Patents

Literature

1233results about How to "Increase warmth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof garment with invisible barrier seam

InactiveUS20120282425A1Good seamsImprove breathabilityBaby linensThin material handlingMechanical engineeringEngineering

Owner:COHESIVE SYST

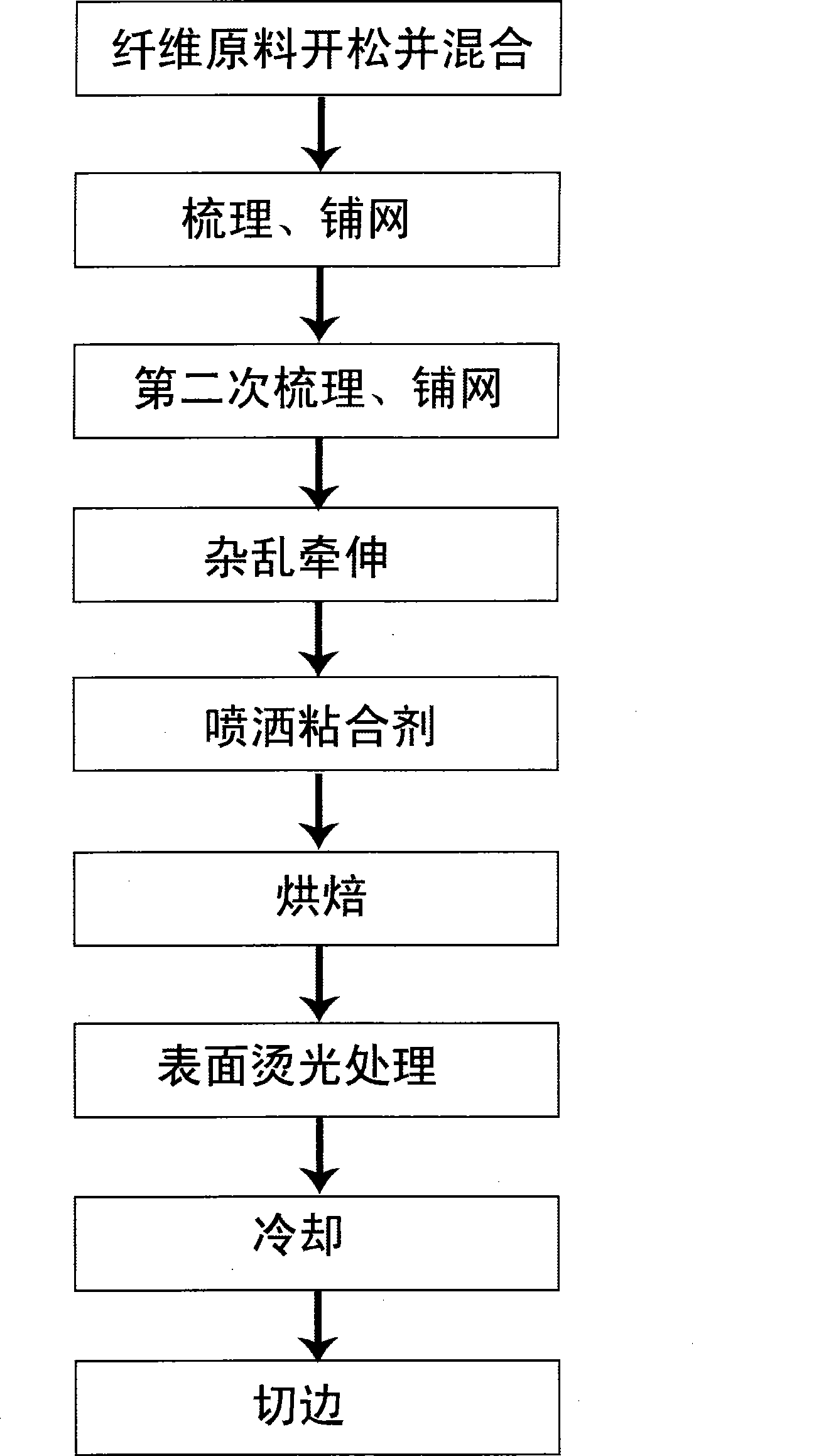

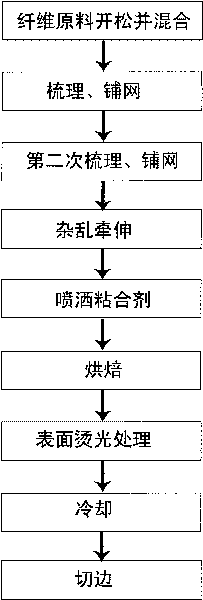

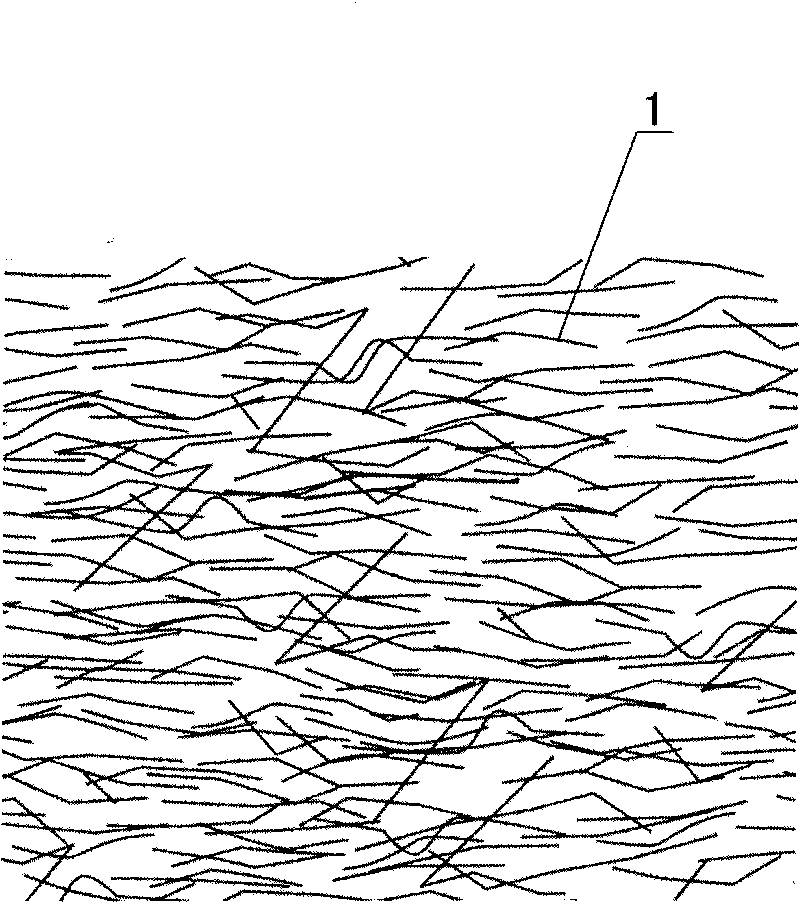

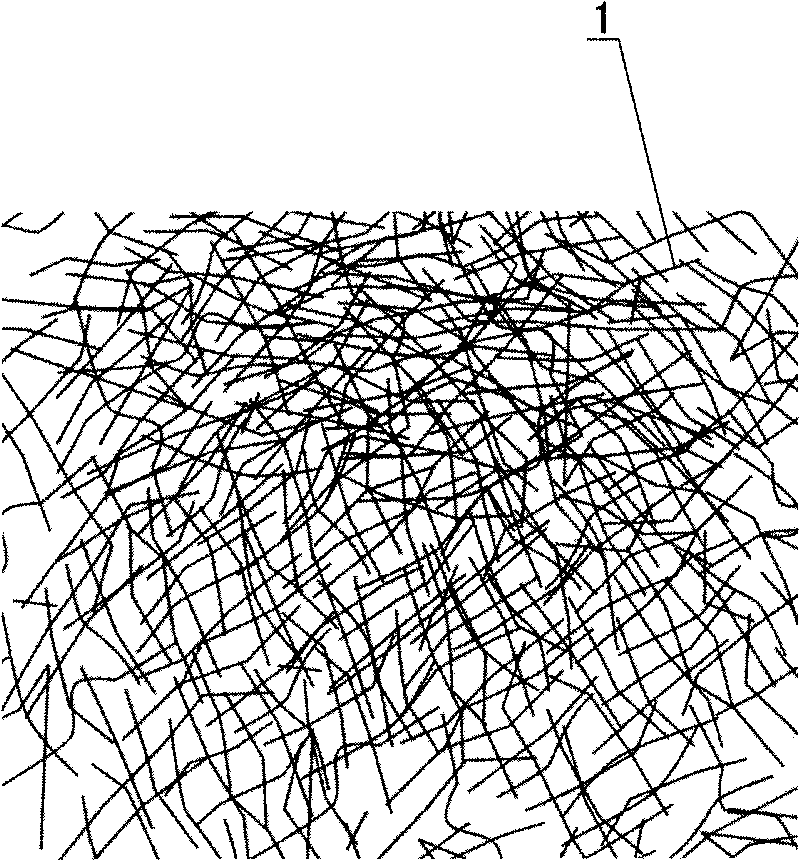

Thermal protection flocculus and manufacturing method thereof

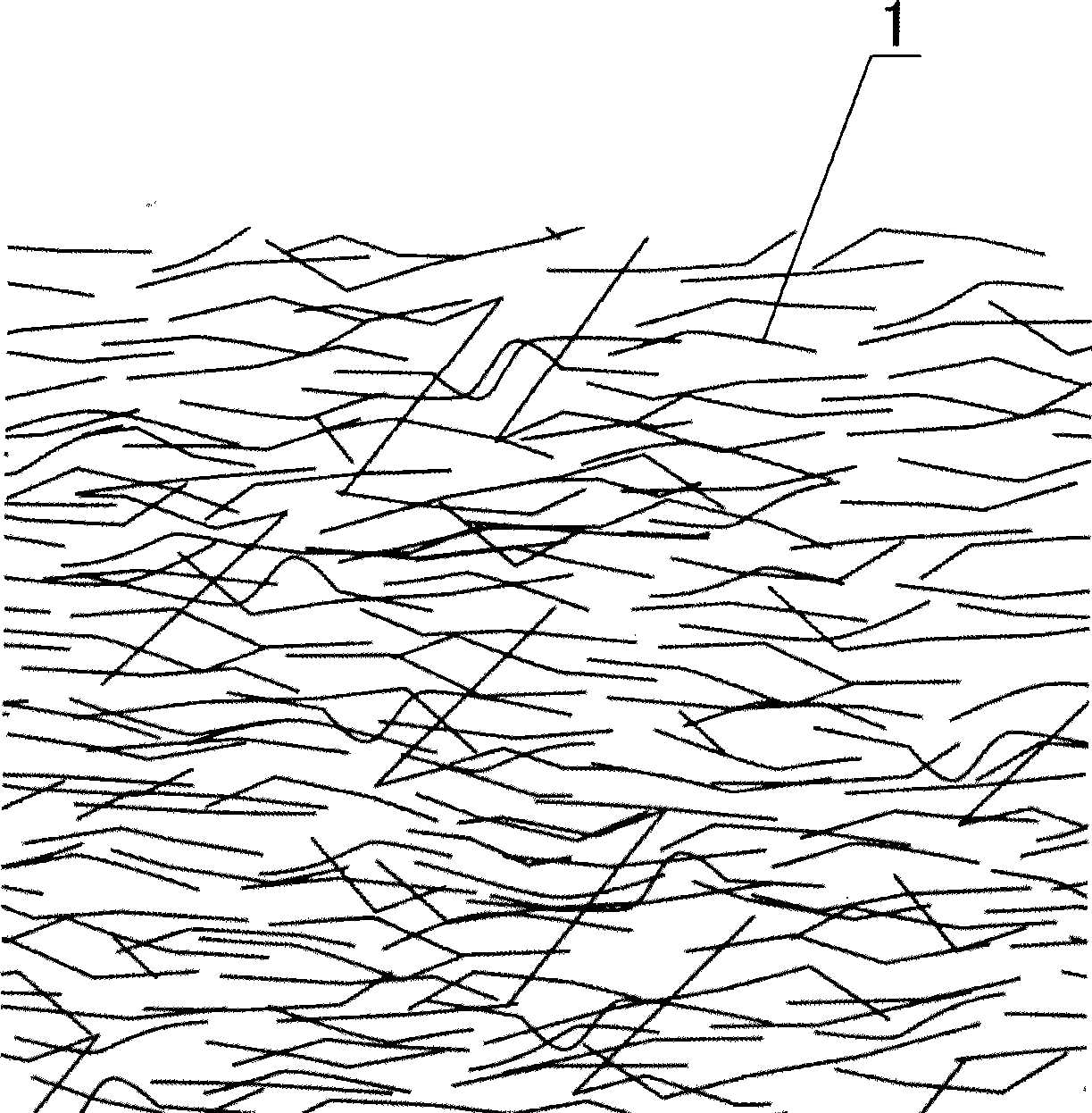

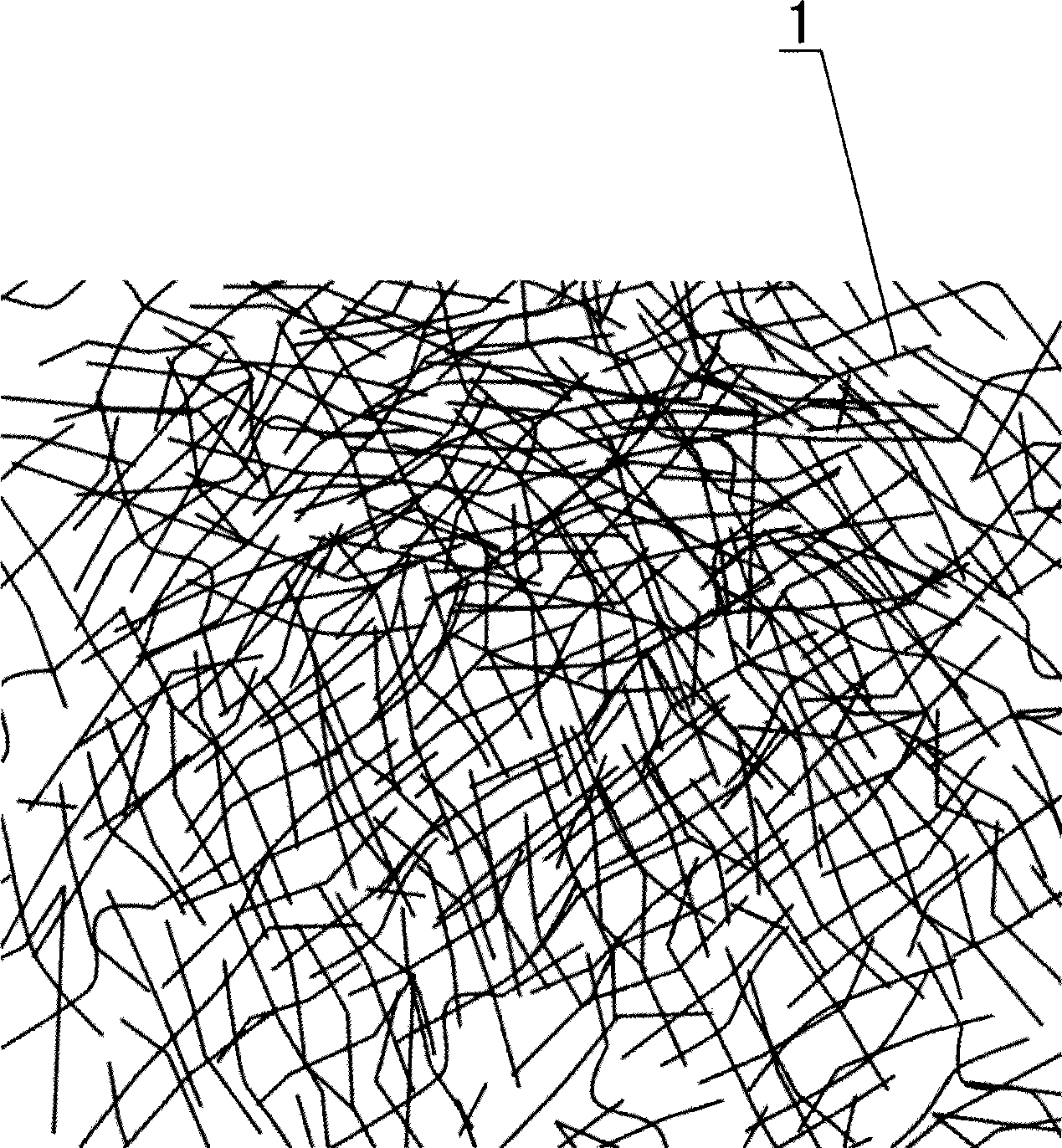

InactiveCN101476212AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberNet shape

The invention provides a keeping warm flocculus which is prepared from raw material by weight including 56%-85% fine denier fibre and / or super fine denier fibre, 0-30% hollow fibre, 5-30% felt fibre. The preparing method includes steps as follows: loosing and mixing various fibre raw material; then combing, lapping for forming fibre net; then processing disorder drafting to the felt net for forming solid net shape crossing struture; then heating and baking the felt net, at least melting surface of the felt fibre for felting surrounding fibre. The fine denier fibre can increase content of still air in the keeping warm flocculus, reduce heat quantity conduction, and can divide space in the keeping warm flocculus into smaller space for avoiding or reducing air convection, accordingly increase warm keeping property of the keeping warm flocculus; the hollow fibre can increase filling power and compress rebound property of the warm keeping flocculus; filling power and compress rebound property of the warm keeping flocculus are increased after being disorder draft.

Owner:汕头市奥山服饰有限公司

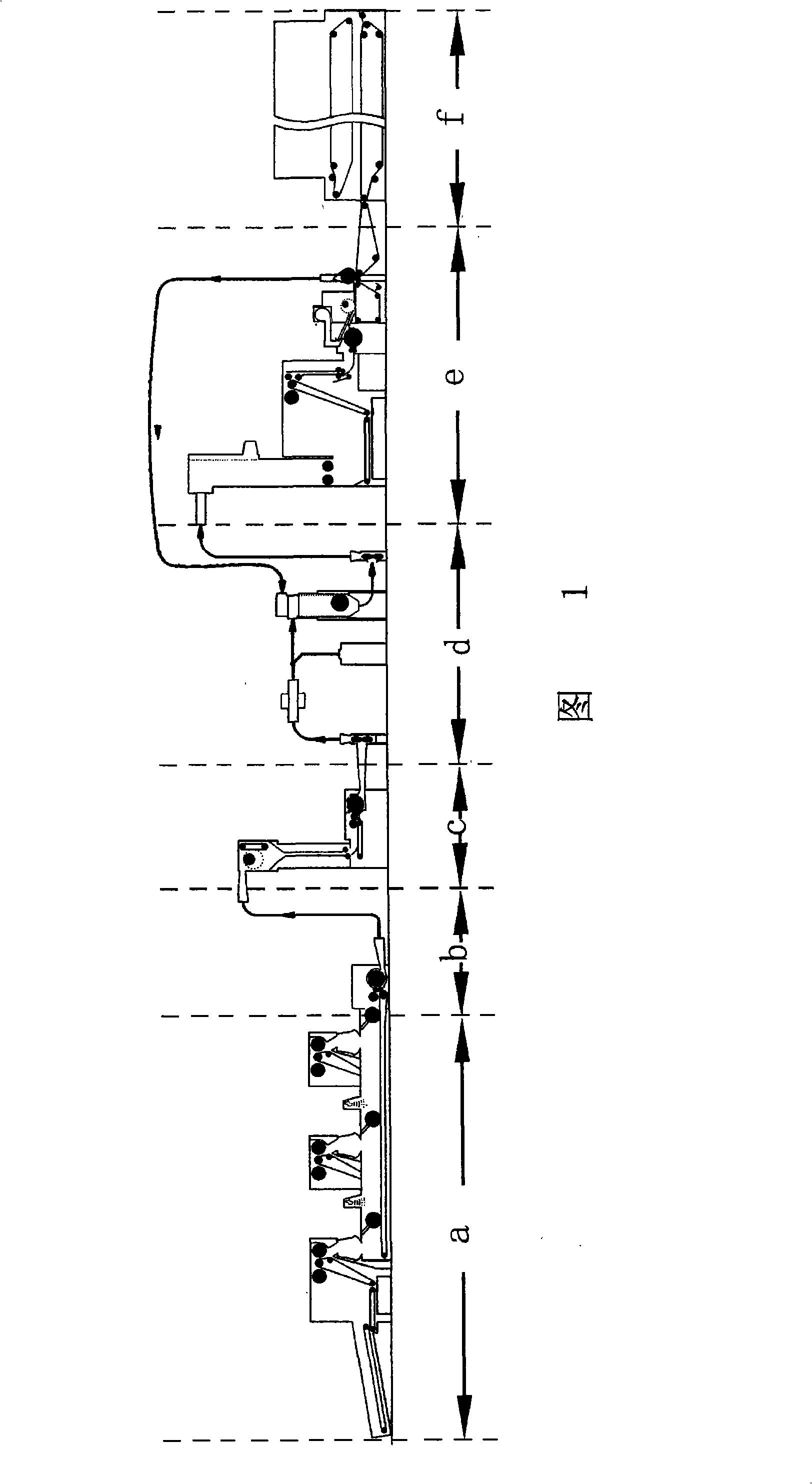

Airflow air laid fiber cotton preparing process and manufactured fibre cotton

ActiveCN101307529AWide selection of materialsImprove product qualityLap forming devicesNon-woven fabricsEngineeringWaste material

The invention discloses a method for preparing air-laying cellucotton and cellucotton produced by the method. Taking low melting point fibers and other fibers as raw material, the cellucotton is produced by rough shape cutting, coarse opening, fine opening, air laying, hot binding and parting cut packaging, wherein the air laying is as follows: the loose fibers which are distributed evenly in a cotton box after fully mixed by the fine opening are further mixed by airflow and delivered by pressurized airflow to between the net forming curtain and the net forming roller to be formed into a required retiform structure. The preparing process has wide range of material selection, is suitable for not only all the raw materials adopted in the prior process, but also the plant fiber widely existing in the natural world which are not used in the prior art such as couch grass, reed, cornstock, straw and bagasse as raw materials, and the waste materials such as wood wool, crushed sponge and wool manufacturing crushed aggregates to reuse and regenerate; in addition, the preparing process has high production efficiency and low energy consumption, and produces the cellucotton with great improvement in the performance, thereby being applied to wider fields.

Owner:广东美梦思床具有限公司

Green totally degradable warming material and producing method thereof

InactiveCN101509175AHigh strengthImprove stabilityHollow filament manufactureFilament/thread formingCardingKapok fiber

A green completely-degradable warm-keeping material and a production method thereof are disclosed, the weight percent of components thereof are: 40-60 parts of kapok fiber, 10-40 parts of polylactic bi-component fiber and 15-40 parts of polylactic hollow fiber; the material is formed by pre-needling at first and then the procedures of hot-melt shaping, cooling, winding, etc. after a fluffy three-dimensional netlike structure fiber net is formed by cotton plucking, cotton mixing, weighting, opening, mechanical carding and disordering. The inventive warm-keeping material employs the completely-degradable raw materials and has no pollution in the entire production process, the product has multiple functions of excellent strength, fluffiness, warm keeping, bacteriostasis and the like, which belongs to green environmentally-friendly products.

