Preparation method of graphene

A graphene and graphite powder technology, applied in the field of graphene preparation, can solve the problems of complex process, difficult single-layer graphene, high production equipment, and high conditions, and achieves low requirements for preparation conditions, simple preparation process, and no structural defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

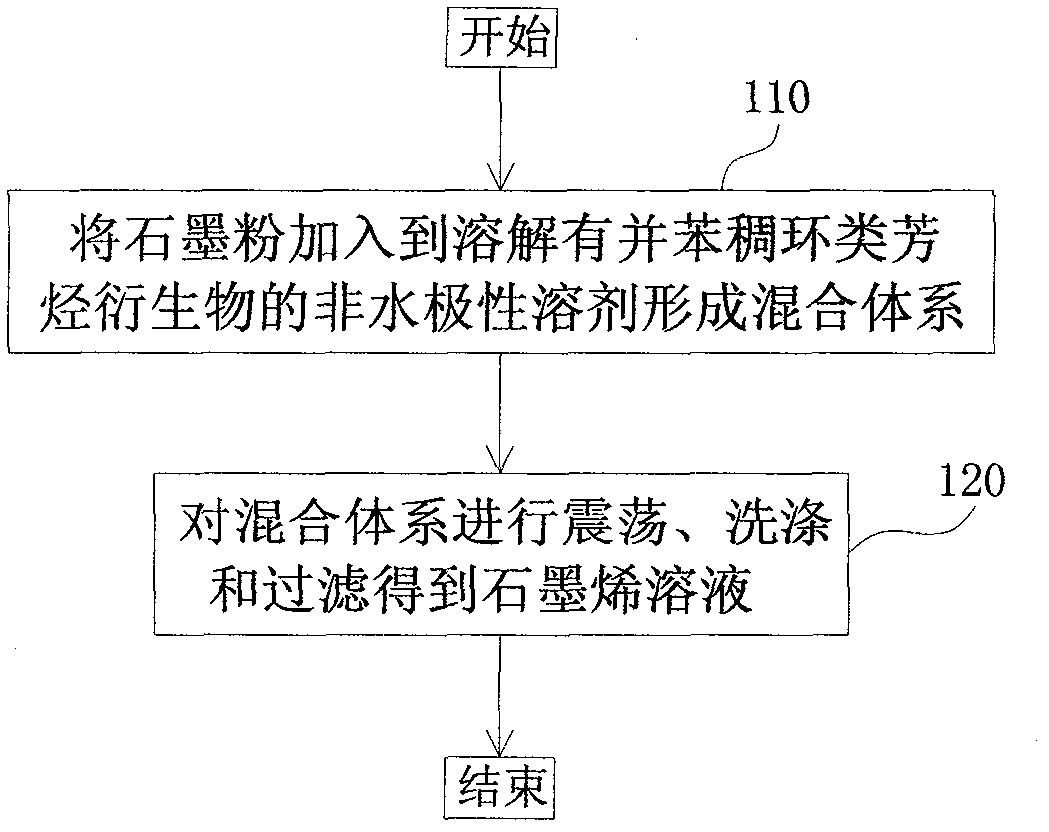

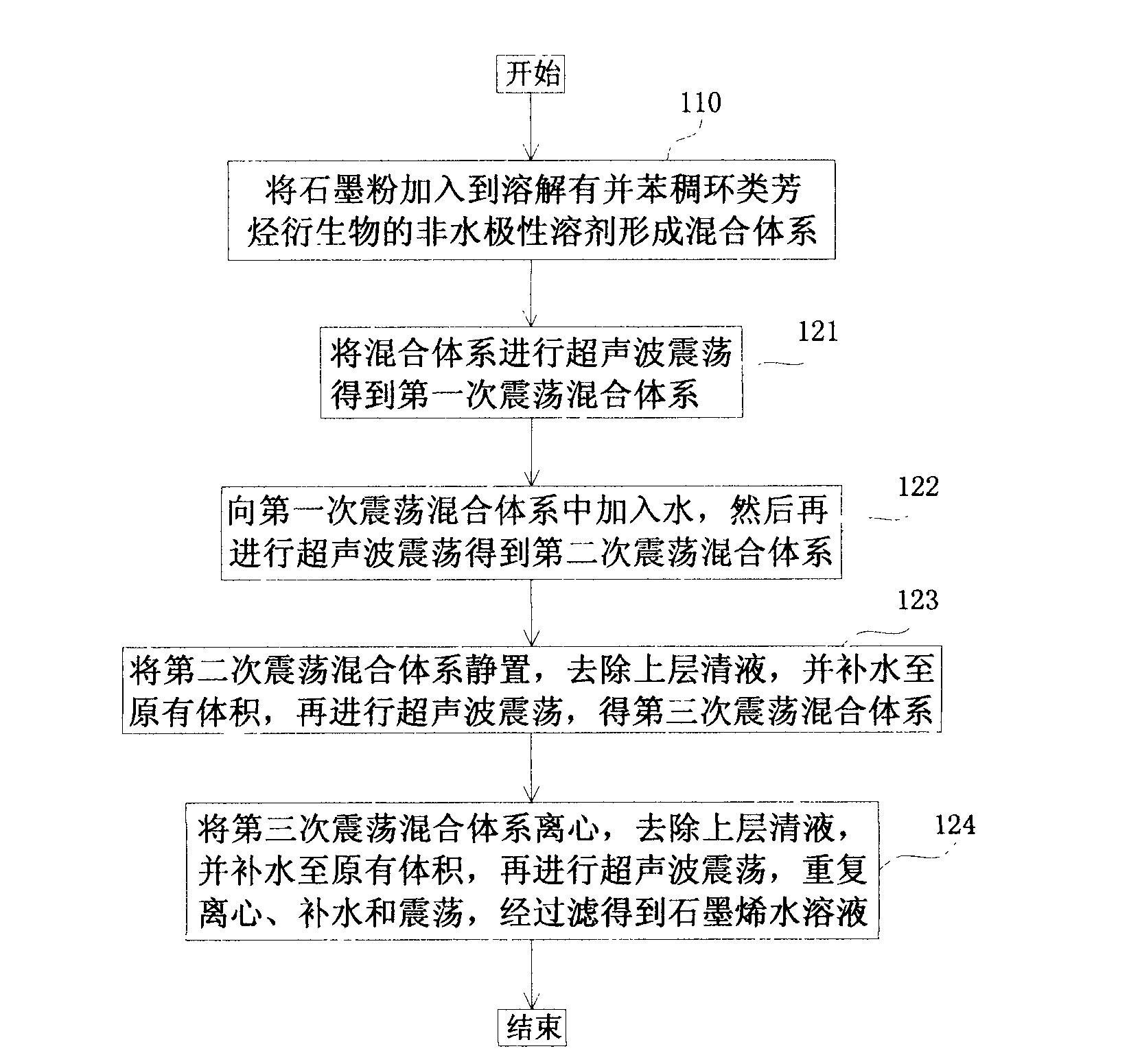

[0022] like figure 1 Shown, a kind of preparation method of graphene, utilizes the acene-condensed-ring arene derivative that contains hydrophilic group as intercalation reagent, and utilizes water and non-aqueous polar solvent as dispersion system, prepares graphite by step-by-step ultrasonic method alkenes, including the following steps:

[0023] In step 110, the graphite powder is added to the non-aqueous polar solvent in which the acene condensed ring arene derivative is dissolved to form a mixed system. Take 1 mg to 1000 mg of graphite particles (with a particle size between 5 μm and 300 μm) and add them to dissolved 1 mg to 500 mg of acene condensed ring aromatic hydrocarbon derivatives (such as naphthoic acid, naphthaldehyde, anthracene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com