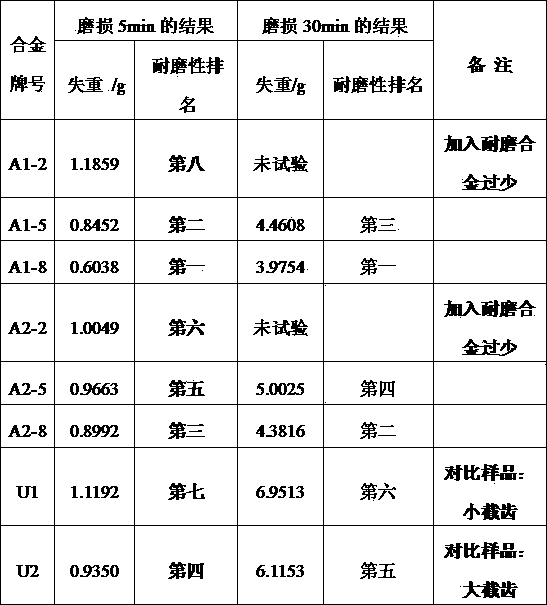

Patents

Literature

328results about How to "Solve wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Giant engineering tire tread rubber and giant engineering tyre using the same

InactiveCN101440176ASolve wear resistanceSolve heat resistanceSpecial tyresHeat resistanceTear resistance

The invention discloses tread rubber for a large project tire and the large project tire using the tread rubber. The tread rubber for the large project tire consists of (A) tread cap rubber, (B) tread center rubber and (C) tread base rubber. On one hand, the invention adopts rubber matrixes with three different formulas to well solve the problem that an outer layer is easy to overcure if the tread rubber for the large project tire is thick; and on the other hand, the tread rubber prepared by the three formulas of the rubber matrixes can obtain superior equilibrium between abrasion resistance, heat resistance, tear resistance, low heat generation and curing speed.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

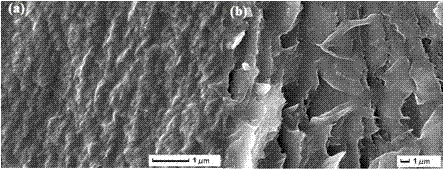

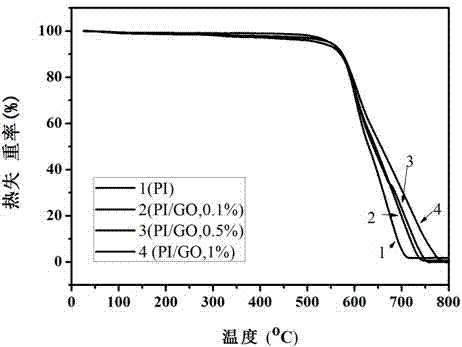

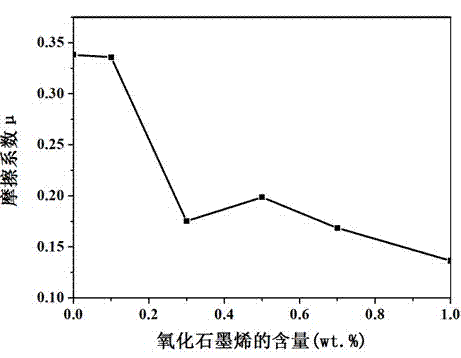

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

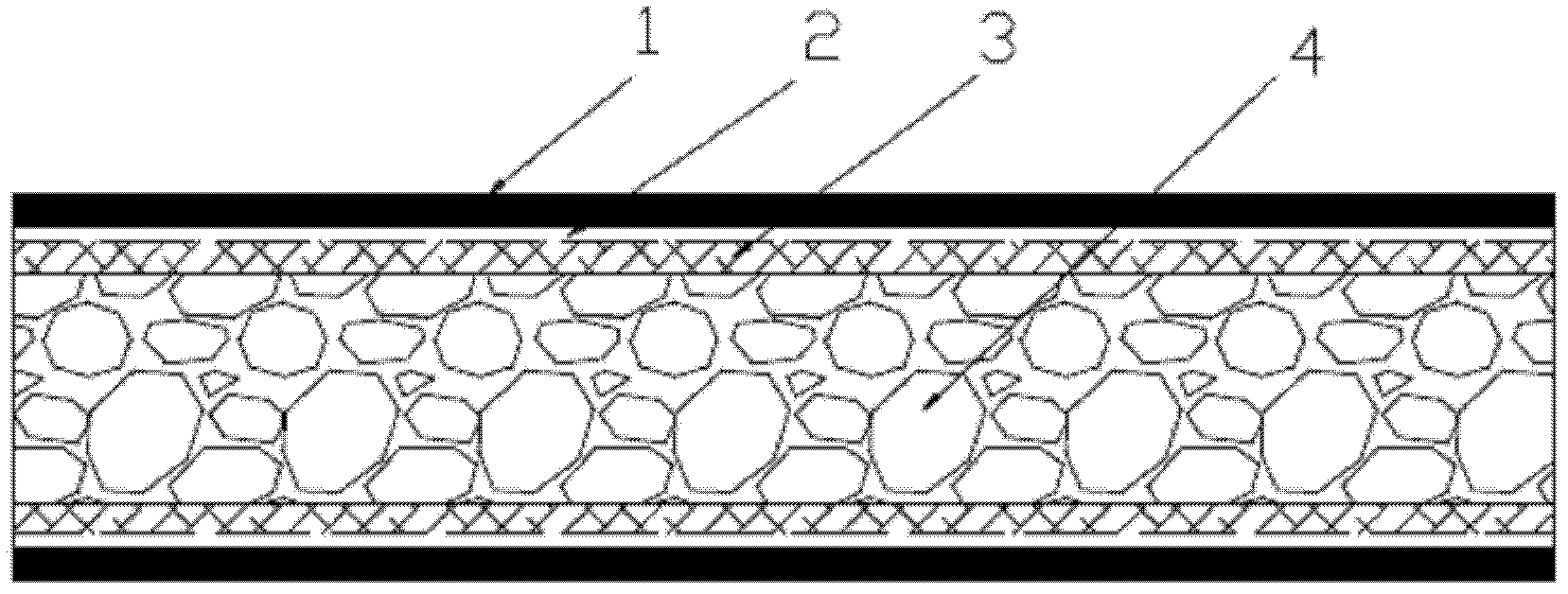

Composite material plate, preparation method and use of composite material plate

InactiveCN103009728AIncrease stiffnessSolve wear resistanceSynthetic resin layered productsLaminationWear resistancePolydicyclopentadiene

The invention relates to a composite material plate. The composite material plate comprises a sandwich layer, two covering layers coating the outer surface of the sandwich layer, and a polydicyclopentadiene layer arranged on the outer surface of at least one of the covering layers. The invention also relates to a preparation method and a use of the composite material plate. According to the composite material plate, outside of a fiber reinforced material is coated by the polydicyclopentadiene layer, so that the problem that a conventional fiber reinforced resin-based composite material is easily suffered from layering failure and is poor in abrasive resistance when being subjected to an impact load is solved. The composite material plate can be widely applied to loading or load-bearing components on mine, railway and road transportation heavy vehicles and goods hoppers. The composite material plate material can be obtained through a reaction injection molding process combined with a vacuum auxiliary molding process, and is suitable for industrial production.

Owner:蓝星环境工程有限公司

Magnesium alloy direct chemical plating NI-P-SiC plating solution formula and plating process

InactiveCN101665930AEasy to prepareFormulated stableLiquid/solution decomposition chemical coatingChemical platingSurface-active agents

The invention provides a magnesium alloy direct chemical plating NI-P-SiC plating solution formula and a plating process. The formula consists of chemical plating Ni-P plating solution and SiC dispersing solution, wherein the chemical plating Ni-P plating solution comprises 20-30g / l of nickel sulfate, 20-30g / l of sodium hypophosphite, 15-30g / l of complexing agent, 15-25g / l of sodium acefate, 10-20g / l of fluoride, 1-2mg / l of stablizer, appropriate amount of PH value modifier and the balance of water; the SiC dispersing solution is formed by stirring 10-80mg / l of surface active agent and 1-8g / lof micron SiC by magnetic force; and after pretreatment of the magnesium alloy, a Ni-P-SiC composite plating layer with thickness being 20-50Mum is obtained under the process conditions that the temperature is 80-90 DEG C, the PH value is 4.8-5.6, and the plating time is 60-120 minutes. In the invention, basic nickel carbonate is replaced by nickel sulfate which is introduced as main salt; and themicron SiC is added to conduct plating directly; on the base of keeping the excellent performance of magnesium alloy chemical plating Ni-P alloy, the rigidity and abrasive resistance of the magnesiumalloy chemical plating layer are greatly improved; the problem of lower abrasive resistance of magnesium alloy nickel-plating layer is solved; and the preparation of the plating solution is convenient, the cost is low, the plating solution is stable and the deposition rate is quick.

