Patents

Literature

413results about How to "Solve processability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

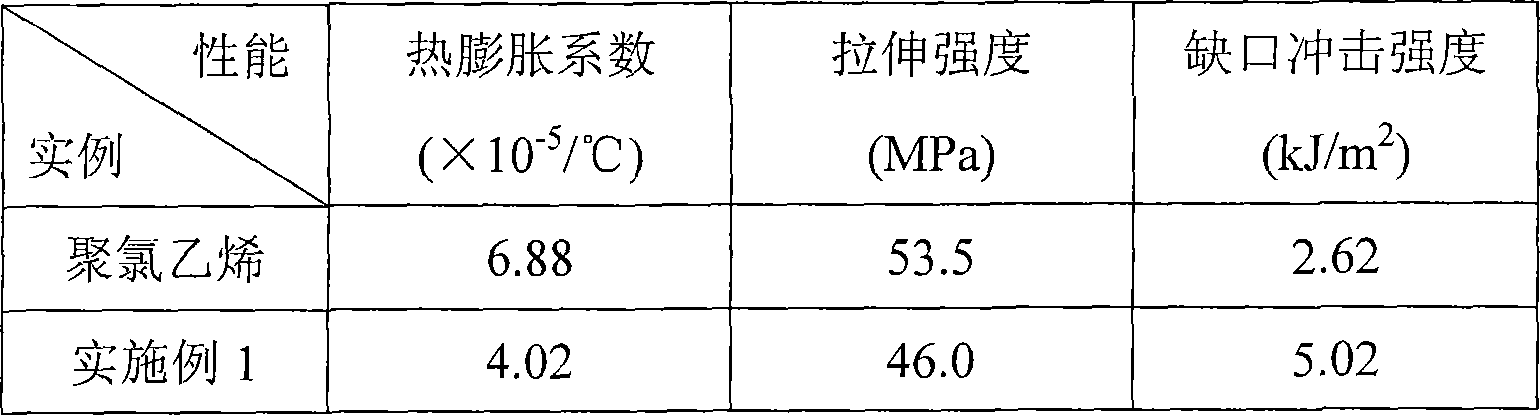

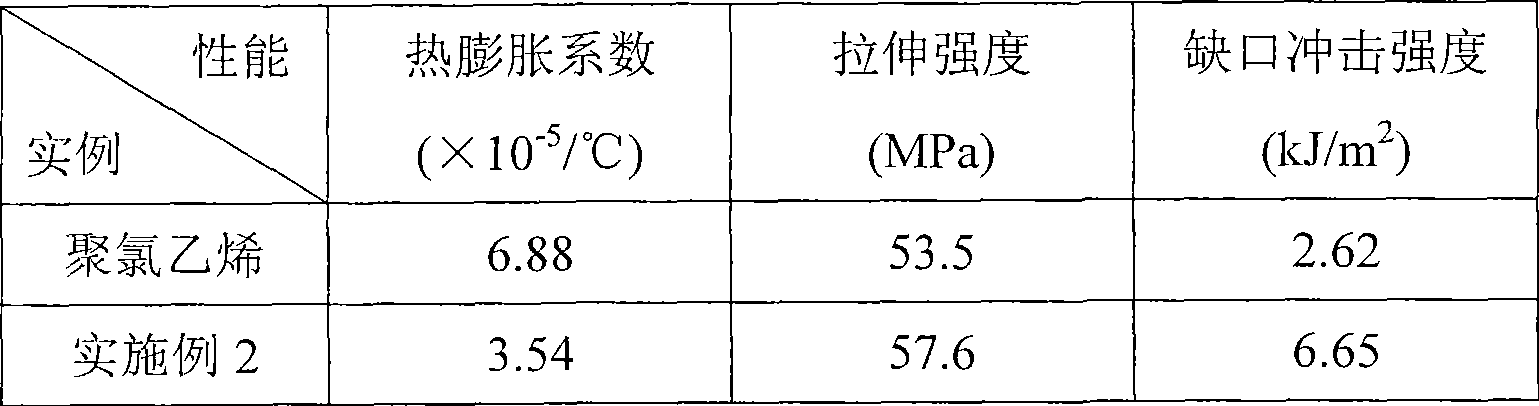

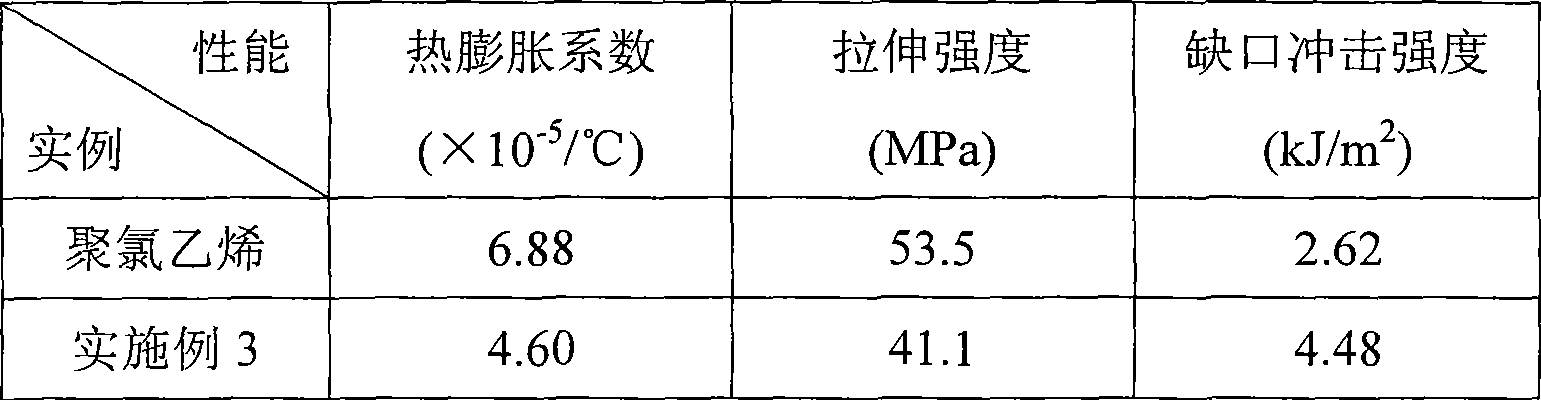

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

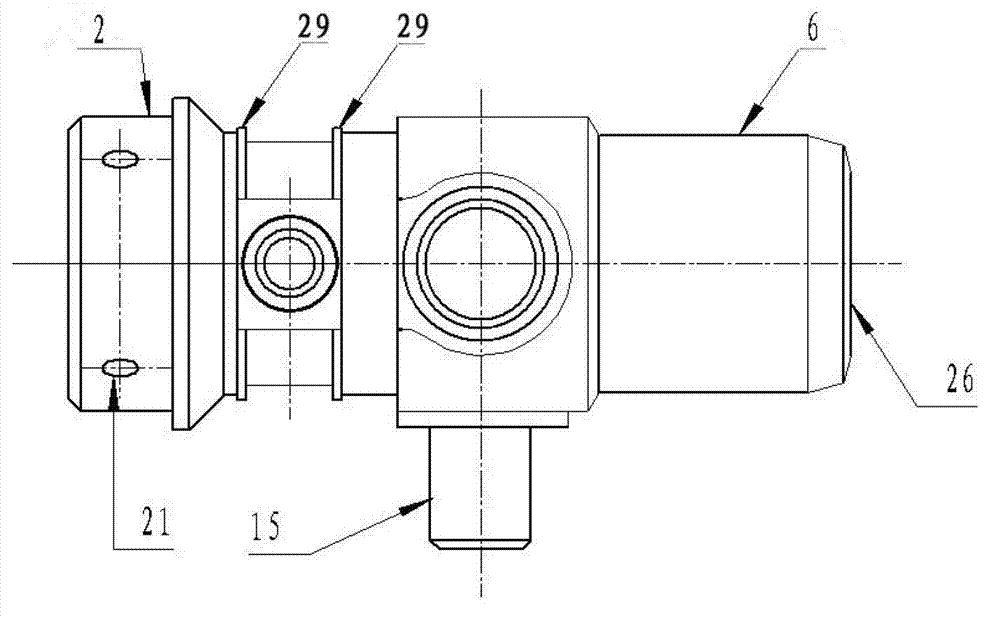

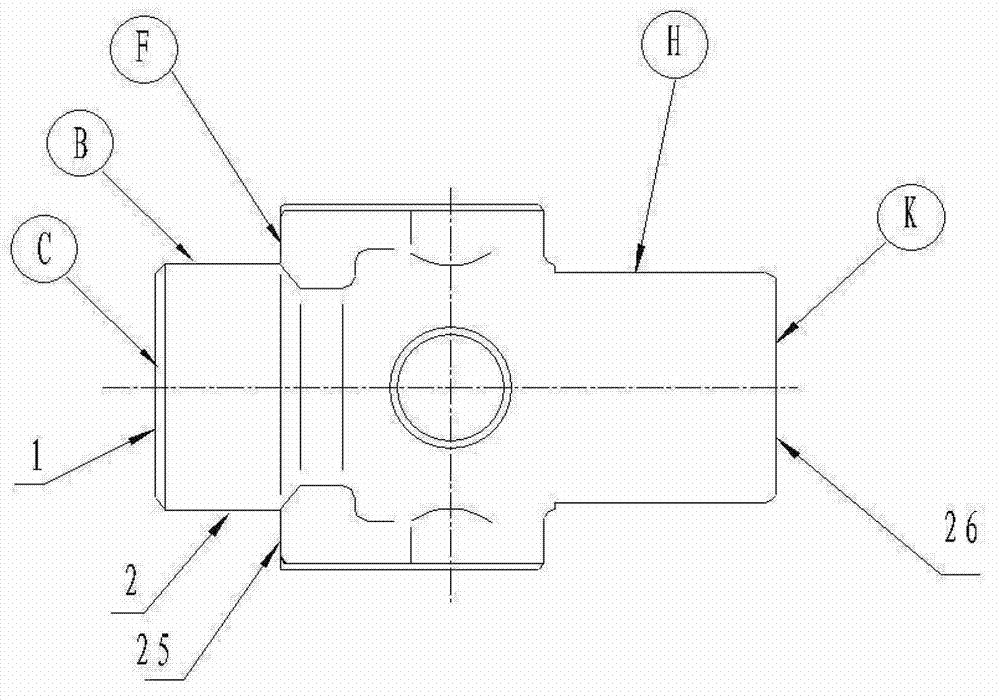

Numerically-controlled processing method of nozzle housing piece

The invention discloses a numerically-controlled processing method of a nozzle housing piece. According to the method, a numerically-controlled machining / milling combined processing center is adopted and comprises two main shafts and an on-line measurement device; the workblank of the nozzle housing piece is a die-forged part, and the die-forged part is made of a nickel-based high-temperature alloy. The method comprises the following steps: designing a nozzle housing processing path; performing polishing treatment on the die-forged part to remove burrs from the die-parting face and end-face die-drawing taper; coarsely machining the tail part of the work piece; performing numerically-controlled machining / milling on the whole work piece; performing numerically-controlled fine machining of the head part of the work piece; cleaning and marking the work piece; and inspecting. The method provides the reasonable designs of processing path and processing method of the work piece as well as the processing positioning reference of the work piece, and completes the processing of the inner cavity, the outer circle, the lateral adapter, the positioning pin and other parts of the nozzle housing piece within one-step loading process. The method solves the problem that the die-forged part has a complex structure and a thin wall and has strict requirements for dimensional precision and positional precision; and overcomes the defects of long processing period, low production efficiency and poor dimensional precision and positional precision.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

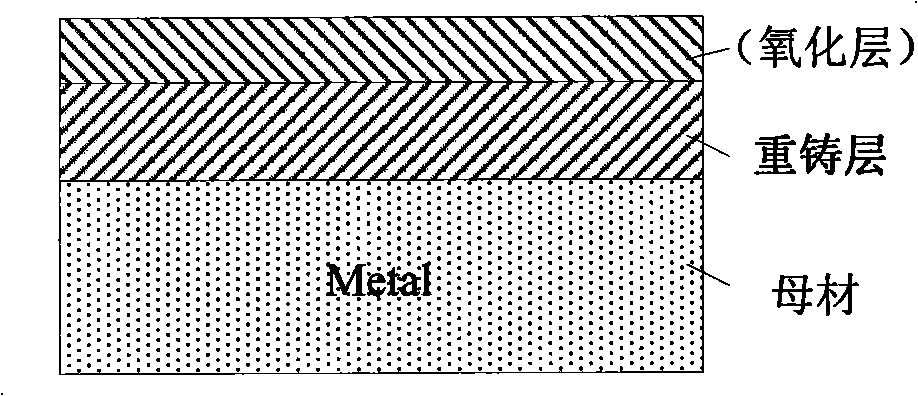

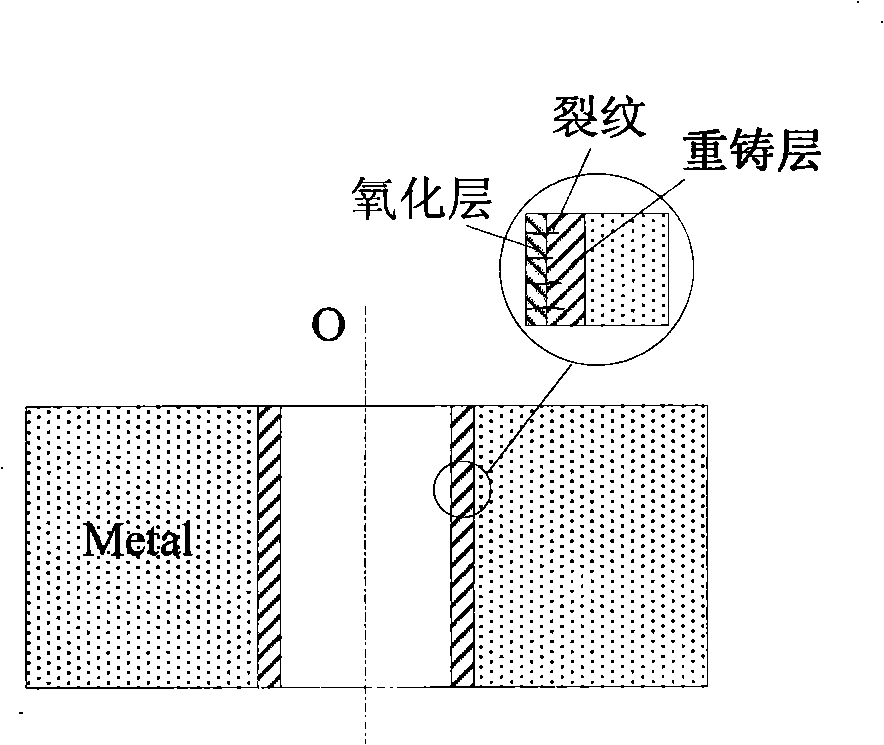

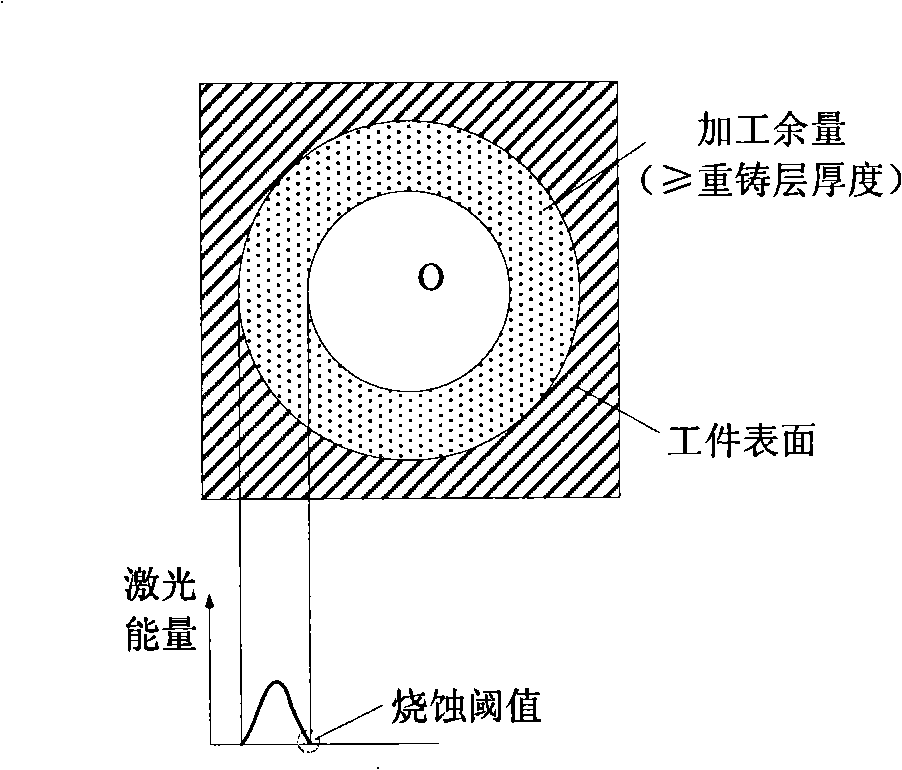

Laser compound processing and modifying method of no-recasting-layer micro deep-hole

ActiveCN101332559AEfficient solutionSolve processabilityLaser beam welding apparatusLong-focus lensHigh power lasers

The invention discloses a laser combined machining and profile modification method of a micro deep borehole without a recast layer. The method of the invention includes the following steps: first, a micro deep cooling borehole of a turbine blade is roughly machined by high power laser or electric sparks, and the like; the allowance for finish of the aperture is more than the thickness of the recast layer produced by using the machining method; and femtosecond laser is used for the secondary finish machining and profile modification of the micro deep cooling borehole; while femtosecond impulse laser is used for performing the finish machining and profile modification of the primarily machined micro deep borehole, under the precondition of guaranteeing the laser energy acting with the recast layer of a workpiece is higher than the ablation threshold of the material, a light beam is inclined for certain angle according to the spiral drilling mode; and the recast layer of the internal wall of the borehole is machined to remove erosion and profile modification by combining the method of lengthening the focal depth by a long focus lens. The concept of the combined machining method and the specific machining technology are used for solving the high-efficiency and high-precision machining problems of micro deep borehole groups of turbine blades.

