Patents

Literature

404results about How to "Avoid process problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

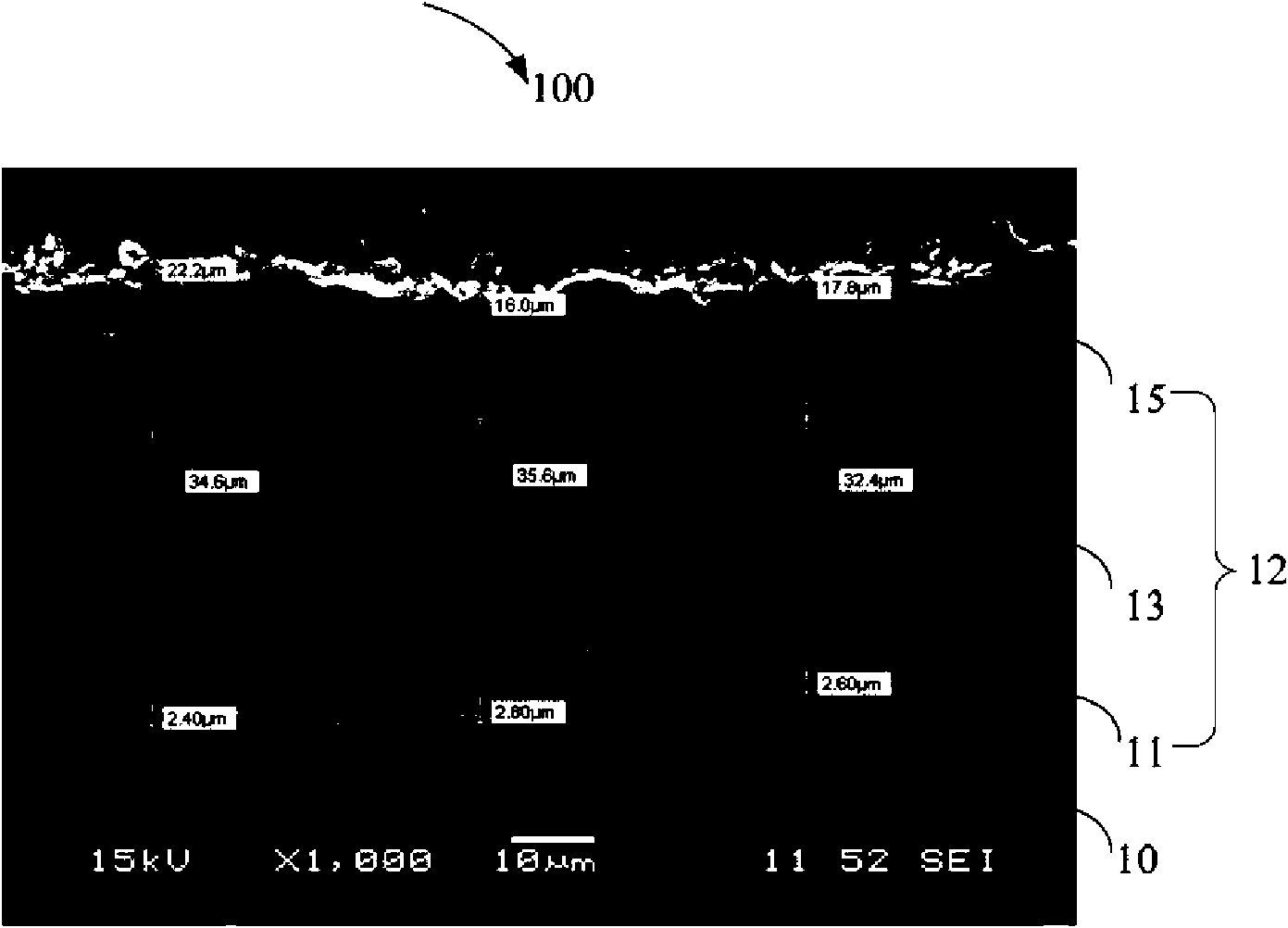

Aluminum alloy with micro-arc oxide ceramic membrane on surface and preparation method thereof

ActiveCN101608332AAvoid process problemsIncrease productivityAnodisationThin material handlingOxide ceramicPlasma electrolytic oxidation

The invention relates to an aluminum alloy which comprises an aluminum alloy matrix and a micro-arc oxide ceramic membrane formed on the surface of the matrix, wherein the ceramic membrane comprises a bottom transition layer, a middle compact layer and a surface compact layer. The preparation method of the aluminum alloy, which is used for forming the micro-arc oxide ceramic membrane without a loose layer on the surface of the aluminum alloy, comprises the following steps: putting the aluminum alloy matrix in an oxidation tank containing electrolyte; carrying out initial oxidation treatment for the aluminum alloy matrix by adopting constant current; and continuously applying oxidation treatment to the aluminum alloy matrix by adopting positive and negative bidirectional pulse voltage, wherein positive and negative voltage keeps constant after rising to the maximum value, wherein the maximum constant positive voltage is 450V-650V, the maximum constant negative voltage is 30V-200V, the width of positive and negative pulse is 1000-10000mus, the pulse interval is 300-2000mus, the continuous oxidation treatment time is 30-180min, and the treatment temperature is between 20 DEG C and 50DEG C.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

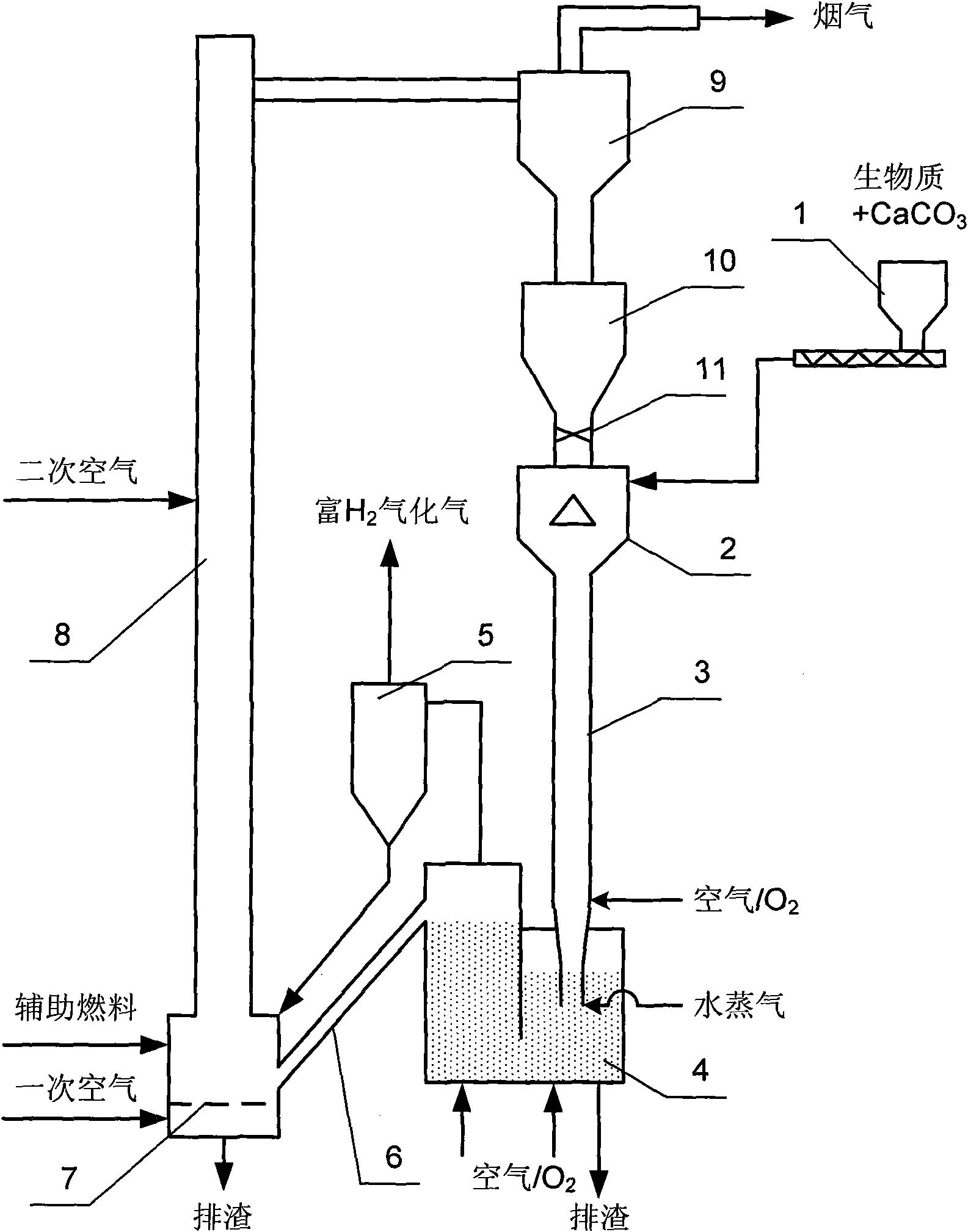

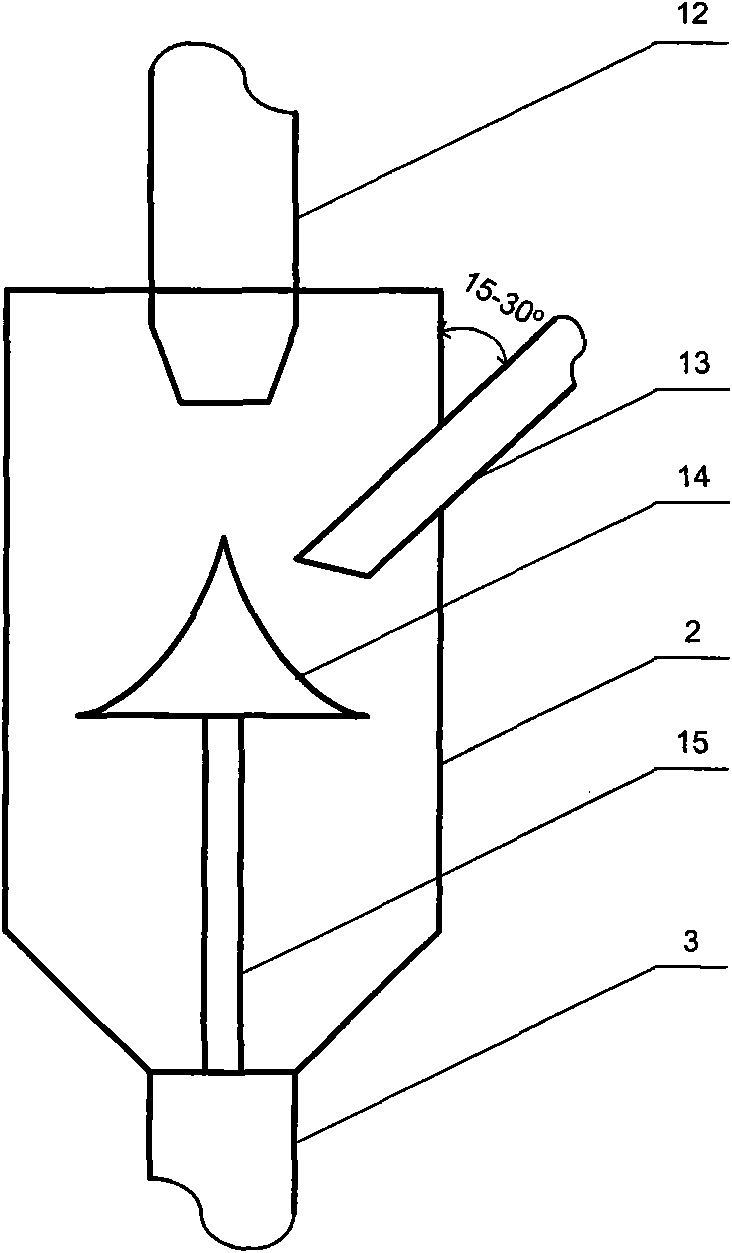

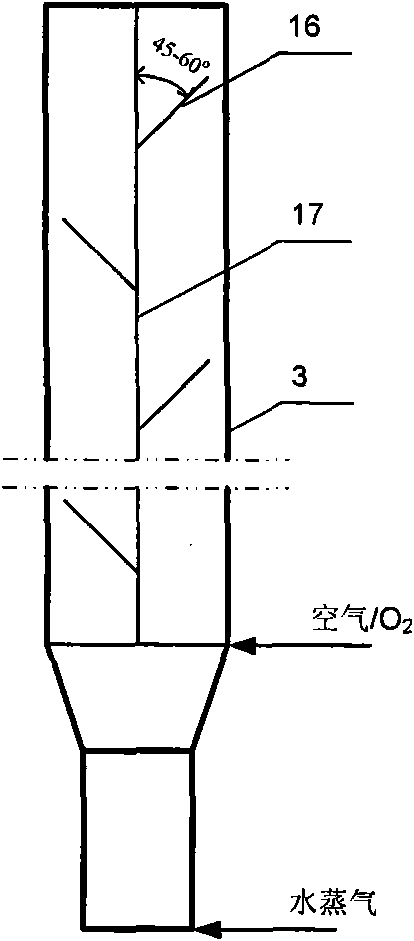

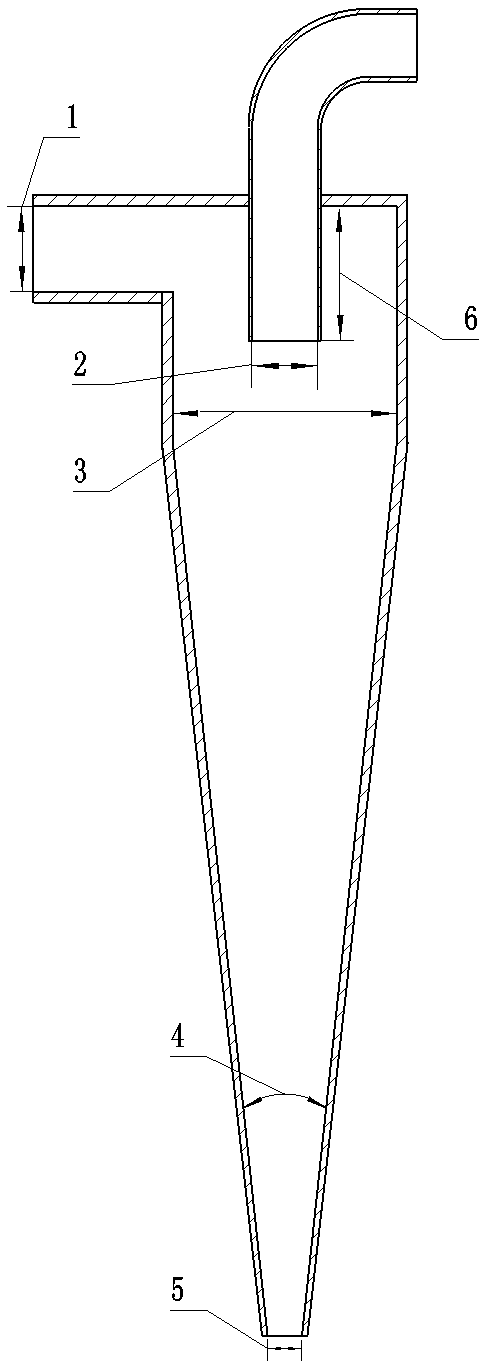

Gasification device and method for preparing hydrogen-rich synthetic gas from biomass

ActiveCN101880552AAvoid aggregate growthUniform temperature distributionGranular/pulverulent flues gasificationTarHeat carrier

The invention provides a gasification device and a gasification method for preparing hydrogen-rich synthetic gas from biomass. The device comprises a biomass feeder, a mixer, a pyrolysis chamber, a gasification chamber, a gasified gas separator, a combustion chamber, a flue gas separator, a bin and a butterfly valve. In the method, the biomass gasifying process is divided into three parts, namelybiomass pyrolysis, semicoke gasification and heat carrier circulation. Through the method and the device, the synthetic gas with the tar content less than 200mg / Nm<3> and the H2 / CO ratio more than 1.1 can be obtained, and the energy utilization rate and the process economy are obviously improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