Owner:CHONGQING UNIV OF TECH

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

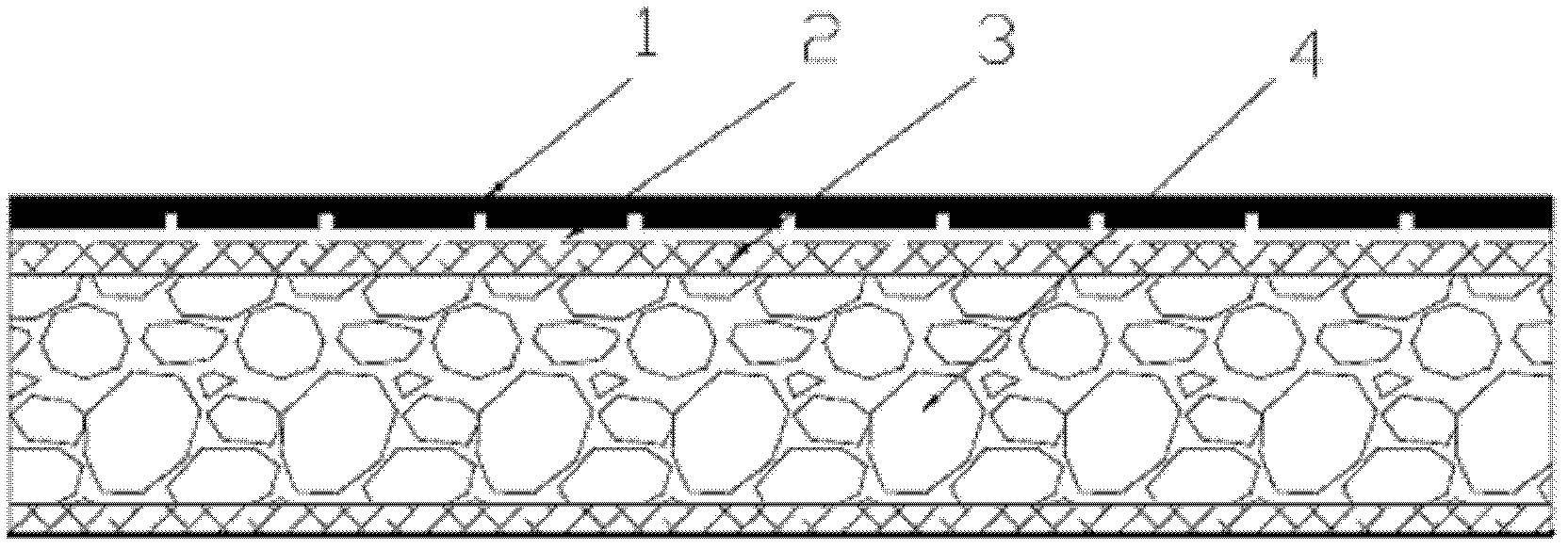

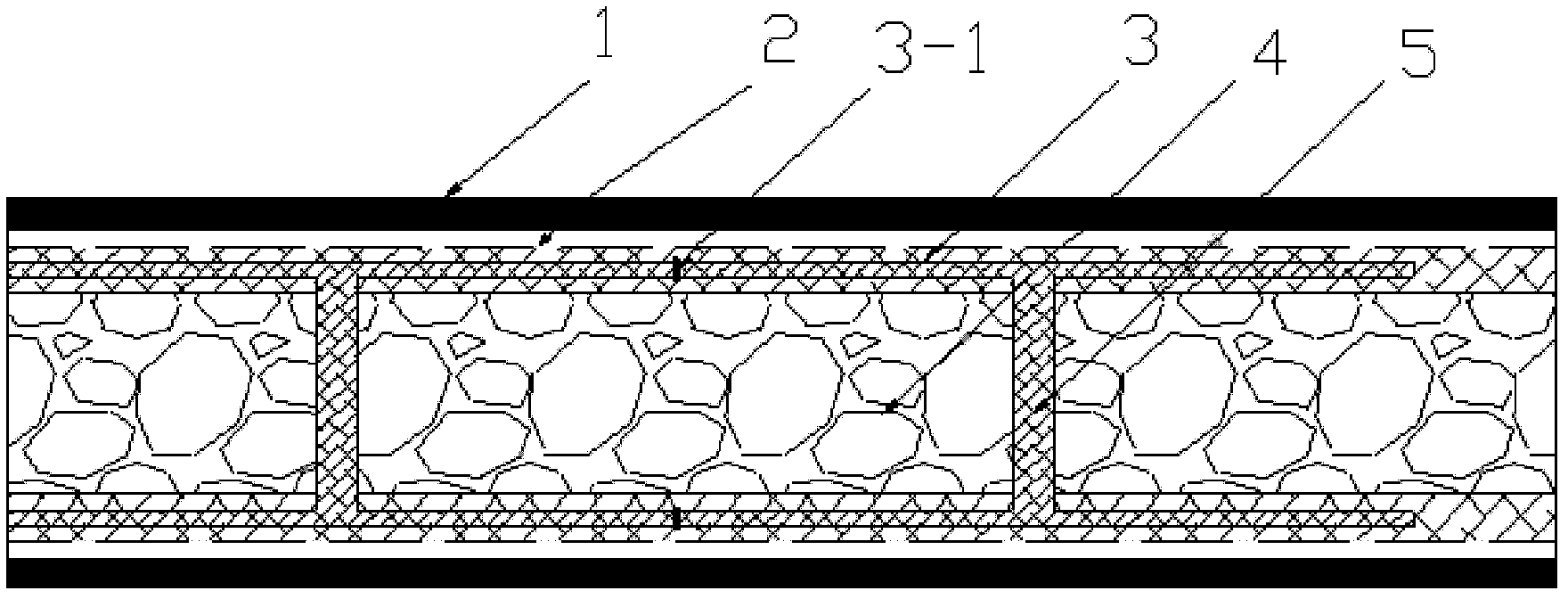

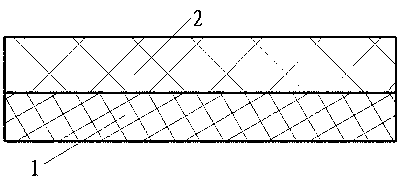

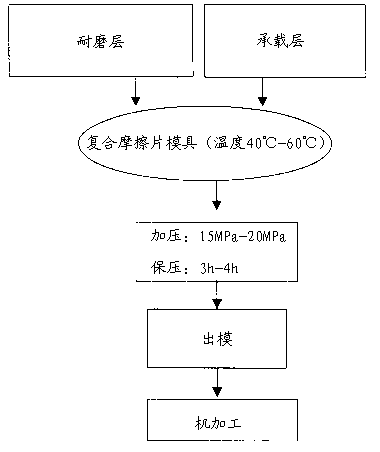

Composite friction plate and preparation method thereof

ActiveCN102705410ASolve wear resistanceSolve the mechanical propertiesFriction liningEpoxyElectricity

The invention provides a composite friction plate and a preparation method thereof. The composite friction plate consists of a wear-resistant layer and a loading layer, wherein the wear-resistant layer is made from basic resin, wear resistant materials and reinforcing materials by blending, modifying and injection molding; the loading layer is a fiber-reinforced epoxy resin composite material; and the loading layer and the wear-resistant layer are bonded by hot pressing to form the composite friction plate. The composite friction plate overcomes the problems in the prior art, such as poor wear resistance, poor mechanical property and poor heat resistance; and has excellent wear resistance and good mechanical property. Besides, the composite friction plate is formed in a way that the loading layer is formed and simultaneously bonded with the wear-resistant layer by hot pressing, which simplifies the production process, increases the production efficiency and ensures stable quality of the product. The product can be widely applied in the fields of automobiles, war industry, wind power generation equipment and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

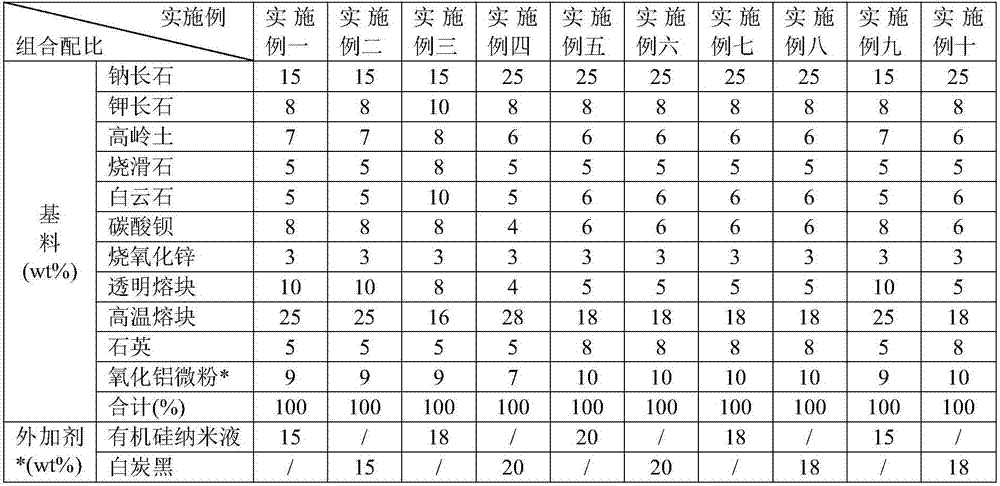

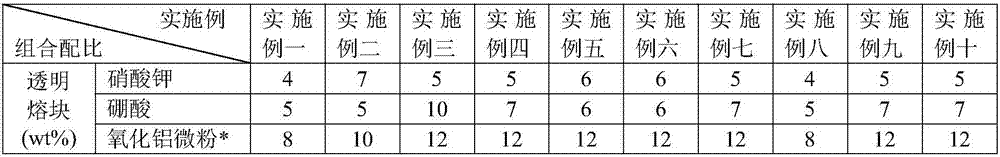

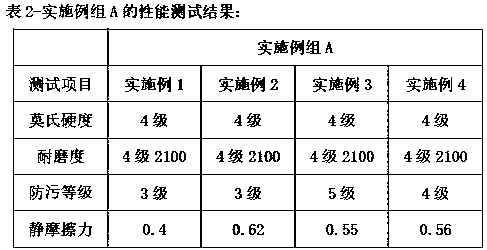

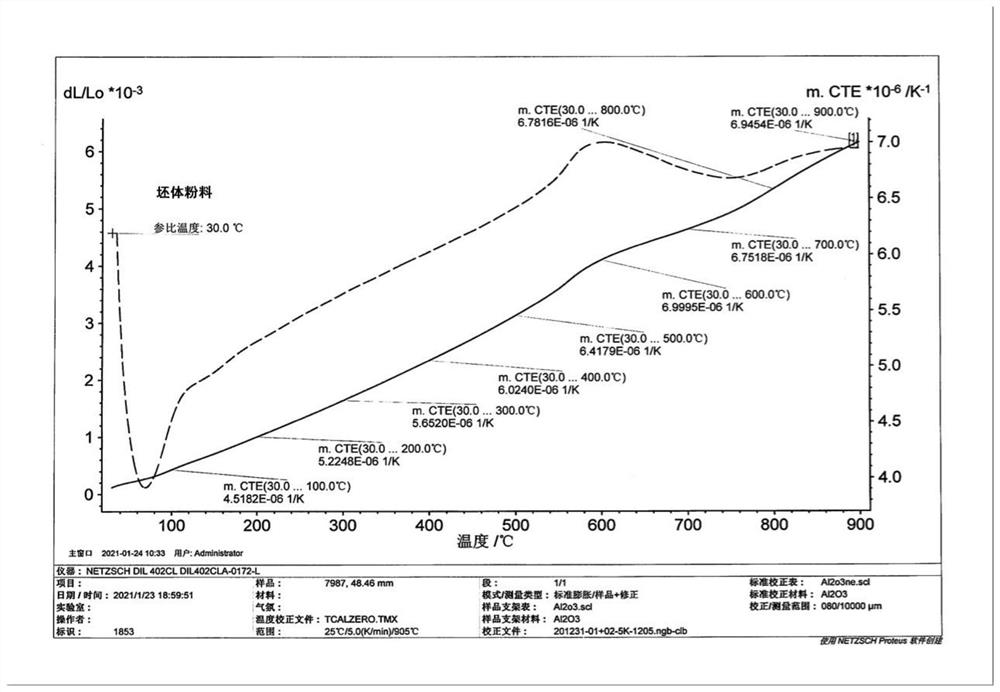

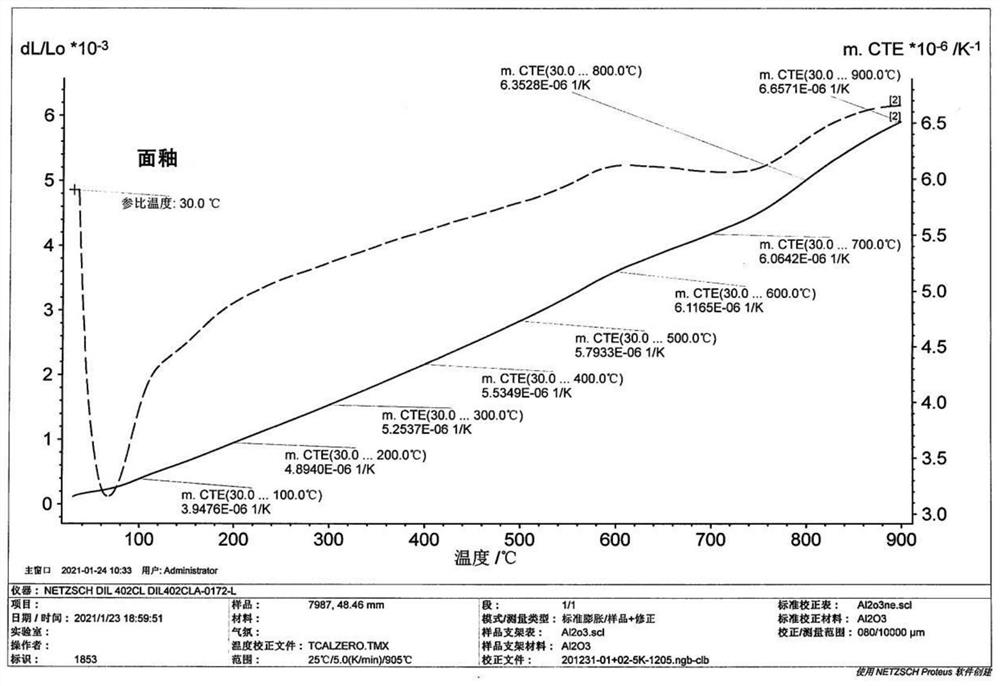

Low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and preparation method thereof

The invention discloses a low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze which contains a base material and an admixture. The base material is prepared from, by weight, 15-25% of albite, 8-16% of potassium feldspar, 6-10% of kaolin, 5-8% of calcined talc, 5-10% of dolomite, 4-12% of barium carbonate, 3-5% of calcined zinc oxide, 4-20% of transparent frit, 16-28% of high-temperature frit, 5%-18% of quartz and 7-15% of alumina micro-powder, wherein the admixture is an organic silicon nano-solution or white carbon black, and the usage amount of the admixture is 15-2% by weight. In addition, the invention further discloses a preparation method of the low-temperature, high-hardness and high-abrasion-resistance fully-polished glaze and a product prepared by the same. The melting temperature is reduced through a reasonable formula system, the melting temperature range of the glaze is enlarged while energy saving and emission reduction are promoted, the hardness and abrasion resistance of the glaze surface are remarkably improved, the higher usage requirements can be very well met, and technical progress and application development of the industry of architectural ceramics are promoted.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Antibacterial ultraviolet-curable coating

InactiveCN102070983ASolve wear resistanceImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesPentaerythritolSilicon oxide

The invention discloses an antibacterial ultraviolet-curable coating, which comprises the following components in percentage by mass: 40 to 60 percent of aromatic polyurethane-acrylate, 25 to 45 percent of crosslinking thinner, 2 to 12 percent of photoinitiator, 5 to 15 percent of nano silicon dioxide, and 0.5 to 1 percent of silver oxide. The nano silicon dioxide is susceptible to agglomeration in the system, so if the nano silicon dioxide is not dispersed uniformly, the transparency and wear resistance of the system may be influenced; and nano silicon dioxide grafted on dipentaerythritol hexaacrylate can well keep the transparency and wear resistance of the system. The combination of silver oxide and aromatic polyurethane-acrylate produces a desirable antibacterial effect.

