Patents

Literature

106results about How to "Improve the quality level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

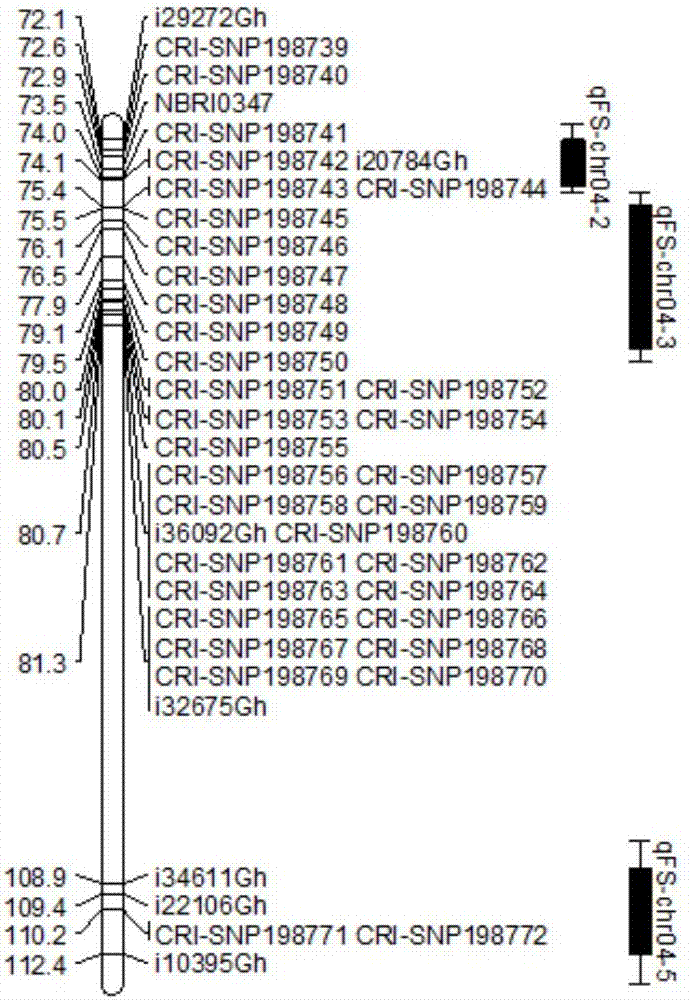

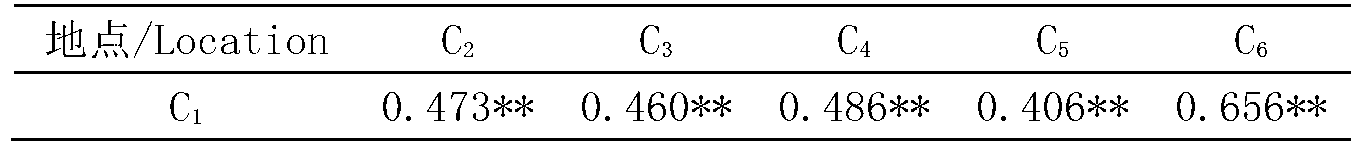

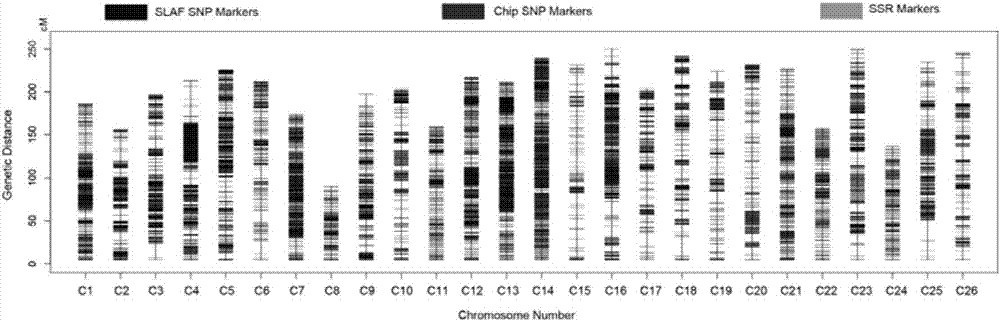

Upland cotton No. 4 chromosome and SNP molecular markers associated with fiber strength

ActiveCN106929574AShorten the breeding cycleImprove breeding efficiencyMicrobiological testing/measurementMolecular breedingSnp markers

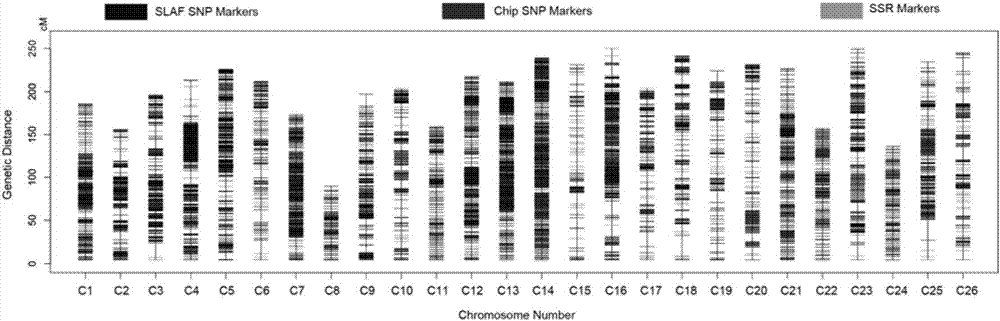

The invention belongs to the technical field of cotton molecular breeding, and discloses SNP molecular markers associated with fiber strength of upland cotton as well as detection of the SNP molecular marker and application of the SNP molecular marker. The SNP molecular marker takes a cotton stable RIL group as a material, and is obtained through a genome re-sequencing method. The SNP markers are utilized to perform molecular marker assisted breeding, so that the breeding period can be greatly shortened, cotton fiber strength is enhanced, and the breeding efficiency is improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

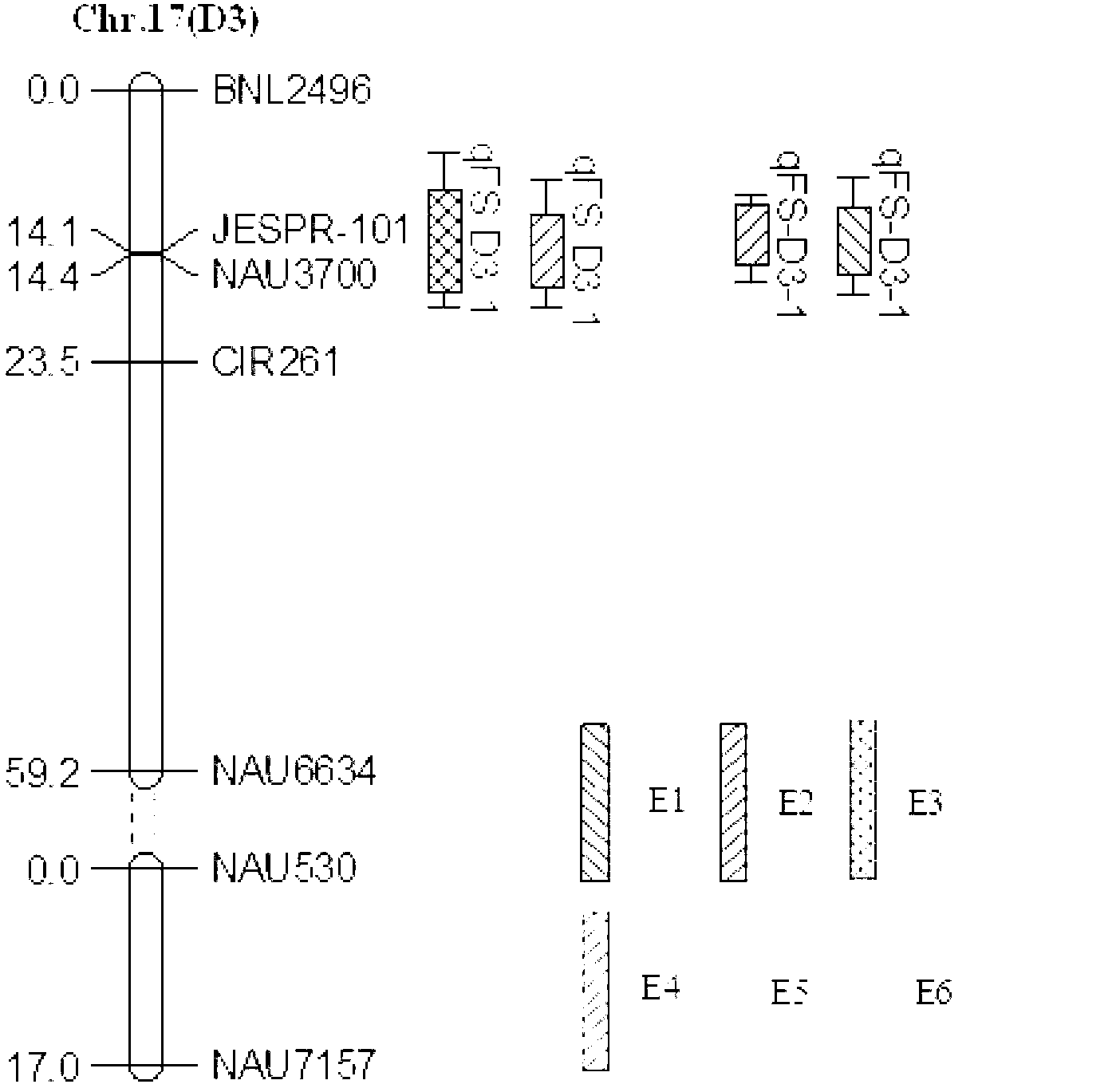

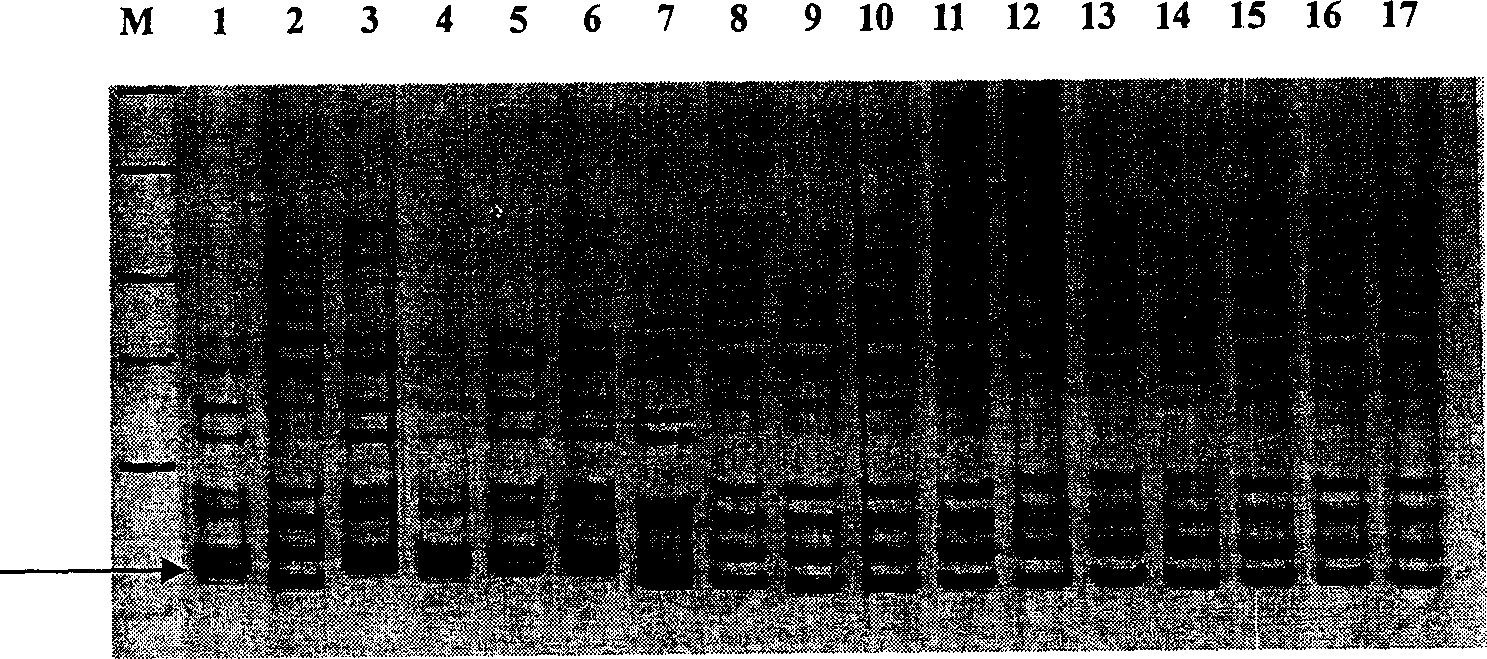

Major QTL (Quantitative Trait Locus) of cotton high-strength fiber and molecular marker and application thereof

ActiveCN103255139AHigh strengthImprove fiber quality levelsMicrobiological testing/measurementVector-based foreign material introductionFiberAgricultural science

The invention discloses a major QTL (Quantitative Trait Locus) of a cotton high-strength fiber and a molecular marker and application thereof. The major QTL of the cotton high-strength fiber is linked with two SSR (Simple Sequence Repeat) markers, is positioned through markers NAU / SSR / FS1195 and JESPR / SSR / FS2127 and is 0.01-2.39 centimeters away from a marker NAU3700; and the major QTL locus can explain 4.51%-17.55% of phenotype variation and achieves the LOD (Limit Of Detection) value between 3.23 and 7.09. The major QTL disclosed by the invention overcomes the defects of high cost, high difficulty and slow progress of quality breeding in the prior art, greatly increases the selection efficiency of the high-strength fiber by utilizing the major QTL locus of a cotton high-strength fiber gene and the molecular marker thereof, can be used for exploring high-quality fiber gene resources, provides the gene resources and a marker auxiliary selection technology for the quality breeding of cotton and can be applied to the production and quality detection of high-strength fiber cotton varieties.

Owner:NANJING AGRICULTURAL UNIVERSITY

Production technique of low-temperature pressed rapeseed oil

InactiveCN102952628AEasily brokenImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringRapeseed

The invention discloses a production technique of low-temperature pressed rapeseed oil, wherein rapeseeds are cleaned, subjected to impurity removal, subjected to wall breaking based on freezing treatment and then fried to 60-70% rape to contribute to the oil leaching, a pressing technique is utilized in the invention, and a specially treated adsorbent is used for decoloring. A technique of heating after freezing is utilized in the invention to facilitate the cell disruption of the rapeseeds so as to improve the oil extraction rate, and the oil extraction rate is 5-6% higher than that of a traditional pressing method; and the oil is extracted by the pressing technique in the invention, so that no pollution exists, the purity of the oil product is guaranteed, and the oil is all natural and meets the demands of green food.