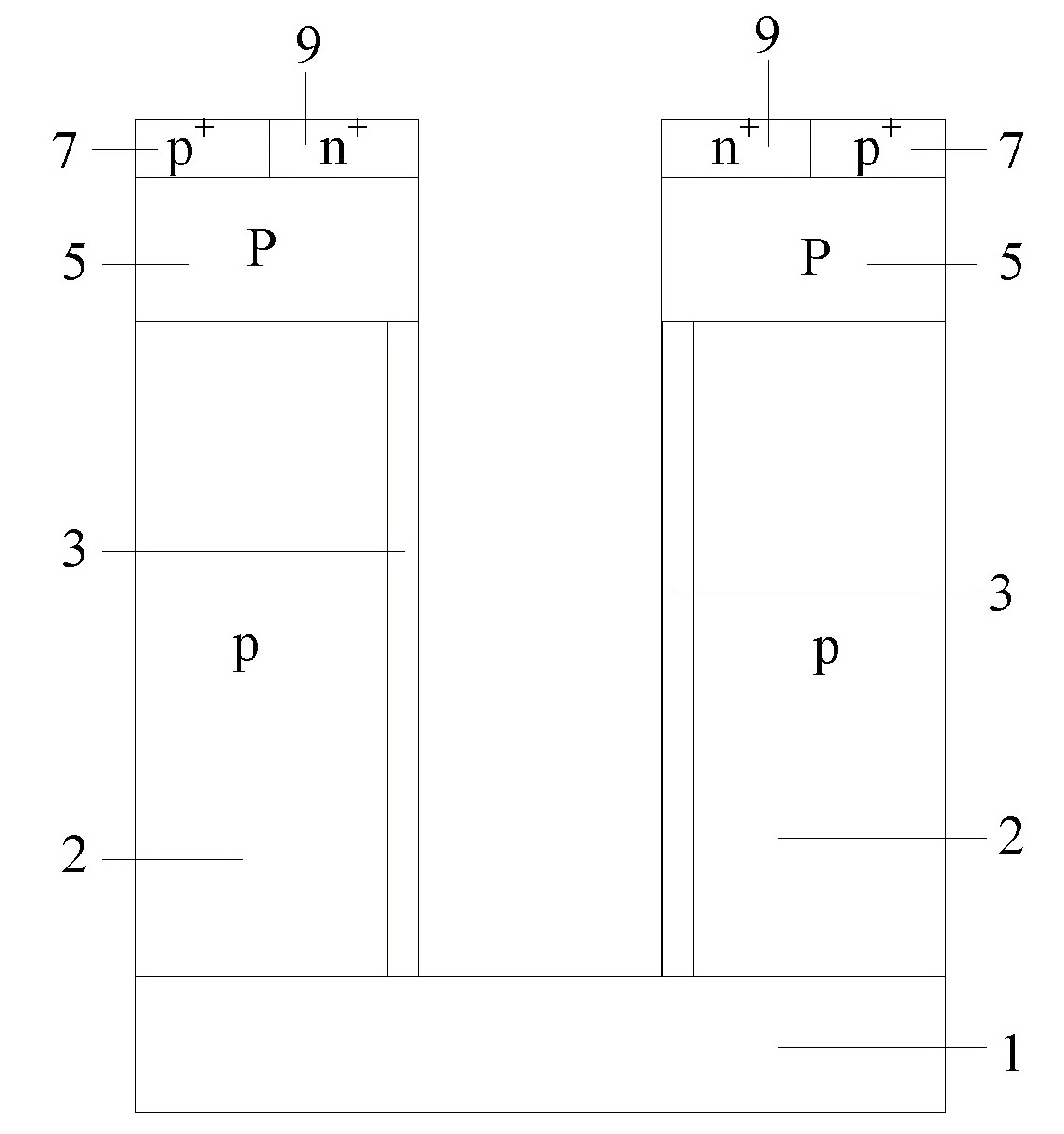

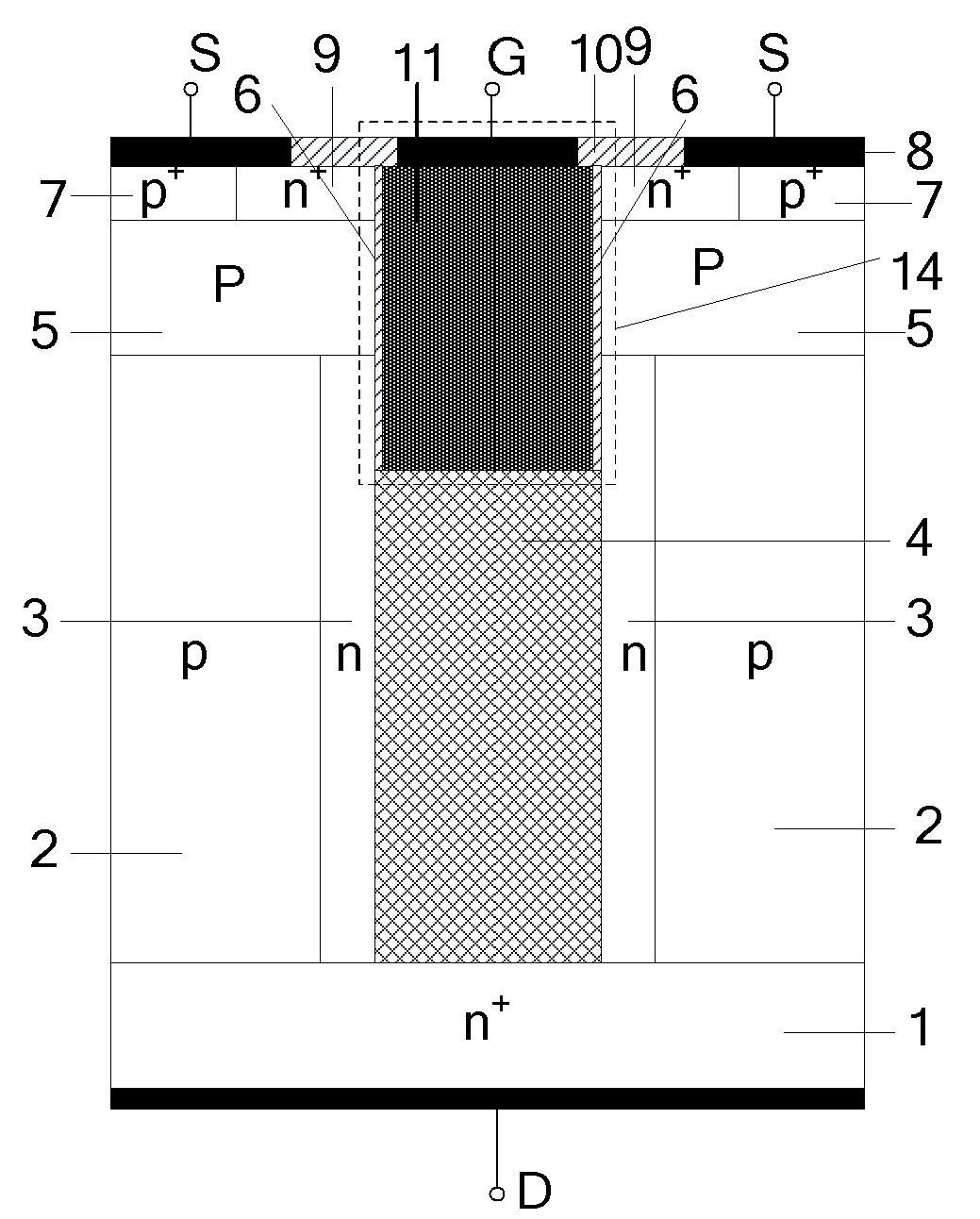

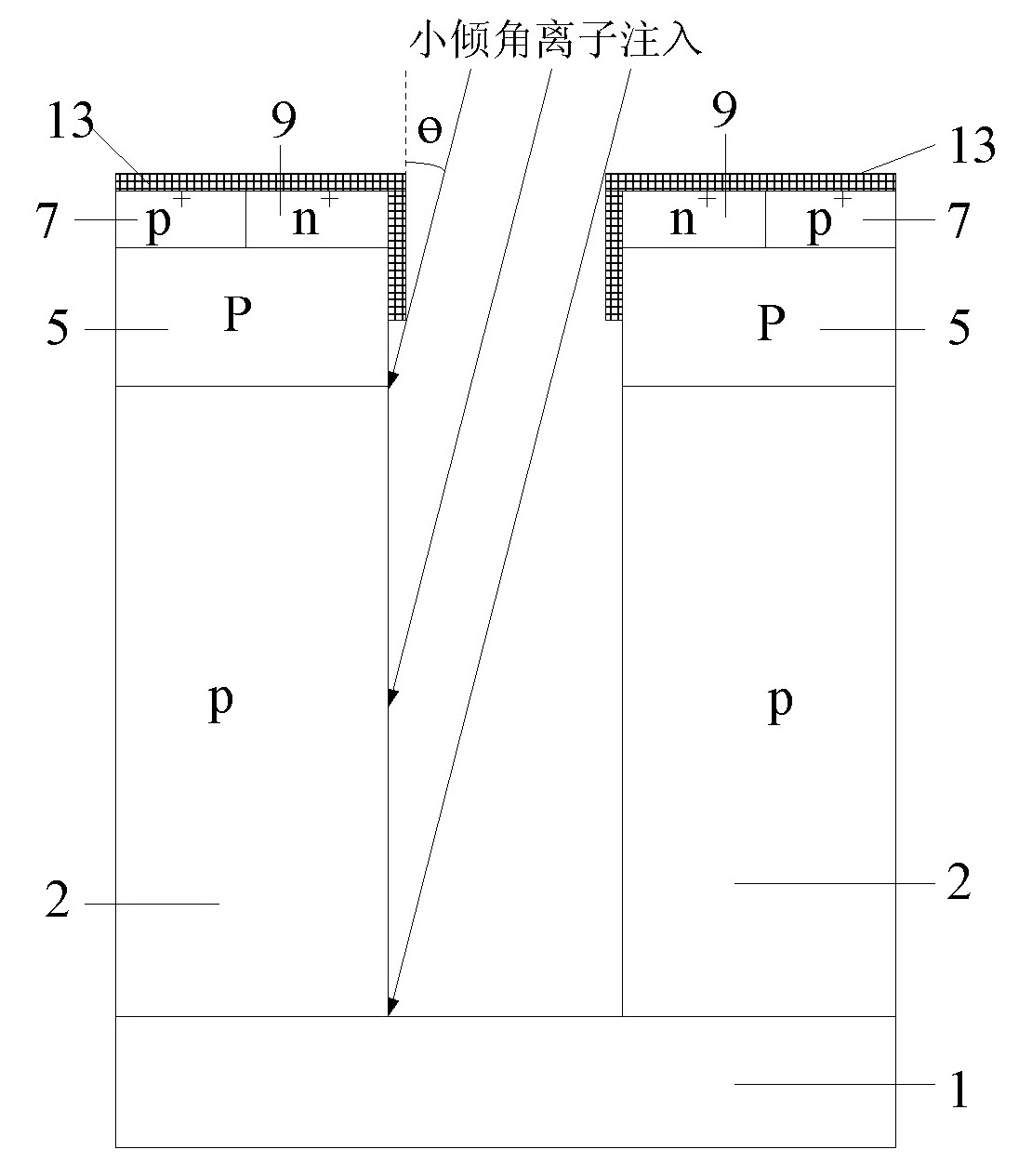

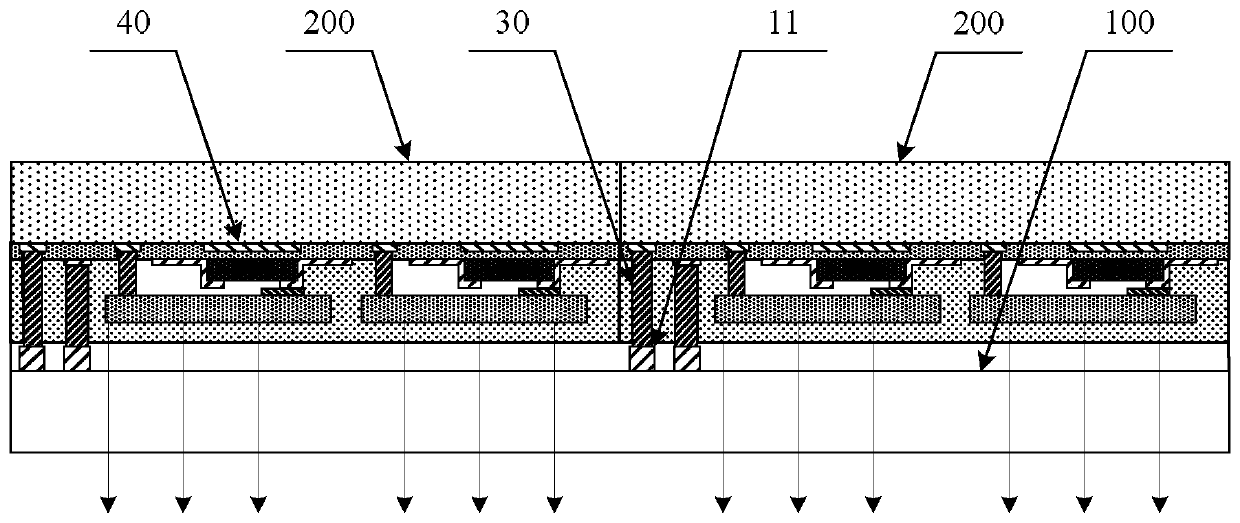

Trench type semiconductor power device

InactiveCN102110716AReduce areaLower on-resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationPower semiconductor device

The invention relates to a semiconductor device. The device comprises a semiconductor substrate, a semiconductor drift region on the semiconductor substrate, a high-K dielectric on the semiconductor substrate, an active region on the semiconductor drift region and a trench gate structure on the high-K dielectric, wherein the semiconductor drift region comprises a first conduction type semiconductor region and a second conduction type semiconductor region which form a super-junction structure; the high-K dielectric is adjacent to the second conduction type semiconductor region; the trench gate structure is adjacent to the active region; and the second conduction type semiconductor region is formed through ion implantation at a small inclination angle, so that the semiconductor device is narrow and has high concentration.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

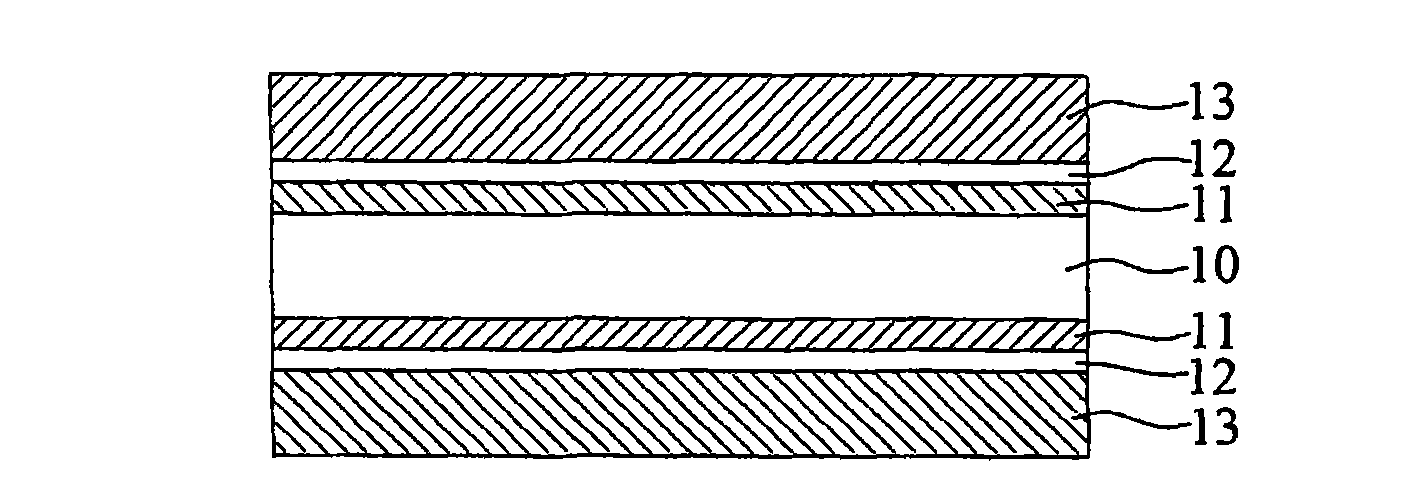

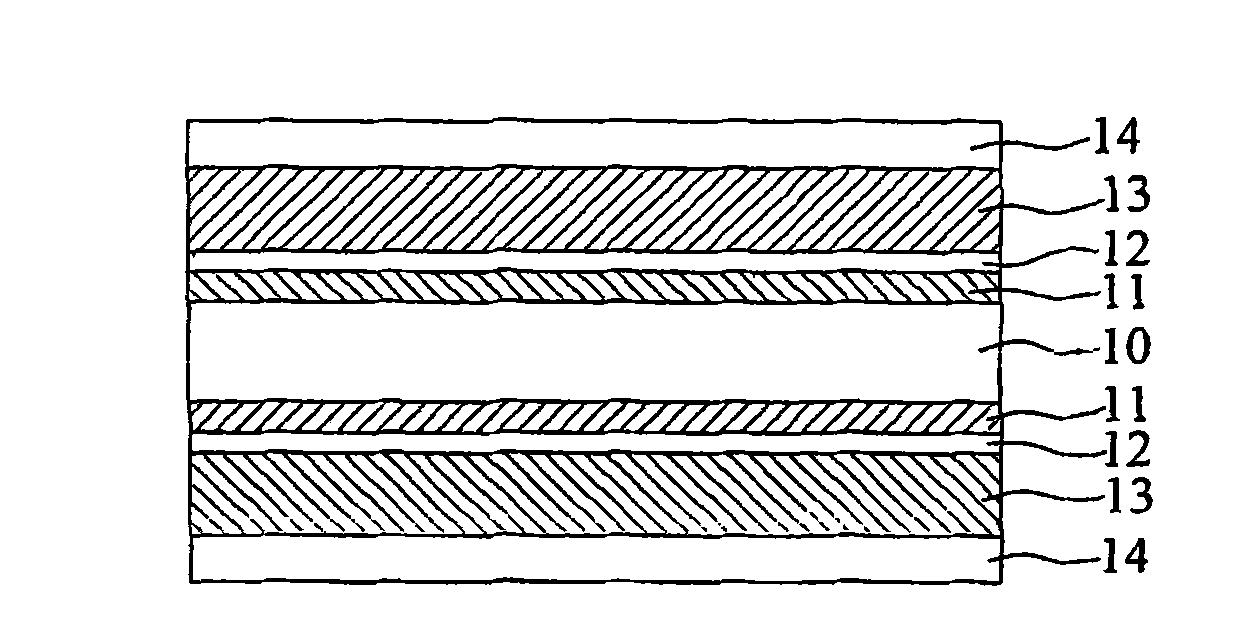

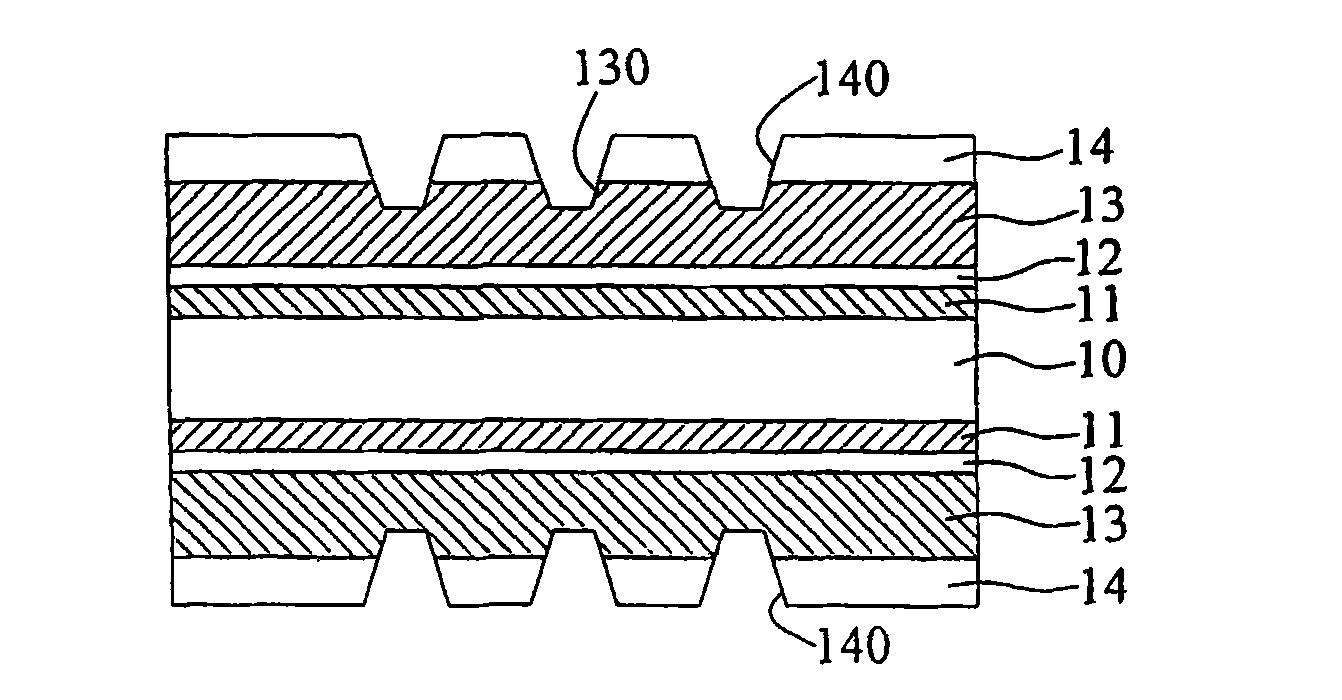

Packaging substrate as well as manufacturing method and base material thereof

ActiveCN101989592ASimple manufacturing processAvoid wastingSemiconductor/solid-state device detailsSolid-state devicesDielectric layerLine structure

The invention discloses a packaging substrate as well as a manufacturing method and a base material thereof. The manufacturing method of the packaging substrate comprises the following steps: two metal layers are mutually laminated, and a dielectric layer is utilized to clad the two metal layers; next, layer increasing line structures are respectively formed at the two sides of the dielectric layer; and finally, the layer increasing line structures at the two sides of the dielectric layer are separated along the interface of the two metal layers so that two packaging substrates are formed. In the invention, the adhesion characteristics of the dielectric layer is utilized so that the two metal layers in the middle cannot be separated in the course of forming the layer increasing line structures in the initial stage, and the dielectric layer part around the two metal layers is cut off to successfully separate the two metal layers so that the manufacturing process is simplified, and the two metal layers in the middle can form a line layer, a metal lug or a supporting structure through the pattering manufacturing process and have no waste.

Owner:UNIMICRON TECH CORP

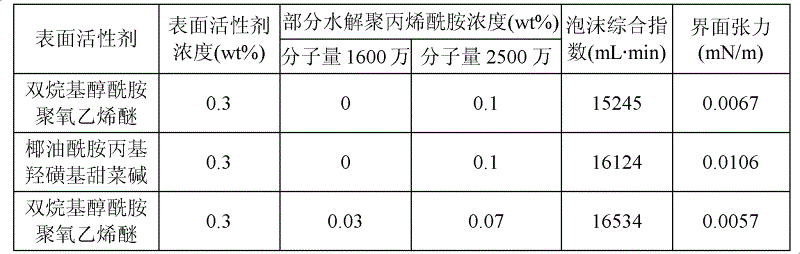

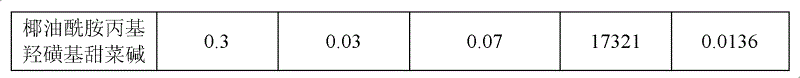

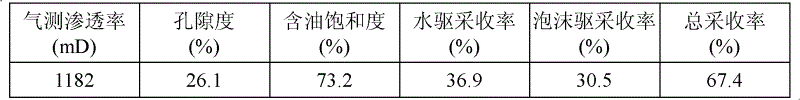

Composite foam flooding method suitable for oil field exploitation

ActiveCN102618246AImprove applicabilityMeet the use requirementsDrilling compositionInjection volumePolymer science

The invention relates to a composite foam flooding method suitable for oil field exploitation, comprising the following steps that: pretreated prepositive polymer plug is injected into the formation, and the injection volume of the polymer plug is 8-15% of the total pore volume of the formation; composite foam flooding auxiliary plug is injected into the formation, and the injection volume of the composite foam flooding auxiliary plug is 5-10% of the total pore volume of the formation; composite foam flooding main plug is injected into the formation, and the injection volume of the composite foam flooding main plug is 30-60% of the total pore volume of the formation; and follow-up protective polymer plug is injected into the formation, and the injection volume of the follow-up protective polymer plug is 10-20% of the total pore volume of the formation. With the adoption of the composite foam flooding method suitable for oil field exploitation, a good flooding effect can be obtained.

Owner:PETROCHINA CO LTD +1

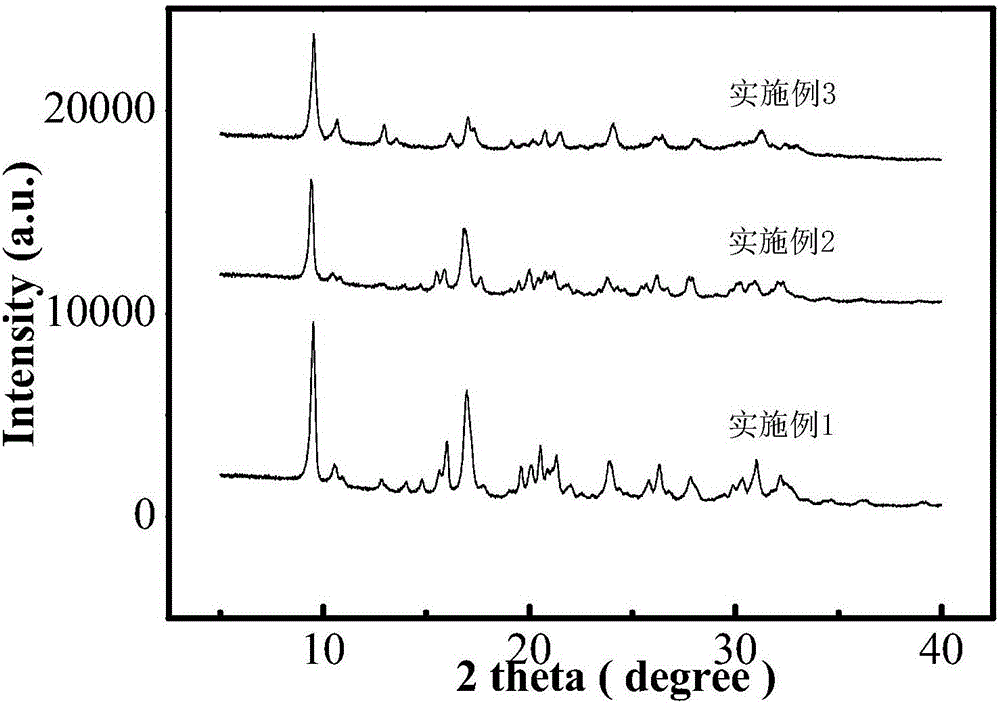

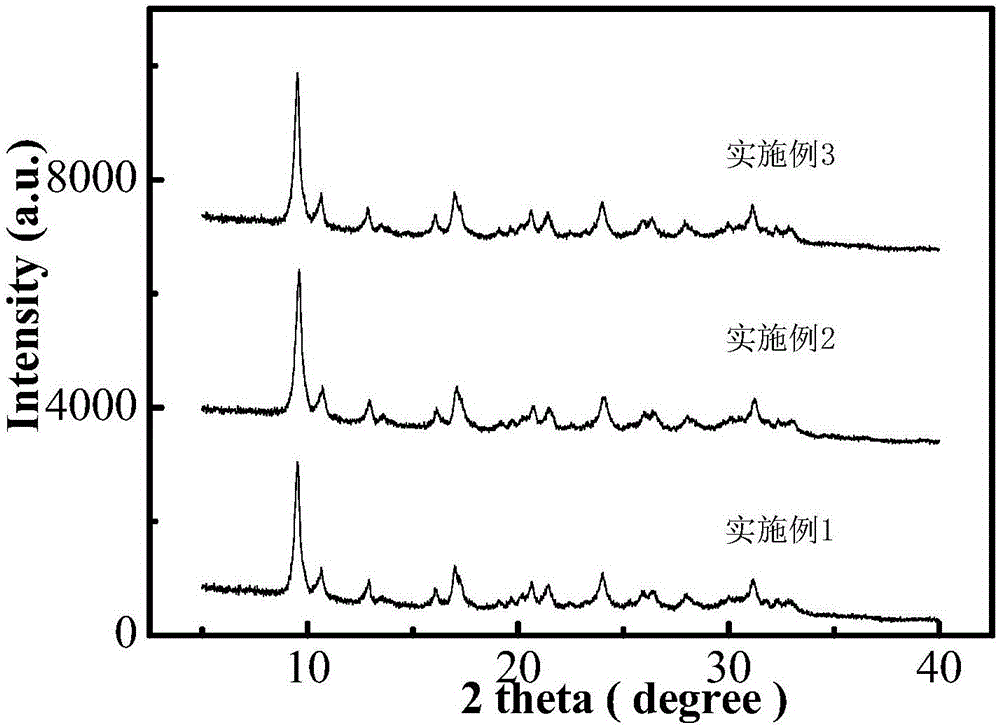

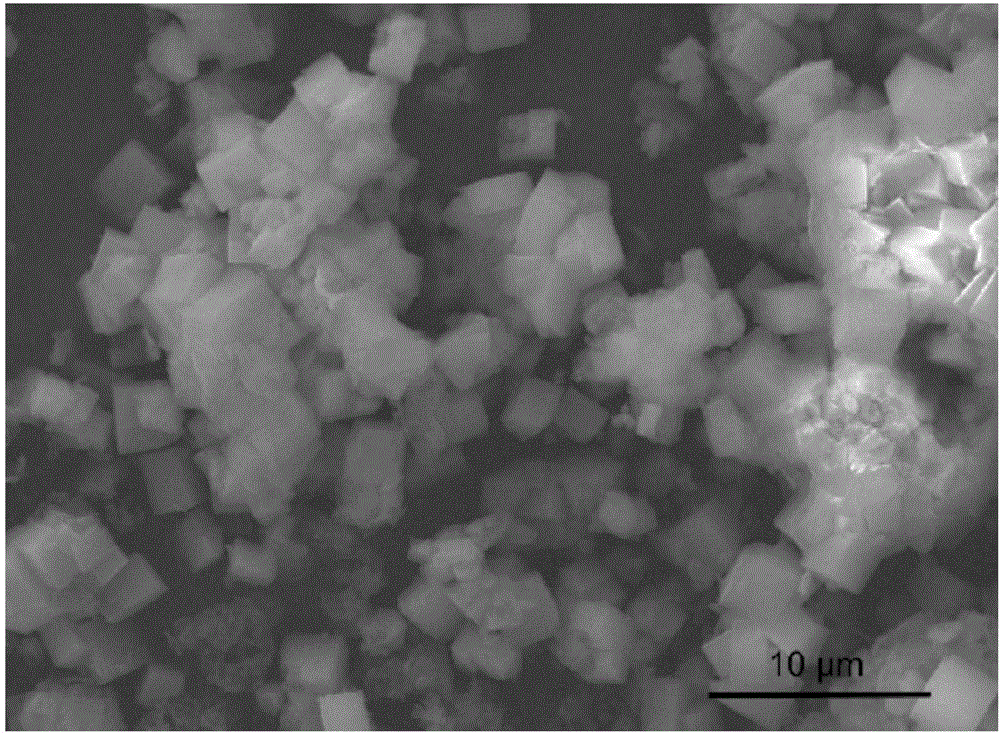

Preparation method for synthesizing Cu-SSZ-39 molecular sieve based catalyst by using one-step method and application