Owner:XI AN JIAOTONG UNIV

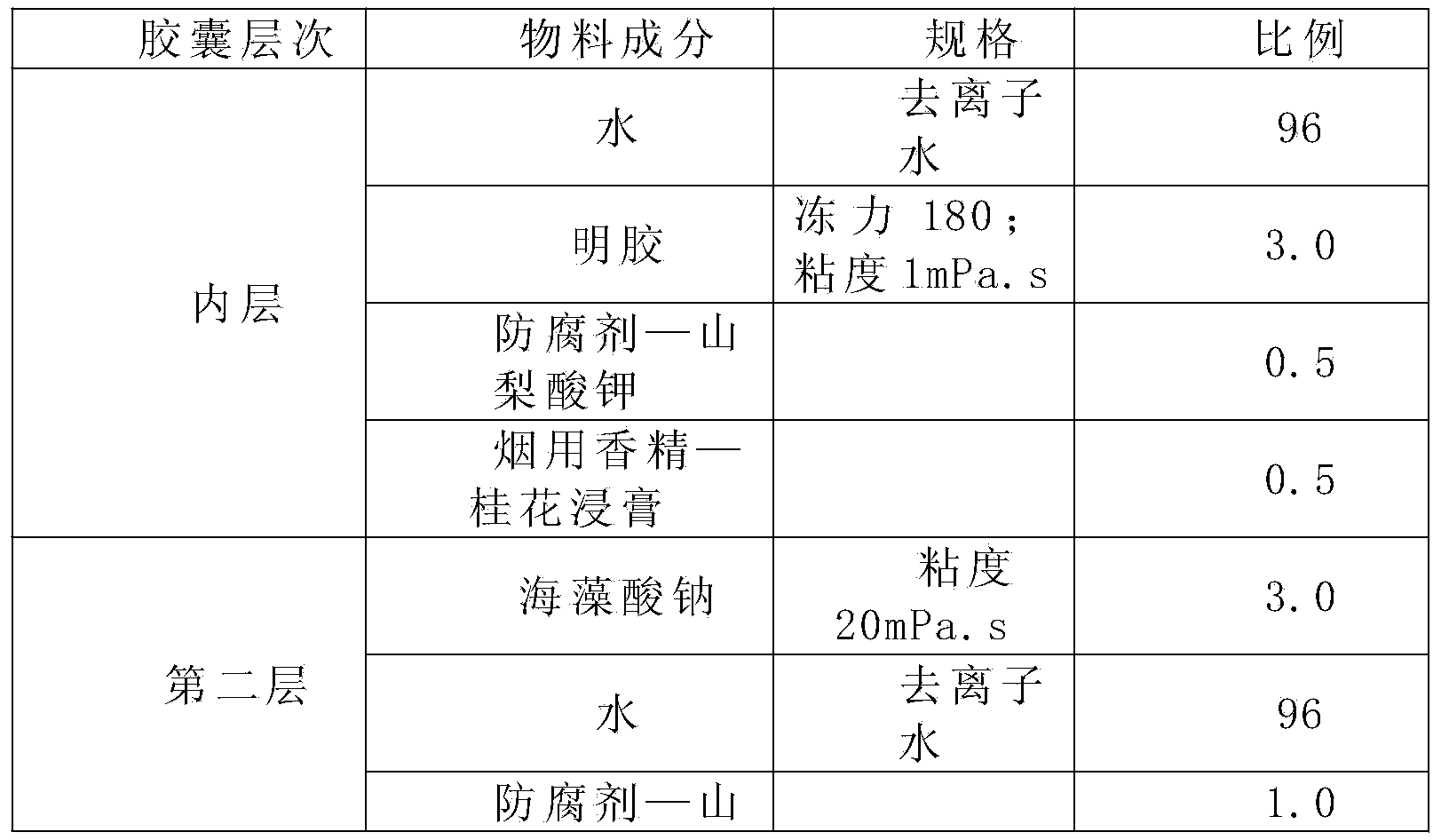

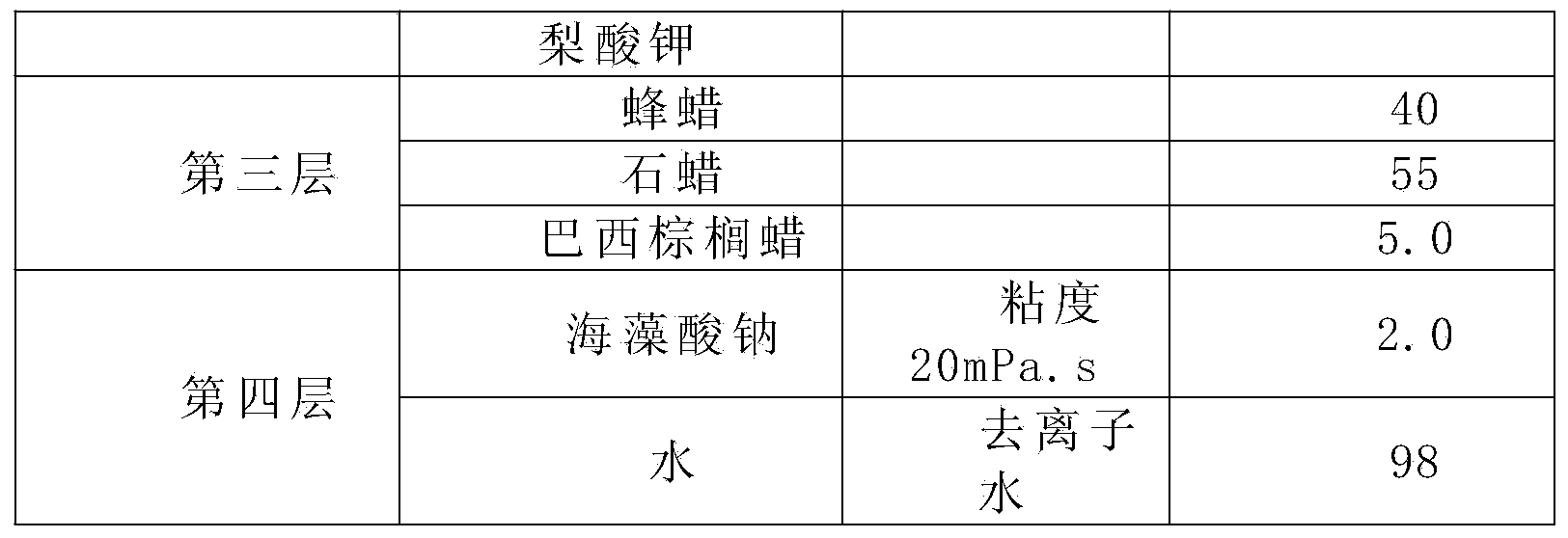

Four-layer water capsule used for cigarettes and manufacturing method of four-layer water capsule

ActiveCN103815542AImproved scrollabilityImprove pressure resistanceTobacco preparationTobacco treatmentWater solubleSolvent

The invention discloses a four-layer water capsule used for cigarettes and a manufacturing method of the four-layer water capsule. According to the four-layer water capsule used for cigarettes, water-soluble essence serves as an inner layer in the capsule, water serves as a solvent to dilute the essence, sodium alga acid complex compounds serve as the middle layer to wrap the water and the essence, waxy material serves as the third layer to prevent possible permeation of the water in the capsule, and sodium alga acid also serves as raw materials for the outermost layer to form a protection film so that cracking of the waxy layer can be reduced and the efficiency of adding the capsule to cigarettes can be improved. The manufacturing method of the four-layer water capsule includes the steps of wrapping a cigarette additive in a special rubber sheet and manufacturing the capsule through a dropping method. Dropping pills of the cigarette additive are manufactured through a dropping mechanism, used for filter tips and wrapped in tobacco bundles, and the additive or the essence is exposed when the four-layer water capsule is used and pinched broken by hand. The method is simple and practicable in process, simple in device, capable of being directly used for cigarette machining and convenient to popularize and apply. Raw materials are wide in source and low in cost.

Owner:HUBEI CHINA TOBACCO IND +1

Efficient silicon carbide corundum rare earth ceramic composite grinding wheel and manufacture method thereof

The invention relates to an efficient silicon carbide corundum rare earth ceramic composite grinding wheel which comprises the following raw materials in percentage by weight: 30-75wt percent of silicon carbide abrasive, 25-70wt percent of corundum abrasive, 12-22wt percent of rare earth ceramic and 3.5-8wt percent of normal-temperature binding agent. The composite grinding wheel is manufactured by the steps of calcining, ball-milling, blending, moulding, drying, sintering, and the like. The grinding wheel of the invention has the advantages of high grinding force for grinding a difficult grinding material, sharp grains, high self sharpening, shedding in time of blunt grinding grains and no burning on workpieces. Compared with the traditional single grinding material common ceramic binding agent grinding wheel, the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously improves the grinding efficiency; and compared with a grinding wheel adopting an expensive superhard grinding material (artificial diamond or CBN (Cubic Boron Nitride)), the efficient silicon carbide corundum rare earth ceramic composite grinding wheel obviously reduces the grinding cost and has wider adaptation and favorable economic and social benefits.

Owner:FUZHOU SHUANGYI GRINDING WHEEL +1

Ultraviolet light cross-linking heat-shrinkage pipe material and method for producing ultraviolet light cross-linking heat-shrinkage pipe

The invention discloses an ultraviolet light cross-linking heat-shrinkage pipe material which comprises the following components in parts by weight: 100 parts of polyolefine and / or ethylene propylene diene rubber, 0.5-10 parts of ultraviolet light initiating agents, 0-20 parts of polymer compatilizers, 0-5 parts of antioxidants, 0-250 parts of fire retardants, 0-3 parts of sensitizers, 0-3 parts of lubricants and 0-20 parts of color masterbatches. The invention also provides a method for producing the ultraviolet light cross-linking heat-shrinkage pipe. The method comprises the following steps of: (1) mixing materials; (2) preparing granular materials; (3) extruding a pipe; (4) carrying out ultraviolet light irradiation; and (5) expanding, and cooling for shaping. The ultraviolet light cross-linking heat-shrinkage pipe material and the method for producing the ultraviolet light cross-linking heat-shrinkage pipe have the characteristics that adopting a method for carrying out ultraviolet light irradiation cross-linking by matching the ultraviolet light initiating agents with a special ultraviolet light source. The method disclosed by the invention has the advantages of low equipment investment cost, low irradiation cross-linking cost, simple process, energy conservation, environment protection, low product cost and good quality.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

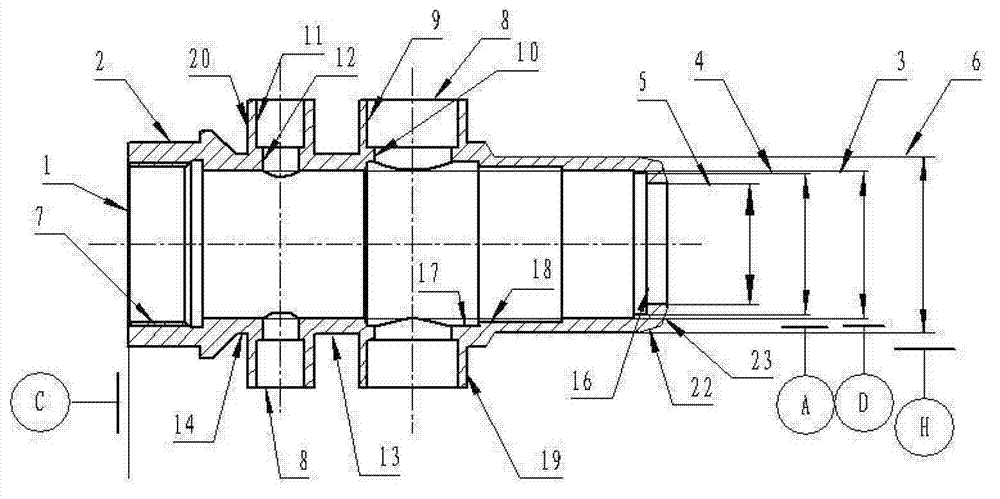

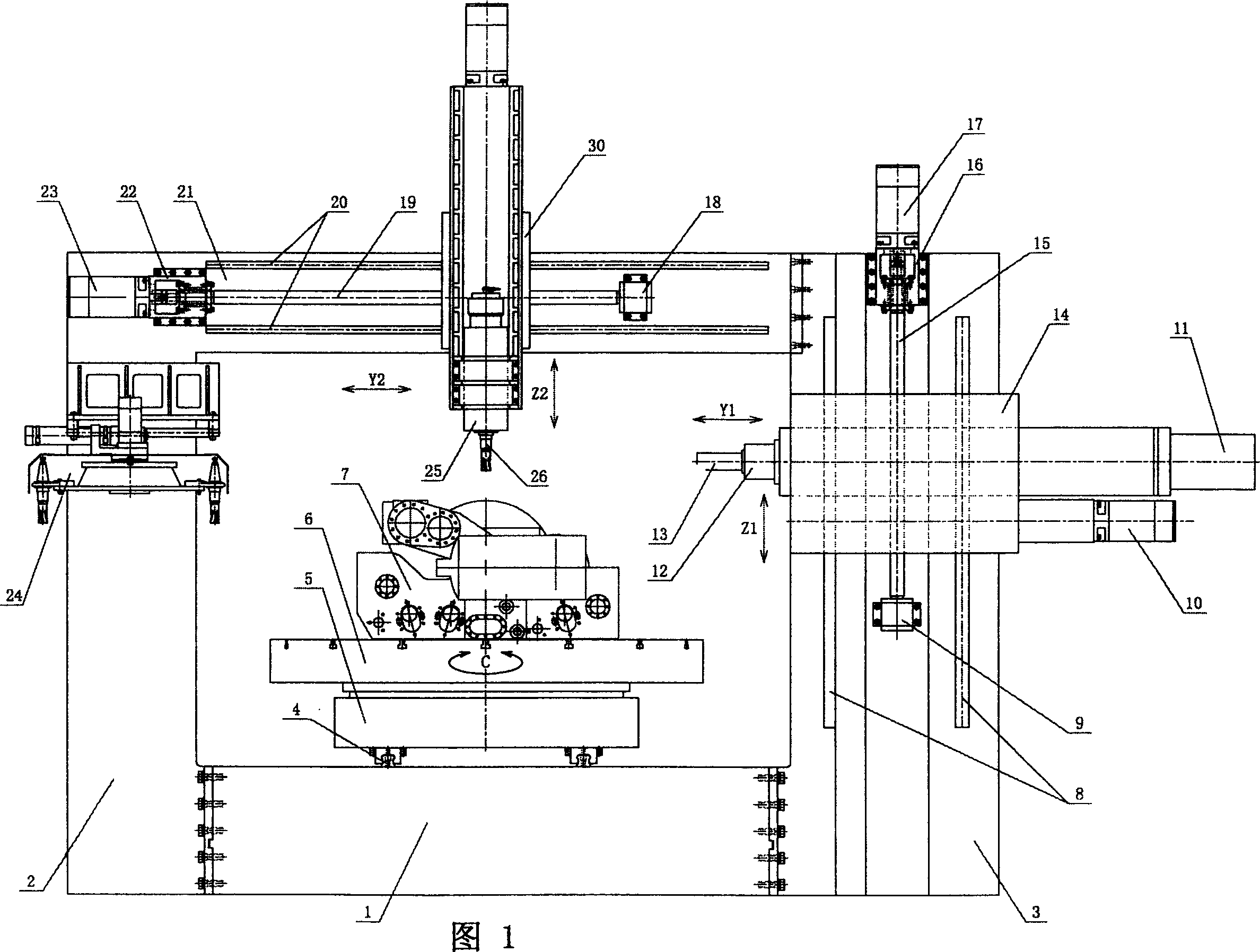

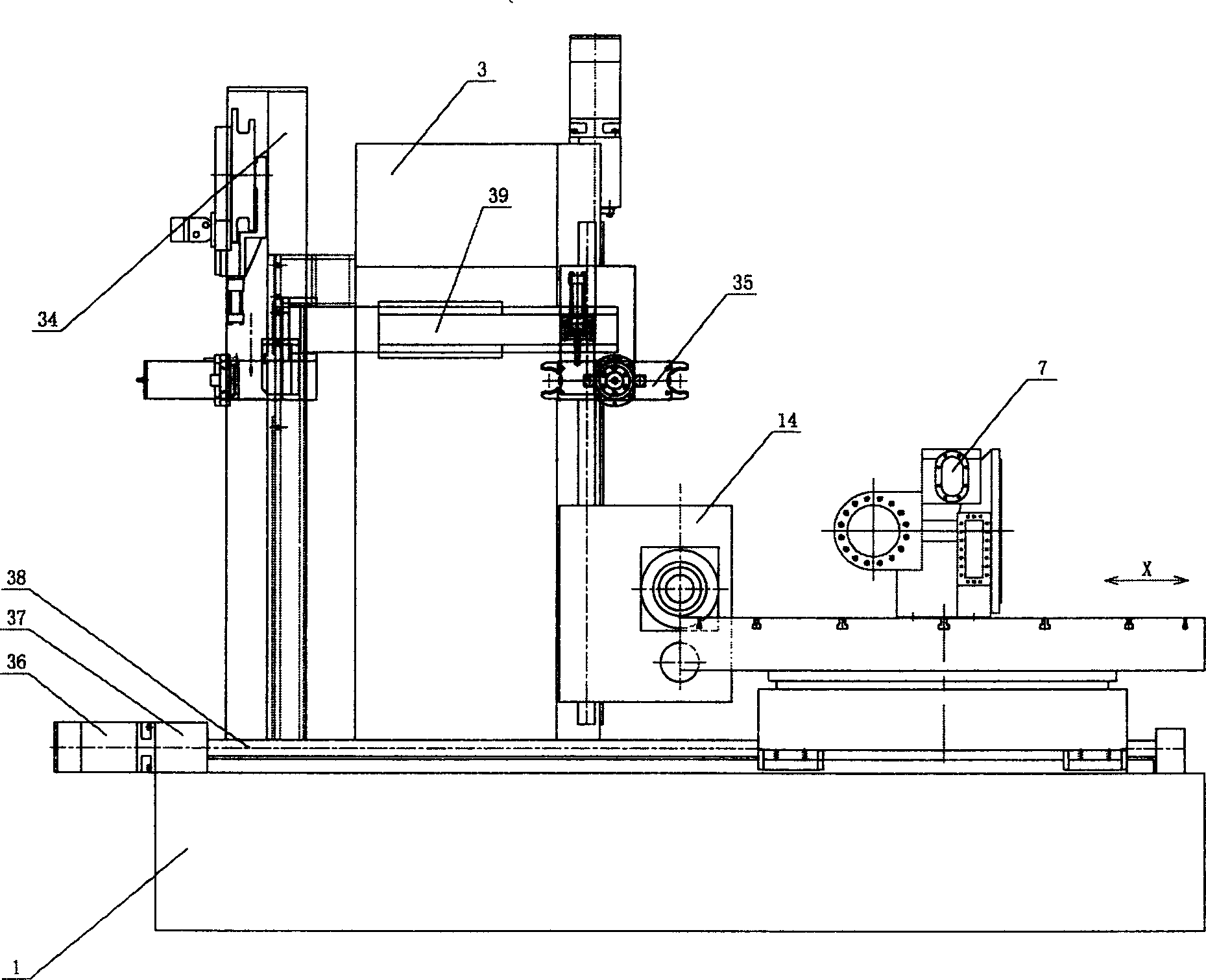

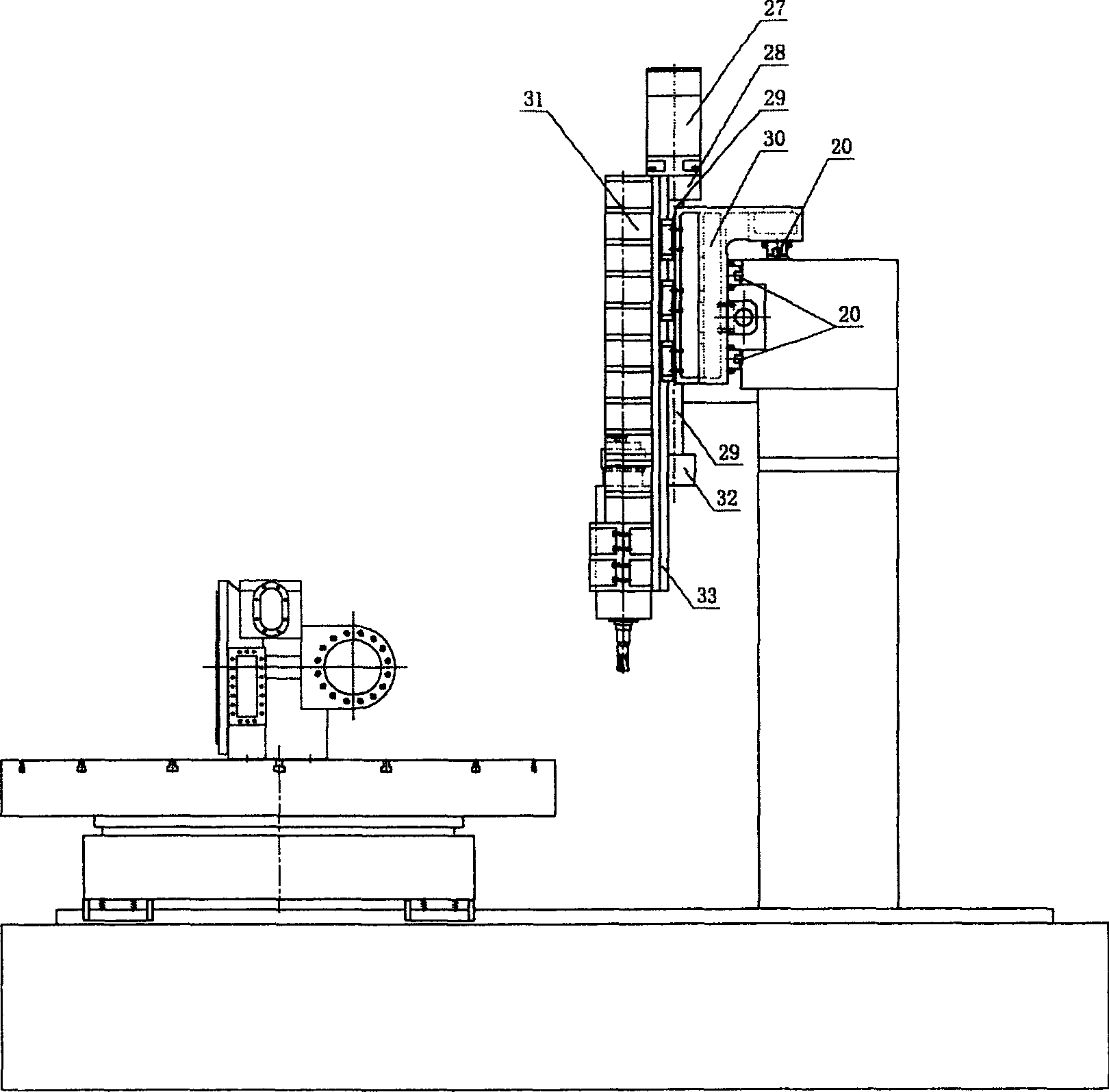

Fast vertical/horizontal type boring and milling automatic processing center

InactiveCN1562556ASolve one-time card loadingSolve processabilityOther manufacturing equipments/toolsBoring/drilling machinesCircular discChain type

An automatic machining center for high-speed vertical and / or horizontal milling and boring is composed of a main body with a base and a frame consisting of left and right vertical volumns and top horizontal beam, an index bench, a horizontal slide platform, rolling guide tracks X, Y and Z, the mainshaft for high-speed milling arranged on horizontal beam, mainshaft stock for boring arranged on right column, the disk-type and chain-type tool libraries, and tool exchanging manipulator.

