Patents

Literature

33results about How to "No structural defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

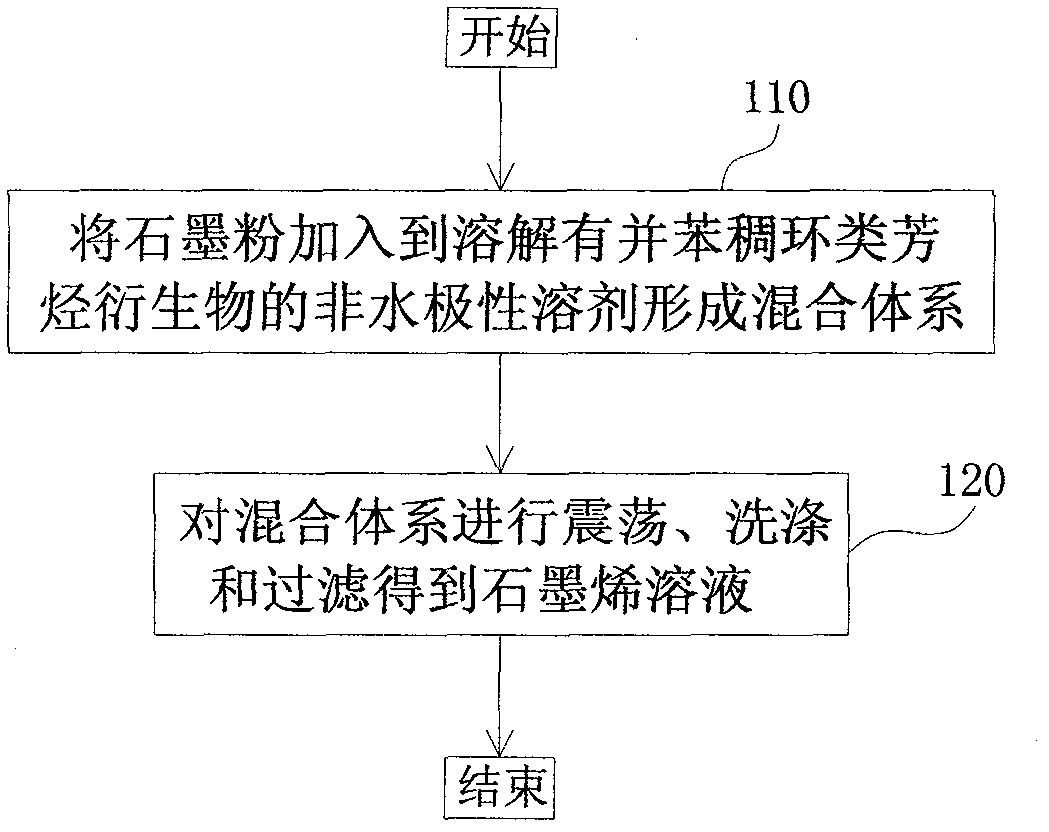

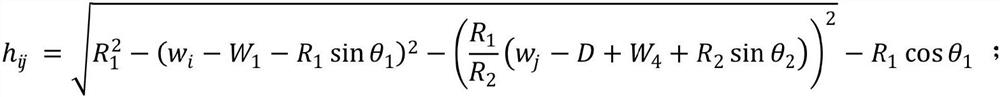

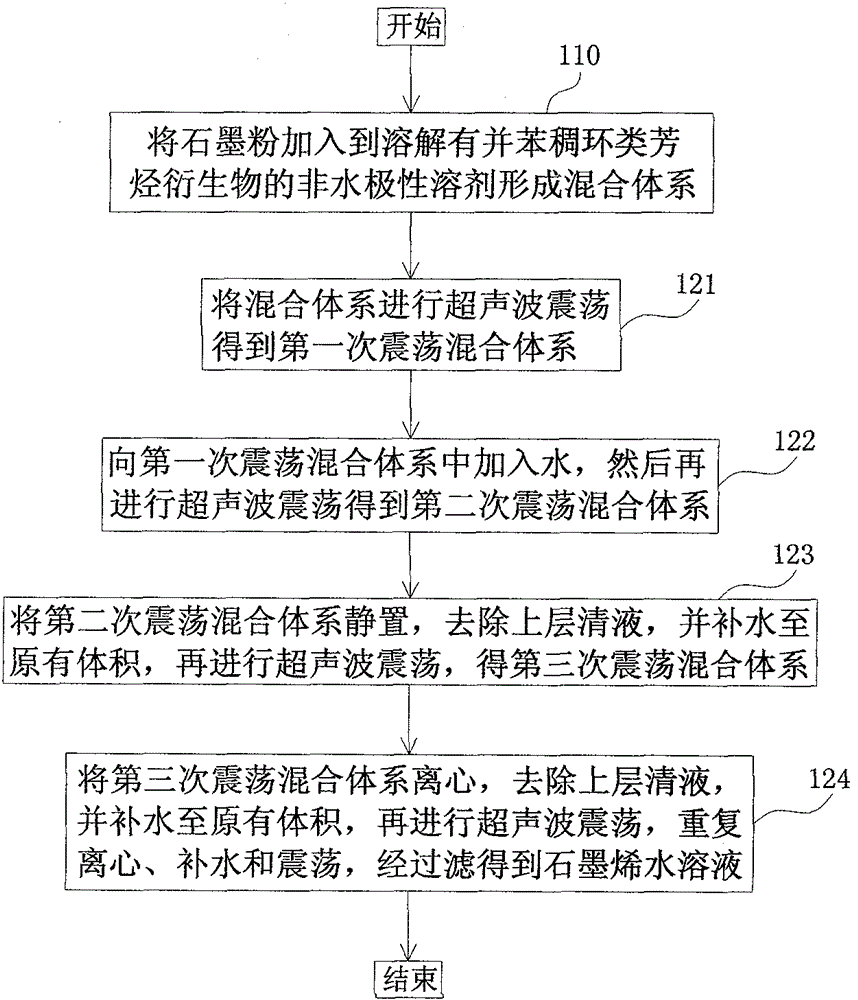

Preparation method of graphene

Disclosed is a preparation method of grapheme. The preparation method of the grapheme comprises the following steps: graphite powder is added to non-water polar solvent dissolved with acene condensed nucleus arene derivative to form a mixed system; the mixed system is shocked, washed, centrifuged and filtered to obtain grapheme solution. The preparation method of the grapheme is not high in requirements for preparation conditions, simple in preparation process, good in quality of obtained grapheme, almost free of structural defects and considerable in productivity.

Owner:XIDIAN UNIV

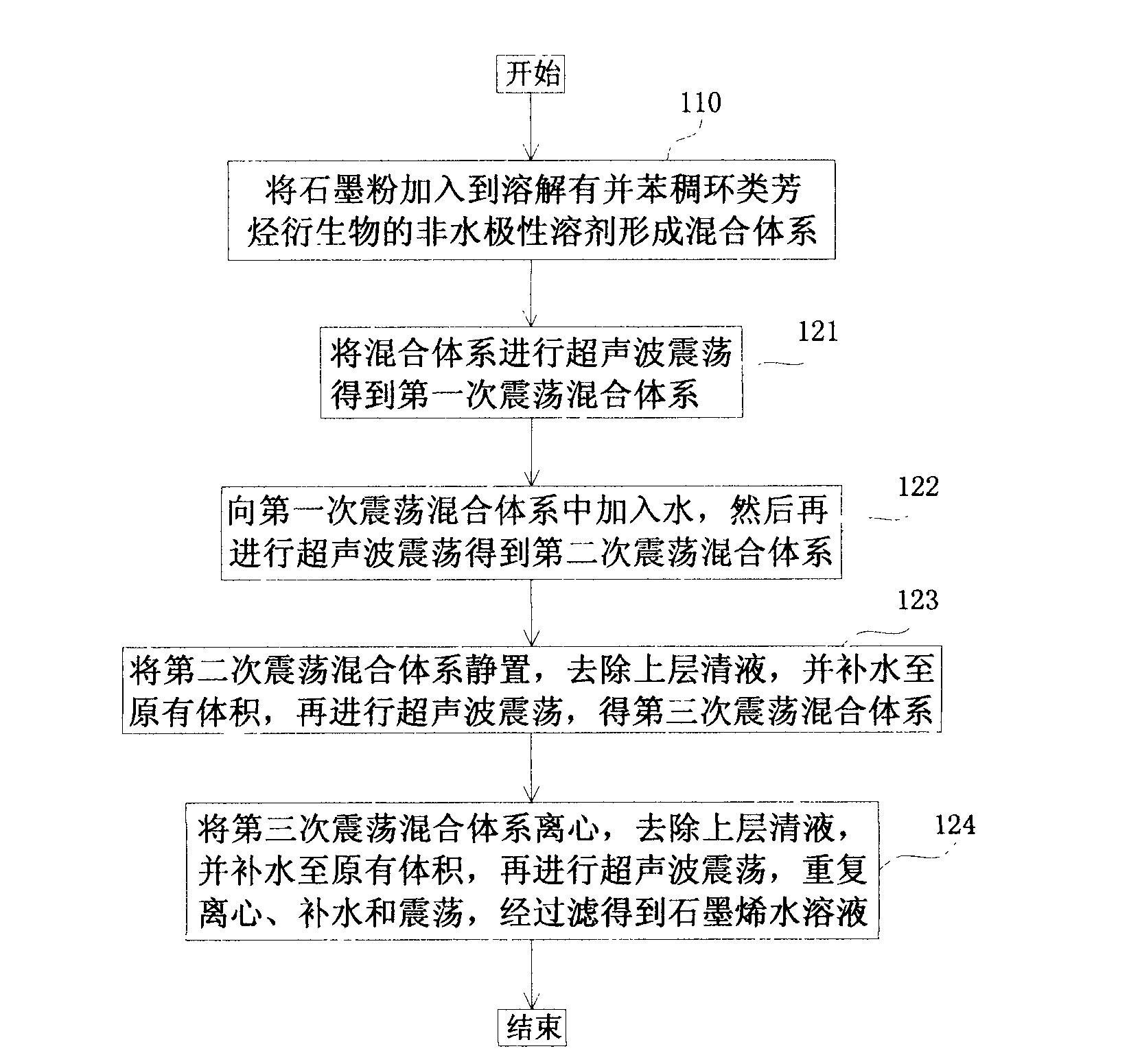

Method for preparing graphene through phase peeling of graphite by using mixed solvent

InactiveCN103172053ATo overcome the deficiency of low concentrationReduce reunionGrapheneSolventCvd graphene

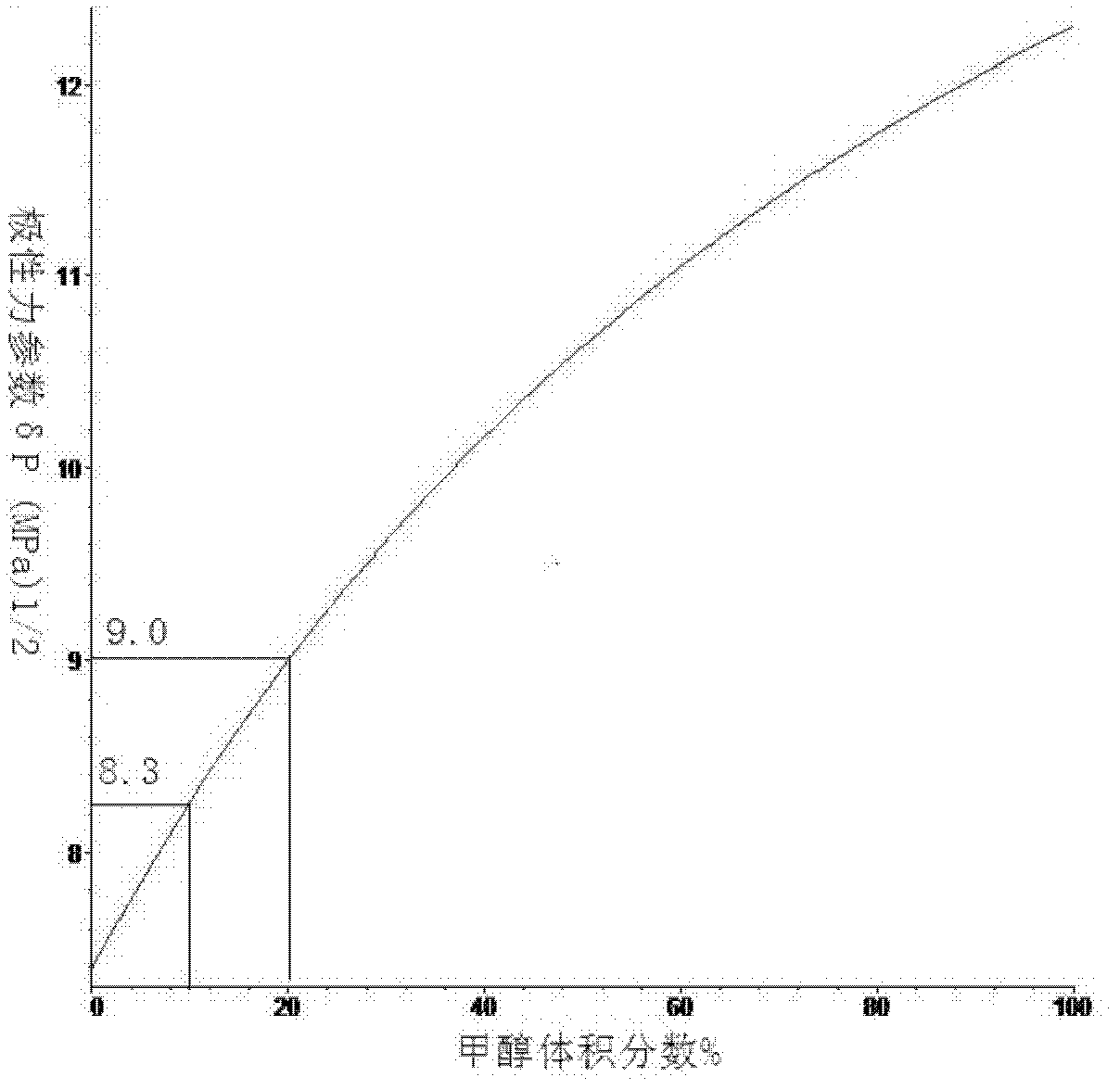

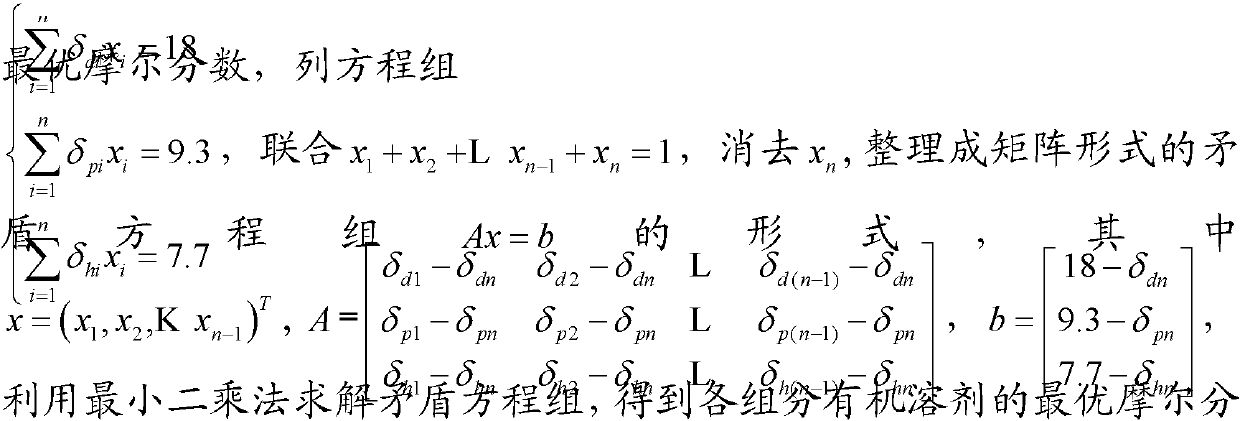

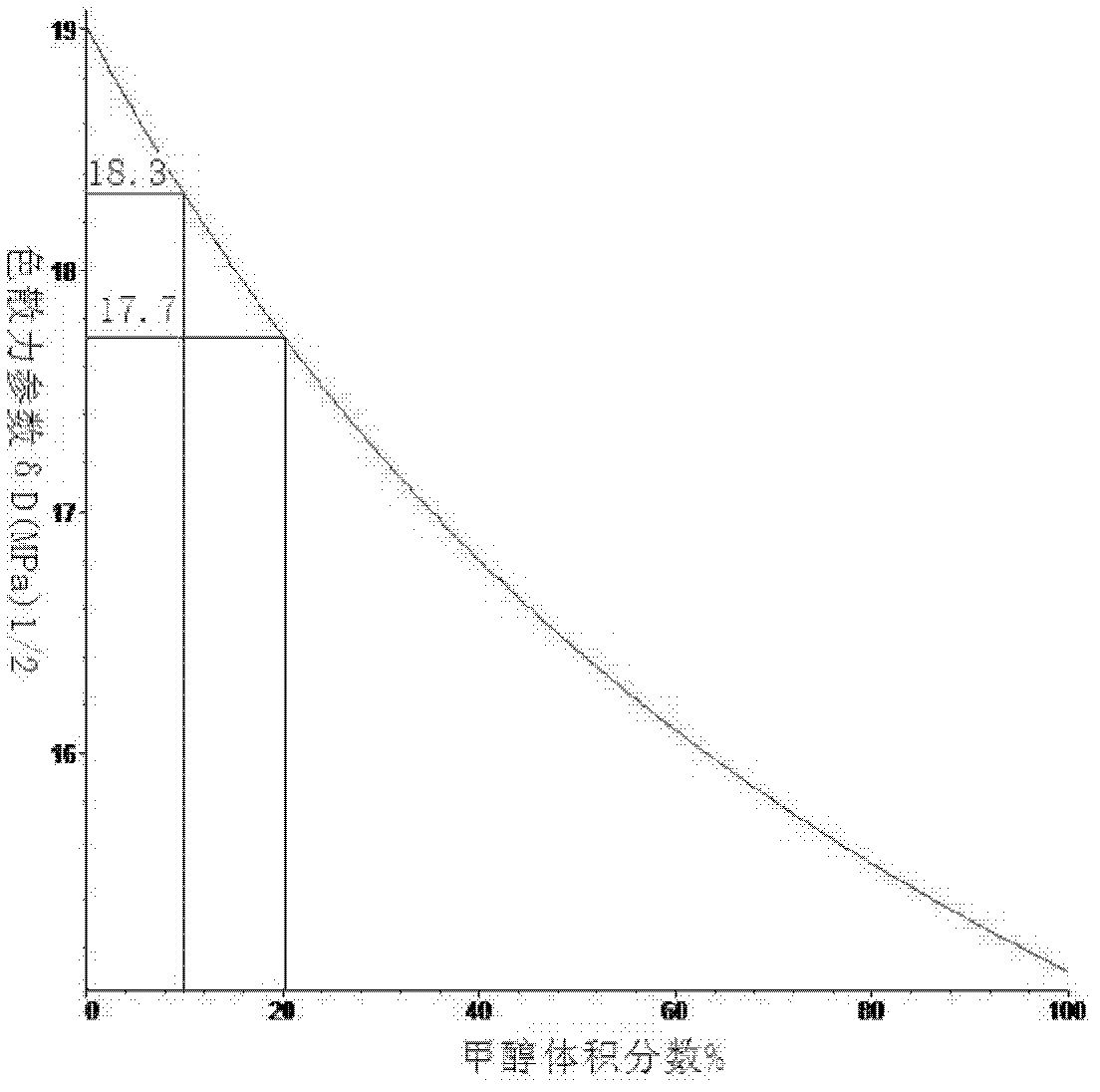

The invention relates to a method for preparing graphene through phase peeling of graphite by using a mixed solvent. The method comprises the following steps: 1, preparing a mixed solvent composed of at least two organic solvents having boiling points of not greater than 100DEG C; 2, adding powdery graphite to the mixed solvent to prepare a mixed solution of the powdery graphite, putting the mixed solution of the powdery graphite in an ultrasonic machine, carrying out water-bath ultrasonic treatment, and centrifuging through using a centrifuge; and 3, taking a supernatant obtained after the centrifuging with a pipette to obtain a graphene dispersion uniformly dispersed in the mixed solvent. The method enables the Hansen solubility parameters of the mixed solvent to reach the Hansen solubility parameters of graphene as possible through adjusting the volume ratio of the organic solvents in order to obtain a solvent which is most suitable for peeling and dispersing graphene, and the solvent is used to carry out the phase peeling of graphene.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

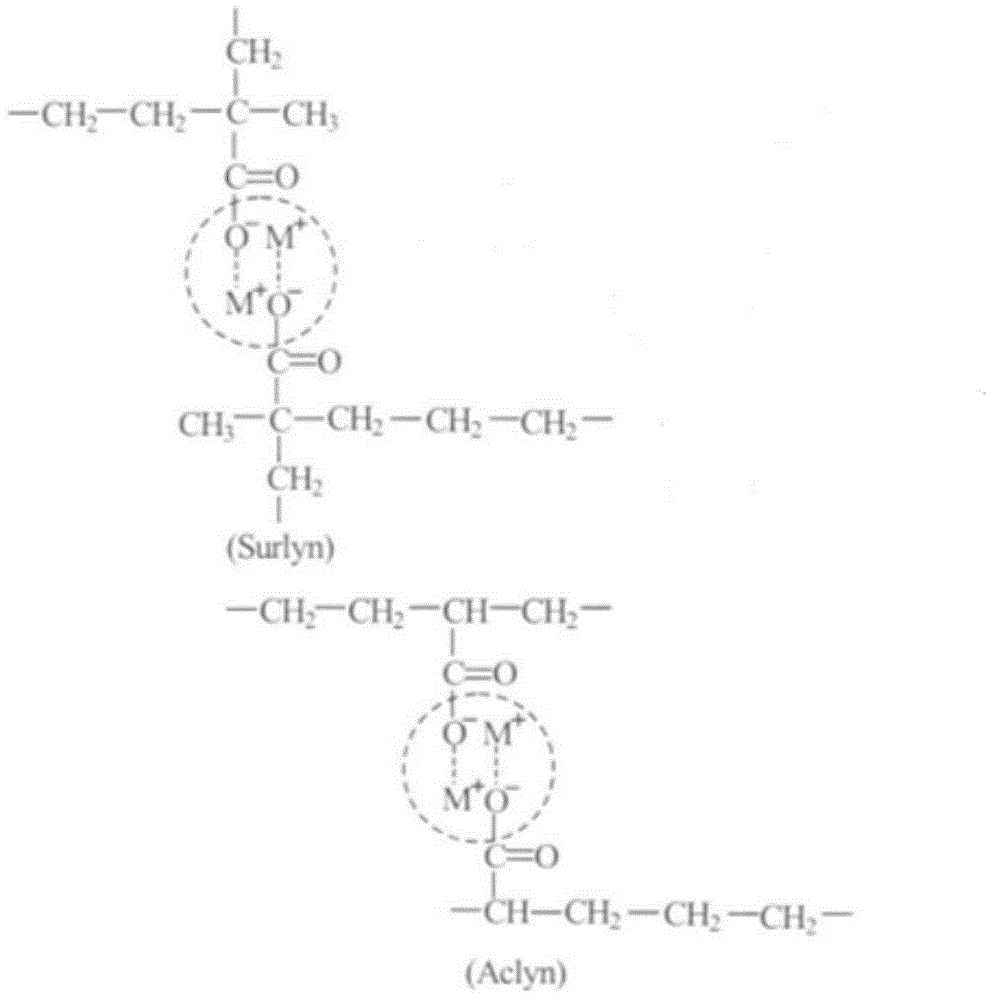

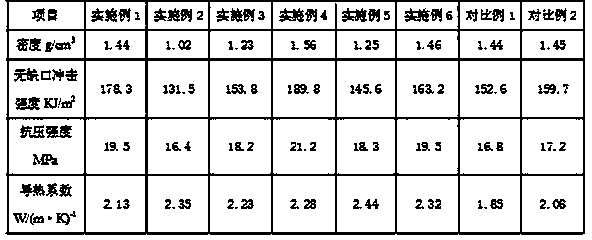

High-toughness polyester resin alloy composition and preparation method thereof

The present invention provides a high-toughness polyester alloy composition and a preparation method thereof, wherein the composition mainly comprises the following raw materials by weight: (A) polybutylene terephthalate, (B) polyethylene terephthalate, and (C) an ionomer compound using an ethylene octene copolymer as a matrix. The preparation method comprises: adding (A) polybutylene terephthalate, (B) polyethylene terephthalate, (C) an ionomer compound using an ethylene octene copolymer as a matrix and other additives to a high speed material mixer, adding to a twin-screw extruder after the mixing, and carrying out melt extrusion granulation. According to the present invention, the polyester resin alloy reinforcing material composition has good impact resistance and good fluidity, and the product prepared by using the high-toughness polyester resin alloy reinforcing material composition has characteristics of low warping, high strength and high toughness, and is suitable for vehicles, mobile phones, and notebook computer products.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

