Method for simultaneously removing PM2.5 granules, SO2 and NOx from flue gas and recycling by-product

A by-product, SO2 technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of reduced dust removal efficiency of PM2.5 particles, insufficient charging of PM2.5 particles, and failure of electrostatic precipitators, etc. problems, to achieve the effect of promoting oxidation absorption and removal, reducing investment and operation costs, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

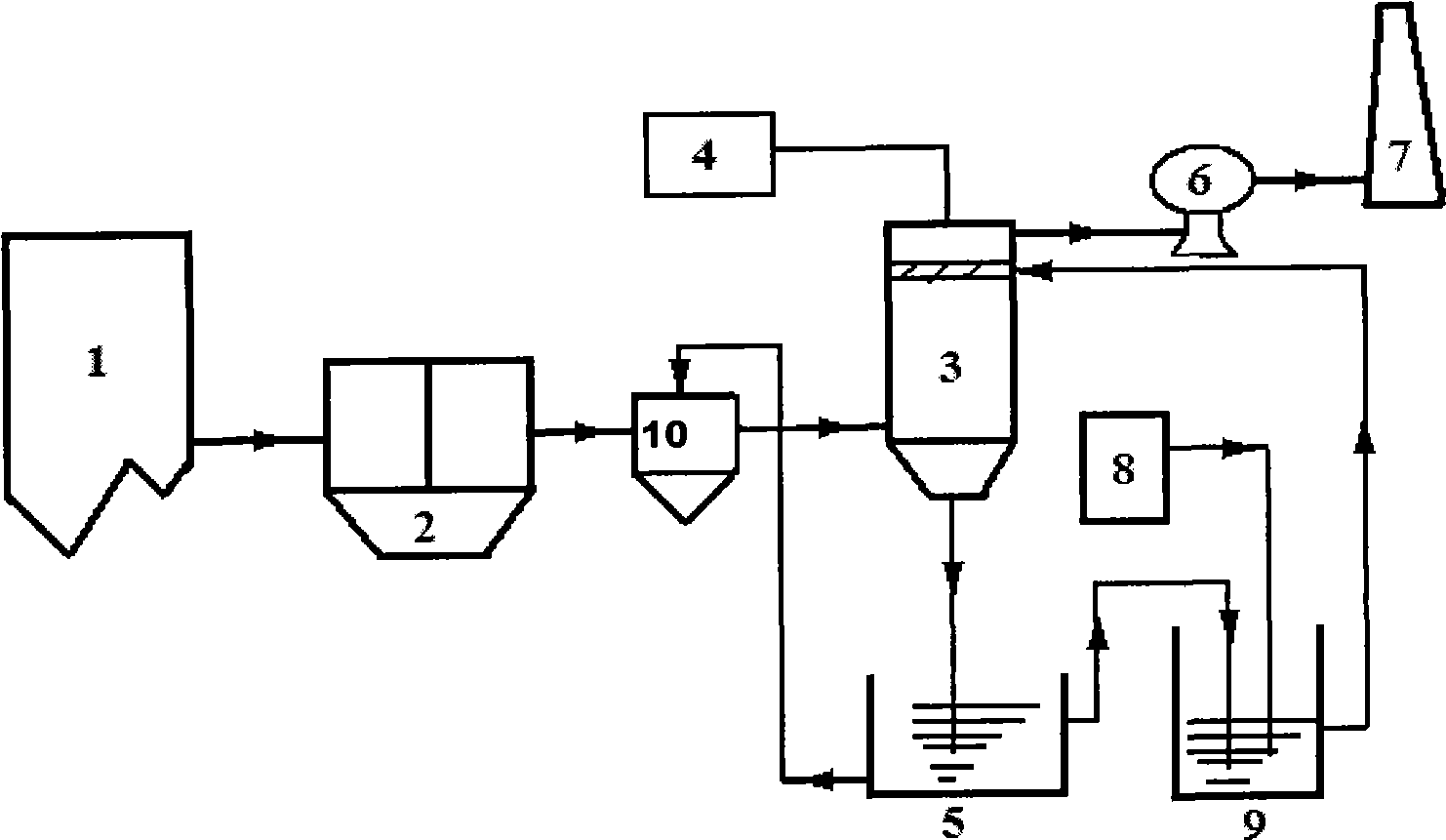

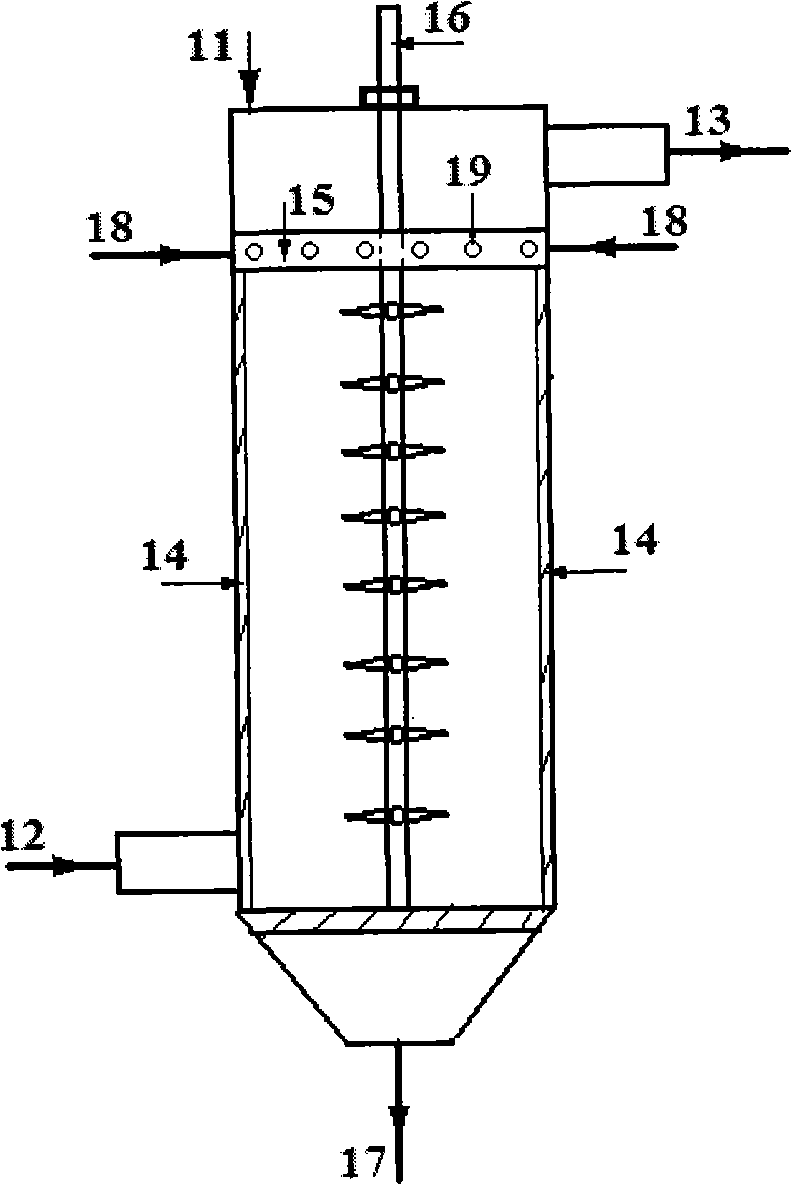

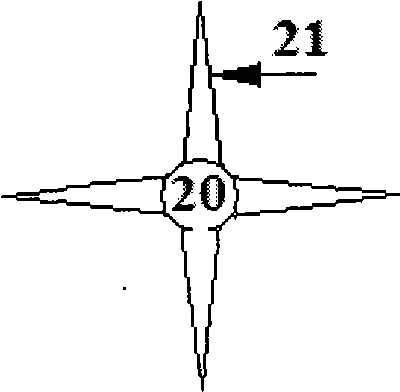

[0019] Such as figure 1 As shown, the flue gas from the boiler 1 first passes through the dust collector 2 to remove the large particle size dust in the flue gas, and then enters the wet corona reactor 3 for PM2.5, SO 2and NOx removal reaction at the same time. The wet corona reactor adopts the pulse high voltage power supply 4, the needle corona wire 16 is connected to the negative pulse high voltage, and the flowing water plate 14 is connected to the positive pulse high voltage. After the pulse high-voltage power supply 4 is switched on, a strong corona discharge can be formed between the needle-shaped corona wire and the running water plate. Simultaneously, ammonia water overflows from the water sprayer 15 near the inner wall of the reactor to form a thin water film on the flowing water pole plate. At this time, PM2.5 particles are charged after being hit by high-energy electrons in the pulsed electric field, and then move to the flowing water plate under the action of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com