Patents

Literature

189 results about "Manganin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganin is a trademarked name for an alloy of typically 84% copper, 12% manganese, and 4% nickel. It was first developed by Edward Weston in 1892, improving upon his Constantan (1887). Manganin foil and wire is used in the manufacture of resistors, particularly ammeter shunts, because of its virtually zero temperature coefficient of resistance value and long term stability. Several Manganin resistors served as the legal standard for the ohm in the United States from 1901 to 1990. Manganin wire is also used as an electrical conductor in cryogenic systems, minimizing heat transfer between points which need electrical connections.

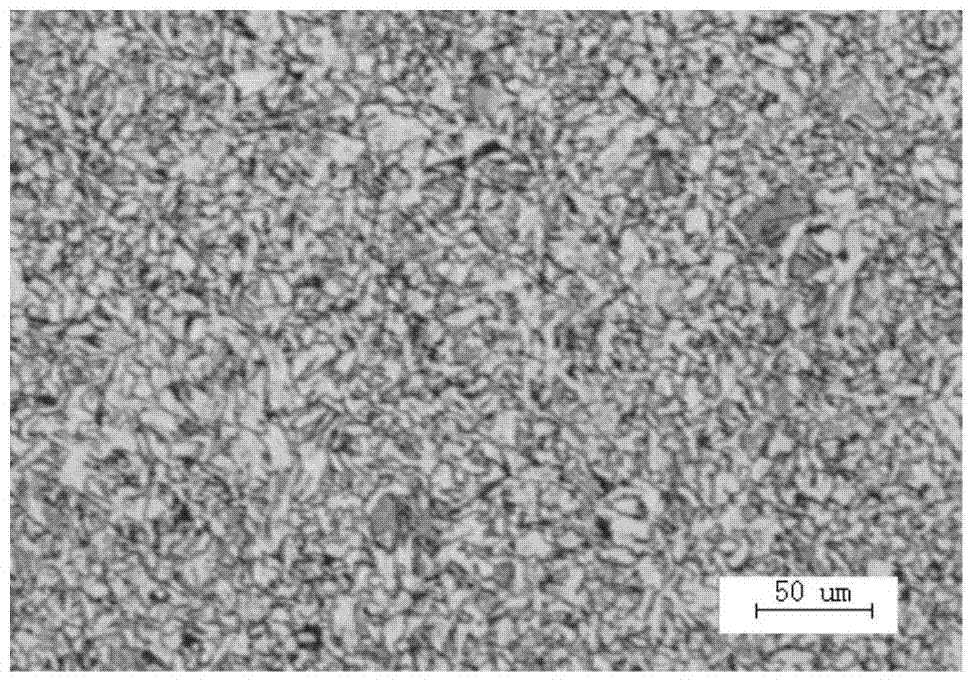

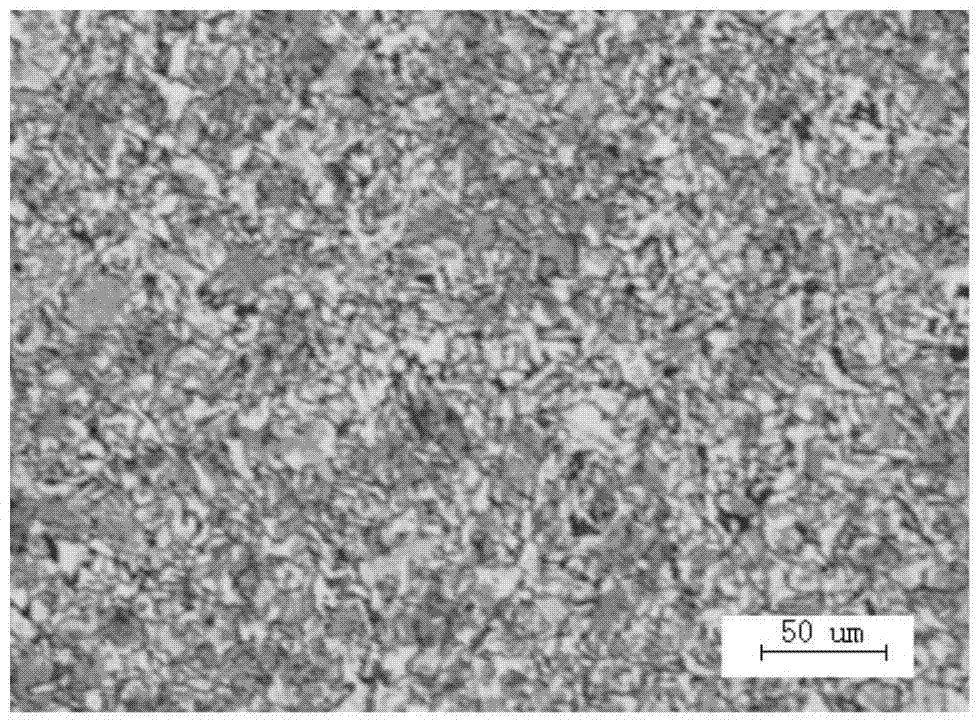

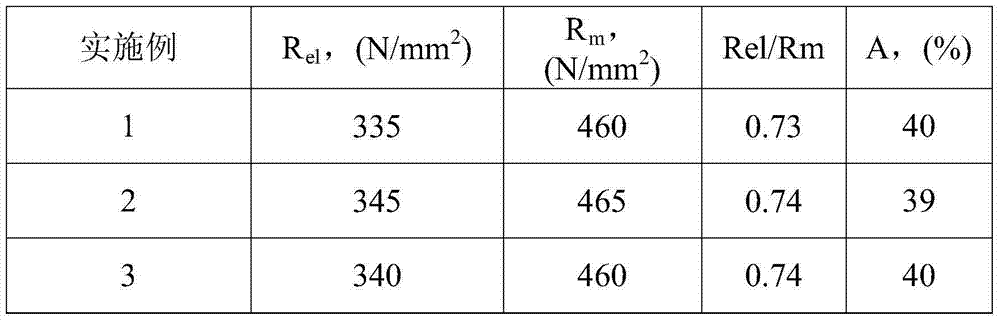

Petroleum casing pipe with high strength and high toughness and preparing method thereof

InactiveCN101586450ALow alloy contentLow costDrilling rodsProcess efficiency improvementAlloyMechanical property

The present invention provides a petroleum casing pipe with high strength and high toughness, wherein the weight of the component element of the casing pipe steel is characterized proportionally. The invention also provides a preparing method for preparing the petroleum casing pipe with high strength and high toughness, wherein the method comprises the following steps: 1. smelting the ingredients and casting the tube blank; 2. punching and tandem rolling of the steel tube; and 3. heat treating. The invention has the following beneficial effects: the performance of the petroleum casing pipe obtained by the method is the performance of the steel with lower content of alloy and the cost is low; a low carbon content is adopted so that the lath martensite tissue is obtained after heat treatment, the high toughness is provided after tempering and a delayed fracture resistance is provided; the complex micro-alloying processing techniques of V, Nb, Ti, B, etc. are adopted for strengthening the matrix, strengthening the grain-boundary strength, increasing the tempering resistance, reducing the content of manganese element, reducing the content of the impurity elements and improving the shape of the inclusion. The rolling ratio is optimized so that the aeolotropism of the material is remarkably reduced and the horizontal and vertical impact toughness of the material is larger than 0.8. The casing pipe of the invention far exceeds the prior highest steel grade requirement of the API standard.

Owner:TIANJIN PIPE GROUP CORP

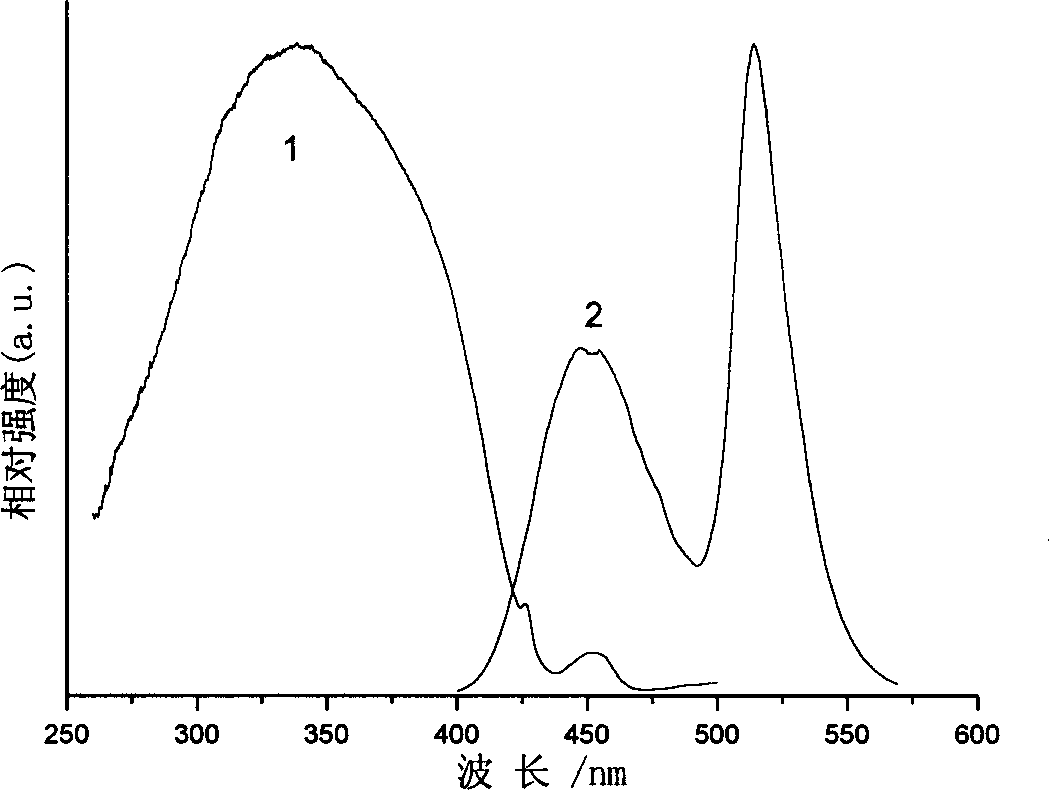

Violet light excitated bicomponent three basic colour fluorescent powder and its preparation method

A laser triggered two-element three-primary-color fluorescent powder contains the blue-green powder, which is the barium magnesium aluminate activated by 2-valence Mn and 2-valence Eu and has main emission peaks in blue and green regions, and the red powder, which is the yttrium thioxide activated by 3-valuence Eu and has main emission peak in red region through proportional mixing and high-temp solid-phase reaction.

Owner:PEKING UNIV

Precision shunt resistor and manufacturing method thereof

InactiveCN1545106AIncrease temperature coefficientSmall temperature coefficientCurrent collector arrangementsResistor manufactureManganinEngineering

Owner:彭德龙

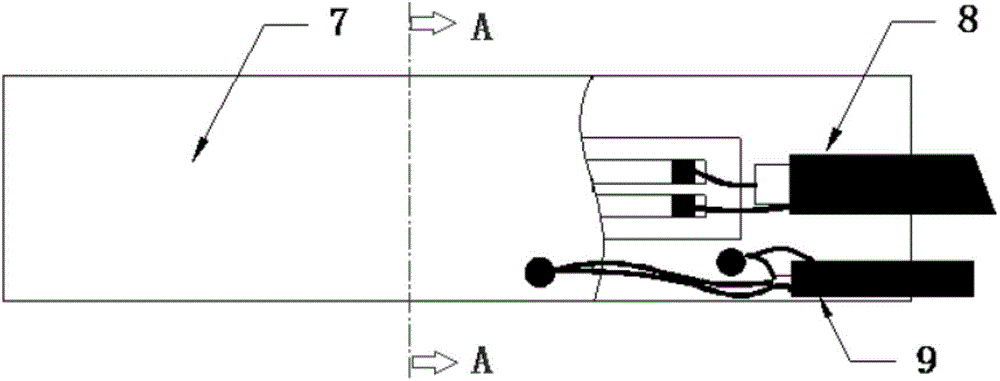

Manganin pressure sensor and device for measuring underwater explosion near-field impact wave pressure

InactiveCN104406728AImprove structural strengthExtend working lifeApparatus for force/torque/work measurementWave pressureManganin

The invention provides a manganin pressure sensor and a device for measuring underwater explosion near-field impact wave pressure and belongs to the technical field of underwater explosive impact measuring. A sensitive element is clamped between two copper-coated thin plates, so that integral structural strength of the sensor is improved, and service life of the sensor is prolonged. The manganin pressure sensor has high anti-interference capability and can resist interference caused to near field measuring by products caused by explosive blasting, residual electric field in water and outside electromagnetic field, and probability is provided for realizing accurate measuring of underwater explosion near-field impact wave pressure.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

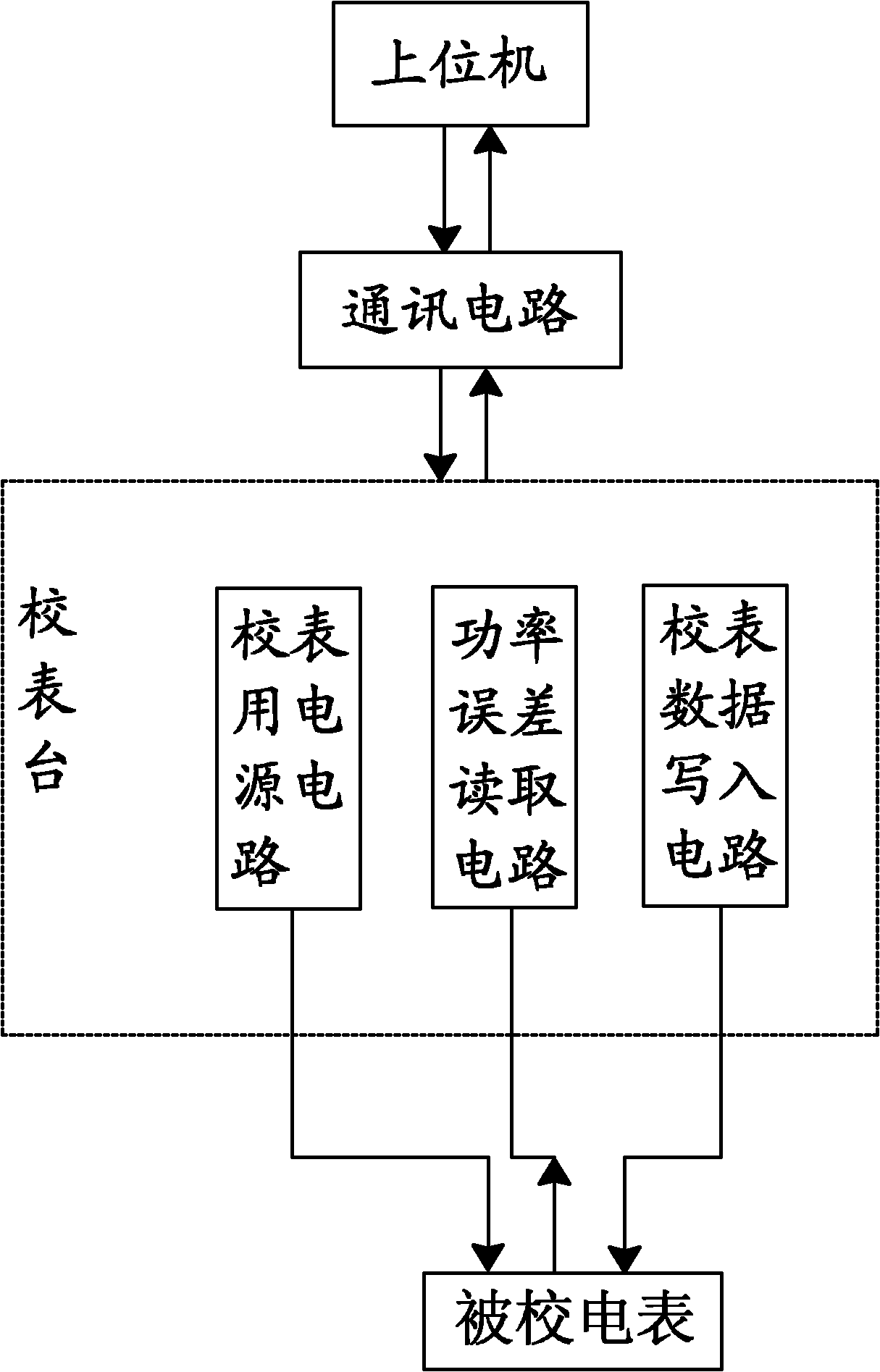

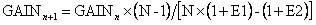

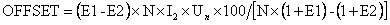

Power meter calibrating system and power meter calibrating method for intelligent electric meter

ActiveCN101915903AMeet the precision requirementsHigh measurement accuracyElectric signal transmission systemsElectrical measurementsTime errorManganin

The invention aims to provide a power meter calibrating system and a power meter calibrating method for an intelligent electric meter. The power accuracy of a manganin sampling-based intelligent electric meter is improved in a mode of meter calibrating to ensure the high efficiency and consistency of quantity production. The meter calibrating system comprises a meter calibrating platform, an upper computer and a communication circuit connected with the meter calibrating platform and the upper computer, wherein the meter calibrating platform is provided with a power supply circuit for meter calibrating, a power error reading circuit and a meter calibrating data writing circuit. In the meter calibrating method, by adopting the meter calibrating scheme of two-point mixing, namely a real-time error value of the intelligent electric meter is read quickly under a heavy current point, and a real-time power value is read stably under a low current point, two meter calibrating parameters of a power gain value and a power biasing value of the electric meter are obtained through calculation by a corresponding algorithm, and the two parameters are written into the electric meter by utilizing meter calibrating data.

Owner:ZHUHAI ZHONGHUI MICROELECTRONICS

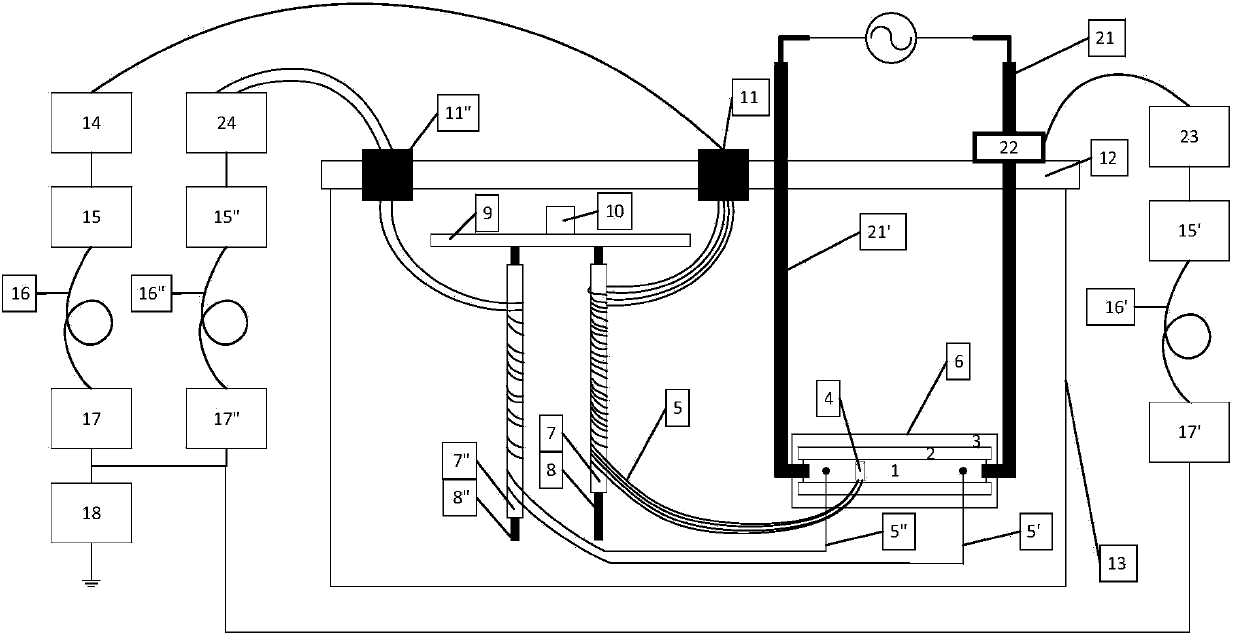

High-temperature superconducting magnet online monitoring system

InactiveCN104198803AMonitor temperatureMonitor currentThermometers using physical/chemical changesMeasurement using digital techniquesManganinHigh-temperature superconductivity

A high-temperature superconducting magnet online monitoring system comprises a high-temperature superconducting magnet system, a conduction cooling refrigeration system, a low-temperature Dewar system, a testing device, a digital voltage meter, a carburizing ceramic temperature sensor, a measuring manganin wire, a heat conduction insulating layer, a temperature transmitter, a fiber converter, a fiber, a compression joint copper sheet and low-temperature high vacuum grease, the cooling refrigeration system comprises a refrigerating machine cold head, a copper cold conduction connecting plate and a copper cold conduction framework, the heat conduction insulating layer coats the copper cold conduction framework, the testing device comprises a computer and a current sensor, the middle of the measuring manganin wire is wound on the heat conduction insulating layer, the carburizing ceramic temperature sensor is directly pressed on the surface of a high-temperature superconducting strip, two ends of the carburizing ceramic temperature sensor are directly fixed on the surface of the high-temperature superconducting strip, gaps among the compression joint copper sheet, the carburizing ceramic temperature sensor and the high-temperature superconducting strip are filled with the low-temperature high vacuum grease for assisting in fixing the carburizing ceramic temperature sensor and conducting heat.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +1

