Inflaming retarding modified PBT (Polybutylene Terephthalate) fiber and preparation method thereof

A fiber and phosphorus-based flame retardant technology, applied in the field of modified PBT (polybutylene terephthalate) fiber and its preparation, can solve the problems that are not conducive to large-scale industrial production, and achieve good hand feeling, Ease of operation and the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Add 55 parts of terephthalic acid, 45 parts of butanediol and 0.4 parts of catalyst tetraethyl titanate into a 2L reactor and react at 230°C until the total amount of distilled water reaches 90% of the theoretical value Above, keep warm for half an hour;

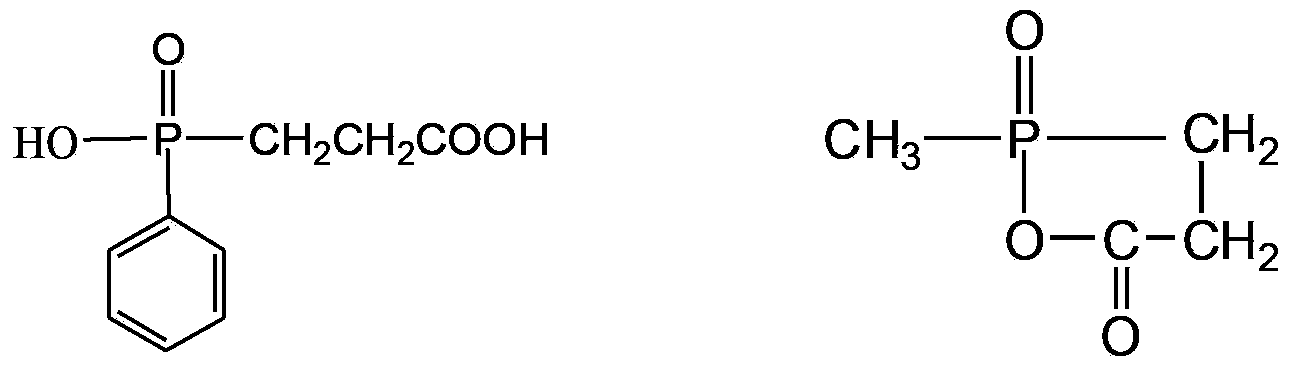

[0041] (2) Add 0.1 part of stabilizer triphenyl phosphate, 5 parts of 2-hydroxyethyl phenylphosphoric acid, 1 part of magnesium hydroxide and 2 parts of aluminum hydroxide (the filler is in the state of single particle dispersion, the particle size is less than 100nm), and then pump Vacuum polycondensation, the temperature of the polycondensation reaction is controlled at 260°C, and the time is 2 hours; when the viscosity of the polymer is in the range of 0.6-0.95, the reaction can be completed to obtain a flame-retardant polyester.

[0042] (3) The flame-retardant polyester obtained in step (2) is melt-spun through a screw spinning machine, and after cooling, oiling, pre-drawing, winding, and drafting are perform...

Embodiment 2

[0045] (1) Add 42 parts of terephthalic acid, 57 parts of butanediol and 0.008 parts of zinc acetate catalyst into a 2L reactor and react at 190°C until the total amount of distilled water reaches more than 90% of the theoretical value. half an hour;

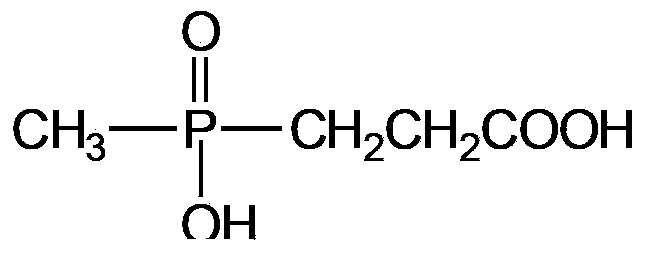

[0046] (2) Add 6 parts of 2-hydroxyethyl methyl phosphate, 2 parts of silicon dioxide, 2 parts of magnesium hydroxide, and 1 part of zirconium hydroxide, and then vacuumize and polycondense. The temperature of the polycondensation reaction is controlled at 240 ° C, and the time is 5h. When the viscosity of the polymer is in the range of 0.6-0.95, the reaction can be completed to obtain the flame-retardant polyester.

[0047] (3) The flame-retardant polyester obtained in step (2) is melt-spun through a screw spinning machine, and after cooling, oiling, pre-drawing, winding, and drafting are performed to obtain uniform structure and controllable fineness flame retardant polyester fiber. Wherein, the spinning temperature is 240°...

Embodiment 3

[0050] (1) Add 60 parts of terephthalic acid, 40 parts of butanediol and 0.8 parts of calcium acetate catalyst into a 2L reactor and react at 240°C until the total amount of distilled water reaches more than 90% of the theoretical value, and keep warm half an hour;

[0051] (2) Add 0.2 parts of stabilizer trimethyl phosphate, 4 parts of 2-hydroxyethyl phenylphosphoric acid, 4 parts of 2-hydroxyethyl methyl phosphate, 0.1 part of silicon dioxide, and then vacuum polycondensation, the temperature of polycondensation reaction Control at 270°C for 3 hours. When the viscosity of the polymer is in the range of 0.6-0.95, the reaction can be completed to obtain the flame-retardant polyester.

[0052] (3) The flame-retardant polyester obtained in step (2) is melt-spun through a screw spinning machine, and after cooling, oiling, pre-drawing, winding, and drafting are performed to obtain uniform structure and controllable fineness flame retardant polyester fiber. Wherein, the spinning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com