InactiveCN106799255AHigh crystallinityGood catalytic activityGas treatmentMolecular sieve catalystsIon exchangeIon

The invention provides a preparation method for synthesizing a Cu-SSZ-39 molecular sieve based catalyst by using a one-step method and application. By using the one-step method, the Cu-SSZ-39 molecular sieve based catalyst is synthesized through a double template; the copper load is controlled at 2.00-5.00 wt.% by controlling the input ratio of copper sulfate-tetraethylenepentamine to the organic template; and meanwhile, the silica-alumina ratio of USY is controlled to reach the silica-alumina ratio of 4.5-16.4 in the controlled product so that the Cu-SSZ-39 molecular sieve based catalyst with higher degree of crystallization, excellent catalytic activity and hydrothermal stability; and the Cu-SSZ-39 molecular sieve based catalyst is suitable for the nitrogen oxide purification processes in diesel vehicle aftertreatment Urea-SCR system catalysts and fixed sources NH3-SCR. Compared with the existing synthetic method, the preparation method for synthesizing the Cu-SSZ-39 molecular sieve based catalyst by using the one-step method, provided by the invention, has the advantages that the process is simple, repeated uses of an ammonium nitrate and copper salt solution ion exchanging and calcining process are avoided, and a defect that the traditional one-step synthetic method can only load an active component through the later ion exchanging process is overcome. By using the cheap template, the preparation method for synthesizing the Cu-SSZ-39 molecular sieve based catalyst by using the one-step method greatly reduces the production cost and is beneficial for industrial amplification applications.

Owner:HUAZHONG UNIV OF SCI & TECH

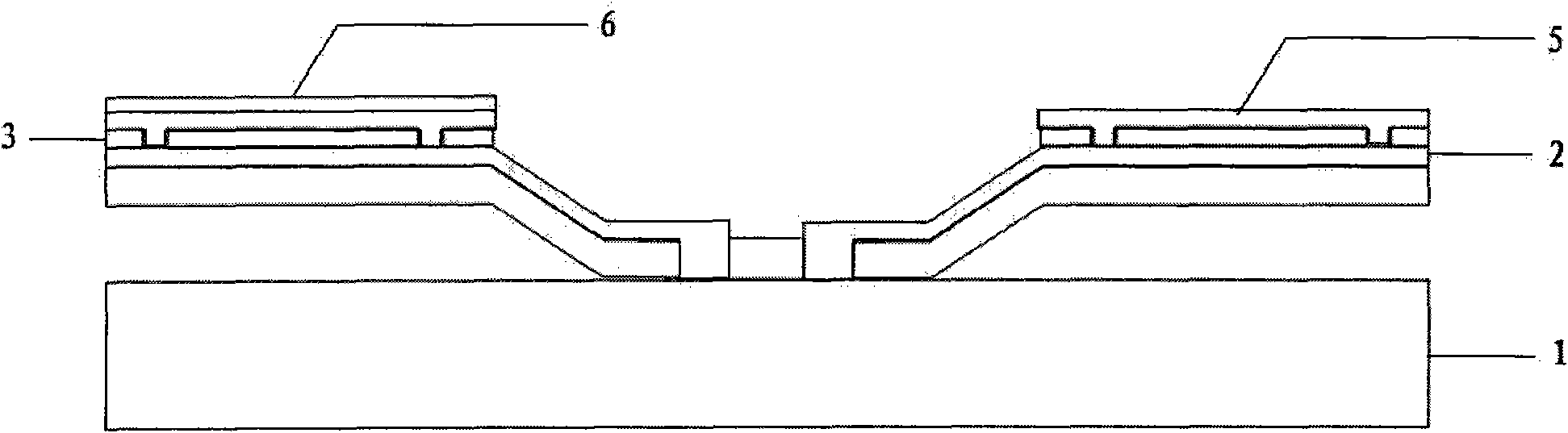

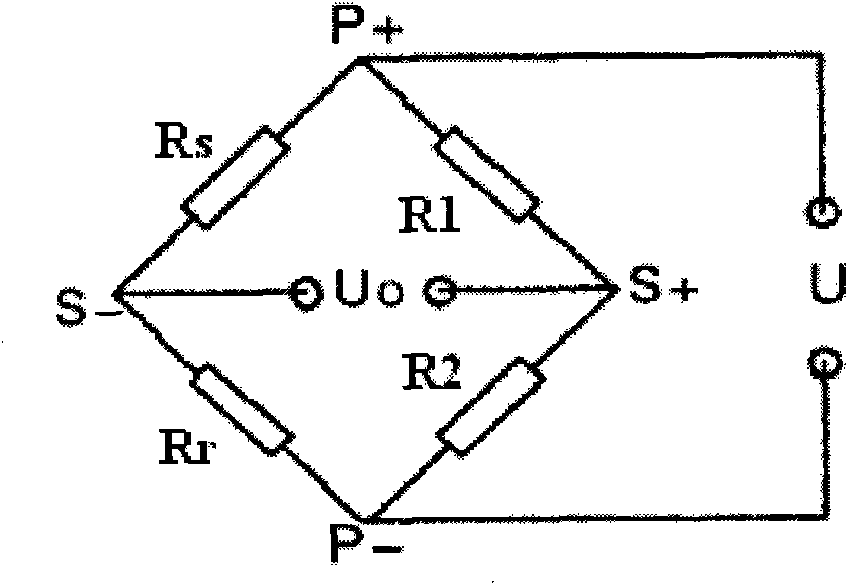

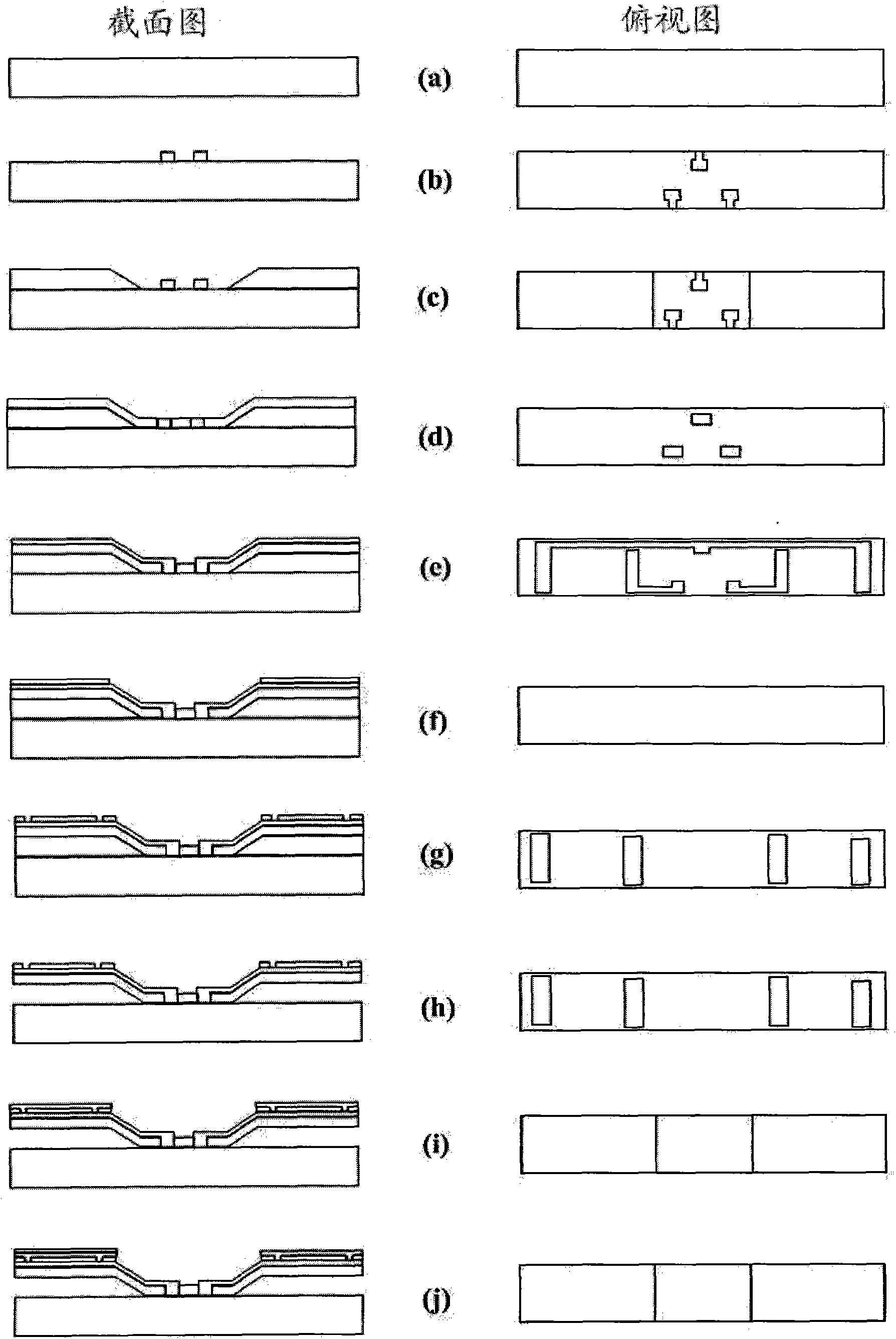

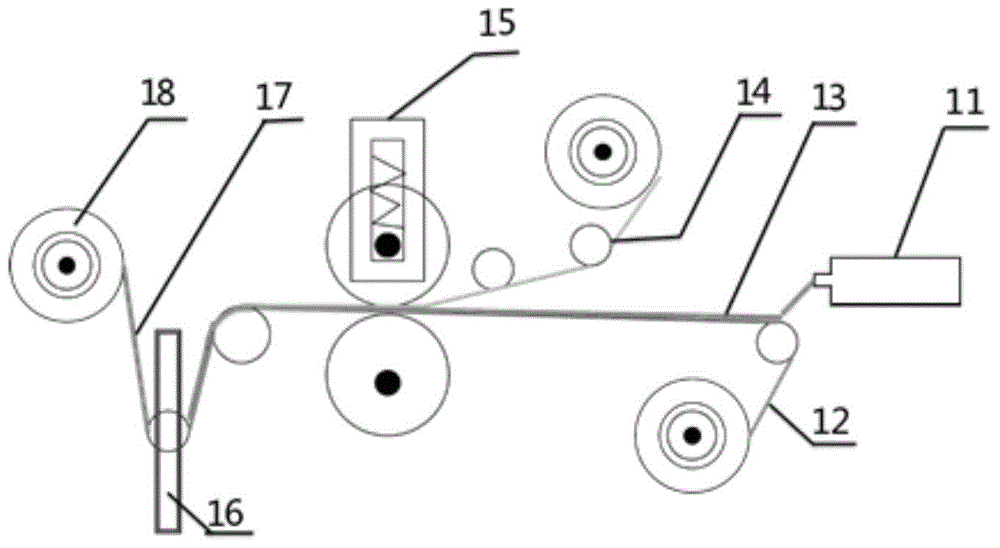

Micro-cantilever gas sensor and manufacturing method thereof

InactiveCN101936937ARealize unilateral manufacturingAvoid process problemsDecorative surface effectsMaterial resistanceElectrical resistance and conductancePolyelectrolyte

The invention discloses a micro-cantilever gas sensor comprising sensing units and is characterized in that each group of sensing units comprises two micro-cantilevers, wherein the two micro-cantilevers can be a measuring cantilever and a reference cantilever, and a Wheaston bridge is formed by the measuring cantilever and the reference cantilever and two matching resistors; the measuring cantilever and the reference cantilever are connected to adjacent bridge arms of the Wheastone bridge, and the surface of the measuring cantilever is provided with a pressure-sensitive layer and an air-sensitive layer; a layer of polyelectrolyte polydiene propyl ammonium chloride film is deposited on the surface of the reference cantilever; and a photosensitive polyimide is used as a sacrifice layer material to connect an upper electrode with a lower electrode of each sensing unit through an inverse-splay window. The sensor has the advantages of simple structure, higher test sensitivity, and has wide application prospect in fields, such as environment monitoring, food safety, military and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

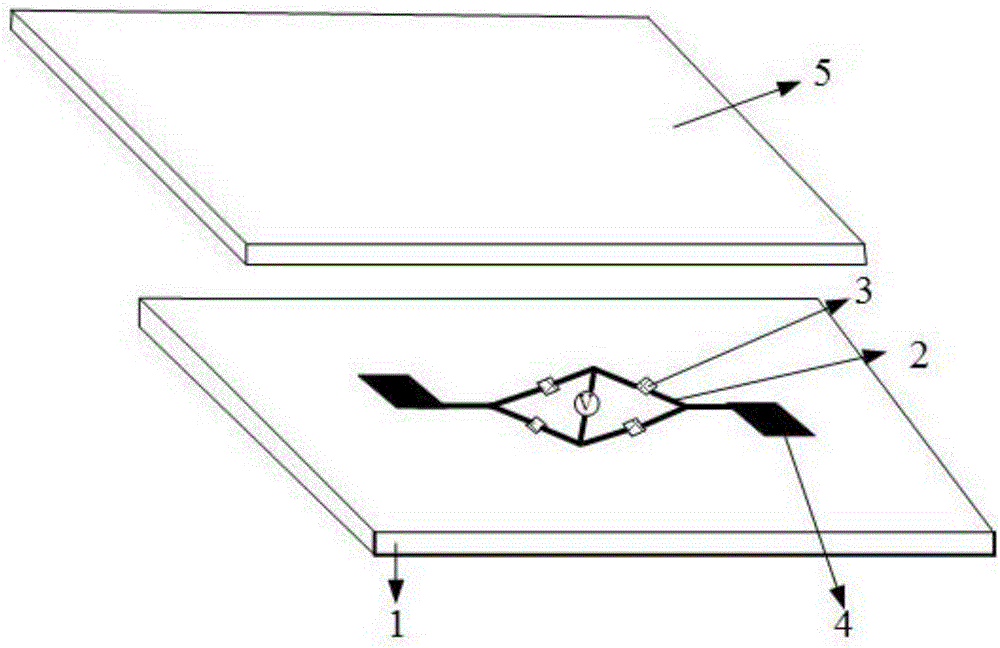

Flexible pressure sensor and preparation method thereof

ActiveCN106441646ARealize integrated manufacturingSimple preparation processForce measurement using piezo-resistive materialsMicro nanoElectrical resistance and conductance

The invention provides a flexible pressure sensor. The flexible pressure sensor comprises a flexible substrate, a flexible upper cover and electrodes arranged between the flexible substrate and the flexible upper cover at intervals. A circuit with semiconductor resistors and conductive channels is arranged between the electrodes. The micro-nano processing technology is combined with the modern printing electronic technology, so the Wheatstone bridge type pressure sensor can be built on the pure flexible substrate, the defects that the process of a technology for preparing a hard substrate (like silicon) pressure sensor through a traditional semiconductor technology is complex, and influences of the high-temperature technology are large are avoided, and integrated preparation of the flexible sensor is achieved. The micro-nano processing technology, the modern printing electronic technology, nano-carbon materials, polymer materials and the like are combined, so the flexible pressure sensor of a Wheatstone bridge structure is prepared on the flexible substrate, and the pressure sensor is simple in preparation process, low in cost, good in performance and suitable for large-scale production.

