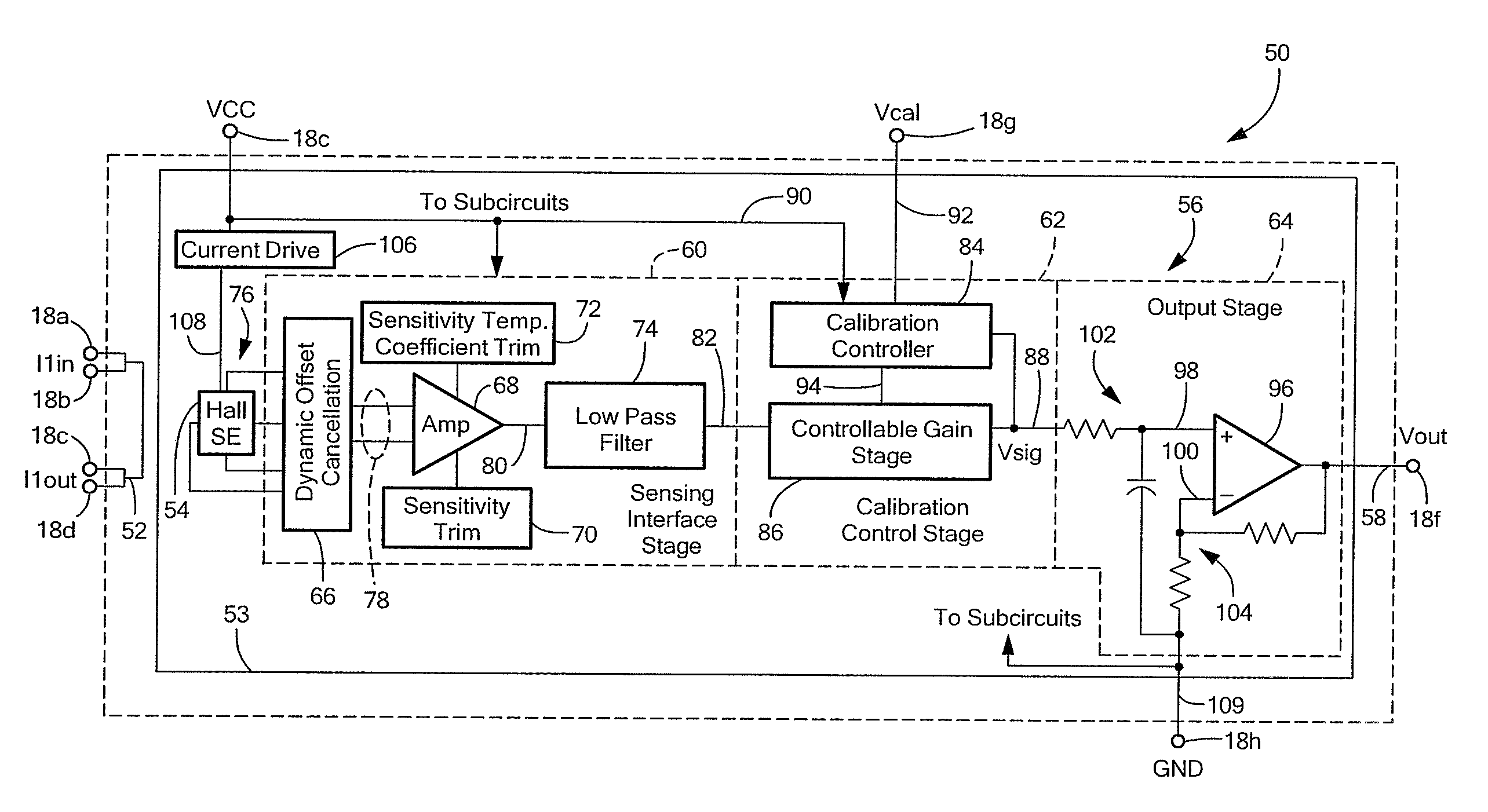

An integrated circuit (IC) current sensor that self-calibrates to adjust its signal gain when employed in a current divider configuration is presented. The current sensor includes an integrated current conductor, a magnetic field transducer, a controllable gain stage and a calibration controller. The integrated current conductor is adapted to receive a portion of a calibration current. The calibration current corresponds to a full scale current. The magnetic field transducer, responsive to the calibration current portion, provides a magnetic field signal having a magnitude proportional to a magnetic field generated by the calibration current portion. The controllable gain stage is configured to amplify the magnetic field signal with an adjustable gain to provide an amplified magnetic field signal. The calibration controller is responsive to a calibration command signal to adjust the adjustable gain of the controllable gain stage to a calibrated gain in order to provide the amplified magnetic field signal at a predetermined voltage level that corresponds to a desired current sensor output signal voltage level if the full scale current were received by the integrated current conductor.

Owner:ALLEGRO MICROSYSTEMS INC

Electrostatic discharge protection circuit

InactiveUS6864536B2Eliminate the problemTransistorSemiconductor/solid-state device detailsCurrent dividerEngineering

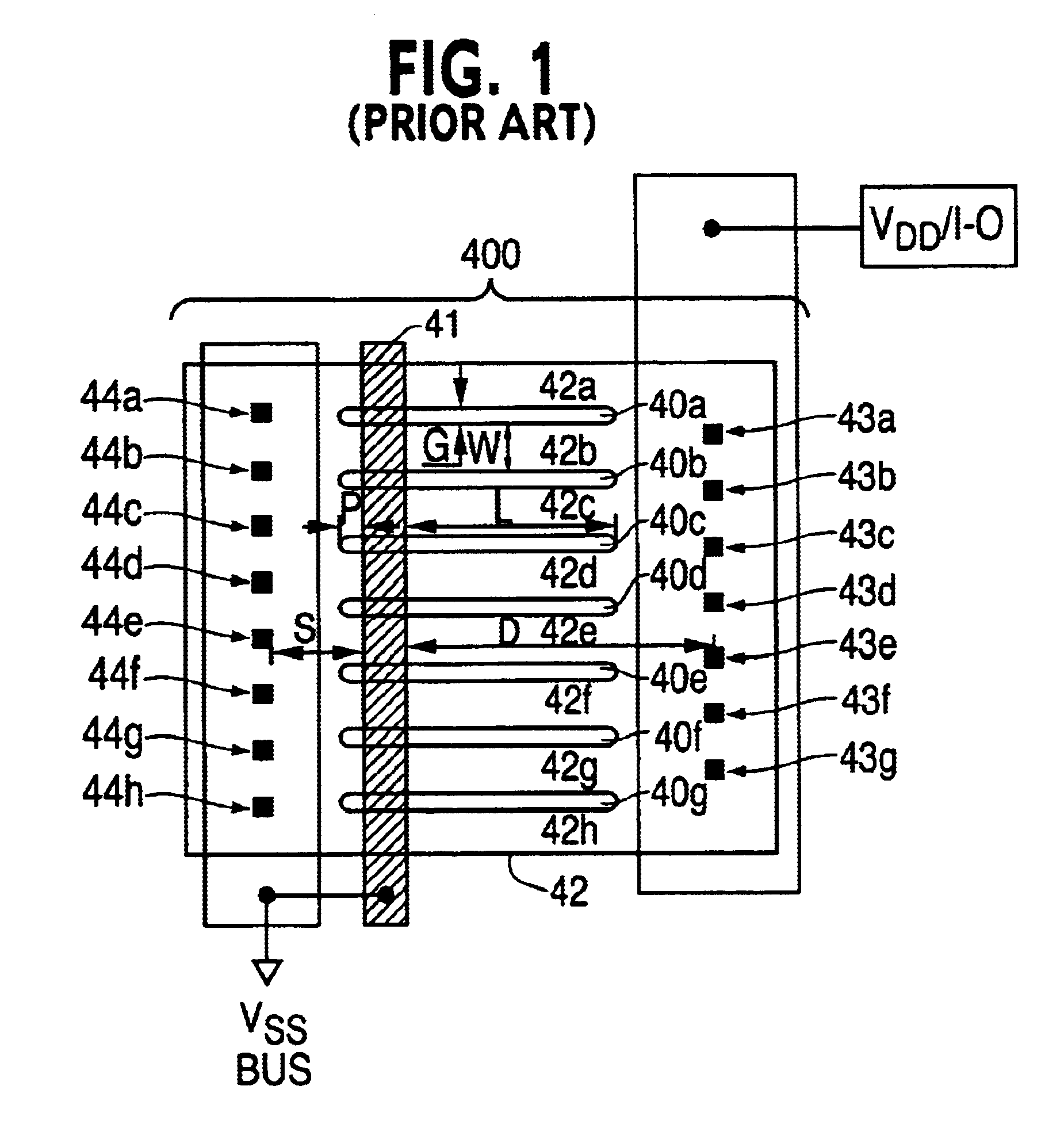

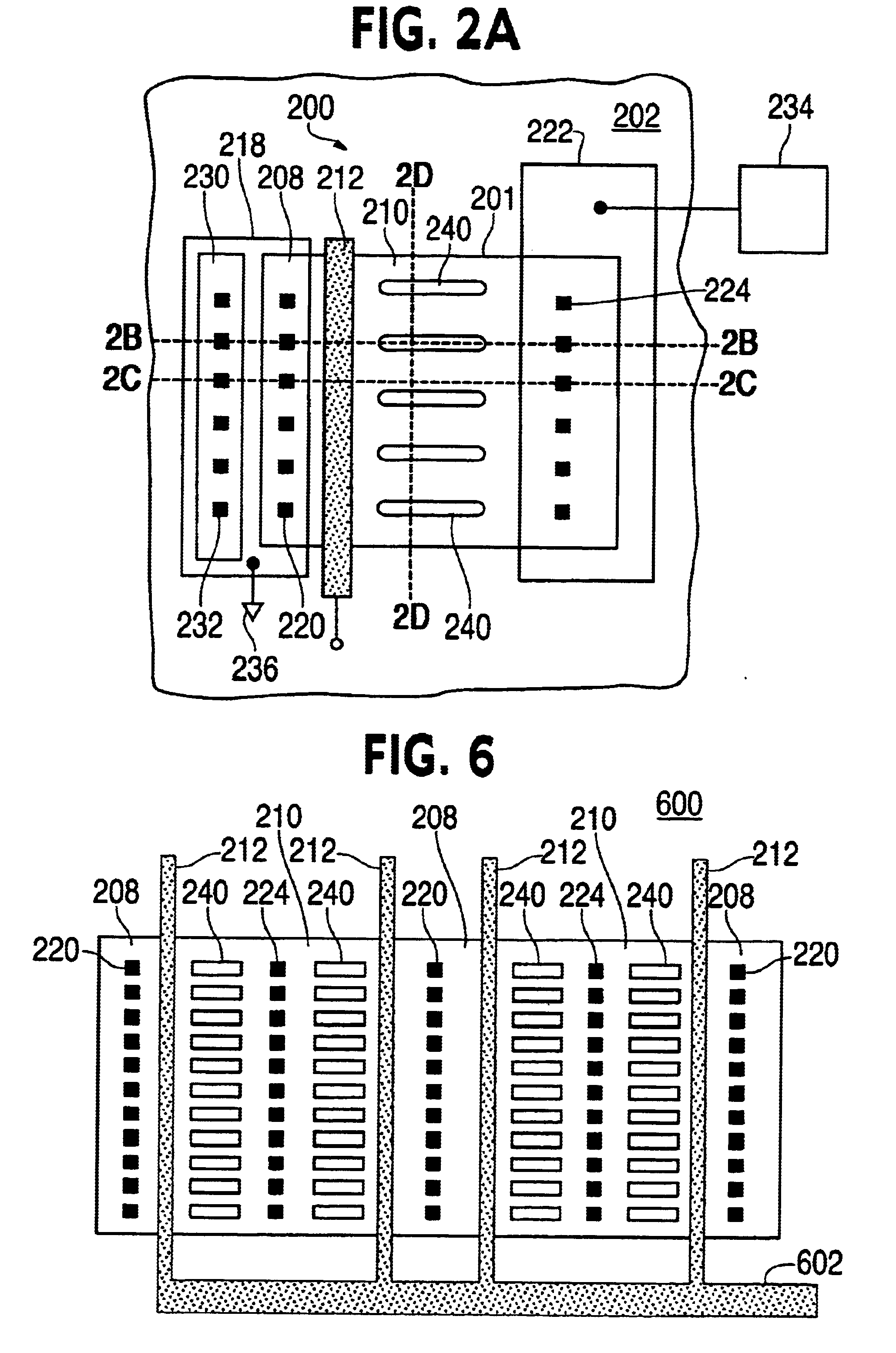

An electrostatic discharge (ESD) protection device includes a semiconductor layer, a source region formed in the layer, a drain region formed in the layer, a channel region in the layer between the source and drain regions, and a gate over the channel region. A plurality of current divider segments are distributed on the drain region and extend between the gate and drain contacts. The segments can be formed of polysilicon or a field oxide.

Owner:WINBOND ELECTRONICS CORP

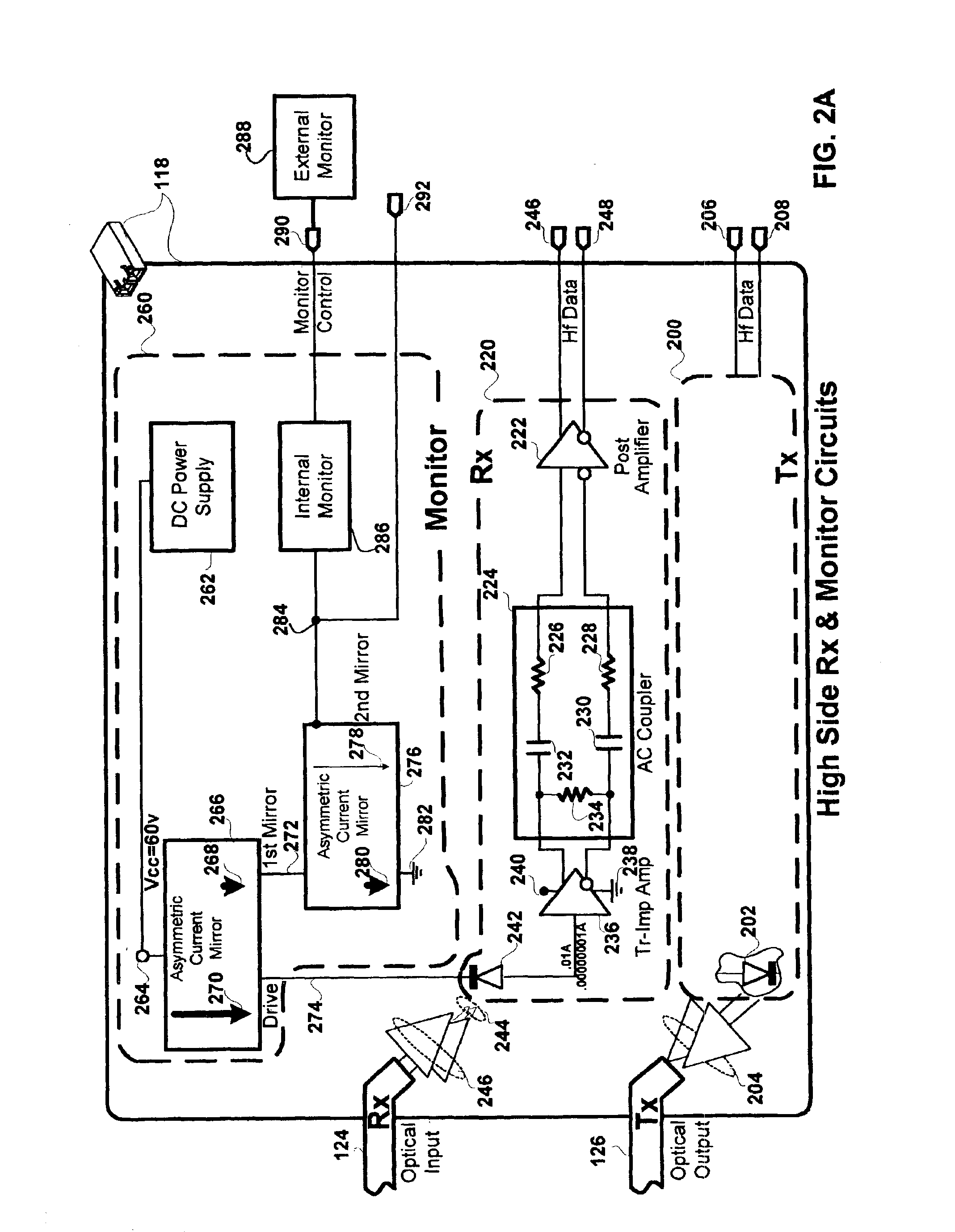

Method and apparatus for monitoring a photo-detector

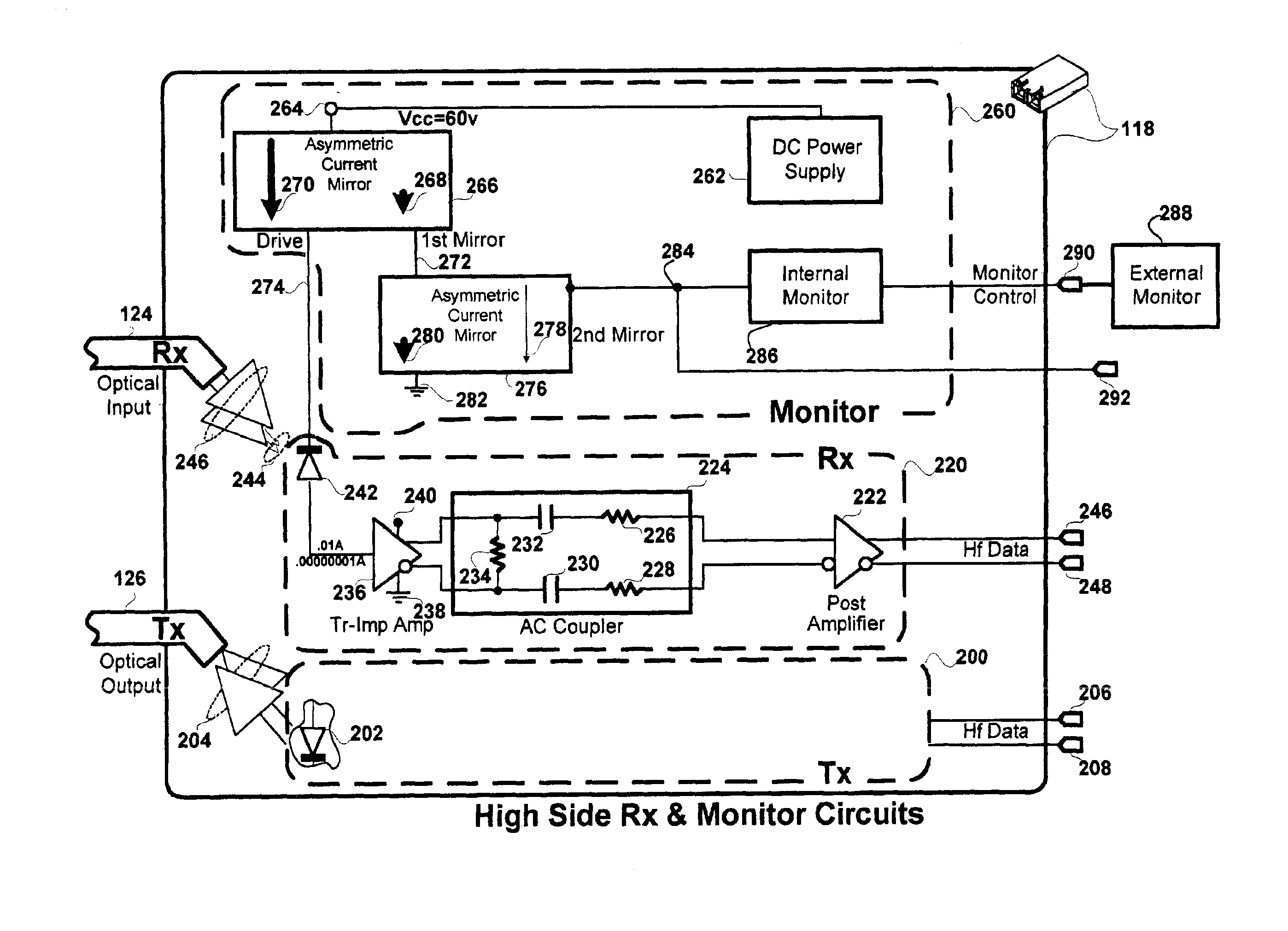

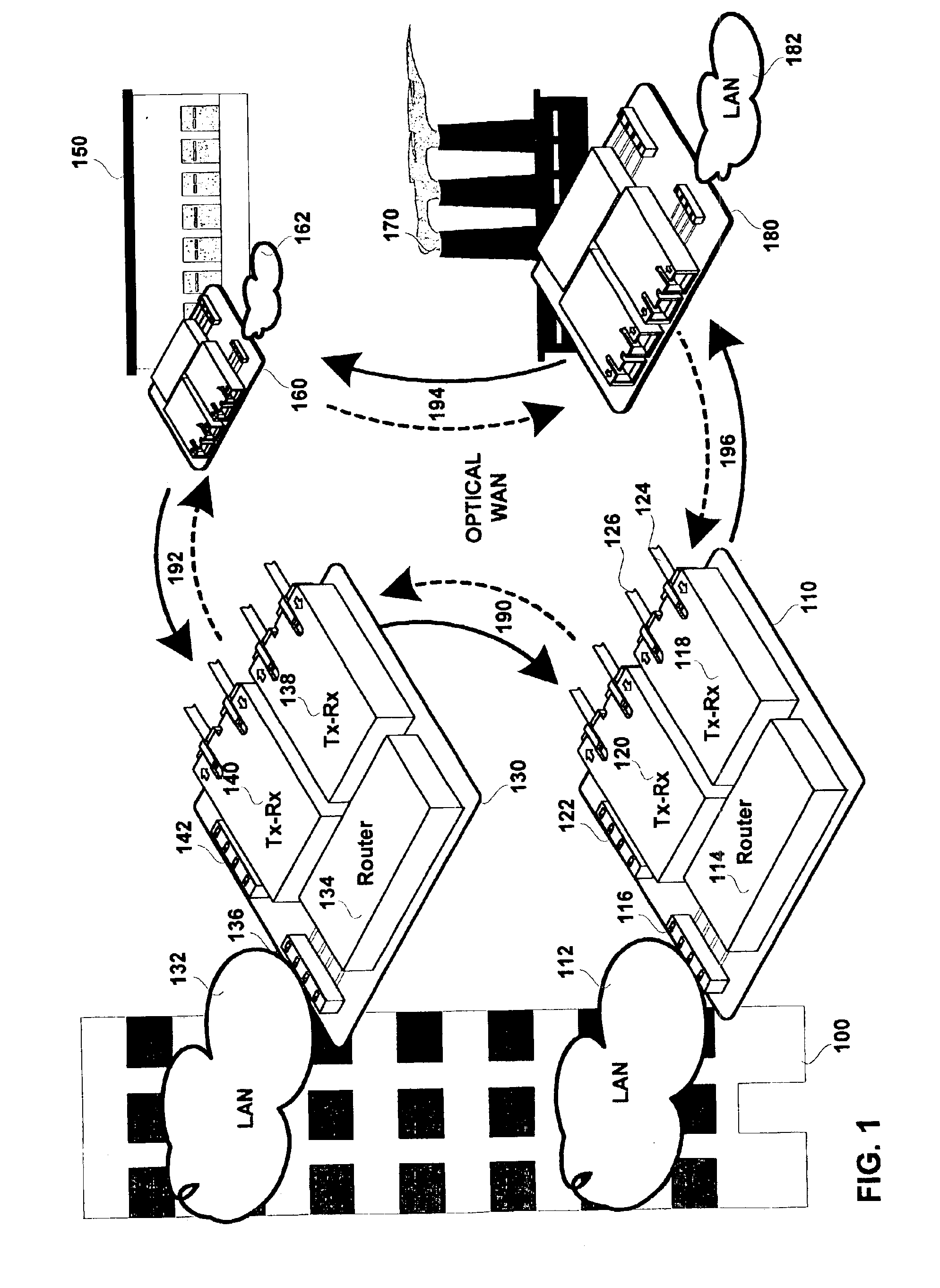

InactiveUS6888123B2Material analysis by optical meansPhotoelectric discharge tubesElectrical resistance and conductanceCurrent divider

An optical signal detector monitoring circuit can include a current divider current mirror (CDCM) and a current multiplier current mirror (CMCM). A mirror leg of the CDCM generates a current corresponding with a part of the CDCM's primary leg current. The CMCM's primary leg couples to the CDCM's mirror leg. The CMCM generates a mirror leg current corresponding with a multiple of its primary leg current. Another circuit can include a first current mirror having a primary current leg (PCL), coupled between an optical signal detector and one of an electrical source and an electrical sink, that exhibits a resistance corresponding with a part of the resistance of the first current mirror's mirror current leg (MCL). The circuit's second current mirror has a MCL that exhibits a resistance corresnonding with a part of the resistance of the second current mirror's PCL, which couples with the first current mirror's MCL.

Owner:II VI DELAWARE INC

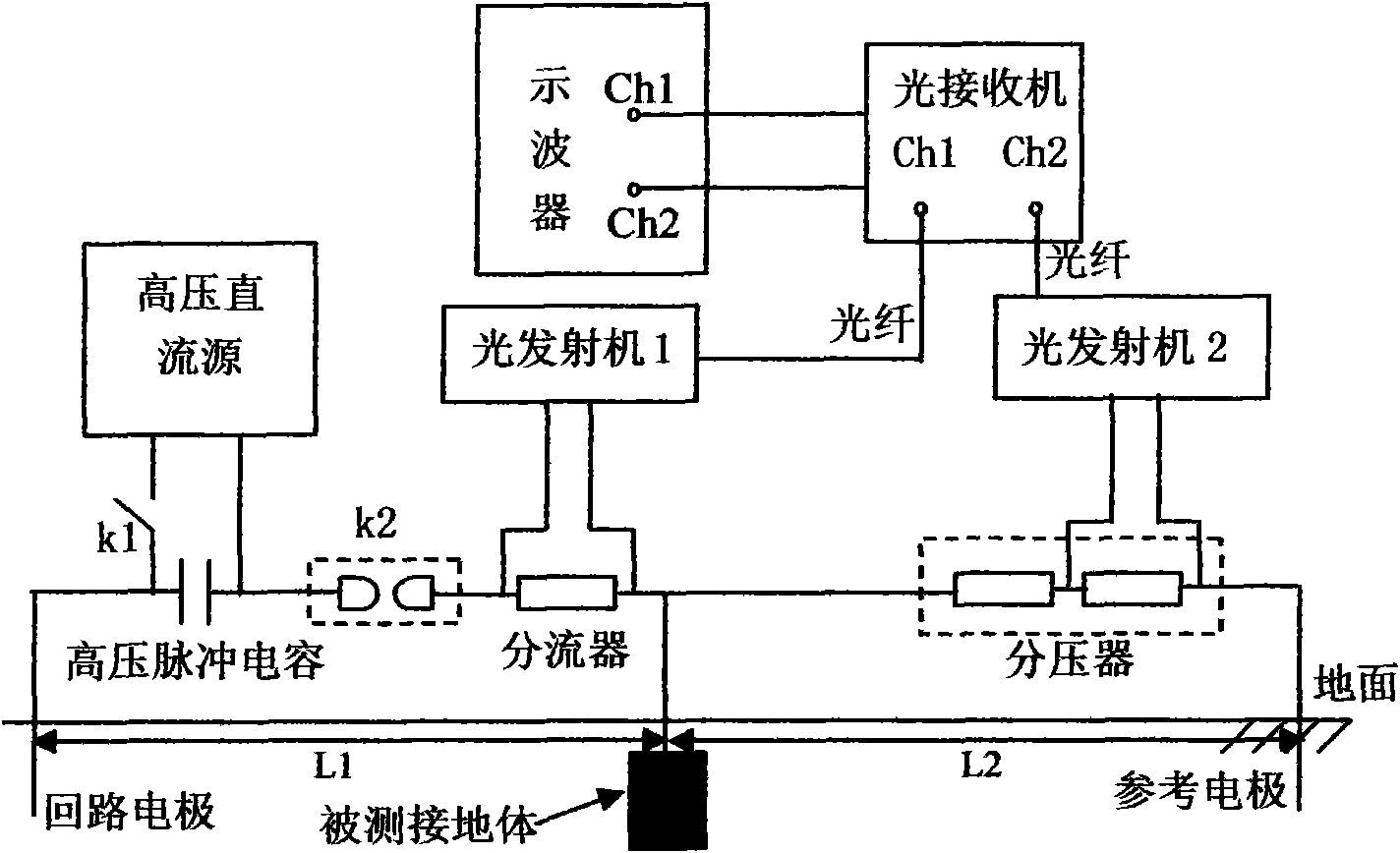

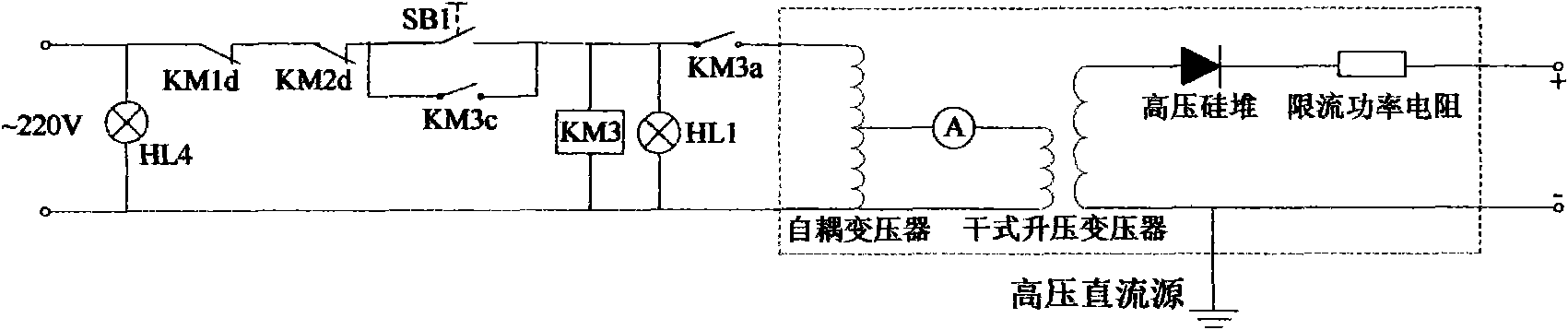

Impact grounding impedance measuring system and measuring method thereof

InactiveCN101819233AEasy to controlIdentify working status in timeEarth resistance measurementsShunt DeviceObservational error

The invention provides an impact grounding impedance measuring system which comprises a high-voltage direct current source, a high-voltage pulse capacitor, a discharging loop, a high-voltage charging switch, a high-voltage discharging switch, a resistance current divider, a water resistance voltage divider, a high-voltage pulse source control table, a digital oscilloscope and an optical fiber signal transmitting system, wherein the resistance current divider is connected with the high-voltage pulse capacitor and the discharging loop in series; the water resistance voltage divider is connected with a reference grounding electrode of the discharging loop; the optical fiber signal transmitting system comprises an optical transmitter, an optical fiber and an optical receiver; the voltage divider and the current divider are respectively connected with the digital oscilloscope through the optical fiber signal transmitting system; and the high-voltage discharging switch is a motion ball gap switch. The invention has the advantages of compact structure, small volume, convenient carrying, simple operation, accurate and stable measuring value, reduction of electromagnetic interference and reduction of measuring error.

