Patents

Literature

442 results about "Hard substrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hard substrates include ceramics such as alumina, aluminum nitride and beryllium oxide, and are desirable for applications where bare die (chips) are used such as in a hybrid module.

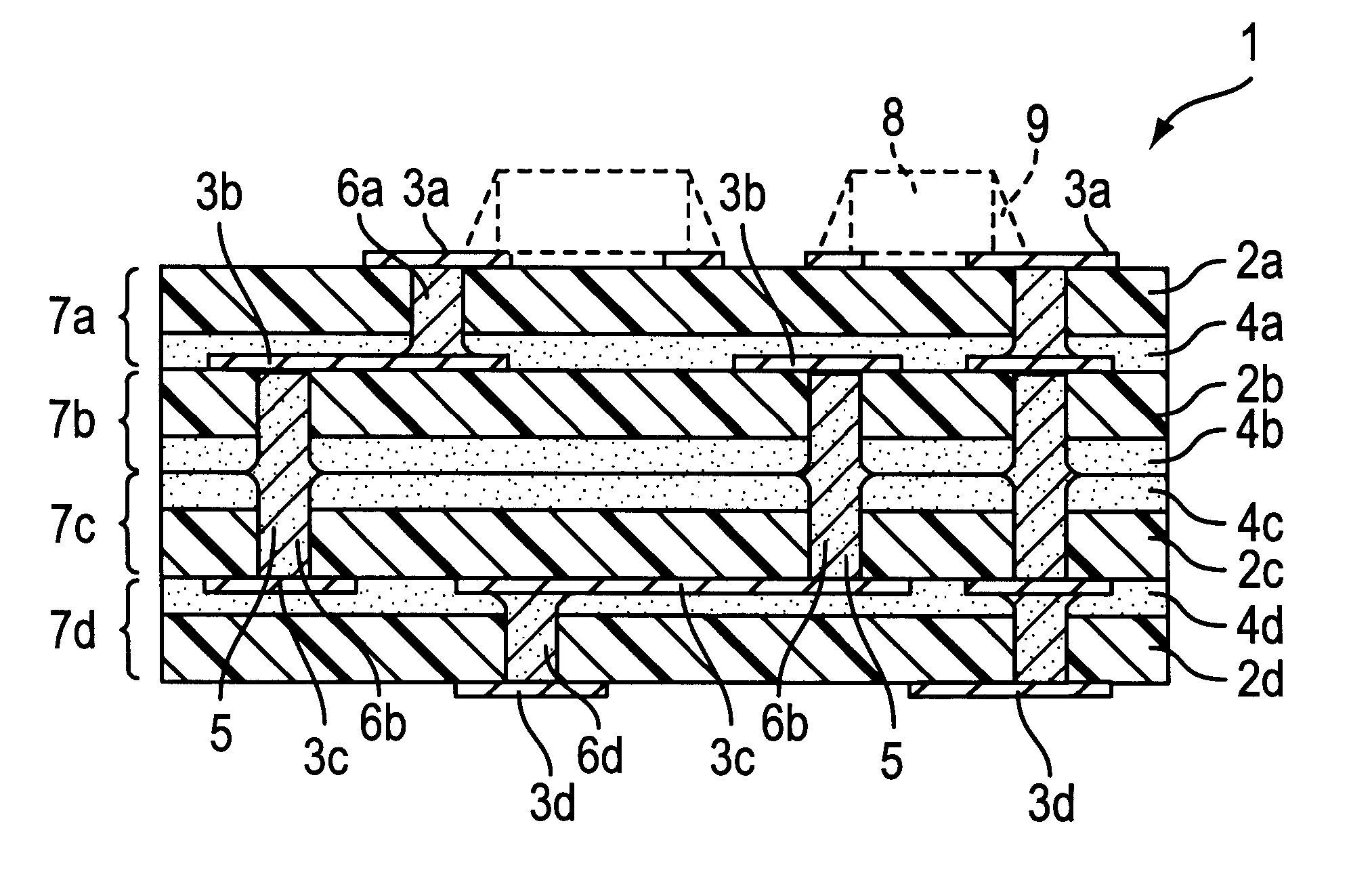

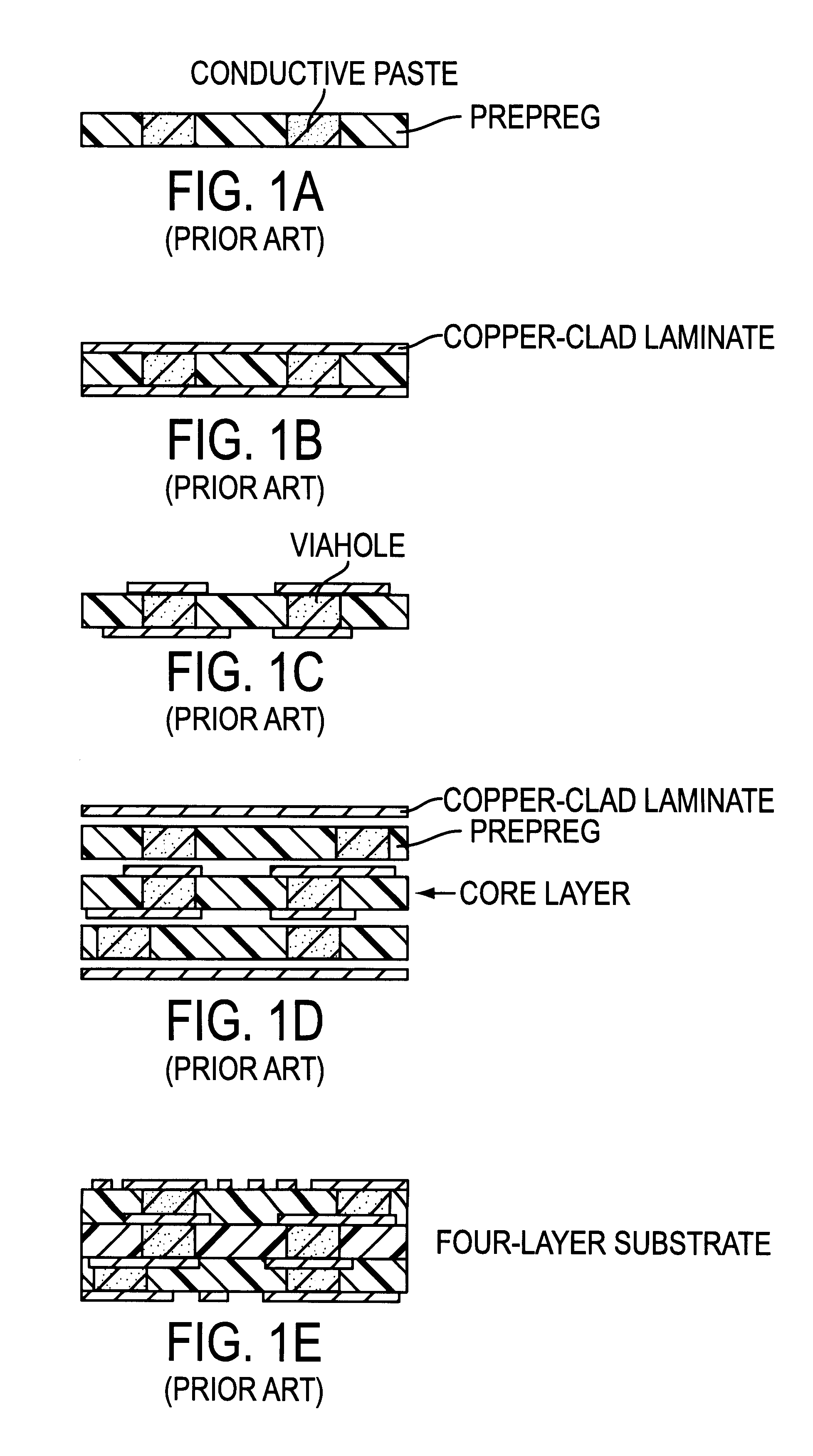

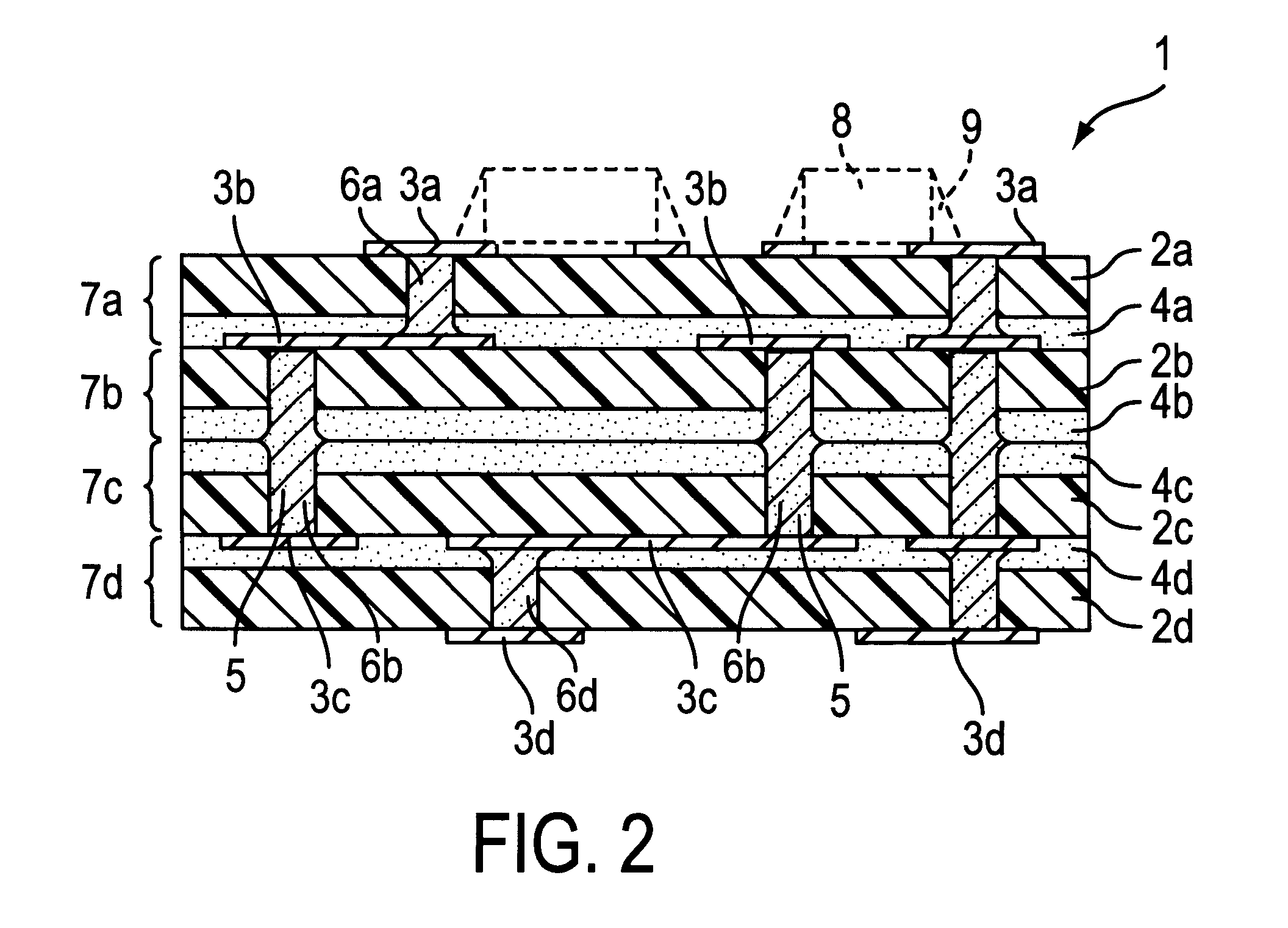

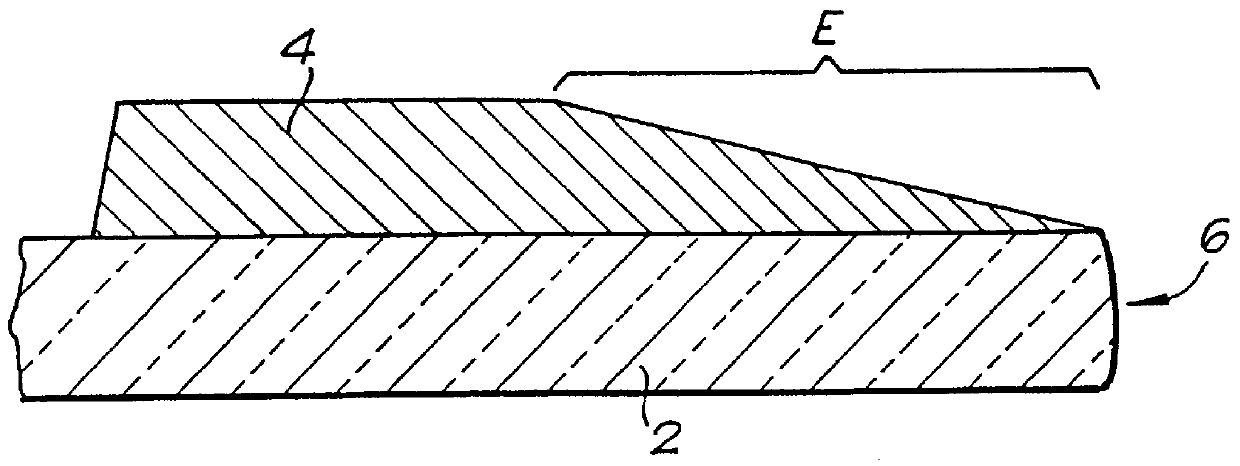

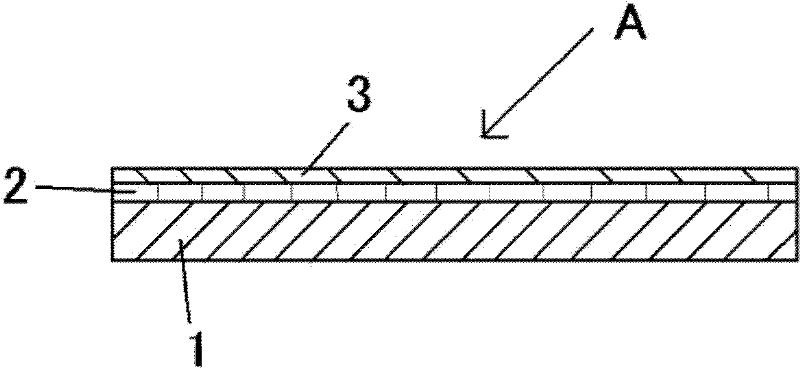

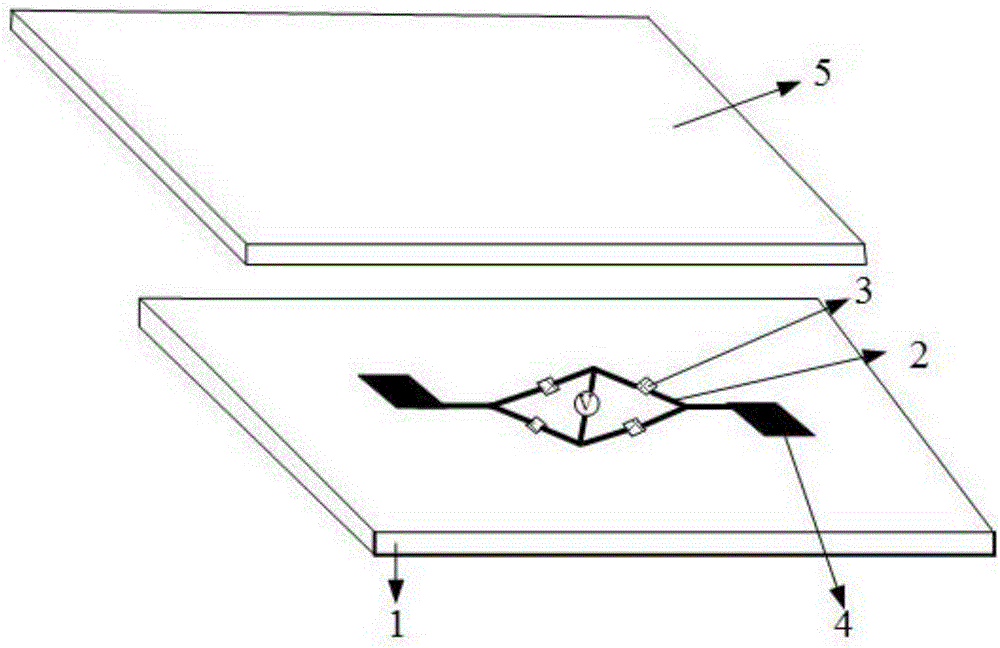

One-sided circuit board for multi-layer printed wiring board, multi-layer printed wiring board, and method of its production

InactiveUS6320140B1Printed circuit aspectsTwo-part coupling devicesConductive pastePrinted circuit board

A single-sided circuit substrate for a multilayer printed writing board has an insulating hard substrate, a conductor circuit formed on a surface of the substrate, an adhesive layer formed on the other surface, and at least one viahole through the substrate and the adhesive layer so as to pass these layers and contact with the conductor. The viaholes are filled with conductive paste. The invention also provides a multilayer printed wiring board having an IVH structure constituted with single-sided circuit hard substrates and a method of efficiently manufacturing the same with high yield.

Owner:IBIDEN CO LTD

Thermoplastic elastomer composition

The present invention relates to a soft thermoplastic elastomer composition that is free of thermoplastic resin that can be utilized in manufacturing shoe sole inserts, seals, gaskets, wheels, and that can be overmolded on a hard substrate, such as a metal or a thermoplastic resin, for grips or handles on various household items. The present invention more specifically discloses a thermoplastic elastomer composition that is made by a process comprising: (1) mixing (A) a block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, (B) a crosslinkable elastomer, and (C) an oil, to produce an un-crosslinked three component blend; and (2) dynamically crosslinking the crosslinkable elastomer in the un-crosslinked three component blend during a thermo-mechanical mixing step; wherein the thermoplastic elastomer composition is void of thermoplastic resins.

Owner:THE GOODYEAR TIRE & RUBBER CO +1

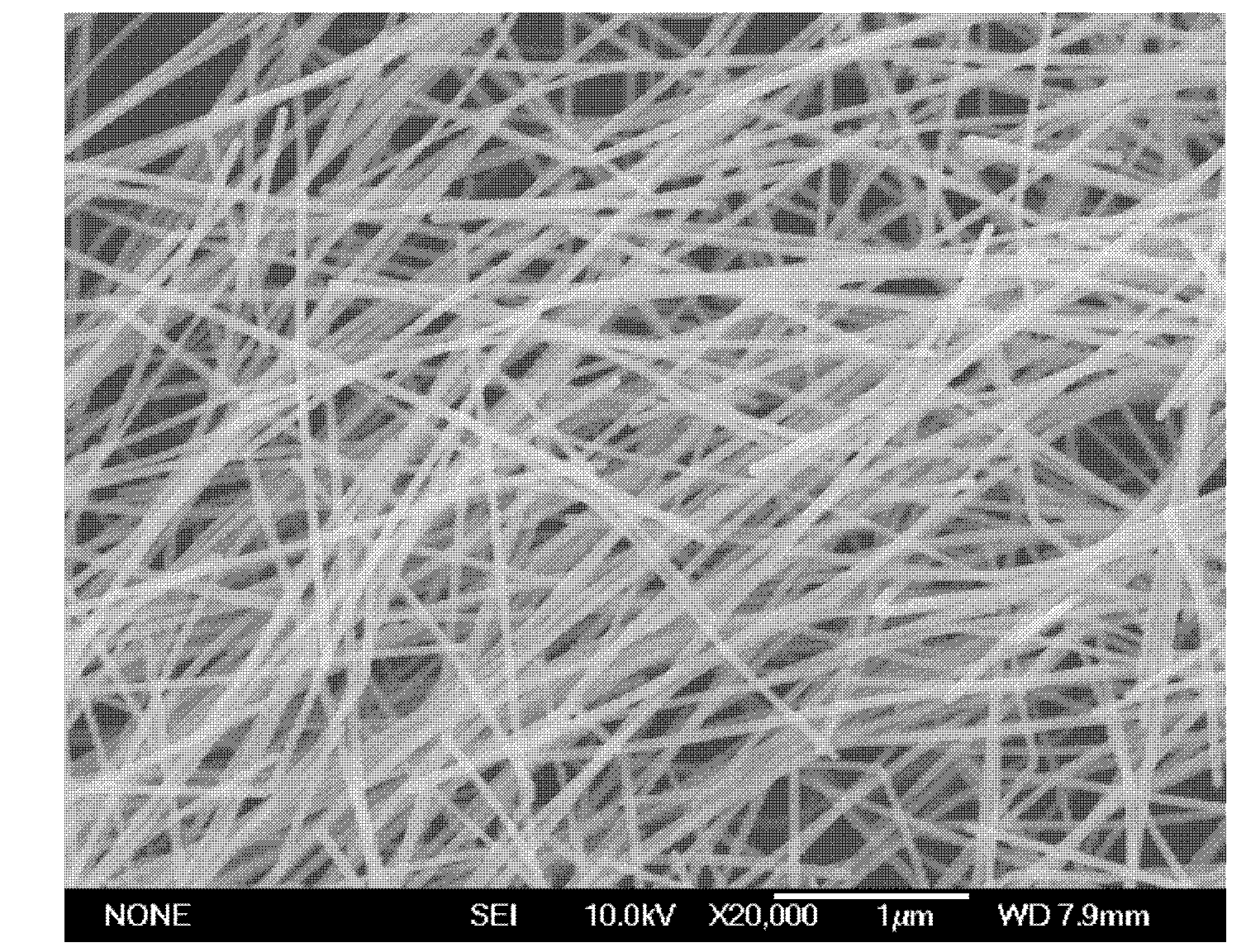

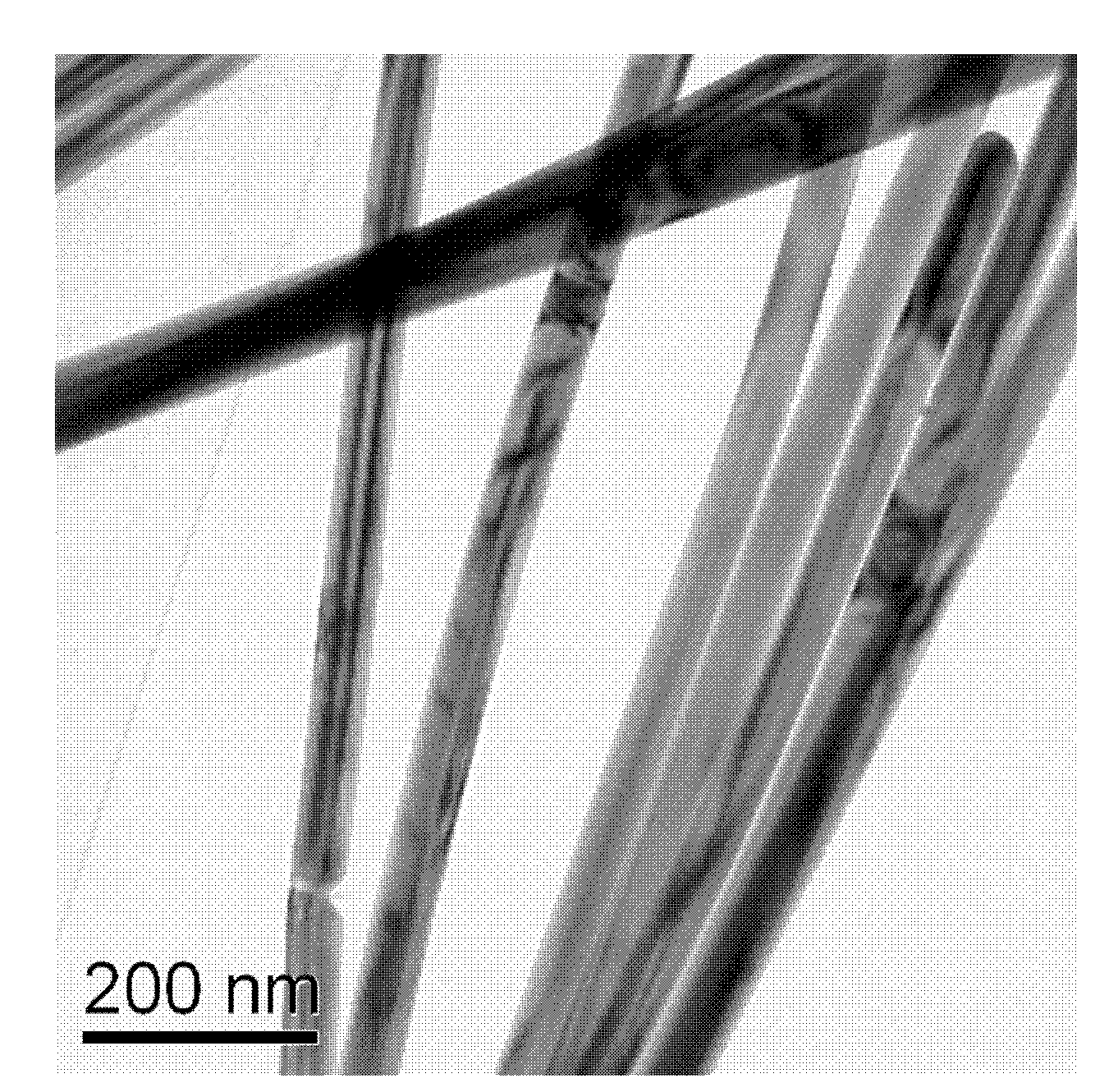

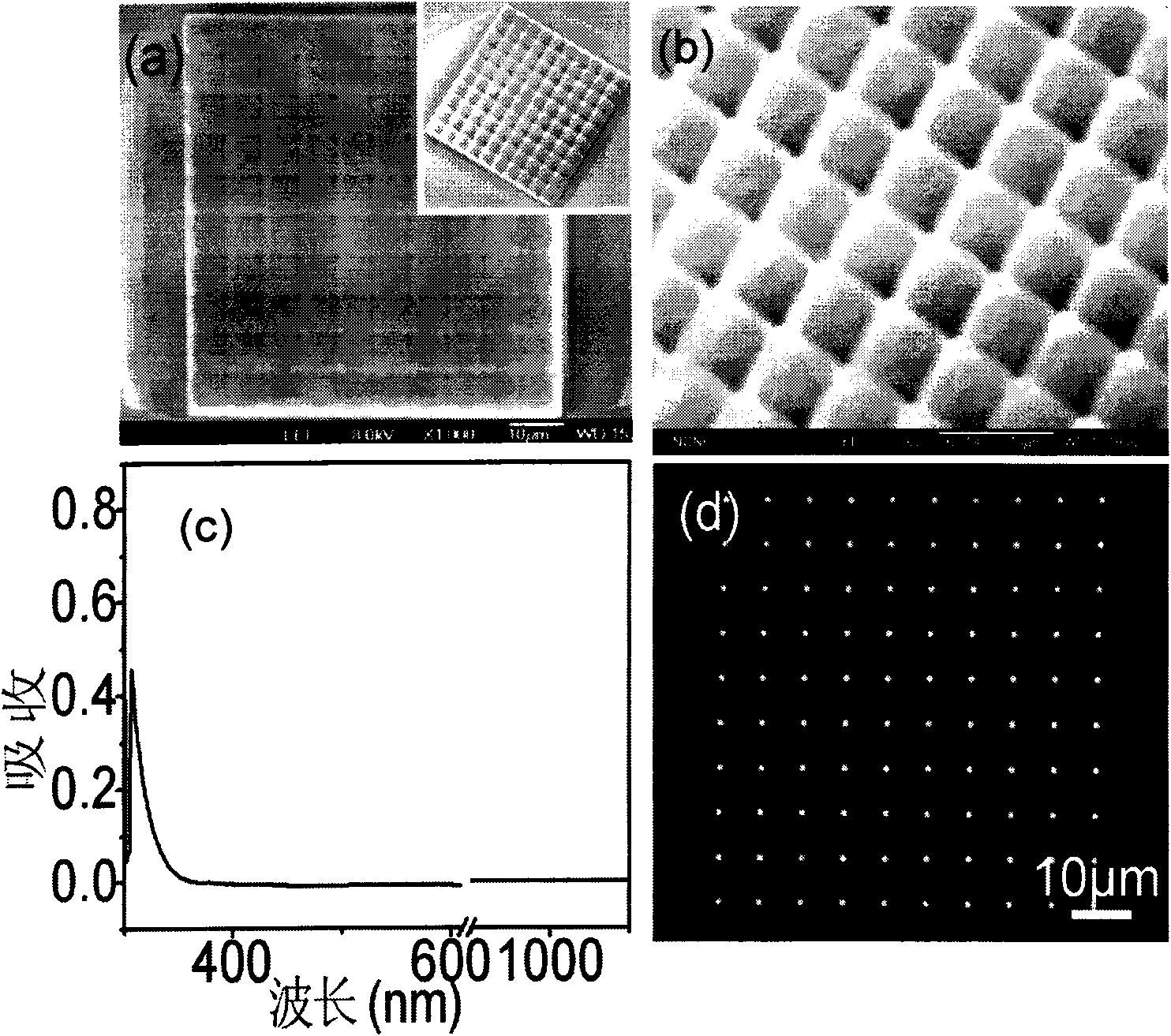

Silver nanowire transparent conductive film based on thermoplastic transparent polymer and preparation method thereof