Owner:江苏科华智能控制设备有限公司

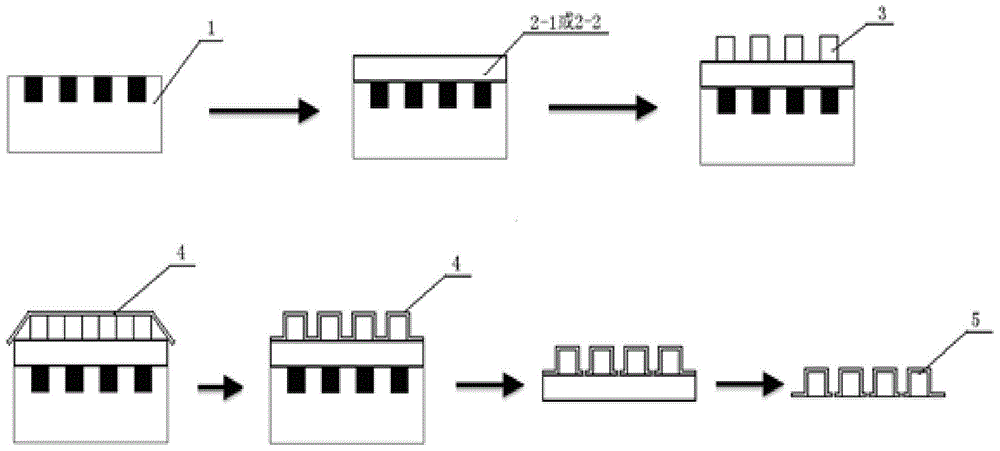

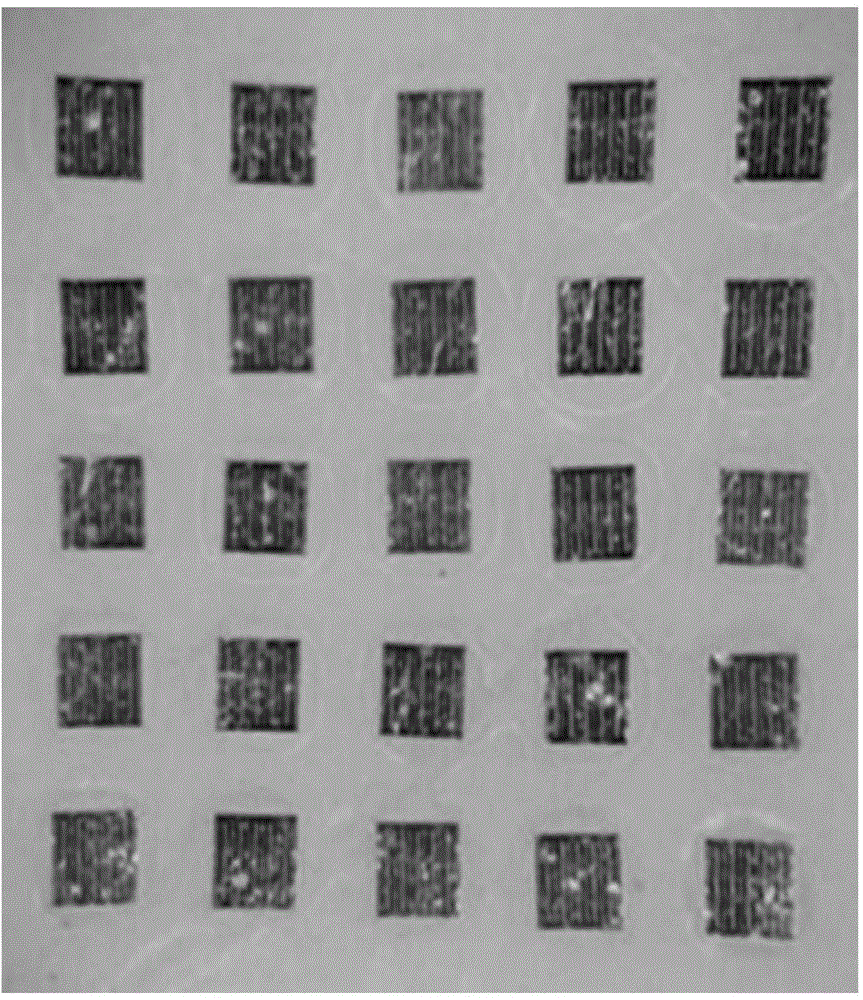

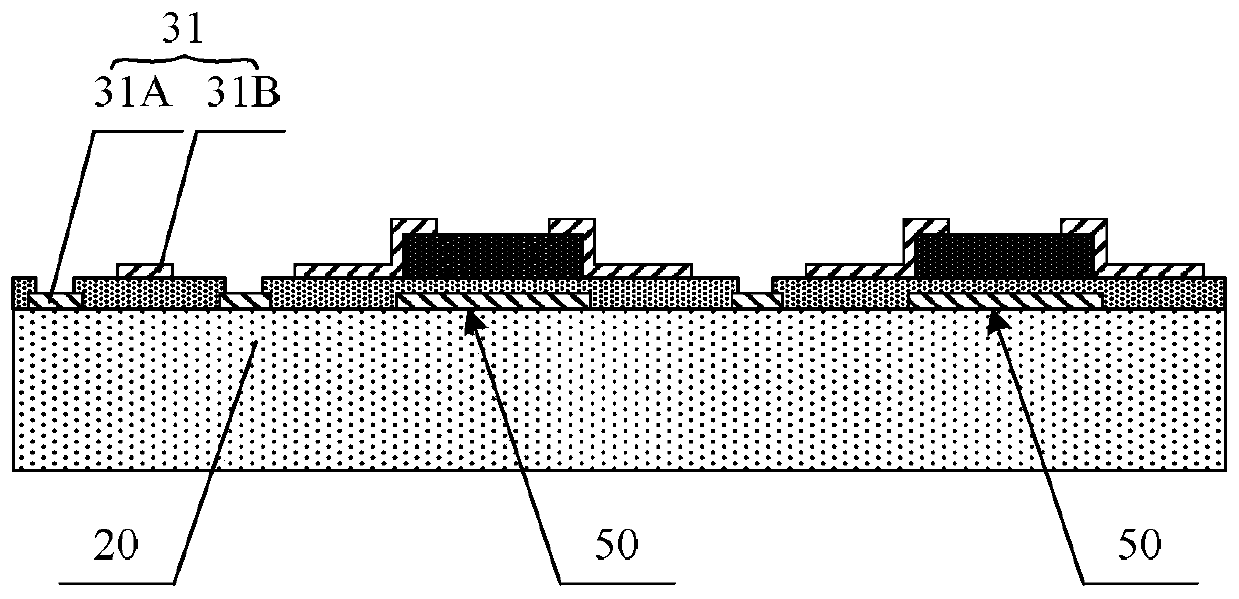

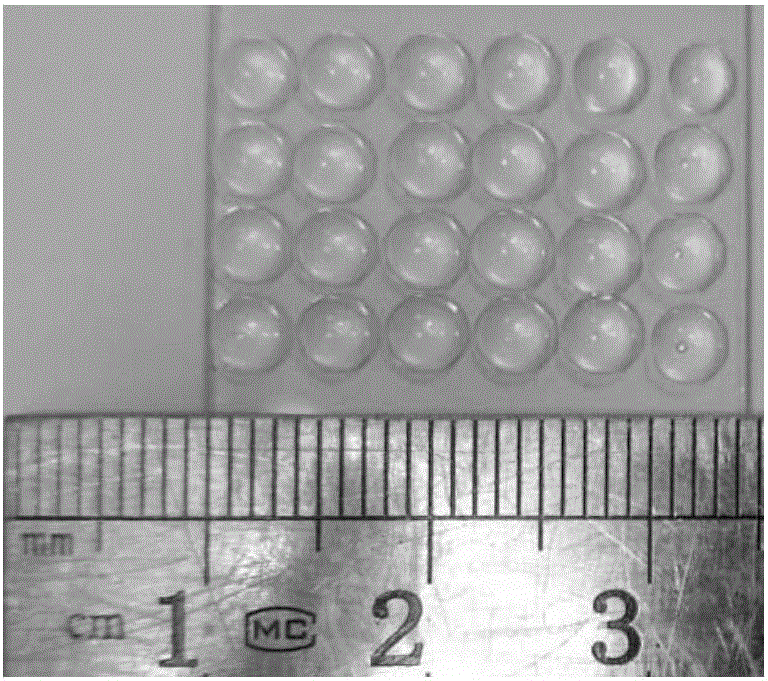

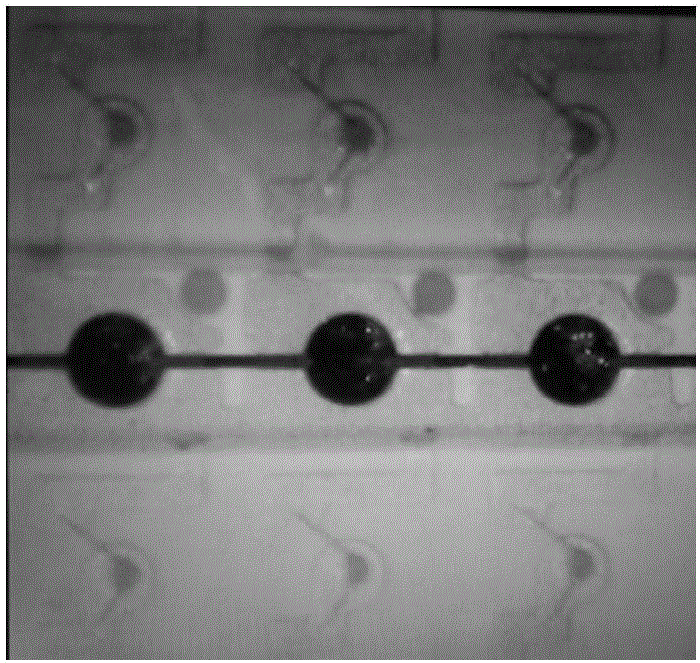

Preparation method for inverted LED white-light chip of chip scale package

ActiveCN104900783AHigh batch stabilityConsistent color temperatureSemiconductor devicesPhosphorEngineering

The invention discloses a preparation method for an inverted LED white-light chip of chip scale package, and the method comprises the following steps: temporarily fixing an UV solidifying adhesive tape (2-1) on the upper surface of a die bonding positioning light cover (1); setting flip chips (3) on the upper surface of the UV solidified adhesive tape (2-1) according to the position of the die bonding positioning light cover (1); employing a fluorescent glue film (4) to cover the flip chips (3); carrying out vacuumizing and heating, and enabling the fluorescent glue film (4) to be solidified and packaged on the flip chips (3); carrying out cutting along gaps among the all packaged flip chips (3); removing the die bonding positioning light cover (1); carrying out UV irradiation and enabling the UV solidified adhesive tape (2-1) to be solidified, and obtaining the inverted LED white-light chip (5) of chip scale package. The method simplifies the technological flow, avoids glue mixing and dispensing in the original technology, improves the production efficiency and yield, and greatly reduces the production cost. The method completely avoids the sinking of phosphor, enables the batch stability of the inverted LED white-light chips (5) to be high, and enabling the color temperature of the inverted LED white-light chips (5) to be consistent.

Owner:TECORE SYNCHEM

Method for producing low temperature cellulase using microbe fermentation

This invention relates to a microbe ferment producing low-temperature cellulose method, which is to domesticate the microbe that produces cellulose gradually under low temperature, which makes the microbe grows better; culturing the domesticated cellulose under 10-16deg C by expanding gradually and then inoculating 3-9% cultured cellulose by ferment liquid volume in the liquid ferment culture medium, when culturing for 72-144h in 10-16deg C, that means the microbe ferment producing low-temperature cellulose is complete; the ferment liquid collects liquid in 4, 000-8, 000rpm by centrifugal separation, the collected liquid is the coarse enzyme liquid; According to the different users and demand, the coarse enzyme can be condensed, separated and purified to be prepared into the enzyme preparation with different activity and pure. '

Owner:迟乃玉 +1

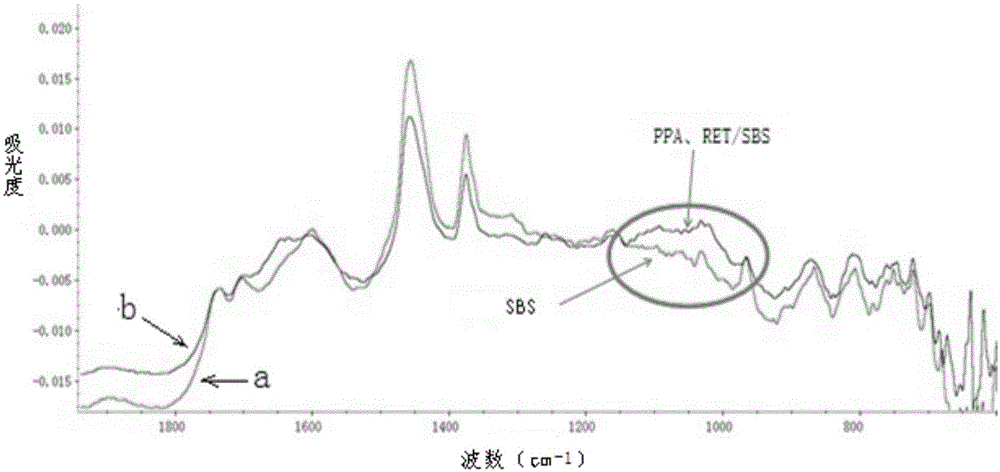

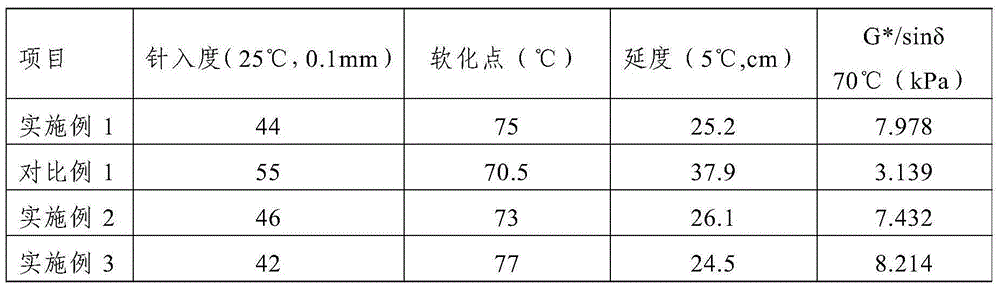

SBS modified asphalt and preparation method thereof

ActiveCN105038280AGood storage stabilityImprove stabilityBuilding insulationsPhosphoric acidHeat stability

The invention discloses SBS modified asphalt. The SBS modified asphalt is prepared with, by weight, 100 parts of matrix asphalt, 2.0-3.5 parts of SBS asphalt modifier, 1-2 parts of RET asphalt modifier, 0.2-0.5 part of polyphosphoric acid, 3-4 parts of compatilizer and 0.1-0.15 part of stabilizer. In addition, the invention further discloses a method for preparing the SBS modified asphalt. The method comprises the steps of 1, heating the matrix asphalt, adding the matrix asphalt into the compatilizer, stirring the mixture uniformly, and obtaining mixed materials; 2, adding the SBS asphalt modifier and the RET asphalt modifier into the mixed materials, stirring the mixture uniformly, conducting cutting, adding the stabilizer, continuing cutting, adding polyphosphoric acid, stirring the mixture uniformly, and obtaining the SBS modified asphalt. The SBS modified asphalt is chemical stabilization type SBS modified asphalt, great high temperature performance and anti-track performance are achieved, and the heat stability of the SBS modified asphalt is superior to that of traditional SBS modified asphalt.

Owner:CHANGAN UNIV

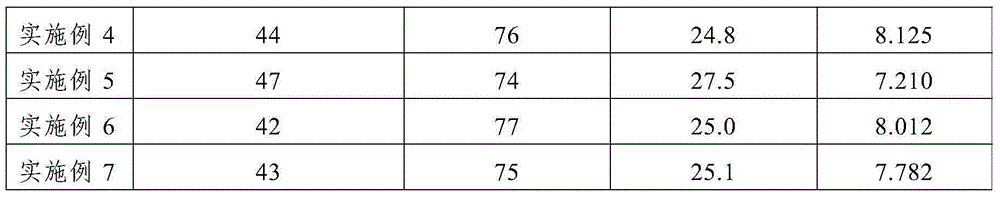

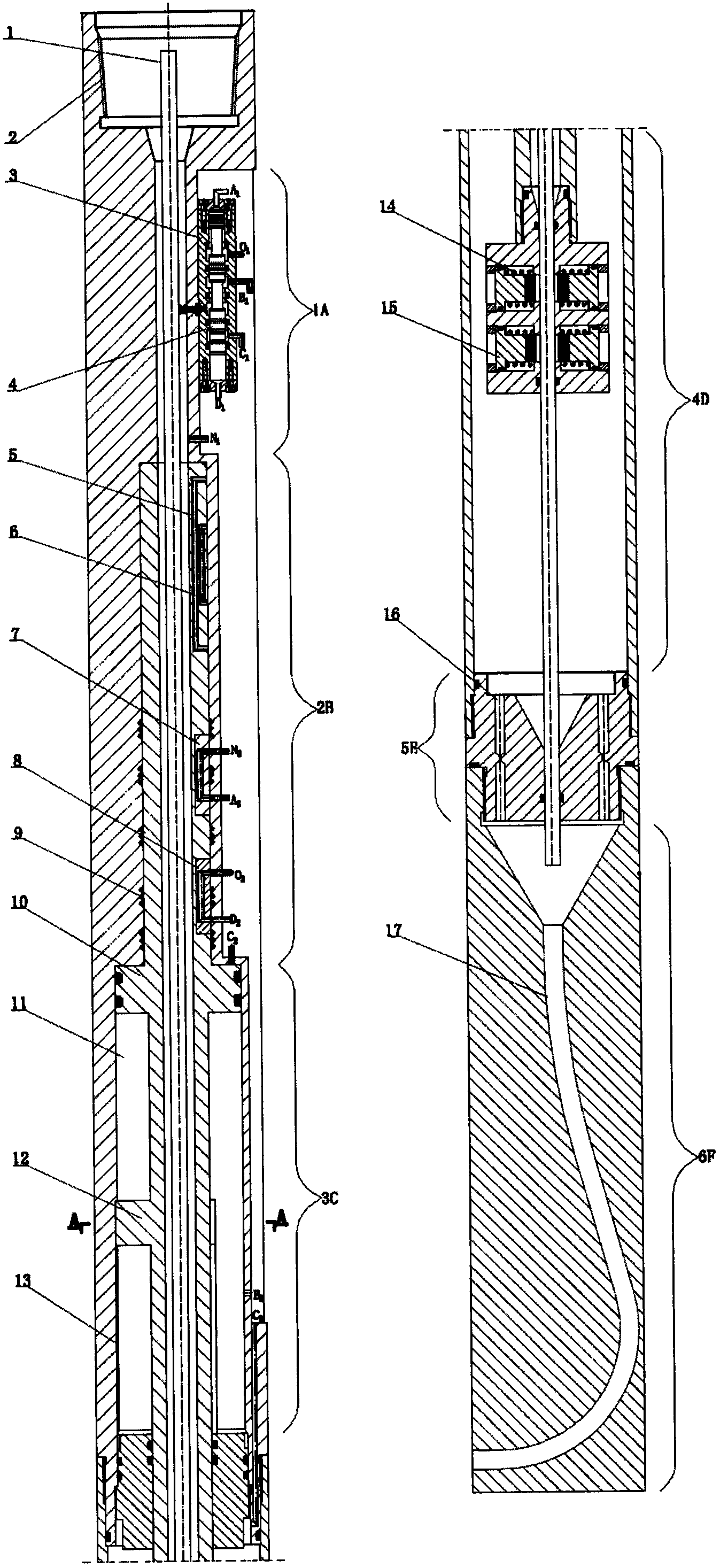

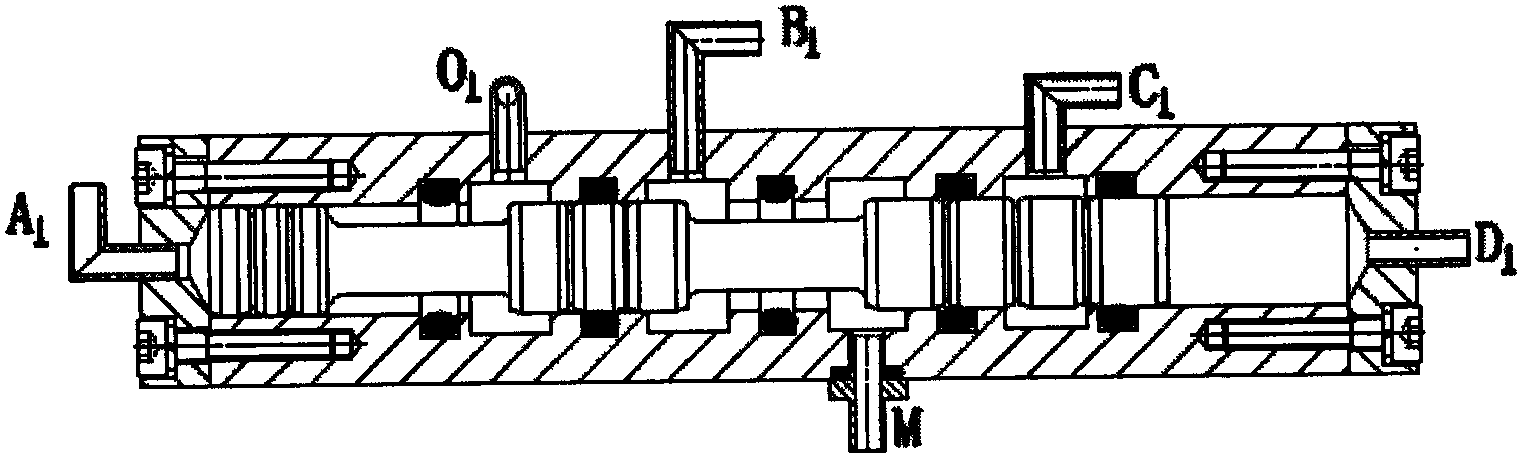

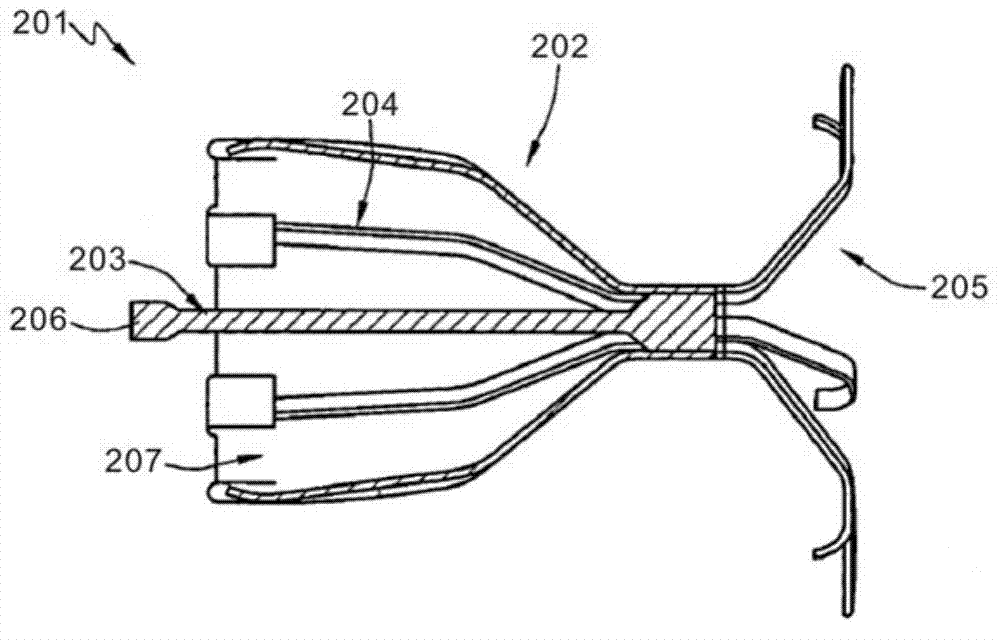

Self-pushed type radial horizontal well steering device

InactiveCN102704840AAvoid casing segment milling and reamingReduce operating costsDirectional drillingAutomatic control for drillingPiston cylinderHigh pressure chamber

The invention relates to a self-pushed type radial horizontal well steering device which is applicable to the fields of transformation of gasoline, natural gas and coalbed methane drilled wells and reservoirs. The self-pushed type radial horizontal well steering device comprises a steering valve, a stroke switch, a piston cylinder assembly, an automatic clamping mechanism, a connector and a steering track and is characterized in that the steering valve is composed of a valve body and a valve core; the stoke switch comprises a runner and a filling block arranged on the upper end of a piston rod; the piston cylinder assembly is mainly composed of a cylinder body, a piston, a wing plate and a limiting groove; the automatic clamping mechanism comprises a spring, a small piston, a rubber block and a pressing cap; the piston automatically holds a high pressure drilling tube tightly when traveling downwards to be fed, and releases vice versa; the connector is used for connecting the high pressure chambers where the piston and the automatic clamping mechanism are located; two flow passages above the connector control the feeding speed; the steering track provides a passage for steering of the high pressure drilling tube inside a casing, so that the complex processes of the milling of a casing section and hole expansion are avoided; the working risk is reduced; and the length of a horizontal section is increased effectively.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

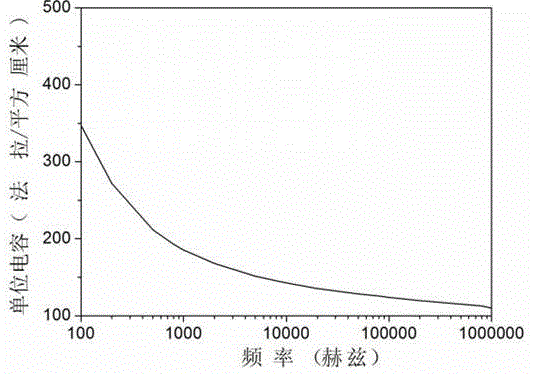

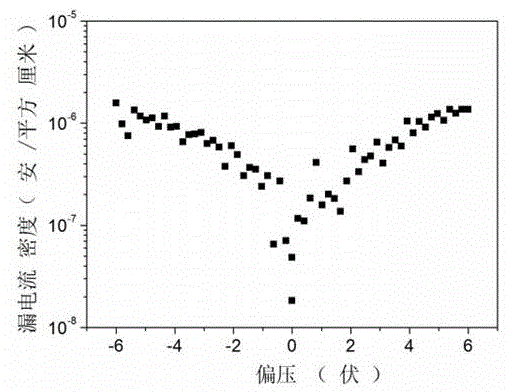

Low-temperature solution preparation method of high-dielectric zirconium oxide thin film

The invention belongs to the fields of new materials and micro-electronics, and particularly relates to a low-temperature solution preparation method of a high-dielectric zirconium oxide thin film. The method comprises the following steps: weighing soluble zirconium salt and measuring a solvent to prepare a zirconium oxide precursor solution with the concentration of 0.01 to 0.5 mole / liter, and performing magnetic stirring and ultrasonic dispersion for 0.1 to 3 hours to form a clarified zirconium oxide precursor solution; preparing a zirconium oxide thin film: coating a cleaned substrate with the zirconium oxide precursor solution to form a zirconium oxide precursor thin film, performing preheating treatment at 50 to 150 DEG C, then performing light wave annealing at certain power and temperature for certain time, coating the zirconium oxide precursor solution for multiple times according to the requirement on the thickness of the zirconium oxide thin film, and annealing to obtain the zirconium oxide dielectric thin film. The zirconium oxide thin film obtained by the method disclosed by the invention is high in dielectric property, and has important application prospect in the micro-electronics field of transistors, capacitors and the like. By means of the process, the conventional high-temperature solution process, the long process cycle or expensive equipment and the like can be avoided; the method is low in cost and suitable for industrial large-scale production.

