Patents

Literature

319 results about "Interlining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interlining, also known as interline ticketing and interline booking, is a voluntary commercial agreement between individual airlines to handle passengers traveling on itineraries that require multiple flights on multiple airlines. Such agreements allow passengers to change from one flight on one airline to another flight on another airline without having to gather their bags or check-in again.

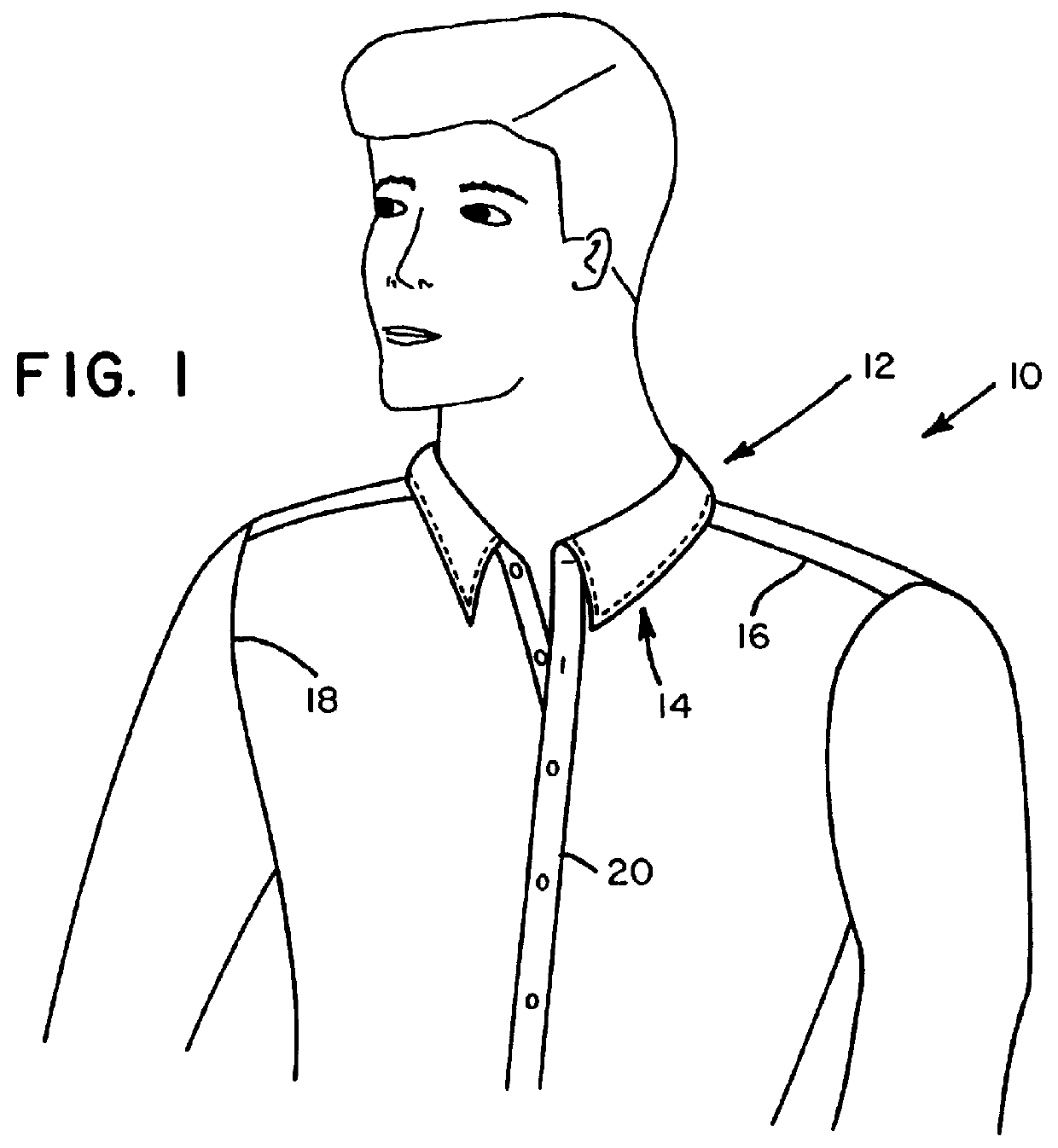

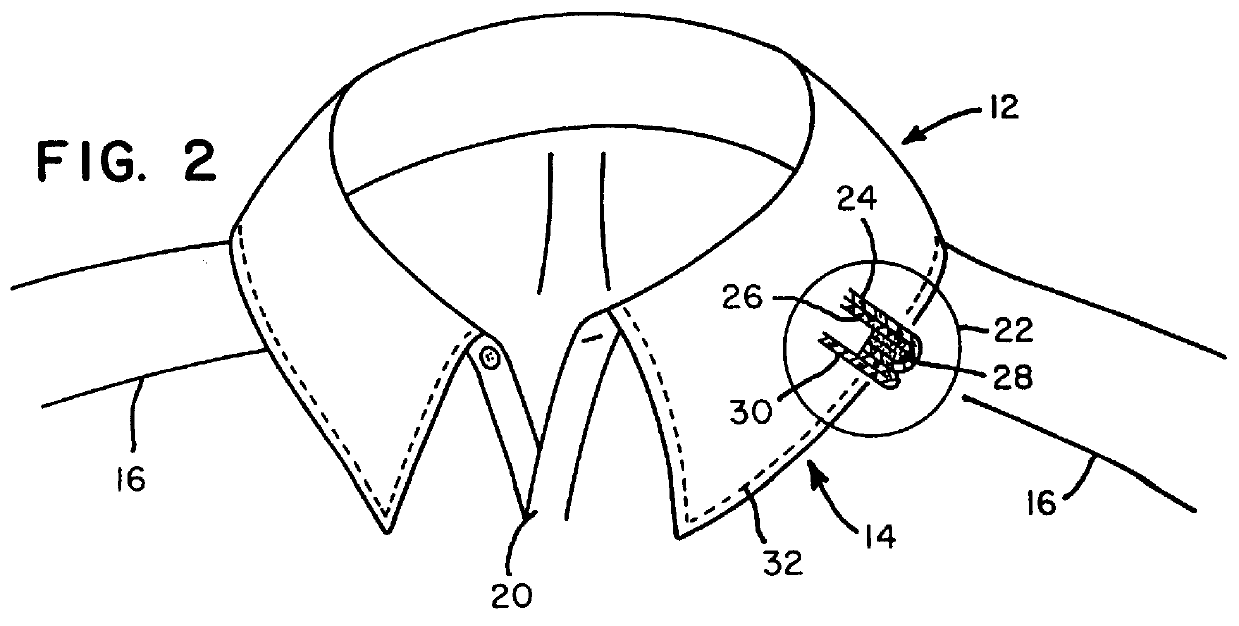

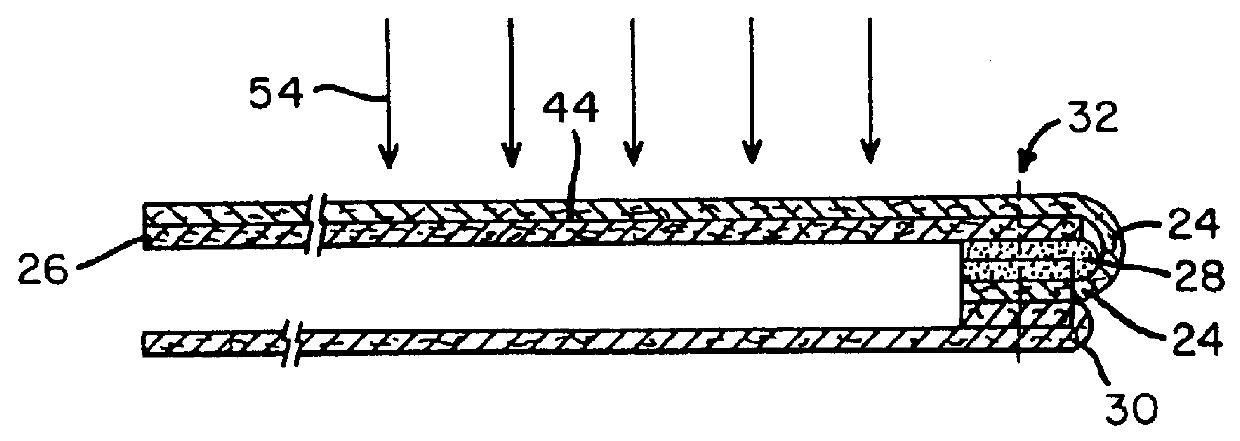

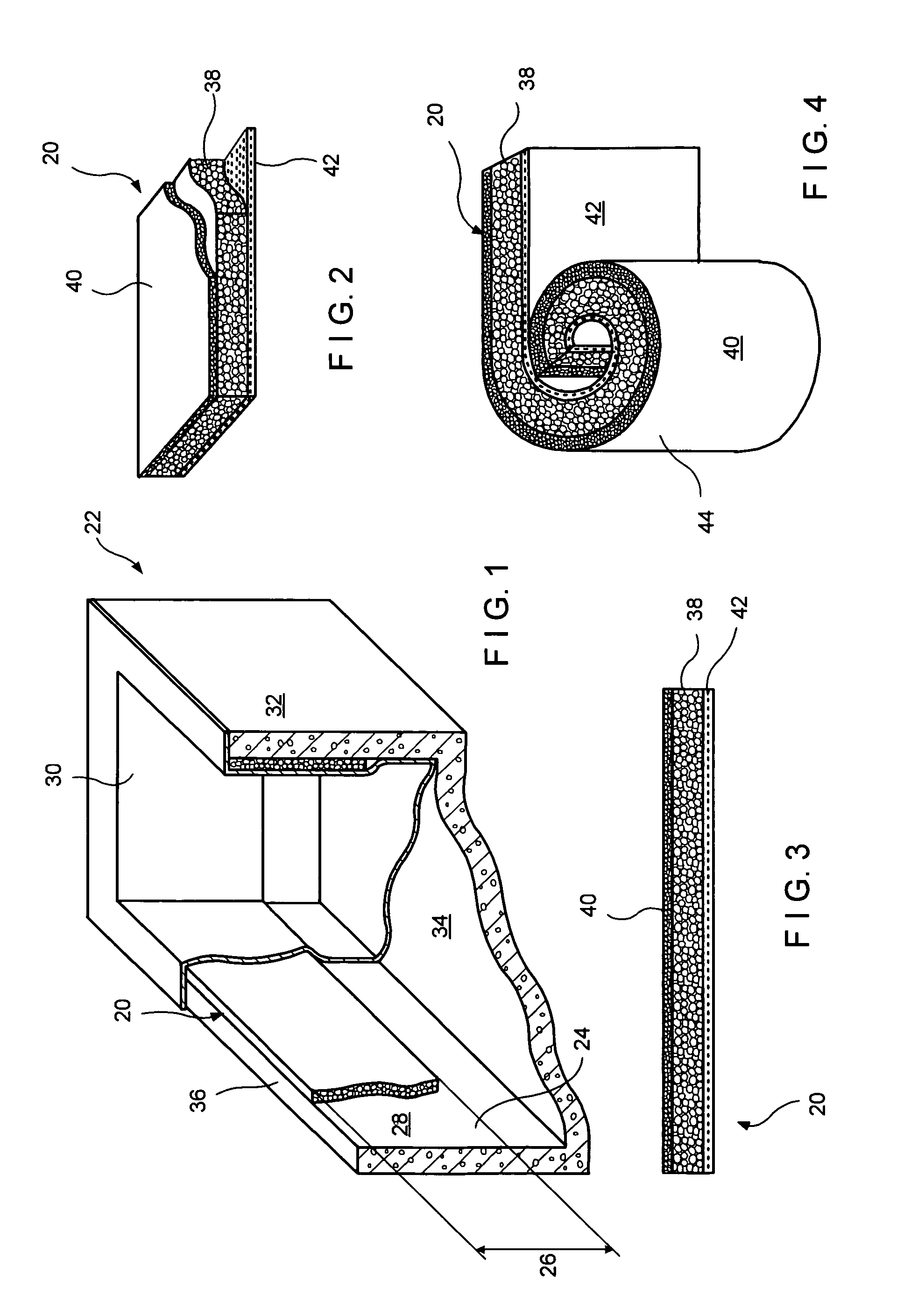

Pucker free collar seam and method of manufacture

A pucker free collar seam providing a garment with a tailored and wrinkle free appearance. The pucker free seam and method for production utilizes a bonding strip, which contains at least a thermal adhesive component which is inserted between a first surface of a first collar component and an interlining along a seam. A sufficient amount of heat and pressure is applied to the seam, causing the adhesive of the bonding strip to flow onto the surfaces of the collar components and the interlining, thereby creating a compressed seam and permanently bonding a first collar component, a second collar component and an interlining together along the seam to eliminate puckering associated with the shrinkage of sewing thread relative to the collar fabric.

Owner:BALDWIN JACK ESQ

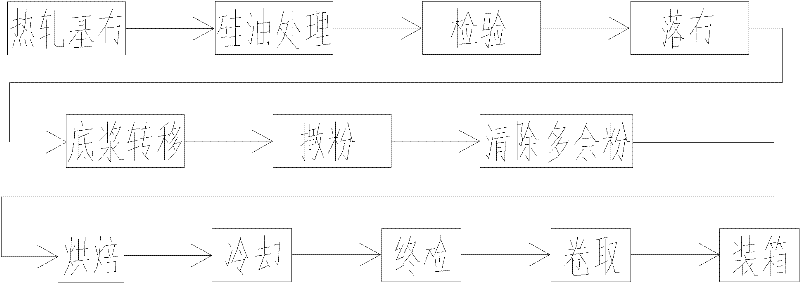

Water-soluble hot melt lining cloth and production method thereof

ActiveCN101353843AEasy to operateGood water solubilityFibre treatmentLiquid/gas/vapor removalInterliningMetallurgy

The invention discloses a water-soluble fusible interlining which is characterized in that longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to one percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. After the interlining is joined with a fabric by ironing, the interlining is treated in the water at the temperature of 35 DEG C for 15 seconds and separated with the fabric. The water-soluble fusible interlining has good water-soluble performance, low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

Ultra-low shrinkage rate purified cotton lining cloth and production method thereof

The invention discloses a purified cotton interlining with an ultra-low shrinkage, and a production method thereof. Longitudinal shrinkage and latitudinal shrinkage of the cotton interlining are less than or equal to 0.8 percent respectively and the formaldehyde emission is less than or equal to 50mg / kg. The production method thereof sequentially comprises the steps of sewing, singeing, bleaching, mercerizing, re-bleaching, drying, dyeing, post-processing, shrink-proof finishing and powder point coating. The cotton interlining the invention has low longitudinal shrinkage and latitudinal shrinkage, good environmental protection performance and easy operation of the production method.