InactiveCN102270524ASolve the problem of easy falling offGood chemical stabilityMaterial nanotechnologyConductive layers on insulating-supportsPolymer scienceFilm base

The invention provides a structure and a preparation method of a silver nanowire transparent conductive film based on a thermoplastic transparent polymer, which is characterized in that the silver nanowire conductive network is uniformly spread on a hard substrate, and then the The method makes a continuous silver nanowire conductive network embedded on the surface of a thermoplastic transparent polymer, and part of the surface of the silver nanowire is exposed to the air to form a silver nanowire conductive film based on the thermoplastic transparent polymer.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

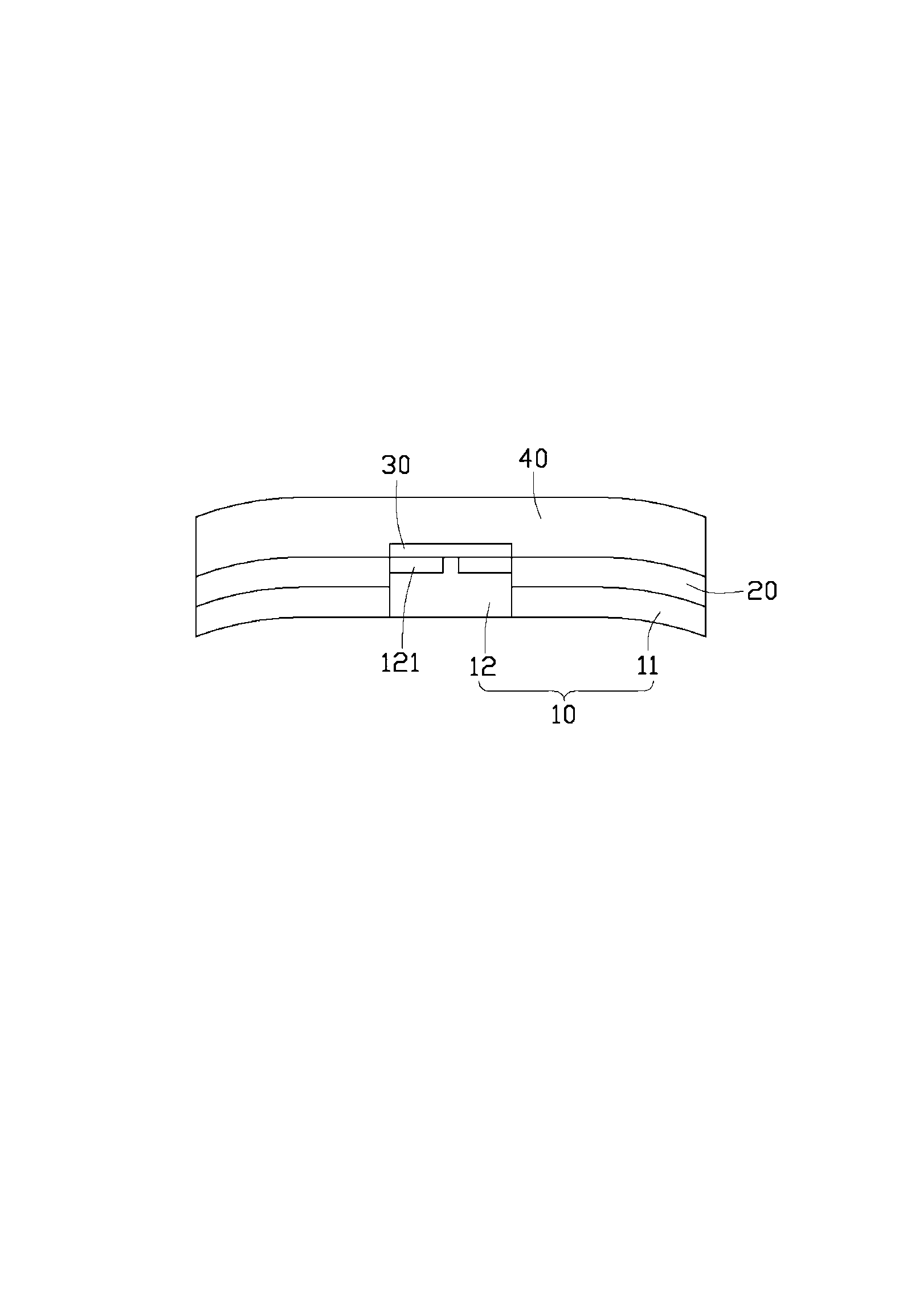

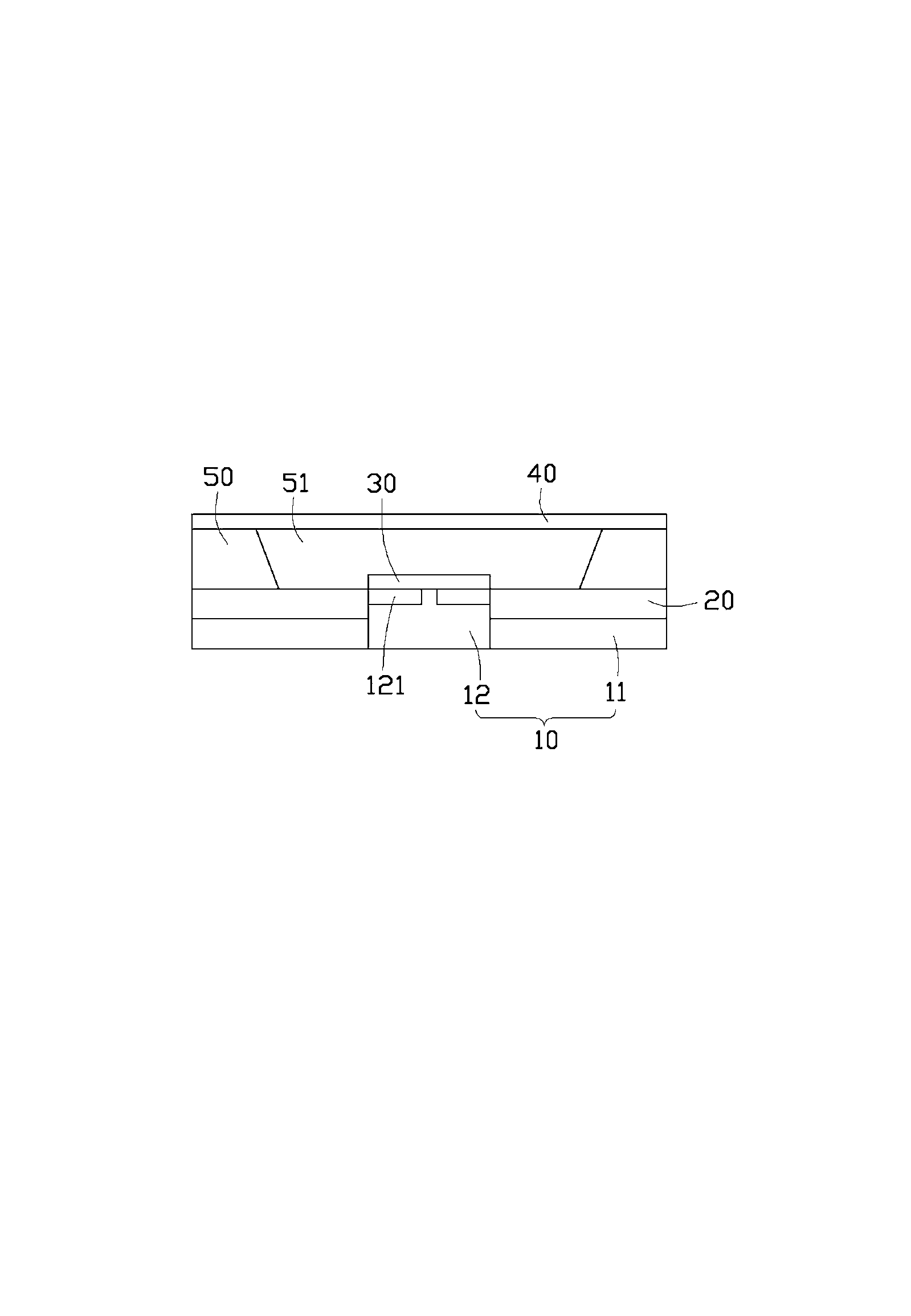

Flexible light emitting diode package structure and manufacturing method thereof

Disclosed is a flexible light emitting diode package structure. The flexible light emitting diode package structure comprises a flexible substrate and a light emitting diode chip which is arranged on the flexible substrate. The flexible substrate comprises a soft substrate and a hard substrate. The hard substrate comprises a top surface, a bottom surface and side surfaces, the bottom surface is opposite to the top surface, and the top surface and the bottom surface are connected by the side surfaces. The light emitting diode chip is disposed on the top surface of the hard substrate, the soft substrate is connected with the side surfaces of the hard substrate in a surrounding mode, and the bottom surface of the hard substrate is exposed out of the soft substrate. The heat dissipation efficiency of the flexible light emitting diode package structure is high. The invention further provides a manufacturing method of the flexible light emitting diode package structure.

Owner:ZHANJING TECH SHENZHEN +1

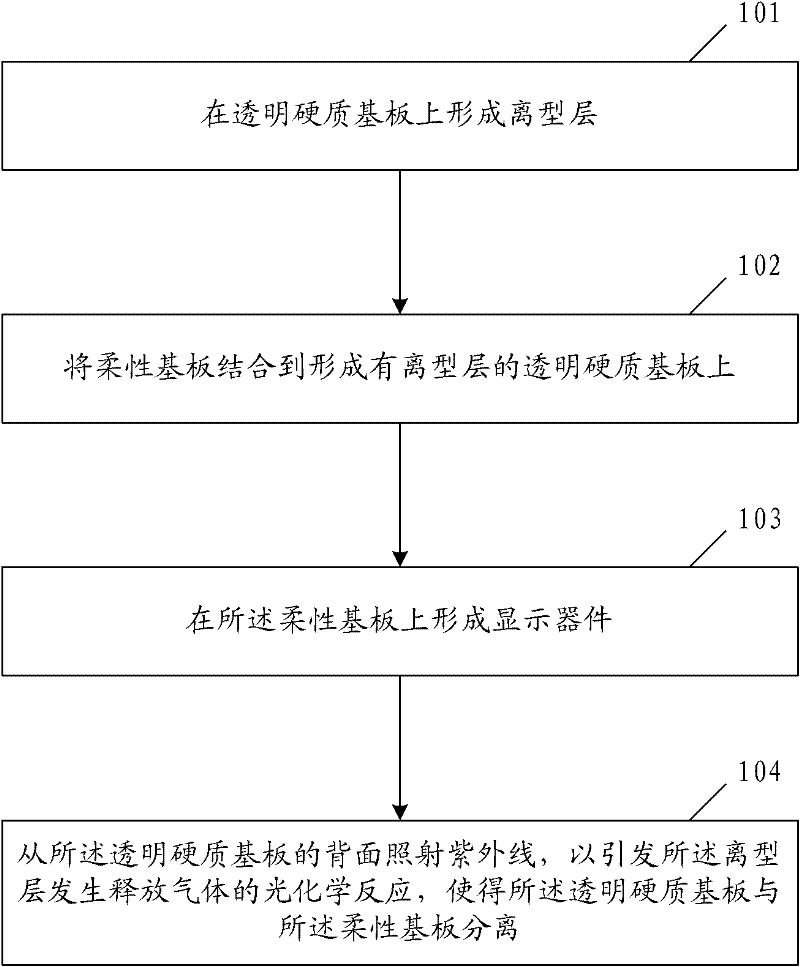

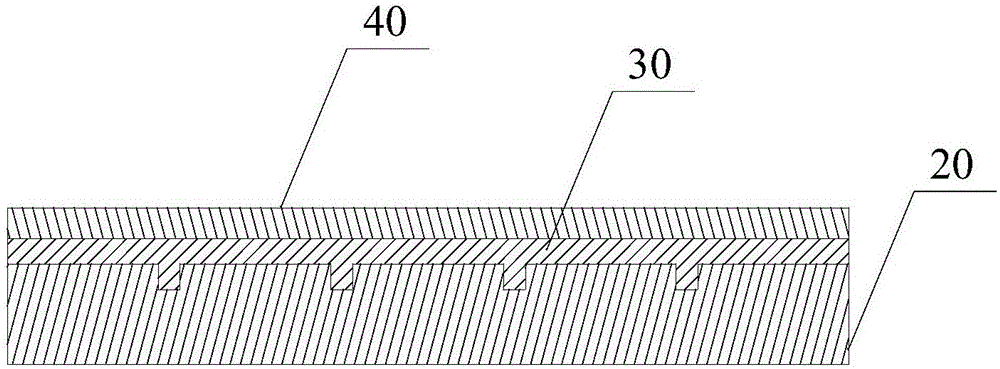

Manufacturing method of flexible display devices

InactiveCN102636898ASimple production processReduce manufacturing costSolid-state devicesNon-linear opticsUltraviolet lightsInert matter

The invention provides a manufacturing method of flexible display devices. The manufacturing method comprises the following steps of: forming a releasing layer on a transparent hard substrate, wherein the releasing layer is made of an ultraviolet light resolving material added with inert matters; combining a flexible substrate to the transparent hard substrate formed with the releasing layer, wherein the flexible substrate is opposite to one side, at which the releasing layer is formed, of the transparent hard substrate; forming a display component on the flexible substrate; irradiating from one side, far away from the releasing layer, of the transparent hard substrate with the ultraviolet ray so as to trigger the releasing layer to have a photochemical reaction which emits gas, so that the transparent hard substrate is isolated from the flexible substrate. According to the manufacturing method, the production process of the flexible display device can be simplified.

Owner:BOE TECH GRP CO LTD

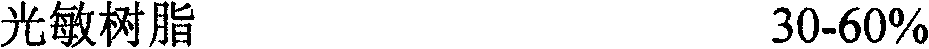

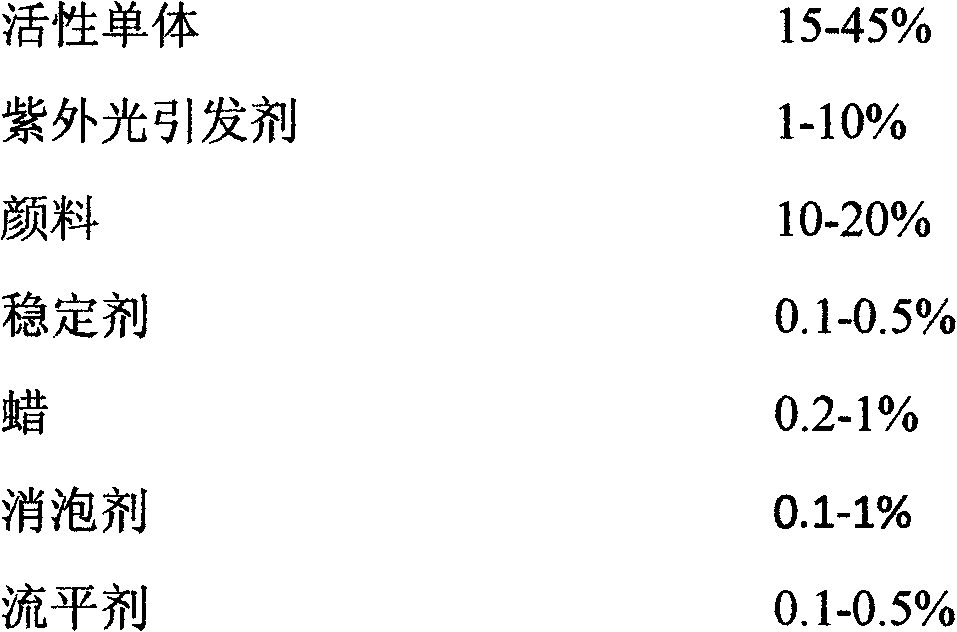

A kind of ultraviolet curing ink and preparation method thereof

The invention relates to an ultraviolet curable ink and a preparation method thereof. The ink comprises 30-60% of light sensitive resins, 15-45% of active monomers, 1-10% of ultraviolet light initiators, 10-20% of pigments and 0.5-2% of auxiliaries by mass and is an ink which is transformed from liquid state to solid state to be cured after binders in the ink are cross-linked under the irradiation of ultraviolet lights with certain wavelengths. The ultraviolet curable ink provided by the invention has the advantages of short light curing time, no need of heating, conservation in energy consumption, no volatile organic solvent VOC (Volatile Organic Compounds) in the ink, no pollution to the atmosphere, smaller effect of temperature variation on system viscosity, high solid content, suitability for multiple production methods and production requirements and excellent comprehensive properties, can be machined and used within a wider temperature range; and very good printing effects of the ultraviolet curable ink on both a hard substrate and a soft substrate can be obtained.

Owner:哈尔滨大东方新材料科技股份有限公司

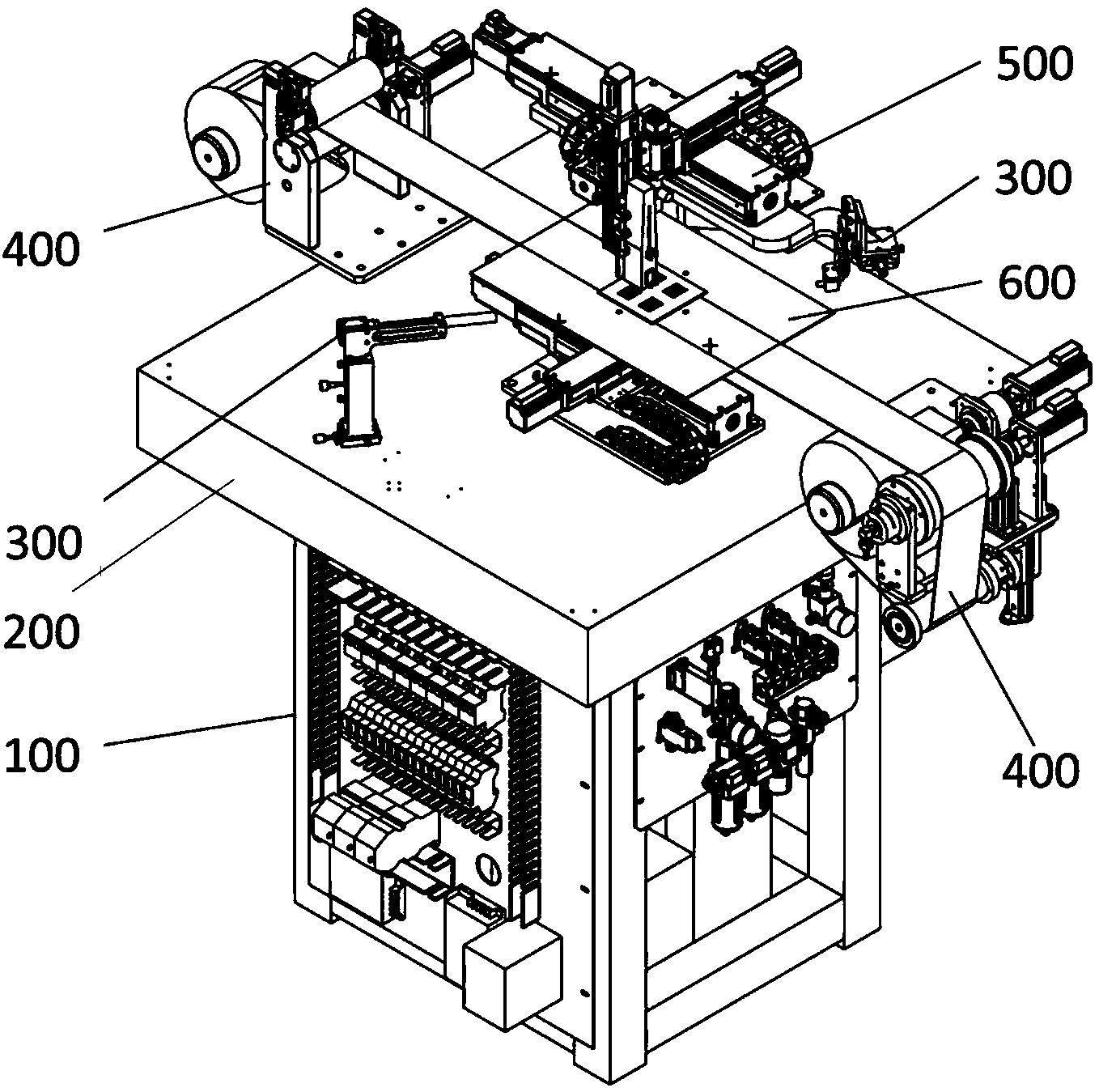

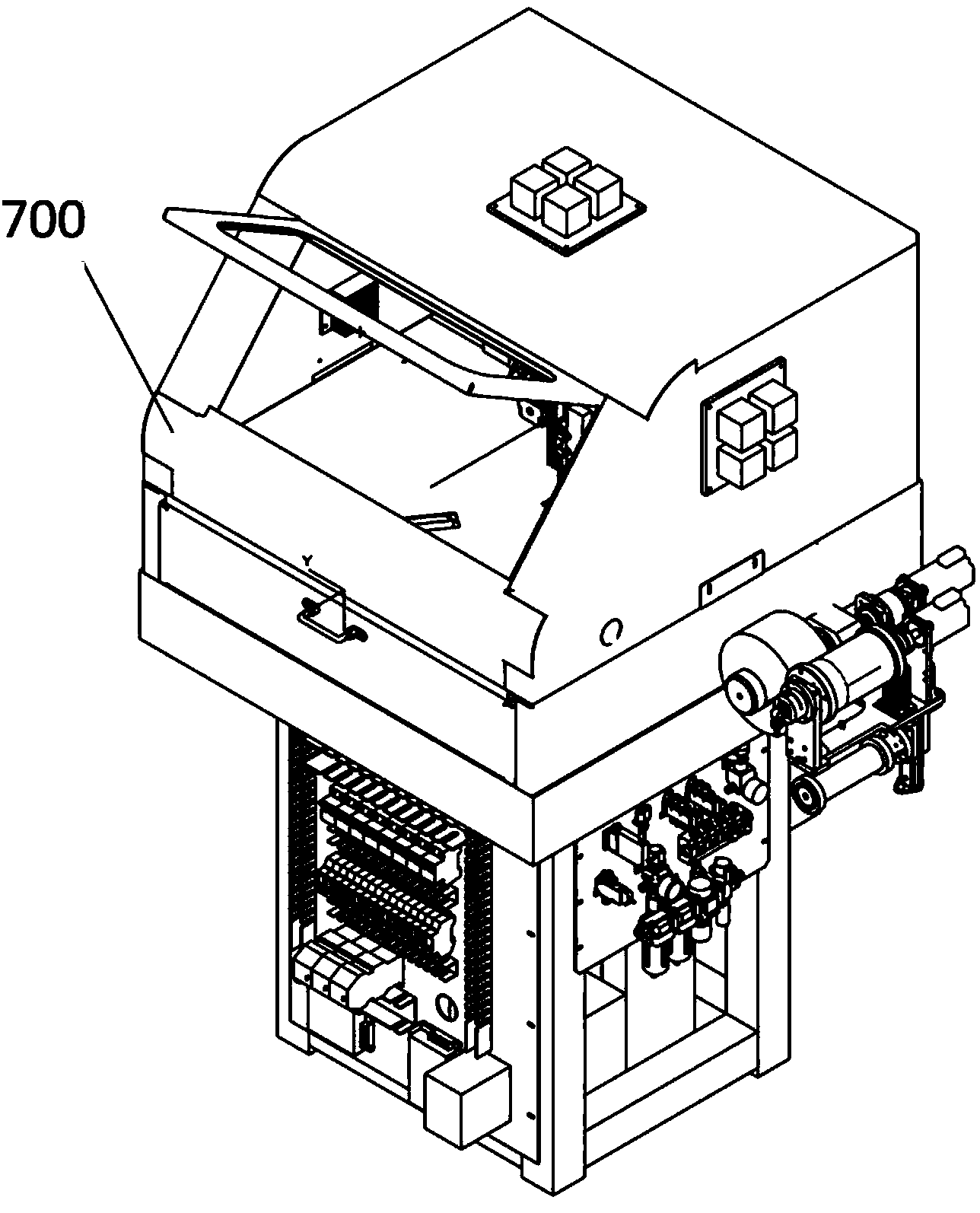

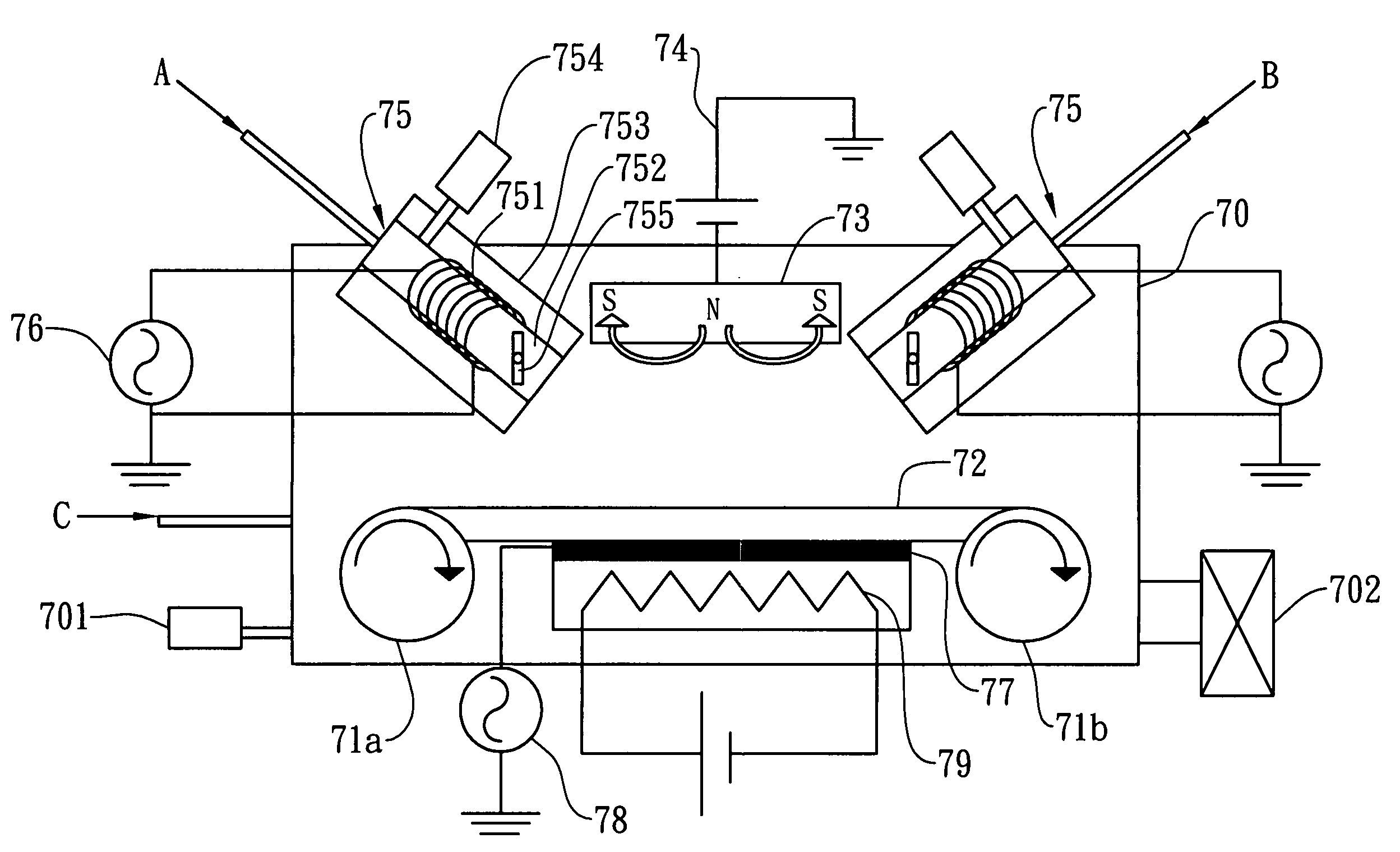

System and method for multifunctional electric fluid ink-jet printing

ActiveCN103895345ADiameter has little effectSimple structureTypewritersPower drive mechanismsMicro environmentControl unit

The invention discloses a system and method for multifunctional high-resolution electric fluid ink-jet printing. The system comprises a control unit, a hard substrate bearing and moving module, a jet printing module, a roll-to-roll thin film substrate conveying module, a jet visual inspection module and a micro-environment control unit defined by a shell box body, wherein the temperature and the humidity of the micro-environment control unit are adjustable. The jet printing module comprises a movement platform controlling a nozzle to move and the nozzle, adjustment and control in three jet printing modes are achieved, and meanwhile a visual system used for observation of patterns on a substrate is arranged. The hard substrate bearing and moving module is used for bearing and fixing a hard printing medium substrate and enabling the substrate to move relative to the nozzle. The roll-to-roll thin film substrate conveying module is used for feeding and adsorbing a flexible substrate and guaranteeing that the surface of the flexible substrate is smooth and the flexible substrate is free of sliding in movement. The jet visual inspection module is used for inspecting a space flight track of a drop. A temperature and humidity control module is used for controlling the temperature and the humidity inside a printing cavity and guaranteeing the printing stability.

