Coatings for cutting tools

a technology of cutting tools and coatings, applied in the field of cutting tools, can solve the problems that titanium is not the only suitable metal for carbonitride coatings, and achieve the effect of improving the adherence and fatigue strength of ceramic coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

COMPARATIVE EXAMPLE

[0026] A tungsten carbide based substrate (94% tungsten carbide, 6% cobalt) of K20 material (K20 is a designation of the type of hard cutting material for machining as set forth in ISO Standard ISO513:1991(E) classified according to the materials and working conditions for which the hard metal cutting material can appropriately be used) was coated according to well-known procedures in a Bemex Programmat 250 coating furnace. The coating process known as chemical vapor deposition (CVD) was used where gasses and liquids (converted to gas) are passed over substrates to be coated at 800° to 1,100° C. and reduced pressures from 50 to 900 mbar. The reactions used to coat the hard metal substrate were as follows:

CVD of TiN−uses H2+N2+Titanium Tetrachloride (TiCl4)

CVD of TiCN−uses H2+N2+TiCl4+Acetonitrile (CH3CN) or CH4

CVD of Al2O3−uses H2+HCl+Aluminum Chloride (AlCl3)+CO2+H2S

[0027] The essential coating periods and atmospheres used to apply the titanium nitride layer, th...

example ii

[0032] A coating, according to this invention, was prepared on a tungsten carbide based substrate in the coating furnace above described with the coating periods and atmospheres as described in Tables IV, V and VI.

TABLE IVRun TimeMillibar Reactor° C. ReactorCoatingMinutesPressureTemp.TiN60160920TiCN240801005Al2O3540601005

[0033]

TABLE VGas ReactantsLiter / MinuteCoatingH2N2CO2CH4HClH2STiN149TiCN11.380.6Al2O3110.60.2.050

[0034]

TABLE VIAlCl3 GasGeneratorLiquid Reactantsl / minml / minCoatingH2HClCH3CN LiquidTiCl4 LiquidTiN2.1TiCN0.9Al2O31.90.8

[0035] Tables IV, V and VI, in addition to showing the run times, reaction pressures and temperatures, show the rate of gas reactants, aluminum chloride generator reactants and the liquid reactants. The gas reactants introduced into the aluminum chloride generator flow over aluminum metal chips producing a quantity of aluminum chloride which is passed into the coating furnace.

[0036] X-ray analysis of the titanium carbonitride layer demonstrated a latti...

example iii

[0038] Example III was prepared the same as Example II except the nitrogen was lower in the coating furnace during the deposition of the carbonitride layer. The lattice spacing in the titanium carbonitride layer was found to be 1.509 which represents a nitrogen to carbon atomic ratio of 21:30 or a nitrogen content of 70%.

