Patents

Literature

1447results about How to "Achieve cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

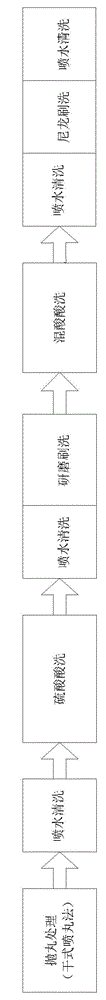

Method for removing scales on surface of hot-rolled stainless steel strip

InactiveCN102719831AAchieve mechanical picklingReduce consumptionWork treatment devicesMetal rolling arrangementsHydrofluoric acidAbrasive blasting

The invention discloses a method for removing scales on the surface of a hot-rolled stainless steel strip. The method comprises the following steps of: performing abrasive blasting treatment on the hot-rolled stainless steel strip to be treated, wherein the abrasive blasting treatment refers to spraying of mixed slurry of water and an abrasive material, and the percent by volume of the abrasive material in the slurry is 30%-40%; after the abrasive blasting treatment, performing primary grinding and scrubbing on the steel strip; after the primary grinding and scrubbing, performing acid-washing on the steel strip with diluted sulphuric acid; cleaning the steel strip subjected to acid-washing by the diluted sulphuric acid by water, and then performing secondary grinding and scrubbing on the steel strip; after the secondary grinding and scrubbing on the steel strip, performing acid-washing on the steel strip with mixed acid of nitric acid and hydrofluoric acid; and after the acid-washing with the mixed acid, cleaning the steel strip with water, then performing third grinding and scrubbing on the steel strip, and finally, washing the steel strip with water. With the slurry spraying technique, as the abrasive material is mixed with the water, the scales on the surface of the hot-rolled stainless steel strip can be removed more effectively; and the consumption quantity of acid in subsequent steps is greatly reduced.

Owner:WISDRI ENG & RES INC LTD

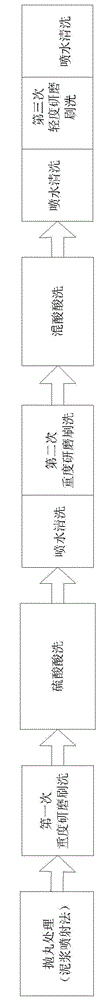

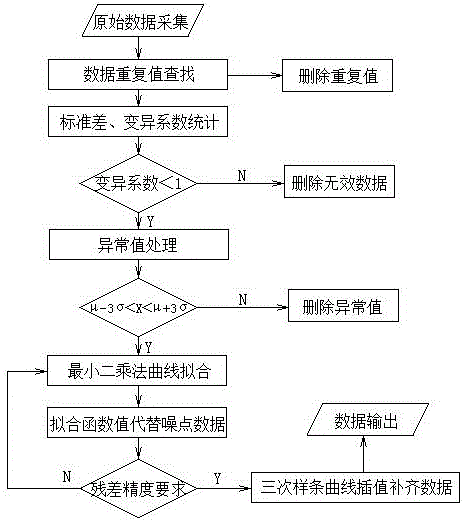

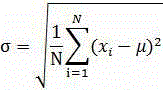

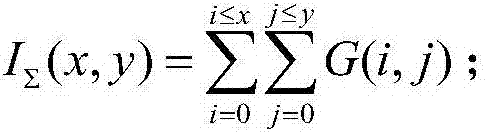

Time-series data cleaning method for pipe net modeling

InactiveCN106649579AAchieve cleaning effectReduce decreaseSpecial data processing applicationsArray data structureMissing data

The invention discloses a time-series data cleaning method for pipe net modeling. The time-series data cleaning method for the pipe net modeling comprises the steps of searching and elimination of duplicate values, data dispersion degree analysis, judgment of outliers, denoising noisy points of curve smoothing, interpolation completion of missing data. The time-series data cleaning method for the pipe net modeling introduces variation coefficient to achieve standardization processing of pressure information and flow data of different dimensions, judges the dispersion degree of arrays and screen the dispersion degree of arrays at the same time. The time-series data cleaning method for the pipe net modeling is characterized in that outlier data at first is searched and processed by a utilizing three times standard deviation method and then is fitted by a least square method, which greatly reduces the effects of outliers on fitting results. At the same time, data smoothing of the noisy points is processed by fitting functions, which can further reduce the presence of outlier data. The least square method can satisfy the data processing which does not conform to the normal distribution. Compared with linear interpolation, cubic spline interpolation utilized in the end can make the data inserted more smooth. The time-series data cleaning method for the pipe net modeling has the advantages of preprocessing the data before the data is imported into a model for calculation, achieving the effect of data cleaning, and providing a guarantee for the calculation of the model.

Owner:苏州航天系统工程有限公司

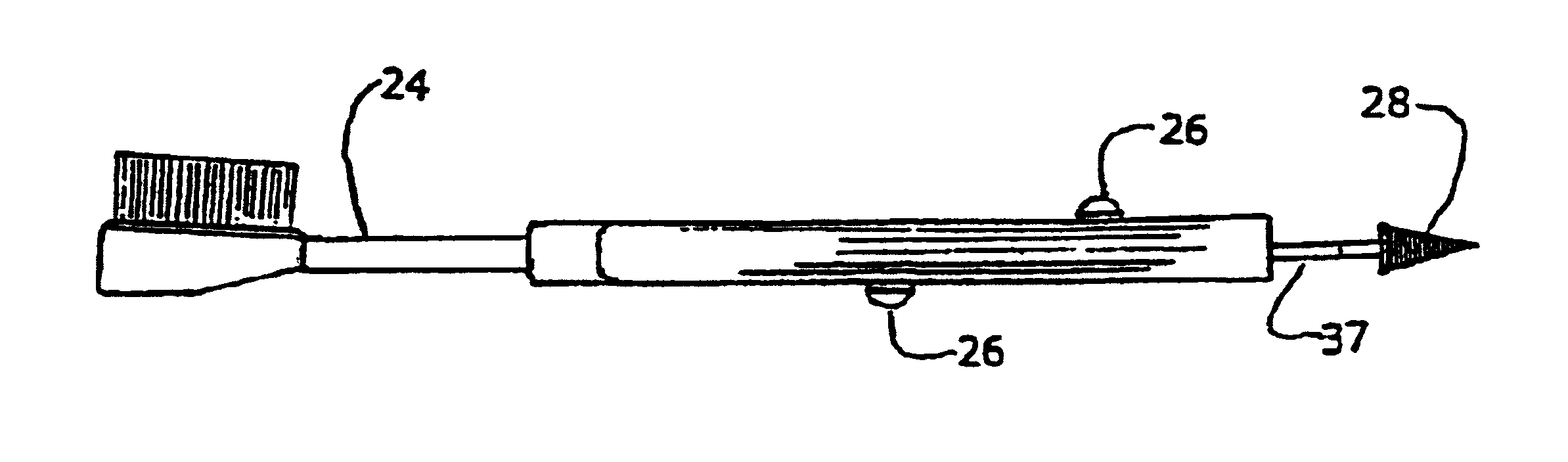

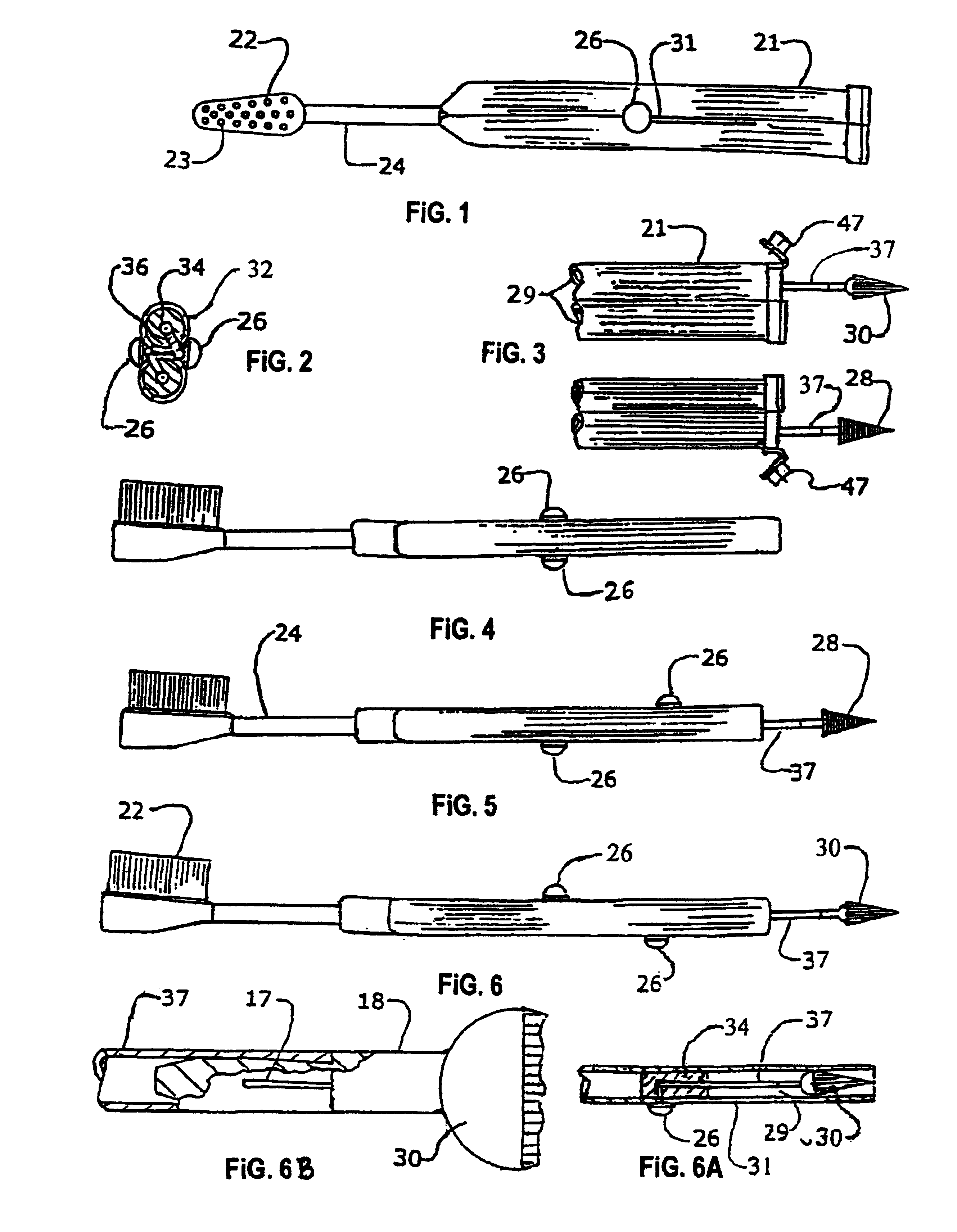

Triple clean toothbrush

A toothbrush that provides, besides the conventional bristles for brushing the teeth, other basic periodontal components recommended by dentists for perfect cleaning, massaging and stimulating the gum tissue, all in one single, convenient artifact. The brush component is molded into one end of the handle, in conventional manner, and the opposite end of the handle contains two parallel cylinders for housing the two periodontal tools which are extended and retracted with buttons, one on each side of the handle, through a slit in each cylinder wall, establishing a means for this movement. The buttons engage two sliders, the ends of each hold extension tubes that capture and retain the dental tools and provide replacement capabililty. Each cylinder contains a hinged close-out cover for protection of the periodontal tools from contamination and loss of the cover.

Owner:CABEDO DESLIERRES MARIA R +1

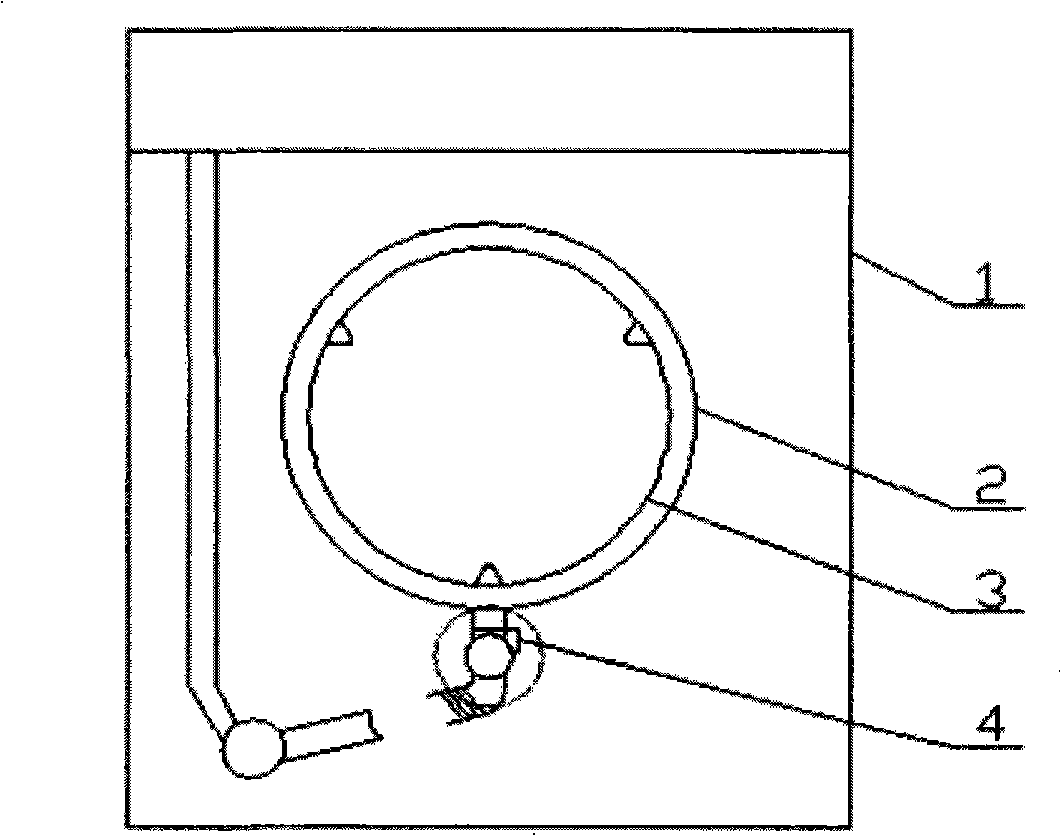

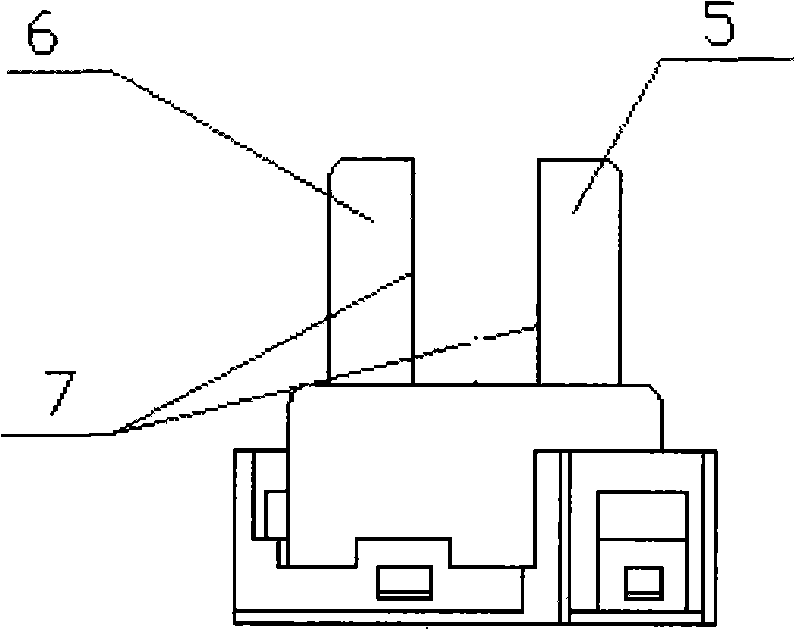

Judgment method of start-up washing machine self-cleaning program

InactiveCN101358421AReflects the degree of accumulated dirtThe judgment result is accurateOther washing machinesControl devices for washing apparatusState of artStart up

The invention discloses a method for determining to start a washing machine automatic cleaning program, which comprises the following steps: an initial value of muddy degree is set for the washing machine; afterwards, every time before or after washing, when the water drainage pipe has no water, the detected value of a muddy degree sensor is recorded as the current value of muddy degree; when the difference of the current value of muddy degree and the initial value of muddy degree is more than the preset threshold of starting the automatic cleaning program, the startup of the automatic cleaning program is determined; the user is reminded to start the automatic cleaning program of the machine starts the automatic cleaning program automatically. Compared with the prior art, the device uses the muddy degree sensor that the prior full automatic washing machines are commonly equipped with to obtain the changes of the detected value of the muddy degree sensor, and the changes are considered as the determining conditions for the need of starting the automatic cleaning program. Through the method, no device needs to be added for the washing machine, so that quite accurate determination results can be obtained, and the automatic cleaning program can be started appropriately.

Owner:HAIER GRP CORP +1

Method for cleaning quartz parts surface in polycrystal etching cavity

InactiveCN101219429AMeet the requirements of normal processAchieve cleaning effectDrying solid materials with heatDrying solid materials without heatOrganic solventMegasonic cleaning

The invention relates to a cleaning method for cleaning quartz part surface in a polycrystal etching chamber, and the core of the method is that ionized water is adopted to clean the quartz part surface and clean high pressure air is applied to blowing and drying the surface of the quartz part; then at least an organic solvent is adopted to clean the quartz part surface and next alkali solvent is used for cleaning the surface which is followed by acid solvent; finally ultrasonic wave is adopted to clean the quartz part. Through the cleaning steps the deposited dirt on the quartz part surface can be removed. By adopting the technique in the cleaning of the quartz part surface which is used for a period of time in the polycrystal etching chamber, the contamination can be completely removed without any damage to the quartz part surface and the quartz part after being cleaned can fully meet the normal technique requirements.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

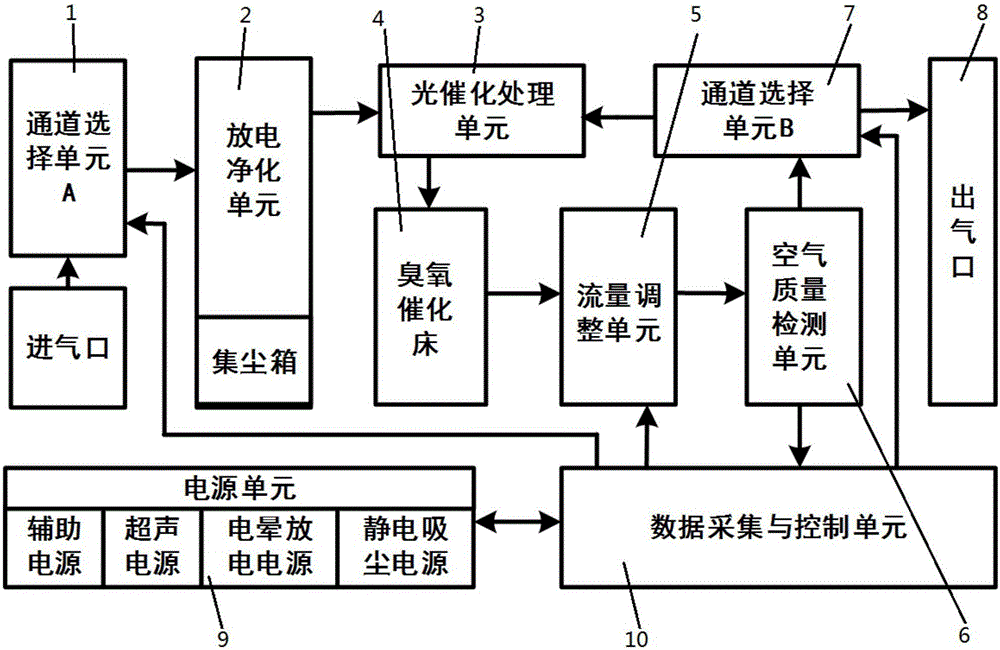

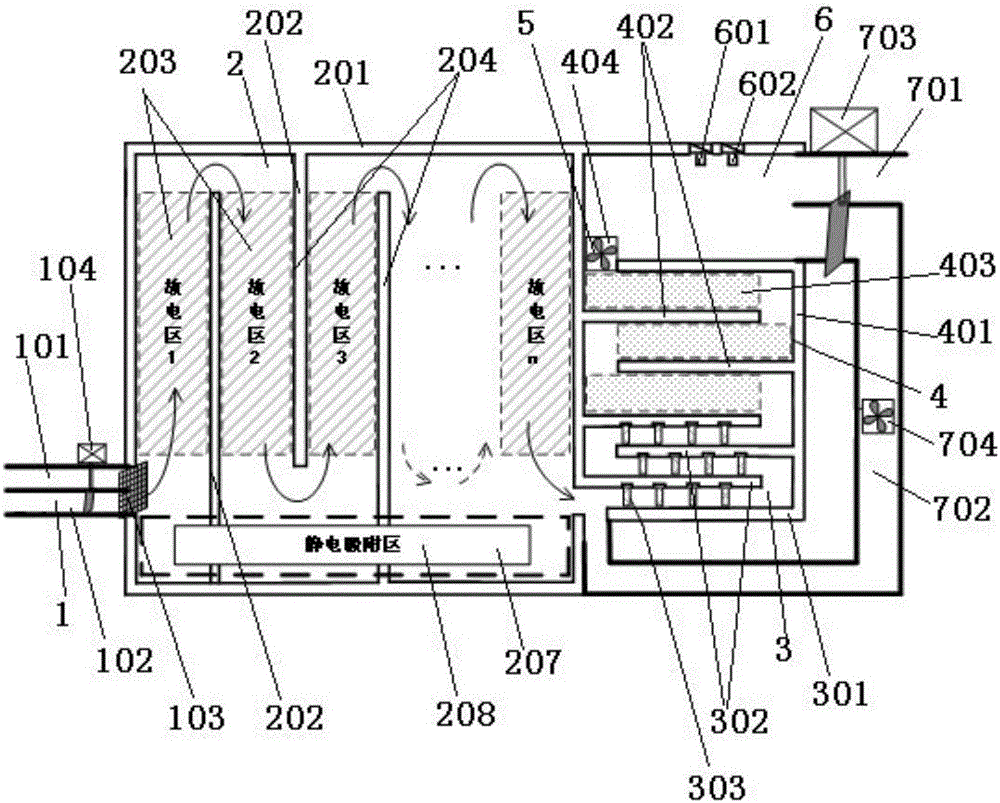

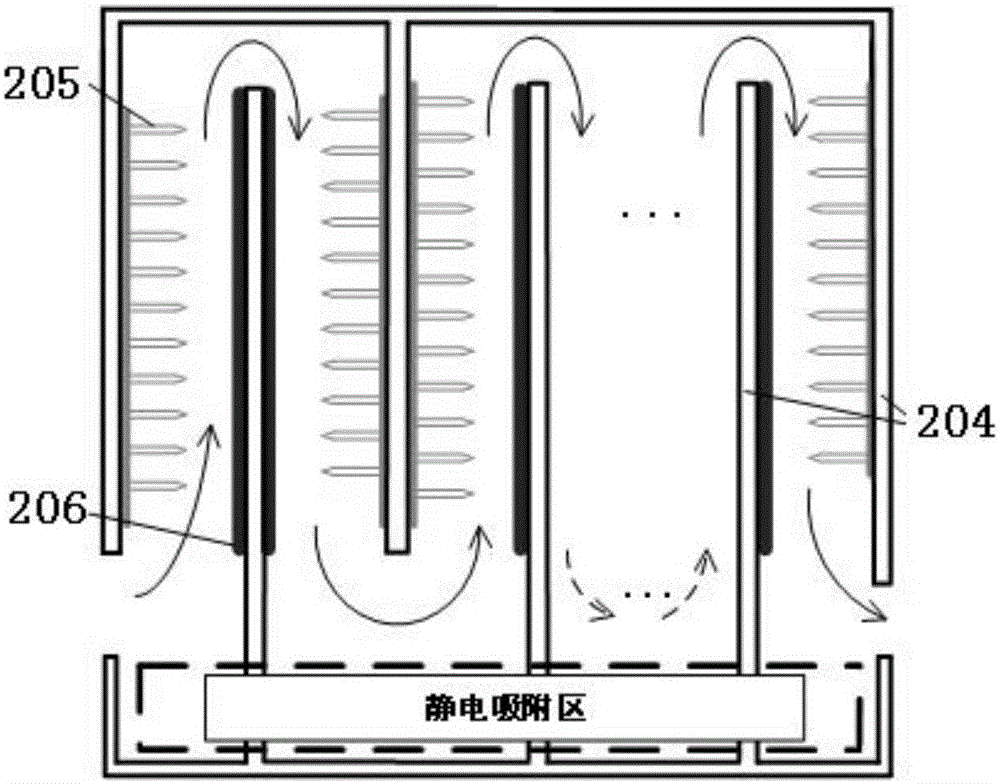

Air purification device adopting cooperation of plasma, ultrasonic technology and catalysis

ActiveCN105003981AAchieve purificationImprove purification efficiencyMechanical apparatusLighting and heating apparatusSolid particleUltrasonic technology

The invention discloses an air purification device adopting cooperation of plasma, an ultrasonic technology and catalysis. The air purification device is characterized by comprising a channel selection unit A (1), wherein an air outlet of the channel selection unit A (1) is connected with an air inlet of a discharge purification unit (2), an air outlet of the discharge purification unit (2) is connected with an air inlet of a photocatalytic processing unit (3), an air outlet of the photocatalytic processing unit (3) is connected with an air inlet of an ozone catalyst bed (4), an air outlet of the ozone catalyst bed (4) is connected with an air inlet of a flow adjusting unit (5), and an air outlet of the flow adjusting unit (5) is connected with an air inlet of an air quality detection unit (6). The air purification device adopting cooperation of the plasma, the ultrasonic technology and the catalysis uses the plasma, the ultrasonic technology and the catalysis technology to purify air and can purify poisonous gas and solid particles in the air quickly and efficiently and realize sterilization.

