Patents

Literature

2806results about How to "Guaranteed cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

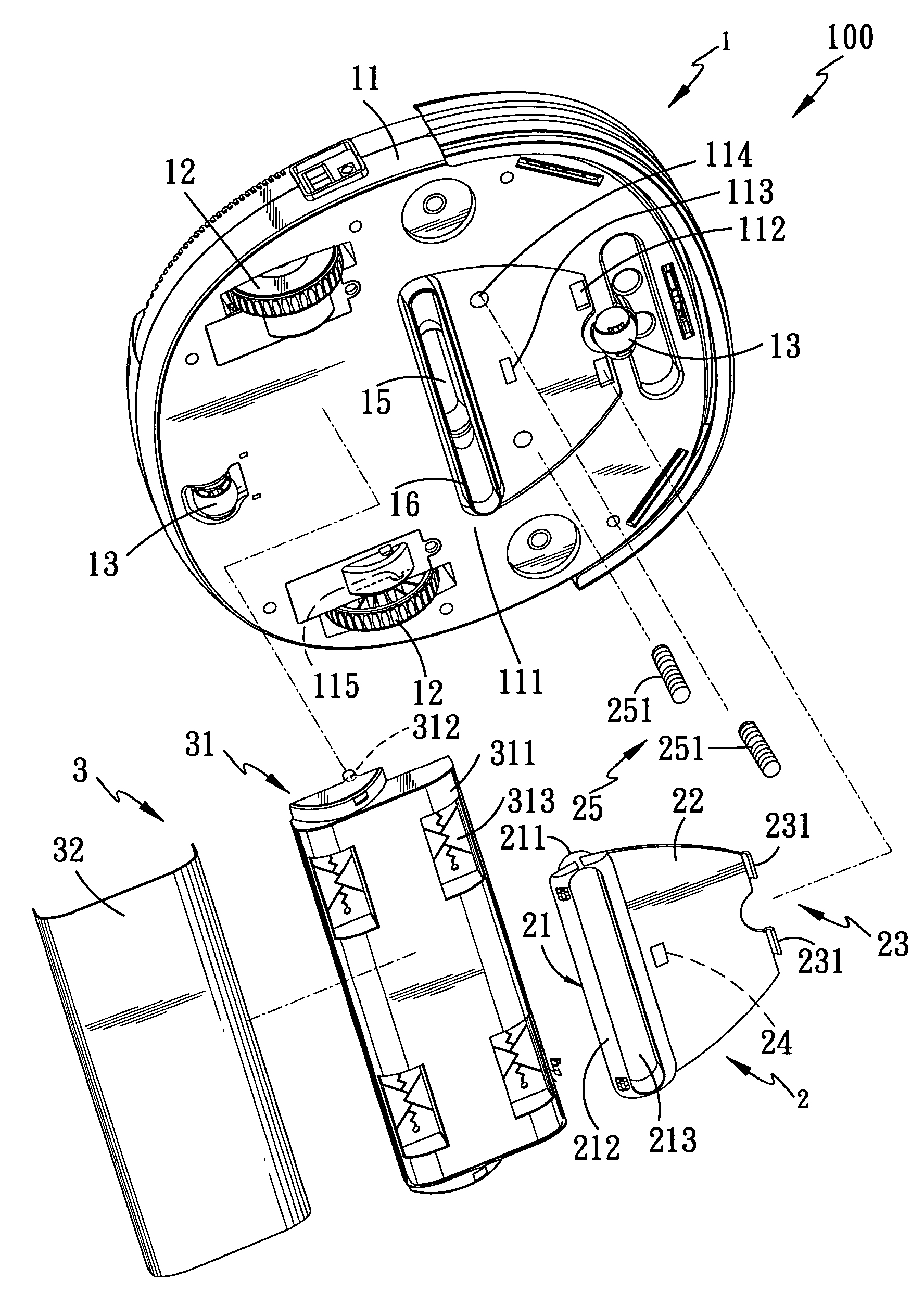

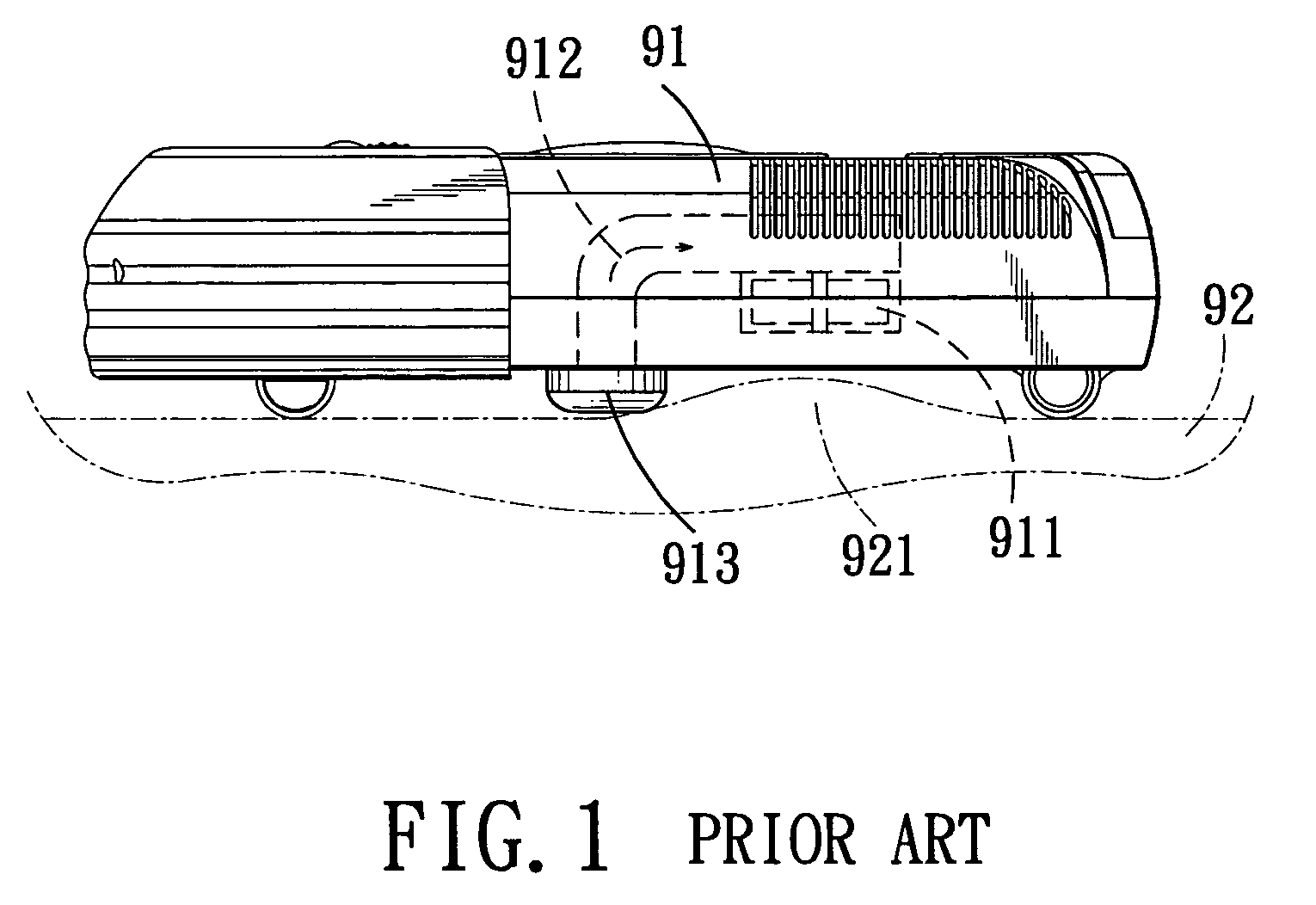

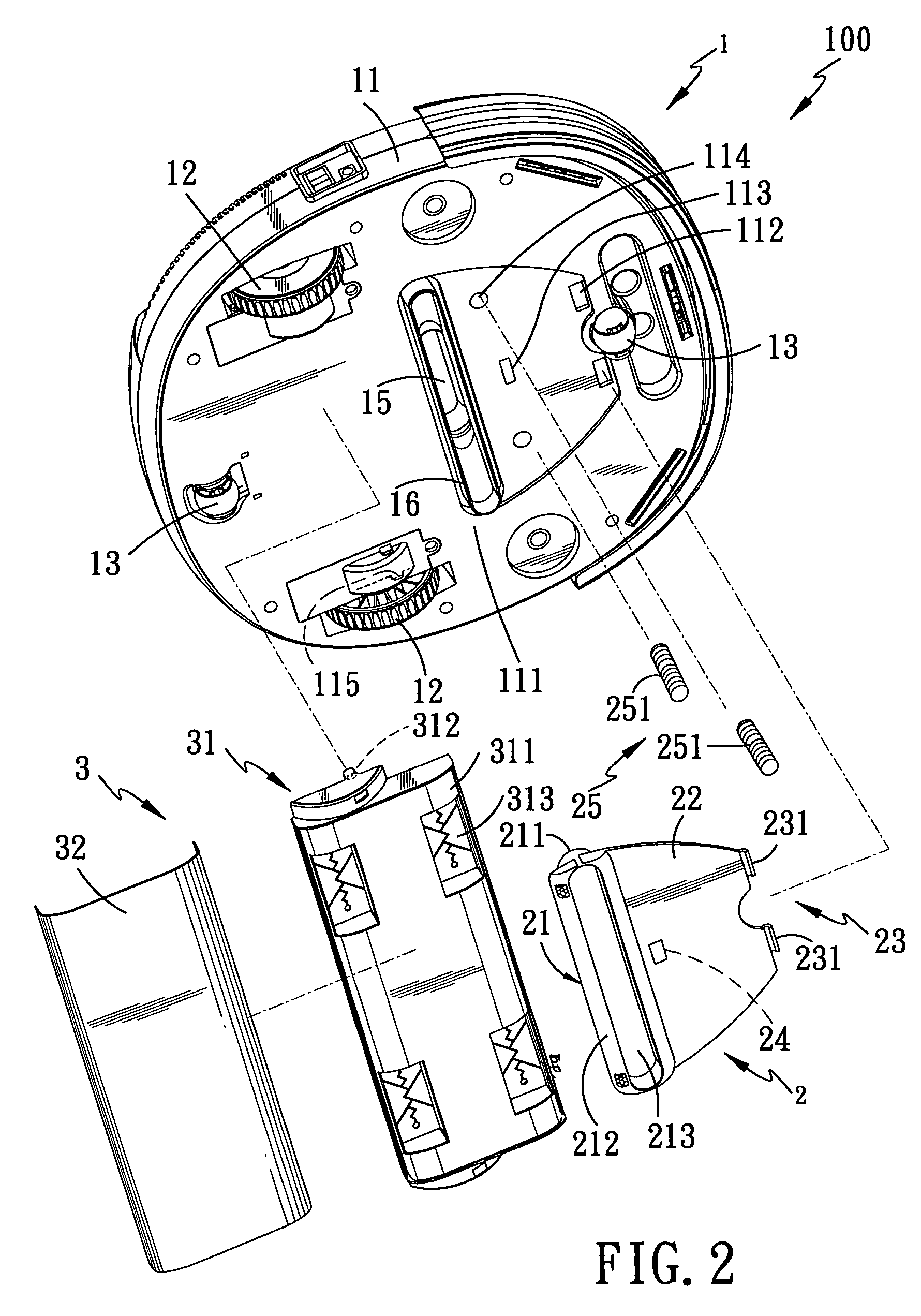

Self-moving vacuum cleaner with moveable intake nozzle

ActiveUS7246405B2Guaranteed cleaning effectAutomatic obstacle detectionTravelling automatic controlImpellerEngineering

Owner:HUNAN GRAND PRO ROBOT TECH

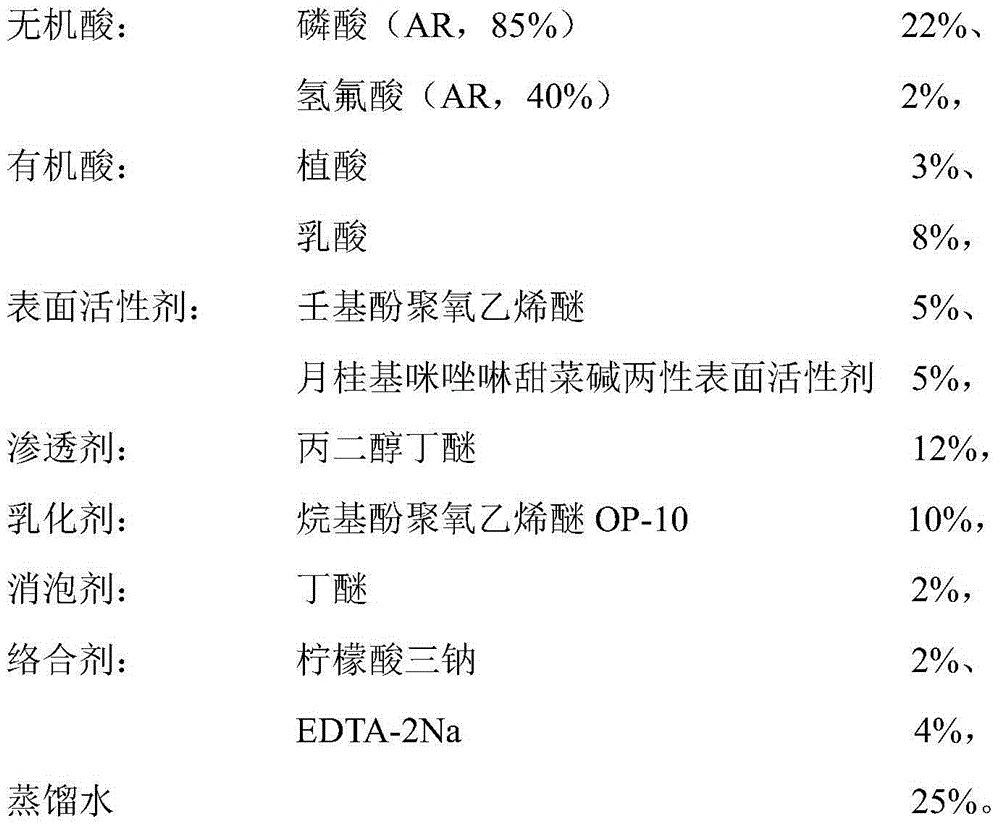

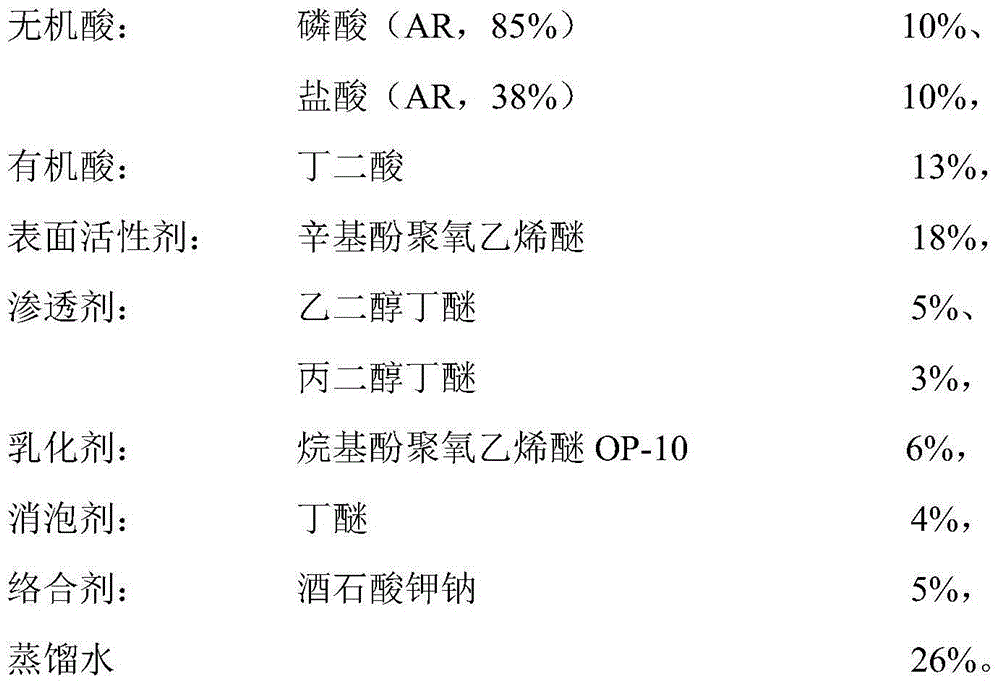

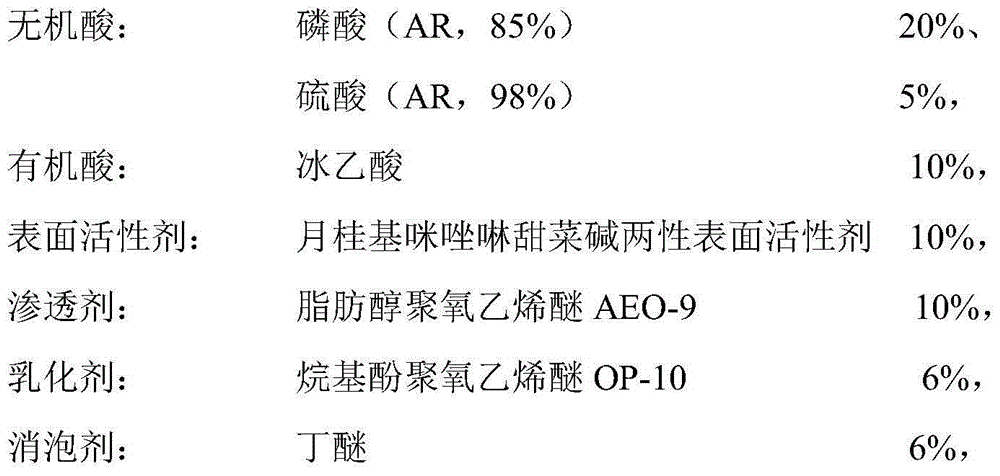

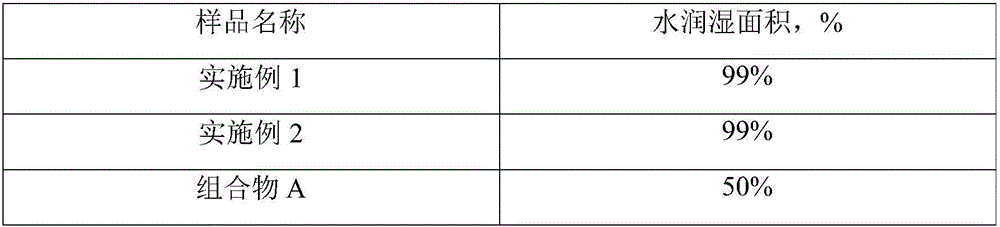

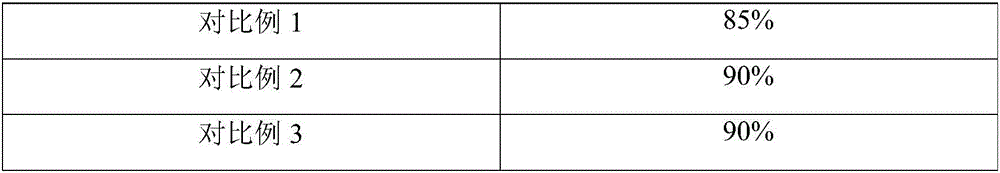

Environment-friendly aluminum cleaning agent and preparation method thereof

The invention discloses an environment-friendly aluminum cleaning agent and a preparation method thereof. The cleaning agent is composed of the following components in percentage by weight: 20% to 25% of inorganic acid, 10% to 20% of organic acid, 10% to 18% of surfactant, 8% to 15% of osmotic agent, 6% to 18% of emulsifier, 2% to 8% of antifoaming agent, 5% to 8% of complexing agent, and 25% to 30% of water. In the provided cleaning agent, the using amount of hydrochloric acid, sulfuric acid, and nitric acid is reduced, the aluminum parts are washed by medium-strong acids and organic acids, and the cleaning agent has a very good oil stain and rust removing ability. The cleaning agent is acidic, the pH value of the cleaning agent is 2.1 to 5.6, and the cleaning agent can well remove the oxide scale on the aluminum surface. Because the acidity of the organic acids is weak, the over-corrosion on work tools and acid volatilization, which can harm the workers' health, are effectively avoided, and the cleaning effect is not influenced at the same time. Moreover the adopted organic acids are easy to decompose, and thus the cleaning agent is environment-friendly.