Owner:FEIXI RONGXIN GRAIN & OIL

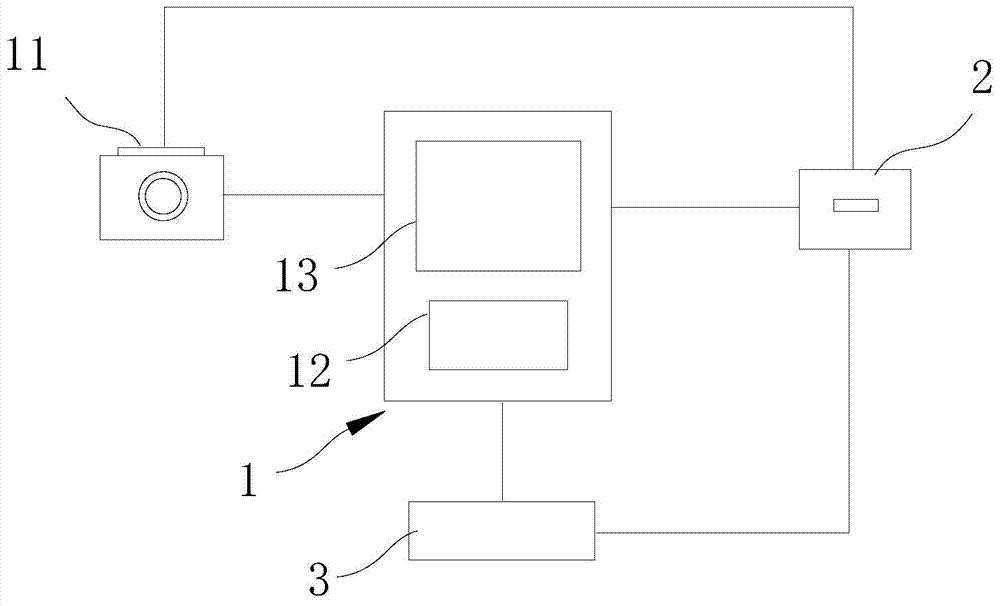

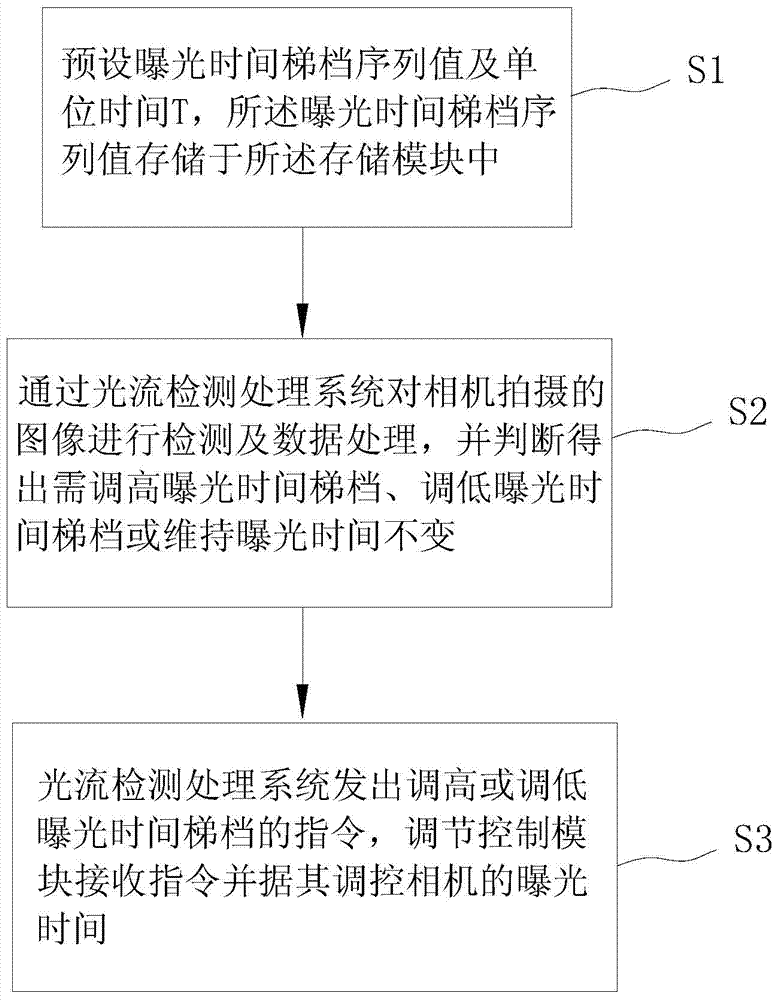

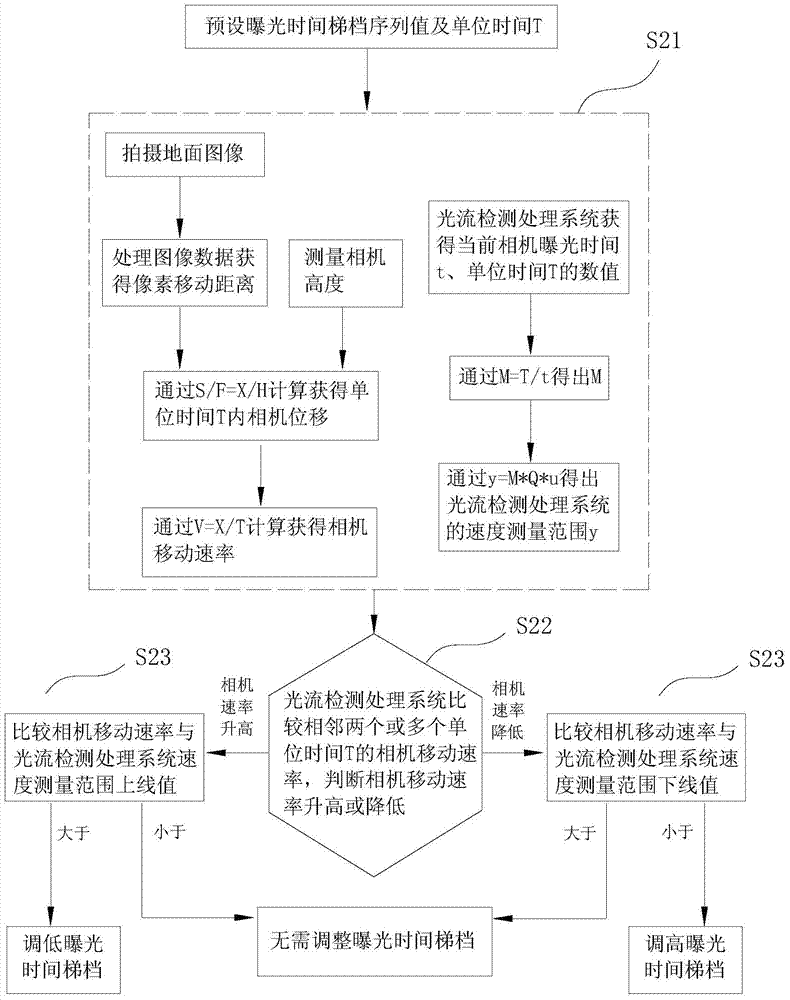

Adaptive camera exposure time adjustment device and method

PendingCN104853113AAdjust exposure timeGuaranteed quantityTelevision system detailsColor television detailsOptical flowUnmanned air vehicle

The invention discloses an adaptive camera exposure time adjustment device and a method. the method comprises steps: an exposure time grade sequence value and a unit time are preset; detection and data processing are carried out on an image photographed by the camera via an optical flow detection and processing system, and an exposure time grade which needs to be adjusted higher, an exposure time grade which needs to be adjusted lower and an exposure time which needs to be kept unchanged are judged and obtained; the optical flow detection and processing system sends an instruction for adjusting the exposure time grade higher or adjusting the exposure time grade lower, and an adjustment control module receives the instruction and adjusts the exposure time of the camera according to the instruction. According to the scheme of the invention, during a process during which the camera moves at a high speed along with an unmanned aerial vehicle, the exposure time of the camera can be adjusted adaptively in real time, and the number and the quality of the photographed images can be ensured.

Owner:ZEROTECH (BEIJING) INTELLIGENCE TECH CO LTD

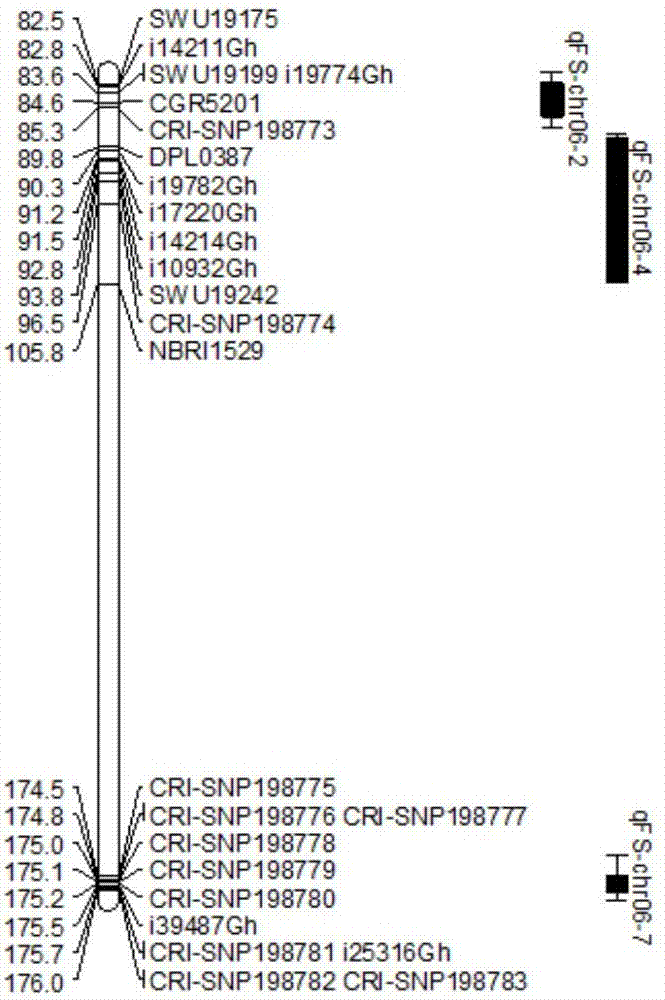

SNP molecular marker associated with chromosome 6 and fiber strength of upland cotton

ActiveCN106868131AShorten the breeding cycleImprove breeding efficiencyMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceMolecular breeding

The invention belongs to the technical field of molecular breeding of cotton and discloses an SNP molecular marker associated with fiber strength of upland cotton as well as detection and application thereof. The SNP molecular marker is obtained by taking stable RIL group of cotton as the material through a genome resequencing method. When the SNP markers are used for carrying out molecular marker-assisted breeding selection, the breeding period can be greatly shortened; the breeding efficiency of the cotton can be improved; the cotton fiber strength can be improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

A kind of instant green tea and production technology

The invention discloses an instant green tea and a production process. The process comprises the following steps: extracting, primary separating, centrifuging or ultrafiltering, nanofiltering, RO (reverse osmosis) concentrating, VO concentrating, UHT (ultra heat treating) and sterilely filling to produce tea juice or atomizing drying to produce tea powder. By adopting the a combined film filtering technology of ultrafiltering, nanofiltering and reverse osmosis, the bitter taste of the green tea extract prepared without an organic solvent to extract is reduced, the cold dissolubility of the green tea extract is improved, the traditional processing method is improved, the bitter of the green tea is greatly reduced, and the product aroma is more unique.

Owner:婺源县聚芳永茶业有限公司

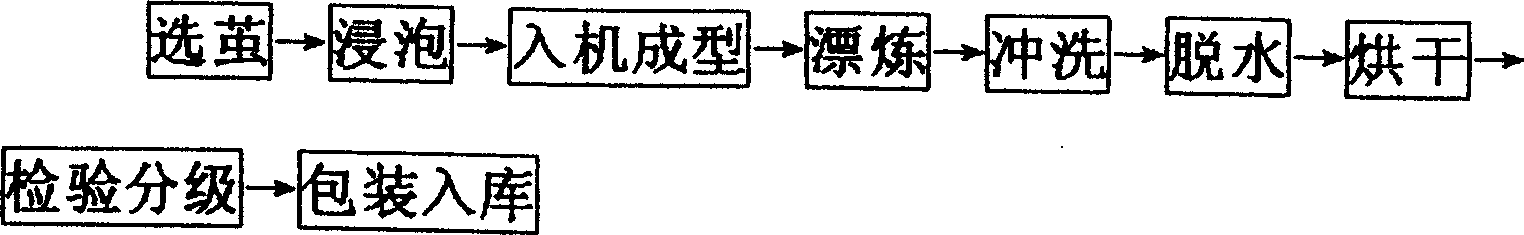

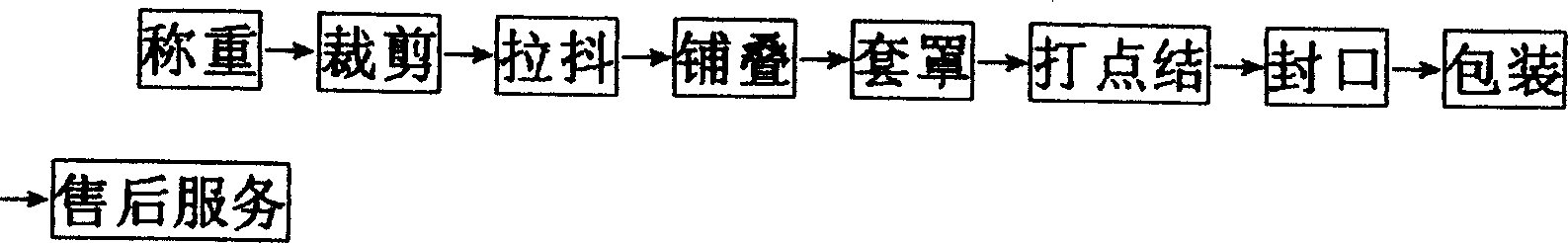

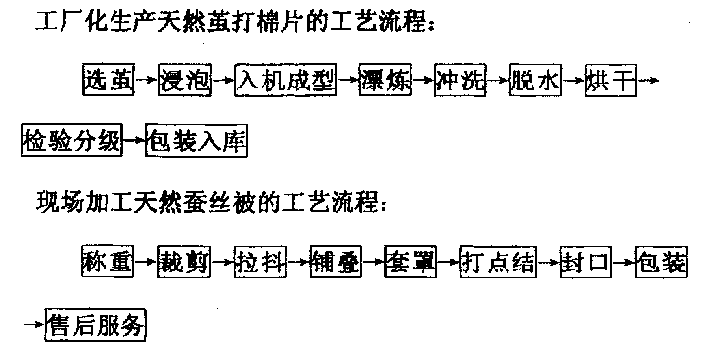

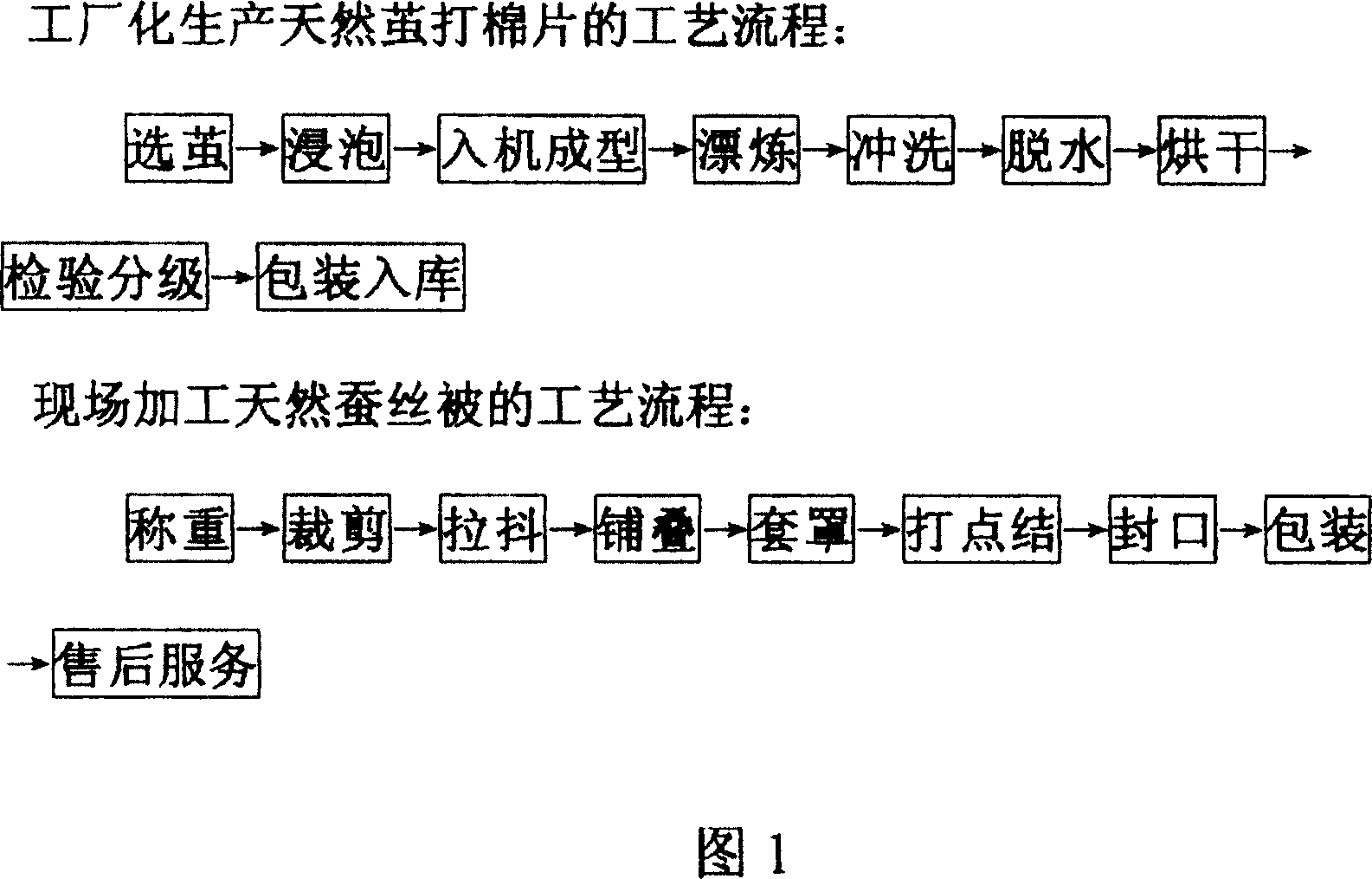

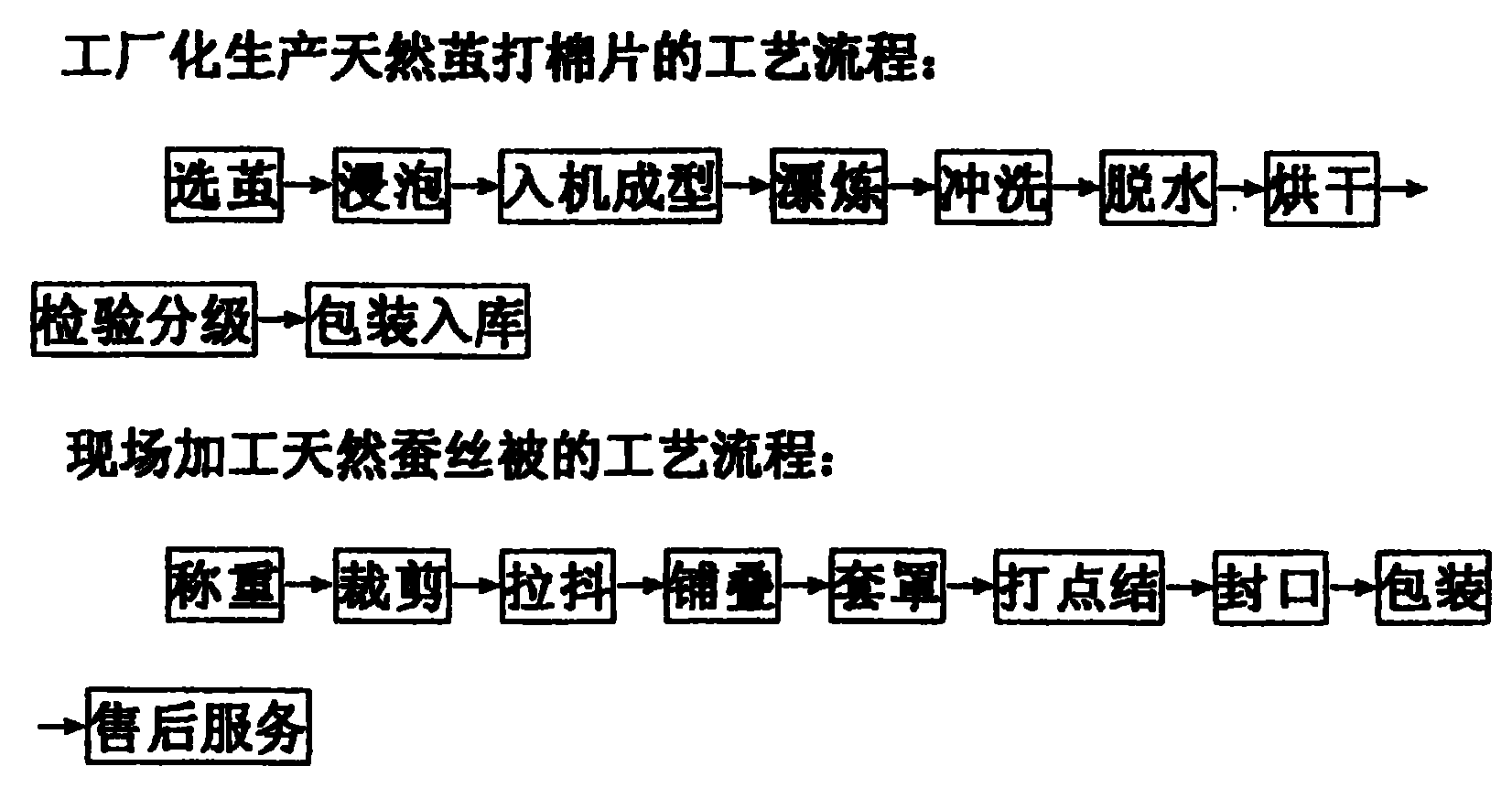

Industrial production of natural cocoon sheet and method of in situ processing natural cocoon silk quilt

A technology for industrially preparing the natural cocoon wool sheet includes choosing cocoon, immersing in warm water, adding caustic soda in the water tank of beating machine, heating the water to80 deg.C, cyclically scalding the cocoon by hot water while pulling silks while removing pupa to become cocoon wool sheet, rinsing in clean water at 90 deg.C for 4-5 hr, flushing, dewatering, baking and packing. A method for in-situ processing the natural silk quilt is also disclosed.