Owner:上海硕律管理咨询有限公司

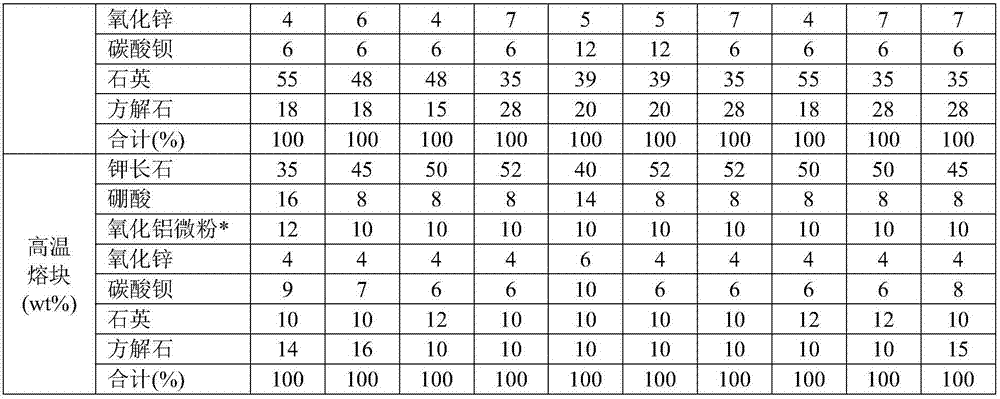

High-performance wear-resistant glaze and preparation method thereof

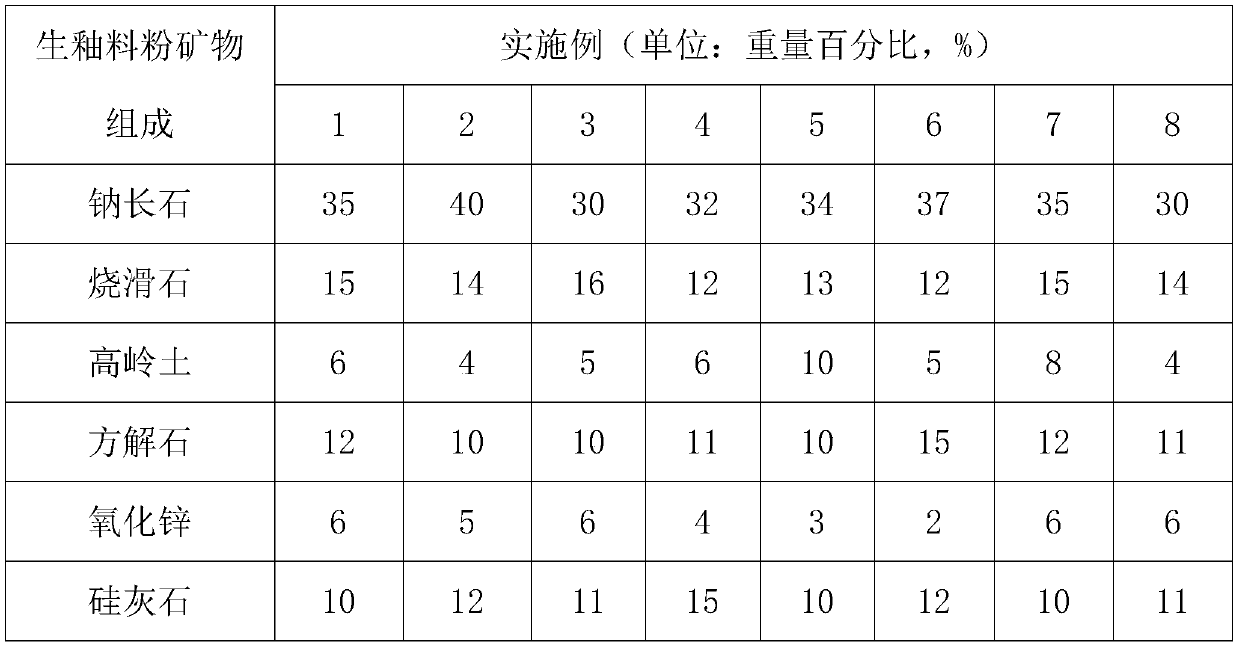

The invention relates to the technical field of building ceramics, particularly to a high-performance wear-resistant glaze and a preparation method thereof, wherein the high-performance wear-resistantglaze comprises, by weight, 65-75% of raw glaze powder and 25-35% of frit powder, the raw glaze powder comprises, by weight, 30-40% of albite, 12-16% of calcined talc, 4-10% of kaolin, 10-15% of calcite, 2-8% of zinc oxide, 10-15% of wollastonite, 10-20% of corundum and 2-8% of barium carbonate. A purpose of the invention is to provide a high-performance wear-resistant glaze and a preparation method thereof, wherein the flatness of the glazed brick prepared from the glaze meets the production process requirements while the contradiction between the transparency and the wear resistance of theglaze layer is solved, and the prepared glazed brick is greatly improved in wear resistance, high in flatness and good in color development.

Owner:FOSHAN DONGPENG CERAMIC +2

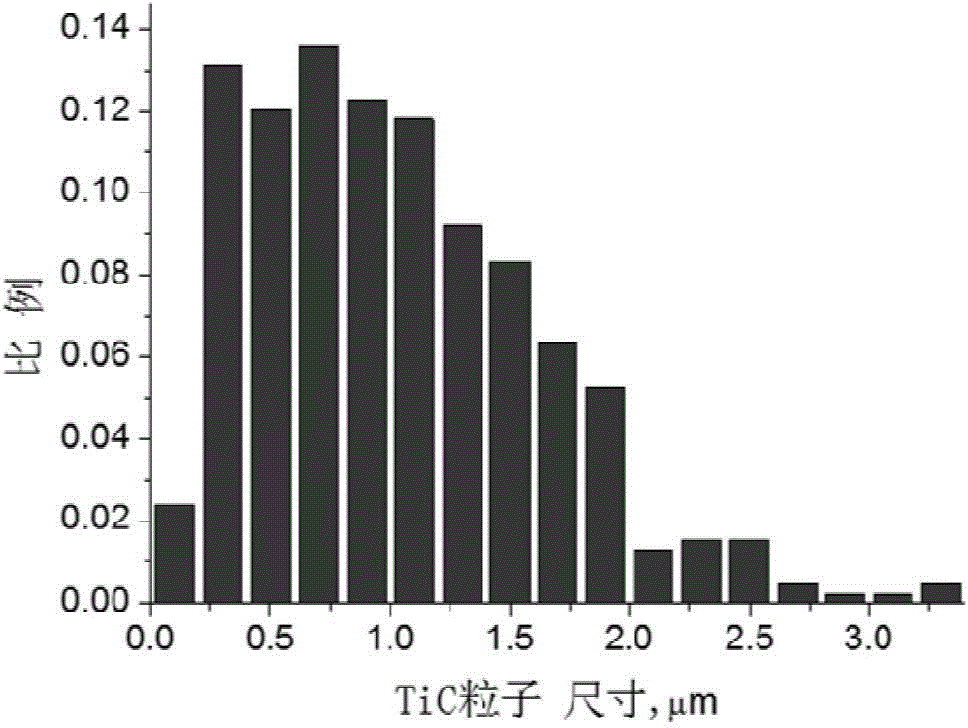

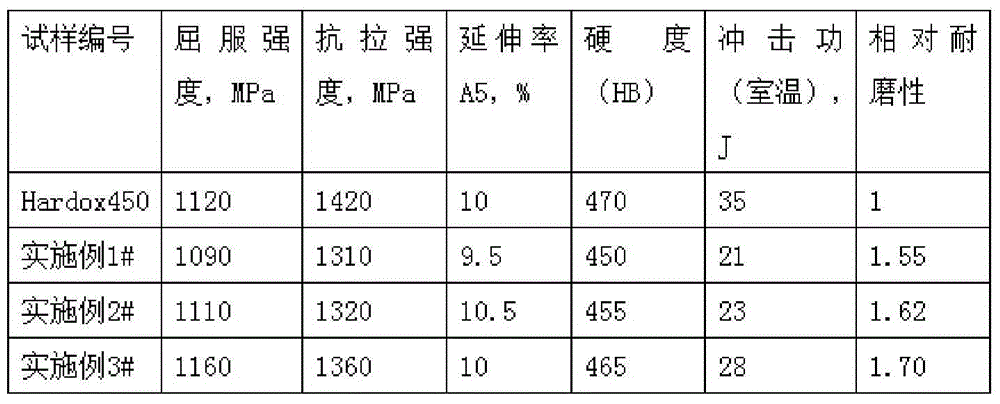

TiC particle enhancement mode complex phase tissue high-ductility wear-resisting steel plate and manufacturing method thereof

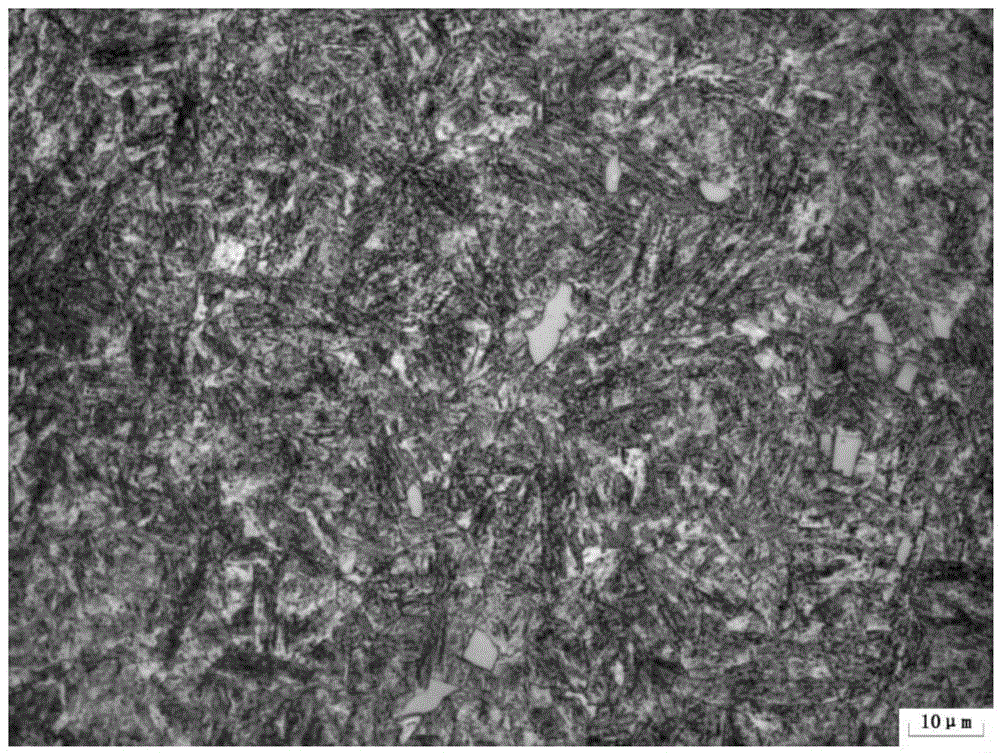

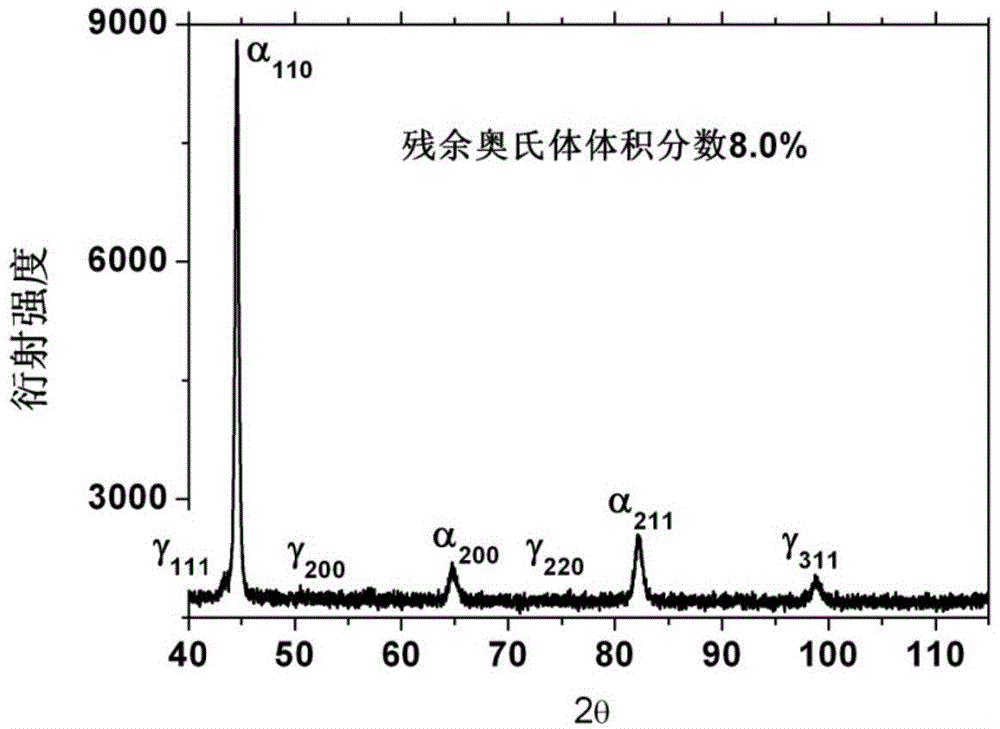

The invention discloses a TiC particle enhancement mode complex phase tissue high-ductility wear-resisting steel plate and a manufacturing method thereof, belonging to the technical field of alloy steel. The steel plate is prepared from the following chemical components in percentage by weight: 0.20-0.40% of C, 1.00-2.50% of Mn, 0.80-1.50% of Si, 0.20-0.60% of Ni, 0.15-0.50% of Mo, 0.40-0.80% of Ti, 0.0005-0.003% of B, less than or equal to 0.005% of S, less than or equal to 0.015% of P, and the balance of Fe and inevitable impurity elements. One or two of alloy elements, namely, 0.00-0.50wt% of Cu and 0.00-0.80wt% of Cr, are further added. The manufacturing method comprises the following steps: smelting by using a converter or an electric furnace, performing external refining, performing continuous casting or die casting on a slab, heating, rolling, cooling and performing thermal treatment. Complex phase tissue of granular bainite, lath martensite and TiC particles is obtained from rolling, the granular bainite comprises bainite ferrite / martensite austenite islands, the volume fraction of the residual austenite is about 6-12%, the volume fraction of TiC precipitated phase is about 0.5-1.5%, the average particle size is about 1mu m, the hardness of the steel plate is HB370-420, the wearing resistance is superior to or equal to Hardox450, the processing property and the welding property are excellent, and manufacturing requirements of relevant equipment are met.

