Patents

Literature

48results about How to "Not easy to overlap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

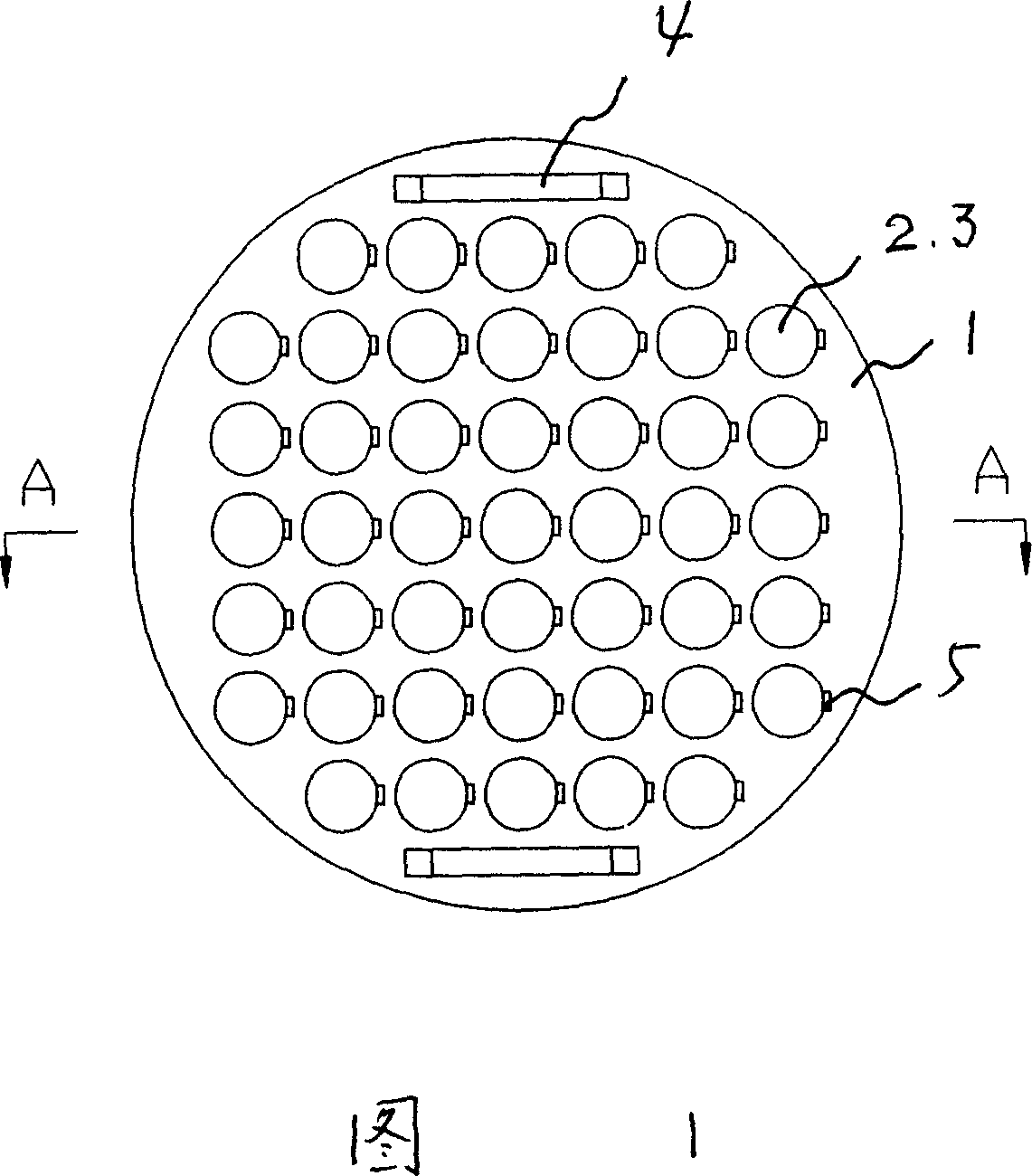

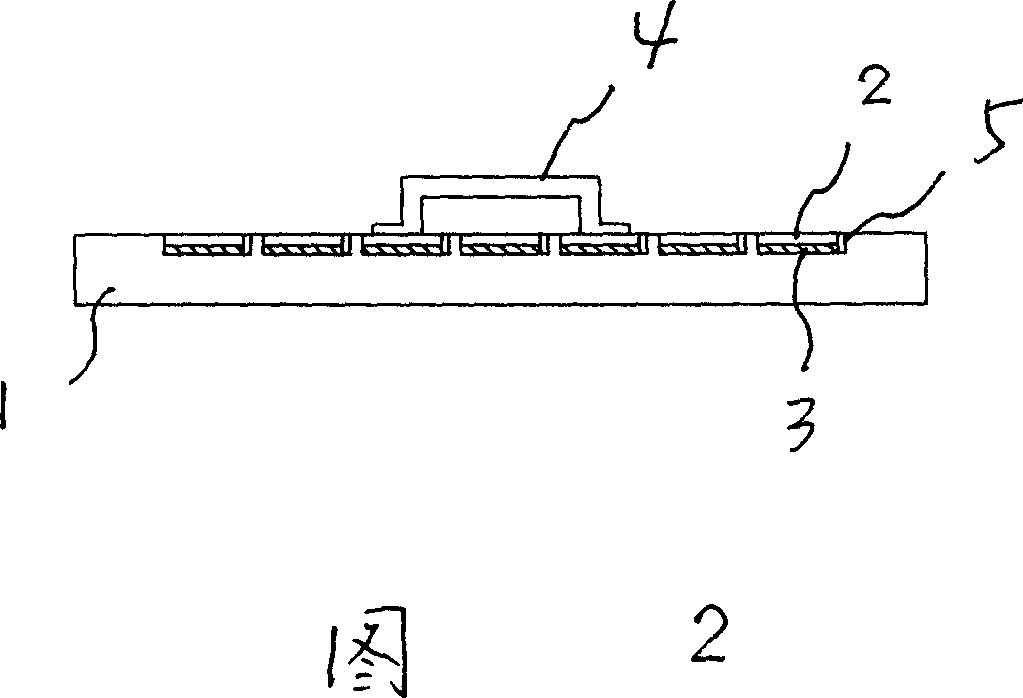

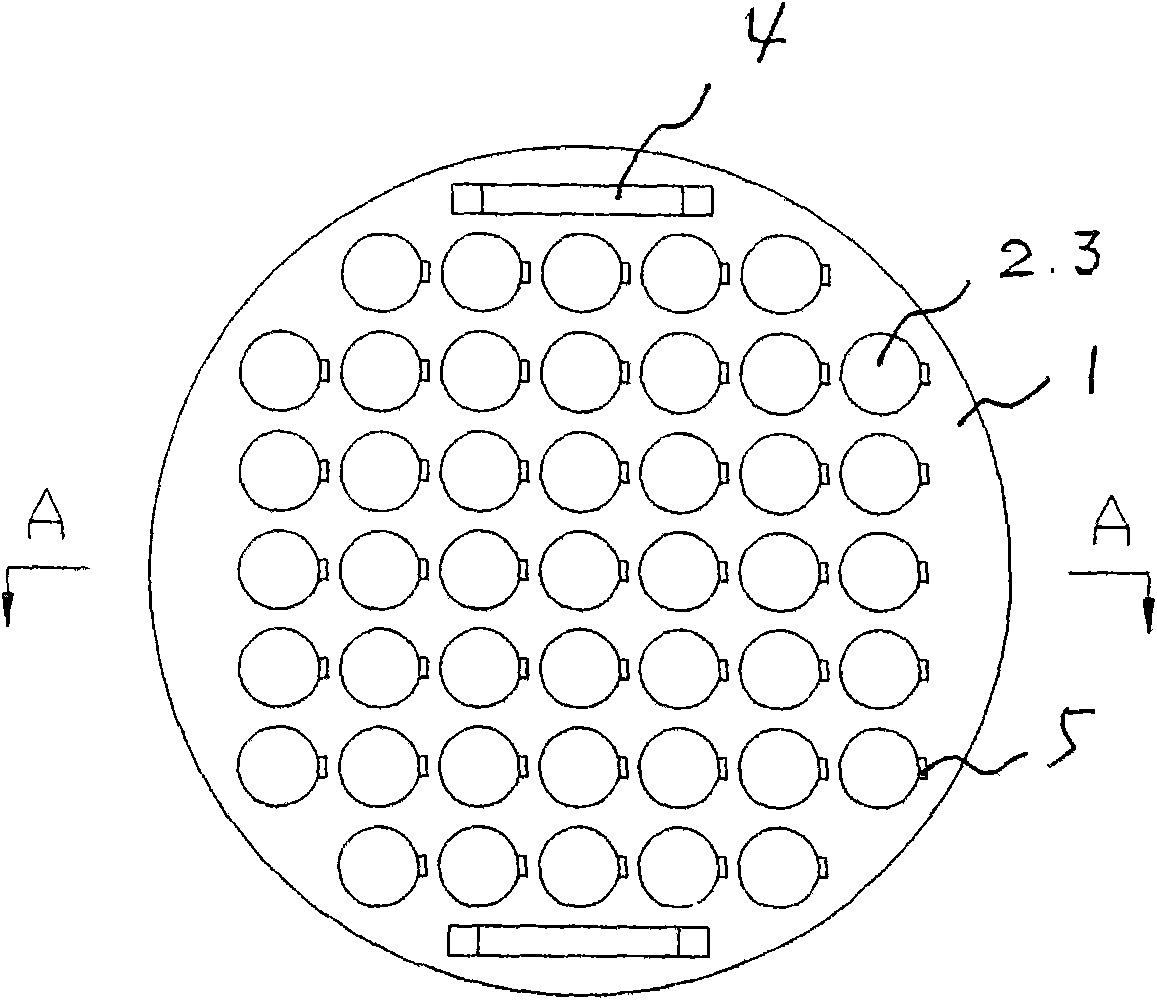

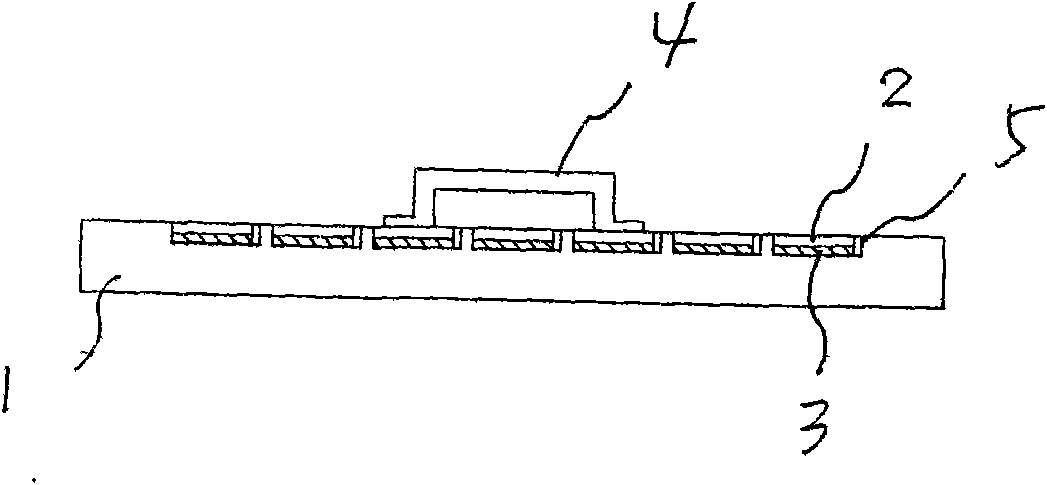

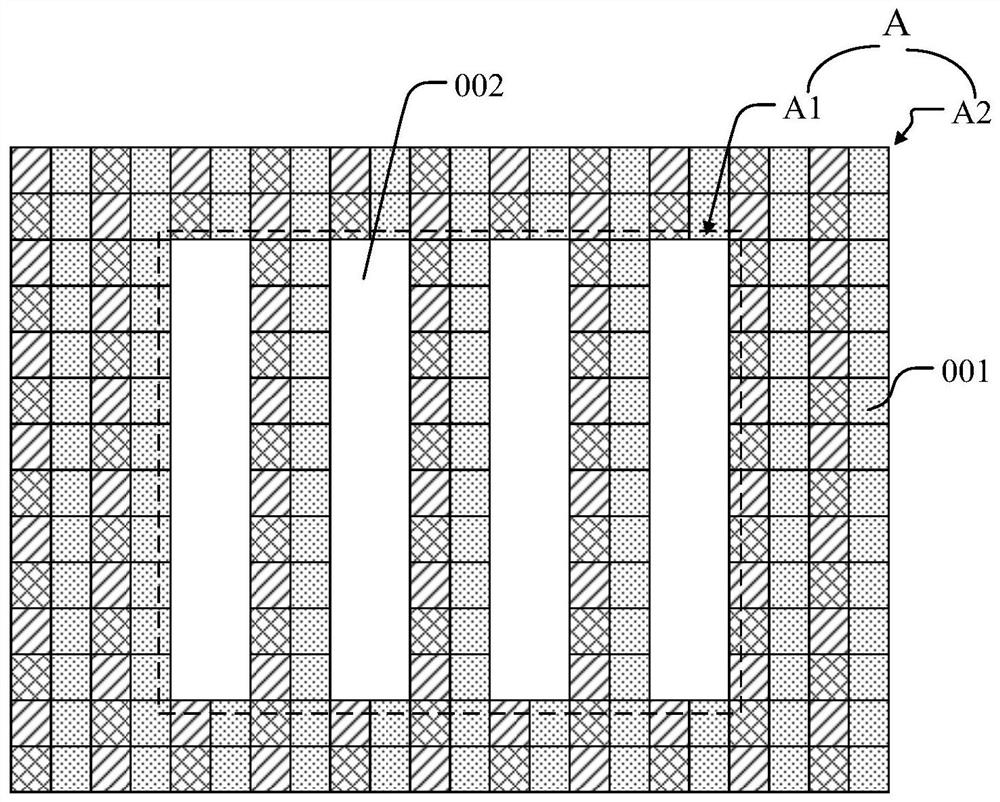

High-density array type cell slide culture apparatus, storage apparatus and experimental apparatus

ActiveCN1928063APromote growthImprove cultivation efficiencyTissue/virus culture apparatusHigh densityShape matching

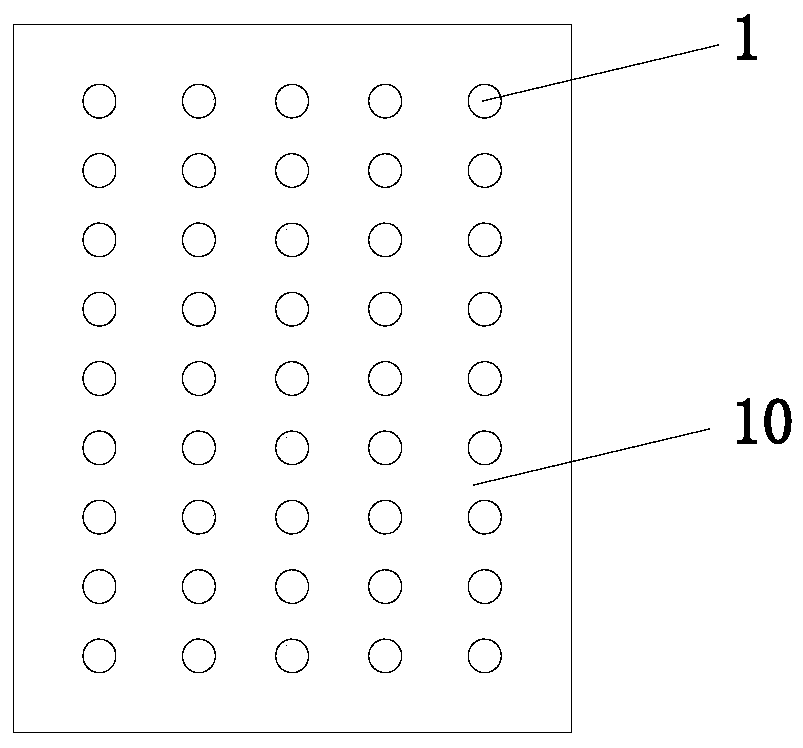

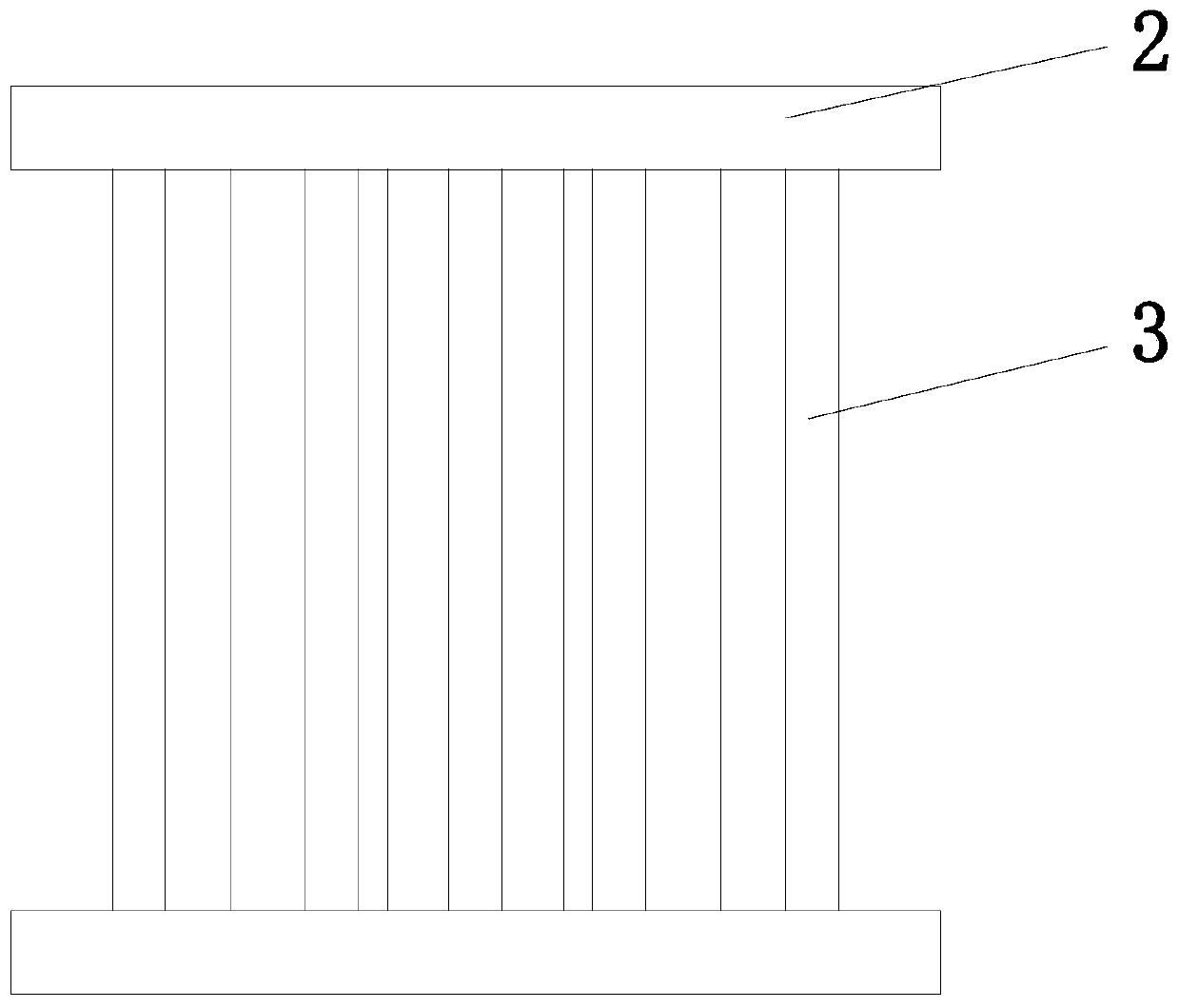

The present invention discloses one kind of high density array type cell culturing device, storing device and experiment device. The cell culturing device includes carrier plate with ordered arranged slots of 0.3-0.4 mm depth and glass slides inside the slots. The storing device has one holder with ordered arranged openings for the circular sheets to be set in, and the openings have length smaller than the diameter of the circular glass slide, end width of 0.15-0.18 mm and middle width greater than the end width. The experiment device has experiment plate with ordered arranged notches for the sheets to be set in, and the notches have cross section shape matching the glass slides and depth of 4-6 mm. The present invention has the advantages of convenient use, high efficiency, high identity, etc.

Owner:李宏 +5

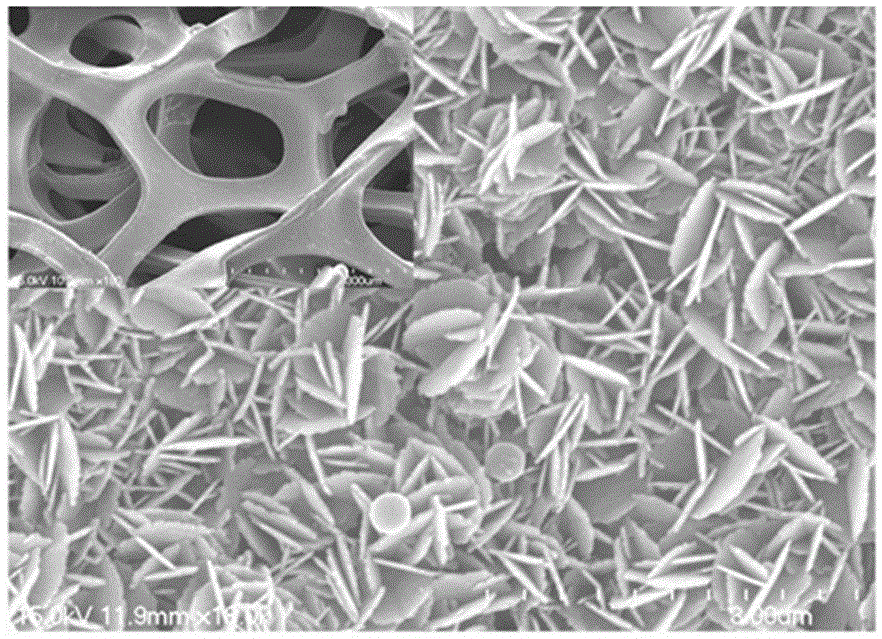

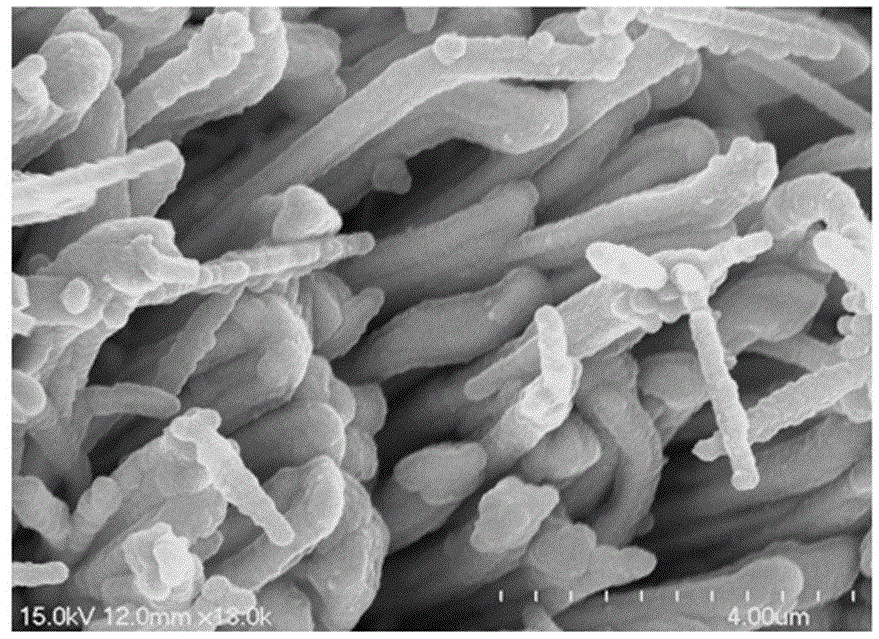

Composite material for visible light catalysis, preparation method thereof and application thereof in water treatment

InactiveCN106732679AIncrease profitThe method is simplePhysical/chemical process catalystsWater/sewage treatment by irradiationMicro nanoSynthesis methods

The invention discloses a composite material for visible light catalysis, a preparation method thereof and an application thereof in water treatment. A macroscopic visible light catalysis composite material is synthesized through a one-pot method, and the composite material can degrade and remove organic matters (such as organic dyestuff) in a water body. Specifically, firstly the one-pot method and a solvothermal method are firstly adopted to directly synthesize bismuth oxyiodide or bismuth oxyiodide / bismuth oxychloride to be loaded on a metallic nickel foam composite material through binary composite photocatalysis, and the composite material can be synthesized only by one step. The simple and convenient synthetic method greatly lowers the process difficulty and cost of synthesis, and provides possibility for further industrial promotion. Under the visible light, the composite material can realize high-efficiency removal of molecules of organic pollutants in the water body; and under the macroscopic condition of catalyzing light with a micro-nano size, the composite material takes advantage of the excellent conductivity of nickel foam to improve the overall performance of the composite material, and is convenient to recycle and reuse in use, thereby improving the comprehensive processing capacity of the material and prolonging the service life.