Owner:PINGGAO GRP +1

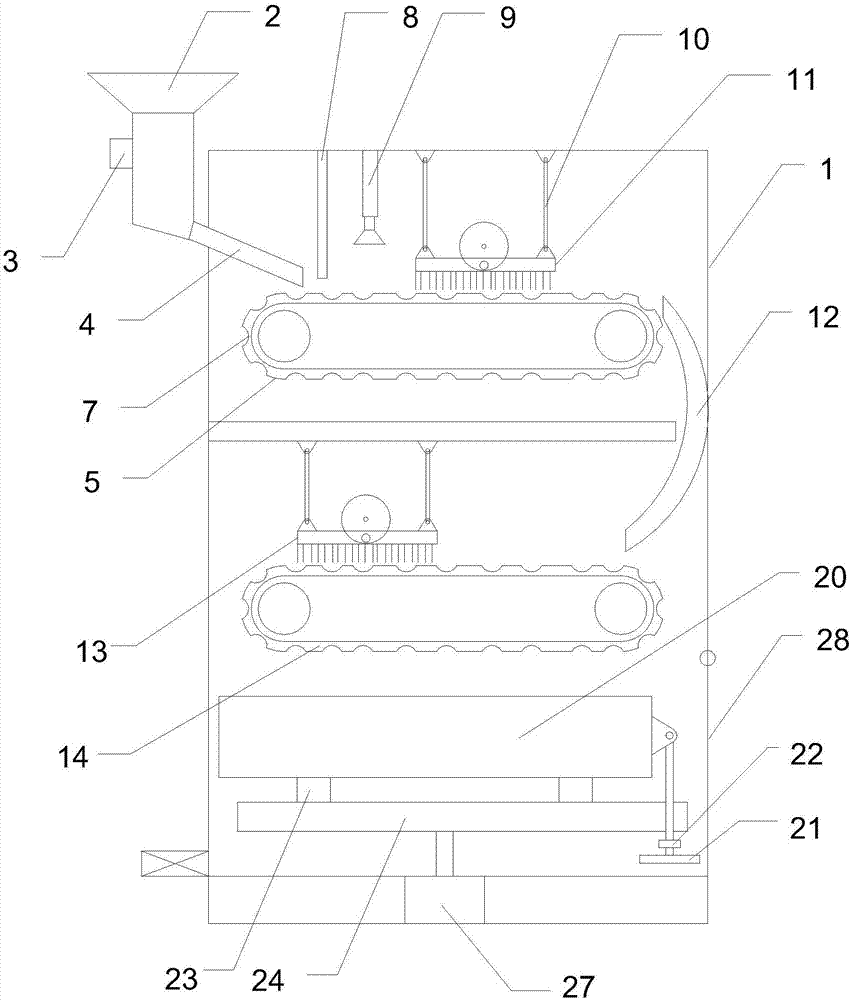

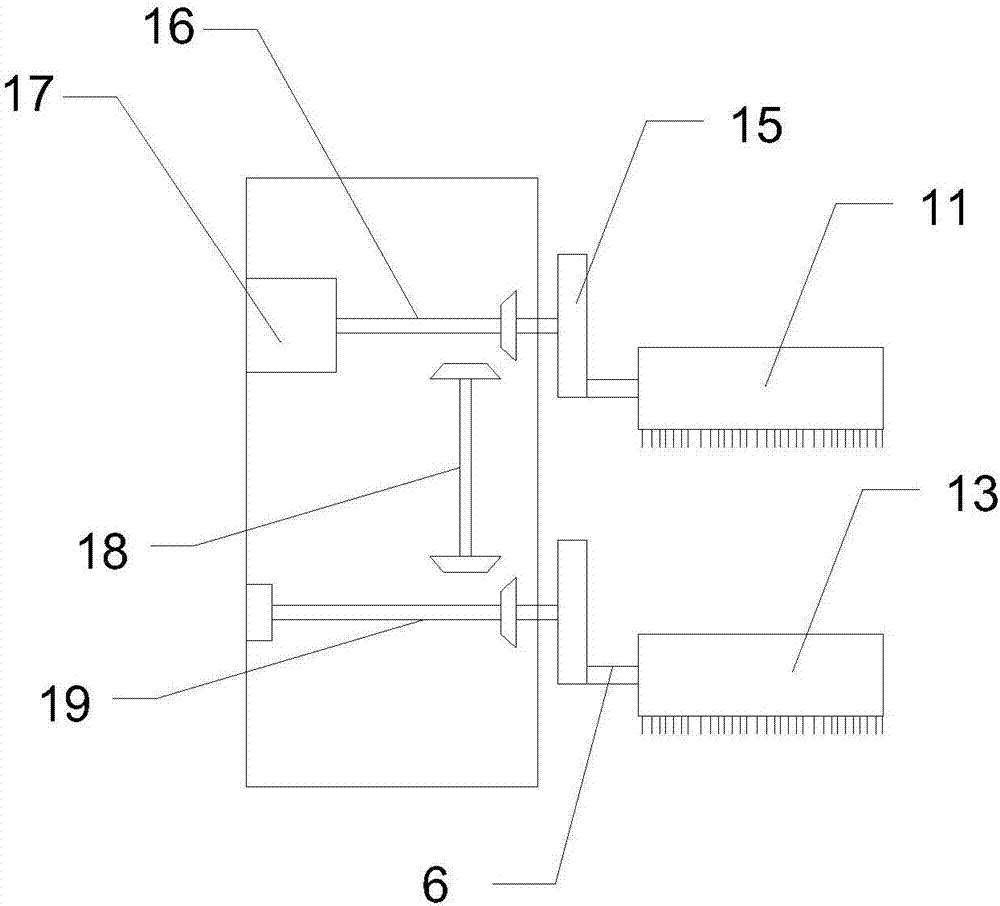

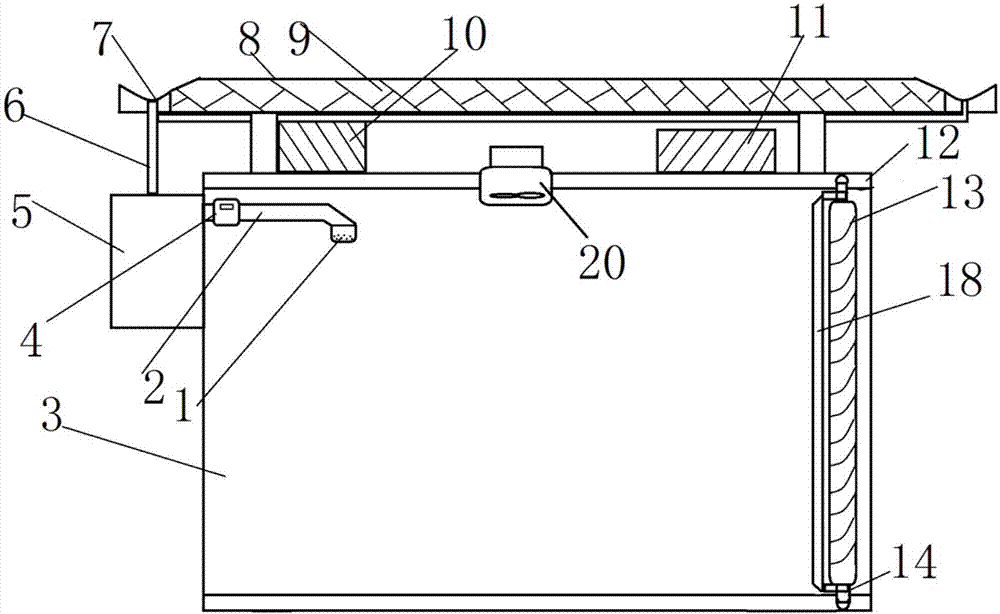

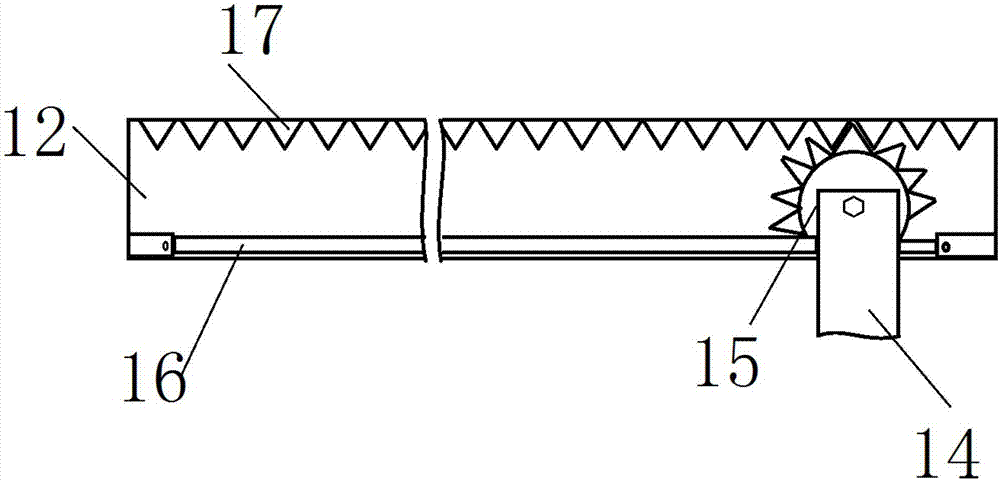

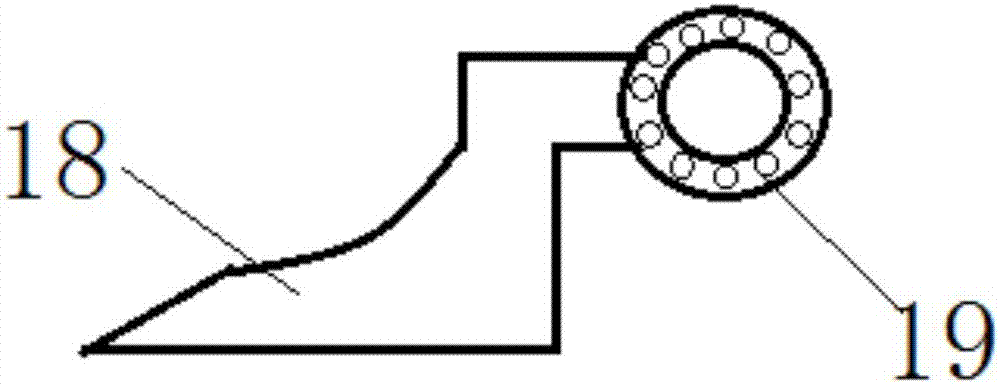

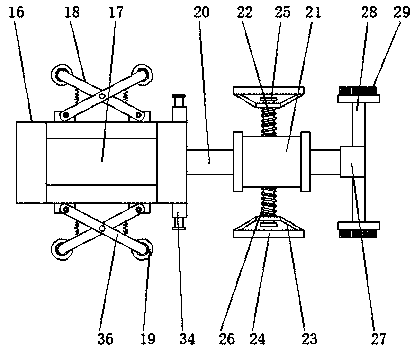

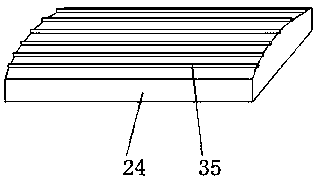

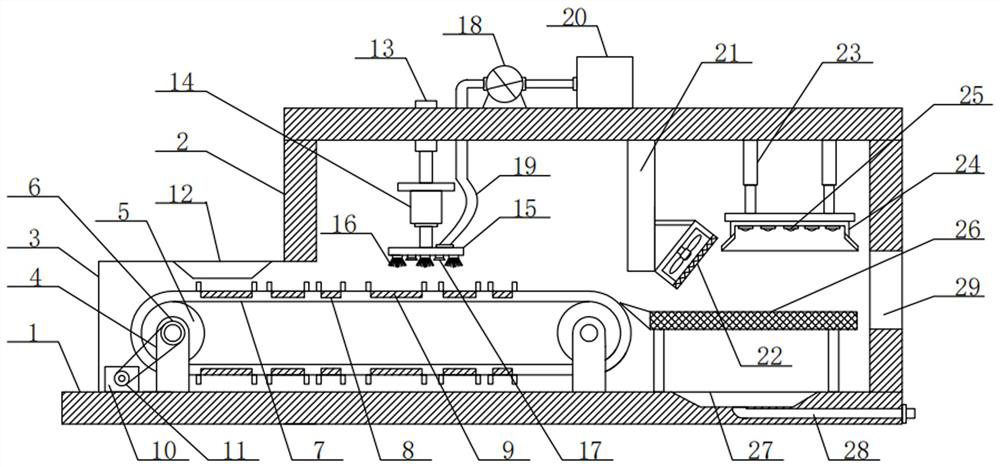

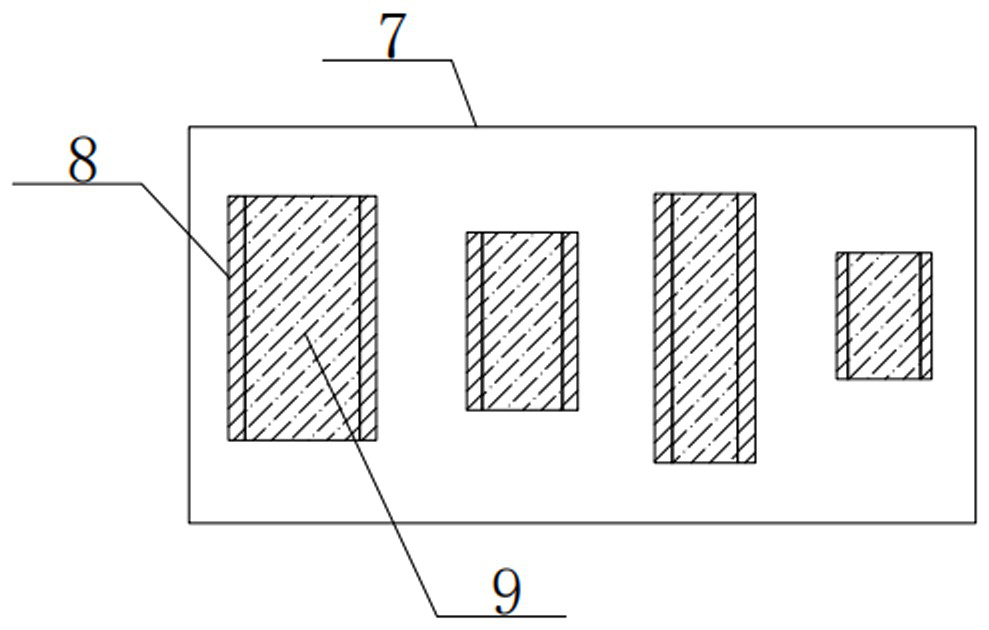

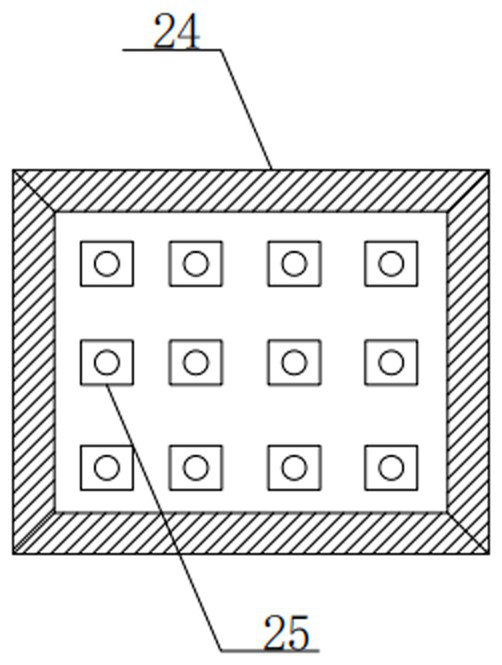

Double-side cleaning device for aquatic products

InactiveCN107006590AFor subsequent scrubbingGuaranteed cleaning effectBivalves processingShrimp/lobster processingAquatic productConveyor belt

A double-sided cleaning device for aquatic products, including a housing, a hopper and a frequency conversion motor; the housing is provided with a first conveyor belt, and the surface of the first conveyor belt is provided with evenly distributed semicircular grooves; the first conveyor belt A baffle is provided above, and a water spray gun is provided on the right side of the baffle; a first brush plate is provided on the right side of the water spray gun; The rotating shaft is connected with a frequency conversion motor; an arc-shaped pipe is arranged on the right side of the first conveyor belt, and a second conveyor belt is arranged under the arc-shaped pipe. The present invention is equipped with a vibrating feeding hopper and a feeding pipeline, so that the aquatic products are evenly spread on the conveyor belt, which is convenient for subsequent brushing. The present invention is equipped with double brushing and conveying devices, so that both sides of the aquatic products are cleaned to ensure cleaning The effect, at the same time has a convenient discharge.

Owner:HEFEI WISDOM DRAGON MACHINERY DESIGN CO LTD

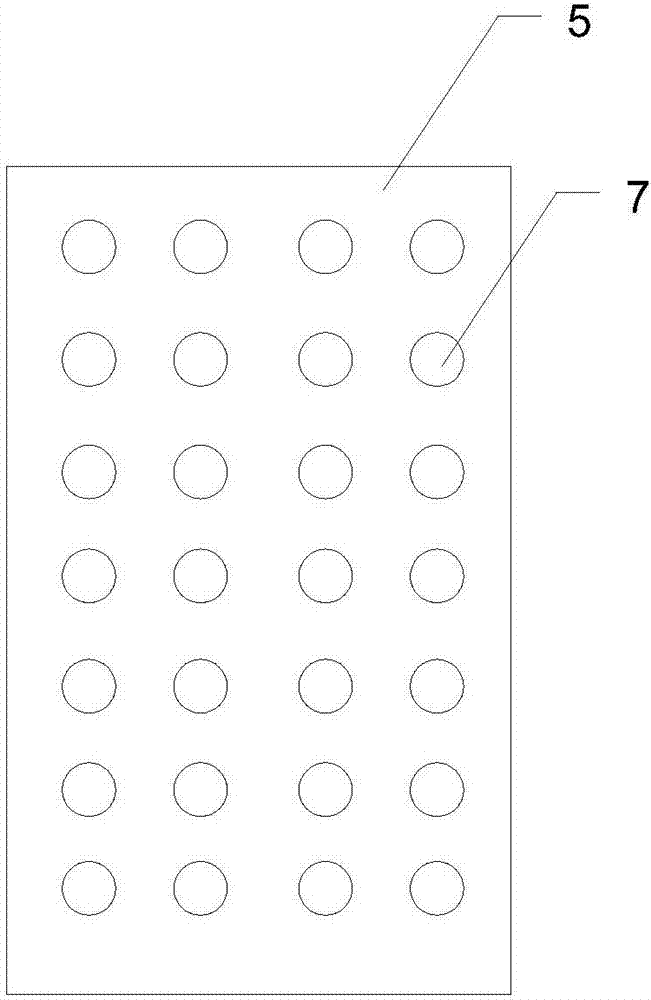

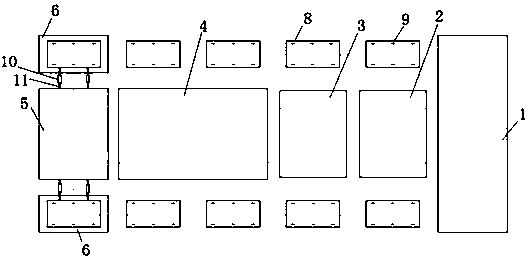

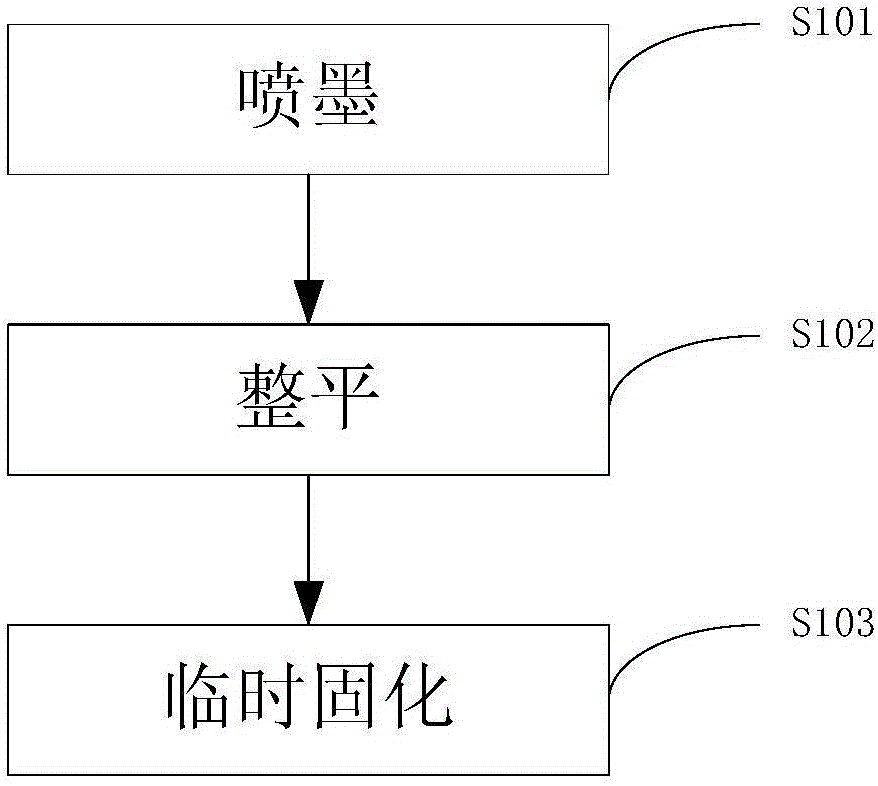

Bidirectional circulating structure prefabricated part production line and control method

InactiveCN107650258AShorten production timeIncrease usageCeramic shaping plantsFeeding arrangmentsProduction lineControl signal

The invention discloses a bidirectional circulating structure prefabricated part production line. The production line comprises a hidden engineering checking area, a concrete distribution area, a moldtable vibration area, a mold table maintenance area, a demolding hoisting area, mold table clearing areas, mold tables, mold table rolling supporting devices, mold table ferry devices, ferry rails and a control system. The production line further comprises a steel bar distribution trolley used for carrying out hoisting and steel bar cage binding on molds according to a mold locating line, a locating line used for determining the mold tables and pre-buried parts and a lineation device for spraying a release agent. The mold table rolling supporting devices are arranged on the two sides of the mold tables. The control signal input end of the steel bar distribution trolley, the control signal input end of the lineation device, the control signal input ends of the mold table rolling supportingdevices, the control signal input ends of the mold table ferry devices, the control signal input end of a concrete distribution machine and the control signal input ends of the mold table vibration devices are all connected with the control signal output end of the control system. According to the bidirectional circulating structure prefabricated part production line, unremittance of production is guaranteed, the mold table transfer time is shortened, and the production efficiency is improved.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD

Process method of producing high-grade TC4 alloy hot rolled plate with high material-obtaining rate and low cost

ActiveCN103045906ANovel process routeGood product performanceMetal rolling arrangementsHot rolledAtmosphere

The invention presents a process method of producing a high-grade TC4 alloy hot rolled plate with a high material-obtaining rate and low cost, which comprises the following steps: slab ingot preparation through an EB, grinding, heat rolling, atmosphere annealing, sand blasting, pickling, grinding and sizing to obtain an annealed TC4 hot rolled plate, wherein a coloring and inspection technology is applied for the surface detection of a cogging bland and for the surface quality detection of a fire rolling blank. According to the invention, the EB is adopted to smelt and roll blank; the material-obtaining rate from the raw materials to slabs is improved to 92 percent, and the material-obtaining rate from the raw materials to finished products is improved to 69-73.6 percent; cracks are ensured to be removed completely, so as to achieve the purpose of no grinding or less grinding in follow-up rolling, and accordingly the labor and material cost for grinding is greatly reduced; and the prepared plate has the tensile strength of 950-1100 MPa, the yield strength of 880-980 MPa, and the elongation percentage among 14-20 percent, and meets the standard requirements of GB / T3621-2007, GT / B14845-2007 and ASTMB265-2006.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

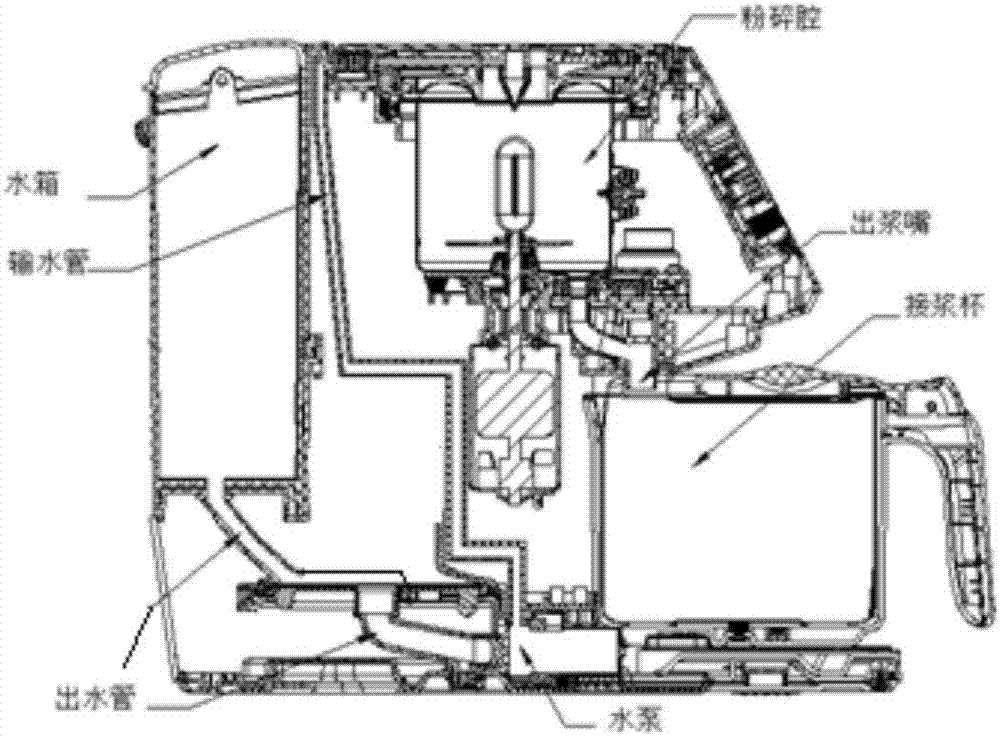

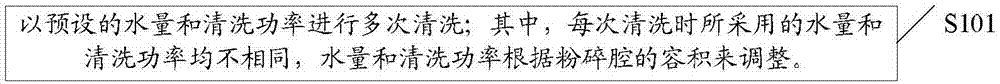

Washing method of cooking equipment

PendingCN107184104AEasy to cleanGuaranteed cleaning effectBeverage vesselsWater deliveryWaste management

The embodiment of the invention discloses a washing method of cooking equipment. The cooking equipment comprises a smashing cavity, a water tank, a water pump, a water outlet pipe connected with the water tank and the water pump and a water delivery pipe connected with the smashing cavity and the water pump, the water pump pumps water in the water tank through the water outlet pipe, and the pumped water is delivered into the smashing cavity through the water delivery pipe to wash the smashing cavity. The method comprises the step of conducting washing many times with the preset water capacity and washing efficiency, wherein the water capacity and the washing power adopted in each time of washing are both different, and the water capacity and the washing power are adjusted according to the volume of the smashing cavity. According to the washing method of the cooking equipment, an ideal washing effect can be achieved by using a small amount of water.