Owner:JIAXING UNIV

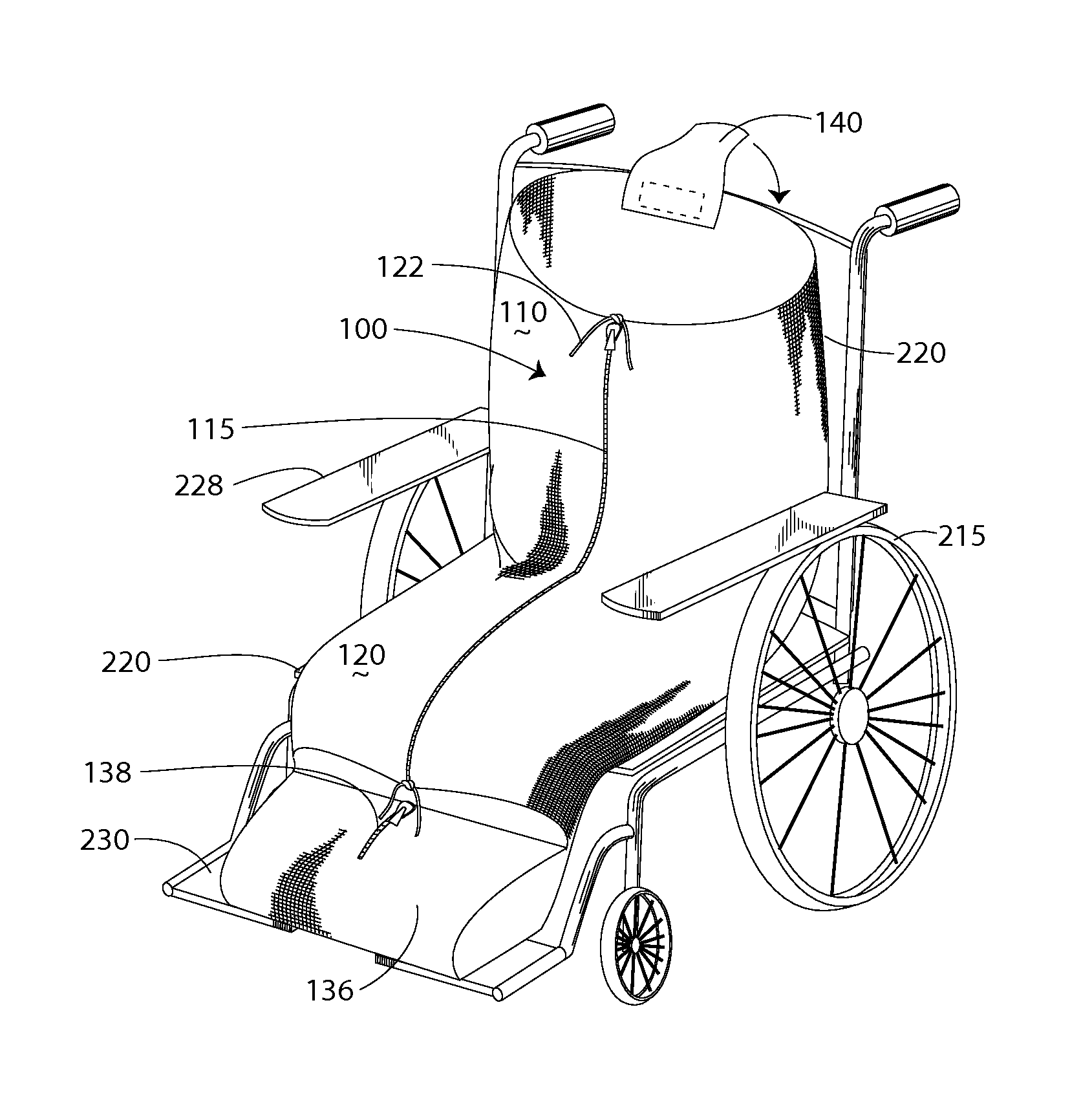

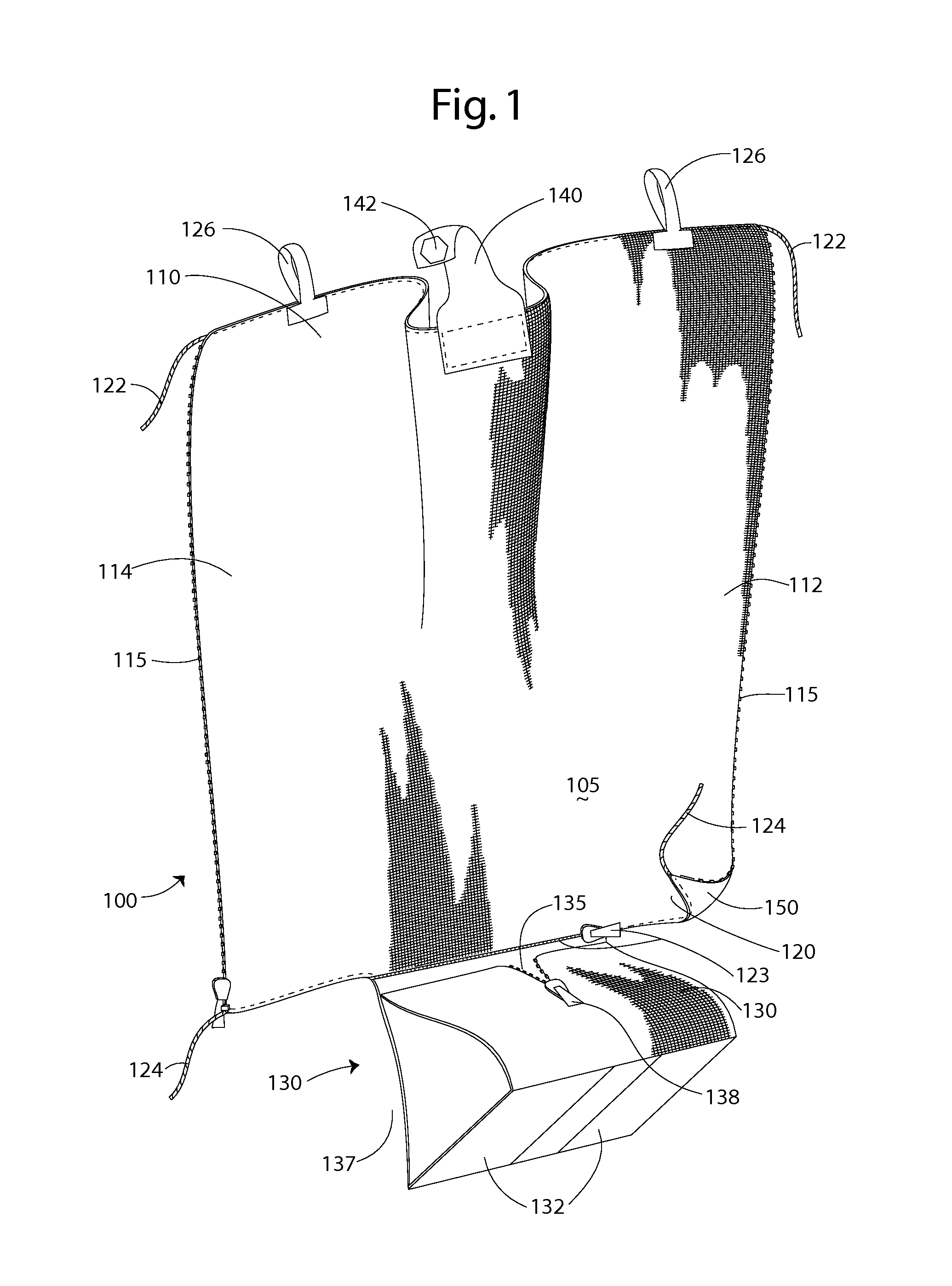

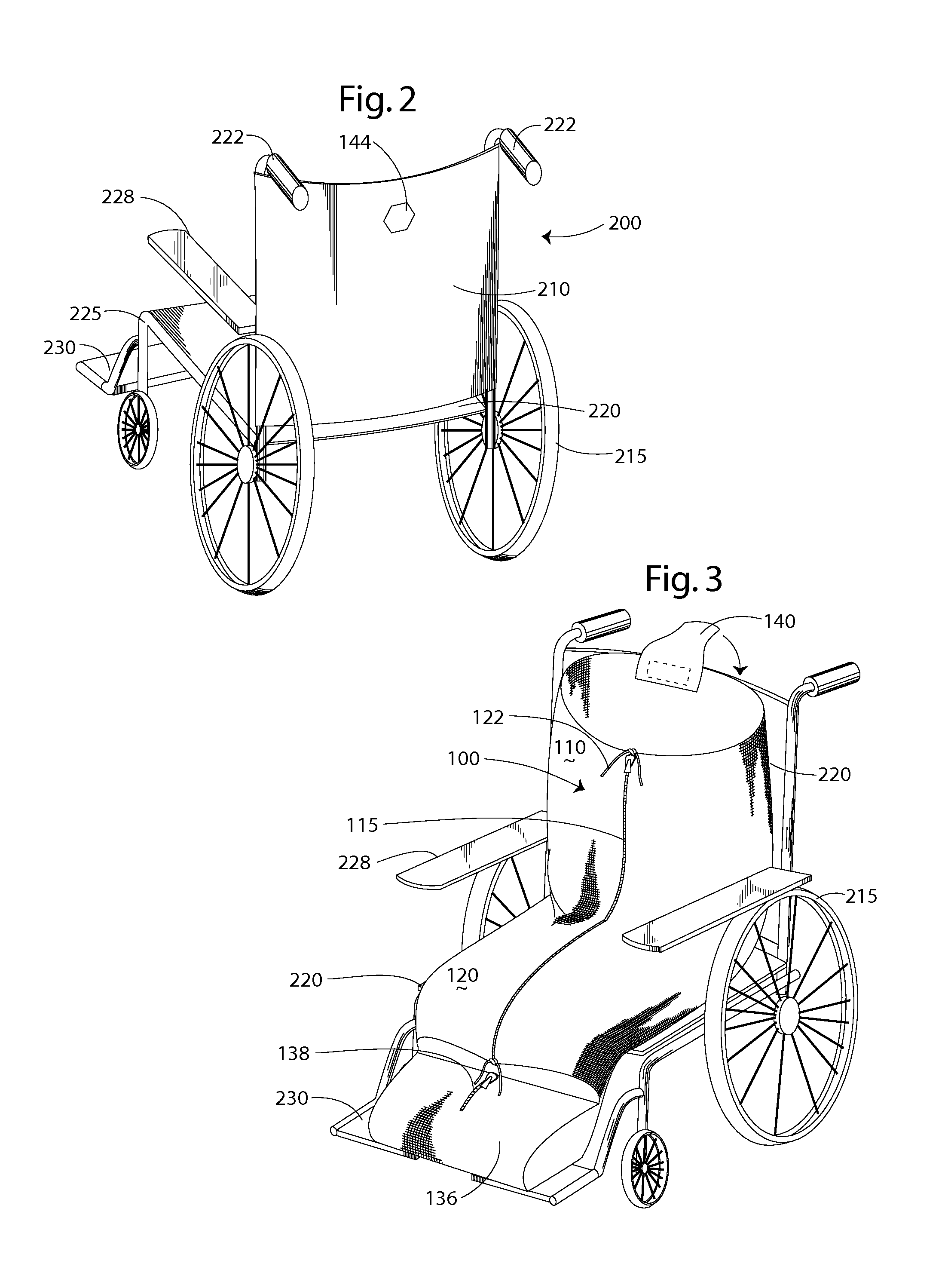

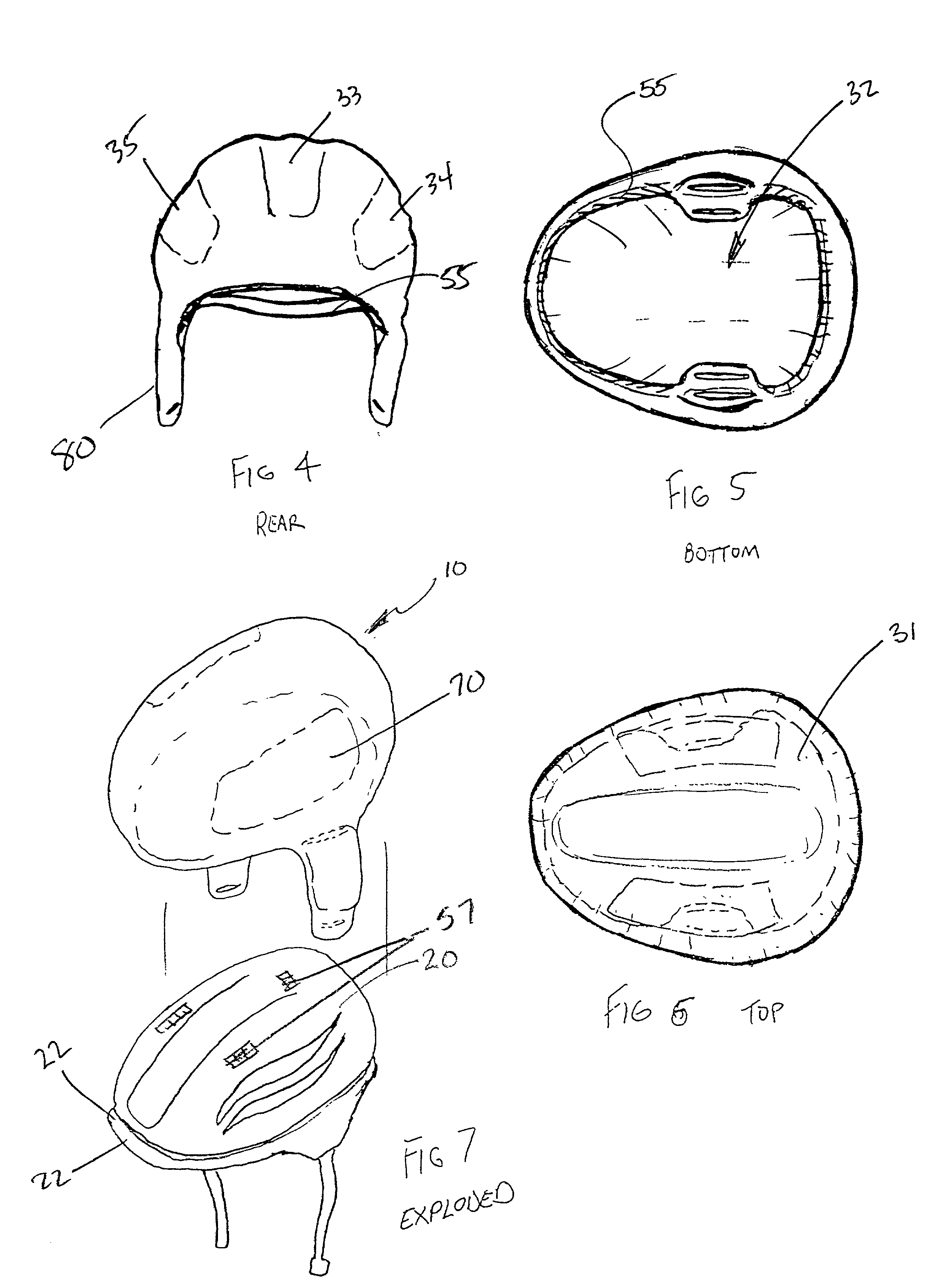

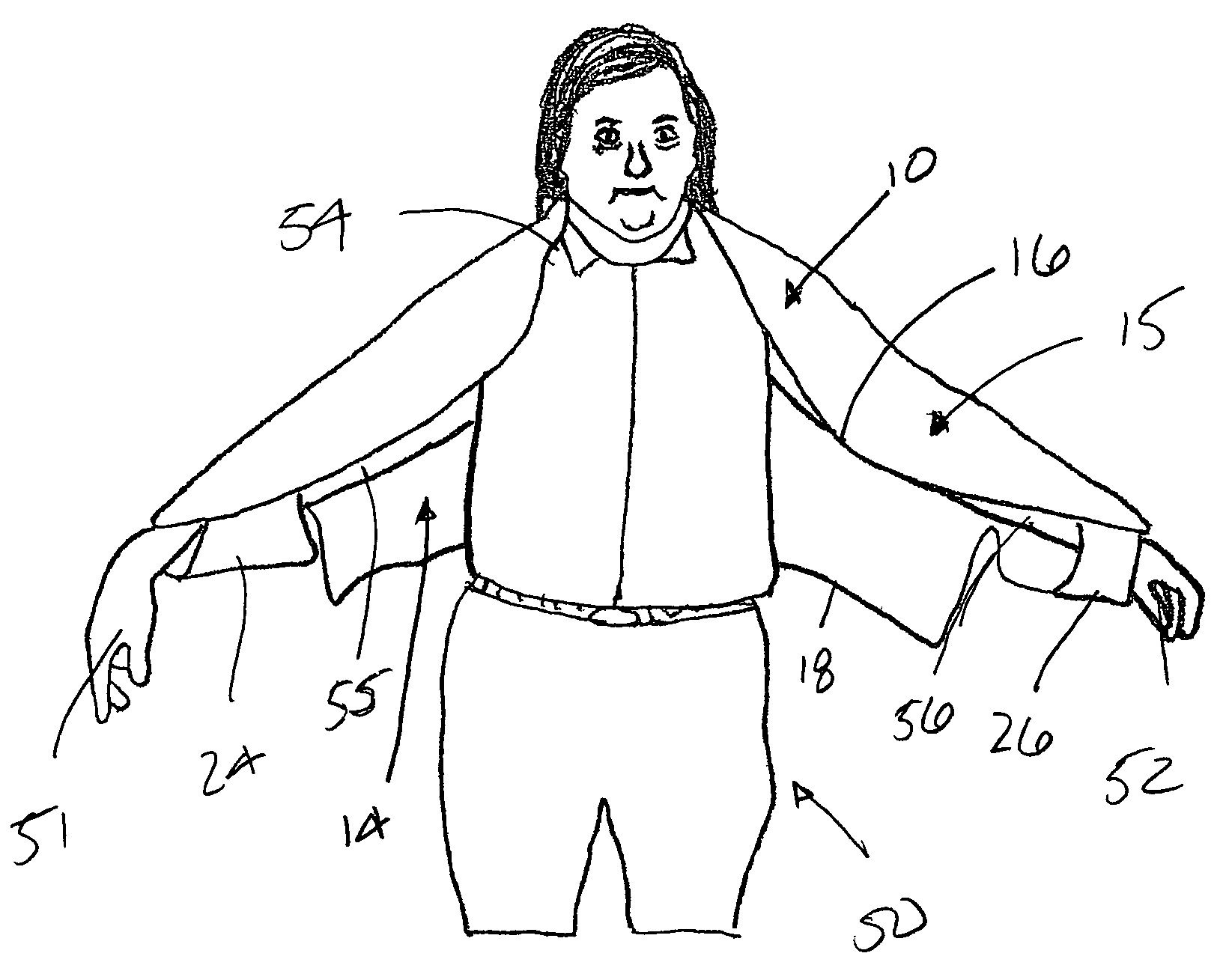

Chair blanket, and method for covering chair occupant

InactiveUS7581259B2Stable positionIncrease warmthTravelling rugWheelchairs/patient conveyanceWheelchairEngineering

A blanket for a chair occupant, the chair having a seat and a back. The blanket includes an upper end, a lower end, opposing sides, an outer surface to be placed onto the seat of the chair, an inner surface on which the occupant sits, and a connector for connecting the opposing sides over the occupant when the occupant is seated onto the inner surface of the blanket. Preferably, an attachment device is provided for releasably securing the blanket to the chair before the occupant is seated. A method for covering a wheelchair occupant is also provided, having the steps of providing the blanket, placing the blanket over the seat of a wheelchair, attaching a flap on the upper end of the blanket to the wheelchair to keep the blanket from shifting, seating the occupant onto the blanket in the wheelchair, folding the opposing sides of the blanket over the occupant, and zipping the opposing sides together.

Owner:THOMPSON JOE

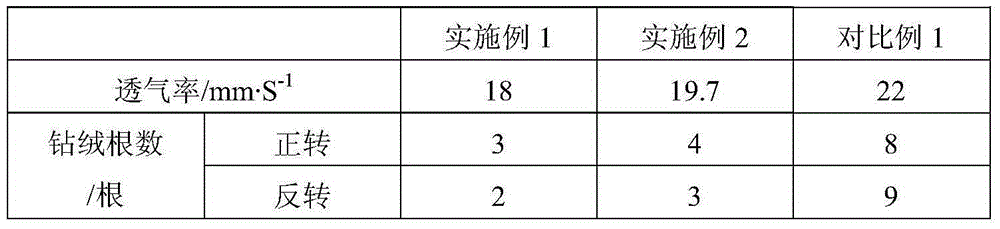

Spinning process of covering yarn with high hollowness degree, prepared covering yarn and process for weaving towel by utilizing covering yarn

ActiveCN102888686AIncrease warmthHigh hollownessBiochemical fibre treatmentBleaching apparatusCotton fibreEngineering

The invention provides a spinning process of covering yarn with high hollowness degree, a prepared covering yarn and a process for weaving towel by utilizing the covering yarn. The spinning process comprises the following steps of: compositing and twisting two crude cotton yarns and water-soluble vinylon filament with number of 4.1-7.3 tex to prepare a spun yarn with cotton fiber covering the water-soluble vinylon filament; and hydrolyzing the water-soluble vinylon filament to obtain the covering yarn with the high hollowness degree. The strength and the hollowness degree of the covering yarn with the high hollowness degree, prepared by the spinning process disclosed by the invention, are higher than the strength and the hollowness degree of a common hollow covering yarn with the same yarn count, the overing yarn with the high hollowness degree is soft and fluffy and has strong water absorbability and improved heat insulation performance; and the woven towel prepared by the process of the invention is light and fluffy, and has good heat insulation performance and resilience, high water absorption speed, large unit-area water absorption amount and high drying speed.

