Patents

Literature

1991results about How to "Wind evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for supporting energy conversion modules

ActiveUS7647924B2Stable geometryReduce in quantityPhotovoltaic supportsSolar heating energyCollection systemEnergy analysis

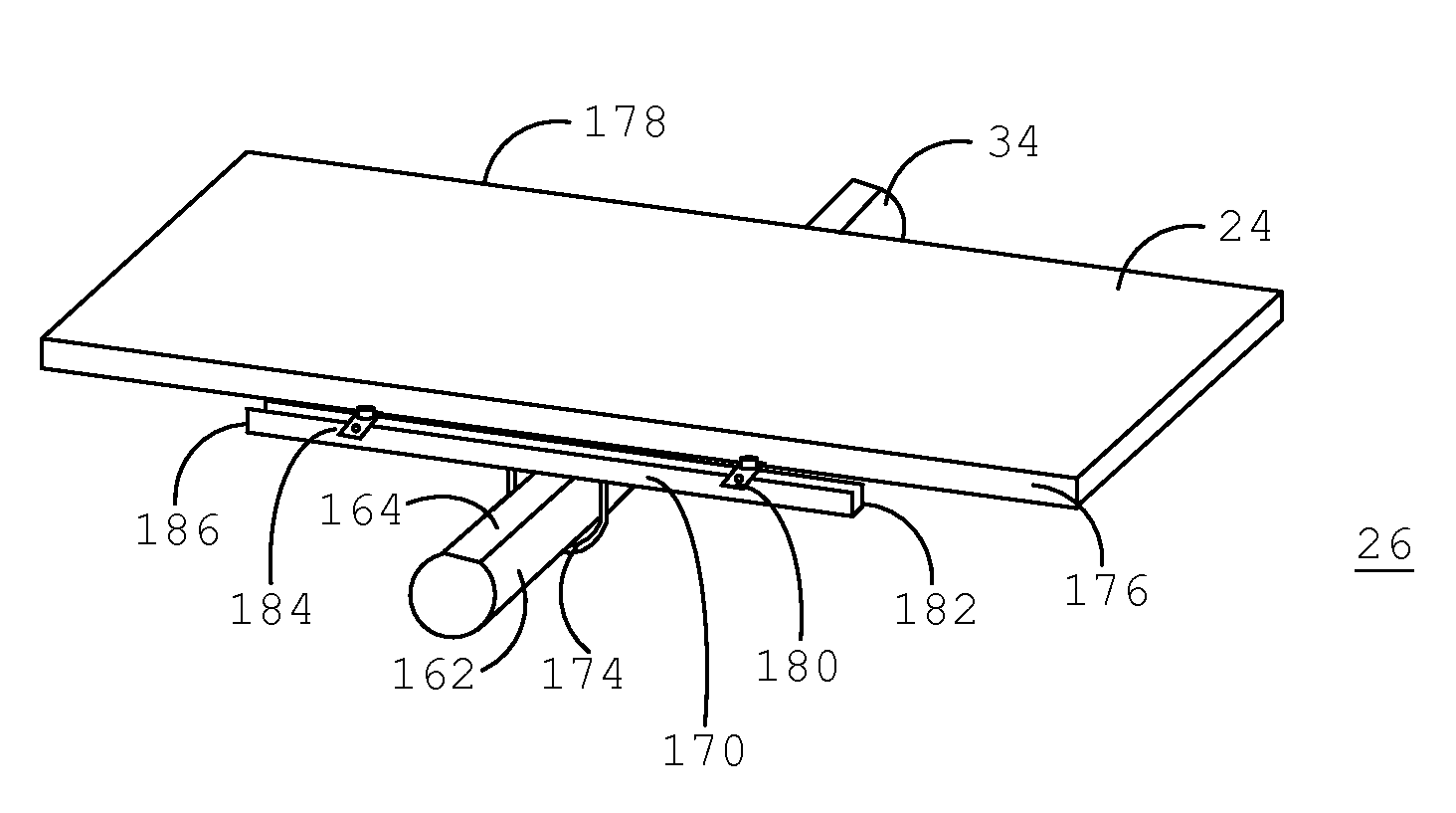

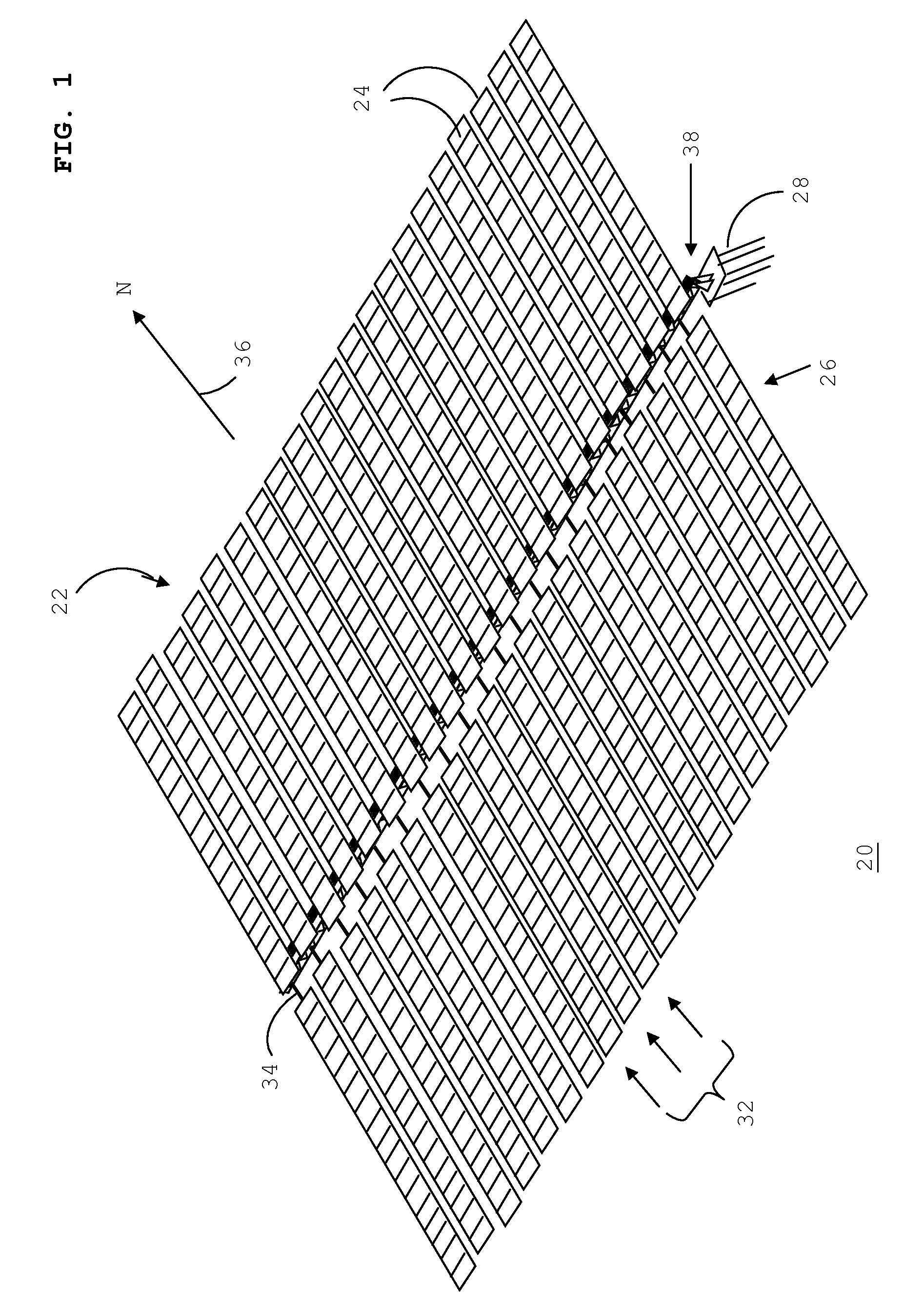

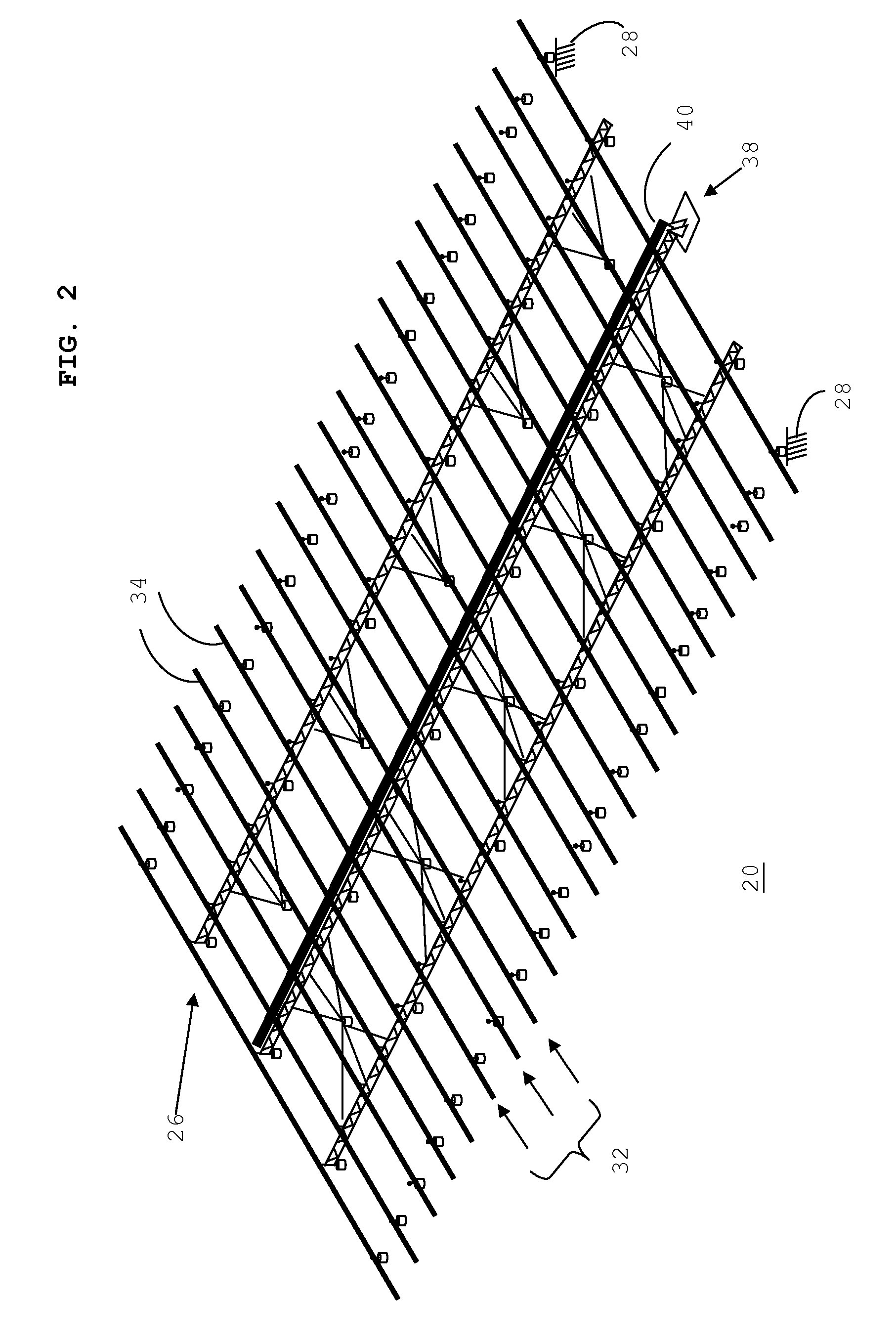

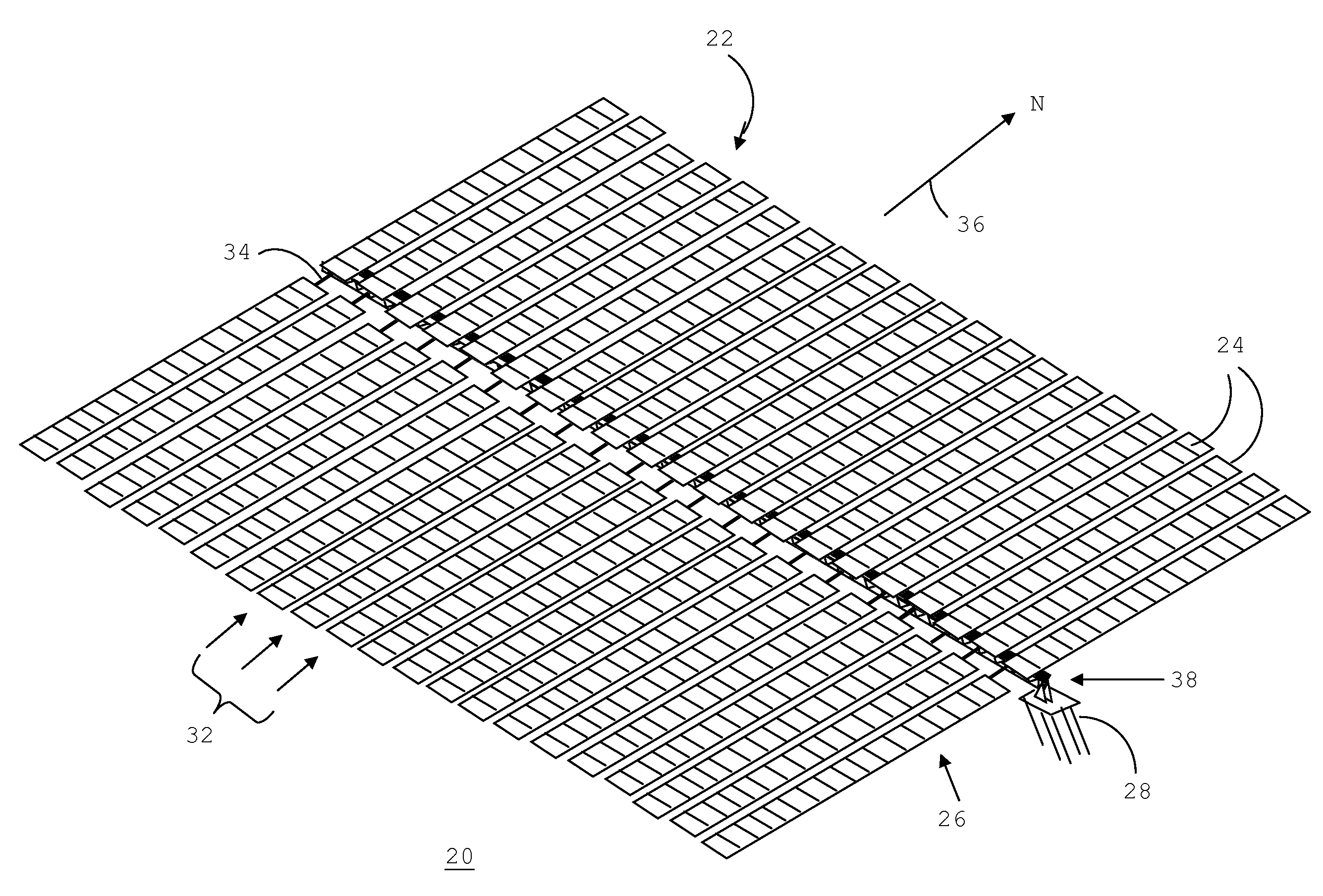

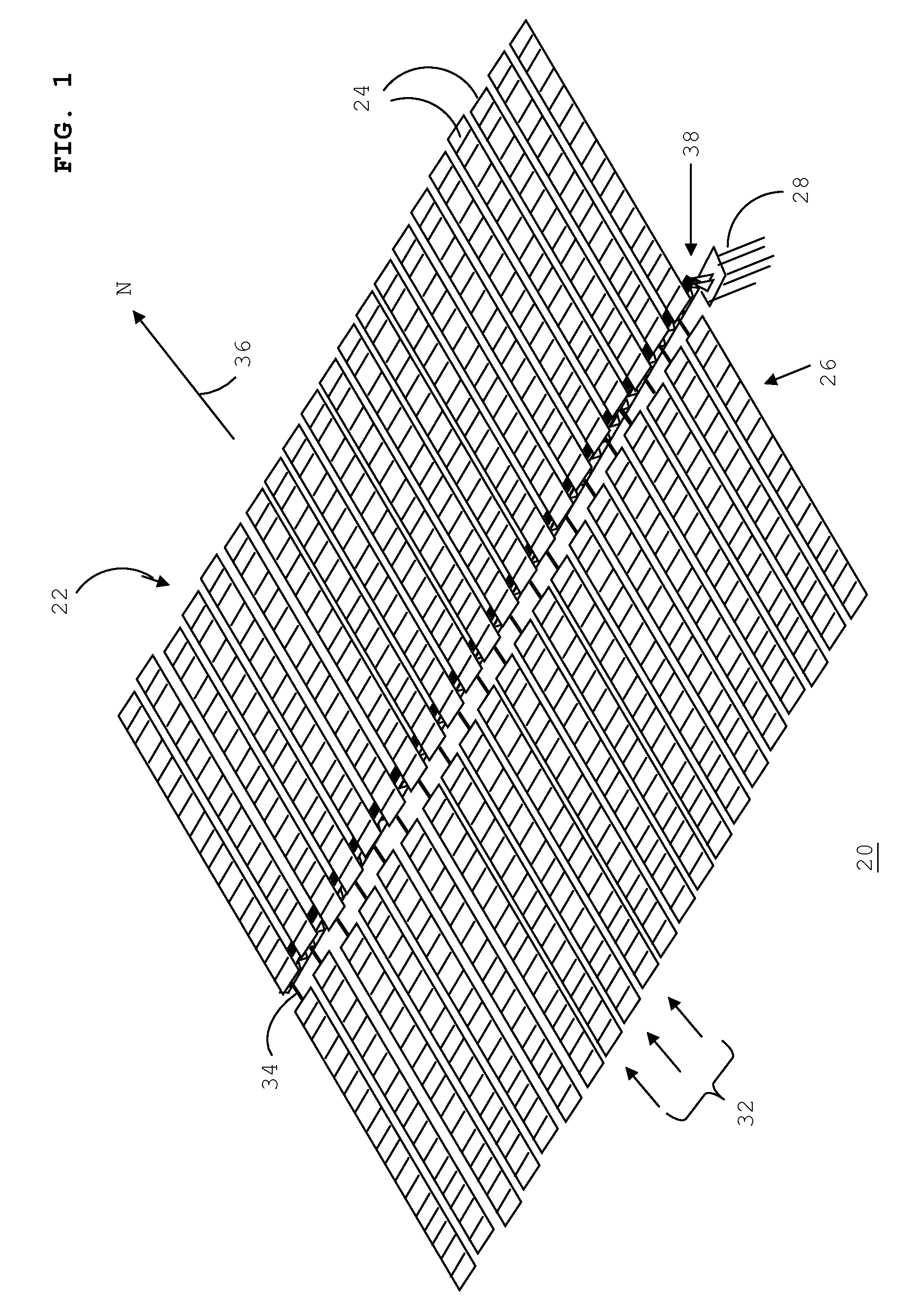

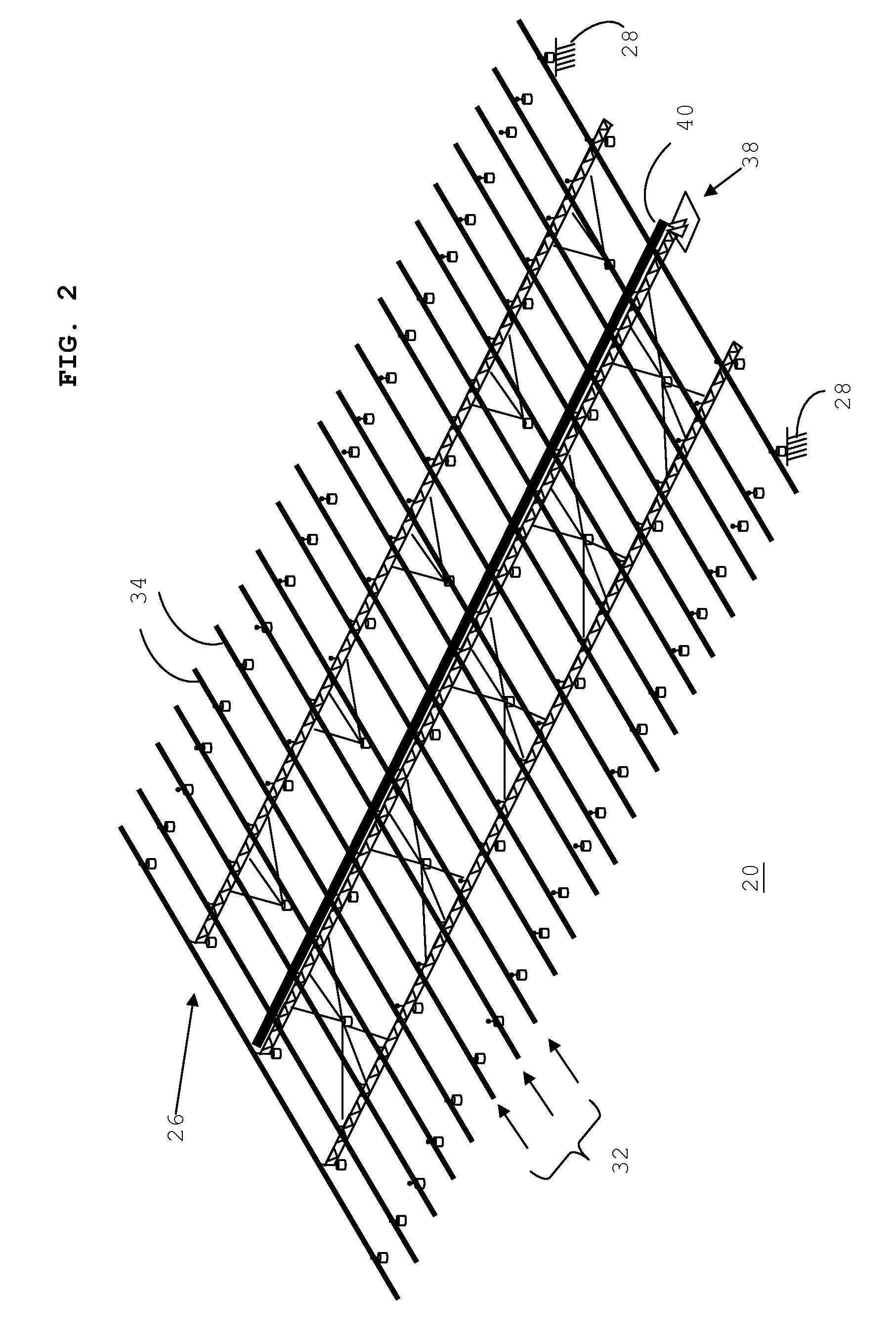

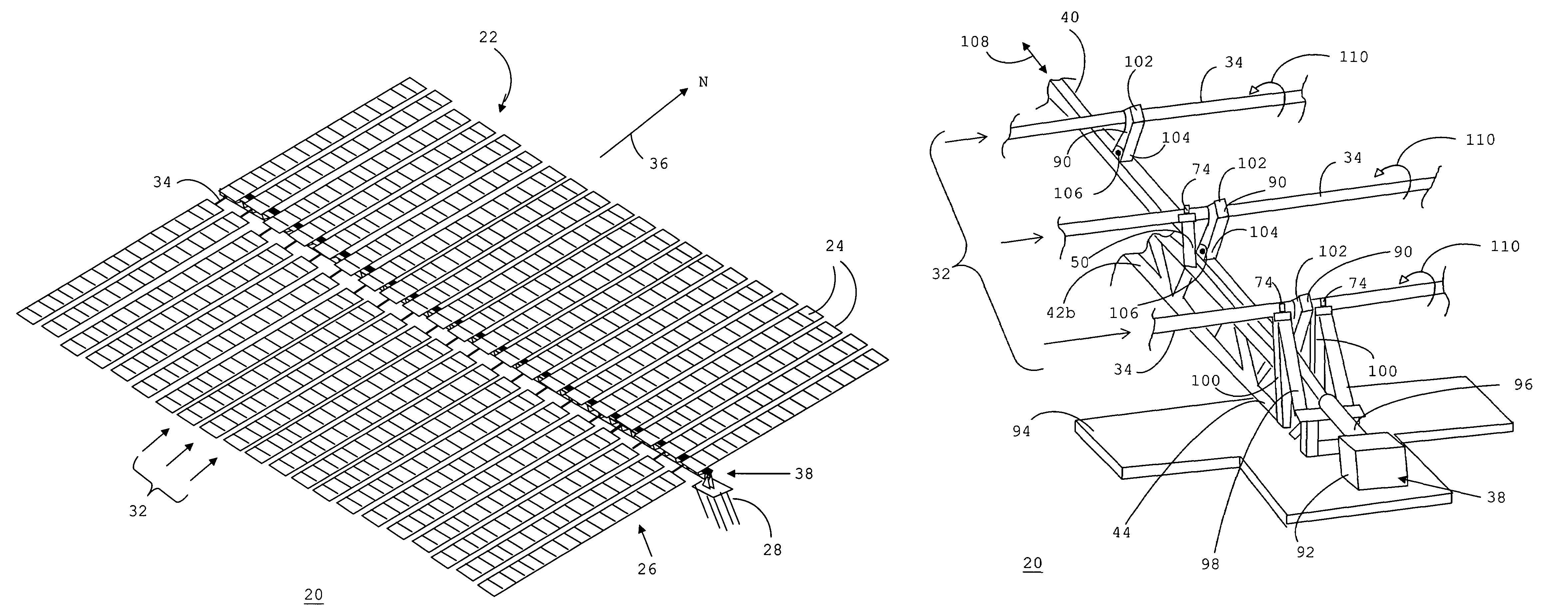

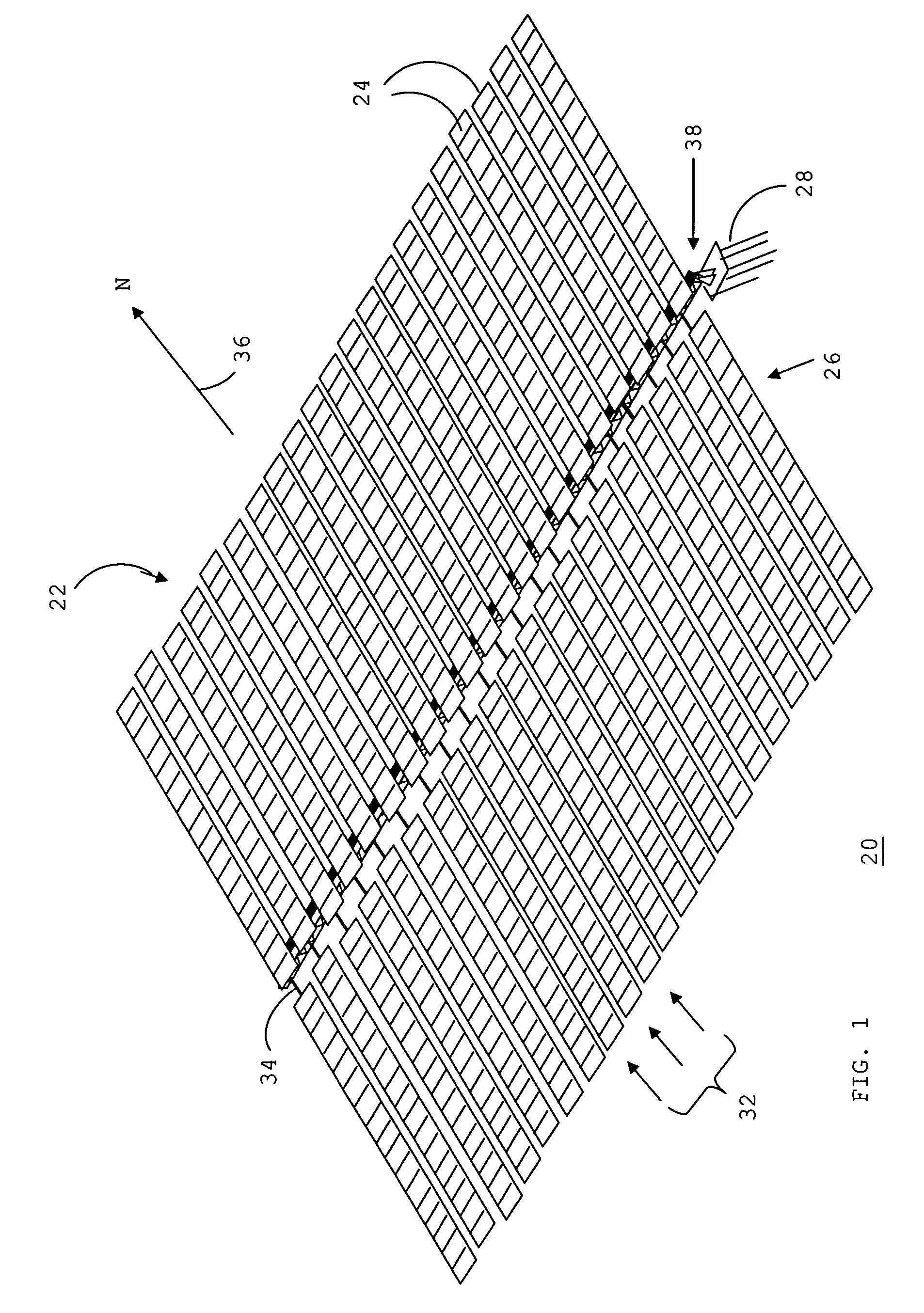

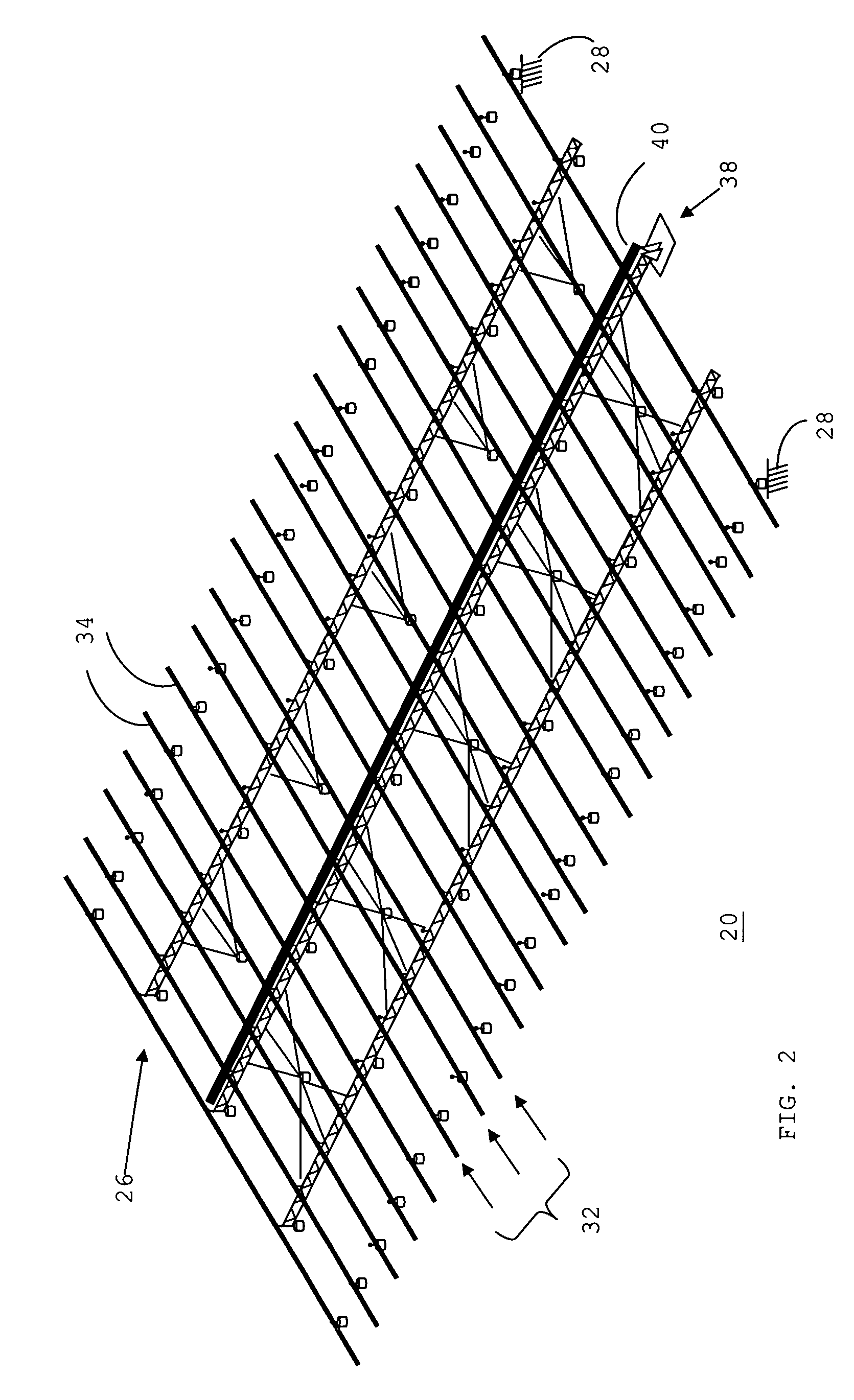

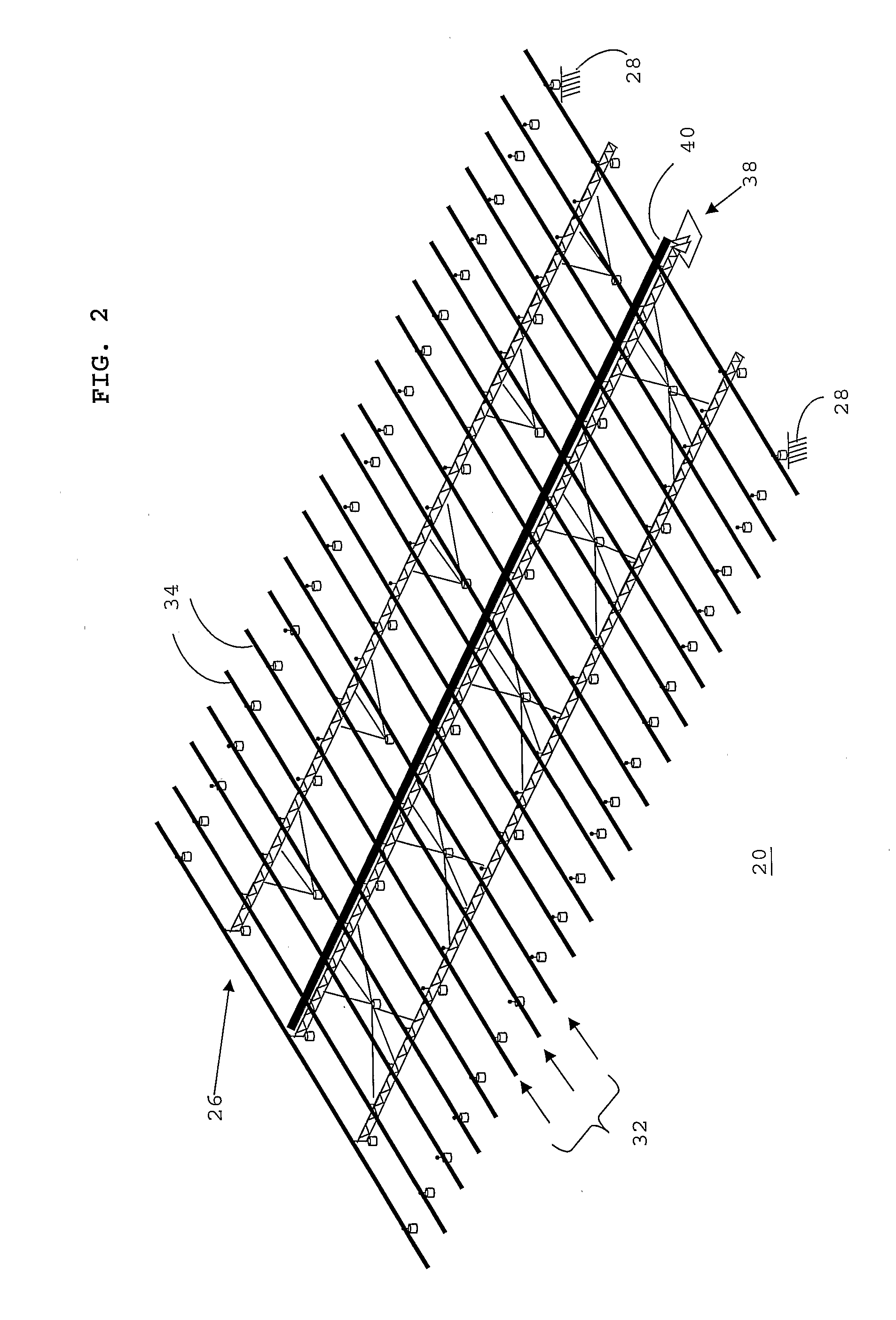

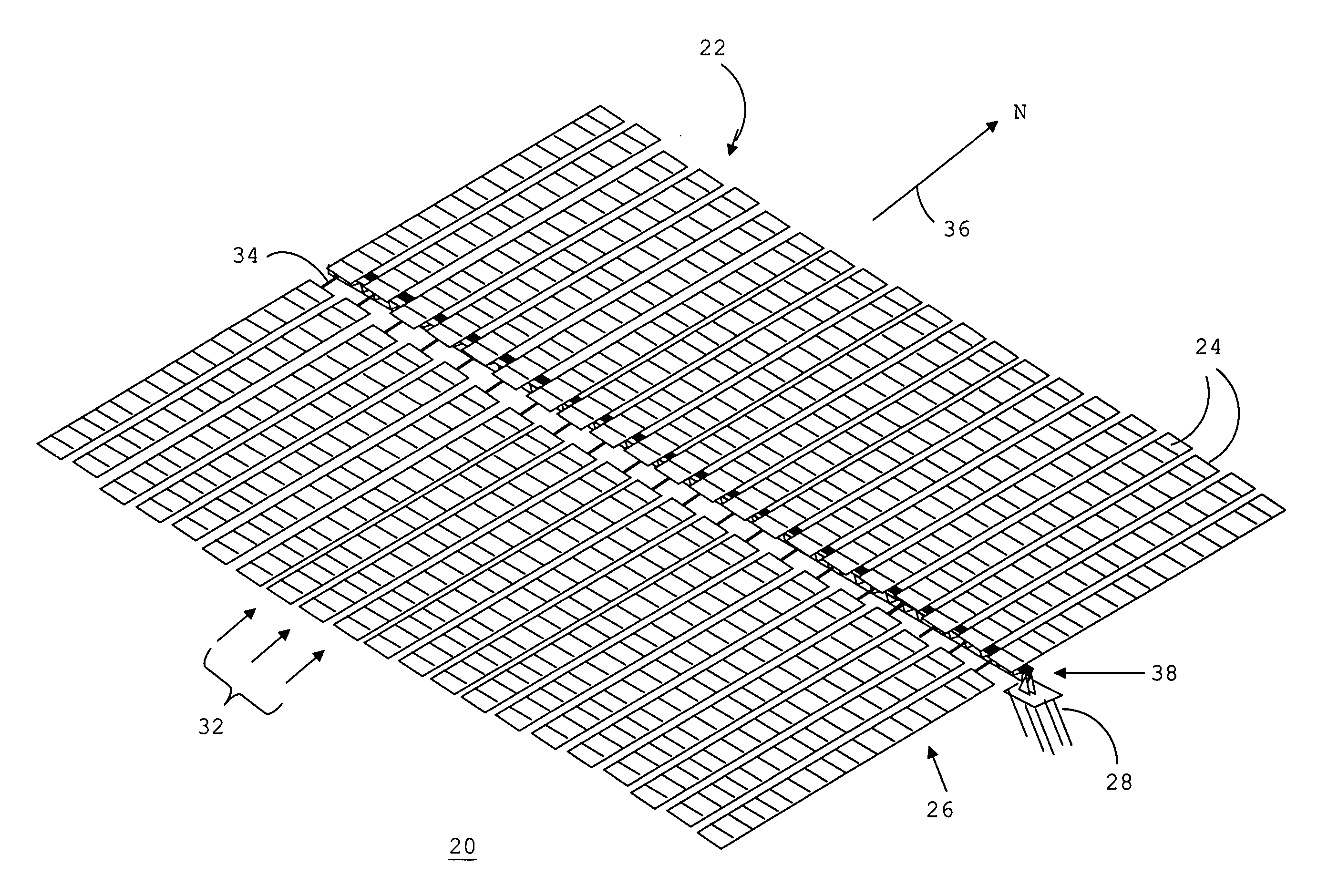

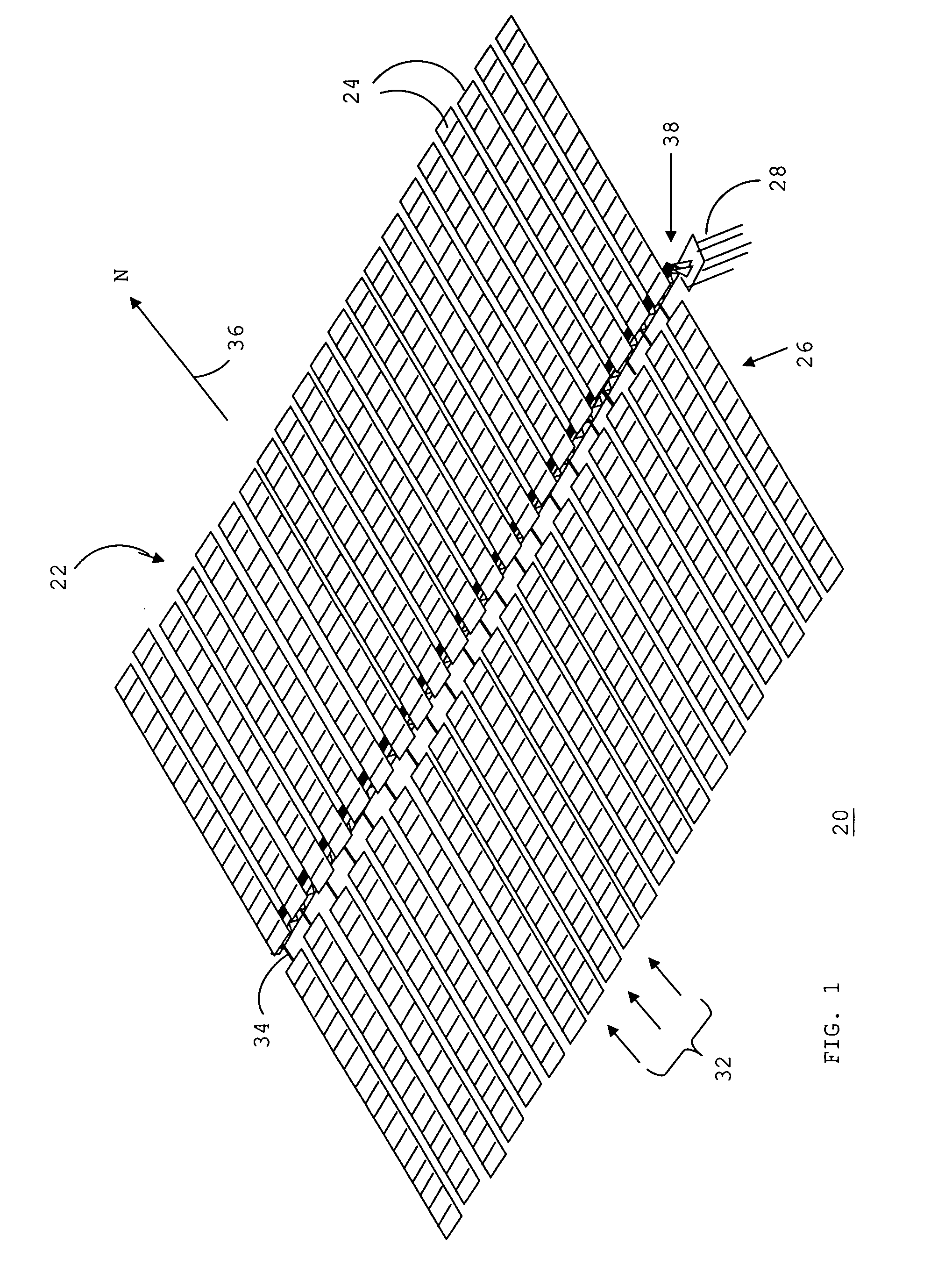

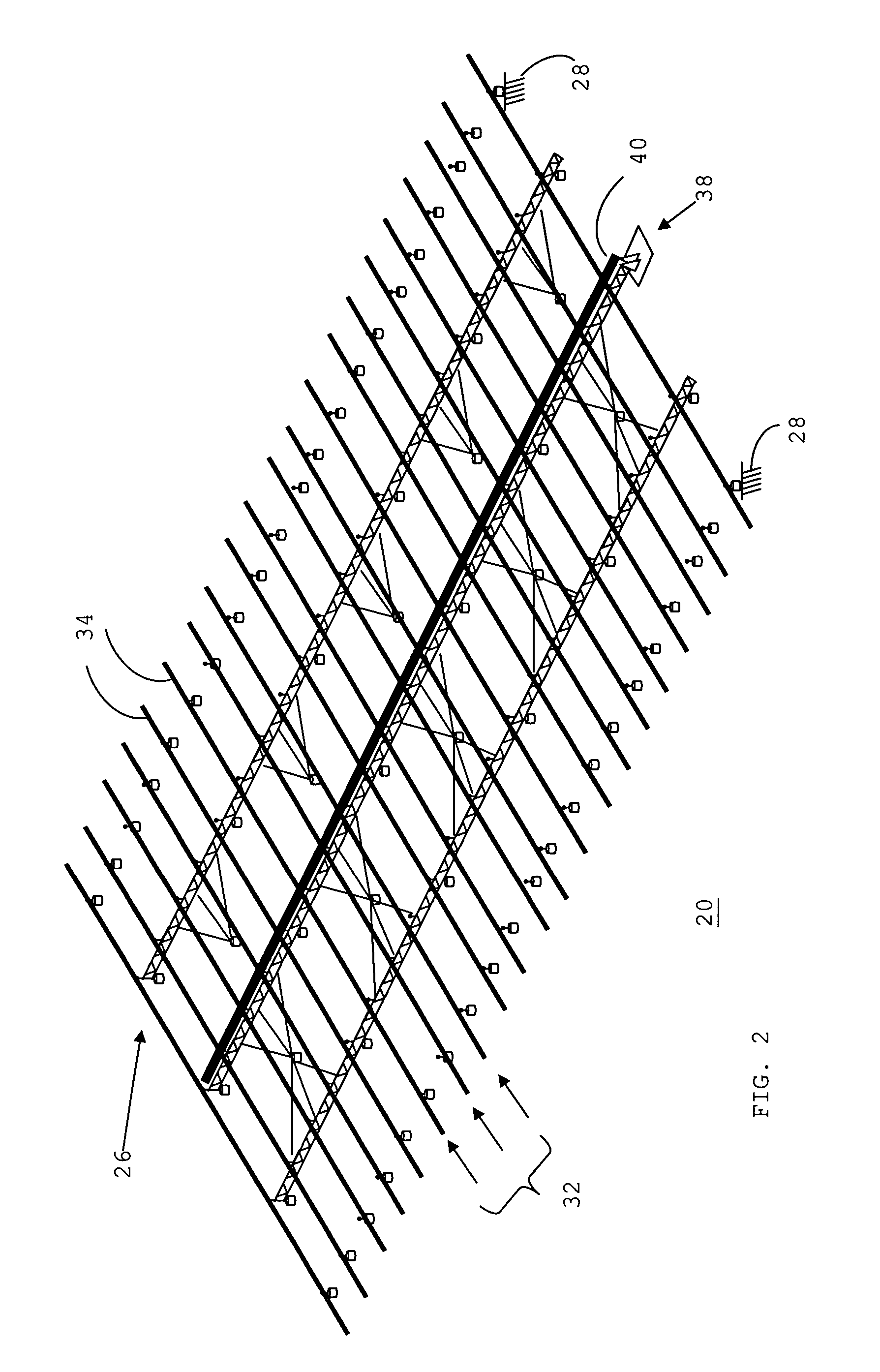

A structure (26) for supporting an array (22) of solar panels (24) in a solar energy collection system (20) includes a support assembly (42) formed from a rigid subassembly (44). The subassembly (44) includes a truss (68), a post (46) downwardly extending from the truss (68) for attachment to a footing (48), and posts (50) upwardly extending from the truss (68). The structure (26) further includes torsion tubes (34), each of which is pivotally retained by one of the posts (50) to form parallel rows (32) of torsion tubes (34). Multiple ganged piers (44) can be interconnected to increase the number of rows (32) of the system (20). The solar panels (24) are attached to the torsion tubes (34) to form the array (22). Each of the torsion tubes (34) may have a flat surface (164) for ready alignment and attachment of solar panels (24) onto the torsion tubes (34).

Owner:UNIRAC INC

System for supporting energy conversion modules

ActiveUS20080236567A1Stable geometryReduce in quantityPhotovoltaic supportsSolar heating energyCollection systemEnergy analysis

