Patents

Literature

73results about How to "Overcome rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

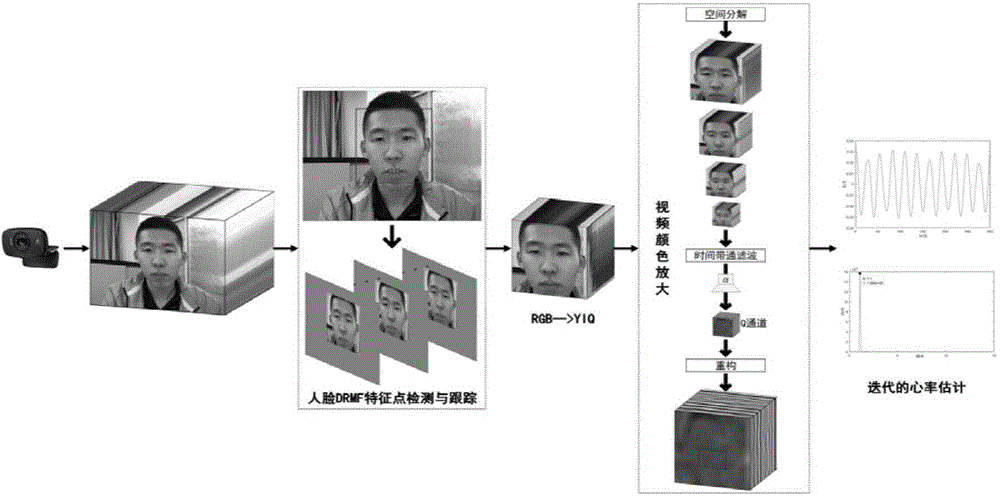

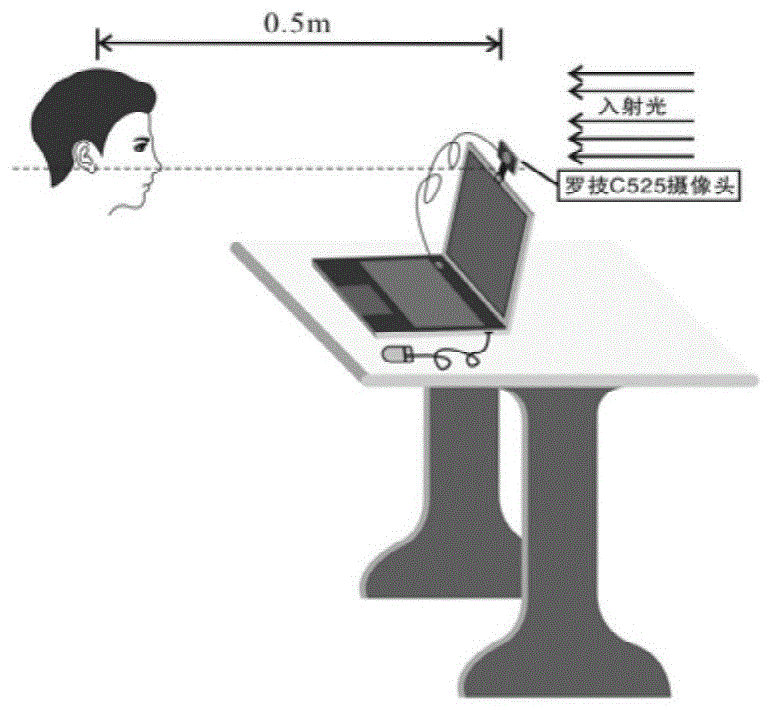

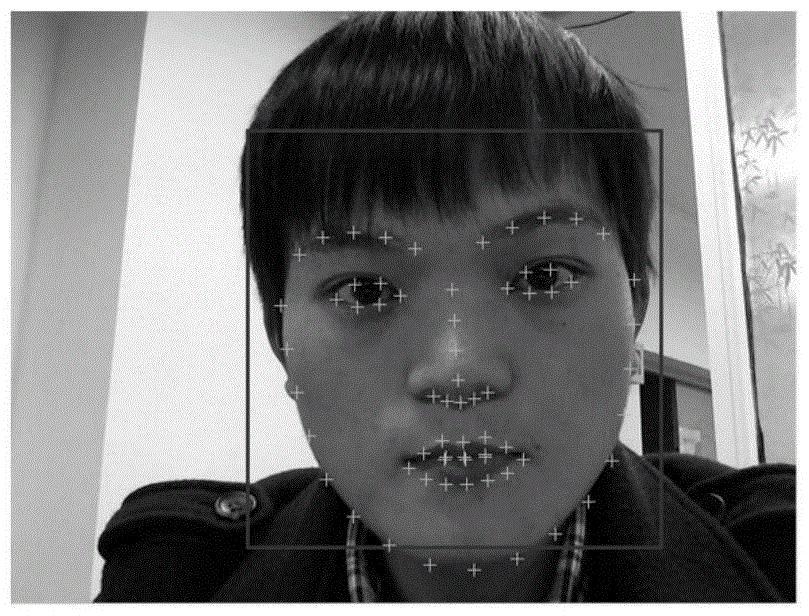

Human face video processing-based heart rate detection method

InactiveCN105989357AImprove comfortLow costCharacter and pattern recognitionSensorsFrequency domainColor space

The invention discloses a human face video processing-based heart rate detection method. The method is implemented by the steps of (1) controlling a camera to acquire a video that the camera is over against a human face for 10s; (2) performing human face characteristic point detection and tracking on the acquired video, and performing tilt correction to obtain a stable human face video; (3) performing color space conversion on the human face video; (4) extracting a clean BVP (Blood Volume Pulse) signal from the human face video by utilizing video color amplification; and (5) performing iterative frequency domain analysis on a BVP and computing the frequency of the BVP signal to estimate a heart rate. According to the method, the interferences of a background and a rigid head motion are eliminated by utilizing human face characteristic point detection and tracking, the clean BVP signal is extracted through the video color amplification, and the iterative heart rate estimation is carried out, so that the accuracy of heart rate detection is improved and very good robustness is ensured; and the method can be used for non-contact heart rate detection in a real scene under cooperative and non-cooperative conditions.

Owner:HEFEI UNIV OF TECH

Polypropylene thermoplastic elastomer for automobile safety airbag cover board and preparation method thereof

The invention discloses a polypropylene thermoplastic elastomer for an automobile safety airbag cover board; the polypropylene thermoplastic elastomer comprises 21-48% of high melt strength polypropylene (HMSPP), 10-50% of olefin polymer, 10-40% of styrenic thermoplastic elastomer and 2-15% of compatilizer by weight; a preparation method of the polypropylene thermoplastic elastomer comprises the steps as follows: adding the above components to a double-screw extruder respectively according to a proportion, melting, mixing and dispersing, setting a temperature of each section of the extruder at 230-265 DEG C, extruding and granulating to obtain the product finally. As the high melt strength polypropylene (HMSPP) is adopted as a matrix resin of the thermoplastic elastomer, and the olefin polymer and the styrenic thermoplastic elastomer are used for toughening synergistically, the prepared elastomer material has excellent high temperature and low temperature bursting properties and can meet the requirements that the automobile safety airbag cover board cannot be deformed to fly out and torn excessively during high temperature blasting (85 DEG C.) and does not generate fragments during low temperature blasting (-35 DEG C.); and therefore, the polypropylene thermoplastic elastomer can replace the conventional thermoplastic polyolefin (TPO) to apply to different types of automobile safety airbag cover boards.

Owner:TIANJIN KINGFA NEW MATERIAL

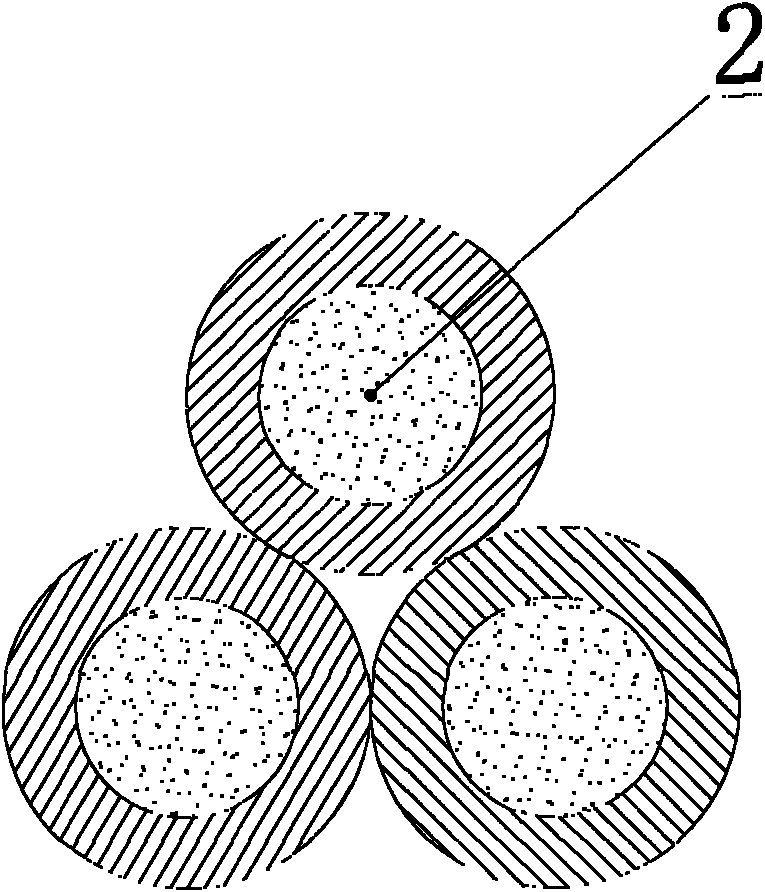

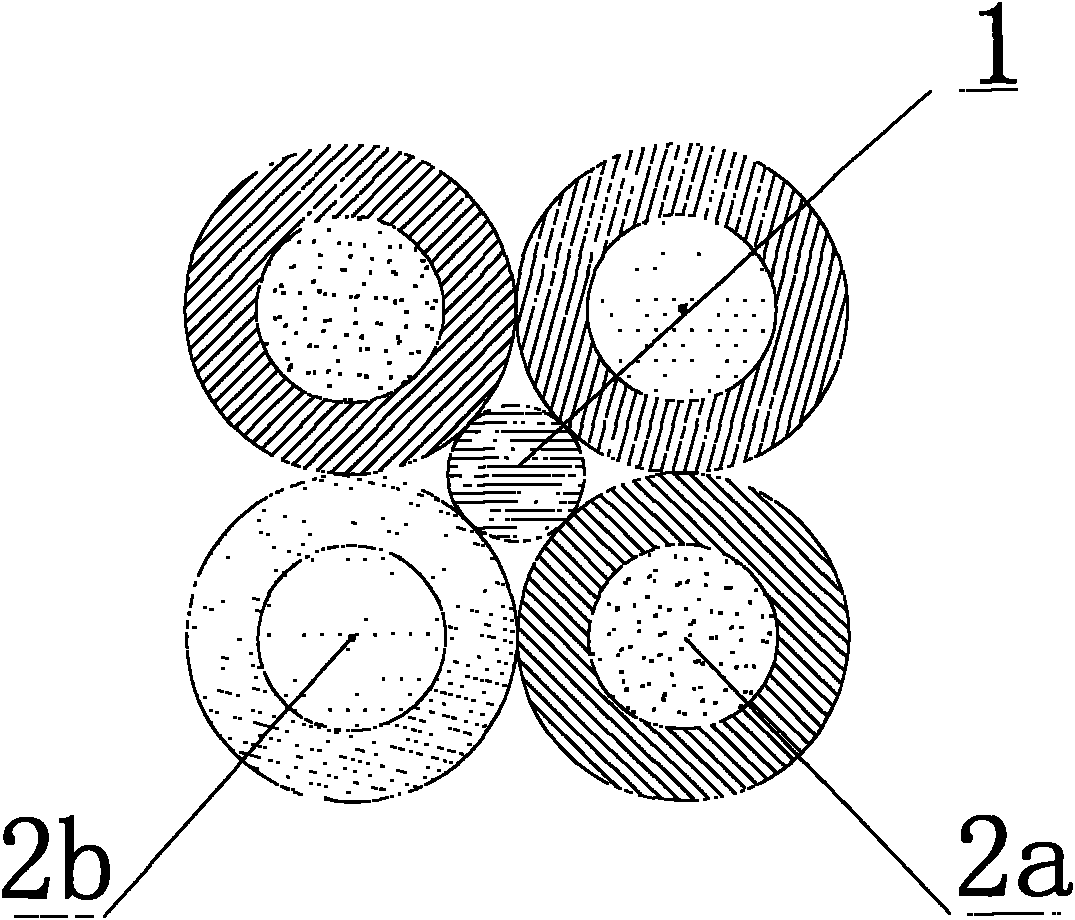

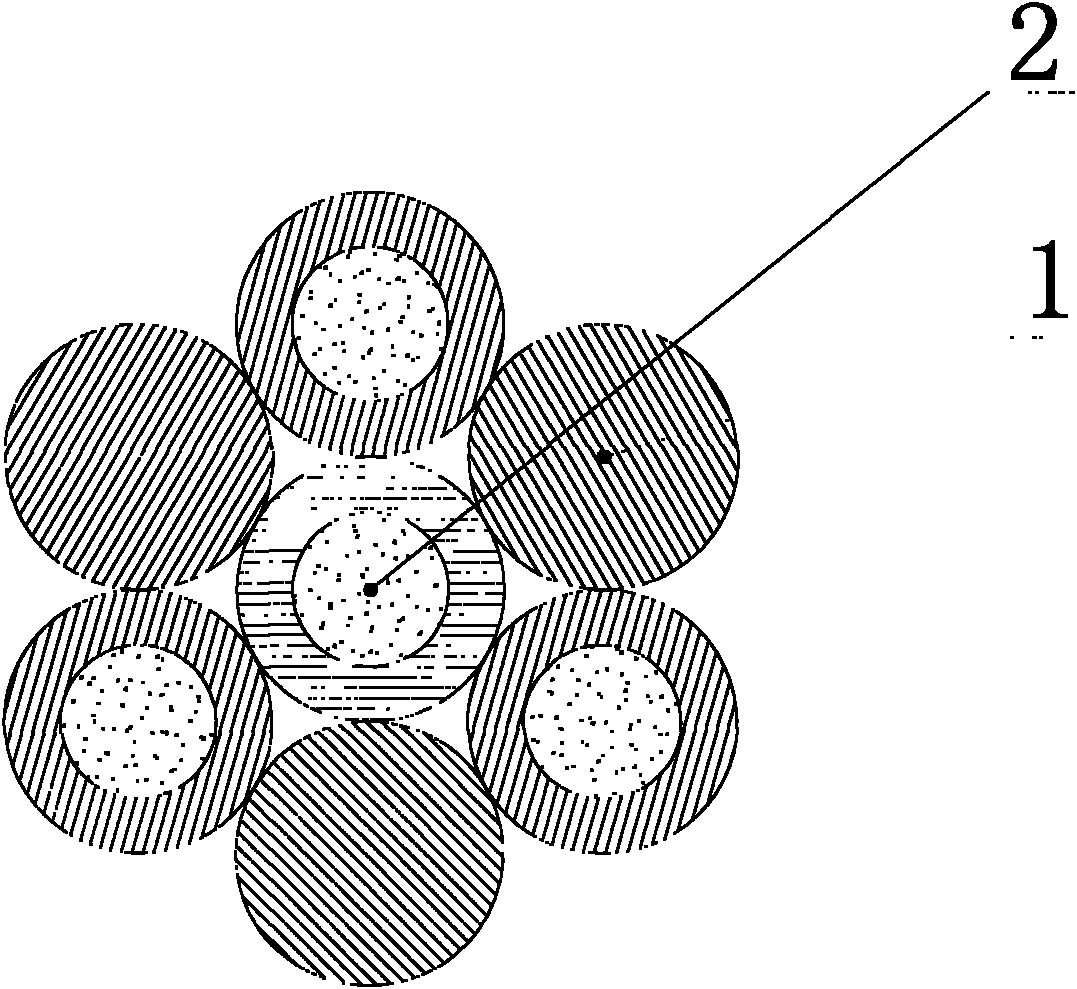

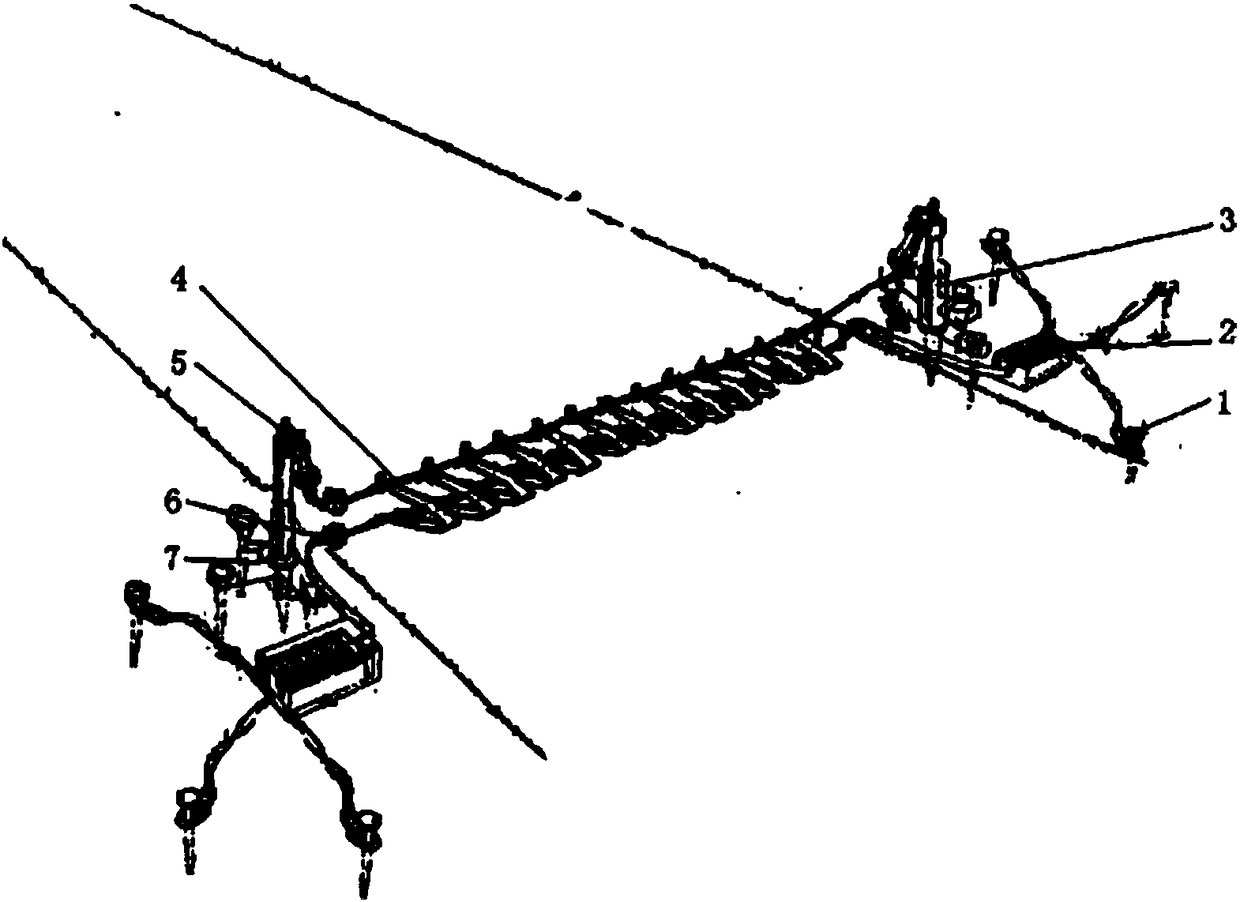

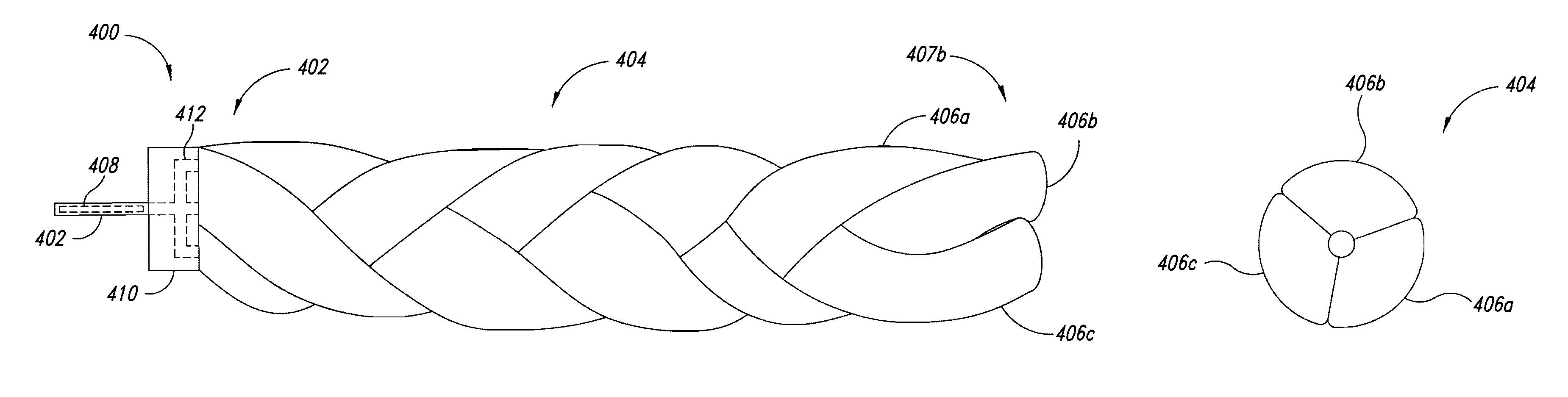

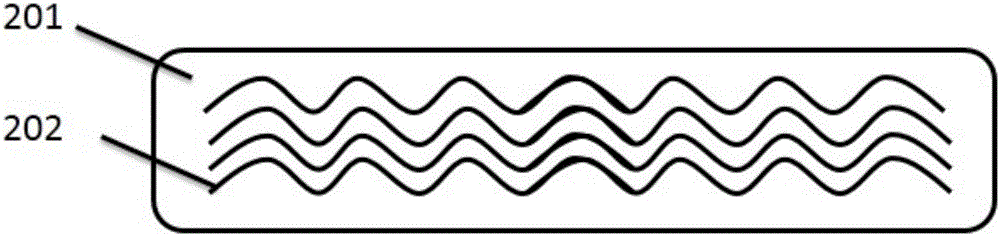

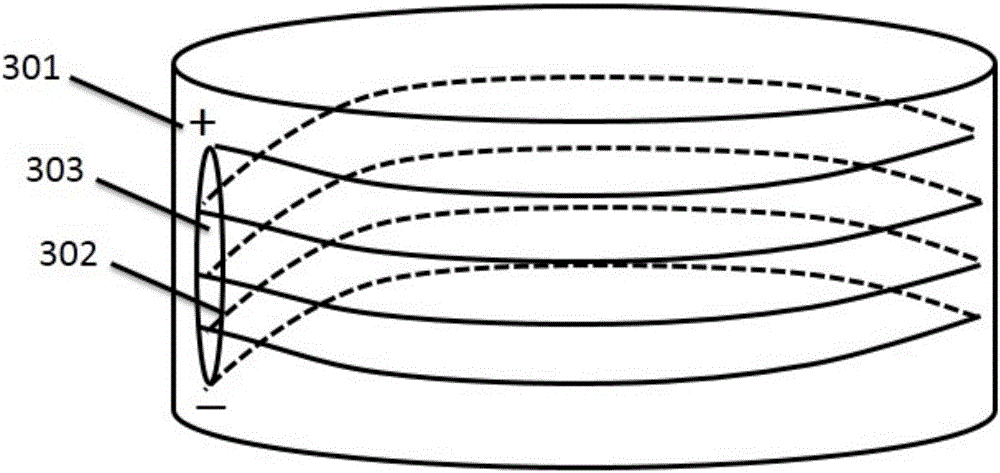

Multi-stranded welding wires

InactiveCN101559543AOvercoming not easy to coilOvercome rigidityWelding/cutting media/materialsSoldering mediaEngineeringLarge applications

The invention relates to multi-stranded welding wires, comprising solidwires and flux-cored wires; stranded solidwires and flux-cored wires are twisted and stranded to form an integral part or multistrand flux-cored wires are twisted to form an integral part; wherein, welding wires positioned in the center are called core wires; the other welding wires twisted around the core wires in the center are called peripheral wires. The invention resolves the defects of the traditional flux-cored wires such as small diameter, difficult swirling when the diameter of the traditional flux-cored wires is increased, poor rigidity and the like; the diameter of the stranded flux-cored wires has a wide variation range, thus obtaining larger weld depth, weld width or wider deposited layer which are in favor of the welding of large scale metal construction. Stranded flux-cored wires feature deep weld depth, large weld width, high deposition efficiency, simple process, high efficiency, strong swirling and good rigidity, thus being capable of obtaining larger weld depth, weld width or wider deposited layer and has a larger application range.