Owner:沈阳工业学院

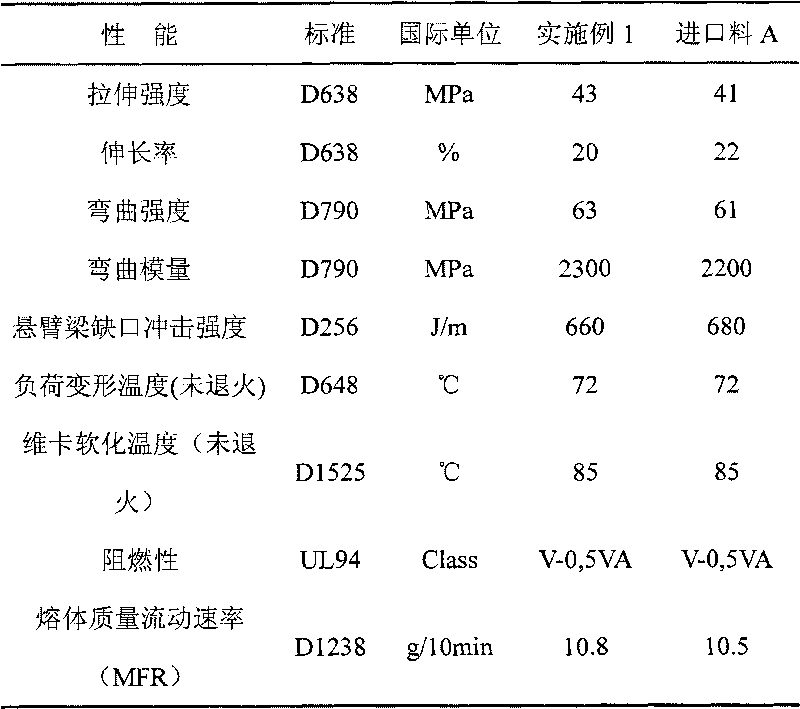

PVC/ABS alloy material and preparation method thereof

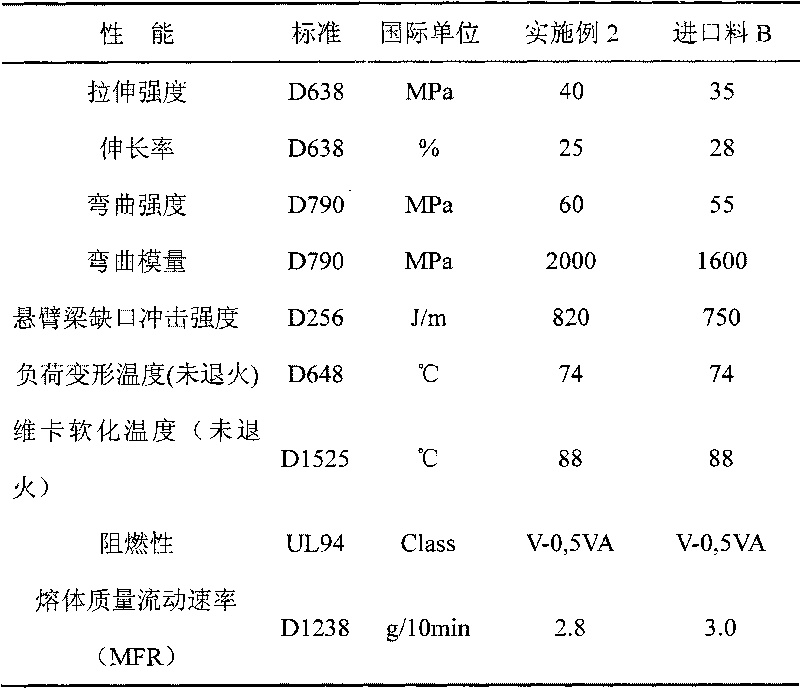

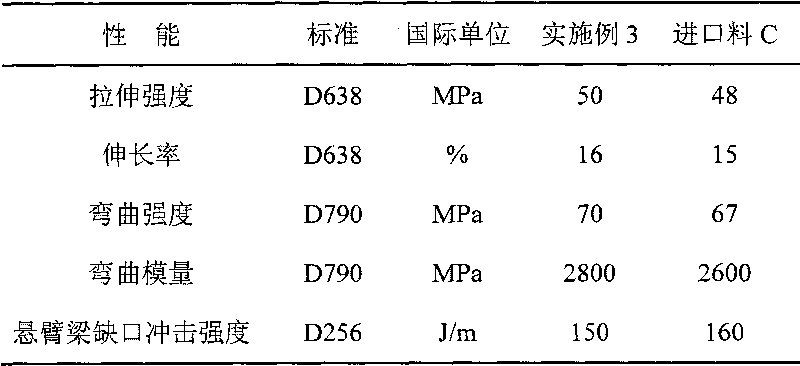

The invention discloses a PVC / ABS alloy material and a preparation method thereof. The PVC / ABS alloy material contains the following components by weight percent: 20-80 of PVC resin, 10-70 of ABS resin, 1-6 of heat stabilizer, 2-10 of processing aid, 1-15 of compatible and impact-resistant modifier, 1-30 of heat-resistant agent, 1-3 of fire retardant and 0-8 of other aids. The invention fundamentally solves the difficulty that high using performance and high processing performance of the PVC / ABS alloy material cannot be obtained simultaneously, and improves the product fluidity, the heat resistance, the fire resistance and the like on the premise that the physical and mechanical properties are excellent. The invention creatively realizes the optimum comprehensive balance between the using performance and the processing performance of PVC resin and ABS resin, breaks through the barriers set by foreign countries in PVC alloy material production technology, firstly reaches the international advanced level in the PVC alloy material field and further comprehensively promotes the technological level of China in alloy materials.

Owner:KINGFA SCI & TECH CO LTD +1

Method for making stewed duck with bean sauce

InactiveCN101715974ASolve processabilitySolve for uniformityFood preparationBiotechnologyAdditive ingredient

The invention relates to the field of food processing and discloses a method for making a stewed duck with bean sauce. In the invention, injection seasoning technology, vacuum massaging technology and compression marinating technology are integrated into a novel processing technique. The stewed duck with bean sauce made by the invention has the advantages of rich sauce fragrance, tender meat quality, proper elasticity and unique taste. The method overcomes the defects that the traditional stewed ducks with bean sauce cannot be pickled uniformly and the making period is too long, can effectively keep nutrient components in the duck, and can prolong the shelf life of the finished product. The raw materials and making parameters of the method are quantified, so the method can ensure the stable quality of products, facilitates the quality control, and has a prospect for large-scale industrialized production.

Owner:夏威夷

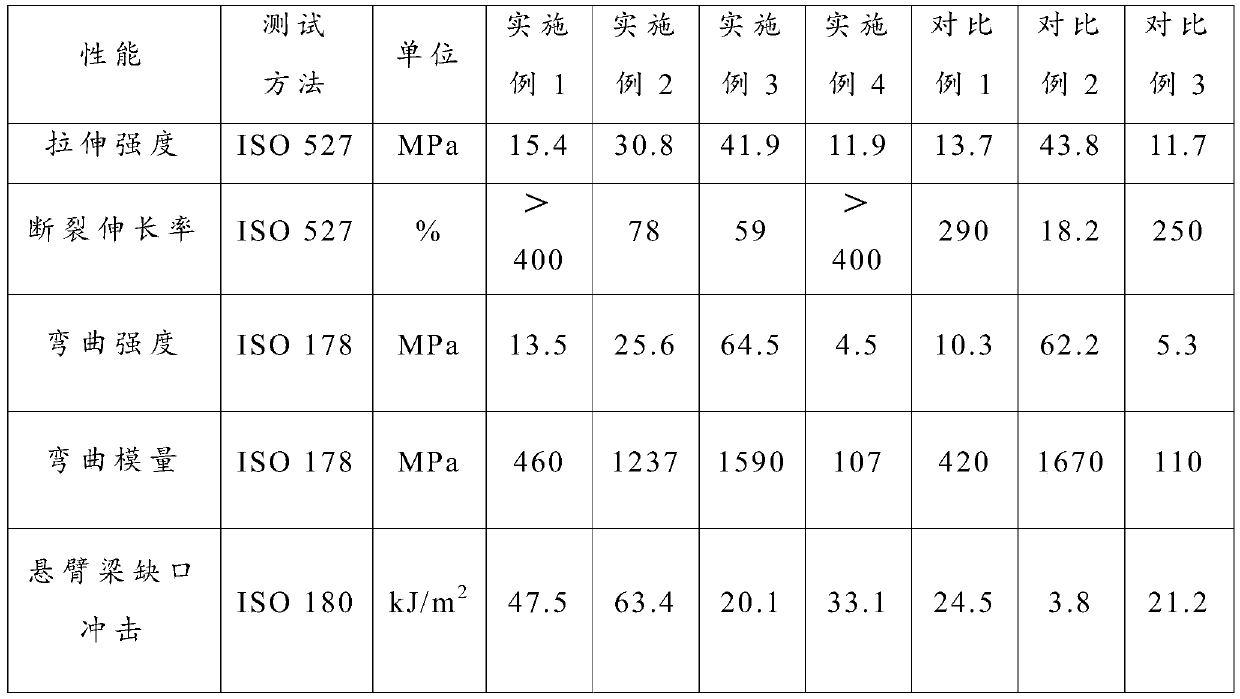

Starch-filled PLA/PBAT full-biodegradable composite material and preparation method thereof

The invention provides a starch-filled PLA / PBAT full-biodegradable composite material and a preparation method thereof, and belongs to the field of high polymer materials. A purpose of the invention is to solve the problems of poor toughness, brittleness and easy breaking of polylactic acid and the technical problems of difficult processing of starch, poor compatibility with PLA / PBAT resins and the like. The starch-filled PLA / PBAT full-biodegradable composite material comprises, by weight, 5-90 parts of polylactic acid, 10-90 parts of polyadipic acid / butylene terephthalate, 10-50 parts of starch, 2-15 parts of a plasticizer, 0.1-5 parts of a coupling agent, 0.1-0.5 part of a dispersing agent, 0.1-1 part of a compatibilizer and 0.1-0.5 part of an antioxidant. According to the invention, thepreparation method can be applied to preparation of starch-filled PLA / PBAT full-biodegradable composite materials.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

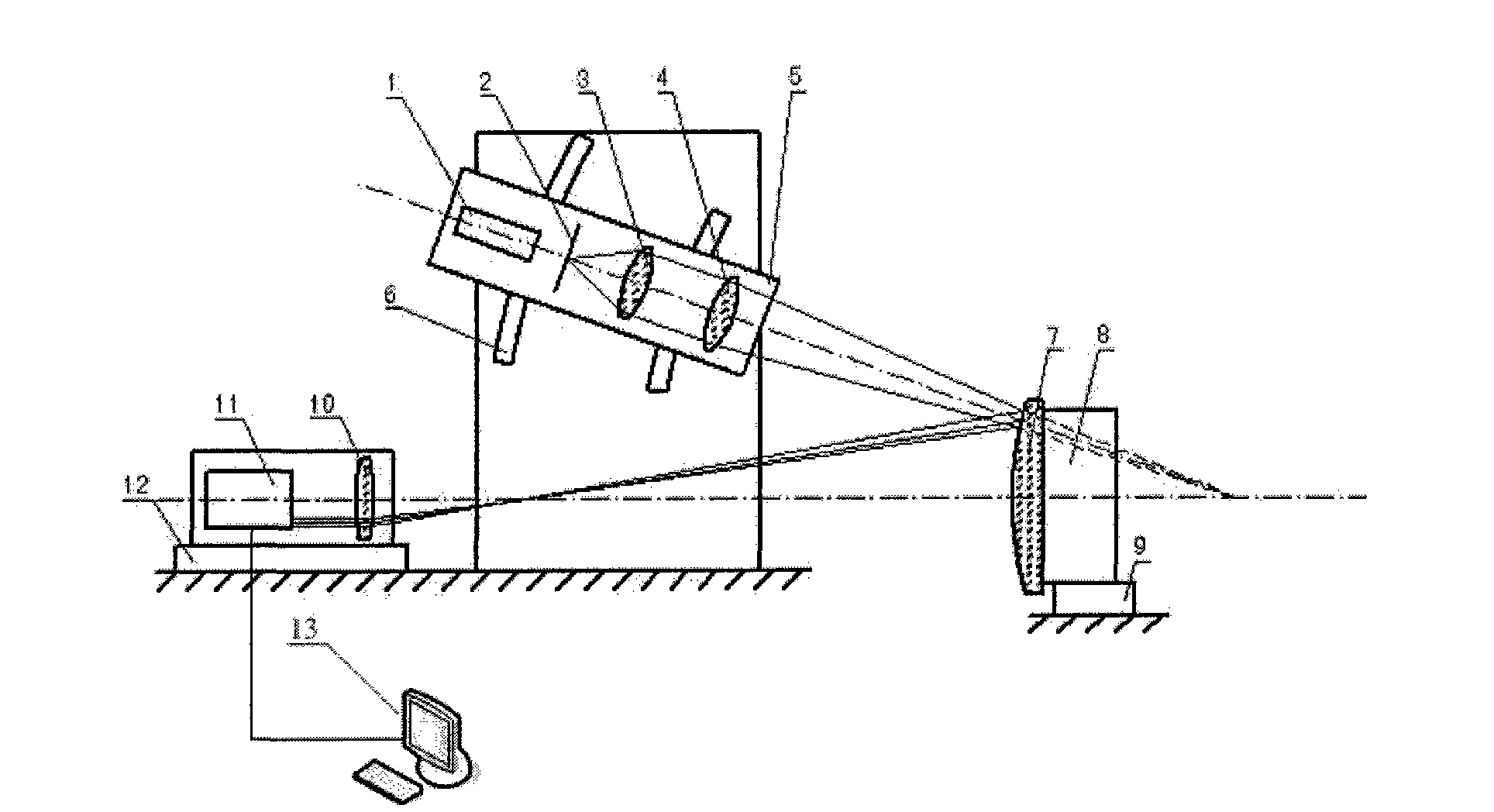

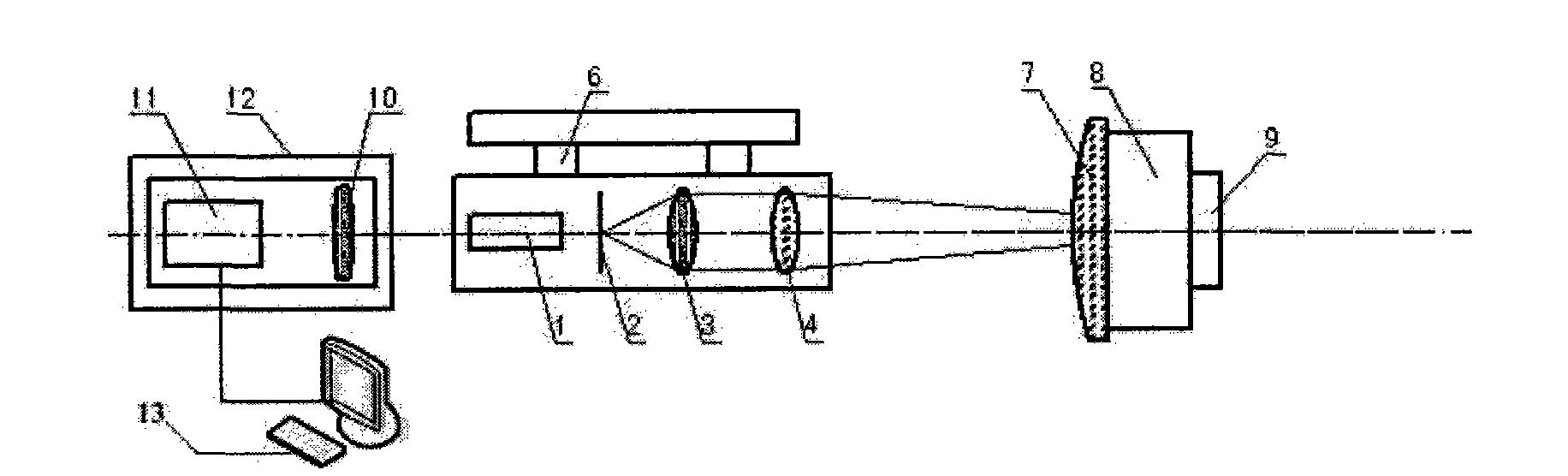

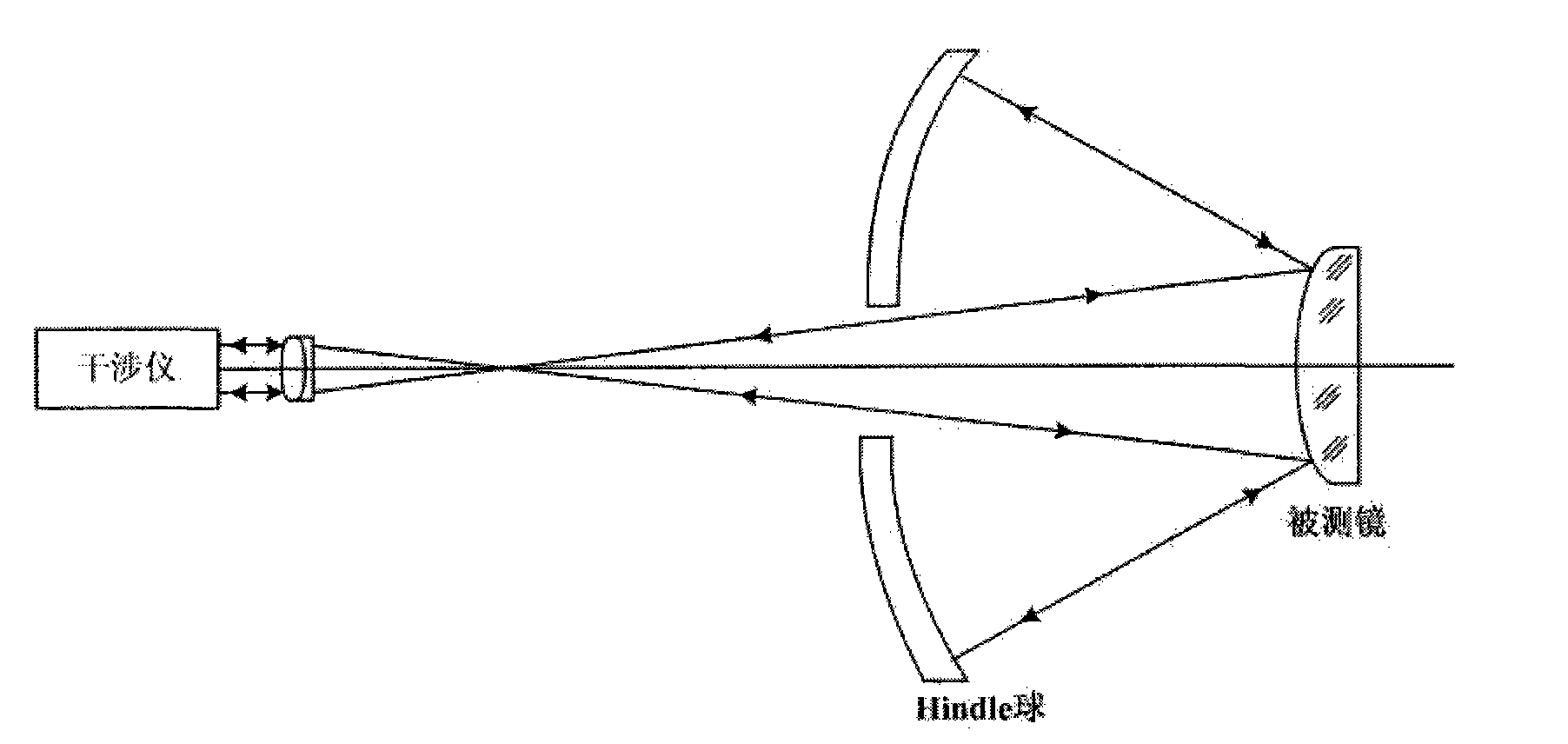

Detecting method and detecting device of surface-shape error of double curved surface convex reflecting mirror

The invention relates to a detecting method and a detecting device of the surface-shape error of a double curved surface convex reflecting mirror, which takes an aberrationless laser convergent beam as an incident beam scanning the convex of the detected reflecting mirror and takes wavefront detector as a measuring tool to coincide the focus of the incident beam with the virtual focus of the detected double curved surface reflector; the incident beam is imaged at the real focus of the detected double curved surface reflecting mirror after being reflected by the detected reflector, an imaging beam enters in the wavefront detector after being collimated by an anaberration collimating lens, and the surface-shape error of a local area is detected by the wavefront detector; the incident beam radically scans around the virtual focus of the detected double curved surface reflector, the detected double curved surface reflecting mirror rotates a circle around an optic axis when the incident beam scans each step, and the surface-shape error of each local area inside a whole mirror surface is detected circularly; and the detected surface-shape error of the local area is subject to matching and Zernike polynomial polynomial fitting to obtain the surface-shape error of the whole double curved surface convex reflecting mirror. The invention provides a low-cost and high-precision detection means of the large-caliber double curved surface convex reflecting mirror.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

