Patents

Literature

1350 results about "UHMWPE polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

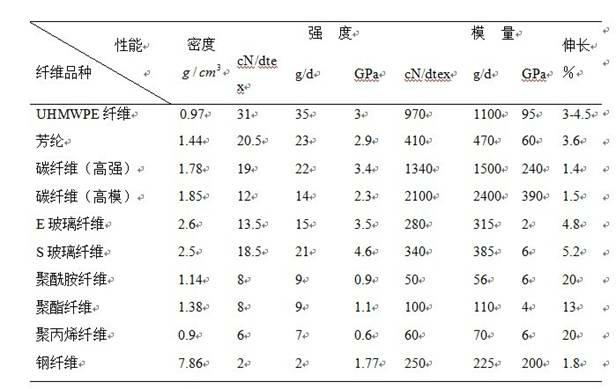

Ultra-high-molecular-weight polyethylene. Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu.

Sealing stopper for a syringe and a prefilled syringe

There can be provided a sealing stopper for a syringe, having very high sealing property and sliding property, and a prefilled syringe using this sealing stopper and capable of preserving a medicament for a long time and operating in easy and precise manner during injecting. This syringe is also excellent in sanitary and operating property during a step of formulation or preservation of a medicament. In this sealing stopper for a syringe, a surface of the rubber body is laminated with a tetrafluoroethylene resin film or ultra-high molecular weight polyethylene film having an average roughness Ra on the central line of the surface in a range of at most 0.05 mu m and a kinematic friction coefficient of at most 0.2.