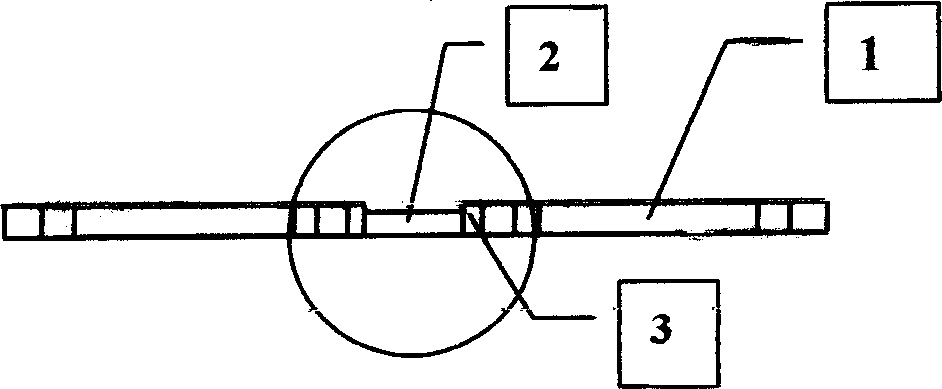

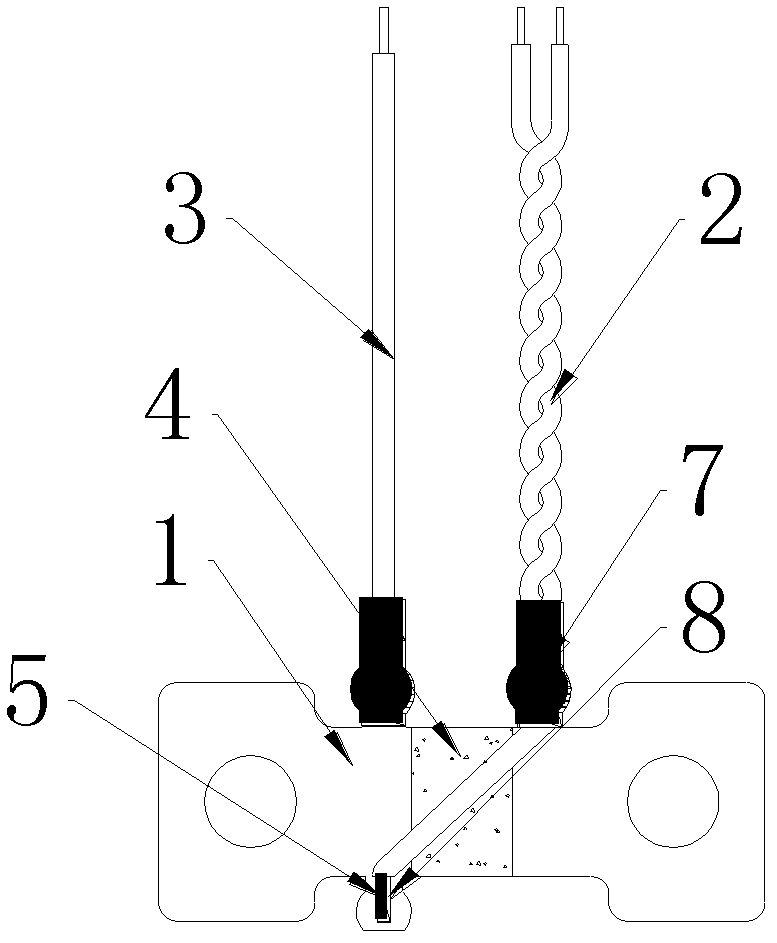

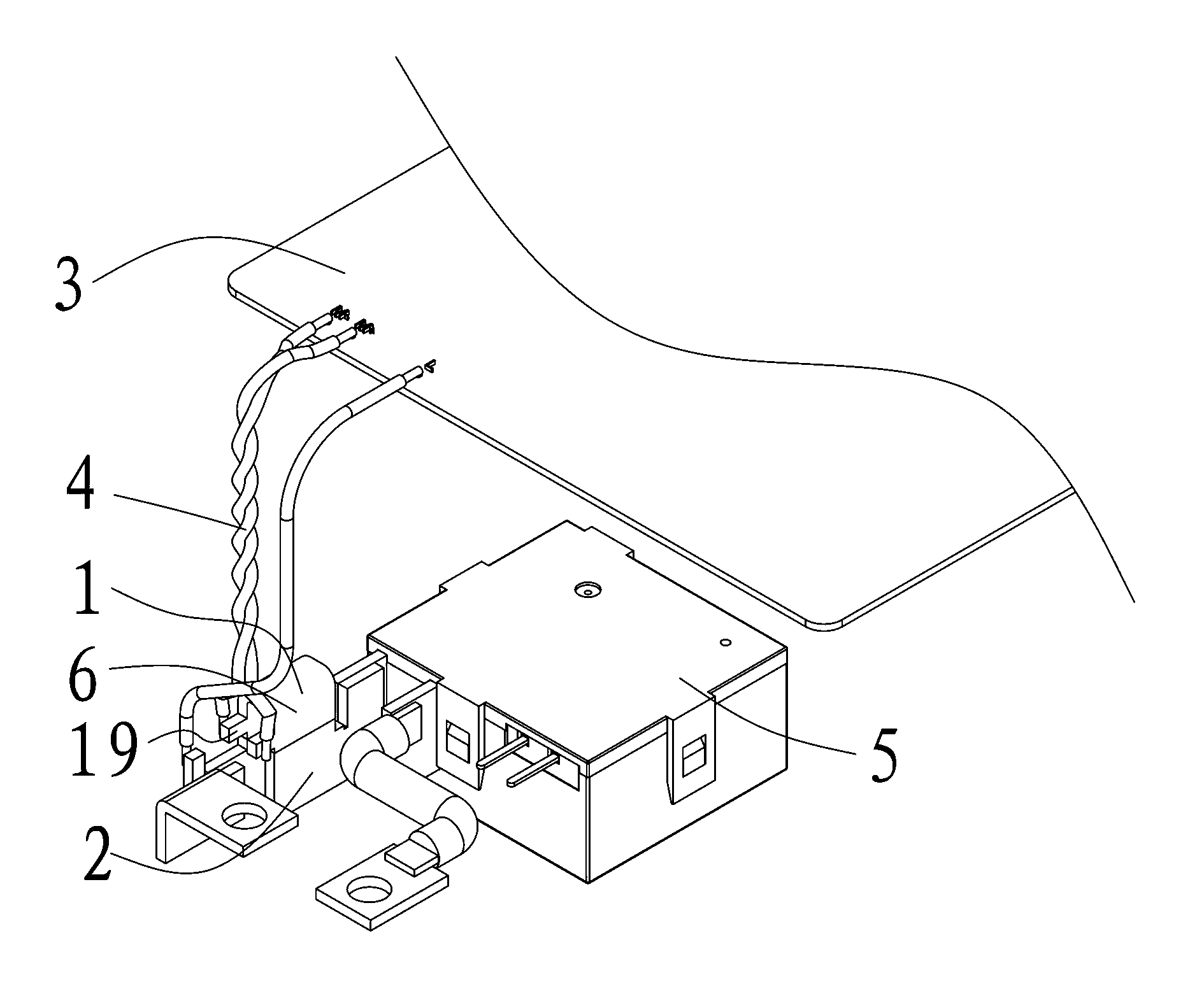

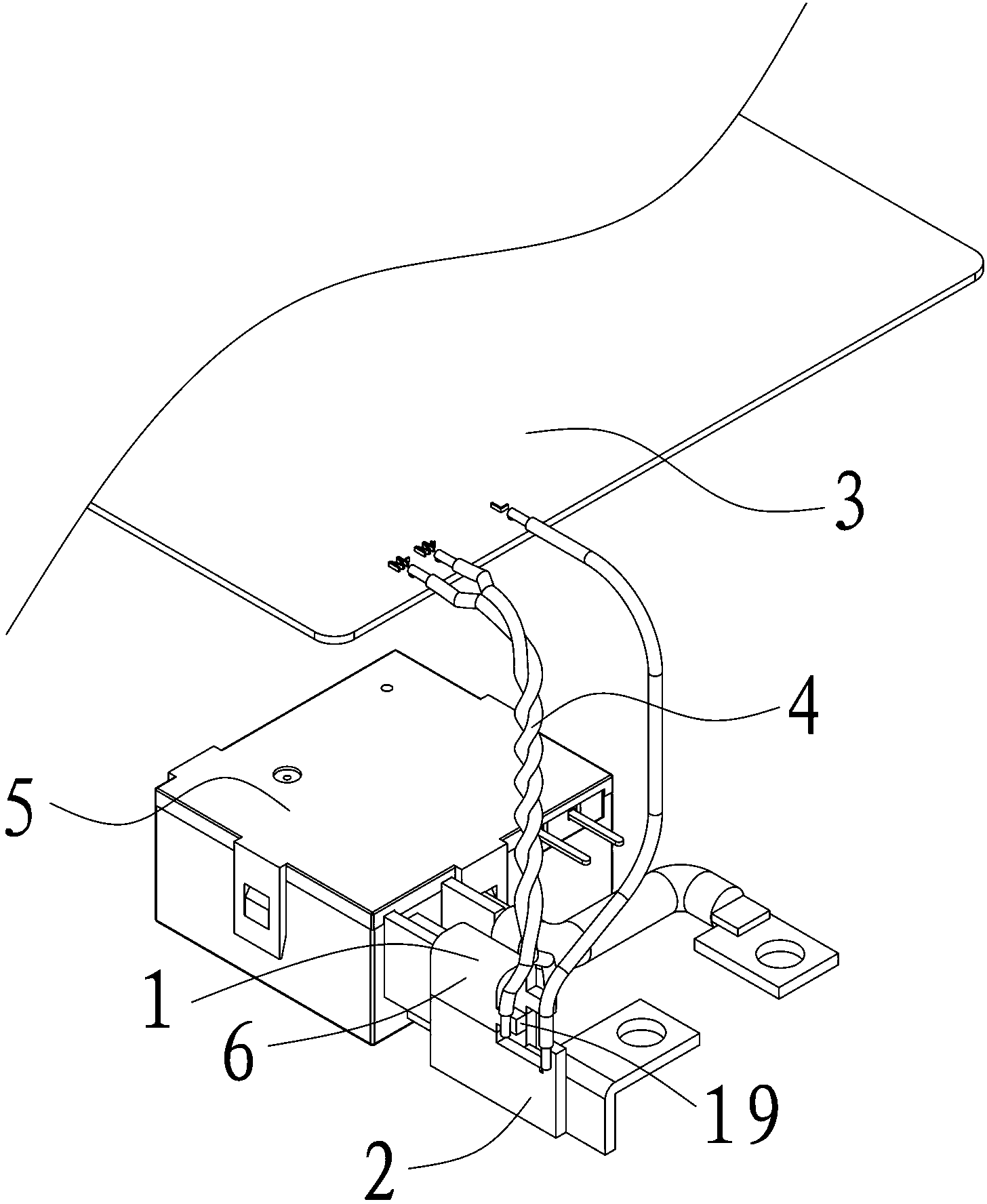

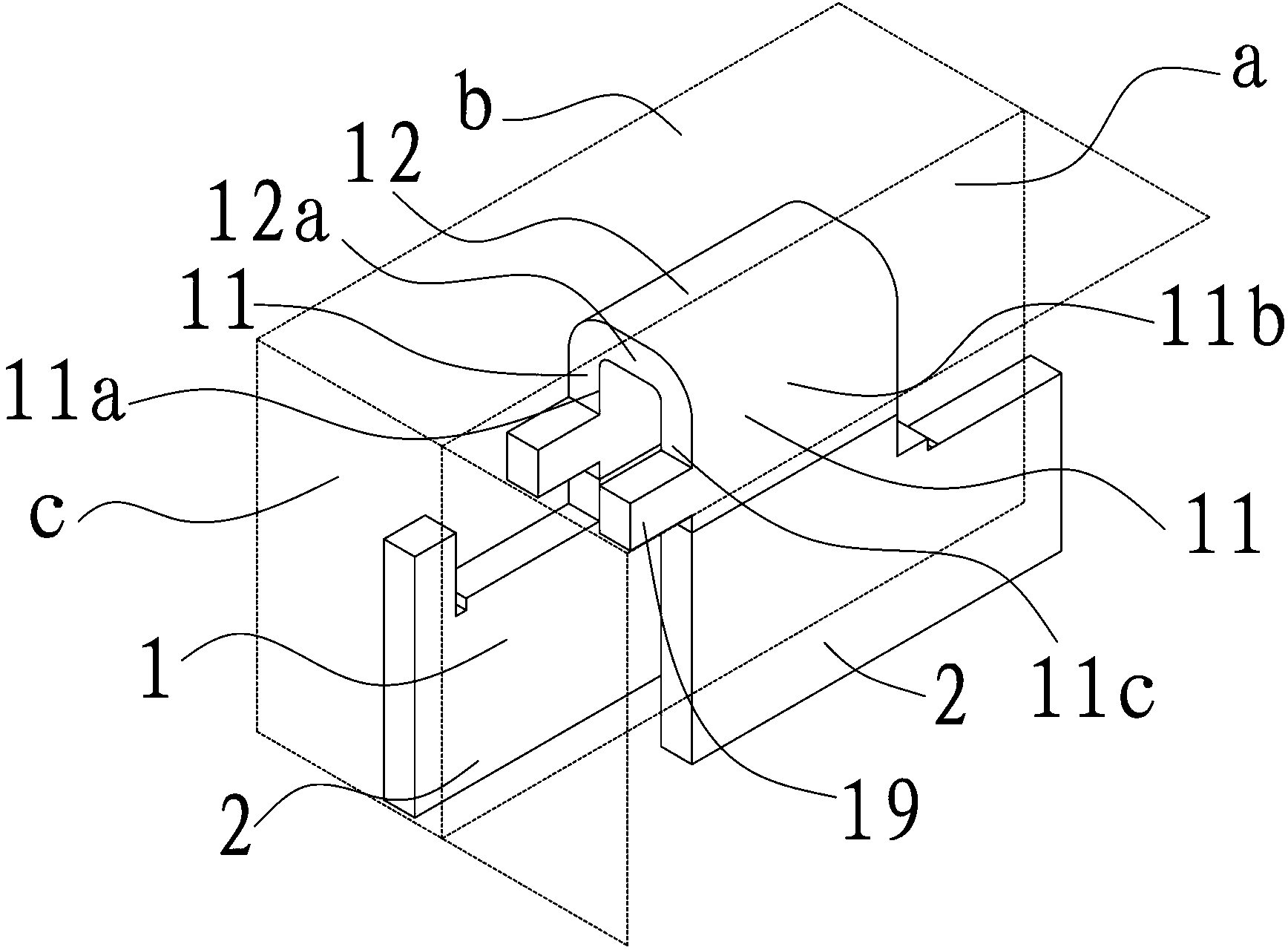

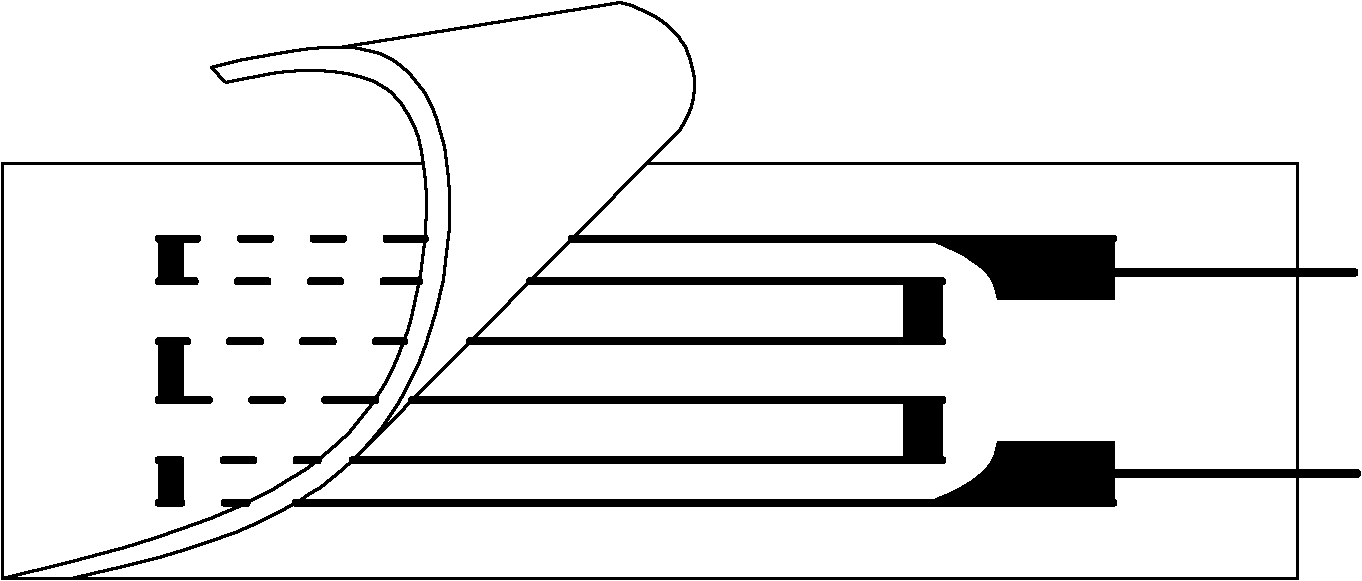

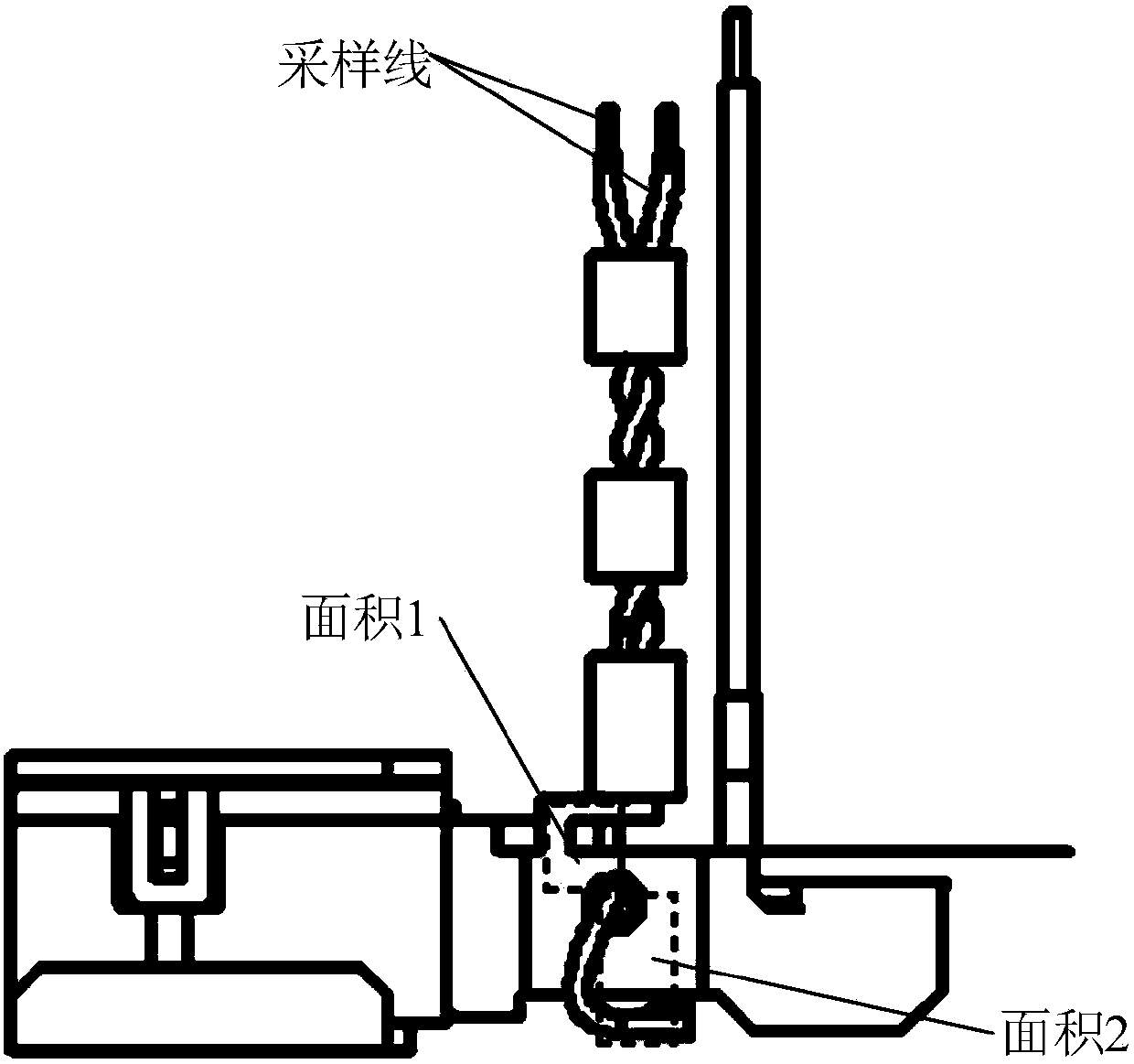

Alternating magnetic field-resistant manganin current divider

ActiveCN102323459AExtended service lifeSimple structureElectrical measurement instrument detailsTime integral measurementShunt DeviceElectrical resistance and conductance

The invention designs an alternating magnetic field-resistant manganin current divider, which mainly comprises a manganin resistor and sampling end points of a current divider, wherein a wire is arranged on one side of the current divider; a sampling end point is arranged on both sides of the current divider and is connected with a sampling line; the sampling line on one side is pulled to the other side; and the manganin resistor is divided into two regions of the same area; meanwhile, the sampling line is fixed with the sampling line on the side and the two sampling lines are spirally stranded to extend. In the alternating magnetic field-resistant manganin current divider, the sampling line on the side close to the manganin resistor is pulled to the other side close to the manganin resistor, and the manganin resistor is averagely divided into two regions of the same area, so that induction voltage and electromotive force are produced on the sampling line on the other side close to the manganin resistor according to faraday law of electromagnetic induction when the current divider is interfered by an external alternating magnetic field and are balanced with the induction voltage and the electromotive force produced on the manganin resistor, namely the interference of the alternating magnetic field on the current divider can be prevented.

Owner:TONGXIANG WEIDA ELECTRONICS

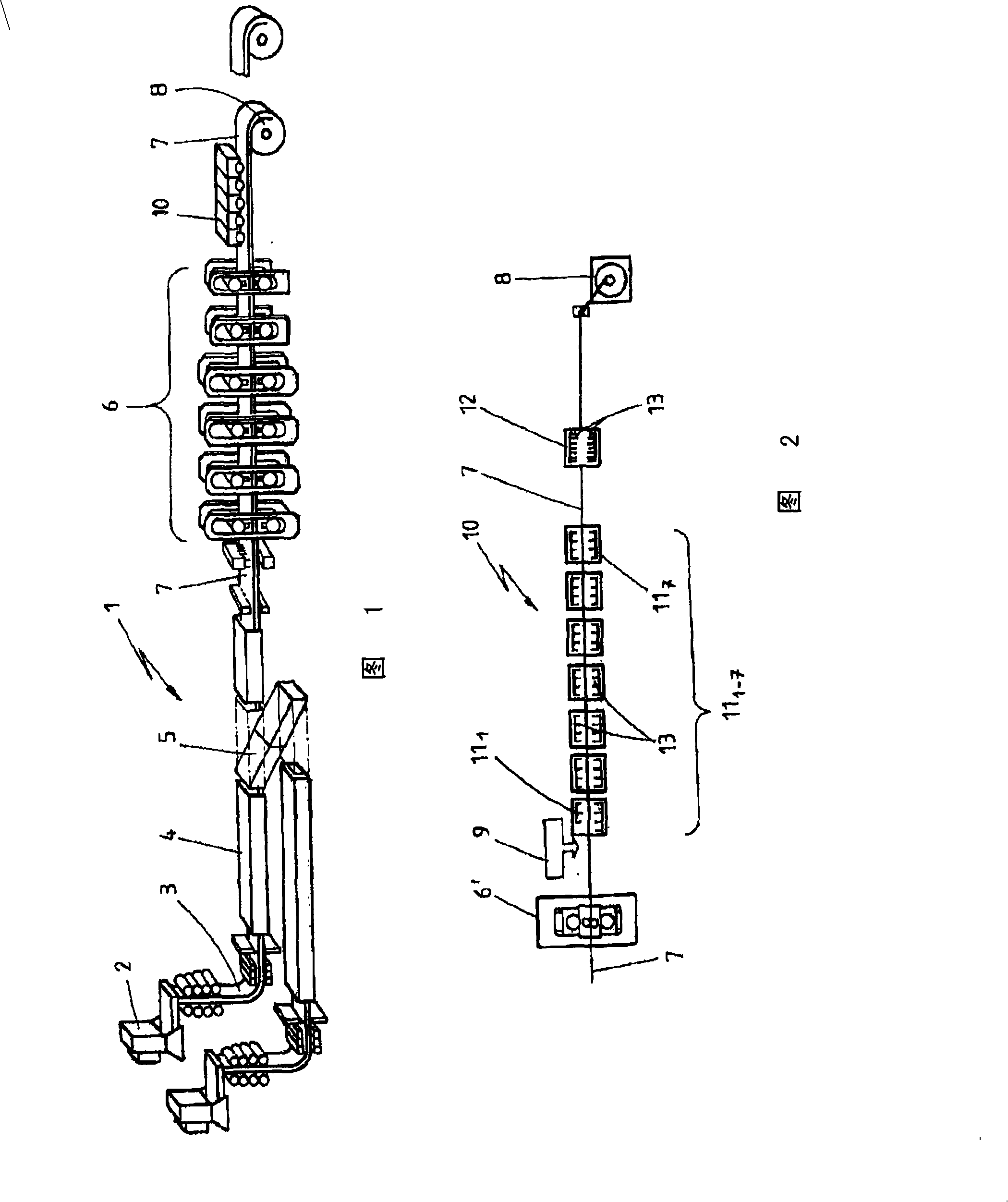

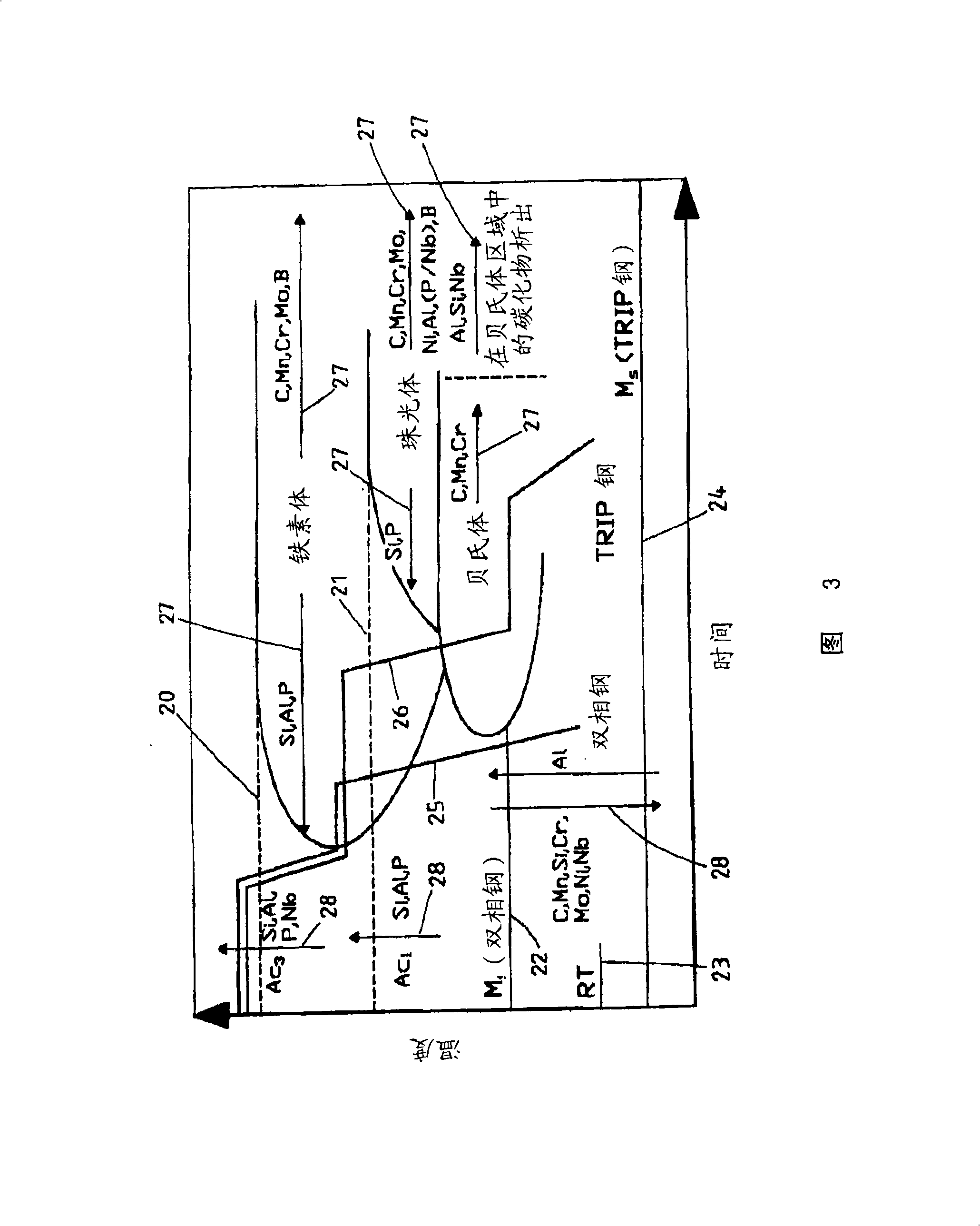

Method for producing hot strip with a multiphase structure

For the production of hot strip referred to as TRIP steel (transformation induced plasticity), with a multiphase structure and with outstandingly good deformation properties along with high strengths, from the hot-rolled state, the invention proposes a method which is carried out with a predetermined chemical composition of the steel grade used within the limits 0.12 - 0.25% C; 0.05 - 1.8% Si; 1.0 -2.0% Mn; the remainder Fe and customary accompanying elements and with a combined rolling and cooling strategy in such a way that a structure comprising 40 - 70% ferrite, 15 - 45% bainite and 5 - 20% residual austenite is obtained, wherein the finish rolling of the hot strip (7) is performed to set a very fine austenite grain (d < 8 [mu]m) in the final forming operation (6') at temperatures between 770 and 830 DEG C just above Ar3 in the region of the metastable austenite, and a controlled two-stage cooling (10, 11, 12) is carried out after the last rolling stand (6') of the hot strip (7) to a strip temperature in the range of bainite formation of 320 - 480 DEG C, with a holding time of about 650 - 730 DEG C,; the beginning of which is determined by the entry of the cooling curve into the ferrite region and the duration of which is determined by the transformation of the austenite into at least 40% ferrite.