Owner:CENT IRON & STEEL RES INST +1

Wear-resistant antifouling glazed brick glaze and preparation method thereof

The invention discloses a wear-resistant antifouling glazed brick glaze and a preparation method thereof. The wear-resistant antifouling glazed brick glaze comprises raw glaze powder, No.1 frit powderand No.2 frit powder, wherein the raw glaze powder comprises the following raw materials in percentage by weight: 8-12% of kaolin, 10-18% of calcined kaolin, 12-20% of quartz, 12-20% of dolomite, 8-15% of calcined talc, 1-5% of wollastonite, 8-15% of nepheline, 5-10% of zinc oxide, 0-5% of calcite and 6-12% of strontium carbonate, wherein the No.1 frit powder is prepared from kaolin, calcined talc and fluorite, and the No.2 frit powder is prepared from zinc oxide, strontium carbonate and borax. The wear-resistant antifouling glazed brick glaze contains a large number of cordierite microcrystals, and the cordierite microcrystals have the characteristics of transparency, high hardness and the like, so that the wear resistance and the antiskid effect of a glaze layer can be enhanced, and thecontradiction between the transparency and the wear resistance of the glaze layer can be solved.

Owner:佛山市东鹏陶瓷发展有限公司

Stain-resisting ultraviolet curing painting

InactiveCN102070984ASolve wear resistanceSmall particle sizeAntifouling/underwater paintsPaints with biocidesPolymer sciencePhotoinitiator

The invention discloses a stain-resisting ultraviolet curing painting, which comprises the following components in percentage by mass: 35 to 55 percent of photosensitive resin, 20 to 40 percent of crosslinking diluent, 2 to 12 percent of photoinitiator, and 10 to 25 percent of fluorine modified resin. By adding the fluorine modified resin into the formula, the stain-resisting ultraviolet curing painting is hydrophobic and oleophobic under the action of fluorine with lower surface tension, so the stain-resisting ultraviolet curing painting has the characteristic of stain resistance.

Owner:上海硕律管理咨询有限公司

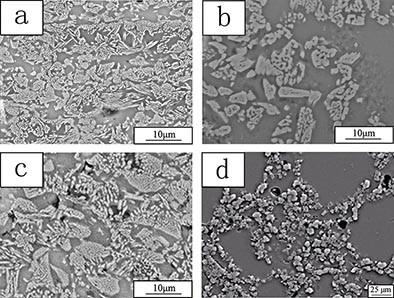

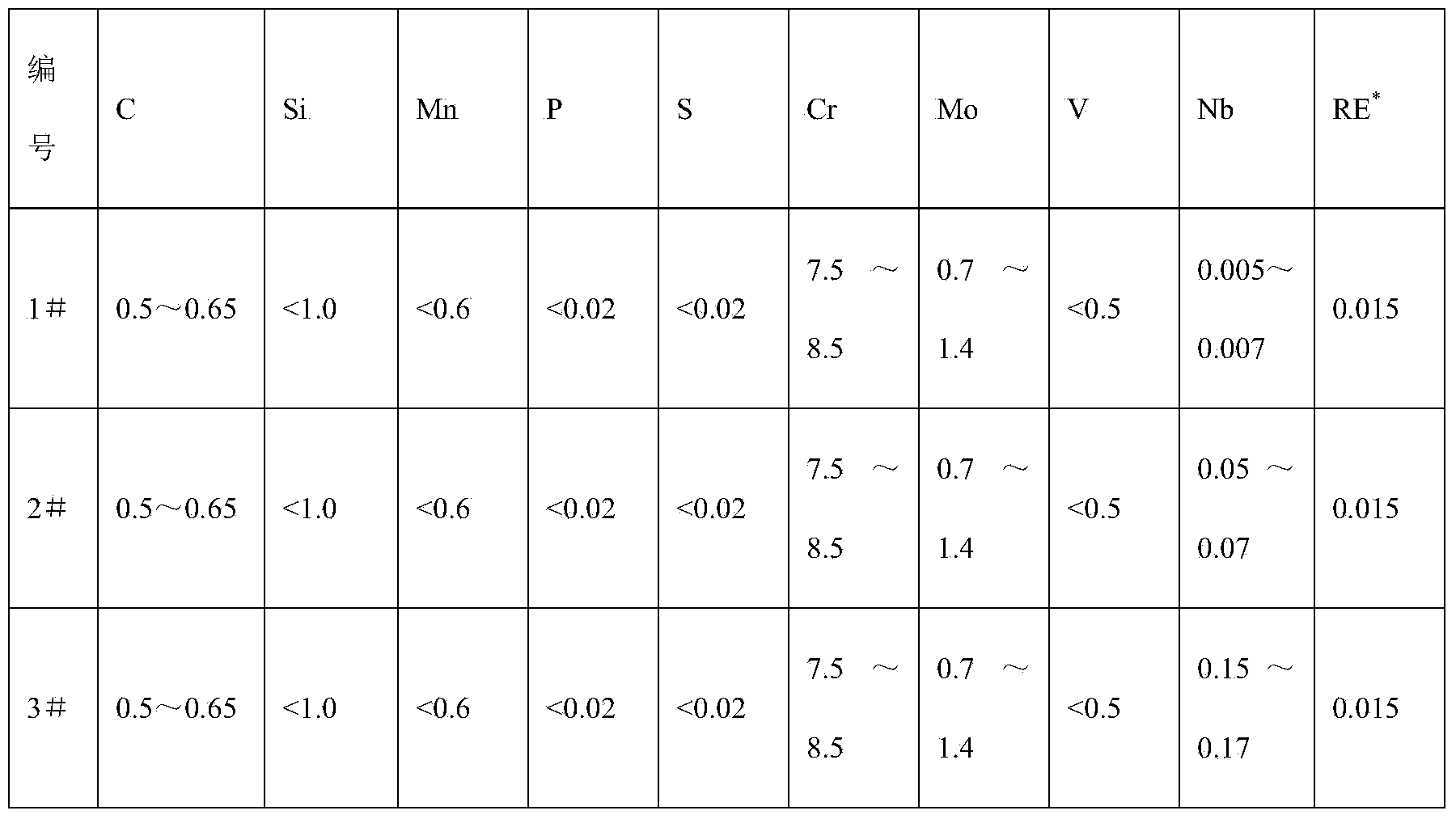

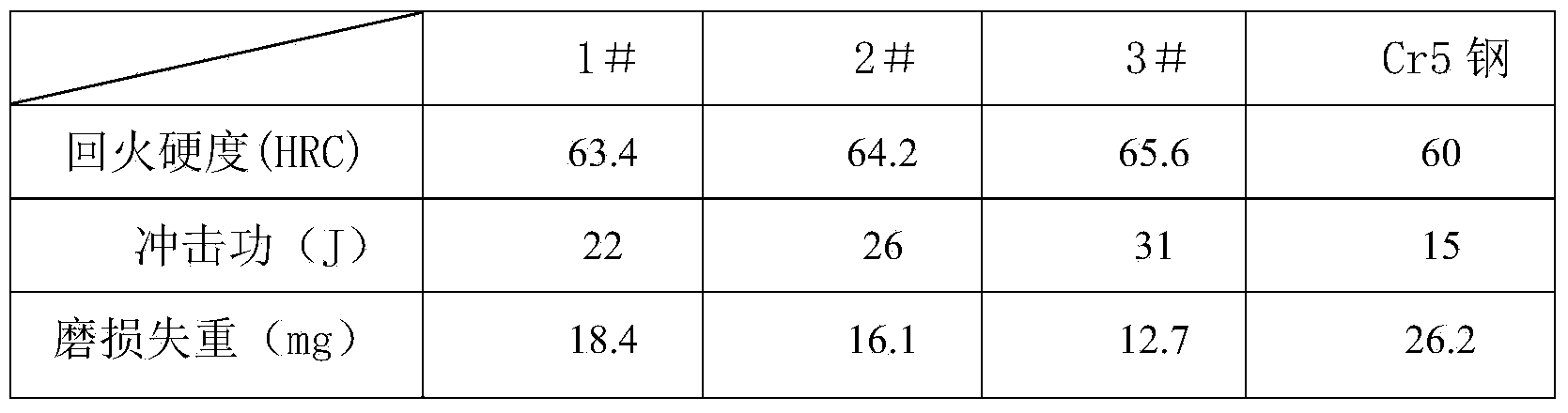

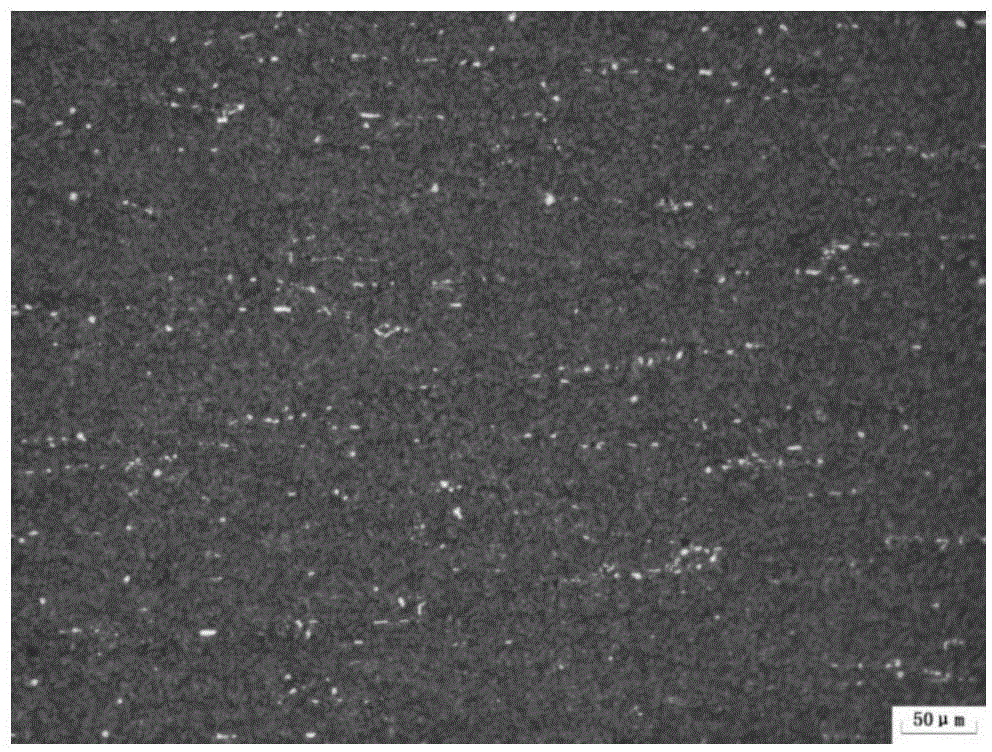

Improved Cr8 steel roll and preparation method thereof

The invention discloses an improved Cr8 steel roll and a preparation method thereof. Based on the Cr5 steel, the Cr8 steel roll also comprises microalloying Nb and RE, wherein Nb is mainly used for refining the crystalline grain, and RE is mainly used for purifying molten steel. The Cr8 steel roll comprises the following components: 0.50-0.65% of C, less than or equal to 1.0% of Si, less than or equal to 0.60% of Mn, less than or equal to 0.020% of S, less than or equal to 0.020% of P, 7.5-8.5% of Cr, 0.70-1.40% of Mo, less than or equal to 0.50% of V, 0.005-0.20% of Nb, 0.003-0.02% of RE, and the balance of Fe and impurities. By combining solidification refining, deformation recrystalization refining and thermal treatment refining, the method refines the tissue of a high chrome ledeburite die steel and obtains fine plate martensite with the length less than 30micron and width less than 0.5micron. Due to rare earth modification, carbide segregation is reduced, and the morphology of the included foreign substances and eutectic carbide is improved. Due to the adoption of proper thermal treatment technology, compared with Cr5 steel, the Cr8 steel roll not only has higher toughness, but also improves the abrasion performance, and greatly prolongs the service life.

Owner:UNIV OF SCI & TECH BEIJING

Anticorrosive wear-resistant paint for oilfield pipelines

InactiveCN104130662AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to an anticorrosive wear-resistant paint for oilfield pipelines. The paint is characterized by comprising the following components by weight: 25-35 parts of epoxy resin, 5-15 parts of organic silicon resin, 0.5-5 parts of ceramic micropowder, 10-20 parts of nano-graphite powder, 5-15 parts of an epoxy resin curing agent, and 10-20 parts of butanone. The paint provided by the invention can provide a protective coating with high corrosion resistance, wear resistance, high adhesion and impact resistance for various steel pipelines of oilfield.

