Patents

Literature

570results about How to "Guaranteed pure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical industry sewage treatment composite microbial agent and screening and preparing methods thereof

PendingCN109402016AStrong specific degradation performanceGuaranteed Multifunctional FunctionalityFungiBacteriaChemical industryChemical oxygen demand

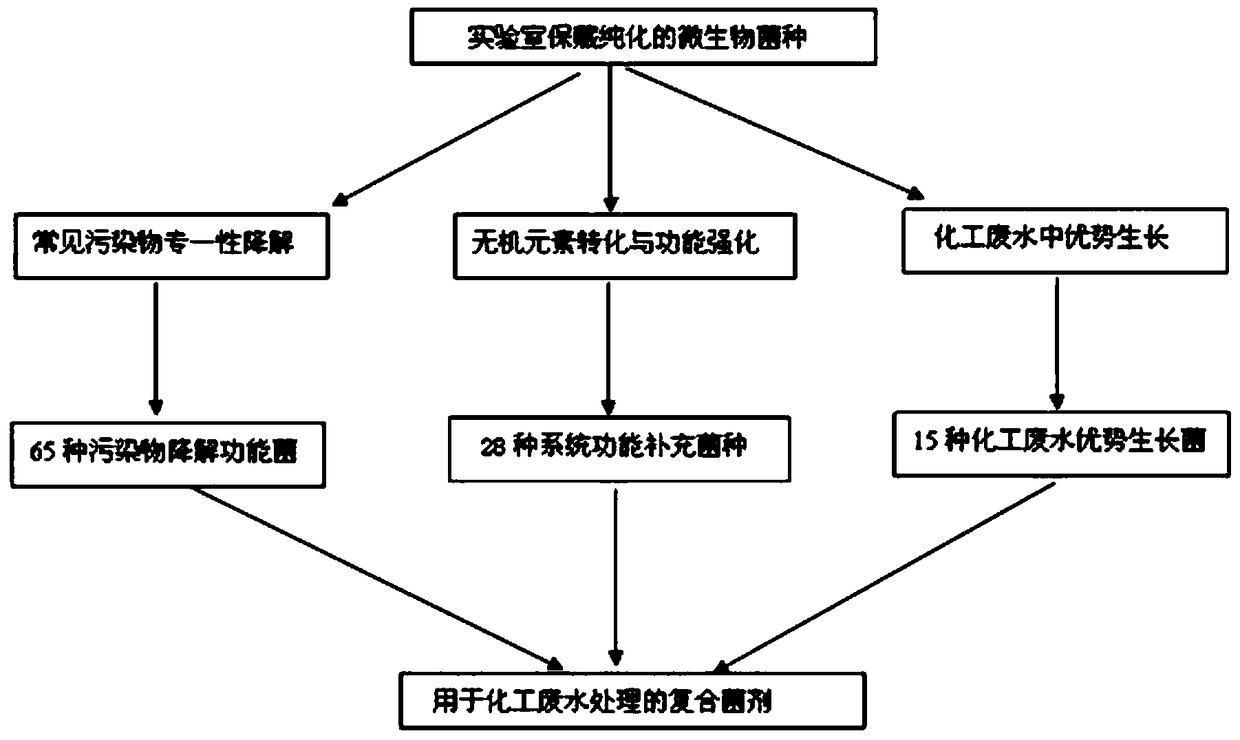

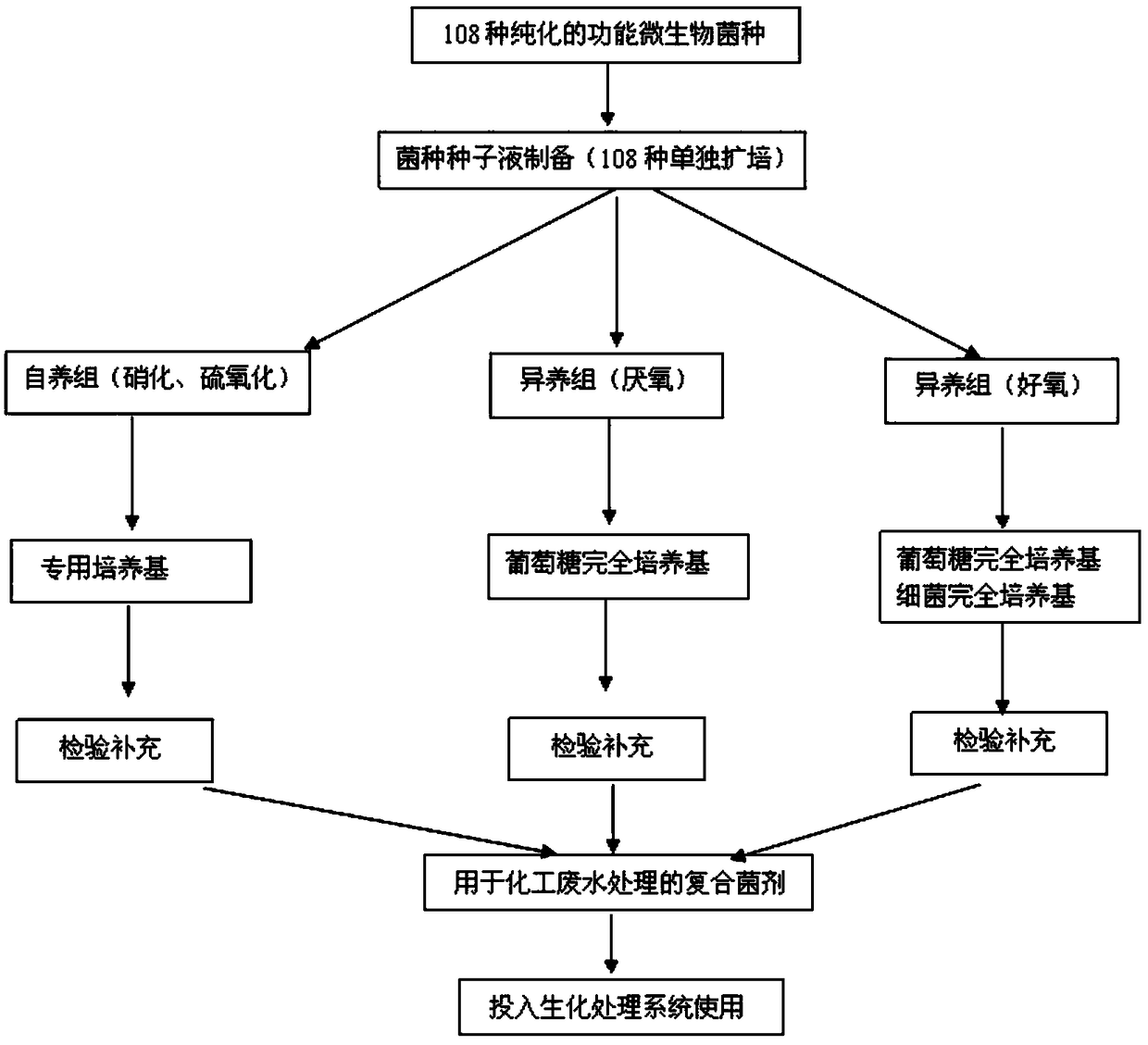

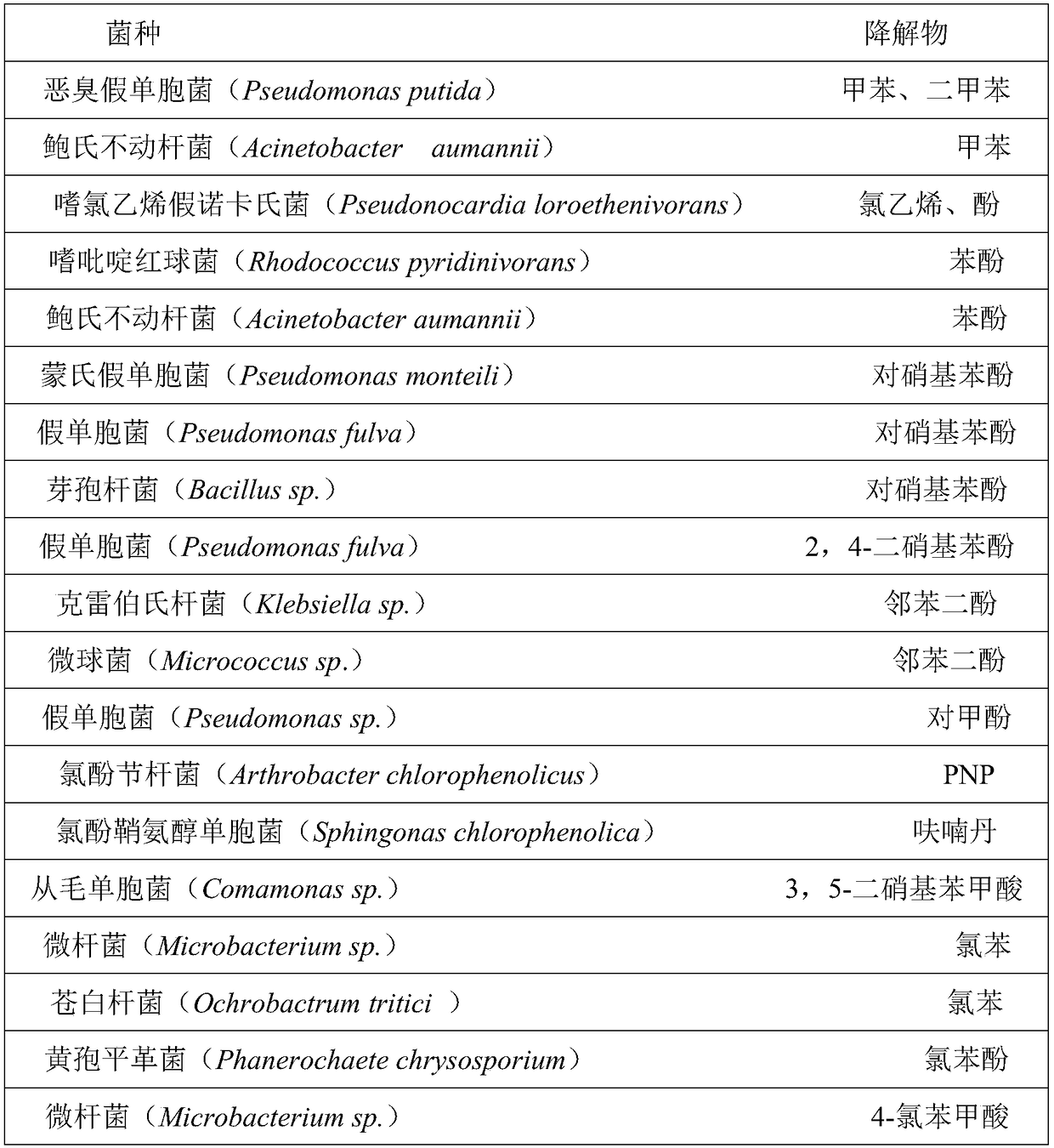

The invention comprises a composite microbial agent applicable to efficiency enhancement of common chemical industry sewage treatment systems. The composite microbial agent applicable to efficiency enhancement of the common chemical industry sewage treatment systems meets the demands on treatment on comment pollutants in existing chemical industry and environmental production as well as on establishment of functional bacteria required by a stable bacteria flora. According to one of the schemes, the composite microbial agent is composed of 108 microorganisms of three major functional types. When the composite microbial agent is added together with microbial growth promoting carriers, nutrient agents and the like into a biochemical system, the composite microbial agent can promote establishment of a complete food chain in the biochemical system through various microorganisms with special pollutant degrading capabilities and comprehensive metabolic manners to enhance utilization and metabolic decomposition of pollutants in sewage through the microorganisms, thereby achieving efficient reduction of COD (chemical oxygen demand), ammonia nitrogen, phosphorous, sulfur and like.

Owner:江苏宜裕环保科技有限公司

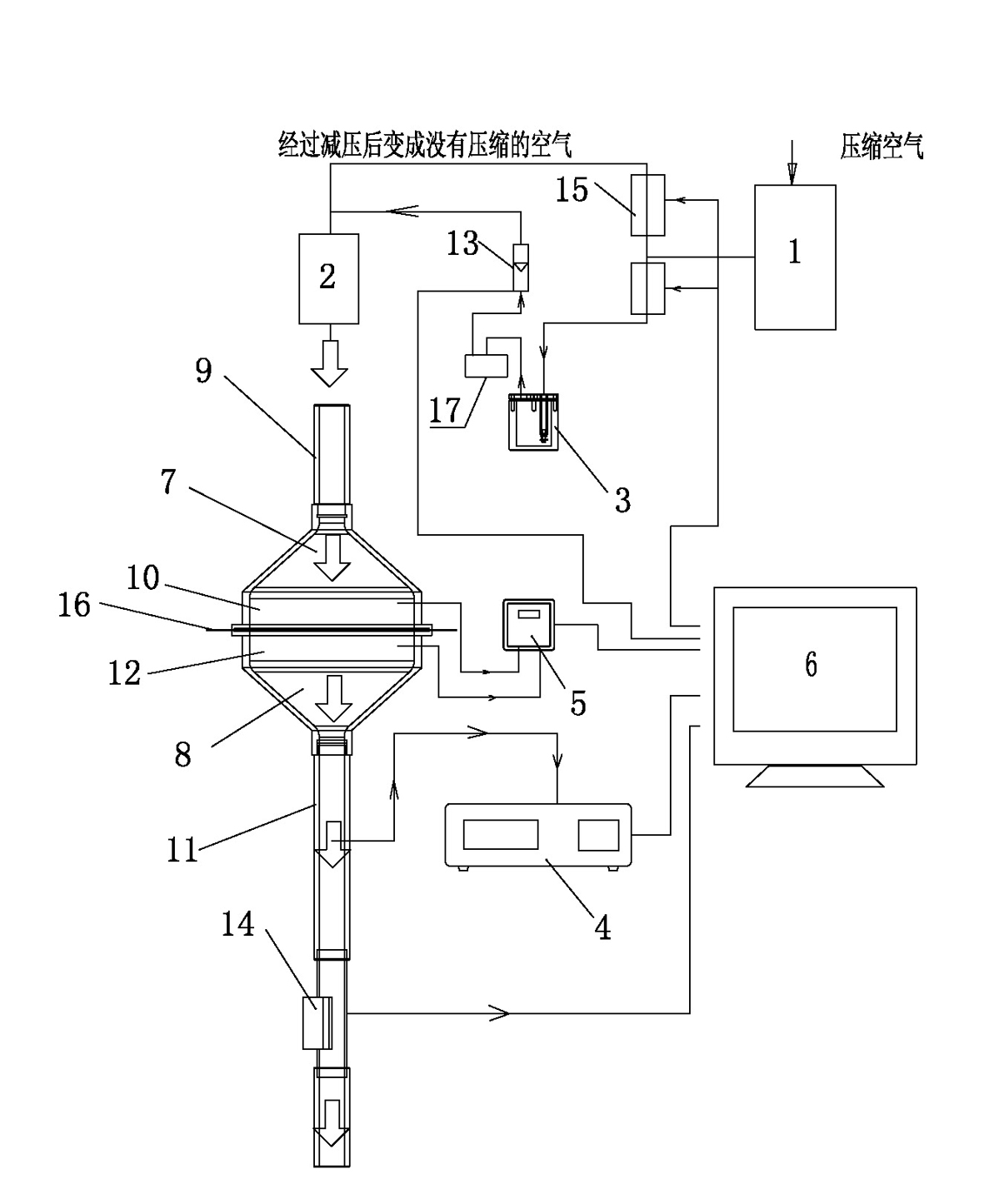

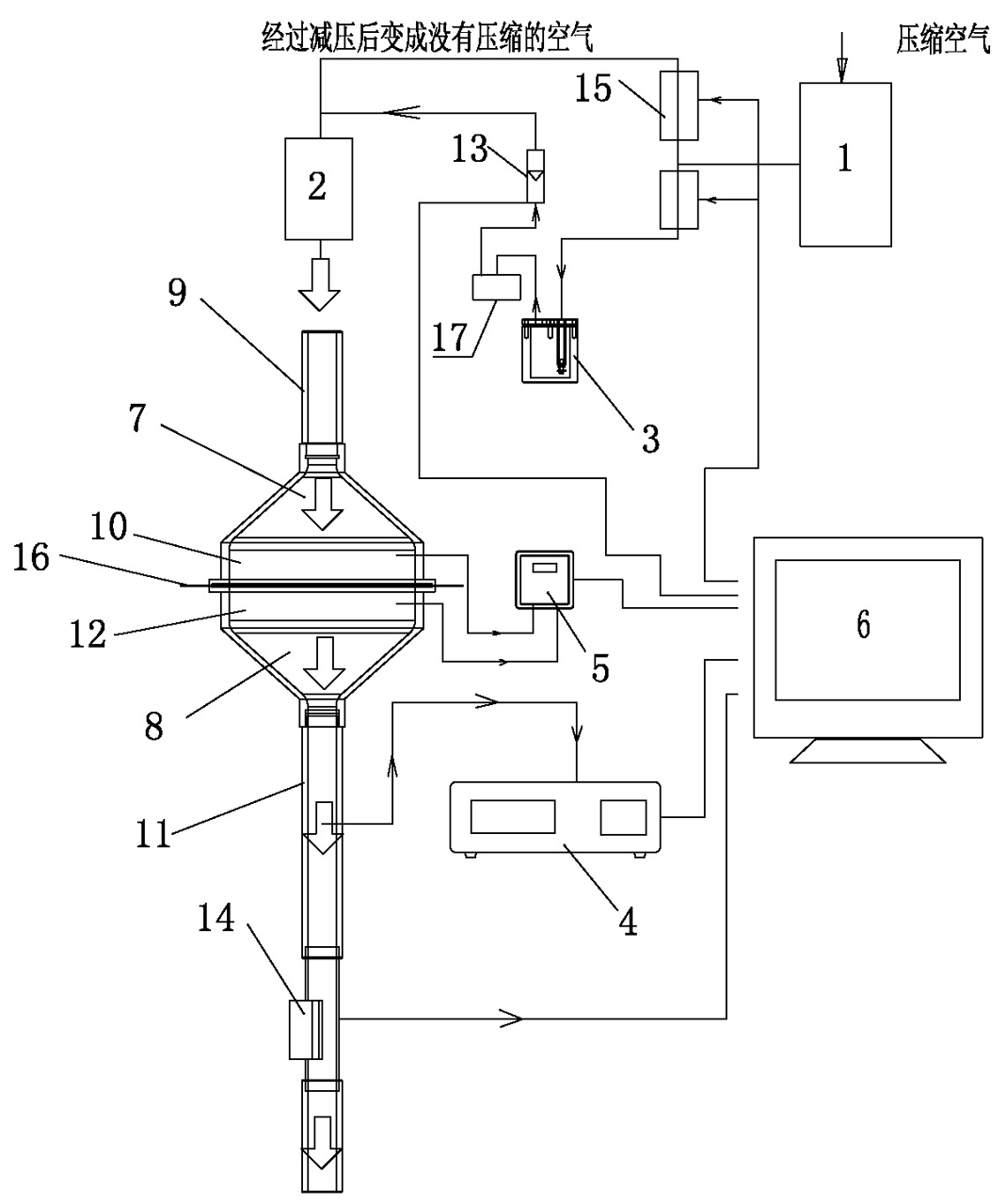

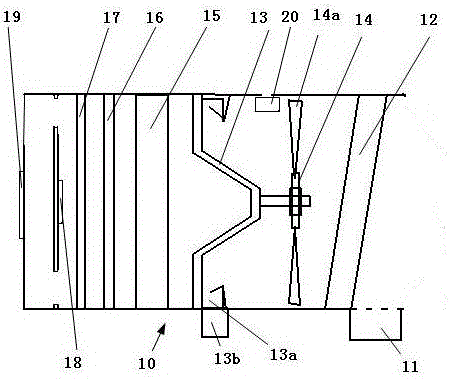

Air filtering material tester

InactiveCN101995372AWide range of industriesGuarantee effective detection dataPermeability/surface area analysisAir filtrationAutomatic control

The invention relates to an air filtering material tester which comprises a high efficiency filter, a corona neutralizer, a filter clamp, an aerosol generator, a laser particle counter, a differential pressure meter and a computer, wherein an outlet of the high efficiency filter is respectively connected with an inlet of the corona neutralizer and an inlet of the aerosol generator through pipelines, and an outlet of the aerosol generator is connected with the inlet of the corona generator through a pipeline; the filter clamp is formed by hermetically assembling an upstream clamp and a downstream clamp, wherein the upstream clamp comprises an air inlet pipeline and an air inlet chamber, the downstream clamp comprises an air outlet pipeline and an air outlet chamber, and the outlet of the corona neutralizer is connected with the air inlet pipeline of the upstream clamp; the laser particle counter is connected with the air outlet pipeline of the downstream clamp, and the differential pressure meter is respectively connected with the air inlet chamber and the air outlet chamber; and the laser particle counter and the differential pressure meter are respectively connected with the computer. The air filtering material tester has the advantages of high detection efficiency and sensitivity and fully-automatic control of detection process.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION +1

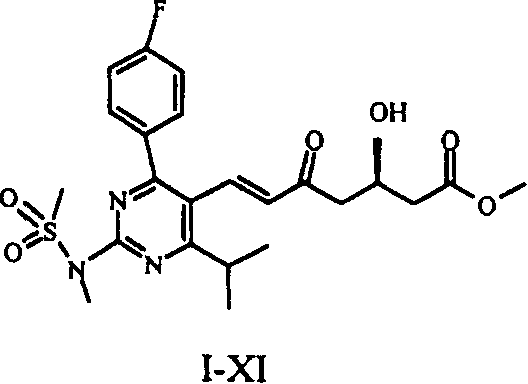

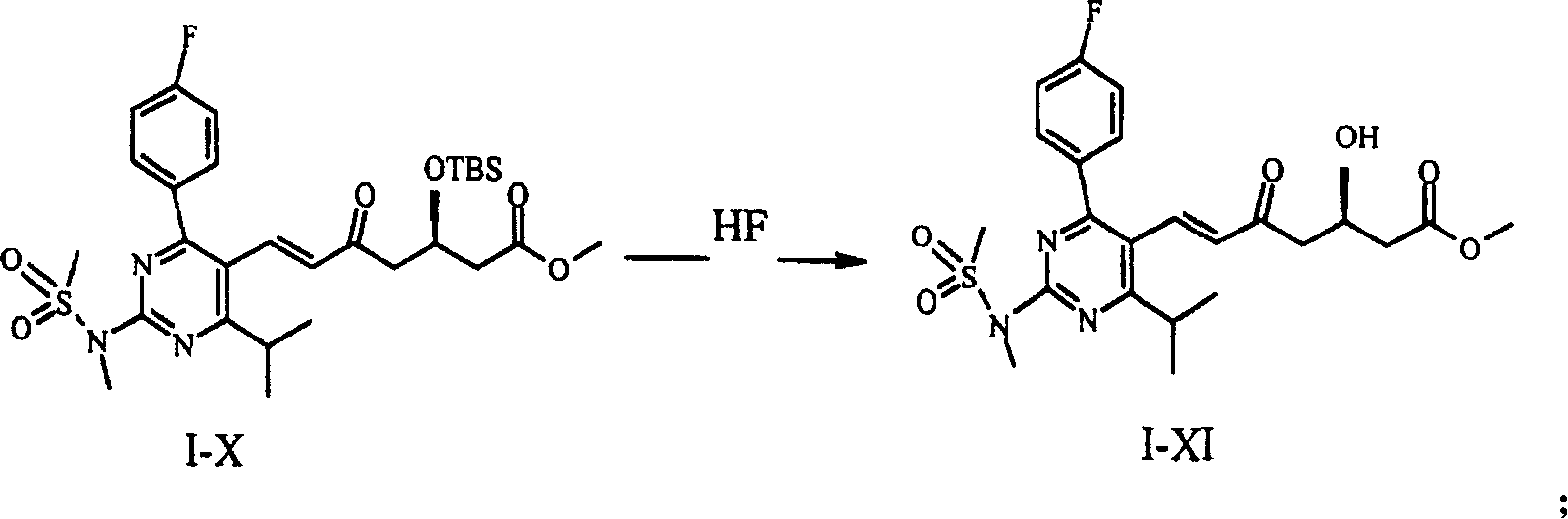

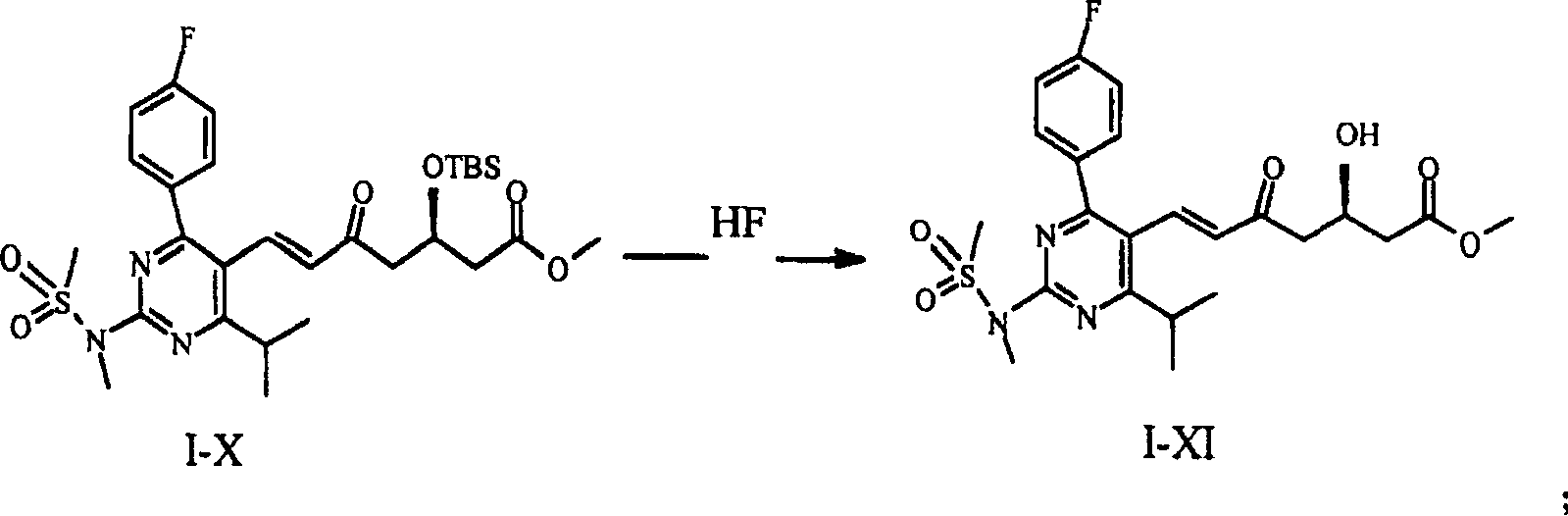

Method for preparing Rosuvastatin Calcium and key intermediate

InactiveCN1872841AGuaranteed pureComplete stereoselectivityOrganic chemistryCombinatorial chemistryRosuvastatin Calcium

This invention provides a method for preparing rosuvastatin intermediate compound I-XI. The method can ensure a high purity of I-XI, thus ensuring the completeness of the stereoselectivity in subsequent reactions. Although the yield of I-XII from I-X in this invention is a little lower than that in the invention EP 0,521,471 A1, the purification of I-XII only needs a low-efficiency chromatographic column. The method thus has such advantages as low cost and high efficiency.