Owner:SUNVIM GROUP

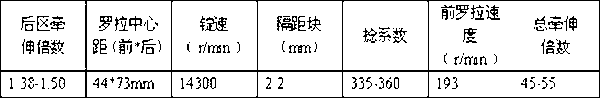

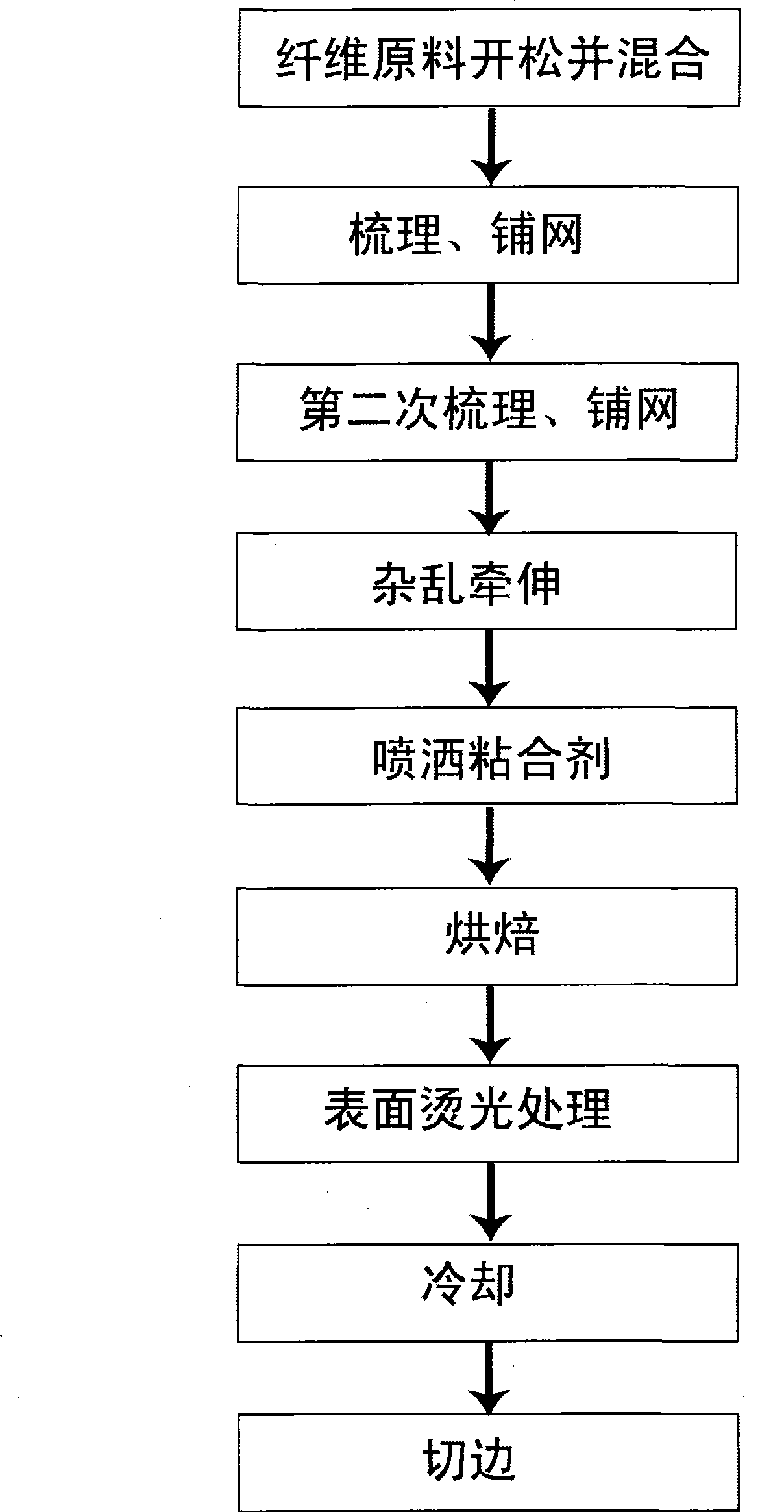

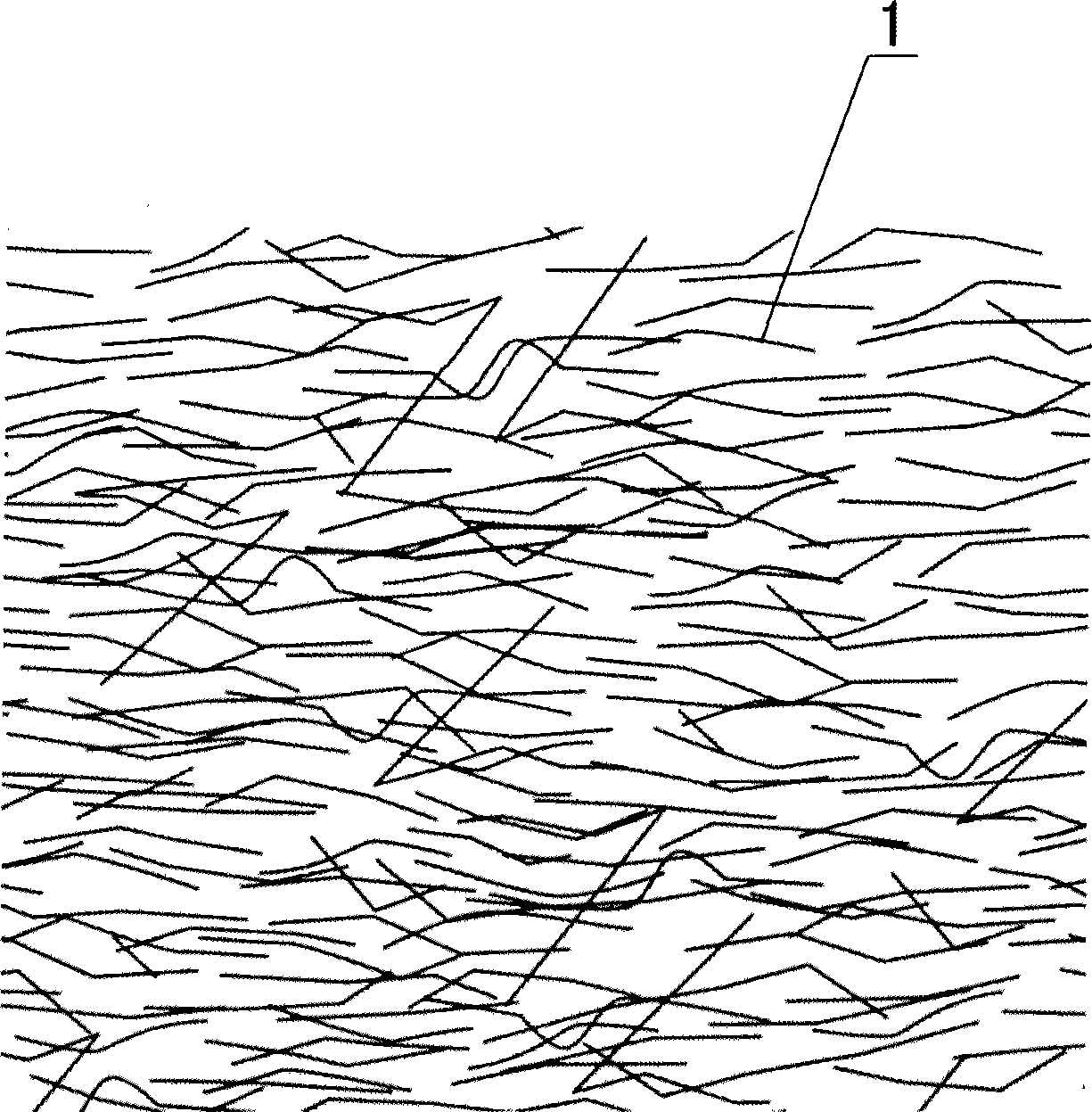

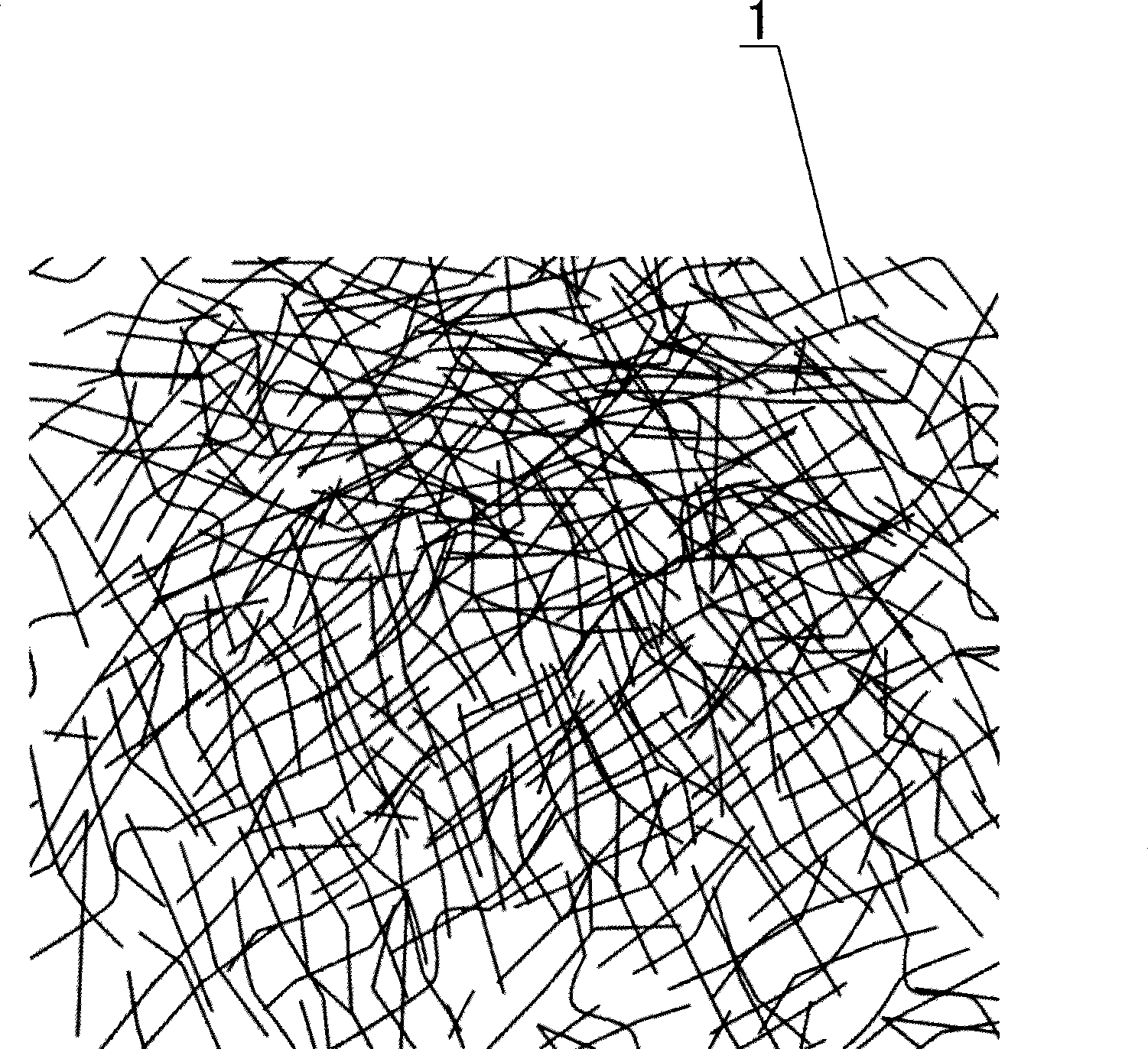

Insulation flocculus and manufacture method thereof

InactiveCN101718024AReduce conductionReduce convectionNon-woven fabricsAdhesivesCross ventilationRaw material

The invention relates to insulation flocculus which is made by 20-80 percent by weight of superfine denier fiber, 10-70 percent by weight of fine denier fiber, 5-30 wt% of tacky fiber and 0-5 wt% of bond. The insulation flocculus is made by adopting the following steps of: loosening and mixing the fiber raw materials; carding and lapping to form a fiber web; carrying out disorder traction on the fiber web to enable the fiber web to form a solid meshy across structure; spraying the bond on the two faces of the fiber web; heating and baking the fiber web to enable the tacky fiber to bond the fiber around and to solidify the bond. In the invention, due to the adoption of the superfine denier fiber and the fine denier fiber, heat conduction can be effectively reduced, cross ventilation in the space can be prevented or reduced, and the insulation property of the insulation flocculus is improved. In addition, due to the adoption of the tacky fiber and the bond, the fill power and the compression resilience of the insulation flocculus can be improved, and the fill power and the compression resilience of the insulation flocculus are higher through disorder traction.

Owner:汕头市奥山服饰有限公司

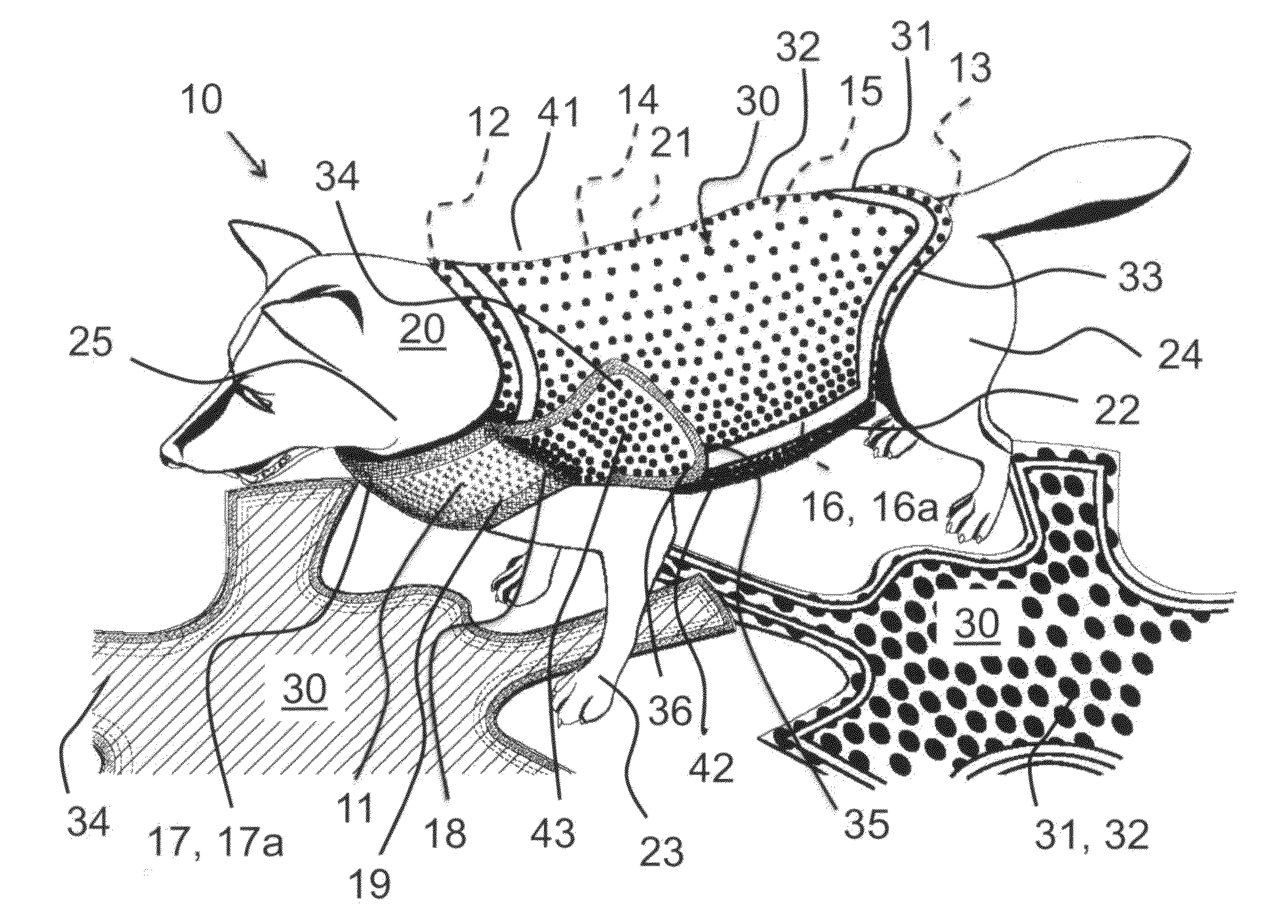

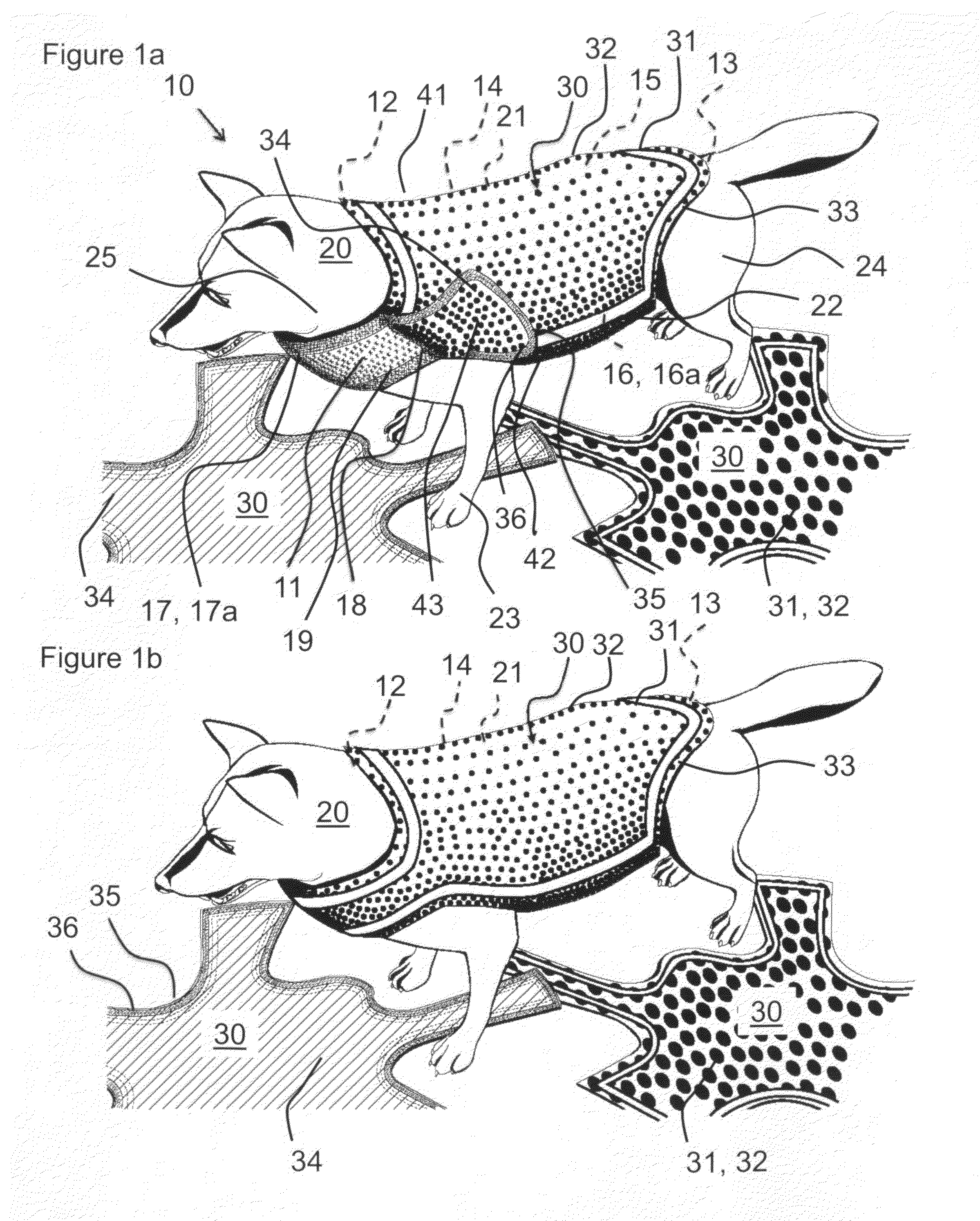

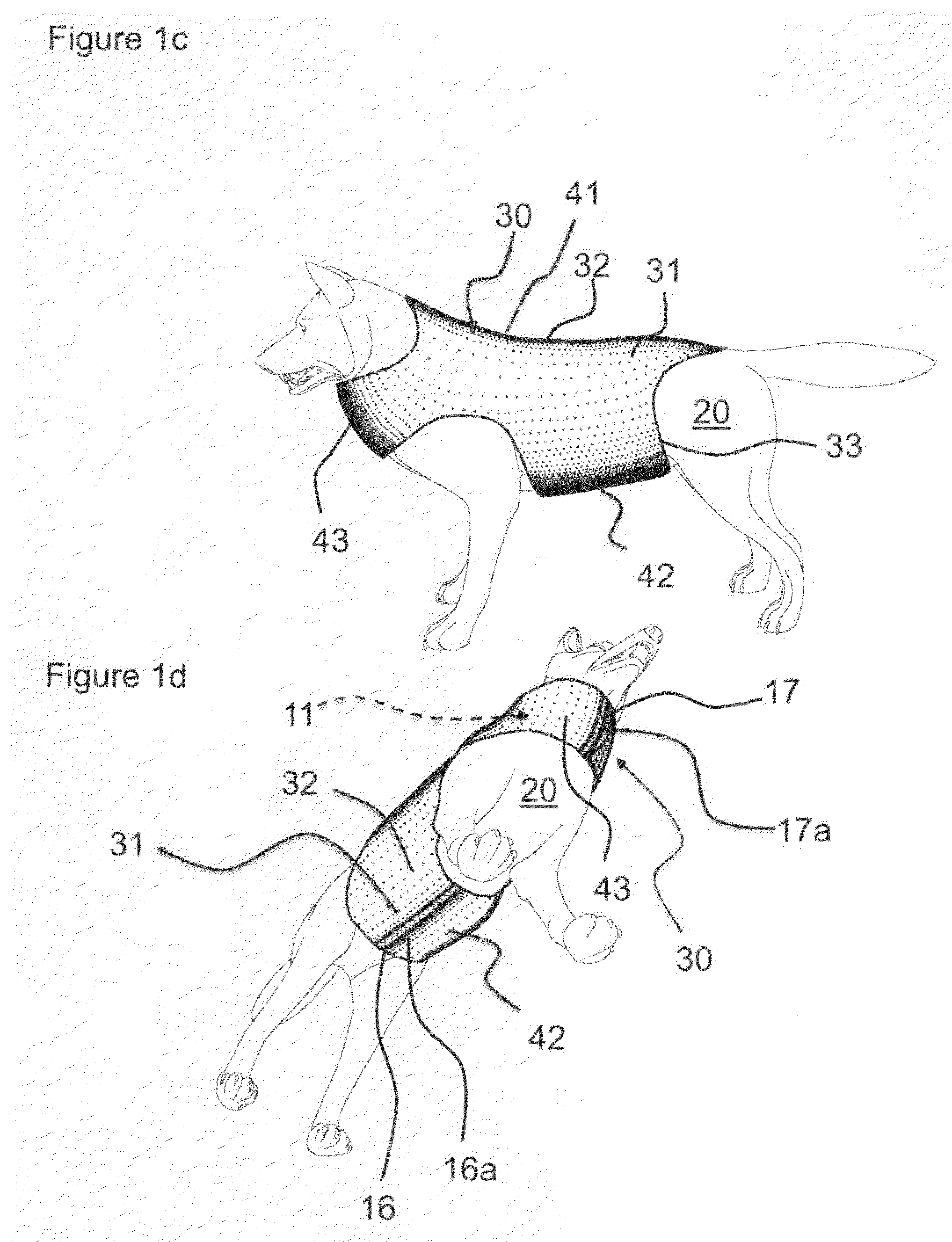

Interchangeable attachments for accessories for pets

InactiveUS20100277945A1Readily change lookIncrease awarenessSafety beltsLighting support devicesVisibilityFiber

An article forming pet gear appointed to be worn by a pet, including pet coats, jackets, shirts or sweaters, has a plurality of interchangeable attachments appointed to modify the article's look, feel and function. The article comprises a proximal end, distal end and a central section having at least one connection means appointed to receive the interchangeable attachment. The interchangeable attachment includes a top wall having a show surface and a back wall having a securing member adapted to engage with the connection means of the article for removably attaching the interchangeable attachment to the article. The interchangeable attachments have a plethora of designs and may include LED, fiber optic and / or reflective properties to provide aesthetic appeal, the ability to design one's own accessory, enhanced visibility, and / or increased safety of the pet during nighttime or dusk hours. They may also be treated with insect repellent, fragrance enhancers, and / or water repellant agents; and layered to provide increased warmth or a cooling effect to accommodate for changes in weather conditions.