Owner:JOYOUNG CO LTD

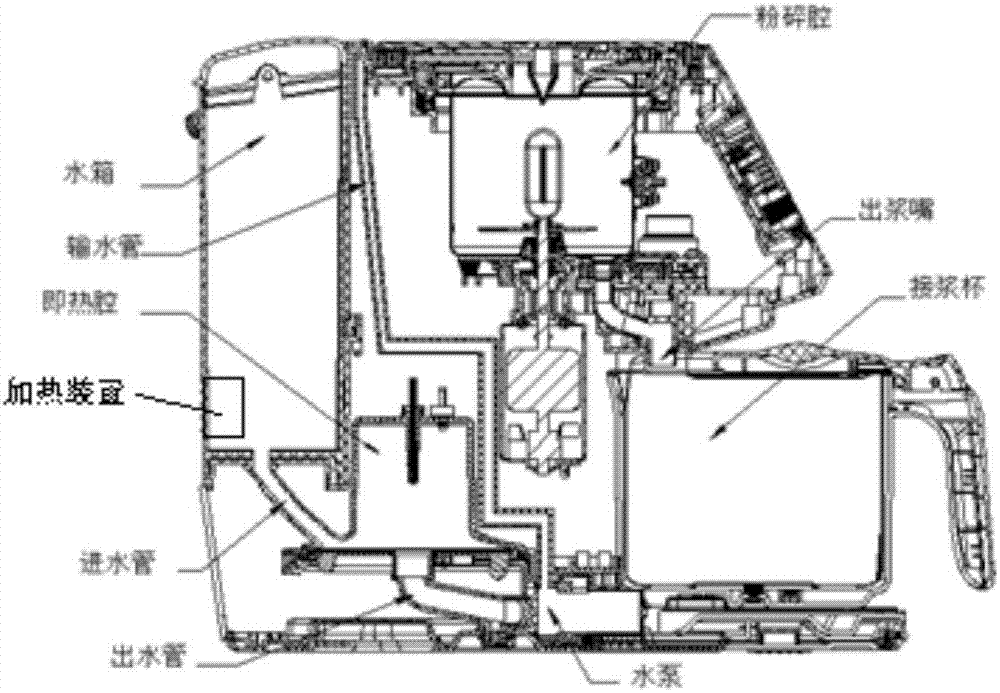

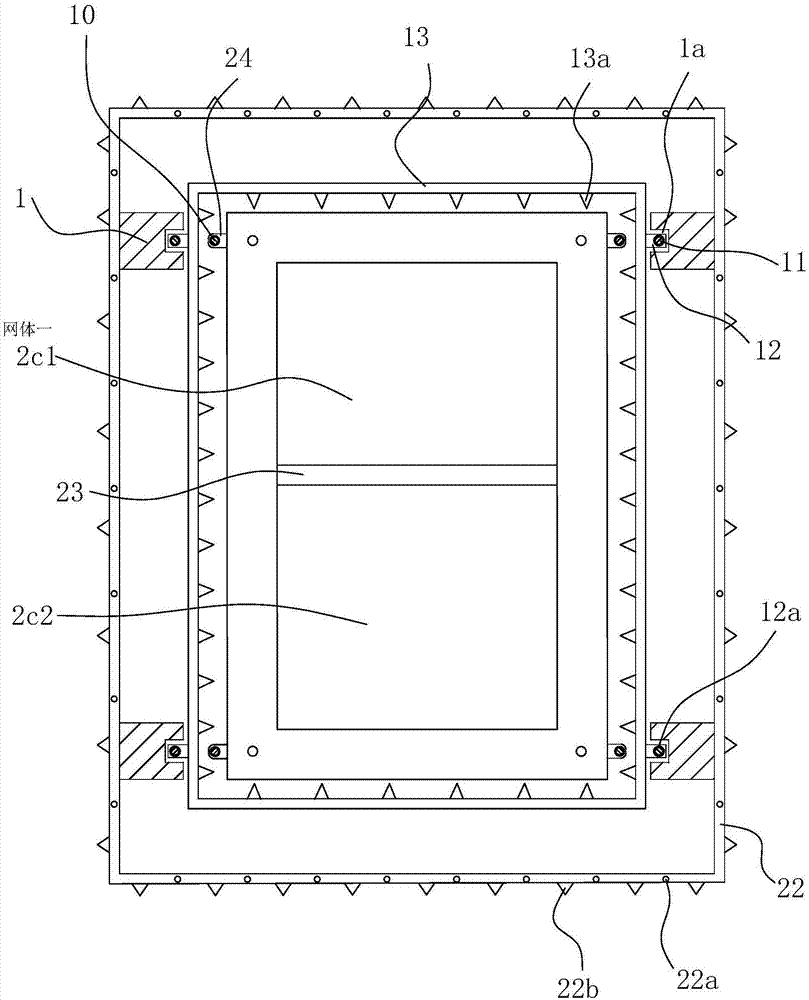

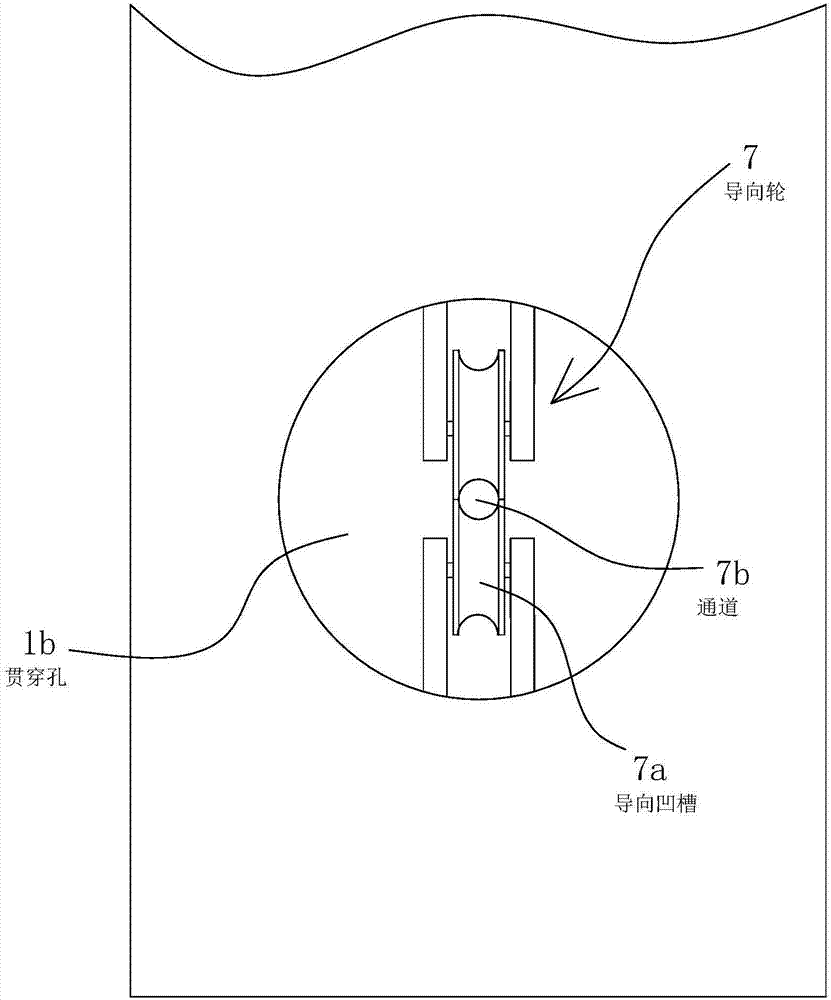

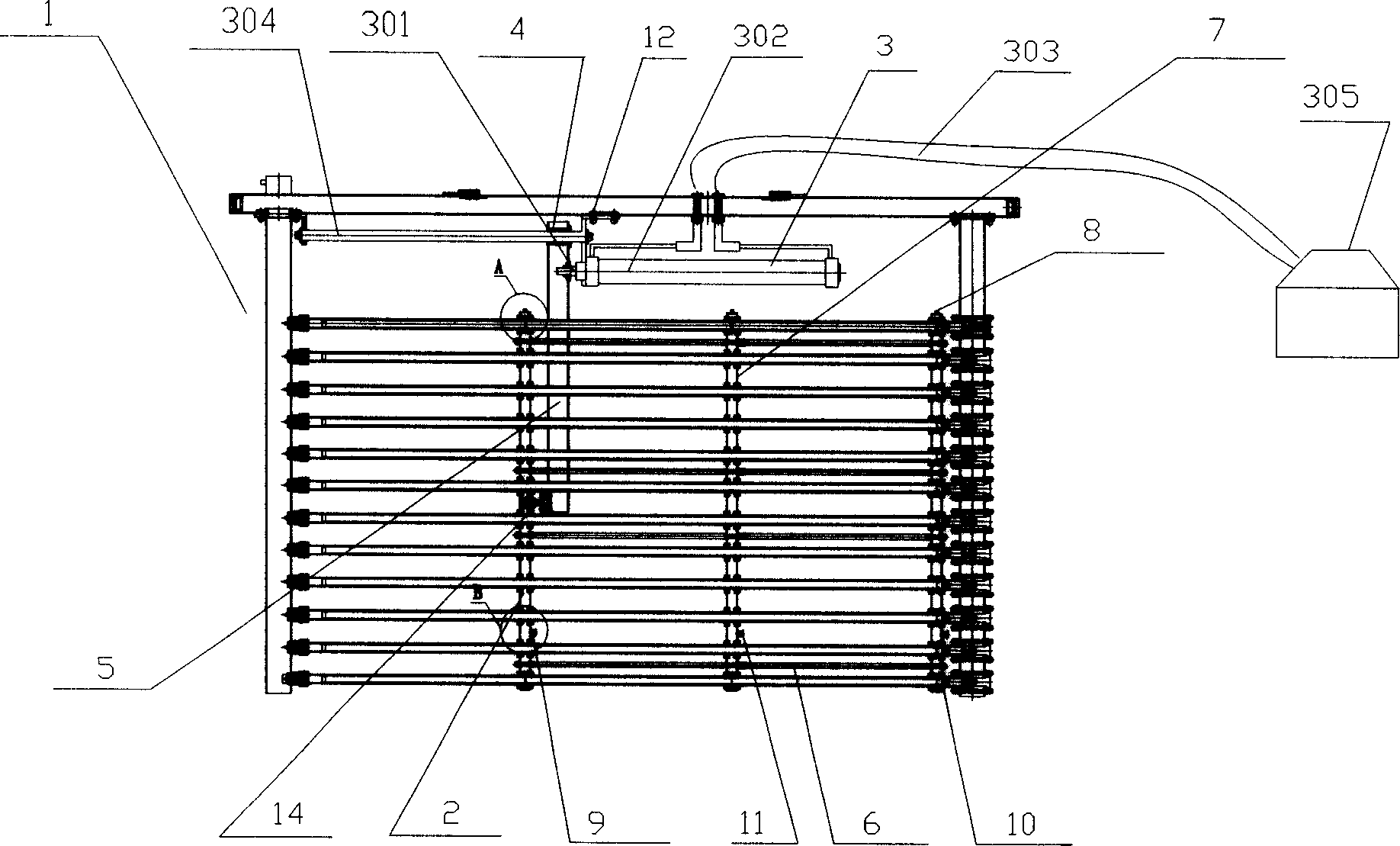

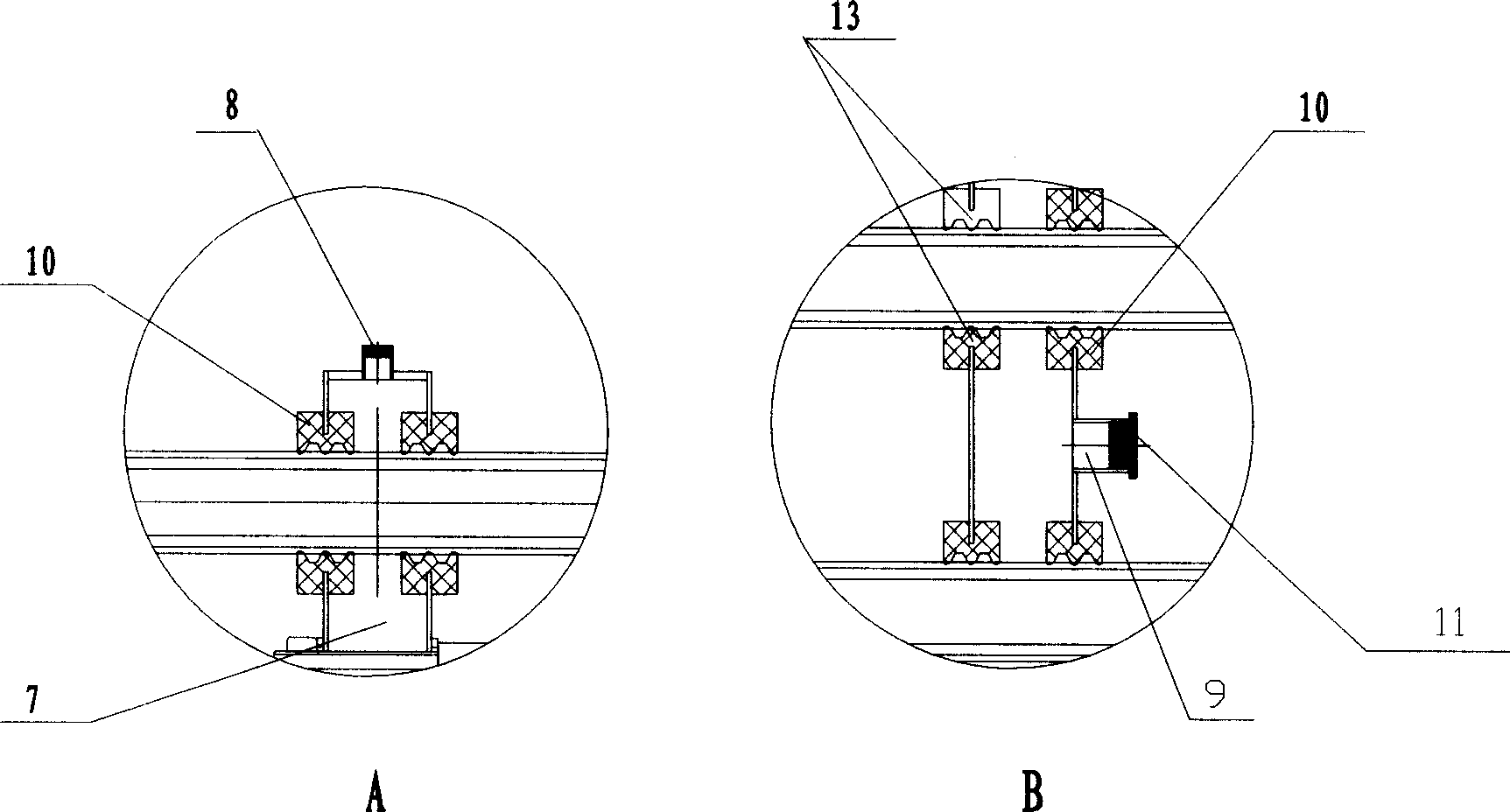

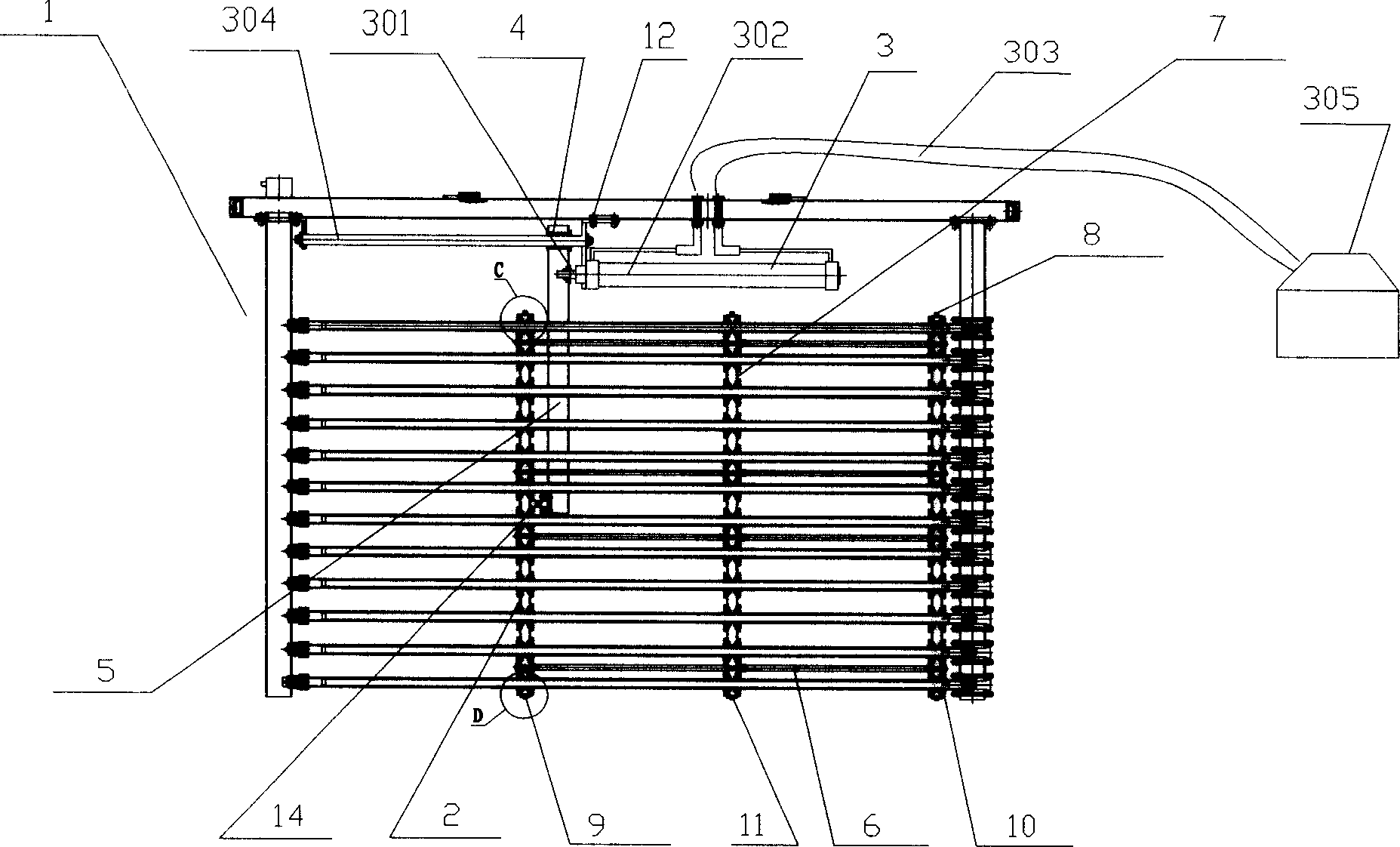

Marine aquaculture net cage

ActiveCN107439448AReduce the cost of farmingImprove qualityClimate change adaptationHollow article cleaningSpray nozzleSeawater

The invention provides a marine aquaculture net cage, and belongs to the technical field of aquaculture equipment. The marine aquaculture net cage comprises a rectangular upper floating body, a bottom plate, four upright columns, cleaning pipes and a water pump. A net cage opening is formed in the upper floating body, netting is arranged between the upper floating body and the bottom plate, the four upright columns are positioned at four corners of the outer side of the upper floating body, a guide rod is vertically arranged on each upright column, four guide sleeves are arranged at the edge of the upper floating body, are in one-to-one correspondence to the guide rods and are slidably arranged on the corresponding guide rods, the rectangular cleaning pipes are arranged on the outer side of the netting in an enclosed manner, a plurality of spray nozzles are arranged on the cleaning pipes and directly face the netting, the water pump is arranged on one of the upright columns and is communicated with the cleaning pipes via hoses, and a driving mechanism for driving the corresponding cleaning pipe to move up and down along the vertical direction is arranged on each upright column. The marine aquaculture net cage has the advantages that the netting can be automatically cleaned, marine organisms can be prevented from being attached onto the netting, and the like.