A structure (26) for supporting an array (22) of solar panels (24) in a solar energy collection system (20) includes a support assembly (42) formed from a rigid subassembly (44). The subassembly (44) includes a truss (68), a post (46) downwardly extending from the truss (68) for attachment to a footing (48), and posts (50) upwardly extending from the truss (68). The structure (26) further includes torsion tubes (34), each of which is pivotally retained by one of the posts (50) to form parallel rows (32) of torsion tubes (34). Multiple ganged piers (44) can be interconnected to increase the number of rows (32) of the system (20). The solar panels (24) are attached to the torsion tubes (34) to form the array (22). Each of the torsion tubes (34) may have a flat surface (164) for ready alignment and attachment of solar panels (24) onto the torsion tubes (34).

Owner:UNIRAC INC

Structure for supporting energy conversion modules and solar energy collection system

InactiveUS7252083B2Stable geometryReduce in quantityPhotovoltaic supportsSolar heating energyCollection systemActuator

A structure (26) for supporting an array (22) of solar panels (24) in a solar energy collection system (20) includes a support assembly (42) formed from a rigid subassembly (44). The subassembly (44) includes an elongated truss (68), a base (46) coupled to the truss (68) for attachment to a footing (48), and posts (50) extending from a top edge of the truss (68). The structure (26) further includes torsion tubes (34), each of which is pivotally retained by one of the posts (50) to form parallel rows (32) of torsion tubes (34). A number of rigid subassemblies (44) can be interconnected to further increase the number of rows (32) of the system (20). The solar panels (24) are attached to the torsion tubes (34) to form the array (22), and a drive mechanism (38) pivots the torsion tubes (34) via a single elongated actuator and multiple torque arms (90).