Owner:HOHAI UNIV CHANGZHOU

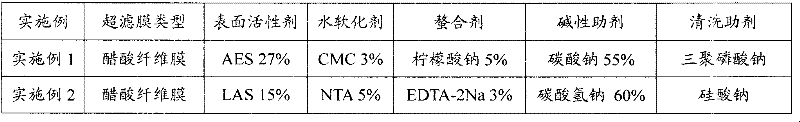

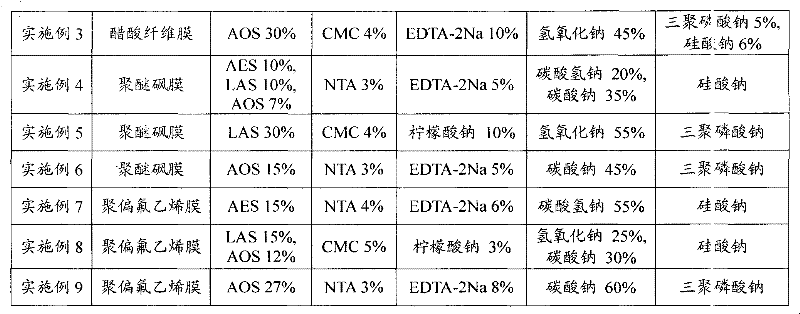

Ultrafiltration membrane alkaline cleaner

InactiveCN102343217AReasonable formulaImprove cleaning qualitySemi-permeable membranesUltrafiltrationChemistry

The invention discloses an ultrafiltration membrane alkaline cleaner which is suitable for cleaning an ultrafiltration membrane used by filtering gulonic acid mash. The alkaline cleaner comprises the following components in percent by mass: 15-30 percent of surfactant, 3-5 percent of water softening agent, 3-10 percent of chelant, 45-60 percent of alkali assistant and 5-15 percent of cleaning aid. According to the ultrafiltration membrane alkaline cleaner, the cleaning steps can be simplified, the cleaning cost is reduced, the corrosion to equipment is lightened, and the pollution of cleaning waste liquid to the environment can be reduced.

Owner:HEBEI XIETONG ENVIRONMENTAL PROTECTION TECH CO LTD

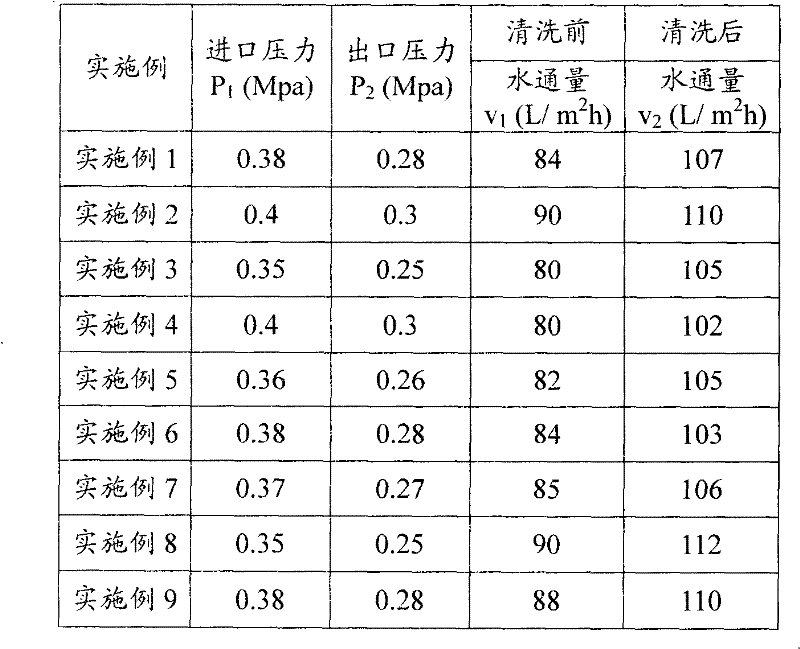

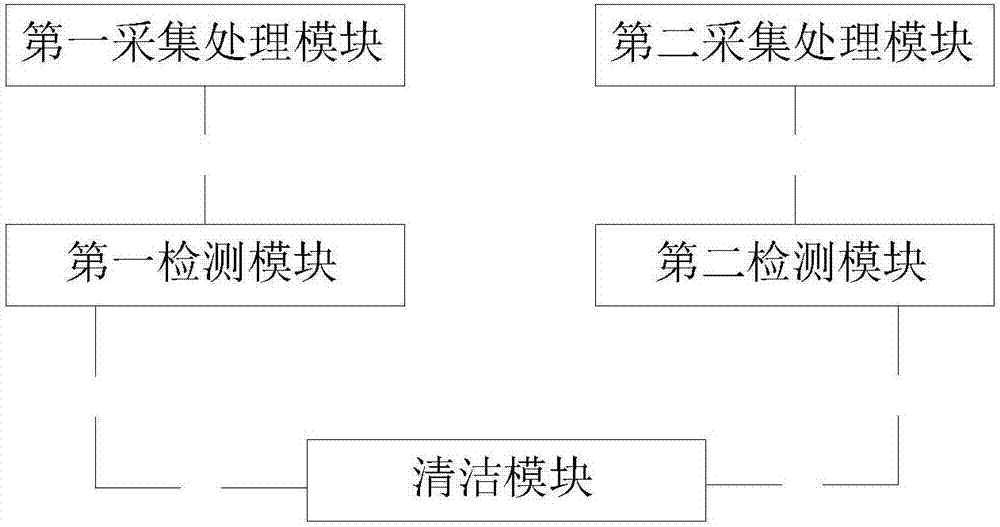

Method and system for automatic detection and cleaning of dirt based on intelligent closestool

ActiveCN106894481AAvoid dirty cleaningGuaranteed pertinenceLavatory sanitoryCharacter and pattern recognitionComputer scienceAutomatic testing

The invention discloses a method and system for automatic detection and cleaning of dirt based on an intelligent closestool. The method includes the following steps that 1, image information of the inside of the closestool is collected, according to the collected image information of the inside of the closestool, regional division is conducted, gray-scale processing is conducted on the image information of the inside of the closestool, according to the gray-scale processing result, the dirt in the closestool is detected, and the region where the dirt is located is positioned; 2, the region where the dirt is located is cleaned through a cleaning device; 3, after cleaning is completed, the image information of the inside of the closestool is collected again, and the gray-scale processing is conducted on the image information of the inside of the closestool again; 4, according to the gray-scale processing result obtained in the step 3, whether dirt exists in the closestool or not is judged, if no, cleaning is stopped, if yes, the region where the dirt is located is positioned, and the step 2 is repeated until the gray-scale processing result obtained in the step 3 shows that no dirt exists in the closestool.

Owner:杨徐子谦

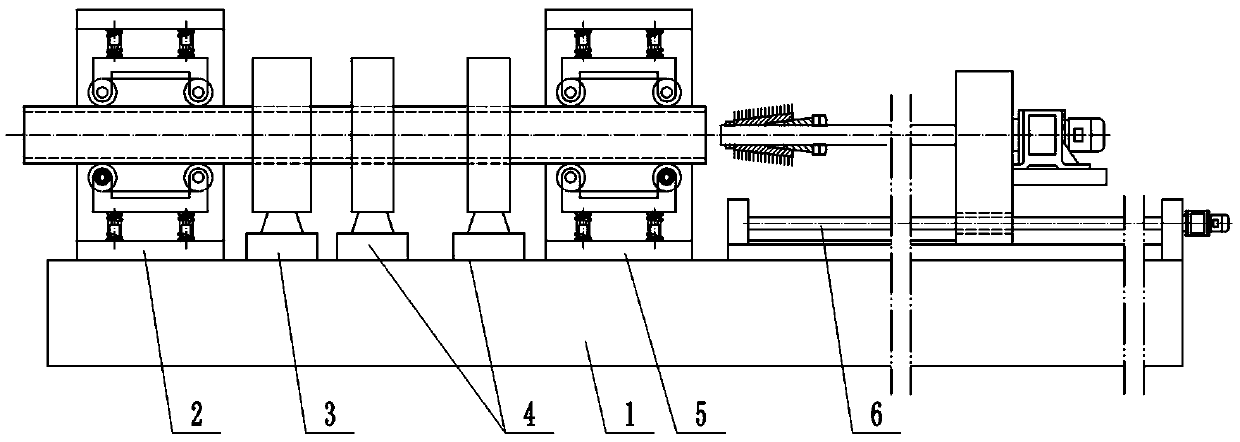

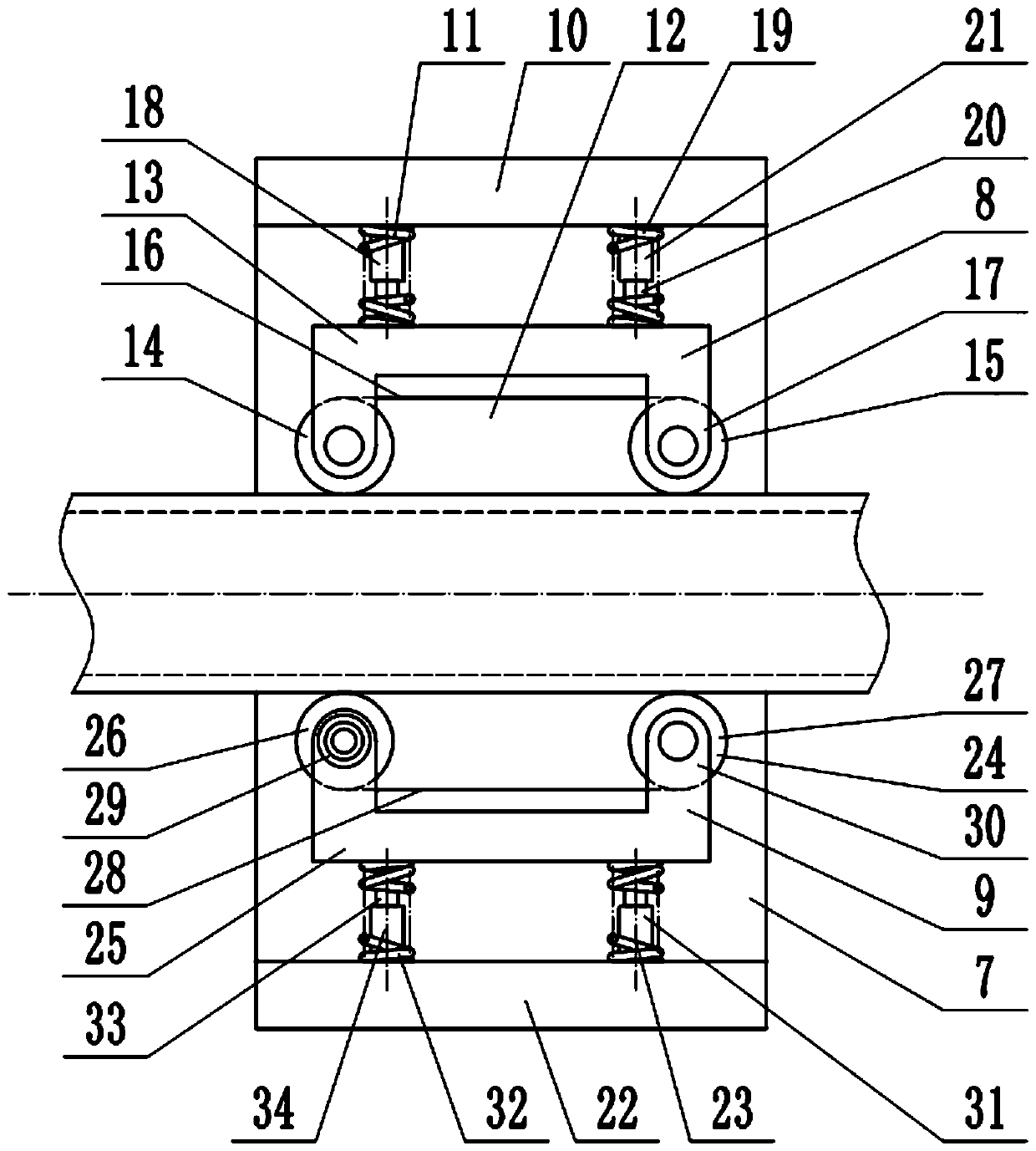

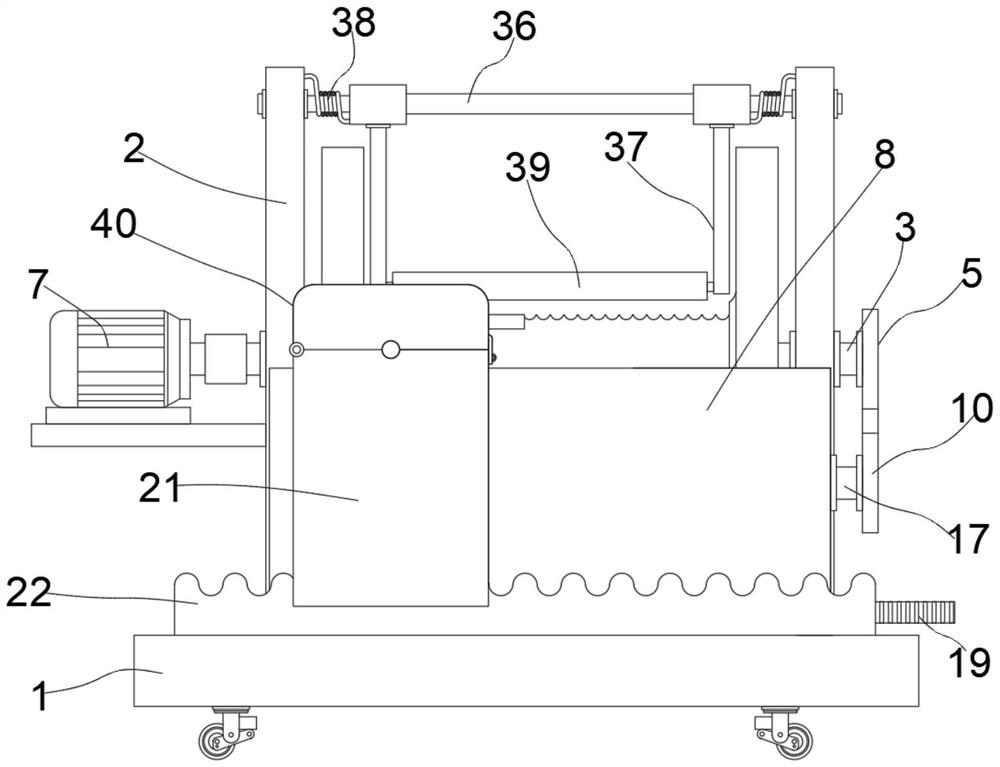

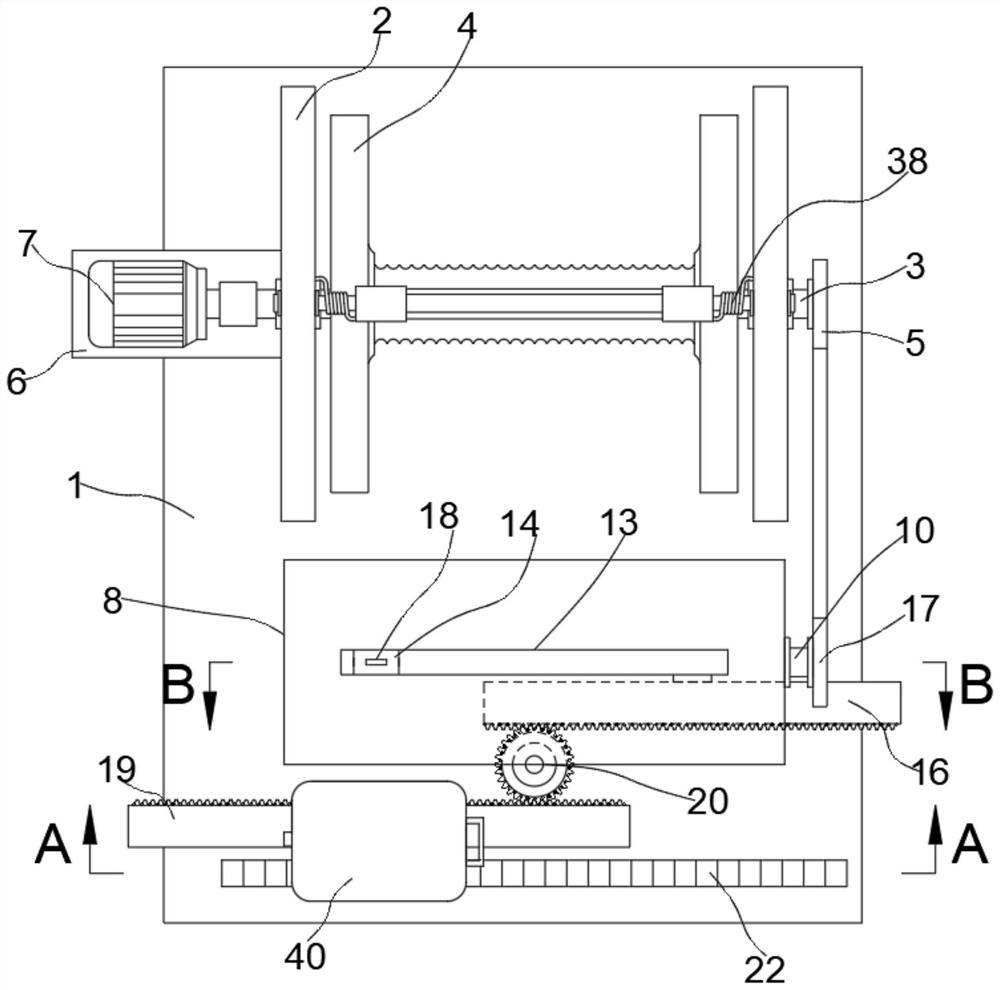

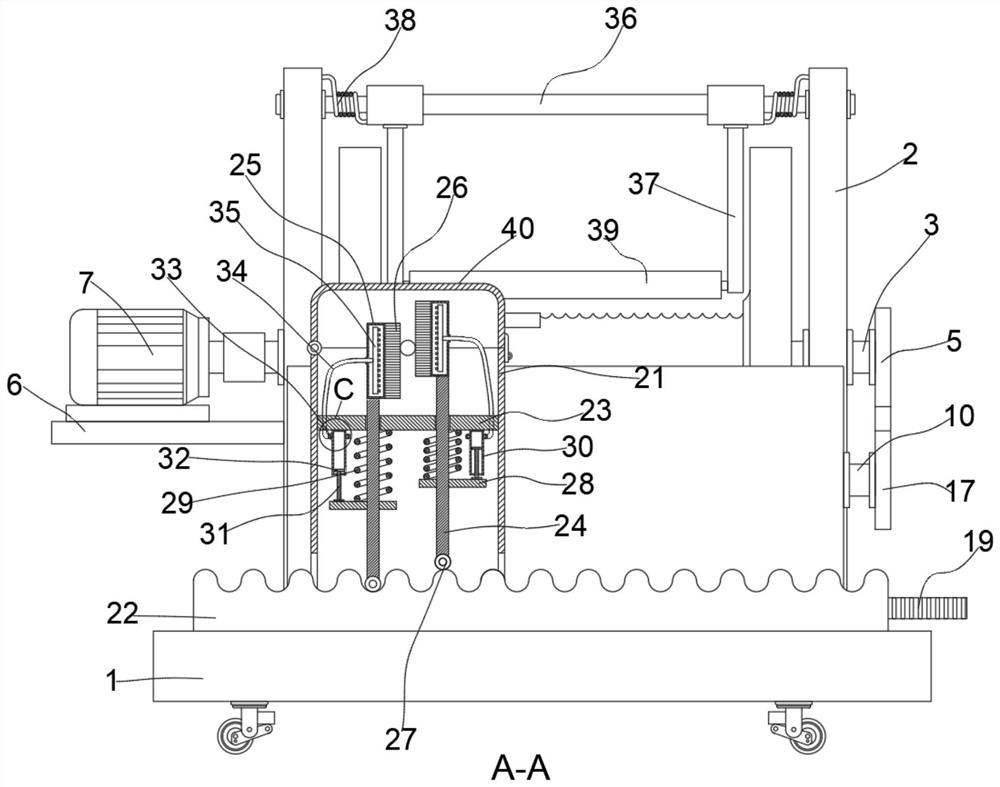

Steel pipe inner and outer wall cleaning machine

ActiveCN110788086AEasy to cleanFavorable delivery orientationHollow article cleaningConveyor partsSteel tubeBuilding material

The invention provides a steel pipe inner and outer wall cleaning machine, and belongs to the technical field of building materials. The steel pipe inner and outer wall cleaning machine comprises a cleaning machine base, a feeding and conveying component, an outer wall cleaning component, a centering and guiding component, a discharging and conveying component and an inner wall cleaning component.The feeding and conveying component, the outer wall cleaning component, the centering and guiding component, the discharging and conveying component and the inner wall cleaning component are all arranged on the cleaning machine base and are arranged from left to right in sequence. According to the steel pipe inner and outer wall cleaning machine, the outer wall of a steel pipe is firstly cleaned,then the inner wall of the steel pipe is cleaned with the cleaned outer wall of the steel pipe as the standard, the cleaning effect of the inner wall of the steel pipe is especially good, and use ofa subsequent formed pipeline is convenient; and dust, rust blocks and other impurities on the inner wall and the outer wall of the steel pipe are effectively removed in a physical manner, and liquid in the subsequent formed pipeline cannot be contaminated.