Owner:SMS DEMAG AG

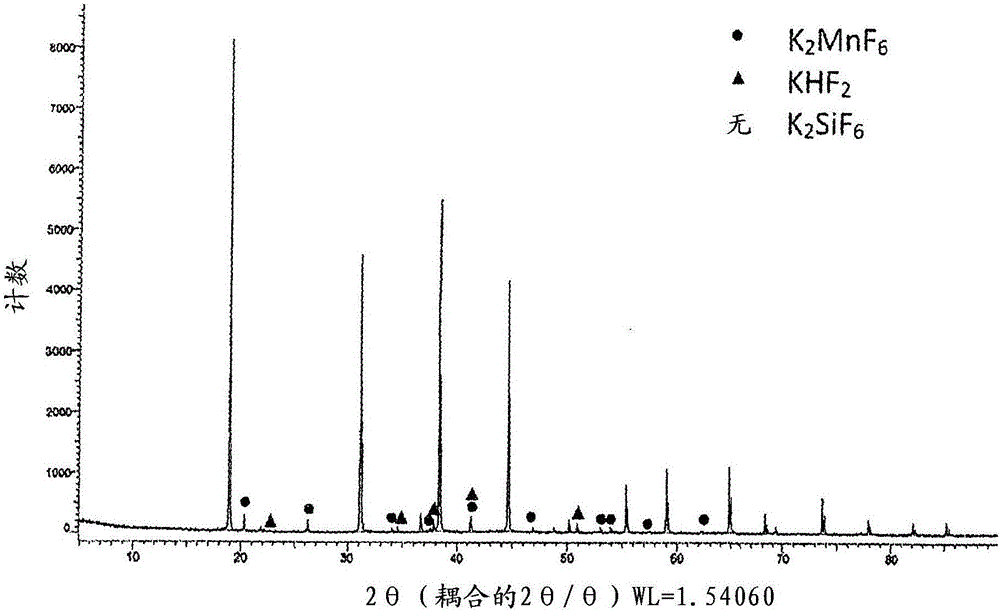

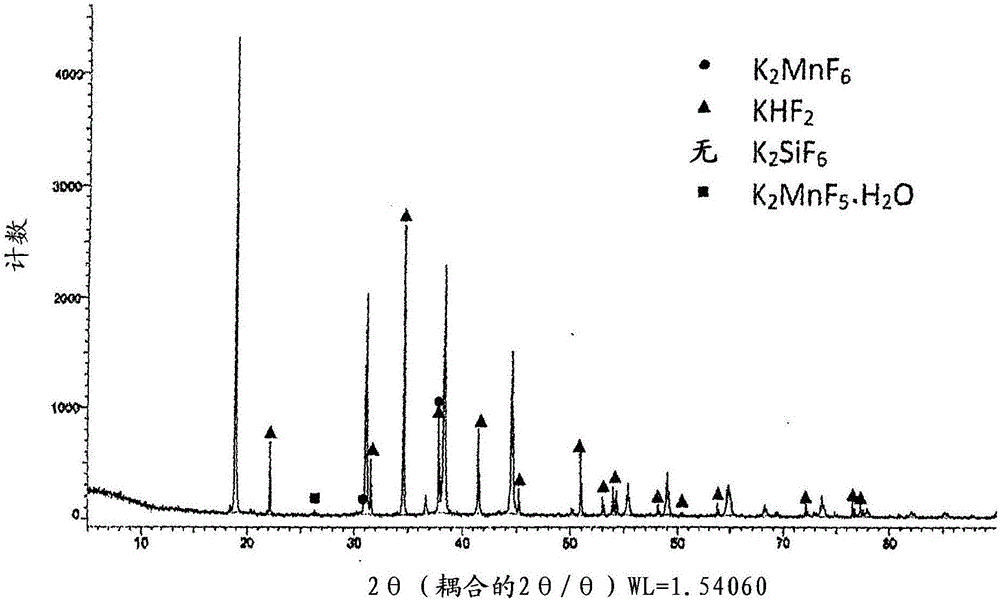

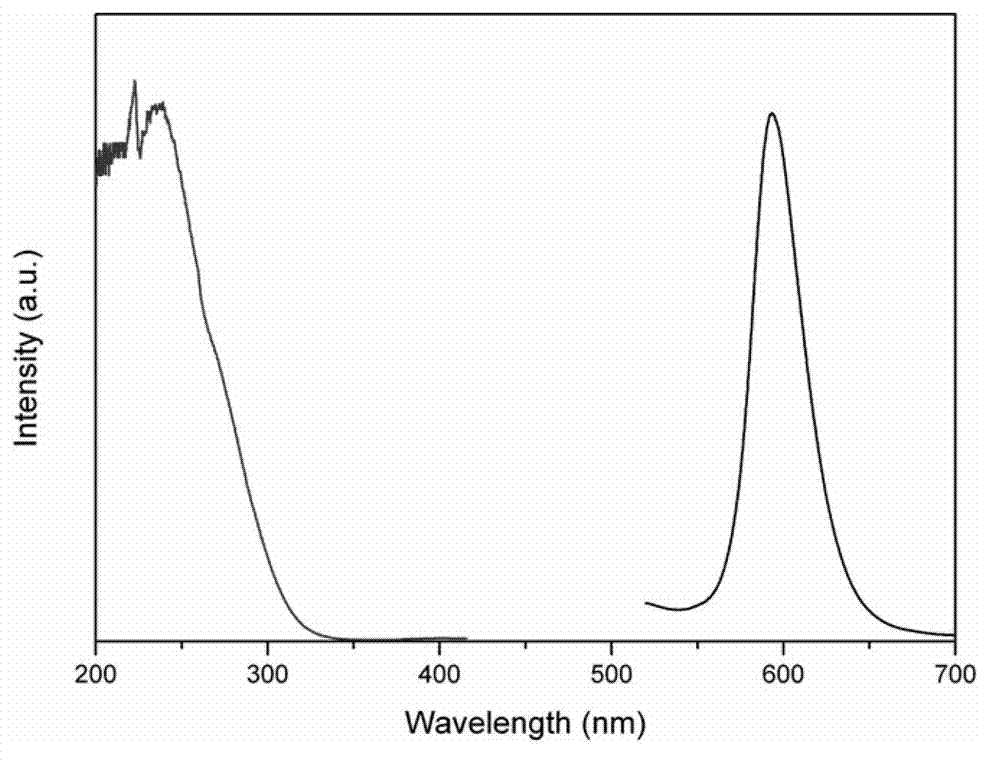

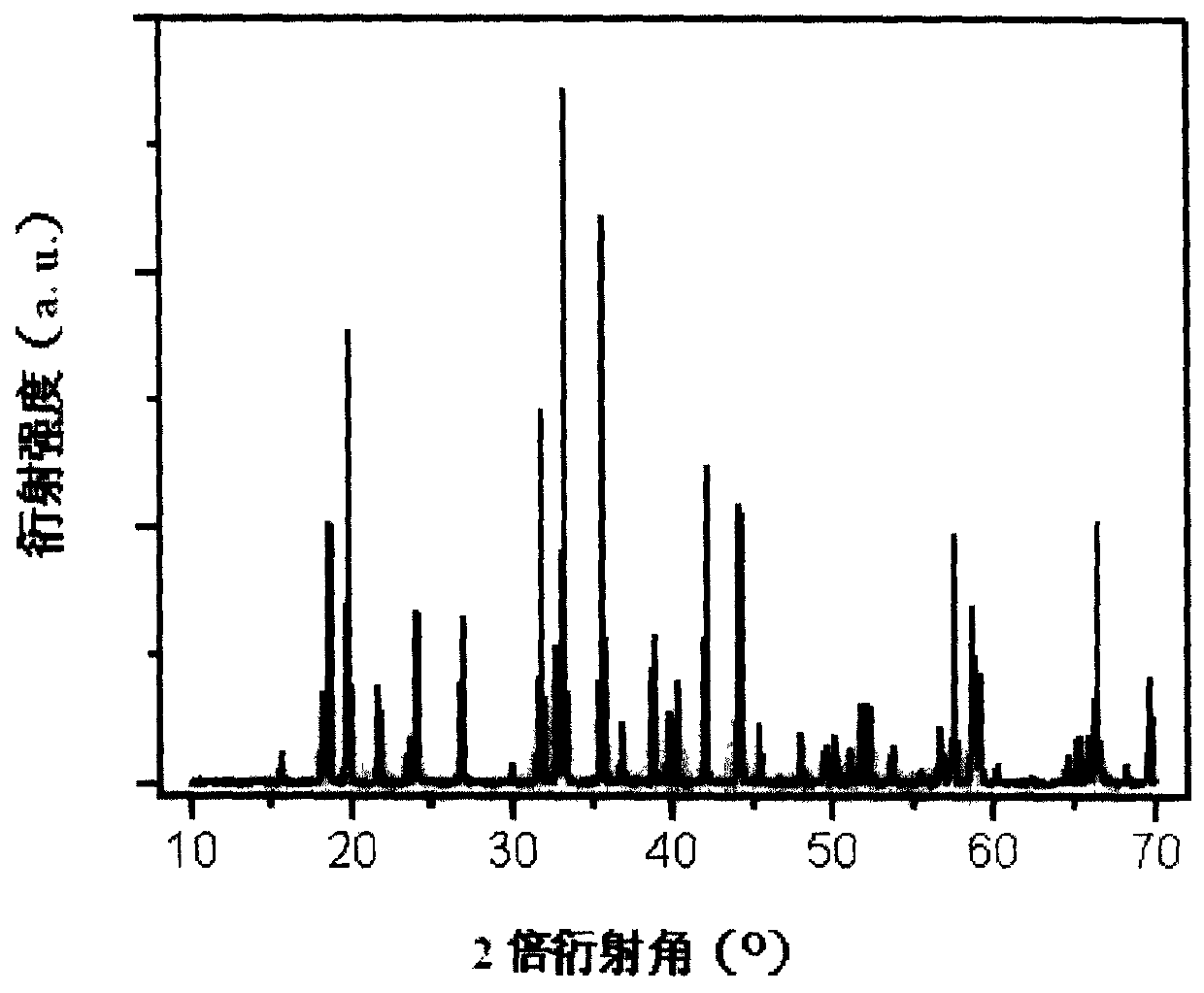

Method for producing and method for processing complex fluoride phosphor

ActiveCN105980523AExcellent luminous propertiesImprove moisture resistanceLuminescent compositionsHydrofluoric acidManganin

Provided is a method for producing a red phosphor which is a Mn-activated complex fluoride represented by formula (1), A2MF6: Mn (1) (M is one type or more of a tetravalent element selected from Si, Ti, Zr, Hf, Ge, and Sn, and A is one type or more of an alkali metal selected from Li, Na, K, Rb, and Cs, and includes at least Na and / or K.), wherein, as a reactive source, a solid of a complex fluoride represented by formula (2), A2MF6 (2) (M and A are as described above) and a solid of a manganese compound represented by formula (3), A2MnF6 (3) (A is as described above) are mixed and heated at a temperature of from 100 DEG C to 500 DEG C. According to the present invention, a Mn-activated complex fluoride phosphor having favorable luminescence properties can be obtained without using hydrofluoric acid in a main step.

Owner:SHIN ETSU CHEM CO LTD

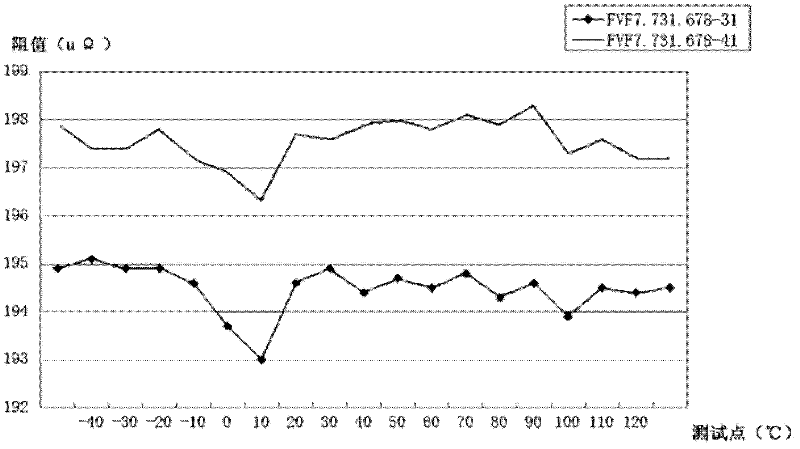

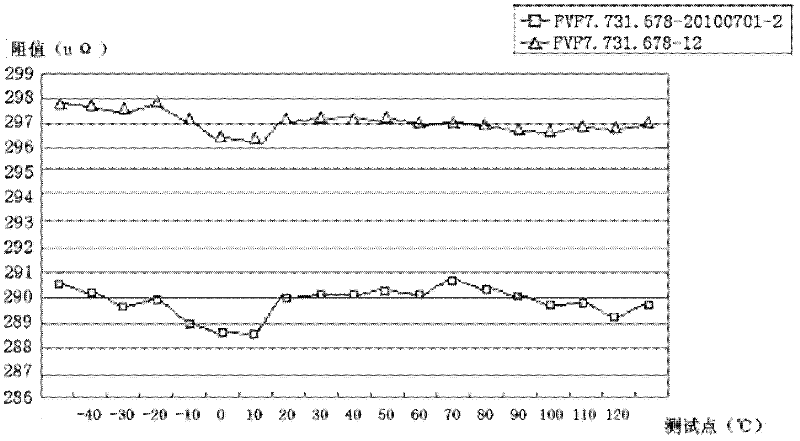

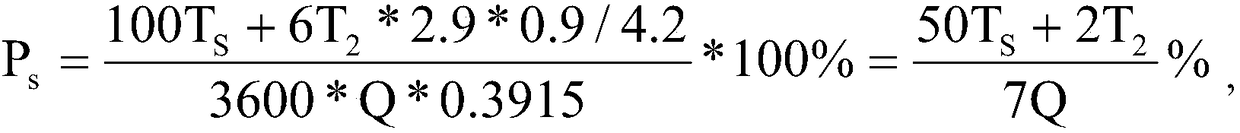

Method for performing temperature compensation on metering chip and manganin sheet in electric meter

InactiveCN102445576ARealize dynamic adjustmentControl precisionTime integral measurementManganinEngineering

The embodiment of the invention provides a method for performing temperature compensation on a metering chip and a manganin sheet in an electric meter. The method comprises the following steps of: determining temperature rise error delta of the metering chip according to a current temperature value of the metering chip; determining temperature rise error alpha of the manganin sheet according to a current effective value of the manganin sheet and a temperature rise error curve of the manganin sheet; converting the temperature rise error delta of the chip and the temperature rise error alpha of the manganin sheet into a temperature compensation value err of the electric meter; and performing the temperature compensation on output power of the electric meter by using the temperature compensation value err of the electric meter. In the method provided by the embodiment of the invention, the temperature rise error delta of the metering chip and the temperature rise error alpha of the manganin sheet are comprehensively considered, the output power of the electric meter can be dynamically adjusted under different temperature conditions, the influence caused to the accuracy of the electric meter by the temperature is overcome, and the accuracy of the electric meter in a temperature rise process is effectively controlled.

Owner:BEIJIG YUPONT ELECTRIC POWER TECH

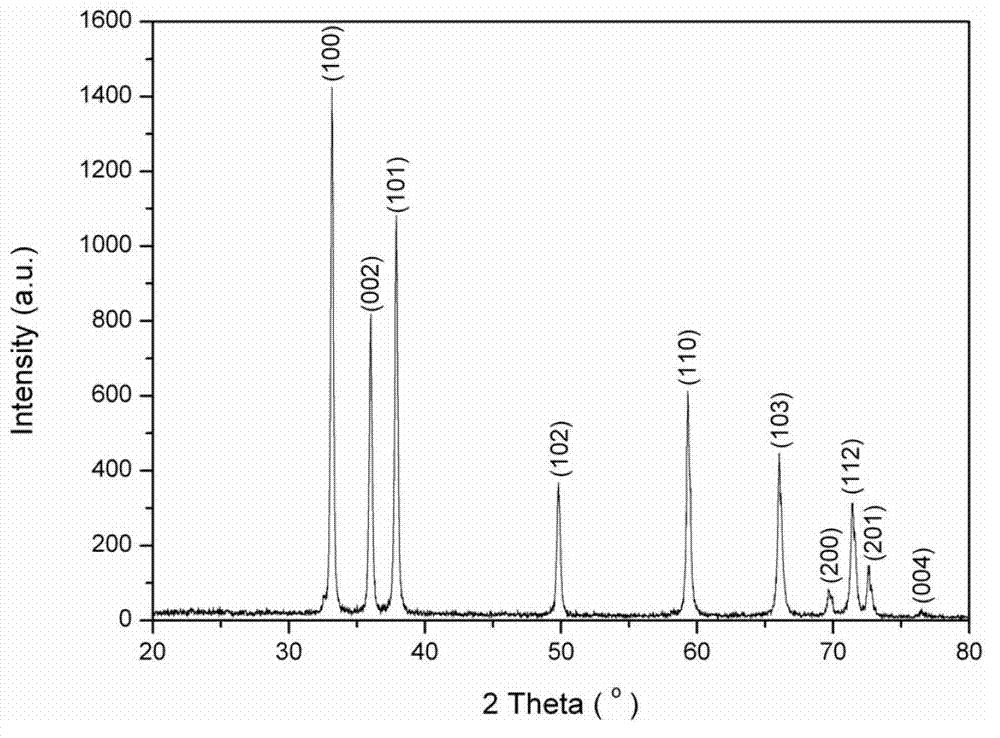

Aqueous phase method for manufacturing core formation doping ZnS:Mn and ZnS:Mn/ZnS nanocrystalline

InactiveCN101245242AHigh fluorescence intensityGood light stabilityLuminescent compositionsSolubilityWater baths

The invention discloses a water phase preparation method of nucleating doped nano-crystal of ZnS: Mn and ZnS: Mn or ZnS, deionized water is regarded as solvents, zinc salt is regarded as the source of zinc ion, manganese salt is regarded as the source of manganese ion, sodium sulfide is regarded as the source of sulfur ion, mercapto carboxylic acid is regarded as stabilizer, water bath or oil bath is used for controlling the reaction temperature, the whole reaction process is carried on in the air, the method has the advantages of the low cost, the simple operation, the whole process being carried on in the air, innocuity, and no pollution, the nano-crystal of ZnS: Mn and ZnS: Mn or ZnS has the high strength, the good light stability, and the good water solubility, the method of the invention can realize the mass production of the nano-crystal of ZnS: Mn and ZnS: Mn or ZnS.

Owner:CENT SOUTH UNIV

Novel composite aluminium alloy plates and prepn. method

This invention discloses a method for manufacturing a new type of aluminum alloy composite sheets, and solves the problems of low mechanical properties and low yield existing with present aluminum alloy composite sheets. The sheets are composed of three parallel sheets. The top and the bottom sheets are composed of Si 9.4-10 wt.%, Fe 0.4 wt.%, Cu 0.2 wt.%, Mn 0.1 wt.%, Mg 1.2-1.8 wt.%, Zn 0.2 wt.% and Al as balance. The middle sheet is composed of Si 0.4 wt.%, Fe 0.4-0.6 wt.%, Cu 0.07-0.15 wt.%, Mn 1.1-1.3 wt.%, Ti 0.02-0.03 wt.% and Al as balance. The thickness ratio of the three sheets from top to bottom is 1:2.5~13:1. The sheets are manufactured by: smelting the three alloy ingots, casting into sheets, heating and rolling the top and the bottom sheets, chemically washing and welding, hot-rolling, cold-rolling and annealing the intermediate products to obtain the final products. The aluminum alloy composite sheets have good mechanical properties, and the yield of the final products is increased by more than 15%.

Owner:NORTHEAST LIGHT ALLOY CO LTD

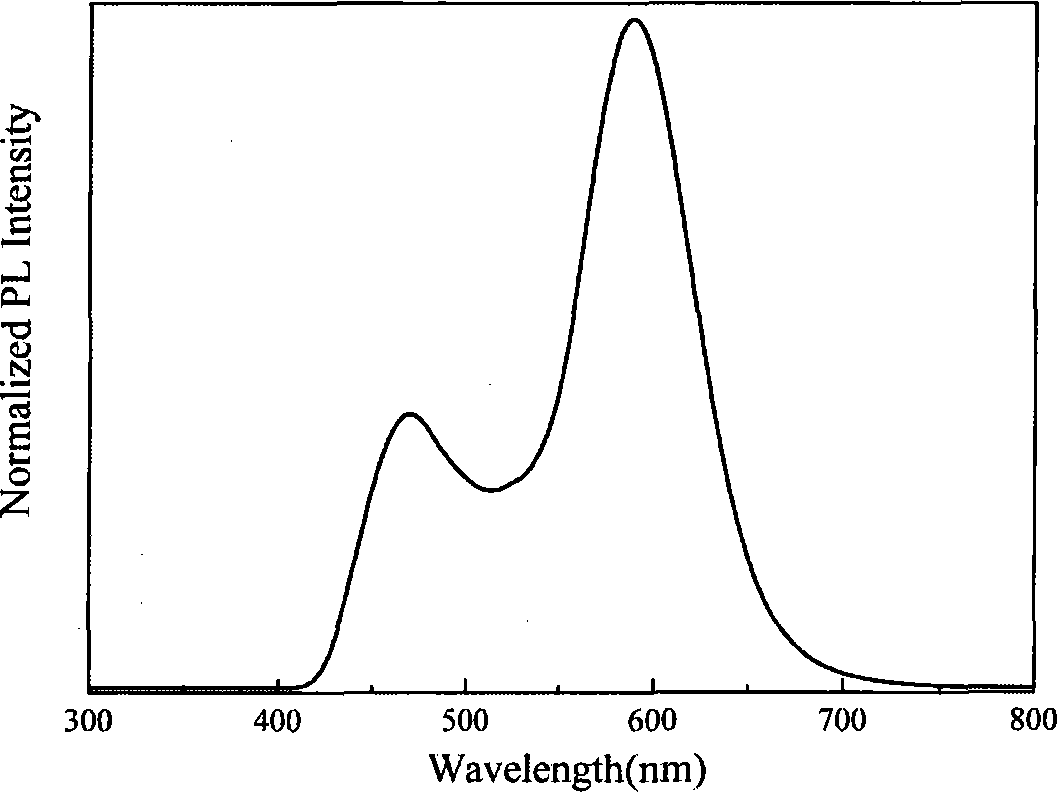

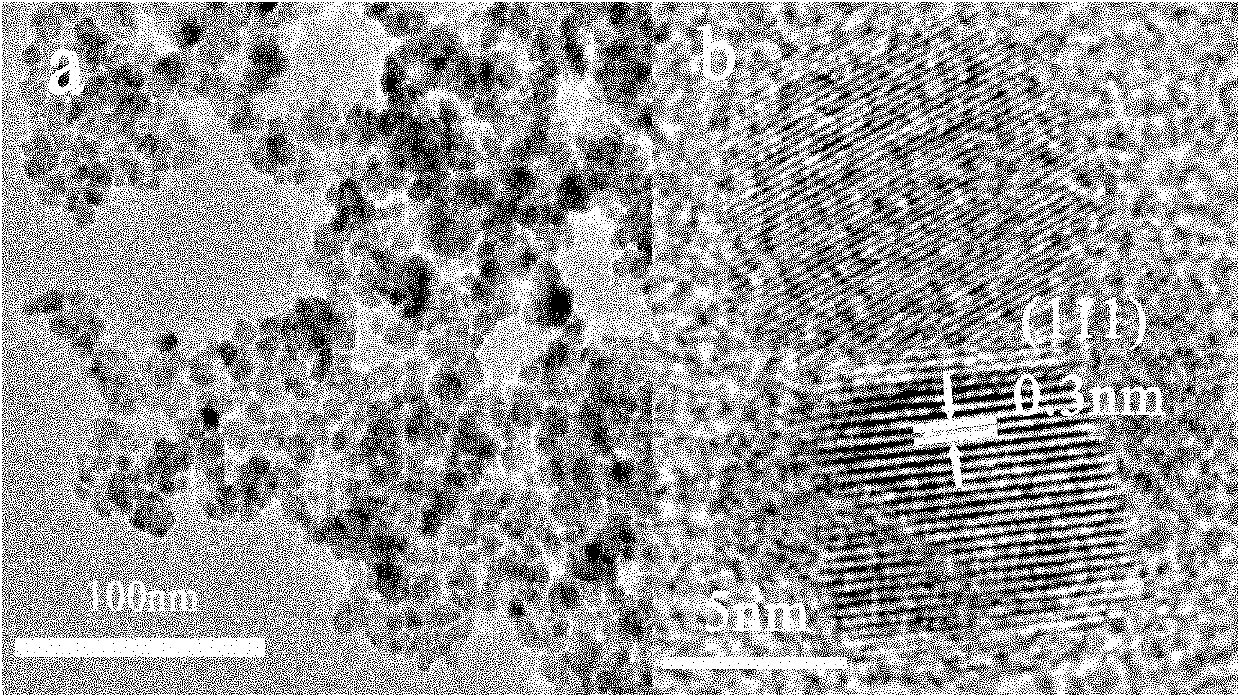

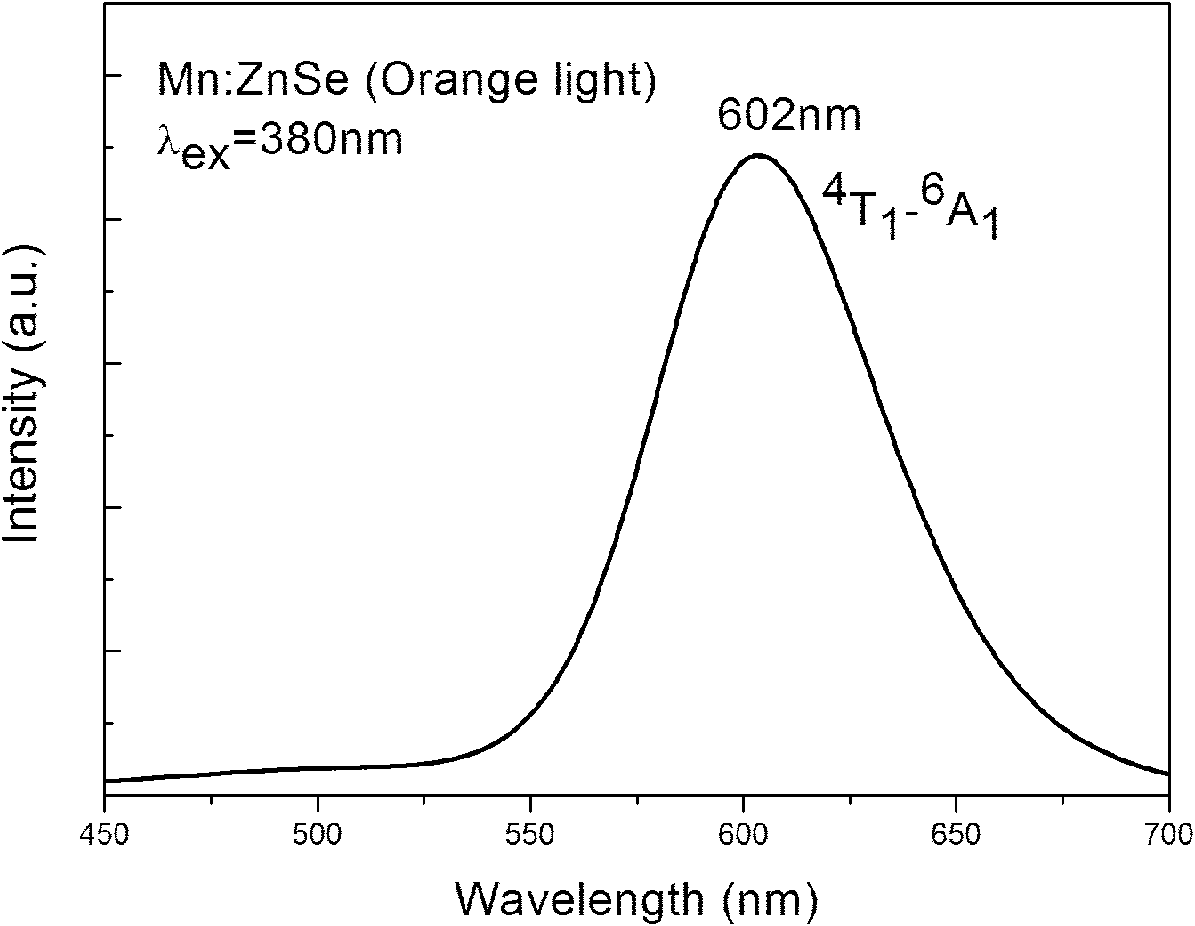

Method for aqueous phase synthesis of manganese-doped zinc selenide adjustable-colour fluorescent quantum dot

InactiveCN101948686AReduce energy consumptionSimple processLuminescent compositionsQuantum yieldZinc selenide

The invention relates to a method for the aqueous phase synthesis of a manganese-doped zinc selenide adjustable-colour fluorescent quantum dot. Firstly, MnSe / ZnSe crystal nucleus is generated; and then, a method of stabilizer coating and the epitaxial growth of a ZnSe shell is used, the separation of crystal nucleation and growth steps is controlled to regulate the shell framework growth mode andthe reaction time, and an MnSe:ZnSe quantum dot is synthesized in the aqueous phase, thus an Mn ion 4T1-6A1 fluorescence emission center is strengthened (Mn / Zn mutual-melting interface) to increase the quantum yield to 4.8%, and the fluorescence launch emission spectrum is controlled and adjusted to 602 nm from 572 nm by prolonging the epitaxial growth time of the ZnSe shell. The invention has simple preparation technology, requires simple production equipment and is easy to realize industrial production.