Owner:SHANGHAI SINE PHARMA LAB

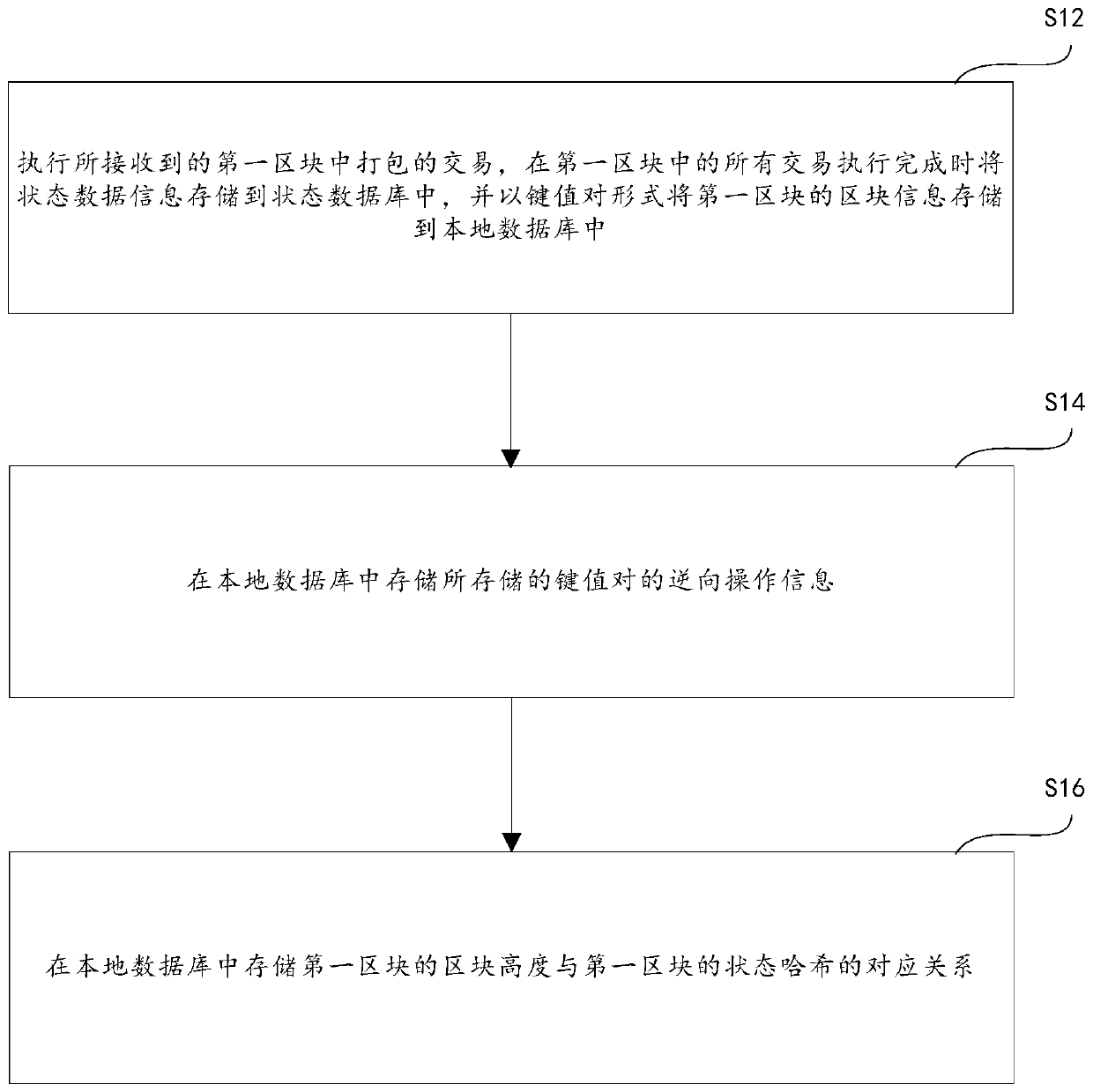

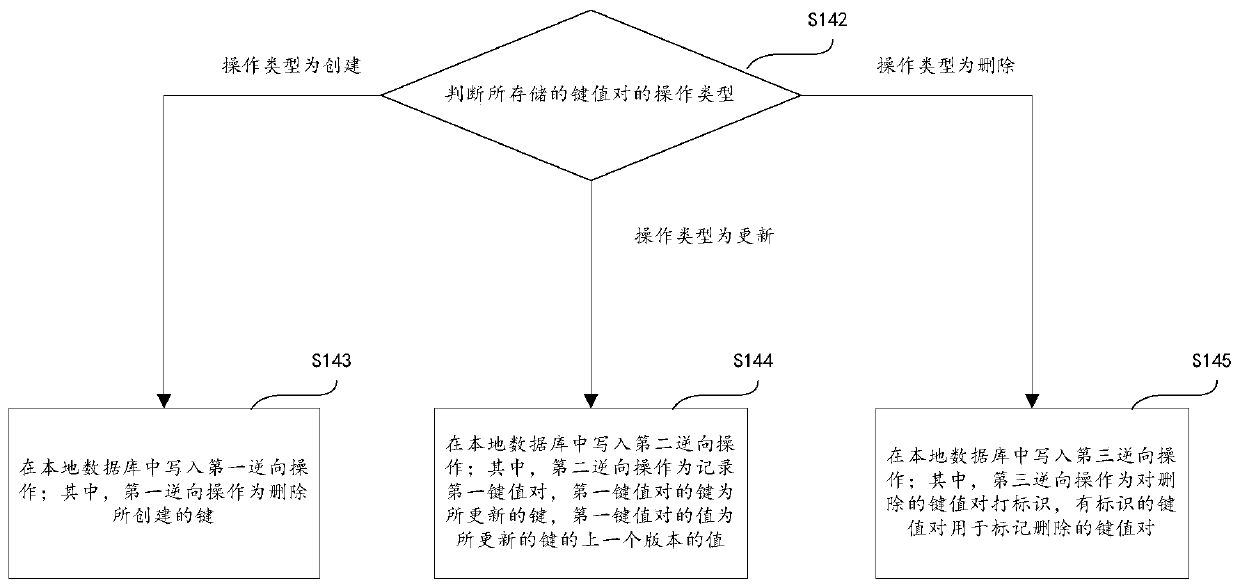

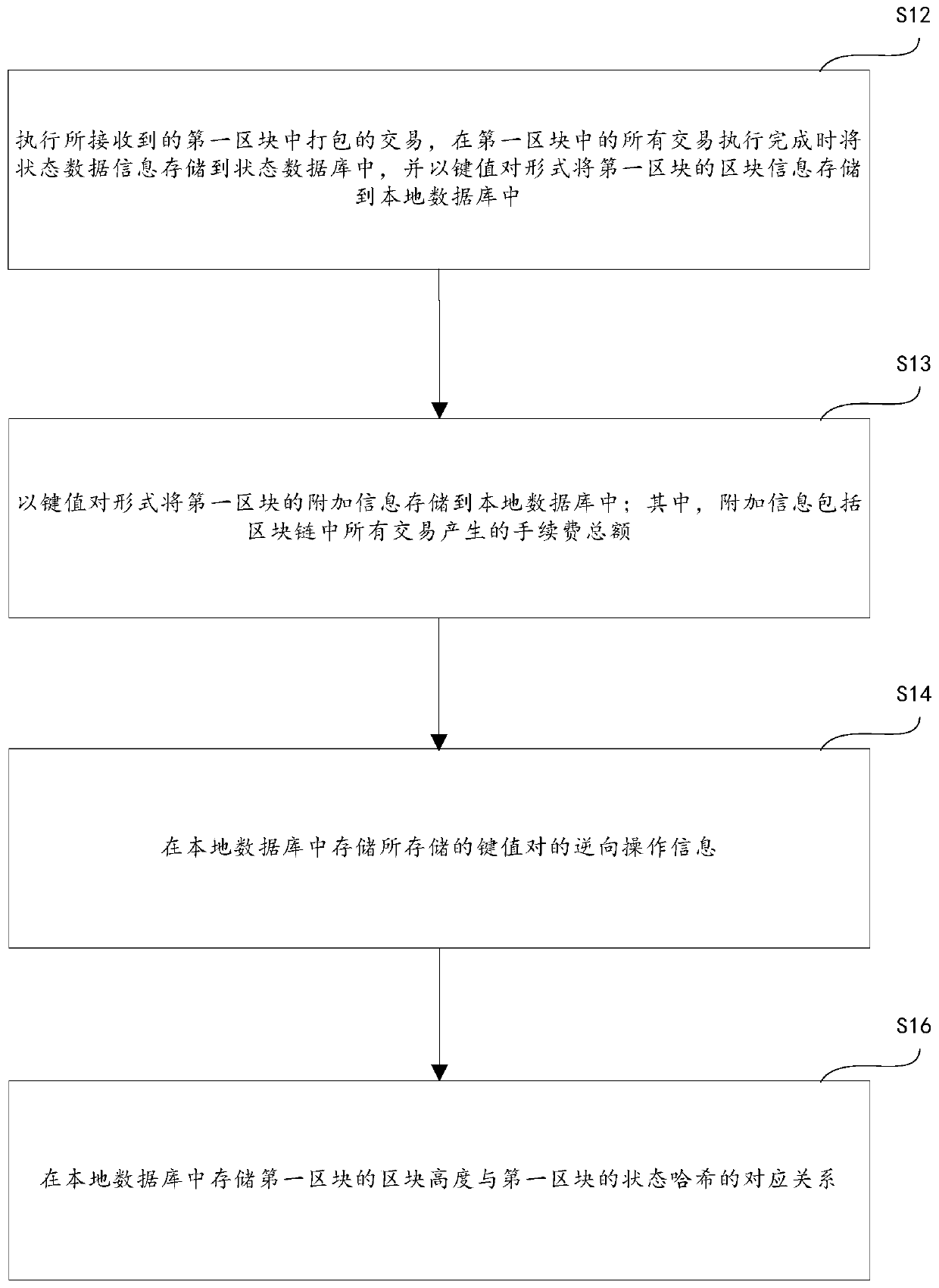

Data storage method, data rollback method, equipment and storage medium

ActiveCN109933592AReduce data storageImprove experienceRedundant operation error correctionSpecial data processing applicationsData informationFinancial transaction

The invention provides a data storage method, a data rollback method and device and a storage medium, and the method comprises the steps: executing a received transaction packaged in a first block, storing state data information into a state database when all transactions in the first block are executed, and storing the block information of the first block into a local database in a key value pairform; storing the reverse operation information of the stored key value pairs in a local database; and storing a corresponding relationship between the block height of the first block and the state hash of the first block in a local database. According to the method, only the most important state data information is stored in the state database, the data storage amount of the state database is reduced, the reading efficiency is improved, and the user experience is improved.

Owner:HANGZHOU FUZAMEI TECH CO LTD

Production technique of low-temperature pressed rapeseed oil

InactiveCN102952628AEasily brokenImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionProcess engineeringRapeseed

The invention discloses a production technique of low-temperature pressed rapeseed oil, wherein rapeseeds are cleaned, subjected to impurity removal, subjected to wall breaking based on freezing treatment and then fried to 60-70% rape to contribute to the oil leaching, a pressing technique is utilized in the invention, and a specially treated adsorbent is used for decoloring. A technique of heating after freezing is utilized in the invention to facilitate the cell disruption of the rapeseeds so as to improve the oil extraction rate, and the oil extraction rate is 5-6% higher than that of a traditional pressing method; and the oil is extracted by the pressing technique in the invention, so that no pollution exists, the purity of the oil product is guaranteed, and the oil is all natural and meets the demands of green food.

Owner:FEIXI RONGXIN GRAIN & OIL

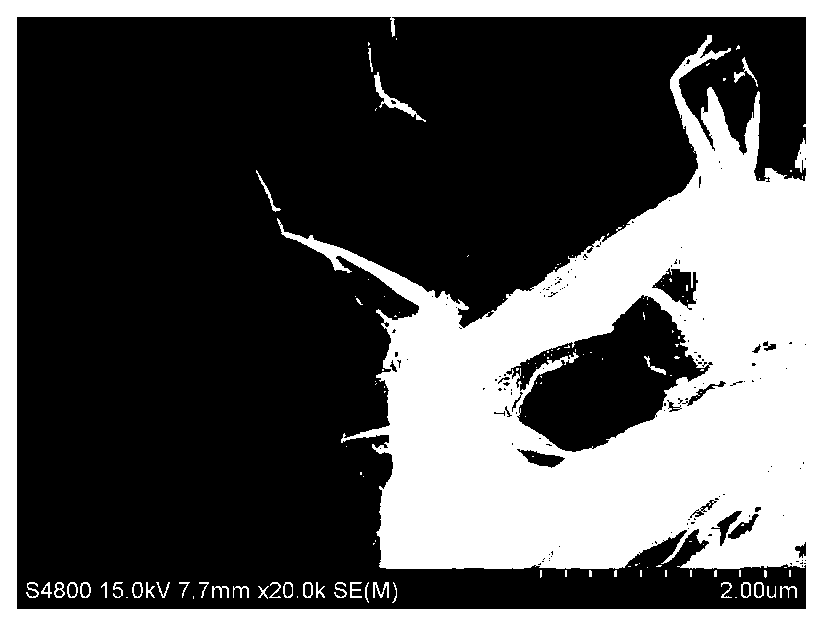

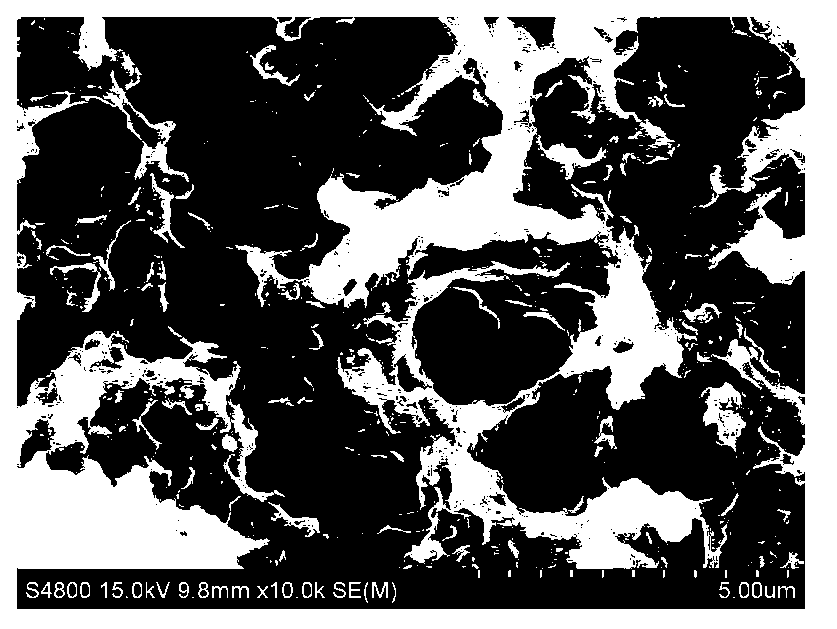

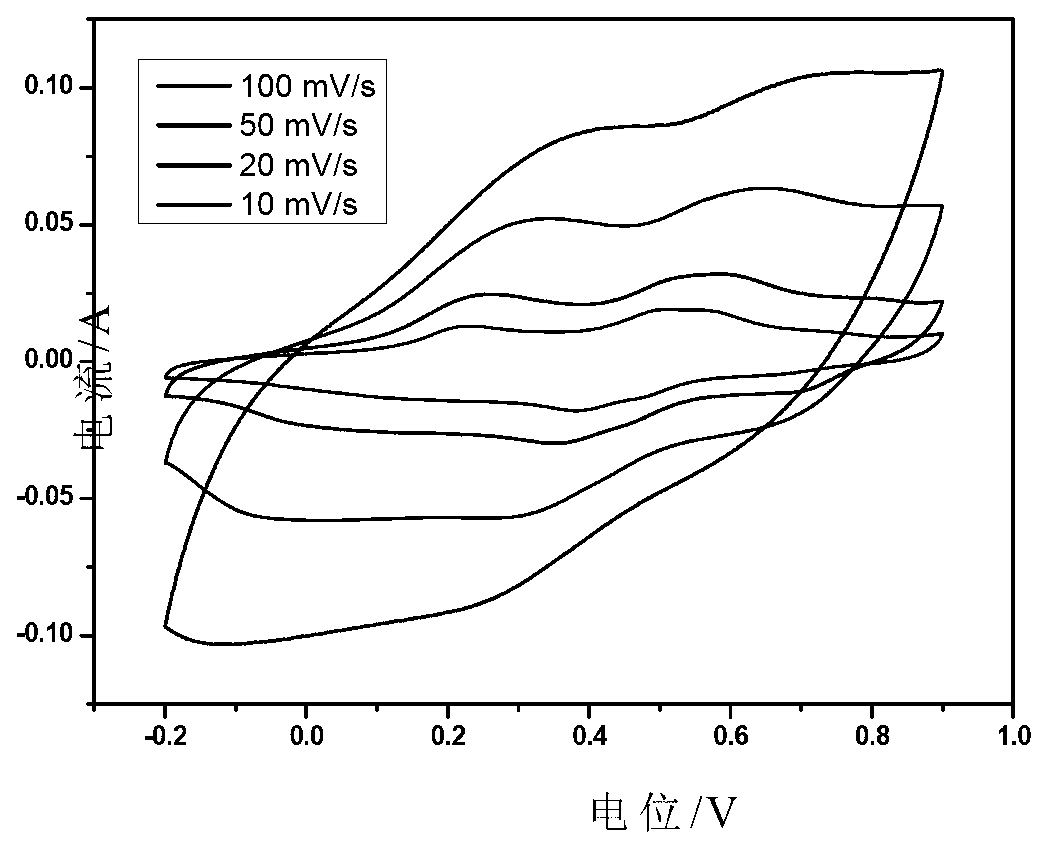

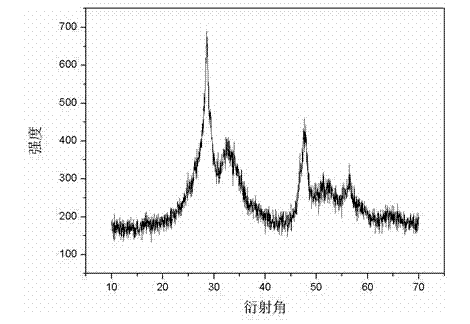

Grapheme-polyaniline super capacitor electrode material and preparation method thereof

InactiveCN103137342ASimple preparation processLow costHybrid capacitor electrodesHybrid/EDL manufactureCvd grapheneAuxiliary electrode

Owner:YANSHAN UNIV

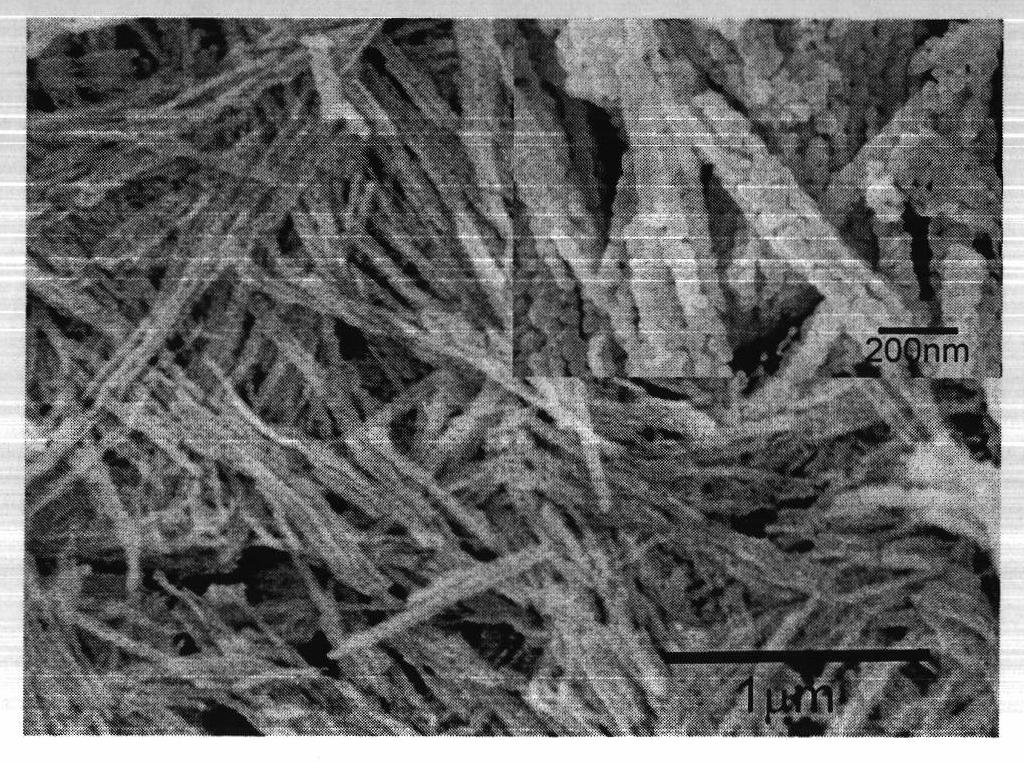

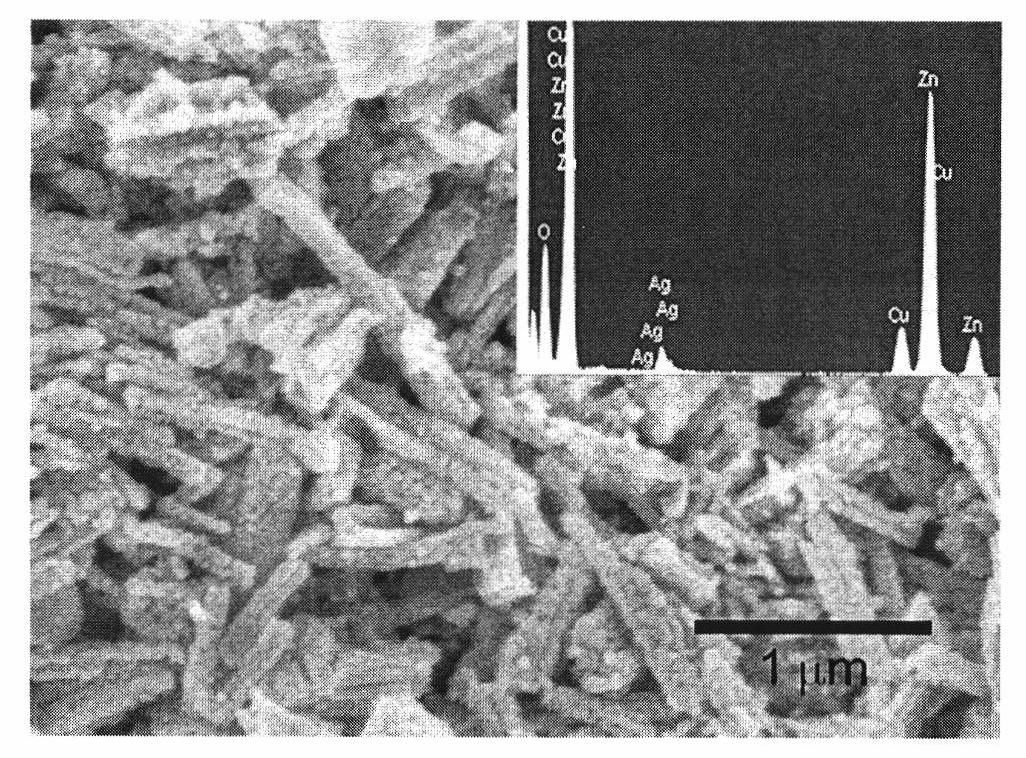

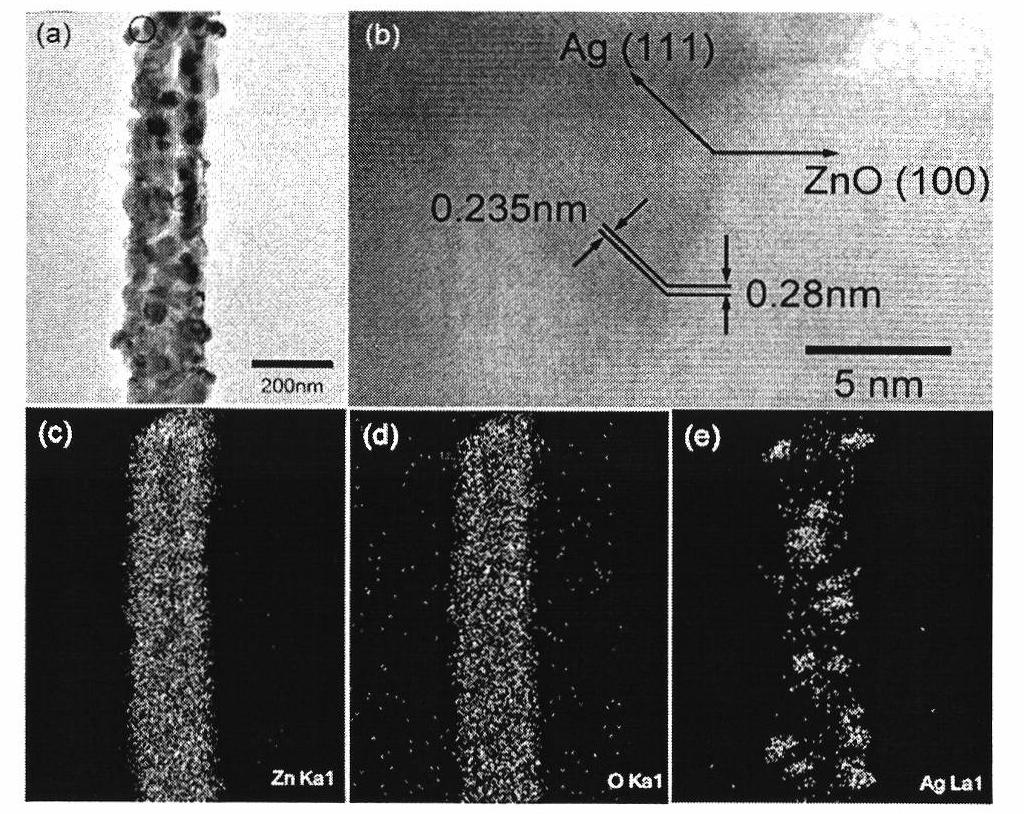

Porous zinc oxide-silver composite nanorod, as well as preparation method and application thereof

