Grapheme-polyaniline super capacitor electrode material and preparation method thereof

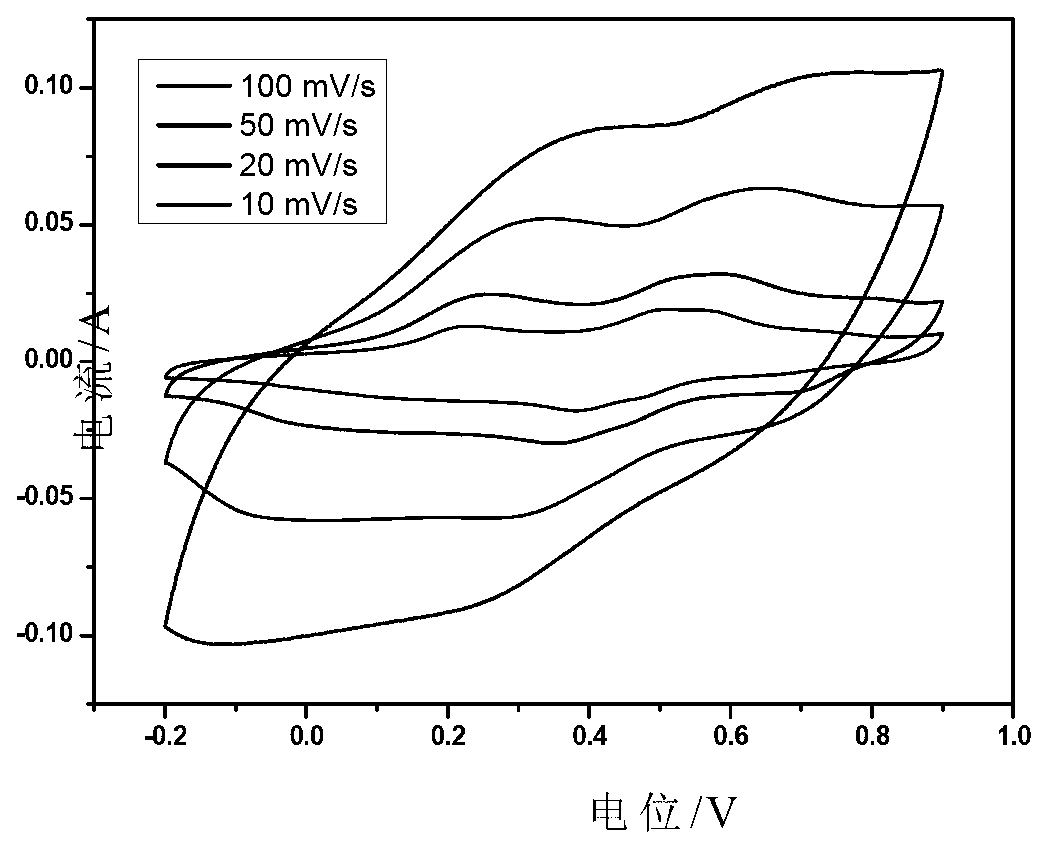

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. The effect of pseudocapacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