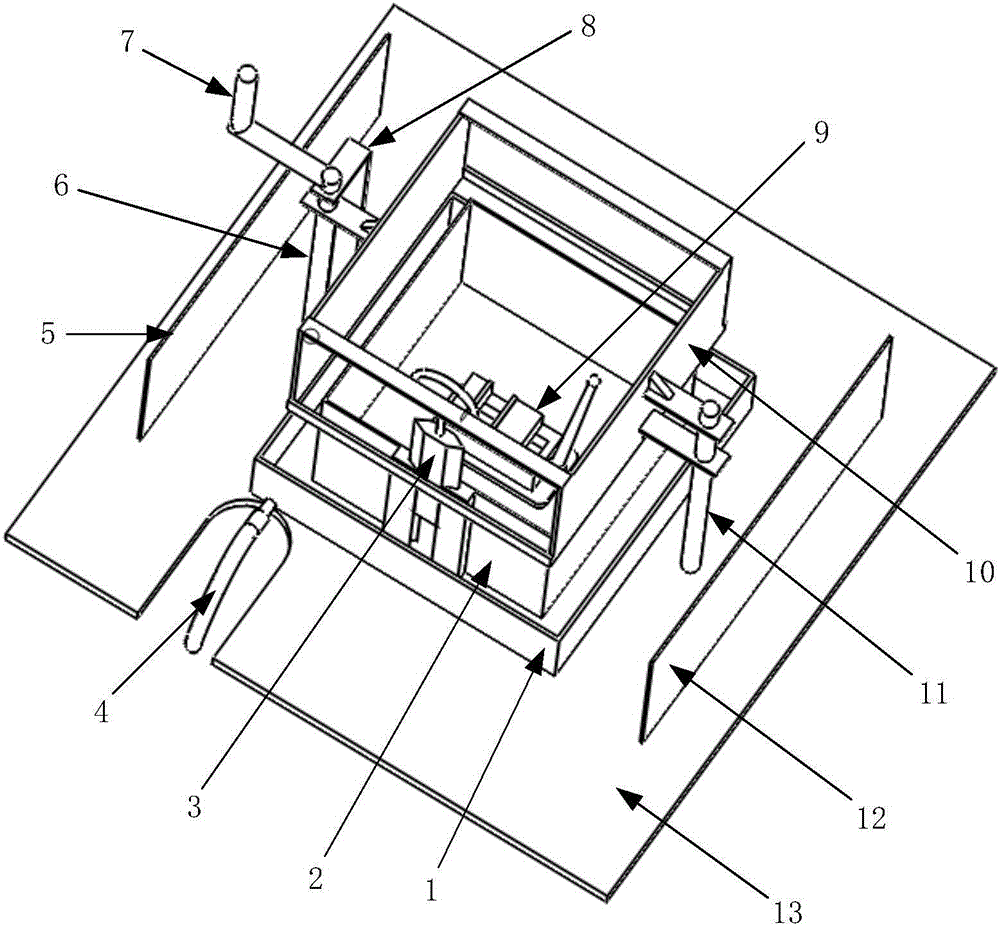

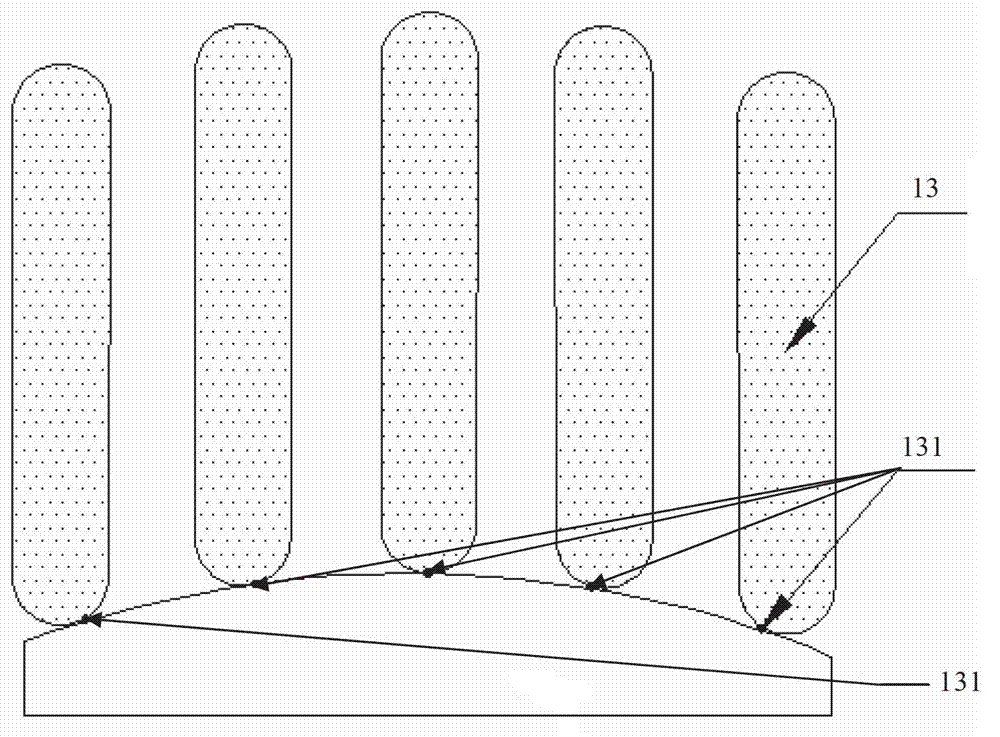

Flexible clamp for milling thin-walled workpiece with complex curved surface

ActiveCN106514369AEven by forceReduce processing deformationMilling equipment detailsPositioning apparatusMachining deformationMagnetorheological fluid

The invention discloses a flexible clamp for milling a thin-walled workpiece with a complex curved surface, and belongs to the field of machining. The flexible clamp comprises a vice clamp, a fluid carrying trough for accommodating a magnetorheological fluid, a magnetoresistive plate frame arranged at the upper part of the fluid carrying trough, and plate electrodes for providing a horizontal magnetic field, wherein the left side of the magnetoresistive plate frame is connected with a lead screw through threads; the right side of the magnetoresistive plate frame sleeves a supporting and positioning rod in a matching way; the upper end of the lead screw is connected with an operating crank; and the operating crank can drive the lead screw to rotate and drive the magnetoresistive plate frame to rise and fall. The flexible clamp provided by the invention can effectively reduce the machining deformation of the thin-walled workpiece with the curved surface, effectively restrains the vibration of the thin-walled workpiece with the curved surface during milling, lowers the machining noise, reduces the machining error, and guarantees high machining efficiency and high surface machining quality.

Owner:SHANDONG UNIV

Method for preparing dried fowls egg

InactiveCN101243887ARealize industrial productionCater to dietary habitsFood preparationFowlCounter pressure

The invention relates to the preparation method of a dried poultry egg which is characterized in that 2 to 5 portions weight of agar powder and 0.1 to 1 portions weight of konjak gum are dissolved in 10 to 20 portions weight of the distilled water and stir the mixture to mix well; then, the stirred and mixed poultry egg plup of 80 to 100 portions weight is poured into the mixture and the stirring is made under the temperature of 70 to 80 DEG C; the stirred and mixed liquid is poured into the anti-viscous mould and is steamed. The sopping is made according to the preparation method and is heated to 80 to 90 DEG C. After being taken out from the mould, the steamed material is put into the sopping, steeped under the temperature of 80 to 90 DEG C in 1 to 2 hours. Then the dried poultry egg is taken out and is dried under the temperature of 55 to 65 DEG C in 20 to 60 minutes. After being dried, the poultry egg is cut into different shapes and sizes according to different needs; then the vacuum packaging is made. The packaged product is made counter-pressure sterilization under the high temperature of 100 to 121 DEG C in 10 to 60 minutes. After being made stepped cooling, wiping water on the surface, further air-drying, sticking label, printing code and packaging, the product is produced finally.

Owner:SICHUAN UNIV

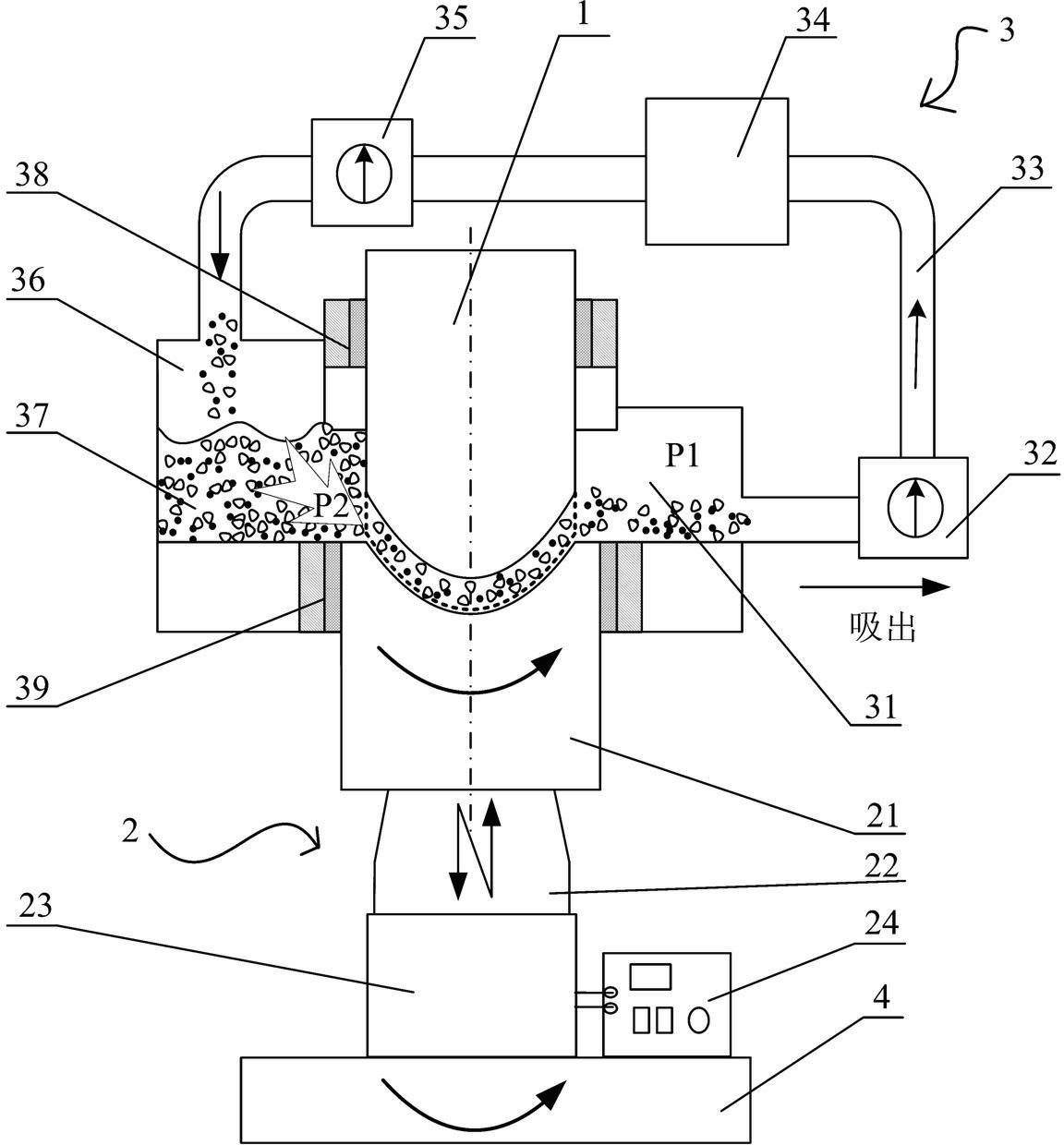

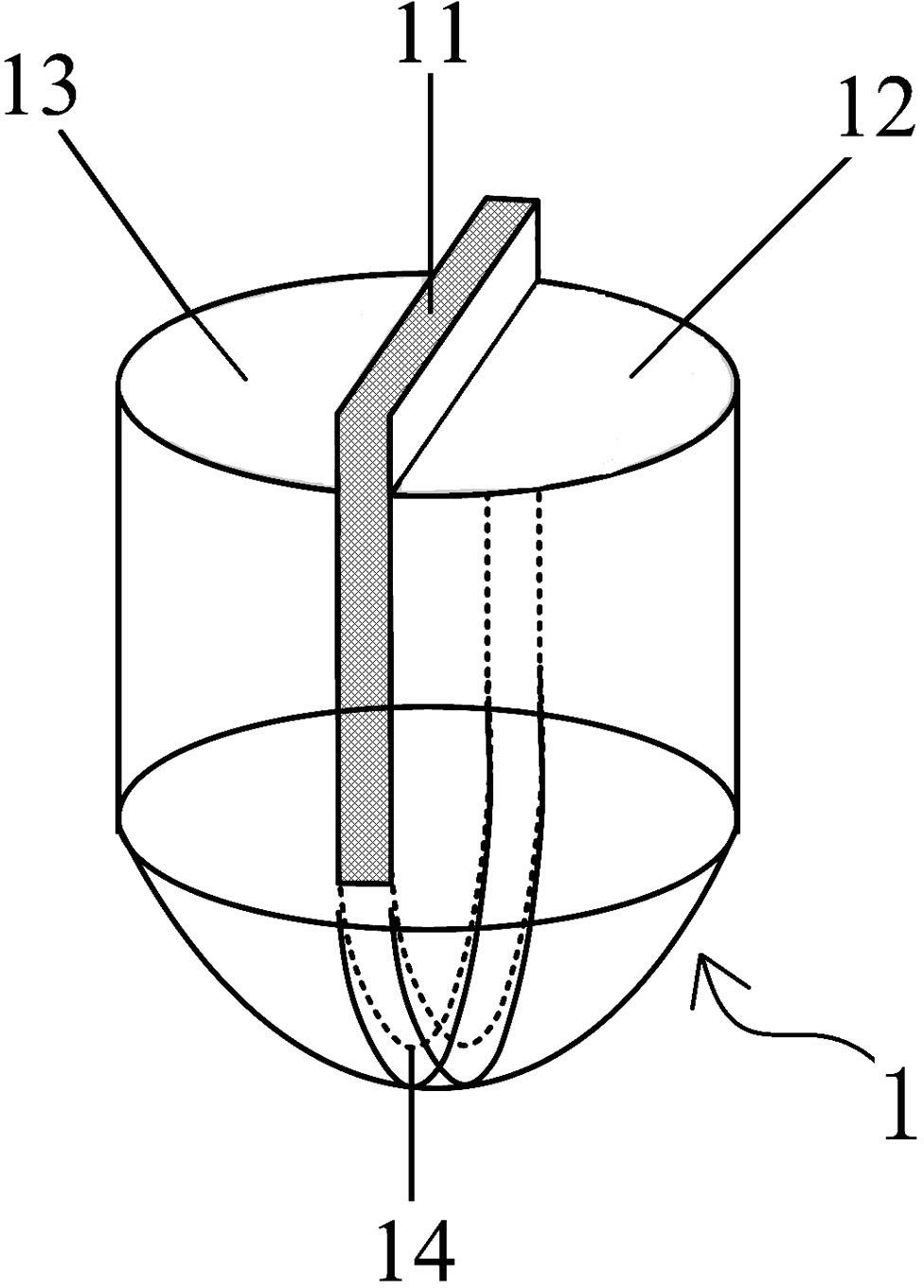

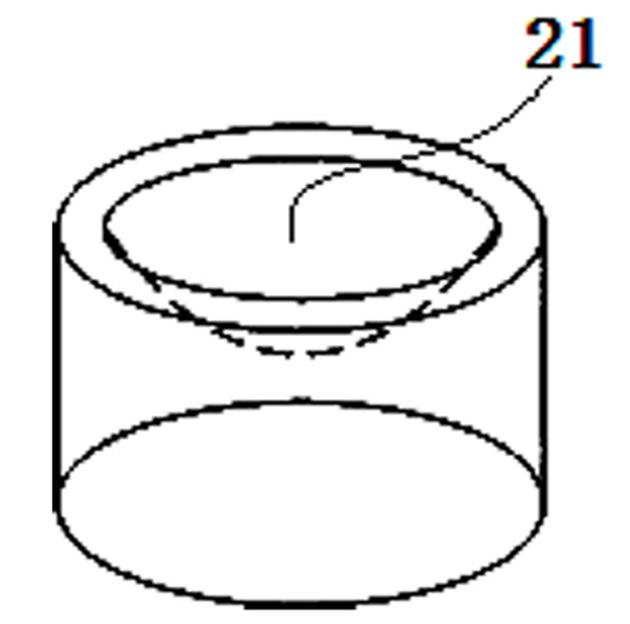

Method and device for polishing small-bore optical element

InactiveCN102672554AIncrease mobilityImprove clippingPolishing compositions with abrasivesMaterial removalEngineering

The invention discloses a method and a device for polishing a small-bore optical element, and belongs to the technical field of ultraprecise optical polishing. A throttling block of which the shape is matched with that of a surface to be machined and which is provided with a slot way is fixed on the upper part of the surface to be machined of a workpiece; the workpiece rotates around the own rotating shaft; a flexibly cyclic polishing belt is formed on the slot way by using fine abrasive particle fluid and machines the surface of the workpiece. By using pressure difference and a mode of fluid suction, the fluidity and sliding friction property of the fine abrasive particle fluid is enhanced; by adoption of ultrasonic vibration of an axisymmetric rotating curved-surface workpiece, the impact effect and cutting effect of fine abrasive particles on the workpiece are enhanced, so that the material removal rate is enhanced, the surface with high quality is obtained efficiently, and surface scatheless trace removal is realized. The method and the device are applied to ultraprecise polishing of curved surfaces of various rotationally-symmetrical optical elements and are high in practical value in the aspect of automatic processing.

Owner:HUNAN UNIV

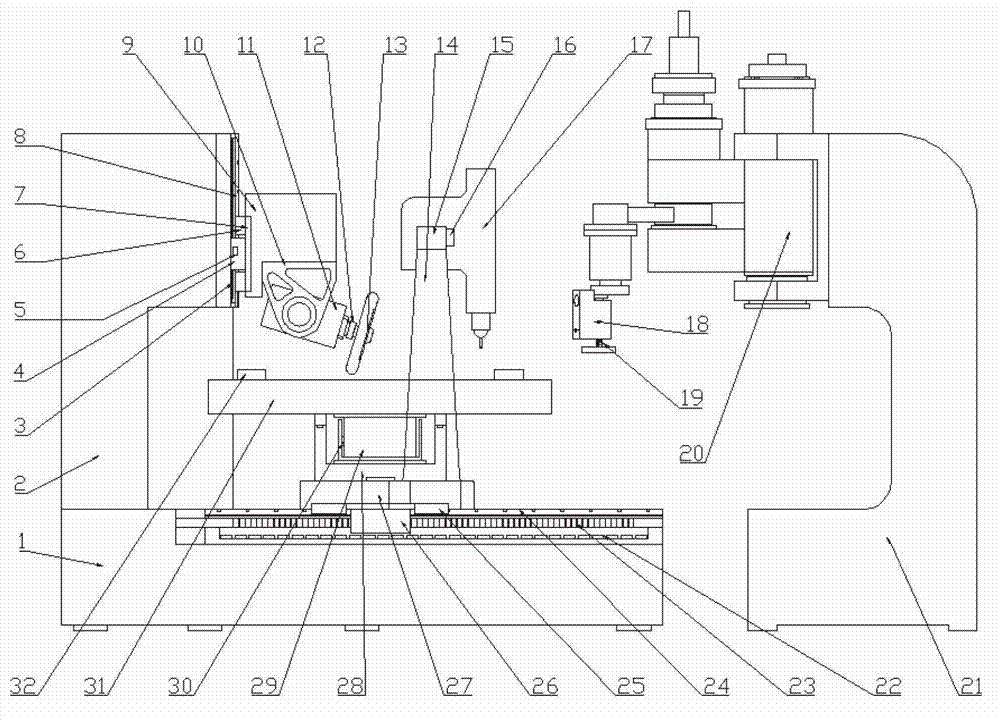

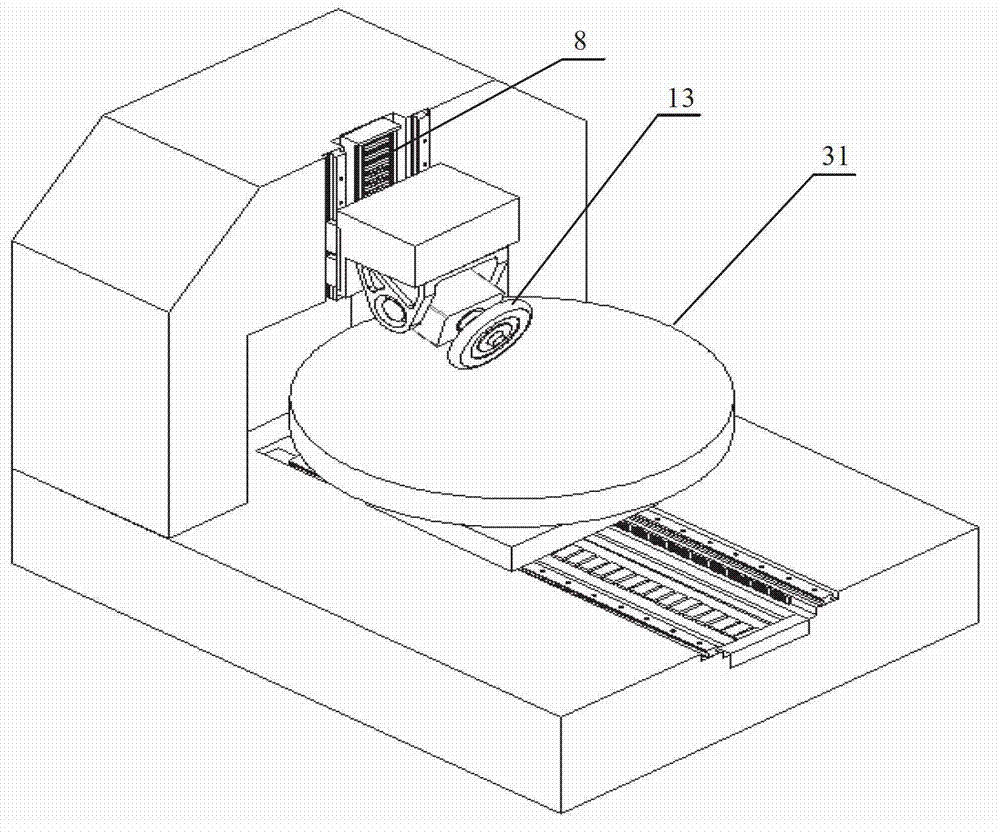

Ultra-precise processing integrated platform for large caliber optical mirror surface

ActiveCN102756316AEasy to moveAchieve multi-axis ultra-precision grindingOptical surface grinding machinesOptical processingSurface grinding

An ultra-precise processing integrated platform for a large caliber optical mirror surface solves the problem that processing and detection are not integrated while processing the large caliber optical mirror surface in the conventional optical processing technical field. The platform integrates grinding, detection and milling for processing the large caliber optical mirror surface, and comprises a base, a horizontal moving device, a rotation device, an ultra-precise grinding device, a mirror surface detection device and a milling device, wherein the horizontal moving device drives the rotation device to move to a workpiece mounting position, a grinding position, a surface shape detection position and a milling position in a horizontal direction; a vertical moving device drives a spindle system and a diamond grinding wheel to move up and down in a vertical direction; the spindle system can adjust the inclined angle of the diamond grinding wheel; the diamond grinding wheel has a cambered surface; when in the workpiece mounting position, the rotation device can conduct cambered surface grinding on a workpiece; when in the surface shape detection position, the rotation device can conduct surface shape detection on the workpiece; when in the surface shape detection position, the rotation device can mill the workpiece.