Owner:西安和泰化工有限公司

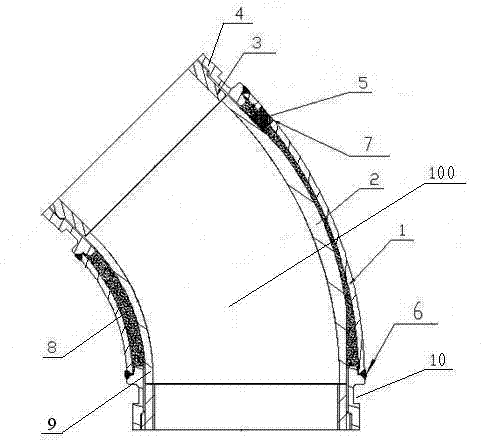

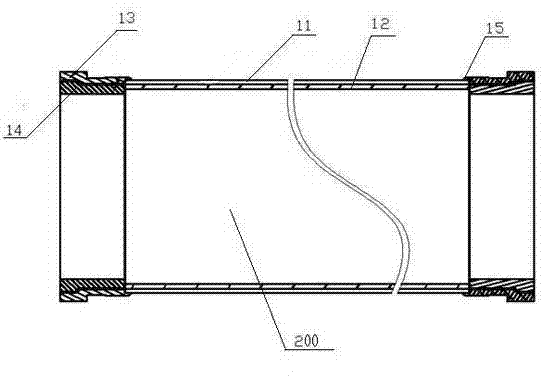

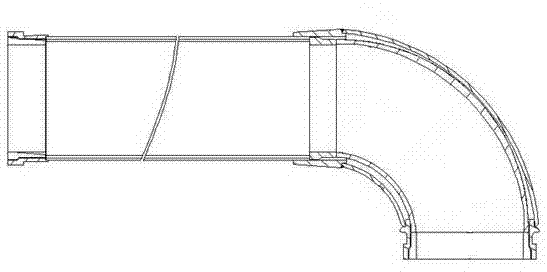

A concrete delivery pipe and its manufacturing method

InactiveCN102297304AImprove toughnessHigh strengthFlanged jointsPipe protection against damage/wearStraight tubePipe

A concrete conveying pipe, including a bend pipe and a straight pipe, the bend pipe includes a bend wear-resistant pipe, a bend outer pipe and a bend pipe flange, the bend wear-resistant pipe is set in the bend outer pipe, and the bend wear-resistant pipe and the bend outer pipe With a filling layer, the elbow flange is connected to the outer elbow pipe, and the inner elbow flange has an inner elbow sleeve; the straight pipe includes a straight wear-resistant pipe, a straight outer pipe and a straight pipe flange, and the straight wear-resistant pipe is placed on the straight outer In the pipe; the straight pipe flange is connected with the straight outer pipe, and the straight pipe flange has a straight pipe inner sleeve. Bend wear-resistant pipes, straight wear-resistant pipes and inner sleeves of bent pipes and inner sleeves of straight pipes are made of new hypereutectic high-chromium white cast iron materials, which are formed by investment mold, sand mold or centrifugal casting to meet the requirements of high wear resistance; The pipe and straight outer pipe are formed by hot push or cold drawing of low-carbon high-strength steel pipe, which has the characteristics of low cost and easy forming. The contradiction between high toughness and high wear resistance.

Owner:李宗仙

Ultra-hard particle-enhanced martensitic wear-resistant steel plate and manufacturing method thereof

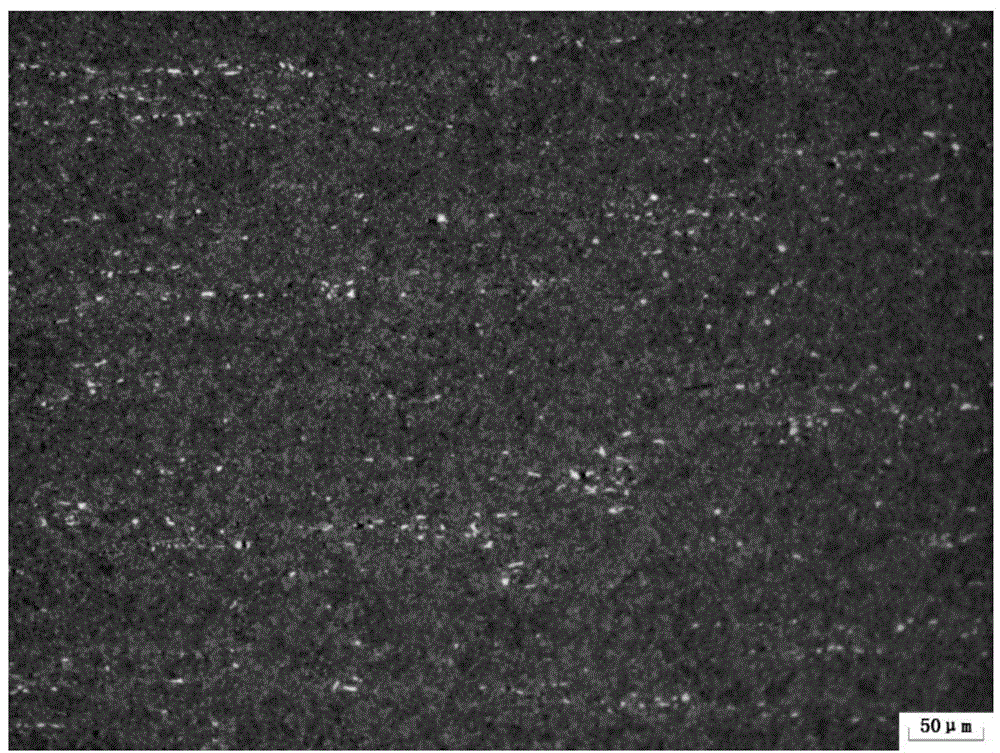

The invention relates to an ultra-hard particle-enhanced martensitic wear-resistant steel plate and a manufacturing method thereof and belongs to the technical field of alloy steels. The wear-resistant steel plate comprises the following chemical components in percentage by weight: 0.20-0.40% of C, 0.50-1.00% of Mn, 0.30-0.60% of Si, 0.50-0.80% of Cr, 0.40-0.60% of Ni, 0.30-0.40% of Mo, 0.40-0.80% of Ti, 0.30-0.50% of Cu, 0.0005-0. 003% of B, less than or equal to 0.005% of S, less than or equal to 0.015% of P and the balance of Fe and unavoidable impurity elements. The manufacturing method of the wear-resistant steel plate comprises the following steps: smelting in a converter or an electric furnace, carrying out external refining, carrying out continuous casting or die casting of slab, heating, rolling, cooling and carrying out heat treatment. According to the components and process, about 0.5-1.5% (volume fraction) of precipitated phases are obtained in the rolled products, the average particle size is about 1mu m; the hardness of the steel plate is HB400-500, the wear resistance reaches above 1.5 times of Hardox450 and the steel plate has excellent processing and welding performances and meets the manufacturing requirements of the relevant device.

Owner:CENT IRON & STEEL RES INST +1

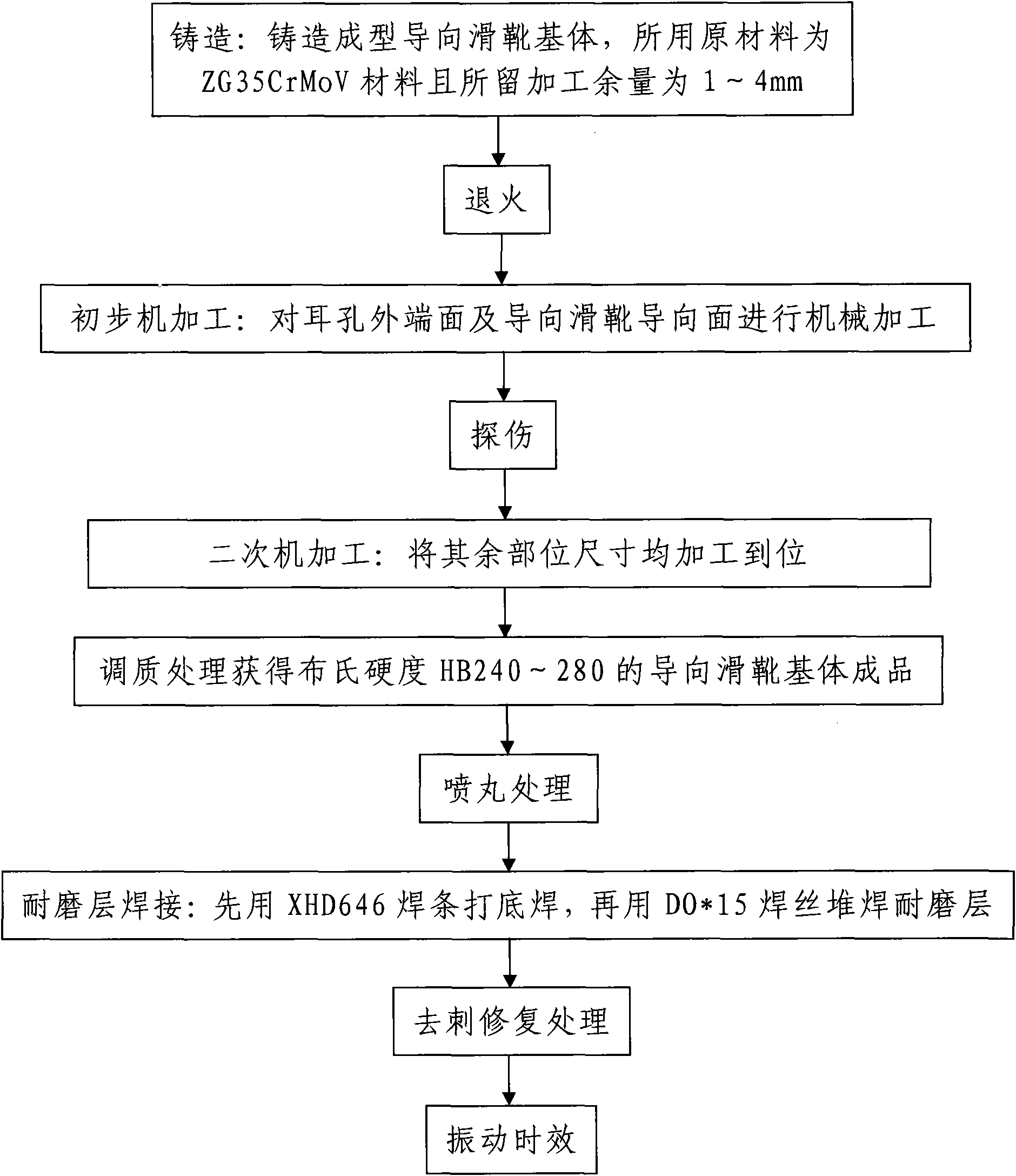

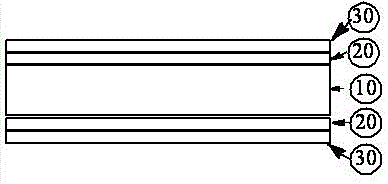

Processing technology for prolonging service life of guiding slide shoes

ActiveCN101608546AReasonable design of process stepsSimple and efficient operationFoundry mouldsSlitting machinesEngineeringHardness

The invention discloses a processing technology for prolonging the service life of guiding slide shoes. The processed guiding slide shoes consist of guiding slide shoe base bodies and wear-resisting layers, wherein the wear-resisting layers are welded on guiding surfaces. The technology comprises the following steps: firstly, casting: the guiding slide shoe base bodies are cast and shaped, the raw material is ZG35CrMoV, and the remained processing tolerance is from 1 mm to 4 mm; secondly, annealing; thirdly, primary machining: the outer end surfaces of lugs and the guiding surfaces are machined; fourthly, fault detection; fifthly, secondary machining: the rest part size is respectively machined; sixthly, quality regulation treatment: the finished guiding slide shoe base bodies with the brinell hardness of 240 to 280 are obtained; seventhly, peening treatment; eighthly, welding of wear-resisting layers: XHD646 welding bars are used for carrying out bottom welding firstly, and then DO*15 is used for carrying out surface welding on the wear-resisting layers; ninthly, deburring and repairing treatment; and tenthly, vibration aging. The invention has the advantages of reasonable design and convenient operation, and the processed guiding slide shoes have the advantages of high quality and long service life.

Owner:XIAN COAL MINING MACHINERY

Antistatic pad and tray as well as manufacturing method thereof

InactiveCN103552334AGuaranteed stabilitySolve wear resistanceSynthetic resin layered productsCoatingsThermoplasticAntistatic agent

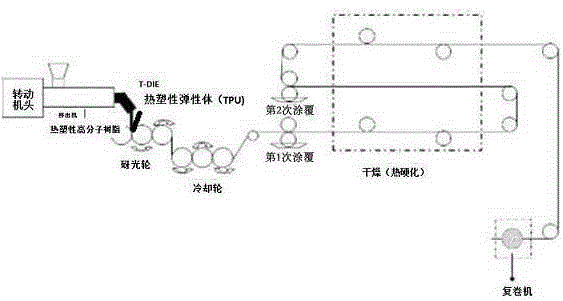

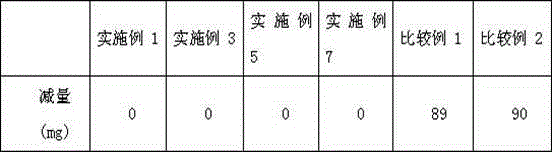

The invention relates to an antistatic pad and an antistatic tray as well as a manufacturing method thereof, and particularly relates to an antistatic pad and an antistatic tray which respectively comprise a thermal plastic elastomer and are favorable in abrasion resistance and shock resistance, and a manufacturing method for manufacturing the antistatic pad and tray. The method is characterized in that in the process of manufacturing the antistatic pad after the insulator thermoplastic macromolecule resin is extruded, through a one-step technology, a layer of thermal plastic elastomer (TPE) such as thermoplastic polyurethane (TPU) is formed on one surface of the antistatic pad; at the stage of forming antistatic coating layer by utilizing an antistatic coating liquid, the antistatic pad is manufactured through a one-step (in-line) technology. The manufacturing method of the antistatic pad, which is provided by the invention, can enable the production process of the antistatic pad with favorable abrasion resistance and shock resistance to keep excellent production efficiency; the antistatic pad manufactured by utilizing the method can be used for manufacturing an antistatic tray which is better in abrasion resistance and molding effect and is used for electronic fitting vacuum molding, antistatic products and the like.