Owner:PLA UNIV OF SCI & TECH

Method for measuring impact current division coefficient of power transmission line tower with lightning conductor

ActiveCN103823101ARealize measurementImprove accuracyCurrent/voltage measurementShunt DeviceLow voltage

The invention provides a method for measuring an impact current division coefficient of a power transmission line tower with a lightning conductor. The method comprises the steps of firstly, collecting tower parameters, including the diagonal length of a tower grounding device and the form of the tower, secondly, driving an auxiliary grounding electrode in ground near the tower in such a manner that the distance between the auxiliary grounding electrode and the tower is more than two times the diagonal length of the tower grounding device, connecting a high-voltage end of impact power output with a current divider in series through a high-voltage conductor and then connecting to the joint of the tower and the lightning conductor, and connecting a low-voltage end of impact power output with the auxiliary grounding electrode, wherein the resistor R of the current divider is a high-precision non-inductive resistor of 0.01 ohm. The method is capable of measuring the impact current division coefficient of the power transmission line tower with the lightning conductor, avoiding errors caused by theoretical assumption and improving the accuracy of lightning protection counterattack calculation of the power transmission line.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

Detection method and device for design of grounding grid of substation

ActiveCN102495327AAchieve correct calculationGuarantee the safety of lifeImpedence measurementsFault locationGrounding gridElectrical resistance and conductance

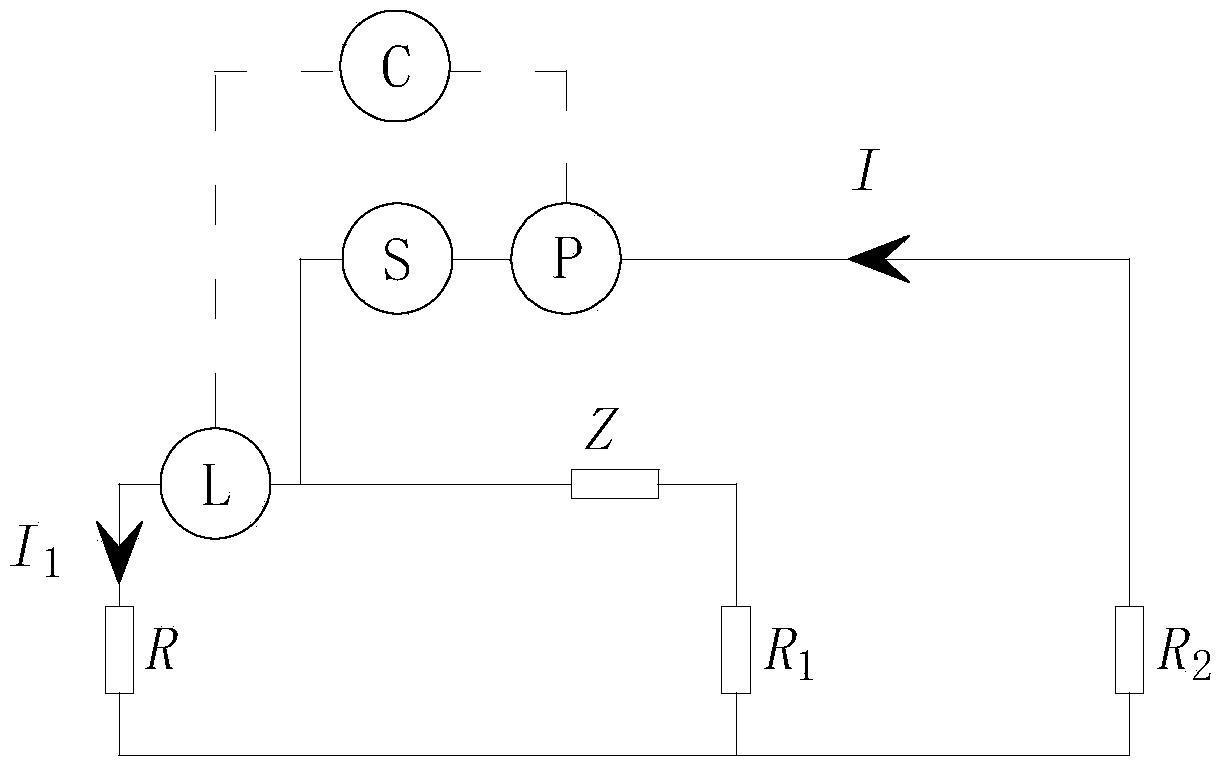

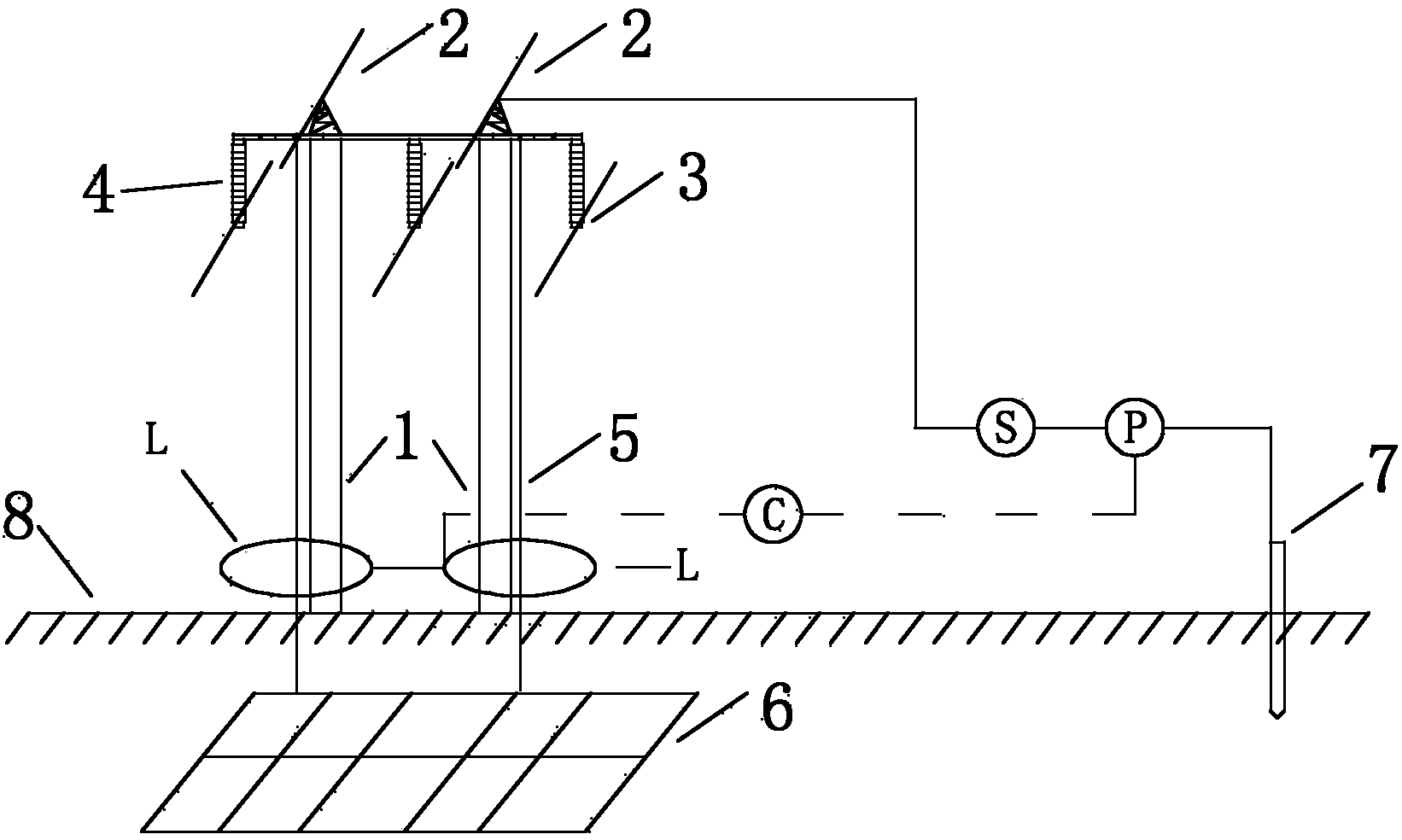

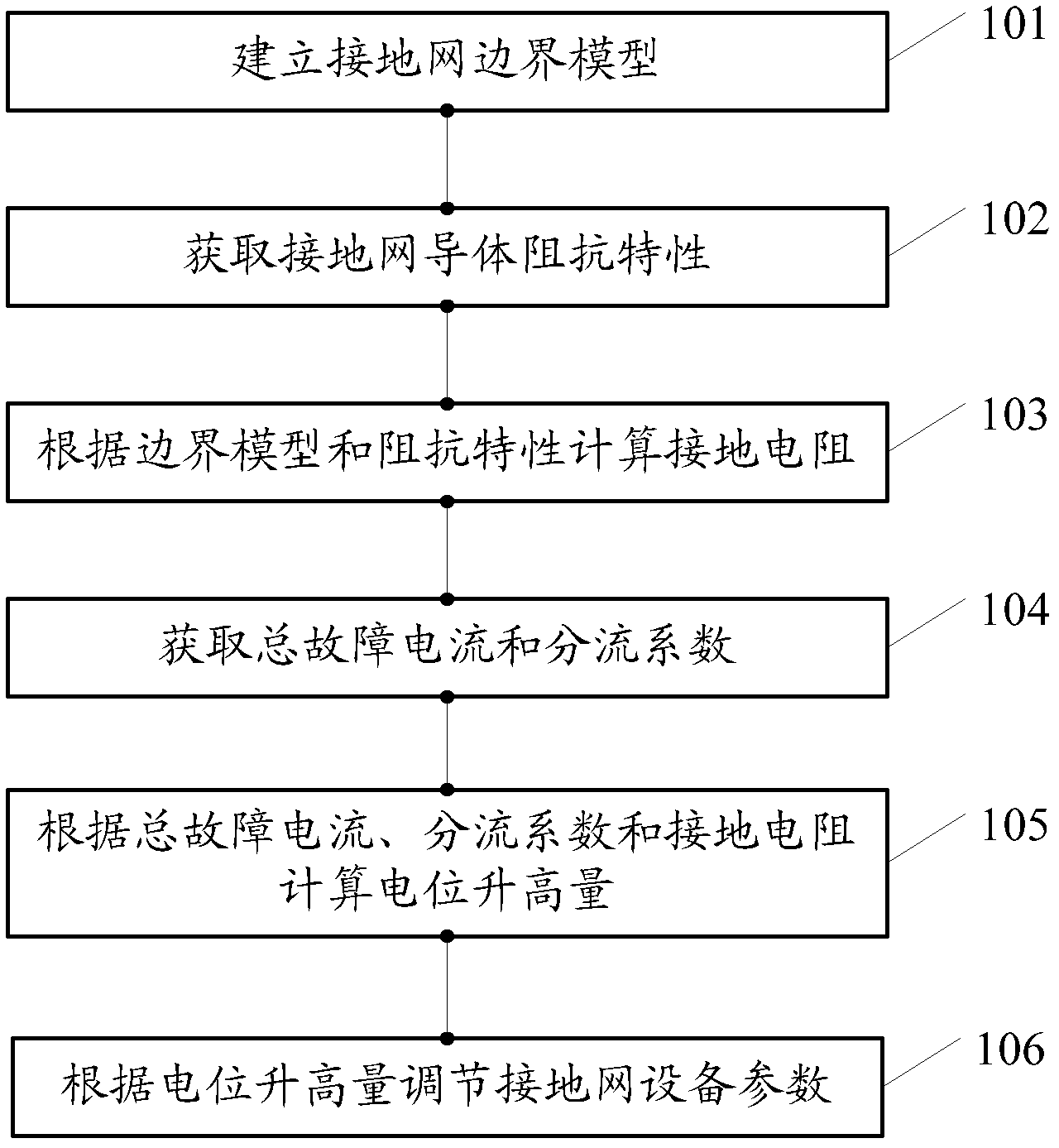

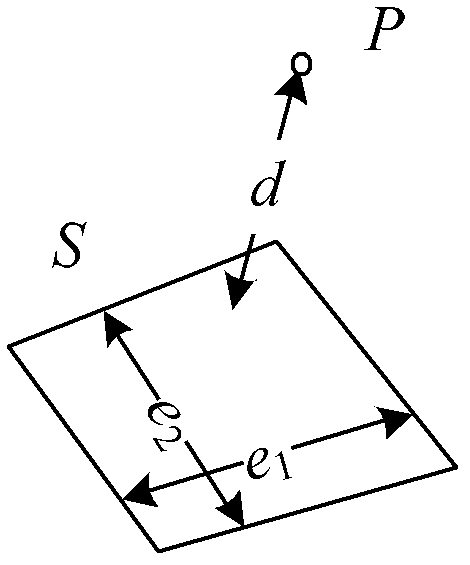

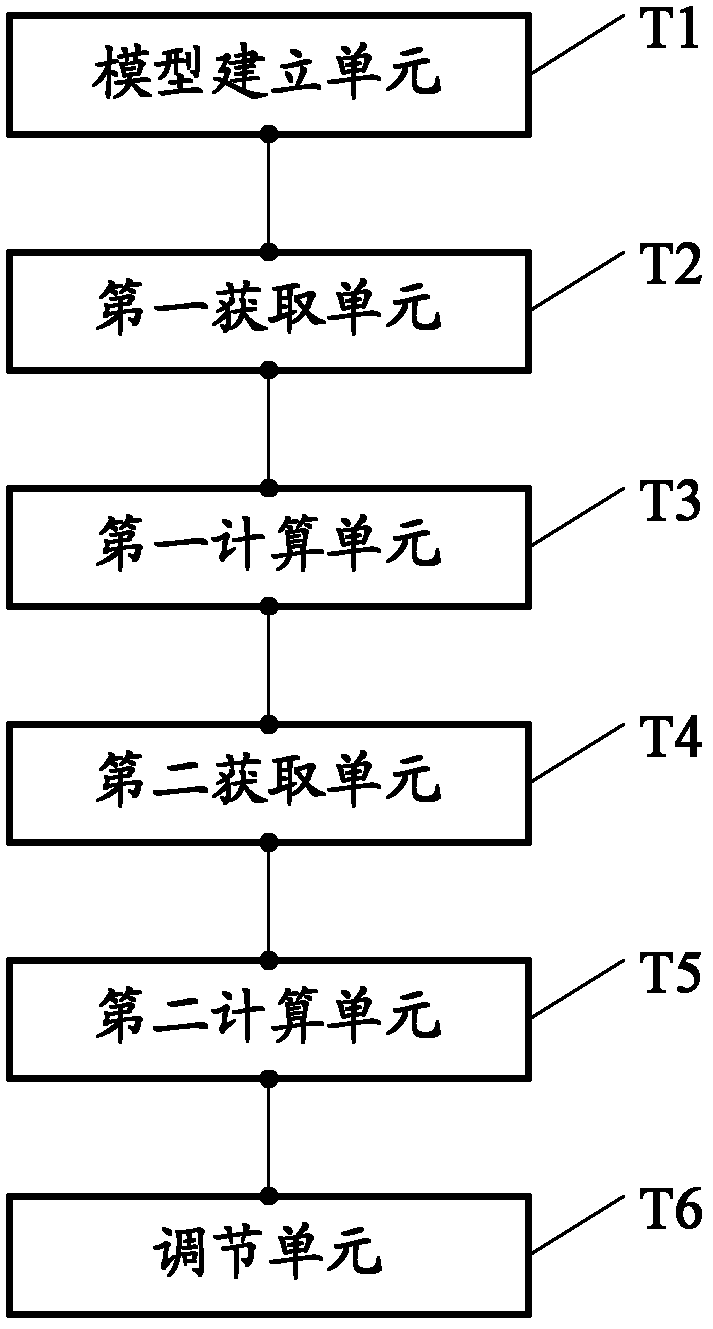

The invention provides a detection method for the design of a grounding grid of a substation, which includes the steps: building a boundary element model of the grounding grid; obtaining impedance characteristics of a grounding grid conductor; computing the grounding resistance of the grounding grid according to the impedance characteristics of the grounding grid conductor and the built boundary element model; obtaining total fault current and current divider coefficient of the grounding grid; determining the quantity of potential rise caused by the grounding grid according to the total fault current, the current divider coefficient and the grounding resistance of the grounding grid; and adjusting equipment parameters corresponding to the grounding grid according to the quantity of potential rise caused by the grounding grid. The invention further provides a detection device for the design of the grounding grid of the substation, which can be used for increasing the accurate rate of the grounding resistance of the grounding grid of the substation, increasing the accurate rate of the quantity of potential rise caused by the grounding grid and ensuring safety of staff and normal power transmission.

Owner:ZHUHAI POWER SUPPLY BUREAU GUANGDONG POWER GIRD CO

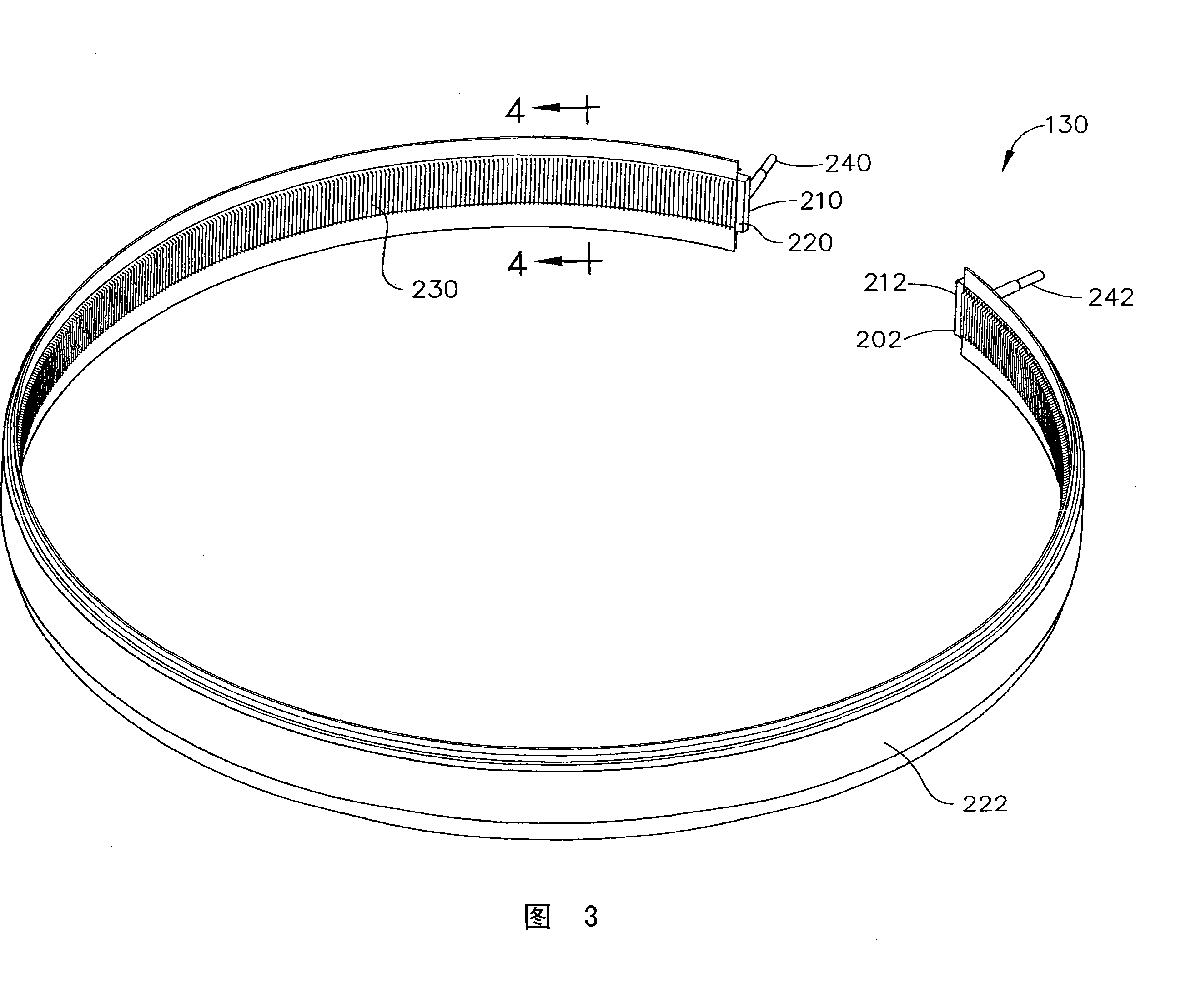

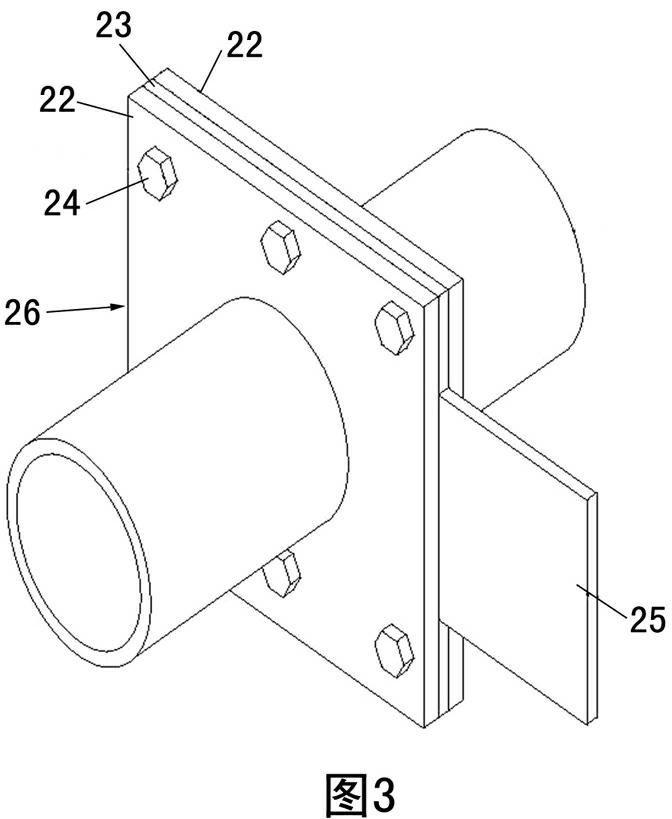

Heat exchanger assembly for a gas turbine engine

InactiveCN101178027ATurbine/propulsion engine coolingEfficient propulsion technologiesCurrent dividerGas turbines

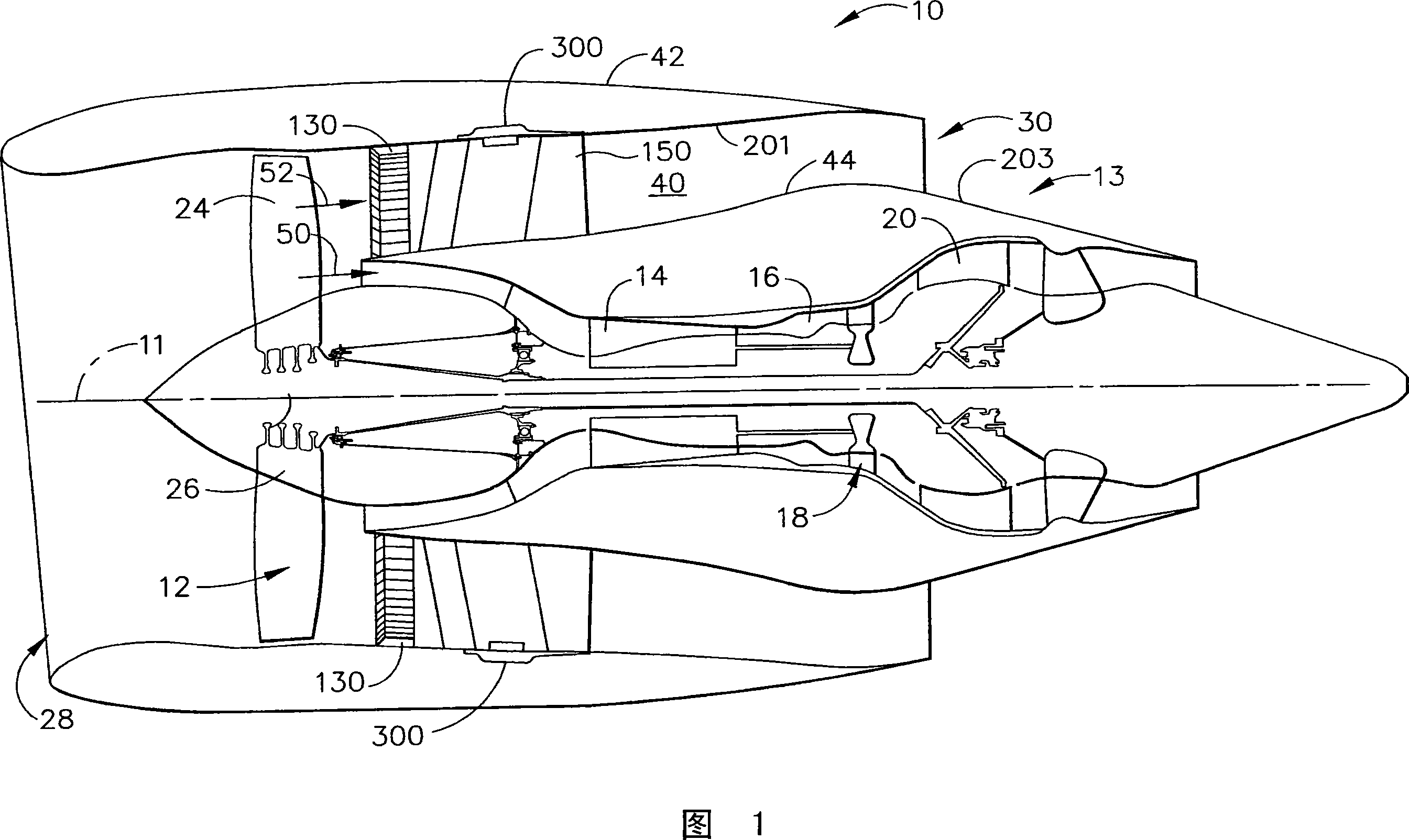

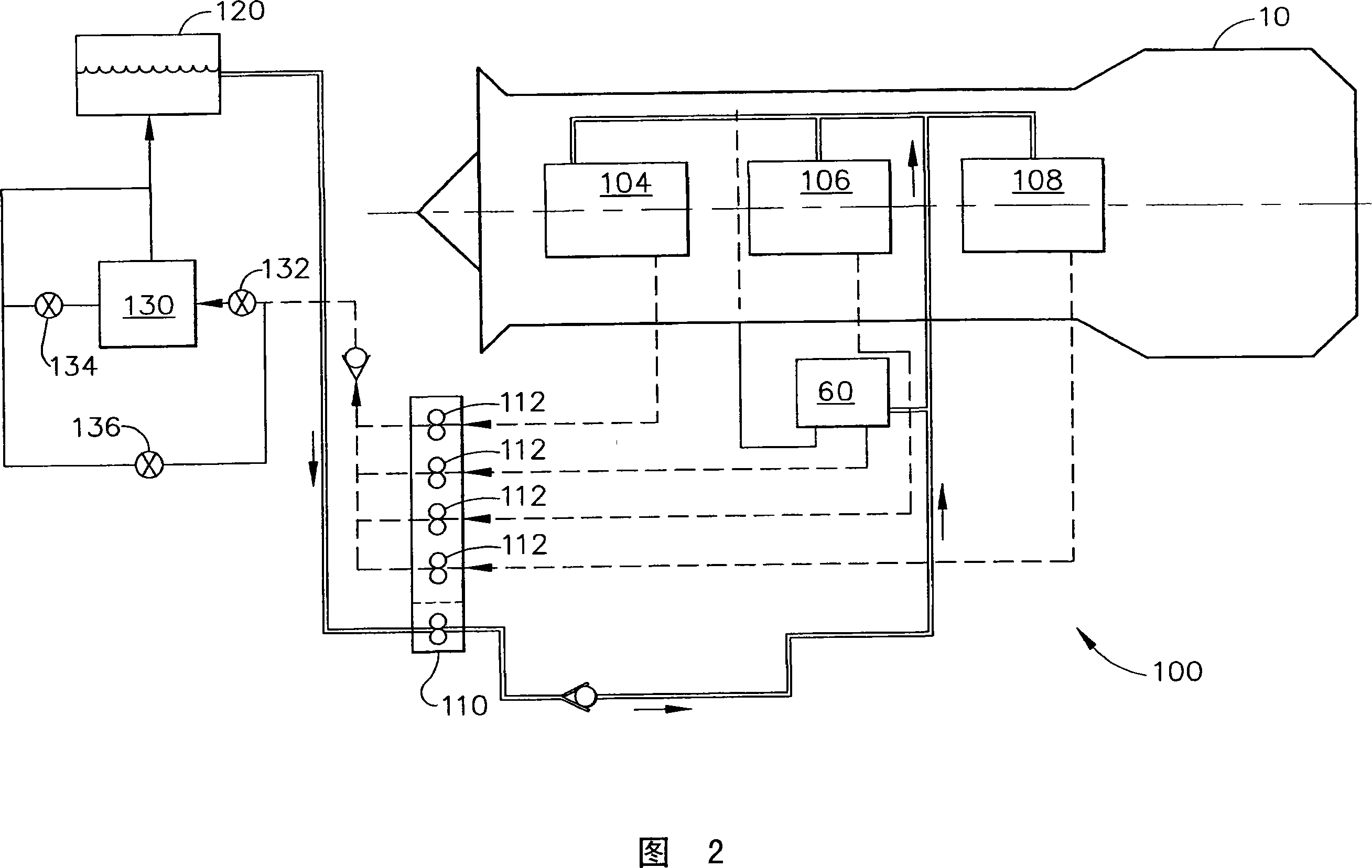

The invention relates to heat exchanger device (130) for a gas turbine (10). The invention comprises a fan (12), a fan cover (42) which is used for basically limiting the fan, a central gas turbine (13), and a current divider (44) which is used for basically limiting the central gas turbine. Therefore, a by-pass pipe (40) is limited between the fan cover and a separator. The heat exchanger comprises an arc longitudinal inner plate (360), and an arc longitudinal outer plate (270) which is connected with the longitudinal inner plate. Therefore, a cavity (364) is formed between the longitudinal inner plate and the longitudinal outer plate, and at least part of an arc heat exchanger (300) is connected with the cavity. Therefore, the heat exchanger is connected with the fan cover, and the heat exchanger is positioned upstream or downstream from the fan.