Owner:DONGHUA UNIV

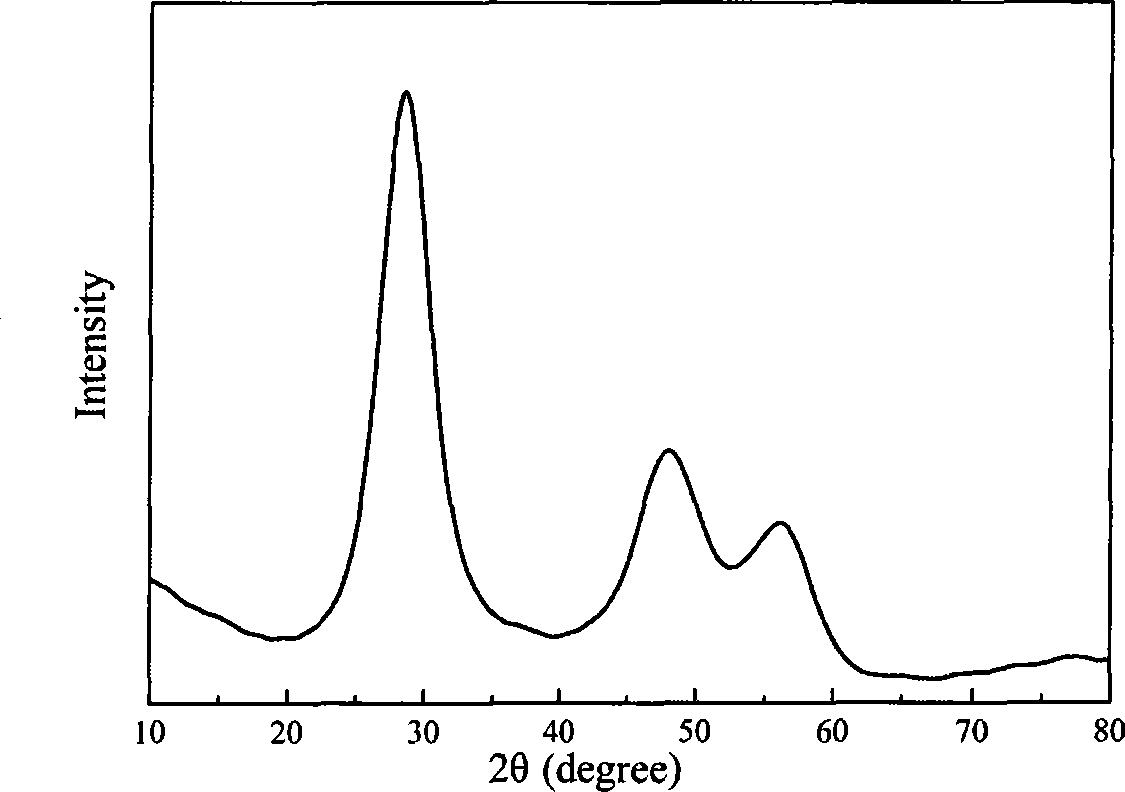

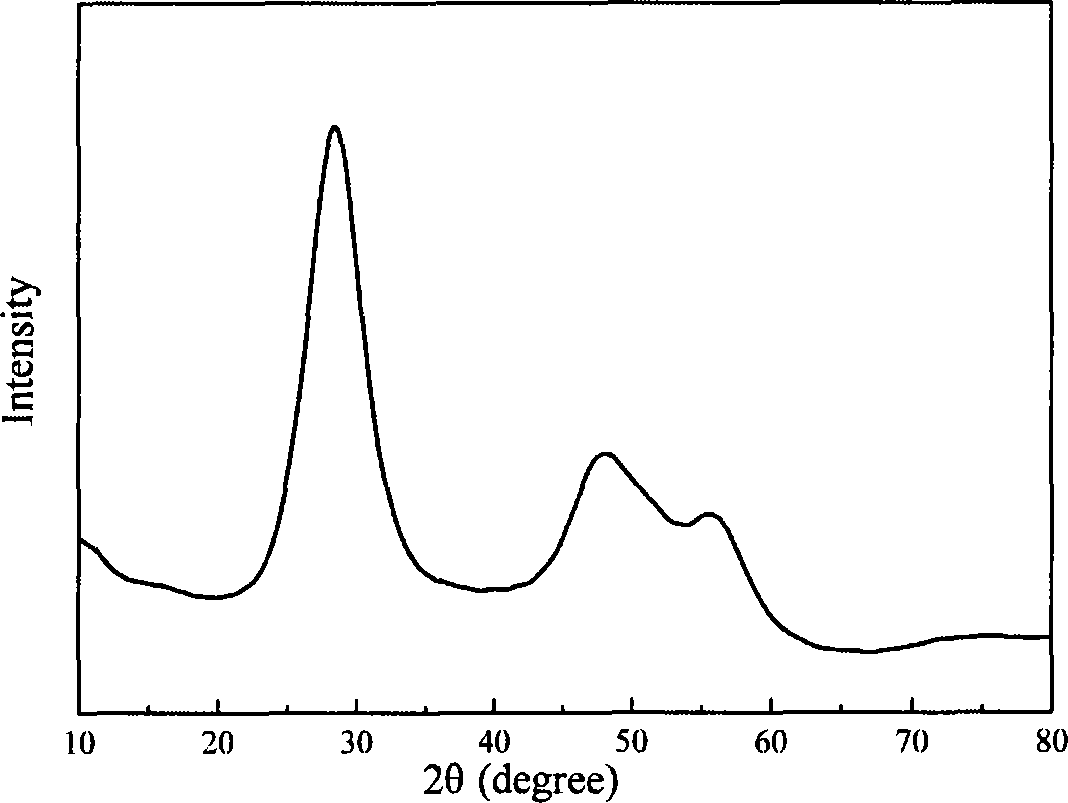

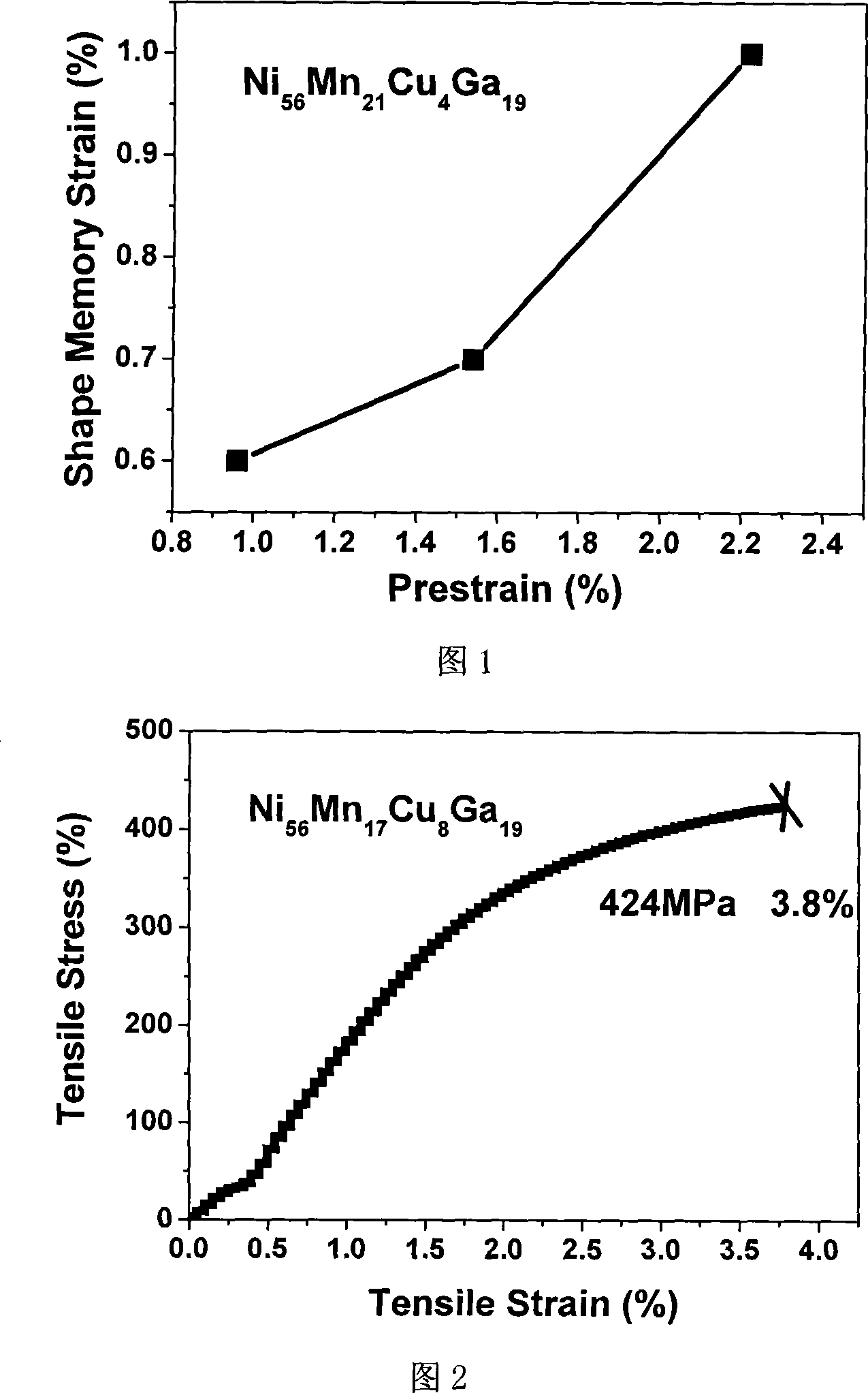

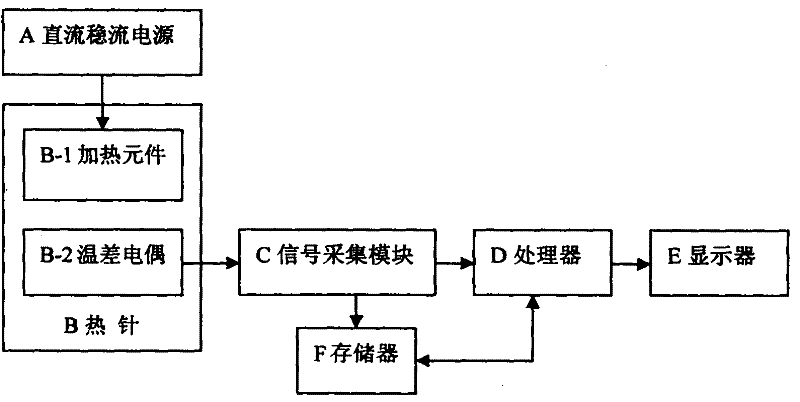

Nickel manganin gallium high-temperature shape memory alloy and method for making same

The present invention provides one kind of high temperature shape memory Ni-Mn-Cu-Ga alloy with high martensitic transformation temperature and high plasticity and its preparation process. The shape memory Ni-Mn-Cu-Ga alloy consists of Ni 50-57 at.%, Mn 17-25 at.%, Cu 1-8 at.% and Ga 17-25 at.%. It is prepared with Ni, Mn, Cu and Ga through vacuumizing and argon protected smelting in a furnace to obtain alloy ingot, heat treatment at 850-900 deg.c and cooling inside the furnace, hot rolling at 850-950 deg.c into alloy sheet, wire electrode cutting into required shape, heat treatment and final quenching in ice water to obtain high temperature shape memory Ni-Mn-Cu-Ga alloy.

Owner:XIAMEN UNIV

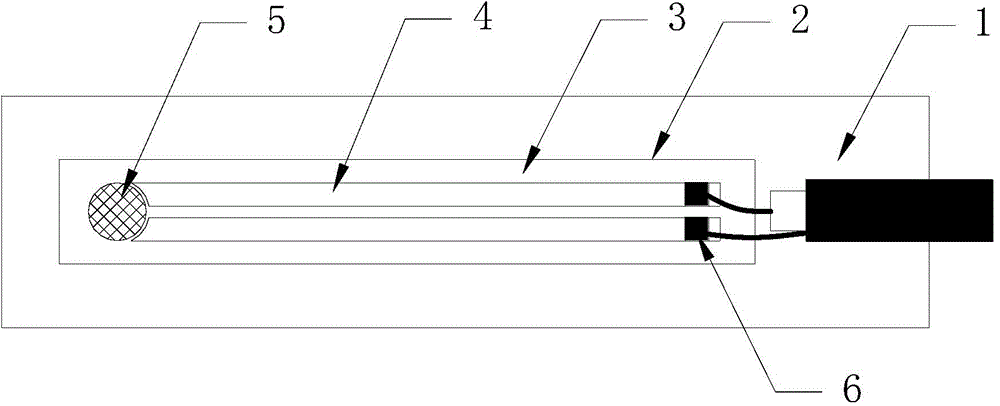

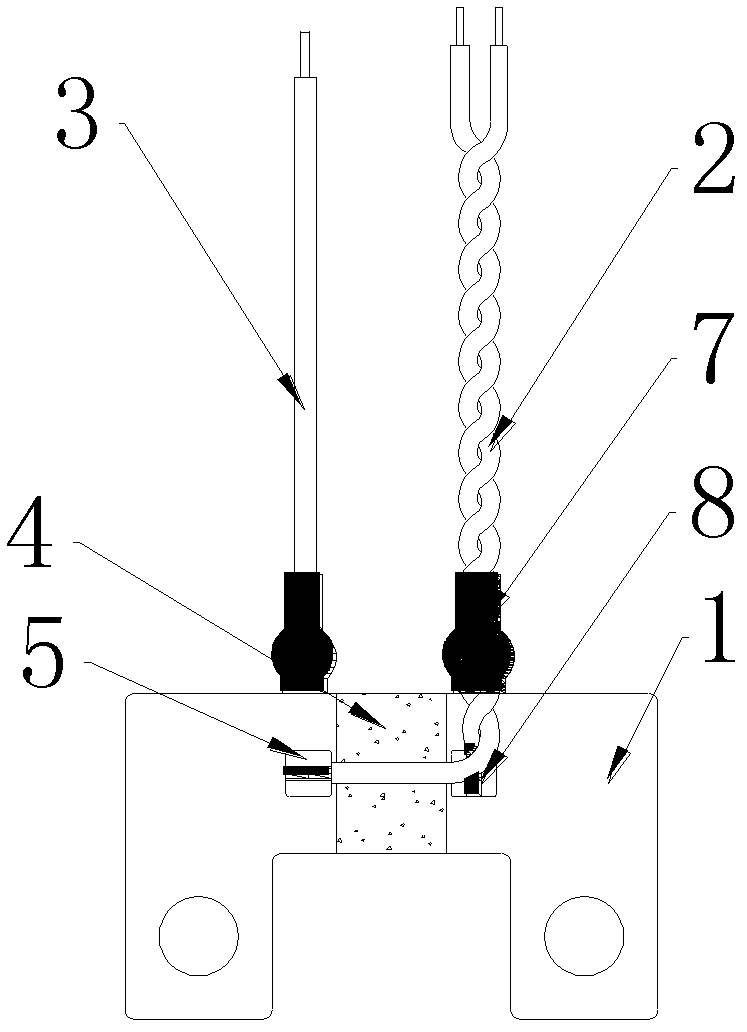

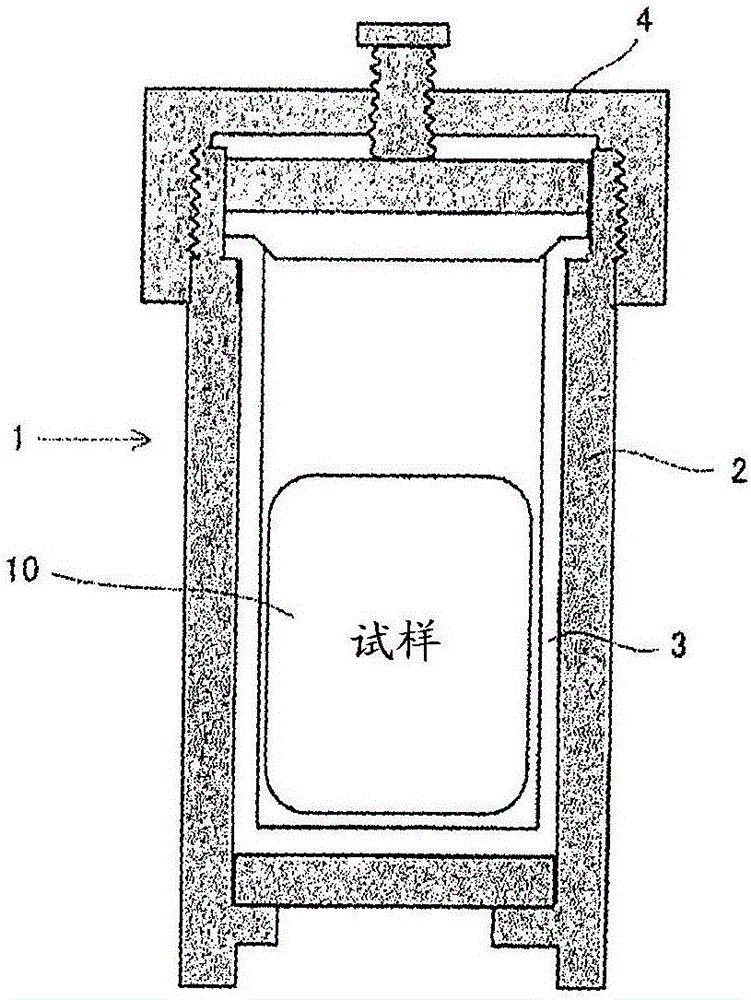

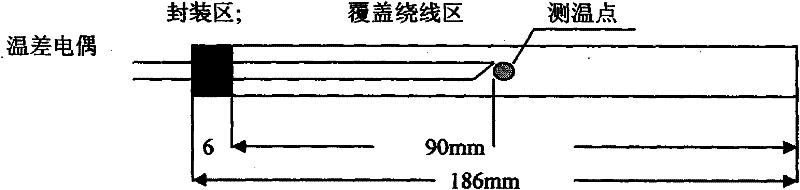

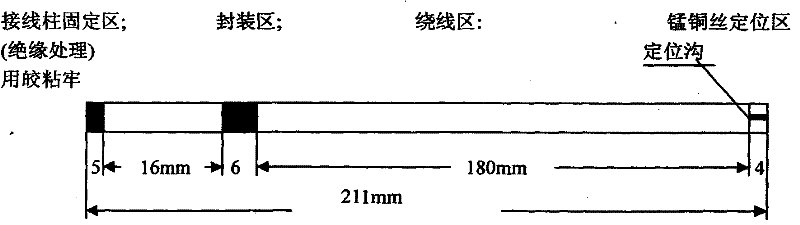

Thermal-property transient measurement method and device

InactiveCN102183544AShort time required for transient measurementsEasy to fixMaterial heat developmentSpecific gravity measurementCarbon fibersRegular pattern

The invention discloses a thermal-property transient measurement method and device, which are used for automatically measuring thermal conductivity, thermal diffusion coefficient, specific heat at constant pressure and density of a material and are also used for analysing the regular pattern of the thermal property of the material near the room temperature along the change of the temperature. The method comprises the following steps of: placing a cylindrical hot needle in a uniform and infinite medium; and continuously heating the medium by a constant thermal flow through the hot needle to form a one-dimensional cylindrical heat-transferring model in the radical direction. The measurement device comprises a direct-current stable-current power supply, the hot needle, a temperature signal collecting module, a signal processor, a memory and a display. A column body of the hot needle is made of carbon fibre and is composed of a core column and a sleeve pipe; the electric heating element is wounded on the core column through a double-head manganin lacquered wire and the double-head manganin lacquered wire is formed by doubling and winding one manganin lacquered wire along the central point; and an thermoelectric couple is formed by welding one copper wire and one konstantan wire in the thermoelectric couple grade.