Owner:WUHAN GUOCHUANGKE OPTOELECTRONIC EQUIP CO LTD

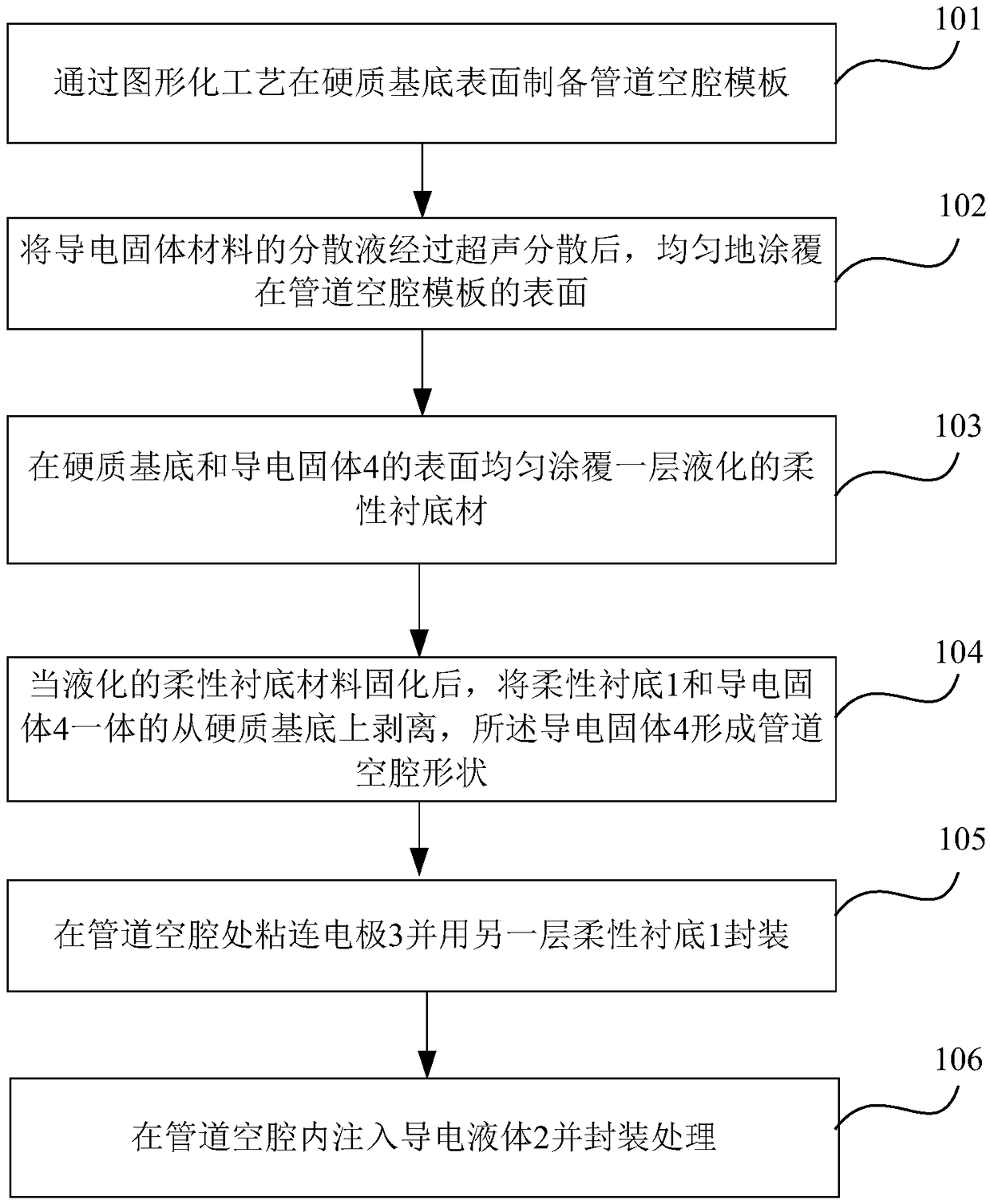

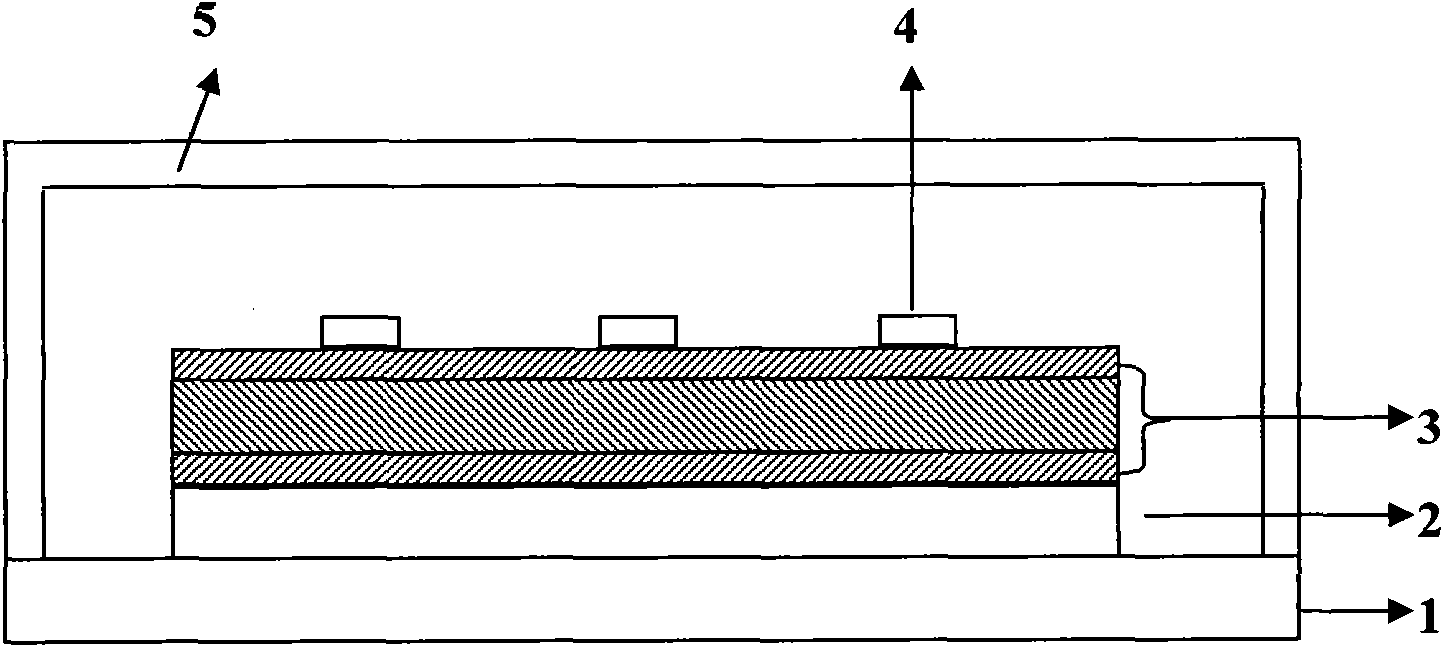

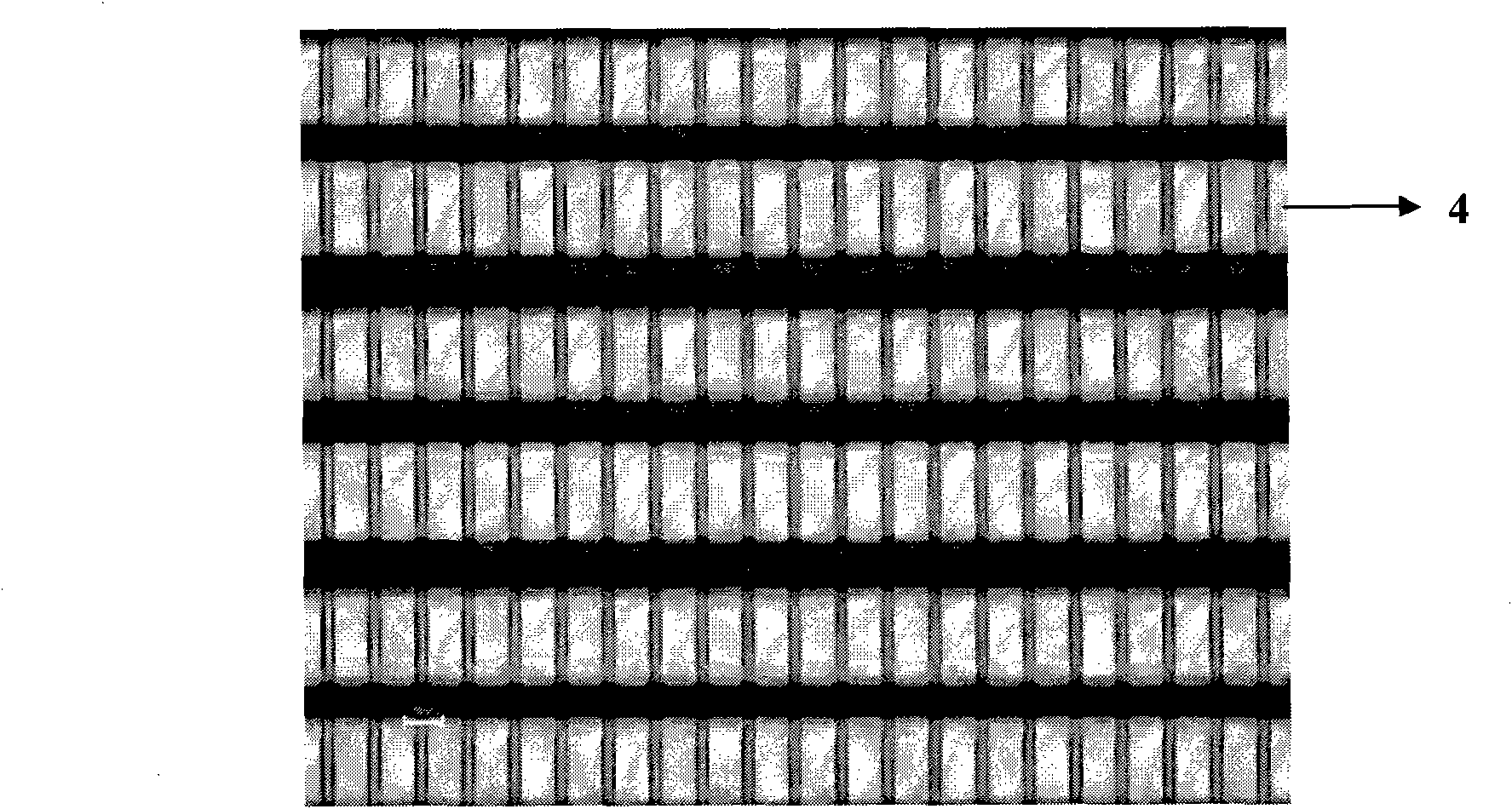

Flexible sensor and preparation method thereof

The embodiment of the invention provides a flexible sensor and a preparation method thereof. The sensor comprises two layers of flexible substrates, electrodes and a sensing layer. A closed pipeline cavity is arranged between the two layers of flexible substrates. The closed pipeline cavity includes the sensing layer. The sensing layer is composed of a conductive solid and conductive liquid or composed of the conductive solid and a metal film. The electrodes are connected with the sensing layer and outwardly stretch out of the boundary of the flexible substrates. The preparation method of thesensor comprises the steps that a pipeline cavity structure is prepared on a hard substrate, the liquefied conductive solid or the flexible substrate plate is coated on the pipeline cavity to form thepipeline cavity structure, the electrodes are adhered and then another flexible substrate is packaged and then the conductive liquid is injected so that the sensor is obtained. The sensor has high sensitivity, high stretchable rate and high tolerability and can be applied to the wearable electronic equipment and can rapidly respond to face surface, body movement, pulse, respiration and multiple other life signals.

Owner:SUN YAT SEN UNIV

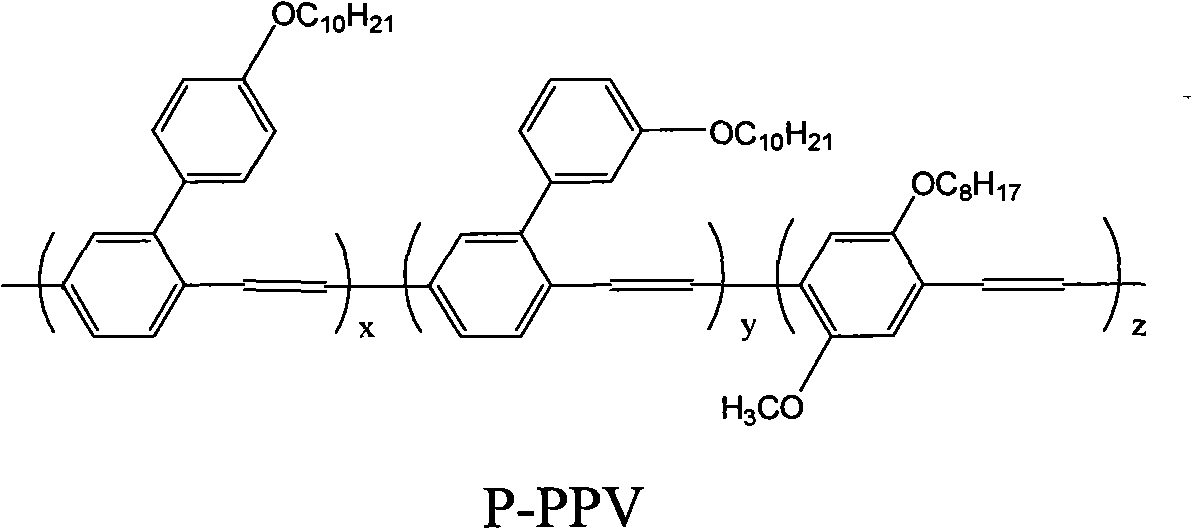

Method for preparing organic light-emitting diode (OLED) display screen by full printing process

ActiveCN101916831ALow affinityHigh affinitySolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodePolymer

The invention relates to a method for preparing an OLED display screen by a full printing process. The OLED display screen is formed by sequentially laminating a substrate, a substrate electrode, organic functional layers and a back electrode, wherein the substrate is made of a hard substrate or a soft substrate; the substrate electrode is a transparent or semi-transparent anode; the organic functional layers at least comprise light-emitting layers; the back electrode is prepared into a cathode by a printing process; the organic functional layers are prepared by performing rotary coating, ink-jet printing, screen printing, pulling and spraying on non-polar organic light-emitting polymers, small molecules or tree-like compounds on the substrate electrode. The method can completely simply the manufacturing process of full-color OLED display screens, further reduce the equipment requirement and manufacturing cost, greatly promote the solution for the high cost problem of the conventional OLEDs, and especially provide a brand-new technical scheme for manufacturing large-area OLED display screens without using an expensive and time-wasting vacuum vapor deposition system.

Owner:SOUTH CHINA UNIV OF TECH

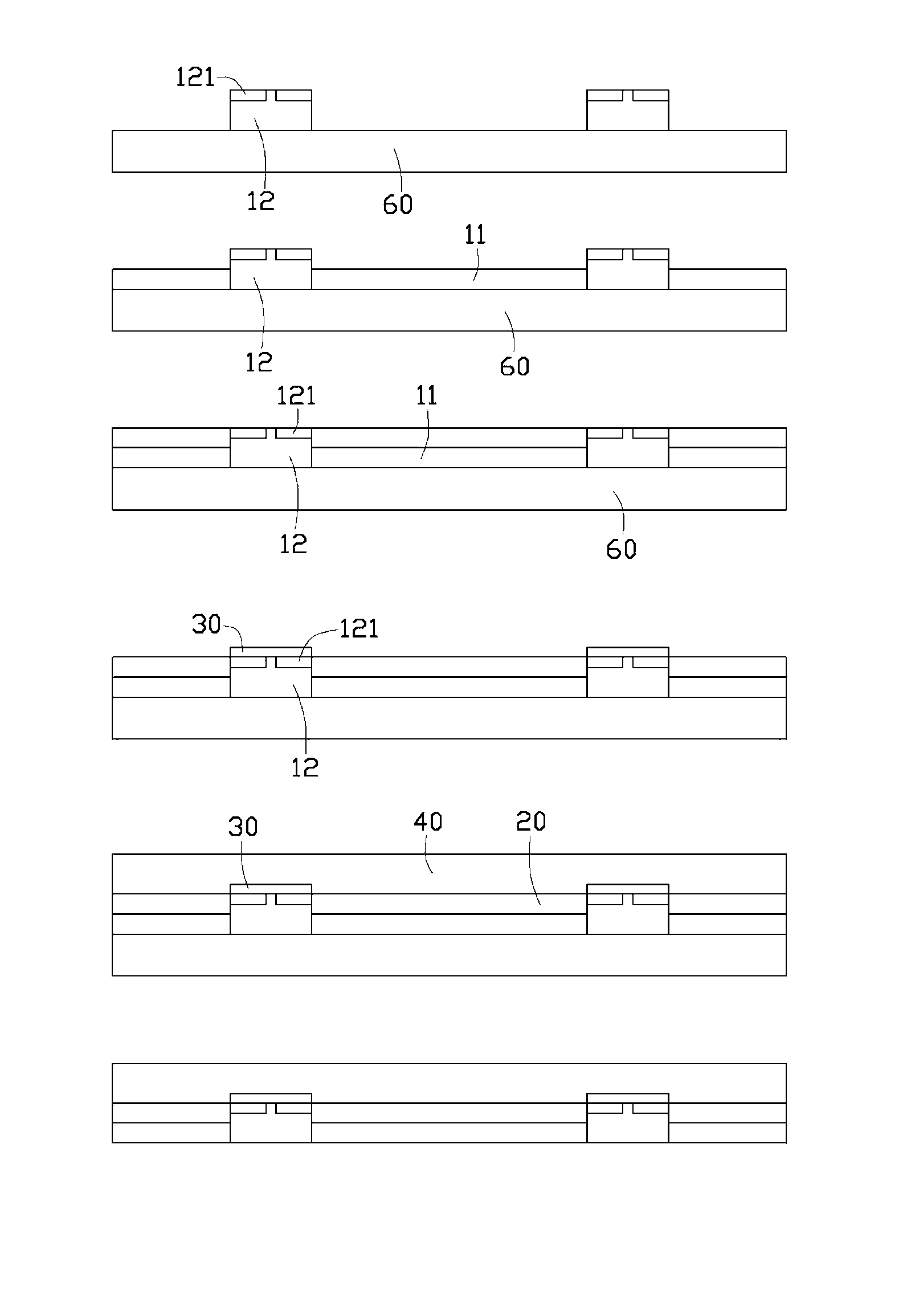

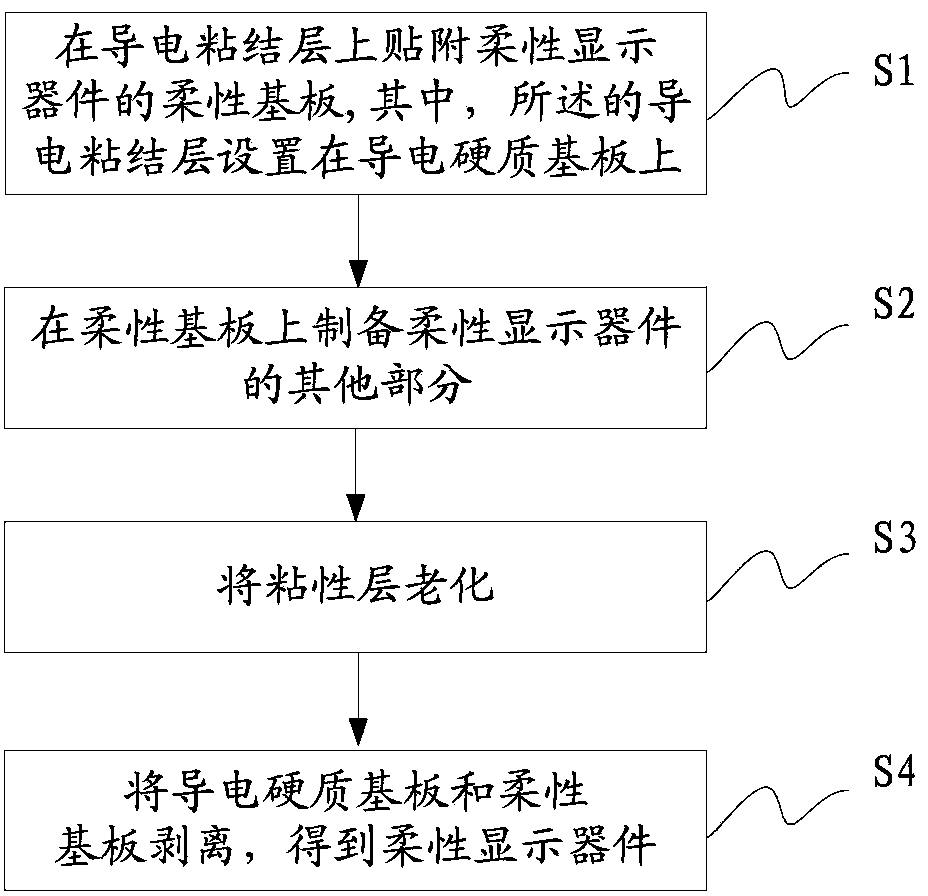

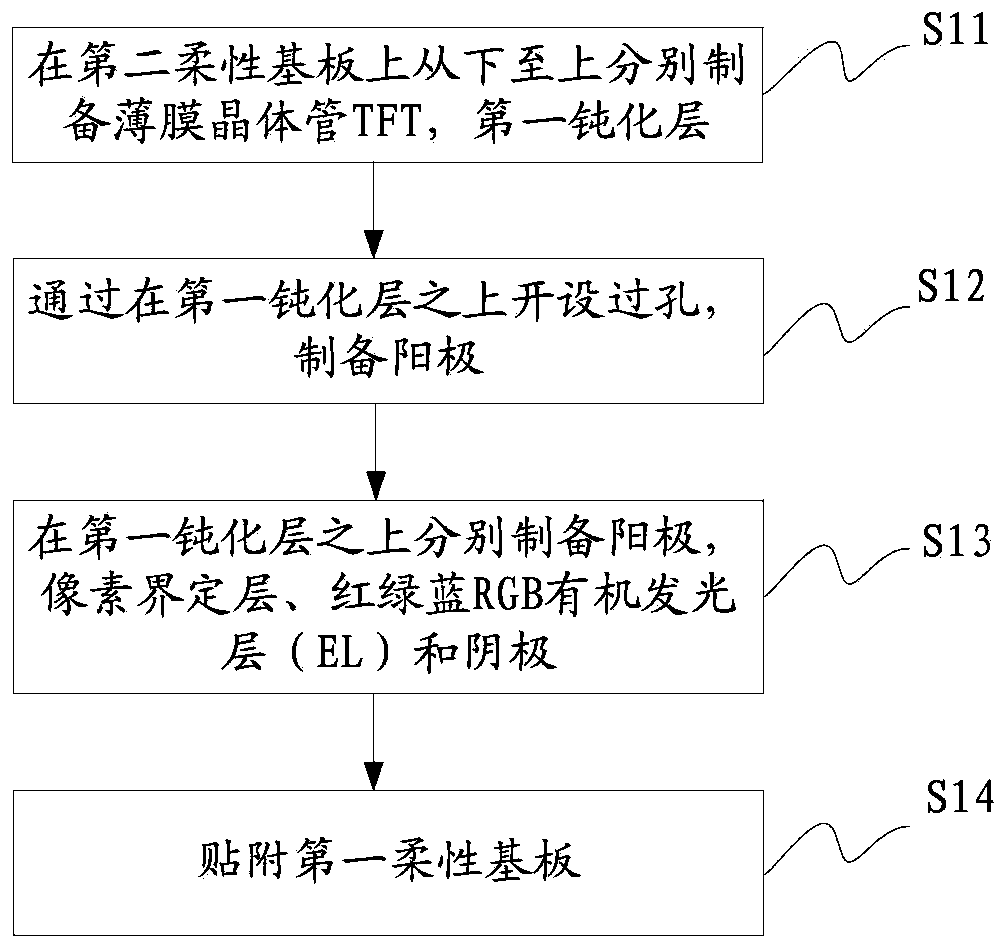

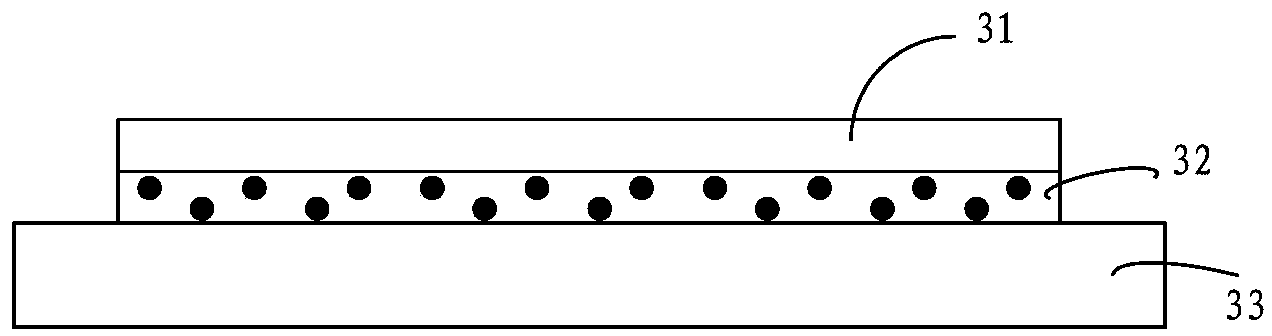

Manufacturing method and device of flexible display device

InactiveCN103413775ALead away in timeImprove yieldFilm/foil adhesivesSemiconductor/solid-state device detailsElectricityEngineering

The embodiment of the invention provides a manufacturing method and device of a flexible display device. Static electricity generated in the manufacturing process of the flexible display device can be conducted away in time through an electricity conduction hard substrate, damage of the static electricity to the flexible display device is avoided, and the manufacturing yield of the flexible display device is improved. The manufacturing method of the flexible display device comprises the steps of attaching a flexible substrate of the flexible display device to an electricity conduction bonding layer, wherein the electricity conduction bonding layer is arranged on the electricity conduction hard substrate, then manufacturing other parts of the flexible display device on the flexible substrate, aging the electricity conduction bonding layer, and finally enabling the electricity conduction hard substrate and the flexible substrate to be stripped to obtain the flexible display device.