Owner:恩斯盟防静电材料(镇江)有限公司

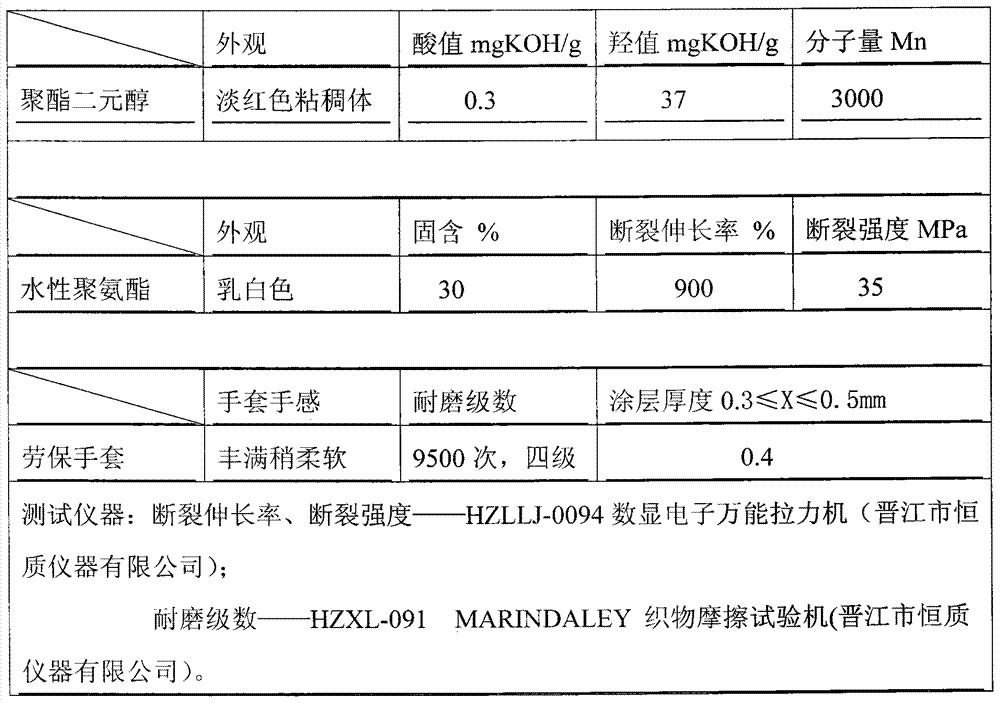

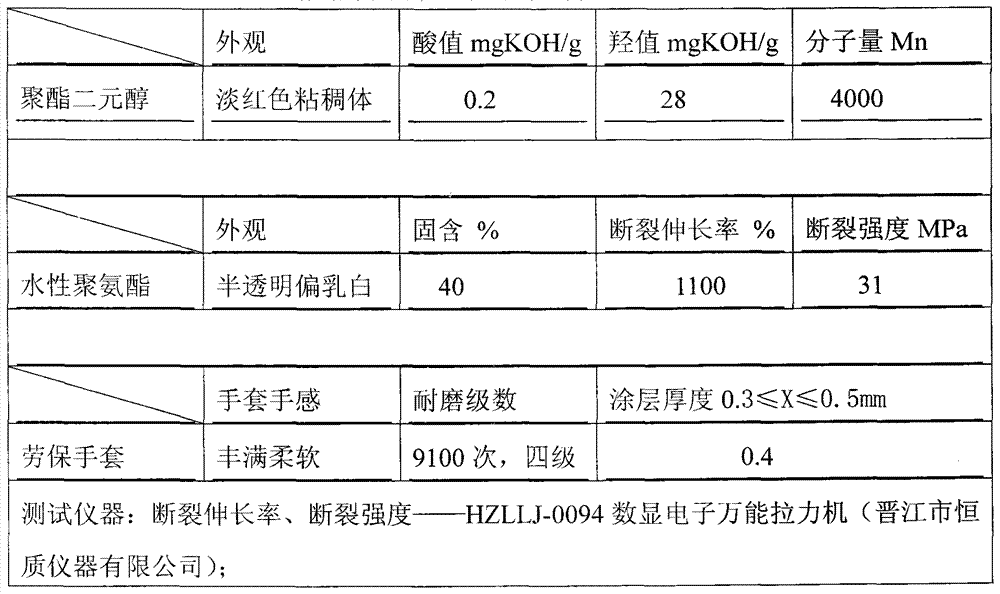

Super-elastic wear-resisting waterborne polyurethane resin and composition and application of super-elastic wear-resisting waterborne polyurethane resin and composition

InactiveCN104497258ASolve the hard feelingSolving Elasticity ProblemsAbrasion resistant fibresPolyesterSlurry

The invention discloses super-elastic wear-resisting waterborne polyurethane resin which is prepared by polymerizing polyester glycol and polyisocyanates. The invention further discloses a preparation method of the resin. By adopting the super-elastic wear-resisting waterborne polyurethane resin disclosed by the invention, slurry can be prepared to coat the surfaces of knitted gloves, so that the problems that in the prior art, knitted gloves made by using a conventional method are hard in hand feeling, poor in resilience, low in wearing resistance, and the like.

Owner:ANHUI LINGDA CHEM TECH

Coating method for DLC (diamond-like carbon) coating on spinning reed and equipment

InactiveCN102534614AImprove performanceExtended service lifeVacuum evaporation coatingSputtering coatingDlc coatingSpinning

The invention discloses a coating method for a DLC (diamond-like carbon) coating on a spinning reed. The coating method comprises the steps of preparing a metal depletion layer through a vacuum sputter coating or multi-arc ion beam technology and preparing the DLC coating through a vacuum ion coating technology. The invention further discloses equipment capable of applying the coating method. The invention has the outstanding effects as follows: the DLC coating is successfully applied to the spinning reed, so as to solve the problem on surface abrasion resistance of the reed and improve the film rigidity of the reed to HV0.025 2500 to 3500; and the DLC coating has the properties of abrasion resistance, corrosion resistance, high binding force and low friction coefficient, thereby effectively improving the property of the reed, prolonging the service life of the reed, improving the spinning efficiency, saving the spinning cost and ensuring the quality of textile products.

Owner:STARARC COATING TECH SUZHOU

Production process of superfine dry-particle ceramic large plate and product of same

The invention discloses a production process of a superfine dry particle ceramic large plate and a product of the same. The production process comprises the following steps: (1) brushing a green body and spraying water to wet the green body; (2) sequentially spraying overglaze on the surface of the green body and carrying out ink-jet printing on the surface of the green body; (3) spraying dry granular glaze slip on the surface of the green body obtained in the step (2) in a bell jar mode, and the dry granular glaze slip comprises, by weight, 110-130 parts of a suspending agent, 35-45 parts of superfine dry granules and 4.5-11 parts of raw transparent glaze; wherein the superfine dry particles comprise 19-21% of corundum powder; and (4) firing, brushing and throwing to obtain the superfine dry particle ceramic large plate. According to the invention, the dry granular glaze is sprayed on the surface of the green body, so that fine and smooth small particles with frosted texture are formed on the surface of the prepared large ceramic plate, thereby improving the wear resistance and skid resistance of the large ceramic plate, and solving the problems of poor wear resistance and poor skid resistance of the existing large ceramic plate.

Owner:FOSHAN DONGPENG CERAMIC +3

Flexible ceramic coating and its production

InactiveCN101074340ASolve wear resistanceSolve corrosiveAnti-corrosive paintsEpoxy resin coatingsEpoxyCeramic coating

A flexible ceramic coating and its production are disclosed. The coating is made up of double components. The first component consists of ceramic powder, modified epoxy resin, diluting agent and dispersant; the second component consists of modified ammonia-curing agent. The process is carried out by mixing while dipping for ceramic powder at normal temperature and pressure by diluting agent, agitating, adding into modified epoxy resin, diluting agent and dispersant, rolling slurry to obtain the first component, mixing with the second component and agitating. It has better surface hardness, excellent corrosive-proof and abrasive abilities, acid and alkaline resistances.

Owner:沈阳市航达科技有限责任公司

Composite board and preparation method thereof, and dumper compartment

InactiveCN103010316AAddressing Layered FailuresSolve wear resistanceSynthetic resin layered productsWood layered productsEngineeringPolydicyclopentadiene

The invention discloses a composite board which comprises two skin layers, wherein an intermediate layer is formed between the two skin layers and an inner stiffening beam is arranged between the two skin layers, a core material is filled in the intermediate layer, an outer stiffening beam is arranged between the core material and at least one skin layer, and a polydicyclopentadiene layer is arranged outside the at least one skin layer. The invention also discloses a preparation method of the composite board. The invention further discloses a dumper compartment comprising the composite board. The dumper compartment has the characteristics of strong bearing capacity, remarkable weight reducing effect, oil consumption saving, carbon dioxide emission reducing, long service life and the like.

Owner:蓝星环境工程有限公司

Multi-functional polyethylene tube and manufacturing method thereof

The invention discloses a multi-functional polyethylene tube and a manufacturing method thereof, belonging to a polymer composite material. The multi-functional polyethylene tube is prepared by blending and modifying the following raw materials in parts by mass: 30-50 parts of high-density polyethylene (HDPE), 70-90 parts of ultrahigh molecular weight polyethylene (UHMWPE), 10-15 parts of polyoctene rubber (TOR), 1.5-2.0 parts of nano rare earth beta-nucleating agent, 1.0-1.5 parts of dicumyl peroxide (DCP), 3-5 parts of silicone polymer flame retardant and 3-5 parts of color masterbatch. The invention has the advantage that the problems of low-temperature brittleness, abrasive resistance, corrosion resistance, ageing resistance, heat resistance, processability, flame retardancy, and the like of the polyethylene tube are solved. The invention can be widely applied to the fields of water supply and drainage, sewage discharge, oil gas, coal power, mining industry, gas supply, heating, chemical industry, power communication, ocean, dredging, and the like.