Owner:DAIKYO SEIKO LTD

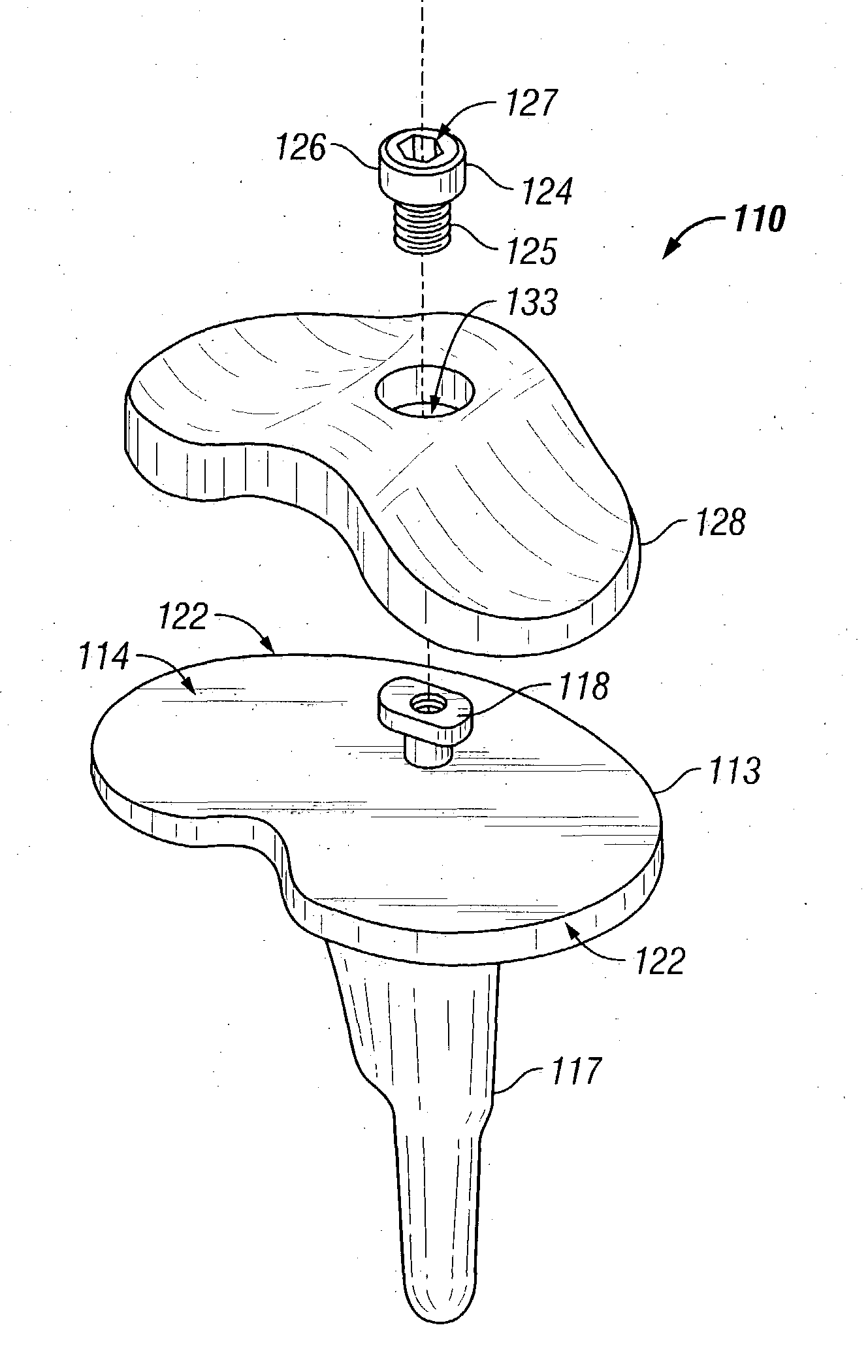

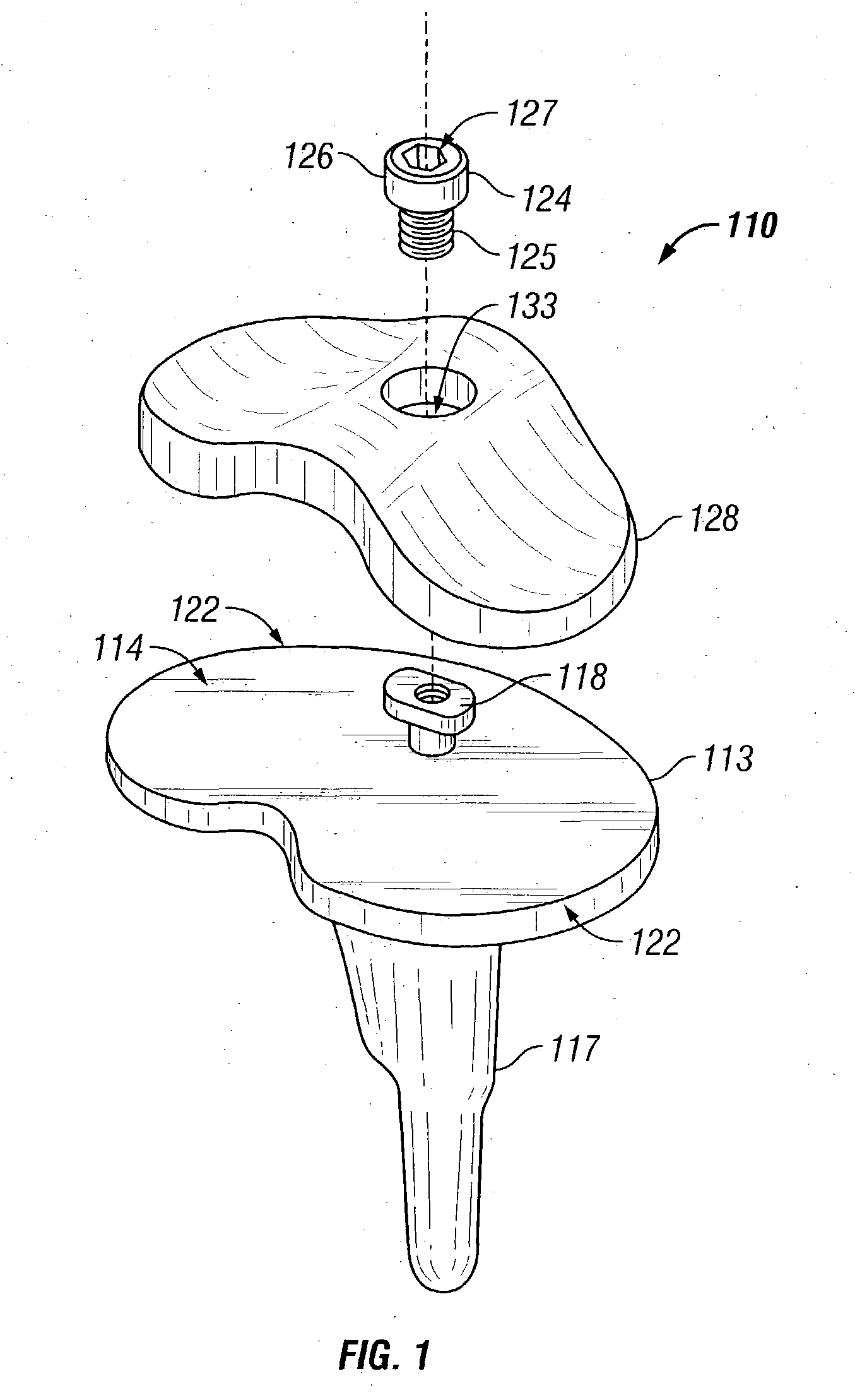

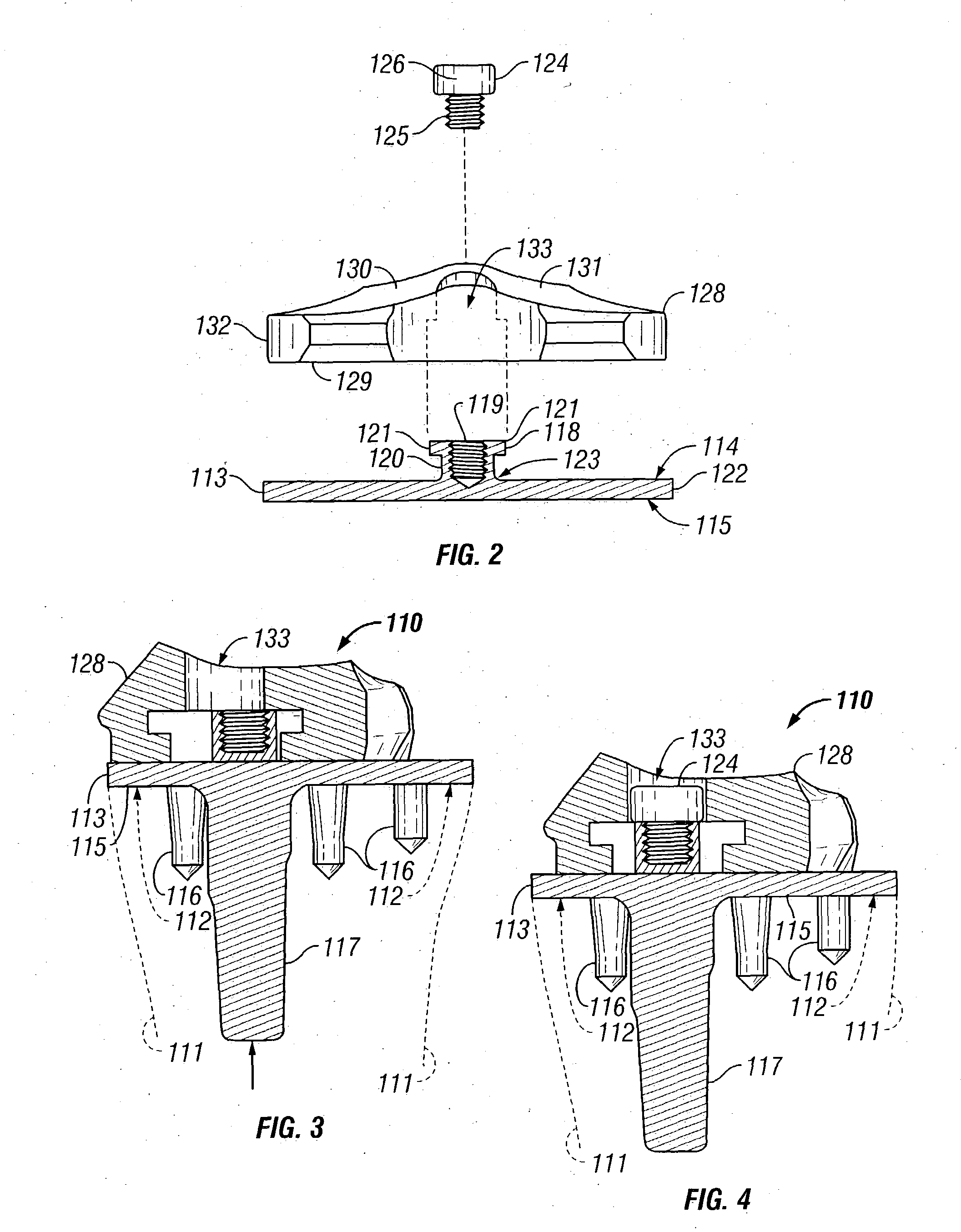

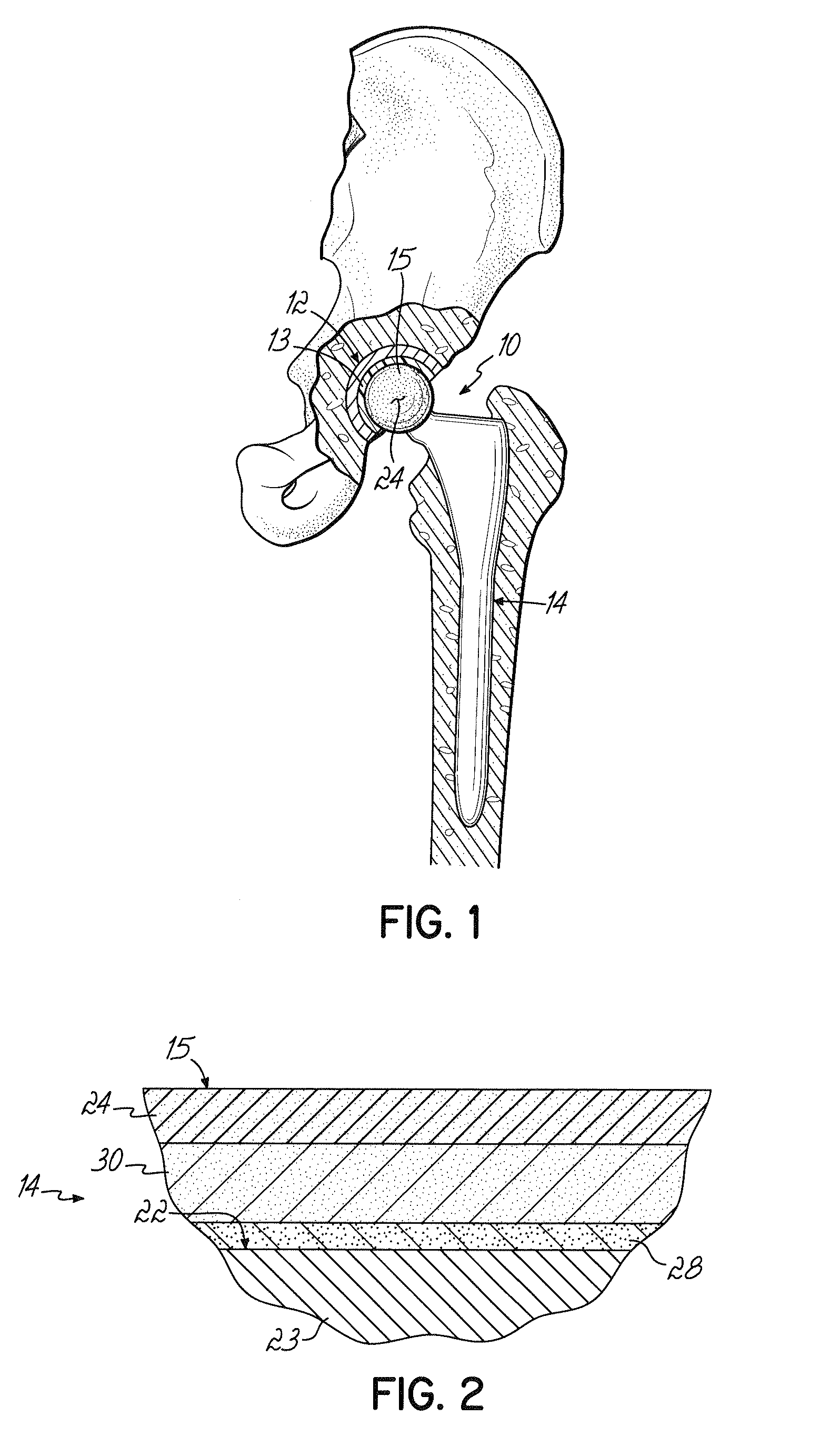

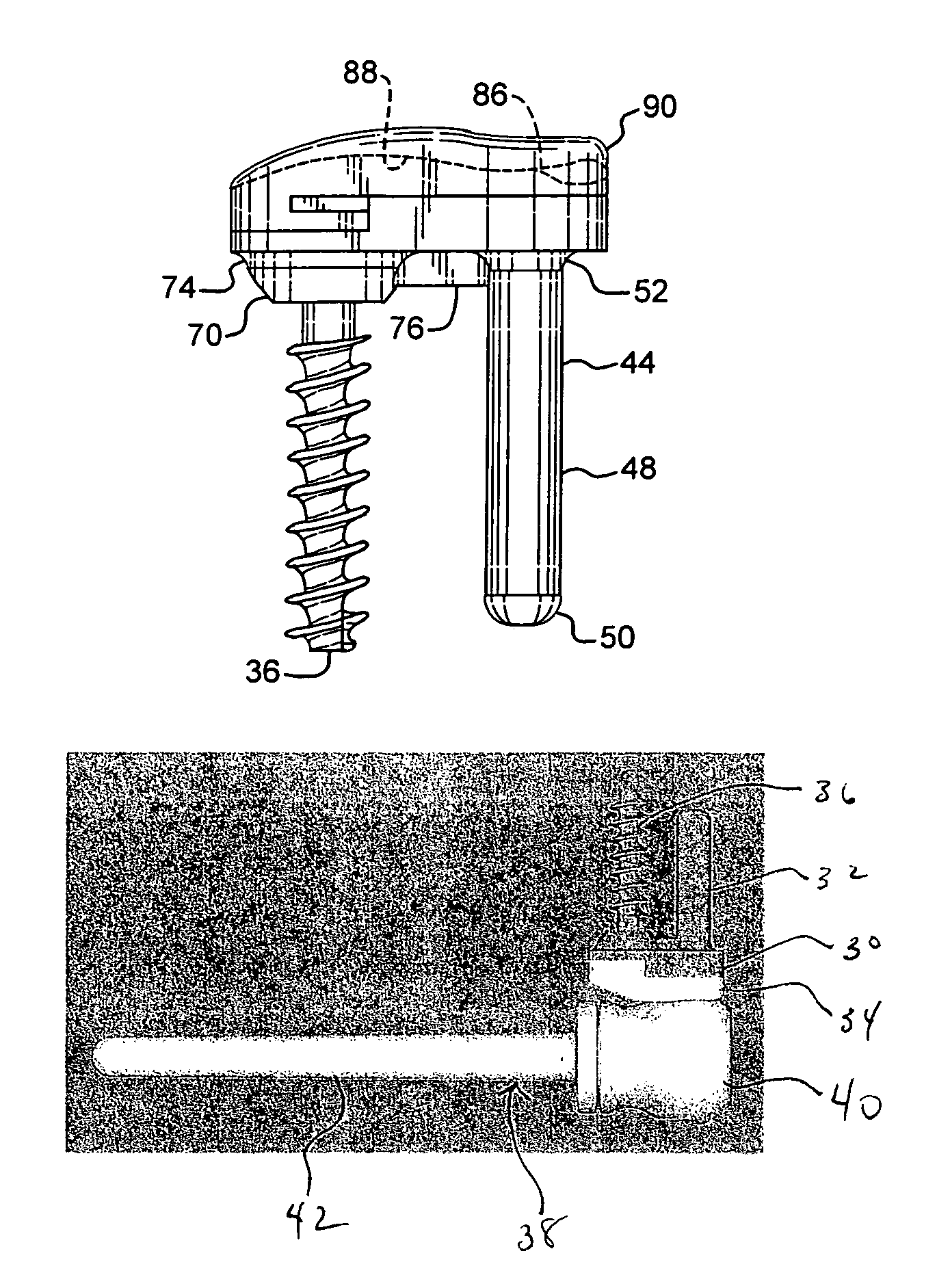

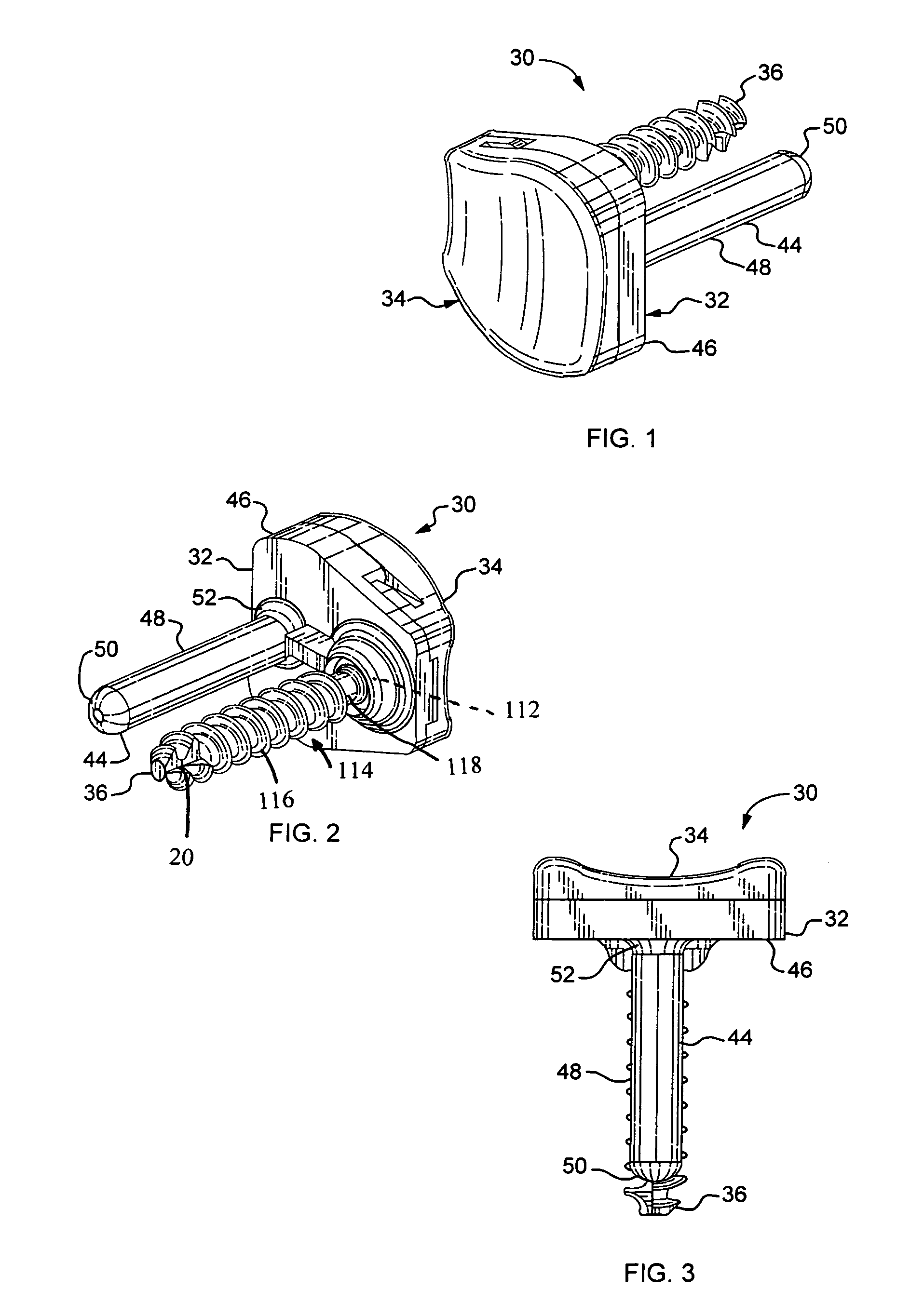

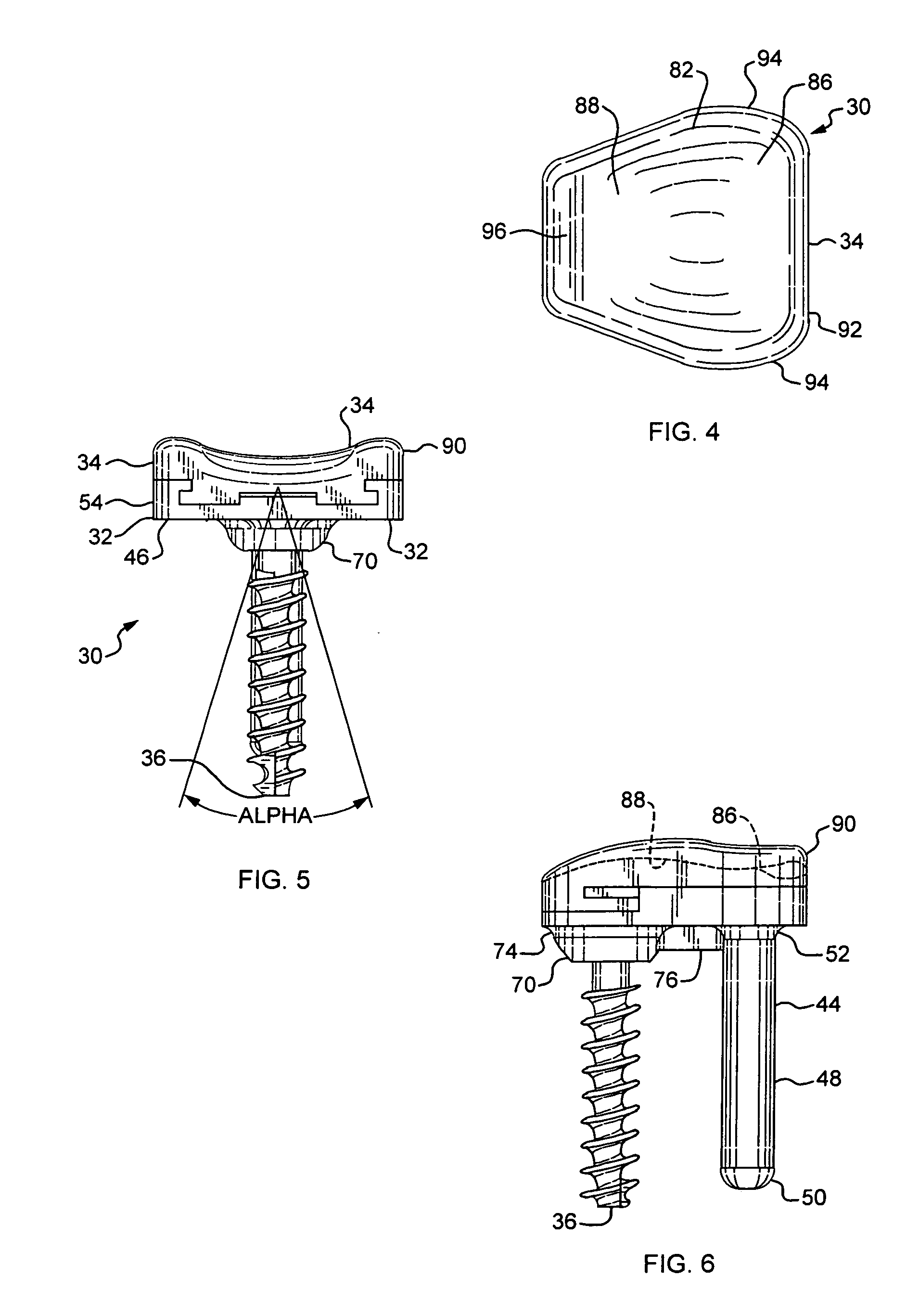

Mobile bearing tibial base prosthetic devices employing oxidized zirconium surfaces

An orthopedic implant with a diffusion-hardened surface on non-load bearing areas of the implant for interaction with non-load bearing surfaces of a polymeric bio-compatible material, such as UHMWPE (ultra-high molecular weight polyethylene). The orthopedic implant is a mobile-bearing knee prosthetic and system where a coating of oxidized zirconium is formed on the post of the tibial tray of the prosthetic for interaction with an opening of a polymeric tibial insert. The diffusion-hardened surface of the orthopedic implant provides a strengthened post and reduction in wear in the opening of the polymeric insert.

Owner:SMITH & NEPHEW INC

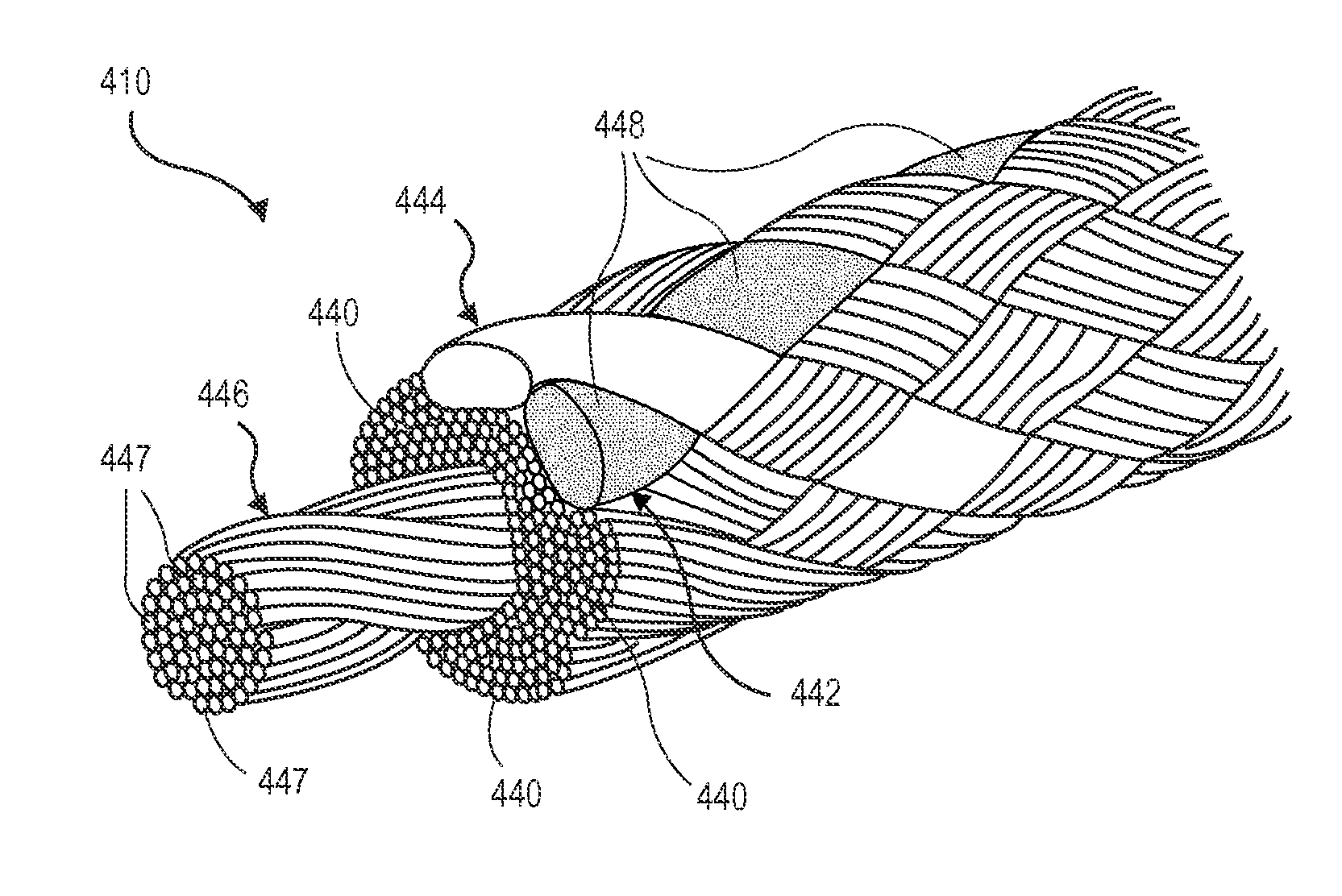

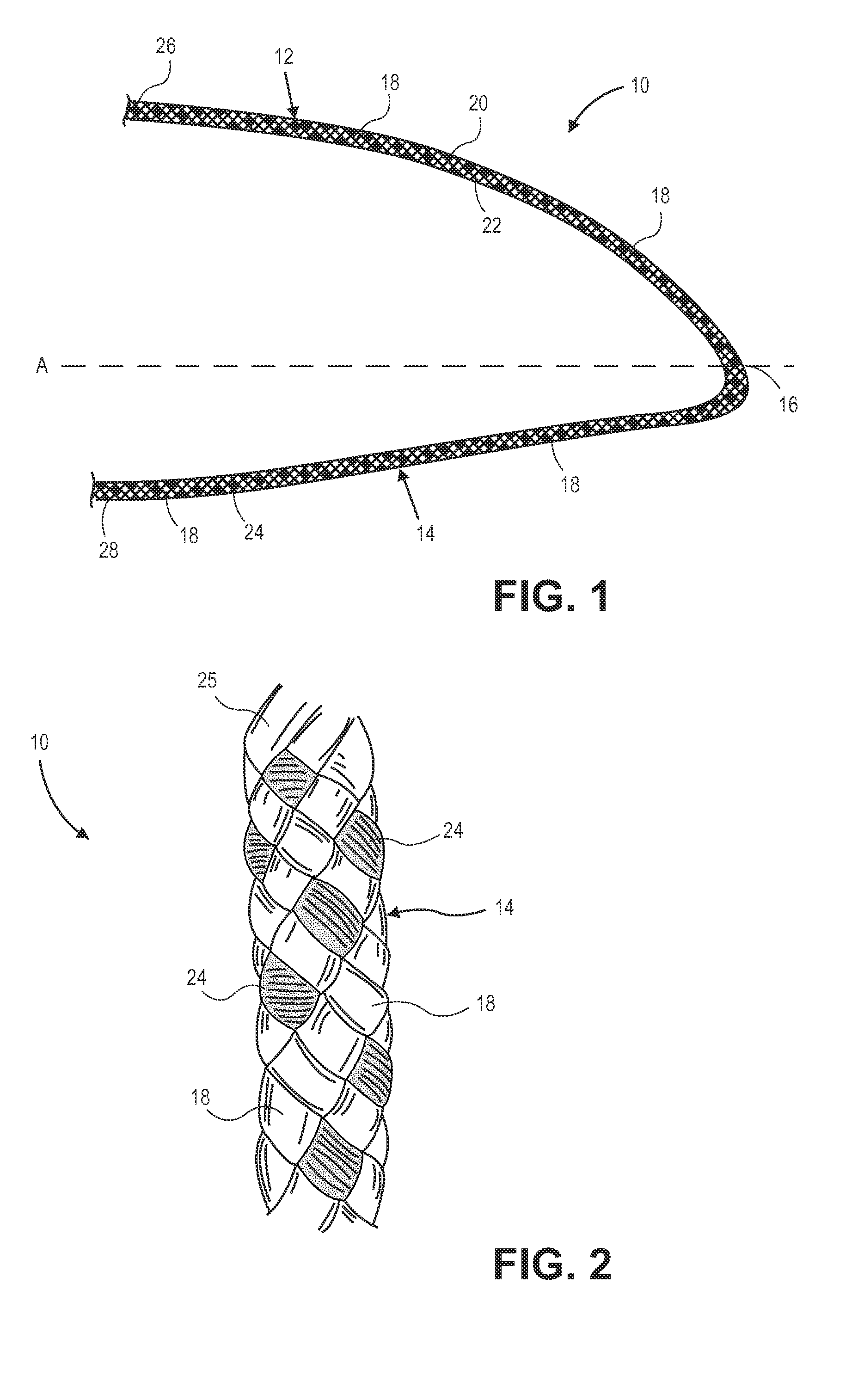

Colored Suture Construction

A colored suture includes an elongate woven braid of filaments including one or more ends made of an ultra high molecular weight polyethylene (UHMWPE). The suture also includes second and third ends which can be colorable or dyeable before or after incorporation into the elongate woven braid. This invention provides surgeons with improved recognition of suture ends in surgery by construction of a bi-colored co-braid with at least two ends of different color schemes or patterns braided into a UHMWPE construction. One of the colored ends runs continuously from one end of the suture to the other end. The other colored end can be colored only on one half of the end. This provides a suture with two distinguishable ends, while still maintaining a continuous line of color along the length of the suture.

Owner:TELEFLEX MEDICAL INC

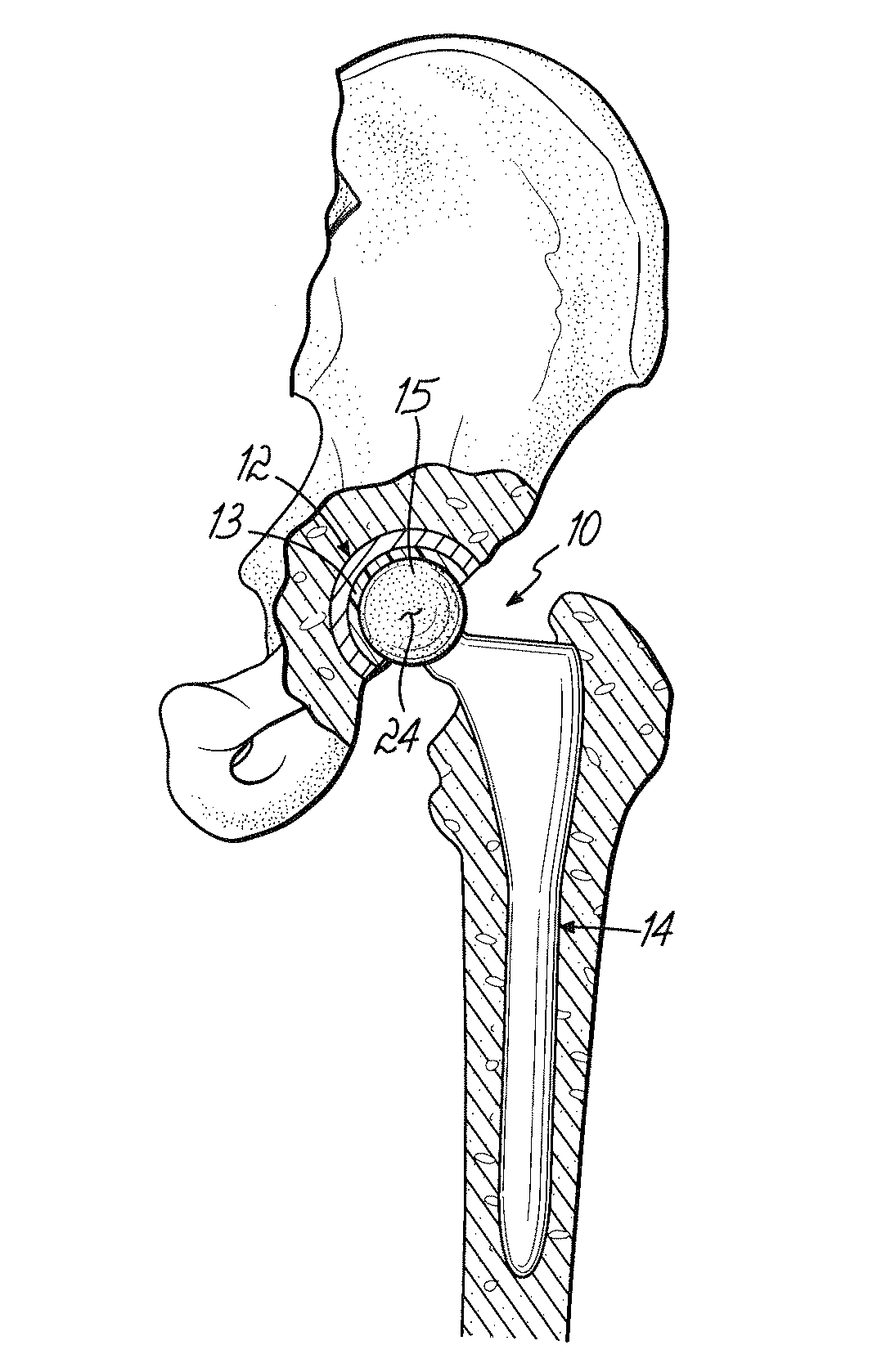

Titanium alloy with oxidized zirconium for a prosthetic implant

A prosthetic device having a generally fixed member formed from a low friction material such as ultra-high molecular weight polyethylene and an articulating titanium member, which includes an articular bearing surface. The articular surface is a zirconium oxide layer formed by applying a coating of zirconium onto the titanium member and heating this in an oxygen-containing environment. This causes the zirconium to oxidize and further causes the zirconium to migrate into the titanium member forming a titanium zirconium diffusion layer, which prevents delamination.