Owner:SUZHOU UNIV

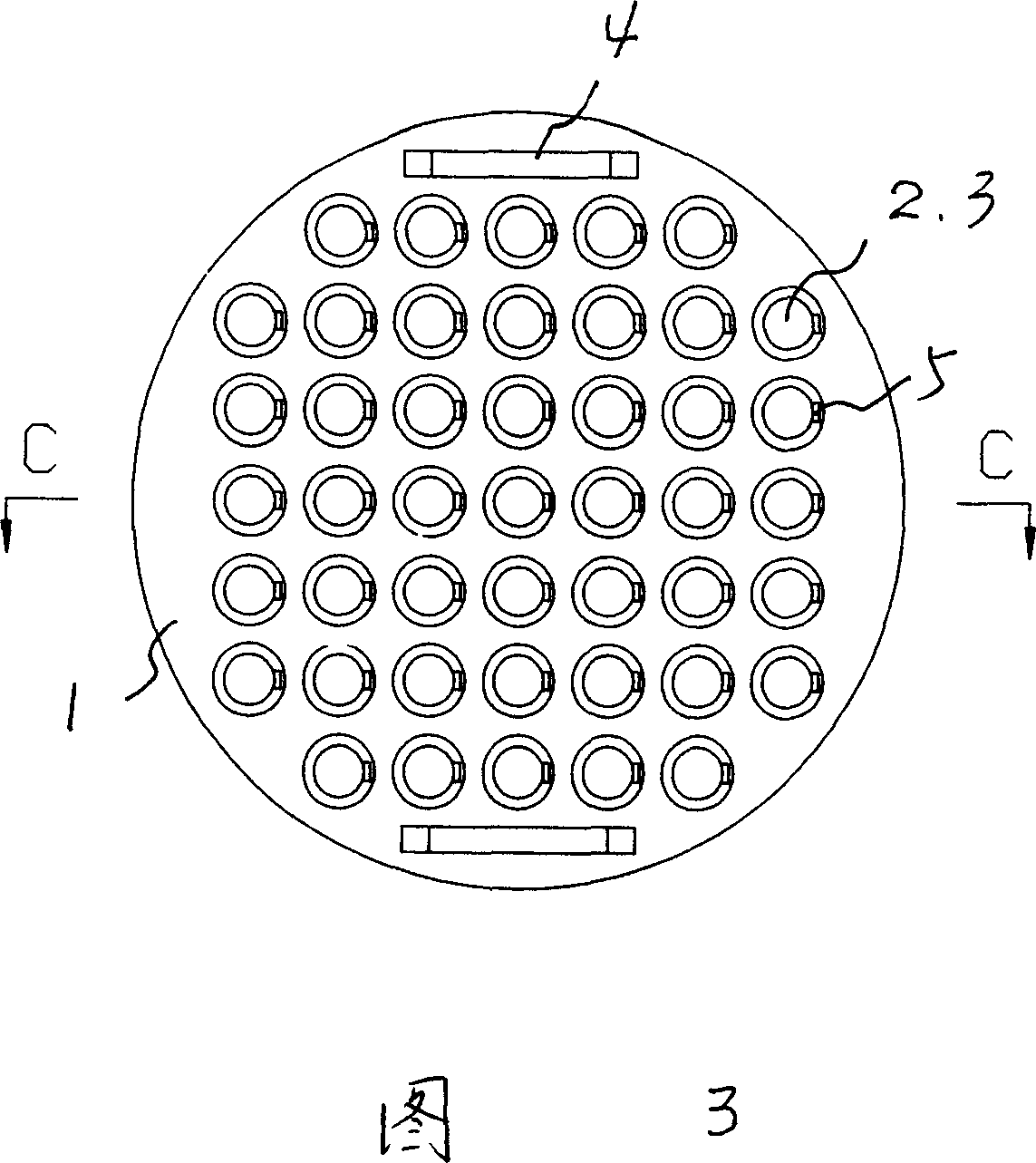

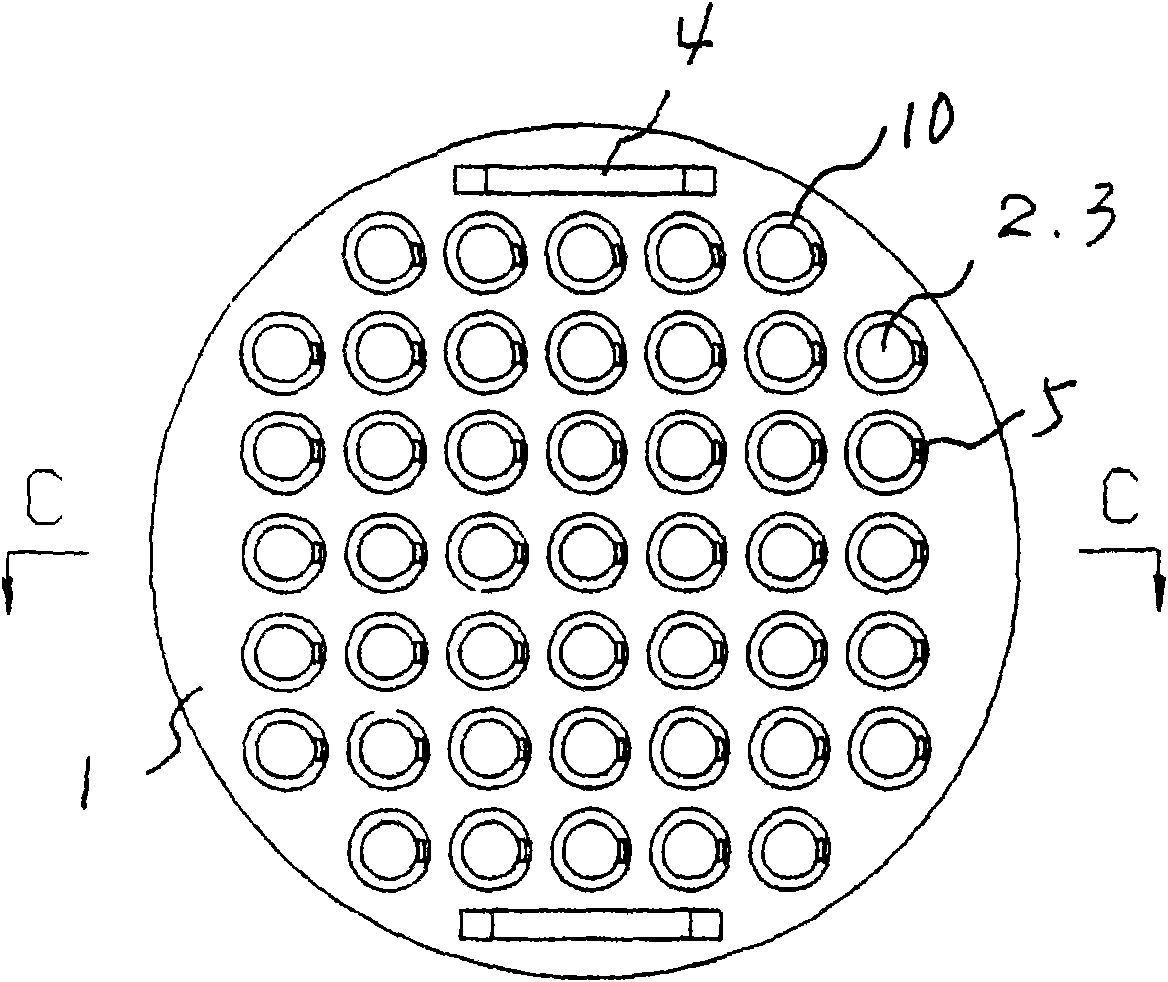

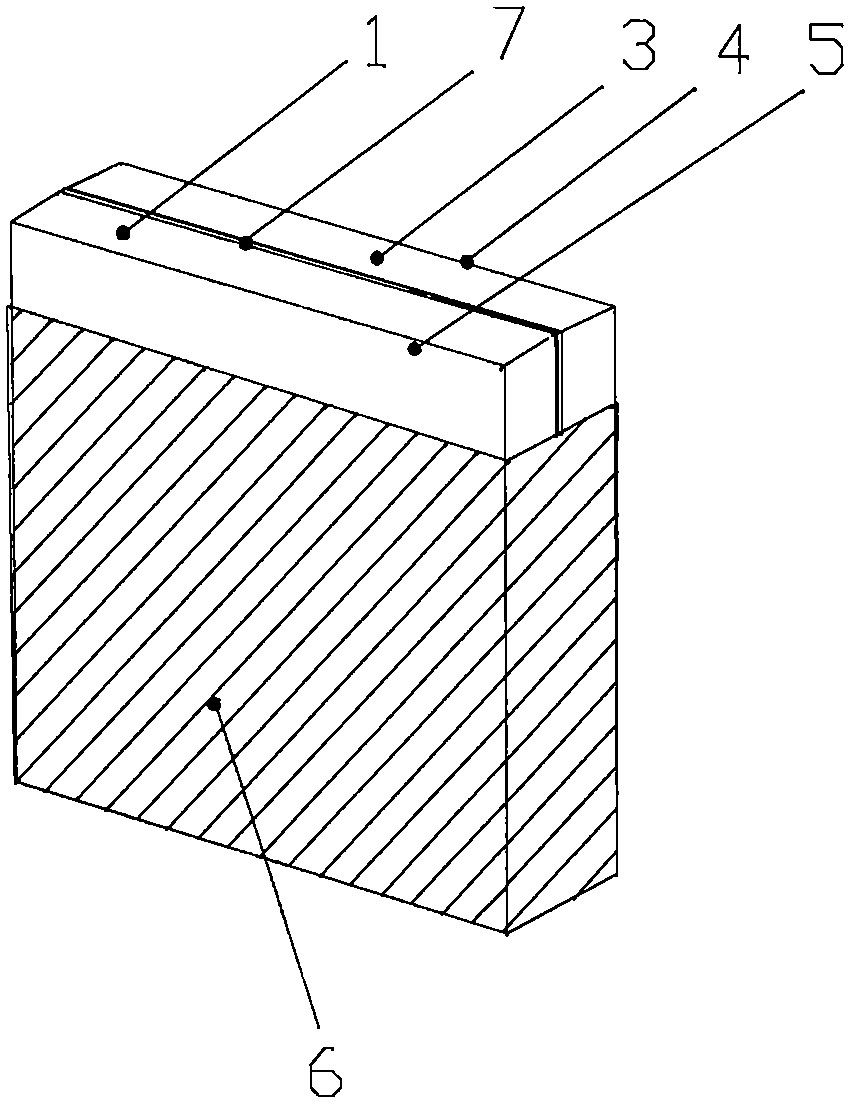

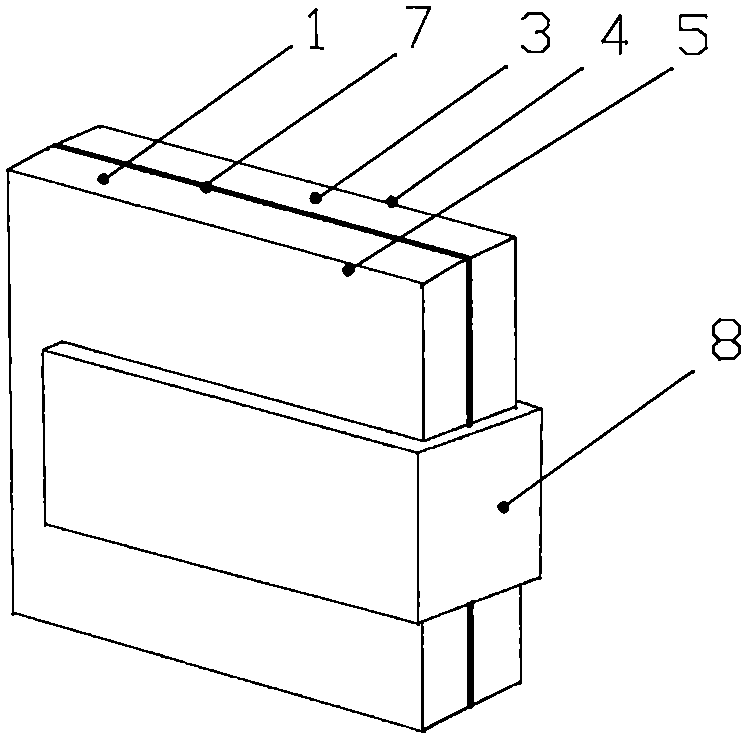

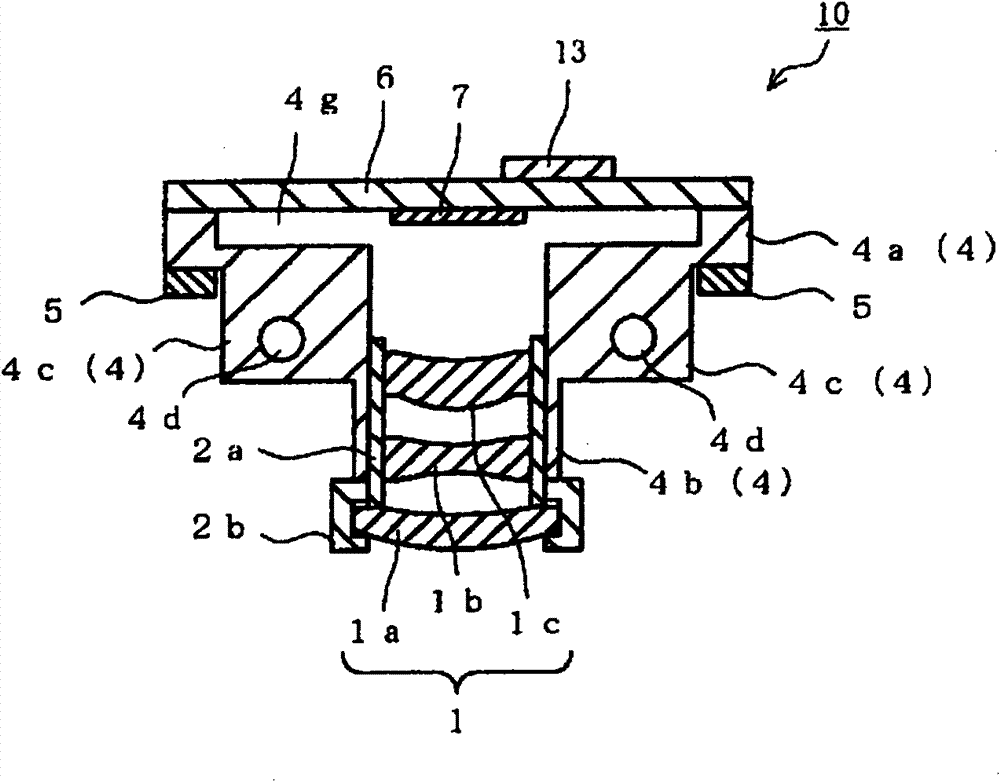

High-density array type cell growth cover glass experimental device

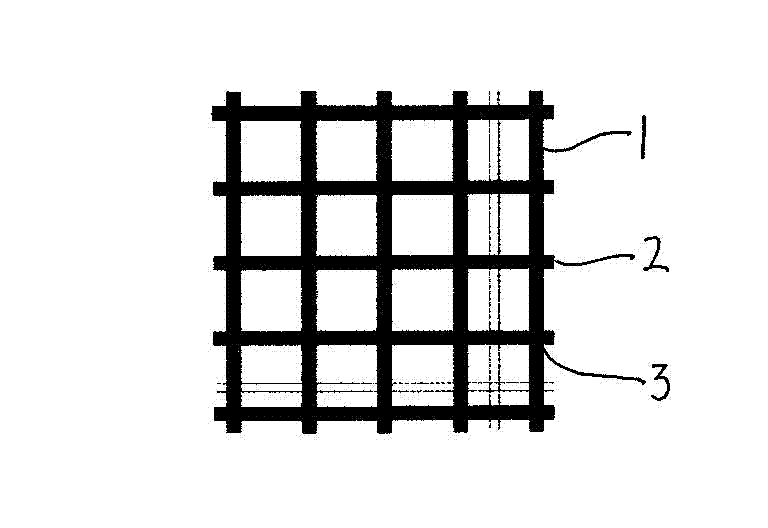

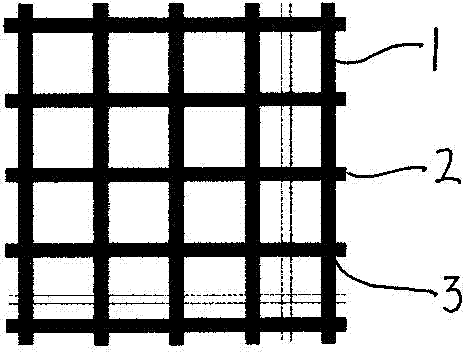

InactiveCN101665767AImprove cultivation efficiencyNot easy to overlapTissue/virus culture apparatusEngineeringGrowth cell

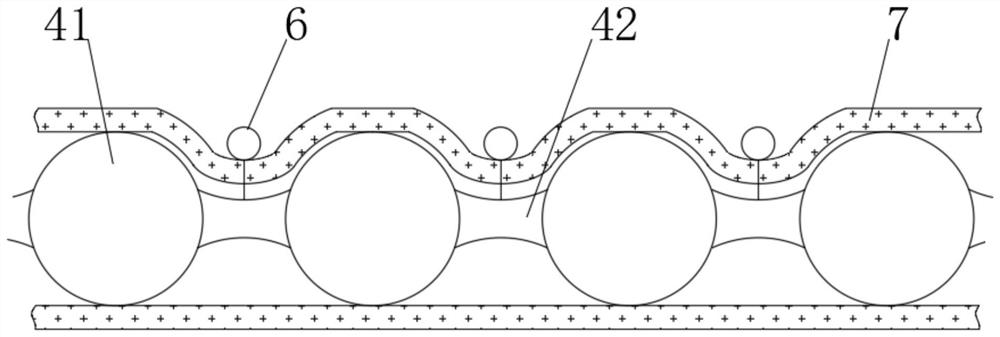

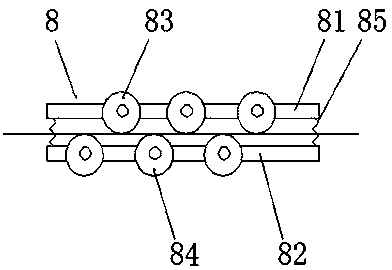

The invention discloses a culture device, a storage device and an experimental device for high-density array type cell growth cover glass. The culture device is provided with a slide plate (1), slotsin ordered arrangement are arranged on the slide plate (1), the depth of each slot (2) is 0.3-0.4mm, and a slide (3) which is matched with the bottom shape of the slot (2) is arranged in the slot (2).The storage device is provided with a bracket (6) which is provided with a plurality of openings (7) which are in ordered arrangement and are used for placing a round growth cover glass, the length of the opening (7) is smaller than the diameter of the round slide (3), the middle width of the opening (7) is bigger than that of two ends, and the width of two ends is 0.15-0.18mm. The experimental device is an experimental plate (8) which is provided with a plurality of grooves (9) which are in ordered arrangement and are used for placing the growth cover glass, the shape of the cross section ofthe groove (9) is matched with the shape of the slide (3), and the depth is 4-6mm. The invention has the advantages of convenient use, high efficiency, favourable identity and the like.

Owner:李宏 +5

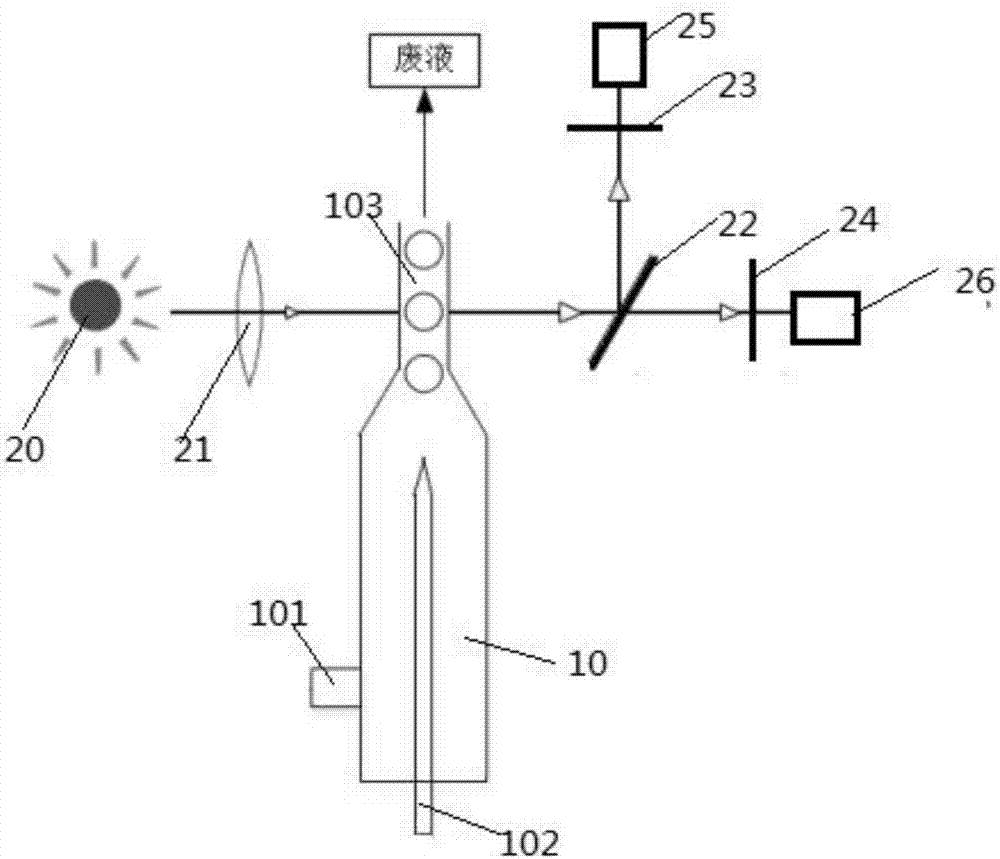

Liquid-phase chip detection system and method based on quantum dots

InactiveCN107991486ANot easy to overlapReduce complexityBiological testingFluorescence/phosphorescenceSignal processing circuitsQuantum dot

The invention discloses a liquid-phase chip detection system and method based on quantum dots. The liquid-phase chip detection system comprises a liquid-phase chip, a sheath flow formation module, a fluorescence excitation light source, an optical signal detection device and a circuit module, wherein the liquid-phase chip is a quantum dot encoding fluorescent microsphere subjected to chemical modification; the sheath flow formation module comprises a microfluidic channel; the liquid-phase chip is covered with sheath fluid and a laminar flow state is formed in a flowing chamber; then the liquid-phase chip passes through the microfluidic channel in sequence in a single-row straight line and the optical signal detection device is used for detecting to obtain a fluorescent signal; the circuitmodule is composed of a microprocessor and a signal processing circuit. The system disclosed by the invention has the advantages of simple and easy-to-realize structure and high fluorescent detectionaccuracy; interference, caused by the fact that emitted light is overlapped, on a detection result is avoided; the system has the characteristics of high accuracy, high sensitivity and low cost and has a wide market application prospect.

