Mask cleaning method and cleaning device

A technology for cleaning device and mask, which is applied to cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., and can solve problems such as unclean mask cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0048] The present invention provides a solution to the technical problem of unclean mask cleaning in the prior art.

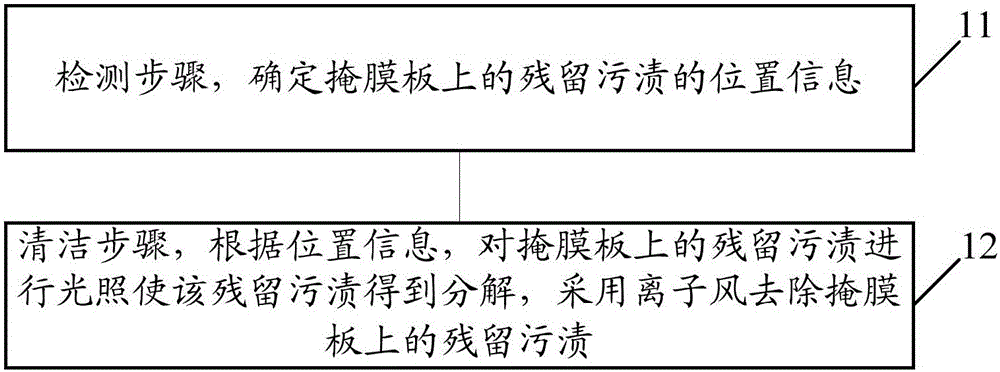

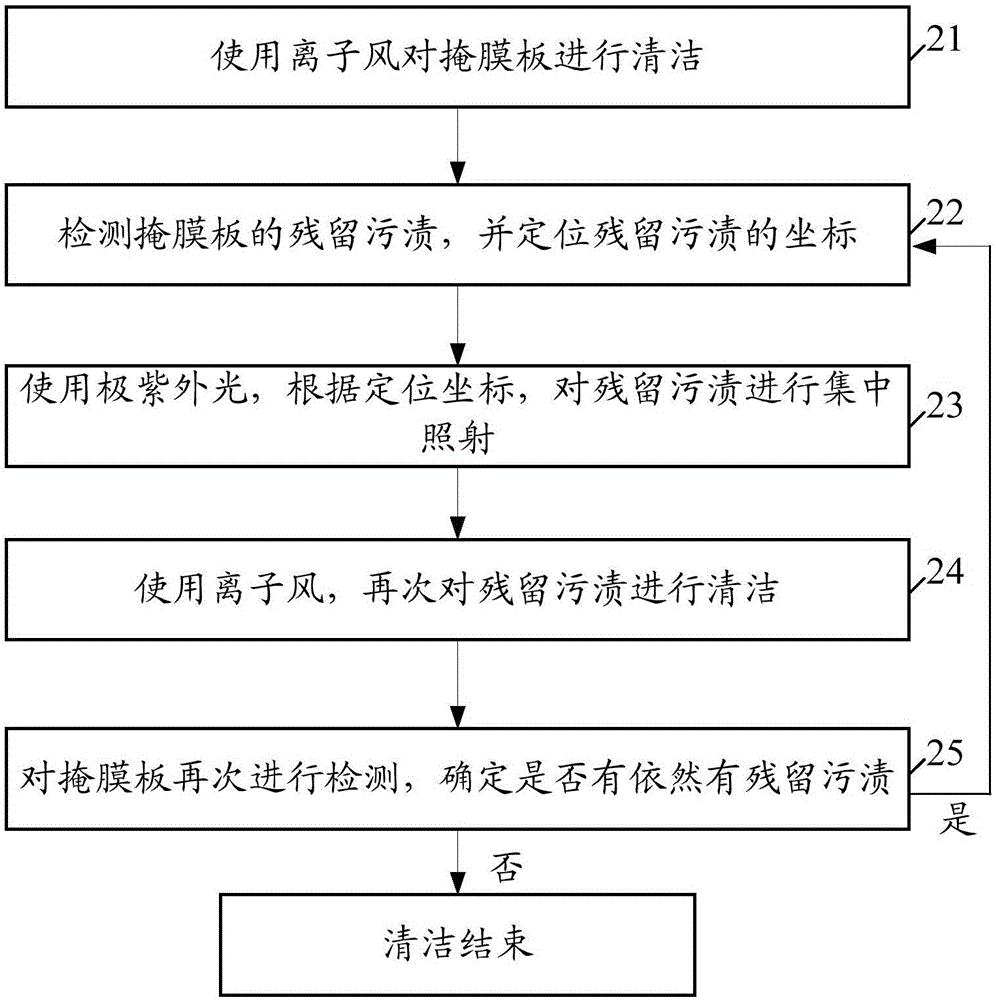

[0049] On the one hand, embodiments of the present invention provide a mask cleaning method, such as figure 1 shown, including:

[0050] Detection step 11, determining the position information of the residual stain on the mask;

[0051] Cleaning step 12, according to the position information, illuminate the residual stains on the mask plate to decompose the residual stains, and use the ion wind to remove the residual stains on the mask plate; wherein, the ion wind can make the residual stains and the mask plate band Have the same charge, so that the residual stain and the mask will have a certain repulsion force, increasing the release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com