Patents

Literature

61results about How to "Lower calcium levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

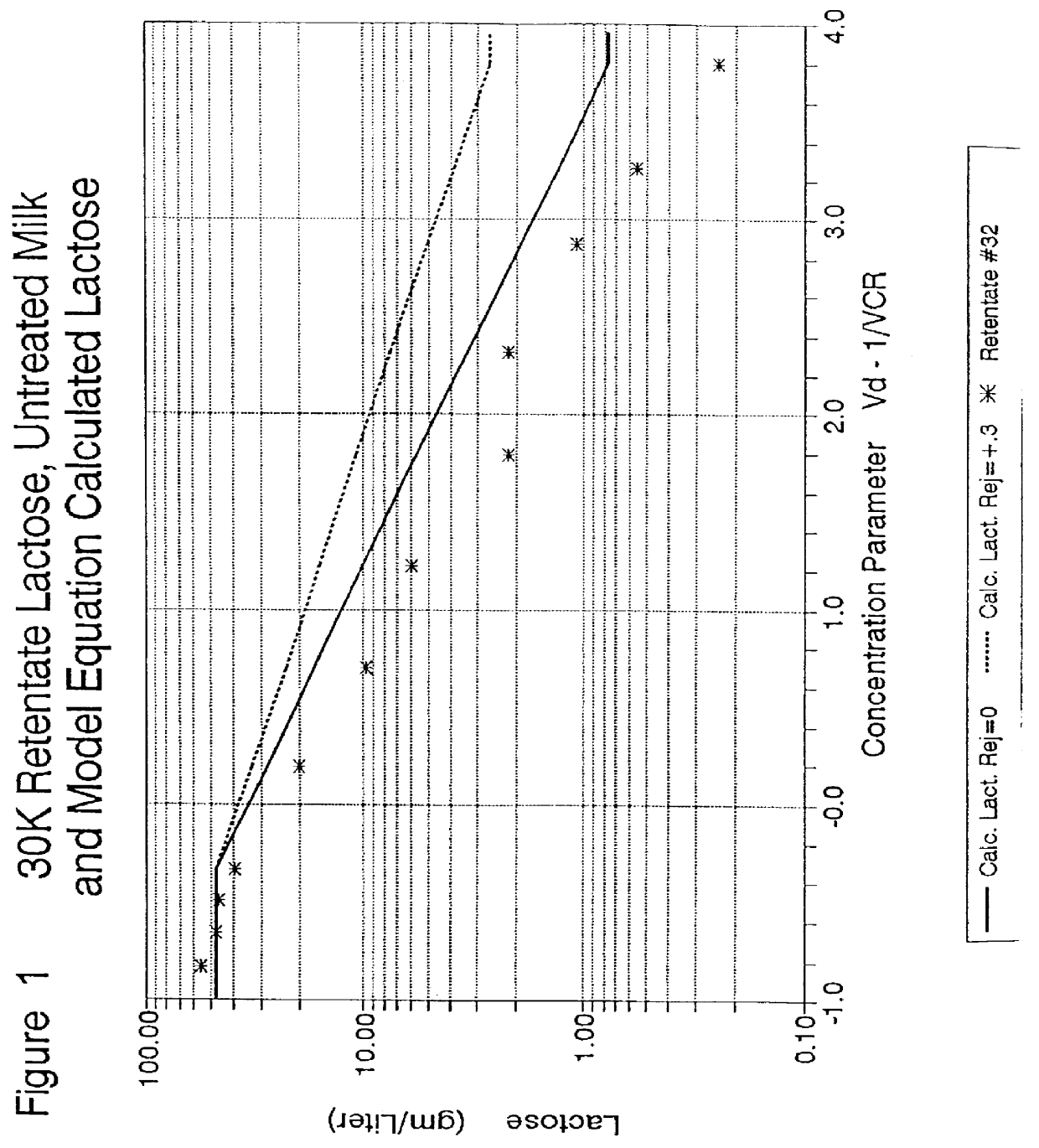

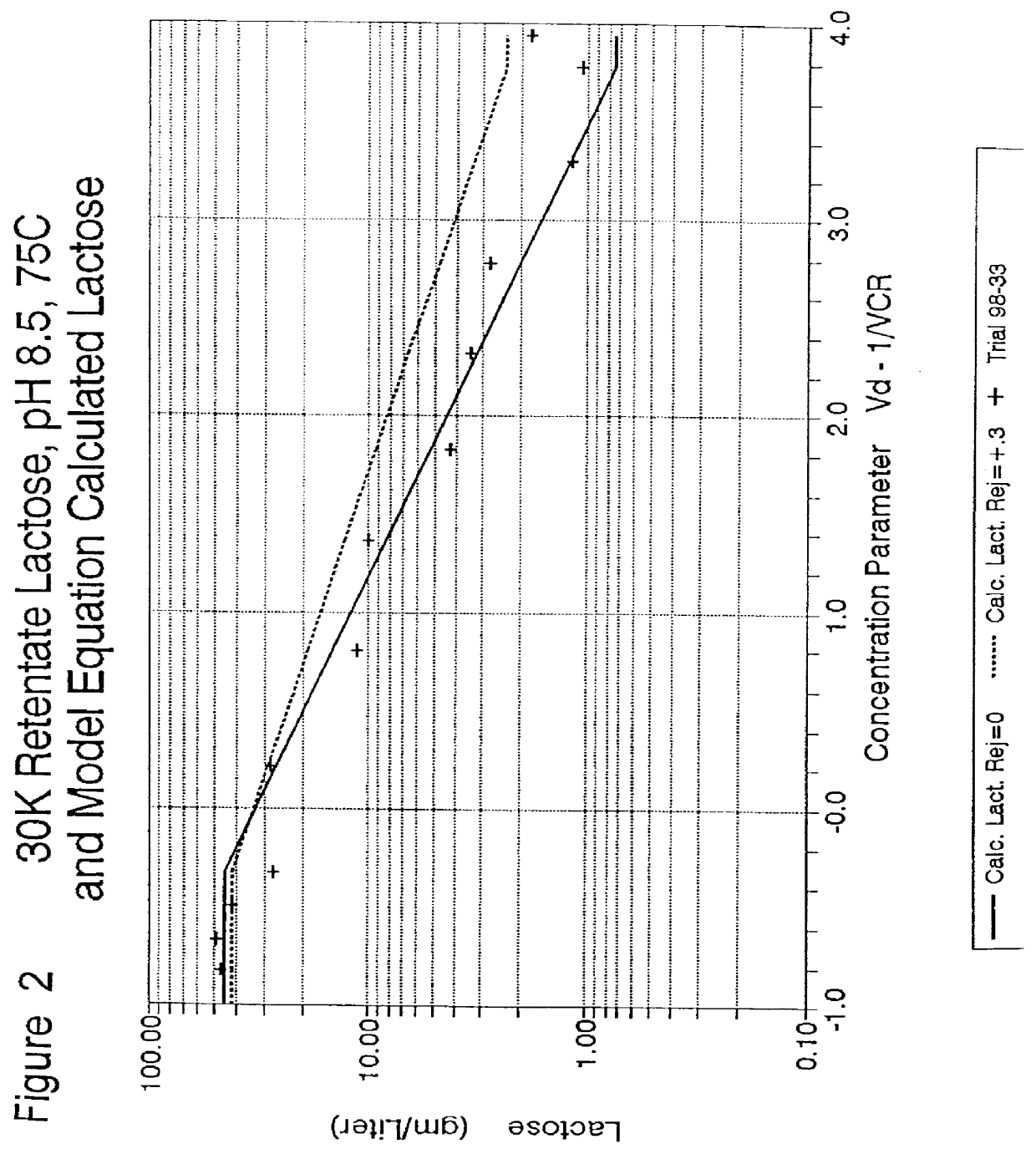

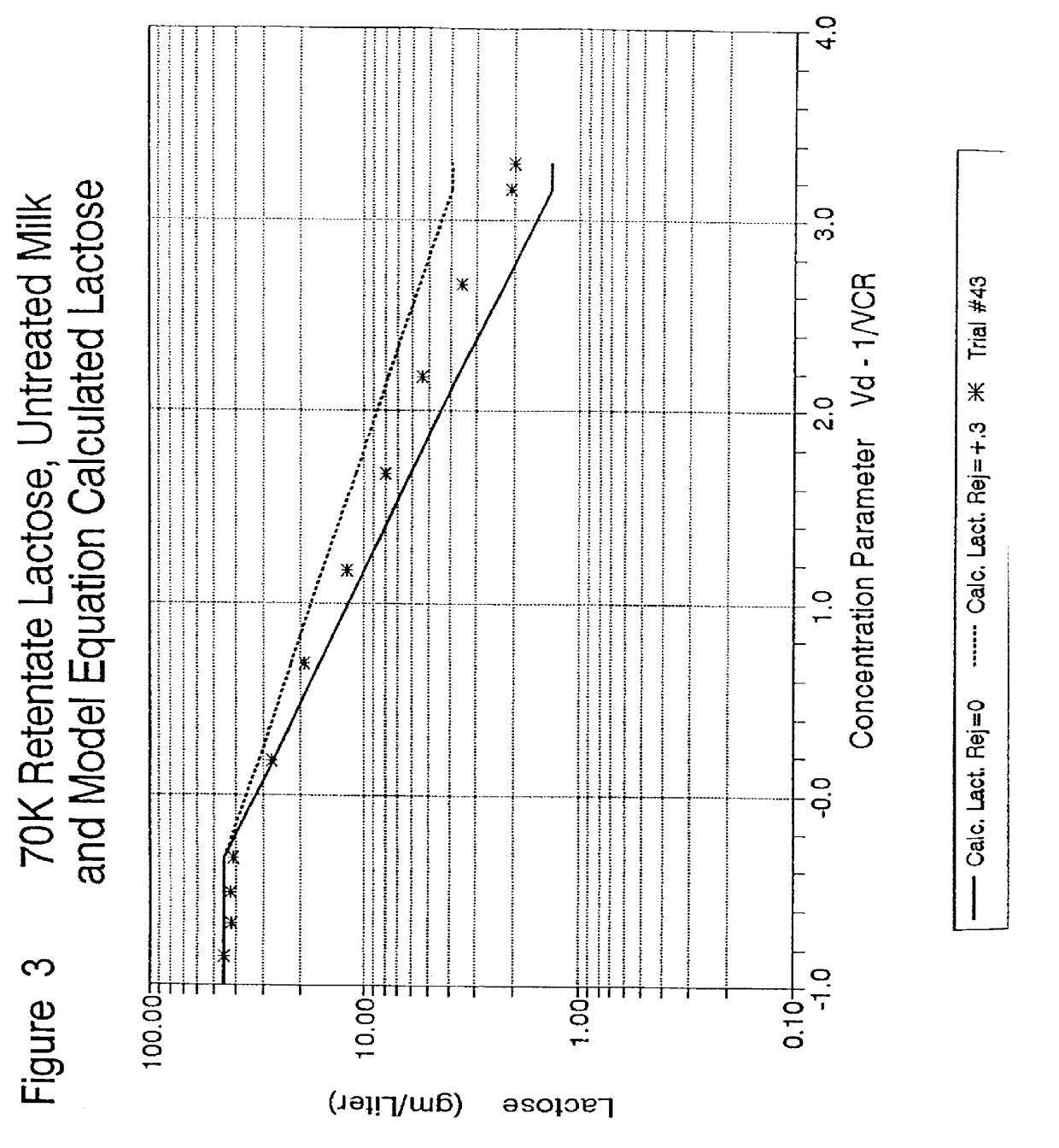

Membrane filtered milk proteins varying in composition and functional attributes

InactiveUS6139901AEasy to separateReduce opacityMilk preparationProtein composition from milkUltrafiltrationFlavor

A process is described for treating an approximately neutral fluid milk composition, including milk protein concentrate and milk plus added whey, by selecting an alkali, adjusting the pH upward, heating, cooling, selecting an acid, and adjusting the pH down before ultrafiltering and, in a more preferred process, thereafter diafiltering the treated composition. Selection of the appropriate alkali, pH values, temperatures, acid, and membrane filter porosity results in improved yields of retentate proteins having selected compositions with improved utility, including a more palatable flavor, a brod range of solution viscosities, an increase in the solubility of the dried retentates in cold water to nearly 100%, and an increase in the calcium content of the membrane filtered retentate by about 50% compared to a similar retentate from standard milk. Appropriate selection of processing conditions can result in at least one filter permeate with a protein composition enriched in alpha lactalbumin, a protein that is highly beneficial for human nutrition.