Owner:BOE TECH GRP CO LTD

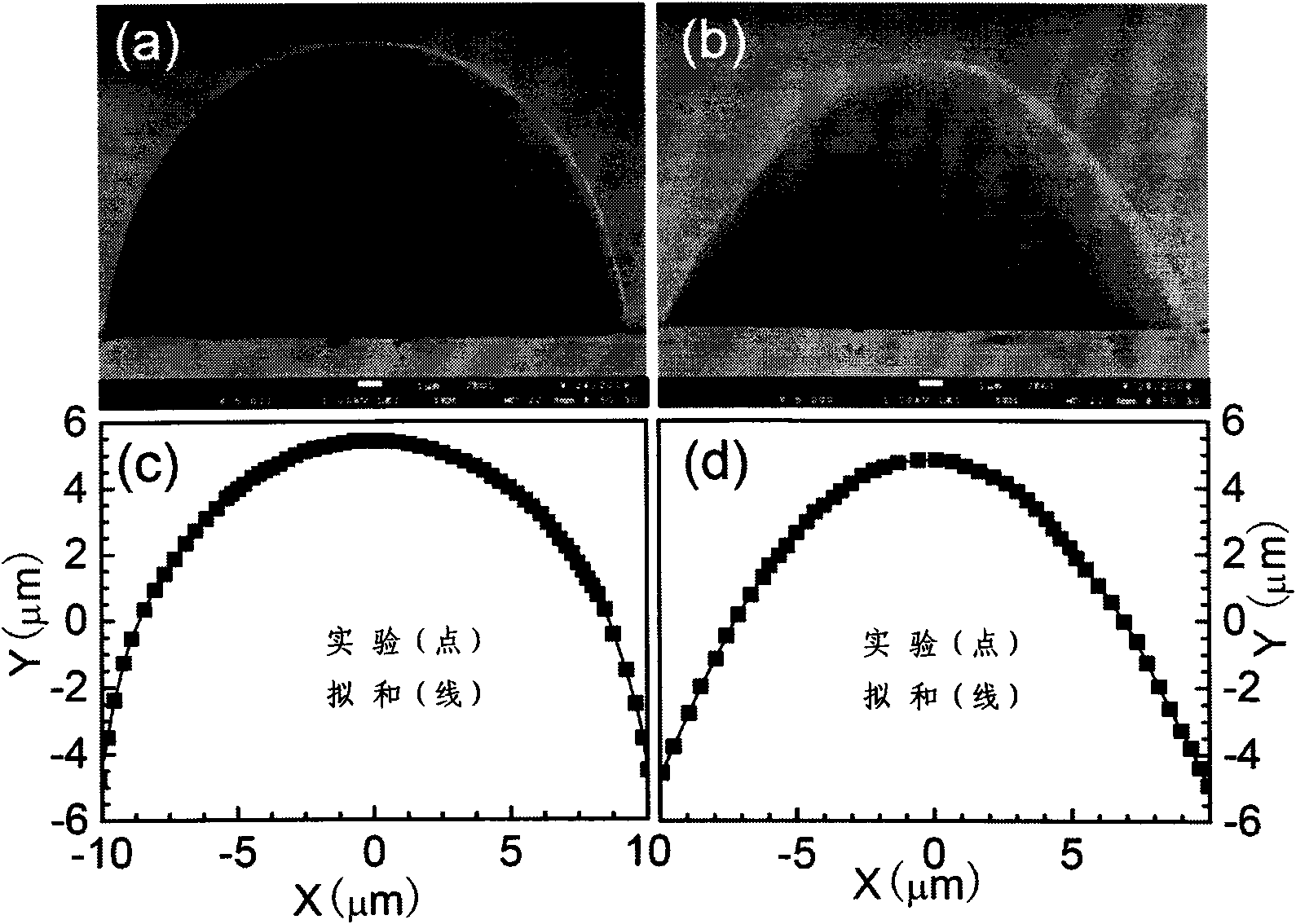

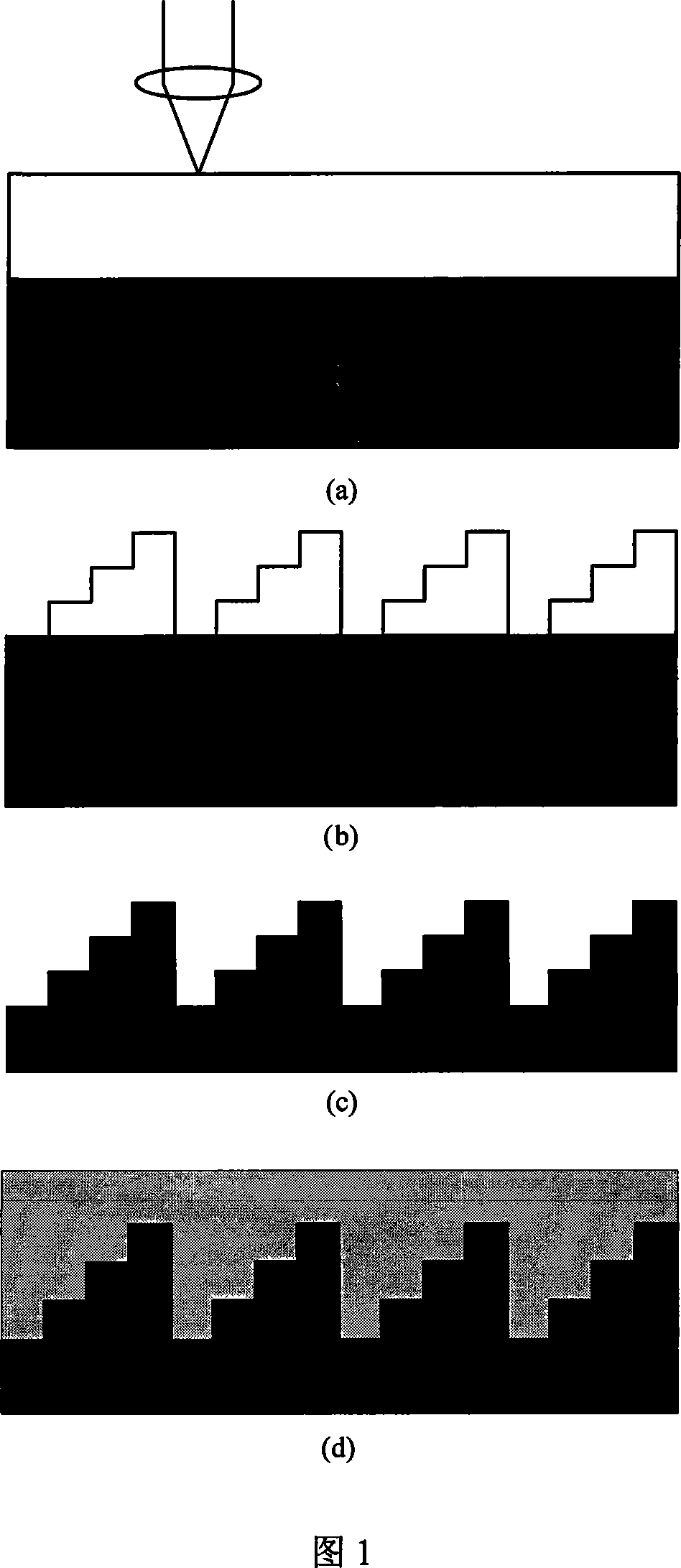

Laser three-dimensional preparing method of non-spherical micro-lens

The present invention belongs to the technical field of micro-manufacturing, and specifically to a method for preparing non-spherical micro-lens and micro-lens array with laser three-dimensional processing. Firstly computer software is compiled for obtaining the point cloud data of non-spherical micro-lens model. Then the curable material is coated on the surface of hard substrate. Then the curable material is gradually scanned and solidified under the control of computer program through a laser three-dimensional processing system according to the point cloud data of non-spherical micro-lens model. The non-spherical micro-structure is obtained after developing. The micro-structure is used as a stencil. The non-spherical micro-lens and array of substrate material are obtained through etching. The method of the invention overcomes the boundary that a hot melting method only can prepare the spherical micro-lens and the diamond milling method is hard for preparing the micro-lens array. The non-spherical micro-lens and array with random profile in the vertical and horizontal direction can be obtained. 100% filling probability can be realized for the micro-lens array. Simultaneously the adjustable non-spherical micro-lens and array with the numerical aperture of 0-1 can be obtained.

Owner:JILIN UNIV

Overmolded grip

InactiveUS7264868B2Low costReduce hardnessSynthetic resin layered productsFilament/thread formingElastomerPolymer science

The present invention discloses an article of manufacture comprising a soft thermoplastic elastomer composition overmolded onto a hard substrate, wherein the soft thermoplastic composition includes (a) 5 to 60 parts by weight of a thermoplastic resin, (b) 5 to 70 parts of a rubbery elastomer comprised of repeat units that are derived from a conjugated diene monomer, wherein the rubbery elastomer is optionally at least partially crosslinked, and wherein the rubbery polymer is a solution polymer, (c) 5 to 90 parts of a highly saturated elastomer selected from the group consisting of styrene-ethylene butylene-styrene polymers, styrene-ethylene propylene-styrene polymers, hydrogenated polybatadiene, hydrogenated polyisoprene, hydrogenated styrene-isoprene random copolymers, hydrogenated styrene-butadiene random copolymers, and (d) 15 to 200 parts by weight of an oil.

Owner:THE GOODYEAR TIRE & RUBBER CO

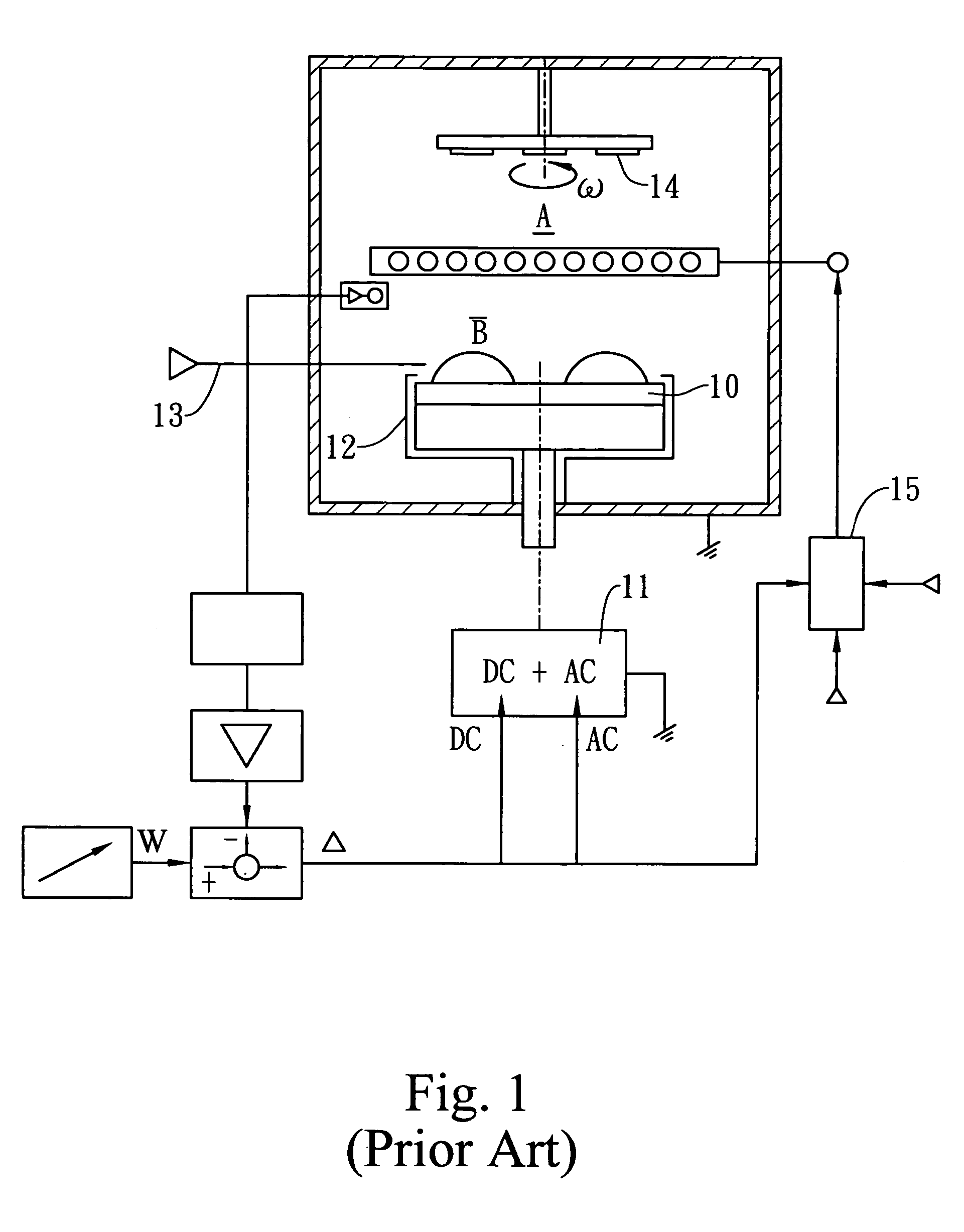

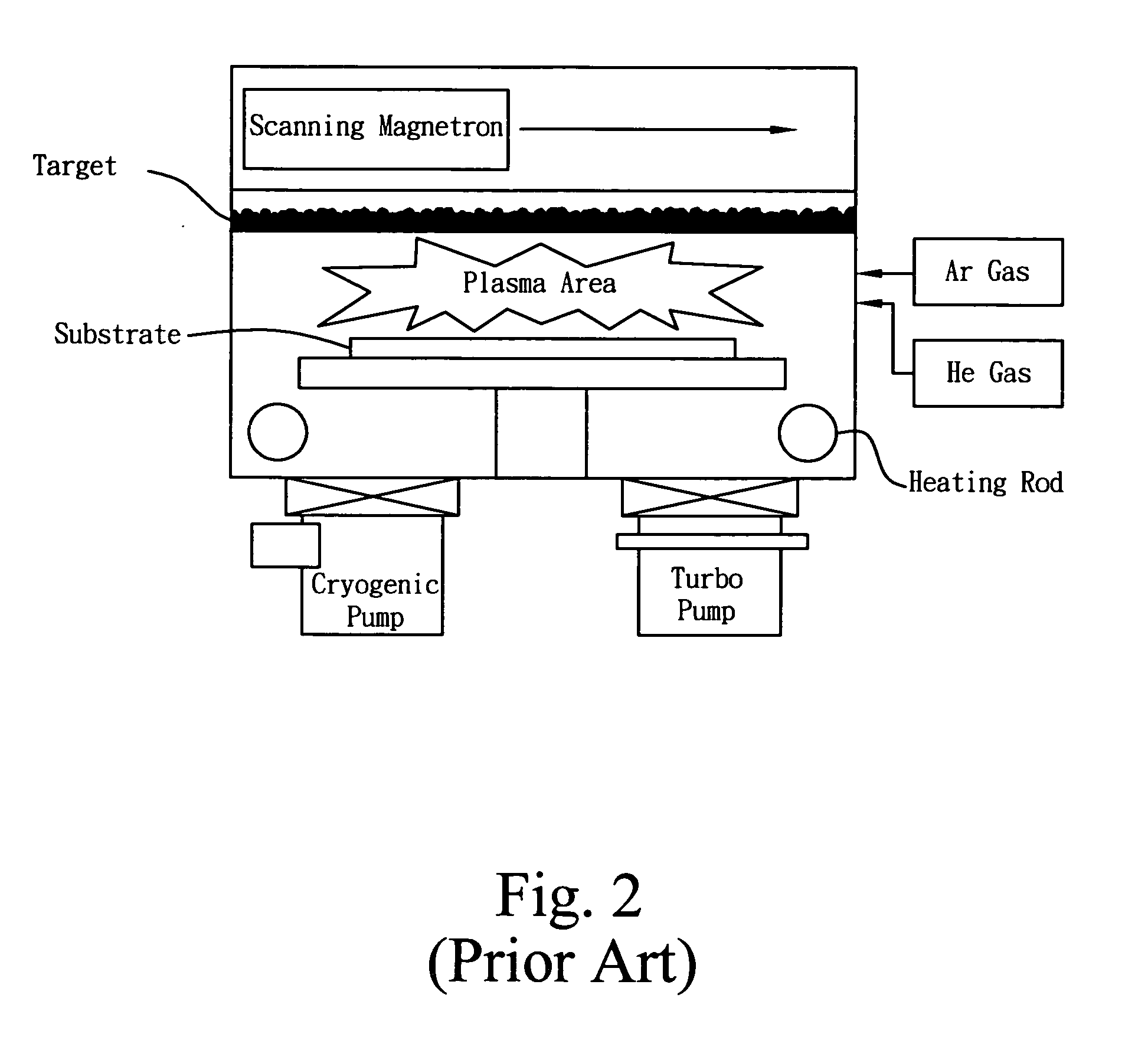

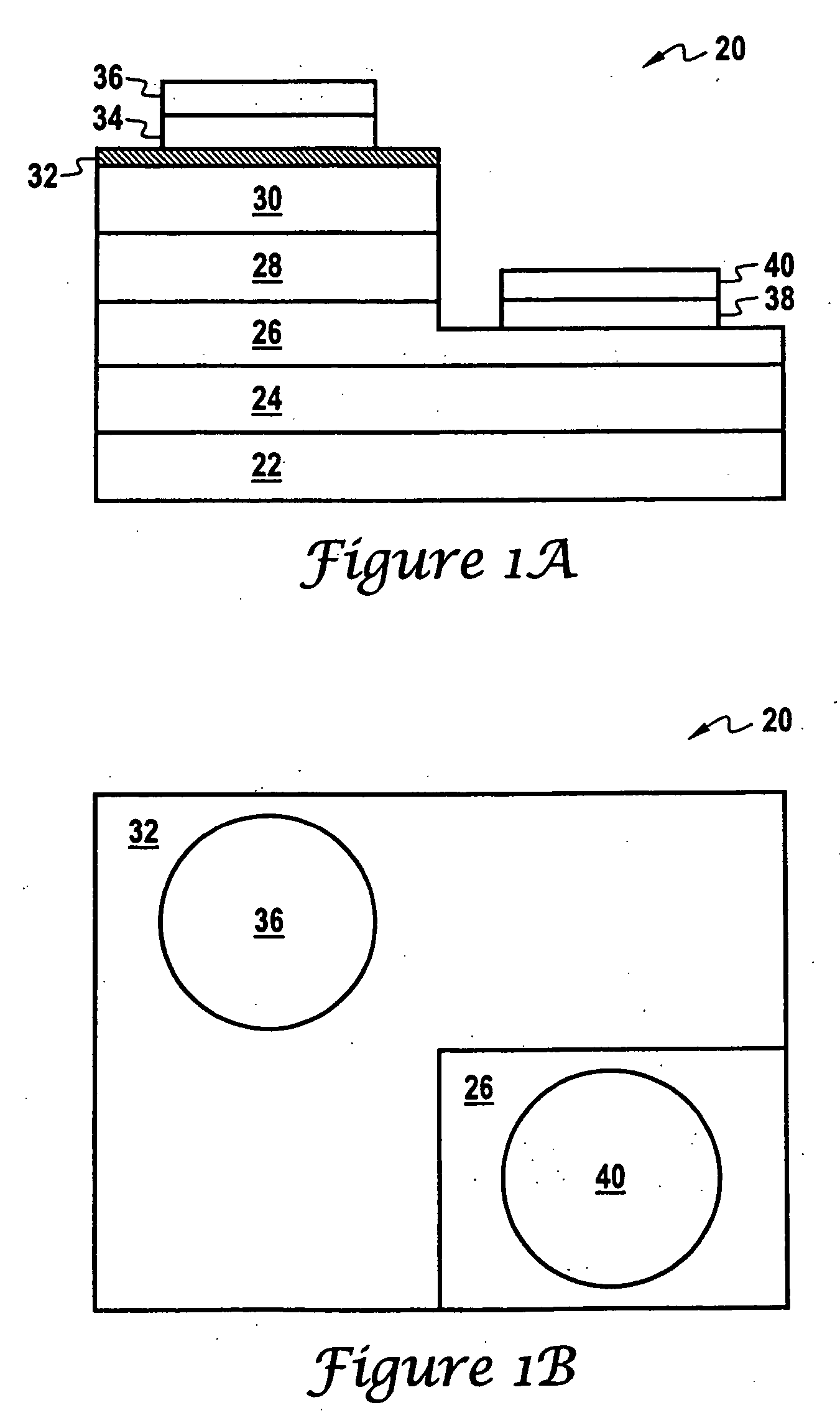

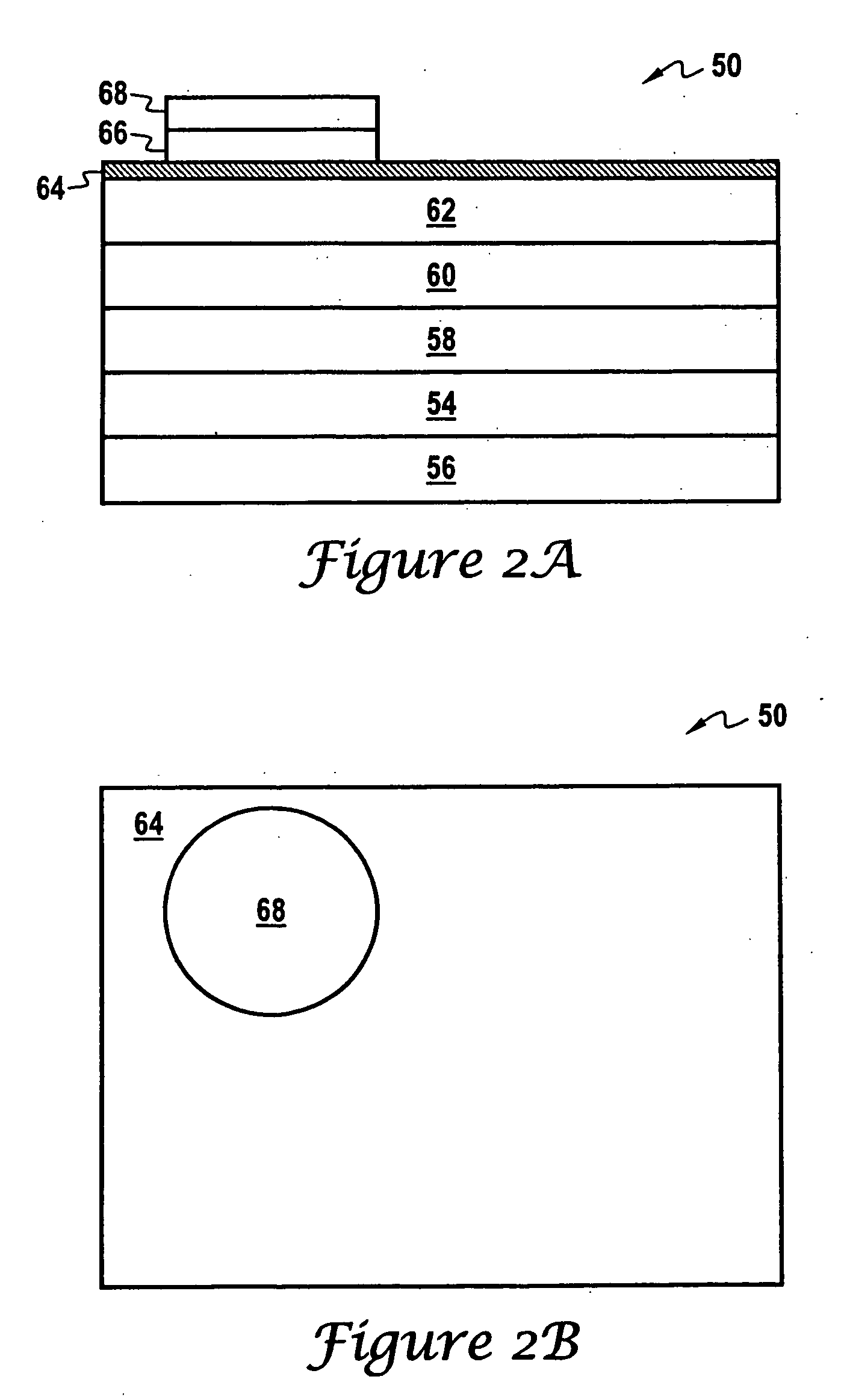

Sputtering system providing large area sputtering and plasma-assisted reactive gas dissociation

InactiveUS20070181421A1Improve propertiesComposition is limitedCellsElectric discharge tubesSputteringComposite film

This invention provides a sputtering system providing large area sputtering and plasma-assisted reactive gas dissociation. A plurality of plasma sources is provided in a reaction chamber to dissociate at least one reactive gas. The dissociated reactive gas is doped in a film during the deposition of the film so as to control the composition of the film. The property of the film is thus improved. A composite film can be formed on the substrate by the present sputtering system. The present sputtering system is suitable for film deposition on a large-area hard substrate and flexible substrate.