Owner:陈昭栋

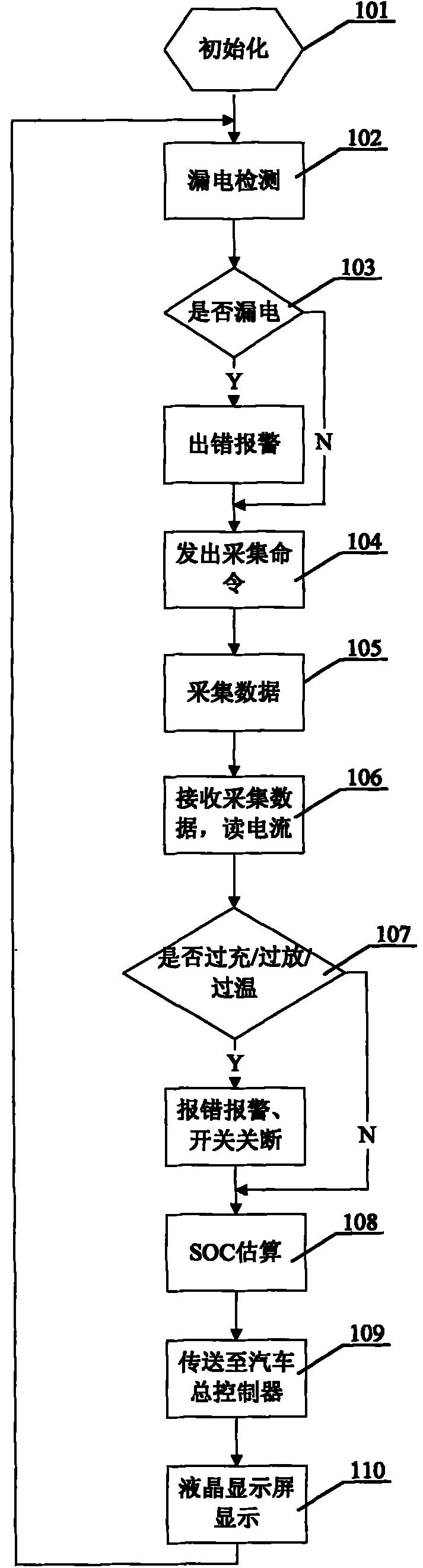

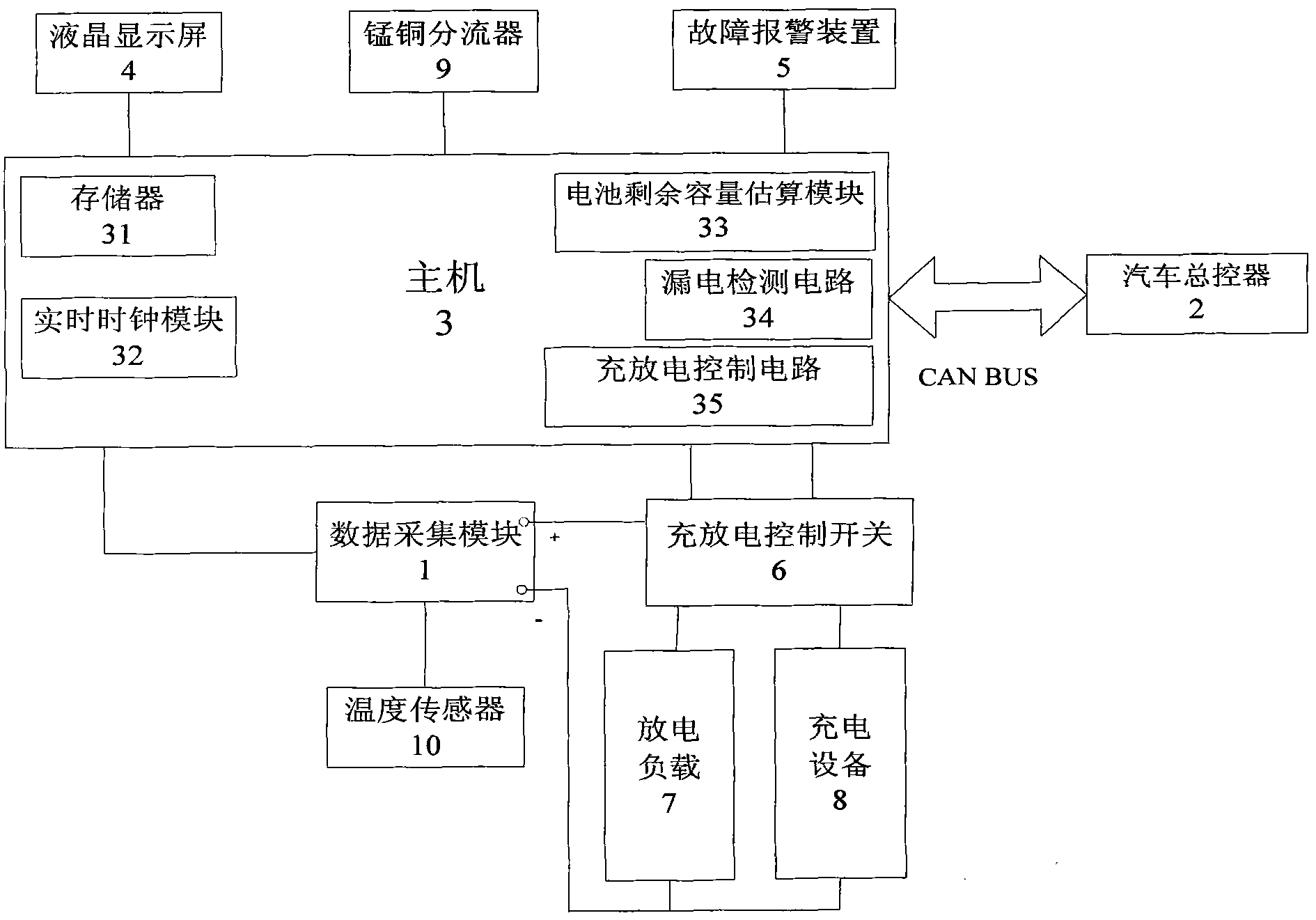

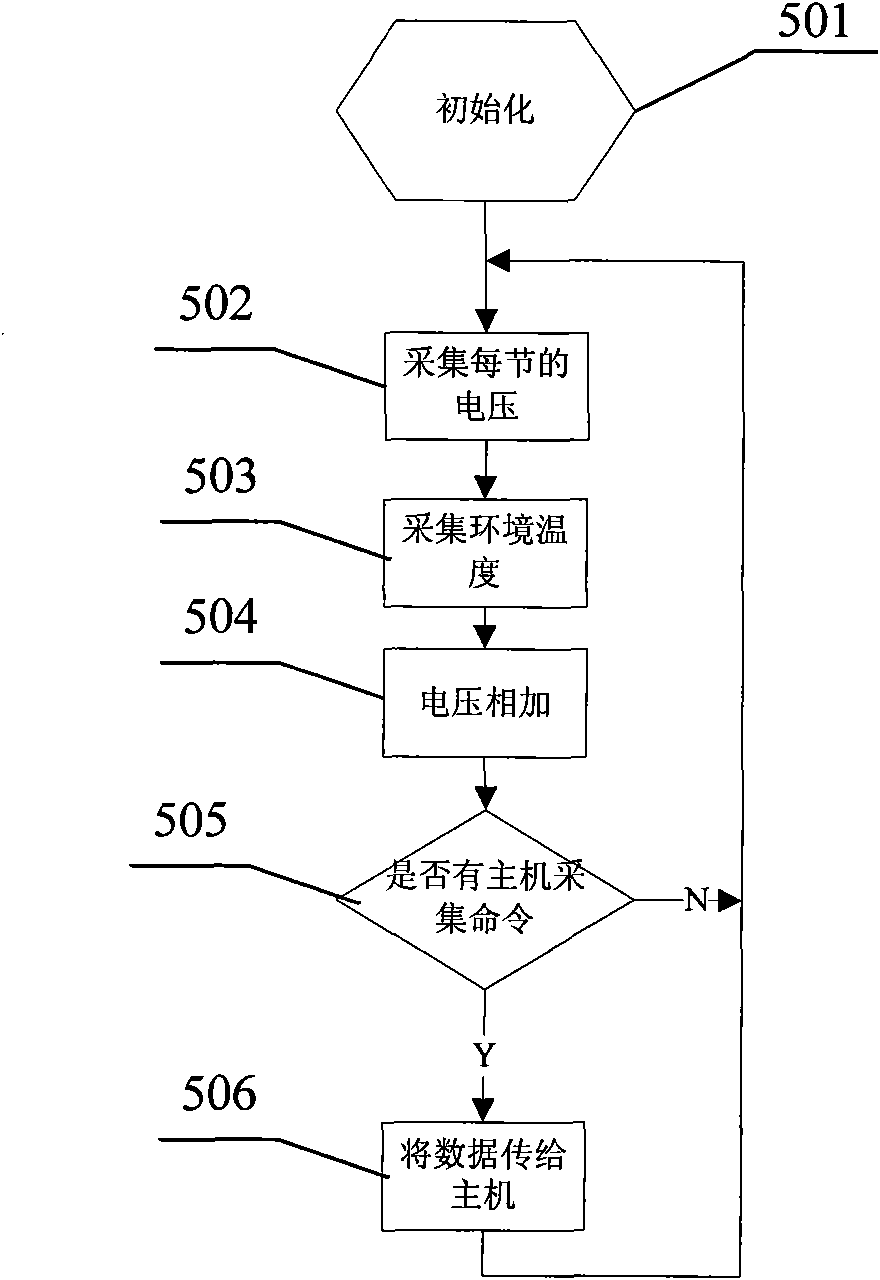

Ferric phosphate lithium battery detection processing method and device

InactiveCN102147449AImprove securityReal-time detection of working statusElectrical testingPhosphateElectrical battery

The invention relates to a ferric phosphate lithium battery detection processing method. The method comprises the following steps of: (1) performing system initialization; (2) judging whether electric leakage exists by an electric leakage detecting circuit; (3) if so, giving alarm by a fault alarm device; if not, executing a step 4; (4) sending a data collecting command to a data collecting module by a host; (5) after the data collecting module receives the command, collecting data of a battery and transmitting the collected data to the host through an RS485 bus; (6) receiving the collected data and reading the current of a manganin diverter by the host; (7) judging whether the battery is overcharged, over-discharged and overheated by the host according to all collected voltages and environmental temperatures: (8) if the battery is overcharged, or over-discharged or overheated, giving alarm by the fault alarm device and turning off a charge / discharge control switch under the control of a charge / discharge control circuit; otherwise, executing a step 9 and the like. Compared with the prior art, the ferric phosphate lithium battery detection processing method has the advantages of high precision, good safety and the like.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

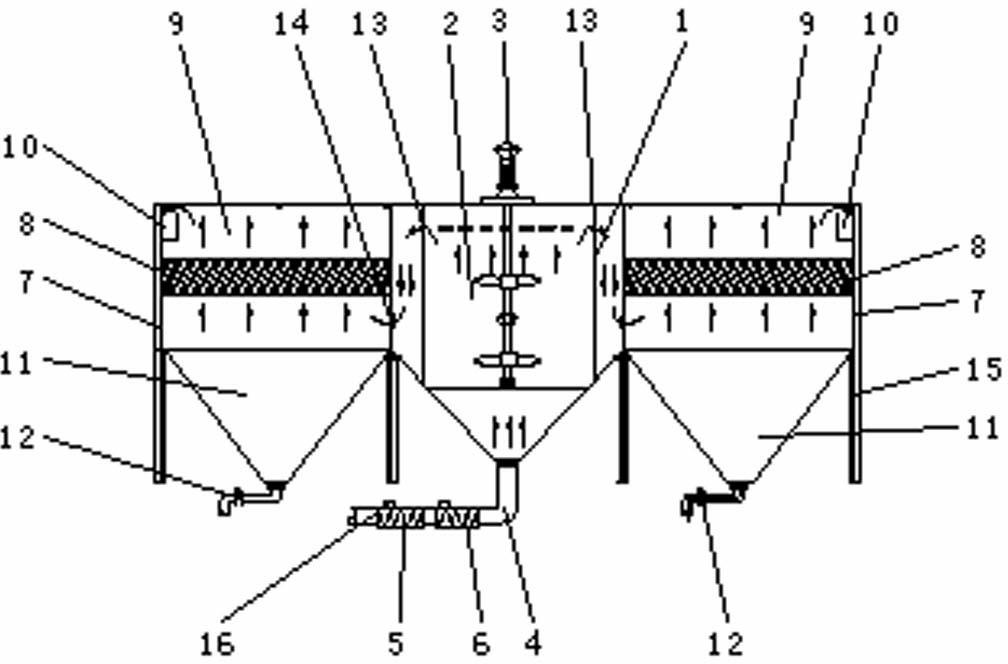

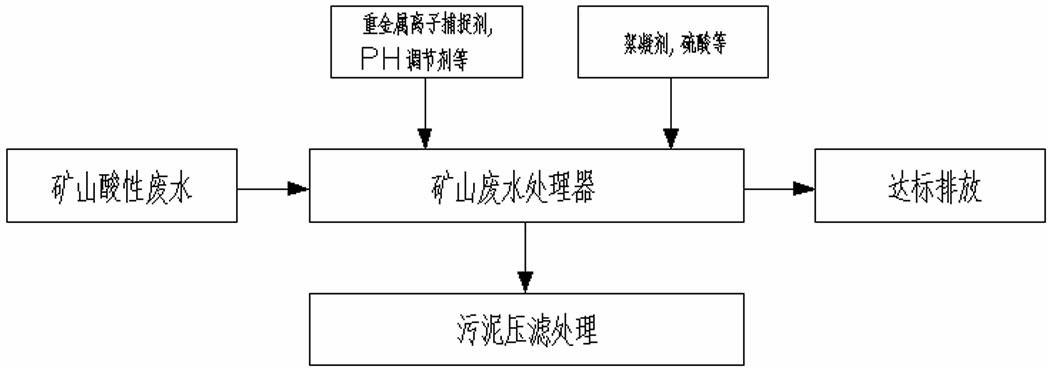

Mine wastewater treatment device and treatment method thereof

ActiveCN102101731ASimple processCompact structureMultistage water/sewage treatmentSludgePolyvinyl chloride

The invention relates to a mine wastewater treatment device and a treatment method thereof. The bottom of the reactor is communicated with a water inlet pipe; a first pipe mixer and a second pipe mixer, which are made of unplasticized polyvinyl chloride (UPVC), are arranged in the water inlet pipe; a stirrer is arranged in the middle of the reaction chamber of the reactor; the four sides of the reactor are communicated with an inclined tube sedimentation area respectively; an inclined tube filler with a diameter of 40 millimeters is arranged in the middle of the inclined tube sedimentation; a clear water area is formed above the inclined tube filler in the inclined tube sedimentation area; clear water is discharged out from a water discharge tank; and a conical cavity below the inclined tube filler in the inclined tube sedimentation area is a sludge area. Effluent obtained after treatment by the device and the method reaches the following standards: the pH value is 6 to 9; the suspended matter concentration is less than or equal to 20mg / L; the total lead concentration is less than or equal to 0.0001mg / L; the total cadmium concentration is less than or equal to 0.0001mg / L; the total arsenic concentration is less than or equal to 0.0001mg / L; the zinc concentration is less than or equal to 0.2mg / L; the manganese concentration is less than or equal to 0.2mg / L; the total mercury concentration is less than or equal to 0.0001mg / L; the hexavalent chromium concentration is less than or equal to 0.0001mg / L; the CODcr concentration is less than or equal to 20mg / L; and the copper concentration is less than or equal to 0.0001mg / L.

Owner:韶关市雅鲁环保实业有限公司

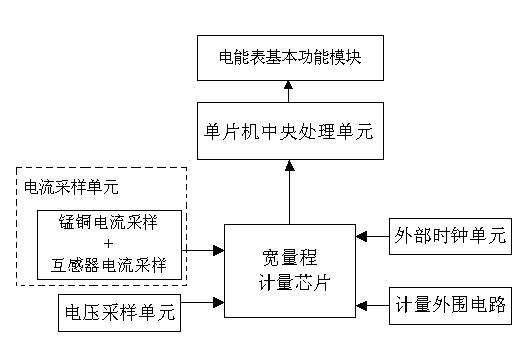

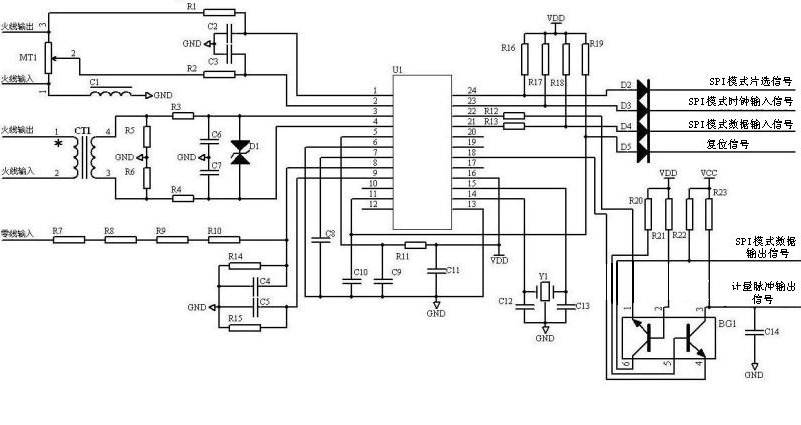

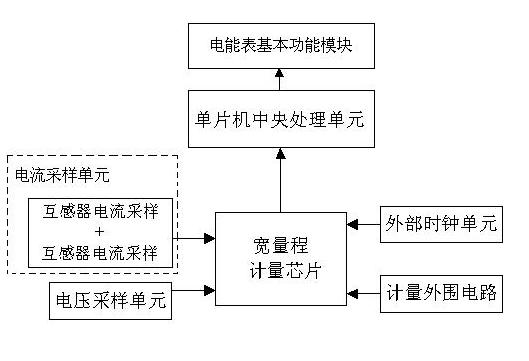

Wide-range high-accuracy electric energy meter

ActiveCN102426290AIn line with the development trend of wide range and high precisionLarge rangeElectrical measurementsMicrocontrollerEngineering

The invention relates to the technical field of electric energy meters, and provides a wide-range high-accuracy electric energy meter. The wide-range high-accuracy electric energy meter comprises a single-chip central processing unit and an electric energy meter metering unit, wherein the electric energy meter metering unit consists of a current sampling unit, a voltage sampling unit, an externalclock unit, a wide-range metering chip and a peripheral circuit thereof; output ends of the current sampling unit and the voltage sampling unit are connected with an input end of the wide-range metering chip respectively; the wide-range metering chip is connected with the external clock unit; and an output end of the wide-range metering chip is connected with the single-chip central processing unit. In the electric energy meter, current sampling is performed by shared manganin and mutual inductor or two mutual inductors on hardware to meter current of a live wire; and an automatic current tracking technology is applied on software, the range is changed by controlling channel selection through a single-chip, the limitation to the dynamic range of the metering chip is broken through, the aim of expanding the range is fulfilled, and the development trend of wide range and high accuracy for single-phase / three-phase electric energy meter is met.

