Multilayer coil

A technology of stacking coils and coils, applied in transformer/inductor coils/windings/connections, inductors, printed inductors, etc., can solve problems such as interlayer peeling, different linear expansion coefficients, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

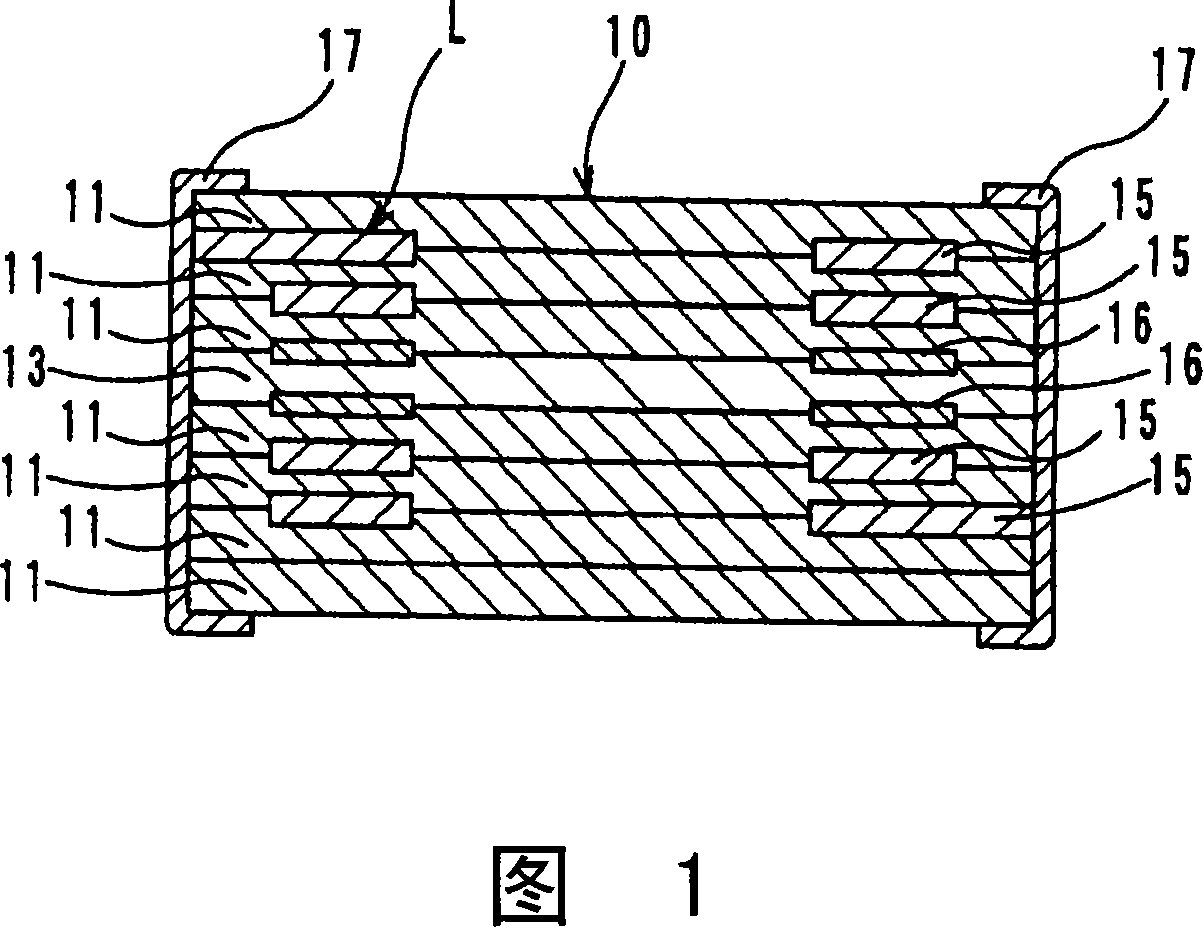

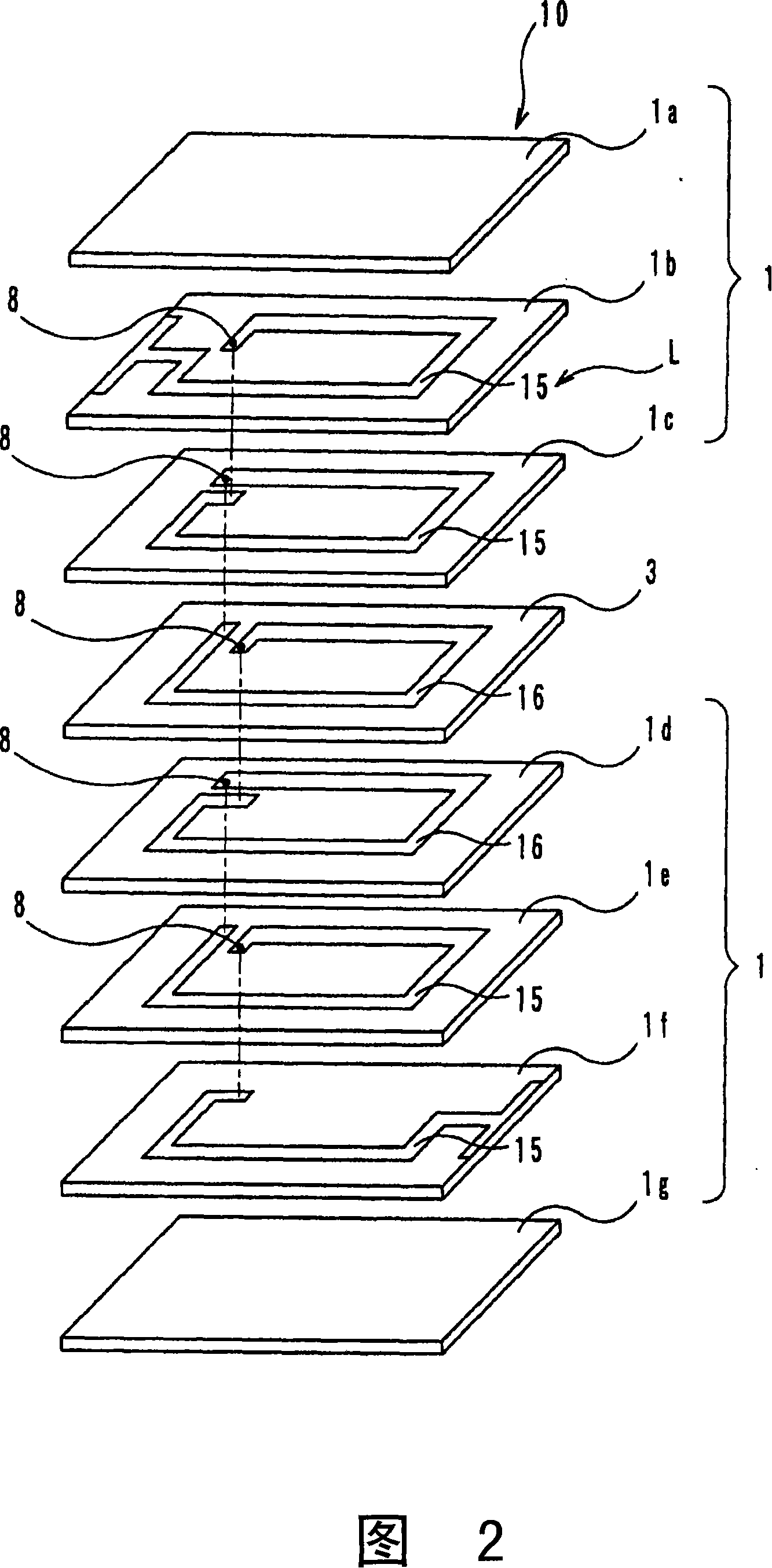

[0018] Fig. 1 is a schematic sectional view of a laminated coil in a first embodiment of the present invention. The laminated coil includes: a laminated body 10 composed of a plurality of magnetic layers 11 and non-magnetic layers 13, a coil L formed by spirally connecting coil conductors 15 and 16 formed in the laminated body 10, and an external electrode 17 and 17. In addition, the magnetic layer 11 is formed on both main surfaces of the nonmagnetic layer 13 .

[0019] As shown in FIG. 1 , the coil conductor 16 located on both main surfaces of the nonmagnetic layer 13 is thinner than the coil conductor 15 having a predetermined thickness not located on both main surfaces of the nonmagnetic layer 13 . Specifically, it is less than 0.6 times the thickness of the magnetic layer 11 and the thickness of the nonmagnetic layer 13, and is thicker than 0.1 times the thickness of the coil conductor 15 that is not located on both main surfaces of the nonmagnetic layer 13. .

[0020]...