Owner:SHANGHAI JIAO TONG UNIV

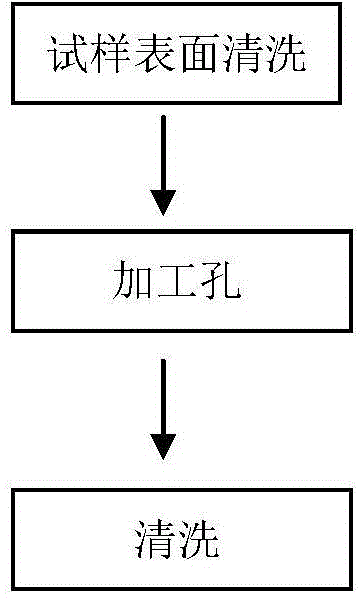

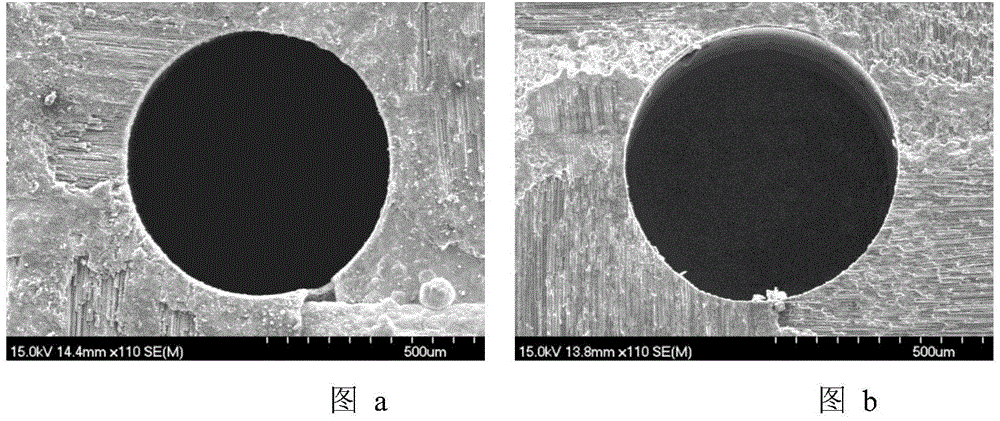

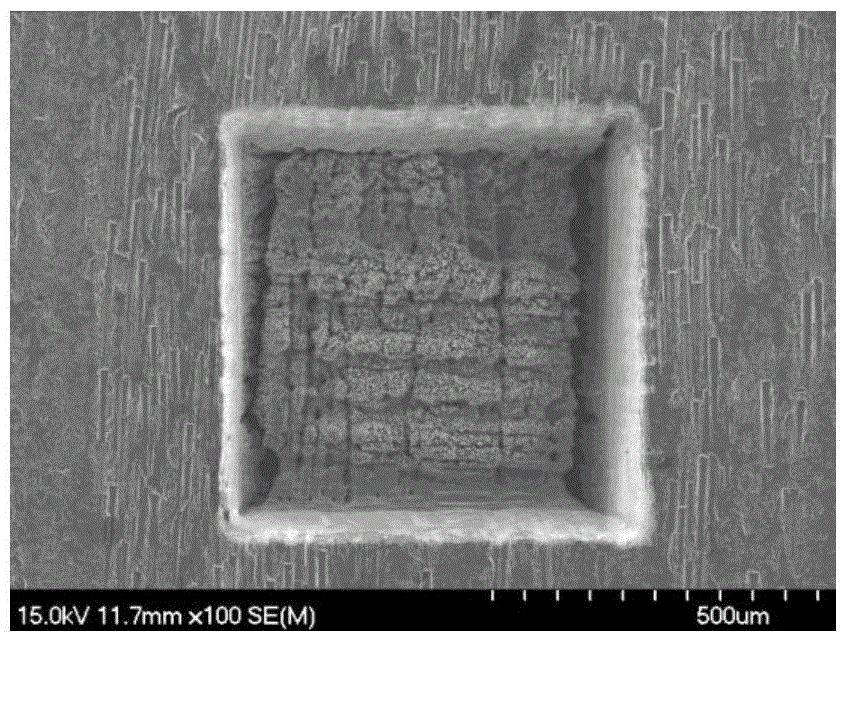

Method for machining micro holes in ceramic matrix composite through femtosecond lasers

ActiveCN104607808AHigh peak powerShort pulse widthWelding/soldering/cutting articlesLaser beam welding apparatusWavelengthLayer removal

The invention relates to a method for machining micro holes in a ceramic matrix composite through femtosecond lasers. According to the method, the silicon carbide ceramic matrix composite sample is placed on a working table and machined layer by layer in a spiral line mode through the femtosecond lasers or machined in a linear scanning mode, wherein the thickness of the sample is smaller than 3 mm; in the micro-machining process, the wave length of femtosecond laser machining ranges from 400 nm-1500 nm, the pulse width ranges from 80 fs to 500 fs, the output power of the lasers is determined according to the requirements of micro-machining and ranges from 20 mW to 20 W, and the repetition frequency of the lasers is determined according to the requirements of micro-machining and ranges from 50 K to 25 MHz; the sample is machined in a layer-by-layer removal mode, wherein the rotation speed of a machining head is 2400 rev / s. In the machining process, the method has the advantages that machining damage is small, and because material around the damage region is still in a cold state after machining, the heat effect is small; machining precision is high, energy of the femtosecond lasers is in Gaussian distribution, absorption and action of the energy in the machining process are limited within the size of which the focus center is quite small, and the machining dimension is expressed from a micro form to a sub-micro form.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

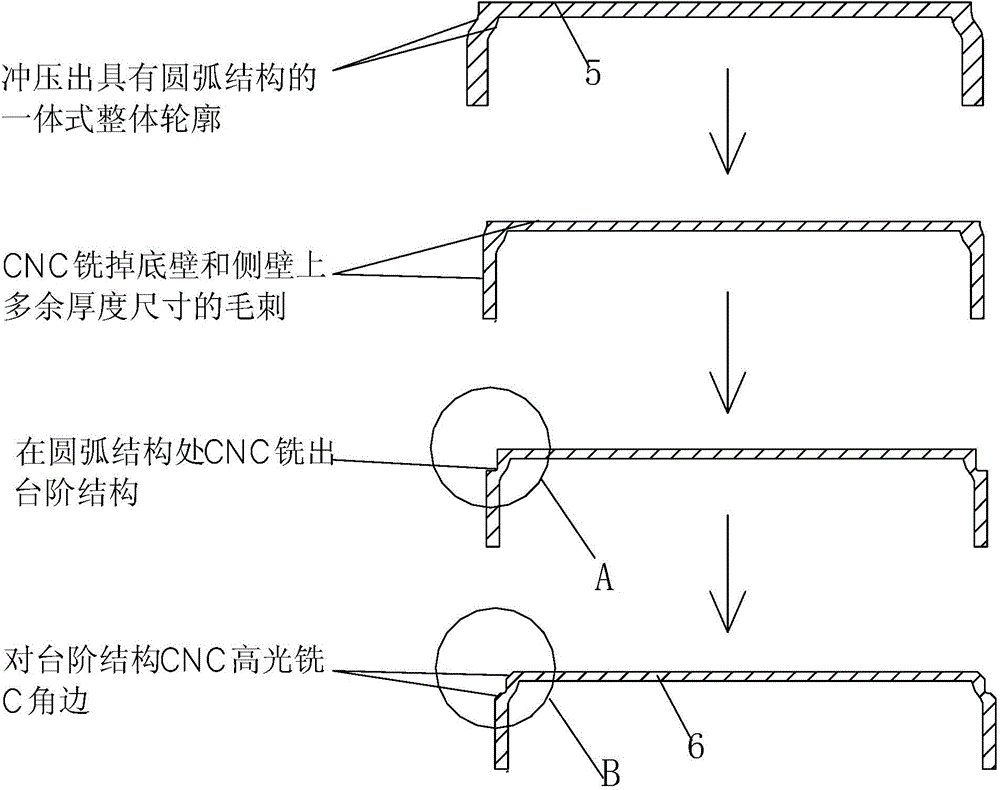

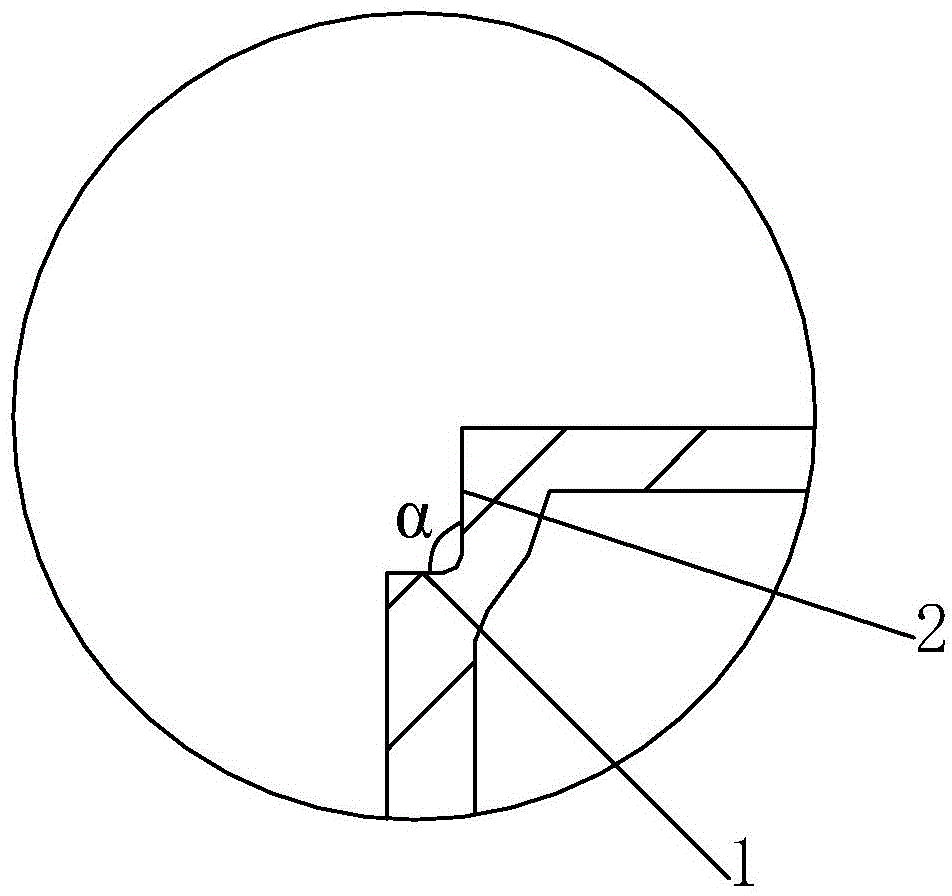

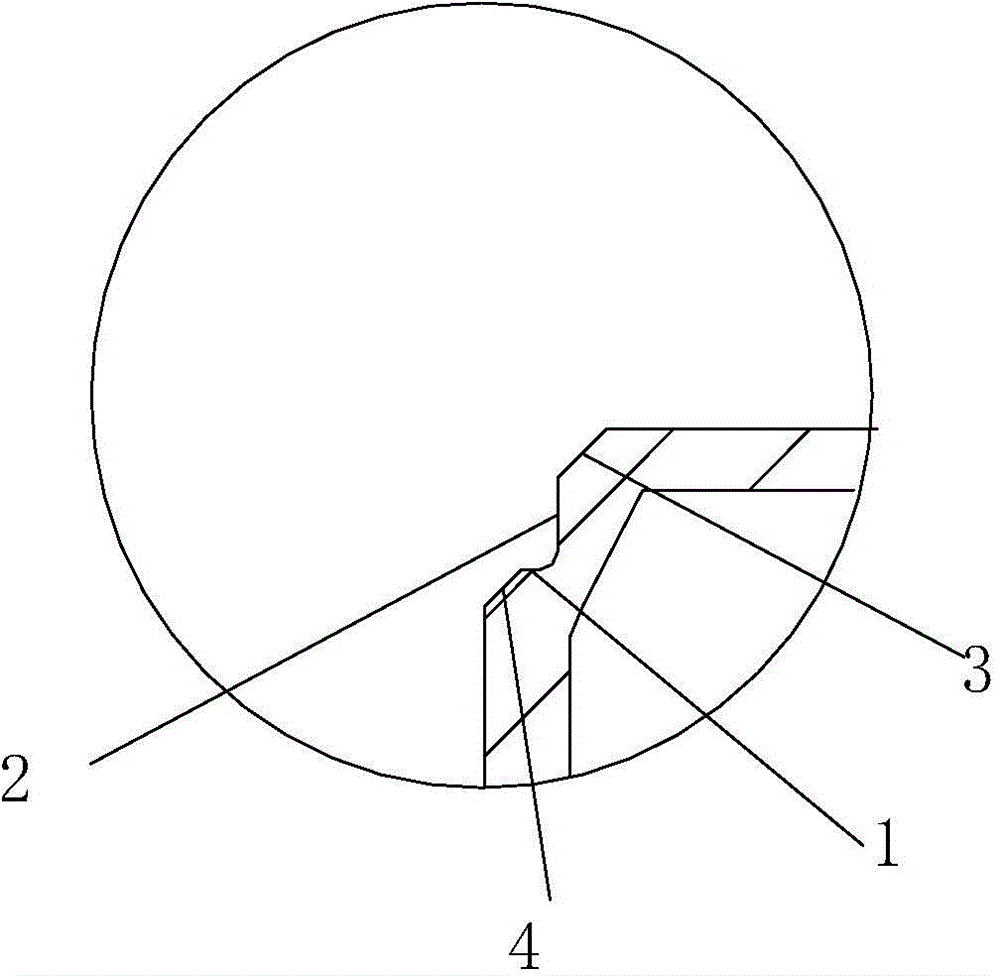

Method for forming metal mobile phone shells

ActiveCN104476136AProcessing time is shortSolve processabilitySubstation equipmentNumerical controlWork in process

The invention discloses a method for forming metal mobile phone shells, and relates to the technical field of mobile phones. The method for forming the metal mobile phone shells includes stamping and bending metal plates to obtain integral outlines of the integrated mobile phone shells so as to obtain initial blank products; carrying out CNC (computer numerical control) machining on the initial blank products to obtain semi-finished products of the metal mobile phone shells; carrying out post-processing on the semi-finished products of the metal mobile phone shells to obtain the metal mobile phone shells. Arc structures are arranged between the side walls and the bottom walls of the integral outlines of the integrated mobile phone shells. CNC machining procedures include (1), milling off burrs on redundant thickness-size sides of the bottom walls and the side walls of the initial blank products under the CNC; (2), inwardly milling the outer walls of arc corners between the side walls and the bottom walls of the initial blank products under the CNC to obtain step structures and respectively forming C-angle edges at the step structures; (3), finely milling the C-angle edges of the step structures under the CNC. The C-angle edges are close to the bottom walls and the side walls of the initial blank products. The method has the advantages that a stamping forming procedure and a CNC machining procedure are combined with each other, so that the metal mobile phone shells can be formed, and the method is stable in process, high in machining precision and production efficiency, short in machining elapsed time and low in production cost.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