Owner:WUHAN SAN FRAN ELECTRONICS CO LTD

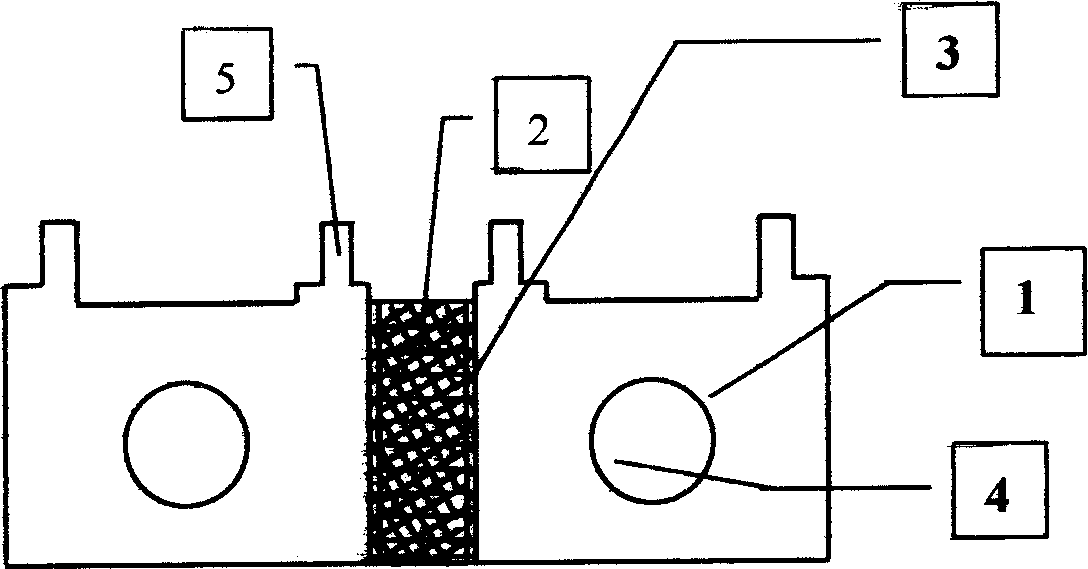

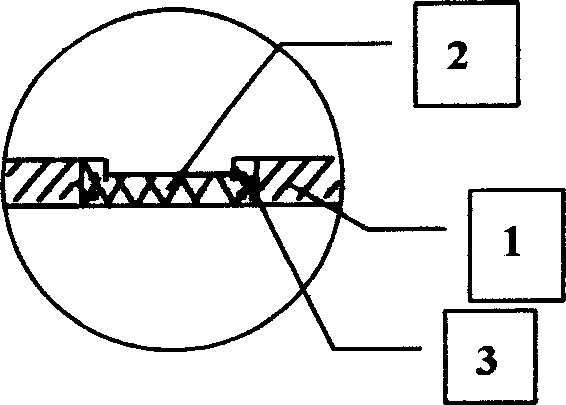

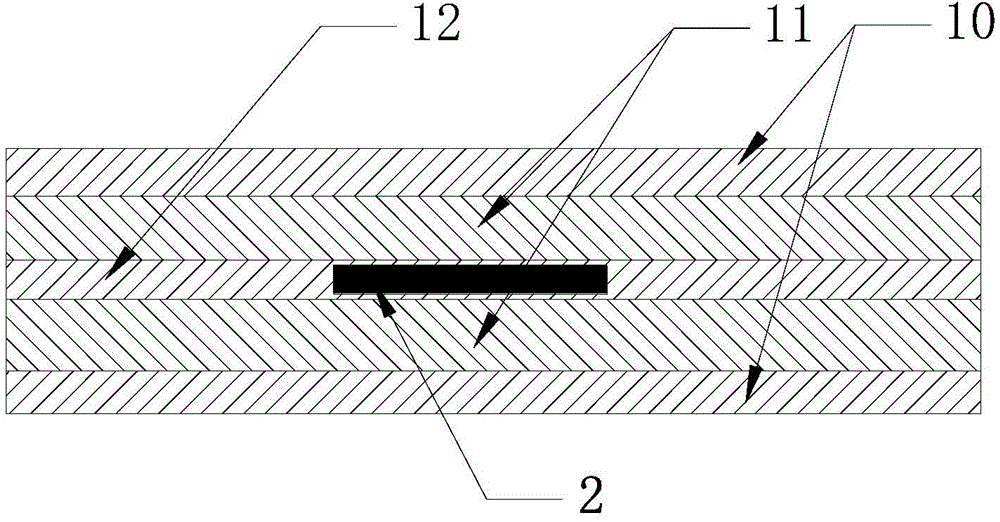

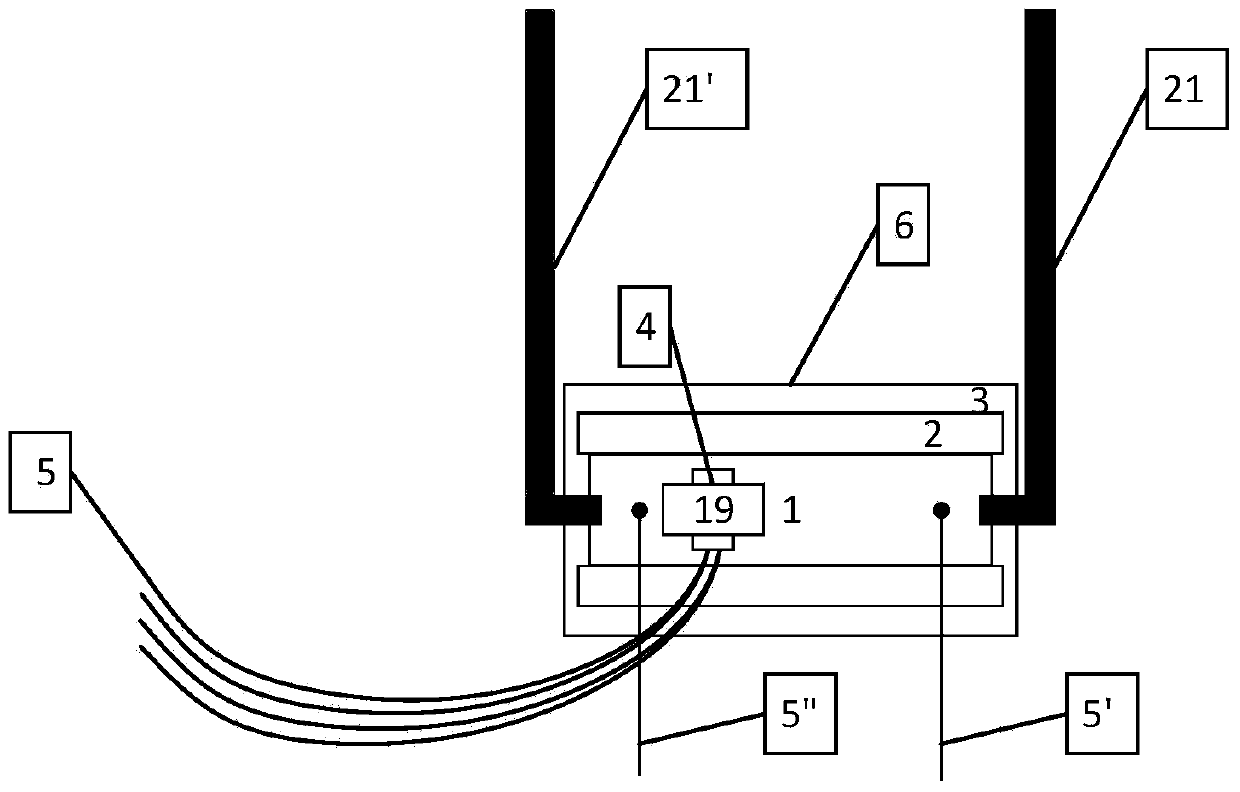

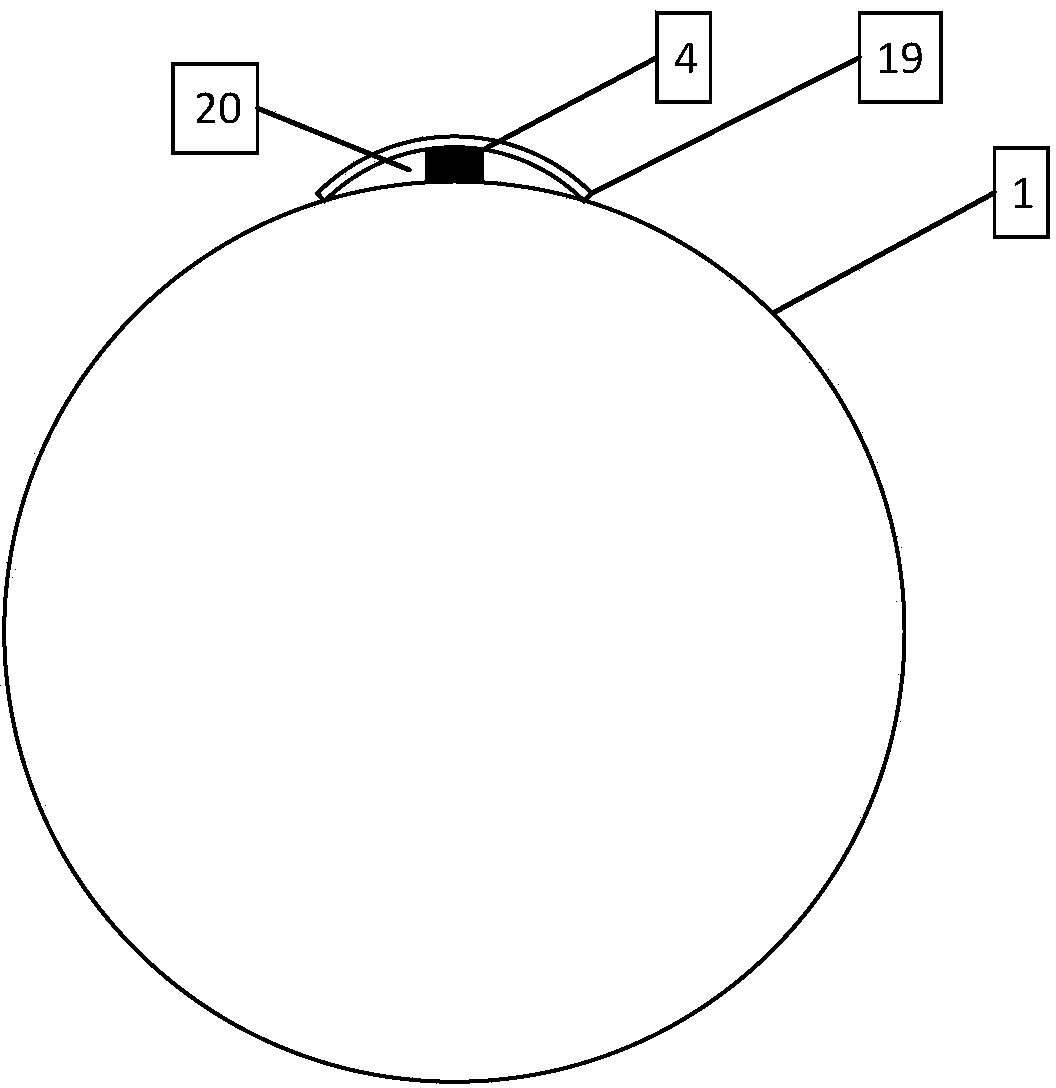

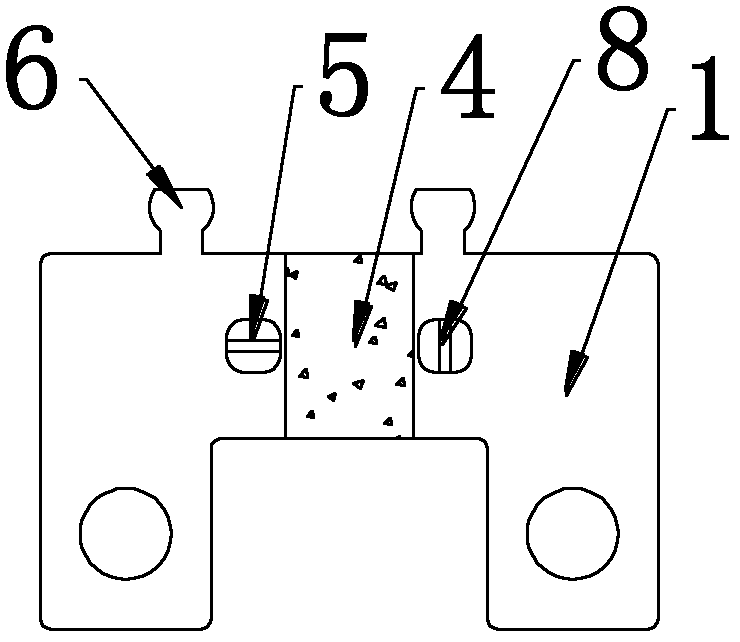

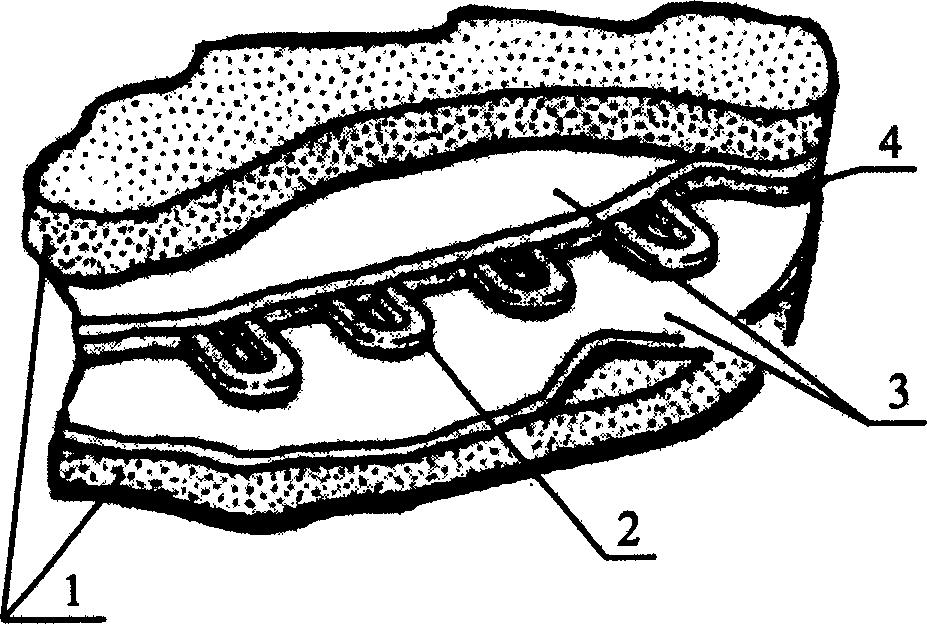

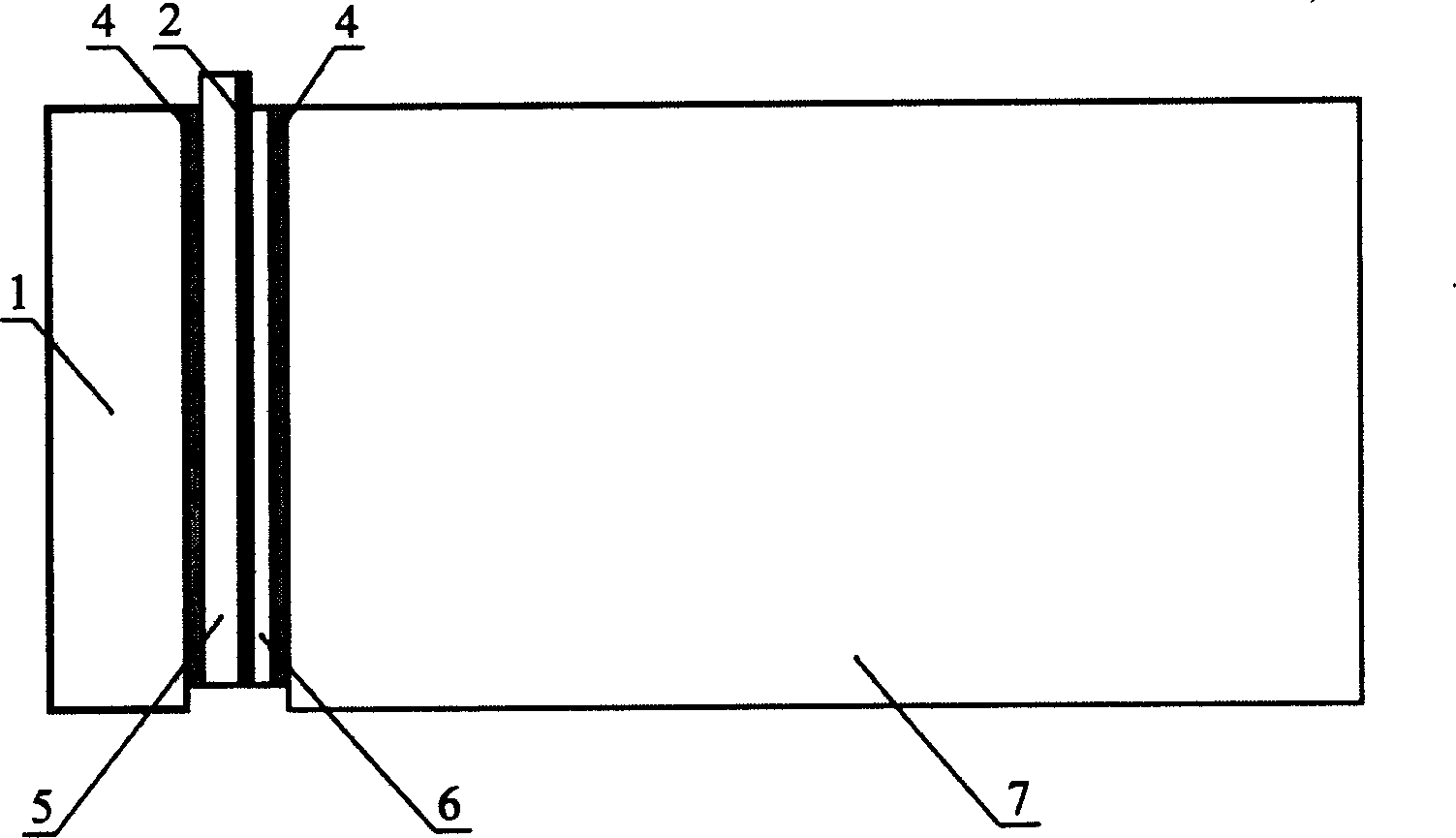

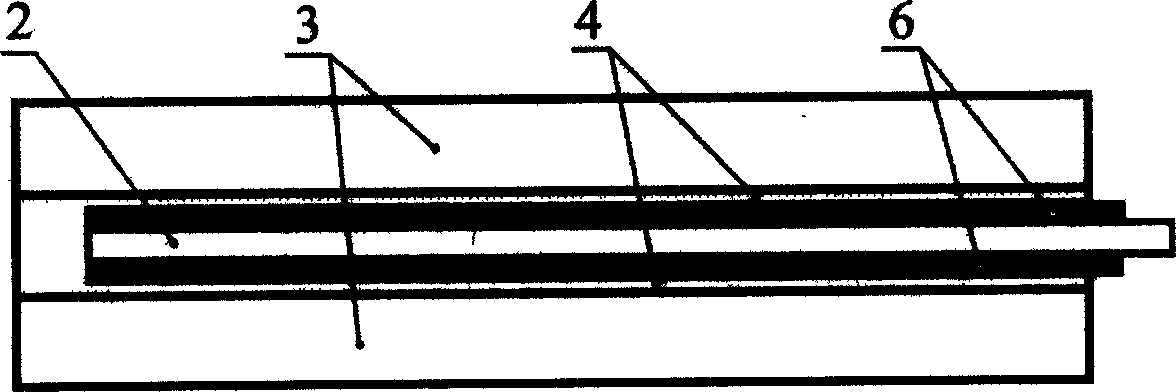

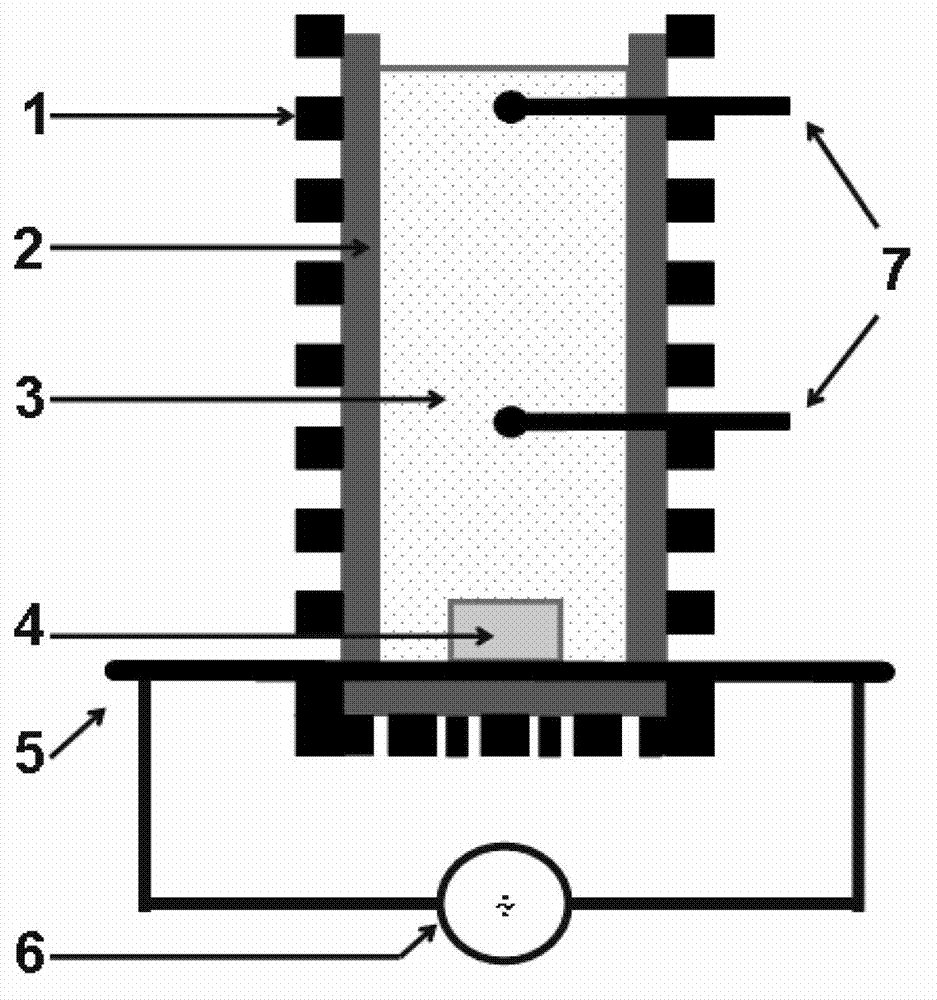

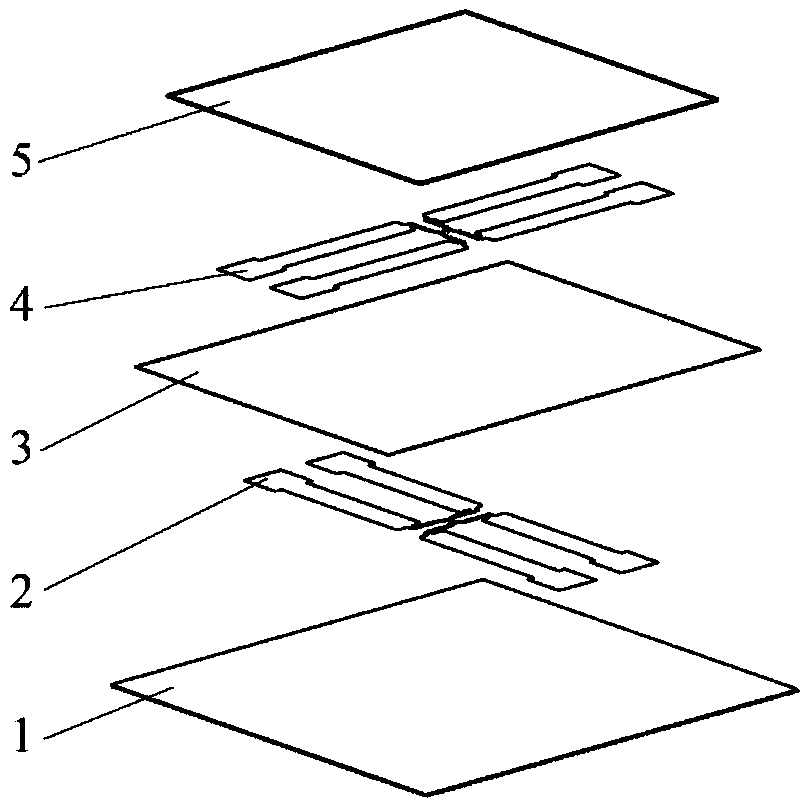

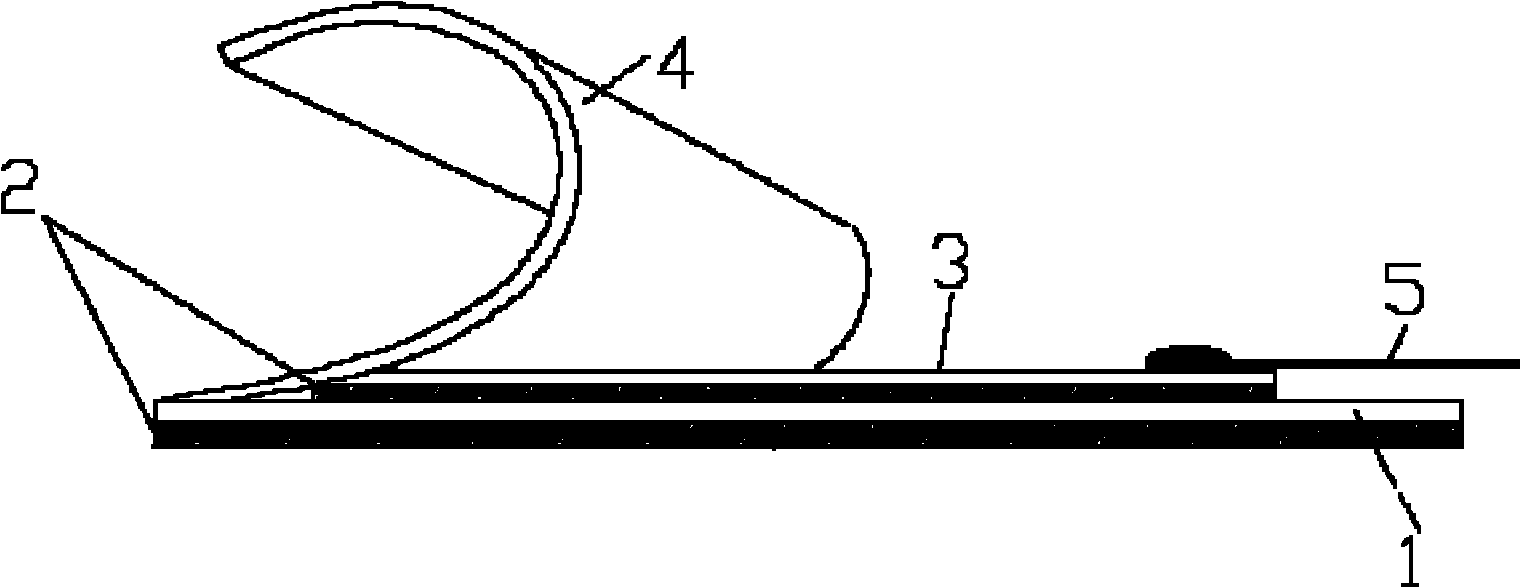

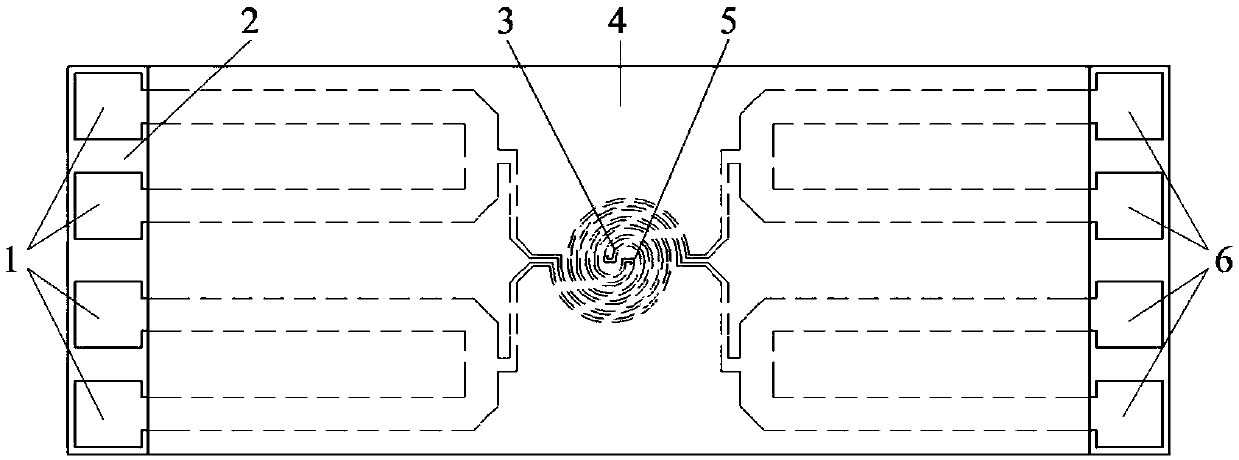

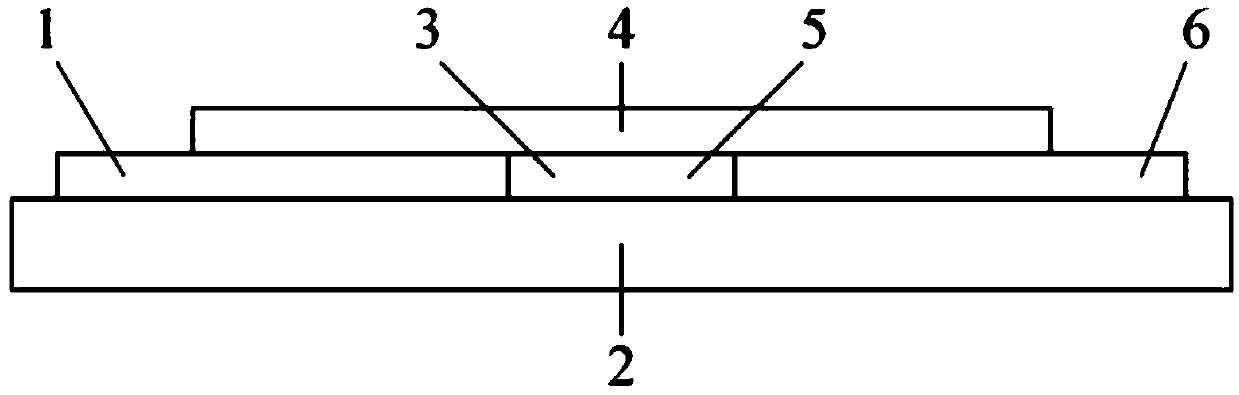

Compositely packaged foil type manganin superhigh pressure sensor

InactiveCN1789940AEliminate high voltage bypass effectIncreased upper limitForce measurement using piezo-resistive materialsManganinAdhesive

The invention discloses a composite packing foil-type manganin super-pressure sensor, which comprises the following parts: manganin voltage-sensitive element (2), organic insulating film (3), adhesive (4) and inorganic insulating film (6), wherein the inorganic insulating film (6) is composed of aluminum oxide and magnesium oxide, whose thickness is 1-30 ª–m; the inorganic insulating film (6) is set on front-to-back face of manganin voltage-sensitive element (2), which makes the organic insulating film (3) on two faces of the inorganic insulating film (6) through adhesive (4). The invention realizes the organic-to-inorganic composite pack, which can measure the pressure more than 50 GPa with simple structure and high precision.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

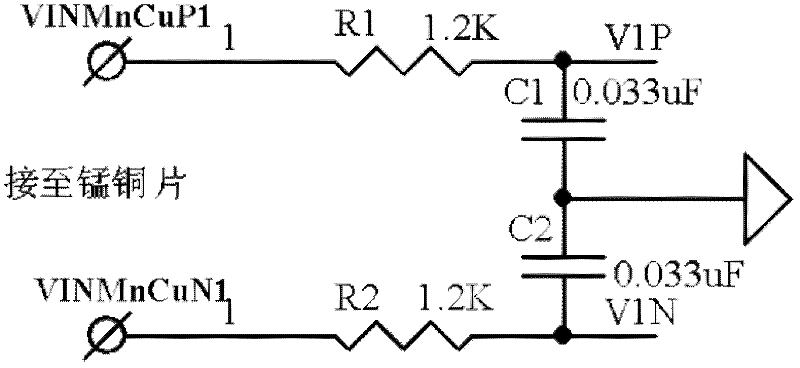

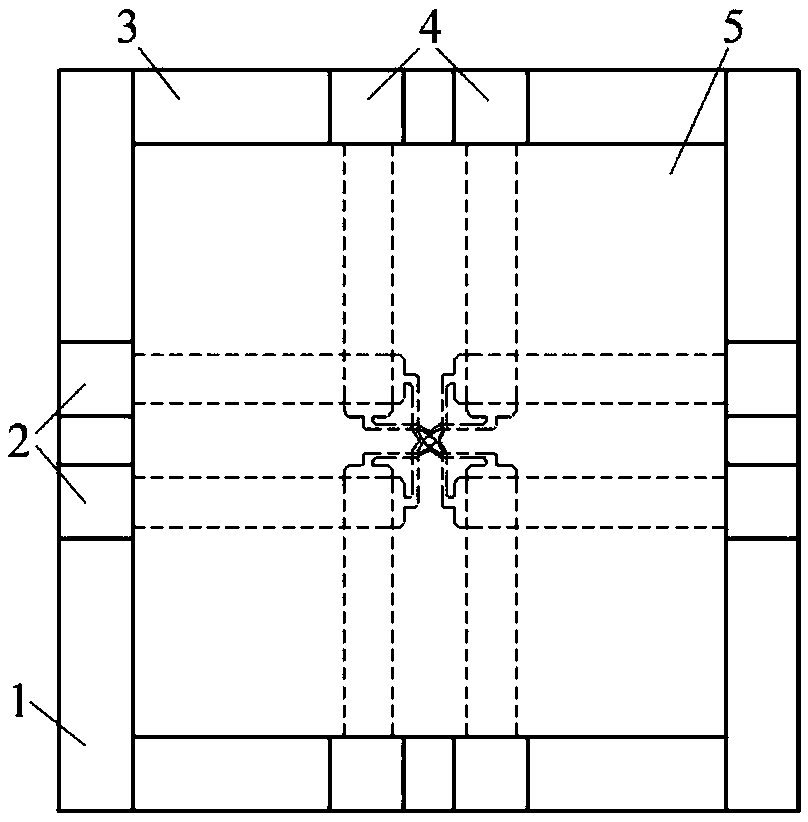

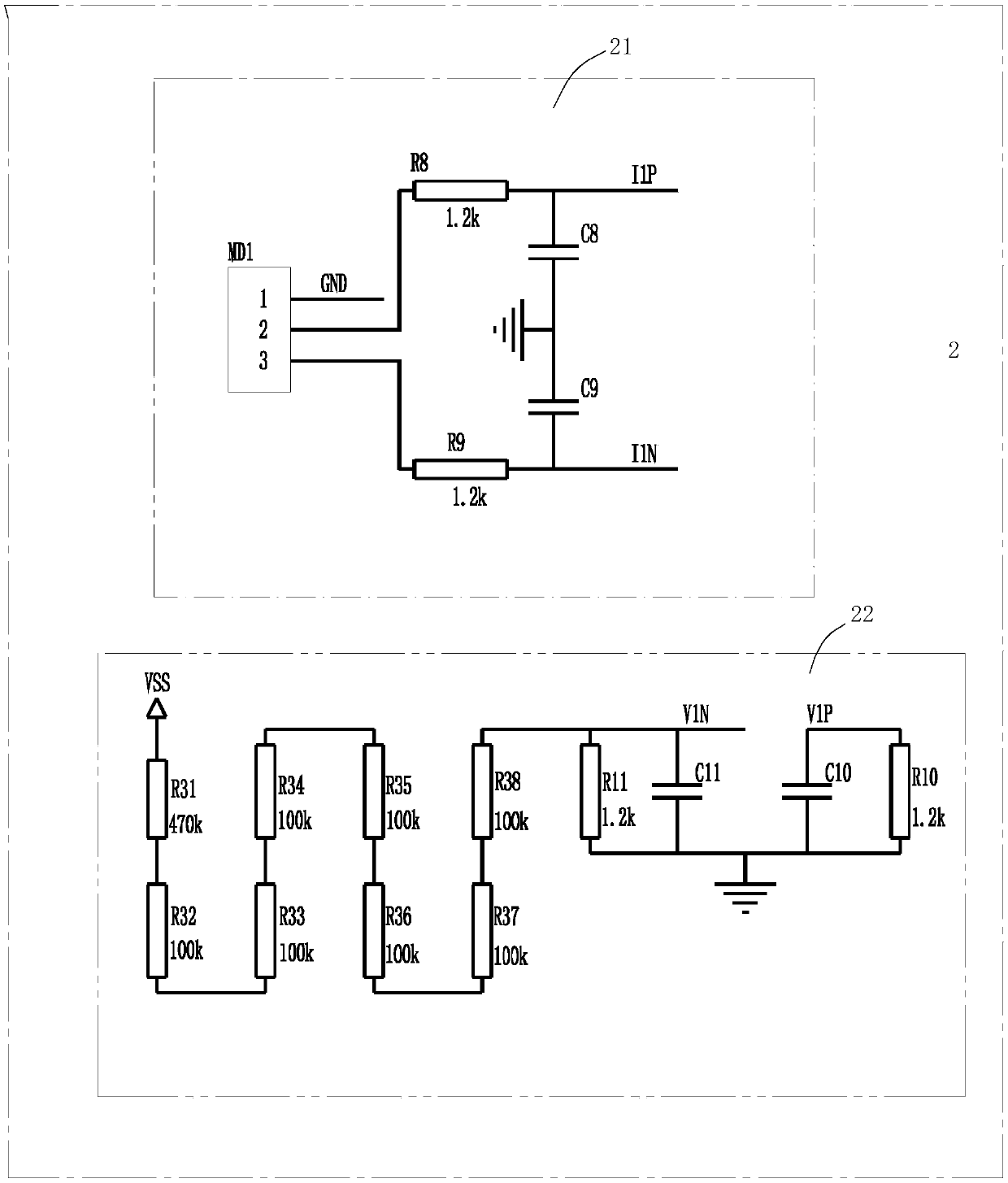

Anti-interference intelligent electric meter and anti-interference method of intelligent electric meter

The invention provides an intelligent electric meter which is capable of effectively reducing outer magnetic field interference, and provides a method of reducing the outer magnetic field interference of the intelligent electric meter. The anti-interference intelligent electric meter comprises a relay, a diverter and an electricity meter circuit board, the diverter comprises conducting plates on the two sides of the diverter and a manganin sampling plate, the relay is connected with the conducting plate on one side of the diverter, the conducting plates on the two sides are respectively connected at the two ends of the manganin sampling plate, binding posts are respectively arranged at the two ends of the manganin sampling plate, the binding posts at the two ends of the manganin sampling plate are respectively connected with the electricity meter circuit board through two-strand sampling wire, the manganin sampling plate is provided with three base planes which are perpendicular to each other in the space, the two ends of the mangnin sampling plate is distributed in a bilateral symmetry mode centering on one base plane, projected area of the mangnin sampling plate on the center base plate is larger than the projected area of the mangnin sampling plate on the other two base planes.