InactiveCN102649060ALarge specific surface areaImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsZinc Acetate DihydrateMaterials science

The invention discloses a porous zinc oxide-silver composite nanorod, as well as a preparation method and application thereof. The composite nanorod is formed by zinc oxide particles; sliver particles are loaded on the surface of the in porous rodlike zinc oxide, meso pores are formed between zinc oxide and / or silver particles, the rod length of the porous rodlike zinc oxide is 0.6-3 mum, the rod diameter is 90-150 nm, the specific surface area is 18-22m<2> / g, the particle size of the zinc oxide is 10-30nm, the size of the silver particles is 20-30nm, and the meso pore diameter is 3-30nm. The method comprises the following steps of: firstly mixing zinc acetate ethanol solution and ethanol oxalate dehydrate solution; putting the mixture in a seal state; insulating for at least 5h at the temperature of 70-90 DEG C; centrifuging, washing and drying; annealing the obtained zinc oxalate for at least 2h at the temperature of 430-470 DEG C; adding the zinc oxalate into silver nitrate ethylene glycol solution; stirring for at least 15min under visible light; and centrifuging, washing and drying, thereby preparing a target product. The porous zinc oxide-silver composite nanorod can be used for carrying out visible light catalytic degradation in water polluted by organic matters.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

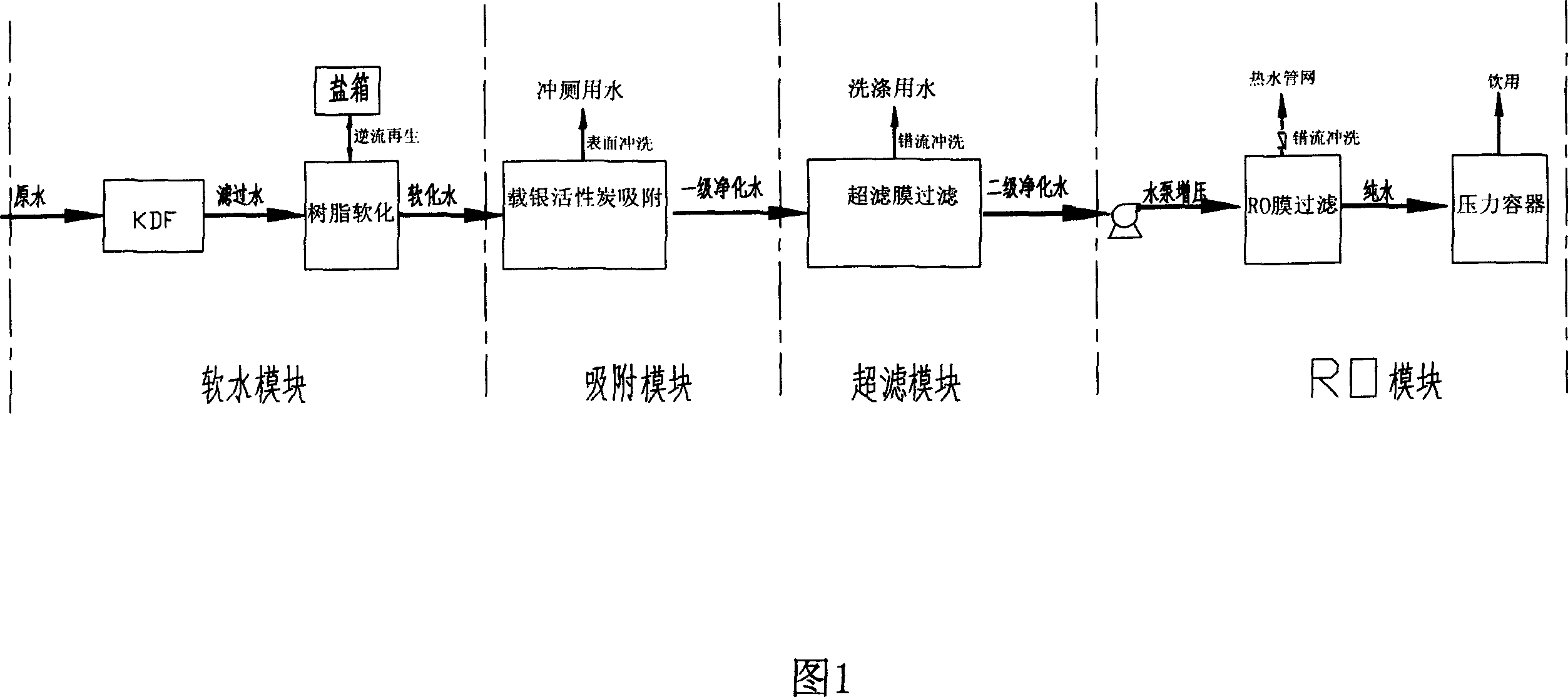

Household different water supply system

ActiveCN1944816AEliminate Concentration PolarizationExtend your lifeGeneral water supply conservationMultistage water/sewage treatmentWater softeningActivated carbon

The dual water supply system for household includes a soft water module with KDF filter connected to the raw water pipeline, a water softening resin device with salt box and resin jar, an adsorbing module with active carbon with water outlet connected to toilet water pipeline, an ultrafilter module, an RO module with pressurizing water pump, a bath water inlet pipeline, and a pressure container connected to the pure water outlet of the RO module. The dual water supply system makes the drinking water and the living use water flow separately, and has reverse resin regeneration, active carbon surface flushing and ultrafiltering membrane cross flow filtering to complete the timely system washing for eliminating pollutant and prolonging service life.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

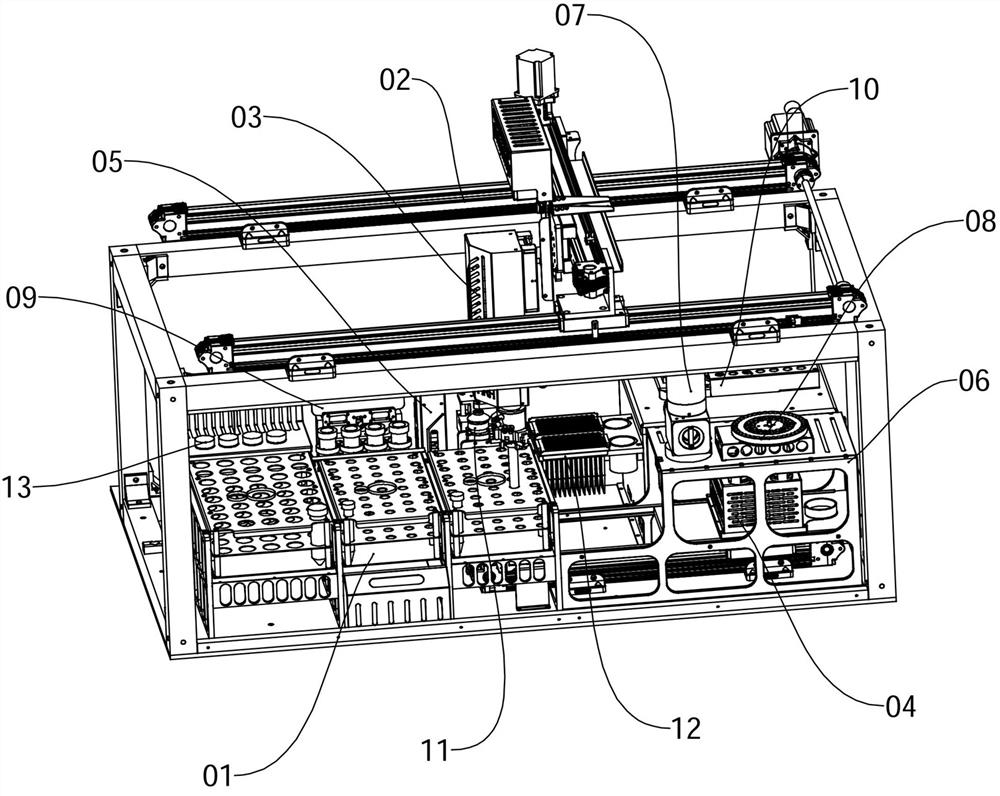

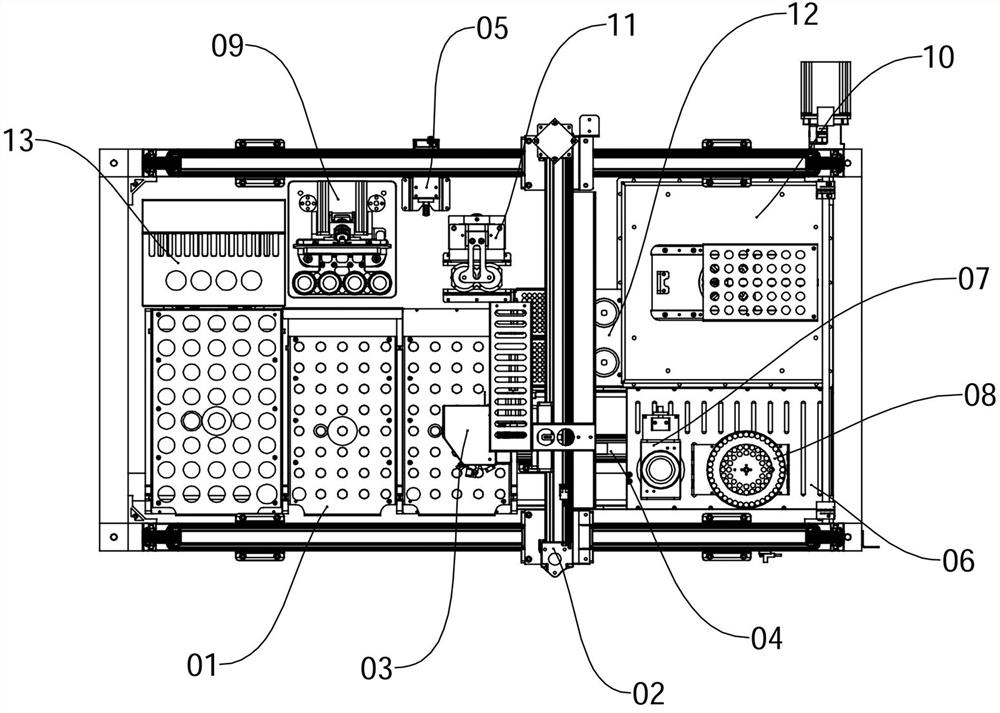

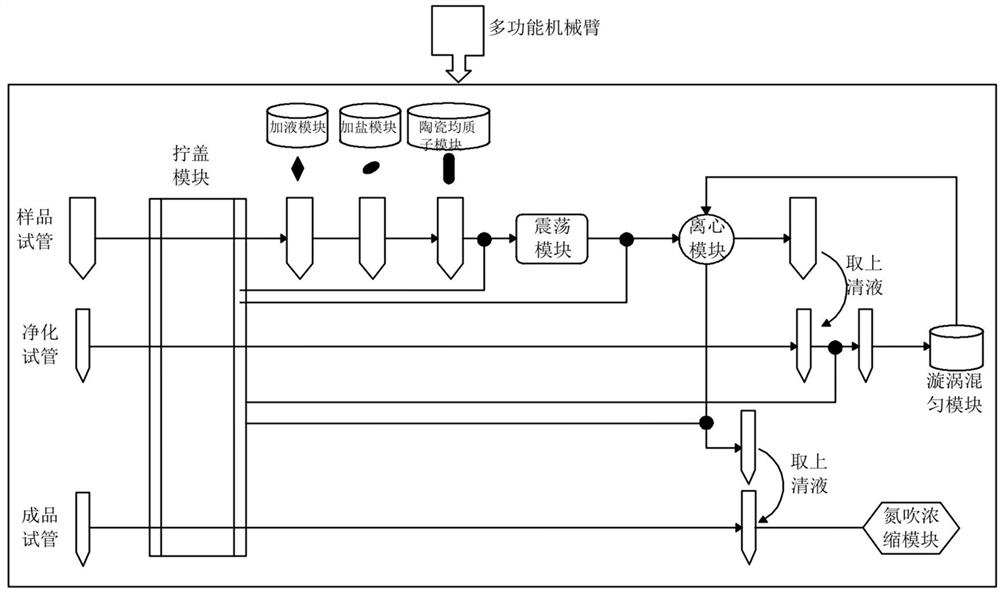

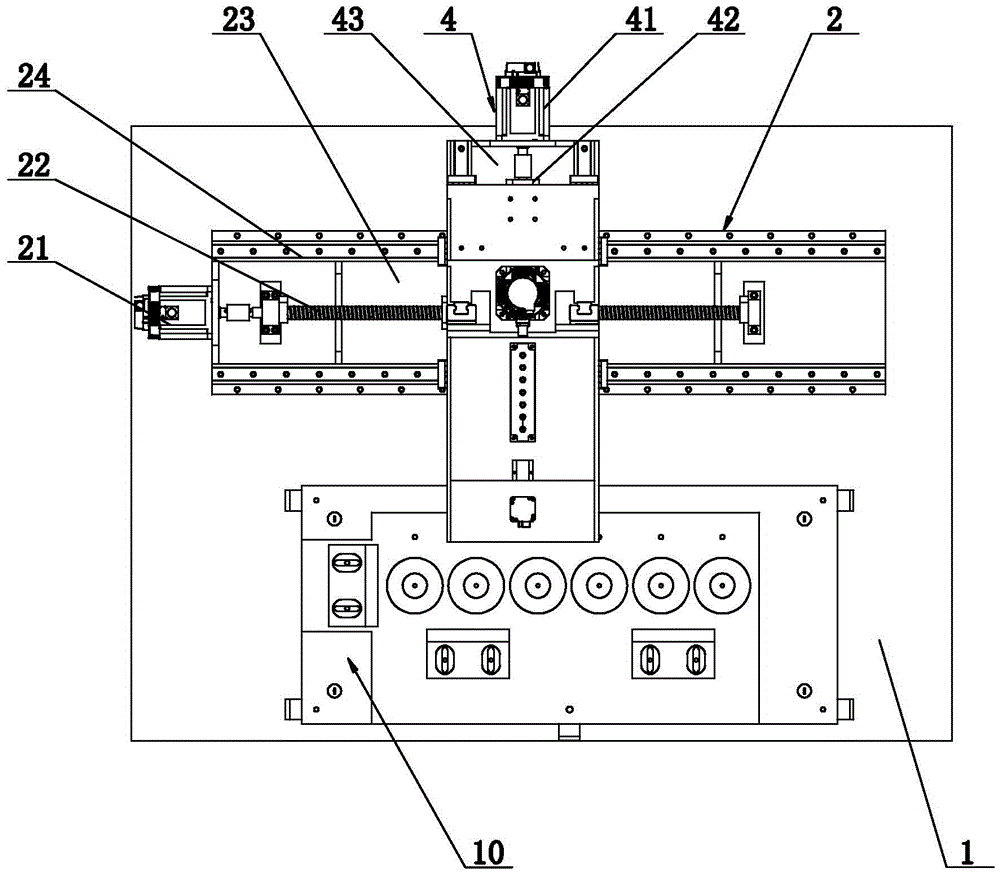

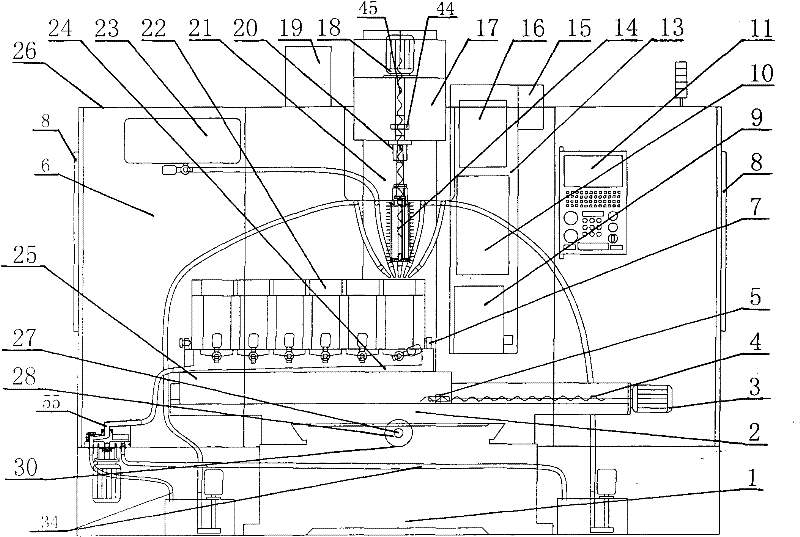

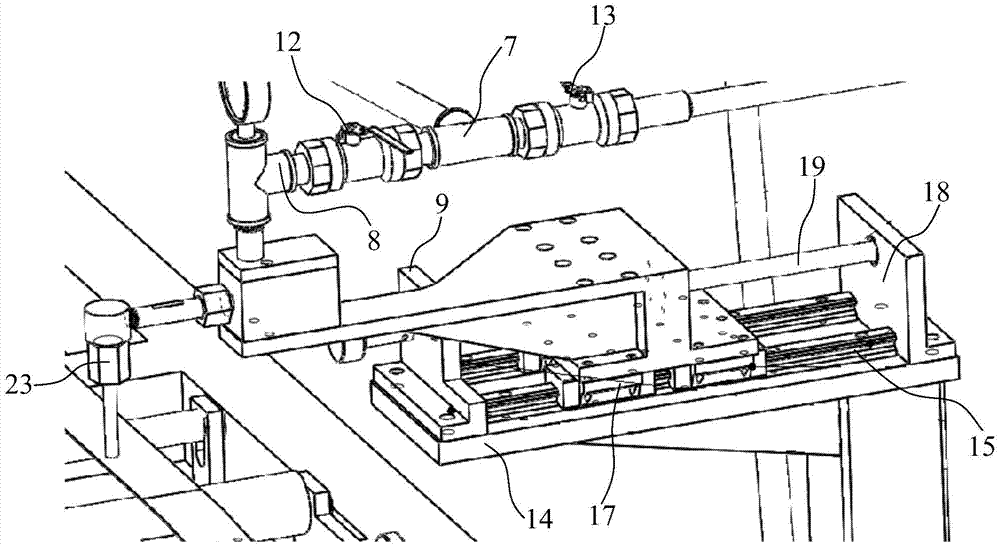

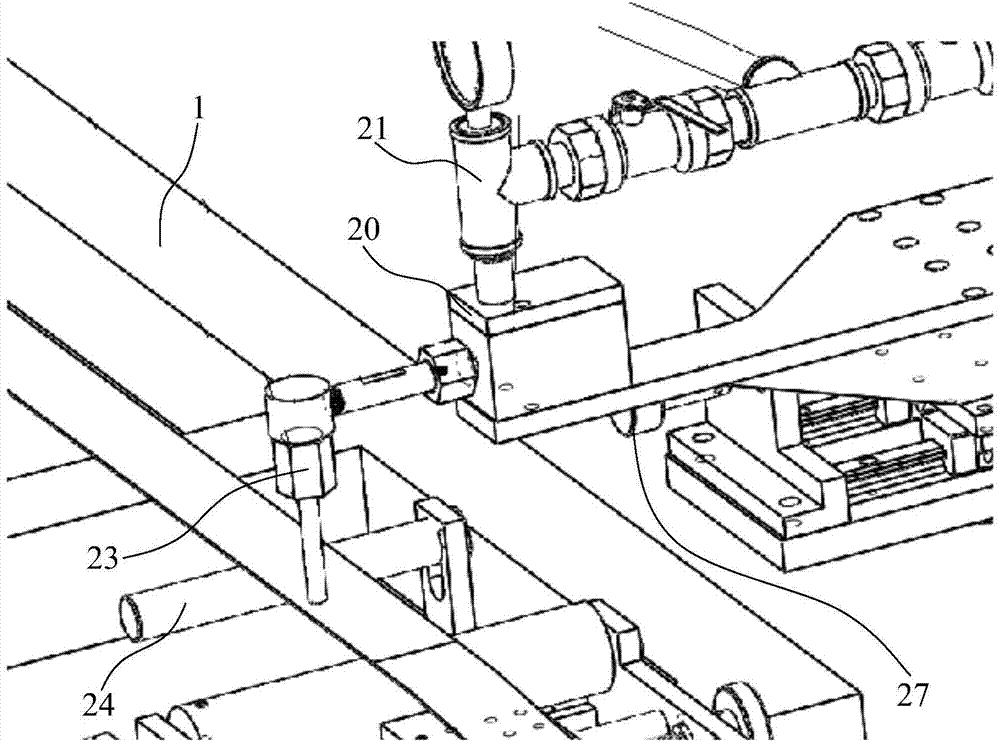

Full-automatic QuECHERS experimental device and experimental method

ActiveCN112198324AHigh degree of experiment automationImprove experimental efficiencyPreparing sample for investigationExperimental methodsSolid phase extraction

The invention discloses a full-automatic QuECHERS experimental device and an experimental method. The full-automatic QuECHERS experimental device comprises a multifunctional mechanical arm, a cap screwing module, a liquid adding module, a centrifugal module, a salt adding module, a ceramic proton homogenization module, a nitrogen blowing concentration module, a vortex uniform mixing module and anoscillation module, and can automatically complete sample transferring, addition of extraction liquid, extraction salt and ceramic homogenization protons, oscillation uniform mixing, centrifugal separation and vortex uniform mixing actions; A method adopting the full-automatic QuECHERS experimental device to carry out experiments mainly integrates the processes of sample liquid adding extraction,centrifugal separation, solid phase extraction and nitrogen blowing concentration, so that the time is saved, the manual operation is reduced, the automation is improved, and the errors are reduced.

Owner:BEIJING HUIRONGHE TECH

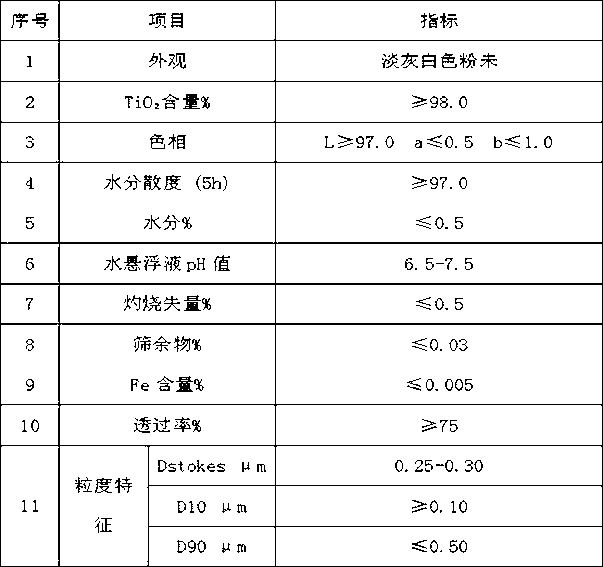

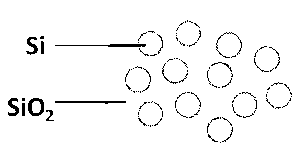

Method for preparing titanium dioxide for delustering chemical fibers

The invention belongs to the field of fine chemical engineering, and particularly relates to a method for preparing titanium dioxide for delustering chemical fibers. The method comprises the following technological flows: slurry making, iron-removal filtering, wet grinding, diluting, iron-removal filtering, grading, surface treatment, washing settling, atomized drying, grinding and packaging. The method provided by the invention has the advantageous effects as follows: 1, the prepared products have controllable particle sizes and stable dispersity; 2, the impurity removal effect is good; 3, the removal effect of soluble slats is good; and 4, the product quality is guaranteed.