Owner:UNIRAC INC

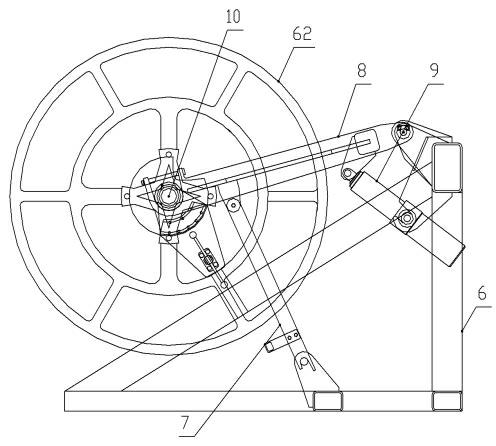

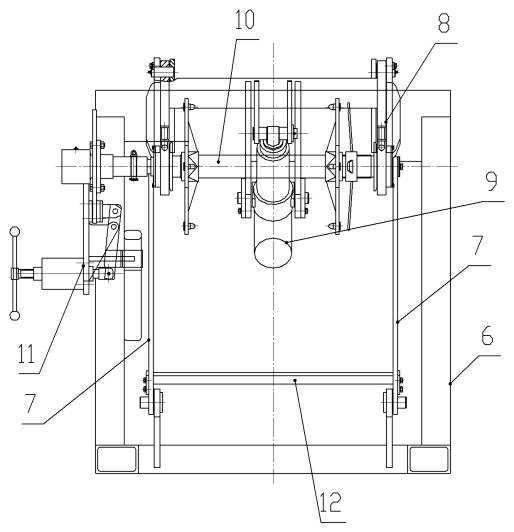

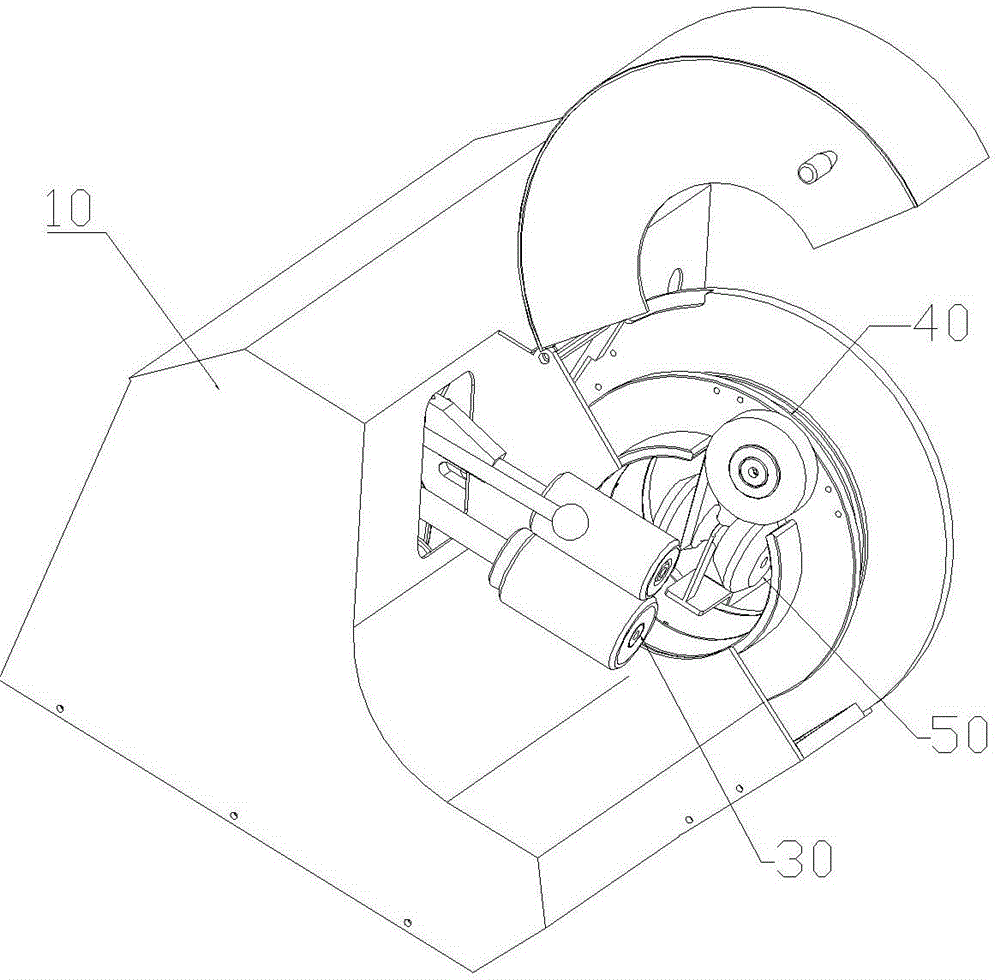

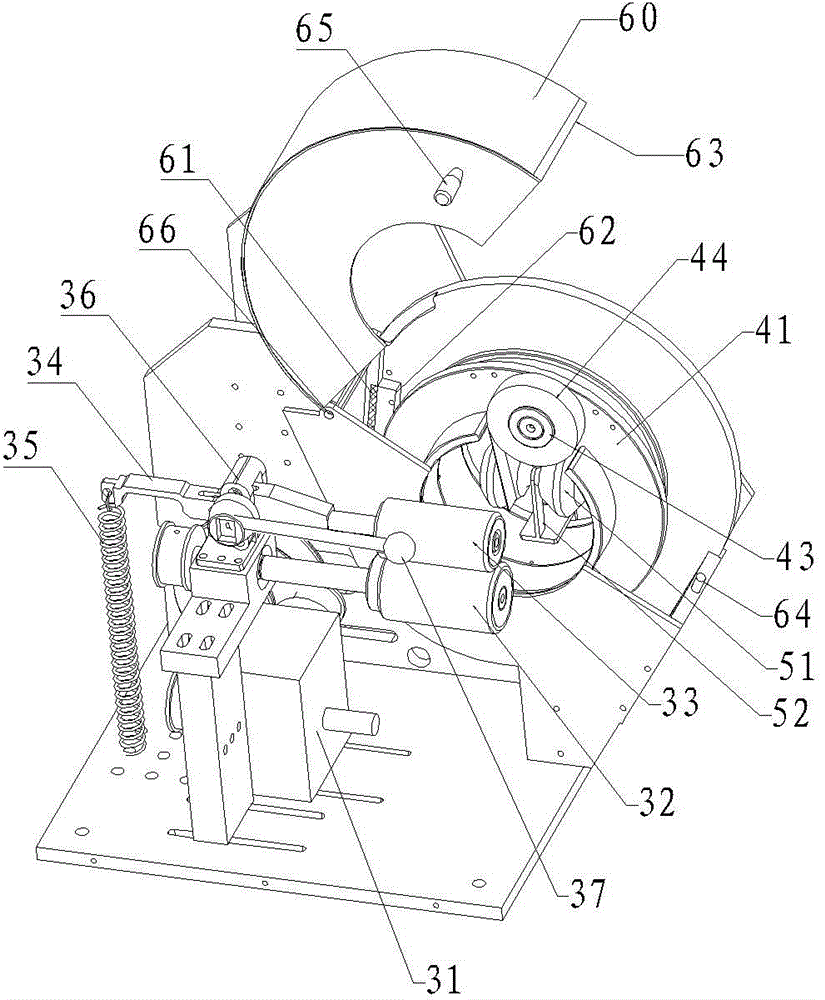

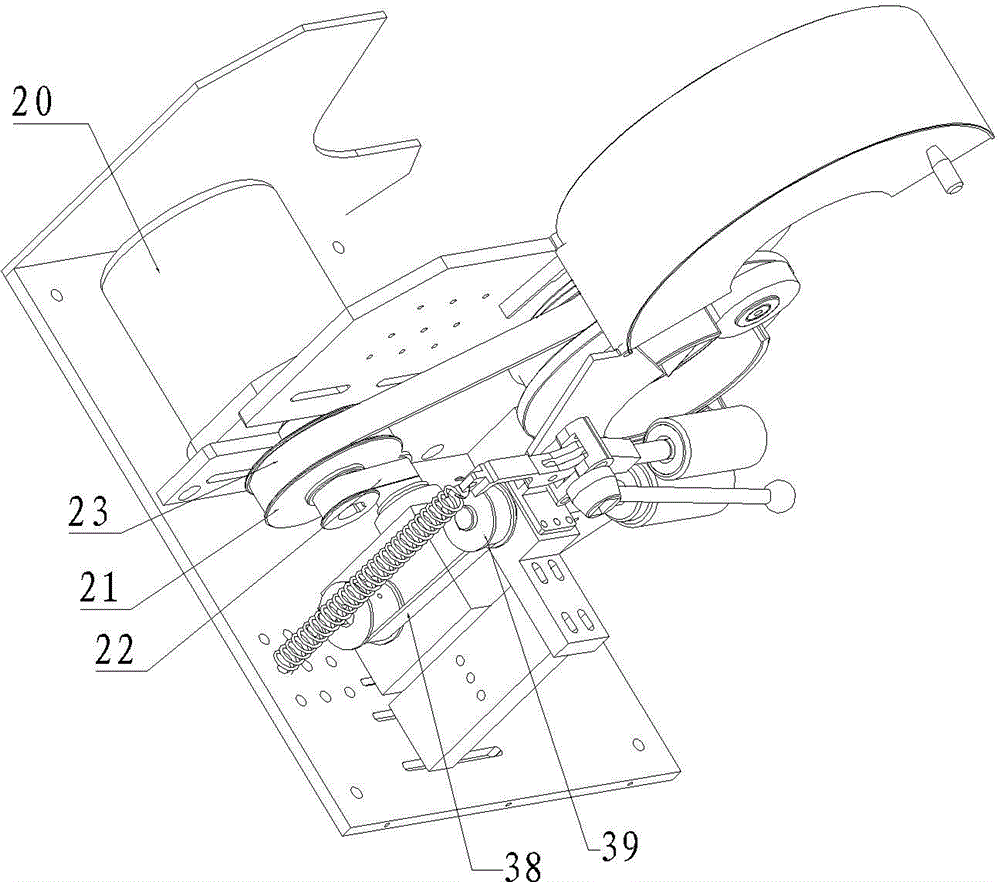

Cable tension self-adjustment winch and control method thereof

ActiveCN106946097AImprove Motion Control AccuracyOvercoming Low Intensity ProblemsFilament handlingMaximum torqueAutomatic control

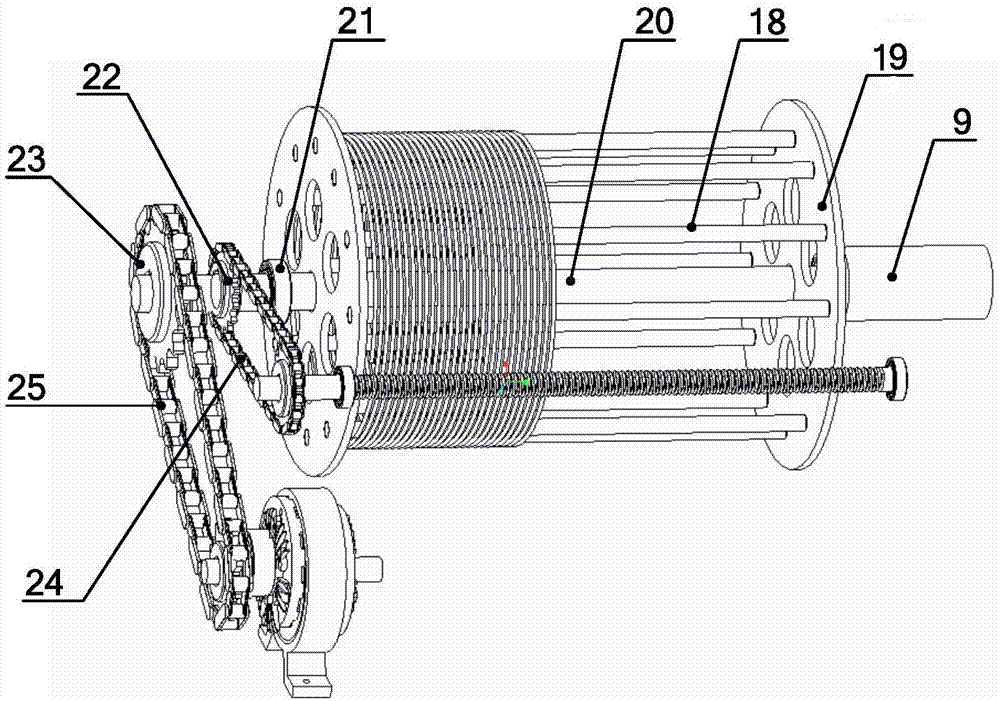

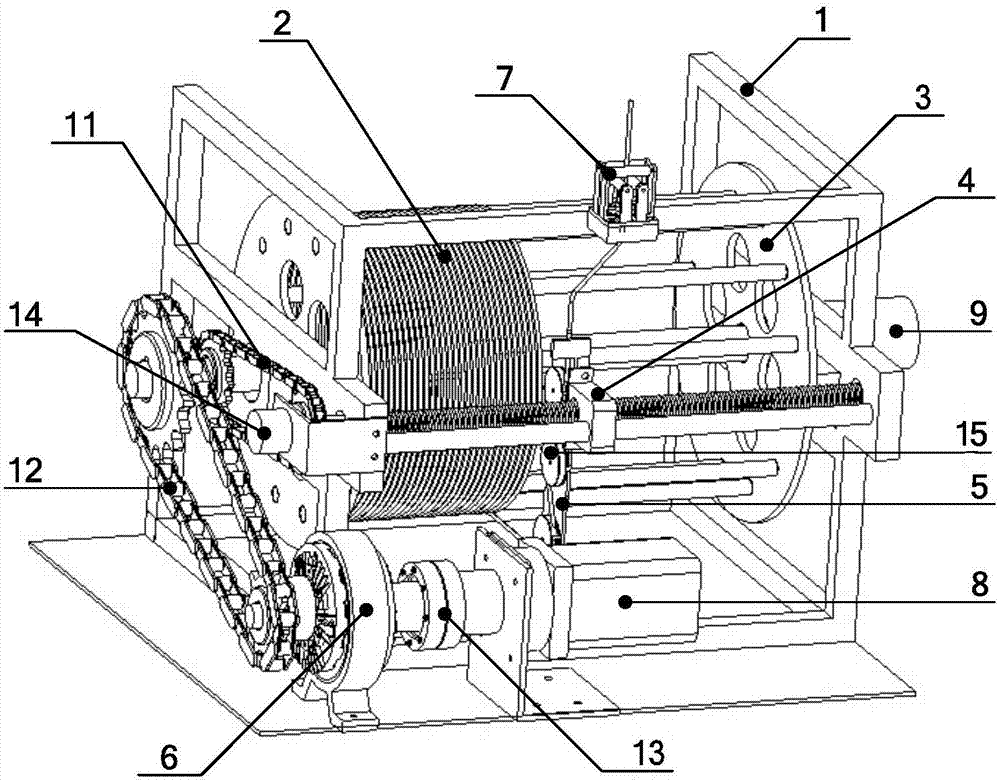

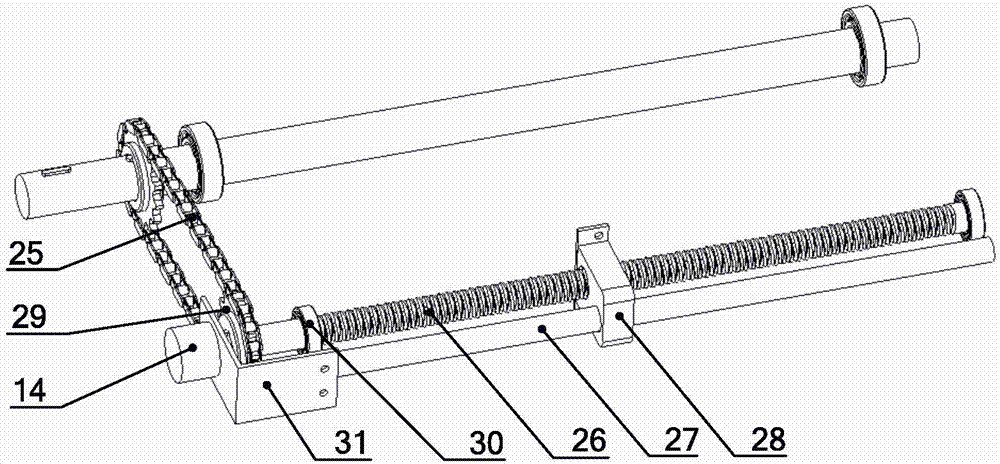

The invention discloses a cable tension self-adjustment winch and a control method thereof, and belongs to the field of automatic control. The cable tension self-adjustment winch comprises a winding drum and a driving device driving the winding drum to rotate; the driving device is electrically connected with a control device; a winding displacement device parallel to the axial direction of the winding drum is arranged on the outer side of the winding drum; the winding drum is linked with the winding displacement device; a tension detection device is arranged on the winding displacement device, is located between the winding displacement device and the winding drum, and is electrically connected with the control device; and a tension protection device is connected with between the driving device and the winding drum, limits maximum torque output by the driving device and is connected with the control device. Through the measurement on winding and unwinding stressed states and winding and unwinding movement states of a cable and a clutch state of the tension protection device, self-adaption control is carried out on a rotating speed and torque of the winding drum, so that winding and unwinding movement of the cable is coordinated with active movement of a high-speed mobile object, and cable breakage is avoided.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

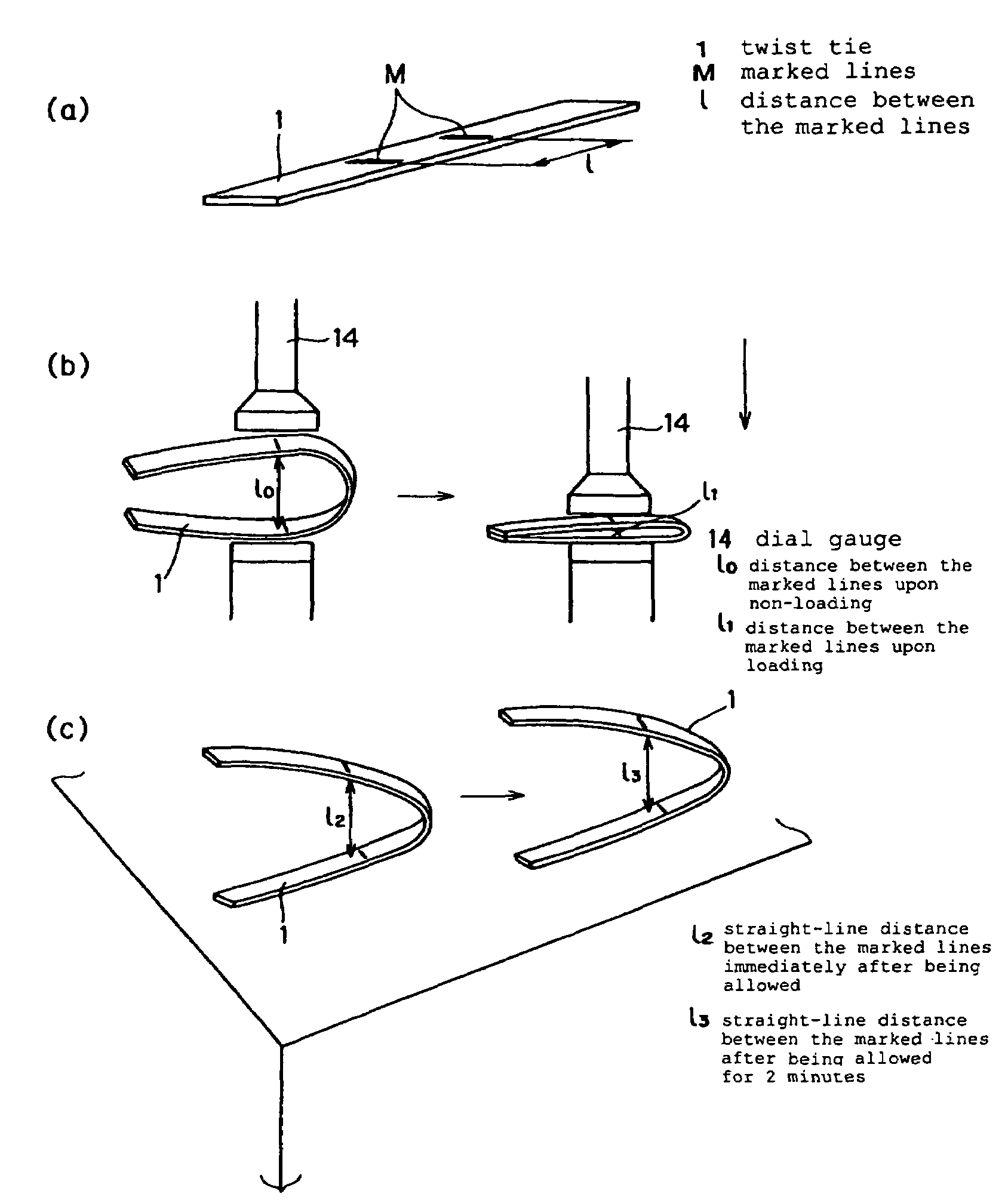

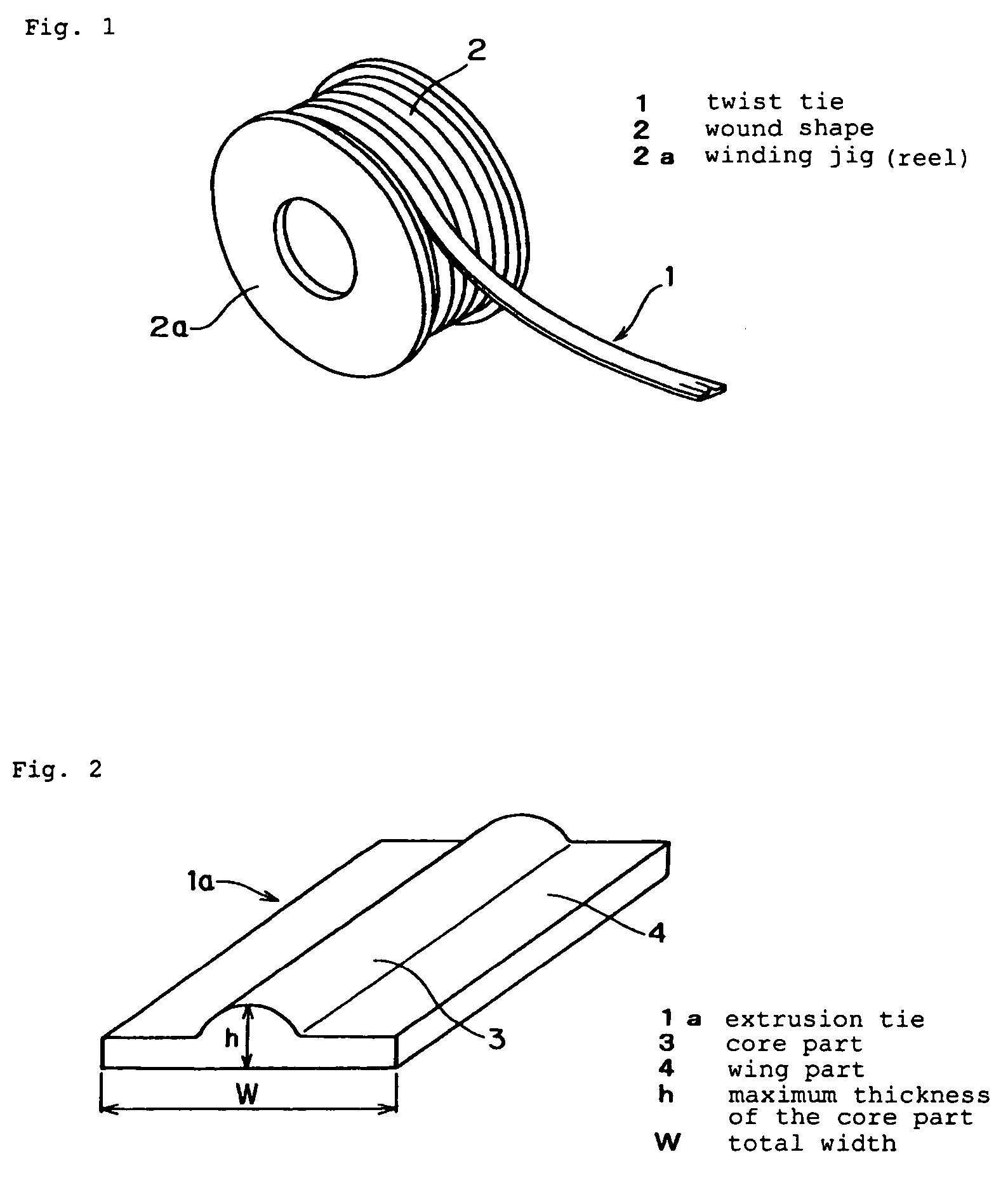

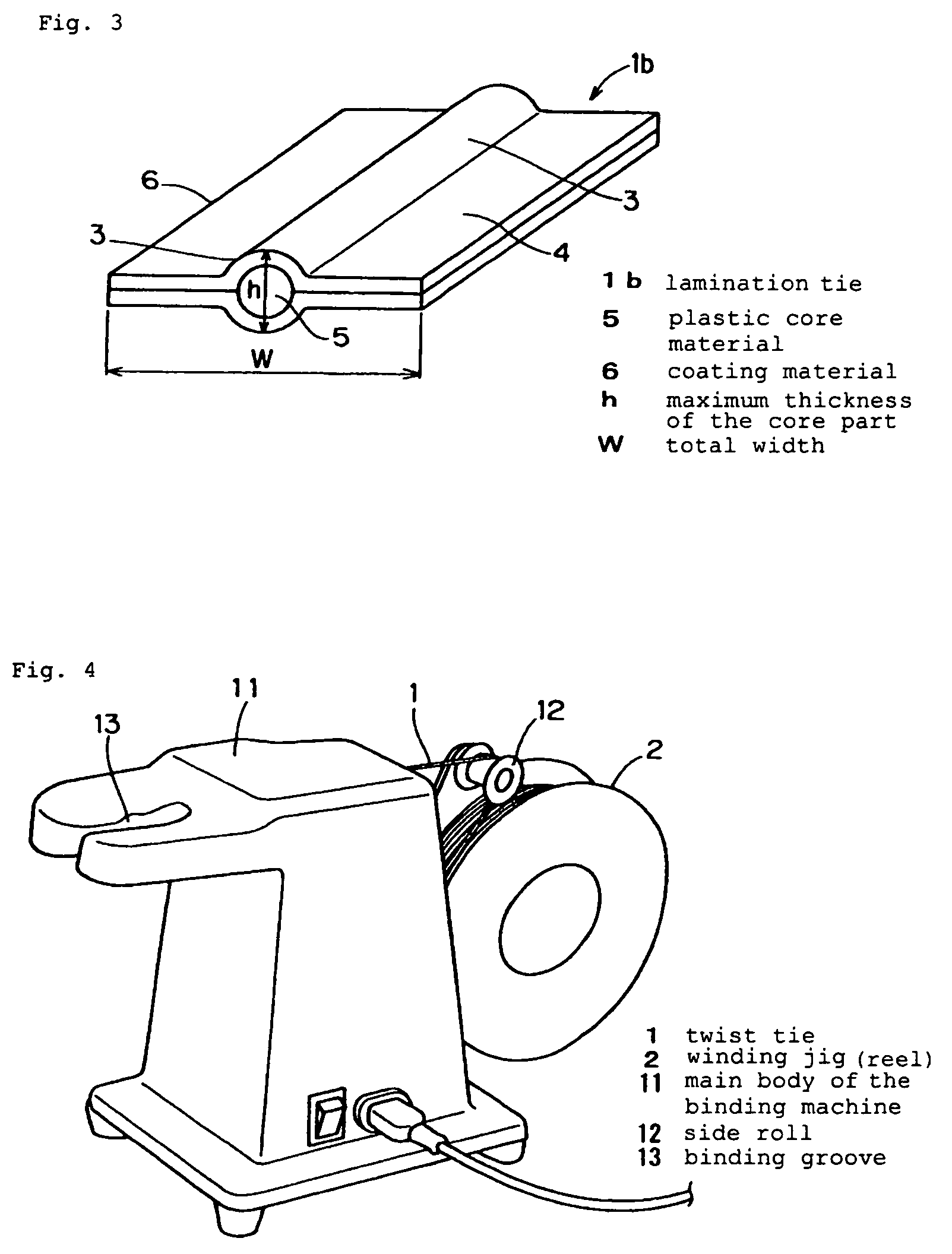

Non-metallic twist tie

The present invention provides a nonmetallic twist tie in which the function inherent to the twist tie is of course available and the twist tie is easily made into a shape of being wound in a bundle with no slipping down of the tie into gap, no torsion of the tie itself, no curl, no twining and tangling of ties and no loosening or disjoining from a reel whereby its drawing-out from the wound shape is able to be carried out smoothly. The nonmetallic twist tie having a core part and a wing part constituted from a non-halogenous material is characterized in that (1) a shape having a total width is 1.5 to 20.0 mm, the average thickness of the wing part is 0.02 to 0.20 mm and the maximum thickness of the core part is 0.04- to 0.30-fold of the total width, (2) a binding property where a torsion strength is 5.0 to 15 N, (3) a rigidity where a tensile elasticity is 5,000 to 30,000 Mpa, (4) a property of forming a fixed shape where the property is 90% or more and a property of retaining a fixed shape where the rate of retaining the fixed shape is 70 to 95%, and (5) a drawing-out property where a degree of curving to the drawing-out direction is 10° or less and a curl radius to the winding direction retains the range of 50 to 200 mm.