Owner:曹平

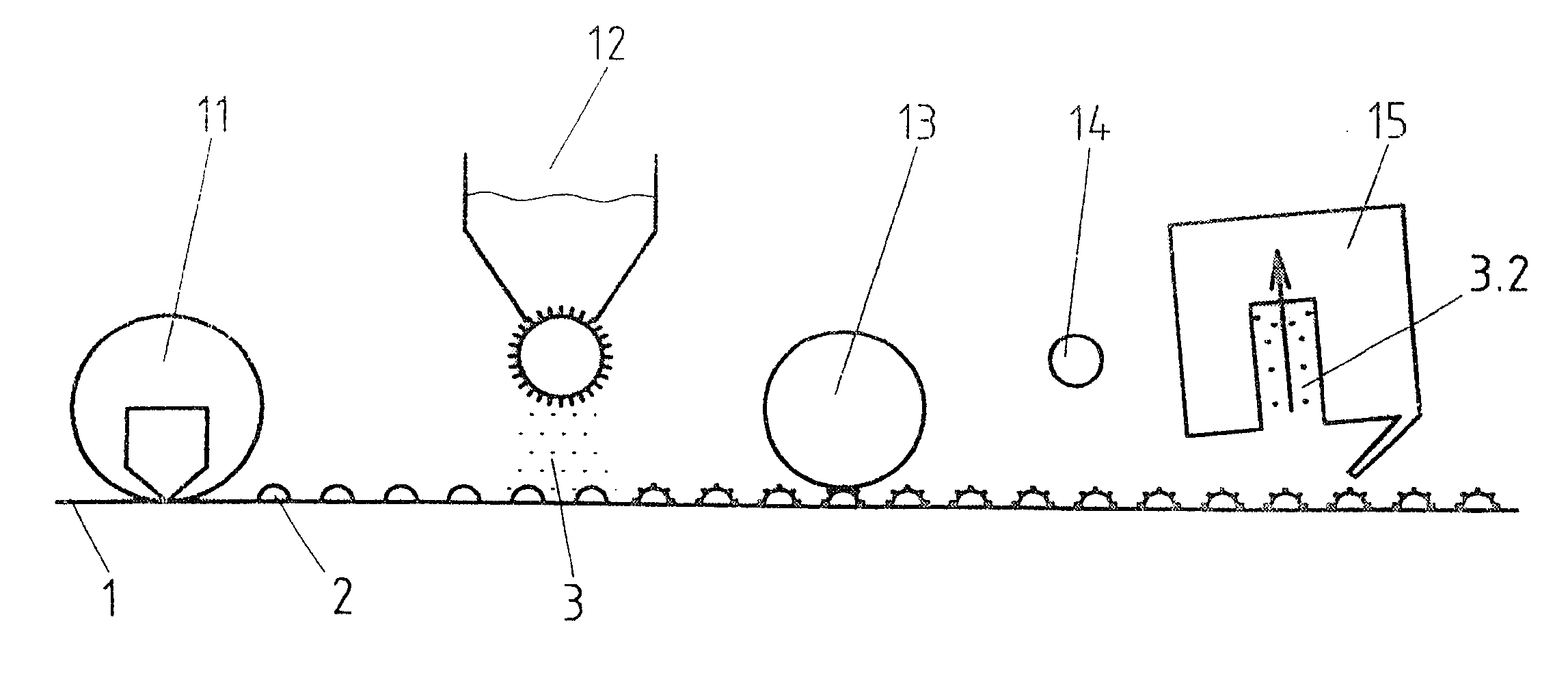

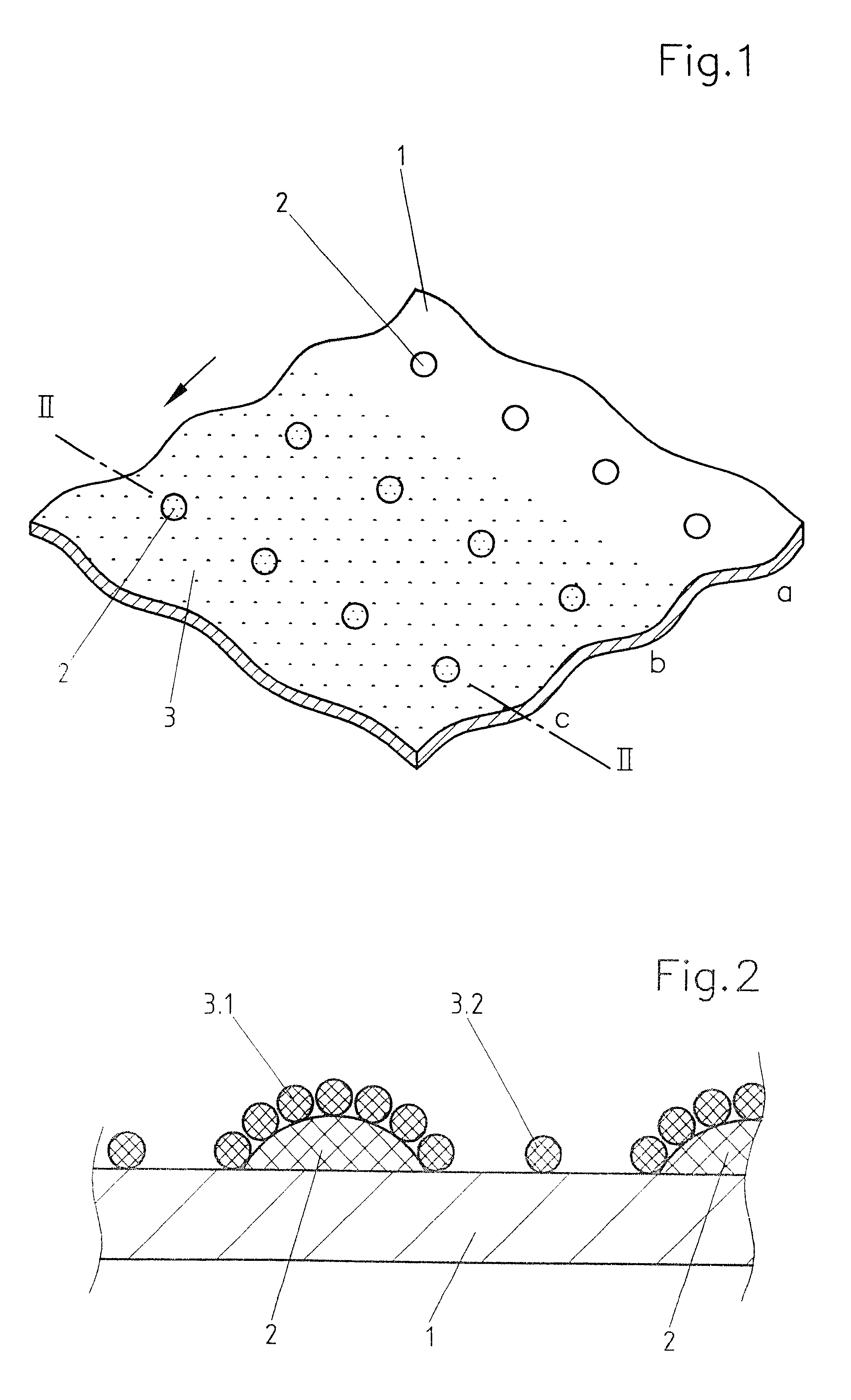

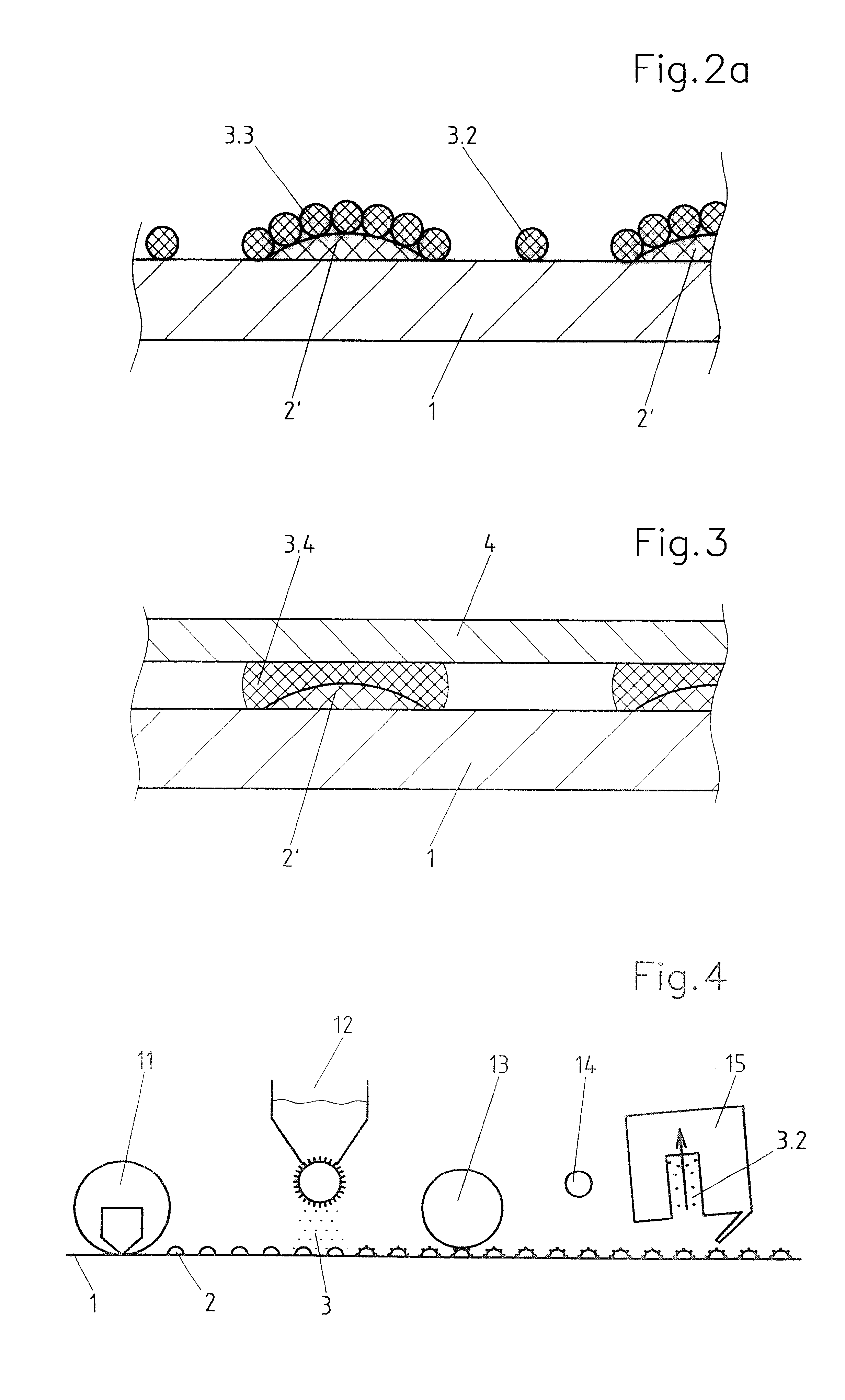

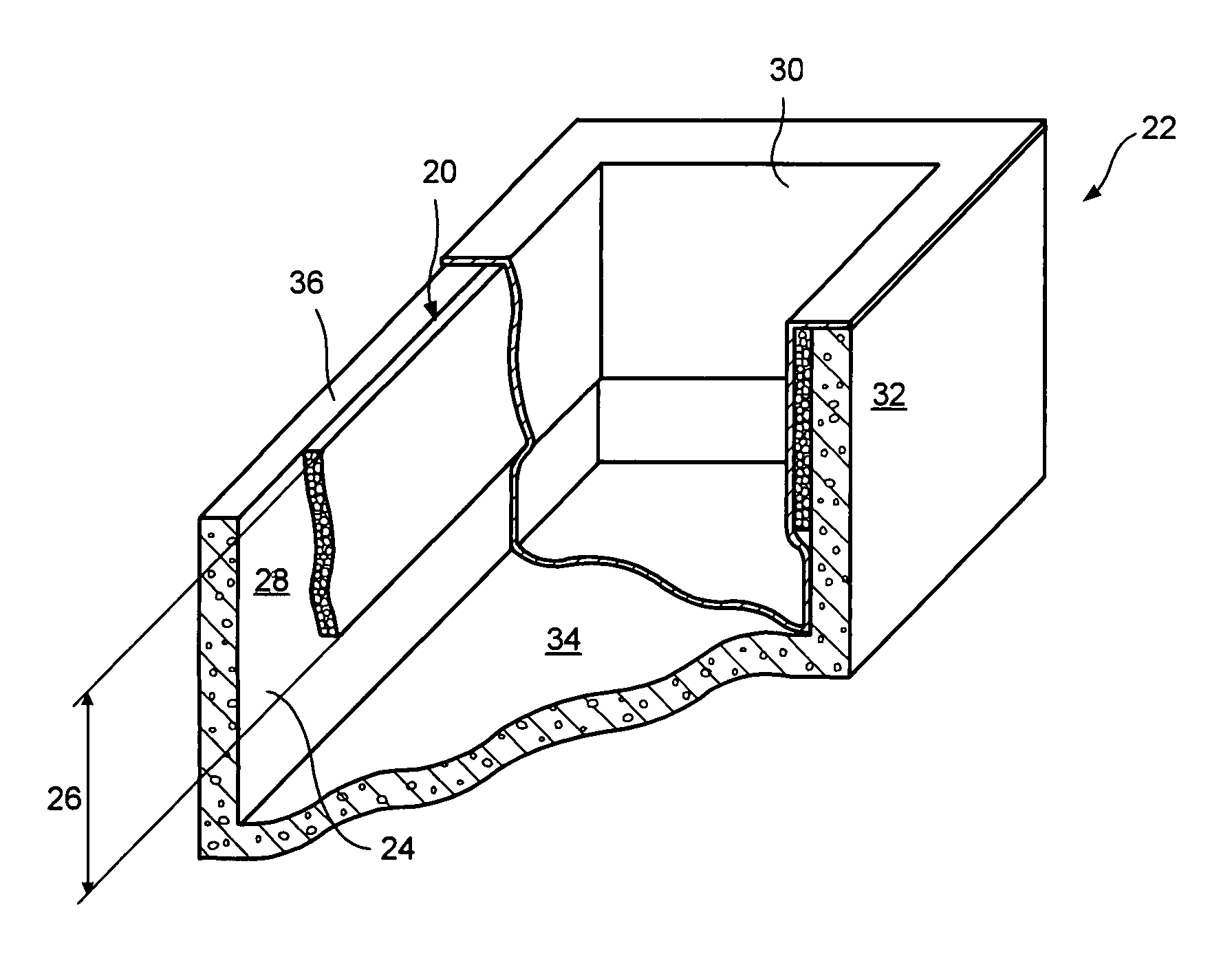

Process for the production of fusible interlining fabrics

InactiveUS6344238B1Reduce the temperatureLittle stressAdhesive processesLayered productsInterliningParticulates

A process for the production of fusible interlining fabrics, wherein an interlining fabric (1) is discontinuously printed over its area with a reactive adhesive (2), and a particulate hot-melt glue (3) is applied to the adhesive (2) while it is still reactive. In another step, particles (3.1) can be pressed on, and subsequently the excess particles (3.2) of the hot-melt glue (3) can be removed.

Owner:CARL FREUDENBERG KG

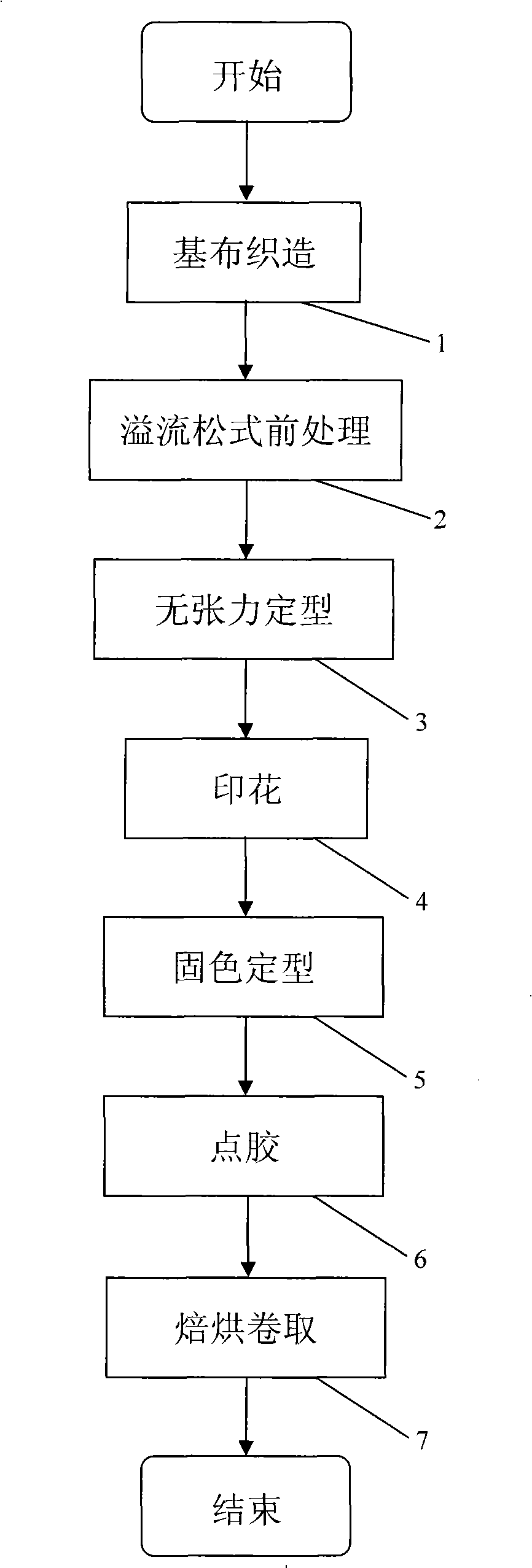

Technique for preparing multifunctional liner of printing sarcenet

The invention discloses a production technology of multifunctional liner of printing lining, which sequentially includes the steps of basic fabric weaving, loosening overflow pretreatment, tension-free shaping, printing, color fixing and shaping, gluing, baking, rolling, etc. By adopting the loosening pre-shrinking shaping technology, the invention can cause fiber pores to be tighter, thus generating loose and clean appearance. Dual point coating is conducted by adopting thermosetting-typed hot melt glue of polyurethane and polyamide; the hot melt glue of polyurethane after heating loses cross linking generated by hydrogen bonds in polyurethane molecules and changes into melt viscous fluid, and after cooling, the hot melt glue of polyurethane recovers to the original property; both the polyurethane and the polyamide at the upper layer have good elasticity and strength and comparatively good affinity and can integrate with each other and endure various washing methods. The production technology is applicable to various fiber fabrics without glue seeping and can realize the integration of products with fabrics by ironing. The interlining produced by the technology is light and soft and has good drape property and is applicable to being as the fabrics of upscale wear of women.