Owner:ZIMMER INC

Methods for making oxidation resistant polymeric material

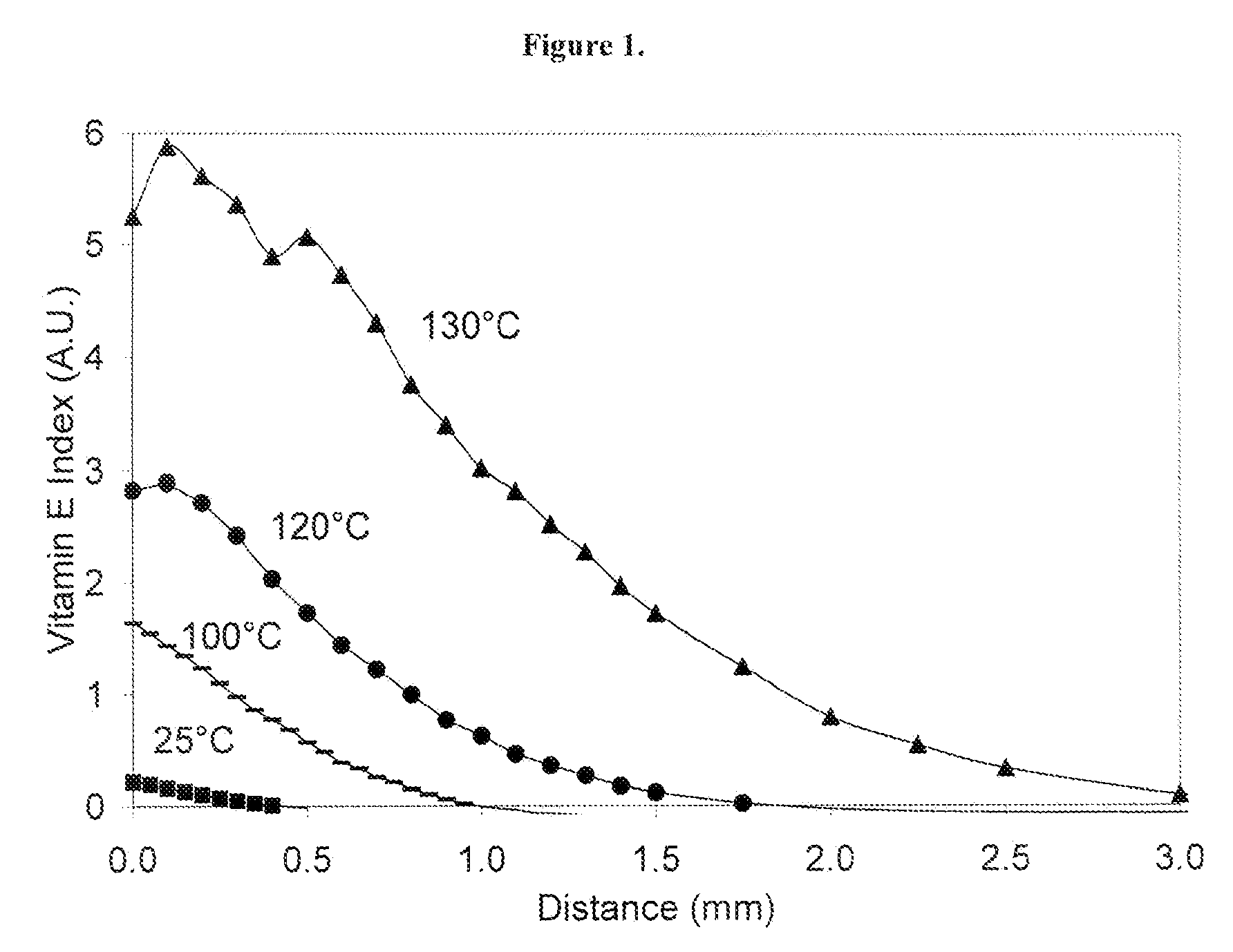

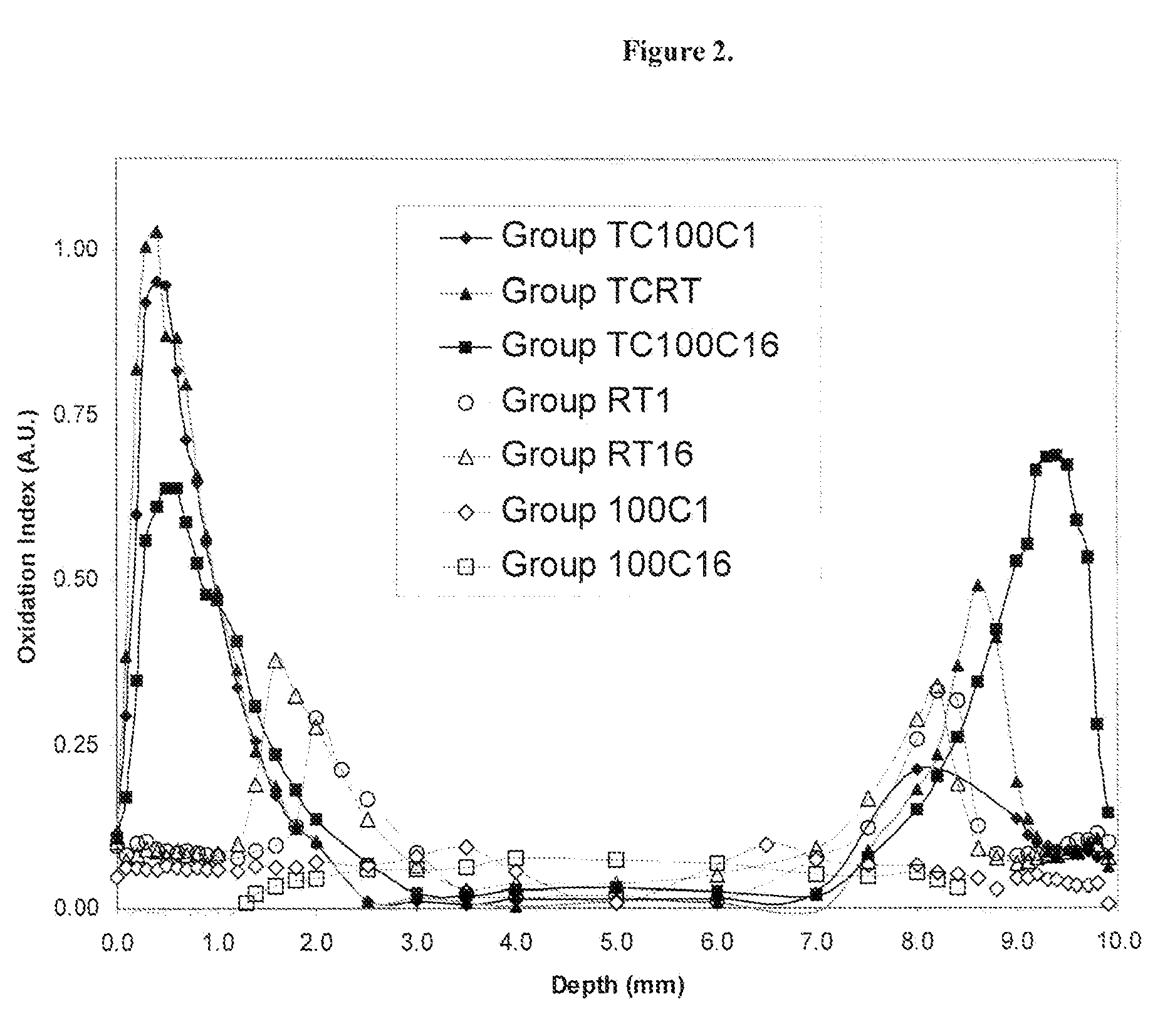

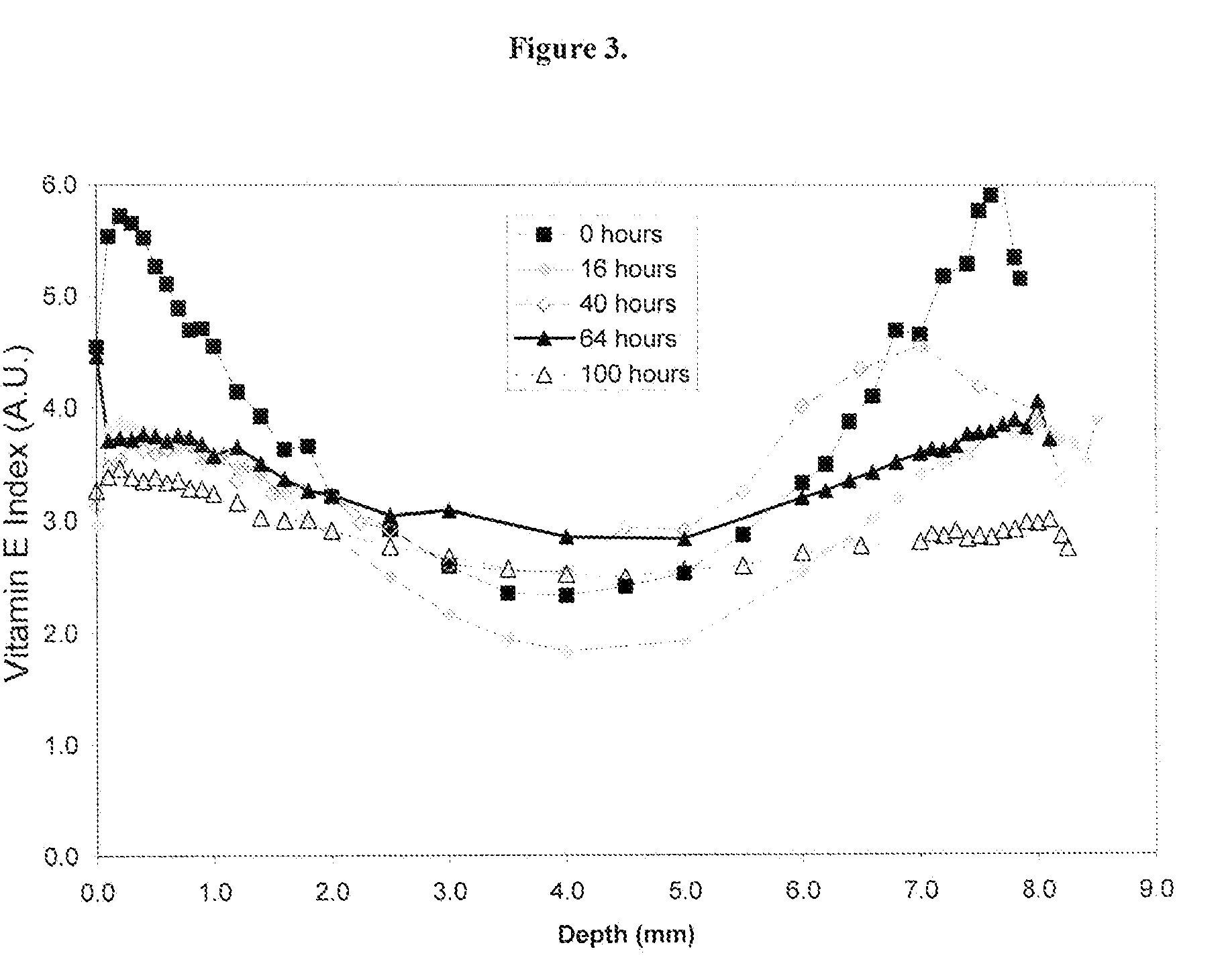

The present invention relates to methods for making oxidation resistant medical devices that comprise polymeric materials, for example, ultra-high molecular weight polyethylene (UHMWPE). The invention also provides methods of making antioxidant-doped medical implants, for example, doping of medical devices containing cross-linked UHMWPE with vitamin E by diffusion and materials used therein.

Owner:CAMBRIDGE POLYMER GROUP

Sigmoid notch implant

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Prosthetic device and method of making the same

A method of making a non-modular prosthetic device for a joint arthroplasty. The method comprises molding a polymer interlayer between a porous metal structure and a polymer insert, wherein the insert generally comprises conventional or cross-linked ultra high molecular weight polyethylene (“UHMWPE”).

Owner:ZIMMER TECH INC

Catalyst for producing an ultrahigh molecular weight polyethylene (UHWMP) and method for producing an UHWMP using the same

InactiveUS6559249B2High bulk densityNarrow particle distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceUHMWPE polyethylene

The present invention provides a catalyst for producing an ultra high molecular weight polyethylene and also a method for preparation of an ultra high molecular weight polyethylene with the use of said catalyst. The catalyst of the present invention is prepared by a process comprising: (i) producing a magnesium compound solution by contact-reacting a magnesium compound and an aluminum or boron compound with alcohol; (ii) contact-reacting the said solution with an ester compound containing at least one hydroxy group and a silicon compound containing an alkoxy group; and (iii) producing of a solid titanium catalyst by adding a mixture of a titanium compound and a silicon compound thereto. The catalyst prepared by the present invention has excellent catalytic activity, and it helps to produce an ultra-high molecular weight polyethylene with large bulk density and narrow particle distribution without too large and minute particles.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

Method for improving creep resistant performance of ultra-high molecular weight polyethylene fiber

ActiveCN102493168AHigh surfaceIncrease internal cross-link pointsPhysical treatmentFibre typesFiberPolymer science

The invention relates to a method for improving the creep resistant performance of an ultra-high molecular weight polyethylene fiber; and the method is characterized by jointly triggering crosslinking by using a photosensitizer and a thermal initiating agent, thereby crosslinking points of the surface and interior of the ultra-high molecular weight polyethylene fiber are increased, the crosslinking efficiency of a cross-linking agent is improved, the relative slippage among molecules of the ultra-high molecular weight polyethylene fiber is effectively impeded and the creep resistant performance of the fiber is increased.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