Embodiment 2

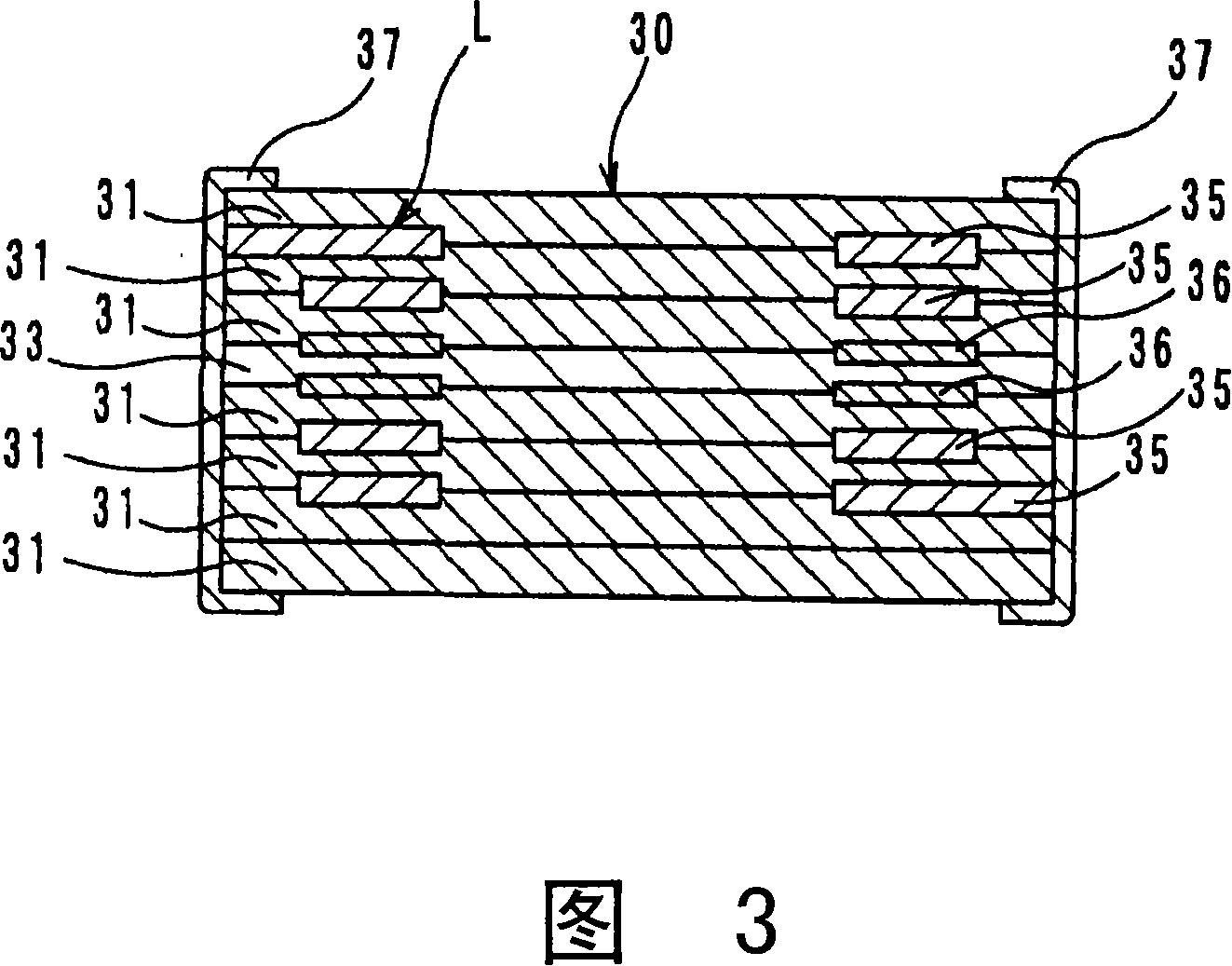

[0038] Fig. 3 is a schematic sectional view of a laminated coil in a second embodiment of the present invention. In addition, in FIG. 3 , descriptions of parts that are the same as or corresponding to those in FIG. 1 are appropriately omitted.

[0039] As shown in FIG. 3 , the laminated coil includes a laminated body 30 formed by forming a plurality of magnetic layers 31 on both main surfaces of a non-magnetic layer 33 , and coil conductors 35 and 36 formed in the laminated body 30 are connected in a spiral manner. A coil L formed in a shape, and external electrodes 37 and 37. Then, the thickness of the coil conductor 36 located on both main surfaces of the non-magnetic material layer 33 is thinner than the other coil conductor 35 having a predetermined thickness which is not located on both main surfaces of the non-magnetic material layer 33 . Specifically, the thickness of the coil conductor 36 positioned on both main surfaces of the nonmagnetic layer 33 is less than 0.6 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com