Owner:严华荣

Process for preparing anti-static adhesive interlining of all-wool fabric

ActiveCN103767201AImprove conductivityEliminate static electricityFibre treatmentGarmentsYarnPolyester

The invention discloses a process for preparing an anti-static adhesive interlining of an all-wool fabric. The process sequentially includes the following steps of weaving base cloth, conducting preprocessing in an overflow releasing mode, conducting water washing, inputting the base cloth, forming a hot melt adhesive coating, conducting baking, conducting winding and conducting final inspection package. According to the process, special 75D polyester drawn textured yarn is adopted, composite carbon fiber excellent in conductivity is introduced into warp yarn in the base cloth weaving process, static electricity on the base cloth can be eliminated through the discharging and leaking action of conductive fiber, and conductivity of the base cloth is stable and can not be lowered along with the number of the washing times; anti-static agents are added into the hot melt adhesive layer, an adhesive body with the anti-static effect is formed, and therefore the anti-static effect of lining cloth is better matched with clothes fabrics, textile fiber can be effectively prevented from falling, tiny dust particles can be effectively prevented from leaking out of gaps of the fabric, and the process is widely applied to industries which are sensitive to static electricity and have a high requirement for cleanliness, for example, the micro-electronics industry, the photoelectricity industry, the precise instrument industry and the aerospace industry.

Owner:ZHEJIANG KINGSAFE INTERLINING

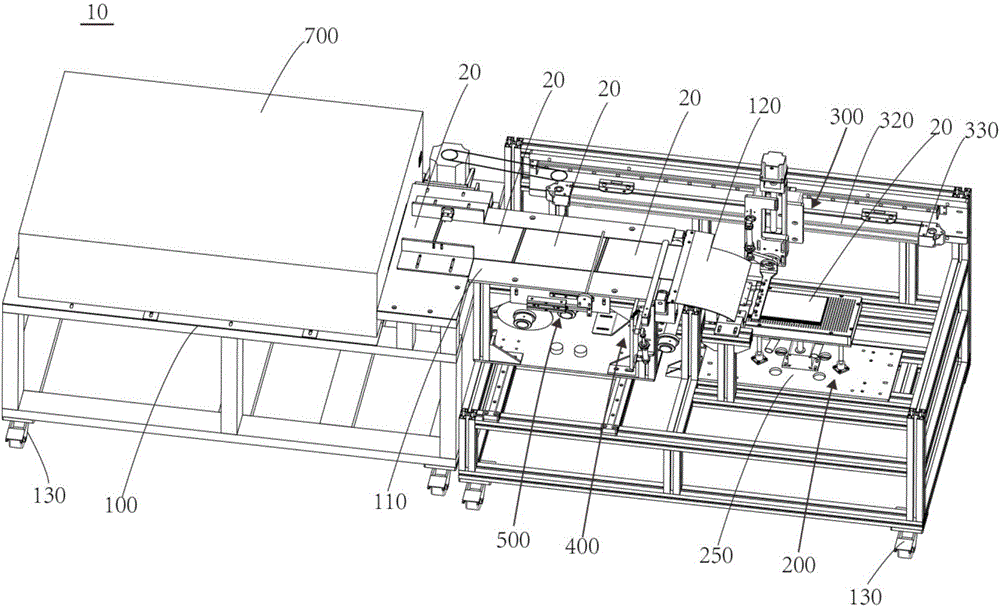

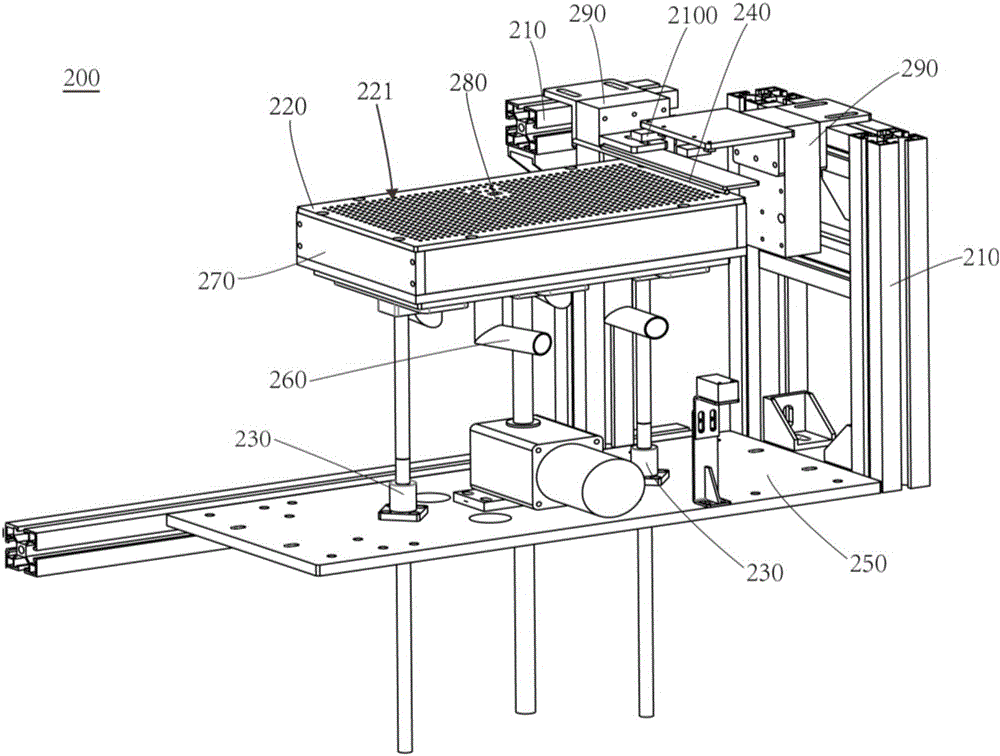

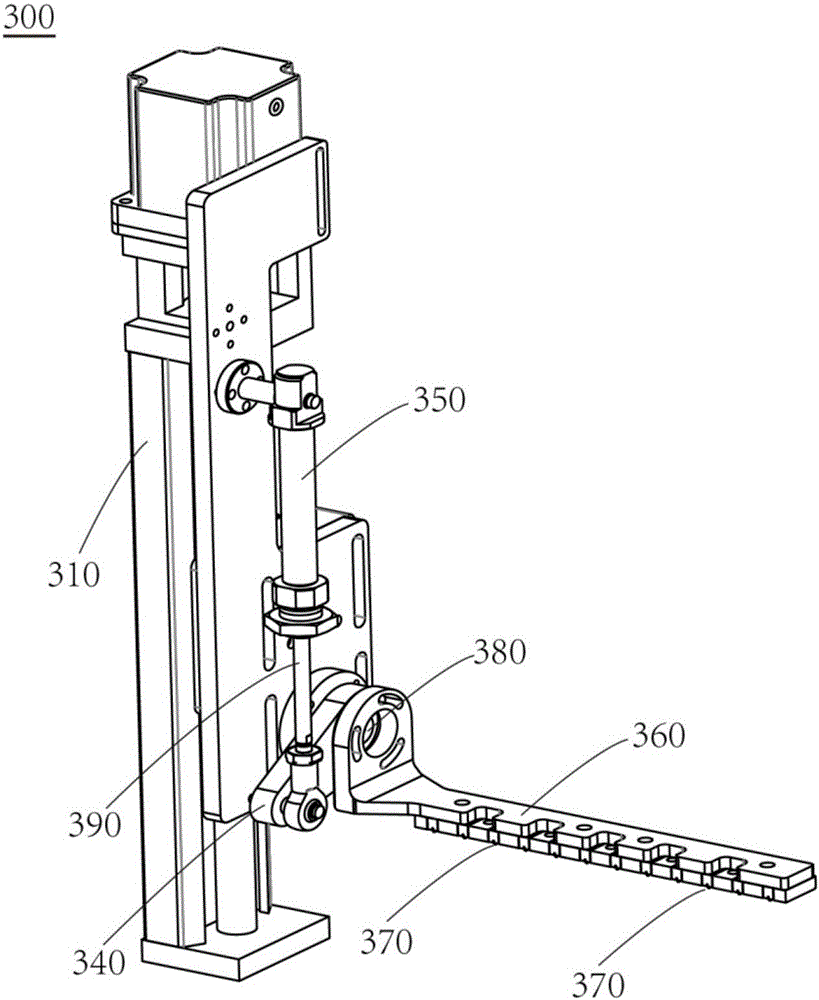

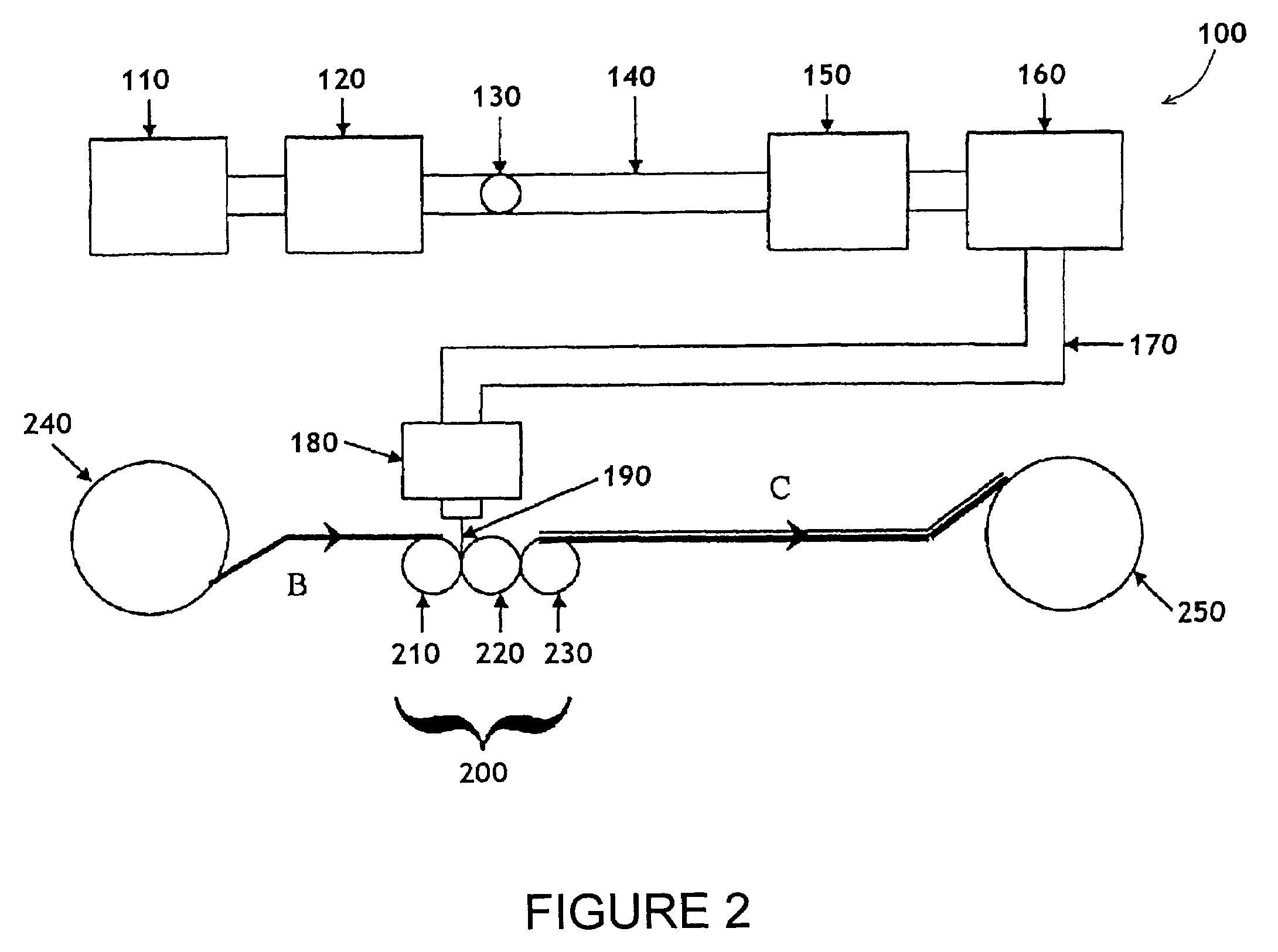

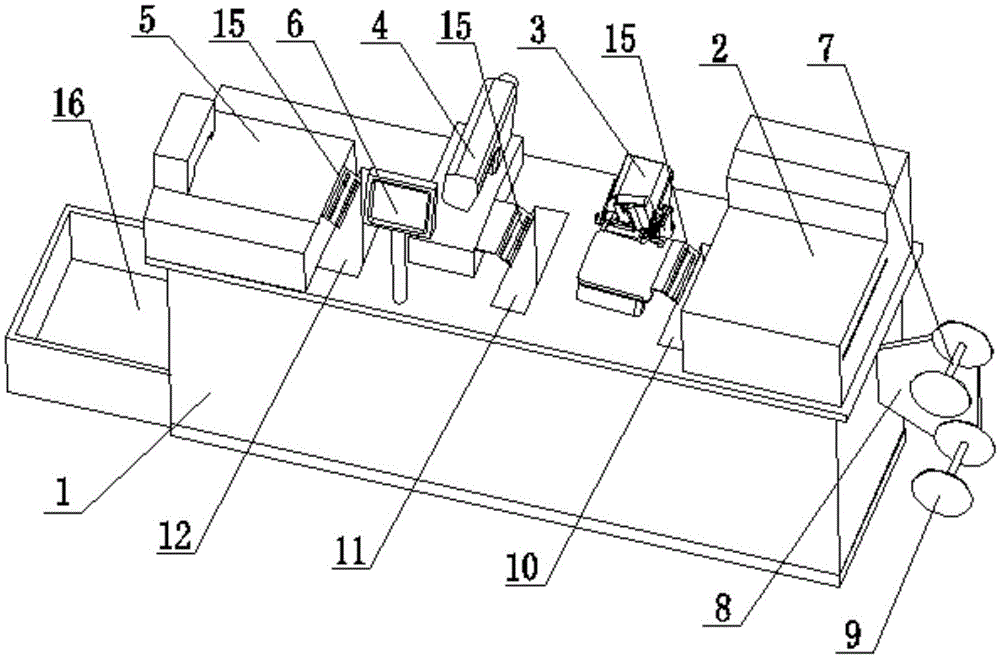

Ironing and interlining system

ActiveCN106087277ARealize automatic reclaimingRealize automatic feedingSewing-machine elementsClothes making applicancesInterliningFeed drive

The invention discloses an ironing and interlining system which comprises a machine, a feeding device, a taking device and an ironing and interlining device. A conveying surface is arranged on the machine, and can be used for holding interlining ribbons. The feeding device is provided with a support, a feeding plate, feeding drive components and a positioning blowpipe, the support is connected to the machine, the feeding drive component is arranged on the machine and connected to the feeding plate to drive the feeding plate to move, the feeding plate is used for overlap placement of multiple cut-parts, the feeding plate is provided with fixing air suction holes, and the positioning blowpipe is arranged on the support and located above the feeding plate. The taking device is arranged on the machine and used for getting the cut-parts from the feeding plate and moving the cut-parts to the interlining ribbons located on the conveying surface. The ironing and interlining device is arranged on the machine and used for ironing and interlining the interlining ribbons and the cut-parts. The ironing and interlining system is timesaving, laborsaving and high in ironing and interlining efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

High-count pure-cotton formaldehyde-free bright adhesive interlining and production method thereof

ActiveCN104544647AImprove the quality levelReduce qualityGarmentsDyeing processColour fastnessInterlining

The invention discloses a high-count pure-cotton formaldehyde-free bright adhesive interlining and a production method thereof. The high-count pure-cotton formaldehyde-free bright adhesive interlining is characterized in that the surface of a coating is bright; the free formaldehyde and hydrolysis formaldehyde are less than 20mg / kg; the peeling strength of hot melt adhesive points is not less than 10N; the warp and weft water washing dimension change rate is -1.0 to 0.5%; the colorfastness to washing is not less than 4-5 levels. The adhesive interlining is free of formaldehyde, so that the processed clothes can be healthy and safe; the surface is bright, thus the quality and level are increased, and the defects such as missing point and missing coating can be easily found during appearance inspection, and as a result, the loss on degradation caused by that the defect of the adhesive interlining is not influenced before being manufactured into clothes products can be avoided for a clothes enterprise; adhesive interlining is high in peeling strength, small in wrap and weft shrinkage, and high in color fastness, so that the quality of high-level clothes cannot be decreased due to poor color fastness of the adhesive interlining; the production method is easily operated, and environmentally friendly.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