Owner:SUZHOU YUQIAN INFORMATION TECH CO LTD

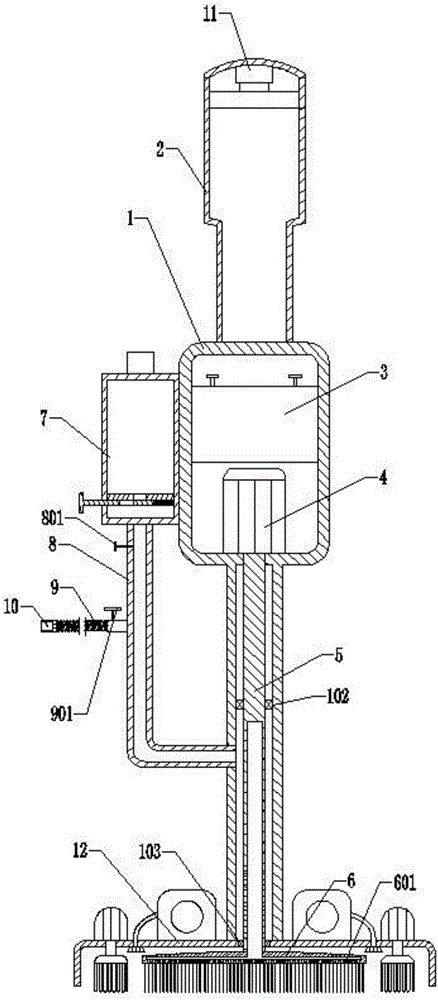

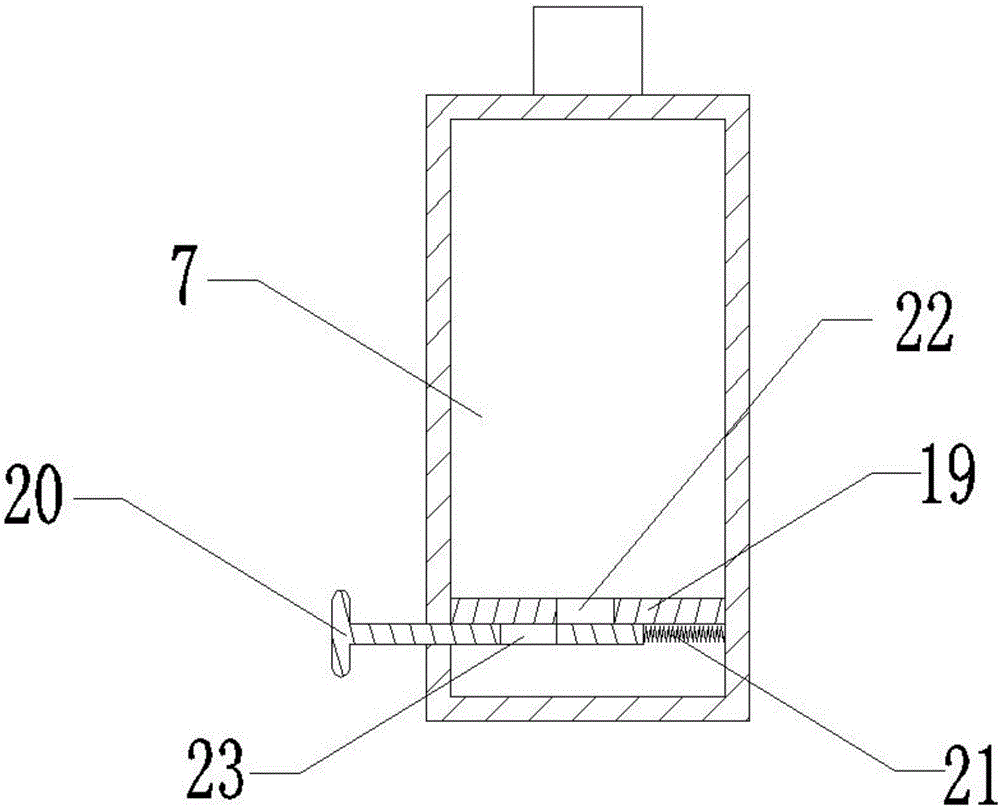

Bathroom electric cleaning device

InactiveCN105919520AAchieve cleaning effectPrevent falls, etc.Carpet cleanersBrush bodiesElectric machineryEngineering

The invention discloses a bathroom electric cleaning device which comprises a long rod, a handle, a storage battery, a motor, a rotating shaft, a hairbrush, a cleaning agent storing box, a water pipe, a corrugated pipe, a connector, a switch button, a protection cover, a second motor, a second rotating shaft, a second hairbrush, a dryer, a pipeline, a drying head, a fixing plate, a sliding plate, a spring, a first filtering hole and a second filtering hole. The bathroom electric cleaning device is simple in structure and powerful in function; the motors when being turned on drive the hairbrushes to clean a floor, so that cleaning by workers is replaced, and labor is reduced; the floor is flushed by a cleaning agent and water while the hairbrushes are in friction with the floor, so that consumption of the cleaning agent and the water is reduced, and cost is saved.

Owner:YANGTZE UNIVERSITY

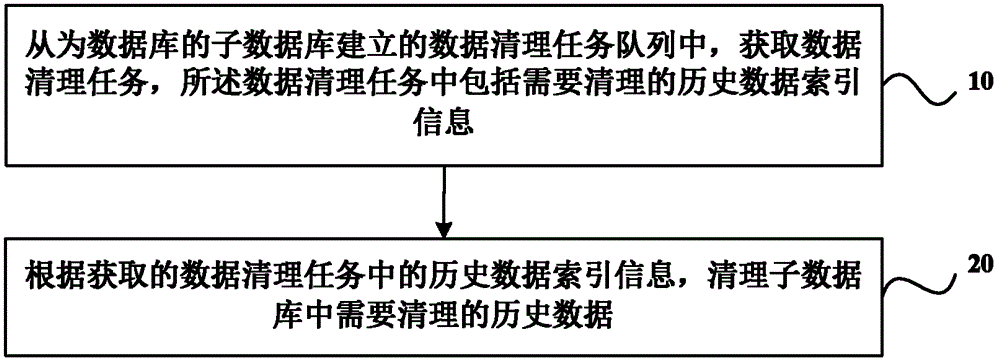

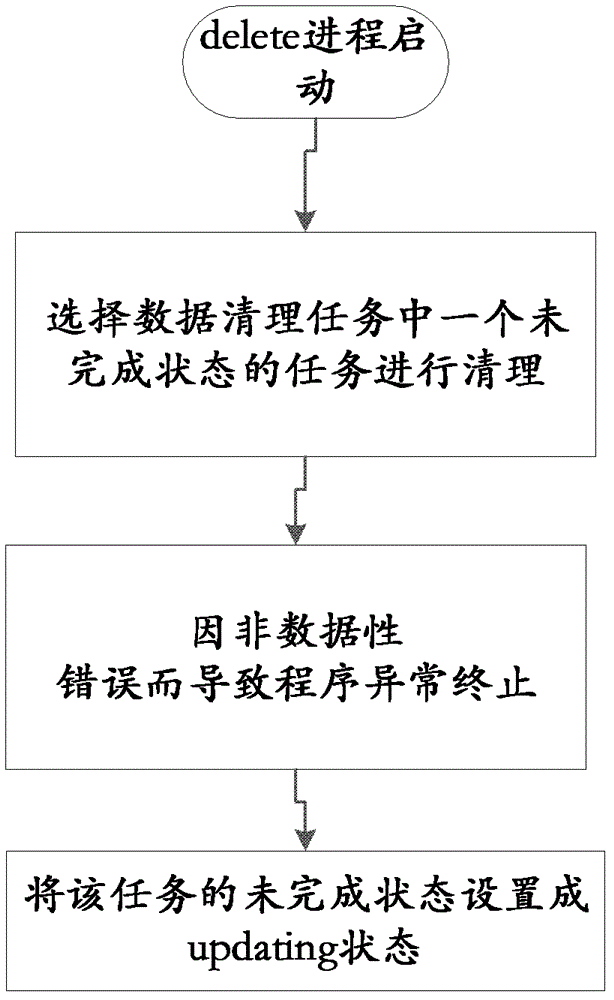

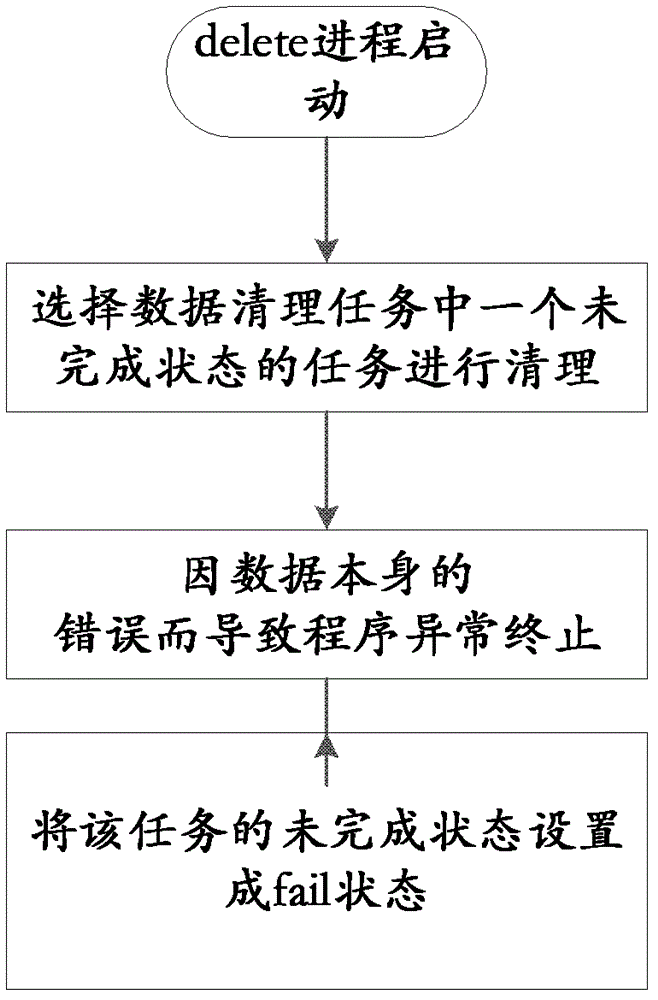

Method of cleaning database history data and system thereof

The invention discloses a method of cleaning database history data and a system of the method of cleaning the database history data. The method of cleaning the database history data includes the following steps: obtaining a data cleaning task from a data cleaning task queue established by a sub-data base of the database, wherein the data cleaning task comprises history data index information needing cleaning, the data base is divided into more than two sub-data base, and each sub-data base of all the sub-data base corresponds to the data cleaning task queue established by each sub-data base; cleaning history data needing cleaning in the database according to the obtained history data index information of the data cleaning task. Due to the technical scheme, efficiency of cleaning the data is improved.

Owner:ADVANCED NEW TECH CO LTD

Method for manufacturing easy-to-clean artificial leather

ActiveCN102851994AGood anti-pollutionAchieve cleaning effectPattern makingSynthetic resin layered productsPolyvinyl chlorideSolvent

The invention discloses a method for manufacturing easy-to-clean artificial leather. The method comprises stirring 100 parts of a polyvinyl chloride resin, 30-50 parts of a plasticizer, 30-50 parts of a filler, 0.5-1 part of a lubricant, 2-5 parts of a heat-resistant stabilizer, 3-5 parts of a pigment, 30-50 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent, or 100 parts of a polyurethane resin, 10-50 parts of a solvent, 10-50 parts of a filler, 3-5 parts of a pigment, 1-5 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent in a high-speed dispersing mixer at 120-130 DEG C for 150-250 s, mixing, milling, calendering, base bonding or coating to form a semifinished product, and performing surface treatment and hot pressing on the semifinished product. The surface of the product manufactured by the inventive method has excellent anti-contamination effects, and contaminants on the surface of the manufactured product can be cleaned by wiping through common base cloth, without destroying the surface effects of the product.

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

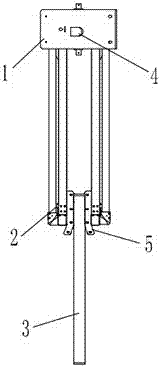

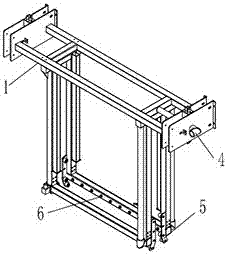

Mud scraping device in sewage treatment equipment

PendingCN107042027AAchieve cleaning effectEasy to cleanFiltration separationEngineeringSewage treatment

The invention discloses a mud scraping device in sewage treatment equipment. The mud scraping device comprises a lifting frame and two sets of mud scraping devices located at the lower end of the lifting frame, wherein the two sets of mud scraping devices are located at two sides of a vertically arranged to-be-cleaned filter plate separately; the mud scraping devices lift along with the lifting frame at the same time; a square frame plate formed by inclined edges and straight edges is arranged in the filter plate; a boss is arranged on the surface of the frame plate; a rotatable and telescopic scraper blade is arranged on each mud scraping device; each scraper blade is always matched with the irregular surface of the filter plate; a water spray device is also arranged on the lifting frame and communicates with a water inlet pipe located at one side of the lifting frame; and the water spray device is matched with the mud scrapping devices to spray and clean the filter plate. Aiming at the defects of the prior art, each scraper blade is partitioned, and propulsion and rotation control of each block are individually controlled, so that efficient cleaning on a polygonal filter plate or a non-flat filter plate is achieved through coordination with the water spray device, thereby improving the operation efficiency.

Owner:广州铭远机械设备有限公司

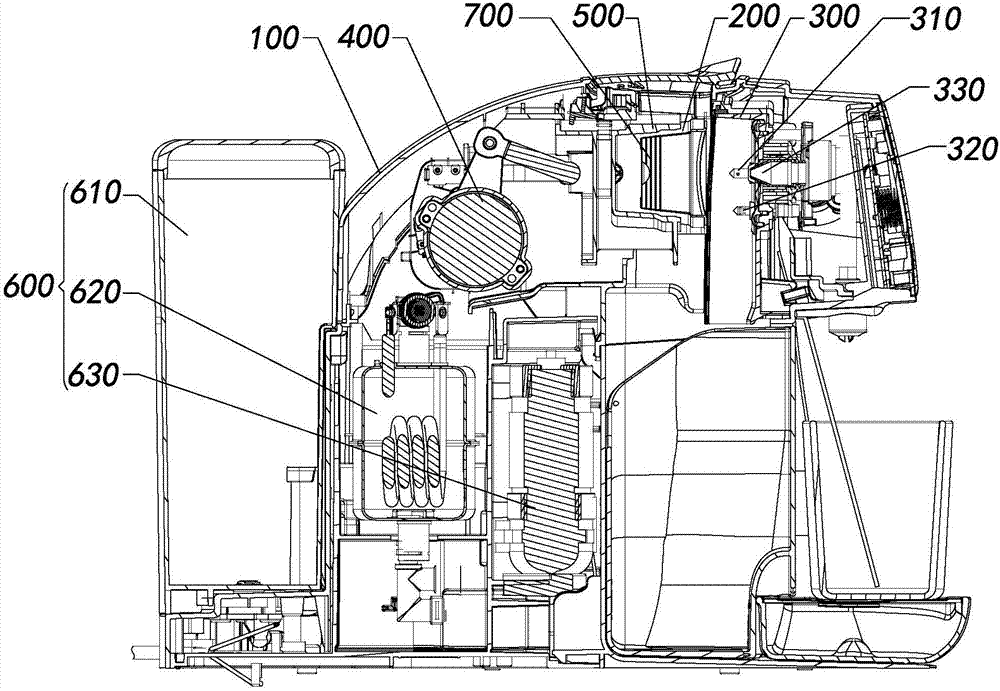

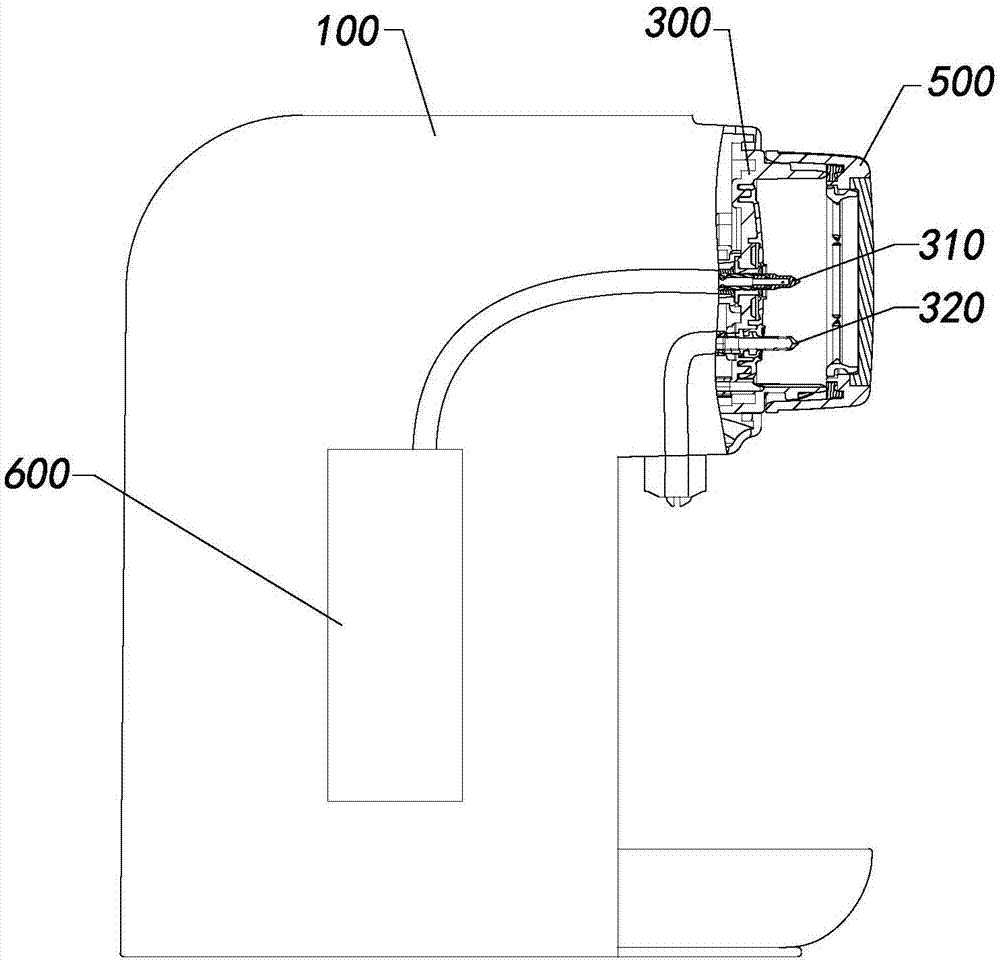

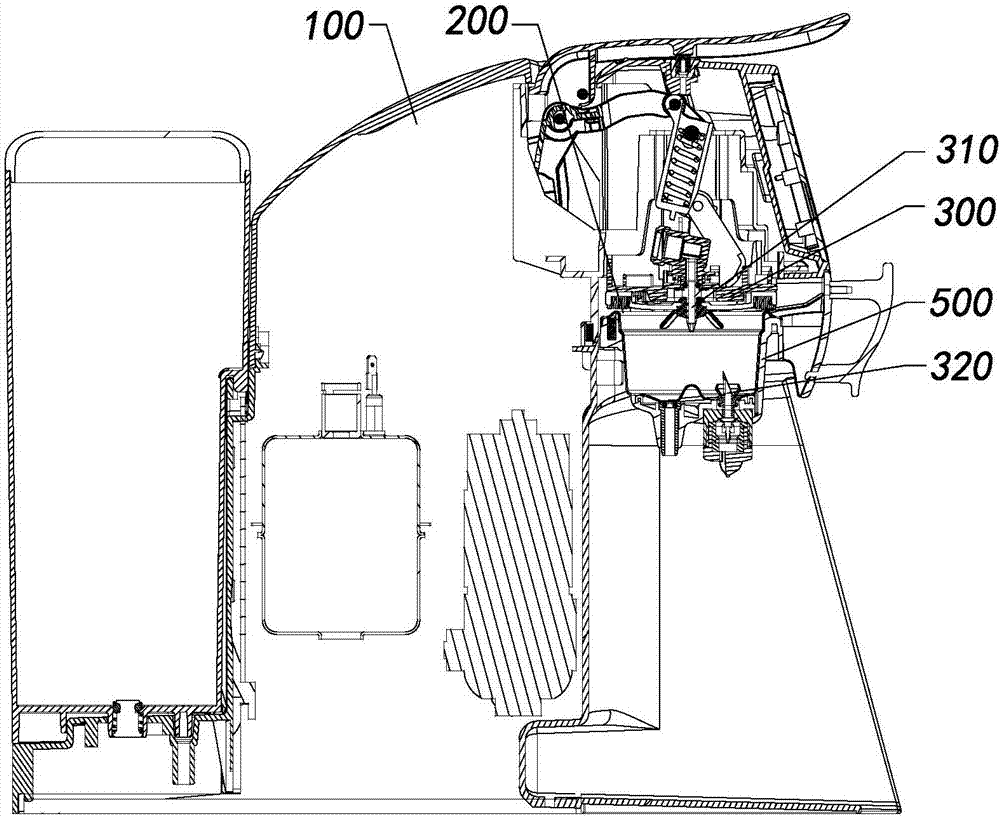

Method for cleaning capsule beverage dispenser

The invention discloses a method for cleaning a capsule beverage dispenser, and belongs to the technical field of beverage preparation. The problems that wasting of water is caused in the cleaning process of an existing capsule beverage dispenser and the cleaning effect is poor are solved. The capsule beverage dispenser comprises a machine base with a brewing cavity, a liquid feeding mechanism, an input module and a control module. The control module controls the capsule beverage dispenser to be cleaned according to signals of the input module. The cleaning method includes a first cleaning stage and a second cleaning stage capable of being selected to be executed. The first cleaning stage at least includes a first washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a first power P1 for cleaning. The second cleaning stage at least includes a second washing step in which the liquid feeding mechanism leads liquid into the brewing cavity at a second power P2 for cleaning. The rated power of the liquid feeding mechanism is PE1, and P1<P2<=PE1. The method disclosed by the embodiment of the invention is used for cleaning the capsule beverage dispenser. The capsule beverage dispenser can be a capsule coffee maker, a capsule soybean milk machine and the like.