Owner:IND TECH RES INST

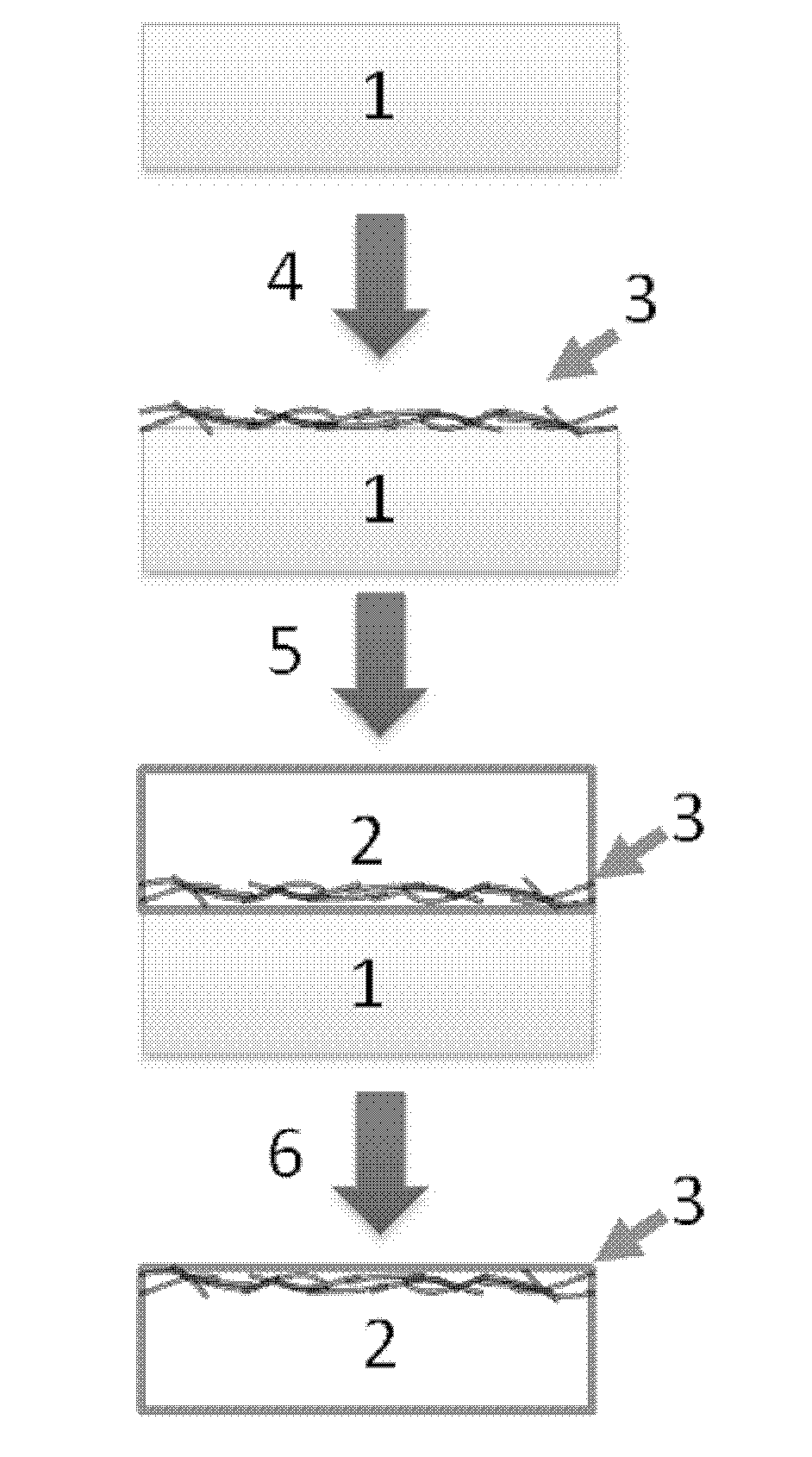

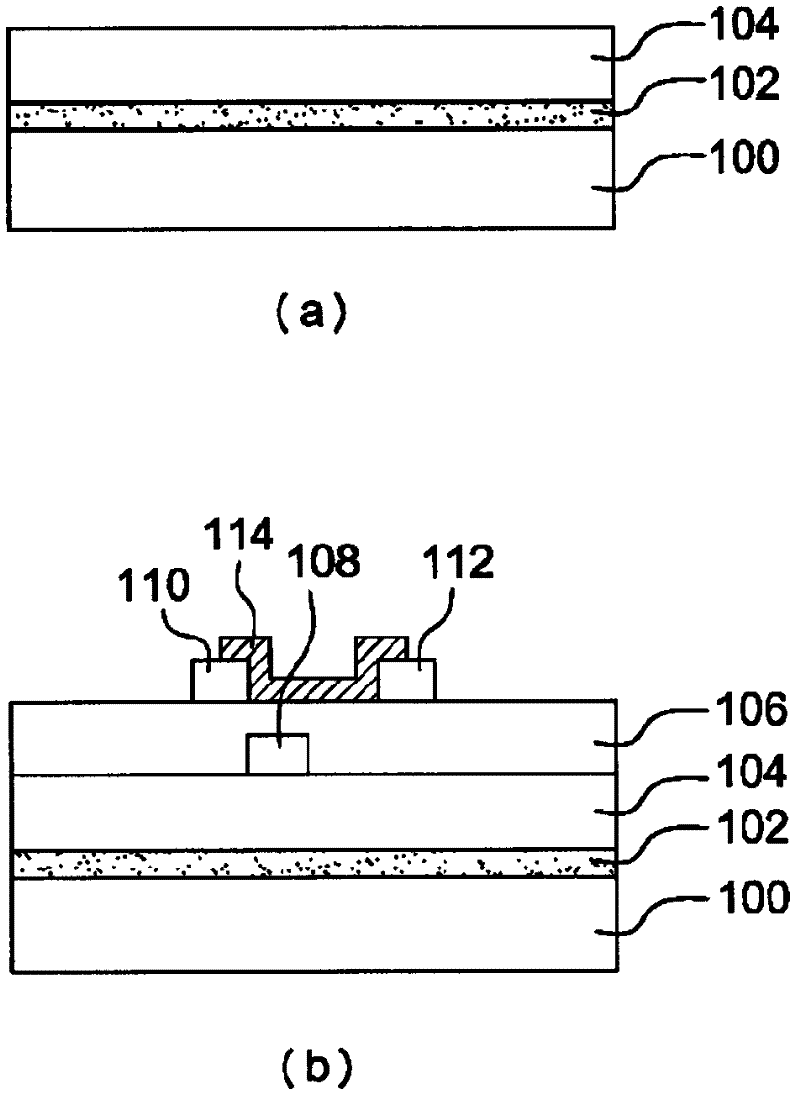

Manufacturing method for flexible element

ActiveCN102231359AEasy to separateEasy to removeFinal product manufactureSolid-state devicesEngineeringHard substrate

The invention provides a manufacturing method for flexible elements, which is characterized in that a hard substrate is provided and formed with an adherence layer with predetermined patterns. A soft base layer is formed on the hard substrate. Part of the soft base layer contacts with the hard substrate so as to form a first contact interface and the rest part of the soft base layer contacts with the adherence layer so as to form a second contact interface. At least one element is formed on the surface opposite to the contact surface of the soft base layer with the first contact interface. The soft base layer is separated from the hard substrate form the first contact interface.

Owner:ETERNAL MATERIALS CO LTD

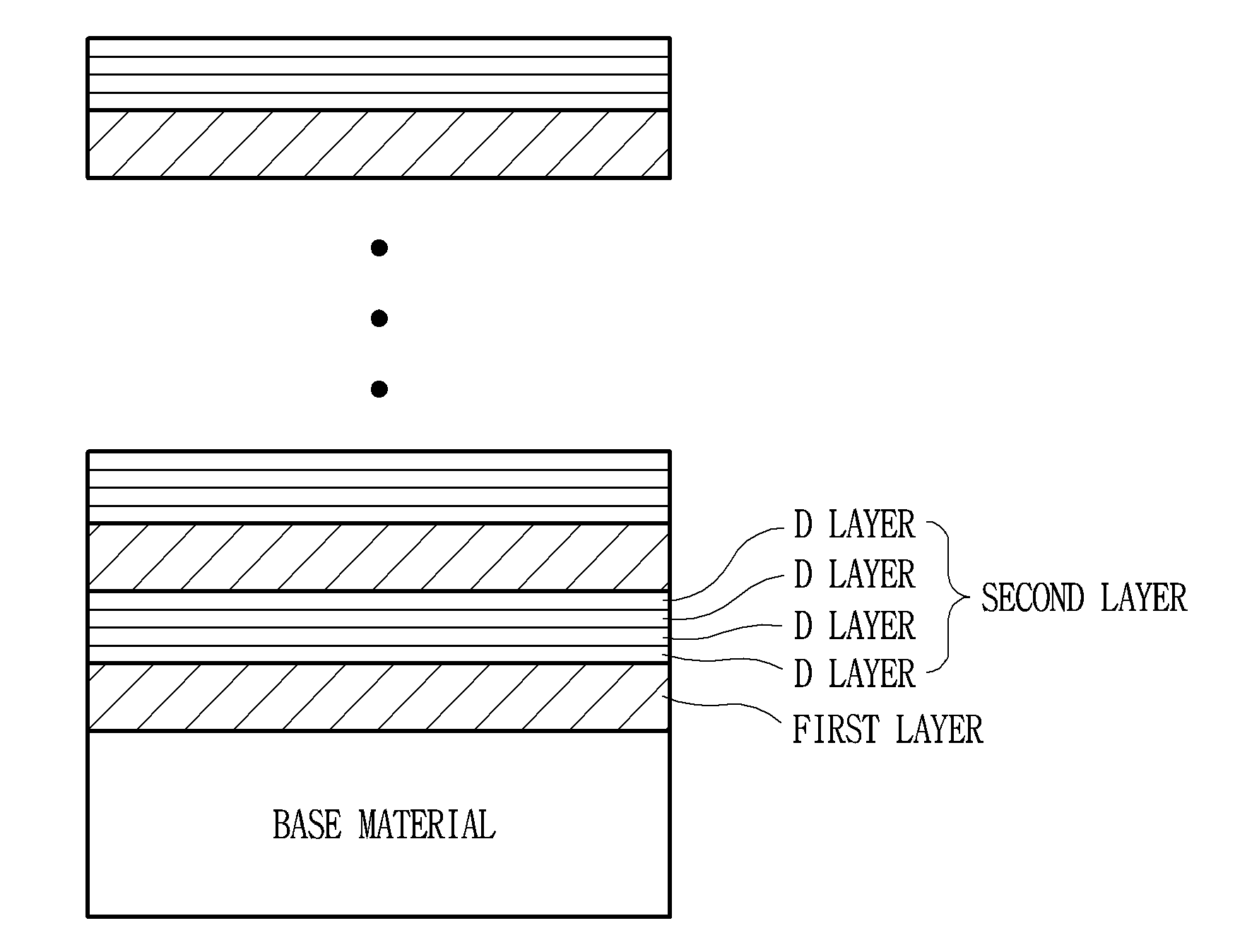

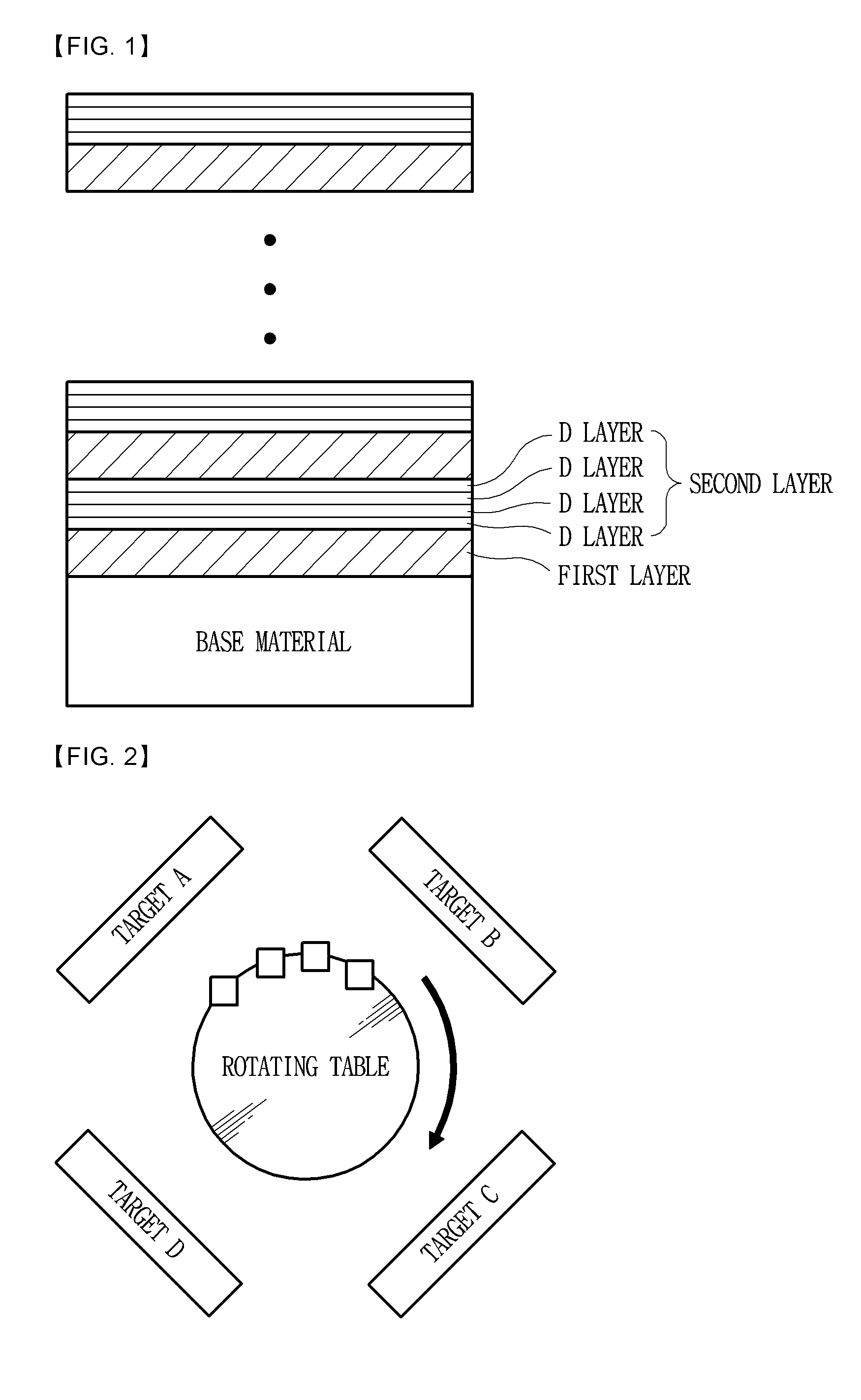

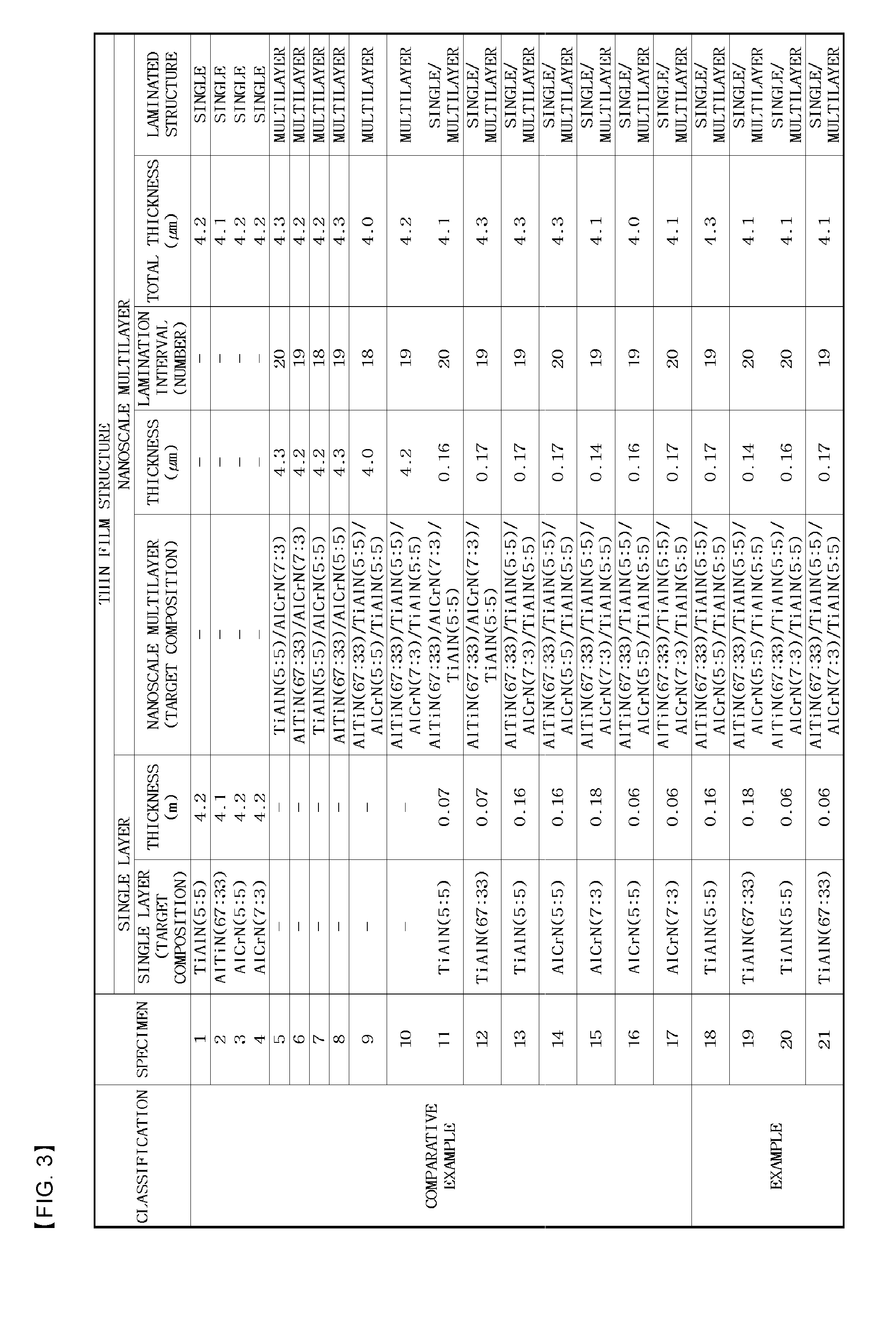

Hard coating film for cutting tools

ActiveUS20160193662A1Improve wear resistanceExtended service lifeLayered productsVacuum evaporation coatingThin layerThin membrane

Disclosed is a hard coating film formed on a hard base material such as cemented carbide. The hard coating film has a nanoscale multilayered structure to have improved oxidation resistance and wear resistance. The hard coating film is a hard coating film formed on the base material. The first layer is composed of a TiAl nitride having a composition of Ti1-aAla (0.3≦a≦0.7), and the second layer has a nanoscale multilayered structure or a structure in which the nanoscale multilayered structure is repeatedly laminated at least two times, the nanoscale multilayered structure including a thin layer A composed of an AlTiSi nitride, a thin layer B, a thin layer C composed of a AlCr nitride, and a thin layer D having thicknesses of 3 nm to 20 nm. The thin film B and the thin film D are composed of a TiAl nitride.