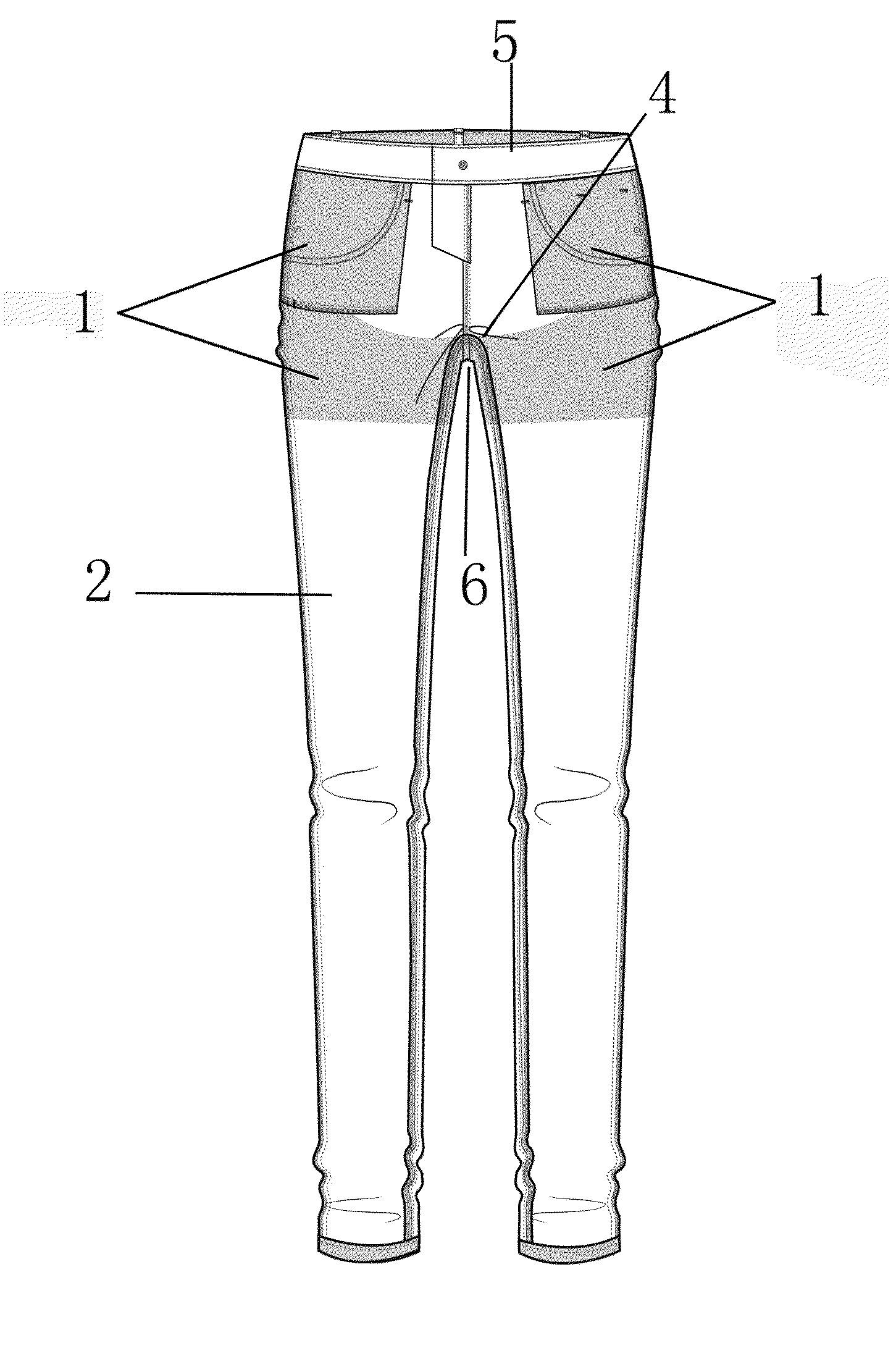

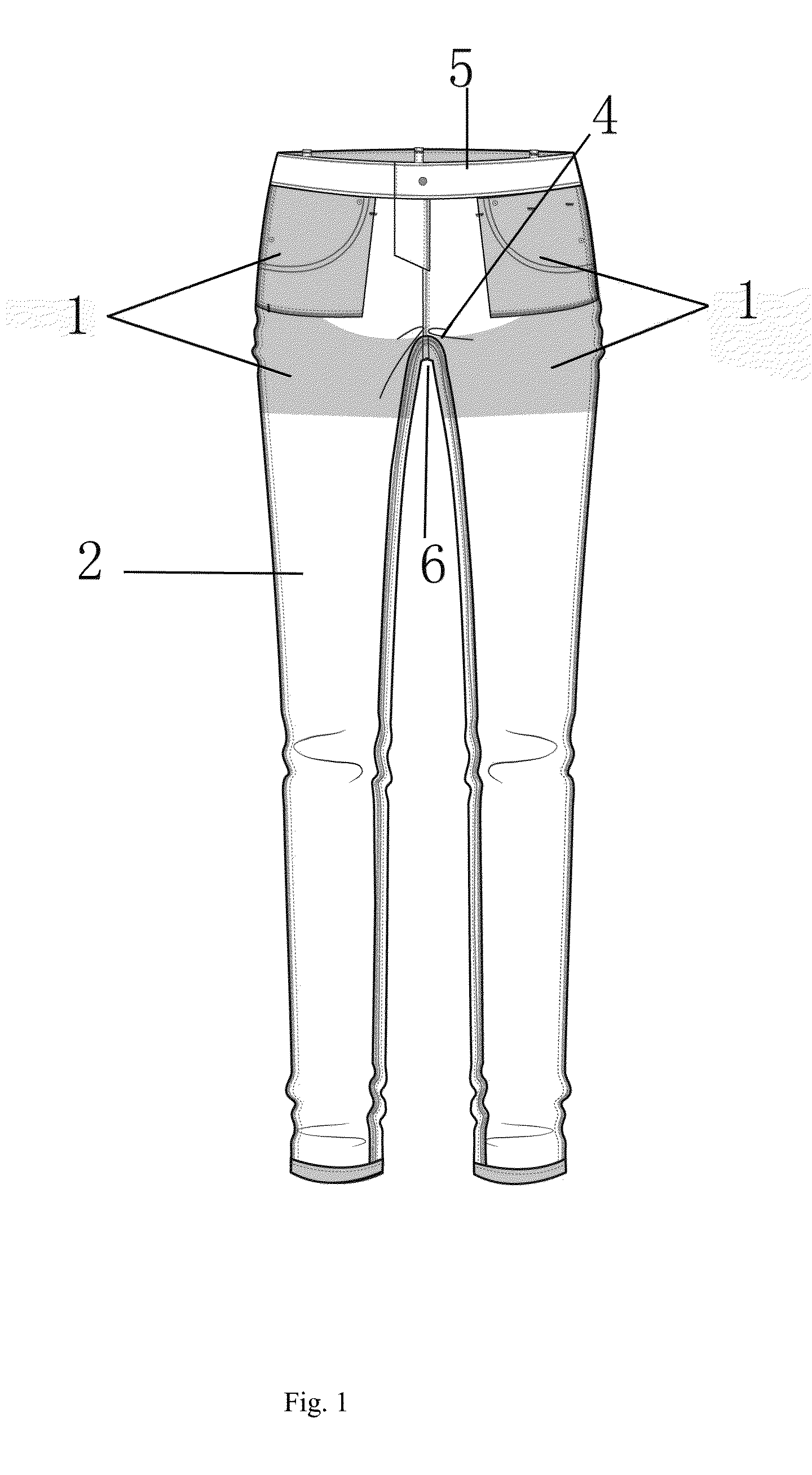

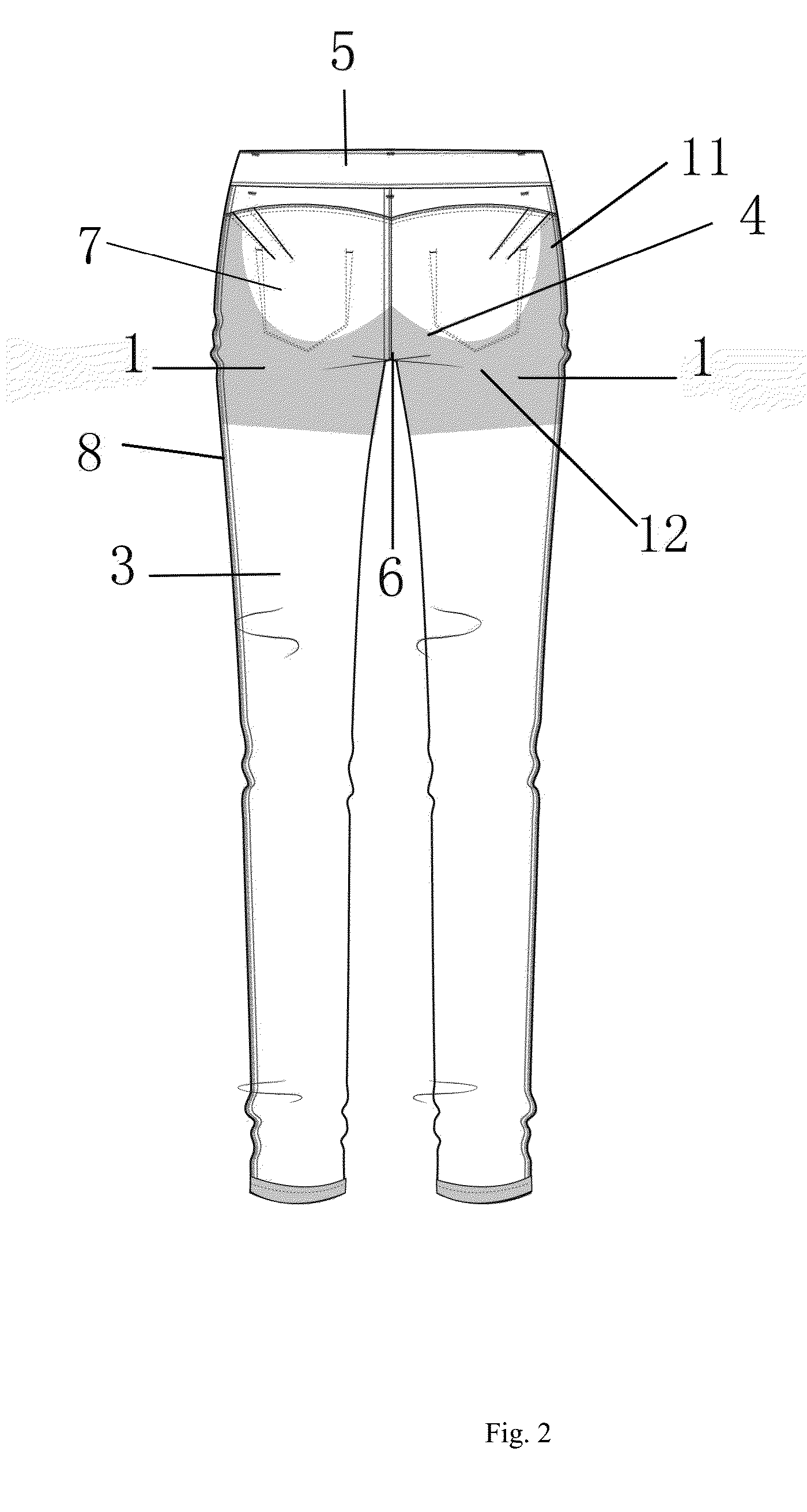

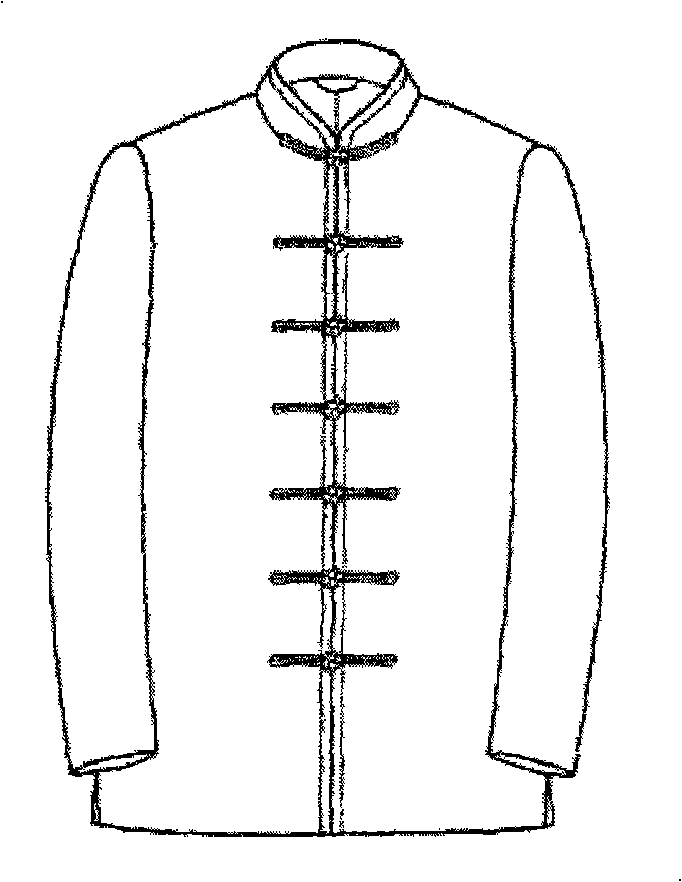

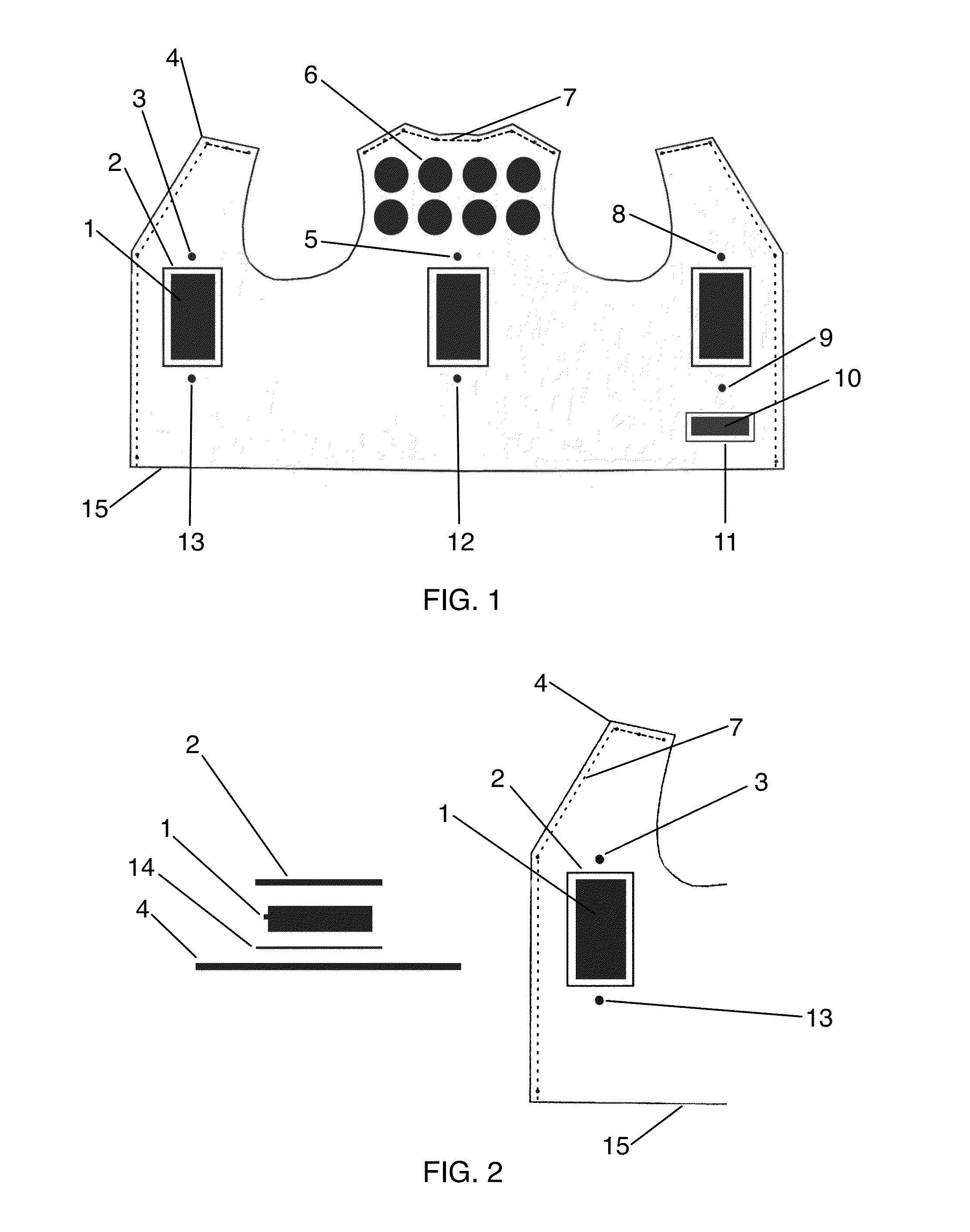

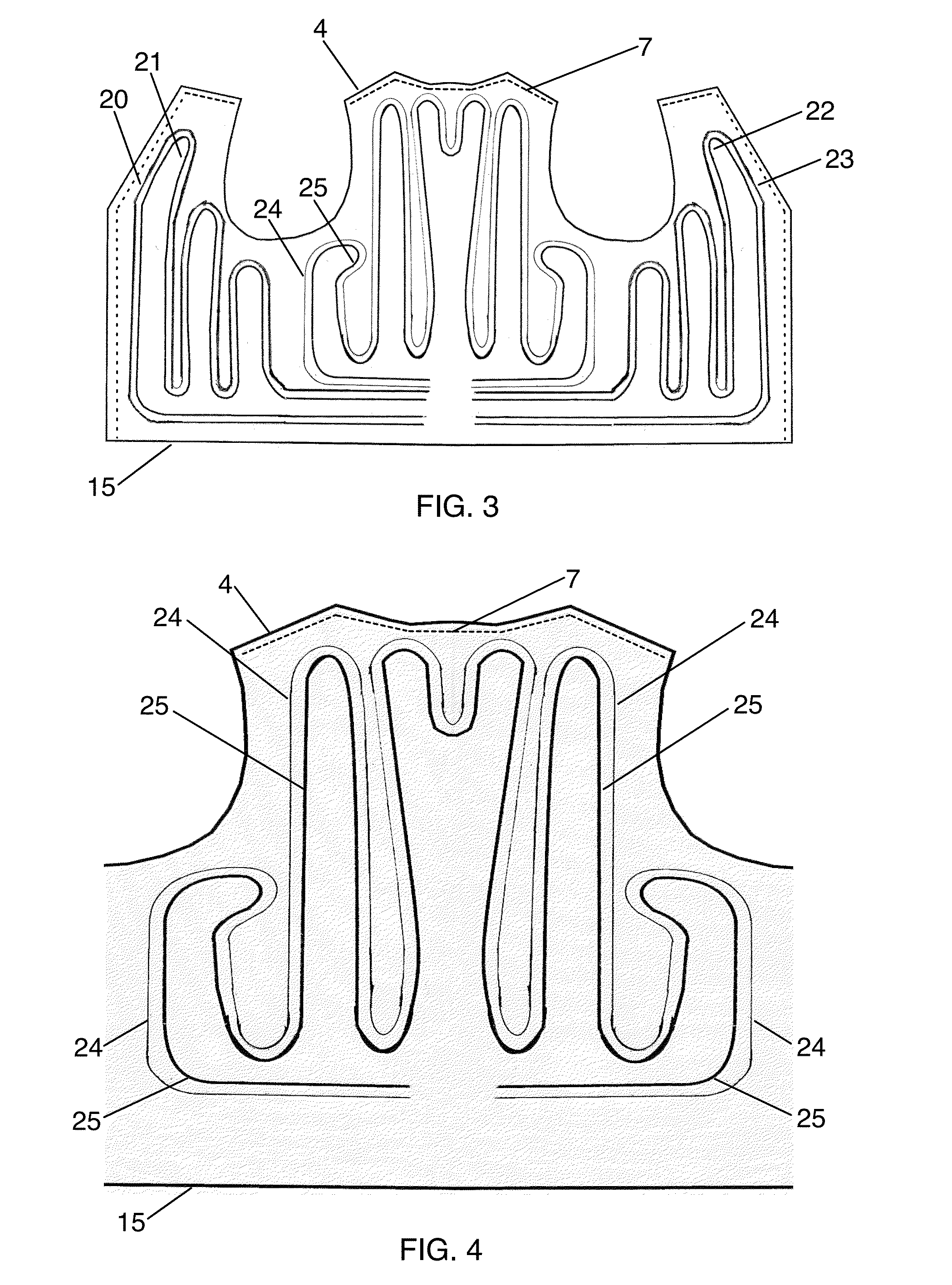

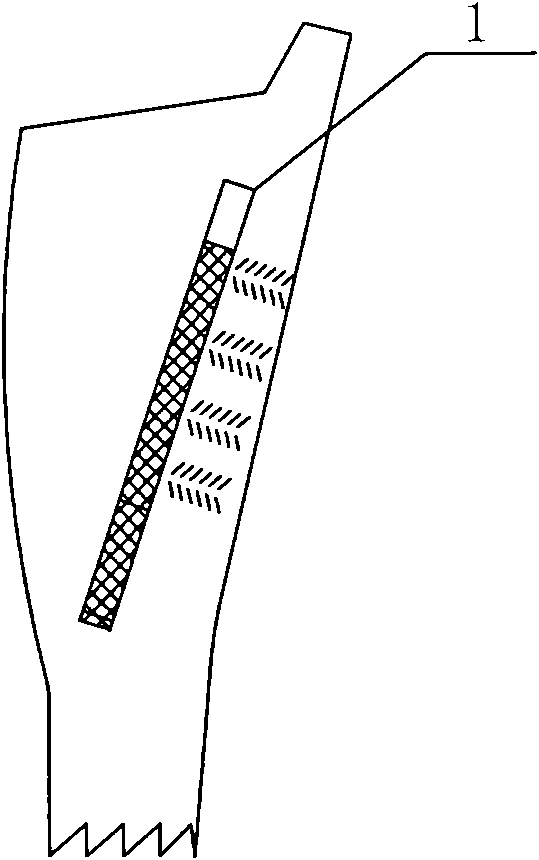

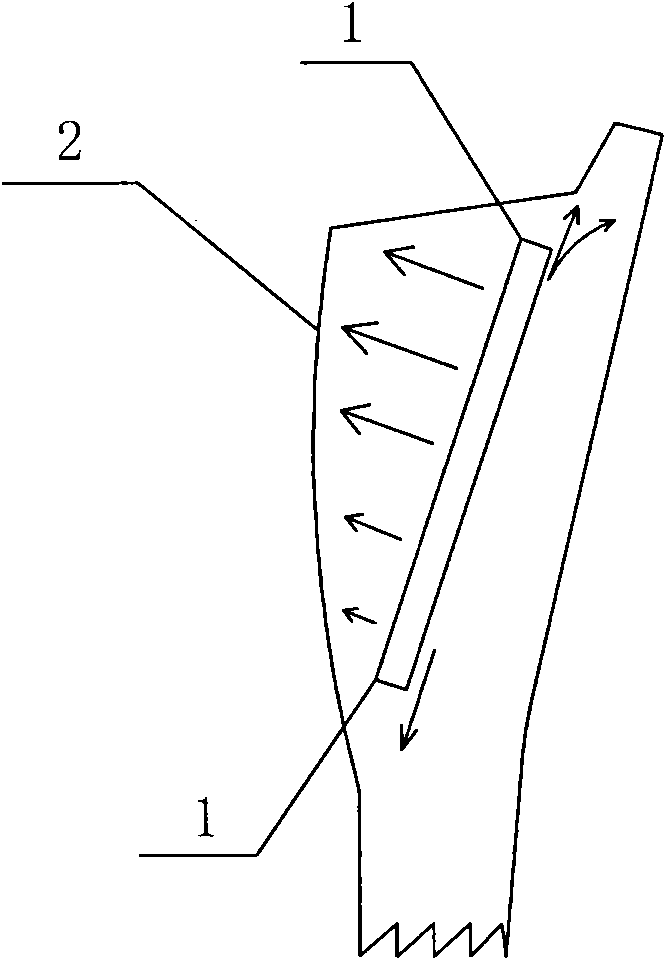

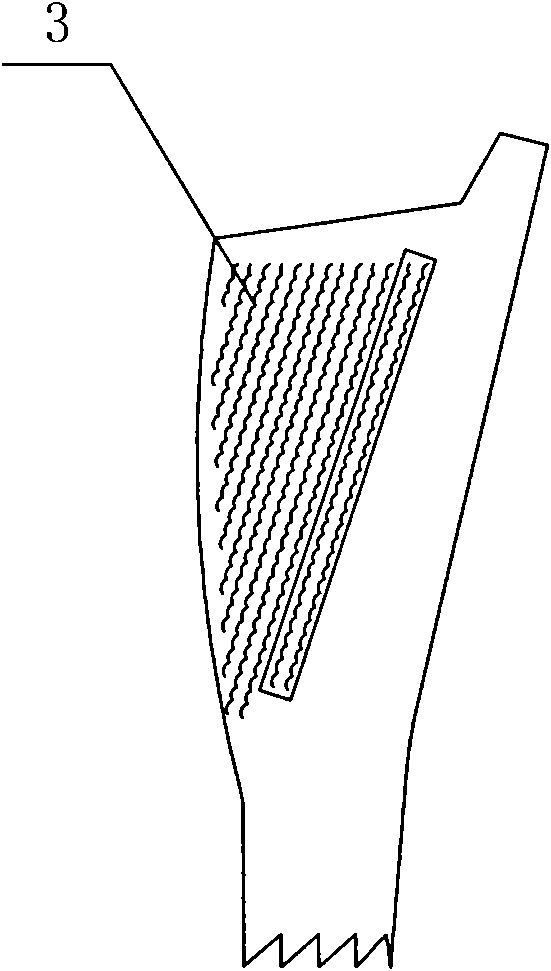

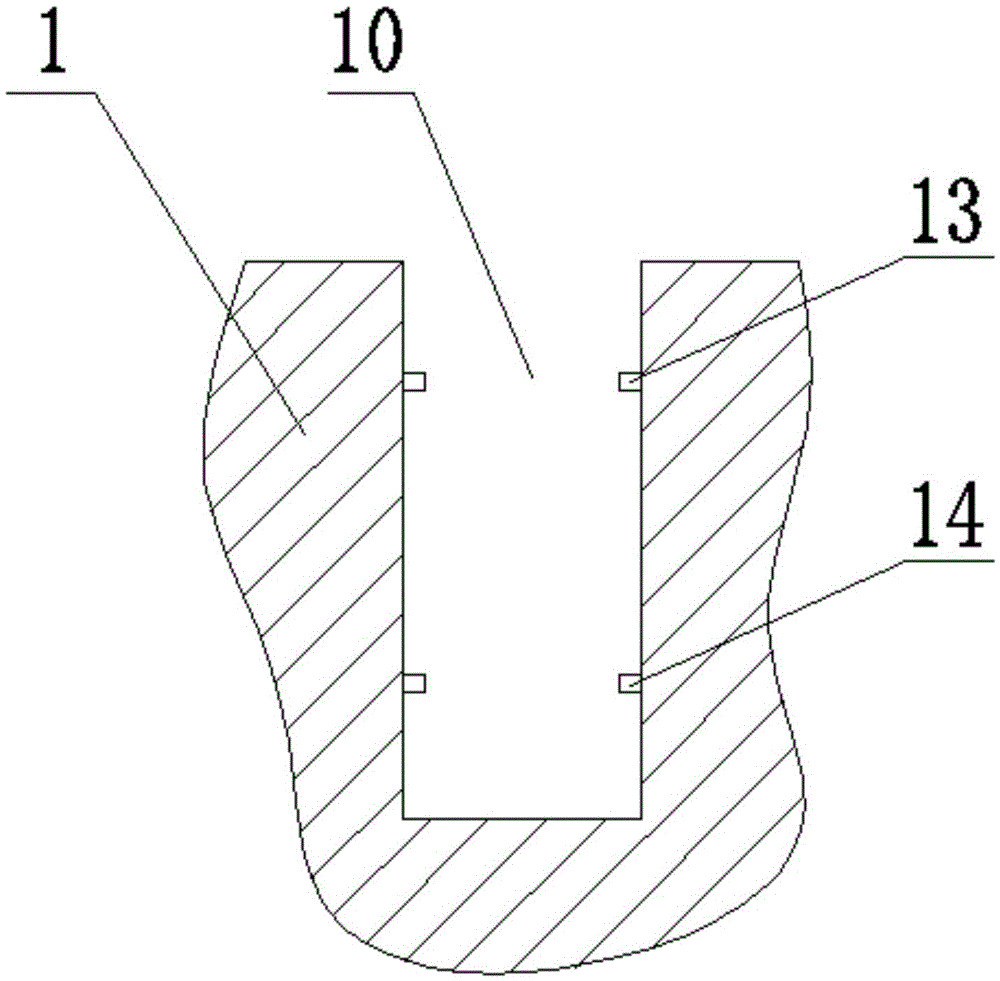

Pushup Jeans and Related Production Process

InactiveUS20150201679A1Easy to shapeEffective areaGarment special featuresTrousersInterliningEngineering

The invention provides a pair of pushup jeans and a production process thereof. The pushup jeans comprise jeans and fusible interlining, each pant leg comprises a front panel and a back panel, the fusible interlining is disposed on the back panel and adhered close to the bottom and outside of hip; a fusible interlining is disposed on the inside of the front panel and opposite to the fusible interlining of the back panel; the fusible interlining has an arc-shaped portion, and the arc-shaped portion is recessed downwards. The outer edge of the fusible interlining is aligned with the outer edges of the front panel and back panel. The distance between the position extending 2-15 cm downwards from the crotch and the lower edge of the waistband is the length of the fusible interlining.

Owner:CRYSTAL APPL

Preparation technology of fusible interlining special for silicon processing fabrics

ActiveCN103767196ADoes not affect the smooth feelAvoid glue bleedingFibre typesGarmentsInterliningPolymer solution

The invention discloses a preparation technology of a fusible interlining special for silicon processing fabrics. The preparation technology sequentially comprises the following steps of base fabrics weaving, overflow loose type pretreatment, padding treatment, a first curing, fabric inputting, hot melt adhesive coating, a second curing, batching and final inspecting and packing. The preparation technology arranges base fabrics of the fusible interlining through an organic siloxane polymer solution, and applies polyurethane and polyesteramide system to conduct two points coating. After a product glues with silicon-based fabrics, the original smooth feel of the fabric is not influenced at all. Meanwhile, due to the plasticity of the polyurethane, a strike through phenomenon of the hot melt adhesive is avoided. The product is high in bonding strength, capable of resisting dry, washable and capable of being wildly applied in garment making of all kinds of smooth fabrics with silicon, and the problem of large tension of a surface when a lining cloth glues with the fabrics. The preparation technology also innovates in coating technology, and the hot melt adhesive on the surface of the lining cloth can be fast permeated and transferred on the fabrics when the lining cloth glues with the fabrics, so that the fabrics and the lining cloth can have a better adhesion.

