Fluffy melt-blow cloth preparation method

A melt-blown cloth and fluffy technology, which is applied in the field of fluffy melt-blown cloth preparation, can solve the problems of hard hand feeling of the cloth surface, unsatisfactory fluffy softness of the melt-blown cloth, cloth surface thickness, and poor fiber fluffiness, etc., and achieve soft and fluffy hand feeling Good performance, satisfying fluffy and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

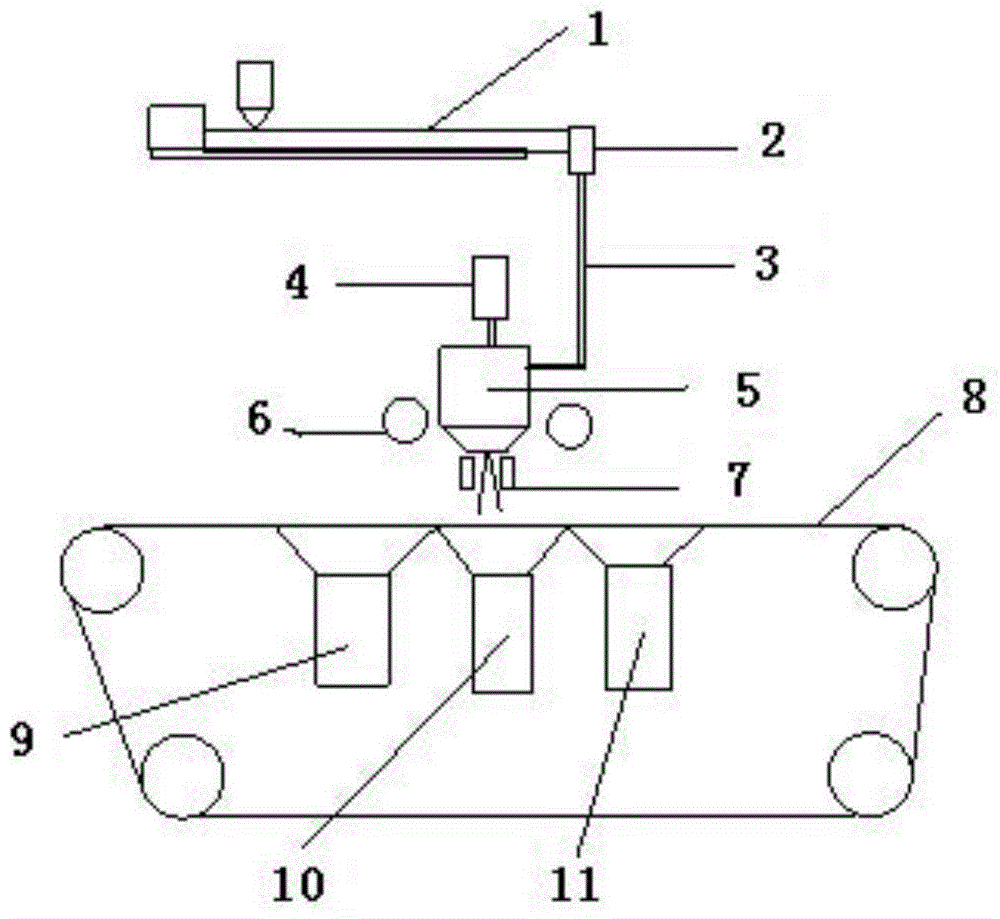

[0015] See figure 1 , select polypropylene pellets with a melt index of 1200-1800 to transport them to the hopper of the screw extruder, heat and melt them through the screw extruder 1, transport them to the die head 5 for spinning, and draw them into fine fibers in the high-speed hot air 6, After the cooling of the side blower 7, the fibers are laid and bonded into cloth with the assistance of the front overflow fan 9, the suction fan 10 and the rear overflow fan 11.

[0016] The temperature of the screw extruder 1 is 170-190°C in the first zone, 225-245°C in the second zone, 230-250°C in the third zone, 230-250°C in the fourth zone, and 230-250°C in the fifth zone. ℃, the temperature of zone 6 is 230-250℃, the temperature of filter 2 is 230-250℃, the temperature of pipeline 3 is 230-250℃, the temperature of die head 5 is 230-250℃, the temperature of side blower 7 is 11-13℃, cooling fan The output ratio is 45%-55%, the temperature of drafting hot air 6 is 230-250°C, the outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com