Patents

Literature

203results about How to "Non-corrosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified composite material of woods and plastics as well as its usage and manufacturing method

A modified wood-plastics composition is prepared from wood flour, plastic, assistant, and grafting agent through graft modifying of wood flour and plastics, and continuous extruding out. Its advantage is high tension strength, bending strength and impact strength.

Owner:BEI JING NEW BUILDING MATERIALGRP

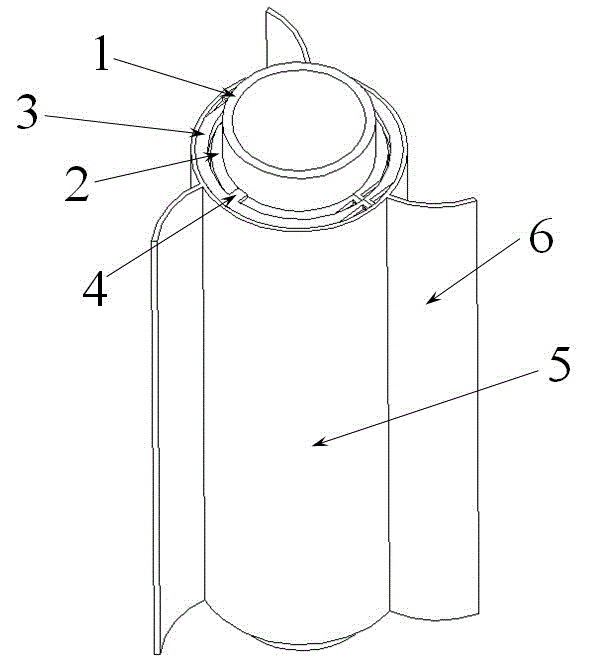

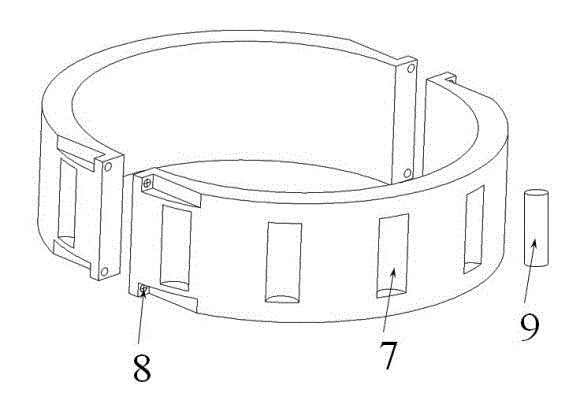

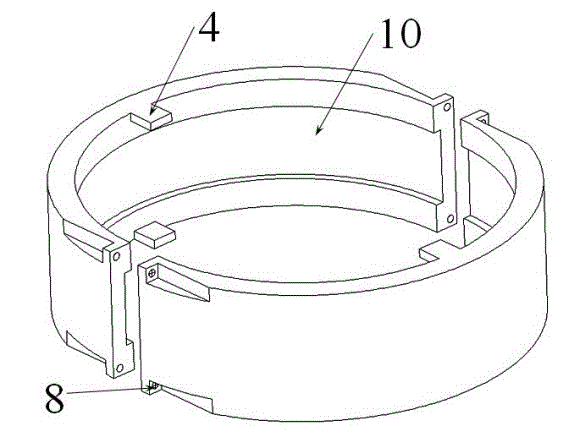

Free-rotation impeller device for inhibiting eddy induced vibration of marine riser

InactiveCN102943634AImprove fatigue lifeAchieve free spinsDrilling rodsFluid dynamicsImpellerFree rotation

The invention relates to a free-rotation impeller device for inhibiting eddy induced vibration of a marine riser. The free-rotation impeller device consists of a plurality of basic elements, wherein the basic elements are serially connected along the axis direction of the marine riser, each basic element comprises two rotary modules and an impeller module, each rotary module consists of an inner circle, a cylindrical roller and an outer circle, the impeller module is a whole body consisting of a sleeve and impeller blades and is processed by a plastic die, the upper end and lower end of the impeller module are respectively provided with one rotary module, the impeller module is sheathed on the outer circle of each rotary module, the inner circle of each rotary module and the marine riser are tightened and connected by a bolt, and the impeller module freely rotates around the marine riser by the rotary modules. The free-rotation impeller device has the advantages that the structure is simple, the performance is reliable, the on-site installation is convenient, the free rotation is realized, the eddy induced vibration caused by flows from any direction can be effectively inhibited, and the influence on the fatigue life of the marine riser is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of orderly porous matrix shaping composite phase change material

InactiveCN103923614AImprove thermal stabilityHigh porosityHeat-exchange elementsMesoporous silicaVolumetric Mass Density

The invention provides a preparation method of an orderly porous matrix shaping composite phase change material, and belongs to the field of a composite phase change material. The preparation method comprises the following steps: firstly preparing an orderly mesoporous silica carrier, and designing, adjusting and controlling the porous-channel structure, pore size and surface property of the carrier; secondly, using a phase change core material for preparing corresponding liquor, dispersing the prepared porous carrier in prepared phase change core material liquor, adsorbing the phase change core material by using the relatively strong capillary action, surface tension and the like of the porous carrier material so as to realize the high-efficiency filling of the core material in combination of the bonding effects of functional groups on the surface of the carrier on the core material, and drying so as to obtain the composite phase change material with relatively good heat storage capacity and relatively high stability. The composite phase change material has the advantages that the carrier is large in specific surface area, high in porosity and small in pore diameter, has orderly porous-channels and strong immobilization capacity on the phase change core material and is difficult to leak, the filling quantity of the core material is large, and the composite phase change material is high in energy storage density, good in heat stability, widely applied, difficult to burn, green and safe in use.

Owner:UNIV OF SCI & TECH BEIJING

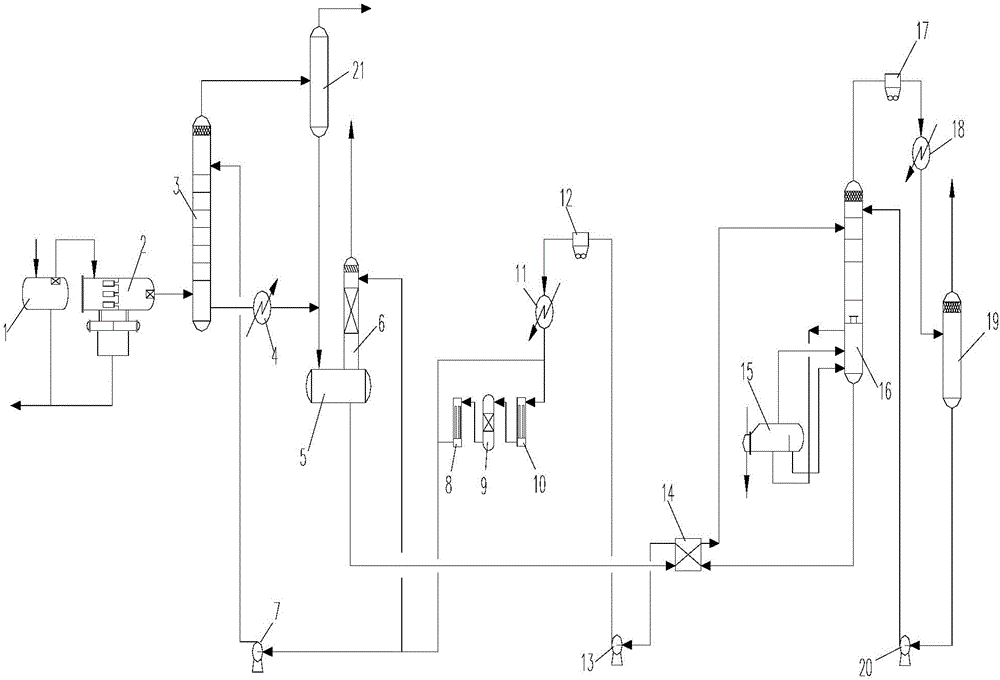

High-efficiency composite desulphurization solvent and system and method for removing acidic gas and organic sulfur

InactiveCN105126576AHigh acid gas loadNon-corrosiveDispersed particle separationAir quality improvementSolventHeterocyclic amine

The invention discloses a high-efficiency composite desulphurization solvent and a system and method for removing acidic gas and organic sulfur. The high-efficiency composite desulphurization solvent comprises, by mass, 70-85% of compound amine, 10-20% of a desulfurization enhancer, 10-30% of a physical solvent, 0.01-0.1% of an antifoaming agent, 0.5-2% of a benzylamine anti-oxidant and 0.5-2% of a heterocyclic amine antiseptic. The high-efficiency composite desulphurization solvent has the advantages of large acidic gas load, low sulfur content of purified gas, stable solvent performances and no corrosion on equipment, and can remove most of H2S and a large part of organic mercaptan from mixed gas. The high-efficiency composite desulphurization solvent and the system and method can greatly reduce a gas purification cost and reduce total sulfur content of the purified gas. The high-efficiency composite desulphurization solvent and the system and method can be used for removing H2S, CO2 and organic mercaptan in natural gas, petroleum refinery gas and synthetic gas.

Owner:CHINA GASOLINEEUM ENG +1

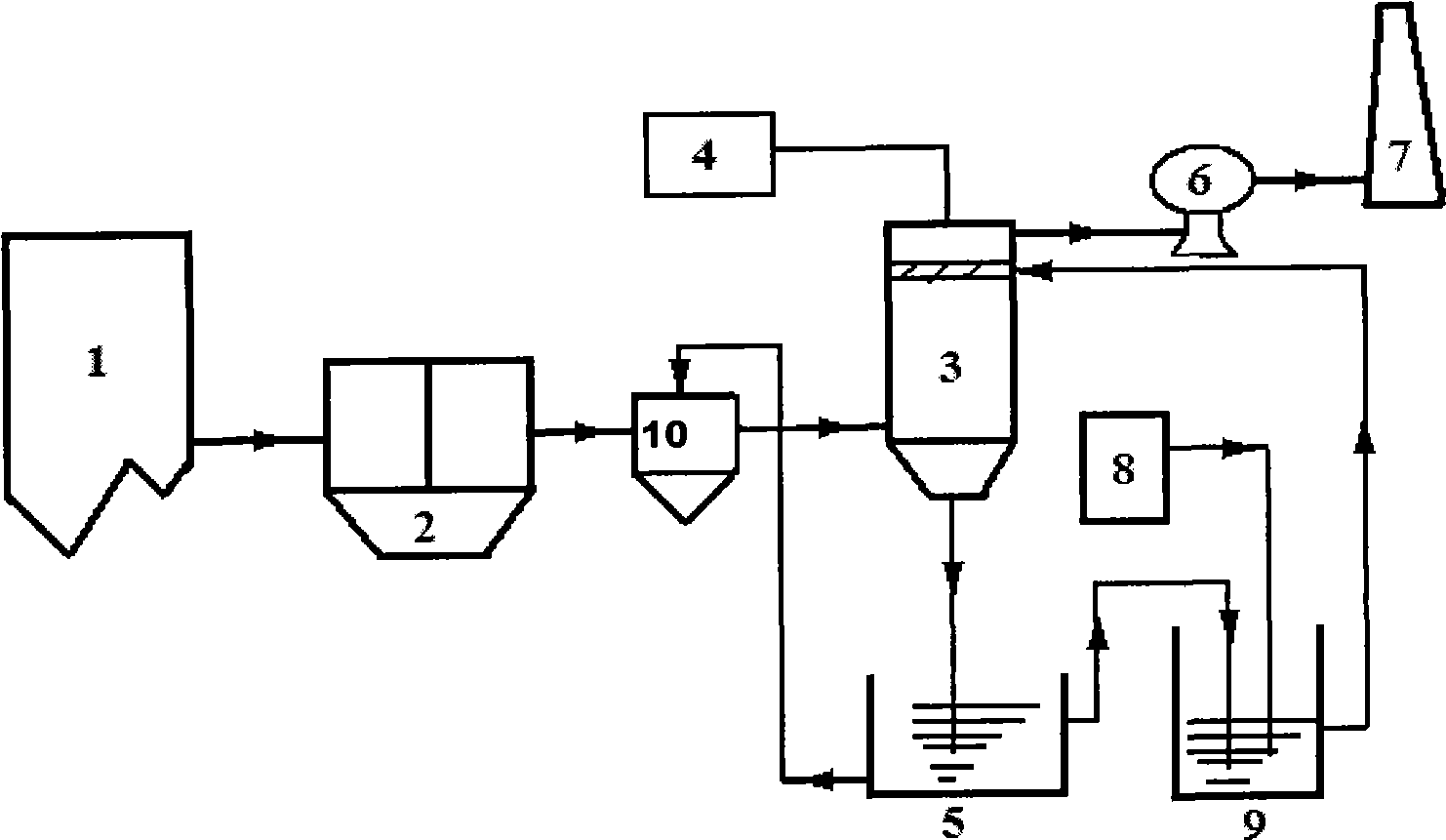

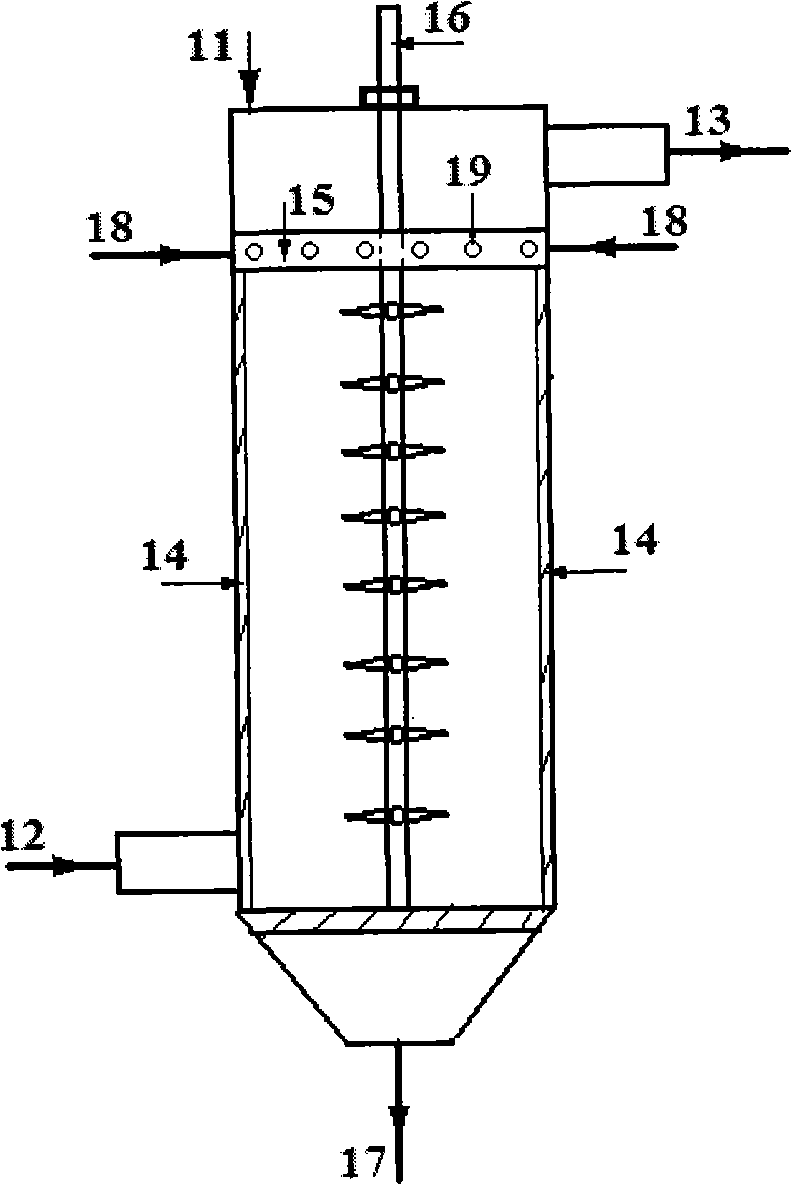

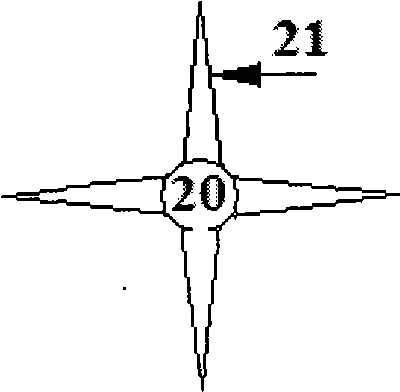

Method for simultaneously removing PM2.5 granules, SO2 and NOx from flue gas and recycling by-product

