Patents

Literature

335results about How to "Fluffy good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

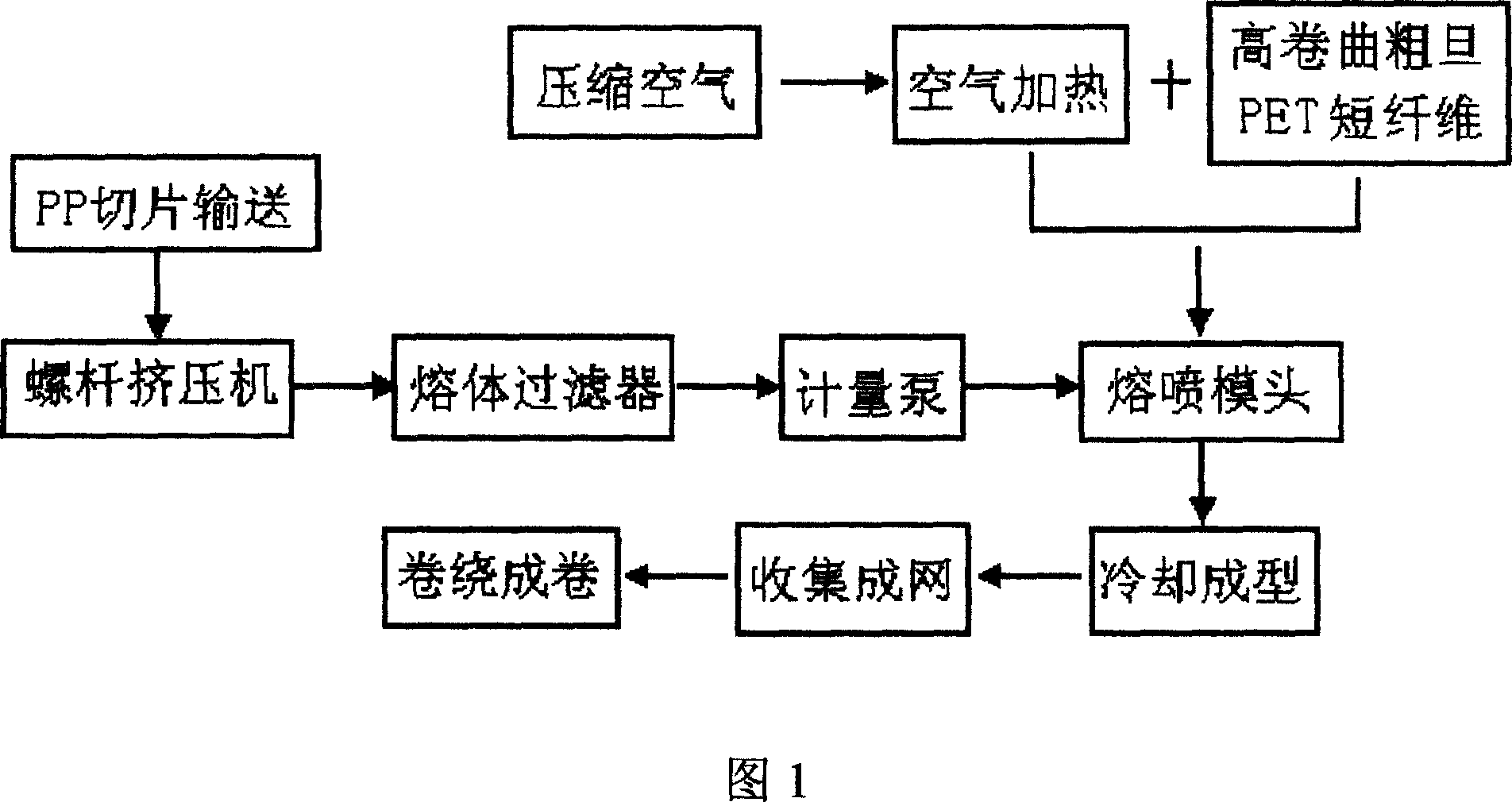

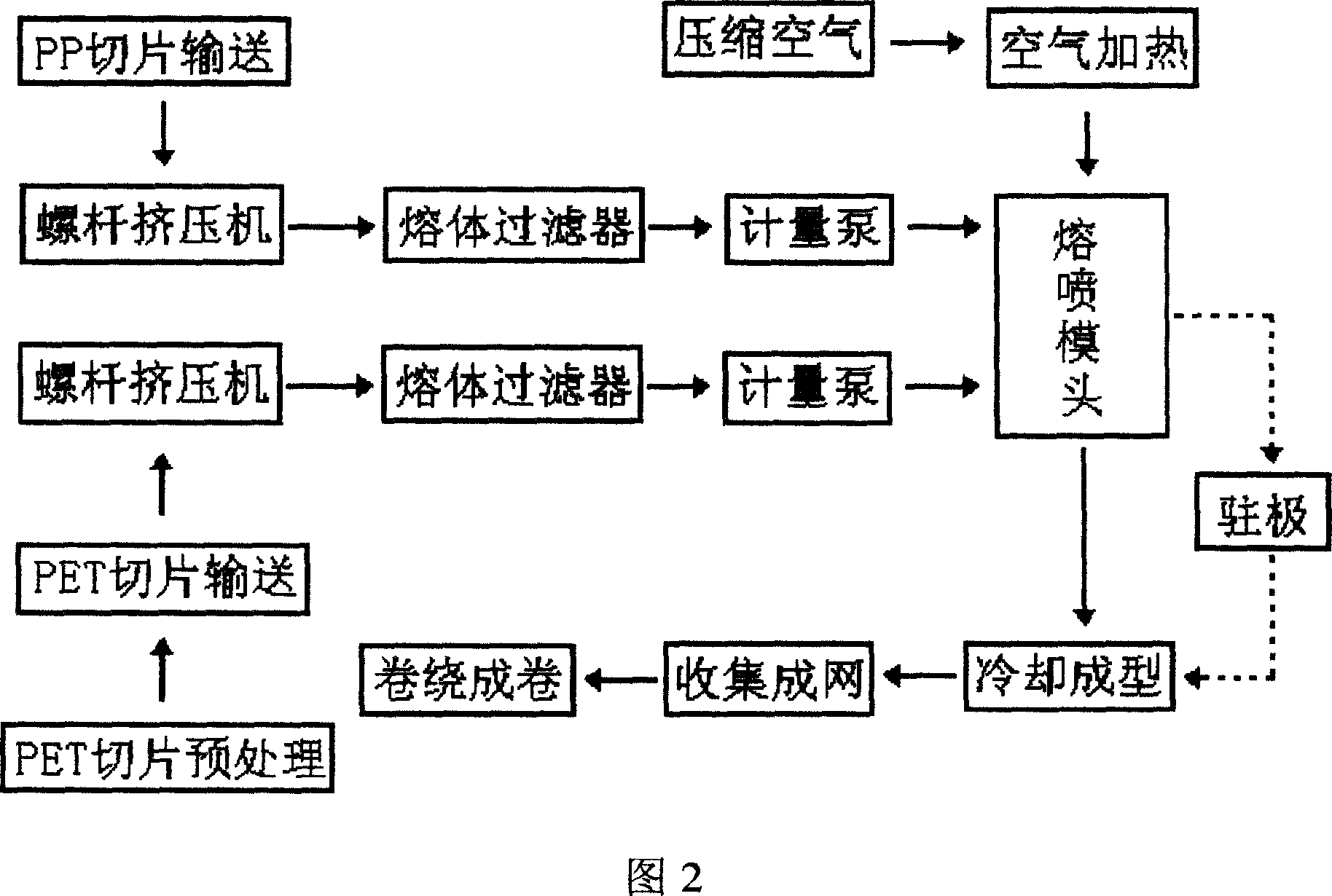

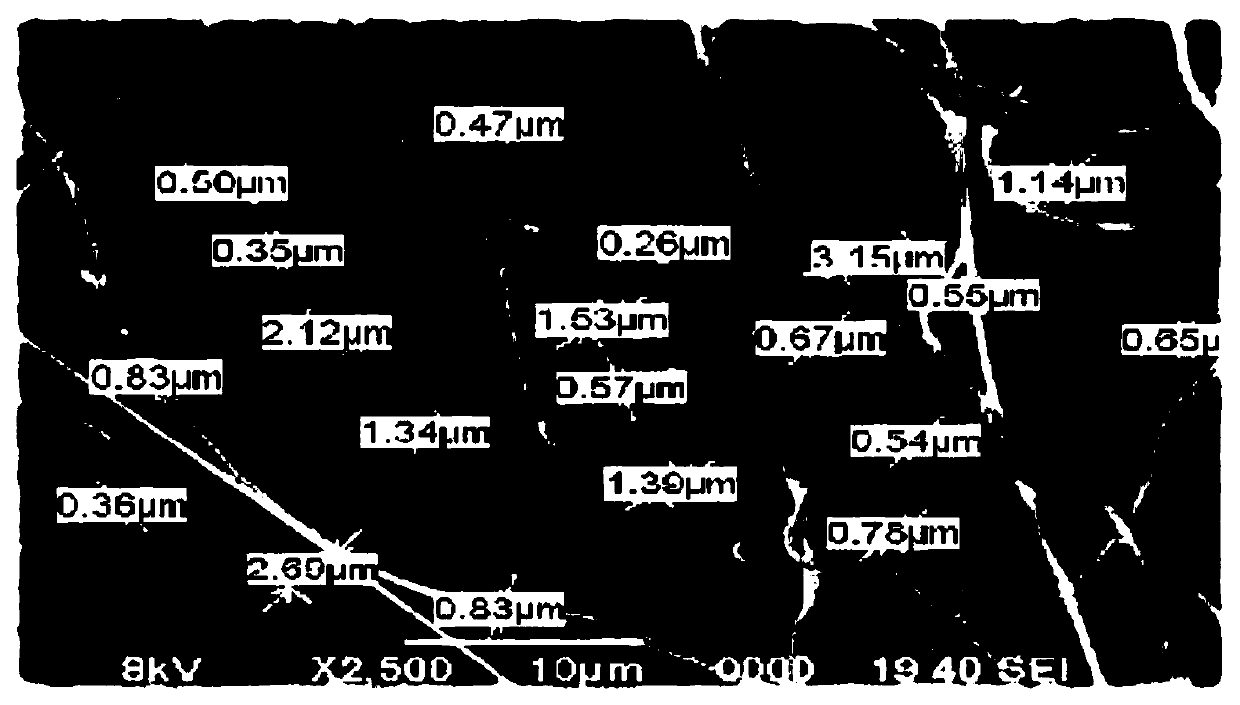

Double component molten and jetted non-woven fabric and its making process

InactiveCN1974906ASimple processEasy to controlFilament/thread formingMonocomponent polypropylene artificial filamentFiberMetallurgy

The present invention relates to one kind of double component molten and jetted non-woven fabric and its making process. The non-woven fabric is made with parallel double molten and jetted fiber components. The fiber has titer of 0.01-2 micron, average titer of 0.5-0.7micron and components of titer below 1 micron accounting for 50-70 %, and consists of PP 30-70 wt% and PET 70-30 wt%. The making process of the non-woven fabric includes the following steps: 1. drying PET; and 2. melting and jetting to compound and spin PP / PET and to make the double component molten and jetted non-woven fabric. The non-woven fabric is used as heat insulating material and filtering material, and possesses high bulkiness, high softness, high air permeability, high heat retaining power and high filtering efficiency.

Owner:TIANJIN TEDA FILTERS +1

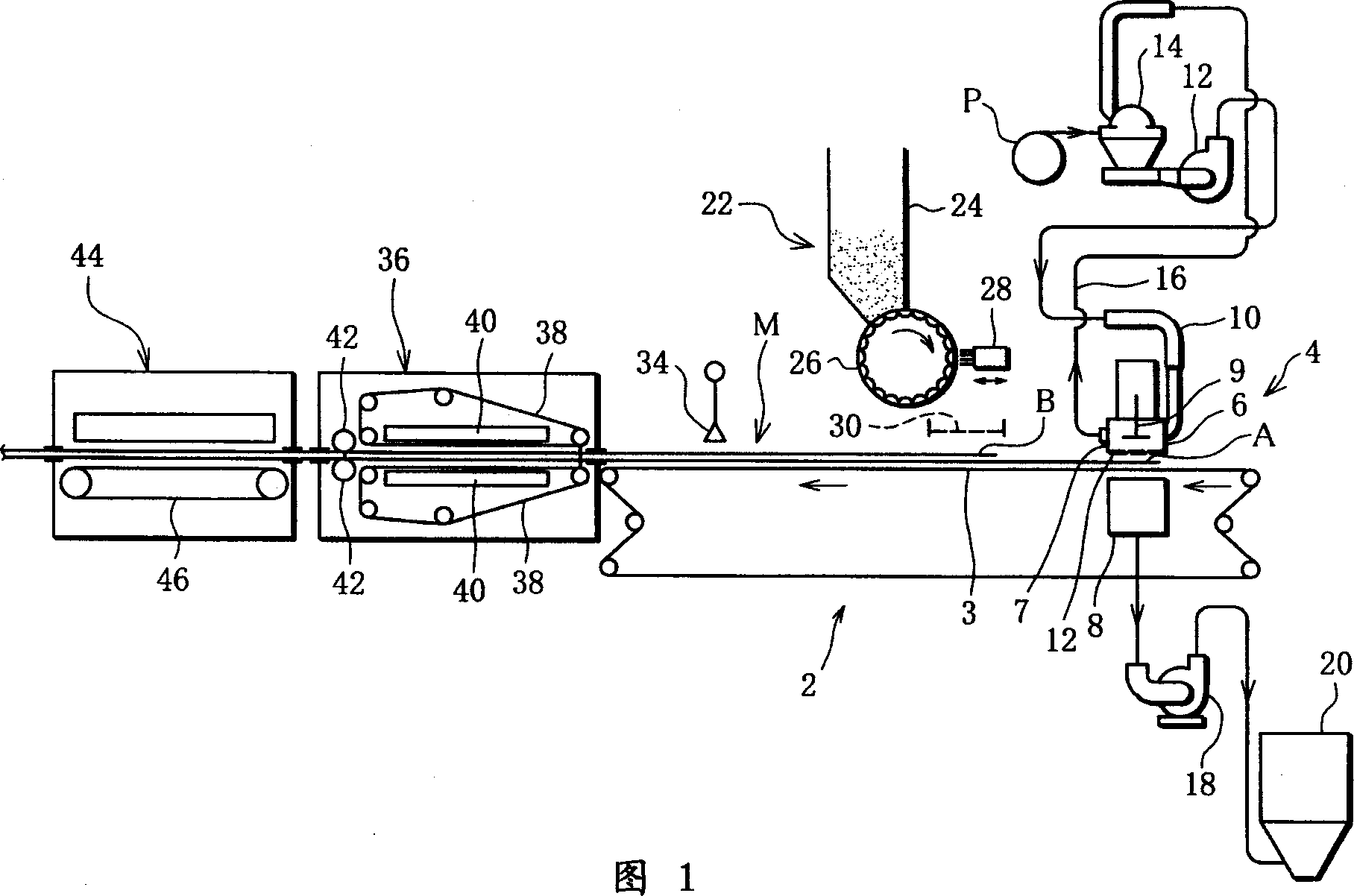

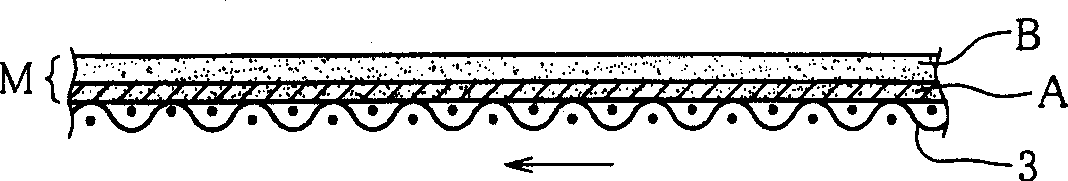

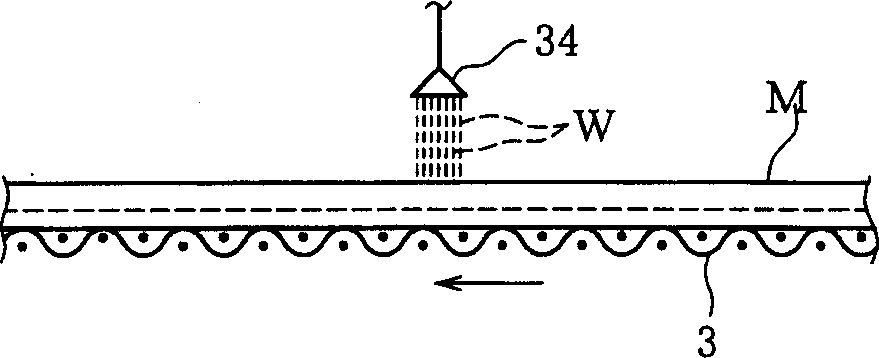

Sheet tobacco and method and system for producing same

InactiveCN1353583AImprove reusabilityFluffy goodTobacco preparationTobacco treatmentManufacturing technologyPowder mixture

Sheet tobacco according to the present invention includes a carrier sheet made of nonwoven plant fibers, and a tobacco powder layer formed on the carrier sheet and containing a powder mixture of tobacco lamina powder and binder powder. In a sheet tobacco manufacturing process according to the present invention, a carrier sheet of plant fibers is formed by a nonwoven fabric production process, a tobacco powder layer is formed by spreading the powder mixture on the carrier sheet, and a cover sheet of plant fibers is optionally formed on the tobacco powder layer. Subsequently, the carrier sheet, the tobacco powder layer and the optical cover sheet are all together subjected to heating and pressing, thereby producing sheet tobacco with a two- or three-layer structure. The present invention also provides a manufacturing system for carrying out the sheet tobacco manufacturing process.