Owner:ZHEJIANG LIHUI ELECTRIC COMPANY

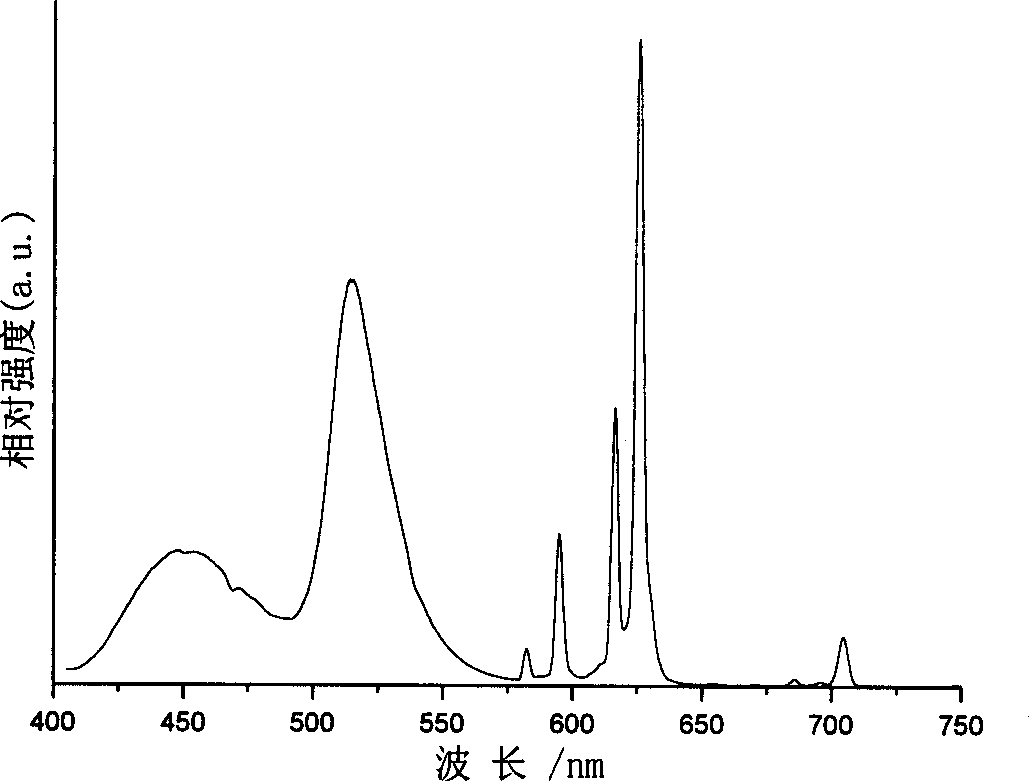

Mn-doped aluminum nitride-based red phosphor powder and preparation method of red phosphor powder

The invention discloses Mn-doped aluminum nitride-based red phosphor powder and a preparation method of the red phosphor powder. A chemical formula of the phosphor powder is Al1-xN:Mnx, wherein x is more than or equal to 0.01 and smaller than or equal to 0.1. The preparation method of the red phosphor powder comprises the steps of 1) weighing Al powders, AlN powders and compound powders containing Mn according to the weight of the target phosphor powder to be prepared, mixing uniformly and sieving, wherein the mass ratio of the Al powders to the AlN powders is 3:7-6:4; 2) adding the powders into a multi-hole graphite crucible, then putting into a high-pressure reaction container, vacuumizing, and introducing nitrogen; 3) igniting a ignition agent block at the powder bottom by lighting a graphite paper tape, and charging the graphite paper tape for 5-10s to initiate the combustion reaction under the conditions that the current is 20-30A and the voltage is 50-70V to obtain an incompact massive product; and 4) grinding, crushing and sieving the product to obtain the AlN:Mn2 red phosphor powder. The phosphor powder has the advantages that the light emitting efficiency is high, and the quality is stable. The preparation method has the advantages that the cost of raw materials is low, the process is simple, the speed is high, the needed production device is simple, the energy consumption is loss, and the industrial production is easy to realize.

Owner:XI AN JIAOTONG UNIV

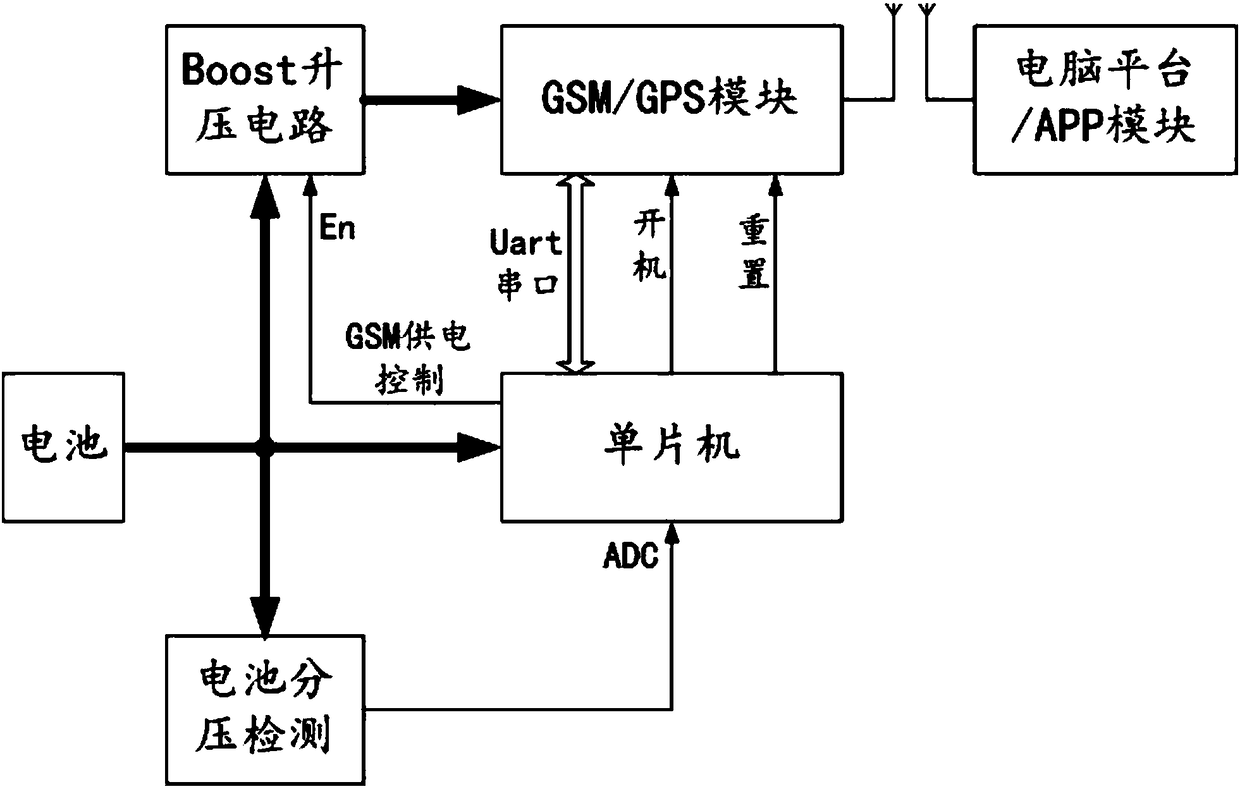

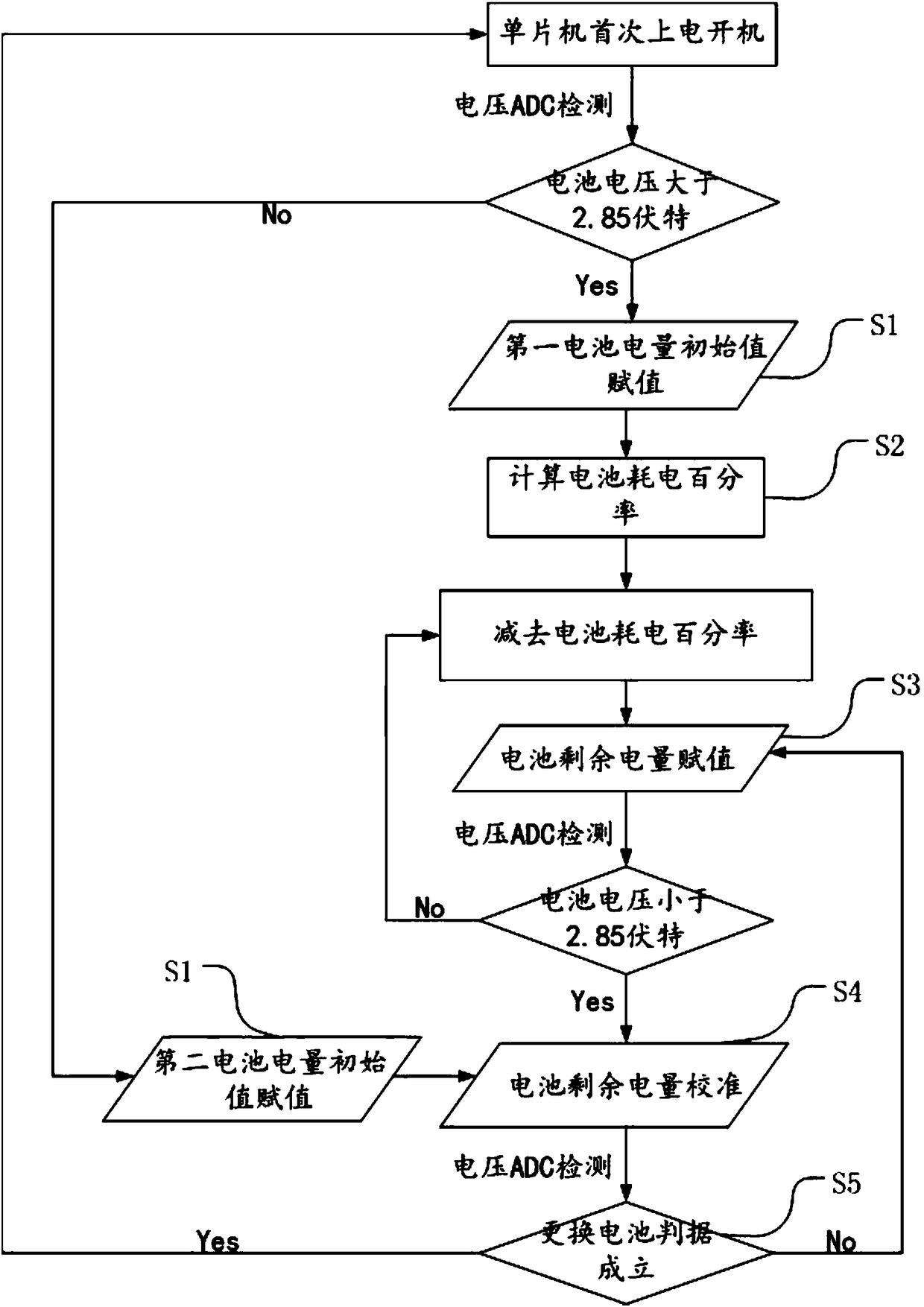

Method for calculating electric quantity of lithium-manganese disposable battery in super-long standby tracker and tracker

ActiveCN108663623ALow costDoes not increase power consumptionElectrical testingCell testing apparatusMicrocontrollerPower-on reset

The invention discloses a method for calculating the electric quantity of a lithium-manganese disposable battery in a super-long standby tracker and the tracker. The method comprises the steps of s1,GSM assigning an initial value to electric quantity of a first battery or a second battery if a single-chip microcomputer shows a power-on reset mark, and the acquired voltage of a battery is larger than a first preset voltage value; s2, calculating the power consumption percentage of the battery after the initial value of the electric quantity is assigned to the first battery; s3, assigning the remaining electric quantity of the battery; s4, calibrating the remaining electric quantity of the battery if the recollected voltage of the battery is smaller than the first preset voltage value, andotherwise, assigning the remaining electric quantity of the battery again; s5, determining whether the replacement battery criterion is met or not, and if so, returning to the s1, and if not, the stepcorresponding to assigning the remaining electric quantity of the battery; calibrating the remaining electric quantity of the battery after the initial value of the electric quantity of the second battery is assigned, and then determining whether a new battery is replaced or not. The tracker does not need to add a new device, so that the electric quantity calculation can be realized, and the calculation precision is high. The intelligent learning can be carried out according to historical data statistics stored in the GSM.

Owner:SHENZHEN JIMI SOFTWARE CO LTD

Micro-scale flexible composite ultrahigh pressure sensor and manufacturing method thereof

ActiveCN109163837AReduce flexibilityReduce the impact of detonation wavesForce measurementMeasurement of explosion forceTransverse axisManganin

The invention discloses a micro-scale flexible composite ultrahigh pressure sensor and a manufacturing method thereof. The sensor comprises a substrate; a constantan sensitive element and first electrodes are sputtered on the substrate through an MEMS process; the input end and the output end of the constantan sensitive element are connected with the two first electrodes respectively; the surfacesof the constantan sensitive element and the first electrodes are covered with an insulating layer; a manganin sensitive element and second electrodes are sputtered on the insulating layer through theMEMS process; the input end and the output end of the manganin sensitive element are connected with the two second electrodes respectively; and the manganin sensitive element and the constantan sensitive element are arranged in a vertical alignment mode, the second electrodes and the first electrodes are arranged in a vertical manner of a transverse axis, and the surfaces of the manganin sensitive element and the second electrodes are coated with a protective layer. The sensor has the characteristics of small sizes of the sensitive elements, high measuring range, high precision, large outputsignal, flexibility and the like, is suitable for measurement of micro-scale explosive-loading detonation pressures under multiple working conditions, and also can be expanded to the measurement of other micro-scale axisymmetric dynamic high-pressure flow field pressures.

Owner:XI AN JIAOTONG UNIV

Foil type sensor with function of automatically accumulating resistance

InactiveCN102023179AImprove heat resistanceEasy to joinMaterial resistanceFatigue damageElectrical resistance and conductance

The invention relates to a foil type sensor with a function of automatically accumulating resistance. The senor comprises a foil type sensitive grid, a base, a covering layer and a lead, wherein the surface of the base is sequentially provided with the foil type sensitive grid and the covering layer, and the foil type sensitive grid is connected with the lead; and the foil type sensitive grid is made of a foil material of copper-nickel-manganese-iron-silicon alloy through a photochemical method according to the designed sensor structure. Under the effect of fatigue loading, the sensor has the function of automatically accumulating resistance, is suitable for monitoring the accumulation of fatigue damages of a bridge structure, has the capacity of temperature self-compensation and is suitable for complicated and variable climatic environments of bridge structures. The sensor has larger resistance accumulation increment and excellent fatigue service life and can be guaranteed to work for a long time without being frequently changed. The sensor also has a lower resistance accumulation strain threshold value and can be directly bonded on the surface of a structure for use. The sensor has low production cost and can be industrially applied in a large scale.

Owner:CENT SOUTH UNIV

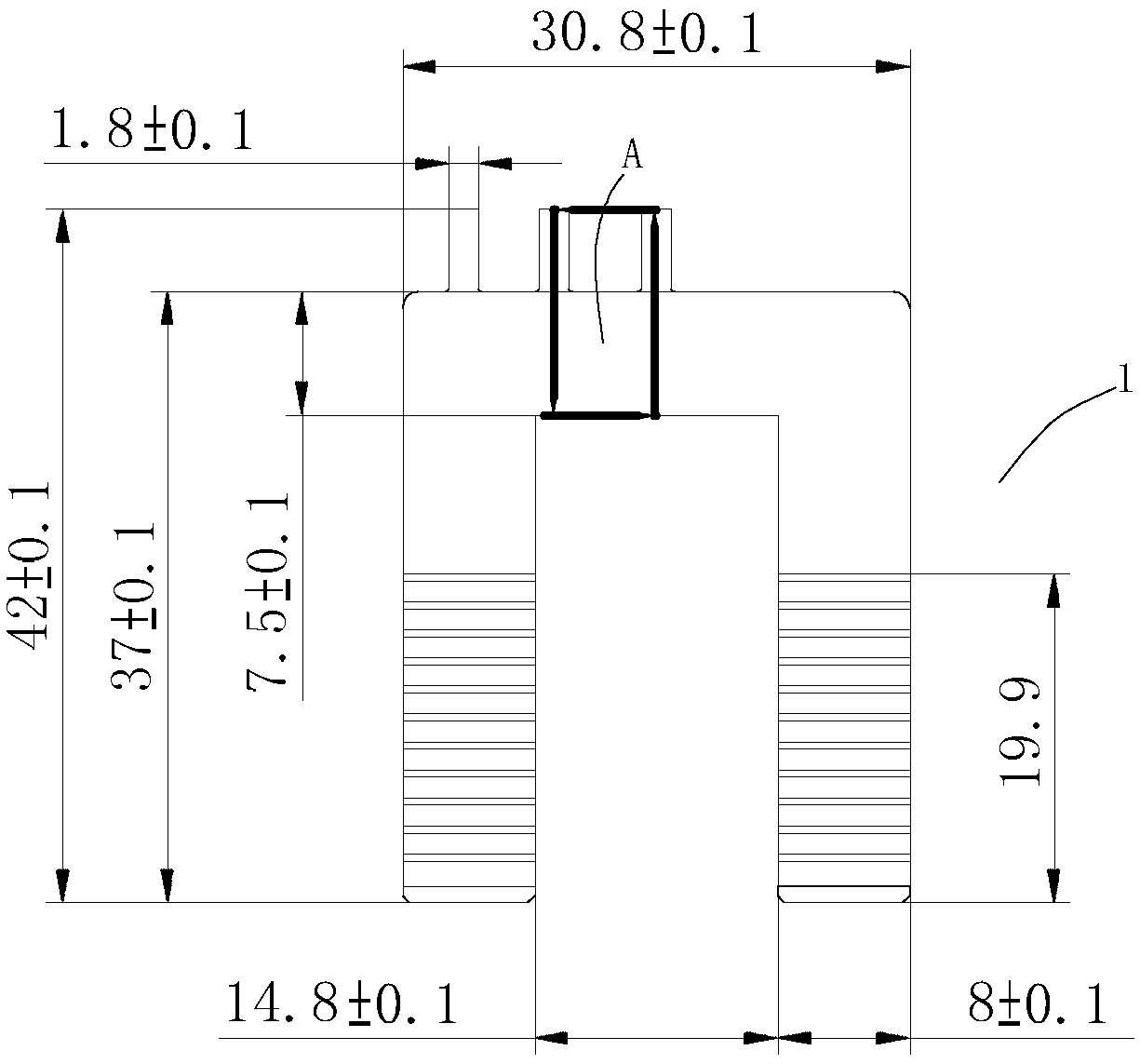

Current sampling power frequency anti-magnetic electric energy meter

PendingCN107621561AReduce measurement errorImprove accuracyTime integral measurementCurrent sampleManganin

The invention relates to a current sampling power frequency anti-magnetic electric energy meter, which comprises a manganin shunt (1), a first current sampling module (21) connected with the manganinshunt (1) for acquiring current signals formed on the manganin shunt (1) and a control module (4) receiving the information acquired by the first current sampling module (21) for analysis and processing, and is characterized in that the manganin shunt (1) and the first current sampling module (21) are connected through a cross loop B. In comparison with the prior art, the magnetic field generateddue to the self structure of the electric energy meter in the case of interference of an external power frequency magnetic field can be effectively reduced, accurate sampling is thus ensured, and themetering precision is improved.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

High-plasticity steel hot-rolled coil for welded gas cylinder and production technology of high-plasticity steel hot-rolled coil

The invention discloses a high-plasticity steel hot-rolled coil for a welded gas cylinder. The high-plasticity steel hot-rolled coil comprises the following chemical components in percentage by mass: 0.10-0.15 percent of C, 0.50-1.50 percent of Mn, 0-0.018 percent of P, 0-0.015 percent of S, 0.015-0.040 percent of Als, and Fe and impurity elements in balance amount; the technological parameters of rolling are as follows: heating temperature is 1180-1220 DEG C, blooming temperature is 1150-1180 DEG C, precision rolling temperature is 950-1000 DEG C, finish rolling temperature is 800-900 DEG C, interval type water curtain layer cooling is adopted in the cooling process, water cooling rate is 10-50 DEG C / S, and final cooling temperature is 600-630 DEG C. the welded gas cylinder steel has a uniform structure, in addition, the strength and plasticity are improved, the performance is stable, the welded gas cylinder forming rate is improved greatly, and the production cost is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

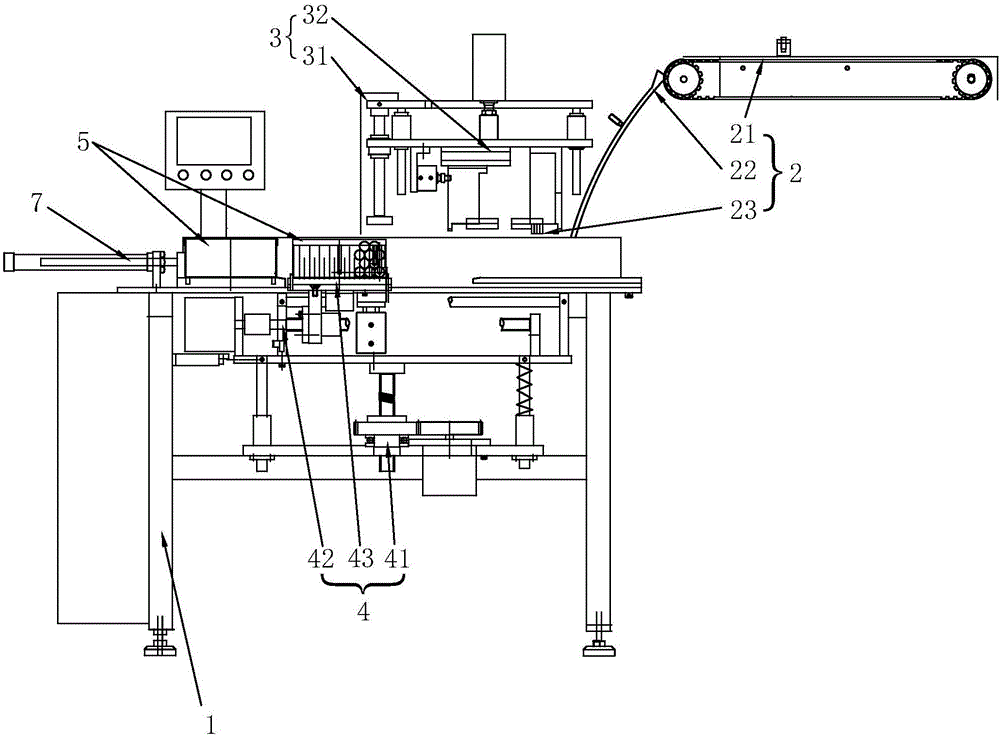

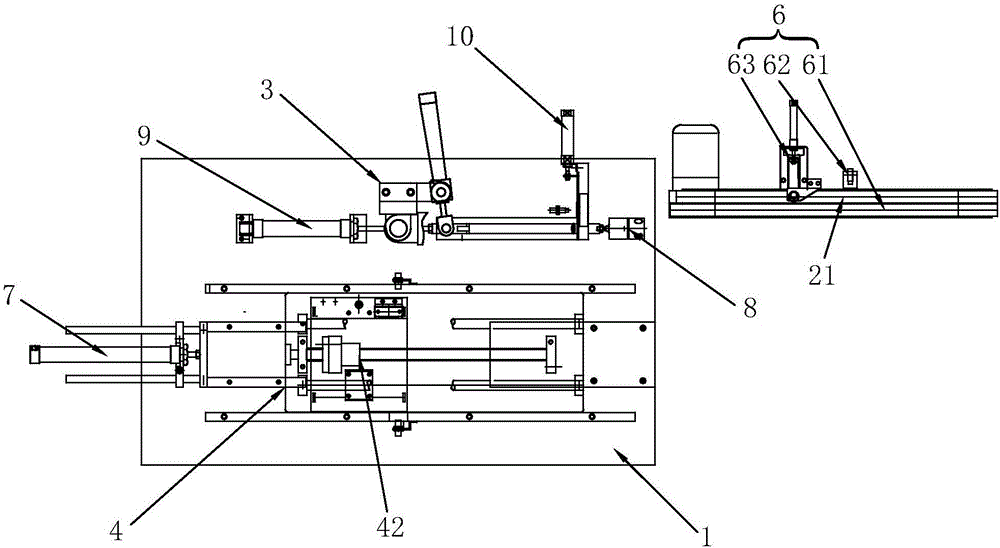

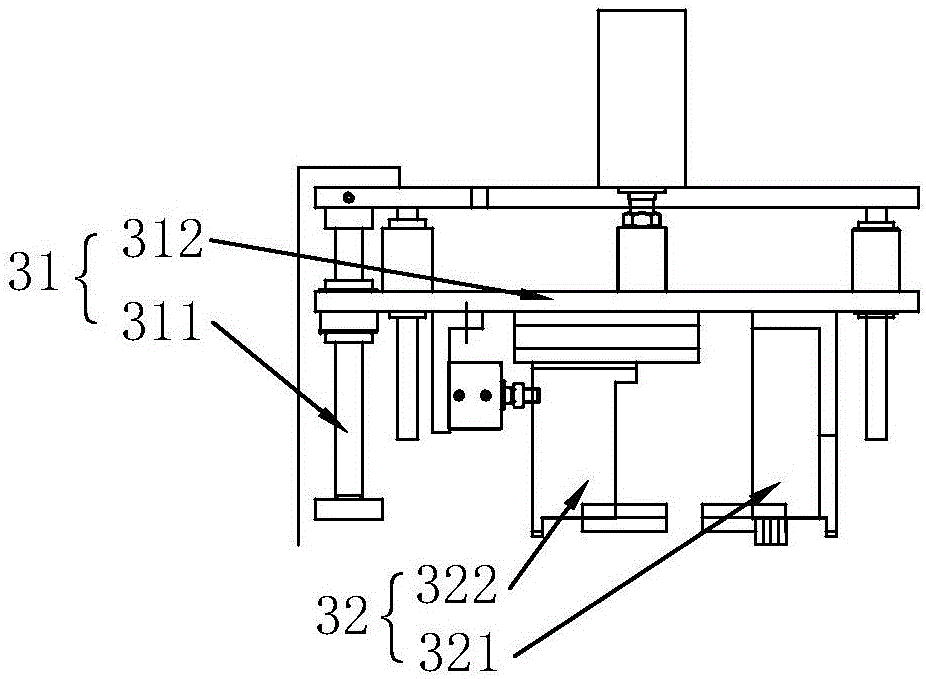

Automatic box packing machine

The invention discloses an automatic box packing machine. The box packing machine comprises a machine frame; a feeding device, a clamping device and a box moving device are arranged on the machine frame; the feeding device is stocked with a certain amount of battery positive plates; the stocked battery positive plates are gripped by the clamping device to a slice box of the box moving device; and finally the packing process is completed by the coordinated work of the clamping device and the box moving device. The problems that manual operation causes low efficiencies and the like are solved, automation is achieved, labor productivity is increased, and the technical problems that the weak strength of the thin sheet of manganese powder tablet leads to easy fragmentations, bad stack and easy damage in transport and the like are solved.