Owner:NEW ZEALAND DAIRY BOARD

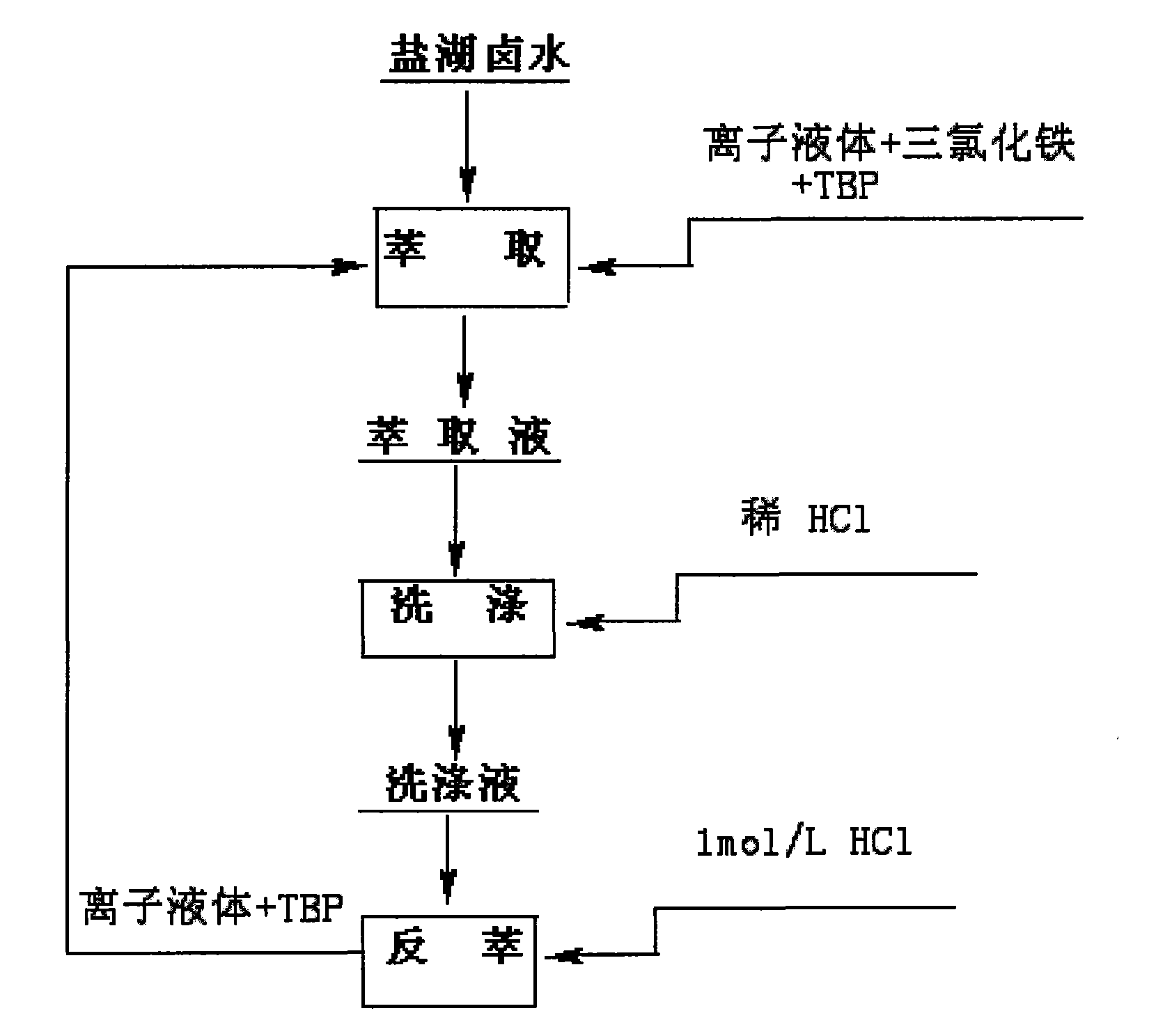

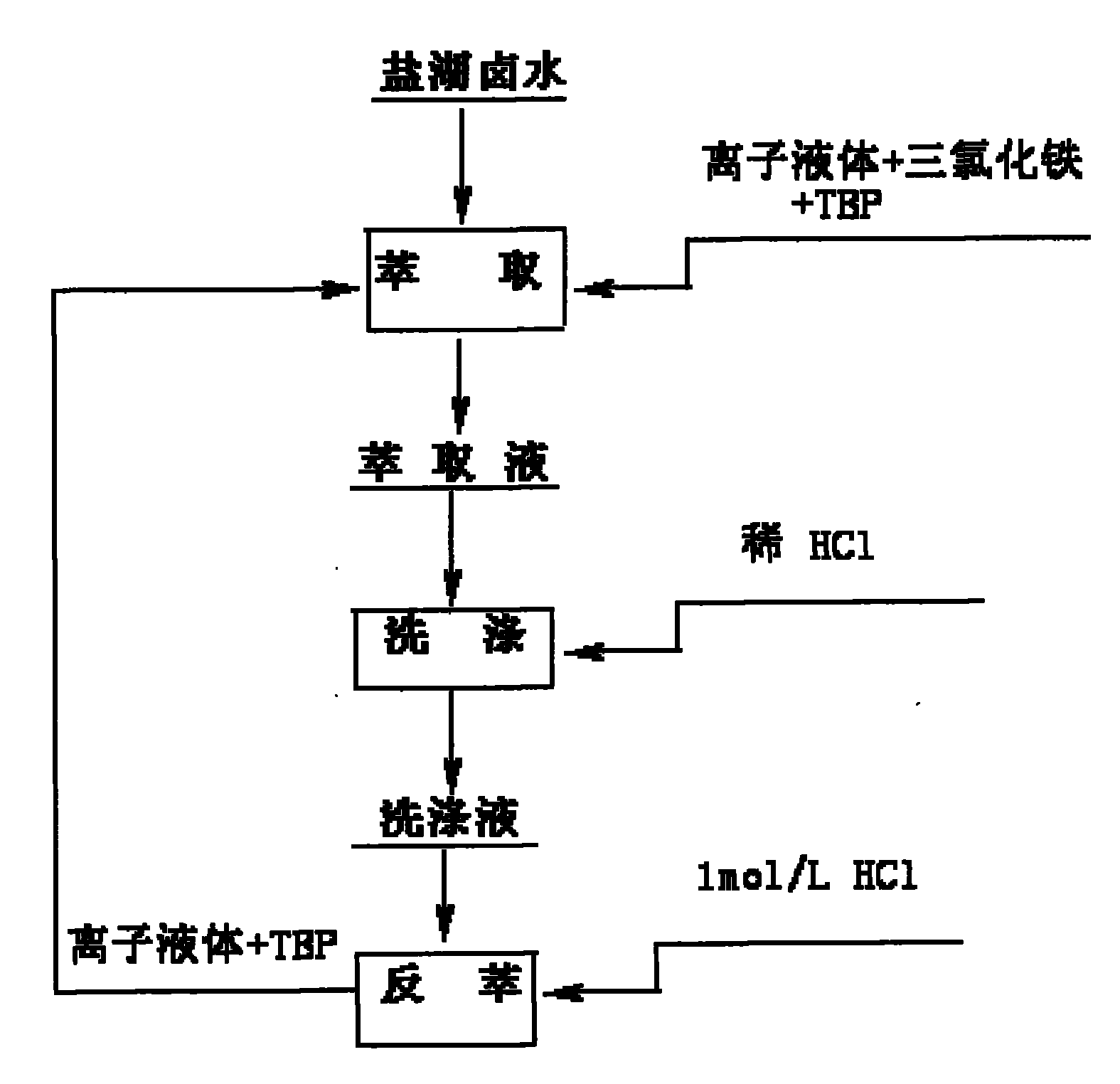

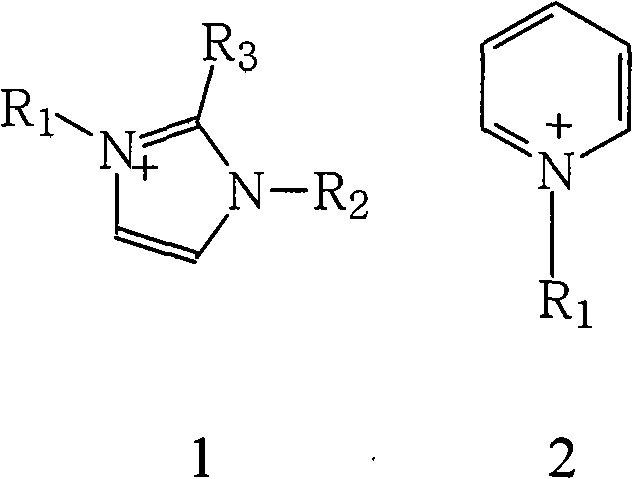

Method for extracting lithium from salt lake brine

InactiveCN101767804AImplement selective extractionHigh extraction rateLithium compoundsHigh concentrationOrganic solvent

The invention provides a method for extracting lithium from salt lake brine, comprising the following steps: 1) mixing organic phase composed of salt lake brine, extracting agent and extracting medium with synergist, extracting the mixture and collecting the organic phase; 2) mixing the organic phase in step 1 with hydrochloric acid solution and carrying out back-extraction on the mixture, collecting aqueous phase to obtain aqueous solution of Lithium-ion; the step is characterized in that the extracting medium is hydrophobic ionic liquid. Compared with the traditional method for extracting lithium from salt lake brine with solvent gasoline as the medium, the method of the invention employs green and environmental-friendly ionic liquid as the medium; as a result, lithium salt extraction efficiency is improved, back-extraction acidity is lowered, what is more important is that environmental pollution and equipment corrosion due to use of a great deal of volatile organic solvent and high-concentration hydrochloric acid are avoided. In addition, the organic phase of the invention features fine cyclic applicability, thus greatly reducing production cost for extracting lithium from the salt lake brine.

Owner:JIANGNAN UNIV

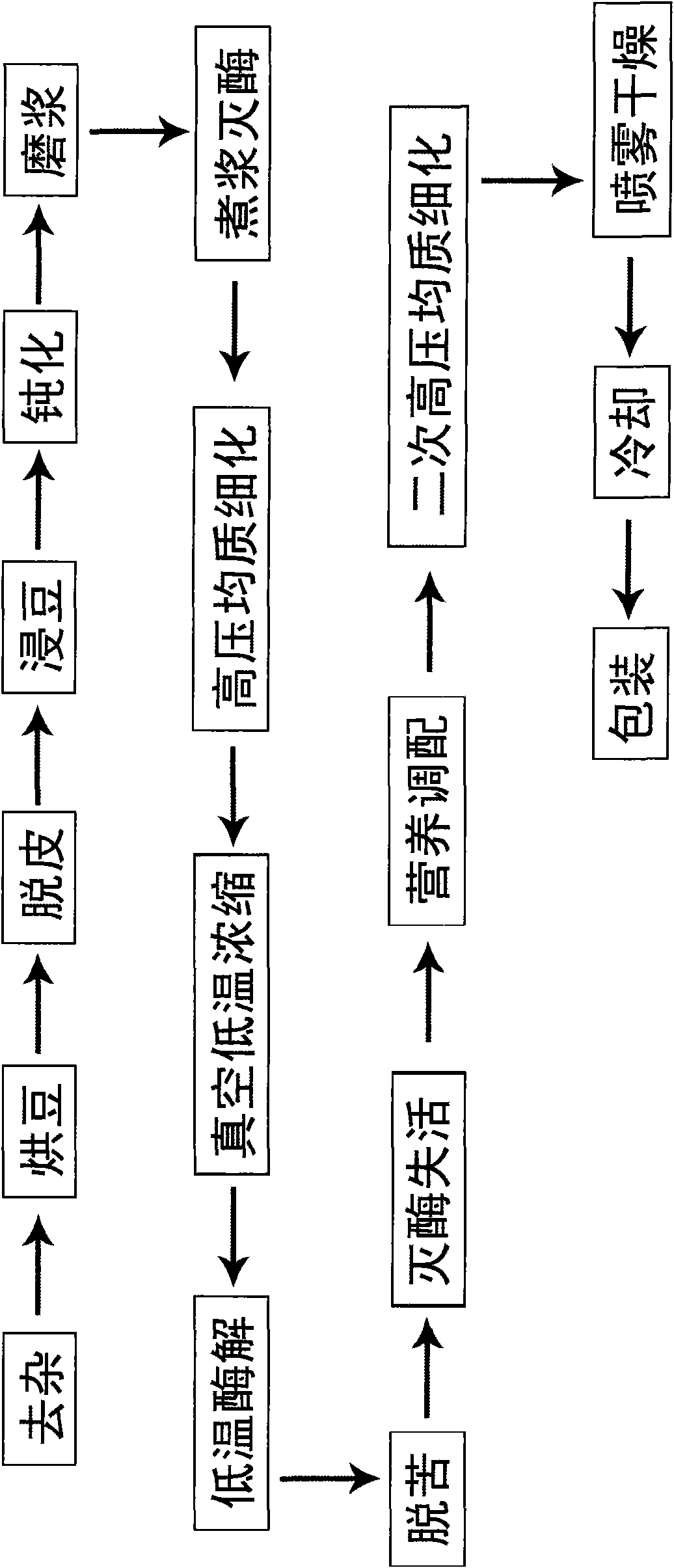

Dual-protein based polypeptide soy-bean milk powder and preparation method thereof

The invention discloses a dual-protein based polypeptide soy-bean milk powder and a preparation method thereof. The dual-protein based polypeptide soy-bean milk powder adopts the following raw materials by weight percentage: 30-45 percent of soy-bean milk containing soy-bean polypeptide (calculated by dry weight), 20-30 percent of milk powder, 15-30 percent of malt syrup, 10-20 percent of white sugar, 3-10 percent of edible soy-bean oil, 2-5 percent of soy-bean cellulose, 1-4 percent of soy-bean oligosaccharides and 1 percent of edible calcium carbonate. The dual-protein based polypeptide soy-bean milk powder is prepared by the following steps of: using the raw materials mentioned above: (1) preparing the soy-bean milk containing soy-bean polypeptide, (2) mixing nutrients, (3) high-pressure homogenizing and refining, and (4) spraying and drying. The invention takes soy-bean as main raw material, therefore, the cost is low; soy-bean not only provides soy-bean protein and parts of soy-bean protein is turned into soy-bean polypeptide by enzymolysis, therefore, the source of raw materials is rich. The dual-protein based polypeptide soy-bean milk powder has abundant nutrients and smooth, aromatic and pure mouth feel and no bean tastes basically.

Owner:BLACK COW FOOD

Calcium treatment process of rod wire alloy steel

The invention belongs to the technical field of metallurgy of iron and steel, and particularly relates to a calcium treatment process of rod wire alloy steel. The invention adopts a converter smelting-LF (ladle furnace) refining-RH refining-square billet continuous casting production technique. The calcium treatment process is implemented in a way that: after the LF refining finishes, feeding an iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.08-0.16%; after the soft blow, carrying out RH treatment; after the RH treatment finishes, carrying out calcium carbonate treatment, and feeding the iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.04-0.08%; and carrying out soft blow, and casting. When the treatment process is used for producing high-quality steel, the inclusion level can not deteriorate, the castability of the molten steel is good, the number of continuous casting furnaces is increased, the calcium content of the molten steel is low but does not influence the casting performance, and the treatment process plastifies the inclusions and improves the mechanical properties of steel.

Owner:NORTHEASTERN UNIV +1

ER70S-6 hot rolled wire rod and preparation method thereof

ActiveCN104498818AHigh in calciumLower calcium levelsProcess efficiency improvementWire rodThermal insulation

The invention relates to the technical field of steel and iron materials and in particular relates to an ER70S-6 hot rolled wire rod and a preparation method thereof. In the process steps, deoxidation treatment is performed on the liquid steel by use of a non-calcium alloy material to avoid the increase of the calcium content in the steel, and furthermore, splashing in the process of welding is avoided. The carbon content in the steel is reduced so that the strength of the wire rod can be reduced; the percentage of area reduction and the percentage elongation of the wire rod are increased, in other words, the plasticity of the wire rod is improved, and consequently, the wire rod can be drawn into a welding wire directly without annealing and the production cost of a welding wire factory is reduced; besides, in the preparation process, the quality of the ER70S-6 hot rolled wire rod is improved by controlling the contents of various elements, such as carbon, silicon and magnesium, so that the welding property of the welding wire is improved; in the cooling process of rolling, draught fans on an air cooling line are all turned off and thermal insulation covers are all closed so that the highest tensile strength of the wire rod does not exceed 550MPa and the plasticity of the wire rod is good.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

Method for strongly leaching laterite-nickel ore at normal pressure by using sulphuric acid

InactiveCN103146919AImprove leaching rateHighly corrosiveProcess efficiency improvementThermal insulationEmission standard

The invention relates to a method for strongly leaching laterite-nickel ore at normal pressure by using sulphuric acid, which comprises the following steps of: adding laterite-nickel ore into leacheate, mixing and ball-milling to be less than or equal to 100 mesh, adding concentrated sulphuric acid according to the liquid-solid ratio of (4-9):1, increasing the temperature to 150-160 DEG C, maintaining reaction for 20-60 minutes, decreasing the temperature to 80-100 DEG C, filter pressing, and pressing filtrate in a thermal insulation storage tank; adding leacheate, the volume of which is the same to that of a filter cake, to carry out pressure washing and filter pressing, obtaining filtrate and the filter cake again, also pressing the filtrate in the thermal insulation storage tank, discharging the filter cake, mixing and washing by using hot water so that crystal substances are thoroughly dissolved, and filtering to obtain the filtrate and the filter cake; and purifying the filtrate and removing impurities from the filtrate, continuously carrying out pressure washing by using clean water through the filter cake in a counter-current manner, and continuously detecting the pH value of pressure washing liquid until leached residues achieve emission standard. According to the invention, the leaching efficiency of nickel-cobalt can be increased by above 99wt%; most of all metallic elements which can be dissolved by sulphuric acid can be leached; silica gel does not exist in the leaching process; and the filtering performance of the leached residues is good.

Owner:广西冶金研究院有限公司

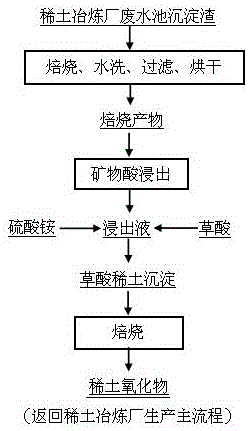

Method for extracting rare earth from precipitation sludge of rare earth wastewater pool

ActiveCN106636689ASimple processEasy to operateProcess efficiency improvementSolid phasesAmmonium sulfate

The invention discloses a method for recovering rare earth from precipitation sludge of a rare earth wastewater pool, comprising the main steps: firstly, preroasting the precipitation sludge of the rare earth wastewater pool, then leaching the roasted product with mineral acid to obtain a leach solution containing rare earth, and sequentially adding ammonium sulfate and oxalic acid to the leach solution so the rare earth is separated from soluble impurities in a manner of solid phase precipitation. The method has a simple process, convenient operation and low cost, solves the problem of difficult complete separation in a condition of coexistence of rare earth and calcium in a solution, can efficiently recover the rare earth in the precipitation sludge of the rare earth wastewater pool, and realizes separation of rare earth from calcium, aluminum and iron; the recovery rate of rare earth reaches above 99%; and the recovered rare earth oxide can be returned to a production main flow of a rare earth smeltery.