Owner:I DID IT

Preparation method of thermoregulation cellulose fiber with intelligent thermoregulation function

InactiveCN1995497APrevent leakageHigher than the surfaceHeat-exchange elementsArtifical filament manufactureHeat stabilityCellulose fiber

The invention relates to a manufacturing method for tempering cellulose fiber with intelligent tempering performance, characterized in that microcapsule grout of phase change energy storage materials with the weight of 10-230% of the fiber is put into the fiber stock solution of cellulose so as to form spinning dope by even mixture, which enters into the dilute caustic soda solution and dilute sulfate in turn to form the fiber; tempering cellulose fiber is formed by dilute acid decoppering, washing and drying. It is provided with simple process, low manufacturing cost and wide applicable range. The tempering cellulose fiber has the base material of cellulose fiber and the functional additive material of microcapsule of phase changer energy storage materials. The phase change energy storage materials are not easy to leak and is provided with good heat stability and tempering effect. When it is applied in down-proof fabric and duvay the phase change energy storage materials can strengthen the tempering performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

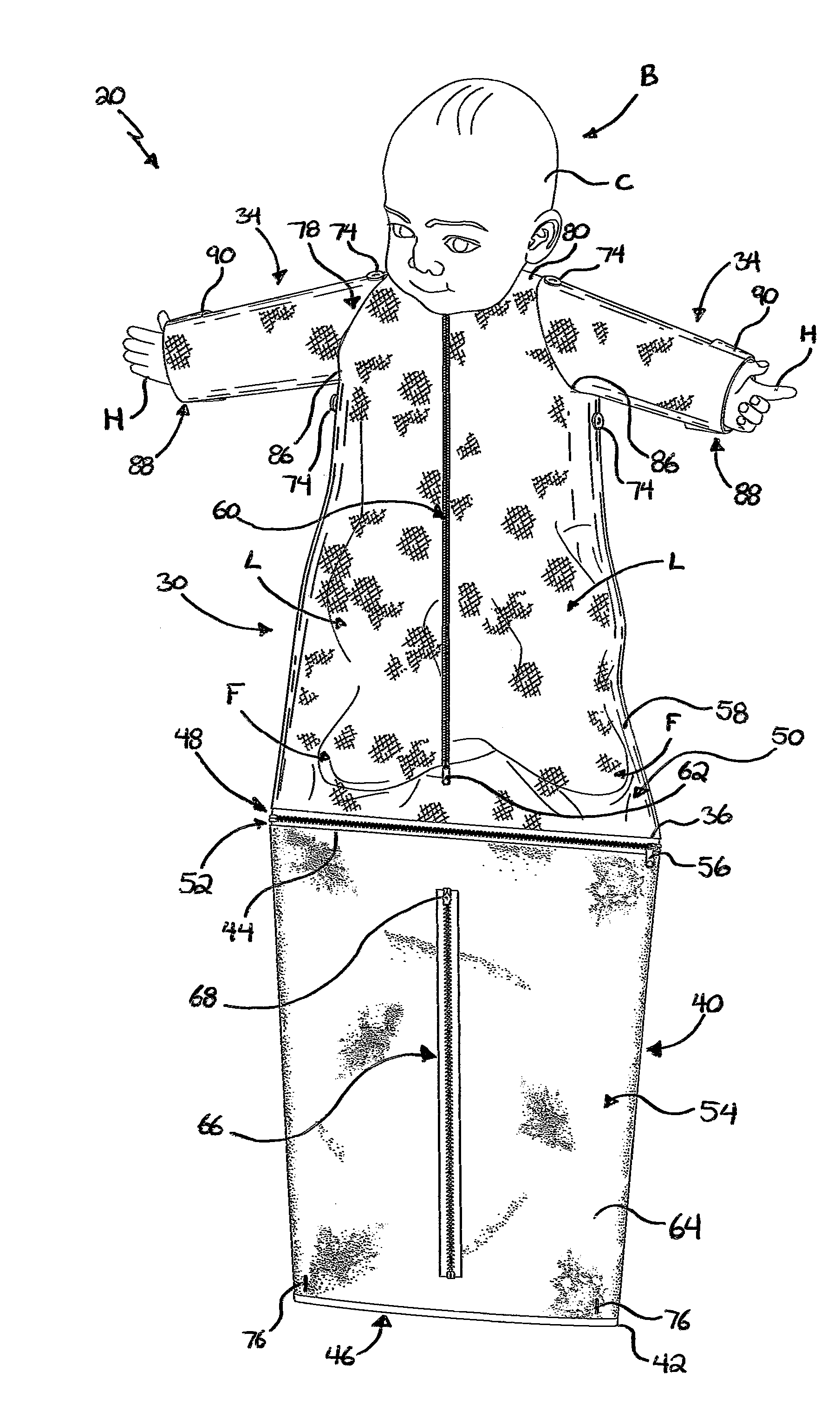

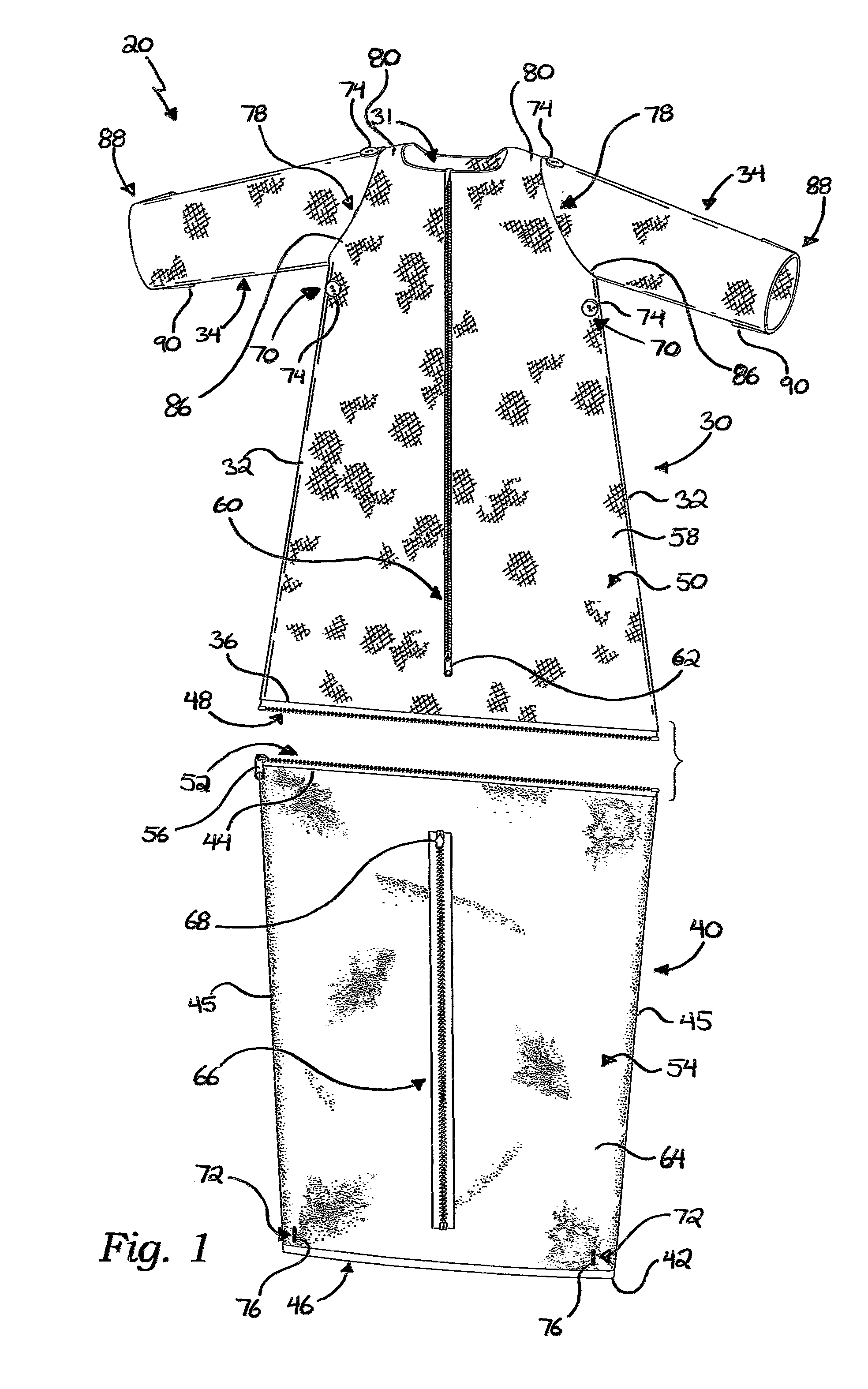

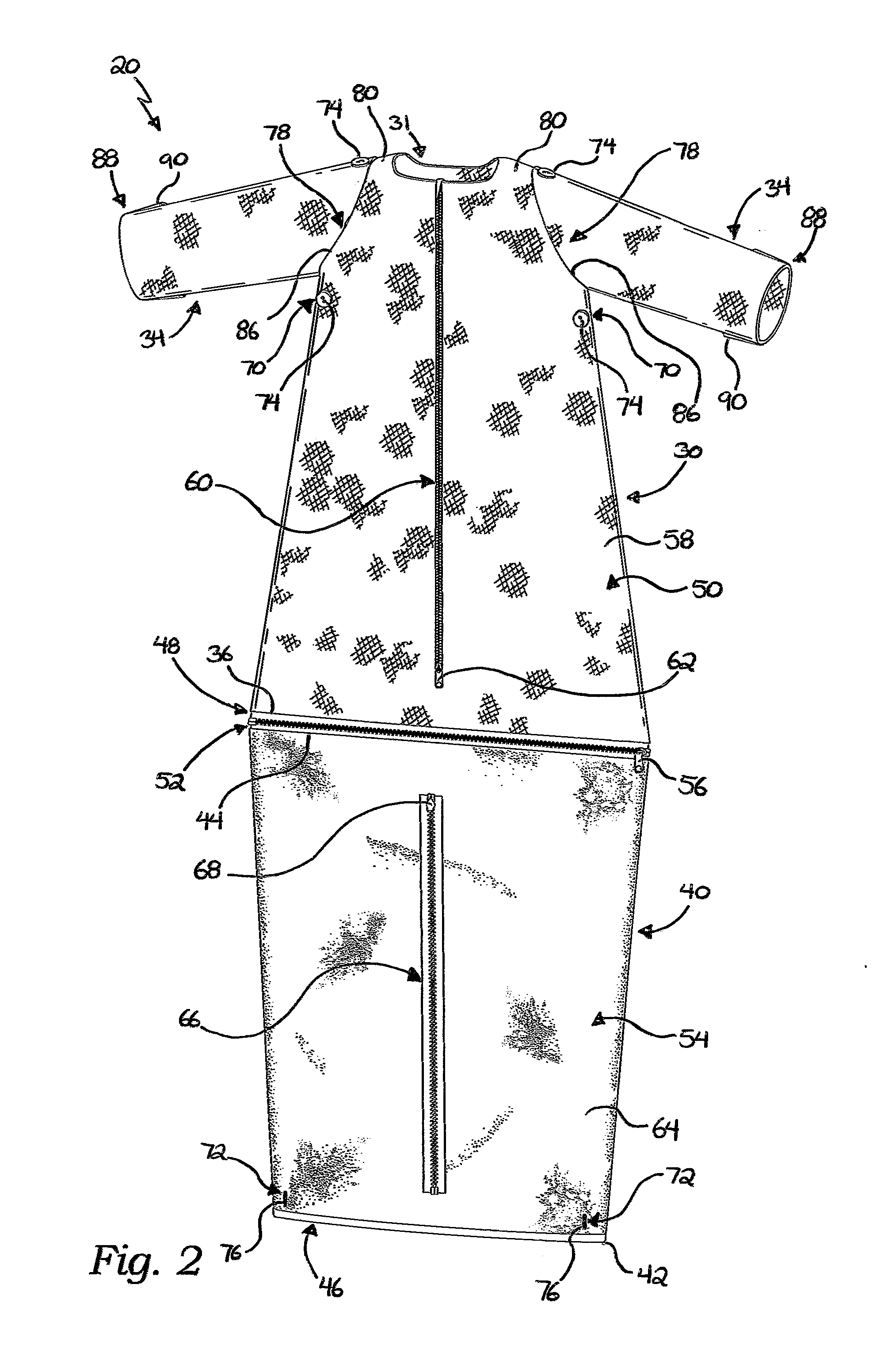

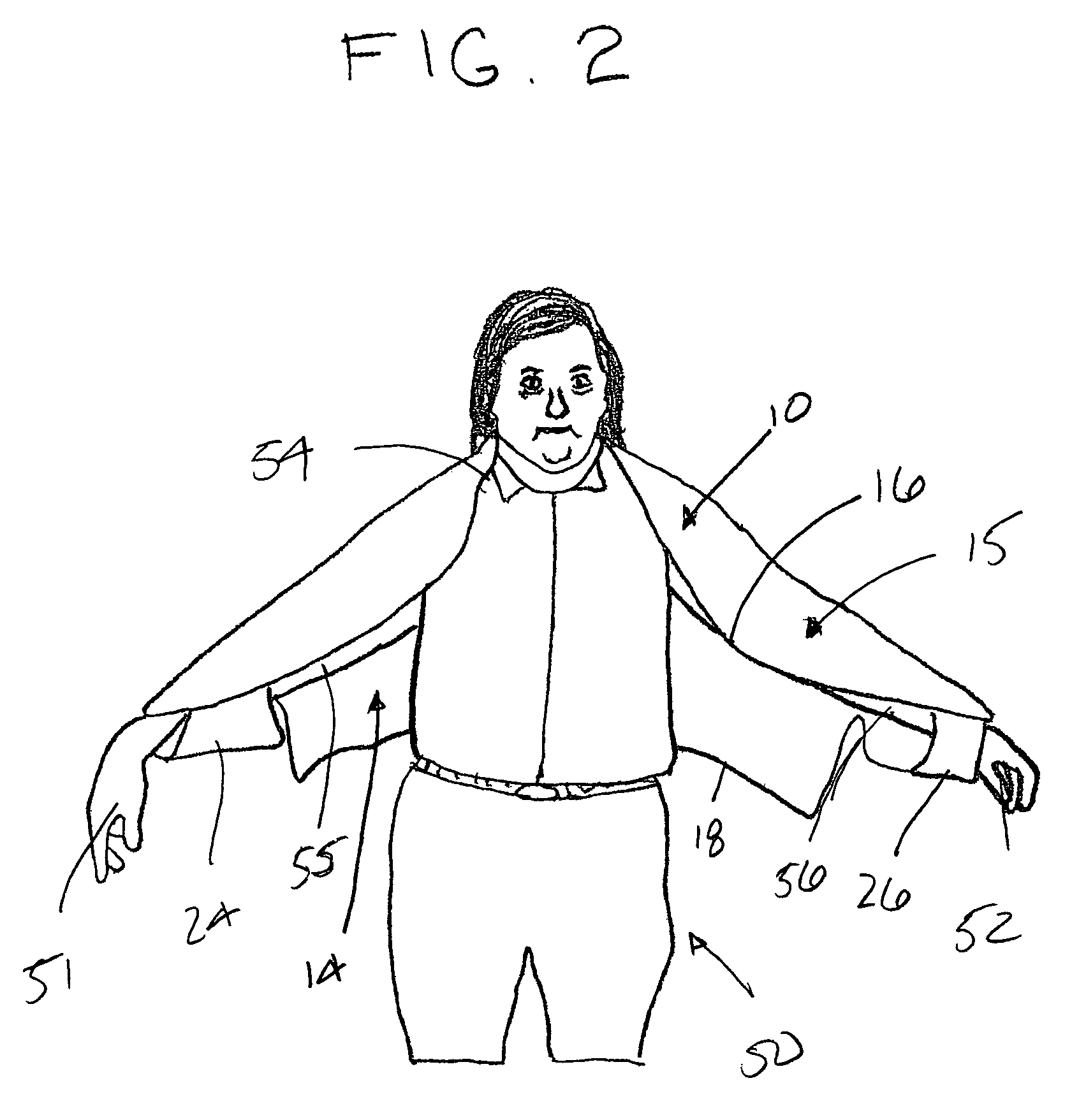

Baby clothing apparatus

ActiveUS20140165257A1Increase warmthPreventing waking up the baby unnecessarilyBaby linensEngineeringMechanical engineering

A clothing apparatus for a baby comprising of a garment containing a plurality of sleeves, a neck aperture, and a closed bottom edge. The garment of the clothing apparatus may be coupled to a Cover by a plurality of securing means and in one preferred embodiment, the Cover is in the form of a blanket which can be positioned over the baby's torso region inside the garment. The clothing apparatus is adjustable and can be configured in a variety of ways to accommodate for changes in temperature.

Owner:WYNH JENNIFER

Thermal woven and producing method thereof

InactiveCN101463523AIncrease warmthFluffy and softDry-cleaning apparatus for textilesWoven fabricsYarnFiber

The invention provides a cold-proof fabric and a manufacturing method thereof, and is characterized in that the manufacturing method comprises the steps: water soluble fiber is taken as core yarn or spinning yarn, and cotton, wool, terylene or acrylic staple fibre is taken as outer wrapping fiber or winding fiber to be wrapped into core spun yarn or Sirofil yarn; the obtained core spun yarn or Sirofil yarn is utilized for weaving; and the water soluble fiber is the obtained fabric is dissolved by solution. The invention has the advantages of simple technology, easy realization, low cost price, fluffy and soft effect, good heat retention and excellent ventilation property.

Owner:DONGHUA UNIV +2

Elastic cotton

InactiveCN1397671AIncrease elasticityIncrease warmthNon-woven fabricsAdhesivesThermal insulationEngineering

An elastic fabric belonging to non-woven one is prepared from a curled hollow fibre and a fibre with low smelting point, and features that its fibres are distributed in 3D mode. Its advantages are high elasticity, good thermal insulation and long service life (up to 50 years).

