Preparation method of graphene

A graphene and graphite powder technology, applied in the field of graphene preparation, can solve the problems of complex process, difficult single-layer graphene, high production equipment, and high conditions, achieve low requirements for preparation conditions, no structural defects, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

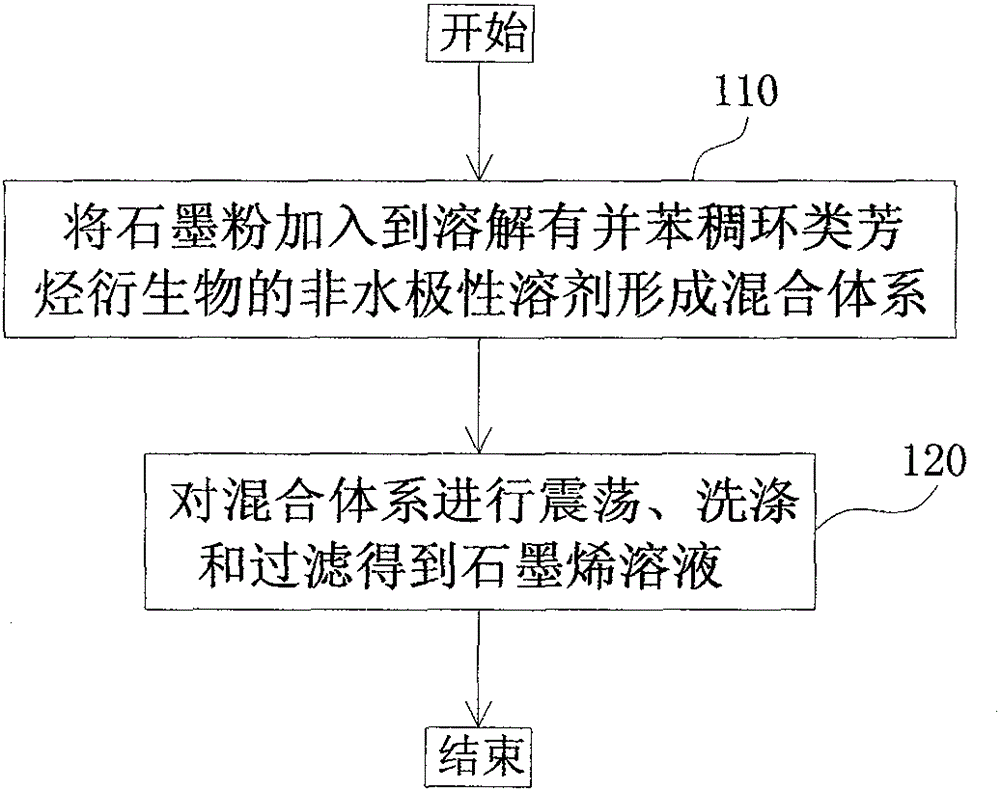

[0022] Such as figure 1 所示,一种石墨烯的制备方法,利用含亲水基团的并苯稠环类芳烃衍生物作为插层试剂,且利用水及非水极性溶剂作为分散体系,分步超声波法制备石墨烯,包括以下步骤:

[0023] 步骤110中,将石墨粉加入到溶解有并苯稠环类芳烃衍生物的非水极性溶剂形成混合体系。取1mg至1000mg的石墨微粒(粒径在5μm至300μm之间)加入到溶解有1mg至500mg的并苯稠环类芳烃衍生物(如萘甲酸、萘甲醛、蒽甲酸、蒽甲醛、菲甲酸、菲甲醛、苊甲酸、苊甲醛、芴甲酸、芴甲醛、芘甲酸等)的10ml至1000ml非水极性溶剂中(如甲酰胺、乙腈、甲醇、乙醇、丙醇、乙酸、二恶烷、N-N二甲基甲酰胺等)。