Owner:CHINA UNIV OF MINING & TECH

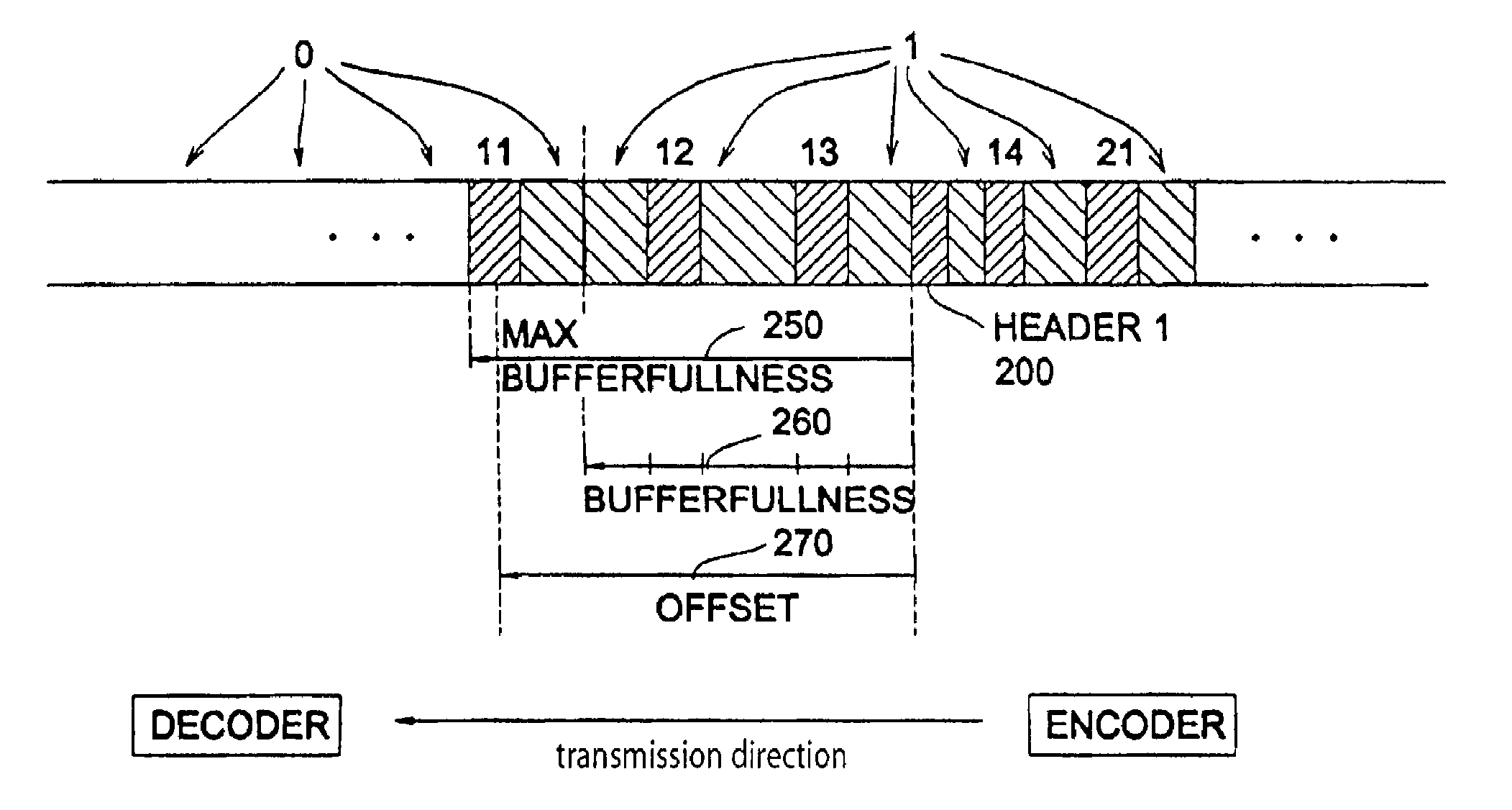

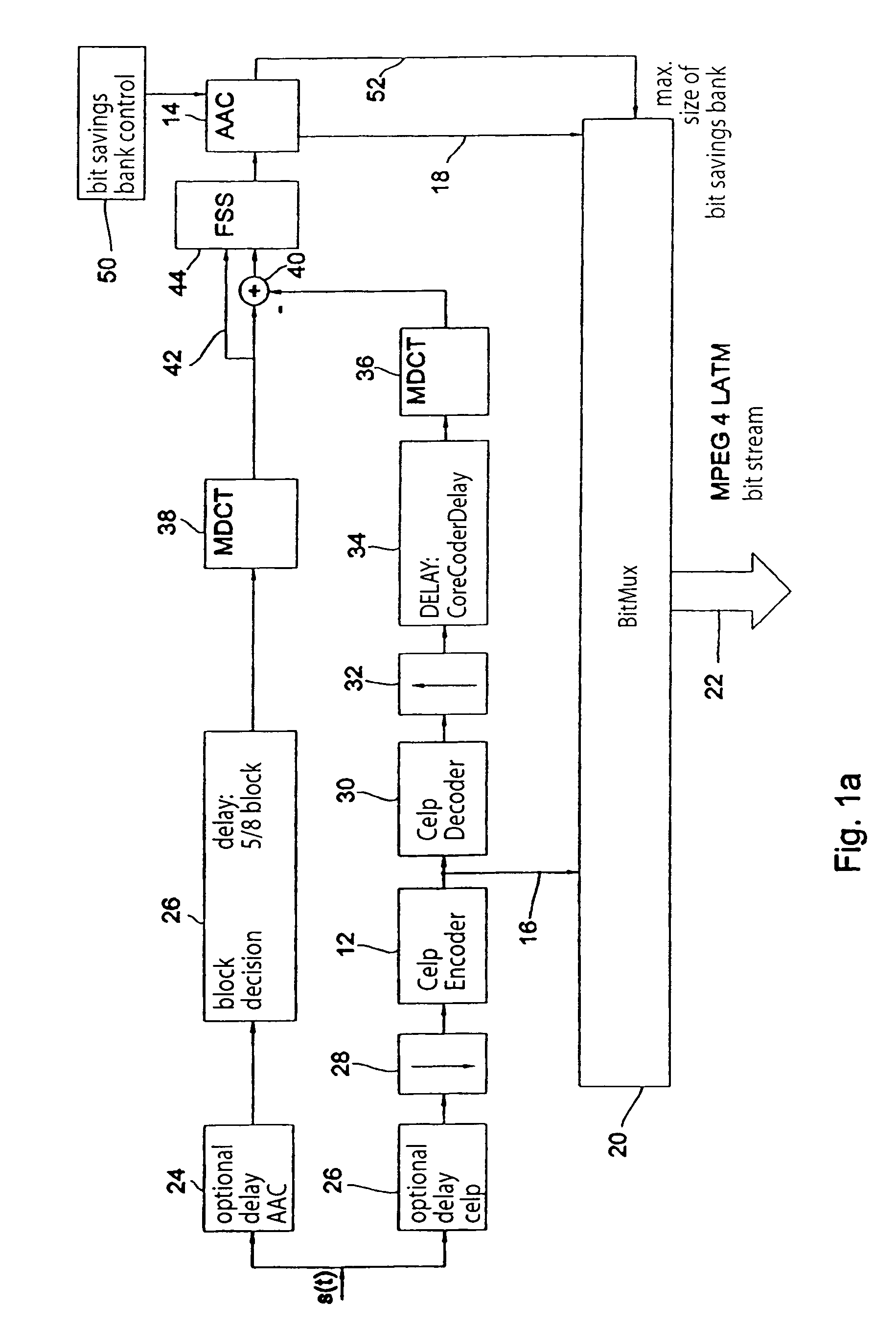

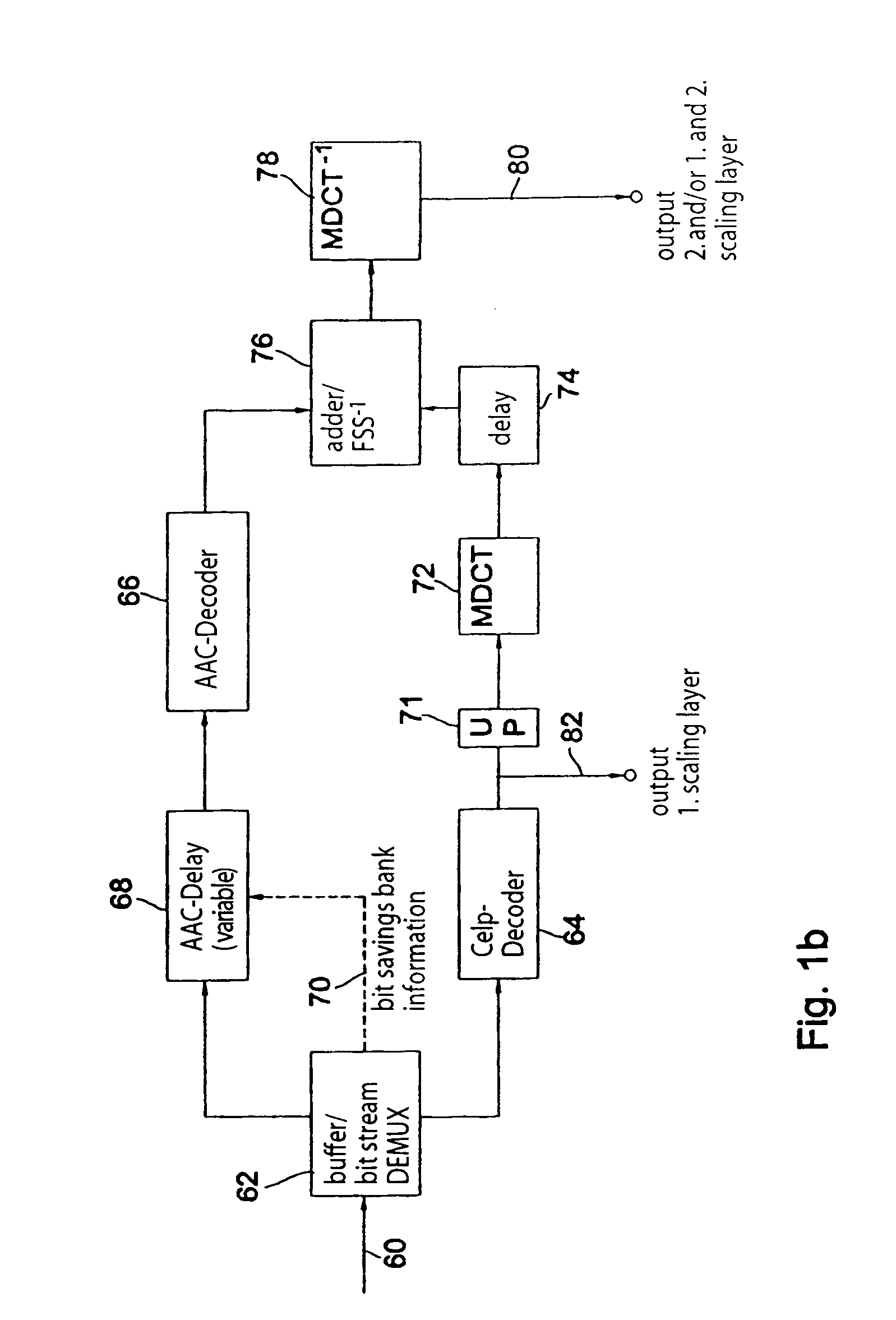

Method and device for the generation or decoding of a scalable data stream with provision for a bit-store, encoder and scalable encoder

ActiveUS7516230B2Reduction of audio qualityImprove sound qualitySpeech analysisCode conversionComputer hardwareData stream

In a method for generating a scalable data stream, when a block of output data of a first encoder is present, this block of output data is written into the scalable data stream. If output data of a second encoder is present for a preceding period of time, this output data for the preceding section is written in transmission direction behind the block of output data of the first encoder into the data stream. When the output data of the scalable encoder for the current section is present, the output data of the second encoder is written into the bit stream subsequent to the output data of the first encoder. A determining data block is generated and written into the bit stream delayed by a period of time which corresponds to the size of the bit savings bank of the second encoder. Finally, buffer information is written into the bit stream, which indicates, where the beginning of the output data of the second encoder for the current section regarding the determining data block is, wherein the buffer information corresponds to the bit savings bank level. Thus, it is possible to simply signalize a bit savings bank in a scalable data stream. The maximum size of the bit savings bank may further be adjusted depending on the intended decoder delay and be communicated to a decoder by positioning the determining data block in the scalable data stream without an effort of additional bits in order to reduce the initial delay of the decoder.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Blended yarn containing polytetrafluoroethylene fiber and preparation method of blended yarn

The invention discloses blended yarn containing polytetrafluoroethylene fiber and a preparation method of the blended yarn. The blended yarn is prepared from, by weight, 5-80% of polytetrafluoroethylene fiber, 20-95% of flame-retardant fiber and 0-5% of conductive fiber. The blended yarn containing polytetrafluoroethylene fiber is prepared by adding a certain proportion of conductive fiber, preprocessing the raw material before spinning, adding an antistatic agent for being still standing for at least 8 hours for antistatic processing, strictly controlling the technological conditions of all the procedures in the processing process, and controlling the temperature and relative humidity of the carding, drawing, roving and spinning procedures. The severe static problem during spinning of polytetrafluoroethylene fiber is effectively solved, and yarn quality is ensured.

Owner:SHANGHAI IBENA TEXTILE PROD

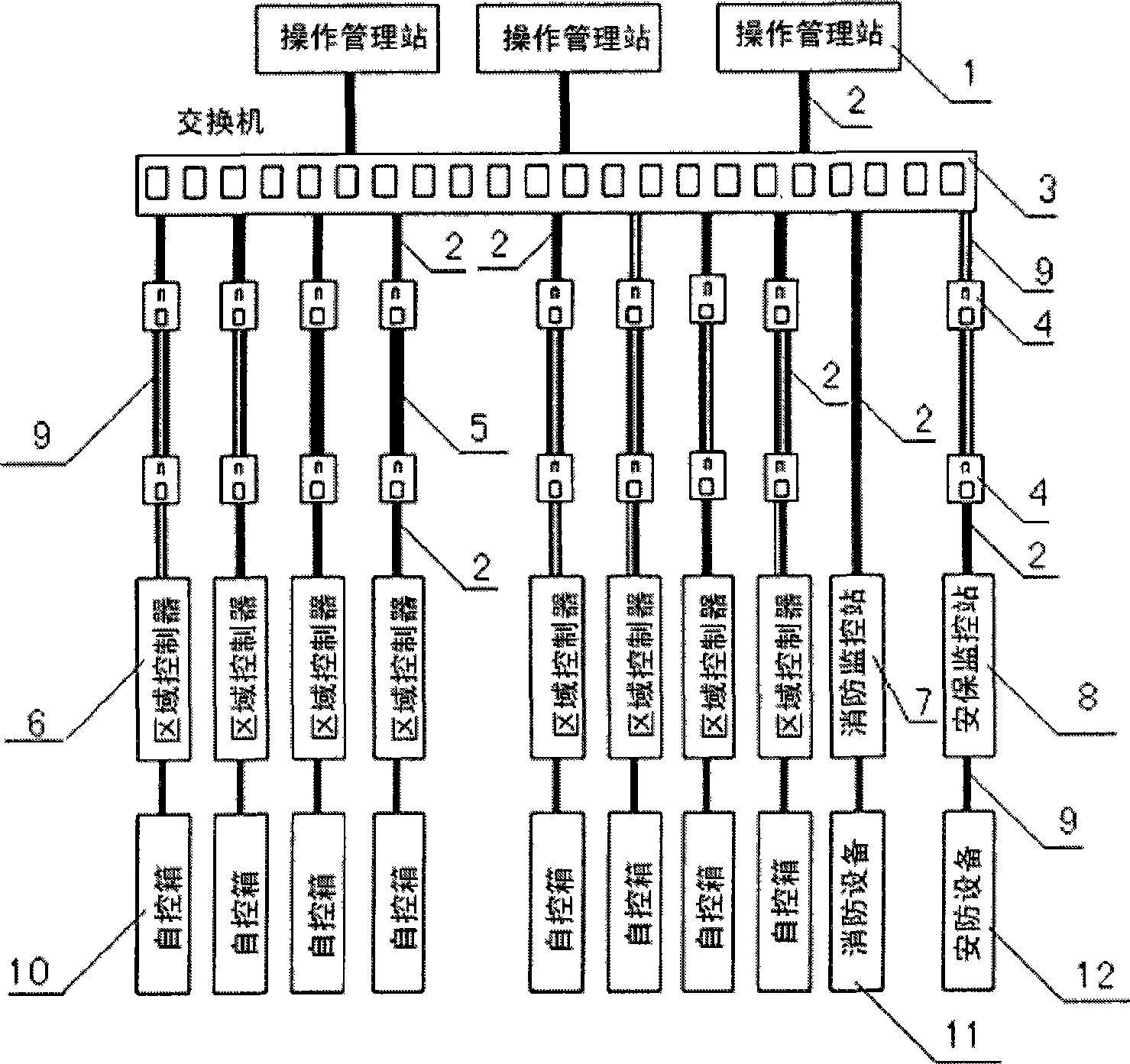

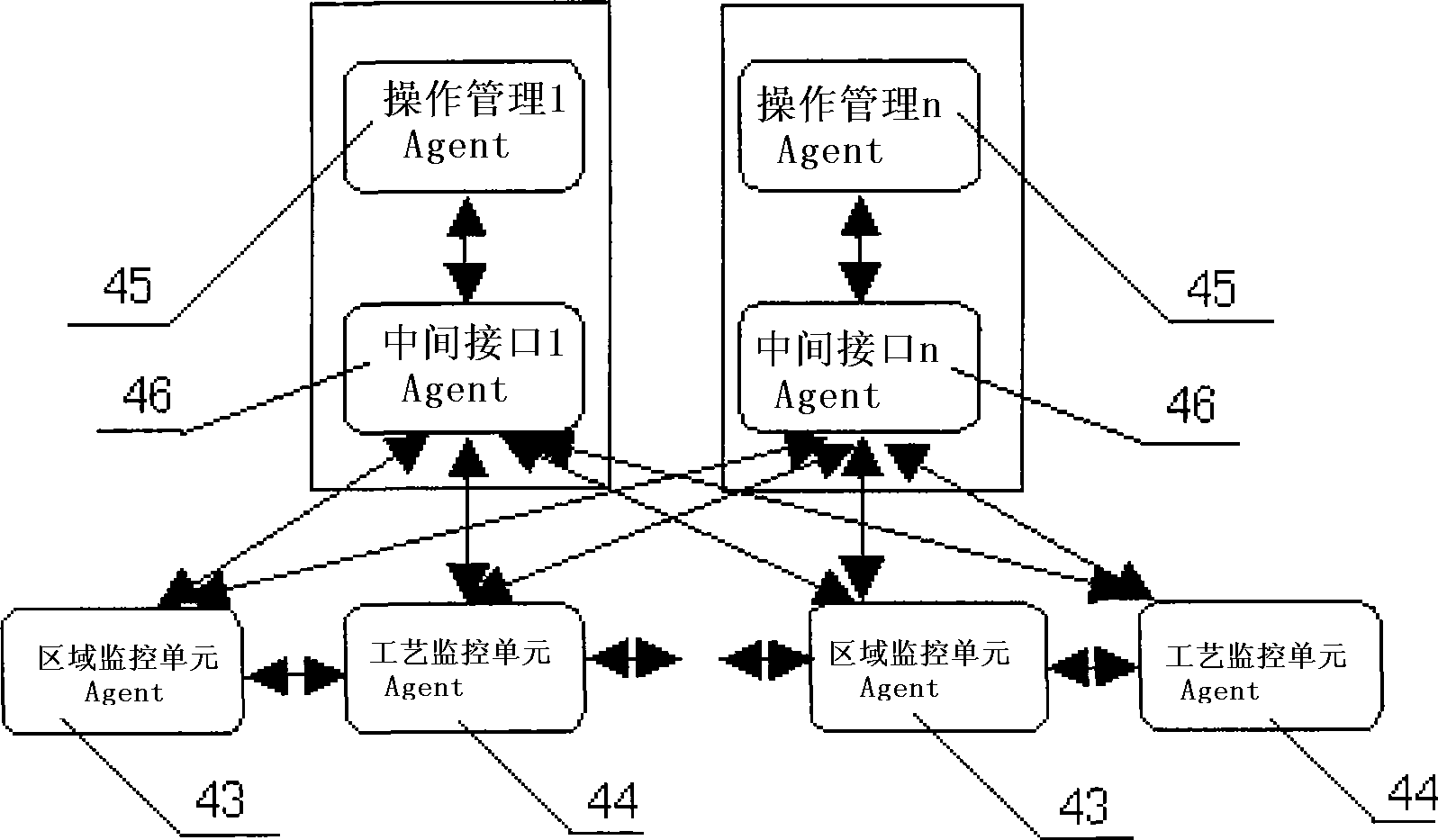

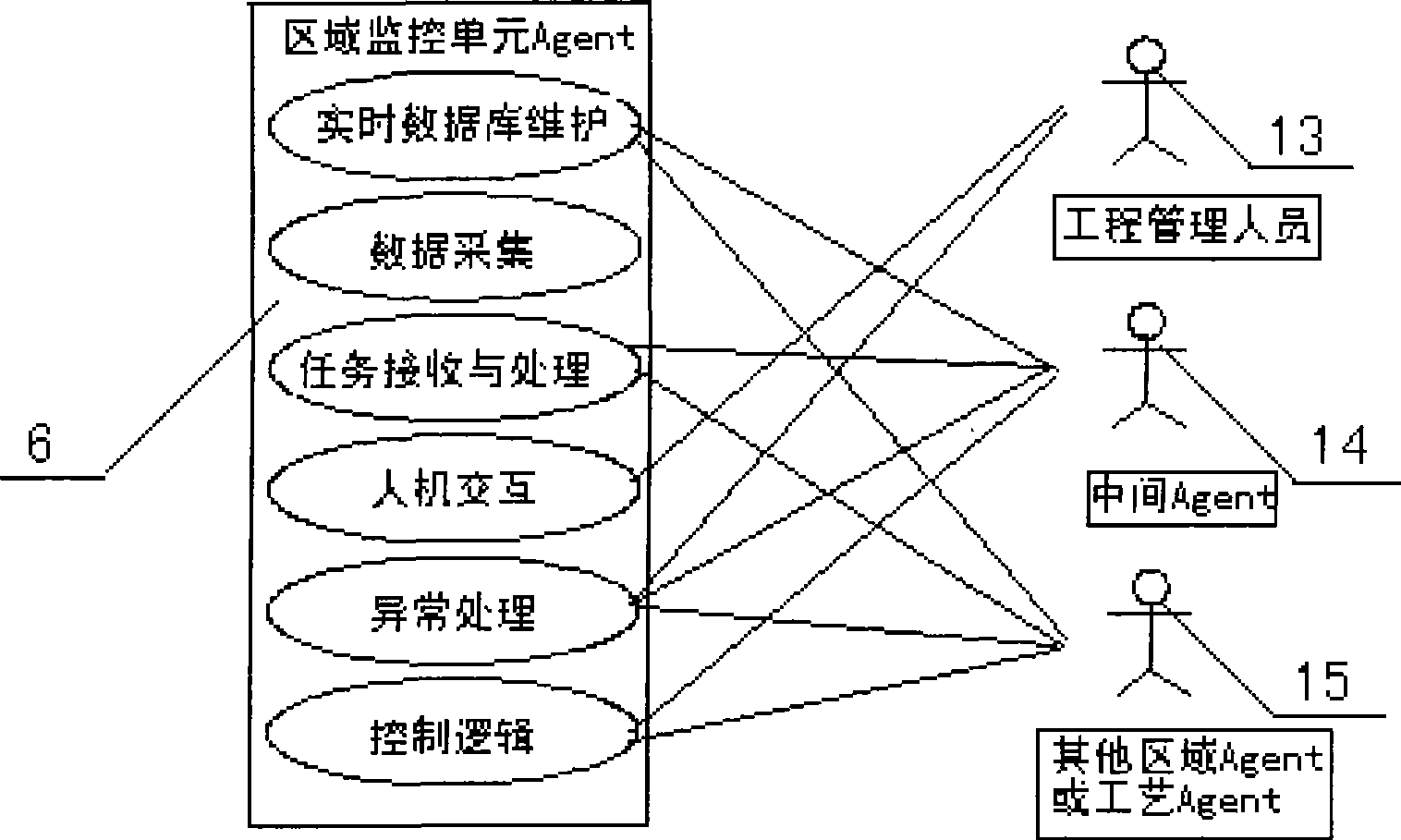

Multi entity monitoring decision support system and method for downhole entironment

ActiveCN101364104AOvercome rigidityAchieve interactionProgramme total factory controlAutomatic controlFire control

The invention relates to an underground intelligent control system, particularly an underground environment multi-cognition solid monitoring decision support system and the method thereof, which can automatically detect the underground environment, adapt the underground environment integrally and achieve the effects of underground environment optimization, management optimization and personnel optimization. The underground environment multi-cognition solid monitoring decision support system comprises an operation management station, an exchanger, a system interface, an area controller, a fire-control monitoring station, a security monitoring station, an automatic control cabinet, a fire-control device and a security device. Compared with the conventional intelligent system, the underground environment multi-cognition solid monitoring decision support system as the multi-cognition solid system and the method thereof are characterized in that: the system and the method are capable of interacting, coordinating and cooperating with other cognition solid systems and humans in various environments; and are applicable to the intelligent control system for the underground construction engineering in the mining enterprises.