Owner:SHENZHEN UNIV

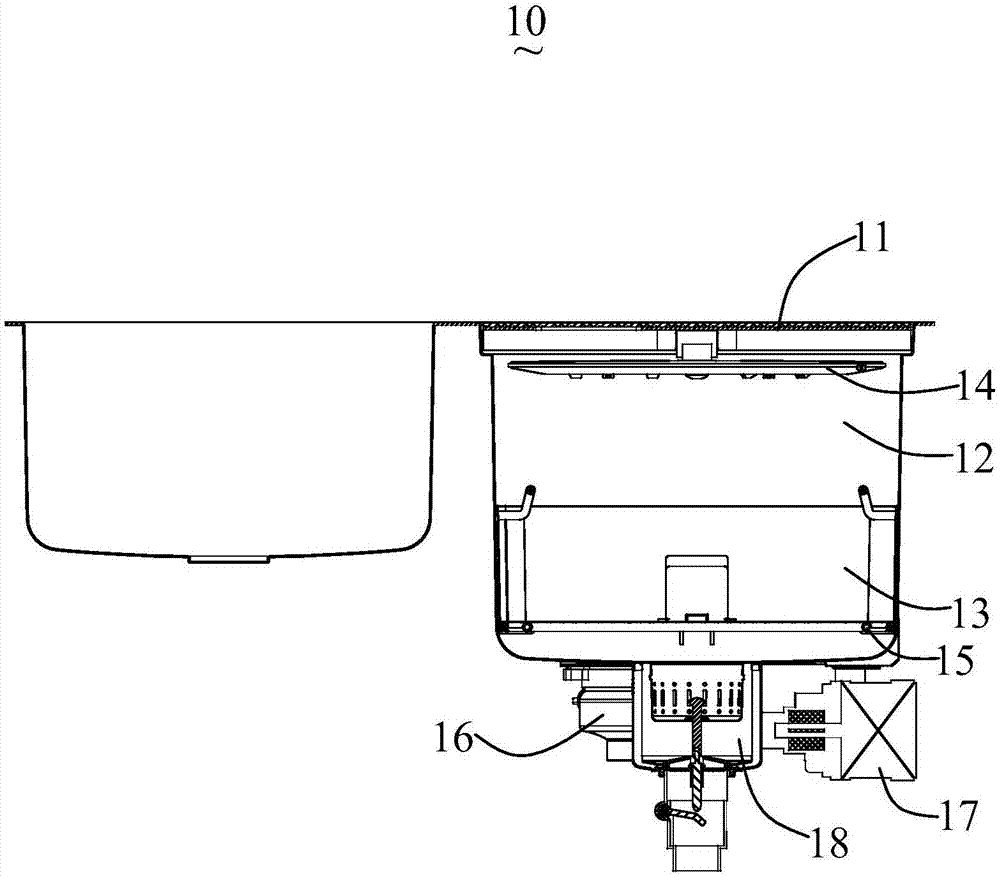

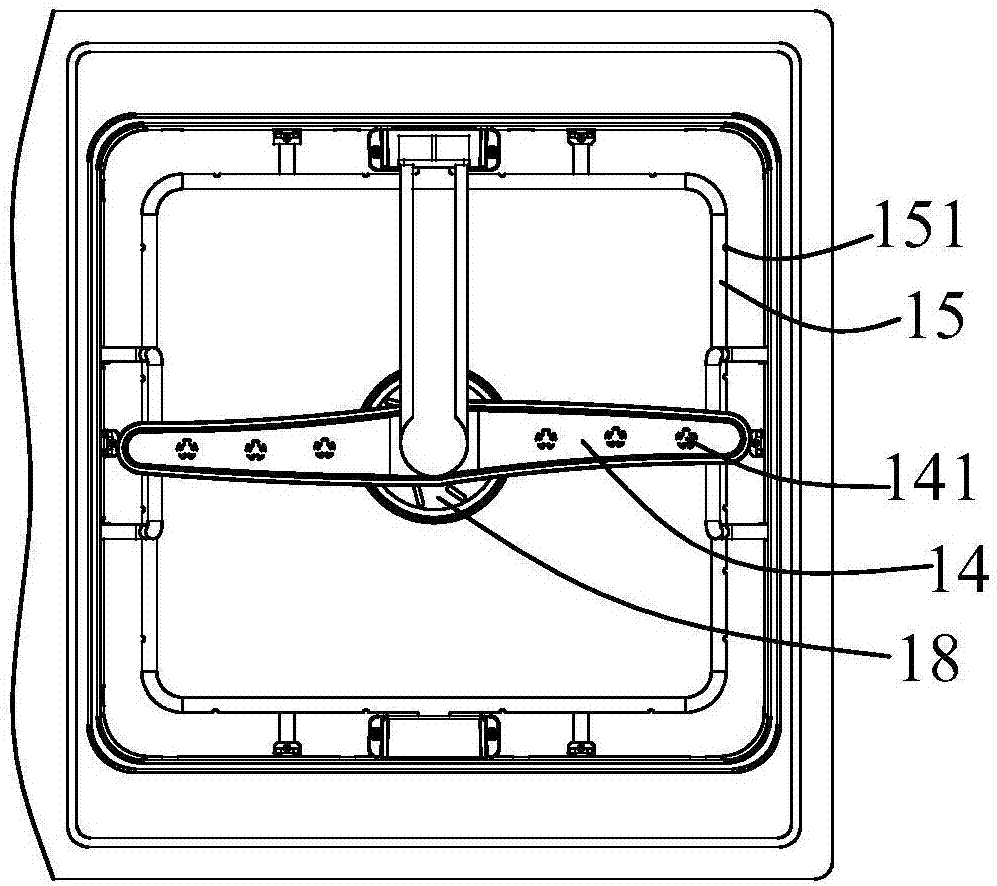

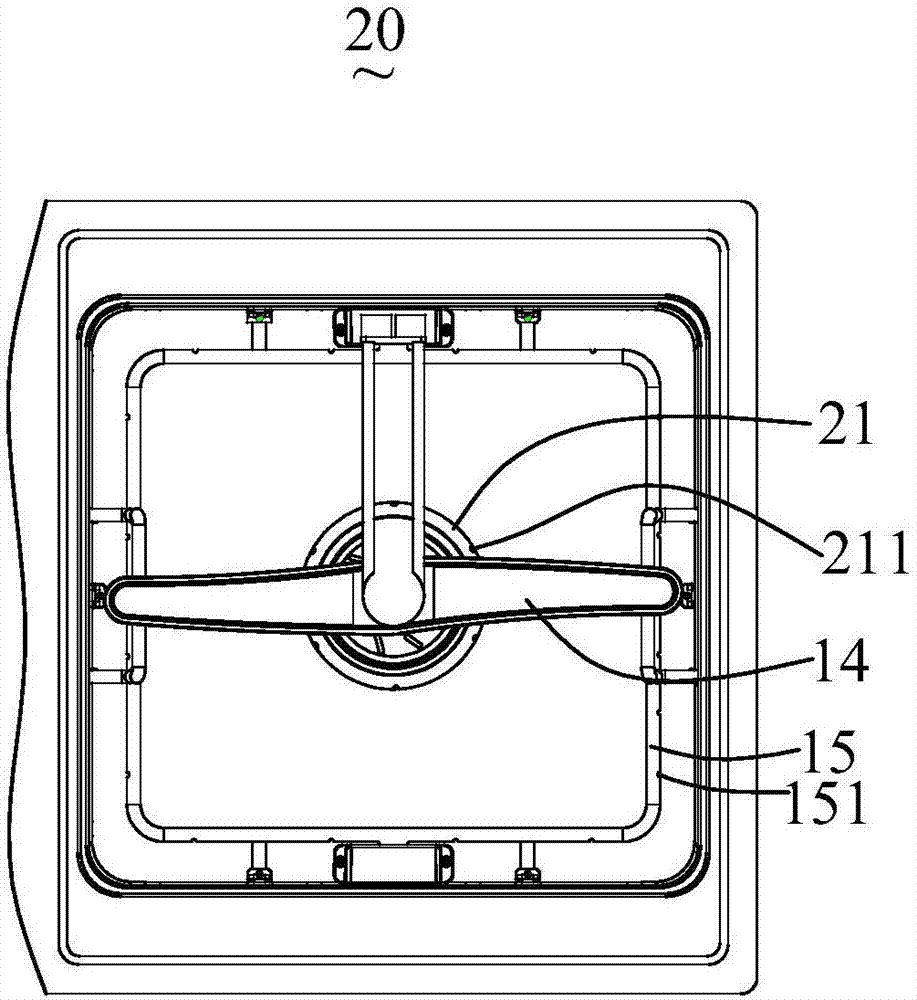

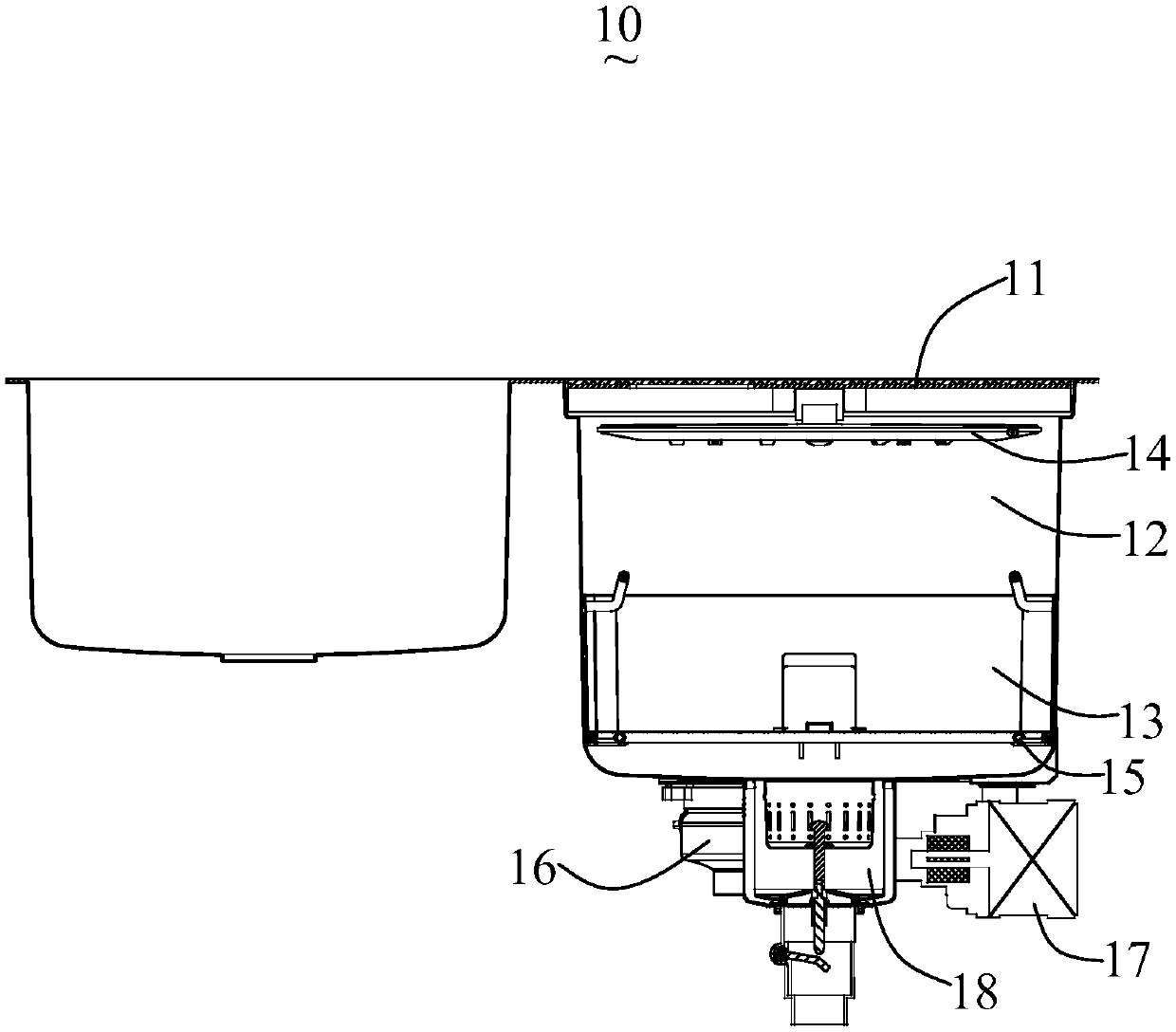

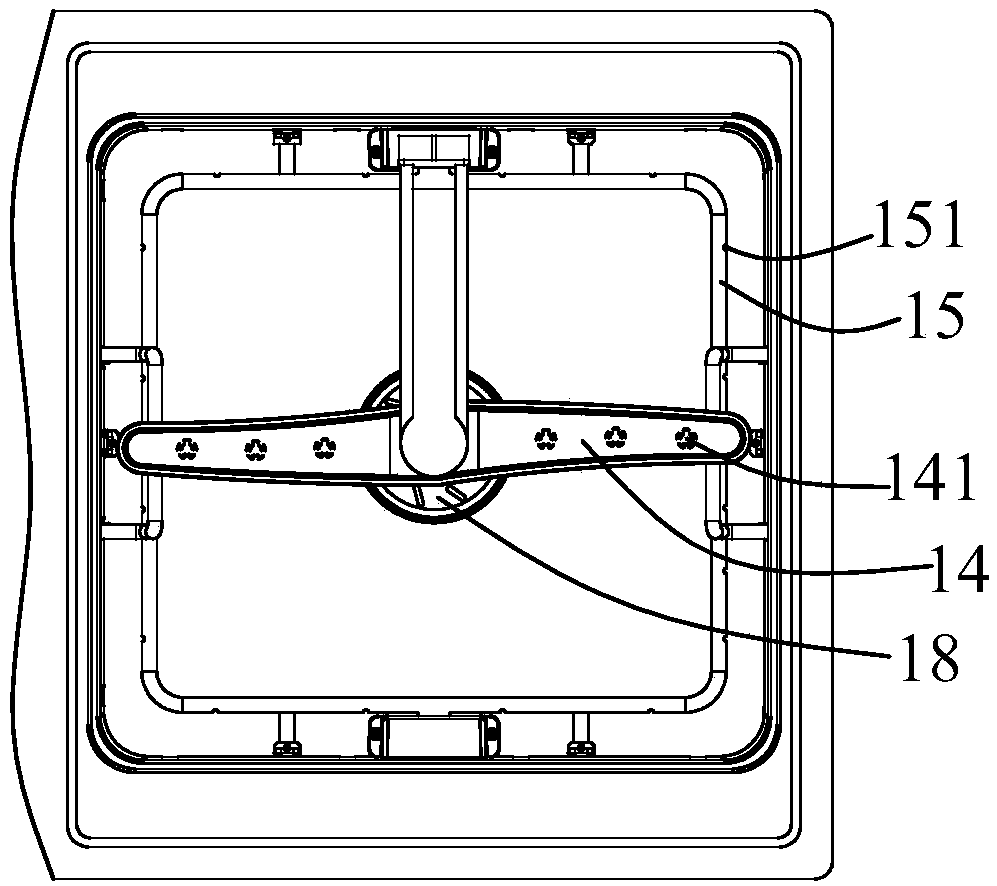

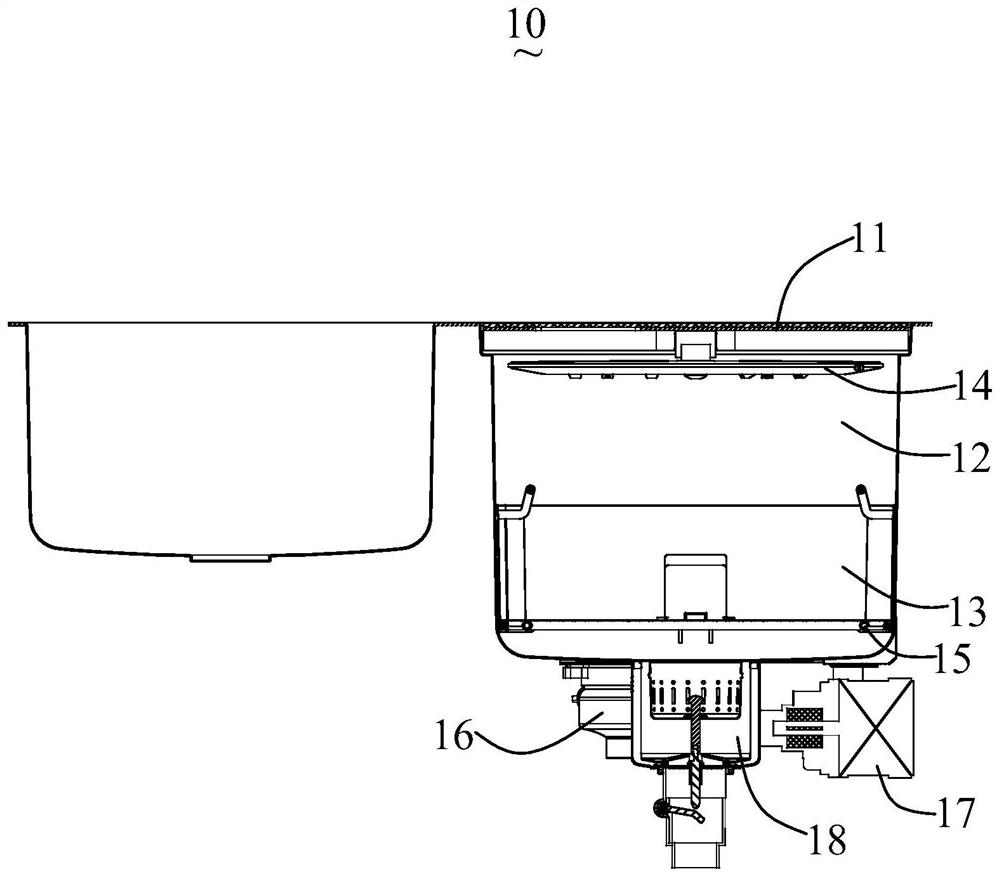

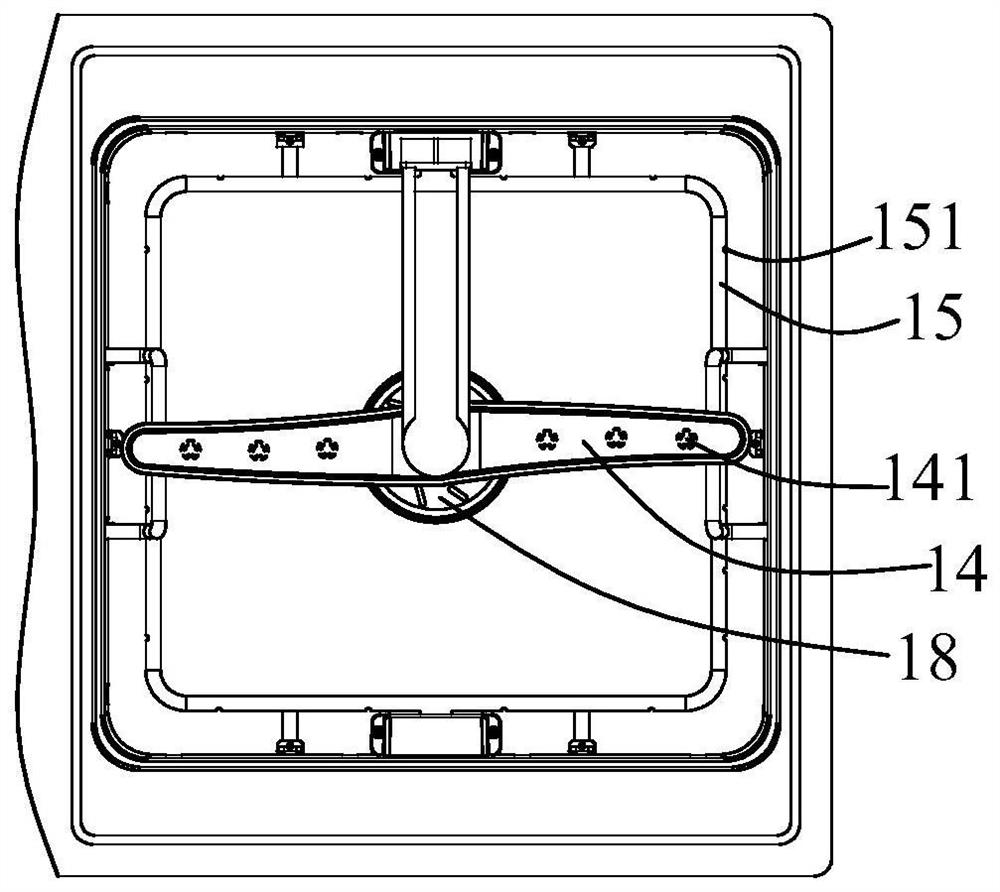

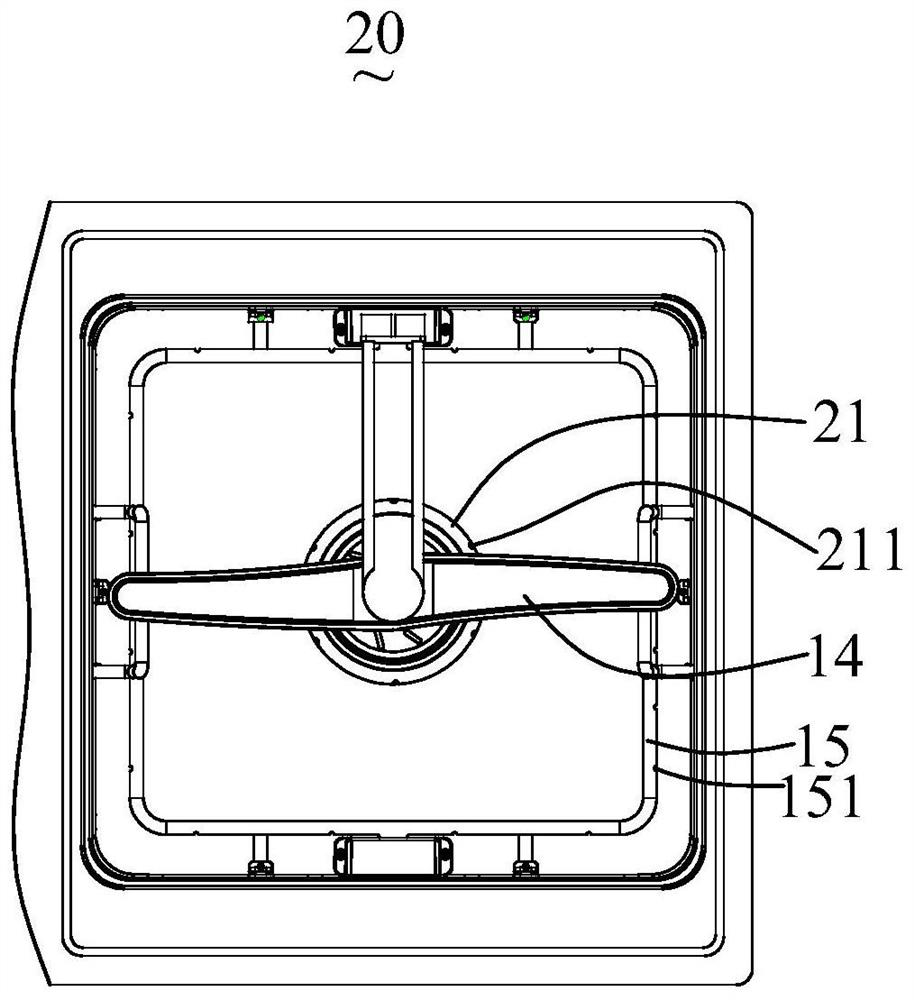

Water-tank-type cleaning machine with bubble cleaning basket

The invention relates to a water-tank-type cleaning machine with a bubble cleaning basket. The machine comprises a cover body, a water tank, the cleaning basket which is contained in the water tank and a rotation spraying arm. The cover body seals an opening of the water tank, a first air guide channel is formed in the bottom of the cleaning basket, and air outlets are formed in the first air guide channel; an air pump is arranged on the outer portion of the water tank and communicated with the first air guide channel, and the rotation spraying arm rotates relative to the water tank. The water-tank-type cleaning machine is characterized in that spraying holes in the rotation spraying arm are formed in the projection range of the first air guide channel. Compared with the prior art, the water-tank-type cleaning machine with the bubble cleaning basket has the advantages that bubbles from the air outlets of the first air guide channel exert application force to fruits and vegetables whichare gathered close to the side wall of the water tank in the rising or blasting process, the fruits and vegetables roll to the center of the water tank or upward, and 360-degree cleaning in all directions in the rolling process is achieved, so that the fruits and vegetables are cleaned more completely.