InactiveCN101496986ANon-corrosiveNo cohesionCombination devicesExternal electric electrostatic seperatorWater vaporHigh pressure

The invention discloses a method for simultaneously removing PM2.5 particles, SO2 and NOx of smoke gas and reclaiming byproducts. The smoke gas to be treated is introduced to a pulse corona electric field and absorption liquid is sprayed to purify the smoke gas at the same time; the pulse corona electric field is produced by an acicular corona wire connected with negative pulse high voltage and a netty metal electrode connected with positive pulse voltage; the absorption liquid is sprayed on the netty metal electrode to form liquid film; after the PM2.5 particles are charged, the PM2.5 particles move to the liquid film by electrostatic force and are adsorbed and caught by the liquid film; vapor and oxygen of the smoke gas are decomposed into O, OH, O3, HO2 and other oxidative free radicals; SO2 and NO of the smoke gas are oxidized into high valent state substances which are easy to absorb; subsequently, the substances are absorbed by the absorption liquid; and the reacted absorption liquid is crystallized through sensible heat drying of the smoke gas to be treated to generate reclaimable byproducts. The method realizes simultaneous removing of the PM2.5 particles, SO2 and NOx of the smoke gas and recycles the removed byproducts.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Urea grease composition and preparation method thereof

ActiveCN101368129AImprove water resistanceImprove performanceThickenersAdditivesSulfurExtreme pressure additive

The invention relates to a urea grease composition and a preparation method thereof; the urea grease composition consists of base oil, thickener and additive; wherein, the base oil is various mineral base oil, synthetic oil or the mixture of the mineral base oil and the synthetic oil, and the base oil accounts for 85 percent to 95 percent of the total amount of the grease; the thickener is composed of diurea compound and the amount of the thickener accounts for 4 percent to 15 percent of the total amount of the grease; the additive consists of T361A borate extreme pressure and antiwear additive, anti-oxidant and anti-corrosion additive and anti-oxidant; wherein, the addition amount of the borate extreme pressure and antiwear additive accounts for 1 percent to 3 percent of the total amount of the grease, the addition amount of the anti-oxidant and anti-corrosion additive accounts for 0.5 percent to 2 percent of the total amount of the grease and the addition amount of the anti-oxidant accounts for 0.3 percent to 1 percent of the total amount of the grease; the invention combines the advantages of the borate and the traditional sulfur-phosphorous additive and the urea grease added with the borate extreme pressure and antiwear additive still has excellent water resistance, thus improving the comprehensive performance of the product and reducing the cost.

Owner:杭州得润宝油脂股份有限公司

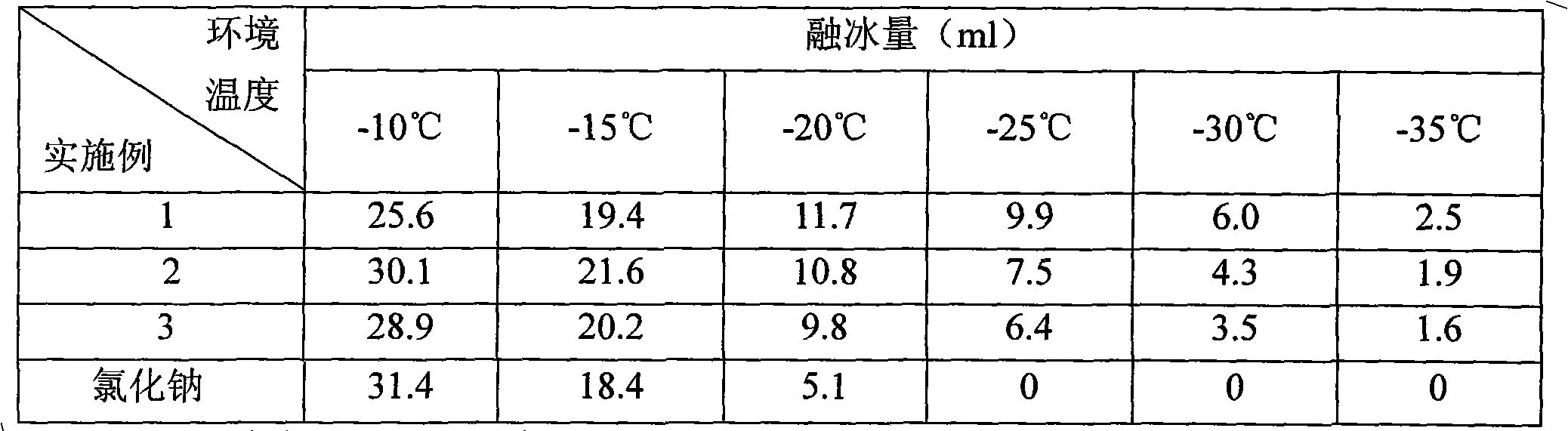

Environment protection snow-dissolved agent and preparation method thereof

The invention relates to an environment protection snow-dissolved agent, which is composed of magnesium nitrate and sodium acetate. Each reactant is fully mixed and smashed according to ratio; then, the reactant is fully mixed with slip proofing agent to be filled into a plastic film for sealing; and a woven bag is arranged outside for sealing, so that the environment protection snow-dissolved agent of the invention is obtained. The snow-dissolved agent overcomes the damages in the traditional snow-dissolved agent, such as corrosion to roads and bridges and influence on farmland crops and green plants on two sides of roads and the like. The invention has fast snow dissolving speed, favourable effect, low cost and wide using temperature range, and the applicable temperature range is minus 5 DEG C-minus 35 DEG C, so the invention has favourable promotion and application prospect.

Owner:SOUTH CHINA UNIV OF TECH

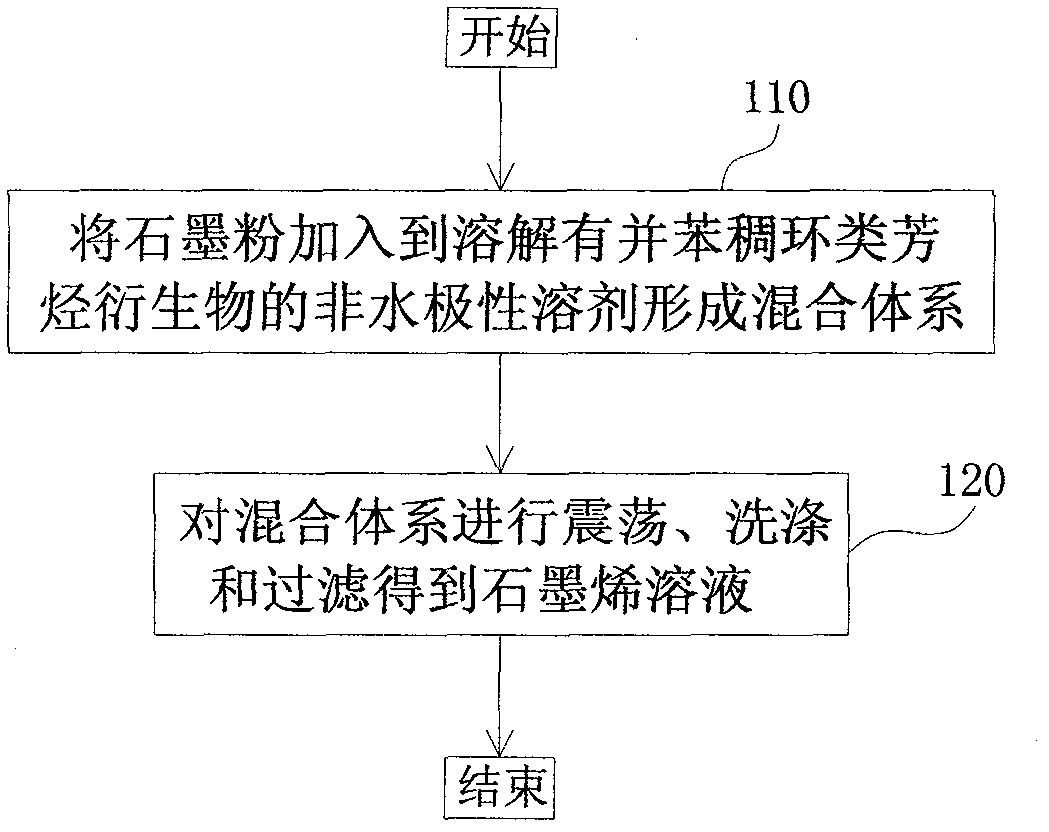

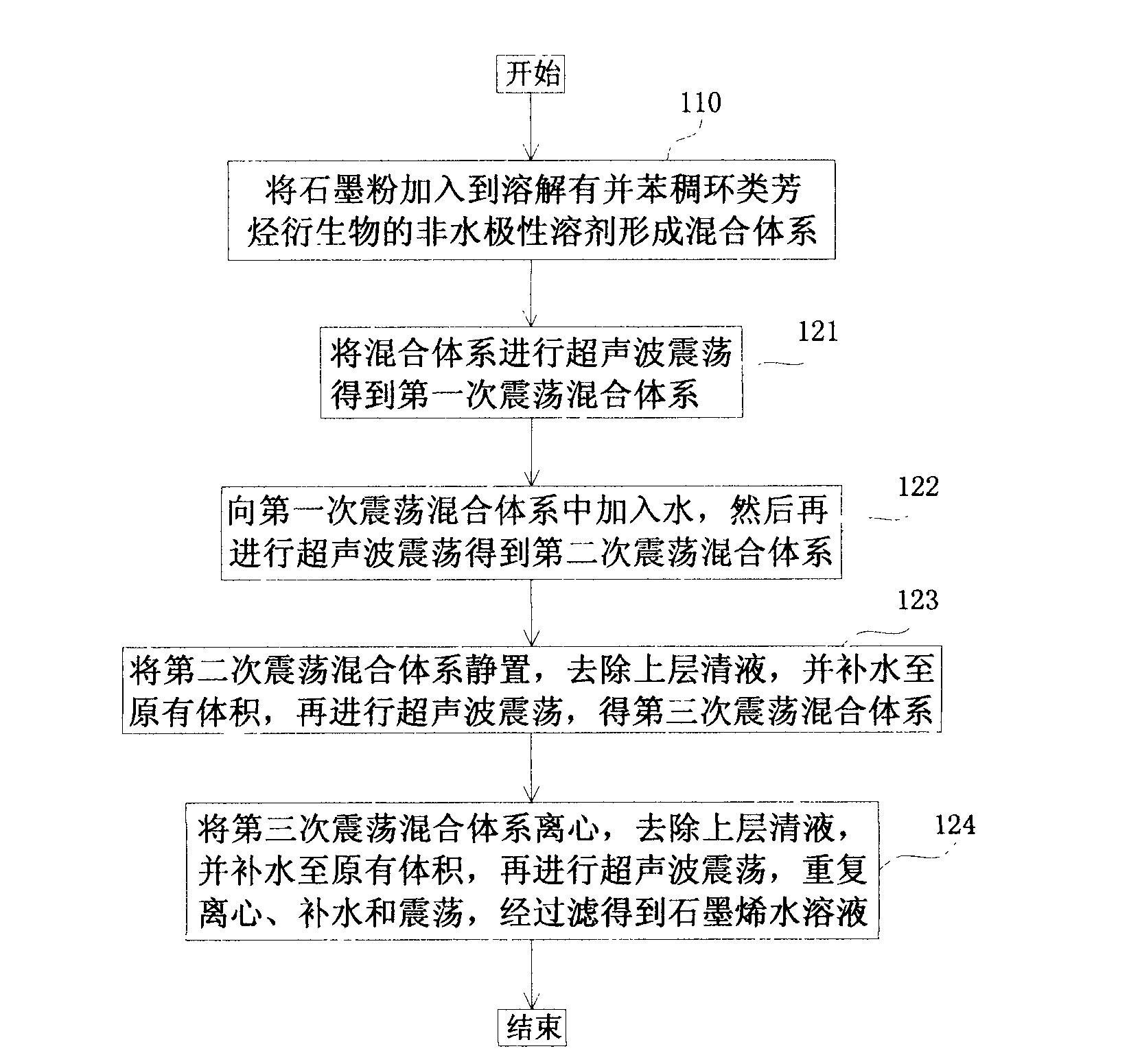

Preparation method of graphene

Disclosed is a preparation method of grapheme. The preparation method of the grapheme comprises the following steps: graphite powder is added to non-water polar solvent dissolved with acene condensed nucleus arene derivative to form a mixed system; the mixed system is shocked, washed, centrifuged and filtered to obtain grapheme solution. The preparation method of the grapheme is not high in requirements for preparation conditions, simple in preparation process, good in quality of obtained grapheme, almost free of structural defects and considerable in productivity.