Owner:唐懿

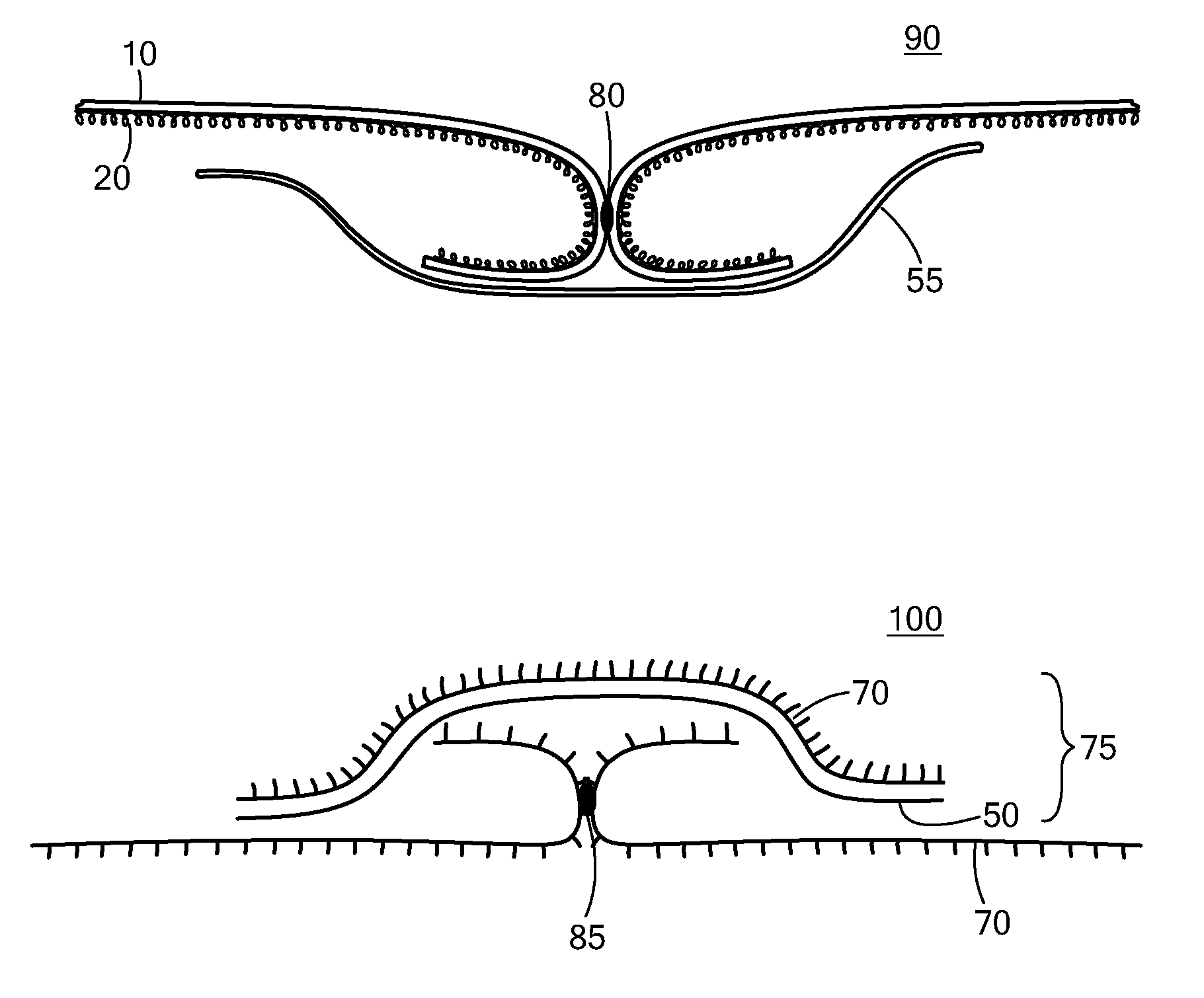

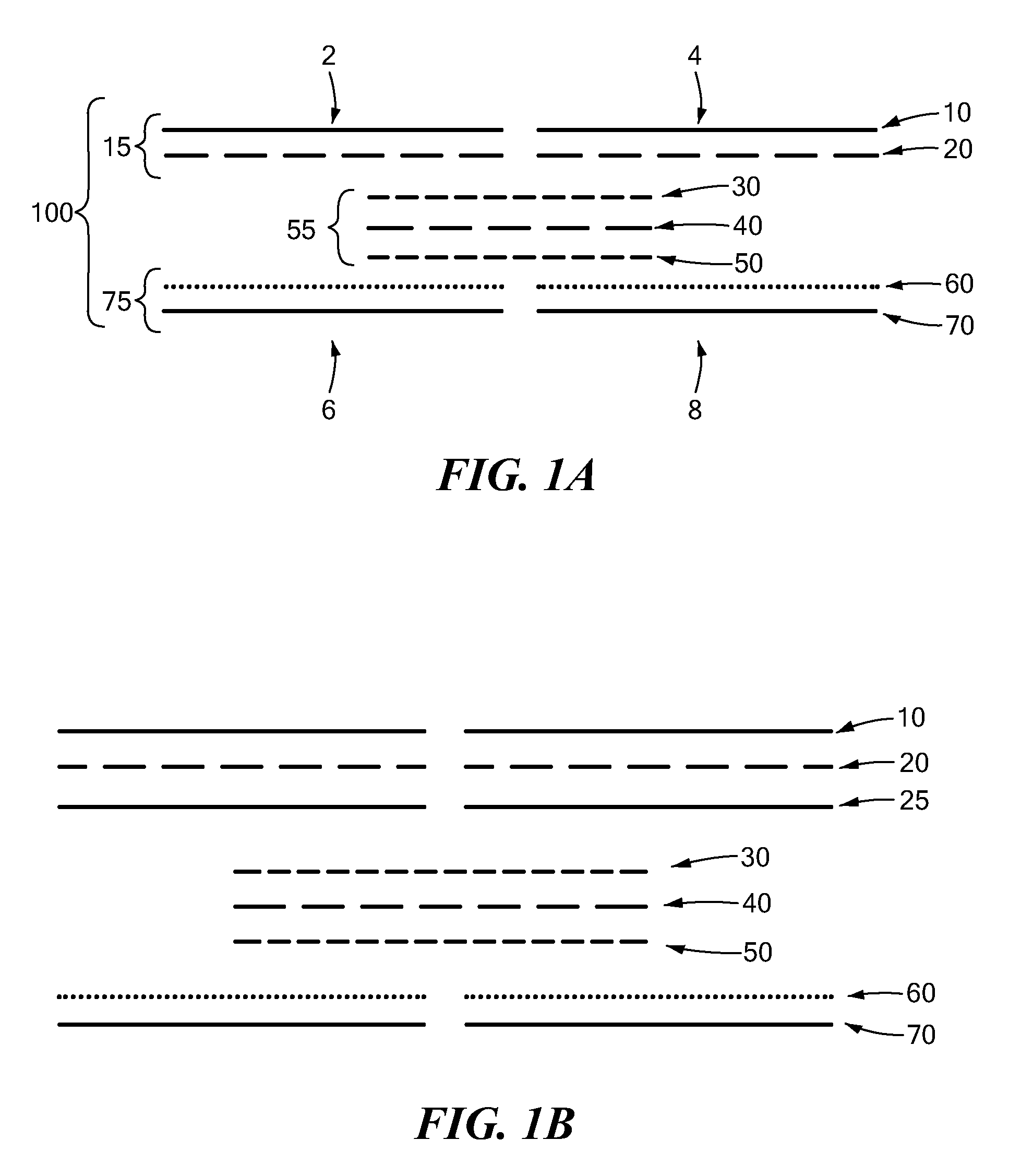

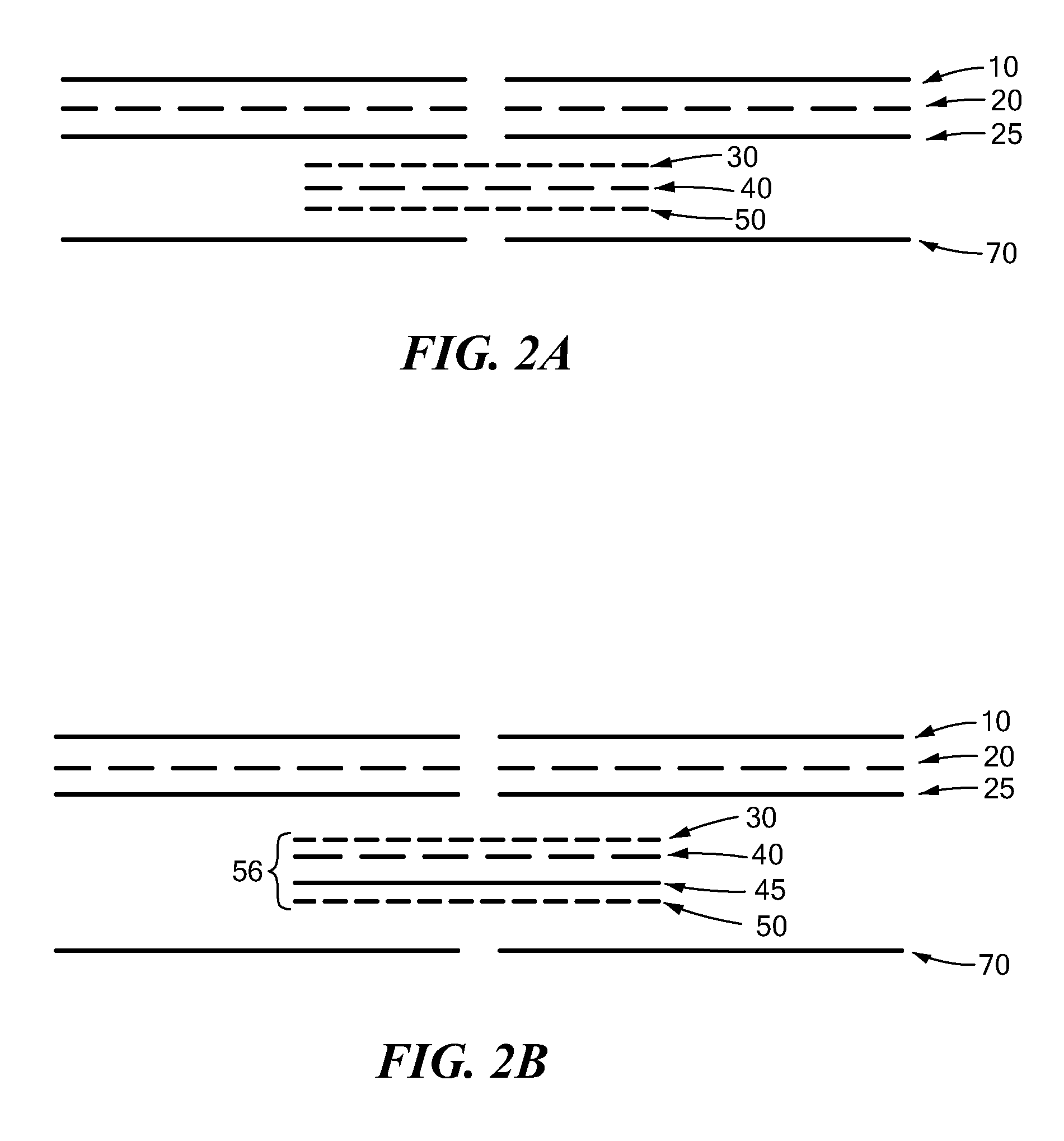

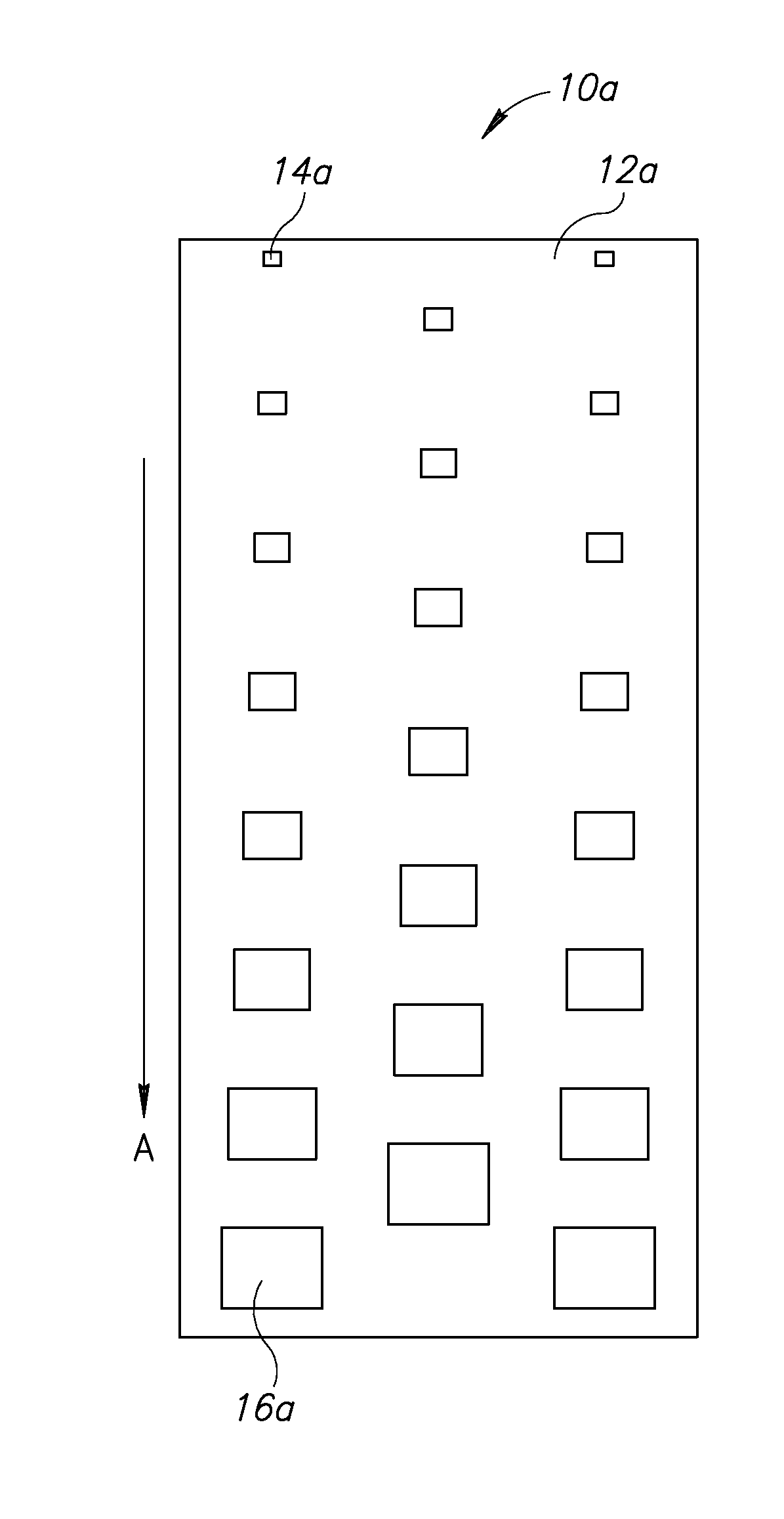

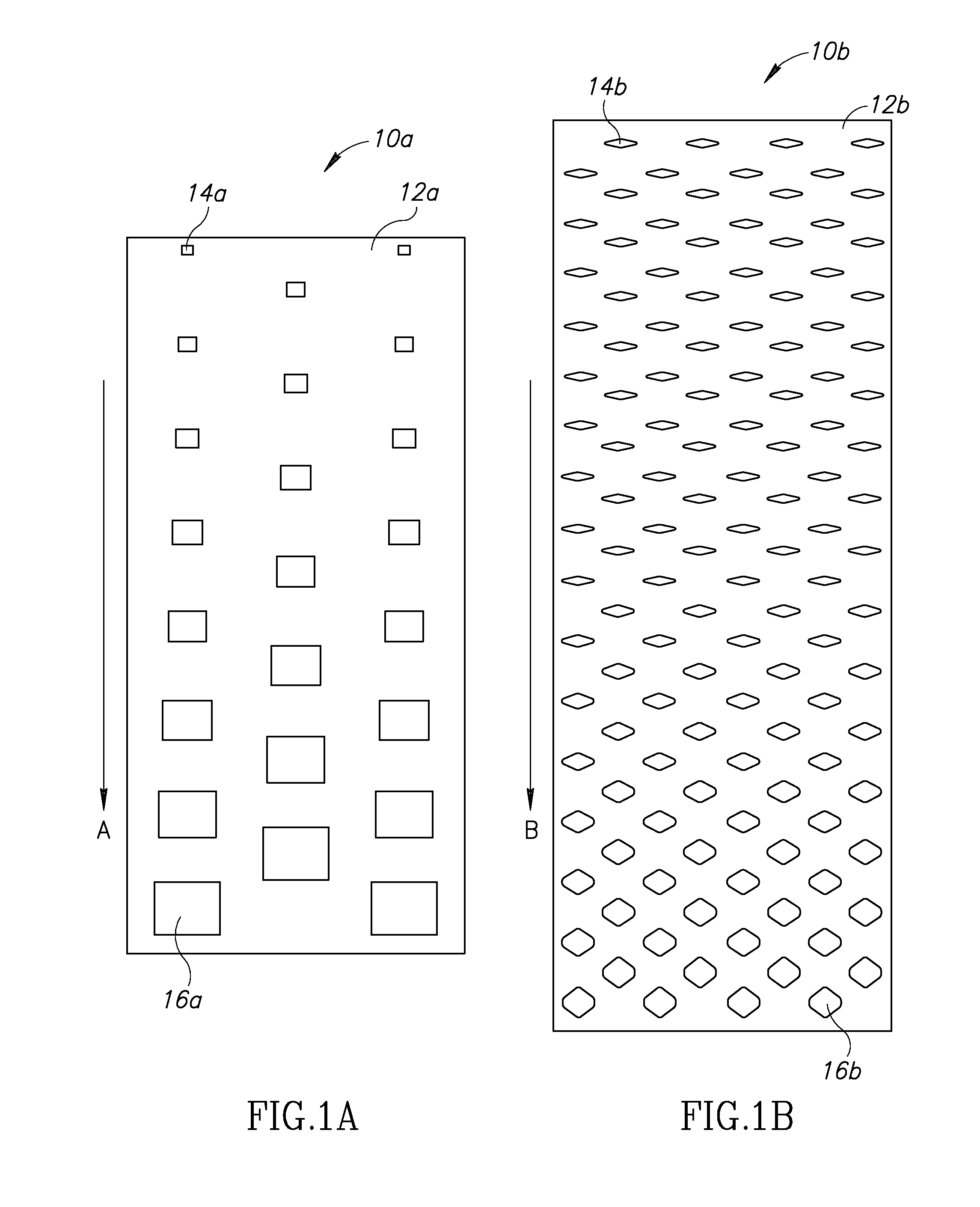

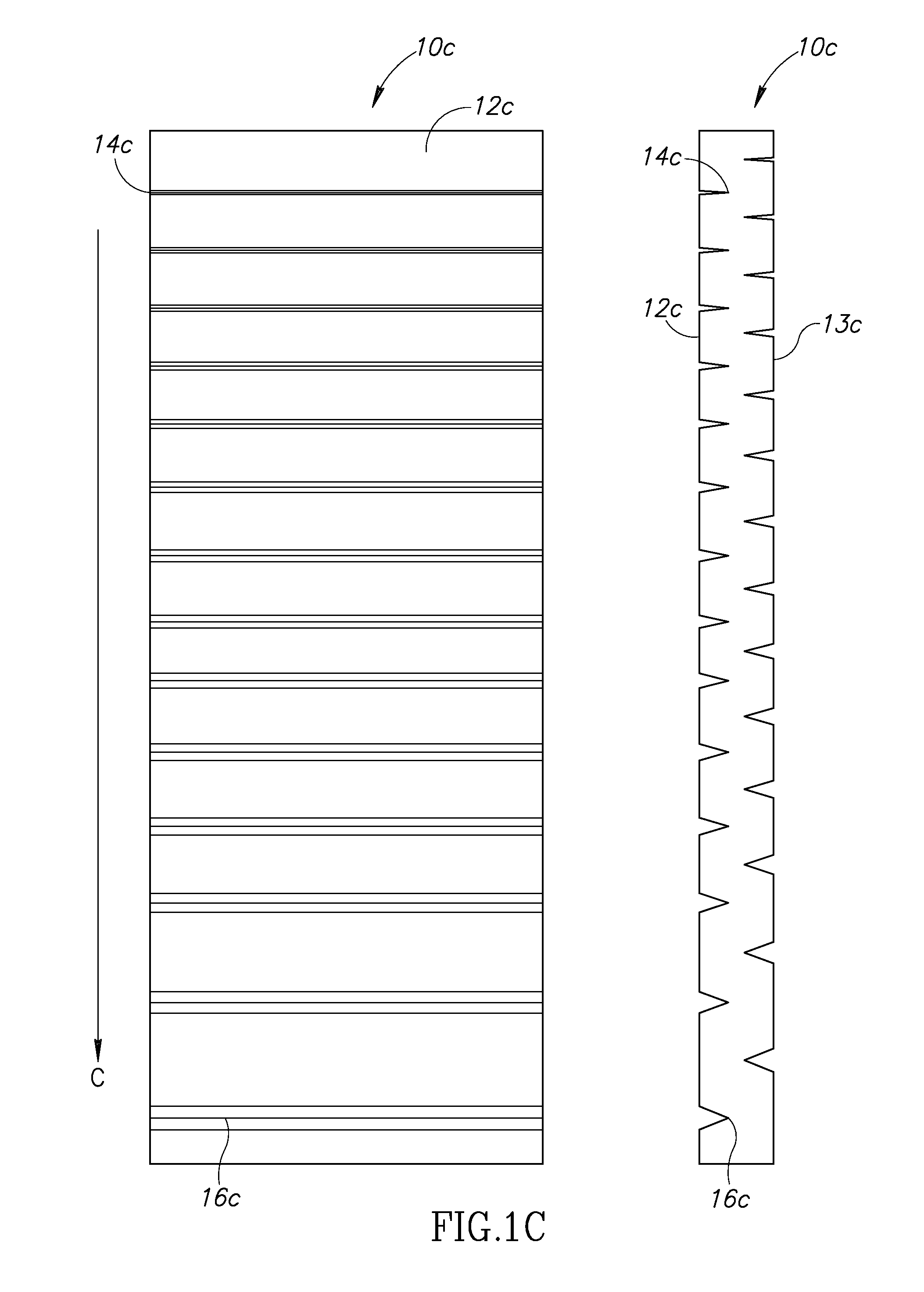

Compressible, low-weight insulation material for use in garments

InactiveUS20170028669A1Improve breathabilityRaise the ratioLayered productsOvergarmentsFiberMaterial Perforation

A compressible insulating material for use in active garments and other gear is provided herein. The material comprises an insulating material including one or more types of fiber, with portions of the insulating material removed or cut to improve the warmth-to-weight and compression characteristics of the insulating material. In some embodiments, the insulating material is an elastic insulating material that defines perforations or other features that expand or contract depending on stretching or relaxation of the elastic insulating material. Stretching and relaxation may vary an insulating property of the compressible, low-weight insulating material. The material may further be secured to a stretch-resistant material to provide a reference point for stretching and for and elastic memory. A garment comprising one or more panels of a compressible, low-weight insulating material as described herein is also provided. Strategic placement of the insulating material can improve ventilation of the garment during activities.

Owner:PATAGONIA

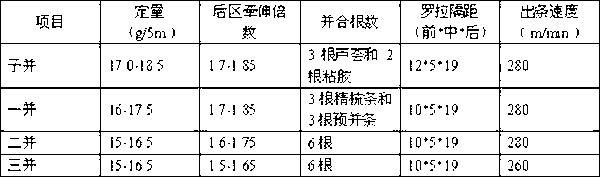

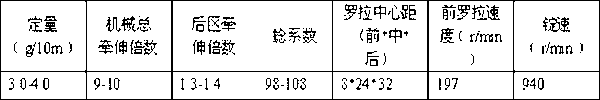

Cotton fiber, aloe fiber and viscose fiber blended yarn and yarn spinning process thereof

The invention discloses cotton fiber, aloe fiber and viscose fiber blended yarn and a yarn spinning process thereof. The blended yarn comprises the components by fiber-content blended ratio: 50 percent of cotton fiber, 30 percent of aloe fiber and 20 percent of viscose fiber, and the fibers are spun into the yarn through a blending process. The aloe fiber and the viscose fiber are subjected to coating mixing, and card slivers formed through working procedures such as blowing and cotton carding and cotton-fiber fine combing slivers are subjected to sliver mixing to form the yarn. A compact Siro spinning technique and the reasonable raw material collocation are adopted, so that the problems that the fiber of the aloe fiber is short, the viscose fiber is easy to deform, the elastic recovery properties are poor, the abrasive resistance is poorer, the fiber is not resistant to acid and the like are solved, and the advantages of the aloe fiber, the viscose fiber and the cotton fiber are exerted. A mixing mode of one pre-drawing and three mixing-drawing is adopted, the accurate blending ratio is favored, and the components are uniform. The produced single yarn evenness is uniform, the single yarn strength is high, the neps are less, and the yarn defects are less.

Owner:山东超越纺织有限公司

Thermal protection flocculus and manufacturing method thereof

InactiveCN101481851AReduce conductionConduction block or decreaseNon-woven fabricsAdhesivesFiberSurface layer

The invention discloses a heat insulation flocculus which is made from the following fiber: 10-64wt / % of fine denier fiber and / or superfine denier fiber, 31-80wt / % of hollow fiber and 5-30wt / % of tacky fiber. The heat insulation flocculus is manufactured by the following method: shredding and mixing various fiber raw materials; carding and spreading webs to form a fiber web; then performing random drafting on the fiber web to cause the fiber web to form a 3D network crossed structure; heating and baking the fiber web to cause at least the surface layer of the tacky fiber to be melted, and binding the surrounding fiber of the fiber web. The use of the fine denier fiber greatly increases the content of still air in the heat insulation flocculus, reduces heat conduction, can divide the space in the heat insulation flocculus into smaller spaces, and prevents or reduces air convection, thus improving the heat insulation performance of the insulation flocculus; the hollow fiber can improve bulkiness and compression resilience of the heat insulation flocculus; and the random drafting causes the bulkiness and the compression resilience of the heat insulation flocculus to be higher.

Owner:汕头市奥山服饰有限公司

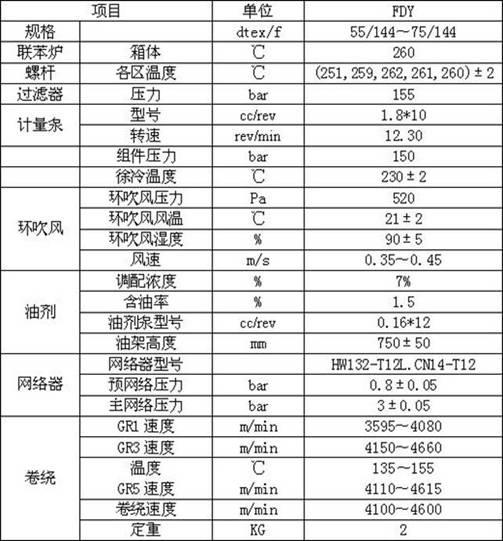

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

Manufacturing technology for far-infrared polyester short fibers

InactiveCN102560732ALow costPromote environmental protectionHollow filament manufactureArtificial filament heat treatmentPolyesterManufacturing technology

The invention discloses a manufacturing technology for far-infrared polyester short fibers, which takes recycled PET (Polyethylene Terephthalate) as a raw material, and the recycled PET is processed sequentially through pretreatment, rotating drum drying, melt spinning, cooling formation, winding, drawing, curling, oil application, cutting and heat setting, so as to obtain finished products, wherein in the rotating drum drying step, the recycled PET is dried for 5.5 to 6.5 hours firstly, then far-infrared master batches are added, the final mass fraction of the far-infrared master batches ranges from 5 to 7 percent, the total drying time ranges from 9.5 to 10.5 hours, and far-infrared ceramic powders account for 19 to 21 percent in the far-infrared master batches; in the melt spinning step, the temperatures of a screw bolt and a spinning box body of a screw bolt extruder range from 268 to 278 DEG C, and cooling formation is carried out through circular air blow; in addition, the total drawing ratio is 3.0 to 3.5, the heat setting temperature ranges from 162 to 168 DEG C, and the heat setting time ranges from 8 to 12 minutes. The manufacturing technology can save cost and is beneficial to environmental protection, and the prepared finished products achieve good warmth retention and health protection properties.