Owner:JOYOUNG CO LTD

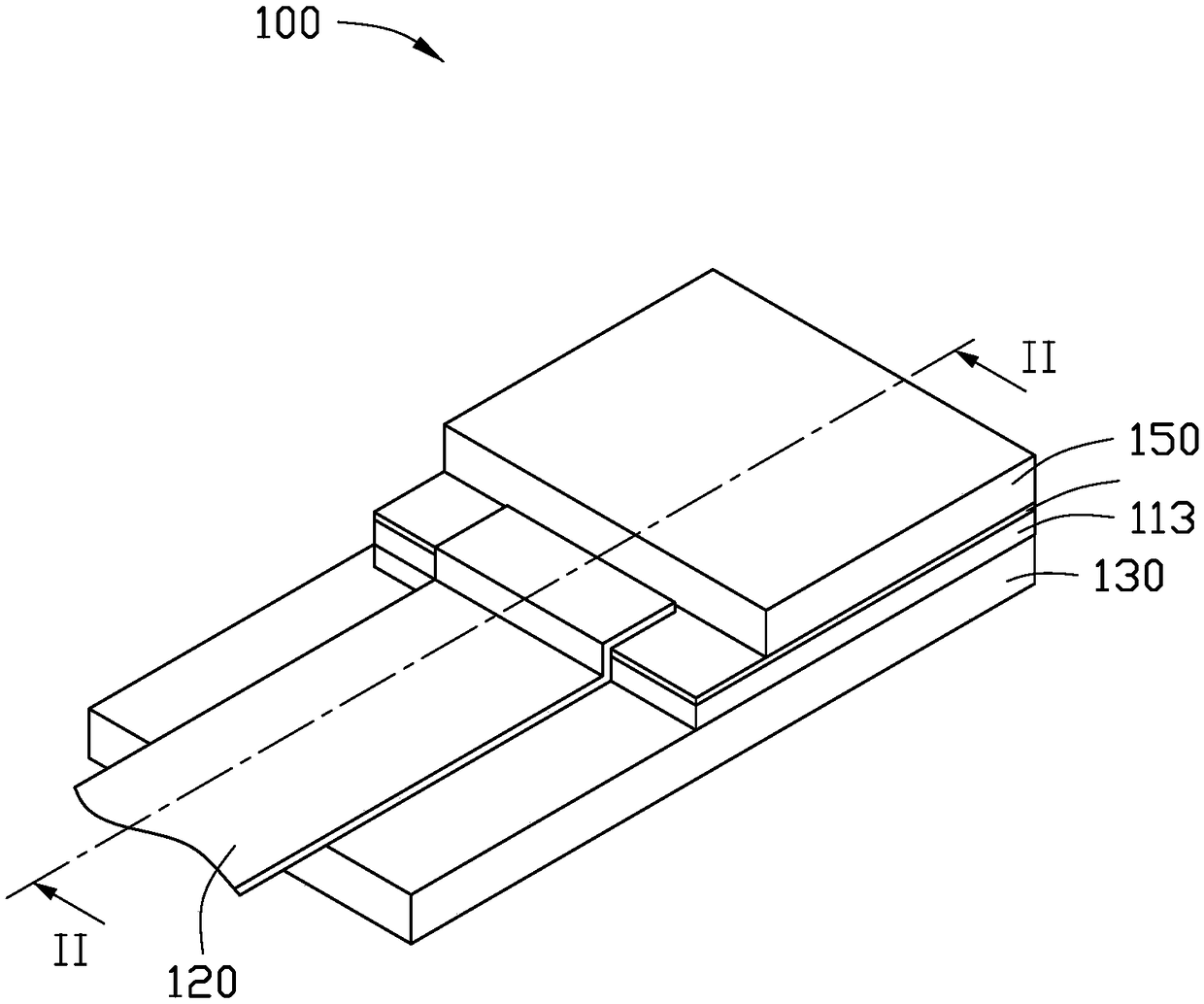

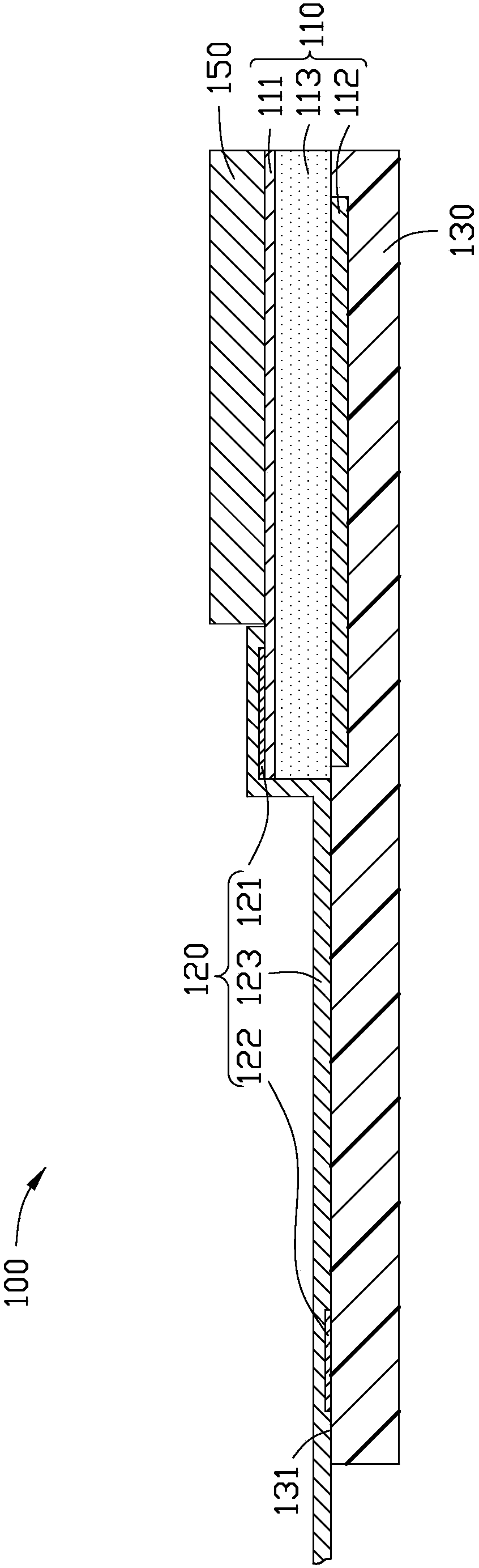

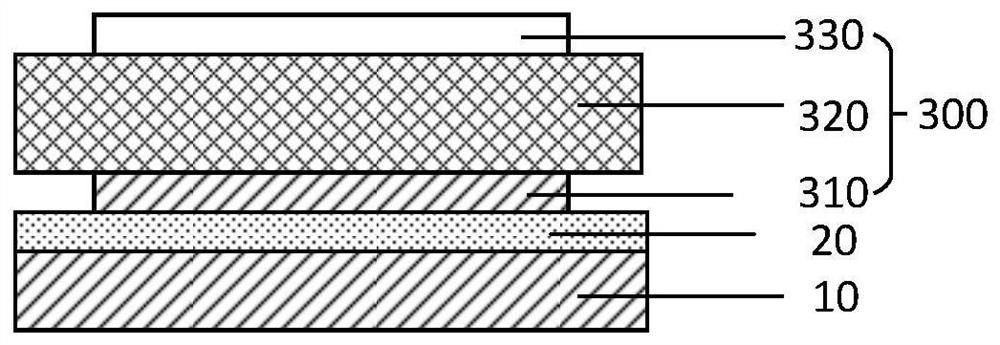

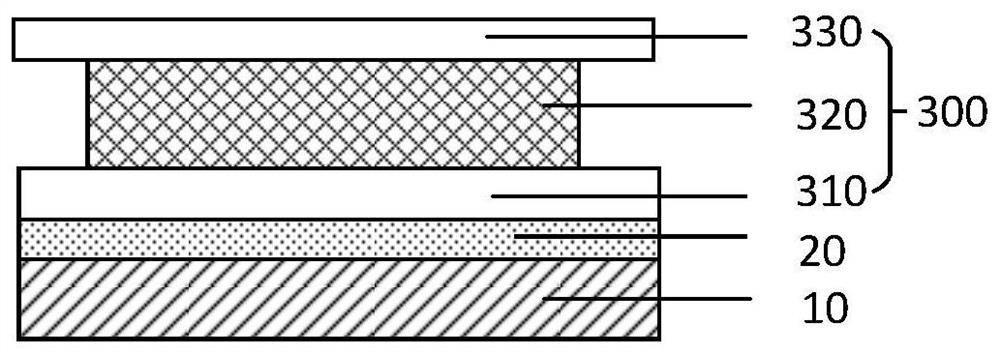

Ultrasonic fingerprint identification device and manufacturing method thereof and electronic device using ultrasonic fingerprint identification device

ActiveCN108846318AFirmly connectedLap simplePiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationIdentification deviceElectron

The invention provides an ultrasonic fingerprint identification device comprising a circuit board substrate which includes the circuit; a piezoelectric layer which is arranged on one surface of the circuit substrate; a first electrode which is arranged on one side surface of the piezoelectric layer away from the circuit substrate, wherein the thickness range of the first electrode is from 0.005 mum to 1 mum; and a second electrode which formed on the circuit substrate and in contact with the surface of the piezoelectric layer away from the first electrode, wherein the piezoelectric layer is electrically connected to the circuit through the second electrode. The invention also provides a preparation method of the ultrasonic fingerprint identification device and an electronic device using the ultrasonic fingerprint identification device.

Owner:RECO TECH CHENGDU CO LTD

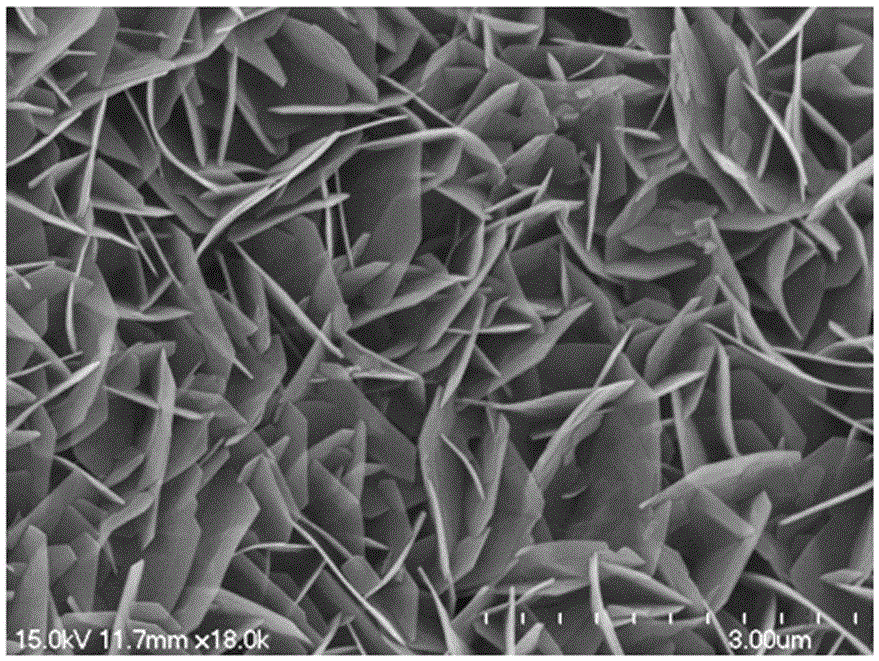

Lasagna nano graphene and preparation method and application thereof

InactiveCN106653379AReduce voidsImprove stabilityHybrid capacitor electrodesGrapheneHigh energySupercapacitor

The invention discloses a lasagna nano graphene and a preparation method and application thereof. The graphene has a diameter of 50 to 300 nm and a thickness of 1 / 5 to 1 / 2 of the diameter. Small graphene sheets are vertically supported between slice layers, and the spacing between the slice layers is 0.7 to 1 nm. The preparation method comprises the steps of first, preparing nano slice layered precursor, and then performing high-temperature roasting to generate a porous pie oxide template; and after carbon deposition under a high temperature, removing the oxide template and conducting drying. The preparation method has the characteristics of simple operation, high yield, low cost and easy expansion. The performance advantage lies in that when a large amount of lasagna nano graphenes are stacked, the lasagna nano graphenes are anti-compression and hard to overlap, and the stacked structure is not easy to swell by an electrolyte. The lasagna nano graphene is suitable for use as an electrode material of a super capacitor under high voltage, and has the characteristics of having a high energy density per unit area and being not easy to attenuate.

Owner:TSINGHUA UNIV

Cap-shaped nanometer graphite as well as preparation method and application thereof

ActiveCN103086365ALow cost of preparationIncrease energy densityMaterial nanotechnologyCarbon compoundsElectrochemical energy storageEnergy density

The invention discloses cap-shaped nanometer graphite as well as a preparation method and an application thereof, and belongs to the technical field of nanometer material preparation and electrochemistry energy storage. The preparation method comprises the following steps of: firstly preparing a template agent capable of generating nonuniform carbon deposition under chemical vapor deposition atmosphere, generating cap-shaped nanometer graphite on the prepared template agent, and finally removing and drying the template agent so as to prepare the cap-shaped nanometer graphite. The prepared cap-shaped nanometer graphite is in a cap-shaped structure, the diameter of the widest part of the cap-shaped nanometer graphite is 6-1000nm, and the height of the cap-shaped nanometer graphite is 1 / 5-1 / 2 of the diameter of the widest part of the cap-shaped nanometer graphite, and the specific surface area of the cap-shaped nanometer graphite is 80-2000m<2> / g. The cap-shaped nanometer graphite served as an electrode material is used for manufacturing a supercapacitor, wherein the mass percent of the cap-shaped nanometer graphite to the supercapacitor is 20-40%; the preparation method disclosed by the invention has the advantages of simple operation, low cost and environment protection; the utilization rate of the specific surface area and the energy density of the prepared cap-shaped nanometer graphite are high; and the effect is good when the prepared cap-shaped nanometer graphite serving as the electrode material is used for manufacturing the supercapacitor.