Owner:JIAXING GAOSHENG NEW MATERIAL TECH

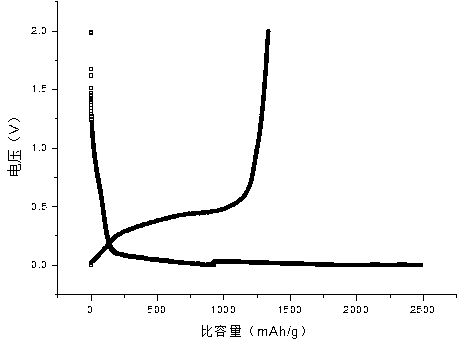

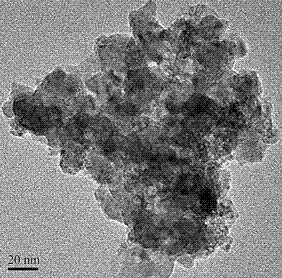

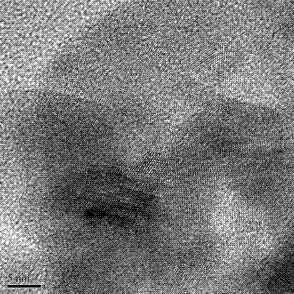

Lithium ion battery silicon-based negative material and preparation method thereof

InactiveCN103236517ASmall particle sizeAlleviate volume effectCell electrodesSilicon monoxideSilicon oxide

The invention relates to a lithium ion battery silicon-based negative material and a preparation method thereof, which belong to the technical field of lithium ion battery negative materials. The lithium ion battery silicon-based negative material is prepared from silicon monoxide; the macroscopic particle diameter of the negative material is 10-25 micrometers; according to a microstructure, the negative material is composed of nanometer silicon particles covered with silica; the internal silicon particle diameter of the negative material is 20-30 nanometers; and at 0.1C discharge rate, the first discharge capacity of the negative material reaches 2010-2640 mAh / g, and is 420-790 mAh / g after 50 cycles. The negative materials with the structure characteristic combines the dispersion and the reduction of silicon particles; and on one hand, the silicon particles can be dispersed by a pore channel structure of silica so as to provide a space for the expansion of silicon in charge and discharge processes, on the other hand, the particle diameter of silicon can be reduced, and therefore, a volume effect of silicon in the charge and discharge processes can be weakened.

Owner:中国东方电气集团有限公司

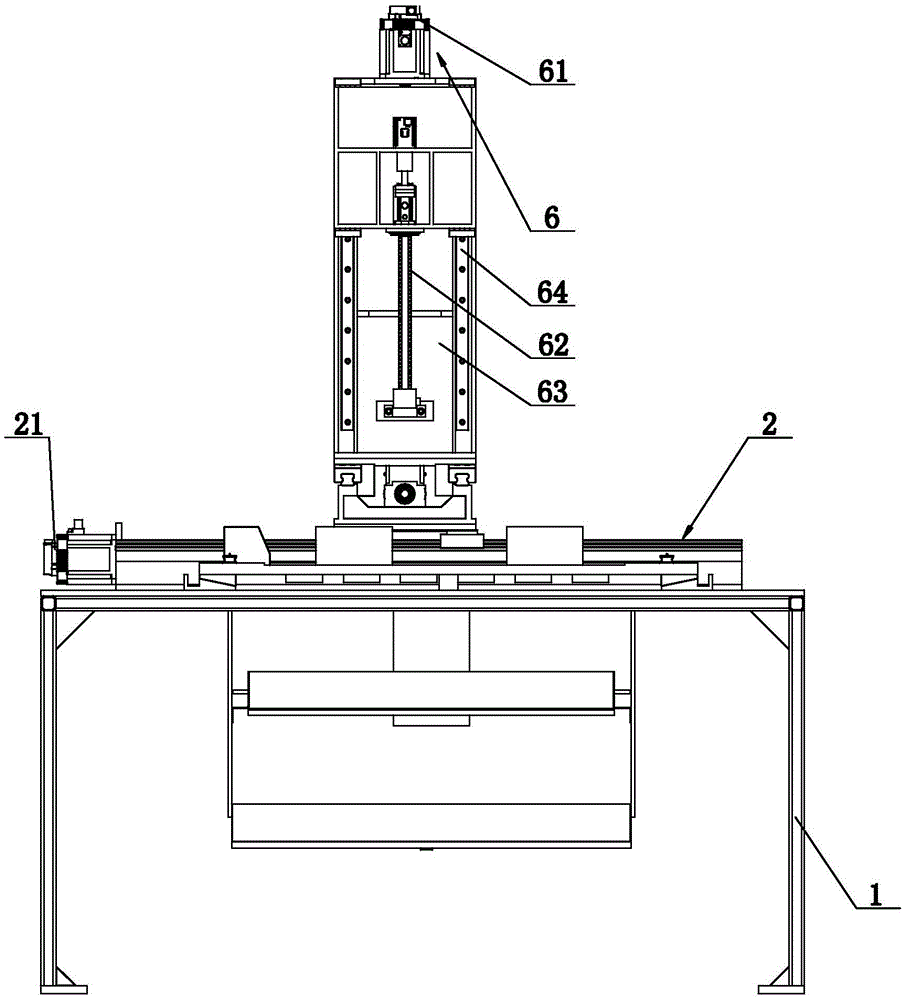

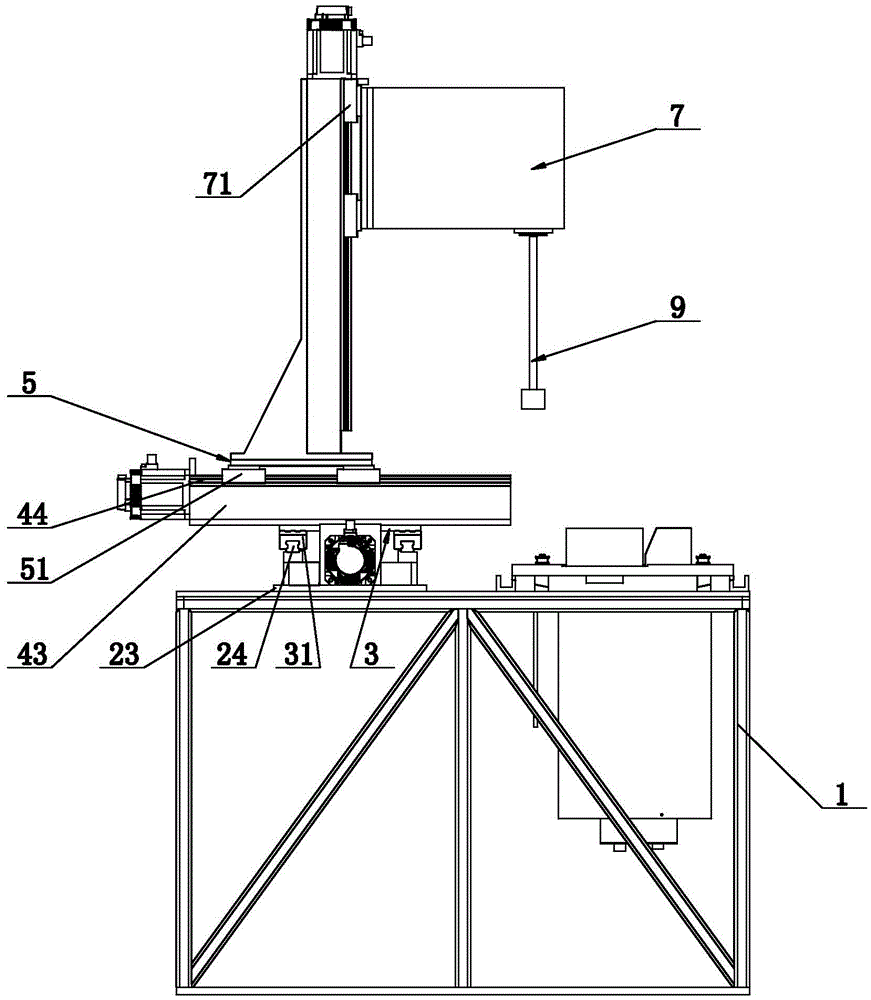

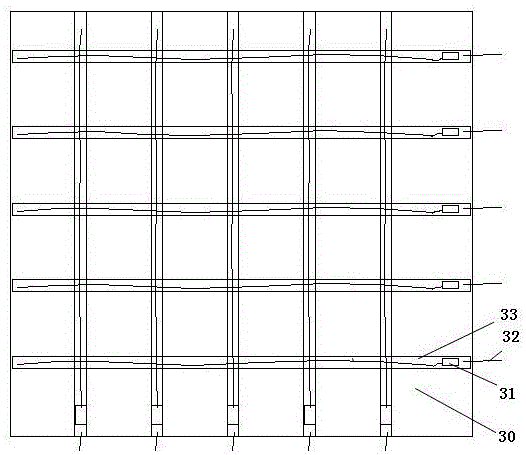

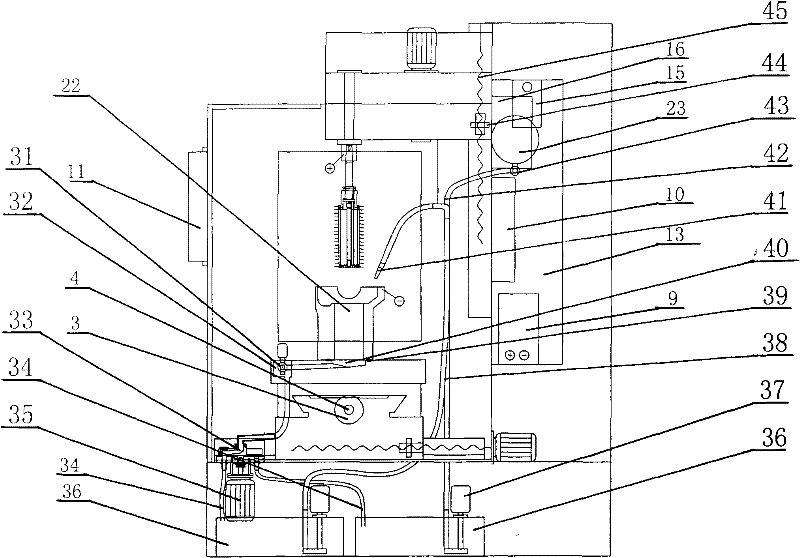

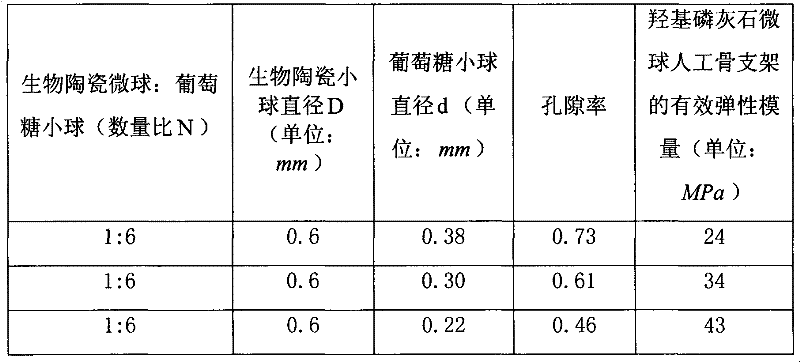

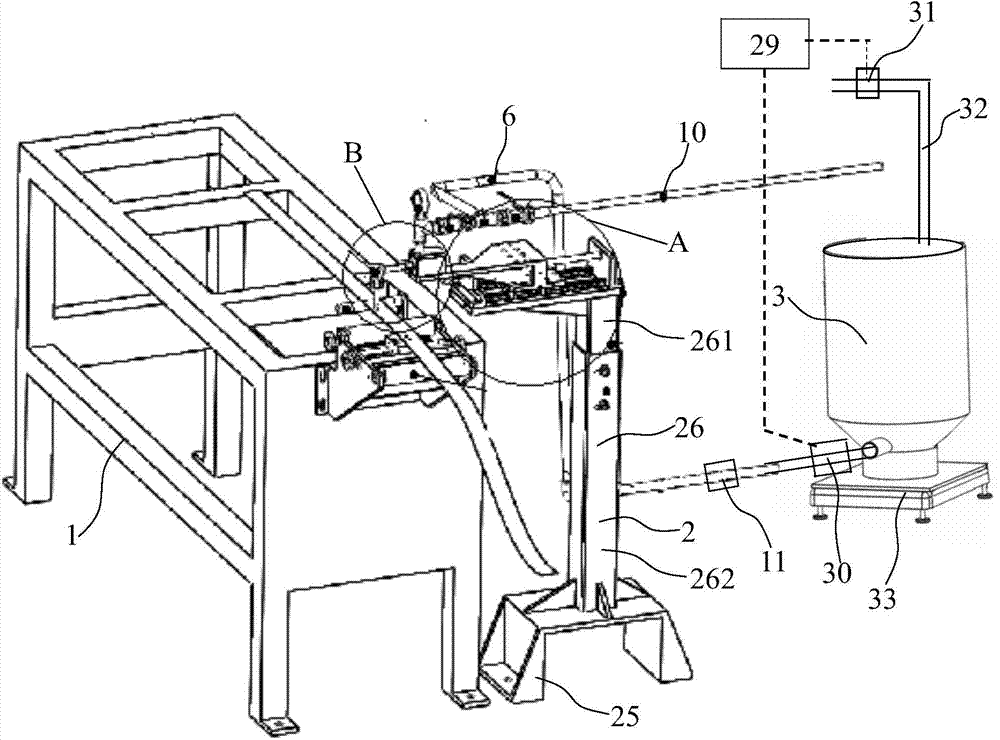

Automatic brush electroplating equipment

The invention discloses automatic brush electroplating equipment belonging to the technical field of engine reproduction equipment. The automatic brush electroplating equipment comprises a rack, wherein the rack is slidably provided with a first slide box driven by a first power device along the X direction; the first slide box is slidably provided with a second slide box driven by a second power device along the Y direction; the second slide box is slidably provided with a third slide box driven by a third power device along the Z direction; the third slide box is rotationally provided with a plating pen driven by a fourth power device and arranged along the Z direction; the side, located on the first slide box, on the rack is fixedly provided with a clamp for clamping a workpiece; and the rack is also provided with a plating solution supply and recovery system. By using the automatic brush electroplating equipment provided by the invention, automatic operation is realized, the motion control is precise, the uniformity of a plating layer is ensured, the labor efficiency is increased, and the repaired workpiece is small in size difference; and the automatic brush electroplating equipment is suitable for mass remanufacture.

Owner:WEICHAI POWER CO LTD

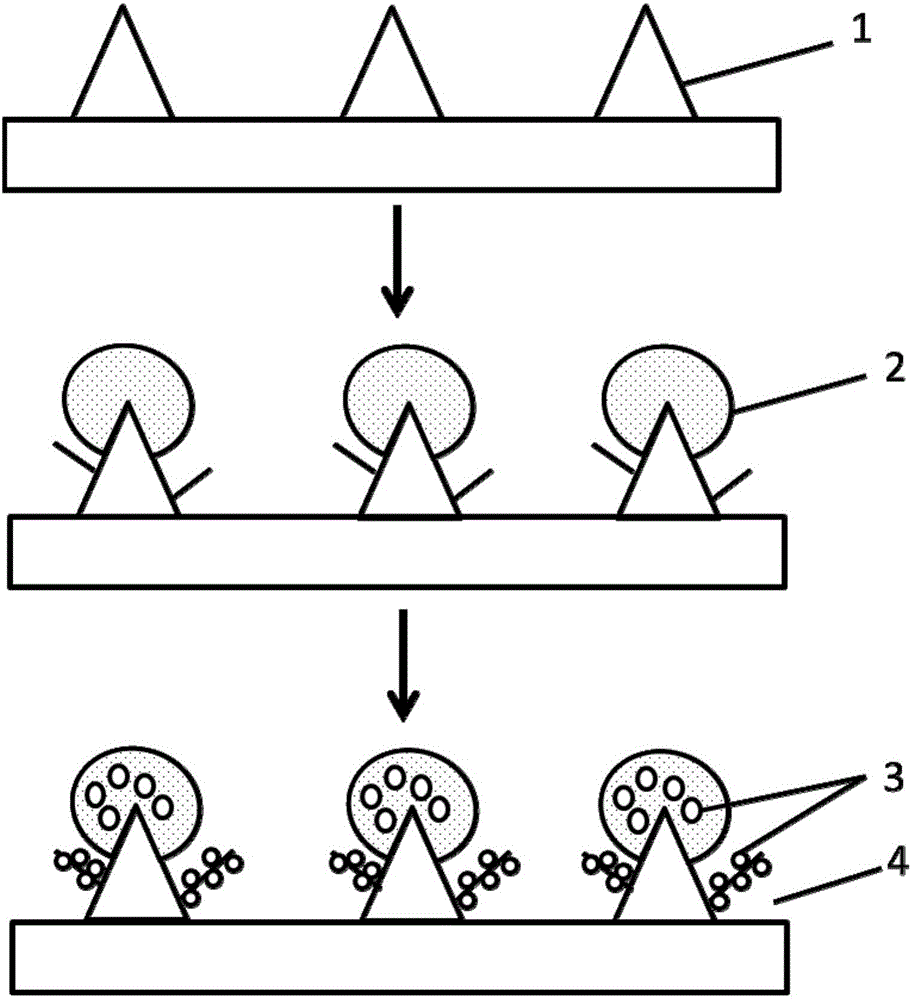

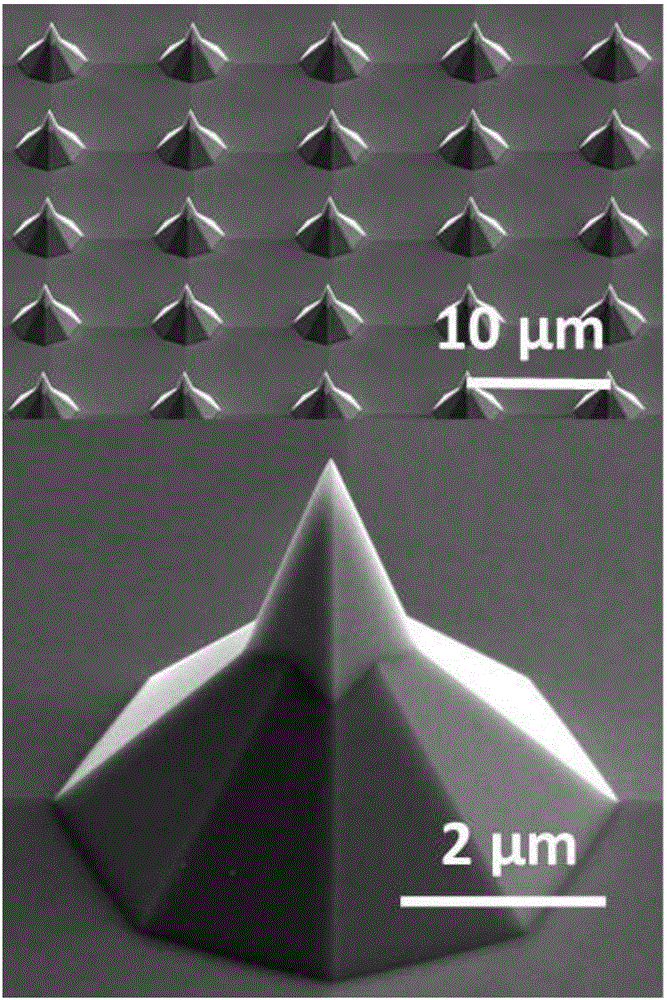

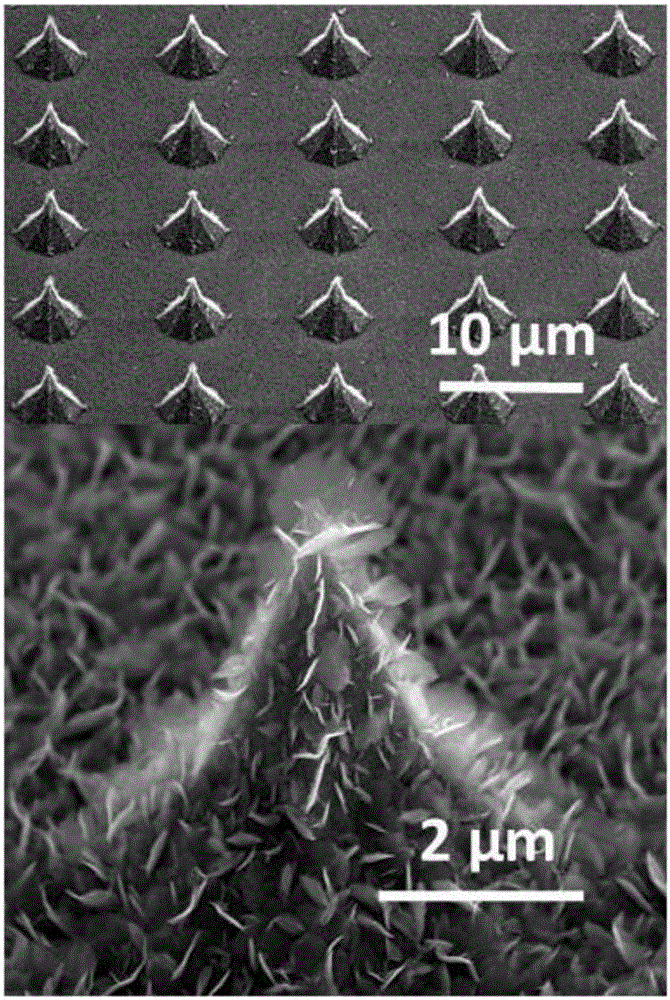

Preparation method for surface-enhanced Raman substrate and surface-enhanced Raman substrate structure

The invention provides a preparation method for a surface-enhanced Raman substrate and a surface-enhanced Raman substrate structure, belonging to the field of preparation of micro-nano structures. The preparation method comprises the following steps: selecting a silicon substrate and etching the silicon substrate to produce a silicon pyramid array; putting the silicon pyramid array into a microwave plasma chemical vapor deposition system for growth of a graphene nanoflake; and coating the surface of the graphene nanoflake with a layer of metal particles so as to obtain the surface-enhanced Raman substrate. The surface-enhanced Raman substrate structure is prepared by using the preparation method. The preparation method in the invention can prepare the uniform surface-enhanced Raman substrate with a large area and ensure the metal particles to be pure and free of contaminations. Meanwhile, the preparation method is simple and convenient, and is low in cost. The surface-enhanced Raman substrate prepared in the invention has strong Raman enhancement characteristics and high sensitivity.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