Owner:XIDIAN UNIV

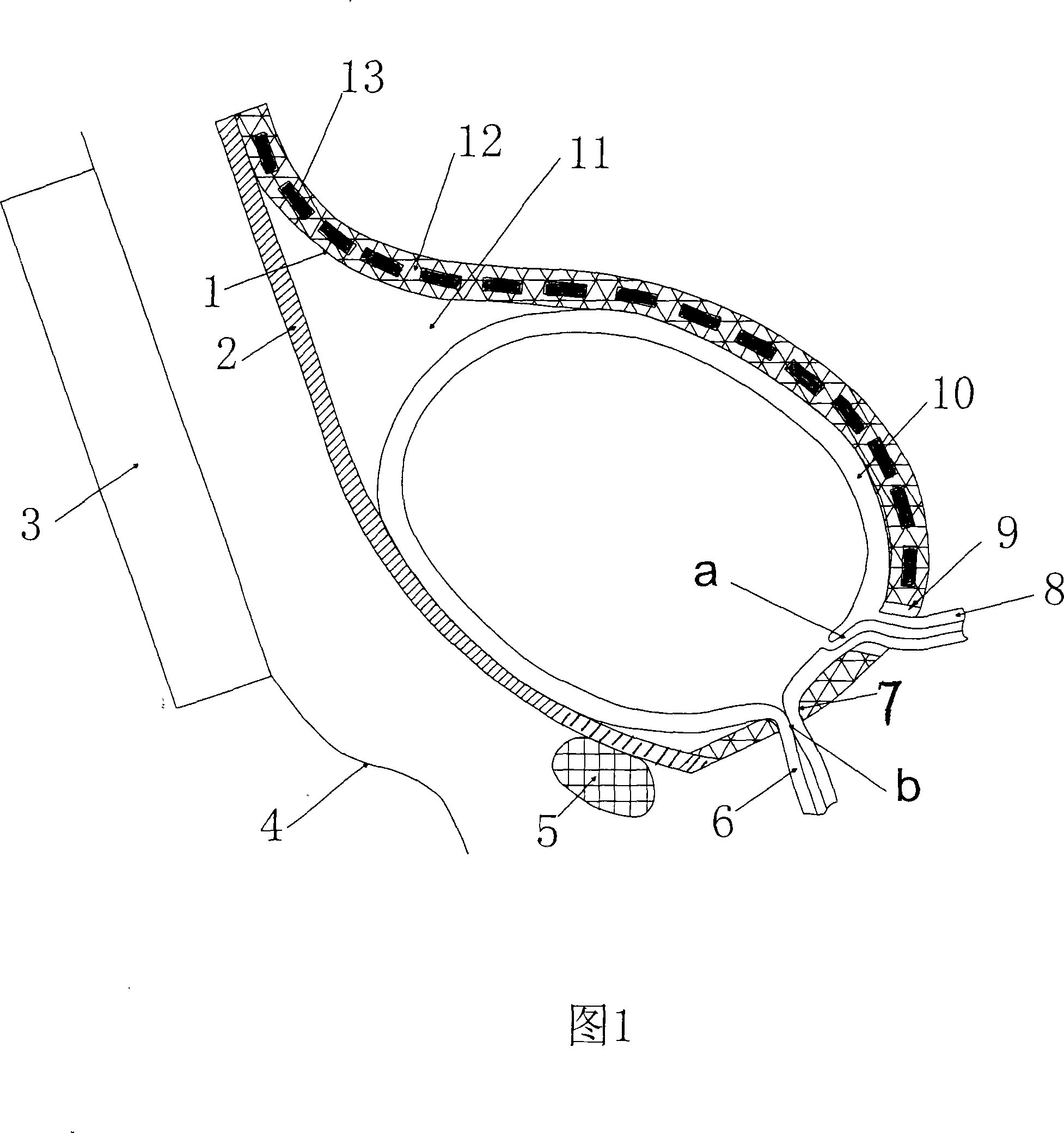

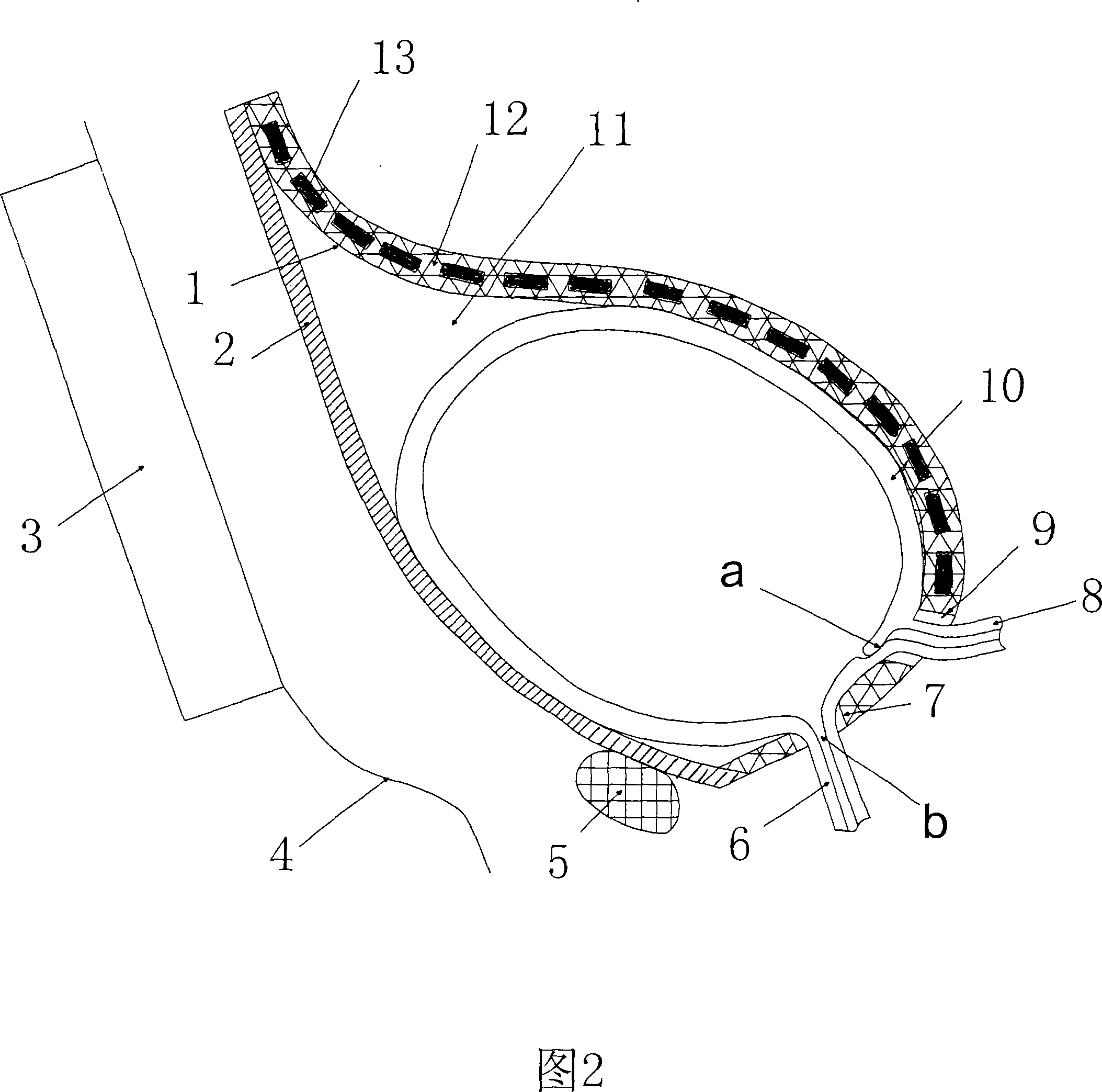

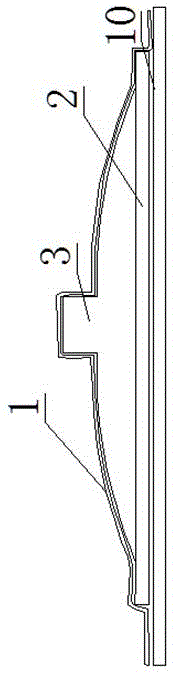

Urinary bladder power pump driven by external electromagnetism

InactiveCN101176689ANot cause infectionCause infectionFlexible member pumpsPositive-displacement liquid enginesMagnetic tension forceEngineering

The invention relates to a bladder power pump utilizing the magnetic force to assist the bladder to urinate, which comprises a magnetic active cell (1), a stator (2) and a magnetic controller (3), wherein, the magnetic controller (3) generates magnetic field if switched on and enables the magnetic force to work on the magnetic active cell (1); the magnetic active cell (1) comprises a flexible sheet (12) and a plurality of permanent magnetic sheets (13), and the permanent magnetic sheets (13) are enwrapped with the flexible sheet (12); the flexible sheet (12) enwrapping the permanent magnetic sheets (13) surrounds a gourd-shaped structure with the stator (2) to circle the outside of the bladder (10) to build a variable working cavity (11); the upper end of the flexible sheet (12) enwrapping the permanent magnetic sheets (13) is contacted and adhered with the stator (2); a through hole (9) of ureter communicating a ureter (8) with a ureter port (a) inside the bladder wall, and a urethra bayonet (7) held at a urethral meatus (b) of a urethra (8) are respectively arranged at the lower end of the flexible sheet (12) where the permanent magnetic sheets (13) are not enwrapped; and the lower end of the flexible sheet (12) where the permanent magnetic sheets (13) are not enwrapped is contacted and adhered with the stator (2). The invention can effectively assist the neurogenic bladder dysfunction sufferer to realize emiction and has the advantages of ingenious design, simple structure, safe use, convenience and practicality.

Owner:GUANGDONG UNIV OF TECH

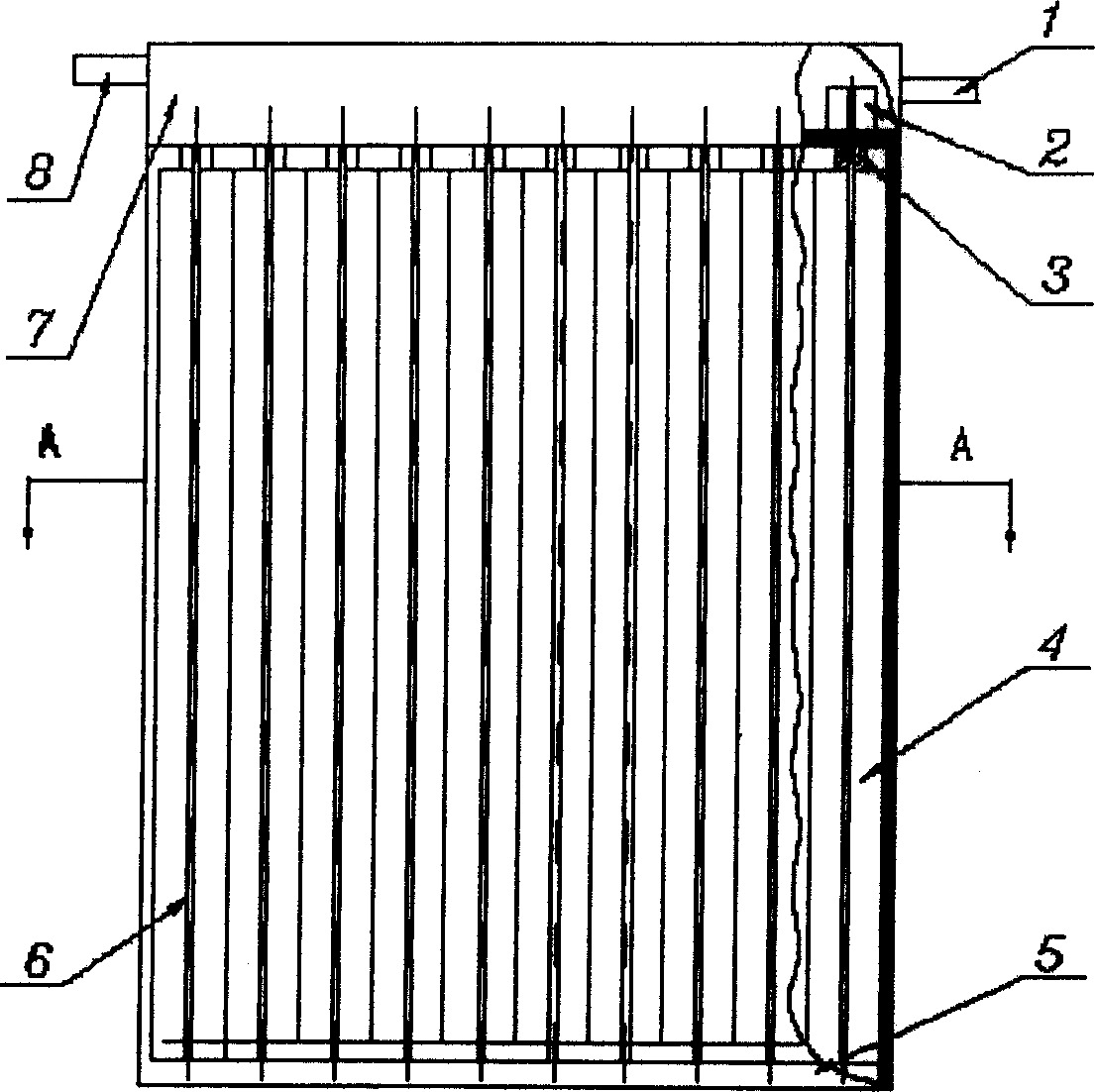

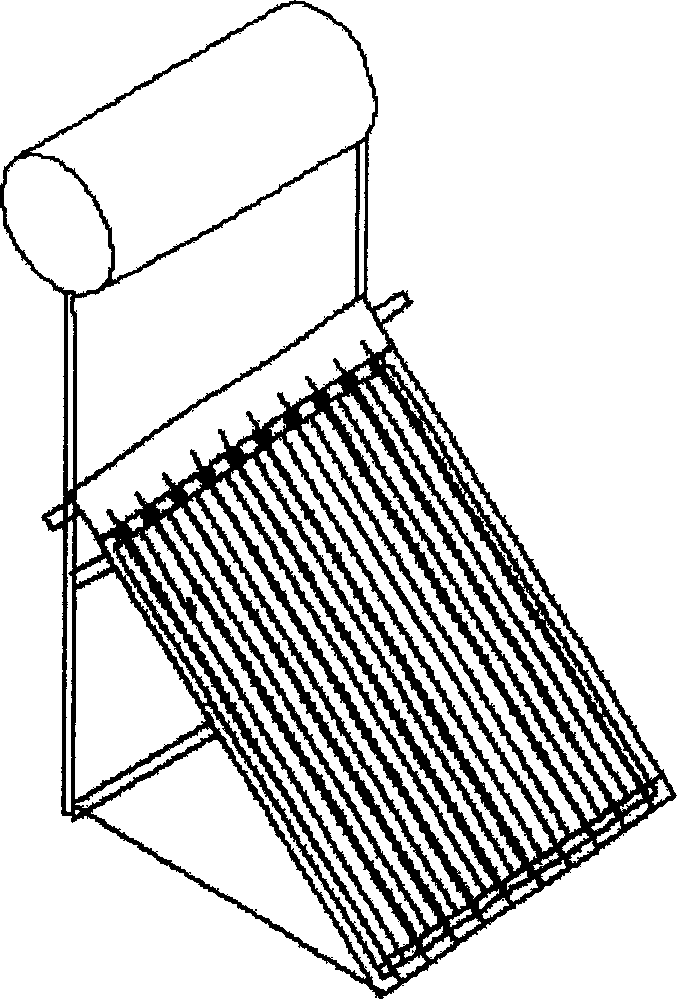

Flat-type solar water heater with vacuum glass cover plate heating tubes

InactiveCN1595010AStart fastHigh sensitivitySolar heating energySolar heat devicesFlat glassEngineering