Owner:许景峰

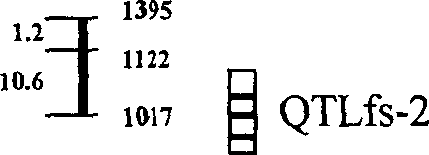

Cotton high-strong fiber gene major gene site and moloecular labelling thereof

InactiveCN1528912AImprove selection efficiencyEasy to industrializeMicrobiological testing/measurementFermentationFiberAgricultural science

The invention discloses major gene resistance locus and the molecular mark of cotton high intensity fiber, which is used auxiliary selection of molecular mark of cotton fiber intensity quickly. The major gene resistance locus QTLfs-2 has three SSR marks H H which connect with it, they are located by mark NAU / SSR / FS1130, NAU / SSR / FS2160, NAU / SSR / FS3160, and it can explain 16.9% phenotype variation in F2:3 of HS427-10xTM-1. Most of high intensity fibers have the same gene QTLfs-2, it has high application value. The expression is stable. It can enhance the fiber quality of cotton in our country and accelerates the industrialization of high intensity cotton seeds.

Owner:NANJING AGRICULTURAL UNIVERSITY

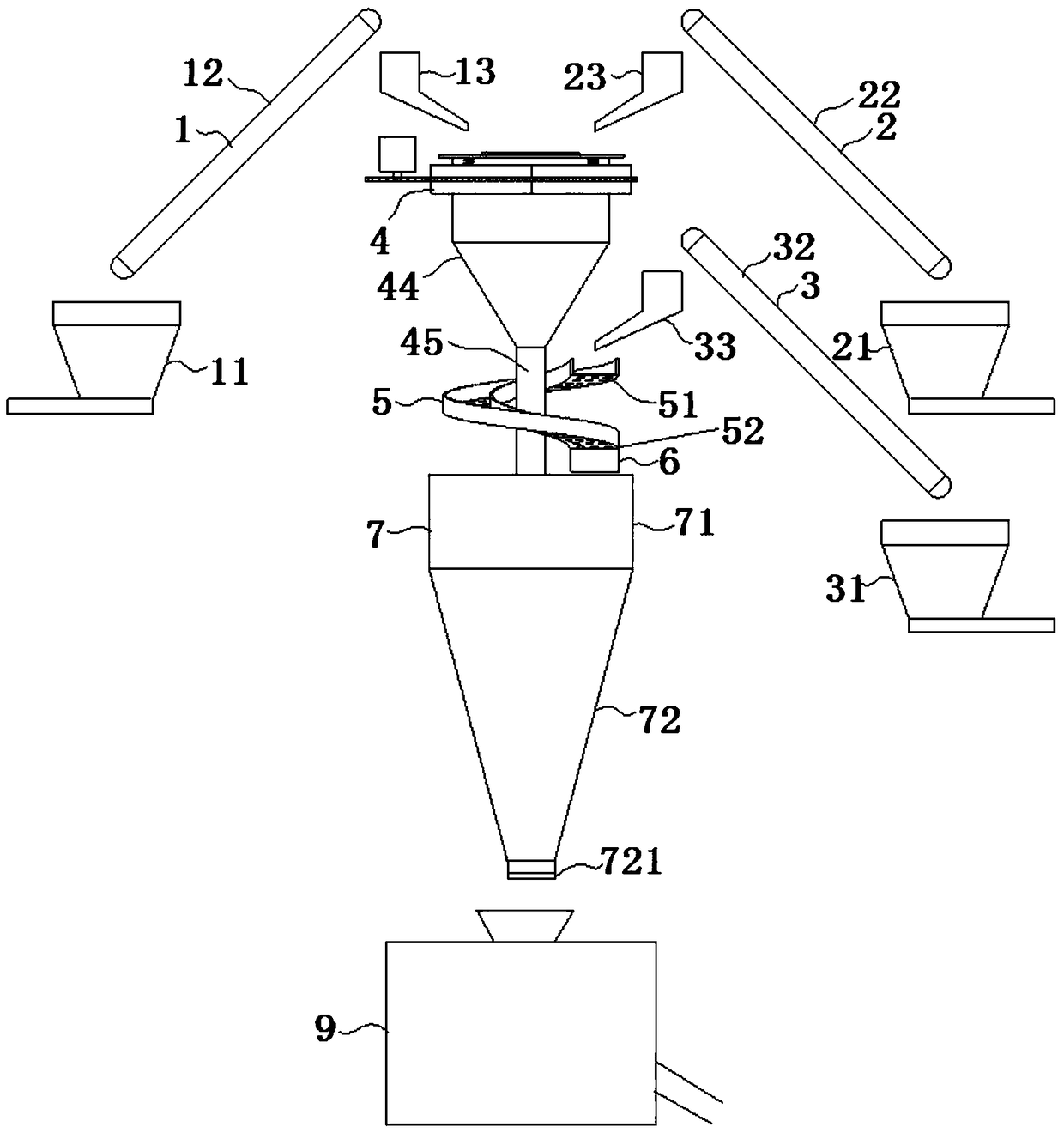

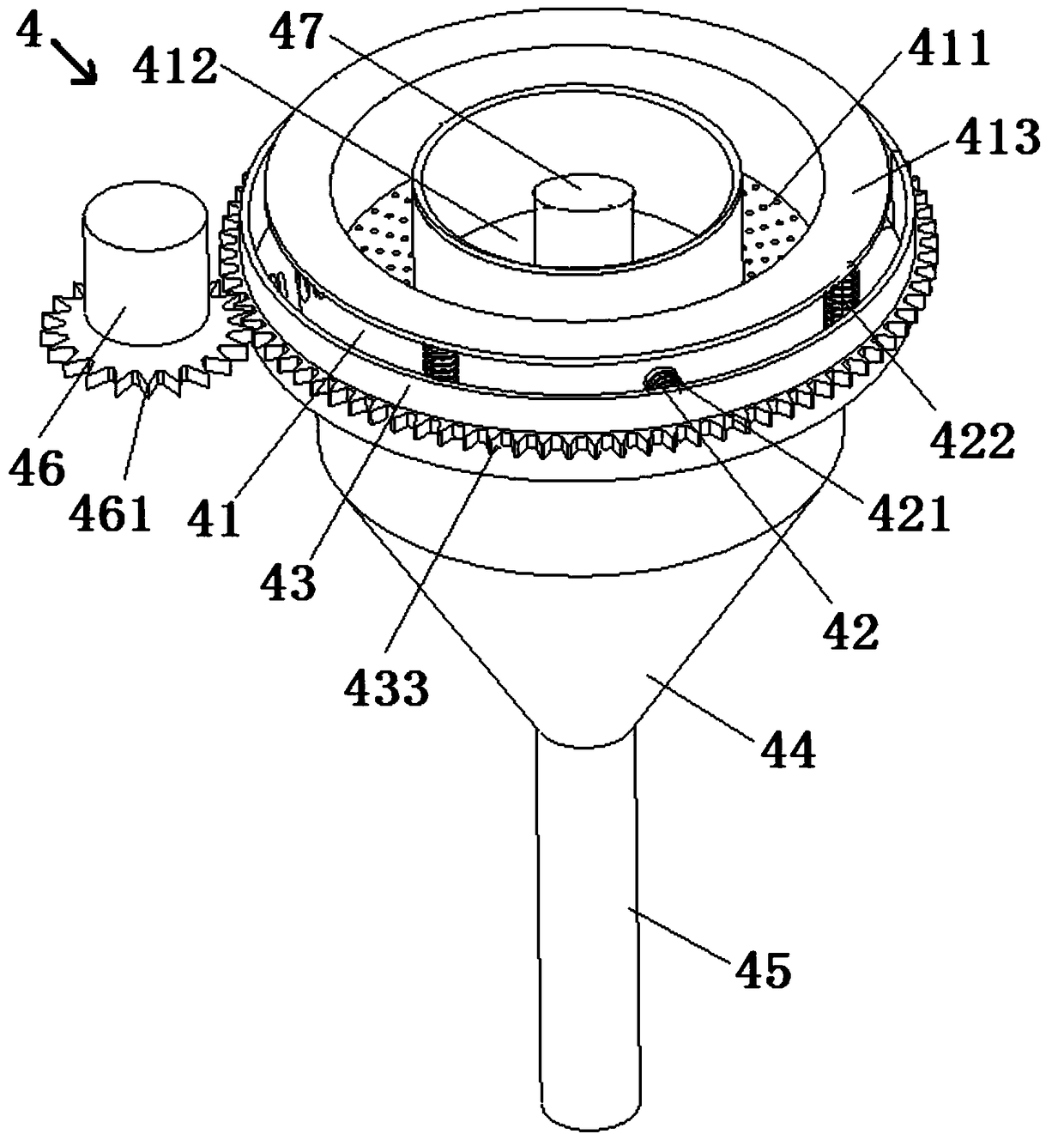

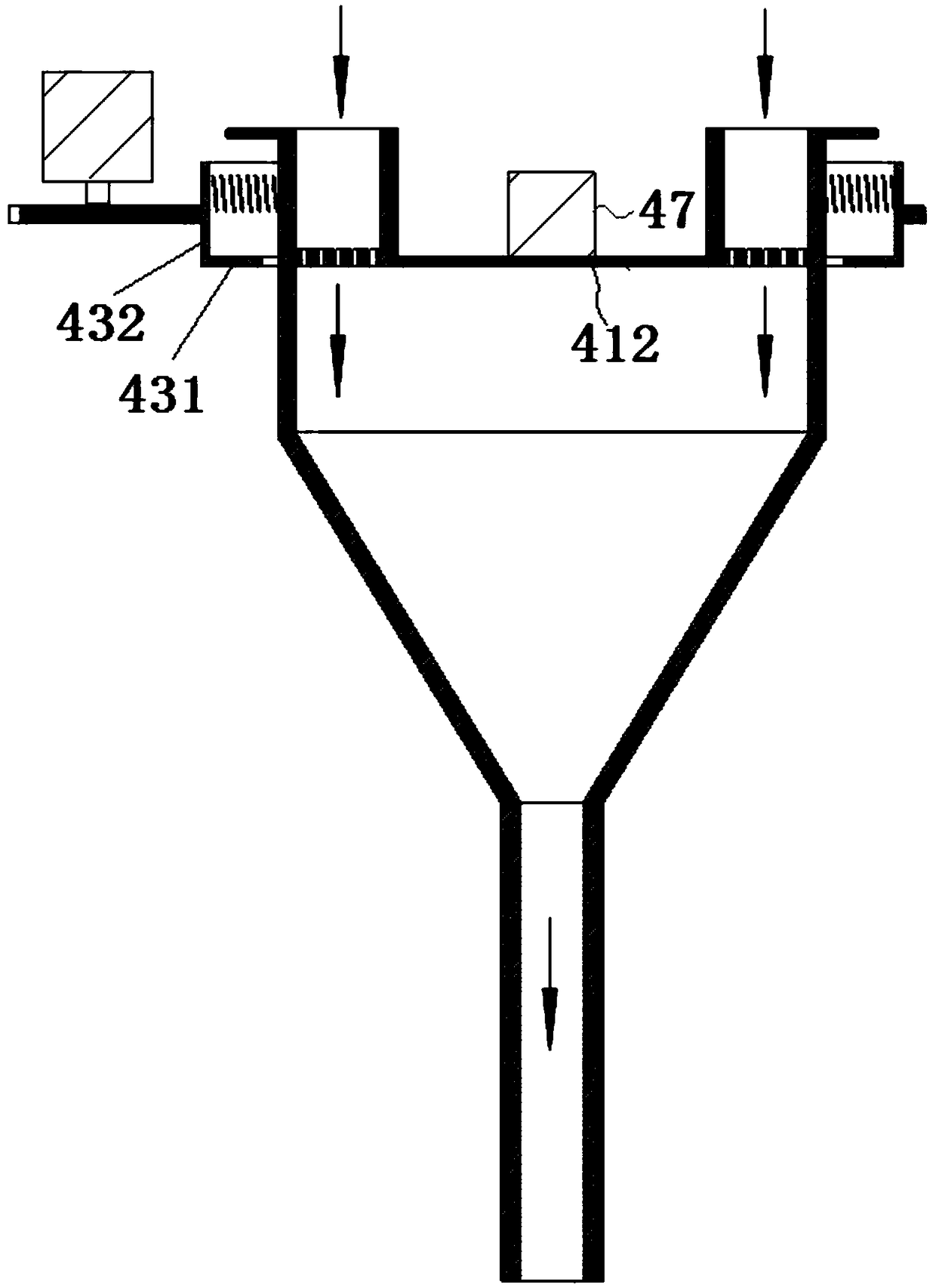

Concrete production system and production method thereof

ActiveCN109366742AImprove the quality levelShorten mixing timeMixing operation control apparatusPretreatment controlMaterials scienceRaw material

The invention discloses a concrete production system and a production method thereof. The concrete production system comprises a sand feeding device, a cement feeding device, a gravel feeding device,a sand-cement mixing device, a gravel screening spiral material guide groove, a sand-cement-gravel mixing device and a concrete mixer; the sand feeding device can supply raw material sand required byconcrete to the sand-cement mixing device, the cement feeding device can supply raw material cement required by the concrete to the sand-cement mixing device, and the sand-cement mixing device can mixthe supplied sand with the supplied cement; and the gravel feeding device can be used for screening raw material gravel required by the concrete through the gravel screening spiral material guide groove and then supplying the gravel to the sand-cement-gravel mixing device, the sand-cement-gravel mixing device can be used for mixing the mixed sand and cement with the gravel, and then the mixture is stirred by the concrete mixer to form the concrete. According to the concrete production system and the production method thereof, the mixing uniformity of all the raw materials required by the concrete is ensured, and the quality grade of the concrete is improved.