Owner:KYOWA LTD

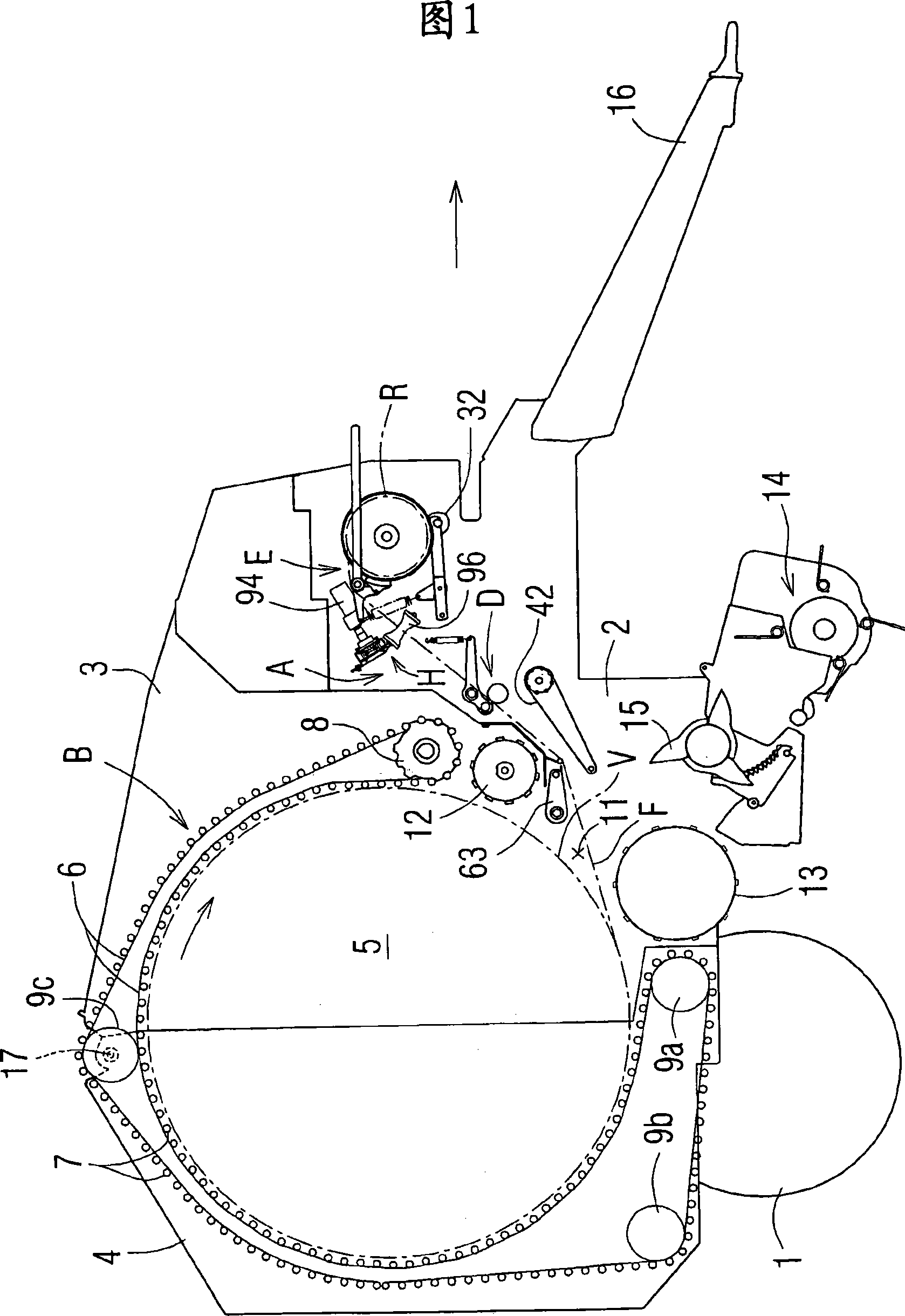

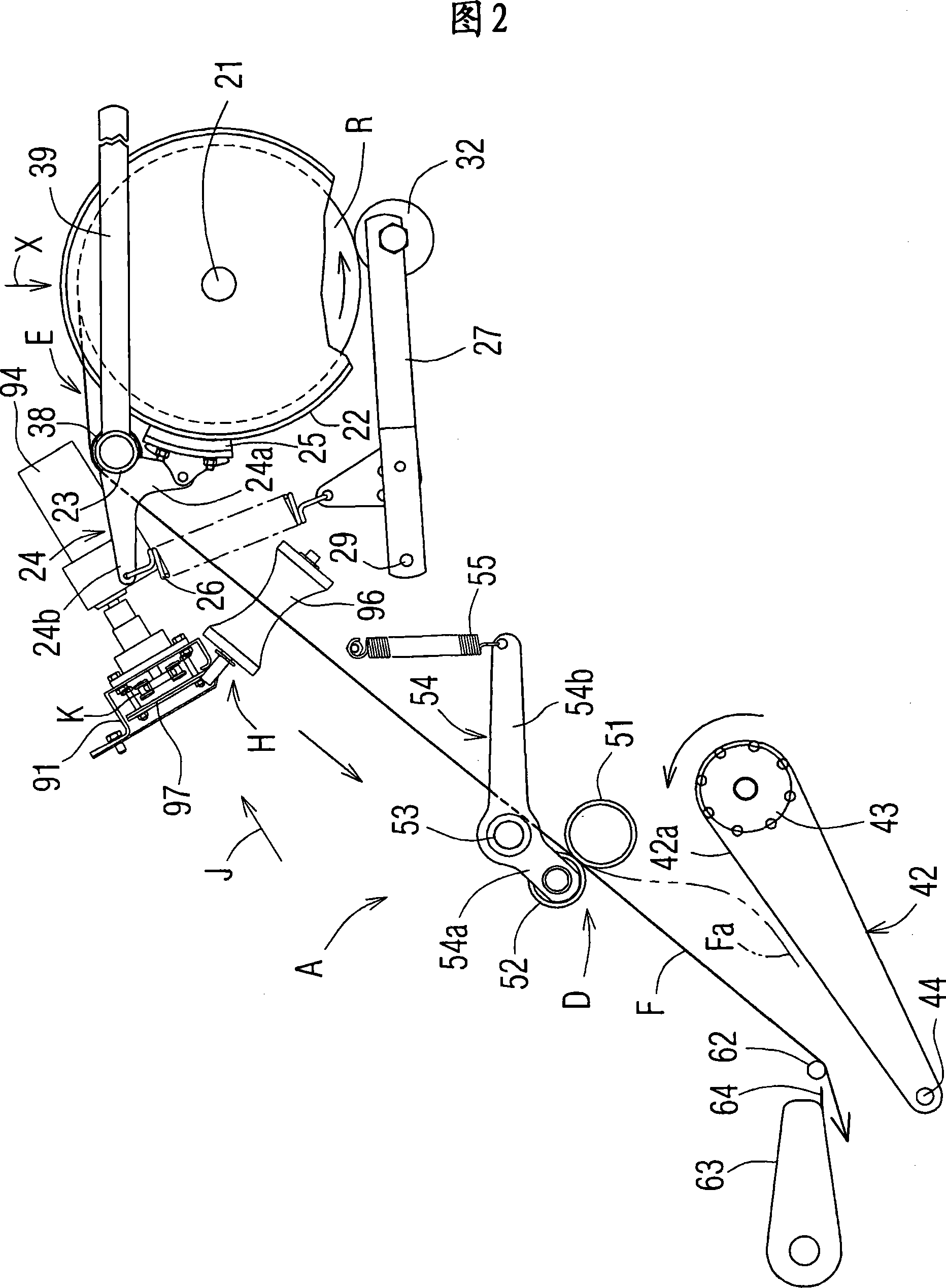

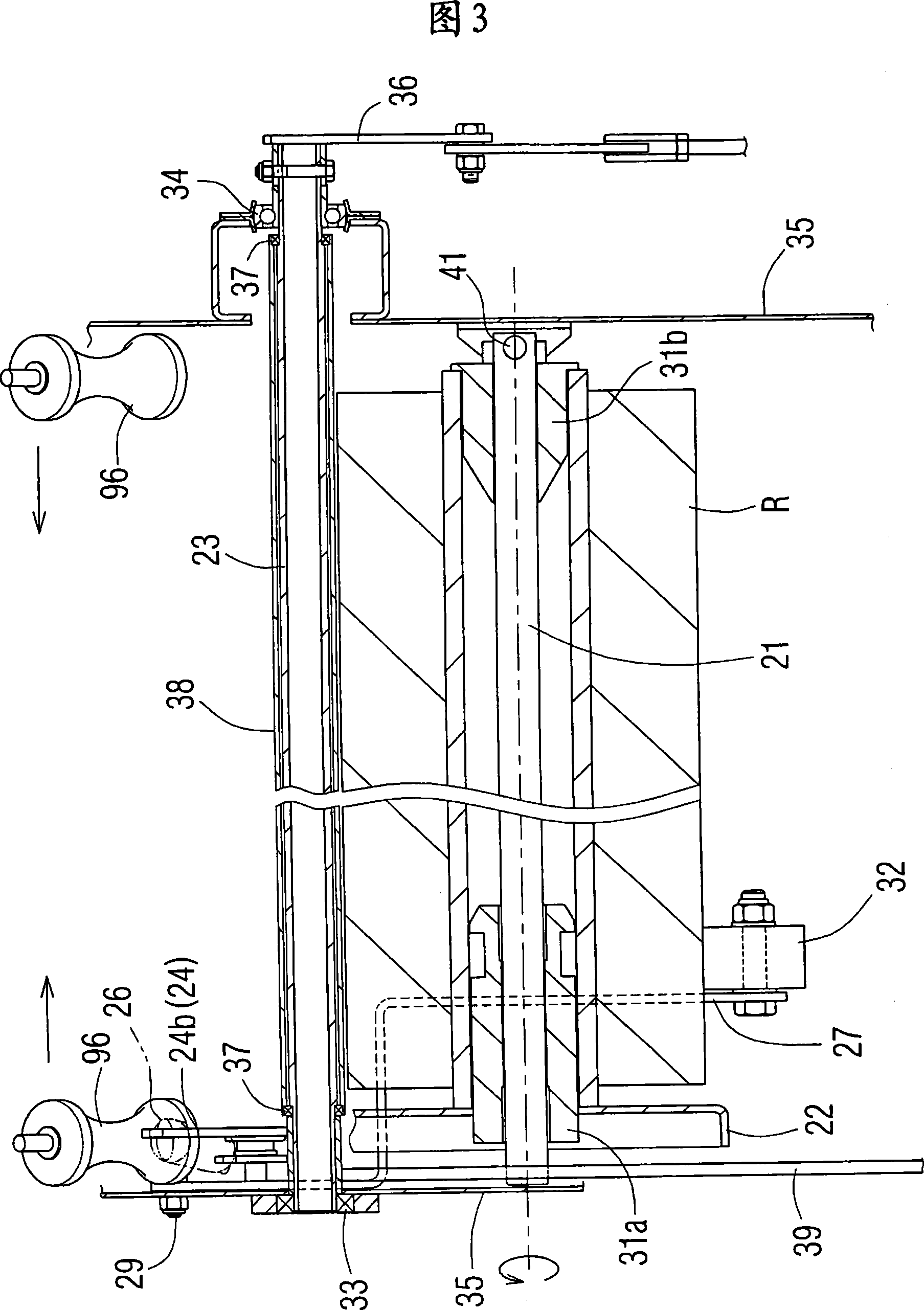

Film letting-off device for roll baler, and method for winding film on rolled bale

ActiveCN101096228ANo damageEliminate damageWrapping material feeding apparatusBalingEngineeringMechanical engineering

Owner:德佳达有限公司

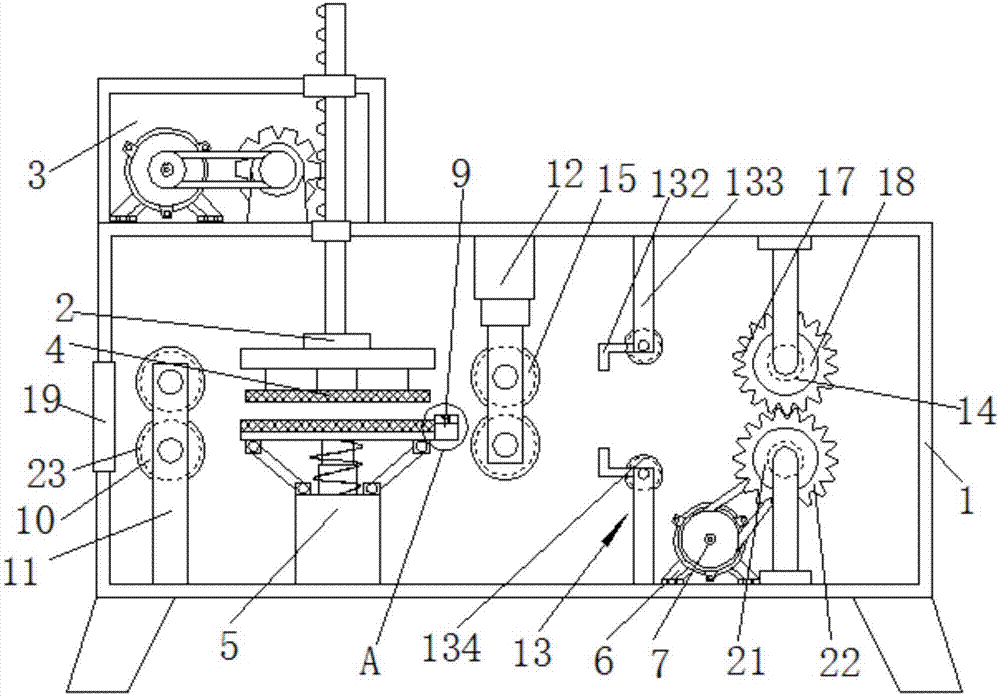

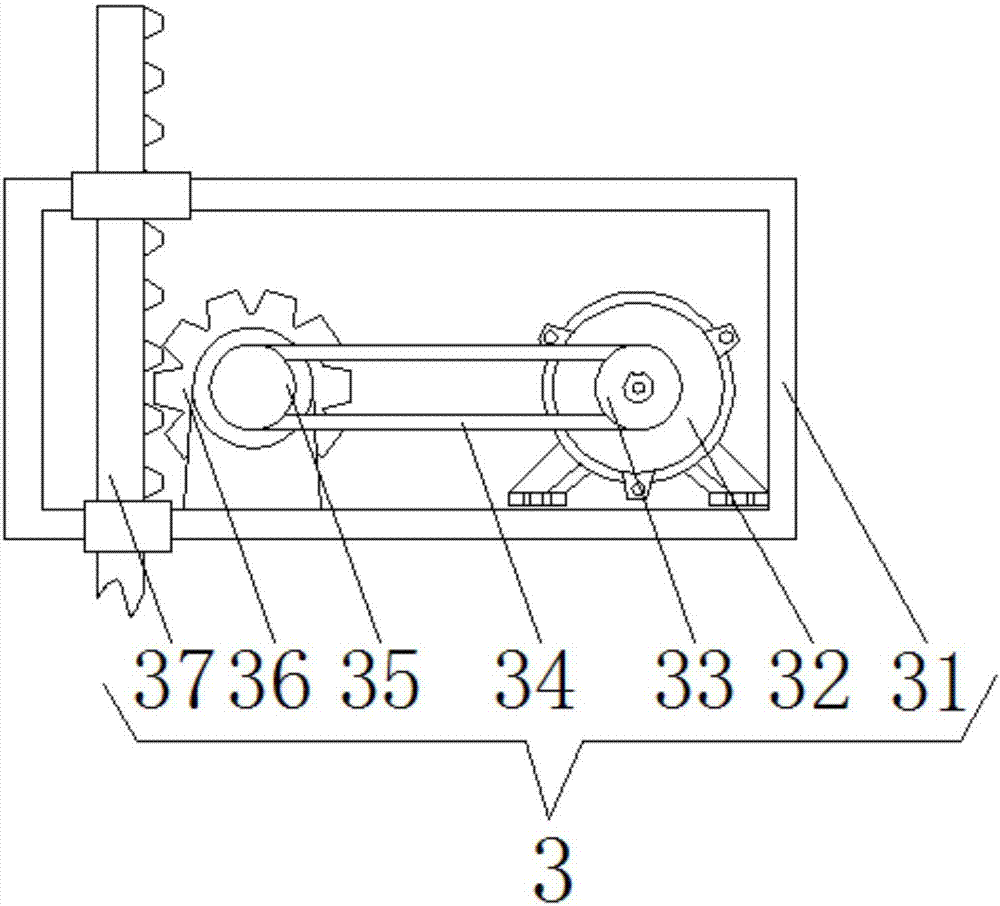

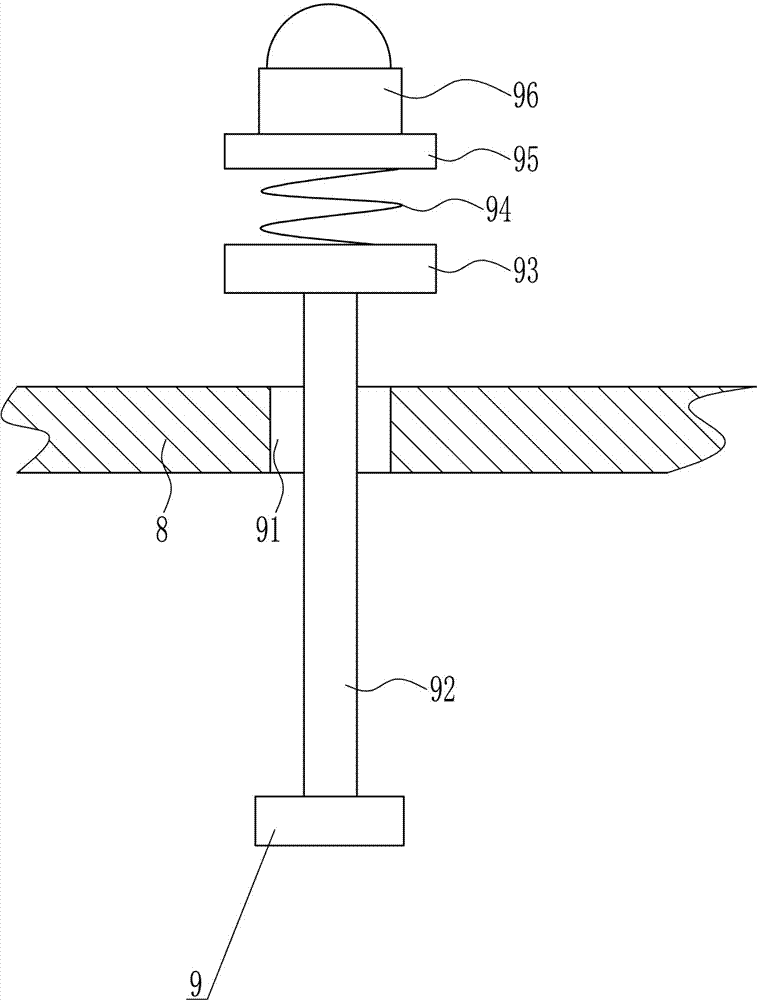

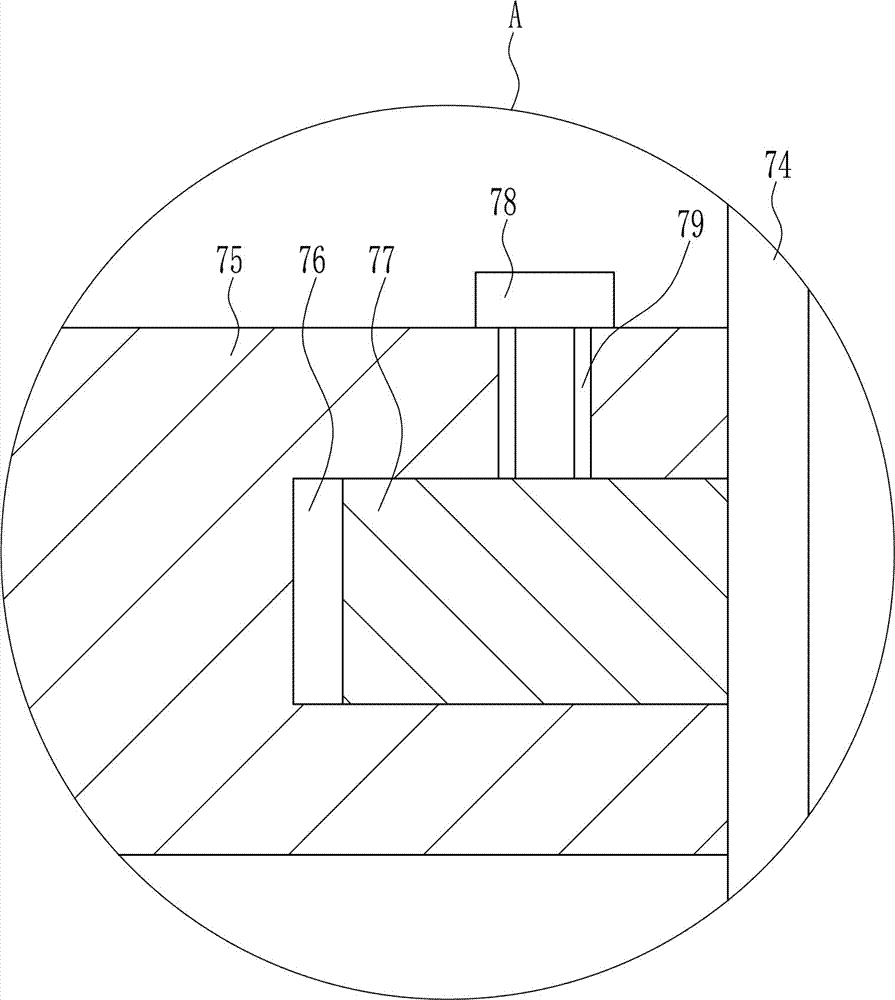

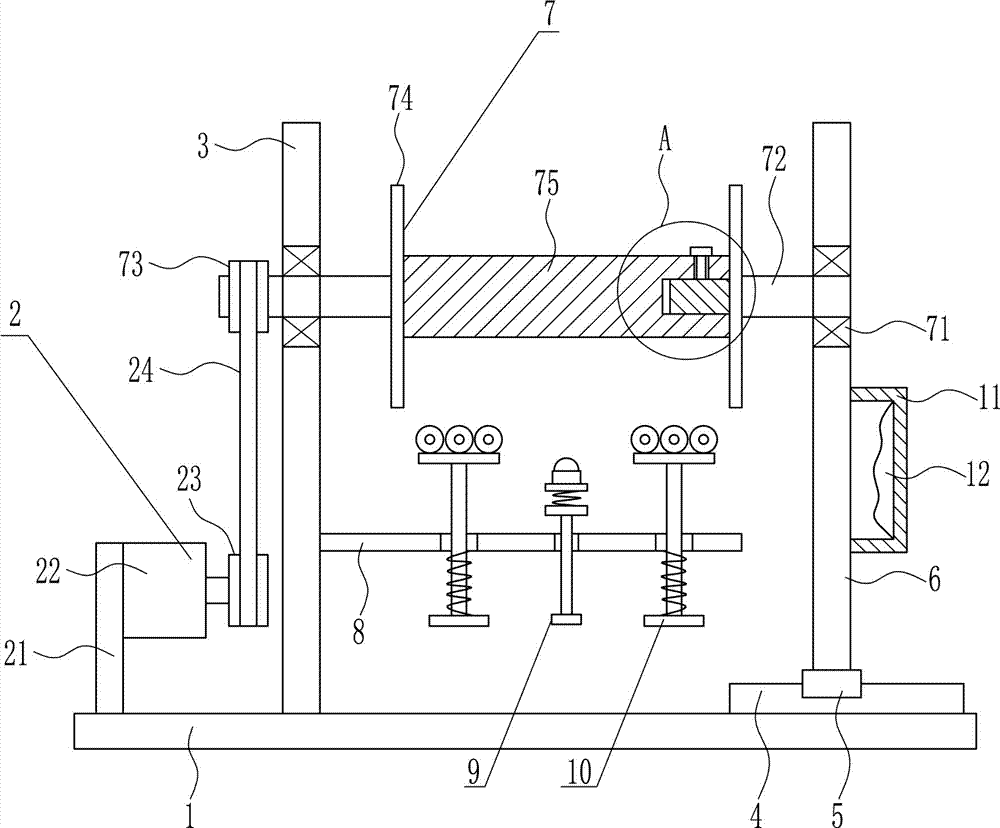

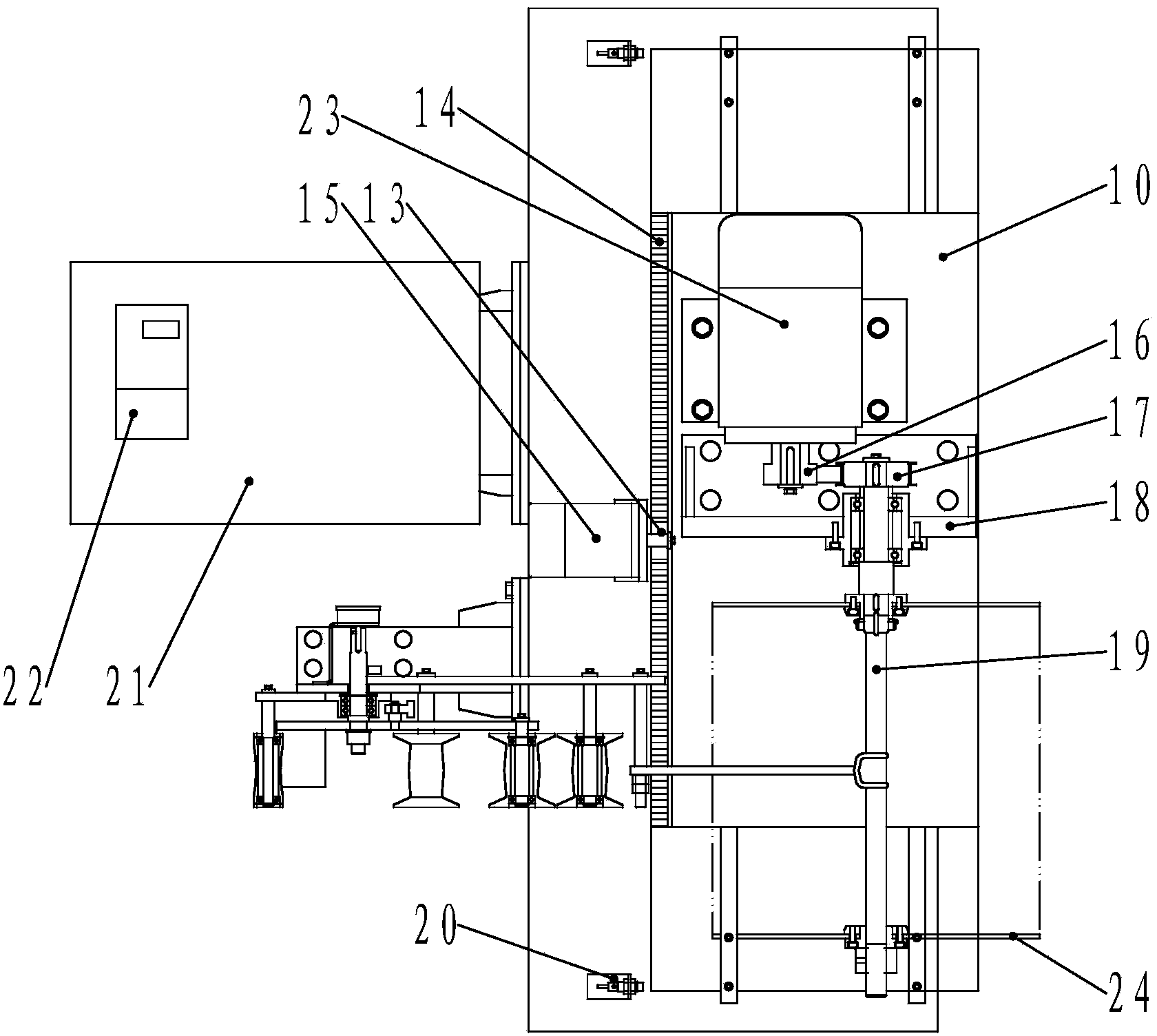

Automatic coiling and uncoiling device for distribution circuit power cable

The invention discloses an automatic coiling and uncoiling device for a distribution circuit power cable. The automatic coiling and uncoiling device comprises a base, wherein a chamber I is arranged at the bottom of the base; a sliding plate is arranged in the chamber I; universal idler wheels are arranged at four corners at the lower end of the sliding plate; an extension spring is arranged between the sliding plate and the top wall of the chamber I; a jacking device is arranged on the base; a coiling device, a tensioning device and a cable uncoiling device are arranged on the base in turn; the coiling device comprises an outer support ring and an inner support ring; a rolling structure is arranged between the outer support ring and the inner support ring; a rotating ring is fixedly connected with the middle part of the inner support ring; coiling plates are respectively arranged at the two ends of the rotating ring; the tensioning device comprises a tensioning bracket and a tensioning roller; the two ends of the tensioning roller are arranged on the tensioning bracket; and the cable uncoiling device comprises an uncoiling mechanism capable of reciprocating and an uncoiling driving motor connected with the uncoiling mechanism. According to the invention, the coiling device, the tensioning device and the cable uncoiling device are successively arranged, so that the automatic coiling and uncoiling of the cable can be realized and the winding intensity, tightness and uniformity of the cable can be guaranteed.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