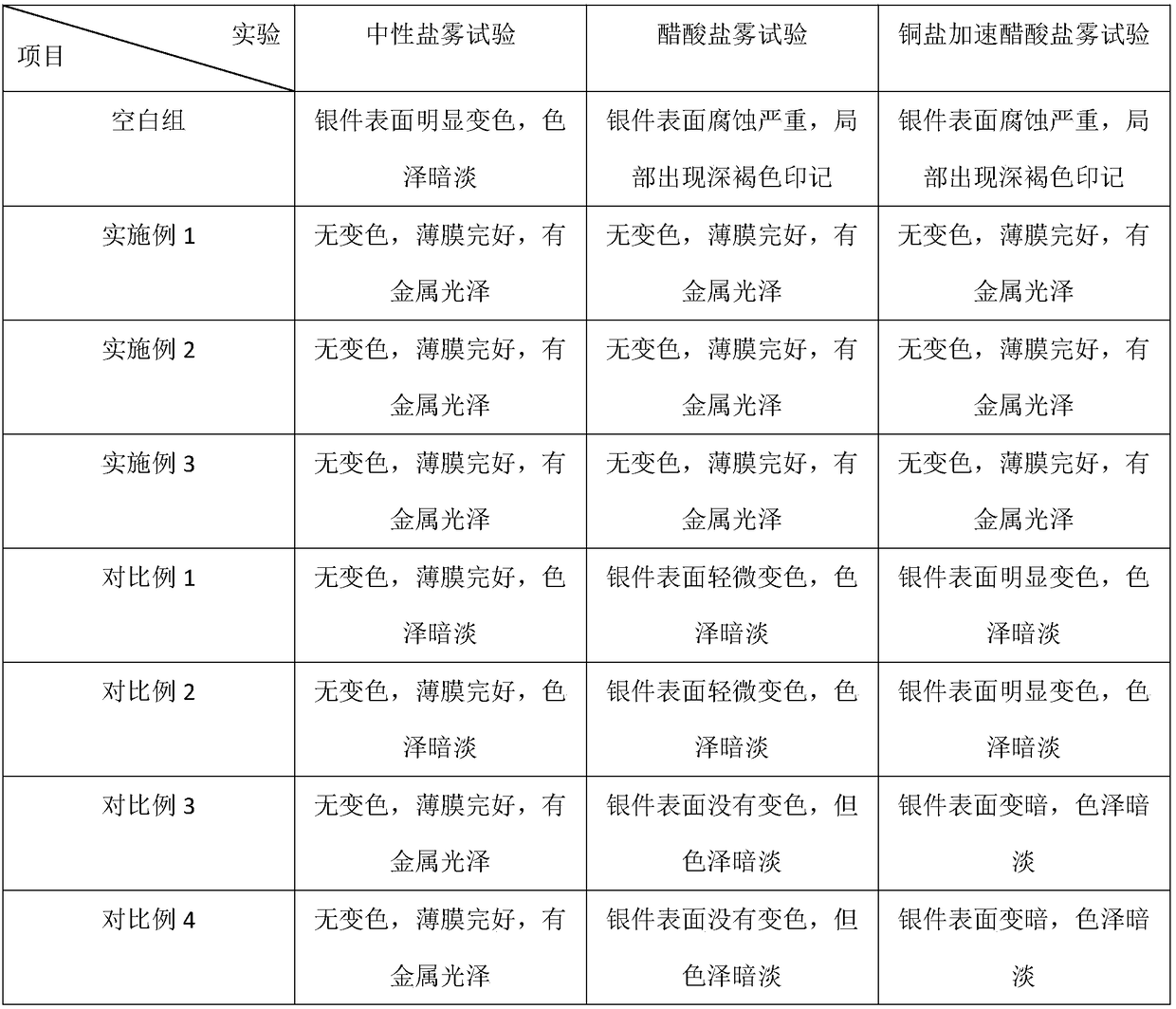

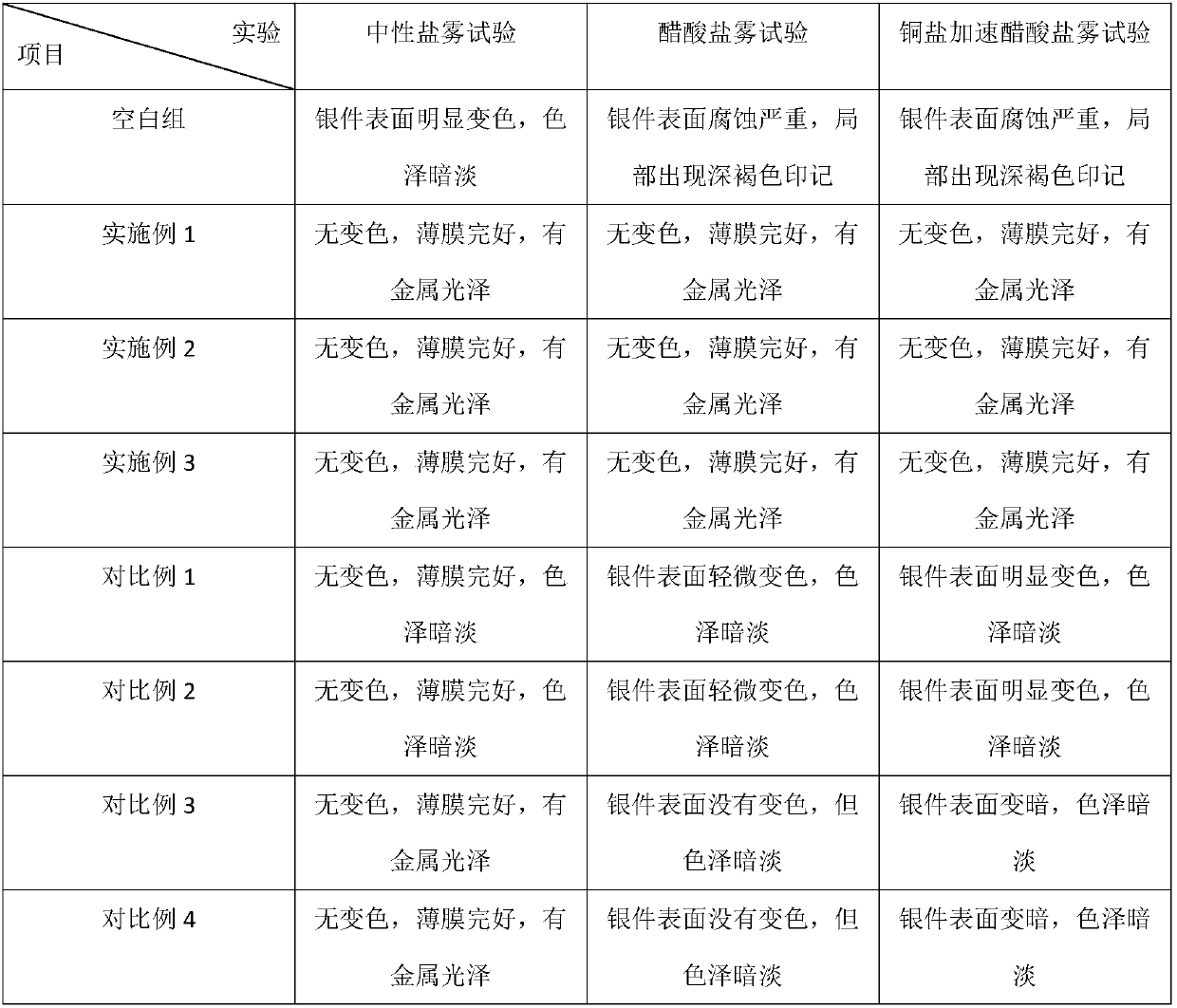

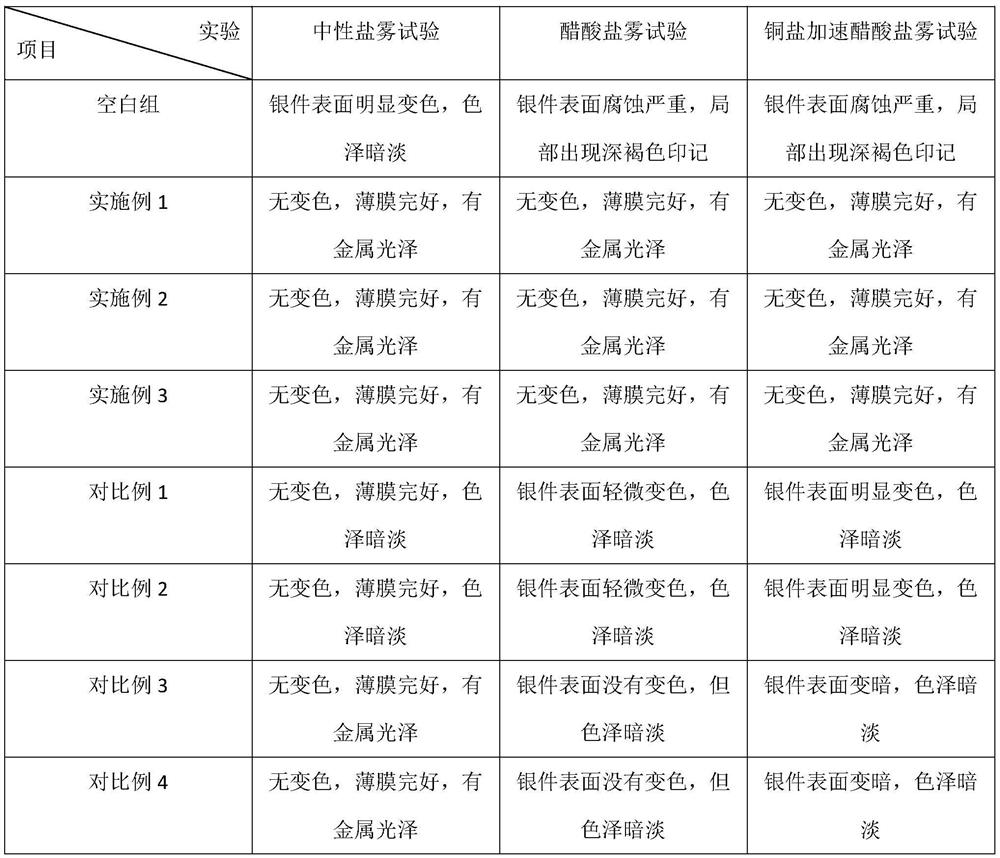

Silver discoloring preventive intermediate, composition and discoloring preventive silver and preparation method

ActiveCN109338340AReduce energy consumptionAvoid an increase in the glass transition temperatureLiquid/solution decomposition chemical coatingBoron trioxideCorrosion

The invention discloses a silver discoloring preventive intermediate, a composition and discoloring preventive silver and a preparation method. The intermediate is a mixed solution comprising tetraethoxysilane, boric acid, bismuth nitrate and an organic solvent, wherein the weight ratio of tetraethoxysilane to boric acid to bismuth nitrate is 10-13: 1.5-3: 7-10. The composition is a glass body andcomprises silicon dioxide, diboron trioxide and bismuth trioxide based on the weight ratio of 30-35: 10-15: 50-55. The discoloring preventive silver is synthesized by the following steps: (1) mixingboric acid and tetraethoxysilane organic solutions to obtain a solution A; (2) mixing the solution A and bismuth nitrate to obtain the silver discoloring preventive intermediate; (3) soaking silver inthe silver discoloring preventive intermediate; moving out; and forming an intermediate layer on the surface of silver; and (4) thermally processing the intermediate layer; heating; and then decreasing the temperature to obtain the discoloring preventive silver. With the adoption of the silver discoloring preventive intermediate, the color remaining time of the discoloring preventive silver can be prolonged, and meanwhile, the corrosion resisting effect of the discoloring preventive silver can be improved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

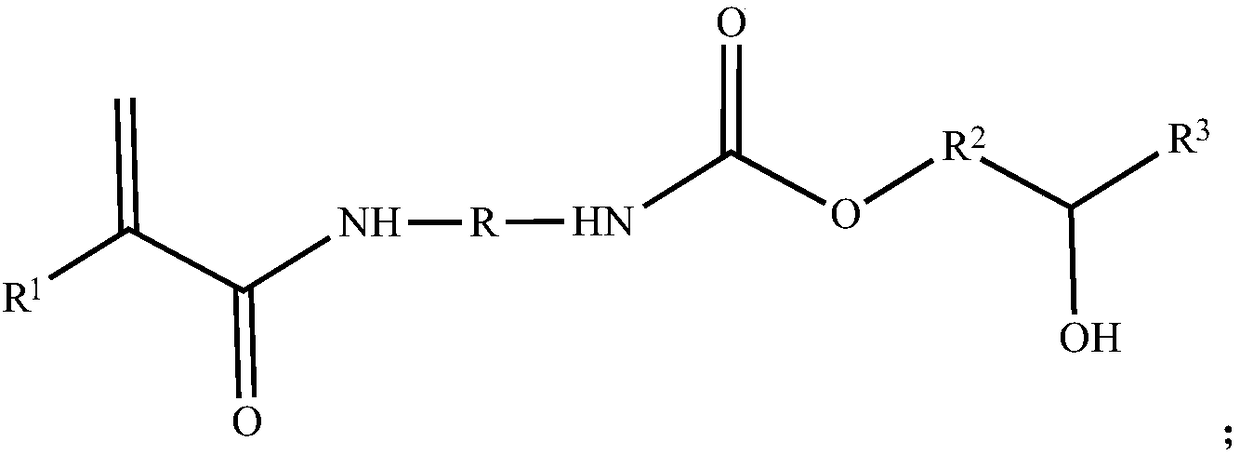

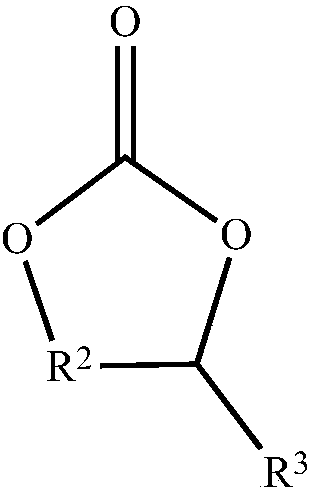

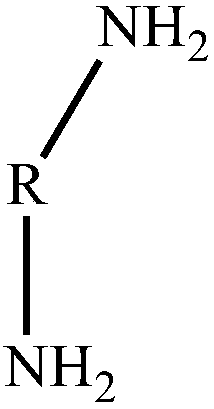

Non-isocyanate polyurethane monomer and preparation method thereof

InactiveCN109369462ASimple and cheap to makeSimple preparation processCarbamic acid derivatives preparationOrganic compound preparationDouble bondCorrosion

The invention discloses non-isocyanate polyurethane monomer and a preparation method thereof. The non-isocyanate polyurethane monomer is of a structure shown as follows, wherein R is selected from saturated alkane, unsaturated alkane or aromatic hydrocarbon, R1 is methyl or hydrogen group, R2 is alkyl, and R3 is hydrogen or alkyl. The non-isocyanate polyurethane monomer has double-bond groups, thereby being very easy to form polymer and copolymer, has non-isocyanate polyurethane special groups, has good corrosion resistance, chemical resistance, hydrolysis resistance and penetration resistanceand makes up weak-bond structure in conventional polyurethane molecules; the preparation process only includes two times of amidation reaction, so that the preparation method is simple in preparationprocess.

Owner:SICHUAN UNIV

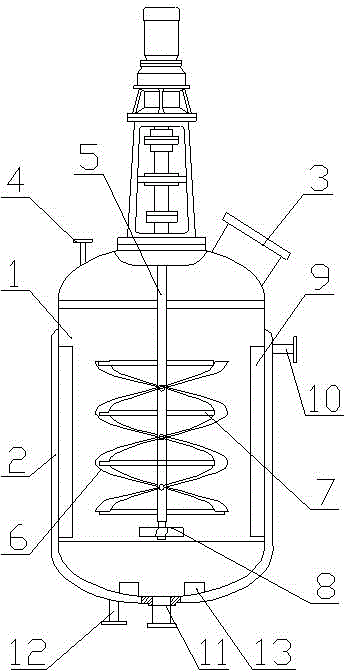

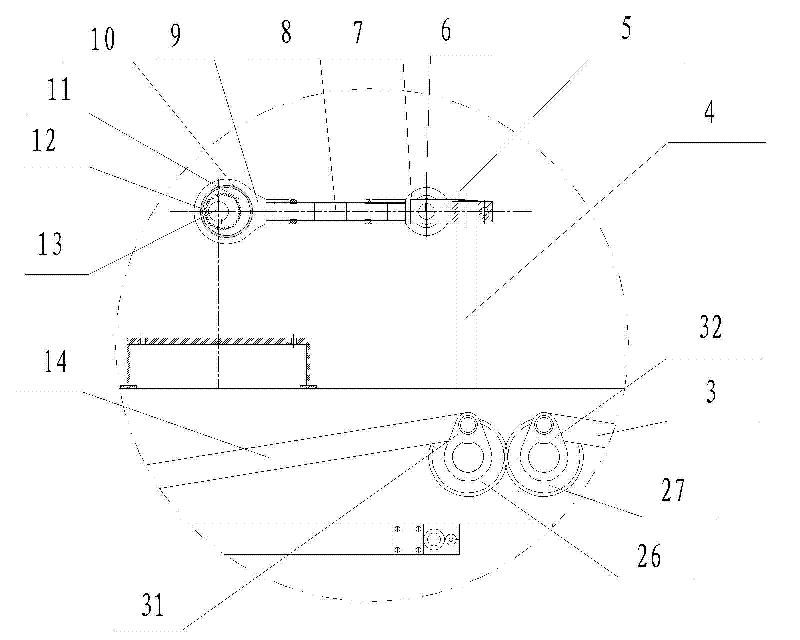

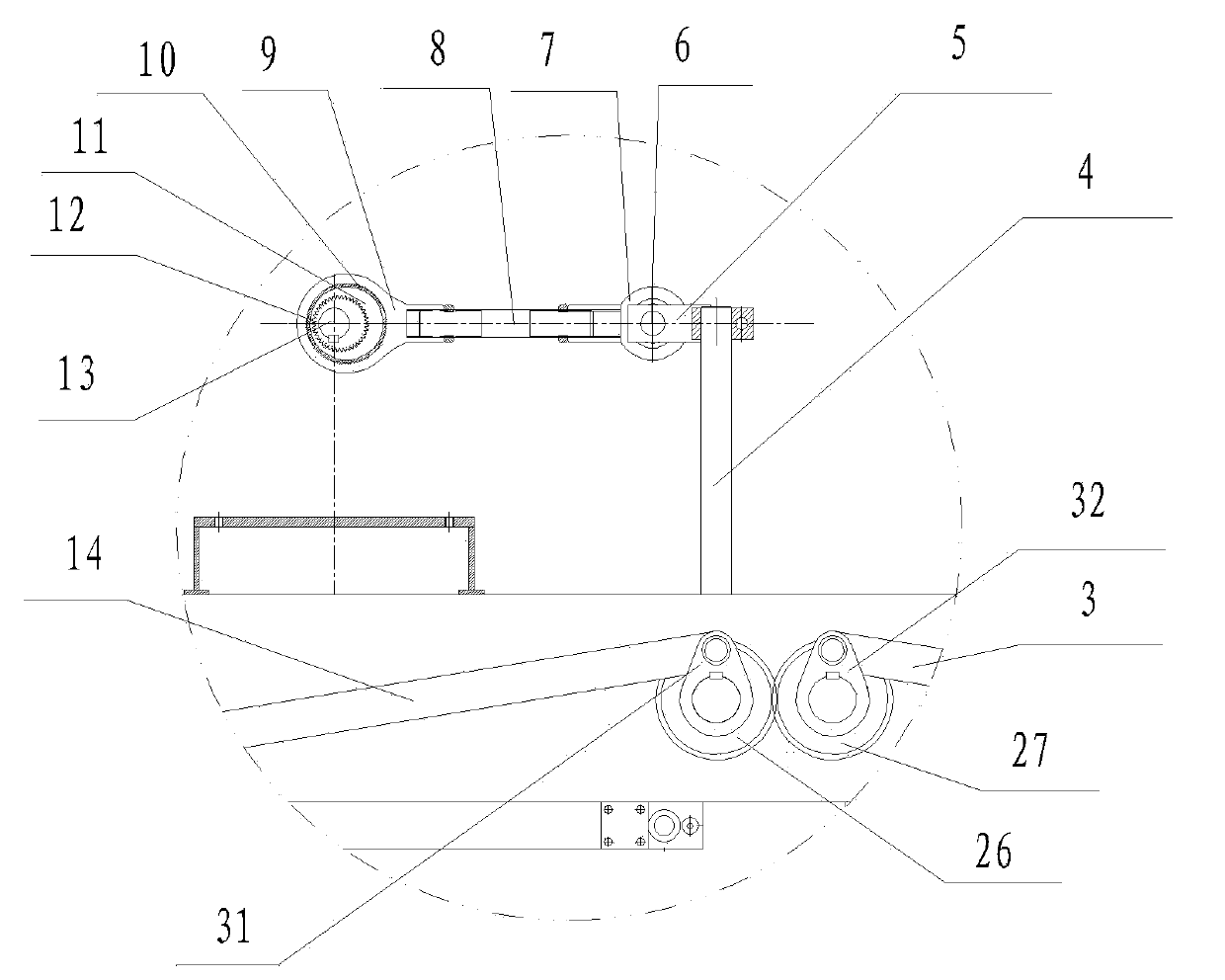

Graphite chemical substance intercalation reaction vessel and technological method thereof

InactiveCN105521752AFree to useWon't happenChemical/physical/physico-chemical stationary reactorsIntercalation reactionSulfur

The invention relates to a graphite chemical substance intercalation reaction vessel and a technological method thereof. The reaction vessel comprises a reaction vessel body (1), a mixer shaft (5) is arranged on the central part of the reaction vessel body (1) along the vertical direction, two spiral stirring vanes (6) are arranged on the mixer shaft (5), the two spiral stirring vanes (6) symmetrically wind around the mixer shaft (5) in a spiral mode, spiral directions of the two spiral stirring vanes (6) are opposite, a support (7) is arranged between the two spiral stirring vanes (6), multi-strip elastic racks (9) are uniformly arranged on an inner wall of the reaction vessel body (1), and a supersonic generator (13) is arranged at the bottom of the reaction vessel body (1). The invention provides the graphite chemical substance intercalation reaction vessel and the technological method thereof, pollution by harmful gas such as SOx and NOx or heavy metal ions cannot be generated during a production process, sulfur residue does not exist in the product, oxidation resistance is good, defect of graphene is not generated easily, and final product quality can be effectively guaranteed.