Disclosed is a solar energy water heater of vacuum glass cover heat pipe plane type, comprising tank consisted of thermal insulating material and outer gimbal, vacuum plane glass above the tank, absorber plate consisted of heating pipe and fin, condensing zone of the heat pipe and recycling water tank are connected, the water tank and water storage are connected or the condensing zone of heat pipe is directly connected to water storage, and absorber plate is under the vacuum plane glass. The invention has no problems of icing, scale formation and atmospheric corrosion, fairly good red flared radiation can be emitting from heat collector inside because of high level of transparency of the vacuum plane glass to sun radiation but opaque to red flared radiation, decreasing radiation heat loss to absorber plate. Besides, heat pie has fast start-up, high sensitiveness, wide work range, fast heat transfer, only oneway heat exchange between heat collecting pie, and when the sun radiation is fairly low, heat elimination of heating working substance to environment can be reduced.

Owner:ZHEJIANG UNIV

Extraction process of coconut oil

Owner:海南建邦制药科技有限公司

Ceramic tile and its preparing process

The invention discloses a kind of ceramic tile and its manufacture craft. It relates to a kind of ceramic tile used for building fitment and its manufacturer craft. The ceramic tile includes following weight percents of raw material to be fired: Jin'an pottery clay 50% - 70%, Hushan pottery clay 10% - 25%, and bamboo carbon powder 15% - 35%. The ceramic tile manufactured through the technological project of the invention has such effects as moisture-proof, bacteriostasis and environmental purification. The ceramic tile manufactured through the craft has high intensity and rigidity, and can greatly save raw materials. It can be widely used in ceramic tile industry.

Owner:汤建华

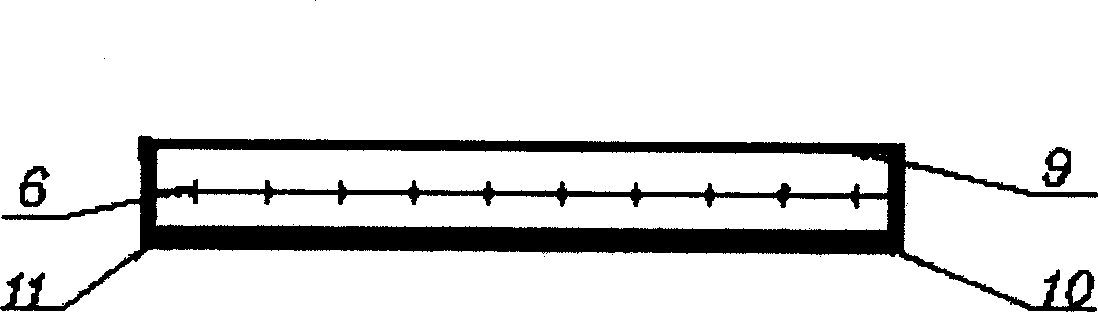

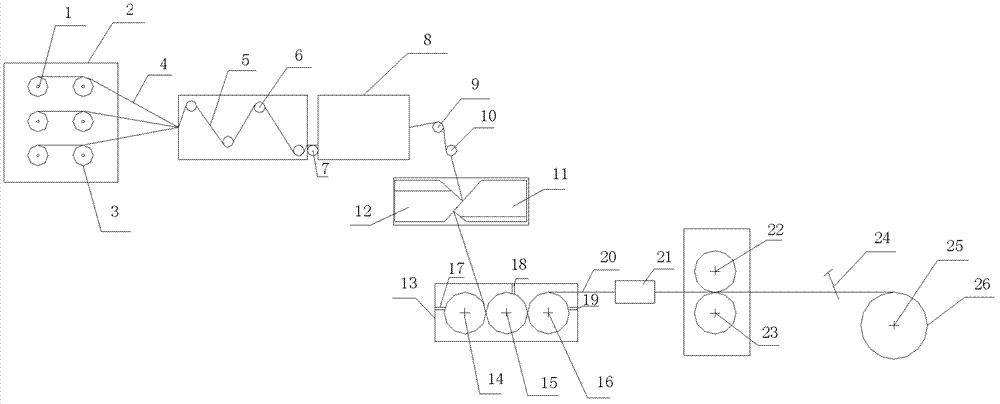

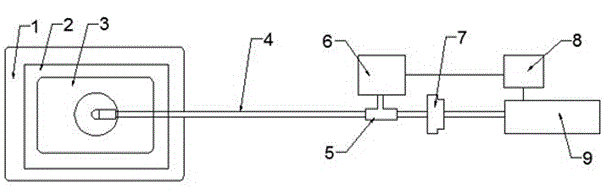

Packing belt and manufacturing method thereof

The invention relates to a packing belt and a manufacturing method thereof. According to the invention, a continuous fiber bundle (4) is led out from a continuous fiber roll (3) on a yarn creel (2), and is unfolded through a tension roller (6); the continuous fiber bundle (4) is delivered into a preheating device (8) through a delivery roller (7), and is delivered into a continuous opening-and-closing double-extrusion die-head set where pre-impregnation is carried out upon the fiber bundle (4) and molten thermoplastic resin; the fiber bundle (4) is delivered into a impregnation calendaring roller, and is impregnated and subjected to primary setting, such that a continuous fiber belt (20) is formed; the continuous fiber belt (20) is delivered through a heating baking oven (21) and is directly subjected to creasing cooling setting through a creasing roller; the continuous fiber belt (20) is cut by using a cutter (24), and is rolled and set in a rolling device (25), such that a continuous fiber-reinforced thermoplastic material packing belt roll (26) is obtained. Compared with prior art, the packing belt provided by the invention has the advantages of no corrosion, higher strength, low elongation rate and low recovery rate, good continuous tension, good aging resistance, long service life, and the like.

Owner:LIAONING LIAOJIE SCI & TECH

Method for preparing superfine magnesium hydroxide sizing agent by wet method

ActiveCN106115748AImprove stabilityHigh solid contentMagnesium hydroxidePhysical chemistrySolid content

The invention relates to a method for preparing a superfine magnesium hydroxide sizing agent by a wet method. The method comprises the following steps of step 1, adding 1-10 parts by weight of a high efficiency surfactant, and 10-30 parts by weight of a grinding aid to 70-700 parts by weight of water, and performing uniform dispersion for standby application; step 2, weighing 50-150 parts by weight of magnesium hydroxide powder, adding the weighed magnesium hydroxide powder to a solution for standby application in step 1 and performing dispersion so as to prepare a magnesium hydroxide suspension to be ground; step 3, adding 400-600 parts by weight of grinding medium balls to the magnesium hydroxide suspension to be ground in step 2 for grinding until a superfine magnesium hydroxide sizing agent with a target particle diameter is obtained; and step 4, adding 0.1-5 parts by weight of a composite stabilizing additive to the superfine magnesium hydroxide sizing agent in step 3. The method disclosed by the invention is favorable for environmental protection and low in production cost, and under the premise that a high solid content is unchanged, the stability of the magnesium hydroxide sizing agent is improved.