Owner:ZHEJIANG KINGSAFE INTERLINING

Water-soluble hot-melting adhesive interlining with very low shrinkage rate and production method thereof

ActiveCN103478937AEnvironmental protection is goodEasy to operateLiquid surface applicatorsGarmentsInterliningSolubility

The invention discloses a water-soluble hot-melting adhesive interlining with very low shrinkage rate and a production method thereof. Dimensional change rate in the warp and weft direction after washing is -0.6%-0.5%. After the hot-melting adhesive interlining is combined with fabric through pressing, time for separating the hot-melting adhesive interlining from the fabric in 35-DEG C water is less than 15 seconds. Free and hydrolyzing formaldehyde is equal to or less than 35 mg / kg. The production method sequentially includes seam inverting, singeing, desizing, scouring, bleaching, secondary bleaching or dyeing, post-processing, liquid ammonia finishing, shrink resistant finishing, mechanical pre-shrinking and powder dot coating. The shrinkage rate in the warp and weft direction is low, water-solubility is good, the free and hydrolyzing formaldehyde amount is the minimum, and the production method is easy to operate.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

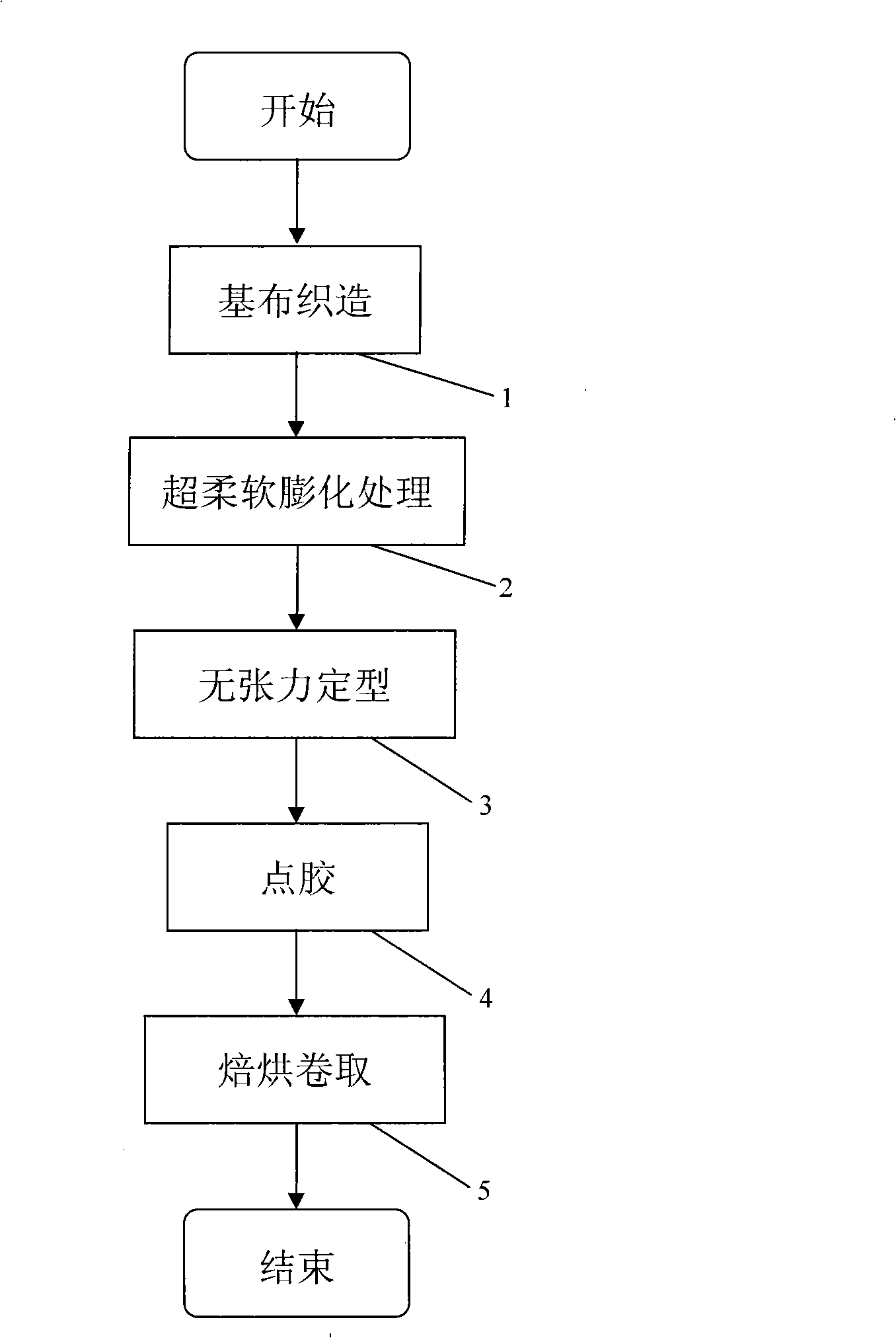

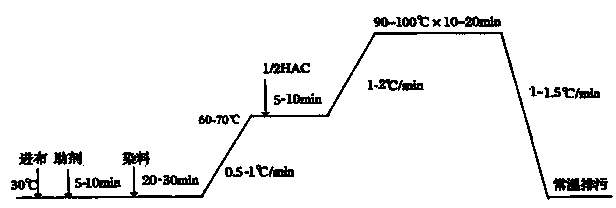

Technique for preparing bonding fabric

The invention discloses a production technology of adhesive interlining, which sequentially includes the steps of basic fabric weaving, super-soft swelling treatment, tension-free shaping, gluing, baking, rolling, etc. The super-soft swelling treatment is conducted to the basic fabrics and dual point coating is adopted; powderless basic pulp is adopted as underside pulp and super-low temperature modified nylon PA glue is adopted as the surface glue. The super-soft swelling treatment can soften and loosen the fibers, thus gaining the soft effect. A high-mesh coating adopted can solve not only the problem of handfeel but also the problem of the partial glue seeping; the ironing temperature of the adhesive interlining is only 90 DEG C to 120 DEG C, thus effectively remaining the style of the fabrics. The interlining is particularly soft in handfeel and has excellent elasticity. The products are mainly applied to various thin elastic clothes. The clothes selecting the interlining are voluminous, smooth, beautiful and comfortable and can eliminate 'ripple ring' appearing in super-thin Lycra fabrics after the ironing and realize the texture of transparence and integrating with the fabric.

Owner:ZHEJIANG KINGSAFE INTERLINING

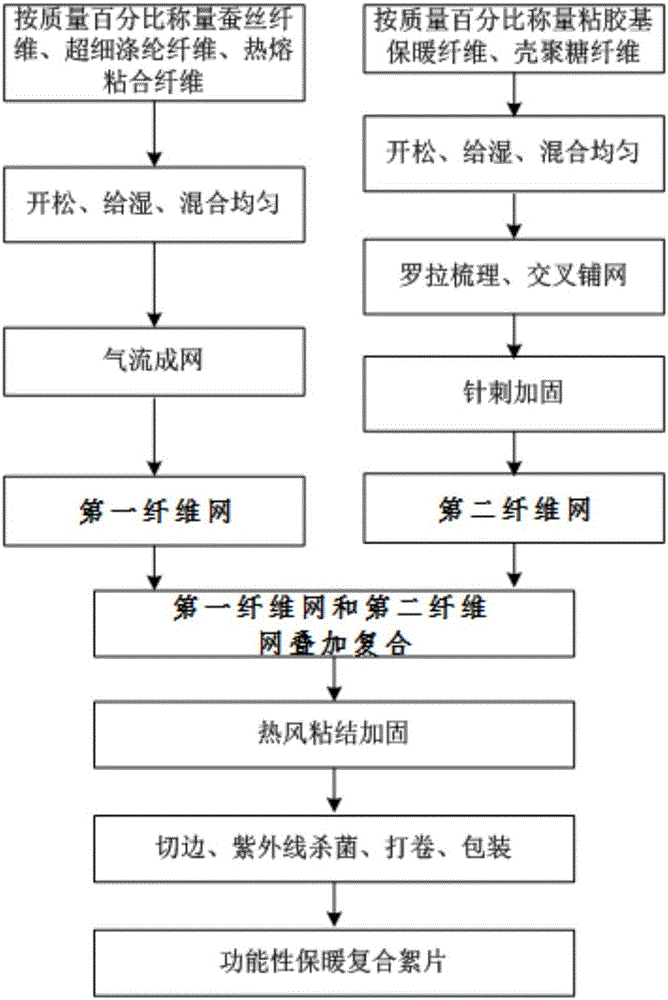

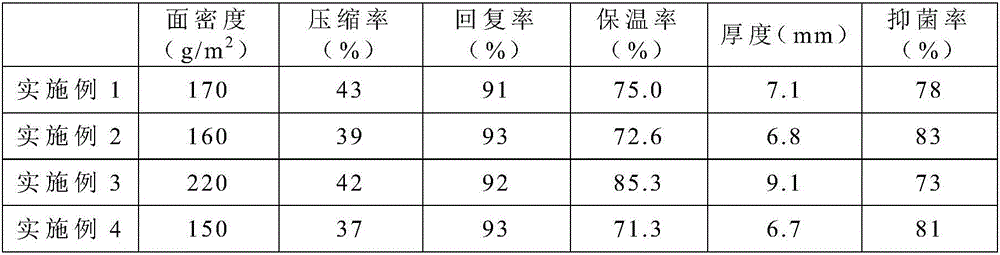

Preparation method of functional warm-keeping composite interlining

ActiveCN106192200AAggregation antibacterialGather soft comfortNon-woven fabricsAdhesivesInterliningPolyester

The invention discloses a preparation method of a functional warm-keeping composite interlining. The preparation method comprises the following steps: weighing, opening and moistening silk fibers, ultrafine polyester fibers and hot-melt adhesive fibers according to the mass percent, and uniformly mixing; carrying out air flow web formation to form a first fiber web; weighing, opening and moistening viscose-based warm-keeping fibers and chitosan fibers according to the mass percent, and uniformly mixing; carrying out roller carding and crossed web spreading; conveying a mixture into a needling machine and carrying out needling reinforcing to obtain a second fiber web; overlapping and compounding the first fiber web and the second fiber web and conveying the mixture into a hot air drying room; carrying out hot air sticking reinforcing to obtain the interlining; and carrying out edge cutting, ultraviolet sterilization, rolling and packaging on the interlining. By adopting a manner of combining carding web formation and the air flow web formation, the composite interlining containing a plurality of types of fibers is prepared; and the interlining gathers the antibacterial property of the chitosan fibers, the softness and comfort of the silk fibers, the bulkiness of the polyester fibers, heat absorption and energy storage of the warm-keeping fibers and good warm-keeping property.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST

Production process of double-point non-woven fusible interlining

InactiveCN102389174AConsider softnessTaking into account the costFibre typesPolyureas/polyurethane adhesivesInterliningPolyester

Owner:温州鸿马科技有限公司

Tang style clothing manufacturing method

The invention provides a manufacture method of tang suits (traditional Chinese garments), which comprises plate making and cutting. The invention is characterized in that the method also comprises the following steps: (1) fusible interlining, (2) putting together and unplugging of front garment pieces and rear garment pieces, (3) making front facing and lining and opening of inner pockets, (4) making side seams, (5) making shoulder parts, (6) making collar, (7) edge piping, (8) attaching collar, (9) making hemline, (10) making sleeves, (11) putting on the sleeves, (12) fastening, (13) hemming and finally ironing, and a tang suit is manufactured. The tang suit manufactured by the method not only reflects the characteristics of the manufacture techniques of traditional Chinese clothes, but also contains the manufacture techniques of modern clothes. After the tang suit is shaped, the clothes body is stiff and unwrinkled, the twisted buttons arranged at the collar and the edges of the clothes are proper, the shoulder parts are prostrate and the sleeves are smooth at both the front and rear parts.

Owner:SHANGHAI CITY INST OF COSTUME

Autonomous Heated Interlining

ActiveUS20140131341A1Easy to operateTransformersOhmic-resistance heatingMicrocontrollerTablet computer

Owner:ROTHSCHILD MICHAEL BENN

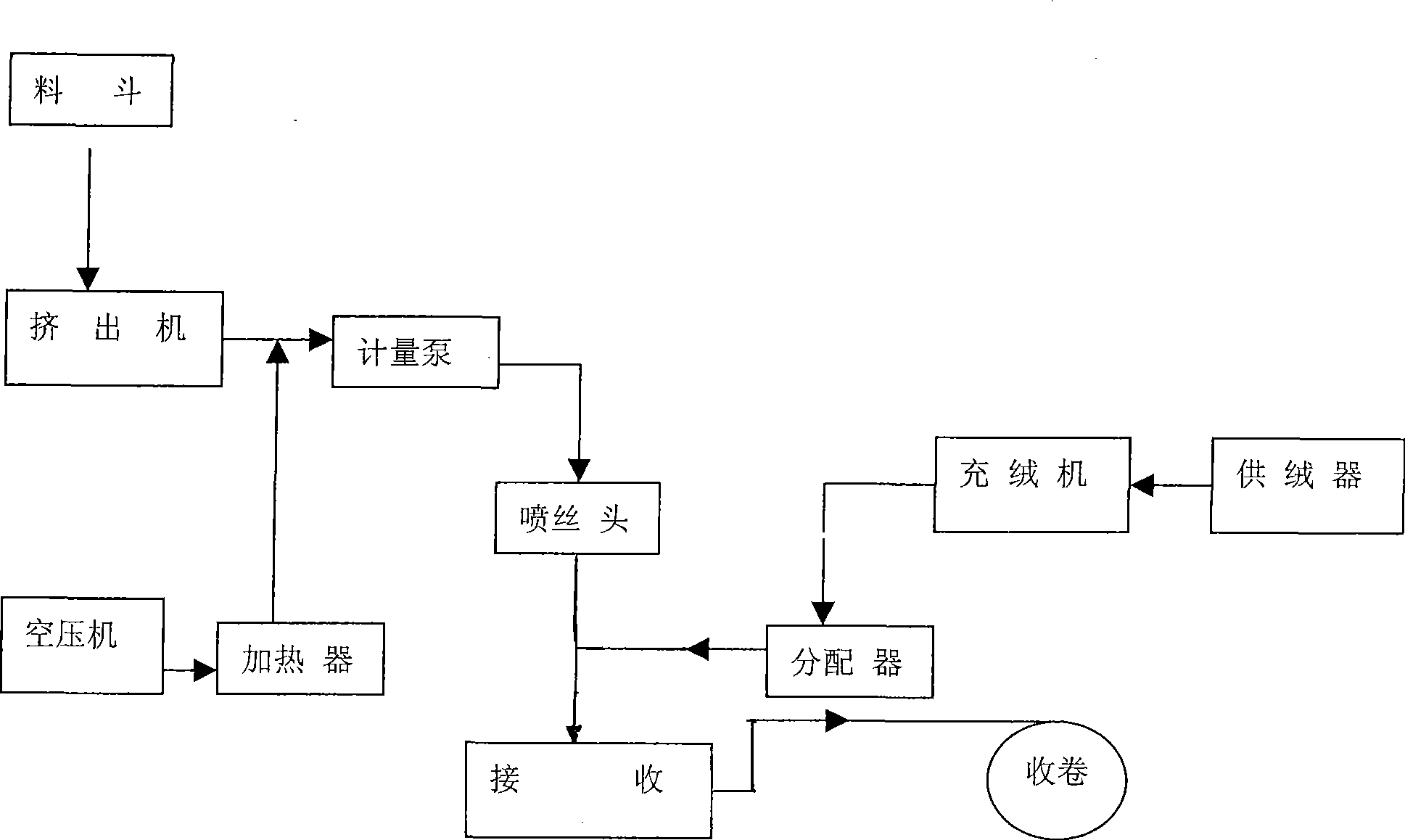

Method for producing melt-blown nonwoven down dual constituent thermal insulating interlining

InactiveCN101392432AHigh resilienceHigh longitudinal and transverse tensile strengthNon-woven fabricsMolten stateInterlining

The invention relates to a method for forming dual-component heat-insulating wadding by combining molten-spraying nonwoven fabrics and down. Specifically, the method comprises the following steps: heating polymer resin slices into molten state, then extruding, measuring and distributing the resin slices evenly to a hole of a spinneret device, and then stretching the resin slices into superfine fiber by hot air. Then the down is adhered with polymer fiber which is treated with fiber-stretching and is still not cured so as to form a net after being distributed by loosening, velvet-supplying and velvet-filling , and then a receiver and a finishing reel wind the net into the wadding. The invention adds down material into the existing molten-spraying production process, which can improve the heat-insulating rate and rebound elasticity of the wadding and can improve the transverse and longitudinal tensile strength of the wadding.