Owner:江苏碳谷二维世界科技有限公司

Preparation method of anti-corrosion film

InactiveCN109530193ASmall impact on structureAvoid influencePretreated surfacesCoatingsPhysical chemistryBoric acid

The invention discloses a preparation method of an anti-corrosion film. The preparation method comprises the following steps that (1), boric acid and tetraethyl orthosilicate solutions are mixed to obtain a solution A; (2), the solution A is mixed with bismuth nitrate to obtain an anti-corrosion intermediate body; (3), the intermediate body is filmed to obtain an intermediate body film; and (4), the intermediate body film is subjected to heat treatment, and is heated firstly and then cooled to obtain the anti-corrosion film. The corrosion resistance time of the anti-corrosion film is prolonged, and the higher corrosion resisting effect is achieved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

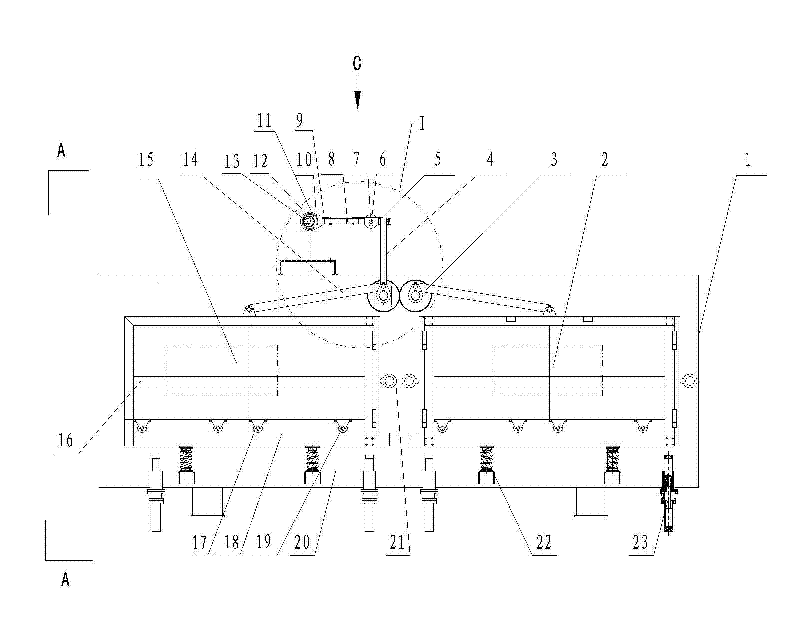

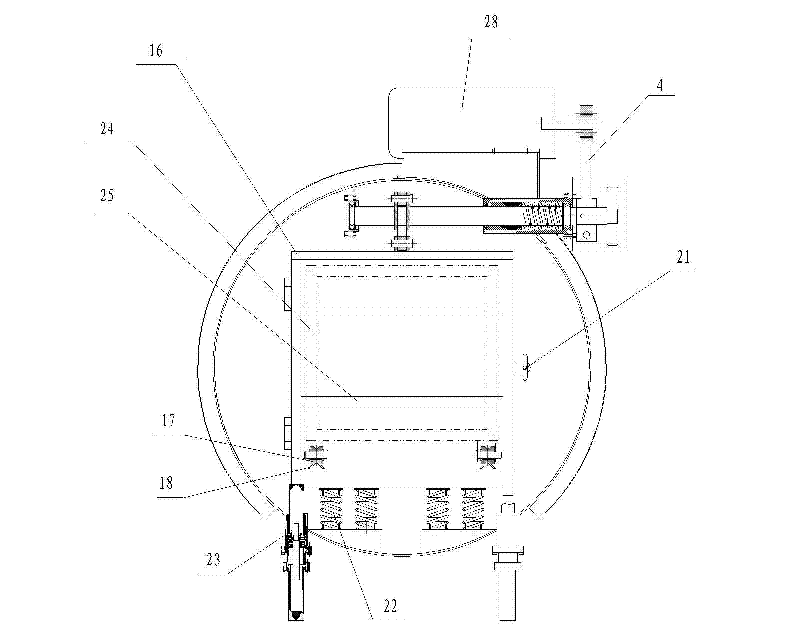

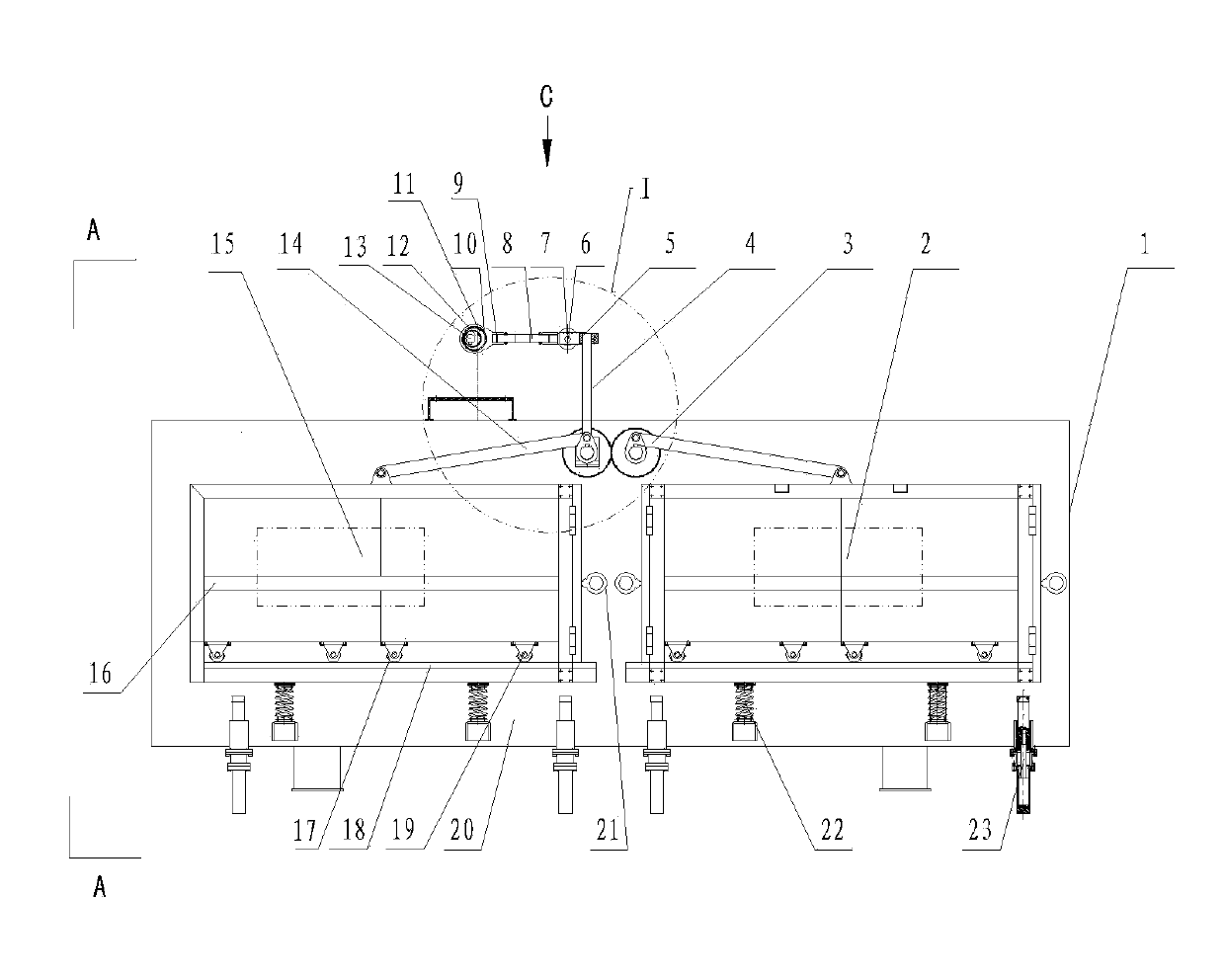

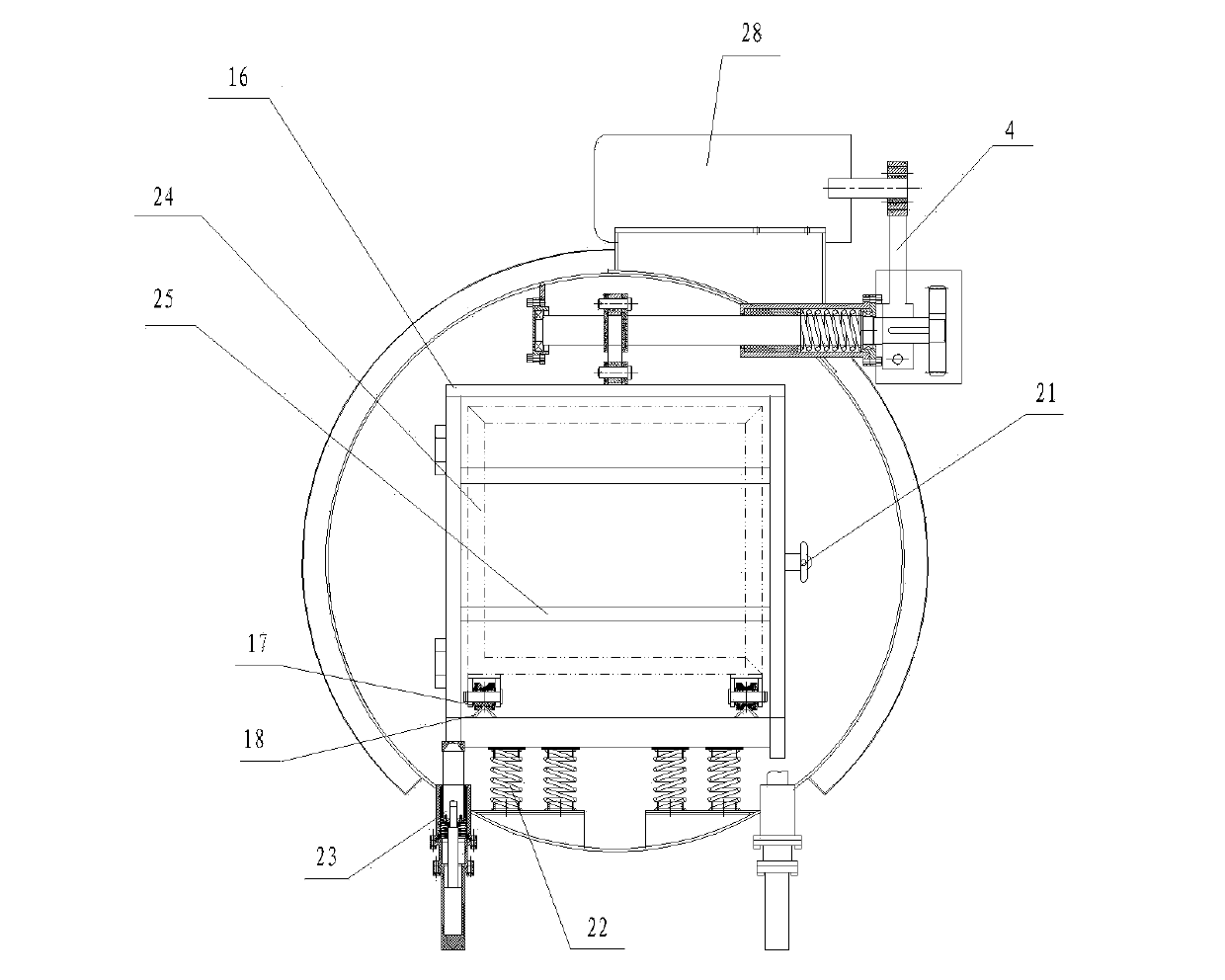

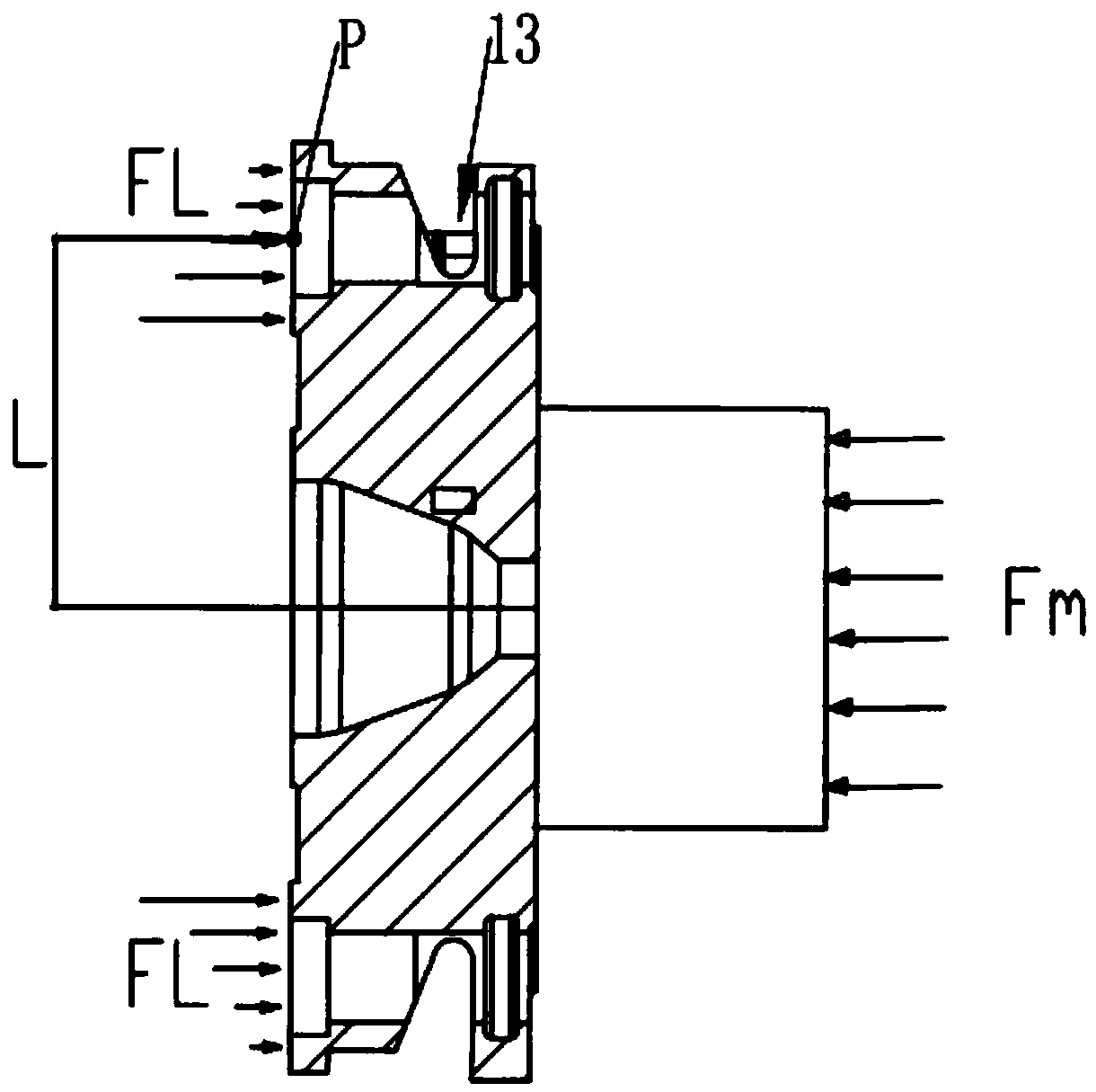

Cooling and sterilizing process for protein preparation and special horizontal type shaking table thereof

ActiveCN102247609AProcess parameters are easy to controlGood antibacterial effectLavatory sanitoryHeatGear wheelReducer

The invention relates to a cooling and sterilizing process for a protein preparation and a special horizontal type shaking table thereof. In the prior art, a sterilizing device for the protein preparation has the defects of poor stability and difficult control of parameters. The special shaking table comprises a cycloidal pin wheel speed reducer, a driving motor and a shaking table, wherein an eccentric outer gear, an eccentric inner gear, a gear shaft sleeve and a left gear base are fixedly arranged on the cycloidal pin wheel speed reducer and an output shaft of the driving motor; the left gear base is connected with one end of a regulating lead screw; the other end of the regulating lead screw is connected with a right bearing base; a shaking amplitude adjustment device is connected with the bearing base and one end of a shaking oscillating bar; the other end of the shaking oscillating bar is connected with one end of a rotating shaft of the shaking oscillating bar; and the other end of the rotating shaft of the shaking oscillating bar is connected with the shaking table by a transmission device in a shaking table cylinder body. The special horizontal type shaking table has a reasonable and compact structure, is reliable in strength, rigidity and toughness of key positions, small in assembly stress of parts and high process performance, process parameters are easy to control, and the optimal bacteriostatic effect can be achieved.

Owner:华原谷道生物科技西安有限公司

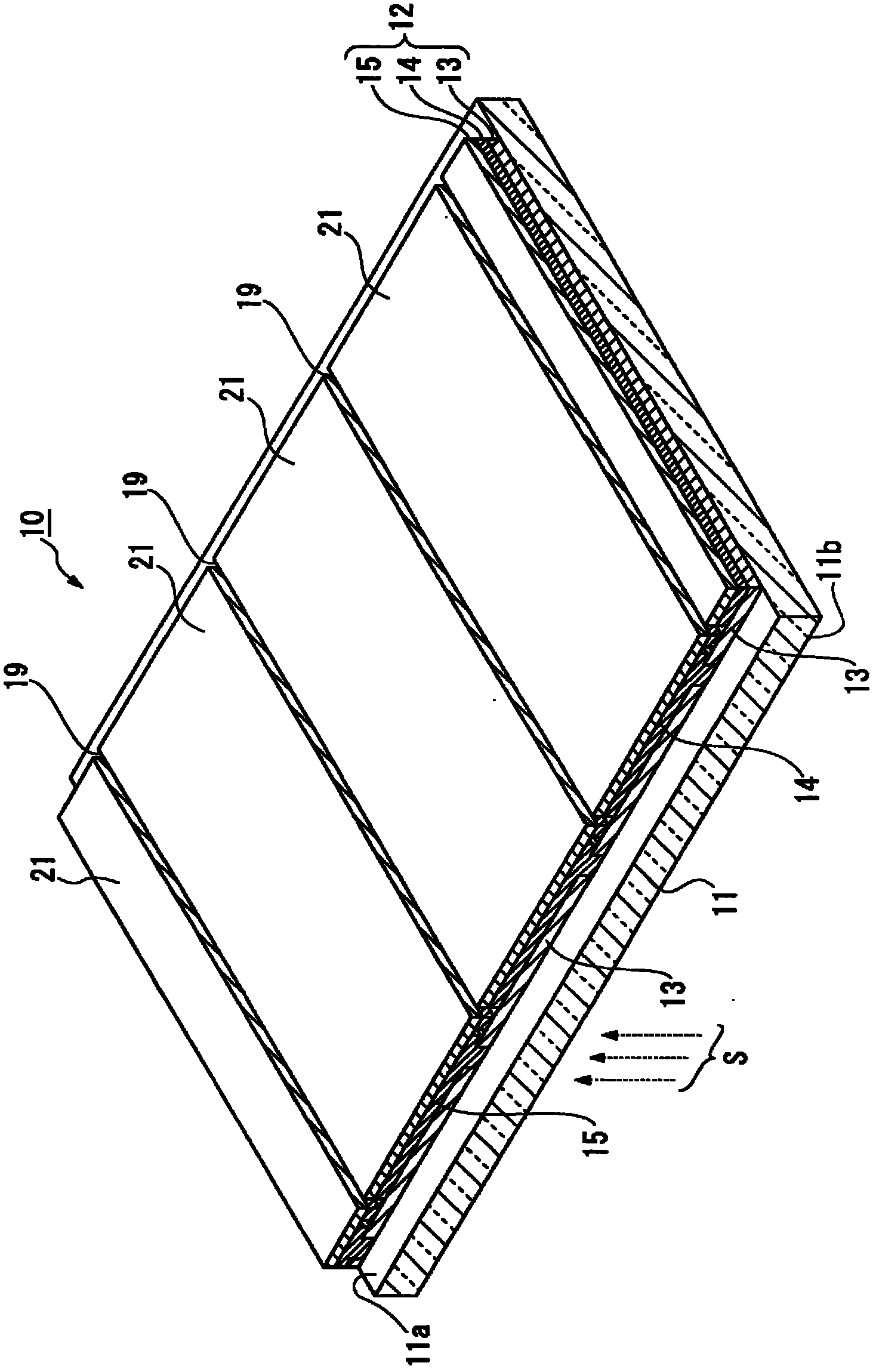

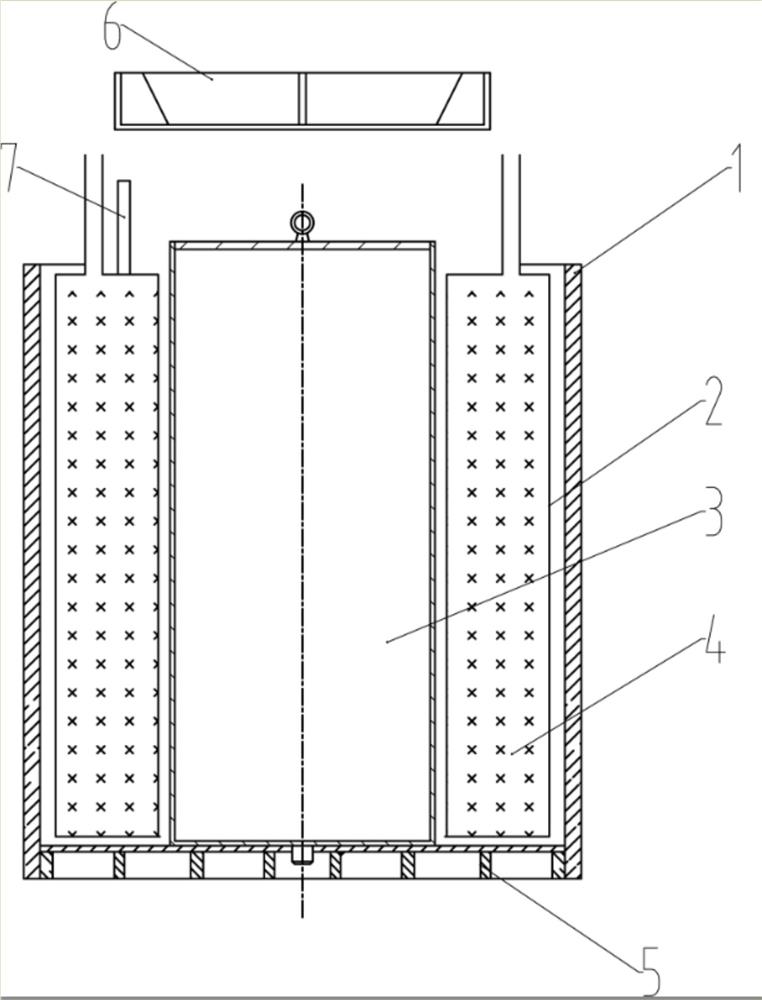

Energy-saving sheet material and manufacturing method thereof

ActiveCN104341094ARealize full planarizationIncrease usage intensityGlass reforming apparatusUltimate tensile strengthExhaust pipe

The invention provides an energy-saving sheet material and a manufacturing method thereof. The energy-saving sheet material comprises at least one layer of upper sheet material, at least one layer of lower sheet material, at least one layer of inner sheet material and a plurality of support structures, wherein the upper edge of the upper sheet material and the lower edge of the lower sheet material are respectively straight lines; the inner sheet material is arranged between the upper sheet material and the lower sheet material, and the sheet materials in adjacent layers are separated by the support structures; an exhaust port is formed in the side of the inner sheet material, and is a through groove penetrating through the upper surface and the lower surface of the inner sheet material; the edges of the upper sheet material, the lower sheet material and the inner sheet material are sealed and closed by a sealing material, so that vacuum layers are formed among the sheet materials; an exhaust pipe is arranged in the exhaust port, the open end of the exhaust pipe is positioned on the inner side of the exhaust port, and the closed end of the exhaust pipe is positioned on the outer side of the exhaust port and exists in the space formed between the upper sheet material and the lower sheet material. The energy-saving sheet material is fully planar and is free of structure defect, so that the using strength of the energy-saving sheet material is enhanced.