Owner:JIANGXI UNIV OF SCI & TECH

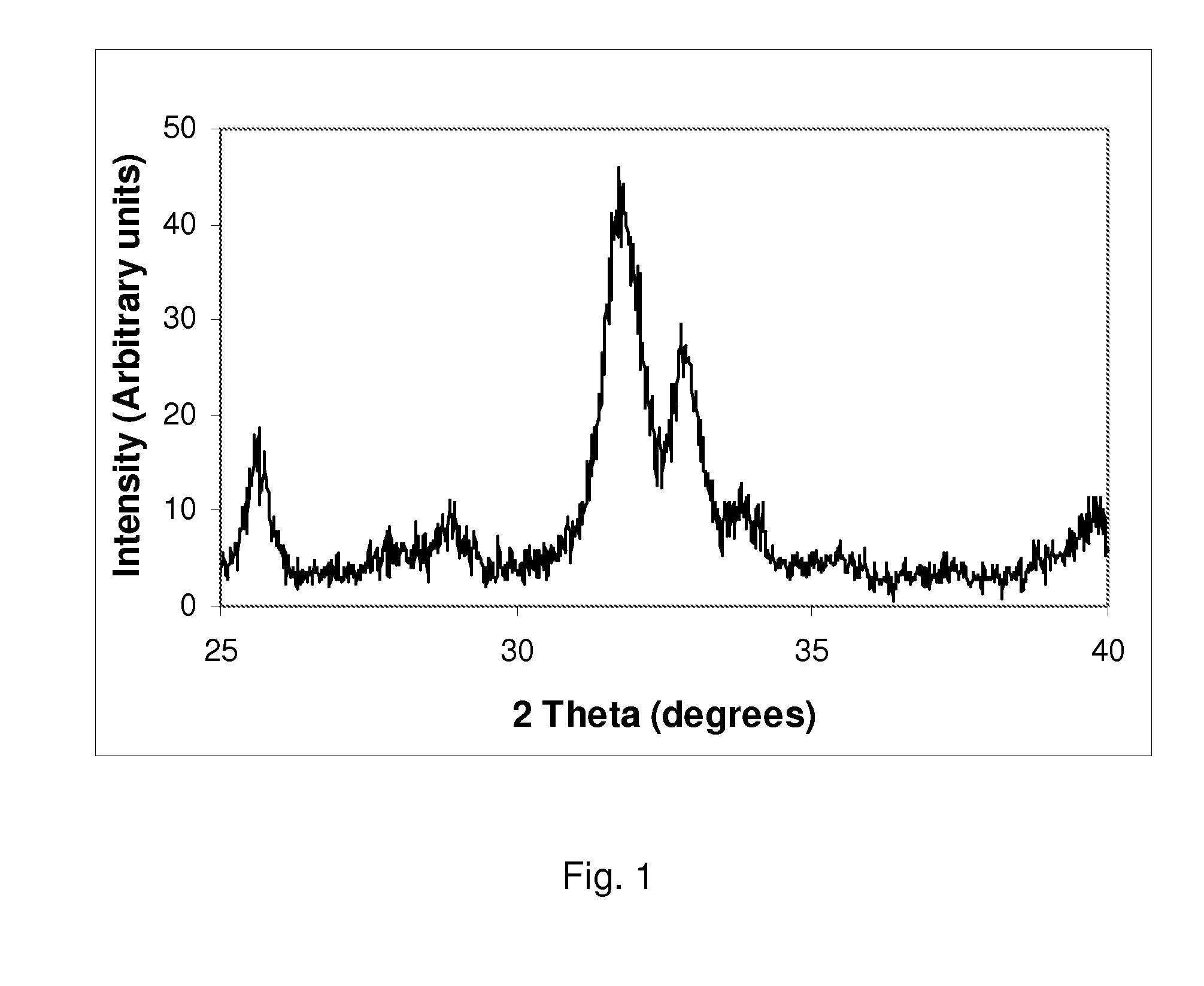

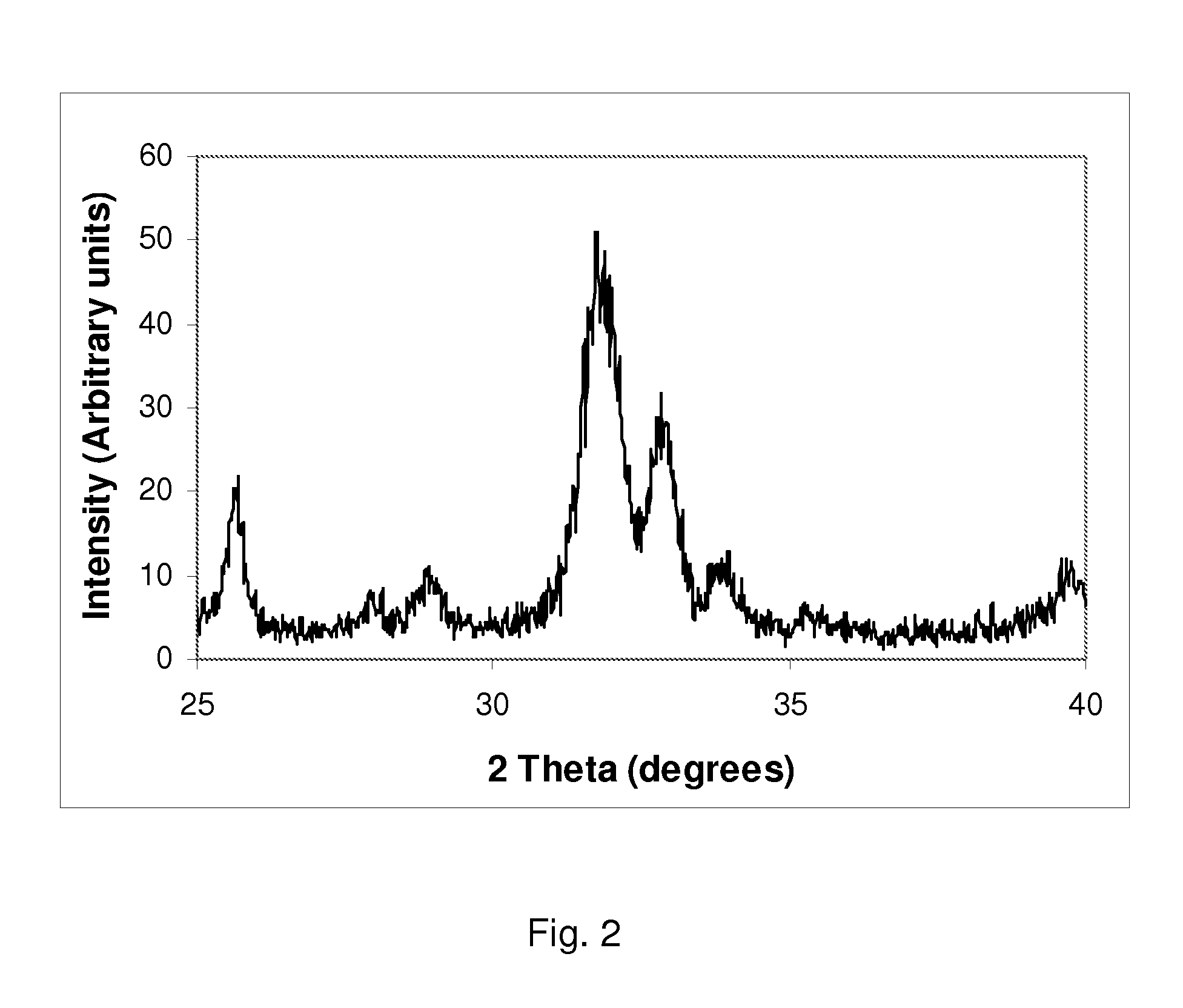

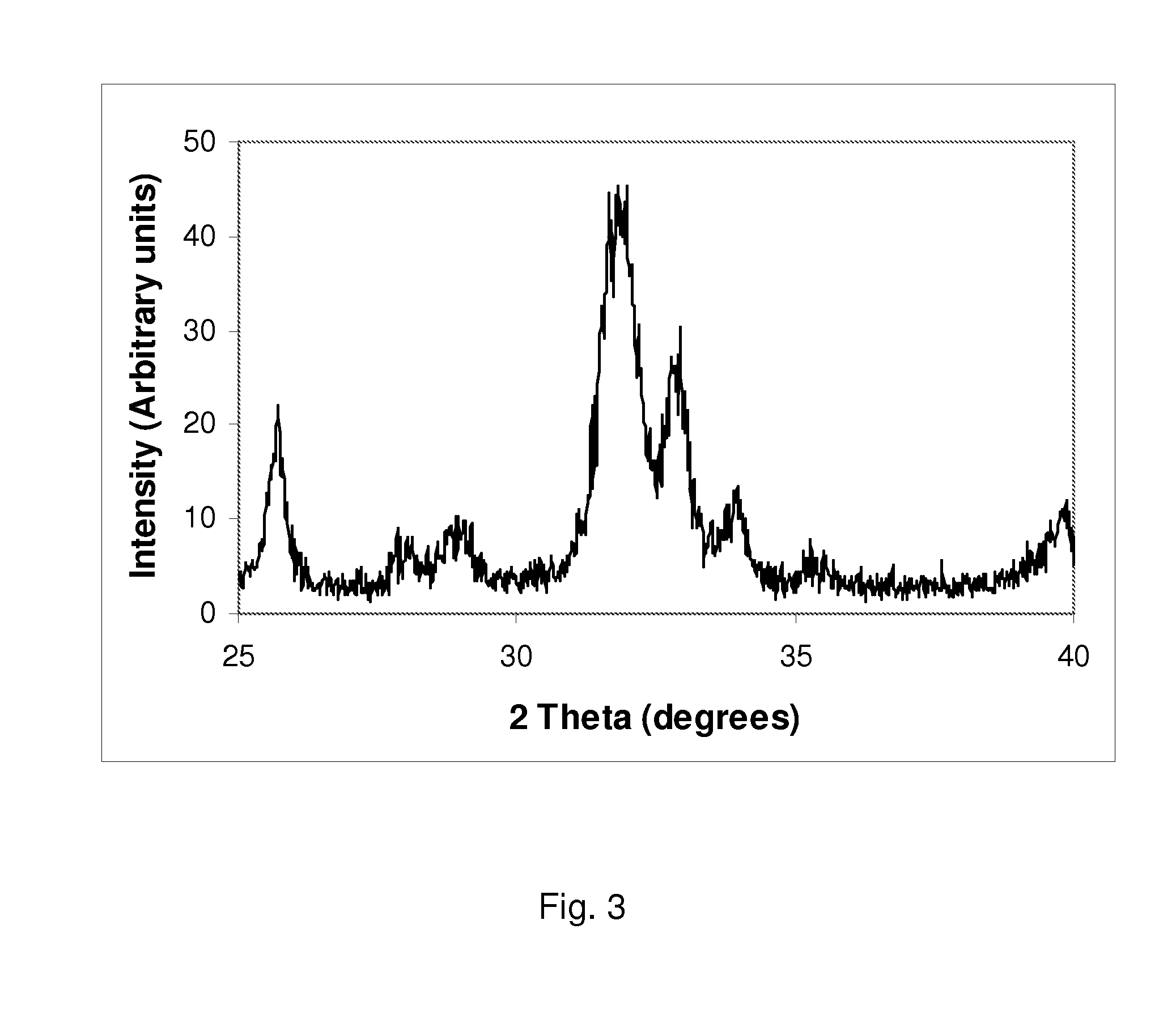

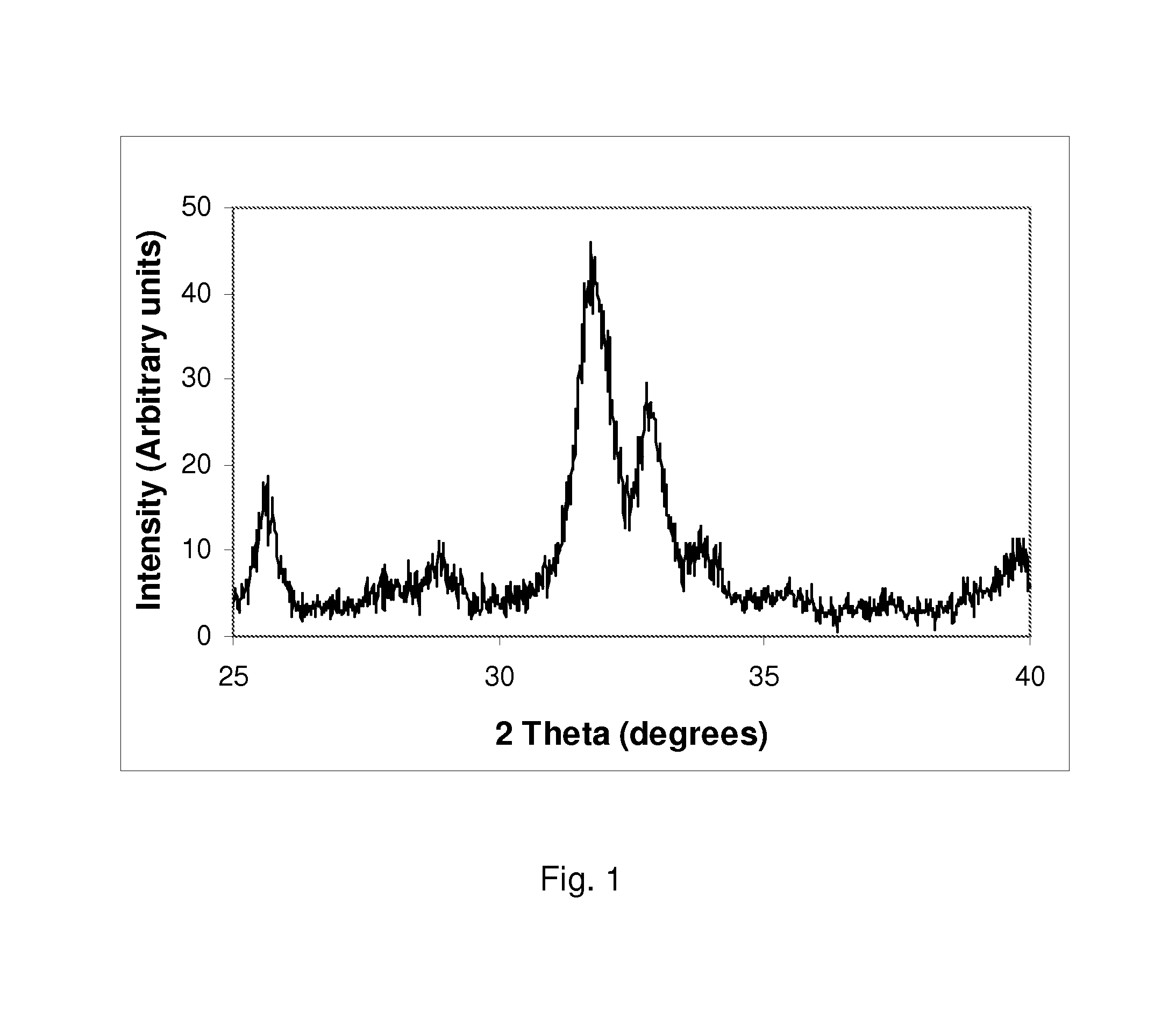

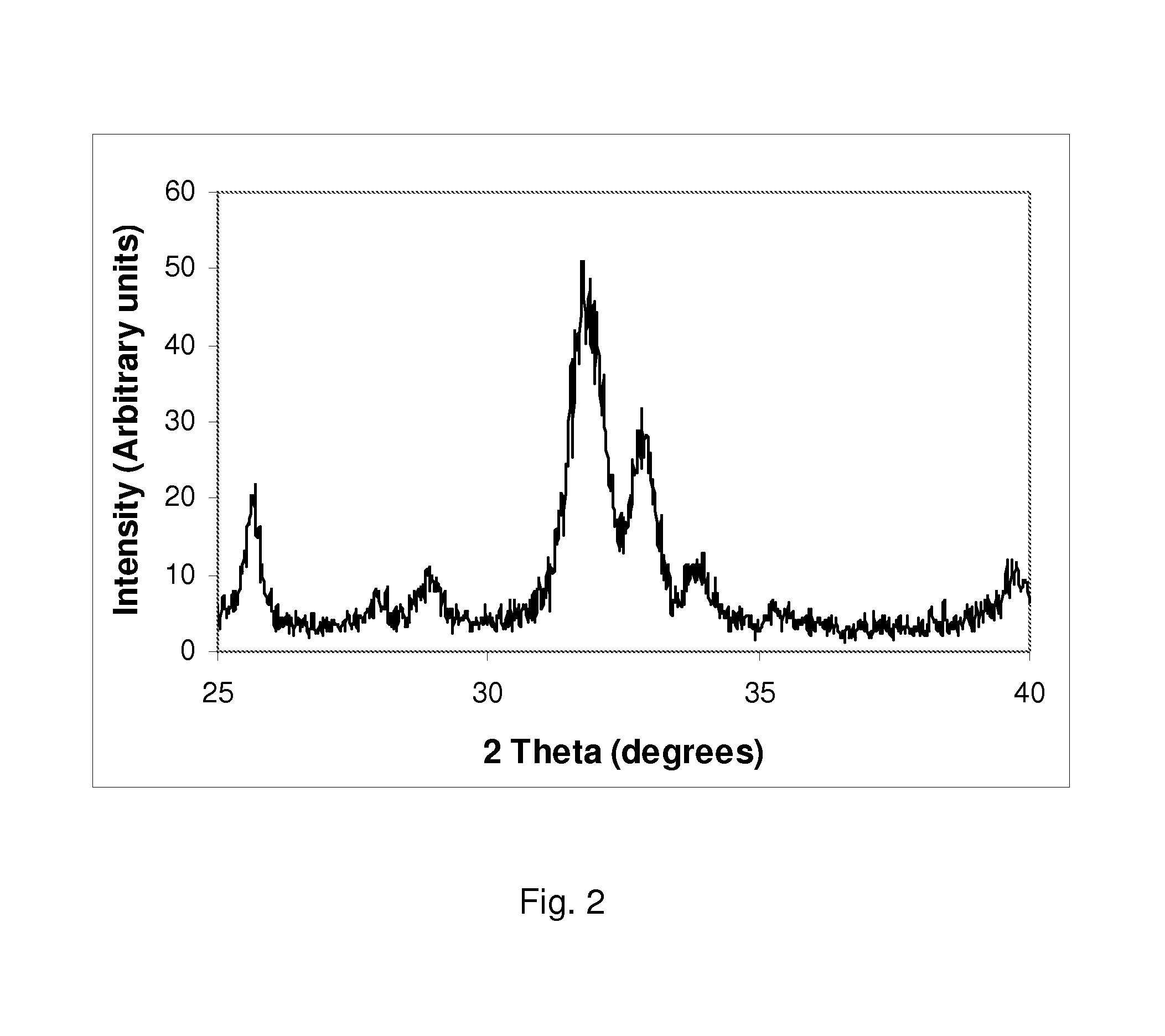

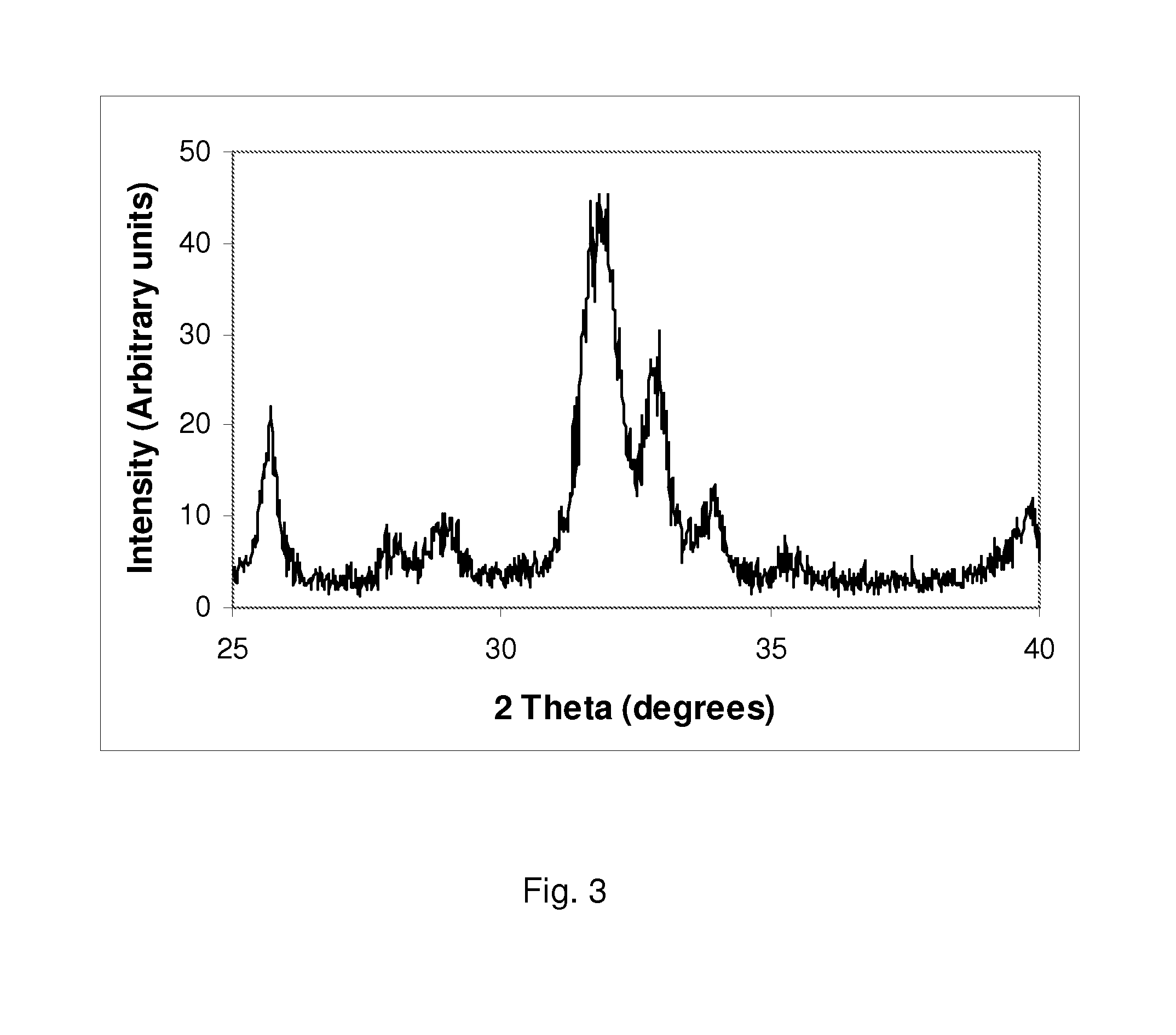

Silicate-substituted hydroxyapatite

ActiveUS20100173009A1Ease of mass productionImprove the level ofBiocideImpression capsCalcium biphosphateSolubility

An inorganic silicate-substituted calcium phosphate hydroxyapatite, useful as a biomaterial, has a Ca / P molar ratio in the range 2.05 to 2.55 and a Ca / (P+Si) molar ratio less than 1.66. The hydroxyapatite can be substantially free of carbonate ions. The material has relatively high solubility and is able to release silicon into solution.

Owner:SIRAKOSS

Flotation calcium-removing agent and method for magnesite

InactiveCN106345616ALower calcium levelsIncrease decalcification rateFlotationSodium silicateChemistry

The invention discloses a flotation calcium-removing agent and method for magnesite. Hydrochloric acid, sodium phosphate, dodecylamine, sodium hydroxide, sodium silicate, sodium hexametaphosphate, oleic acid and FZ-8 are taken as flotation calcium-removing agents, and different scientific and reasonable agent formula systems are adopted at different flotation stages, so that calcium content of the magnesite can be lowered effectively; meanwhile, a process flow of combining reverse flotation and positive flotation and adding flotation agents with a reasonable formula segmentally is adopted, so that the calcium content of the magnesite can be lowered effectively; as proved by detection, the MgO content of concentrated magnesite obtained by the flotation calcium-removing