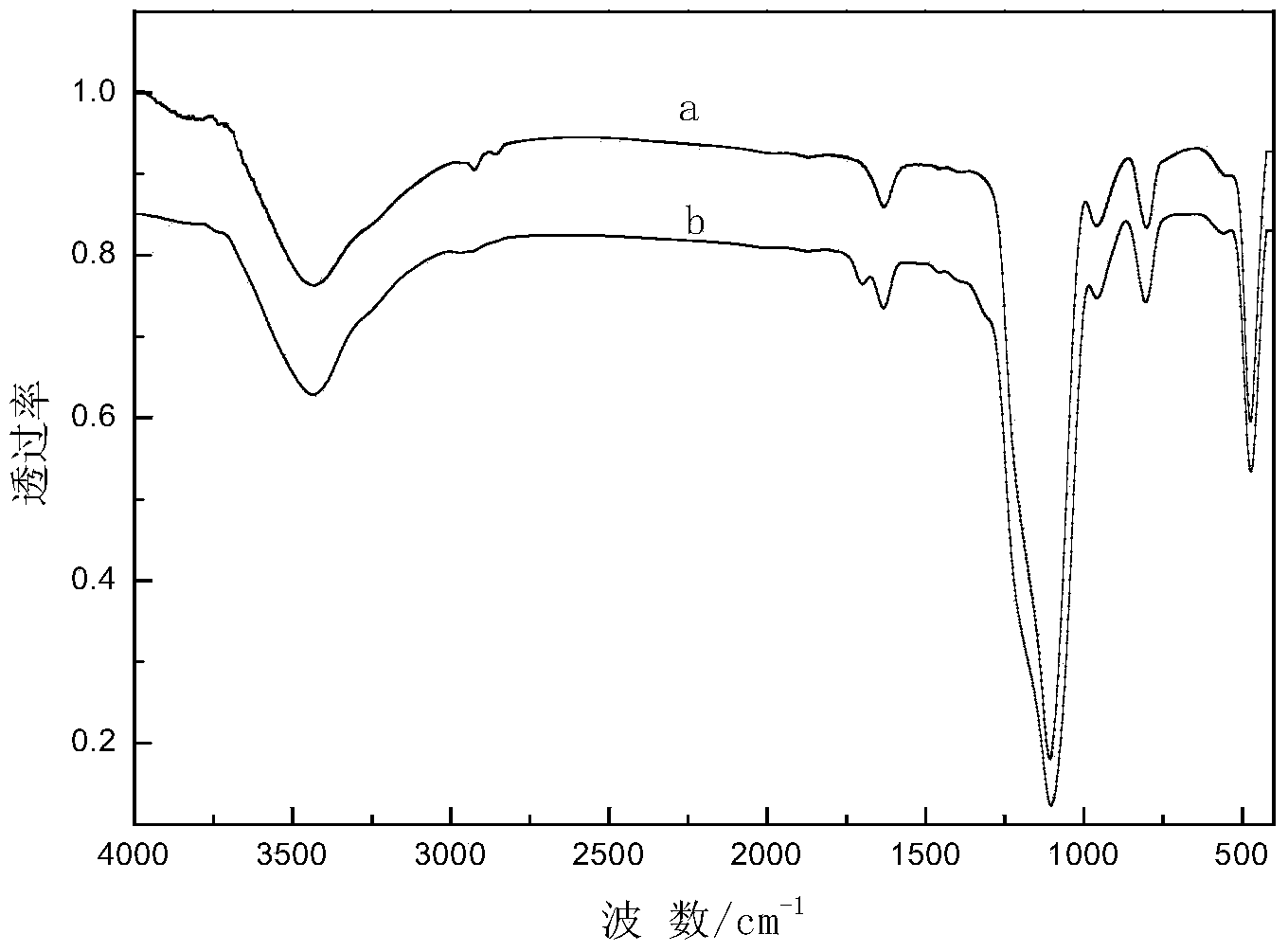

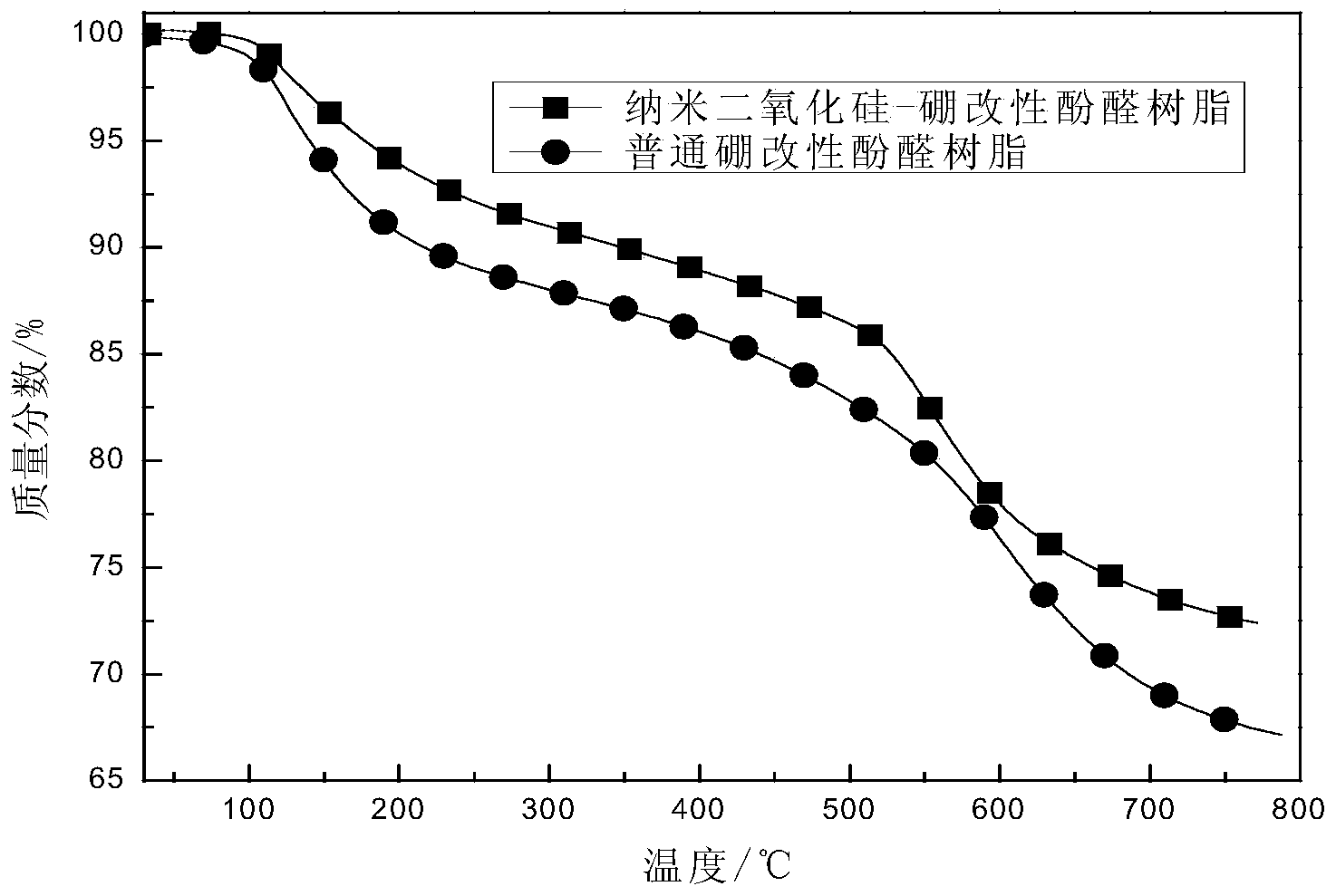

Method for preparing nano-silica-boron modified phenolic resin

The invention discloses a method for preparing nano-silica-boron modified phenolic resin, and relates to phenolic resin. Firstly, a silane coupling agent gamma-methylacryloyl acyloxy propyl group trimethoxy silane is adopted to modify hydrophilic nano-silicon to obtain hydrophobic nano-silica. Secondly, reaction is carried out on phenol and formaldehyde under the condition that sodium hydroxide serves as catalyst to obtain phenolic resin emulsion, and the modified nano-silicon which is dispersed by anhydrous ethanol solution in an ultrasonic mode is added to the phenolic resin emulsion to be reacted. Lastly, boric acid is added, polymerization reaction is carried out on the phenolic resin micromolecule and the boric acid, and the nano-silica-boron modified phenolic resin is prepared. The nano-silica is added with part organo-functional groups through silane coupling agent gamma-methylacryloyl acyloxy propyl group trimethoxy silane so that the problems that the nano-silica is poor in dispersity, solubleness and machinability can be solved. The carbon yield of the prepared nano-silica-boron modified phenolic resin is 72.40%, and the thermal performance is improved by about 5% compared with the thermal performance of ordinary boron modified phenolic resin.

Owner:XIAMEN UNIV

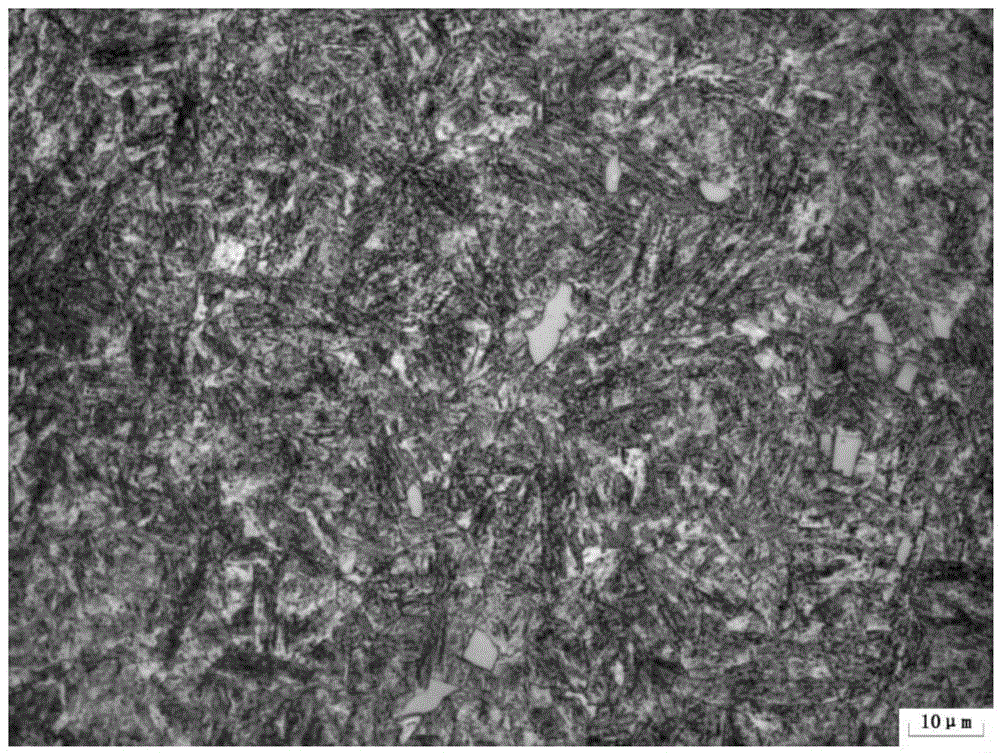

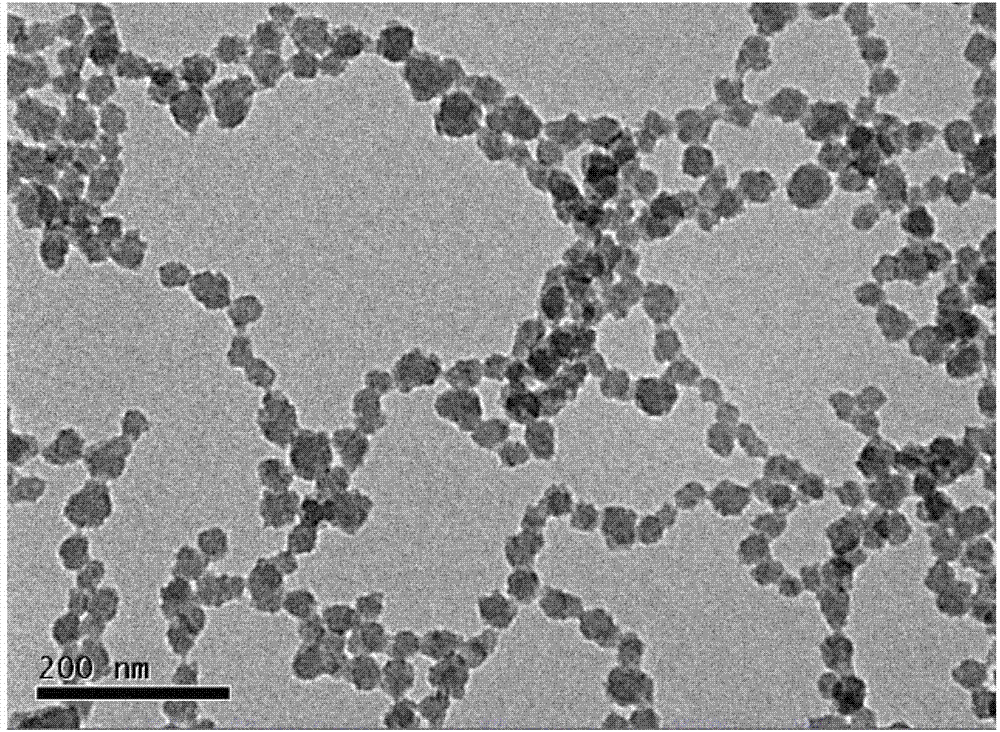

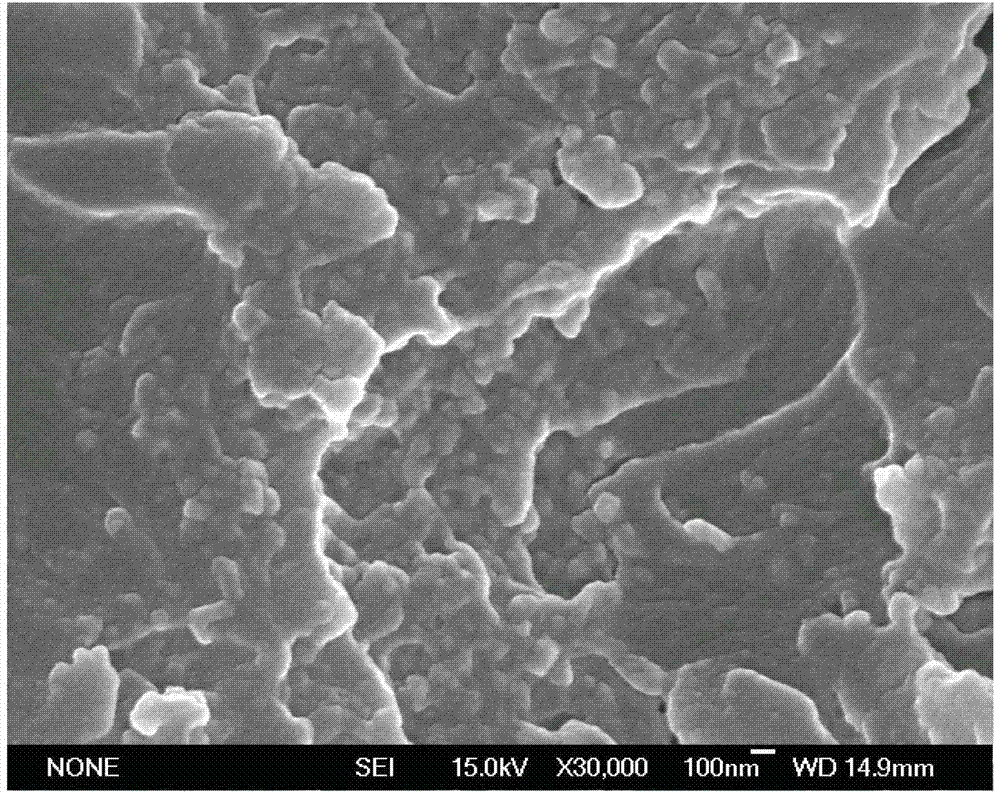

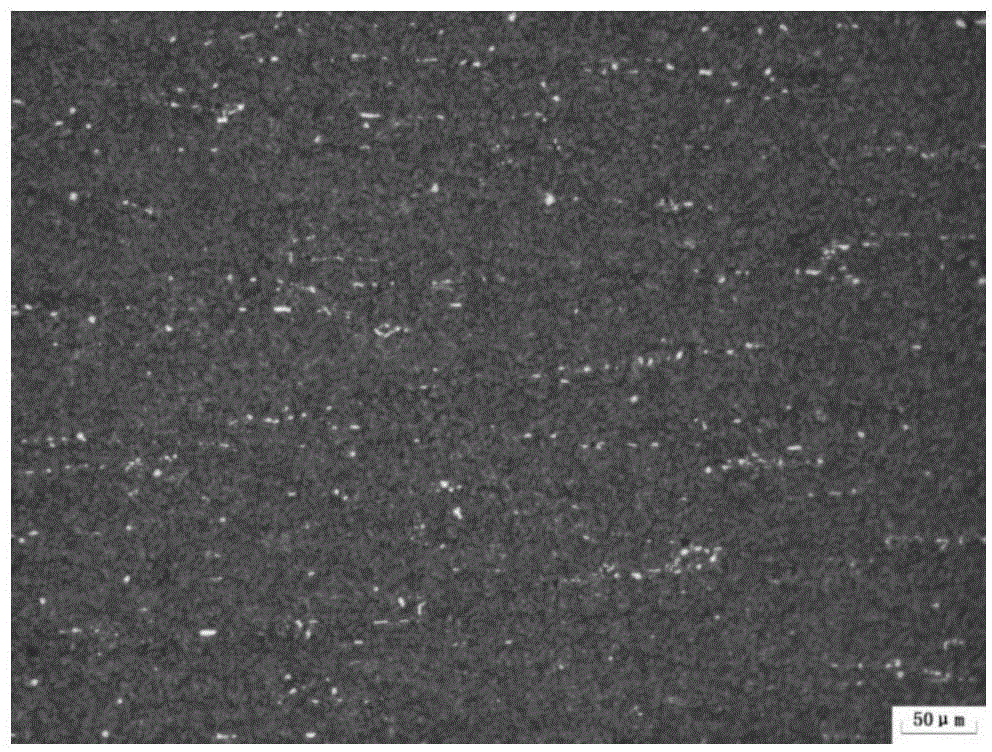

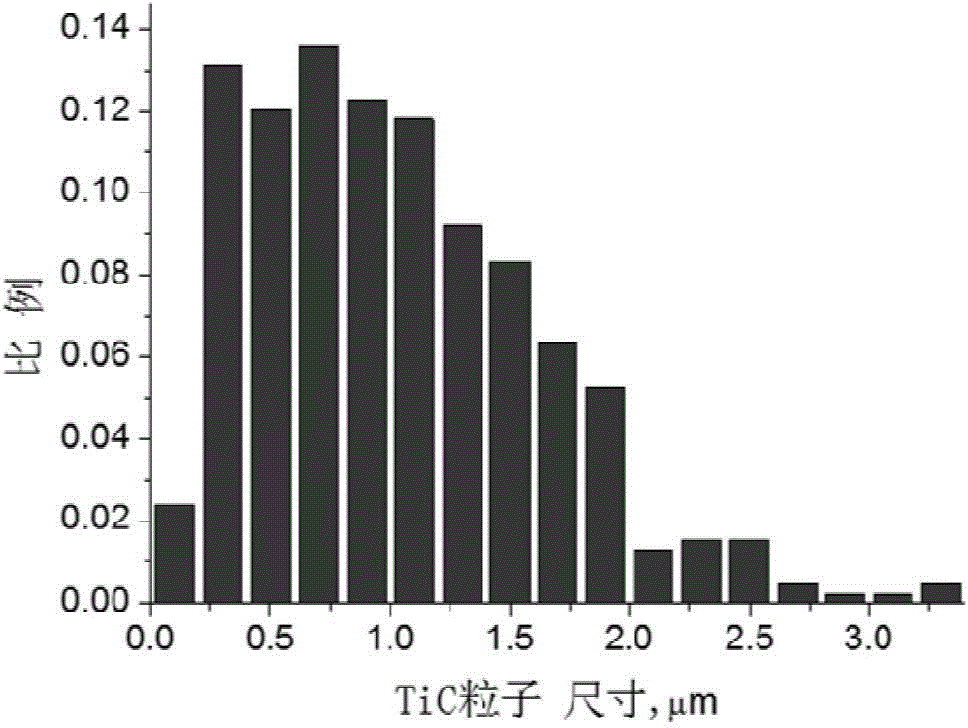

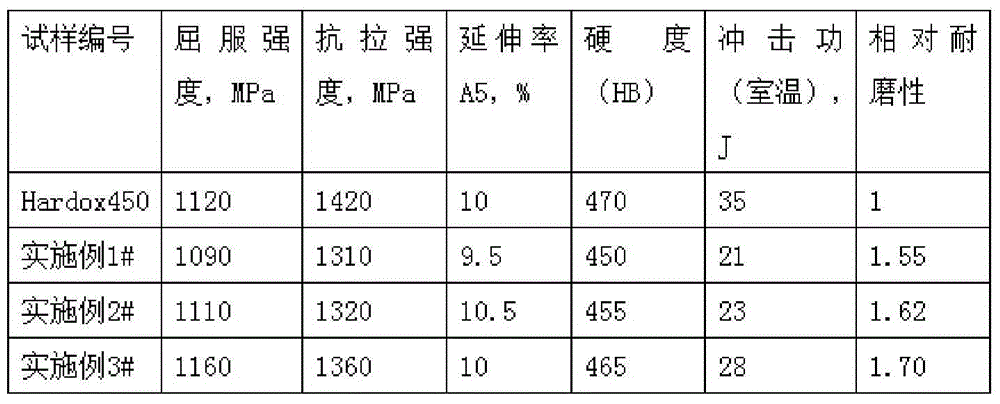

TiC particle enhancement mode complex phase tissue high-ductility wear-resisting steel plate and manufacturing method thereof

The invention discloses a TiC particle enhancement mode complex phase tissue high-ductility wear-resisting steel plate and a manufacturing method thereof, belonging to the technical field of alloy steel. The steel plate is prepared from the following chemical components in percentage by weight: 0.20-0.40% of C, 1.00-2.50% of Mn, 0.80-1.50% of Si, 0.20-0.60% of Ni, 0.15-0.50% of Mo, 0.40-0.80% of Ti, 0.0005-0.003% of B, less than or equal to 0.005% of S, less than or equal to 0.015% of P, and the balance of Fe and inevitable impurity elements. One or two of alloy elements, namely, 0.00-0.50wt% of Cu and 0.00-0.80wt% of Cr, are further added. The manufacturing method comprises the following steps: smelting by using a converter or an electric furnace, performing external refining, performing continuous casting or die casting on a slab, heating, rolling, cooling and performing thermal treatment. Complex phase tissue of granular bainite, lath martensite and TiC particles is obtained from rolling, the granular bainite comprises bainite ferrite / martensite austenite islands, the volume fraction of the residual austenite is about 6-12%, the volume fraction of TiC precipitated phase is about 0.5-1.5%, the average particle size is about 1mu m, the hardness of the steel plate is HB370-420, the wearing resistance is superior to or equal to Hardox450, the processing property and the welding property are excellent, and manufacturing requirements of relevant equipment are met.

Owner:CENT IRON & STEEL RES INST +1

Manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe

The invention discloses a manufacturing method for X90 pipeline steel longitudinal submerged arc welding pipe, the mass percent of the X90 pipeline steel consisting of: C 0.04-0.08%, Mn1.60-2.0%, Si 0.15-0.45%, S<=0.006%, P<=0.010%, Ni 0.20-0.50%, Mo 0.10-0.30%, Ti 0.010-0.020%, Al 0.015-0.050%, Nb 0.05-0.10%, V<= 0.05%, N <= 0.01%, Cu 0.10-0.30%, Cr <= 0.35%, B <= 0.004%, the rest is Fe, wherein Ceq <= 0.50, Pcm<= 0.25; the inside welding and outside welding adopt 4-wire submerged arc automatic welding. The welding pipe of the invention has advantages of tenacious welding joints and uniform performance.

Owner:CNPC BOHAI EQUIP MFG +2

Epoxy resin silica sol, epoxy resin organic-inorganic nano hybrid material and preparation method thereof

The invention discloses epoxy resin silica sol which is characterized by being prepared from the following components: epoxy resin, organic silicon, silane coupling agent, organic solvent and ammonia water at a molar ratio of 1:(0.1-2):(0.01-2):(0.9-18):(0.001-0.06). The invention also discloses a preparation method of the epoxy resin silica sol. The invention also discloses an epoxy resin organic-inorganic nano hybrid material adopting the epoxy resin silica sol, which is characterized in that the epoxy resin curing agent is one or more of methylhexahydrophthalic anhydride, methylhexahydrophthalic anhydride acid, 4,4-diaminodiphenylmethane and 4,4-diamino diphenyl sulfone. The invention also discloses a preparation method of the epoxy resin organic-inorganic nano hybrid material. The product provided by the invention has excellent insulating property, and the method is stable and efficient.