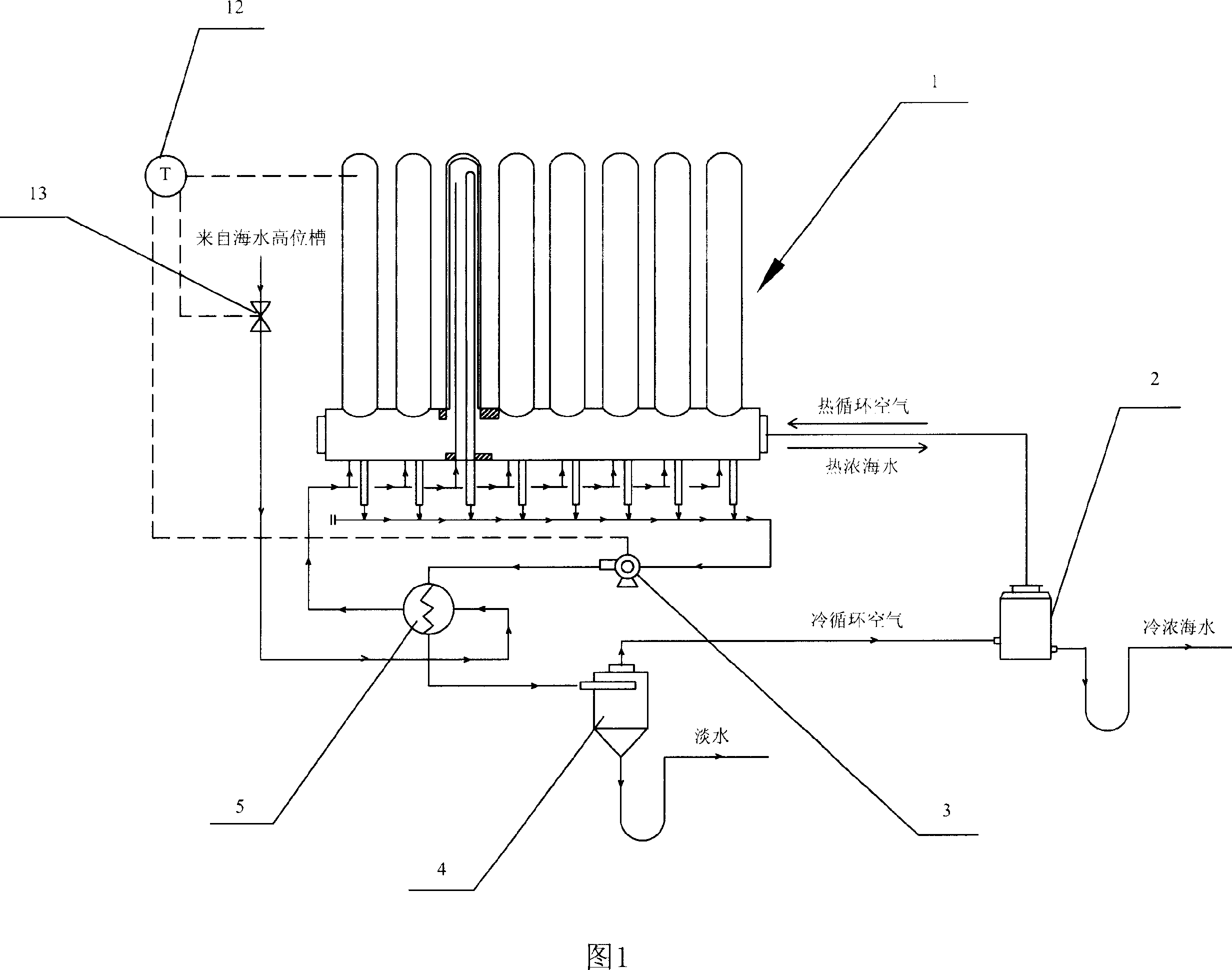

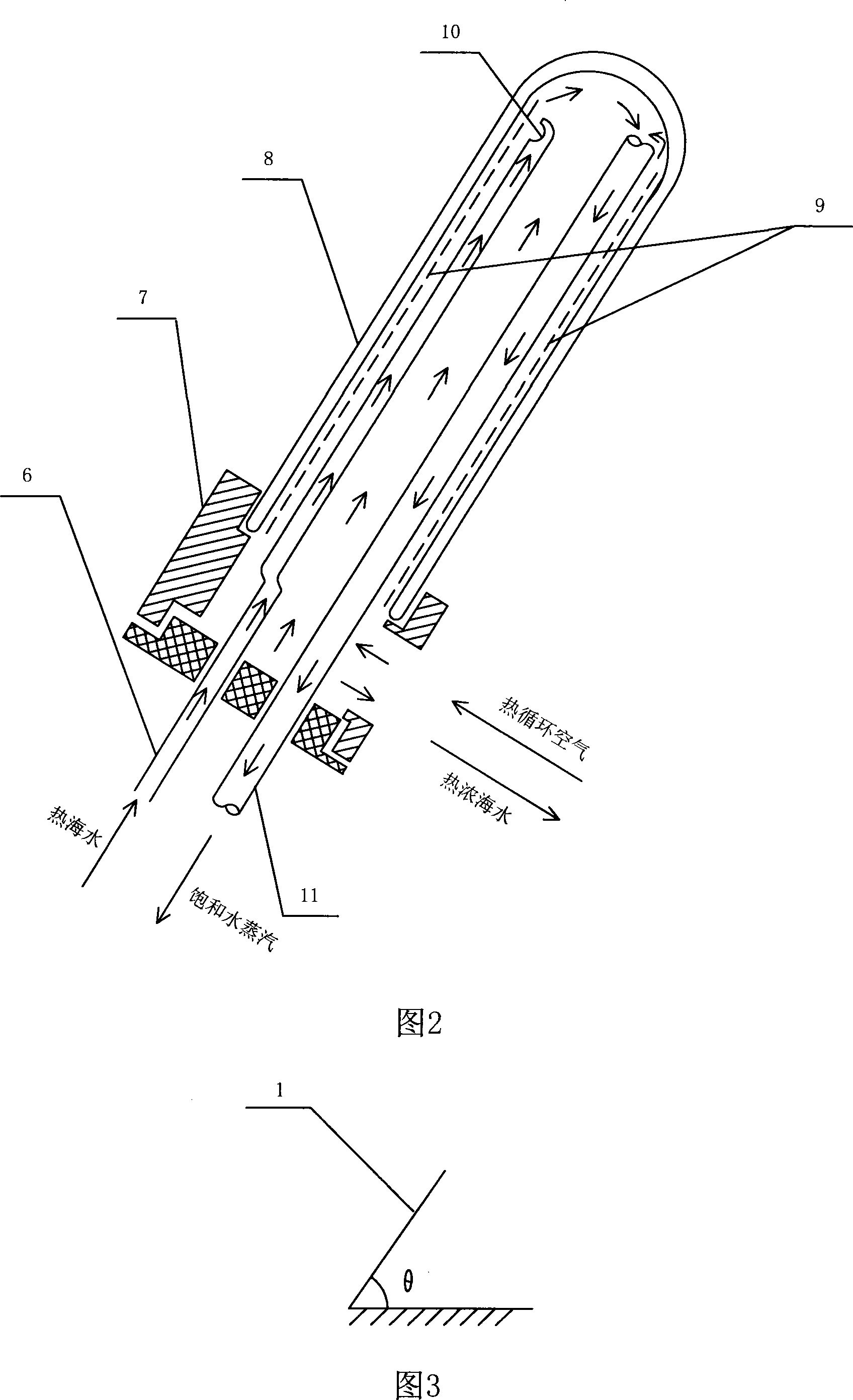

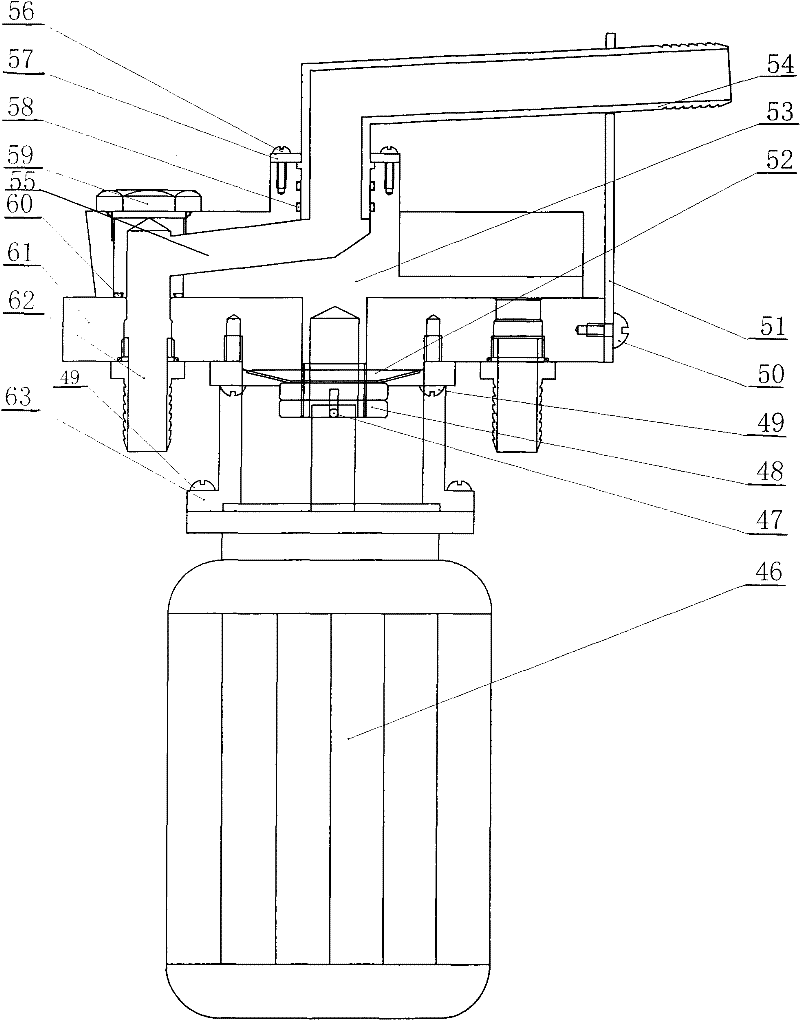

Integral solar energy sea water desalination production apparatus

InactiveCN101117246AIncrease profitIncrease productivitySolar heating energyGeneral water supply conservationTemperature controlWater desalination

The invention discloses an integrated solar energy overall production device for seawater desalting, comprising a heat collecting and diaphragm transferring distiller, a heat exchanger, a blower, a cyclone separator, a temperature sensor and so forth, the distiller consists of a connecting box, a vacuum tube plugged on the connecting box, a seawater input tube inside the vacuum tube and a saturate vapor output tube, the internal side wall of the vacuum is provided with a wet diaphragm; with using the utility model, the heat collecting temperature of solar energy can be controlled within a low heat range from 40 to 60 DEG C, the light-heat exchanging rate can be increased; the side wall at the upper end of the seawater input tube is provided with a water distribution hole, the seawater is sprayed to the wet diaphragm through the water distribution hole, so the processes of heat collecting, diaphragm transferring distillation and micro negative pressure distillation can be conducted simultaneously, a diaphragm distilling area of seawater can be increased, the invention solves the problems where the utilization rate of solar energy light-heat is lower, the production efficiency is low, the clear water is easy to be polluted., etc, the efficiency can be largely increased, the cost is decreased.

Owner:贾海滨 +1

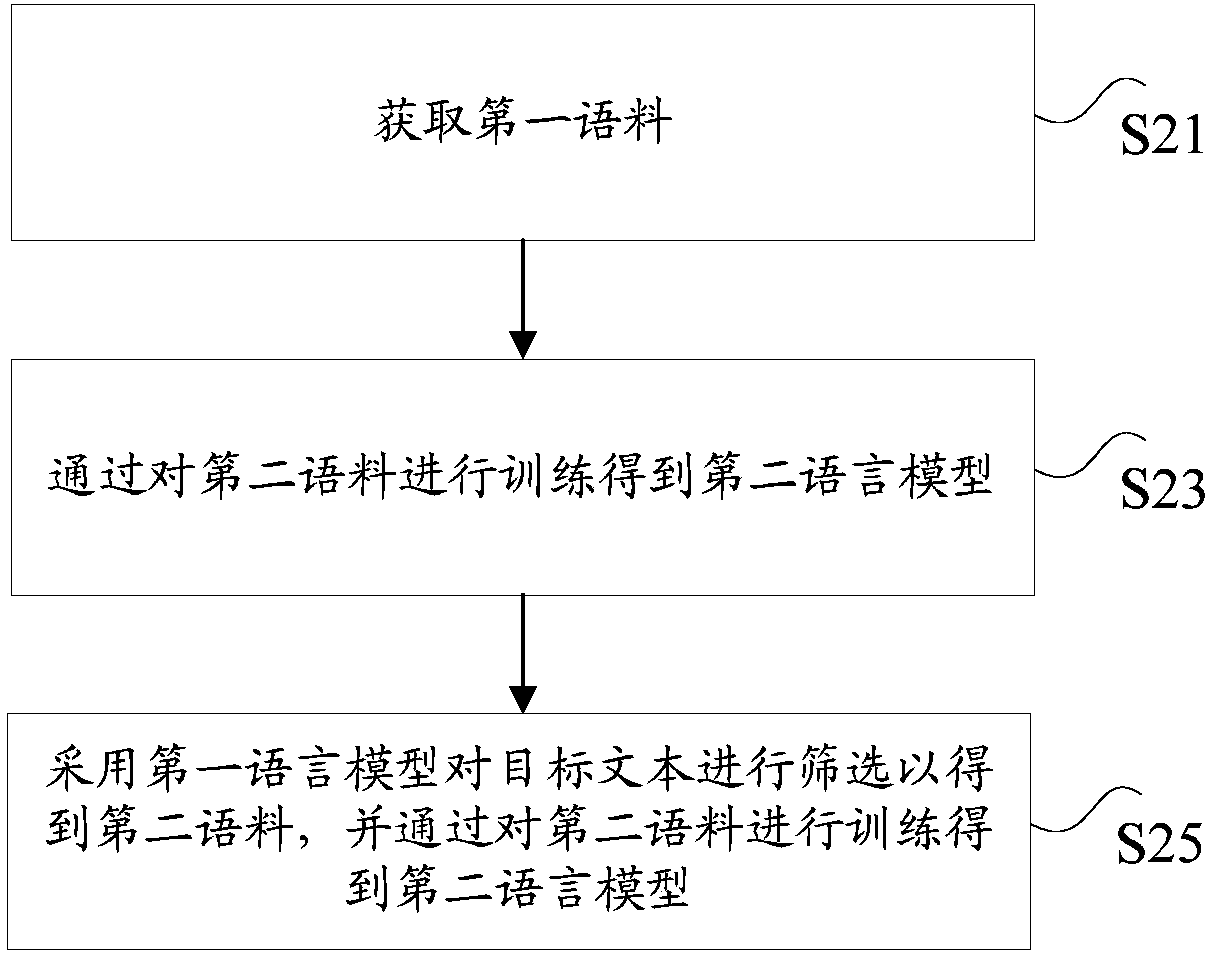

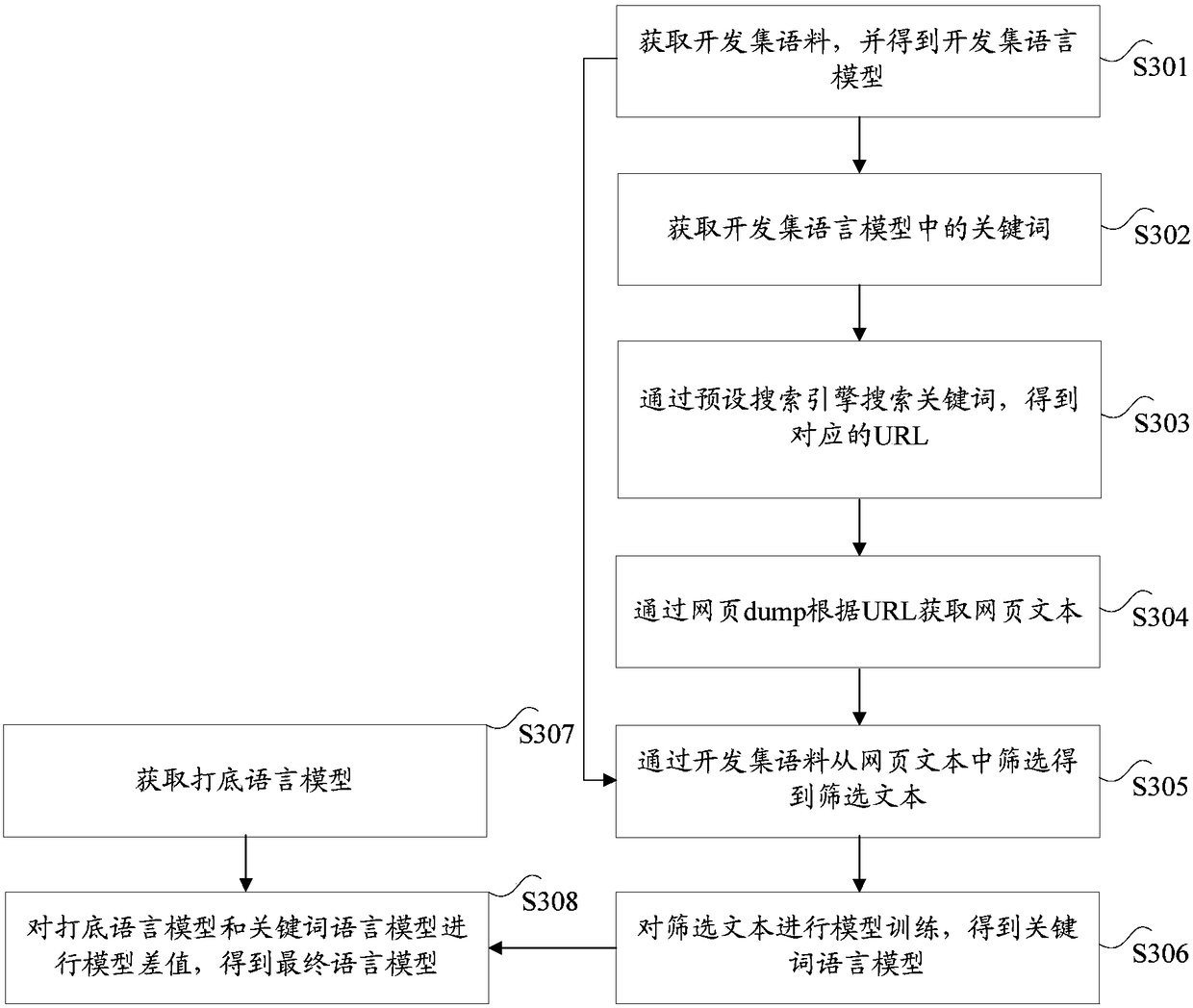

Method and apparatus for determining language model

ActiveCN109388743AStrong correlationGuaranteed pureNatural language data processingSpeech recognitionAlgorithmTarget text

The invention discloses a method and a device for determining a language model. The method comprises the following steps: acquiring a first corpus, wherein the first corpus is a language text selectedin a preset context; Obtaining a first language model by training the first language data; adopting A first language model to filter the target text to obtain a second corpus, and acquiring a secondlanguage model by training the second corpus, wherein the target text is retrieved using a keyword set extracted from the first corpus as an index. The invention solves the technical problem that theperformance of the corpus is low because the language model in the prior art is only acquired through the strategy of piling up the corpus.

Owner:ALIBABA GRP HLDG LTD

Heat dissipation mechanism for gearbox of wind driven generator

PendingCN111412118AImprove cooling effectFast circulationGear lubrication/coolingMachines/enginesWind drivenEngineering

The invention discloses a heat dissipation mechanism for a gearbox of a wind driven generator. A horizontal partition plate is fixedly arranged in an outer case, a water-cooling heat dissipation mechanism is installed at the upper end of the partition plate, a heat dissipation pipe is connected with the water-cooling heat dissipation mechanism, and the heat dissipation pipe extends downwards to the position below the partition plate; and the gear box is located in the middle of the lower end of the outer case, connecting frames are fixedly connected with the lower end of the partition plate, the two connecting frames are located on the two sides of the gear box correspondingly, and the connecting frames are parallel to the side wall, provided with a heat dissipation opening, of the outer case. According to the heat dissipation mechanism, two heat dissipation fans drive air around the gear box to distribution rapidly, low-temperature air dissipates heat of the gear box, the heat dissipation effect on the gear box is improved through air cooling circulation, meanwhile, circulated distribution cooling water in a water cooling heat dissipation mechanism conducts the heat of the gear box, and air cooling and water cooling are carried out synchronously, so that the heat dissipation efficiency and the heat dissipation effect of the gear box are ensured.

Owner:HUANENG NEW ENERGY CO LTD

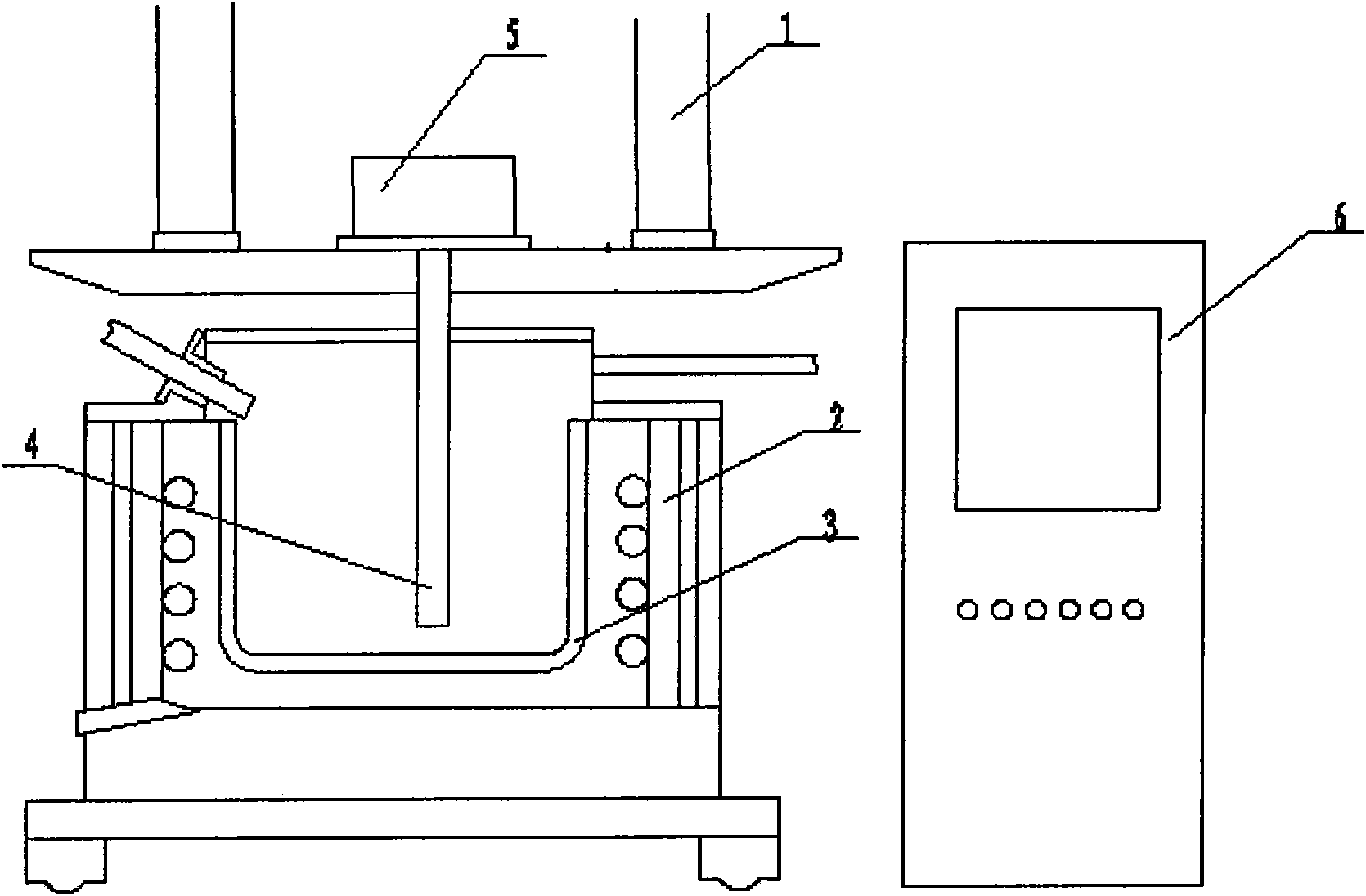

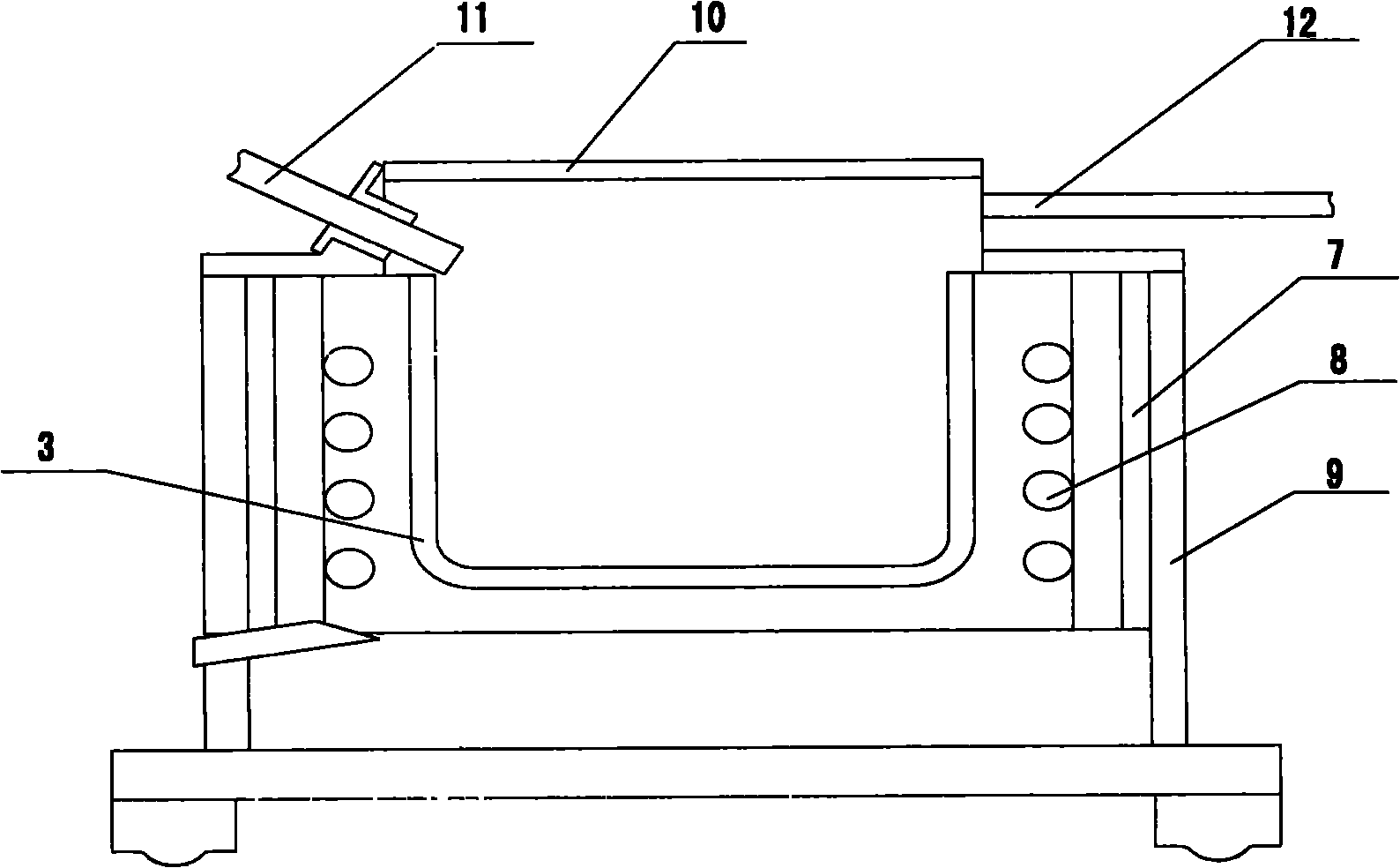

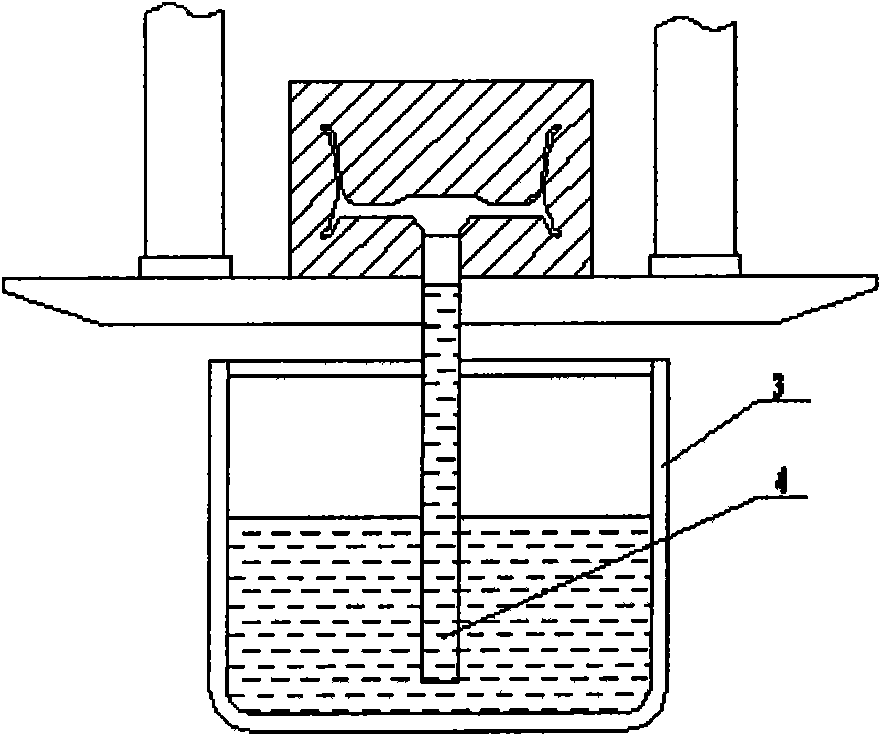

Low-pressure die casting machine for magnesium alloy automobile wheels

The invention discloses a low-pressure die casting machine for magnesium alloy automobile wheels. The low-pressure die casting machine comprises a main casting machine, a holding furnace, a die, a real-time casting monitoring console and a liquid lifting tube, wherein, the die and the holding furnace which are arranged above the main casting machine are communicated with each other through the liquid lifting tube; the holding furnace comprises a furnace lining, an electrical heating wire, a furnace shell, a crucible, a furnace cover, a fully enclosed liquid filler and a protective gas access device; the furnace shell is internally equipped with the crucible; the furnace lining is arranged between the furnace shell and the crucible, and the inner side of the furnace lining is equipped with the annular electrical heating wire for heating the crucible; and the furnace cover is arranged above the furnace shell, the furnace cover and the furnace shell are sealed by a high-temperature resistant seal ring, and the furnace cover is equipped with the fully enclosed liquid filler, the protective gas access device and the liquid lifting tube. In the invention, a die temperature gradient field conforming to the requirement is established, the furnace temperature can be monitored in real time and the casting quality of the magnesium alloy product is improved.