method is over 99 percent, the total impurity content is lower than 1.0 percent, and the CaO content is lower than 0.80 percent. By adopting the flotation calcium-removing agent and method, the calcium removal rate can be increased effectively, and the quality of the magnesite is improved; moreover, the method is easy and convenient to operate, is simple in process, has contribution to popularization, and has a considerable application prospect.

Owner:肃北镁弘科技有限公司

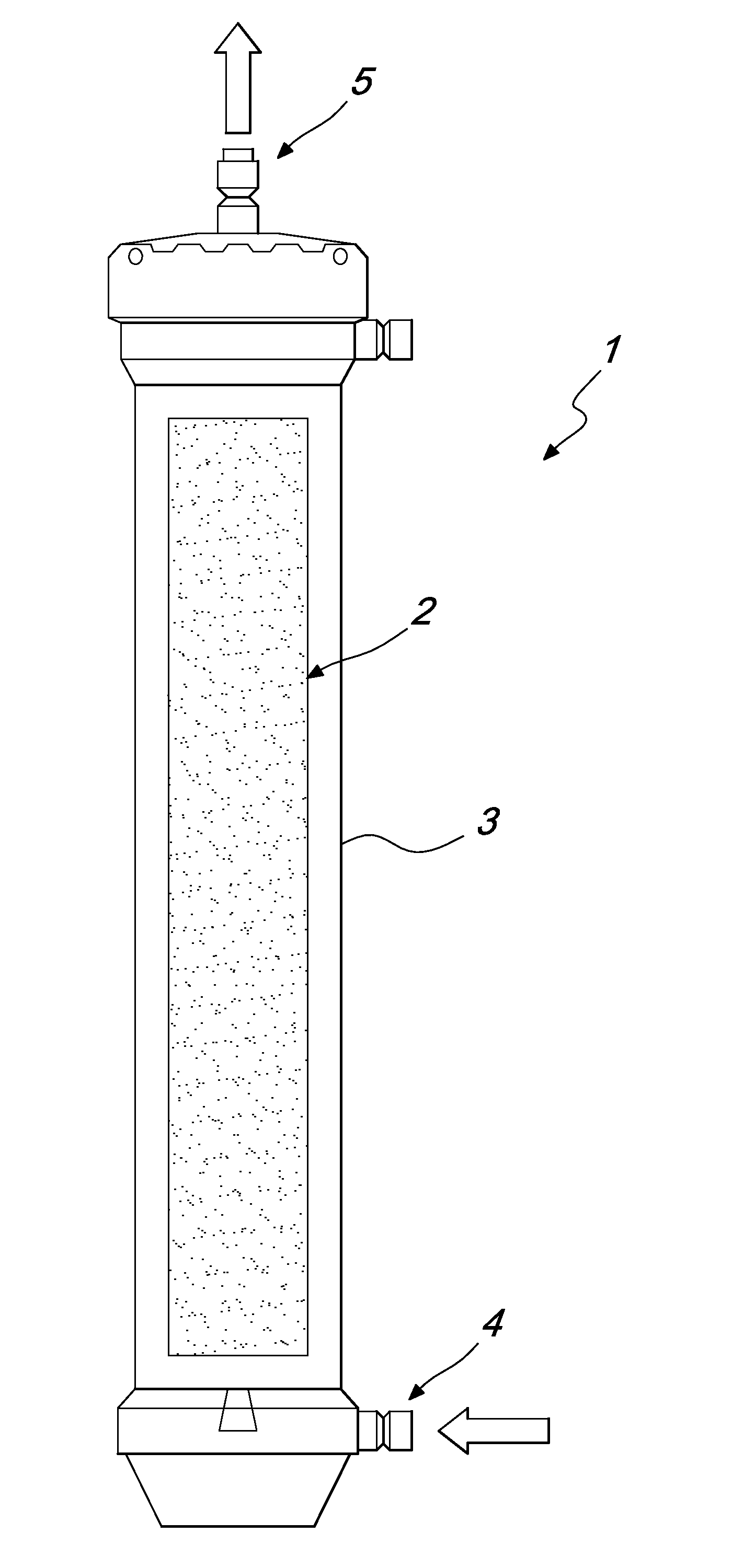

Device for reducing the content of polluting and/or unwanted substances, particularly in water and other fluids

InactiveUS20140224721A1Reduce contentAvoid dischargeScale removal and water softeningLoose filtering material filtersHazardous substanceLyase

Owner:ARCHIMEDE R&D

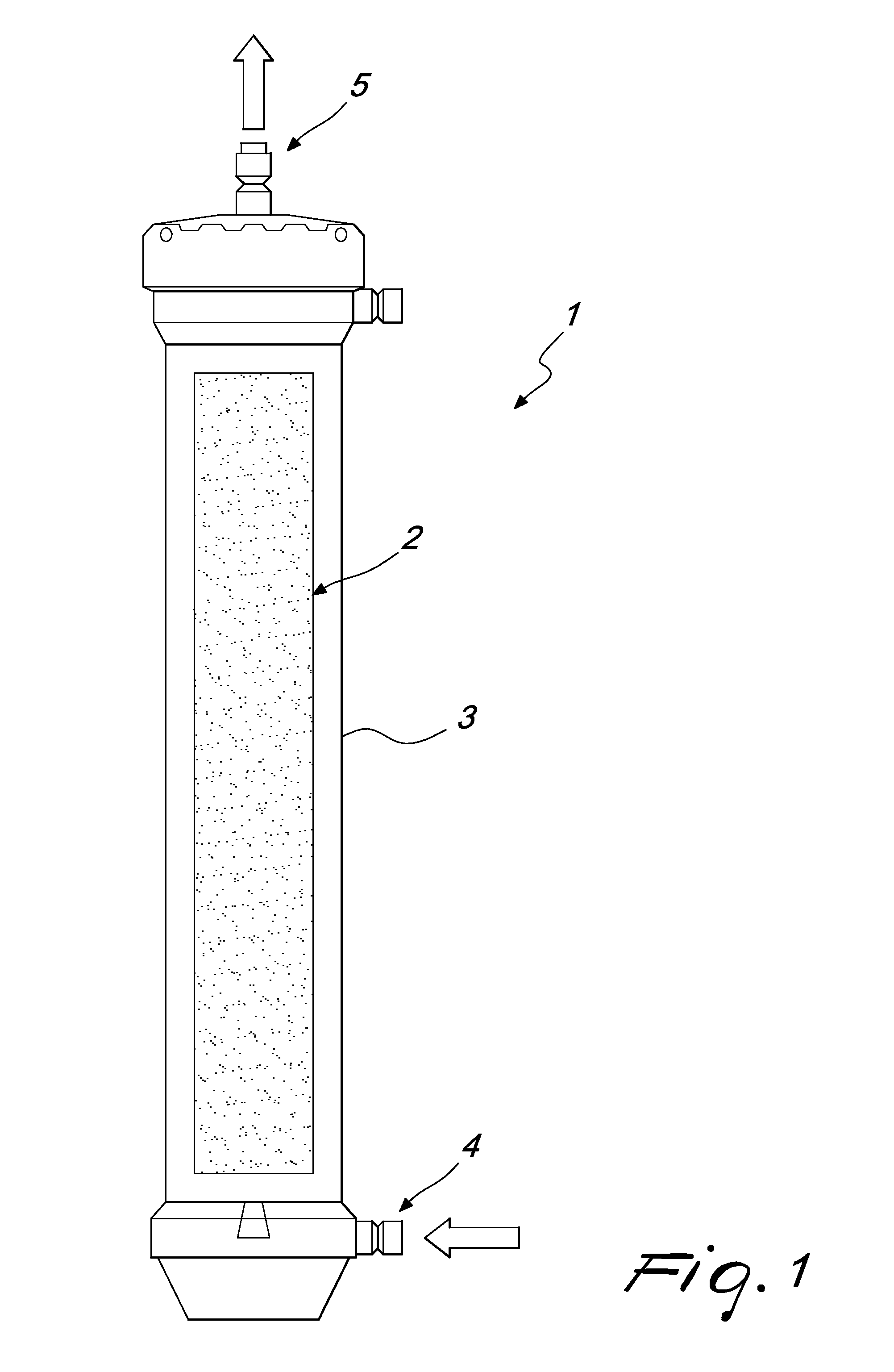

Novel calcium-supplementing candy and preparation method thereof

InactiveCN106720883APromote absorptionFit for consumptionConfectionerySweetmeatsAlcohol sugarsMethyl cellulose

The invention provides a novel calcium-supplementing candy and a preparation method thereof. The novel calcium-supplementing candy is prepared from the following components in parts by weight: 330-410 parts of milk mineral salt, 2.5-4 parts of colostrum basic protein, 320-410 parts of whole milk powder, 8-10 parts of mushroom powder, 140-180 parts of sugar alcohol, 5-7 parts of magnesium stearate and 1.5-2 parts of hydroxypropyl methyl cellulose. The novel calcium-supplementing candy provided by the invention adopts high-quality calcium source, is high in calcium content, is easily absorbed by human body, is simple in preparation process, tastes nice and is a calcium-supplementing healthcare food high in nutrition value.