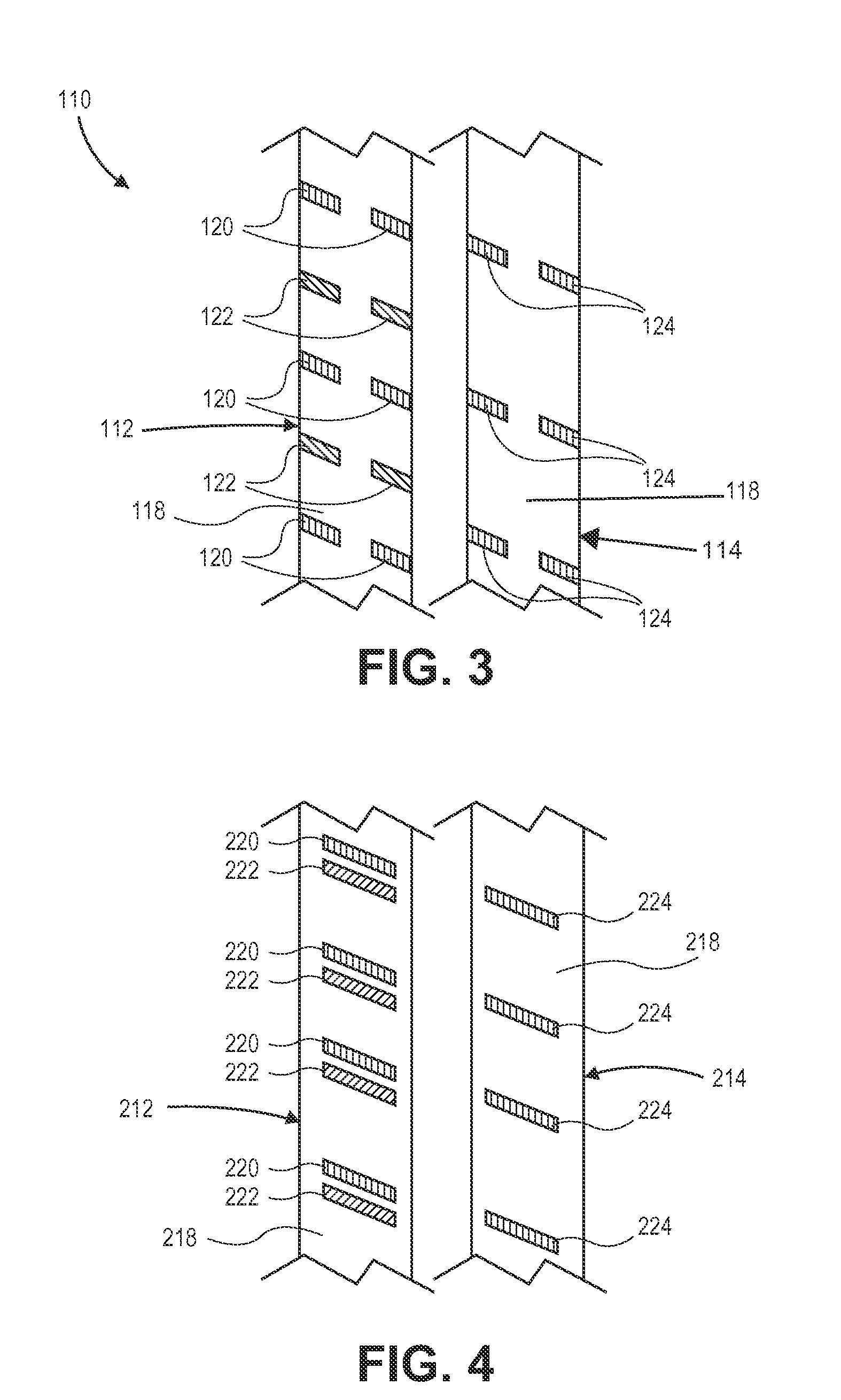

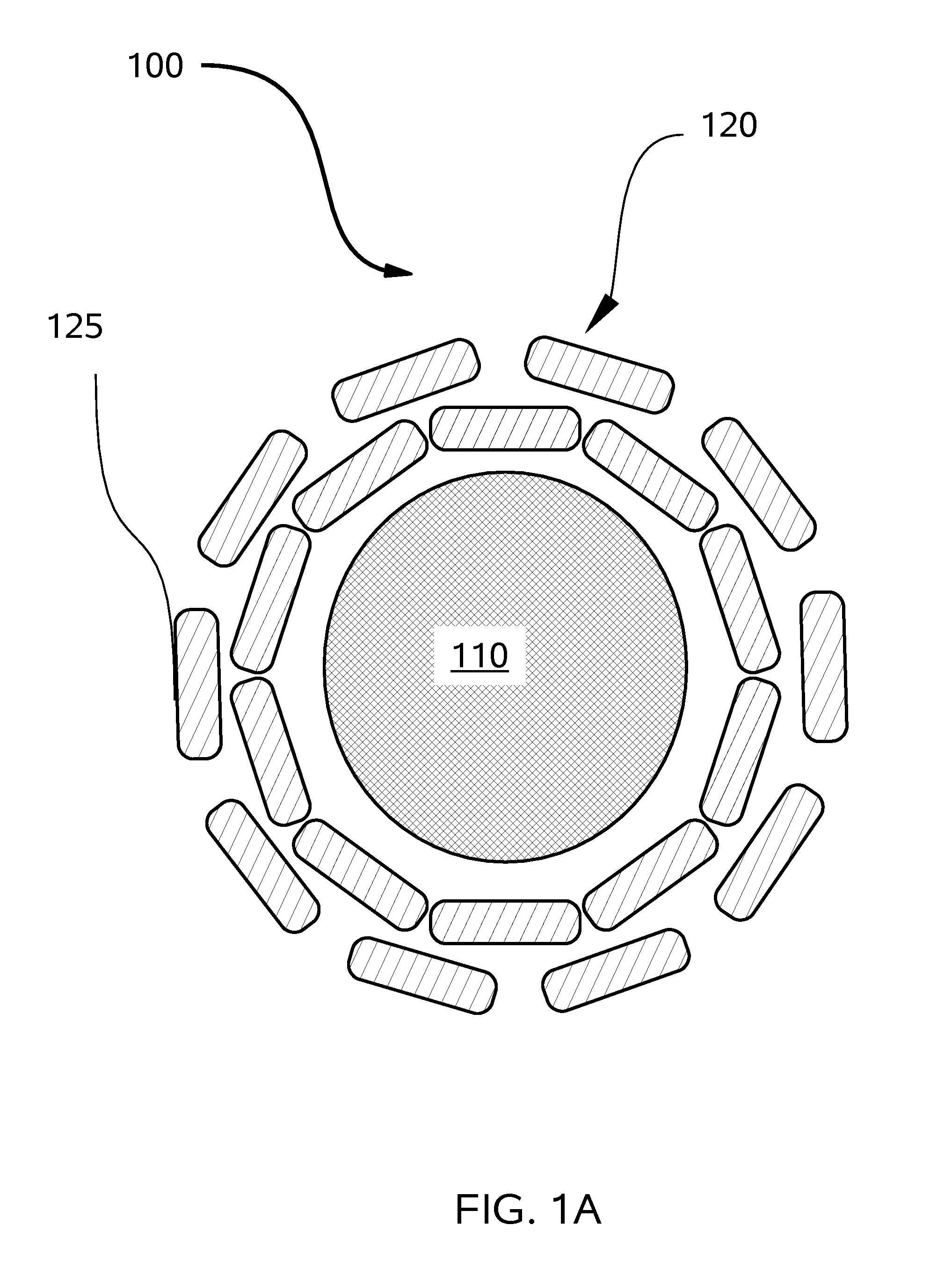

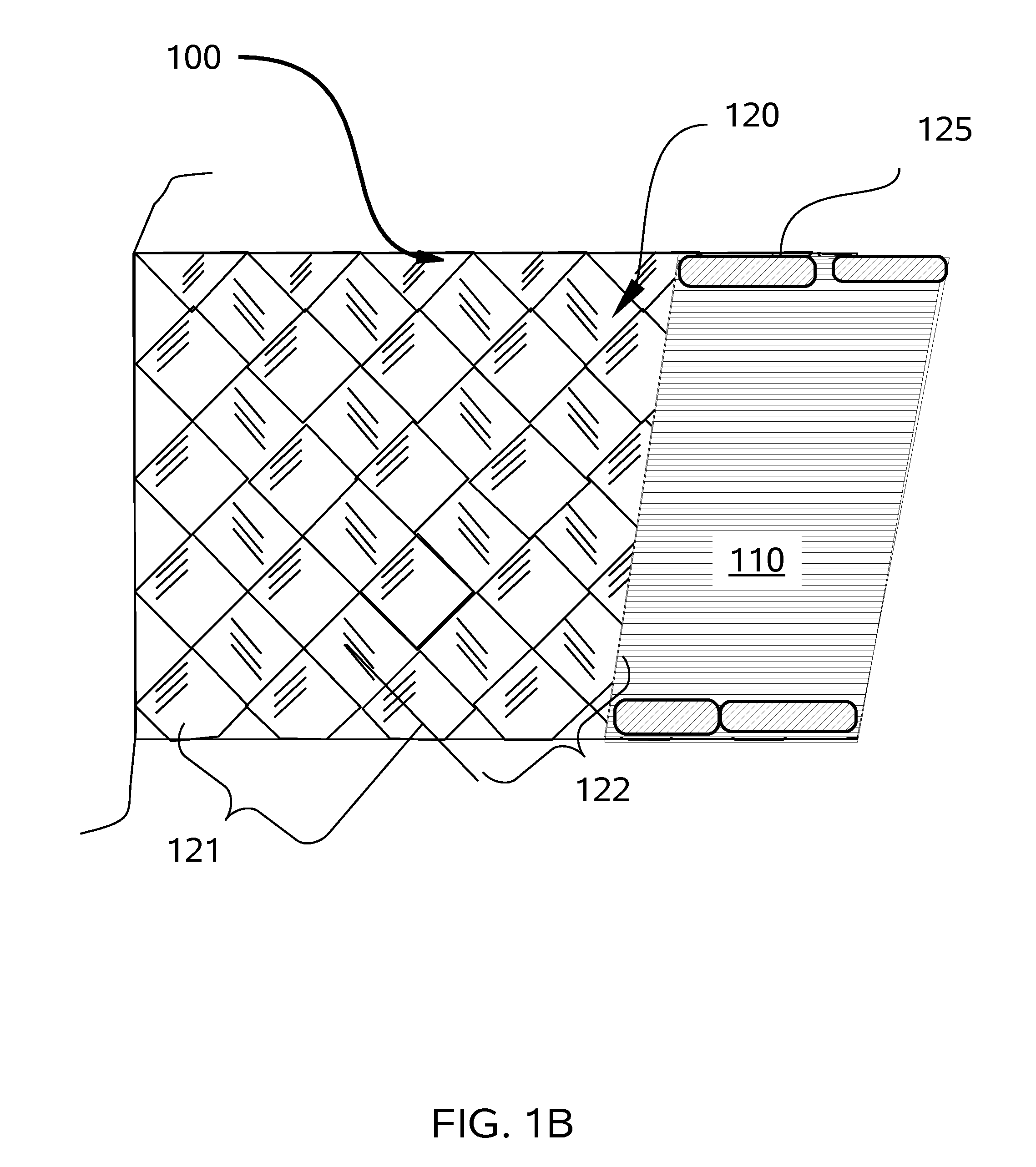

Abrasion resistant cords and ropes

InactiveUS20100101833A1Enhanced abrasion resistance propertyReduce volumeAgriculture tools and machinesInsulated cablesFiberUltrahigh molecular weight polyethylene

The abrasion resistance of organic fiber based ropes and cords is increased by a outer woven cover of tapes of high molecular weight and more preferably ultrahigh molecular weight polyethylene.

Owner:POLTECO

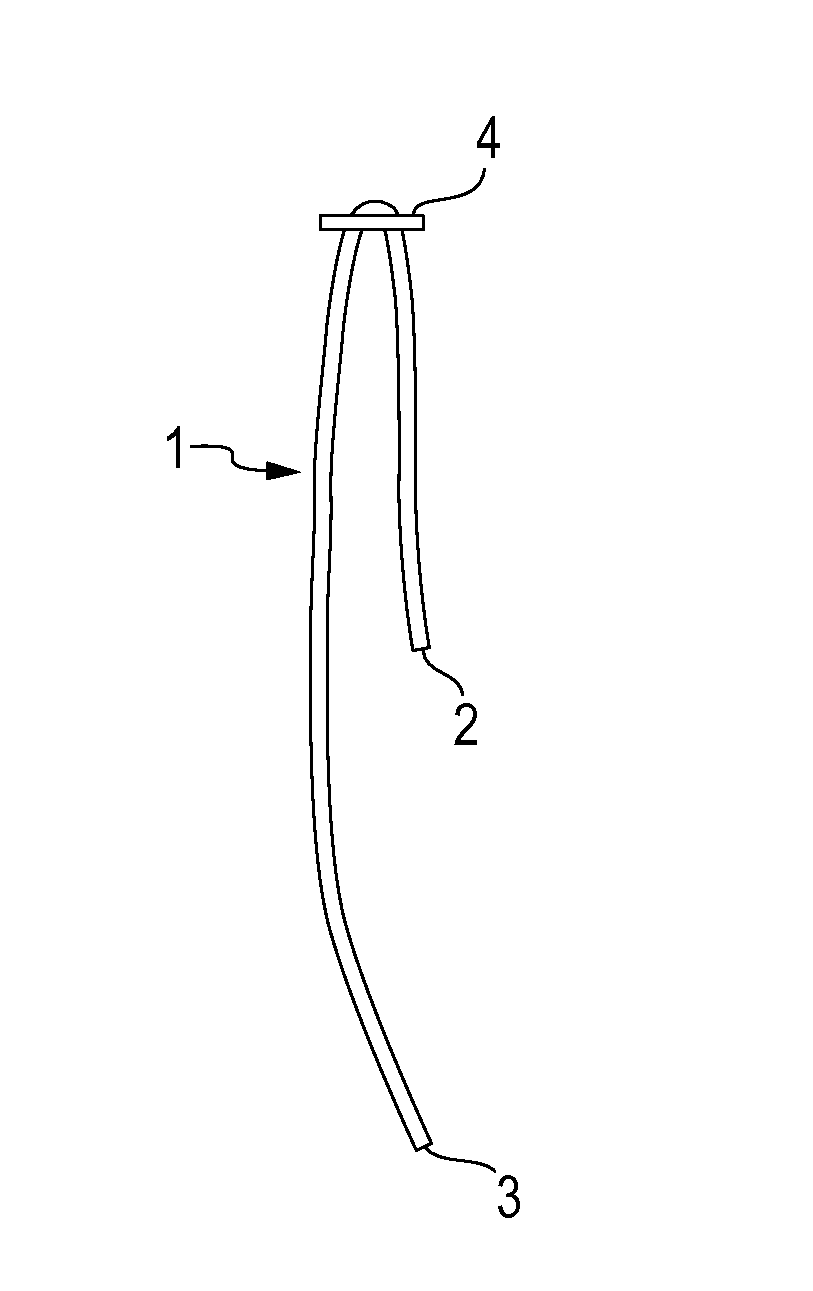

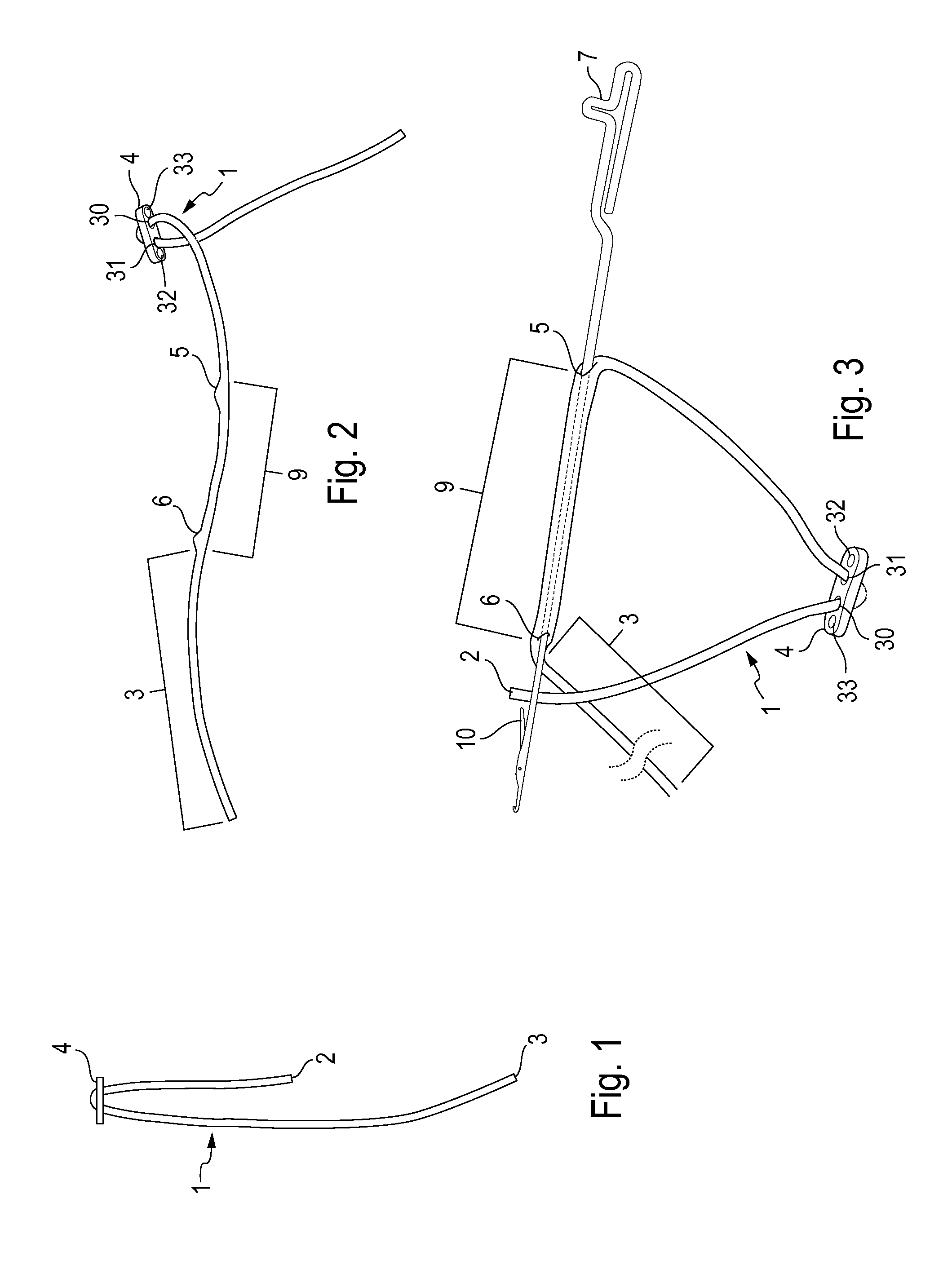

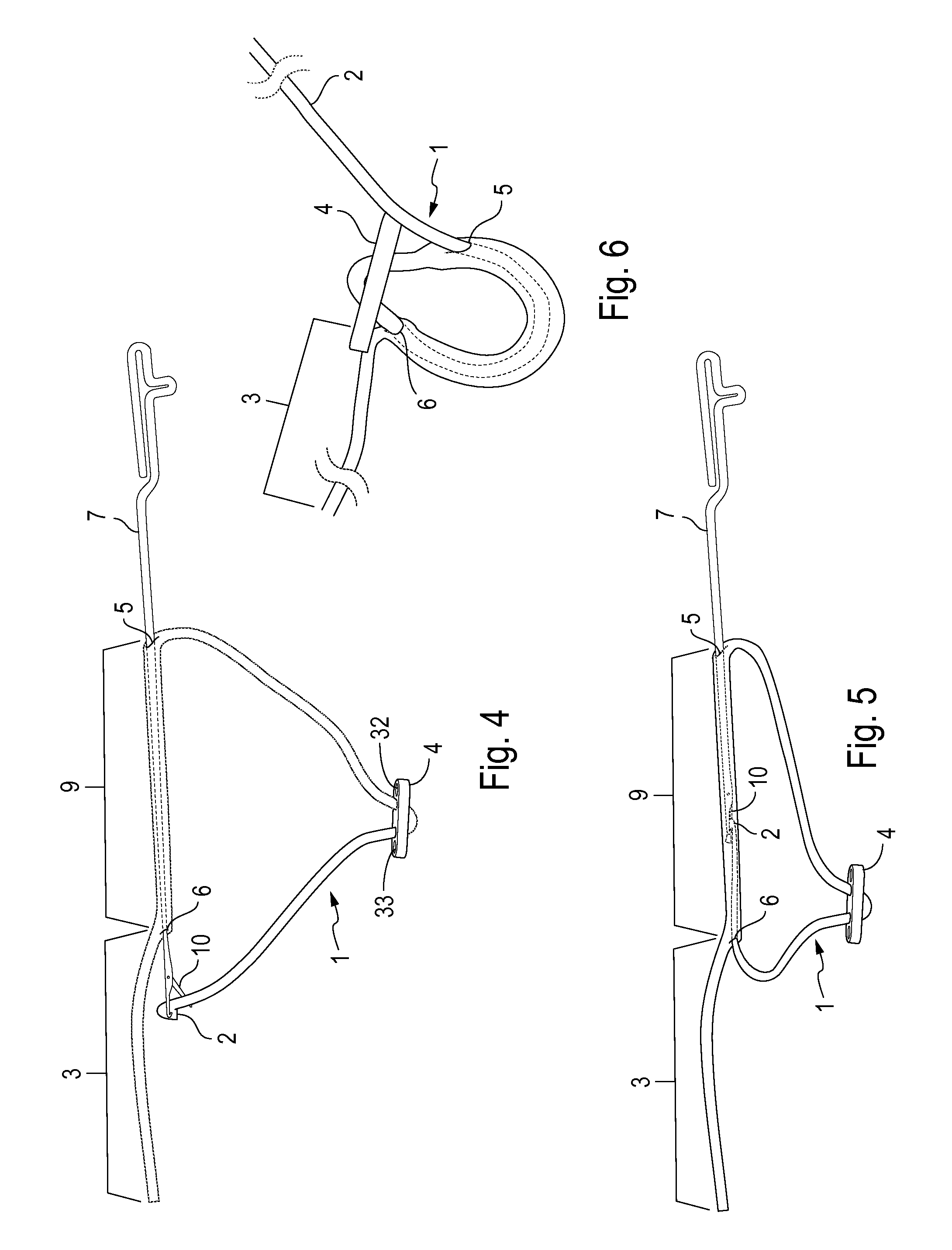

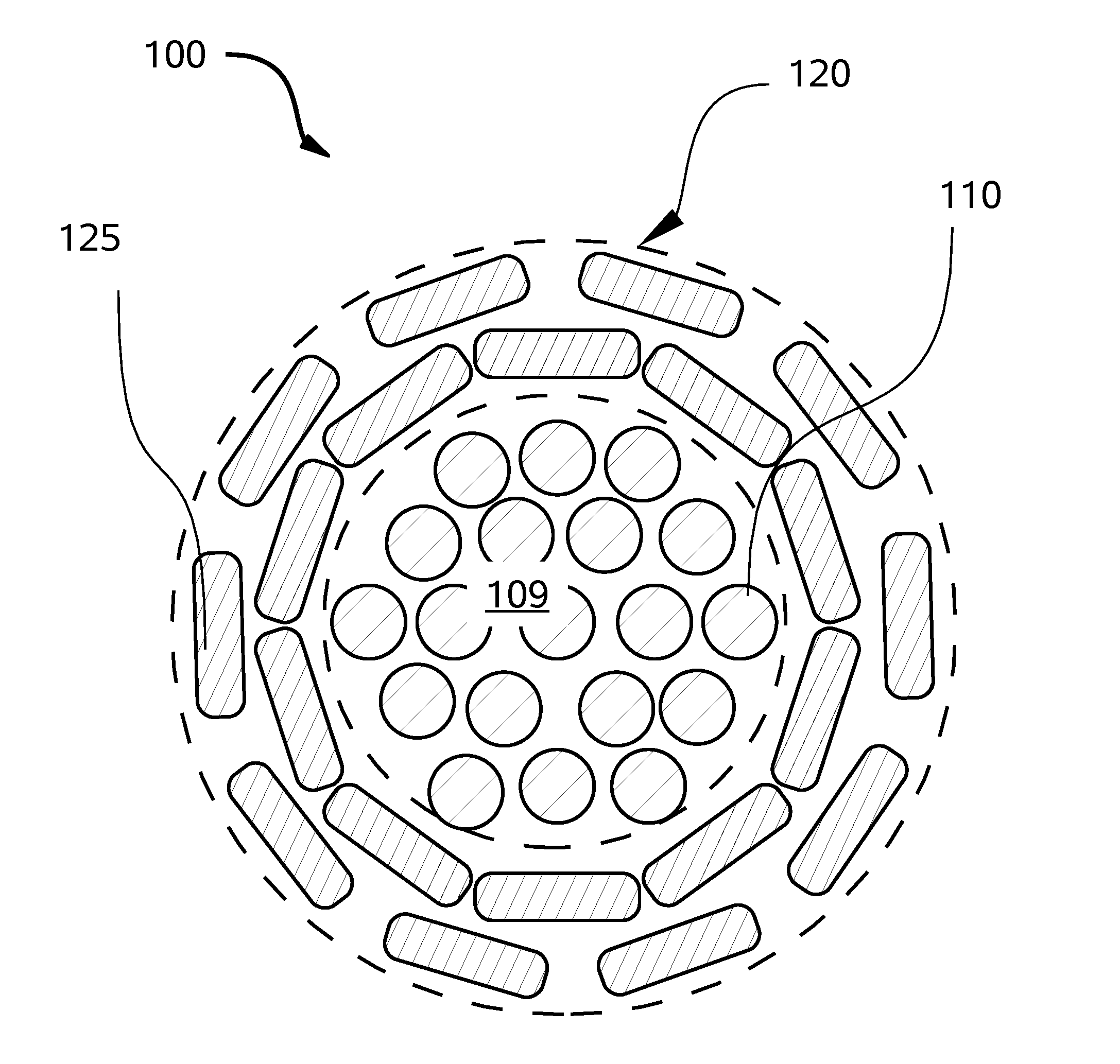

Continuous Loop and Button Assembly

Fixation assemblies having a button captured by a continuous (i.e., closed) loop of thread, such as ultra high molecular weight polyethylene (UHMWPE) fiber are disclosed herein. Preferred assemblies are constructed such that the intact button cannot be detached from the continuous loop without breaking or opening the loop of fiber. The closed fiber advantageously contains at least one or two stitched, or otherwise secured or reinforced, sections positioned on the loop.