Owner:GENERAL ELECTRIC CO

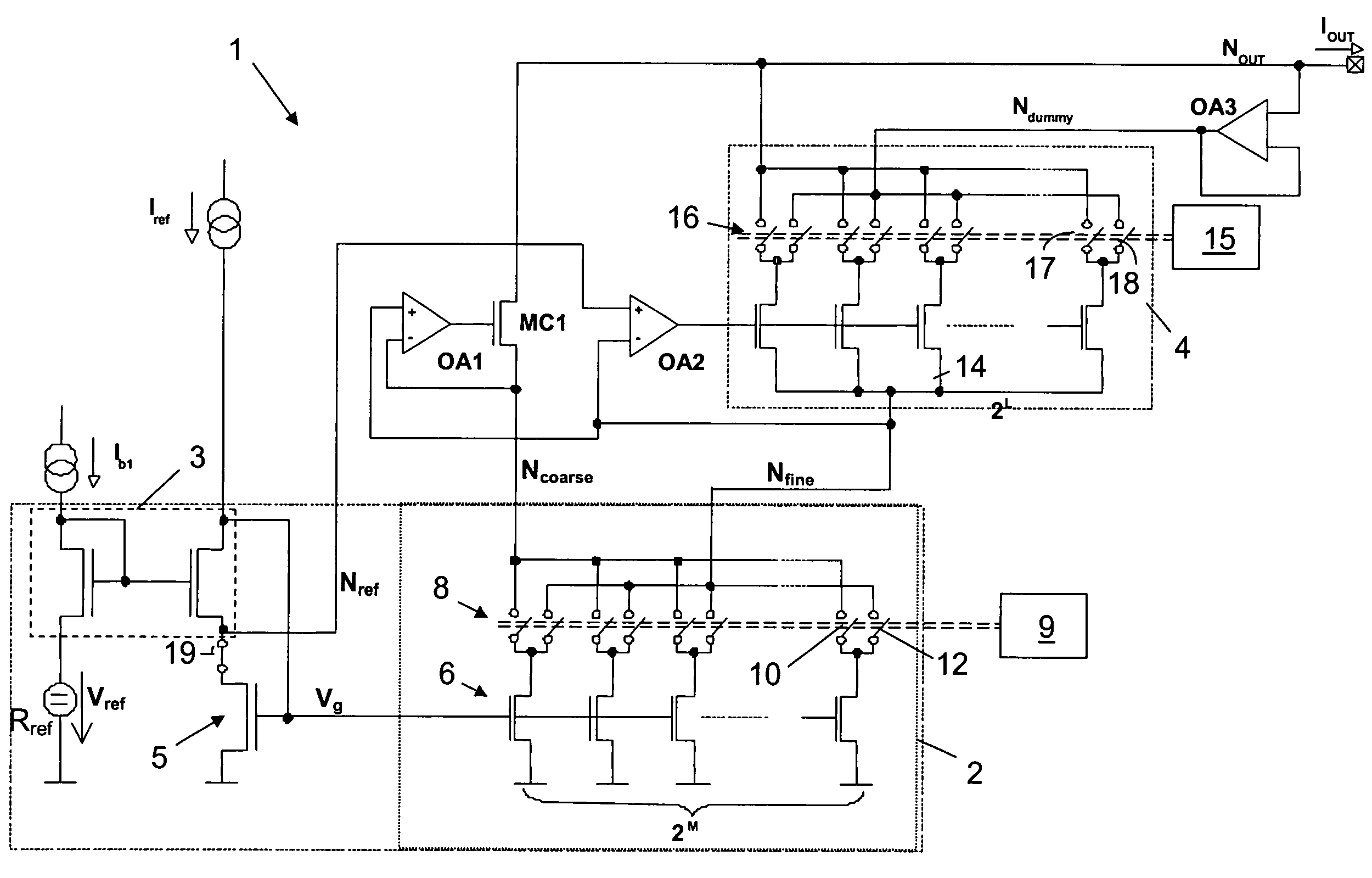

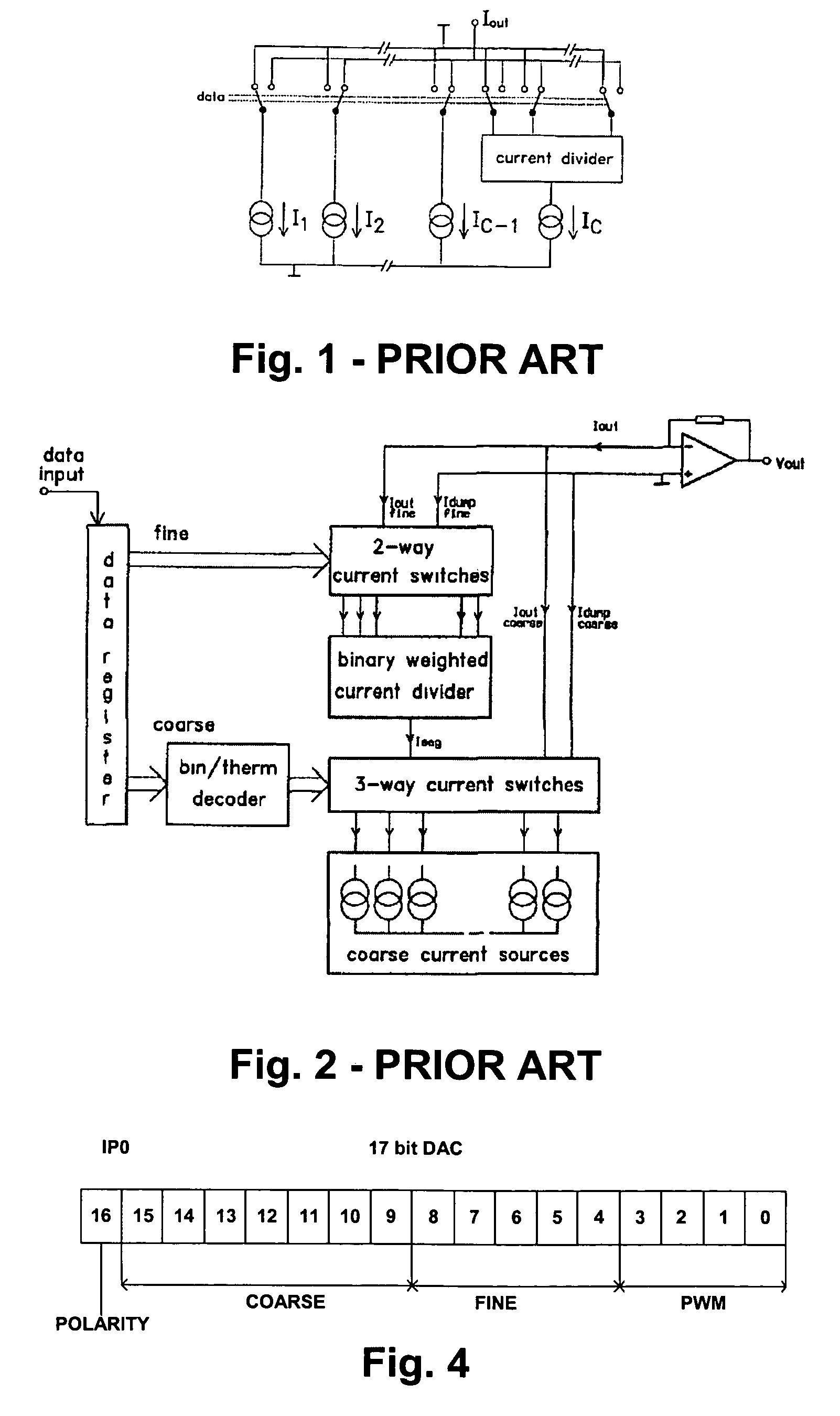

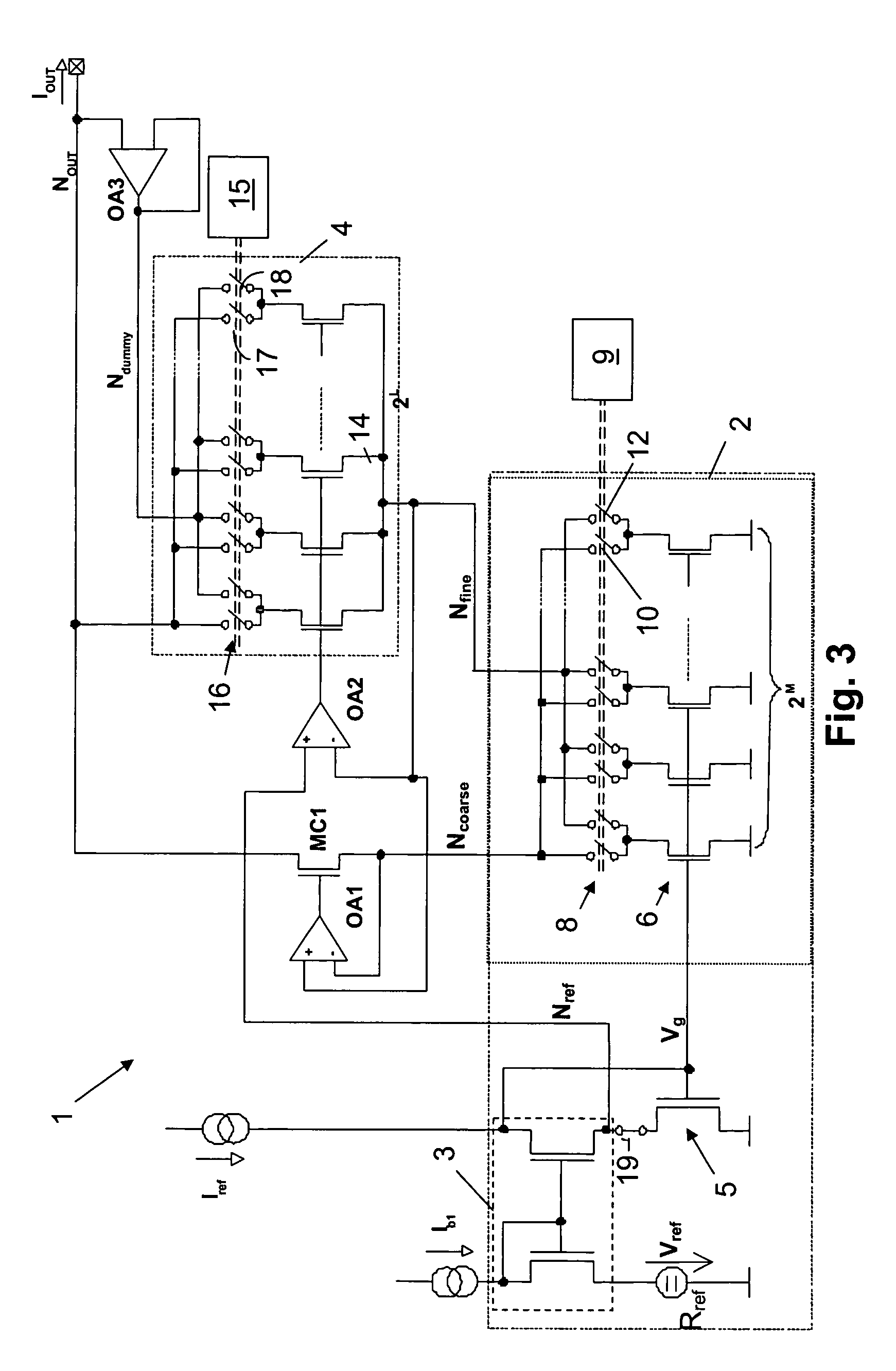

Monotonic precise current DAC

ActiveUS7026971B2Save power consumptionElectric signal transmission systemsDigital-analogue convertorsDigital analog converterCascode

A monotonic digital-to-analog converter (DAC) for converting a digital input signal into an analog output signal comprises:an input node for receiving the digital input signal having at least M+L bits,an output node for delivering the analog output signal corresponding to the received digital input signal,a coarse conversion block comprising current sources and first switching means for converting M more significant bits of the digital input signal into a coarse block output current,a fine conversion block comprising a current divider and second switching means for converting L less significant bits of the digital input signal into a corresponding current value, the fine conversion block having means for receiving current from a first unselected current source of the coarse conversion block, anda first cascode means for active cascoding the coarse block output current,a second cascode means, for active cascoding the current from the first unselected current source.A method for converting a digital input signal into an analog output signal is also provided.

Owner:AMI SEMICON BELGIUM

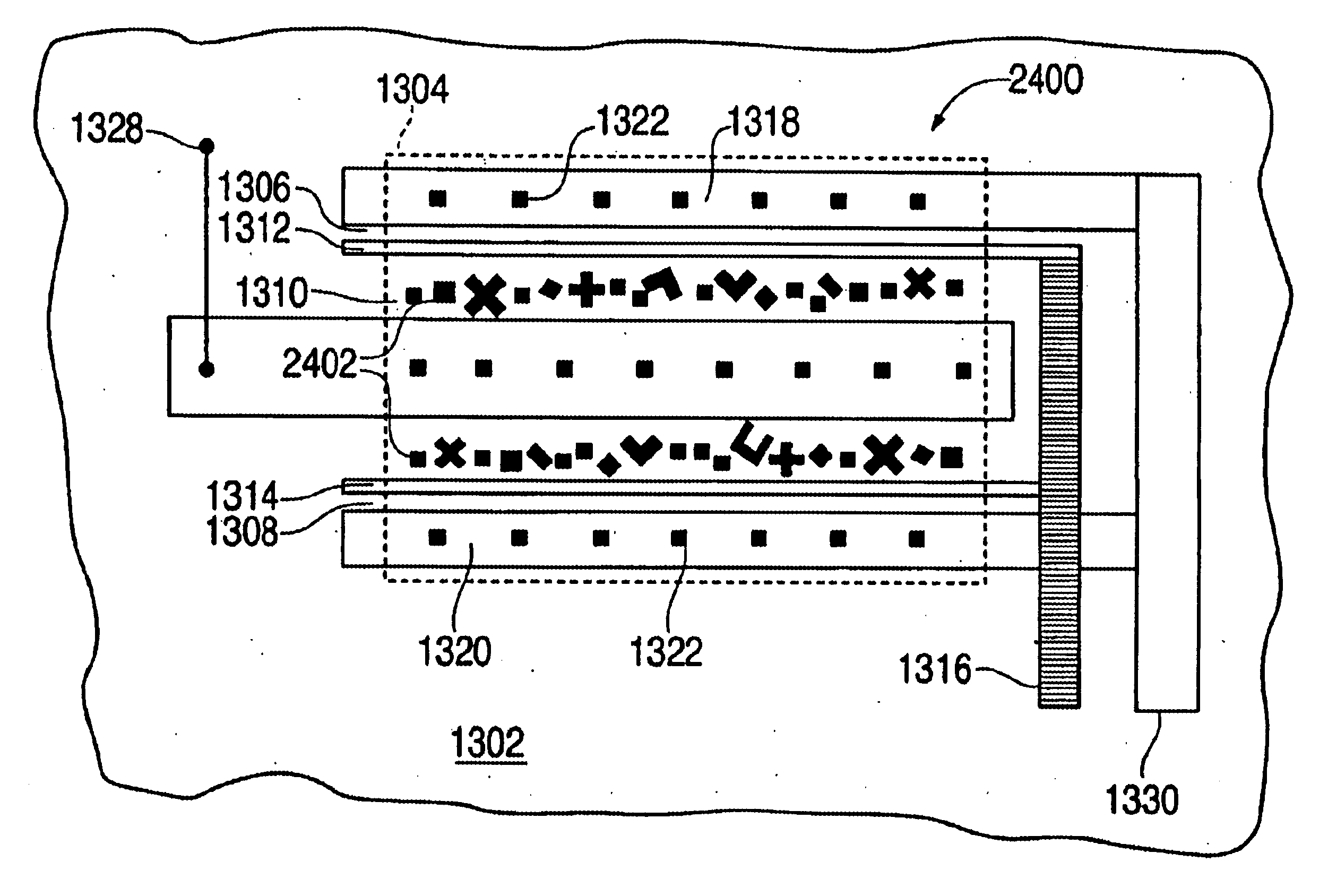

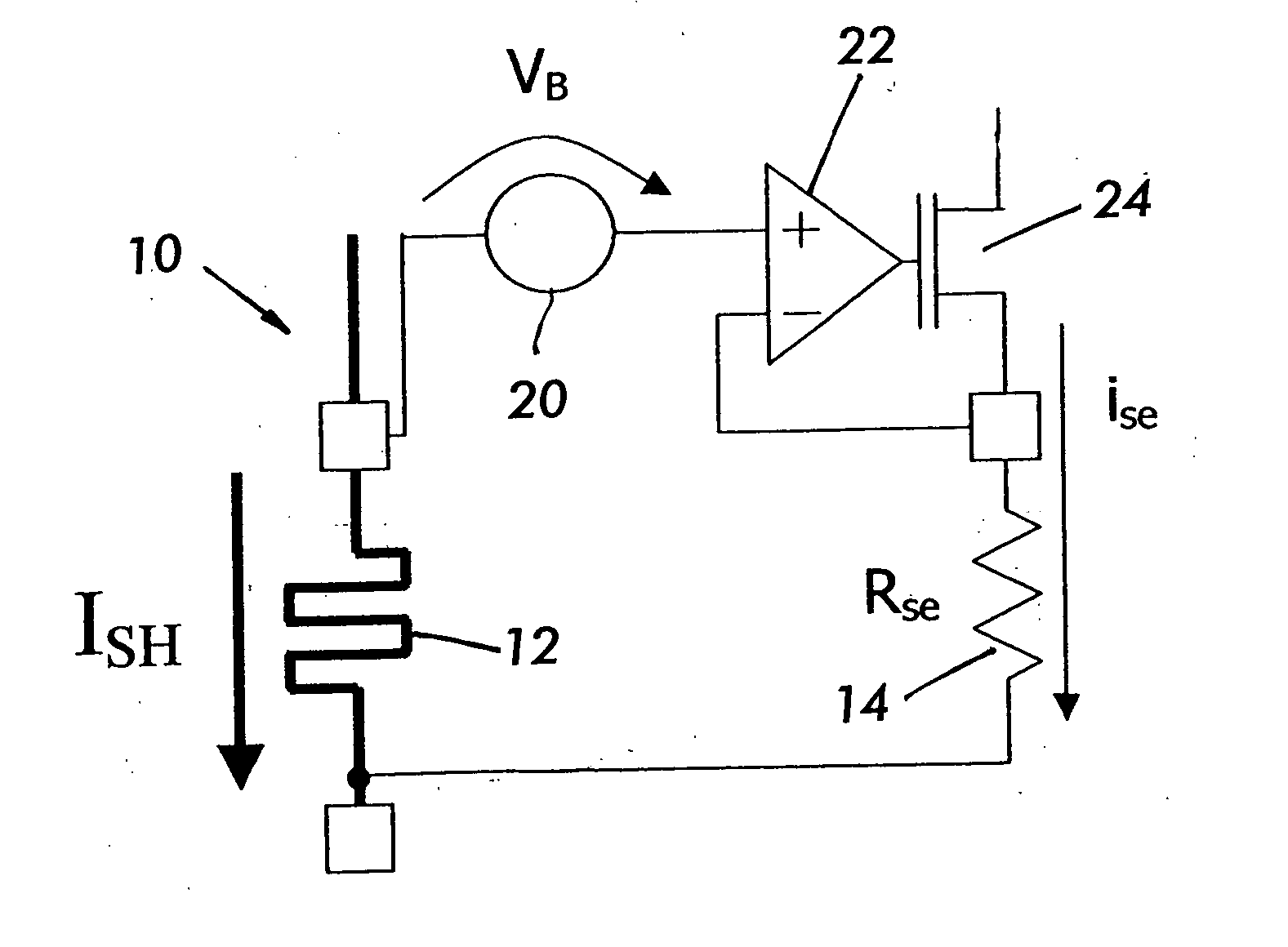

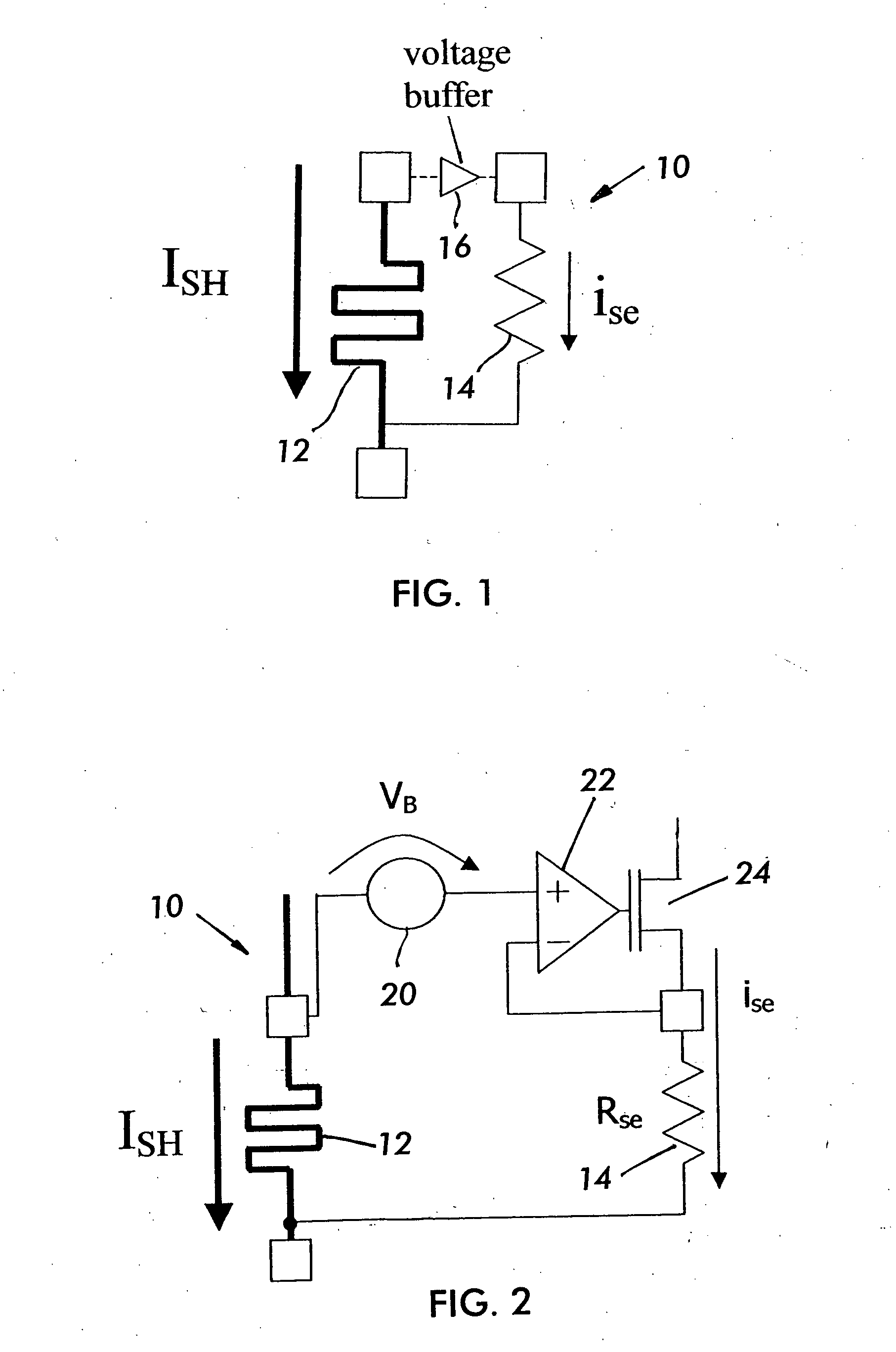

Method and apparatus for high current measurement

InactiveUS20090284248A1Current/voltage measurementBase element modificationsElectricityElectrical conductor

In order to extend the measurement range of a current sensor, a current divider is formed by a first conductor formed in a current sensor that is mounted on a printed circuit board and a second conductor on the printed circuit board that electrically shorts at least one input terminal of the current sensor to at least one output terminal of the current sensor. The input terminal of the current sensor supplies the current to be measured to the first conductor and the output terminal supplies the measured current back to the printed circuit board.

Owner:SILICON LAB INC

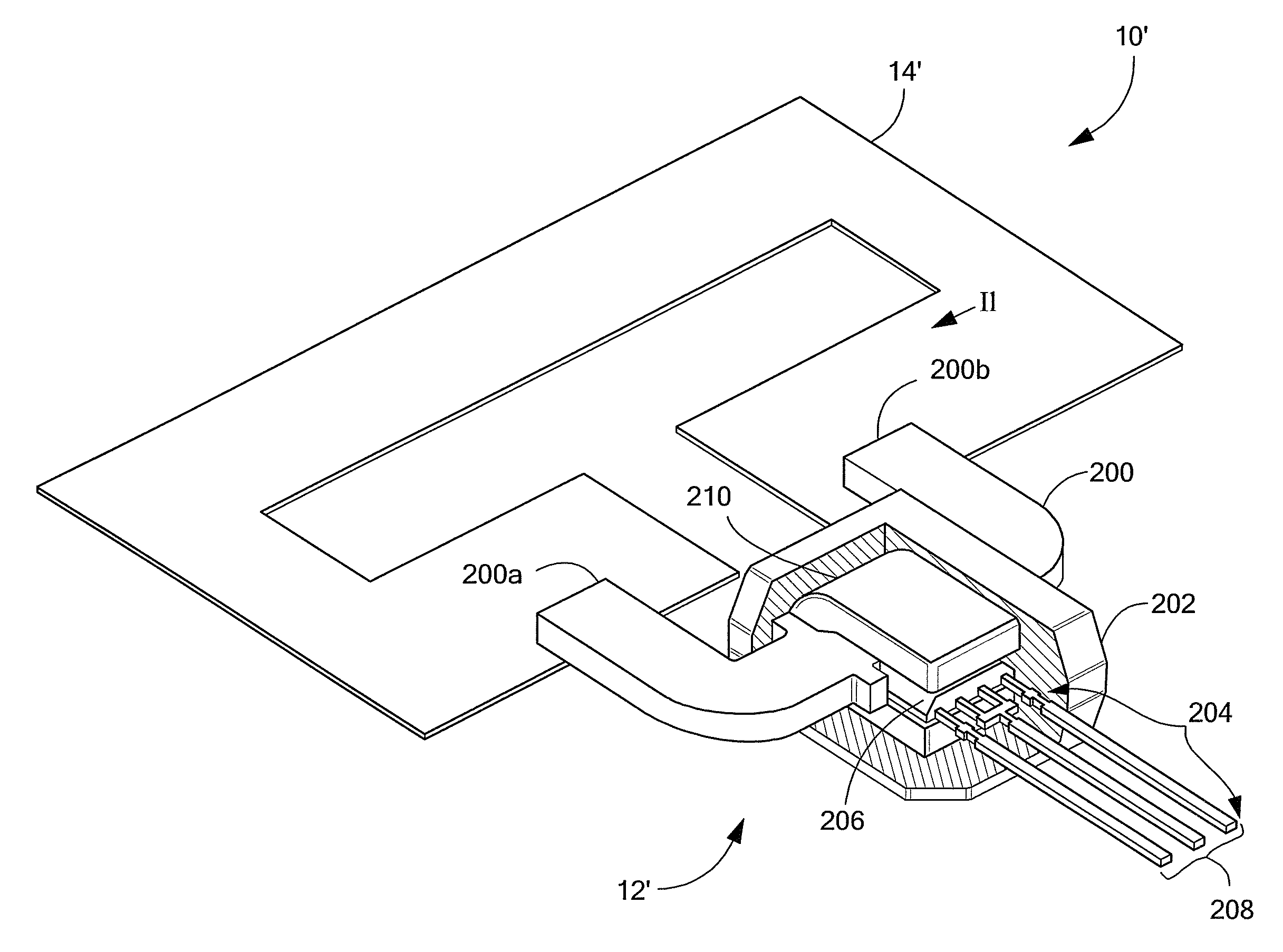

Current sensor with calibration for a current divider configuration

ActiveUS8604777B2Measurement using dc-ac conversionAcceleration measurement using interia forcesShunt DeviceElectrical conductor