Owner:JAPAN TOBACCO INC +1

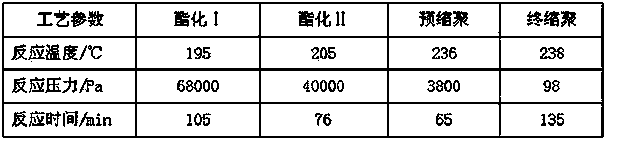

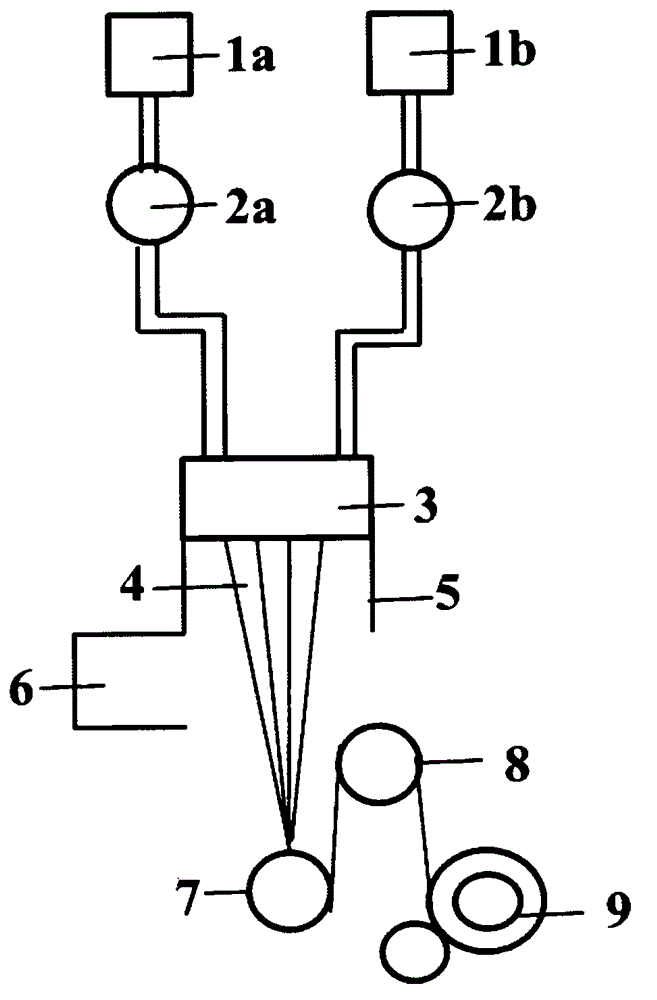

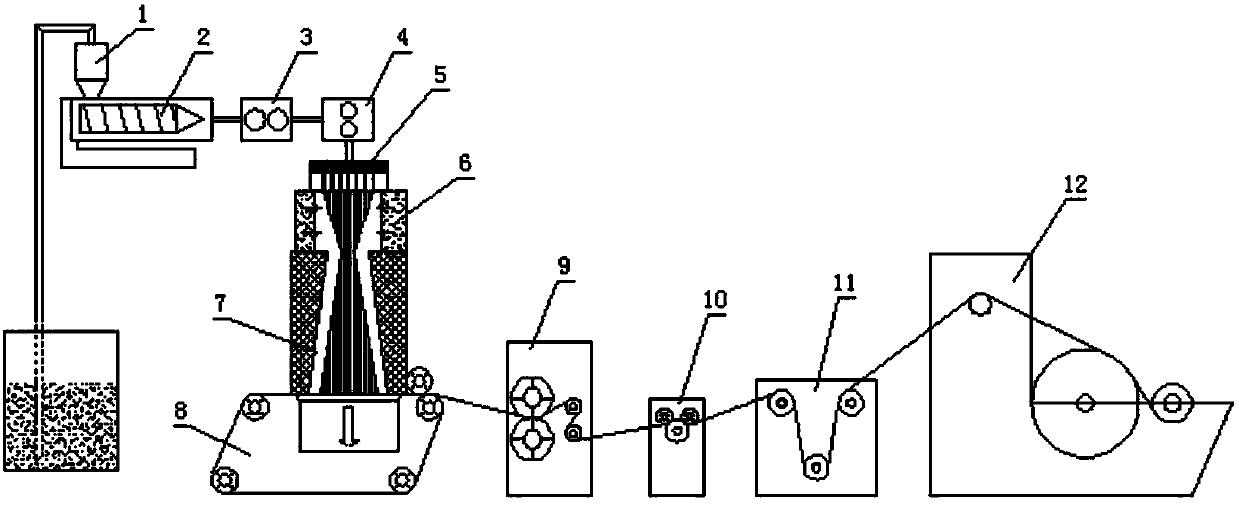

Copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and preparation method thereof

InactiveCN103526323AFull effectVersatileMonocomponent copolyesters artificial filamentMelt spinning methodsYarnPolyethylene glycol

The invention relates to a copolyester melt direct-spinning controllable multiple differential shrinkage composite fiber and a preparation method thereof. Terephthalic acid and ethylene glycol serve as raw materials, a third component of polyethylene glycol, a fourth component of diethylene glycol and a fifth component of pentaerythritol are added for copolymerization, a copolyester melt is prepared, pressurized through a melt pipeline and a pressurizing pump, conveyed to a spinning box, divided into two ways through two metering pumps, sent into a spinning assembly and a spinneret plate for extrusion and cooled and solidified to form two bundles of yarn, FDY (fully drawn yarn) is obtained after oiling wheel oiling, pre-interlacing, drawing and heat setting of one of the two bundles of yarn, the other bundle of yarn is oiled through an oil spraying nozzle and then led to two yarn guiding disks to obtain POY (polyester pre-oriented yarn), the FDY and the POY are input into a yarn doubling device and a main interlacing device simultaneously for composition, and the composite fiber is obtained after ultra-high-speed winding molding. The composite fiber adopts the better fine three-dimensional multi-layer structure and is large in potential controllable hot-shrinkage rate difference, good in fluffiness, hygroscopicity, air permeability, moisture retention, chromaticity and high color rendering uniformity, multiple in product function and high in additional value.

Owner:SUZHOU UNIV

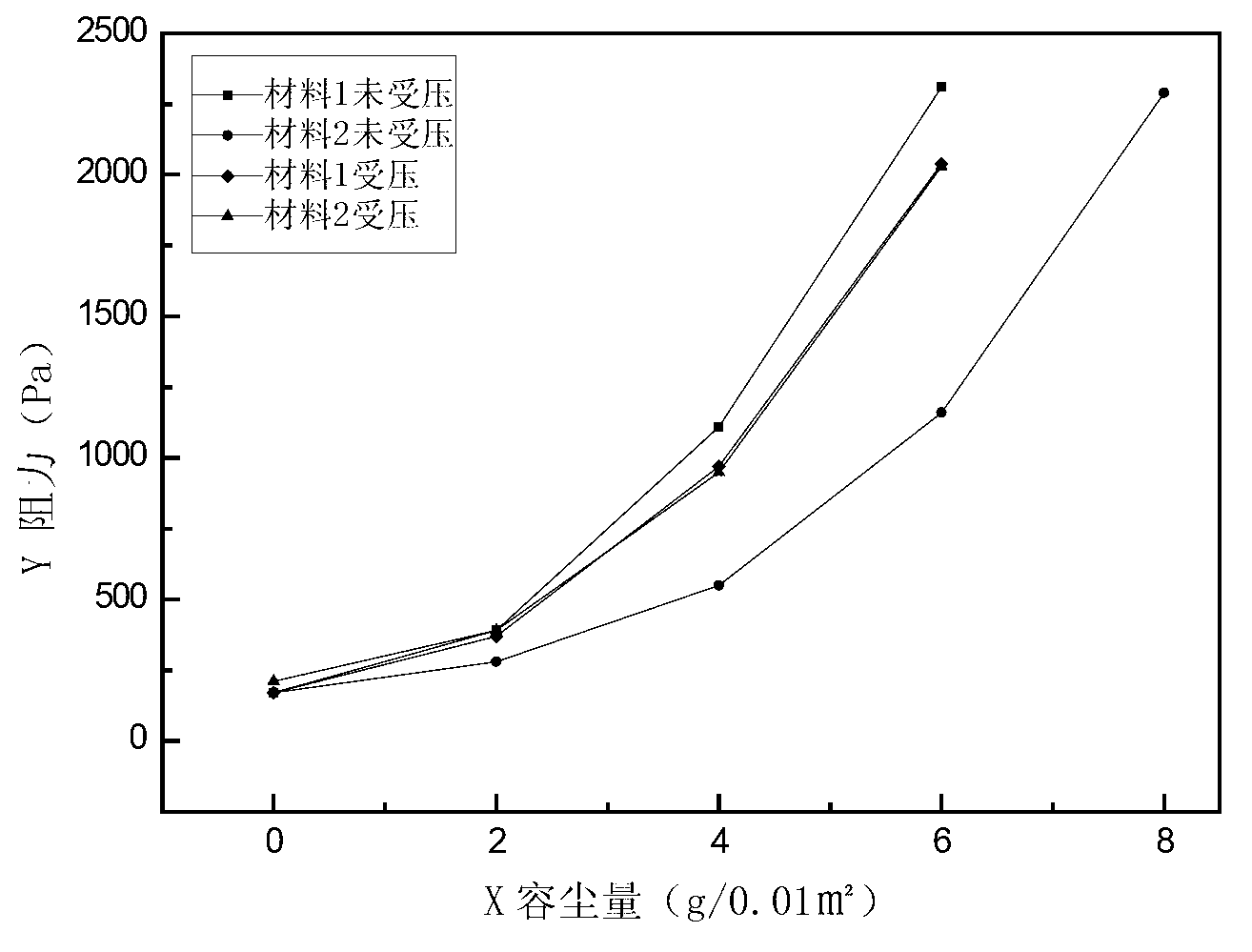

Melt spinning non-woven material and production method and application thereof

InactiveCN103046231AImprove interception effectSmall pressure lossSuction filtersLayered productsCrude fibrePolymer science

A melt spinning non-woven material is characterized in that the weight of the non-woven material weights 35 to 500 g / m<2> and being obtained by a polymer slice being directly melting to spin and the spine being weaved into webs. The melt spinning non-woven material consists of superfine fibers and crude fibers, the crude fibers are used as a framework and the superfine fibers are filled into the framework to form a fiber web to form a thickness matching structure. The fiber web has one layer or more, and when the layer number of the fiber web is more than one, a thickness increasing or gradient structure is formed through a multilayer structure. By means of the optimization of raw materials and process, the melt spinning non-woven material and a production method and an application of the melt spinning non-woven material can control a fiber web structure of the melt spinning non woven material: the distribution of fiber finenesses is controlled in a reasonable range, the fiber web has a large amount of superfine fibers and a certain amount of crude fibers; the crude fibers being used as a framework and the superfine fibers being filled into the framework improve the fluffiness of the material, and the material can still maintain some recovery capability when in use; and the fiber web forms a structure with some gradients.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

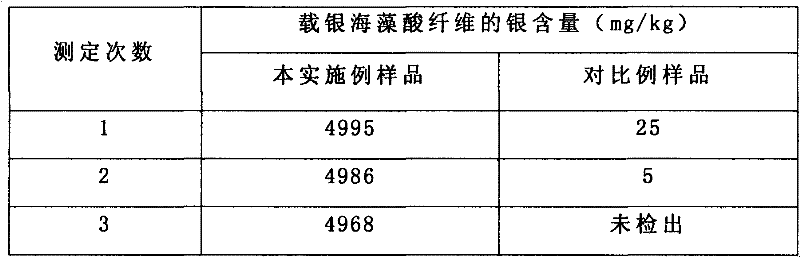

Silver-carried alginic acid fiber and preparation method thereof

ActiveCN102373618AGood antibacterial propertiesGood fluffiness, softnessFibre treatmentChemistryAlginic acid

The invention relates to a medical disinfecting and sterilizing dressing raw material and a preparation method thereof, in particular to a silver-carried alginic acid fiber and a preparation method thereof. The preparation method comprises the following steps of: impregnating the alginic acid fiber in a water solution of nano silver with the concentration of 20-1000 ug / L, wherein the bath ratio is 1:10-200, and the impregnation time is 2-60 min; than, taking out the silver-carried alginic acid fiber absorbing elementary silver particles in an enrichment method, washing and drying the silver-carried alginic acid fiber through a water solution of organic solvent to obtain an alginic acid fiber with 0.01-4% of silver by weight and having good bulkiness and strong sterilization effect. The preparation method of the alginic acid fiber absorbing silver in an enrichment method provided by the invention has simple and feasible process, safe and nontoxic production process and practical application value.