Owner:RIVERPOINT MEDICAL

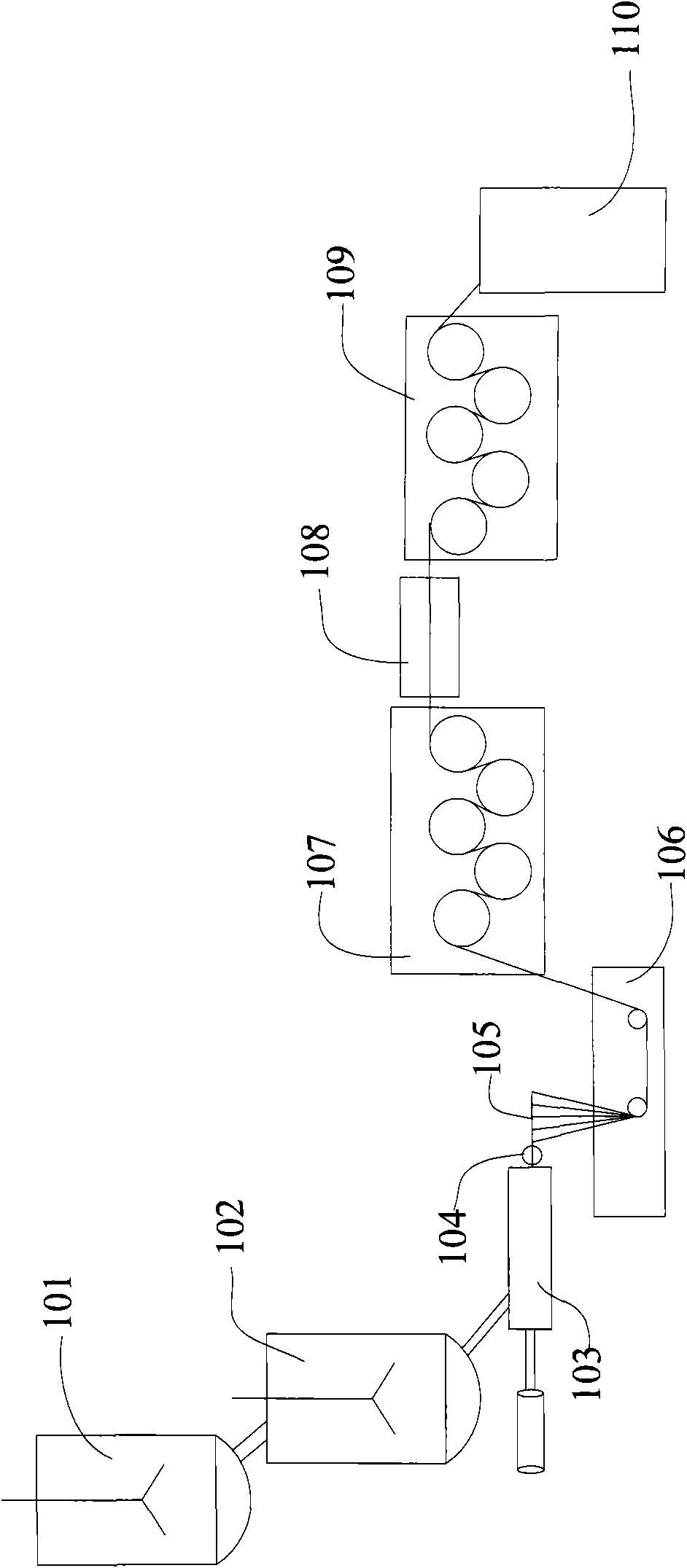

Preparation method of ultra-high molecular weight polyethylene fiber

InactiveCN101575742AImprove mechanical propertiesReduce internal stressArtificial filament washing/dryingWet spinning methodsFiberPolymer science

The invention relates to a preparation method of ultra-high molecular weight polyethylene fiber, which comprises the following steps: firstly, mixing ultra-high molecular weight polyethylene powder with solvent for swelling to obtain suspending liquid, and then extruding and dissolving the suspending liquid through a double screw extruder to obtain 4-25 percent of spinning solution, wherein the solvent is liquid hydrocarbon under room temperature; secondly, spraying and cooling the spinning solution to obtain gel filament; thirdly, applying 1-10 times of pretensioning to the gel filament, settling the pretensioned gel filament for 12-48h, extracting and drying the gel filament; fourthly, applying 4-130 times of heat drawing to the dried gel filament 70-160 DEG C to obtain the ultra-high molecular weight polyethylene fiber. After the gel filament is formed and pretentioned to a certain degree, the primary filament can be more uniform and has higher tension property , and the ultra-high molecular weight polyethylene fiber with excellent property can be prepared.

Owner:杨珍芬

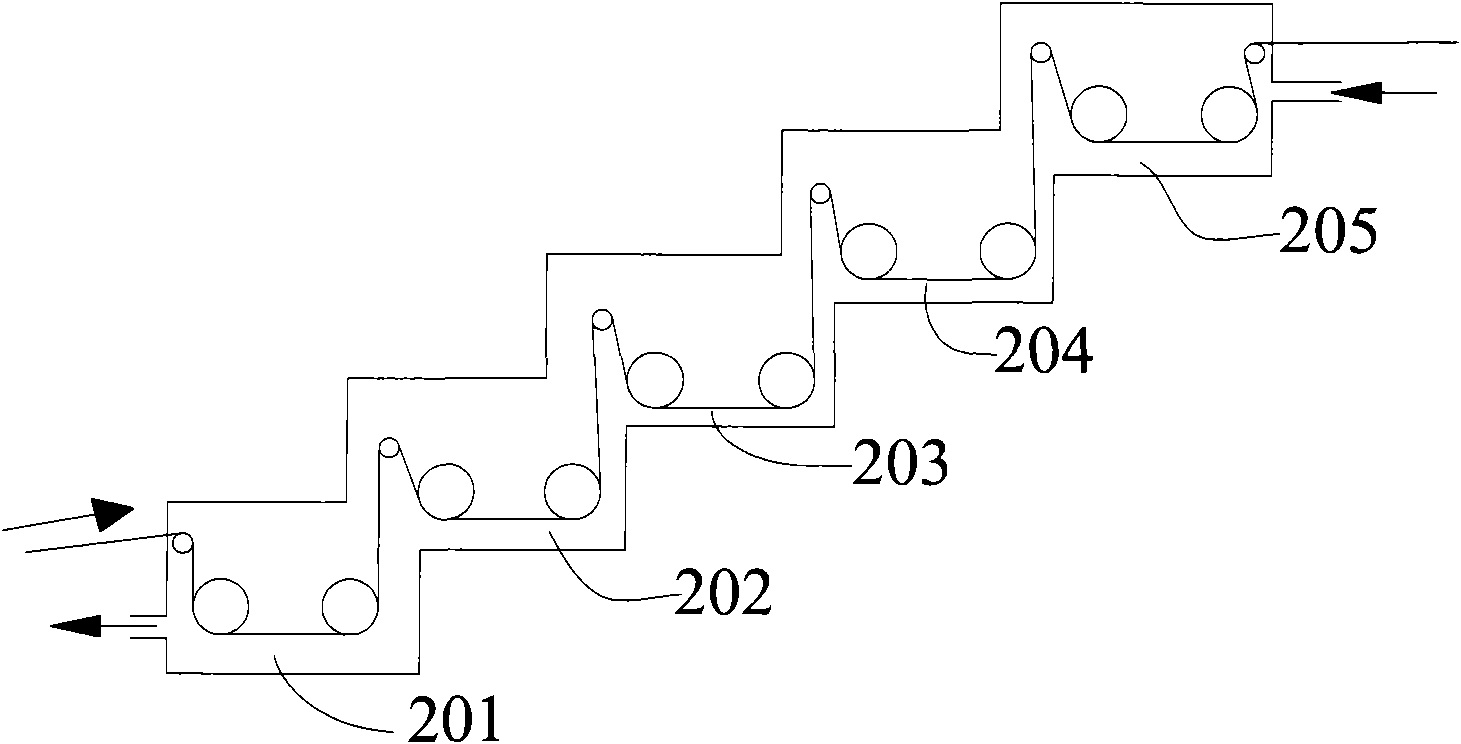

Preparation method of ultra-high molecular weight polyethylene fiber

ActiveCN102002769ANo force lossHigh strengthSpinning head liquid feederArtificial filament washing/dryingEnvironmental resistanceYarn

The invention relates to a novel production method for preparing a high-strength and high-elongation polyethylene fiber at low energy consumption and low cost. The method comprises the following two steps: 1, preparing a polyethylene modified master batch; and 2, uniformly mixing ultra-high molecular weight polyethylene resin with the prepared polyethylene modified master batch to prepare an ultra-high molecular weight polyethylene melt spinning yarn, wherein the fiber strength of the prepared ultra-high molecular weight polyethylene fiber is 15-25 CN / dtex, and the breaking elongation is 5-8%. The invention has the advantages of short production flow, low energy consumption, environment friendliness, low manufacturing cost and high single-machine productive capacity. Besides, the product can be widely used in various fields such as the cable twisting and weaving field, the fishnet knitting field, the industrial cloth and belt weaving field and the like and the effective use of the fiber strength can be maintained.

Owner:宁波大盛新材料有限公司

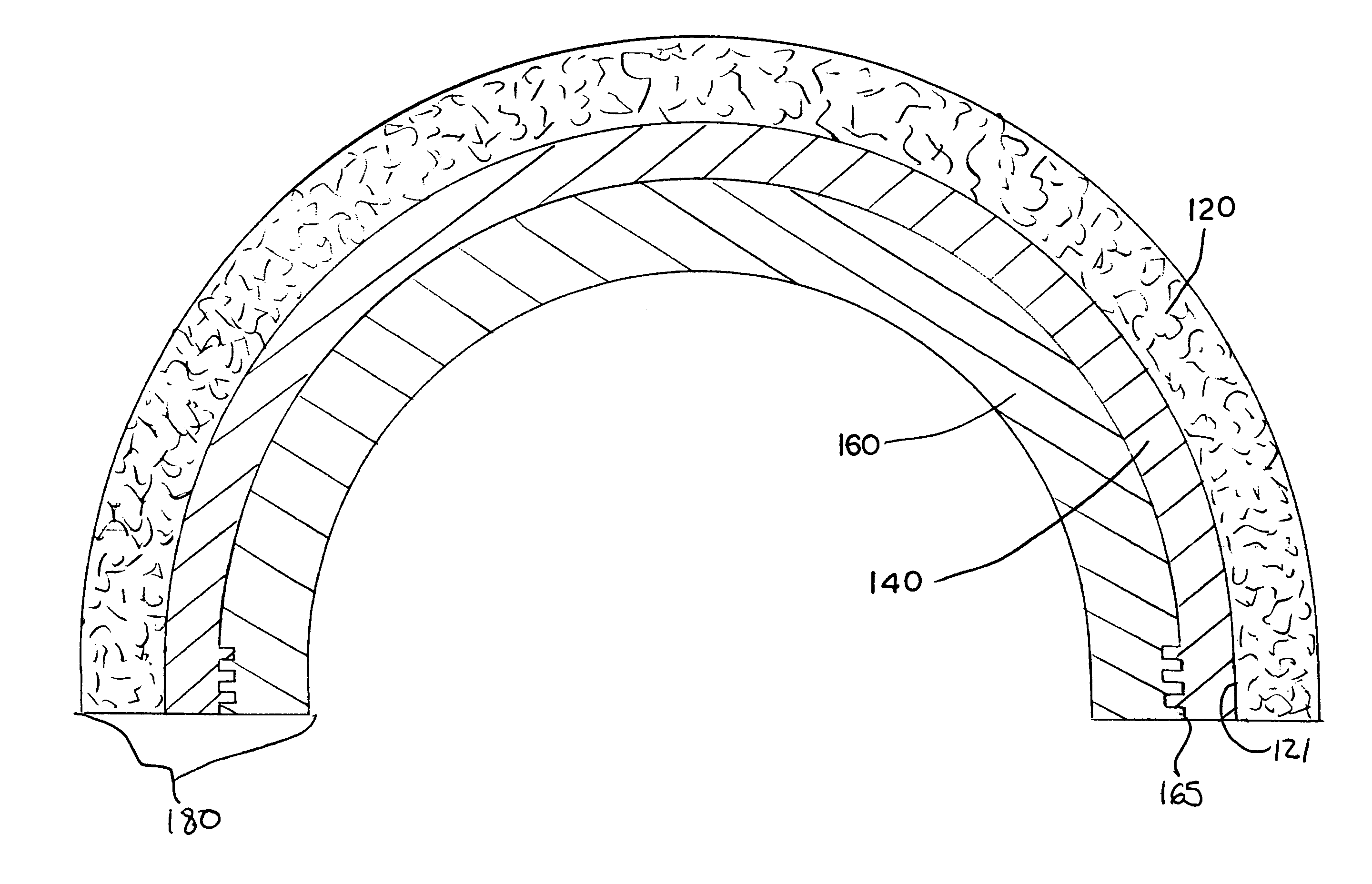

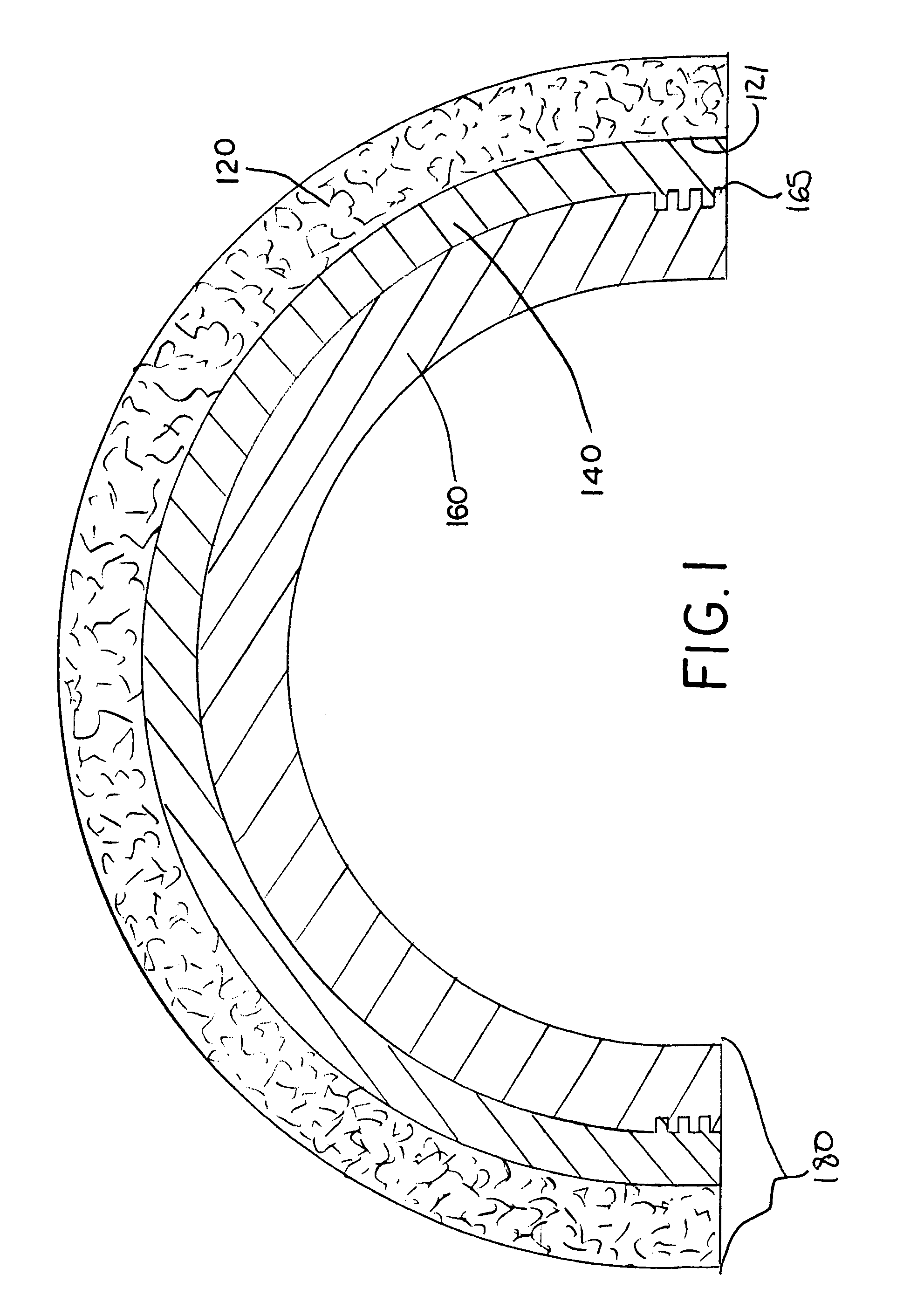

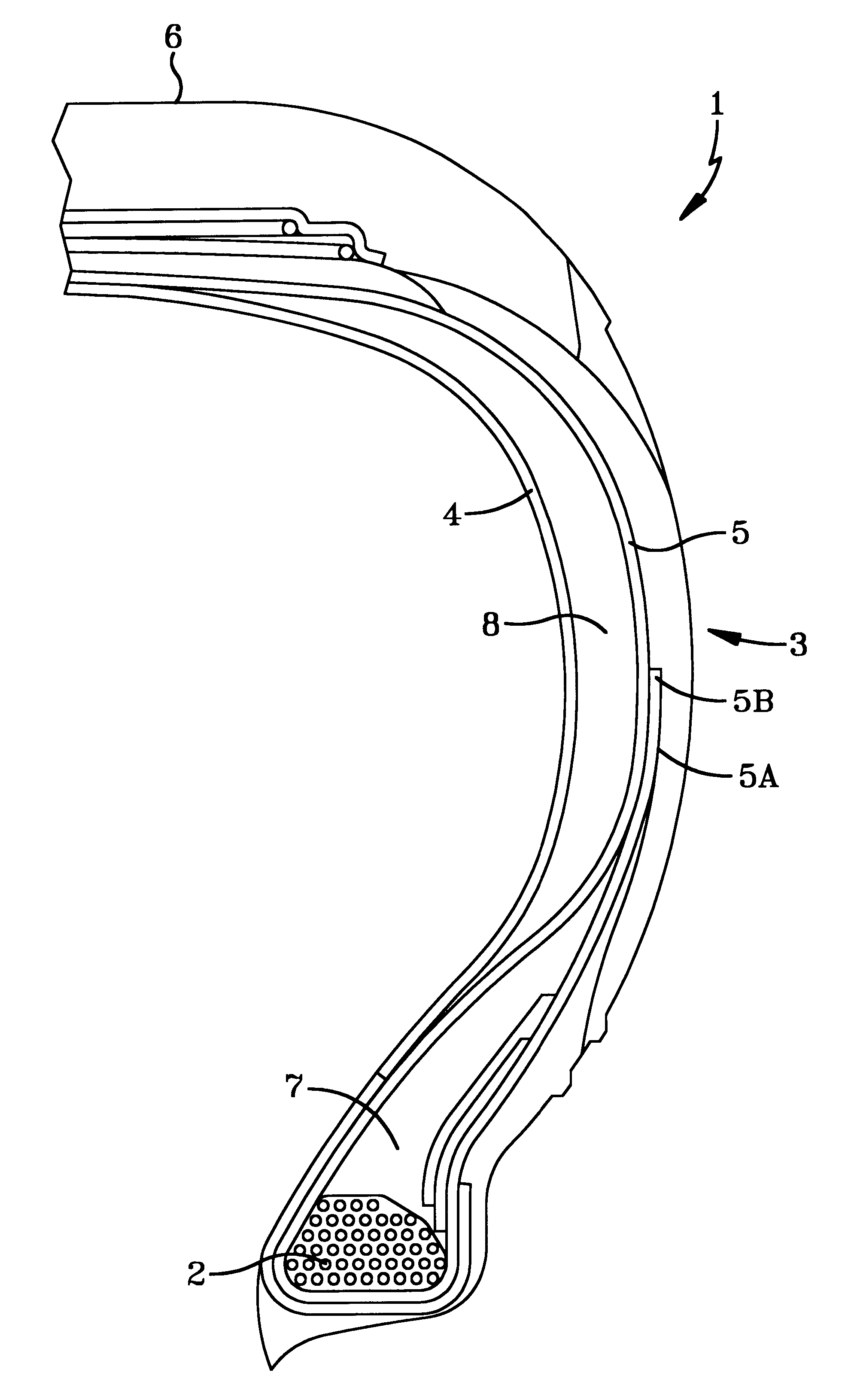

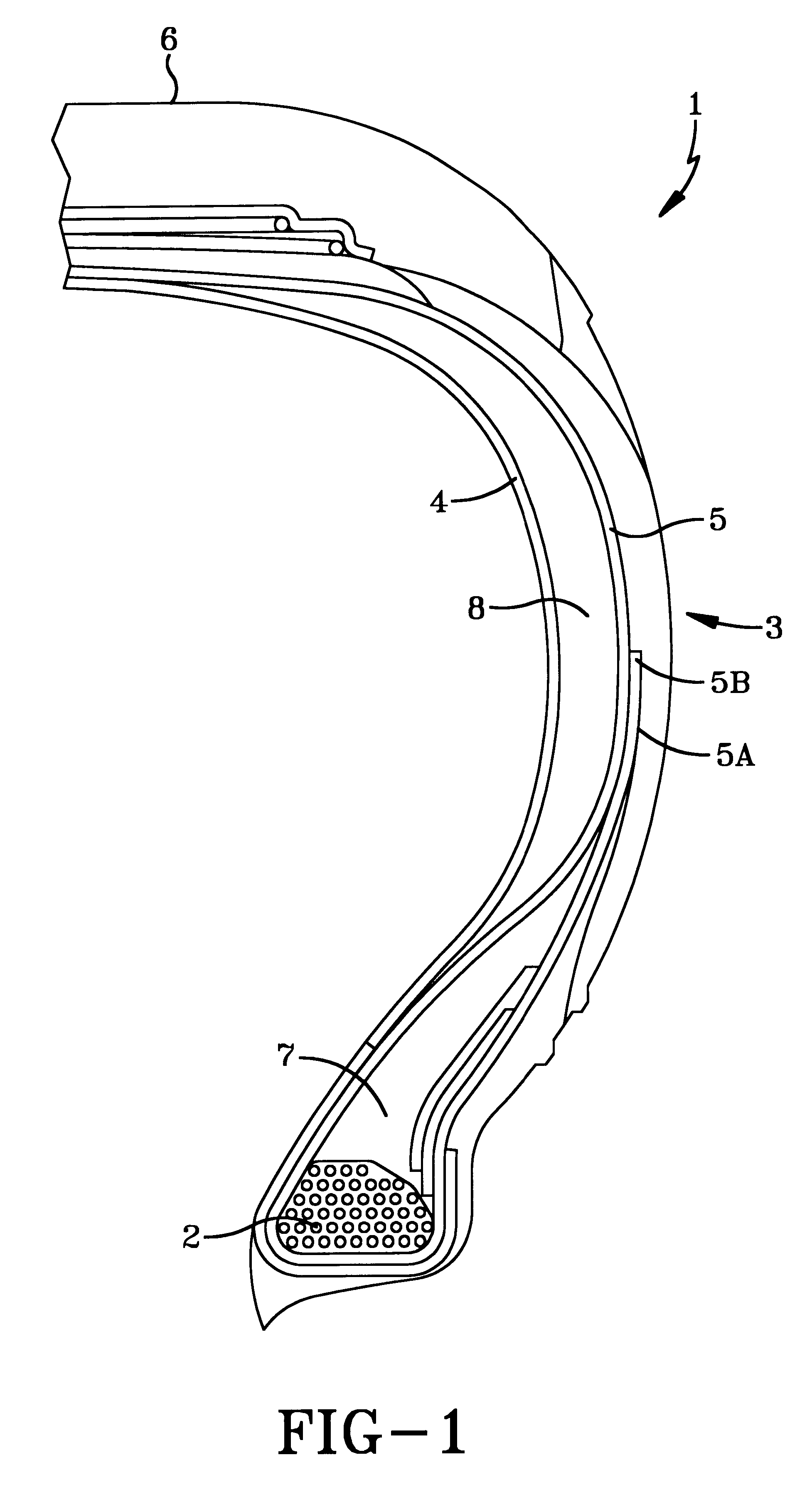

Tire with sidewall rubber insert

InactiveUS6202726B1Improve propertyHigh modulusPaper coatingSpecial tyresUltra-high-molecular-weight polyethyleneMechanical engineering

A pneumatic tire has a sidewall rubber insert axially inward of at least one carcass ply. Such insert may, for example, be an apex extending radially outward from the bead core region of the tire into the tire sidewall. Alternatively, it may be positioned higher in the sidewall portion of the tire and away from the bead core. Such insert is a rubber composition containing a dispersion of an ultra high molecular weight polyethylene and a dispersion of a starch composite.