Owner:杭州易杯食品科技有限公司

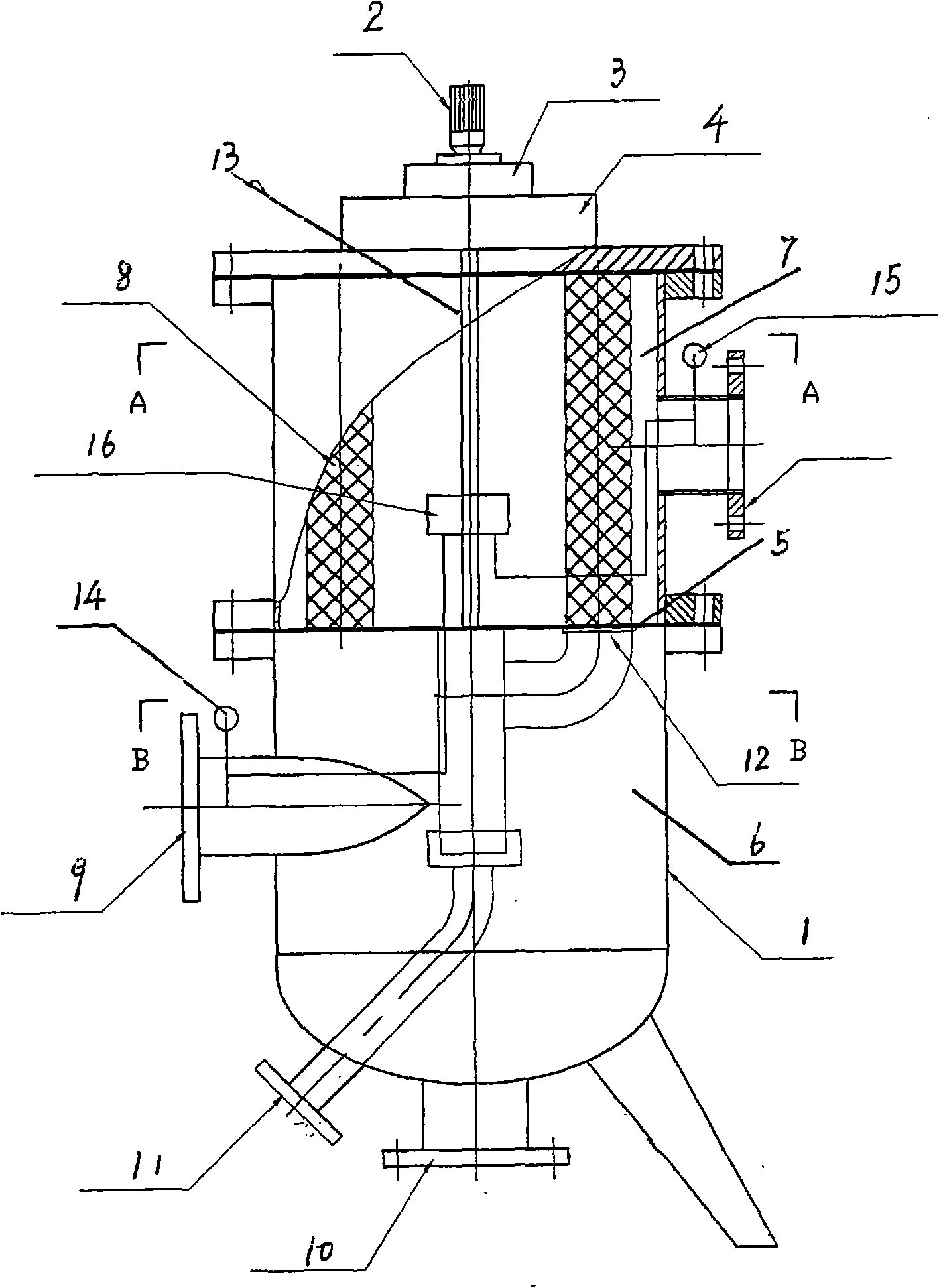

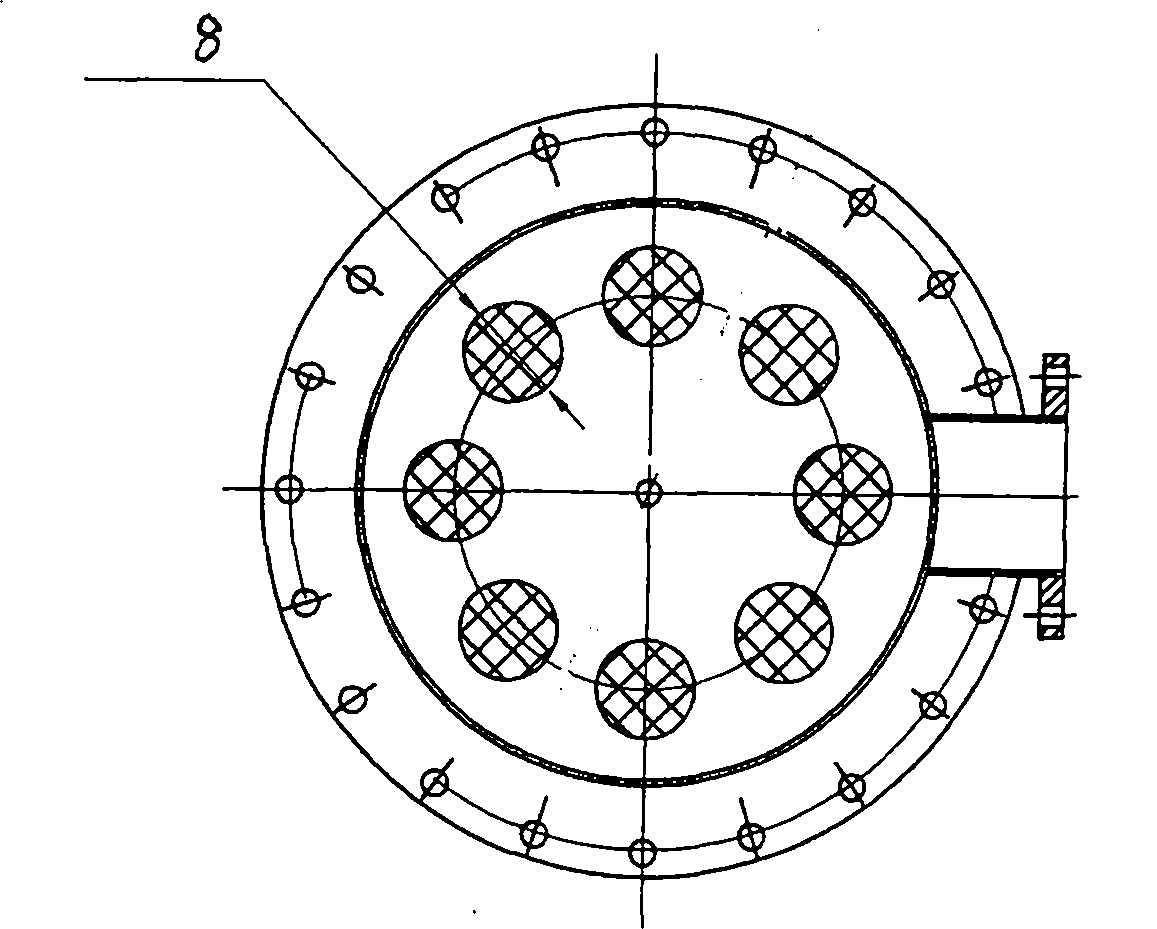

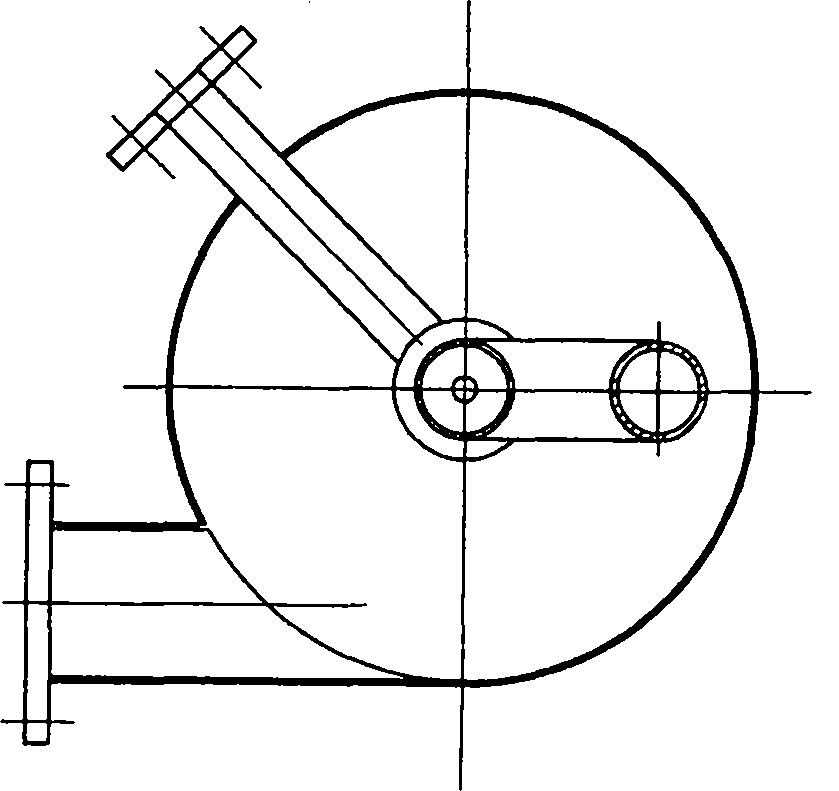

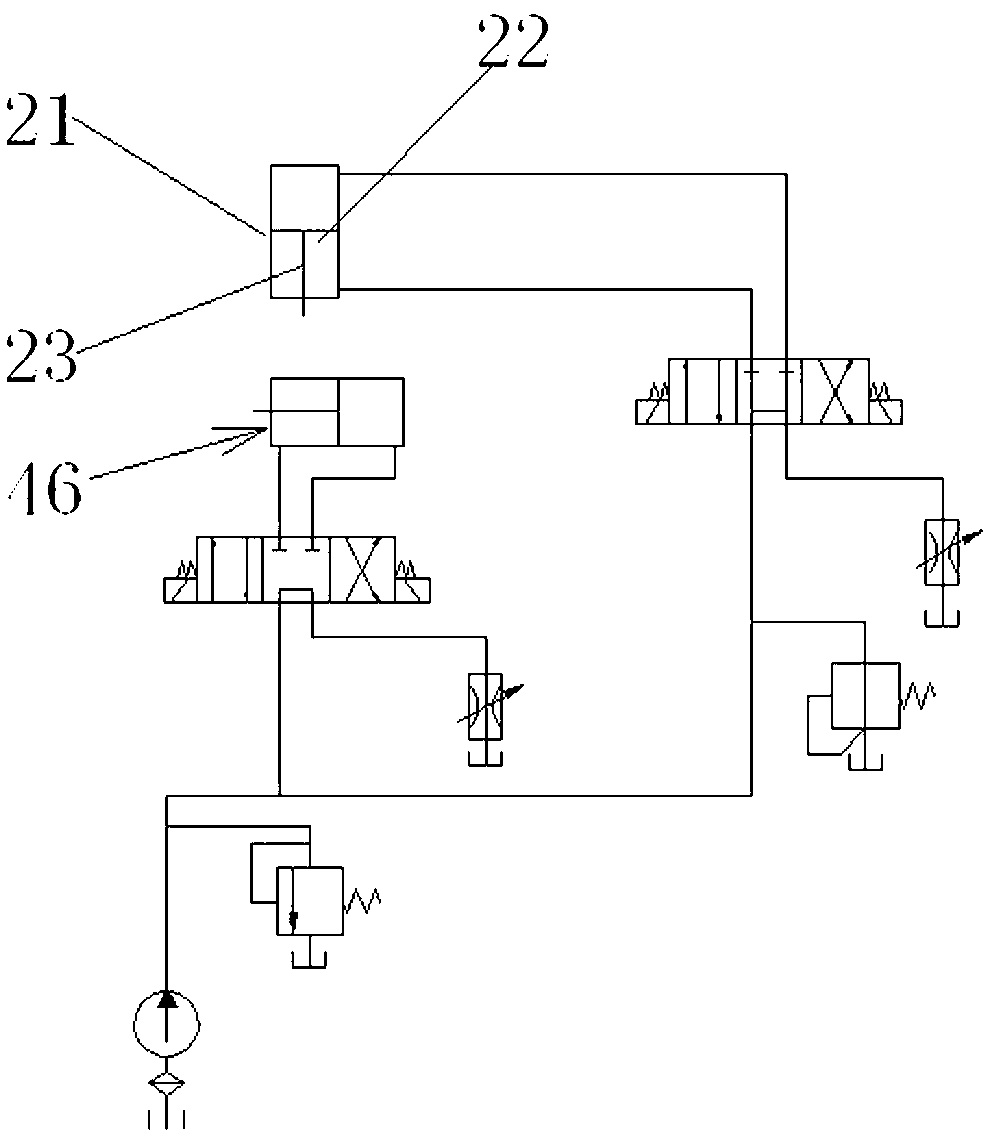

Differential-pressure swirl-type backwashing filtration system

InactiveCN102107100ANot easy to bruiseExtend your lifeStationary filtering element filtersFiltrationDrive shaft

A differential-pressure swirl-type backwashing filtration system. An indexing mechanism and a transmission mechanism are disposed on the top of a filter cylinder body; the internal cylinder body is divided into a water-inlet chamber and a water-outlet chamber by a clapboard; eight filter cores are disposed in the water-outlet chamber and are distributed uniformly and circumferentially; a water inlet is disposed along a tangent of the cylinder wall of the water-outlet chamber; a sewage draining exit and a dirt discharging exit are disposed in the water-inlet chamber; a sucking disc is disposed between the dirt discharging exit and the clapboard, and is driven to rotate by a transmission shaft of the transmission mechanism. The device adopts eight groups of filter core structures, and by using the hydrodynamics principle, the device has the advantages of less no-load pressure loss, less backwashing water consumption, good filtering effect, compact structure, and reliable operation, and can perform backwashing under low differential pressure.

Owner:天津富斯特环保设备有限公司

Mask cleaning method and cleaning device

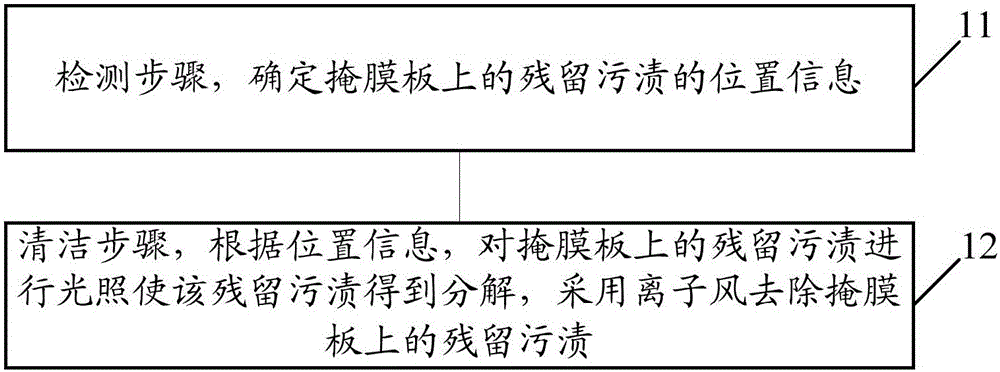

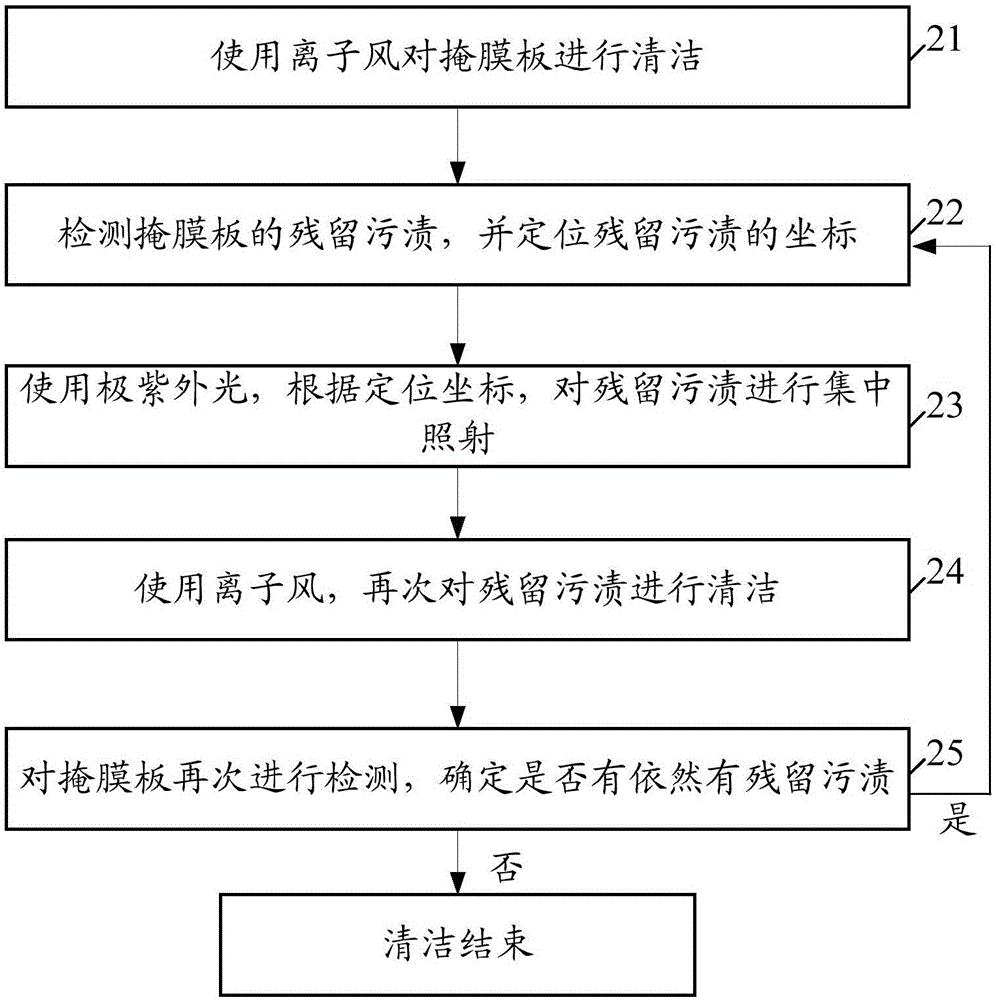

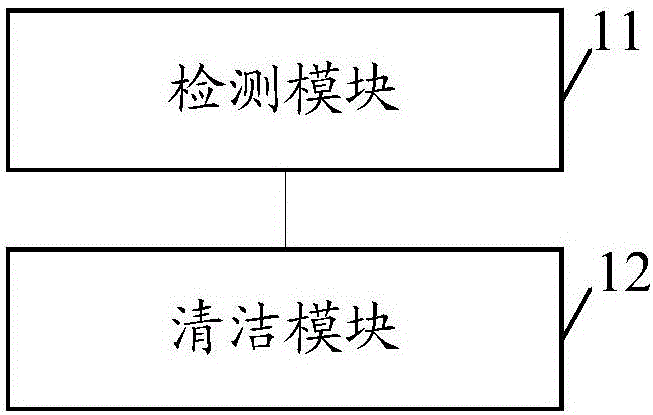

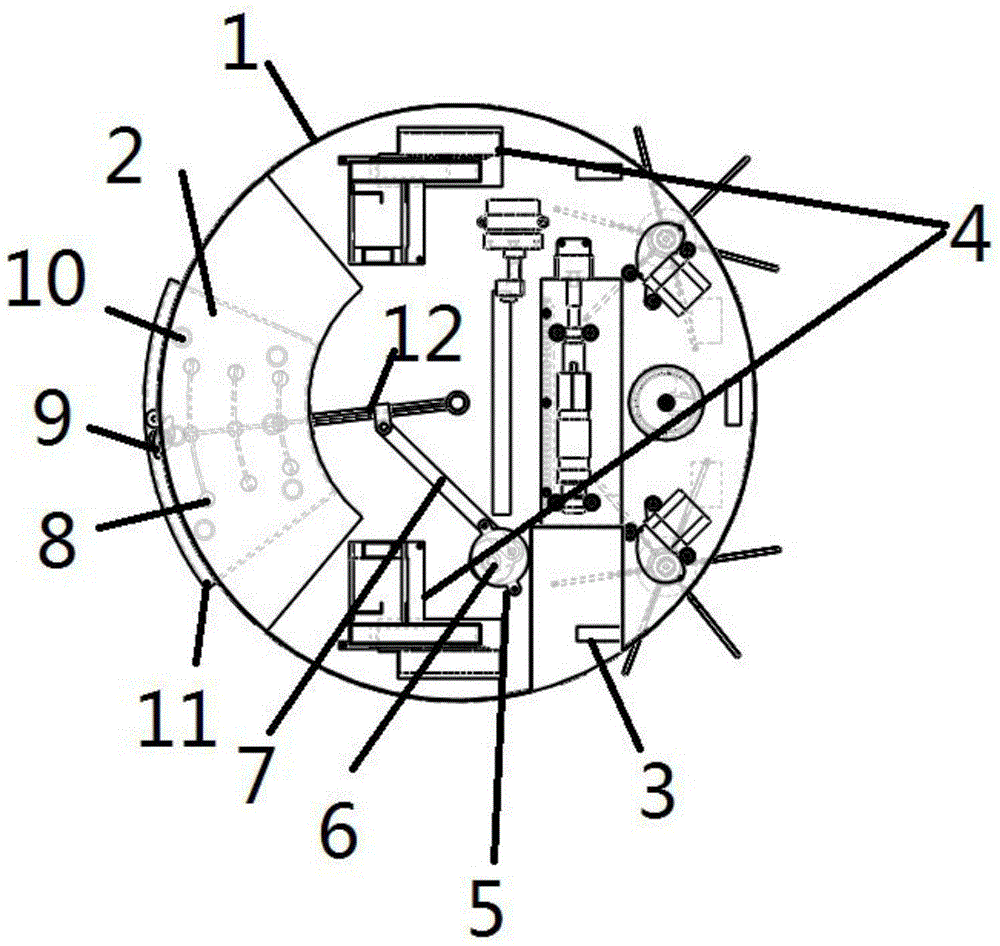

InactiveCN106269707AAchieve cleaning effectOriginals for photomechanical treatmentCleaning using gasesCleaning methodsEngineering

The invention provides a mask cleaning method and cleaning device. The cleaning method comprises: a detection step for determining the position information of residual stains on a mask; and a cleaning step for illuminating to decompose the residual stains on the mask, and removing the residual stains on the mask by ionic wind. After normal mask cleaning, some residual stains still exist. Generally, the residual stains are oily stains such as fingerprints left by technicians in a mask operation process; and in the cleaning method provided by the embodiment, the residual stains are positioned and then accurately illuminated according to the positioning effect, so that the residual stains are decomposed and loosened on the mask, and then the loose residual stains are blown off the mask by use of ionic wind to realize a cleaning effect.