Owner:HANGZHOU BEST CHEM FIBER

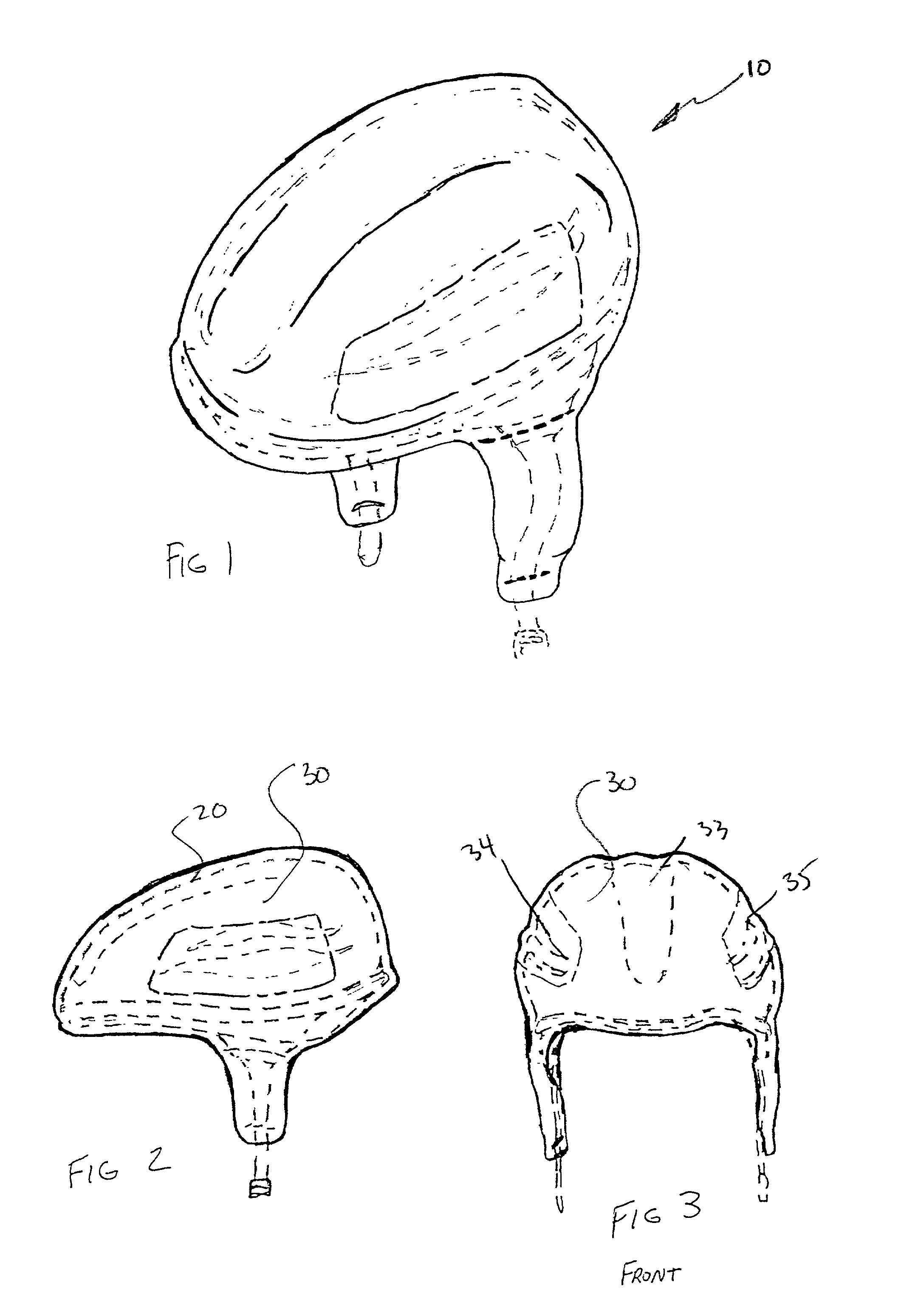

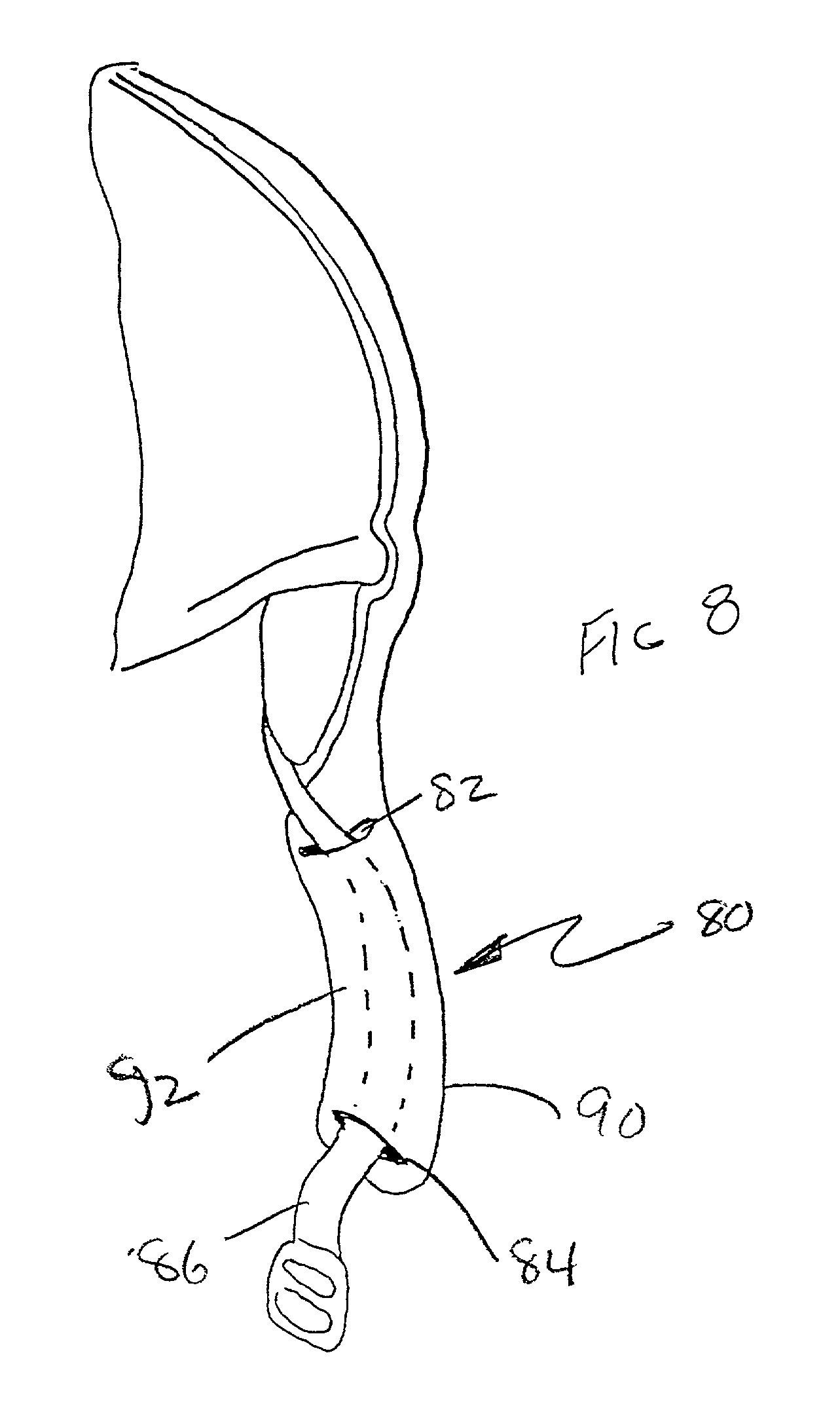

Slip-on, insulating and decorative cover for bicycle safety helmets

InactiveUS20010004773A1Good adhesionEasy to disassembleSport apparatusHelmetsBicycling helmetEngineering

A slip-on, insulating and decorative cover for bicycle safety helmets is provided by which bicycle helmets are provided with an overall covering complete with integral ear flaps. The ear flaps can be folded down to protect the ears and keep them warm in cold weather. The ear flaps have slots in them, thru which the helmet straps are routed. The decorative cover is readily attached and easily removed from the bike helmet to allow for removal during warm weather or for washing.

Owner:MOORE TONI

Three-dimensional loop flannelette shell fabric and preparation method thereof

ActiveCN103696111AIncreasing the thicknessIncrease warmthSucessive textile treatmentsWeft knittingYarnPolyester

The invention relates to a three-dimensional loop flannelette shell fabric and a preparation method thereof. The shell fabric is in a plating lining loop structure, the shell yarn is pure cotton combed yarn, the middle connecting yarn is filament polyester fiber, and the velvet lining yarn is polyester and cellulosic fiber blended yarn or pure cotton yarn. The preparation method comprises the steps of untwisting, knitting, fabric slitting, curling and finishing, rubber carpet shrunk finishing, and dyeing finishing. The three-dimensional loop flannelette shell fabric recovers the characteristics that ordinary non-napping loop flannelette is not ordered enough in loop and not fluffy enough for hand feeling, the thickness and heat retention property of the shell fabric are increased, and the additional value of the product is improved, so that the three-dimensional loop flannelette shell fabric is more advantageous in market competition, and is low in cost, simple in technology and good in market prospect.

Owner:NINGBO DAQIAN TEXTILE

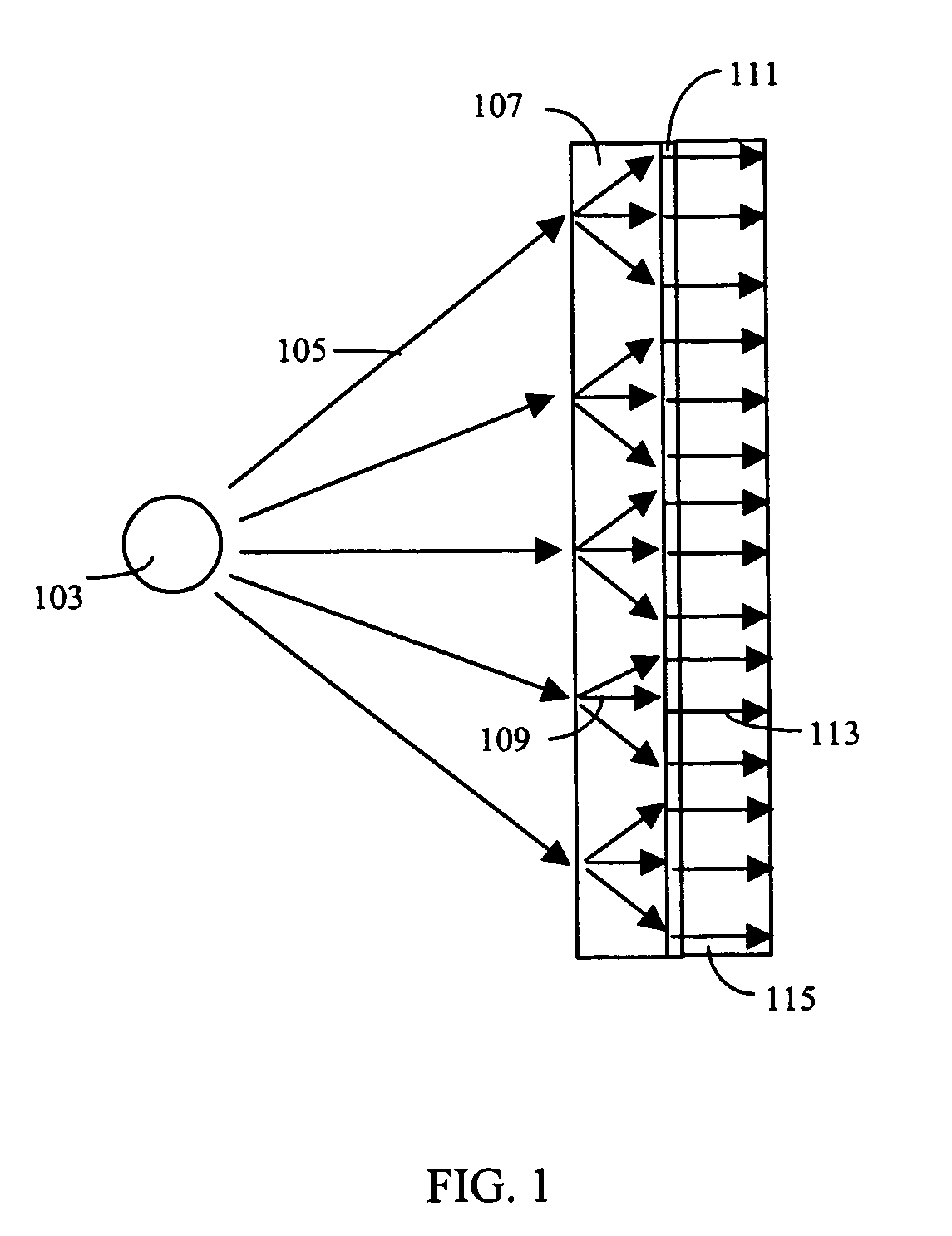

Translucent wood veneer lighting system

ActiveUS7090380B2Increase warmthControlled ambient toneNon-electric lightingPoint-like light sourceWood veneerWarm environment

Owner:GERFERS III C ARTHUR

Bombax cotton thermal shell fabric and its manufacturing method

The invention discloses a kapok warm face material. The fiber ingredients and the ratio are: natural kapok fiber 10-100%, cotton or other fiber 0-90%, urethane elastic fiber and other elastic fiber 0-50%. The invention also discloses the manufacture method including the following steps: selecting the fiber ingredients; spinning after mixing the raw material; weaving on the knitting great circle machine; dyeing and after processing. The advantage of the invention is good warm effect, soft tactility and comfort.

Owner:DONGHUA UNIV

Soft polyester cotton down-proof fabrics and processing method thereof

The invention provides a soft polyester cotton down-proof fabrics and a processing method thereof; the fabrics is formed by interlacing warp yarns and filling yarns according to a plain structure; the warp yarn uses super fine denier terylene low elasticity filament with fineness of 50-75 D; the filling yarn uses polyester cotton blended yarn with fineness of 40-60s. The processing method is to process the warp yarn and filling yarn through the following steps in sequence: warping, slashing, drafting and denting, weaving, grey singeing, desizing, boiling-off and bleaching, tentering, sanding, soft windproof arrangement, moulding, calendering and preshrinking. The fabrics is lasting and excellence in down-proof performance, thin and soft, and small in sound.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

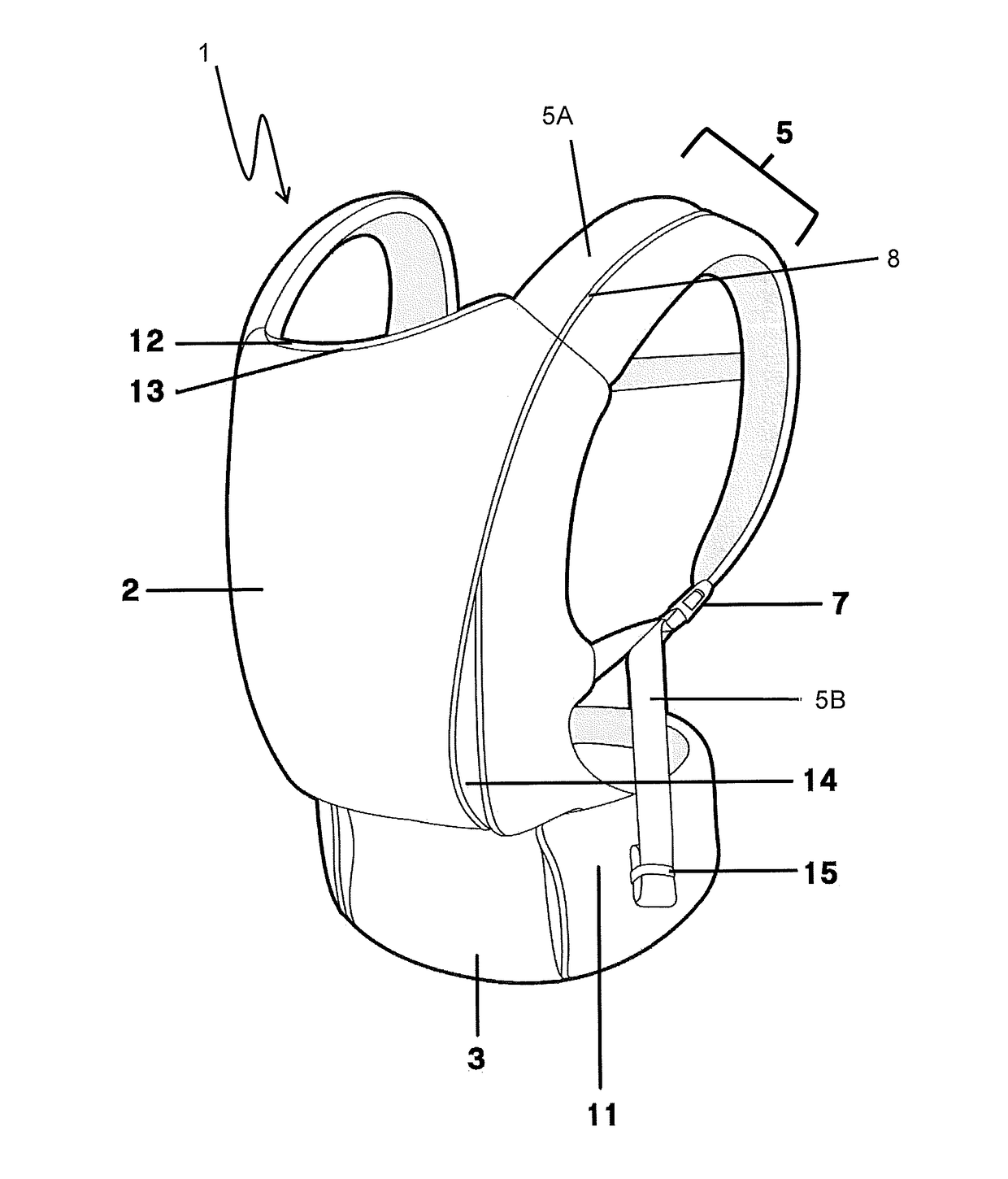

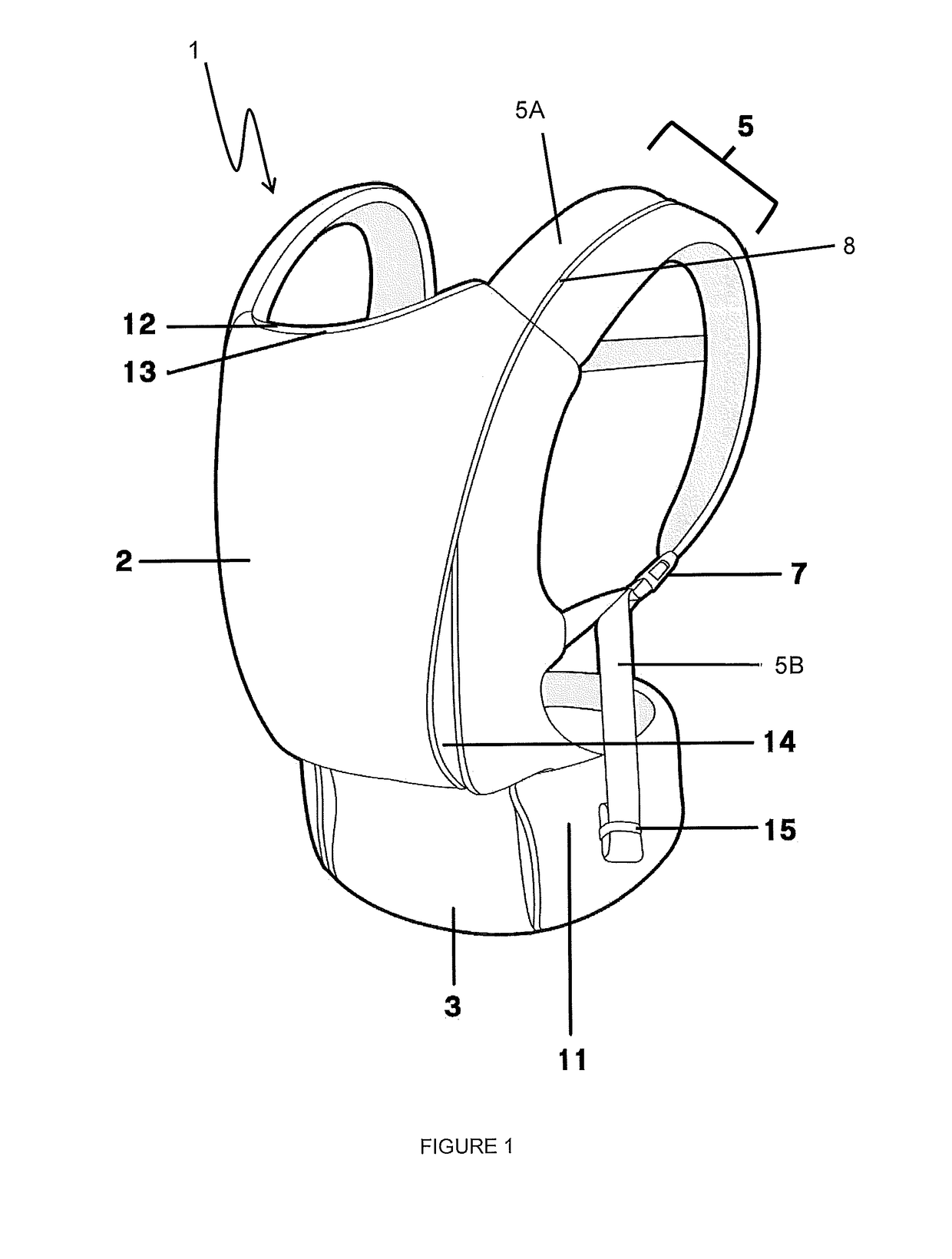

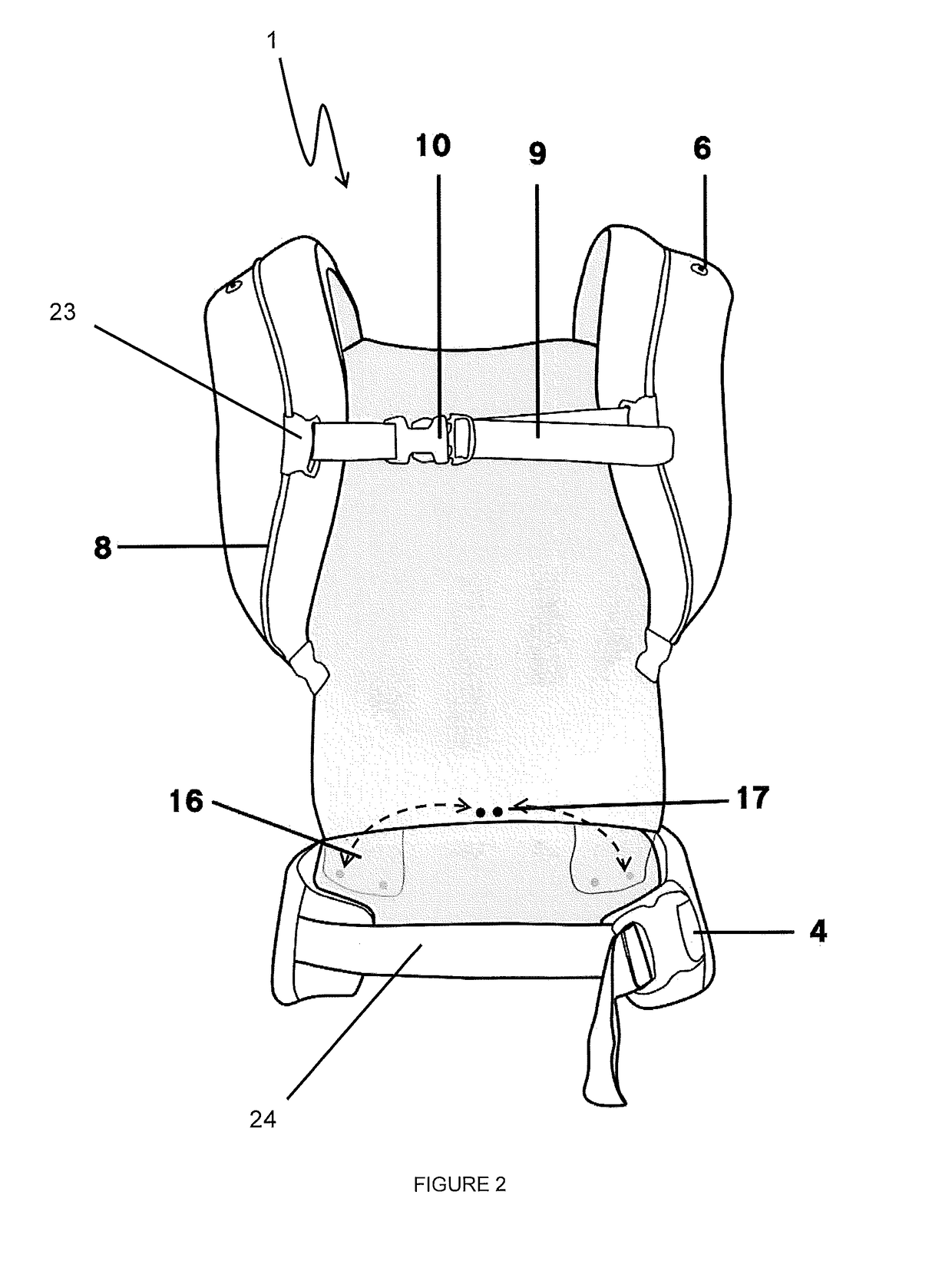

A baby carrier

Described herein is a baby carrier and insert therein. In particular, a multi functional baby carrier that transitions seamlessly from one mode to another to allow the carrying of a child from newborn baby through to a toddler wherein the main body forms an adjustable seat width position to address ergonomic concerns when in a particular carrying mode. The main body portion also comprises a hands through pouch configured to allow a wearer to pass their hands through for additional support when carrying the child. The insert includes an adjustable length back support and is configured to engage with the main body of a multi functional baby carrier without requirement of separate fasteners to retain the insert within the main body of the multi functional baby carrier.

