Flexible pressure sensor and preparation method thereof

A pressure sensor, flexible technology, applied in the field of semiconductors, can solve the problems of easy aggregation of carbon nanotubes, low repeatability, poor stability, etc., and achieve the effect of simple preparation process, good performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

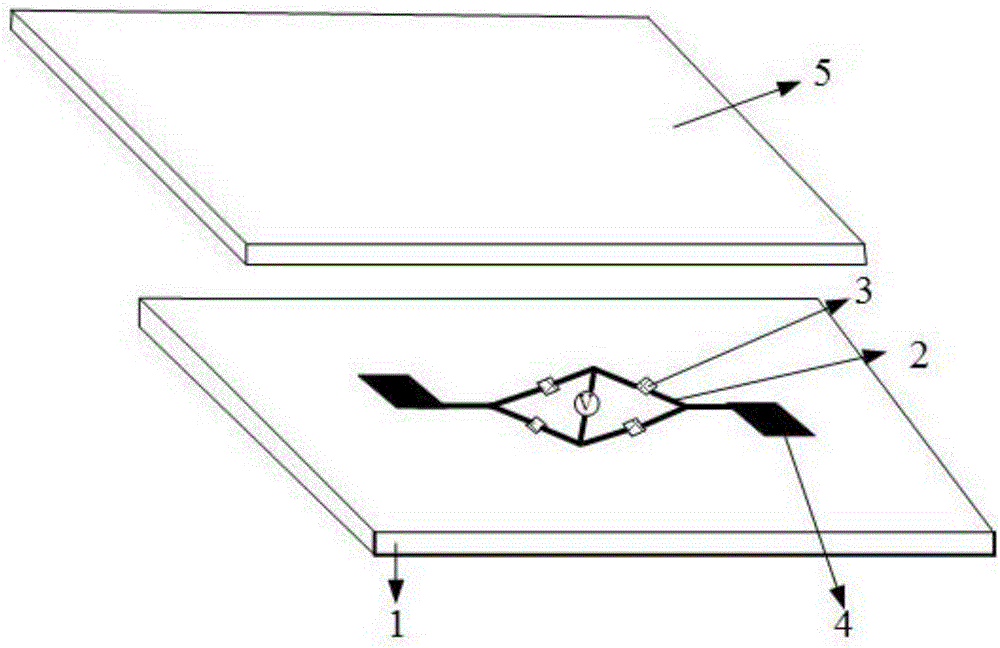

[0039] Such as figure 1 Shown: a flexible pressure sensor, including a flexible substrate 1, a flexible upper cover 5 and electrodes 4 spaced between the flexible substrate 1 and the flexible upper cover 5, the electrodes 4 are arranged between There is a circuit composed of a semiconductor resistor 3 and a conductive channel 2.

[0040] The circuit is a Wheatstone bridge, and the material of the electrode 4 is Au.

[0041] The semiconductor resistor 3 is made of carbon nanotube / polyimide composite material.

[0042] The material of the flexible substrate 1 and the flexible upper cover 5 is polyimide.

[0043] Preparation

[0044] A method for preparing a flexible pressure sensor, comprising the steps of:

[0045] 1. The flexible substrate 1 is formed on a hard substrate by spin coating and then solidified. Specifically, the hard substrate is a silicon substrate. First, the silicon substrate is cleaned and cleaned with dilute sulfuric acid solution, Acetone solution, etc....

Embodiment 2

[0058] A flexible pressure sensor, comprising a flexible substrate 1, a flexible upper cover 5, and electrodes 4 spaced between the flexible substrate 1 and the flexible upper cover 5, and semiconductor resistors are arranged between the electrodes 4 3 and the circuit composed of conductive channel 2.

[0059] The circuit is a Wheatstone bridge. The material of the electrode 4 is Ti / Cu.

[0060] The semiconductor resistor 3 is made of carbon nanotube / polyethylene terephthalate (PET) composite material.

[0061] The material of the flexible substrate 1 and the flexible upper cover 5 is polydimethylsiloxane (PDMS).

[0062] Preparation

[0063] A method for preparing a flexible pressure sensor, comprising the steps of:

[0064] 1) The flexible substrate 1 is formed on a hard substrate by spin coating and then solidified. Specifically, the hard substrate is a silicon substrate. Acetone solution, etc. are used for pollutant treatment, and then ultrasonically cleaned with deio...

Embodiment 3

[0077] A flexible pressure sensor, comprising a flexible substrate 1, a flexible upper cover 5, and electrodes 4 spaced between the flexible substrate 1 and the flexible upper cover 5, and semiconductor resistors are arranged between the electrodes 4 3 and the circuit composed of conductive channel 2.

[0078] The circuit is a Wheatstone bridge. The material of the electrode 4 is Ag.

[0079] The semiconductor resistor 3 is made of carbon nanotube / graphene composite material.

[0080] The material of the flexible substrate 1 is polyethylene terephthalate (PET).

[0081] The material of the flexible upper cover 5 is micro polyimide.

[0082] Preparation

[0083] A method for preparing a flexible pressure sensor, characterized in that it comprises:

[0084] (1) The flexible substrate 1 is formed on the hard substrate by spin coating and then solidified. Specifically, the hard substrate adopts a PET substrate. First, the PET substrate is cleaned and cleaned with dilute sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com