Owner:THE GOODYEAR TIRE & RUBBER CO

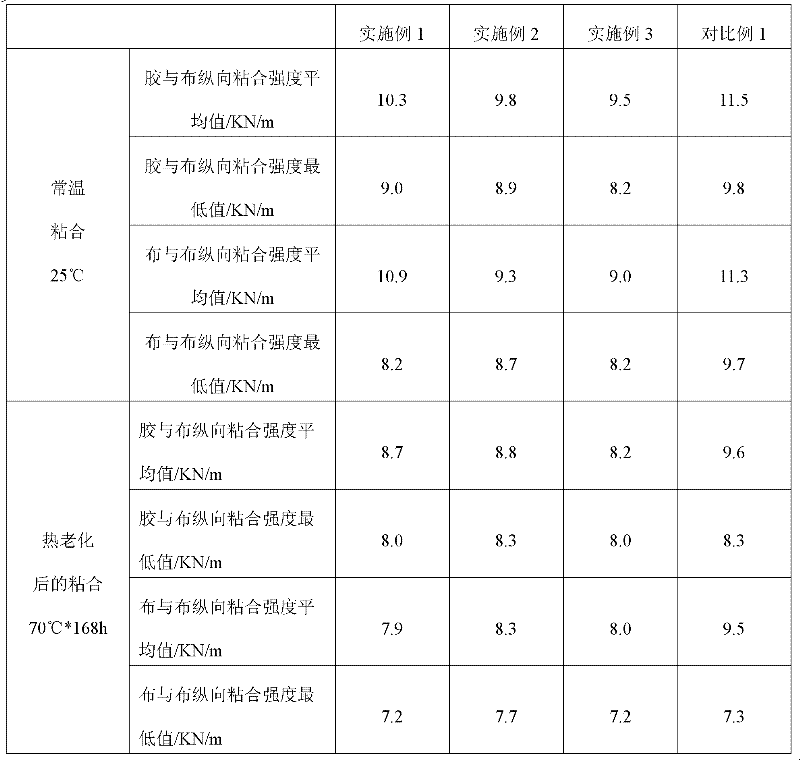

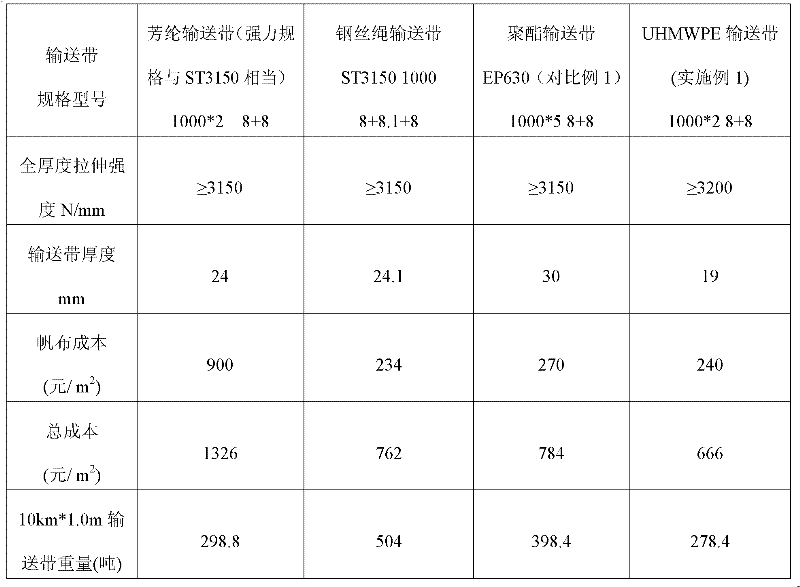

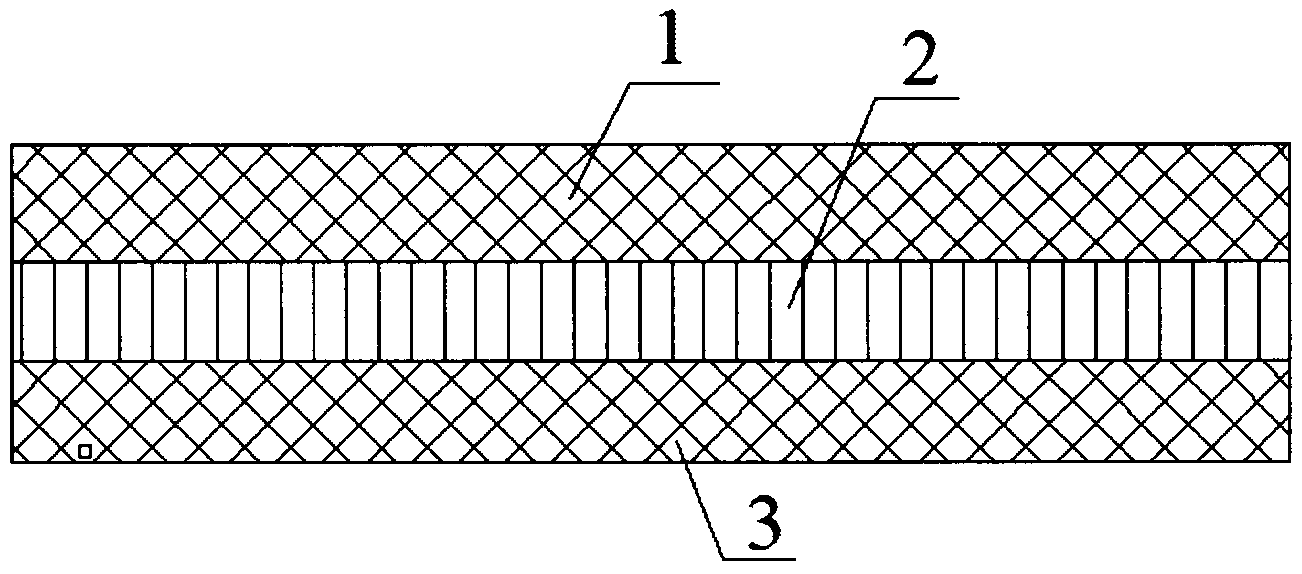

Light and high-strength rubber conveyor belt and preparation method thereof

The invention relates to a light and high-strength rubber conveyor belt and a preparation method tof the conveyor belt. The conveyor belt comprises a framework layer, an adhesive glue, and upper and lower cover rubber laminated structures; the framework layer adopts mixed woven canvas of ultra-high molecular weight polyethylene fibers and polyester fibers which are treated by plasma, simultaneously adopts low-temperature vulcanization technology to be subjected to covulcanization with the adhesive glue and a cover rubber at a low temperature, and solves the problem of the bonding of ultra-high molecular weight polyethylene fiber cloth and rubber. Compared with the conventional high-strength conveyor belt of wire rope core, the light and high-strength rubber conveyor belt in the invention not only has high strength, and good corrosion resistance, wear resistance, shock resistance and fatigue resistance, but also greatly reduces the weight and thickness, thereby reducing the conveying power energy consumption, which is expected to have long service life and good energy saving and environment friendly performances. Therefore the light and high-strength rubber conveyor belt disclosed in the invention is particularly suitable for the long-distance material conveying in the industries of coal mine, metallurgy, mine and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Abrasion resistant cords and ropes

ActiveUS20110197564A1Improve wear resistanceLower the volumeSynthetic resin layered productsYarnFiberPolymer science

The abrasion resistance of organic fiber based ropes and cords is increased by a outer woven cover of tapes of high molecular weight and more preferably ultrahigh molecular weight polyethylene

Owner:POLTECO

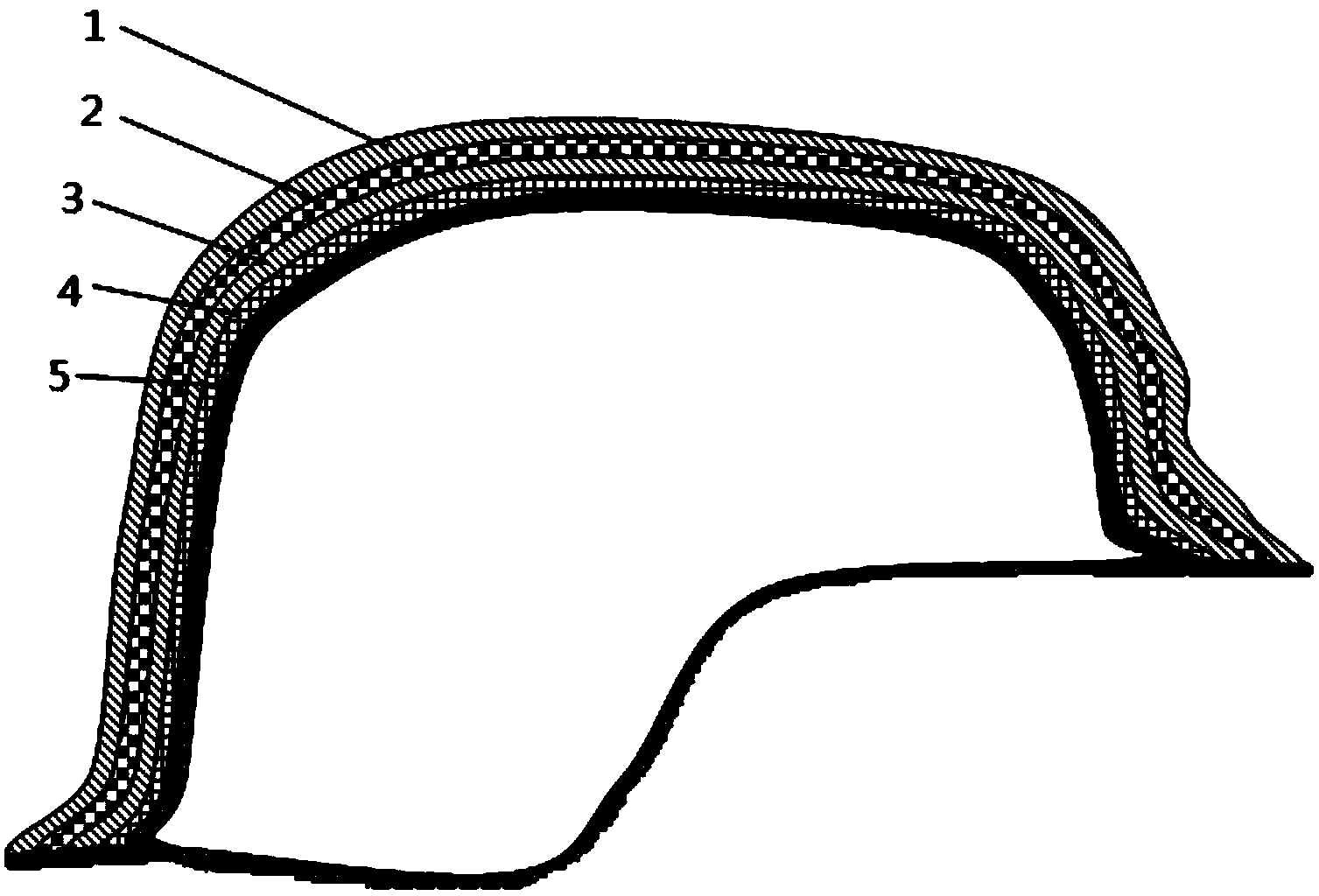

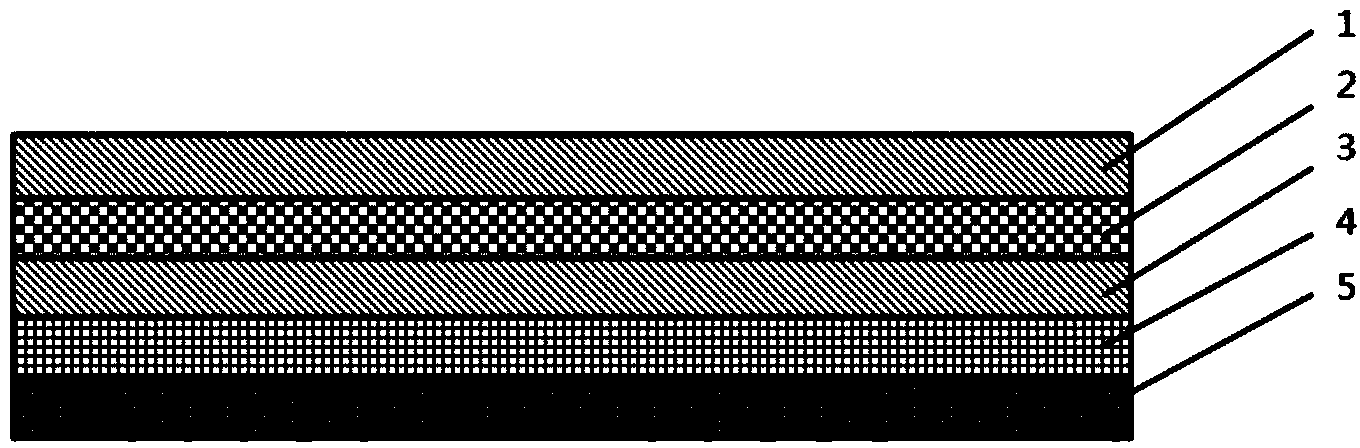

Multifunctional composite material bullet-proof helmet and manufacturing method thereof

ActiveCN104236393AHigh strengthIncrease stiffnessSynthetic resin layered productsLaminationCarbon fibersVideo transmission

The invention relates to a multifunctional composite material bullet-proof helmet and a manufacturing method of the multifunctional composite material bullet-proof helmet. The manufacturing method of the multifunctional composite material bullet-proof helmet comprises the steps that a hybrid fabric is manufactured from two or more than two of high-performance carbon fiber, aramid fiber and ultra-high molecular weight polyethylene fiber, and then a prepreg is manufactured from a thermosetting / thermoplastic composite resin adhesive containing a special filler; the bullet-proof helmet is manufactured in a mold pressing process through a combined paving technology of multiple materials, and electronic information components are embedded in a prepreg layer in the mold pressing process. The bullet-proof helmet formed by the technology comprises a rigid strengthening layer, a bullet-proof layer, a back bulge prevention layer, a buffer layer and multiple structures of an embedded electronic information module and the like, has the advantages of light weight, high strength, high rigidity, corrosion resistance, low bullet-proof back bulge, good water resistance and the like, and is integrated with various electronic information functions of infrared stealth, GPS (Global Position System) positioning, night vision, video transmission and the like.

Owner:SHANDONG UNIV +1

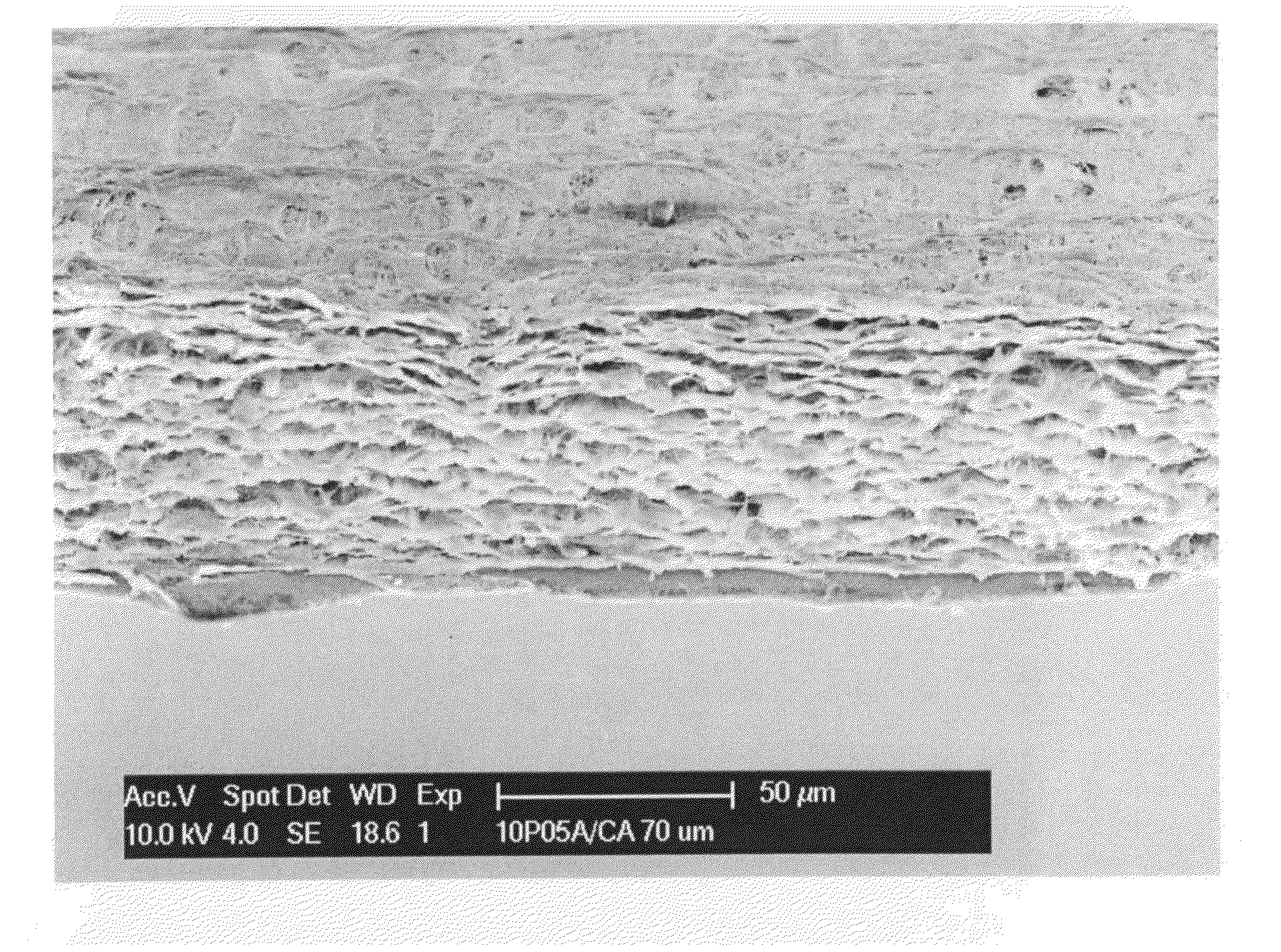

Osmosis membrane with improved flux rate and uses thereof

A membrane structure suitable for use in forward osmosis processes, which membrane structure is comprised of a support membrane comprised of ultra high molecular weight polyethylene and having an active surface which active surface contains a cellulosic coating.