Owner:PHIL & TEDS DESIGN

Shawl

Owner:HOUGHTON CLAIRE +1

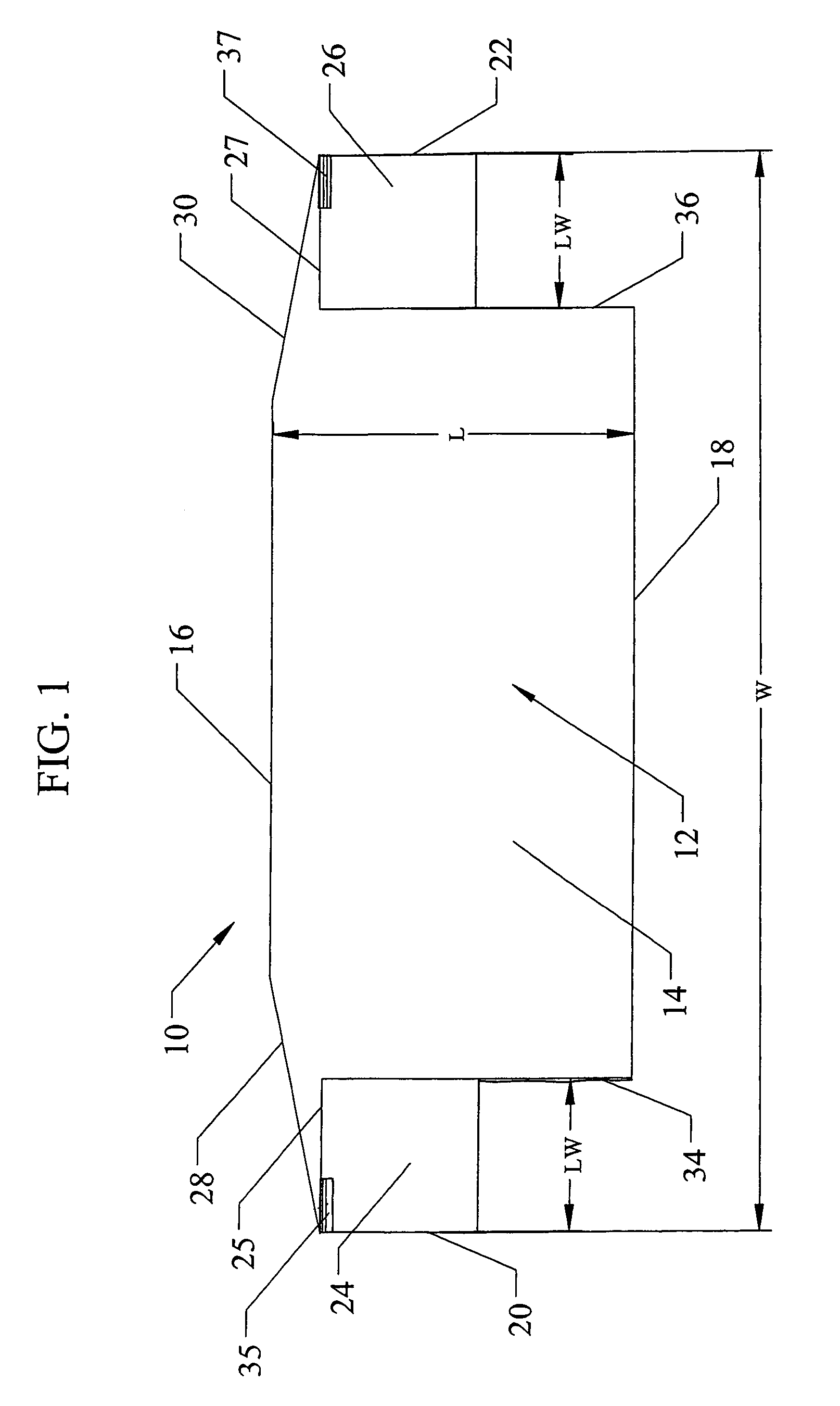

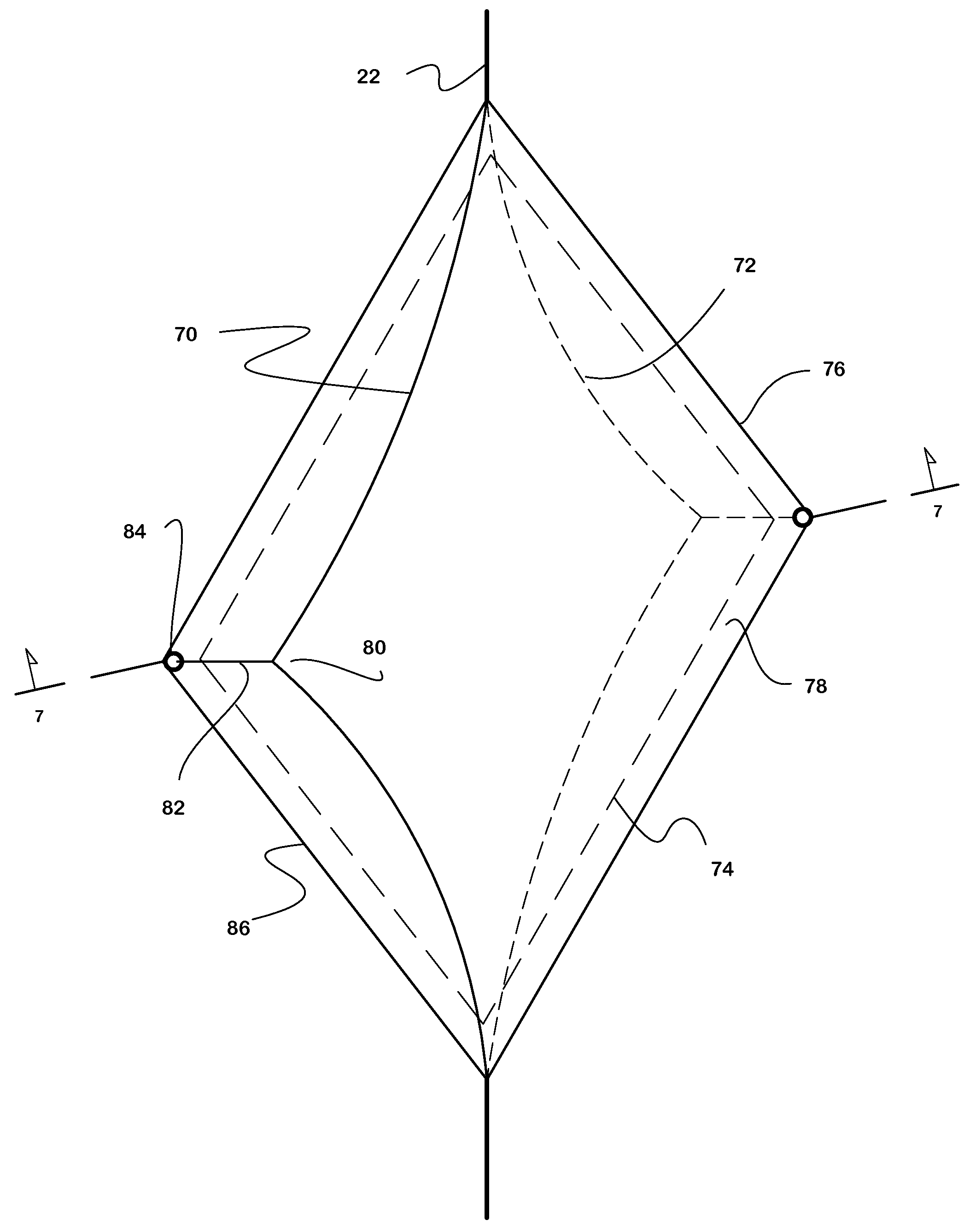

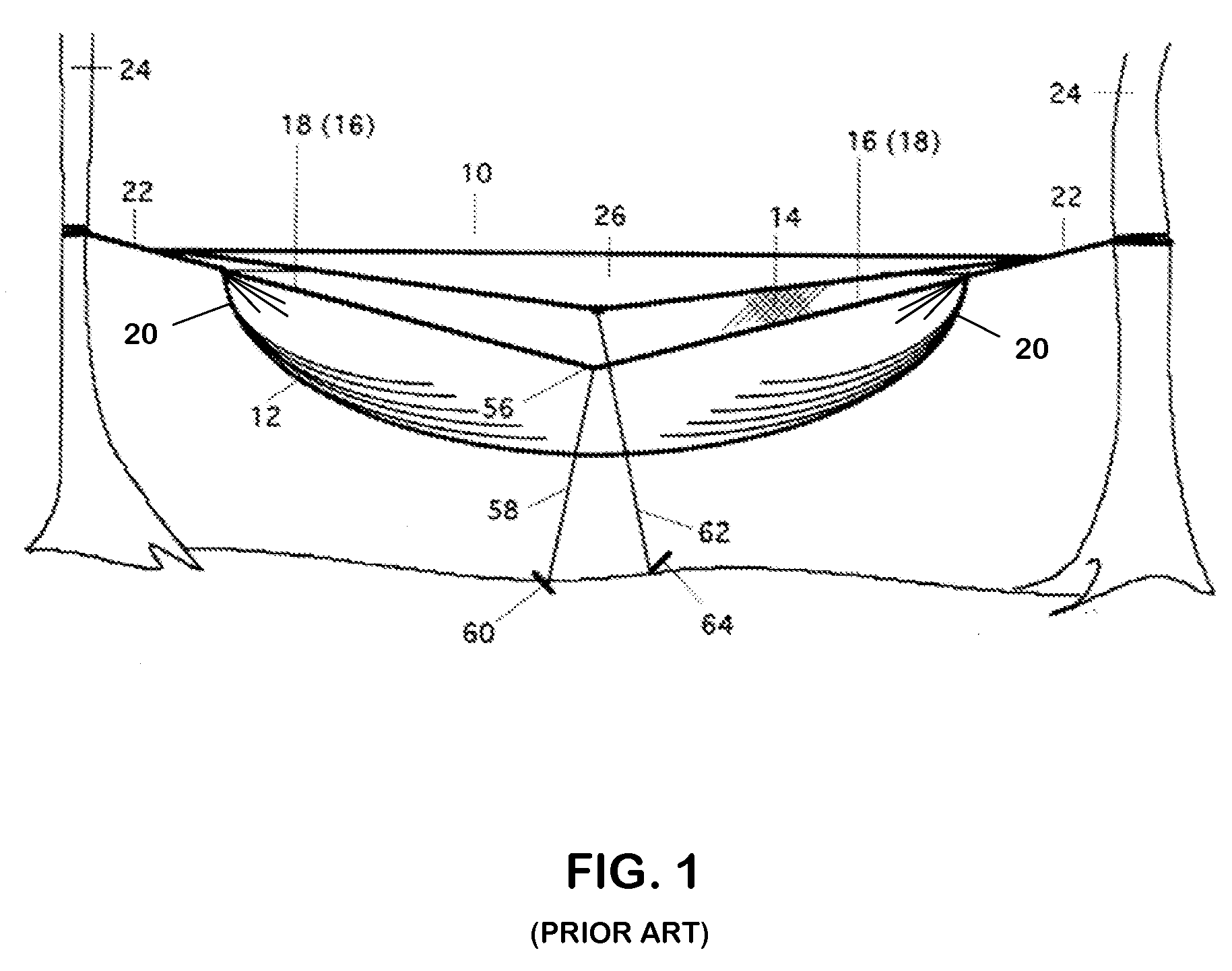

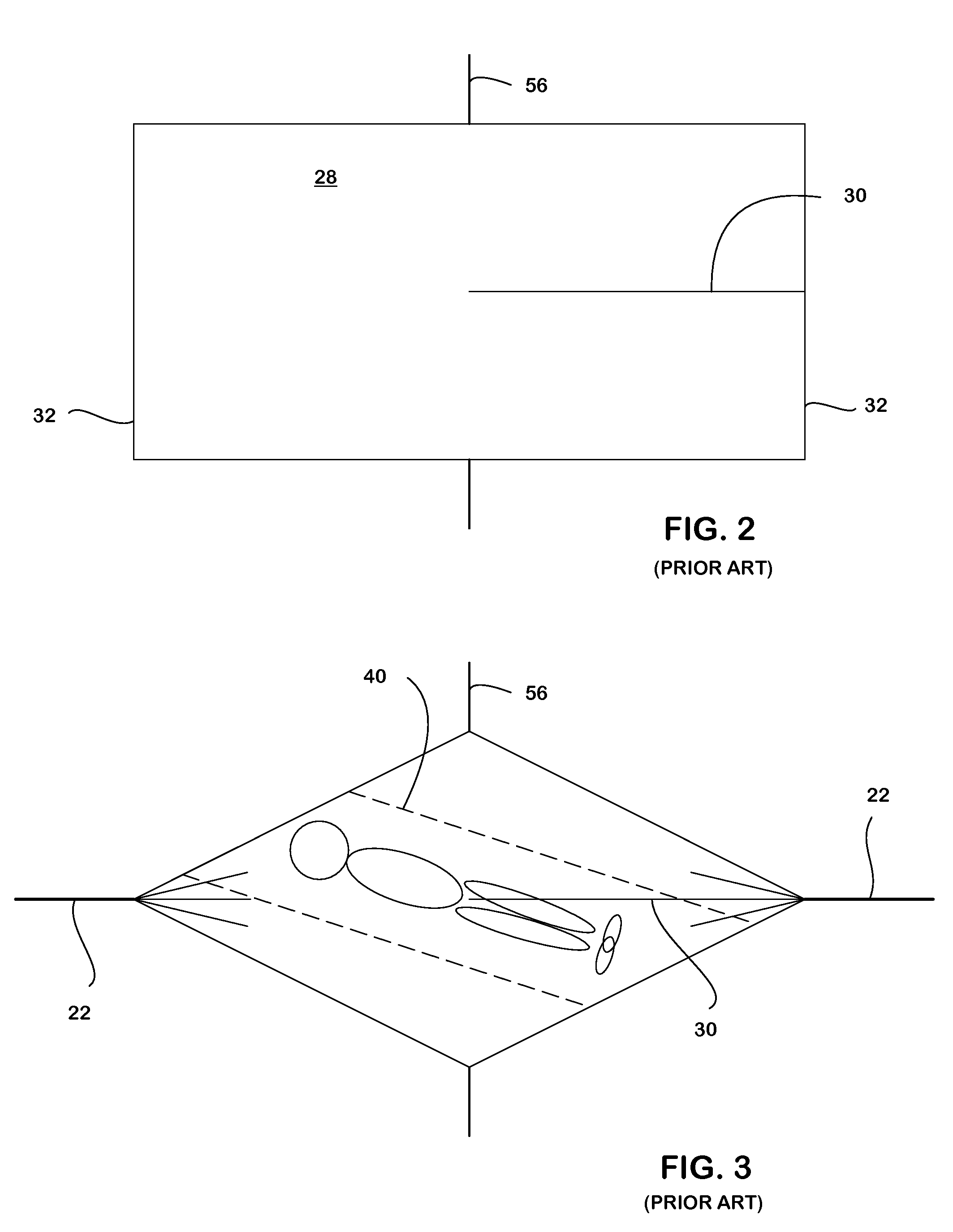

Hammock Having Insulation Retaining Panels

A thermally insulated hammock is provided with a pair of insulation retaining panels, one secured to either side of the hammock bed. The panels can be drawn across the bottom surface of the hammock and fastened so as to hold one or more insulation pads against the bottom surface of the hammock bed in cold weather. The retaining panels may be rolled up out of the way and tied at the edges of the hammock when insulation is not needed.

Owner:HENNESSY HLDG

Preparation method of fabric with far-infrared warm keeping function

InactiveCN105200620AStrong and goodGood warmth retentionShrinkingHeating/cooling textile fabricsPlasma technologyWool

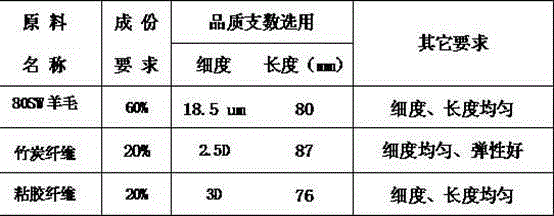

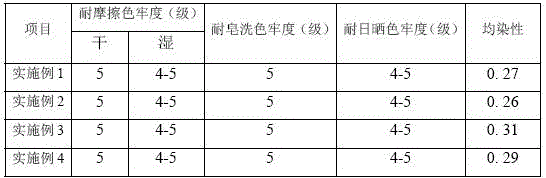

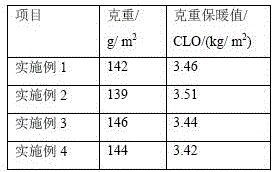

The invention discloses a preparation method of a fabric with a far-infrared warm keeping function. The fabric is prepared from the following materials: 60 to 70 percent of 80S wool, 10 to 30 percent of 2.5D bamboo charcoal fiber, and 10 to 30 percent of viscose. The preparation method comprises the following steps: sufficiently tendering bamboo charcoal according to a cold plasma technology, carrying out repeated ball milling with a planetary ball mill to obtain sub-nanometer bamboo charcoal particles, uniformly blending the sub-nanometer bamboo charcoal particles into polyester fiber according to a melt spinning program, and carrying out drawnwork according to a biochemical technology to obtain bamboo charcoal fiber which is relatively high in strength. The fabric has the advantages that the favorable performance of bamboo charcoal fiber is sufficiently played; the variety of woolen fabric is enriched; the grade and the added value of the fabric are improved; not only are the functions of temperature adjustment, humidification, anion release for air purification, far infrared ray release for heat storage and heat preservation, bacterium resistance, mold prevention and the like realized, but also the flexible, smooth, soft and warm characteristics of wool / viscose fiber are embodied, so that the fabric is an ideal fabric for production of female suits and male casual wear.

Owner:JIANGSU JIANLU WOOLEN

Manufacturing method of polar fleece fabric

InactiveCN106192180AGood warmth retentionPermanent antistaticElectroconductive/antistatic filament manufactureWeft knittingPolyesterFiber

The invention relates to the technical field of woven fabrics and particularly relates to a manufacturing method of a polar fleece fabric. The manufacturing method comprises the following steps: (1) by taking hollow polyester fibers and conductive fibers as bottom yarns and taking ultrafine polyester fibers as surface yarns, carrying out weft knitting and weaving to form blank cloth, wherein the adding amount of the conductive fibers is 6%-8% of the weight of the bottom yarns; (2) pre-shaping the blank cloth; (3) carrying out pre-treatment on the pre-shaped blank cloth by adopting pre-treatment liquid, washing with water and airing; dissolving and dispersing dyestuff by adopting supercritical carbon dioxide fluid, and dyeing the blank cloth; washing the dyed blank cloth with water and drying; and (4) carrying out softening, galling, combing, cropping, fleecing and re-shaping on the blank cloth subjected to dyeing treatment. The manufacturing method of the polar fleece fabric, provided by the invention and has a simple process and small pollution to the environment; and the prepared product has stable quality, is light and has a good warm-keeping property, has good wearing comfort and hand feeling and has a good antistatic property.