Owner:TSINGHUA UNIV

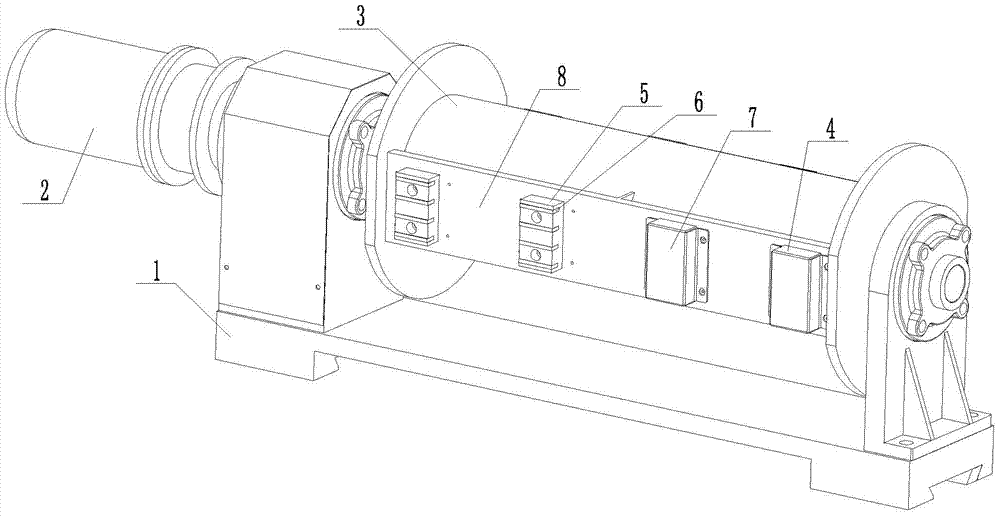

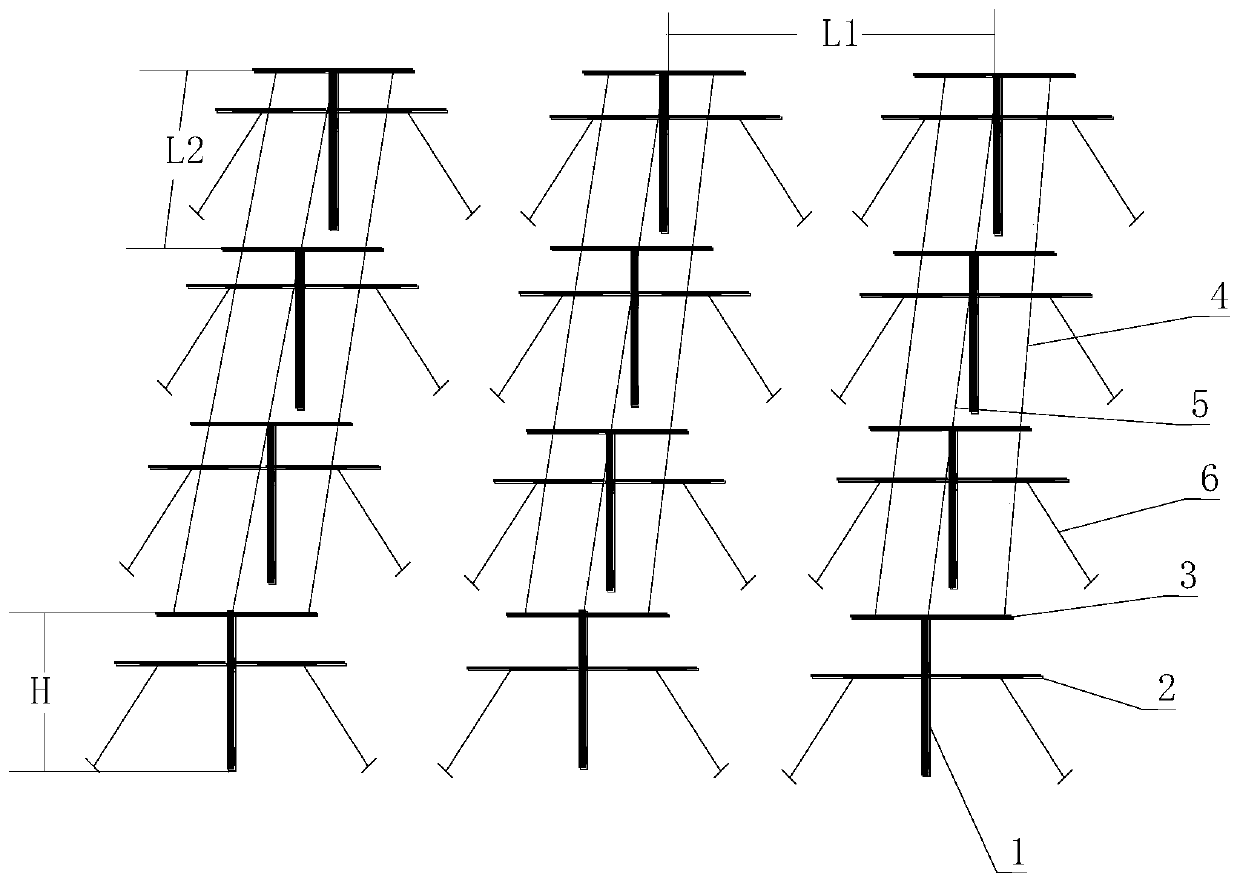

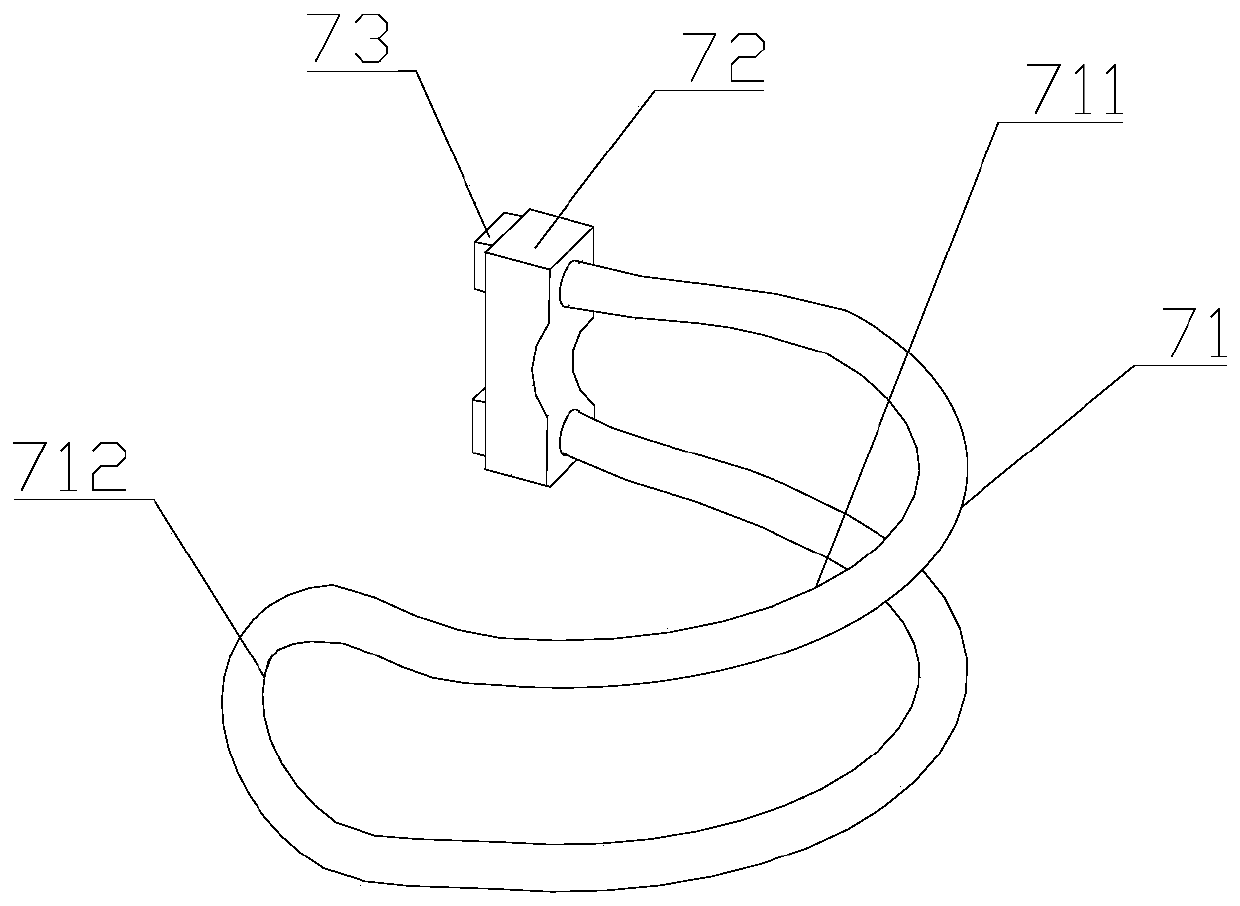

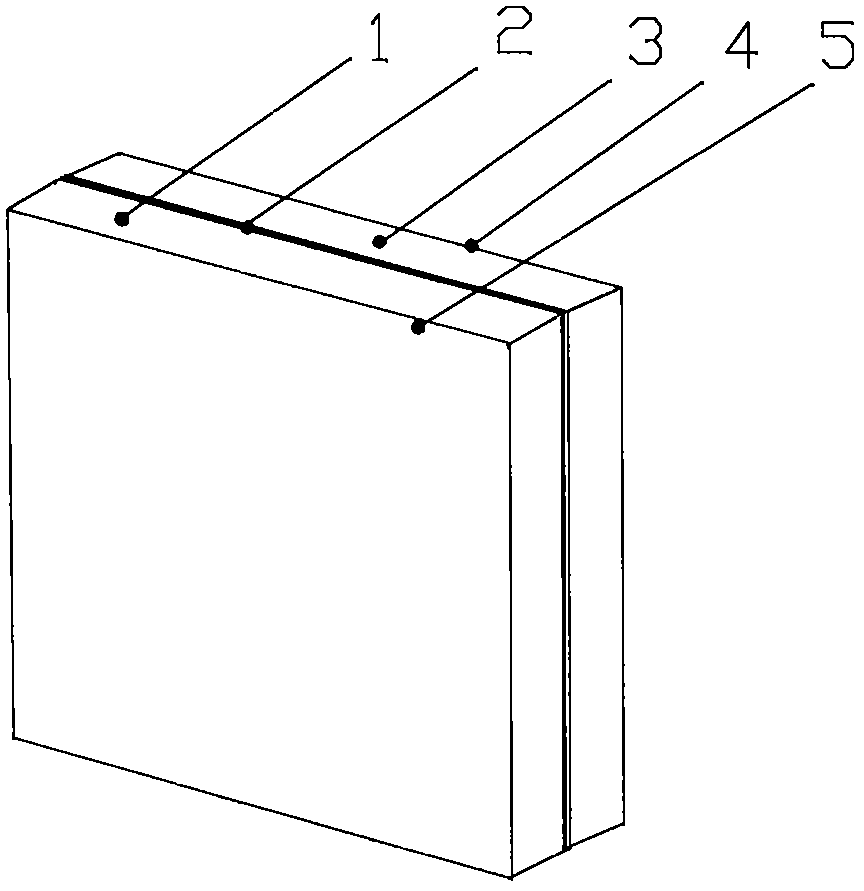

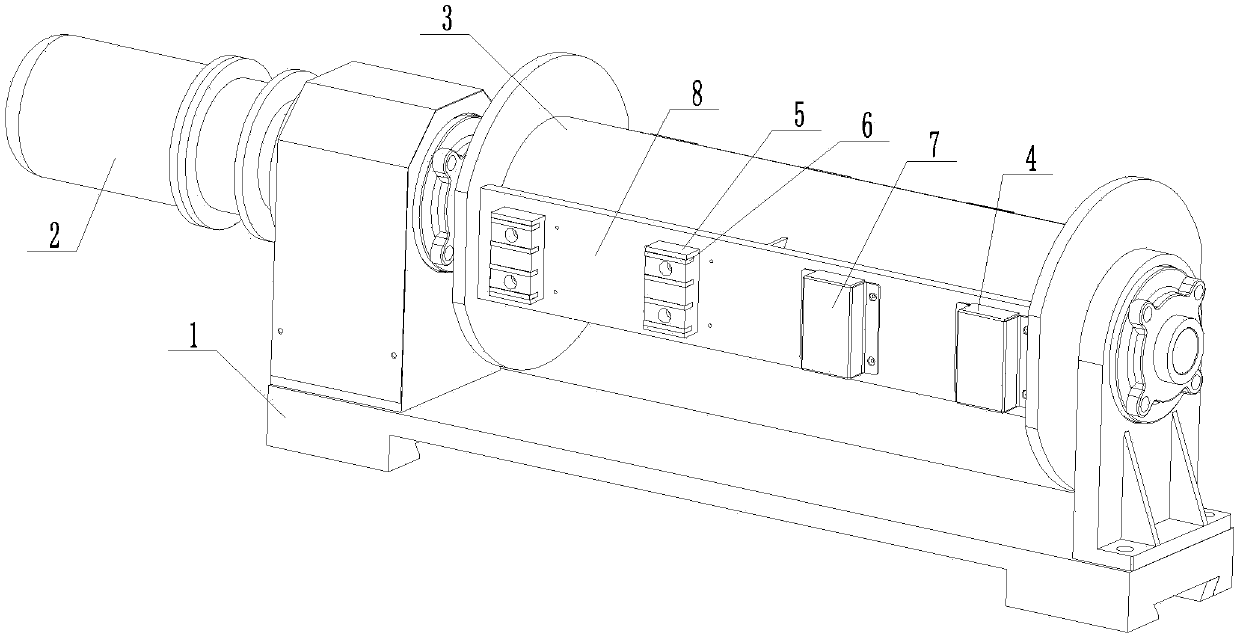

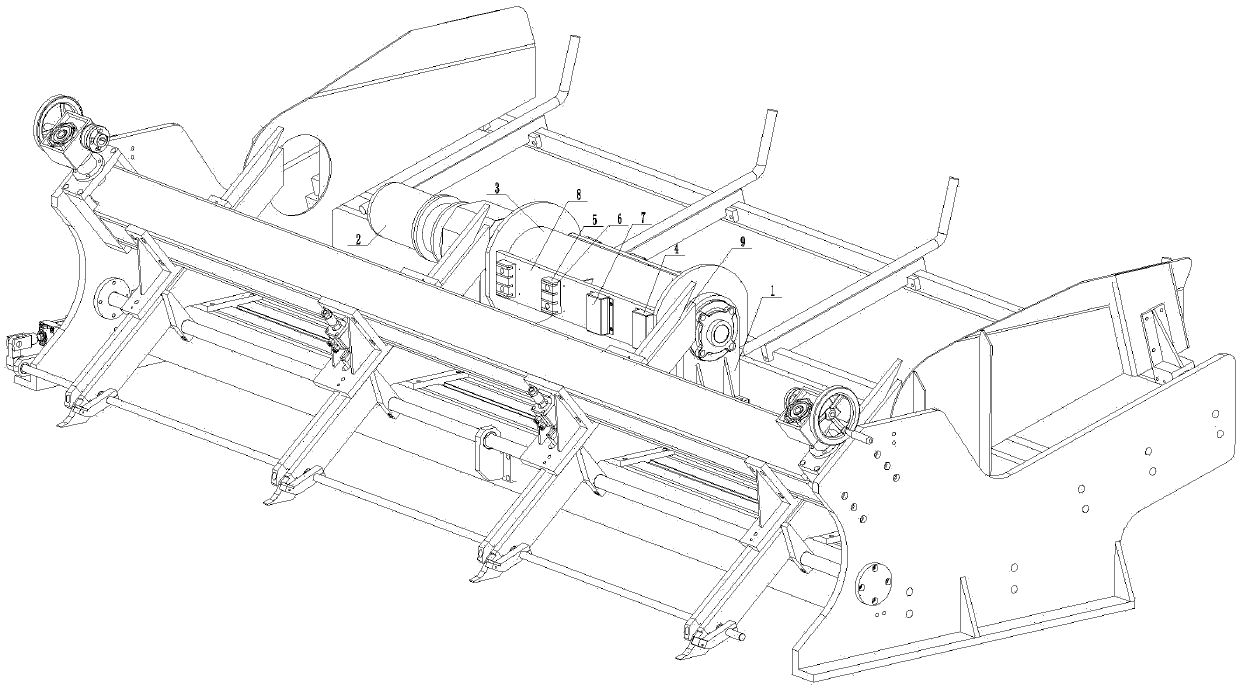

Magnetic suction mechanism

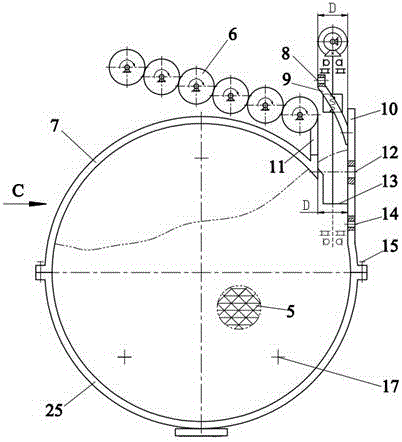

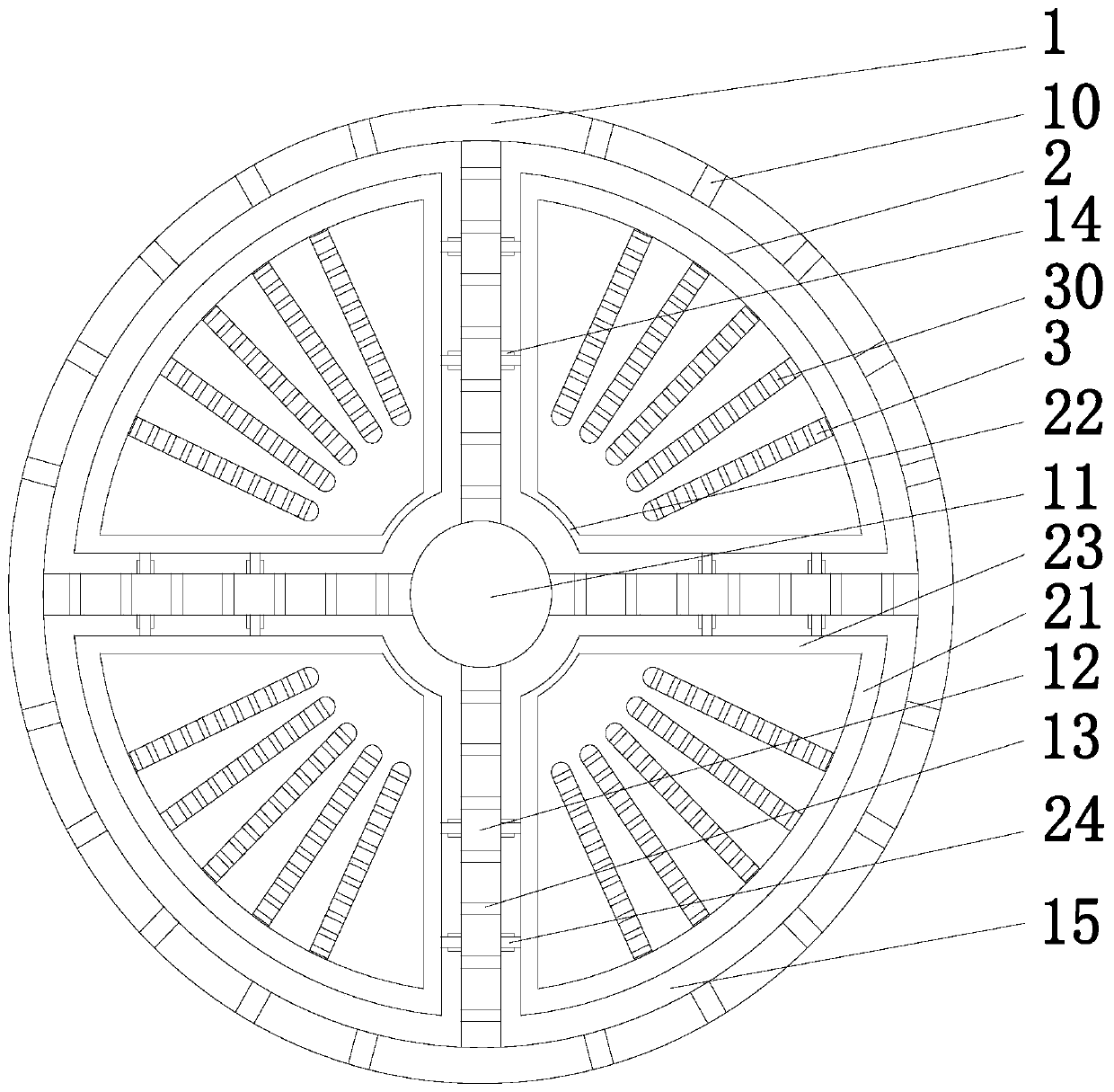

ActiveCN103587902ANot easy to overlapWith magnetic concentrationConveyor partsRotary conveyorsRebarMagnet

The invention discloses a magnetic suction mechanism which has centralized magnetic force and good directionality; sucked rebars rarely cross-stack. The magnetic suction mechanism comprises a frame (1), a motor (2), a roller (3), and a plurality of rows of magnetic units, all evenly distributed on the periphery of the roller (3). The magnetic units (4) in each row are evenly distributed along the axial direction of the roller (3). Each magnetic unit (4) comprises a support (5) made of antimagnetic material, a plurality of magnets (6), and a cover (7) made of antimagnetic material admitting permeation of magnetism. Every support (5) is connected with the cylindrical surface of the roller (3). The magnets (6) are evenly arranged on the supports (5) from top to bottom. The covers (7) cover the supports (5) so as to cover the magnets (6).

Owner:NINGBO XINZHOU RESISTANCE WELDER

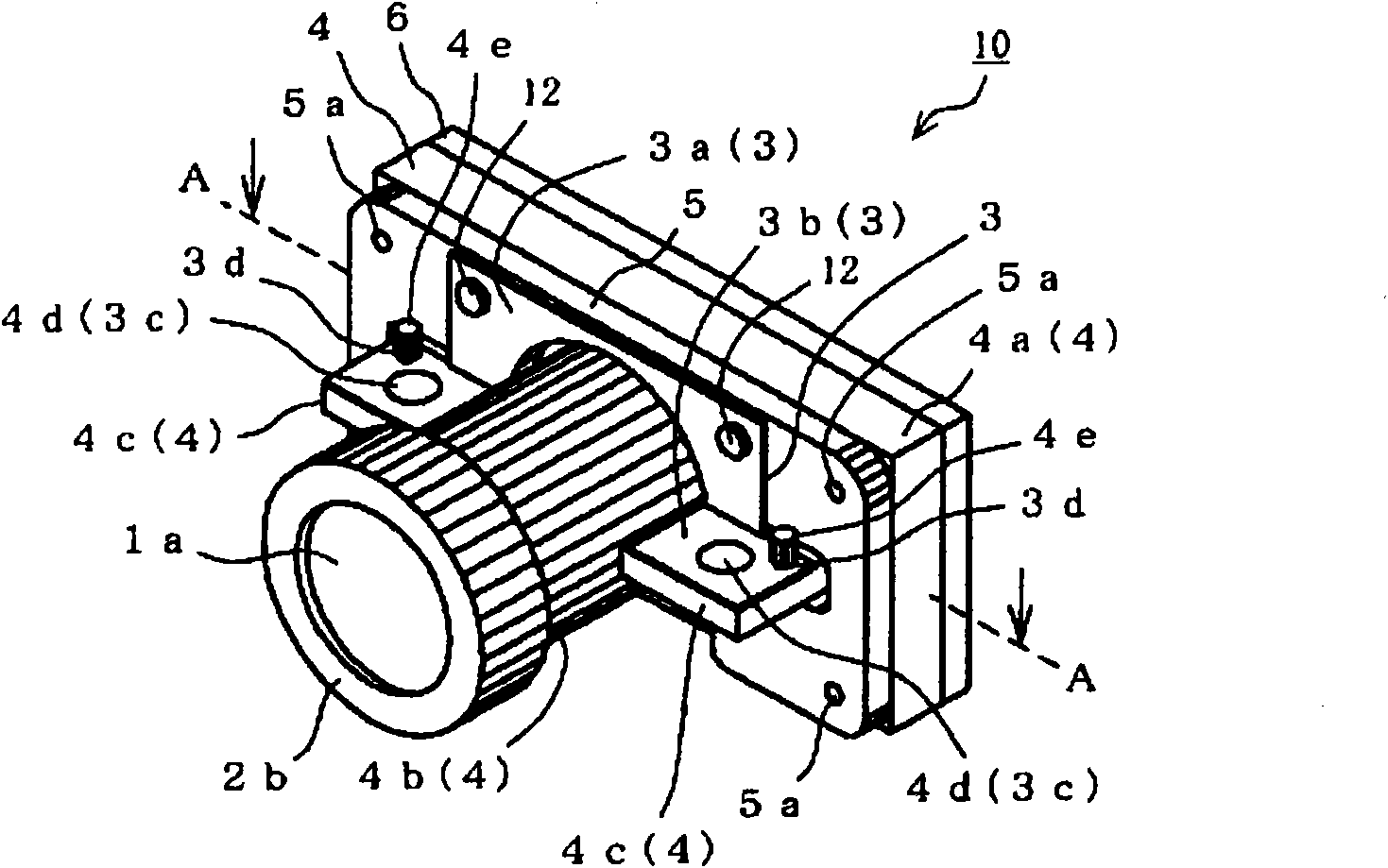

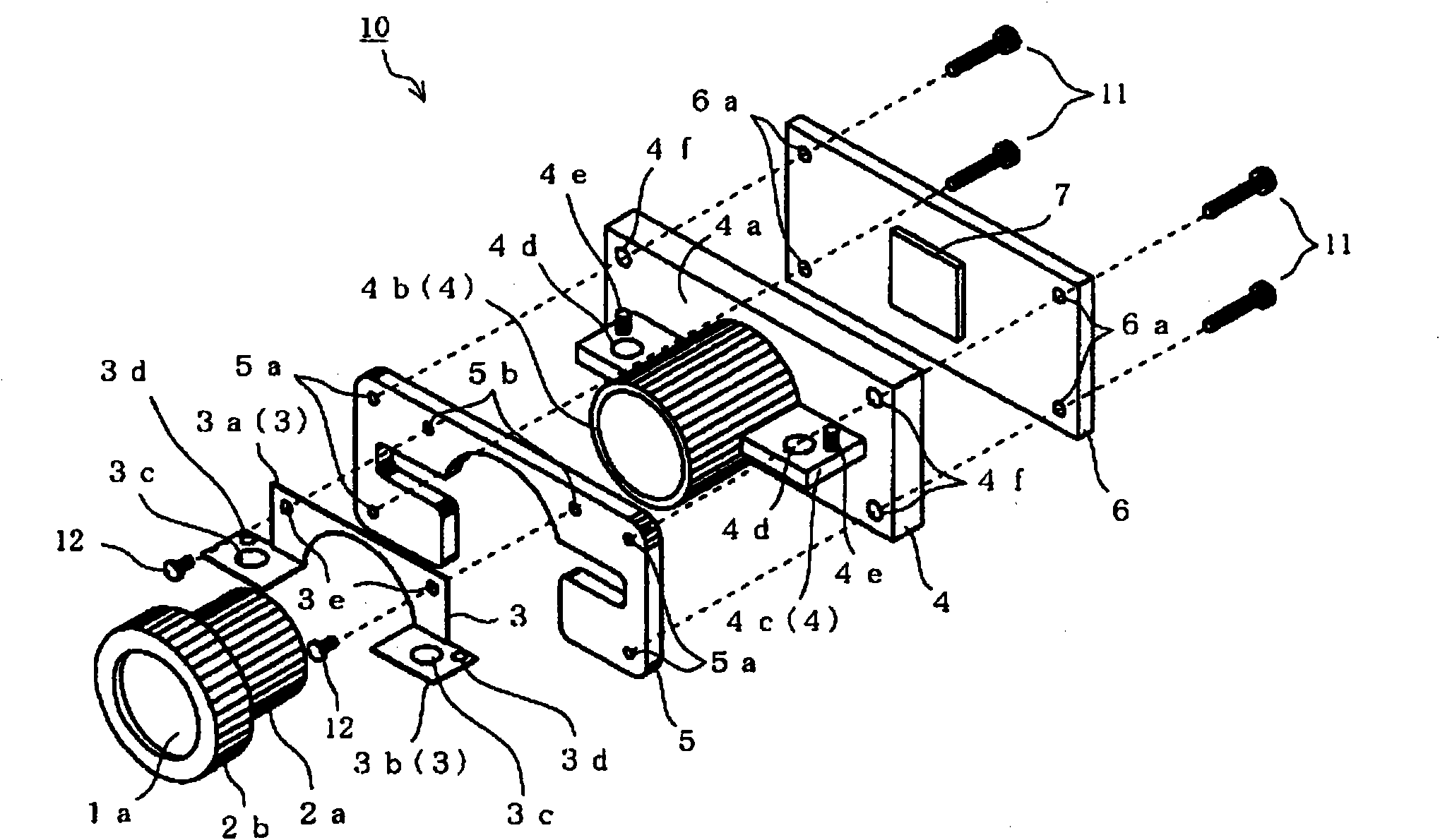

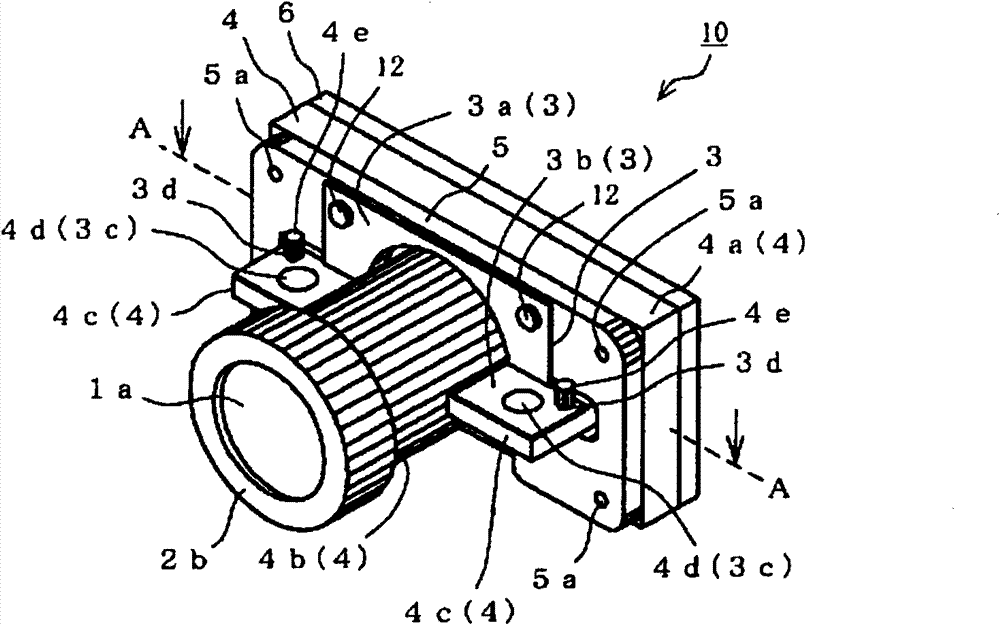

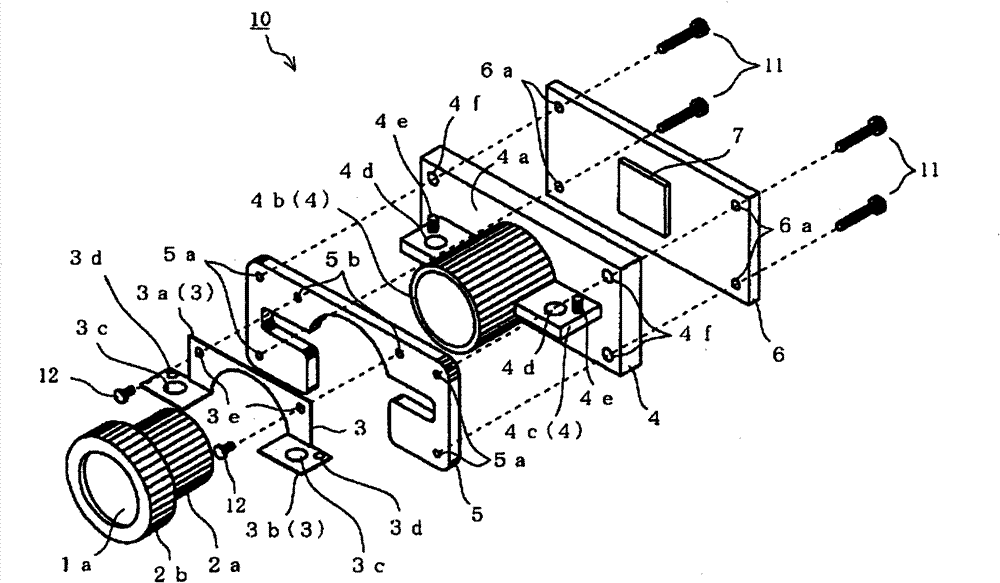

Imaging module

InactiveCN101981914AHigh precisionReduce usageTelevision system detailsMagnetic/electric field screeningComputer moduleEngineering

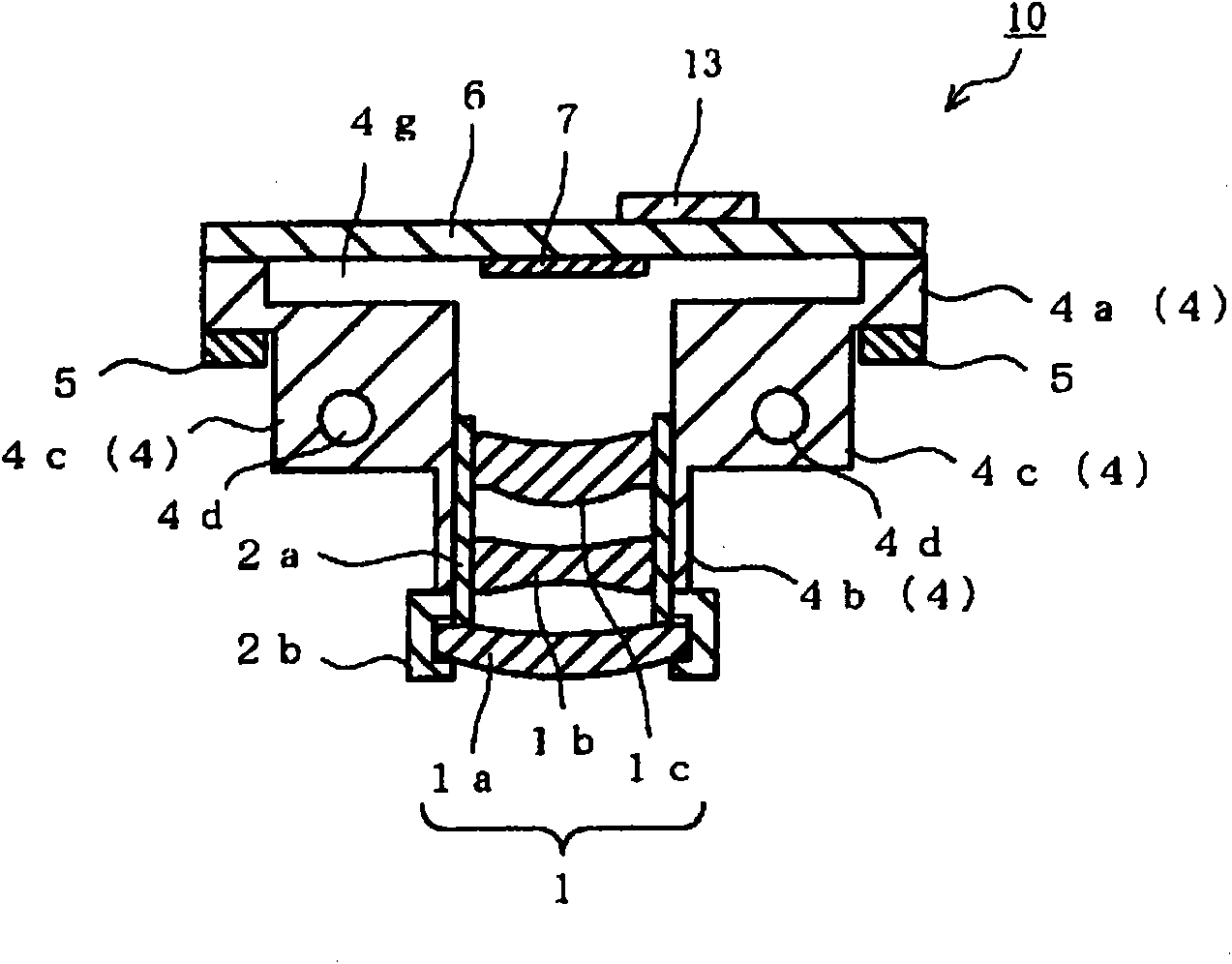

Provided is an imaging module, which can be reduced in weight so that it can be stably held in an external structure and can acquire a highly precise image. The imaging module (10) comprises an imaging substrate (6) mounting an imaging element thereon, a resin holder (4) including a substrate fixing portion (4a) fixing the imaging substrate (6), a lens supporting cylinder (4b) supporting a lens (1) therein, and holding portions (4c) protruding from the substrate fixing portion (4a) to an object side and having through holes (4d) to be held by an external structure, a fixing member (5) made ofa metal and arranged on the object side of the substrate fixing portion (4a) of the holder (4), and a holding plate member (3) made of a metal and including a fixed area fixed on and electrically connected with the fixing member (5), and holding portion adjoining regions (3b) having through holes (3c) overlapping the peripheries of the through holes (4d) of the holding portions (4c) and leading to the through holes (4d). The imaging module (10) can be reduced in weight so that it can be stably held in the external structure and can acquire a highly precise image.