Owner:郭武胜

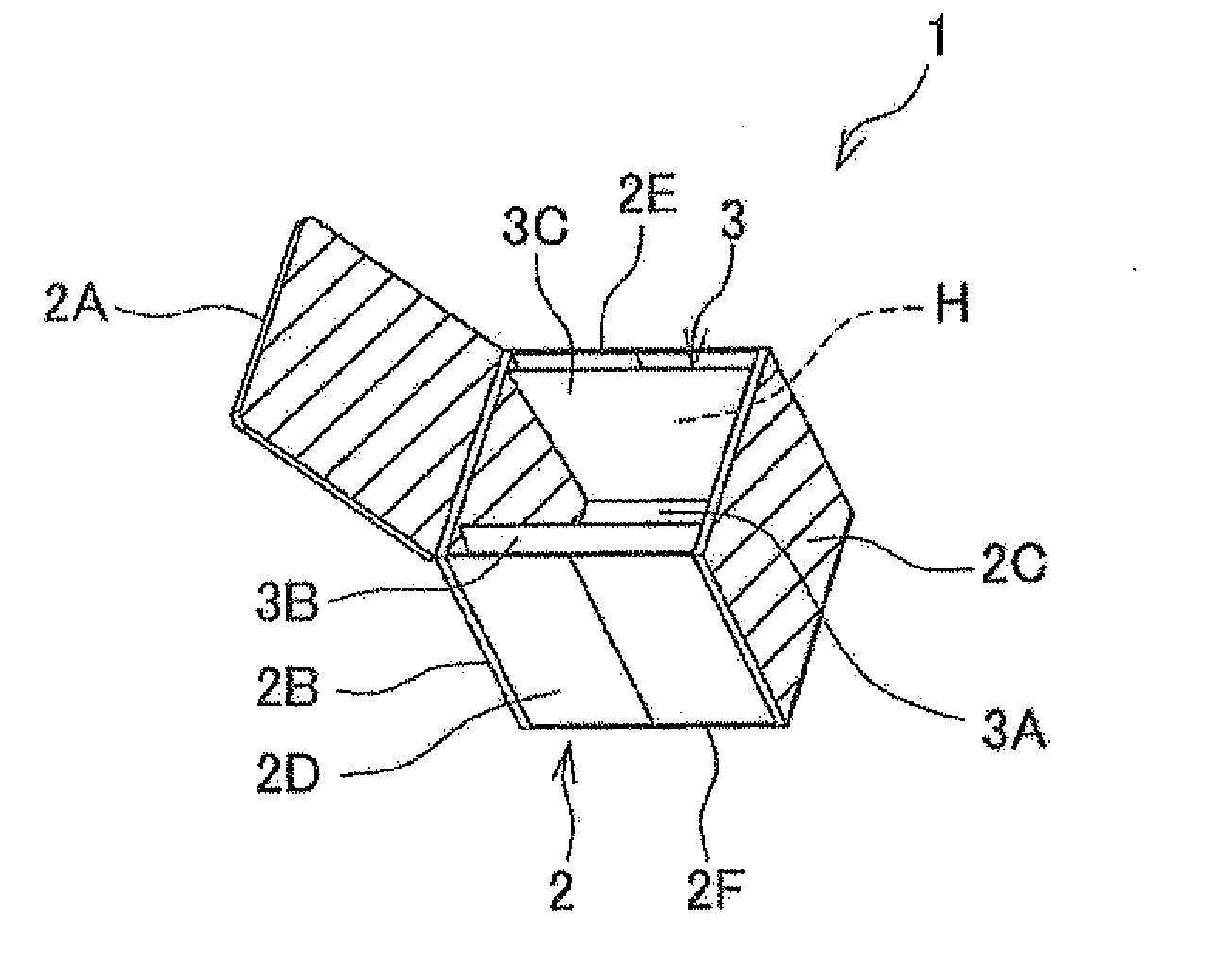

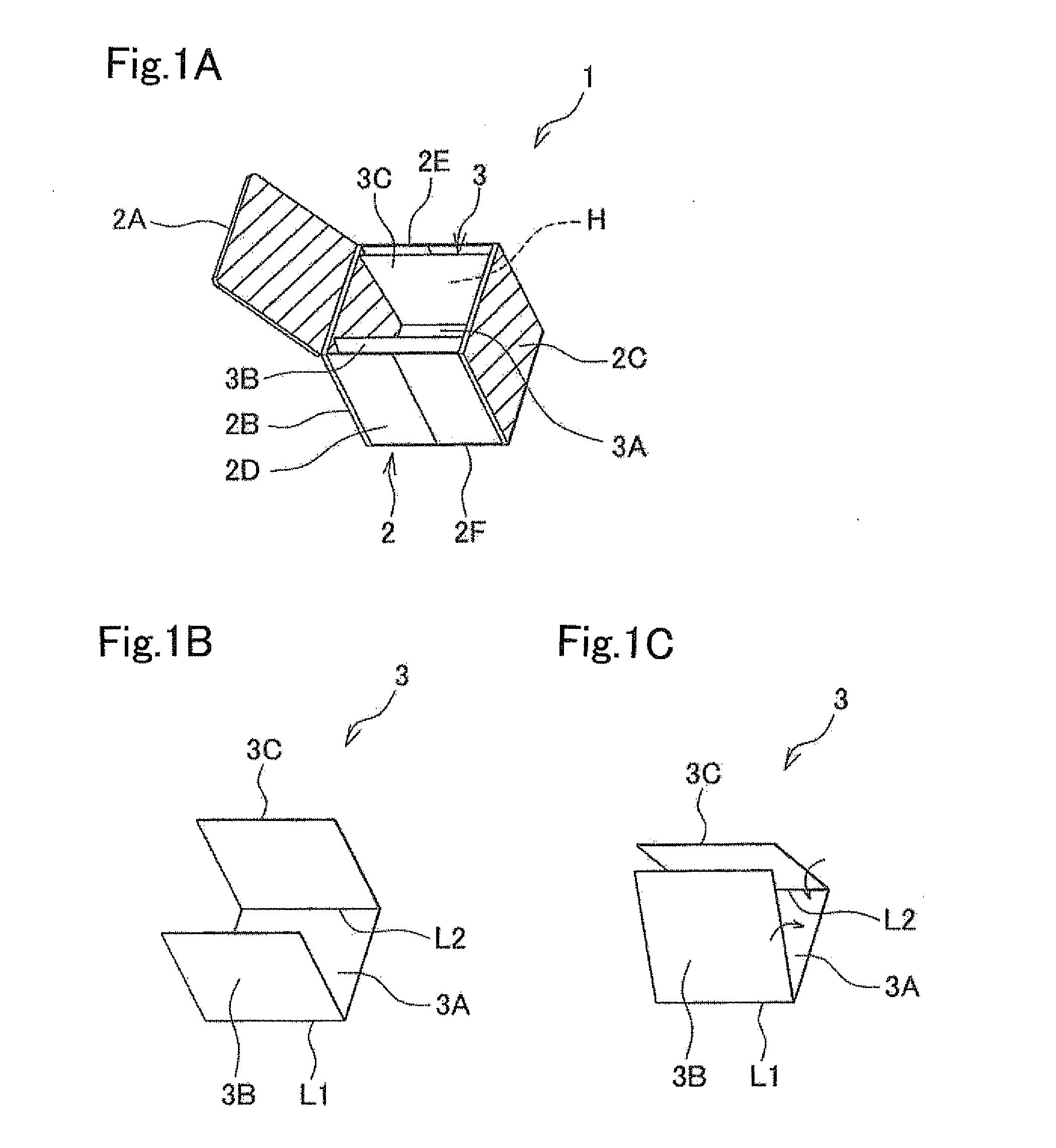

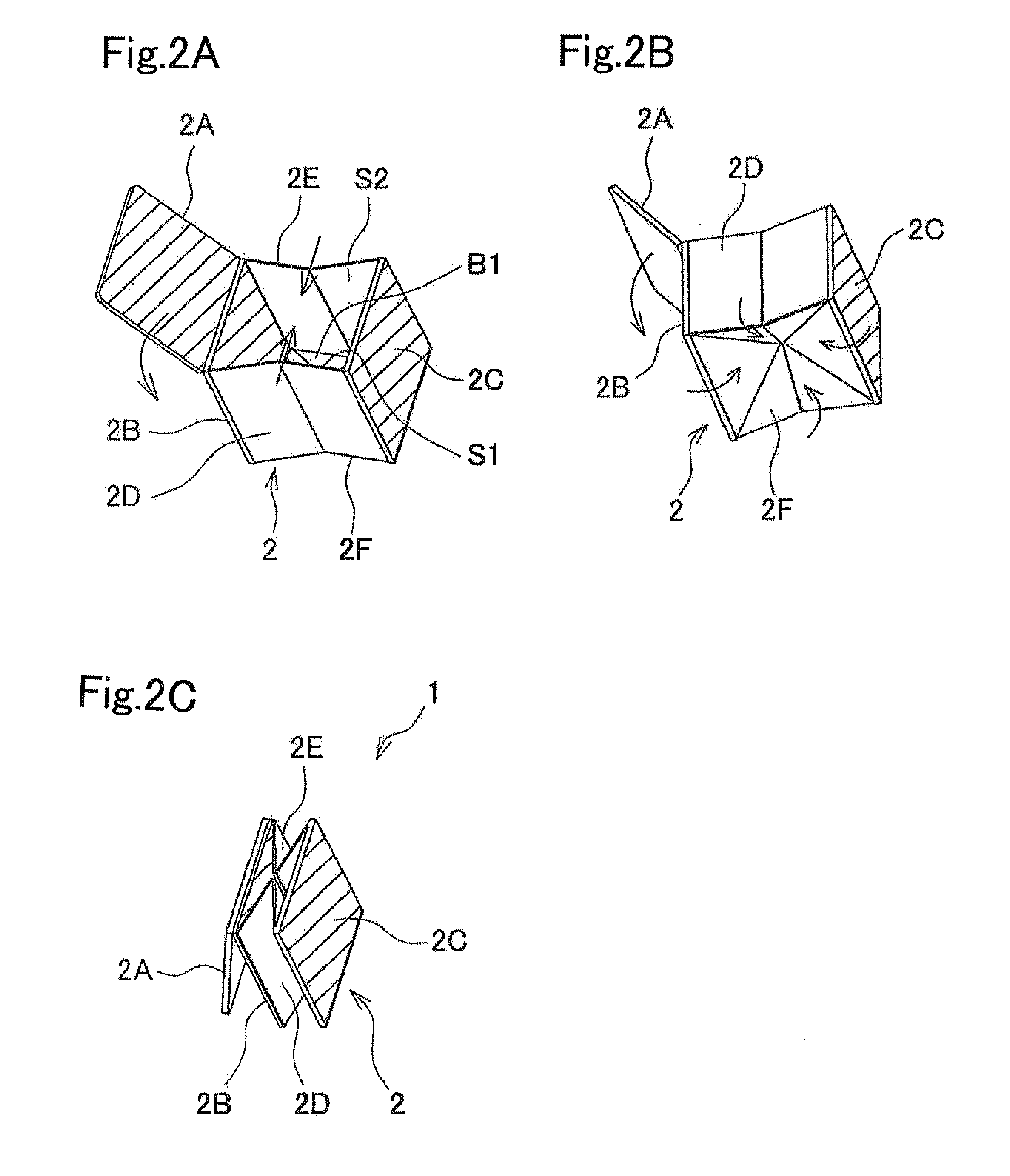

Tool storage bag

A tool storage bag includes a hexahedral fabric bag body and openable only at a top side or at the top side and a bottom side, and an interlining material at least provided at three adjoining sides of the bag body. The interlining material includes plural flat plates corresponding to the three sides. At least one of the flat plates is detachable from a corresponding one of the sides of the bag body, while the bag body is foldable without folding the sides provided with the interlining material. The bag body with at least one flat plate detached from the corresponding side is folded down by overlapping, on one of the unfoldable sides of the bag body, the side other than the above one side and provided with the interlining material.

Owner:MAKITA CORP

Extensible Fibers-Method for Their Production and Use

The present invention relates to a bonded nonwoven having extensive fibers for use in articles such as diapers and other hygienic articles, wipes, interlinings and other articles requiring some degree of elasticity. Specifically it relates to bicomponent fibers where one component is an elastic thermoplastic and another component employed as a binder having a lower melting point than the elastic component. On bonding the binder melts to form bonding points exposing the elastic core. The present invention contemplates a bonded nonwoven article or a component thereof, comprising a blend of extensible bicomponent fibers, an absorbent, and optionally low melt binder fibers, or synthetic fibers, or both. The present invention also contemplates a method of producing a nonwoven by mixing the fibers described above, either by the dry laid or wet laid process, and heating the mixture to bond the fibers into a nonwoven article or a component thereof.

Owner:INVISTA NORTH AMERICA R L

Perlite heat-insulating plate for filling anti-fire door and preparation thereof

The invention relates to a perlite heat-insulating shield for filling a fire-proof door and a method for the production thereof, which mainly comprises expanded perlite powder particles of 75 to 100 parts and fireproof adhesive of 10 to 65 parts by weight, the heat-insulating shield also contains 40 to 70 parts of water by weight before drying the base body of the heat-insulating shield for adjusting the degree of dryness of the formed materials, the fireproof adhesive is a modified sodium silicate fireproof adhesive prepared by mixing 80 to 95 parts of sodium silicate, 2 to 6 parts of sodium carbonate and 4 to 20 parts of magnesium silicate by weight. The perlite heat-insulating shield solves the problems of large unit weight, bad high temperature heat insulation effect and low intensity of the prior art, and is mainly used for being filled in interlinings of fire-protecting devices such as fire-proof doors for fire protection and thermal insulation.

Owner:吕博

Production method of methanal-free purified-cotton woven adhesive interlining

ActiveCN103462264AStrong damageSmall dimensional change rate after washingGarmentsDyeing processCross-linkInterlining

The invention discloses a production method of a methanal-free purified-cotton woven adhesive interlining. The production method comprises the steps of pretreatment and mechanical shrunk finish; in the step of pretreatment, a cold pad-batch pretreatment production process is adopted, dyeing is performed by adopting a cold pad-batch dyeing production process with reactive dyes, glyoxal is taken as an anti-wrinkling finishing agent, a low-temperature tide-state cross-linked production process is adopted, hot melt powder with high bonding strength is adopted for powder point coating, and the number of coatings is controlled, so that after a combined sample is baked, the stripping strength is not less than 15N; in the step of mechanical shrunk finish for fabric subjected to powder point coating, the preshrunk quantity is controlled so as to ensure that after finishing, dimensional changes after laundering, in warp and weft directions, of the adhesive interlining are not less than -0.8 percent. According to the production method, a cold pad-batch process is adopted to perform the pretreatment, the dyeing and the shrink resistant finish, energy-saving and environment-friendly effects are realized, and the produced purified-cotton woven adhesive interlining does not release methanal, is barely damaged by strong force and is small in the dimensional changes after laundering.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

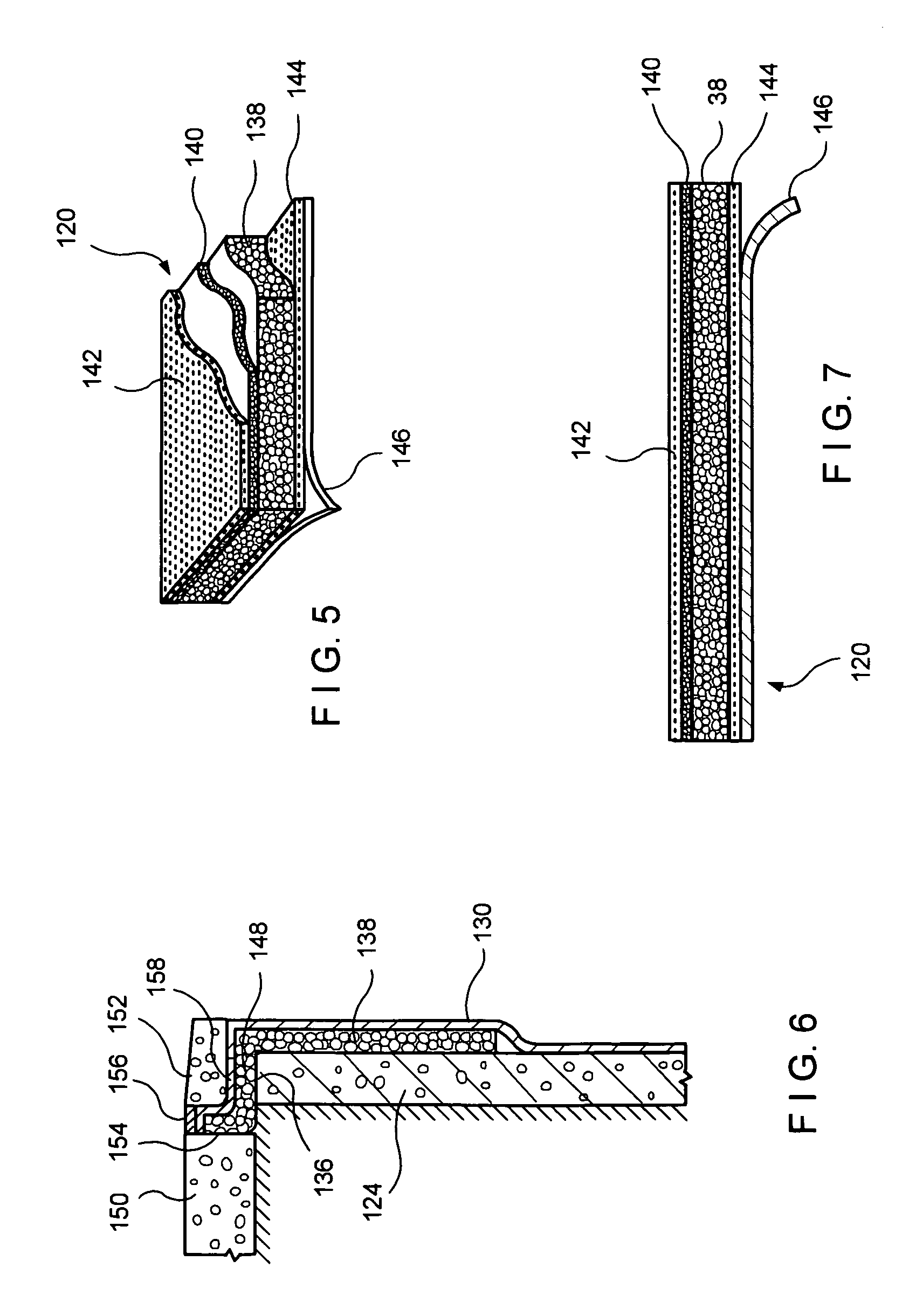

Heat-reflective nonwoven liner material

InactiveUS7452833B2High retention rateCost efficientSynthetic resin layered productsWoven fabricsInterliningThermoplastic

A heat reflective garment interlining laminate is provided that includes a continuous filament layer and a metallized thermoplastic film. The laminate is characteristically low-cost and suitable for such apparel applications as sports clothing, military clothing, camping gear, hunting / fishing clothing, and the like.