Owner:ZHEJIANG OCEAN UNIV

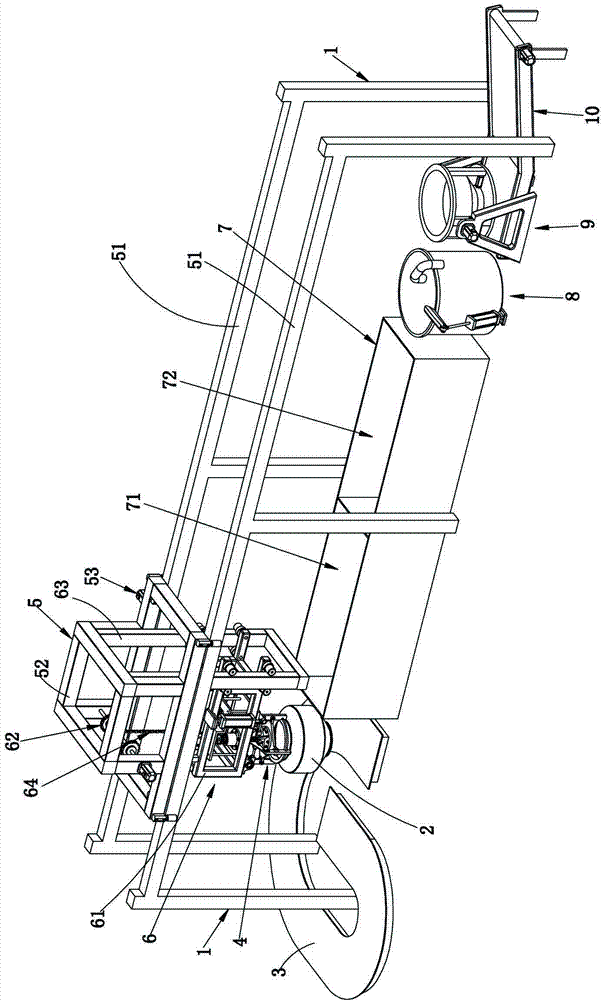

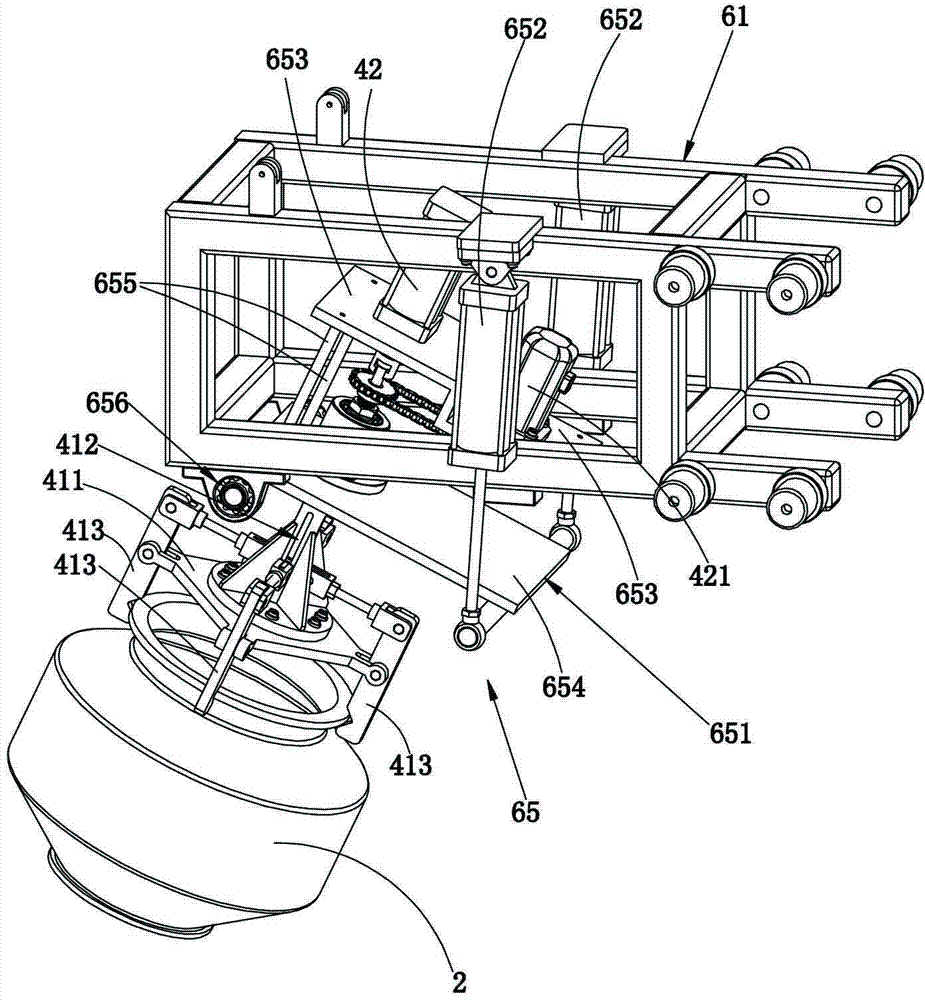

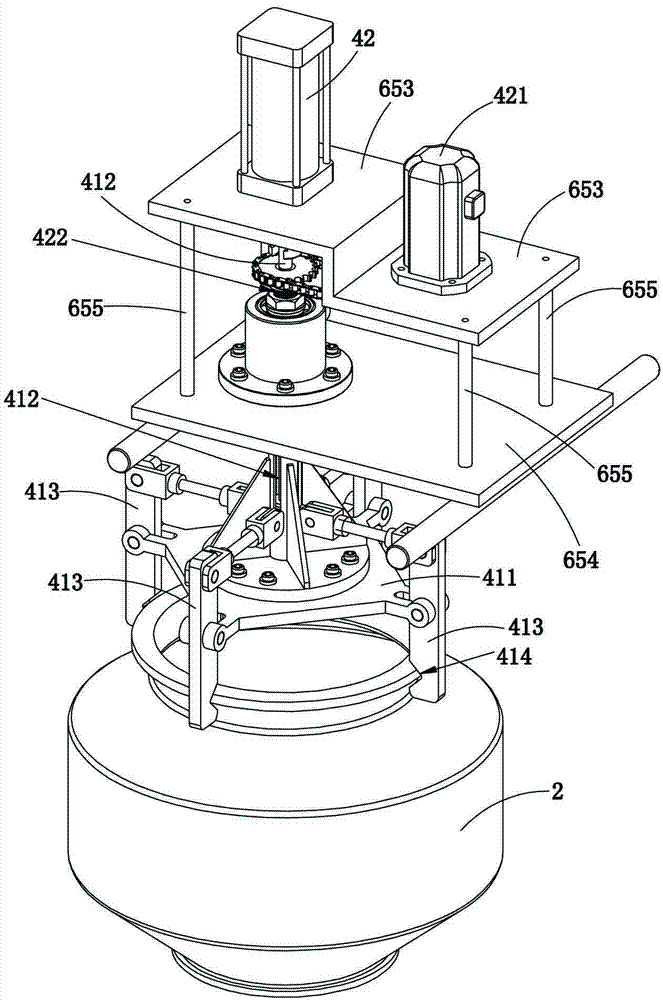

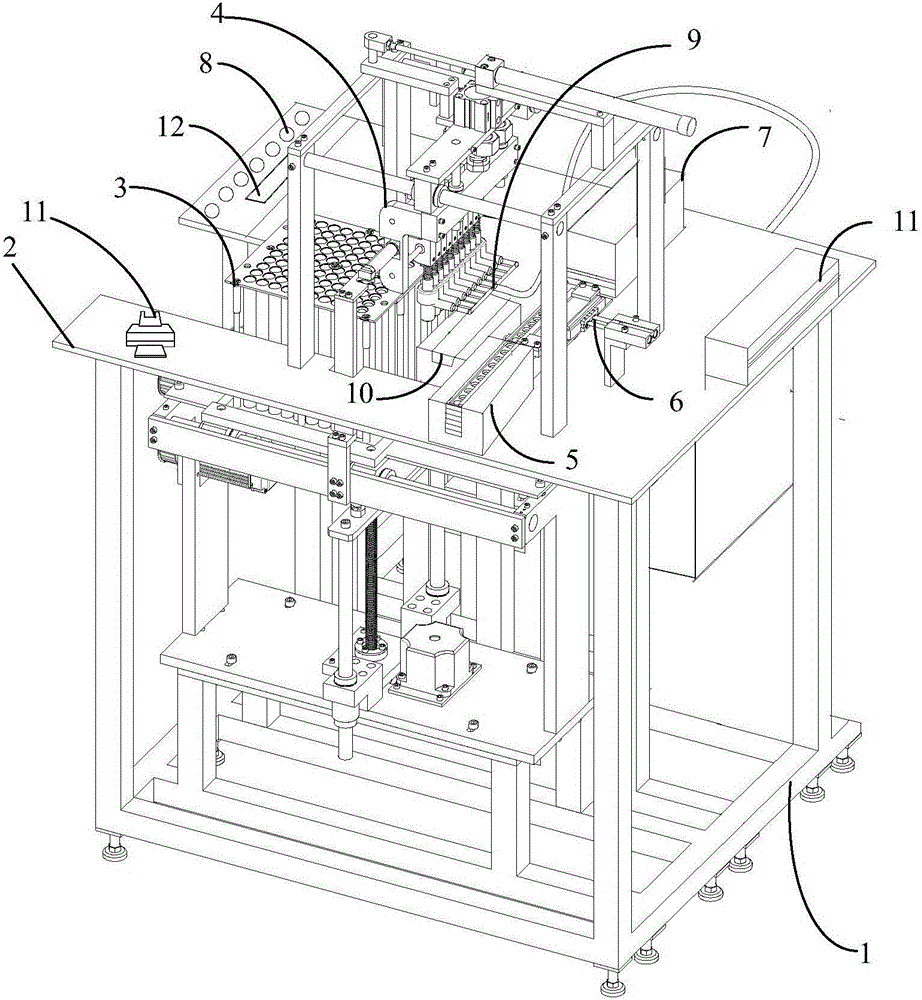

Machine for washing zipper heads

ActiveCN103878138AImprove cleaning efficiencyImprove drying efficiencyCleaning using liquidsEngineeringMechanical engineering

The invention relates to a machine for washing zipper heads. The machine for washing zipper heads comprises a main rack body, a washing bucket, a clamping mechanism, a horizontal moving mechanism, a lifting mechanism, a washing groove and a drying mechanism, wherein the washing bucket is used for containing the zipper heads, and the clamping mechanism is used for clamping the washing bucket; the horizontal moving mechanism is movably assembled on the main rack body; the clamping mechanism is assembled on the lifting mechanism, the lifting mechanism is used for driving the clamping mechanism to lift, and the lifting mechanism is assembled on the horizontal moving mechanism; washing liquid is contained in the washing groove, the washing groove is used for washing the zipper heads in the washing bucket, and the drying mechanism is used for drying the zipper heads in the washing bucket. The zipper heads can be continuously washed and dried with the washing machine, and the washing and drying efficiency of the zipper heads can be greatly improved; in the whole process, all the working procedures are controlled through intelligent programs, the washing effect can be guaranteed, the quality of the surfaces of the zipper heads sprayed with paint or the electroplated zipper heads is improved, and labor intensity of workers is relieved.

Owner:FUJIAN SBS ZIPPER SCI & TECH CO LTD

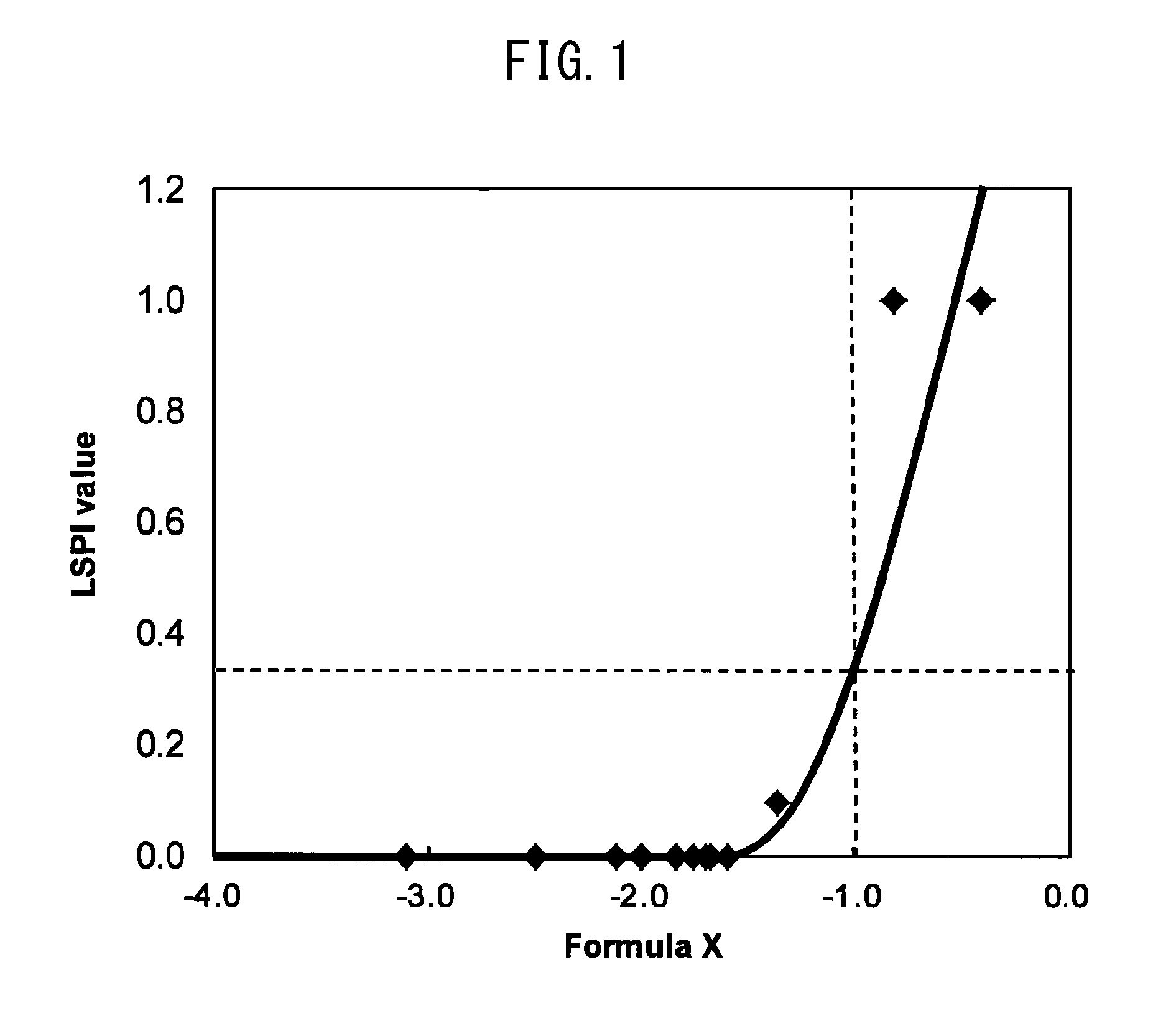

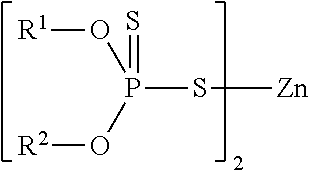

Lubricating oil composition

ActiveUS20170022441A1Reduce frequencyHigh-temperature cleaning performanceAdditivesChemical compositionNitrogen

A lubricating oil composition which can reduce the occurrence frequency of LSPI and which can ensure detergency. The lubricating oil composition which includes a lubricant base oil, a compound having calcium and / or magnesium, a compound having molybdenum and / or phosphorus, and an ashless dispersant having nitrogen and which satisfies X≦−0.85 and Y≧0.18 (wherein X is calculated according to formula (1): X=([Ca]+0.5[Mg])×8−[Mo]×8−[P]×30 and Y is calculated according to formula (2): Y=[Ca]+1.65[Mg]+[N]). The lubricating oil composition for use in an internal combustion engine, more particularly, a lubricating oil composition for use in a supercharged gasoline engine.

Owner:EXXON RES & ENG CO +1

Method for cleaning polished sapphire substrate wafer

InactiveCN102962226AGuaranteed cleaning effectAvoid the phenomenon of blowingCleaning using liquidsWaferingRoom temperature

The invention provides a method for cleaning a polished sapphire substrate wafer and belongs to the technical field of crystal processing and manufacturing. By the method, manual cleaning can be replaced completely and the one-step cleaning passing rate reaches the advanced level in the industry. The method comprises the following steps: soaking the polished sapphire substrate wafer into SM-007 acidic liquid at room temperature and cleaning for 15 to 30 minutes; soaking the sapphire substrate wafer into pure water at room temperature and ultrasonically cleaning for 5 to 10 minutes; soaking the sapphire substrate wafer into SP-2200 alkaline liquid and DP-020 alkaline liquid respectively at the temperature of 45 DEG C, performing ultrasonic treatment and throwing up and down at the same time, cleaning in the SP-2200 alkaline liquid for 15 to 20 minutes and cleaning in the DP-020 alkaline liquid for 10 to 15 minutes; between the two-time cleaning steps and at room temperature, soaking the sapphire substrate wafer into pure water, performing ultrasonic treatment and cleaning for 1 to 5 minutes by throwing up and down at the same time; and performing quick dump rinse (QDR) cleaning on the wafer and spin-drying.

Owner:江苏吉星新材料有限公司

Full-automatic size edge sealing production line and production method

InactiveCN102125903AEnabling Bionic ExtrusionExtended service lifeSpraying apparatusCleaning using toolsProduction lineMeasurement device

The invention relates to a full-automatic size edge sealing production line and a production method. A glass carrying device is arranged in a sheet discharge table; the conveying device is an open conveying mechanism, and a photoelectric thickness measurement device is arranged in a transition section or a sheet feeding table; two synchronous belt conveying mechanisms in the open conveying mechanism are arranged in parallel at interval, wherein one is an adjustable synchronous belt conveying mechanism, the other one is a fixed synchronous belt conveying mechanism, the distance between the adjustable synchronous belt conveying mechanism and the fixed synchronous belt conveying mechanism is automatically adjusted through a distance adjusting mechanism, and two synchronous belts in the adjustable synchronous belt conveying mechanism and the fixed synchronous belt conveying mechanism are driven to rotate by a servo driven synchronous transmission mechanism; and the glue driving head is provided with an electric cleaning head, the electric cleaning head vertically ascends and descends through a pneumatic lifting mechanism, and the pneumatic lifting mechanism is connected with a pneumatic horizontal driving mechanism and driven by the pneumatic horizontal driving mechanism to move horizontally.

Owner:杭州精工机械有限公司

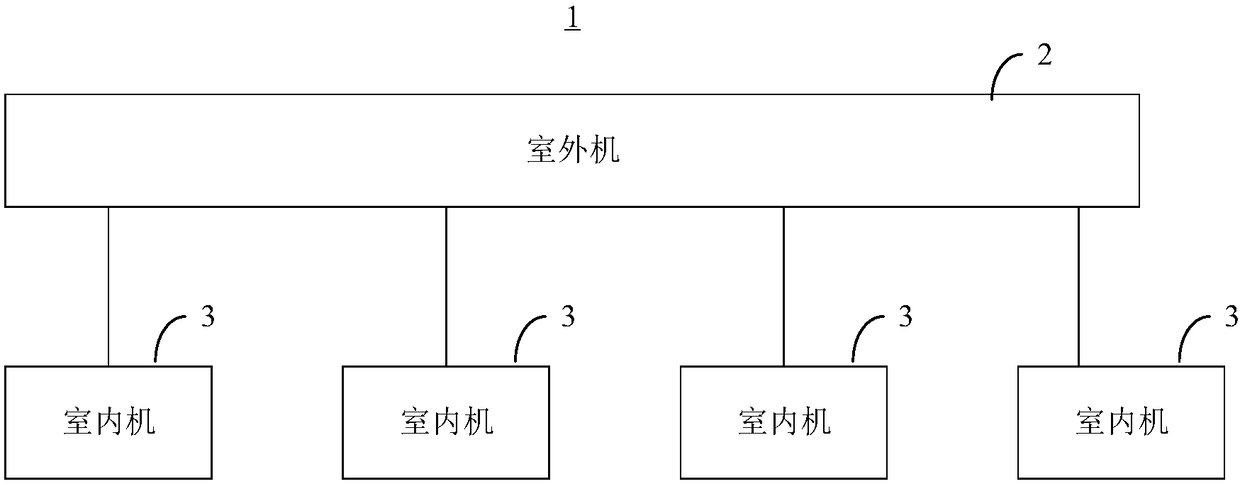

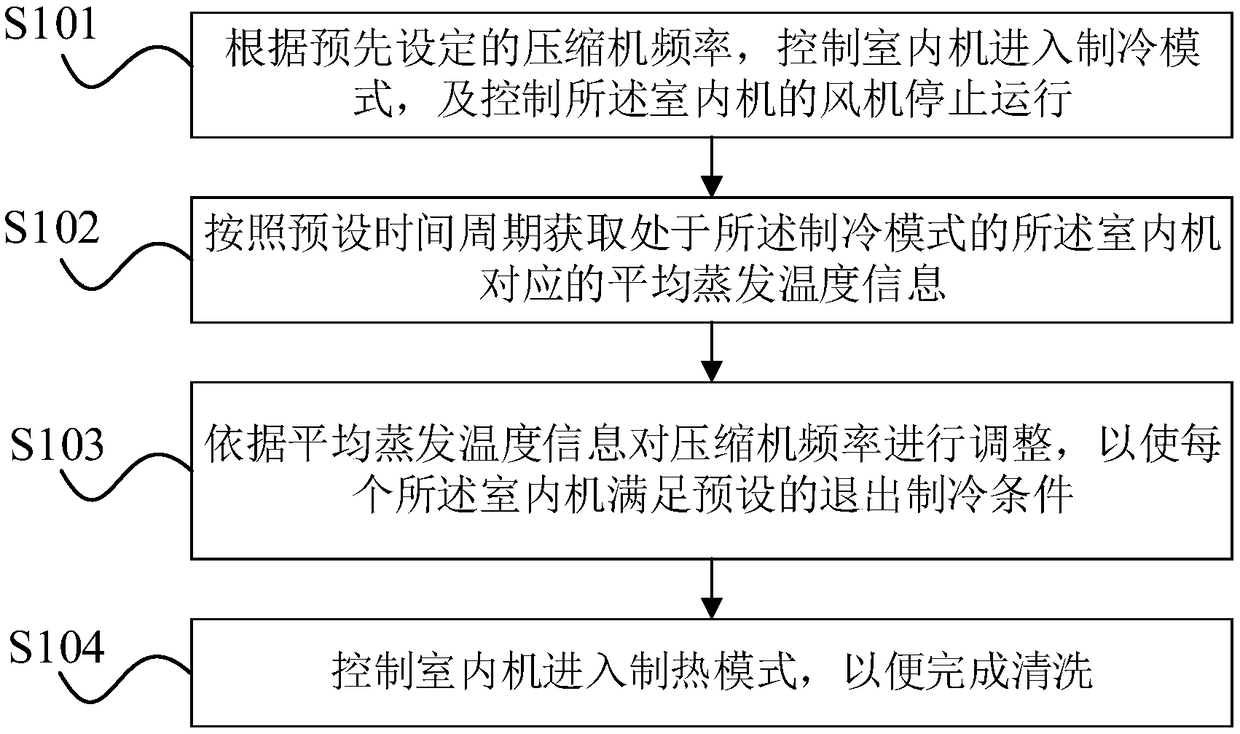

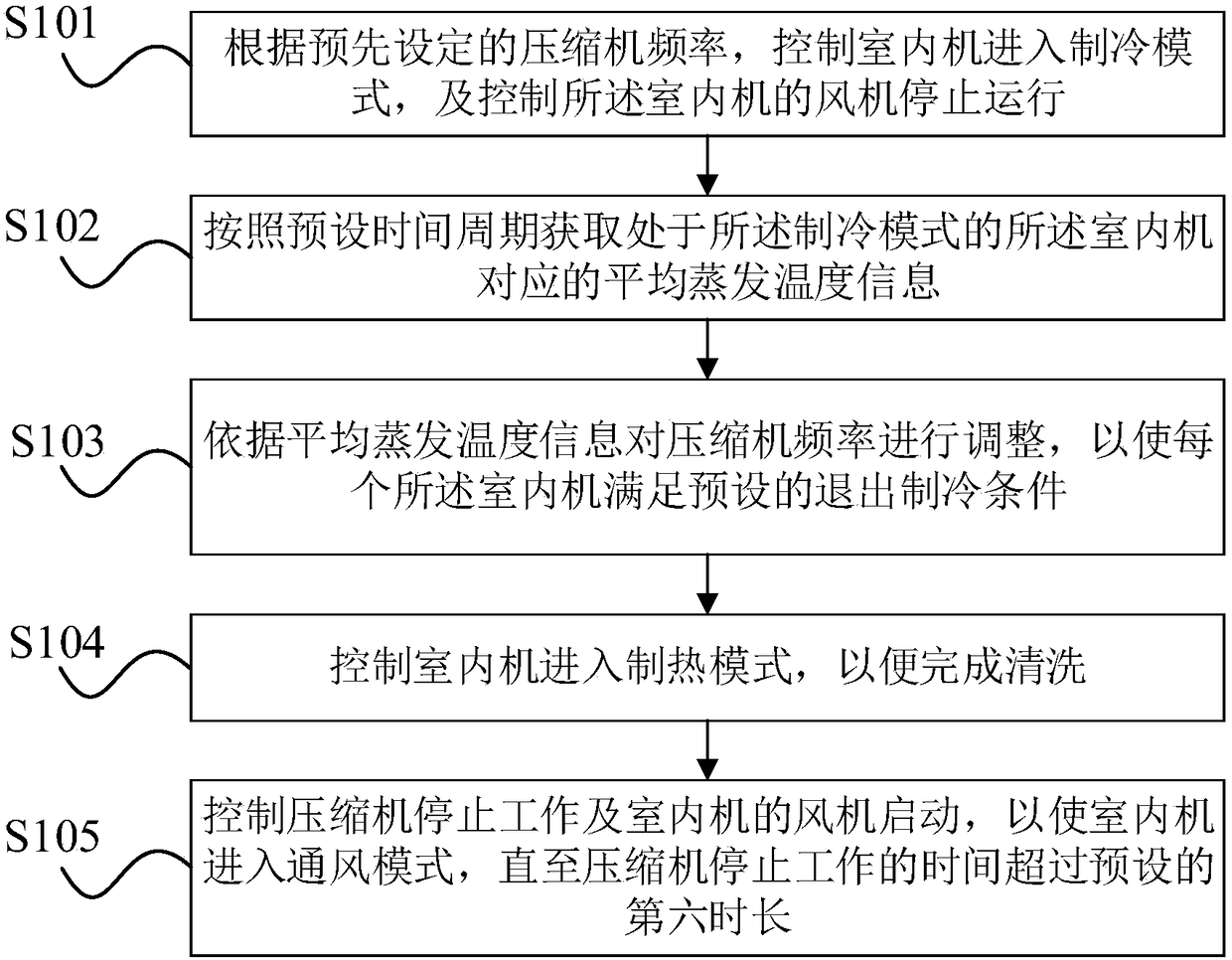

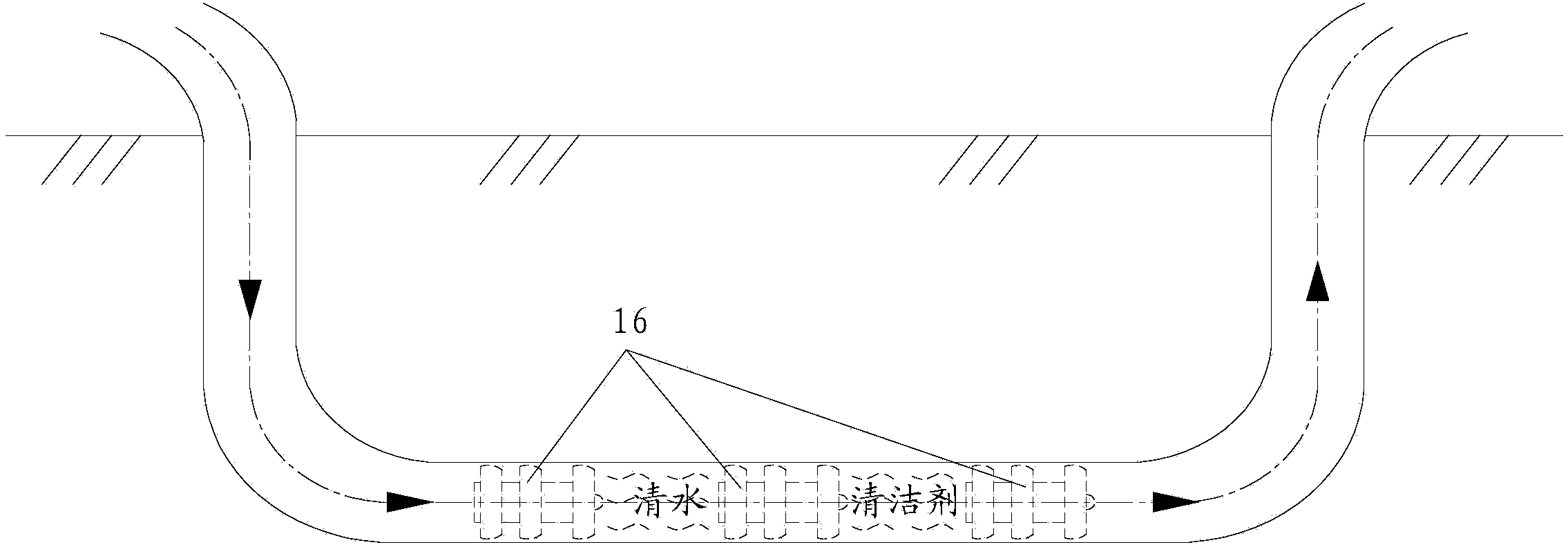

Multiple on-line self-cleaning method and multi-split air conditioning system

ActiveCN108361931AIdeal for frostingGuaranteed cleaning effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringCleaning methods

The embodiment of the invention provides a multiple on-line self-cleaning method and a multi-split air conditioning system. The multiple on-line self-cleaning method is applied to the multi-split airconditioning system, and the multi-split air conditioning system comprises a plurality of indoor units. The multiple on-line self-cleaning method includes the steps that the indoor units are controlled to start a cooling mode according to a preset compressor frequency, and fans of the indoor units are controlled to stop running; average evaporation temperature information corresponding to the indoor units in the cooling mode is acquired according to a preset time period; the compressor frequency is adjusted according to the average evaporation temperature information, so that the indoor unitsall satisfy a preset refrigeration exit condition; and the indoor units are controlled to start a heating mode to complete cleaning. According to the scheme, the compressor frequency is adjusted according to the average evaporation temperature information of the indoor units which still operate in the cooling mode, it is ensured that each indoor unit can reach the ideal frosting effect, and the final cleaning effect of each indoor unit is ensured.