Owner:ICESUN VACUUM GLASS

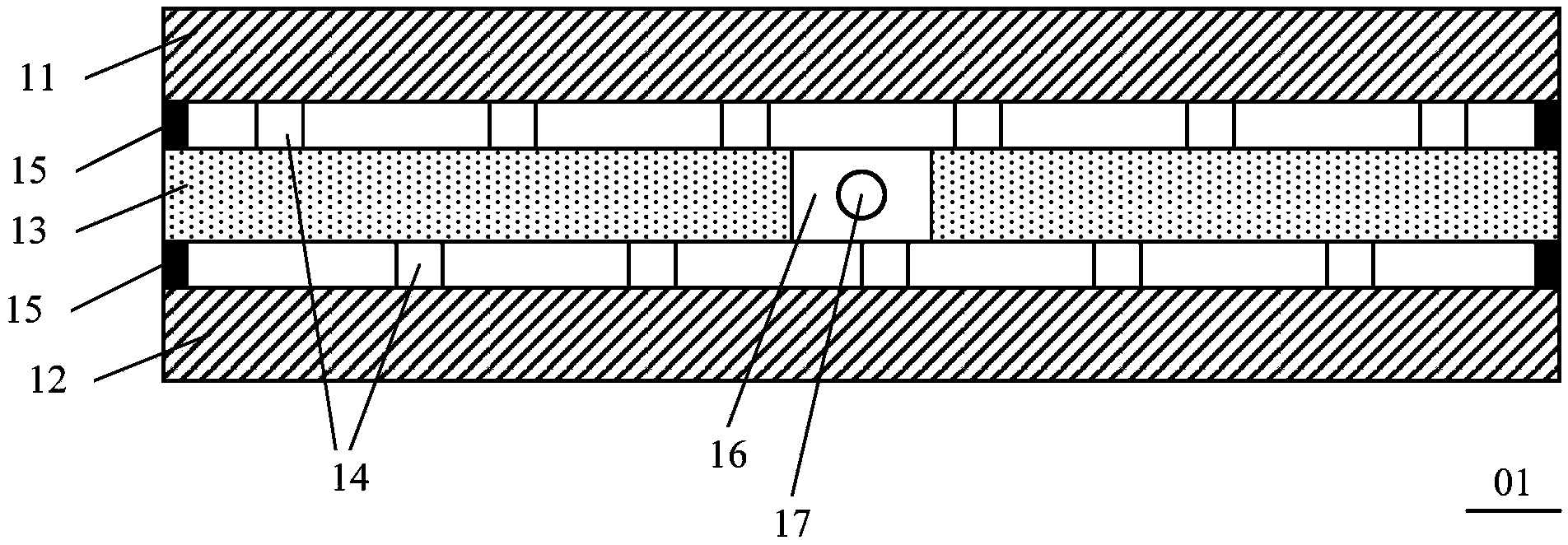

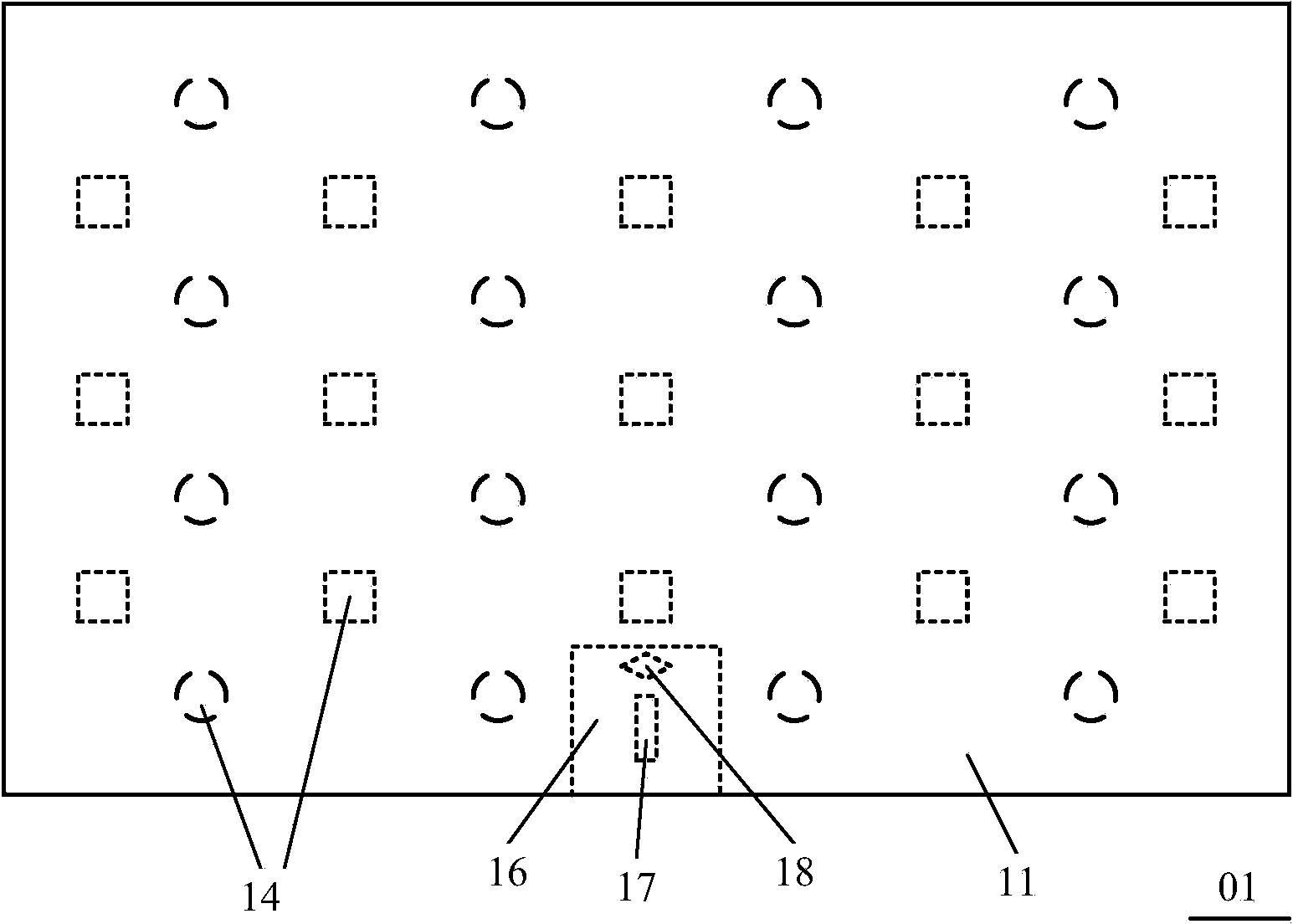

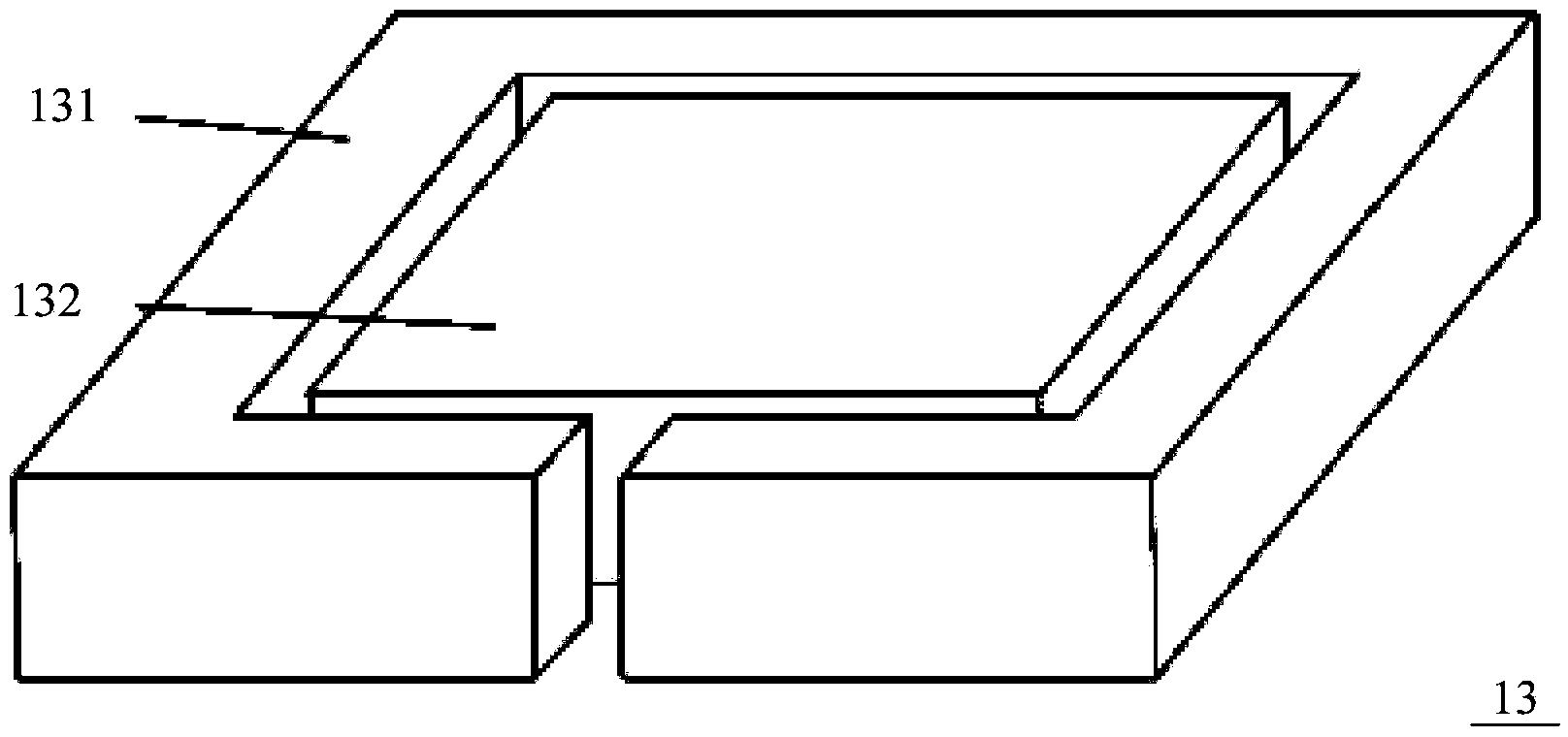

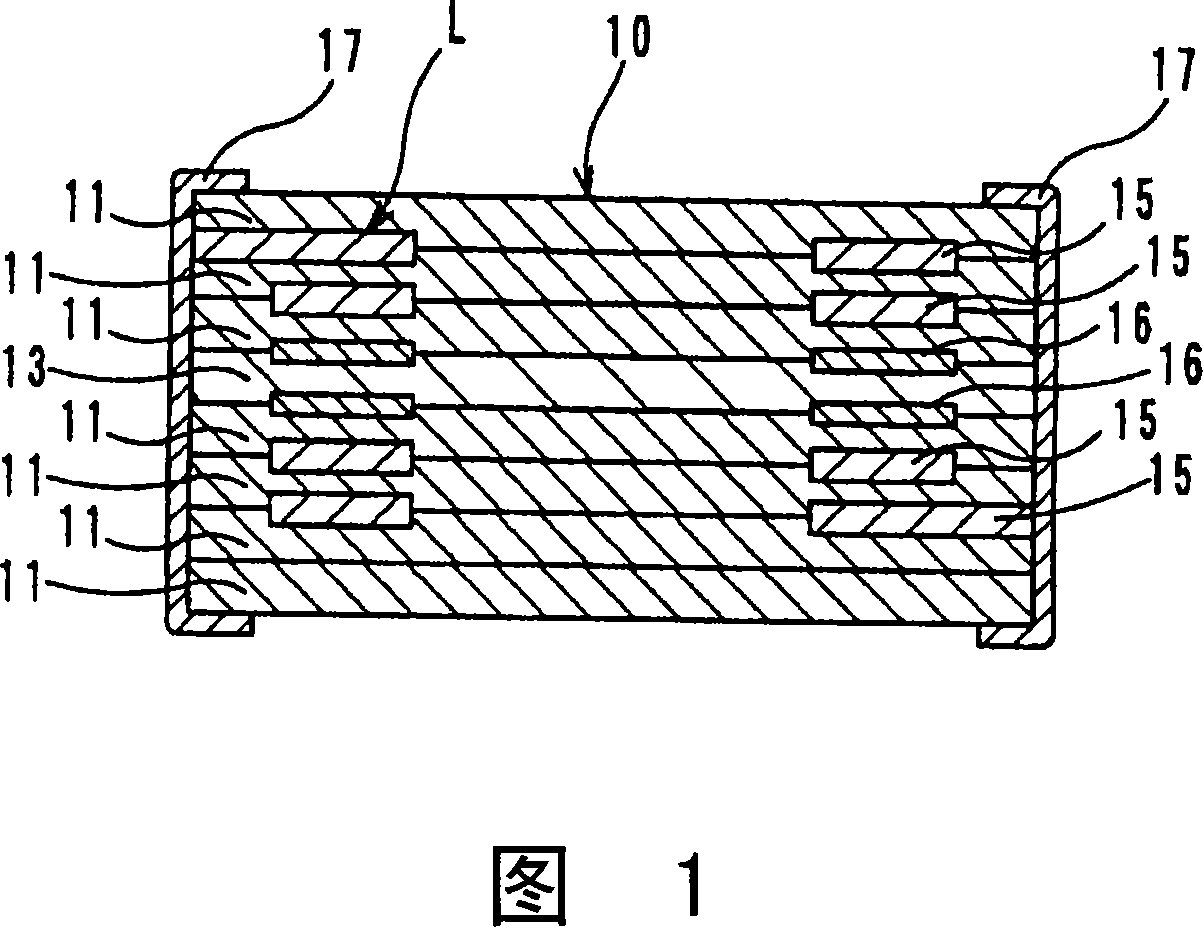

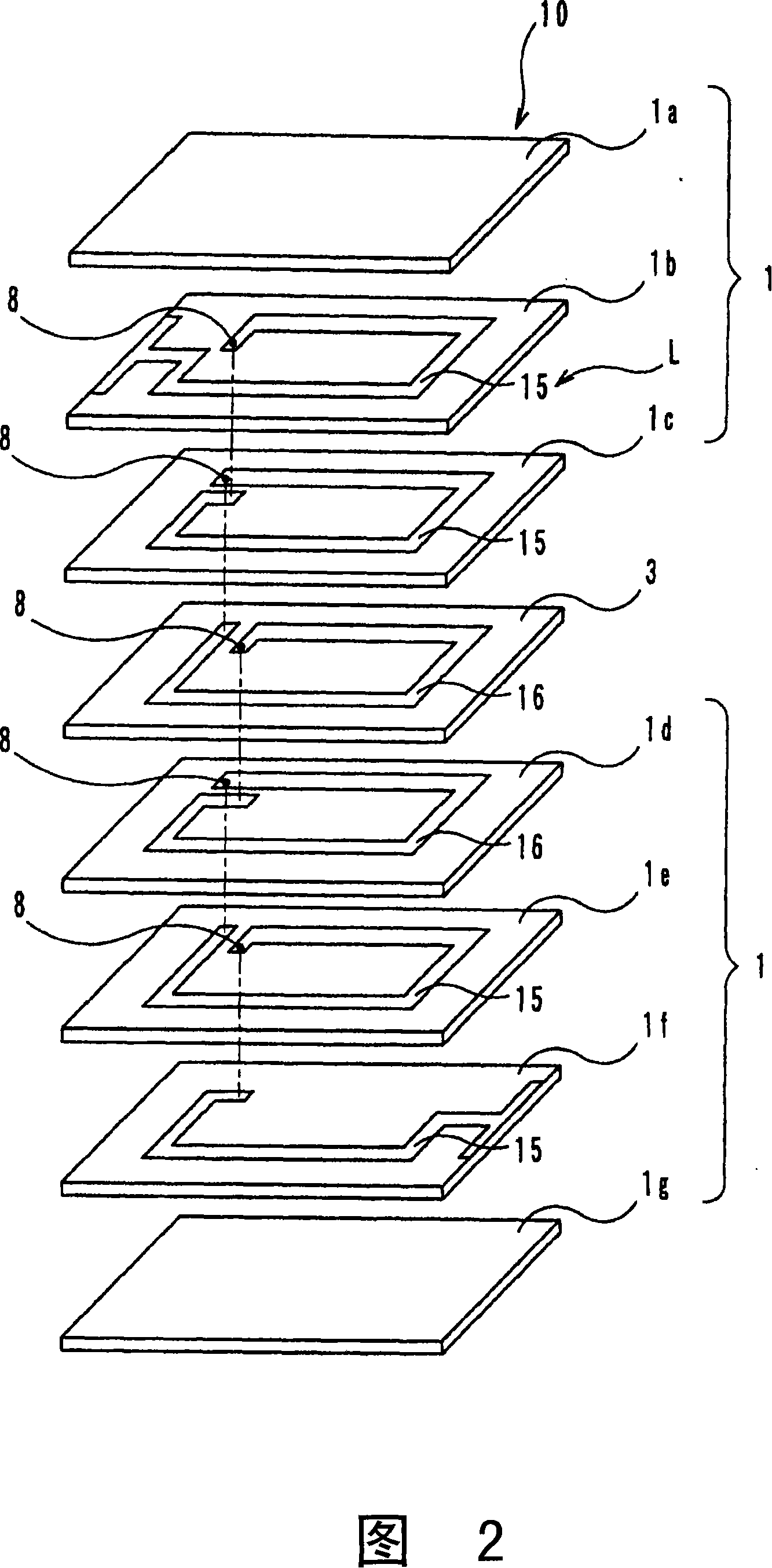

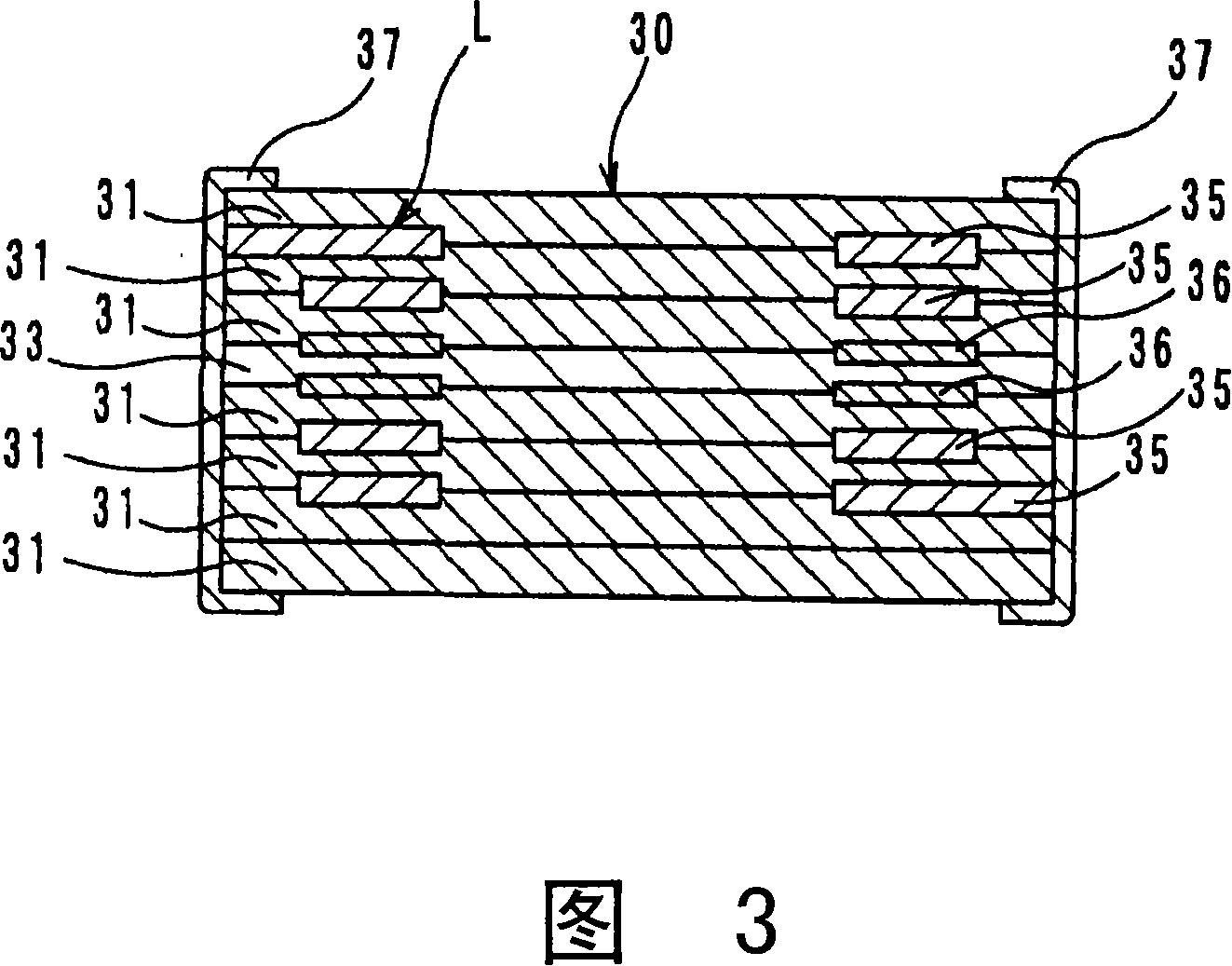

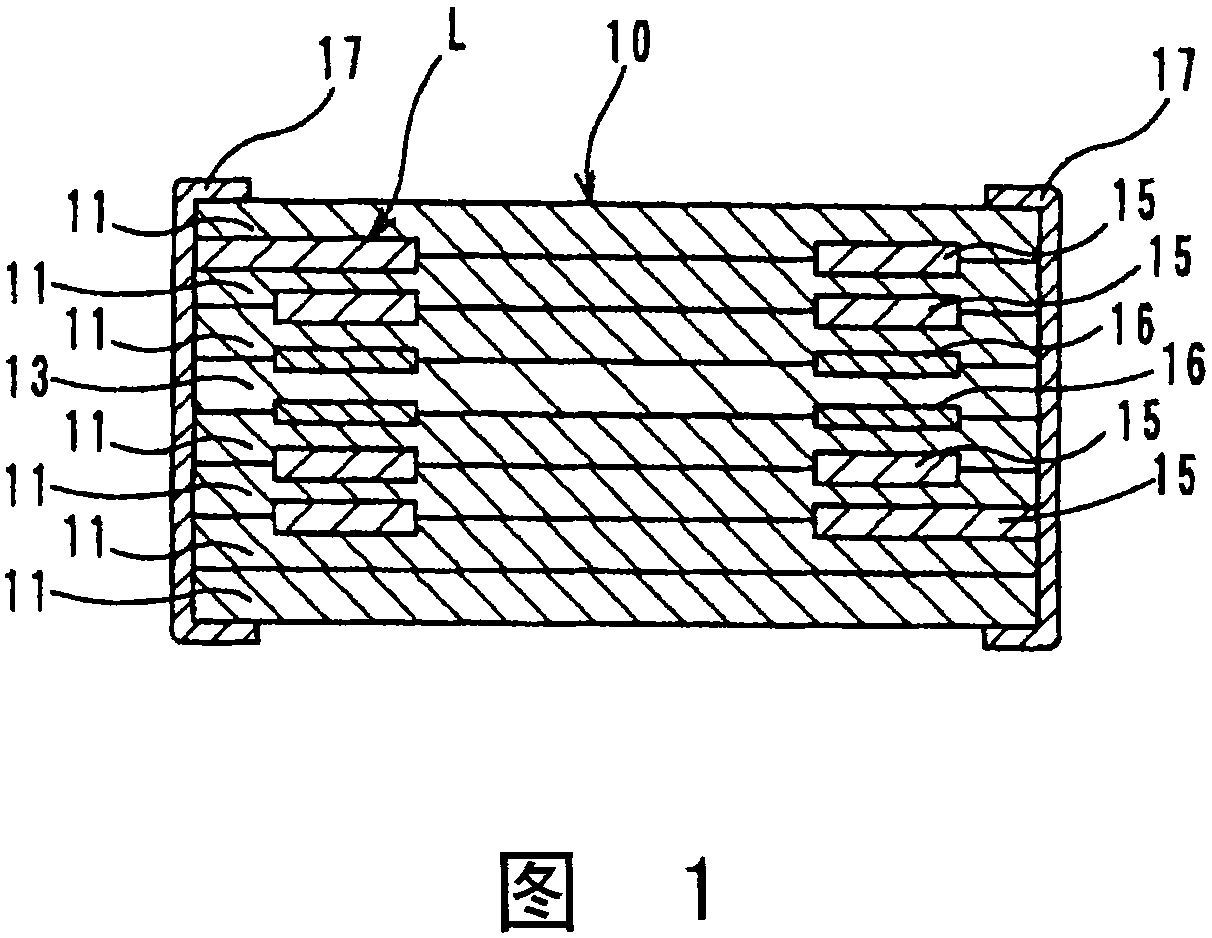

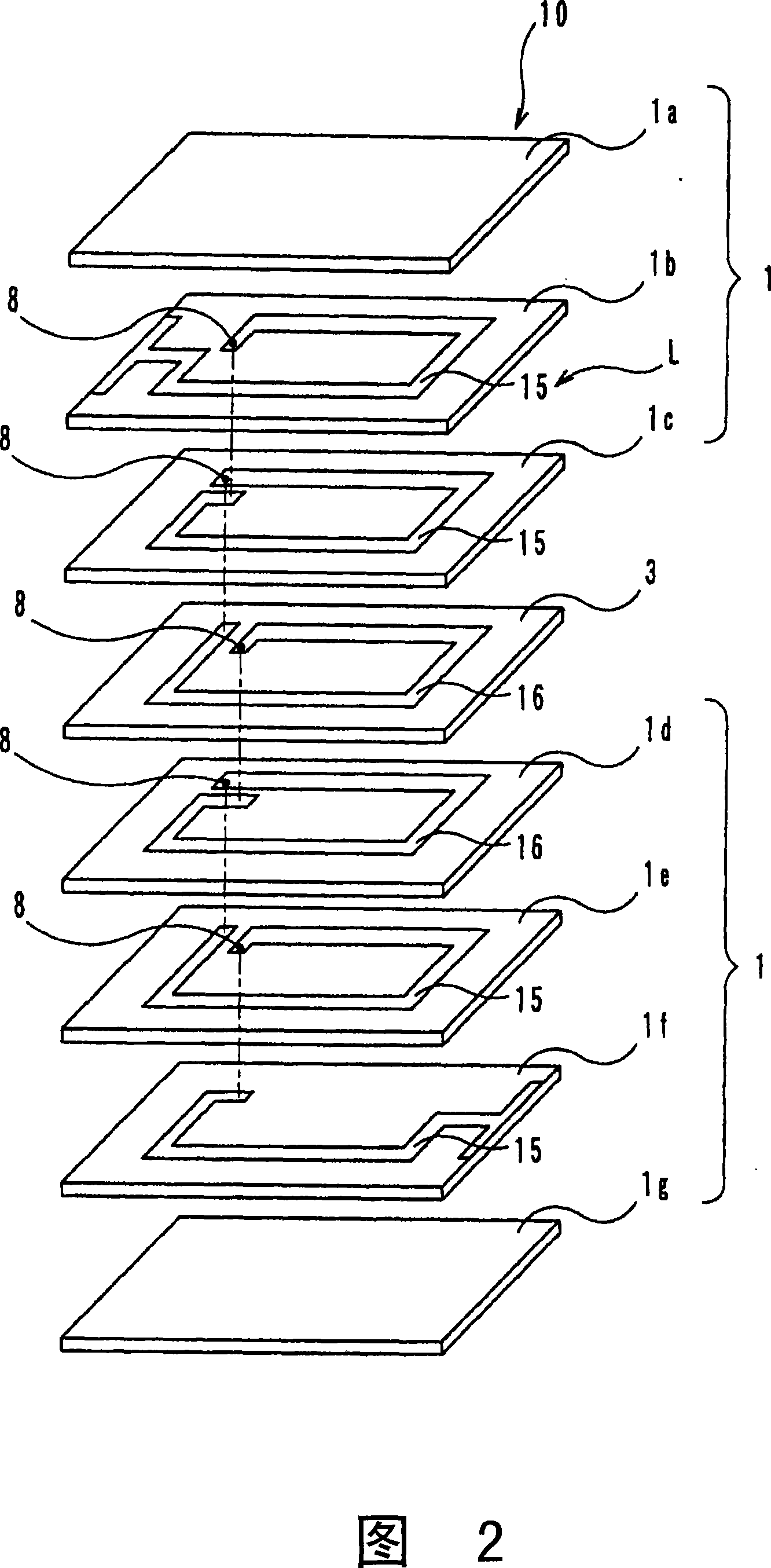

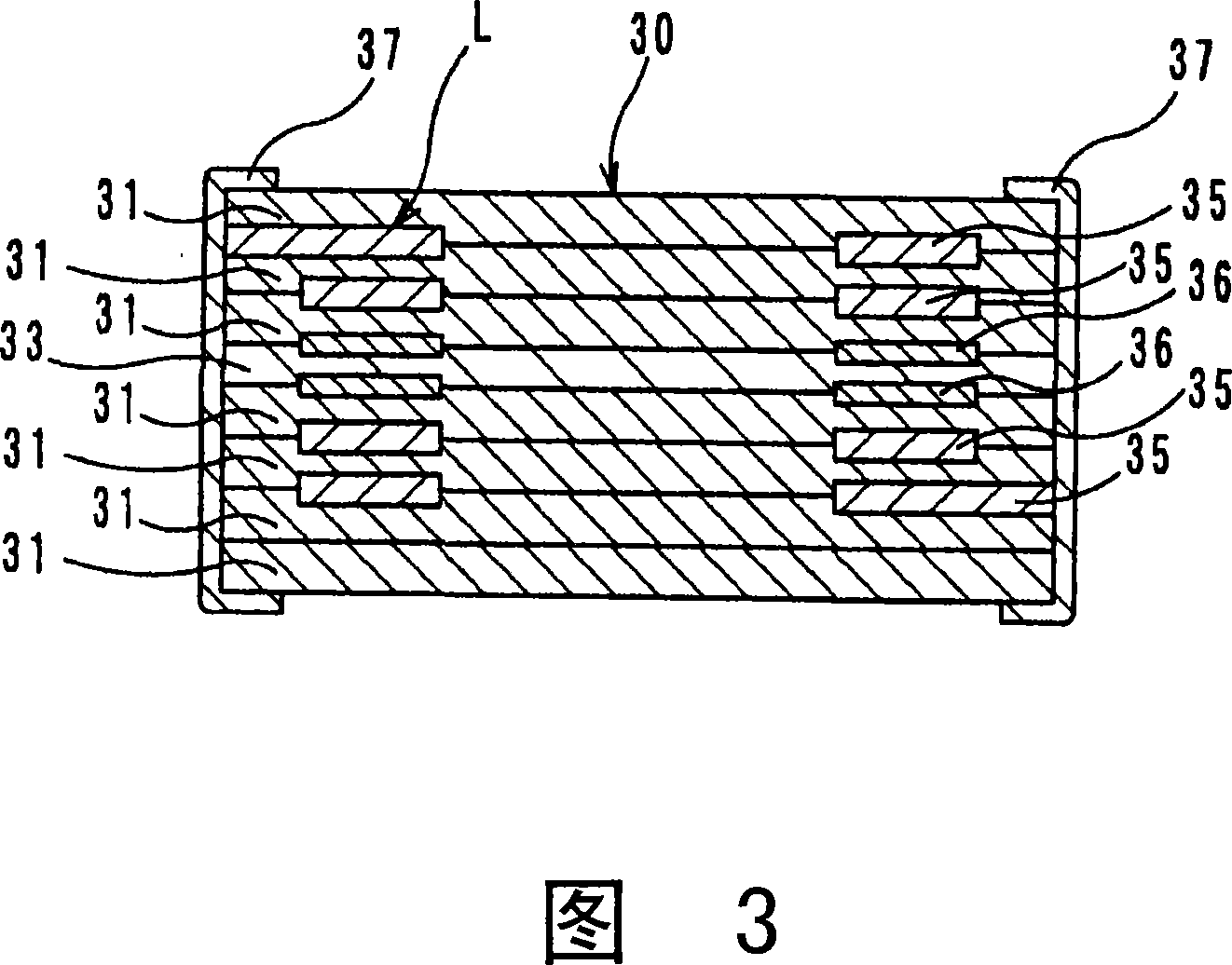

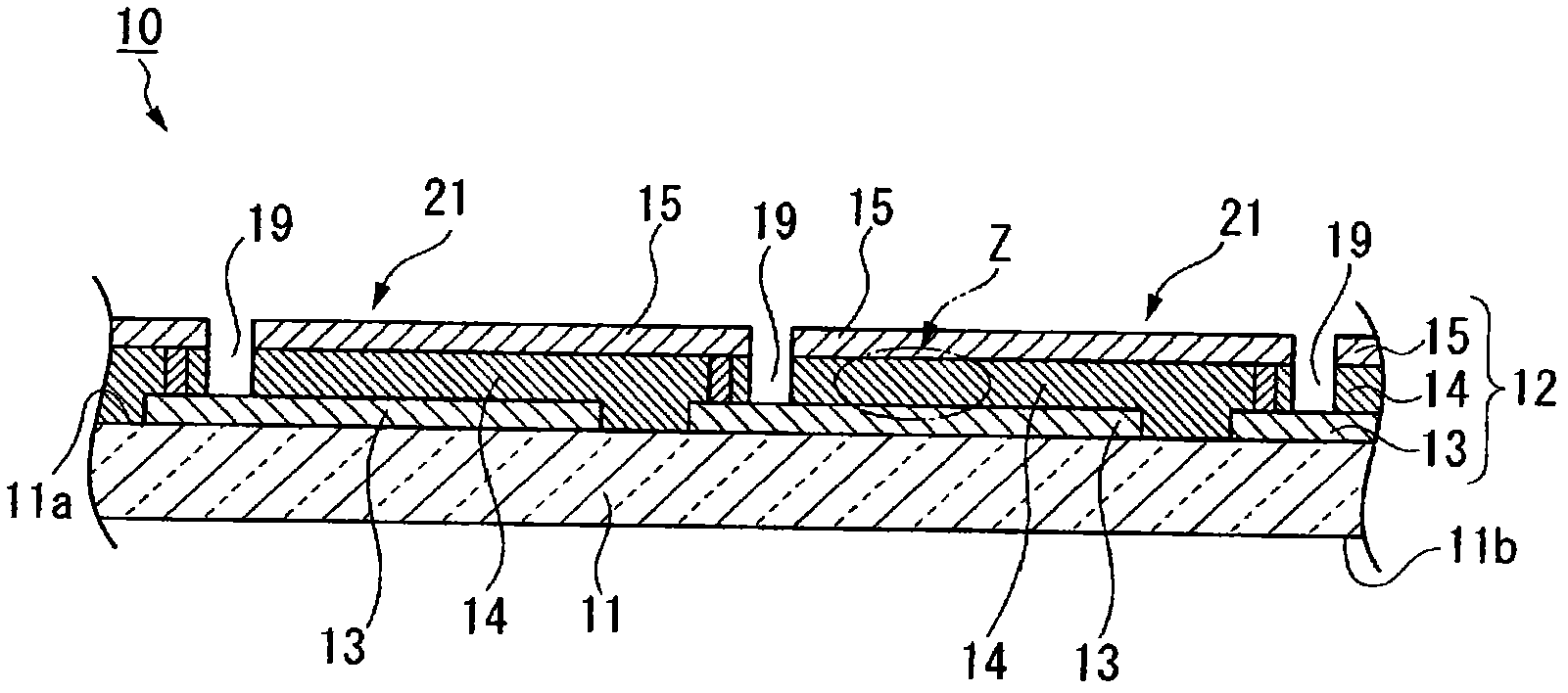

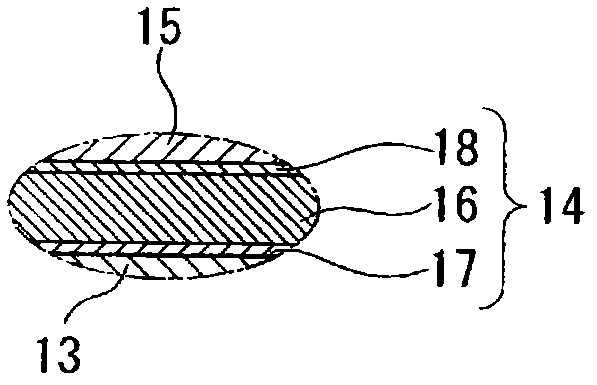

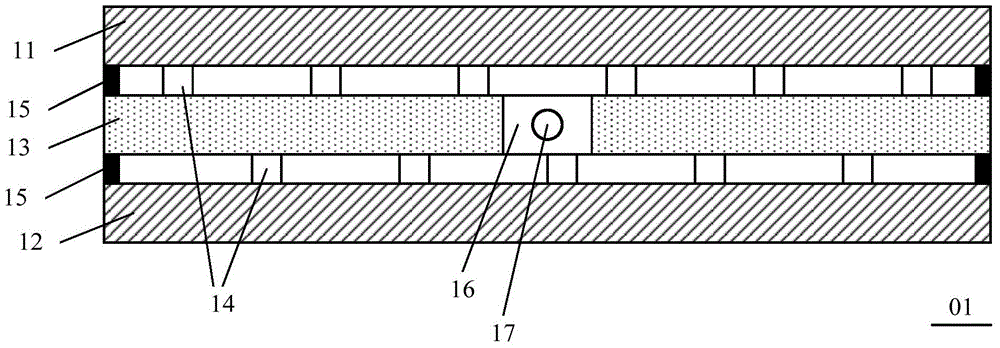

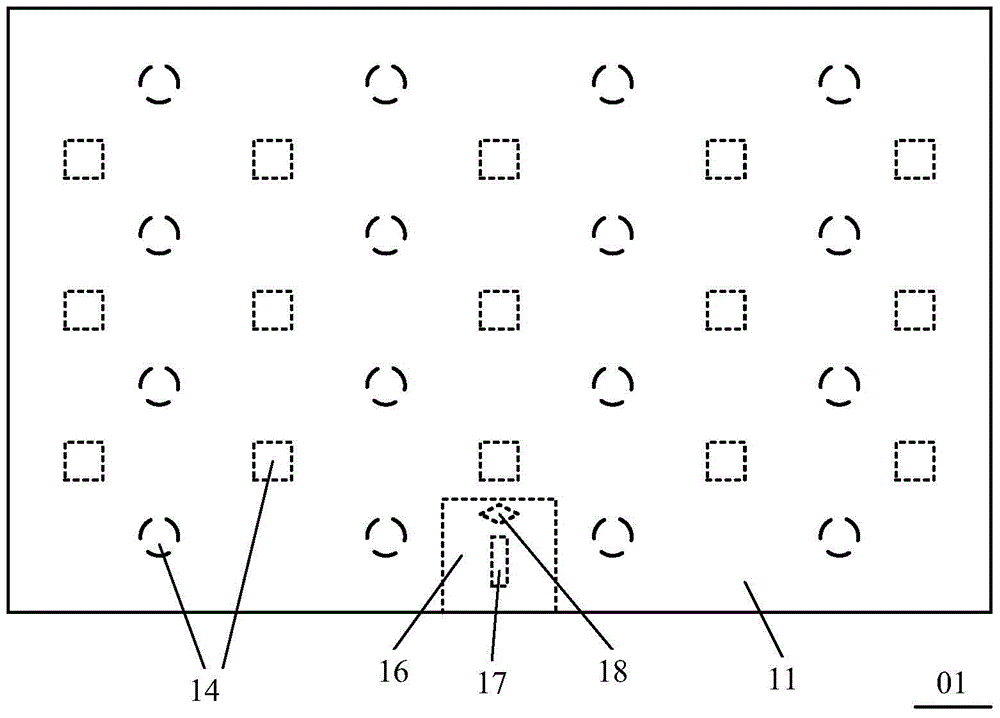

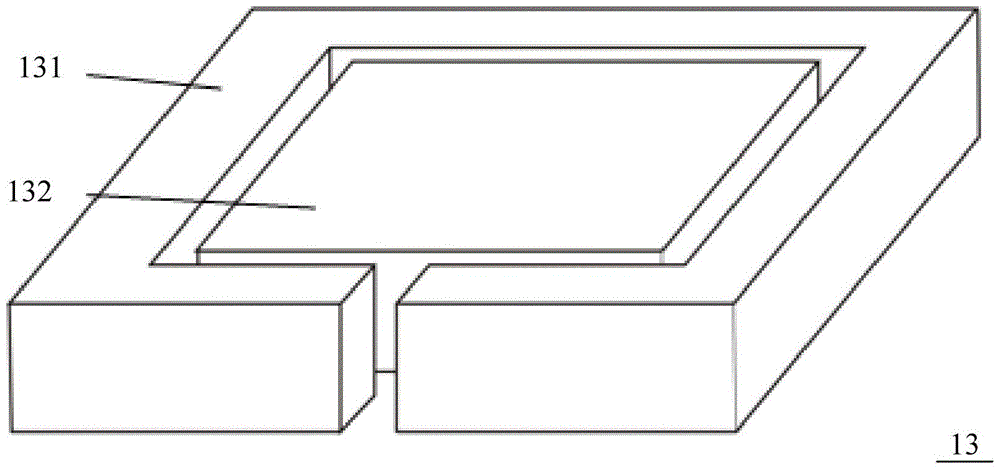

Multilayer coil

InactiveCN101133467ANo structural defectsTransformers/inductances coils/windings/connectionsPrinted inductancesElectrical conductorMagnetic layer

An open magnetic circuit type multilayer coil free from a structural defect such as interlayer separation or cracking. On both major surfaces of a nonmagnetic layer (13) are provided a layered body (10) where magnetic layers (11) are formed and a coil (L) where coil conductors (15, 16) that are formed on the layered body (10) and have a specified thickness are spirally interconnected. The coil conductor (16), out of the coil conductors (15, 16) formed in the layered body (10), located on the major surface of the nonmagnetic layer (13) has a small thickness that is not greater than 0.6 times those of the magnetic layer (11) and the nonmagnetic layer (13) but is greater than 0.1 times that of the coil conductor (15) not located on the major surface of the nonmagnetic layer (13).

Owner:MURATA MFG CO LTD

Multilayer coil

InactiveCN101133467BNo structural defectsTransformers/inductances coils/windings/connectionsPrinted inductancesElectrical conductorMagnetic layer