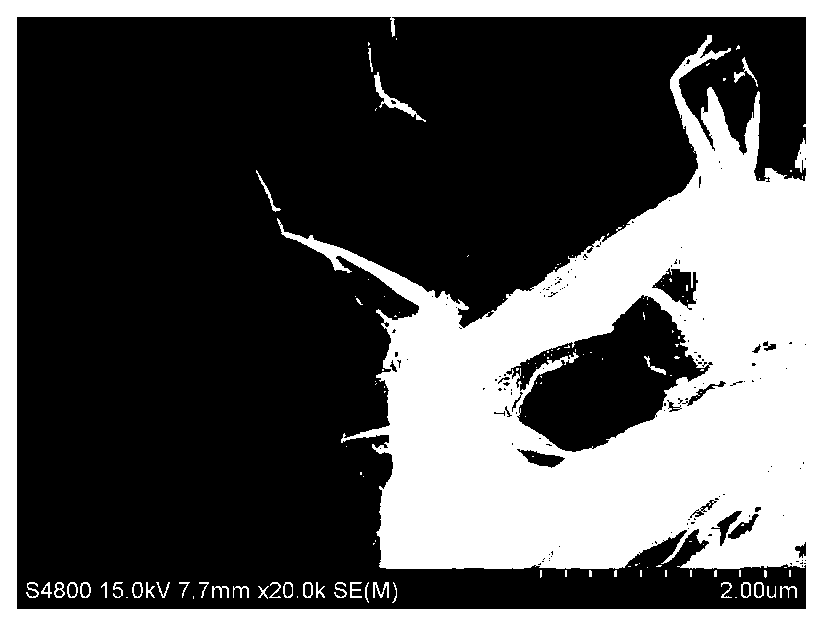

[0032] Example 1

[0033] Cut the graphite paper sheet into a 1×3cm rectangle with scissors, and the edges of the cut graphite paper sheet should be neat. Use a red carbon pen to draw a line 1cm away from one end of the graphite paper on one side of the graphite paper to make it a 1×1cm square as the electrolysis site. Add 20mL of electrolyte solution into a round dry and clean glass dish with a specification of 50×30mm. The electrolyte solution is sulfuric acid with a pH value of 1.3. The electrolysis device is a DC power supply. Take two cut graphite paper sheets and connect them to the power supply For the positive and negative electrodes, the ends (1×1cm) of the two pieces of graphite paper closest to the straight line are completely submerged below the liquid level of the electrolyte, the straight line is level with the liquid level, and the two electrodes are facing each other in parallel with a distance of 1 cm. When starting electrolysis, slowly adjust the voltage to ...

Example Embodiment

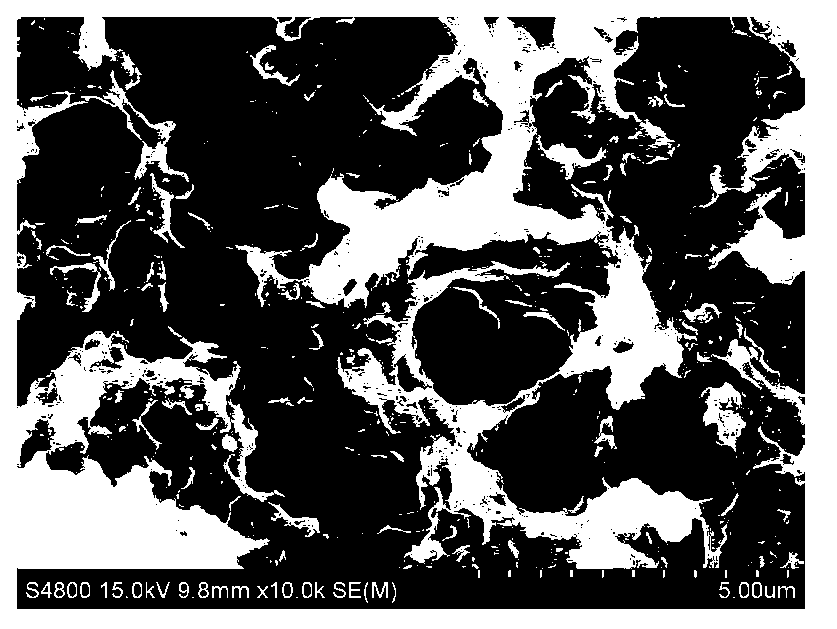

[0038] Example 2

[0039] Cut the graphite paper sheet into a 1×3cm rectangle with scissors, and the edges of the cut graphite paper sheet should be neat. Use a red carbon pen to draw a line 1cm away from one end of the graphite paper on one side of the graphite paper to make it a 1×1cm square as the electrolysis site. Add 20mL of electrolyte solution into a round dry and clean glass dish with a specification of 50×30mm. The electrolyte solution is sulfuric acid with a pH value of 2.3. For the positive and negative electrodes, the ends (1×1cm) of the two pieces of graphite paper closest to the straight line are completely submerged below the liquid level of the electrolyte, the straight line is level with the liquid level, and the two electrodes are facing each other in parallel with a distance of 1 cm. When starting electrolysis, slowly adjust the voltage to 8.0V (the field strength is 800V / m), and the electrolysis time is 10min, then take out the graphite paper sheet of the...

Example Embodiment

[0043] Example 3

[0044] Cut the graphite paper sheet into a 2×4cm rectangle with scissors, and the edges of the cut graphite paper sheet should be neat. Use a red carbon pen to draw a straight line 2cm away from one end of the graphite paper on one side of the graphite paper to make it a 2×2cm square as the electrolysis site. Add 30mL of electrolyte solution into a round dry and clean glass dish with a specification of 50×30mm. The electrolyte solution is hydrochloric acid with a pH value of 1.0. The electrolysis device is a DC power supply. Take two cut graphite paper sheets and connect them to the power supply For the positive and negative electrodes, the ends (2×2cm) of the two pieces of graphite paper closest to the straight line are completely submerged below the liquid level of the electrolyte, the straight line is level with the liquid level, and the two electrodes are facing each other in parallel with a distance of 5 cm. When starting electrolysis, slowly adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com