Method for cleaning capsule beverage dispenser

A beverage machine and capsule technology, which is applied to the cleaning field of capsule beverage machines, can solve problems such as inability to guarantee cleanliness, adjustment, and inability to achieve ideal cleaning effects, and achieves the effect of increasing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

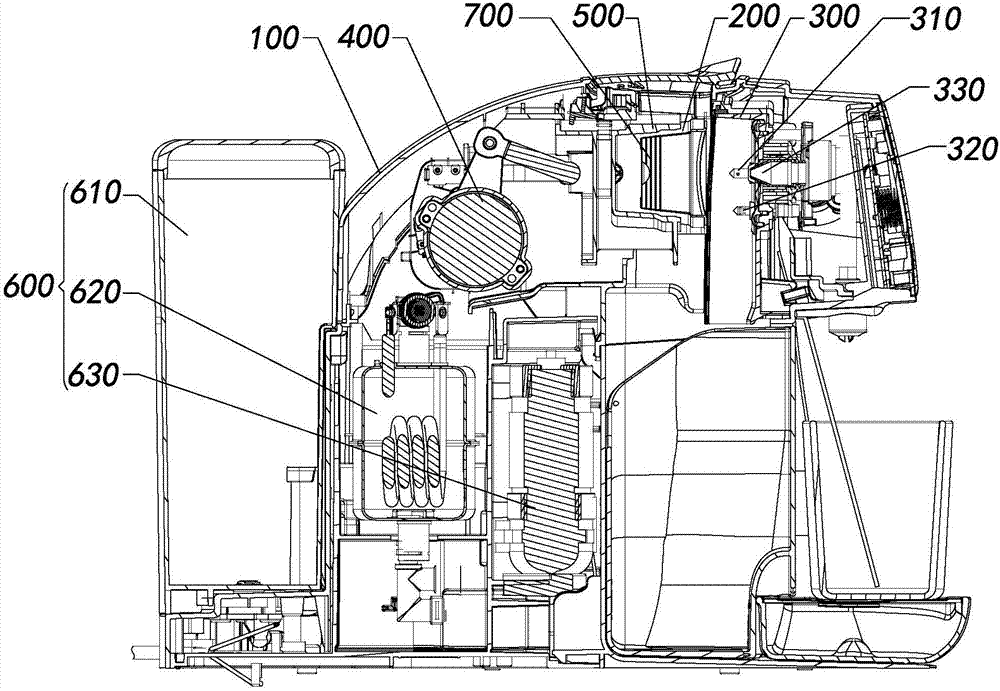

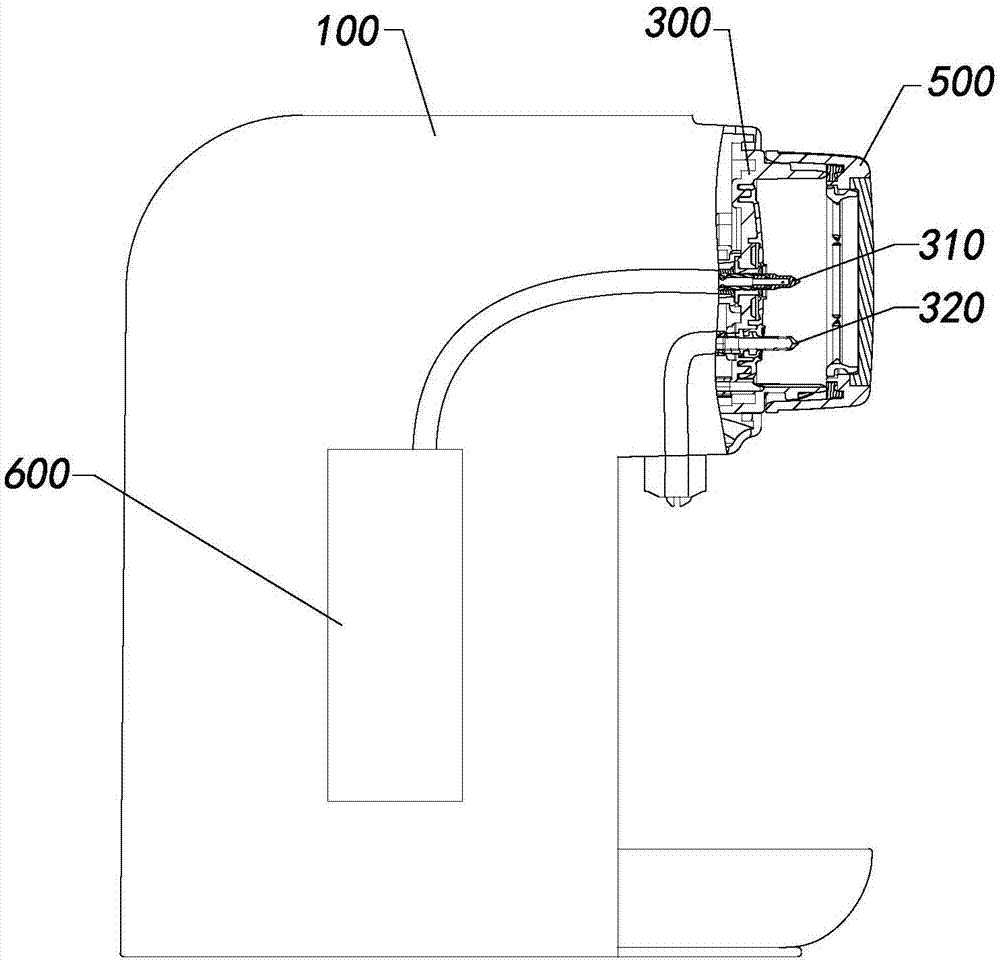

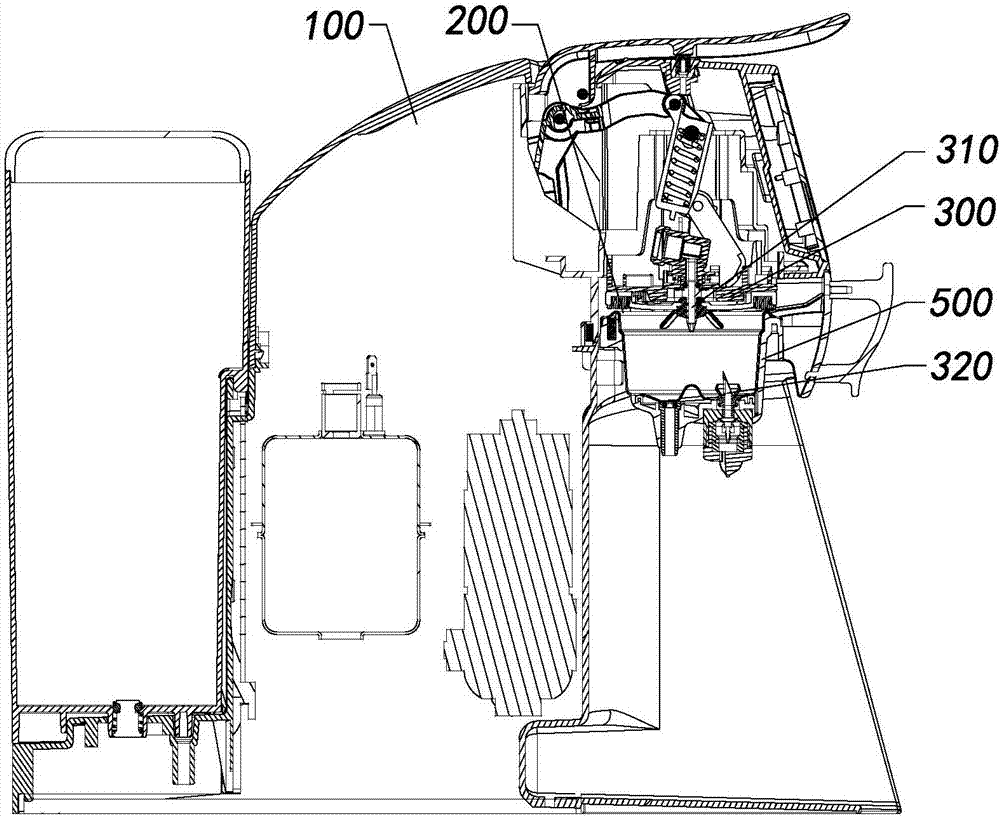

[0046] refer to figure 1 , the cleaning method of the capsule beverage machine proposed in Embodiment 1 of the present invention, the capsule beverage machine includes a machine base 100 with a brewing chamber 200, a liquid supply mechanism 600, an input module and a control module, and the control module controls the capsule beverage according to the signal of the input module Machine cleaning, cleaning methods include:

[0047] The first cleaning stage includes at least a first water washing step in which the liquid supply mechanism 600 introduces liquid into the brewing chamber 200 with the first power P1 for cleaning, and

[0048] The second cleaning stage that can be selected at least includes the second water washing step in which the liquid supply mechanism 600 introduces liquid into the brewing chamber 200 with the second power P2 for cleaning,

[0049] The rated power of the liquid supply mechanism 600 is PE1, where P1

[0050] Specifically: the capsule beve...

Embodiment 2

[0074] The capsule beverage machine described in this embodiment is basically the same as the first embodiment, but an air supply mechanism is added on the basis of the first embodiment, and the air supply mechanism can be various known components that can provide high-pressure