Owner:QILU UNIV OF TECH

Method for preparing ultrafine high-whiteness active barite powder

ActiveCN102616824AConserve waterFully washedCalcium/strontium/barium sulfatesOXALIC ACID DIHYDRATEHydrogen Sulfate

The invention relates to the field of mineral materials, in particular to a method for preparing ultrafine high-whiteness active barite powder. The method comprises the following steps of: (1) preparing pulp from 325-mesh barite powder, and performing wet ultrafine grinding until the particle size is less than 10mu m; (2) filtering the barite pulp subjected to wet ultrafine grinding, and drying; (3) adding mixed acid into the dried ultrafine barite powder, and performing oxidation leaching reaction with stirring, wherein the mixed acid is a mixed solution of sulfuric acid, hydrofluoric acid and oxalic acid; (4) filtering the barite powder subjected to oxidation leaching reaction by the mixed acid, and washing until the pH is 6 to 7; and (5) performing pressure filtration, and drying to obtain the ultrafine high-whiteness active barite powder. The preparation method is simple and controllable and easy to popularize, equipment can be localized completely, over 99 percent of prepared barite product has the particle size of -10mu m, and the whiteness is over 90 percent.

Owner:WUHAN UNIV OF TECH

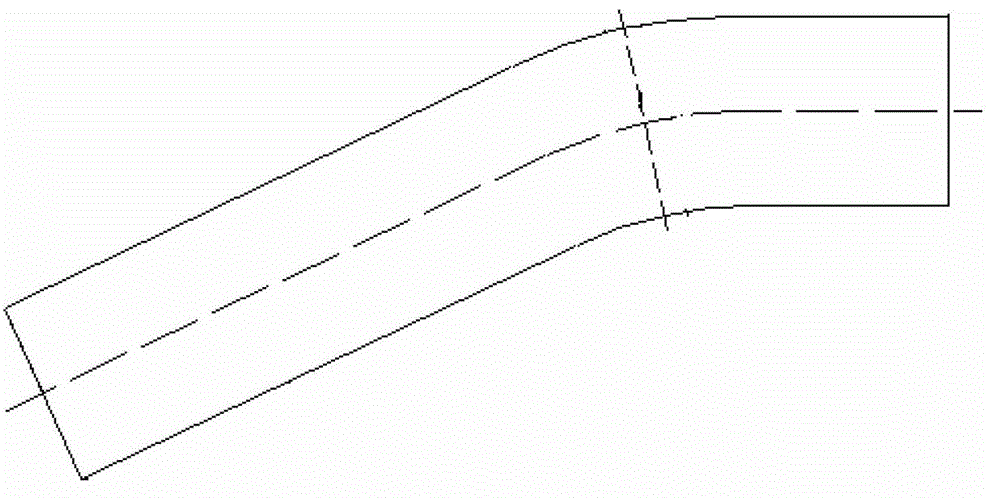

Simple bending method of large-diameter thin-walled aluminum tube

The invention discloses a simple bending method of a large-diameter thin-walled aluminum tube. The simple bending method includes the steps of firstly, filling core material, namely mixture of melted rosin and fine sand, into the large-diameter thin-walled aluminum tube; secondly, cooling the large-diameter thin-walled aluminum tube after the core material is filled in; thirdly, performing stretch bending to the cooled large-diameter thin-walled aluminum tube to form a bent tube by a stretch bender; fourthly, removing the core material filled in the bent tube; and fifthly, washing the bent tube. Simple bending of the large-diameter thin-walled aluminum tube is achieved by the method, and the bent tube formed by the method is high in precision and small in section distortion and overcomes the defects of wrinkle, crushing, cracking and the like compared with that in a bending forming process without filling. Compared with a numerical-control bent tube process, the method is simple in bent condition, simple to operate and short in processing period, reduces costs of using a special numerical-control tube bender and manufacturing a bent tube mould and avoids a large amount of process exploration and repeated mould repairing.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

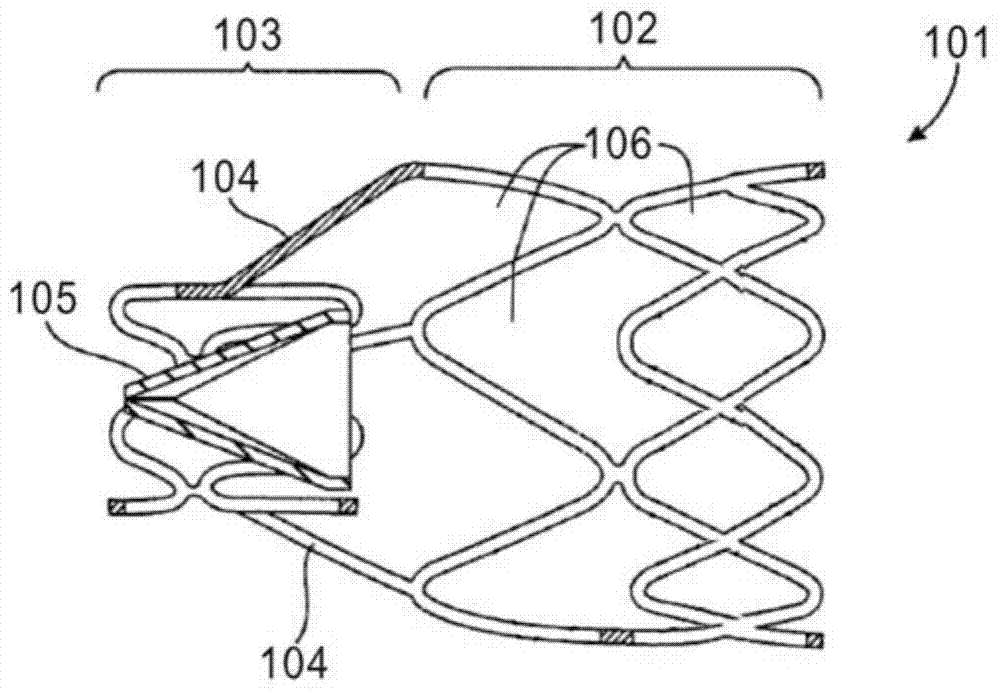

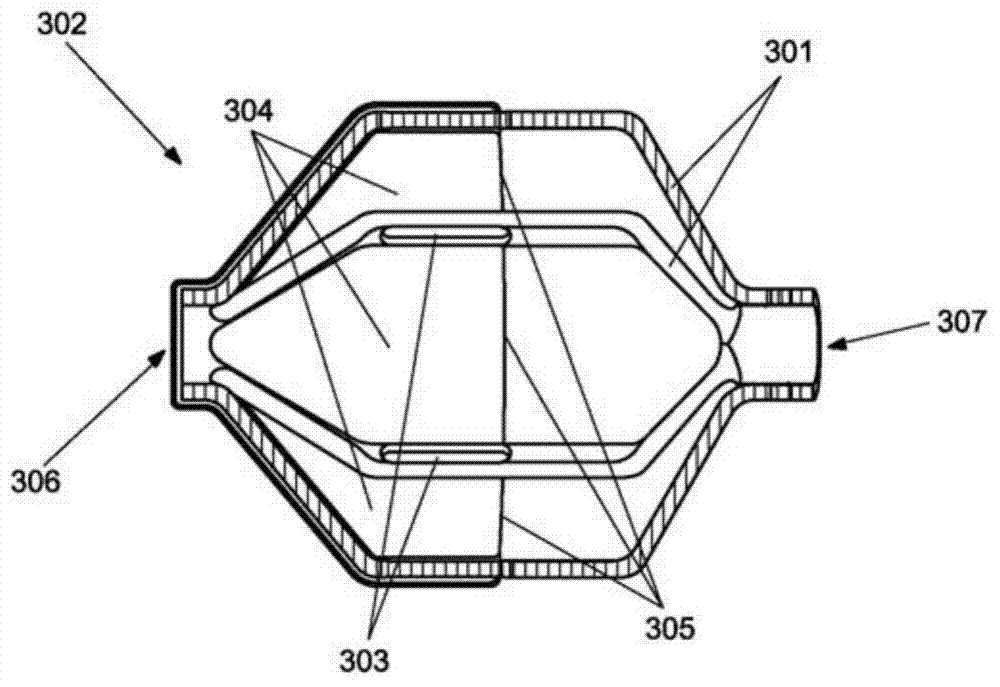

Unidirectional flap

ActiveCN103750920AProtruding Node ReductionReduce damage rateSurgeryTubular organ implantsBronchial tubeEngineering

The invention discloses a unidirectional flap. The unidirectional flap comprises a framework and an isolation membrane, wherein the framework comprises a far end, a near end and at least three vertical beams which are arranged between the near end and the far end; membrane-coating loca are arranged on the surfaces of the vertical beams; convex points are arranged on the membrane-coating loca and used for increasing friction force between the unidirectional flap and a bronchial tube; at least one isolation membrane penetrates through the membrane-coating loca to be covered on the surface of the far end; a mesh is arranged at the far end; and the near end is a closed structure which is composed of 2-3 sealed, mutually-separated and flap-shaped structures. According to the unidirectional flap, due to the adoption of the closed framework structure, support force and stability of the framework are improved; and quoin points, contacted with the inner wall of the bronchial tube, of the framework are reduced; damage rate of the inner wall of the bronchial tube caused due to machines is reduced; and occurrence probability of bronchitis is reduced.

Owner:SHENZHEN LIFETECH RESPIRATION SCI CO LTD

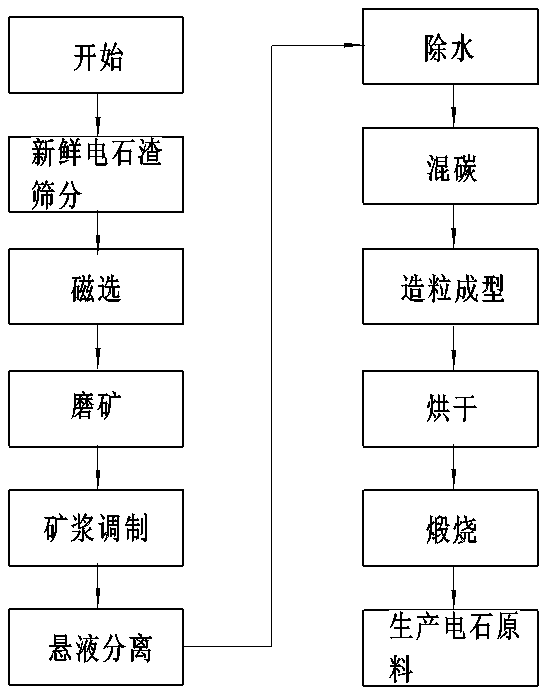

Method for producing calcium carbide raw materials through carbide slag

ActiveCN105502460AAvoid influenceImplement extractionCalcium/strontium/barium oxides/hydroxidesCalcium hydroxideSlag

The invention relates to the field of carbide slag recycling in calcium carbide method acetylene production, in particular to a method that after physical separation is performed on carbide slag impurities, a calcium hydroxide component in the carbide slag impurities is extracted, and then calcium carbide raw materials are produced through carbide slag. The method for producing the calcium carbide raw materials through the carbide slag mainly comprises the following steps of fresh carbide slag screening; magnetic separating; ore grinding; ore pulp preparing; suspension separating; dewatering; carbon mixing, wherein filter cakes which are obtained after dewatering is performed and contain certain moisture are mixed with carbon material particles of which the particle size is smaller than or equal to 2 mm and the fixed carbon content is larger than or equal to 70% in a mixing machine according to the mass fraction ratio of 1.63:1-2.91:1; granulating and forming; drying; calcining. According to the method for producing the calcium carbide raw materials through the carbide slag, the shortcomings and defects in the prior art can be effectively overcome, reclamation recycling of the carbide slag is achieved, the impurities in the carbide slag can be effectively removed, the technology is simple and convenient, and the economical efficiency and practicability are achieved.

Owner:丰镇市嘉鑫硅锰合金有限公司

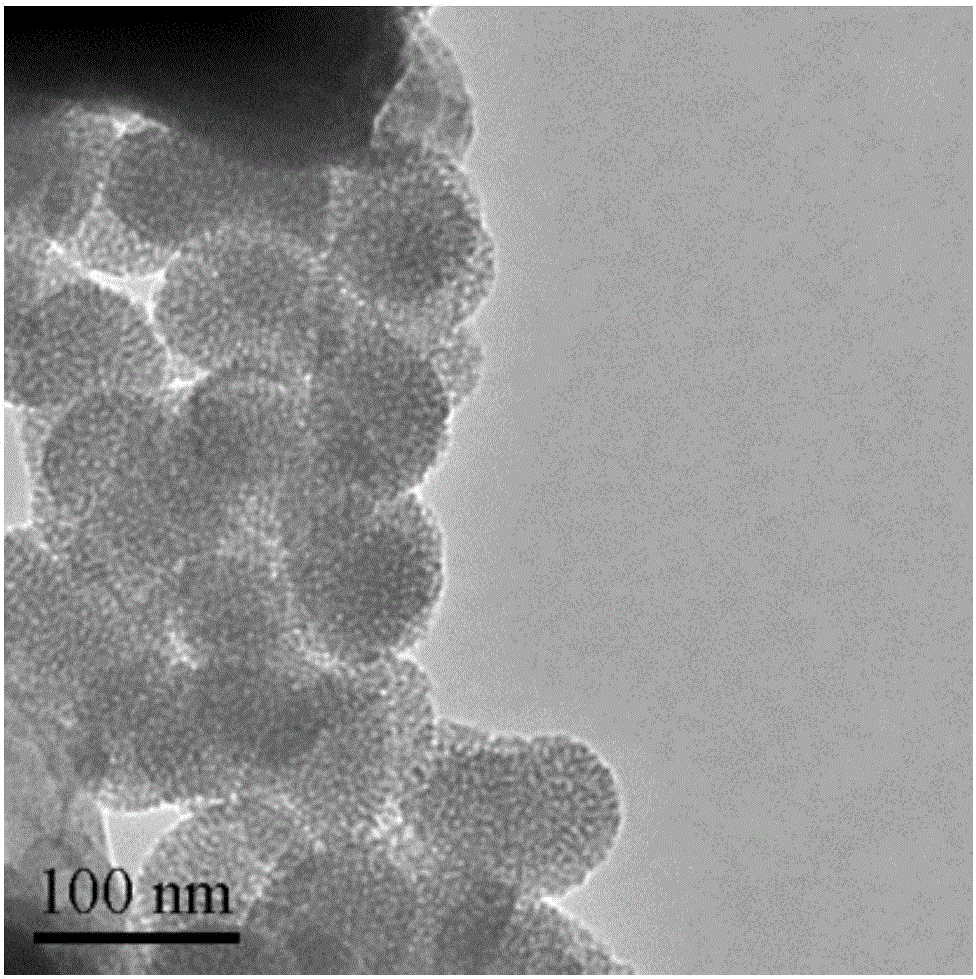

Preparation method of meso-porous silica nanoparticles

InactiveCN106587078AThe synthesis method is simpleMild reaction conditionsSilicaNanotechnologySilica nanoparticlesMesoporous silica

The invention discloses a preparation method of meso-porous silica nanoparticles. The method comprises the following steps: mixing ethanol with distilled water according to a certain ratio in order to obtain a solvent, adding triethanolamine used an alkali and a chelating agent, adding cetyltrimethylammonium chloride used as a template, heating the above obtained solution to 25-80 DEG C, adding ethyl orthosilicate within 2-3 min, stirring and reacting the above substances for 0.5-6 h, carrying out solid-liquid separation on a product obtained after the above reaction solution cools to room temperature, washing obtained solid with water and ethanol, removing the template, respectively washing the above obtained material with distilled and anhydrous ethanol multiple times, and dispersing obtained meso-porous silica nanoparticles in 25 mL of water to form a colloid. The colloid has high stability, is degradable and can be applied to the field of biomedicines. The preparation method has the advantages of simple process, easiness in operation, good repeatability and cheap and easily available raw materials, and the prepared meso-porous silica nanoparticles has the advantages of monodispersion, controllable morphology and large specific surface area.