Owner:南京宏客泰贸易有限公司

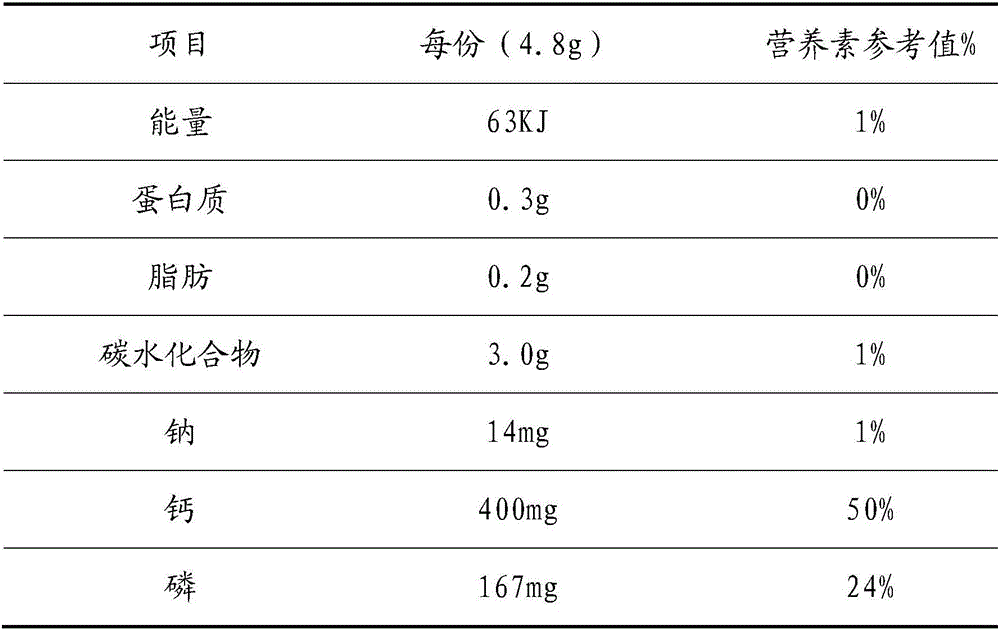

Lubricant system for cold forming, process and composition therefor

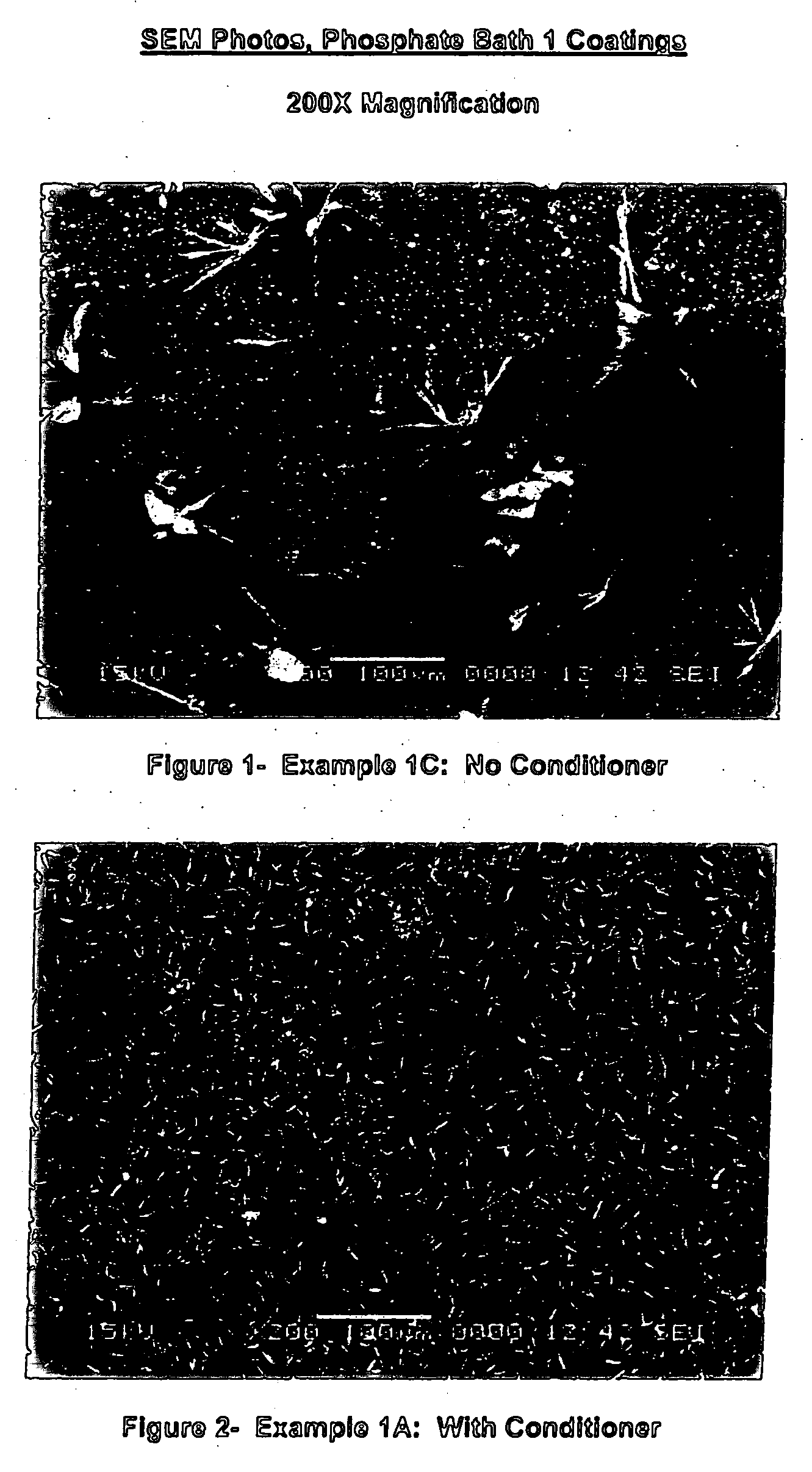

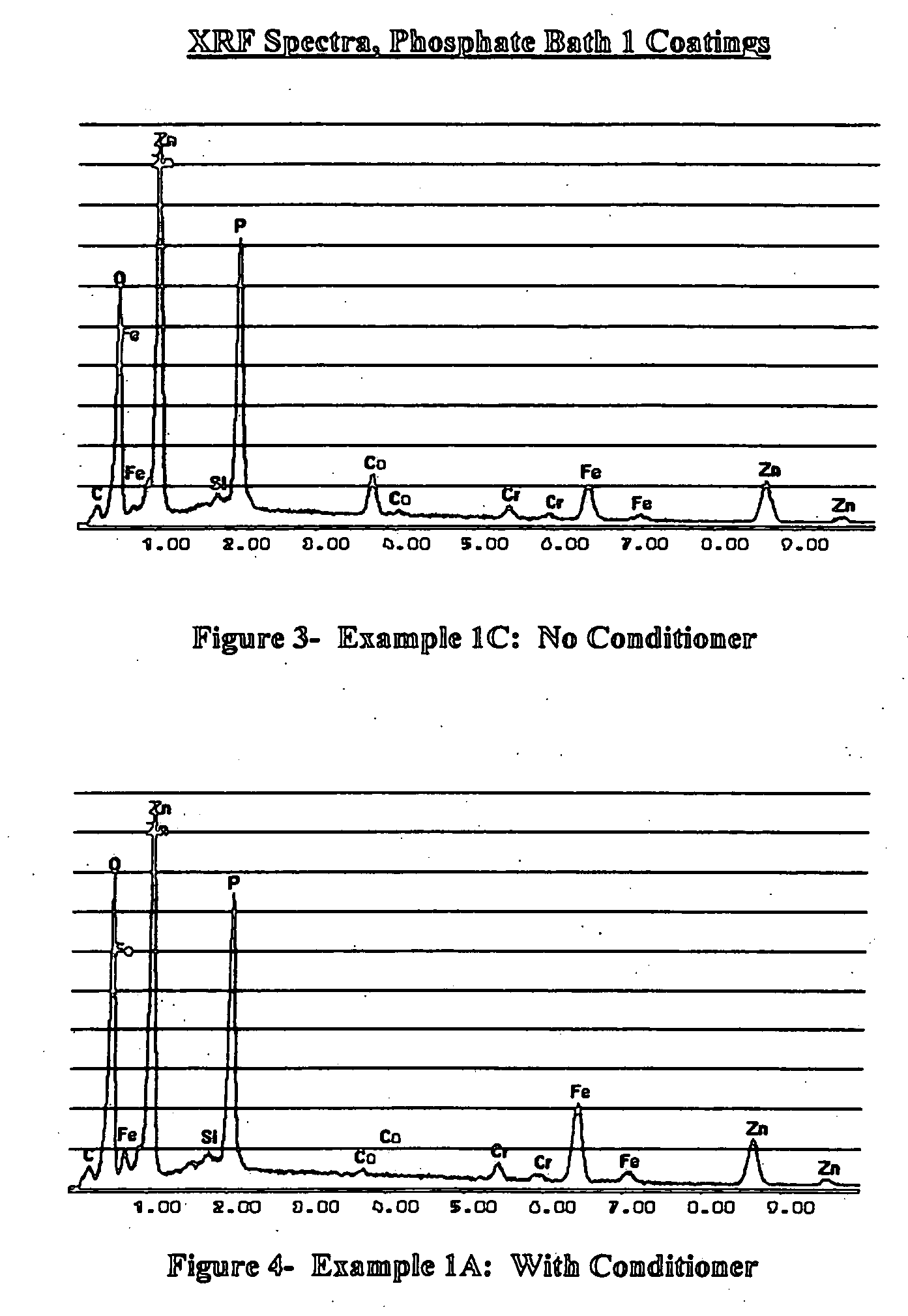

InactiveUS20060060265A1Solution to short lifeImprove adhesionMetallic material coating processesAdditivesHydroxylamineCold formed

The invention is directed to a combination of a conditioner bath and a calcium modified zinc phosphating solution optionally containing hydroxylamine which provide an improved phosphate coating on the surface of ferrous metal articles. In a preferred embodiment, the treatment process further comprises coating the workpiece with a second lubricant. The three treatments work together to provide finer grained phosphate coatings, longer life of the second lubricant bath and improved adherence of the second lubricant, as compared to a similar phosphating bath that is used alone or with a similar second lubricant.

Owner:HENKEL KGAA

Compound Chinese medicine preparation of breviscapine

InactiveCN101015592AHigh degree of automationQuality controllableOrganic active ingredientsPill deliveryConvalescenceOrally disintegrating tablet

This invention relates to a Breviscapine compound Chinese medicinal preparation for treating cardio-cerebrovascular diseases. The preparation is prepared from Breviscapine, ginkgo leaf extract, Ginesenoside, schisandra propinqua extract and medicinal auxiliary materials by making into oral preparation including orally disintegrating tablet, dispersible tablet, dripping pill, soft capsule, hard gelatin capsule, and pelletized granule. Product has effects in promoting flow of qi and blood circulation, dissipating blood stasis, and smoothing collaterals, and health protection and theraupetic effect for treating cardio-cerebrovascular disease such as convalescence of apoplexy, coronary heart disease, and angina pectoris, and aneuria and senile dementia.

