Polypropylene-based filament elastic super-soft non-woven material and production method thereof

A non-woven material, polypropylene-based technology, used in non-woven fabrics, spray/jet textile material processing, textiles and papermaking, etc., can solve the problems of non-woven material flexibility and bulkiness, etc. Safe, fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

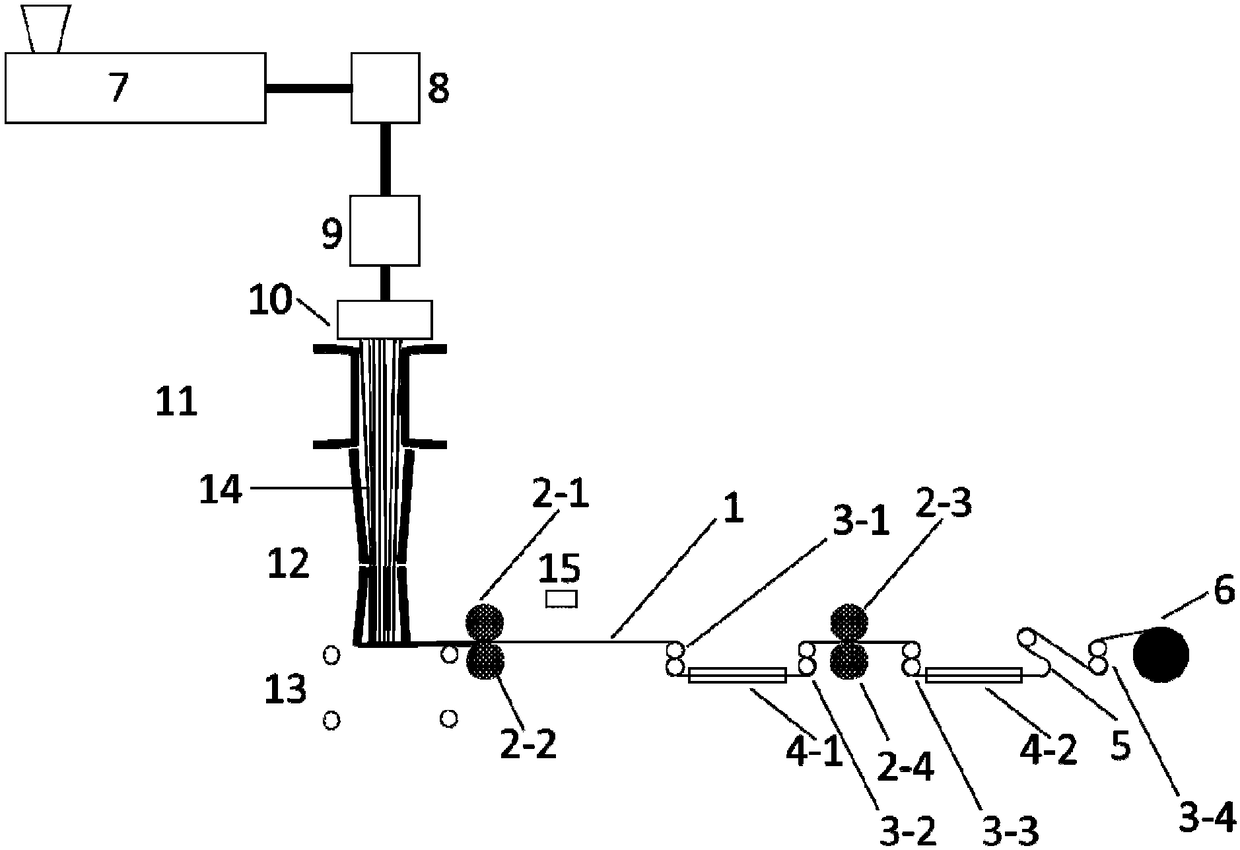

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] Such as figure 1 As shown, first, 0.01-2wt% of erucamide, 5-15wt% of polyethylene glycol and 40-80wt% of polypropylene are melt-blended and modified by a screw granulator to prepare polymer particles, and then the The polymer particles are blended with the polyolefin elastic copolymer and ultra-high molecular weight polyethylene chips; the preferred screw granulator has 5 heating zones, the aspect ratio is 30, and the temperature in the first zone is 160-190°C , the temperature in the second zone is 180-210°C, the temperature in the third zone is 200-230°C, the temperature in the fourth zone is 230-250°C, and the temperature in the fifth zone is 240-260°C.

[0039] Thereafter, the polymer melt is fed into the spunbond forming system to form a polypropylene-based filament web 1, and then the pre-fixed web, pre-wet, first-stage hot drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com