Owner:NINGBO AUX ELECTRIC

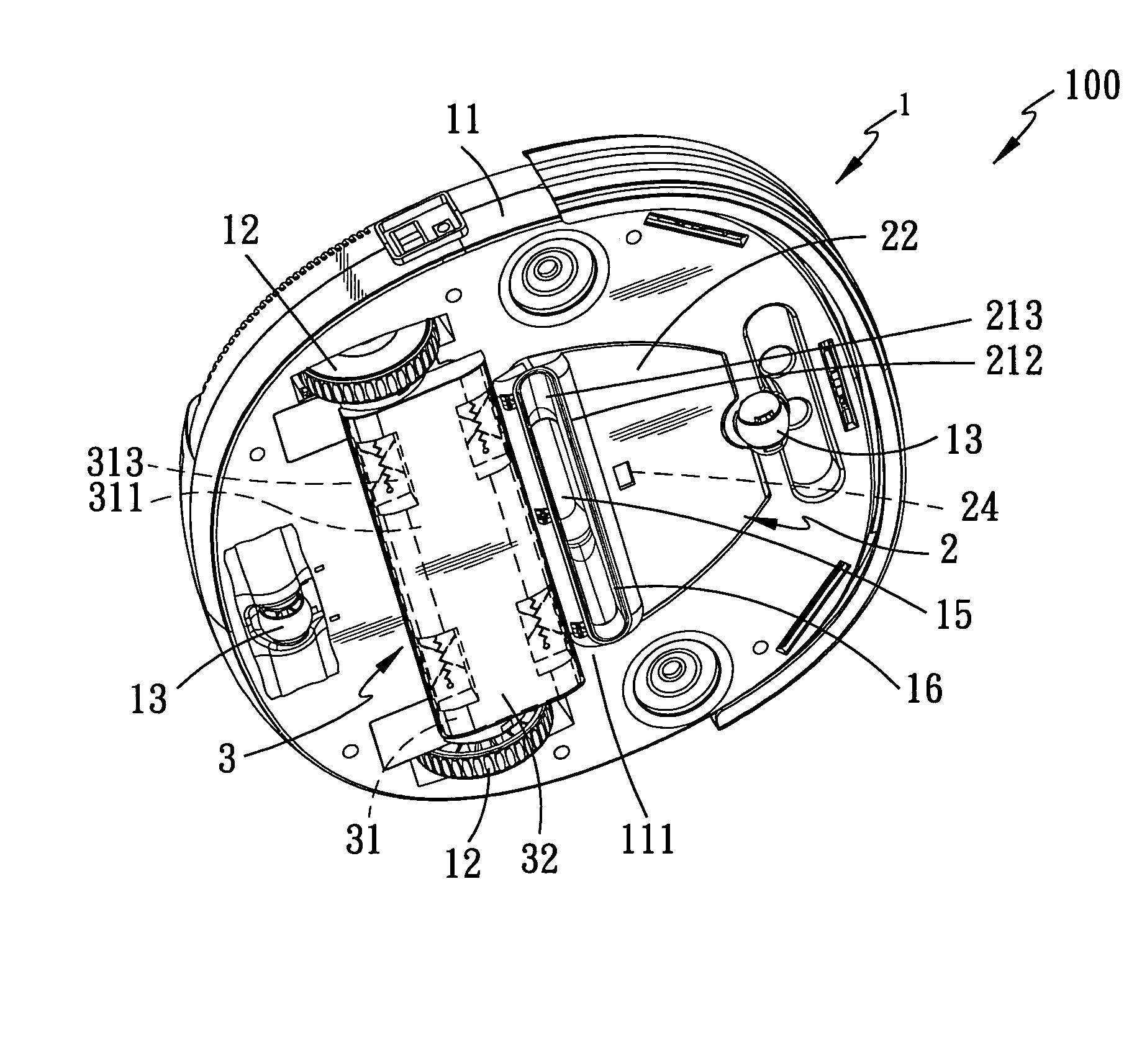

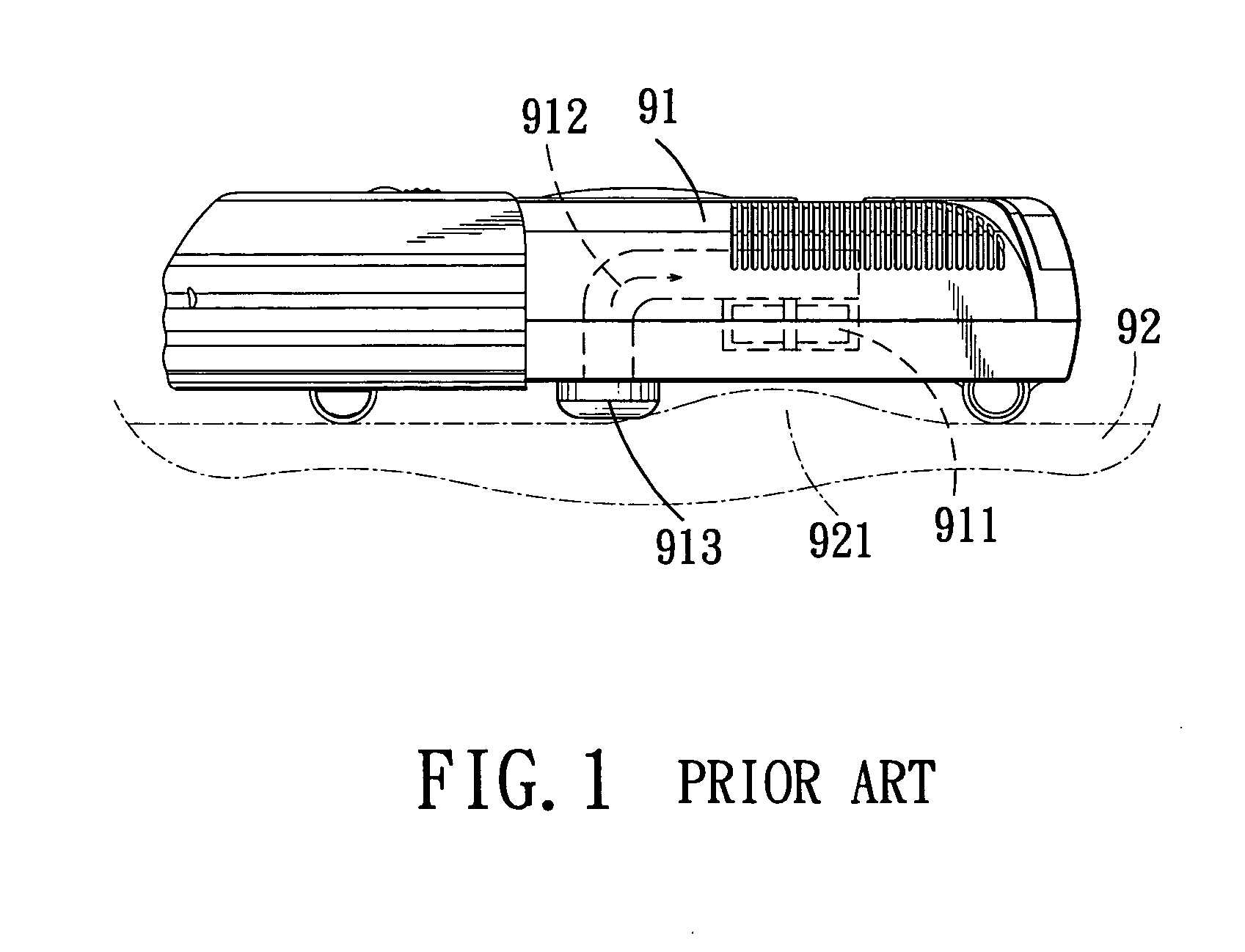

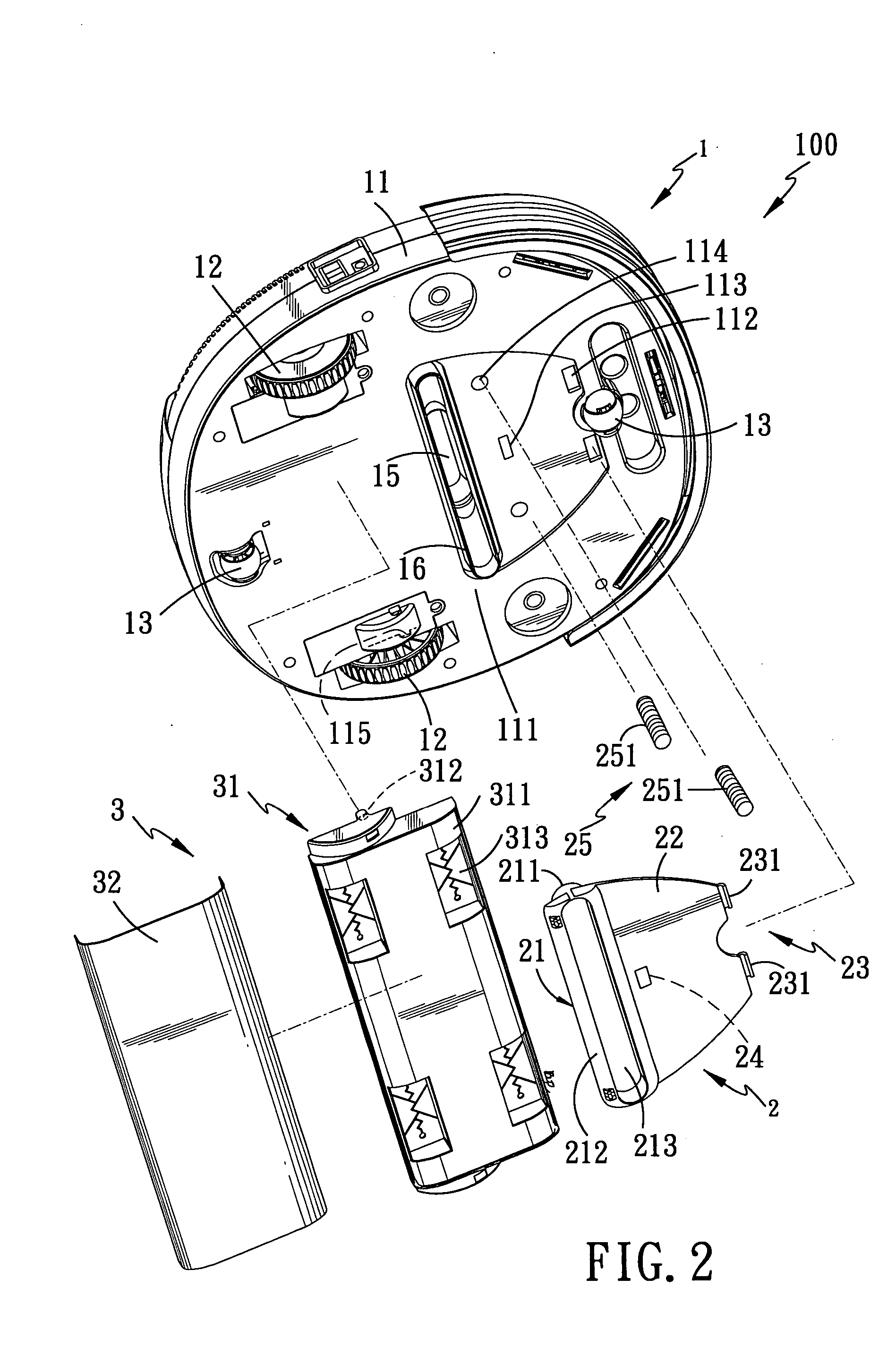

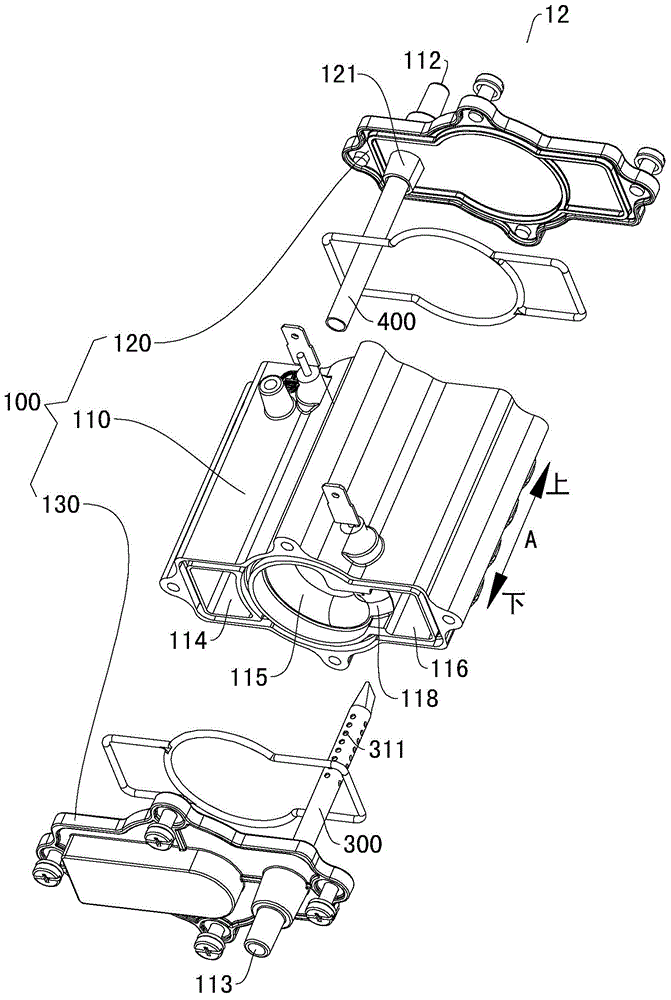

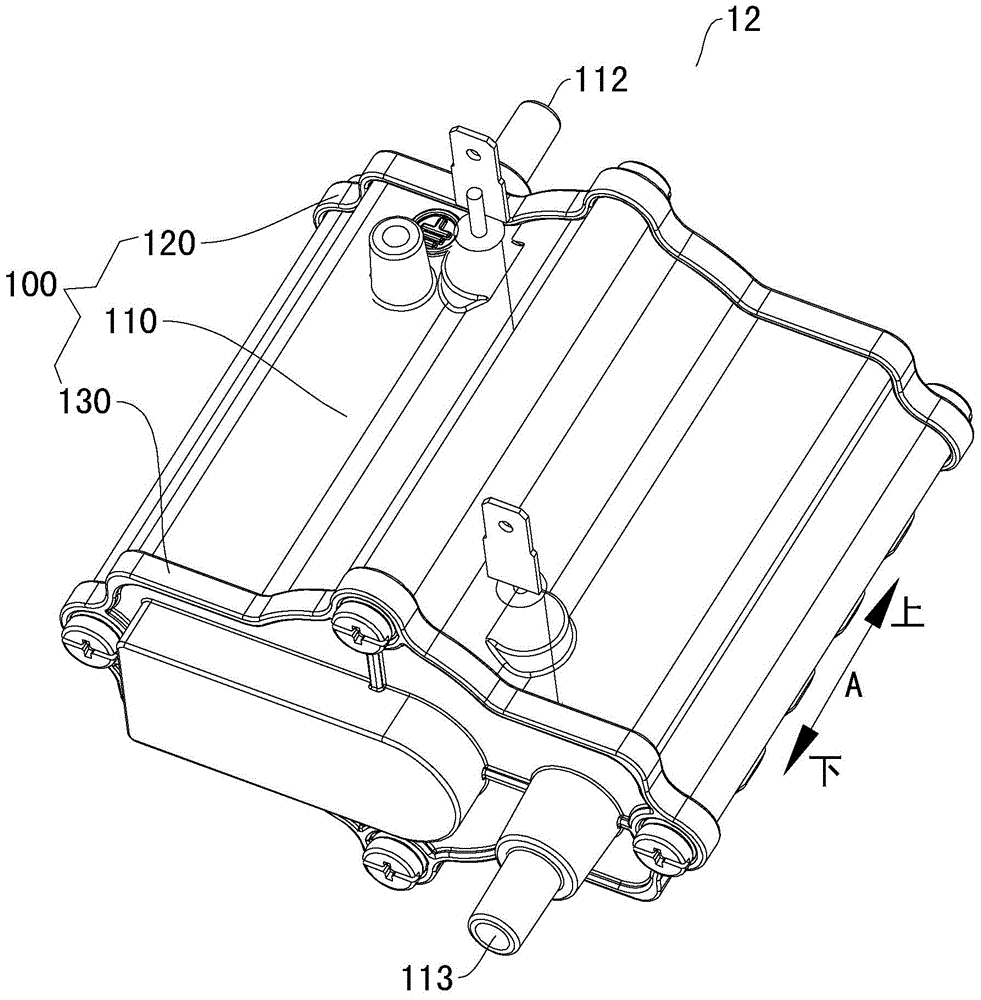

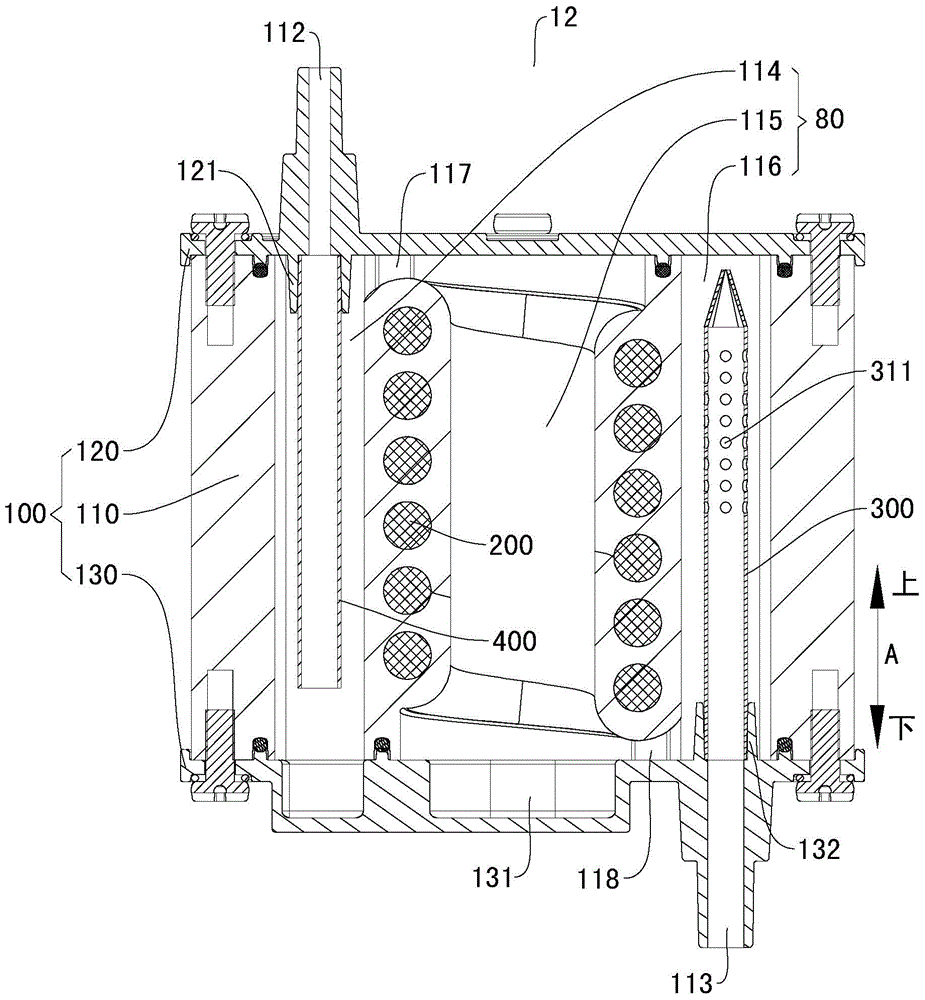

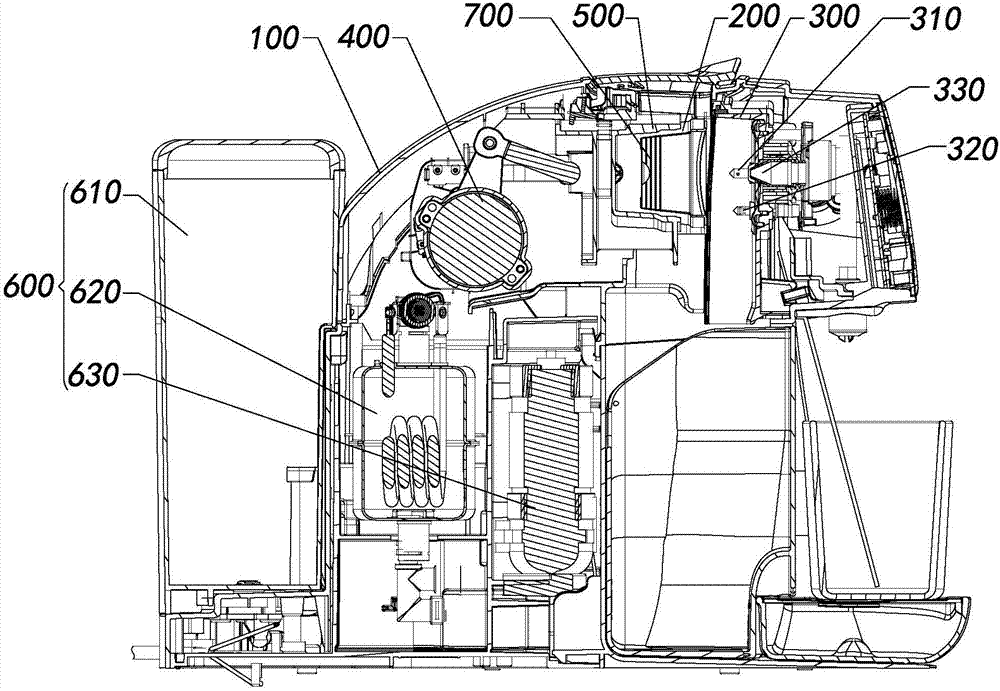

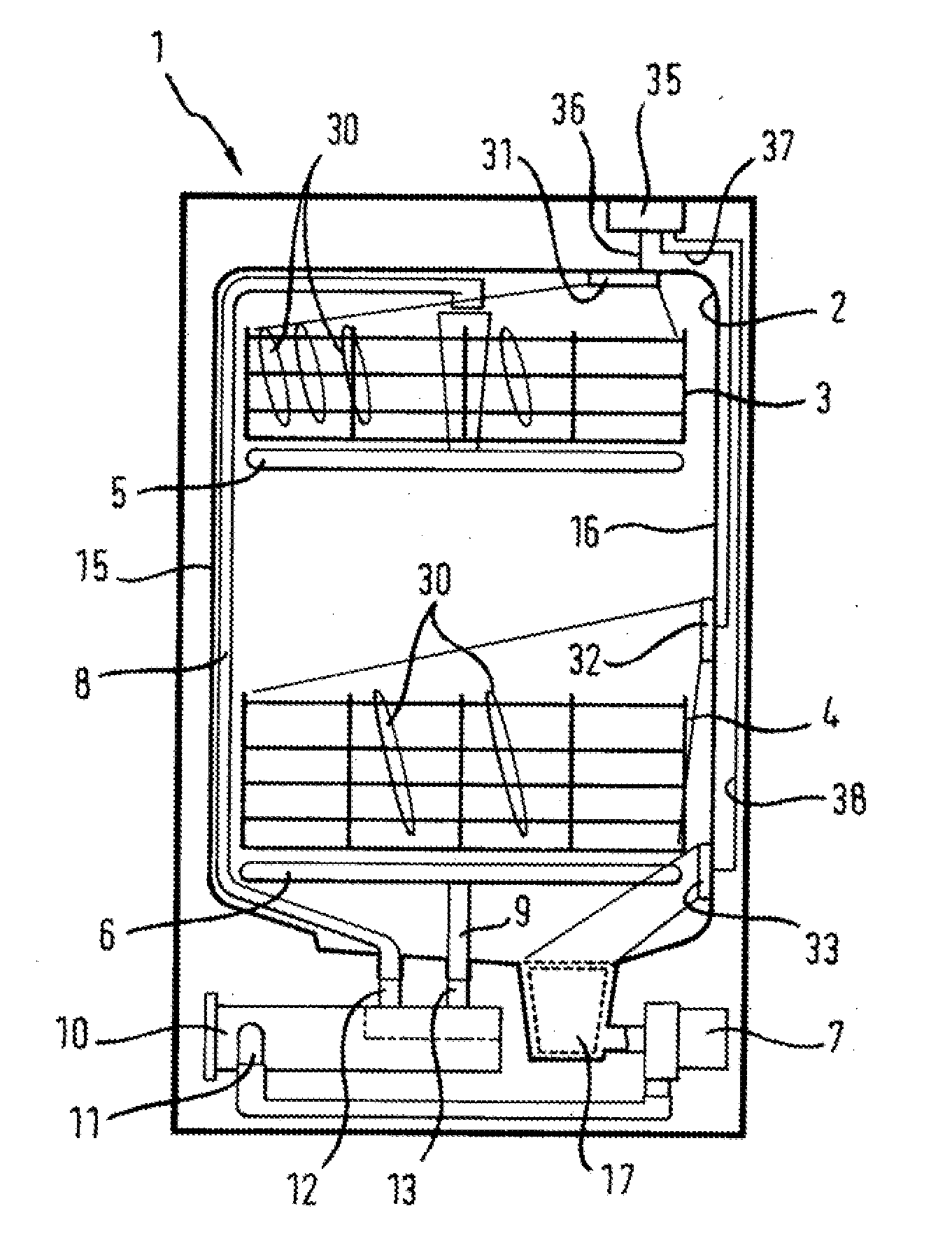

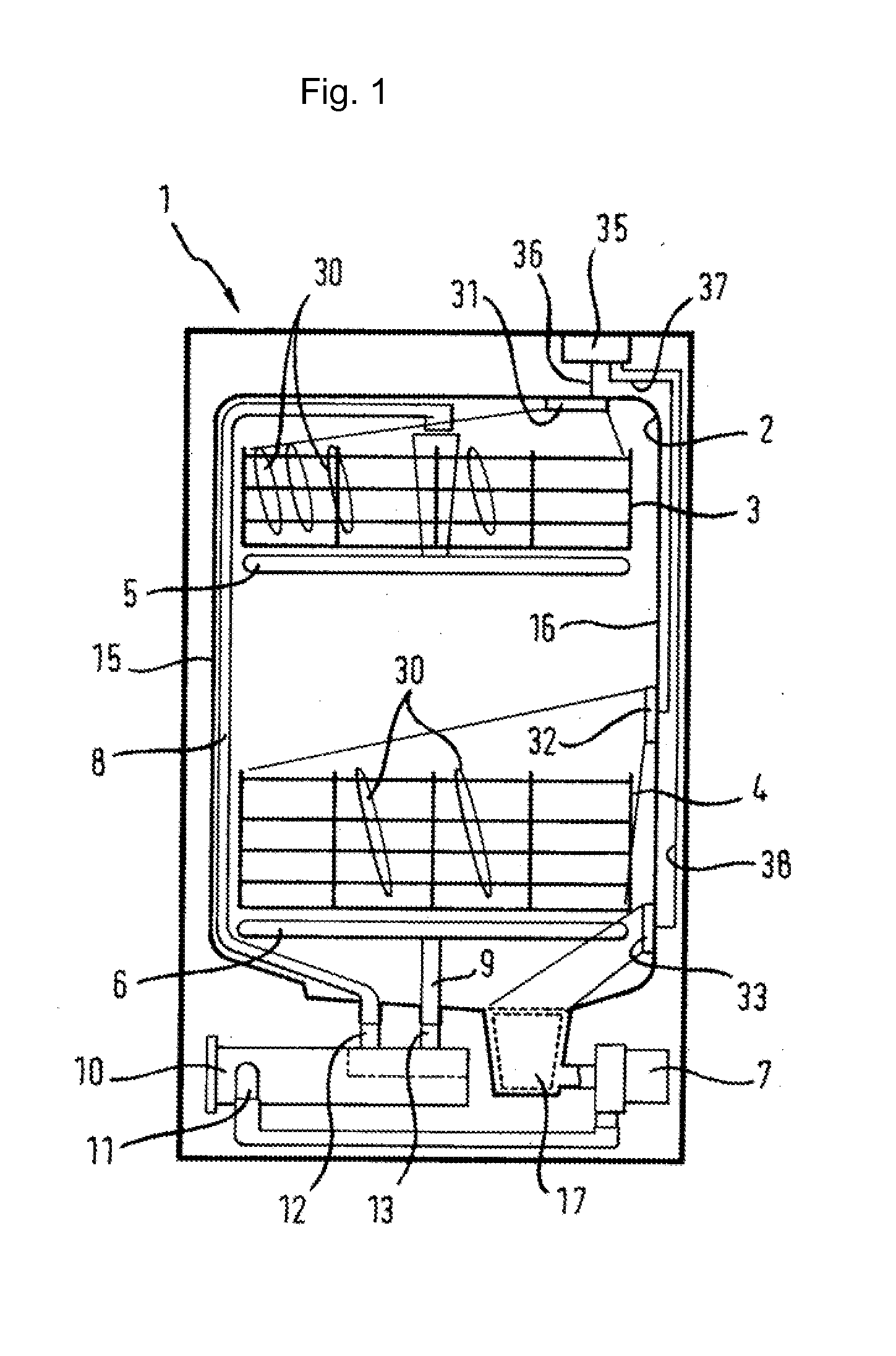

Self-moving vacuum cleaner

ActiveUS20050076466A1Improve cleanlinessGuaranteed cleaning effectAutomatic obstacle detectionTravelling automatic controlImpellerEngineering

A self-moving vacuum cleaner includes a duct disposed in a casing and having a vacuum inlet which extends downwardly of a bottom wall of the casing, and an impeller disposed to draw dust from the floor surface through the vacuum inlet into the duct. An intake nozzle includes a tubular nozzle body which has an upper end communicated with and retainingly slidable relative to the vacuum inlet so as to enable a lower end of the nozzle body to be movable between upper and lower positions, and an anchoring member which is hinged to the bottom wall such that the nozzle body is swingable between the upper and lower positions in response to unevenness of the floor surface, thereby enabling the lower end to keep trailing on the floor surface when the casing moves.

Owner:HUNAN GRAND PRO ROBOT TECH

Outdoor LED display screen easy to clean

InactiveCN107274795AAvoid the effects of receiving direct sunlightAvoid rain corrosionFlexible article cleaningCleaning using toolsLED displayWater storage tank

The invention discloses an outdoor LED display screen easy to clean. The LED display screen comprises a spraying nozzle, a water conveying pipe, an LED display screen main body, a pressurizing device, a water storage device, a water inlet pipe, grooves, a rain-shading and sun-shading plate, a solar cell panel, sliding grooves, a cleaning roller and flat teeth, wherein the rain-shading and sun-shading plate is arranged at the top end of the LED display screen main body; the solar cell panel is paved on the rain-shading and sun-shading plate; the grooves are formed in two sides of the rain-shading and sun-shading plate; the bottom ends of the grooves are connected to the water inlet pipe; the other end of the water inlet pipe is connected to the water storage tank; the water conveying pipe is arranged on the water storage tank; the spraying nozzle is arranged at the outlet end of the water conveying pipe; the pressurizing device is arranged on the water conveying pipe; the sliding grooves are formed in the upper and lower sides of the LED display screen main body; a rotating shaft is arranged on the surface of the LED display screen main body; the cleaning roller sleeves outside the rotating shaft; and electric telescopic rods are arranged at two sides of he rotating shaft. The device (the LED display screen) provided by the invention can be protected from getting corroded by direct sunlight and rain damage, so that service life is prolonged; the LED display screen can be automatically cleaned and can avoid manual output; and the LED display screen is safe and reliable, and is simple to operate. Occurrence of accidents can be relieved; and the LED display screen is simple in structure, convenient to use and conducive to popularization.

Owner:FOSHAN ZHENGLUE INFORMATION TECH CO LTD

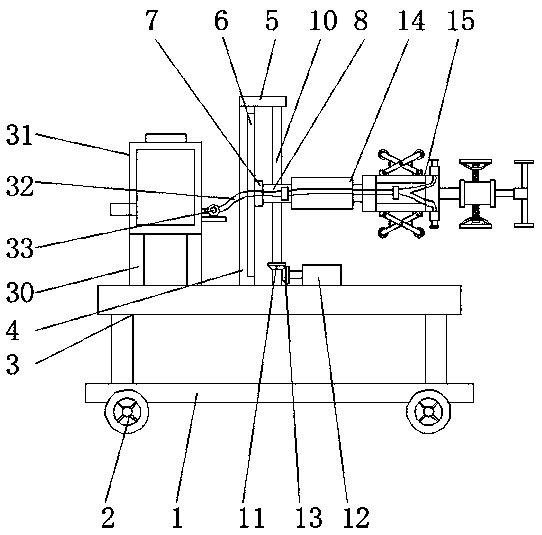

Petroleum pipe inner wall cleaning equipment

InactiveCN110142264AEasy height adjustmentClean and stableHollow article cleaningGear wheelEngineering

The invention discloses petroleum pipe inner wall cleaning equipment. The equipment comprises a base plate; universal wheels are arranged at the bottom of the base plate; a bracket is arranged above the base plate; a vertical plate is arranged at the top of the bracket; a top plate is arranged at the top of the vertical plate; a slide rail is arranged on one side of the vertical plate; a slide block is matched on the slide rail; a thread block is fixed on one side of the slide block; a screw rod is vertically downwards arranged at the bottom of the top plate; the thread block sleeves the screwrod; a first bevel gear fixedly sleeves the lower end of the screw rod; a first motor is arranged at the bottom of one side of the screw rod; a second bevel gear sleeves an output shaft of the firstmotor, and is in engaged connection with the first bevel gear; an electric extension rod is fixedly mounted on the side, far from the vertical plate, of the thread block; a cleaning device is mountedat the end part of the electric extension rod; the cleaning device comprises a cylindrical shell, a second motor and a scraping mechanism; and the end, penetrating through the cylindrical shell, of anoutput shaft of the second motor is fixedly connected with a rotating rod. The equipment is convenient to use, and can finish the cleaning process of flushing during removing of dirt.