Owner:KPC PHARM INC

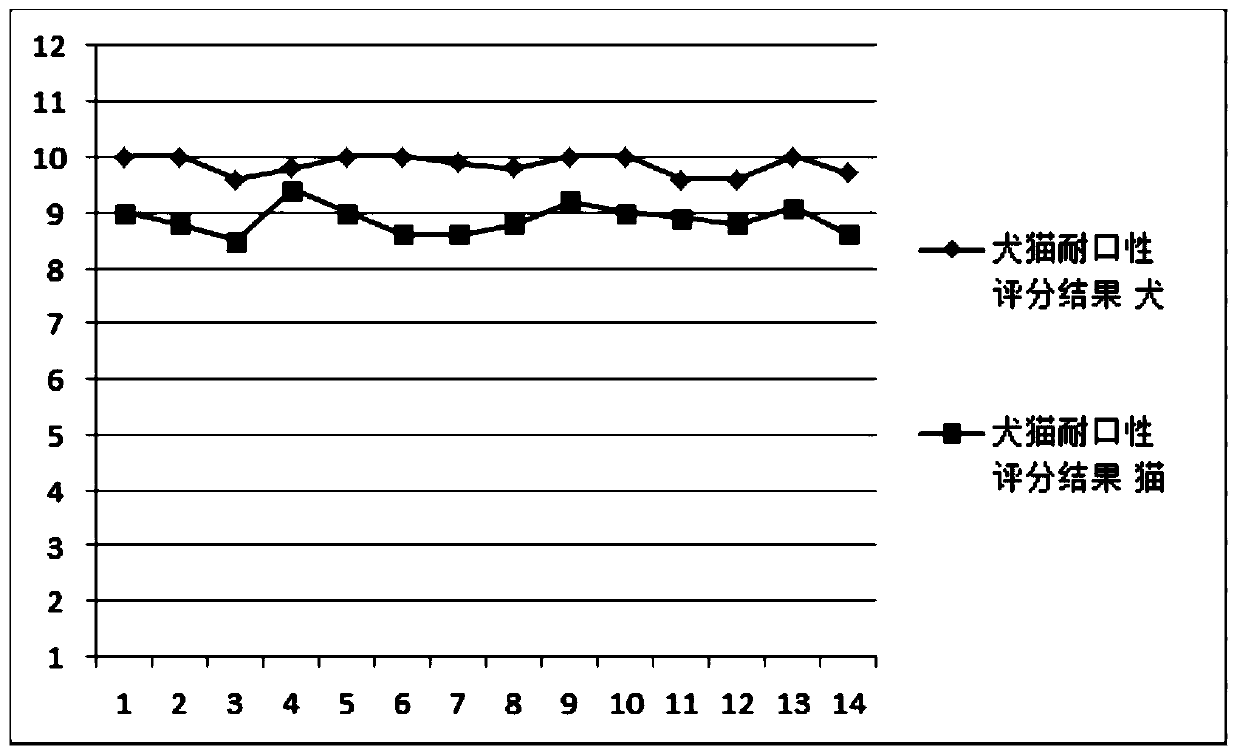

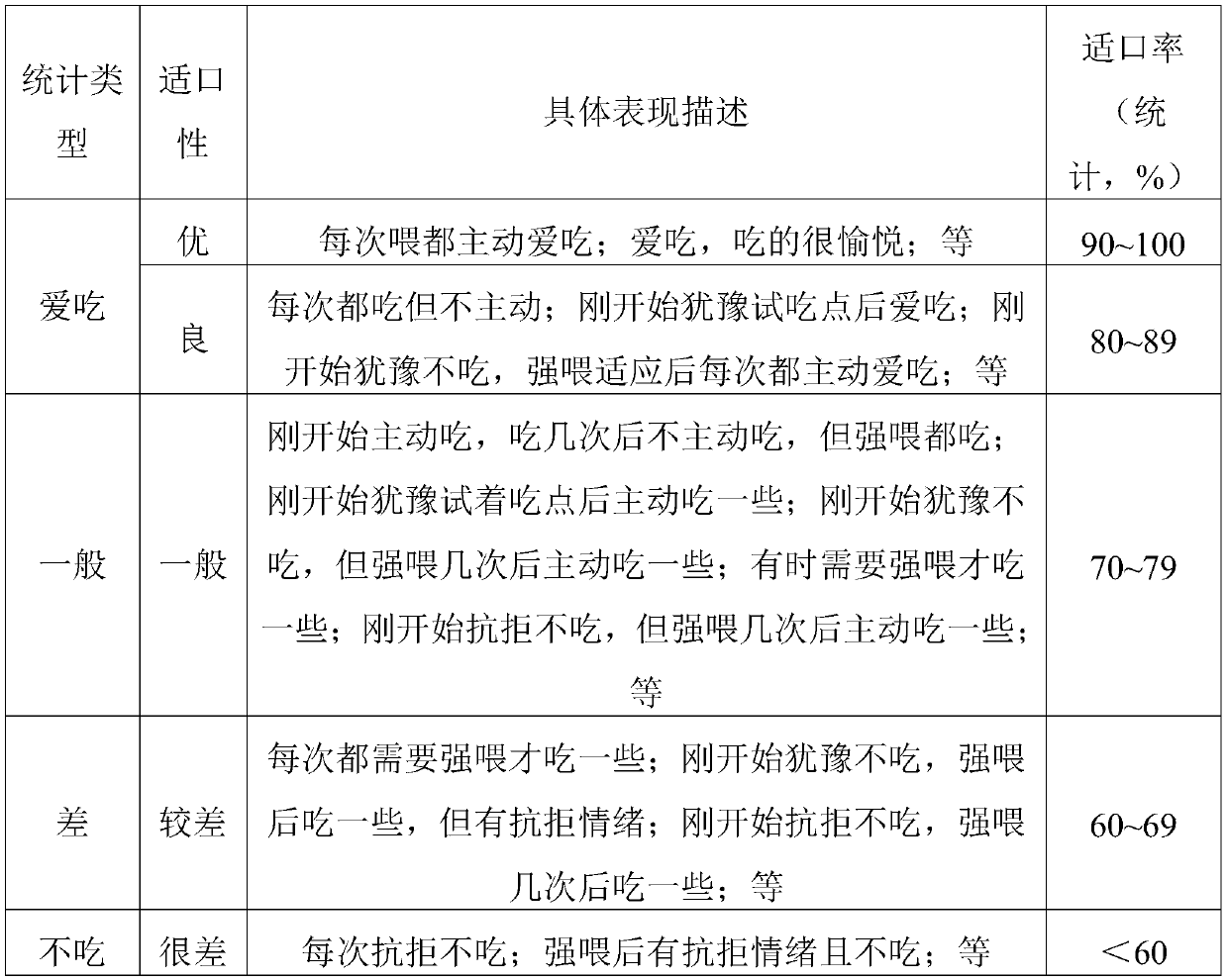

Composition, preparation method and application of composition in preparation of medicine, health care product and food for treating pet joint diseases

PendingCN110859247APromote healingEasy to synthesizeAlgae medical ingredientsSulfur/selenium/tellurium active ingredientsBiotechnologyDisease

The embodiment of the invention discloses a composition, a preparation method and an application of the composition in preparation of medicines, health-care products and foods for treating pet joint diseases. The composition comprises glucosamine, chondroitin sulfate, dimethyl sulfone, green mussels, haematococcus pluvialis, frankincense, curcumin, coix seeds and rhizoma smilacis glabrae. The composition fundamentally inhibits and relieves arthritis from the aspects of eliminating free radicals, neutralizing free radicals, inhibiting proinflammatory cell generation and the like, supplements necessary nutrient substances for cartilage cell growth, promotes synthesis of new cartilage, and achieves the effect of treating both symptoms and root causes in combination with traditional Chinese medicine components for rapid detumescence and pain relief.

Owner:SHENZHEN REDRAY BIOTECHNOLOGY CORP LTD

Calcium remover for aluminum-silicon alloy and preparation method thereof

The invention belongs to the field of metal material, which is a calcium remover for aluminum-silicon alloy and a preparation method thereof. The calcium remover comprises aluminum and fluorine; the calcium remover is characterized by further comprising nickel, silicon, boron and carbon, the mass percentage of each element is as follows: 11.0-21.0% of the aluminum, 24.0-44.0% of the fluorine, 5.0-30.0% of the nickel, 7.0-35.0% of the silicon, 0.1-5.0% of the boron and 5.0-20.0% of the carbon. The preparation method comprises the following steps: weighing each material according to the mass percentage, 35-65% of AlF3, 20-50% of master alloy Ni-Si-B and 5-20% of carbon powder; performing rapid solidification processing of argon aerosol to the master alloy Ni-Si-B, obtaining granular master alloy Ni-Si-B; uniformly mixing the AlF3 powder, the granular Ni-Si-B powder and the carbon powder, using a briquetting machine to press the powder, and preparing into lumpish calcium remover. The calcium remover for the aluminum-silicon alloy of the invention is highly efficient and environmentally friendly, simple in preparation process, good in process stability, low in cost and the like; when the adding amount is 0.2%, the calcium content in the industrial aluminum-silicon piston alloy is reduced lower than 20 ppm, and the calcium remover for the aluminum-silicon alloy is a novel modification agent similar to eutectic Al-Si alloy.

Owner:SHANDONG UNIV

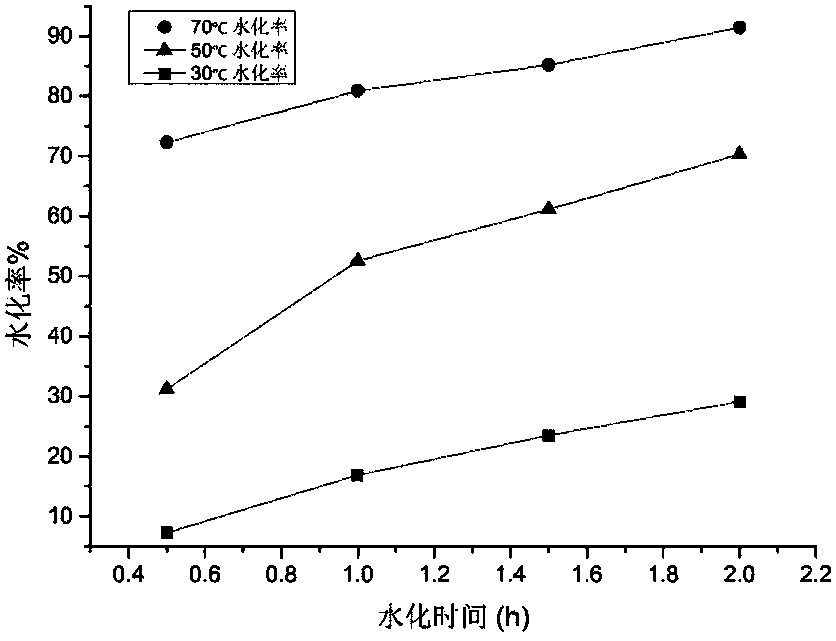

Method for preparing chromium-containing magnesia from magnesite light burning powder

InactiveCN108046620ASolve the technical problem of uneven precipitationImprove uniformityDispersityCalcium hydroxide

The invention discloses a method for preparing chromium-containing magnesia from magnesite light burning powder. The method is characterized by comprising the following steps: pretreating light burning powder at the temperature of 850 DEG C or higher to obtain pretreated light burning powder; hydrating the pretreated light burning powder with water to obtain ore pulp, adding a magnesium source tothe ore pulp, and removing calcium to obtain calcium-free ore pulp; adding a Cr source to the calcium-free ore pulp; performing chromium precipitation reaction, and performing solid-liquid separationto obtain a precursor; and sintering the precursor to obtain the chromium-containing magnesia. Through a lot of researches, inventors find that the light burning powder is preheated to the set temperature so as to be pretreated, then hydration is preformed, the magnesium source (providing Mg<2+>) is added to the ore pulp obtained by hydration, calcium hydroxide impurities are converted through theprecipitation conversion mechanism, and then, the Cr source (providing Cr<3+>) is added; and through the precipitation conversion mechanism, formed chromium hydroxide is avoided from falling and separating from the surface of a magnesium oxide source, and the uniform dispersity of the chromium hydroxide in the precursor is greatly improved, thereby obtaining the chromium-containing magnesia withexcellent performance.

Owner:CENT SOUTH UNIV

Silicate-substituted hydroxyapatite

Owner:SIRAKOSS

Inoculant products comprising bismuth and rare earths

ActiveUS20060113055A1Good grain stabilityImprove stabilityBlast furnace componentsBlast furnace detailsSilicon alloyRare earth

The invention relates to an inoculant mixture for the treatment of molten cast iron, comprising 5 to 75% by weight of a ferro-silicon alloy of type A where Si / Fe>2, containing 0.005 to 3% by weight of rare earths, 0.005 to 3% bismuth, lead and / or antimony and less than 3% calcium, with a ratio (Bi+Pb+Sb) / TR of between 0.9 and 2.2 and 25 to 95% of at least one alloy of type B, based on silicon or ferro-silicon such that Si / Fe>2, containing calcium to a level such that the total amount of calcium in the mixture is from 0.3 to 3%. The above mixtures have a good granulometric stability over time and provide an efficient inoculation of cast pieces, in particular of thin pieces.

Owner:FERROPEM SAS

Method of preparing low-calcium polymeric aluminum chloride water purifier from aluminum ash, hydrochloric acid, and optical red mud

InactiveCN109896605AFix stability issuesSolve the harmless problemWater/sewage treatment by flocculation/precipitationSlagRed mud

The invention provides a method of preparing a low-calcium polymeric aluminum chloride water purifier from aluminum ash, hydrochloric acid, and optical red mud. The preparation method comprises following steps: burning aluminum ash, calcium carbonate, and / or calcium oxide in an oxidative atmosphere; burning the obtained material, reacting the burned material with hydrochloric acid and optical redmud to prepare slurry containing polymeric aluminum chloride, adding sodium sulfate to carry out reactions; filtering the slurry, wherein the filtrate is the water purifier, washing the filter residues by water, and utilizing the obtained solid slag or stacking / burying the solid slag. A problem that when aluminum is hydrolyzed or acid-hydrolyzed, hydrogen is generated and the hydrogen is combustible and explosive is solved. A problem that when aluminum nitride is hydrolyzed, ammonia is generated and the water purified by the water purifier is polluted by ammonia nitrogen is solved. The low activity alumina, which comprises alpha-alumina, can be activated. The fluorine containing aluminum ash is stabilized and detoxicated. Moreover, a low-calcium polymeric aluminum chloride water purifierand a low-calcium polymeric ferric aluminum chloride water purifier are prepared, and the hardness of the processed water is barely increased, during the application process of the water purifier. Thetechnology is simple, the investment and operation cost is low, and the obtained solid slag is common solid wastes.

Owner:山东铝晖环保科技有限公司

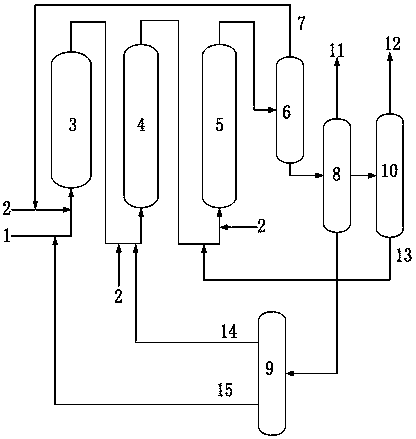

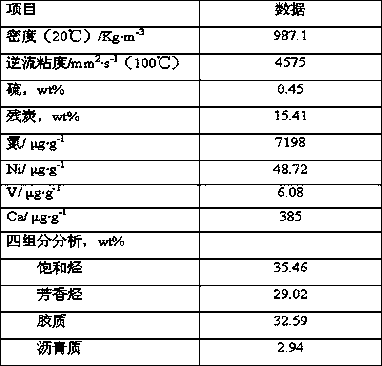

Processing method of residual oil with high calcium and nitrogen content and high viscosity

ActiveCN108102707ALow viscosityLower calcium levelsTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxChemistry

The invention discloses a processing method of residual oil with high calcium and nitrogen content and high viscosity. The method comprises steps as follows: raw oil enters a suspended bed reactor andsubjected to a reaction under the action of hydrogen and a suspended bed catalyst; obtained hydrogenated oil enters a fluidized bed reaction unit for a reaction, the fluidized bed reaction unit comprises two fluidized bed reaction zones connected in series, the two fluidized bed reaction zones comprise a first-stage fluidized bed reaction zone and a second-stage fluidized bed reaction zone, the hydrogenated oil is subjected to atmosphere-vacuum distillation and fractional distillation by a fractionating tower, and gasoline, light diesel oil, heavy diesel oil, wax oil and vacuum residual oil are obtained. According to the method, the process is simple, impurities in raw materials can be removed effectively, and the raw materials are converted into light fractions effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