Owner:BOE TECH GRP CO LTD +1

Sweeping robot

InactiveCN105212842AIncreased recoilAchieve cleaning effectMachine detailsFloor-scrubbing machinesEngineeringSmall hole

The invention relates to a sweeping robot. The sweeping robot comprises a round shell and a water tank. A power switch is arranged on the upper portion of the round shell. Two power off-road wheels are arranged at the bottom of the round shell. A sweeping motor, a short sweeping connection rod and a long sweeping connection rod are arranged in the round shell. A vibrating reed and a water tank rubber plug are arranged on the upper portion of the water tank. Seepage holes are formed in the lower portion of the water tank. A sweeping mop is arranged on the lower portion of the water tank. A water tank dragging handle is arranged on the front section of the water tank. The sweeping motor is fixed into the round shell, and is connected with the water tank dragging handle through the short sweeping connection rod and the long sweeping connection rod. The sweeping robot has the advantages that the sweeping mop is wetted by water in the water tank through the seepage holes during sweeping, pressure on the water tank is generated under the vibration effect of the vibrating reed, recoil of the water tank is increased, the whole pushing force is transmitted to the sweeping mop through the two power off-road wheels, and accordingly, really good ground cleaning effect is achieved easily.

Owner:武玉妹

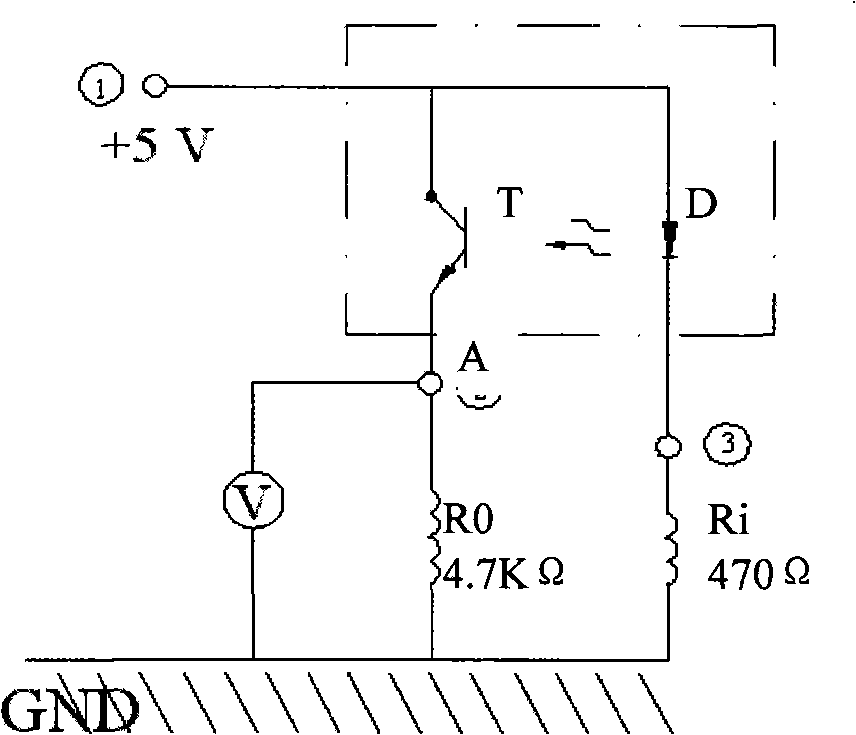

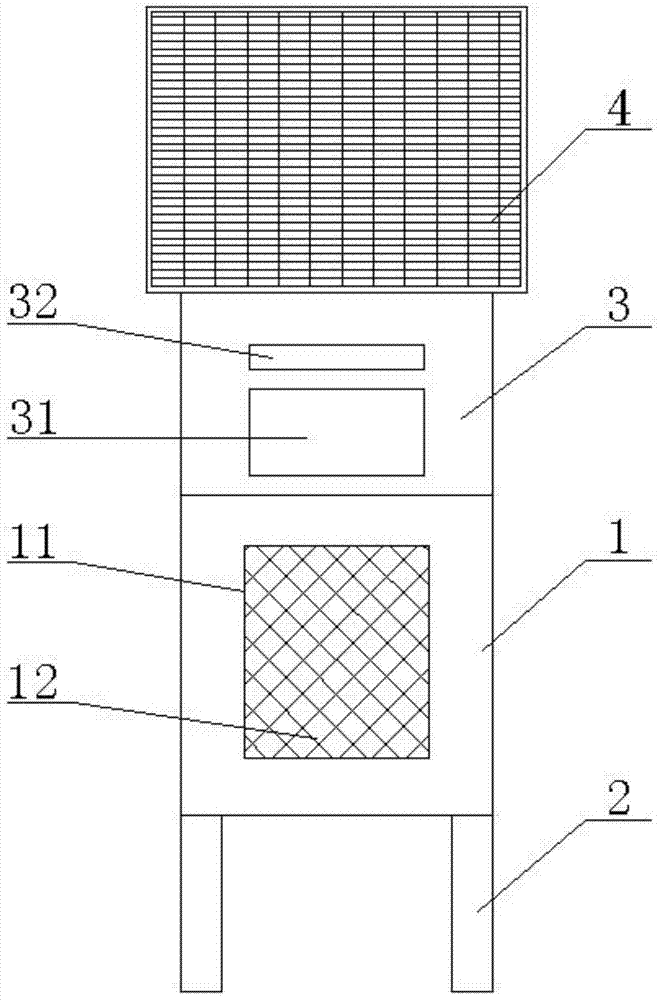

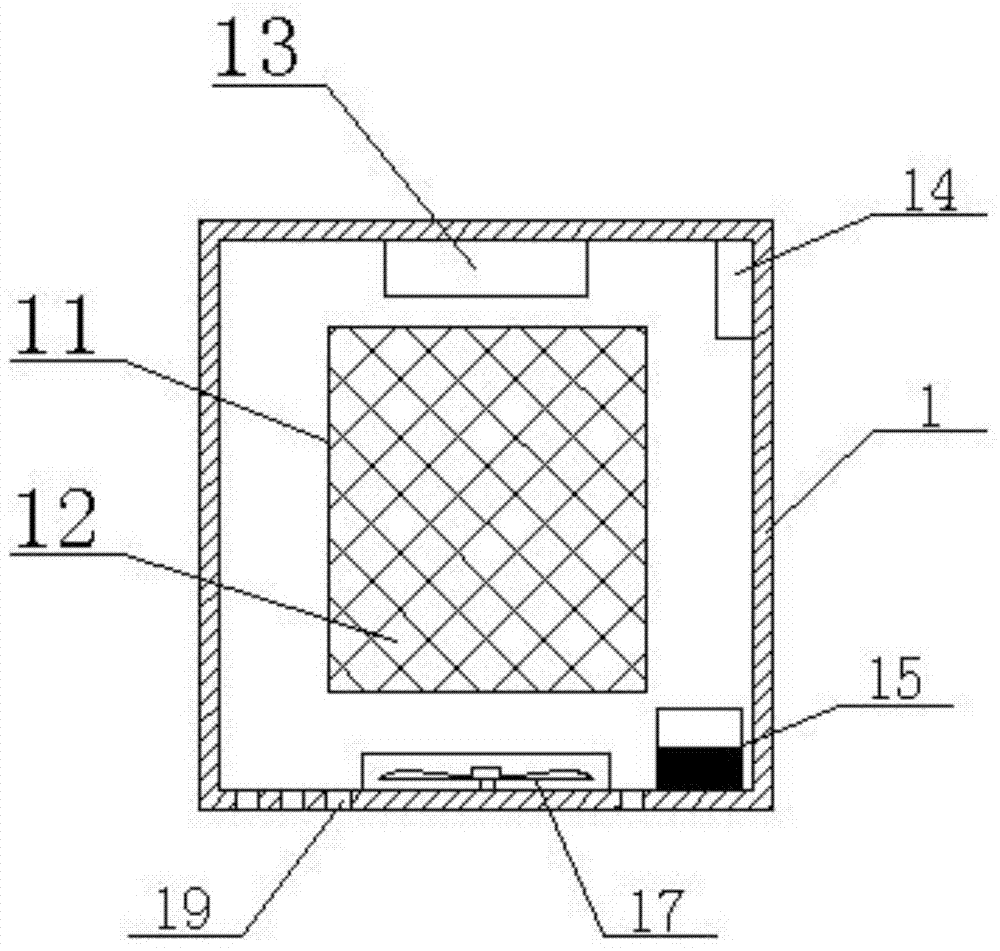

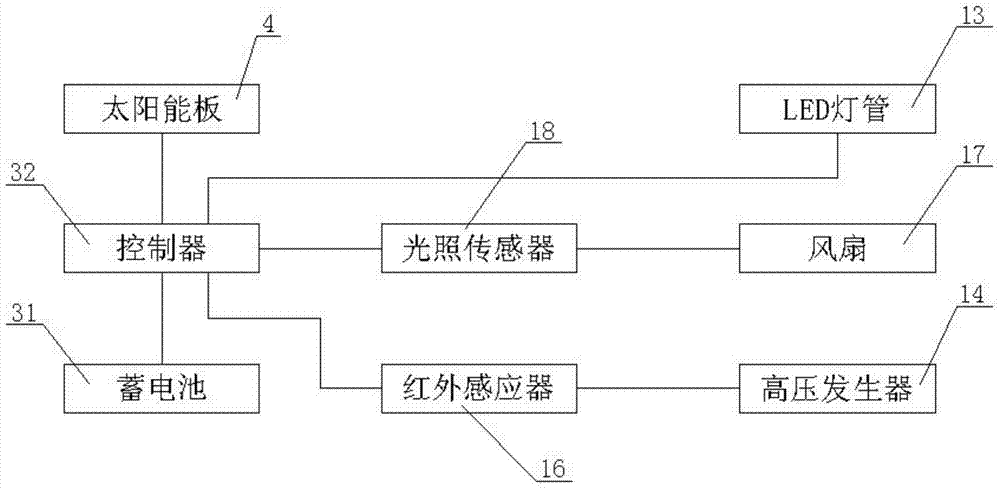

Physical pest killing device for use in gardens

InactiveCN103749411ASolve pollutionResidue reductionInsect catchers and killersPower gridHigh voltage pulse

The invention discloses a physical pest killing device for use in gardens. The physical pest killing device comprises a bracket, an LED (Light-Emitting Diode) pest killing lamp fixed to the bracket, and a control box, wherein a storage battery and a controller which are connected with each other are arranged in the control box; the control box is provided with a solar panel which is connected with the controller; the LED pest killing lamp is provided with a light-transmitting window; a high-voltage pest killing power grid is arranged on the light-transmitting window; an LED lamp tube, a high-voltage generator connected with the high-voltage pest killing power grid, and an infrared sensor for sensing the invasion of pests are arranged in the LED pest killing lamp; the controller is connected with the high-voltage generator, the LED lamp tube and the infrared sensor respectively. According to the physical pest killing device, pests are attracted and killed by combining a plurality of light sources and using pest attractants, a high-voltage pulse discharge net and the like, and environmental pollution is avoided. Meanwhile, by adopting the infrared sensor and an illumination sensor, intelligent control and clear of pests are realized.

