A kind of composite sliding bearing and its preparation method

A technology of sliding bearings and aluminum foam, applied in shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of weakened thermal conductivity improvement effect, large gap in thermal expansion coefficient, degumming of composite material interfaces, etc., achieving outstanding application value , excellent performance and excellent tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

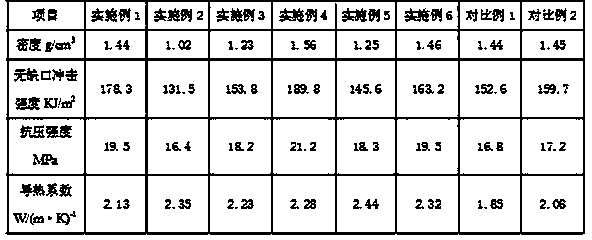

Examples

Embodiment 1

[0035] The aluminum foam / polymer three-dimensional interpenetrating composite sliding bearing is produced according to the following steps:

[0036] Preparation of POM composite filler: After drying 60 parts by weight of POM (polyoxymethylene), 20 parts by weight of potassium hexatitanate whisker (PTW), and 20 parts by weight of PTFE (polytetrafluoroethylene) solid lubricant, add 0.3 parts by weight 1 part by weight of antioxidant B225 and 0.1 part by weight of triethanolammonium were mixed in a high-speed mixer, extruded and granulated at a temperature of 160°C to 190°C, and then dried for use.

[0037] The foamed aluminum blanks with a porosity of 60%, a pore diameter of 2mm, an inner diameter of Φ45mm, an outer diameter of Φ62mm, and a length of 62mm were sequentially washed in 3wt% NaOH aqueous solution for 6 minutes, and acid-washed in 3wt% HCI aqueous solution for 6 minutes. Minutes; rinse with water to make the rinse solution of foamed aluminum neutral; dry at a tempera...

Embodiment 2

[0041] The aluminum foam / polymer three-dimensional interpenetrating composite sliding bearing is produced according to the following steps:

[0042] Preparation of POM composite filler: After drying 70 parts by weight of POM, 10 parts by weight of potassium hexatitanate whisker (PTW), and 10 parts by weight of PTFE solid lubricant, add 0.1 parts by weight of antioxidant B225 and 0.3 parts by weight of three Ethanolammonium is mixed in a high-speed mixer, extruded and granulated at a temperature of 160°C to 190°C, and then dried for use.

[0043] The foamed aluminum blanks with a porosity of 80%, a pore diameter of 4mm, an inner diameter of Φ45mm, an outer diameter of Φ62mm, and a length of 62mm were sequentially washed in 8wt% NaOH aqueous solution for 4 minutes, and acid-washed in 8wt% HCI aqueous solution for 4 minutes. Minutes; rinse with water to make the rinse solution of foamed aluminum neutral; dry at a temperature of 80-100°C; then use 3wt% KH570 coupling agent hydroly...

Embodiment 3

[0047] The aluminum foam / polymer three-dimensional interpenetrating composite sliding bearing is produced according to the following steps:

[0048] Preparation of POM composite filling: After drying 65 parts by weight of POM, 15 parts by weight of potassium hexatitanate whisker (PTW), and 15 parts by weight of PTFE solid lubricant, add 0.2 parts by weight of antioxidant B225 and 0.2 parts by weight of three Ethanolammonium is mixed in a high-speed mixer, extruded and granulated at a temperature of 160°C to 190°C, and then dried for use.

[0049] The foamed aluminum blanks with a porosity of 70%, a pore diameter of 4mm, an inner diameter of Φ45mm, an outer diameter of Φ62mm, and a length of 62mm were sequentially washed in 5wt% NaOH aqueous solution for 5 minutes, and pickled in 5wt% HCI aqueous solution for 5 minutes. Minutes; rinse with water to make the rinse solution of foamed aluminum neutral; dry at a temperature of 80-100°C; then use 2wt% KH560 coupling agent hydrolyzat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com