Owner:DSSUN NEW MATERIAL SHANDONG

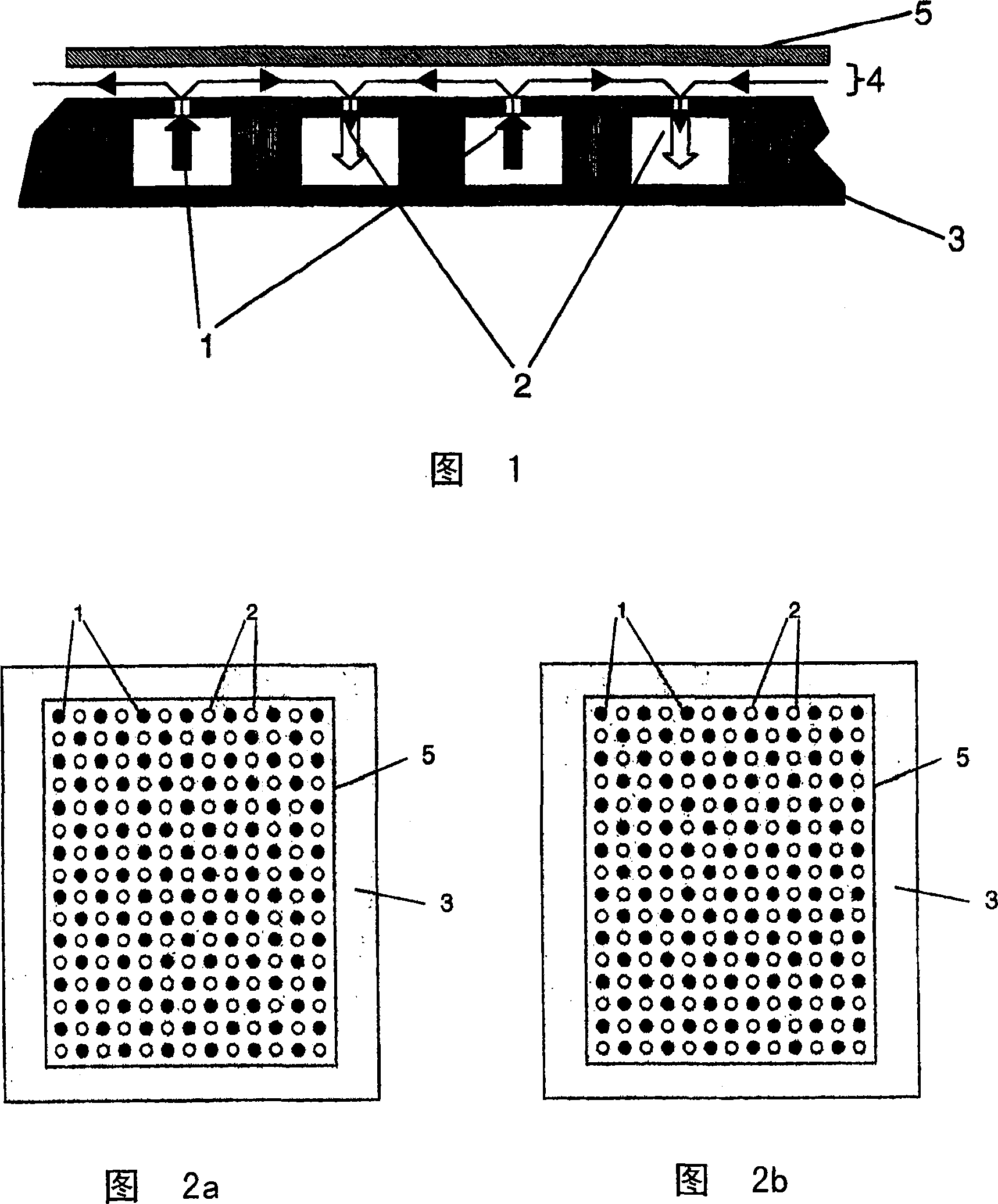

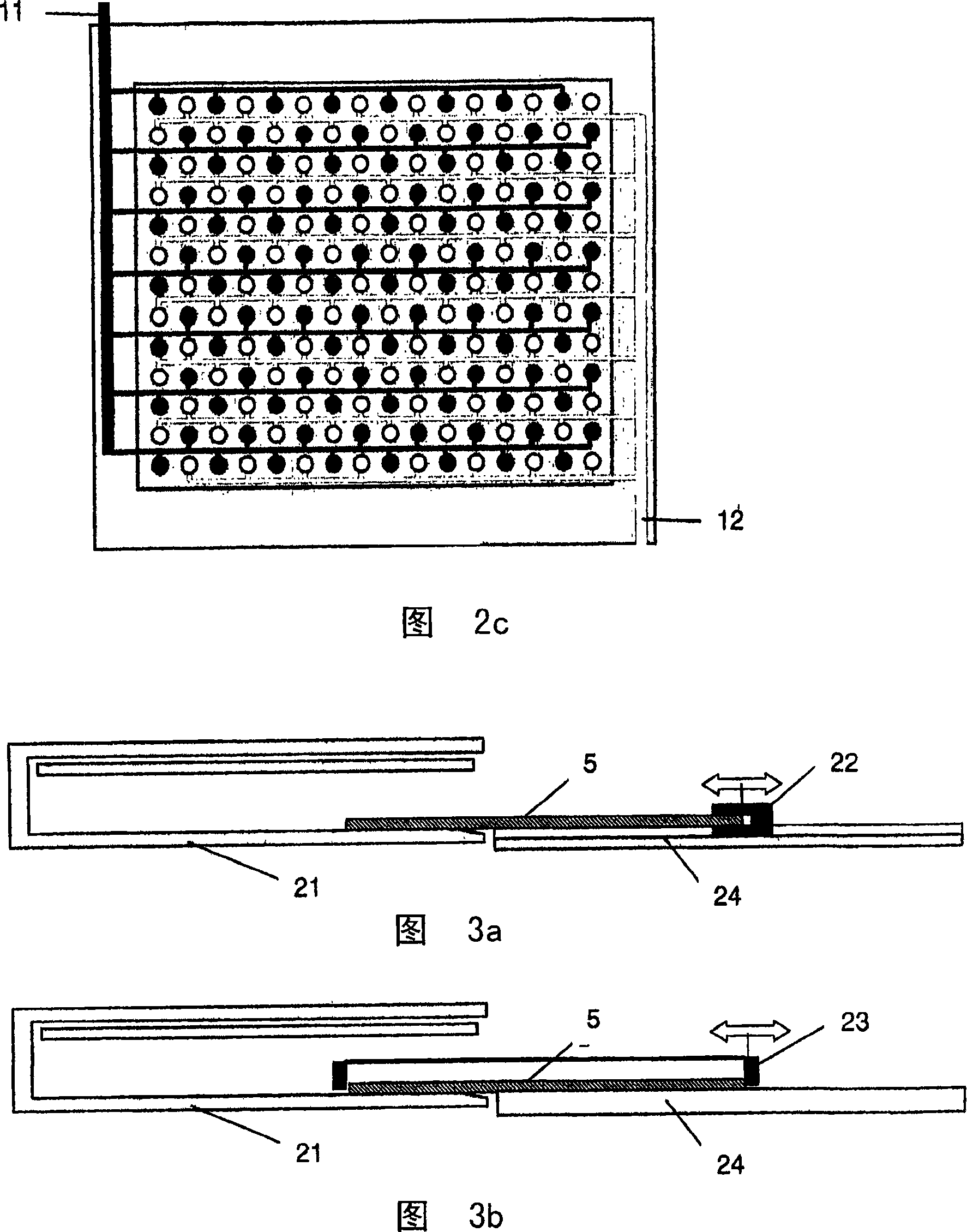

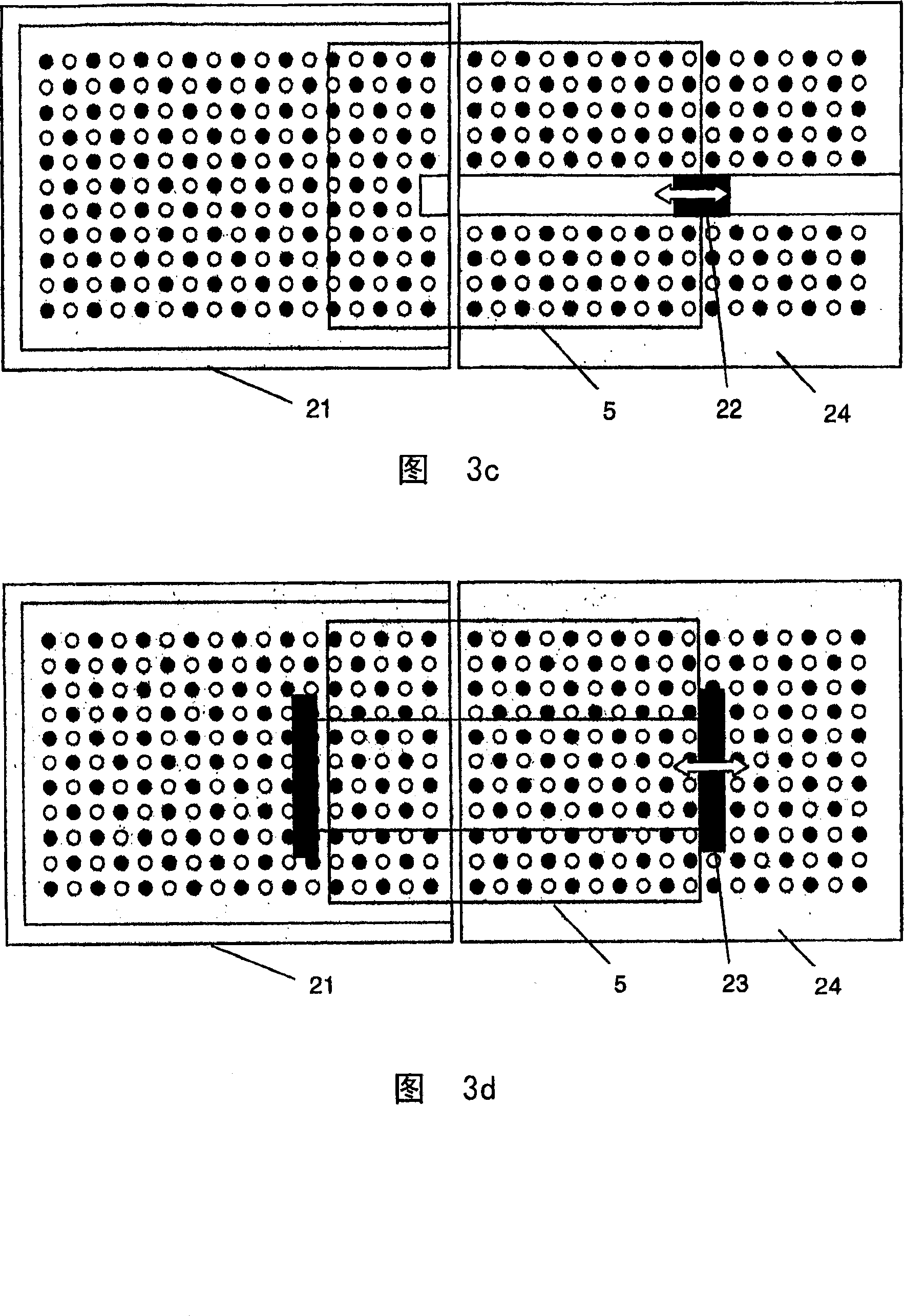

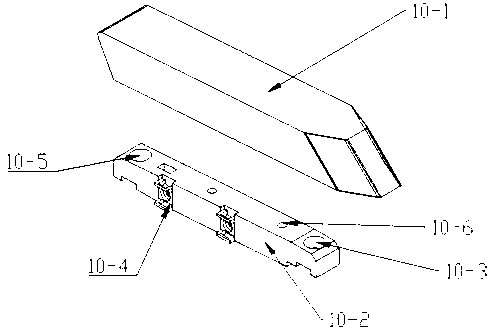

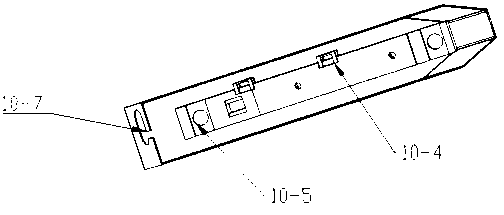

Gas bearing substrate-loading mechanism process

InactiveCN101023011AReduce the overall heightReduce gapConveyorsSemiconductor/solid-state device manufacturingLevitationAir bearing

A levitation apparatus for use under vacuum or near vacuum conditions comprises a levitation plate (3) with a plurality of injection points (1) and adjacent suction points (2) for gas, creating an air bearing (4) and thereby supporting a thin plate-like substrate (5). Further embodiments comprise a transport mechanism for supported substrates and / or a tilting mechanism to incline the levitation plate.

Owner:OERLIKON SOLAR IP

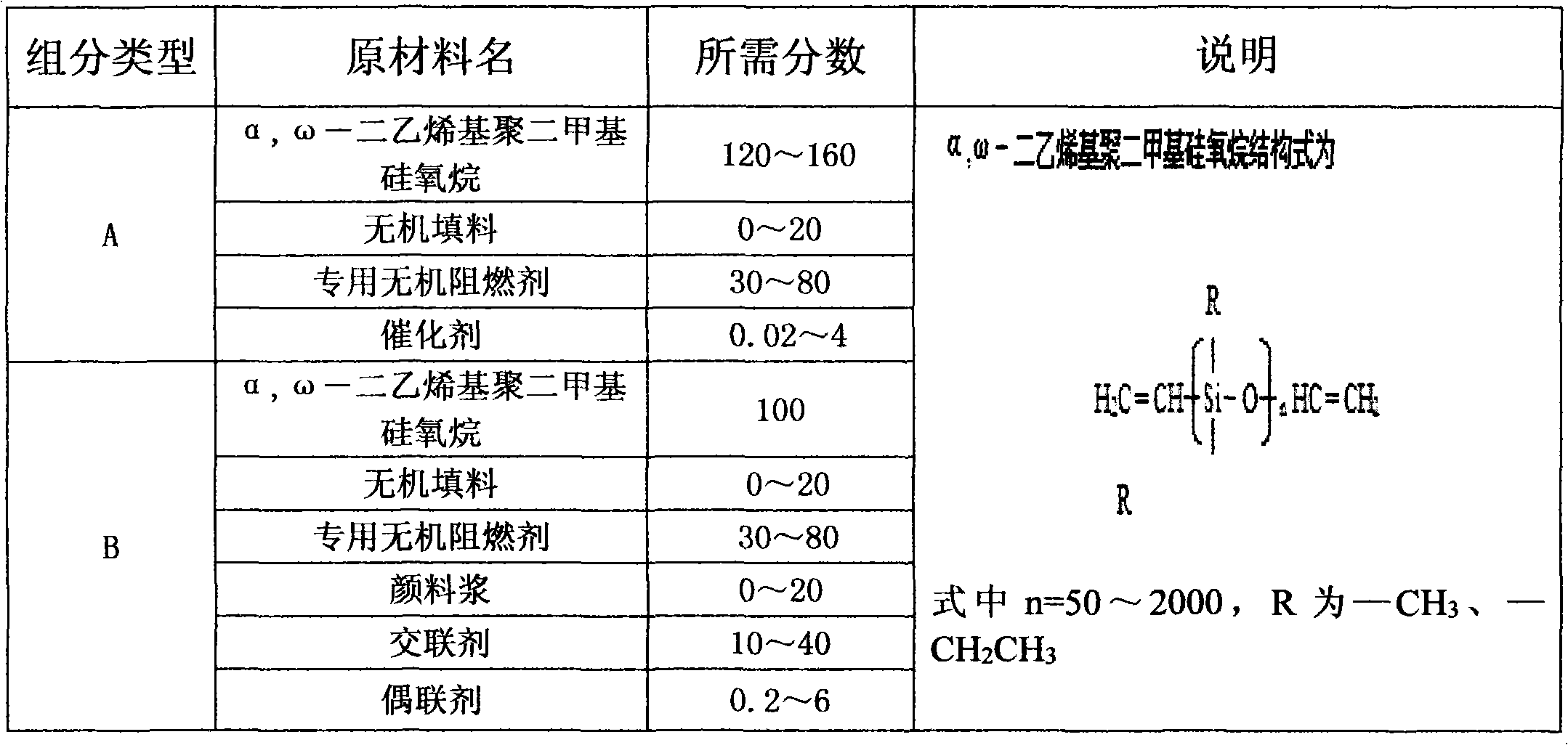

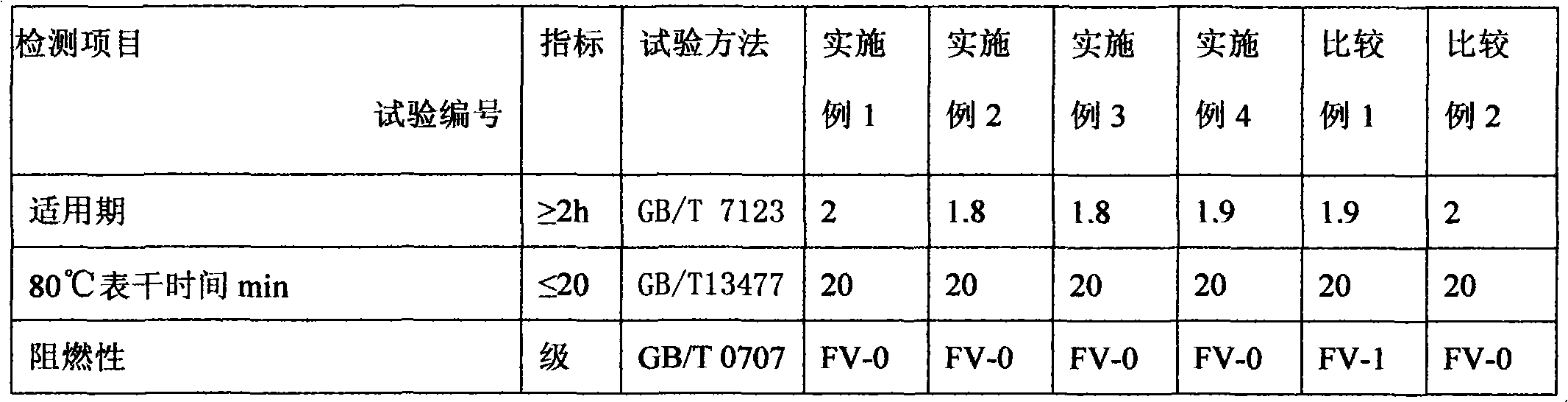

Additional organosilicon fireproof pouring sealant for electronics and preparation method thereof

InactiveCN102399445ANo pollution in the processNo low toxicityOther chemical processesSealantPollution

The invention discloses an additional organosilicon fireproof pouring sealant for electronics and a preparation method thereof. The preparation method comprises the following steps that alpha, ohm-divinylpolydimethylsiloxane as a base material, a special inorganic fire retardant as a fire retardant, an appropriate amount of an inorganic filling material as an improvement agent, and appropriate amounts of a cross-linking agent, a coupling agent and a catalyst are respectively prepared into a component A and a component B; the component A and the component B undergo a heating sulfuration addition reaction to produce the additional organosilicon fireproof pouring sealant for electronics, wherein the additional organosilicon fireproof pouring sealant for electronics does not produce pollution on a base material, and has excellent flame resistance, waterproof properties and dustproof properties. Through utilization of the special inorganic fire retardant, when a flame retardation grade reaches a level FV-0, storage properties of the additional organosilicon fireproof pouring sealant for electronics is improved, and deaeration properties and fluidity of the additional organosilicon fireproof pouring sealant for electronics are greatly improved in use. The component A and the component B compose the additional organosilicon fireproof pouring sealant for electronics, wherein the additional organosilicon fireproof pouring sealant for electronics does not produce pollution on a base material, and has stable flame resistance and storage properties and excellent operationality, and a high flame retardation grade reaching the level FV-0. Through the inorganic fire retardant which is adopted by the preparation method and is subjected to special treatment, an addition proportion, finished product storage stability and used product fluidity are effectively improved.

