Multi-stranded welding wires

A multi-strand stranded welding wire, welding wire technology, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of coilability, poor rigidity, inconvenient welding of large metal components, and difficulty in ensuring welding quality and other problems, to achieve the effect of strong coilability, high deposition efficiency and large melting width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

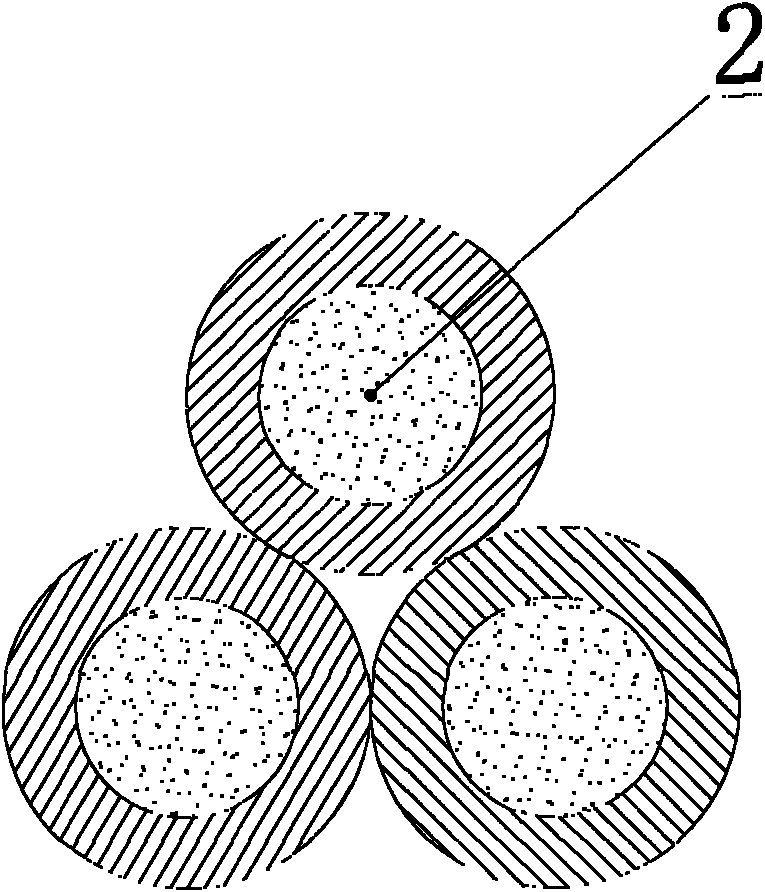

[0011] Embodiment one, figure 1 Shown is a cross-sectional view of an example of a three-strand stranded welding wire, which is twisted together by three flux-cored welding wires (2), which are called peripheral wires, and a solid-cored welding wire or a flux-cored welding wire can be selected as the core wire in the middle according to needs. The chemical composition of the three flux-cored wires is the same, the main components are carbon (C) 0.04%, nitrogen (N) 0.12%, manganese (Mn) 1.2%, silicon (Si) 0.7%, nickel (Ni) 4.0%, chromium (Cr ) 12.5%, molybdenum (Mo) 0.4%, iron (Fe) balance. The diameters of the three strands of flux cored wire are the same. When the diameter of each strand is: 4.8mm, 5.0mm and above, the diameter of the core wire can be: 0.7mm, 0.8mm and above, and the diameter after stranding can reach 10.4mm, 10.8mm and above. above.