Owner:ZHANGJIAGANG NELLNANO TECH +1

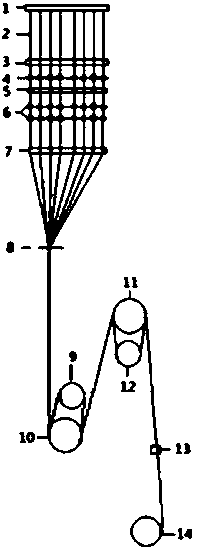

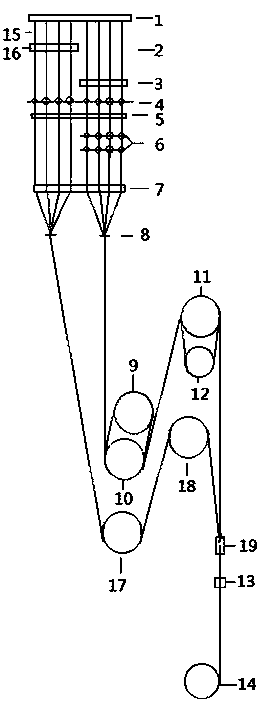

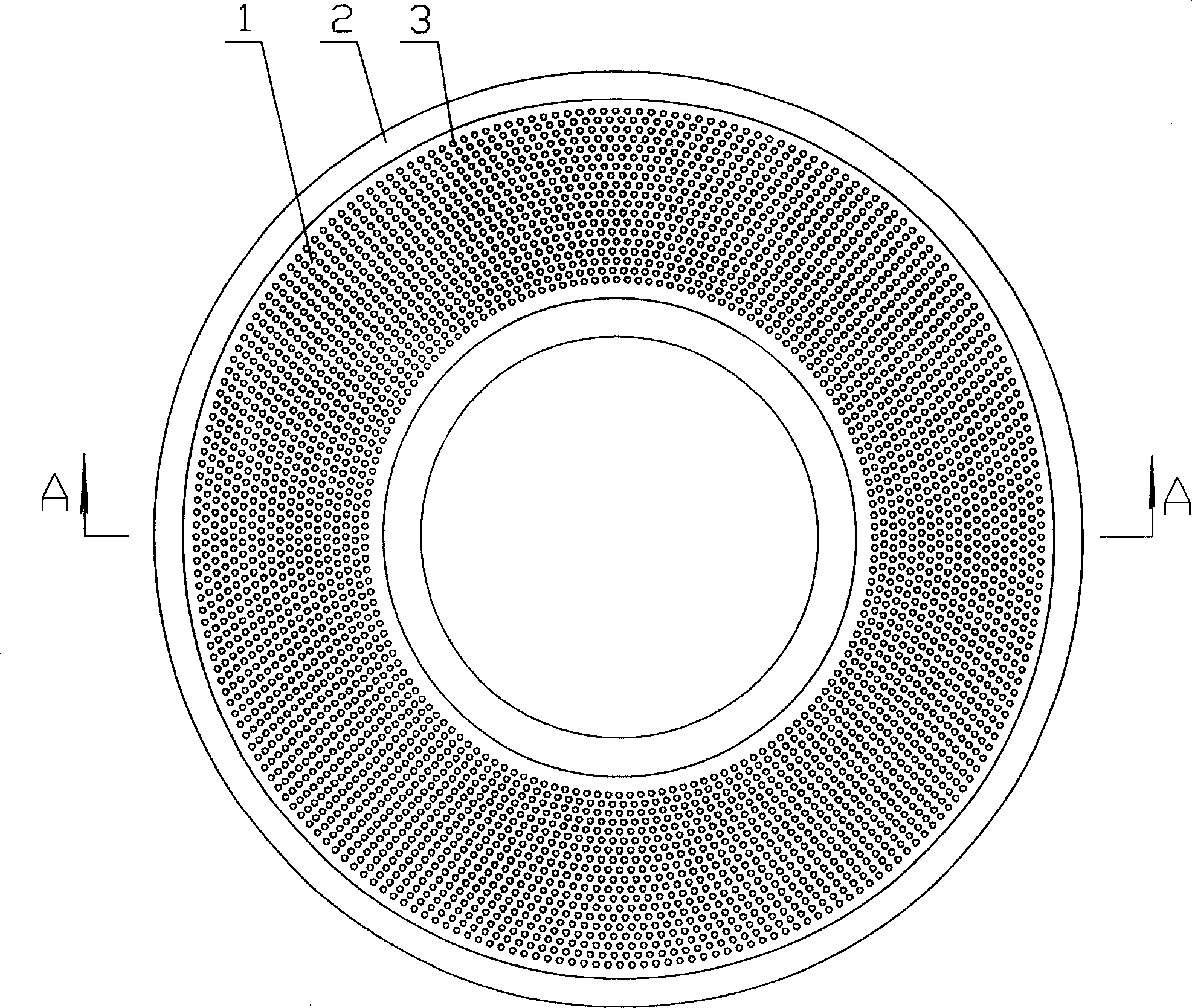

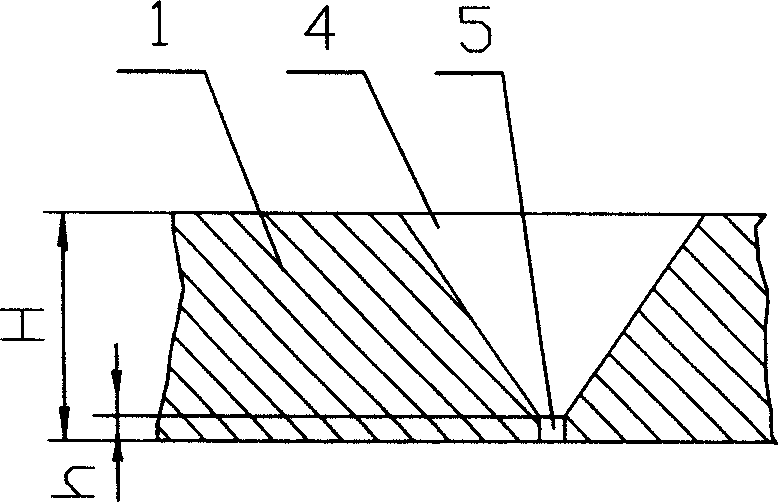

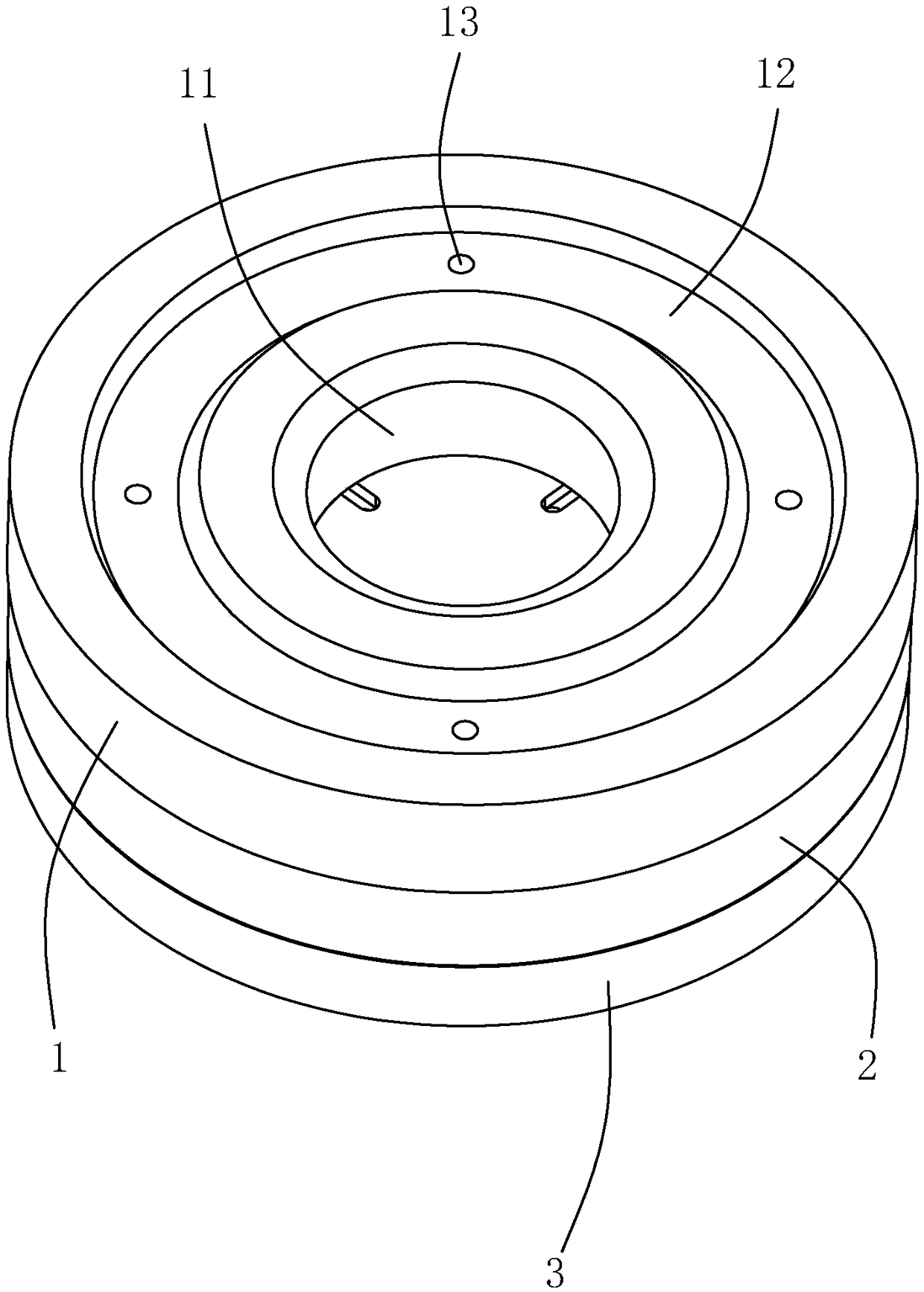

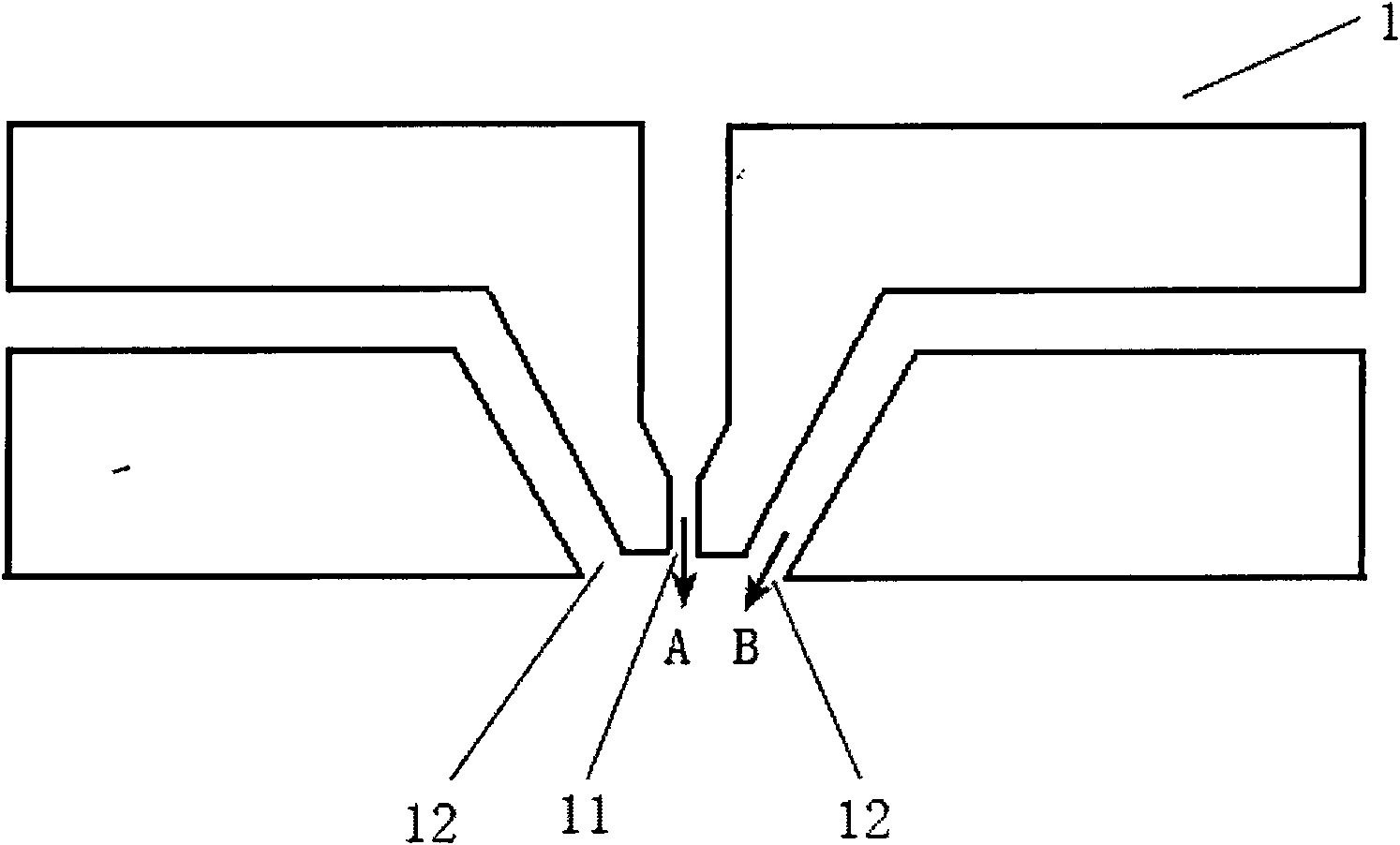

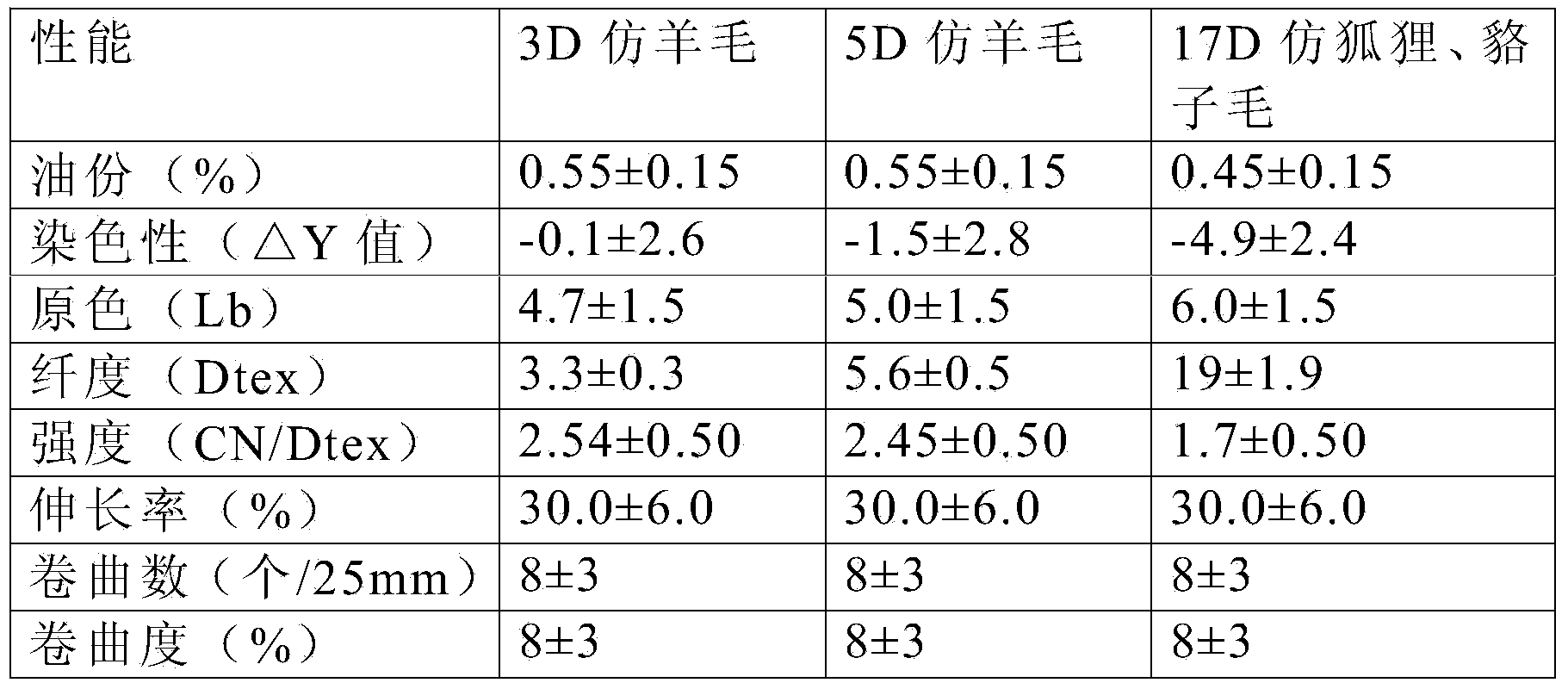

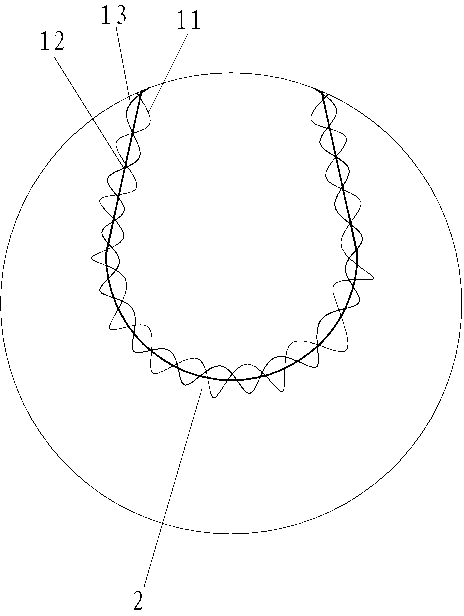

Method for making acrylic fibre by fine denier dry method and spinning nozzle

InactiveCN1752301AGood spinnabilityGood spinning position stabilitySpinnerette packsMonocomponent synthetic polymer artificial filamentAcrylic fibreProcess engineering

The present invention optimizes and properly regulates the technological conditions of original Dupont dry spinning of acrylic fibre, such as properly raising temperature difference of internal and external side temperatures of mass, reasonably controlling nitrogen gas temperature and flow rate, water-washing temperature and draft multiple and speed and using cotton type oil agent to oil, etc. and reasonably designs the spinneret with high-density nozzle hole, its hole number is 3600-4400, its aperture is 0.09-0.13 mm, and the holes are arranged and distributed on 15-21 concentric circles, so that it can implement industrial production of fine-denier dry acrylic fibre.