Owner:KORLOY

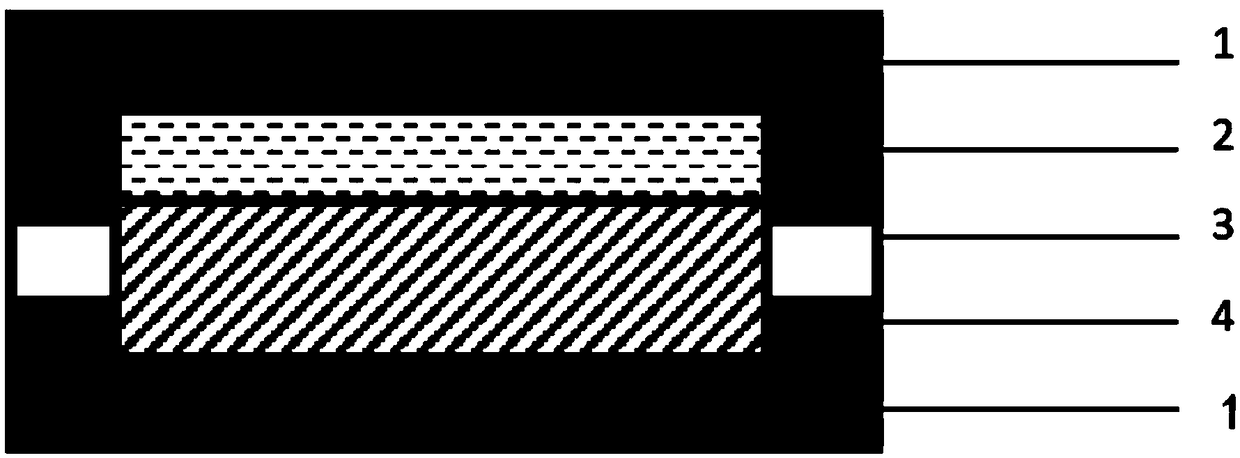

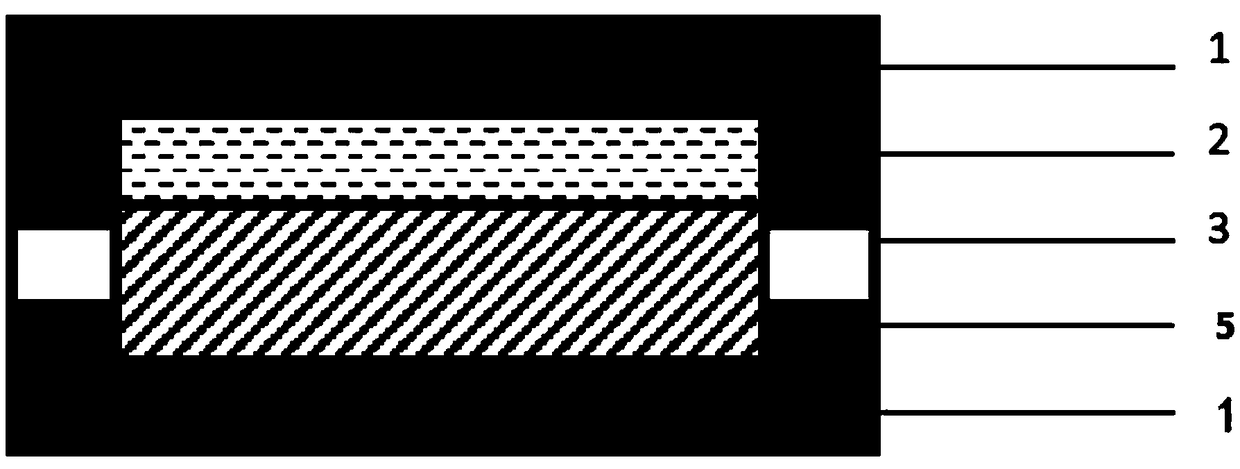

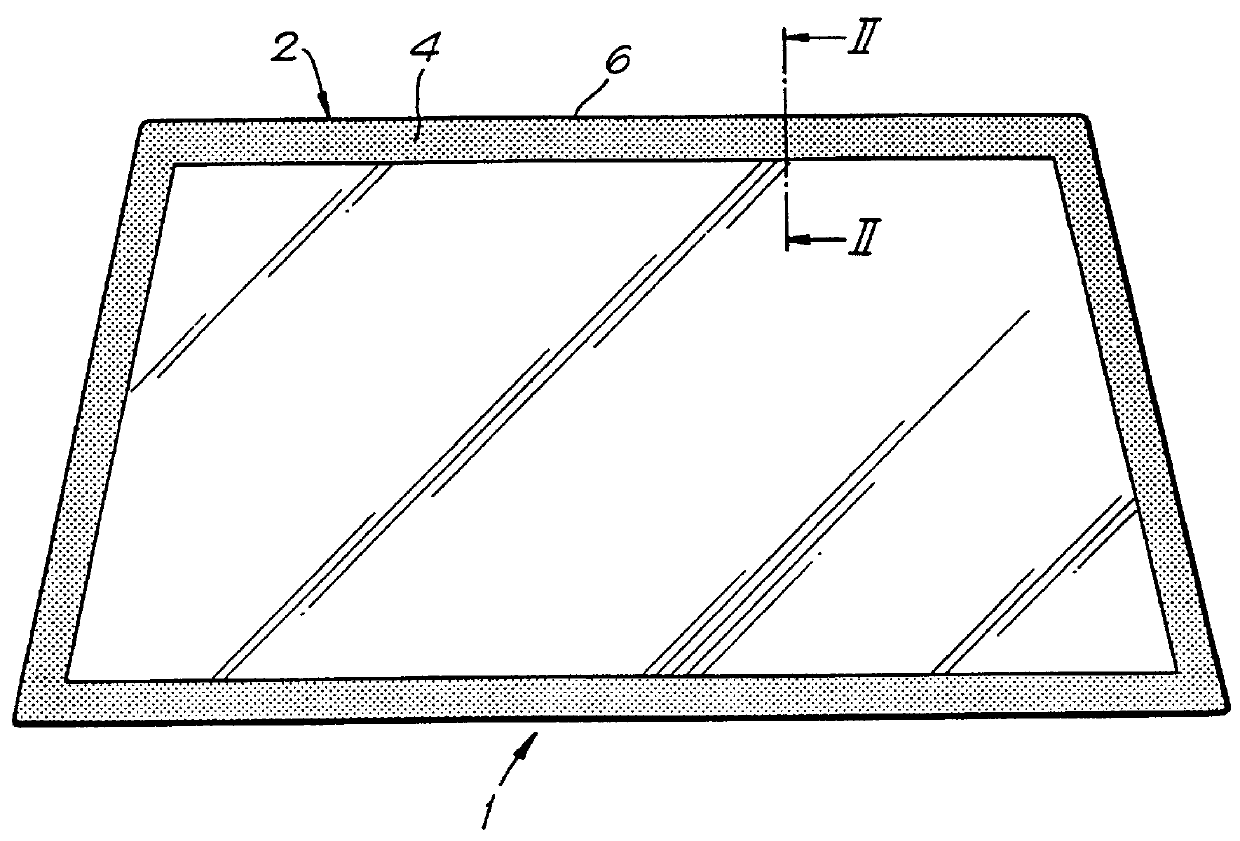

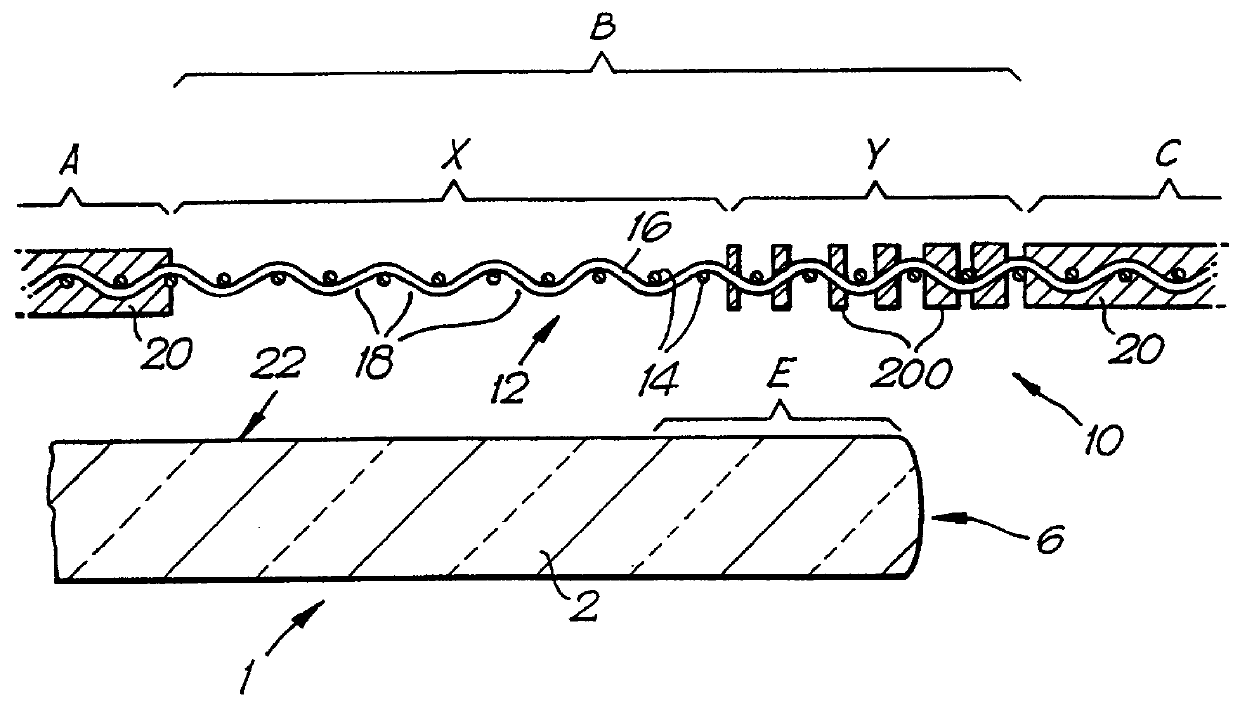

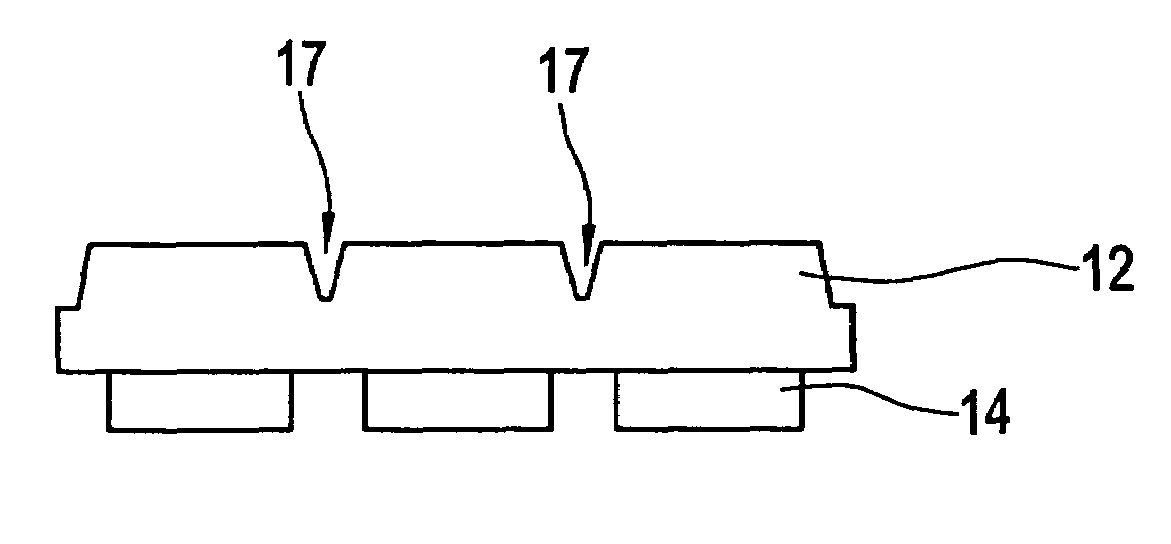

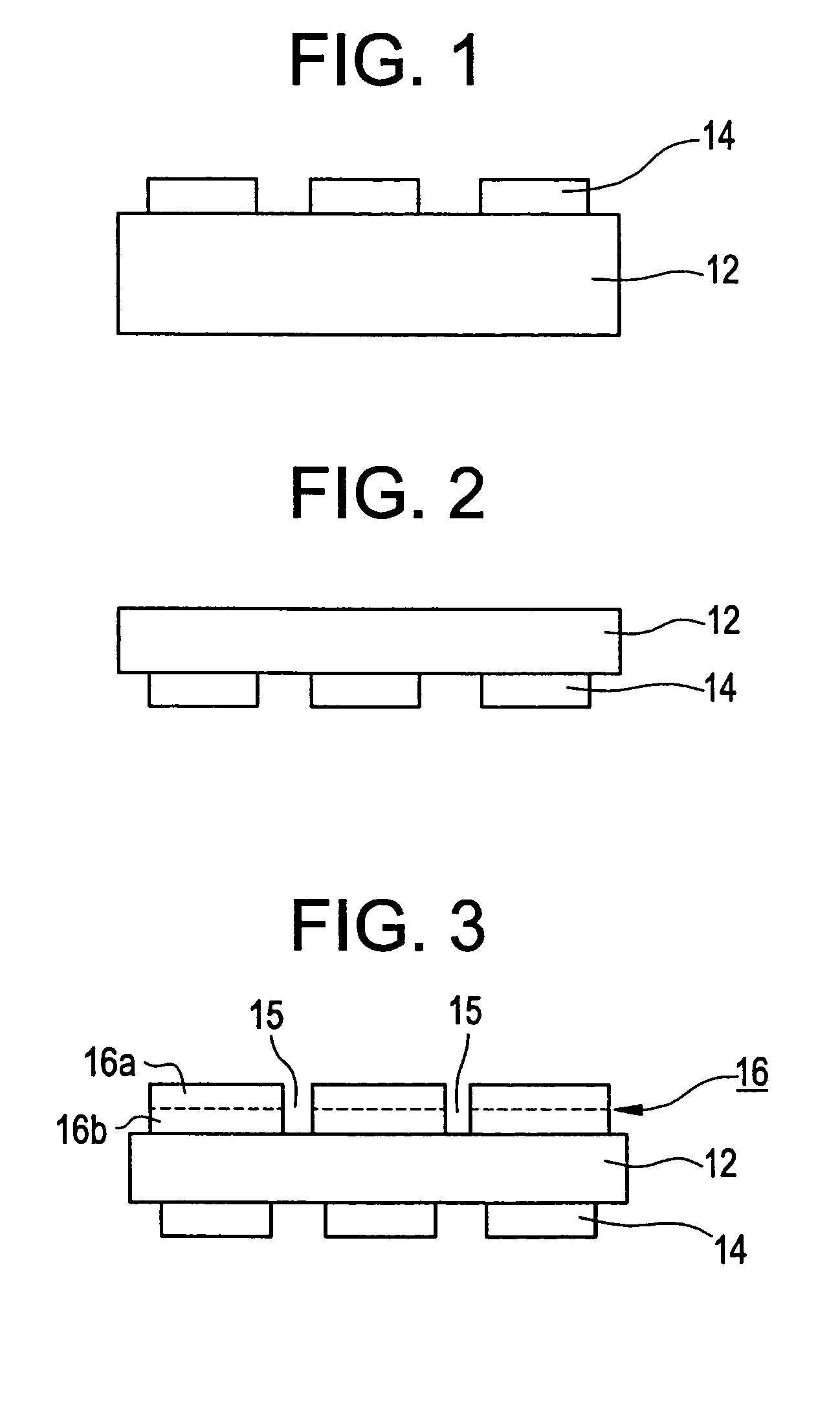

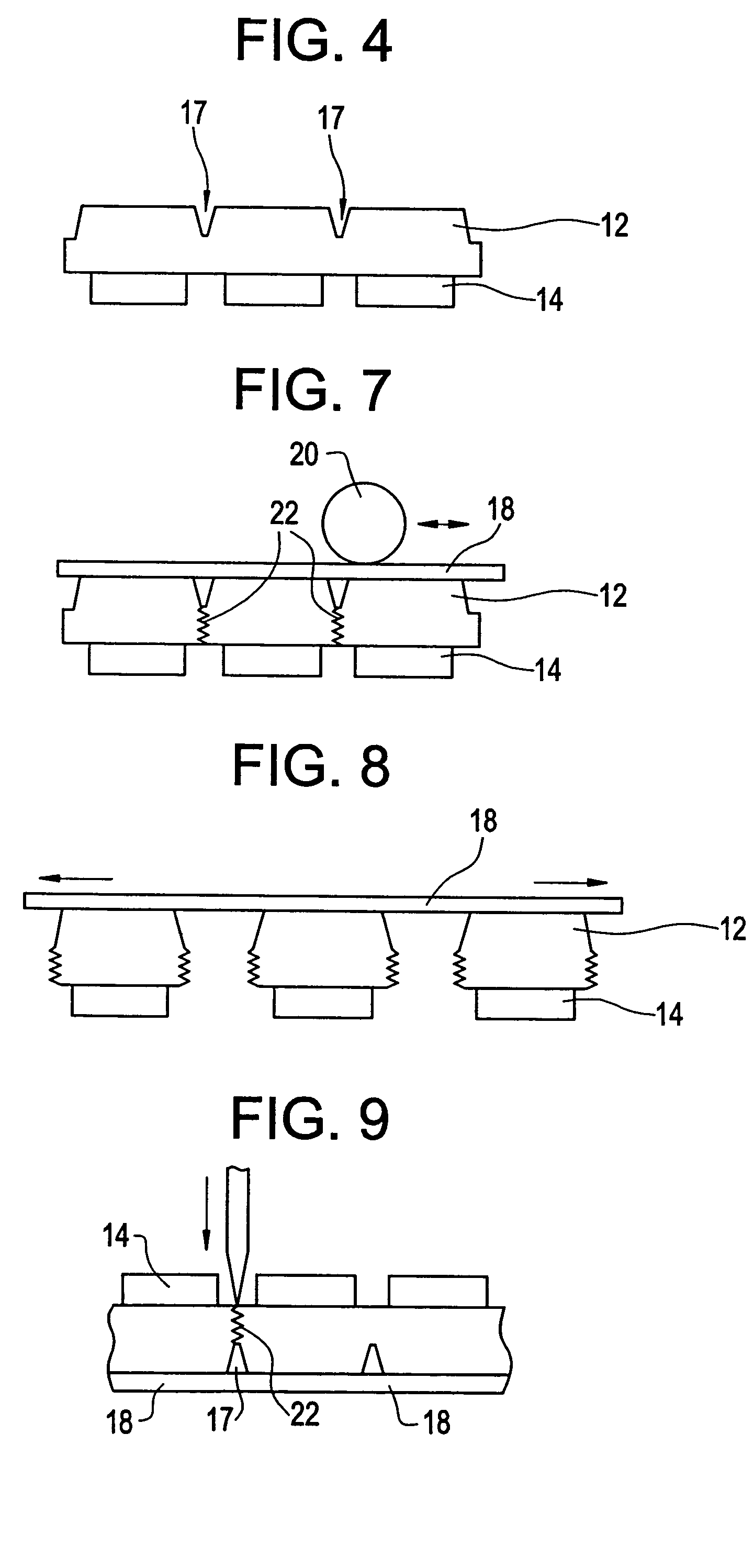

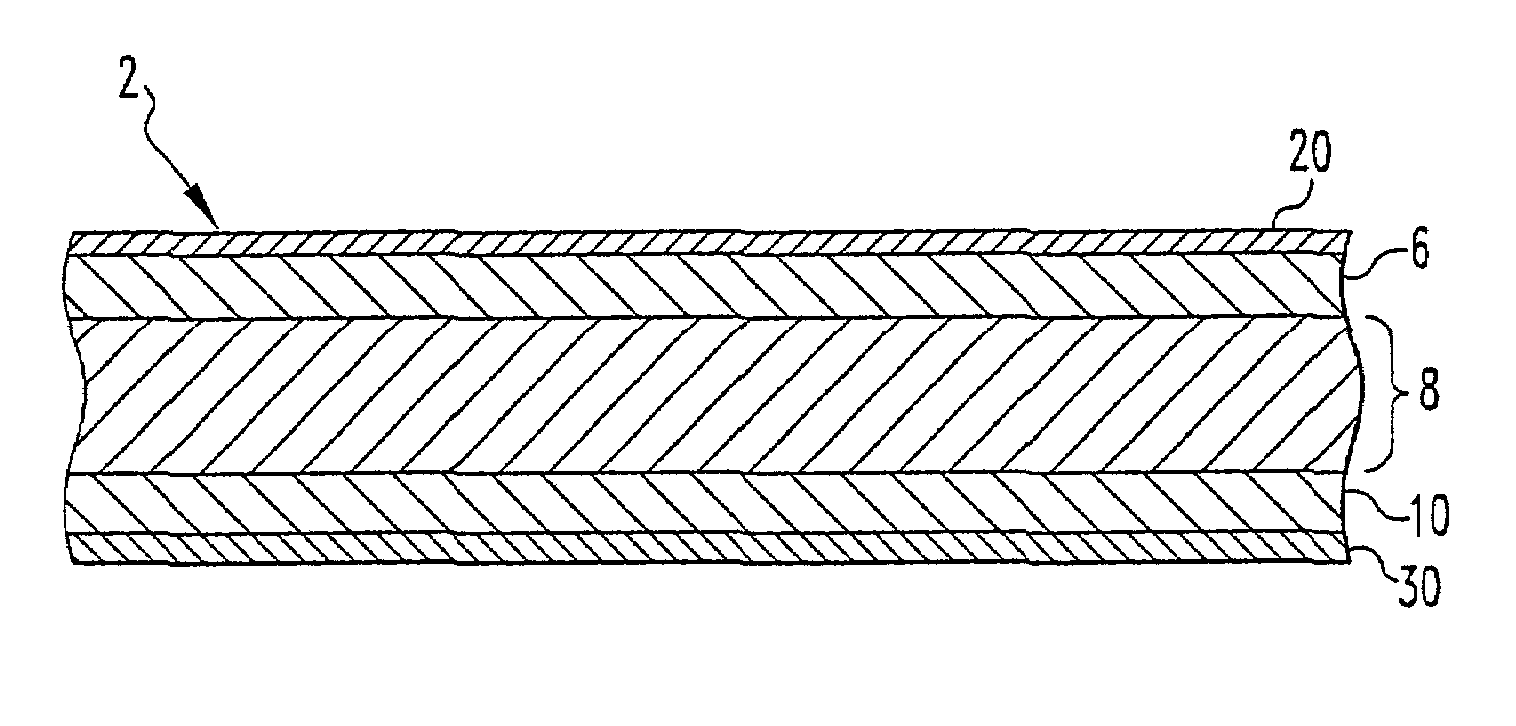

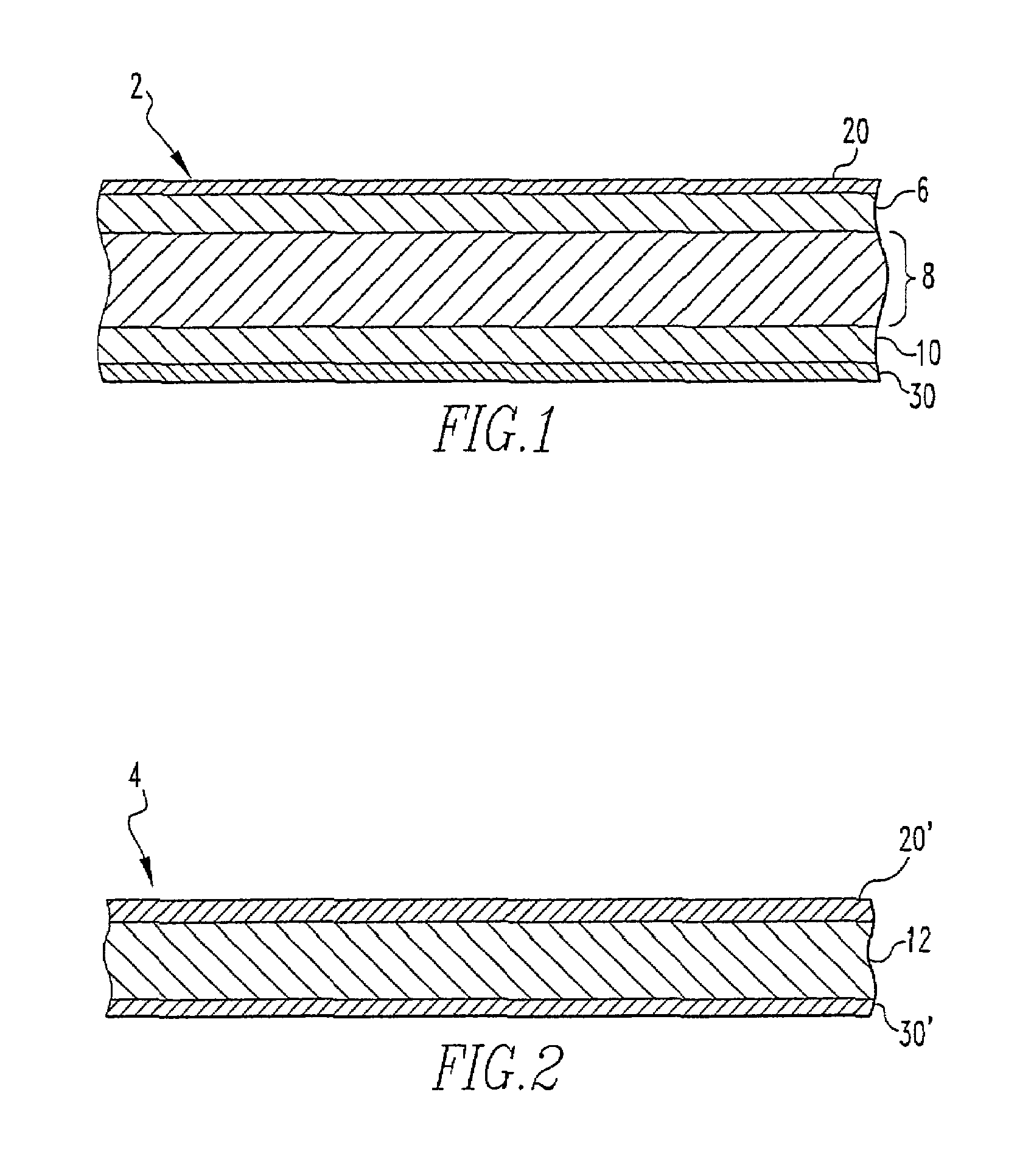

Method and apparatus for screen printing on a hard substrate

InactiveUS6032576AReduce processing timeReduced carrying capacityLiquid surface applicatorsScreen printersScreen printingEngineering

PCT No. PCT / GB96 / 01215 Sec. 371 Date Jan. 27, 1998 Sec. 102(e) Date Jan. 27, 1998 PCT Filed May 21, 1996 PCT Pub. No. WO96 / 40525 PCT Pub. Date Dec. 19, 1996A method of screen printing on to a hard non-absorbent substrate (1) involves using a screen (10) which has an ink permeable area (B) whose pattern corresponds to whatever is to be printed. The area B is divided into two parts (X and Y). Part X is of normal, maximum, ink carrying capacity and part Y is of reduced ink carrying capacity. The ink carrying capacity of the reduced ink carrying capacity part Yis determined by the extent to which it is coated with ink / impenetrable emulsion (20), the size of the pores (18) in the screen (10) and the type of ink used. The ink carrying capacity of the part Y reduces with distance away from part X. The emulsion coating (20) may be in the form of dots (200), with the dots (200) increasing in diameter with distance away from part X. During printing, the reduced ink carrying capacity part Y is located over the edge region (E) of the substrate (1), and the substrate is printed up to but not on to its edge (6).

Owner:PILKINGTON AUTOMOTIVE UK

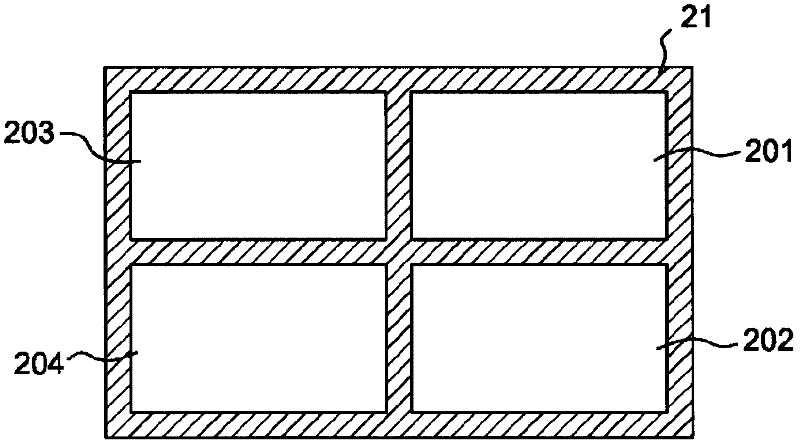

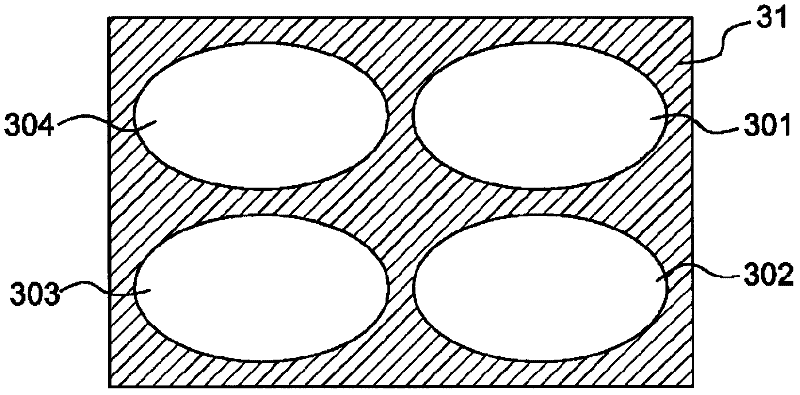

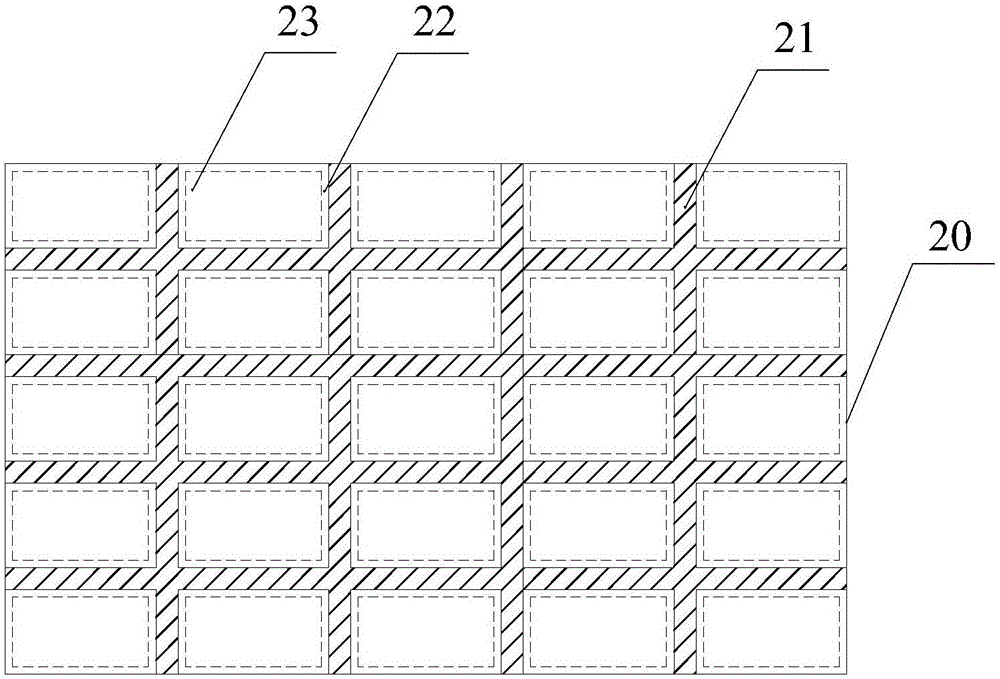

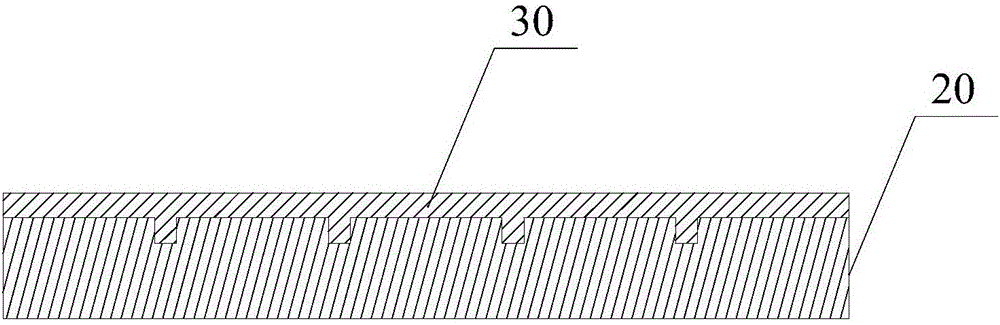

Flexible display panel and preparation method thereof

ActiveCN106057864AUse thin and lightEasy to removeSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayHard substrate

The invention provides a flexible display panel and a preparation method thereof. The flexible display panel comprises a flexible substrate, an Array plate, an OLED element and a TFE layer. The preparation method is simple and comprises the steps of: etching a hard substrate and forming crisscrossed grooves; utilizing a coating or a spraying mode to coat heatproof glue on the hard substrate; then pasting the flexible substrate on the hard substrate coated by the heatproof glue, and obtaining the hard substrate pasted by the flexible substrate; successively arranging the Array plate, the OLED element and the TFE layer on the hard substrate pasted by the flexible substrate, and then carrying out lamination; and carrying out cutting along the edge of a display effective area, separating the hard substrate from the heatproof glue, the flexible substrate, the Array plate, the OLED element and the TFE layer, and obtaining the flexible display panel. The flexible display panel and the preparation method thereof effectively solve problems that the separation between an existing flexible panel and the hard substrate is difficult, and the preparation process of the flexible display panel is complex, high in cost and low in yield rate.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for manufacturing flexible display device and flexible display device

ActiveCN104465475AReduce manufacturing costIncrease productivityFinal product manufactureSolid-state devicesEngineeringFlexible display

The invention discloses a method for manufacturing a flexible display device and the flexible display device obtained through the manufacturing method. The method comprises the steps that a conductive layer is formed on the surface of a hard substrate; an inverse electrostriction thin film layer is formed on the conductive layer; a flexible base material is attached to the surface of the inverse electrostriction thin film layer; a display element layer is manufactured on the flexible base material; after the display element layer is manufactured, alternating currents are applied to the conductive layer, and the hard substrate and the flexible base material are separated through the micromechanical vibration of an inverse electrostriction thin film. The inverse electrostriction thin film layer on the hard substrate is adopted as a release layer, after the alternating currents are applied, mechanical stress between the inverse electrostriction thin film and the flexible base material is far smaller than binding force between the inverse electrostriction thin film and the lower hard substrate, the flexible base material and the hard substrate can be separated, the hard substrate can be used repeatedly, manufacturing cost is greatly saved, production efficiency is improved, and the product yield is improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Thermoplastic elastomer composition

The present invention relates to a soft thermoplastic elastomer composition that is free of thermoplastic resin that can be utilized in manufacturing shoe sole inserts, seals, gaskets, wheels, and that can be overmolded on a hard substrate, such as a metal or a thermoplastic resin, for grips or handles on various household items. The present invention more specifically discloses a thermoplastic elastomer composition that is made by a process comprising: (1) mixing (A) a block copolymer comprising a first polymeric block that is comprised of repeat units that are derived from a vinyl aromatic monomer and a second block that is comprised of repeat units that are derived from a conjugated diolefin monomer, wherein the repeat units in the second block are hydrogenated, and wherein the repeat units in the second block are elastomeric in nature, (B) a crosslinkable elastomer, and (C) an oil, to produce an un-crosslinked three component blend; and (2) dynamically crosslinking the crosslinkable elastomer in the un-crosslinked three component blend during a thermo-mechanical mixing step; wherein the thermoplastic elastomer composition is void of thermoplastic resins.