Owner:NINGBO JINYI AGRI

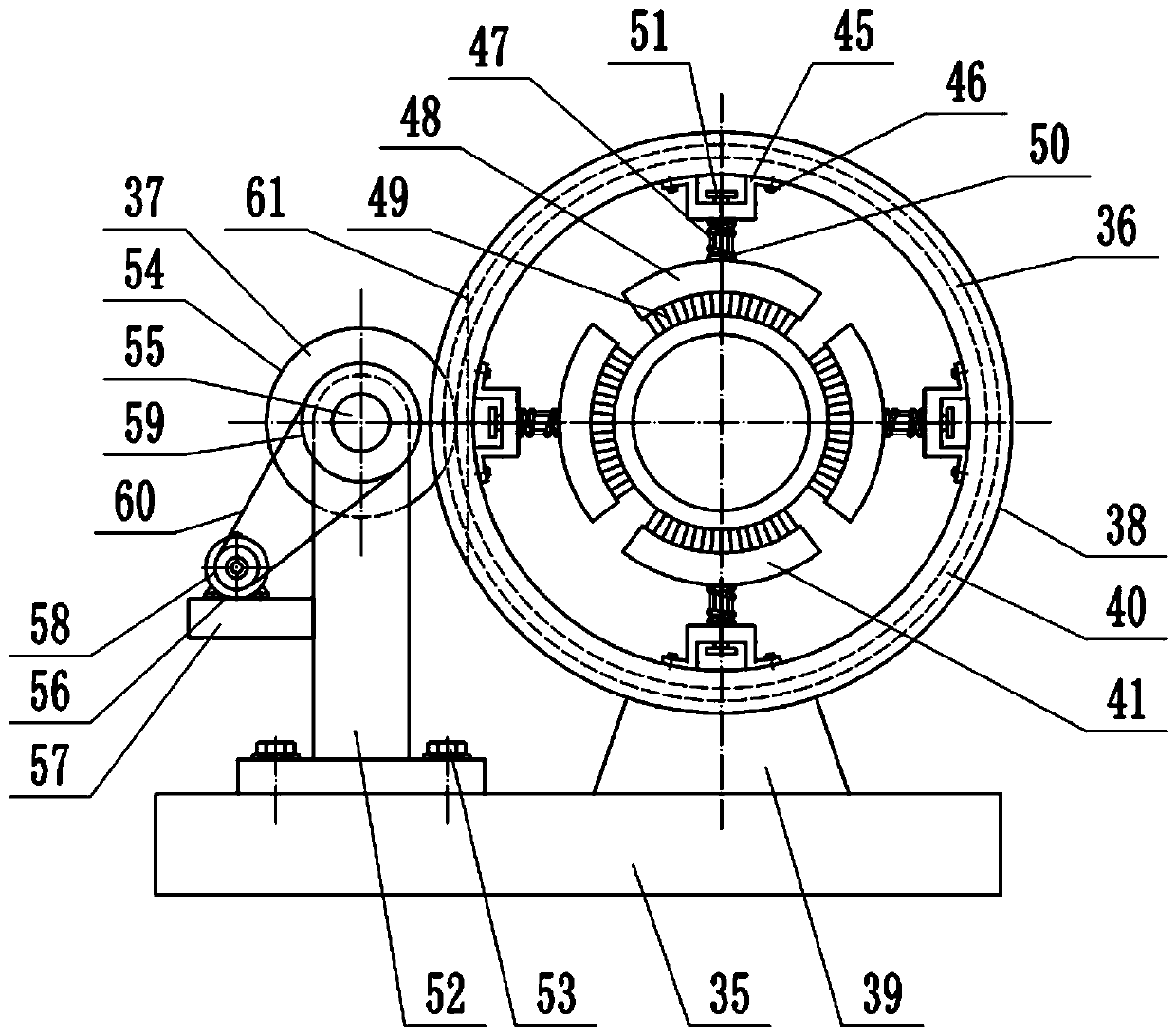

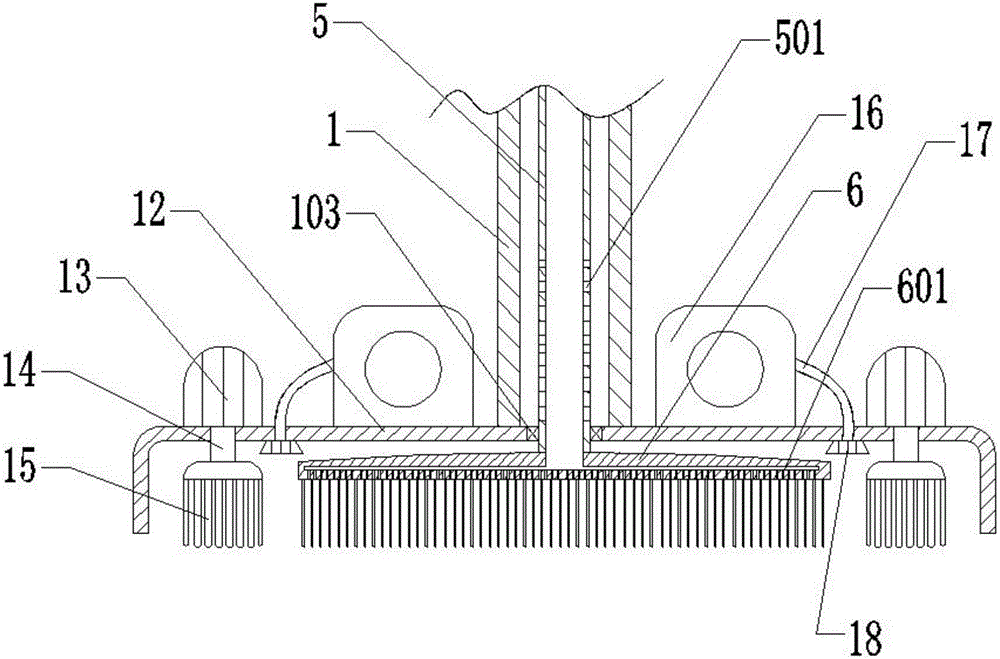

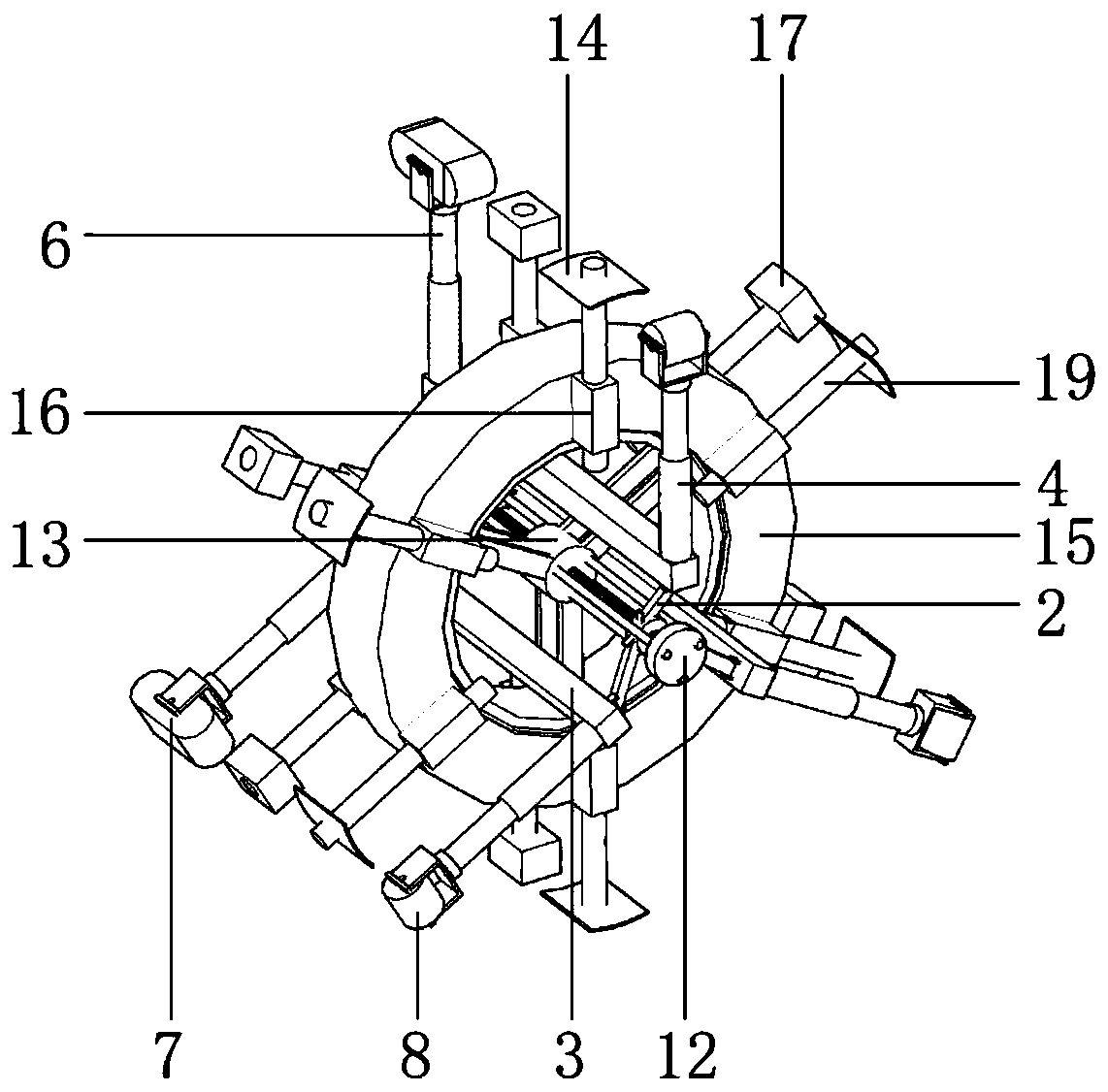

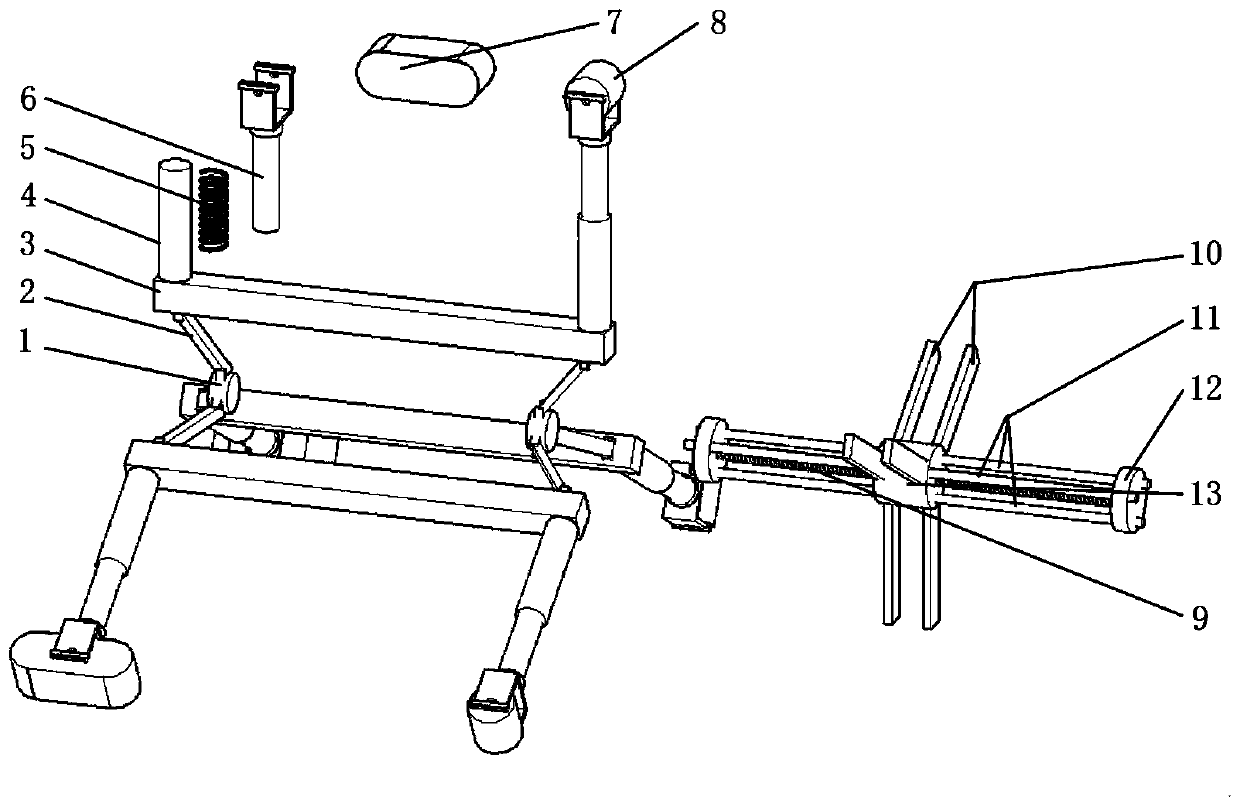

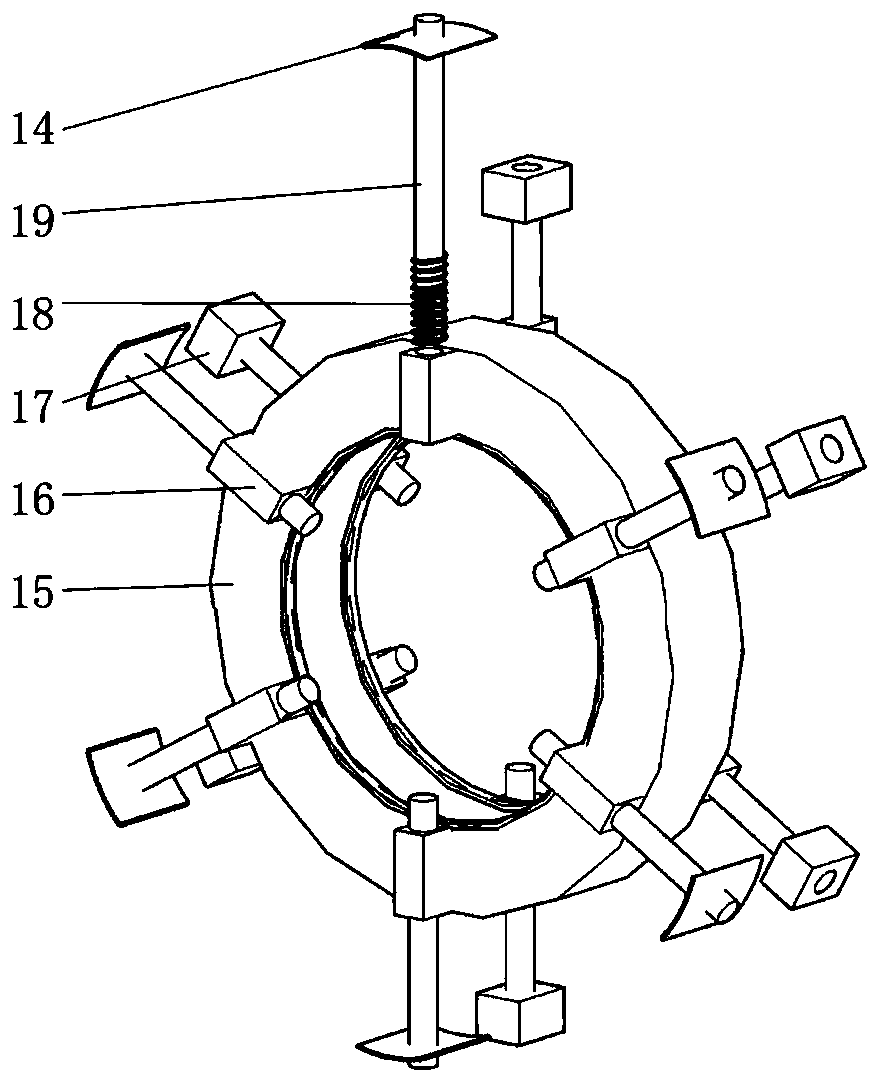

Petroleum pipeline cleaning and detecting robot

ActiveCN110701429AEnsure stabilityWon't wash awayHollow article cleaningPigs/molesGear wheelControl engineering

The invention discloses a petroleum pipeline cleaning and detecting robot. The petroleum pipeline cleaning and detecting robot comprises a walking mechanism, a cleaning and detecting mechanism and a control mechanism; the walking mechanism is provided with an axis motor, through forward and reverse rotation of the motor, lead screws are driven to rotate, then lead screw slide blocks and slide rodsare made to move to the two sides or to the middle, and the height of a transverse beam and the height of wheels are changed to achieve diameter varying, so that different pipe diameters are adaptedto; the control mechanism is provided with a control module and gear sets which are covered with a shell, the control module of the control mechanism comprises a power source, a motor and a single-chip microcomputer, and the control mechanism is furthermore connected to the walking mechanism through a support, and conducts information interaction with the axis motor of the walking mechanism and pressure sensors at the legs; the cleaning and detecting mechanism covers the outer side of the control mechanism, and through the arrangement of a runner, a replaceable tool, a brush and a detection instrument are carried. The overall structure of the petroleum pipeline cleaning and detecting robot is annular, the influence of the robot on the flow of fluid of a pipeline caused when the robot worksin the pipeline can be effectively lowered, the efficiency of cleaning and detecting the pipeline is improved, and the petroleum pipeline cleaning and detecting robot has the advantages of being reasonable in structure, high in working efficiency and strong in practicability.

Owner:XI'AN PETROLEUM UNIVERSITY

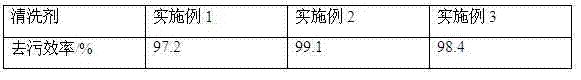

Printing ink cleaning agent and preparation process thereof

InactiveCN102775840AImprove cleanlinessSimple preparation processChemical paints/ink removersPolyethylene glycolPrinting ink

The invention relates to a printing ink cleaning agent for washing printing ink of printing machines, printing plates, rubber covered rollers, rubber cloth and the like and a preparation process of the printing ink cleaning agent. The printing ink cleaning agent is composed of the following raw materials by weight 15-25% of symplectic alkyl phenol polyethylene glycol ether, 5-15% of oleic acid, 3-7% of sodium oleate, 2-8% of oil soluble essence, 5-15% of sodium alkyl benzene sulfonate and the balance of softened water. According to the printing ink cleaning agent and the preparation process provided by the invention, an organic solvent such as gasoline and kerosene can be replaced and the safety, high efficiency and environmental protection can be realized, and hydrophobic groups in emulsion can well dissolve oiliness content in the ink to achieve washing effects. The printing ink cleaning agent is simple in preparation process, and has the advantages of being low in cost, simple in preparation process, free of damage to the rubber covered rollers, non-ignitable, good in clearing performance, free of damage to skin and the like compared with the existing cleaning agent.

Owner:HONGBO CO LTD

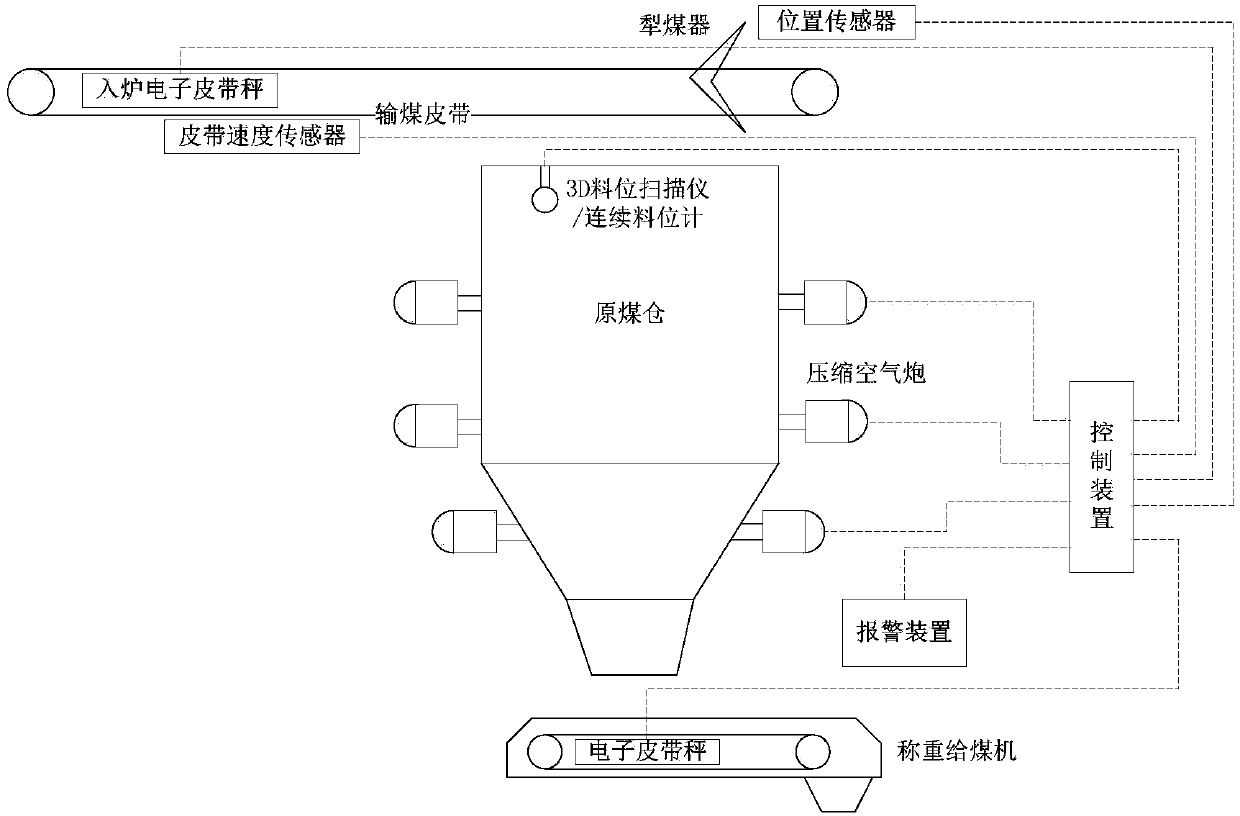

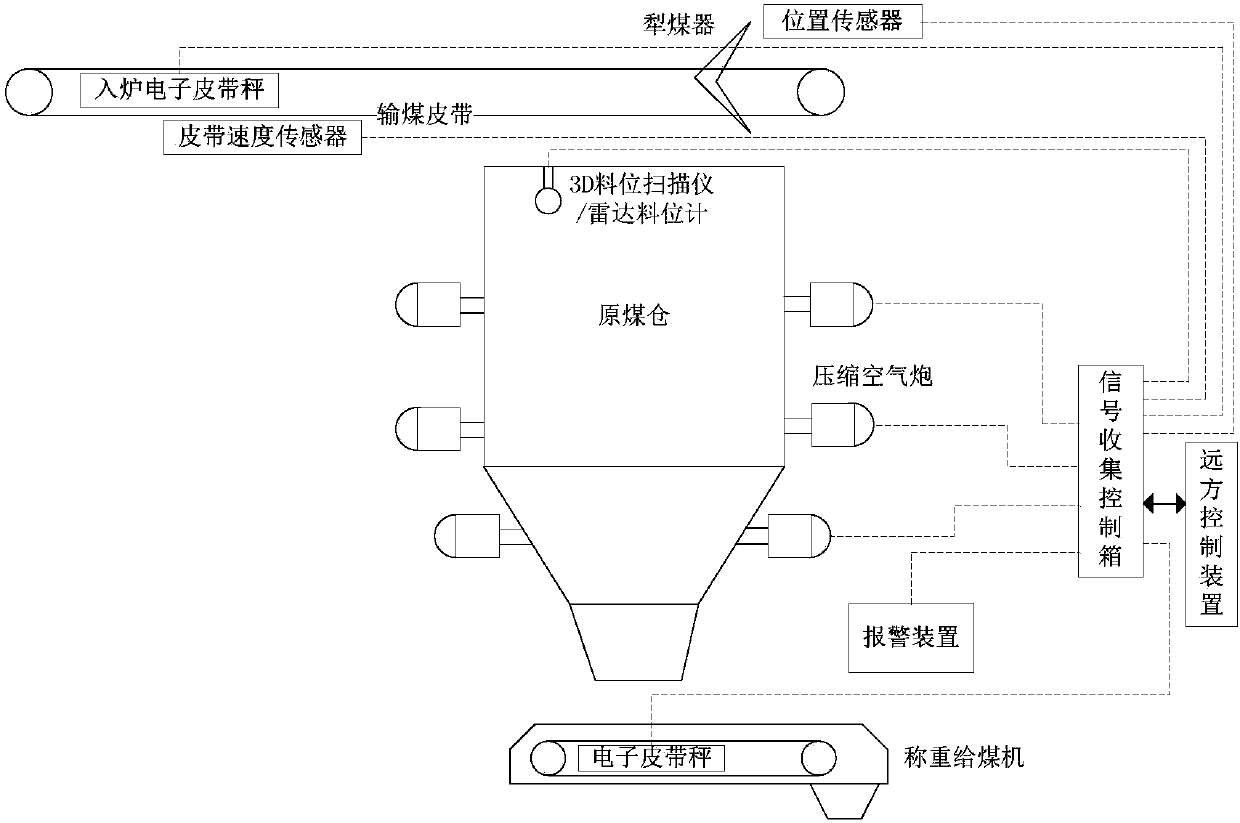

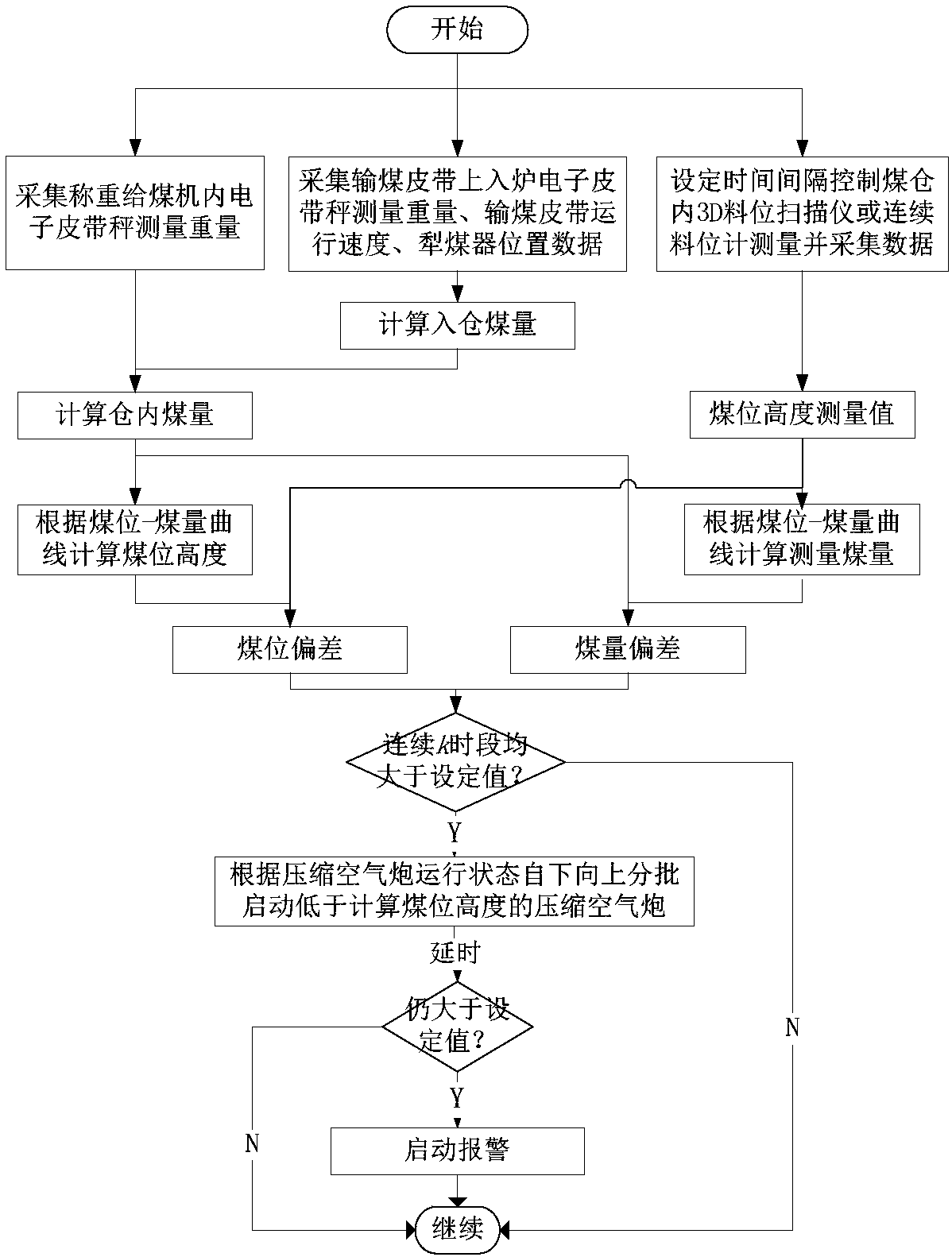

Control system and method for automatically judging and eliminating coal blockage of raw coal bunker

ActiveCN107054911ARealize automatic judgment functionAchieve cleaning effectLarge containersLoading/unloadingCommunication interfaceControl system

The invention discloses a control system and method for automatically judging and eliminating coal blockage of a raw coal bunker. When the control system is arranged on the spot, a control device is connected with a charging electronic belt weigher, a belt running speed sensor, a coal plough position sensor, a 3D material scanner or continuous material level gauge in the bunker, an output end and a communication interface of an electronic belt weigher arranged in a coal weighing feeder, input ends of compression air cannons and an input end of an alarming device; when the control system is arranged in the distance, a signal collecting control box is additionally arranged on the spot to be connected with the devices and the sensors and connected with a remote control device; the control system calculates the coal quantity and the coal level in the bunker through measured data of collecting equipment and the sensors, and coal blockage is judged by comparing the coal quantity and the coal level in the bunker with the coal level and the coal quantity which are measured by the 3D material scanner or continuous material level gauge; when coal blockage occurs, the compression air cannons are controlled to be started layer by layer in batches to eliminate coal blockage; when coal blockage can not be eliminated, the alarming device is started. According to the control system and method, the automatic judging, automatic cleaning and eliminating and automatic alarming functions on coal blockage of the raw coal bunker can be achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Working table for avoiding scattering of scraps in mechanical part machining process

InactiveCN105328462AAvoid scatterRealize unified recyclingWork benchesLarge fixed membersFront edgeMachining process

The invention discloses a working table for avoiding scattering of scraps in the mechanical part machining process. The working table comprises a square table body, wherein a baffle plate No.1 and a baffle plate No.1 perpendicular to the upper surface of the table body are respectively arranged at the front edge and the rear edge of the upper surface of the table body; a sliding groove is formed in the inner surface of each of the baffle plate No.1 and the baffle plate No.1 on the axial direction, and a roller is arranged in each sliding groove; the two rollers are connected through a scratch board, and the bottom edge of the scratch board is adjacent to the upper surface of the table body; drawers are arranged in the left side surface and the right side surface of the table body. The working table solves the problem that scraps generated in the mechanical part machining process in the prior art is not conveniently swept and realizes the purpose of conveniently and quickly sweeping the scraps on the mechanical part machining working table.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