Owner:KYOCERA CORP

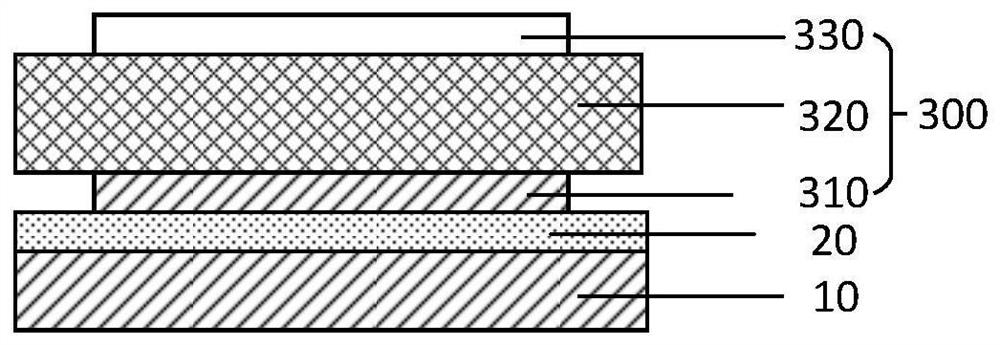

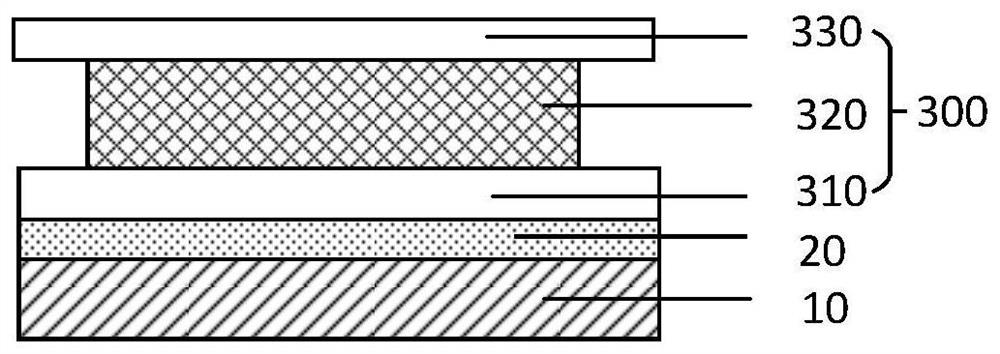

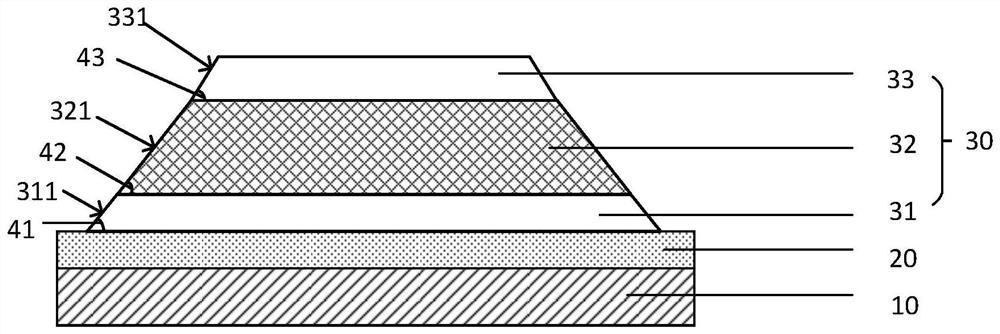

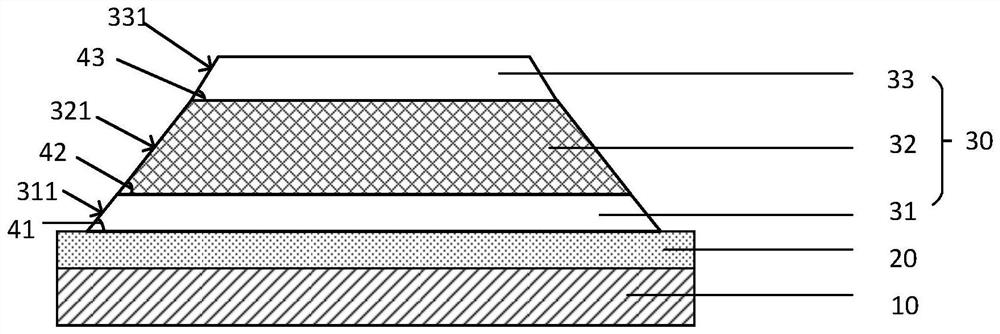

Array substrate, preparation method thereof and display panel

ActiveCN112542502AImprove reflectivityImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingComposite electrodeEngineering

The invention discloses an array substrate, which comprises a flat layer and a composite electrode arranged on the flat layer, wherein at least one undercut structure is formed by the side surface ofthe edge of the composite electrode and the surface of the flat layer, the composite electrode comprises at least one metal electrode and at least one transparent electrode, and the metal electrodes and the transparent electrodes are alternately stacked.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Preparation technology of high strength net false roof for underground coal mining

The invention which belongs to the technical field of protective articles for coal mining discloses a preparation technology of a high strength net false roof for underground coal mining. The main technology is characterized in that: a mixture, which is composed of polypropylene, a fire retardant and an antistatic agent and is added to a mixer to be uniformly stirred, is filled into a preheated plastic extruder to extrude high strength guipures; the guipures are cooled, embossed and arranged on a welding frame; nodes of vertical high strength guipures and transverse high strength guipures are welded by an ultrasonic welding machine to form the high strength net false roof for underground coal mining; and the high strength net false roof is sheared by a polishing machine and rolled into roll shape and enters a storehouse after examination. According to the present invention, the high strength net false roof for underground coal mining prepared by the technology, which allows static electricity not easily to be generated by friction, flame resistance to be fine, rust-proof capability to be strong, construction and transport to be convenient and carrying ability to be strong, can be used to support a whole roadway roof, so joints are reduced, the work efficiency is improved, and the false roof effect is achieved when the false roof is pre-embedded in a coal seam when coal is mined layer by layer.

Owner:HENGSHUI BAOLI ENG PLASTIC

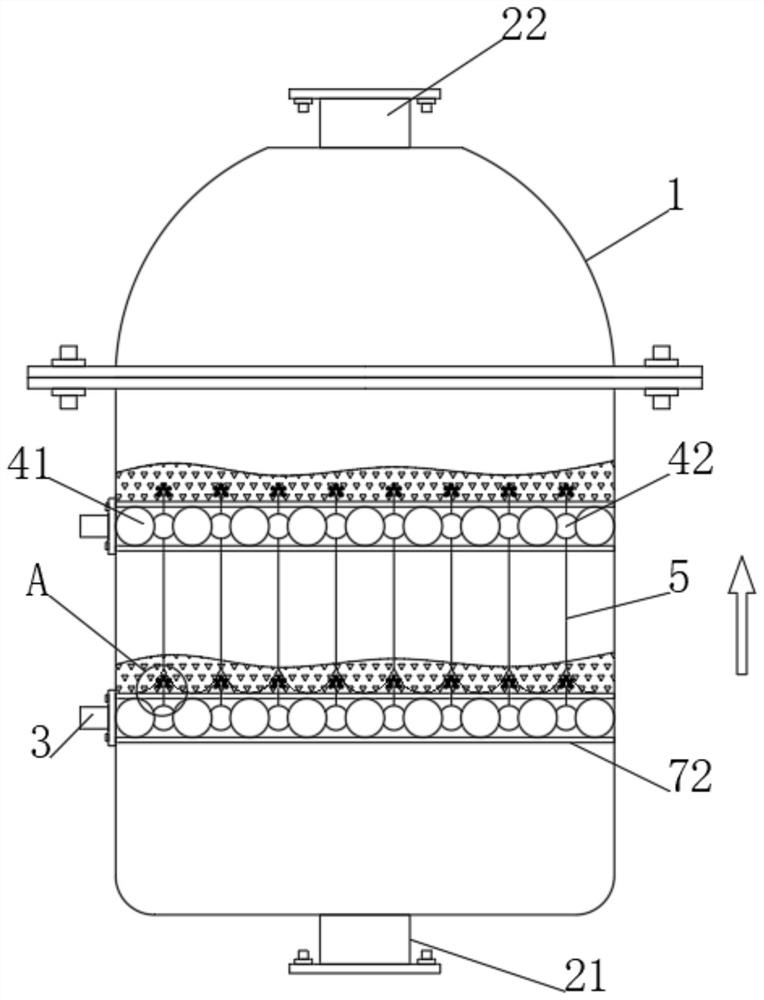

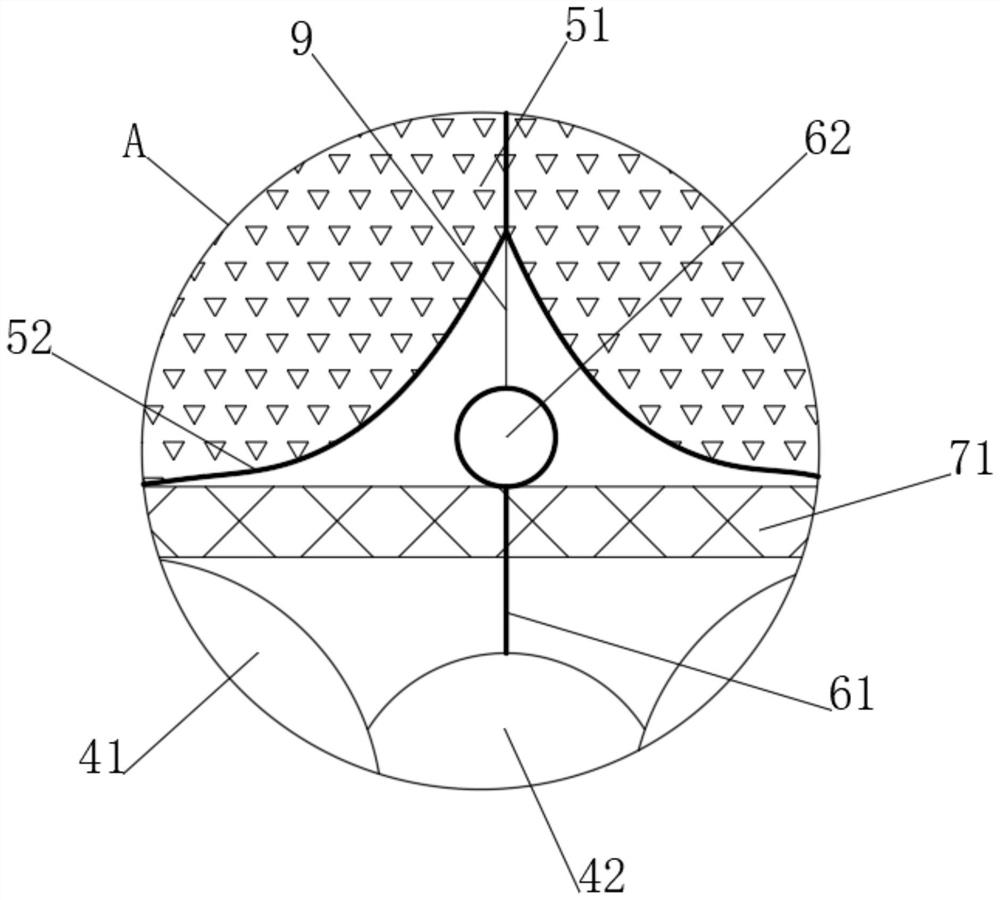

Efficient combined desulfurization and denitrification device and method

PendingCN112933781AAchieve flipping effectReduce replacement frequencyGas treatmentDispersed particle filtrationPneumatic filterSorbent

The invention discloses an efficient combined desulfurization and denitrification device and method, and belongs to the technical field of denitrification and devulcanization. According to the device and the method, through the arrangement of a double-layer pneumatic filter screen, the device and the method compared with the prior art have advantages that relatively thicker adsorbent particles can be laid, and after waste gas treatment is conducted for a period of time, different bidirectional air ports can be alternately inflated and deflated at intervals, so that the bulb plate part is continuously bulged and shrunken, and an upper variable net, in contact with adsorbent particles, in the double-layer pneumatic filter screen is driven to be continuously bulged and sunken, and therefore the effect that the adsorbent particles on the screen can be turned over and can be in full contact with waste gas; the relatively high utilization rate of the adsorbent particles can be guaranteed under the condition of relatively thick laying, meanwhile, the replacement frequency of the adsorbent particles can be effectively reduced, and the influence on the denitration and desulfurization efficiency is reduced.

Owner:宁夏煜隆科技有限公司

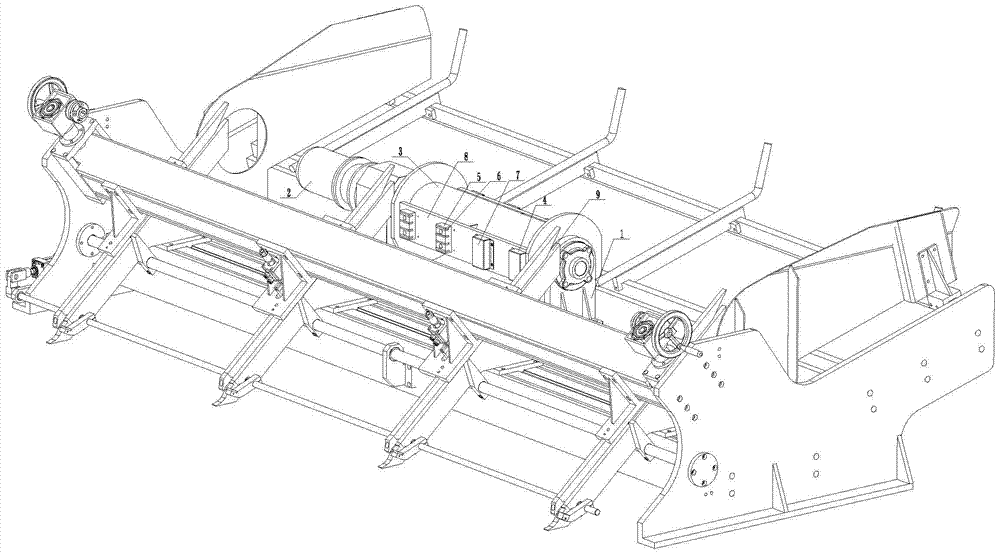

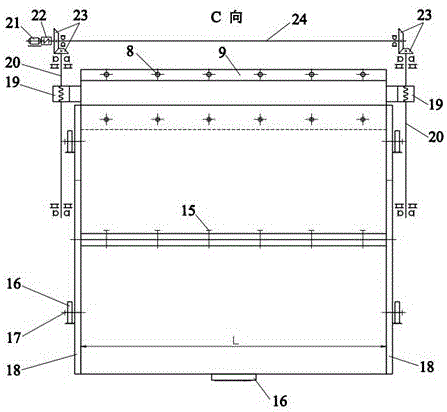

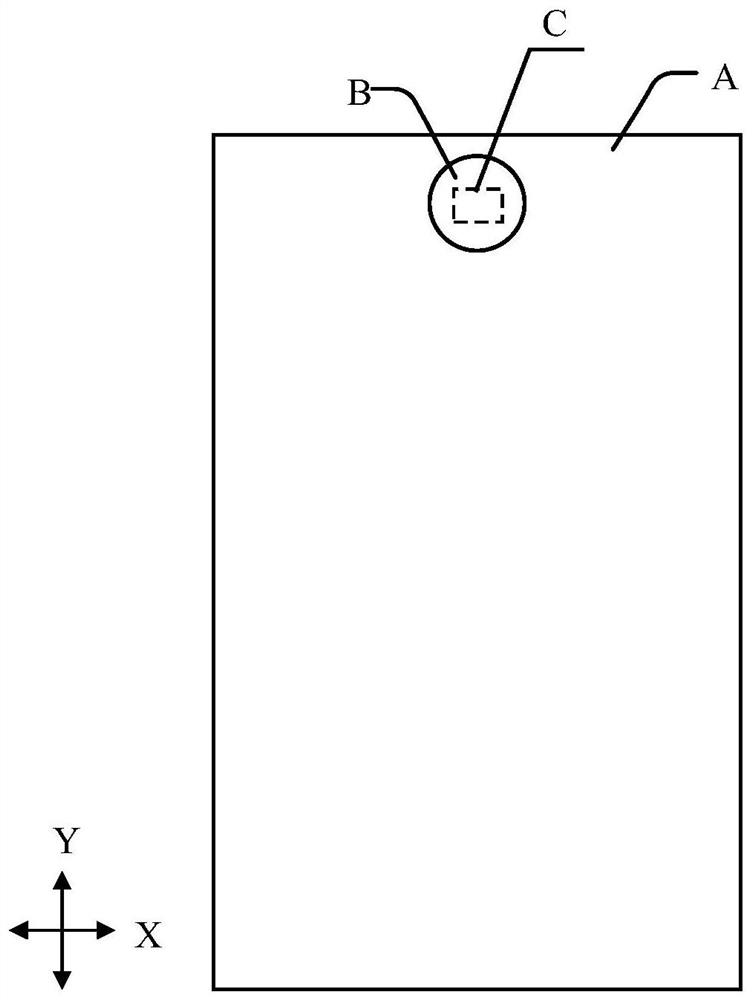

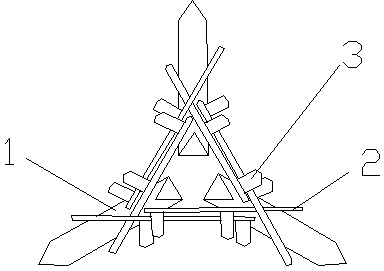

Production method and forming device for cylindrical reconstituted bamboo lumber

ActiveCN105835206AImprove stabilityLap simpleCane mechanical workingWood working apparatusVolumetric Mass DensityEngineering

Provided is a forming device for cylindrical reconstituted bamboo lumber. A mold of the forming device is composed of an upper formwork (7), a lower formwork (25) and end covers (18). A cylindrical cavity is formed by the upper formwork (7), the lower formwork (25) and the end covers (18) in a surrounded mode. A square window with the width being D and the length being larger than or equal to L is formed in the upper formwork, guiding plates (10 and 11) are arranged on the two long sides of the square window correspondingly, the distance between the inner walls of the two guiding plates is D, an arc pressing plate (9) is arranged between the two guiding plates, and a vertical feeding channel is jointly formed by the two guiding plates and the arc pressing plate. A driving roller set (6) inclining towards the square window is mounted above the mold, and a material pressing system is composed of a motor (21), a transmission part thereof and the arc pressing plate (9). A method for producing the cylindrical reconstituted bamboo lumber includes the first step of manufacturing triangular bamboo splits, the second step of drying, gluing and re-drying, the third step of mounting special equipment, the fourth step of feeding, the fifth step of pressing, the sixth step of solidifying and the seventh step of demolding and discharging. By means of the device and method for producing the cylindrical reconstituted bamboo lumber, raw bamboo is saved, the density is low and uniform, pressure is small, stability is good, and production cost is low.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Washing method of water tank type washing machine with bubble washing basket

The present invention relates to a washing method of a water tank type washing machine with a bubble washing basket. The washing machine comprises a cover body, a water tank, a washing basket and a rotating spray arm accommodated in the water tank, the cover body closes an opening of the water tank, a first air guide channel is arranged at a bottom part of the washing basket, air outlet holes arearranged in the air guide channel, an air pump is arranged outside the water tank, the first air guide channel is in communication with the air pump, the rotating spray arm performs a rotary motion relative to the water tank, and spray holes in the rotary spray arm are arranged within a projection range of the first air guide channel. The washing method comprises a complete soaking and washing stage, and in the complete soaking and washing stage, the rotating spray arm drives water to enable fruits and vegetables to diffuse outward to perform a rotating movement, and the first air guide channel produces bubbles to drive the fruits and vegetables to conduct a self-rotation movement inwardly and upwardly. Compared with the prior art, the fruits and vegetables can achieve a 360-degree all-dimensional washing and can be washed more cleanly and thoroughly.