Owner:江西信源建材科技集团有限公司

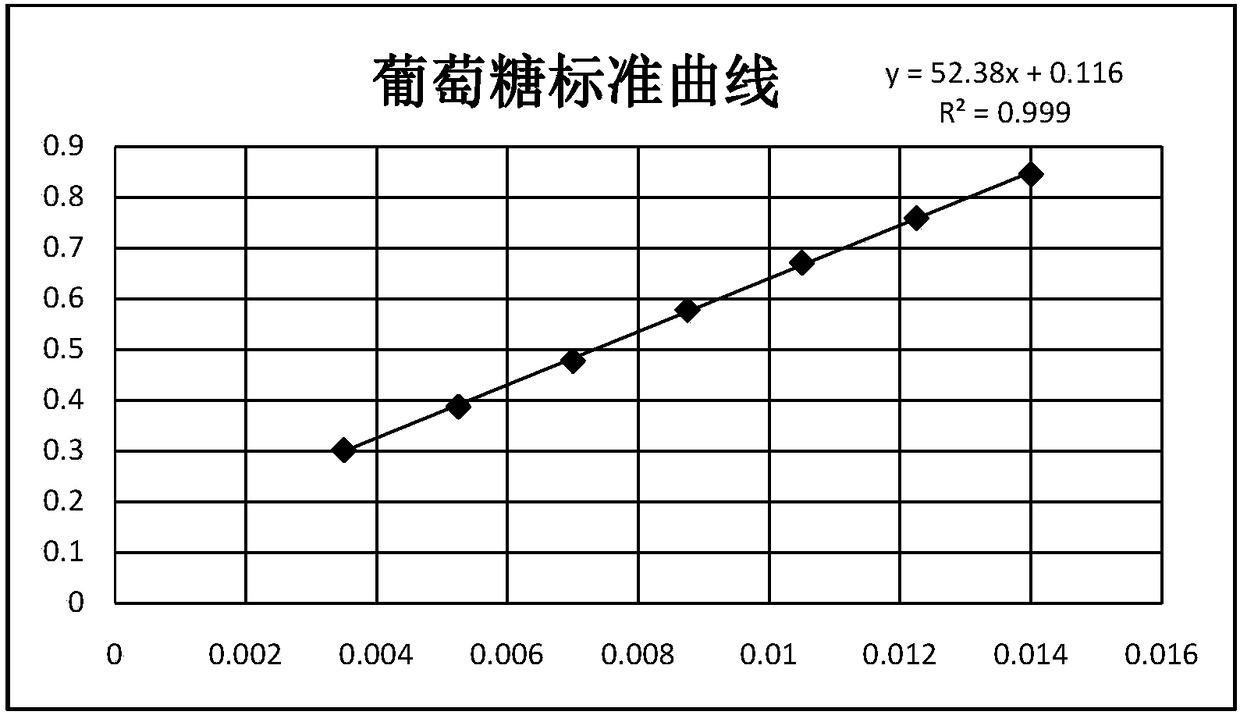

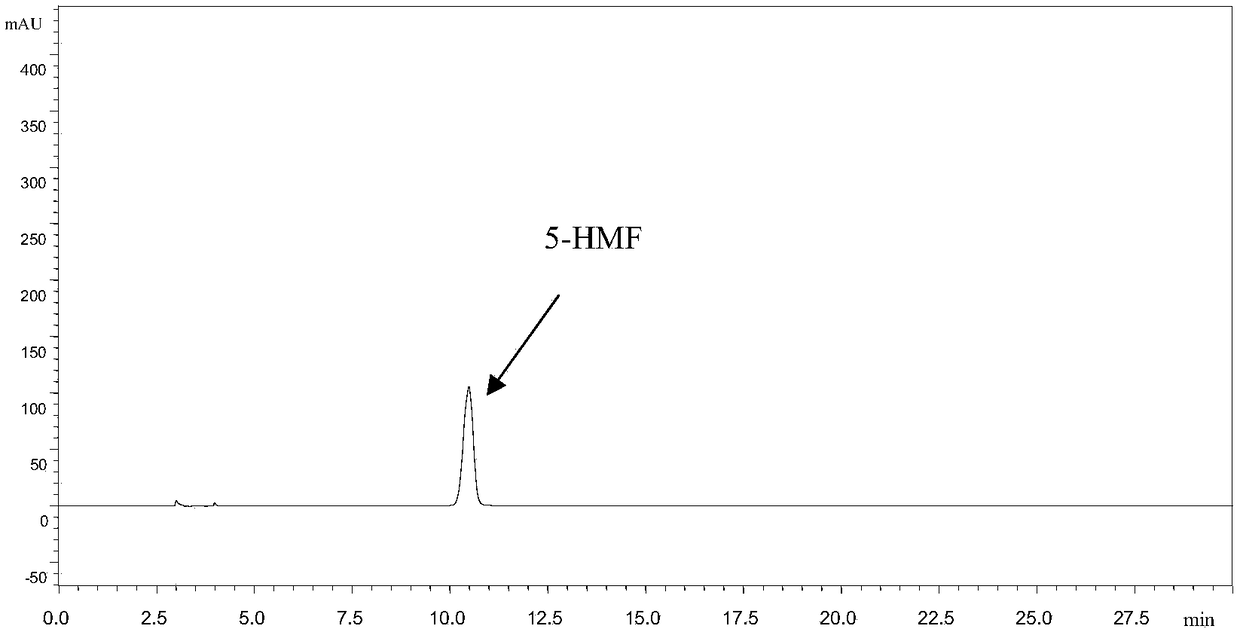

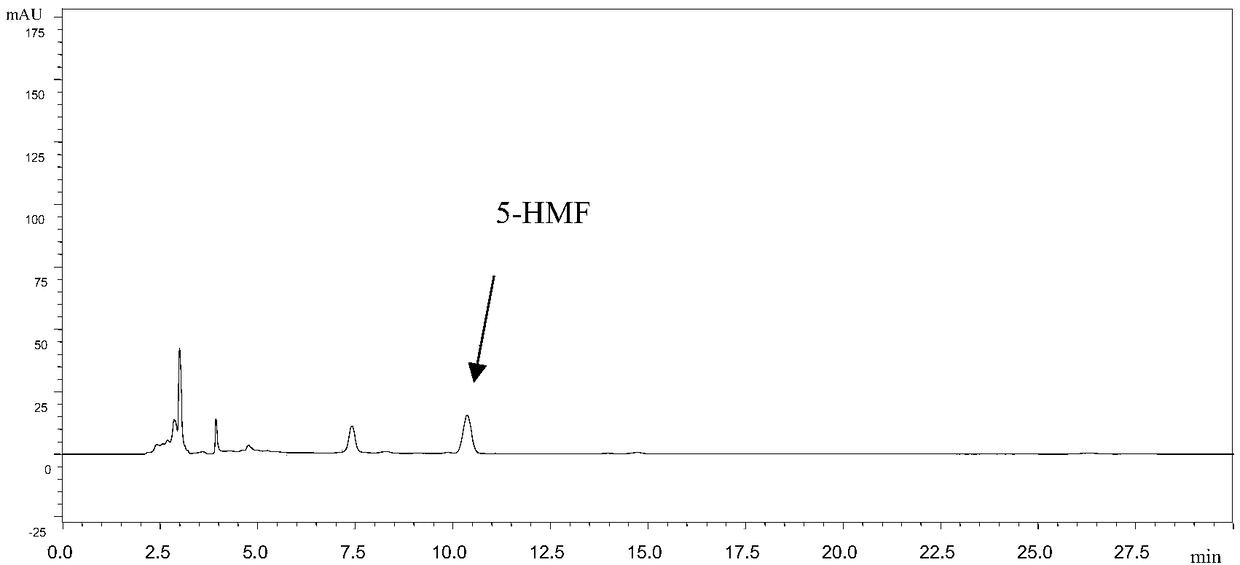

Steamed polygonatum rhizome quality detection and analysis method

PendingCN108362788APromote technological innovationGuarantee the interests of purchasing high-quality steamed Polygonatum productsComponent separationWater solubleMaterials processing

The invention discloses a steamed polygonatum rhizome quality detection and analysis method. The method comprises the following steps: taking fresh steamed polygonatum rhizome, and investigating appearance color, blackening deterioration and rot of materials; and performing further detection on 5-HMF content, diosgenin content, polysaccharide content, water-soluble leaching object content, ash content and moisture content in a qualified steamed polygonatum rhizome sample. The steamed polygonatum rhizome quality detection and analysis method aims at shortage of an uniform standard for evaluating quality of the steamed polygonatum rhizome, by combining with morphology and the quality characteristic of the steamed polygonatum rhizome, a proper detection analysis mode and parameter condition can be screened, the detection analysis result can accurately reflect the quality of the steamed polygonatum rhizome, provides the guidance for traditional Chinese medicinal material processing enterprises, and provides reference for choosing the high-quality steamed polygonatum rhizome for consumers.

Owner:CHENGDU UNIV OF TRADITIONAL CHINESE MEDICINE

Pure cotton bleaching bright adhesive interlining and production method thereof

ActiveCN104544646AImprove the quality levelHigh peel strengthFibre treatmentGarmentsInterliningShrinkage rate

The invention discloses a pure cotton bleaching bright adhesive interlining and a production method of the adhesive interlining. The surface of a coating is bright, the peeling strength of hot melt adhesive points is greater than or equal to 16N, the warp and weft direction water washing dimension variation rate is -1.0 percent to 0.5 percent, and the free and hydrolysis formaldehyde is less than or equal to 40 mg / kg. The pure cotton bleaching bright adhesive interlining and the production method have the advantages that the surface of the adhesive interlining is bright, the quality and the grade of the adhesive interlining are improved, flaws such as leaking points and missed coating can be easily inspected during the appearance inspection, the generation of unqualified products due to leaking points and missed coating is enabled to be avoided during garment press ironing, the peeling strength of the adhesive interlining is high, the warp and weft direction shrinkage rate is low, the free and hydrolysis formaldehyde is low, and the operation of the production method is easy.

Owner:NANTONG HAIHUI SCI & TECH DEV CO LTD +1

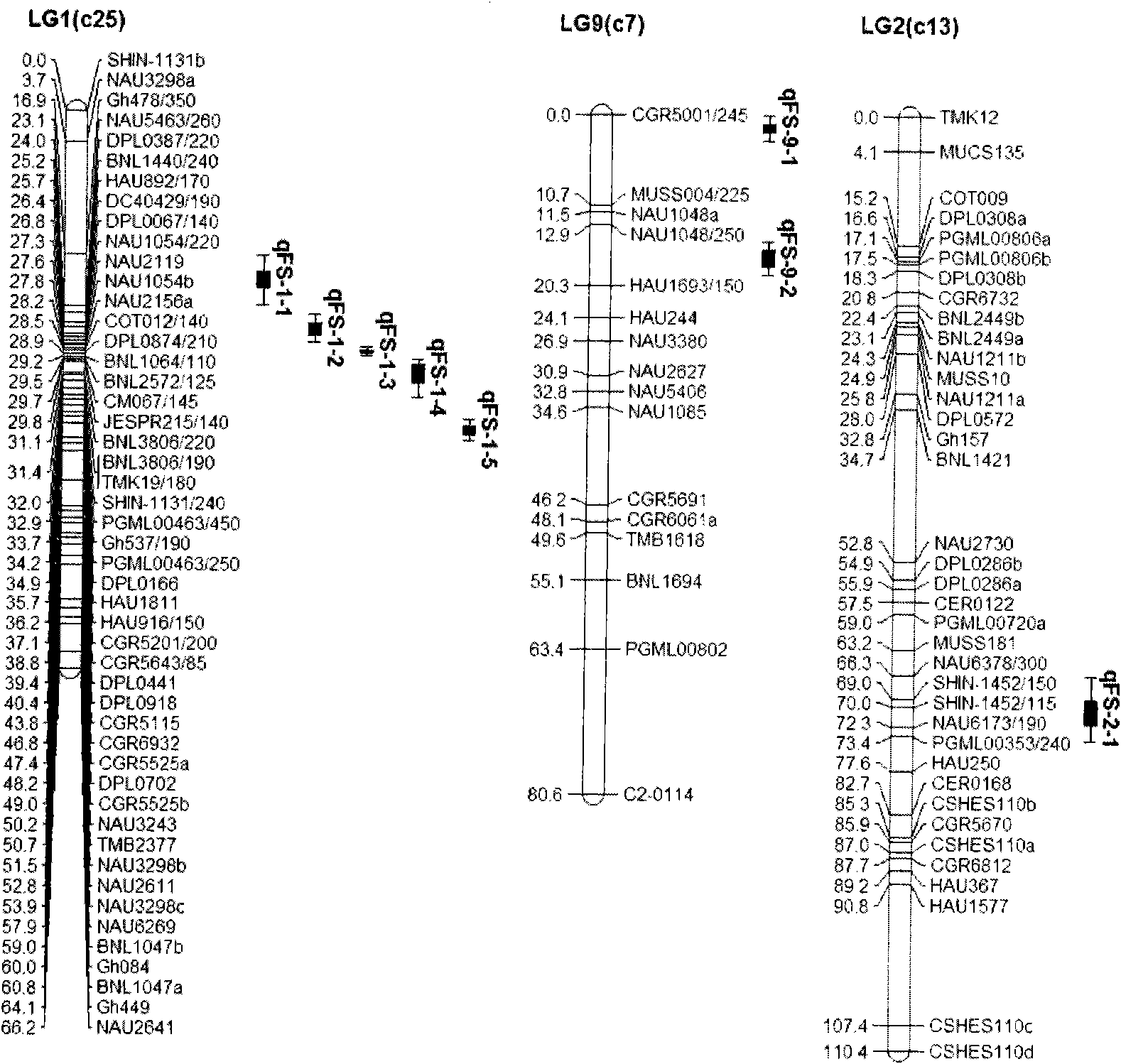

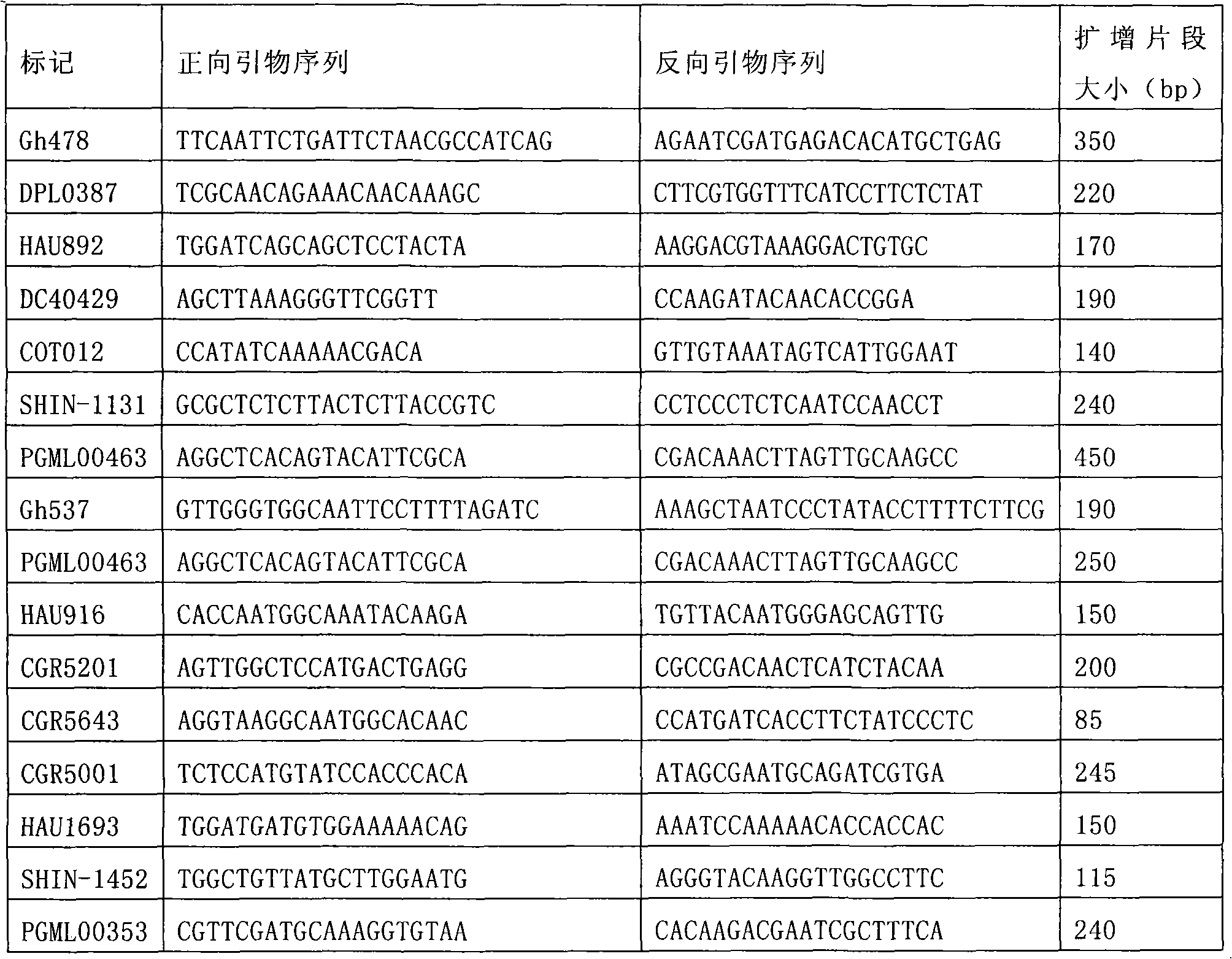

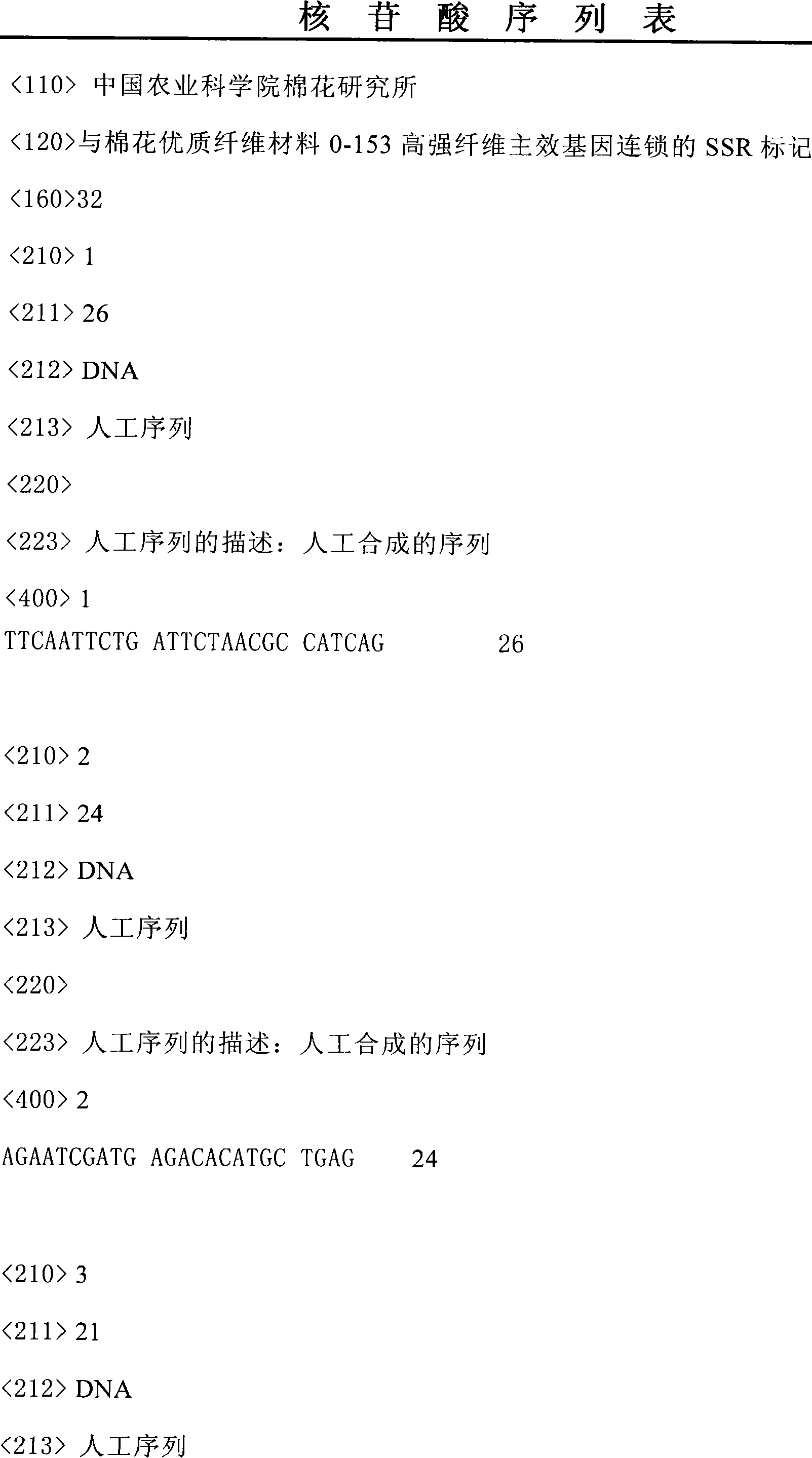

SSR (Single Sequence Repeats) marker interlocked with high-quality cotton fibre material 0-153 high-strength fibre major-effect genes

ActiveCN102220318APositioning results are reliableImprove the quality levelMicrobiological testing/measurementDNA preparationCotton fibreSingle sequence

The invention discloses an SSR (Single Sequence Repeats) marker interlocked with high-quality cotton fibre material 0-153 high-strength fibre major-effect gene points, namely qFS-1-1, qFS-1-2, qFS-1-3, qFS-1-4, qFS-1-5, qFS-9-1, qFS-9-2 and qFS-2-1, wherein qFS-1-1, qFS-1-2, qFS-1-3, qFS-1-4 and qFS-1-5 are positioned on c25 chromosomes, qFS-9-1 and qFS-9-2 are positioned on c7 chromosomes, qFS-2-1 is positioned on a c13 chromosome, the marker interlocked with the qFS-1-1 is Gh478350, the marker interlocked with the qFS-1-2 is DPL0387220, HAU892170 and DC40429190, the marker interlocked withthe qFS-1-3 is COT012140, the marker interlocked with the qFS-1-4 is SHIN-1131240, PGML00463450, Gh537190 and PGML00463250, the marker interlocked with the qFS-1-5 is HAU916150, CGR5201200 and CGR564385, the marker interlocked with the qFS-9-1 is CGR5001245, the marker interlocked with the qFS-9-2 is HAU1693150, and the marker interlocked with the qFS-2-1 is SHIN-1452115 and PGML00353240. By utilizing the SSR markers interlocked with the cotton high-strength fibre major-effect genes to carry out auxiliary selection, the efficiency of the cotton fibre quality breeding can be greatly improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