Owner:DONGGUAN TEXWINCA HLDG

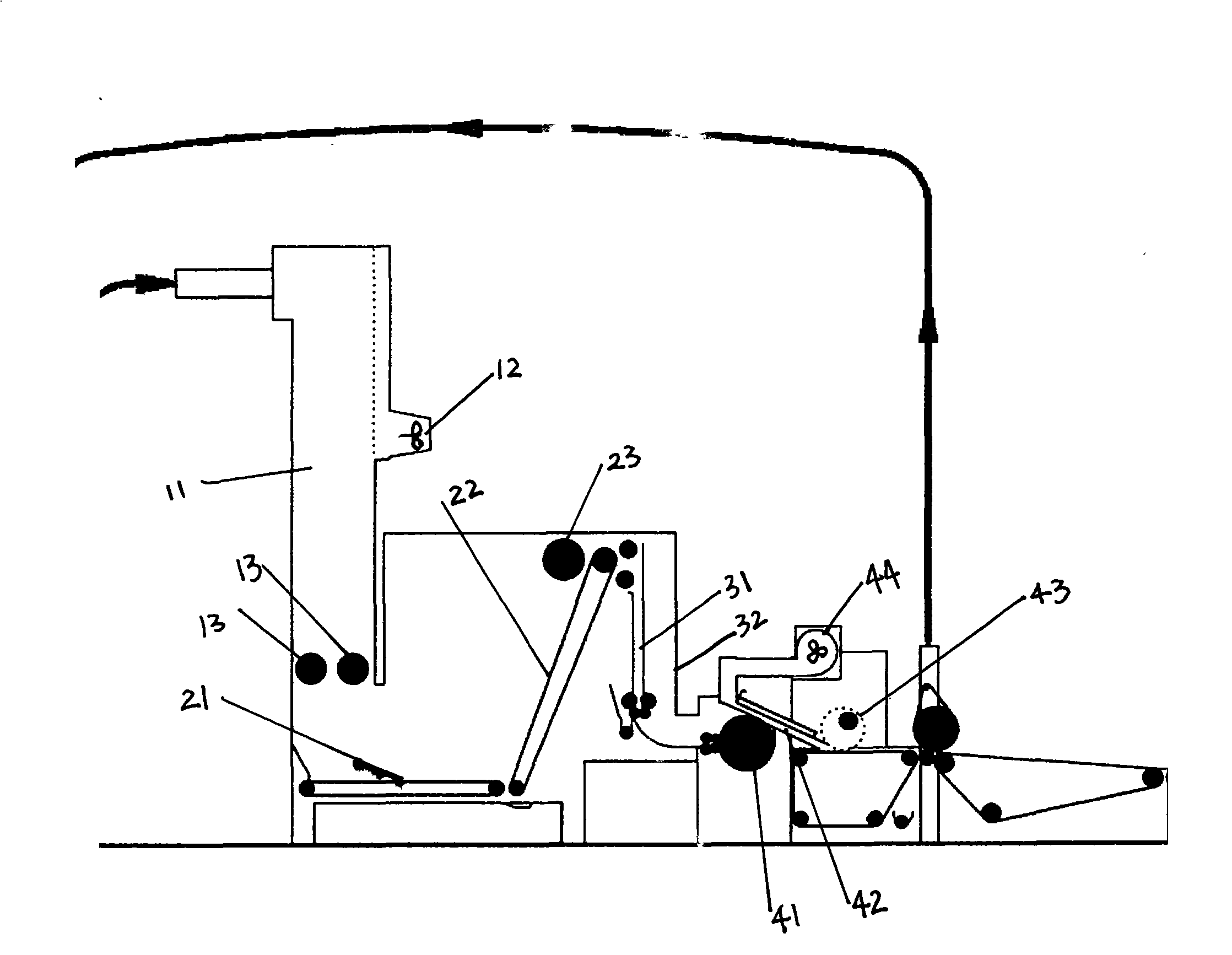

Method for producing melt-blown nonwoven down dual constituent thermal insulating interlining

InactiveCN101392432AHigh resilienceHigh longitudinal and transverse tensile strengthNon-woven fabricsMolten stateInterlining

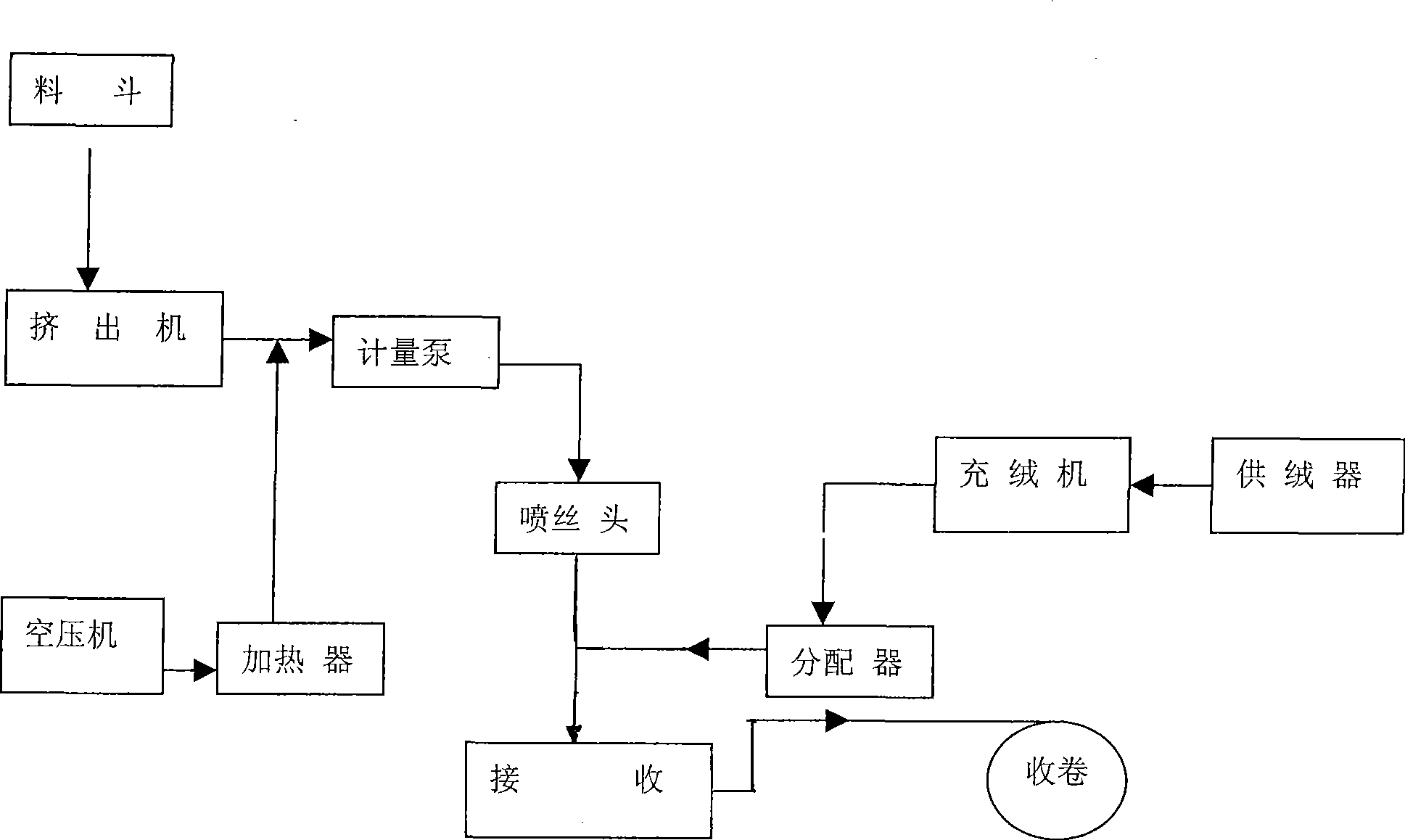

The invention relates to a method for forming dual-component heat-insulating wadding by combining molten-spraying nonwoven fabrics and down. Specifically, the method comprises the following steps: heating polymer resin slices into molten state, then extruding, measuring and distributing the resin slices evenly to a hole of a spinneret device, and then stretching the resin slices into superfine fiber by hot air. Then the down is adhered with polymer fiber which is treated with fiber-stretching and is still not cured so as to form a net after being distributed by loosening, velvet-supplying and velvet-filling , and then a receiver and a finishing reel wind the net into the wadding. The invention adds down material into the existing molten-spraying production process, which can improve the heat-insulating rate and rebound elasticity of the wadding and can improve the transverse and longitudinal tensile strength of the wadding.

Owner:郭武胜

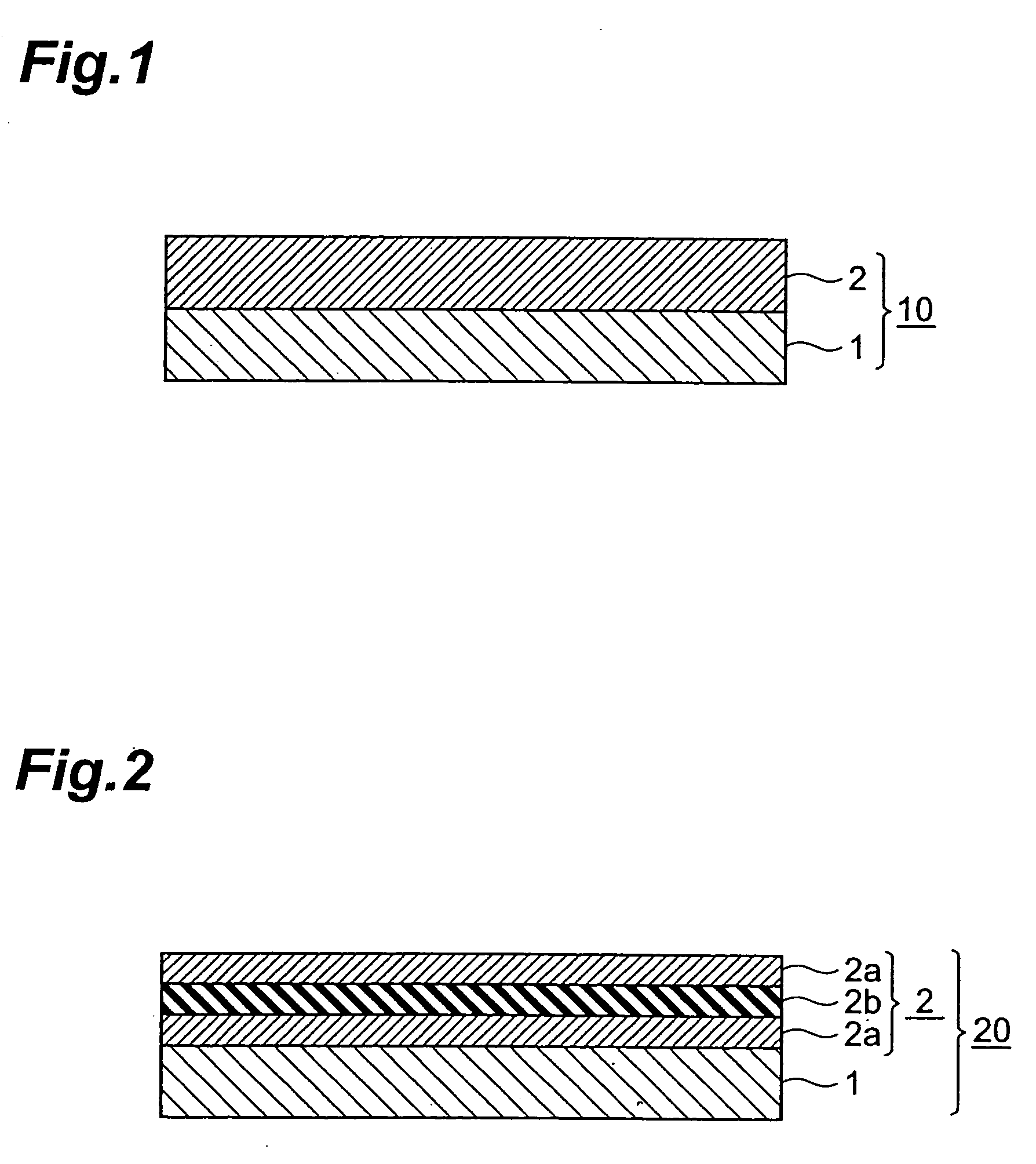

Warming patch

InactiveUS20060093656A1Pleasant stimulationStimulationBiocideHydroxy compound active ingredientsPolyethylene glycolBiomedical engineering

A warming patch 10 comprising a support 2 and adhesive layer 1 disposed on at least one surface of this support 2, wherein the adhesive, layer 1 contains a warming material, 1-menthol and polyethylene glycol as an irritation reducing agent.

Owner:HISAMITSU PHARM CO INC

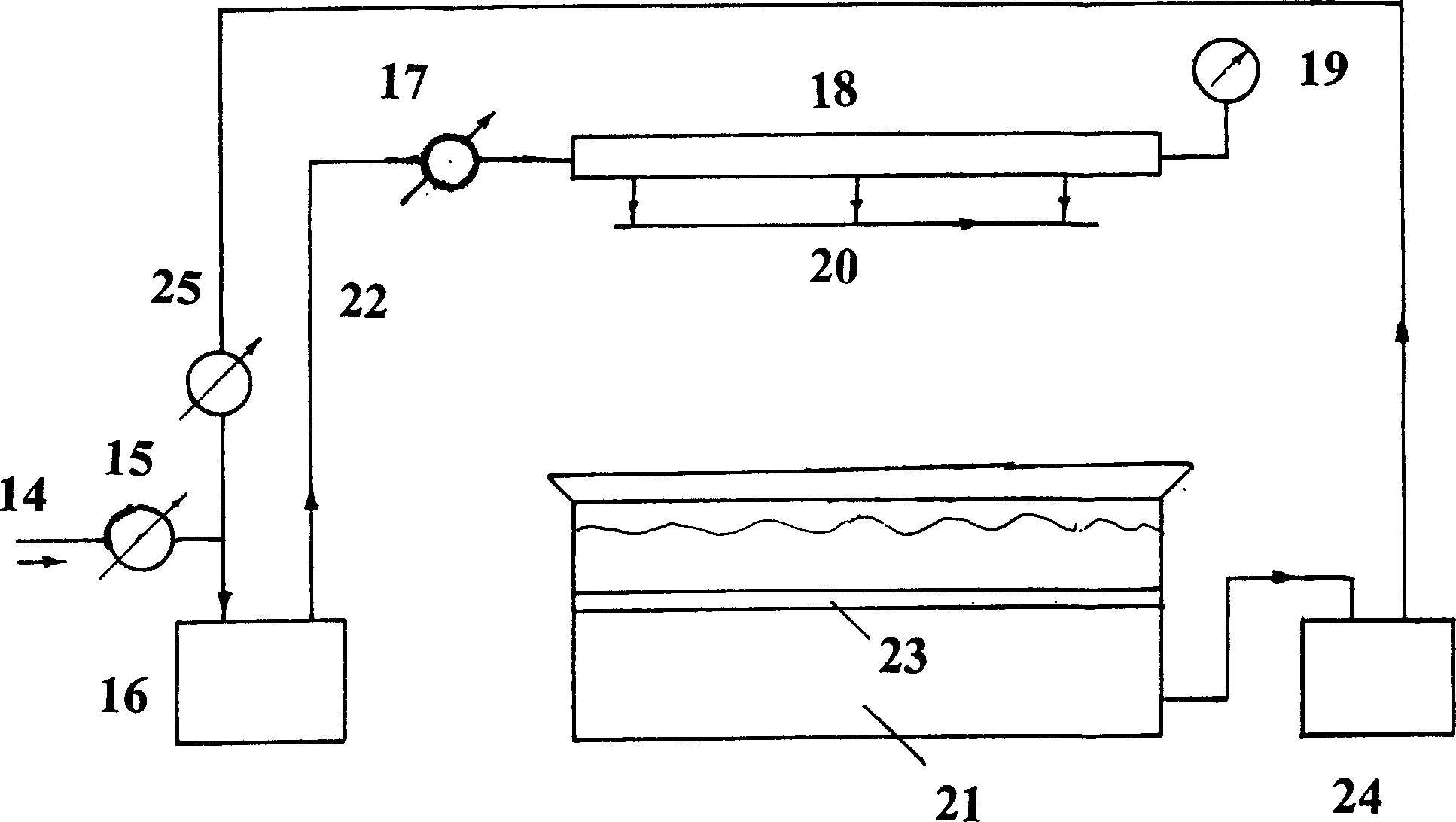

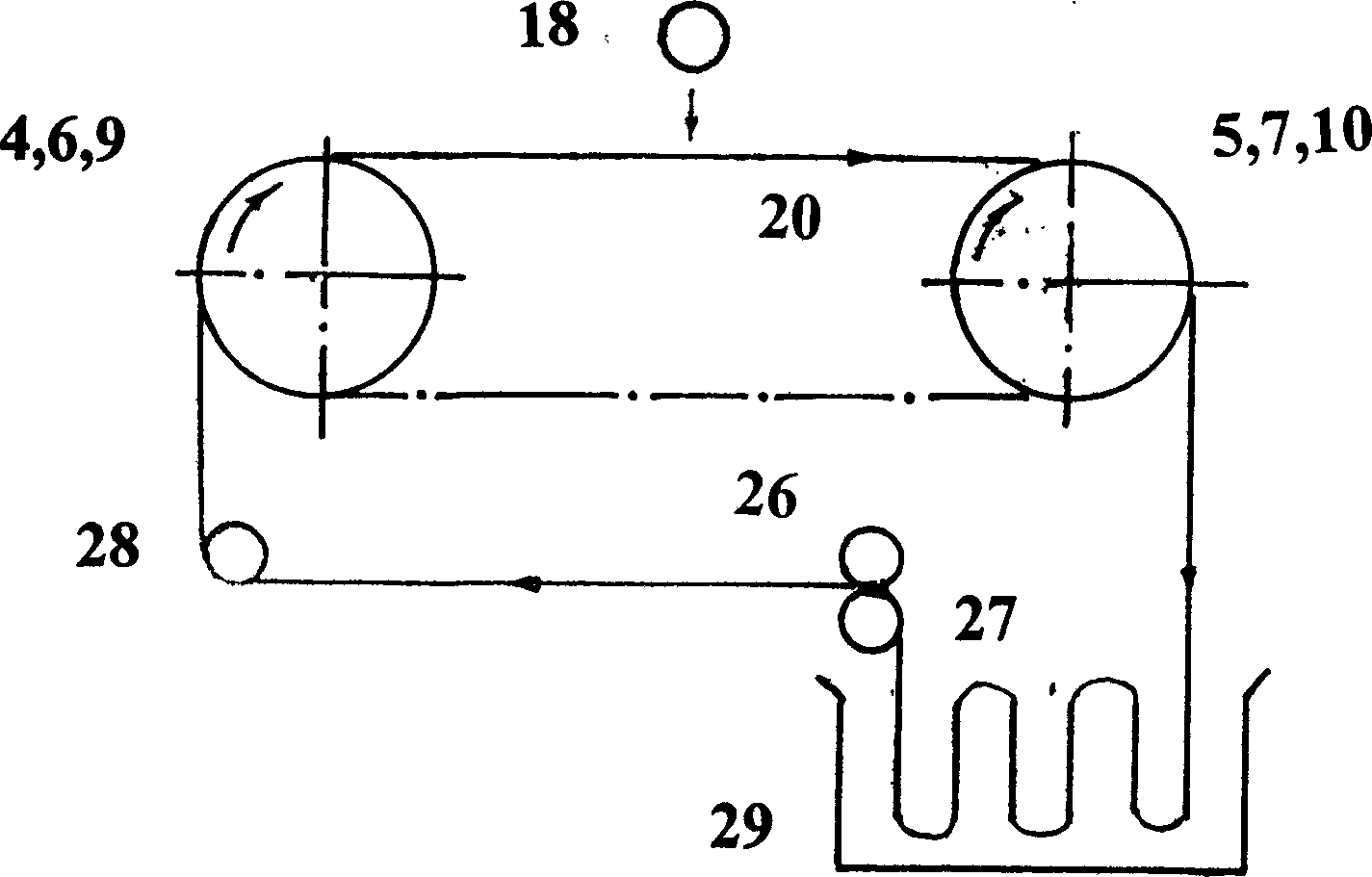

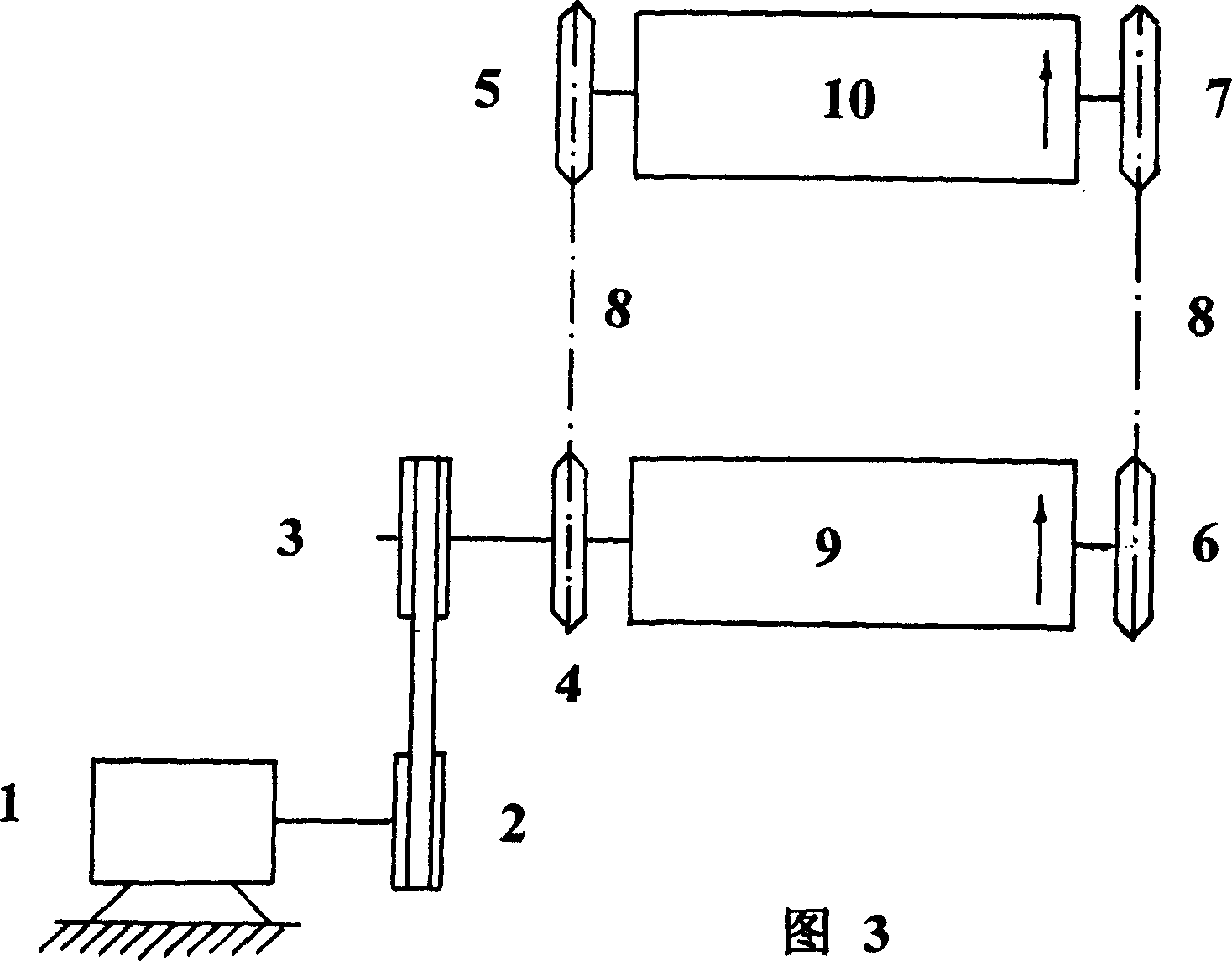

Method and device of high pressure water flow treating machine woven fabric

InactiveCN1556271AIncreasing the thicknessIncrease warmthTextile treatment by spraying/projectingTextile shapingWater sourceControl system

A method for finishing fabric by high-pressure water stream features that the high-pressure (2-8 MPa) water is sprayed onto the fabric conveyed at uniform speed (0.1-1.0 m / min). Its apparatus is composed of high-pressure water system consisting of high-pressure water source, pipeline, valves, water spraying tube and pressure meter, fabric conveying system, water circulating system and control system.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com