Owner:浙江金甬腈纶有限公司

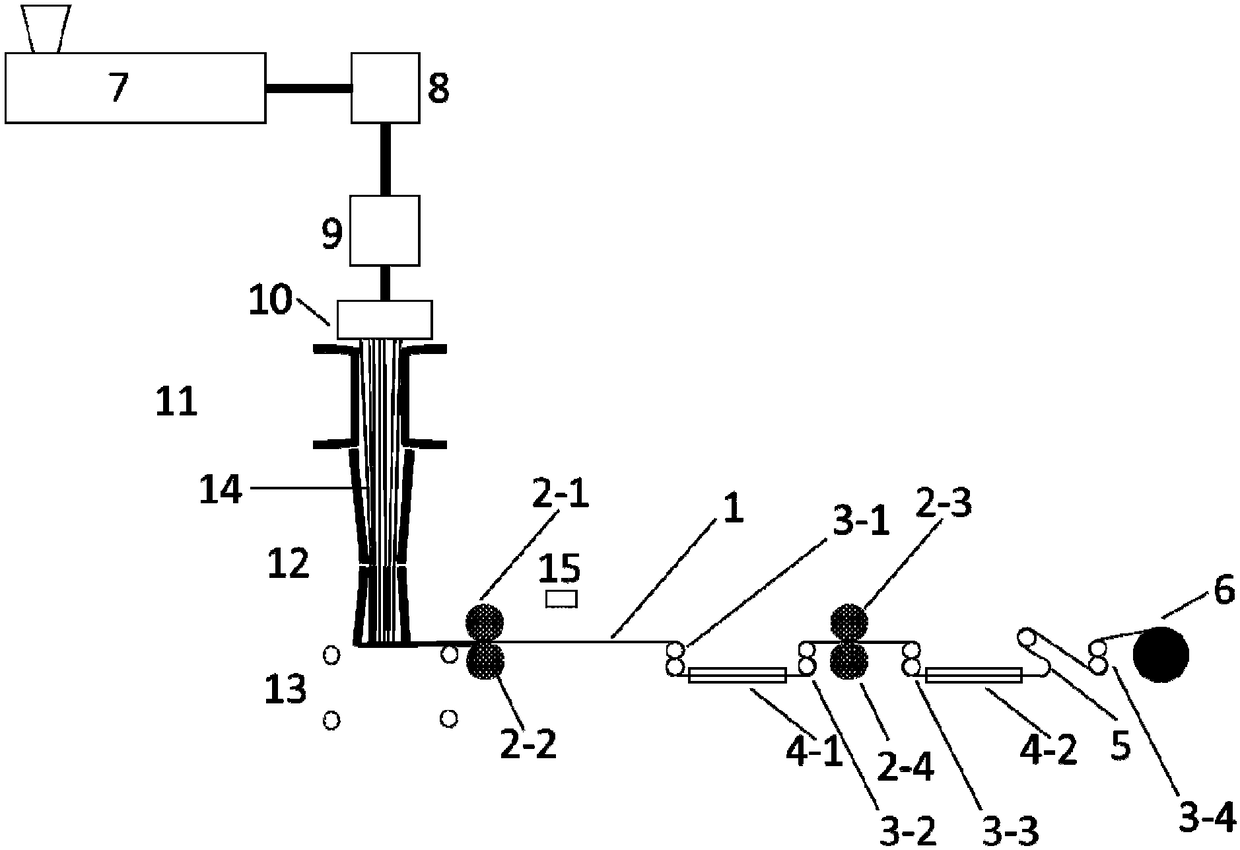

Graphene polylactic acid bicomponent composite fiber and preparation method and equipment thereof

ActiveCN109487352AConductiveBacteriostaticArtificial thread manufacturing machinesFilament/thread formingGrapheneUltimate tensile strength

The invention relates to a graphene polylactic acid bicomponent composite fiber and a preparation method and equipment thereof, and belongs to the technical field of melt-spinning fibers. The preparation method comprises the following steps: respectively drying and mixing 60-75wt% of polylactic acid slices and 25-40wt% of graphene master batches to obtain a component A; drying the polylactic acidslices as a component B; respectively melting and extruding the component A and the component B, and then spinning together. The bicomponent composite fiber prepared by the graphene polylactic acid bicomponent composite fiber and preparation method and equipment thereof has obvious crimping effect, excellent elasticity and fluffiness, and good effects of strength, wear resistance, heat preservation, bacteriostasis and conduction.

Owner:杭州三信实业有限公司

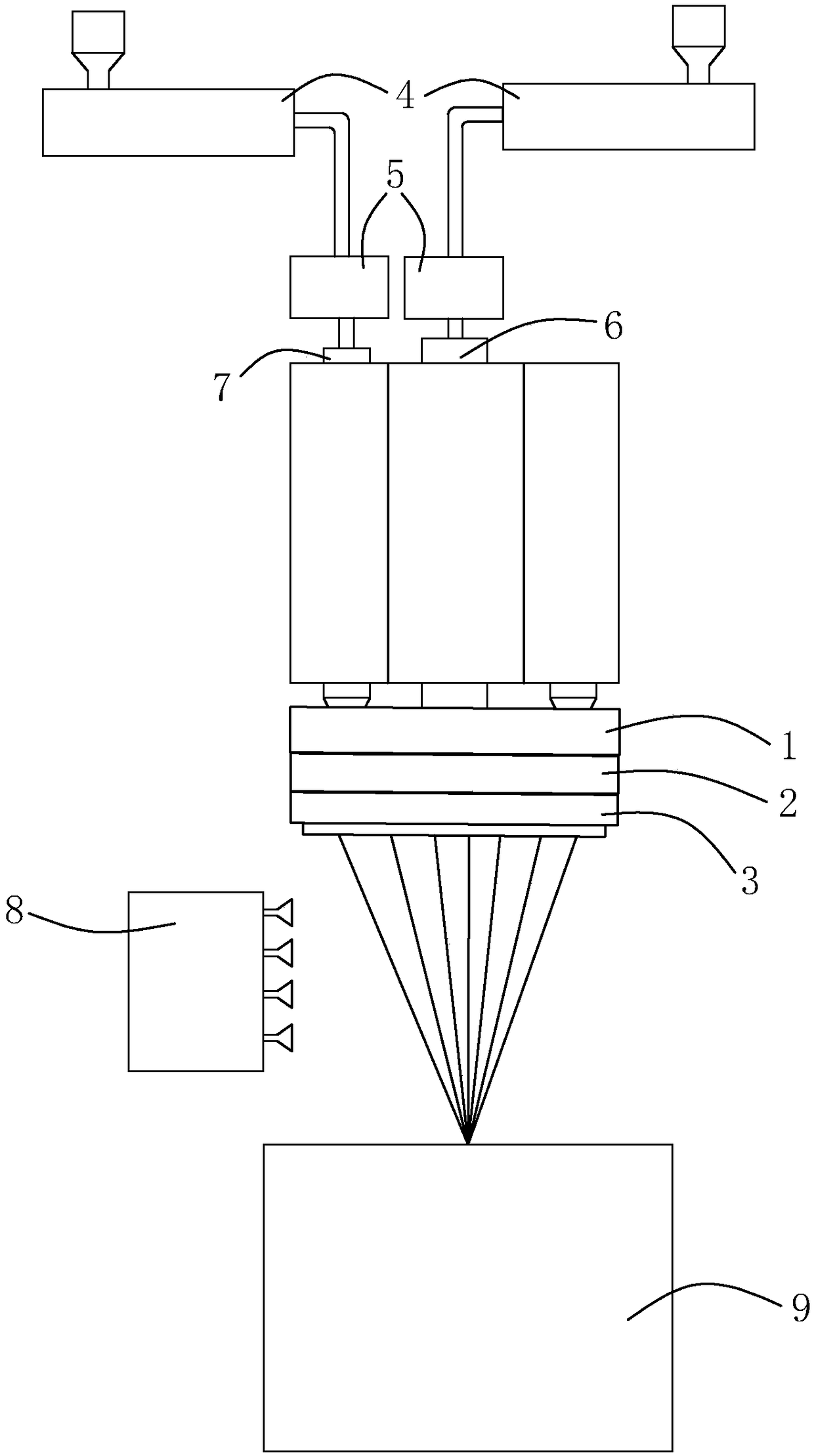

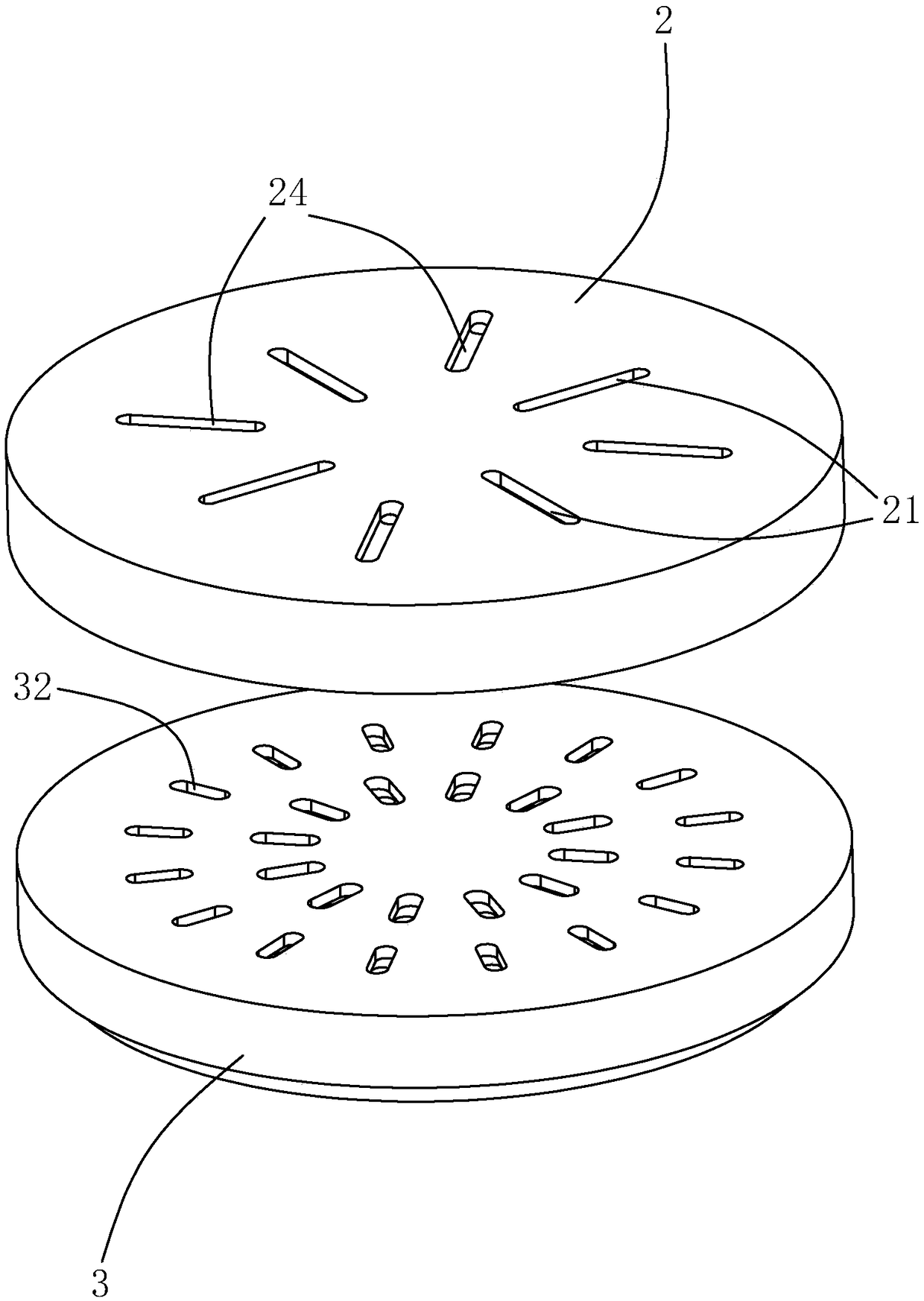

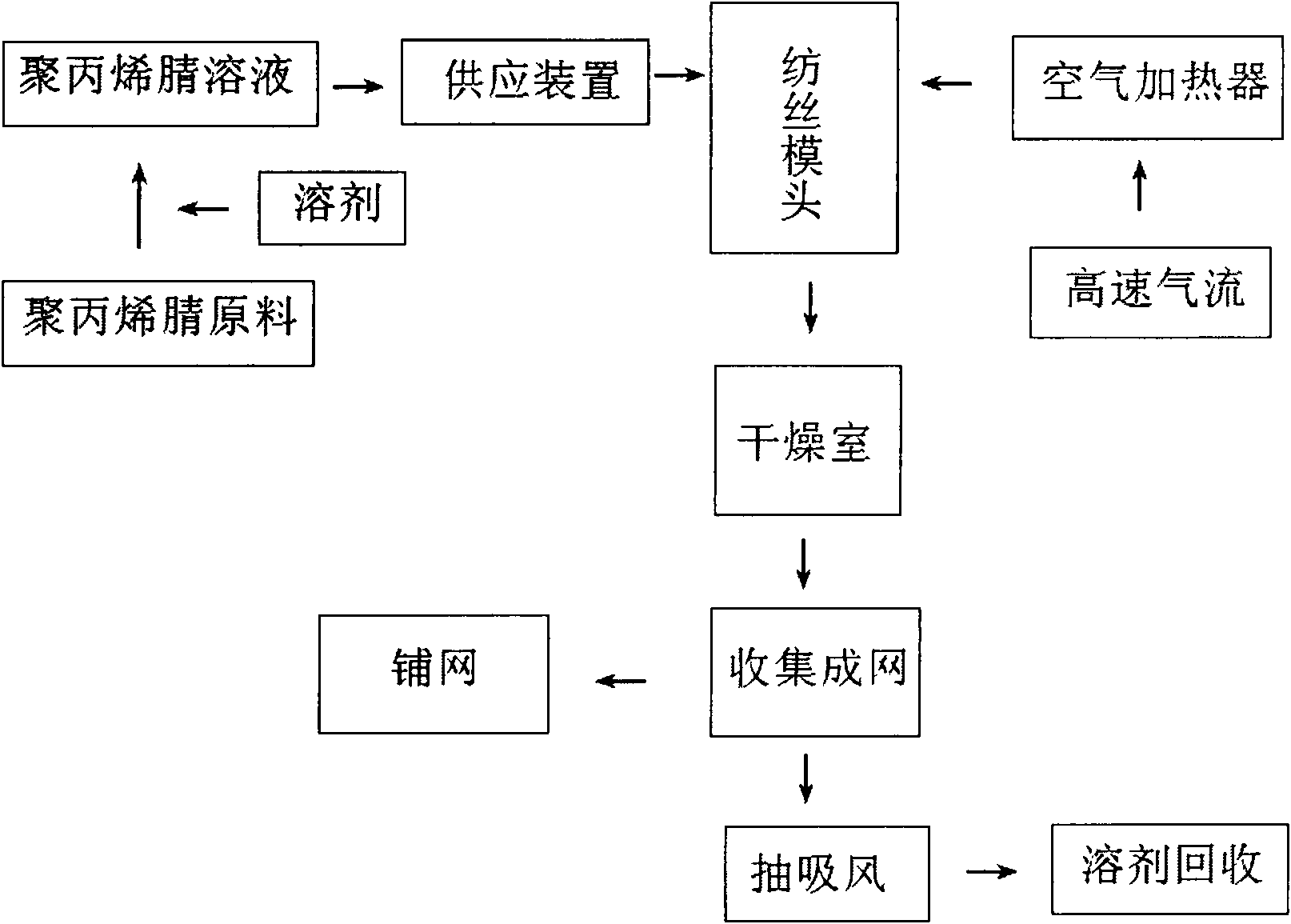

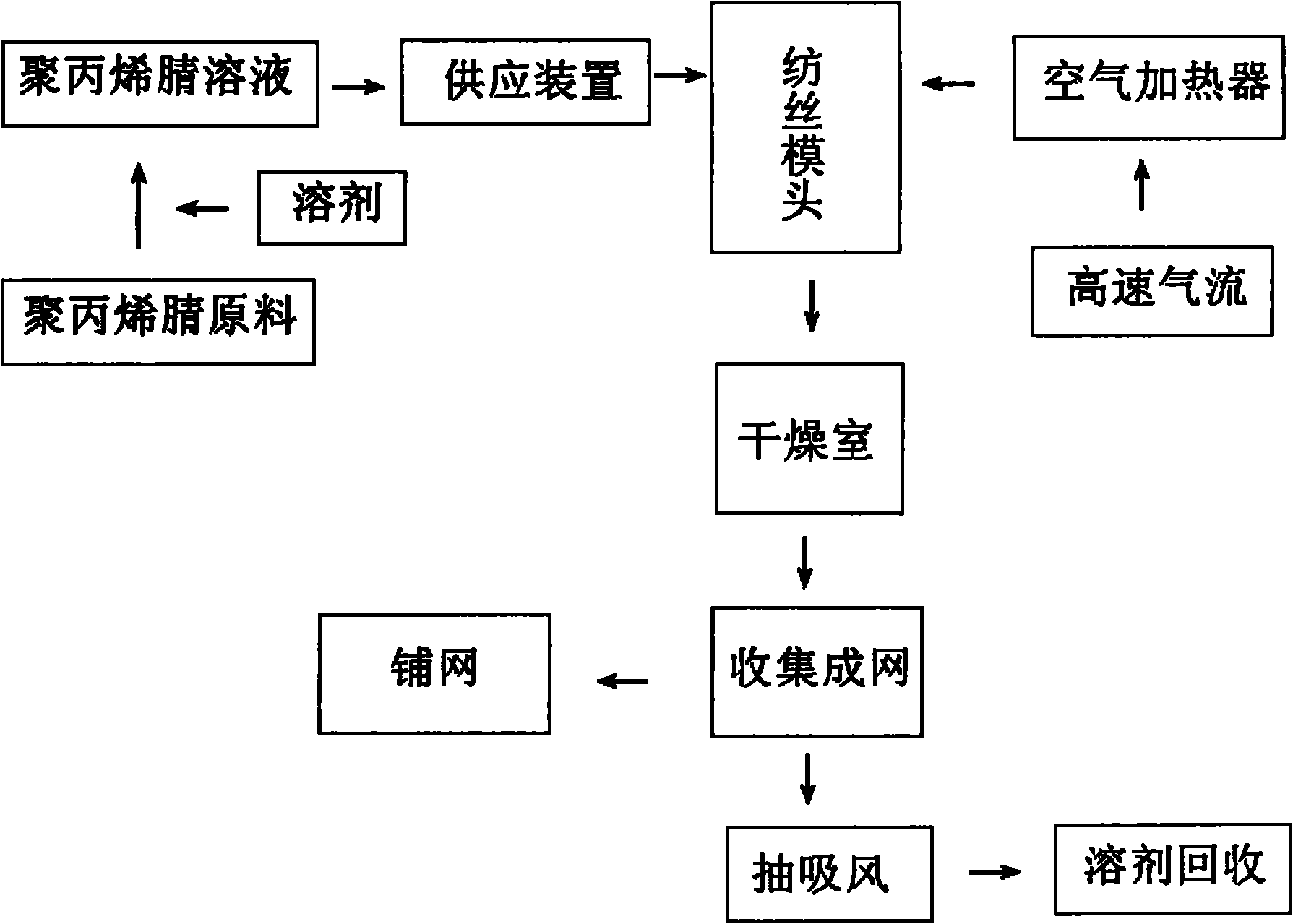

Method for preparing sound-absorbing and heat-insulating materials formed by superfine fiber nonwovens

InactiveCN102121173AIncrease productivityOvercoming the disadvantages of processing high melt fluidity raw materialsMonocomponent synthetic polymer artificial filamentNon-woven fabricsEngineeringSolvent

The invention discloses a method for preparing sound-absorbing and heat-insulating materials formed by superfine fiber nonwovens. The method comprises the following steps: dissolving polyacrylonitrile in a solvent to form spinning solution, supplying the spinning solution to a spinning die head containing a series of spinneret orifices via a supply device and extruding the spinning solution out of the spinneret orifices of the spinning die head to form spinning solution trickles; simultaneously at least a high-speed jet stream heated by an air heater entering into the spinning die head and blowing the extruded spinning solution trickles via the air gaps on the spinning die head at a jet angle of 15-60 degrees; realizing drawing and thinning of the spinning solution trickles and simultaneously accelerating volatilization of the solvent in the spinning solution to form superfine fibers; collecting the superfine fibers on the web curtain by utilizing the high-speed jet stream and suction stream to form webs, thus forming the sound-absorbing and heat-insulating materials formed by polyacrylonitrile superfine fiber nonwovens; and lapping the formed sound-absorbing and heat-insulating materials formed by polyacrylonitrile superfine fiber nonwovens on multiple layers according to the design requirements.