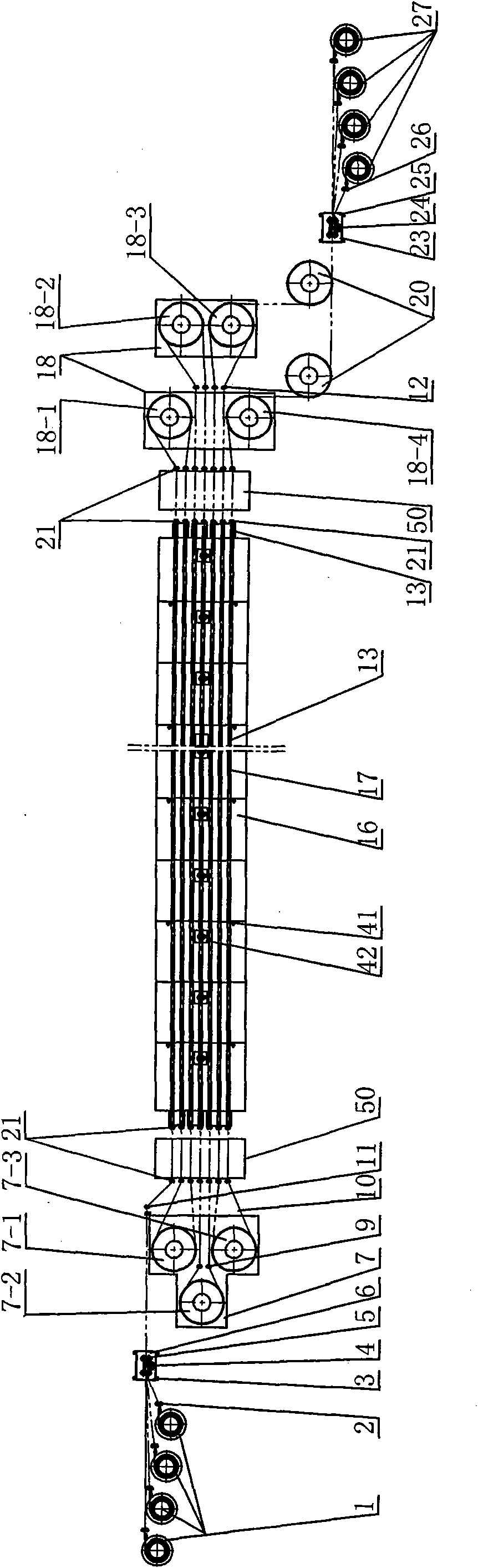

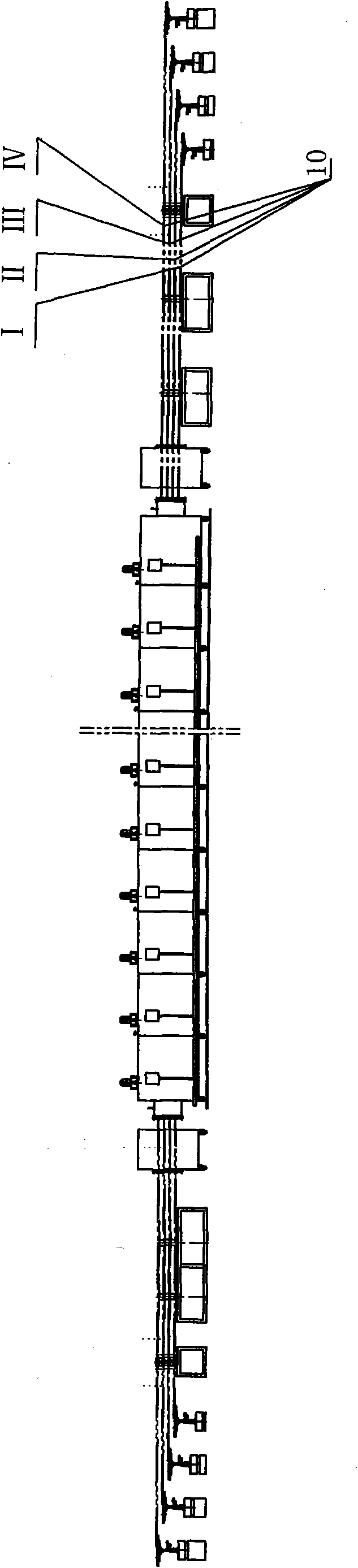

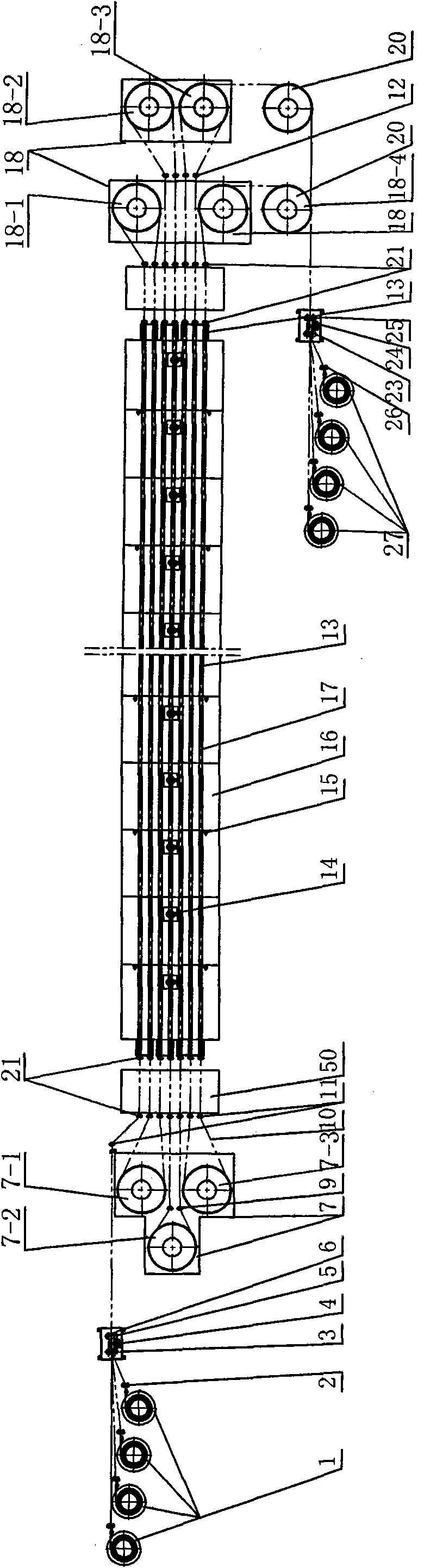

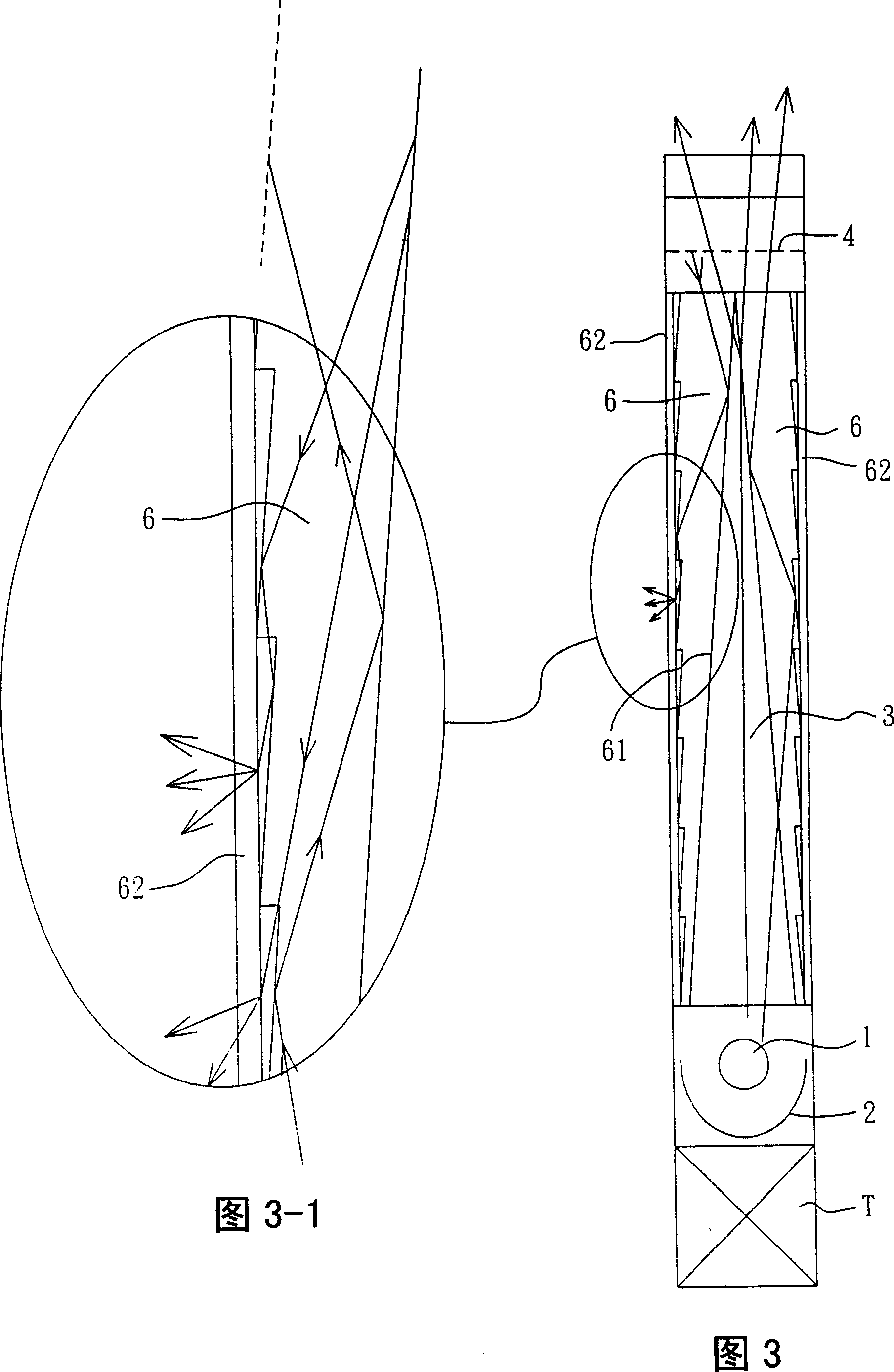

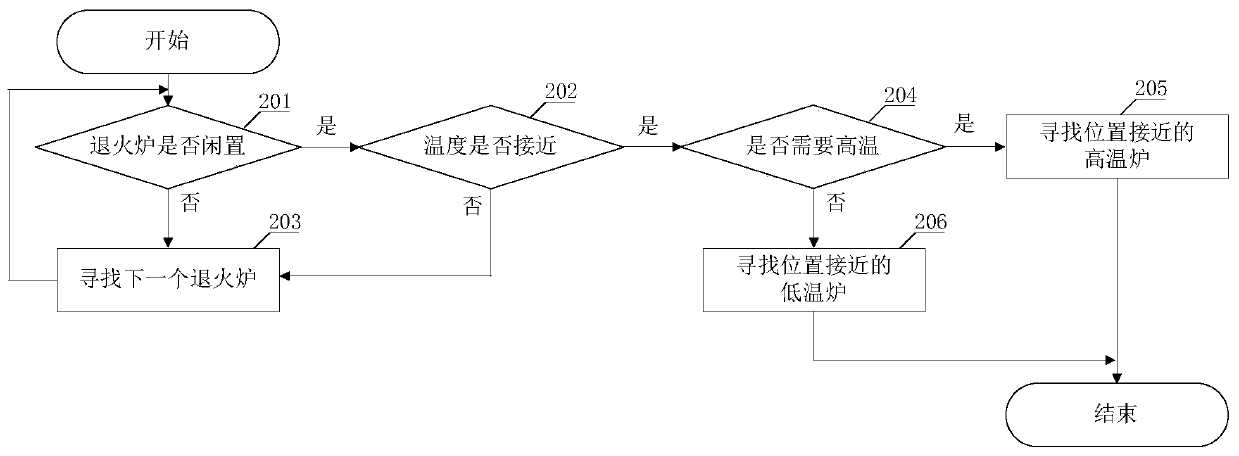

Online full-automatic tempering equipment and technology for same-furnace multi-strip bimetal strip saw

ActiveCN102002574ASolve the accuracy problemIncrease heating speedFurnace typesHeat treatment furnacesProduction lineHigh energy

The invention discloses online full-automatic tempering equipment and technology for a same-furnace multi-strip bimetal strip saw, and relates to tempering equipment and tempering technology. The invention solves the problems that the conventional tempering equipment and technology for the bimetal strip saw cannot finish the tempering technology on one production line at one time, the tempering technology has low production efficiency and high energy consumption and the like. The tempering equipment comprises a front rotating device, a box-type tempering furnace and a rear rotating device. The production efficiency of the saw is improved by 5 to 8 times, the energy consumption is greatly reduced, a great amount of energy is saved, the energy consumption of the box-type tempering furnace is reduced by over 60 percent compared with that of a bell-type tempering furnace or a well-type tempering furnace due to calculation, the occupancy area is reduced by over 90 percent, the problems that the bell-type tempering furnace or the well-type tempering furnace has non-uniform inner and outer temperature field and upper and lower temperature field, the bending stress of the saw is non-uniform, and the saw is easily upwarped are solved, repeated rewinding processes needed by the box-type tempering furnace or the well-type tempering furnace are canceled, and the problem of difficulty in controlling the saw tempering technology and quality and the problem of difficulty in maintaining the equipment are solved.

Owner:曹玉贵

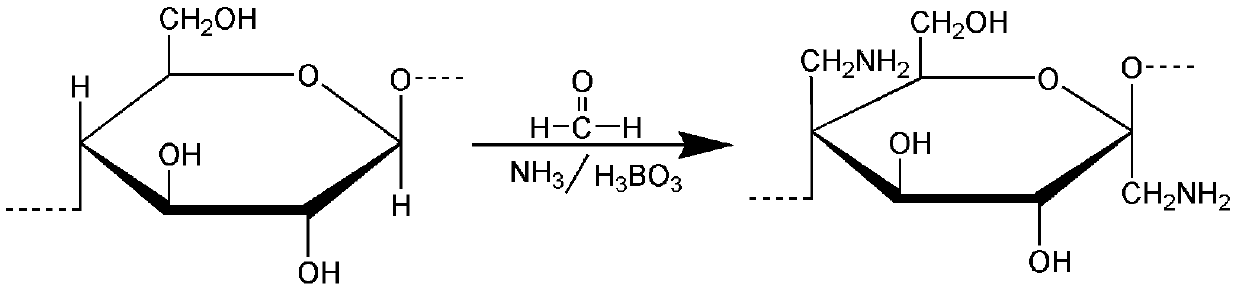

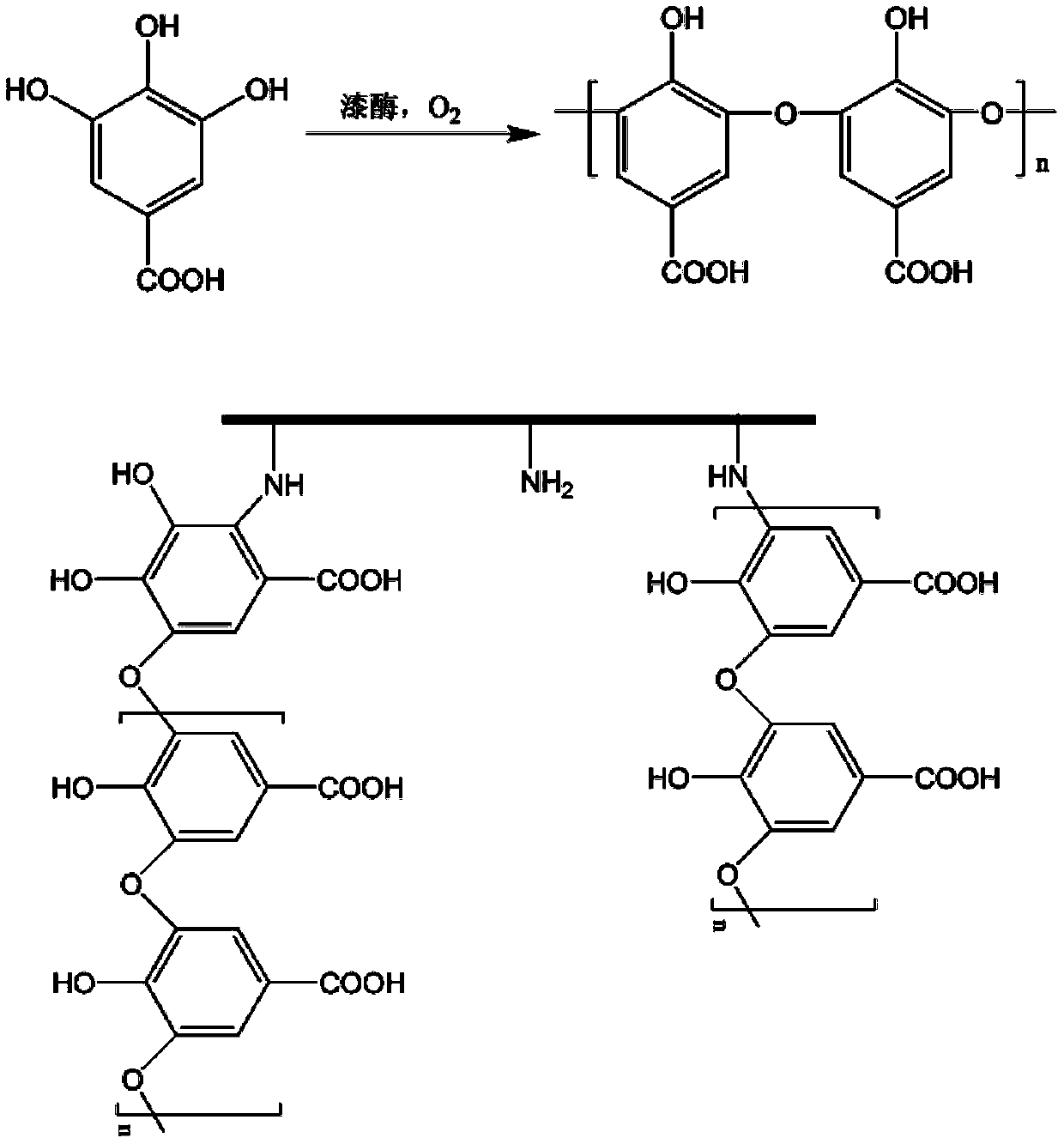

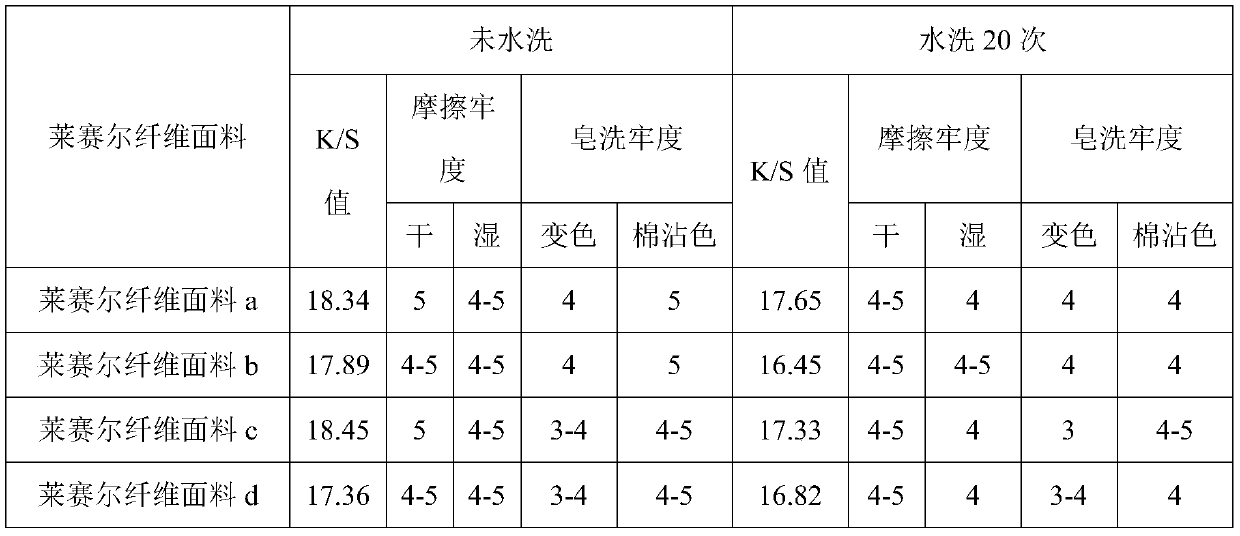

Enzyme staining Lyocell fiber fabric and preparation method thereof

The invention relates to an enzyme staining Lyocell fiber fabric and a preparation method thereof. A Lyocell fiber fabric is ammonified and modified, the ammonified and modified Lyocell fiber fabric is cultured in laccase and organic monomer environments, and organic monomers are polymerized and grafted to the Lyocell fiber fabric under the action of laccase to prepare the enzyme staining Lyocellfiber fabric. The rubbing fastness and the soaping fastness of the enzyme staining Lyocell fiber fabric are at optimal level and cannot be obviously reduced after the enzyme staining Lyocell fiber fabric is washed for 20 times. Successful application of enzyme staining provides a selectable scheme for substituting synthetic dyes for staining, and the staining method is almost free from wastewaterdischarge and of great significance for environmental protection and sustainable development of resources.

