Pretreatment method for cooperatively treating fly ash by cement kiln

A co-processing and cement kiln technology, applied in cement production, etc., can solve problems affecting the normal operation of evaporation and crystallization equipment, increase the cost of hardening of water washing liquid treatment, and adverse effects of cement production process, so as to improve the significance of resource utilization and increase resource utilization. The effect of globalization advantages and long-term promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

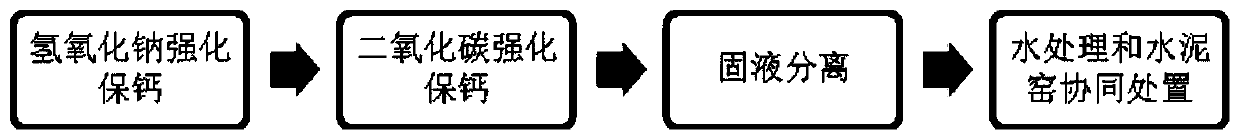

[0031] A technical method for strengthening calcium retention in the process of cement kiln co-processing fly ash water washing pretreatment, the operation steps include:

[0032] 1) Sodium hydroxide strengthens calcium preservation. After the fly ash and water are mixed, use a stirrer to stir and wash with water, and add a certain amount of sodium hydroxide during the stirring process.

[0033] In order to ensure this step 1), the following conditions need to be controlled: the water-cement ratio is 5mL / g, the washing time is 10min, the washing temperature is 20°C, and the ratio of sodium hydroxide to fly ash is 1g / 10g.

[0034] Before adding sodium hydroxide, the calcium content in the washed fly ash was 159.57g / kg; after adding sodium hydroxide, the calcium content in the washed fly ash was 185.73g / kg.

[0035] 2) Carbon dioxide strengthens calcium preservation. After step 1) is completed, carbon dioxide is introduced.

[0036] In order to ensure this step 2), the follow...

Embodiment 2

[0040] The fly ash used in the following experiments is 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com