Owner:WESTERN MINING CO LTD

Inflaming retarding modified PBT (Polybutylene Terephthalate) fiber and preparation method thereof

InactiveCN104120505AFluffy goodFeel goodFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberHeat stability

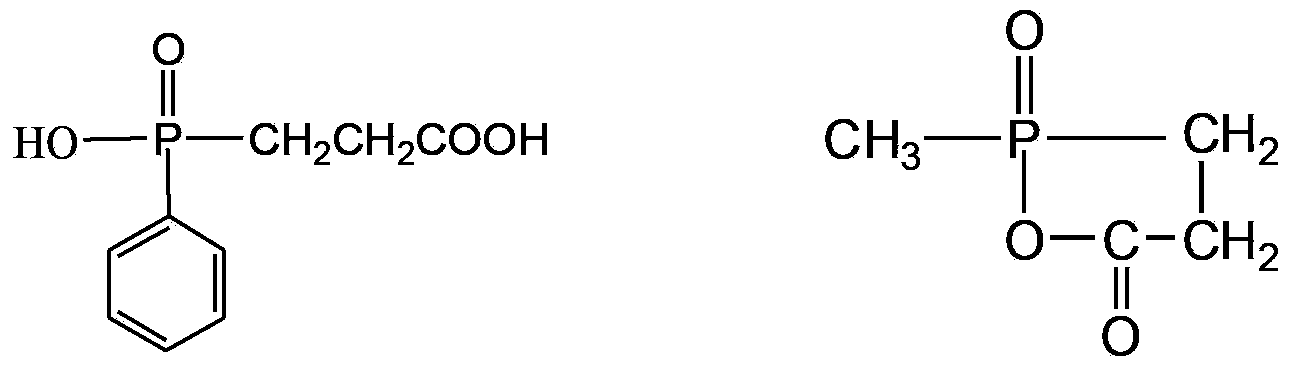

The invention belongs to the field of fiber preparation and relates to an inflaming retarding PBT (Polybutylene Terephthalate) fiber and a preparation method thereof. The inflaming retarding PBT fiber is prepared from the following components in parts by mass: 42-65 parts of terephthalic acid, 35-58 parts of butanediol, 0.008-1.3 parts of a catalyst, 0-0.5 part of a stabilizing agent, 5-10 parts of a phosphorus based flame retardant and 0.1-10 parts of an inorganic nano material. Compared with the prior art, the preparation method is simple and is easy to operate; a textile processed by the fiber has the advantages of good fire resistance, heat resistance, washing durability and the like; meanwhile, the phosphorus based flame retardant and the inorganic nano material are added to achieve a synergic inflaming retarding effect; the inorganic nano material is added so that polyester is good in spinnability, fiber forming property and heat stability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

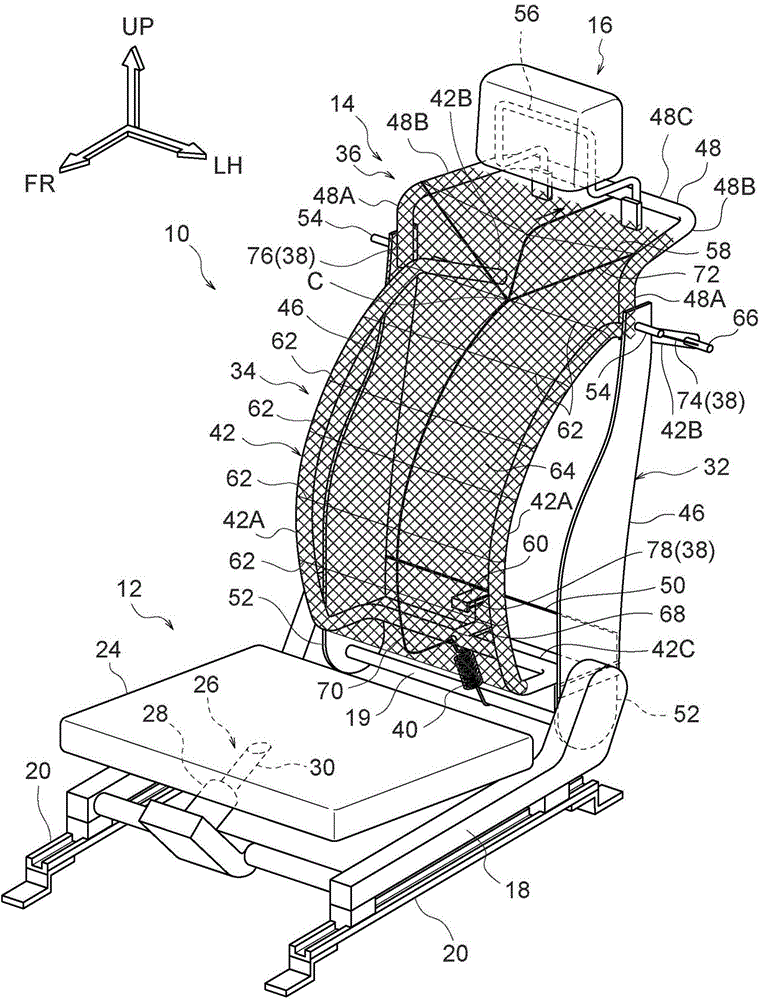

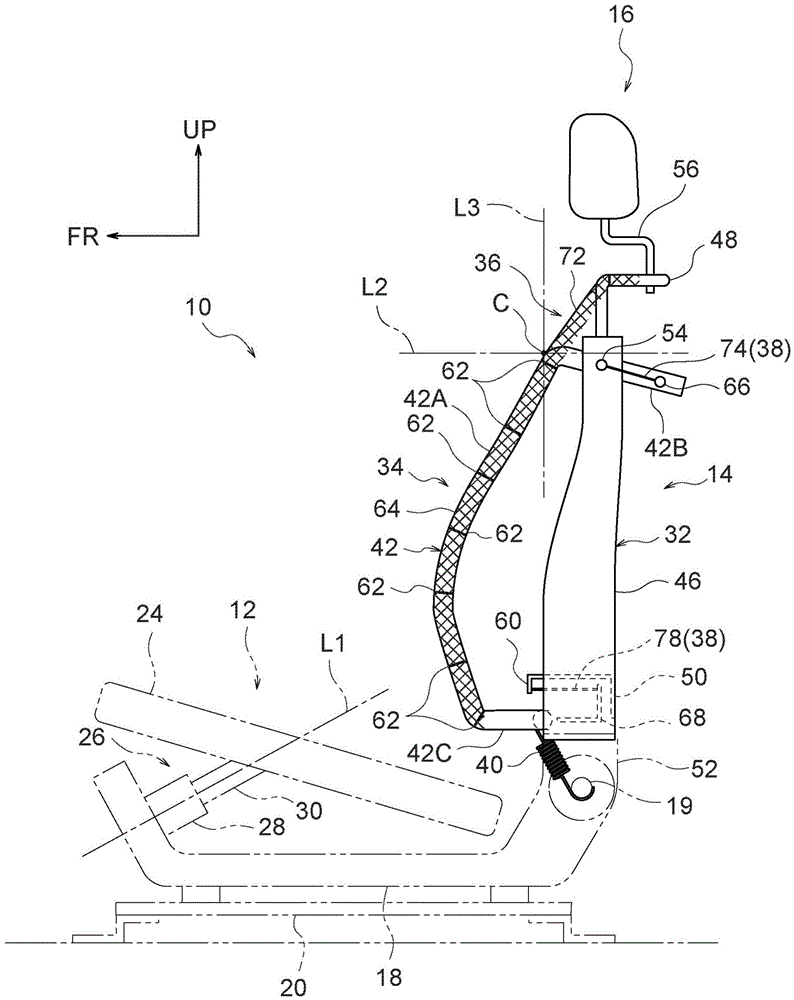

Vehicle seat

Owner:TOYOTA JIDOSHA KK

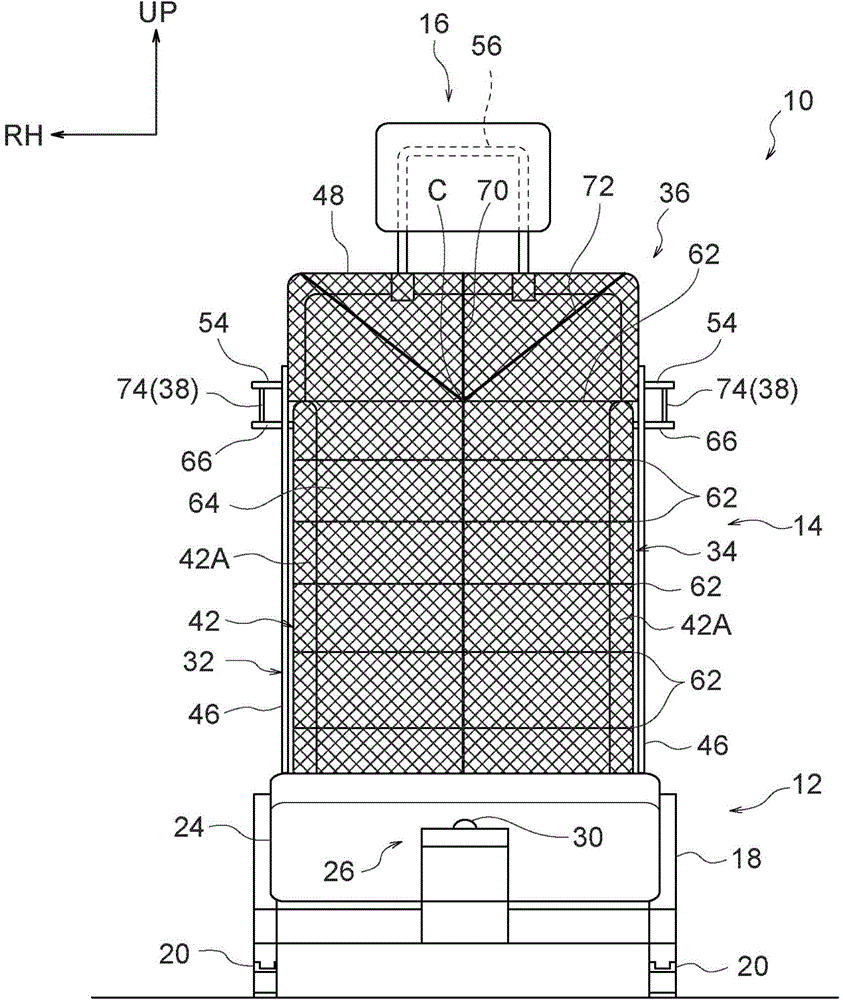

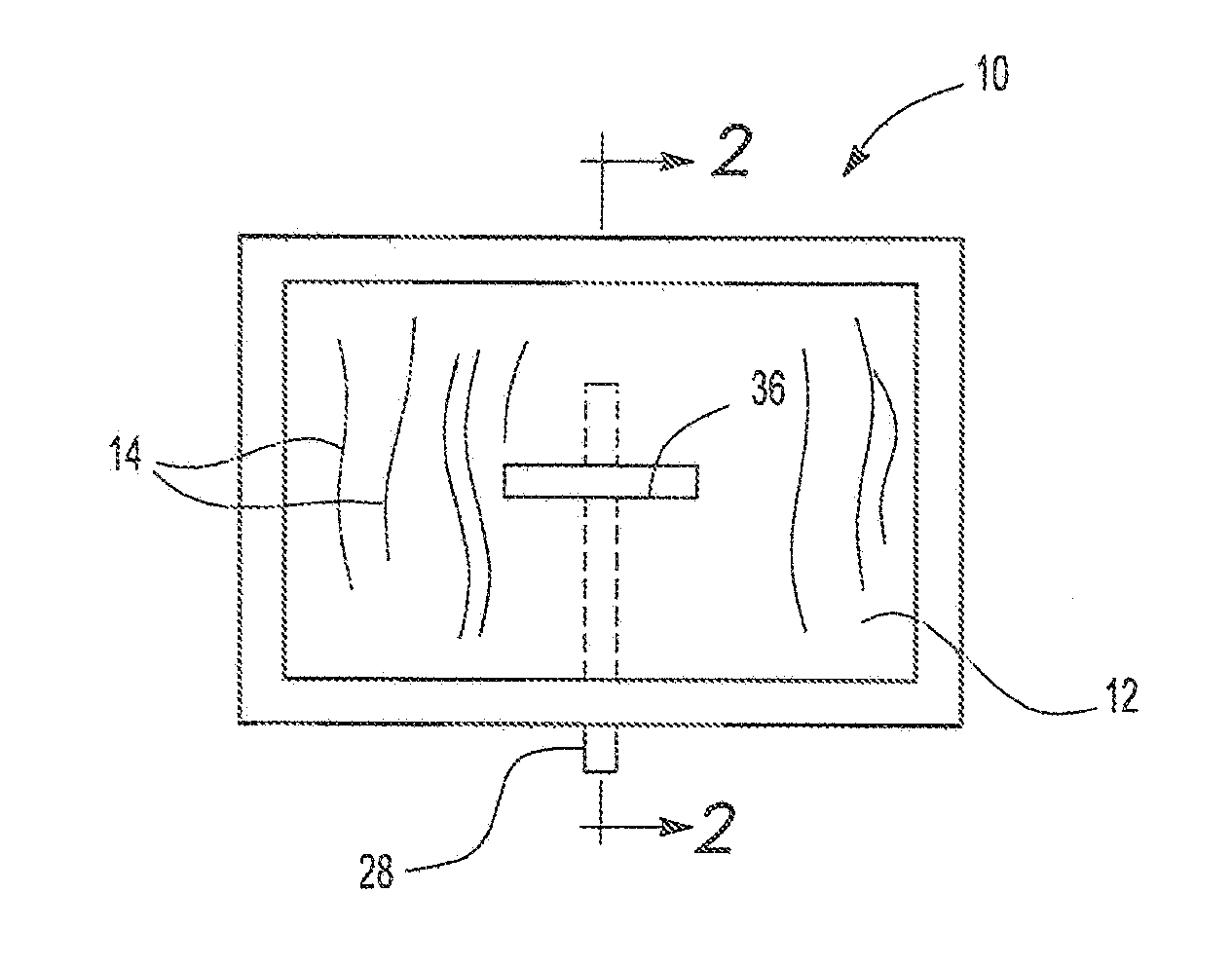

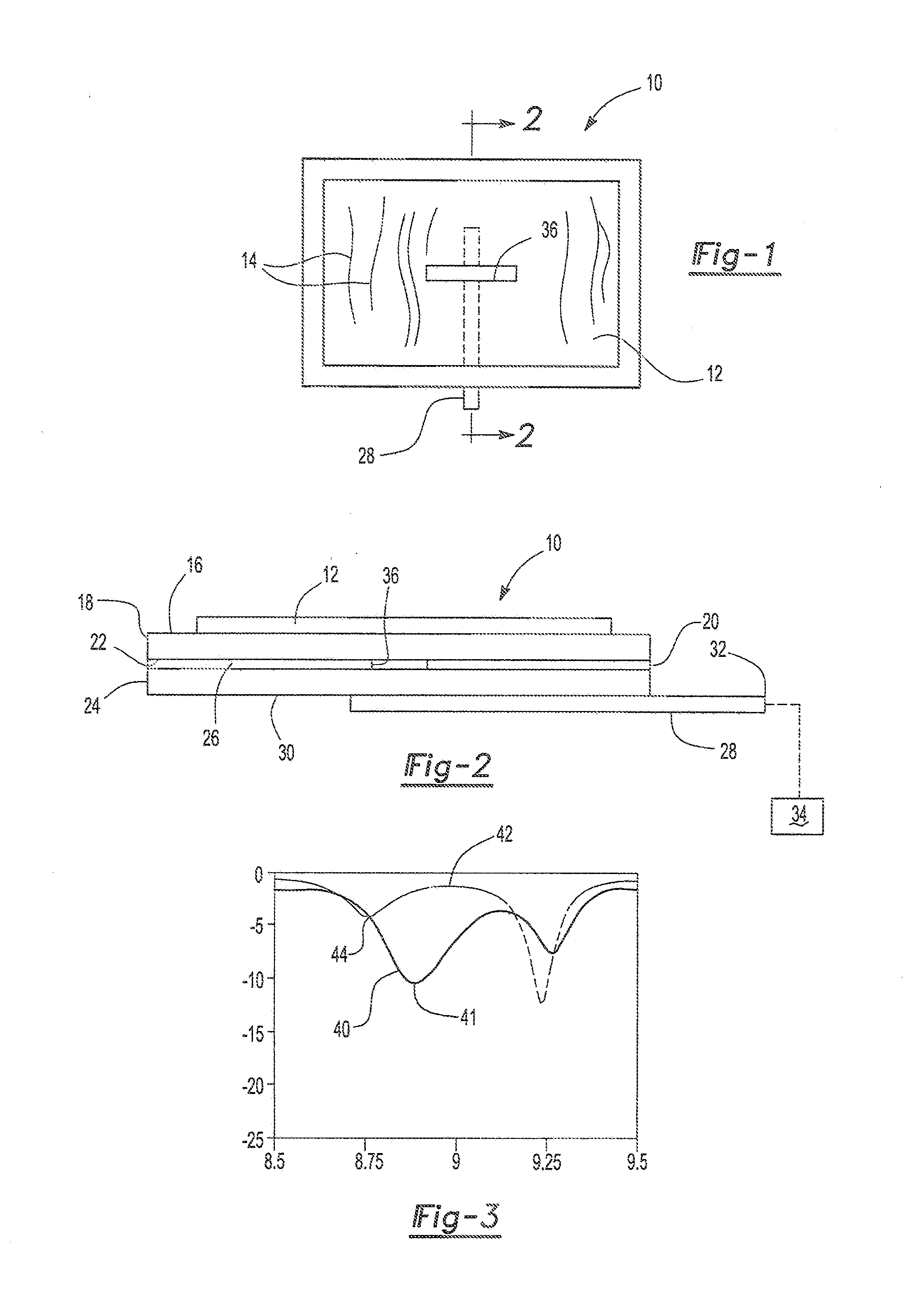

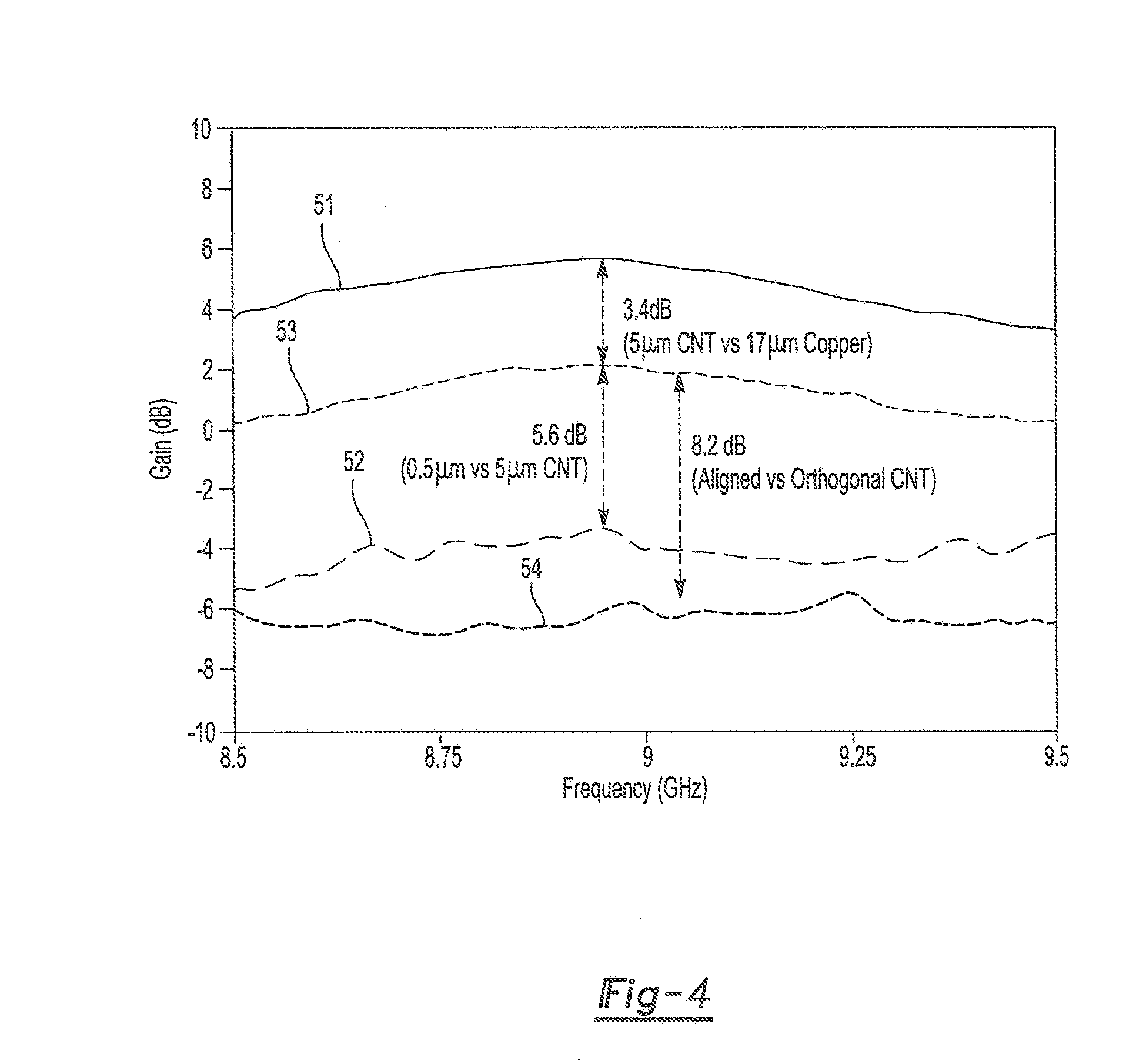

Radio frequency anisotropic patch antenna and polarization selective surface

ActiveUS20160126633A1Overcome rigidityImprove efficiencyNanoinformaticsAntenna detailsFiberCarbon nanotube

A radio frequency patch antenna having a radiator patch constructed of an anisotropic material, such as carbon nanotube sheet material. Such material is flexible so that the antenna may be wearable and / or integrated into a textile substrate. A feed line couples the radio signal to the patch. Furthermore, the efficiency of radiation from the patch is directly related to the orientation of the fibers or carbon nanotubes in the anisotropic material relative to the orientation of the feed line. Dual polarized radiators can be constructed from two orthogonal layers of CNT patches fed with correspondingly orthogonal feed lines.

Owner:US SEC THE ARMY THE

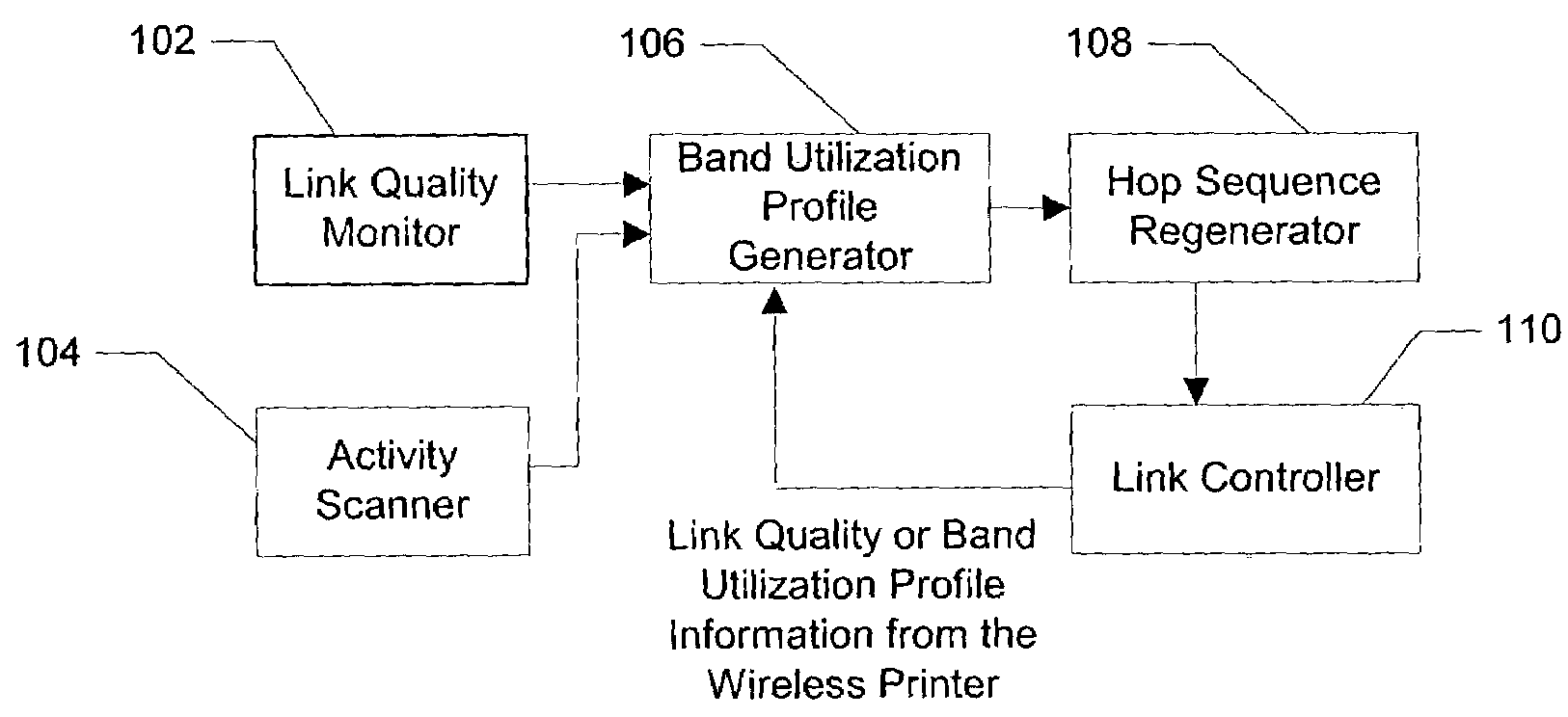

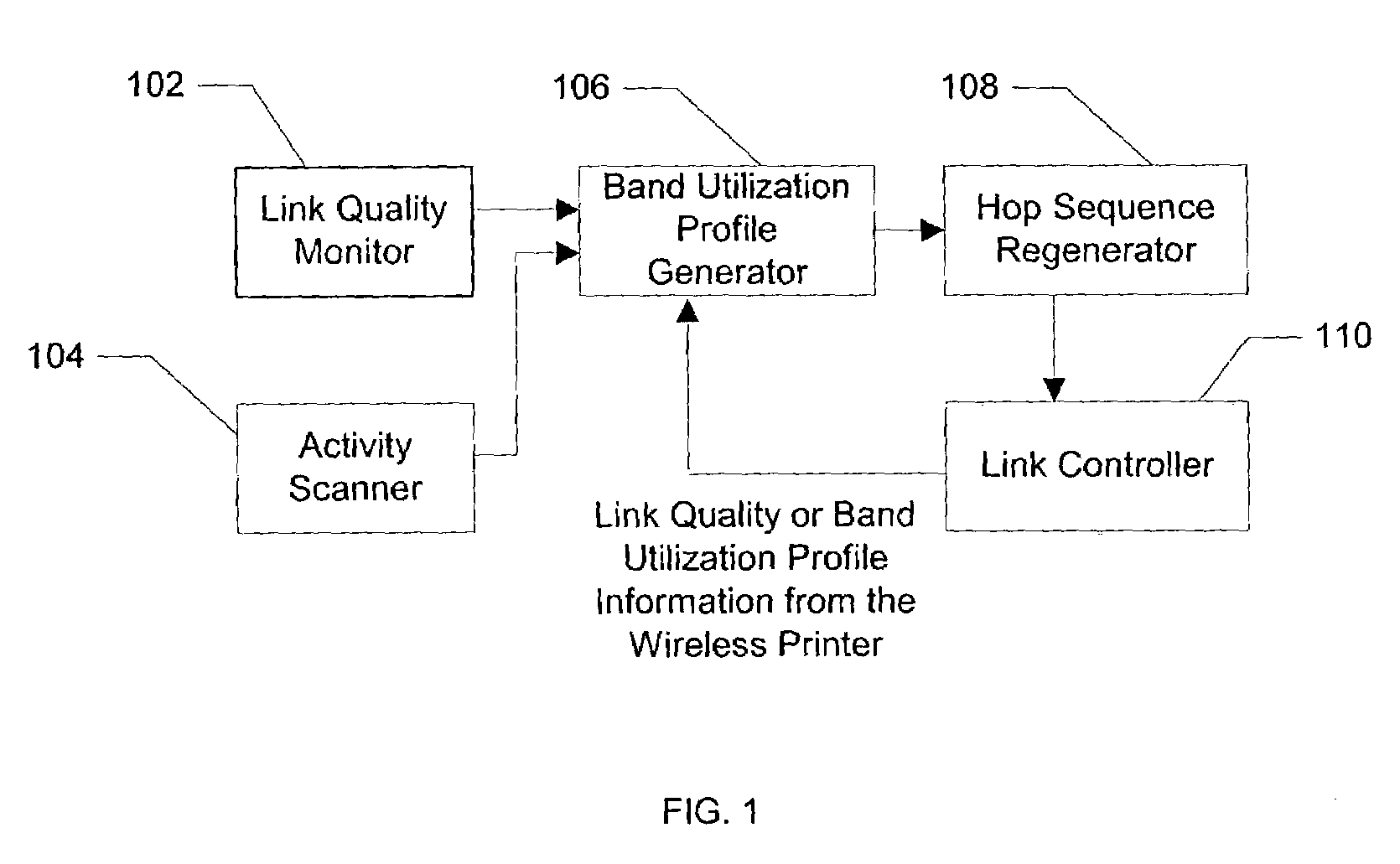

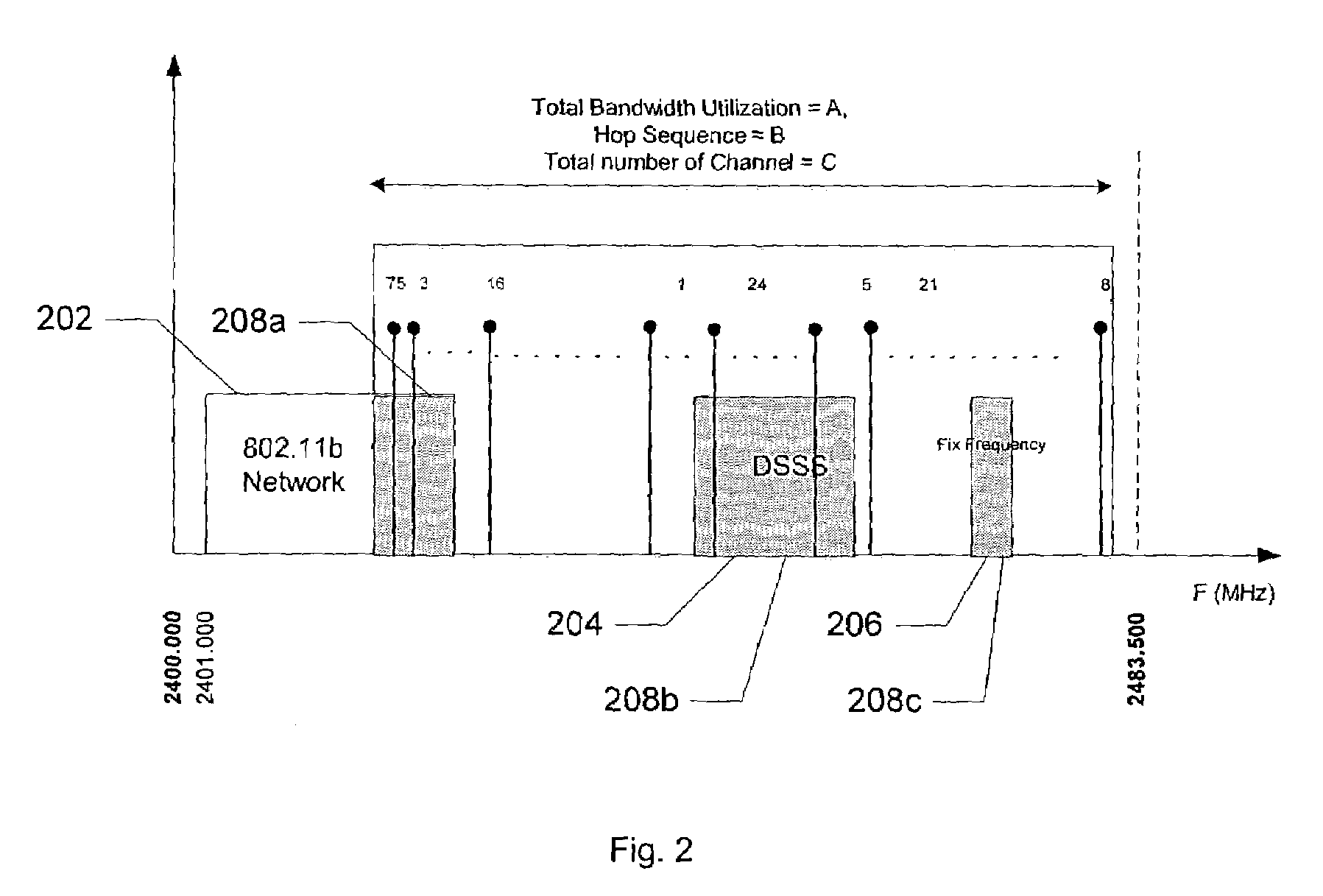

System and method for adaptive bandwidth utilization for interoperability

InactiveUS7610385B2Reduce distractionsImprove performanceError preventionTransmission systemsFrequency spectrumTelecommunications link

Bandwidth usage in a radio communication device is readjusted to eliminate overlapping communication system bandwidth. The readjustment is made in consideration of communication channel quality and other activity in the spectrum in which the radio communications are desired. Using this information, a communication link is set up to avoid overlapping with other radio communications already present in the band. Frequencies at which significant degradation in the communication occurs are also avoided. In addition, for frequency hopping devices, hop sequence is readjusted in accordance with the newly assigned channels.