Owner:WUHAN TEXTILE UNIV

Method for cleaning circulation tailings generated in polycrystalline-silicon ingot-casting half-melting technology

InactiveCN106115715AReduce manufacturing costIncreased furnace capacitySilicon compoundsQuality levelImpurity

The invention discloses a method for cleaning circulation tailings generated in the polycrystalline-silicon ingot-casting half-melting technology, and relates to the solar silicon material cleaning technology. The method includes the following steps that a, impurities with which the surfaces of the tailings are covered are cleanly removed with compressed air; b, soaking is carried out with cleaning liquid, wherein hydrofluoric acid, hydrogen peroxide and pure water are prepared into the cleaning liquid; c, after impurities in tailing gaps are cleaned and removed, the surface covered substances are washed down with pure water; d, cleaning is carried out with acid mixed liquid, wherein nitric acid and electronic-grade hydrofluoric acid are prepared into the acid mixed liquid, acid cleaning is carried out, and then rinsing is carried out with pure water; e, ultrasonic cleaning is carried out, wherein dirt in the surfaces, dirt in silicon material gaps and acid liquid residues are cleaned and removed, and clean tailings are obtained. The method has the advantages that according to preparing of different kinds of acid liquid and multiple-time cleaning, waste cutting liquid and impurities generated in the on-line cutting process in the circulation tailing gaps in the ingot-casting half-melting technology are thoroughly removed, the quality level of the half-melting tailings is improved, the ingot-casting production cost is reduced, the furnace putting quantities of the circulation materials are increased accordingly, and the aims of reducing the cost and improving the efficiency are achieved.

Owner:HENAN SHENGDA PHOTOVOLTAIC TECH CO LTD

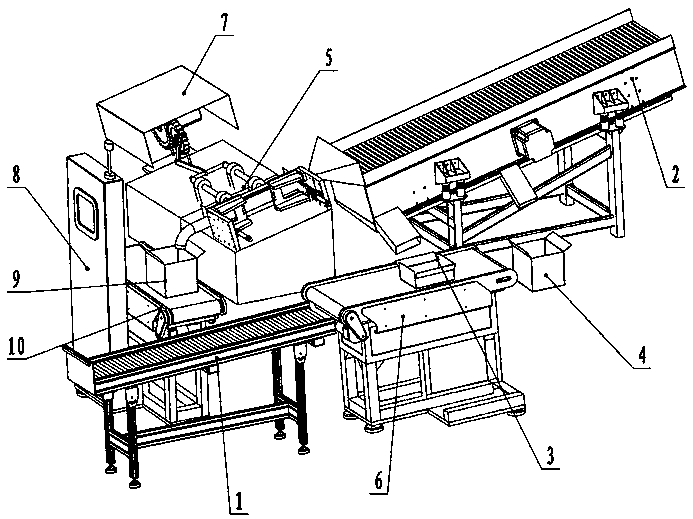

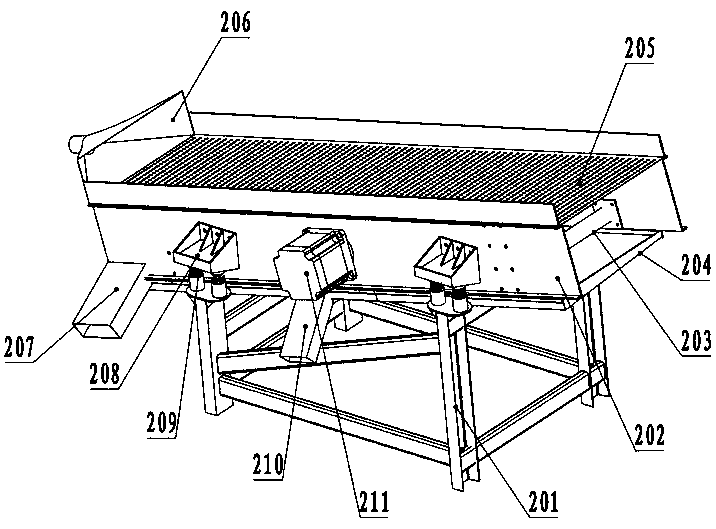

Agricultural product screening and weighing system

PendingCN111136005AImprove sorting efficiencyUniform particlesSievingScreeningAgricultural engineeringStructural engineering

The invention discloses an agricultural product screening and weighing system which comprises a sorting device, an opening device, weighing-conveying belts, a packaging box conveying roller bed, a protective cover and a console, wherein the sorting device mainly comprises a screening body; the screening body is composed of lateral plates, a bottom tray and a screening plate which are supported bya bracket; through the vibrating action of vibrating motors fixed on two sides of the screening body, hazelnuts are subjected to three-stage impurity removal and classification by utilizing the natural slope of the screening plate and by adopting the vibrating screening principle; defective hazelnuts obtained from the classification and screening process are boxed and collected through a first discharging port; second-stage non-defective products are loaded into packaging boxes through a second-stage discharging port; through a lateral non-defective product weighing-conveying belt, the second-stage non-defective products are conveyed to a discharging roller bed for quantitative packaging after being weighed; finally-sorted high-quality hazelnuts reach the opening mechanism through an end-part discharging hopper and are opened under the squeezing action of a motor connecting rod; finally, the high-quality hazelnuts are loaded into the packaging boxes; and through a lateral high-qualityproduct weighing-conveying belt, the high-quality hazelnuts are conveyed to the discharging roller bed for quantitative packaging after being weighed. The integrated flow operation of impurity removal, screening, opening, weighing and packaging is achieved.

Owner:董昊

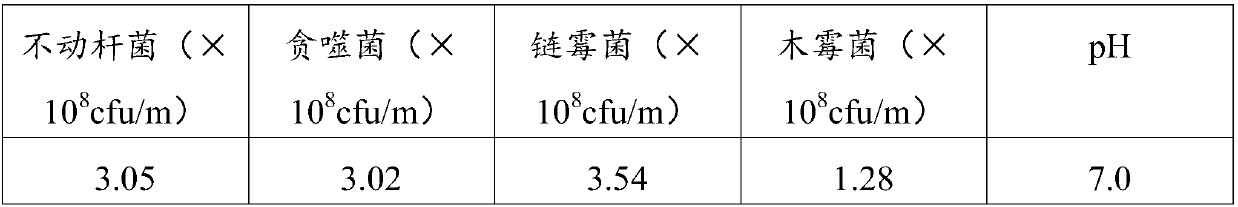

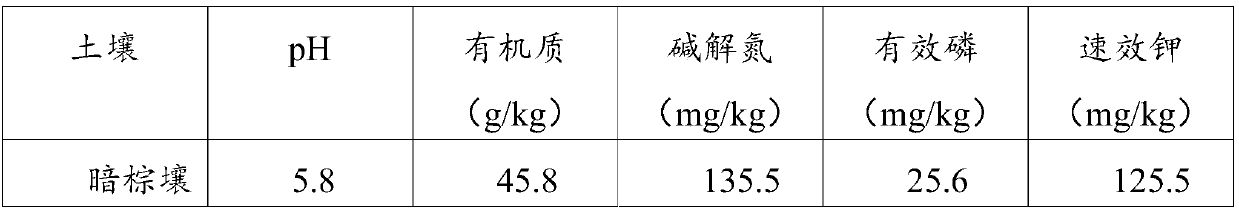

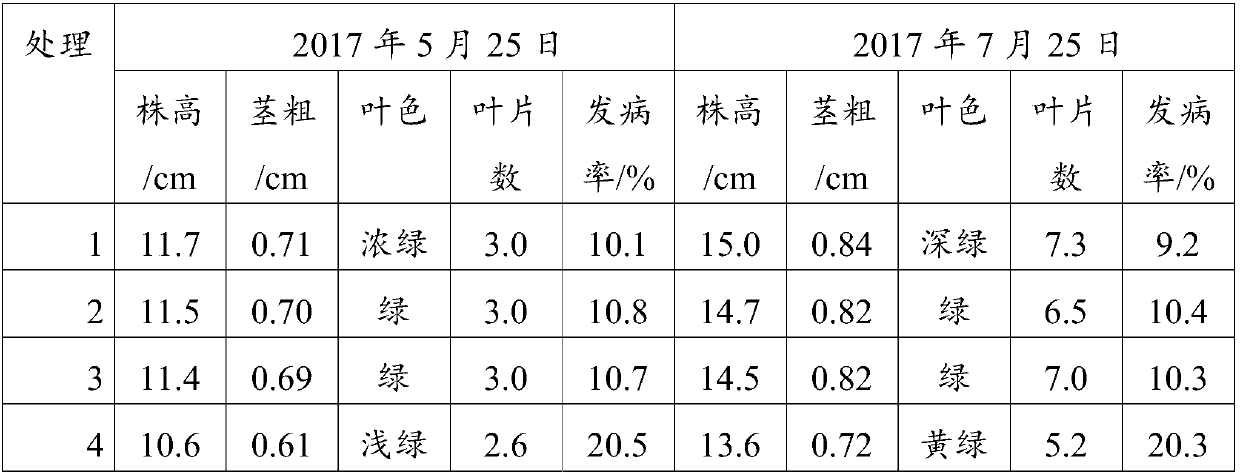

Compound microbial fertilizer for preventing continuous cropping of ginseng and preparation method thereof

InactiveCN107759362APromote growth and developmentImprove stress resistanceMagnesium fertilisersAlkali orthophosphate fertiliserContinuous croppingTrichoderma sp.

The invention discloses a compound microbial fertilizer for preventing continuous cropping of ginseng. The fertilizer comprises an organic fertilizer, an inorganic fertilizer and compound functional bacteria, wherein the organic fertilizer comprises Chinese medicine residues, humic acid, diatomite, pelelith, bentonite, zeolite, charcoal, grain byproducts, sugar, enzyme microorganisms and water; the grain byproducts are bran or rice bran; the inorganic fertilizer comprises potassium nitrate, urea, potassium dihydrogen phosphate, potassium sulfate and potassium fulvic acid; the compound functional bacteria comprise acinetobacter, variovorax, streptomycetes and trichoderma sp. The compound microbial fertilizer is an organic, inorganic and biological ternary compound fertilizer. The fertilizeralso contains biological stimulin such as humic acid and fulvic acid and trace elements in natural mineral sources. The fertilizer for ginseng production has the effects of promoting growth and development, improving output and reducing diseases, can prevent influence of auto-toxic matters caused by allelochemicals secreted by ginseng root systems, and prevents continuous cropping of ginseng favorably.

Owner:SHENGTAI BIOENG CO LTD OF JILIN WANTONG PHARMACY GRP CO

Method for cleaning debris in monocrystal silicon wire-cut electrical discharge machining

ActiveCN105887206AReduce dosageReduce manufacturing costPolycrystalline material growthAfter-treatment detailsHydrofluoric acidIngot casting

A method for cleaning debris in monocrystal silicon wire-cut electrical discharge machining relates to solar silicon washing techniques and comprises the following sequential steps: a, charging debris into a cleaning basket of pp, and soaking in HF (hydrofluoric acid); b, adding KOH into a cleaning tank, placing the basket holding the debris from monocrystal silicon wire-cut electrical discharge machining into an alkaline solution, stirring and cleaning with a polytetrafluoroethylene rod, and rinsing with purified water; c, preparing mixed liquid with HCL, HF and purified water, placing the basket holding the debris from monocrystal silicon wire-cut electrical discharge machining into the mixed liquid, stirring, cleaning and rinsing; d, adding purified water, heating to 40-50 DEG C, ultrasonically cleaning, transferring to a cleaning liquid, drying to obtain circulation tailing meeting the standard for ingot casting. The method has the advantages that for the debris from monocrystal silicon wire-cut electrical discharge machining, cutting waste liquid residue and metal impurity produced during cutting procedure are thoroughly removed by blending different chemical reagents via multiple cleaning, quality level of monocrystal debris is increased, ingot production cost is reduced, and feedable quantity of fragmented silicon is increased so that cost reduction and efficiency increasing are achieved.

Owner:HENAN SHENGDA PHOTOVOLTAIC TECH CO LTD

Saline-alkali soil repairing novel fertilizer produced by taking high-silicon iron tailings as raw materials

InactiveCN105819963AImprove fertilityIncrease the granular structureCalcareous fertilisersSuperphosphatesAlkali soilOyster

The invention discloses a saline-alkali soil repairing novel fertilizer produced by taking high-silicon iron tailings as raw materials.The fertilizer is prepared by stirring and mixing, by weight, 60-70 parts of the high-silicon iron tailings, 2-8 parts of calcium sulfate, 1-6 parts of zinc sulfate, 1-6 parts of plant ash, 5-12 parts of ammonuim humate, 3-8 parts of potassium humate, 1-6 parts of calcium superphosphate, 5-12 parts of bran, 1-6 parts of ammonium molybdate, 3-8 parts of ferric citrate, 3-8 parts of magnesium sulfate heptahydrate, 2-7 parts of monopotassium phosphate, 1-6 parts of potassium chloride, 14-20 parts of fermented chicken manure, 12-18 parts of fermented sheep manure and 10-15 parts of oyster shell powder.According to the saline-alkali soil repairing novel fertilizer produced by taking the high-silicon iron tailings as the raw materials, the soil fertility can be improved, and the ventilation, water seepage, fertilizer conservation and water conservation capacities of saline-alkali soil can be enhanced.

Owner:BEIJING QING MAI HUA QING HLDG GRP CO LTD

Production method for carrying out garment dyeing by utilizing fruit natural dyestuff

PendingCN108774902AReduce color flowerRaise the level of qualityDyeing processEngineeringNatural dye

The invention discloses a production method for carrying out garment dyeing by utilizing a fruit natural dyestuff. According to the production method, fruits with high pigment content are selected asraw materials of natural dyeing, and any chemical auxiliary agent and any dyestuff are not added; after the garment dyeing is selected, dehydration and drying are carried out; then water washing is carried out; then secondary drying is carried out; then the garment dyeing is carried out through selecting a dyeing vat with a dyeing channel having a relatively great pipe opening diameter. The methoddisclosed by the invention has the beneficial effects that a production process has the advantages of low carbon and environment protection; a novel fruit natural dyeing technology is used for replacing a traditional chemical dyeing technology; fruit dyed garments produced by the method disclosed by the invention have good quality, are green and healthy and have a good market prospect.

Owner:何炽斌

Industrial production of natural cocoon sheet and method of in situ processing natural cocoon silk quilt

InactiveCN1313665CIncrease productivityReduce labor intensityNon-woven fabricsCooking & bakingWarm water

A technology for industrially preparing the natural cocoon wool sheet includes choosing cocoon, immersing in warm water, adding caustic soda in the water tank of beating machine, heating the water to 80 deg.C, cyclically scalding the cocoon by hot water while pulling silks while removing pupa to become cocoon wool sheet, rinsing in clean water at 90 deg.C for 4-5 hr, flushing, dewatering, baking and packing. A method for in-situ processing the natural silk quilt is also disclosed.