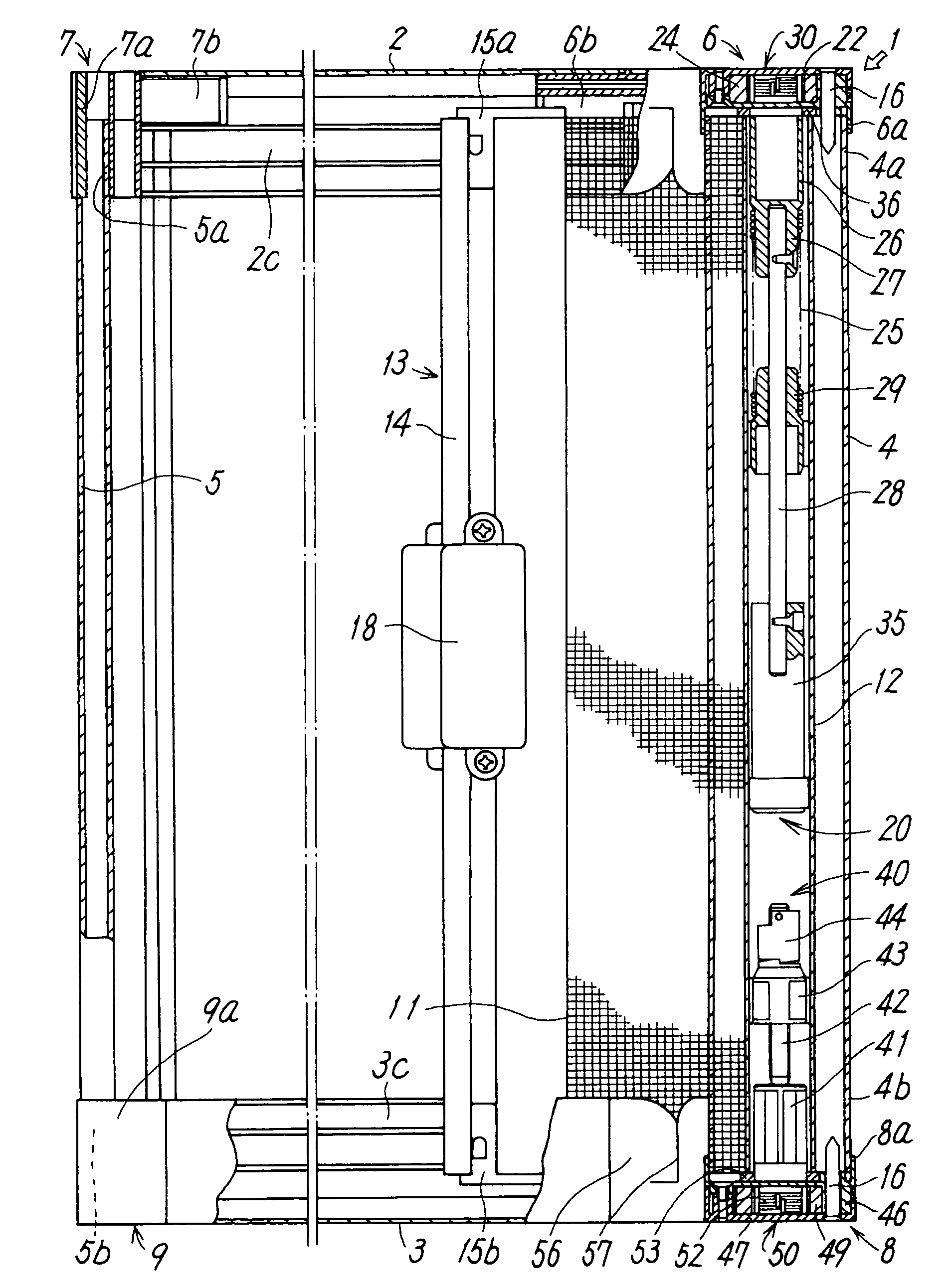

Take up-type screen device

A retractable screen device including a screen frame formed by upper and lower frame members and right and left side frames, each having a fixed cross section along its entire axis, and corner linking members linking the ends of the frame members and side frames together at four corners of the screen frame. One of a pair of corner linking members situated at the ends of the side frame carrying a screen winding shaft includes a winding mechanism that is movable into and out of the winding shaft to cause the winding shaft to wind a screen thereon with aid of an adjustable spring force, while the other corner linking member includes a stopper mechanism that is movable into and out of the winding shaft to define an adjustable limit to a degree of unwinding of the screen from the winding shaft.

Owner:SEIKI SOGYO

Cable sheath removal and recycling device

InactiveCN107482541AImprove work efficiencyImprove peeling efficiencyFilament handlingApparatus for removing/armouring cablesEngineeringElectric wire

The invention discloses a cable peeling recovery device, which comprises a device outer frame and supporting legs arranged at the bottom of the device outer frame, a cable inlet is opened on the left side wall of the device outer frame, and the inside of the device outer frame is installed in sequence from left to right There are: the first guide wheel is used to guide the cable to move to the right; the pressure plate is used to press the cable and remove the stain on the cable surface, and the lower end of the pressure plate is fixed with a cleaning block; the cutter device is used to cut the cable skin; the second guide wheel is used for Fix the cable above the cutter device and guide the cable to move to the right; the cable skin recovery wheel and the cable core recovery wheel are used to strip the cable inner core from the cable skin and recover the cable inner core and cable skin. The invention solves the problems that the existing electric wire recycling device cannot peel and classify the electric wires, is not suitable for recycling cables with different diameters, and has low working efficiency.

Owner:邹晶明

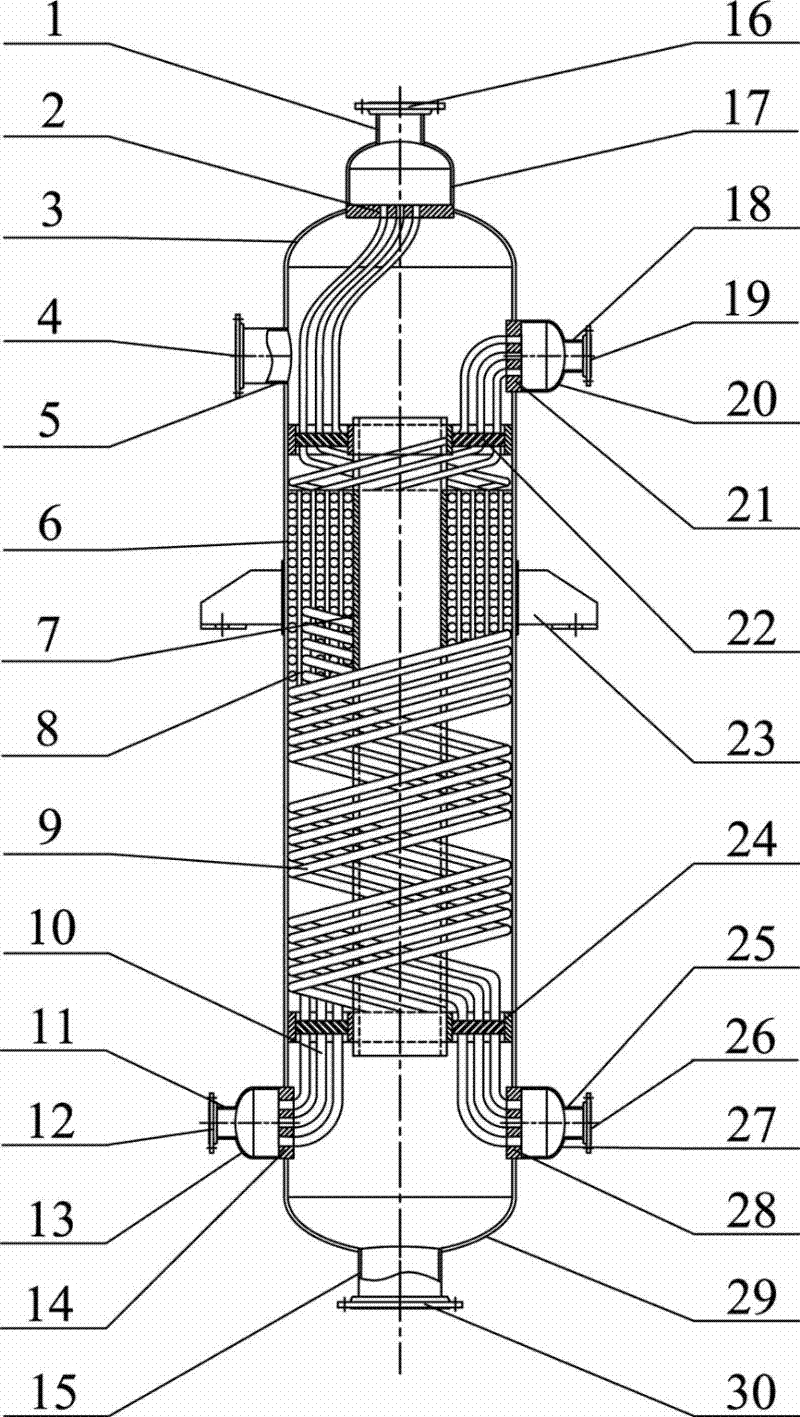

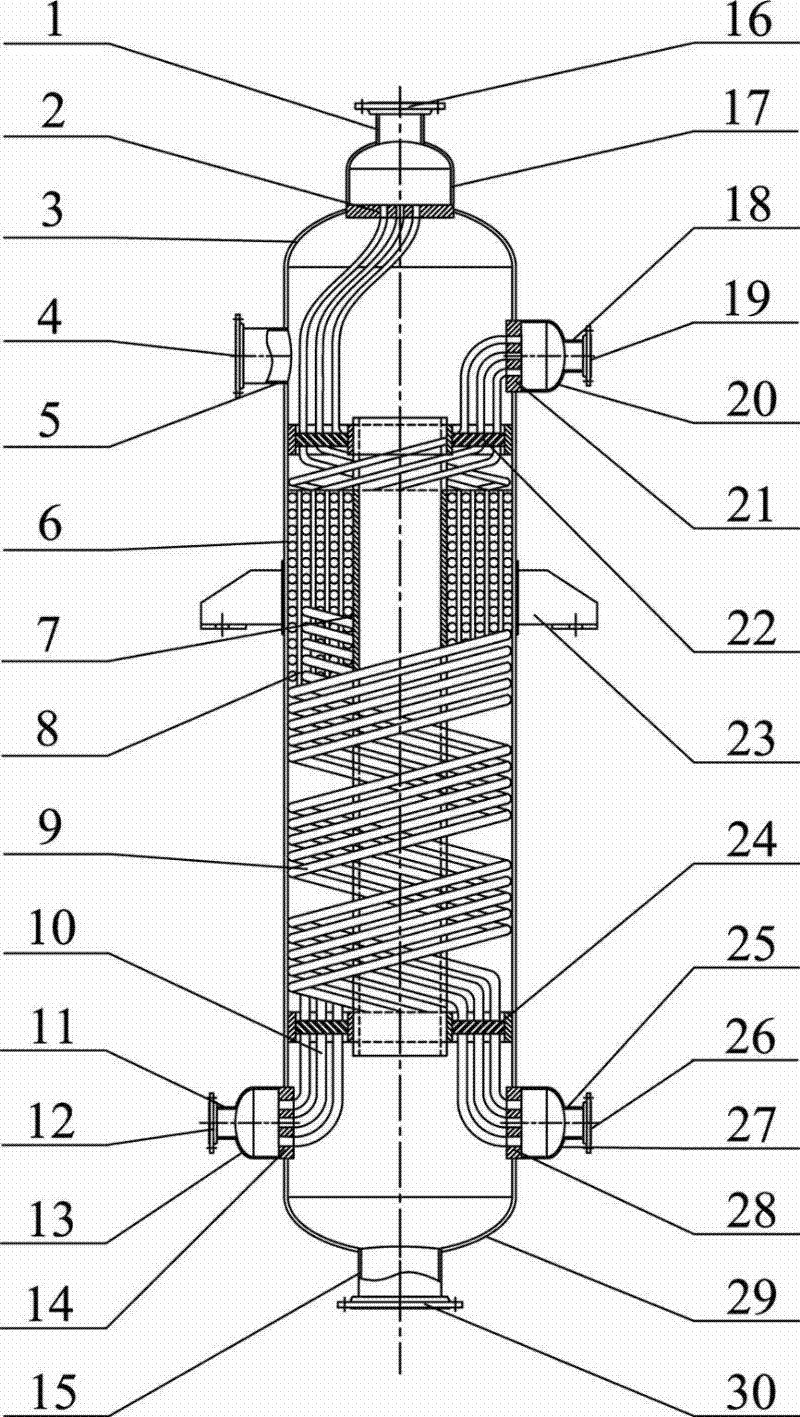

Liquefied natural gas (LNG) low temperature liquefied three-level refrigeration spiral wound tube type heat exchanger

InactiveCN102538387AWith self-tightening adjustment functionReduce volumeSolidificationLiquefactionThree levelSpiral wound

The invention belongs to the field of natural gas low temperature liquefied technology, and relates to a liquefied natural gas (LNG) three-level low temperature liquefied process device and a mixed refrigerant refrigeration technology, which cools 6.0MPa, -120DEG C natural gas into -164DEG C to be liquefied in two-steam spiral wound tube type heat exchanger by applying a certain proportion of non-azeotropic N2-CH4 mixed refrigerant, thereby being convenient for LNG to be stored in a surpercooling mode and being convenient to transport. The non-azeotropic N2-CH4 mixed refrigerant is firstly precooled and liquefied by a three-level refrigerant spiral wound tube type heat exchanger, and is throttled to a shell pass after being liquefied to cool a LNG tube bundle and a N2-CH4 mixed refrigerant precooling tube bundle from a secondary outlet in -120DEG C, thereby leading natural gas and precoolded refrigerant in the tube pass to be liquefied, and achieving the purpose of precooling mixed refrigerant before throttling and liquefying nature gas at low temperature. The LNG three-level low temperature liquefied process device is compact in structure and high in heat exchange efficiency, can be used to exchange heat for mixed gas with low-temperature phase transition, solves the difficult problem of LNG three-level low temperature technology, and increases low temperature heat exchange efficiency of a LNG system.

Owner:张周卫

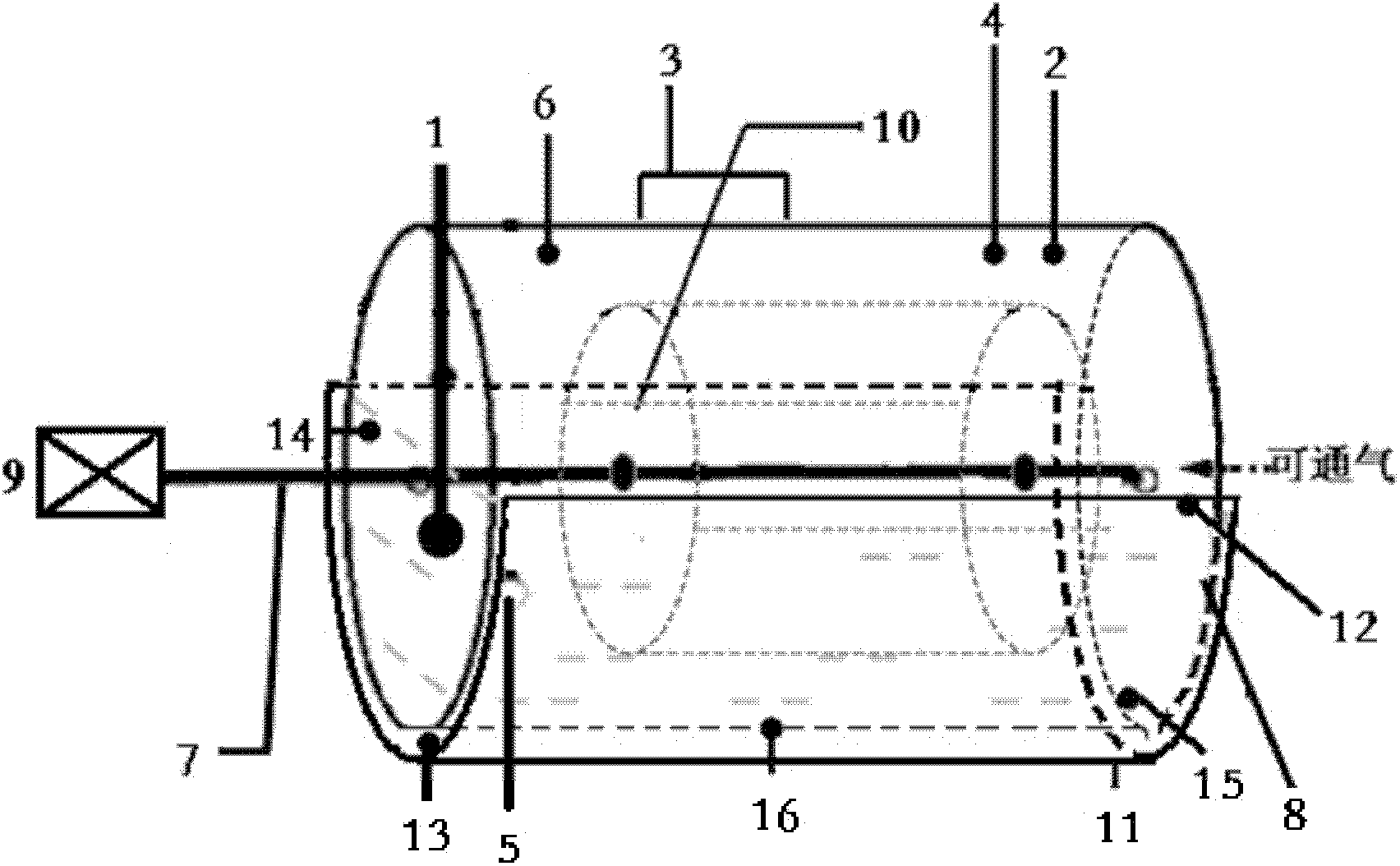

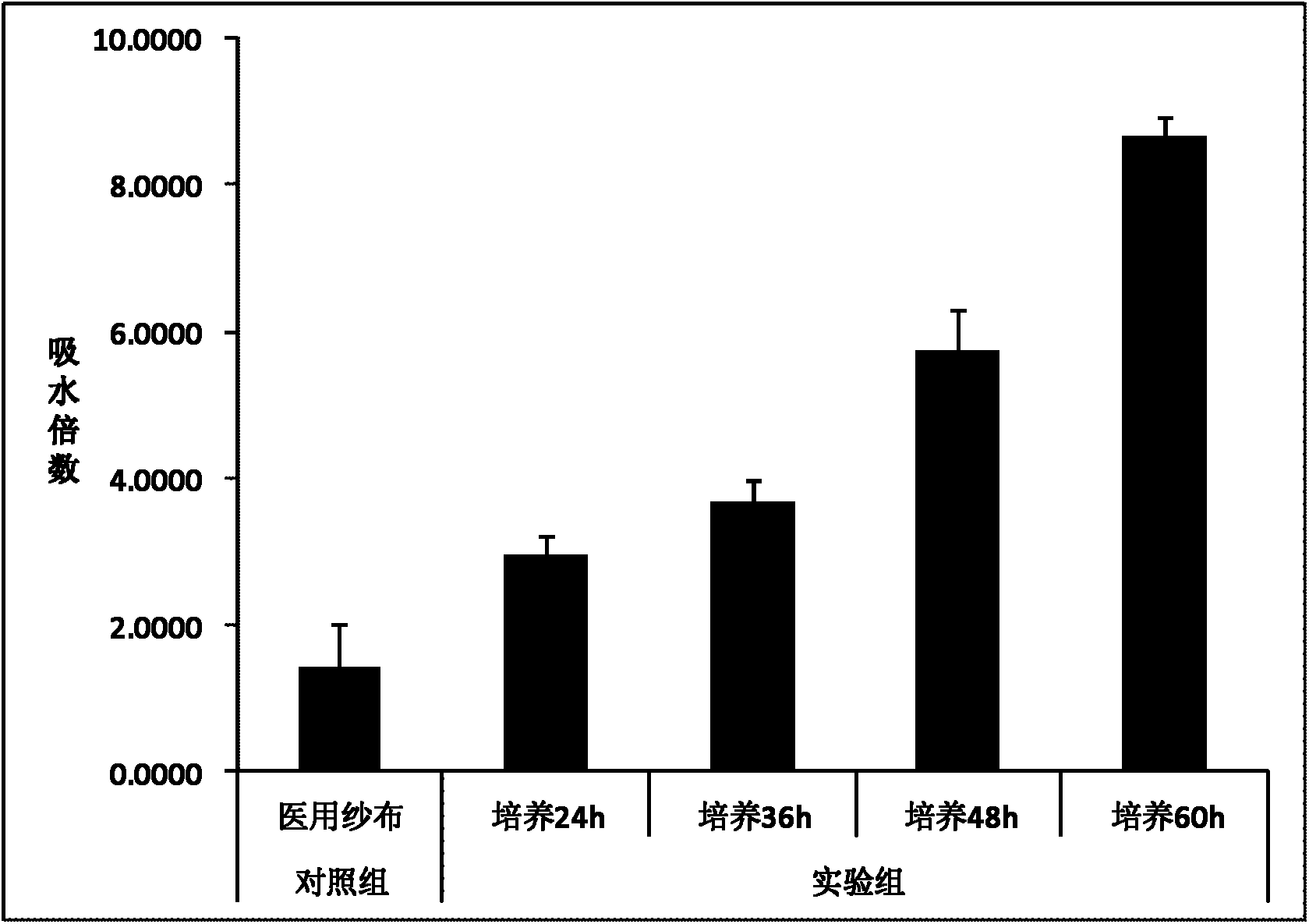

Method and device for preparing bacterial cellulose composite material quickly on large scale

ActiveCN102533904AReduce dosageGuaranteed StrengthBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid mediumFermentation

The invention relates to a method and device for preparing bacterial cellulose composite materials quickly on a large scale. The method comprises the steps as follows: (1) a bacterial cellulose producing strain is inoculated in liquid medium for propagation and then transferred into a biological reactor containing framework material for perturbation cultivation, so that bacterial cellulose composite material can be obtained; and (2) bacterial cellulose of the bacterial cellulose composite material is peeled off from the framework material or the cellulose composite material is soaked in NaOH solution to be washed. The device comprises a thermometer opening, an acid liquor and alkali liquor feeding opening, a handle, an air vent, a pH meter opening, a nutrition feeding opening, a rotating shaft, a fermentation tank, a motor, a rotating drum, a fermentation tank jacket, a circulating water inlet, a circulating water outlet, a nutrient fluid inlet, a nutrient fluid outlet and a condensed water outlet. The rotating drum is fixed on the rotating shaft in the fermentation tank. The device provided by the invention has the advantages of simplicity, convenience, detachable die, low cost, high production efficiency and high degree of automation; and the obtained bacterial cellulose composite material can be widely applied.