air sources. For example, an air pump is preferred, and air blowing steps are introduced in the first cleaning stage and the second cleaning stage (both the cleaning liquid and the cleaning air are introduced into the brewing chamber through the water-inlet puncture needle), so as to further improve the cleaning quality of the brewing chamber. Reduces liquid residue in the brewing chamber.

[0075] Taking brewing soybean milk as an example, the specific cleaning method is as follows:

[0076] According to the detection signal of the input module, the control module determines that the capsule beverage machine has executed the soymilk brewing procedure last time, and thus selects the following cleaning s...

Embodiment 3

[0093] The difference between this embodiment and Embodiment 1 or Embodiment 2 is that the capsule beverage machine also includes an operation panel, and the operation panel is provided with a cleaning button. The cleaning button can be a mechanical button or a touch button, and the cleaning button is pressed The capsule beverage machine can be triggered to execute the cleaning program. Therefore, in this embodiment, the input module is the above-mentioned cleaning button, and the control module selects the corresponding cleaning method according to the button signal of the input module. This design allows the user to choose the capsule according to actual needs. The cleaning program of the beverage machine can satisfy the pleasure of manual operation of some users. For example: two cleaning buttons are set on the operation panel of the capsule beverage machine, which are the normal cleaning button and the powerful cleaning button. If the user presses the normal cleaning button...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com