Owner:卢李娜

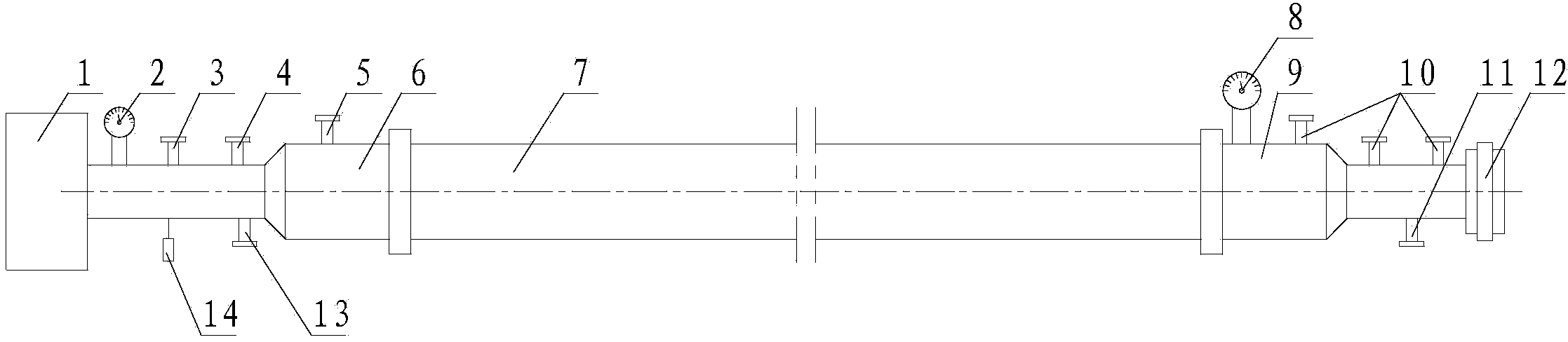

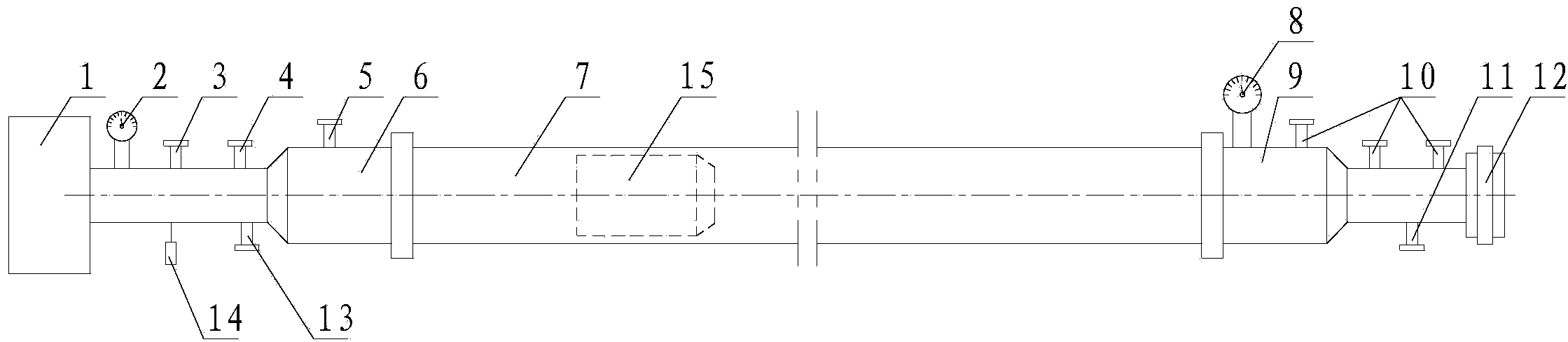

Process for cleaning whole inner wall of long pipeline for high-purity gas

ActiveCN104014562ASpeed upImprove cleanlinessDrying solid materials without heatHollow article cleaningImpurityRust

The invention relates to a process for cleaning the whole inner wall of a long pipeline for high-purity gas. The process includes the following steps that (1), present situation investigation and processing are carried out on the pipeline; (2), rust removal and dedusting cleaning processing is carried out on the inner wall of the pipeline, wherein a leather cup steel brush pipe cleaner and a foam pipe cleaner are pushed through oil-free compressed air to rapidly move in a laid long-distance pipeline in one direction so as to push quantities of residues and other impurities in the long-distance pipeline out of the pipeline; (3), drying processing is conducted on the inner wall of the pipeline, wherein a large-scale compressor and a gas storage tank accumulator are utilized to purge a pipeline system; (4) protection is conducted on a finished pipeline. The process for cleaning the whole inner wall of the long pipeline for high-purity gas is reasonable in design, easy and convenient to operate and especially applied to processing the inner wall of the pipeline for high-purity gas. By the adoption of the process, the construction progress can be quickened, construction quality can be improved, manual operation can be reduced, construction cost can be saved, and efficiency of construction operation is effectively improved.

Owner:TIANJIN PIPELINE ENG GROUP

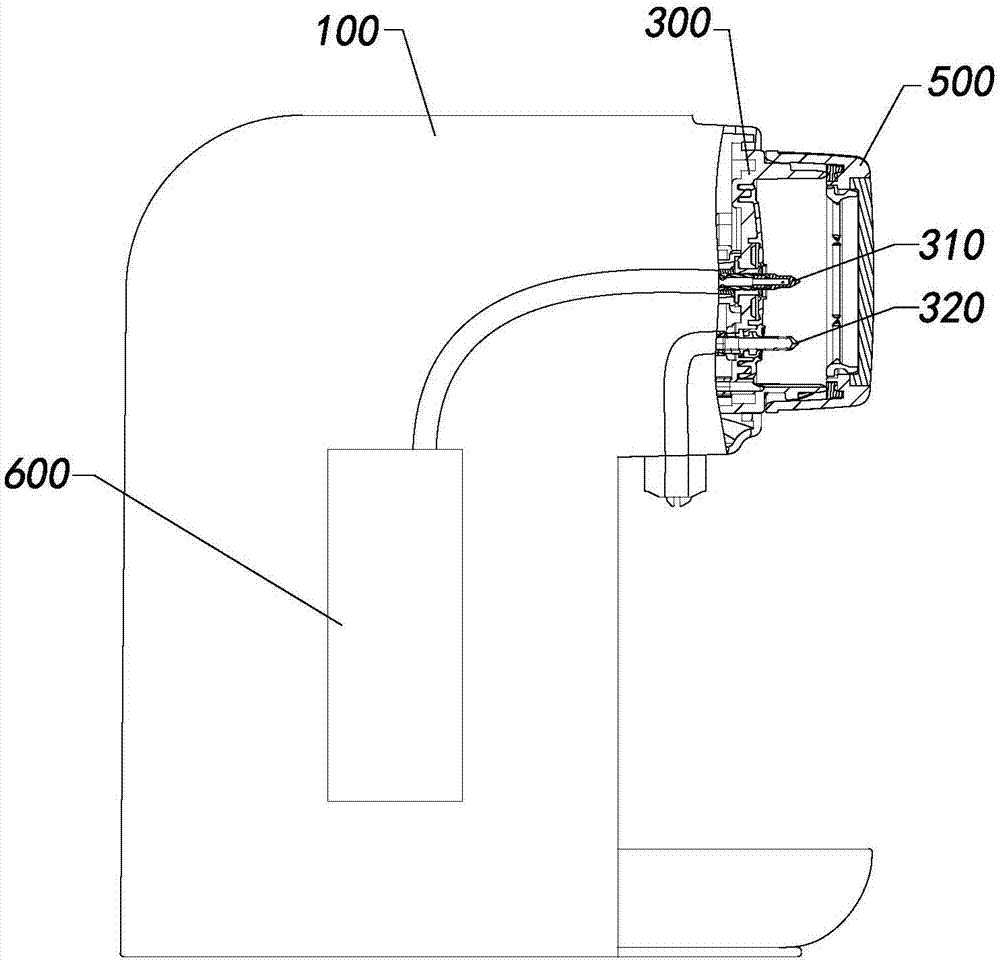

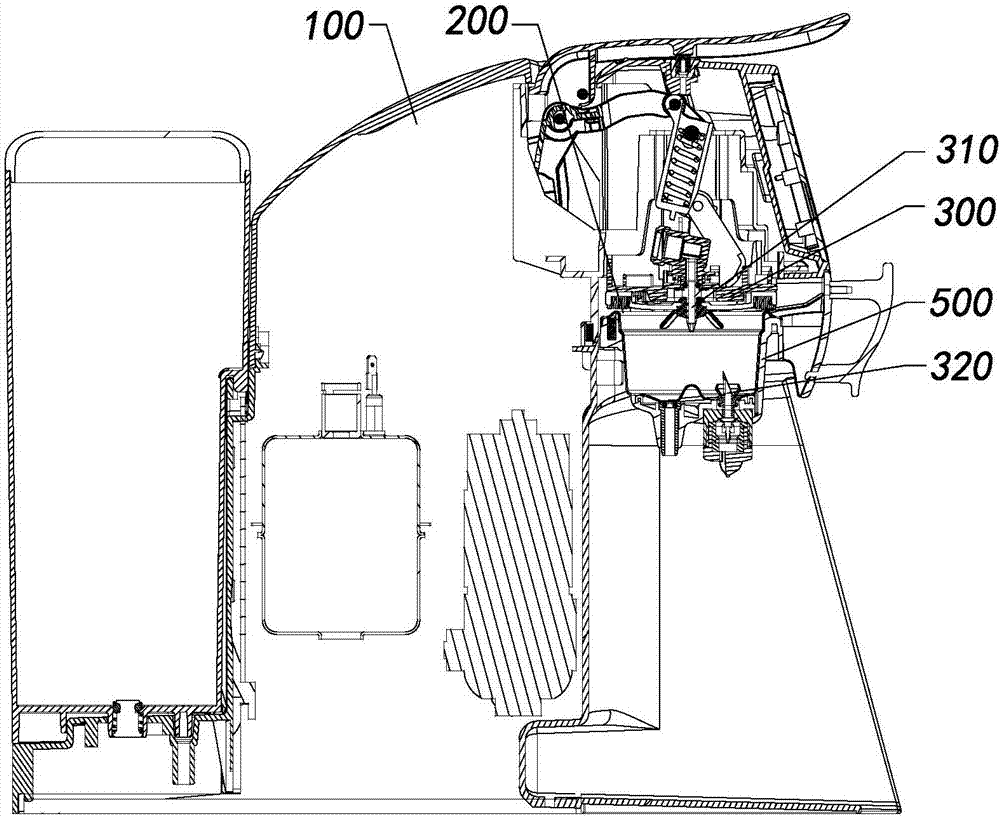

Vapor generator, washing system and range hood

InactiveCN104421988APrevent outflowAvoid enteringSteam generation heating methodsDomestic stoves or rangesVapor generatorChemical engineering

The invention discloses a vapor generator, a washing system and a range hood. The vapor generator comprises a body, a heating member and an eduction pipe, wherein the body is internally provided with a heating cavity, and the heating cavity is provided with an inlet and an outlet; the heating member is arranged on the body and used for heating a liquid inside the heating cavity; the eduction pipe is arranged in the heating cavity, the upper end of the eduction pipe is closed, the lower end of the eduction pipe is opened, the lower end of the eduction pipe is connected with the outlet of the heating cavity, and the eduction pipe is provided with a plurality of eduction pores. According to the vapor generator of the embodiment, generated water scale can be prevented from flowing out, the water scale can be further prevented from entering a spraying pipe, the potential danger that the spraying pipe is blocked can be eliminated, and the spraying force and washing effect of the spraying pipe can be guaranteed.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Method for cleaning capsule beverage dispenser

The invention discloses a method for cleaning a capsule beverage dispenser, and belongs to the technical field of beverage preparation. The problems that wasting of water is caused in the cleaning process of an existing capsule beverage dispenser and the cleaning effect is poor are solved. The capsule beverage dispenser comprises a machine base with a brewing cavity, a liquid feeding mechanism, an input module and a control module. The control module controls the capsule beverage dispenser to be cleaned according to signals of the input module. The cleaning method includes a first cleaning stage and a second cleaning stage capable of being selected to be executed. The first cleaning stage at least includes a first washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a first power P1 for cleaning. The second cleaning stage at least includes a second washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a second power P2 for cleaning. The rated power of the liquid feeding mechanism is PE1, and P1<P2<=PE1. The method disclosed by the embodiment of the invention is used for cleaning the capsule beverage dispenser. The capsule beverage dispenser can be a capsule coffee maker, a capsule soybean milk machine and the like.