An open magnetic circuit type multilayer coil free from a structural defect such as interlayer separation or cracking. On both major surfaces of a nonmagnetic layer (13) are provided a layered body (10) where magnetic layers (11) are formed and a coil (L) where coil conductors (15, 16) that are formed on the layered body (10) and have a specified thickness are spirally interconnected. The coil conductor (16), out of the coil conductors (15, 16) formed in the layered body (10), located on the major surface of the nonmagnetic layer (13) has a small thickness that is not greater than 0.6 times those of the magnetic layer (11) and the nonmagnetic layer (13) but is greater than 0.1 times that of the coil conductor (15) not located on the major surface of the nonmagnetic layer (13).

Owner:MURATA MFG CO LTD

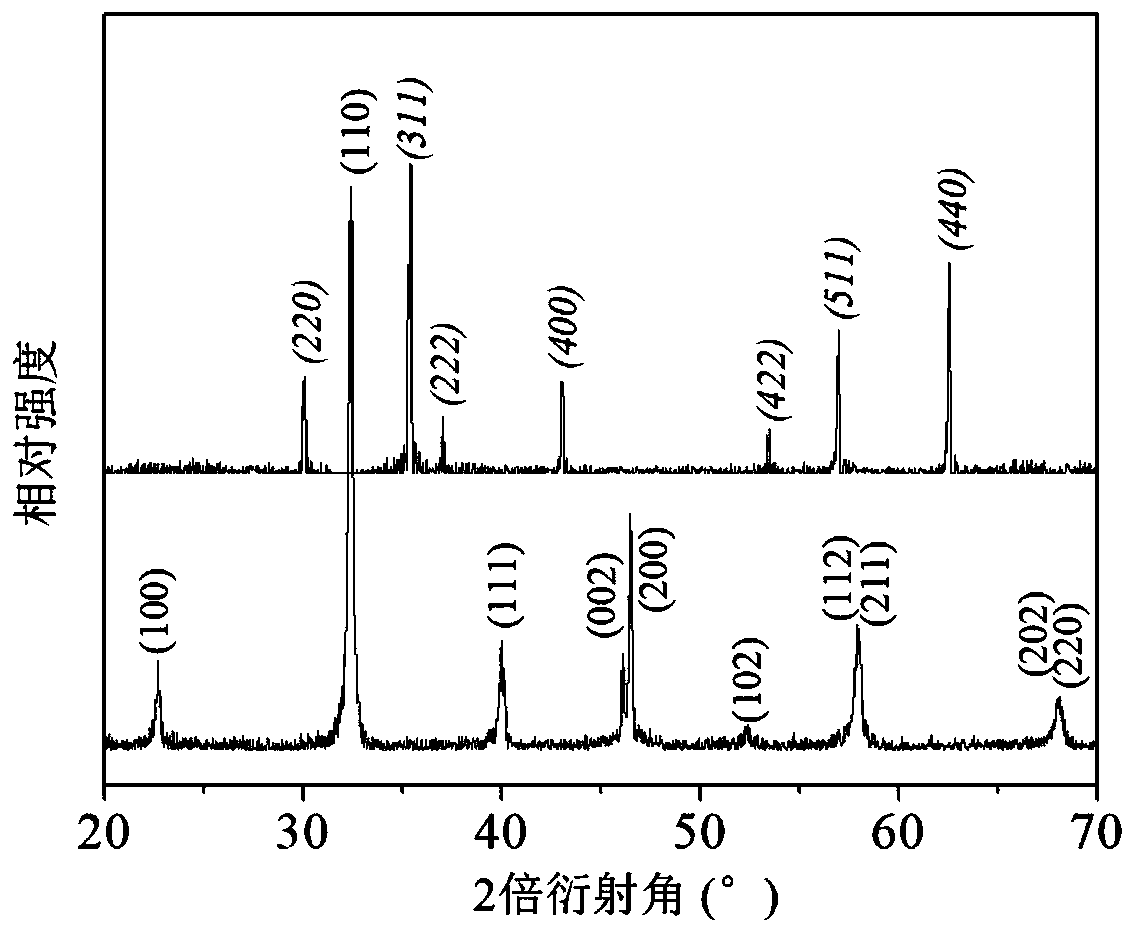

Interface coupling enhanced layered magnetoelectric composite ceramic and preparation method thereof

The invention discloses interface coupling enhanced layered magnetoelectric composite ceramic and a preparation method thereof. The layered magnetoelectric composite ceramic is formed by laminating, co-firing and compounding a modified Bi0. 5Na0. 5TiO3-based piezoelectric phase and a spinel ferrite magnetostrictive phase. The invention also comprises a preparation method of the composite magnetoelectric ceramic. The layered magnetoelectric composite ceramic has good piezoelectric property, magnetostriction property and high magnetoelectric voltage coefficient and is simple in preparation process, stable in performance, environment-friendly and harmless and is suitable for the field of electronic devices such as magnetoelectric sensors, energy collectors and filters.