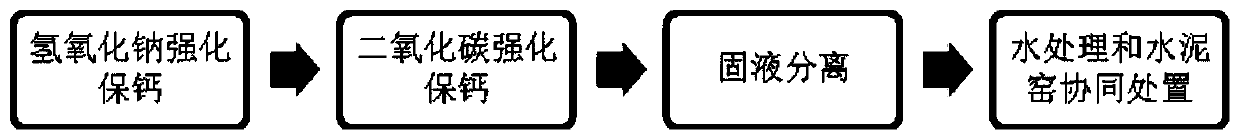

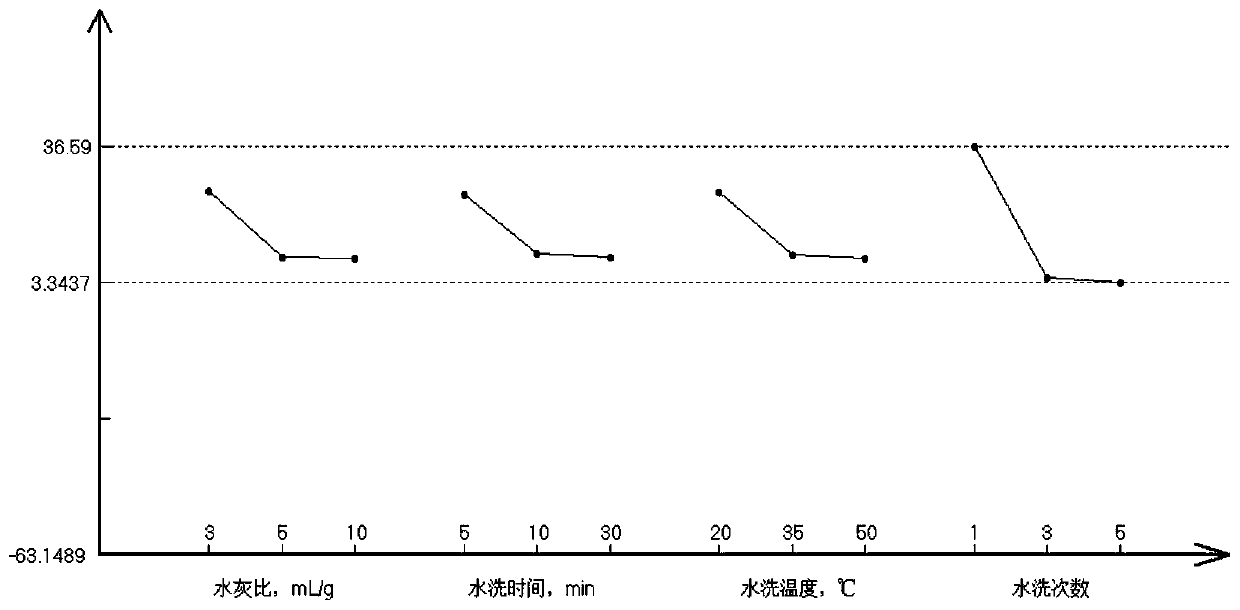

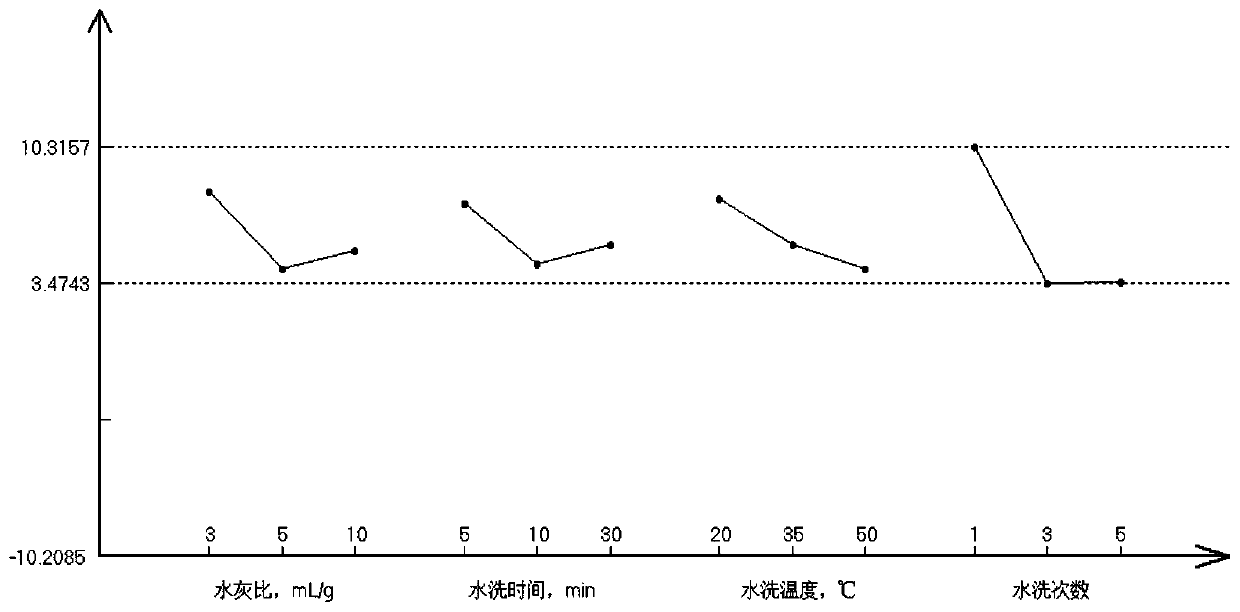

Pretreatment method for cooperatively treating fly ash by cement kiln

ActiveCN109748525APromote resource utilizationLower calcium levelsCement productionPretreatment methodPre treatment

The invention discloses a pretreatment method for cooperatively treating fly ash by a cement kiln, and belongs to the technical field of fly ash pretreatment. Quantitative sodium hydroxide is firstlyadded in a fly ash washing and stirring process, then quantitative carbon dioxide is introduced, after water-ash mixed liquid is subjected to solid-liquid separation, the content of calcium in the pretreated fly ash is increased, the content of calcium in washing liquid is reduced, and meanwhile, the pH value of the washing liquid is adjusted.

Owner:北京精刻环保科技有限公司

Refractory material for iron and steel metallurgy

The invention provides a refractory material for iron and steel metallurgy. The refractory material solves the problem that the existing agitator has a short service life because of structure spalling and thermal spalling caused by poor erosion resistance, severe molten iron erosion and poor thermal shock resistance. The refractory material comprises 10 to 20 parts by weight of sillimanite, 1 to 3 parts by weight of Ti3AlC3, 10 to 20 parts by weight of calcium hexaluminate, 10 to 20 parts by weight of white corundum, 5 to 15 parts by weight of chrome corundum, 5 to 10 parts by weight of sillimanite micro-powder, 3 to 5 parts by weight of cuprospinel micro-powder, 3 to 8 parts by weight of aluminum-rich spinel powder, 3 to 5 parts by weight of nickel oxide powder, 2 to 5 parts by weight of pure calcium aluminate cement, 2 to 4 parts by weight of aluminum gel powder and 0.35 parts by weight of additives. The above raw materials are blended according to the above ratio so that the refractory castable material for a desulfurization gun is obtained.

Owner:嘉兴新耐建材有限公司

Traditional Chinese medicinal liquor for treating hyperostosis and preparation method of traditional Chinese medicinal liquor

InactiveCN104800663ALower calcium levelsCalcium levels dropAlcoholic beverage preparationSkeletal disorderLiver and kidneySide effect

The invention relates to traditional Chinese medicinal liquor for treating hyperostosis and a preparation method of the traditional Chinese medicinal liquor. The traditional Chinese medicine composition consists of the following raw materials according to a certain weight ratio: hoya lancilimba, twitch-grass leaves, pterospermum grande craib, climacium dendroides, root of rosthorn bigginseng, litsea cubeba, root of tube clematis, phyllanthus reticulata, pearly maesa, phlegmariurus hamiltonii, herb of glabrous sarcandra, polypodium hymenodes kunze, marsdenia longipes, polygonum amplexicaule, flos pyrethri tatsienensis, procris laevigata, elatostema stewardii merr, silene baccifera, cissus assamica craib, herb of japanese saussurea, herb of scape-like sage, euonymus chinensis Lindl, mistletoe and bulbil. The traditional Chinese medicinal liquor is researched on the basis of dialectical therapy of the traditional Chinese medicine according to the clinical tests and has functions for dispelling the wind, eliminating the dampness, promoting blood circulation to remove meridian obstruction, eliminating the stagnant blood, alleviating the pain, tonifying the liver and kidney and strengthening the bones. The traditional Chinese medicinal liquor has the advantages that the clinical healing rate is high, safety, convenience, non-toxicity and no side effect.

Owner:宁波好口味食品有限公司

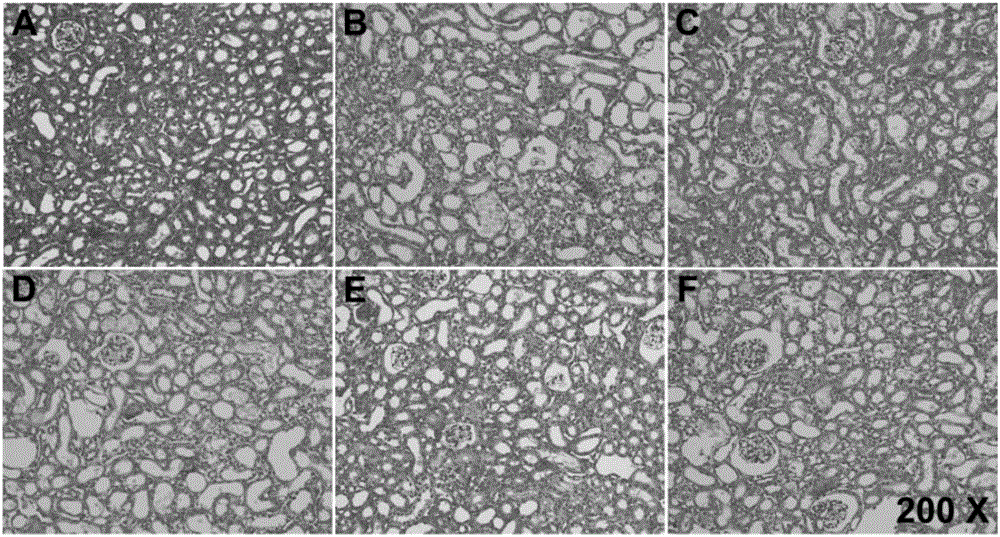

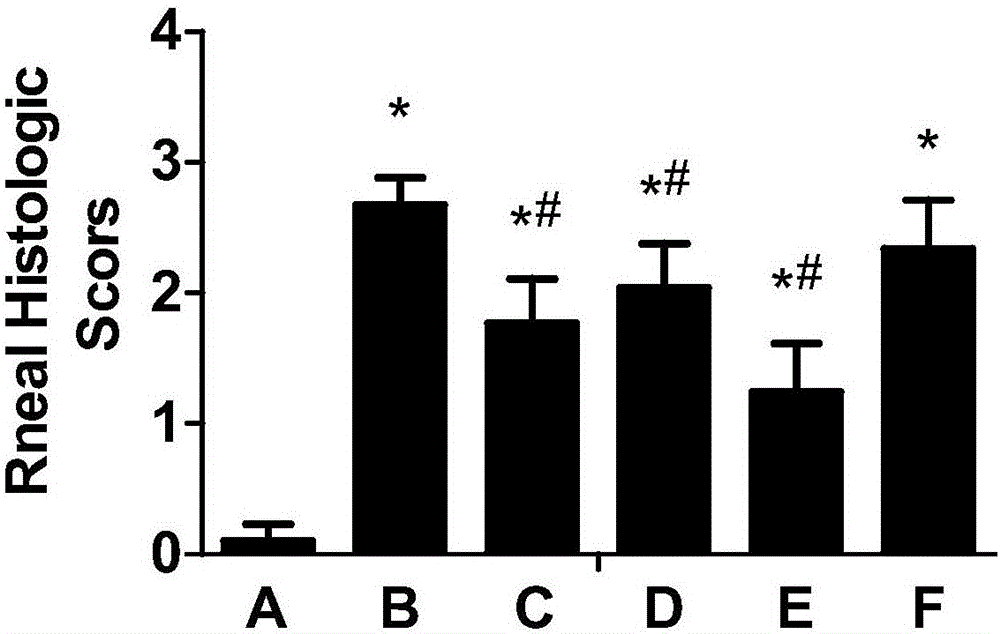

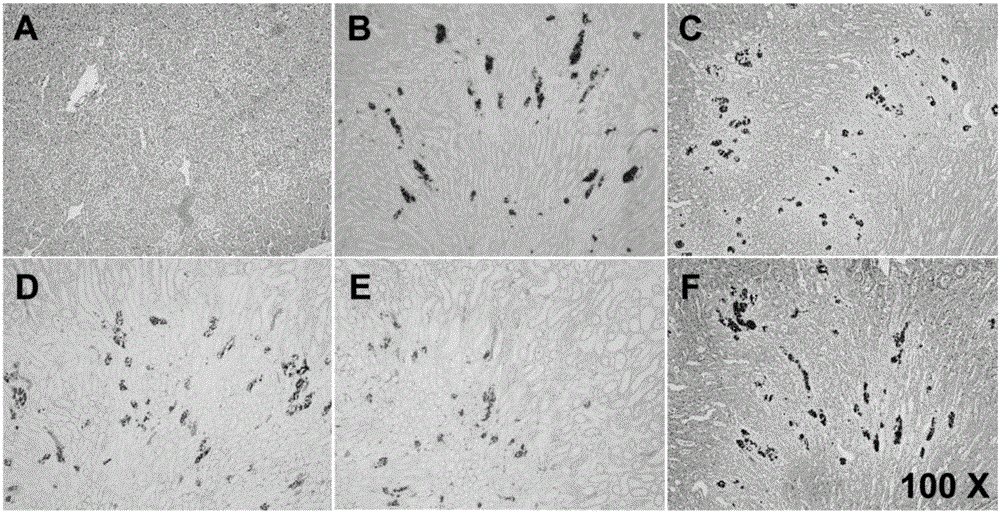

Application of desmodium styracifolium extract in urinary calculus

InactiveCN105982930ALower calcium levelsAvoid damageUrinary disorderPlant ingredientsCreatinine riseDesmodium styracifolium

The invention belongs to the technical field of medicines, and particularly relates to application of desmodium styracifolium extract in urinary calculus. Three positions of desmodium styracifolium are extracted, and the effect of each part on calcium oxalate crystal is studied by adopting a mouse calcium oxalate crystal model which is manufactured by injecting a glyoxylate solution into the peritoneal cavity. Results indicate that the desmodium styracifolium extract can be used for promoting the serum creatinine and urea nitrogen content of a mouse to be remarkably reduced, the calcium content of kidneys to be remarkably reduced, the calcium oxalate crystal deposition in kidney tissues and kidney pathological tissue injury to be remarkably alleviated, the levels of CAT, CuZn-SOD, GSH, osteopontin, CD44, TRPV5, Calbindin-D28 and Ki67 to be remarkably increased, and the content of MDA and TUNEL to be remarkably reduced.

Owner:SHANGHAI NATURE STANDARD R&D & BIOTECH +2

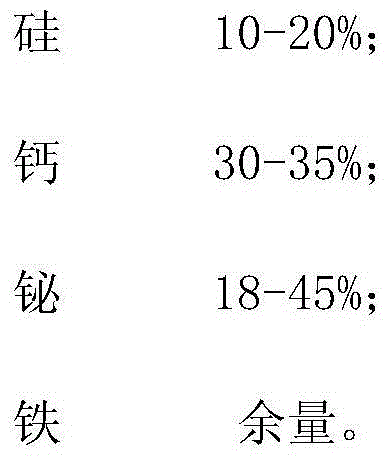

Si-Ca-Bi-Fe alloy for alloying refined steel

InactiveCN104630419AShorten deoxidation and desulfurization treatment timeHigh in calciumAlloyMolten steel

The invention discloses a Si-Ca-Bi-Fe alloy for alloying refined steel. The alloy comprises the following components in percentage by weight: 10-20% of Si, 30-35% of Ca, 18-45% of Bi and the balance of Fe. Since the Ca content is increased properly, the capability of deoxygenation and desulfuration is increased and deep deoxygenation and desulfuration can be realized, deoxygenation and desulfuration speed is increased, the time of deoxygenation and desulfuration of molten steel is shortened, the production efficiency is enhanced; in addition, Bi is added and the Si content is reduced; the Si-Ca-Bi-Fe alloy can be used for refining low-SI steel.