Owner:DONGHUA UNIV

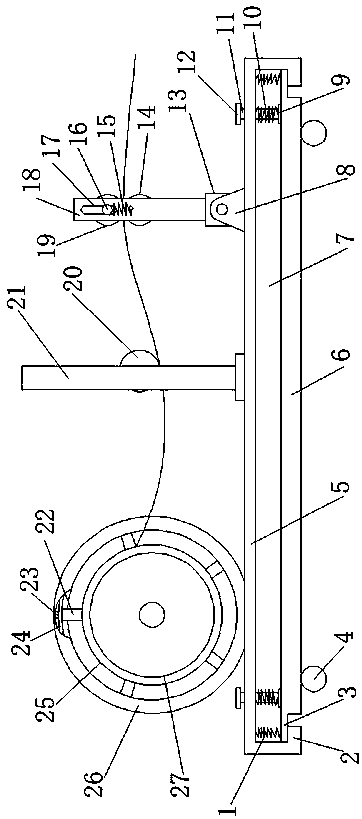

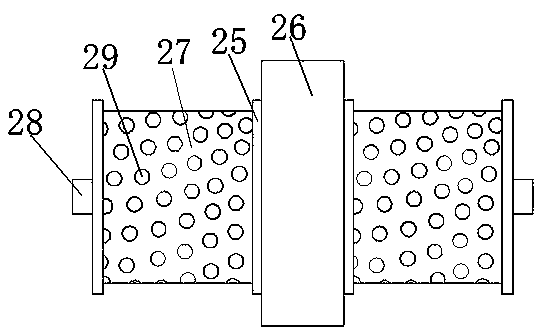

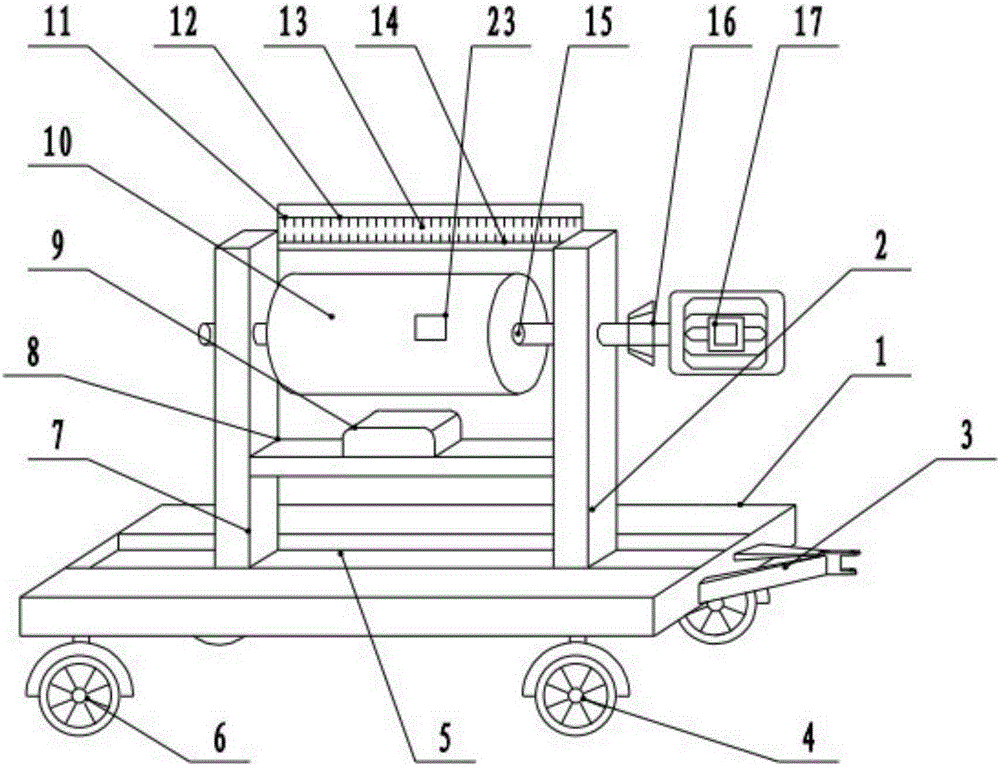

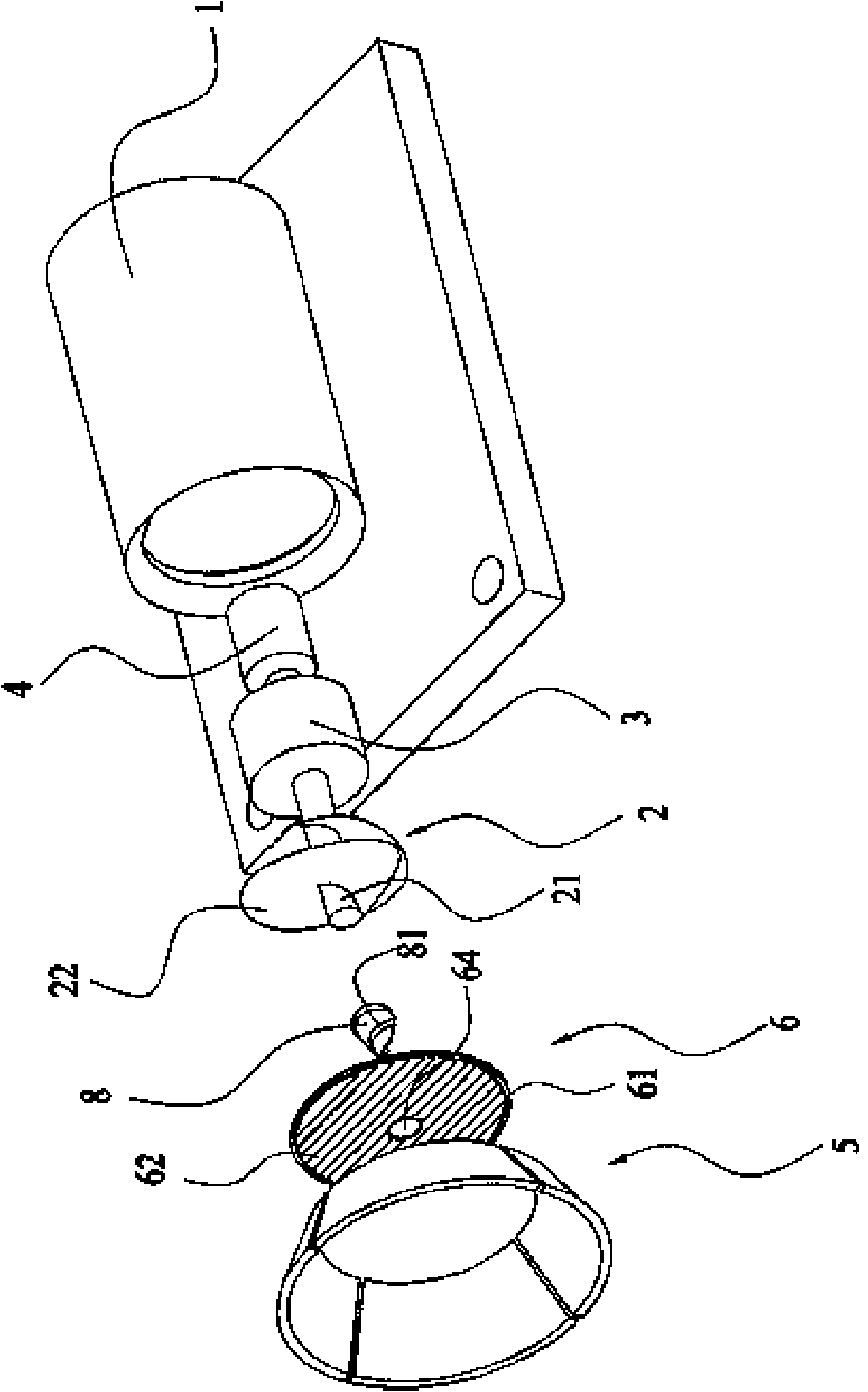

Electric cable quick winding equipment used for electric cable machining

The invention relates to electric cable winding equipment, in particular to electric cable quick winding equipment used for electric cable machining. According to the electric cable quick winding equipment used for electric cable machining, time and labor are saved in the conveying process, and uniform electric cable winding can be conducted on cable discs. The electric cable quick winding equipment used for electric cable machining comprises supporting pillars, mounting plates, a first sliding rail, first sliding blocks, first screws, first nuts, supporting plate, bearing seats, first rotating rods, a first gear, a first motor and the like. The mounting plates are mounted on the upper ends of the two supporting pillars in a welded mode, and the first sliding rail is mounted on the upper sides in the mounting plates in a bolted connection mode. According to the electric cable quick winding equipment used for electric cable machining, the effects that time and labor are saved in the conveying process, and uniform electric cable winding can be conducted on cable discs are achieved, and the mode that the cable discs are conveyed by leftwards and rightwards moving and lifting a storing plate is achieved.

Owner:南昌安润科技有限公司

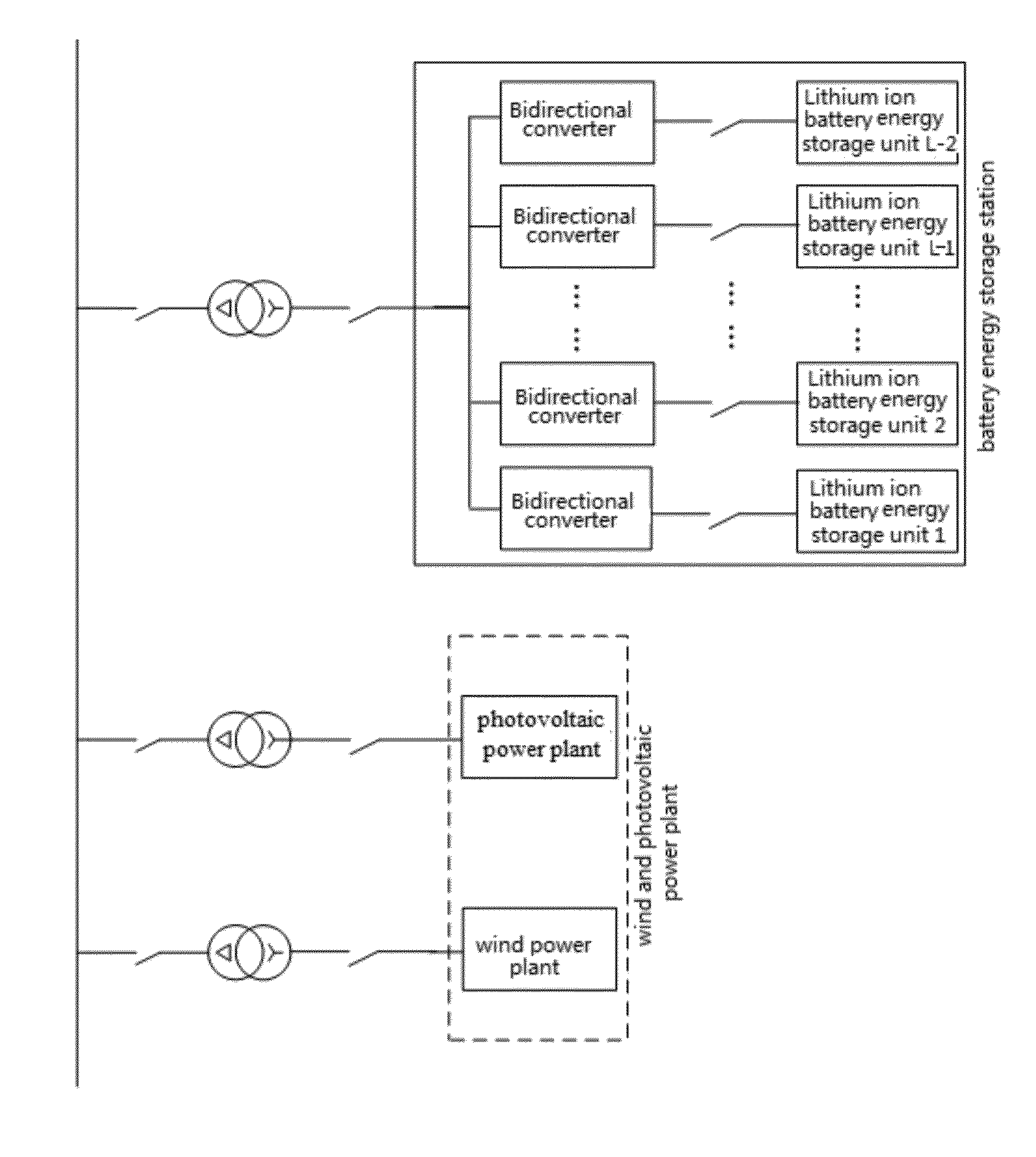

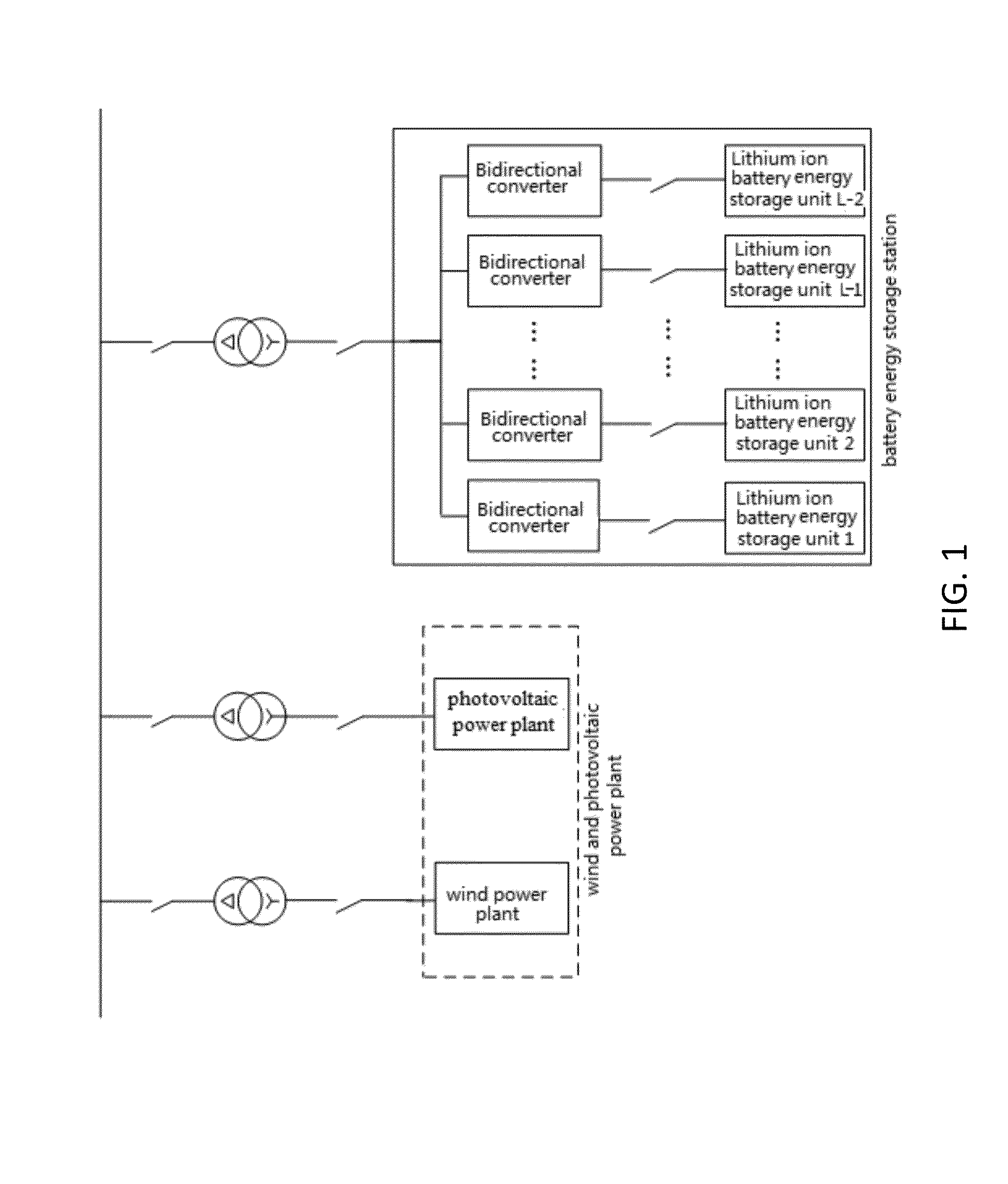

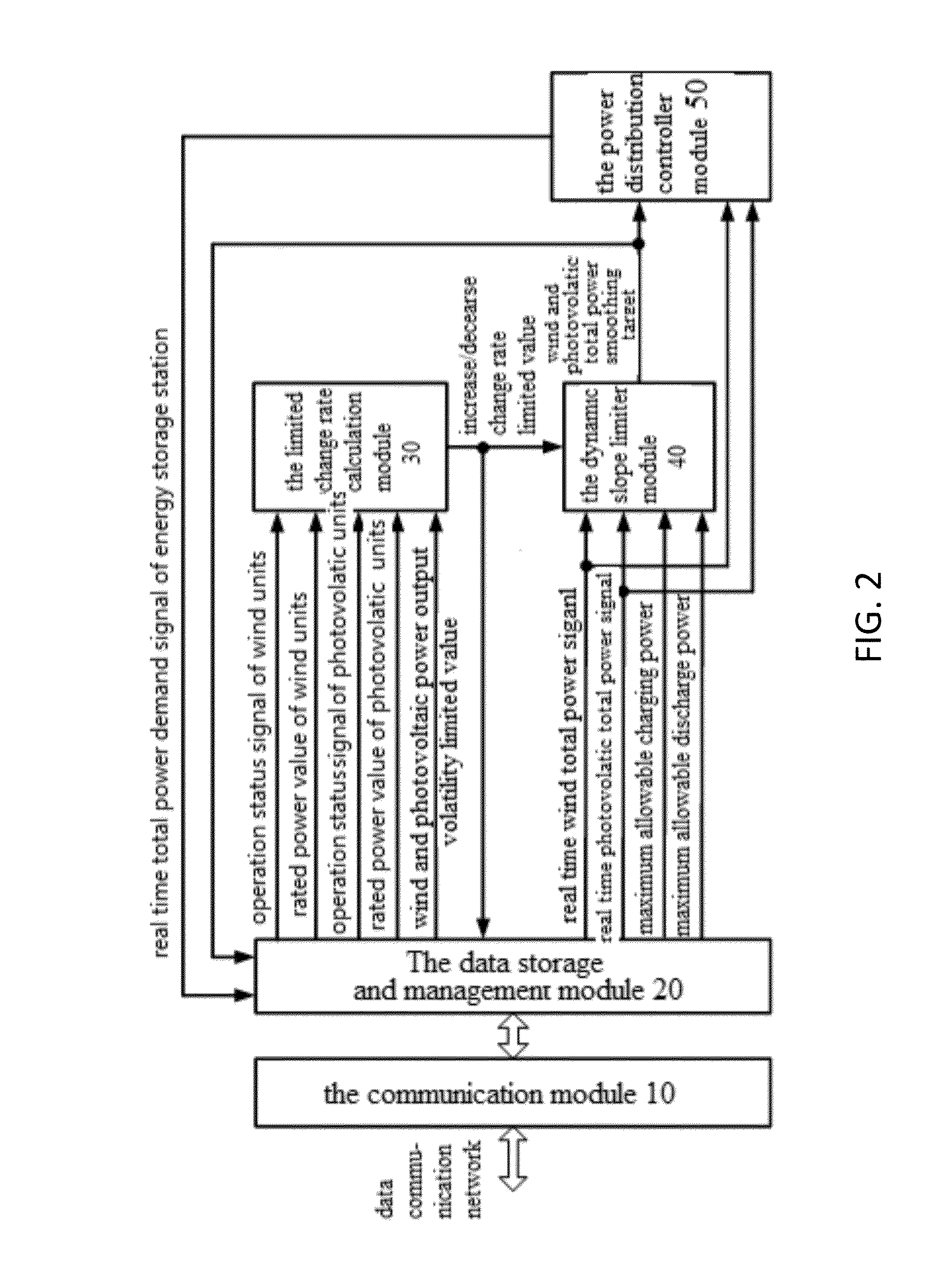

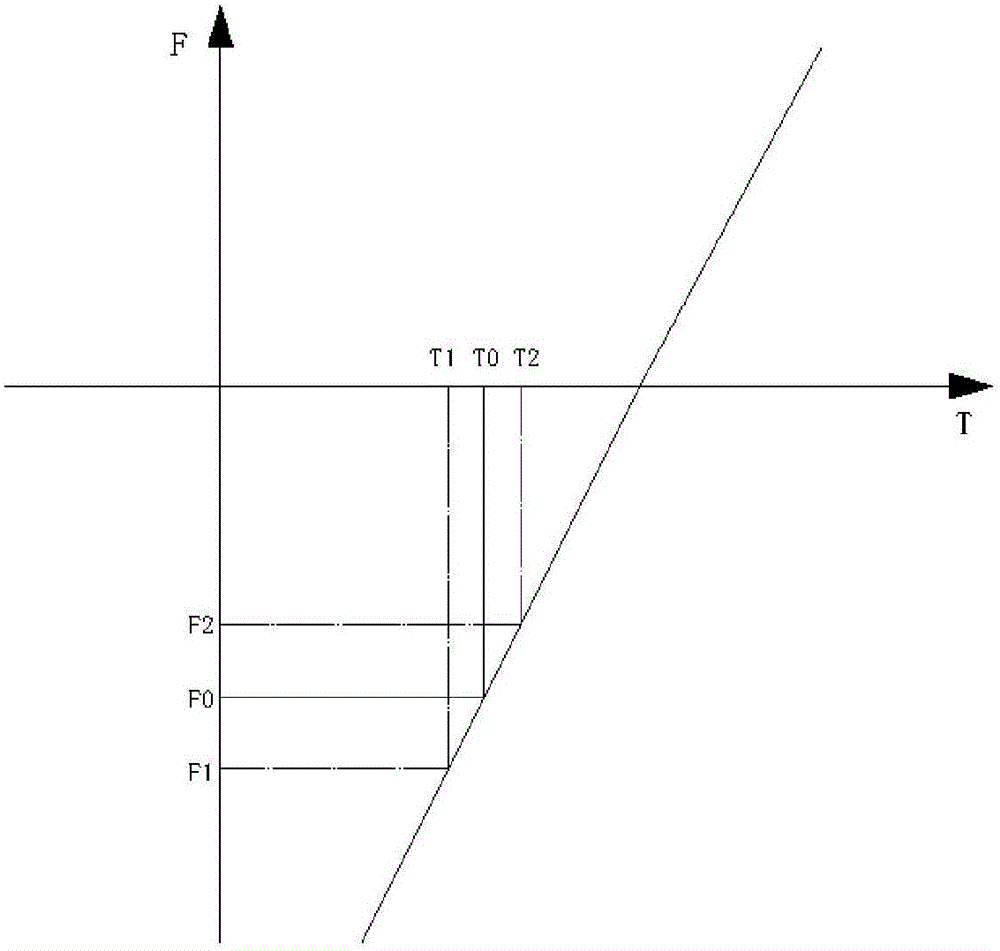

A method and system for control of smoothing the energy storage in wind phtovolatic power fluctuation based on changing rate

InactiveUS20160233679A1Wind evenlyAvoid windingWind motor with solar radiationWind motor controlEngineeringLimit value

The invention relates to a method and system for smoothing the energy storage wind and photovoltaic power fluctuation based on rate control, including: reading and processing data; determining the signal change rate of the dynamic slope limiter; calculating the smoothing target value of the wind and photovoltaic total power; calculating total power demand of battery energy storage power station; and outputting data. The invention can effectively suppress wind and photovoltaic power fluctuation under the fluctuation rate limited value, can effectively smooth wind and photovoltaic power output. Thus it smoothens wind and photovoltaic power output, reduces the energy storage battery burden, and effectively controls battery energy storage power station system.