Owner:ALLEGRO MICROSYSTEMS INC

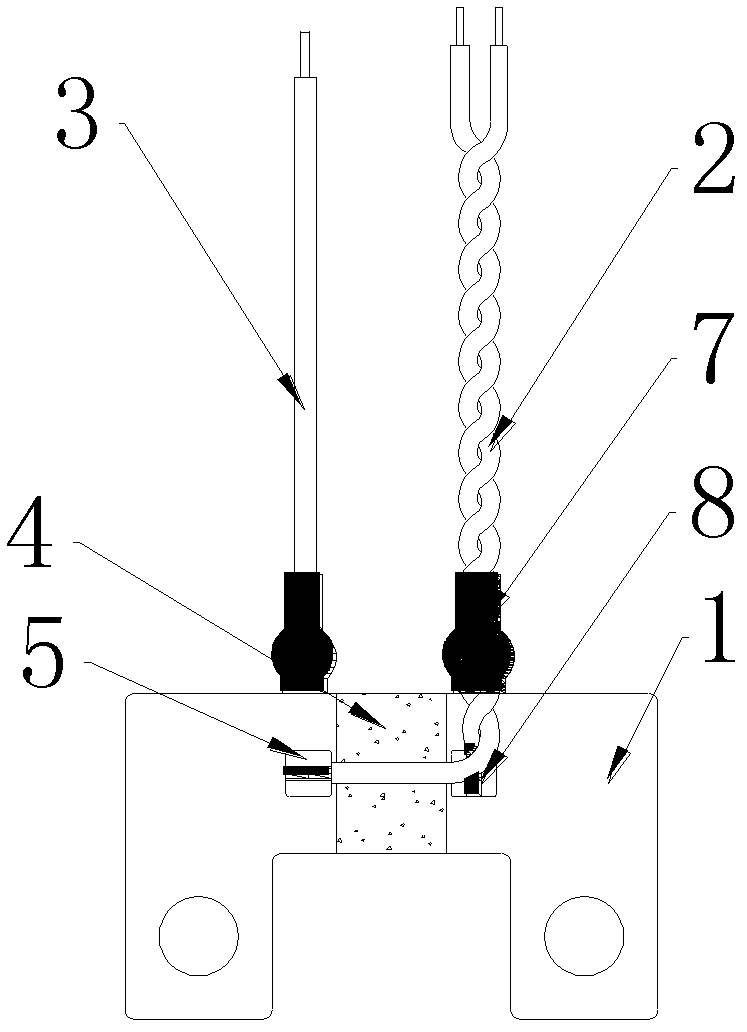

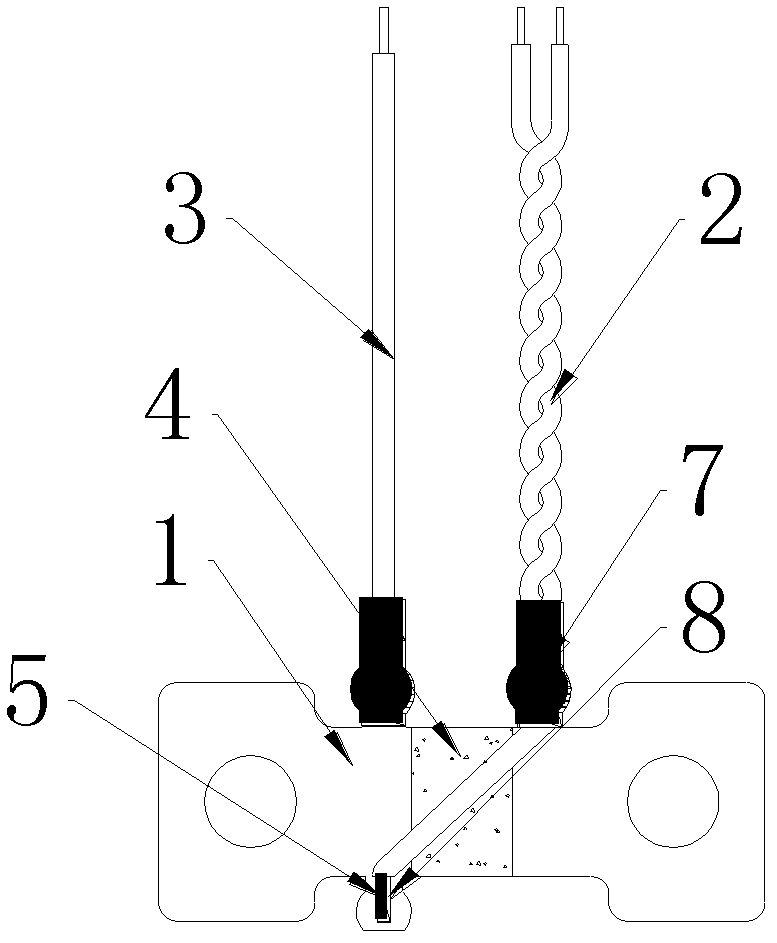

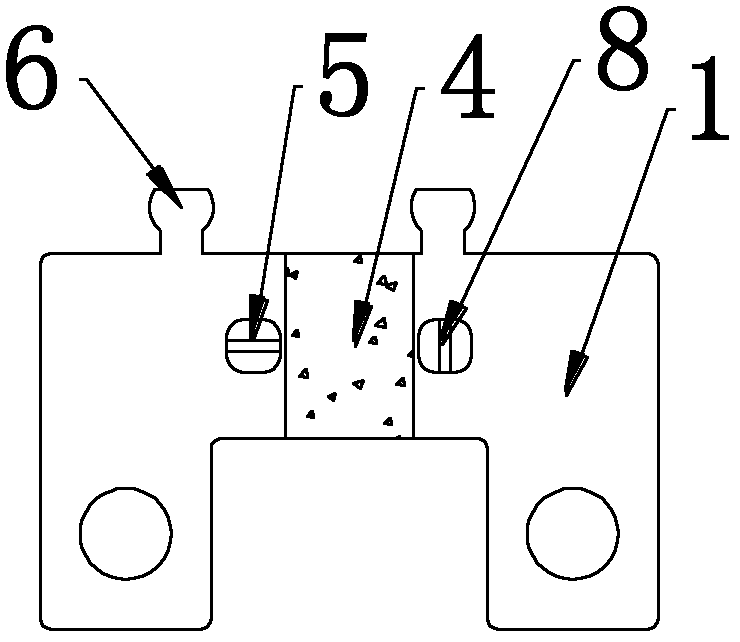

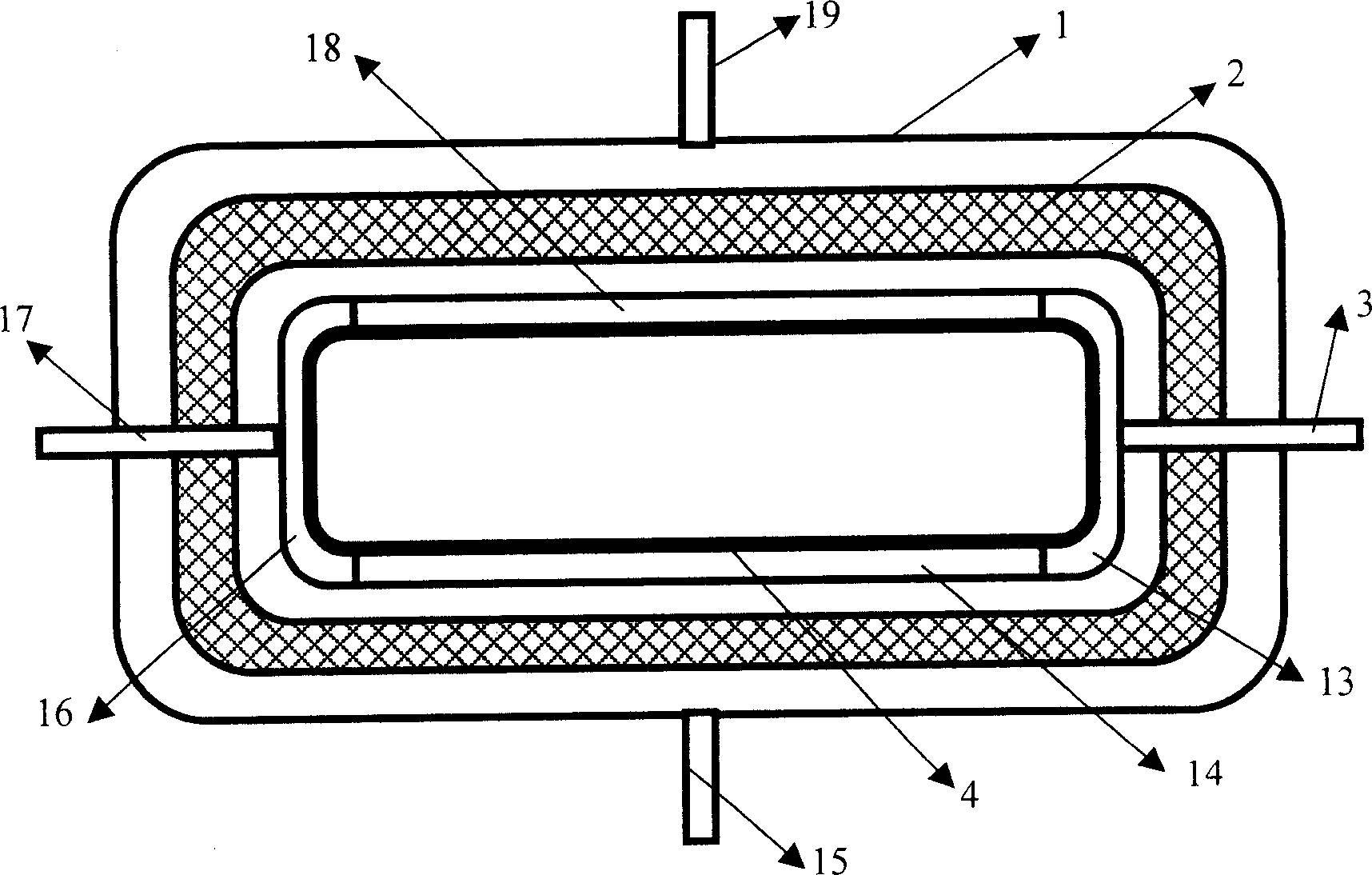

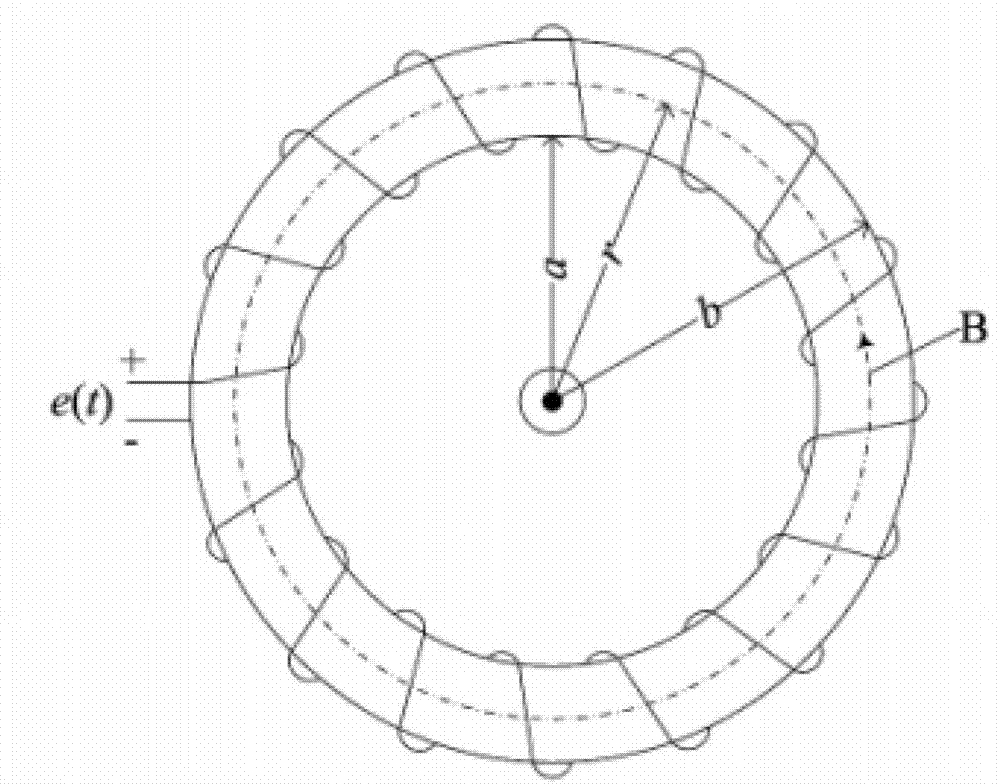

Alternating magnetic field-resistant manganin current divider

ActiveCN102323459AExtended service lifeSimple structureElectrical measurement instrument detailsTime integral measurementShunt DeviceElectrical resistance and conductance

The invention designs an alternating magnetic field-resistant manganin current divider, which mainly comprises a manganin resistor and sampling end points of a current divider, wherein a wire is arranged on one side of the current divider; a sampling end point is arranged on both sides of the current divider and is connected with a sampling line; the sampling line on one side is pulled to the other side; and the manganin resistor is divided into two regions of the same area; meanwhile, the sampling line is fixed with the sampling line on the side and the two sampling lines are spirally stranded to extend. In the alternating magnetic field-resistant manganin current divider, the sampling line on the side close to the manganin resistor is pulled to the other side close to the manganin resistor, and the manganin resistor is averagely divided into two regions of the same area, so that induction voltage and electromotive force are produced on the sampling line on the other side close to the manganin resistor according to faraday law of electromagnetic induction when the current divider is interfered by an external alternating magnetic field and are balanced with the induction voltage and the electromotive force produced on the manganin resistor, namely the interference of the alternating magnetic field on the current divider can be prevented.

Owner:TONGXIANG WEIDA ELECTRONICS

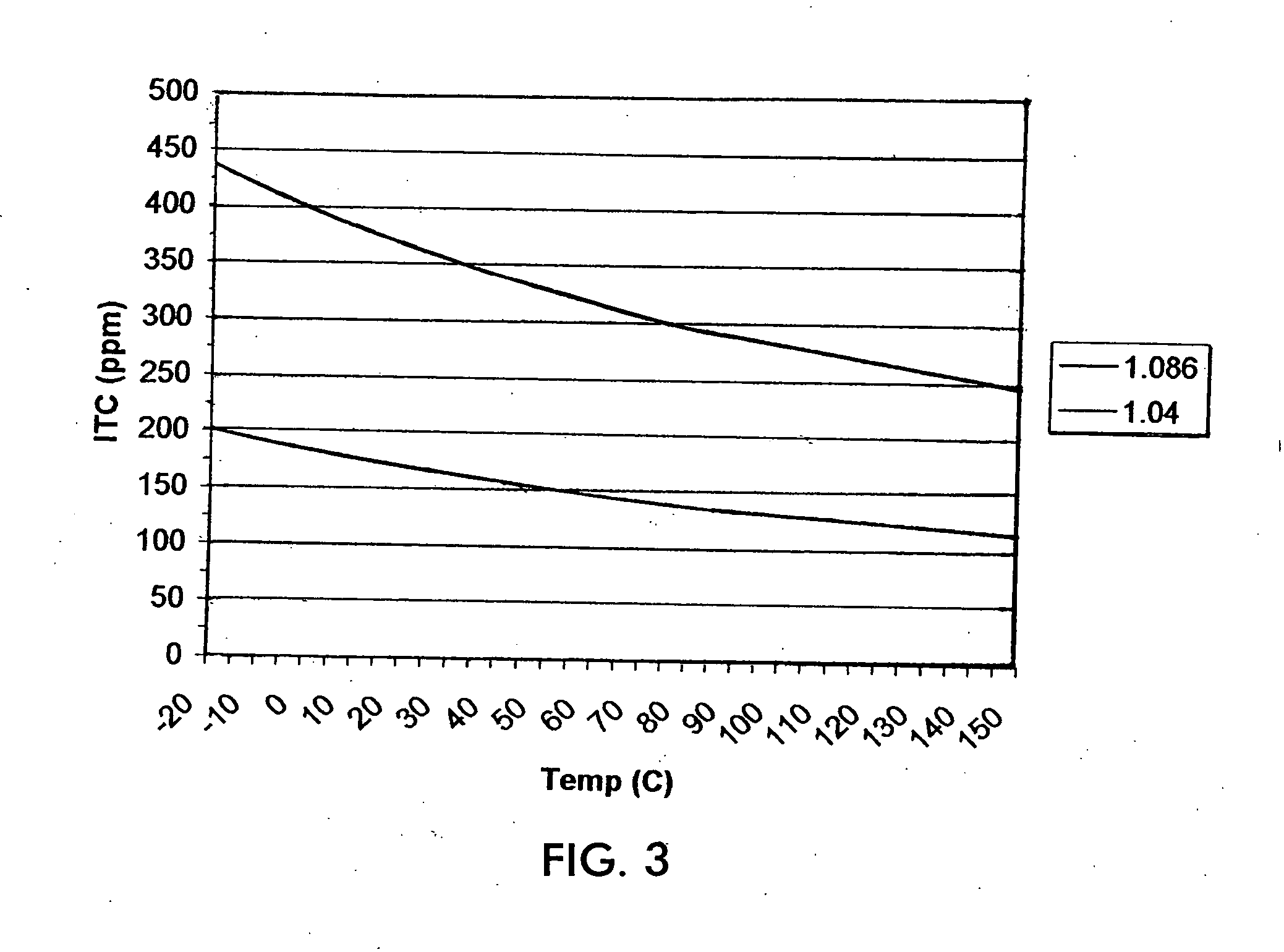

Current sense shunt resistor circuit

InactiveUS20050017760A1Reduced dynamic rangeBase element modificationsCurrent measurements onlyEngineeringCurrent divider

Current through a wire is sensed with a shunt resistor and a sense resistor in a current divider circuit. The values of the shunt resistor and sense resistor are related to provide a specified gain ratio to increase a dynamic range of current measurement. The sense resistor is a trimmable resistor, the configuration of which can be discerned from a look-up table based on a level of precision needed for current measurement. The two resistors can also be related by thermal coefficients to improve linearity of current measurements.

Owner:INTERNATIONAL RECTIFIER COEP

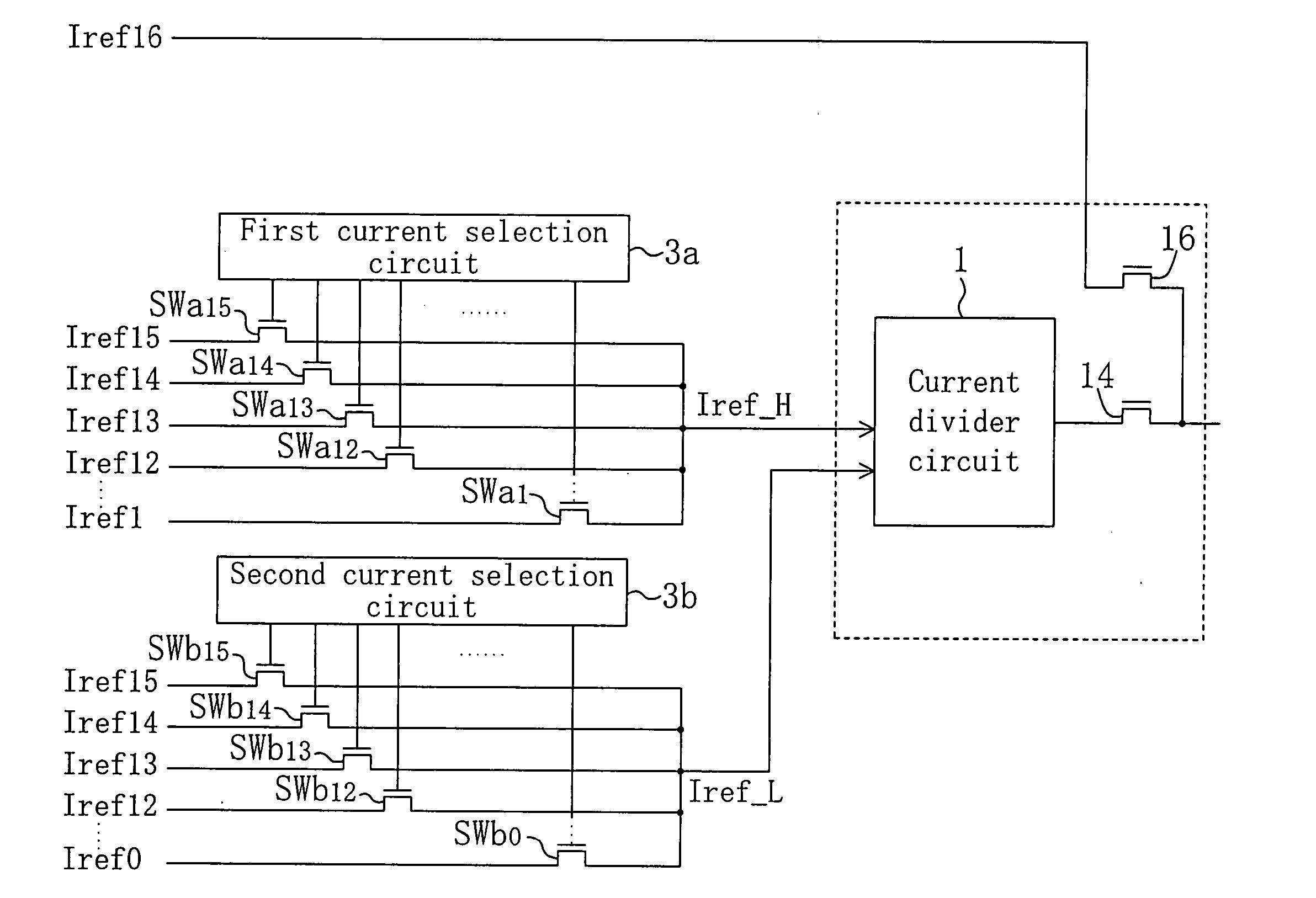

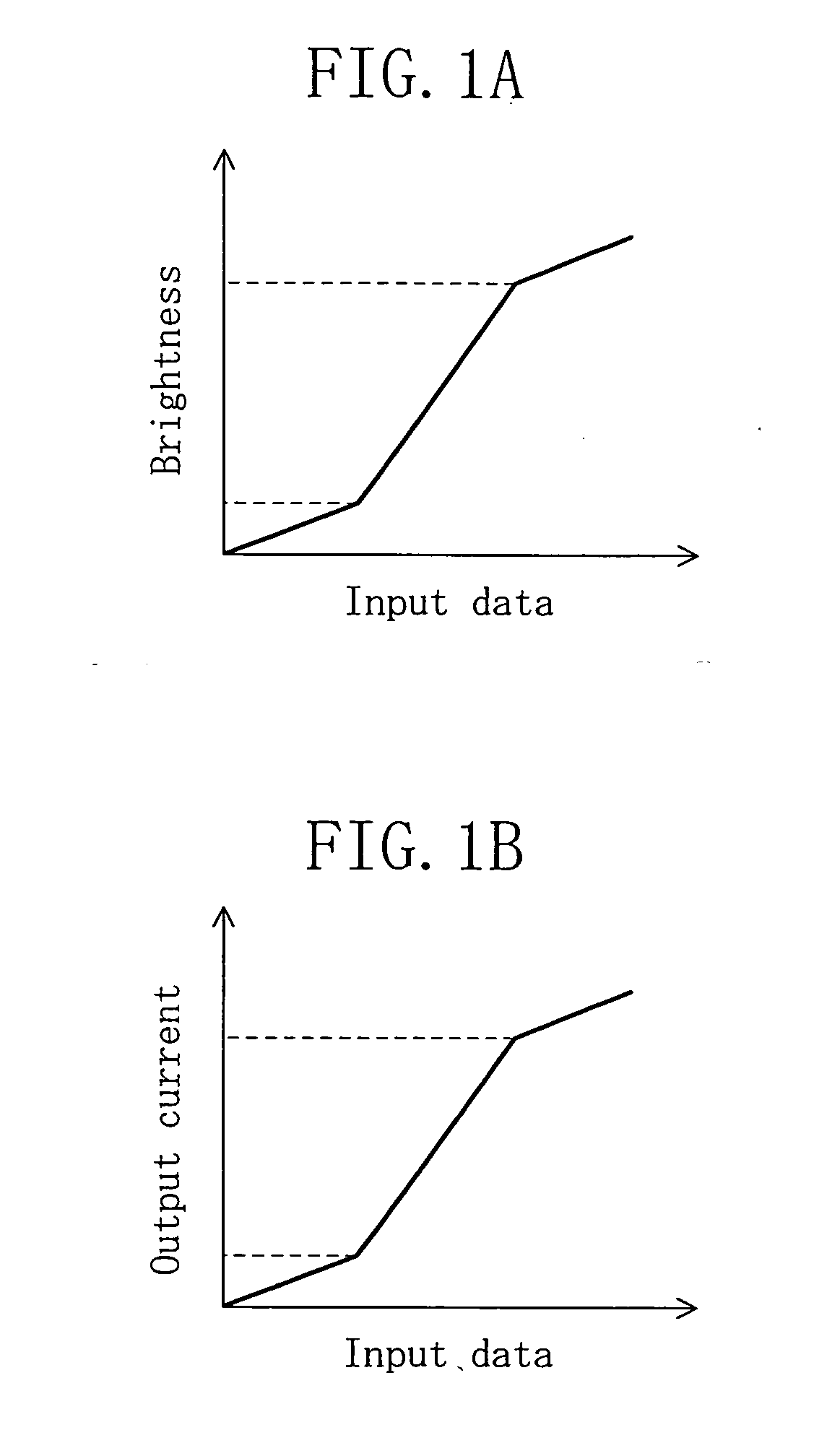

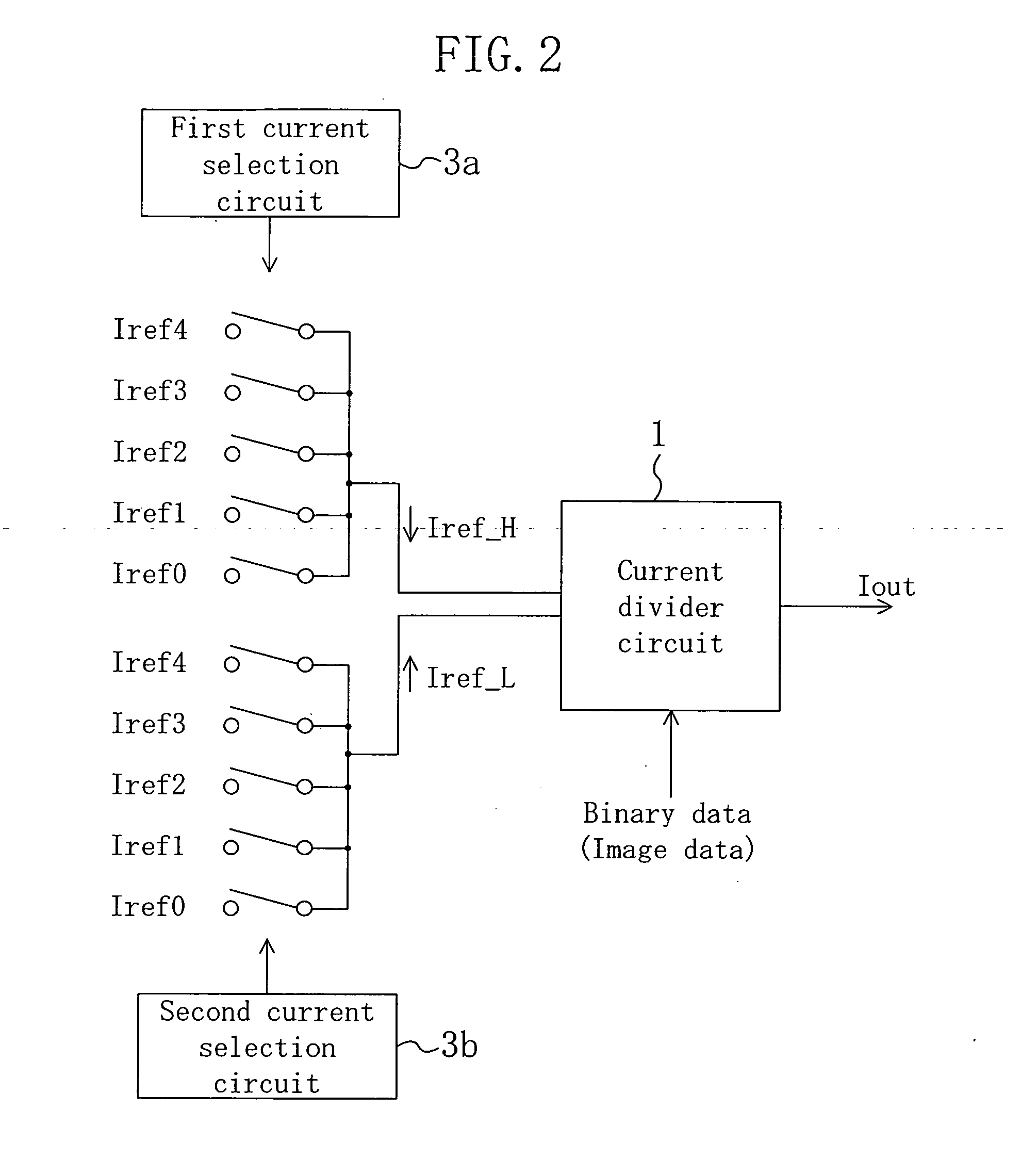

Current driver and display device

InactiveUS20050057457A1Improve accuracyIncrease brightnessElectroluminescent light sourcesSolid-state devicesReference currentDisplay device

A current driver to which image data including a plurality of grayscale values is input and which outputs an electric current according to the grayscale values of the image data, the current driver comprising: a first input section to which a first reference current is input, a current value of the first reference current being changed according to the grayscale values of the image data; a second input section to which a second reference current is input, the second reference current having a current value different from that of the first reference current; and a current divider circuit which uses the second reference current and the first reference current to output an electric current, the electric current having a value equal to or higher than that of the first reference current and equal to or lower than that of the second reference current.

Owner:GK BRIDGE 1

Forming method of current divider

InactiveCN101097232AReduce feverSmall temperature coefficientTime integral measurementElectrical resistance and conductanceShunt Device

The invention discloses a forming method of diverter used in electric energy meter, specially a forming method of diverter made by resistance metal material and conducting metal material. The purpose of the invention is providing a forming method of diverter whose operation is easy, performance is stable, and efficiency is high. The method includes three steps of selecting material, welding and punching figuration. The forming method of diverter possesses characters that course of production is unpolluted, precision is high.

