Polyurethane-acrylic ester composite emulsion of core-shell interpenetrating polymer network structure and preparation method thereof

An interpenetrating network structure and acrylate technology, which is applied in the field of polyurethane-acrylate composite emulsion and its preparation, can solve the problems of low film-forming temperature of water-based polyurethane, pollution of organic solvent process, good wear resistance, etc., and can reach the film-forming temperature Low, avoids the cumbersome process of extracting organic solvents in the later stage, and has good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

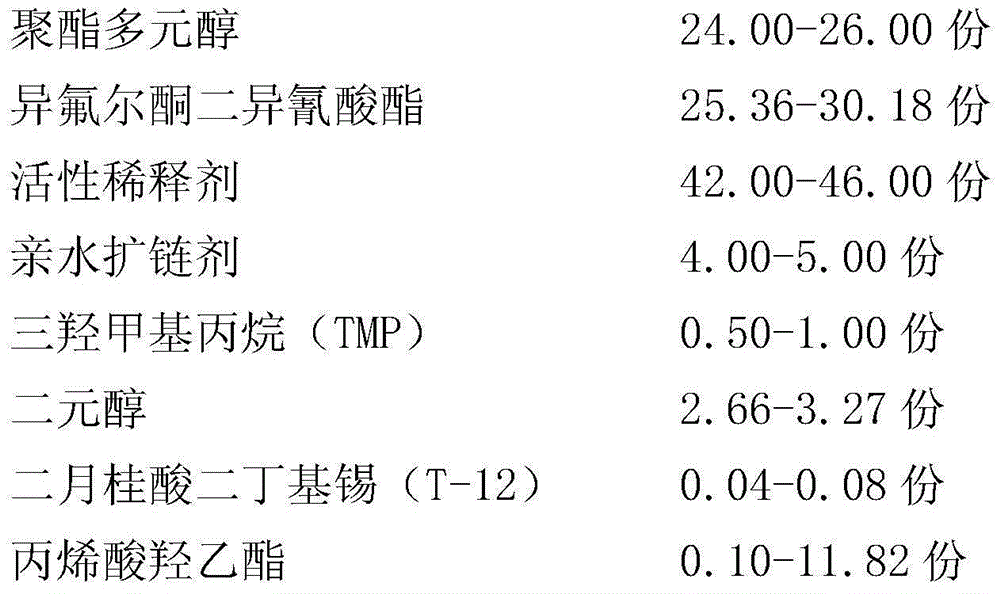

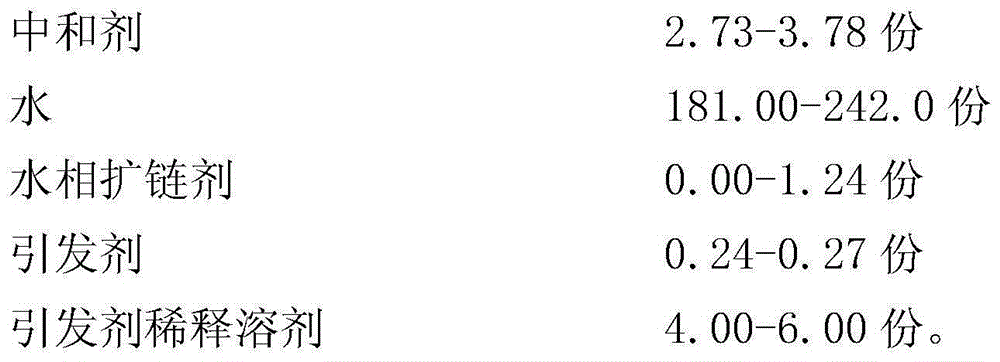

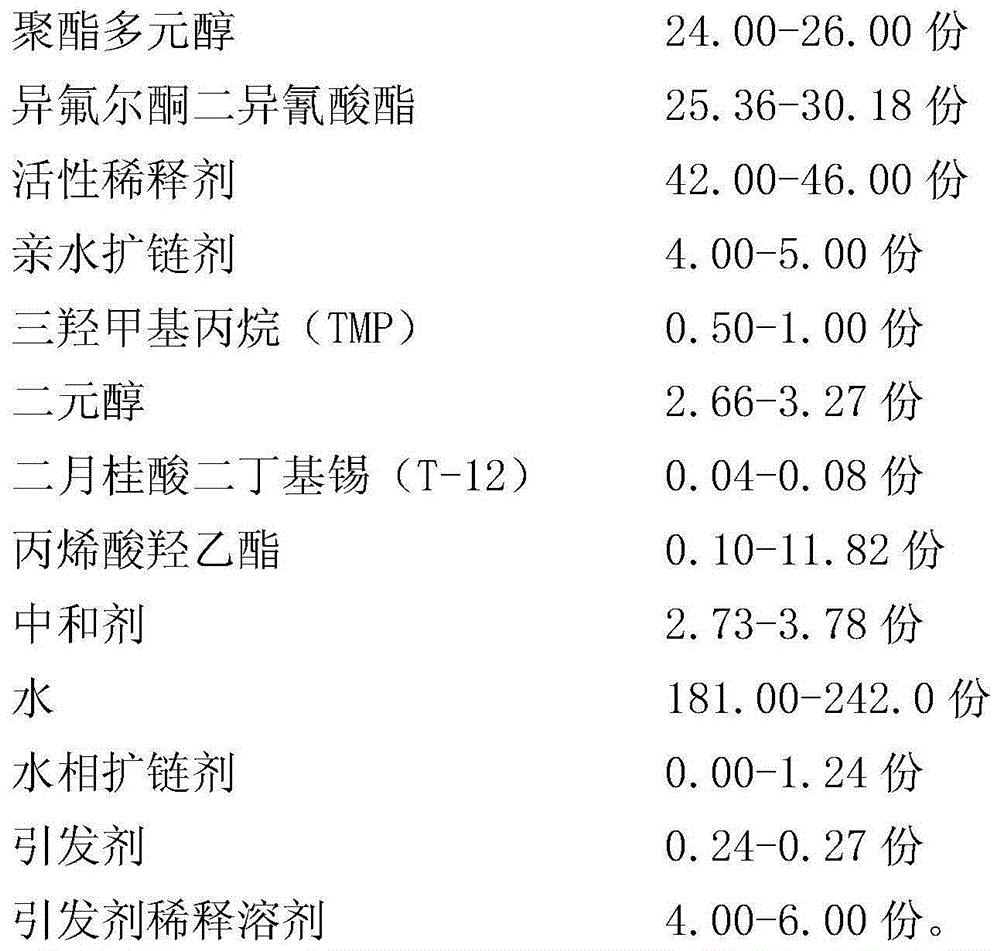

[0041] A polyurethane-acrylate composite emulsion with a core-shell interpenetrating network structure, which is formulated from the following components in the following parts by weight ratio:

[0042]

[0043] A method for preparing a polyurethane-acrylate composite emulsion with a core-shell interpenetrating network structure, comprising the following steps in sequence:

[0044] 1) Prepare polyurethane prepolymer:

[0045]Add 24.00-26.00 parts of polyester polyol and 25.36-30.18 parts of isophorone diisocyanate into the reactor, control the stirring speed of the reactor at 300-500rpm, heat to 80-85°C under the protection of nitrogen, and react to the measured The obtained -NCO content reaches the theoretical value, then add 42.00-46.00 parts of active diluent to adjust the viscosity of the system, then add 4.00-5.00 parts of hydrophilic chain extender, 0.50-1.00 parts of trimethylolpropane (TMP), 2.66-3.27 parts of dihydric alcohol, 0.04-0.08 parts of dibutyltin dilaura...

Embodiment 1

[0056] A polyurethane-acrylate composite emulsion with a core-shell interpenetrating network structure, which is formulated from the following components in the following parts by weight ratio:

[0057]

[0058] A kind of preparation method of the polyurethane-acrylic ester composite emulsion emulsion with core-shell interpenetrating network structure, comprises the following steps in sequence:

[0059] 1) Preparation of polyurethane prepolymer:

[0060] In a 500mL four-necked flask equipped with a stirrer, a thermometer, and a condenser tube, add 25 parts by mass of polyester polyol and 25.36 parts by mass of isophorone diisocyanate, and heat to 85°C at a stirring speed of 500rpm under nitrogen protection. To the measured -NCO content reaches the theoretical value (16.94%), then add 13.2 parts by mass of methyl methacrylate, 30.8 parts by mass of butyl methacrylate to adjust the viscosity of the system, then add 5 parts by mass of hydrophilic extender Chain agent 2,2-dime...

Embodiment 2

[0068] A polyurethane-acrylate composite emulsion with a core-shell interpenetrating network structure, which is formulated from the following components in the following parts by weight ratio:

[0069]

[0070]

[0071] A kind of preparation method of the polyurethane-acrylic ester composite emulsion emulsion with core-shell interpenetrating network structure, comprises the following steps in sequence:

[0072] 1) Preparation of polyurethane prepolymer:

[0073] In a 500mL four-neck flask equipped with a stirrer, a thermometer, and a condenser tube, add 24.00 parts by mass of polyester polyol and 30.18 parts by mass of isophorone diisocyanate, stir at 500 rpm, and heat to 85°C under nitrogen protection. React until the measured -NCO content reaches the theoretical value (18.76%), then add 11.2 parts by mass of methyl methacrylate, 30.8 parts by mass of butyl methacrylate to adjust the viscosity of the system, and then add 4.00 parts by mass of hydrophilic Chain extende...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com