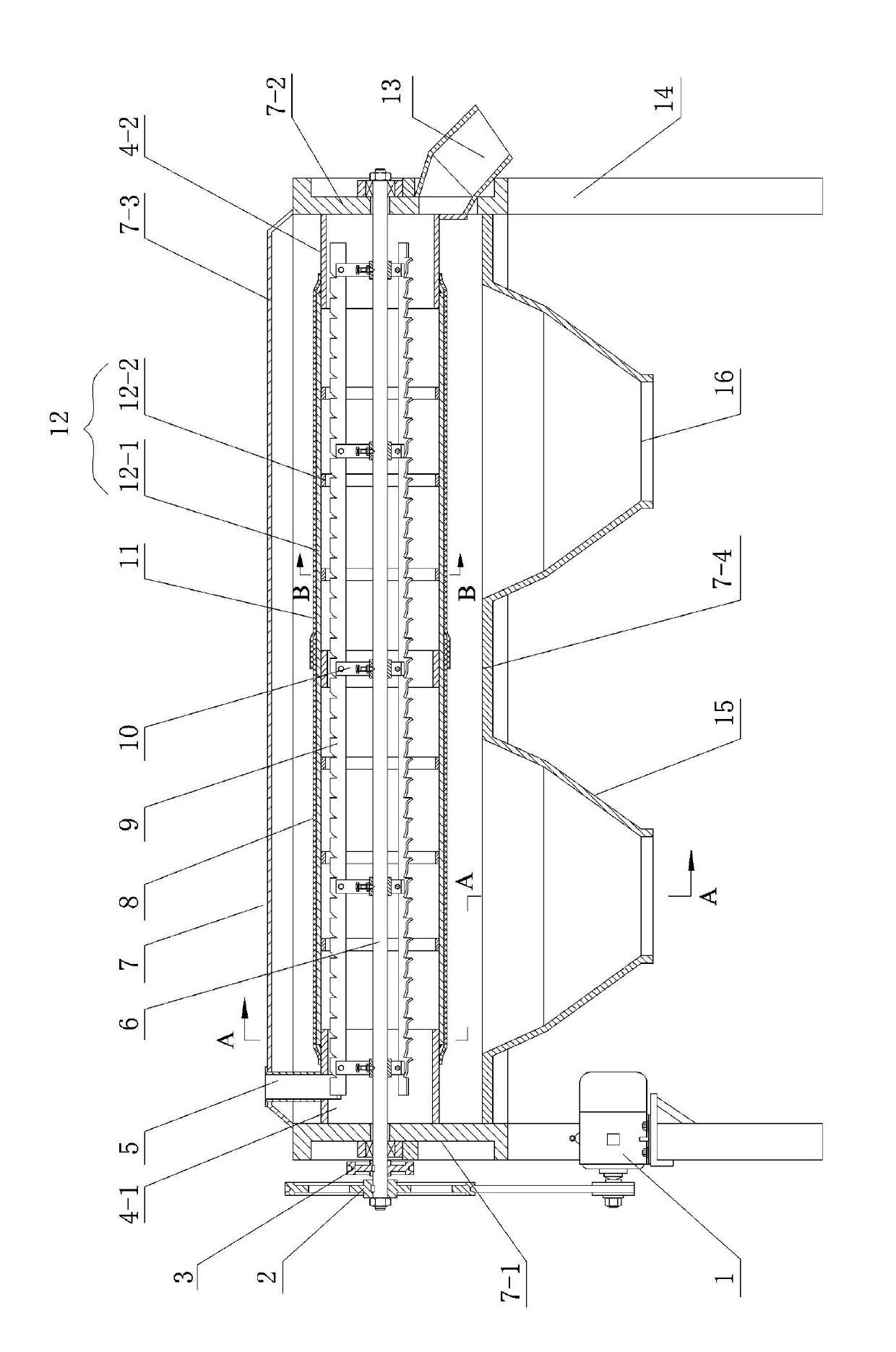

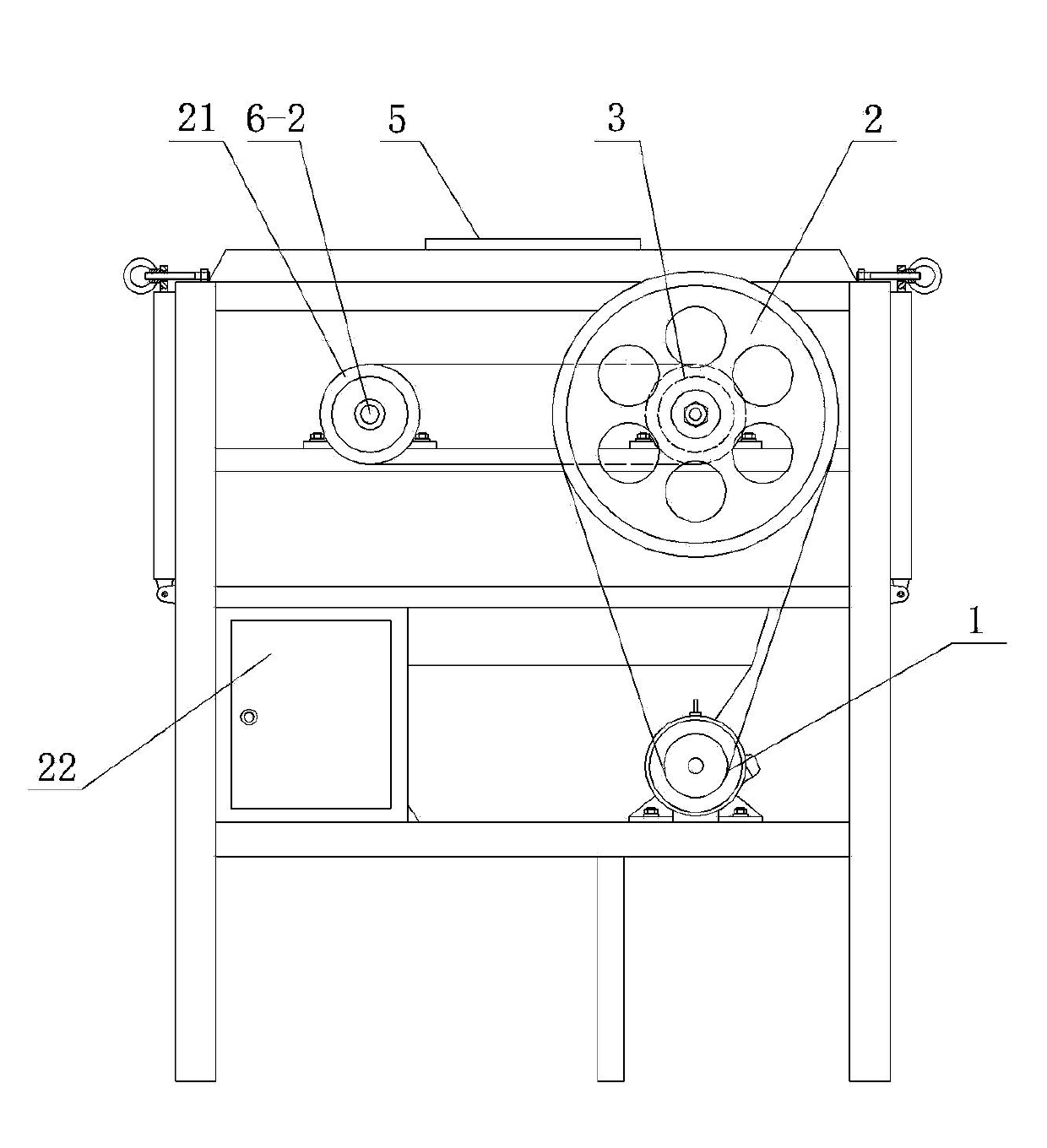

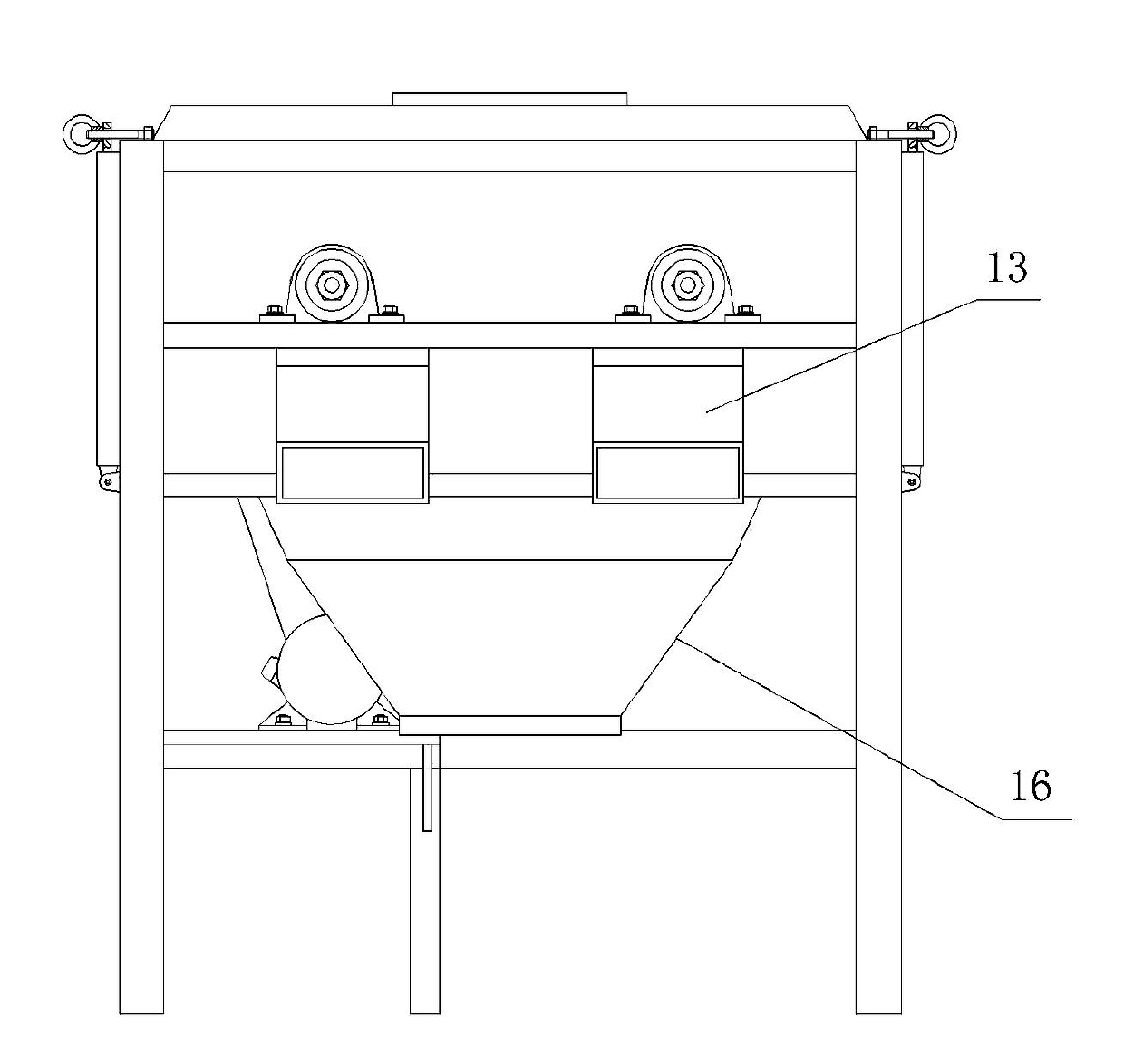

Plant fiber sizing screen powder machine

InactiveCN102652941ALiquidityGood fractionation effectSievingGas current separationMechanical engineeringPlant fibre

The invention discloses a plant fiber sizing screen powder machine, and belongs to the technical field of sifting machines. The plant fiber sizing screen powder machine comprises a rack and a machine shell, wherein the machine shell is formed by a front standing plate, a rear standing plate, a top shell and a bottom plate, and the machine shell is provided with a screen door; a screen drum is fixed between the front standing plate and the rear standing plate, the screen drum comprises front and rear end drums, a screen mesh frame and a screen mesh, the screen mesh comprises a first order screen mesh and a second order screen mesh, and the screen holes of the second order screen mesh are greater than that of the first order screen mesh; and the screen drum is internally provided with a pneumatic conveying device, the upper part of the machine shell is provided with a feeding bin, the lower part of the machine shell is provided with a first order discharge hopper and a second order discharge hopper, and the rear part of the machine shell is provided with a rear discharge port. The plant fiber sizing screen powder machine provided by the invention is used for screening plant fiber power, the structure that a screen drum is fixed and screen mesh is sectionalized is adopted, and the pneumatic conveying device is utilized to deliver powder; and the screening thing uniformly passes in a screening process, the liquidity is strong, the fractionation effect is good, and the output and the quality of the products are notably improved.

Owner:XUZHOU FUYANG ENERGY TECH

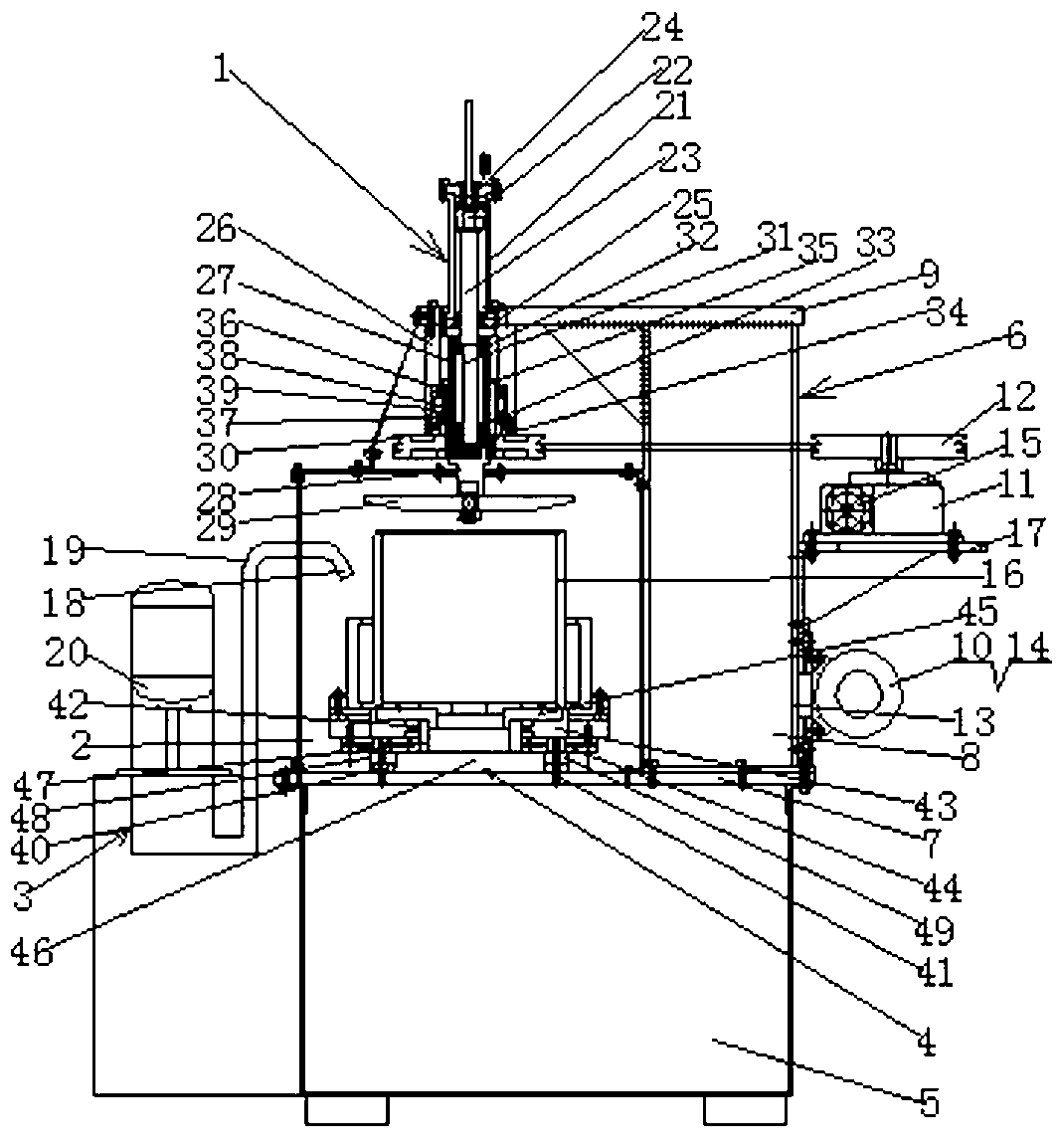

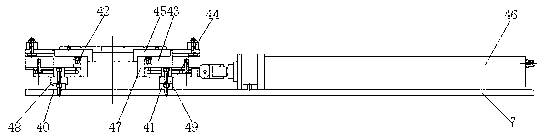

Pressing-type rotary cleaning machine for cylindrical roller bearings

A pressing-type rotary cleaning machine for cylindrical roller bearings comprises a rotary feeding oil cylinder, an oil tank cleaning chamber, a motor, a speed reducer, a supporter, a spline shaft, a workbench, a rotatable workbench and a movable platform. The workbench is fixed on an upper end cover of the oil tank and the cleaning chamber is arranged on the workbench. A pressing plate push rod is connected on a lower end of a piston rod of the rotary feeding oil cylinder. The spline shaft is equipped on the pressing plate push rod and a spline shaft sleeve is equipped on the spline shaft. The spline shaft sleeve is connected with a second belt pulley which is connected with a first belt pulley on an output shaft of the speed reducer through a belt. Two tracks are arranged on a lower end surface of the movable platform. The two tracks are in sliding fit with two tracks arranged on the workbench. The rotatable workbench is arranged on the movable platform. A spline shaft joint is connected on the lower end of the spline shaft. A pressing plate is fixed on the spline shaft joint. A spray head is arranged in the cleaning chamber. The rotary cleaning machine for cylindrical roller bearings forcibly cleans each set of bearings in a spraying and meanwhile rotating manner so as to increase cleaning effect.