Embodiment 2

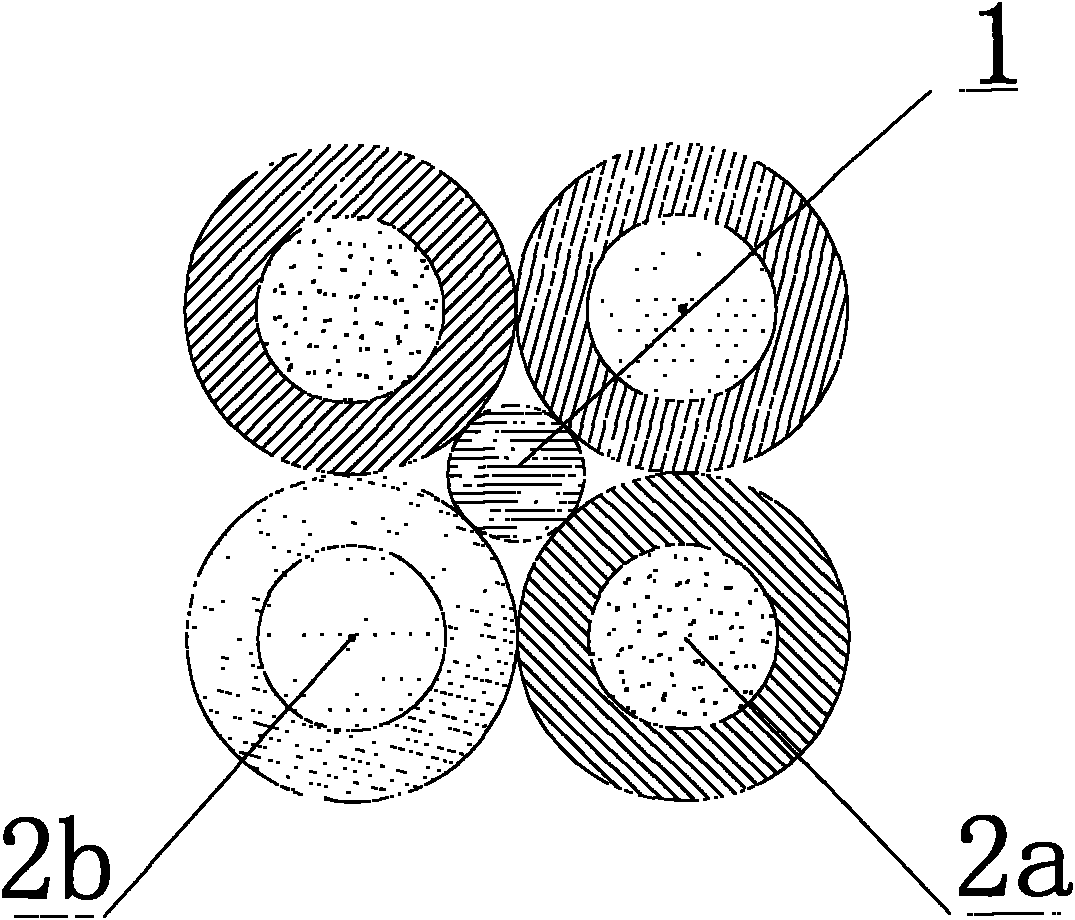

[0012] Embodiment two, figure 2 Shown is a cross-sectional view of an example of a five-strand stranded welding wire, which can be divided into core wire and peripheral wire from the structural point of view. The core wire is a solid core wire (1), and its main chemical composition is carbon (C) 0.5%, Vanadium (V) 0.5%, manganese (Mn) 1.5%, silicon (Si) 1.0%, tungsten (W) 1.5%, chromium (Cr) 7.0%, molybdenum (Mo) 1.5%, iron (Fe) balance. The peripheral wire is four strands of flux-cored welding wire (2), and the chemical composition of each two strands of welding wire is the same, wherein: the main chemical composition of flux-cored welding wire 2a is carbon (C) 0.45%, vanadium (V) 1.2%, tungsten (W) 1.5% , chromium (Cr) 5.5%, molybdenum (Mo) 1.1%, iron (Fe) balance; the main chemical composition of flux cored wire 2b is carbon (C) 0.45%, vanadium (V) 2.7%, tungsten (W) 2.0 %, chromium (Cr) 3.1%, molybdenum (Mo) 2.0%, iron (Fe) balance. The diameter of the core wire is smal...