Owner:JOYOUNG CO LTD

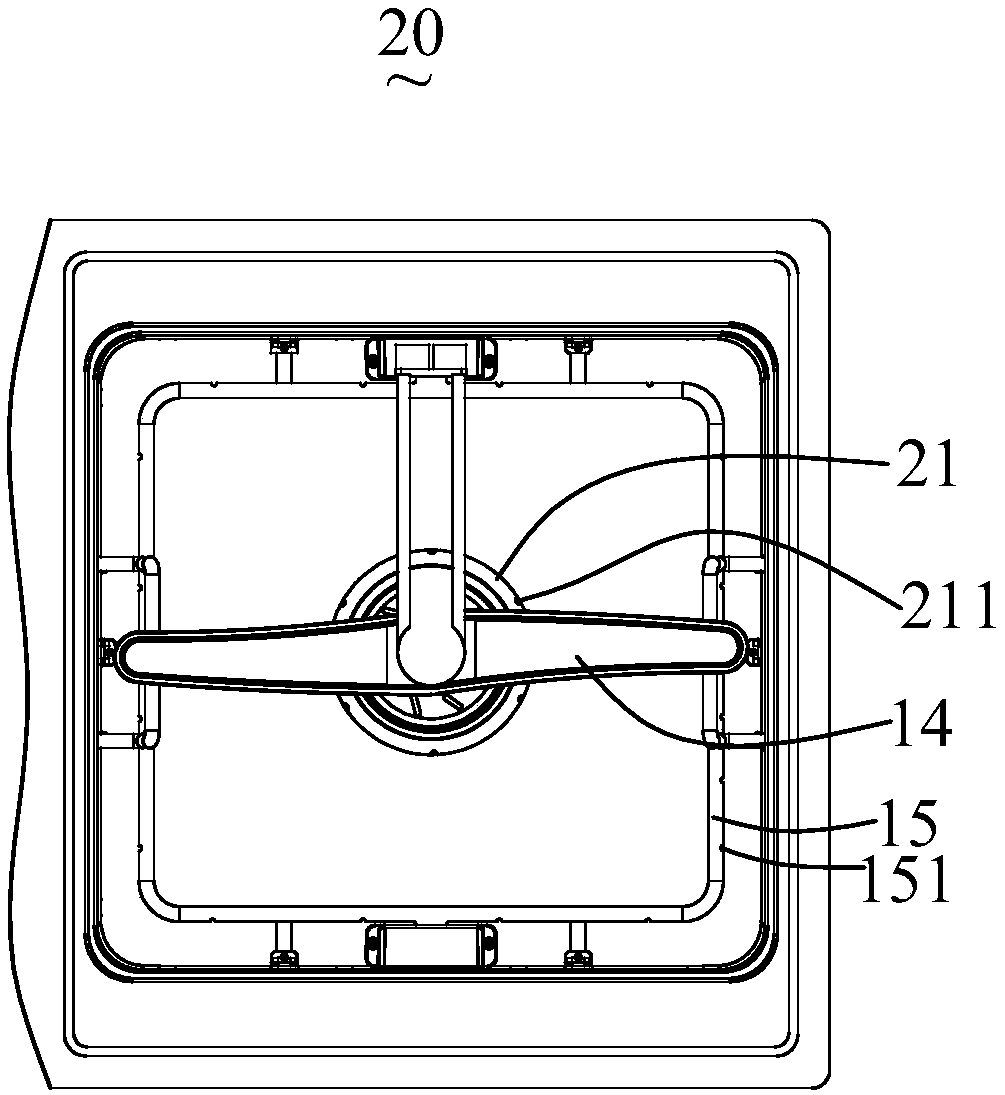

Passion fruit cultivating method

InactiveCN110915572APromote growthNot easy to overlapPlant supportsFruit crop cultivationBud growthPassion fruit

The invention discloses a passion fruit cultivating method. The passion fruit cultivating method comprises the following steps of (1) building a fruit shed: wherein the fruit shed consists of a plurality of rows of pergolas, and each row of the pergolas consists of a plurality of stand columns, first cross bars, second cross bars and creeping wires; (2) performing field planting on fruit seedlings: performing field planting on passion fruit seedlings near the stand columns, wherein the plant distance is 4-6cm; (3) performing main tendril cultivation: before passion fruit trunks creep the pergolas, removing lateral buds, reserving main buds for growth, and when the trunks reach the height of the creeping wires, performing development into two main tendrils; (4) combing bearing branches andtendrils: combing and trimming bearing branches and tendrils growing on the main tendrils, and inducing the bearing branches and tendrils; (5) trimming the bearing branches and tendrils: after ripe fruits on the bearing branches and tendrils are picked, trimming the bearing branches and tendrils, of which the flower forming capacity is reduced, from basal parts; and (6) continuously repeating thestep (4) and the step (5) to continuously induce formation of new bearing branches and tendrils. According to the cultivation method disclosed by the invention, the passion fruit main tendrils twine along the creeping wires, the bearing branches and tendrils bear fruits in a curtain falling manner along the creeping wires, passion fruit branches and leaves are not liable to overlap too much, daylighting is good, growth of passion fruits is facilitated, besides, the bad fruit rate is reduced, and picking is also facilitated.

Owner:南宁海卫施特生物科技有限公司

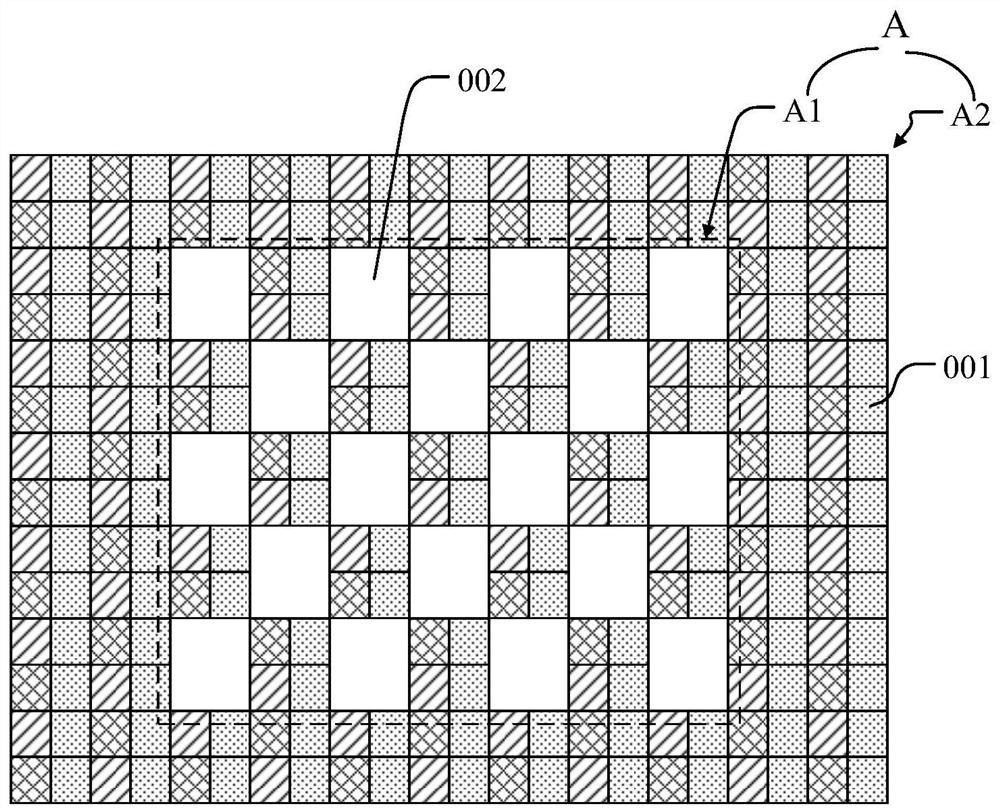

Display panel and terminal equipment

PendingCN112234083AEasy to take picturesEasy to shootSolid-state devicesSemiconductor devicesComputer graphics (images)Imaging quality

The invention relates to a display panel and terminal equipment, and relates to the technical field of display. The display panel comprises a display area, at least parts of the display area is a transparent area, the transparent area is provided with a plurality of pixel rows distributed in a column direction, each pixel row comprises a plurality of pixels and a plurality of transparent parts, the pixels and the transparent parts are alternately arranged in a row direction, and each pixel comprises a plurality of sub-pixels adjacently arranged in the row direction; each pixel row comprises aplurality of first pixel rows and a plurality of second pixel rows, a transparent part between every two adjacent pixels in the first pixel rows is a first transparent part, and a transparent part between every two adjacent pixels in the second pixel rows is a second transparent part; and the width of the first transparent part in the row direction is larger than that of the second transparent part in the row direction. According to the display panel and the terminal equipment, the imaging quality of under-screen camera shooting can be improved.

Owner:BOE TECH GRP CO LTD

A sink type cleaning machine with bubble cleaning basket

ActiveCN107981745BClean thoroughlyNot easy to overlapKitchen equipmentAir pumpEnvironmental engineering

The invention relates to a sink type cleaning machine with an air bubble cleaning basket, comprising a cover body, a water tank, a cleaning basket accommodated in the water tank and a rotating spray arm, the cover closes the opening of the water tank, and a second An air guide channel, an air outlet is provided on the first air guide channel, an air pump is arranged outside the water tank, the first air guide channel communicates with the air pump, the rotating spray arm rotates relative to the water tank, and it is characterized in that: the rotating The spray hole on the spray arm is set within the projection range of the first air guide channel. Compared with the prior art, the air bubbles coming out of the air outlet of the first air guide passage exert force on the fruits and vegetables gathered near the side wall of the water tank during the rising process or during the blasting process, and the fruits and vegetables move towards the center of the water tank under the action of the air bubbles. , and upward tumbling, forming a 360° all-round cleaning during the tumbling process, making the fruit and vegetable cleaning more clean and thorough.

Owner:JOYOUNG CO LTD

Novel composite magnet

The novel composite magnet is formed by combining two common magnets; and one ends with the same polarity of the two common magnets tightly close together, and the other ends with the same polarity ofthe two common magnets are arranged on the two sides so that the polarity on the two sides of the whole novel composite magnet can be same. Devices can be in mutual repulsion to achieve effects of uneasy overlapping by inlaying or implanting the novel composite magnet at the internals of the devices that need to be classified and sorted or the externals of the devices that need to be classified and sorted; and the novel composite magnet can make the device dispersedly attracted by iron and other paramagnetic substances, so that convenient sorting can be achieved.

Owner:江西上超电器制造有限公司

Cap-shaped nanometer graphite as well as preparation method and application thereof

ActiveCN103086365BNot easy to overlapImprove the utilization of specific surface areaMaterial nanotechnologyCarbon compoundsMaterials preparationGas phase

Owner:TSINGHUA UNIV

Magnetic suction mechanism

ActiveCN103587902BNot easy to overlapWith magnetic concentrationConveyor partsRotary conveyorsEngineeringRebar

The invention discloses a magnetic suction mechanism which has centralized magnetic force and good directionality; sucked rebars rarely cross-stack. The magnetic suction mechanism comprises a frame (1), a motor (2), a roller (3), and a plurality of rows of magnetic units, all evenly distributed on the periphery of the roller (3). The magnetic units (4) in each row are evenly distributed along the axial direction of the roller (3). Each magnetic unit (4) comprises a support (5) made of antimagnetic material, a plurality of magnets (6), and a cover (7) made of antimagnetic material admitting permeation of magnetism. Every support (5) is connected with the cylindrical surface of the roller (3). The magnets (6) are evenly arranged on the supports (5) from top to bottom. The covers (7) cover the supports (5) so as to cover the magnets (6).

Owner:NINGBO XINZHOU RESISTANCE WELDER

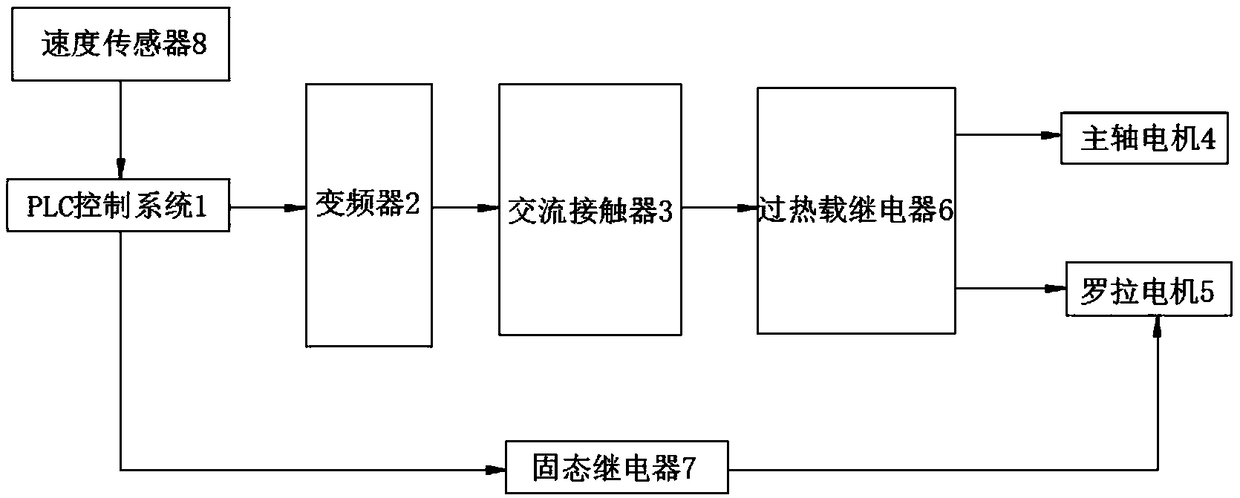

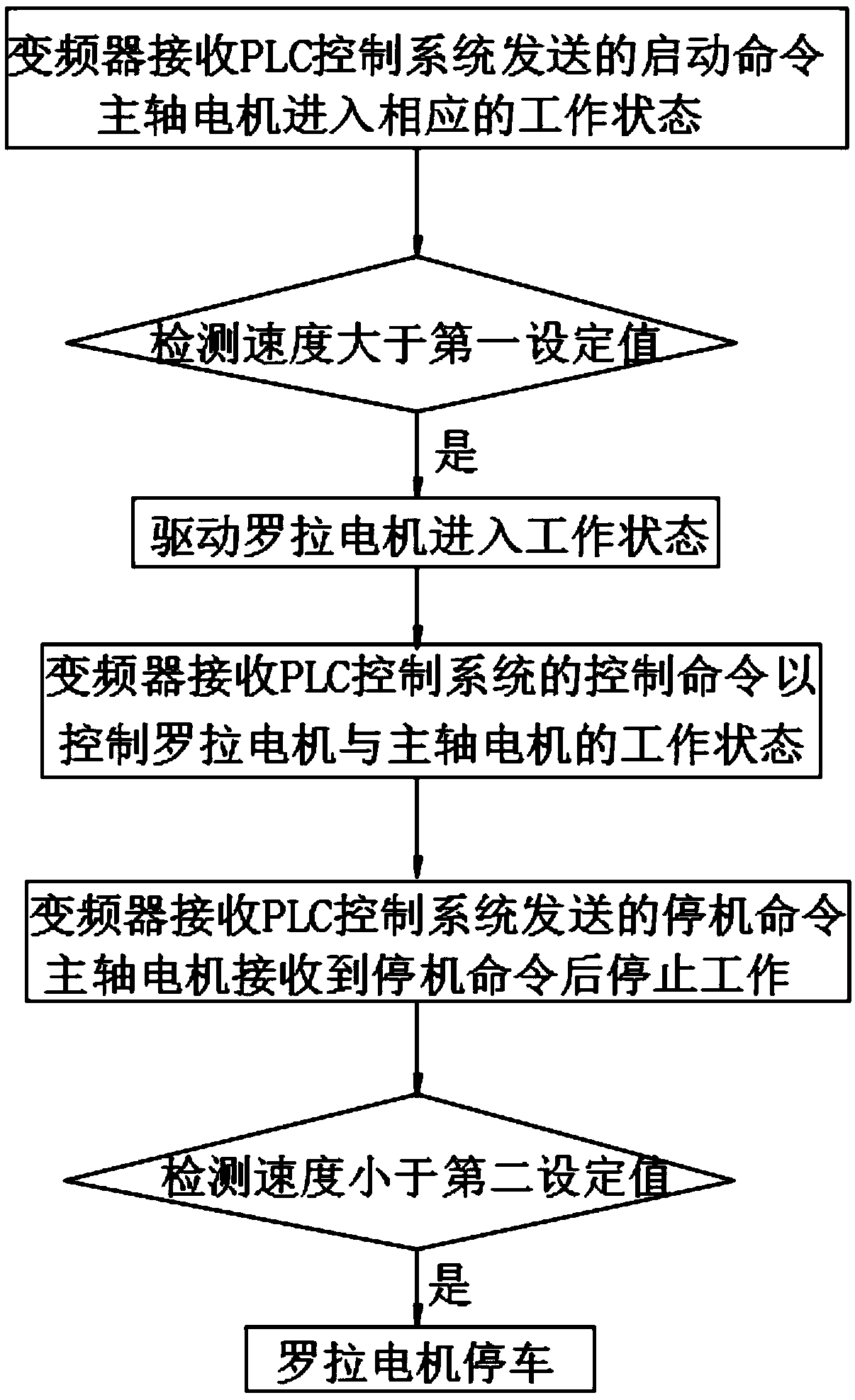

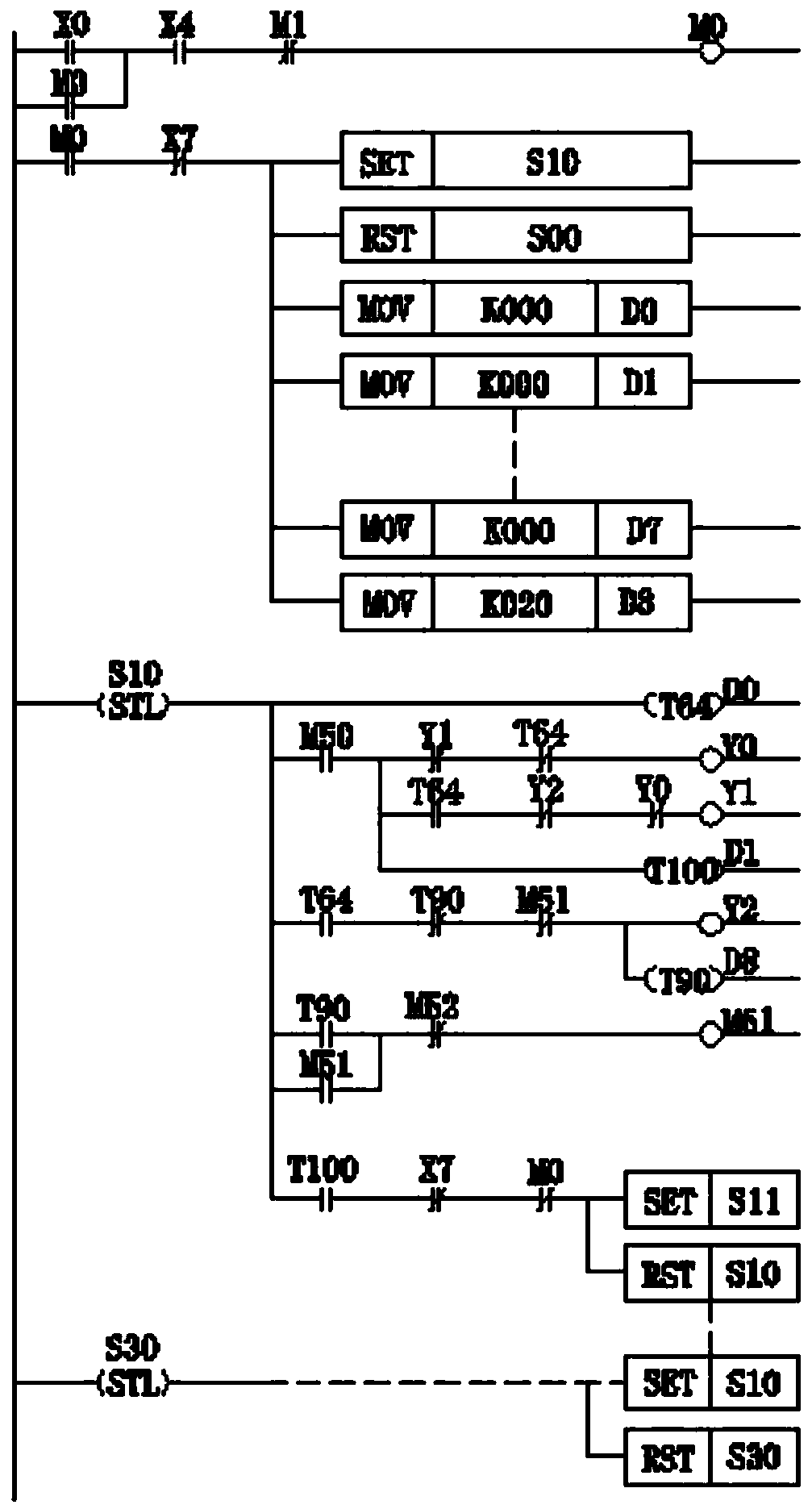

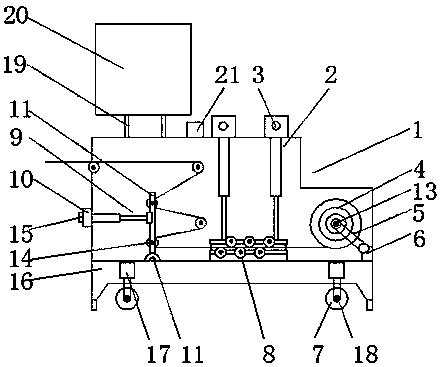

Electric control system and method for slubby chenille yarn

The invention discloses an electric control system and method for slubby chenille yarn. The electric control system comprises a power supply circuit and a PLC system which is connected to the power supply circuit. The PLC system is connected to a spindle motor and a roller motor through a frequency changer and an alternating current contactor respectively, the output end of the spindle motor is provided with a speed sensor which is used for detecting the speed of the output end of the spindle motor, and the speed sensor is connected to the PLC system. By arranging the speed sensor at the output end of the spindle motor, it can be ensured that the roller motor is not stopped under the condition that the spindle motor is not stopped, the problem is avoided that when the roller motor is stopped, and the spindle motor continues to conduct twisting, so that twisting degree of cloth cover is uneven.

Owner:ZHEJIANG MEILAIYA TEXTILE

Energy-saving and environment-friendly wire drawing device

InactiveCN109590343APlay a supporting roleAvoid disconnectionBatteries circuit arrangementsElectric powerEngineeringSolar cell

The invention discloses an energy-saving and environment-friendly wire drawing device which comprises a device body and a supporting base. A take-up carrier roller is fixed to the left end of the device body and connected with the device body in a transmission manner through a rotating bearing. The take-up carrier roller is connected with a rotating end of a motor in a transmission manner througha connecting belt. Two pneumatic telescoping columns are fixed to the upper end of the device body. A grinding device is fixed to the lower end of the device body. An upper base plate is fixedly connected with the telescopic ends of the two pneumatic telescoping columns. A lower base plate is fixedly connected with the lower end of the device body. A wire straining device is arranged at the left lower end of the device body. The telescopic rod end portion of a second electric telescoping rod is fixedly connected with a universal wheel through a hinge shaft. A solar cell panel is arranged at the upper end of the device body. The wire drawing device has the beneficial effects that people can adjust tightness of drawn wires conveniently at any time, wire breaking is avoided, mutual wire pressing and overlapping do not occur easily, moving and using are convenient, safe and stable performance is high, and the wire drawing device saves energy and is environmentally friendly.

Owner:ZHENJIANG RUIDE ENERGY SAVING TECH

Curtain fabric cleaning drum

PendingCN110699923AGuaranteed cleaning effectClean upOther washing machinesTextiles and paperIndustrial engineeringSupport plane

The invention discloses a curtain fabric cleaning drum which comprises a drum body, a center column, a plurality of first partition plates, a plurality of second partition plates, a supporting frame,a plurality of first through holes and a plurality of second through holes. The drum body is provided with a cylinder, an opening is formed in the upper end of the cylinder, the first through holes are formed in the side wall of the drum body, the vertical center column is arranged at the center of the drum body, the first partition plates are radiated outwards and vertically fixed onto the centercolumn, the tail ends of the first partition plates are fixed on the inner wall of the drum body, the second through holes are formed in the first partition plates, the inner area of the drum body isdivided into a plurality of cleaning sub-areas by the first partition plates and the center column, a cleaning frame is arranged in each cleaning area and comprises two frames and a plurality of second partition plates, and the two frames are vertically distributed. According to the curtain fabric cleaning drum, the center column, the first partition plates and the second partition plates are matched with each other, so that a curtain fabric cannot be easily overlapped when being cleaned, cleaning effect is ensured, and the curtain fabric is more effectively cleaned up.