Owner:SHANGHAI YOUNAI ORGANOSILICON MATERIAL

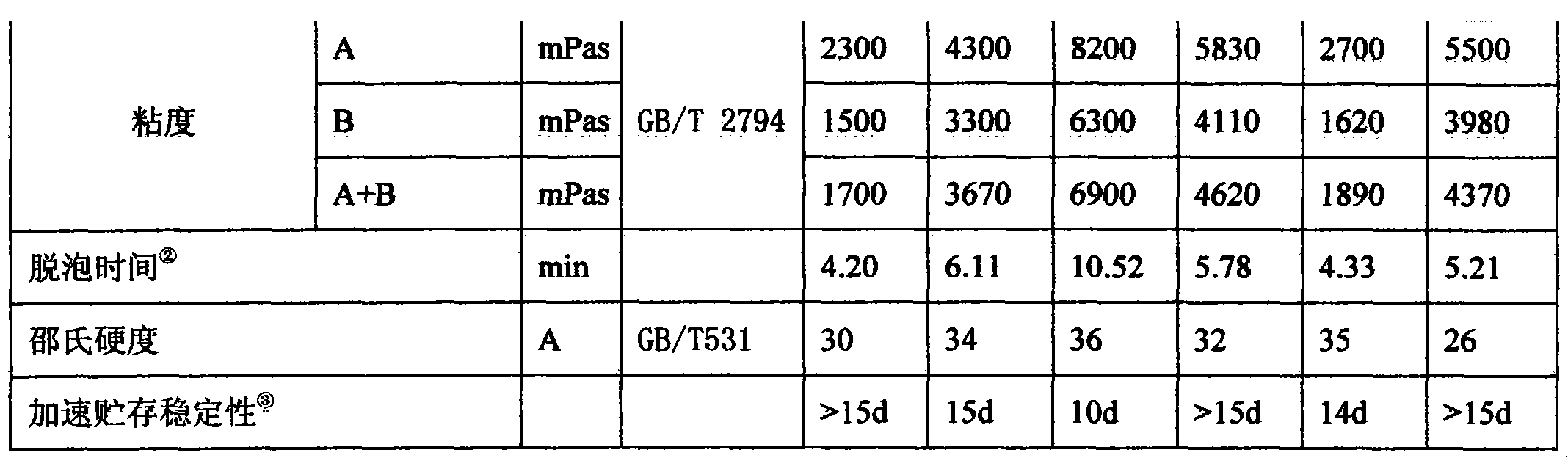

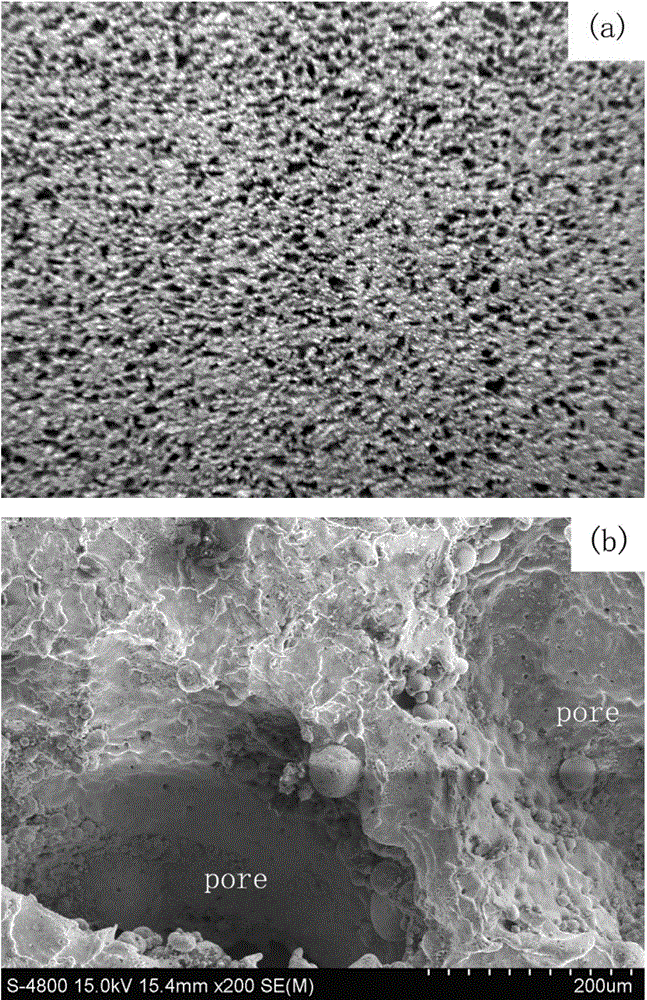

Preparation method of pore-opening foamy copper having controllable porosity and pore diameter

The invention discloses a preparation method of pore-opening foamy copper having controllable porosity and pore diameter. The method comprises the steps: adopting a powder metallurgy method, mixing uniformly rock candy particles with an electrolytic copper powder and an additive anhydrous ethanol, then pressing to obtain a green blank, placing the green blank in boiling water, rinsing to thoroughly dissolve and remove the rock candy particles, after washing and drying, placing the obtained article in an inert gas atmosphere for sintering, cooling together with a furnace to the room temperature, and thus obtaining the pore-opening foamy copper product constructed by a three-dimensional interconnected space network and having the porosity of 50-85% and the average pore diameter of 0.2-2 mm. The obtained pore-opening foamy copper has higher sintering quality, and has quite good mechanical properties and compressive energy absorption characteristic.

Owner:HEBEI UNIV OF TECH

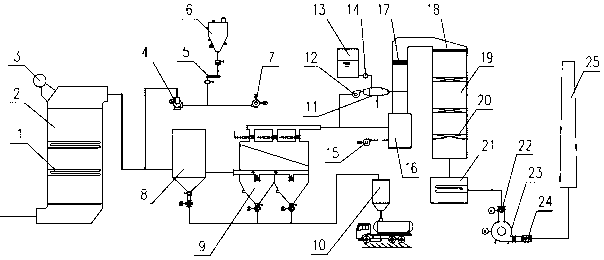

Coke oven flue gas comprehensive treatment system based on sodium-based dry process and low-temperature SCR denitration

InactiveCN108201781ASimple structureEasy to operateDispersed particle separationOven incrustations prevention/removalBaghouseCoke oven

The invention provides a coke oven flue gas comprehensive treatment system based on a sodium-based dry process and low-temperature SCR denitration. The coke oven flue gas comprehensive treatment system comprises a cooling mechanism, a desulfurizer supply mechanism, a desulfurizing tower, a bag-type dust collector, an ammonia gas supply mechanism and a denitration tower, wherein the gas inlet of the cooling mechanism is connected with a flue of coke oven flue gas; the gas outlet of the cooling mechanism is connected with the gas inlet of the desulfurizing tower through a first pipeline; the desulfurizer supply mechanism is connected with and arranged on the first pipeline; the gas outlet of the desulfurizing tower is connected with the gas inlet of the bag-type dust collector; the gas outlet of the bag-type dust collector is connected with the gas inlet of the denitration tower through a second pipeline; the ammonia gas supply mechanism is connected with and arranged on the second pipeline; and a regenerative furnace used for heating flue gas is arranged between the ammonia gas supply mechanism and the denitration tower. The system provided by the invention has simple structure, isconvenient to operate, has high removal efficiency to pollutants in the coke oven flue gas, is free of corrosivity, can stably operate for a long time, and has good emission effect and wide adaptationrange.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

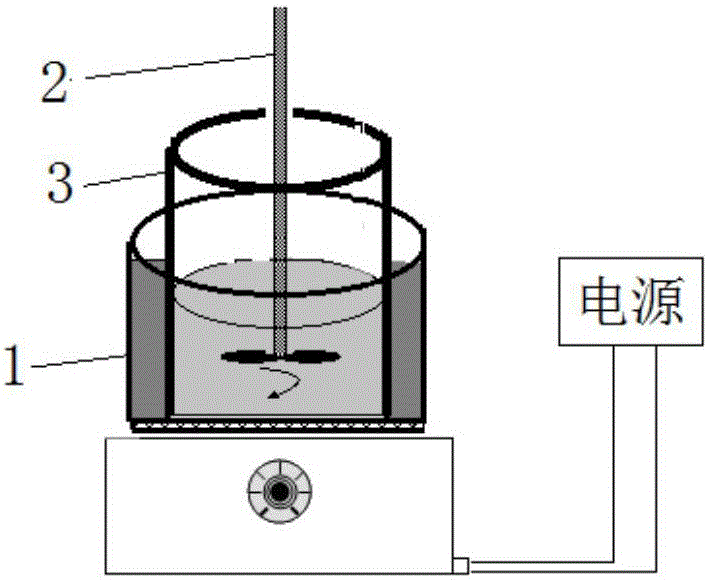

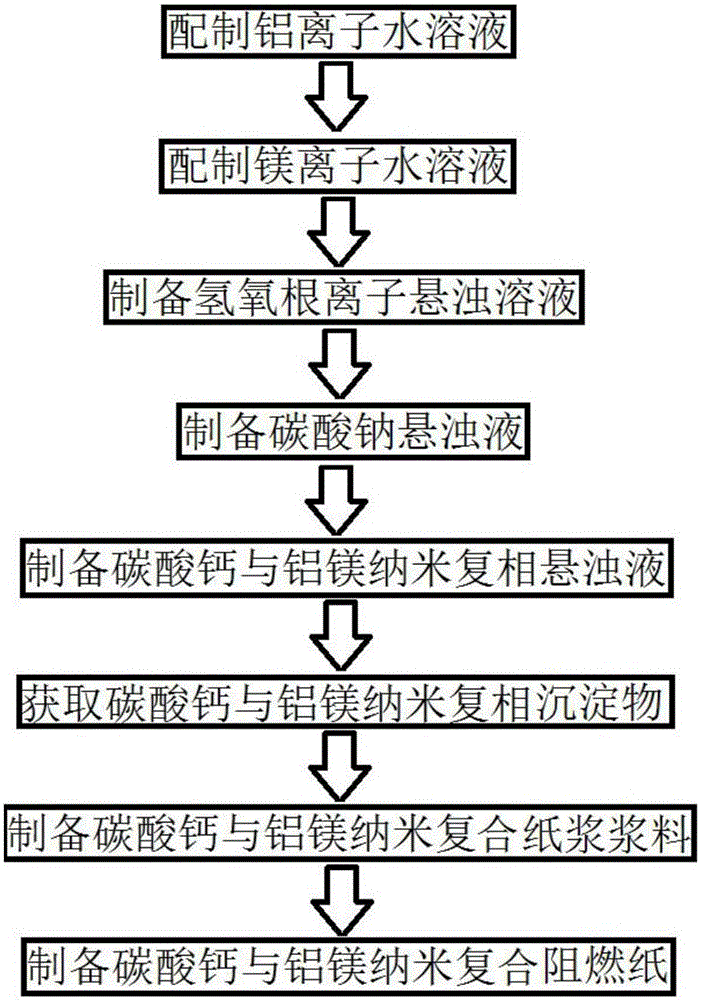

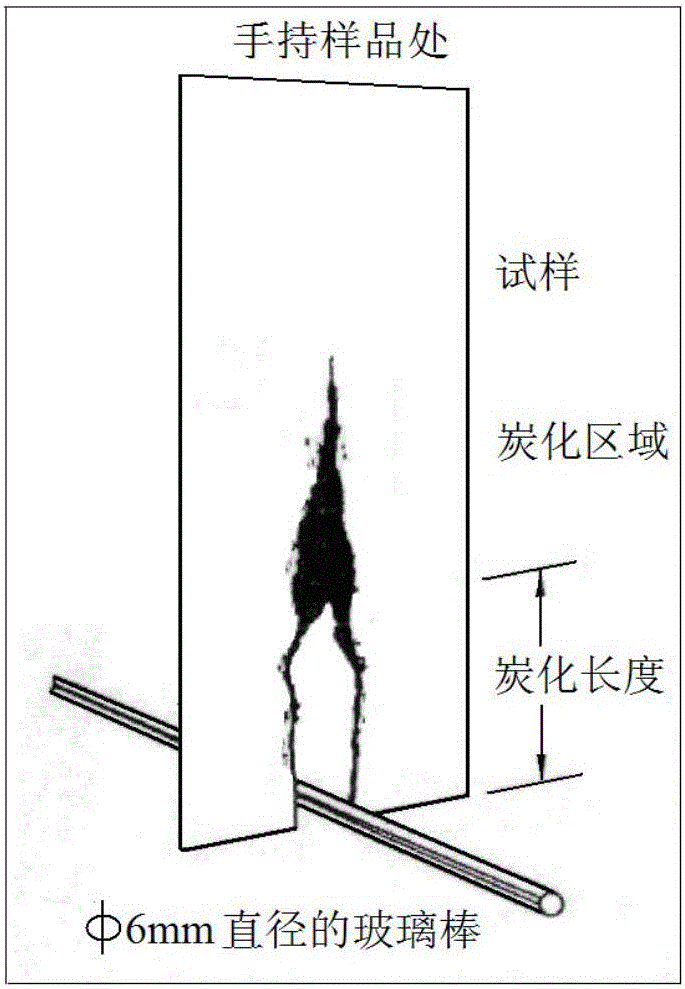

Calcium carbonate and aluminum magnesium composite flame-retardant paper, and preparation method thereof

ActiveCN106049161AHalogen freeNon-corrosivePaper/cardboardIgnifugeants additionAluminum IonPrecipitation

The invention discloses a calcium carbonate and aluminum magnesium composite flame-retardant paper, and a preparation method thereof. The invention aims at solving the problems of low flame-retarding effect, poor corrosion resistance, high preparation cost, and environment pollution of prior arts. The invention adopts the following realization scheme: a 1.62-7.02mol / L hydroxide ion suspension liquid is added into a prepared mixed liquid of a 0.42-1.82mol / L magnesium ion solution, a 0.18-0.78mol / L aluminum ion solution and a 0.24-1.04mol / L sodium carbonate suspension liquid; heating and stirring, precipitation and washing are sequentially carried out, such that calcium carbonate and aluminum magnesium nano-grade multiphase precipitate is obtained; waste shredded paper is added into the multiphase precipitate; heating and stirring are carried out, such that flame-retardant paper pulp is obtained; and water removing and air-drying are carried out, such that the calcium carbonate and aluminum magnesium composite flame-retardant paper is obtained. The flame-retardant paper has the advantages of good flame-retarding effect, no corrosion, no pollution and low preparation cost. The flame-retardant paper can be used in the construction industry of large office occasion indoor decoration, packaging, and fire prevention.

