Manufacturing method for flexible element

A component and flexible technology, applied in the direction of electrical components, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as increased manufacturing costs, unstable quality, poor heat resistance of release layers or adhesives, etc. , to achieve the effect of reducing deviation and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

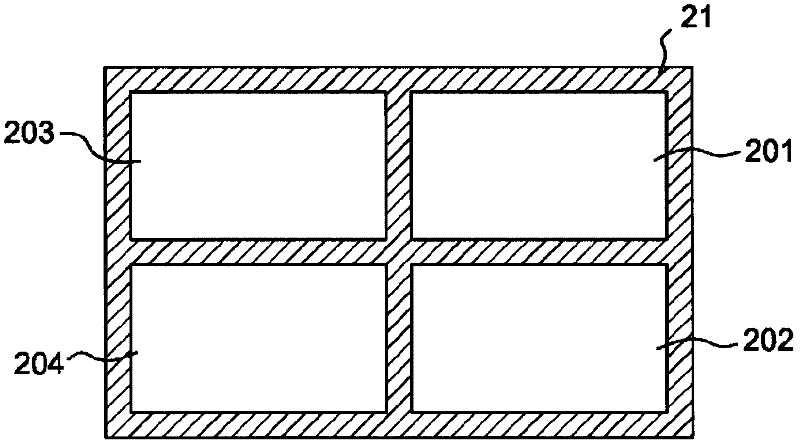

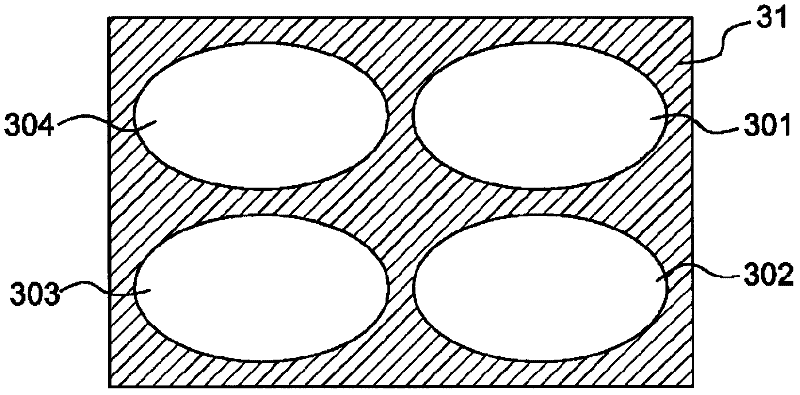

[0043] The term "release area" used herein refers to the area where the flexible substrate is to be separated from the rigid carrier in the method of the present invention.

[0044] The term "adhesion region" used herein refers to the region where the flexible substrate and the rigid carrier are to be in contact through the adhesion promoting layer in the method of the present invention.

[0045] As used herein, the term "a portion of the flexible substrate layer" refers to about 50% to about 99.9% of the flexible substrate layer, preferably about 80% to about 99.5% of the flexible substrate layer.

[0046] The rigid substrate used in the present invention can be any rigid substrate known to those skilled in the art, including but not limited to: glass, quartz, wafer, ceramic, metal or metal oxide.

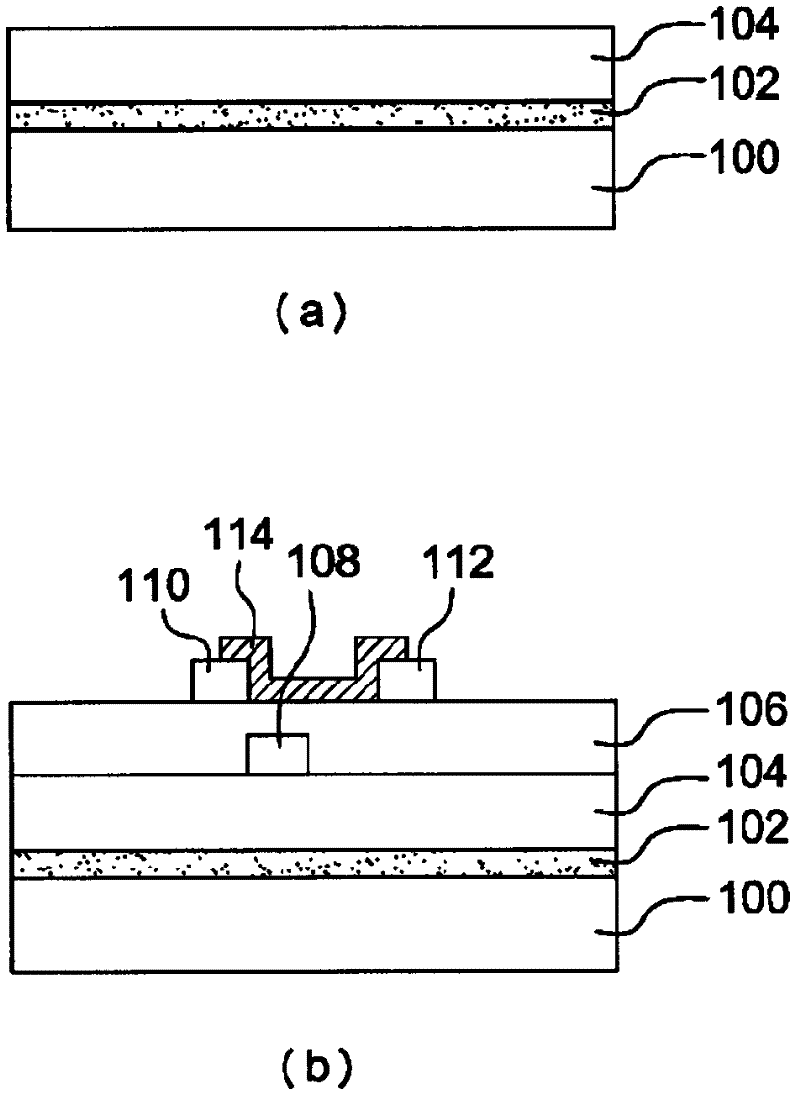

[0047]The key point of the method of the present invention is: before forming the soft substrate layer, an adhesive layer with a predetermined pattern is formed on the rigid carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com