MEMS flexible manganin-constantan composite ultra-high pressure sensor and manufacturing method thereof

An ultra-high pressure, composite technology, which is applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problem that the manganin sensor cannot use the constantan sensor, the lateral stretching error, the ultra-high pressure sensor is not applicable, and the pressure flow is affected. Field and other problems, to avoid calculation errors, reduce the impact, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

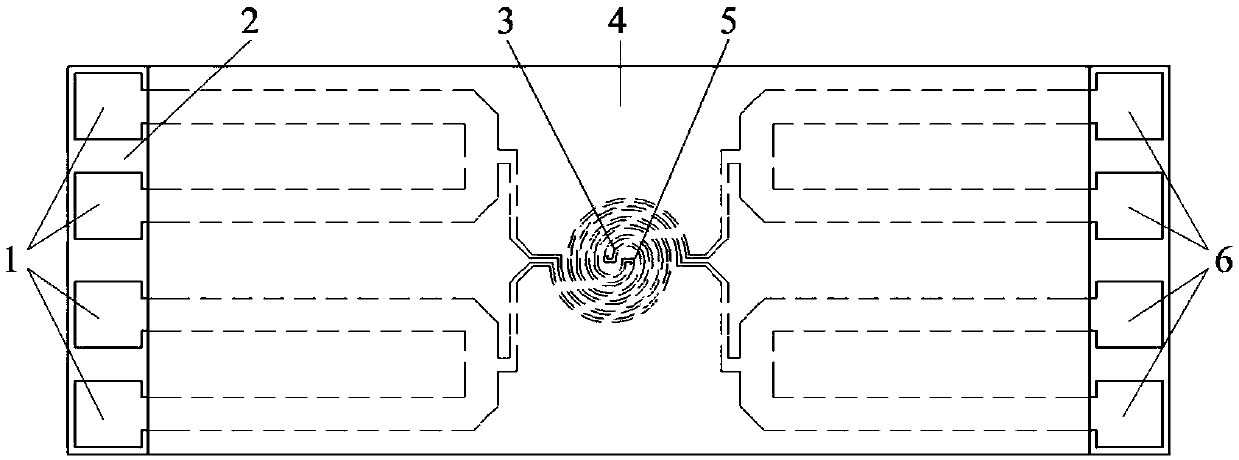

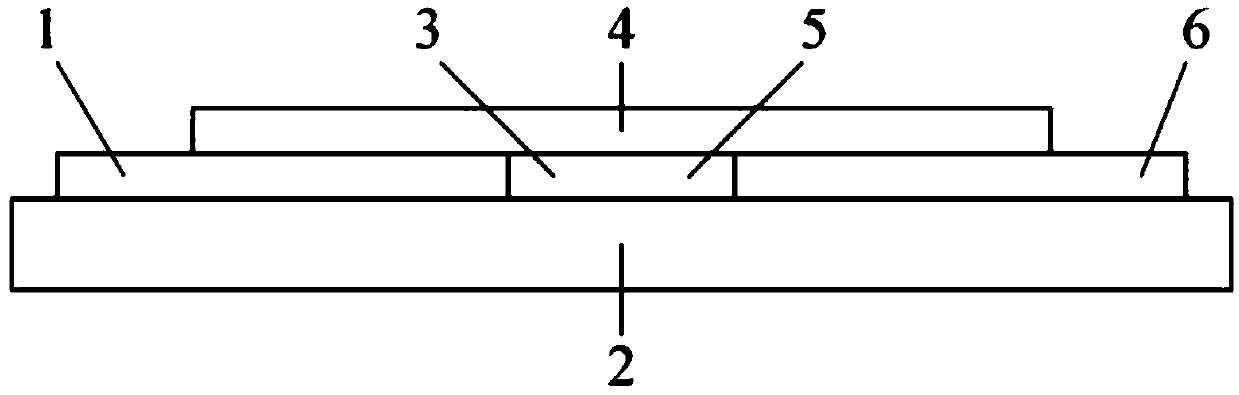

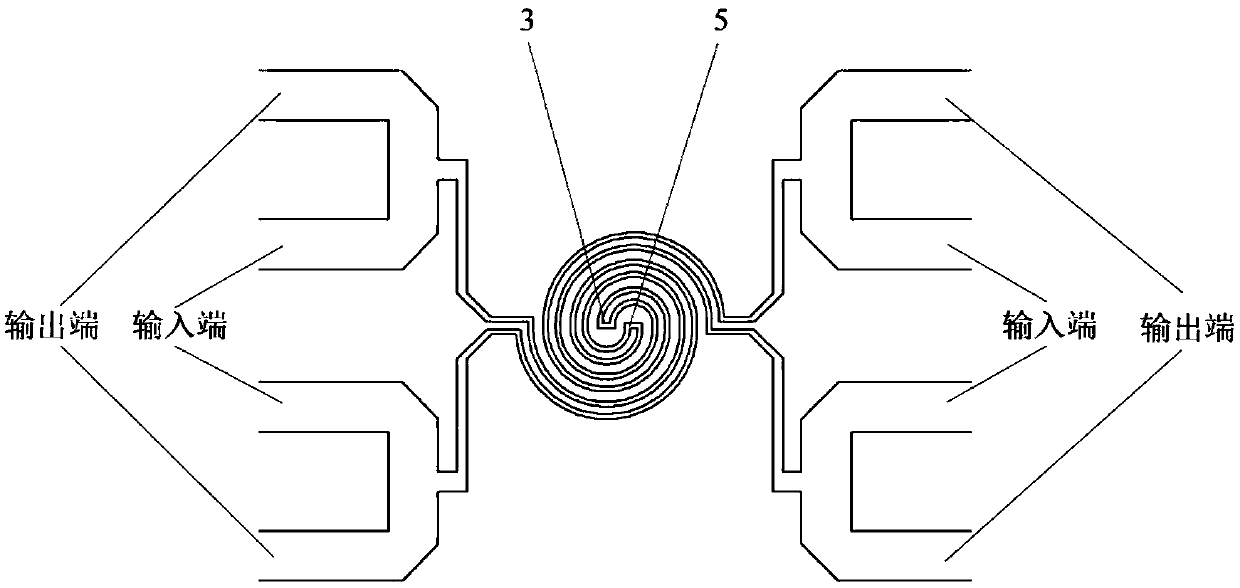

[0022] refer to figure 1 , figure 2 and image 3 , a MEMS flexible manganin-constantan composite ultra-high pressure sensor, including a substrate 2, a manganese-copper sensitive element 3 and its corresponding four first electrodes 1 are sputtered on the substrate 2 through a MEMS process, and a constantan sensitive element The element 5 and its corresponding four second electrodes 6, the input end and output end of the manganin sensitive element 3 are respectively connected to two first electrodes 1, and the input end and output end of the constantan sensitive element 5 are respectively connected to two second electrodes 1. The surfaces of the electrode 6 , the manganin sensitive element 3 , the constantan sensitive element 5 , the first electrode 1 and the second electrode 6 are covered with an insulating layer 4 .

[0023] The manganese-copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com