Owner:许景峰

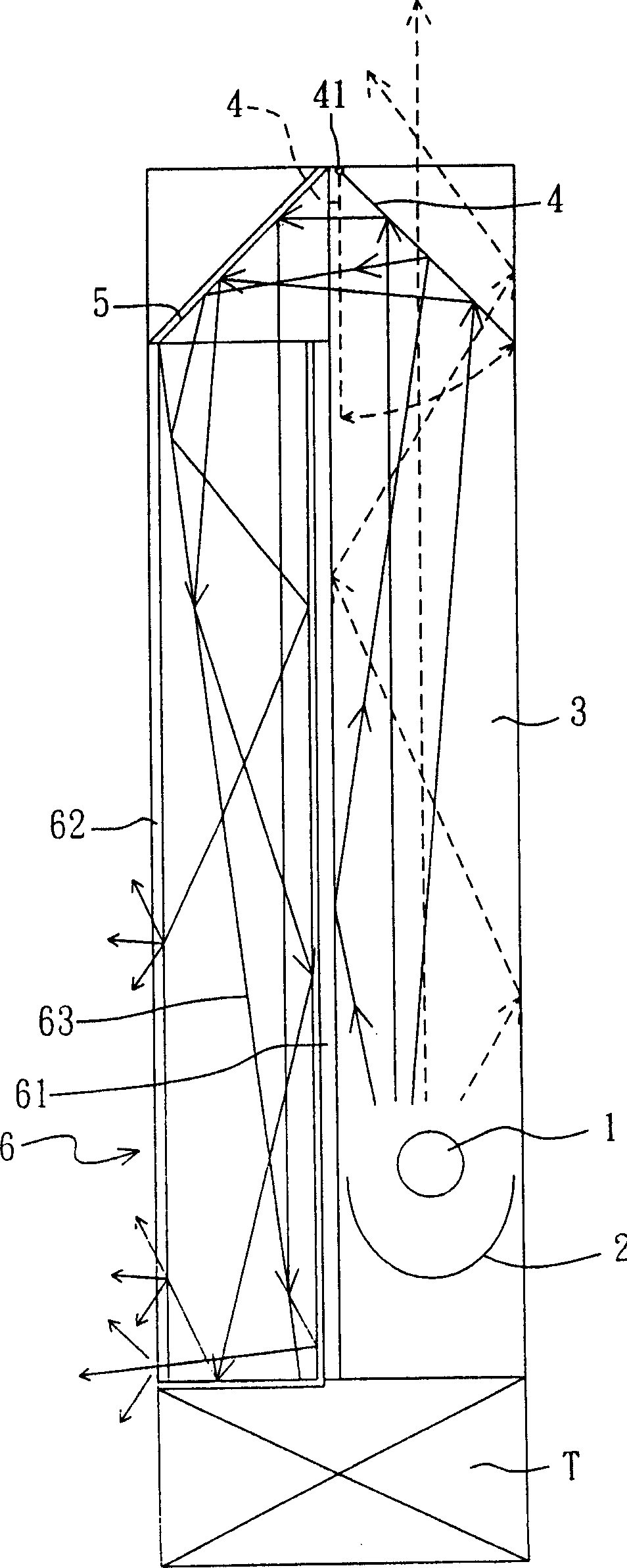

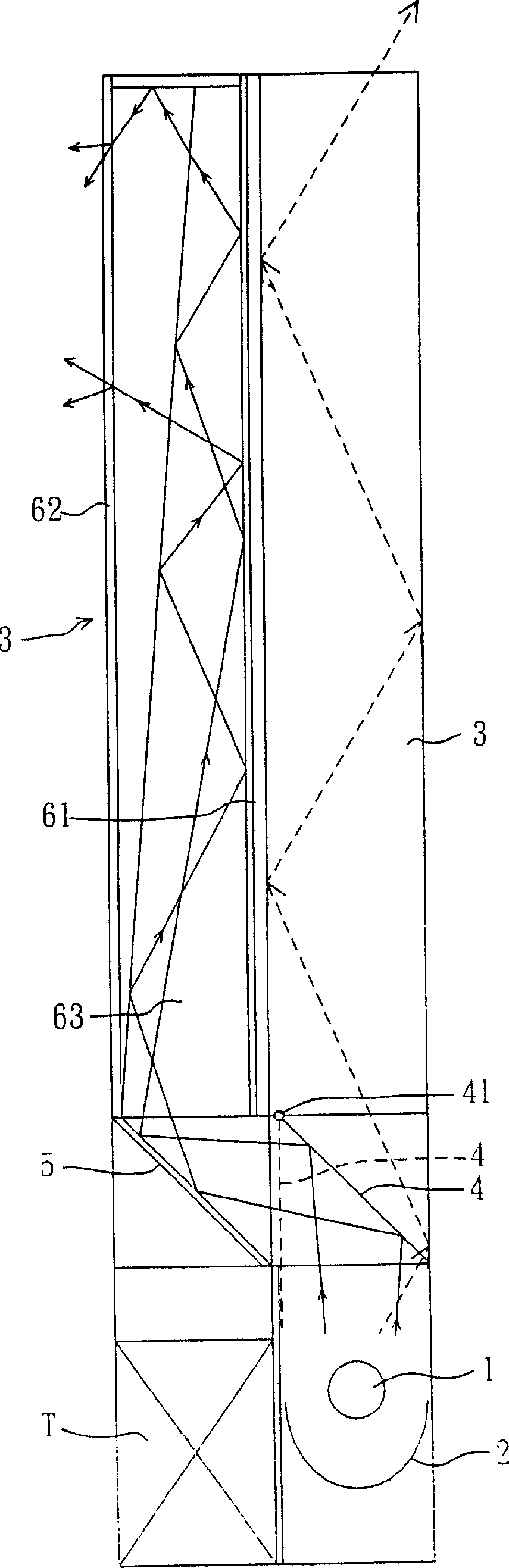

Multifunctional lamp

InactiveCN1840957AImprove the quality levelMeet different lighting needsMechanical apparatusFibre light guidesOptoelectronicsLight source

The invention discloses a multiple-functional lamp, which comprises the following parts: light source, first reflector, second reflector, first light conductive part and second light conductive, wherein the first reflector can receive the projected light of light source; the second reflector can receive the light of first reflector, which reflects again; the first light conductive part is set between light source and first reflector or one end of first reflector opposite to the light source; the second light conductive part can guide the reflected light of the second reflector out.

Owner:徐佳义

Binder and coating paint for coating base paper in inkjet paper production

InactiveCN1938160AIncrease color depthReduce color depthCoatings with pigmentsDuplicating/marking methodsLacquerPaper production

The aim of said invention is to obtain a binder for a coating paint used for producing a low-cost and good quality inkjet paper providing with the inkjet colours of relatively high colour densities, thereby substituting in many cases highvalued and expensive qualities of inkjet-photopaper. For this purpose, said invention is characterised in that the inventive binder comprises gelatine in the form of the first component thereof, fractions of at least one type of another binder component selected from vinylalcohol polymers and copolymers, carbohydrates and the derivatives thereof, wherein the gelatine solid content in the binder is greater than the sum of solid content of the other binder component(s).

Owner:GELITA AG

Adhesive

InactiveCN1727427AImprove adhesionImprove flatnessEster polymer adhesivesAdhesiveButyl cyanoacrylate

An adhesive for the wound of the pearl-culturing clam is proportionally prepared from alpha-butyl cyanoacrylate, alpha-isobutyl cyanoacrylate, hydroxymethyl cellulose, phenyldiphenol, and toluenesulfonic acid. Its advantages are short setting time, high water-proofing nature, and low dead rate of clam.

Owner:商菁华

Ganoderma lucidum in applcation of producing tobacco products

An application of ganoderma in tobacco products is disclosed, which features high quality of tobacco product and less damage of smoking to human body.

Owner:宋和清

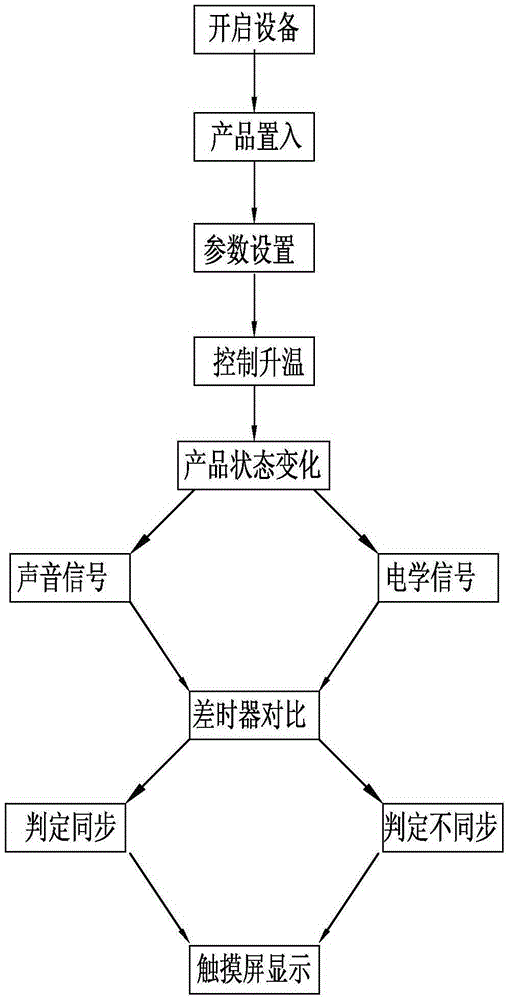

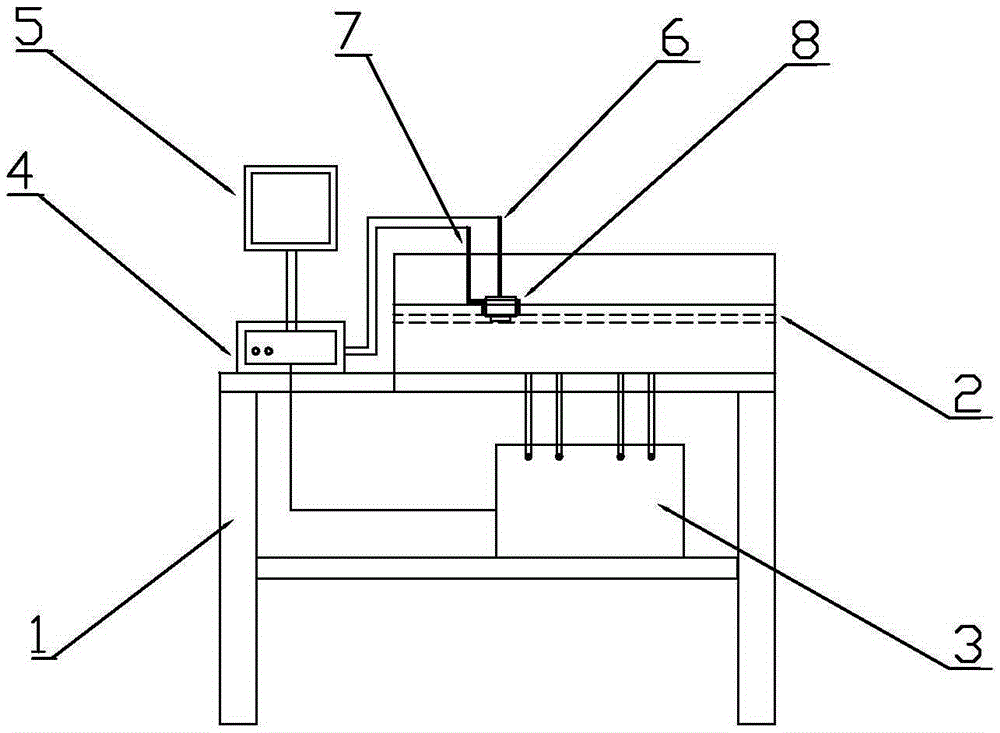

Single-circuit snap action temperature controller synchronization test method

ActiveCN105259893AReduce labor intensityRealize full inspectionElectric testing/monitoringTemperature controlElectricity

The invention discloses a single-circuit snap action temperature controller synchronization test method, which comprises synchronization test equipment and synchronization test procedures. The synchronization test method uses the synchronization test equipment, and carries out a synchronization test on a tested product according to the synchronization test procedures. The synchronization test equipment comprises a test frame, a test box, a temperature control device, PLC processor, a touch display screen, an electric signal line, an acoustic signal line and a tested product. The test method comprises an initial state, a temperature control state, a dynamic state, signal acquisition, time-differential comparison and a test result. According to the invention, the closed test box is designed, time difference analysis is carried out on circuit signals and acoustic signals, the signal reception time difference is quantified by using a time-differential device, and a synchronization characteristic of a temperature controller is accurately judged; the labor intensity is reduced, and the level of the product quality is improved; and indexes required by a customer are ensured to be reached through voluntarily adjusting the judgment time difference standard, and rising in product defective rate caused by overhigh synchronization standards is avoided at the same time.

Owner:LIGHTCOUNTRY CHANGSHU

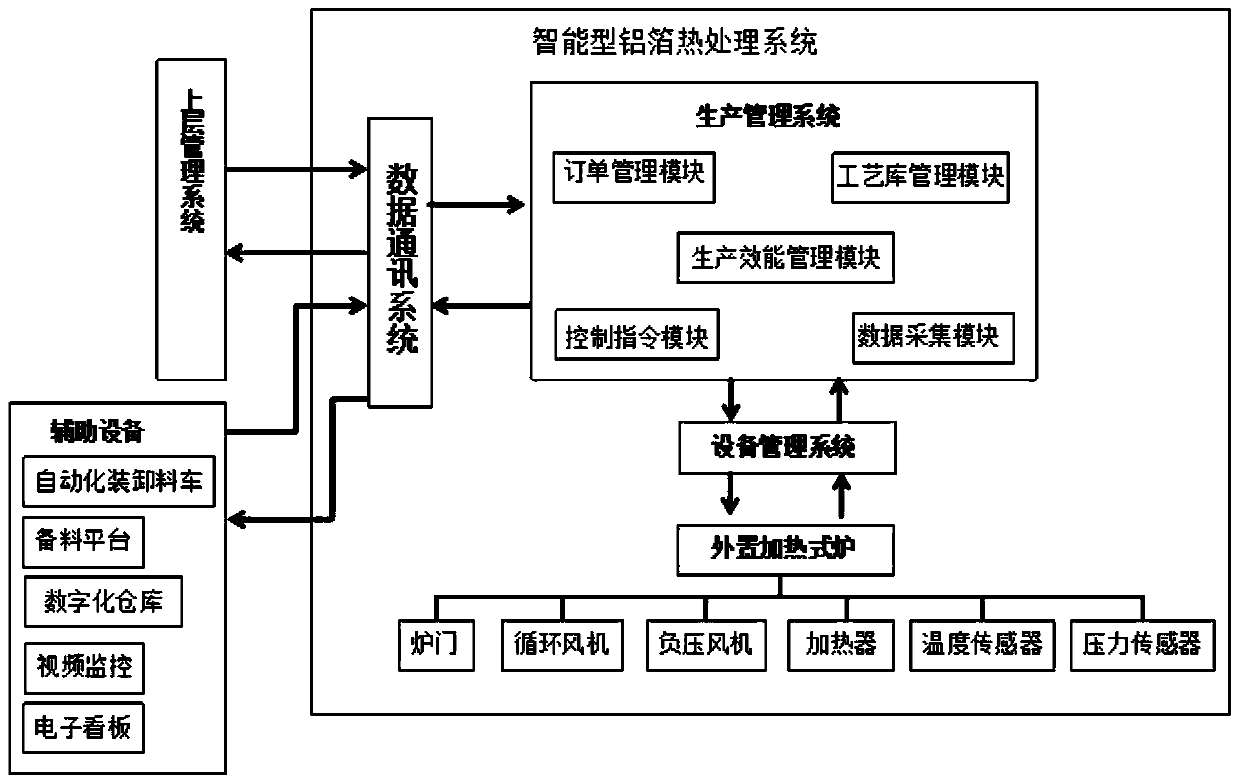

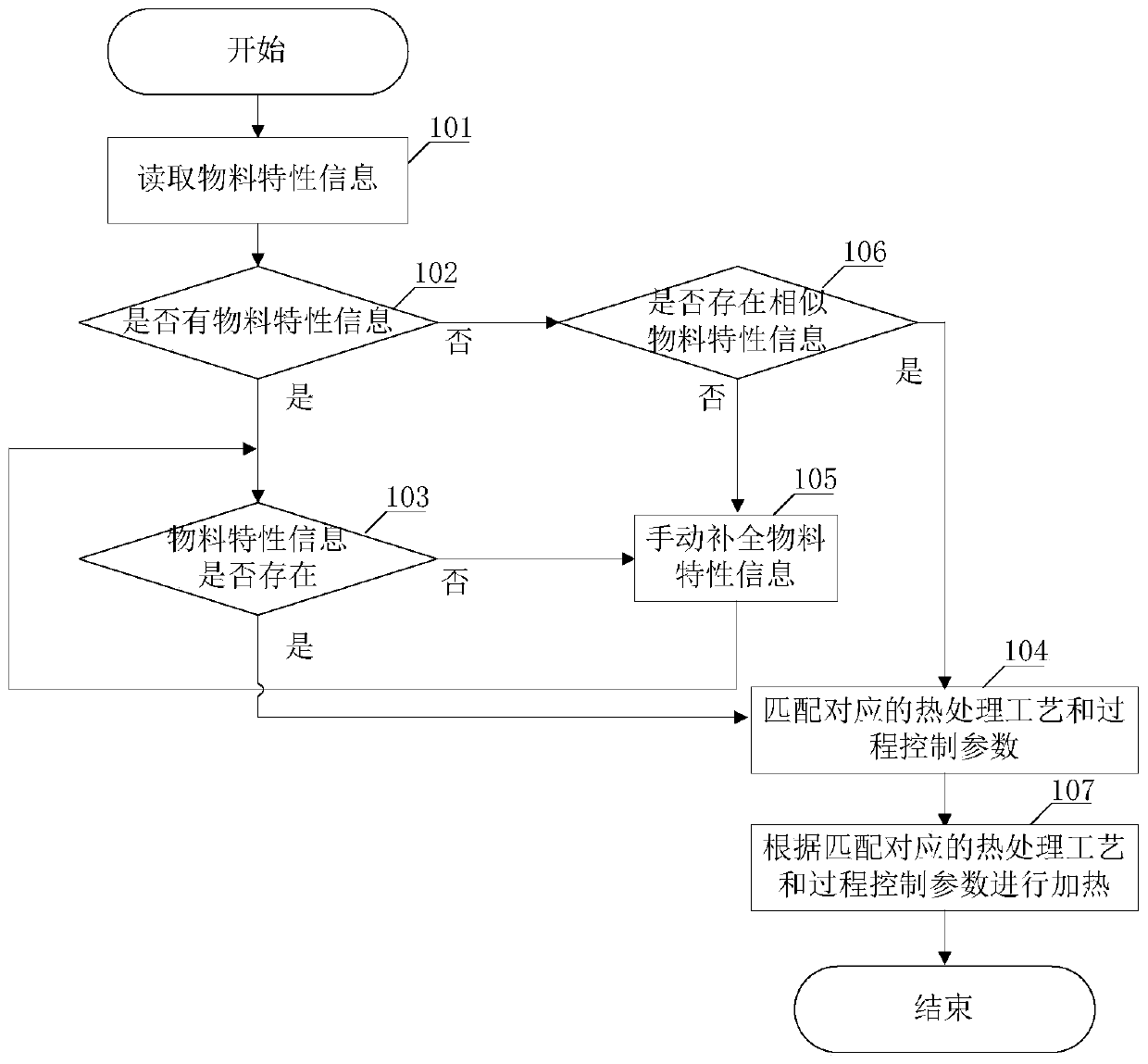

Intelligent aluminum foil heat treatment system

PendingCN110735029AExcellent heat field uniformityRaise the quality levelFurnace typesHeat treatment process controlPhysicsProcess engineering

The invention provides an intelligent aluminum foil heat treatment system. The intelligent aluminum foil heat treatment system comprises a production management system, a device management system, a data communication system, and an external heating furnace. The aluminum foil heat treatment technology and process can be intelligently and accurately controlled according to order requirements, the production process, technological control, yield energy consumption, product quality, and device status and collected, counted, and analyzed, the thermal field is excellent in uniformity during heat treatment, energy saving and efficient effects are achieved, the quality level of aluminum foil products is improved, and the future system requirements of high-precision of aluminum foil heat treatmentquality and intellectualization of aluminum foil heat treatment process are effectively met.