Owner:江苏圆通汽车零部件有限责任公司

Preparation method of copper zinc tin sulfide/graphene oxide composite semiconductor photocatalyst

InactiveCN103611549AImprove solubilityAccelerated corrosionPhysical/chemical process catalystsWater/sewage treatment by irradiationZinc compoundsSulfur

The invention discloses a preparation method of a copper zinc tin sulfide / graphene oxide composite semiconductor photocatalyst. The photocatalyst comprises copper zinc tin sulfide coated by graphene oxide. The preparation method comprises the following steps: step 1) uniformly mixing and dispersing 0.05%-0.2% of graphene oxide, 32%-34% of copper compound, 16%-18% of zinc compound, 21%-23% of tin compound and 26%-29% of sulfur compound in a carrying solution to form a precursor solution; step 2) enabling a reaction precursor to react at high temperature so as to prepare the copper zinc tin sulfide / graphene oxide composite semiconductor photocatalyst. The copper zinc tin sulfide / graphene oxide composite compound photocatalyst prepared by the preparation method disclosed by the invention improves the resistance to light dissolution and the resistance to light corrosion, and enables the photocatalyst to stably degrade organic pollutants in a water body for a long time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

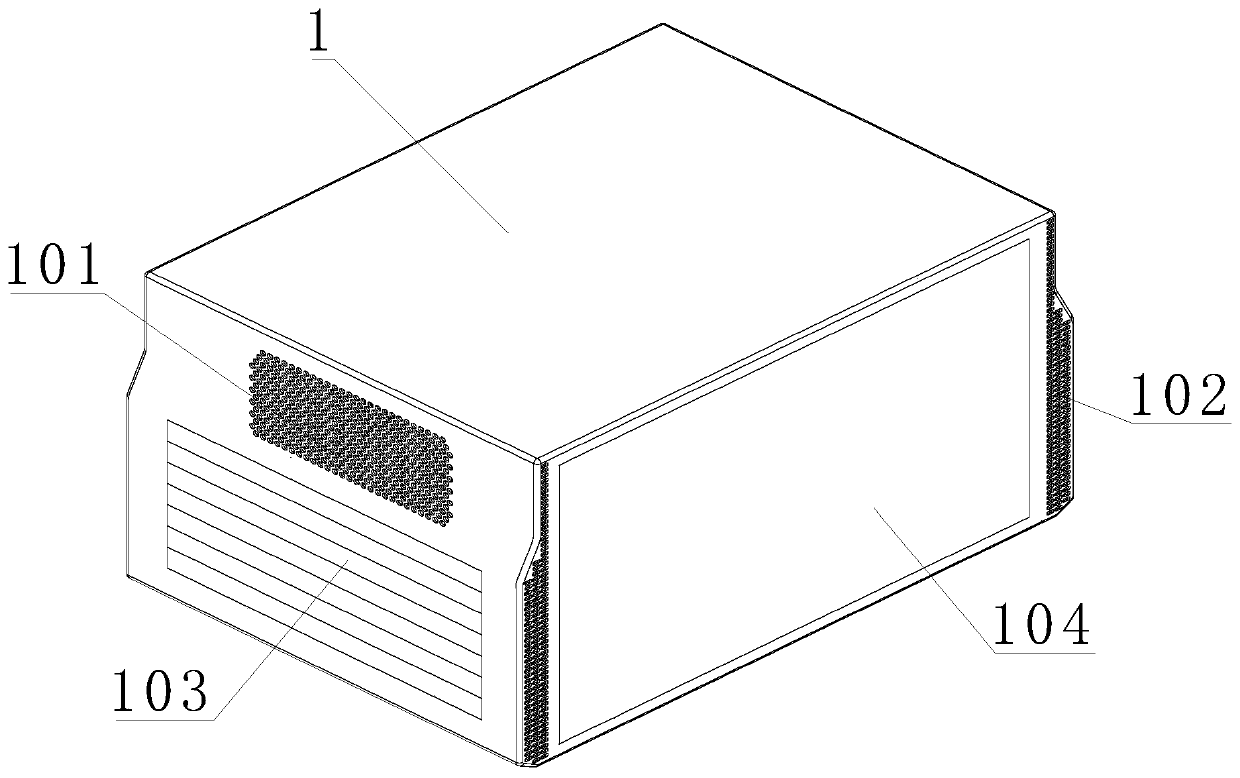

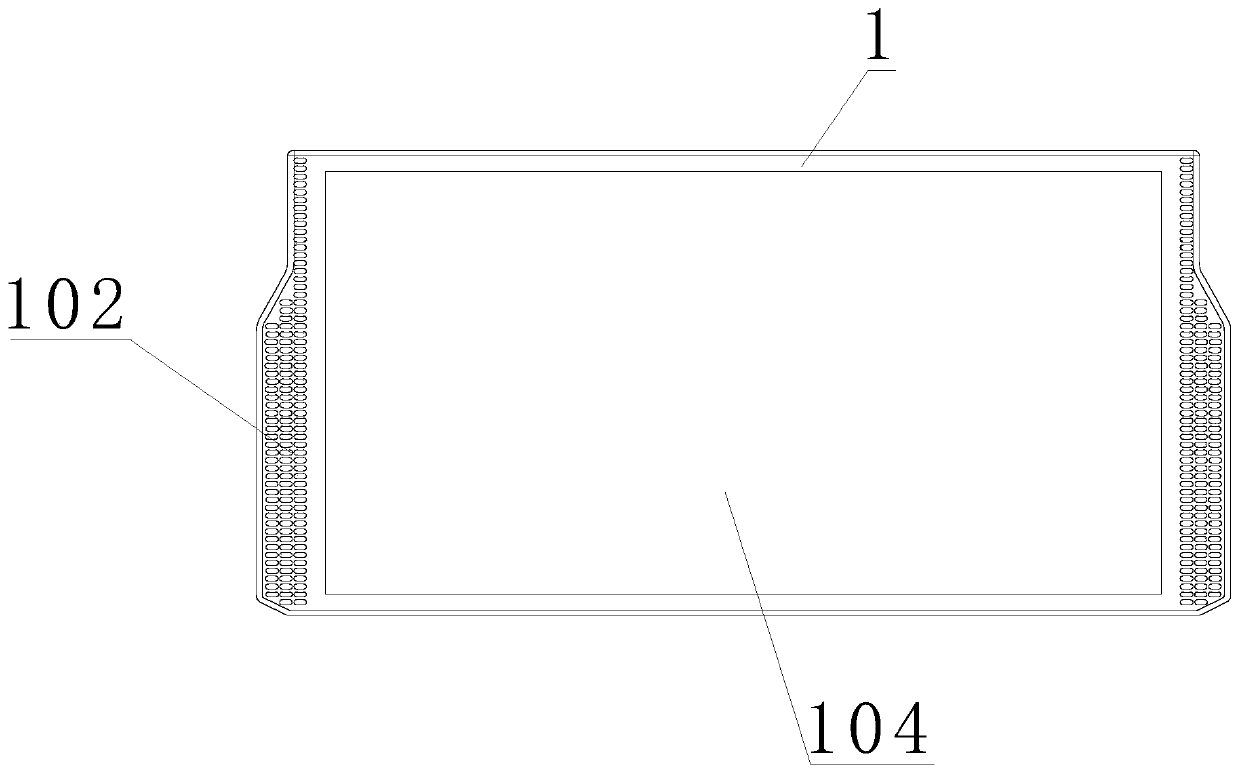

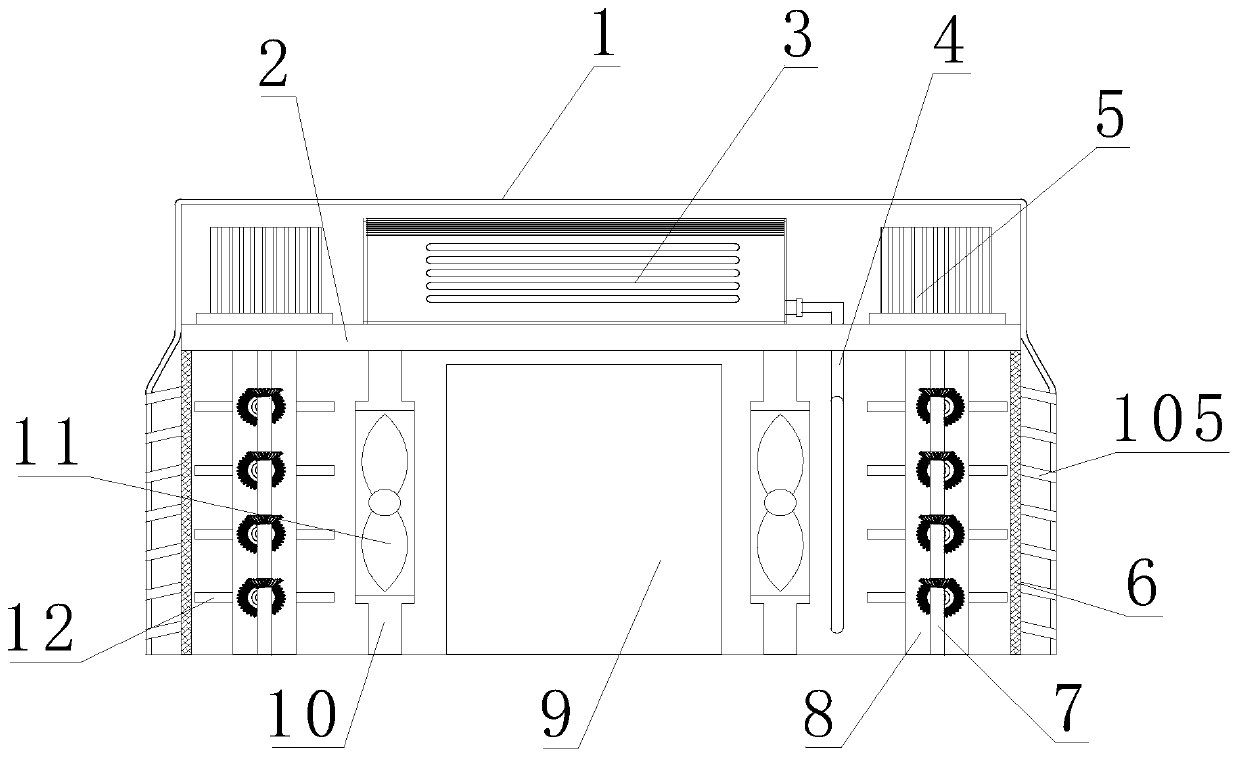

Intelligent indoor air replacement and purifying device and method

InactiveCN106152288AAvoid cloggingSolution to short lifeMechanical apparatusSpace heating and ventilation safety systemsGas detectorCarbonization

The invention discloses an intelligent indoor air replacement and purifying device and method and belongs to the field of indoor and outdoor fresh air purifying devices. The indoor air replacement and purifying device is internally provided with a plurality of filters comprising the heating carbonization ceramic filter, the bilateral rotation draught fan and the conical ceramic filter; the heating carbonization ceramic filter and the conical ceramic filter are spongy micropore ceramic filters; the upper portion of the heating carbonization ceramic filter inclines towards the outer side; the periphery of the intelligent indoor air replacement and purifying device is provided with an automatic sample connection communicating with the interior of a room; the automatic sample connection is provided with a gas detector; the intelligent indoor air replacement and purifying device is internally provided with an electric current detector and further configured with an intelligent controller; the acquisition cost of an air purifying device, the consumable investment and the installation and maintenance cost can be reduced through the intelligent indoor air replacement and purifying device; the air purifying effect of the intelligent indoor air replacement and purifying device is improved; the device manufacturing cost is reduced; and intelligent operation of the air purifying device is achieved.

Owner:ANYANG HENGAN MOTOR

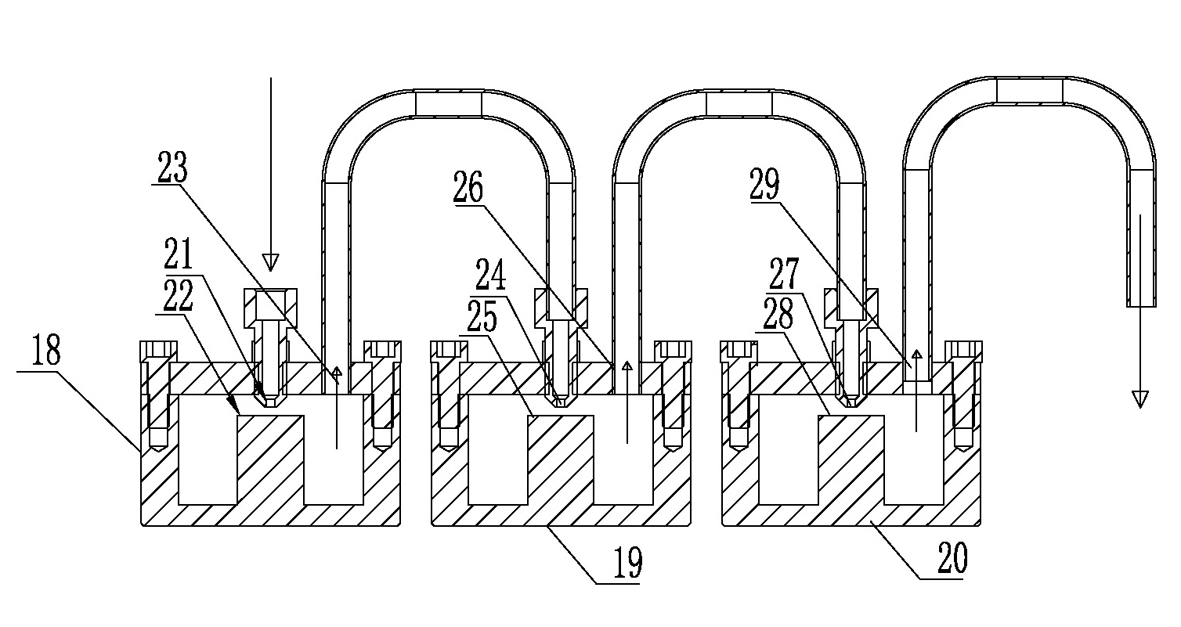

Engine cylinder body full-automatic vertical electro brush plating equipment

The invention discloses engine cylinder body full-automatic vertical electro brush plating equipment with X, Y and Z three-dimensional slide guides to perform accurate positioning, wherein the working procedure and the steps are controlled by a microcomputer procedure. The equipment comprises a 'plating solution providing and recovering system' which automatically injects according to the working procedure and storing in a classifying and recovering way with a solution dividing pan; a 'centered plating head' which is installed on a main spindle box on the Z slide guide, is provided with electrolysis material, and is connected with a sealed chamber; a nonmetal 'insulating platform' with the multifunction of insulating, self-weight multi-position sealing, plating solution collecting and positioning work piece bearing; a cylindrical 'temperature-increasing system' which is hung behind a shield cover for heating cleaning water before and after changing the solution; a 'temperature-reducing system' of a microcomputer and a program control electrical cabinet large-power brush plating electric source; an 'exhausting device' for volatilizing gas of the plating solution; and a 'vertical electro brush plating center' which performs one-off clamp multi-work position electro brush plating repair for worn and broken 'multi-pore workpieces' and can be continuously produced with large power and on a large scale.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

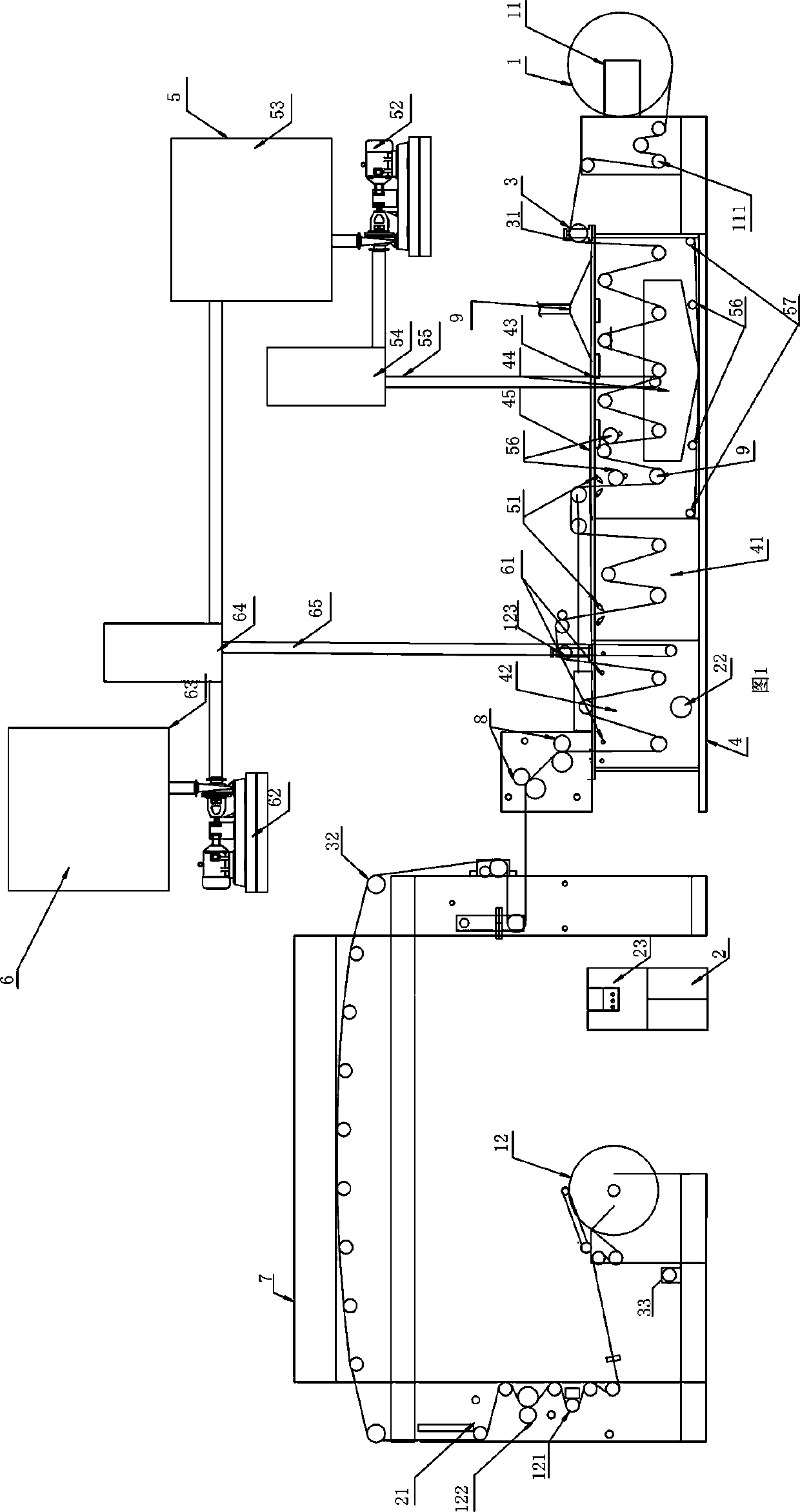

Method and device for removing aluminum of base membrane

ActiveCN103990620AImprove utilization efficiencyReduce usageDirt cleaningCleaning using toolsSuspended matterChemistry

The invention discloses a method for removing aluminum of a base membrane. The method is characterized by including the following steps: (1) feeding the base membrane with the surface containing an aluminum coated layer into a cleaning solution to carry out aluminum removing, (2) feeding the base membrane into clear water to carry out cleaning, and (3) drying the base membrane. A device for removing the aluminum of the base membrane is adopted in the method for removing the aluminum of the base membrane and comprises a cleaning groove, a base membrane reeling-unreeling mechanism and a drying oven. The cleaning groove is divided by a partition plate into a cleaning solution groove and a clear water groove, the drying oven is located behind the cleaning groove, and the base membrane reeling-unreeling mechanism sequentially passes through the cleaning groove and the drying oven. The device for removing the aluminum of the base membrane is characterized by further comprising a cleaning solution circulation filtering mechanism. According to the method and device, the cleaning solution circulation filtering mechanism is additionally arranged in an aqueous alkali circulation system, the cleaning solution located at the top is overflowed from the cleaning solution groove to the cleaning solution circulation filtering mechanism, suspended matter in the cleaning solution is filtered out, the filtered cleaning solution returns to the interior of the cleaning solution groove again through circulation to be continuously used, and the use efficiency of the cleaning solution is improved.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