Owner:XIDIAN UNIV

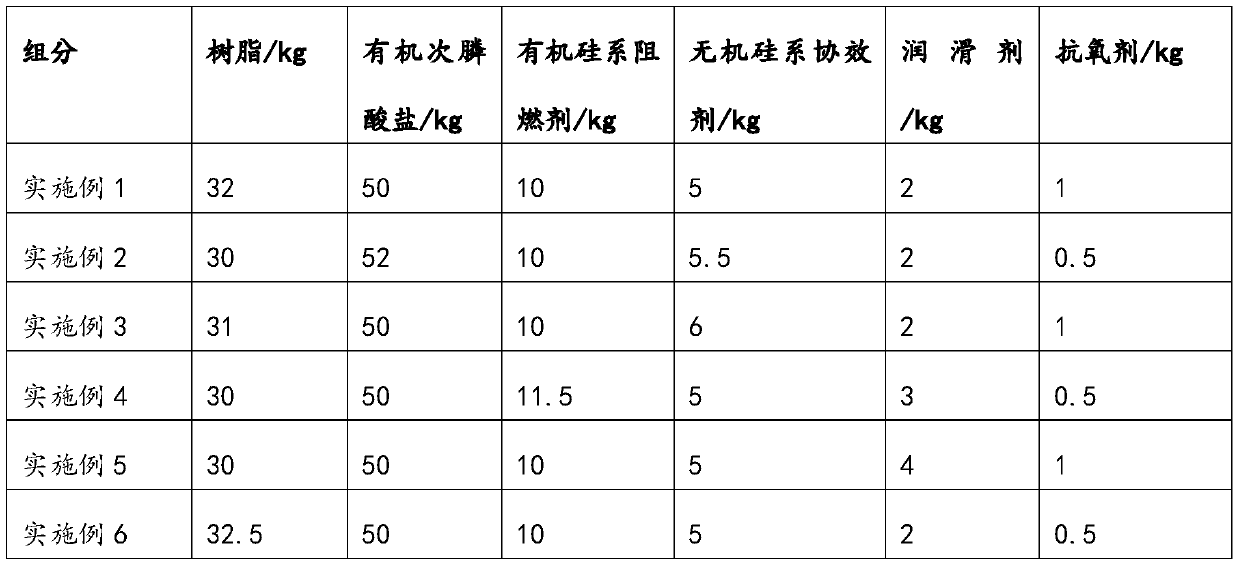

Halogen-free flame-retardant master batch and preparation method thereof, and glass fiber reinforced nylon material and preparation method thereof

Owner:江苏蔚观新材料科技有限公司

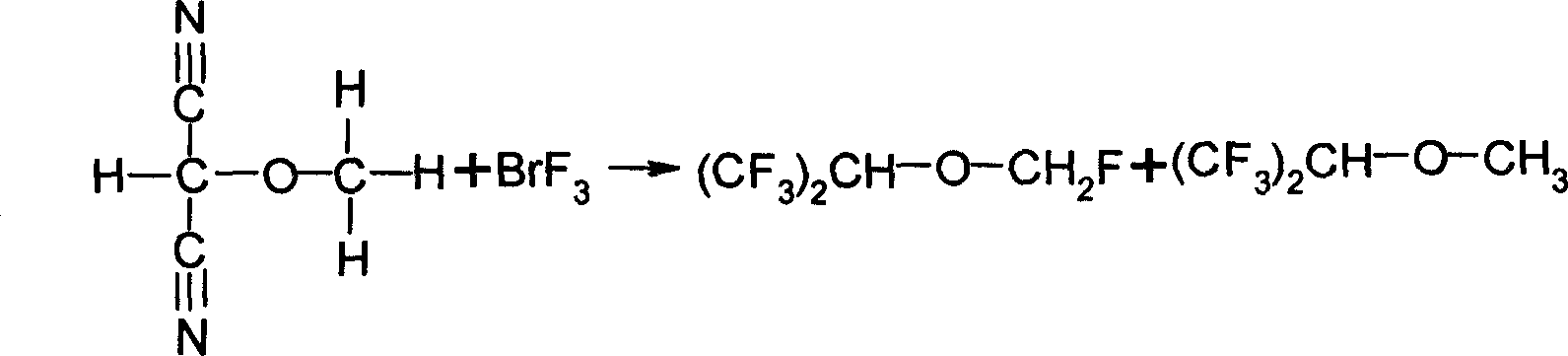

Method of synthesizing fluoromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether

InactiveCN101058533ALow priceEasy to removeOrganic compound preparationEther preparationPropanolEther

The invention discloses a synthesizing method of fluomethyl-1,1,1,3,3,3-hexafluoroisopropyl ether, which comprises the following steps: 1) reacting 1,1,1,3,3,3-hexafluorine-2-propanol and ,3,5-trioxymethylene or oligoformaldehyde and Lewis acid chloride to generate chloromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether as intermediate and HOAlCl2 as by-product; adding 6N HCl to disintegrate to remove by-product HOAlCl2; 2) reacting chloromethyl-1,1,1,3,3,3-hexafluoroisopropyl ether and fluorination agent and solvent to produce the product; improving the selectivity of intermediate; removing by-product easily.

Owner:SHANGHAI HUMEI CHEM IND TECH DEV

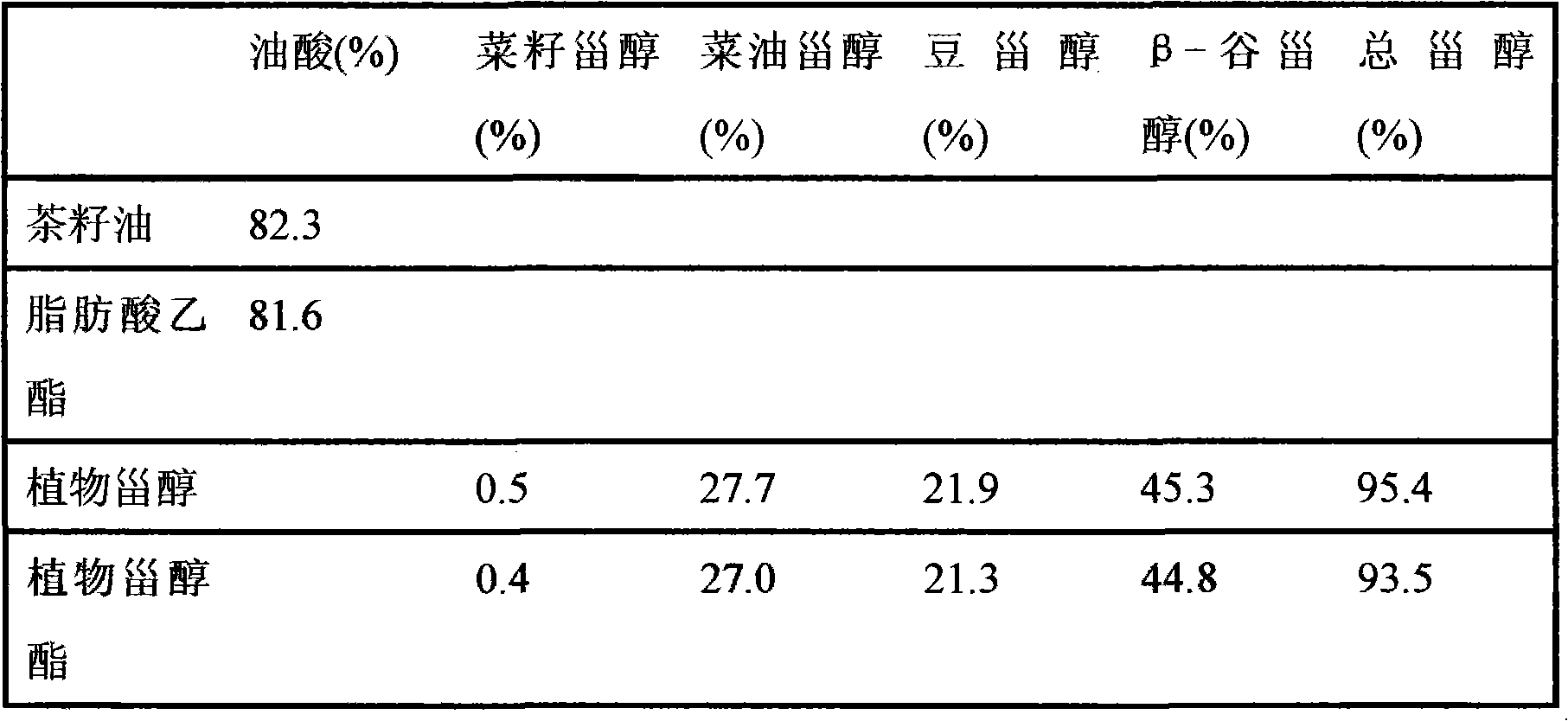

Preparation method of phytosterin ester rich in oleic acid

InactiveCN101538306AHigh yieldNon-corrosiveOrganic-compounds/hydrides/coordination-complexes catalystsSteroidsVegetable oilOrganic solvent

The invention provides a preparation method of phytosterin ester rich in oleic acid, which comprises the following steps: firstly, leading seed fat rich in oletic acid and ethanol to perform alcoholysis reaction under the action of catalyst to obtain fatty acid ethyl ester rich in oleic acid; secondly, leading the fatty acid ethyl ester rich in oleic acid and phytosterin to perform the ester exchange reaction under the action of the catalyst, and removing unreacted ethanol and redundant fatty acid ethyl ester so as to obtain crude phytosterin ester rich in oleic acid; thirdly, obtaining primrose yellow to white thick fluid by decoloring the phytosterin ester, i.e. refined phytosterin ester. The oleic acid content of the seed oil is more than 60 percent; and high-content oleic acid reduces the side reaction and improves the yield of the phytosterin ester. The preparation method does not use deleterious organic solvent and produce deleterious materials during the whole preparation, has lower requirement on reaction condition, and is suitable for industrial mass production of food.

Owner:中粮工科(西安)国际工程有限公司

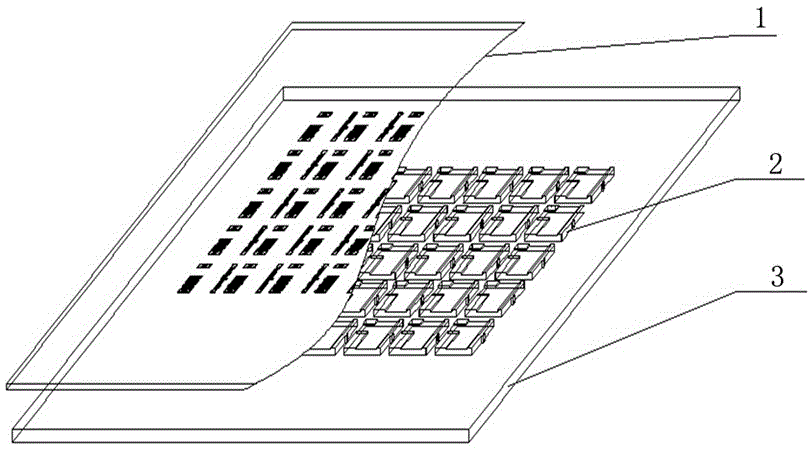

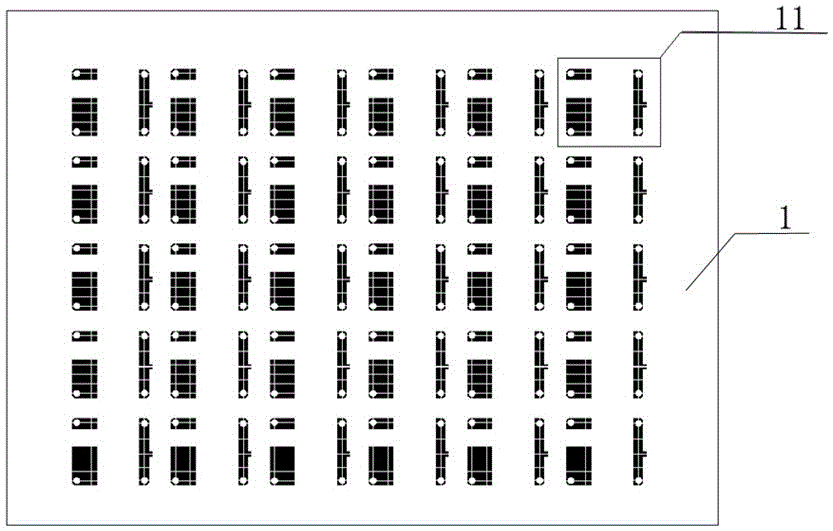

Machining method for soldering micro-strip boards by using printing solder paste

ActiveCN106513897AEasy to operateImprove the efficiency of printing solder pasteSoldering apparatusEngineeringSolder paste

The invention relates to a machining method for soldering micro-strip boards by using printing solder paste. The machining method comprises the following operation steps: (1) the micro-strip boards and substrates are cleaned; (2) four or more cleaned substrates are respectively placed in positioning grooves of positioning baseplates; (3) net plates are placed on the four or more substrates; and mesh units uniformly distributed on the net plates are respectively corresponding to the four or more substrates; (4) the net plates are uniformly coated with the printing solder paste; and (5) the net plates are taken down; the corresponding micro-strip boards are placed on the uniformly deposited solder paste; and each micro-strip board is corresponding to one substrate to form a welding module. The conventional steps of pressing block fixation, welding, pressing block disassembly, cleaning and detection are performed; reflow soldering is adopted; and the reflow soldering is performed by four temperature phases. The machining method saves such complex operation flows as solid-state soldering lug shearing, size control, oxide layer removal, screw hole protection, solder resisting adhesive tape protection and flux coating, reduces the machining cost, and is high in product soldering rate and suitable for batch production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Energy-saving discharge-reducing methanol diesel oil

InactiveCN101215483AEasy to prepareImprove cold start performanceLiquid carbonaceous fuelsVegetable oilHazardous substance

Energy-saving emission-reducing type carbinol diesel, the weight by parts proportion of auxiliary raw materials which are used is that carbinol is 1-35 parts, diesel is 61-80 parts, methyl tert-butyl ether is 2-5 parts, vegetable oil acid is 1-5 parts, thick tea water is 1-2 parts, hexane is 0.2-0.5 part, isopropanol is 0.3-0.5 part, tert-butanol is 0.25-0.6 part, and the above auxiliary raw materials should only be mixed evenly under normal temperature and nor pressure. The carbinol diesel does not separate layers in long-term storage and has good intersolubility, the tryout on diesel-engine road vehicles shows that compared with pure national standard diesel which uses the same mark number, the carbinol diesel saves fuel consumption by 5-10% for 100 kilometers, the discharging end gas does not have black smoke, the content of harmful substances as CO, NO X, HC and the like is greatly reduced, and the fuel does not exist corrosion and swelling problems to metal pieces and rubber pieces in oil ways. The invention has simple preparation, high heat quality of the product and low cost, and not only can save the fuel consumption and the emission of the harmful substances but also can overcome the drawbacks such as corrosiveness, swellability and poor motivation which occur when existing carbinol diesel is in use.