Owner:DALIAN GRANDWAY BEARING

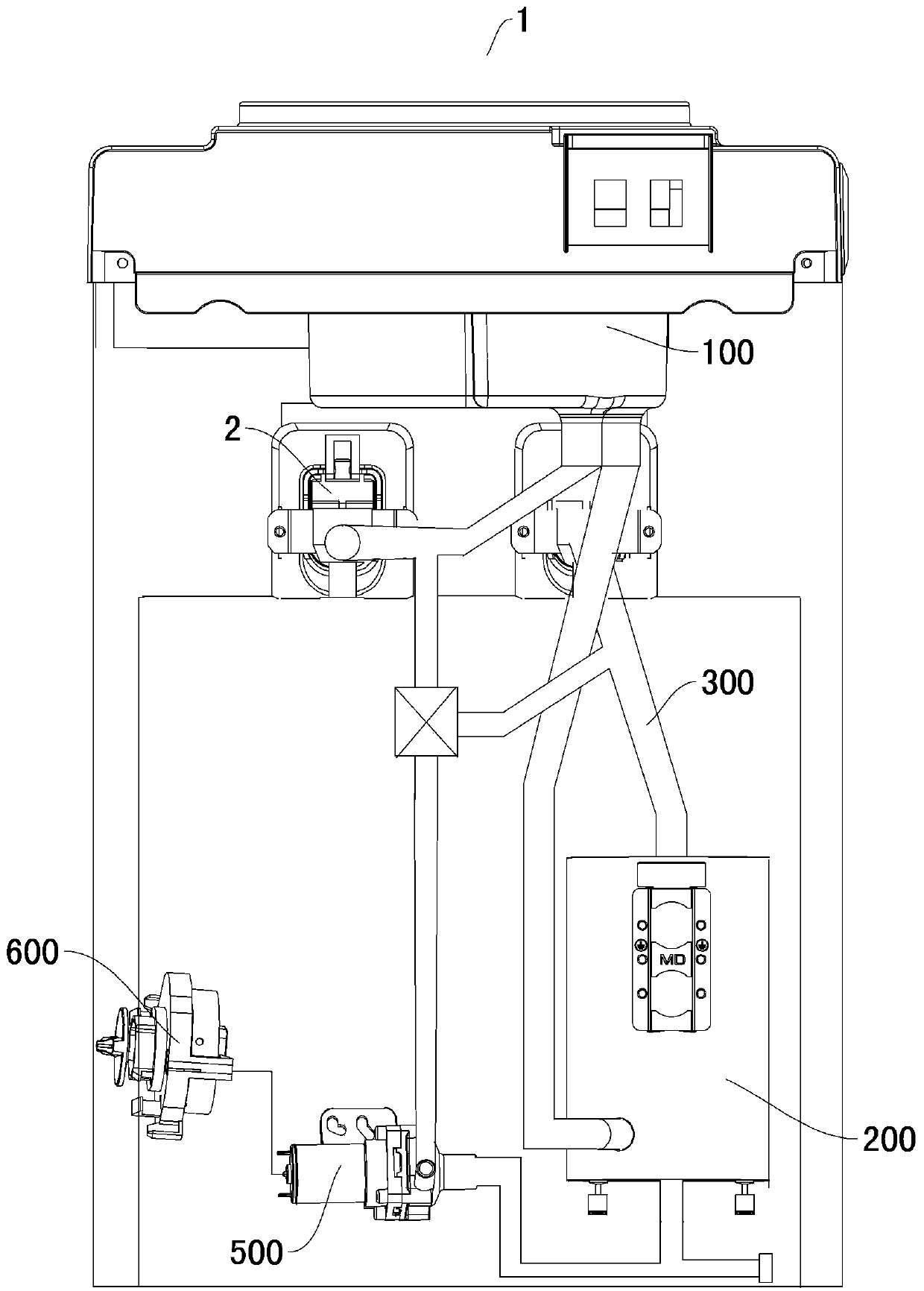

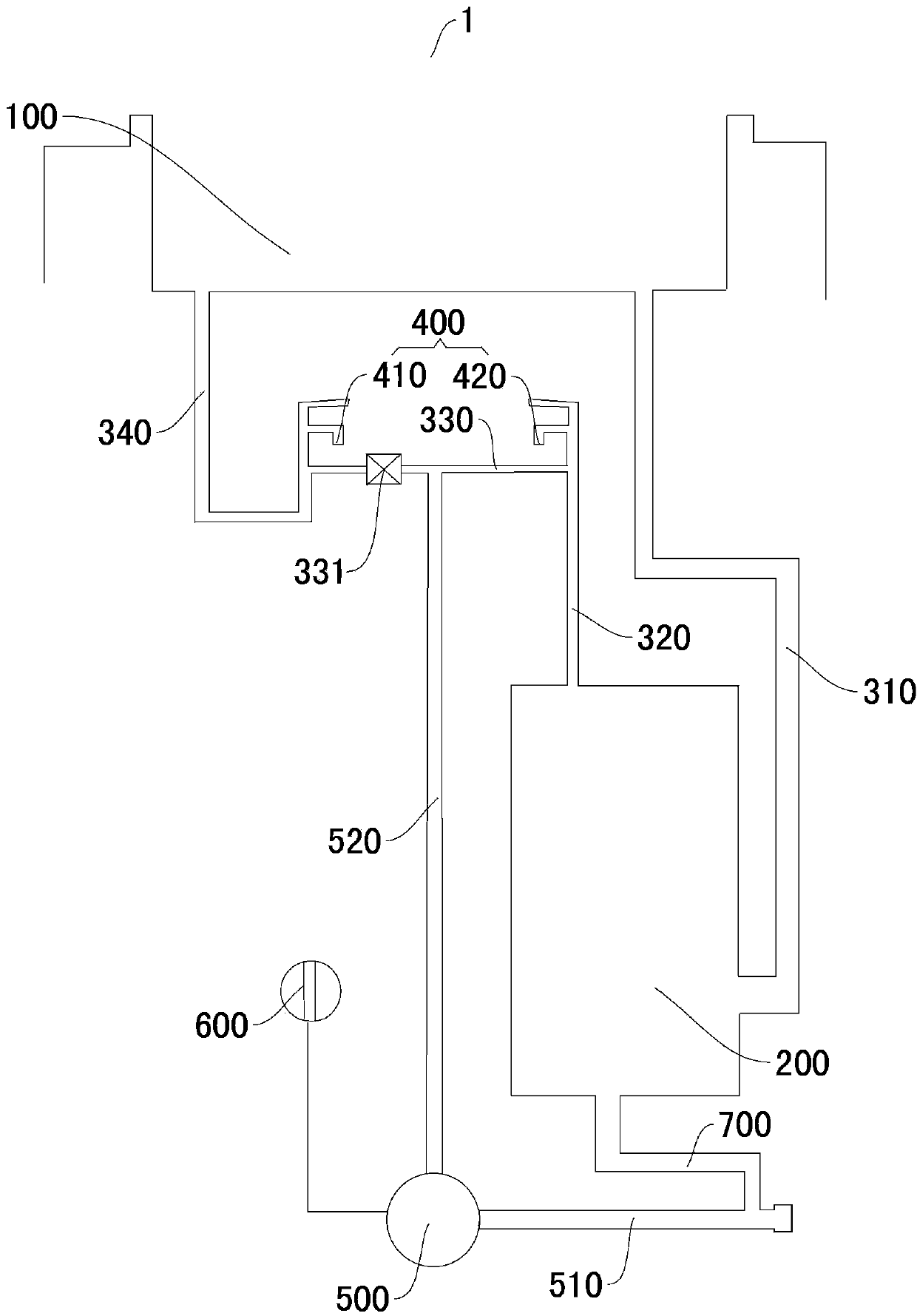

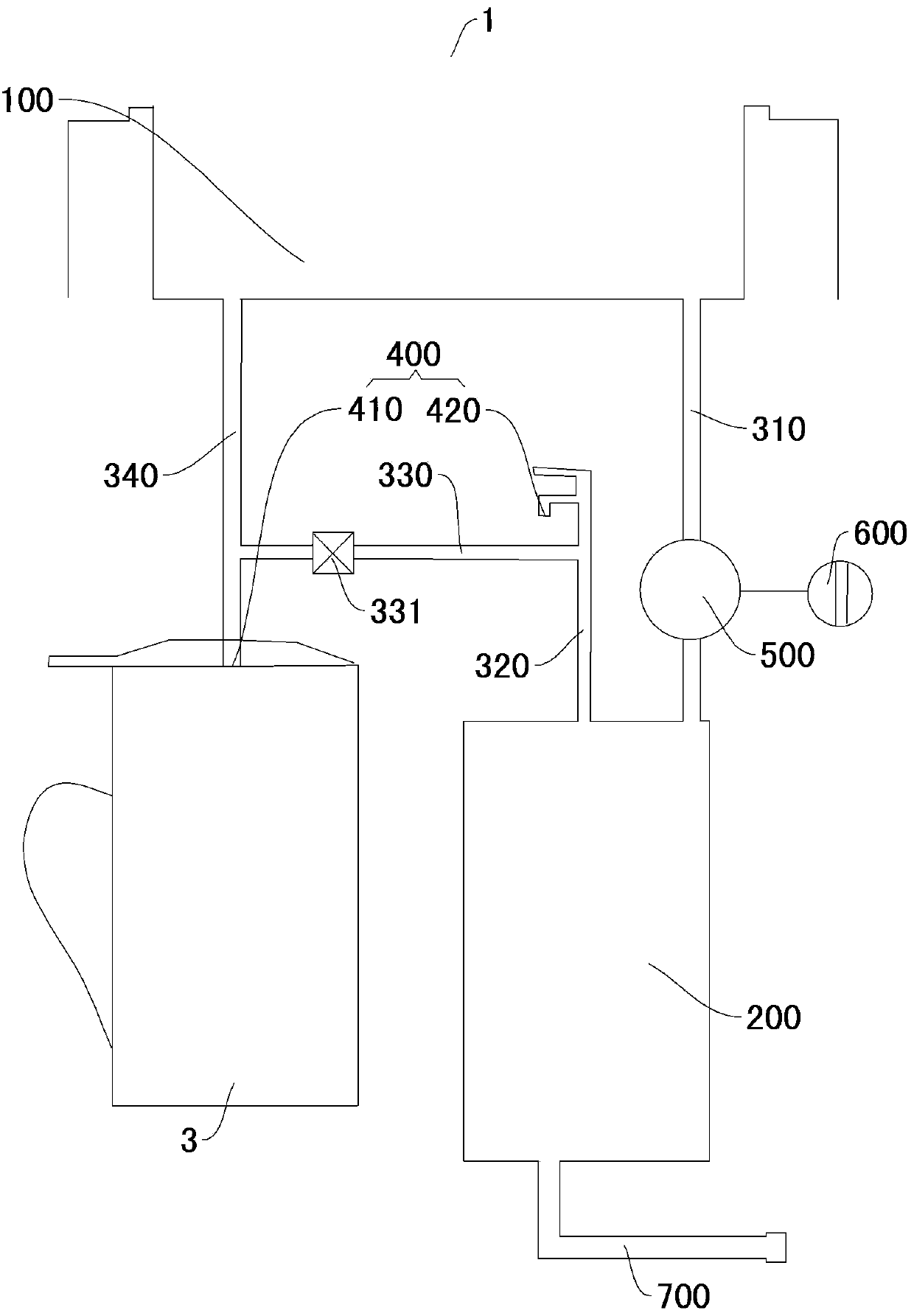

Water dispenser

The invention discloses a water dispenser. The water dispenser comprises a water source tank, a tank body, a circulating pipeline and a water pump, wherein the circulating pipeline is respectively connected with the water source tank and the tank body; a water outlet is formed in the circulating pipeline; the water pump is connected with at least one of the water source tank, the tank body and the circulating pipeline and is used for driving water to form a circulating water channel in the water source tank, the tank body and the circulating pipeline. The water dispenser disclosed by the embodiment of the invention has the advantages of simpleness and convenience for cleaning, high cleaning efficiency, low cleaning expenses, low production cost and the like.

Owner:MIDEA GRP CO LTD +1

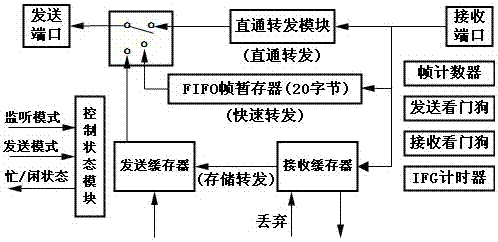

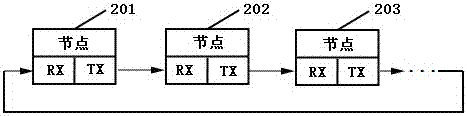

Unidirectional loop network controller and usage method thereof

ActiveCN106899472AAvoid circular forwardingAchieve cleaning effectData switching networksMonitor modeStore and forward

The present invention discloses an unidirectional loop network controller. The controller comprises a receiving port, a direct connection forwarding module, a sending port and an IFG timer; and the controller also comprises a control state module configured to control a node to be located at a monitoring mode or the sending module or at a busy state or an idle state, a forwarding switching switch configured to switch a forwarding line between a receiving port and the sending port to forward line connection between the receiving port and the sending port through one of the direct connection forwarding, the fast forwarding or storage forwarding, and a frame timer configured to record the number of the data frames actively sent by one node in the unidirectional loop network. The unidirectional loop network controller solves the problem that the current unidirectional loop network cannot perform multi-frame forwarding at the same time, and provides cleaning and fault location of error data frames in the unidirectional loop network through the unidirectional loop network controller.

Owner:熊厚德

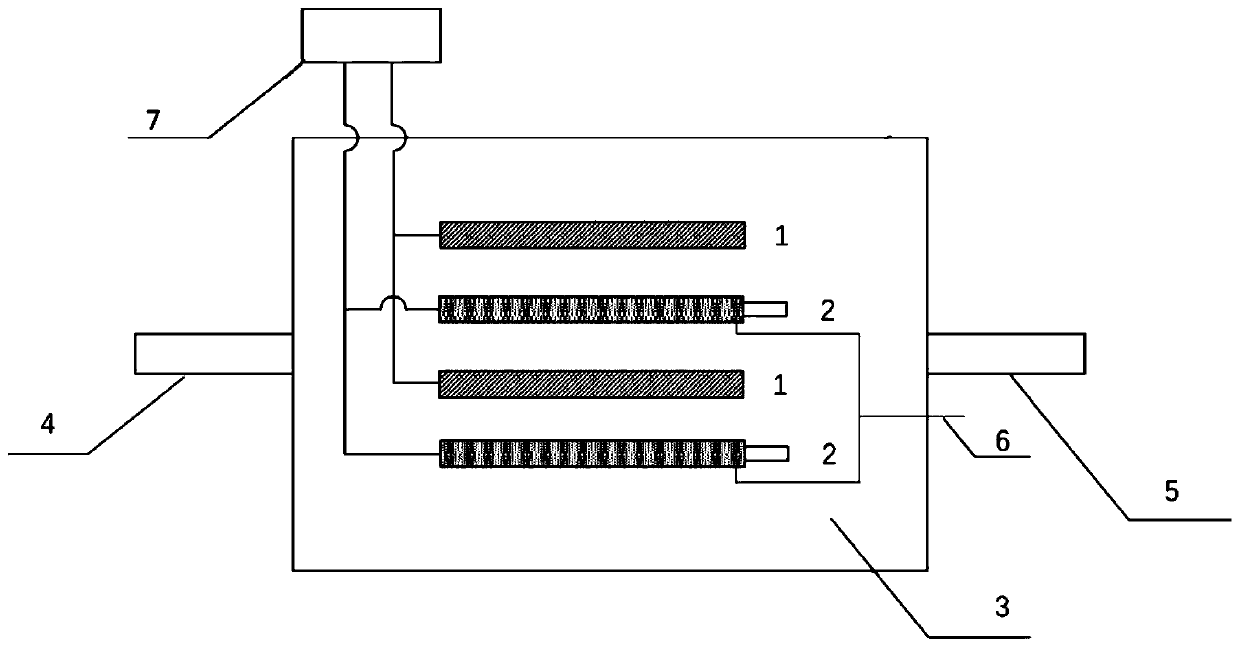

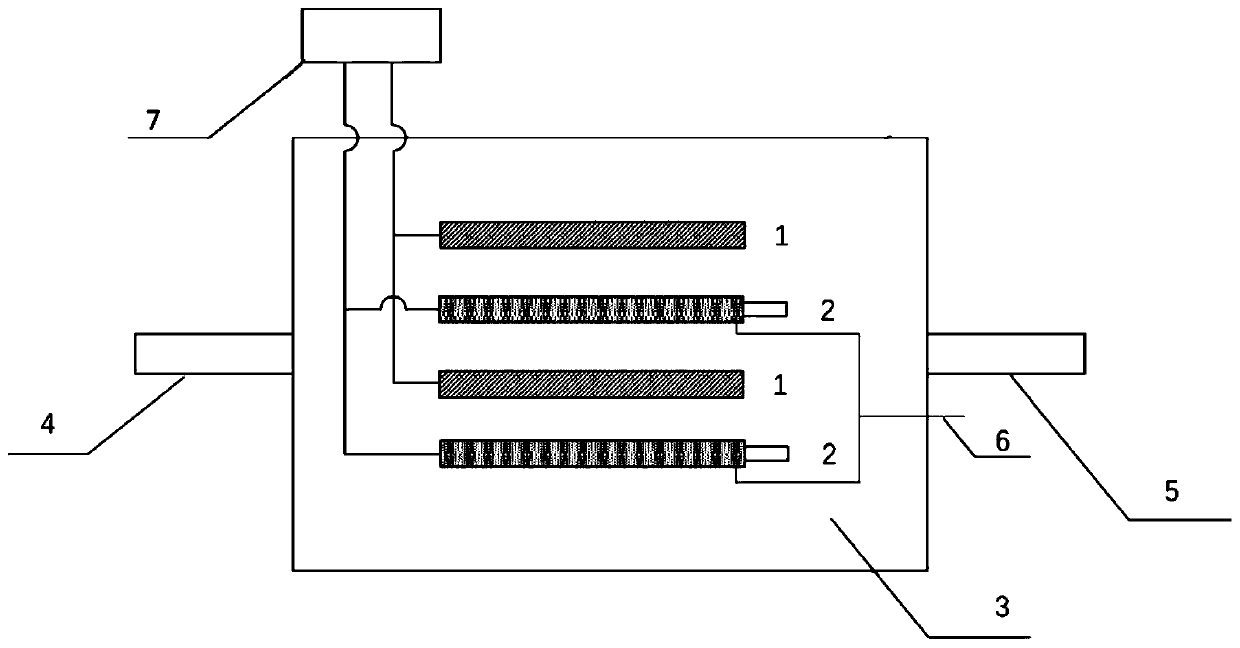

Electrochemical-membrane separation water-treatment plant and treatment method thereof

InactiveCN110002548AGuaranteed water permeabilityAchieve cleaning effectSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisWater qualityElectrochemistry

The invention provides electrochemical-membrane separation water-treatment plant and a treatment method thereof. The plant comprises a reaction tank, inside which a membrane module is arranged. The membrane in the membrane module is a conductive membrane. A positive plate is arranged parallel to the membrane module at one side of the membrane module. The membrane module, which is used as a negative plate, and the positive plate are connected with an external power source. The main body of the reaction tank is equipped with a water inlet and a water outlet. An outlet of the membrane module is connected with the water outlet on the main body of the reaction tank. By combining electrochemistry and membrane separation process, polluted water is pretreated by electrooxidation or electric flocculation to form a pollutant filter cake layer, and the membrane module having the conductive membrane is used as the cathode to degrade the pollutant. Thus, membrane pollution is alleviated and the membrane cleaning effect is also achieved, the service cycle of the membrane is prolonged, and service life of the membrane is prolonged. Meanwhile, separation efficiency of pollutants in water is enhanced, and the water quality of effluent is improved.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

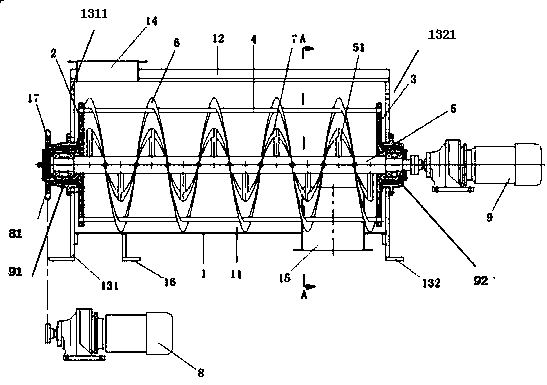

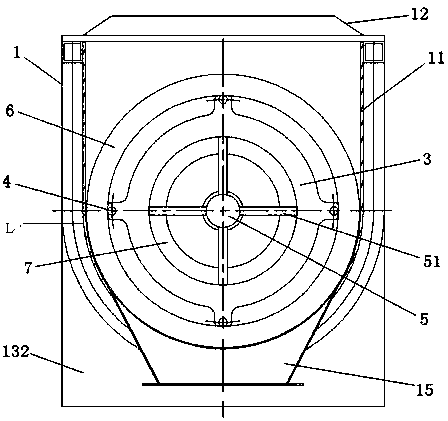

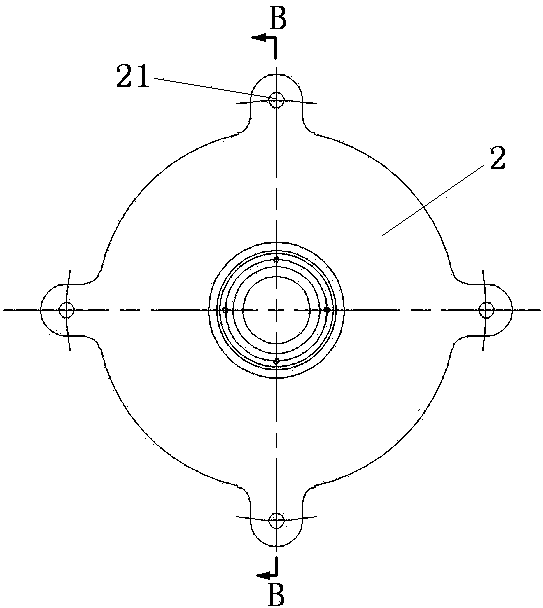

Self-cleaning type double-helical-ribbon differential velocity mixer

InactiveCN103768973AAchieve cleaning effectImprove mixing uniformityRotary stirring mixersMixer accessoriesMotor driveEngineering

The invention relates to a self-cleaning type double-helical-ribbon differential velocity mixer. According to the self-cleaning type double-helical-ribbon differential velocity mixer disclosed by the invention, feeding and discharge holes are formed in the two ends of a U-shaped casing respectively, a spindle is fixed on left and right side plates of the casing respectively by virtue of left and right bearing seats, inside and outside helical ribbons are driven by two motors respectively, the spindle is provided with a plurality of support rods, and the inner helical ribbon is fixed at the spindle by virtue of the support rods and is driven by the corresponding motor; the outer helical ribbon is fixed at the peripheries of a plurality of connecting rods which are connected with drive discs; the drive discs are installed at the outer rings of the left and right bearing seats and include a driving disc with mounting holes and a driven disc with mounting holes, and the mounting holes are circumferentially formed in the driving disc and the driven disc uniformly with equal quantity; one end of each connecting rod is fixed on each mounting hole of the driving disc, and the other end of each connecting rod is fixed on each mounting hole of the driven disc, so that the plurality of connecting rods are arranged on the outer side of the spindle in parallel, and the other motor drives the driving disc to enable the outer helical ribbon to rotate; the outer helical ribbon is close to the lower part of the inner wall of the U-shaped casing. With the adoption of the self-cleaning type double-helical-ribbon differential velocity mixer, when materials are mixed, the rotational directions of the inner and outer helical ribbons are opposite, and a differential velocity can be adjusted; during discharging, the rotational directions of the inner and outer helical ribbons are the same so as to increase the discharge speed.

Owner:SHANGHAI TIANYI GAODE ELECTROMECHANICAL

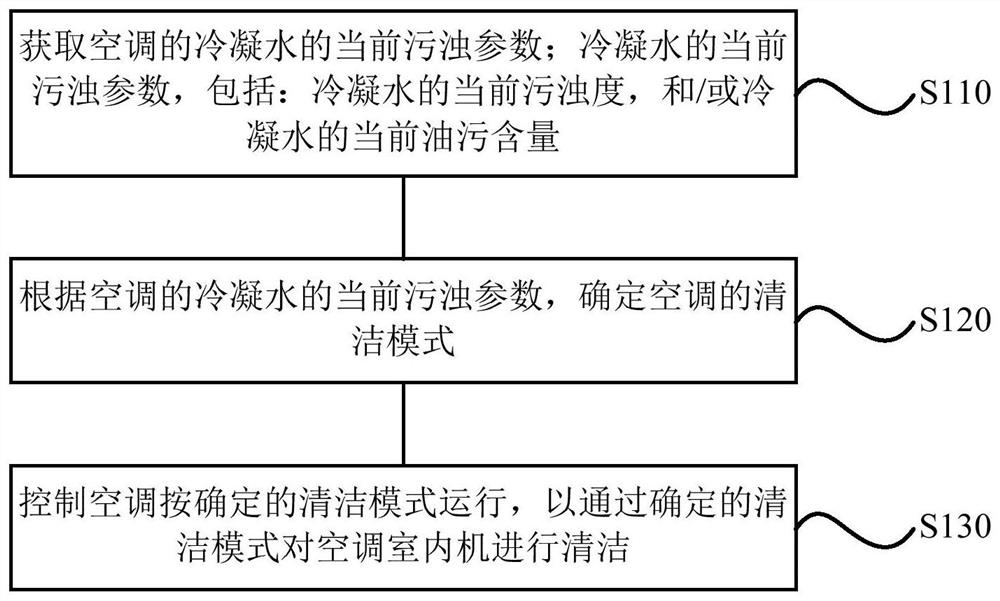

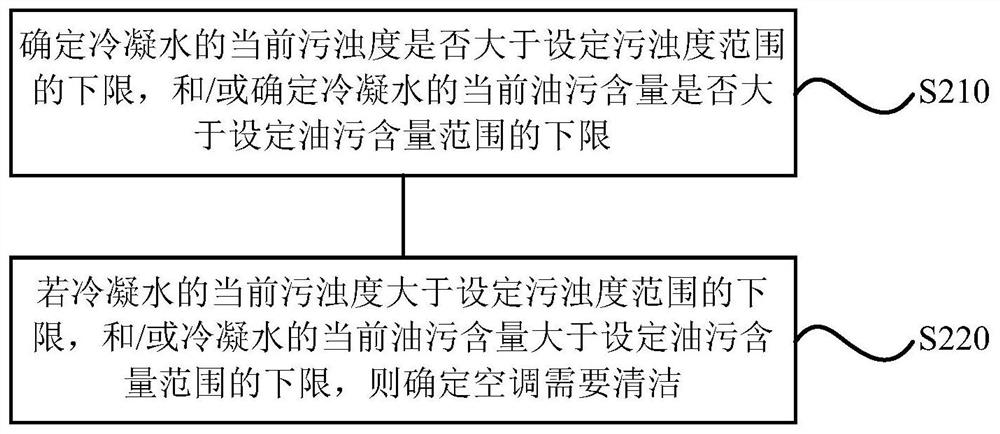

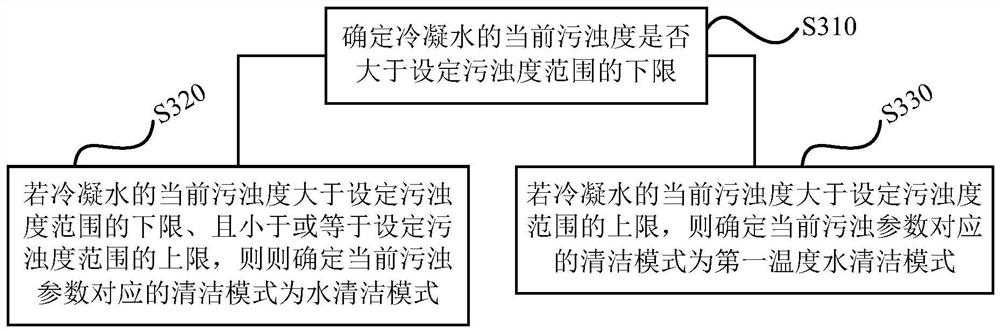

Cleaning control method, cleaning control device, air conditioner, storage medium and processor

InactiveCN111811106AImprove convenienceAchieve cleaningMechanical apparatusSpace heating and ventilation safety systemsCondensed waterPollution

The invention discloses a cleaning control method, a cleaning control device, an air conditioner, a storage medium and a processor. The cleaning control method comprises the steps of obtaining a current air conditioner condensate water pollution parameter which comprises a current pollution degree of condensate water and / or a current oil pollution content of the condensate water, determining a cleaning mode corresponding to the current pollution parameter according to the current air conditioner condensate water pollution parameter, and controlling the air conditioner to operate in the determined cleaning mode so as to realize the cleaning of an indoor unit of the air conditioner through the determined cleaning mode. The solution of the invention solves the problem of inconvenient cleaningof the air conditioner due to the fact that the air conditioner is relatively simplistic in self-cleaning mode and can not be correspondingly cleaned according to the pollution degree of the air conditioner, and achieves the effects of diversifying the cleaning modes of the air conditioner and performing corresponding cleaning according to the pollution degree of the air conditioner so as to improve the cleaning convenience of the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

Cable winding equipment for power maintenance

The invention discloses cable winding equipment for power maintenance. The cable winding equipment comprises a base; a cleaning mechanism, a wire arrangement mechanism and a winding mechanism are sequentially mounted at the top of the base from front to back; and a driving mechanism used for driving the winding mechanism is mounted on the winding mechanism. By arranging the cleaning mechanism, thewire arrangement mechanism and the winding mechanism, the surface of a cable can be cleaned before winding, the cable can be guided through a wire guiding ring before winding, the situation that thecable is unevenly wound in the winding process and consequently knotted when used next time can be prevented, meanwhile an air injection mechanism is driven to clean a brush while the cable is cleanedthrough the brush, and thus the effect that the brush is cleaned while the surface of the cable is cleaned is achieved.

Owner:JIANGSU ELECTRIC POWER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com