Owner:杭州易杯食品科技有限公司

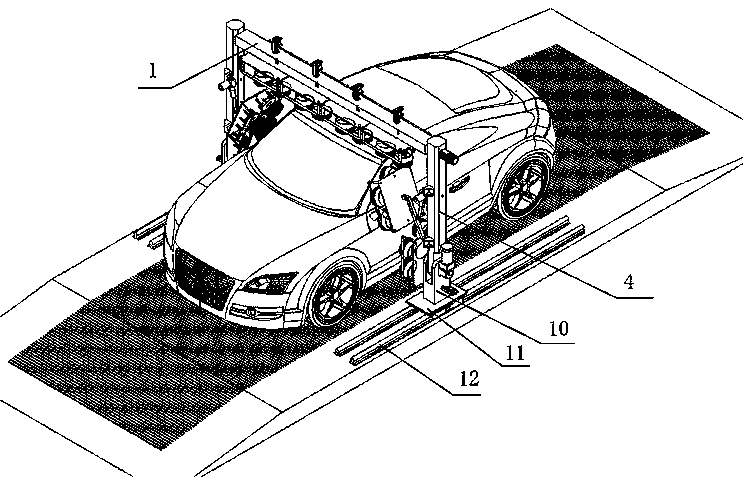

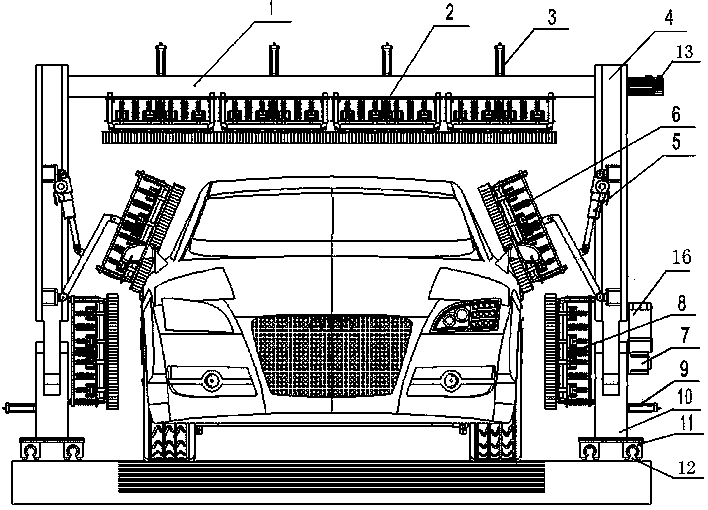

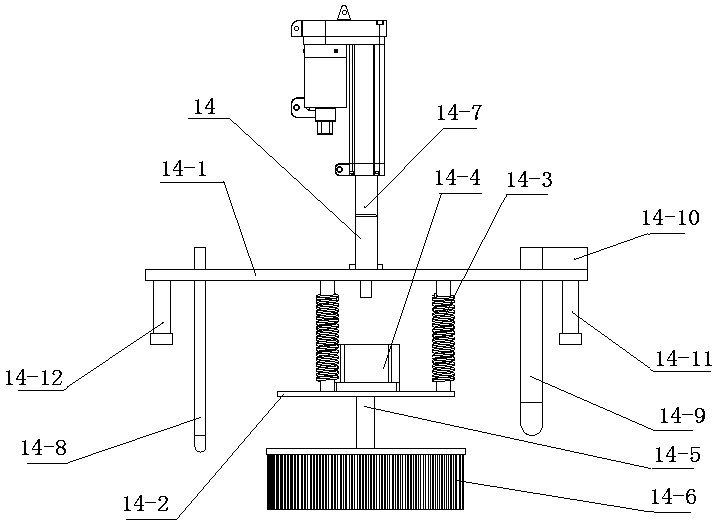

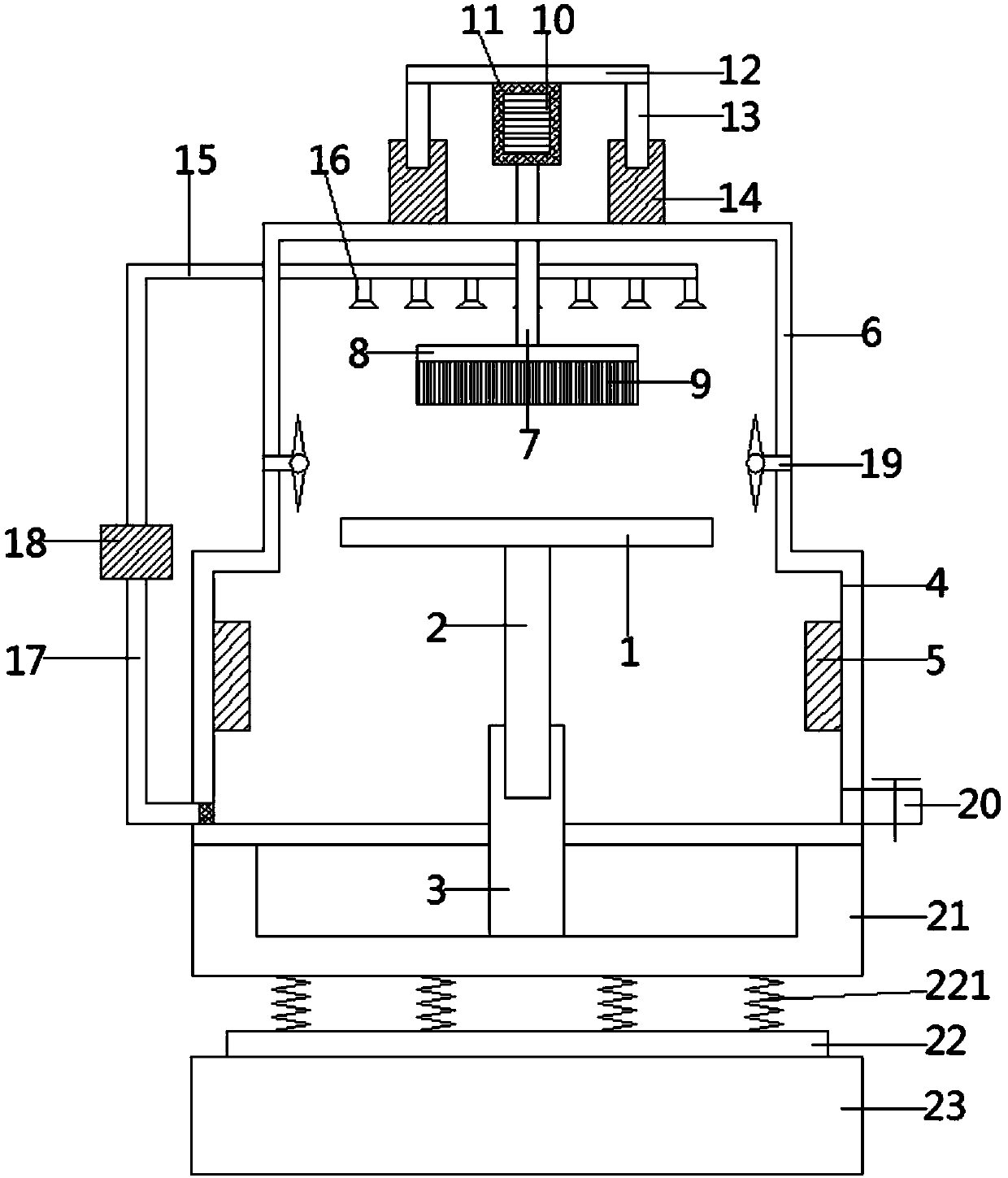

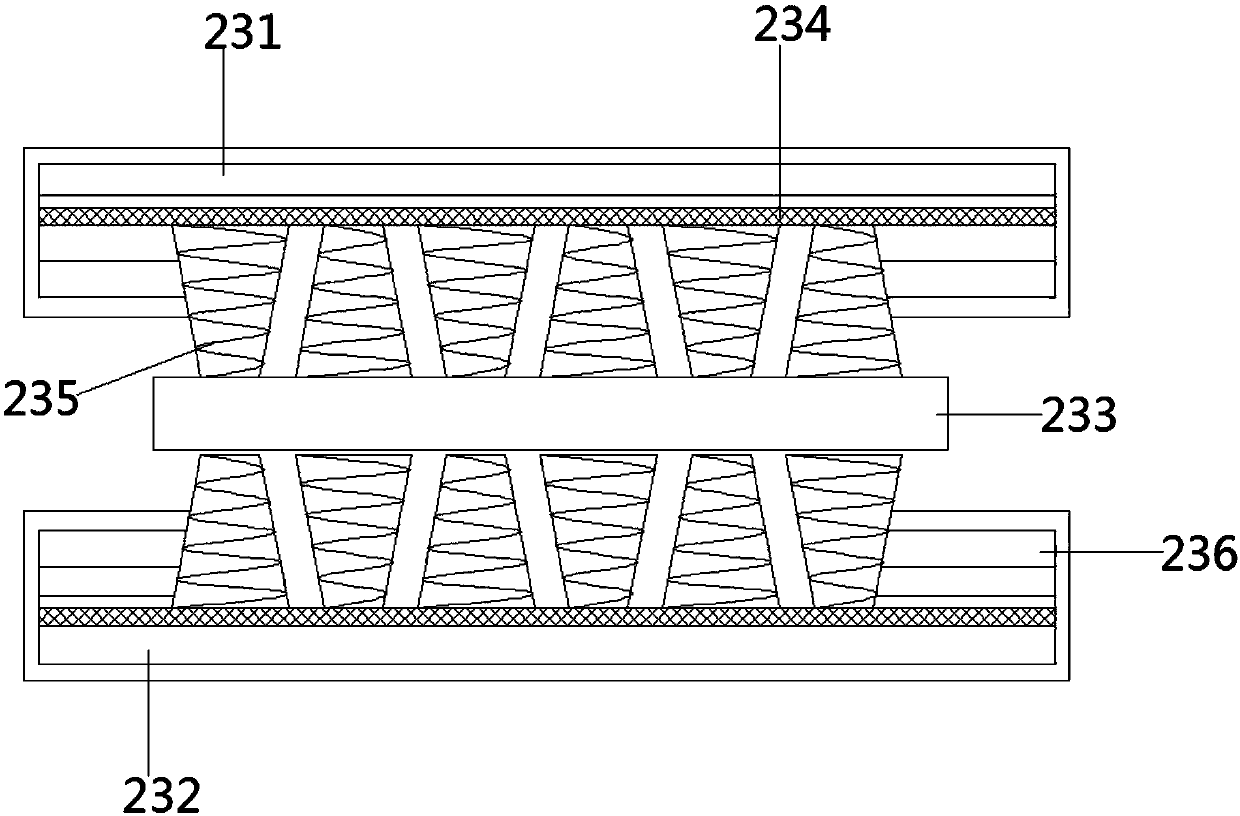

Gantry swing arm type automatic vehicle cleaning mechanism

PendingCN107685717AReduce volumeImprove cleanlinessCleaning apparatus for vehicle exteriorsStructural engineeringControl theory

The invention discloses a gantry swing arm type automatic vehicle cleaning mechanism which comprises fixing guide rails, movable sliders, swing arm supports, gantry swing arms and a gantry transversebeam. The fixing guide rails are arranged on the ground, the movable sliders can slide on the fixing guide rails in the front-back directions, the swing arm supports are fixed onto the movable sliders, the gantry swing arms are arranged on the swing arm supports and are connected with the swing arm supports by connecting shafts, and the gantry transverse beam is arranged on the two gantry swing arms and is connected with the gantry swing arms by shafts; bottom electric push rods are arranged on the swing arm supports, and bottom cleaning devices are arranged at the front ends of the bottom electric push rods. The gantry swing arm type automatic vehicle cleaning mechanism has the advantages that the gantry swing arm type automatic vehicle cleaning mechanism is of a gantry structure, two side arms of a gantry can swing, accordingly, the gantry swing arm type automatic vehicle cleaning mechanism can be easily matched with vehicle shapes, and vehicles can be efficiently automatically cleaned in a high-quality manner; the gantry swing arm type automatic vehicle cleaning mechanism is small in occupied area, simple in integral structure and quite suitable for popularization and utilization.

Owner:HEBEI BOYI GONGJI SCI & TECH DEV CO LTD

Cleaning device for gear machining

InactiveCN107716389AGuaranteed cleanlinessPrevent rustNon-rotating vibration suppressionDrying gas arrangementsHydraulic cylinderGear wheel

The invention discloses a cleaning device for gear machining. The cleaning device comprises a cleaning table face, the lower side of the cleaning table face is connected with a lifting column, the bottom end of the lifting column is connected with a hydraulic cylinder, the cleaning table face is arranged on the inner side of a water tank, the inner walls of the left side and the right side of thewater tank are provided with ultrasonic wave cleaners correspondingly, the upper side of the water tank is provided with a support, the bottom end of the support is fixedly connected to the water tank, a rotating shaft is vertically arranged on the center of the upper side of the support, the bottom end of the rotating shaft is connected with a horizontally-arranged brush handle, and a cleaning brush is fixedly arranged on the lower side of the brush handle. According to the cleaning device for gear machining, circulating spraying, lifting brushing and ultrasonic wave cleaning are adopted forcleaning a gear, the cleaning effect is good, the efficiency is high, manual operation is not needed, the labor intensity is lowered, resources are saved, the using cost is reduced, moreover, a casting can be subjected to air drying after being cleaned, casting rusting is effectively avoided, vibration produced by the device can be reduced in all directions, noise is reduced, safety is improved, and the service life is prolonged.

Owner:ZHENJIANG QILONG TECH CO LTD

Ultraviolet sterilizer with automatic cleaner

ActiveCN1745851ADoes not affect the disinfection effectEasy to cleanHollow article cleaningRadiationUv disinfectionSewage

An ultraviolet disinfector with automatic washing unit for the fluid (sewage or running water) is composed of the annular rubbing-washing plates, pull rod, slide rod and its guide rod, supporting rods, liquid detergent box vertically fixed to said supporting rods, liquid detergent supplying tube connected to the liquid detergent inlet of said box, the sealing unit for the liquid detergent outlet of said box, the ultraviolet tube in the sleeve pipe and passing through said rubbing-washing rings which can run through the holes on the opposite walls of said box, and drive unit.

Owner:FUJIAN NEWLAND ENTECH CO LTD

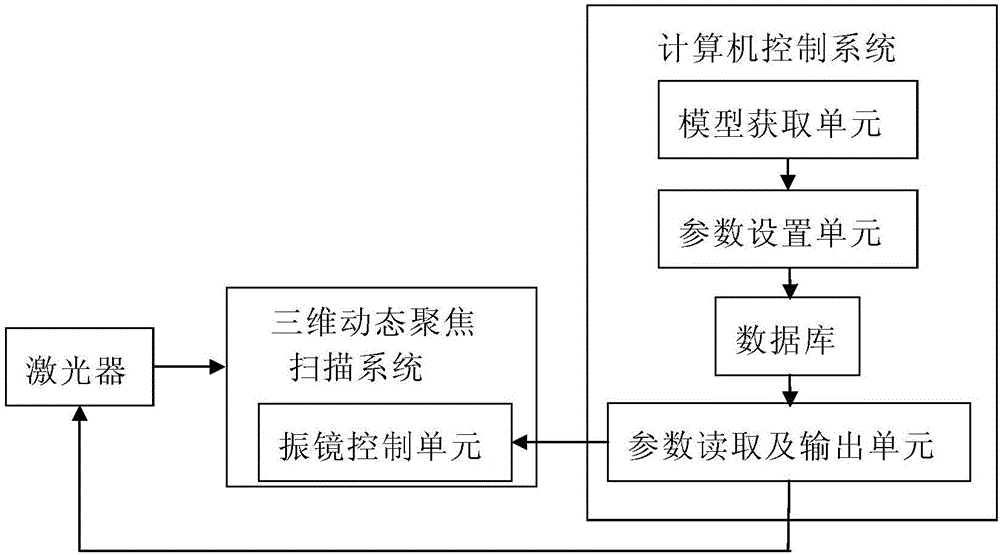

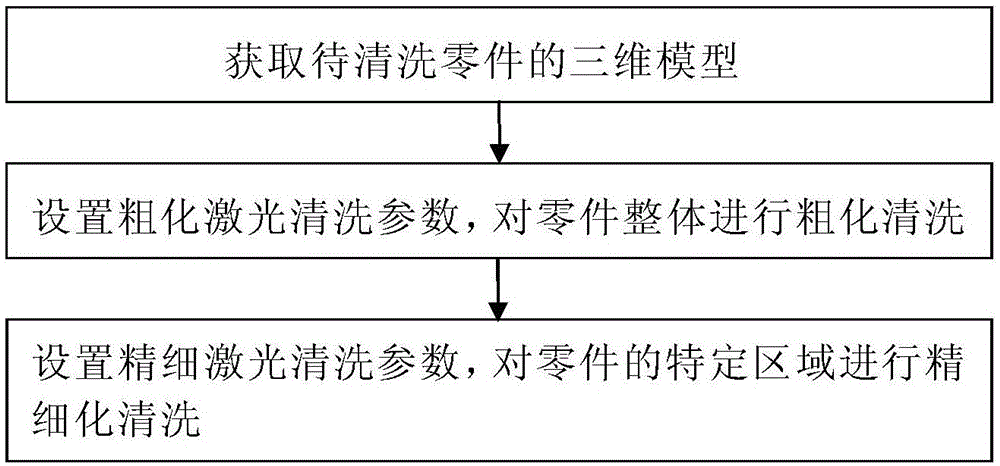

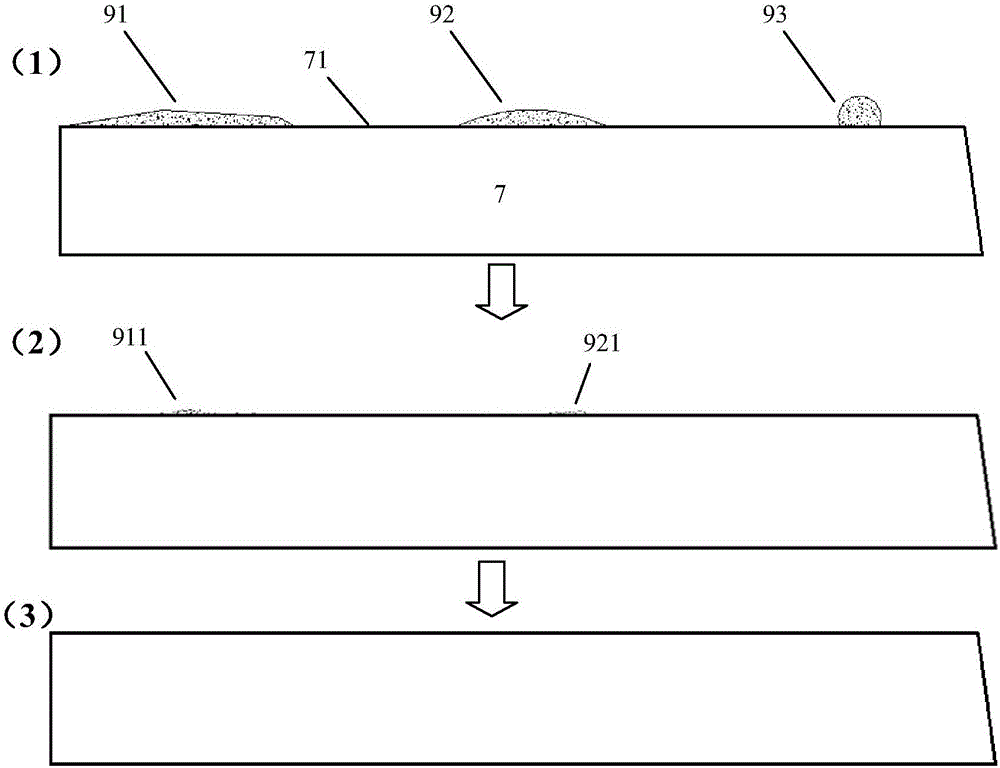

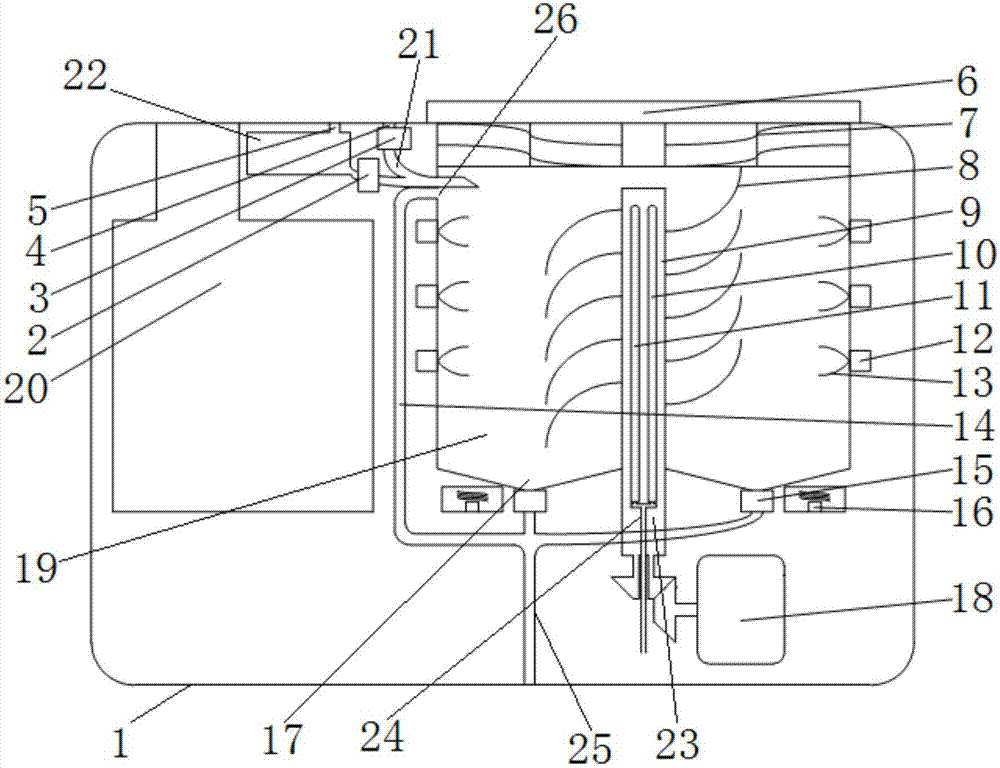

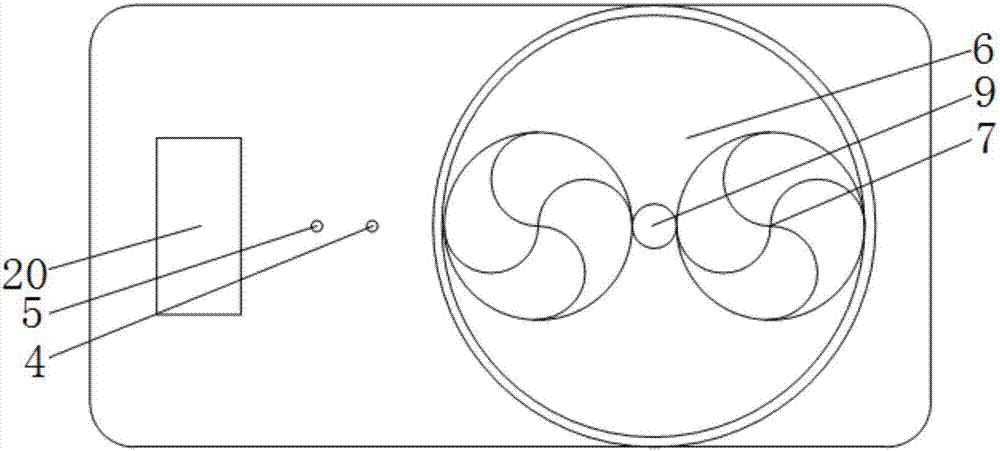

Laser precise cleaning device and method of part

InactiveCN106493122AImprove cleaning efficiencyWash thoroughlyCleaning processes and apparatusThree dimensional modelEngineering

The invention discloses a laser precise cleaning device and method of a part. The method includes the steps that a three-dimensional model of a to-be-cleaned part is obtained; coarse laser cleaning parameters are set, coarse processing layer data are generated, and a three-dimension dynamic focusing scanning system is adopted to rapidly and integrally clean the part according to the coarse processing layer data; and fine laser cleaning parameters are set, fine processing layer data are generated, and the three-dimension dynamic focusing scanning system is adopted to conduct fine cleaning on a specific area of the part according to the fine processing layer data. Accordingly, the cleaning efficiency can be improved, the problem of excessive cleaning or incomplete cleaning can be avoided, the cleaning effect is good, and precise profiling cleaning of parts of large sizes, small sizes or special structures can be achieved.