Owner:HUNAN INSTITUTE OF ENGINEERING

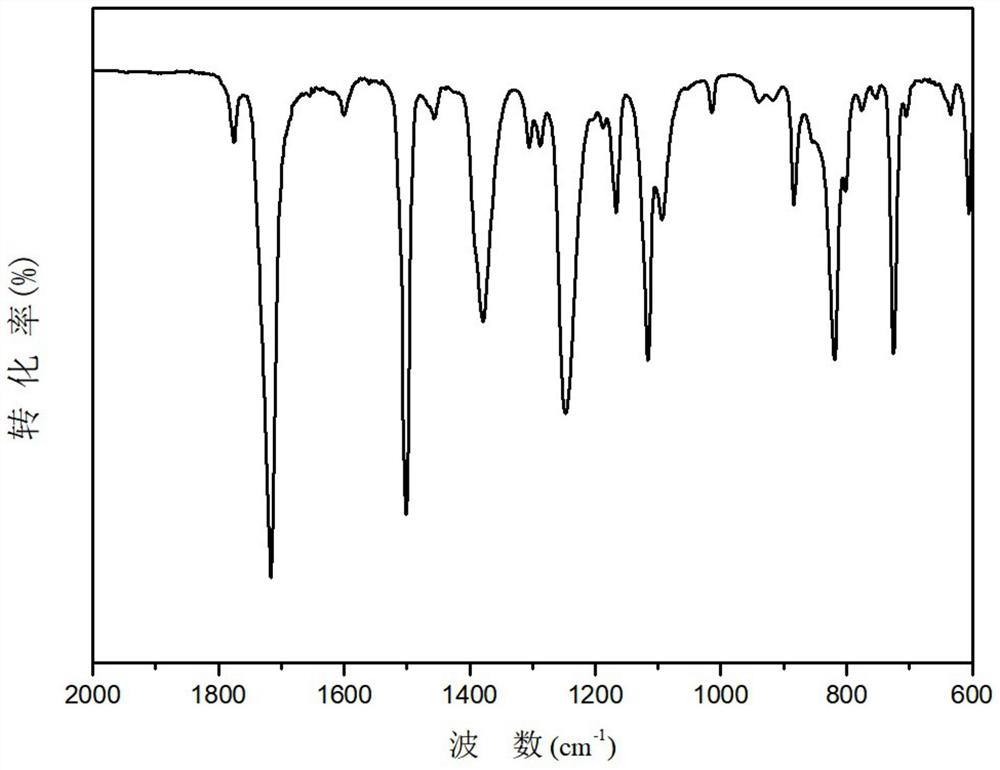

Degradable poly (butylene adipate-co-terephthalate) composite high-oxygen-barrier film as well as preparation method and application thereof

ActiveCN114539730ASimple preparation processMild reaction conditionsBio-packagingPolymer scienceAdipic acid

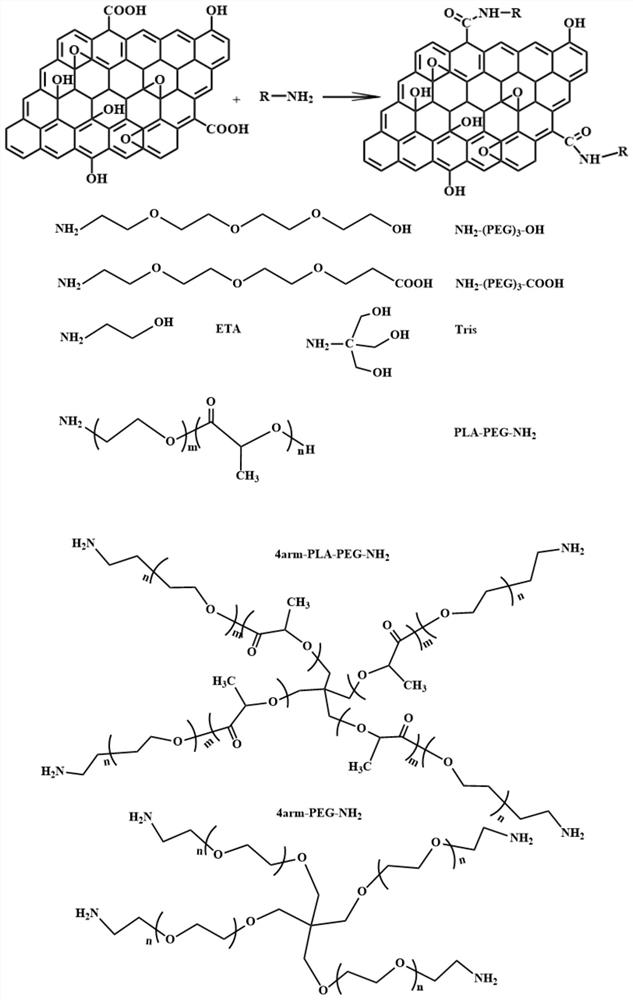

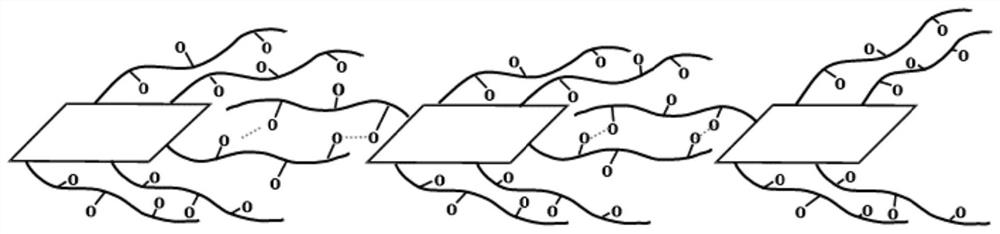

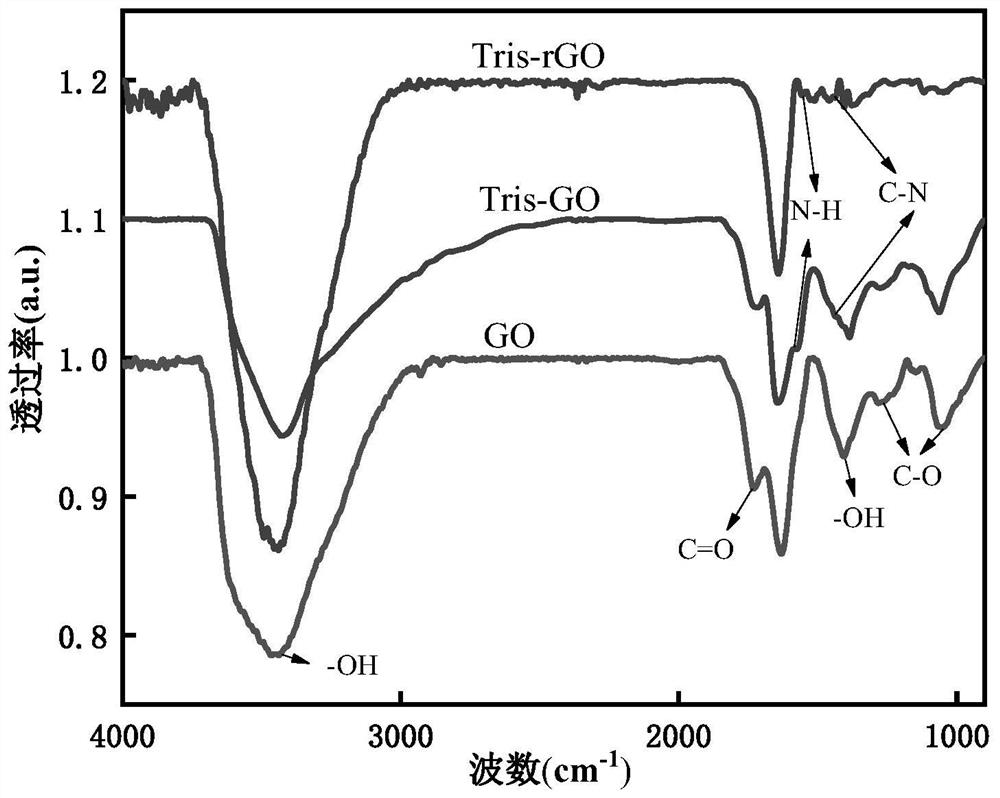

The invention discloses a degradable poly (butylene adipate-co-terephthalate) composite high-oxygen-barrier film as well as a preparation method and application thereof. The composite film is obtained by removing bubbles from a film-forming solution, pre-curing the film-forming solution in a closed environment and drying the pre-cured film-forming solution, the film forming liquid is obtained by heating an edge modified graphene oxide solution or an edge modified graphene solution and a poly (butylene adipate-co-terephthalate) solution at 60-80 DEG C for 1-4 hours after the edge modified graphene solution and the poly (butylene adipate-co-terephthalate) solution are mixed; the edge modified graphene oxide is prepared by carrying out amidation reaction on a polar molecular chain of which the tail end contains amino and edge carboxyl of graphene oxide, and the edge modified graphene is prepared by reducing the edge modified graphene oxide. The prepared composite film has the advantages of being degradable, excellent in oxygen barrier property, simple in preparation method and the like, and has good application value in the field of packaging.

Owner:SOUTH CHINA UNIV OF TECH

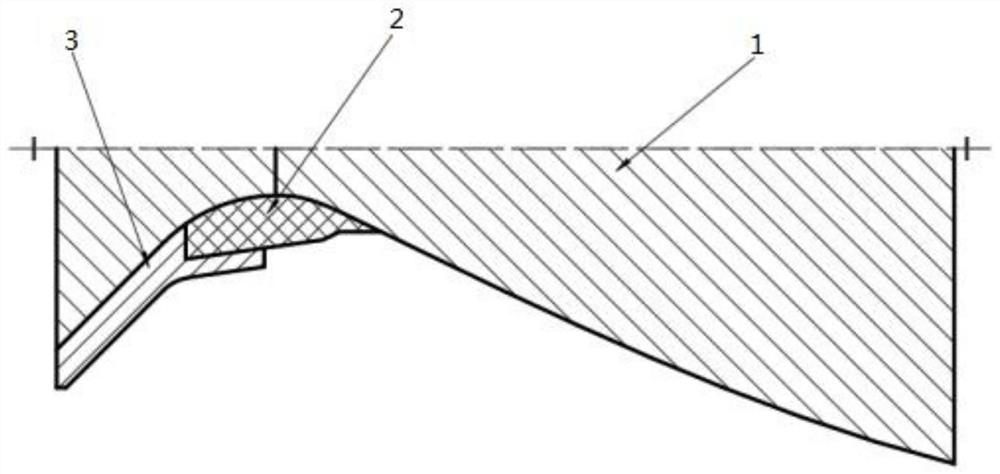

Method for manufacturing solar cell

InactiveCN102113128AAvoid bad influenceStructural defects noFinal product manufactureEnergy conversion devicesPhotoelectric conversionEngineering

Provided is a method for manufacturing a solar cell wherein a photoelectric conversion body, which has a first electrode layer, a semiconductor layer and a second electrode layer stacked therein in this order, is formed on one surface of a substrate, a connecting portion between the first electrode layer and the second electrode layer is provided, the photoelectric conversion body has a plurality of separated elements which are electrically separated by scribe lines having the semiconductor layer and the second electrode layer removed therefrom, and the separated elements adjacent to each other are electrically connected. The method is provided with a defective region specifying step of specifying a region where a structural defect of the photoelectric conversion body exists, and a repair step of removing or separating the structural defect by irradiating the photoelectric conversion body with a laser beam, forming three repair lines each of which has the semiconductor layer and the second electrode layer removed therefrom, and surrounding the region where the structural defect exists by using the three repair lines and the one scribe line. In a region alpha including a contact section where the semiconductor layer is in contact with the substrate in alpha region between the structural defect and the connecting section in the photoelectric conversion body, one repair line among the three repair lines is formed.

Owner:ULVAC INC

Normal-temperature curable waterborne damping paint

The invention relates to a normal-temperature curable waterborne damping paint, which is composed of the following raw materials by weight: 30-50 parts of a water-based acrylic emulsion; 35-55 parts of filler; 0.2-1 part of a dispersing agent; 3-10 parts of a film-forming agent; 0.3-1 part of a defoaming agent and 0.3-1 part of an adhesion promoter; 0.1-0.4 part of an antirust agent; 1-4 parts ofpurified water; 0.5-3 parts of a thickening agent; and 0.05-0.3 part of a multifunctional assistant. The damping paint has the advantages of high damping properties, strong bonding force, high self-strength, flash rust resistance, corrosion resistance, environmental friendliness and the like.

Owner:三友(天津)高分子技术有限公司

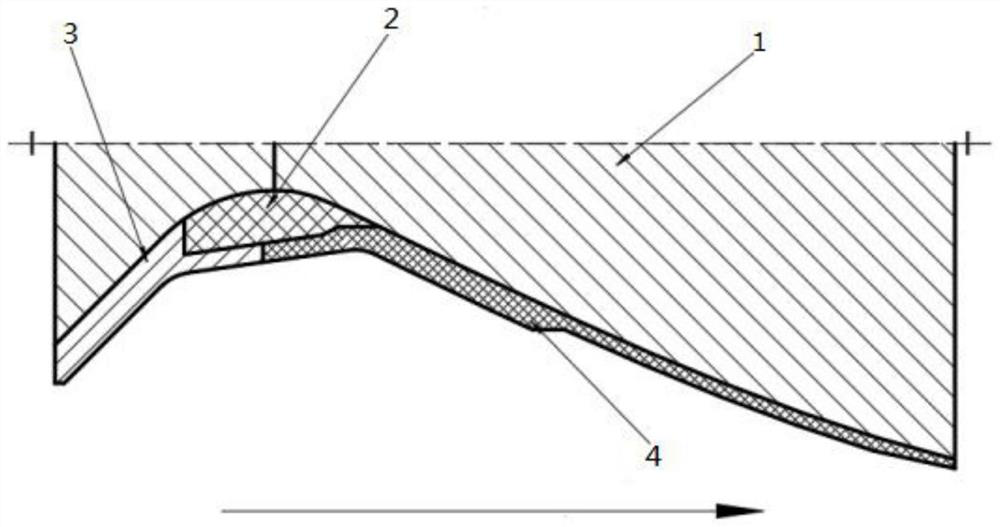

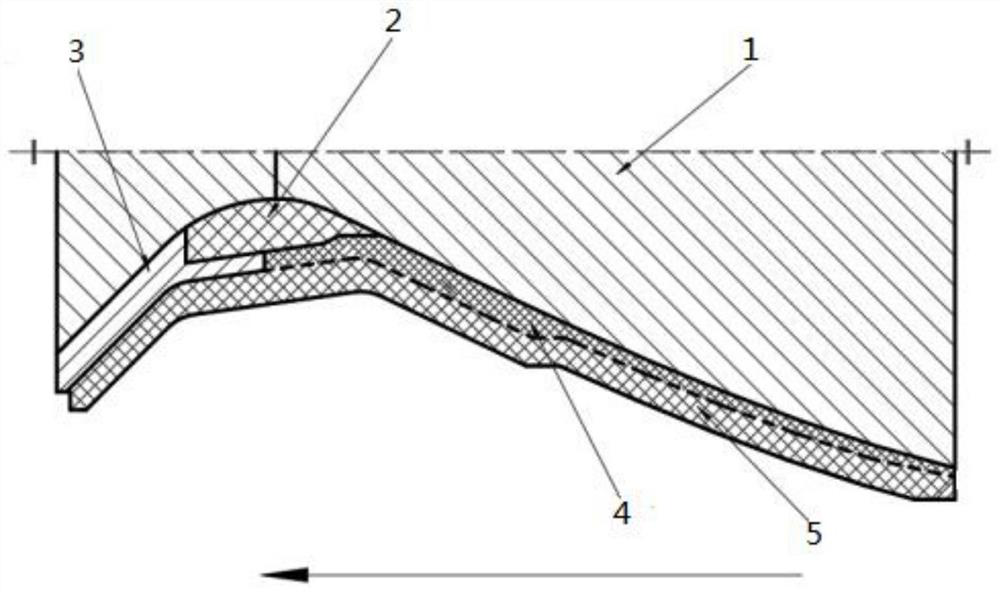

All-composite material engine nozzle formed through one-time curing

ActiveCN114198223ASimple production processShorten the production cycleRocket engine plantsTubular articlesFiberCarbon fibers

The invention relates to a one-time curing molding all-composite material engine jet pipe, which comprises a throat liner, a convergent section, a heat insulation layer, an inner ablation layer and a composite material shell, the throat liner is used as an initial surface layer, and the convergent section, the ablation layer, the heat insulation layer and the composite material shell are sequentially rotated from inside to outside to form the jet pipe; after all winding work is completed, one-time hot-pressing curing forming is integrally carried out; the convergence section is formed by integrally winding carbon fiber cloth tape prepreg; the ablation layer is formed by winding fibers or cloth tapes on the throat liner and the mold; the thermal insulation layer is formed by obliquely winding fibers or cloth tape prepreg on the outer side of the ablation layer; and the composite material shell is formed by laying or winding fibers or cloth tapes on the outer side of the heat insulation layer. Through the co-curing technology of the transition structure resin, curing of different structures and functional layers of the composite material spray pipe is completed at a time, chemical structural mutation does not exist on an interface, therefore, the interface strength is improved, the debonding risk does not exist, and meanwhile the production period of the all-composite material spray pipe is shortened.

Owner:湖北航泰科技有限公司

Polyimide film and preparation method thereof

The invention belongs to the technical field of heat conduction materials, and particularly relates to a polyimide film and a preparation method thereof. The invention provides a polyimide film preparation method, which comprises: 1, dissolving a diamine monomer and a dianhydride monomer in an aprotic polar solution under a protection atmosphere, and stirring at a low temperature to prepare a first polyamide acid solution; 2, sequentially carrying out low-temperature standing defoaming and vacuum defoaming treatment on the precursor polyamic acid solution to obtain a second polyamide acid solution; and 3, coating the second polyamide acid solution on a base material, drying, carrying out a thermal imidization reaction, and separating the polyimide film from the base material to prepare thepolyimide film. The invention provides the polyimide film and a preparation method thereof. The technical defects that an existing polyimide film is uneven in thickness and incomplete in thermal imidization can be effectively overcome.

Owner:GUANGDONG UNIV OF TECH

Energy-saving board and manufacturing method thereof

ActiveCN104341094BRealize full planarizationIncrease usage intensityGlass reforming apparatusEngineeringExhaust pipe

The invention provides an energy-saving sheet material and a manufacturing method thereof. The energy-saving sheet material comprises at least one layer of upper sheet material, at least one layer of lower sheet material, at least one layer of inner sheet material and a plurality of support structures, wherein the upper edge of the upper sheet material and the lower edge of the lower sheet material are respectively straight lines; the inner sheet material is arranged between the upper sheet material and the lower sheet material, and the sheet materials in adjacent layers are separated by the support structures; an exhaust port is formed in the side of the inner sheet material, and is a through groove penetrating through the upper surface and the lower surface of the inner sheet material; the edges of the upper sheet material, the lower sheet material and the inner sheet material are sealed and closed by a sealing material, so that vacuum layers are formed among the sheet materials; an exhaust pipe is arranged in the exhaust port, the open end of the exhaust pipe is positioned on the inner side of the exhaust port, and the closed end of the exhaust pipe is positioned on the outer side of the exhaust port and exists in the space formed between the upper sheet material and the lower sheet material. The energy-saving sheet material is fully planar and is free of structure defect, so that the using strength of the energy-saving sheet material is enhanced.

Owner:ICESUN VACUUM GLASS

Special horizontal type shaking table for cooling and sterilizing process for protein preparation

ActiveCN102247609BProcess parameters are easy to controlGood antibacterial effectLavatory sanitoryHeatGear wheelDrive motor

The invention relates to a cooling and sterilizing process for a protein preparation and a special horizontal type shaking table thereof. In the prior art, a sterilizing device for the protein preparation has the defects of poor stability and difficult control of parameters. The special shaking table comprises a cycloidal pin wheel speed reducer, a driving motor and a shaking table, wherein an eccentric outer gear, an eccentric inner gear, a gear shaft sleeve and a left gear base are fixedly arranged on the cycloidal pin wheel speed reducer and an output shaft of the driving motor; the left gear base is connected with one end of a regulating lead screw; the other end of the regulating lead screw is connected with a right bearing base; a shaking amplitude adjustment device is connected with the bearing base and one end of a shaking oscillating bar; the other end of the shaking oscillating bar is connected with one end of a rotating shaft of the shaking oscillating bar; and the other end of the rotating shaft of the shaking oscillating bar is connected with the shaking table by a transmission device in a shaking table cylinder body. The special horizontal type shaking table has a reasonable and compact structure, is reliable in strength, rigidity and toughness of key positions, small in assembly stress of parts and high process performance, process parameters are easy to control, and the optimal bacteriostatic effect can be achieved.

Owner:华原谷道生物科技西安有限公司

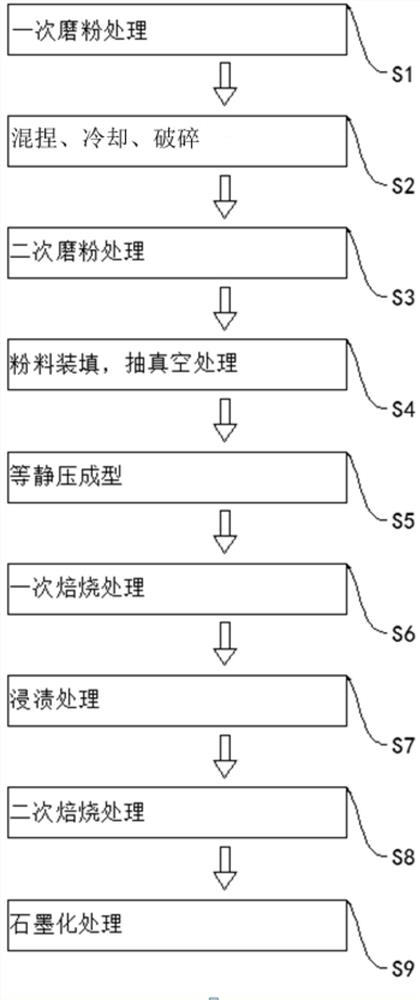

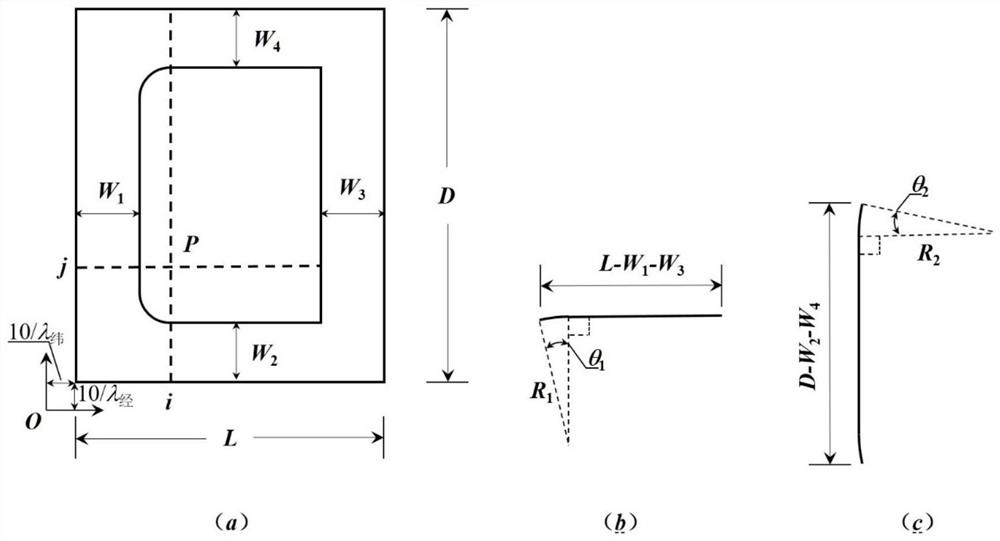

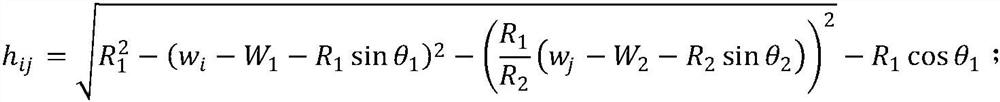

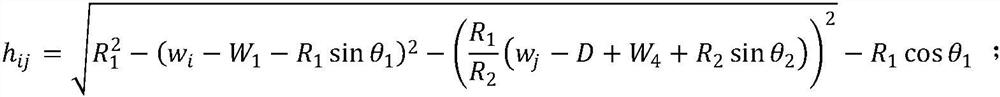

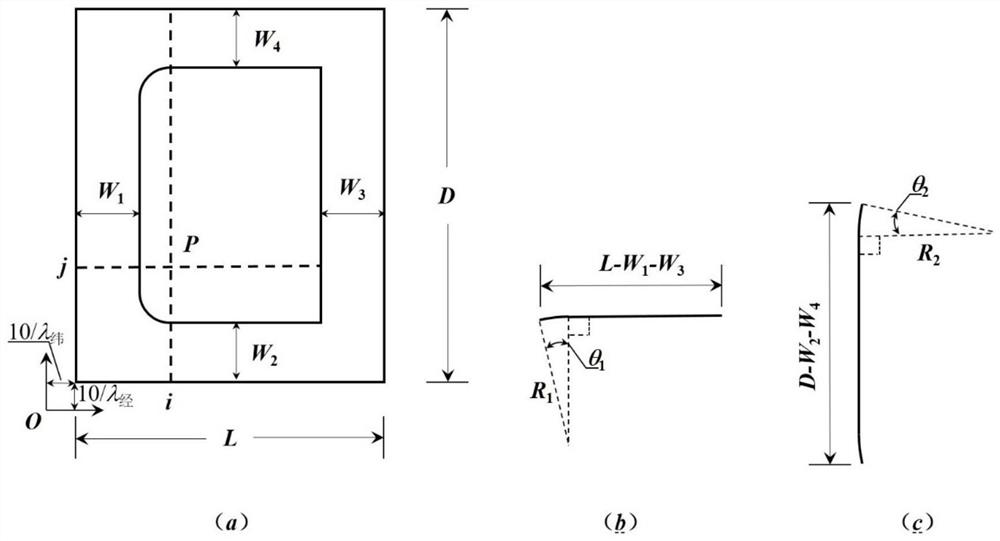

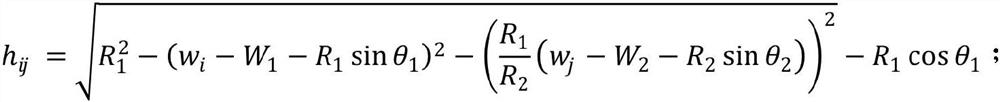

A processing method for producing isostatic cylindrical graphite using an isostatic graphite cylindrical material forming die

The invention discloses a processing method for producing isostatic cylindrical graphite by using an isostatic pressing graphite barrel forming die, and relates to the technical field of isostatic pressing graphite processing. The processing method of isostatic pressing cylindrical graphite, the mold comprises a mold steel barrel, a plastic bag, an inner core barrel, a base, a support ring and an evacuation tube, and the diameter of the inner core barrel is smaller than the diameter of the mold steel barrel and the plastic bag, The plastic bag and the inner core barrel are installed on the base, the base is sleeved on the bottom of the lower end of the mold steel barrel, the plastic bag is laid in the gap between the inner core barrel and the mold steel barrel, and the vacuum pipe is connected to the mold steel barrel. The inside of the plastic bag is communicated, and the support ring is sealed and installed at the inner opening of the plastic bag to seal and vacuumize; the method includes a plurality of steps, and the present invention has the advantages of being able to mass-produce large-diameter barrel materials, and optimizing the internal Structural defects, good quality and high isotropy.