Owner:VTECH TELECOMM

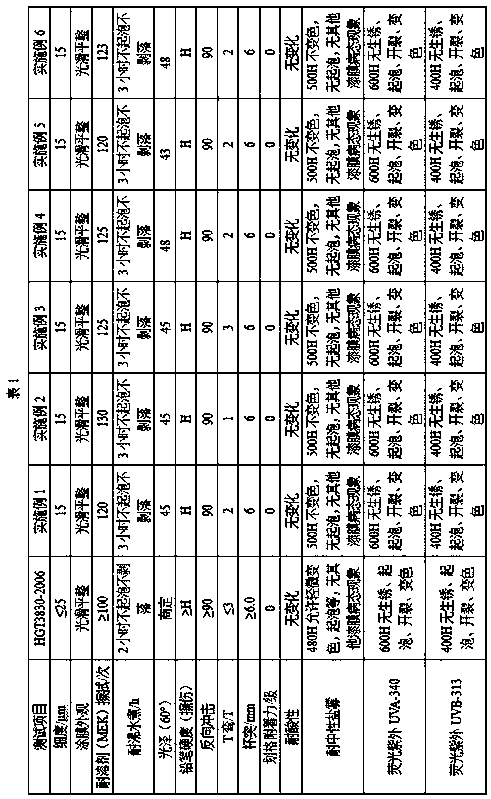

Finishing coat of waterborne coiled steel coating and preparation method of finishing coat

ActiveCN109468029AGood flexibilityOvercome resilienceAnti-corrosive paintsPolyester coatingsSolvent basedPolyester resin

The invention relates to the field of waterborne coatings and particularly discloses a finishing coat of a waterborne coiled steel coating and a preparation method of the finishing coat, wherein the finishing coat of the waterborne coiled steel coating comprises the following components: a waterborne polyester resin, a rust-proof sizing agent, an amino resin, an acid catalyst, a wetting agent, a levelling agent, a defoamer, an adhesion promoter, a wetting dispersant, an anti-settling agent, a PH regulator, a cosolvent and water. the provided finishing coat of the coiled steel coating is a waterborne product, the VOC (volatile organic compounds) content is very low, the environment pollution is small, the performance of a T-bend is greatly improved, the T-bend does not crack in winter and is anti-sticking in summer, and the physical and mechanical properties equivalent to those of the solvent based coating are achieved.

Owner:南通科顺建筑新材料有限公司

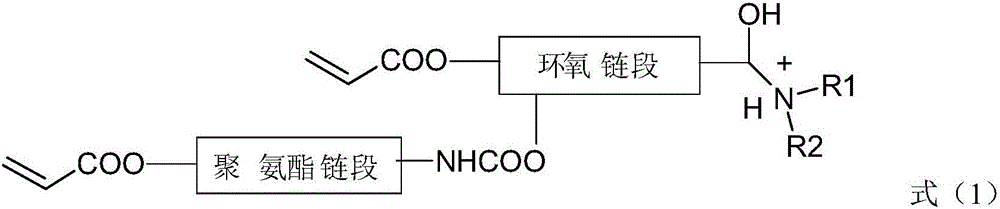

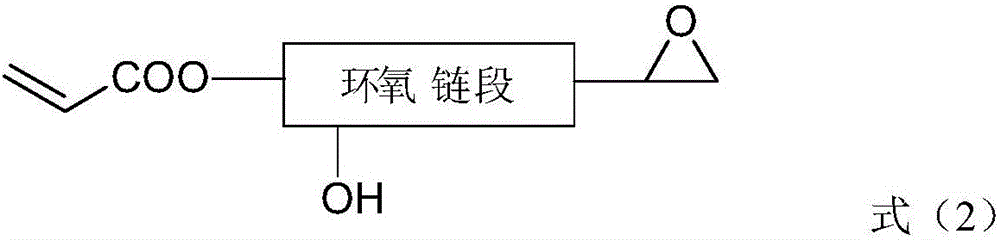

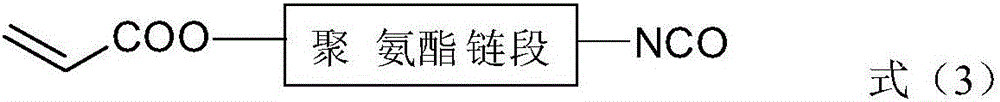

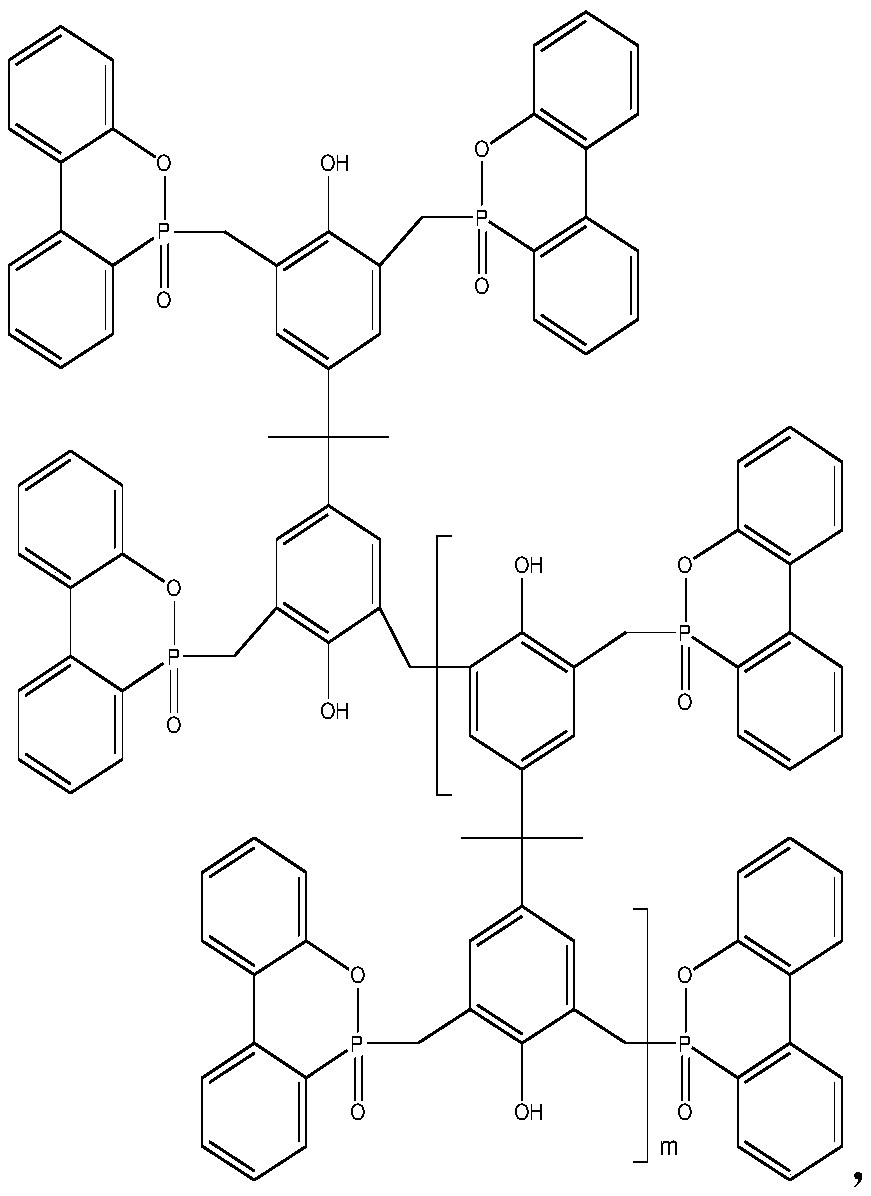

Polyurethane acrylate modified ultraviolet light cured water-dilutable resin and preparation method thereof

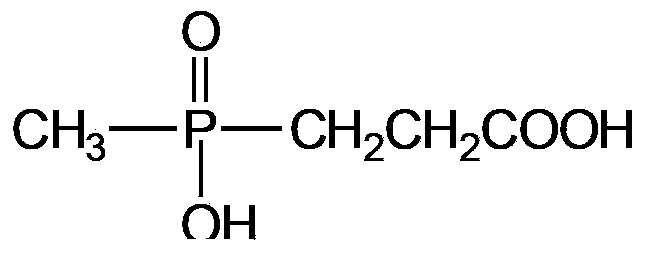

The invention provides polyurethane acrylate modified ultraviolet light cured water-dilutable resin and a preparation method thereof.The structure of the polyurethane acrylate modified ultraviolet light cured water-dilutable resin is shown in the formula (1), wherein R1 represents CH3 or CH2CH3 or CH2CH2OH or CH2CH2CH3 or CH2CH2CH2CH3, and R2 represents CH3 or CH2CH3 or CH2CH2OH or CH2CH2CH3 or CH2CH2CH2CH3.According to the technical scheme, the resin structure is provided with a polyurethane flexible chain segment and an epoxy rigid chain segment, a cured film has good abrasion resistance and hardness, and the after-curing hardness is H or above; meanwhile, curing can be conducted by means of ultraviolet light, and use is more convenient; water can serve as a diluent, and the toxicity and irritation of a system are reduced.

Owner:SHENZHEN POLYTECHNIC

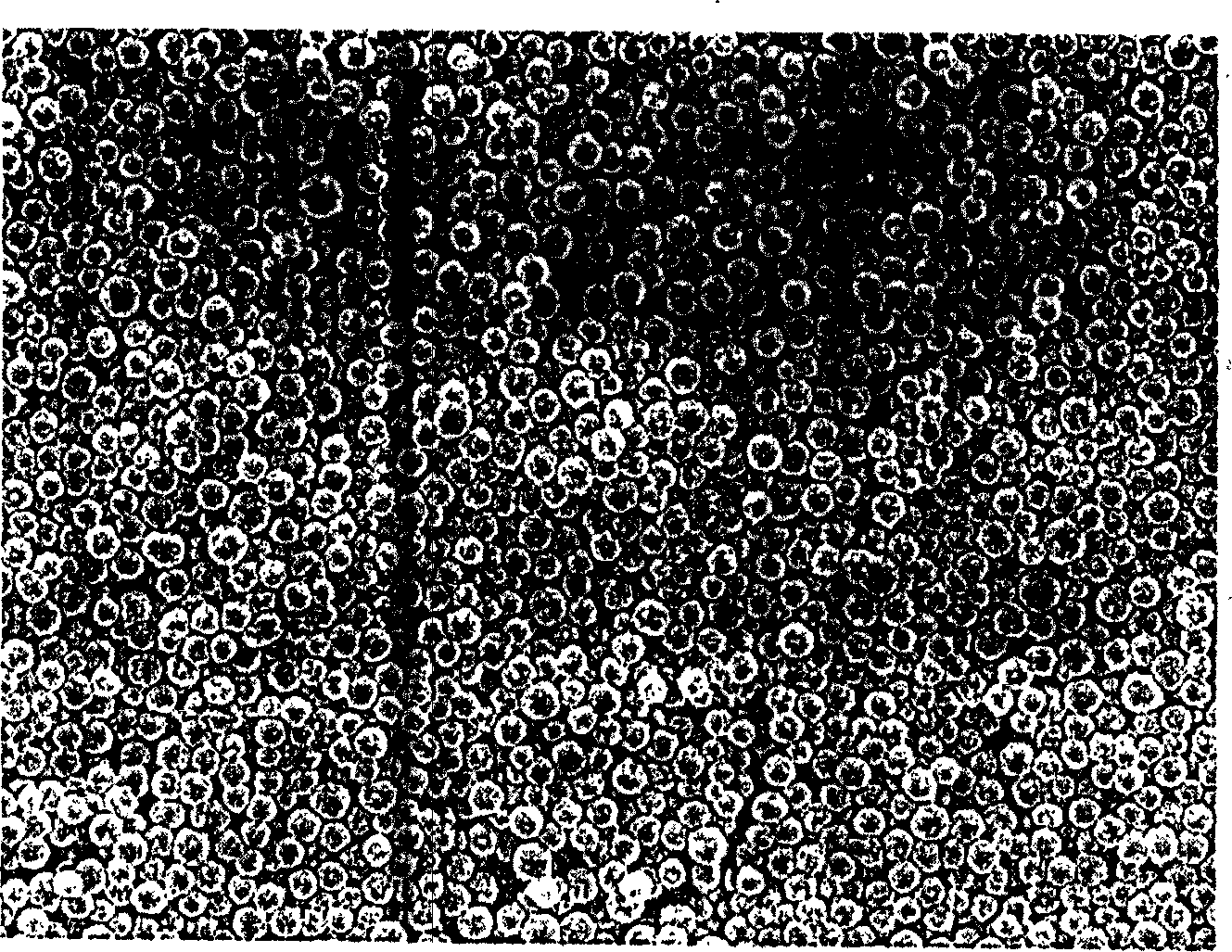

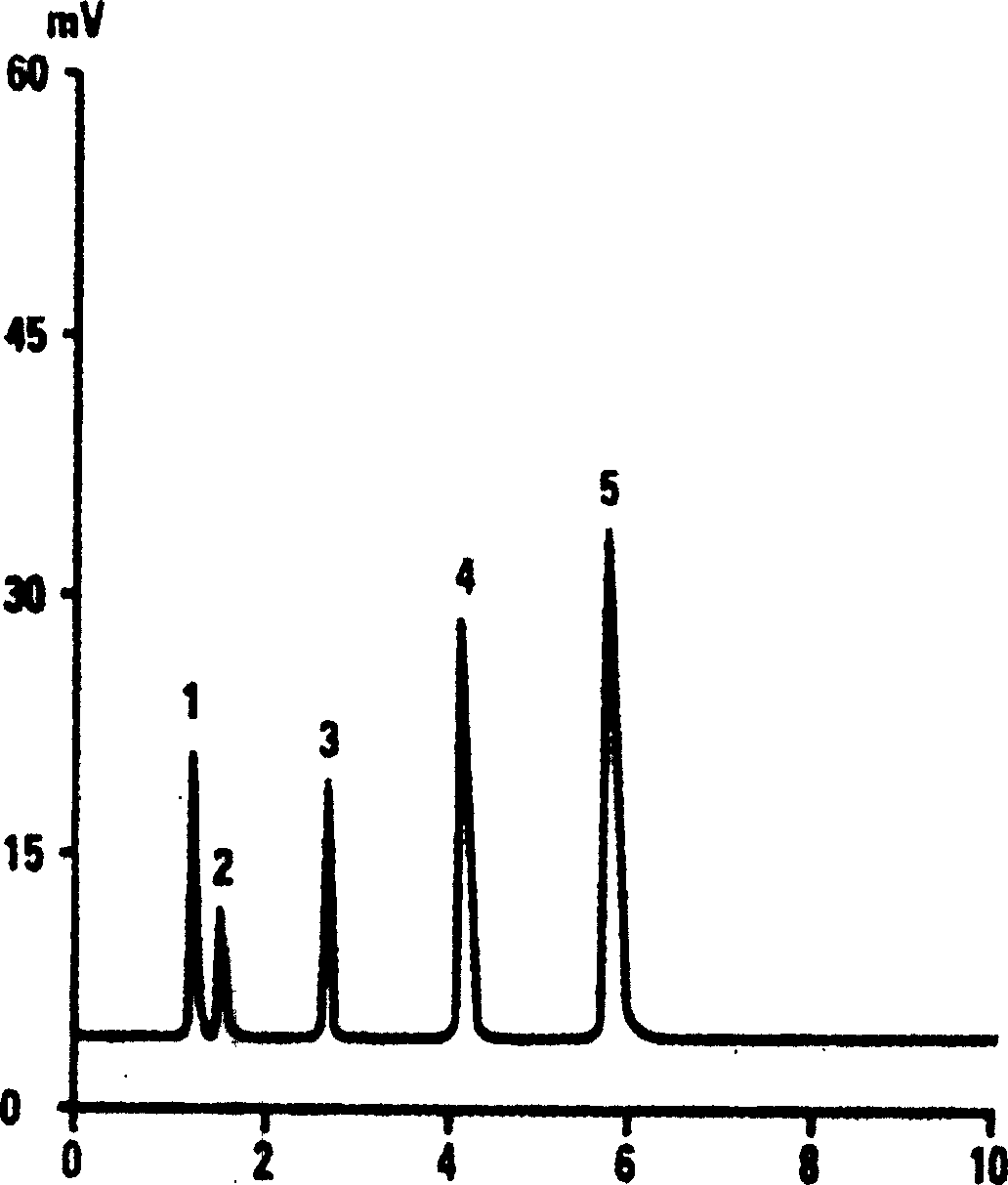

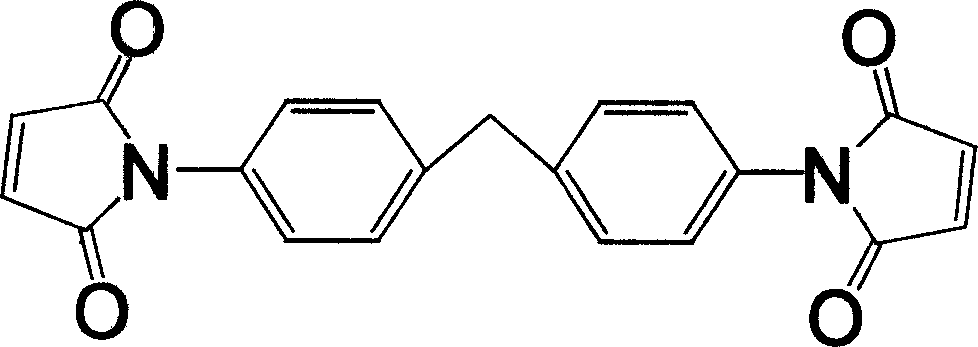

Dimaleimide resin microball, its preparation method and application thereof

InactiveCN1624042AEasy to wash cleanOvercoming heat resistanceComponent separationOrganic solventMicrosphere

A kind of bimaleimide resin micropheres used as the ideal liquid-phase chromatographic filler is prepared through proportionally mixing the prepolymer of bimaleimide resin, inertial thermoplastic resin, and optional allylbiphenol A, moulding, solidifying at 150-180 deg.C for 2-5 hr and then at 180-250 deg.C for 2-8 hr, and washing with organic solvent for removing inertial thermoplastic resin.

Owner:桂林电子工业学院

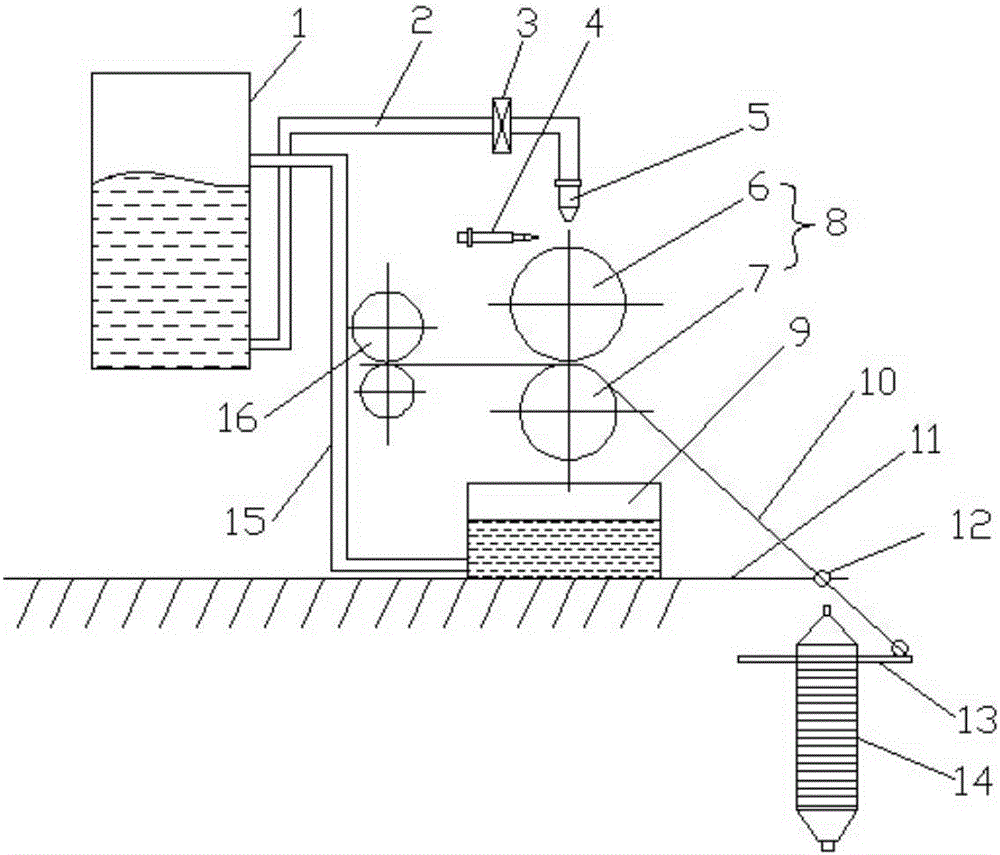

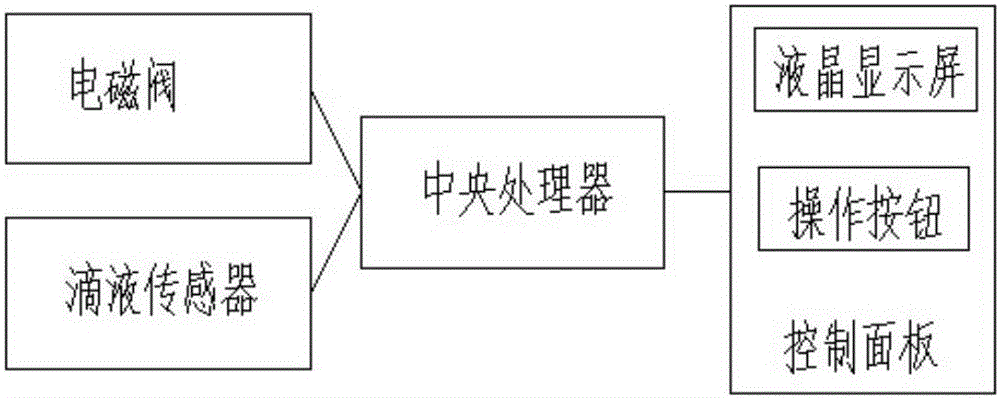

Spinning device adopting moistening method and spinning technology adopting moistening method

The invention provides a spinning device adopting a moistening method and a spinning technology adopting the moistening method, and belongs to the field of textile industry. The spinning device and the spinning technology are used for improving strength and softness of spun yarns, and reducing spun yarn hairiness. The spinning device adopting the moistening method comprises upper drafting rollers, lower drafting rollers, guide wires, bead rings, spinning spindles and a fiber moistening device. The spinning technology adopting the moistening method comprises the steps that 1, a water tank is placed below the lower drafting rollers, and liquid dropping heads of a liquid dropping device are installed above the upper drafting rollers; 2, an operating button on an operating control panel enables size or water to drop from the liquid dropping heads; 3, fibers to be spun penetrate through gaps between the upper drafting rollers and the lower drafting rollers, and the size or the water adhering to the surfaces of the upper drafting rollers moistens the fibers passing through the portion below the upper drafting rollers along with rotating of the upper drafting rollers; 4, the moistened fibers are spun into yarns under rotating of the spinning spindles, and the yarns are wound around the spinning spindles after penetrating through the guide wires and the bead rings.