Owner:NINGBO SACHSEN IND TECH CO LTD

Rapeseed oil production process

InactiveCN102942989BEasily brokenImprove oil yieldFatty-oils/fats refiningEssential-oils/perfumesThermodynamicsProcess engineering

The present invention discloses a rapeseed oil production process, wherein rapeseed is subjected to impurity removing through a cleaning sieve, and then is subjected to a freezing treatment to carry out wall breaking so as to easily achieve oil leaching. According to the present invention, a levigation process is adopted, and decoloration adopts a specially-treated absorbent; processes of freezing and heating are sequentially performed, such that wall breaking of rapeseed cells is easily achieved, and an oil yield of the production process of the present invention is increased, and is increased by 5-8% compared with an oil yield of the conventional pressing method; and the levigation process is adopted to take oil, such that no pollution is generated, oil product purity is ensured, a pure nature characteristic is provided, and green food requirements are met.

Owner:李学超

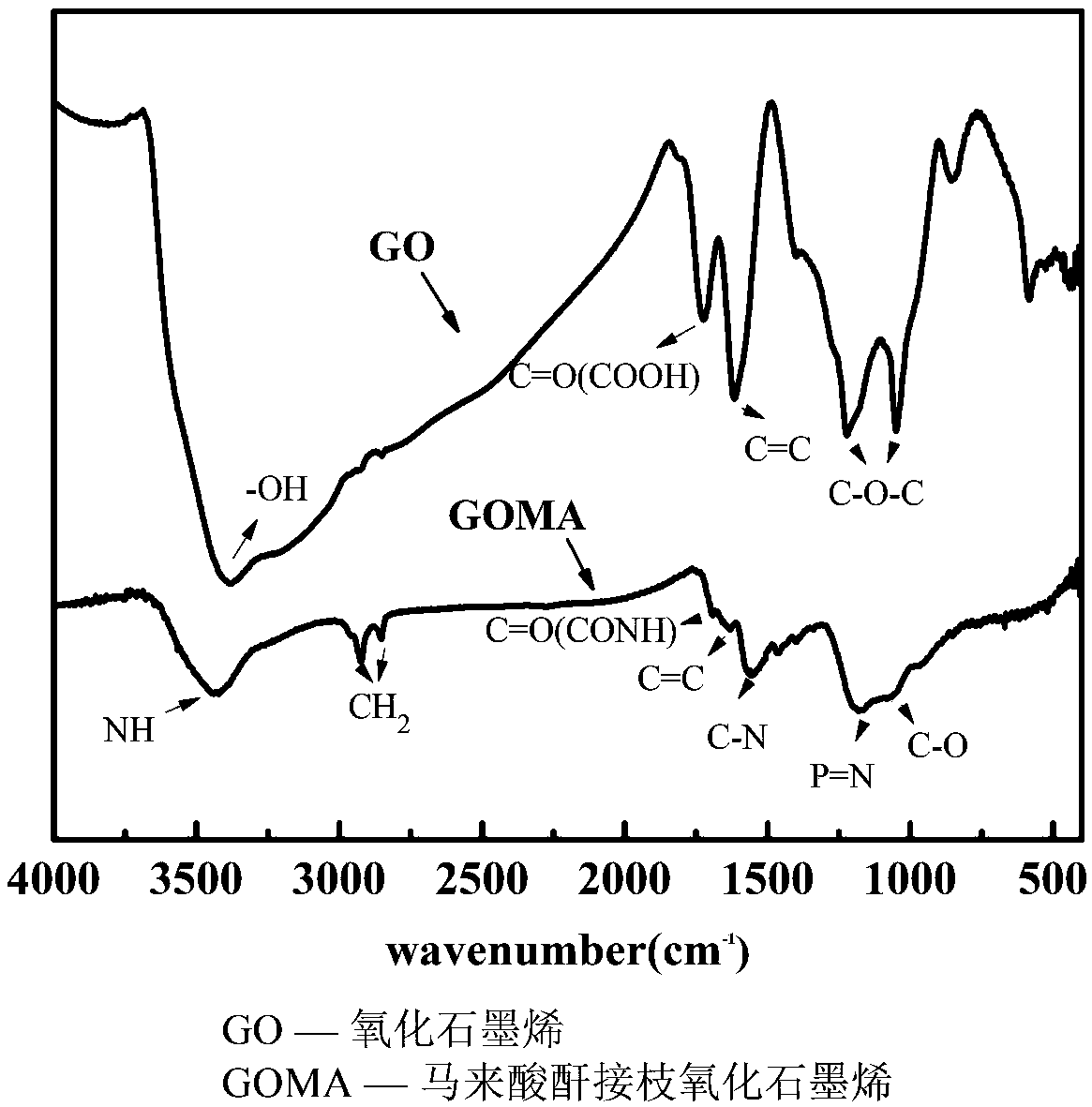

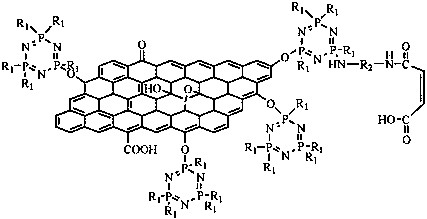

Graphene modified vinyl acetate-maleic anhydride copolymer flame-retardant leather retanning agent preparation method

ActiveCN108467465AImprove dispersion stabilityImprove conductivityTanning treatmentPersulfateCarvacryl acetate

The invention relates to a graphene modified vinyl acetate-maleic anhydride copolymer flame-retardant leather retanning agent preparation method. The method comprises the steps that graphene oxide reacts with a chlorinating agent and diamine to obtain amino graphene oxide, a maleic anhydride monomer is grafted to aminated graphene oxide, sulfate serves as an initiator, vinyl acetate, maleic anhydride, maleic anhydride modified graphene oxide, acrylamide and the like serve as comonomer, and by means of free radical polymerization, a graphene-based vinyl acetate-maleic anhydride copolymer flame-retardant leather retanning agent is obtained. Modified graphene is connected with vinyl acetate-maleic anhydride copolymer macromolecules through covalent bonds, the very good dispersible uniformityand stability are achieved, the retanning agent is used for retanning and filling of leather, the properties such as flame retardance and conductive, heat resistant, tear resistant and antibacterial property of the leather can be effectively improved, and the finished product level and international competitiveness of leather goods are improved.

Owner:SICHUAN UNIV

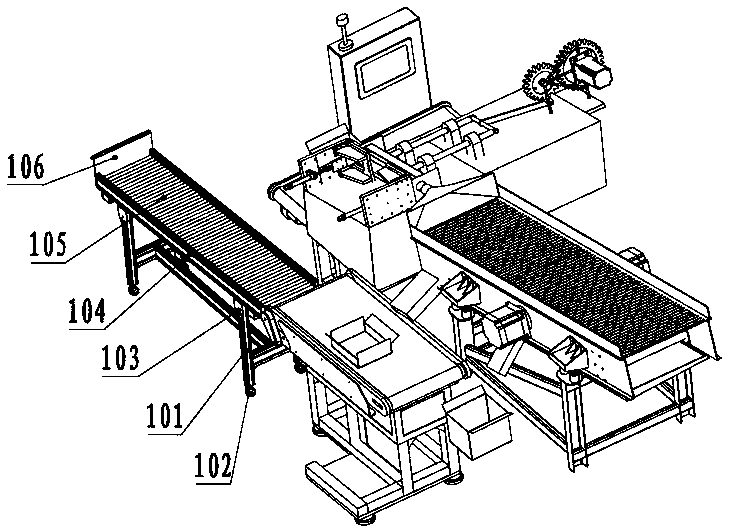

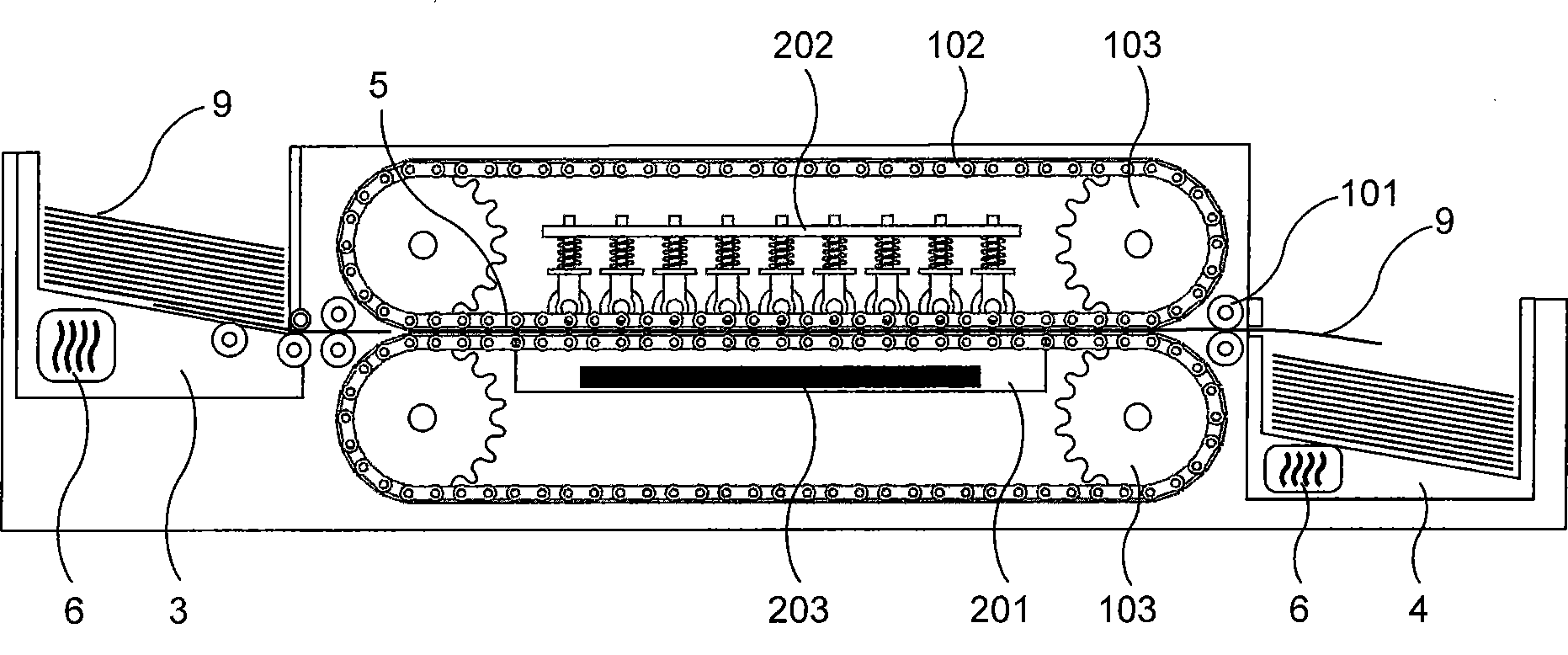

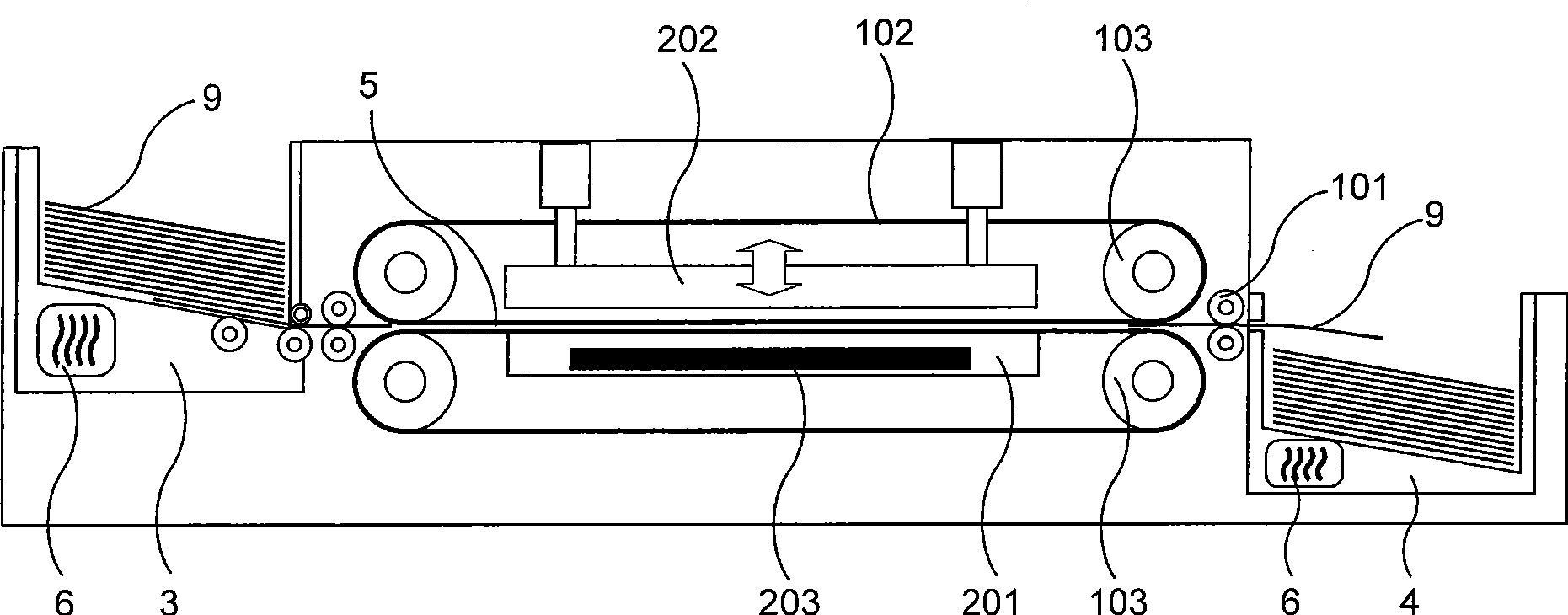

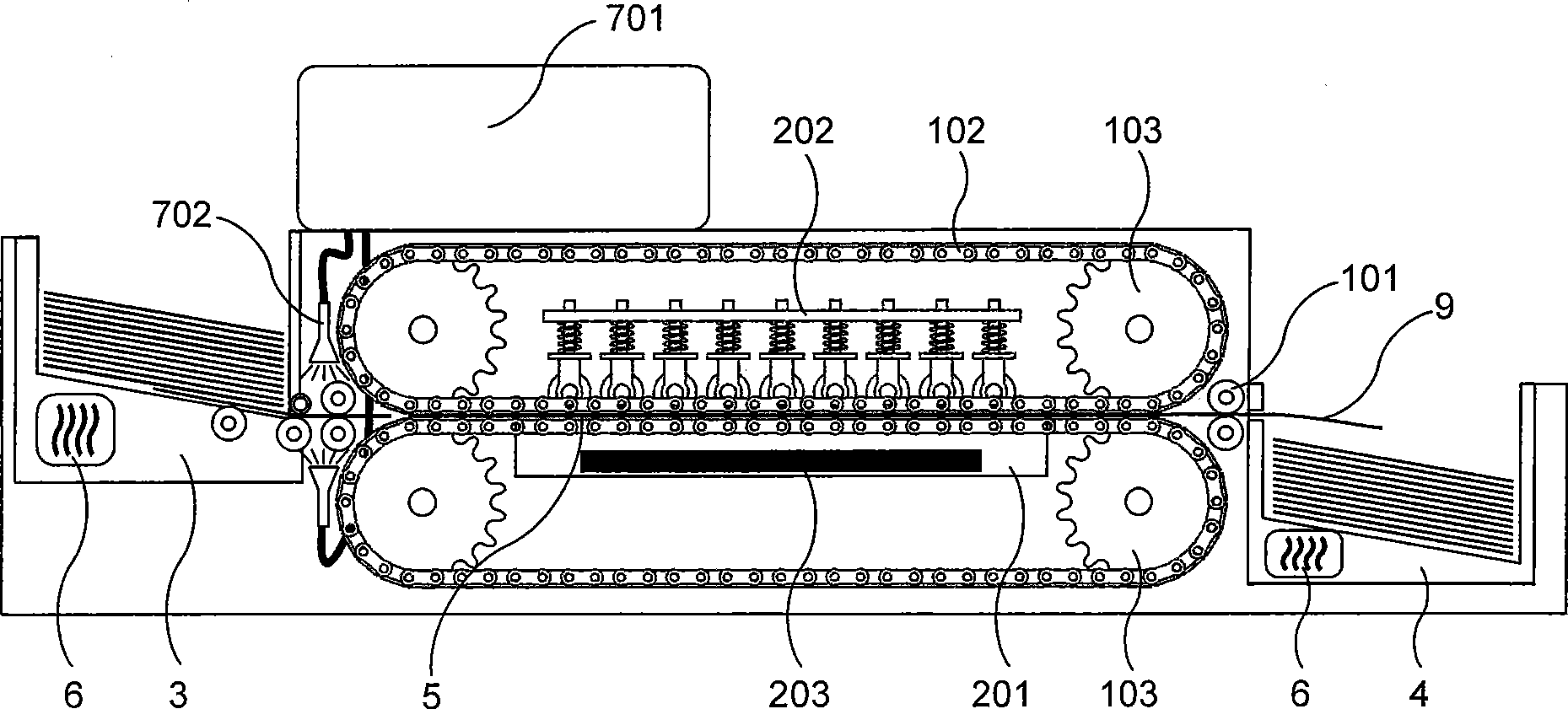

Banknote ironing and sterilizing device capable of increasing the quality and life of the banknote and method thereof

The invention discloses a bill processing device which is characterized in that: bills (9) in a bill inlet grid (3) are sent to a bill outlet grid (4) through a bill ironing channel (5) by a conveyor roller (101) and a conveyor belt (102), a disinfector (703) is sprayed on the bills (9) through a spray nozzle (702) before the bills (9) enter the bill ironing channel (5), when the bills (9) are passing the bill ironing channel (5), pressure and heat are applied to the bills (9) passing by an ironing device (2) to iron the bills (9) and the disinfector (703) on the bills (9) is heated with the heat, thereby the bills (9) are treated by disinfection. The quality of the bills (9) which are processed by the bill processing device can be increased by one to two levels and the service life of the bills (9) can also be extended, furthermore, after disinfection treatment, most virus and bacteria on the bills (9) are killed, thus preventing virus from spreading through the bills (9).

Owner:黄金富

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com