Owner:浙江喜创联电子商务有限公司

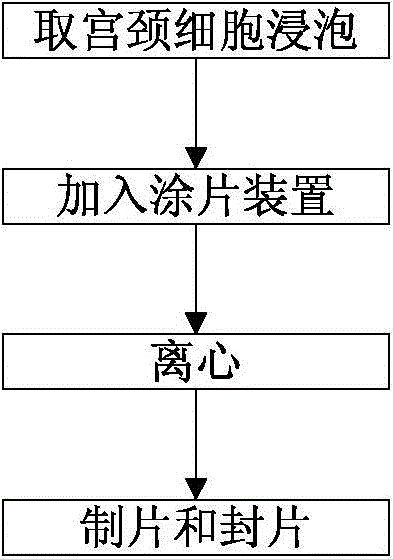

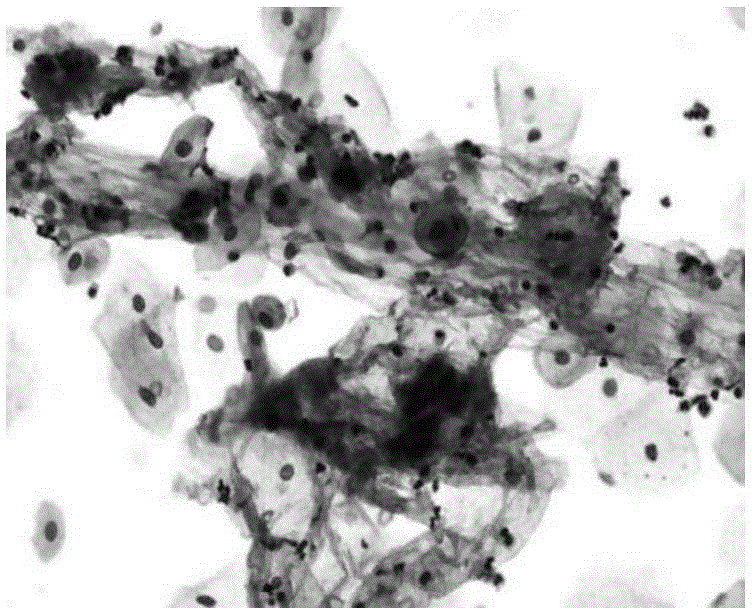

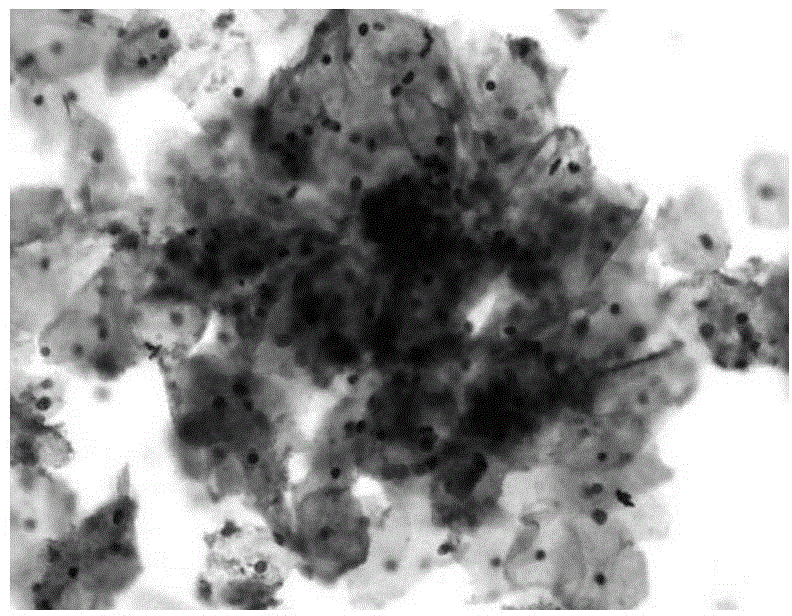

Endocervical cell preserving fluid and method for preparing endocervical cell specimen

InactiveCN103875653BMorphological integrityComplete structurePreparing sample for investigationDead animal preservationChemistryCysteine

The invention discloses endocervical cell preserving fluid and a method for preparing an endocervical cell specimen. The endocervical cell preserving fluid comprises N-acetyl-3-cysteine, anhydrous alcohol, sodium chloride, disodium hydrogen phosphate, sodium dihydrogen phosphate, glacial acetic acid, concentrated hydrochloric acid and distilled water. The method for preparing the endocervical cell specimen comprises the following steps; soaking endocervical cells in a collection tube of the endocervical cell preserving fluid, uniformly oscillating, adding the endocervical cells in a smear device, arranging the smear device in a centrifugal machine for centrifuging, and taking a glass slide with a uniform thin-layer cell smear; and fixing the obtained glass slide with the cell smear by a fixing solution, dyeing, dehydrating, making the glass slide transparent, and finally, mounting to obtain a specimen smear for diagnosis. The endocervical cell preserving fluid and the method for preparing the endocervical cell specimen are reliable and practical, are low in cost, and have useful effects, thus being suitable for large-scale popularization.

Owner:THE MILITARY GENERAL HOSPITAL OF BEIJING PLA

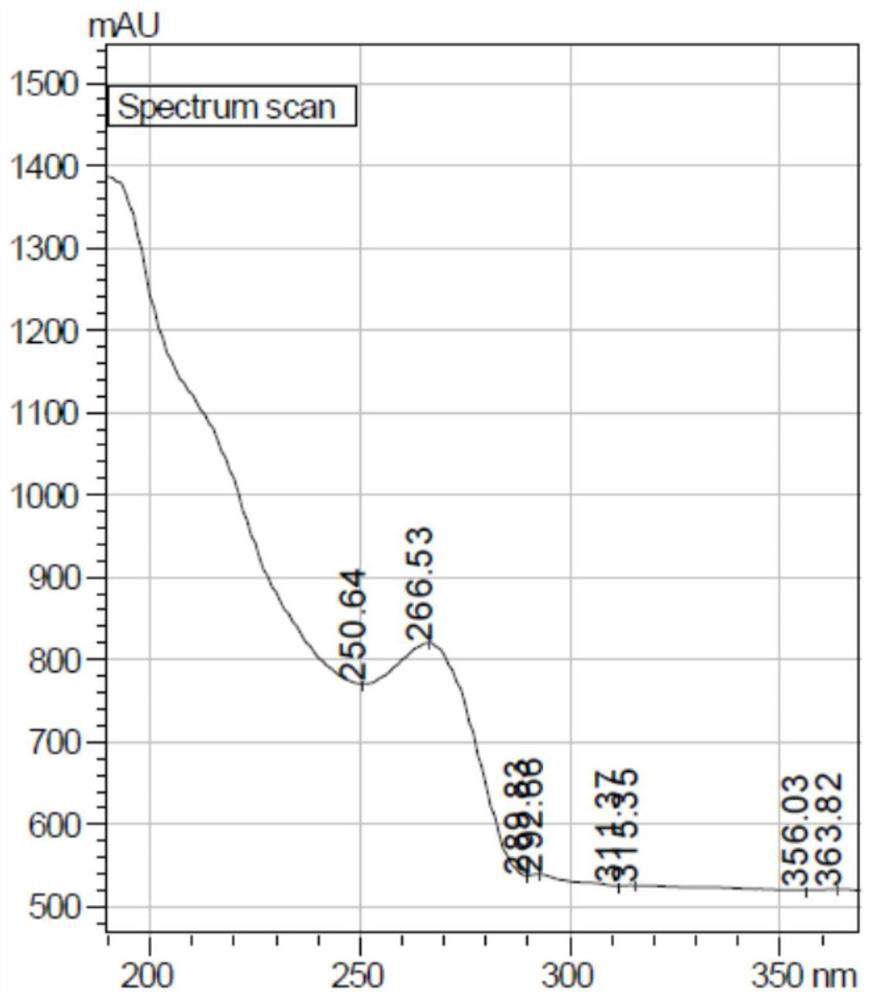

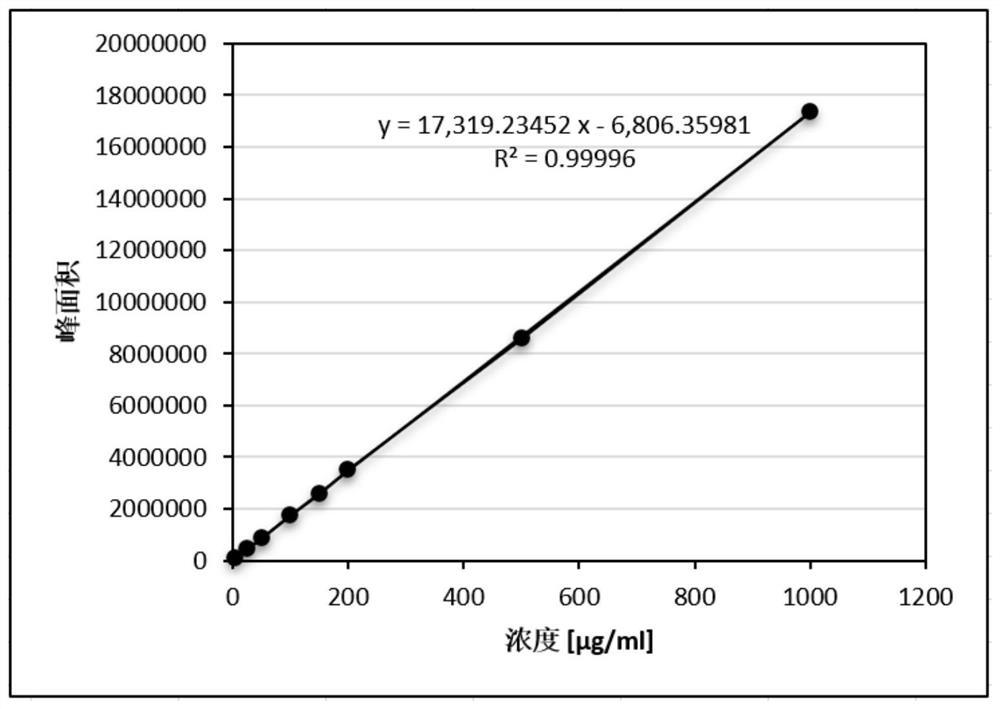

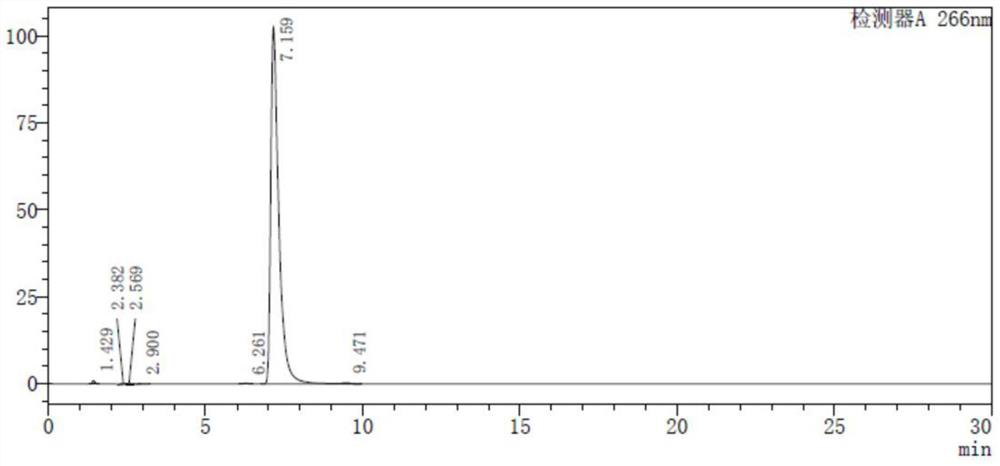

Detection method of beta-nicotinamide mononucleotide

PendingCN114660219AHigh resolutionGood linear relationshipComponent separationChromatographic columnPeak area

The invention discloses a method for detecting beta-nicotinamide mononucleotide. The method comprises the following steps: (1) chromatographic conditions: a chromatographic column: a filler is amino bonded silica gel; the mobile phase is obtained by mixing an inorganic phase and an organic phase; the detection wavelength is 190 to 280 nm; the detection flow rate is 0.8 to 1.2 ml / min; the column temperature is 25-35 DEG C; (2) preparing a sample to be tested and a control sample: weighing the beta-nicotinamide mononucleotide standard sample as the control sample, weighing the beta-nicotinamide mononucleotide crystal sample as the sample to be tested, and dissolving the sample to a constant volume by using a mobile phase; and (3) determination method: filtering the control sample solution and the test sample solution, injecting into a high performance liquid chromatograph, recording a chromatogram, and calculating the peak area. The detection method is not easy to coincide with other substances, and the separation degree is high; the linear relation is good in a wide range, and the method is suitable for accurate quantification of the NMN; direct sample loading is achieved, operation is easy and convenient, and time is saved; and the cost is low.

Owner:ANHUI GSH BIO TECH CO LTD

Imaging module

InactiveCN101981914BHigh precisionReduce usageTelevision system detailsMagnetic/electric field screeningEngineeringHigh resolution image

An imaging module is provided that can be made lighter in weight, can be retained in an external structure with stability, and allows acquisition of high-resolution images. An imaging module (10) includes an imaging substrate (6) mounting an imaging device thereon, a resin holder (4) including a substrate securing portion (4a) to which the imaging substrate (6) is secured, a lens support barrel (4b) supporting a lens (1) at an inside thereof, and a holding portion (4c) which protrudes toward a subject from the substrate securing portion (4a) and includes a through hole (4d) configured to permit retention of the holder in an external structure, a metal securing member (5) disposed at a side of the substrate securing portion (4a) of the holder (4) facing a subject, and a metal holding plate (3) including a securing region which is secured to and electrically connected to the securing member (5), and a holding portion adjacent region (3b) which overlaps a part around the through hole (4d) of the holding portion (4c) and includes a through hole (3c) configured to communicate with the through hole (4d). The imaging module can be made lighter in weight, be retained in an external structure with stability, and allows acquisition of high-resolution images.

Owner:KYOCERA CORP

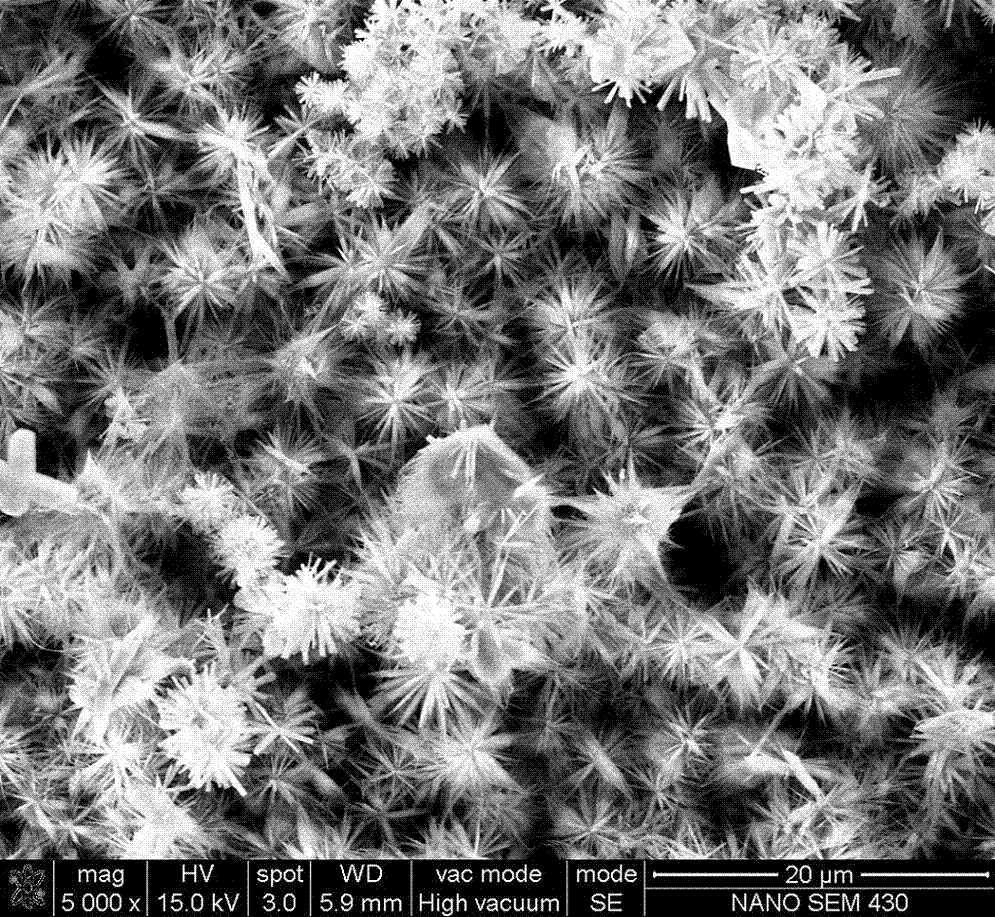

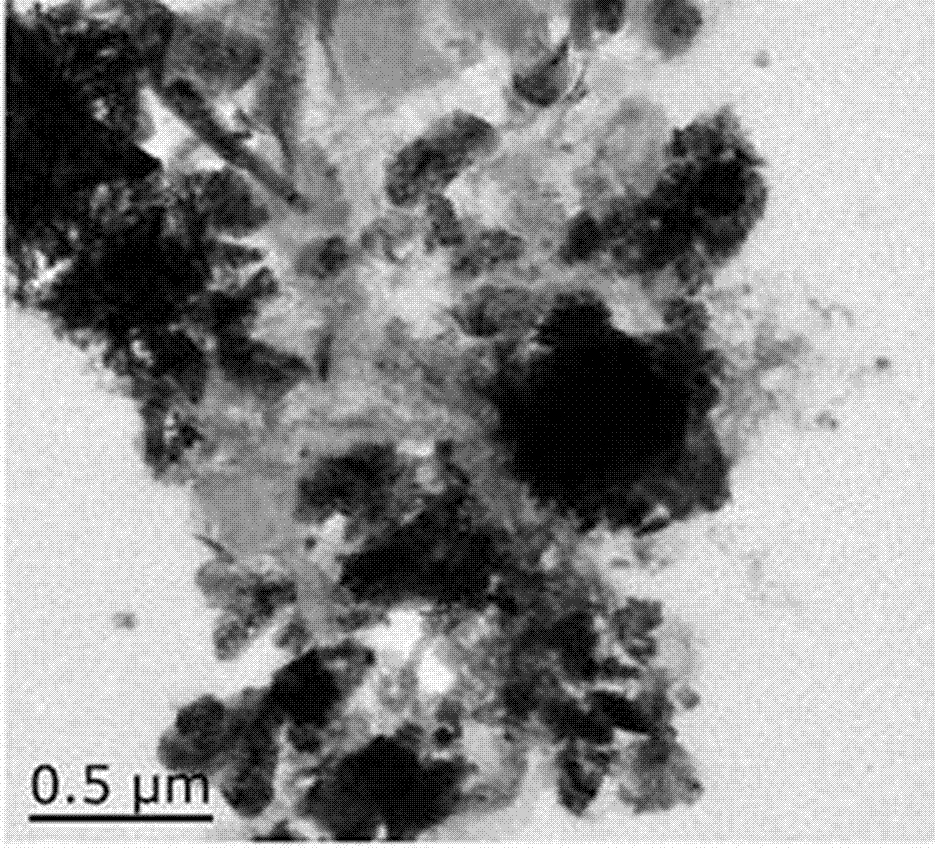

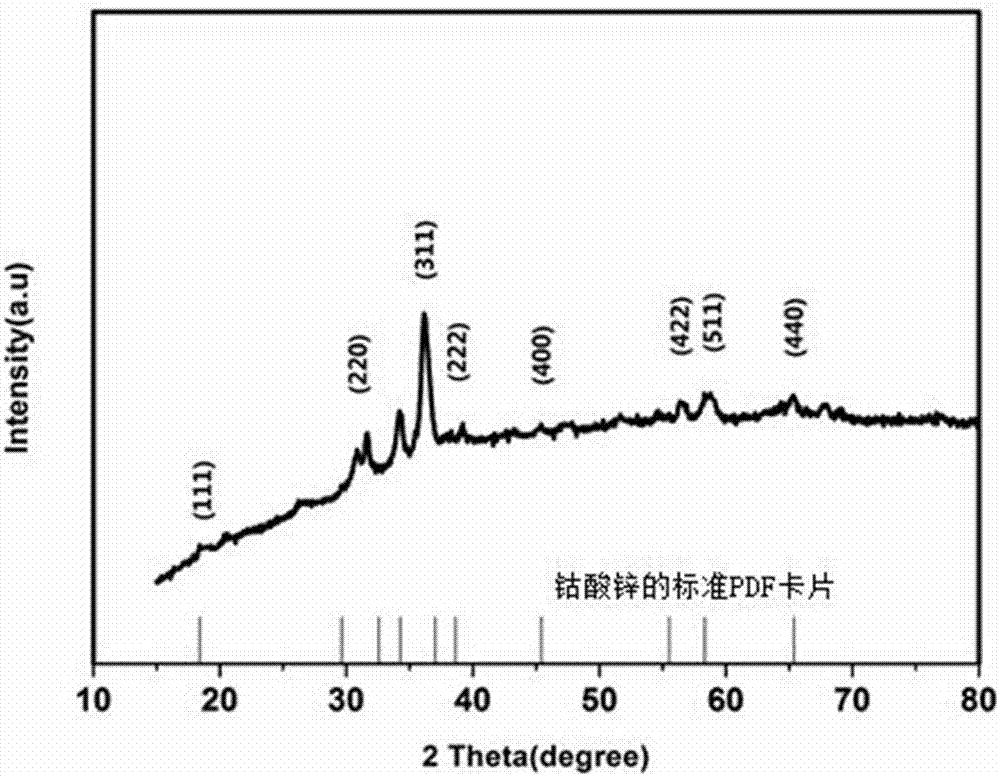

Preparation method and application of nitrogen-doped graphene/nitrogen-doped carbon nanotube/zinc cobaltate composite material

ActiveCN105225844BImprove conductivityImprove charge and discharge cycle stabilityHybrid capacitor electrodesCell electrodesPorous grapheneDoped graphene

The invention discloses a preparation method of a nitrogen-doped graphene / nitrogen-doped carbon nanotube / zinc cobaltite composite material. The method comprises the following specific steps: (a) adding potassium permanganate, hydrochloric acid and hydrogen peroxide to graphene oxide, and carrying out a stirring reaction to obtain porous graphene; (b) dialyzing the porous graphene for 8-12 days, carrying out ultrasonic dispersion, then adding a carbon nanotube, carrying out ultrasonic mixing and carrying out suction filtration to form a film; (c) drying the film, and then adding ammonium hydroxide for reaction for 24 hours; (d) adding zinc nitrate, cobalt nitrate, urea, ammonium fluoride, absolute ethyl alcohol and distilled water for reaction for 4 hours; and (e) transferring a mixture to a tube furnace, and sintering the mixture in a nitrogen atmosphere for 2 hours, so as to obtain the composite material. The composite material has relatively good flexibility; the electrochemical properties are barely changed after the composite material is bent into various angles; the specific capacitance value of the composite material can be up to 1802F / g; compared with relatively simple graphene, the carbon nanotube and most of composite materials of the graphene and the carbon nanotube, the composite material provided in the invention are significantly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Array substrate and preparation method thereof, and display panel

ActiveCN112542502BImprove reflectivityImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingComposite electrodeMetal electrodes

The invention discloses an array substrate, comprising a flat layer and a composite electrode disposed on the flat layer, the edge side surface of the composite electrode and the surface of the flat layer form at least one undercut structure, wherein, The composite electrode includes at least one metal electrode and at least one transparent electrode, and the metal electrode and the transparent electrode are alternately stacked.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

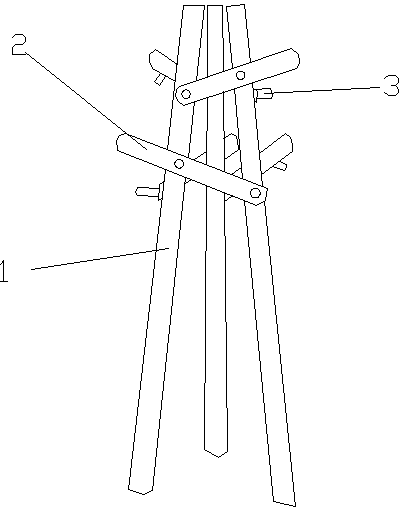

Three-leg coat stand

The invention discloses a three-leg coat stand which comprises supports, horizontal rods and hooks. The number of the supports is three. The supports are arranged to be of a right triangular prism structure. The three supports are distributed in a right triangle structure. The three supports are oblique inwards. The included angles between the three supports and the ground are set to be 75 degrees. The number of the horizontal rods is six. Two through holes are formed in each horizontal rod. The number of the hooks is 12. The hooks are arranged to be of a cylinder structure. Bolts are arranged at the tail ends of the hooks. The upper portions of every two supports are connected through two horizontal rods. Each horizontal rod is fixed on the corresponding supports through the bolts on the two corresponding hooks. According to the three-leg coat stand, through the design of the three supports of the right triangular prism structure, two horizontal rods are connected between every two supports, the horizontal rods are connected with the supports through the hooks, three faces can be provided for people to use, the distance between coats is greatly enlarged, the coats cannot be overlapped easily, the structure is simple, attractive and stable, and using is convenient.

Owner:顾立新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com