Owner:WUHAN TONGZHIXIN TECH DEV

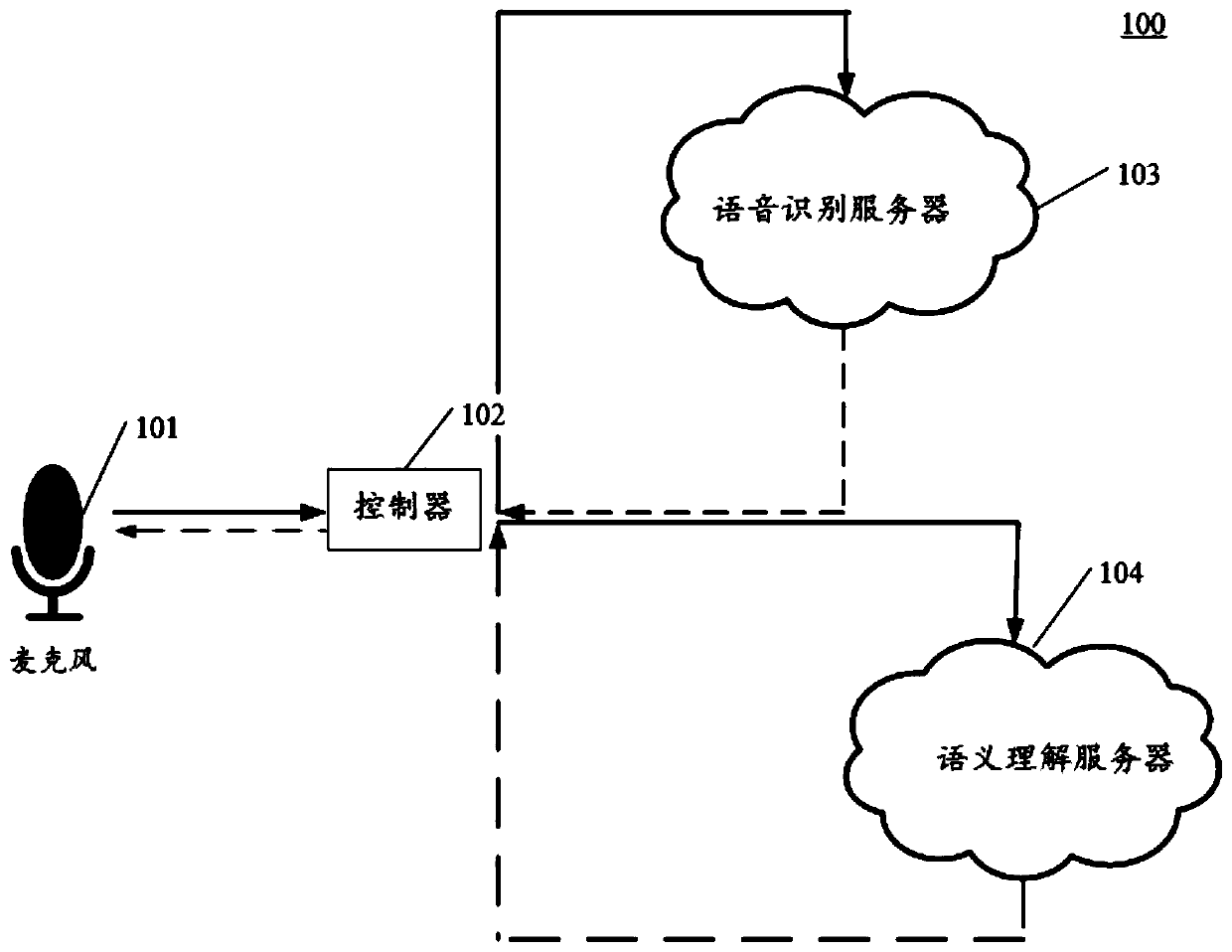

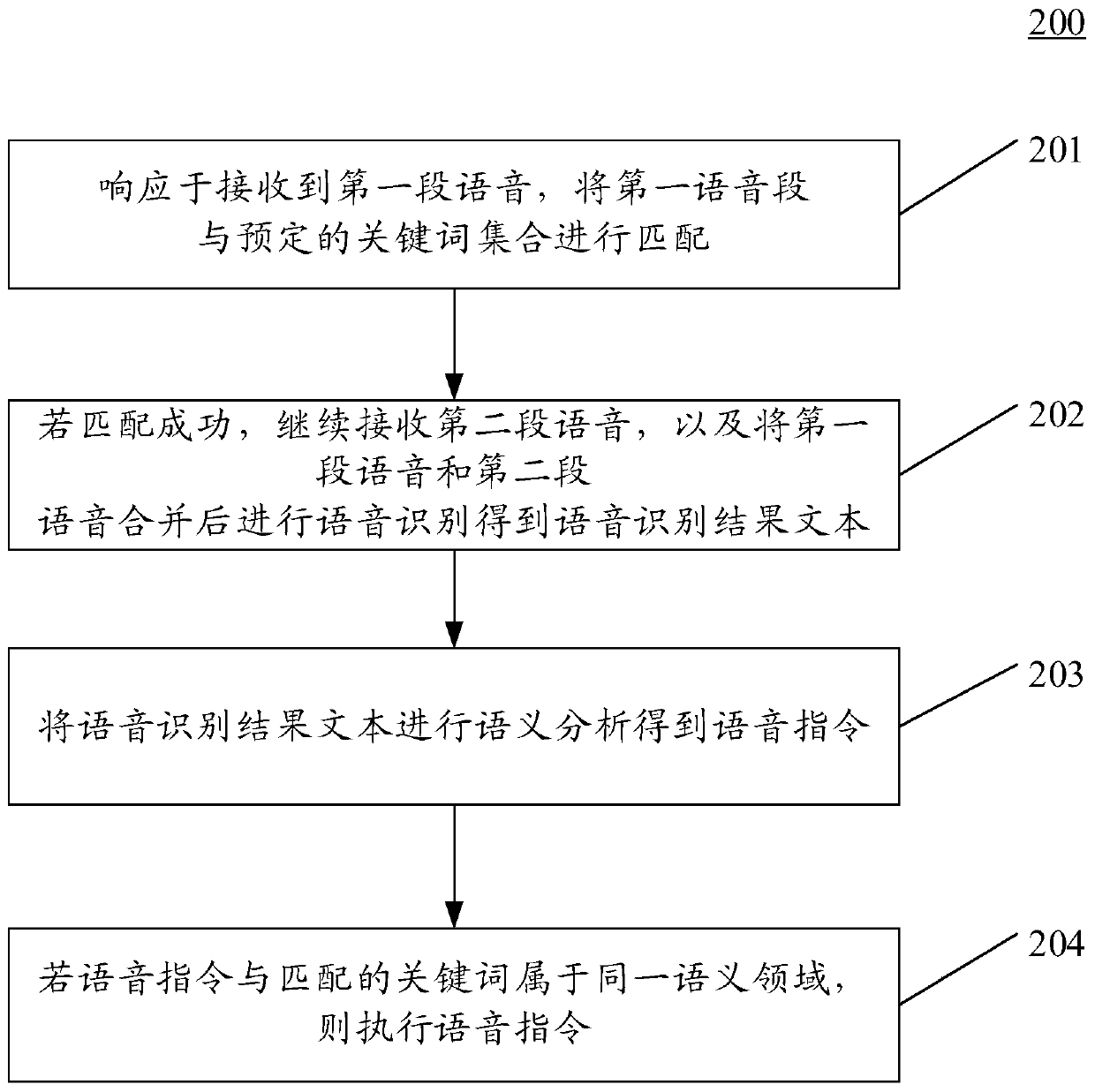

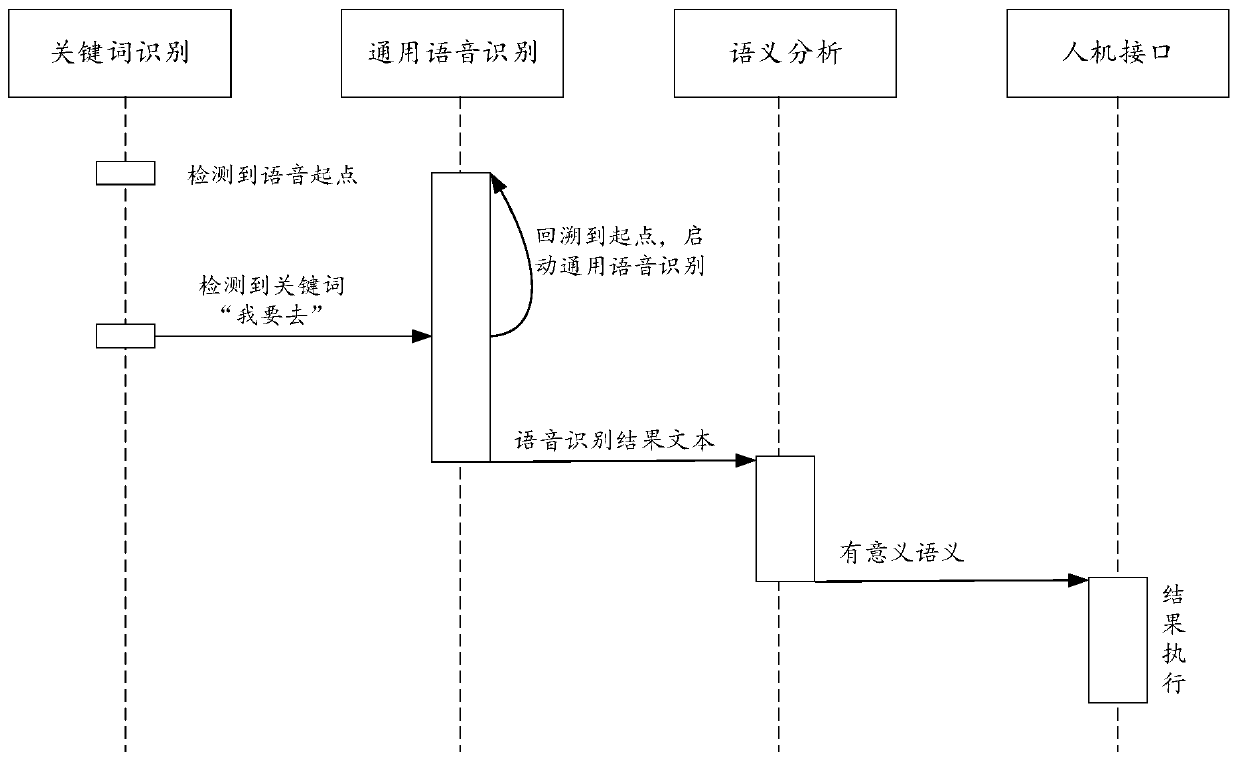

Method and device for speech recognition

ActiveCN110047481AAvoid dullnessOvercome rigiditySpeech recognitionSpeech synthesisSemanticsSpeech sound

The embodiment of the invention discloses a method and device for speech recognition. The method comprises the specific steps that in response to reception of a first section of speech, the first section of speech is matched with a preset keyword set; if matching is successful, a second section of speech continues to be received, and the first section of speech and the second section of speech arecombined for speech recognition to obtain a speech recognition result text; semantic analysis is carried out on the speech recognition result text to obtain a speech command; if the speech command and the matched keyword belong to a same semantic field, the speech command is executed. According to the method and device for the speech recognition, the traditional speech interaction action needingto be completed twice can be reduced to one time. The speech recognition process is combined with the semantics, thereby effectively suppressing false triggering.

Owner:APOLLO INTELLIGENT CONNECTIVITY (BEIJING) TECH CO LTD

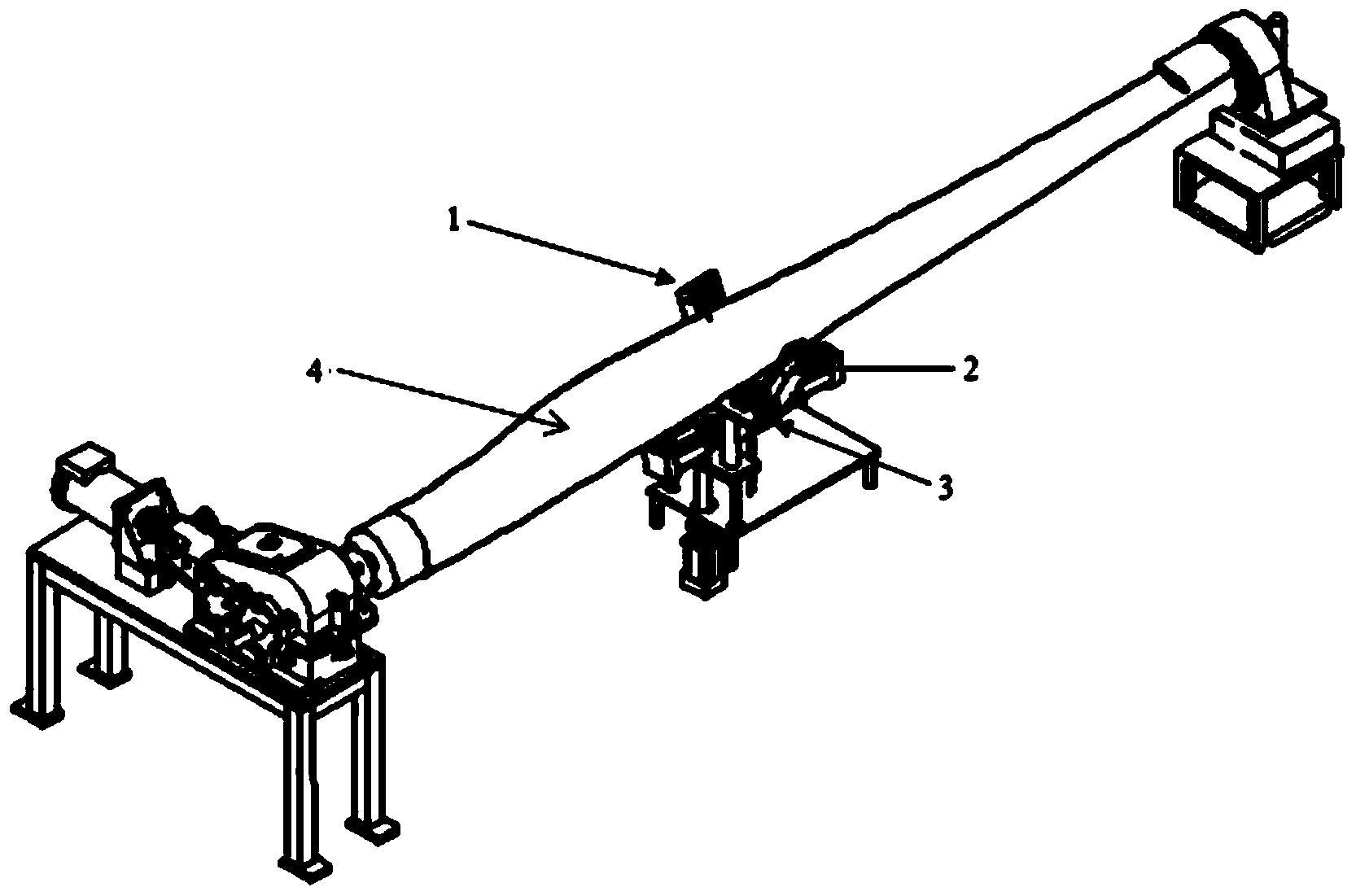

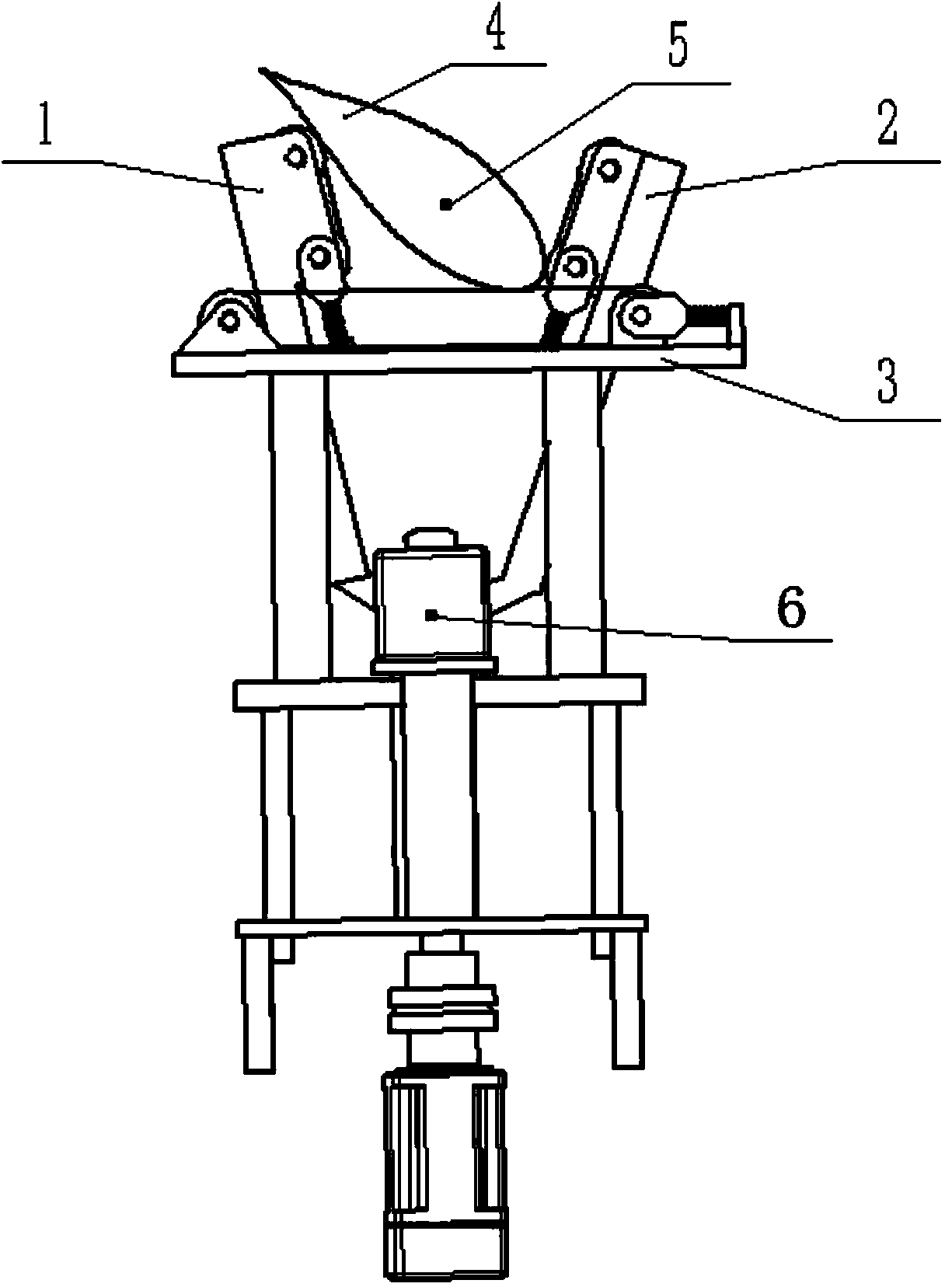

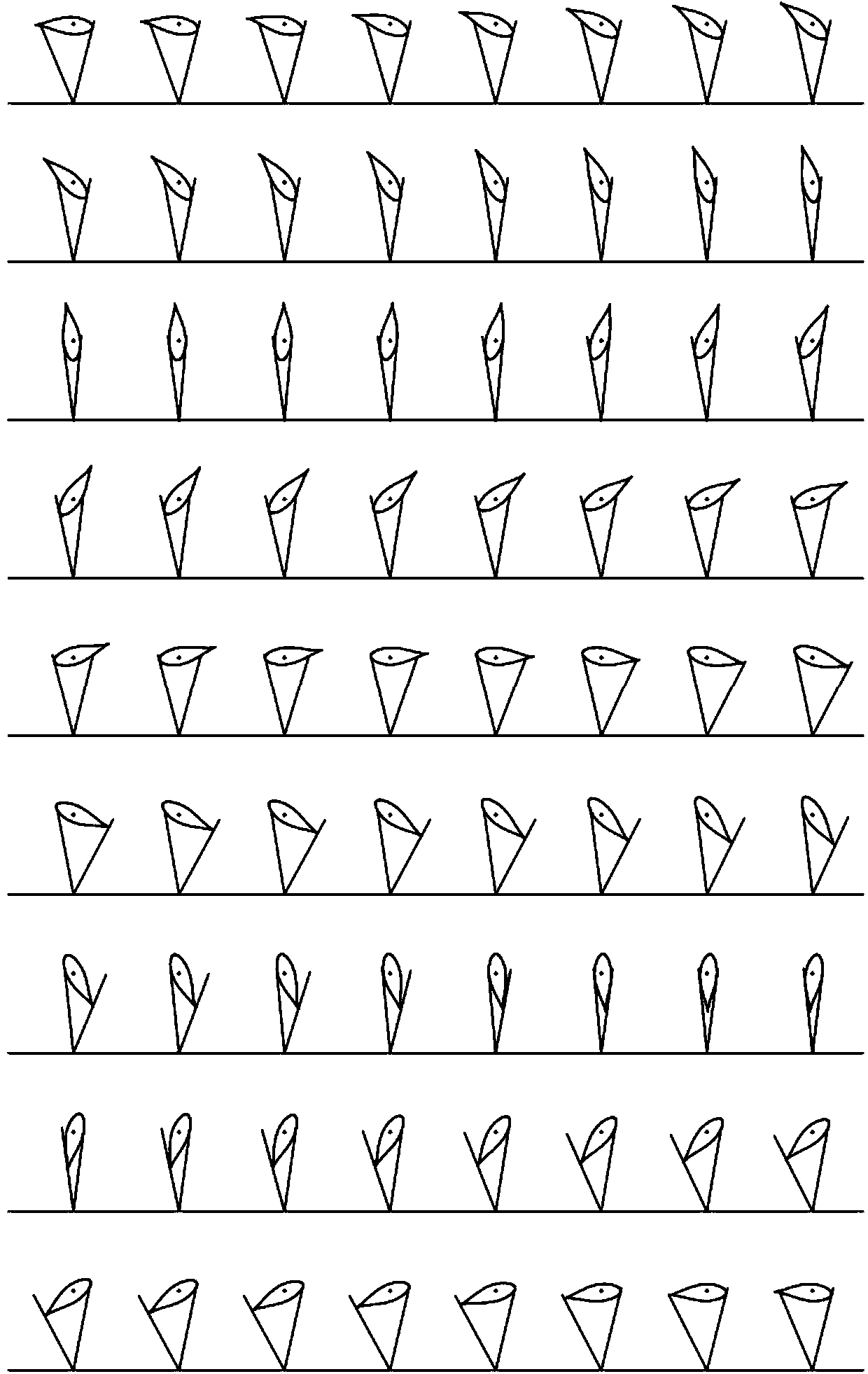

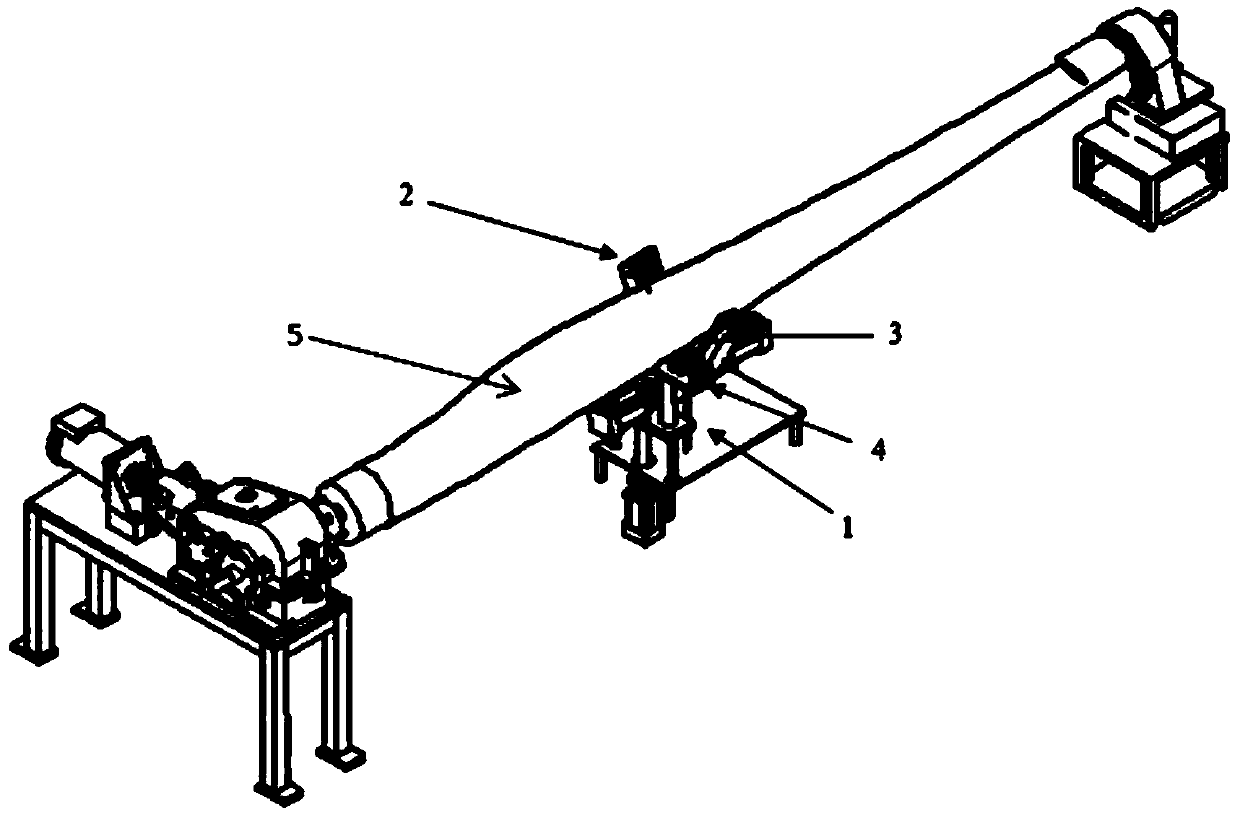

Motion controlling method for middle support device in process of forming large-scale wind turbine blade

The invention belongs to the technical field of machinery and in particular relates to a motion controlling method for a middle support device in a process of forming a large-scale wind turbine blade. Through the method, a left support plate, a right support plate and a middle support plate moves to corresponding positions along with a blade support section when the blade rotates at an angle of delta around a rotation center, so that the automatic control during forming of the blade is realized. The method comprises a method for controlling the left support plate and the right support plate and a method for controlling the middle support plate. The motion controlling method is a key technology for manufacturing large-scale wind turbine blade winding forming equipment and can be popularized in the process of forming non-rotational weak rigidity parts such as helicopter propeller blades and turn-milling machining centers to assist in motion control on support mechanisms.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