Owner:HUBEI UNIV OF TECH

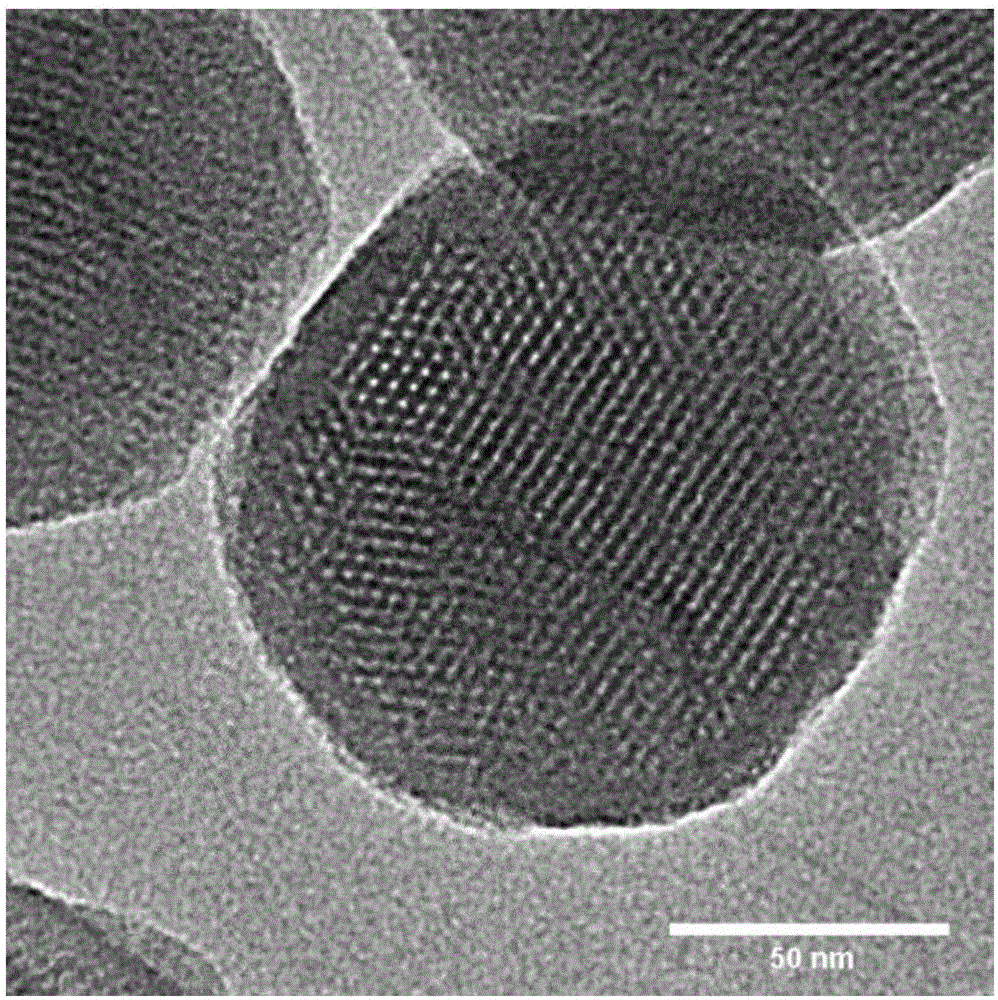

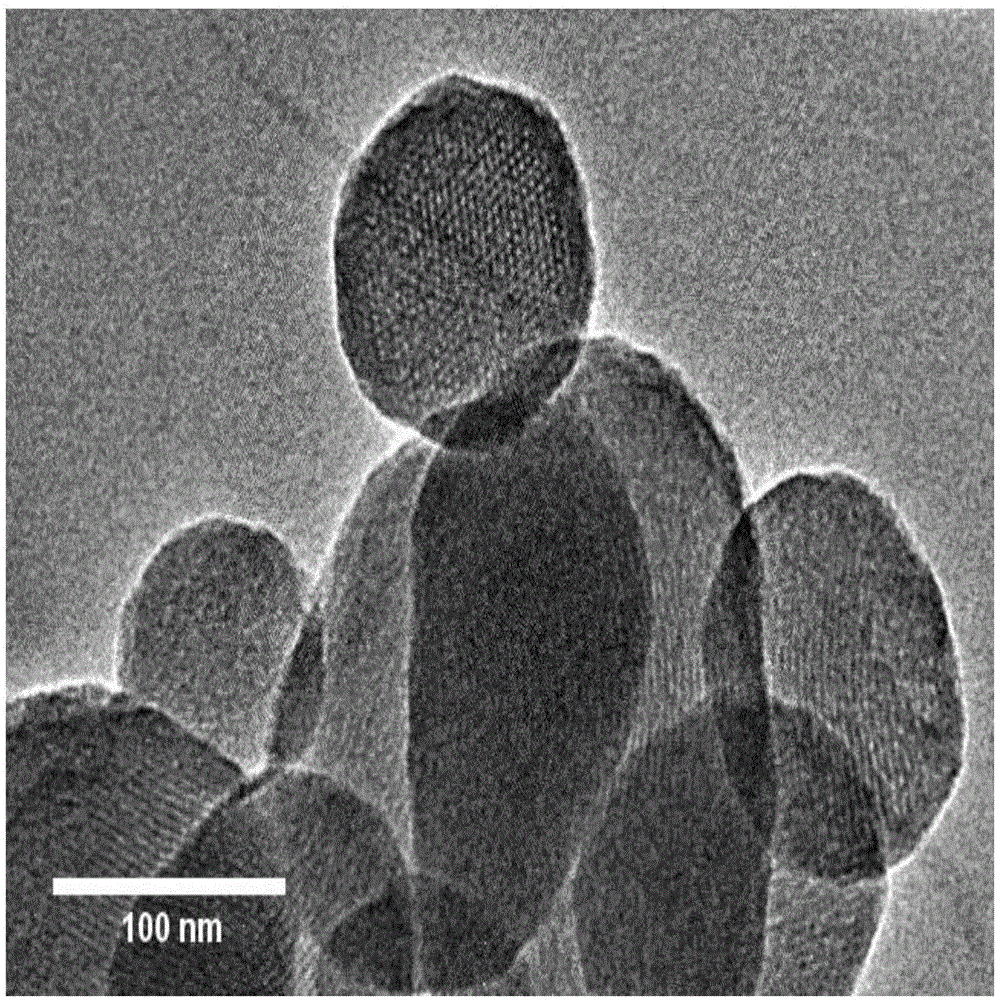

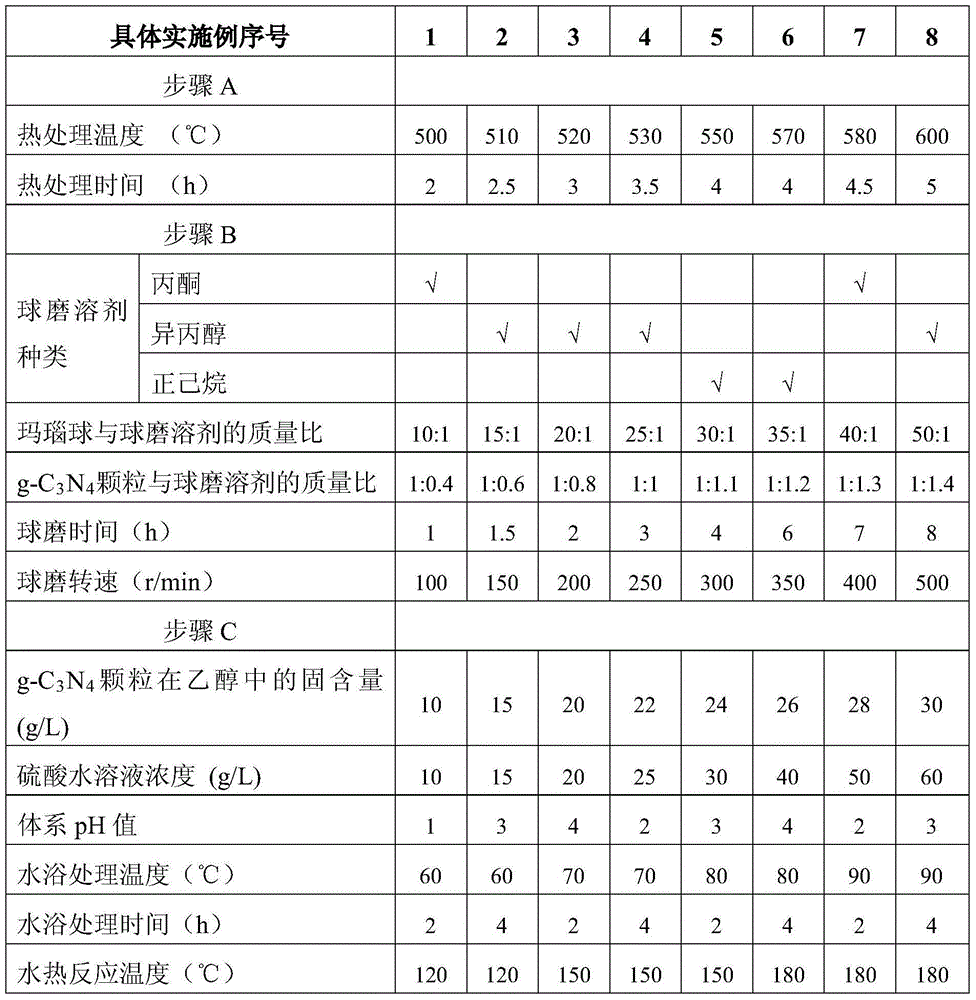

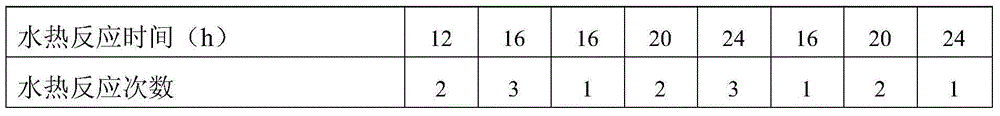

Preparation method of porous g-C3N4 semi-conducting material

InactiveCN104310321AAvoid cumbersome workmanshipExcellent photocatalytic performanceNitrogen and non-metal compoundsSolventPre treatment

The invention relates to the field of semi-conducting materials and provides a preparation method of a porous g-C3N4 semi-conducting material. The preparation method comprises the following steps of putting melamine powder into a crucible boat, putting the crucible boat with melamine powder into a tubular furnace, carrying out heating treatment, carrying out cooling to obtain yellow blocky g-C3N4 solids, carrying out grinding, putting the g-C3N4 particles into a ball milling tank, carrying out ball milling pretreatment, adding the slurry obtained by ball milling with a same ball milling solvent, carrying out drying to obtain g-C3N4 particles, dispersing the g-C3N4 particles into ethanol, carrying out ultrasonic treatment for dispersion, adding sulfuric acid into the ethanol dispersion solution of g-C3N4 to adjust a pH value of the ethanol dispersion solution, and carrying out a hydro-thermal reaction process to obtain the porous g-C3N4. Through combination of a ball milling technology and protonation effects, the preparation method conveniently prepares the porous g-C3N4 and solves the problem that the traditional method produces g-C3N4 having a small specific surface area and low efficiency.

Owner:ZHEJIANG UNIV

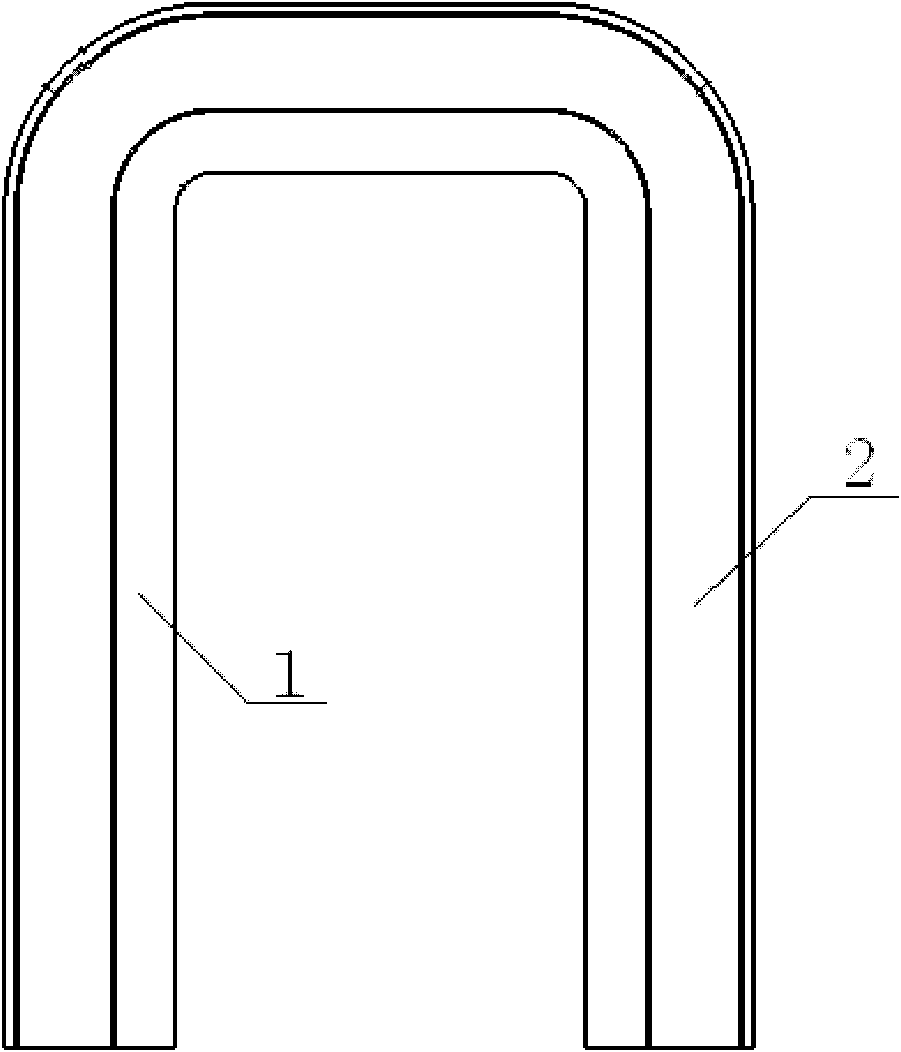

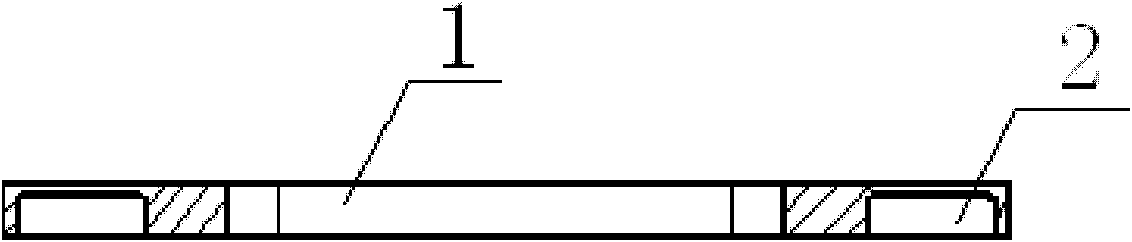

Technology for processing test blanket module (TBM) first wall U-shaped flow-containing cooling pipeline set

The invention discloses a technology for processing a test blanket module (TBM) first wall U-shaped flow-containing cooling pipeline set. The technology comprises the following steps of:1, processing U-shaped frame components by using reduced activation ferritic / martensitic spherical powder; 2, processing a U-shaped groove on each U-shaped frame component in a U-shaped frame direction; 3, performing butt point processing on two U-shaped frame components on which the U-shaped grooves are processed to form a U-shaped cooling pipeline; and 4, vertically and sequentially stacking the U-shaped cooling pipelines, and performing butt joint on the U-shaped cooling pipelines to realize the integration of the first wall U-shaped cooling pipeline set. The technology can greatly improve material utilization rate, quality safety performance, and avoid the problems of high price, large difficulty in a technology and the like in a hot isostatic pressing technology.

Owner:SOUTHWESTERN INST OF PHYSICS

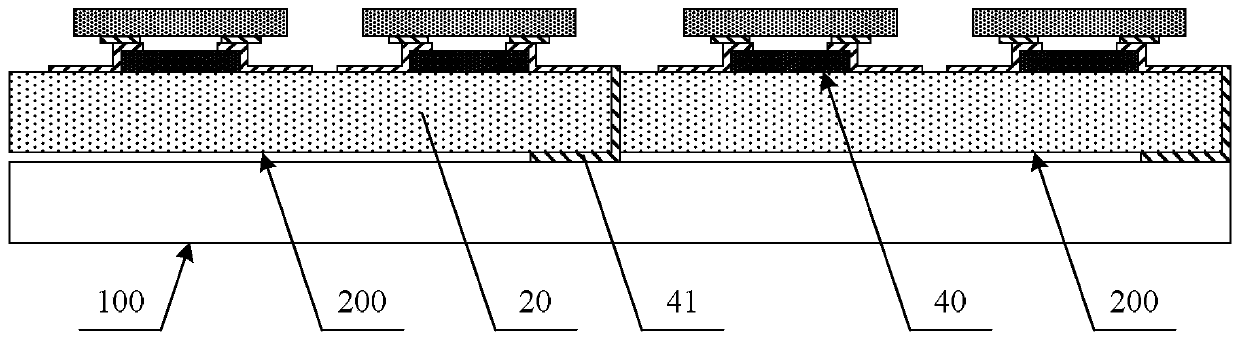

Display panel and preparation method thereof

ActiveCN109888085AAvoid viasAvoid process problemsSolid-state devicesSemiconductor devicesEngineeringBackplane

Embodiments of the invention provide a display panel and a preparation method thereof. The display panel comprises a mother board and a plurality of back boards which are mutually arranged and bound on the mother board; a driving lead is arranged on the mother board; a leading-out electrode and a light-emitting unit are arranged on each back board; the surface of one side, provided with the leading-out electrode and the light-emitting unit, of the back board faces the surface of one side, provide with the driving lead, of the mother board; and the leading-out electrodes on the back boards areconnected with the driving lead on the mother board. According to the display panel, the driving lead is arranged on the mother board, the leading-out electrode is arranged on each back board, and theplurality of back boards are inversely arranged on the mother board, and the leading-out electrodes are connected with the driving lead, so that the phenomenon that a leading-out wire or a through hole penetrating through the back board is arranged on the side edge of the back board or behind the back plate is avoided, the distance between the adjacent back boards is reduced to the largest extent, the non-mature side edge leading wire process and the double-sided process are also avoided, and the process implementation difficulty is reduced to the maximum extent.

Owner:BOE TECH GRP CO LTD +1

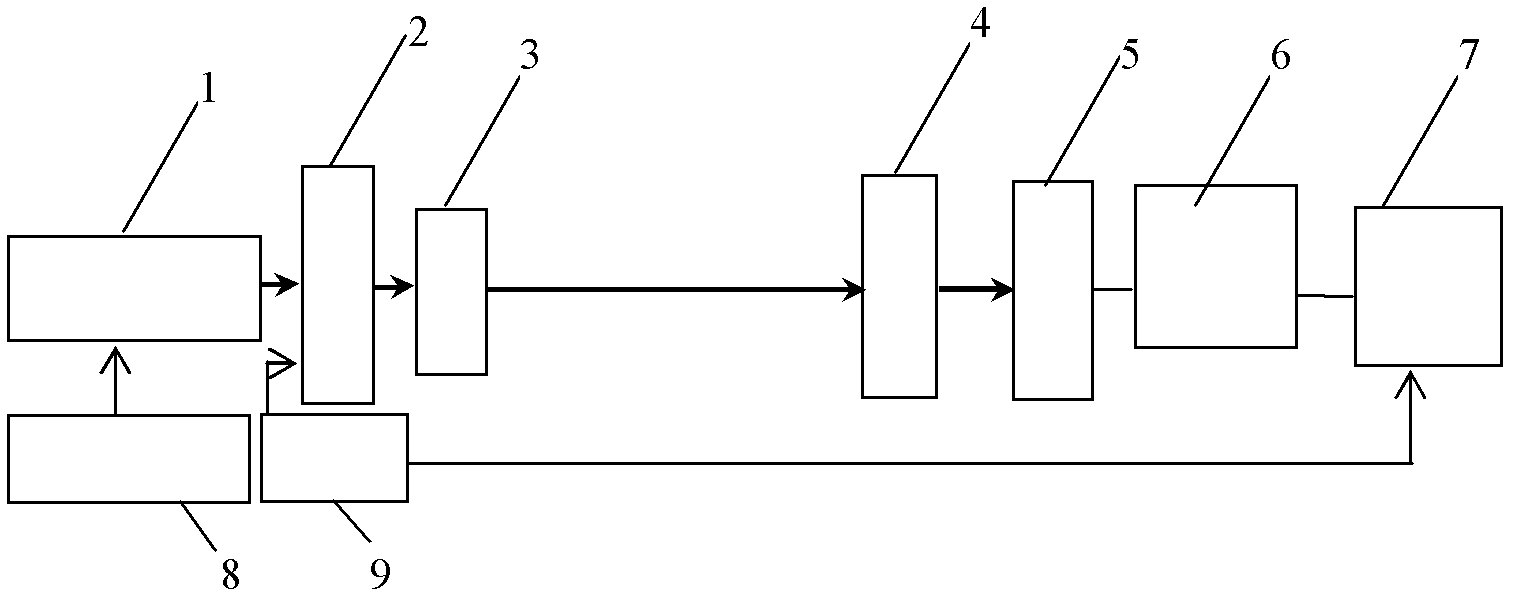

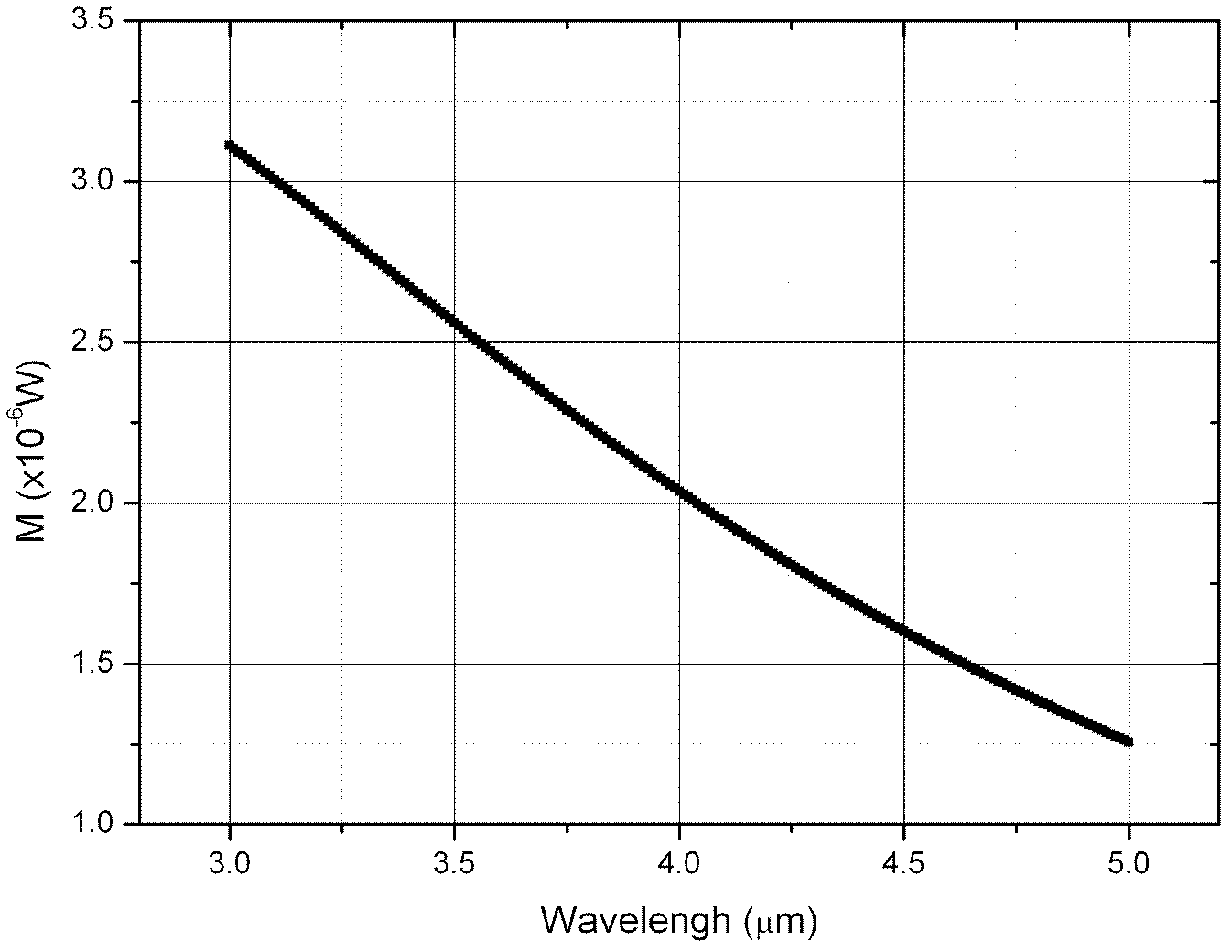

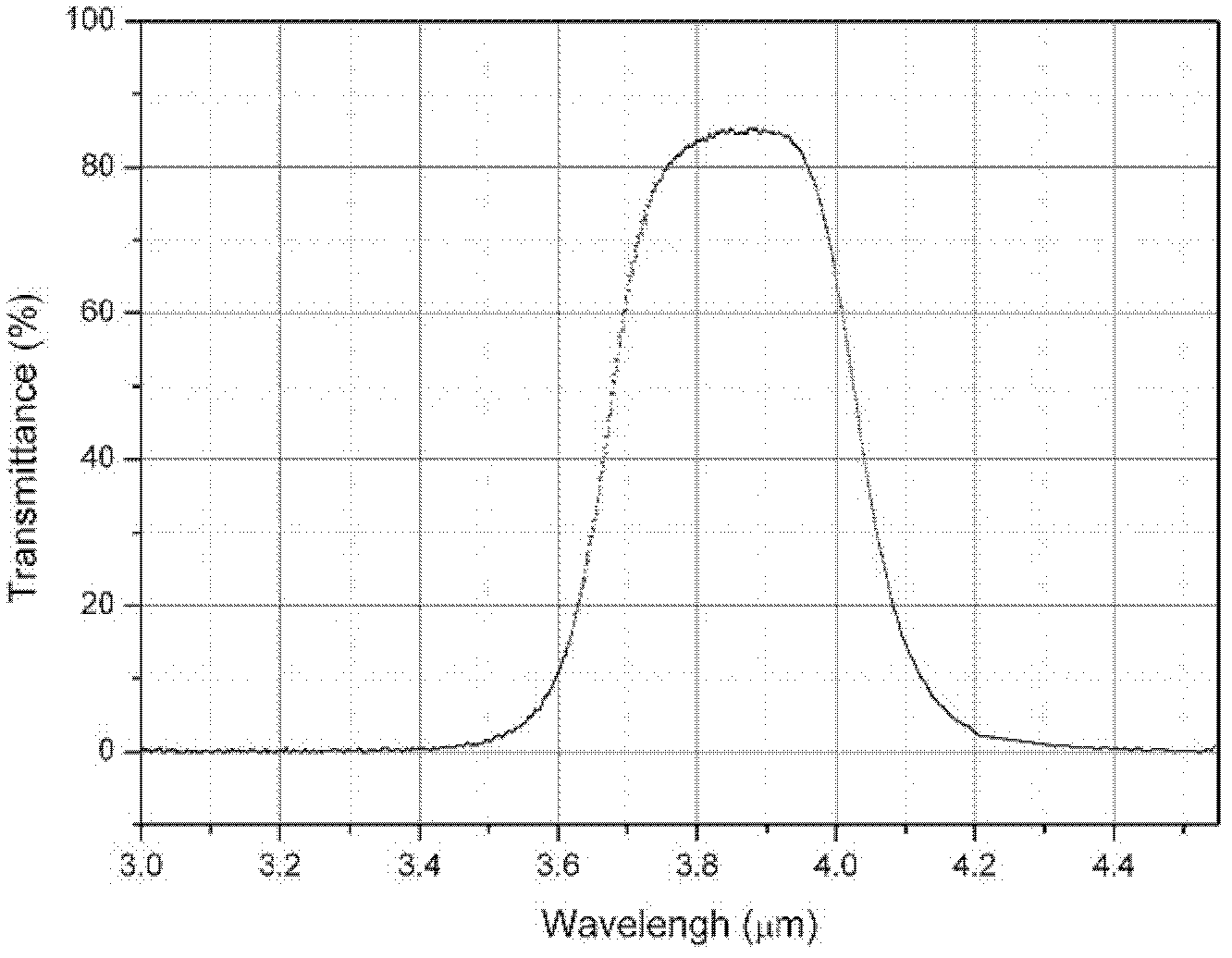

Calibration method of response ratio parameter of infrared detector

The invention discloses a calibration method of absolute response ratio of an infrared detector and a device thereof. By using the method of combining a blackbody origin and a narrow band pass filter, the absolute response ratio parameter of the detector under an appointed wavelength is acquired. According to the method, the blackbody origin is adopted as a calibration light source, so the stability of the uniformity of spatial output light spots is guaranteed; the placement positions of the detectors does not need to be precisely adjusted during calibration measurement, so the calibration efficiency and the precision of batch detectors are greatly improved; and meanwhile, power parameter of light irradiated onto the surfaces of the detectors is acquired through a theoretical calculation method, so errors in the power measurement of weak light signals are overcome. Through changing the wavelength parameter of the pass filter and the blackbody temperature, the method can be applied to parameter calibration of the detectors at various wavelengths, and the applicability is high.