Owner:四川士达特种炭材有限公司

Notebook computer upper cover plate containing fabric and preparation method of notebook computer upper cover plate

ActiveCN112680860AAchieve interweavingIn line with the aesthetic conceptDigital data processing detailsLoomsEpoxyEngineering

The invention relates to a notebook computer upper cover plate containing fabric and a preparation method of the notebook computer upper cover plate. The notebook computer cover plate is mainly composed of cover plate cloth and thermosetting epoxy resin, wherein the cover plate cloth is single-layer plain woven fabric formed by interweaving warp yarn and weft yarn; all the warp yarn on the single-layer plain woven fabric are parallel to the plane where any bent warp yarn is located; all the weft yarn is parallel to the plane where any bent weft yarn is located; and the warp densities and the weft densities of all parts of the single-layer plain woven fabric are the same. The preparation method comprises the following steps: preparing the cover plate cloth by adopting a plain weaving process, putting the cover plate cloth into a mold by adopting a mold injection molding method, and curing by using the thermosetting epoxy resin to prepare the notebook computer upper cover plate. The notebook computer upper cover plate containing the fabric quite conforms to the current aesthetic concept, structural defects do not exist at all positions of the computer upper cover plate, and the bearing capacity of the corners of the computer upper cover plate is higher.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of intermediate, composition, anti-discoloration silver and preparation method for preventing silver discoloration

ActiveCN109338340BSmall impact on structureReduce energy consumptionLiquid/solution decomposition chemical coatingOrganic solventSilicic acid

The invention discloses a silver discoloring preventive intermediate, a composition and discoloring preventive silver and a preparation method. The intermediate is a mixed solution comprising tetraethoxysilane, boric acid, bismuth nitrate and an organic solvent, wherein the weight ratio of tetraethoxysilane to boric acid to bismuth nitrate is 10-13: 1.5-3: 7-10. The composition is a glass body andcomprises silicon dioxide, diboron trioxide and bismuth trioxide based on the weight ratio of 30-35: 10-15: 50-55. The discoloring preventive silver is synthesized by the following steps: (1) mixingboric acid and tetraethoxysilane organic solutions to obtain a solution A; (2) mixing the solution A and bismuth nitrate to obtain the silver discoloring preventive intermediate; (3) soaking silver inthe silver discoloring preventive intermediate; moving out; and forming an intermediate layer on the surface of silver; and (4) thermally processing the intermediate layer; heating; and then decreasing the temperature to obtain the discoloring preventive silver. With the adoption of the silver discoloring preventive intermediate, the color remaining time of the discoloring preventive silver can be prolonged, and meanwhile, the corrosion resisting effect of the discoloring preventive silver can be improved.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

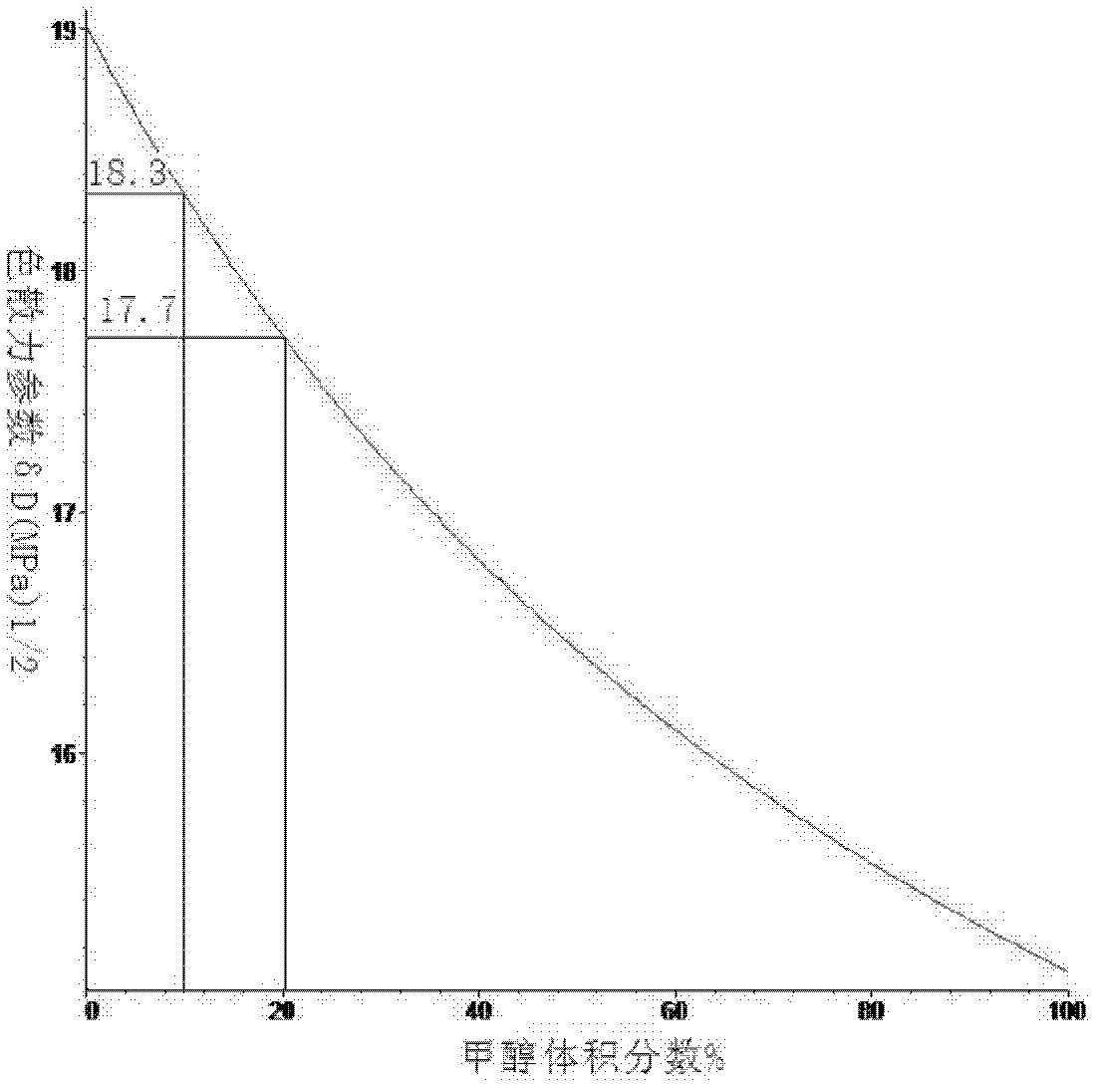

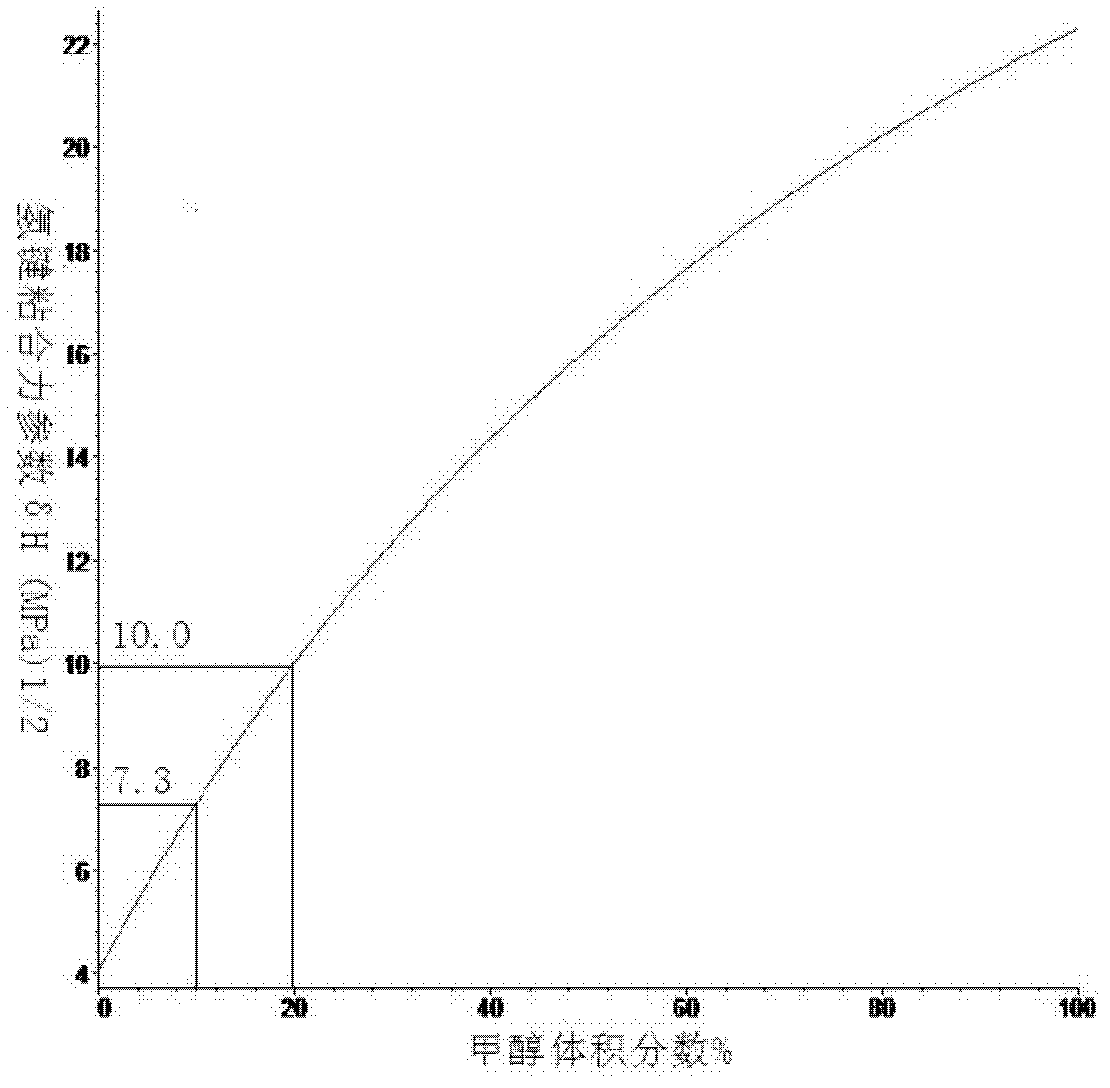

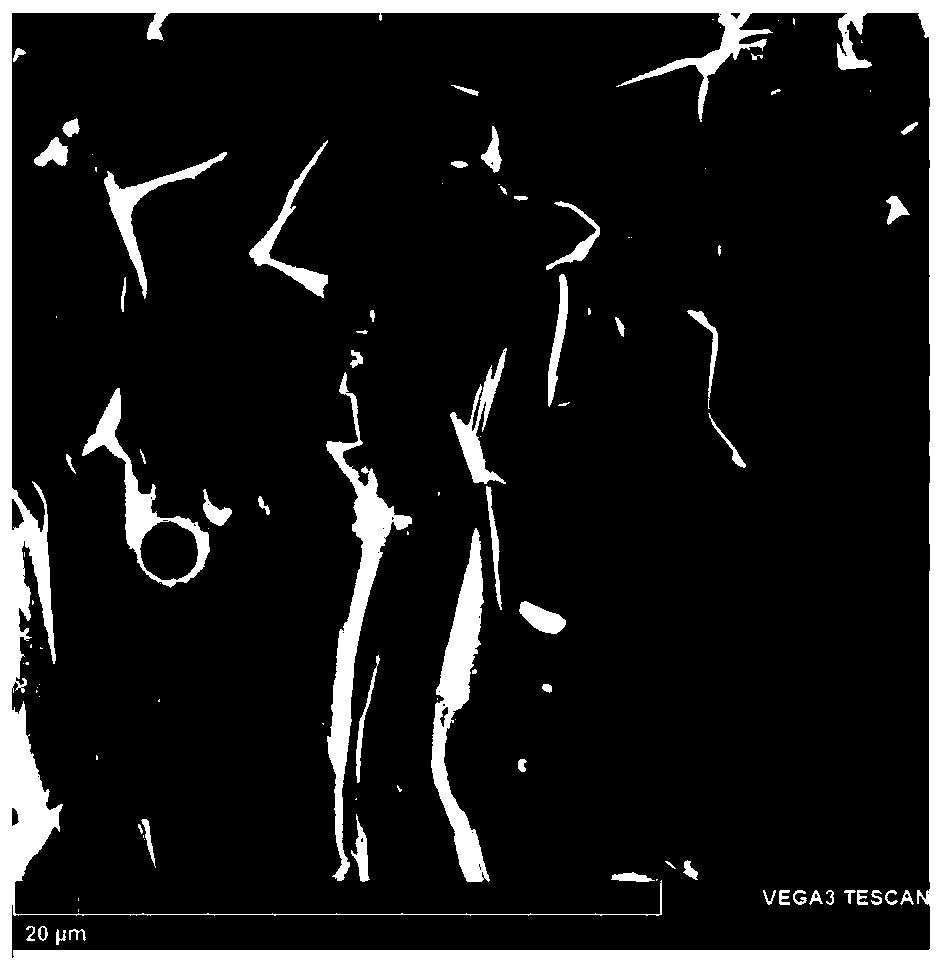

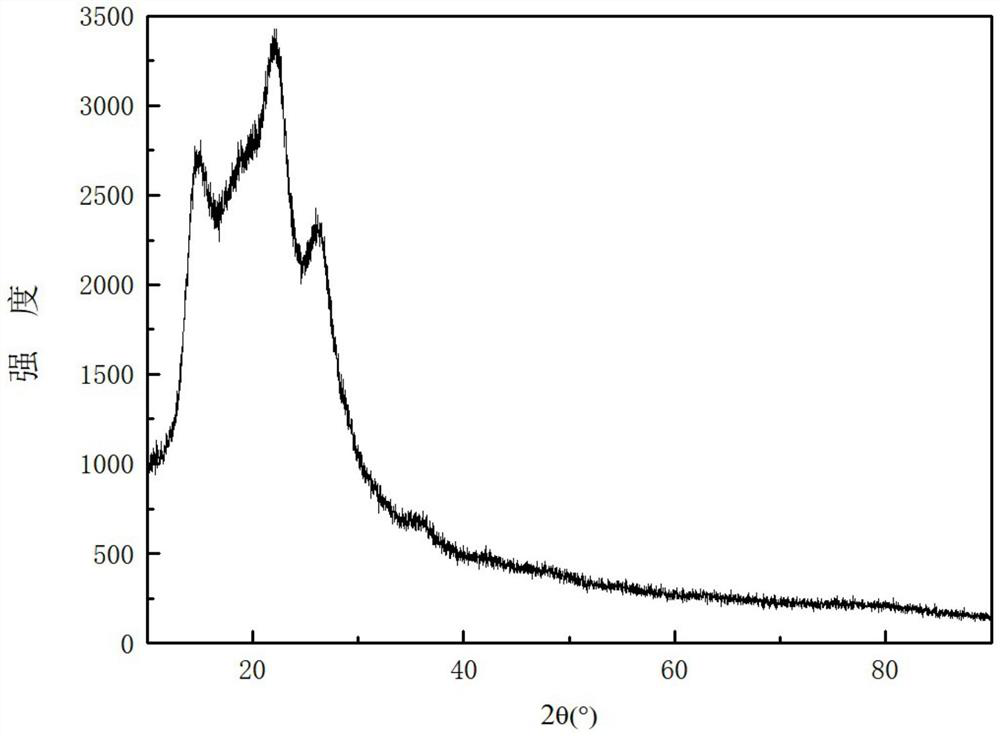

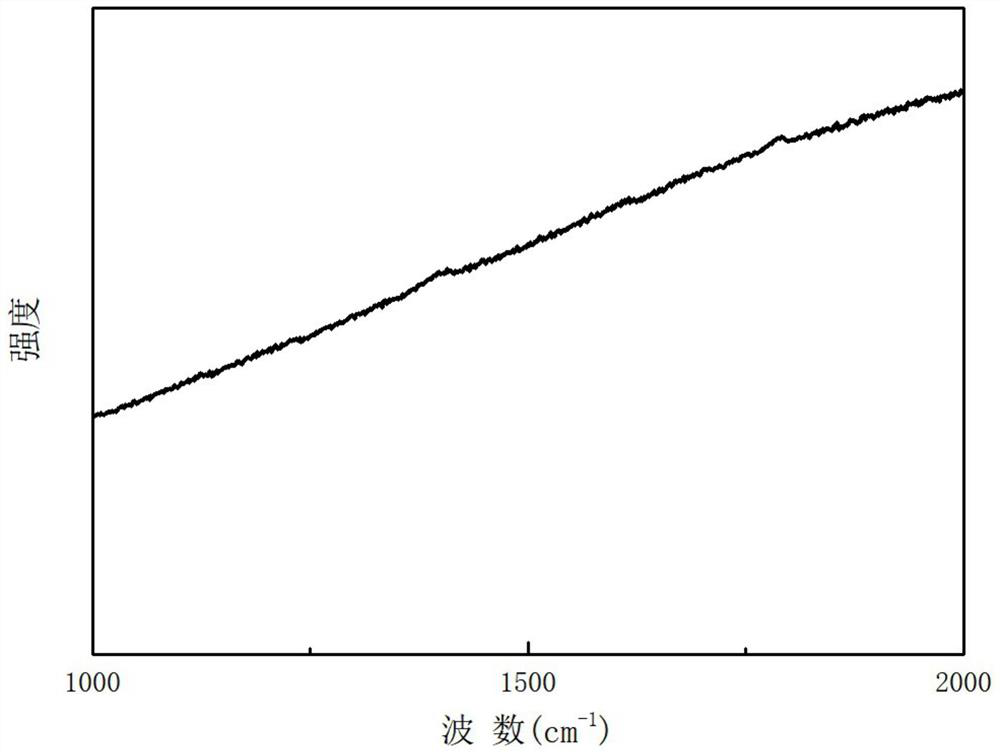

a co 2 Method for preparing graphene by exfoliating natural graphite powder by introducing dislocation slip effect in expanding liquid

ActiveCN105645391BReduce usageThe peeling process is simple and easy to controlGrapheneSolubilityLubrication

The invention provides a method for preparing graphene by stripping natural graphite powder in a CO2 expanded liquid by introducing dislocation glide actions, belonging to the technical field of nano materials. According to the solubility-parameter-based thermodynamic calculation process, the appropriate organic solvent is selected, the system temperature, pressure and CO2 to organic solvent ratio are regulated, the physicochemical properties of the multicomponent system are regulated, and the interaction force between the graphene and organic solvent is changed, so that the surface tension of the mixed system is matched with the surface energy of the graphene. The non-normal force is introduced to generate the dislocation glide acting force, the graphite flakes can transversely slide by using the graphite self lubrication of the graphite, and the intercalation action of the small molecule CO2 is utilized to efficiently strip the graphite powder so as to prepare the graphene. By the aid of the dislocation glide action and energy conversion, the intercalation action of the CO2 small molecule is utilized, thereby enhancing the stripping efficiency. According to the method, the subsequent treatment process is simplified, and the highly-concentrated graphene dispersion solution can be obtained after the pressure relief operation.

Owner:DALIAN UNIV OF TECH

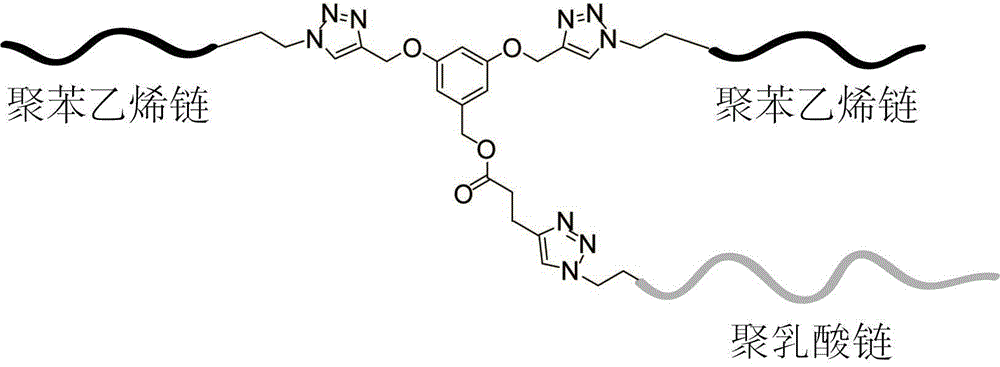

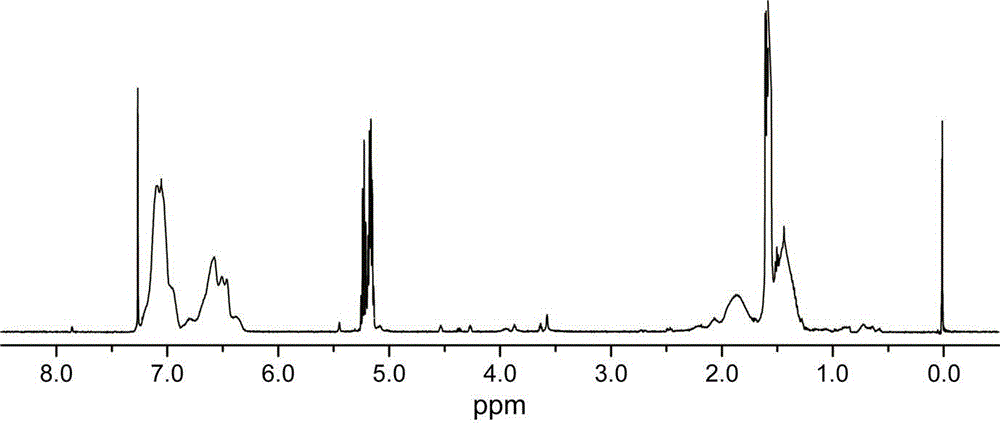

A kind of radial block copolymer and preparation method thereof

The invention belongs to the technical field of polymer materials, and in particular relates to a star-shaped block copolymer and a preparation method thereof. The specific method is: through Huisgen cycloaddition reaction, polystyrene and polylactic acid or polyoxyethylene are successively connected to the same core molecule to form an A2B three-arm star-shaped block copolymer. The three-arm star-shaped copolymer prepared by the present invention has a precise and controllable molecular chain structure, can be used for self-assembly in solution to form core-shell nanomicelles, and can also be used for microphase separation under heating to form regular and ordered Nano-phase separation structure, and further prepared into a nano-organic porous material with regular pore structure and high specific surface area, has broad application prospects in the fields of drug sustained release and nano-separation.