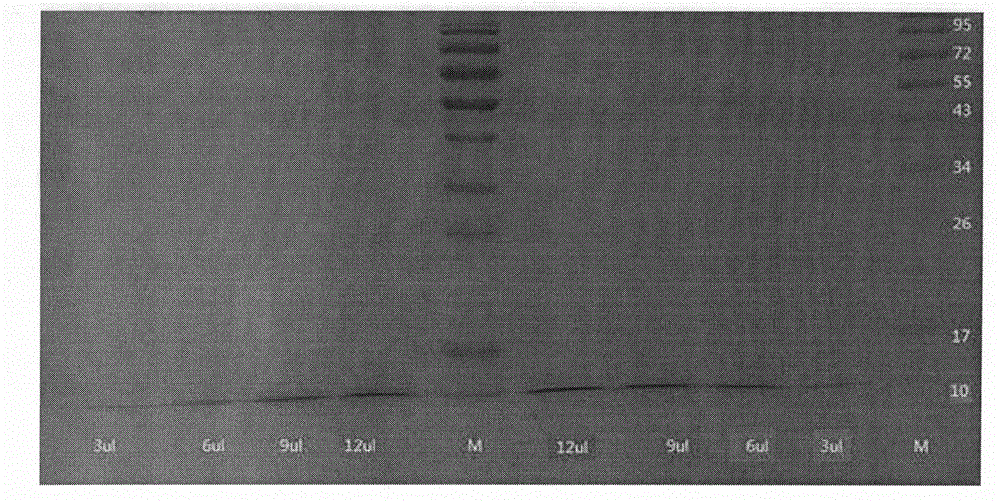

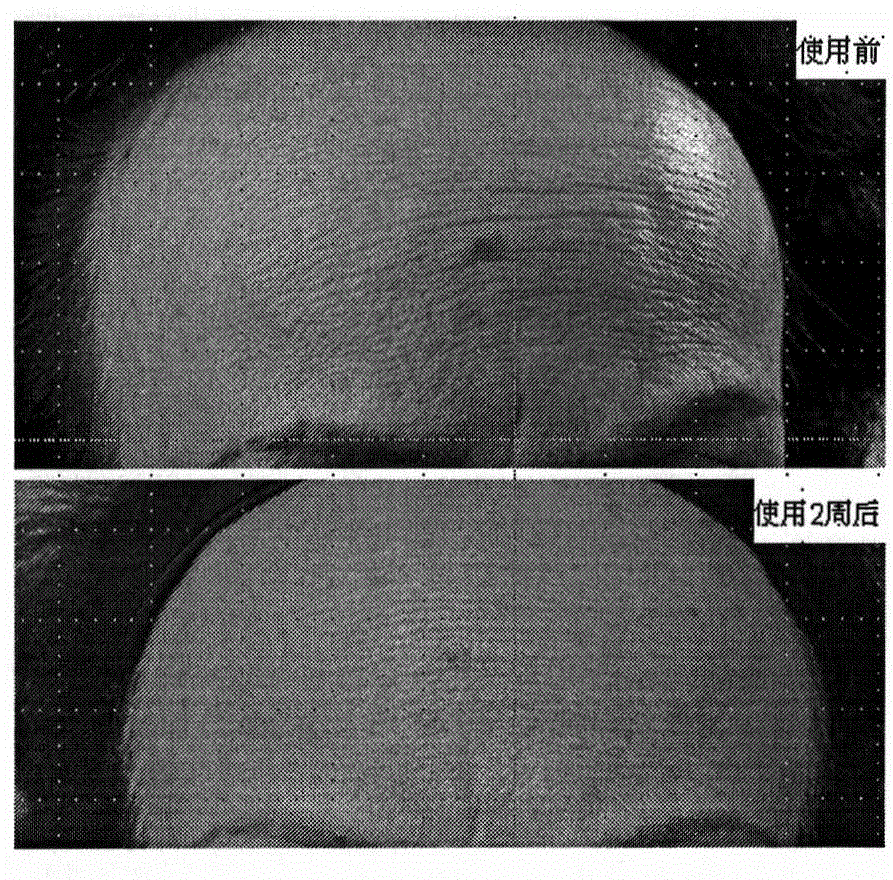

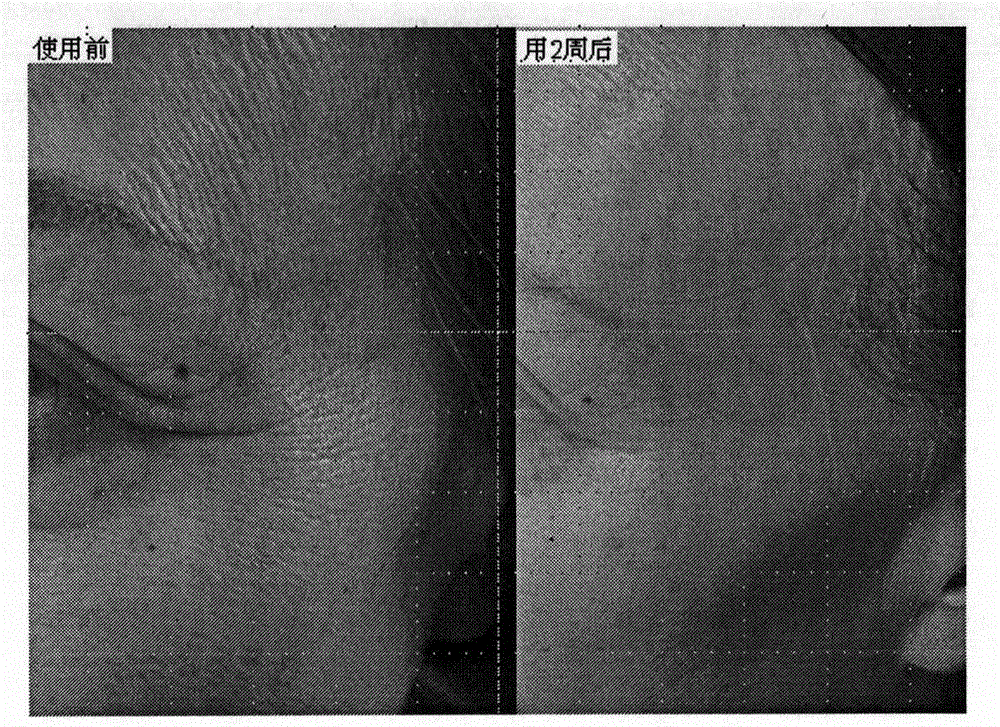

Extraction method of micromolecular sheep placenta extract and application of micromolecular sheep placenta extract in field of skin-care products

InactiveCN104382825AReduce energy consumptionIncrease usageCosmetic preparationsToilet preparationsUltrafiltrationPlacenta extract

The invention discloses an extraction method of a micromolecular sheep placenta extract and application of the micromolecular sheep placenta extract in the field of skin-care products, belonging to the technical field of biology. The extraction method disclosed by the invention comprises the following steps of obtaining a lot of sheep pregnant in the same period by adopting synchronization of estrus, taking out sheep fetus after 85-100 days through an operation method to obtain body homogenate, carrying out repetitive freeze-thawing and splitting cells, degenerating at high temperature, sterilizing, precipitating hybrid protein, carrying out 30 KD ultrafiltration after centrifuging at high speed so as to remove toxic and harmful components and impurities, such as macromolecular hybrid protein, bacteria and endogenous virus, so as to obtain a pure micromolecular sheep placenta extract product, and carrying out ultrafiltration and concentration of the micromolecular sheep placenta extract product by using a 1 KD ultrafiltration component. The micromolecular sheep placenta extract disclosed by the invention can be widely used in the fields of skin-care products, beauty products, wound healing products, health-care products, scientific searches and the like; the extraction method disclosed by the invention provides a novel important way for producing the sheep placenta extract; furthermore, the compositions of the micromolecular sheep placenta extract are authenticated for the first time, and thus, theoretical foundation is provided for scientifically using the sheep placenta extract.

Owner:SHANGHAI TAO TAO ENG

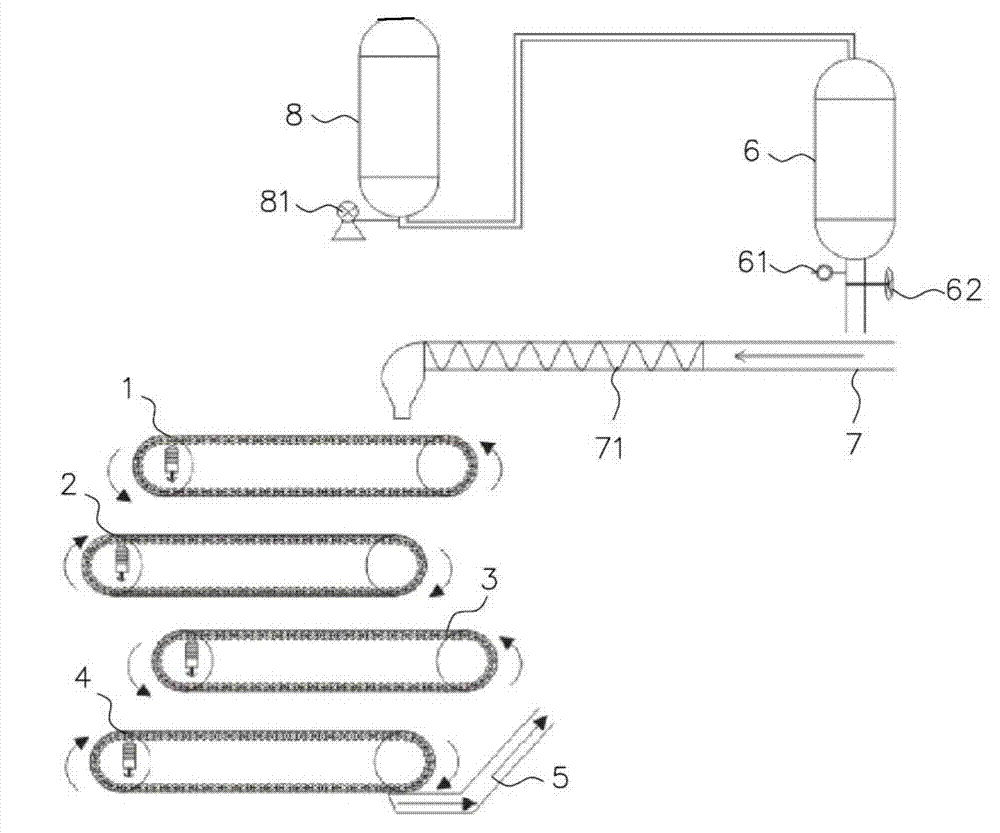

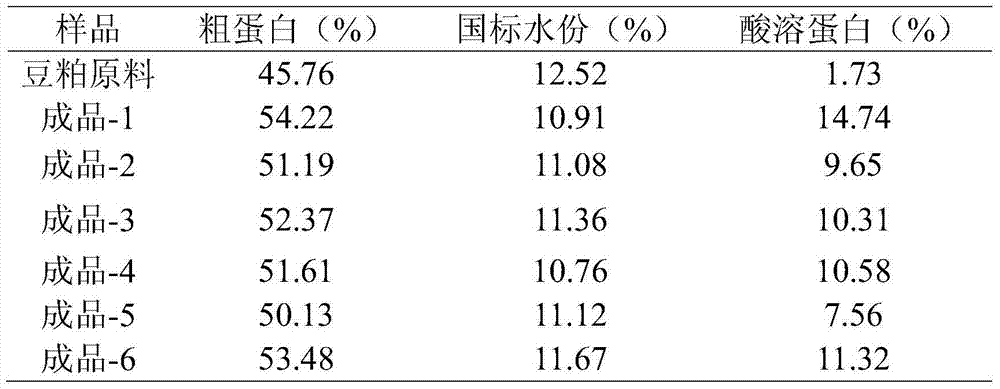

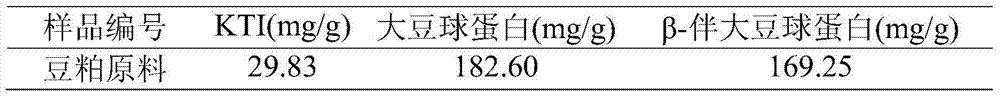

Method for producing bean pulp feed additive

ActiveCN103609864AAvoid unnecessary effects of fermentative transformationGuaranteed pureAnimal feeding stuffFood preparationBiotechnologySmall peptide

The invention discloses a method for producing a bean pulp feed additive. The method comprises the following steps: inoculating bacillus subtilis (Bacillus subtilis) CGMCC No.7690 into a seed medium and cultivating, so as to prepare a seed solution; inoculating the seed solution into a liquid fermentation medium, and gradually carrying out 10-fold amplified fermentation for 2-4 times, so as to obtain a liquid fermented bacterium solution; inoculating the liquid fermented bacterium solution into sterilized bean pulp; carrying out solid fermentation by virtue of a fermentation bed, controlling the temperature of the fermentation bed at 25-60 DEG C, the throughput at 0.1-10 L / min, and the fermentation time at 24-96 hours; reversing the materials for 1-5 times during fermentation, so as to obtain the bean pulp feed additive. Single-strain liquid-solid combined fermentation is carried out by adopting the bacillus subtilis; in the obtained bean pulp feed additive, the small peptide content and the crude protein content are significantly increased, and anti-nutritional factors are greatly degraded.

Owner:浙江科峰生物技术有限公司

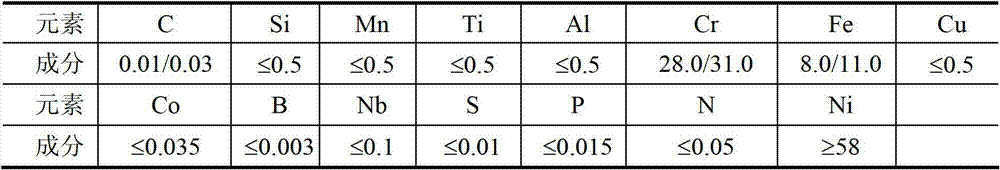

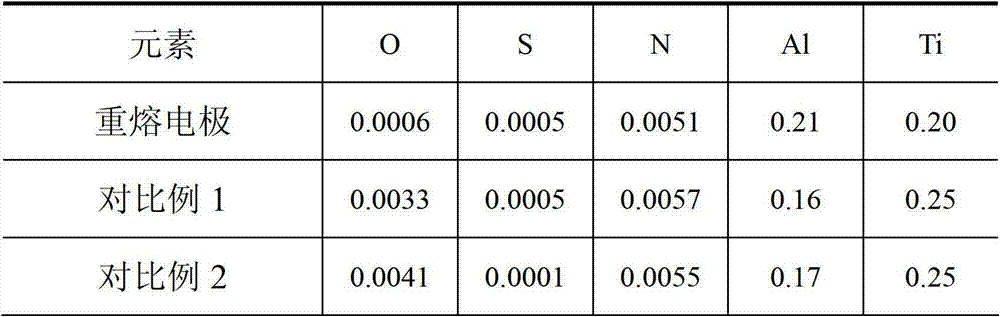

Process method for producing 1 ton of I-690 alloy electroslag remelted ingot in industrialized mode

The invention belongs to the technical field of electroslag remelting, relates to improvement on a process for producing Inconel 690 alloy electroslag remelted ingot in an industrialized mode, in particular to a process method for producing 1 ton of I-690 alloy electroslag remelting ingot in an industrialized mode. A vacuum induction furnace smelts an electrode bar of phi 240 mm; the size of a crystallizer is phi 340 / 380*1,500 mm; the remelting process parameters comprise: remelting voltage of 47 to 55 V, current of 7,500 to 8,500 A and slag quantity of 38 to 45 kg; according to the I-690 alloy component requirement, the remelting adopts a new proportioned pentabasic slag system; the components comprise calcium fluoride, calcium oxide, aluminum oxide, magnesium oxide and titanium dioxide; the purity of each component is required to be more than 98.5 percent; the total content of unstable oxide impurities such as manganese oxide, ferrous oxide and silica is less than 0.5 percent; the granularity is less than 50 meshes; before the remelting process, the electrode is roasted at the temperature of 700 DEG C for 8 to 12 hours and the slag is roasted at the temperature of 680 DEG C for 8 to 12 hours for use; and in the remelting process, argon and burning gas are adopted for protection. By the process, the content of the remelted I-690 alloy is reduced to be below 20 ppm, the sulfur content is reduced to be below 5 ppm, oxide inclusion is effectively removed, and high-quality remelted alloy is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

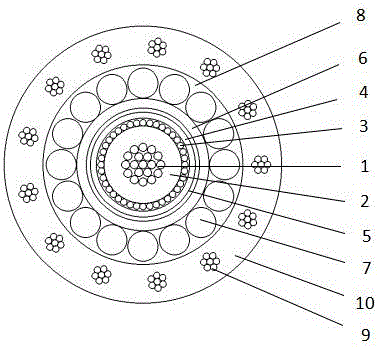

WMF series sealed wear-resisting load-bearing detection cable

ActiveCN106057310AThe shielding effect is thoroughSignal transmission is stableFlexible cablesFlexible conductorsEngineeringWire rope

The invention discloses a WMF series sealed wear-resisting load-bearing detection cable comprising a conductor, an insulating layer, a shielding layer, armor layers, and a sheath layer. The cable is characterized in that the armor layers include an inner armor layer and an outer armor layer; the inner armor layer is formed by twisting multiple round steel wires; and the outer armor layer includes multiple steel wire ropes, and each steel wire rope is formed by twisting multiple fine and soft steel wires. Metal instead of a semi-conductive material is used for shielding purpose, so the shielding effect is more thorough, and signal transmission is more stable. The gaps between the steel wires, between the inner armor layer and the outer armor layer and between the cable and a choke tube are filled with sealant or an extrusion sheath, so it is less difficult to put the cable underground, the service life is prolonged, and environmental pollution is reduced greatly. The outer armor layer is composed of multiple strands of wire ropes instead of multiple round steel wires, so the flexibility and tensile strength of the cable are improved greatly.

Owner:山东希尔电缆有限公司

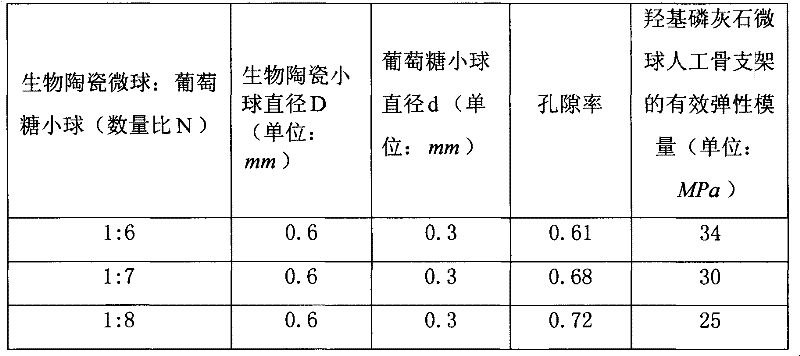

Preparation method of artificial bone support with controllable porosity

The invention discloses a preparation method of an artificial bone support with controllable porosity, which comprises the following steps of: establishing a CAD (Computer-Aided Design) model according to the individual characteristics of patients; introducing the model into a three-dimensional printer; analyzing a particle flow software number value computing result according to a disperse number value; and mixing biological ceramic small balls and biological instantly-dissolved small balls according to a certain proportion; and spraying biological adhesive through the three-dimensional printer to adhere the mixed balls so as to prepare the artificial bone support. In order to overcome the defect that in the prior art, during the preparation process, sintering can cause pollution, in the invention, the porosity is obtained by instantly dissolving the instantly-dissolved small balls into the biological dissolved solution, so that the pollution of the sintering and chemical reaction during the preparation process on the artificial bone support can be avoided, and in addition, by controlling the number and the radius of the instantly-dissolved small balls, the biological ceramic artificial bone support with a certain mechanical property and porosity can be obtained.

Owner:西安博恩生物科技有限公司

Intelligent gel coating device for optical fiber cables

ActiveCN104749720AControl application amountGuaranteed pureLiquid surface applicatorsSpraying apparatusSpray nozzleEngineering

The invention discloses an intelligent gel coating device for optical fiber cables. The intelligent gel coating device comprises a longitudinal covering rack, a support frame, a gel storage tank, a spraying head mechanism, a microcontroller, an electronic scale and a support mechanism, two X-direction linear rails are fixed on the surface of a base station of the support frame, the spraying head mechanism is mounted on a carrying plate and comprises a gel storage cavity, one end of the gel storage cavity is connected with a first port of a tee joint, a second port and a third port of the tee joint are connected with a gel inlet pipe and a pressure gauge respectively, the other end of the gel storage cavity is connected with a gel spraying nozzle, one support rod and the support mechanism are disposed on two sides of the gel spraying nozzle respectively and below the same, passages for conveying a metal strip are formed between the gel spraying nozzle and the support rod as well as between the spraying nozzle and the support mechanism, a gel supplying pipe is connected to the upper portion of the gel storage tank, an electric valve is mounted on the gel supplying pipe, the microcontroller is connected to a servo motor, the electronic scale and the electric valve, and the servo motor is mounted on a gel delivering pipe. The intelligent gel coating device for the optical fiber cables has the advantages that positions of the gel spraying head and the metal strip can be adjusted conveniently, position accuracy in gel spraying is guaranteed, quantity of gel stored in the gel storage tank can be judged automatically, and gel storage and full automation in gel supply are achieved.

Owner:JIANGSU HENGTONG PHOTOELECTRIC

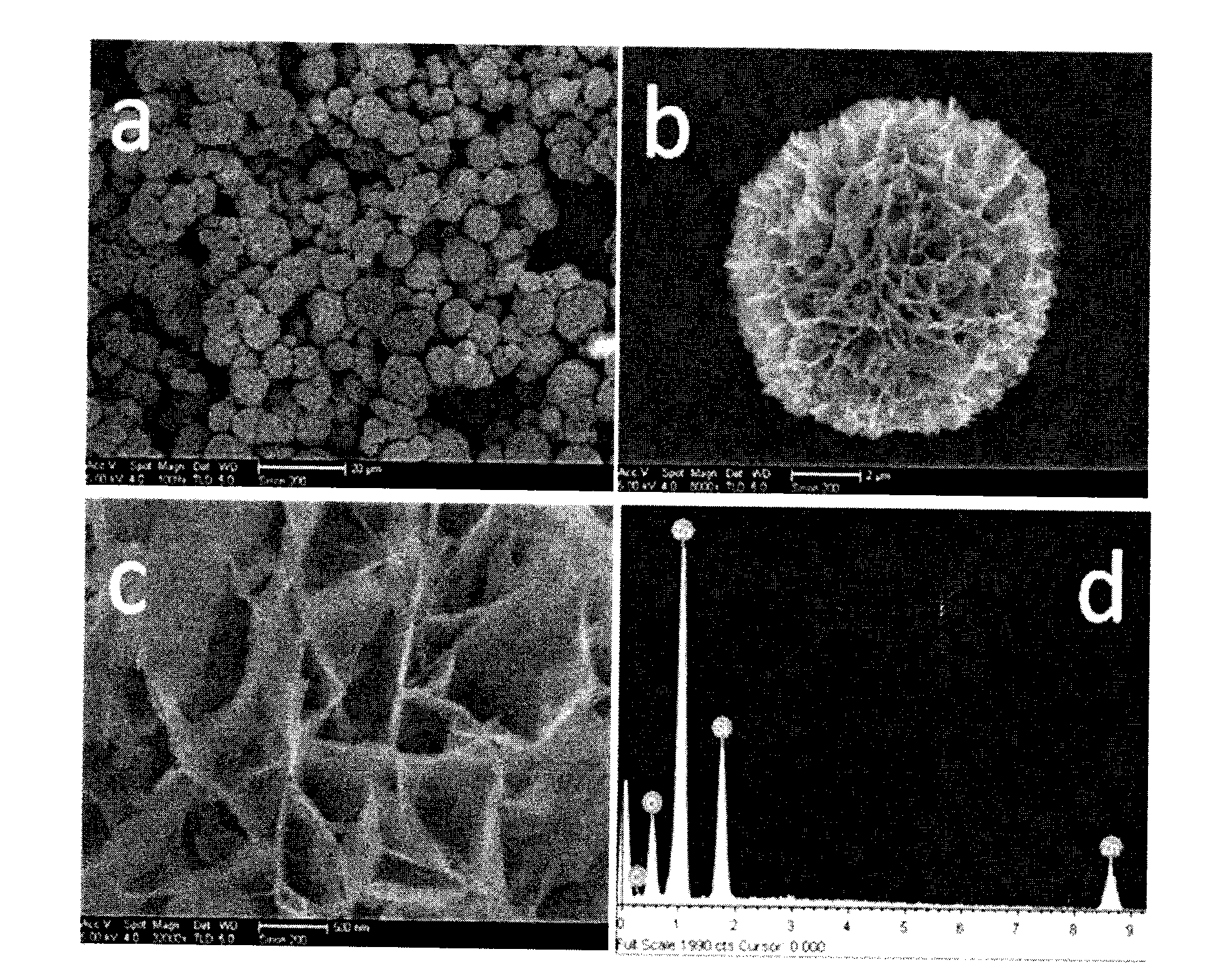

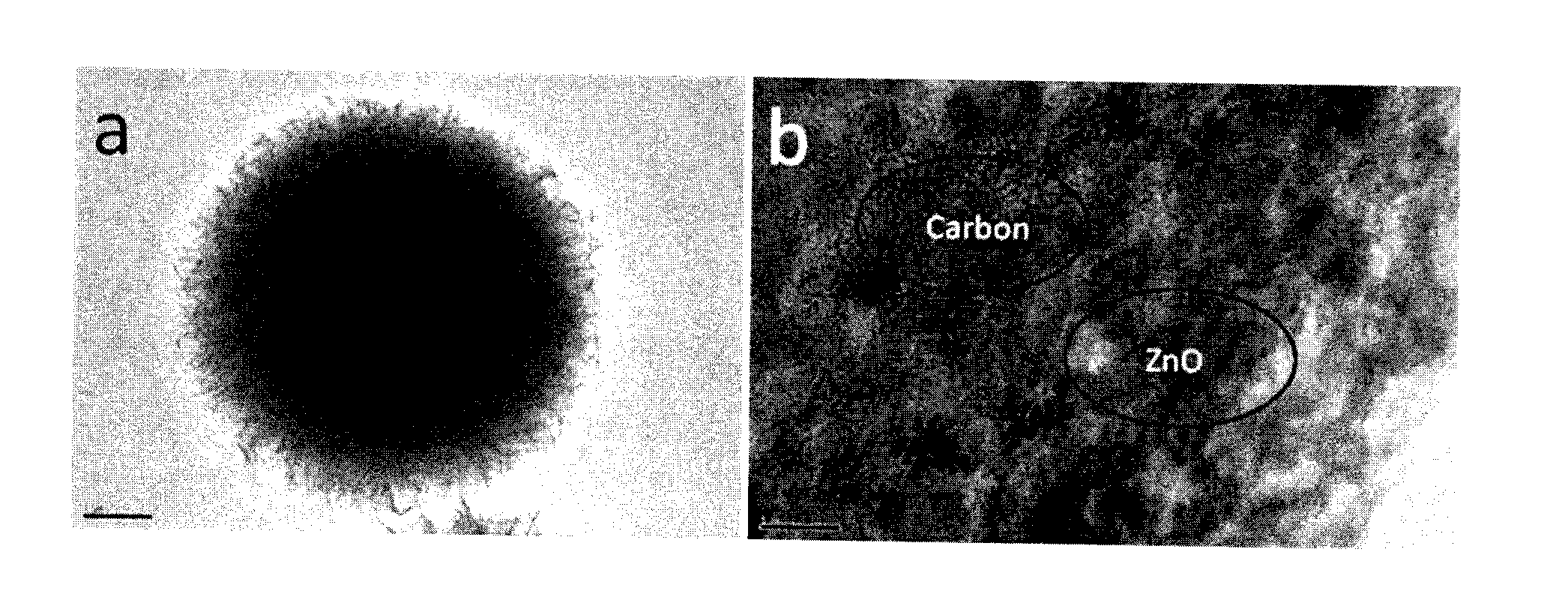

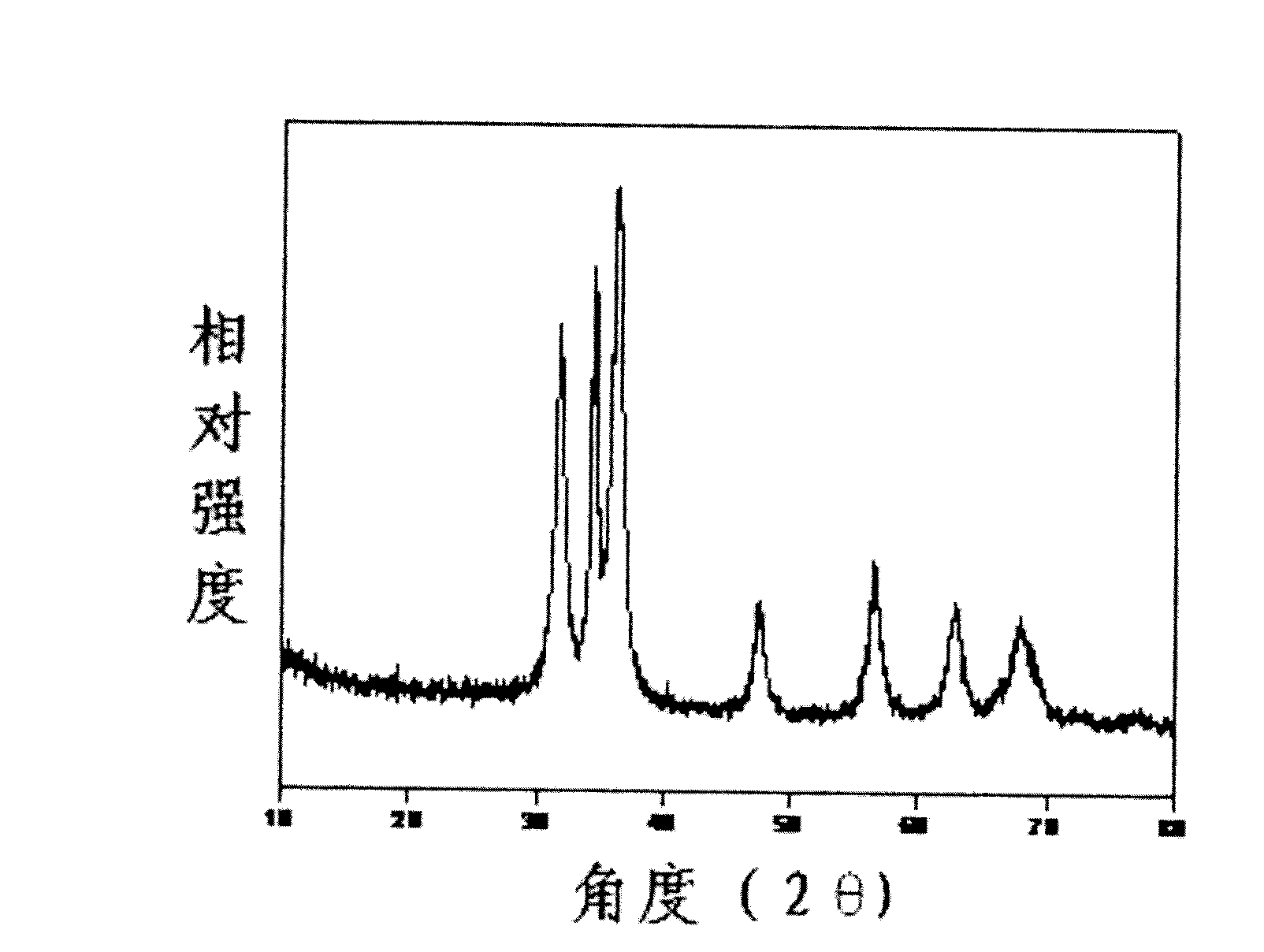

Micro-nano structure zinc oxide-carbon composite pellet and preparation method thereof