Owner:POLYONE CORPORATION +1

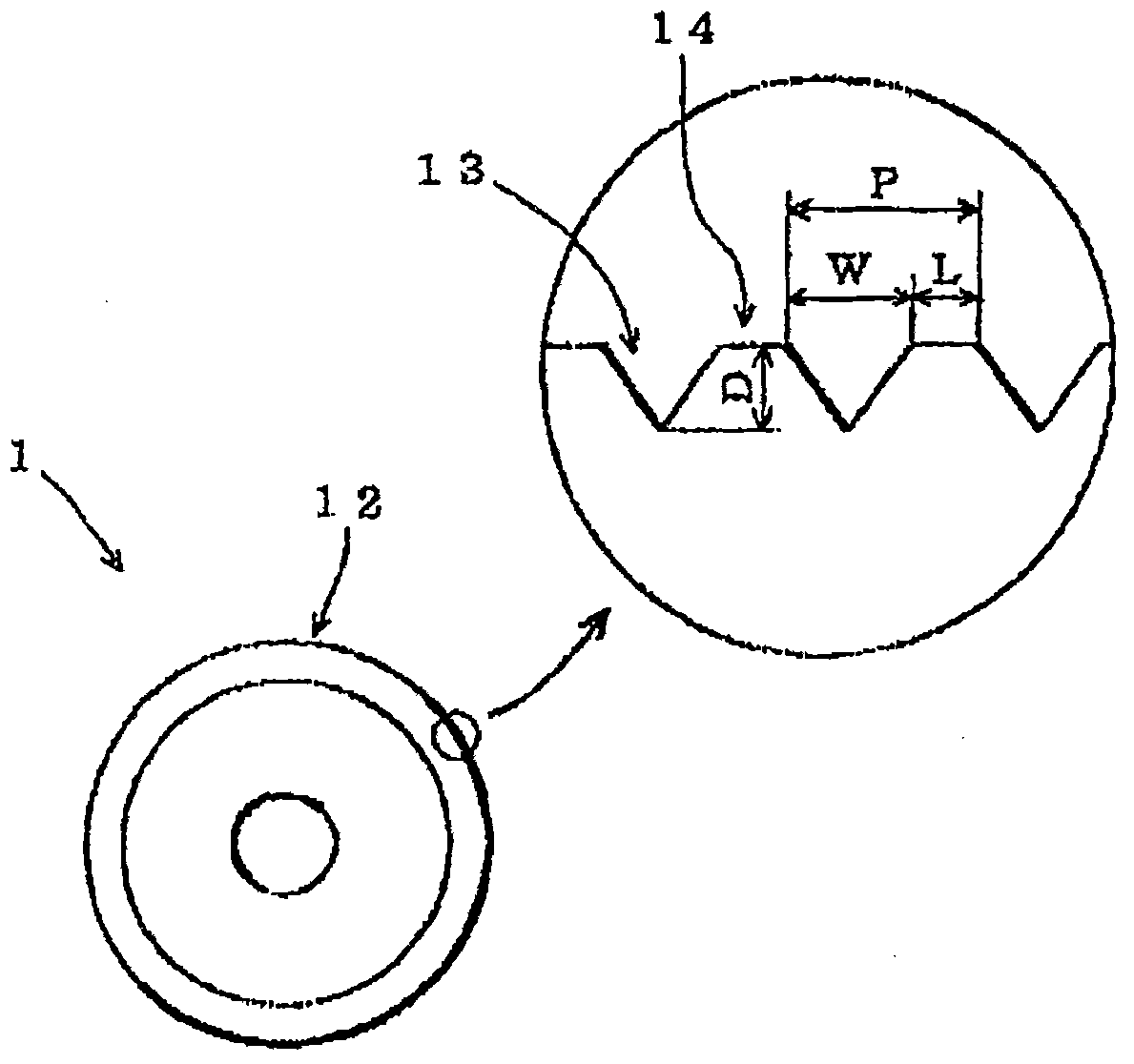

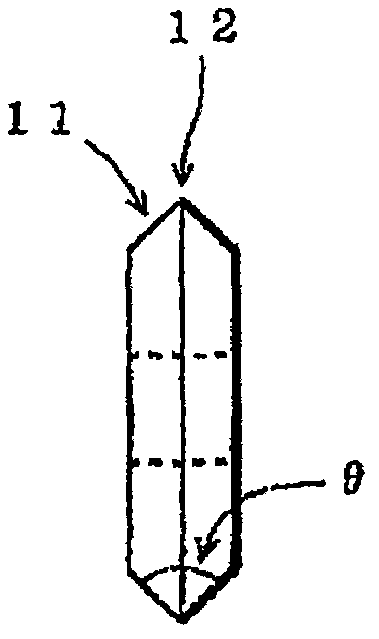

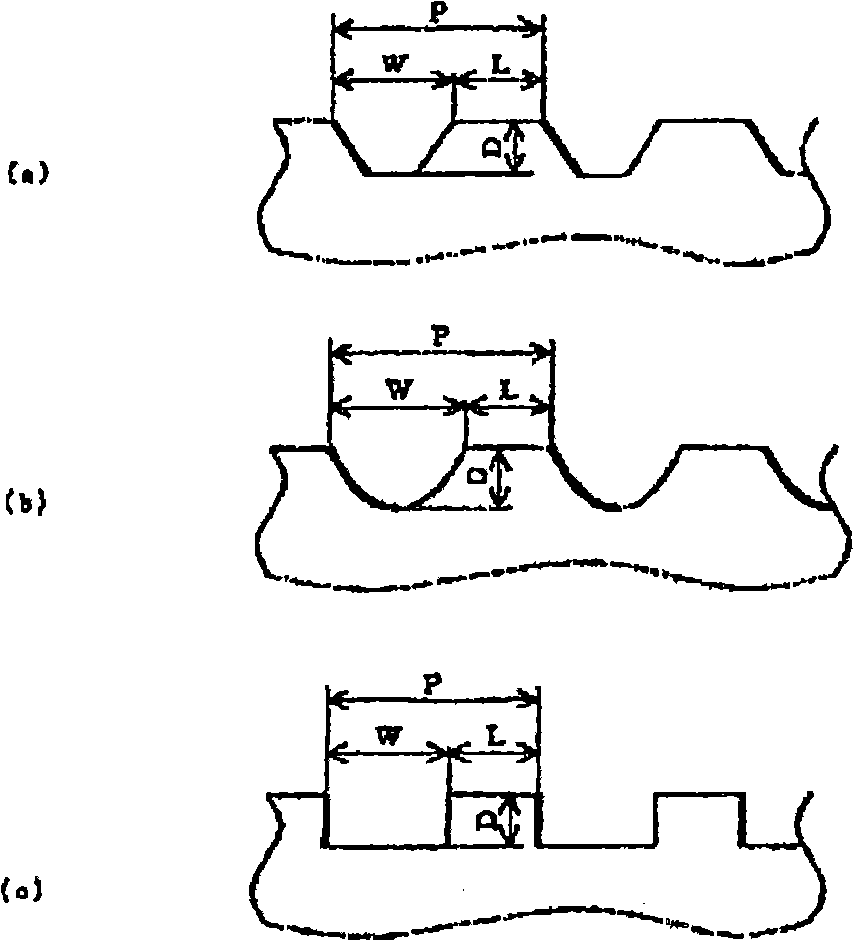

Scribing wheel and method for scribing brittle material substrate

InactiveCN102056719AExtended service lifeReduce wearMetal-working apparatusFine working devicesEngineeringCeramic substrate

Provided is a scribing wheel, which has a long service life with less wearing of a blade edge and can generate a deeper vertical crack as needed, and furthermore, has less blade edge wearing even when a relatively hard substrate, such as a ceramic substrate, is scribed, and generates a vertical crack of a prescribed depth. A plurality of grooves (13) are formed at prescribed intervals on a blade edge (12), i.e., the ridge line of a wheel having an outer diameter within the range of 1 mm-5 mm. The depth (D) of the groove (13) is 25 [mu]m or more, and the length (L) of a ridge line (14) between the grooves is 25 [mu]m or more. The pitch (P) of the groove (13) is preferably within the range of 50 [mu]m-200 [mu]m.

Owner:MITSUBOSHI DIAMOND IND CO LTD

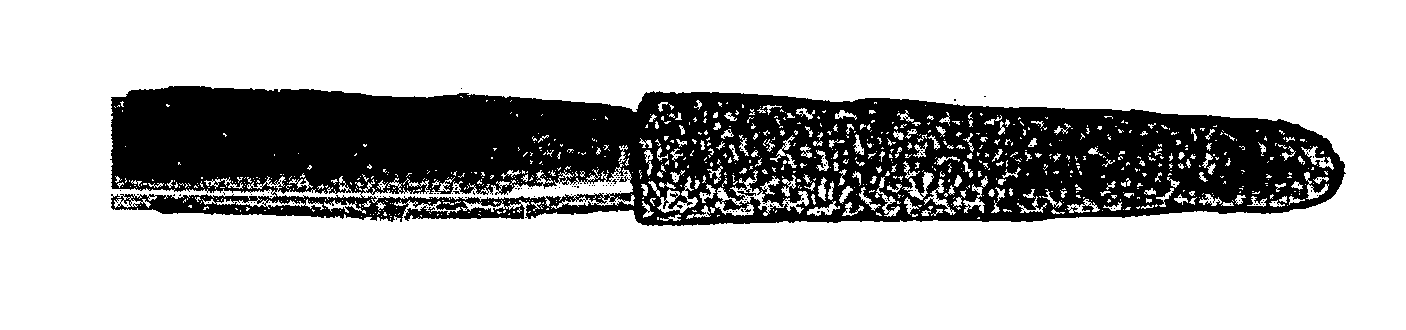

Dental instruments having durable coatings

InactiveUS20060269901A1Extended service lifeUseful for wearTooth pluggers/hammersTeeth cappingSurgical drillDental insert

The present invention relates to dental instruments used in tooth restoration and replacement including dental burs, dental discs, tapes, endodontic files, surgical drills and taps, having abrading working surfaces coated or embedded with diamond particles or chips onto the substrate or shank, the abrading surfaces having a flexible diamond-like carbon (DLC) coating. The substrate may be flexible or the shank may be made of a relatively hard substrate and diamond particles or chips may be coated or embedded onto the substrate or shank through the use of polymeric bonding agents, through embedding in a nickel or nickel alloy matrix, or through chemical vapor deposition, or even direct coating if polymeric substrates are used. The abrading surface may also be formed through the formation of cutting edges or surfaces on the substrate. The present invention further relates to a dental tip, which may be part of an ultrasonic dental insert may be made of a metallic or polymeric substrate which is coated with a flexible and durable coating. The coated tip is bent or can be bent to a desired configuration. The coating is made of a diamond-like-carbon (DLC) coating having at least about 5 atomic percent of hydrogen. The coated abrading surfaces or tips are longer lasting than uncoated surfaces and the coating may also serve as a wear indicator. Further, the coating is present on the surface of the bur or tip during use without obstructing the abrasive function of the dental instruments.

Owner:DISCUS DENTAL LLC

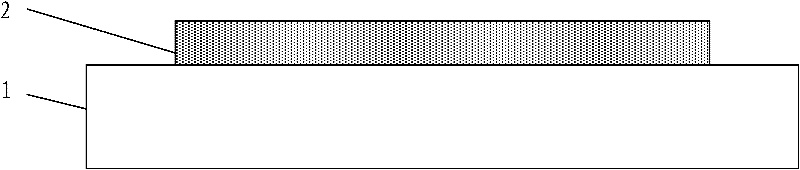

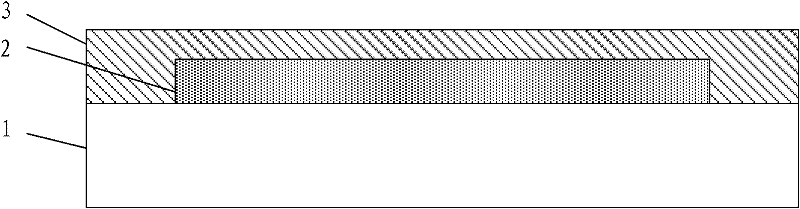

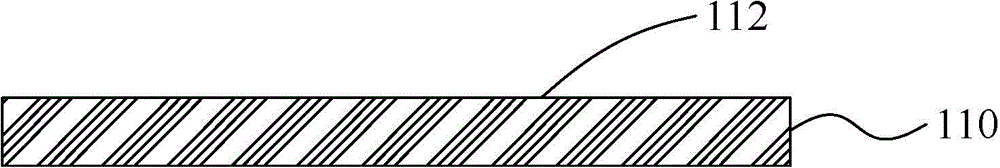

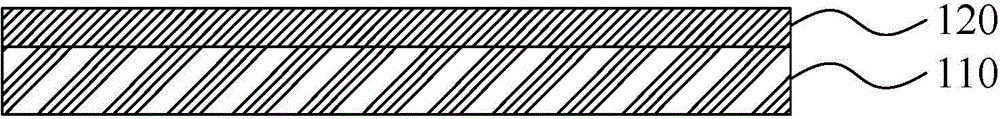

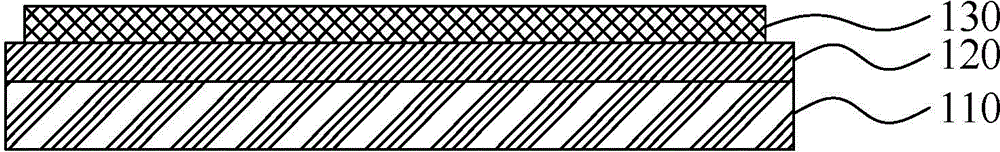

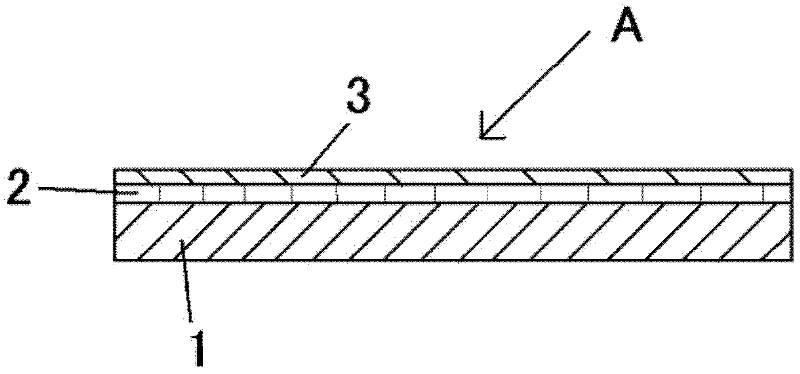

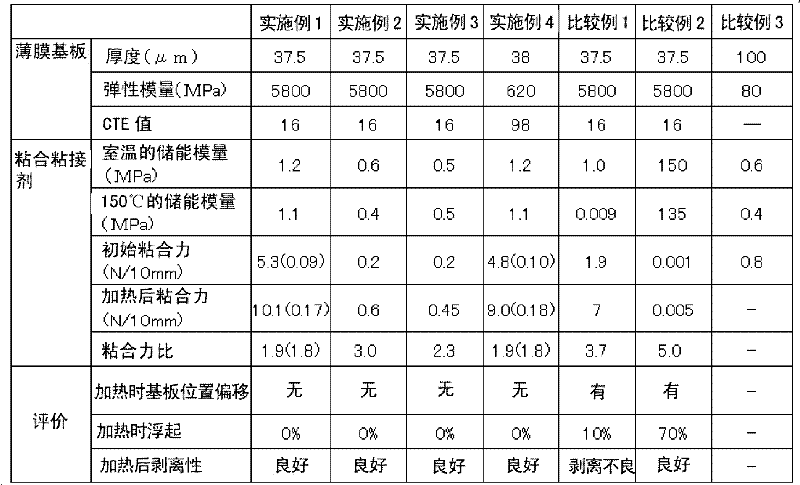

Method for manufacturing thin-film substrate

InactiveCN102655119AControlled Adhesion RiseNo damageFilm/foil adhesivesLayered productsOptoelectronicsMaterials science

The present invention provides a manufacturing method for efficiently and stably forming a pattern on a thin-film substrate. The method for manufacturing the thin-film substrate includes: stacking the thin-film substrate, a tackiness / adhesive agent for temporary fixing and a hard substrate in this order; fixing the thin-film substrate on the hard substrate through the tackiness / adhesive agent; then forming the pattern; and subsequently peeling the thin-film substrate at an interface between the thin-film substrate and the tackiness / adhesive agent.

Owner:NITTO DENKO CORP

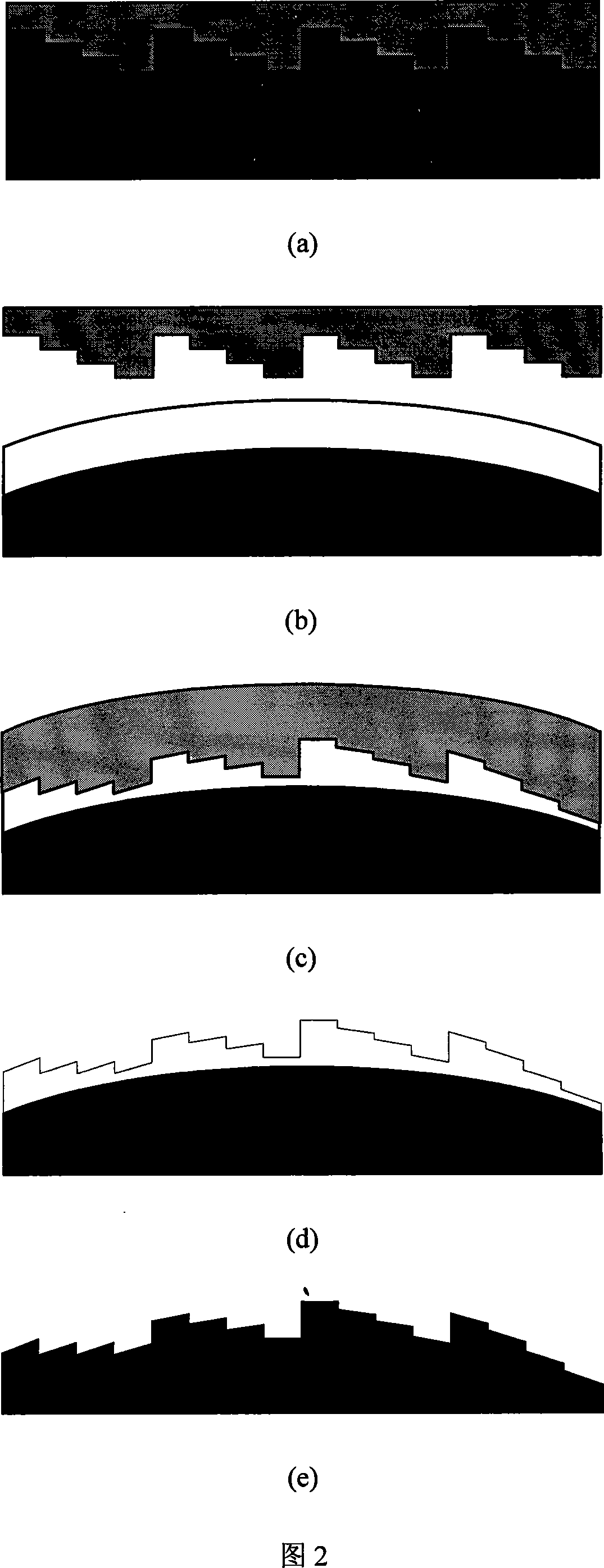

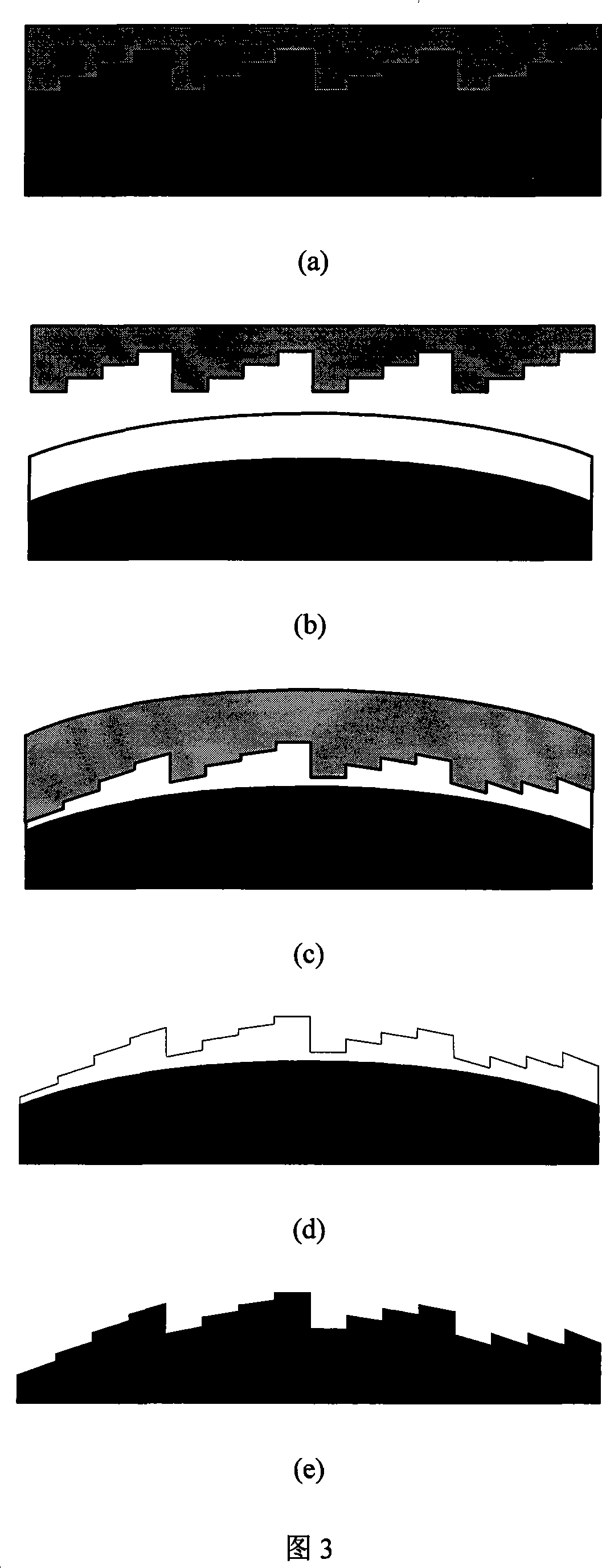

Curved substrate multi-phase micro-optical element processing method based on flexible ultraviolet die mold

InactiveCN101221358AAvoid dependenceRealize processing and manufacturingPhotomechanical exposure apparatusMicrolithography exposure apparatusFine structureUltraviolet

The invention relates to a method for processing curved-surface substrate multi-phrase micro optical elements and a technique of manufacturing the micro optical elements based on a flexible UV pressing die; the method has an additional step which takes a polymer structure as a mask and uses a dry etching technique to form an embossed structure on a substrate to complete the graph transmission form a fine structure to the surface of a hard substrate; a stamping step in which a flexible pressing die creates elastic deformation with external prestress applied during the stamping process to bend into a shape similar to a surface being processed, with the deflection worked out by a method of FEM ( finite element method) simulation; and a step for making a motherboard, in which the shape and size of a fine structure on the surface of a pressing die motherboard is designed according to the deflection for compensation. The method can be used to realize the processing and manufacture of micro optical elements which have a curved-surface substrate of single material and are made of non-polymer hard materials.

Owner:HARBIN INST OF TECH

Flexible pressure sensor and preparation method thereof

ActiveCN106441646ARealize integrated manufacturingSimple preparation processForce measurement using piezo-resistive materialsMicro nanoElectrical resistance and conductance

The invention provides a flexible pressure sensor. The flexible pressure sensor comprises a flexible substrate, a flexible upper cover and electrodes arranged between the flexible substrate and the flexible upper cover at intervals. A circuit with semiconductor resistors and conductive channels is arranged between the electrodes. The micro-nano processing technology is combined with the modern printing electronic technology, so the Wheatstone bridge type pressure sensor can be built on the pure flexible substrate, the defects that the process of a technology for preparing a hard substrate (like silicon) pressure sensor through a traditional semiconductor technology is complex, and influences of the high-temperature technology are large are avoided, and integrated preparation of the flexible sensor is achieved. The micro-nano processing technology, the modern printing electronic technology, nano-carbon materials, polymer materials and the like are combined, so the flexible pressure sensor of a Wheatstone bridge structure is prepared on the flexible substrate, and the pressure sensor is simple in preparation process, low in cost, good in performance and suitable for large-scale production.

Owner:江苏科华智能控制设备有限公司

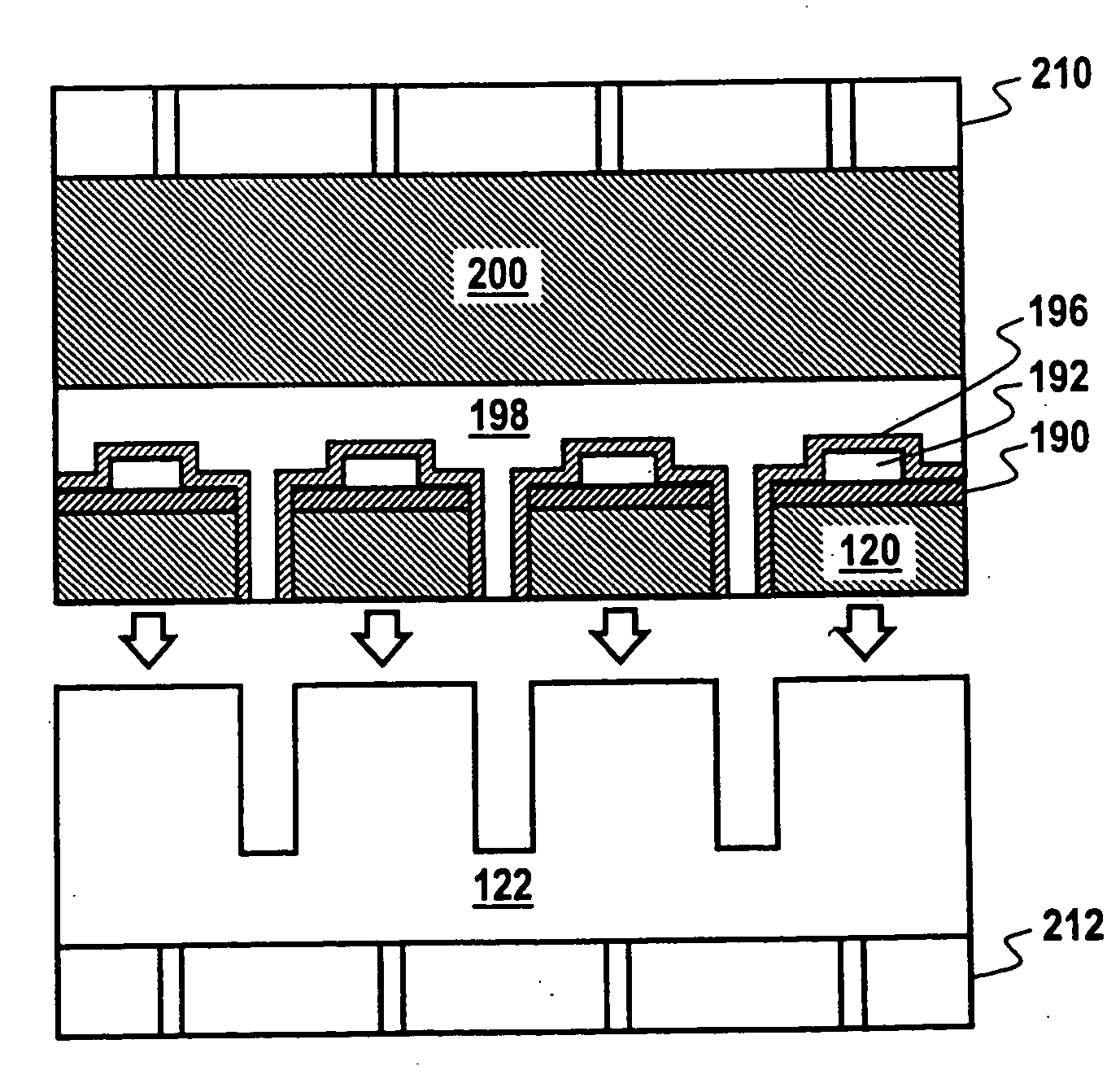

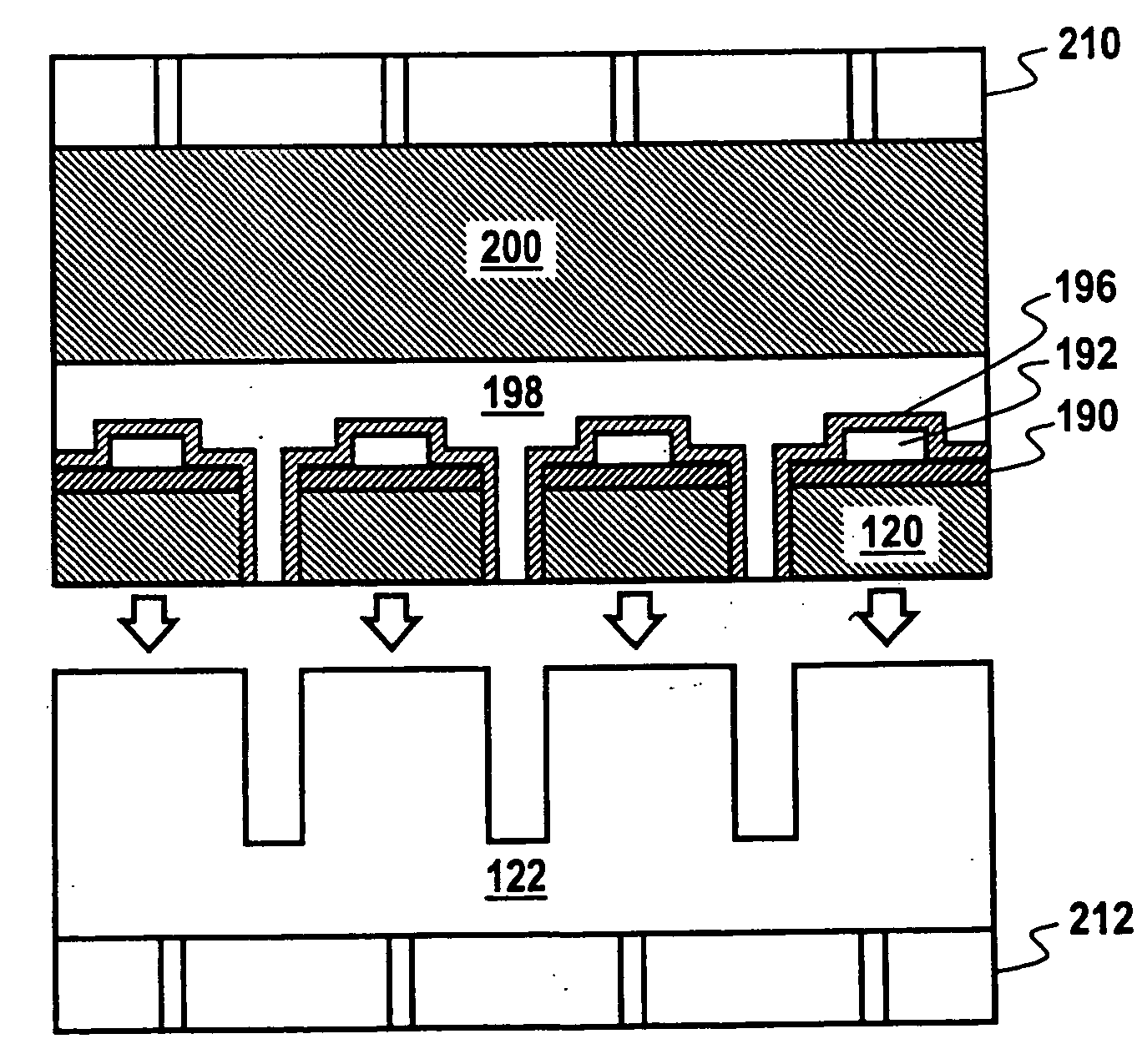

Method of fabricating vertical devices using a metal support film

InactiveUS20060094207A1Avoid damageSemiconductor/solid-state device manufacturingSemiconductor devicesResistDevice material

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal techniques. Trenches that define the boundaries of the individual devices are formed through the semiconductor layers and into the insulating substrate, beneficially by inductive coupled plasma reactive ion etching. A first support structure is attached to the semiconductor layers. The hard substrate is then removed, beneficially by laser lift off. A second supporting structure, preferably conductive, is substituted for the hard substrate and the first supporting structure is removed. Individual devices are then diced, beneficially by etching through the second supporting structure. A protective photo-resist layer can protect the semiconductor layers from the attachment of the first support structure. A conductive bottom contact (possibly reflective) can be inserted between the second supporting structure and the semiconductor layers.