Owner:珠海市冠力电池有限公司

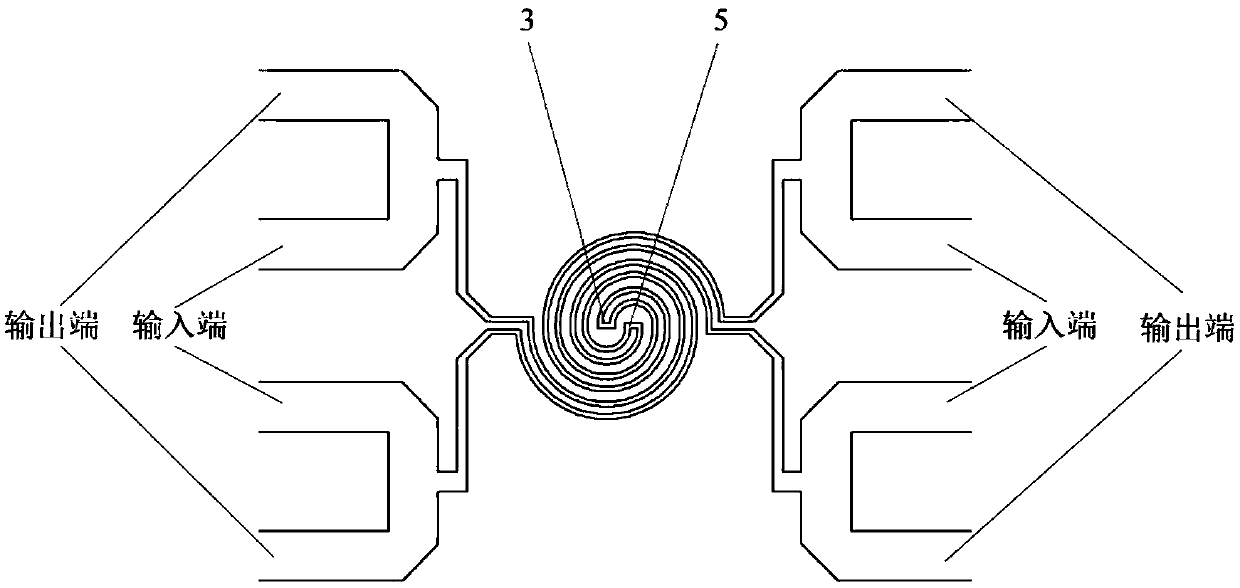

MEMS flexible manganin-constantan composite ultra-high pressure sensor and manufacturing method thereof

ActiveCN108896235AHigh measurement accuracyHigh precisionFluid pressure measurement using ohmic-resistance variationUltra high pressureManganin

The invention relates to an MEMS flexible manganin-constantan composite ultra-high pressure sensor and a manufacturing method thereof. The composite ultra-high pressure sensor comprises a substrate, wherein the substrate is sputtered with a manganin sensitive element, four first electrodes corresponding to the manganin sensitive element, a constantan sensitive element and four second electrodes corresponding to the constantan sensitive element, an input end and an output end of the manganin sensitive element are respectively connected with the two first electrodes, an input end and an output end of the constantan sensitive element are respectively connected with the two second electrodes, and the surfaces of the manganin sensitive element, the constantan sensitive element, the first electrodes and the second electrodes are covered with an insulating layer; and the manganin sensitive element and the constantan sensitive element adopt spiral centrosymmetric distribution, and both the substrate and the insulating layer adopt a polyimide material. The composite ultra-high pressure sensor has the characteristics of high precision, fast response, large output signal and the like.

Owner:XI AN JIAOTONG UNIV

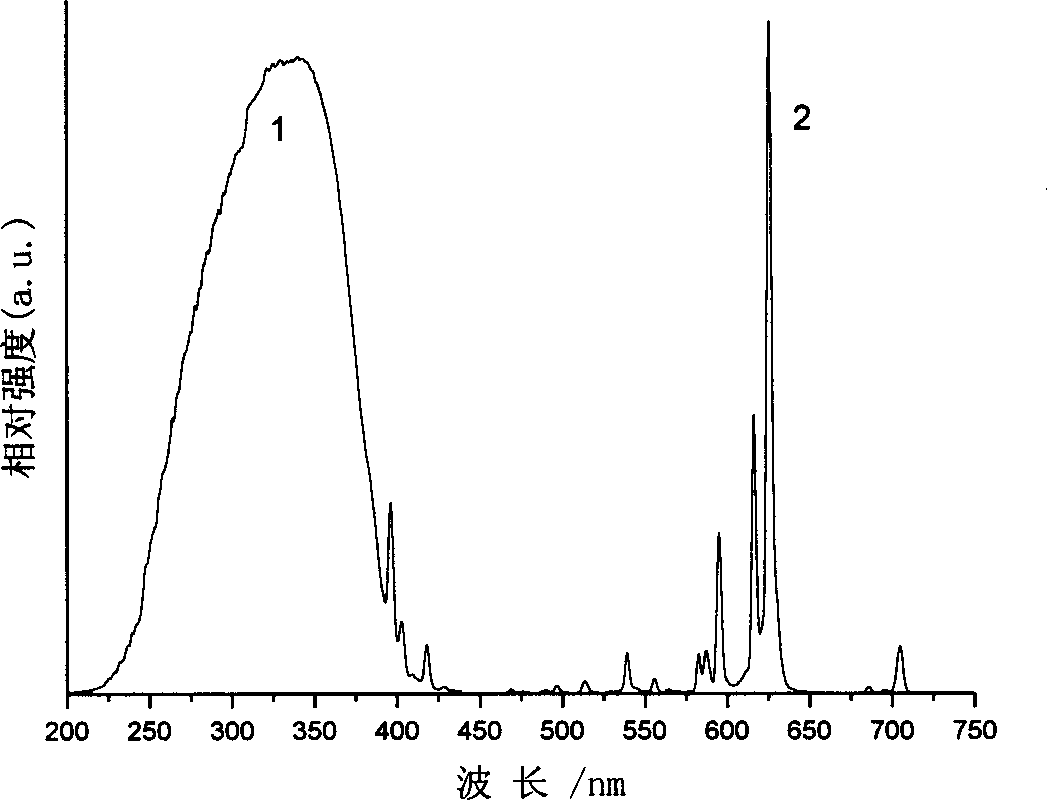

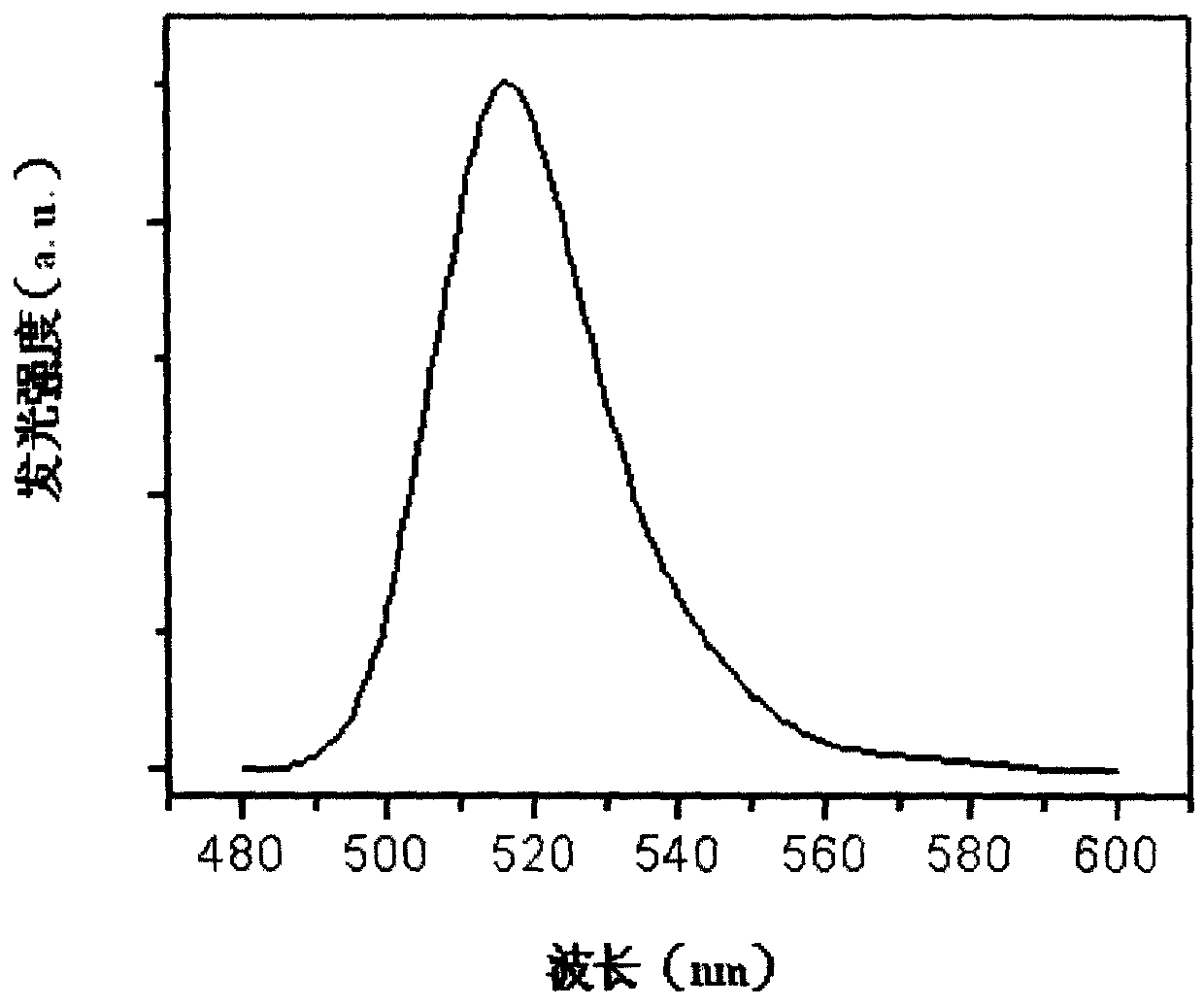

Vacuum-ultraviolet-excited aluminate green luminophore andits production

A vacuum ultraviolet-excited aluminate green luminophor and its production are disclosed. The chemical formula is Ba0.956Mg0.912-xMnxAl10.088017, 0.05<=X<=0.3; The process is carried out by taking aluminum source, barium source, magnesium source and manganese source as raw materials, adding into fusing agent 0-8%mol, mixing, firing at 1350-1700degree in reducing gas for 1-10hrs, and cooling to obtain the final product. The brightness of the luminophor is >BaAl12019:Mn under 147nm vacuum ultraviolet excitation. It's simple and cheap and can be used for plasma planar display device of color large screen.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

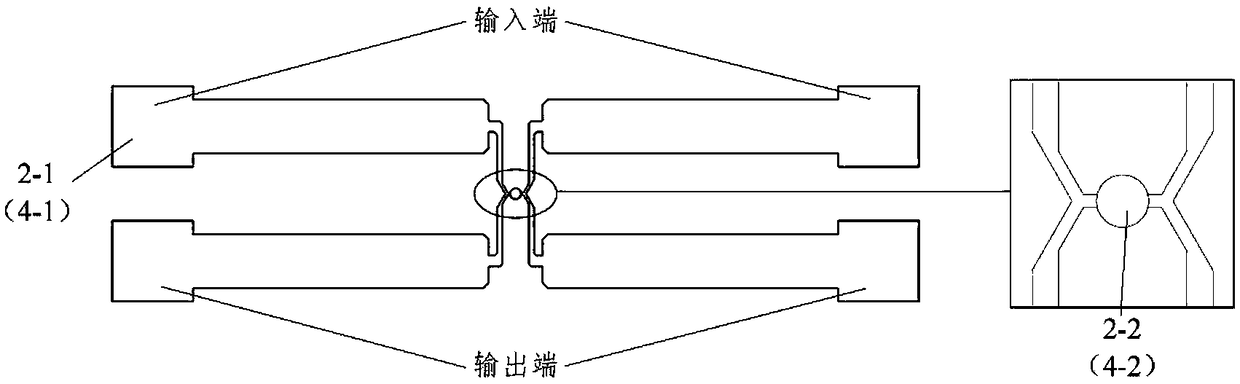

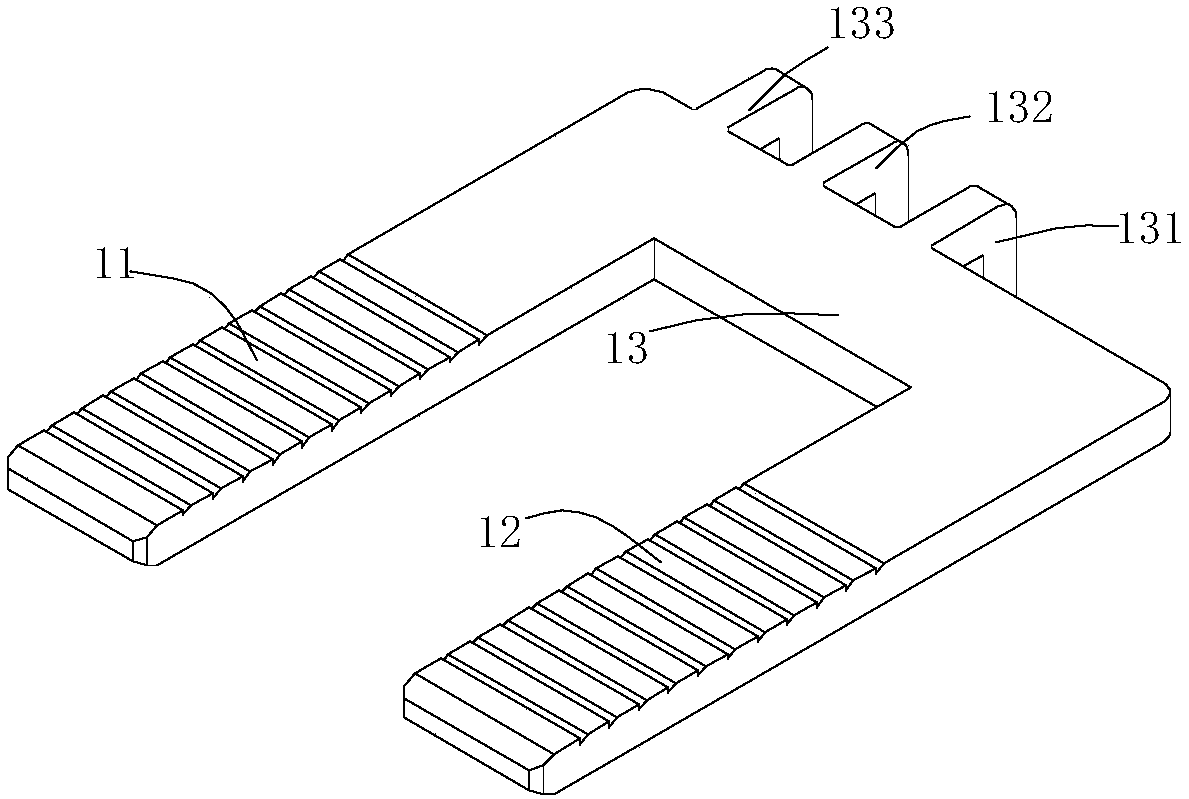

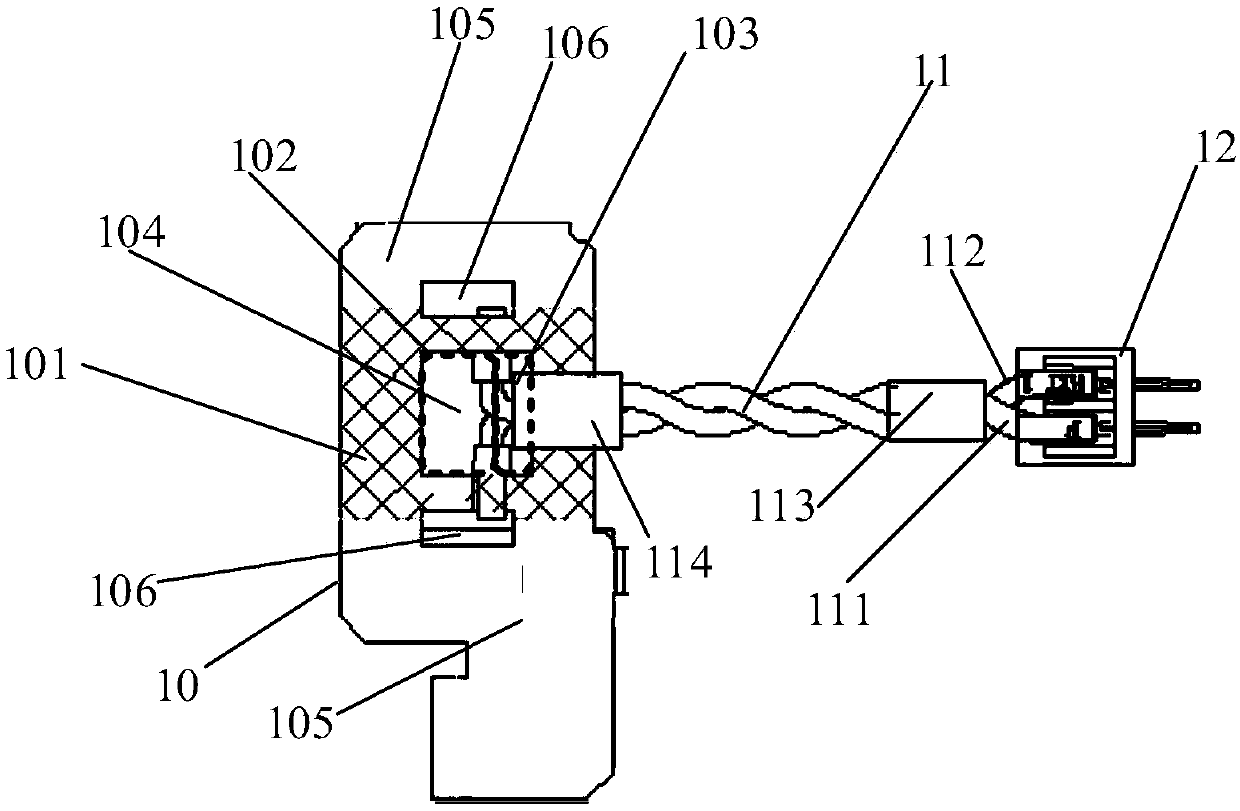

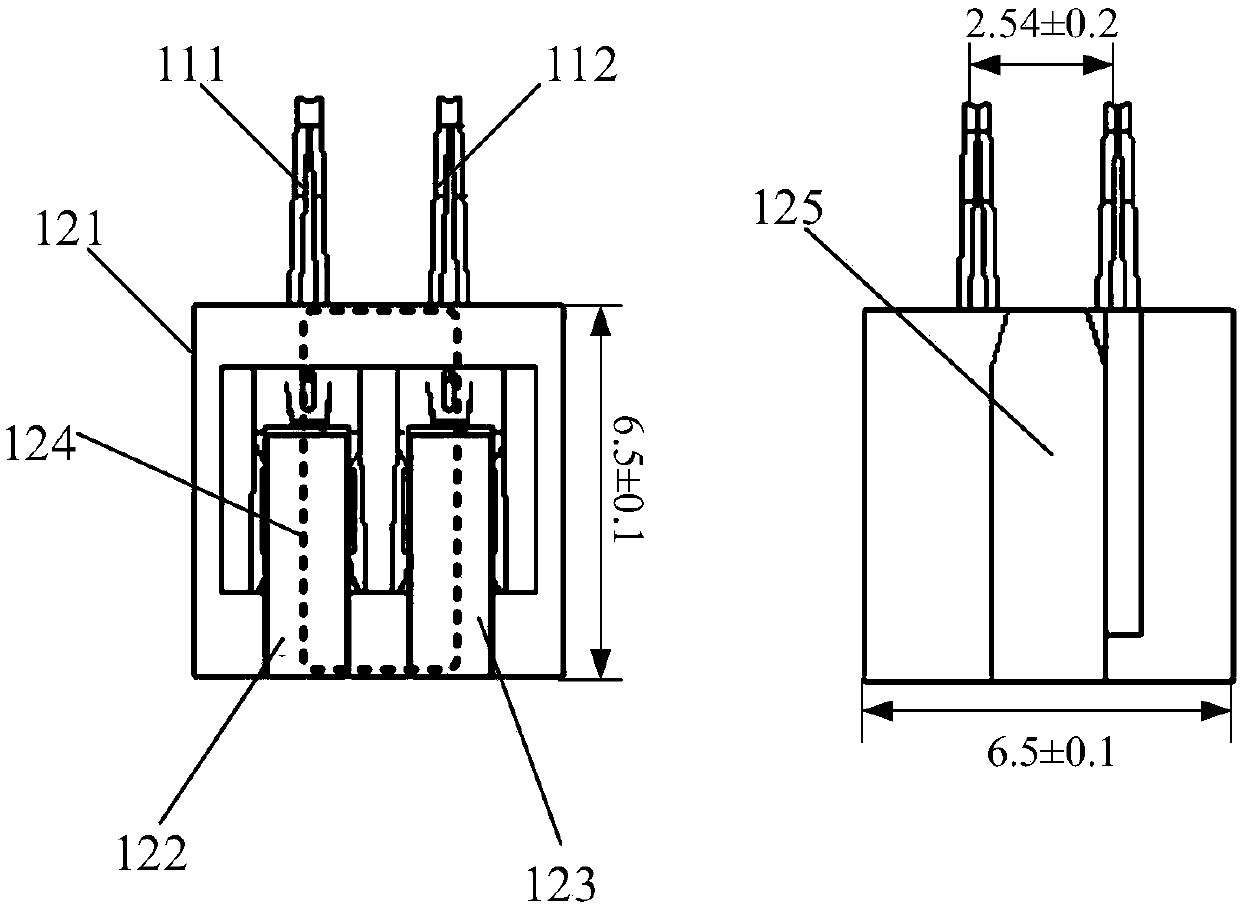

Manganin diverter and electronic watt-hour meter

InactiveCN108508266ASimple preparation processEliminate distractionsTime integral measurementManganinHelix

The invention provides a manganin diverter and an electronic watt-hour meter. In the manganin diverter of the embodiment, a groove penetrating through a manganin sheet is formed in the center of the manganin sheet, and a first connection point connected with the first end of a first sampling line and a second connecting point connected with the first end of a second sampling line are arranged on two sides of the groove respectively. The projections on the first sampling line and the second sampling line on the manganin sheet after twisting divide the groove into a first area and a second area.Two pin plugging channels are formed in a housing of a pin plugging device. The first sampling line and the second sampling line penetrate through the pin plugging channels. The area value of the third area formed between the two pin plugging channels is equal to an absolute value of the difference of the area value of the first area and the area value of the second area. Therefore, process manufacturability is improved and the manual operation difficulty is reduced while the interference of an alternating magnetic field to the manganin diverter is effectively reduced, and thus labor and timeare saved.

Owner:WAHLAP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com