Owner:STATE GRID CORP OF CHINA +1

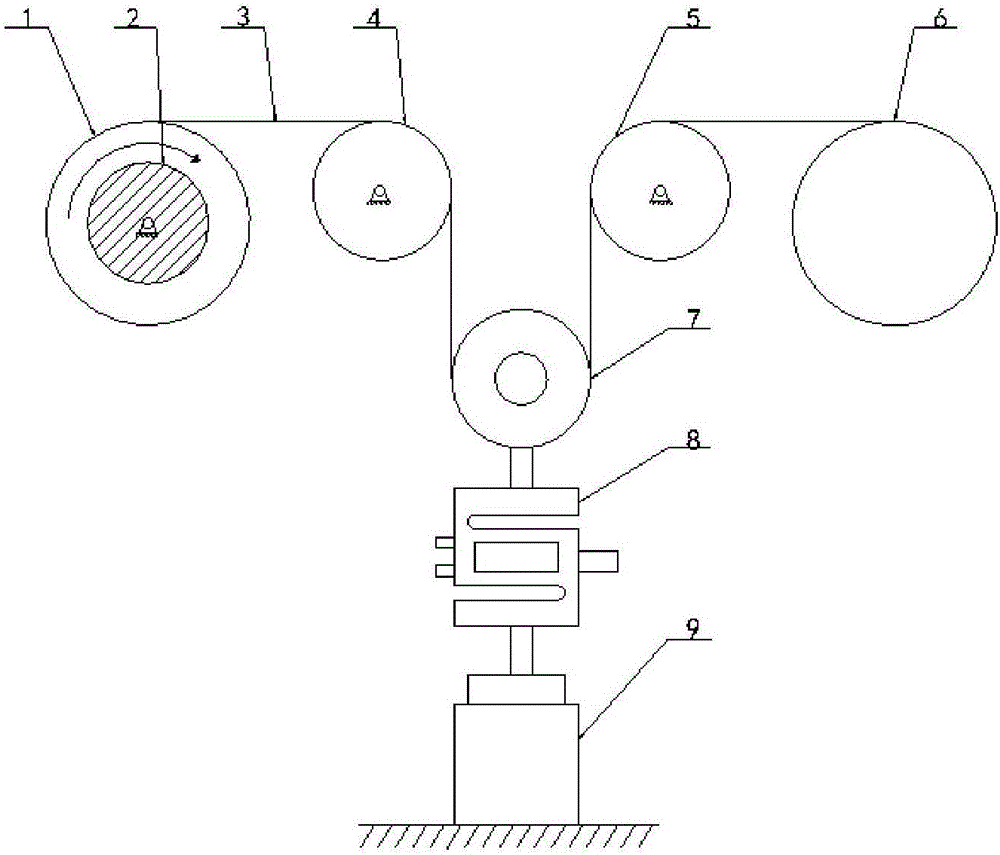

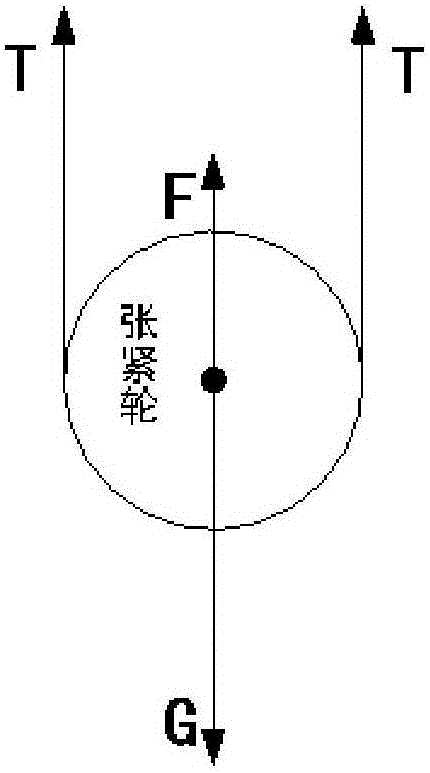

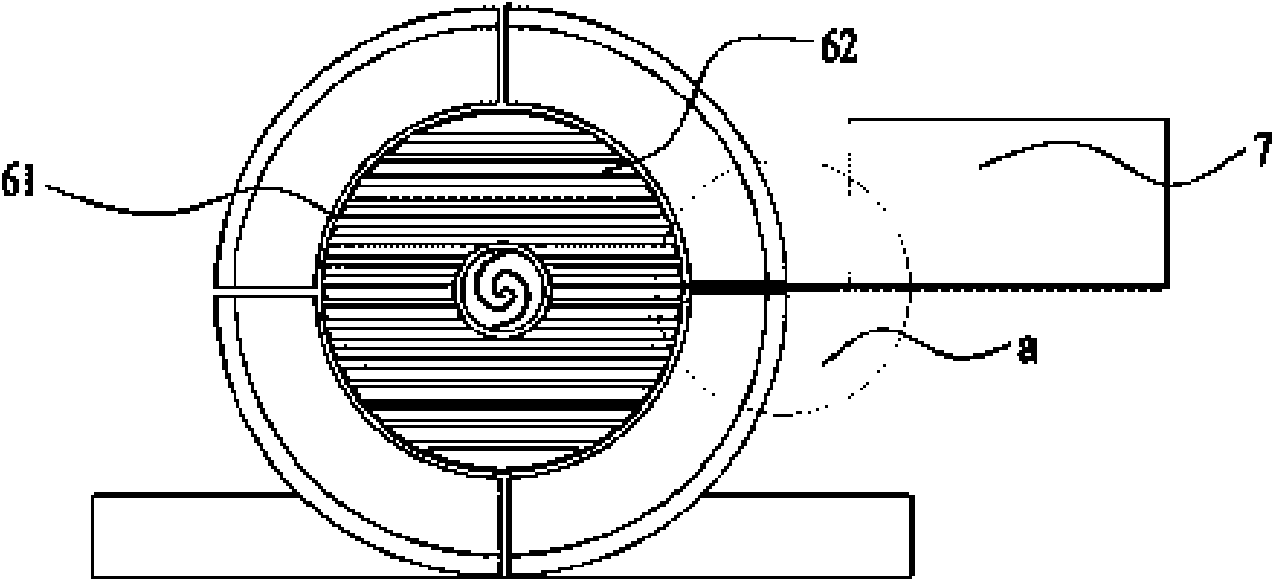

Multi-stage control device and method for dynamic tension of optical fiber winding machine

InactiveCN105800384APrecise controlPowerfulMeasurement devicesFilament handlingWinding machineFibre optic gyroscope

The invention firstly provides a multi-stage control device for the dynamic tension of an optical fiber winding machine. The device comprises a paying-off wheel and a taking-up ring and further comprises a guide wheel A and a guide wheel B. The paying-off wheel, the guide wheel A and the guide wheel B are fixedly arranged in sequence from left to right. The taking-up ring is movably arranged at the tail end of the right side. A tensioning wheel capable of vertically moving is arranged between the guide wheel A and the guide wheel B. The lower portion of the tensioning wheel is sequentially and fixedly connected with a tension and pressure sensor and a micromechanism. The tensioning wheel and the tension and pressure sensor can vertically move at the same time through the micromechannism. The paying-off wheel is connected with a paying-off wheel motor. The micromechanism, the tension and pressure sensor and the paying-off wheel motor are connected with an upper computer. The invention further provides a multi-stage control device for the dynamic tension of the optical fiber winding machine. The multi-stage control technology is adopted, the control precision of the tension of an optical fiber and the quality of an optical fiber loop are improved, it is effectively guaranteed that the optical fiber loop is evenly wound, and the requirement of a high-precision optical fiber gyroscope is met.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

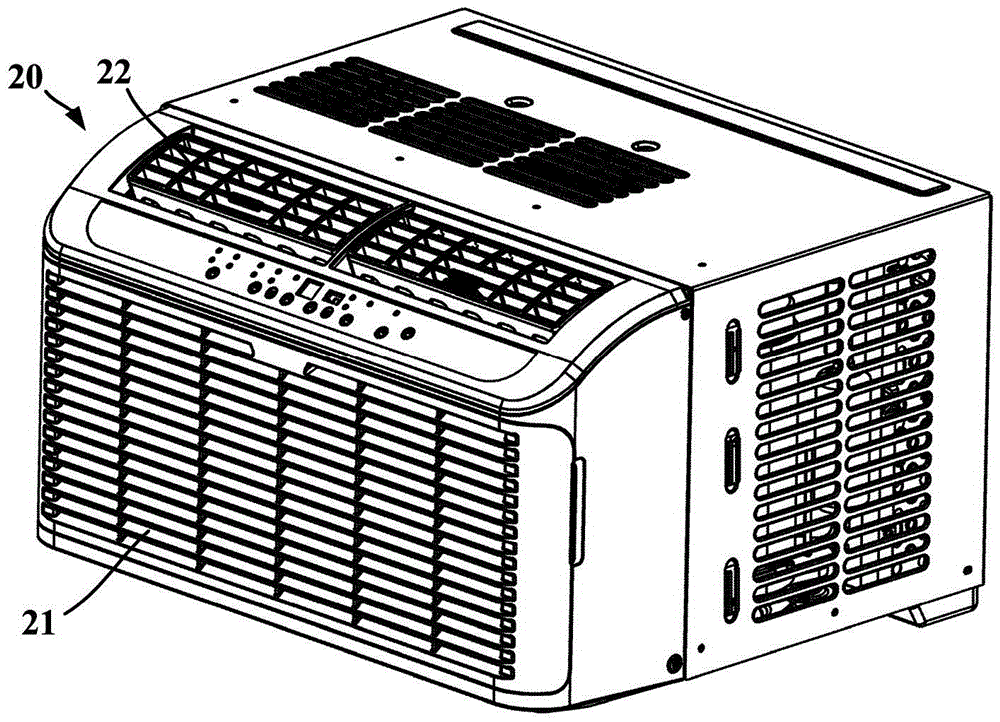

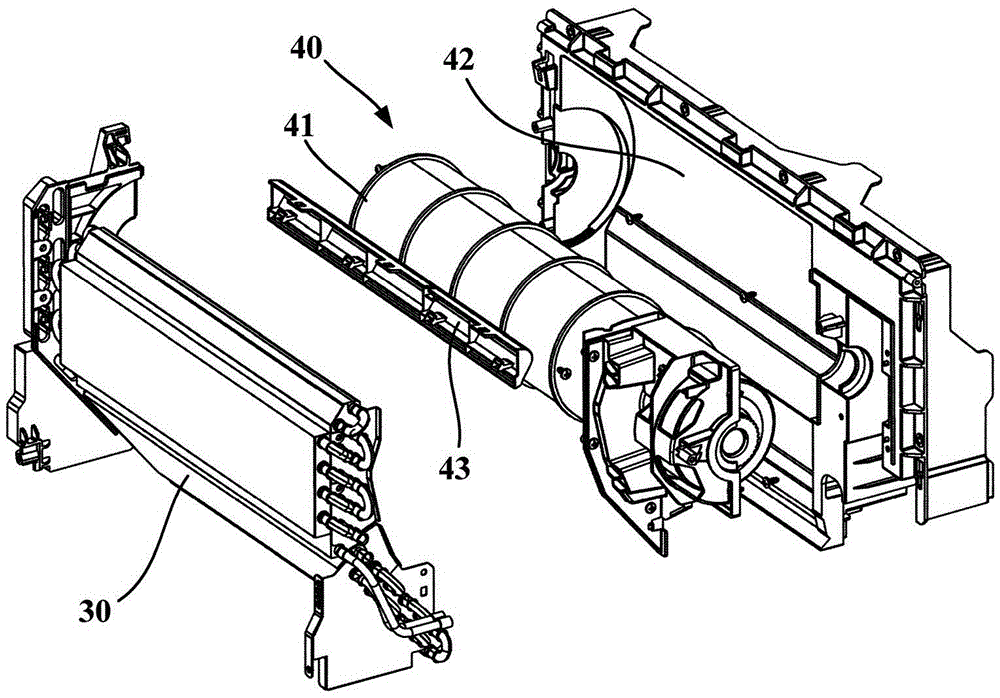

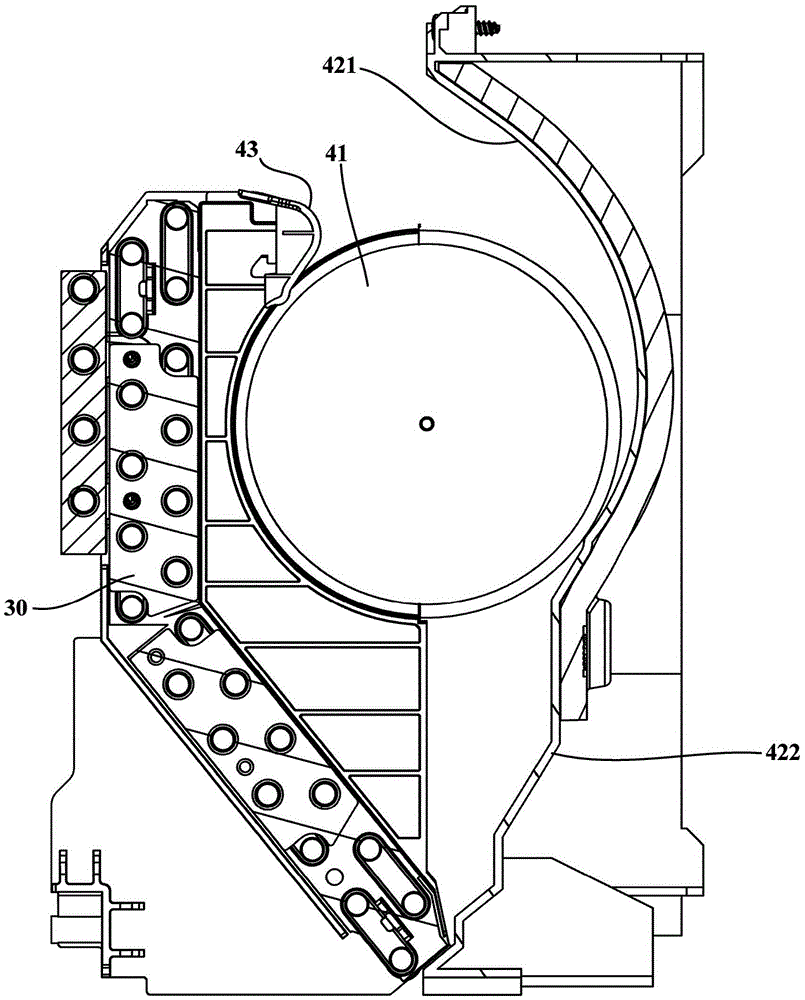

Window type air conditioner

ActiveCN105546666ASmooth air intakeWind evenlyLighting and heating apparatusNoise suppressionAir channelAerospace engineering

The invention provides a window type air conditioner. The window type air conditioner comprises a shell body and a cross-flow fan. The front end of the shell body is provided with an air inlet and an air outlet located above the air inlet. The cross-flow fan is arranged in the shell body and provided with a wind wheel, a volute and a volute tongue which is located on the front side of the volute. The air inlet and the air outlet communicate through a fan air channel limited by the volute and the volute tongue. The projection, in the plane perpendicular to the rotation axis of the wind wheel, of the inner surface of the volute forms the volute profile line of the volute, and the volute profile line is divided into an upper section and a lower section through the point, closest to the rotation axis of the wind wheel, on the volute profile line. In addition, the upper section comprises three circular arc sections connected sequentially and smoothly. According to the window type air conditioner, due to the fact that the volute profile line of the volute comprises the three circular arc sections, the special streamline air channel design structure enables air inflow and air outflow of the window type air conditioner to be smoother, and accordingly noise generated by the window type air conditioner is significantly lowered.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

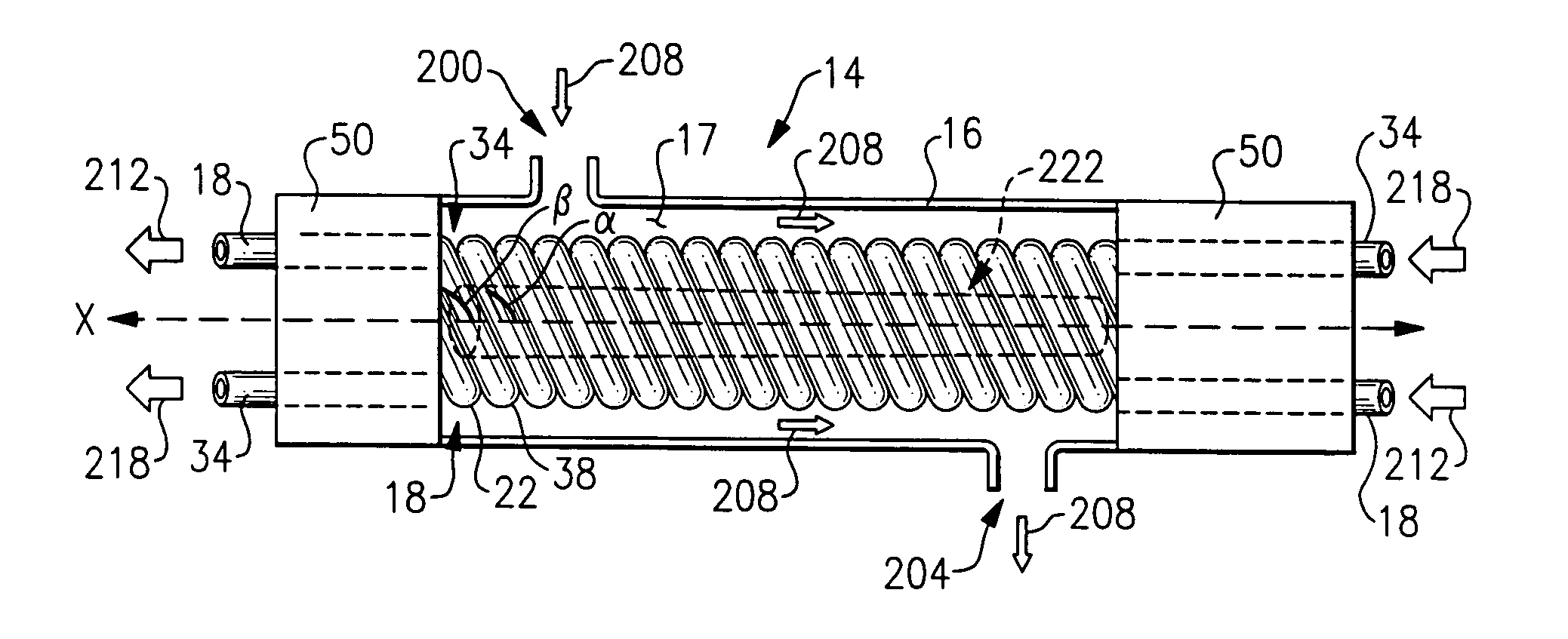

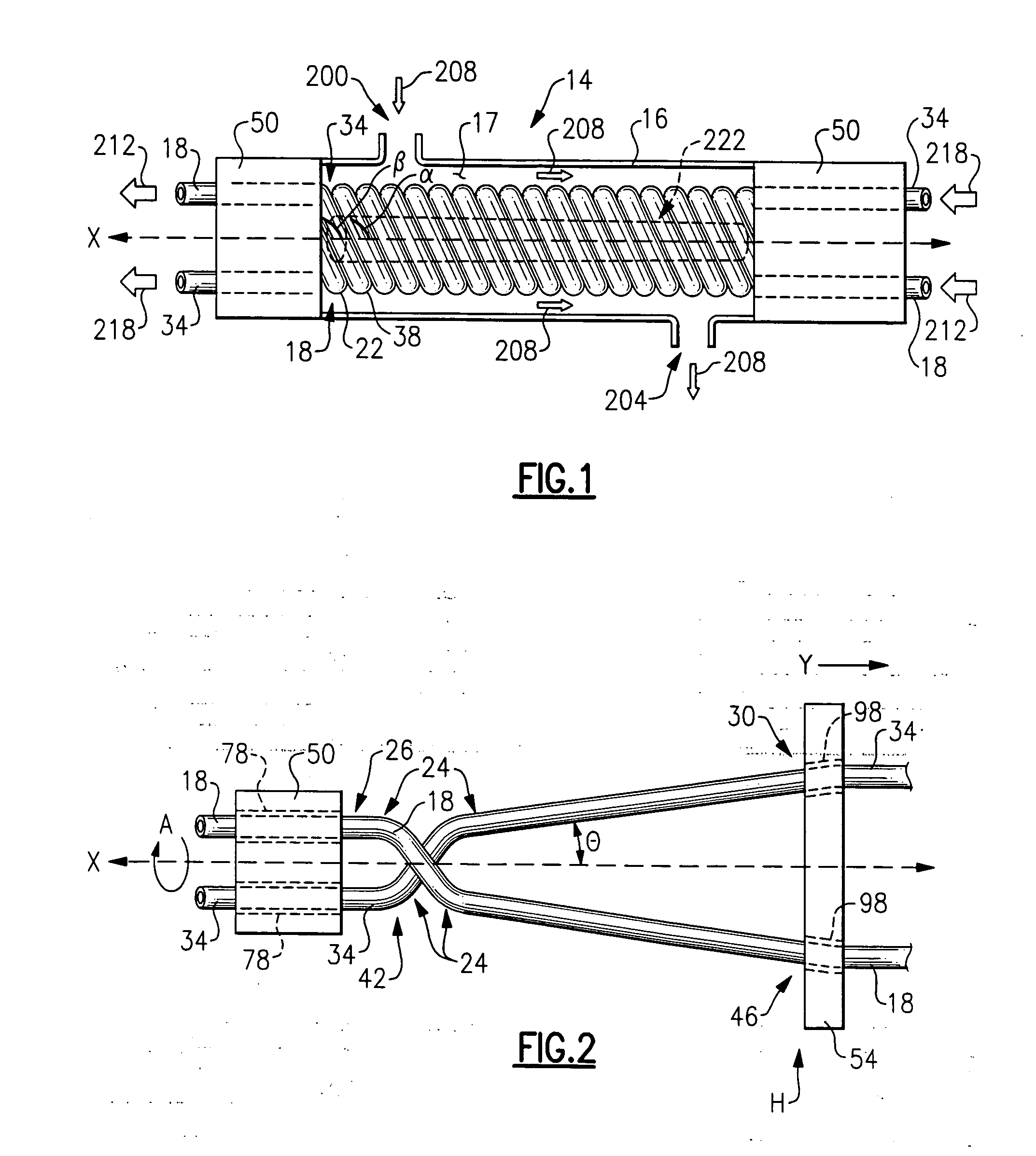

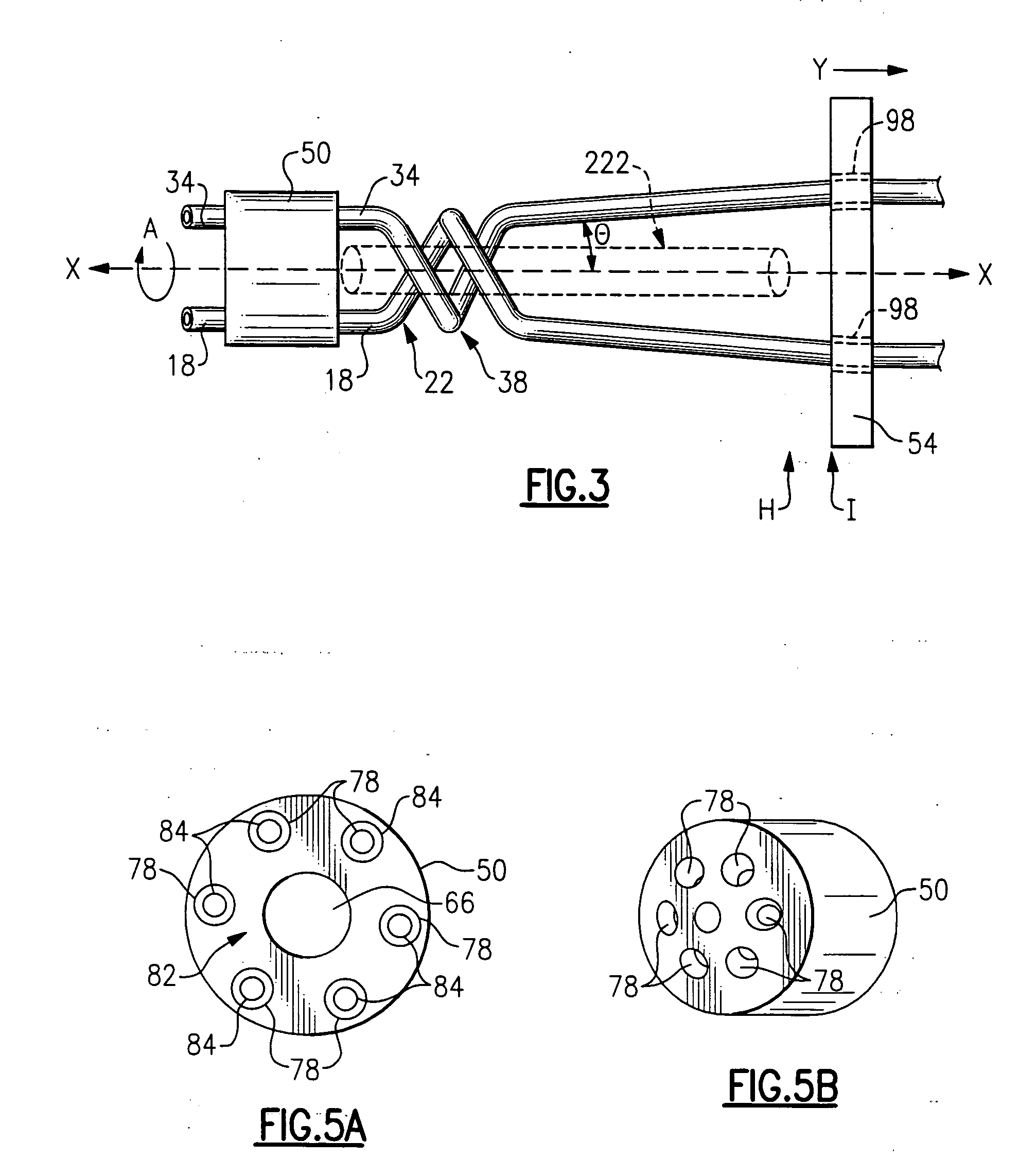

Multi-tube in spiral heat exchanger

InactiveUS20050103482A1Increase surface areaCompact designSafety devices for heat exchange apparatusStationary tubular conduit assembliesEngineeringSpiral heat exchanger

A heat exchanger has a first thermally conductive tube for conducting a fluid and a second thermal conductive tube for conducting a fluid. The first thermally conductive tube forms a first loop while the second thermally conductive tube forms a second loop. The first loop neighbors the second loop.