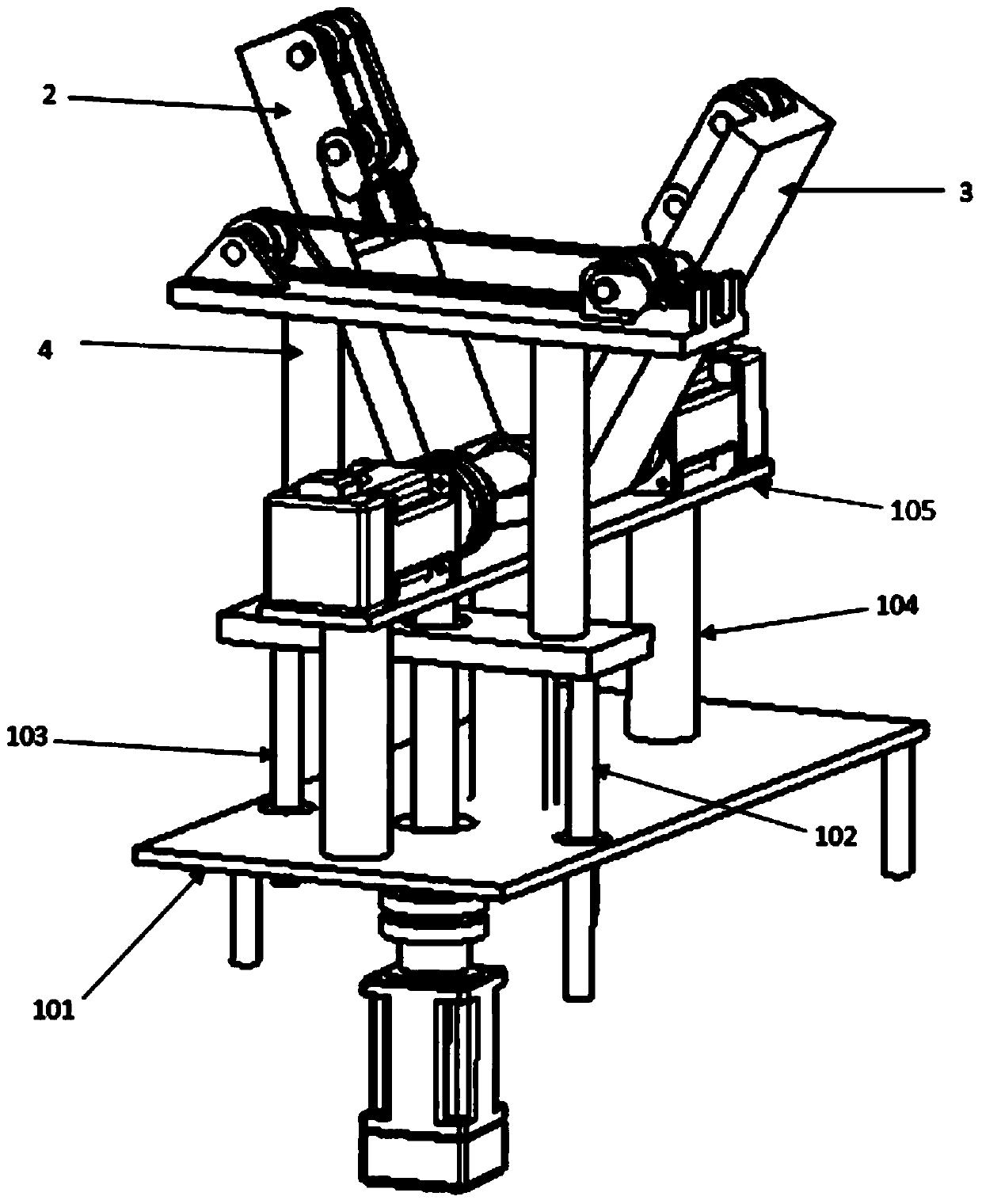

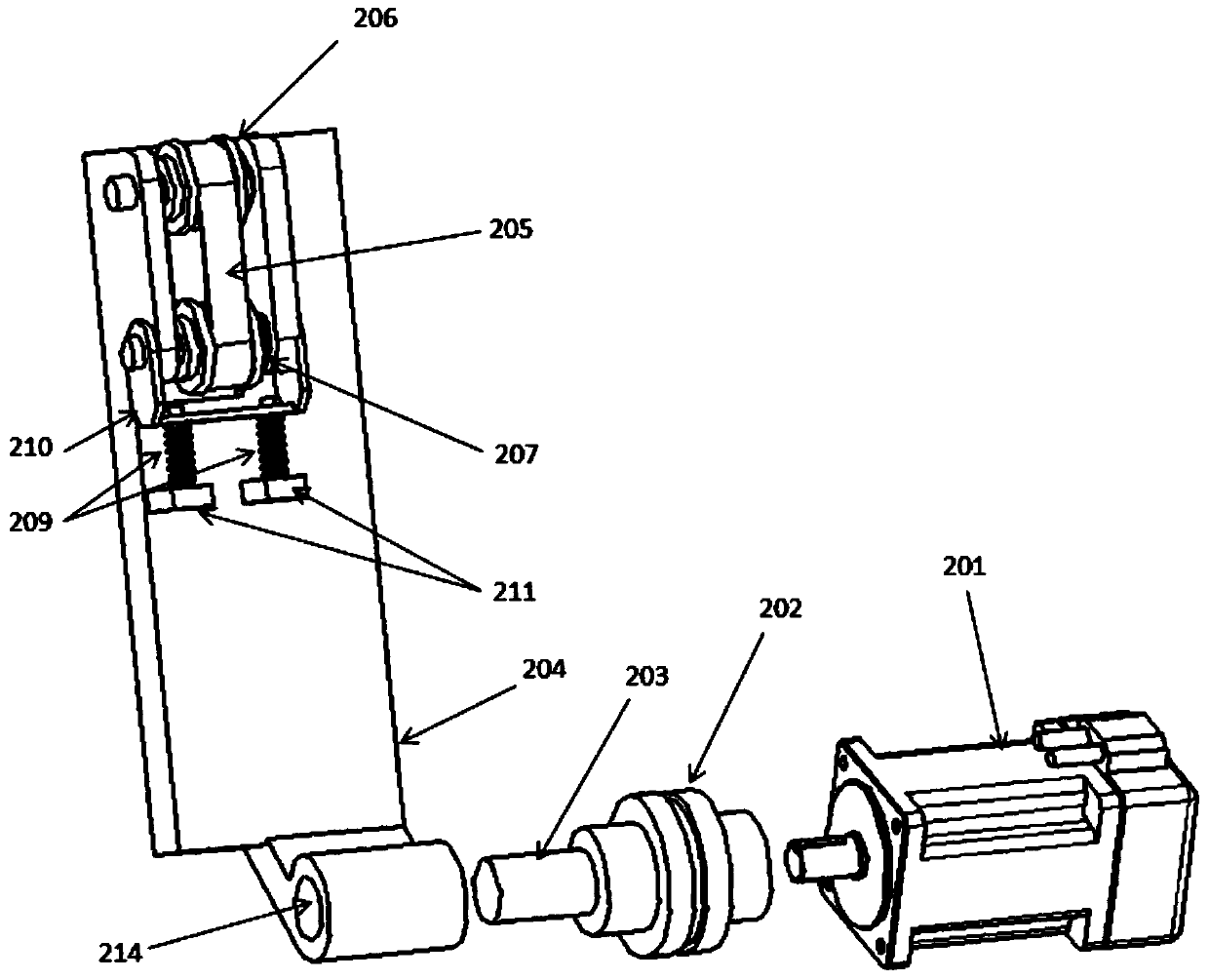

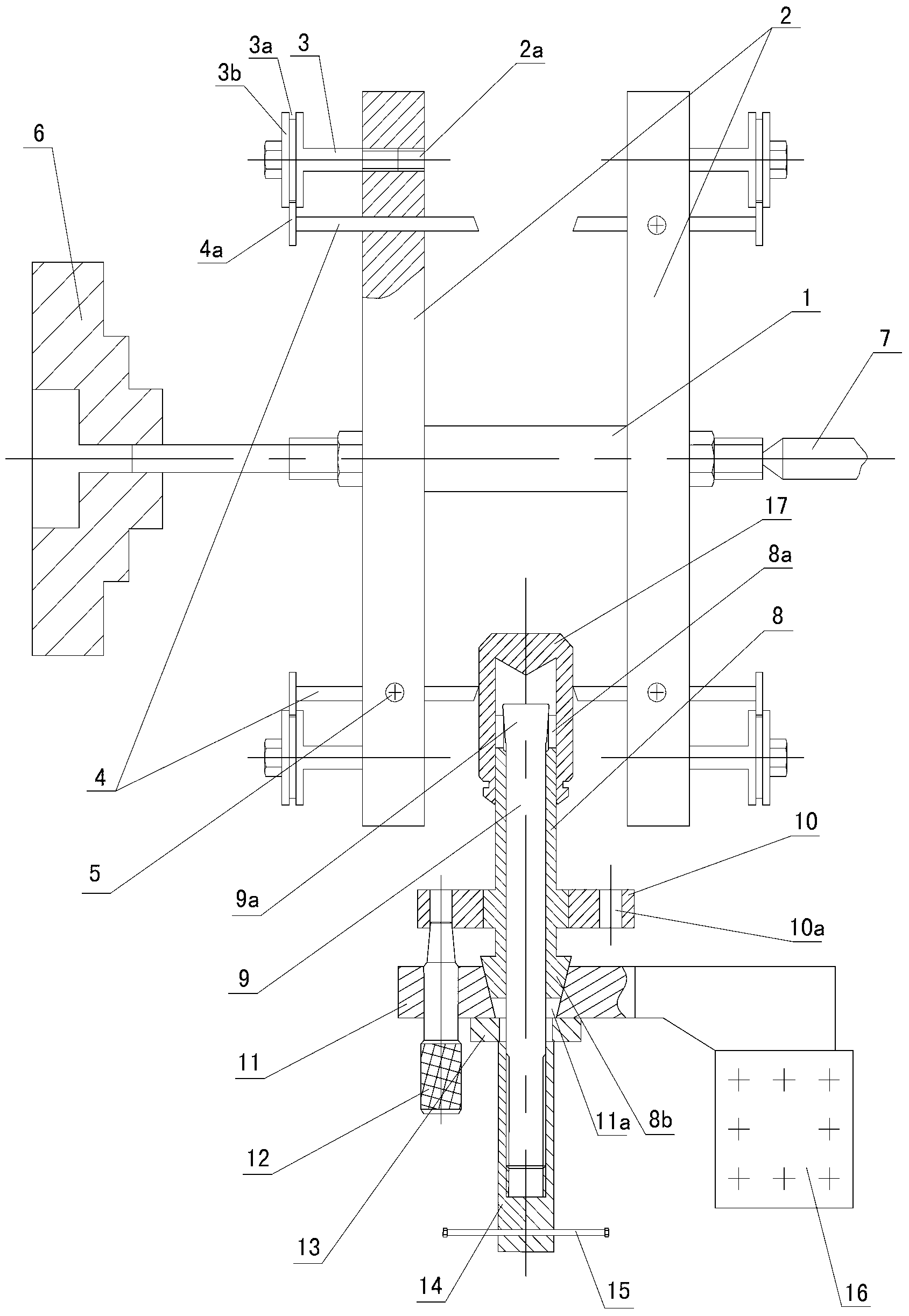

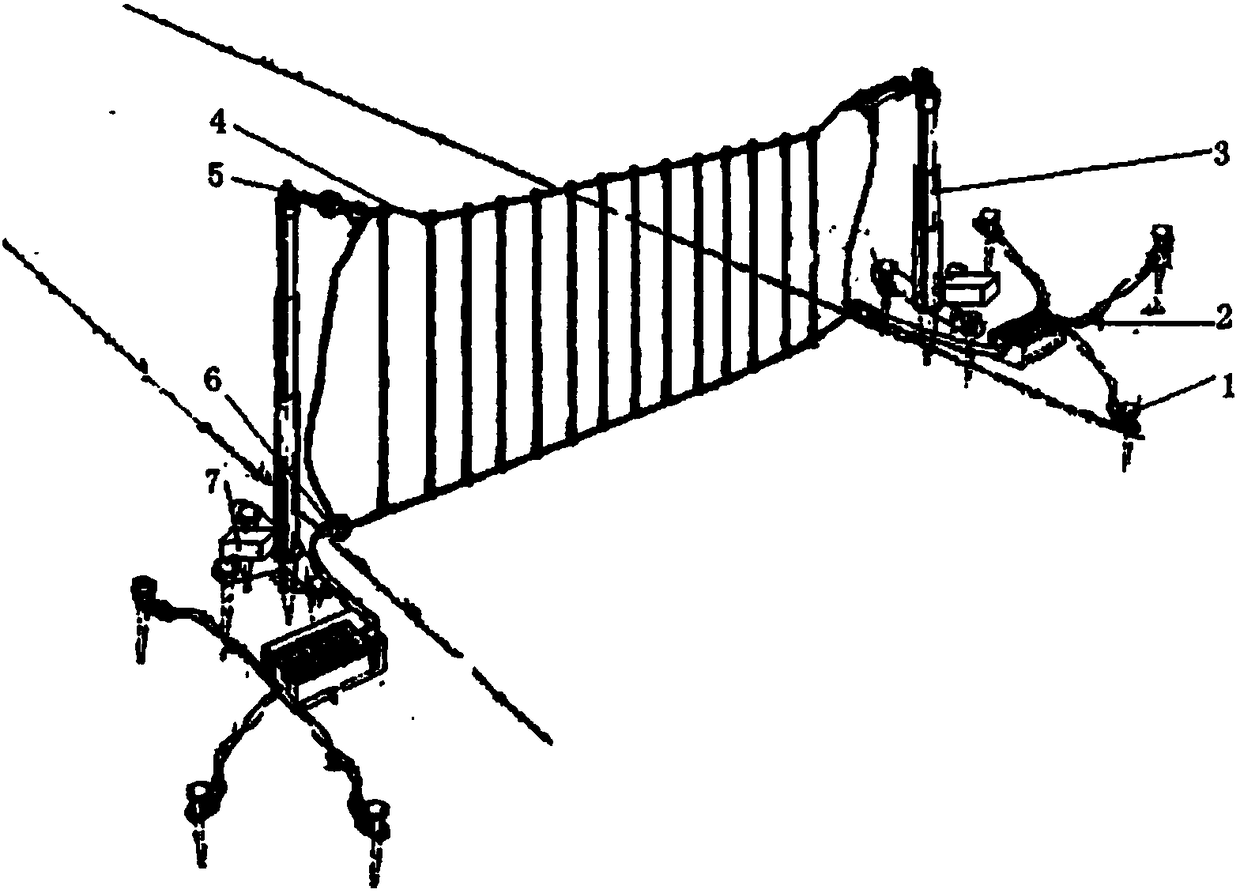

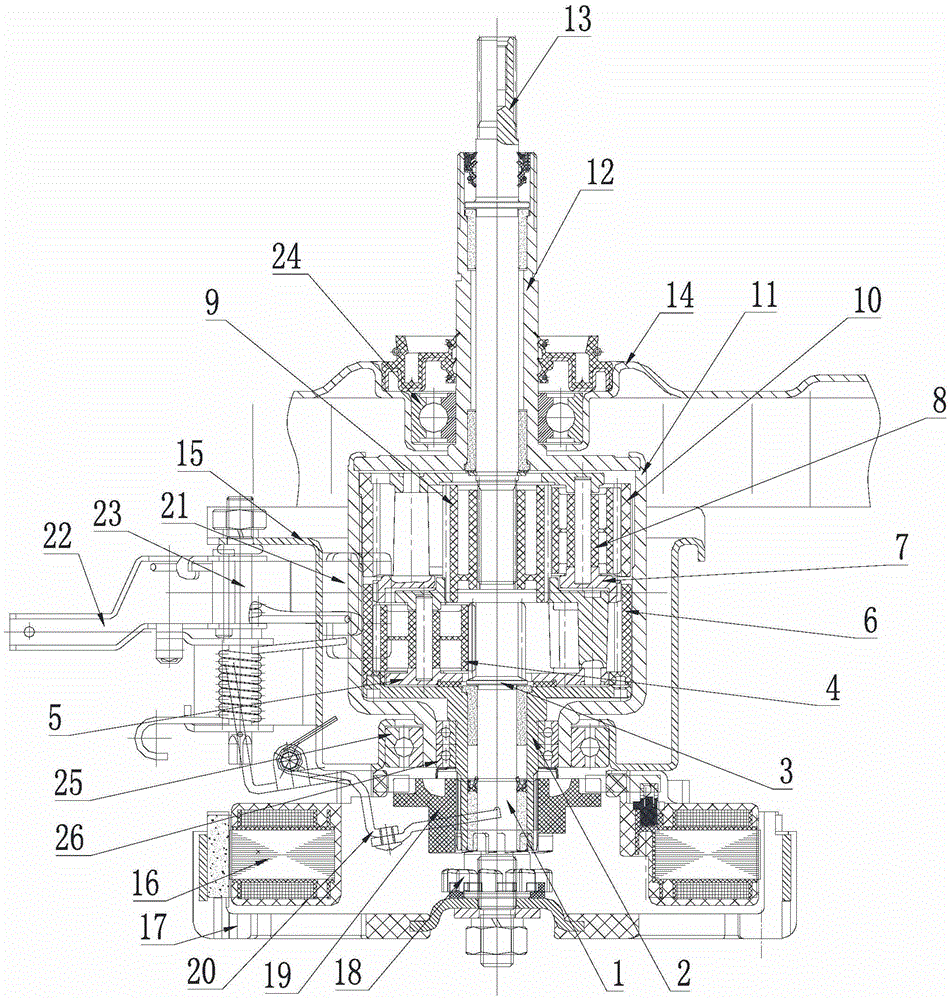

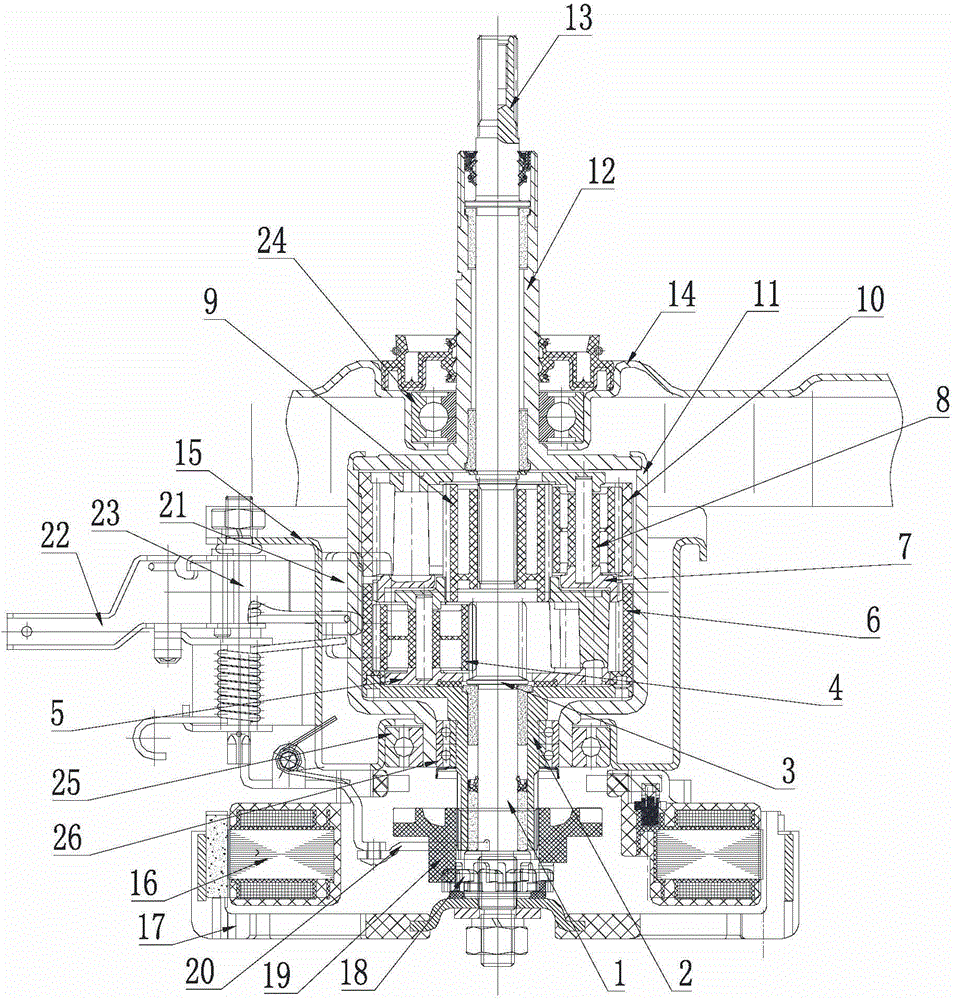

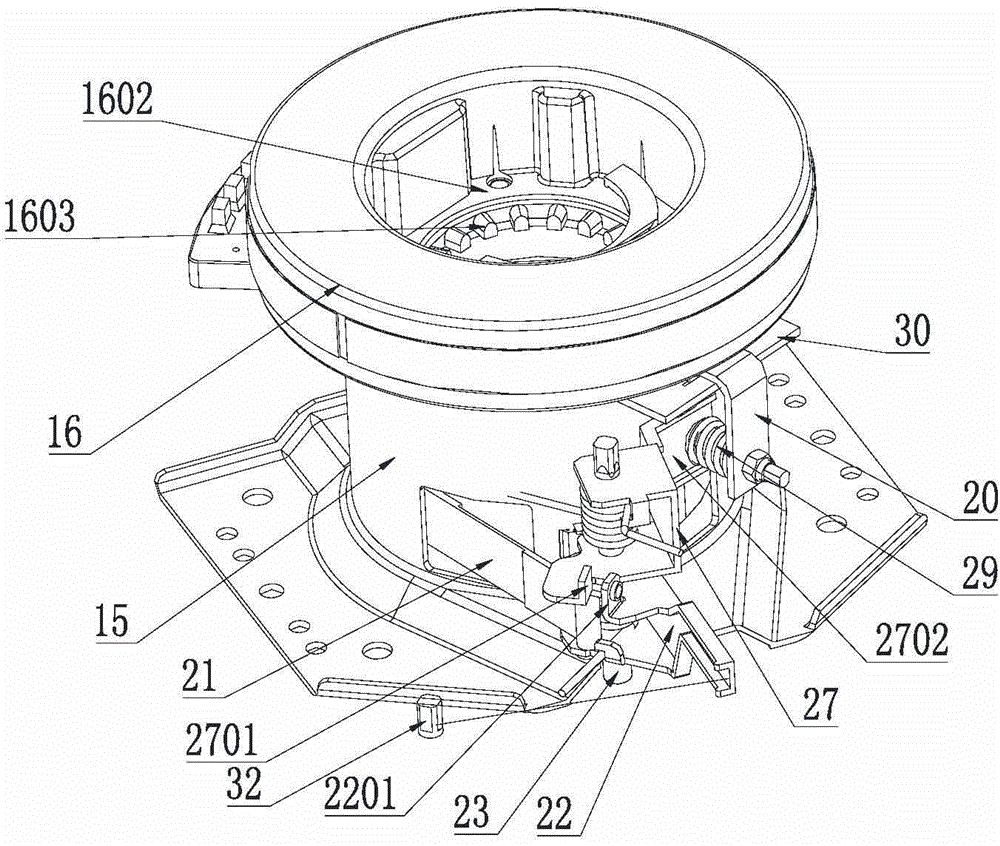

Middle supporting device used in large-size fan blade molding process

The invention relates to a middle supporting device used in a large-size fan blade molding process. The supporting device comprises a mounting base component, a left supporting component, a right supporting component and a middle supporting component, wherein the blade does rotational movement under the drive of an equipment main shaft, a V-shaped supporting is formed for the blade by the left supporting component and the right supporting component, two supporting included angles are automatically adjusted according to the posture of the blade, and the middle supporting component is used for dragging the low end of the blade so as to reduce sliding friction force between the blade and the left supporting component and the right supporting component. The supporting device provided by the invention can be used as an accessory of blade numerical control molding equipment and mainly used for improving the system rigidity and the automation degree in the blade winding and molding process, and meanwhile, the supporting equipment also can be used for winding and molding of other weak-rigidity workpieces.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

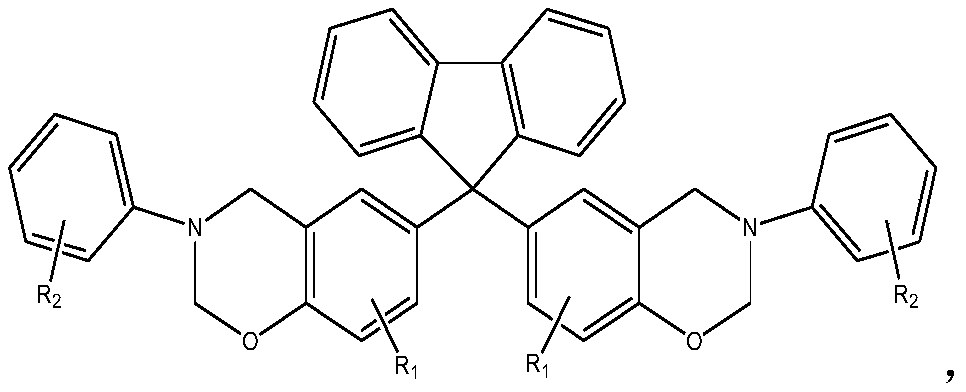

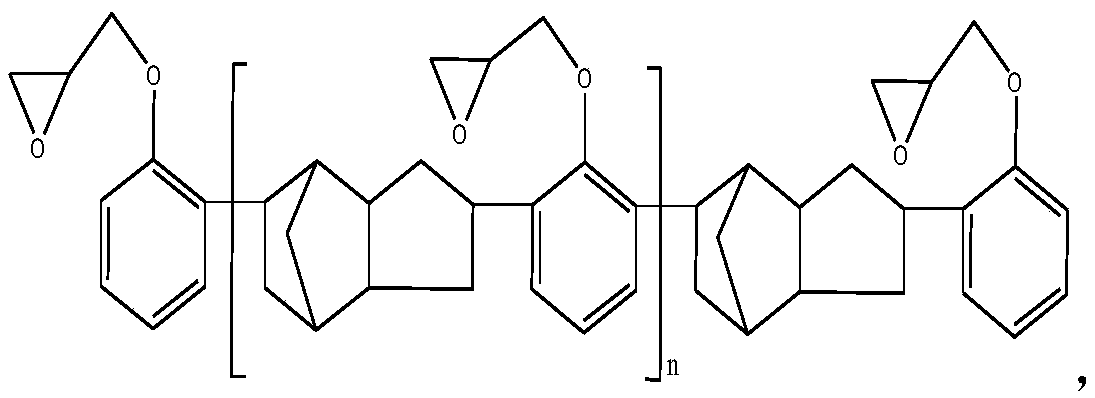

High-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin composition as well as preparation method and application thereof

ActiveCN110183817AIncrease the rate of loopingImprove the reactivity of the alkylation reactionLaminationLamination apparatusFlexural strengthSolvent

The invention discloses a high-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin composition and a preparation method thereof. The high-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin composition is characterized in that the resin is a mixture of resin, an inorganic filler, an accelerator and a solvent, wherein a weight ratio of theresin to the inorganic filler to the accelerator to the solvent is 100:(30-70):(0.01-1):(57-80); the resin is a mixture of benzoxazine resin, DCPD epoxy resin and phosphorus-containing phenolic resin, wherein a weight ratio of the benzoxazine resin to the DCPD epoxy resin to the phosphorus-containing phenolic resin is 100:(40-80):(10-40); and the benzoxazine resin is one or more selected from high-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin and other benzoxazine resin, wherein a weight ratio of the high-heat-resistant high-toughness low-dielectric-constant fluorenyl benzoxazine resin to the other benzoxazine resin is (60-100):(0-40). The composition provided by the invention is used in the fields of laminated boards, integrated circuit packages, high-frequency high-speed copper-clad boards and high-density internet, and has excellent heat resistance, a lower dielectric constant and dielectric loss factor, better flame retardancy and bending strength, a lower water absorption ratio and the like.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

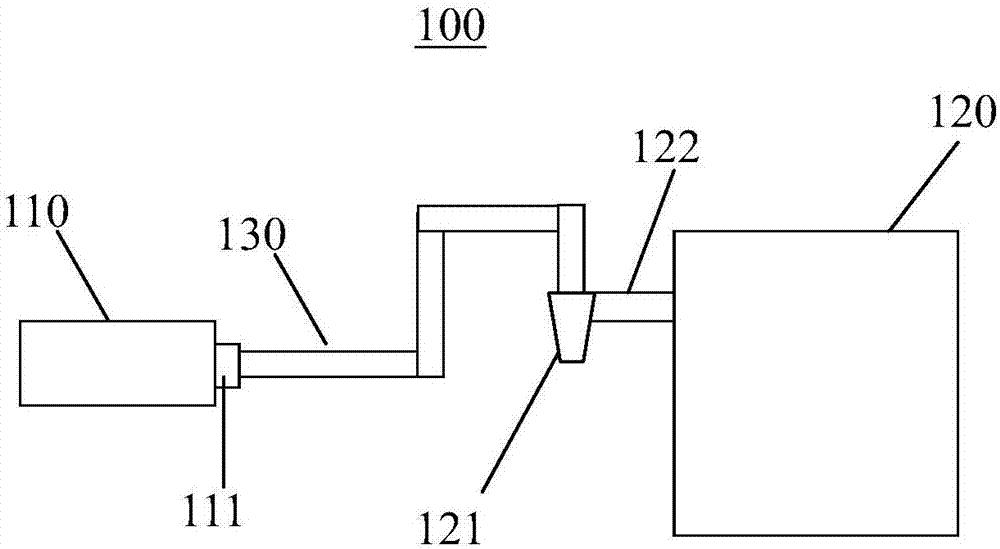

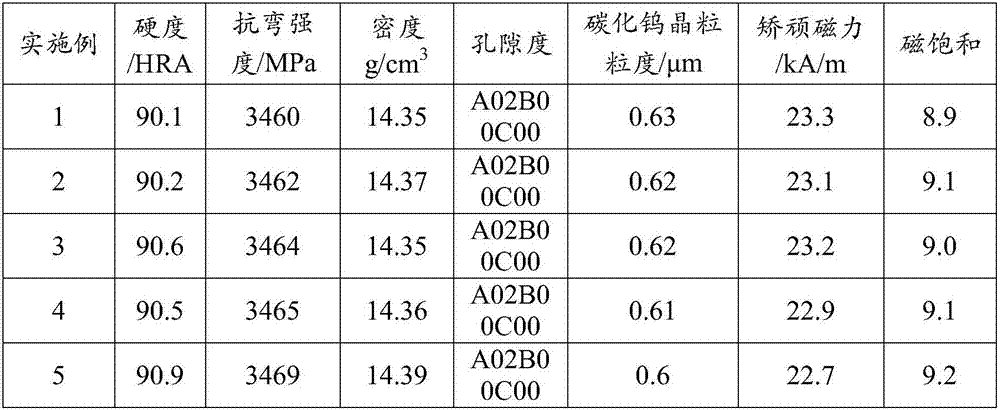

Hard alloy product, preparation method thereof and device for preparing hard alloy product

ActiveCN107321990ARealization of moldless 3D moldingEasy to makeTransportation and packagingMetal-working apparatusNumerical controlAlloy

The invention discloses a hard alloy product, a preparation method thereof and a device for preparing the hard alloy product, and belongs to the field of powder metallurgy. The preparation method of the hard alloy product includes the steps that hard alloy powder and an adhesion agent are mixed and feedstock is prepared; the feedstock is stored in an extruding machine so that the feedstock can be extruded out from a nozzle of a numerical control machine tool which is connected with the extruding machine; and the numerical control machine tool controls the extruded feedstock to be layered-deposited, and the hard alloy product is prepared. The device for preparing the hard alloy product comprises the extruding machine and the numerical control machine tool; the numerical control machine tool comprises a heatable nozzle, the nozzle is the executive component of the numerical control machine tool, and connected with a driving component of the numerical control machine tool; and a material outlet of the extruding machine is connected with the nozzle through a material pipe. According to the hard alloy product, the preparation method thereof and the device for preparing the hard alloy product, a die does not need to be manufactured, complex shapes can be formed, the density of each part of the product is even, deformation is small, and the comprehensive property is high.