Owner:TIANJIN POLYTECHNIC UNIV

Flat acrylic fiber and production method thereof

ActiveCN103882547ALower glass transition temperatureGood flexibilitySpinnerette packsArtificial filament heat treatmentPolymer scienceDouble diffusion

The invention relates to a flat acrylic fiber and a production method thereof. The flat acrylic fiber consists of the following components in percentage by weight: 91-94 percent of acrylonitrile and 6-9 percent of vinyl acetate, wherein the length-width ratio of the flat acrylic fiber is (2-13):1. The method for producing the flat acrylic fiber comprises the following steps: carrying out copolymerization reaction on the acrylonitrile and the vinyl acetate to prepare dried polyacrylonitrile powder, dissolving the powder in a solvent to form a stock solution, extruding from a rectangular hole of a spinneret plate after heating, and performing double diffusion to form a nascent fiber in a coagulating bath; washing the nascent fiber by water, and drawing the fiber through a drawing machine; oiling tows; and drying the tows and setting, so as to obtain the flat acrylic fiber. The contents of the acrylonitrile and the vinyl acetate in a copolymer, the molecular weight of the copolymer and a specific process flow are adjusted, so that the prepared flat acrylic fiber is good in handfeel, the softness and handfeel of the fiber can be improved, the rebound resilience, hydrophobicity and spinnability of the fiber can be guaranteed, and the acrylic fiber is easy to color.

Owner:NINGBO ZHONGXIN ACRYLIC FIBERS

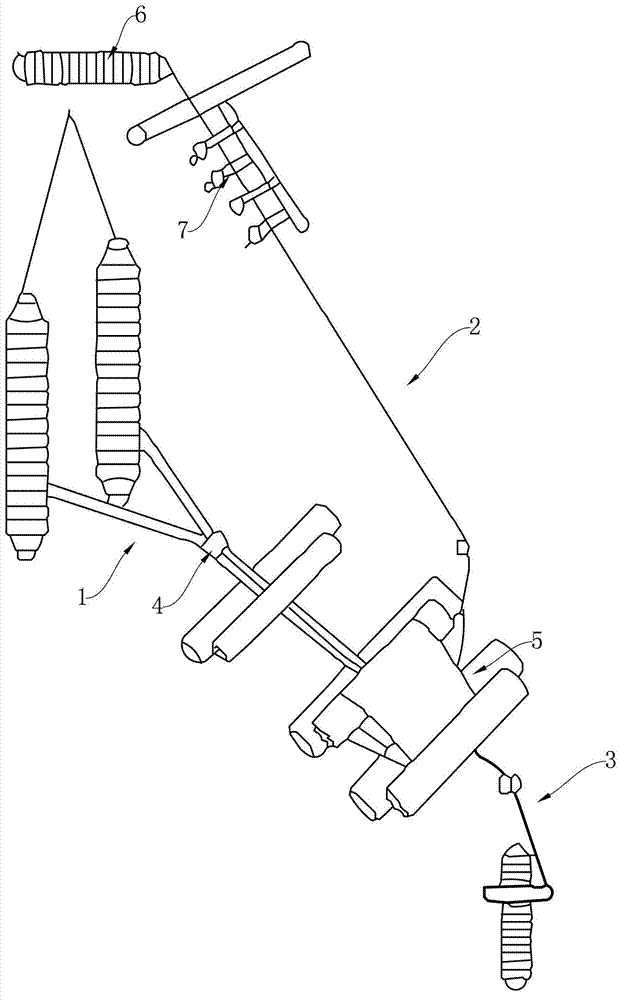

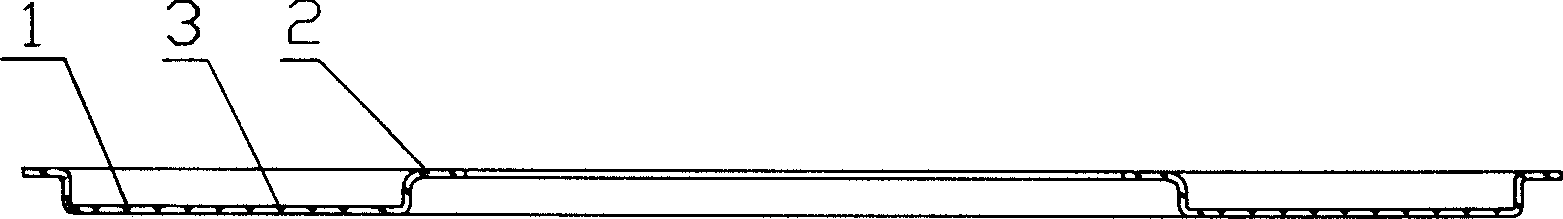

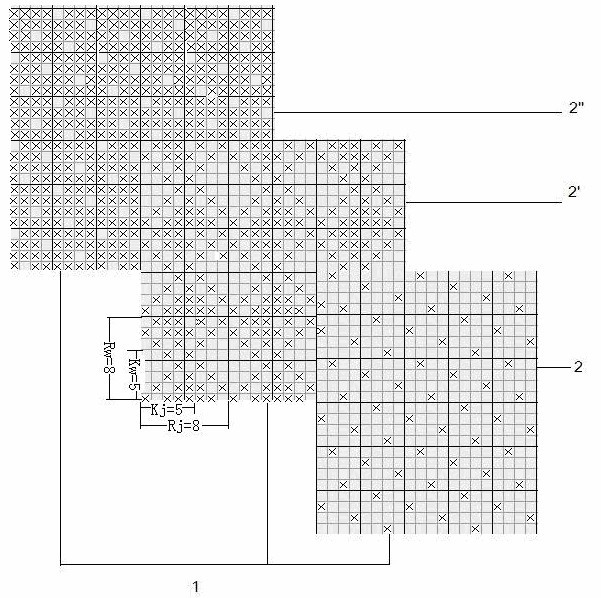

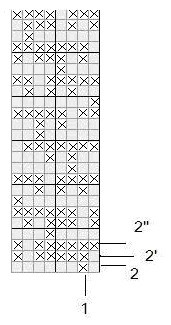

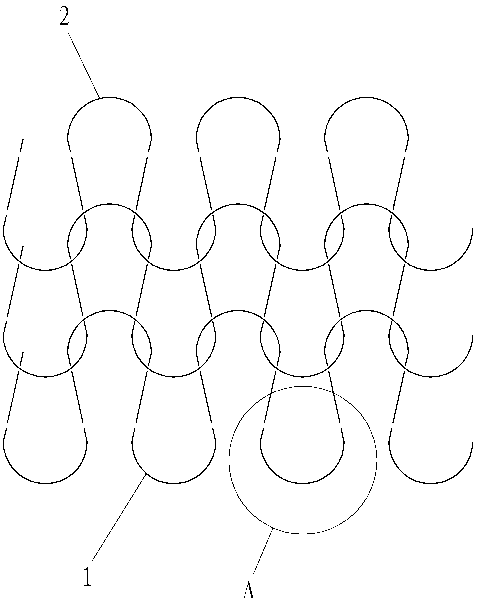

Method for preparing warm composite woven fabric

InactiveCN102181986AElasticIncreased warmth and bulkinessMulti-ply fabricsSwivel-woven fabricsYarnSurface layer

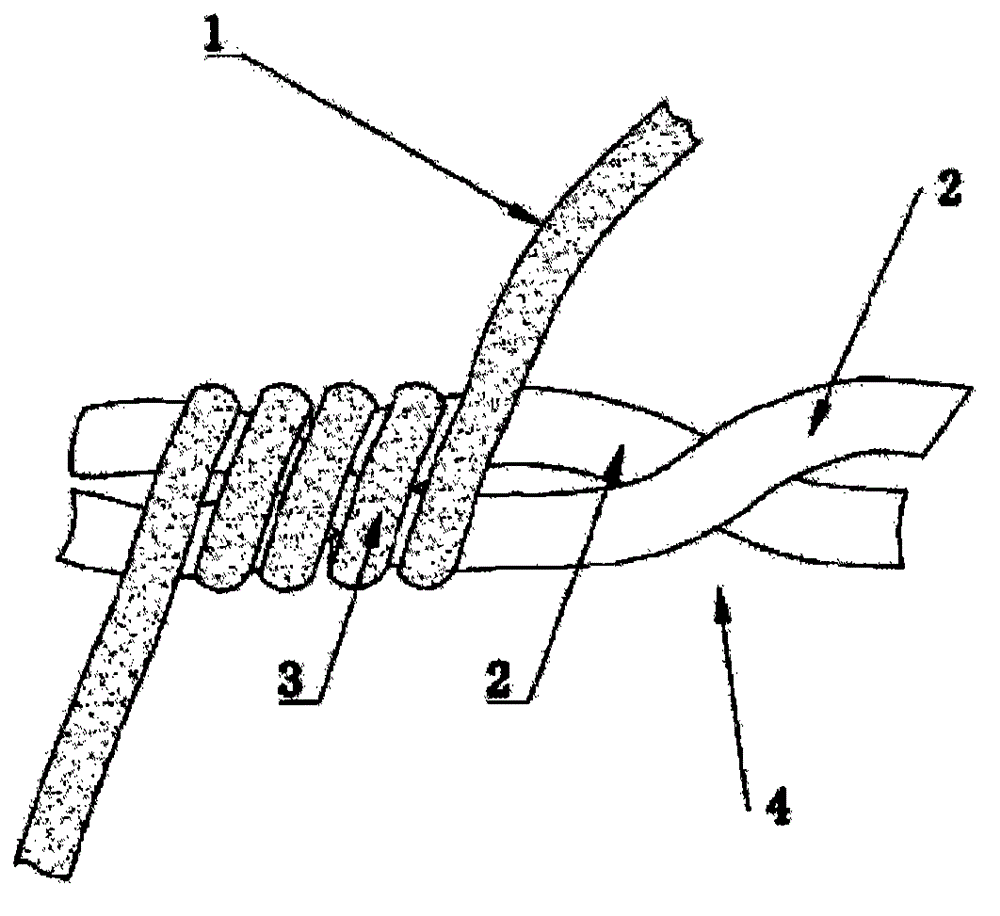

The invention relates to a method for preparing warm composite woven fabric. The warm composite woven fabric is prepared by interweaving a group of warp yarns (1) and three groups of filling yarns in an overlapped way, wherein the three groups of filling yarns are respectively face weft (2), intermediate weft (2') and back weft (2''), the face weft (2), the intermediate weft (2') and the back weft (2'') are arranged according to the proportion of 1:1:1, the warp yarn (1) and the face weft (2) are woven into satin weave which has 8 lines and 5 step weft faces and serves as a surface layer according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the back weft (2'') are woven into satin weave which has 8 lines and 5 step weft faces and serves as a lining according to a mode of an upper needle and seven lower needles and 5 weft step numbers, the warp yarn (1) and the intermediate weft (2') take honeycomb weave as an intermediate layer in terms of Rj equal to Rw and equal to 8, and the Rj and the Rw are respectively the circulated yarn numbers of warp weave and weft weave. The warm composite woven fabric prepared by the method integrates the characteristics of light weight, super warm property, softness, comfortableness, moisture absorption, air permeability, bacterial resistance and bacterial restraint, and the production is simple and easy to implement.

Owner:江苏保丹服饰有限公司

Flame-retardant fabric and processing technique thereof

The invention discloses flame-retardant fabric and a processing technique thereof. The flame-retardant fabric is made by blending, by weight, 40-50% of flame-retardant acrylic fiber, 10-20% of flame-retardant viscose, 30-40% of polysulfonamide and 3-5% of conductive fiber. The flame-retardant acrylic fiber, the flame-retardant viscose, polysulfonamide and the conductive fiber are reasonably combined, the defect that the flame-retardant acrylic fiber is poor in spinnability is overcome, and the flame-retardant fabric has excellent characteristics such as softness, good fluffiness, drapability and breathability, high strength and wear resistance, good cover glossiness and color fastness, and resistance of melting and dropping in case of a fire.

Owner:NANTONG FANGKE TEXTILE TECH

Method for bleaching grey down feather

InactiveCN101705612AThe whiteness is obviously improvedDown damage is smallBleaching apparatusIonChemistry

The invention discloses a method for bleaching grey down feather. The method comprises the following steps: firstly, using ferrous ions to conduct pretreatment on down feather to be treated, then conducting selective oxidation bleaching on the down feather, and finally using thiourea dioxide to conduct reduction bleaching on the down feather, and using clear water to wash the down feather, and drying. The method can effectively eliminate the natural pigment in the down feather, and has less damage to the down feather; the selective oxidation bleaching and reduction bleaching by using the thiourea dioxide (TDO) are combined to treat the down feather; after the TDO is applied to conduct reduction bleaching under the mild condition on the down feather treated by selective oxidation bleaching, thus improving the whiteness of the down feather, leading the decolorization and bleaching of the grey down feather to achieve high-level whiteness, and inhibiting the color reversion of the down feather; and the TDO is an acid reducing agent, can play the role of strong reducing property under the acidulous and neutral conditions, is suitable for the stability condition of the protein fiber in the down feather, and has little damage to the fiber. The whole process for decolorizing and bleaching the down feather is conducted at low temperature, thus not only ensuring the little damage to the fiber, and good bulkiness, but also being beneficial to energy conservation and environmental protection.