Owner:NORTHWEST INST OF NUCLEAR TECH

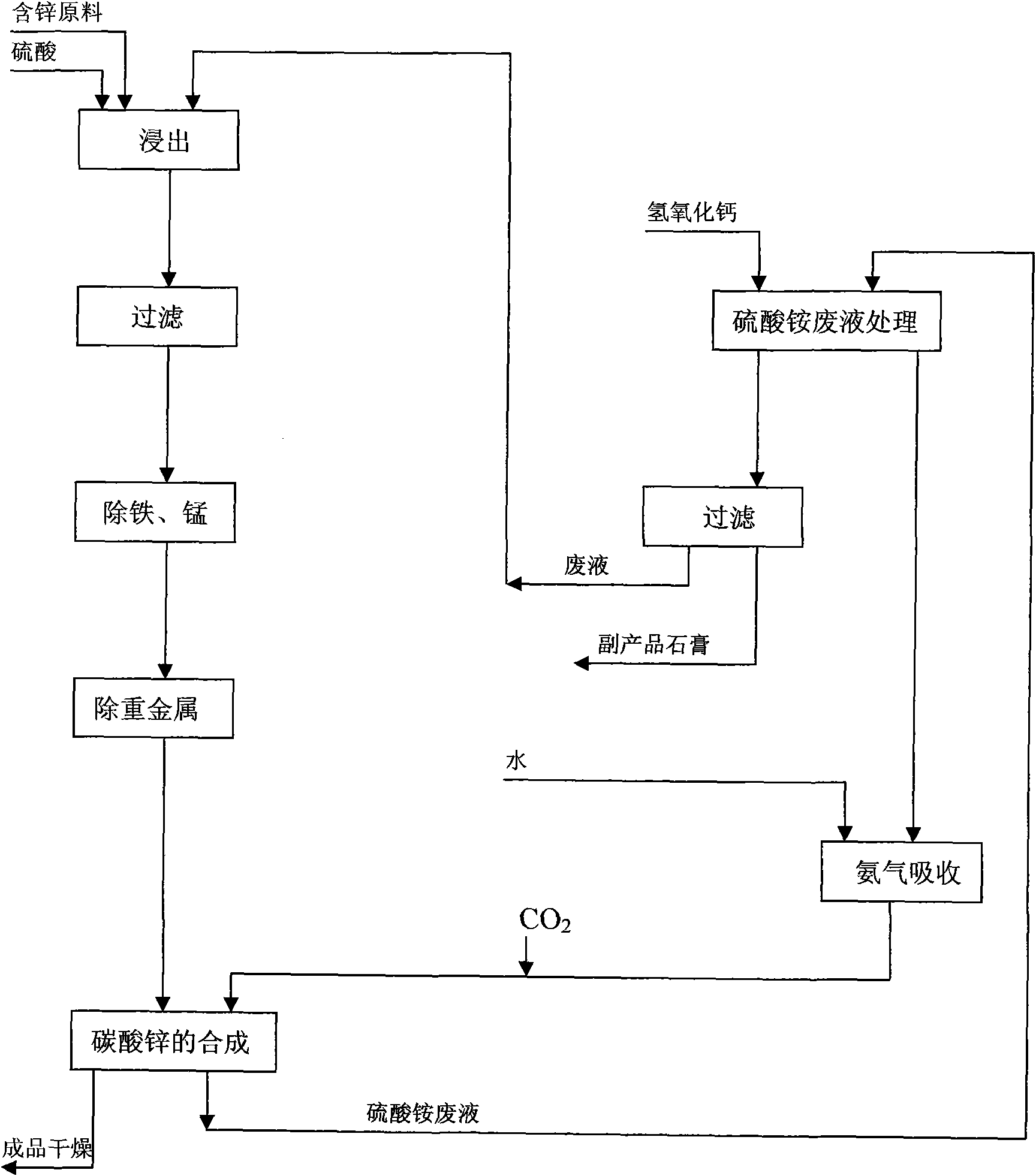

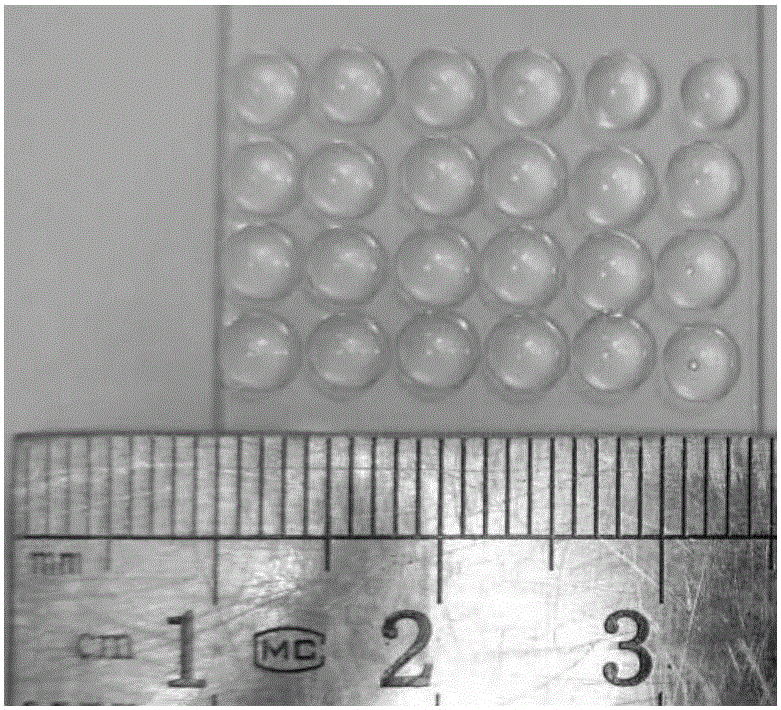

Production of zinc oxide by ammonia water circulation method

InactiveCN101643236AAchieve recyclingNo emissionsZinc oxides/hydroxidesLiquid wasteWater circulation

The invention relates to a production process of zinc oxide by the ammonia water circulation method, which comprises eight procedures of (1) sulfuric acid leaching; (2) removing iron and manganese byoxidation; (3) removing heavy metals by replacement; (4) synthesizing basic zinc carbonate; (5) filtering and drying; (6) calcining and smashing; (7) treating waste liquid of ammonium sulfate; and (8)absorbing ammonia gas, wherein, the treatment of the waste liquid of the ammonium sulfate (7) comprises the steps of adding calcium hydroxide in the waste liquid of the ammonium sulfate, the ammoniagas produced by reaction is introduced into the ammonia gas absorption procedure (8) for generating ammonia water, introducing carbon dioxide into the ammonia water, then returning to the synthesis procedure (4) and continuing the reaction with solution of zinc sulfate, thereby realizing circulation and reutilization of the ammonia water. The production process can avoid the process of concentration and crystallization or heating and steaming of ammonia, be characterized by simple and easy process and low production cost, simultaneously avoid the production of a large number of byproducts of the ammonium sulfate, have no emission of waste water and reduce environmental pollution.

Owner:赵月华

Thixotropic epoxy resin, preparation method and application thereof in LED chip packaging

ActiveCN105936815AEasy to prepareProcess parameters are easy to controlEpoxy resin adhesivesSemiconductor devicesPolymer scienceAntioxidant

The invention discloses thixotropic epoxy resin, a preparation method and application thereof in LED chip packaging. The preparation method consists of: (1) weighing bisphenol A epoxy resin, aliphatic epoxy resin, a thixotropic agent fumed silica, an adhesive force promoter, an antioxidant, an ultraviolet absorbent and a defoaming agent, and mixing them evenly to obtain a mixture 1; (2) weighing anhydride, diol, hydroxyl-terminated polybutadiene, and 2, 6-di-tert-butyl-4-methylphenol to carry out reaction to obtain a mixture 2; and (3) mixing the mixture 1 with the mixture 2, adding a phosphine-containing catalyst, and stirring the substances evenly at room temperature, thus obtaining the thixotropic epoxy resin. The method provided by the invention is simple, the technological parameters are easily controllable, and the preparation process does not involve solvent, and is green and environment-friendly. The obtained thixotropic epoxy resin has long storage life and good packaging effect. The thixotropic epoxy resin can be applied in chip packaging, and is especially suitable for chip packaging on a planar substrate, the glue mixing and dispensing process in original technology can be avoided, the production efficiency is high, the rate of finished products is high, and the cost is low.

Owner:TECORE SYNCHEM OPTOELECTRONIC TECH (TIANJIN) CO LTD

Method for producing low-temperature phytase by fermenting microorganisms

The invention discloses a method for producing low-temperature phytase by fermenting microorganisms. The method comprises the steps of: performing low-temperature domestication on microorganisms producing phytase step by step to ensure that the microorganisms grow well in low-temperature environment; performing amplification culture on phytase-producing bacteria obtained after low-temperature domestication step by step at a temperature of between 12 and 18 DEG C, inoculating into a liquid fermentation culture medium according to the inoculation amount which is 4 to 10 percent of the volume offermentation liquor, and culturing for 72 to 144h at a temperature of between 12 and 18 DEG C, namely finishing the production of the low-temperature phytase by fermenting the microorganisms; centrifuging the fermentation liquor at a rotating speed of between 6,000 and 10,000rpm to collect liquid, wherein the collected liquid is crude enzyme fluid; and further concentrating, separating and purifying the crude enzyme fluid according to different needs and different using objects to obtain enzyme preparations with different activities, purities and formulations.

Owner:DALIAN UNIV

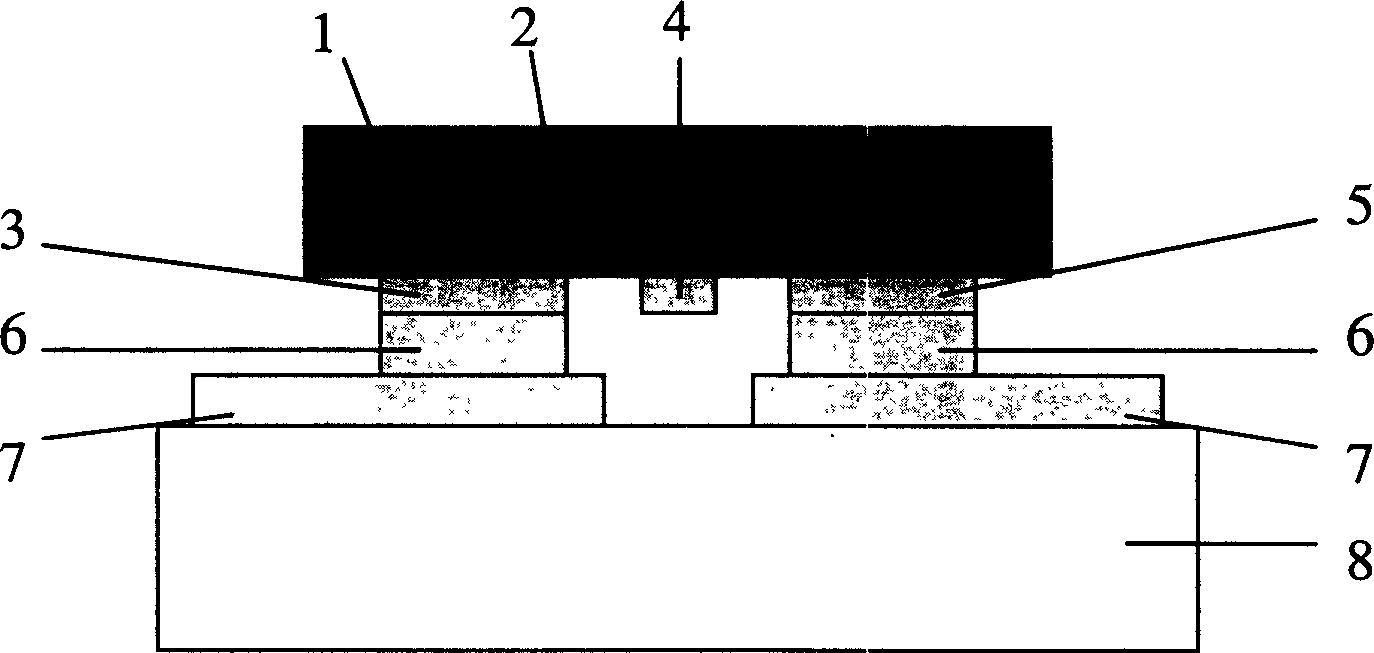

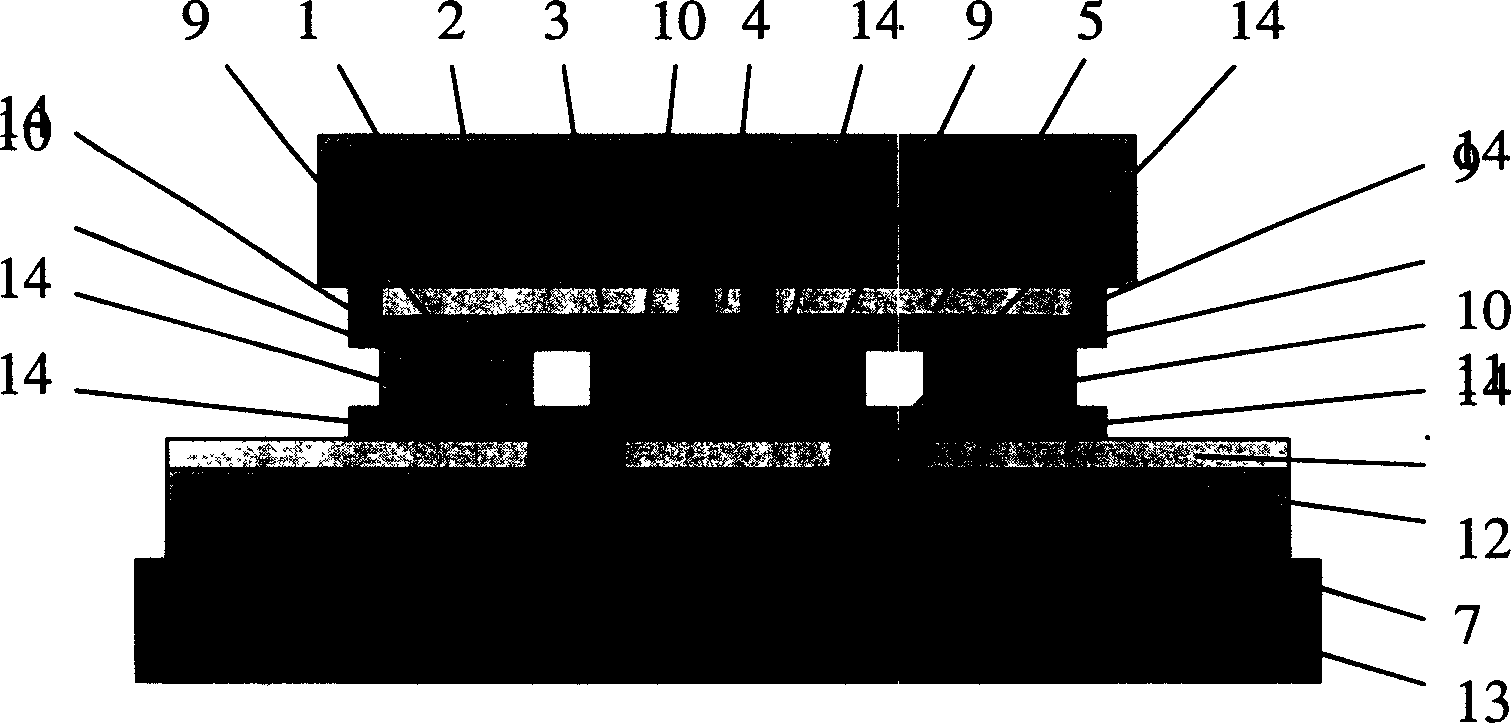

Large-area heat sink structure for large power semiconductor device

InactiveCN1599062AShort heat flow pathDirect heat dissipationSemiconductor/solid-state device detailsSolid-state devicesHeat sinkThermal conductivity

A large acreage thermolysis structure used in the high-power semiconductor device belongs to the field of preparing the high-power semiconductor device. It adopts the hyperbatic welding method, joints the die with the heat sink with high thermal conductivity through the heat conducting insulation film and also can add heat sink to the substrate of the hyperbatic welding chips to form the double ended thermolysis structure. The invention makes the heat source of the device and the metal salient points form the thermolysis thoroughfare through the heat conducting insulation film in the front of the device, can reduce the thermal resistance of the device to extremely low level, thus avoids the effect of self healing when working in heavy duty and increases the stability and reliability of the device. In addition, the method disclosed by the invention is featured by simple technique and low cost and is adaptable to mass production.

Owner:TSINGHUA UNIV

Process method for baking angilica keiskei koidzumi

ActiveCN103719305AGuaranteed nutrition and health careReduce lossesPre-extraction tea treatmentVitamin CTwo step

The invention relates to the field of tea preparation and particularly relates to a process method for baking angilica keiskei koidzumi. According to the process method, an angilica keiskei koidzumi baking technical method, comprising the steps of baking at low temperature, adding jasmine flowers and producing fragrance at high temperature, is established, the steps of a preparation process are simple, the loss of chalcone and vitamin C in angilica keiskei koidzumi during preparation is reduced, and the content of chalcone and vitamin C is obviously higher than that of tea products which are prepared by only frying leaves under conventional process conditions, so that the nutritional healthcare effects of angilica keiskei koidzumi are guaranteed; according to the prepared angilica keiskei koidzumi product, baking and frying processes are replaced with low-temperature baking, so that the tea is uniform in heated degree and good in sensory character, and the problem of charring due to excessive baking and frying is effectively solved; due to the two steps of adding jasmine flowers and producing fragrance at high temperature, the fragrance of angilica keiskei koidzumi is guaranteed.