Owner:成都岷江精密刀具有限公司

Combined tool for turning hexagonal prism type thin-walled aluminium part

A combined tool for turning a hexagonal prism type thin-walled aluminium part is characterized in that a pair of cutter heads is mounted on the mandrel of a cutter tool; cutters are mounted on each cutter head; a tension shaft penetrates the support seat of a workpiece tool; an expansion sleeve is mounted on the shaft segment, on one side of the support seat, of the tension shaft; the shaft segment, on the other side of the support seat, of the tension shaft is in threaded connection with a clamping sleeve; an indexing plate mounted on the expansion sleeve is provided with positioning holes; a positioning pin matched with the positioning hole is mounted on the support seat. One end of the mandrel is clamped by the chuck of a turning machine, a centre is tightly propped against the other end of the mandrel, the support seat is connected with the tool holder of the turning machine, and then the cutter tool and the workpiece tool can be mounted respectively. The aluminium part is mounted at the front end of the expansion sleeve in a sleeving manner, and the clamping sleeve is rotated to clamp the workpiece. The indexing plate is positioned by the positioning pin, and then two side surfaces of the workpiece can be turned at a time; and after all the side surfaces of the workpiece are processed, the clamping sleeve is rotated in the reverse direction to release the workpiece, and then the processed workpiece can be dismounted.

Owner:王宏康 +1

Method for preparing surface molecularly imprinted material based on titania nanowires

InactiveCN104610548AEasy to eluteImprove bindingOther chemical processesCross-linkFunctional monomer

The invention relates to a method for preparing a surface molecularly imprinted material based on titania nanowires. The method comprises the following steps: adding template molecules and functional monomers in an organic solvent for interaction to form a host-guest coordination compound; then adding a cross-linking agent and a titania nanowire carrier, adding acetic acid for catalytic hydrolysis to realize sol-gel reaction, and covering the surface of titania nanowires with a layer of molecularly imprinted polymer with high crosslinking; after high temperature aging, eluting or dissociating the template molecules in the polymer product. The operability is strong, and the manufacture cost is low. Almost all binding sites of surface molecular imprinting are distributed on the surface with good accessibility, and the problems of nonuniform binding sites, poor accessibility, low recognition speed and the like of the molecularly imprinted polymer prepared by the traditional mass polymerization are solved. The elution of the template molecules and the recombination of the template molecules and target molecules are facilitated, and the selectivity of the target molecules is improved.

Owner:INSPECTION & QUARANTINE COMPREHENSIVE TECH CENT JIANGXI ENTRY EXIT INSPECTION & QUARANTINE BUREAU

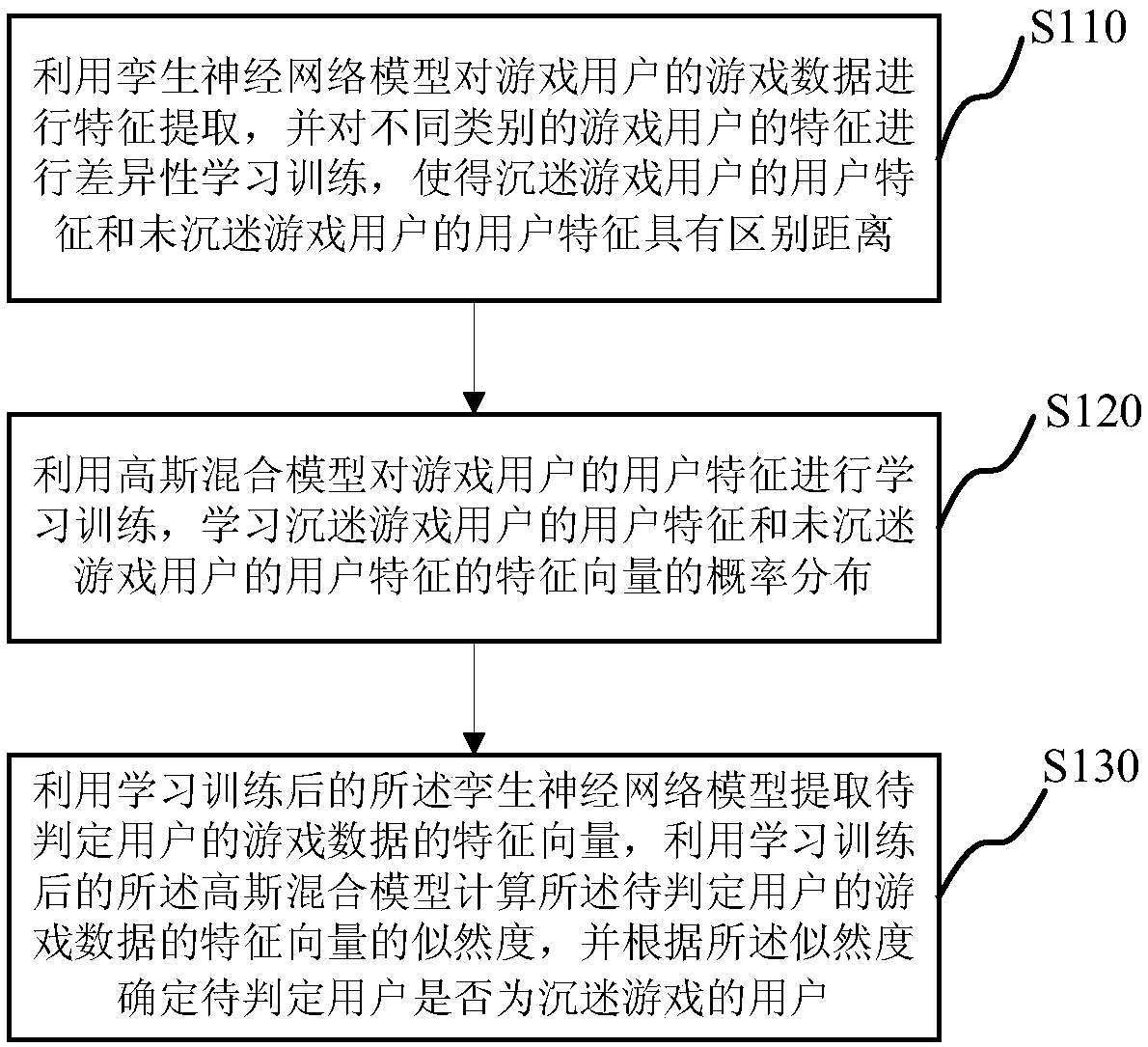

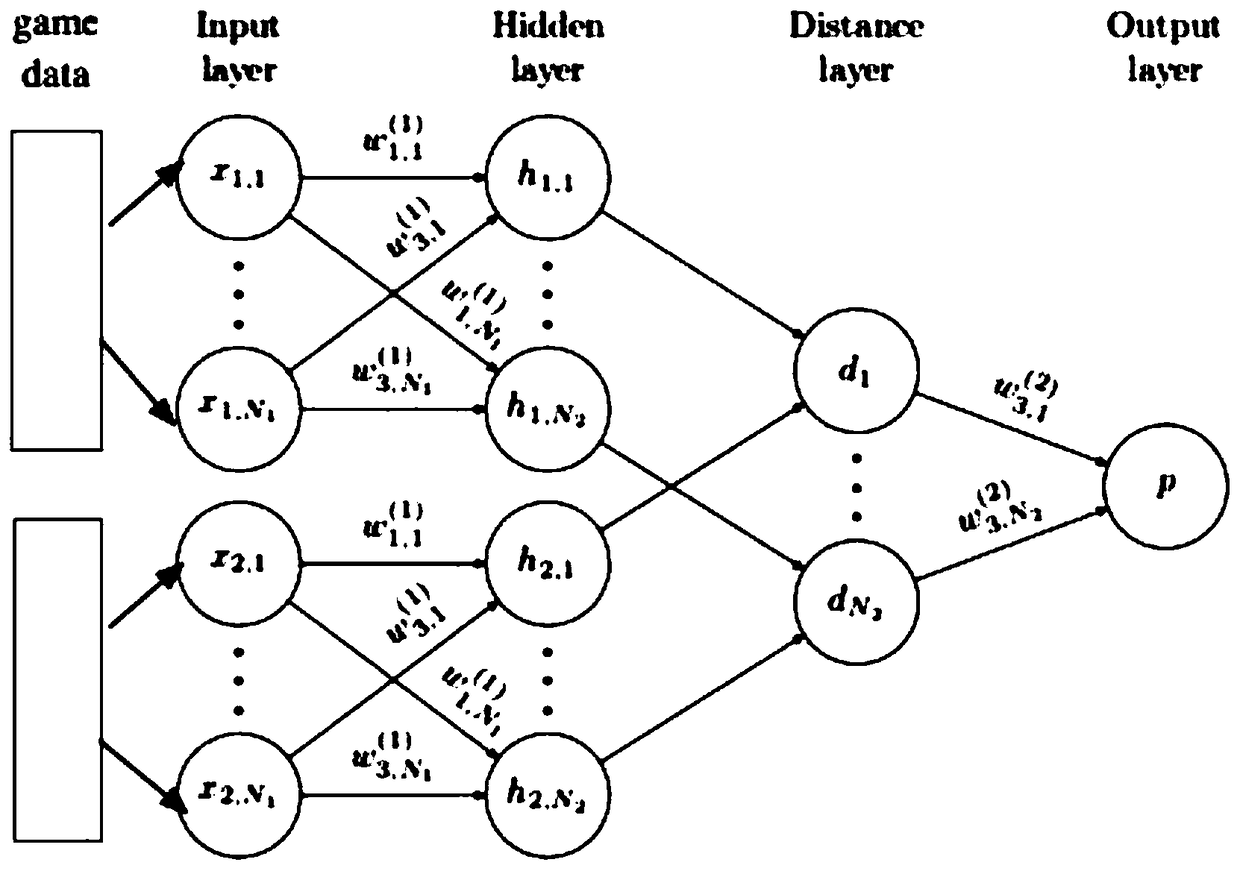

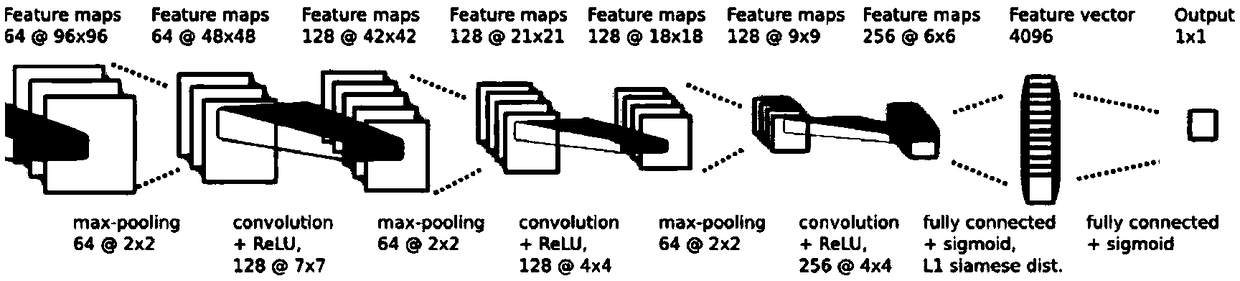

Game anti-indulgence judgment system and method based on twin neural networks and GMM

ActiveCN109214444AOvercome rigidityOvercome accuracyCharacter and pattern recognitionVideo gamesMachine learningNetwork model

The invention provides a game anti-indulgence judgment system and method based on twin neural network and GMM. The method comprises the following steps of: utilizing twin neural network models to extract features of game data of game users, and carrying out difference learning training on features of different types of game users, so that user features of addicted game users and user features of non-addicted game users have different distances; the Gaussian mixture model is used to train the user characteristics of the game users and to learn the probability distribution of the user characteristics of the indulgent game users and the user characteristics of the non-indulgent game users. The trained twin neural network model is used to extract the feature vector of the game data of the userto be judged, and the likelihood of the feature vector of the game data of the user to be judged is calculated by using the trained Gaussian mixture model, and whether the user to be judged is a useraddicted to the game or not is determined according to the likelihood. The invention utilizes a model to judge whether a user is addicted to a game or not.

Owner:XIAOVO TECH +1

Vehicle flexible intercepting device

InactiveCN108221763ATo achieve a safe interception effectOvercoming the poor interception effectTraffic restrictionsEngineeringMechanical engineering

The invention relates to a vehicle flexible intercepting device, in particular to a vehicle flexible intercepting device with a flexible intercepting net. The vehicle flexible intercepting device comprises the flexible intercepting net, energy absorbers, ground anchors and a net spreading mechanism, and is characterized in that the two ends of the upper side of the flexible intercepting net (4) are hung on clips (5) of the net spreading mechanism (3), the two ends of the lower side of the flexible intercepting net (4) are connected with the energy absorbers through connectors (6), and the energy absorbers (2) are fixed to the ground. By means of the vehicle flexible intercepting device, the defects that a vehicle stopping nail is poor in intercepting effect and vehicle destroy and casualties are caused by rigid intercepting are overcome, vehicles can be effectively intercepted, the personal safety of drivers and passengers (hostages) in the vehicles is ensured, secondary injury eventscaused by vehicle disassembly are avoided, and the vehicle flexible intercepting device is a more reasonable and more user-friendly vehicle intercepting device.

Owner:江苏海天科技有限公司

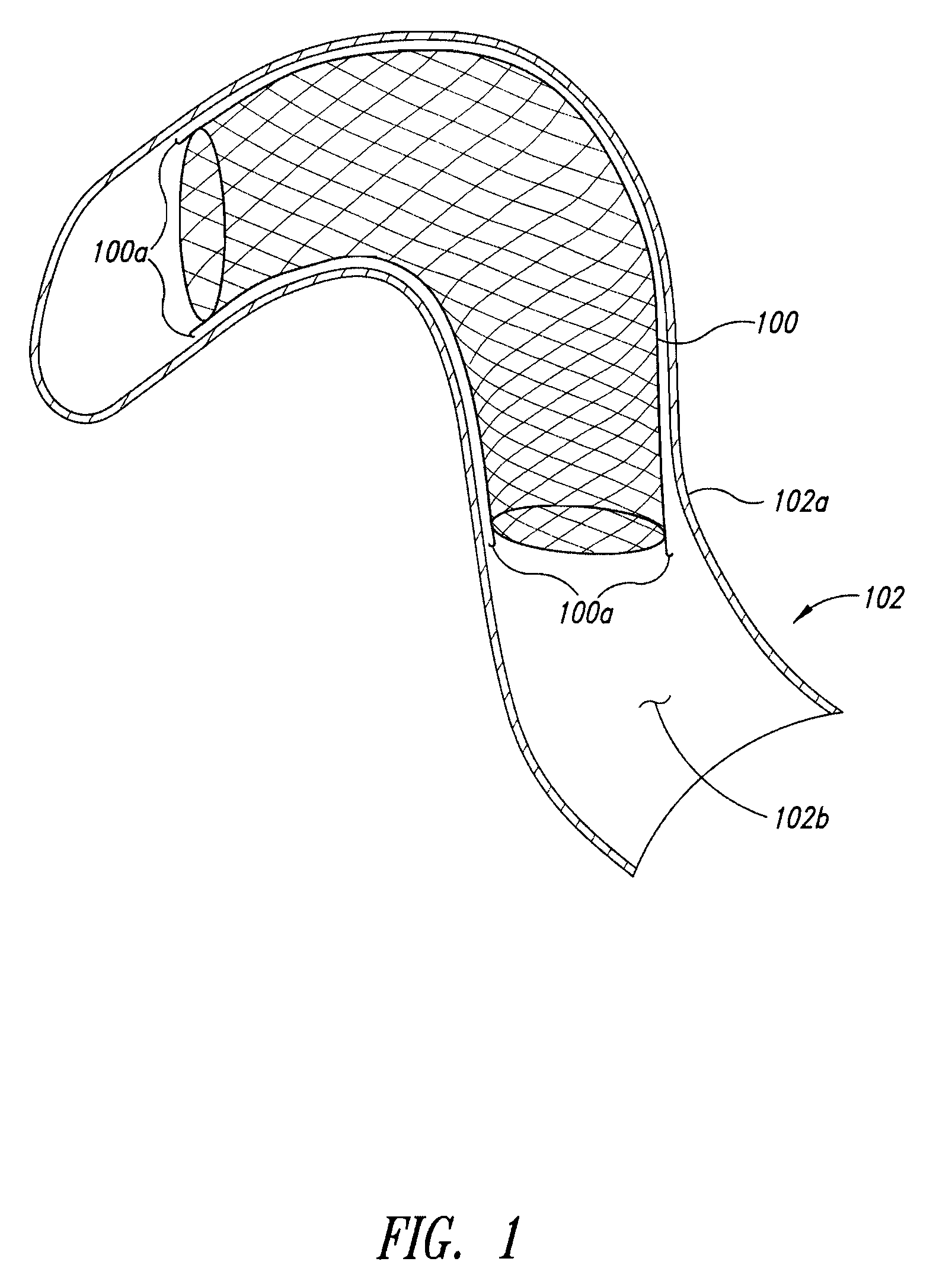

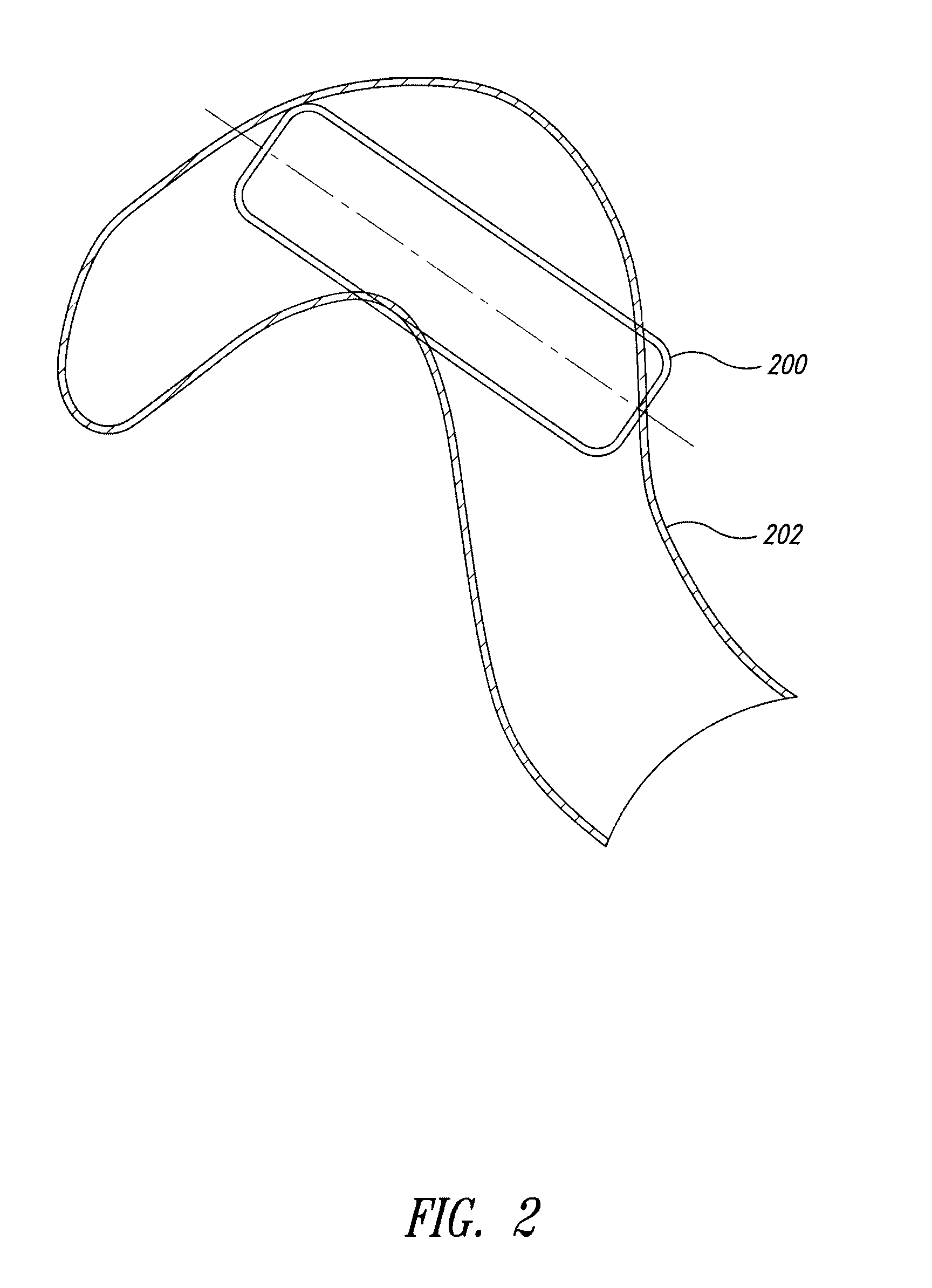

In vivo inflatable structures, for example to expand stents

InactiveUS8758386B2High strengthIncreased riskBalloon catheterSurgeryPercutaneous angioplastyIn vivo

Multi-balloon catheter structures that are able to move with respect to one another may provide superior compliance in tortuous passages to, for example, perform angioplasty and / or expand stents. Two or more balloons may be inflated to equal pressures. A length of the balloons may be sufficiently longer than a length of a stent to accommodate axial movement of the balloons. One or more balloons may be lubricous or carry a lubricant.

Owner:GELBART DANIEL +1

Washing machine and deceleration clutch for same

ActiveCN105734907AImprove transmission efficiencyReduce energy consumptionOther washing machinesWashing machine with receptaclesEngineeringGear train

The invention relates to a deceleration clutch for a washing machine. The deceleration clutch comprises a shell, a brake wheel in the shell and a wheel system in the brake wheel, and further comprises a clutch shaft sleeve capable of sliding up and down and a shifting fork driving the clutch shaft sleeve. A brake belt is arranged between the shell and the brake wheel. The brake belt surrounds the brake wheel, one end of the brake belt is fixedly installed on the shell, and the other end of the brake belt stretches out of the shell to be connected with a brake arm. The brake arm is arranged on a center shaft. The center shaft is fixedly installed on the shell. A connecting arm is arranged on the center shaft and located on the lower portion of the brake arm. The brake arm drives the connecting arm to move. The connecting arm drives the brake belt and the shifting fork to move, and the clutch shaft sleeve is driven to slide up and down to be connected with a torque shaft sleeve and a fixed shaft sleeve respectively to achieve dehydration and washing.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

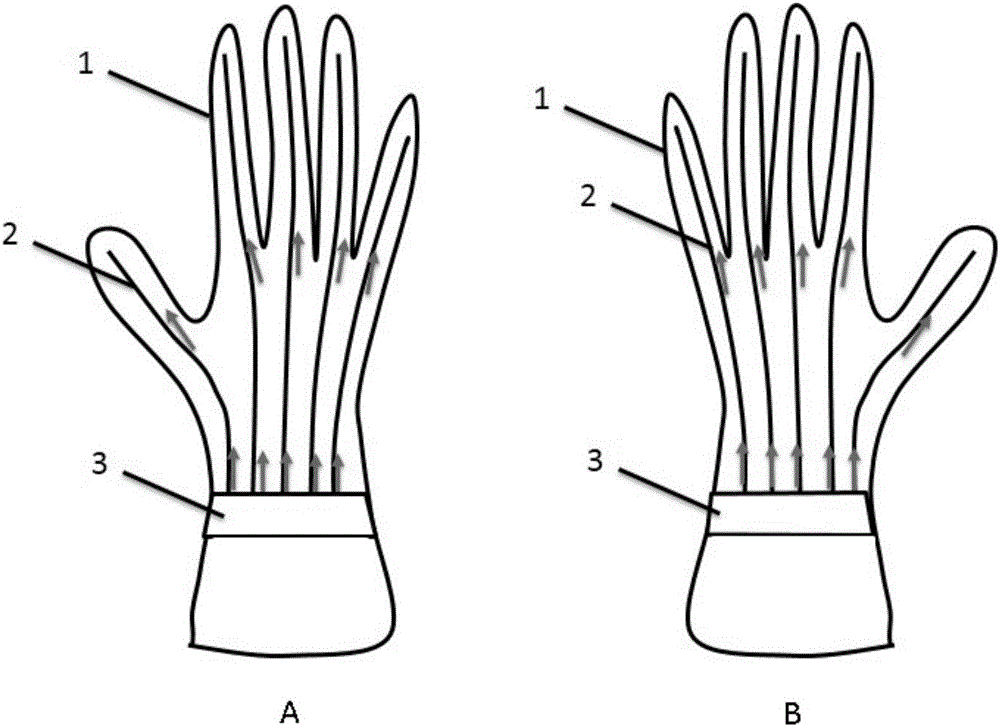

Warm-keeping gloves

The invention relates to a thermal glove, which is at least partially provided with a flexible heat-conducting film on the surface of the thermal glove in direct contact with the skin. The present invention overcomes the defects of using rigid materials, high quality, and poor comfort in the prior art by providing a flexible heat-conducting film on the surface of the glove in direct contact with the skin. It is suitable for the protection of hands, especially fingers prone to frostbite, under long-term exposure to cold environments, and has a broad market prospect.