Owner:TONGXIANG WEIDA ELECTRONICS

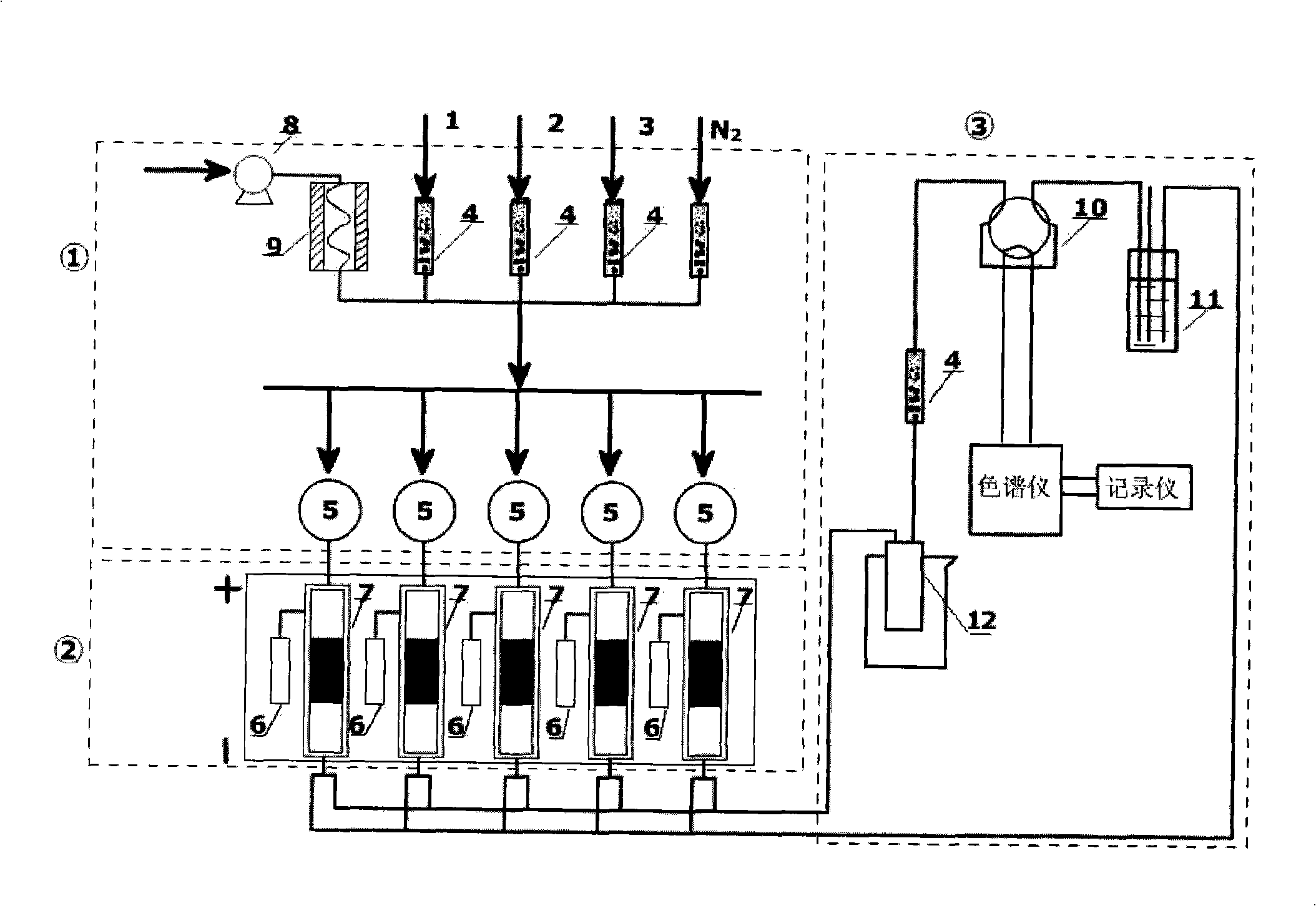

Reaction system for quickly evaluating Claus unit tail gas hydrodesulphurization catalyst

The present invention provides a Claus unit tail gas hydrodesulphurization catalyst fast evaluation reaction system which consists of an air distributing device, a multicenter reaction device and a tail gas detecting and processing device, wherein, the air distributing device consists of an air source, a current divider, a drying pipe (4), a flowmeter (5), a constant flow pump (8) and a preheater (9) which are connected by a pipeline; the multicenter reaction device is a parallel reactor consisting of a plurality of fixed bed reactors (7) in parallel connection; the front end of each reactor is connected with the flowmeter by a pipeline with a valve; the tail end is connected with the tail gas detecting and processing device by the pipeline with the valve, and the reaction temperature of each reactor can be controlled independently by a program temperature controller. The present invention uses the same air source and the parallel operation of a plurality of fixed bed reactors (7) to realize the fast evaluation on the sulfur dioxide hydrogenation activity and / or the organic sulfur hydrolysis activity of the Claus unit tail gas hydrodesulphurization catalyst.

Owner:WUHAN UNIV OF TECH

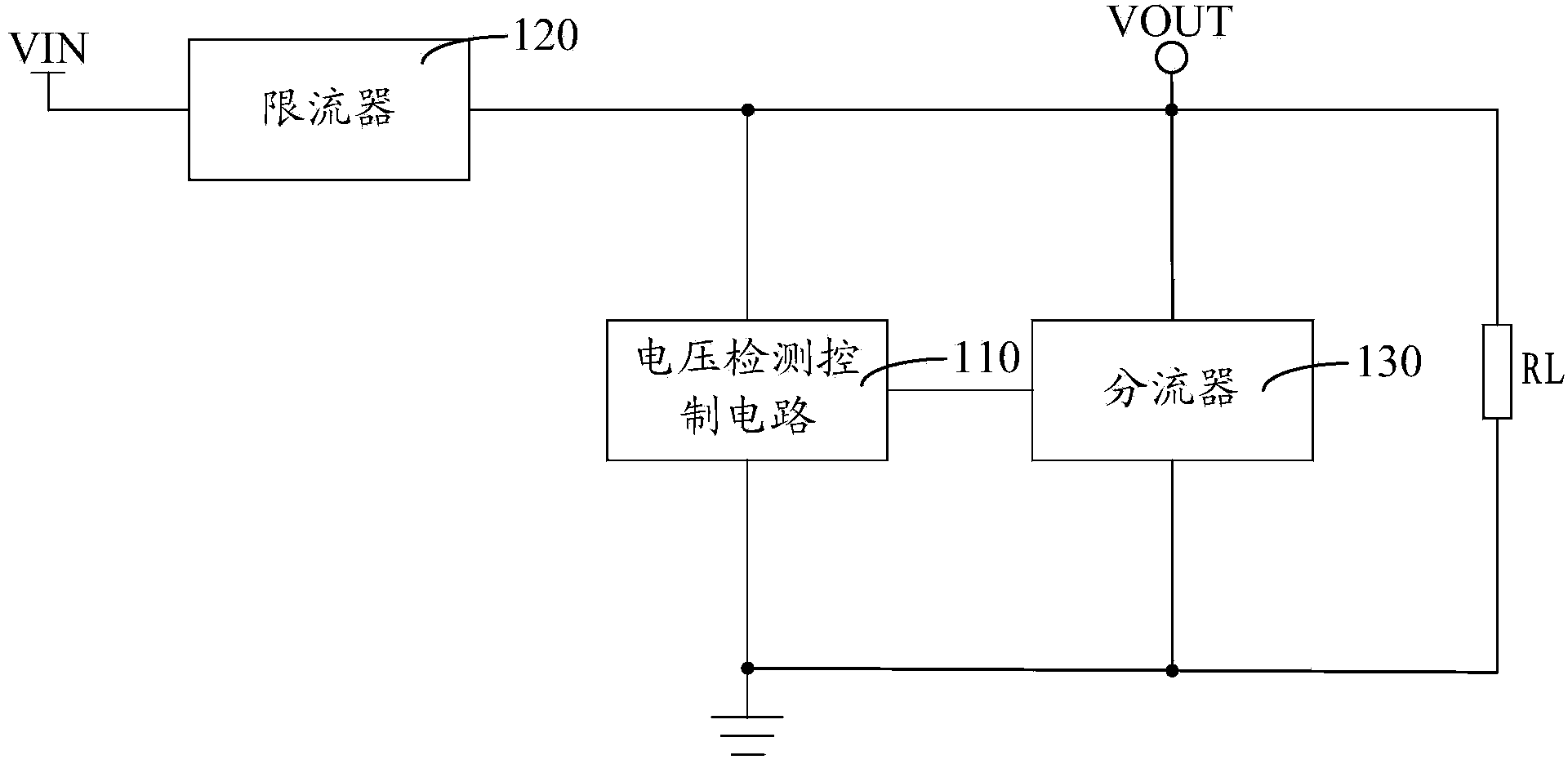

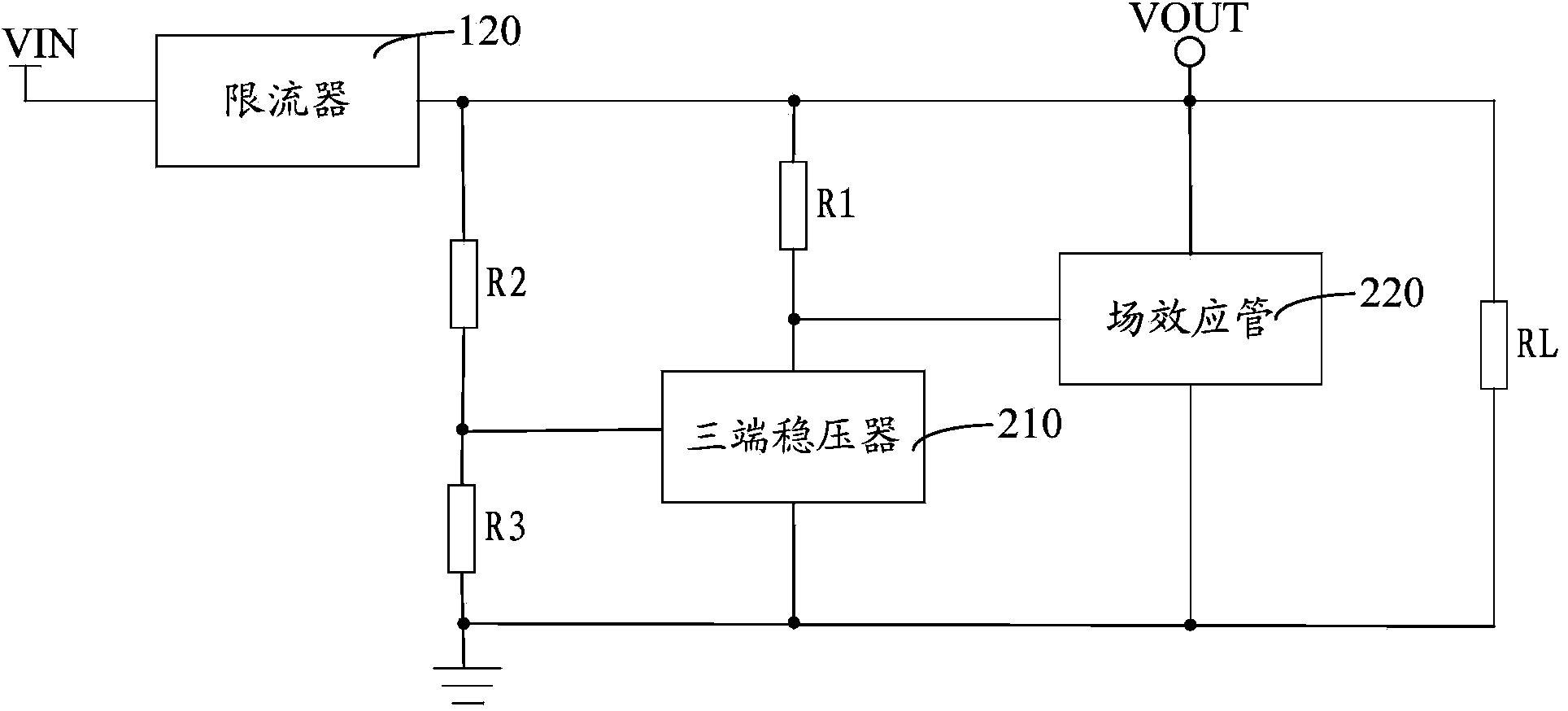

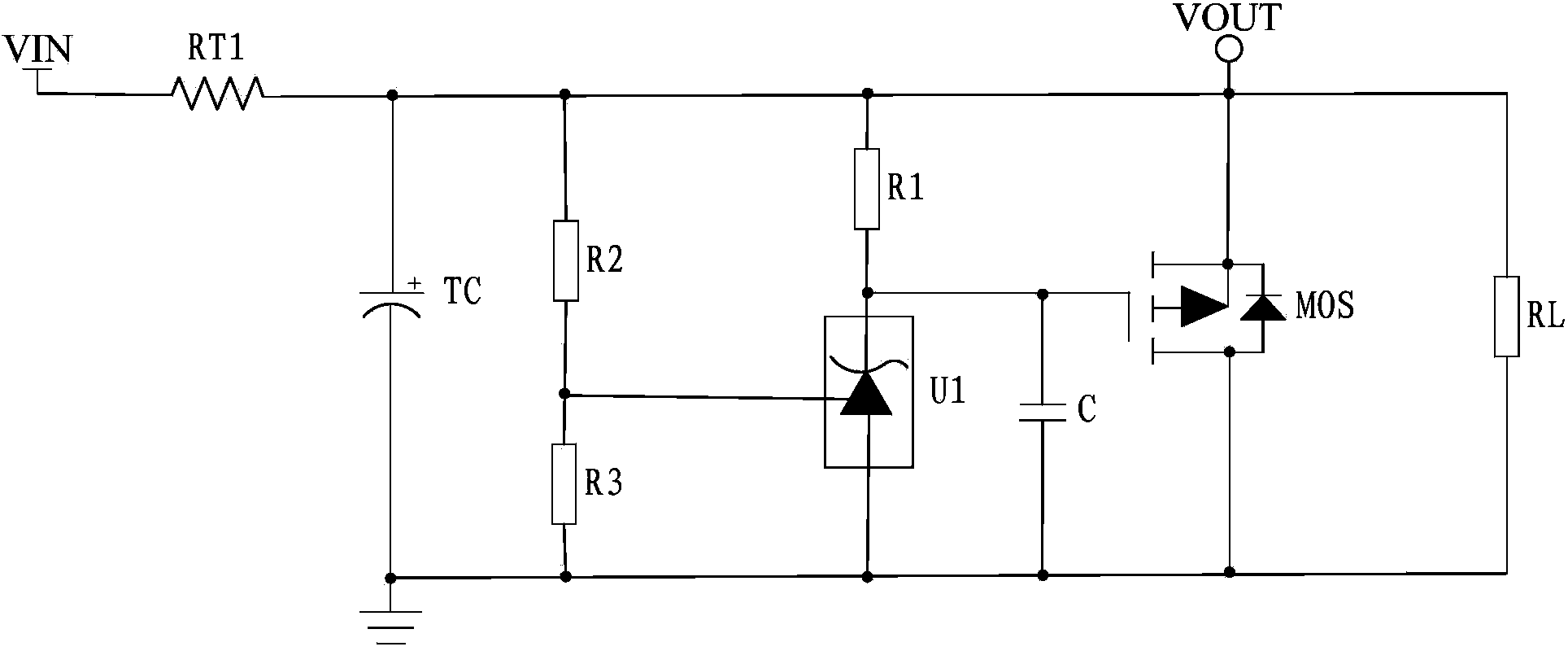

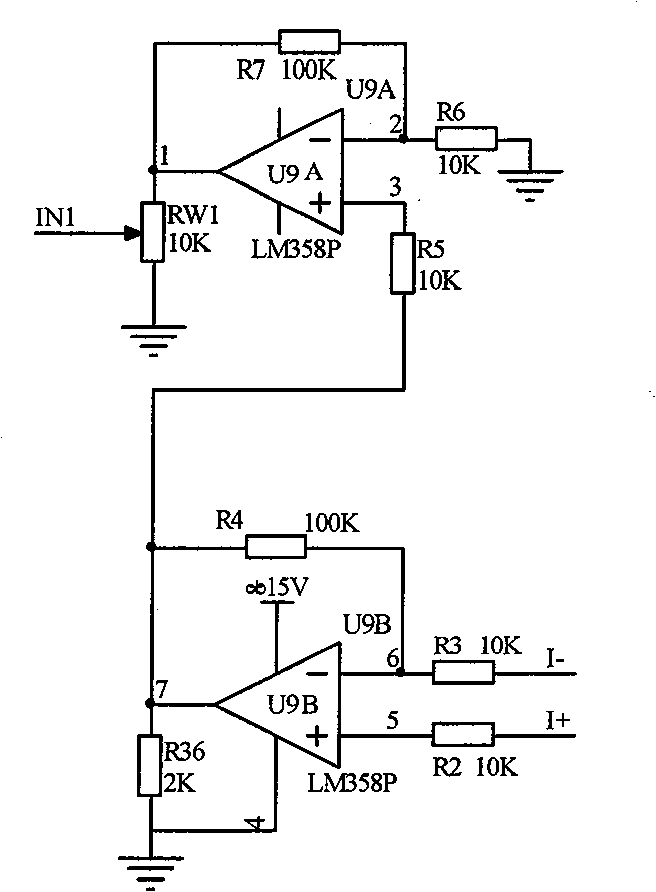

Protective device of equipment power source interface circuit

InactiveCN103545803AAvoid damageReduce output voltageEmergency protective arrangements for limiting excess voltage/currentShunt DeviceCurrent divider

Disclosed is a protective device of an equipment power source interface circuit. The protective device of the equipment power source interface circuit comprises a voltage detection control circuit, a current limiter and a current divider. The input end of the current limiter is connected with an equipment voltage input end. The output end of the current limiter is respectively connected with the voltage detection control circuit and an equipment voltage output end. The voltage detection control circuit is respectively connected with the current divider, the equipment voltage output end and a ground terminal. The current divider is respectively connected with the equipment voltage output end and the ground terminal. The voltage detection control circuit is used for controlling the current divider to reduce an output voltage value of the equipment voltage output end to be a second preset voltage value when an input voltage value is larger than a first preset voltage value. According to the protective device of the equipment power source interface circuit, damage, caused when equipment is charged by an external DC power source or is in the working process with the external power source, to the equipment power source interface circuit is prevented, and damage, caused when main equipment supplies power to external equipment through a USB interface or a DC interface, to a main equipment power source interface circuit can also be prevented.

Owner:GUANGDONG VTRON TECH CO LTD

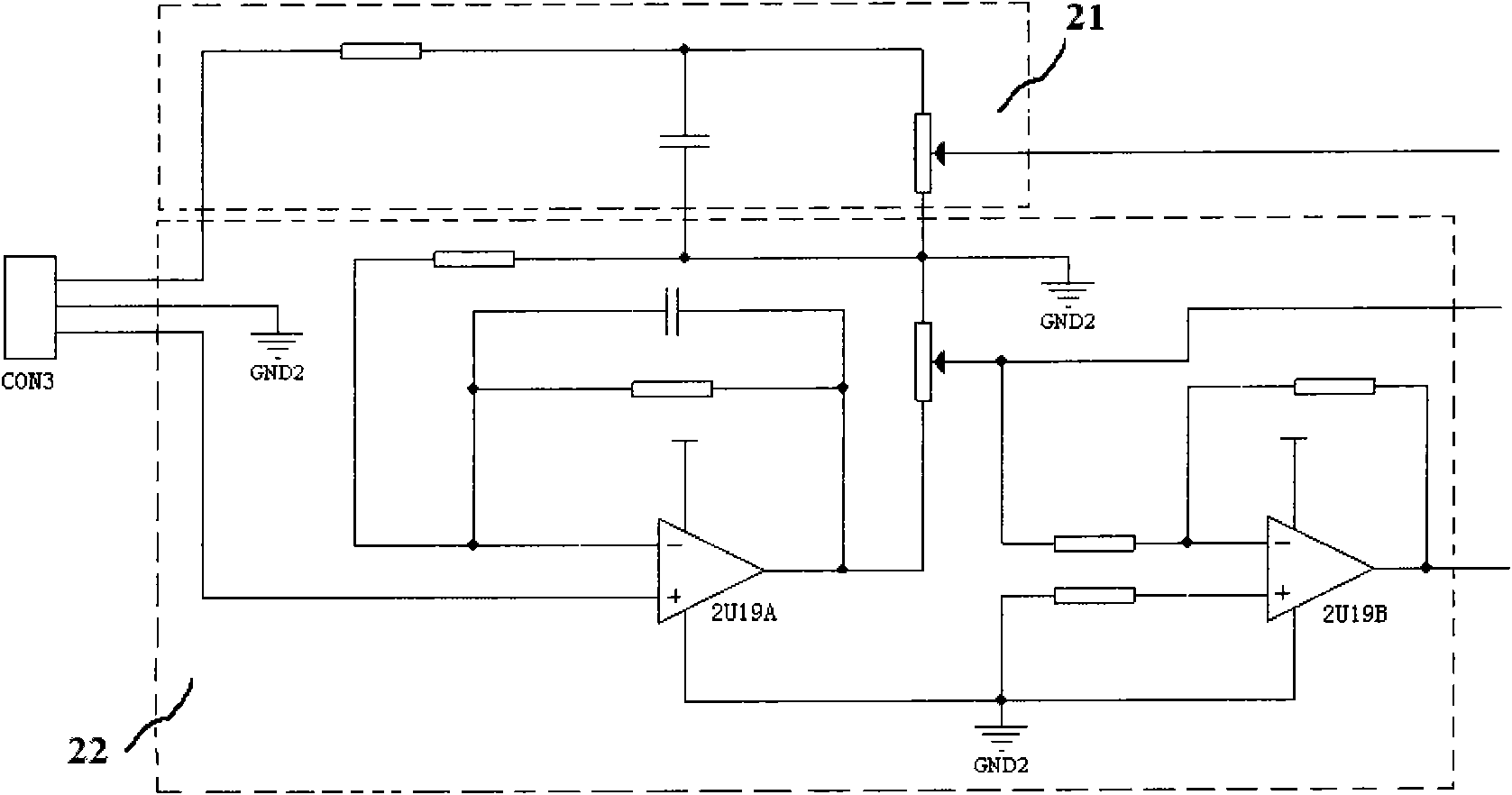

Dynamotor rotor voltage and current measuring method and its device

InactiveCN101055294AStrong resistance to electromagnetic interferenceEliminate the effects ofCurrent/voltage measurementShunt DeviceLow voltage

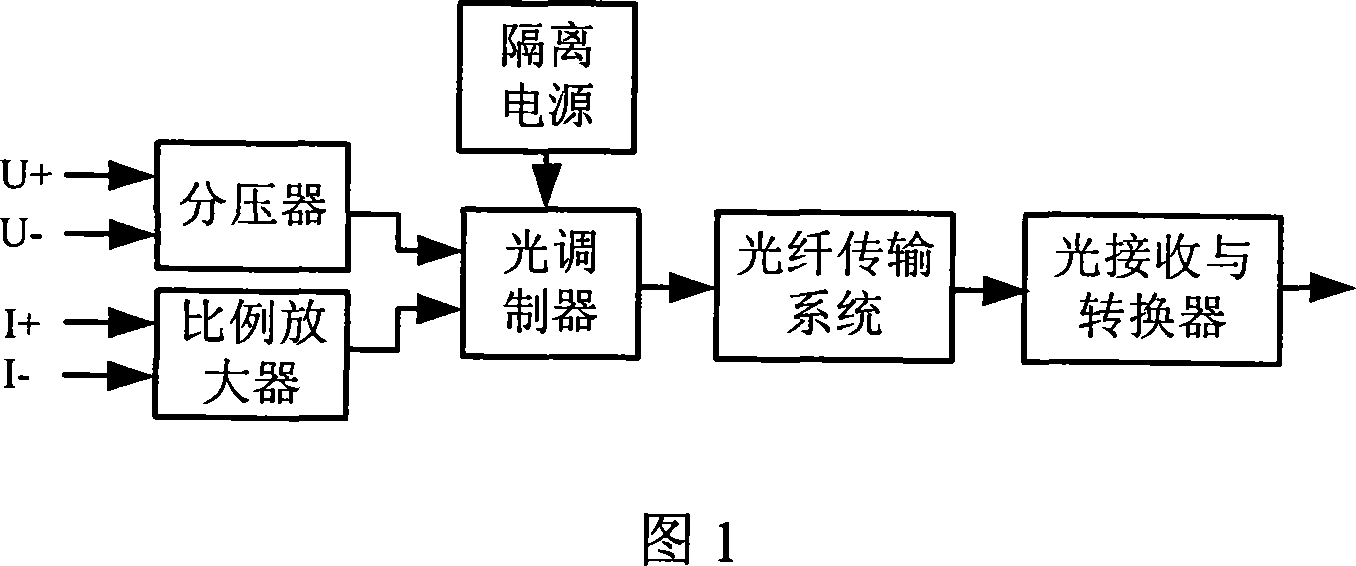

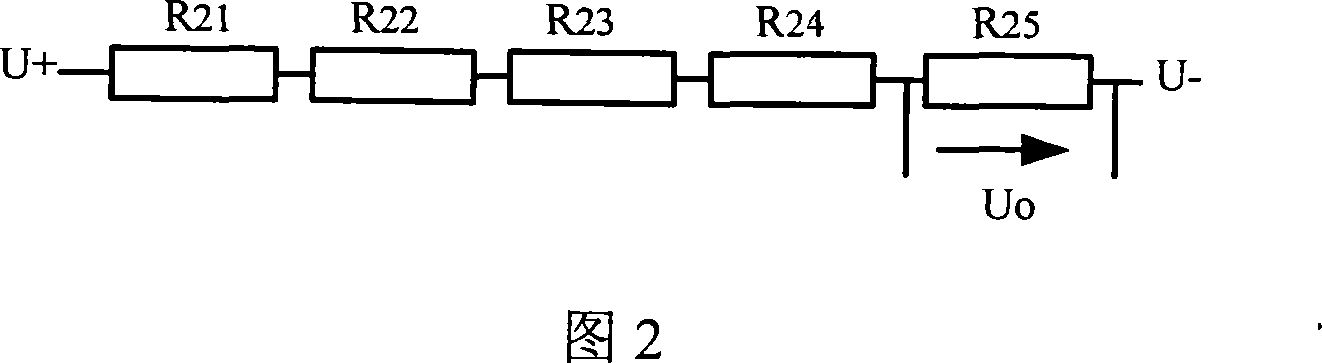

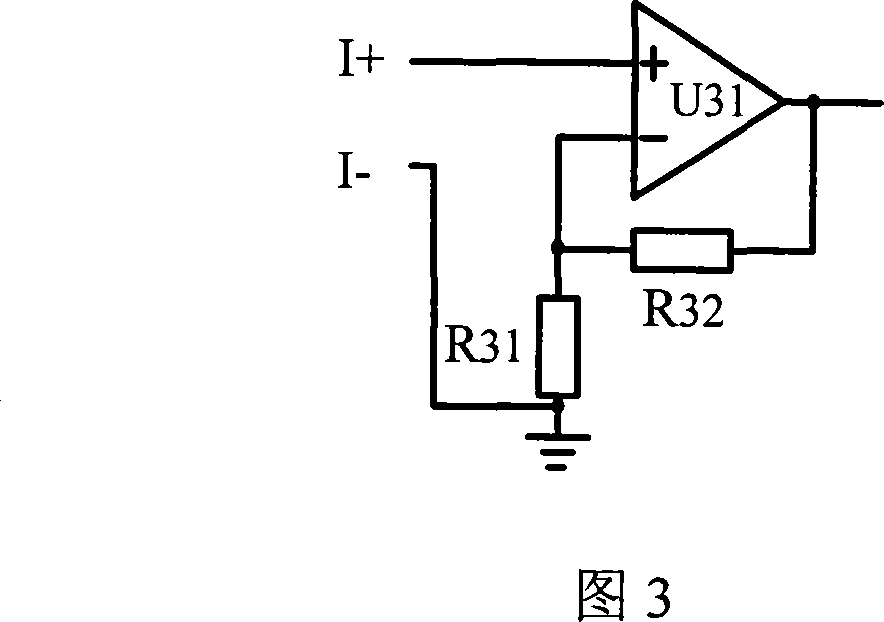

The invention relates to a method and apparatus for measuring voltage and current of generator rotor, which belongs to generator excitation parameter measuring technical field, including: collecting firstly voltage signal and current signal of generator rotor; converting the collected signal into optical signal; transmitting for long distance and receiving the optical signal, and outputting the electrical signal after conversion. The apparatus includes a voltage divider, a proportional amplifier, and an optical modulator of generator rotor side, an optical fiber transmission system, an optical receiving converter and an isolation power source of lower voltage side. The rotor voltage is scaled down by the voltage divider, and the voltage signal for reflecting rotor current variation information outputted by current divider is amplified by the proportional amplifier, then modulated to be optical pulse signal by the optical modulator and transmitted to the optical receiving converter by the optical fiber transmission system, demodulating the optical signal and finally outputting measurement signal of rotor voltage and current. The invention is superior in accurate measurement result, reliability, and excellent temperature stability and anti-vibration characteristics.