InactiveCN103145113ALarge specific surface areaTightly boundMaterial nanotechnologyZinc oxides/hydroxidesCarbon compositesMicro nano

The invention discloses a micro-nano structure zinc oxide-carbon composite pellet and a preparation method thereof. The micro-nano structure zinc oxide-carbon composite pellet is obtained by hybridization compounding of zinc oxide and carbon to obtain a solid pellet having the diameter of 6-12 micrometers, wherein vertical nanosheets having the length of 700-900 nanometers, the height of 700-900 nanometers and the thickness of 15 to 25 nanometers are formed on surfaces of the solid pellet and are connected with each other into a nest; a mole ratio of zinc oxide to carbon is (60-70%): (30-40%); zinc oxide has a hexagonal structure; and carbon comprises amorphous carbon and graphitized carbon and a weight ratio of the amorphous carbon to the graphitized carbon is (85-95%): (5-15%). The preparation method comprises the following steps of dissolving zinc acetate dihydrate, urea, sodium citrate dihydrate and glucose in water to obtain a mixed solution, carrying out hydrothermal treatment on the mixed solution to obtain a reaction solution, orderly carrying out solid-liquid separation, washing and drying to obtain an intermediate product, putting the intermediate product in an inert gas atmosphere, and carrying out annealing to obtain the micro-nano structure zinc oxide-carbon composite pellet. The micro-nano structure zinc oxide-carbon composite pellet can be widely used for fields of catalysis, adsorption and photoelectricity.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI +1

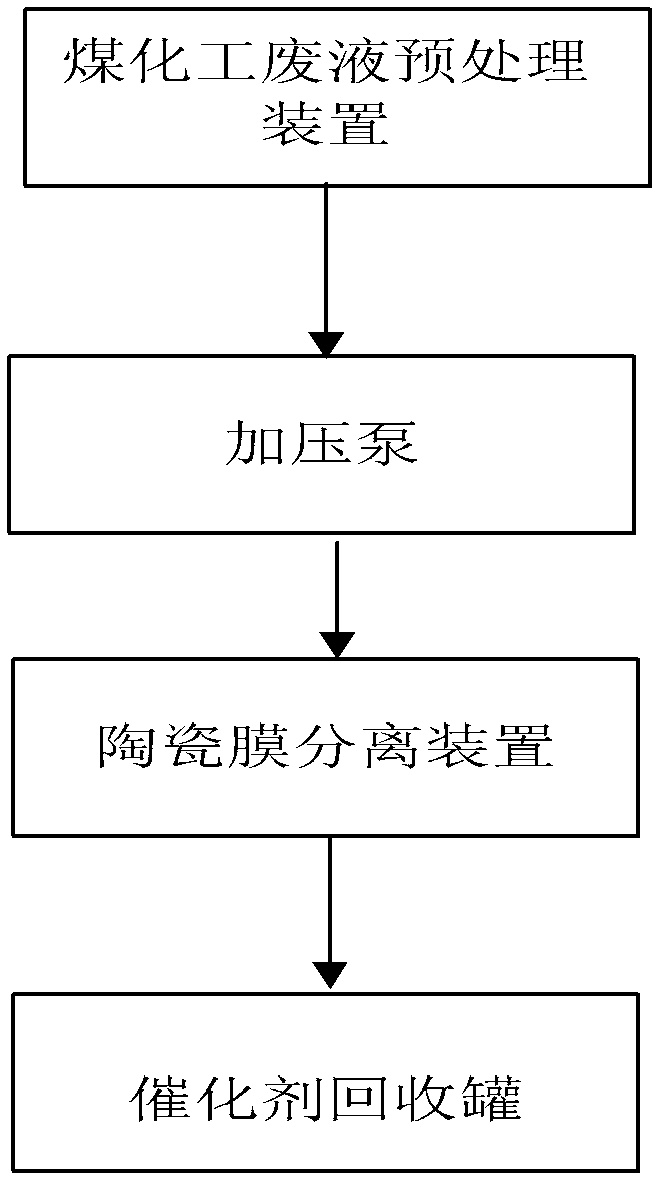

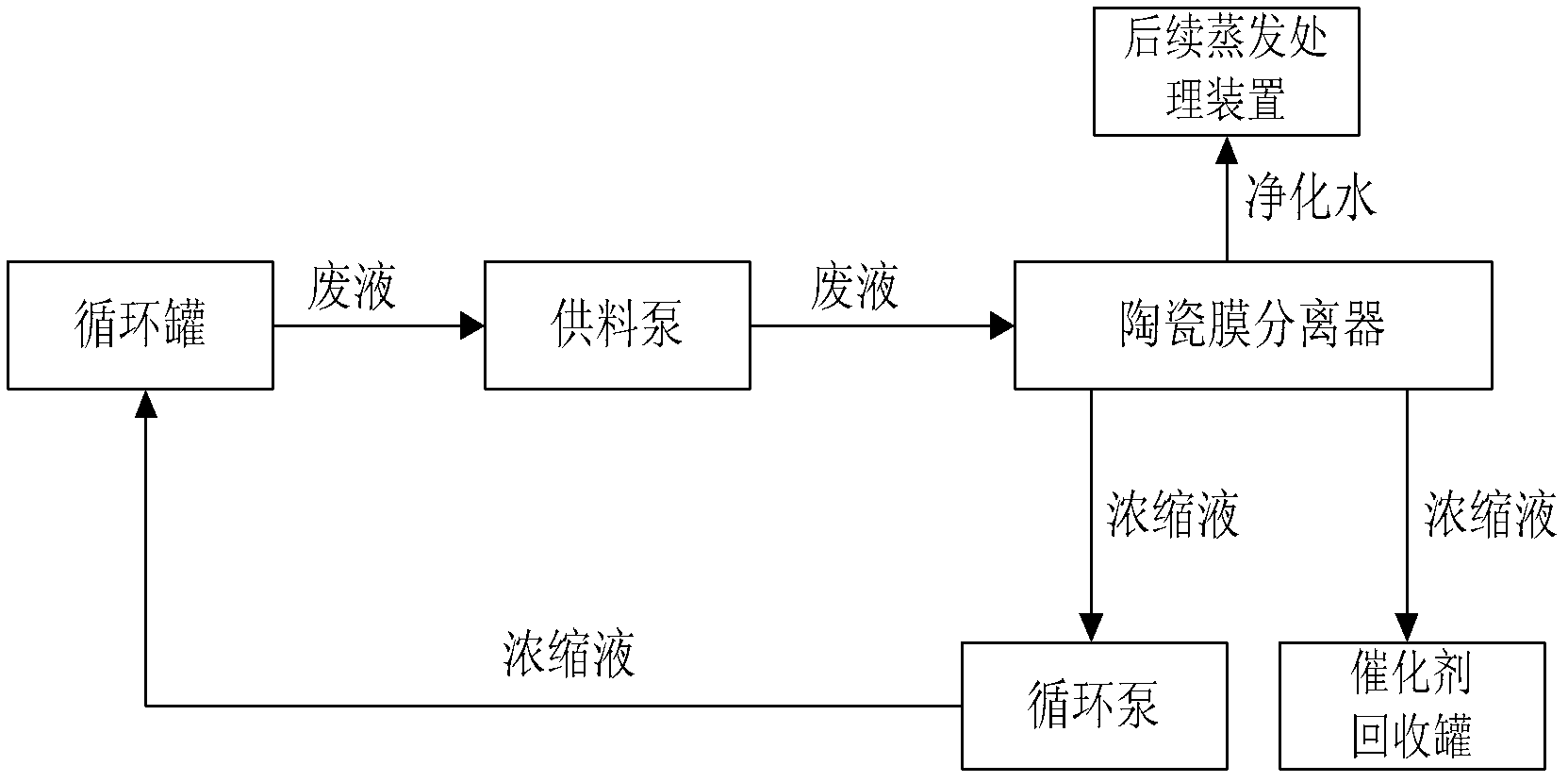

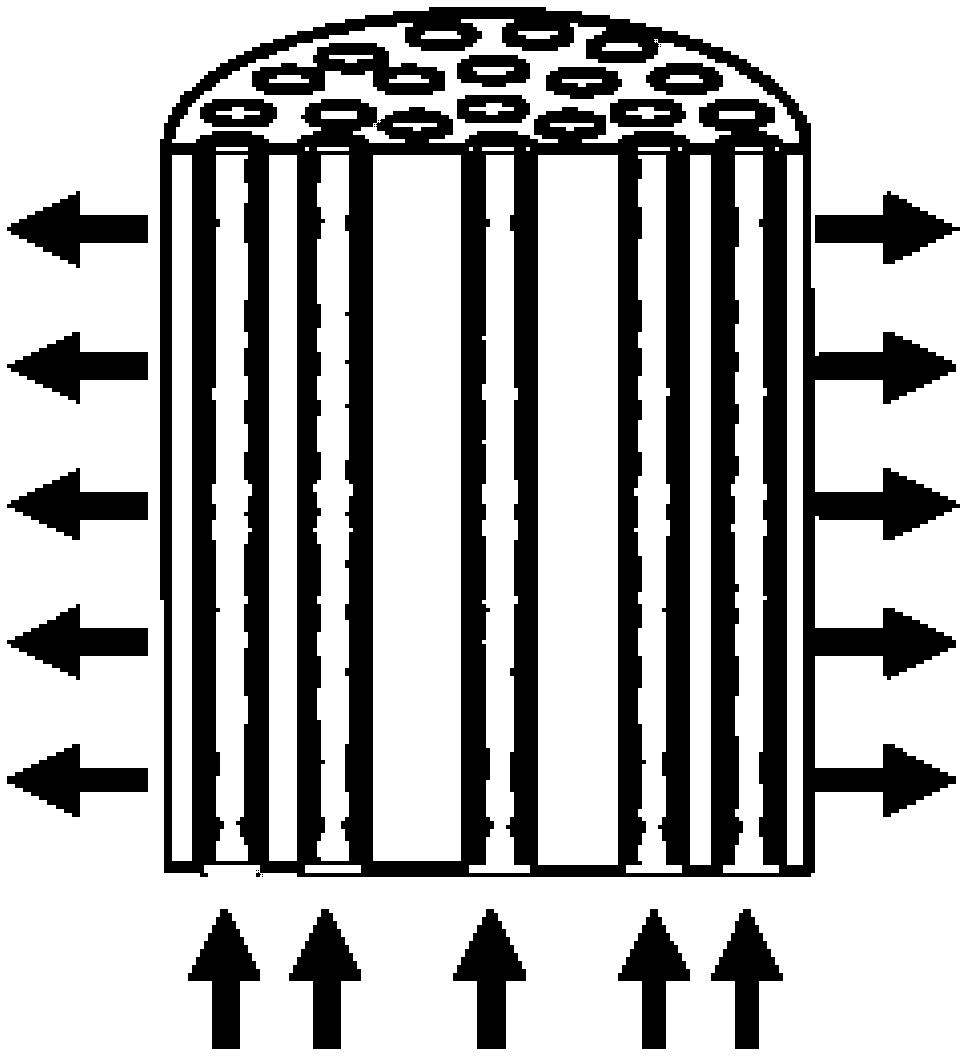

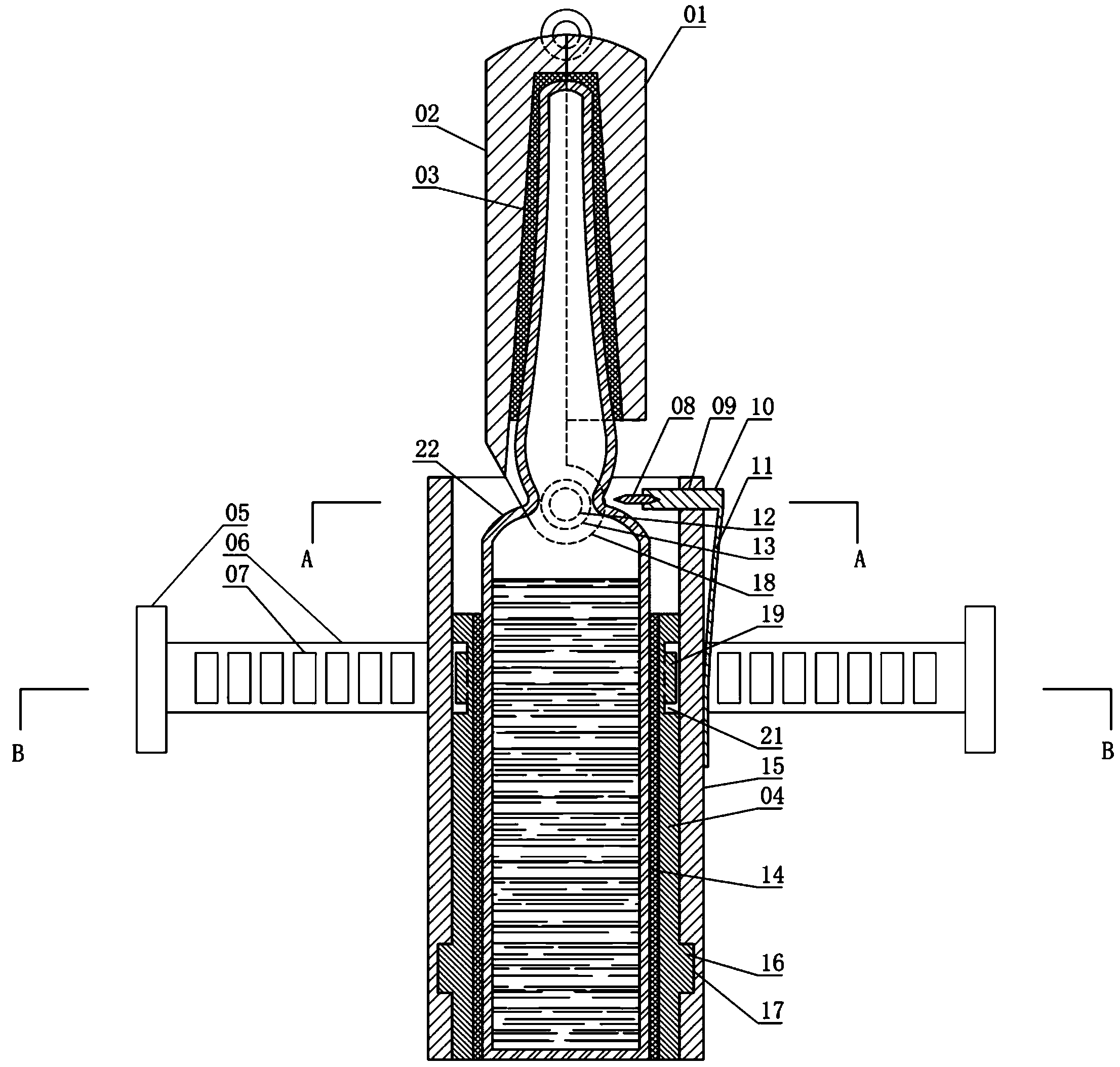

Method and system for recycling catalyst from coal chemical liquid waste

InactiveCN102633378AHigh yieldReduce churnCatalyst regeneration/reactivationWater/sewage treatment bu osmosis/dialysisLiquid wastePollutant emissions

The invention discloses a method and a system for recycling catalyst from coal chemical liquid waste. The method comprises the following steps: pretreatment: removing suspended matters out of the coal chemical liquid waste to obtain preliminary filter liquid waste; and ceramic film separation: pumping the preliminary filter liquid waste in a ceramic film separating device for filtering to obtain concentrated solution, and concentrating and drying the obtained concentrated solution to obtain a catalyst. According to the invention, the ceramic film separating device is used for recycling the catalyst from the coal chemical liquid waste, and the ceramic film separating device is used for recycling and filtering the catalyst for multiple times to obtain purified water and recyclable concentrated solution finally; through adoption of the technical scheme, the material loss caused by drainage during the catalyst production process is reduced, the recycled materials are pure and clean, the yield rate during the catalyst production process is improved, and the effects of pollutant emission reduction and environment protection are achieved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

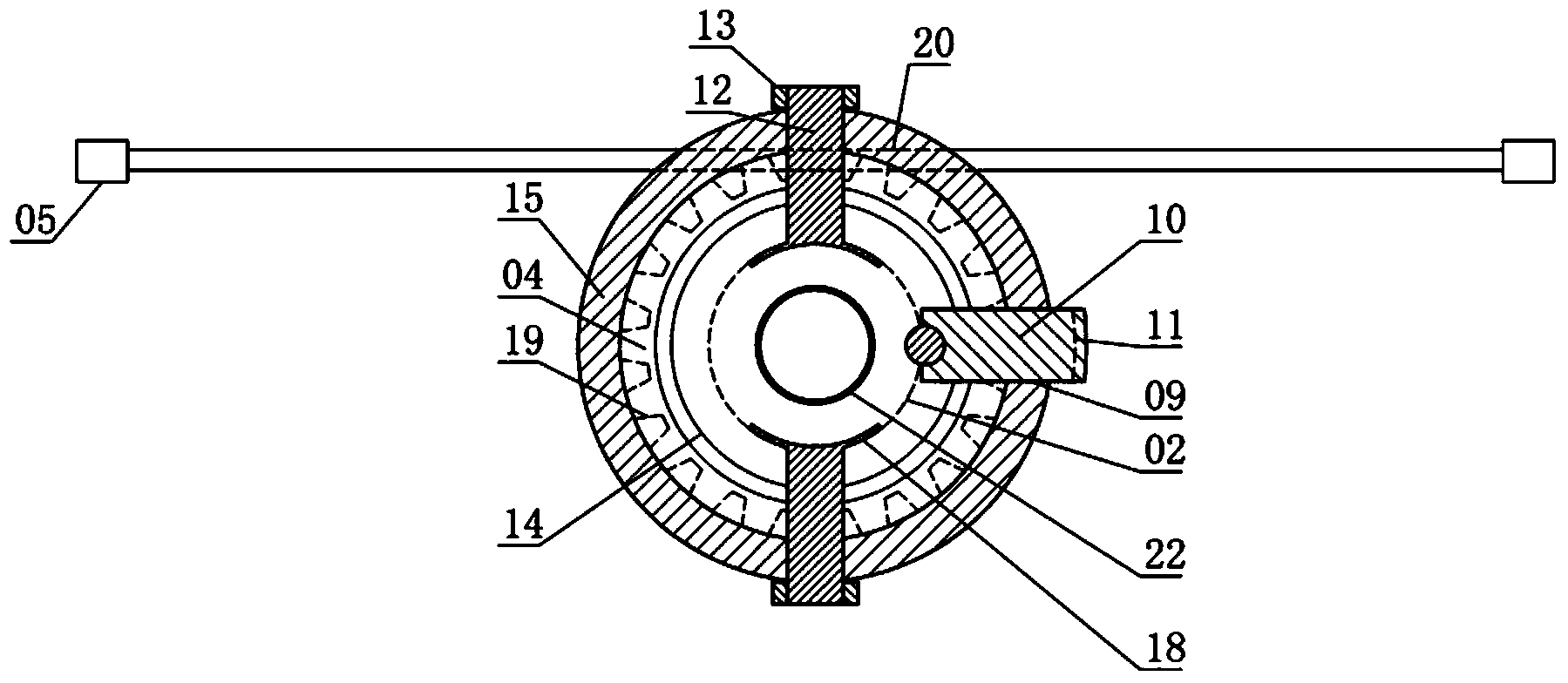

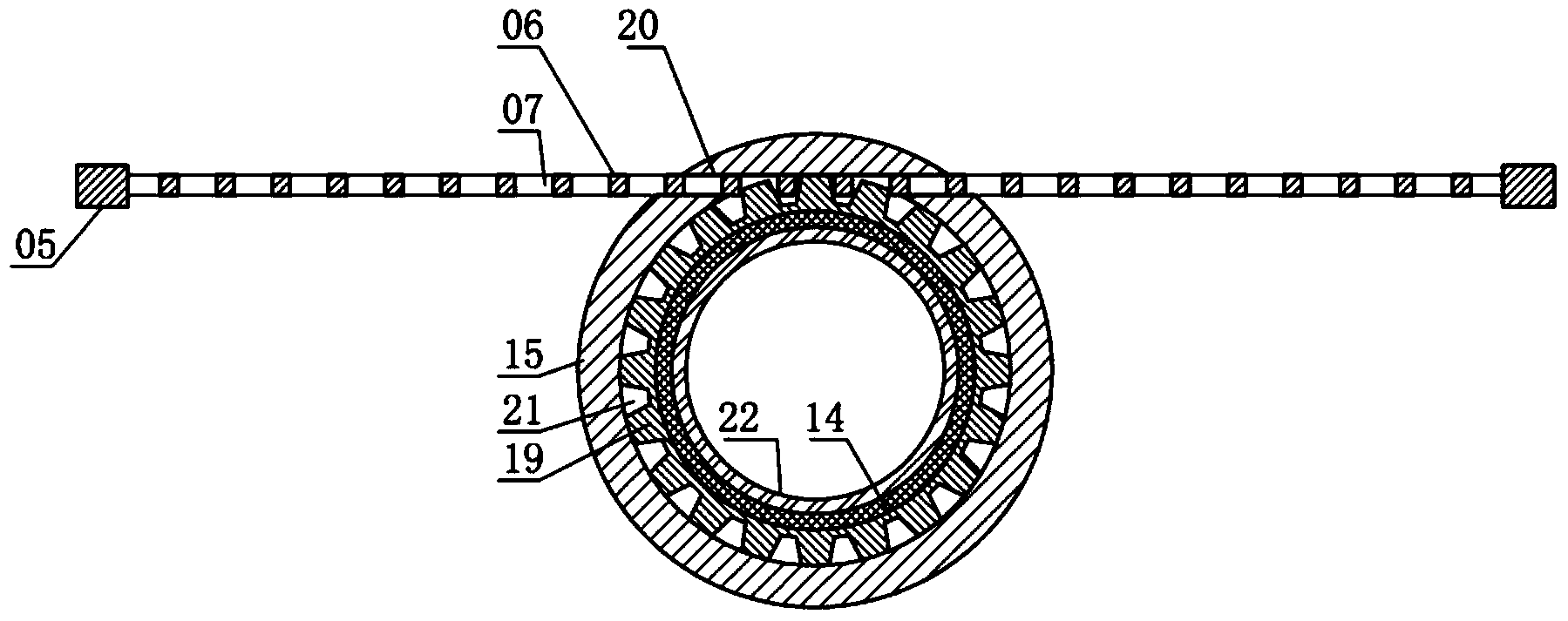

Coaxial pulling-type ampoule opening mechanism

ActiveCN103708394AReduce the difficulty of operationImprove operational efficiencyOpening closed containersBottle/container closureAmpouleGrinding wheel

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com