Owner:JANGBARWALA JUZER

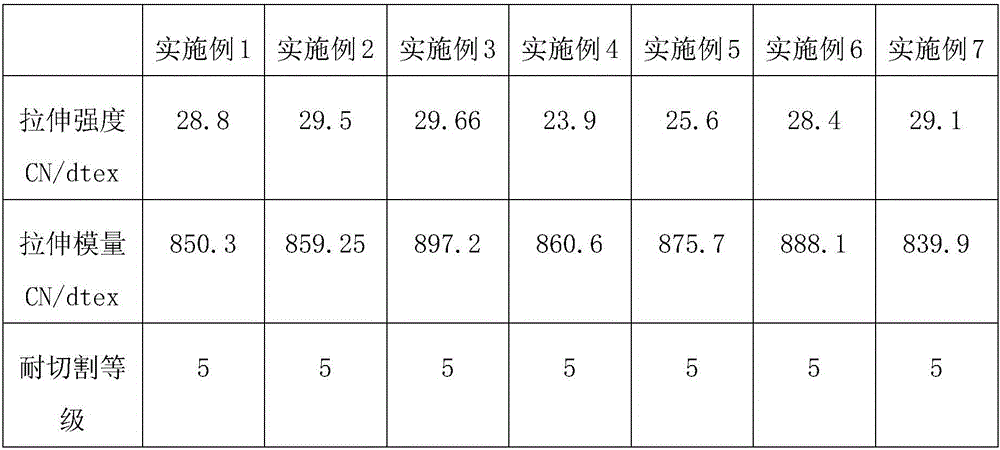

Cut-resistant ultra-high molecular weight polyethylene fibers and preparation technology thereof

ActiveCN106149085AGuaranteed superiorityImprove comfortWet spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses cut-resistant ultra-high molecular weight polyethylene fibers. The cut-resistant ultra-high molecular weight polyethylene fibers consist of ultra-high molecular weight polyethylene, expandable organosilicate clay, modified graphene and an antioxidant, wherein the expandable organosilicate clay accounts for 0.1%-10% of the total mass of the composite fibers; and the modified graphene accounts for 0.1%-5% of the total mass of the composite fibers. The invention provides the technical scheme of preparing cut-resistant fibers by using UHMWPE fibers as bodies (cut-resistant level of fiber bodies only can reach 2 levels or so generally at present), the technological process is simple, the cut resistance of the fibers which are not combined to other hard fibers can be good, and therefore, the comfort level of fiber products is improved.

Owner:南通恒尚新材料科技有限公司 +1

Surface modification of expanded ultra high molecular weight polyethylene (eUHMWPE) for improved bondability

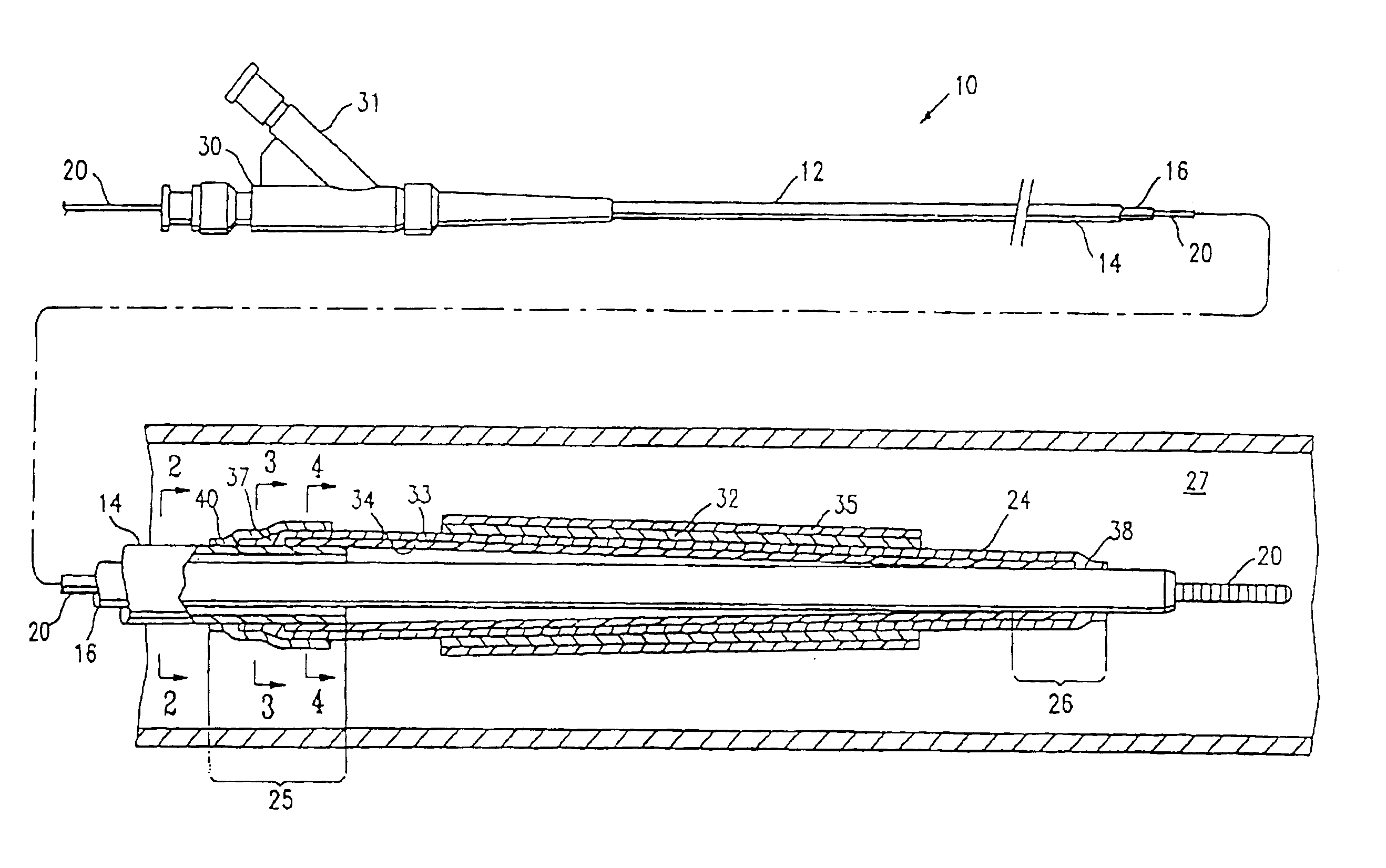

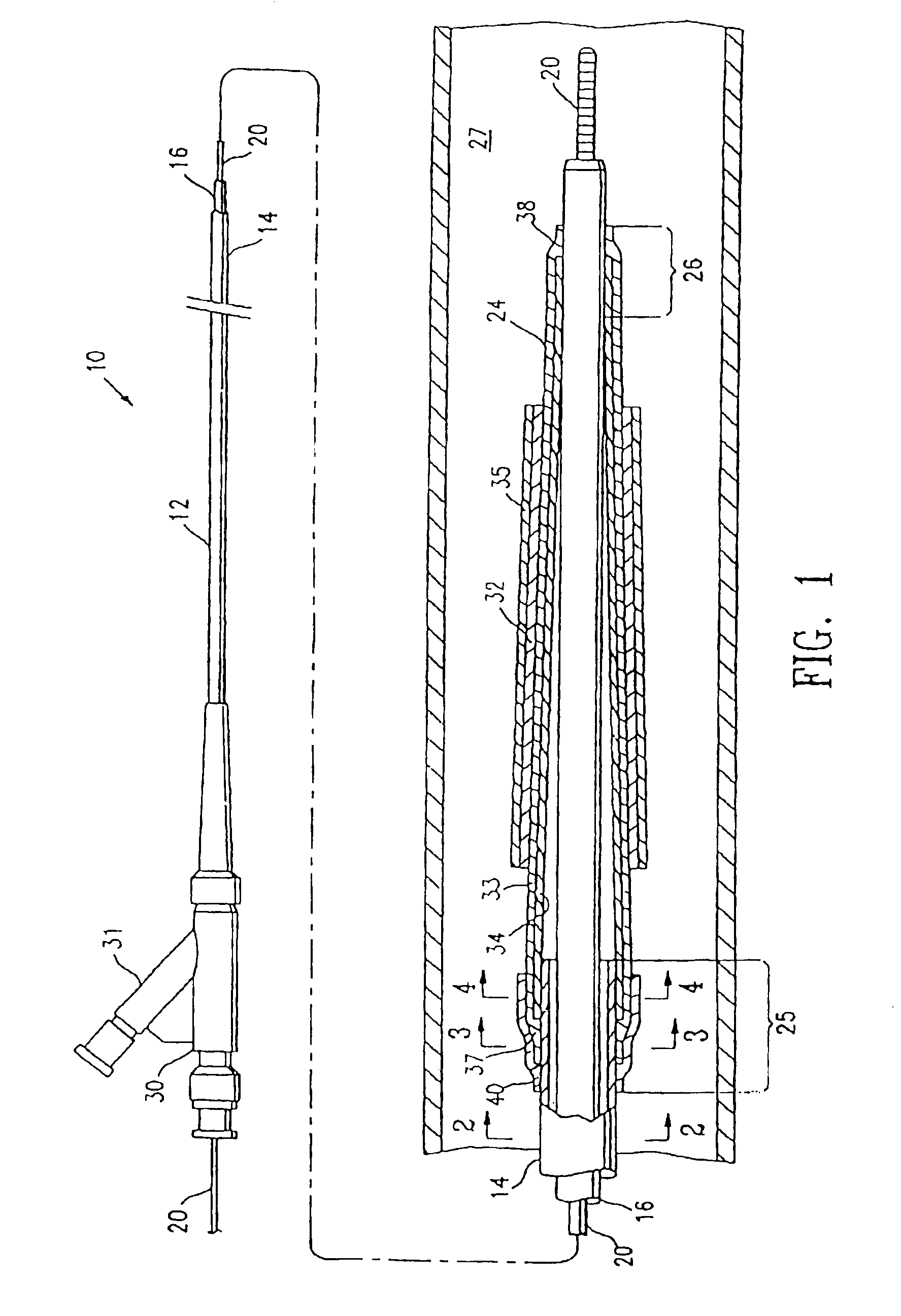

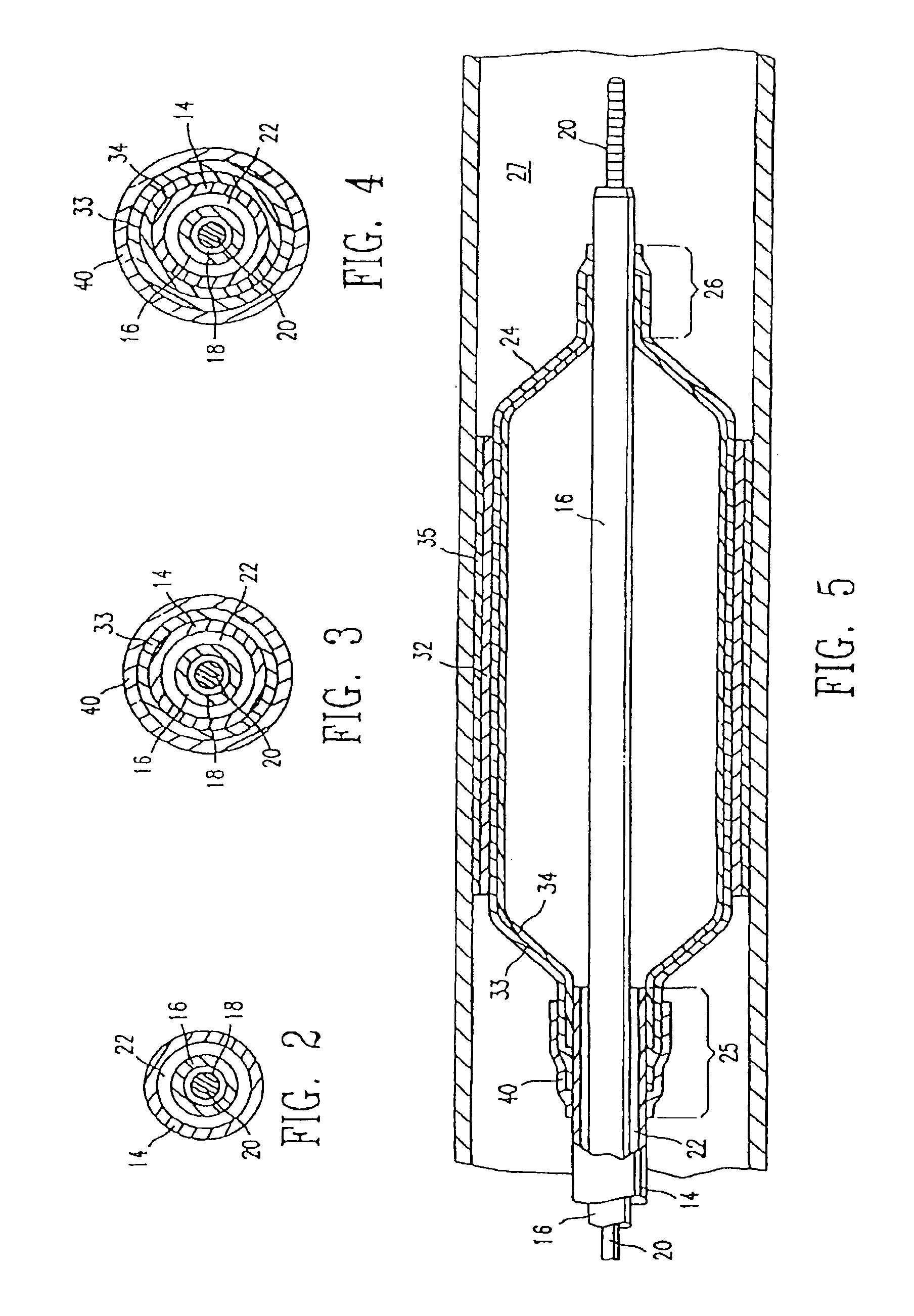

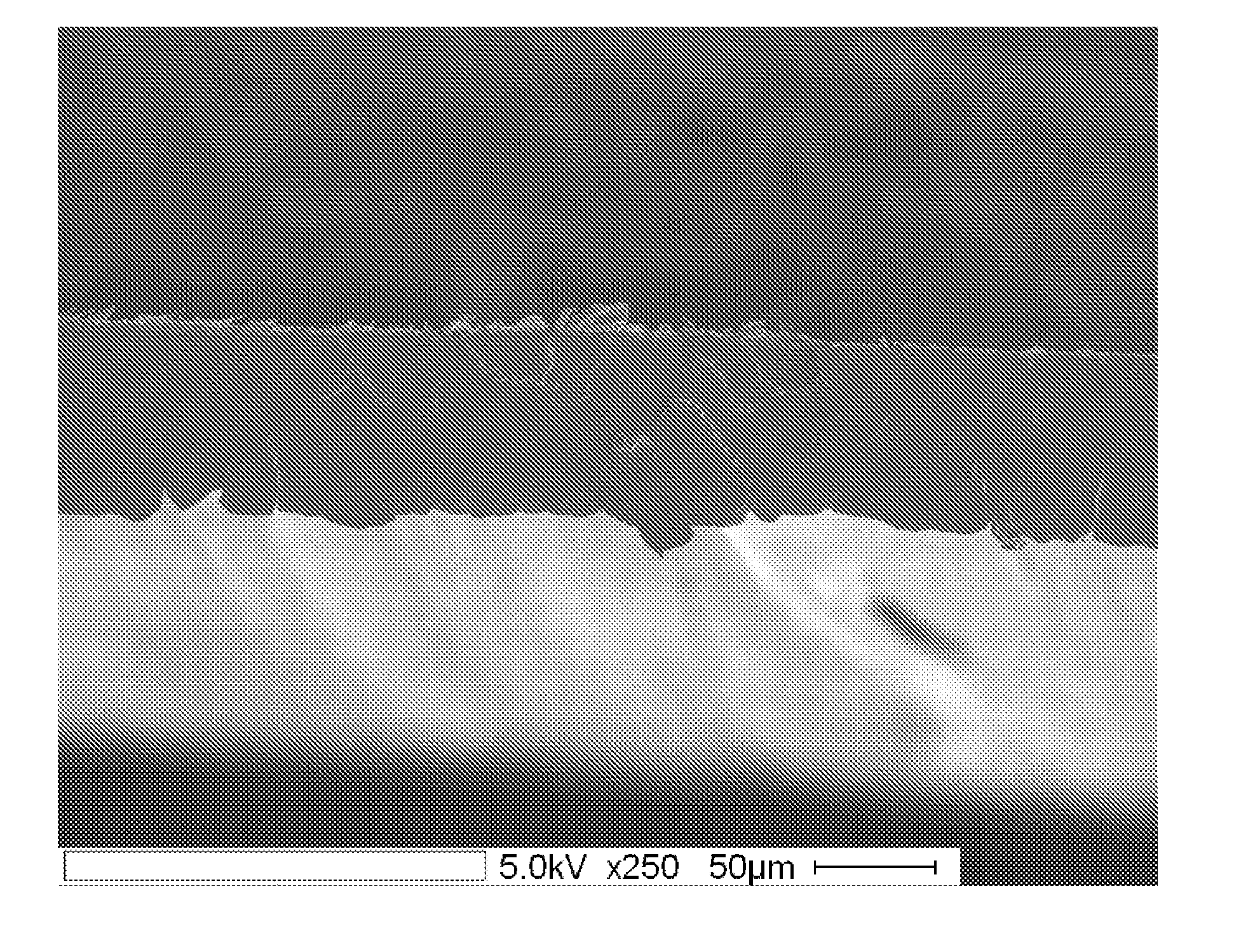

InactiveUS6841029B2Improve bindingHigh bonding strengthBalloon catheterLamination ancillary operationsBalloon catheterUltra-high-molecular-weight polyethylene

A balloon catheter and a method of making the balloon catheter, having a balloon which is bonded to an elongated shaft, and which has a first layer and a second layer and an improved bond between the balloon and the shaft. One aspect of the invention is directed to a balloon in which the balloon first layer includes eUHMWPE and has at least a section that has been oxidized with a chromic acid solution to provide improved bondability.

Owner:ABBOTT CARDIOVASCULAR

Material of polyethylene in super high molecular weight for obstruction guard of highway, and fabricating method

InactiveCN1958274AReduce harmGood value for moneyDomestic articlesUltrahigh molecular weightCarbon steel

An anticollision protecting fence material for highway is prepared from ultrahigh molecular weight polyethene (UHMWPE) through pre-swelling, dissolving and pugging in dual-screw extruder, extruding out for shaping, and stretching for strengthening. It has high longitudinal tension strength (100-180 MPa) and large longitudinal elongation rate at break (50-350%).

Owner:肖久梅 +1

High strength tape articles from ultra-high molecular weight polyethylene

Owner:HONEYWELL INT INC

Formulation for super high molecular weight polythene article and preparation method thereof

The invention discloses a super high molecular weight polyethylene (UHMWPE) product-as the dispense and the method preparing for the pipe materials and the sheet materials, which comprises the following parts: 92%-97% super high molecular weight polyethylene resin, 2-7. 5% lubricant, 0. 05%-0. 7% nuclearyer, 0. 01%-0. 4% rheology processing adjuvant. The method comprises the following steps: adding the every composition meter mixture to a helical rotor force out machine designed according to the approaching fusible point concept; forcing out at 100-200DEG C; plasticizing the materials in the die and cooling, congealing in the shape procedure after preheating the materials; producing the continuously stabilizing UHMWPE pipe materials with 2. 5 million molecular weight and 50-200mm diameter or the sheet materials with (5-20)X500 dimension. The invention can be applied in a plurality of trades and fields.