Owner:青岛海隆达生物科技有限公司

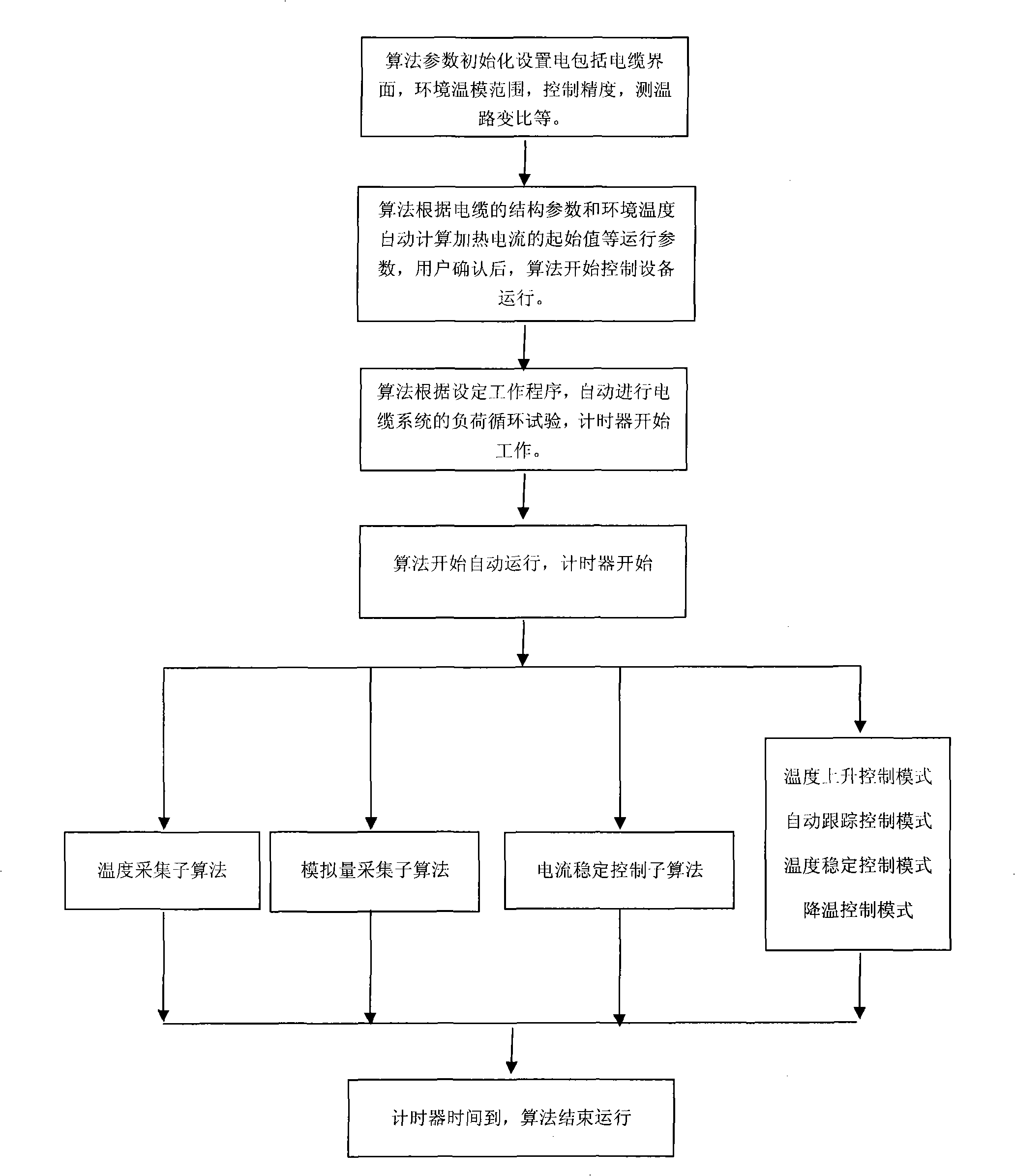

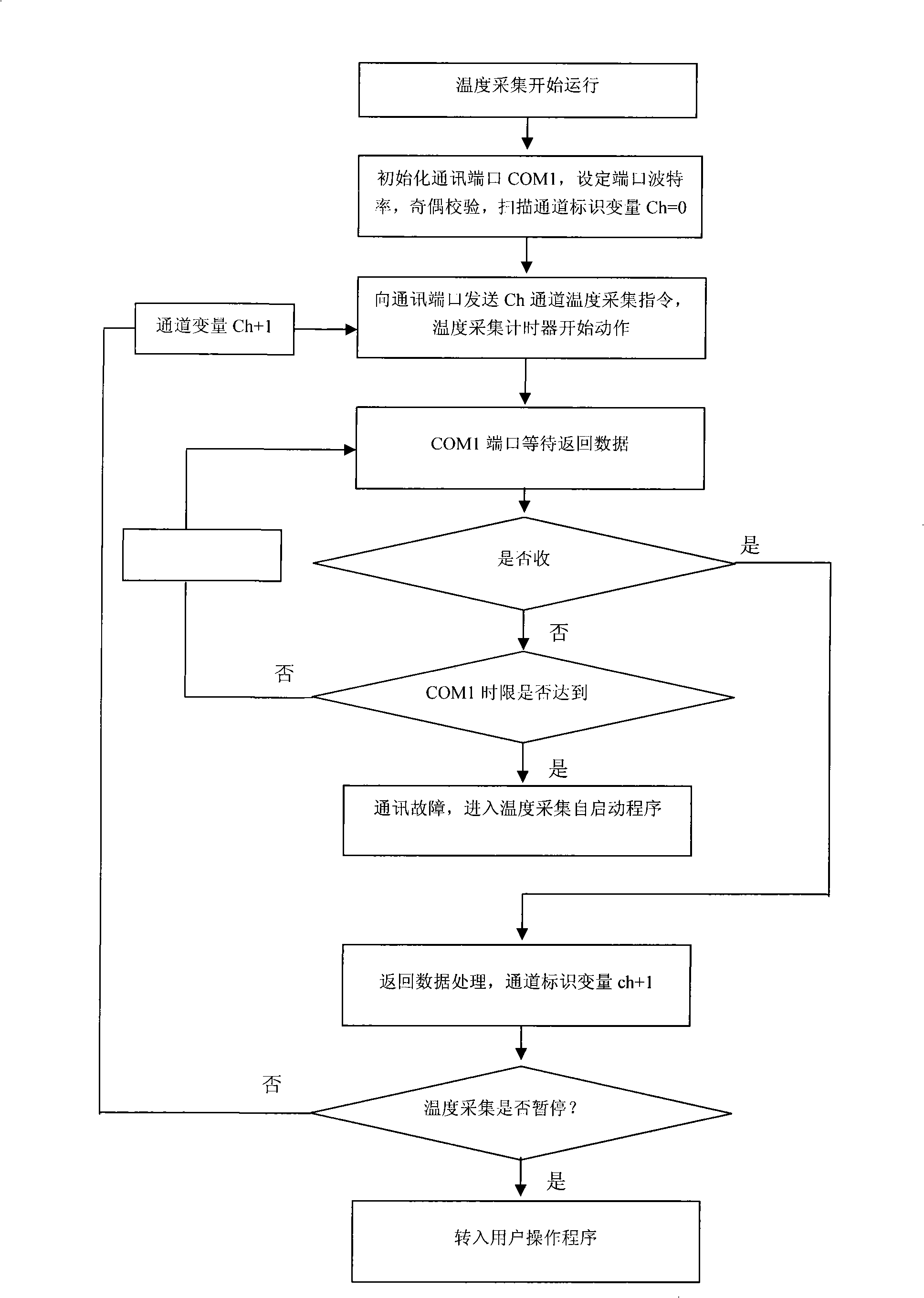

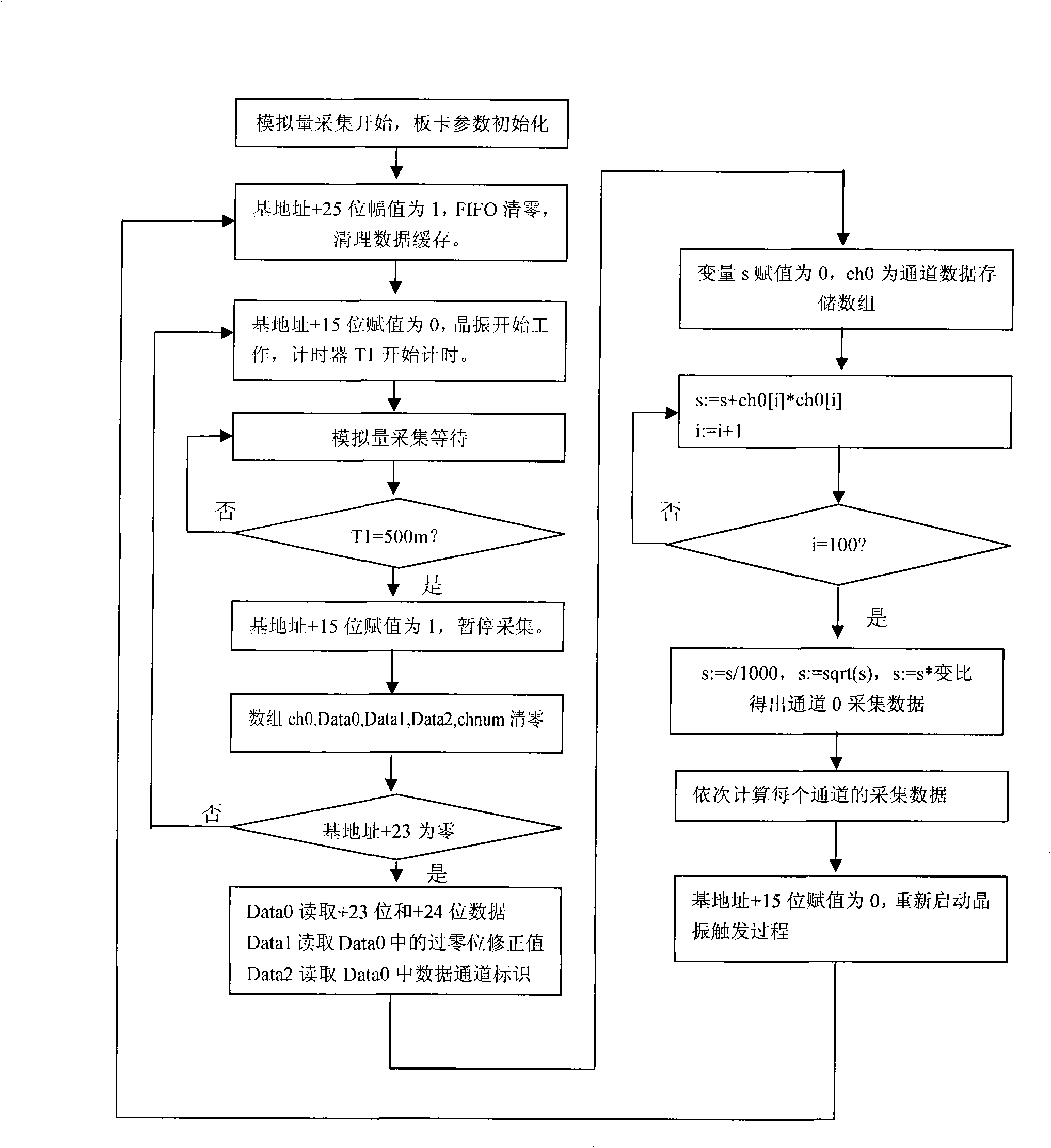

Power cable conductor temperature automatic following and control method

InactiveCN101339442AAvoid precisionAvoid process problemsTemperature control using electric meansElectrical conductorEngineering

The invention relates to a power cable conductor temperature automatic following and controlling method, which is composed of a data processing unit, a data acquisition unit and a control output unit related to the aspect of the hardware, and is logically constituted by a temperature rise controlling mode, an automatic tracking and control mode, a temperature stable control mode and a temperature drop controlling mode comprising: the data acquisition unit real-timely collects the current data and the temperature data of the cable and feeds back to the data processing unit, which determines the implementary adjustment amplitude according to the software algorithm, and the control output unit completes the practical performance, completes the full automatic tracking control of the cable conductor temperature. The invention realizes the temperature control process of the cable conductor with full automation and high precision, completes the automatic track and control on the temperature of the conductor with high precision, thereby effectively avoiding the defects of poor control precision and fussy technology in the traditional hand control method, and the controlling effect is excellent.

Owner:WUHAN HIGH VOLTAGE RESEARCH INSTITUTE OF STATE GRID

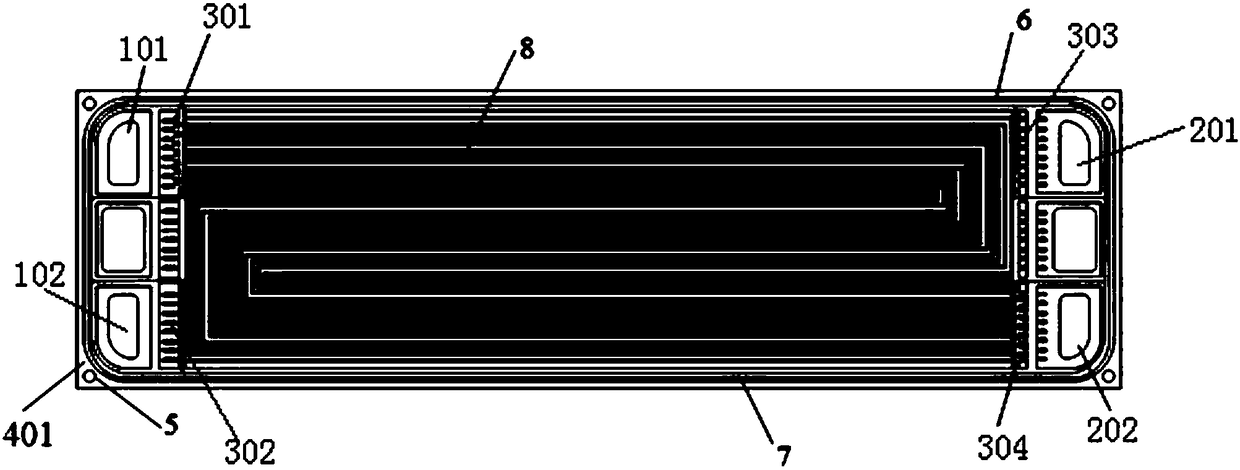

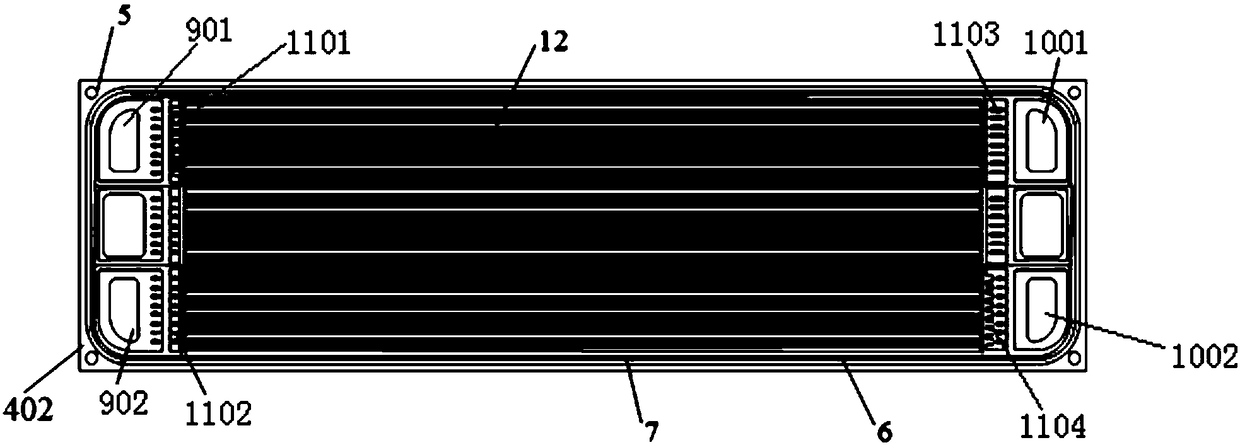

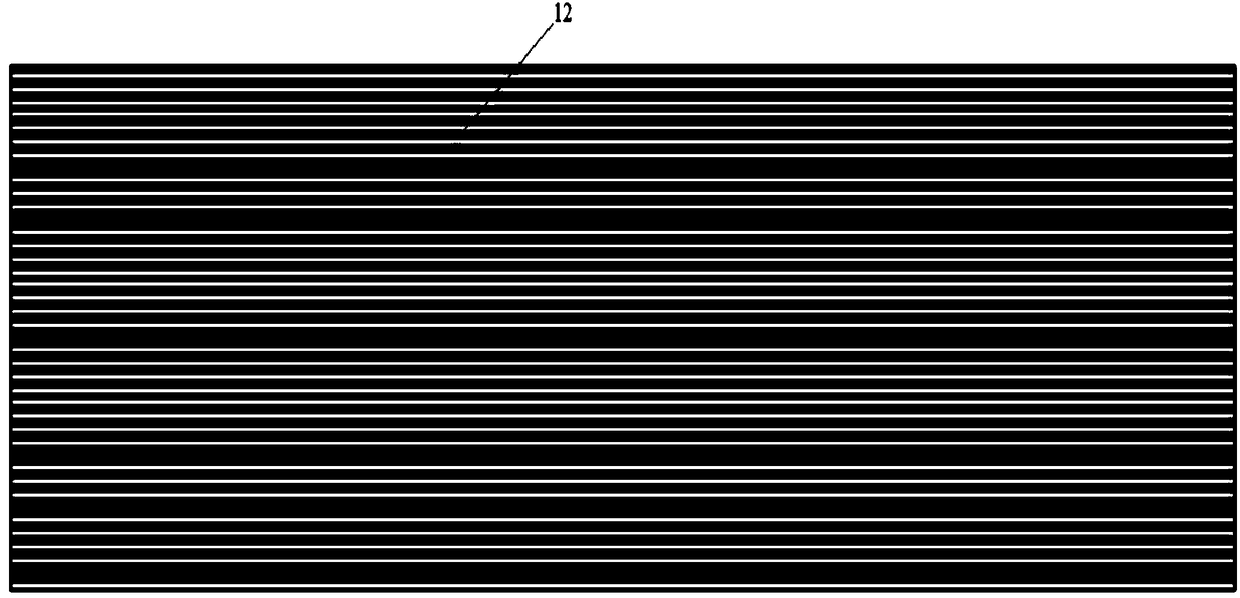

Graphite-metal frame composite bipolar plate and preparation method thereof

ActiveCN108063264AImprove conductivityImprove corrosion resistanceCell electrodesHigh intensityGraphite

The invention relates to a graphite-metal frame composite bipolar plate and a preparation method thereof. The bipolar plate comprises a negative electrode plate and a positive electrode plate; the negative electrode plate and the positive electrode plate are both formed by a metal frame and a graphite plate in a gluing manner separately, wherein the whole graphite plate is glued in the metal framethrough a gluing region on the metal frame; and the negative electrode plate and the positive electrode plate are connected in a sealing manner to form the graphite-metal frame glued composite bipolar plate. The preparation method comprises the steps of preparation of the graphite plate, preparation of the metal frame of the positive electrode plate and preparation of the metal frame of the negative electrode plate. The graphite-metal frame glued composite bipolar plate prepared in the invention has the characteristics of high intensity, excellent conductive performance, high corrosion resistance and the like; the main body of the graphite-metal frame composite bipolar plate is the graphite plate and each frame is a metal plate, so that coating treatment of the large-area metal plate is omitted, and the problem of performance inconsistency and the like caused by troublesome large-area coating process and uneven coating can be avoided, and extremely high application prospect is achieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

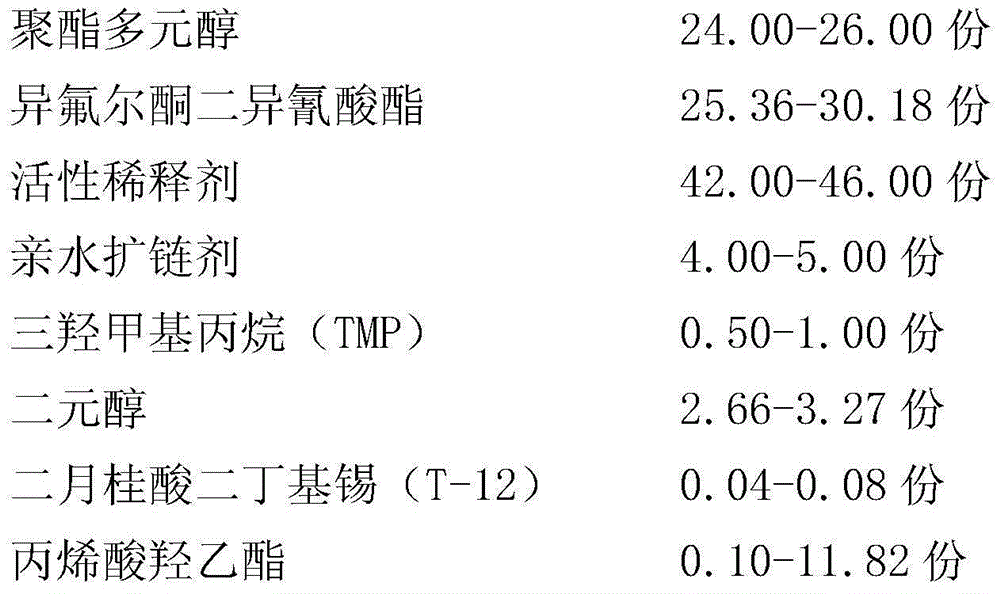

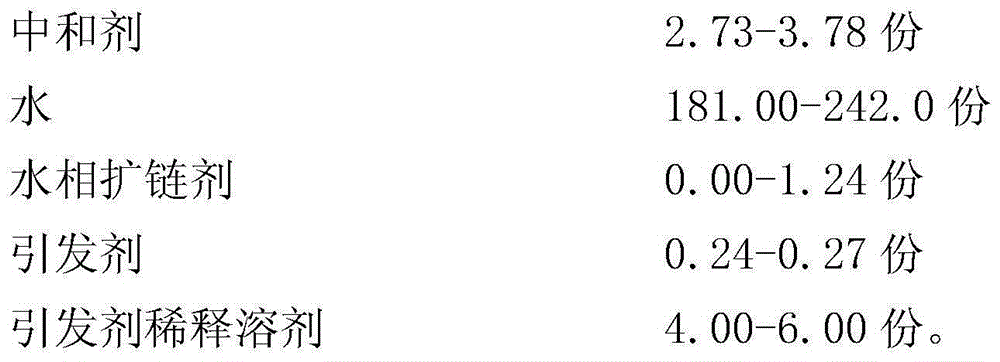

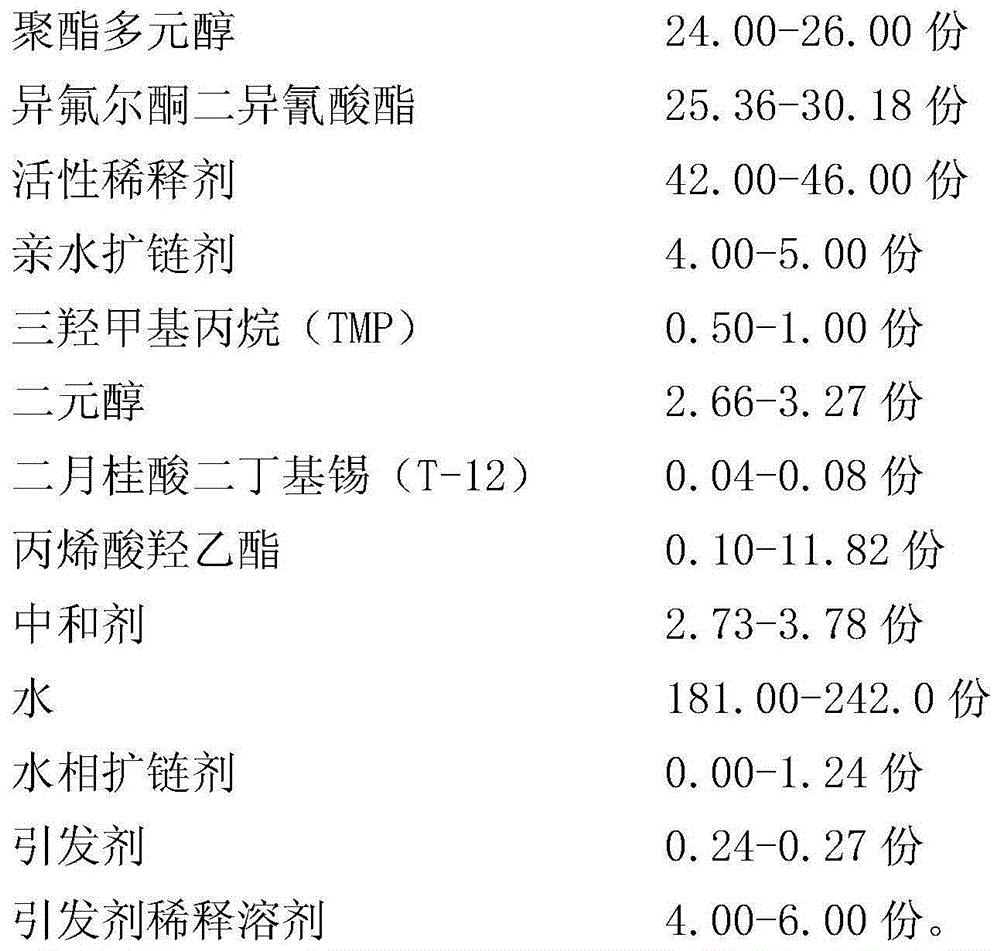

Polyurethane-acrylic ester composite emulsion of core-shell interpenetrating polymer network structure and preparation method thereof

The invention relates to polyurethane-acrylic ester composite emulsion of a core-shell interpenetrating polymer network structure and a preparation method thereof. The polyurethane-acrylic ester composite emulsion is prepared from polyester polyol, isophorone diisocyanate, reactive diluent, a hydrophilic chain-extending agent, trimethylolpropane, dihydric alcohol, dibutyltin dilaurate, hydroxyethyl acrylate, a neutralizing agent, water, an aqueous phase chain-extending agent, an initiating agent and initiating agent diluting solvent. The polyurethane-acrylic ester composite emulsion and the preparation method thereof have the following advantages that the problem that water resistance is lowered due to addition of emulsifier is solved; pollution caused by organic solvent and tediousness of the later-period organic solvent extraction technology are avoided. The emulsion is polyurethane-acrylic ester copolymer emulsion of a core-shell crosslinking interpenetrating polymer network structure.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com