[0024] 步骤120中,对所述混合体系进行震荡、洗涤、离心和过滤得到石墨烯溶液。

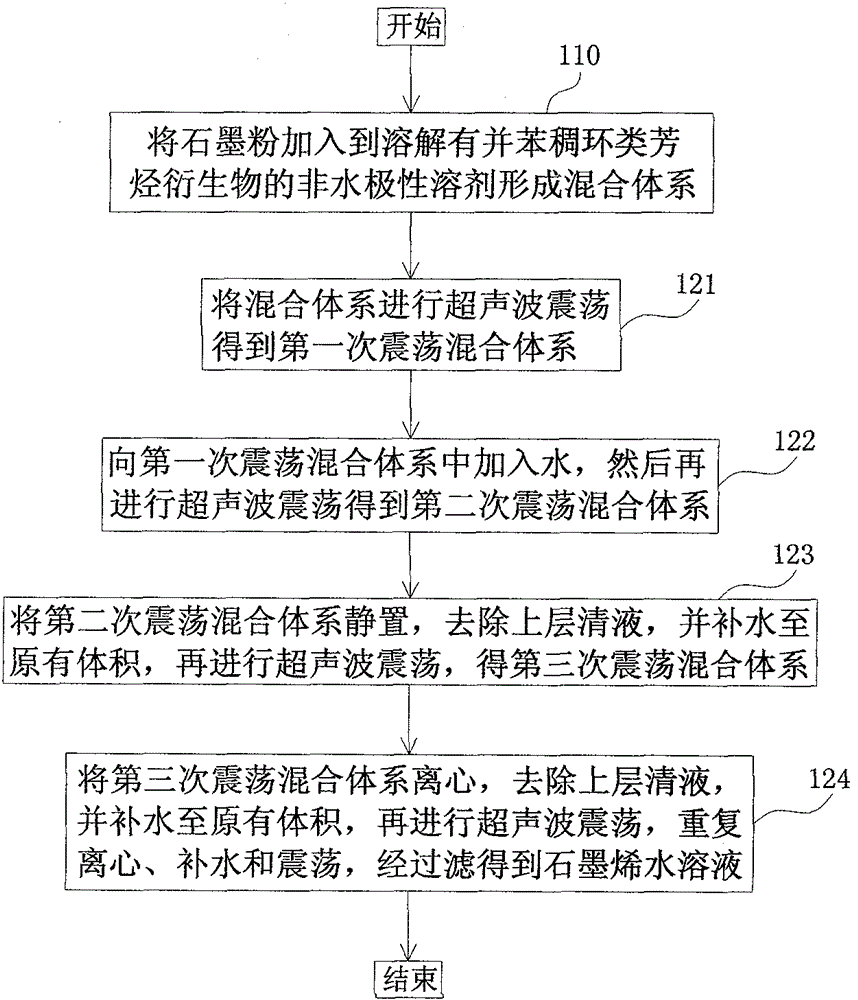

[0025] 上述过程,利用并苯稠环类芳烃衍生物其上的含稠环基团与石墨上π电子的相互作用,在非水极性溶剂中,以一定功率的超声波震荡,起到对石墨插层的效果;再加入极性很强的水做分散剂,利用超声波破坏石墨其上的化学键,此时并苯稠环类芳烃衍生物其上的亲水基团溶于水分散液,帮助石墨烯溶解,避免石墨烯堆积,得到石墨烯原始溶液。再多次利用超声波震荡、洗涤、离心的方法纯化石墨烯溶液,去除原始溶液中过量的并苯稠环类芳烃衍生物及未剥离的石墨,最终得到纯净的石墨烯溶液,产率约为1%。制备过程中可保证每一步均在常温常压下操作,无需加热,无强腐蚀性、剧毒性试剂,制备条件要求不高、制备工艺简单、所得石墨烯品质优良,几乎没有结构缺陷,且产率可观。

[0026] 在本实施例中,混合体系的震荡采用超声波震荡。

[0027] Such as figure 2 所示,在本实施例中,经过步骤110得...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com