Owner:SUZHOU LEKIN SEMICON CO LTD

Method of fabricating vertical devices using a metal support film

A method of fabricating semiconductor devices, such as GaN LEDs, on insulating substrates, such as sapphire. Semiconductor layers are produced on the insulating substrate using normal techniques. Trenches that define the boundaries of the individual devices are formed through the semiconductor layers and into the insulating substrate, beneficially by inductive coupled plasma reactive ion etching. A first support structure is attached to the semiconductor layers. The hard substrate is then removed, beneficially by laser lift off. A second supporting structure, preferably conductive, is substituted for the hard substrate and the first supporting structure is removed. Individual devices are then diced, beneficially by etching through the second supporting structure. A protective photo-resist layer can protect the semiconductor layers from the attachment of the first support structure. A conductive bottom contact (possibly reflective) can be inserted between the second supporting structure and the semiconductor layers.

Owner:SUZHOU LEKIN SEMICON CO LTD

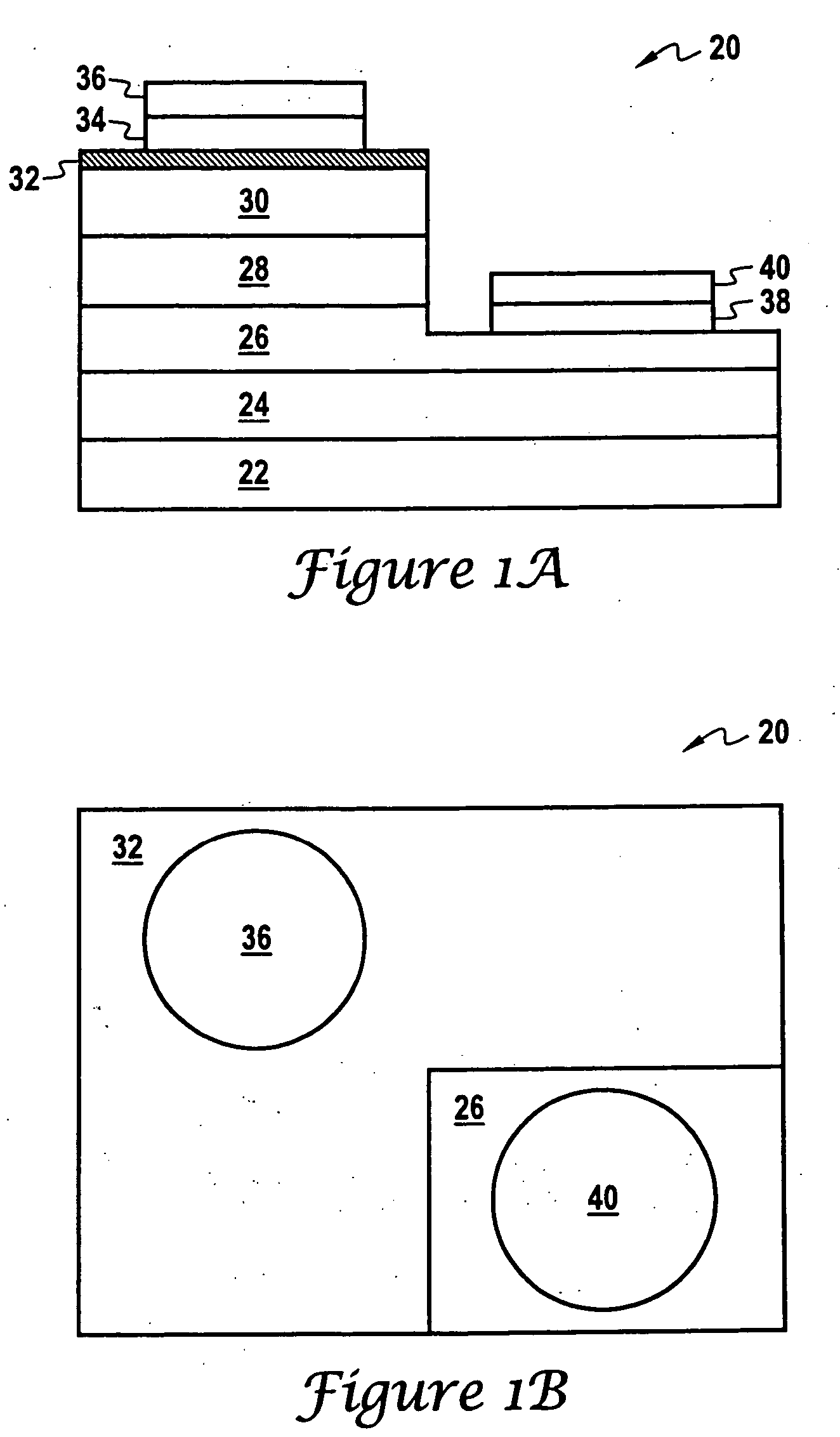

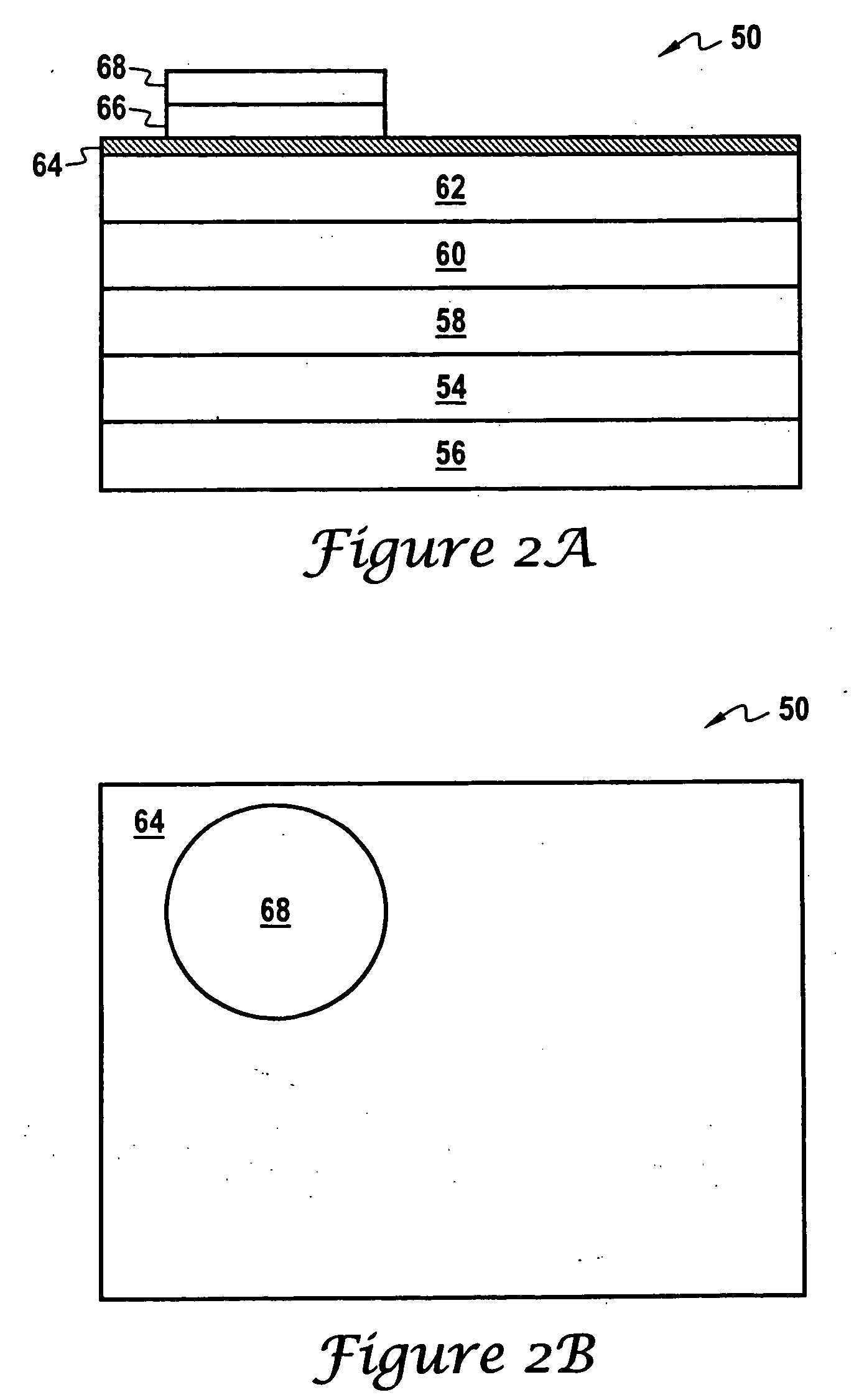

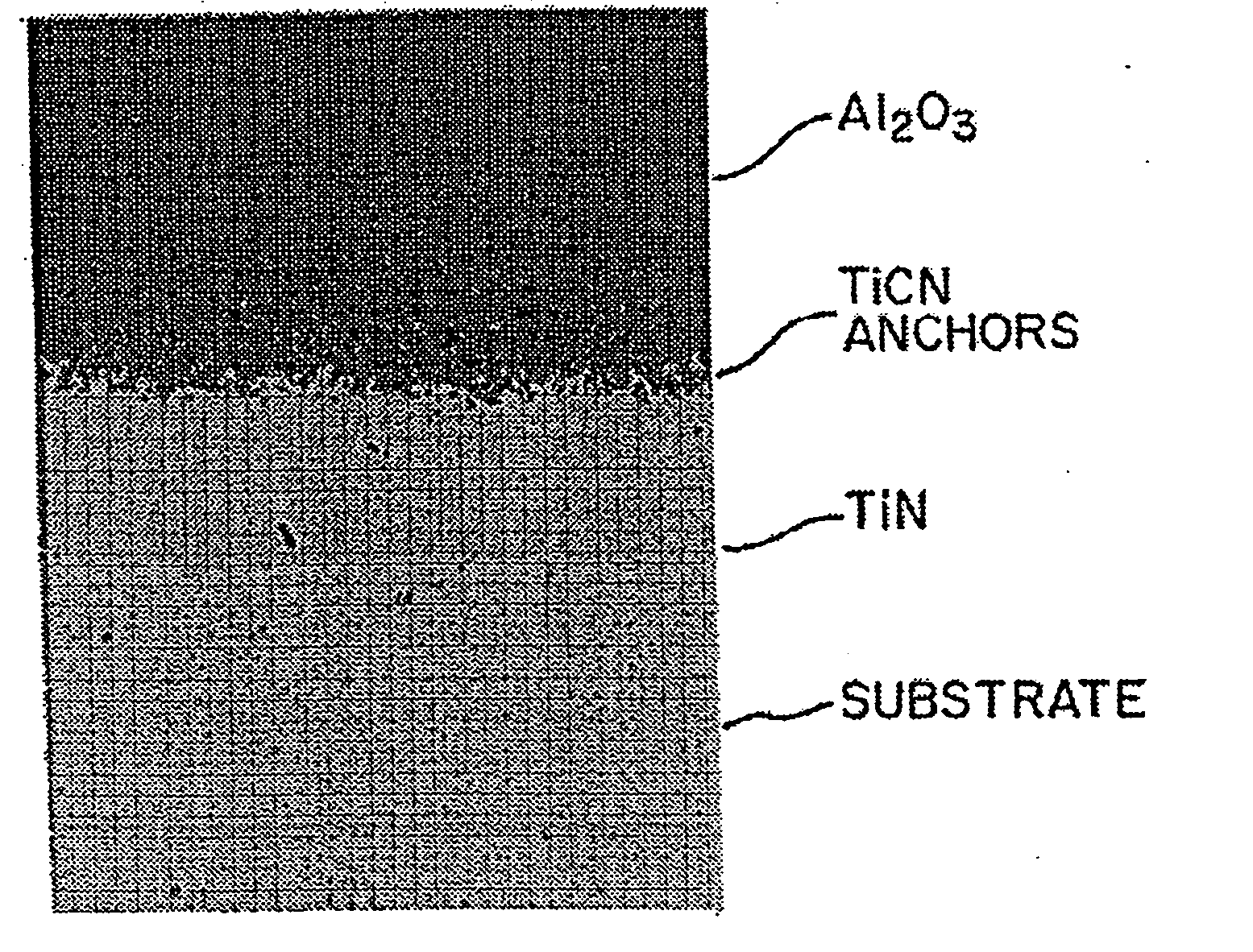

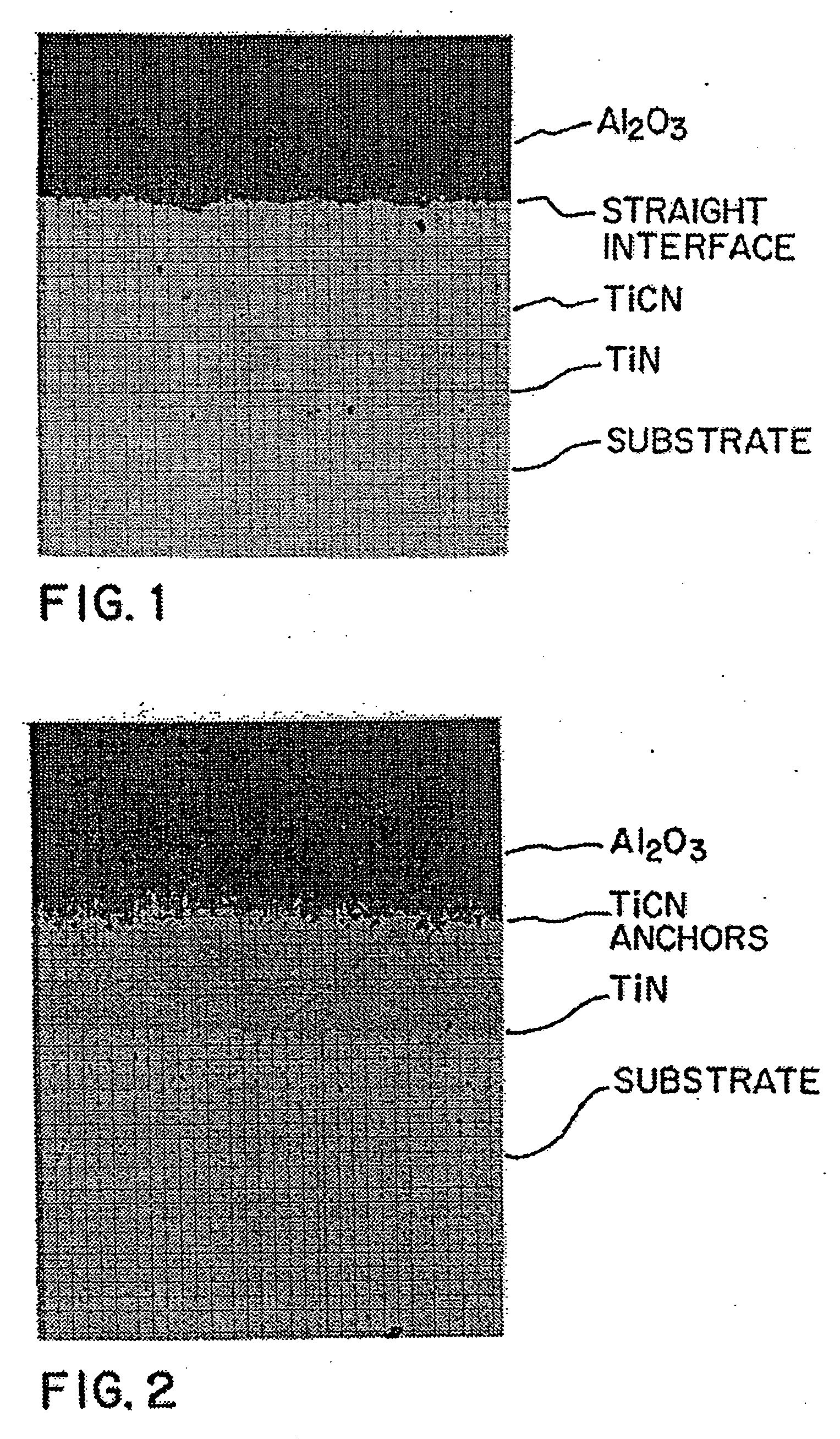

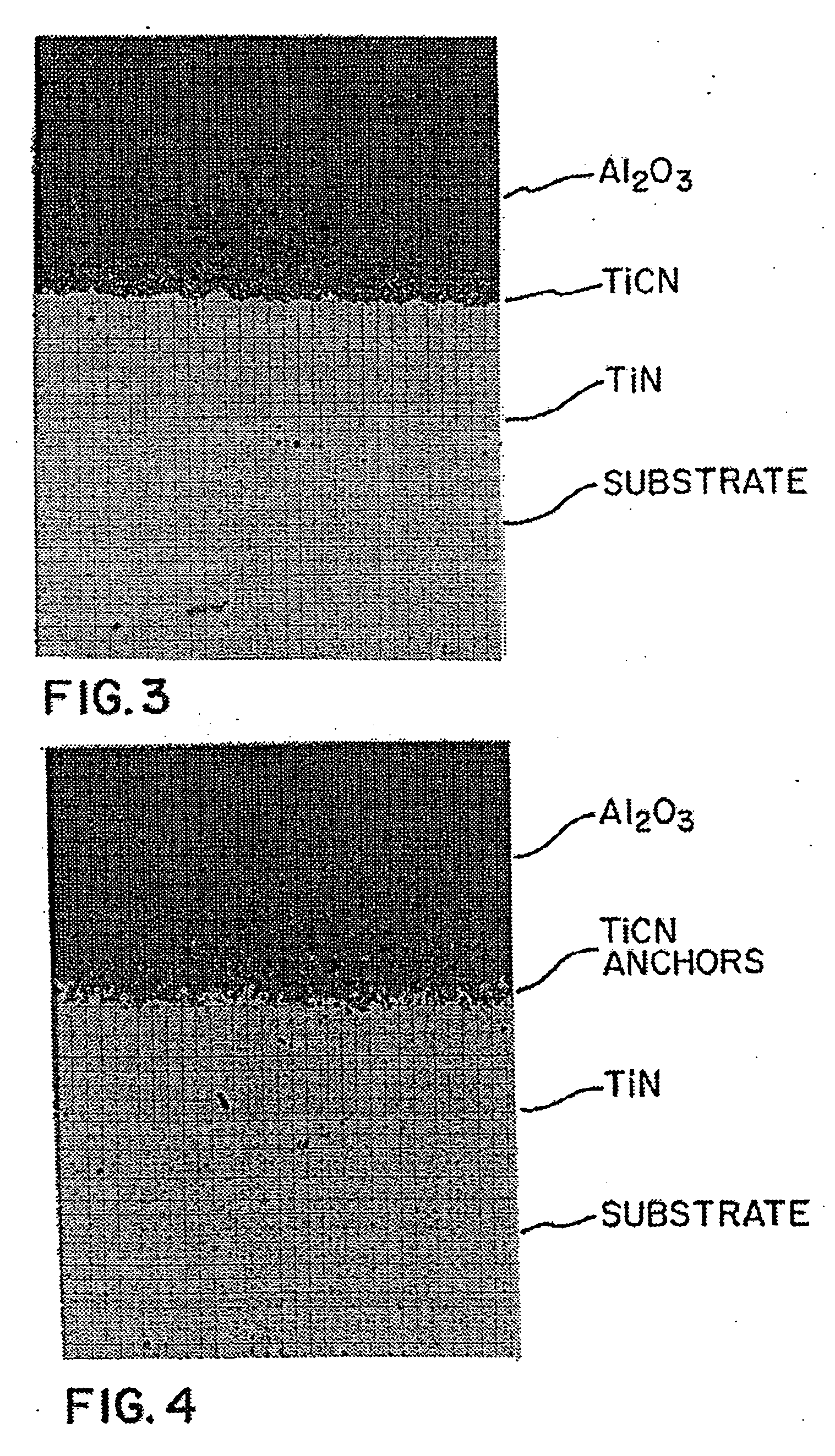

Coatings for cutting tools

InactiveUS20050003238A1Improve adhesionImprove fatigue strengthLiquid surface applicatorsNatural mineral layered productsWear resistantHard metal

A cutting tool insert comprises a hard metal substrate having at least two wear-resistant coatings including an exterior ceramic coating and a coating under the ceramic coating being a metal carbonitride having a nitrogen to carbon atomic ratio between 0.7 and 0.95 which causes the metal carbonitride to form projections into the ceramic coating improving adherence and crater resistance of the ceramic coating. Also disclosed is a cutting tool insert including a hard substrate and at least first and second coatings on at least a portion of said substrate. The first coating is of at least about 2 microns, is in contact with the substrate, and includes at least one of a metal carbide, a metal nitride, and a metal carbonitride of a metal selected from the group consisting of zirconium and hafnium. The second coating may include at least one of a metal carbide, a metal nitride, and a metal oxide of a metal selected from groups IIIA, IVB, VB, and VIB of the periodic table.

Owner:LEVERENZ ROY V +2

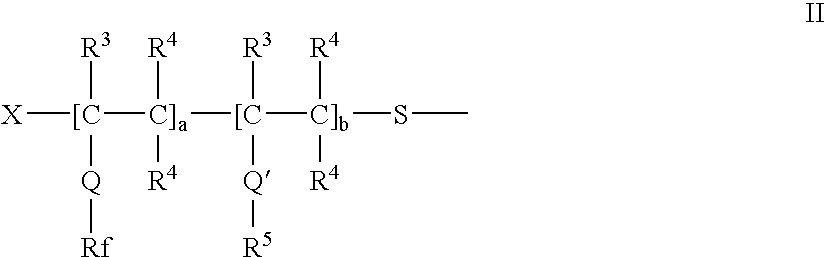

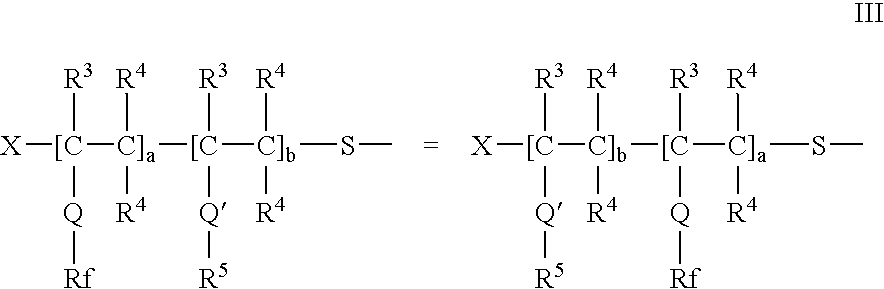

Fluorochemical oligomeric polish composition

InactiveUS20050277718A1Little protectionDifficult to applyFibre treatmentSpecial tyresHard substrateFluorine

A method of treating hard substrates by contacting the substrate with a fluorochemical composition comprising: a fluorochemical urethane component and a base component is described. The compositions provide desirable repellency, antisoiling and anti-staining properties to the substrates.

Owner:3M INNOVATIVE PROPERTIES CO

Method of etching substrates

InactiveUS7012012B2Improve productivityIncrease the number ofPolycrystalline material growthAfter-treatment detailsResistInductively coupled plasma

Thinning and dicing substrates using inductively coupled plasma reactive ion etching (ICP RIE). When dicing, a hard photo-resist pattern or metal mask pattern that defines scribe lines is formed on a sapphire substrate or on a semiconductor epitaxial layer, beneficially by lithographic techniques. Then, the substrate is etched along the scribe lines to form etched channels. An etching gas comprised of BCl3 and / or BCl3 / Cl2 gas is used (optionally, Ar can be added). Stress lines are then produced through the substrate along the etched channels. The substrate is then diced along the stress lines. When thinning, a surface of a substrate is subjected to inductively coupled plasma reactive ion etching (ICP RIE) using BCl3 and / or BCl3 / Cl2 gas, possibly with some Ar. ICP RIE is particularly useful when working sapphire and other hard substrates.

Owner:SUZHOU LEKIN SEMICON CO LTD

Stick resistant ceramic coating for cookware

InactiveUS7093340B2Improve coating adhesionCooking-vessel materialsMolten spray coatingSurface finishCeramic coating

Owner:CLAD METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com