Owner:AVINTIV SPECIALTY MATERIALS INC

Pure cotton bright black adhesive interlining and production method thereof

ActiveCN105696375APrevent penetrationNo skippingWrinkle resistant fibresDyeing processCoated surfaceInterlining

The invention discloses a pure cotton bright black adhesive interlining and a production method thereof. The production method comprises the steps of edge turning, refining, dyeing, chemical shrink resistance finishing, black HDPE powder bright coating, mechanical preshrinking and the like. The adhesive interlining is bright black in coating surface; after the adhesive interlining and a colorful thin type garment material are fitted, the problem of bright white hot melt adhesive speckles will not be generated, and the garment quality is improved. The defects of leakage points, leakage coating and the like can be easily detected during appearance inspection, and it is ensured that a clothing enterprise will not generate degradation losses of products by using a defected adhesive interlining. The free and hydrolysis methyl aldehyde of the adhesive interlining is smaller than or equal to 35 mg / kg, and the warp and weft washing dimensional change rate ranges from -0.8% to +0.5%.The production method is easy to operate, environmentally friendly and excellent in product performance.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD

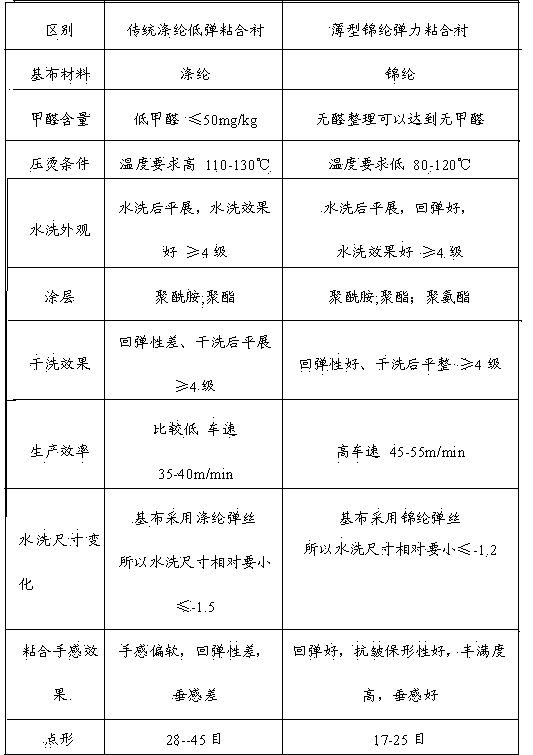

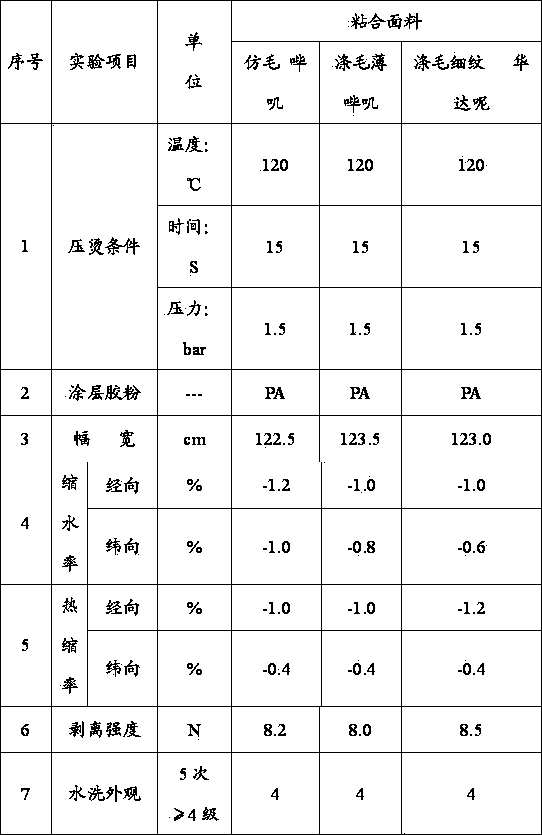

Production process of thin nylon elastic adhesive-bonded interlining

ActiveCN103462263AImprove performanceRaise the gradeLiquid surface applicatorsFibre typesCooking & bakingInterlining

The invention relates to a production process of thin nylon elastic adhesive-bonded interlining. The production process includes the following steps: 1, grey cloth inspecting; 2, cloth turning, print and end stitching; 3, loosening and dyeing; 4, shaping and finishing; 5, coating; and 6, inspecting, wherein the step of coating includes the following processes: unwinding, J-shaped cloth containing box, LG deviation corrector, pasting by a scraper, spreading hotmelt adhesive powder, blowing and sucking powder, edge-detecting, baking, cooling, coating-forming, and coiling. By adopting the production process, product grade can be effectively increased, performance of lining cloth is greatly improved, and the thin nylon elastic adhesive-bonded interlining is preciser in coating process, good in water washing and dry washing effect, low in formaldehyde content and more comfortable to wear, and has wider market prospect and market value.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Making process related to suit lapel

The invention relates to the technical flied of clothing, particularly to a making process related to a suit lapel. The process relates to eleven making steps of: covering a chest interlining, pressing and ironing a front, prizing lapels, pruning the lapels, binding a facing, mounting the facing, trimming lapel corners, ironing a front edge, binding needles on facing stocks, pressing and ironing a top fly and finish-ironing. Through the process, the operation of amount retraction and release as well as shaping can be carried out through various techniques and machines in the making of the suit lapel, so that the lapel can be turned to a position and does not foam or stick up, and the left and right lapels have consistent size and width.

Owner:LAMPO

Manufacturing technology of viscose spunlace of western-style clothes

ActiveCN103156315ASoft touchImprove breathabilityVegetal fibresProtective garmentPolyesterInterlining

The invention discloses a manufacturing technology of viscose spunlace of western-style clothes. The manufacturing technology of the viscose spunlace of western-style clothes comprises the steps of base cloth weaving, finishing, glue dispensing, drying, initial check, take-up, final check and packaging. The differentiation technology is adopted, and viscose fiber and polyester fiber are served as raw materials and combined to be a net through carding. The base cloth is obtained after snarling of spunlace and the drying. The base cloth is soft in touch, attractive in appearance and good in performance. Compared with products with the same fixed quantity, the base cloth seems to be more fluffy and thick. Air permeability and elasticity of an end product are increased, chemical substances are not contained, and stability of the end product is high. Through the finishing of aqueous dispersion shape memory polyurethane emulsion, anti-wrinkle performance of the product is good, and lines made by folding are not easy to form. Besides, when adhesive dispense coating is carried out on adhesive interlining base cloth after finishing, dispensing shapes are fuller. When the base cloth is bonded with shell fabric in a pressing mode, glue points are transferred to the shell fabric more easily. Cooperative degree is good. Transferring degree of melting glue points to the shell fabric reaches more than 45%, and peeling strength and water resistant performance are enhanced.

Owner:ZHEJIANG KINGSAFE INTERLINING

Foam interlining device for swimming pools

ActiveUS8028353B1Economical and easy to installEasy to packFilm/foil adhesivesBathsInterliningMarine engineering

A foam interlining device for swimming pools with pressure activated adhesive is shown. The device is disposed between the pool liner and the swimming pool backup wall. The interlining is also constructed with both a mounting adhesive and a self-sealing coating. The self-sealing coating seals minor punctures and tears of the pool liner. In one embodiment, the edge of the interlining also functions as an expansion joint between a deck and the swimming pool coping and as an underlayment or sill seal for the coping. The interlining device is also shown premounted on the backup-wall-side of the pool liner.

Owner:HOHMANN & BARNARD INC

Full-automatic top fly sewing machine

InactiveCN105525445AEasy to operateImprove processing efficiencyCombination sewing machinesInterliningPulp and paper industry

The invention discloses a full-automatic top fly sewing machine. The sewing machine comprises a rack, an interlining fusing machine, an overlocking machine, a flat seaming machine, a cutting machine and a control device, wherein the control device controls the interlining fusing machine, the overlocking machine, the flat seaming machine and the cutting machine to operate; the interlining fusing machine, the overlocking machine, the flat seaming machine and the cutting machine are sequentially fixed on a workbench on the upper surface of the rack; fabric and an interlining enter the interlining fusing machine after being folded, enter the overlocking machine for overlocking, then enter the flat seaming machine for pressing and finally enter the cutting machine for cutting forming. With the adoption of the full-automatic top fly sewing machine, procedures of fusing, overlocking, pressing, cutting and the like required by traditional top fly production are adopted for processing simultaneously, the processing efficiency is effectively improved, the production technology is simplified, the manpower resource is saved, and the sewing machine is suitable for popularization.

Owner:FAR EAST CLOTHES SUZHOU CO LTD

Polyurethane hot melt adhesive for adhesive interlinings and preparation method thereof

ActiveCN101760164ASimple production processRaw materials are easy to obtainPolyureas/polyurethane adhesivesFibre treatmentInterliningAlcohol

The invention discloses a polyurethane hot melt adhesive for adhesive interlinings. The formula of polyurethane hot melt adhesive includes diisocyanate, dihydric alcohol, chain extender, crosslinking agent, antioxidant, anti-yellowing agent, catalyst, coupling agent and the like, a reaction type double-screw extruder is used for continuous production, the production technique is simple, the efficiency is high, the produced adhesive can be ground into powder under a low temperature, and is coated on a base fabric in the form of points by special-purpose equipment, the base fabric is then dried, so that an adhesive interlining is produced, and the produced adhesive interlining has the advantages of high bonding strength, good water resistance and good handle.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

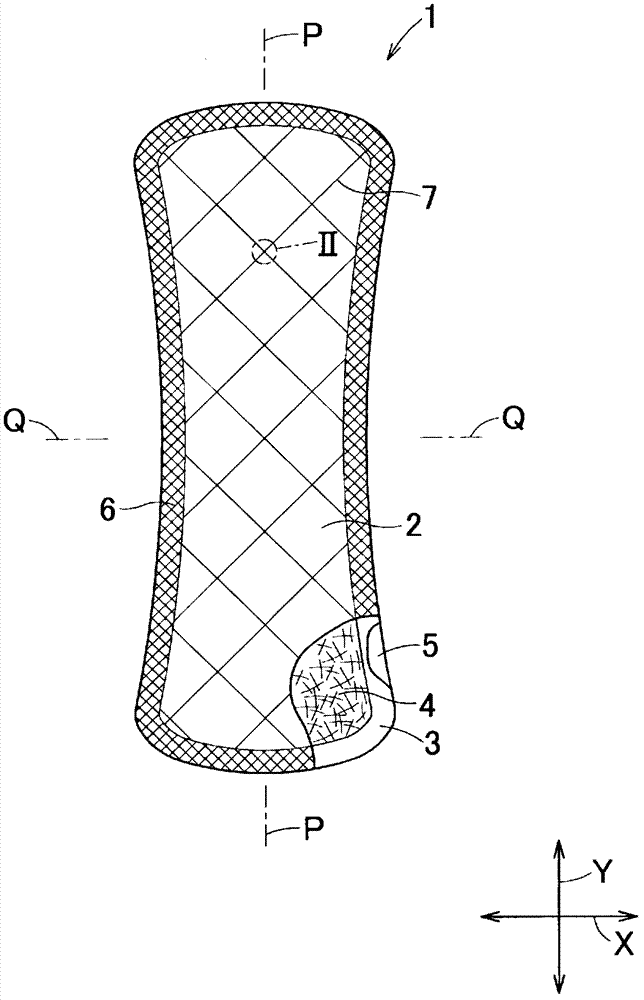

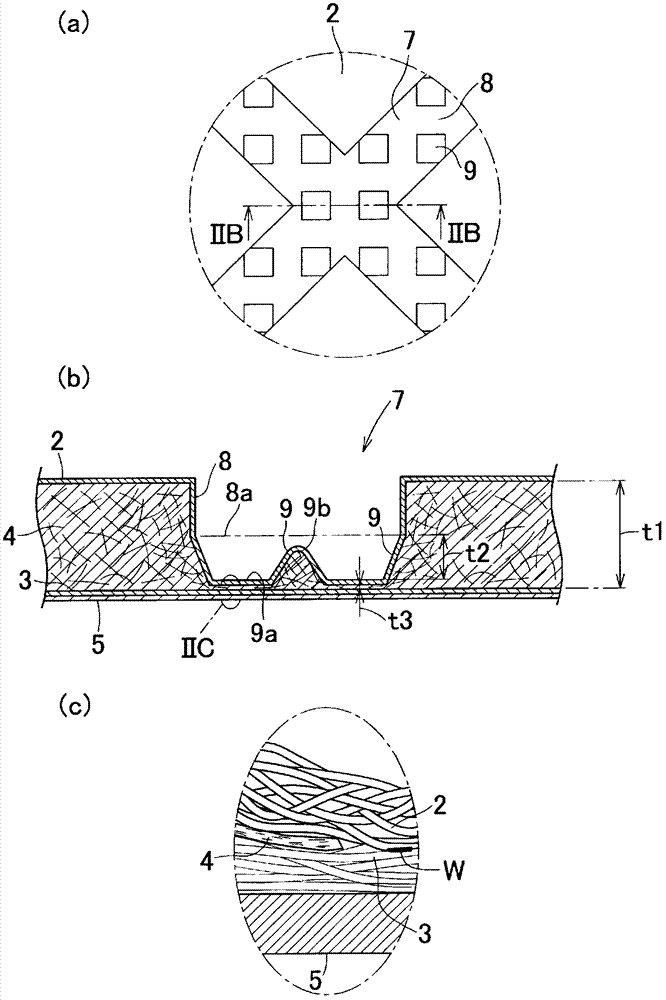

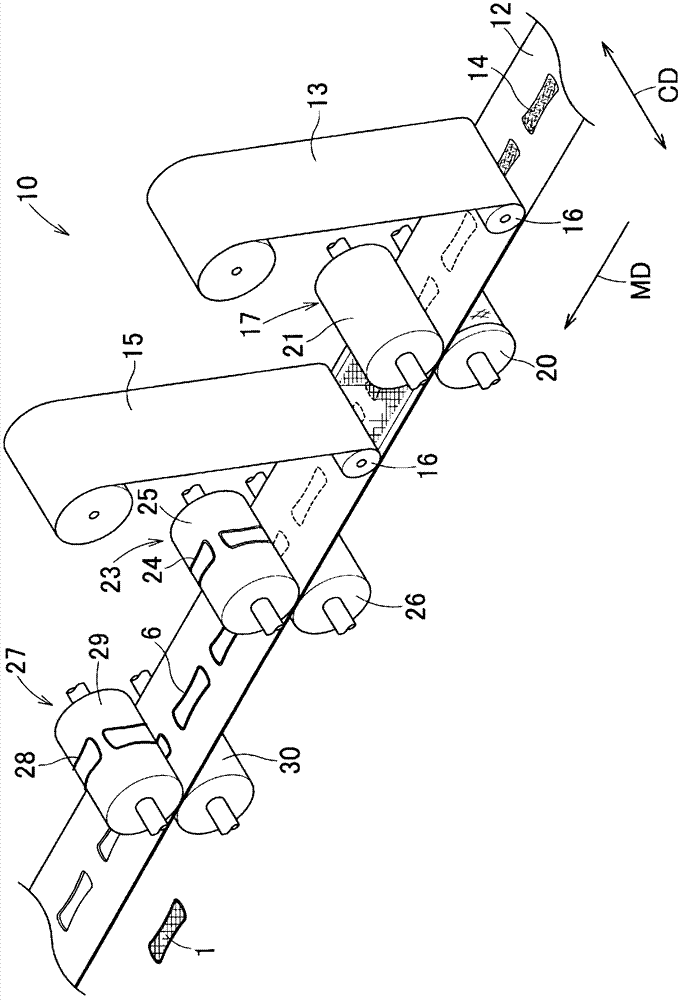

Body fluid treatment article and method for manufacturing same

InactiveCN102821723AAvoid distortionRestricted movementSanitary towelsBaby linensInterliningGrid pattern

The present invention provides a body fluid treatment article wherein twisting while being worn can be inhibited, and a method for manufacturing the same. A panty liner (1) comprises: inner and outer surface sheets (2, 3); a fluid-absorption interlining (4) located between the inner and outer surface sheets (2, 3); and a leakproof sheet (5) with which the outer surface sheet (3) is covered. A fiber nonwoven fabric containing thermoplastic synthetic resin is used as the inner and outer surface sheets (2, 3), and fluff pulp is used as the interlining (4). On the inner surface sheet (2) are formed a plurality of compressed grooves (7) toward the outer surface sheet (3) in a manner that the compressed grooves (7) form a grid pattern by extending so as to cross one another respectively in the lengthwise direction (Y) and the crosswise direction (X). The compressed grooves (7) comprise a first portion formed from the inner surface sheet (2) toward the interlining (4) and second portions each provided with a bottom and formed from the lower part of the first portion toward the outer surface sheet (3) in such a manner that the interval between both of the lateral sides is reduced gradually. At the bottoms of the second portions, at least parts of the fibers forming the inner surface sheet (2) and the fibers forming the outer surface sheet (3) are in contact with each other and welded.

Owner:UNI CHARM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com