Owner:王鹏 +1

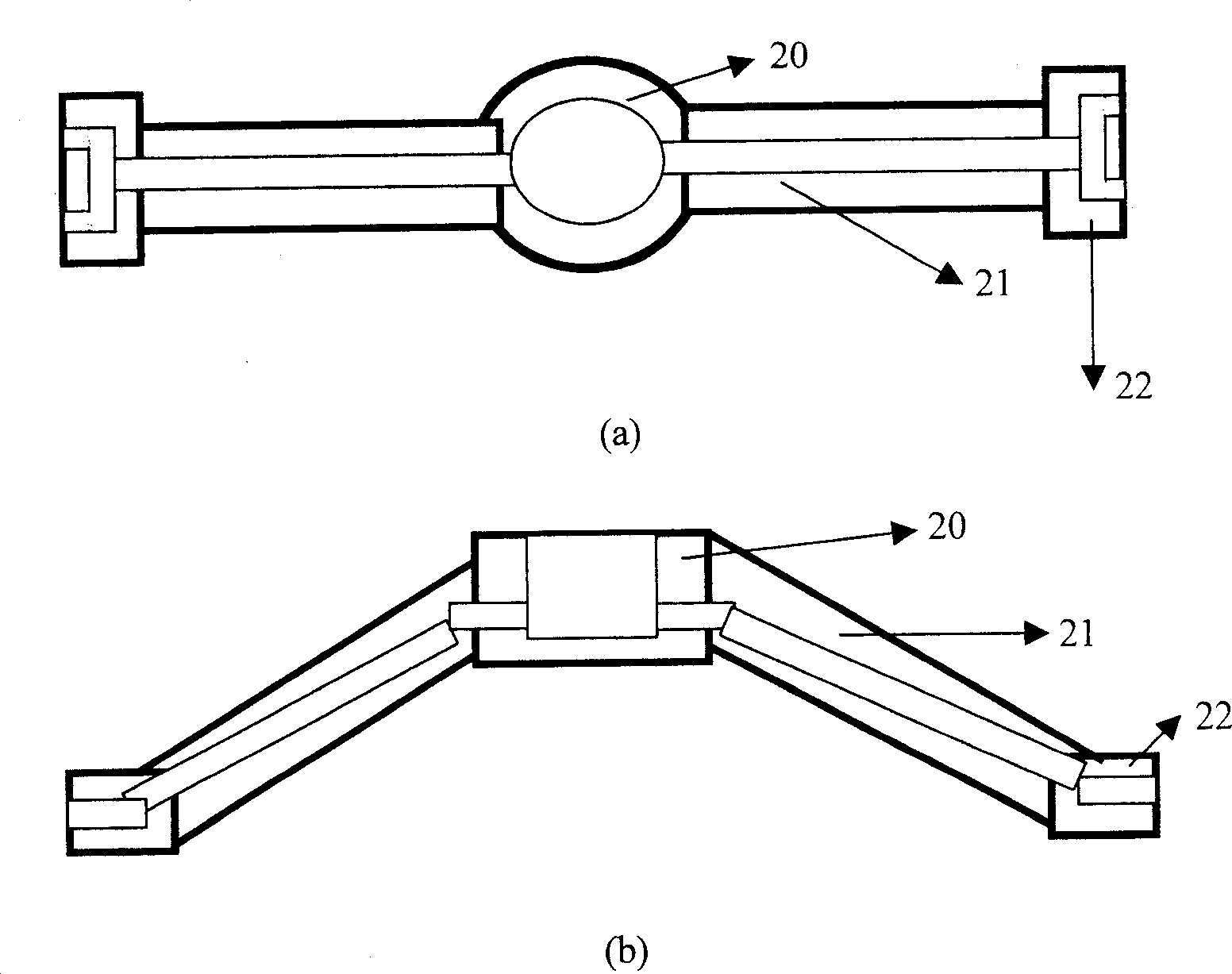

Method and equipment for inhibiting crack of high-alloying aluminium alloy square billet

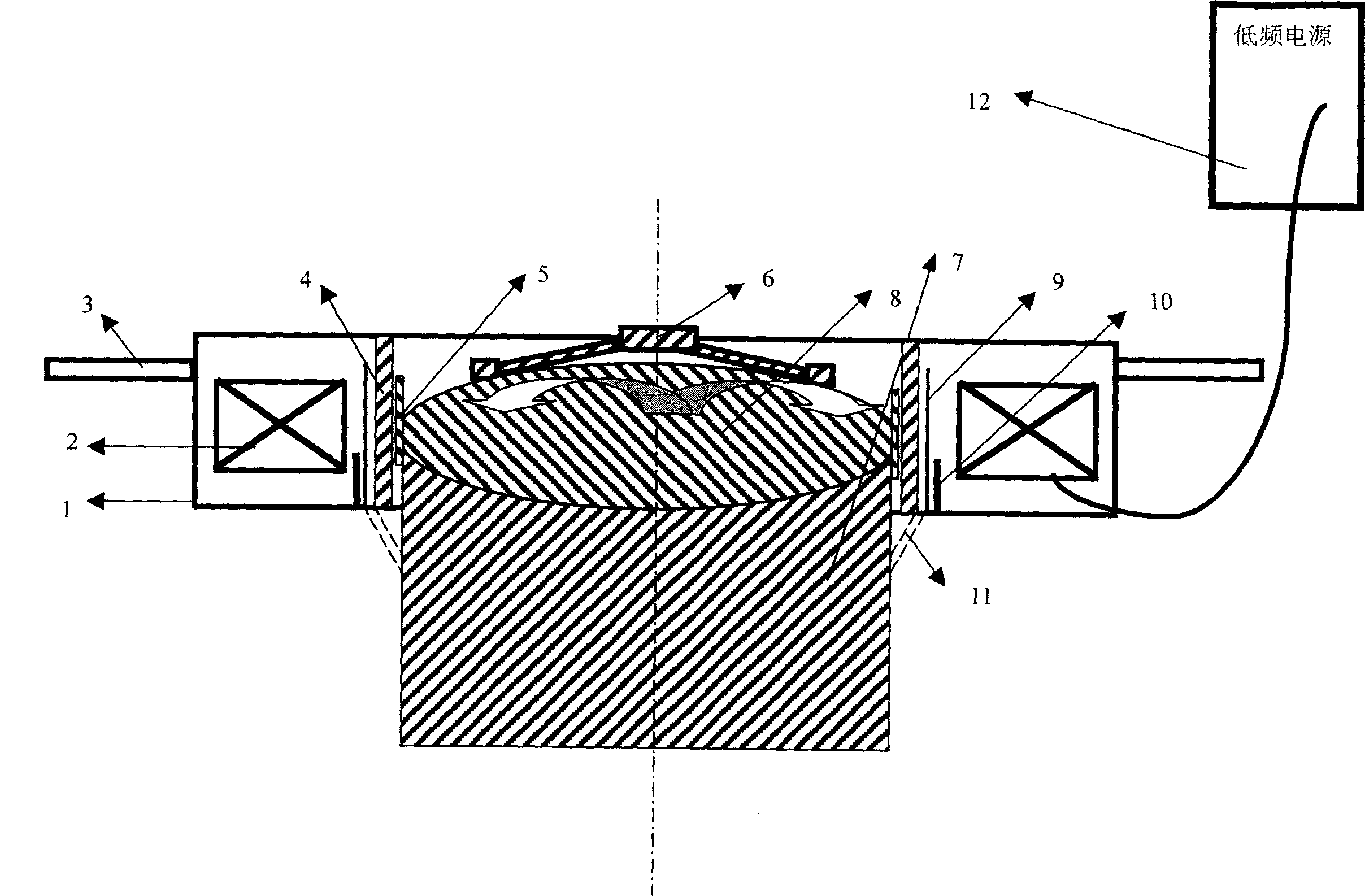

The invention relates to a method for restraining crack of high-alloyed aluminum alloy and relative device. Said device is the plate blank electromagnetic continuous casting crystallizer, while the electromagnetic coil is inside water tank; the water baffle plate is arranged inside the water tank; and the crystallizer comprises four water supply chambers which are independently arranged in two large surfaces and two small surfaces; the water supply chambers supply water independently while the water amount is controllable; a shield matter is arranged at the angle; the inlet of melt aluminum alloy at the upper part of crystallizer is mounted with a bridge fusion current divider; and the inner side of internal wall of crystallizer is adhered with thermal isolated film. When using said device to 7000 alloy square blanks whose thickness is 150-450mm, the frequency should be 10-50Hz, and the intensity of magnetic field should be 10000-80000 ampere-turns; at the different process of casting, the water supply chambers supply different water amount; the casting speed is 20-50% higher than present technique. The invention can effectively restrain the crack of high-alloyed plate blank.

Owner:NORTHEASTERN UNIV

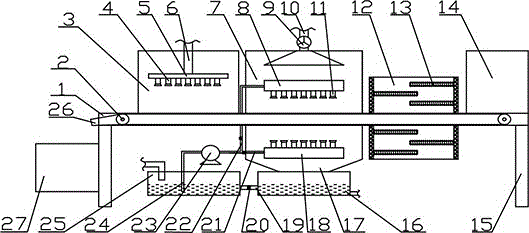

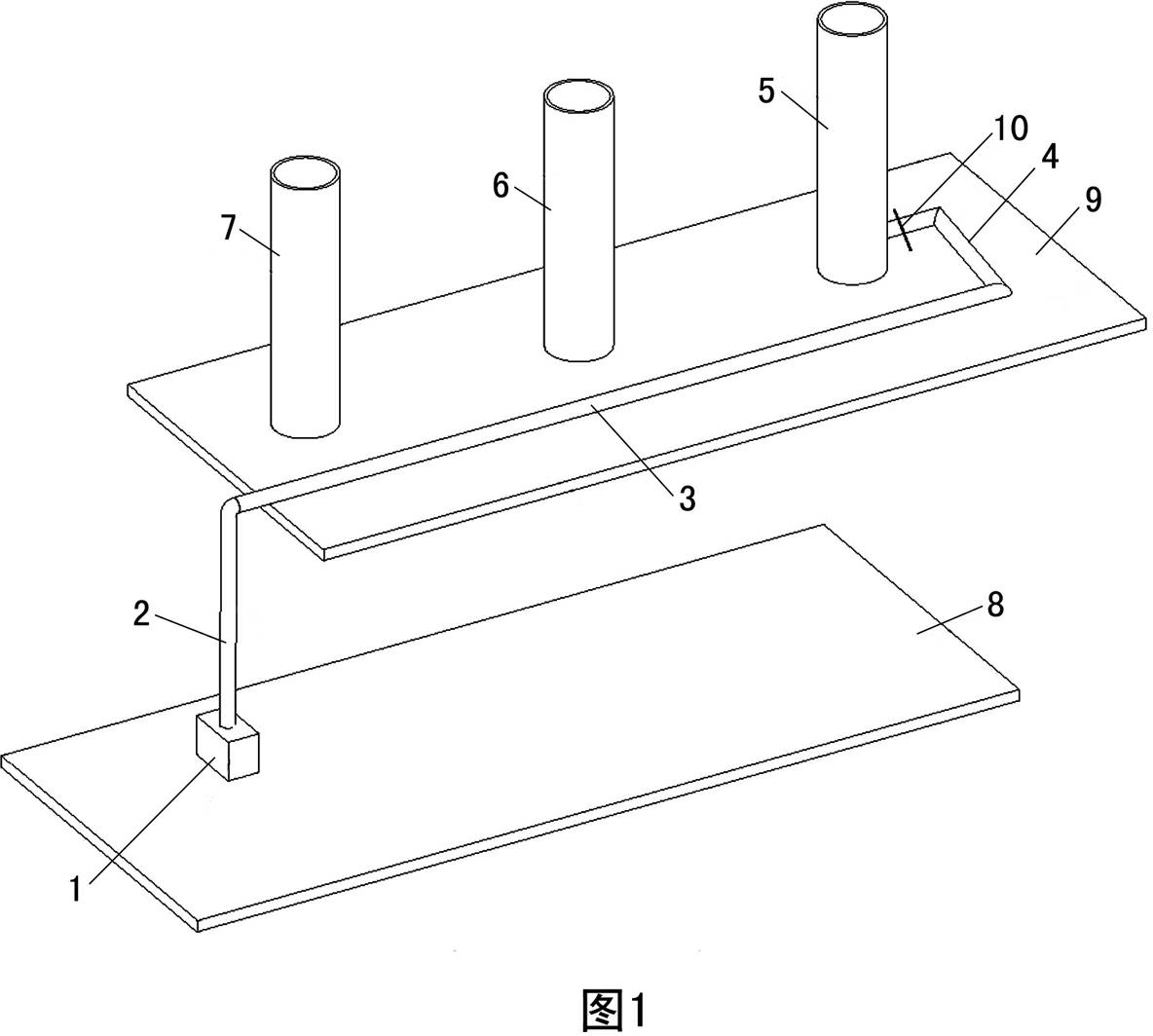

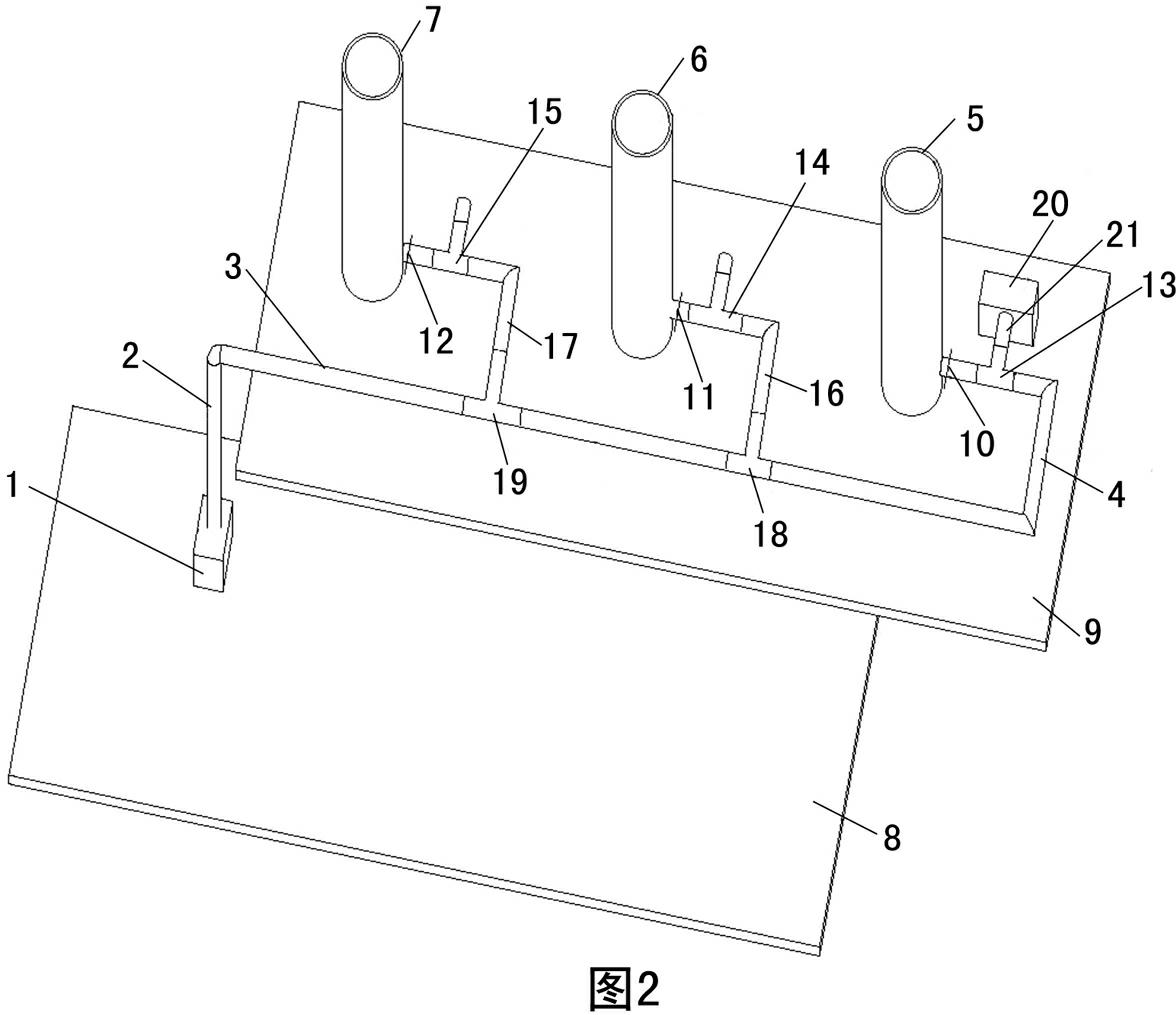

Aluminum profile online uniform quenching device

The invention discloses an aluminum profile online uniform quenching device. The aluminum profile online uniform quenching device comprises a base table, wherein an extrusion forming box, a thermal insulation box, a quenching box, an air cooling box and a material guide chamber are arranged on the base table in sequence. Heating elements are arranged in the thermal insulation box; an upper water injection current divider is arranged on the top of the quenching box, a lower water injection current divider is arranged at the bottom of the quenching box, and both the upper water injection current divider and the lower water injection current divider are provided with water nozzles and are connected with a water purification box through water pipes; the quenching device further comprises a backflow water tank, the water purification box is connected with the backflow water tank through a circulation water pipe, and a filter is arranged in the circulation water pipe; an exhaust fan is further arranged at the inner top end of the quenching box; an air current divider is arranged on the inner top of the air cooling box, and is provided with air nozzles; and a collection bin is arranged outside and below the material guide chamber. The aluminum profile online uniform quenching device is simple in structure, and the quenching temperature and the cooling speed can be adjusted according to the sizes and shapes of aluminum profiles, so that a better quenching effect is achieved.

Owner:四川齐飞新材料科技有限公司

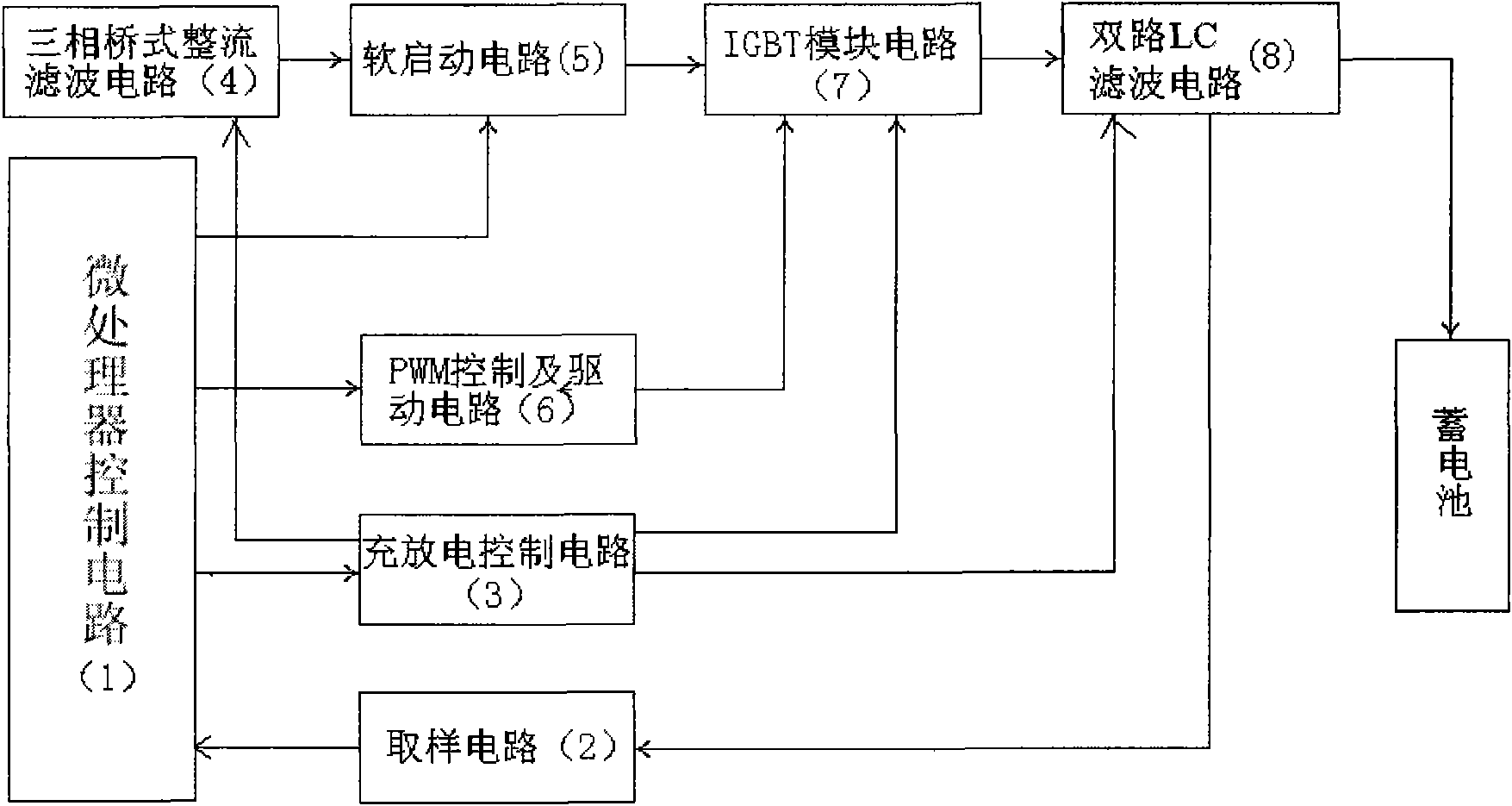

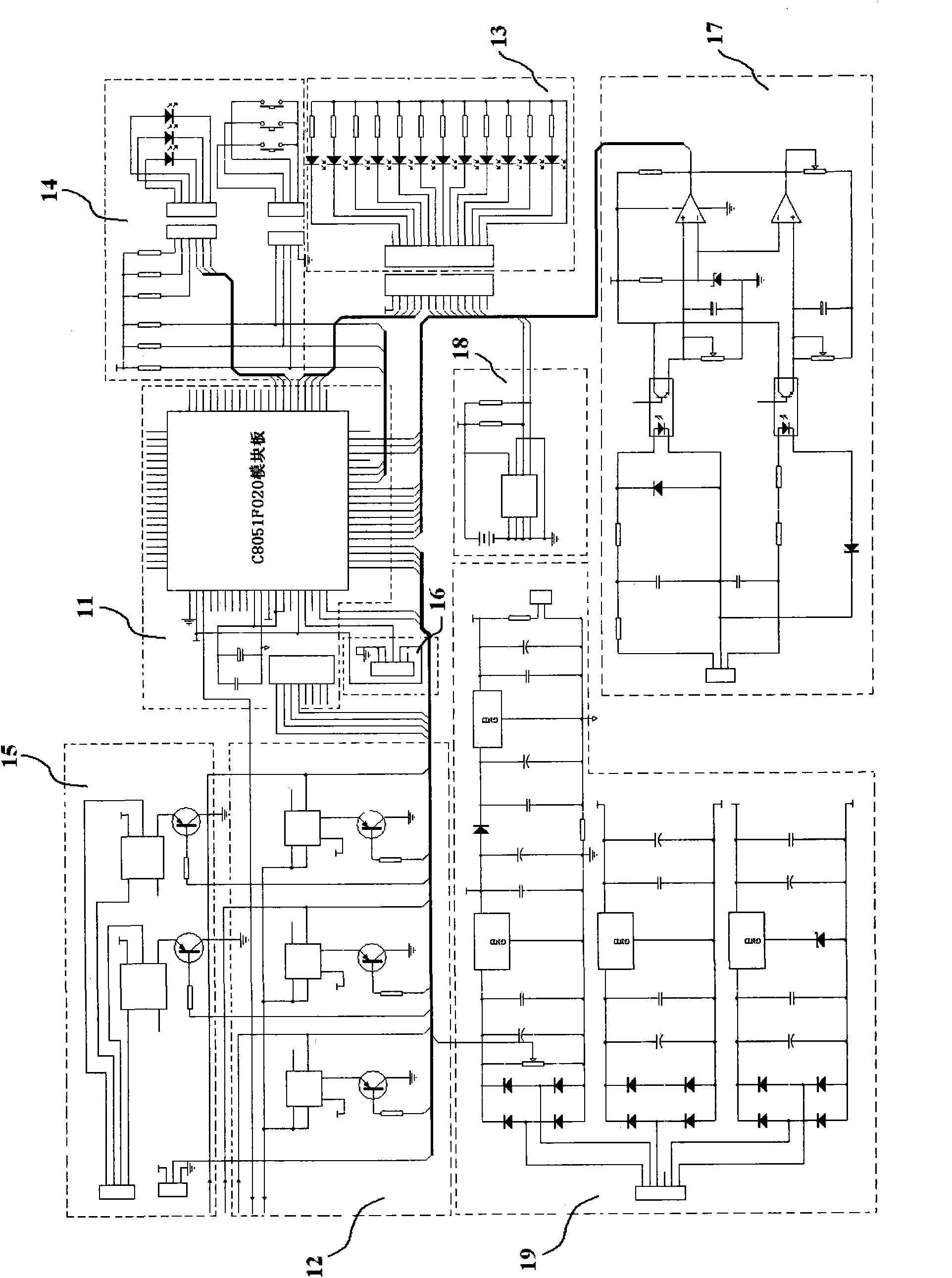

High-power portable intelligent recharge and discharge machine

InactiveCN101888110AIncrease capacityExtended service lifeBatteries circuit arrangementsSecondary cells charging/dischargingShunt DeviceDriver circuit

The invention relates to a recharge and discharge machine, in particular to a high-power portable intelligent recharge and discharge machine. The high-power portable intelligent recharge and discharge machine comprises a machine case and an electric main circuit arranged in the machine case, wherein the electric main circuit comprises a microprocessor control circuit, a sampling circuit, a recharge and discharge control circuit, a three-phase bridge type rectifying filter circuit, a soft start circuit, a PWM control and drive circuit, an IGBT module circuit and a two-way LC filter circuit; and the sampling circuit is connected with a detection current divider in the two-way LC filter circuit. The high-power portable intelligent recharge and discharge machine greatly reduces the volume andthe weight of equipment under the condition of keeping a high-current output state to meet a requirement on portability, greatly improves the efficiency, can recharge and discharge a storage battery by automatically adopting different optimal recharging and activating functions according to different changes of the environment climate temperature, improves the volume of the storage battery, and prolongs the normal service life of the storage battery.

Owner:彭绍岛

Concrete jacking and refluxing system and construction method thereof

ActiveCN102619337AShorten jacking construction timeReduce the incidence of pipe blockage hazardsBuilding material handlingCurrent dividerCheck valve

The invention discloses a concrete jacking and refluxing system and a construction method thereof. The concrete jacking and refluxing system comprises a concrete conveying pump and a concrete conveying pipeline, wherein the concrete conveying pipeline comprises a conveying pipe vertical pipe, a conveying pipe main pipe and conveying pipe branch pipes; the quantity of the conveying pipe branch pipes is the same as that of steel pipe columns which are required to be jacked; the conveying main pipe is communicated with a first conveying pipe branch pipe in the conveying pipe branch pipes; the first conveying pipe branch pipe is communicated with a hole on the lower pipe wall of a first steel pipe column in the steel pipe columns through a steel pipe column check valve; the conveying pipe main pipe is communicated with other conveying pipe branch pipes through main pipe current dividers; and the other conveying pipe branch pipes are communicated with holes on the lower pipe walls of the other steel pipe columns through steel pipe column check valves. According to the concrete jacking and refluxing system and the construction method thereof, concrete waste caused by pipe detachment in the conventional concrete jacking process is reduced, the construction period is saved simultaneously, the construction efficiency in unit time is increased, and the pump pipe blocking probability is lowered.

Owner:中国新兴建设开发有限责任公司

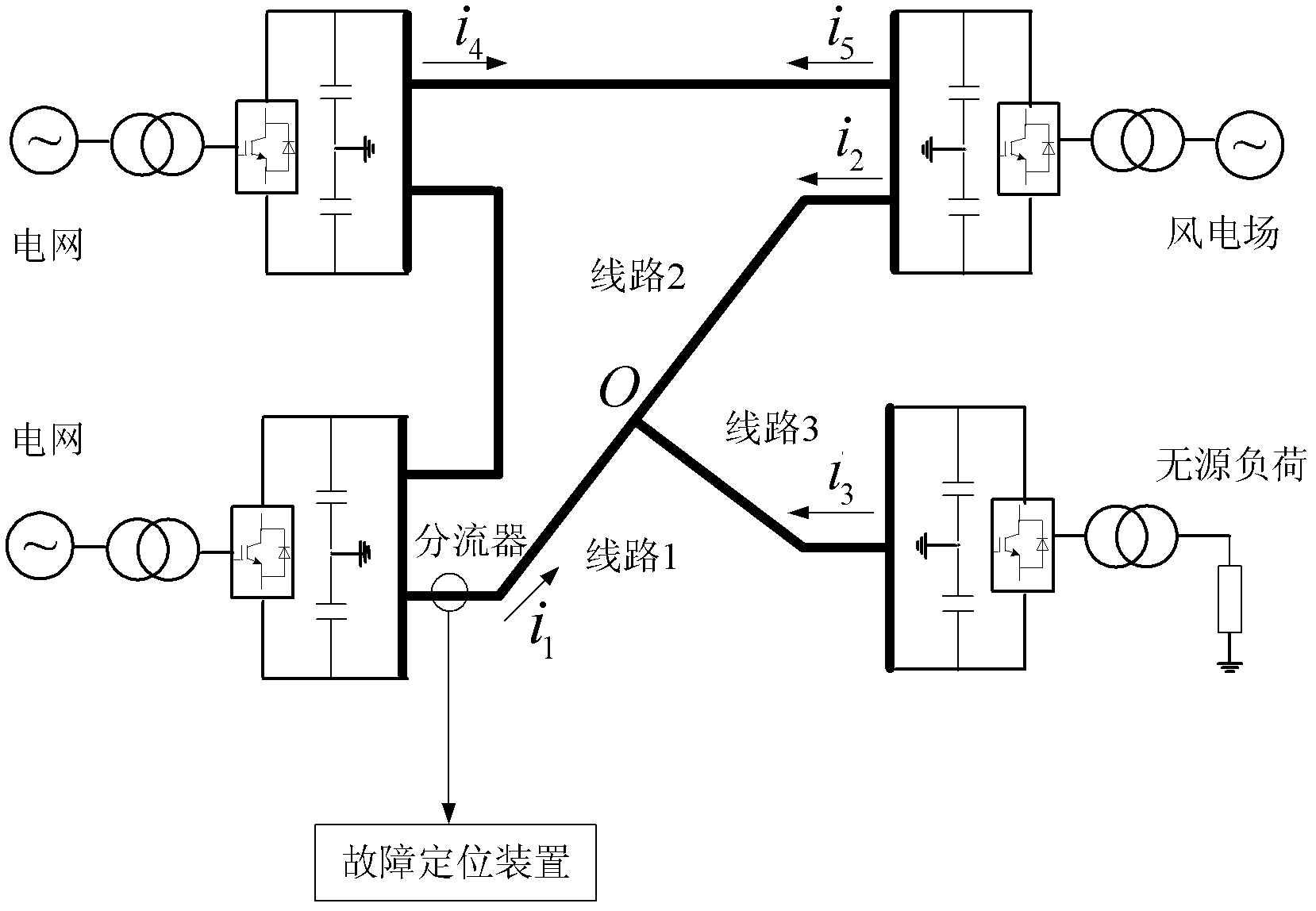

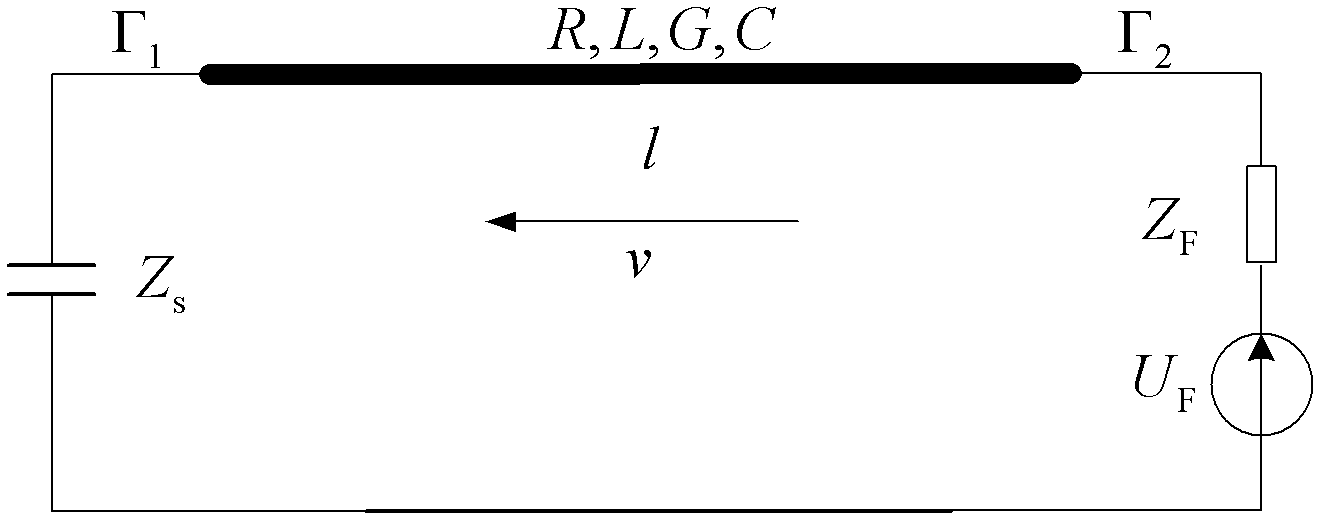

Direct-current line single-terminal fault location method for multiterminal flexible direct-current transmission system

ActiveCN102508121ADistributed parameter characteristics are obviousAccurate fault locationFault location by pulse reflection methodsTransient stateFrequency spectrum

The invention provides a direct-current line single-terminal fault location method for a multiterminal flexible direct-current transmission system. The method comprises the following steps of: 1, acquiring fault transient state current magnitude from a current divider of a direct current line side of the multiterminal flexible direct-current transmission system; 2, extracting a characteristic frequency signal and calculating a characteristic frequency value according to the measured fault transient state current magnitude by spectrum analysis; and 3, calculating a fault distance according to the characteristic frequency value by combining the wave velocity under the characteristic frequency value. According to the method, only the single-terminal current data is used during fault location, the required sampling rate is low, and a calculation step is simple; a travelling wave tip is not needed to be identified, and the method is reliable and safe; and short data window accurate fault location can be realized. The fault location method is suitable for parallel, series and hybrid multiterminal flexible direct-current systems.