Owner:苏州菲镭泰克激光技术有限公司

Multifunctional shoes washing device

ActiveCN107224258AEasy to cleanSave time washing shoesFootwear cleanersRadiationEngineeringUltraviolet germicidal light

The invention relates to a multifunctional shoes washing device. The device comprises a shell body, a cleaning cavity in the shell body, and a water inlet mechanism and a detergent adding mechanism connected with the cleaning cavity respectively; a brush shoes washing mechanism is arranged in the cleaning cavity, and internally provided with an ultrasound wave emitting bar and an ultraviolet sterilization lamp in parallel; multiple rotating shoes clamping mechanisms are arranged on the inside wall of the cleaning cavity, and the bottom part is provided with a draining mechanism; the device further comprises a drying mechanism matched with the cleaning cavity and a controller electrically connected to the water inlet mechanism, the detergent adding mechanism, the brush shoes washing mechanism, the ultrasound wave emitting bar, the ultraviolet sterilization lamp, the rotating shoes clamping mechanism, the draining mechanism and the drying mechanism. Compared with the prior art, the multifunctional shoes washing device can automatically carry out cleaning, drainage, drying and sterilization works in order, and completely clean and rapidly dry the shoes; the cleaning effect is good, the shoes washing time is saved greatly; moreover, the device is high in intellectualization degree and easy to operate.

Owner:SHANGHAI UNIV OF ENG SCI

Cup cleaning device

InactiveCN106670196AAchieve cleaningGuaranteed cleaning effectHollow article cleaningEngineeringElectric motor

Owner:茹朝贵

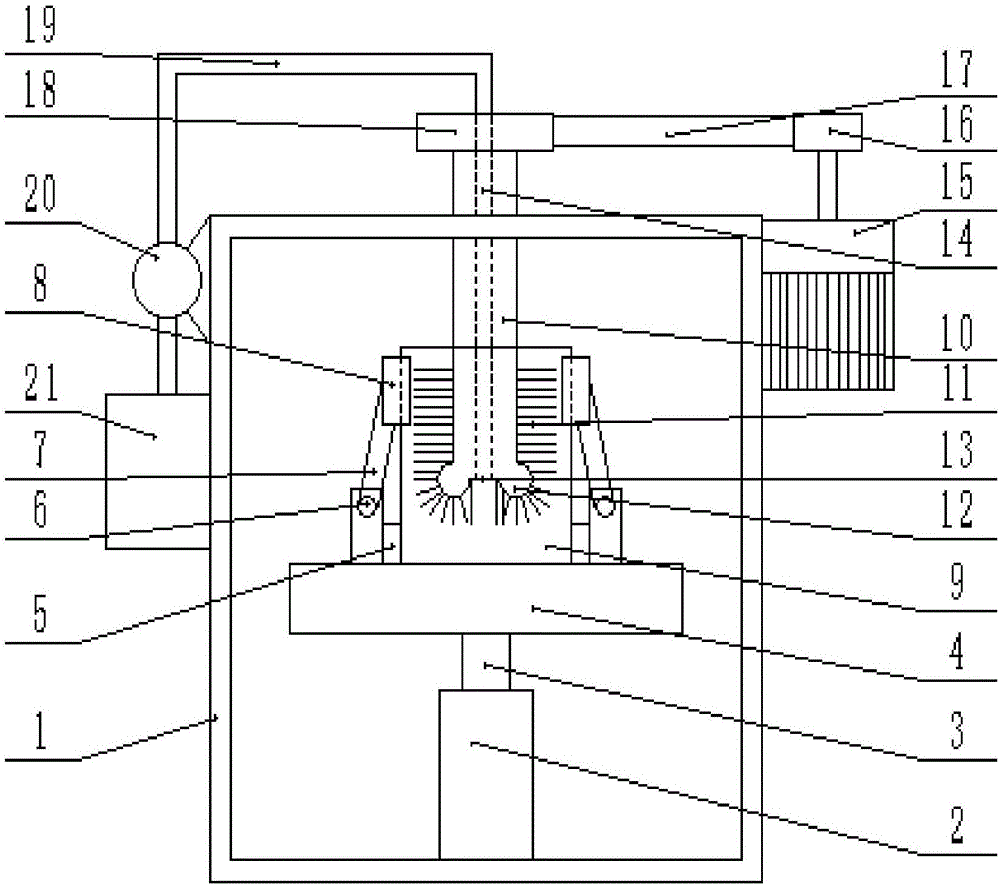

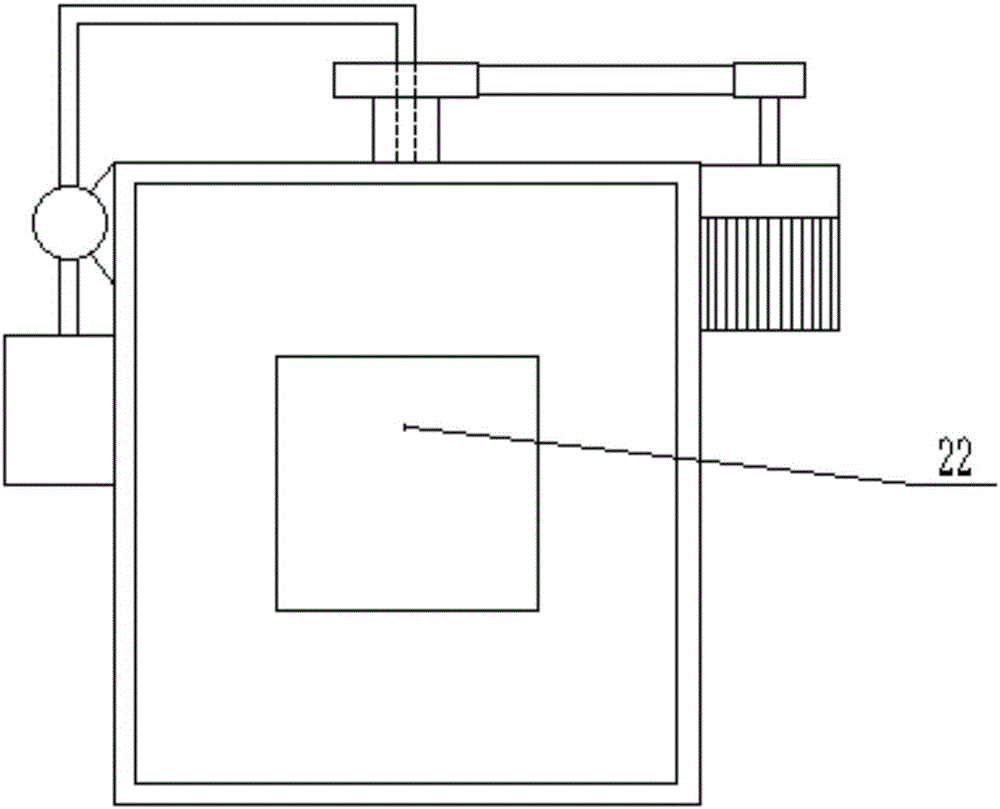

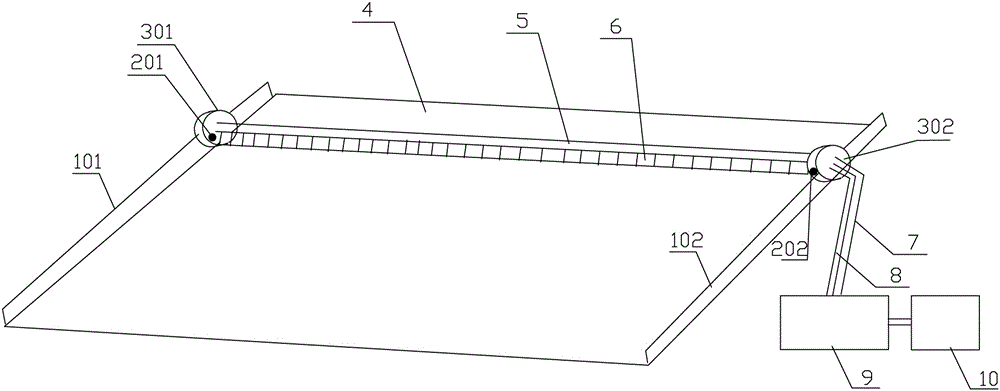

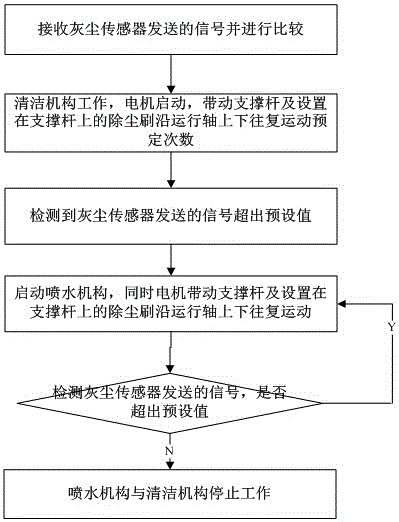

Self-induction solar photovoltaic dust removing system

ActiveCN106391624AReduce water consumptionGuaranteed cleaning effectPhotovoltaicsFlexible article cleaningSelf inductionAdverse effect

The invention discloses a self-induction solar photovoltaic dust removing system. The self-induction solar photovoltaic dust removing system comprises a control unit, a power source, dust sensors, a cleaning mechanism arranged on a photovoltaic panel, and a water spray mechanism connected with the cleaning mechanism. The dust sensors, the cleaning mechanism and the water spray mechanism are connected with the control unit. The cleaning mechanism, the water spray mechanism and the control unit are connected with the power source. The cleaning mechanism comprises operating shafts, motors, a supporting rod and a dust removing brush. The water spray mechanism comprises a water outlet pipe, a water outlet pump, a water outlet pump water source connector and a water spray pipe. According to the self-induction and self-starting solar photovoltaic dust removing system, the dust removing mode combining the cleaning mechanism and the water spray mechanism is adopted, the cleaning effect is ensured, and the adverse effects of factors such as dust and fallen dust on the output efficiency stability and service life of photovoltaic equipment are removed.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Degreasing-free punching cleaning oil for automobile steel plate, and preparation method thereof

ActiveCN106833846AImprove the lubrication effectNo hairNon-ionic surface-active compoundsOrganic detergent compounding agentsAntioxidantImpurity

The invention provides degreasing-free punching and cleaning oil for an automobile steel plate, and a preparation method thereof. The punching and cleaning oil comprises the following components: refined mineral oil, an extreme pressure antiwear additive, an antirust agent, a film-forming agent, an emulsifier, a dispersant, a surfactant and an antioxidant. The punching and cleaning oil integrates cleaning, punching and rust protection and can remove mechanical impurities form the surface of the steel plate when the steel plate is subjected to on-line cleaning and punching formation, and the antirust life of the cleaned steel plate can reach 3 months; the surface of the formed part is clean, does not have punching residues and does not need to be cleaned; a high lubricating property is achieved, the steel plate can be directly subjected to punching formation after being cleaned and does not need to be coated with oil special for punching formation; the residual oil on the surface of the cleaned and punched material piece does not need a degreasing procedure and can be removed through water washing, so the steel plate forming process is simplified, the use amount of punching oil, cleaning oil and a degreasing agent is reduced, energy conservation and environmental friendliness are achieved, and economic benefit is improved.

Owner:SHANGHAI PARKER CHEM IND

Method for detecting the load of items to be washed, and dishwasher machine

ActiveUS20100294311A1Increase clock frequencyProduced cost-effectivelyTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionImage detectionEngineering

A method for determining at least one of the type and the quantity of items to be washed in a dishwasher machine is provided for use with a dishwashing machine having a washing chamber in which the items are placed in receptacles for subsequent washing of the items during a dishwashing program with the respective disposition of the items in the receptacles constituting the load of the receptacles in the washing chamber of the dishwasher machine. The method includes detecting the load of the receptacles by an image detection system that measures distances in a non-contact manner by means of the speed of light such that the measured distances can be evaluated to obtain a three-dimensional image of the washing chamber.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Medicine applying instrument disinfecting and cleaning device for gynaecology and obstetrics

InactiveCN112108438AWash thoroughlyGuaranteed cleaning effectCleaning using toolsCleaning using liquidsEngineeringGynecology department

The invention specifically relates to a medicine applying instrument disinfecting and cleaning device for gynaecology and obstetrics. The medicine applying instrument disinfecting and cleaning devicefor gynaecology and obstetrics comprises a mounting bottom plate; a box body is fixedly arranged at the upper end of the mounting bottom plate; a mounting frame is arranged in a position, at the upperend of the mounting bottom plate, on the right side of the box body; a hydraulic air cylinder is arranged on the left side of the upper end of the box body in a penetrating mode; one end of the hydraulic air cylinder extends into the box body; a vibration motor is mounted at the bottom end of a hydraulic rod of the hydraulic air cylinder through a backing plate; and a high-temperature disinfection sealing cover is horizontally arranged at the bottom end of a hydraulic rod of a telescopic air cylinder. During using, the high-temperature disinfection sealing cover and a high-temperature sterilization and disinfection lamp are pushed by the telescopic air cylinder to move downwards to cover medical instruments; the medical instruments can be more completely sterilized in an oxidized mode byusing the high-temperature sterilization and disinfection lamp in the sterilization and disinfection stage to guarantee the thoroughness of sterilization and disinfection. The medicine applying instrument disinfecting and cleaning device for gynaecology and obstetrics has the advantages that the operation is simple and convenient, the cleaning and disinfecting use requirements of medicine applyinginstruments in the obstetrics and gynecology department are met, the effect is obvious, and the practicability is high.

Owner:王玲

Automatic medical examination blood smear dyeing machine

InactiveCN105021442AAchieve cleaningLarge negative pressure limitPreparing sample for investigationBiochemical engineeringUltimate tensile strength

The invention discloses an automatic medical examination blood smear dyeing machine. According to the invention, a substrate is fixed at the upper part of a frame; a test tube conveyer is arranged in the frame; a test tube suction unit is arranged at the upper part of the substrate; a slide glass conveyer is arranged on the substrate; a sample smearing unit is connected with the slide glass conveyer; a dyeing device is connected with a sample picture device; a controlling unit is arranged on the substrate; a cleaning device is arranged on the test tube suction unit; a waste liquid gathering device is arranged at the lower part of the test tube suction unit; a printing unit is arranged on the substrate; and a network transmission unit is arranged in the controlling unit. The automatic medical examination blood smear dyeing machine can automatically complete operations like uniform mixing and sampling of a blood sample, automatically realizes cleaning via the cleaning device and overcomes the problems of great labor intensity, low detection efficiency, difficulty in guaranteeing smear dyeing quality and the like due to manual or partially machine-aided implementation of the operations in conventional medical examination mechanisms.

Owner:QINGDAO UNIV

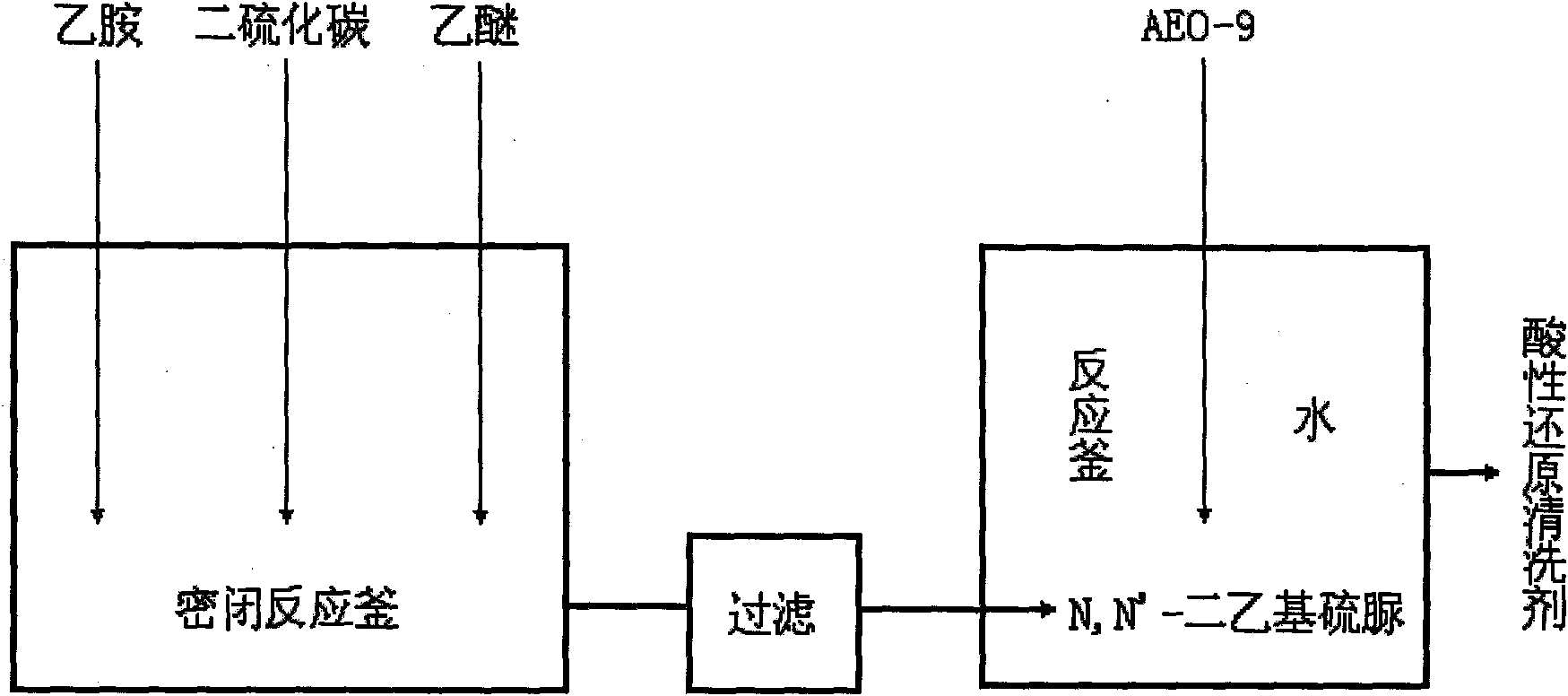

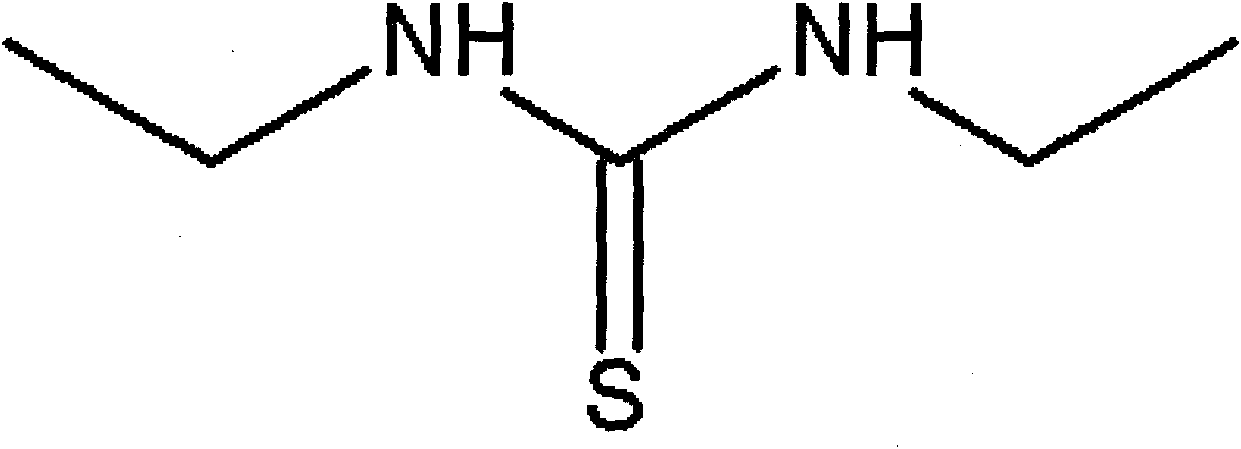

Acidic reduction cleaner

The invention relates to a printing and dyeing assistant for carrying out reduction cleaning on dyed polyester fabrics under acidic condition. Ethylamine reacts with carbon disulfide to generate N,N'-diethyl thiourea, and the N,N'-diethyl thiourea is compounded with fatty alcohol-polyoxyethylene ether to form an acidic reduction cleaner. In the process of reduction cleaning, the N,N'-diethyl thiourea is quickly in contact with the floating color of disperse dyes attached to fabric surfaces under the assistance of the fatty alcohol-polyoxyethylene ether to reduce carbonyl groups, ether bonds and other structures into hydrophilic hydroxyl groups, so that the floating color can be dissolved into water to be cleaned. Residual dyes in a dye bath and the cleaned floating color can also be reduced by the N,N'-diethyl thiourea for losing the capacity of secondary staining. On the premise of ensuring the cleaning effect, the invention can omit the steps of acid cleaning, water cleaning and the like, and the cleaning process can be directly carried out without discharging residual liquid when the dyeing rate of dyes is higher.

Owner:何鹰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com