Owner:上海上惠纳米科技有限公司

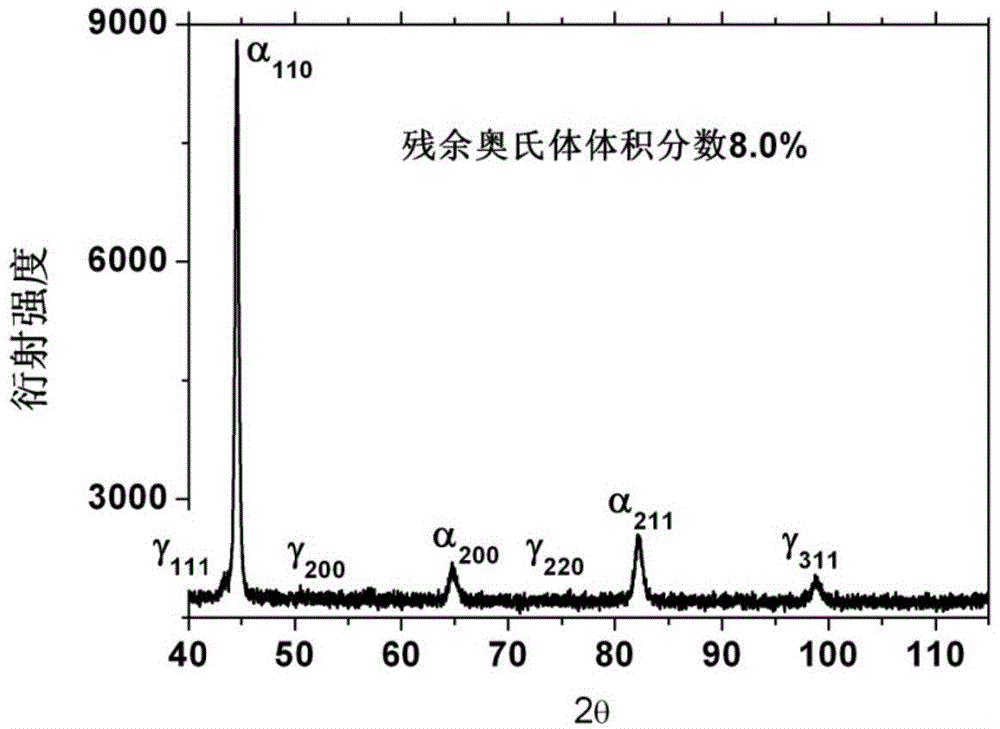

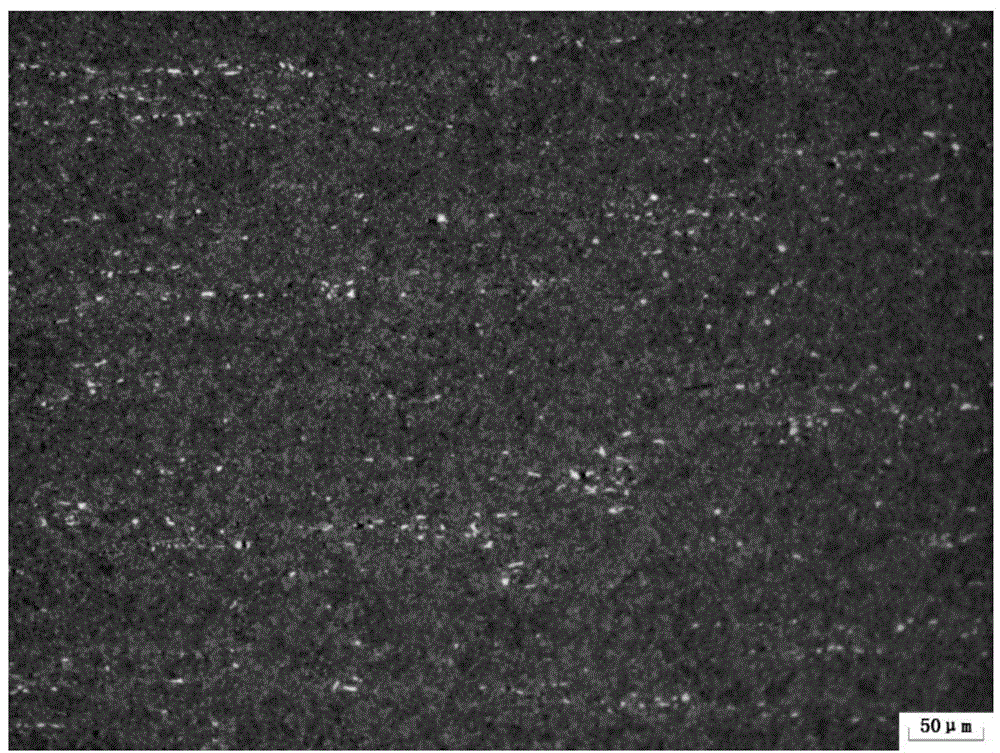

Ultra-hard particle-enhanced martensitic wear-resistant steel plate and manufacturing method thereof

The invention relates to an ultra-hard particle-enhanced martensitic wear-resistant steel plate and a manufacturing method thereof and belongs to the technical field of alloy steels. The wear-resistant steel plate comprises the following chemical components in percentage by weight: 0.20-0.40% of C, 0.50-1.00% of Mn, 0.30-0.60% of Si, 0.50-0.80% of Cr, 0.40-0.60% of Ni, 0.30-0.40% of Mo, 0.40-0.80% of Ti, 0.30-0.50% of Cu, 0.0005-0. 003% of B, less than or equal to 0.005% of S, less than or equal to 0.015% of P and the balance of Fe and unavoidable impurity elements. The manufacturing method of the wear-resistant steel plate comprises the following steps: smelting in a converter or an electric furnace, carrying out external refining, carrying out continuous casting or die casting of slab, heating, rolling, cooling and carrying out heat treatment. According to the components and process, about 0.5-1.5% (volume fraction) of precipitated phases are obtained in the rolled products, the average particle size is about 1mu m; the hardness of the steel plate is HB400-500, the wear resistance reaches above 1.5 times of Hardox450 and the steel plate has excellent processing and welding performances and meets the manufacturing requirements of the relevant device.

Owner:CENT IRON & STEEL RES INST +1

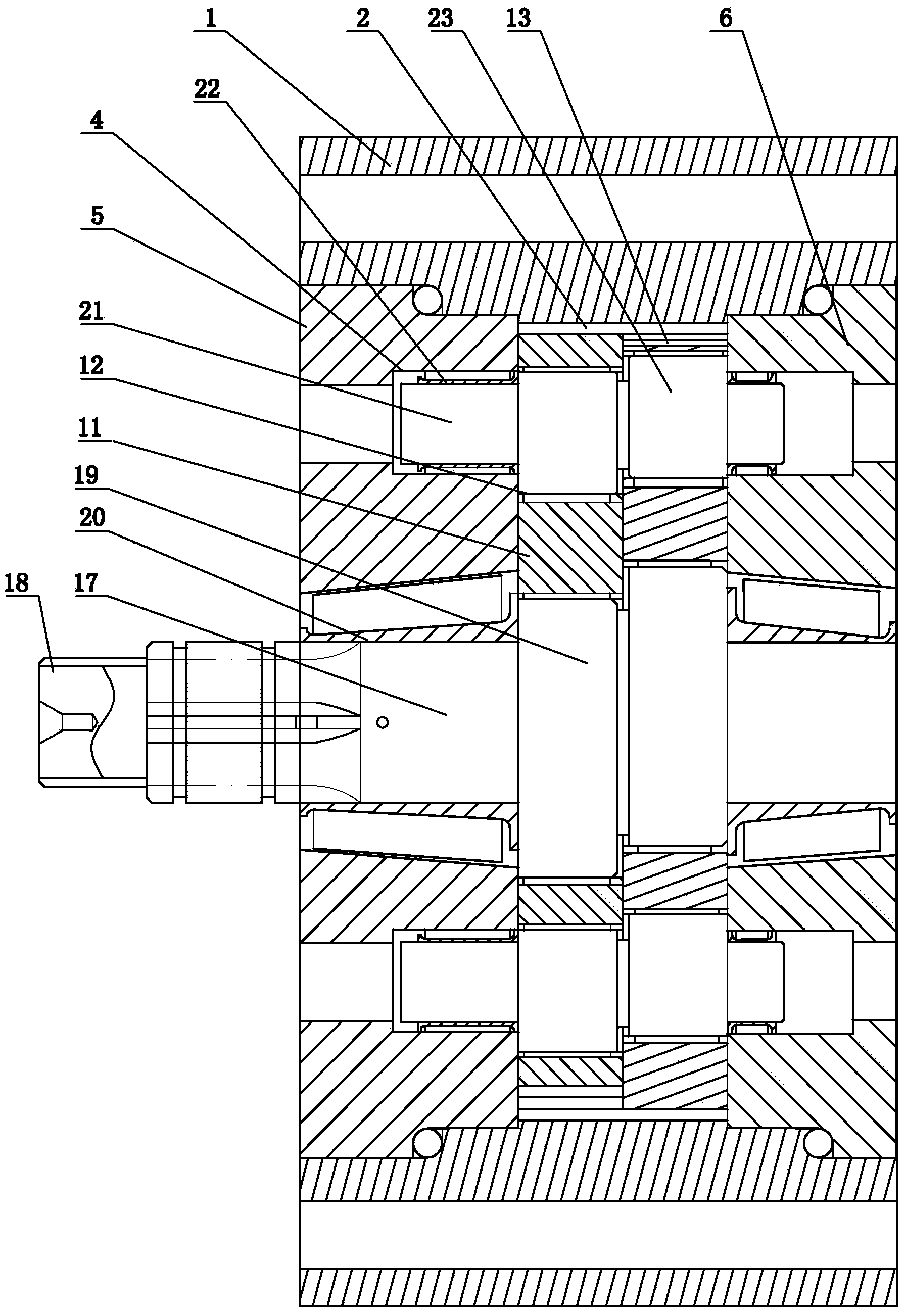

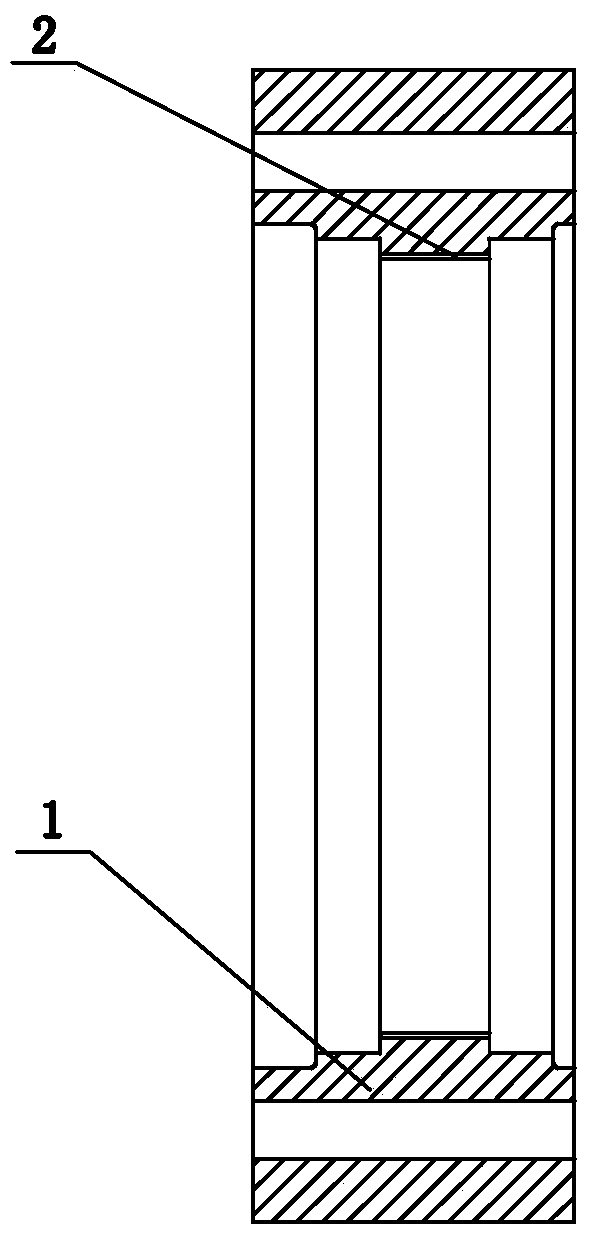

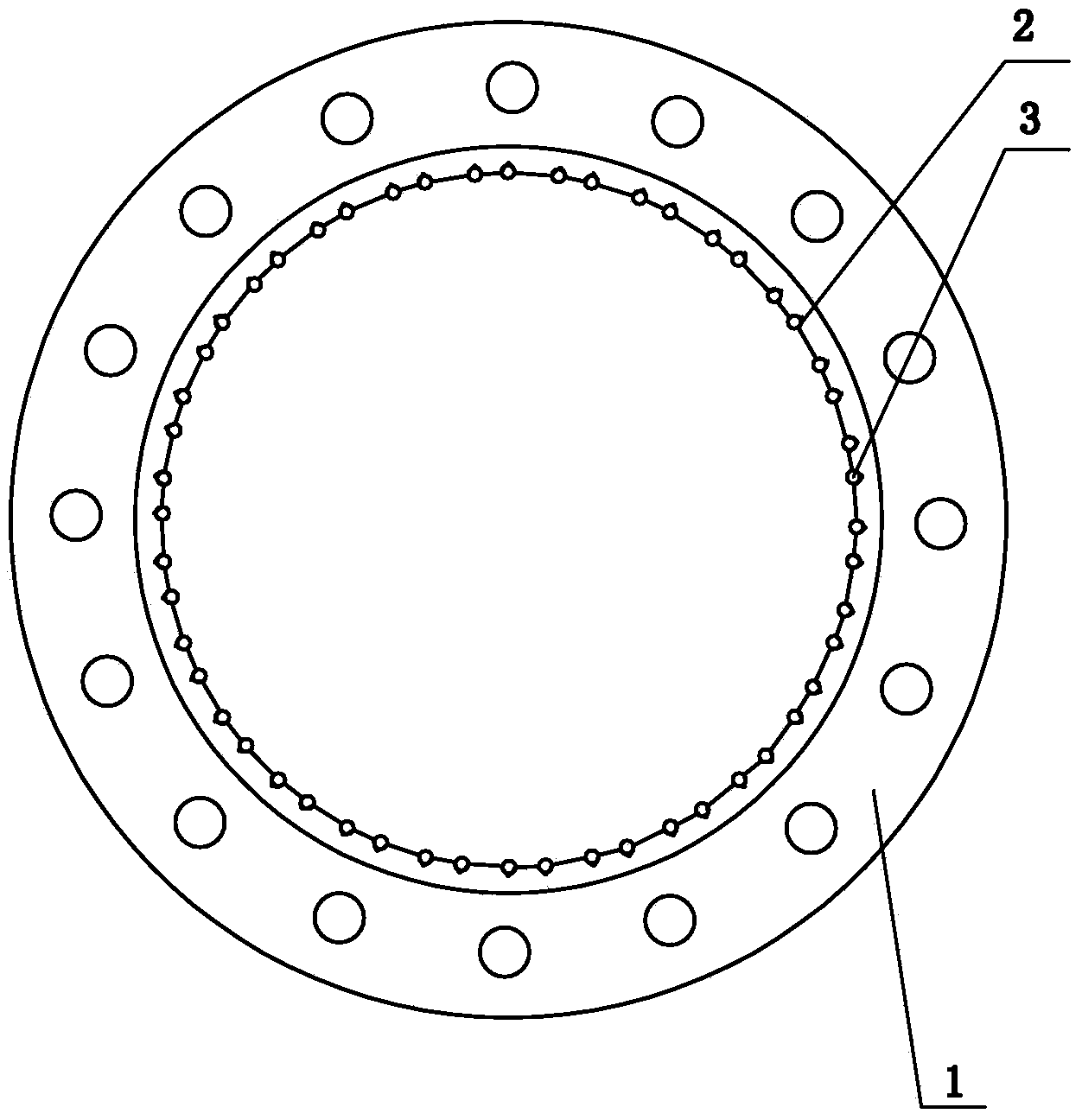

Bearing type RV speed reducer

InactiveCN103527719AReduce processing difficultyHigh transmission reliabilityToothed gearingsGearing detailsDrive wheelReduction drive

The invention discloses a bearing type RV speed reducer, and belongs to the technical field of speed reducers. The speed reducer comprises a pin wheel housing, an installation frame is arranged in the pin wheel housing in a rotary mode, the installation frame is provided with two cycloid gears in transmission connection with the pin wheel housing through needle rollers, the installation frame is rotatably provided with a power input shaft, the power input end of the power input shaft extends out of the installation frame, the power input shaft is provided with two eccentric drive wheels which penetrate through the centers of the two cycloid gears respectively and are matched with the corresponding cycloid gears, the installation frame is rotatably provided with at least two positioning shafts which are symmetric to the rotation center of the power input shaft, and each positioning shaft is provided with two eccentric transmission wheels which penetrate through the two cycloid gears respectively and are matched with the cycloid gears. Power center input and first speed reduction are achieved. Compared with the prior art, the bearing type RV speed reducer reduces the number of power input shafts and use of sun gears and planetary gears, manufacturing cost is low, transmission is reliable, machining and installation are convenient to achieve, and service life is prolonged.

Owner:SHANDONG SHKE MACHINERY MFG

ER70S-6 hot rolled wire rod and preparation method thereof

ActiveCN104498818AHigh in calciumLower calcium levelsProcess efficiency improvementWire rodThermal insulation

The invention relates to the technical field of steel and iron materials and in particular relates to an ER70S-6 hot rolled wire rod and a preparation method thereof. In the process steps, deoxidation treatment is performed on the liquid steel by use of a non-calcium alloy material to avoid the increase of the calcium content in the steel, and furthermore, splashing in the process of welding is avoided. The carbon content in the steel is reduced so that the strength of the wire rod can be reduced; the percentage of area reduction and the percentage elongation of the wire rod are increased, in other words, the plasticity of the wire rod is improved, and consequently, the wire rod can be drawn into a welding wire directly without annealing and the production cost of a welding wire factory is reduced; besides, in the preparation process, the quality of the ER70S-6 hot rolled wire rod is improved by controlling the contents of various elements, such as carbon, silicon and magnesium, so that the welding property of the welding wire is improved; in the cooling process of rolling, draught fans on an air cooling line are all turned off and thermal insulation covers are all closed so that the highest tensile strength of the wire rod does not exceed 550MPa and the plasticity of the wire rod is good.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Preparation method for AuSn20 alloy brazing filler metal used for packaging integrated circuit and usage thereof

ActiveCN102114584ASolve processabilitySolve product problemsWelding/cutting media/materialsSoldering mediaAlloyGraphite

The invention relates to a preparation method for an AuSn20 alloy brazing filler metal used for packaging an integrated circuit, which comprises the following steps: preparing gold and tin in proportions; placing the gold and tin into a casting furnace; sealing the furnace and vacuumizing the furnace; rising the temperature till the gold and tin are completely melted, controlling the temperature of the melt at 500-600 DEG C, refining for the purpose of alloying the gold and tin and degassing, and pouring the alloy in a graphite mould; placing an acquired AuSn20 alloy bar into a quartz tube and heating; sealing the furnace and vacuumizing till the pressure is 4-6Pa; rising the temperature and controlling the temperature rising; after melting the alloy bar, controlling the temperature of the melt to be 500-600 DEG C, and refining for 2-3 minutes; performing the melt-spinning process by using a vacuum quenching melt-spinning machine, controlling the temperature of the melt within 500-600 DEG C in the melt-spinning process, and introducing high-pressure nitrogen from an upper port of the quartz tube, wherein the nitrogen pressure is 10-15Pa; and spraying the alloy melt onto a speedily rotating metal wheel of the vacuum quenching melt-spinning machine from a bottom hole on the quartz tube, thereby acquiring a belt material. The belt material can be milled into a foil belt material or be punched into a slice or annular deeply processed product in the corresponding specification. By using the method, the product having excellent integrated circuit property can be prepared.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

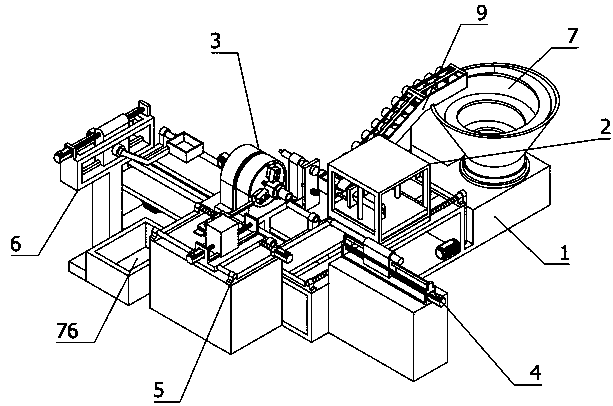

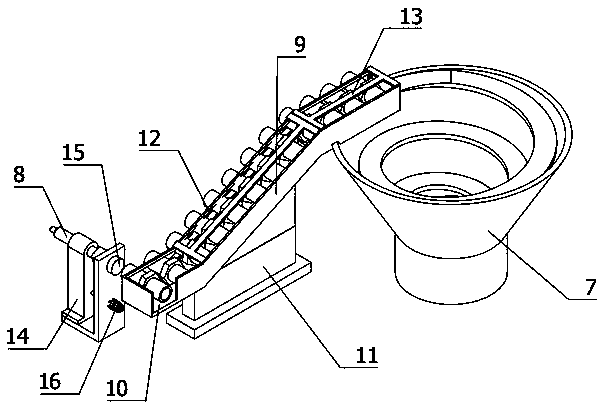

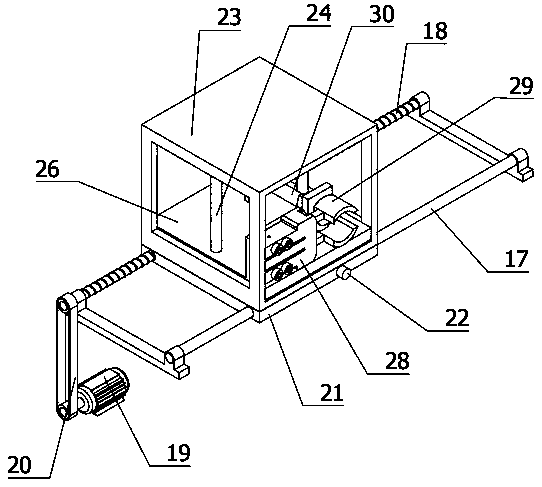

Automatic drilling and external thread machining device for automobile brake pipe joint

ActiveCN111069910ASolve the problem of automatic loading and unloadingSolve automatic drillingOther manufacturing equipments/toolsMetal working apparatusBrakeMachining

The invention relates to the field of machining, in particular to an automatic drilling and external thread machining device for an automobile brake pipe joint. The device comprises a worktable, and further comprises a loading assembly, a feeding assembly, a rotating assembly, a drilling assembly, a machining assembly and a discharge assembly; the loading assembly, the feeding assembly, the rotating assembly, the drilling assembly, the machining assembly and the discharge assembly are all arranged at the top part of the worktable; the discharge assembly is arranged by the side of the worktable; the drilling assembly is located at one side of the rotating assembly; the feeding assembly is located between the rotating assembly and the drilling assembly; the loading assembly is located by theside of the feeding assembly; the machining assembly is located at the side, far away from the loading assembly, of the rotating assembly; the discharge assembly is located at one side of the machining assembly; and the loading assembly includes a vibrating disk and a pushing air cylinder. The device solves the problems that the automobile brake pipe joint cannot be automatically loaded and discharged and automatic drilling and external thread machining cannot be performed at the same time, and thus, time is saved, and the machining efficiency of the automobile brake pipe joint is increased.