Owner:萧山区质量计量监测中心 +1

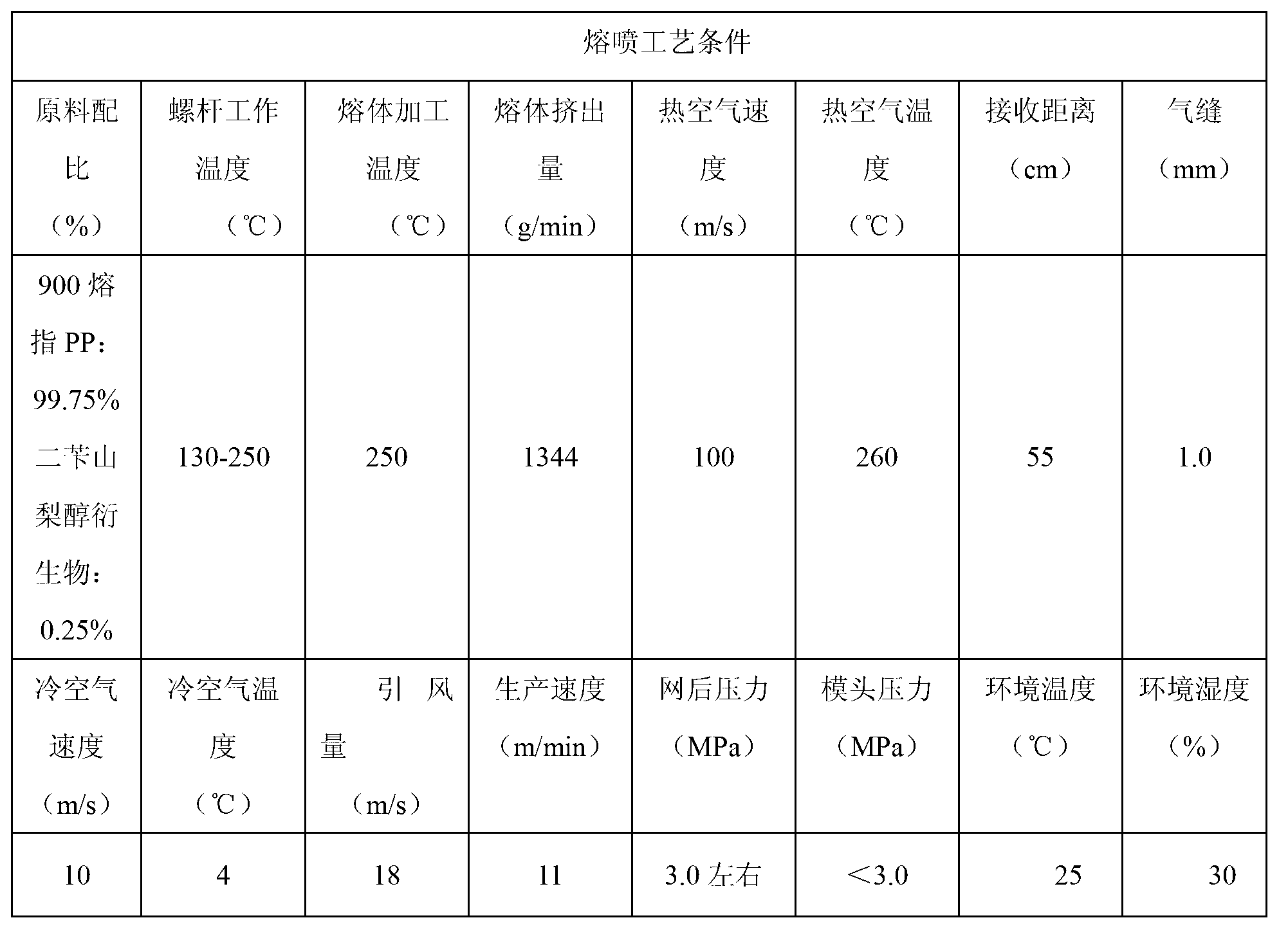

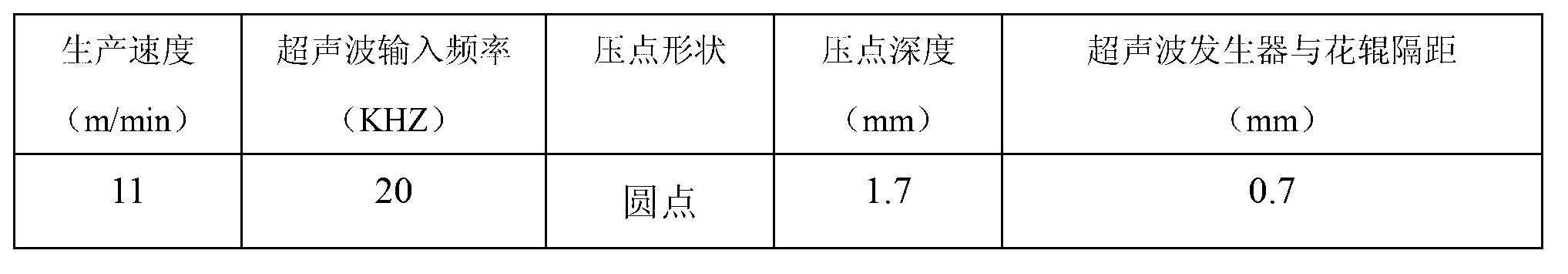

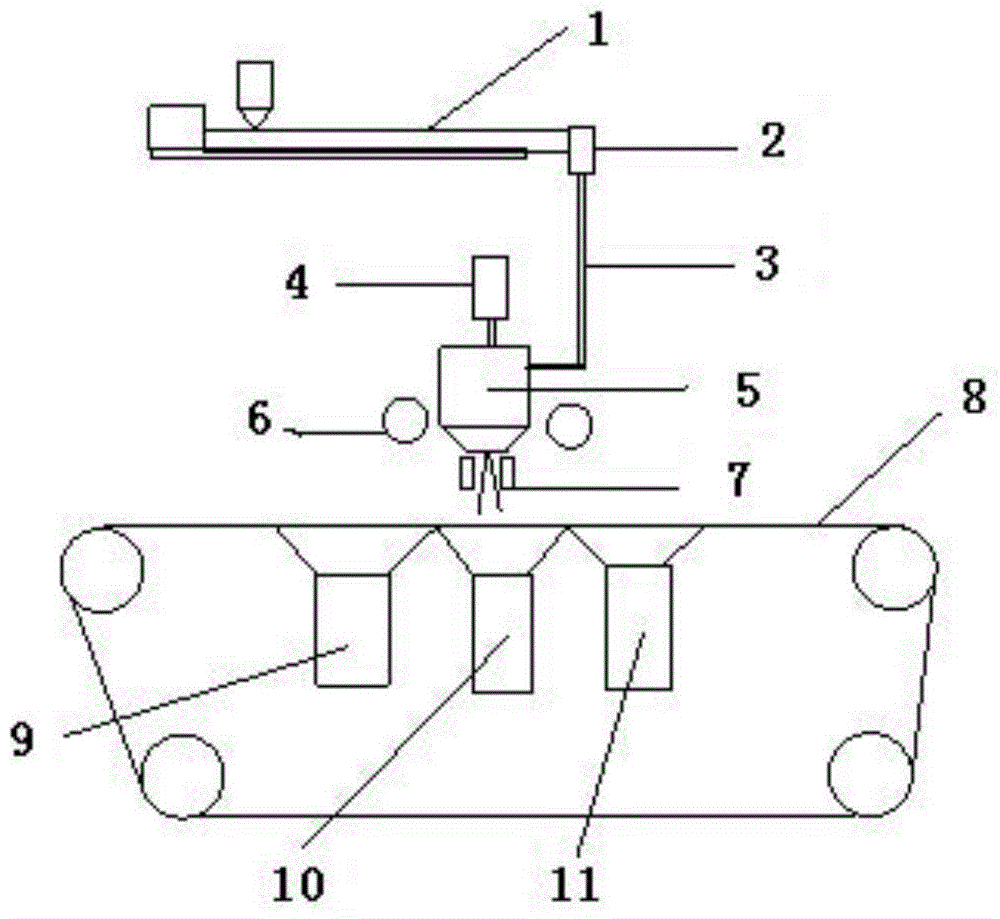

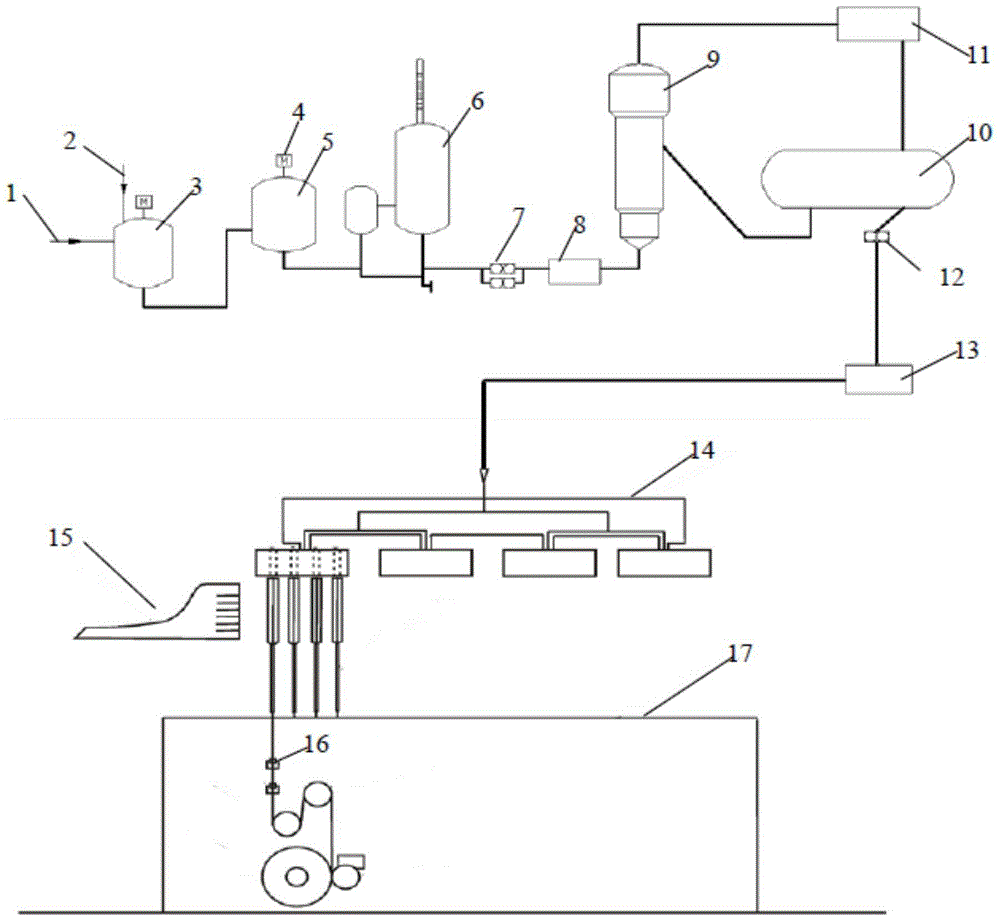

Fluffy melt-blow cloth preparation method

The invention relates to a fluffy melt-blow cloth preparation method. The method comprises the following steps that raw material is heated and melt via a screw extruder and then extruded to be filtered via a filter; then the melt and filtered raw material is conveyed to a metering pump for melt measurement via a pipeline; the melt is sent to a die head and forms fine fibers due to a traction action of high-speed hot air; and the fibers are cooled via cross air blasting and are then lapped on a net forming bench to form a non-woven fabric due to a negative pressure action of a front overflow draught fan, a pumping draught fan and a back overflow draught fan. By the use of the fluffy melt-blow cloth preparation method, problems of hard cloth surface hand feeling and poor fluffy performance of the fibers as well as thin cloth surface can be solved; and the fluffy melt-blow cloth is fluffy, has great tenacity and soft hand feeling.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

Superfine porous dacron irregular-shaped draw textured yarn (DTY) production process

The invention discloses a superfine porous dacron irregular-shaped draw textured yarn (DTY) production process which includes polyester pre-oriented yarn (POY) protofilament, a pre-network, a first yarn feeding roller, a first texturing heater, a cooling plate, a false twister, a second yarn feeding roller, a second auxiliary roller, a second heat box, a third yarn feeding roller, an oil applying rod and DTY winding molding. The second yarn feeding roller speed is 660m / min-700m / min, and drawing multiple of the second yarn feeding roller is 1.610-1.650. Deforming temperature of the first texturing heater is 183 DEG C-188 DEG C, and sizing temperature of the second heat box is 170 DEG C-180 DEG C. A friction disc of the false twister is 1-4-1 disc combination, and D / Y ratio is 1.55-1.63. Sizing overfeeding rate is 4.25-4.90, winding overfeeding rate is 5.00-5.35, and overfeeding rate of the second auxiliary roller is 3.00-3.50. Flannel fabric produced through the process has the performance of rigidity, glittering, fluffiness, pilling resistance, staining resistance and the like.

Owner:JIANGSU DELI CHEM FIBER CO LTD

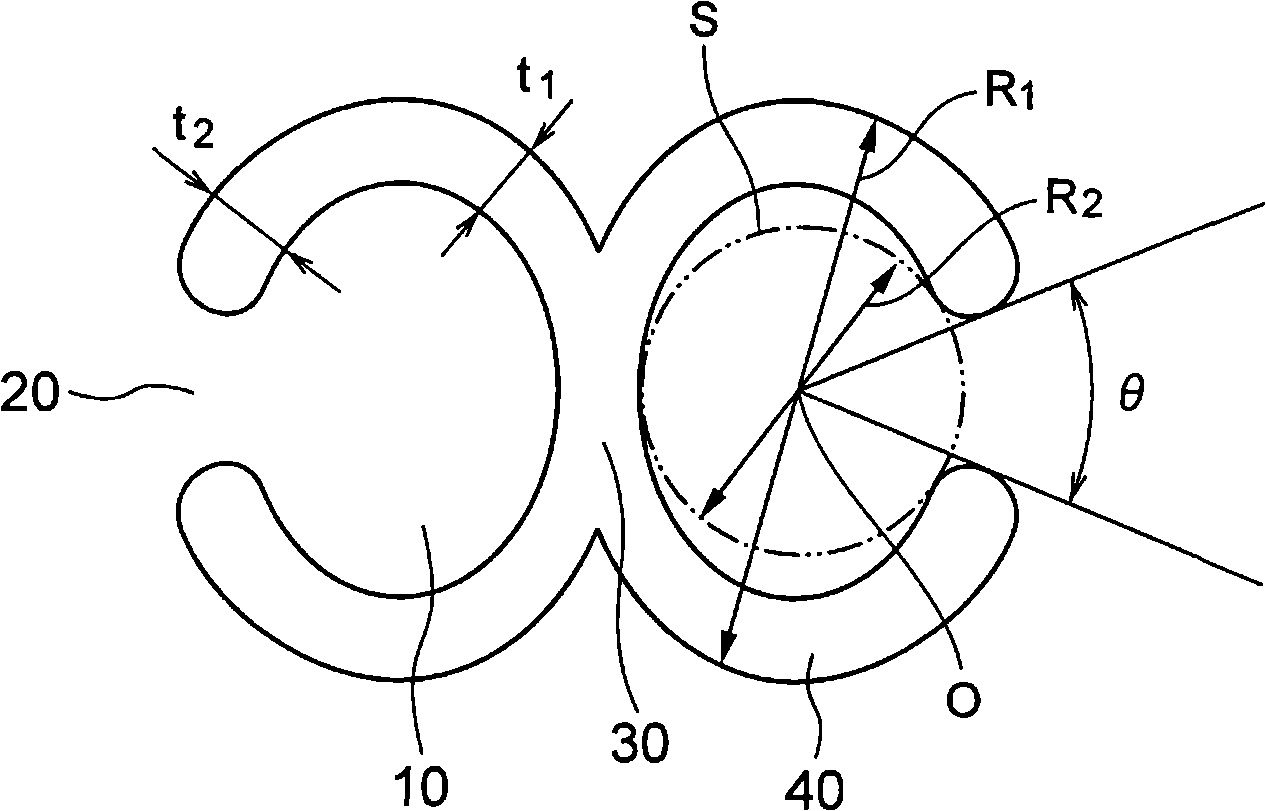

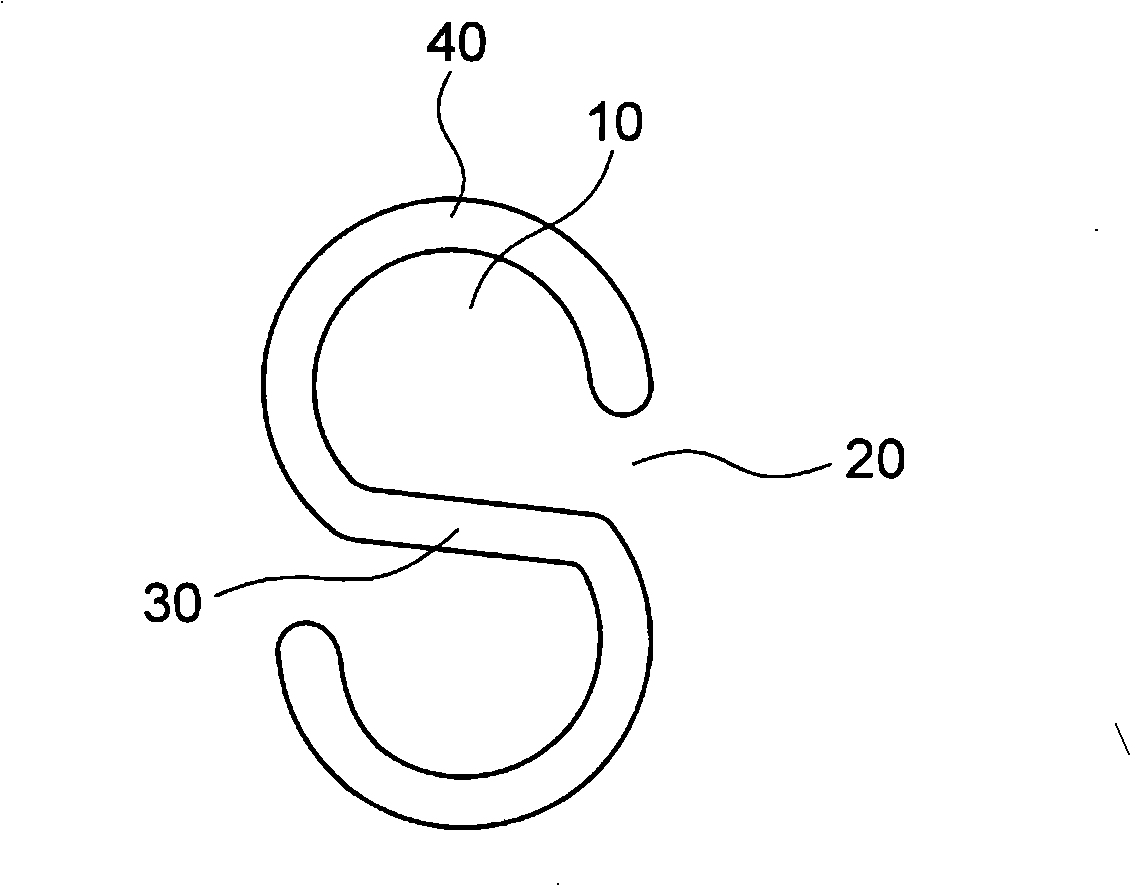

Fiber with modified cross section and fiber for artificial hair formed of the same

The invention provides a fiber with a modified cross section having excellent bulkiness, not fused, and manufacturable stably. In the fiber with the modified cross section, at least two hollow parts with openings that are open in the longitudinal axis of the fiber are formed in the cross section of the fiber. These two hollow parts are symmetrically formed with their backs facing each other, and the cross section of the fiber is formed in such a shape that generally C-shaped portions each curved arcuately are joined with their backs facing each other. Moreover, the shape of each generally C-shaped portion desirably fulfills the requirement of the following expressions: R1 is not smaller than 1.4R2 and not greater than 4.2R2, and theta is not smaller than 10 degrees and not greater than 160 degrees (in the expression, R1 is the maximum outer dimension passing through the center of a hollow part assumed inscribing circle, R2 is the diameter of the hollow part assumed inscribing circle, and theta is the angle formed by the center of the hollow part assumed inscribing circle and the two ends of each generally C-shaped portion).