Owner:JIANGSU BAIANJU PLASTIC PIPE IND CO LTD

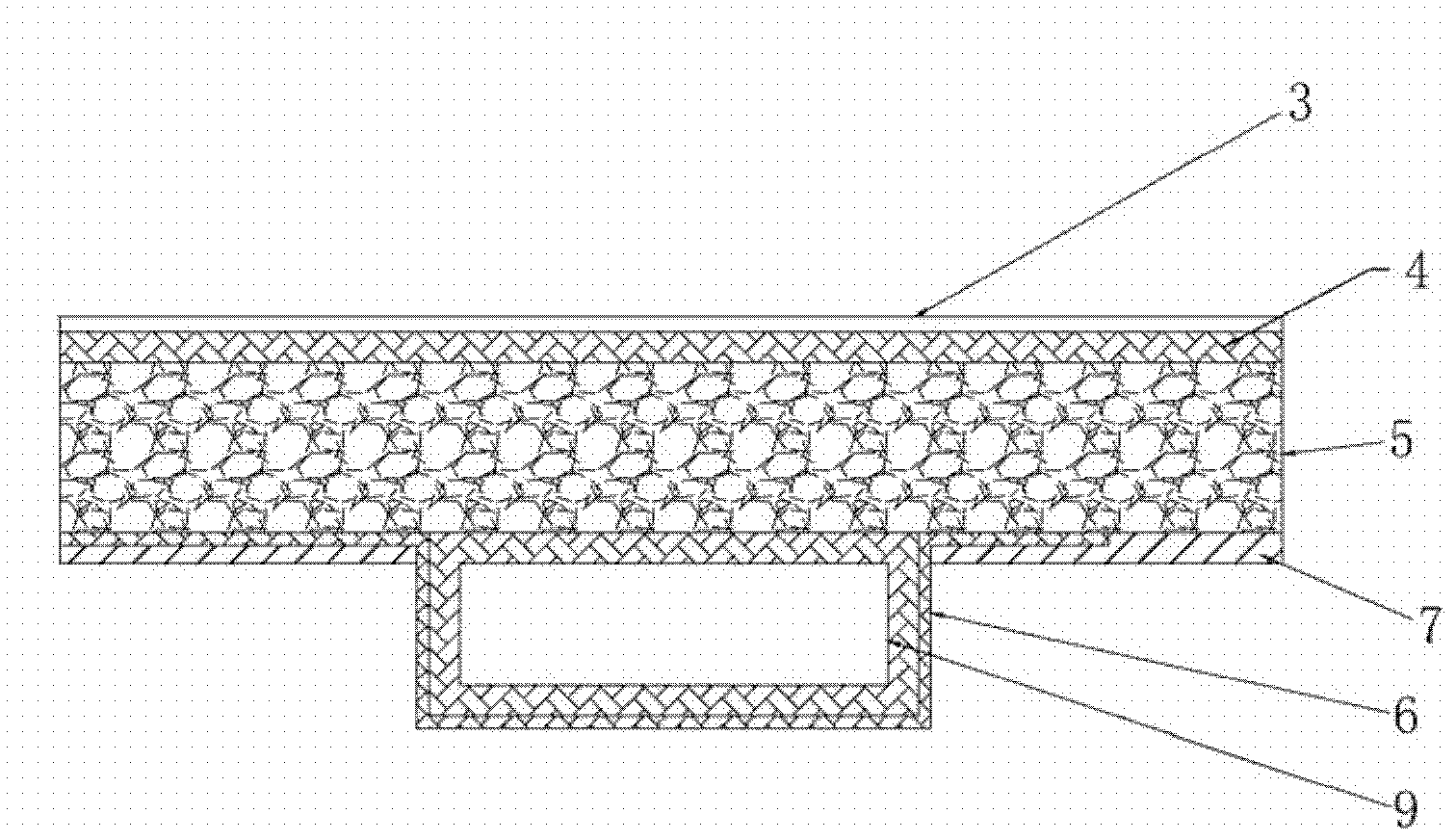

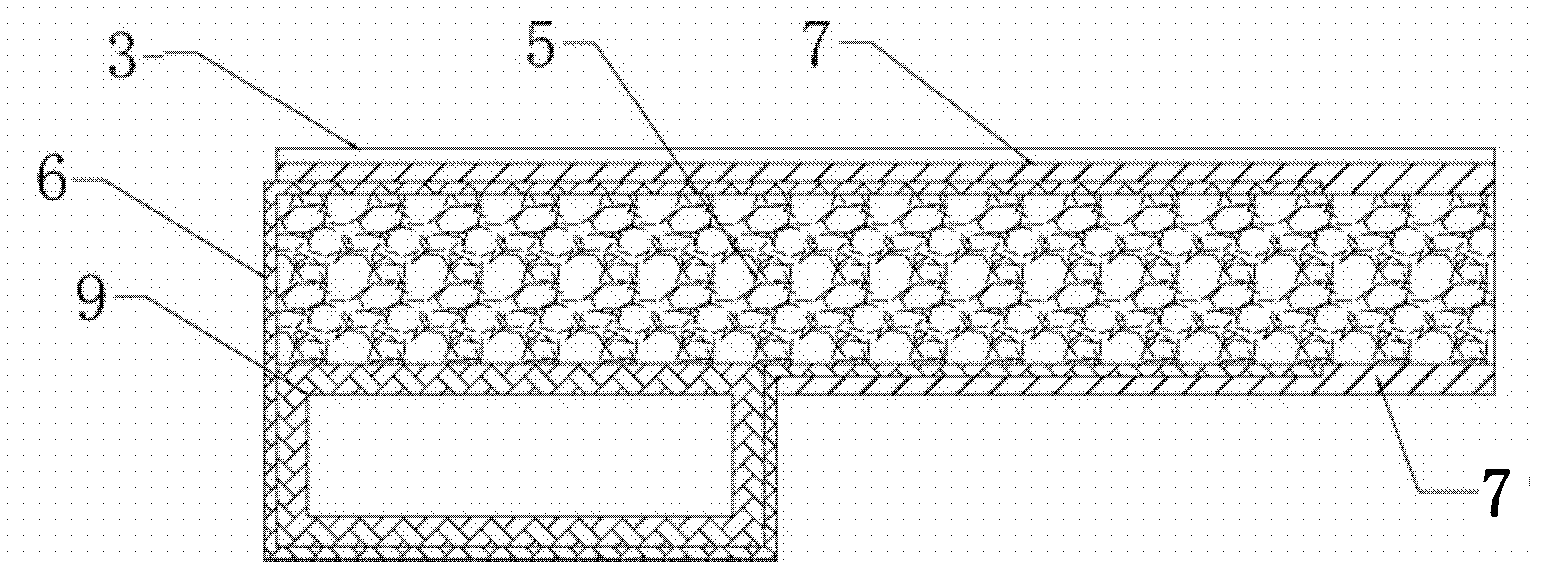

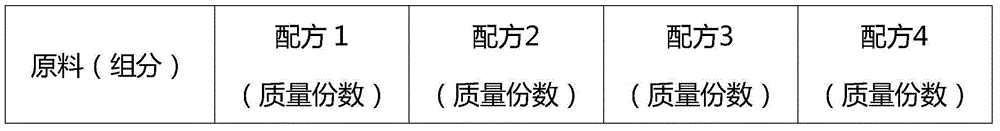

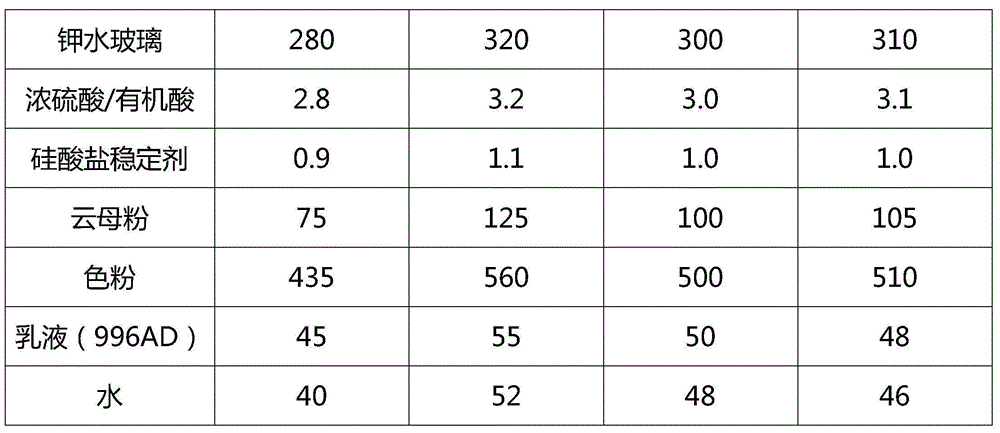

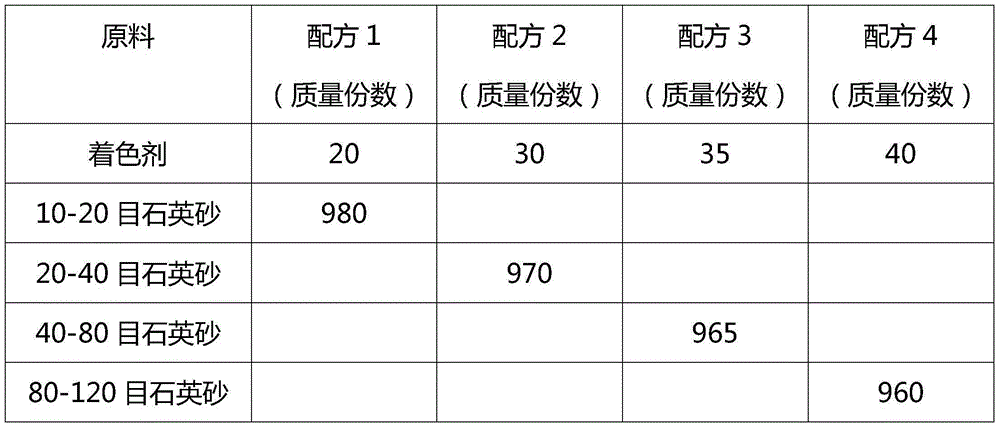

Artificial colored sand coloring agent, artificial colored sand using coloring agent, preparation method of coloring agent, and preparation method of artificial colored sand

The invention provides a composite coloring agent and an artificial colored sand, and also provides a preparation method of the artificial colored sand. The artificial colored sand is prepared by using the composite coloring agent and broken stone sand, wherein the composite coloring agent comprises potash water glass, an aqueous resin emulsion, an inorganic acid or organic acid, a filler, a stabilizer, a curing agent, a toner and water; and the broken stone sand comprises at least one of quartz sand, basalt and calcite, and the particle size of the broken stone sand is 10-120 meshes. The composite coloring agent comprises, by mass, 280-320 parts of potash water glass, 45-55 parts of emulsion 996AD, 2.8-3.2 parts of concentrated sulfuric acid, 0.9-1.1 parts of silicate, 75-125 parts of mica powder, 435-560 parts of the toner and 40-52 parts of water; and a weight ratio of the broken stone sand to the composite coloring agent in the artificial colored sand is 980-960 / 20-40. The artificial colored sand has abundant colors, and is economic and environmentally-friendly.

Owner:上海贝塔建筑科技有限公司

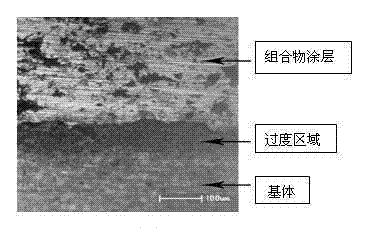

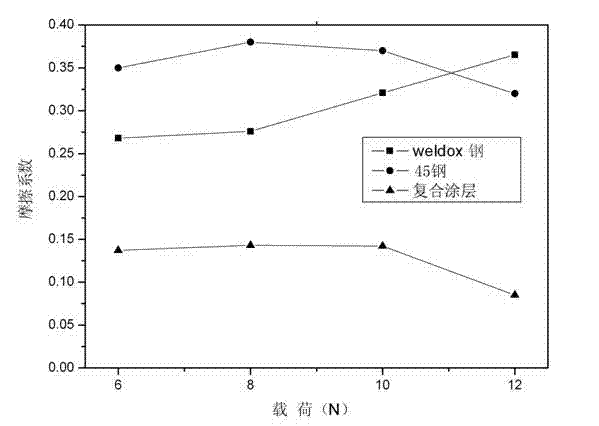

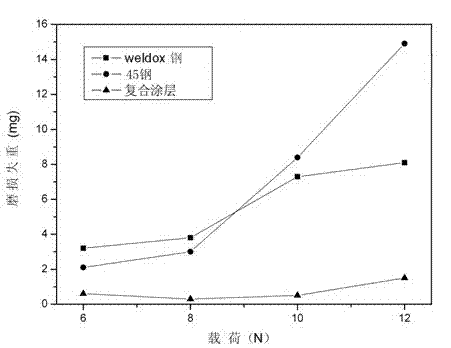

Coating composition with functions of friction resistance and wear resistance

The invention relates to a coating composition with functions of friction resistance and wear resistance, which is a powdered mixture composed of titanium carbide powder, nickel-coated calcium fluoride powder, nickel-coated graphite powder, yttrium oxide powder and nickel-based alloy powder, the weight ratio of each component is that: 23-25, 13-15, 8-10, 1, 50-55, wherein the mass part of each element in the nickel-based alloy are: 0.8% of C, 15.5 of Cr, 4% of Si, 3.5% of B, 15% of Fe and 61.2% of Ni. The coating composition with functions of friction resistance and wear resistance can be deposited on a frictional pair surface of a member through a plasma spraying mode to form a self lubricating coating, and is capable of greatly reducing the frictional coefficient, raising the wear resistance performance of the frictional pair of the member, solving the problems of friction resistance and wear resistance of a stress mechanical device with dry friction and high contact which is exposed in the adverse environment, and reducing the frictional energy consumption of the machinery.