Owner:江苏联冠科技发展有限公司 +1

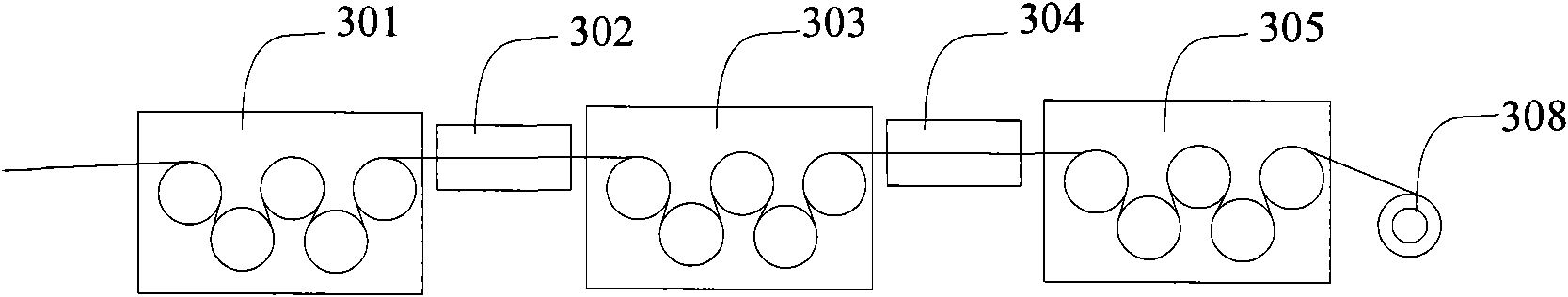

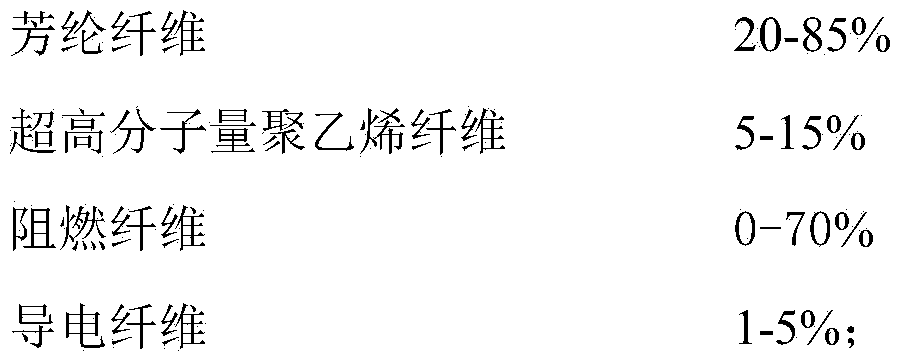

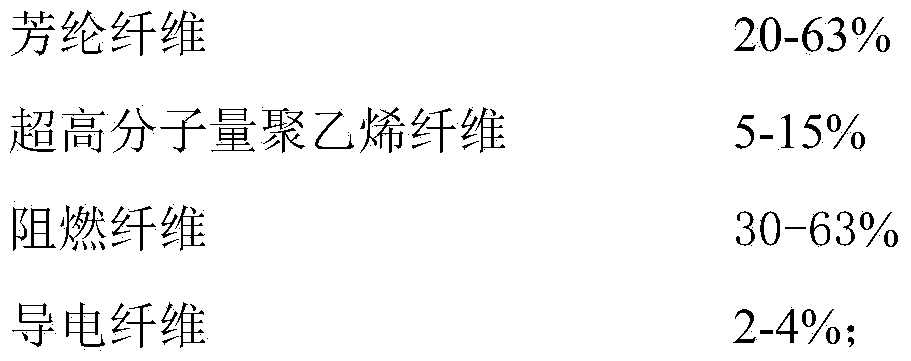

Aramid fiber and ultra-high molecular weight polyethylene blended yarn and production method thereof

The invention discloses an aramid fiber and ultra-high molecular weight polyethylene blended yarn and a production method thereof. The aramid fiber and ultra-high molecular weight polyethylene blended yarn comprises the following components in percentage by weight: 20-85% of aramid fiber, 5-15% of ultra-high molecular weight polyethylene fiber, 0-70% of fire resistant fiber and 1-5% of conductive fiber. The production method comprises the following steps of blending conductive fibers with a certain proportion, and pretreating raw materials before spinning, adding an antistatic agent, and standing for at least 8 hours to preform curing treatment. Technological conditions of each process are strictly controlled in a processing process, and temperature and relative humidity of cotton carding, drawing, roving and spinning processes are controlled, so the problem of serious static of the aramid fiber and the ultra-high molecular weight polyethylene during spinning can be solved well, strong rigidity of the aramid fiber is overcome, and the quality of the yarn is ensured.

Owner:SHANGHAI IBENA TEXTILE PROD

Cold fabric

The invention discloses cold fabric which is formed by interweaving at least one kind of fiber and has at least one layer structure. At least one kind of fiber is cold fiber, and the cold fiber comprises ultra-high molecular weight polyethylene fiber and blended yarn which is made by drawing, twisting and blending the ultra-high molecular weight polyethylene fiber and other kinds of fiber. By the mode, the cold fabric is suitable for being made into various articles needing cooling or keeping a cold effect, such as mattresses, cushions and the like. The cold fabric has the advantages of good air permeability, slow warming effect and good cooling effect.

Owner:邓志健

Method for preparing ultra-high molecular weight polyethylene/polyaniline composite conductive fibre

InactiveCN102720066ADoes not affect mechanical propertiesImprove conductivityPhysical treatmentPolymer scienceOxygen plasma

The invention discloses a method for preparing ultra-high molecular weight polyethylene / polyaniline composite conductive fibre, comprising the steps of: performing low-temperature oxygen plasma treatment on ultra-high molecular weight polyethylene fibre, wherein surface impurities of the fibre are removed, the treatment time is 0.5-1.5 minutes, the reaction power is 50-80W and the oxygen pressure is 30-50Pa; placing the fibre in aniline monomers for 0.5-2 hours, uniformly extruding the fibre after taking out the fibre, and controlling the mass ratio of the fibre and the aniline monomer at 1:1 to 1:1.3; and placing the fibre in a reaction solution at 10-35 DEG C for 0.5-3 hours, so that the fibre containing a uniform and continuous polyaniline conductive layer is obtained. By the method disclosed by the invention, the composite fibre with good conductivity is obtained, textiles or fibre reinforced composites with antistatic, conductive and electromagnetic shielding functions can be prepared, and are applied to fields of individual protection, military industry, electric products, petrochemical industry, machineries and the like.

Owner:SUZHOU UNIV

High tenacity high modulus uhmwpe fiber and the process of making

Processes for preparing ultra-high molecular weight polyethylene (“UHMW PE”) filaments and multi-filament yarns, and the yarns and articles produced therefrom. Each process produces UHMW PE yarns having tenacities of 45 g / denier to 60 g / denier or more at commercially viable throughput rates.

Owner:HONEYWELL INT INC

Catalyst for producing an ultra high molecular weight polyethylene and method for producing an ultra high molecular weight polyethylene using the same

InactiveUS20020045537A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceUltra-high-molecular-weight polyethylene

The present invention provides a method for producing a catalyst for the production of an ultra high molecular weight polyethylene and also a method for preparation of an ultra high molecular weight polyethylene with the use of said catalyst. The catalyst of the present invention is prepared by a process comprising: (i) producing a magnesium compound solution by contact-reacting a magnesium compound and an aluminum or boron compound with alcohol; (ii) contact-reacting the said solution with an ester compound containing at least one hydroxy group and a silicon compound containing an alkoxy group; and (iii) producing a solid titanium catalyst by adding a mixture of a titanium compound and a silicon compound thereto. The catalyst prepared by the present invention has excellent catalytic activity, and it helps to produce an ultra-high molecular weight polyethylene with large bulk density and narrow particle distribution without too large and minute particles.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

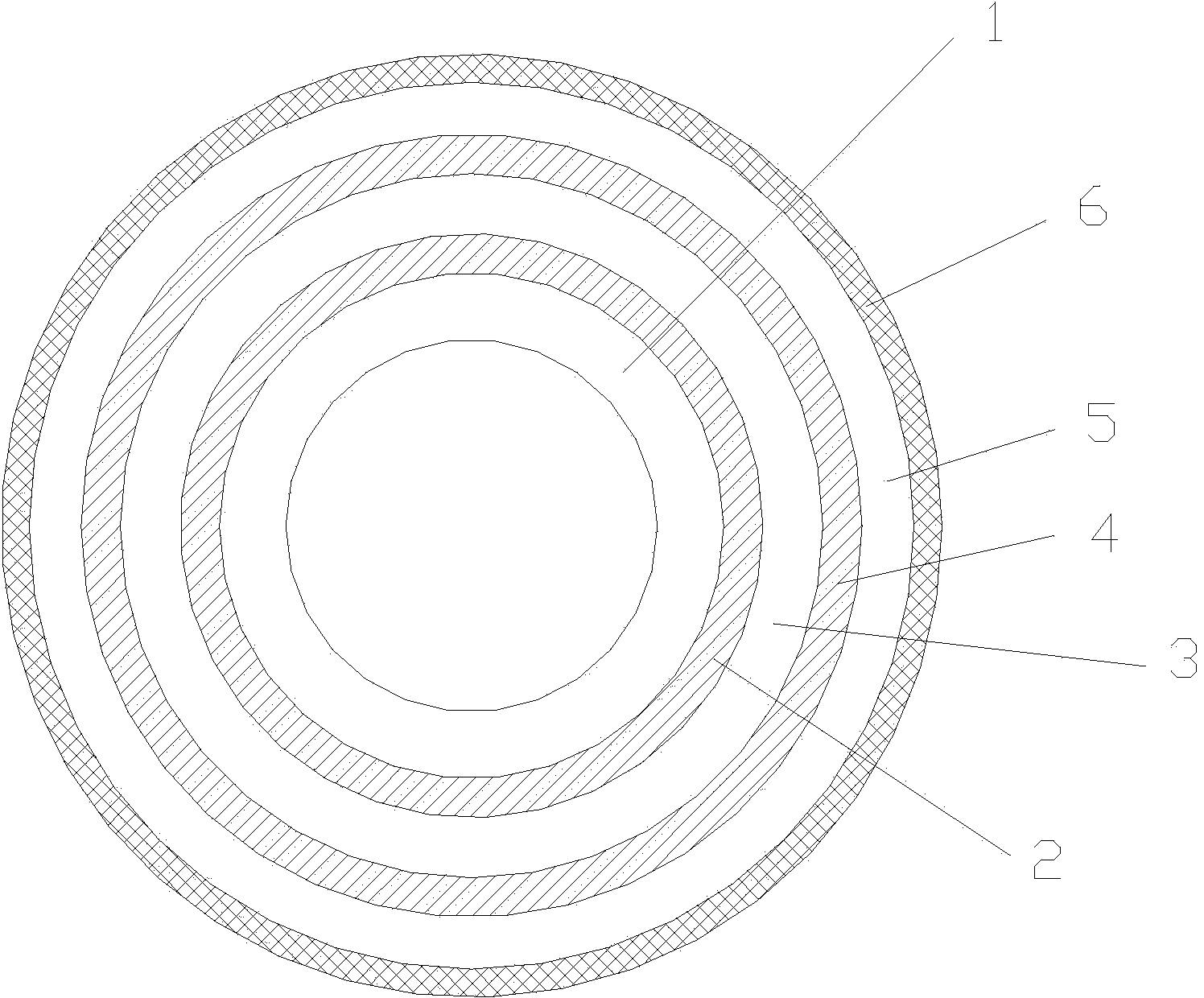

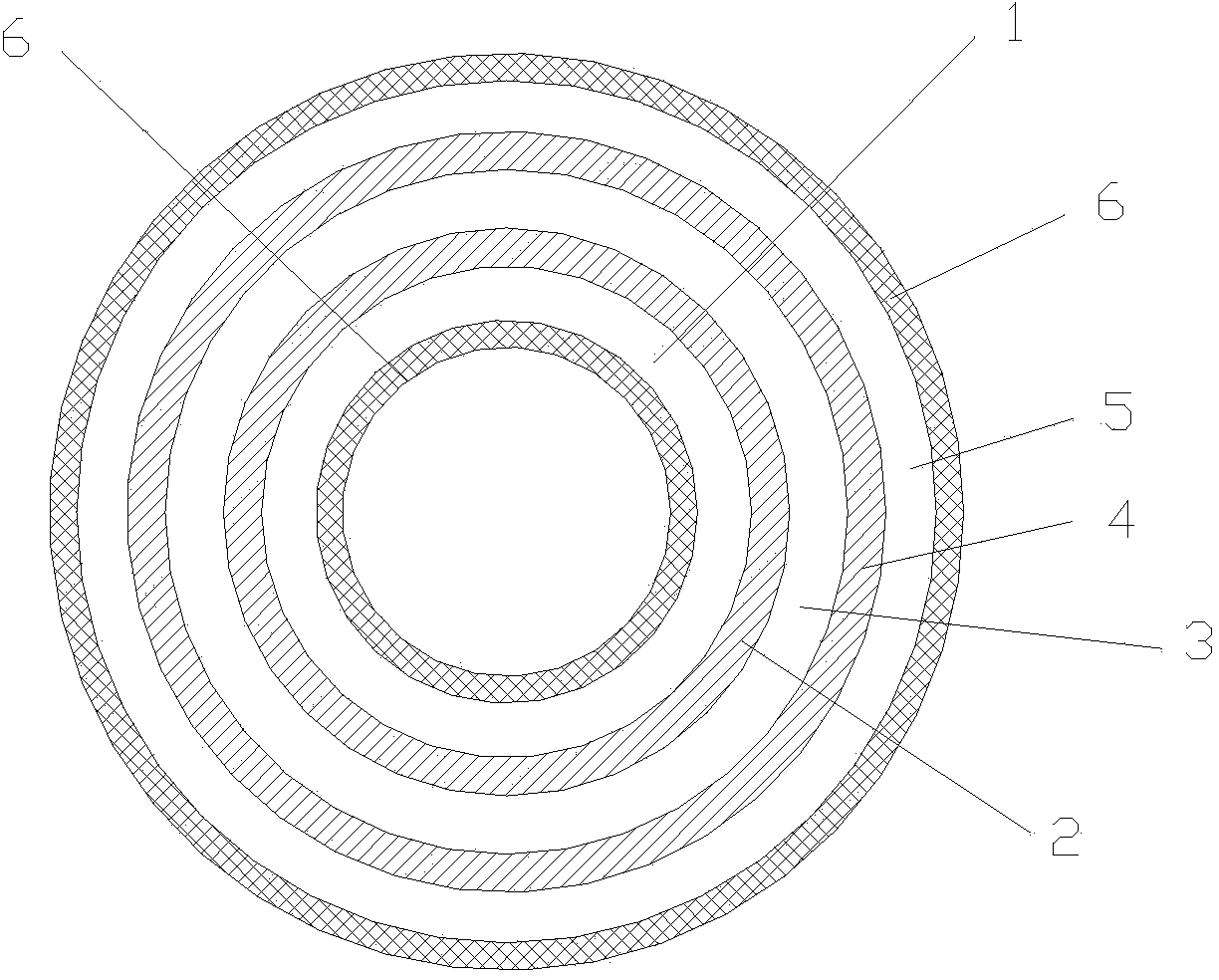

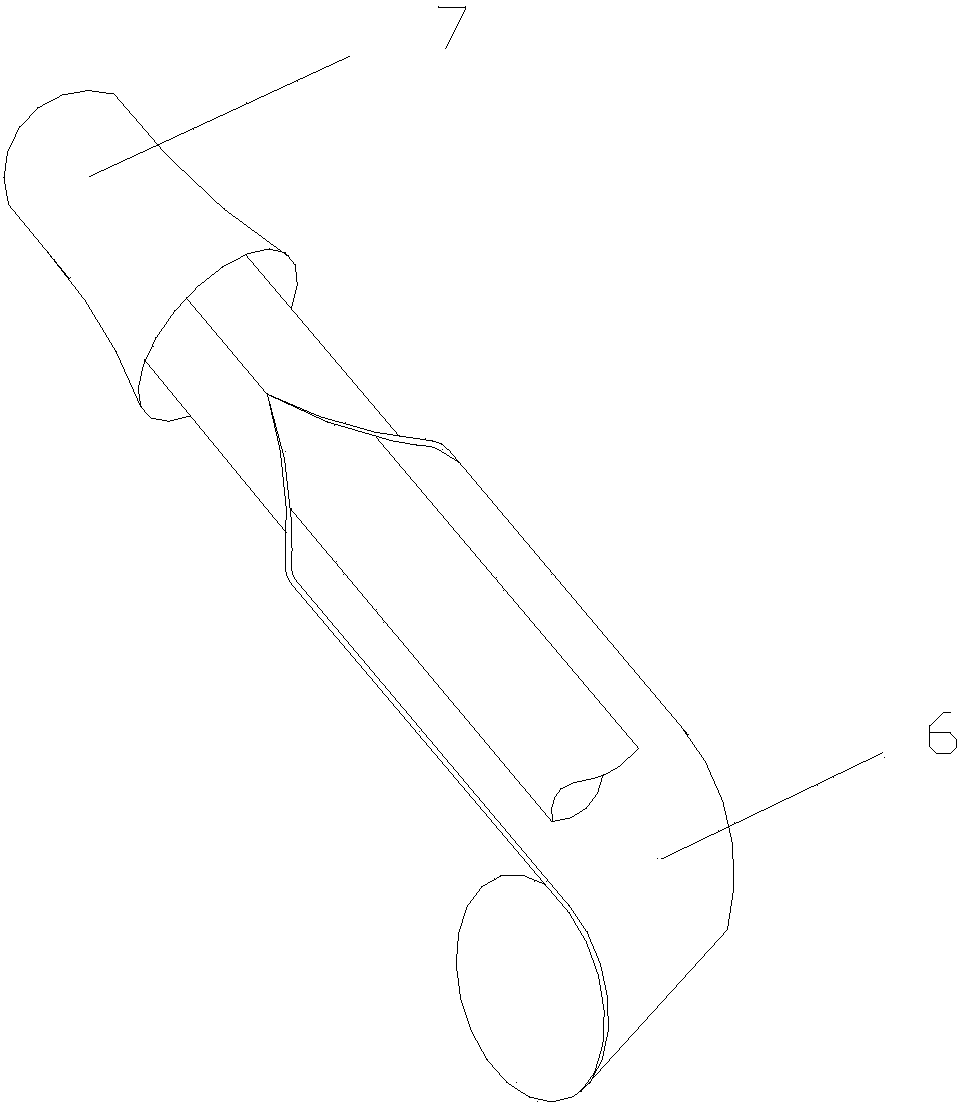

High-pressure rubber hose and production process thereof

InactiveCN103899855ANot easy to delaminateStrong impact resistanceFlexible pipesCoatingsEngineeringStearic acid

The invention relates to a high-pressure rubber hose and a production process of the high-pressure rubber hose. The high-pressure rubber hose includes an inner rubber layer, a first reinforcement layer, a middle rubber layer, a second reinforcement layer, an outer rubber layer and an ultra-high molecular weight polyethylene film from inside to outside in sequence. The outer rubber layer contains 90-110 parts of ethylene-propylene rubber, 4.5-5.2 parts of zinc oxide, 0.8-1.2 parts of stearic acid, 55-65 parts of carbon black, 20-22 parts of dibutyl phthalate, 0.48-0.55 part of dimethylaminoethyl methacrylate, 1.2-1.8 parts of accelerants and 1.2-1.8 parts of sulfur. The production process is characterized in that on the basis of an existing process, the following steps are added: the outer rubber layer is extruded and then passes through a heating cylinder, and when the temperature of the outer rubber layer reaches 120 DEG C to 150 DEG C, the outer rubber layer is coated with the ultra-high molecular weight polyethylene film; water cloth is wound around the outer rubber layer, and then sulfuration is carried out. The high-pressure rubber hose resists shock, corrosion, low temperature and adhesion, and is high in wear resistance, capable of conducting self-lubrication, long in service life, sanitary and non-toxic.

Owner:姚平经

Microporous Polyolefin Membrane And Manufacturing Method

ActiveUS20090081543A1High mechanical strengthImprove permeabilityMembranesSemi-permeable membranesPolyolefinSolvent

A microporous polyolefin membrane having a structure in which its pore size distribution curve obtained by mercury intrusion porosimetry has at least two peaks, which is produced by extruding a melt-blend of a polyolefin composition comprising (a) high density polyethylene resin having a weight average molecular weight of from about 2.5×105 to about 5×105 and a molecular weight distribution of from about 5 to about 100, (b) polypropylene resin having a weight average molecular weight of from about 3×105 to about 1.5×106 and a molecular weight distribution of from about 1 to about 100, and (c) ultra-high molecular weight polyethylene resin having a weight average molecular weight of about 5×105 or higher, and a membrane-forming solvent, cooling the extrudate to form a high resin content gel-like sheet, stretching the gel-like sheet at a high stretching temperature to form a stretched gel-like sheet, removing the membrane-forming solvent from the stretched gel-like sheet to form a membrane, stretching the membrane to a high magnification to form a stretched membrane, and heat-setting the stretched microporous membrane to form the microporous membrane.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com