Owner:陈林 +1

Soil gas flux detector and determination method

The invention relates to a soil gas flux detector comprising a soil ring (1), supporting legs (2), a pedestal (20), a gas chamber (7), a protective cover (8), a line passing shaft (9), and a control box (19). The flux detector is characterized in that a sealing ring (5) and a pressing ring (3) are arranged above the pedestal (20); the supporting legs (2) are arranged below the pedestal (20); supporting led slide grooves (16) and supporting leg rotation shafts (14) are arranged on the supporting legs (2); a buffering device (8-7) is arranged in the gas chamber (7), the protective cover (8), and the line passing shaft (9); and a return button (19-4) is arranged on the control box (19). With the device provided by the invention, problems such as exposed gas pipe and line, gas chamber offset, and large measuring error of soil gas flux detector can be solved.

Owner:北京萨维福特科技有限公司

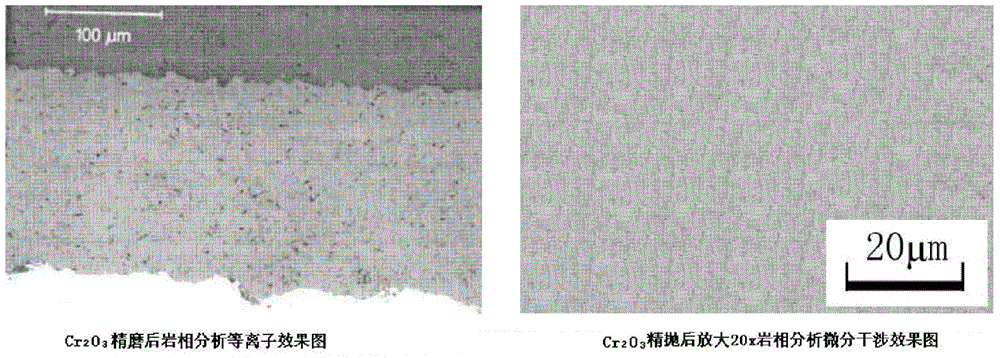

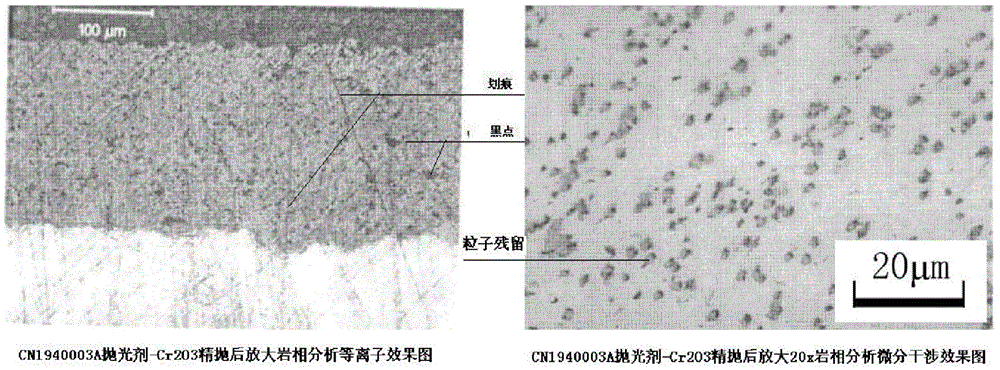

High-efficiency diamond polishing agent and preparation method thereof

ActiveCN104059539APlay a buffer roleImprove polishing effectPolishing compositions with abrasivesOctahedronHigh carbon

The invention discloses a high-efficiency diamond polishing agent which is prepared from the following raw materials in percentage by weight: 5-20 percent of ultra-precision diamond micro powder, 10-20 percent of ethyl orthosilicate, 20-30 percent of solvent, 0.2-0.8 percent of strong acid, 10-30 percent of surface active agent, 10-25 percent of wetting agent, 5-15 percent of dispersing agent and 0.1-5 percent of PH conditioning agent. According to the high-efficiency diamond polishing agent, the diamond micro powder is subjected to surface modification by using ethyl orthosilicate, so that a silicon dioxide coating layer is formed on the surface of the diamond micro powder, and during polishing, the coating layer plays a role in buffering the diamond micro powder on the inner layer; through performing multiple times of crushing and shaping on the diamond micro powder and improving surface modification process, the morphology of the diamond micro powder is closer to an octahedron; the prepared polishing agent has a better polishing effect to high-hardness metal materials such as high-carbon steel, also has a better polishing effect to crisp and hard materials such as Cr2O3, ceramics, jade and quartz, and is capable of completely preventing the damage on the surface of a material to be polished, and free from generating scratches, black points, and particle surface residues during polishing.

Owner:武汉三灵新材料有限责任公司

Method for preparing biodiesel by using palm oil

The invention provides a method for preparing biodiesel by using palm oil, which comprises: (1) pretreatment; (2) pre-esterification; (3) ester exchange reaction; and (4) coarse diesel decolorization. In the pre-esterification, standard raw material oil, methanol and sulfuric acid serving as a catalyst to form a mixed material, then sulfonated polyacrylamide in an amount which is 0.1 to 0.3 percent based on the mass of the standard raw material oil is added for continuous reaction to reduce an acid value, the reaction is finished after lasting for 1 to 2 hours, the reaction mixture is settled and demixed into a solid phase, a water phase and grease, the grease is subjected to ester exchange reaction to form coarse diesel, and finished biodiesel is obtained by decolorization. In the invention, a non-uniform phase reaction mode with a solid alkali as a catalyst is adopted, the catalytic activity of the catalyst is high, side reactions are fewer, separation is easy, corrosion to equipment is reduced, repeated use can be realized, and the amount of produced pollutants is reduced greatly; and an acid resistant water absorber can remove water generated in reaction in time in the pre-esterification process to make the reaction to perform toward a positive direction constantly, the reaction time is reduced effectively, energy consumption is lowered and the consumption of methanol is reduced.

Owner:郑德华

Portable mini vacuum pump negative pressure scar treatment device

InactiveCN104984417AGood treatment effectIncrease elasticityPneumatic massageIntravenous devicesPressure systemEngineering

The invention discloses a portable mini vacuum pump negative pressure scar treatment device which comprises a scar repair paster, a biological semipermeable membrane, a suction cup and a mini vacuum pump. The scar repair paster covers the scar skin. The suction cup covers the scar repair paster. The biological semipermeable membrane covers the scar repair paster and the suction cup. One end of the suction cup is provided with a drainage pipe and connected with the mini vacuum pump through a connecting pipe. The portable mini vacuum pump negative pressure scar treatment device is provided with a pressure detection device, the mini vacuum pump is adopted for generating negative pressure, the system adjusts and controls the negative pressure, a large-capacity lithium battery is used for continuously supplying power, no large center negative pressure system or electric negative pressure instrument is needed, no socket power is needed, and the portable mini vacuum pump negative pressure scar treatment device is small in size, portable and capable of being used for patients inside or outside hospitals for a long time, produces no complication or side effects, is low in price and convenient to use and avoids the risks of chemical substance leakage and corrosion and environment pollution possibly caused when a battery is used for a long time.

Owner:HENAN HUIBO MEDICAL CO LTD

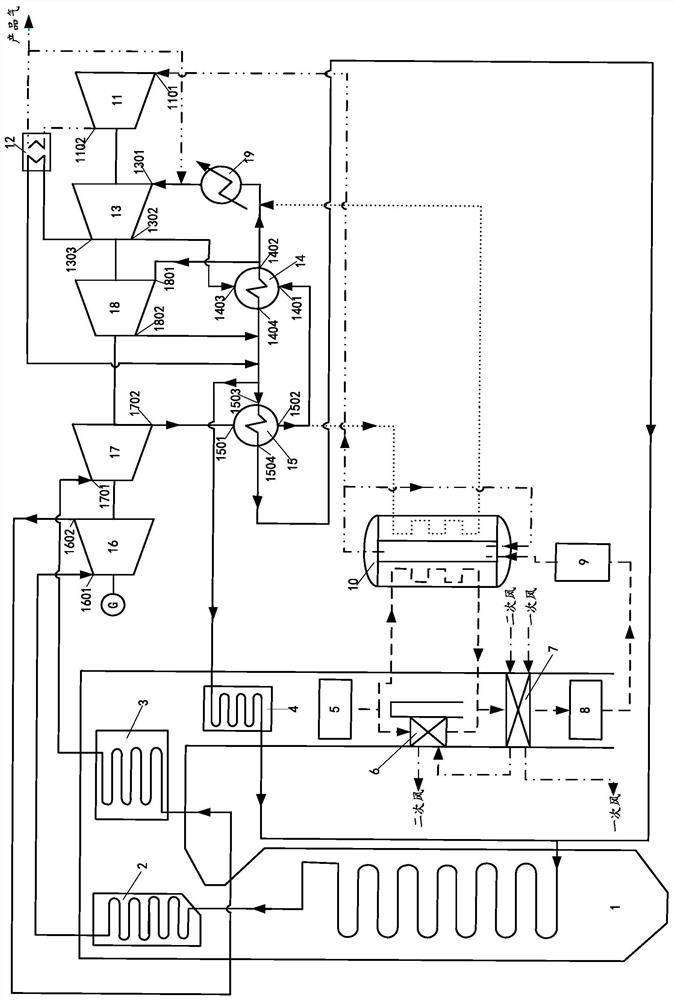

Power station system and method for coupling temperature swing adsorption carbon capture

PendingCN112178672AReduce the temperatureAchieve emission reduction targetsGas treatmentEmission preventionPower stationFlue gas

The invention provides a power station system for coupling temperature swing adsorption carbon capture and a method for coupling temperature swing adsorption carbon capture, and relates to the technical field of supercritical carbon dioxide cycle power generation. The power station system adopts supercritical carbon dioxide cycle power generation, and comprises a coal-fired boiler body, a flue, acarbon capture adsorption tower, a power generation turbine system, a working medium compression system and a product gas recycling system, wherein the coal-fired boiler body generates flue gas containing carbon dioxide; the flue gas is discharged through the flue; the carbon capture adsorption tower captures carbon dioxide in the flue gas through a physical temperature swing adsorption method; the flue gas of a medium-temperature section is used as a first desorption heat source; and high-temperature side outlet working medium exhaust gas of a high-temperature heat regenerator is used as a second desorption heat source. According to the power station system and method for coupling temperature swing adsorption carbon capture provided by the invention, through the physical temperature swingadsorption method, low-grade heat is fully utilized, the overall energy utilization rate is increased, the problem that the exhaust gas temperature is too high can be effectively solved, and emissionof the carbon dioxide is reduced on a large scale.

Owner:XI AN JIAOTONG UNIV

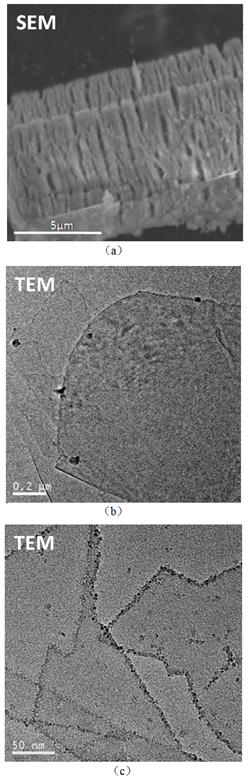

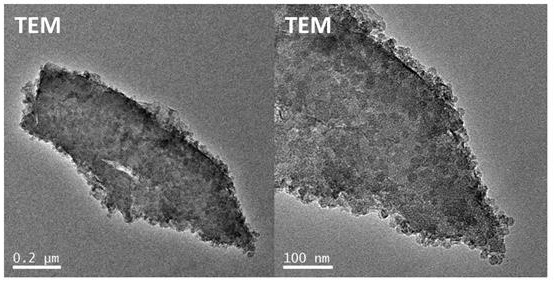

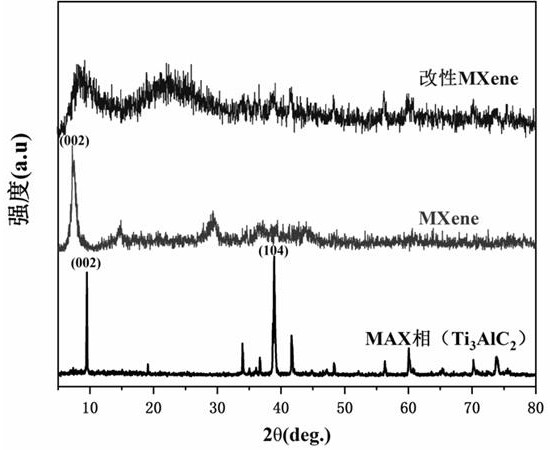

Modified Mxene/PVA flame-retardant composite material and preparation method thereof

The invention discloses a modified MXene / PVA flame-retardant composite material and a preparation method thereof, the flame-retardant composite material is formed by compounding a flame-retardant additive and a resin matrix, the resin matrix is polyvinyl alcohol resin, and the flame-retardant additive is modified MXene. The method comprises the steps: dispersing Mxene in deionized water, and carrying out ultrasonic treatment to obtain Mxene dispersion liquid; adding CTAB, and carrying out magnetic stirring reaction to obtain a mixed solution; adjusting the pH value of the mixed solution, carrying out magnetic stirring reaction, adding tetraethoxysilane, and carrying out magnetic stirring reaction to obtain a precipitate; dissolving the precipitate in an ethanol water solution, dropwise adding a silane coupling agent, carrying out magnetic stirring reaction, and washing to obtain modified MXene; dispersing polyvinyl alcohol in deionized water to obtain a polyvinyl alcohol solution; adding modified MXene; and uniformly dispersing and drying to obtain the multifunctional flame-retardant composite material. The composite material has excellent flame retardant property, good conductivity and electromagnetic shielding property, and can be used in the field of building coatings and other coatings.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com