Owner:TONGJI UNIV

A kind of fabric-containing notebook computer top cover and preparation method thereof

ActiveCN112680860BAchieve interweavingIn line with the aesthetic conceptDigital data processing detailsLoomsEpoxyPlain weave

The invention relates to a notebook computer top cover with fabric and a preparation method thereof. The notebook computer cover is mainly composed of a cover cloth and a thermosetting epoxy resin; the cover cloth is a single layer formed by interweaving warp yarns and weft yarns Plain woven fabric; all warp yarns on a single-ply plain woven fabric are parallel to the plane of any curved warp yarn; all weft yarns are parallel to the plane of any curved weft yarn; and The warp density is the same, and the weft density is the same; the preparation method is: adopt the plain weaving process to obtain the cover cloth, adopt the mold injection molding method, place the cover cloth in the mold, and cure it with thermosetting epoxy resin to obtain the notebook computer. Top cover; a fabric-containing notebook computer top cover of the present invention is very in line with the current aesthetic concept, and there is no structural defect in the computer top cover, and the bearing capacity of the corners of the computer top cover more capable.

Owner:JIANGSU HENGLI CHEM FIBER

Preparation method of graphene

Disclosed is a preparation method of grapheme. The preparation method of the grapheme comprises the following steps: graphite powder is added to non-water polar solvent dissolved with acene condensed nucleus arene derivative to form a mixed system; the mixed system is shocked, washed, centrifuged and filtered to obtain grapheme solution. The preparation method of the grapheme is not high in requirements for preparation conditions, simple in preparation process, good in quality of obtained grapheme, almost free of structural defects and considerable in productivity.

Owner:XIDIAN UNIV

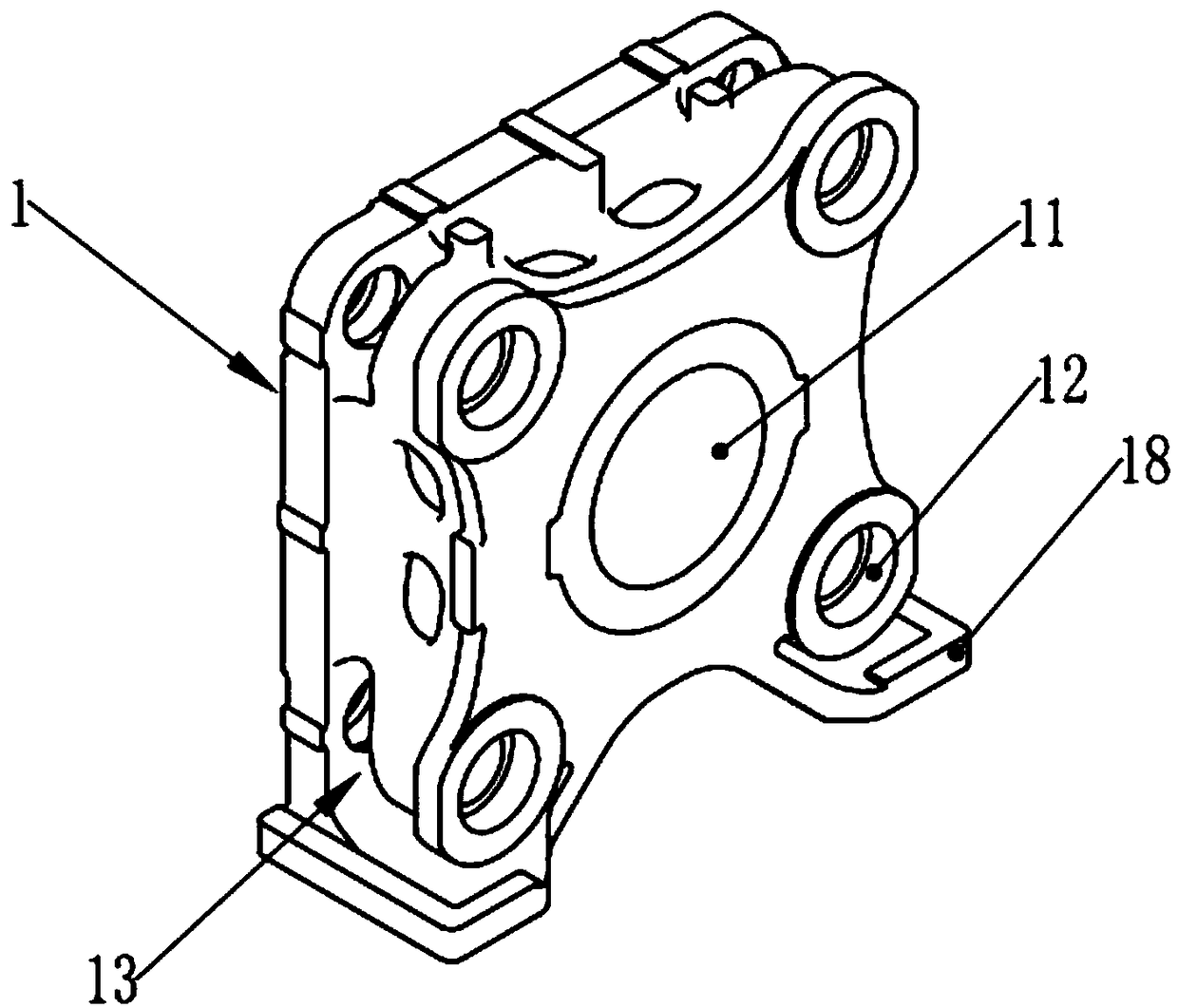

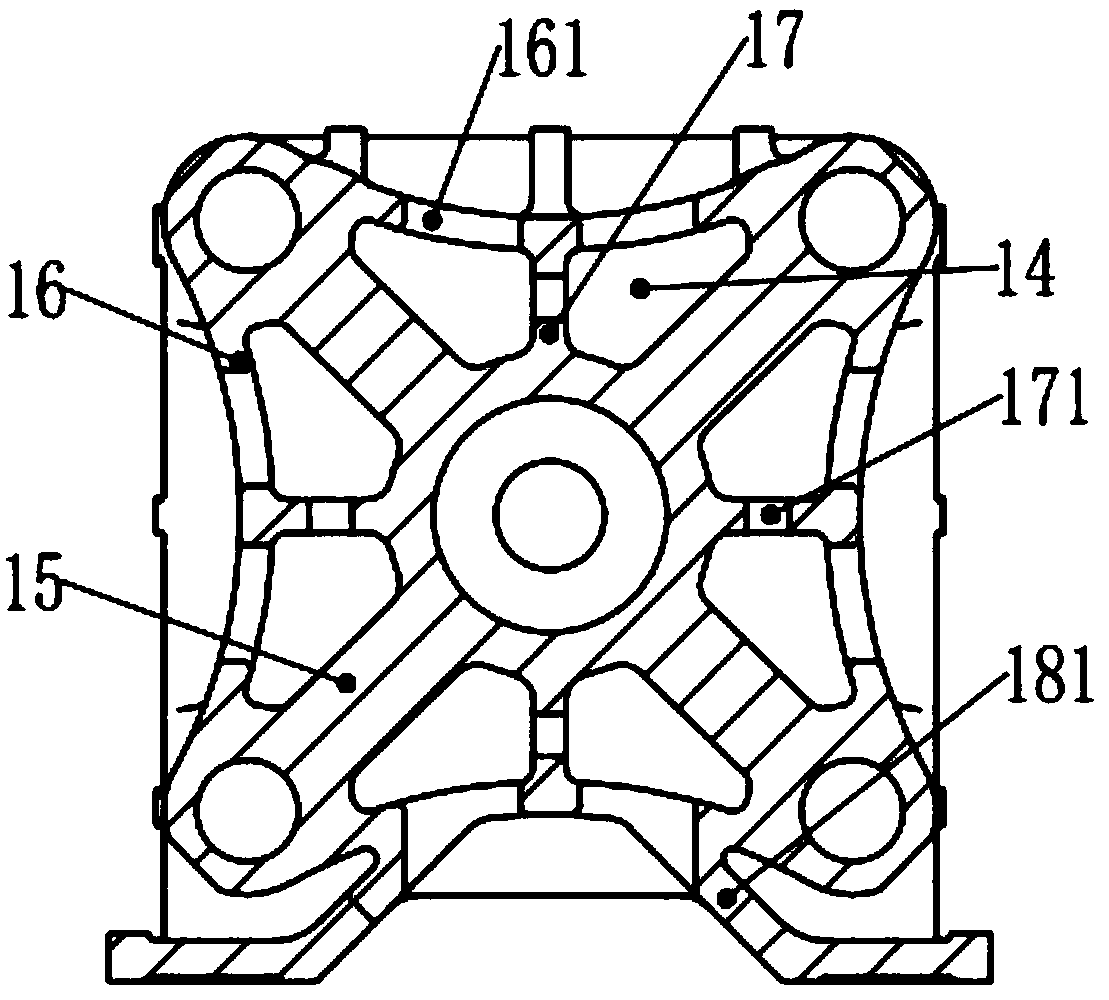

Mold-locking head plate of injection molding machine

A mold-locking head plate of an injection molding machine comprises a body, guiding column mounting holes are formed in the four corners of the body correspondingly, unloading grooves are laterally formed in the four corners of the body correspondingly, the unloading grooves communicate with the guiding column mounting holes, and the unloading grooves are narrowed from groove openings to the groove bottoms. The guiding column mounting holes are used for mounting guiding columns, in the mold locking process, the surface of the body deforms towards the interiors of the unloading grooves, distribution of the tensile force of the guiding columns to the body moves towards the center of the body, action points of the tensile force moves towards the center of the body along with the change trendof stress distribution, thus the force arm from the action points of the tensile force to the center of the body is shortened, the deformation of the middle of the body is decreased, it is ensured that a whole device operates stably in the production process and is small in vibration, the using amount of materials for manufacturing of the mold-locking head plate is decreased, and the cost is lowered; and according to computer finite element analysis comparison, the deformation of the mold-locking head plate is smaller than that of a common mold plate by about 20%, and mold plate rigidity is effectively improved.

Owner:佛山市宝捷精密机械有限公司

A kind of composite sliding bearing and its preparation method

The invention relates to a compound sliding bearing and a preparation method thereof. Foamed aluminum is subjected to degreasing, alkali washing and acid pickling; then, a silane coupling agent is used for surface treatment; a layer of sulfonated graphene is deposited on the hole surface on the foamed aluminum treated in the steps by an electro-deposition method; the foamed aluminum deposited withthe sulfonated graphene is charged into an injection mold; wear-resistant plastic is subjected to injection molding by an injection molding process, and is cooled and formed; the wear-resistant plastic is prepared from at least one of materials from metaformaldehyde, polyether-ether-ketone, polyphenyl thioether, polyfluortetraethylene and ultra-high molecular weight polyethylene; the foamed aluminum before degreasing is prepared from pure aluminum and / or aluminum silicon alloy through foaming; the complete communicating hole system is realized; the porosity is 60 percent to 80 percent; the hole diameter is 2 to 4mm. The technical scheme provided by the invention has the advantages that a sulfonated graphene transition layer is introduced between the foamed aluminum and a polymer two-phaseinterface by an electrodeposition method; the technical problems of great interface heat resistance, interface degumming caused by different thermal expansion coefficients of the foamed aluminum anda polymer material, and the like are effectively solved.

Owner:长沙精达高分子材料有限公司

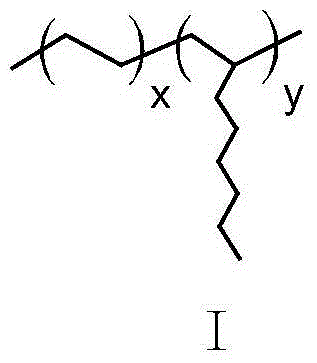

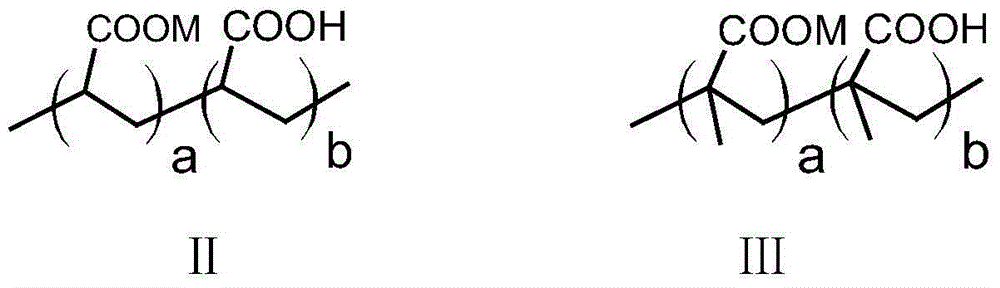

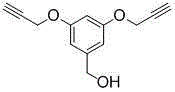

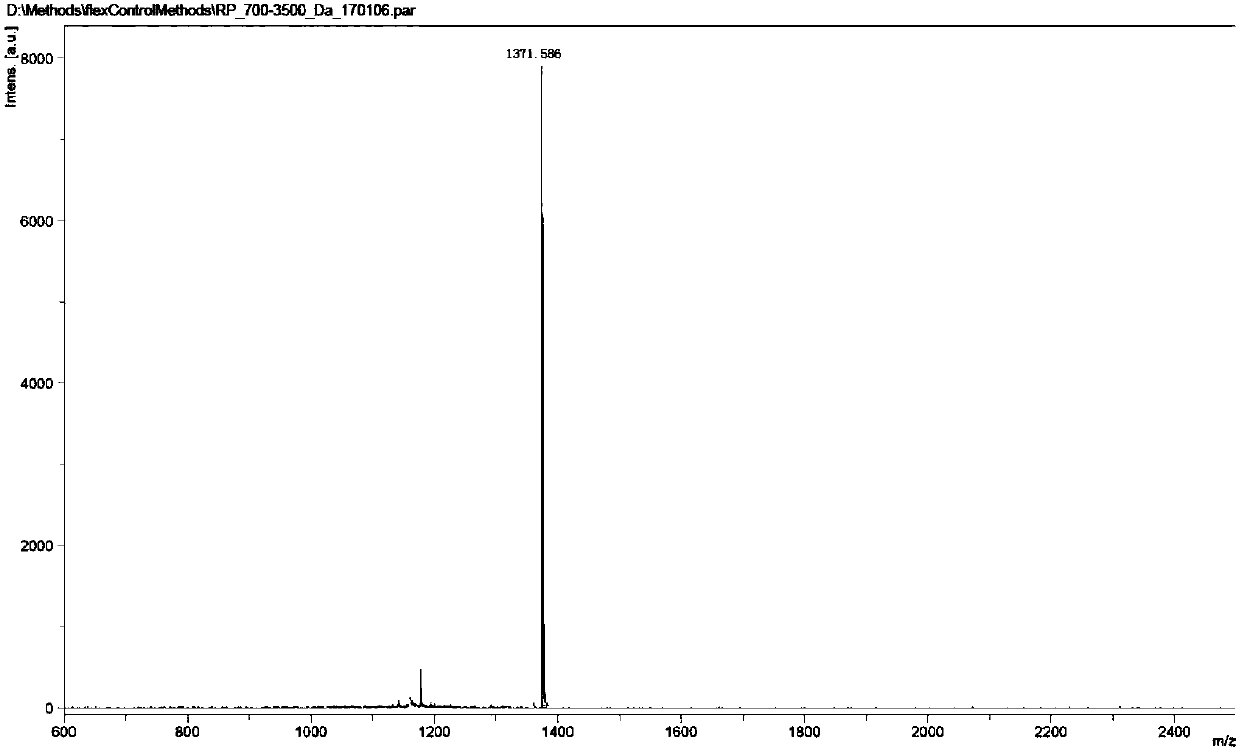

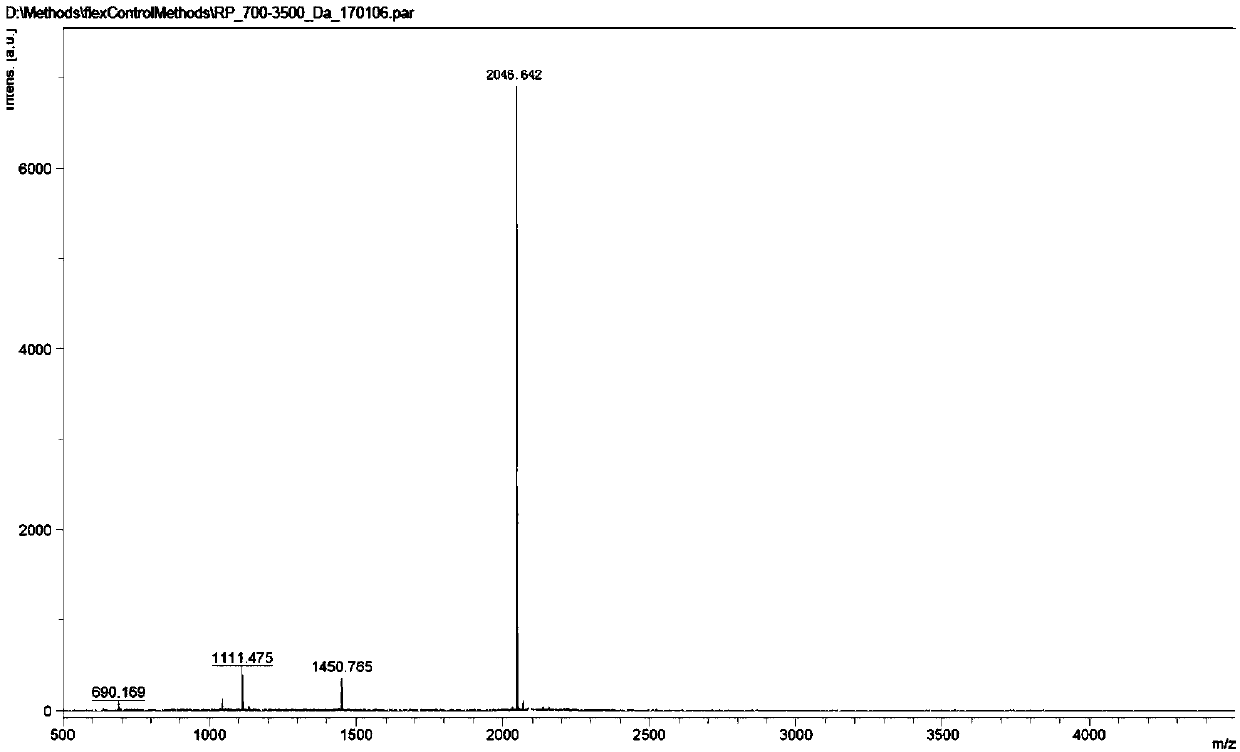

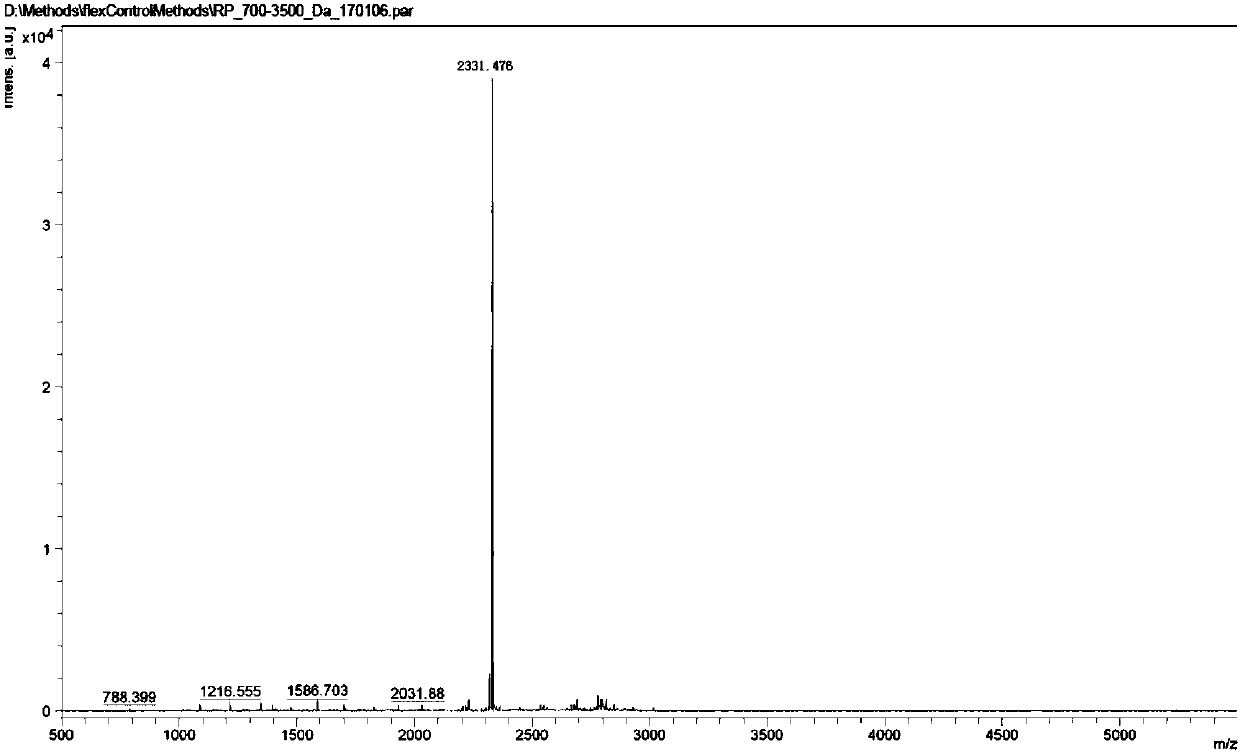

Liquid phase spherical carrier, and preparation method and applications thereof

InactiveCN109988062ANo structural defectsSmall middle resistanceOrganic compound preparationPeptide preparation methodsOrganic chemistryLiquid phase

The invention relates to a liquid phase spherical carrier, and a preparation method and applications thereof, and more specifically discloses a spherical carrier can be used for liquid phase synthesis. The spherical carrier possesses a structure represented by formula I, wherein R is used for representing a functional group selected from groups containing hydroxyl, amino, carboxyl, or halogen preferably. The liquid phase synthesis carrier can be used for liquid phase synthesis of polypeptides. The preparation method is simple; and synthesis efficiency is high.

Owner:HYBIO PHARMA

Method for preparing graphene through phase peeling of graphite by using mixed solvent

InactiveCN103172053BTo overcome the deficiency of low concentrationReduce reunionGrapheneSolubilityWater baths

The invention relates to a method for preparing graphene through phase peeling of graphite by using a mixed solvent. The method comprises the following steps: 1, preparing a mixed solvent composed of at least two organic solvents having boiling points of not greater than 100DEG C; 2, adding powdery graphite to the mixed solvent to prepare a mixed solution of the powdery graphite, putting the mixed solution of the powdery graphite in an ultrasonic machine, carrying out water-bath ultrasonic treatment, and centrifuging through using a centrifuge; and 3, taking a supernatant obtained after the centrifuging with a pipette to obtain a graphene dispersion uniformly dispersed in the mixed solvent. The method enables the Hansen solubility parameters of the mixed solvent to reach the Hansen solubility parameters of graphene as possible through adjusting the volume ratio of the organic solvents in order to obtain a solvent which is most suitable for peeling and dispersing graphene, and the solvent is used to carry out the phase peeling of graphene.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com