Owner:ENG COLLEGE OF ENG CORPS PLA UNIV OF SCI & TECH

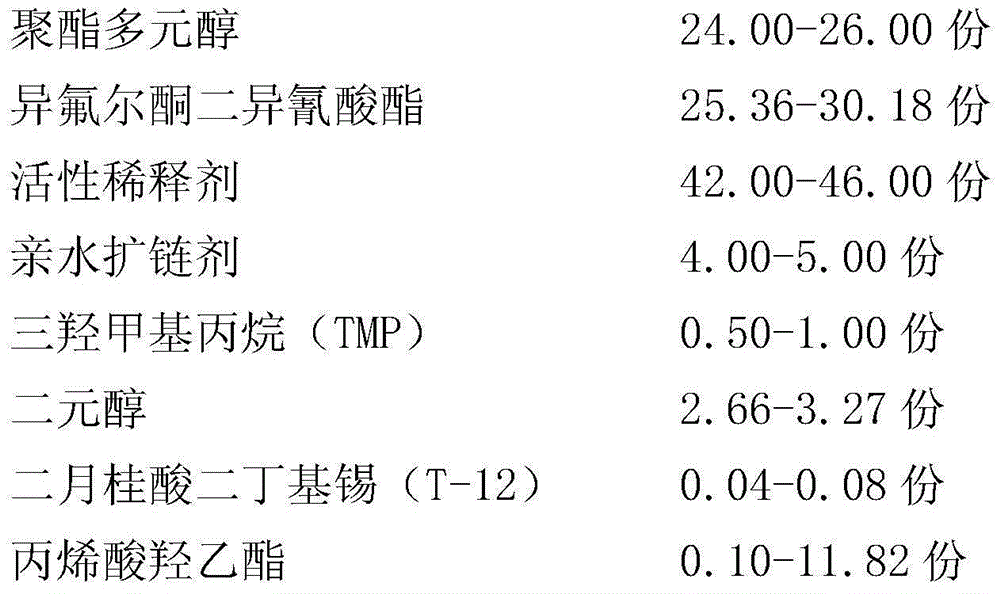

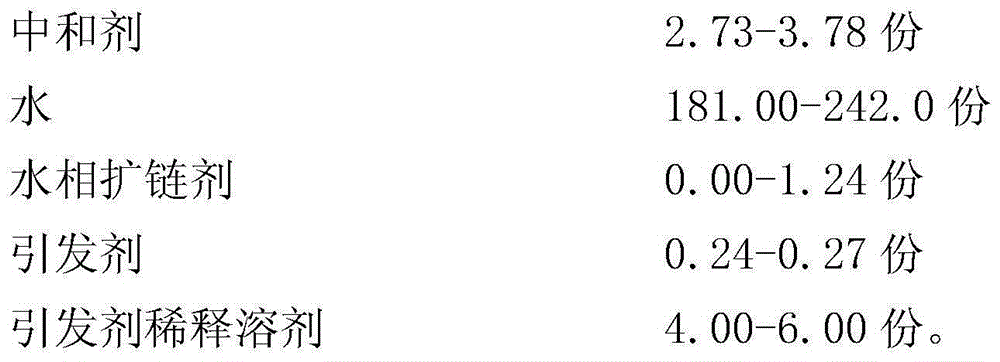

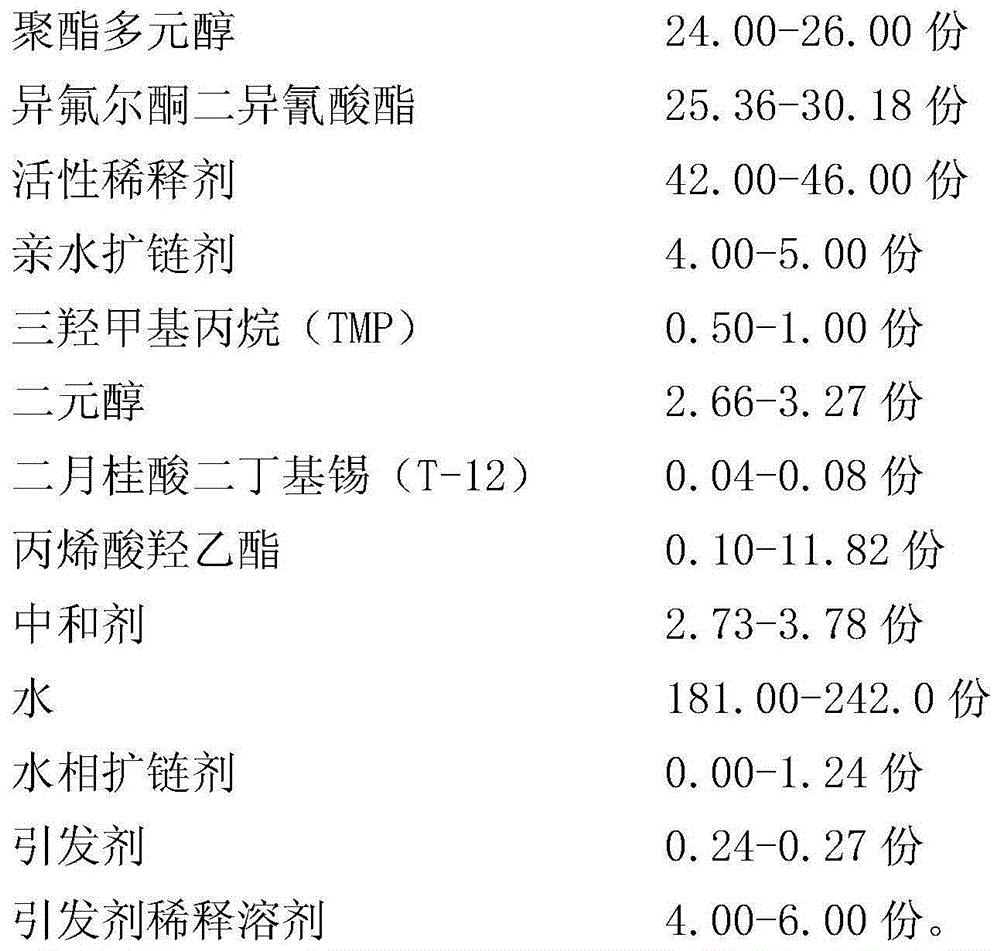

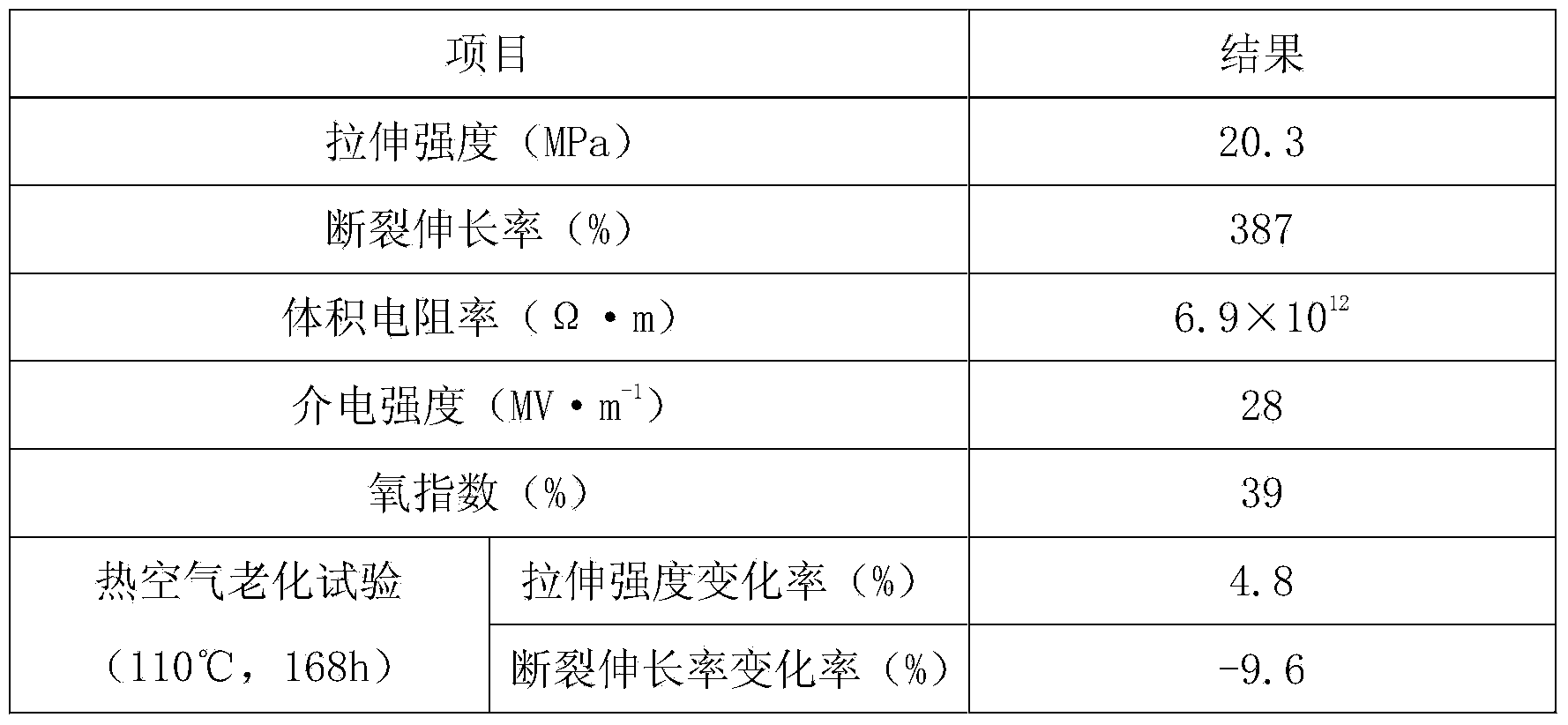

Polyurethane-acrylic ester composite emulsion of core-shell interpenetrating polymer network structure and preparation method thereof

The invention relates to polyurethane-acrylic ester composite emulsion of a core-shell interpenetrating polymer network structure and a preparation method thereof. The polyurethane-acrylic ester composite emulsion is prepared from polyester polyol, isophorone diisocyanate, reactive diluent, a hydrophilic chain-extending agent, trimethylolpropane, dihydric alcohol, dibutyltin dilaurate, hydroxyethyl acrylate, a neutralizing agent, water, an aqueous phase chain-extending agent, an initiating agent and initiating agent diluting solvent. The polyurethane-acrylic ester composite emulsion and the preparation method thereof have the following advantages that the problem that water resistance is lowered due to addition of emulsifier is solved; pollution caused by organic solvent and tediousness of the later-period organic solvent extraction technology are avoided. The emulsion is polyurethane-acrylic ester copolymer emulsion of a core-shell crosslinking interpenetrating polymer network structure.

Owner:SKSHU PAINT

High-voltage transformer substation cable insulating sheath material and preparation method thereof

ActiveCN103524866ASolve flame retardancySolve the mechanical strengthPlastic/resin/waxes insulatorsInsulated cablesWear resistantFumed silica

The invention discloses a high-voltage transformer substation cable insulating sheath material and a preparation method thereof. The sheath material is prepared from the following raw materials in parts by weight: 60-80 parts of metallocene linear low density polyethylene, 25-35 parts of isotactic polypropylene, 10-15 parts of EVA, 8-12 parts of aluminum hydroxide, 5-10 parts of magnesium hydroxide, 4-8 parts of zinc stannate, 12-18 parts of siliceous rock powder, 4-6 parts of polyethylene wax, 2-3 parts of terephthalic acid zinc, 1-2 parts of magnesium oxide, 3-5 parts of dimethyl silicone oil, 2-3 parts of basic lead silicate, 5-10 parts of triallyl trimellitate, 1-2 parts of gamma-methacryloxy propyl trimethoxyl silane, 15-25 parts of fumed silica, 10-15 parts of active calcium carbonate, 1-2 parts of an antioxidant 168, and 3-5 parts of a composite filler. The sheath material has excellent mechanical strength and abrasion resistance, can effectively improve the wear resistant ability and the impact resistant ability of a cable sheath, moreover, has good flame retardancy, is low in smoke and is halogen-free, effectively solves contradictions among the flame retardancy, the mechanical strength and the abrasion resistance of the sheath material, prolongs the service life of the sheath, and guarantees normal working of a high-voltage transformer substation cable.

Owner:PANJIN GUANGLIDA ELECTRIC

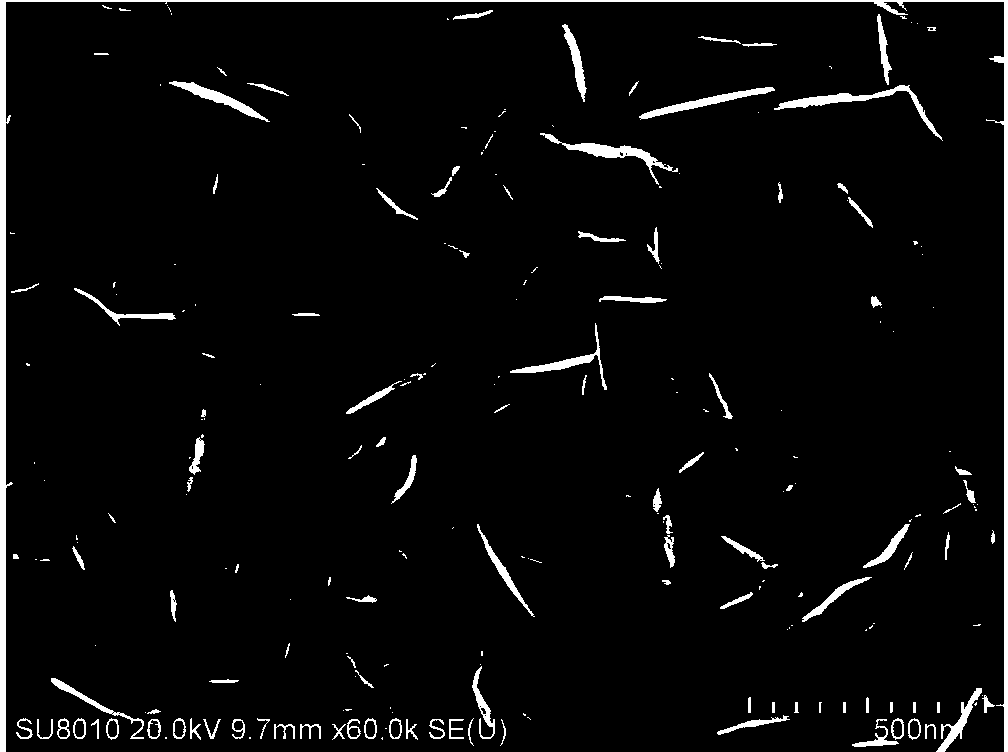

Nano composite abrasion-resistant alloy for abrasion-resistant steel and preparation technology for nano composite abrasion-resistant alloy

The invention relates to a nano composite ceramic abrasion-resistant alloy for abrasion-resistant steel and a preparation technology for the nano composite ceramic abrasion-resistant alloy. The abrasion-resistant alloy is formed by composition of ceramic powder and metal powder, wherein the ceramic powder consists of nano-scale WC, nano-scale TiC, nano-scale SiC, nano-scale Ce2O and nano-scale Y2O3, and the sum of weight of the nano-scale WC, the nano-scale TiC, the nano-scale SiC, the nano-scale Ce2O and the nano-scale Y2O3 accounts for 6-38% of the total weight of the abrasion-resistant alloy; the metal powder is formed by mixing of reduced iron powder, nickel-chromium powder, manganese powder, aluminum powder and magnesium powder, and the addition amount accounts for 62-94% of the total weight of the abrasion-resistant alloy; and the abrasion-resistant alloy is prepared with procedures of mixing, preforming, oxidization, sintering and the like. With the adoption of the abrasion-resistant alloy and the preparation technology for the abrasion-resistant alloy, the technical problem of short service lives of abrasion-resistant steel components is solved, and meanwhile, the consumption of the abrasion-resistant steel can be reduced.

Owner:SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com