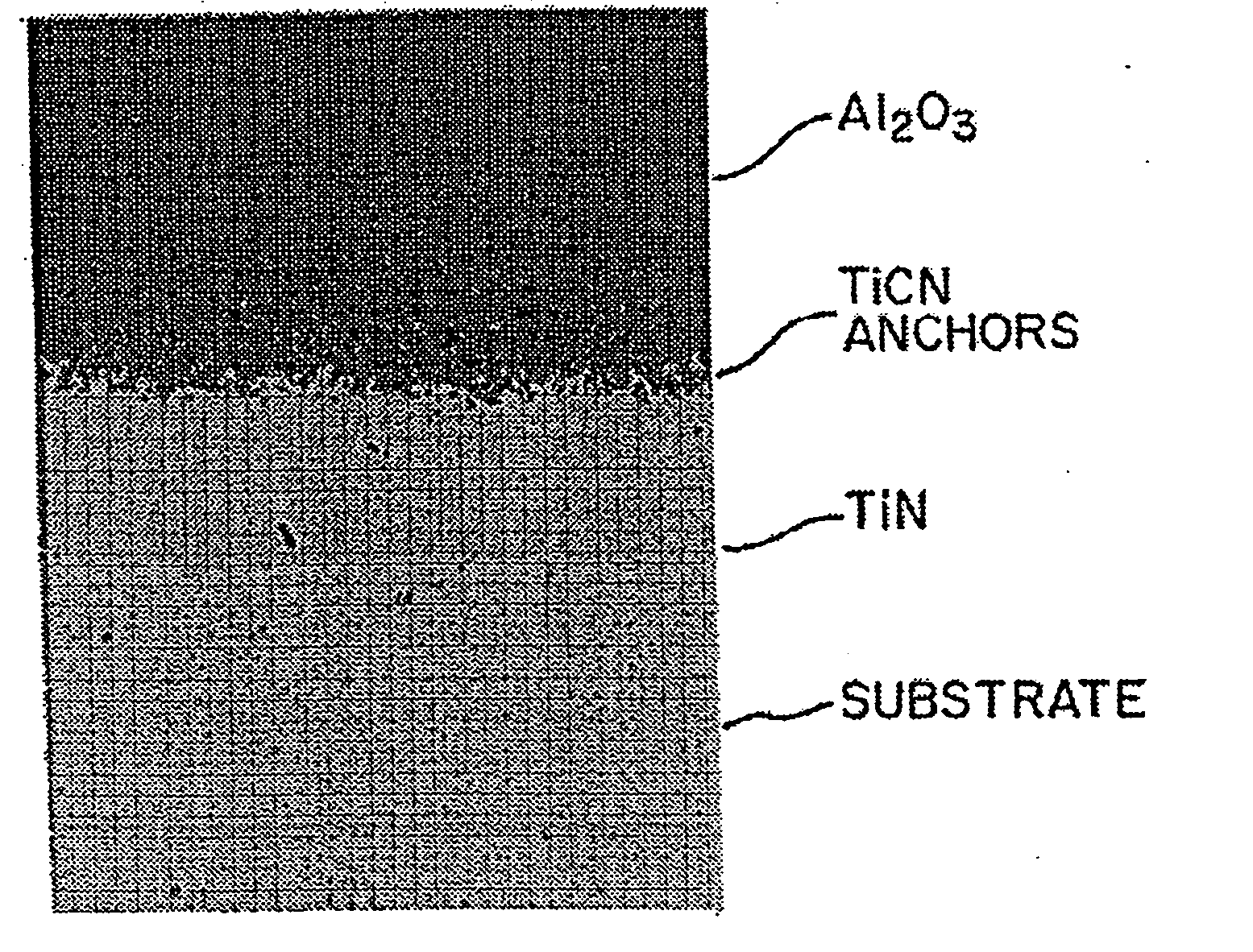

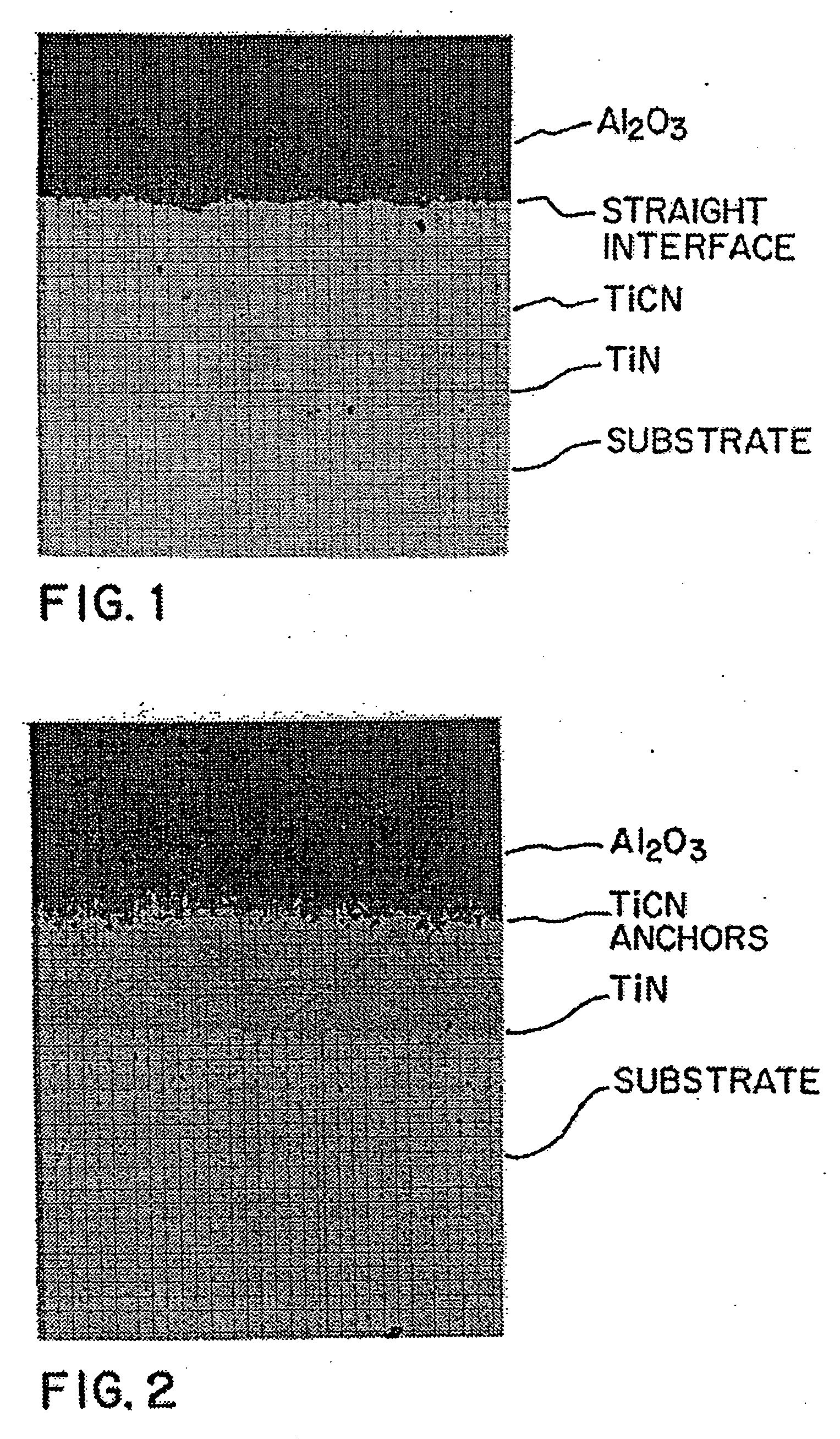

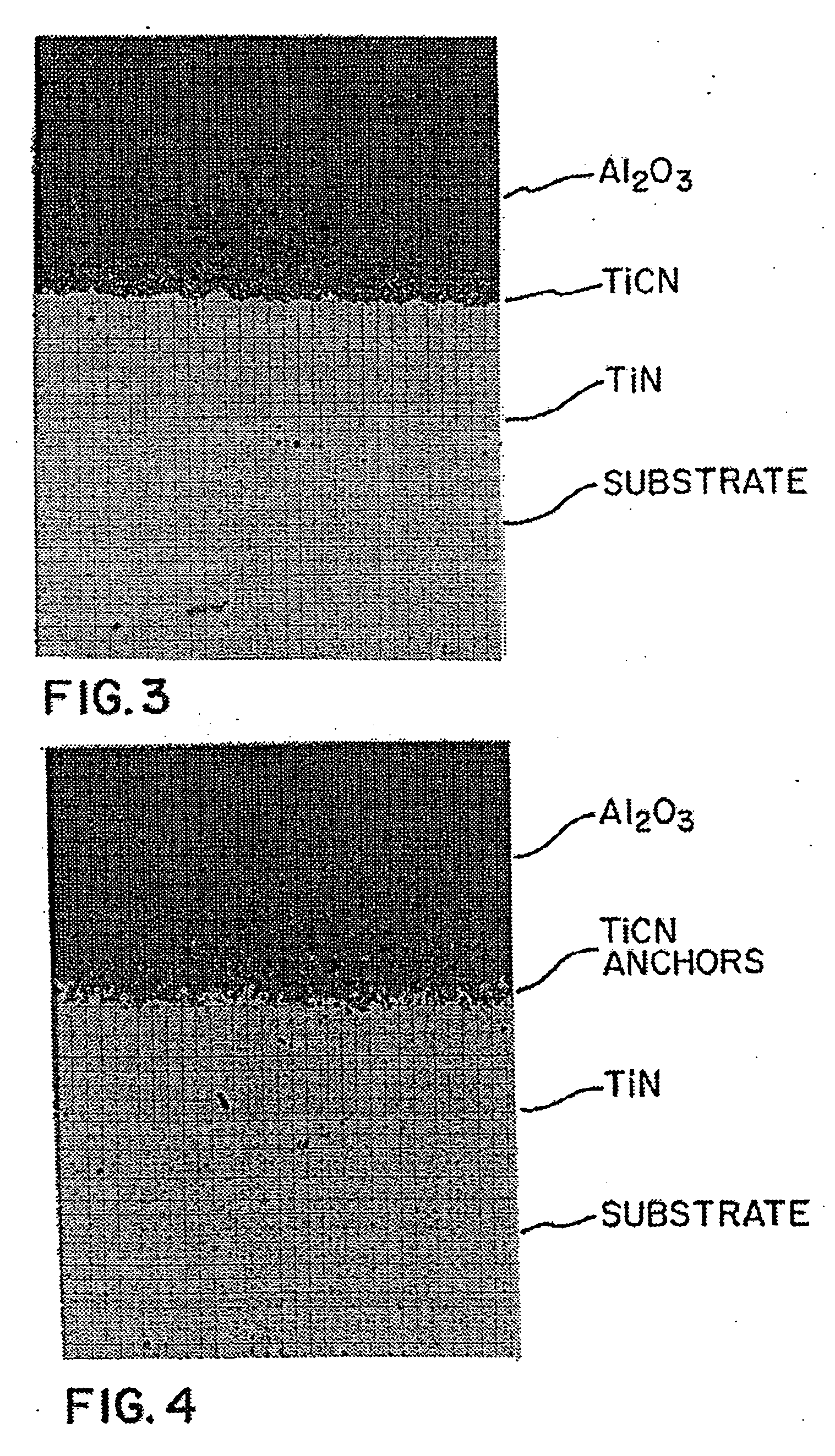

[0039] In the machining test, fretting was displayed only after a 5-inch cut length (estimated 40 to 50 seconds). The microstructure of Example II shown in FIG. 3 anchors between the oxide and the titanium carbonitride layers are displayed but are very minor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com