Owner:DENKA CO LTD

Porous super-bright polyester fiber and preparation method thereof

ActiveCN104532392AGood flexibilityGood compatibilityMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

Owner:JIANGSU HENGLI CHEM FIBER

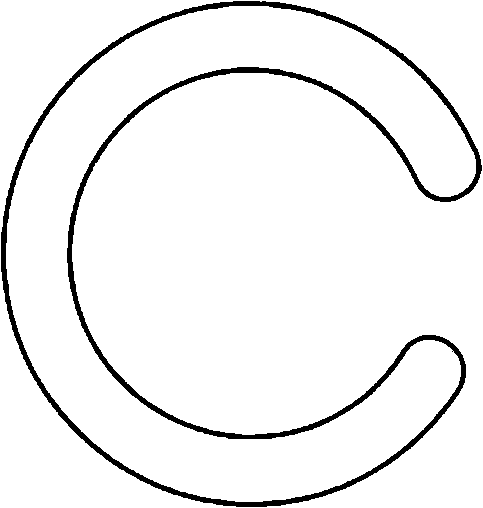

Profiled polylactic acid fiber and preparation method thereof

ActiveCN101608346AImprove hydrophilicityFluffy goodHollow filament manufactureFilament manufactureStretch ratioProcess conditions

The invention discloses a profiled polylactic acid fiber and a preparation method thereof. Cross section of the profiled polylactic acid fiber can be of C shape, hollow circular shape, trilobal shape, cross shape and triangular shape; and compared with common circular polylactic acid fiber, the profiled polylactic acid fiber has good hydrophilicity, bulkiness, flexibility, luster and excellent mechanical properties. The invention also discloses a preparation method of the profiled polylactic acid fiber. The profiled polylactic acid fiber with uniform structure and excellent mechanical properties is prepared by using profiled spinneret orifices in the melt spinning process at moderate spinning speed, lower heat stretching and heat treatment temperature, stretching ratio and mild melt spinning process conditions in a liquid phase thermostatic bath by improving spinning dynamics.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

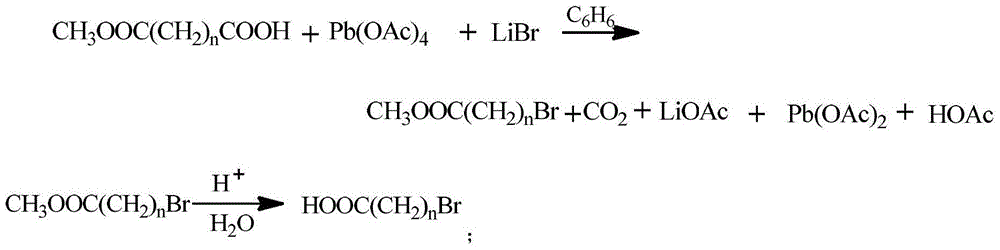

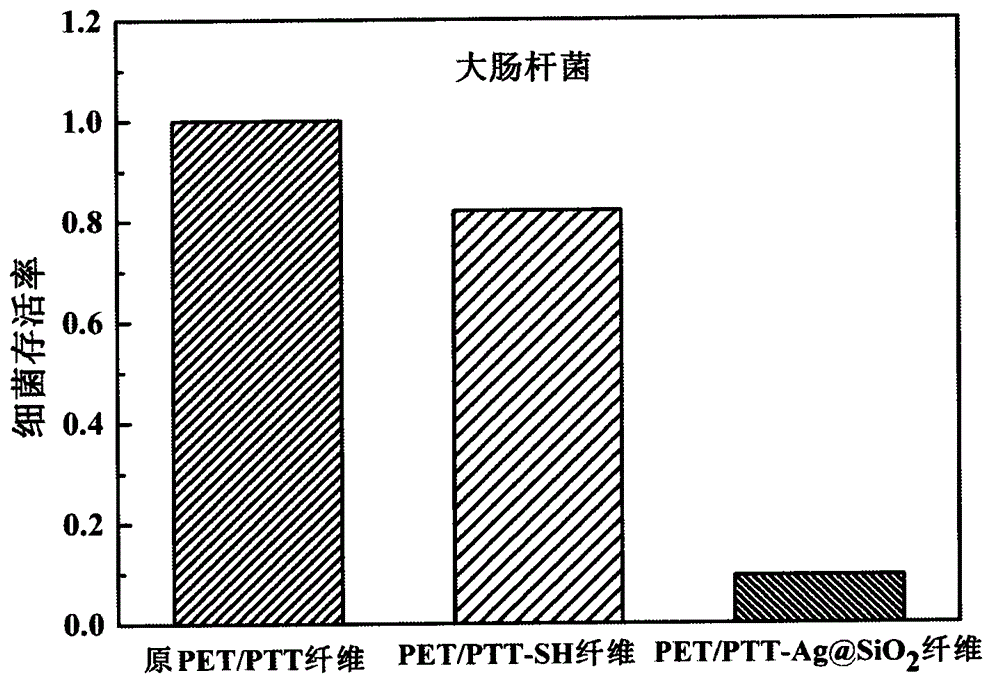

Preparation method of composite yarn

ActiveCN105002614AFluffy goodIncrease elasticityFibre typesConjugated synthetic polymer artificial filamentsYarnFiber

The present invention provides a preparation method of a long-lasting antibacterial and anti-crease composite yarn. According to the method, since methylbenzene has a swelling effect for polyester fibers, GMA is subjected to interfacial free-radical polymerization on the surface of artificial fibers, and generated PGMA can be anchored on the surface of the artificial fibers, and therefore, epoxy groups can be led onto the surface of the fibers; through a grafting reaction, the epoxy groups react with amidogens on cysteamine, so that sulfydryl can be led onto the surface of the fibers; stable S-Ag bonds are formed between the sulfydryl and silver particles, so that composite nanoparticles can be immobilized on the surface of the artificial fibers; and the outer yarn body of the yarn is coated with titanium dioxide / nano silver composite nanoparticles, and the durability of the antibacterial property of the yarn can be improved through the synergistic effect of titanium dioxide and nano silver particles. The composite yarn produced by the preparation method of the invention has the advantages of excellent antibacterial performance and anti-crease effect as well as favorable fluffiness, flexibility and comfort, and excellent gas permeability and moisture absorption performance, and touches soft.

Owner:NINGBO WUTIAN TEXTILE

Chitosan derivative based clean makeup-removing wet tissue with effects of bacterial inhibition and moisture preservation and preparation method of chitosan derivative based clean makeup-removing wet tissue

InactiveCN106309200AWide range of raw materialsLow costCosmetic preparationsMake-upFacial skinGlyceryl Caprate

The invention discloses chitosan derivative based clean makeup-removing wet tissue with effects of bacterial inhibition and moisture preservation. The chitosan derivative based clean makeup-removing wet tissue with the effects of bacterial inhibition and moisture preservation is prepared from raw materials in percentage by weight as follows: 2%-5% of chitosan derivatives, 5%-10% of PEG-8 caprylic / capric glycerides, 3%-8% of butanediol, 2%-5% of glycerin, 1%-3% of trehalose, 1%-5% of olive oil PEG-6 esters, 0.5%-3% of a skin conditioner, 0.15%-0.3% of phenoxyethanol, 0.15%-0.3% of ethylhexylglycerin, 0.1%-0.2% of methylparaben, 0.05%-0.2% of sodium hyaluronate, 0.01%-0.05% of essence and the balance of deionized water. According to the chitosan derivative based clean makeup-removing wet tissue with the effects of bacterial inhibition and moisture preservation and a preparation method, the makeup-removing wet tissue prepared with the preparation method is low in production cost, high in stability and good in cleansing power and realizes deep cleaning, besides, the makeup-removing wet tissue further has the effects of bacterial inhibition and moisture preservation, the facial skin after application of the makeup-removing wet tissue is smooth and tender, and makeup residues on the facial skin are removed.

Owner:湖北立天生物工程有限公司

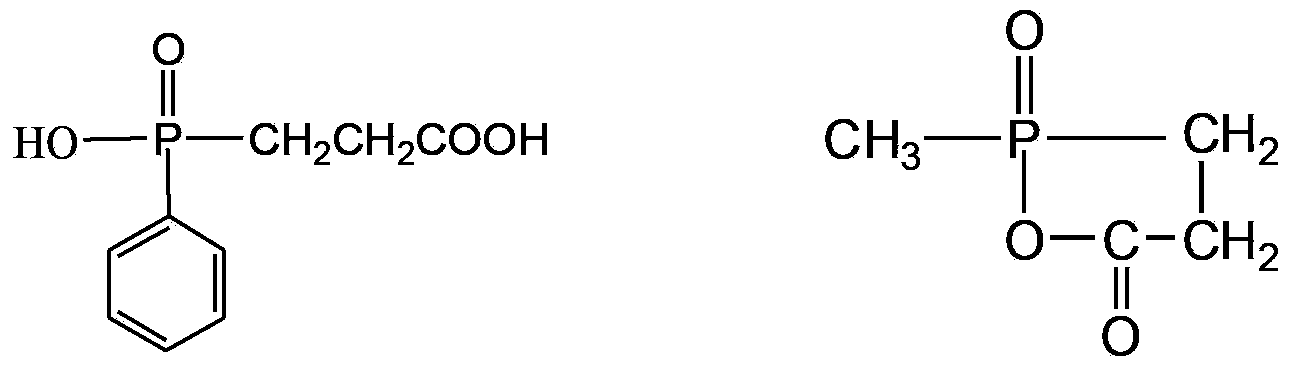

Inflaming retarding modified PBT (Polybutylene Terephthalate) fiber and preparation method thereof

InactiveCN104120505AFluffy goodFeel goodFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberHeat stability

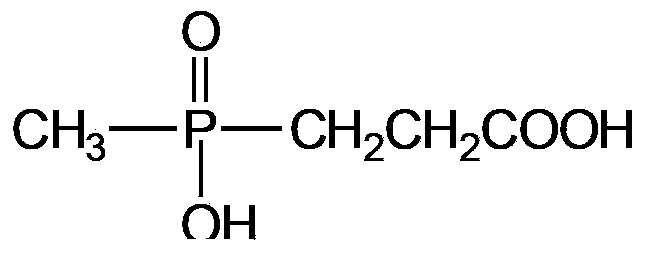

The invention belongs to the field of fiber preparation and relates to an inflaming retarding PBT (Polybutylene Terephthalate) fiber and a preparation method thereof. The inflaming retarding PBT fiber is prepared from the following components in parts by mass: 42-65 parts of terephthalic acid, 35-58 parts of butanediol, 0.008-1.3 parts of a catalyst, 0-0.5 part of a stabilizing agent, 5-10 parts of a phosphorus based flame retardant and 0.1-10 parts of an inorganic nano material. Compared with the prior art, the preparation method is simple and is easy to operate; a textile processed by the fiber has the advantages of good fire resistance, heat resistance, washing durability and the like; meanwhile, the phosphorus based flame retardant and the inorganic nano material are added to achieve a synergic inflaming retarding effect; the inorganic nano material is added so that polyester is good in spinnability, fiber forming property and heat stability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Fine-denier flat yarn and manufacturing method thereof

InactiveCN103603071AImprove unevennessImprove inner qualityFilament forming substance formingArtificial thread manufacturing machinesFiberYarn

The invention relates to the field of polyester fiber production and particularly discloses a fine-denier flat yarn and a manufacturing method thereof. The fine-denier flat yarn has good properties such as glare performance, fluffiness, soiling resistance, pilling resistance and dyeing easiness. According to the manufacturing method, after being pressurized by a booster pump and cooled by a melt cooler through a melt conveying pipeline, spinning melt is distributed into spinning boxes through a distribution valve, then measured through a measuring pump and sent into a special shape yarn spraying assembly for filtering and extrusion and then cooled through circular air blowing to obtain primary fiber; after being processed by an oiling unit, yarn guide hooks, yarn guide plates a pre-weaving unit and the like, the primary fiber enters a winder at a certain tension to obtain the multi-aperture superfine-denier flat yarn. The fine-denier flat yarn has good properties such as glare performance, fluffiness, soiling resistance, pilling resistance and dyeing easiness, overcomes wax type soft and smooth feeling of fabric woven from round-section fiber, provides a specific style and excellent properties for the fabric and is a novel polyester fiber with high added value.

Owner:TONGXIANG ZHONGCHEN CHEM FIBER

Imitation cotton-knitted fabric and production method thereof

InactiveCN103898670ASoft touchStrong cotton feelSucessive textile treatmentsWeft knittingPolyesterFiber

The invention discloses an imitation cotton-knitted fabric and a production method thereof. The imitation cotton-knitted fabric is formed by polyester staple fibers, cotton short fibers and spandex, wherein the polyester staple fibers account for 75%-85%, and bending rigidity of the fabric is 0.02-0.06 Cn.cm<2> / cm. The imitation cotton-knitted fabric not only has soft hand feeling and is high in cotton feeling, but also has the advantages of being light and fluffy, absorbing moisture and being high in drying speed. High comfort is achieved when the imitation cotton-knitted fabric is worn, and decorous feeling and stuffiness do not exist.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