Owner:铜陵百荣木业有限公司

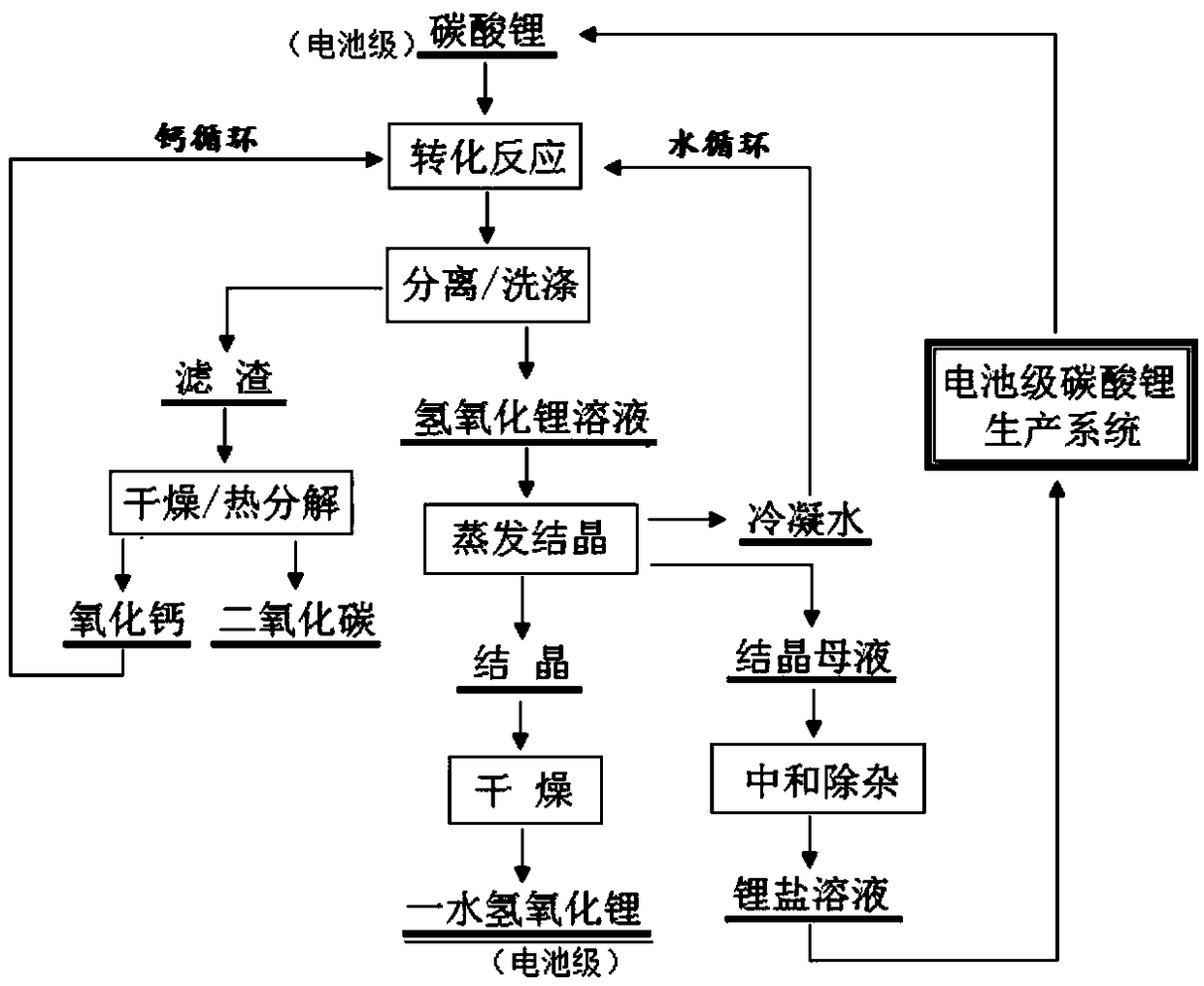

A method of producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate

The invention provides a method for producing battery-grade lithium hydroxide monohydrate from battery-grade lithium carbonate, and belongs to the field of battery-grade lithium hydroxide monohydrate preparation. The method comprises the steps of carrying out conversion reaction on excessive lithium carbonate, water and calcium oxide, separating obtained conversion slag from a lithium hydroxide solution, combining a conversion slag washing liquid into the lithium hydroxide solution, drying the obtained conversion slag and entering generated calcium oxide and unreacted lithium carbonate into a calcium cycle for participating into conversion reaction again; evaporating and crystallizing the obtained lithium hydroxide solution, drying to obtain the lithium hydroxide monohydrate. The battery-grade lithium hydroxide monohydrate is produced from the battery-grade lithium carbonate as the raw material by adopting a calcium cycle method, so that accumulation of main impurities of sodium, potassium, zinc, tin and aluminum in a system is removed, the quality of a product is improved, a lot of impurities in industrial lime are prevented from being introduced into the system, the cost is reduced and the method has a good application prospect.

Owner:JIANGXI HZONE LITHIUM TECH

Method for efficiently preparing low-calcium-content folinic acid

InactiveCN104277044ALower calcium levelsSolid physical propertiesOrganic chemistryControl systemCalcium content

The invention relates to a method for efficiently preparing low-calcium-content folinic acid. The method for efficiently preparing the low-calcium-content folinic acid comprises the following steps: dropwise adding a dissolved folinic acid aqueous solution and diluted hydrochloric acid with certain concentration into water, strictly controlling system temperature and pH value, separating out solids, washing, and drying, so that the low-calcium-content folinic acid is obtained. The obtained low-calcium-content folinic acid product is good in solid physical property and low in calcium content, and operation is easy, so that the method for efficiently preparing the low-calcium-content folinic acid is applicable to industrial production.

Owner:SHANGHAI HUILUN BIOLOGICAL TECH CO LTD

Inoculant products comprising bismuth and rare earths

ActiveUS7569092B2Improve stabilityExtension of timeBlast furnace componentsBlast furnace detailsSilicon alloyFerrosilicon

Owner:FERROPEM SAS

Drug for treating urinary calculi and preparation method thereof

InactiveCN105688056AGood curative effectQuick resultsPowder deliveryInorganic boron active ingredientsModern medicineSide effect

The invention provides a drug for treating urinary calculi. The drug is prepared from, by weight, 20 parts of radish seeds, 18 parts of chingma abutilon seeds, 10 parts of akebia stems, 14 parts of curcuma zedoary, 20 parts of carapax trionycis, 15 parts of spina gleditsiae, 15 parts of radix notoginseng powder, 10 parts of processed myrrh, 14 parts of fresh radix polygoni multiflori, 22 parts of shepherd's purse flowers, 10 parts of rhizoma alismatis, 15 parts of gentian, 8 parts of borax, 12 parts of fresh rhizoma acori tatarinowii, 15 parts of ural licorice root tips, 10 parts of fructus aurantii, 6 parts of green tangerine peel, 9 parts of honeysuckle flowers and 11 parts of herbal ecliptae. According to the traditional Chinese medicine composition, the selected medicinal materials are under proper compatibility, and the drug conforms to the traditional Chinese medicine and modern medicine and pharmacology theories and has a remarkable effect on reducing the degree of calculi and obvious analgesia and diuresis effects. It is clinically verified that the traditional Chinese medicine composition achieves a good curative effect and is small in toxic and side effect, the effect is taken quickly, urinary calculi will not relapse after being cured, and clinical popularization value is achieved.

Owner:QINGDAO YUANZHILIN AGRI SCI & TECH DEV

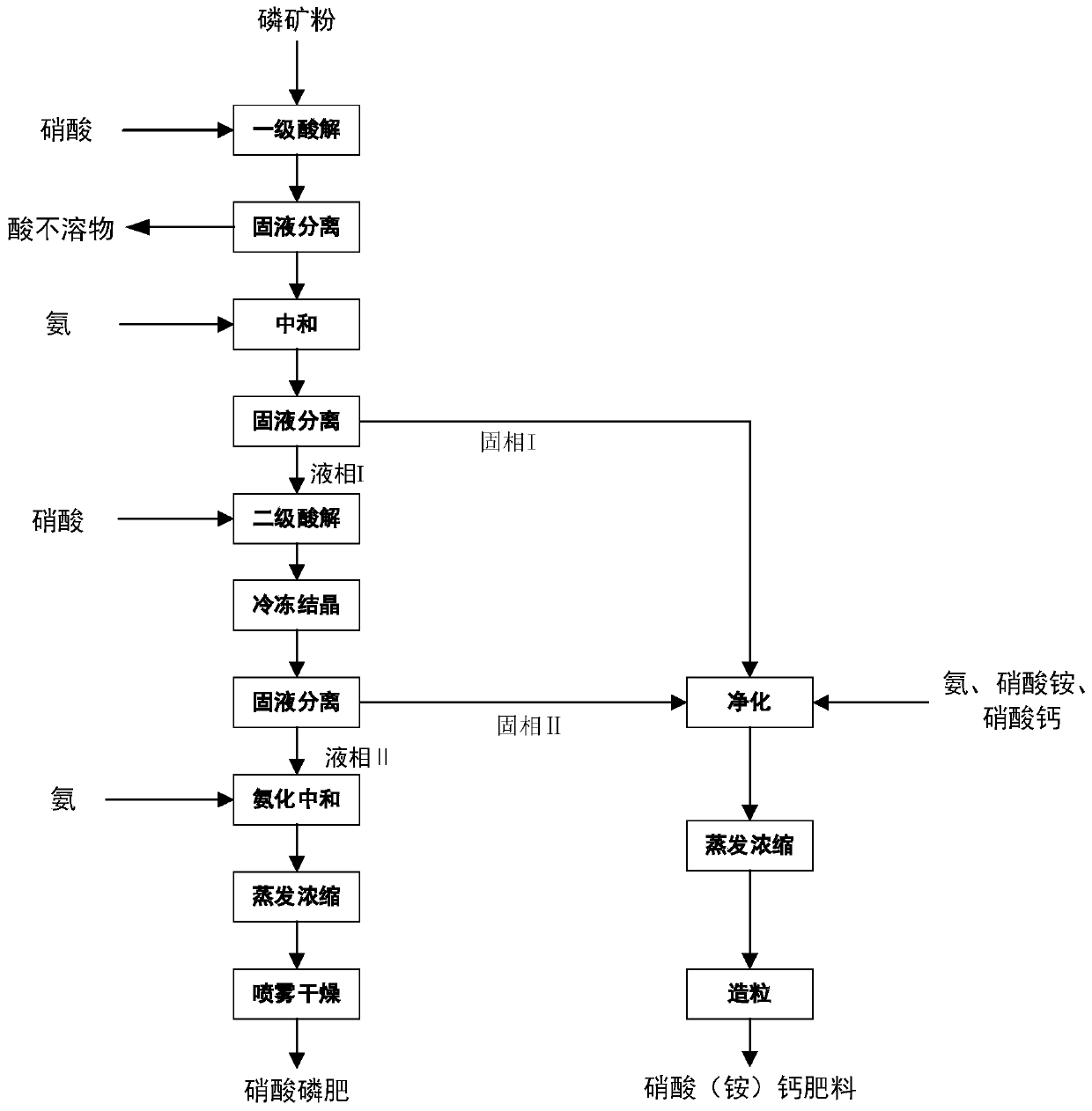

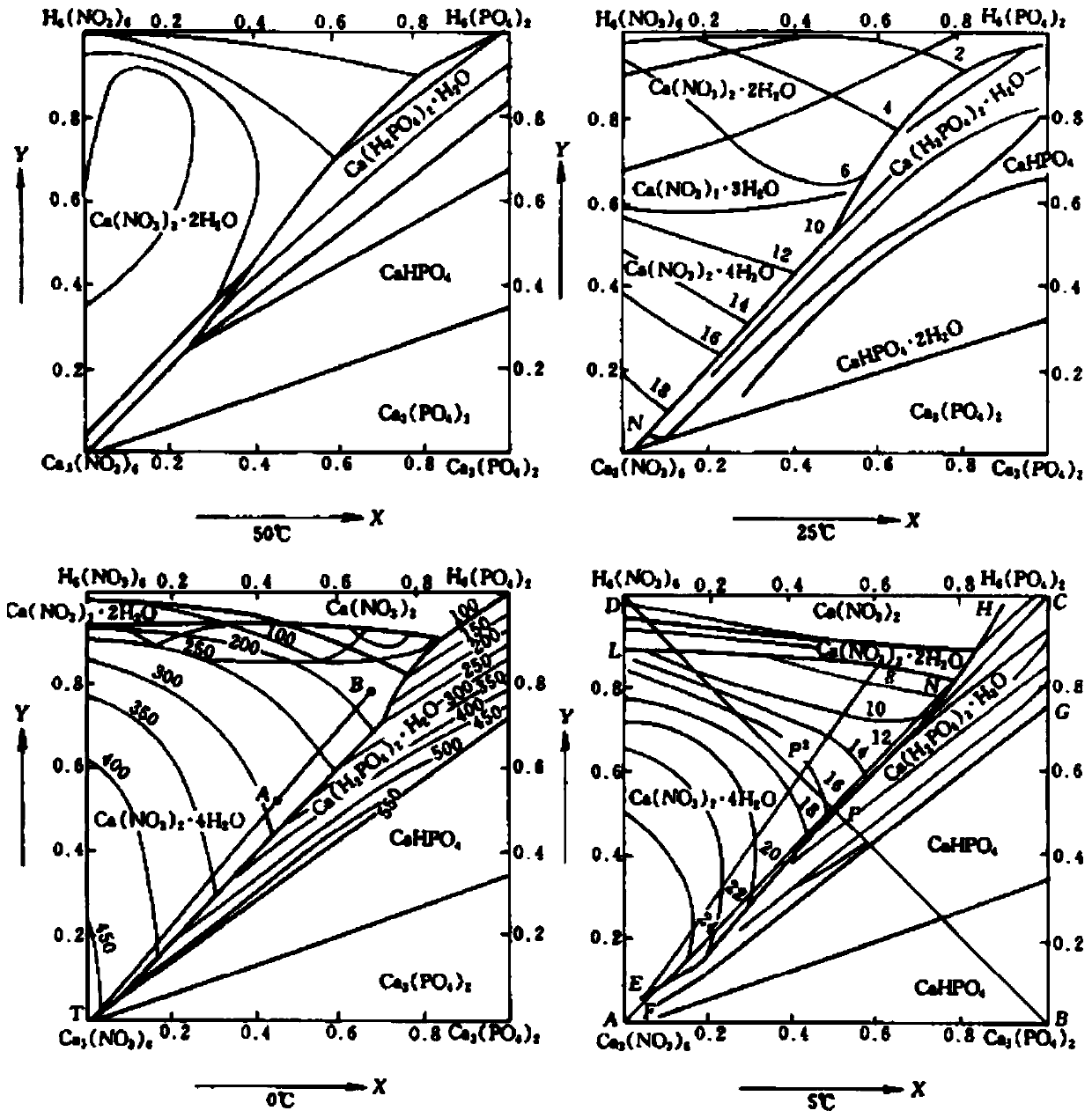

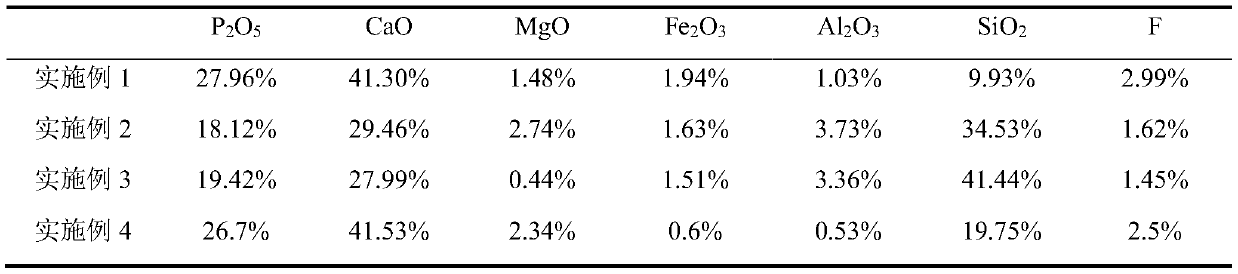

Separation method of P and Ca in medium-low-grade phosphorite and method for producing fertilizer

ActiveCN111517832AHigh element utilizationGood economic benefitsAmmonium nitrate fertilisersNitrate fertilisersFertilizerAgricultural engineering

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com