Owner:BOE TECH GRP CO LTD

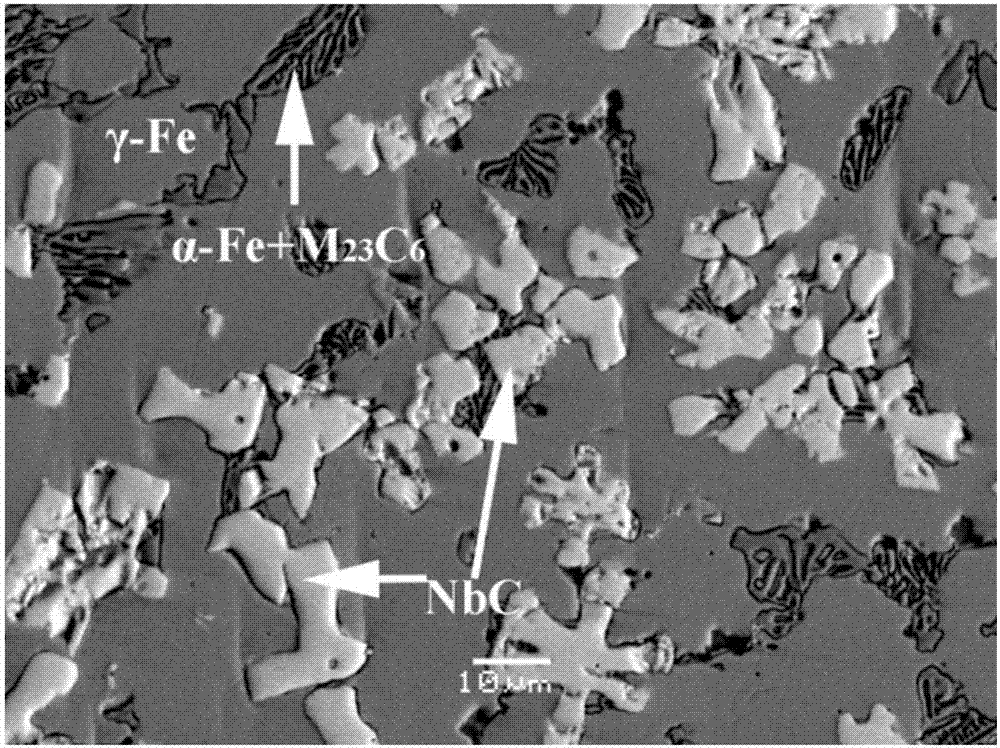

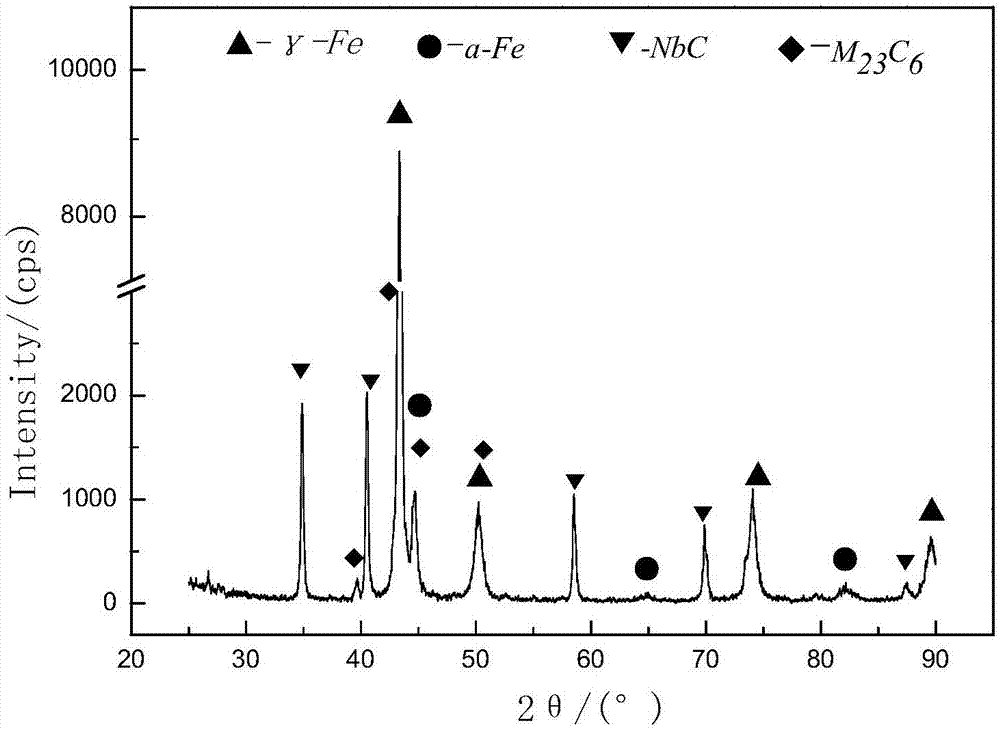

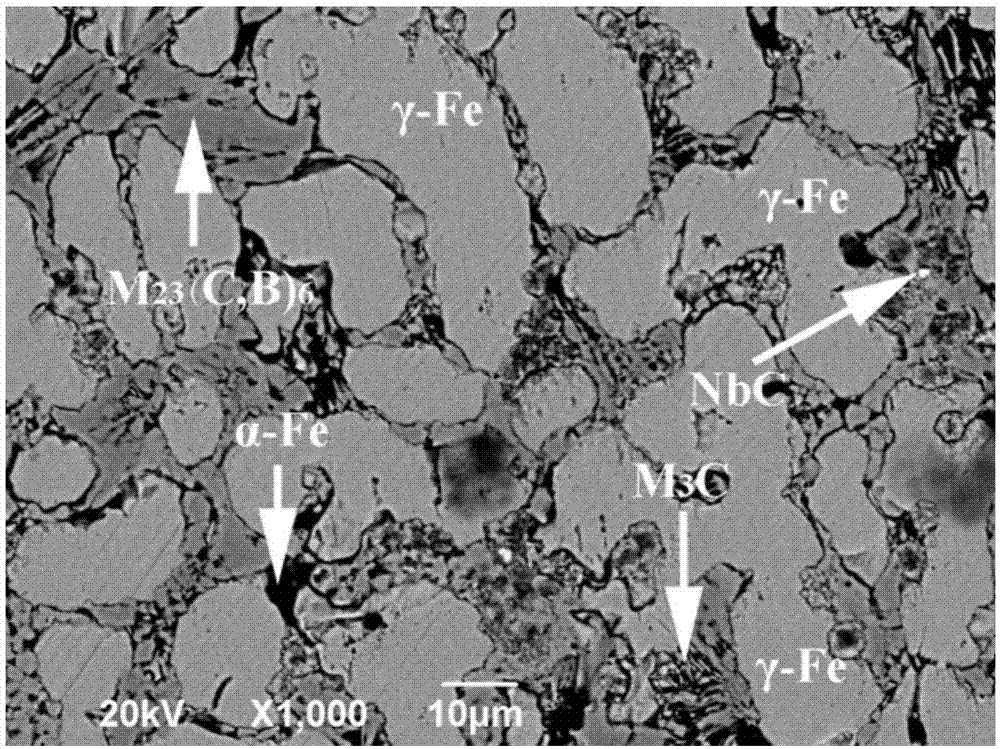

Self-protection open arc surfacing welding austenite matrix flux-cored wire and application method thereof

ActiveCN107363431AGood heat strengthGood high temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaFerrosiliconElectric arc

The invention discloses a self-protection open arc surfacing welding austenite matrix flux-cored wire and an application method thereof. The flux-cored wire is characterized in that an H08A cold rolling thin steel strip serves as outer layer skin, high carbon ferro-chrome, ferroniobium, ferrosilicon, micro-fine graphite, ultra-refining aluminum powder and other metal powder are used in cooperation to form a powder core, and a surfacing alloy with the organization structure that austenite serves as a matrix, separated-out thick NbC serves as a main wear-resisting phase and along-grain dispersed distributed M23C6 type carbide serves as an auxiliary wear-resisting phase is formed. The micro-fine graphite in the powder core is dried at 70 DEG C to 80 DEG C for two hours, and therefore micro-fine graphite particles sufficiently absorb a certain amount of air, and the micro-fine graphite particles have certain flammability; explosive of the particles stimulates Al2O3 to form micro-fine smoke which is expelled and removed under the electric arc blow force effect, but the explosive power cannot expel other thick component particles, welding lines with extremely-small residue amount are obtained, the excellent abrasive resistance is achieved, the self-protection open arc surfacing welding austenite matrix flux-cored wire can be used for medium-high temperature, impulse load frequency changes and other complex abrasion conditions, and air holes are not generated during surfacing welding.

Owner:XIANGTAN UNIV

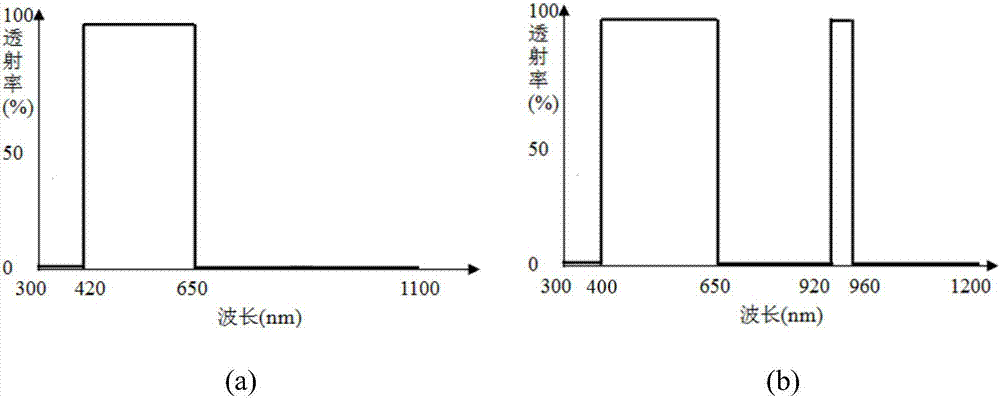

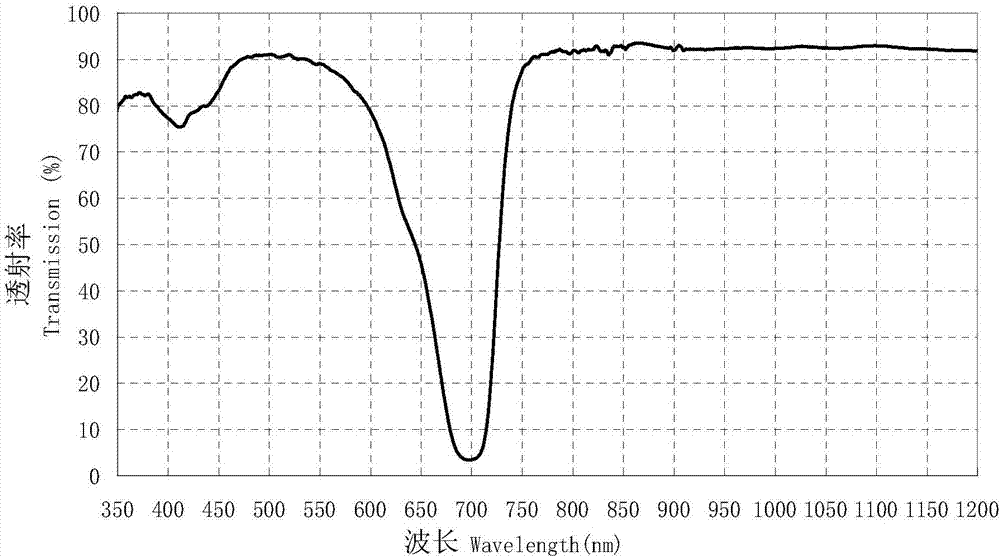

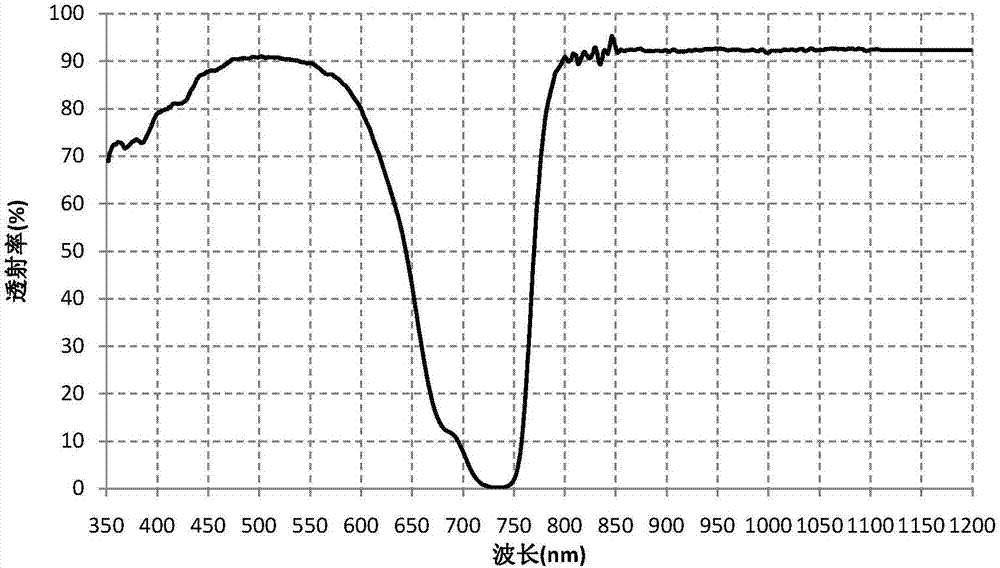

Dual-channel filter and method for preparing dual-channel filter by spin-coating blue dye

PendingCN107315212AOvercome rigidityThe disadvantage of poor adhesion is solvedOptical filtersPhysicsLight filter

The invention discloses a dual-channel filter and method for preparing dual-channel filter by spin-coating blue dye. The filter comprises a glass substrate, a blue dye layer arranged on the surface of one side of the glass substrate, an adhesion layer arranged on the blue dye layer, an ultra wide band reflection film arranged on the adhesion layer and a dual-channel filtering sheet arranged on the surface of the other side of the glass substrate. The method comprises steps of coating the glass substrate with the blue dye layer by use of the spin-coating method; by using the vacuum plating method and combining low-energy ions, carrying out auxiliary deposition on the adhesion layer; and by using the vacuum plating method and combining high-energy ions, carrying out auxiliary deposition on the ultra wide band reflection film and the dual-channel filtering sheet. According to the invention, the glass substrate spin-coated with the dye layer and the dual-channel filter have wide application prospects in the field of mobile phone shooting systems, and security television systems.

Owner:HANGZHOU KOTI OPTICAL TECH

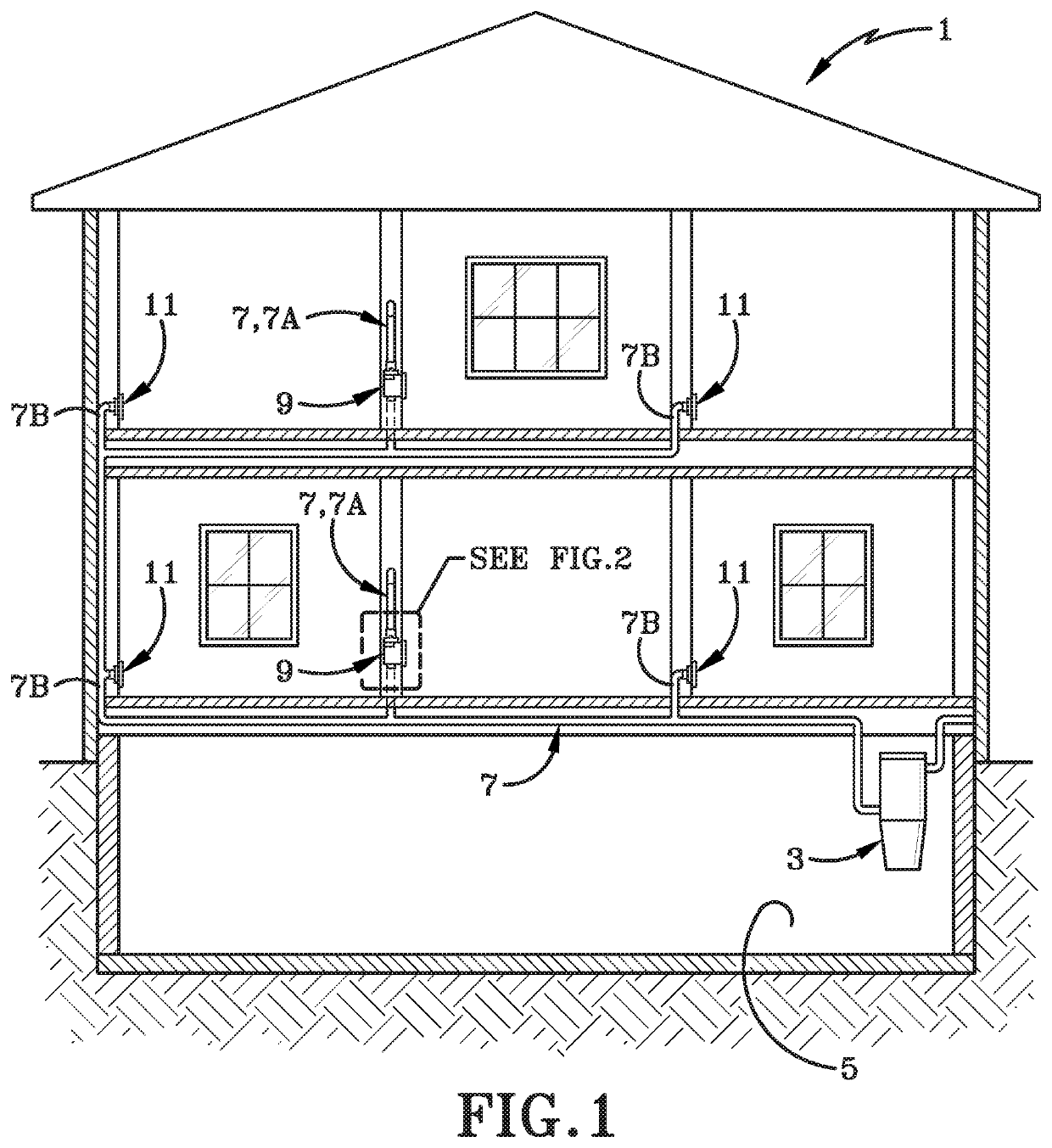

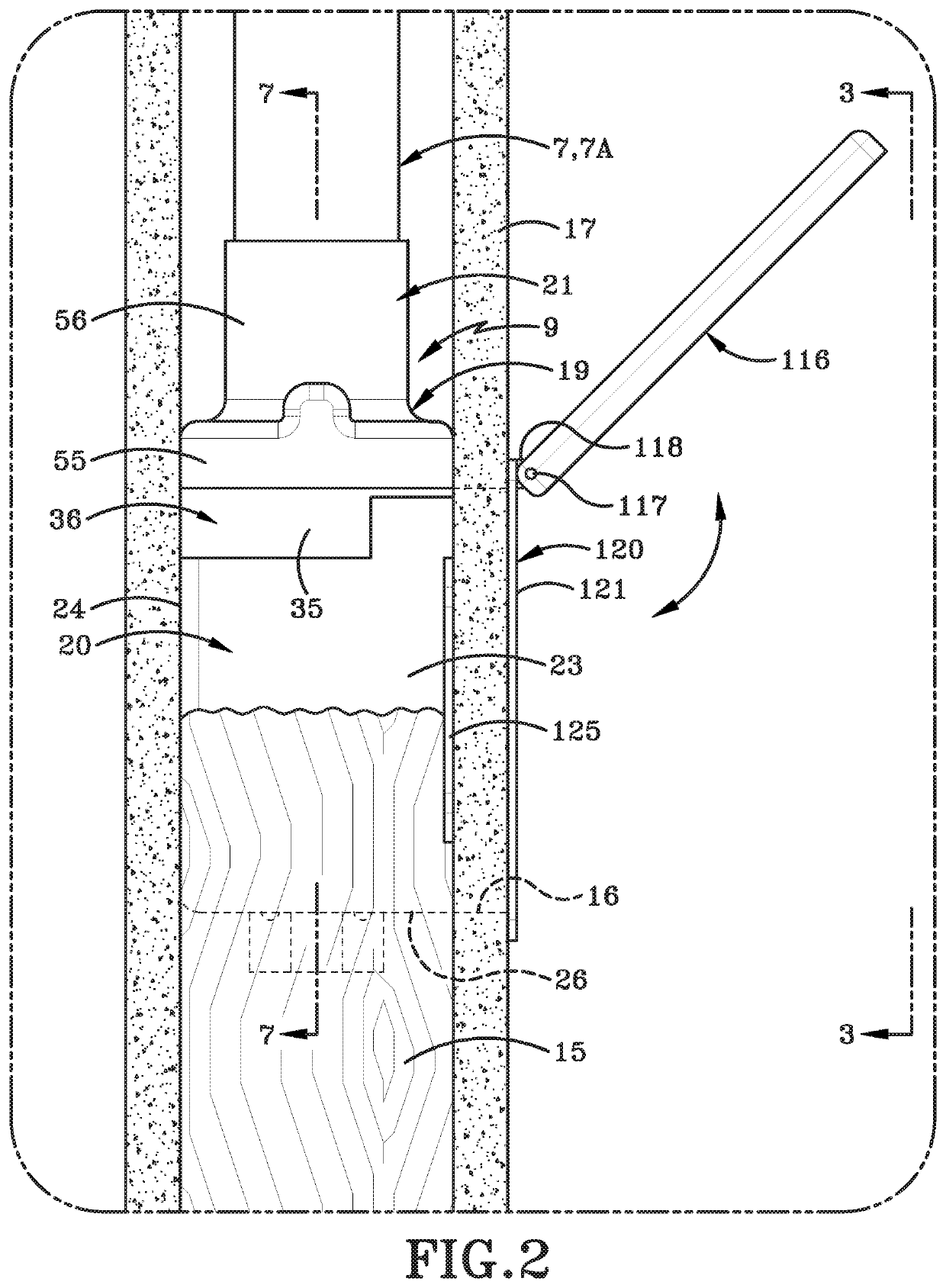

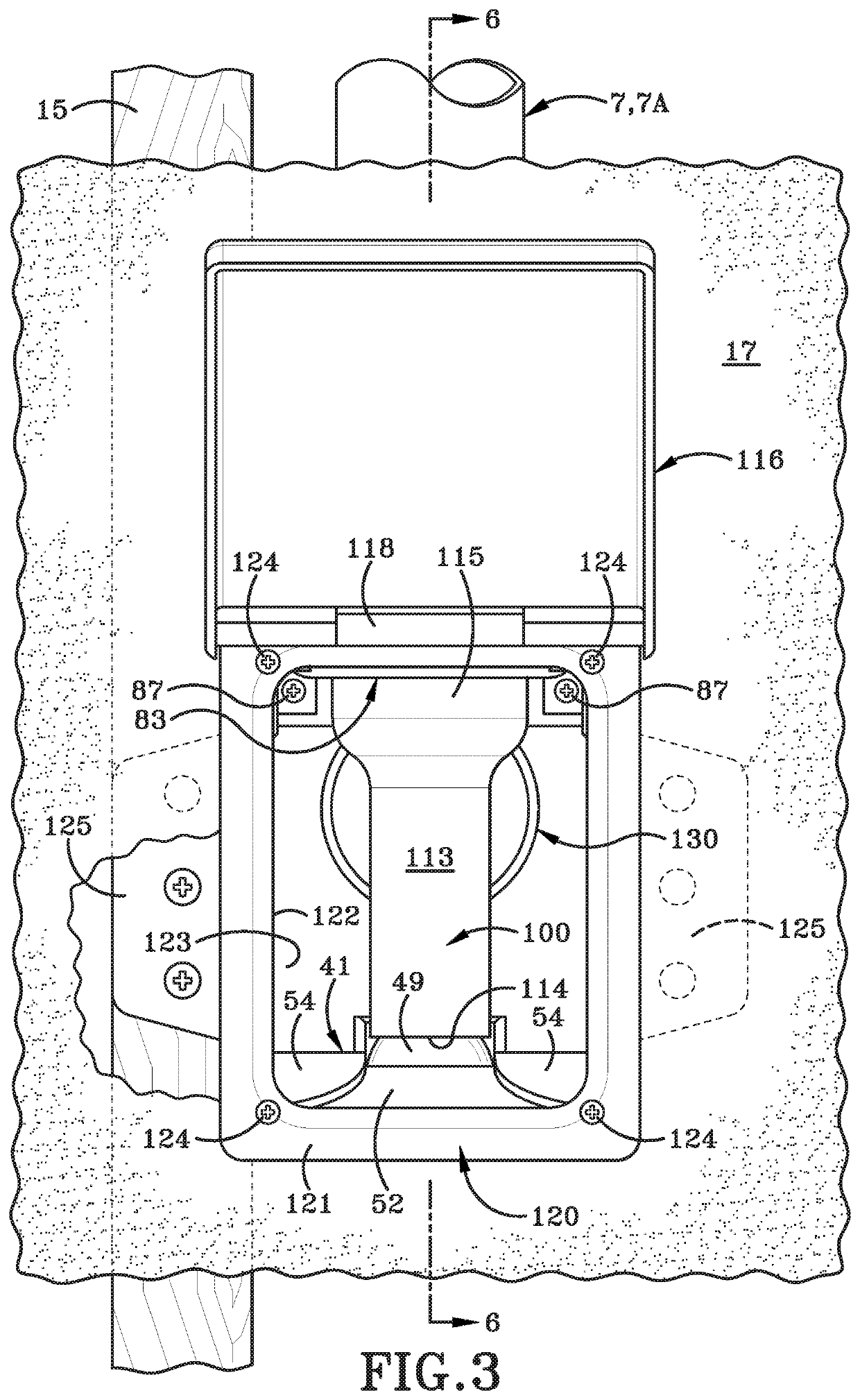

Vacuum inlet valve assembly with a closeable seal

A closure flap on a vacuum inlet valve assembly or housing pivots between an open first position and a closed second position. When the closure flap is in the open first position, it is offset from a central longitudinal axis of the vacuum inlet valve housing. When the closure flap is in the closed second position, it intersects the central longitudinal axis. The closure flap has a resilient and compressible protrusion that releasable locks the closure flap in each position.

Owner:H P PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com