Owner:芜湖挺优机电技术有限公司

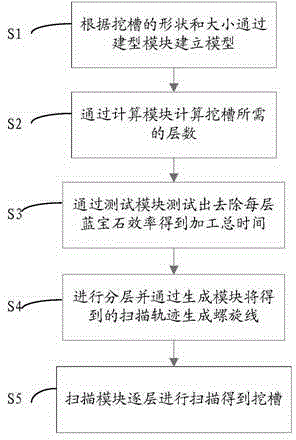

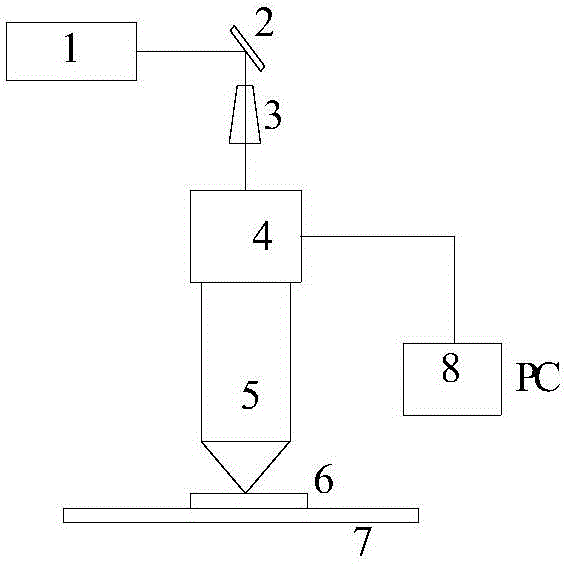

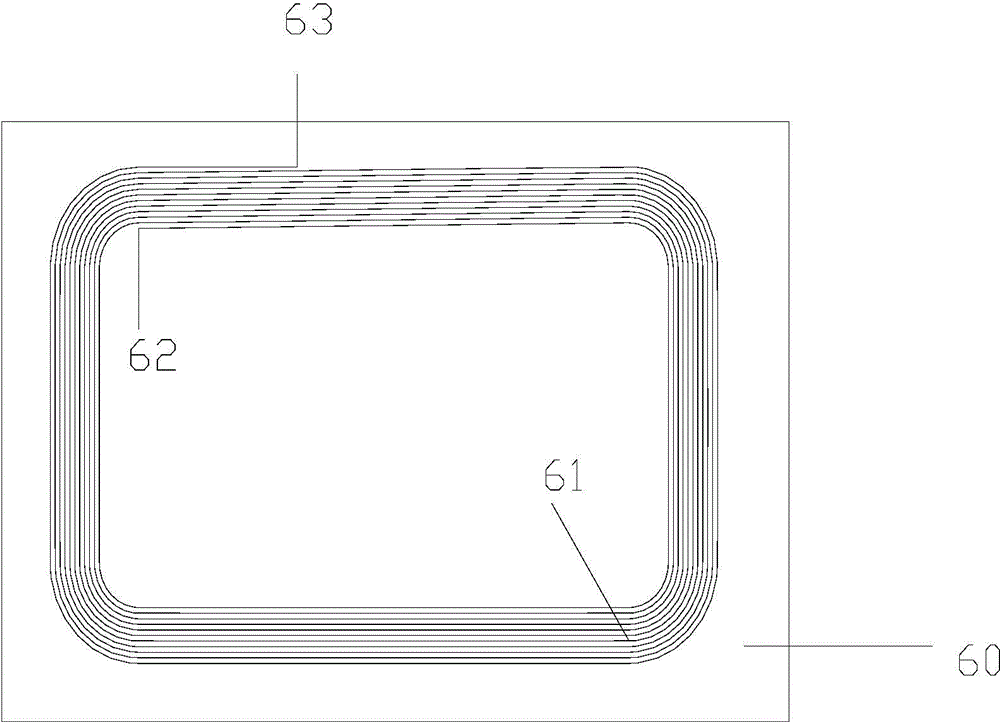

Sapphire laser grooving device and grooving method thereof

ActiveCN105458515ASimple structureFast processingLaser beam welding apparatusGalvanometerLaser scanning

The invention relates to the technical field of laser machining and discloses a sapphire laser grooving device and a grooving method thereof. The sapphire laser grooving device comprises a laser device, a reflecting mirror, a beam expanding lens, a galvanometer, a focusing mirror, a platform and a computer. A to-be-machined sapphire sample is arranged on the platform; the reflecting mirror, the beam expanding lens, the galvanometer and the focusing mirror are arranged above the to-be-machined sapphire sample in sequence from top to bottom; the center of the reflecting mirror, the center of the beam expanding lens, the center of the galvanometer, the center of the focusing mirror and the center of the to-be-machined sapphire sample are located on the same straight line; the laser device is located on one side of the reflecting mirror; the computer is connected with the galvanometer. Compared with a traditional filling type scanning mode, the sapphire laser grooving device and the grooving method thereof have the advantages that a continuous curve mode is adopted, so that the laser grooving effect of machined sapphires is good, the edge breakage quantity is small and cross sections are smooth; besides, scanning is performed according to a spiral line formed by each layer of scanning track so that the problem of poor machining of laser joints during conventional laser scanning can be solved through the scanning tracks, the skipping problem caused by filling type scanning can be avoided, and the machining accuracy can be improved.

Owner:HANS LASER TECH IND GRP CO LTD

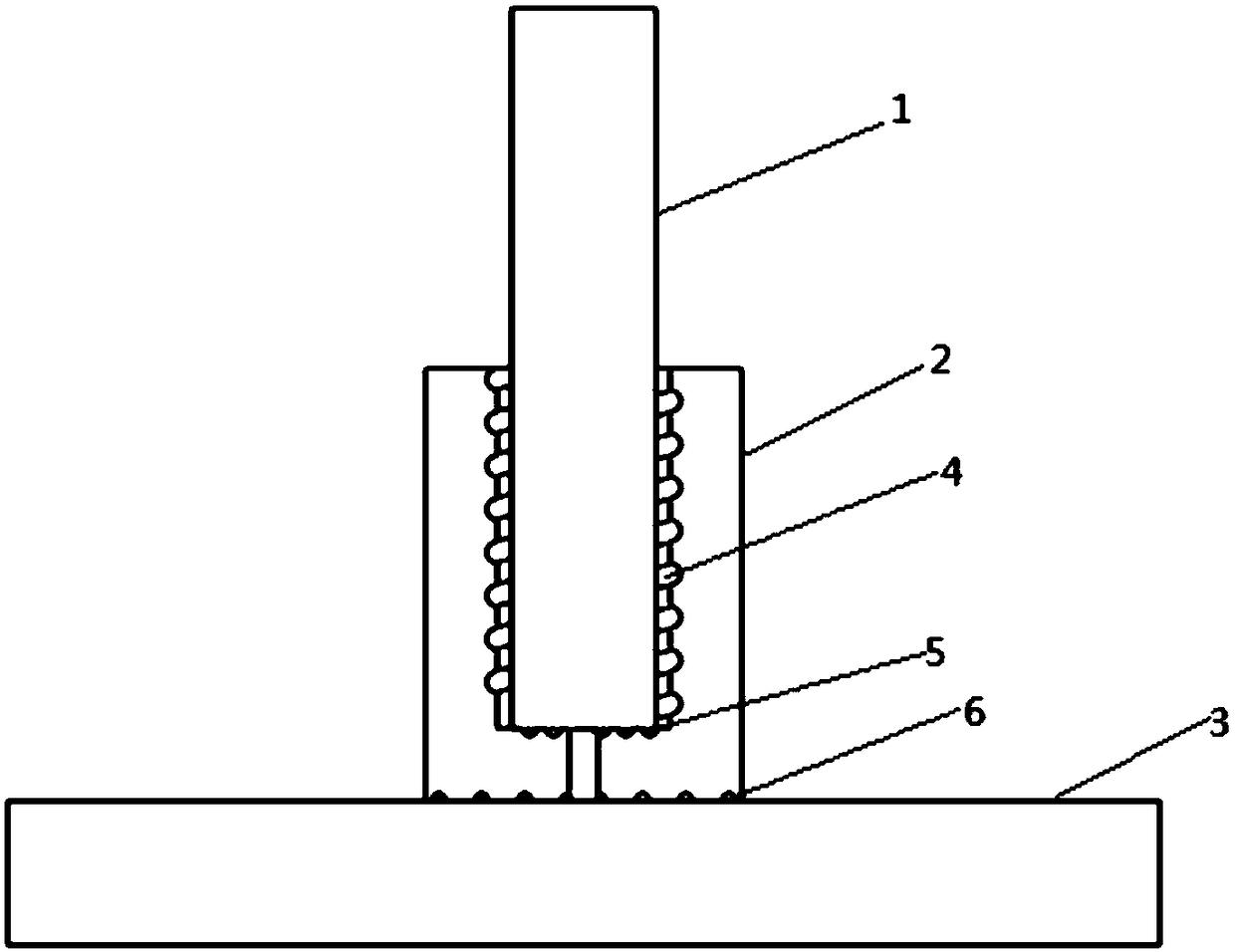

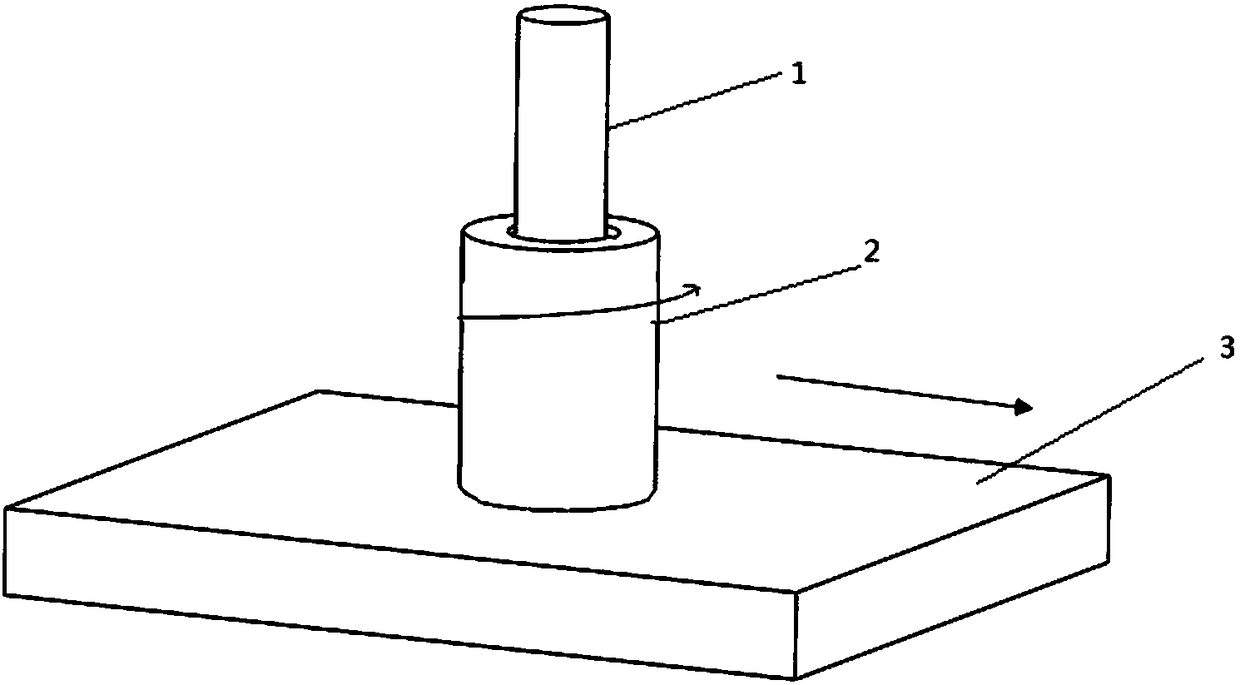

Flowing friction additional material manufacturing device and additional material manufacturing method

ActiveCN109202272AIncrease profitImprove production efficiencyAdditive manufacturing apparatusNon-electric welding apparatusFriction effectAdditive layer manufacturing

The invention relates to a flowing friction additional material manufacturing device and an additional material manufacturing method. The additional material manufacturing device comprises a shaft shoulder, a mother material and a base body. A cavity is formed in the shaft shoulder. A center through hole communicating with the cavity is formed in the lower end, below the cavity, of the shaft shoulder. The mother material is placed in the cavity in the shaft shoulder. Upsetting force exists between the mother material and the bottom face of the cavity in the shaft shoulder. Upsetting force exists between the shaft shoulder and the base body. In the additional material manufacturing process, the shaft shoulder rotates and moves on the surface, with materials to be added, of the base body, the mother material does not rotate, the mother material is subjected to heat plastification under the friction effect, the material subjected to heat plastification flows out along the center through hole in the lower end of the shaft shoulder under the effect of the upsetting force, and under the relative rotating effect of the outer end face of the shaft shoulder and the surface, with the materials to be added, of the base body, and under the upsetting force effect, the material is dispersed and deposited on the surface, with the materials to be added, of the base body. According to the device and the method, the material utilization rate can be increased, the manufacturing efficiency can be improved, and the problems that the working allowance of stirring friction additional material manufacturing is large, and the material utilization rate is low are solved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

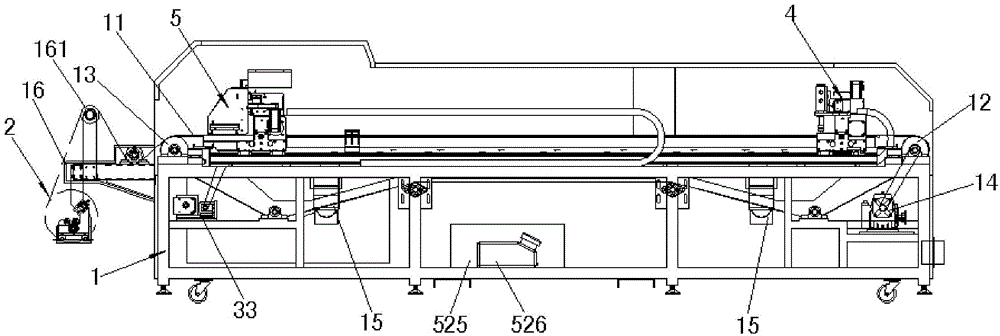

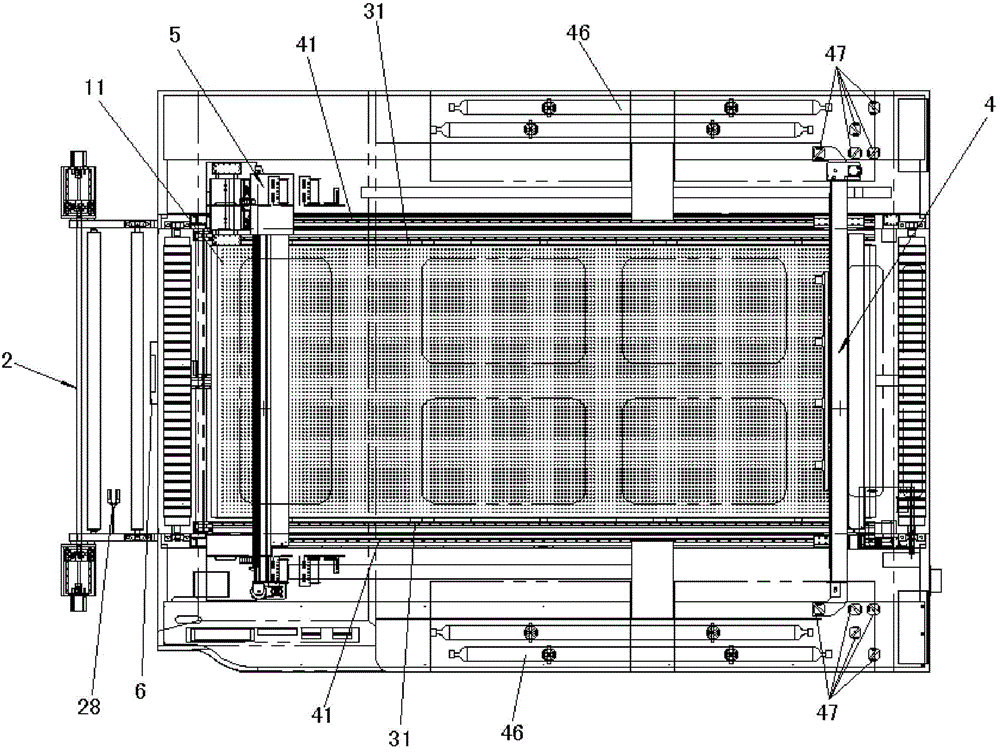

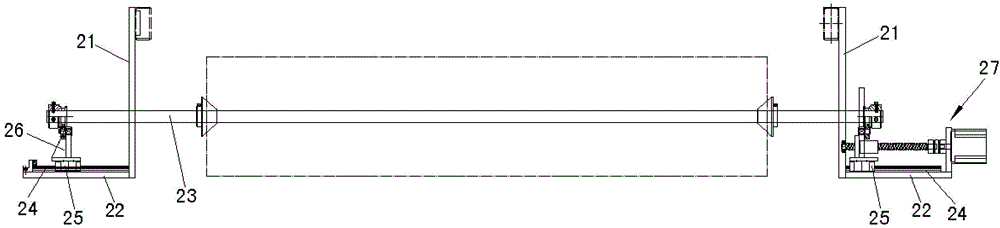

Full-automatic leather printing and cutting machine and printing and cutting method implemented by same

InactiveCN104818350ASolve processabilitySolve the large number of laborLeather clicking/perforating/clickingTypewritersComputer control systemGraphics

The invention discloses a full-automatic leather printing and cutting machine which comprises a framework, an automatic rectifying mechanism, an automatic feeding manipulator, an automatic laser cutting mechanism, an automatic printing mechanism and a control system. A frame and a frame shaft are arranged at the front end of the framework, the frame shaft is arranged on the frame, the automatic rectifying mechanism is arranged at the front end of the framework, the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism are arranged on the framework, and the control system is arranged in the framework and is connected with the automatic feeding manipulator, the automatic laser cutting mechanism and the automatic printing mechanism. The full-automatic leather printing and cutting machine has the advantages that manual production can be truly replaced by machines, accordingly, the leather processing efficiency and processing precision can be greatly improved, and the processing cost can be reduced; optional patterns can be accurately printed by the printing mechanism by the aid of the computer control system, and the problem of asymmetric pattern printing in existing leather processing procedures can be effectively solved.

Owner:DONGGUAN DEL LASER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com