Owner:XI AN JIAOTONG UNIV

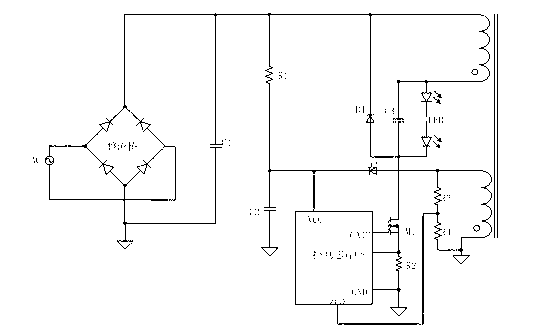

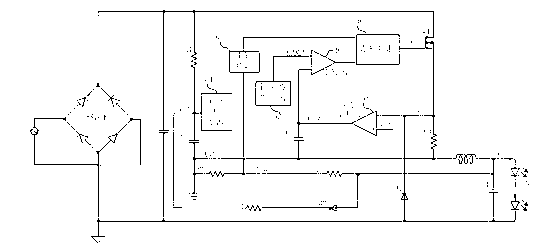

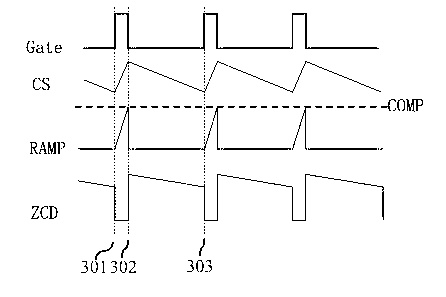

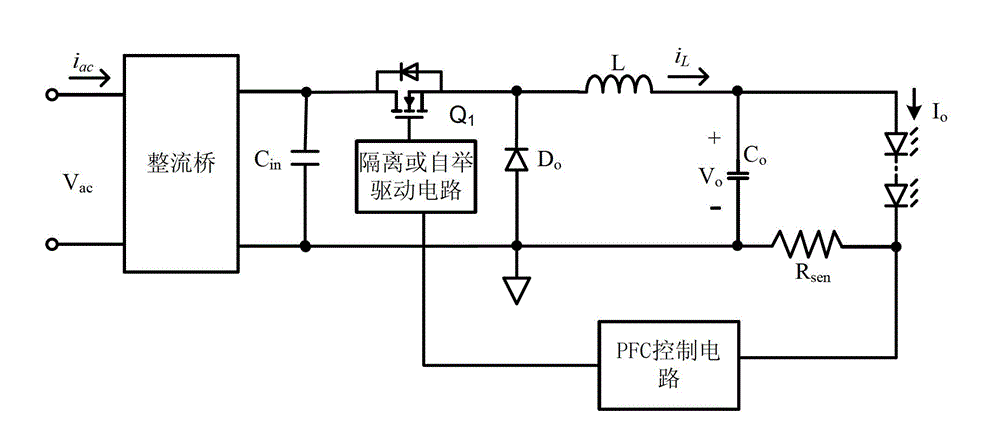

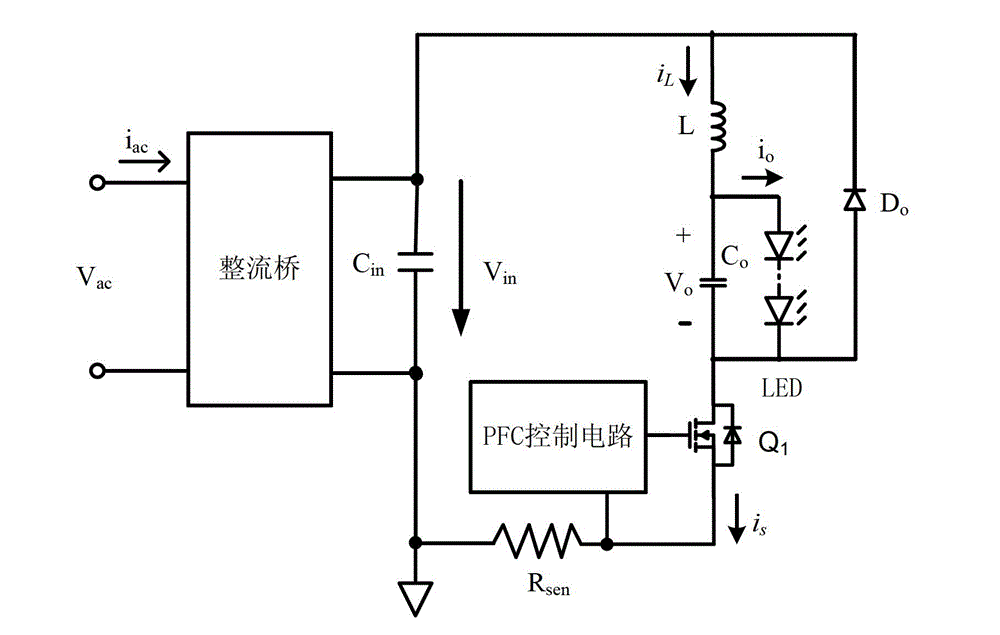

LED driving circuit capable of realizing complete-period sampling of inductive current

ActiveCN103179751AImprove output constant current accuracyReduce designElectric light circuit arrangementLoop controlCurrent divider

The invention discloses an LED driving circuit capable of realizing complete-period sampling of inductive current. The LED driving circuit is used for realizing LED constant-current driving and comprises a rectifier bridge connected with input alternating-current voltage, and an LED load, and the LED load after being connected with an inductor (L1), a power switch (M1) and a sampling resistor (R4) is parallelly connected with a filter capacitor (C1). The LED driving circuit is characterized in that the LED driving circuit switches off the power switch (M1) through a loop control circuit according to current signals flowing through the inductor (L1) when the power switch (M1) is switched on and off and switches on the power switch (M1) according to demagnetizing time of the inductor (L1).

Owner:SHANGHAI BRIGHT POWER SEMICONDUCTOR CO LTD

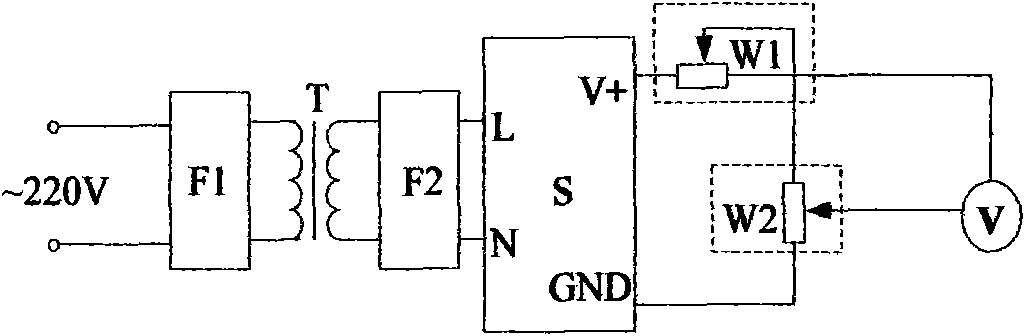

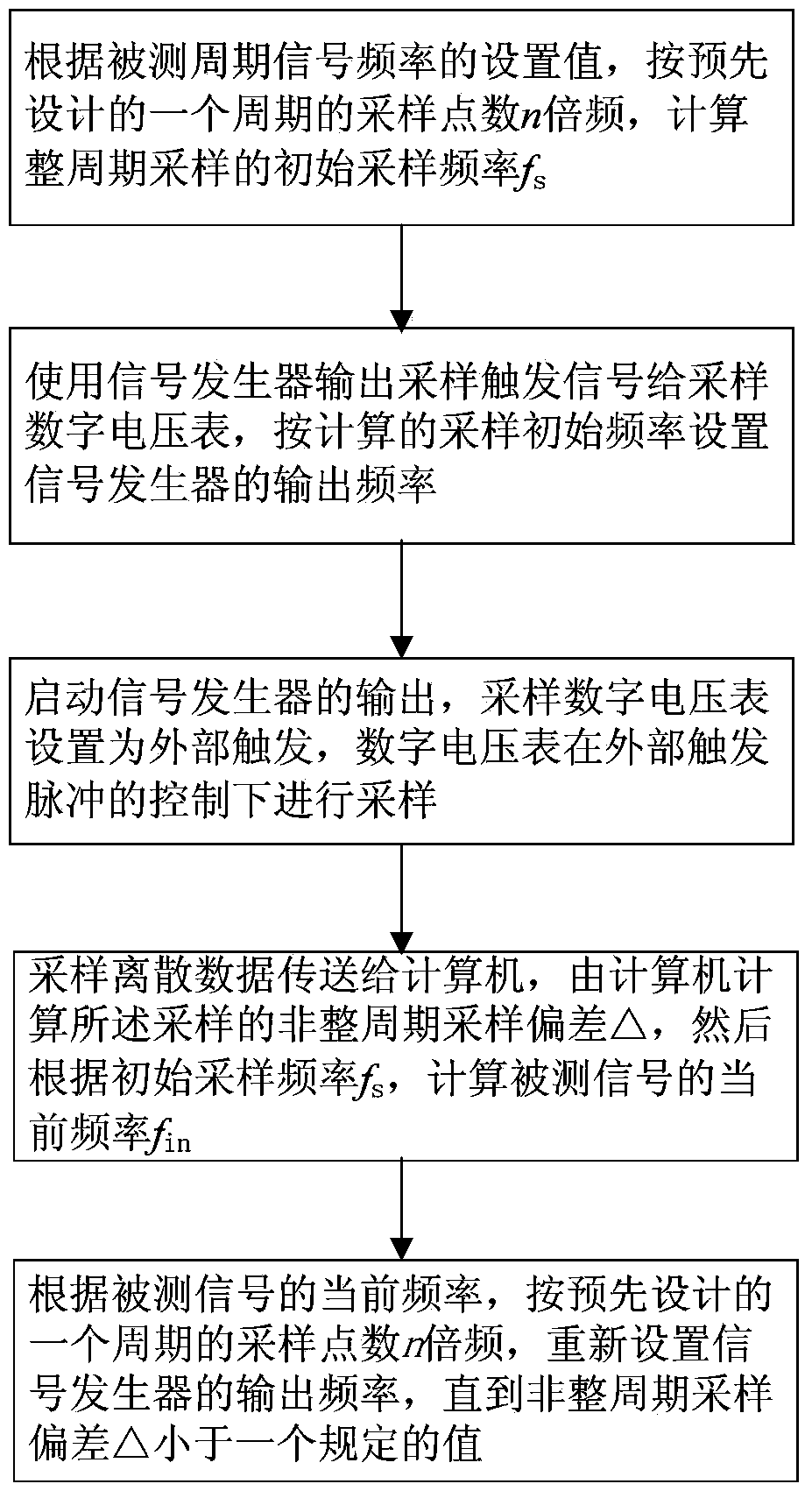

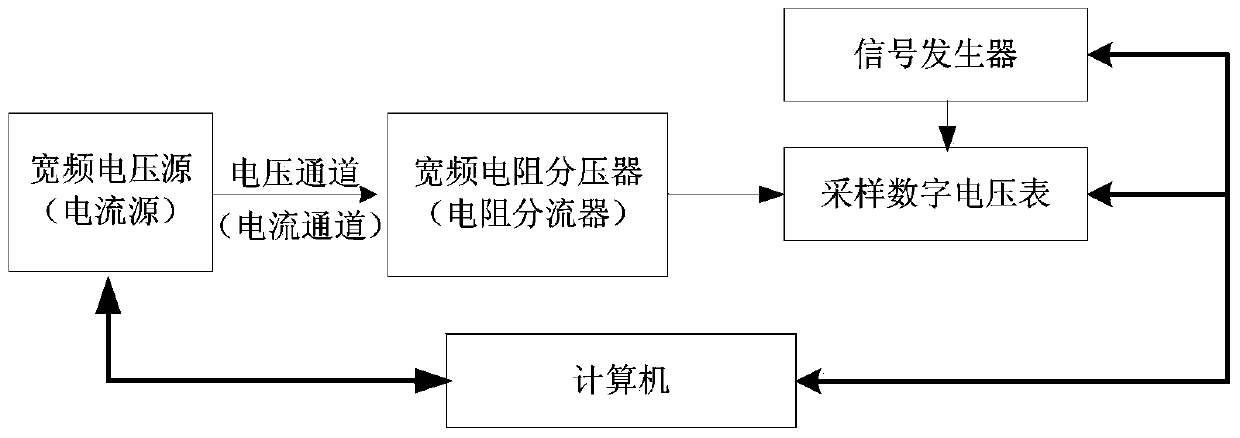

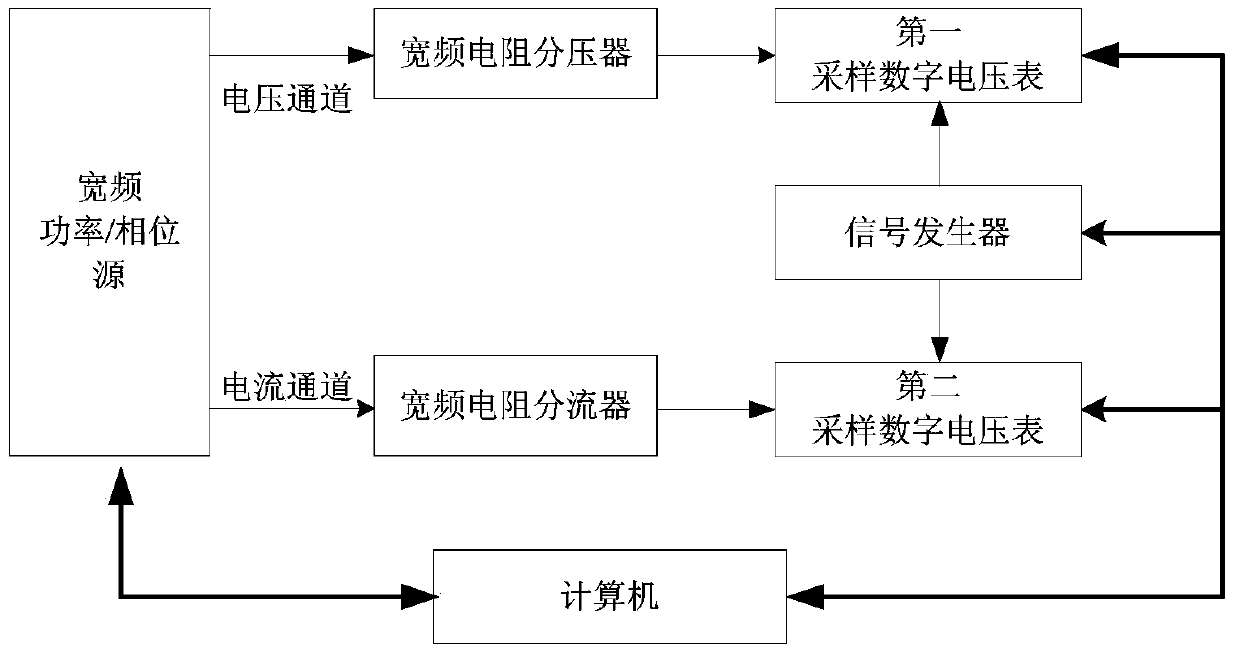

Sampling method based on software frequency tracking and broadband voltage/power calibration device

ActiveCN104237622AHigh measurement accuracyHigh trigger accuracyMeasurement using digital techniquesShunt DeviceElectrical resistance and conductance

The invention provides a sampling method based on software frequency tracking. Non-full-period sampling is adopted, the deviation of the non-full-period sampling is decreased to be lower than a specified value, standard full-period sampling is achieved, and measurement accuracy of the non-full-period sampling is improved. The invention provides a broadband voltage / current calibration device and a broadband power / phase calibration device adopting the sampling method based on software frequency tracking. The broadband voltage / current calibration device comprises a broadband voltage / current source, a broadband resistance voltage / current divider, a sampling digital voltmeter, a signal generator and a computer, wherein the broadband voltage / current source is connected with the sampling digital voltmeter through the broadband resistance voltage / current divider, the output end of the signal generator is connected with an outer trigger port of the sampling digital voltmeter, and the computer is respectively connected with the signal generator, the sampling digital voltmeter and the broadband voltage / current source.

Owner:BEIJING DONGFANG MEASUREMENT & TEST INST

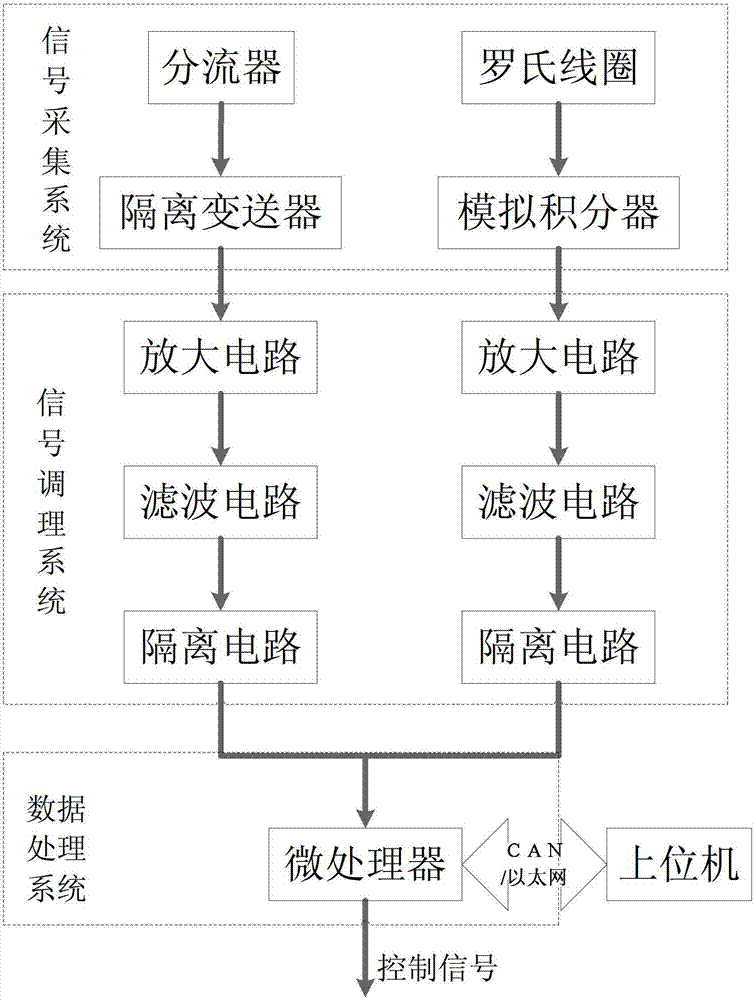

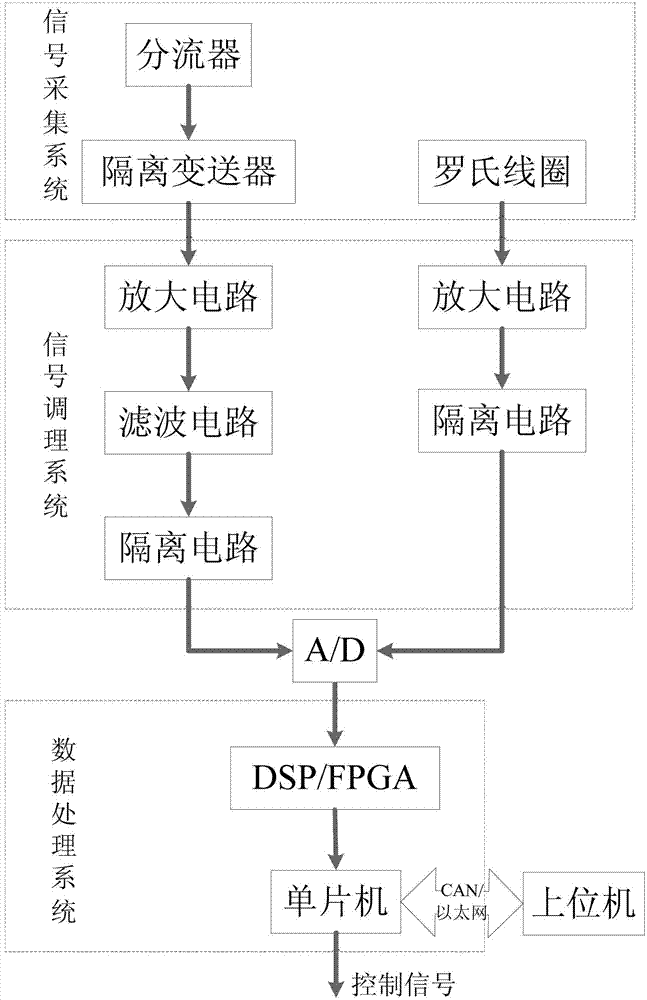

Measuring device and measuring method of reverse small current in direct current distribution system

ActiveCN102818927AAccurate measurementImprove linearityMeasurement using digital techniquesIntegratorControl signal

The invention discloses a measuring device and a measuring method of a reverse small current in a direct current distribution system. The measuring system comprises a signal acquisition system, a signal conditioning system and a data processing system which are mutually connected; the direct current is tested through the combination of a current divider and a Rogowski Coil; the Rogowski Coil is output to an integrator; when an analog integrator and a digital integrator are selected respectively, the system is slightly different; the measuring method is as follows: when in a steady state, the current divider is used for measuring current; when the current is less than a set value, the current divider and the Rogowski Coil are combined to measure small current value, namely, the value measured by the current divider is used as an integral initial value, the Rogowski Coil measures a change rate of the current, the current rate is integrated by the integrator so as to obtain current variable quantity, the current variable quantity is added to the integral initial value so as to obtain a small current value, if the value is less than 0, a control signal is output, and if the value is larger than 0, the measurement is continued. A stable current and the reverse small current in the direct current circuit can be measured precisely; and the measuring device has the advantages of wide measurement range, high precision, rapid response speed, strong overload ability, high linearity, small size and convenience for installation.