Embodiment 3

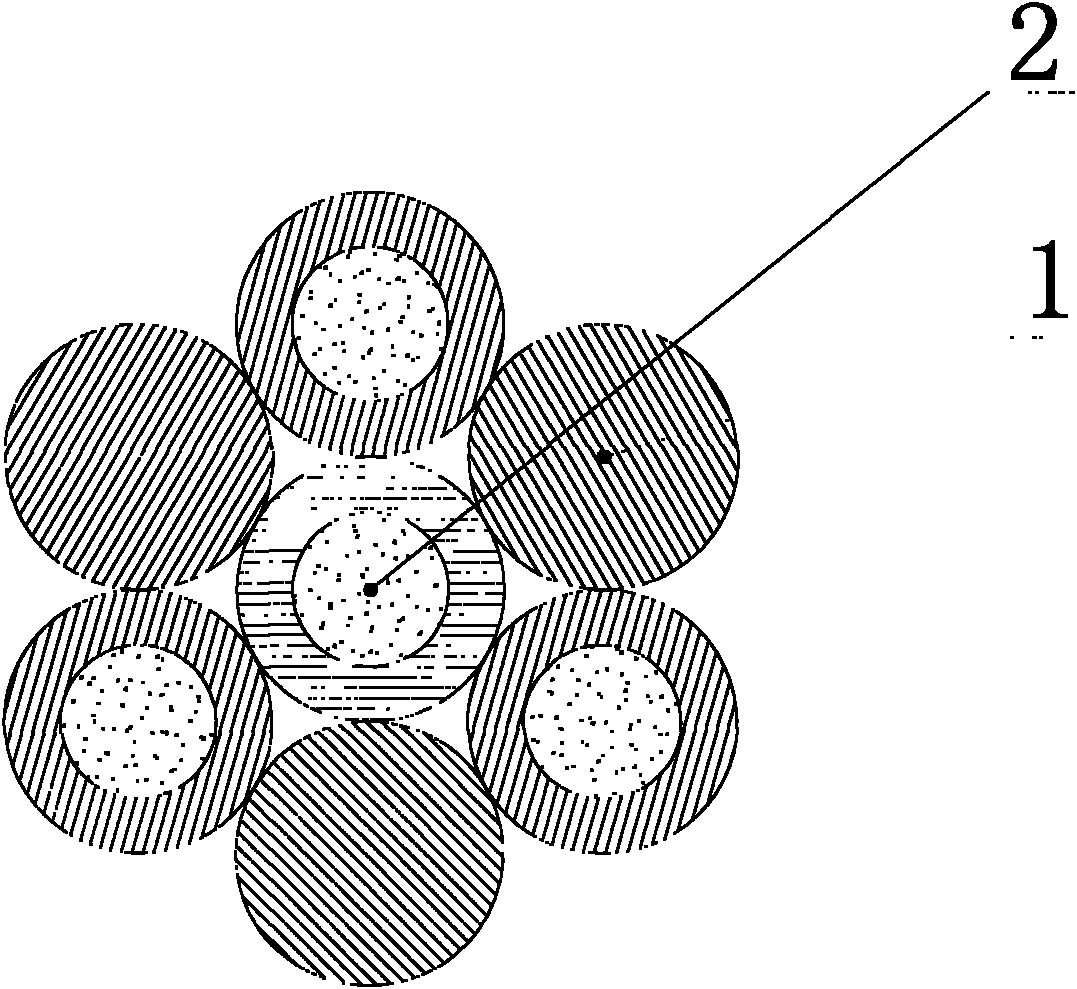

[0013] Embodiment three, image 3 Shown is a cross-sectional view of an example of a seven-strand stranded welding wire, which can be divided into a core wire and a peripheral wire in terms of structure. The core wire is a single flux-cored wire (2), and the peripheral wire is a three-strand flux-cored wire (2) and three Solid wire (1). Among them, the chemical composition of the three strands of solid wire is the same, and the chemical composition is mainly carbon (C) 2.0%, manganese (Mn) 1.0%, silicon (Si) 2.0%, chromium (Cr) 13.0%, molybdenum (Mo) 1.0%, iron (Fe) balance; the chemical composition of the other four strands of flux cored wire is mainly carbon (C) 0.5%, tungsten (W) 1.2%, chromium (Cr) 6.0%, molybdenum (Mo) 1.1%, iron (Fe) balance . According to actual needs, the chemical composition of the three strands of solid wire can be different. The diameters of the seven welding wires are the same, and the diameter of each strand can be: 1.2mm, 1.4mm, 1.6mm and abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com