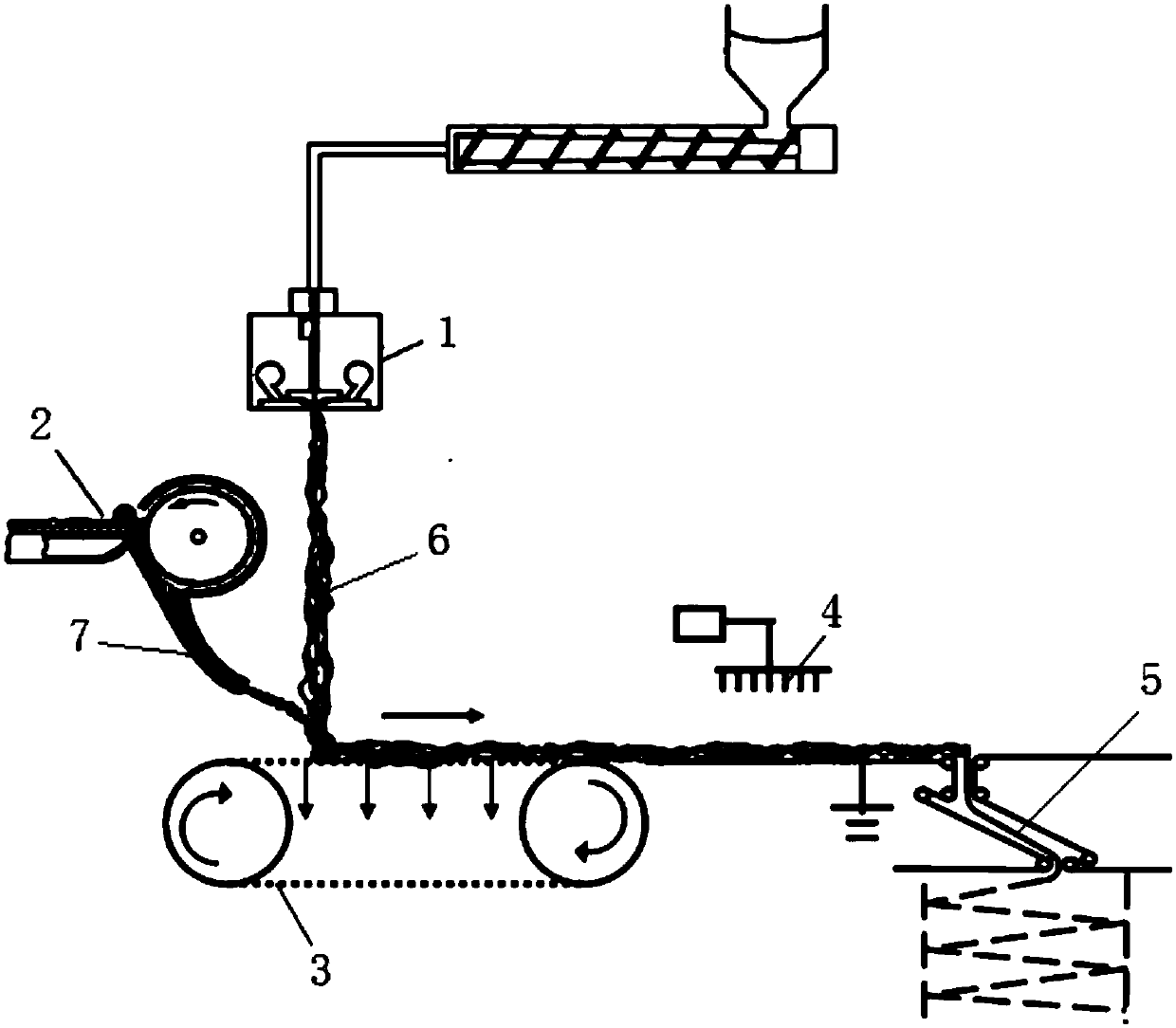

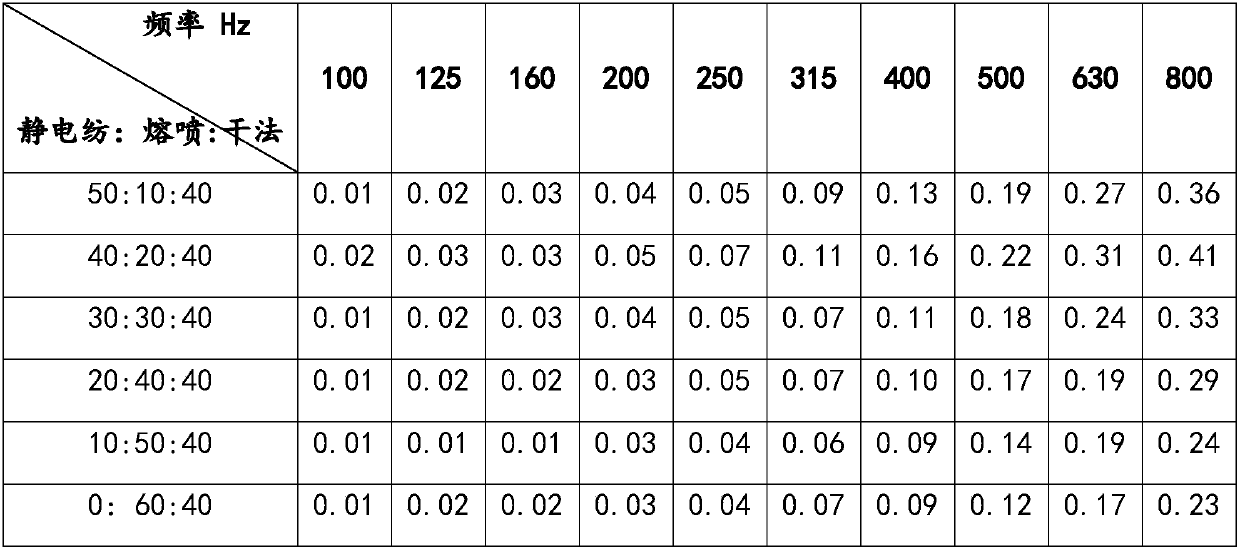

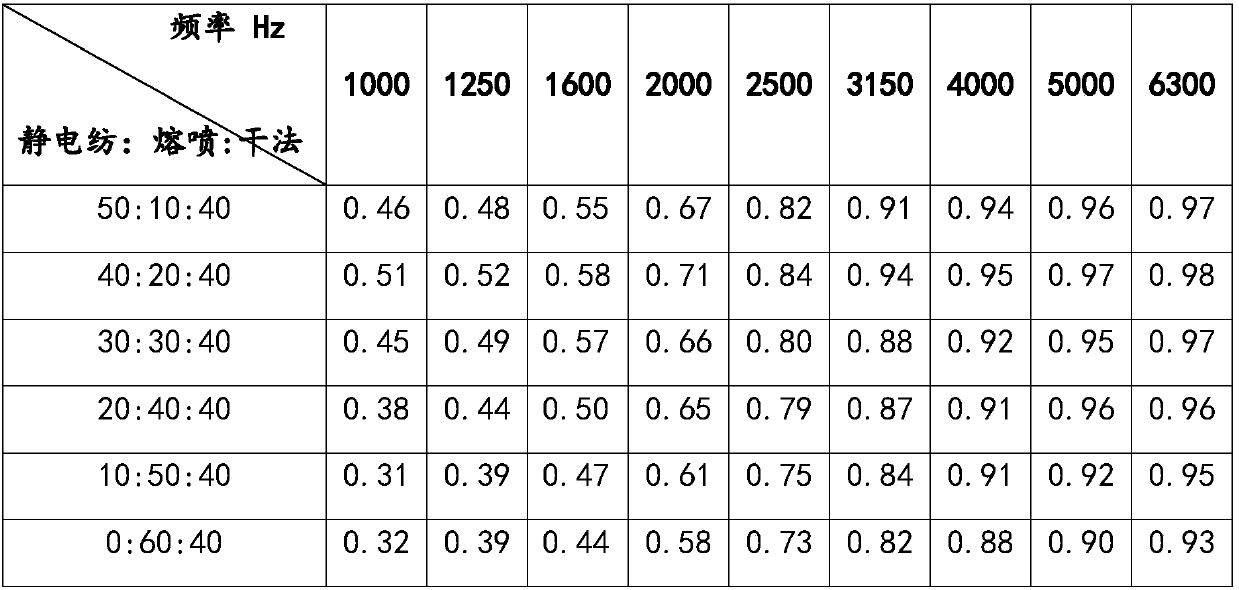

Method and device for preparing three-component sound-absorption cotton through electrostatic spinning-melt blowing-dry laying

The invention relates to a method and device for preparing three-component sound-absorption cotton through electrostatic spinning-melt blowing-dry laying. The method includes the following steps of firstly, mixing 10-65 parts by weight of electrostatic spinning nanofiber, 10-65 parts by weight of melt blowing superfine fiber and 10-40 parts by weight of dry fiber to obtain an electrostatic spinning-melt blowing-dry laying three-component fiber net; secondly, conducting processing after required grams per square meter of net is laid in a crossed mode to obtain the finished sound-absorption cotton product. The electrostatic spinning nanofiber, melt blowing superfine fiber and dry fiber are combined to prepare the three-component sound-absorption cotton, the obtained sound-absorption cotton has nano-scale electrostatic spinning fiber, micron-scale melt blowing fiber and thick dry staple fiber of different fineness degrees, the porosity of the sound-absorption cotton is larger due to the electrostatic spinning fiber of a nanometer structure, the fiber close to nanoscale can resonate with sound waves so as to attenuate energy, and the all-frequency sound absorption effect can be enhanced by reasonably configuring through three types of fibers of different fineness degrees.

Owner:武汉每时工业发展有限公司 +1

Light and thin wool blended fabric and preparation method thereof

The invention discloses a light and thin wool blended fabric. The blended fabric is formed by blending superfine wool fibers and special-shaped superfine dralon acrylic fibers. The weight percentage of the superfine wool fibers in the blended fabric ranges from 60% to 70%. The fineness of warp yarn and weft yarn in the blended fabric ranges from 500 metric number to 600 metric number. The superfine dralon acrylic fibers form an insulating layer due to double-T-shaped sections of the superfine dralon acrylic fibers and air between the fibers. As a result, the superfine dralon acrylic fibers have good bulkiness, coverage and warm keeping performance, and the warm keeping performance per unit weight is 20% higher than that of wool. According to the light and thin wool blended fabric, the superfine wool fibers and the special-shaped superfine dralon acrylic fibers are blended, so that the fabric is light and thin in texture and excellent in warm keeping performance.

Owner:JIANGSU SUNSHINE

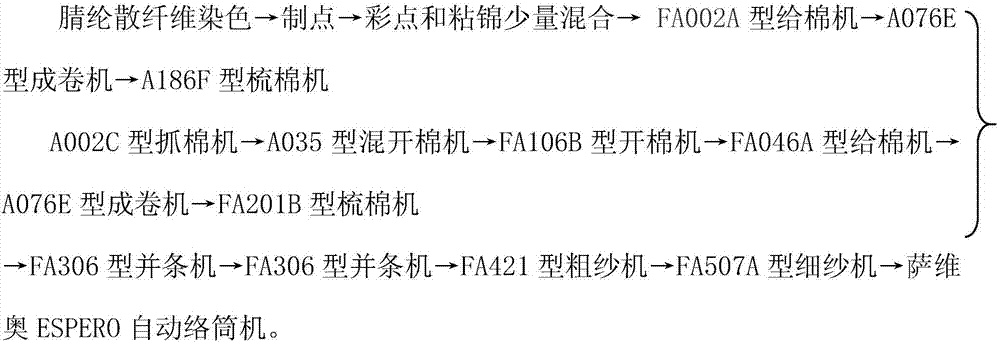

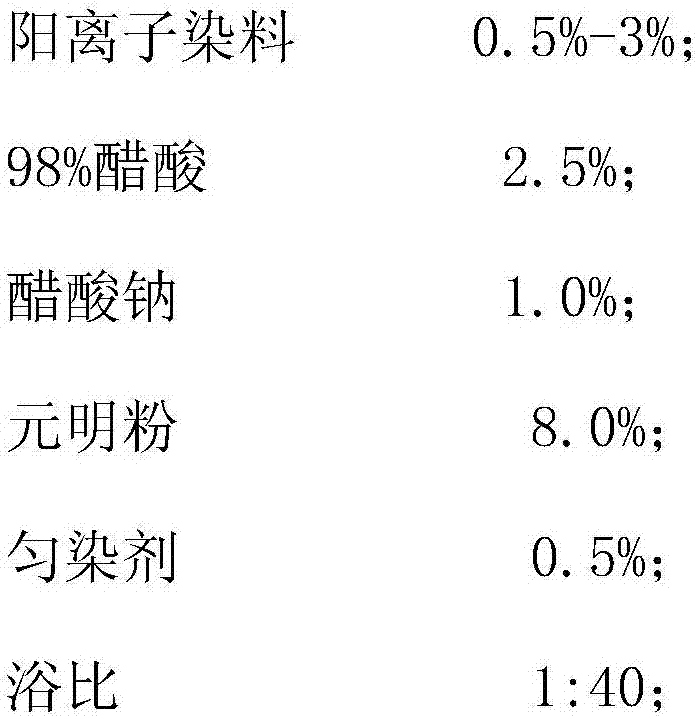

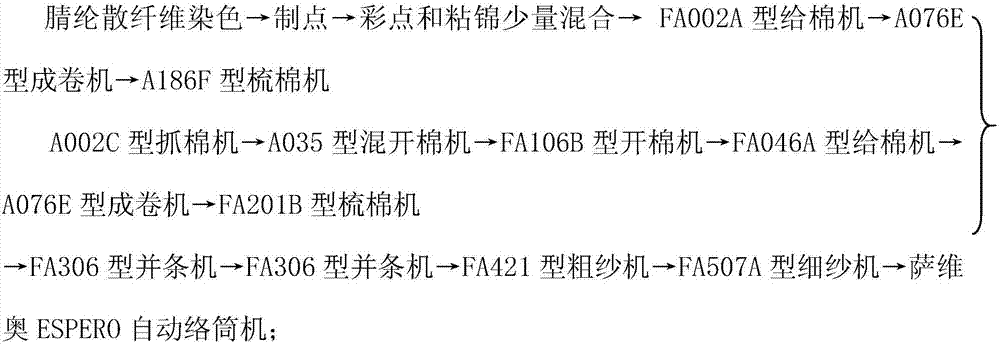

Method for producing PBT (Polythylene Terephthalate) color point core spun yarns

The invention discloses a method for producing PBT (Polythylene Terephthalate) color point core spun yarns. The method comprises the following steps: selecting yarn materials; performing process procedures of the PBT color point core spun yarns; implementing the specific production process. According to the method disclosed by the invention, acrylic fibers serve as raw materials of the points, the color point has rich colors, the color is bright, the stereoscopic impression is excellent, and the price can be saved by 20000 Yuan per tonnage compared with that of common chinlon points. A waterproof agent is diluted according to a ratio and uniformly sprayed onto the points, and the points are dried and roasted at a high temperature, so that the colored point achieves a water-repellent effect, the colored points are prevented from being loosened in the subsequent processing procedure, staining of dyes on the color points is reduced in the dyeing process, the shape and brightness of the color points can be guaranteed, and the quality of the yarns is improved. The PBT serves as the core yarn, viscose cotton serves as an outer packaging material, and the problems that the spandex core-spun yarns are poor in acid resistance and chlorine resistance and have non-ideal dyeing effect are solved. The color point core spun yarns produced by the method disclosed by the invention are excellent in fluffiness and crimpiness and high in elasticity and shape stability and have hand feel of cashmere.

Owner:IANGSU COLLEGE OF ENG & TECH

Polypropylene-based filament elastic super-soft non-woven material and production method thereof

InactiveCN108179549AStable structureReduce distortionHeating/cooling textile fabricsTextile treatment by spraying/projectingPolyolefinPolyethylene glycol

The invention relates to a polypropylene-based filament elastic super-soft non-woven material and a production method thereof. The production method of the polypropylene-based filament elastic super-soft non-woven material comprises the following steps: (1) elastic and super-soft blending modification of a thermoplastic copolymer: carrying out melt blending modification on 40 to 80 weight percentof polypropylene with 0.01 to 2 weight percent of erucyl amide and 5 to 15 weight percent of polyethylene glycol by using a screw pelletizer, thus preparing polymer particles; blending the polymer particles with 18 to 40 weight percent of polyolefin elastic copolymer and 8 to 12 weight percent of UHMWPE (Ultra-high Molecular Weight Polyethylene) slice; (2) spun-bond forming of a polypropylene-based filament net; (3) hot rolling and pre-curing of the polypropylene-based filament net; (4) pre-wetting; (5) first-stage hot drawing; (6) secondary forming through hot rolling; (7) second-stage hot drawing; (8) cooling; (9) coiling. The polypropylene-based filament net prepared by the invention is relatively excellent in elasticity, softness and fluffiness, does not contain substances having adverse effects on a human body and is safe to use.

Owner:苏州多瑈新材料科技有限公司

Blended yarn weaved fabric

The invention provides a blended yarn weaved fabric, comprising blending strips, wherein each blending strip is formed by wool yarns, spun silk yarns and long stapled cotton yarns; the wool yarns, the spun silk yarns and the long stapled cotton yarns are respectively formed by half-wool fibers, silk fibers and long stapled cotton fibers; and the half-wool fibers, the silk fibers and the long stapled cotton fibers are strip-shaped. According to the blended yarn weaved fabric, a stretch breaking machine is firstly used for carrying out stretch breaking on the natural wool fibers into the half-wool fibers with the length which is one half of the previous wool fibers; the length of the half-wool fibers is similar with the length of the silk fibers and the length of the long stapled cotton yarns, so that the half-wool fibers are convenient to spin and the finished-product effect is good; wools and long stapled cotton are interwoven with silks on the basis of multi-compounding to maintain the elasticity, the fluffiness and the heat preservation of the wools; and the blended yarn weaved fabric has the good glossiness of the silks and the moisture adsorption of the long stapled cotton, and the defects that the wools are itchy to wear and are easily fluff and balled up are greatly improved.

Owner:POLARGOOSE CLOTHING

Spun-bonded non-woven fabric for diaper diversion layer and production technology of fabric

InactiveCN107904787AFluffy goodExcellent suction speedNon-woven fabricsBandagesReverse osmosisEngineering

The invention discloses a spun-bonded non-woven fabric for a diaper diversion layer and a production technology of the fabric. The non-woven fabric comprises an absorption core which is formed by coarse denier fiber, the direction of the coarse denier fiber is the longitudinal direction, the pattern of the coarse denier fiber is the strip pattern, the pattern of the absorption core is the patternof the character 'yi', and the pattern direction of the absorption core is consistent with the fiber direction. Compared with the prior art, the fabric has the advantages that a hot wind non-woven fabric can be replaced, the production speed of the spun-bonded non-woven fabric is higher than that of the hot wind short fiber, the cost is low, and the effect is good; the coarse denier product is good in diversion effect, diffusion is accelerated, the diffusion length is increased, and the amount of reverse osmosis is lowered; compared with ordinary hot wind non-woven fabrics and other products,the fluffiness is better, and the liquid absorbing speed is higher.

Owner:山东恒鹏卫生用品有限公司

Water-absorbing melt-blown non-woven fabric and preparation method thereof

ActiveCN110699857AImprove water absorptionEasy to useConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyesterElastomer

The invention provides a water-absorbing melt-blown non-woven fabric and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a first polymer blendingmaster batch composed of polypropylene and a hydrophilic agent and a second polymer blending master batch composed of surface-modified nano silicon dioxide, polyester elastomer and polypropylene, heating and melting by a screw extruder in a sectional temperature control reaction mode, spraying out melt from a spiral nozzle, drafting at high speed through high-temperature air flow, cooling the melt into a net, and collecting the net to obtain the water-absorbing melt-blown non-woven fabric. The fiber structure in the water-absorbing melt-blown non-woven fabric is a side-by-side structure, andthe water-absorbing melt-blown non-woven fabric presents a micro-nano-scale spiral fiber structure, has the characteristics of a three-dimensional crimped fluffy fiber structure, and has excellent water-absorbing performance and mechanical performance.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com