Owner:XI AN JIAOTONG UNIV +1

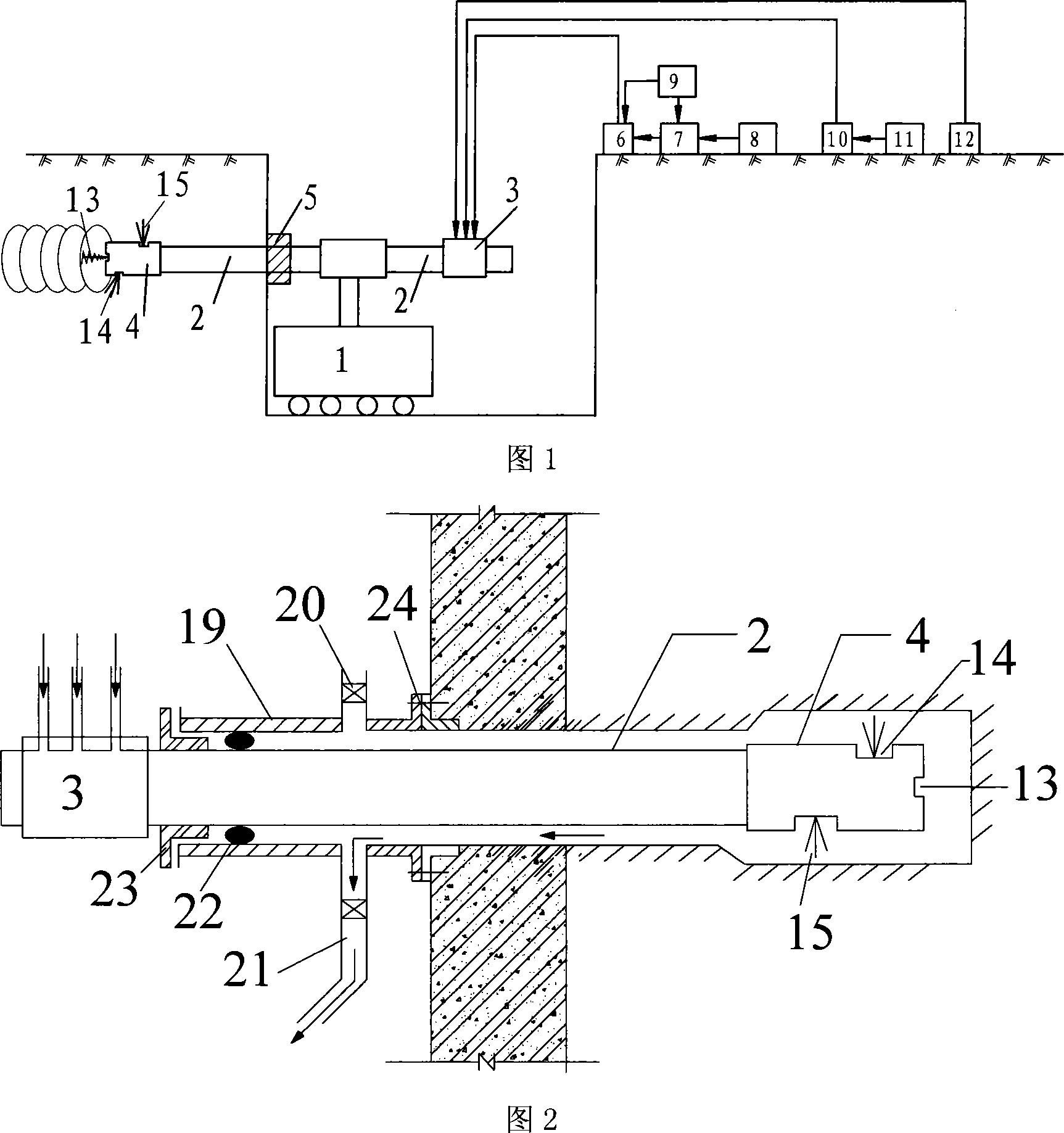

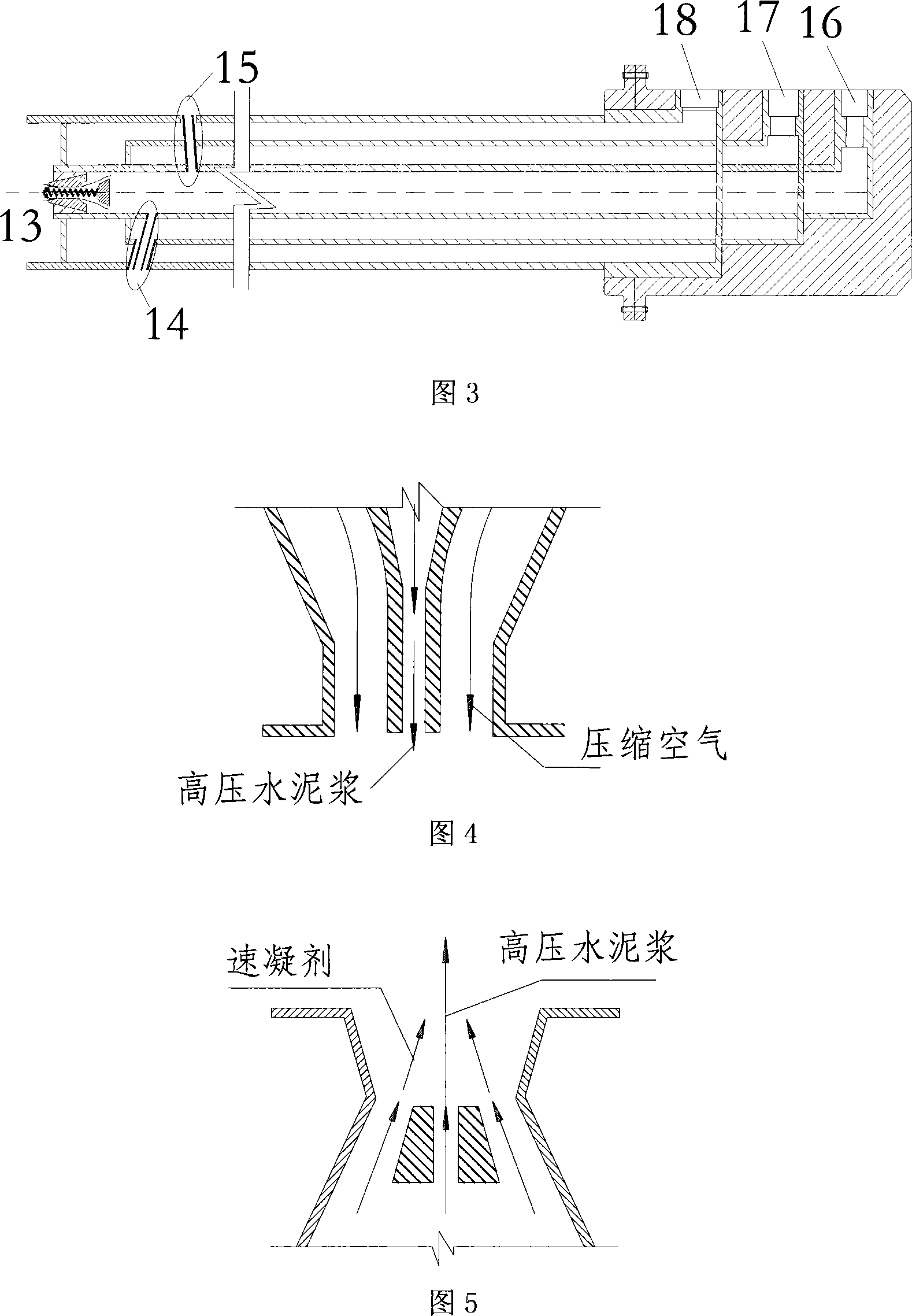

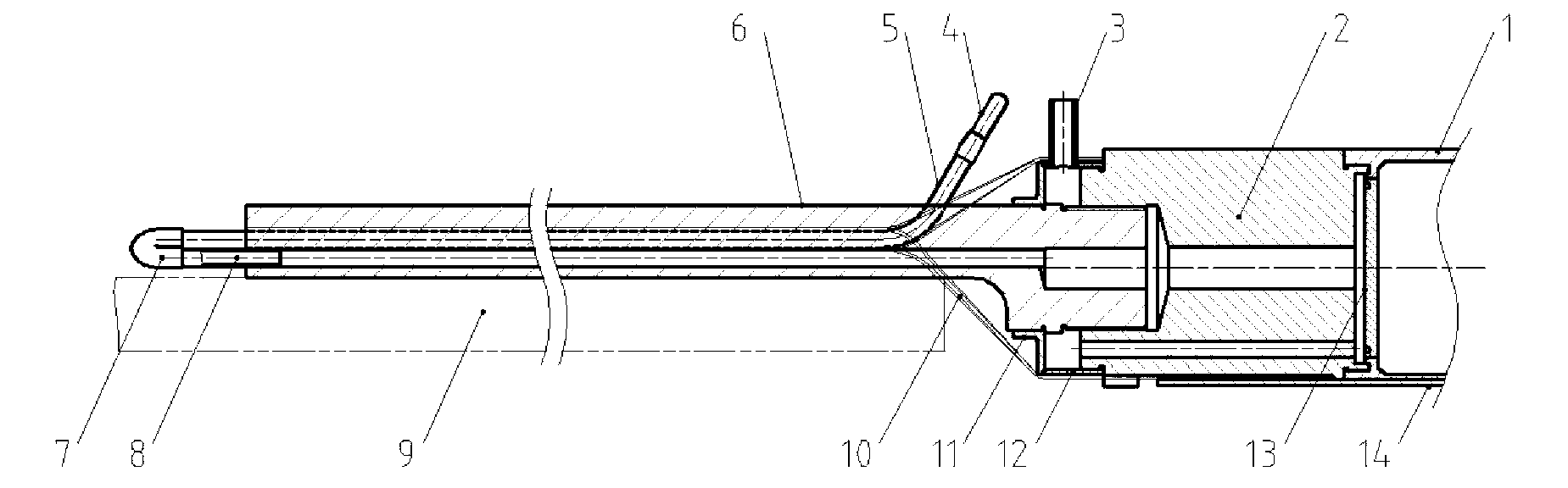

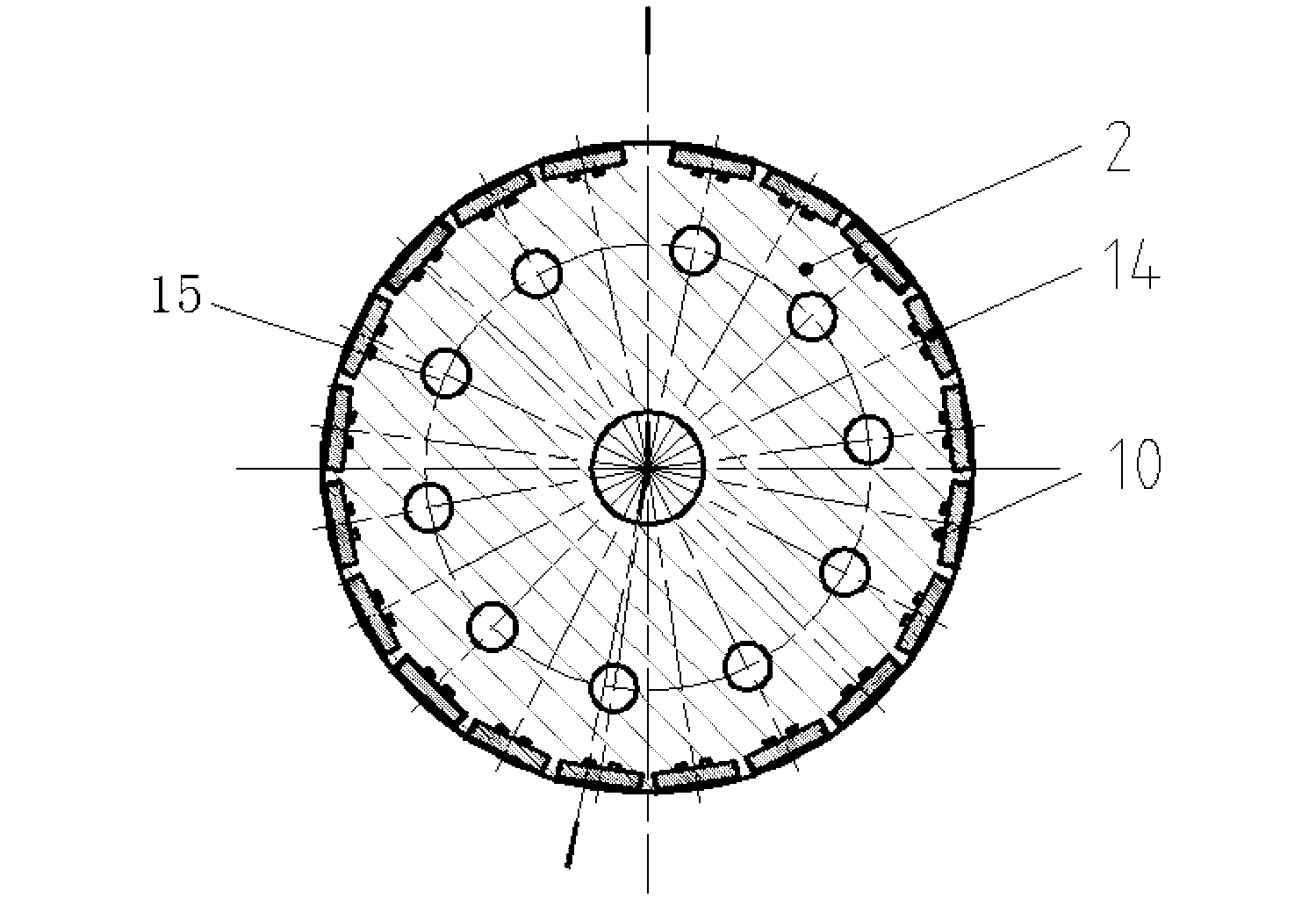

Construction equipment for generating horizontal jet grouting reinforcing body by injecting double-liquid liquid with high-pressure

ActiveCN101245599AEasy to processImprove construction efficiencyUnderground chambersTunnel liningCurrent dividerSlurry

The invention discloses a piece of construction equipment which uses high pressure for spraying two-fluid slurry to generate a horizontal jet grouting reinforcing body and belongs to the field of construction engineering technology, comprising a high pressure pump, a low pressure pump, an air compressor, a current divider, a treble tubular drill spray rod, a multifunctional spray-head, a horizontal drill and an orifice sealing device; wherein, the high pressure pump, the low pressure pump and the air compressor are connected on the treble tubular drill spray rod by the current divider, and the treble tubular drill spray rod is supported and connected by a bracket of the horizontal drill and is controlled by a drive of the horizontal drill to rotate as well as makes advance and retreat movement back and forth and translational movement left and right; one end of the multifunctional spray-head is connected with the treble tubular drill spray rod by a screw thread, the orifice sealing device is arranged at an orifice of a horizontal jet grouting pile, the spray-head and the treble tubular drill spray rod pass through the orifice sealing device to carry out drilling and spraying, and the treble tubular drill spray rod is sealed with the orifice sealing device. The construction equipment overcomes the deficiencies in the existing horizontal jet grouting technique, and a horizontal jet grouting pile body can be formed in a running sand layer, therefore, the efficiency of jet grouting construction is greatly improved.

Owner:SHANGHAI URBAN CONSTRUCTION MUNICIPAL ENGINEERING (GROUP) CO LTD +3

Forced flow cooling low-temperature section directly overlapped with high-temperature superconductor stack

ActiveCN103258615ASimple structureSuperconducting magnets/coilsCurrent dividerHigh temperature superconducting

The invention discloses a forced flow cooling low-temperature section directly overlapped with a high-temperature superconductor stack in a high-temperature superconducting current lead. The forced flow cooling low-temperature section comprises the high-temperature superconductor stack, a cold-end copper structural part, a low-temperature superconducting wire, a copper core tube and a copper connector. The high-temperature superconductor stack is directly connected with the low-temperature superconducting wire in a soldering manner; the high-temperature superconductor stack and the low-temperature superconducting wire are sunk in trenches of a current divider and the cold-end copper structural part to be soldered into a whole; the low-temperature superconducting wire is spirally and tightly wound on the copper core tube prior to soldering; the copper connected is connected with the cold-end copper structural part in a threaded manner, and is provided with an internal cooling flow passage; small hole flow passages are distributed on the cold-end copper structural part and close to an outer circle array; and the low-temperature superconducting wire wound on the copper core tube is soldered with the copper connector. A bottom plane of the copper connector can be connected with a superconducting bus connector for welding. The high-temperature superconductor stack is directly connected with the low-temperature superconducting wire to reach -1n omega, 4.5K low-temperature heat load is just 3.7W, and cooling liquid helium flow resistance is just 0.02bar.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

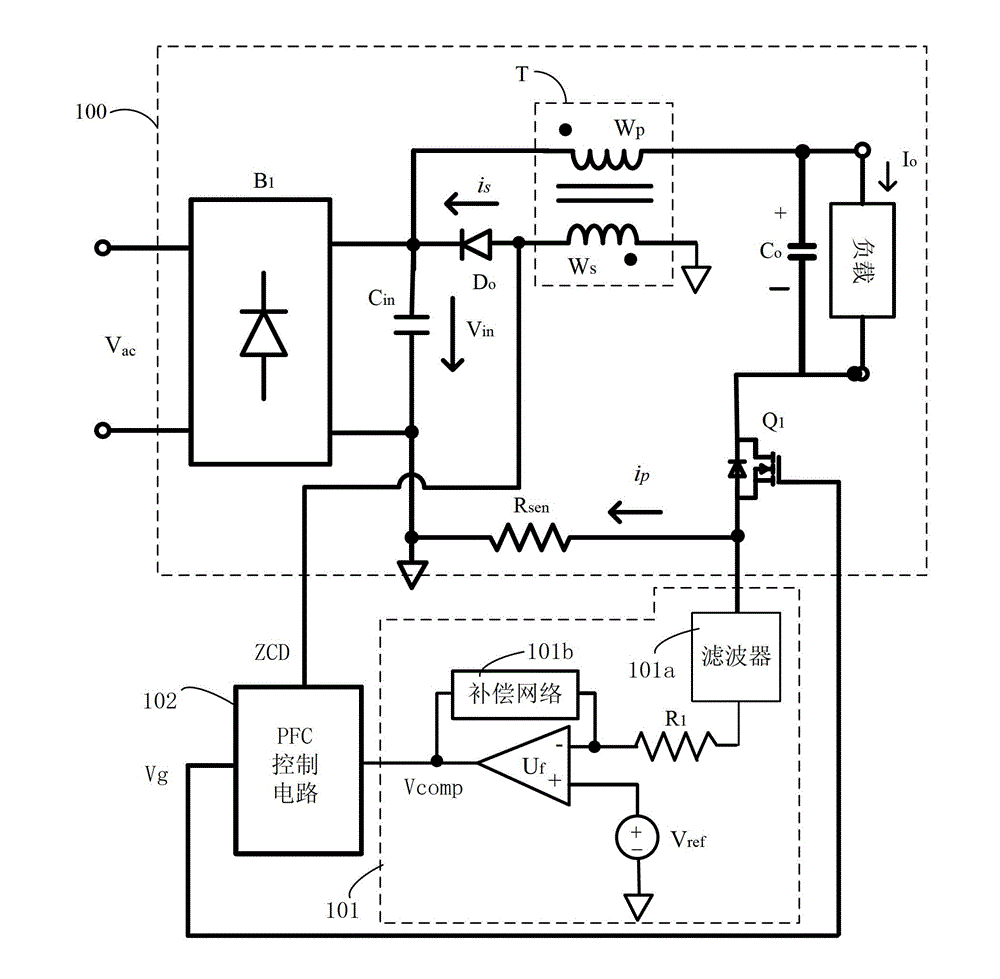

High-power factor constant-current drive circuit and constant-current device

ActiveCN102946196AAchieve direct controlAdjustment accuracy impactEfficient power electronics conversionElectric light circuit arrangementCapacitancePower flow

The invention provides a high-power factor constant-current drive circuit and a constant-current device. The constant-current drive circuit comprises a rectifier bridge, an input capacitor, an output diode, a transformer, an output capacitor and a power switch tube, wherein the first end and the second end of the input capacitor are respectively connected with the positive and negative output ends of the rectifier bridge; the negative pole of the output diode is connected with the first end of the input capacitor; the same-polarity end of the primary winding of the transformer is connected with the first end of the input capacitor, the different-polarity end of the secondary winding of the transformer is connected with the positive pole of the output diode, and the same-polarity end of the secondary winding is connected to the ground; the first end of the output capacitor is connected with the different-polarity end of the primary winding; and the first power end of the power switch tube is connected with the second end of the output capacitor, the second power end of the power switch tube is connected to the ground through a current detection circuit, and the control end of the power switch tube receives an externally input drive signal. The high-power factor constant-current drive circuit and the constant-current device which are provided by the invention can solve the problems of complex power switch tube drive circuit and low current sampling accuracy of the conventional Buck type high-power factor constant-current drive circuit.

Owner:HANGZHOU SILAN MICROELECTRONICS

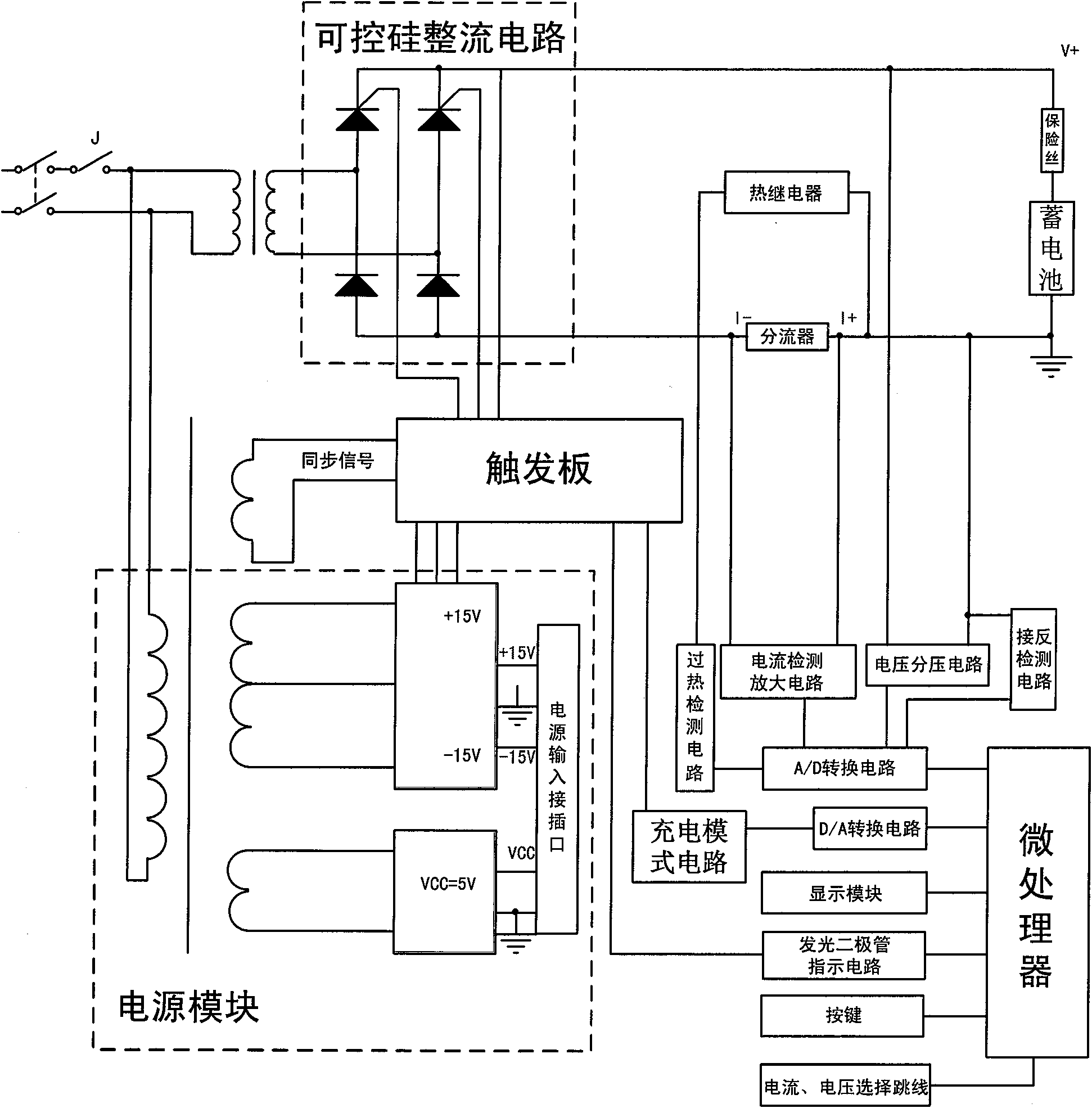

Intelligent charging machine for an electric forklift truck

InactiveCN101567571AWith fault automatic judgment functionChange overchargeBatteries circuit arrangementsElectric powerShunt DeviceSilicon-controlled rectifier

An intelligent charging machine for an electric forklift truck comprises a transformer, two silicon-controlled rectifier circuits arranged at two output terminals of the transformer, an accumulator anode and an accumulator cathode arranged at two output terminals of the silicon-controlled rectifier circuits respectively; a current divider is arranged between the accumulator cathode and the cathode output terminal of the silicon-controlled rectifier circuit; two terminals of the current divider are connected with a current detection amplification circuit; the intelligent charging machine also comprises a micro-processor, an A / D conversion circuit, a D / A conversion circuit and a display module; the A / D conversion circuit is connected with the current detection amplification circuit; the intelligent charging machine also comprises a trigger board which is connected with the control terminal of the silicon-controlled rectifier circuit; and a charging current control circuit is connected between the trigger board and the D / A conversion circuit. The intelligent charging circuit displays various charging parameters by a digitron, automatically judges the charging plenitude of the accumulator comprehensively by various methods, changes the over-charging and under-charging of the accumulator, avoids damaging the accumulator in advance and prolongs the service life of the accumulator.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

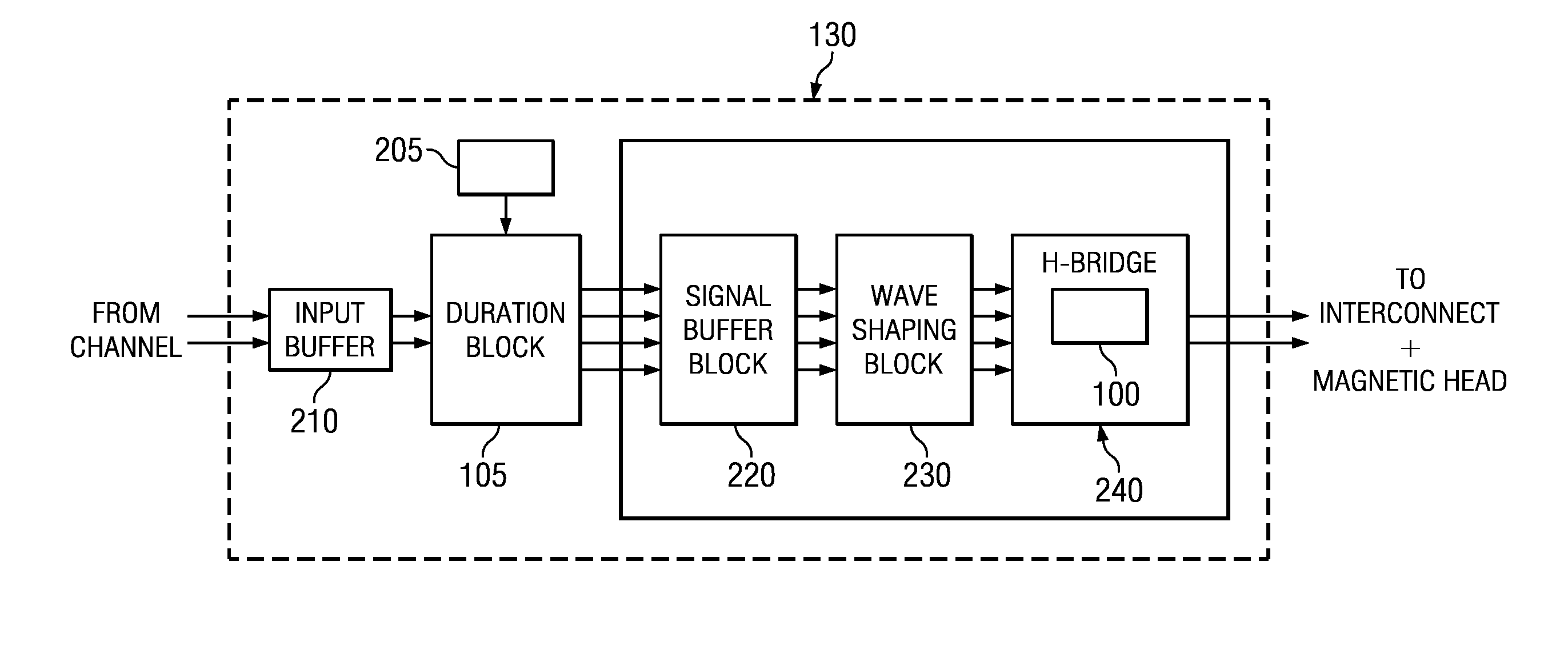

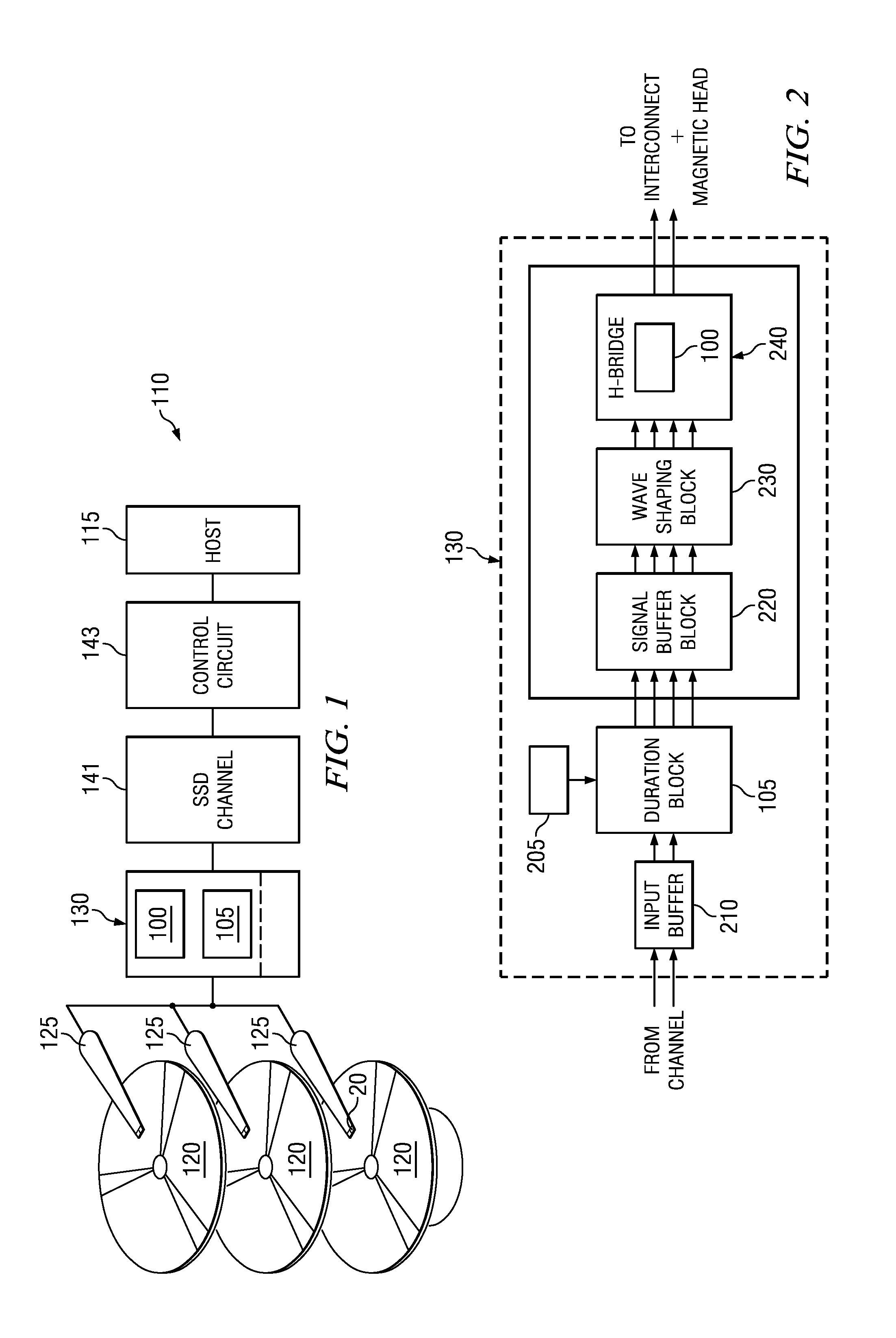

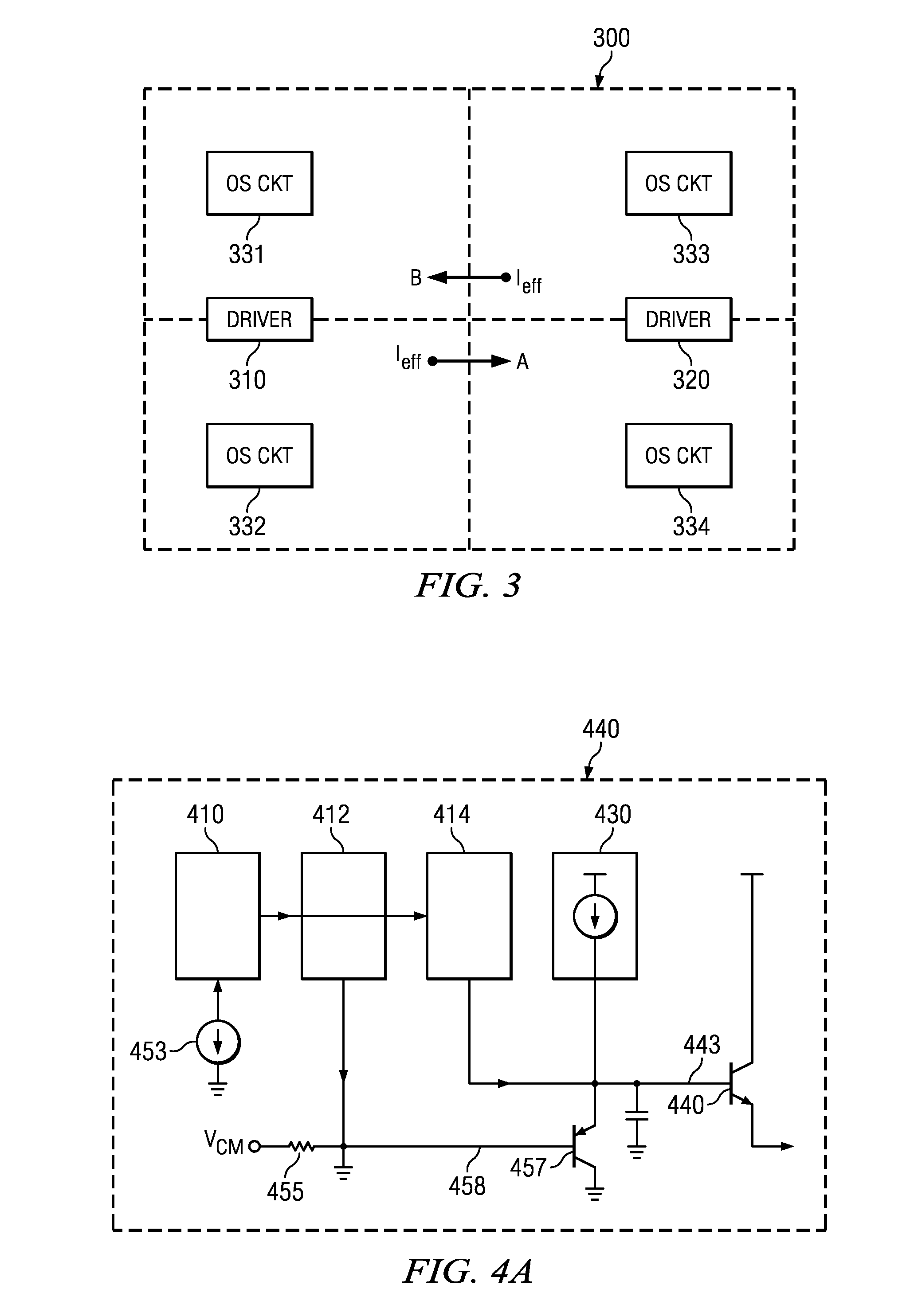

High-Speed, Low-Power Driver System

ActiveUS20100237910A1Amplifier with semiconductor-devices/discharge-tubesRecord information storageDc currentCurrent divider

A reduced power driver is described. This reduced power driver comprises: an input current driver for transmitting a current signal that is a fraction of a DC current signal; a first resistor coupled at one end to a first voltage supply; a first current driver coupled to the input current driver and a first switch control; a second switch coupled a first current driver output, another end of the first resistor, and the output control; a dynamic booster coupled between the first voltage supply and the output control; and wherein the reduced power driver is operative for selectively adding an overshoot current to the output control so that power consumption is reduced, while synchronizing the DC current signal with the overshoot current.

Owner:TEXAS INSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com