Thermal woven and producing method thereof

A manufacturing method and fabric technology, which are applied in the directions of fabrics, textiles, papermaking, and textiles, etc., to achieve the effects of simple technology, low cost and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The short fiber water-soluble yarn is used as the core yarn, the cotton fiber is the outer fiber, the core yarn content is 10wt%, and the outer fiber content is 90wt%. The ring spinning core-spun yarn spinning process is adopted, the twist coefficient is 300, and the speed is 11000r / min. The No. 7 traveler is No. 3 heavier than the traveler used for pure spinning of outsourcing fibers with the same yarn fineness.

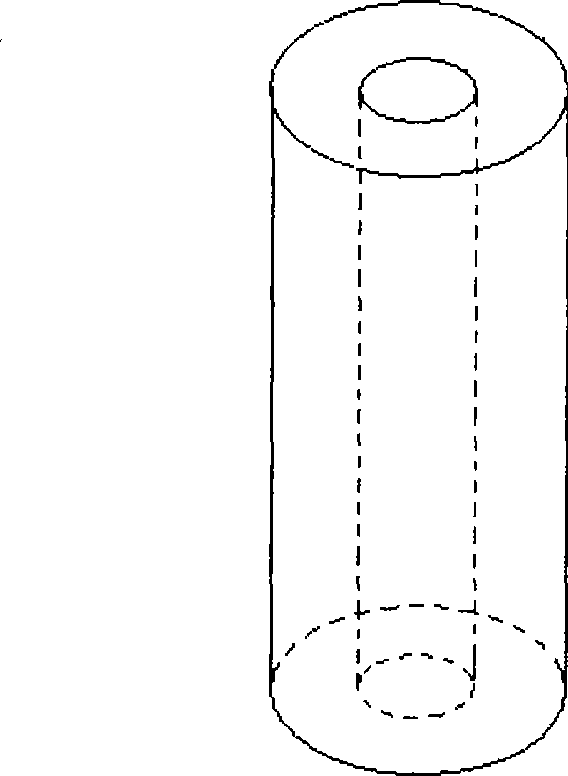

[0026] It adopts circular machine weaving, double rib air layer structure, and the fabric density is the same as the design density.

[0027] The dissolution method is as follows: put the core-spun yarn with the water-soluble fiber as the core into the dosing solution and heat up to 100°C, keep the temperature and boil for 30 minutes to completely dissolve the water-soluble fiber. The components of the solution: water, penetrant JFC 0.6g / L, NaOH 0.6g / L. The bath ratio is 1:10. Rinse with clear water for 20 minutes, and dry to obtain a thermal fabric compose...

Embodiment 2

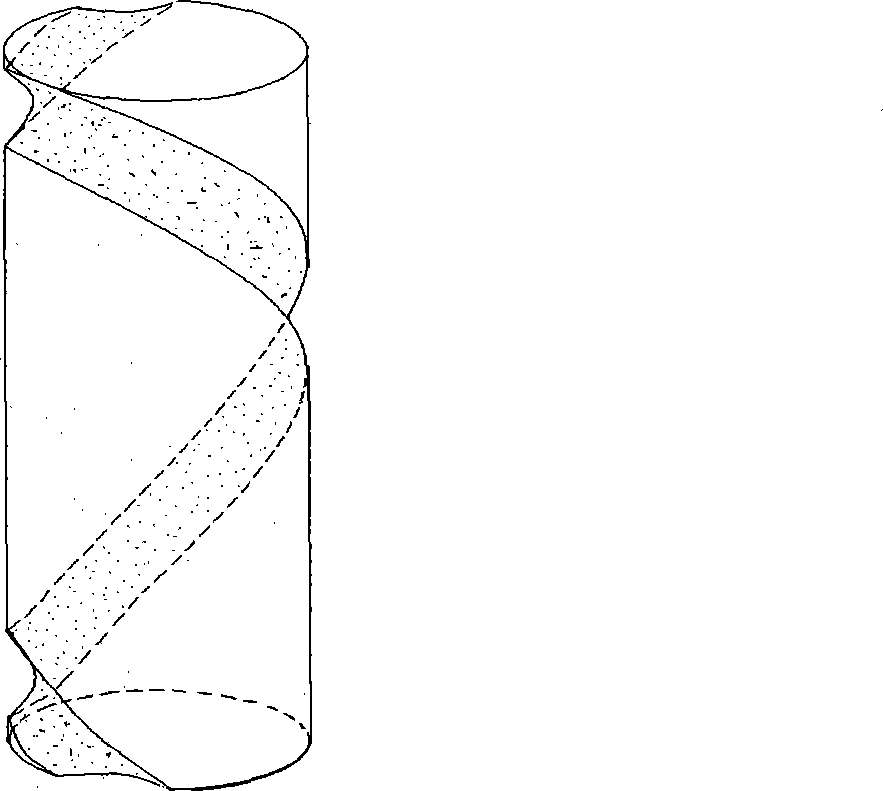

[0030] The short fiber water-soluble yarn is used as the companion spinning, the wool fiber is the intertwined fiber, the content of the companion spinning yarn is 30wt%, and the content of the intertwined fiber is 70wt%. The Sirofill spinning process is adopted, the twist coefficient is 550, and the speed is 12000r / min, the traveler is No. 6, which is No. 1 heavier than the traveler used for pure spinning of outsourcing fibers with the same yarn fineness.

[0031] The weaving method is as follows: a rapier sample loom is used to weave, 5 pieces of 3 flying satin weaves, and the fabric density is increased by 10% compared with the design density.

[0032] The dissolution method is as follows: the water-soluble fiber is sirofil yarn accompanied by spinning, put into the dosing solution and the temperature is raised to 50°C, and the temperature is maintained for 90 minutes to completely dissolve the water-soluble fiber. Components of solution: water, penetrant JFC 0.3g / L, NaOH ...

Embodiment 3

[0035] The staple fiber water-soluble yarn is used as the core-spun yarn, polyester fiber is used as the outer fiber, the content of the core-spun yarn is 23wt%, and the content of the outer fiber is 77wt%. The ring spinning process is adopted, the twist coefficient is 400, the speed is 13000r / min, and the traveler is 8 No. 2 heavier than the traveler used for pure spinning of outsourcing fibers with the same yarn fineness.

[0036] The weaving method is as follows: circular machine weaving, double rib air layer weaving, and the fabric density is increased by 3% compared with the design density.

[0037] The dissolution method is as follows: put the core-spun yarn with the water-soluble fiber as the core into the dosing solution and heat up to 100°C, keep the temperature and boil for 60 minutes to completely dissolve the water-soluble fiber. The components of the solution: water, penetrant JFC 0.48g / L, NaOH 0.48g / L. Bath ratio 1:8.5. Rinse with clear water for 30 minutes, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com