Owner:CARRIER CORP

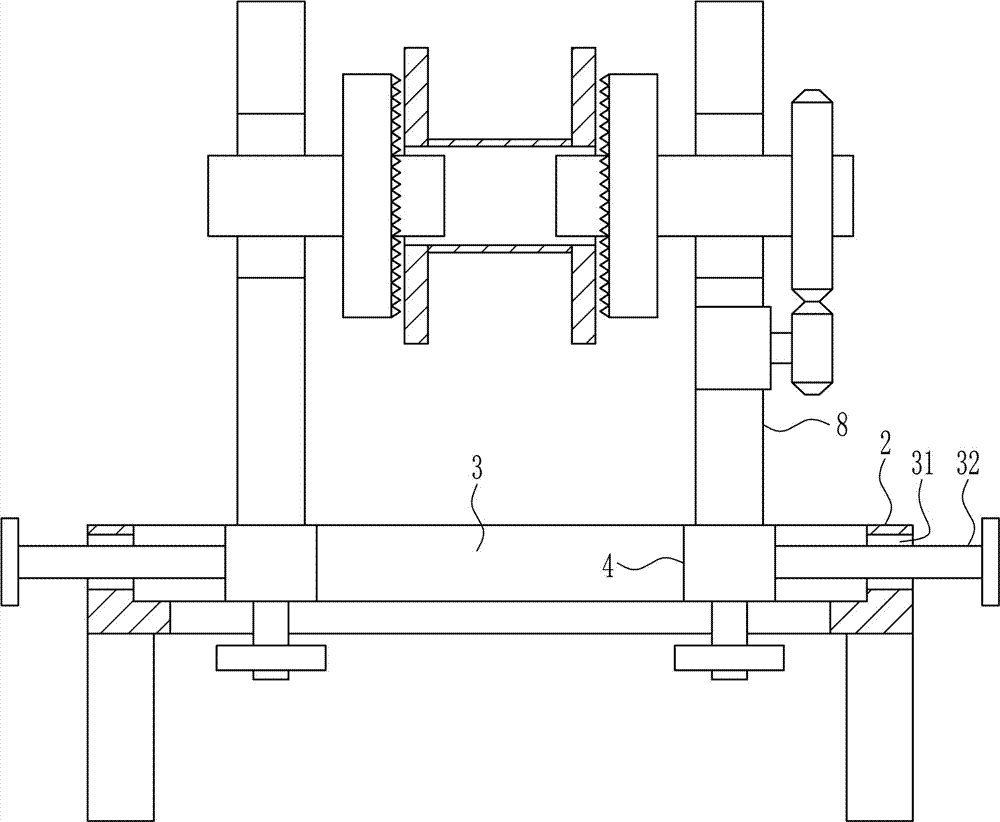

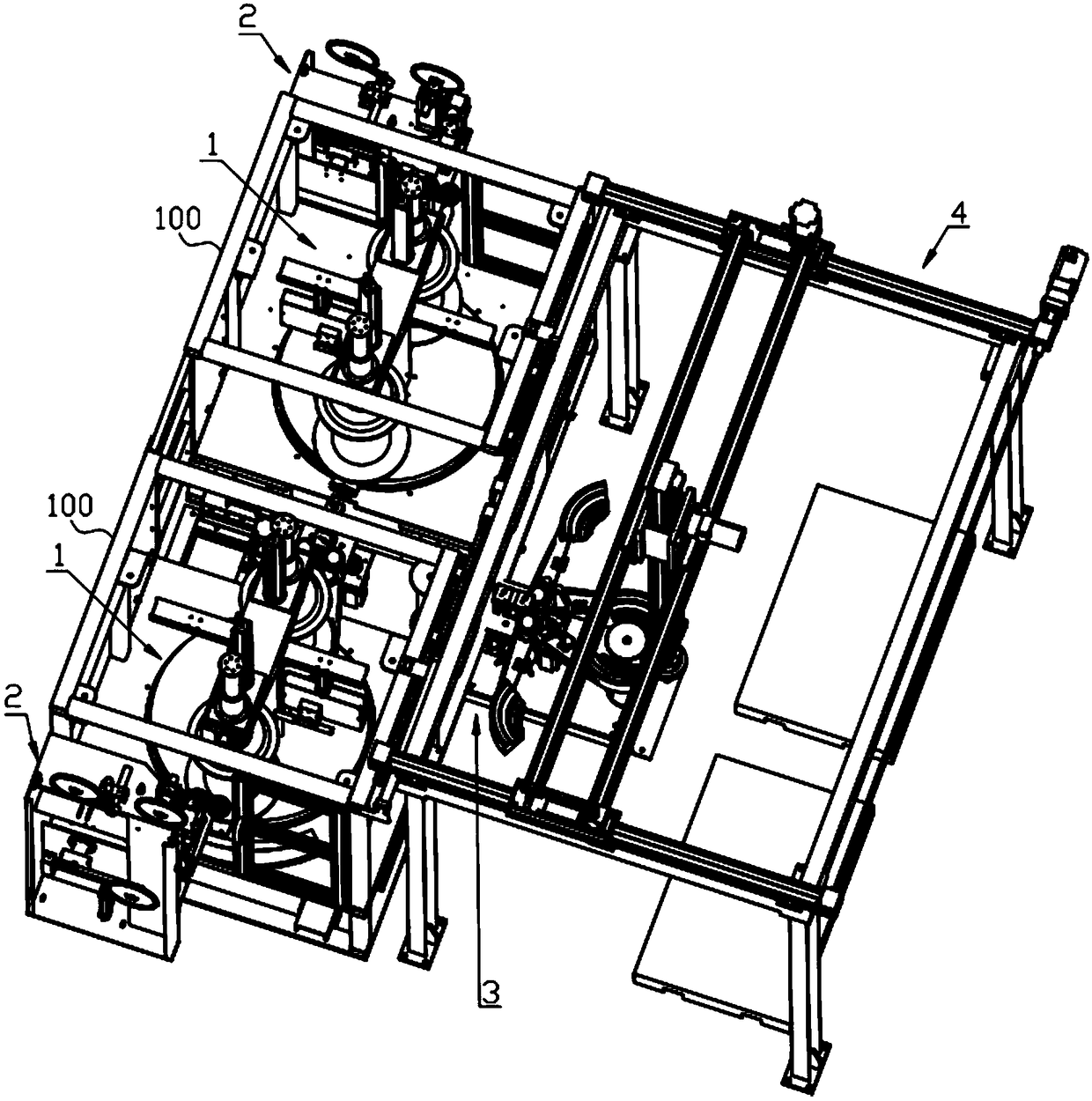

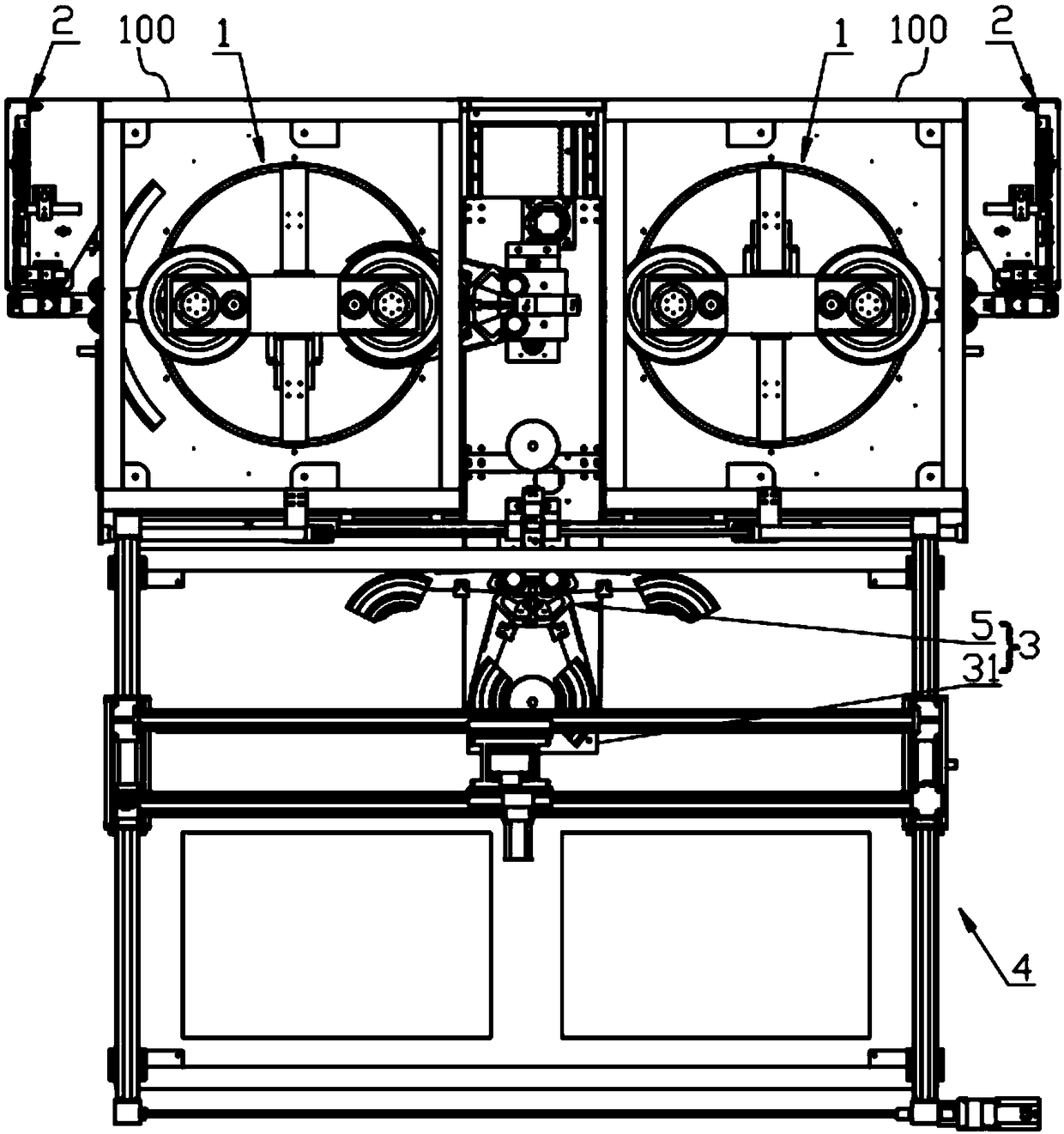

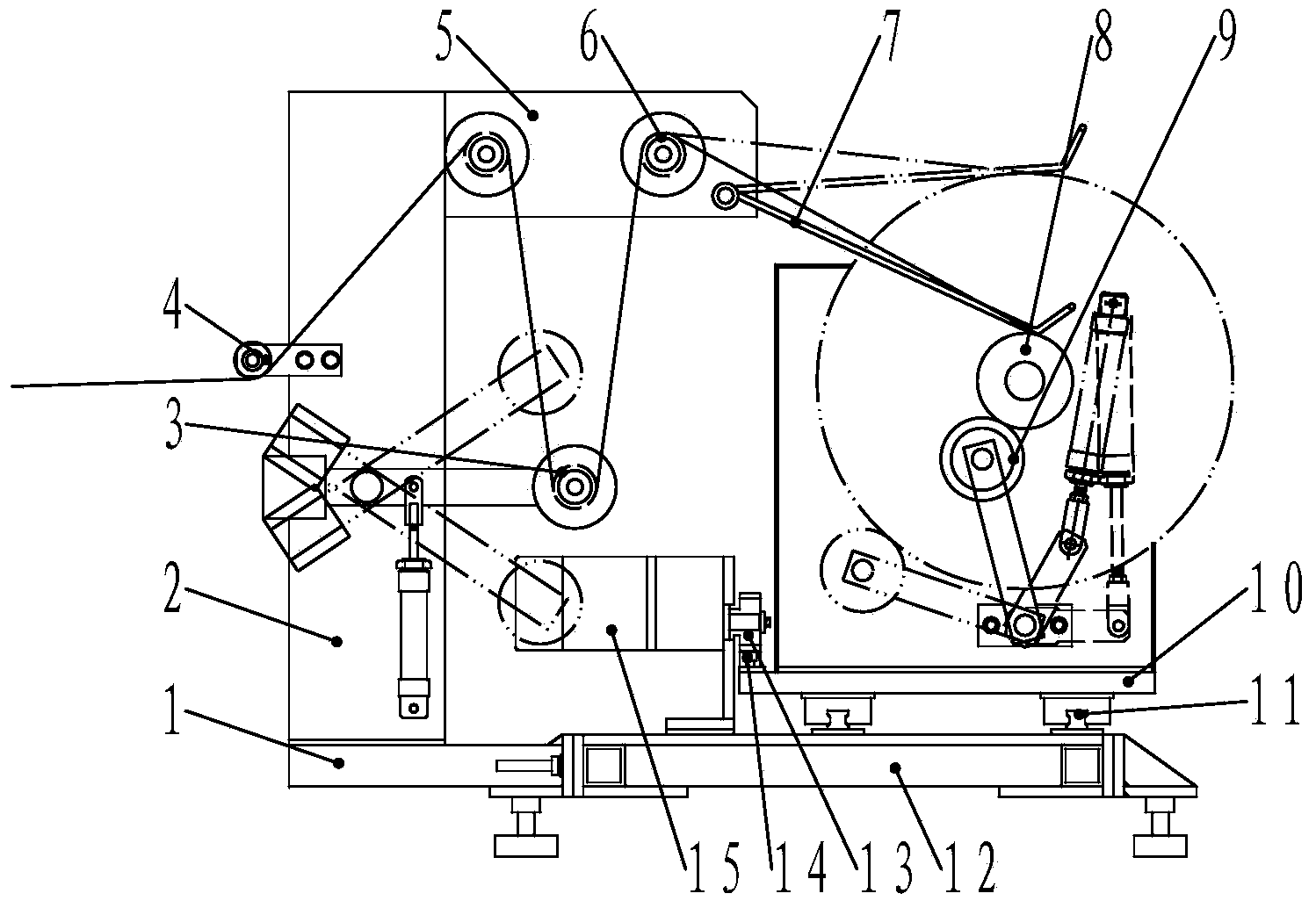

Full-automatic vertical winding machine provided with rotating disk

The invention discloses a full-automatic vertical winding machine provided with a rotating disk. The winding machine comprises a rack; a rotating disk type winding device is arranged on the rack; a guiding support and a reel loading and unloading device are arranged on the two opposite sides of the rack; the reel loading and unloading device extends below a three-coordinate transfer device; the three-coordinate transfer device grasps winding reels by the aid of X-axis, Y-axis and Z-axis frames and grasping heads; the reel loading and unloading device comprises a reel transfer mechanism and a track; the reel transfer mechanism moves on the track through cooperation of a sliding block and a linear guide rail to transfer the winding reels; the rotating disk type winding device comprises the rotating disk, a rotating disk shaft, two winding shafts and a winding supporting plate; the rotating disk shaft is driven by a rotating disk driving mechanism to drive the rotating disk to rotate; andthe lower part of the winding shaft is connected with a winding reel driving mechanism for driving the winding shaft to rotate. By the aid of the winding machine, sequential and stable wire winding and unwinding can be realized, the positions of the two winding reels can be switched quickly by the aid of the rotating disk, and the full-automatic vertical winding machine which is provided with therotating disk and can realize full-automatic wire capturing, disk replacement, wire breakage, grasping and reel transfer can meet the requirement for high-speed production.

Owner:WUXI JUYI TONGCHUANG TECH CO LTD

Automatic wire take-up device for electric power industry

The invention discloses an automatic wire take-up device for electric power industry and belongs to the technical field of power equipment. The automatic wire take-up device comprises a support device and a wire take-up device, wherein the support device comprises a support base and a support frame; a slideway is arranged on the support base; the bottom of the support frame is embedded in the slideway; the support frame comprises a support stand column and a support plate; a motor I is arranged on the support plate; the wire take-up device comprises a reel, a rotation shaft and a motor II; two ends of the rotation shaft are fixed on the support stand column respectively; one end of the rotation shaft is connected with the motor II. The automatic wire take-up device is simple in structure, convenient to operate and high in wire take-up efficiency; the motor II drives the support device to move in a reciprocating manner to uniformly wind cables on the reel; a draft gear is arranged to facilitate movement of the automatic wire take-up device.

Owner:STATE GRID CORP OF CHINA +1

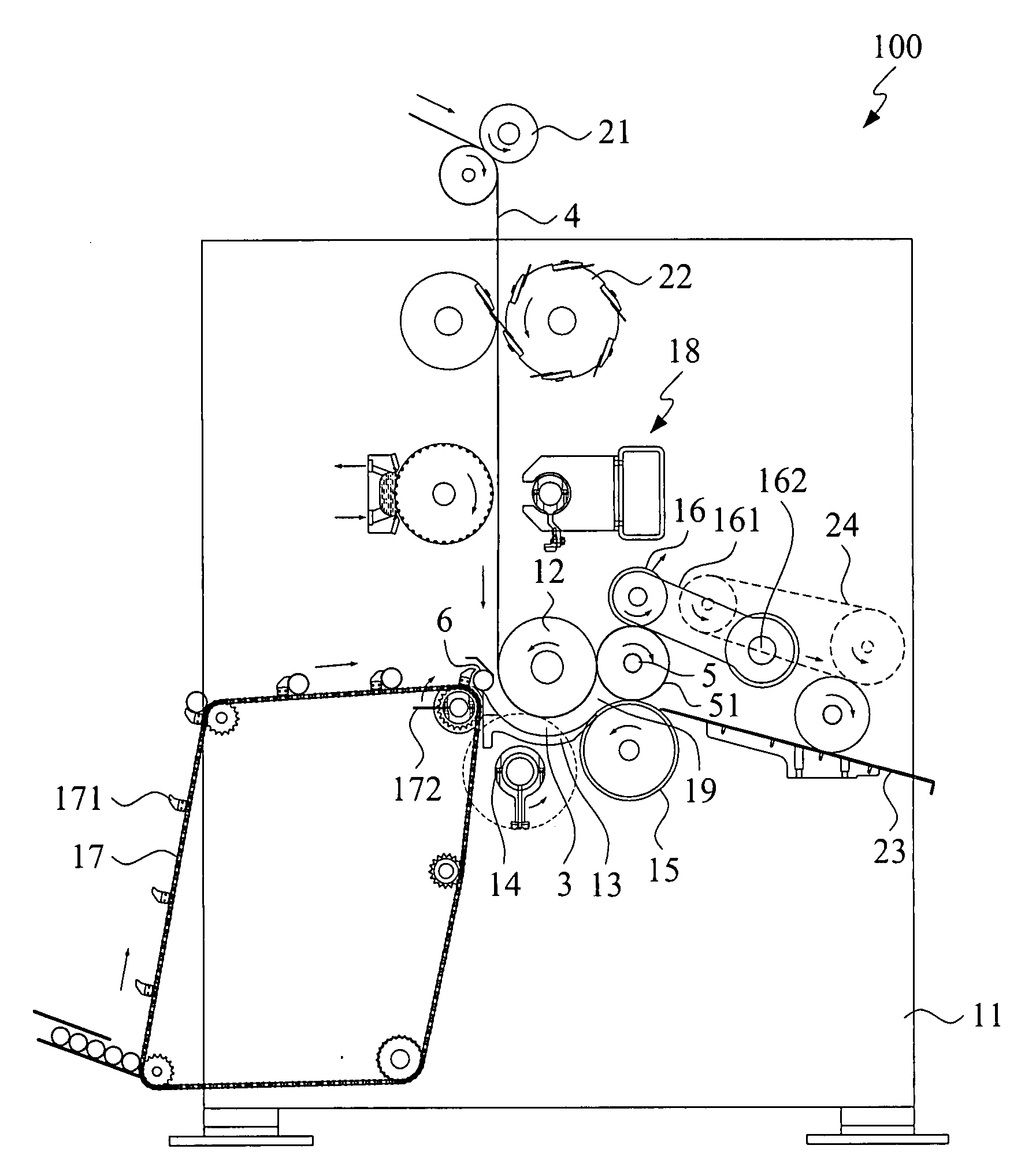

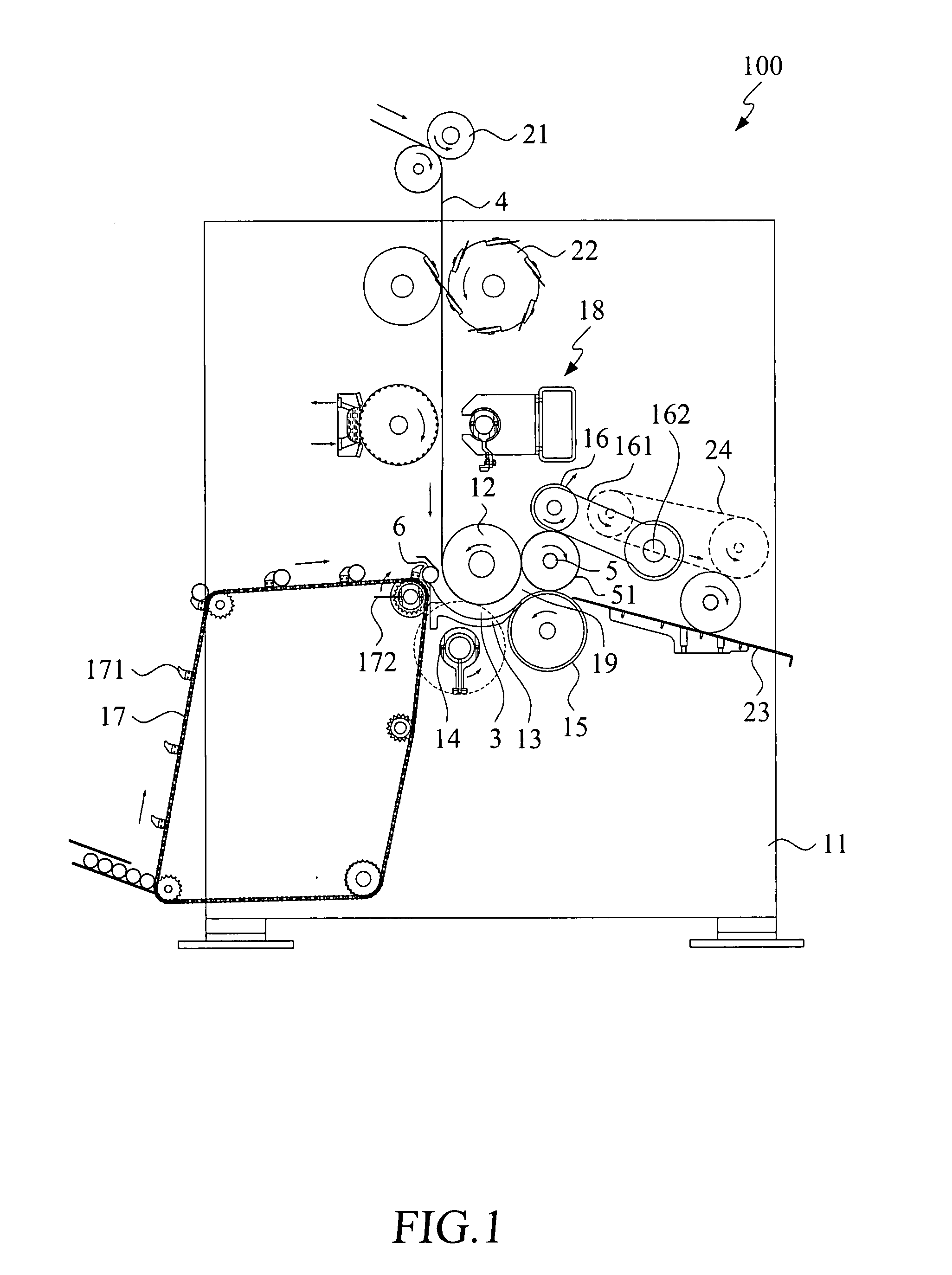

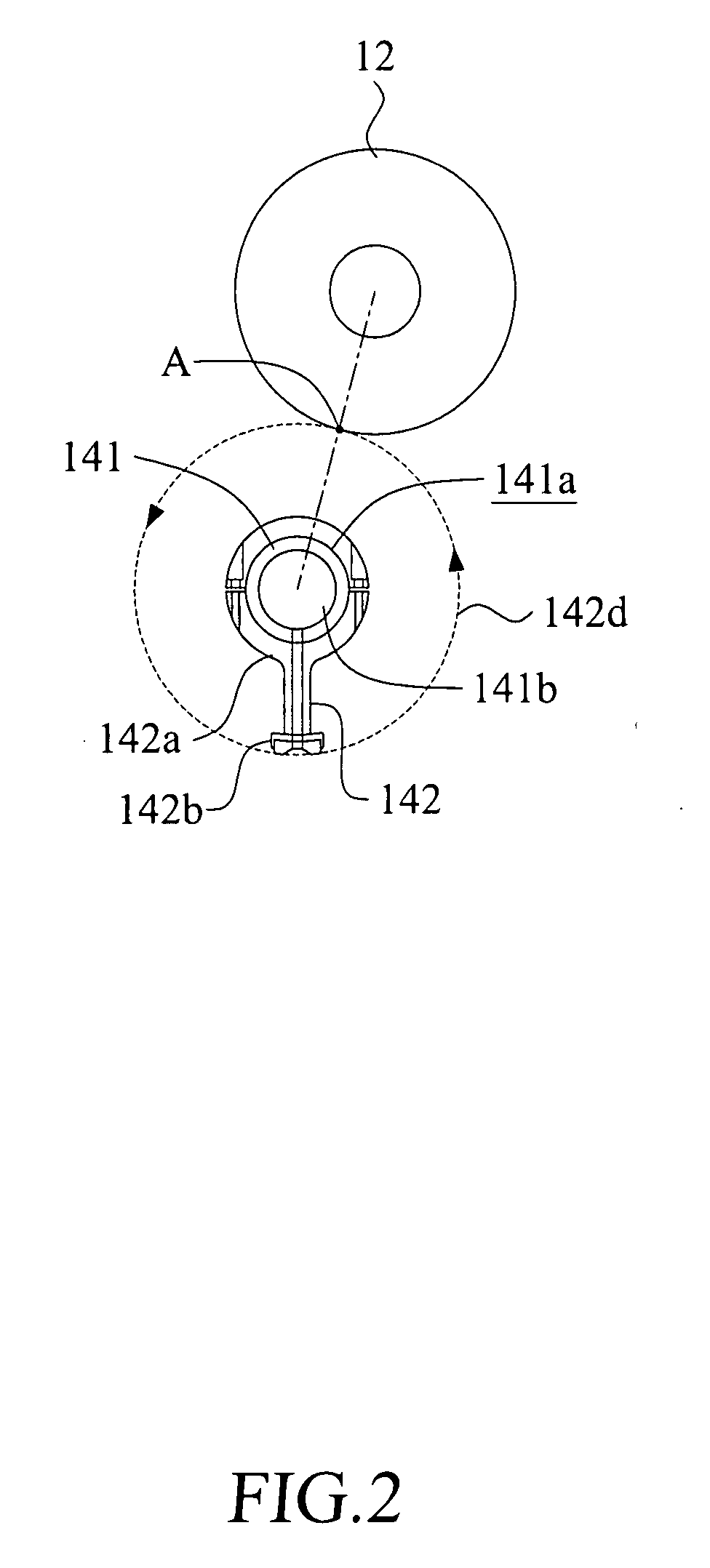

Web separator with reverse rotation mechanism for tissue paper winding machine

ActiveUS20090026299A1Easily pull apartFacilitate smooth windingArticle deliveryWebs handlingPaper sheetCounter rotation

A tissue paper winding machine includes a first winding roller and a web separator arranged below the first winding roller. A tissue paper is fed into the winding machine to bear against a lower circumferential surface of the first winding roller and moves along a predetermined feeding direction for winding around a core. The web separator includes a pivot shaft, at least one pinch arm having a connecting end connected to the pivot shaft and a pressing end radially outward extended from the pivot shaft, and a driving mechanism for driving the pinch arm to turn about the pivot shaft reverse to the feeding direction of the tissue paper. When the pressing end of the pinch arm is turned to a separation position, it cooperates with the first winding roller to clamp the tissue paper therebetween, and applies a reverse pulling force to split the tissue paper.

Owner:CHAN LI MACHINERY

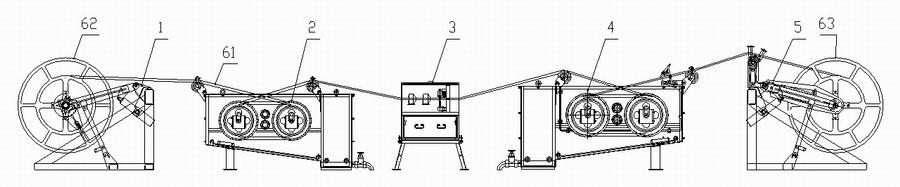

Environment-friendly cleaning and maintenance machine for steel wire rope

ActiveCN102247961AHeight adjustableSatisfy the requirements of pay-offCleaning processes and apparatusEngineeringUltimate tensile strength

The invention discloses an environment-friendly cleaning and maintenance machine for a steel wire rope. The machine comprises a wire pay-off mechanism, a cleaning mechanism, a dirt-removing mechanism, a maintenance mechanism and a wire take-up mechanism, which are arranged in sequence, wherein the steel wire rope is cleaned and maintained by the wire pay-off mechanism, the cleaning mechanism, the dirt-removing mechanism, the maintenance mechanism and the wire take-up mechanism in sequence. By the adoption of the cleaning and maintenance machine disclosed by the invention, the problems of massive dirt accumulation, rust formation and damage happening during the use process of different types of steel wire ropes for constructions can be effectively avoided; and accidents of personal injury, traffic interruption and power failure, which are caused by the breakage of steel wire ropes during the construction process, can be effectively prevented by periodically cleaning and greasing steel wire ropes with the cleaning and maintenance machine every year. The cleaning and maintenance machine disclosed by the invention can be used for cleaning different types of steel wire ropes in a simple and highly-efficient method, has stable performances and good cleaning and maintenance effects. The cleaning and maintenance machine is easy to operate during the use process and has the beneficial effects of reducing the labor intensity, increasing the work efficiency, ensuring the service safety against twisting of steel wire ropes, prolonging the service life and the operating reliability of steel wire ropes and providing powerful guarantee for safety production.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

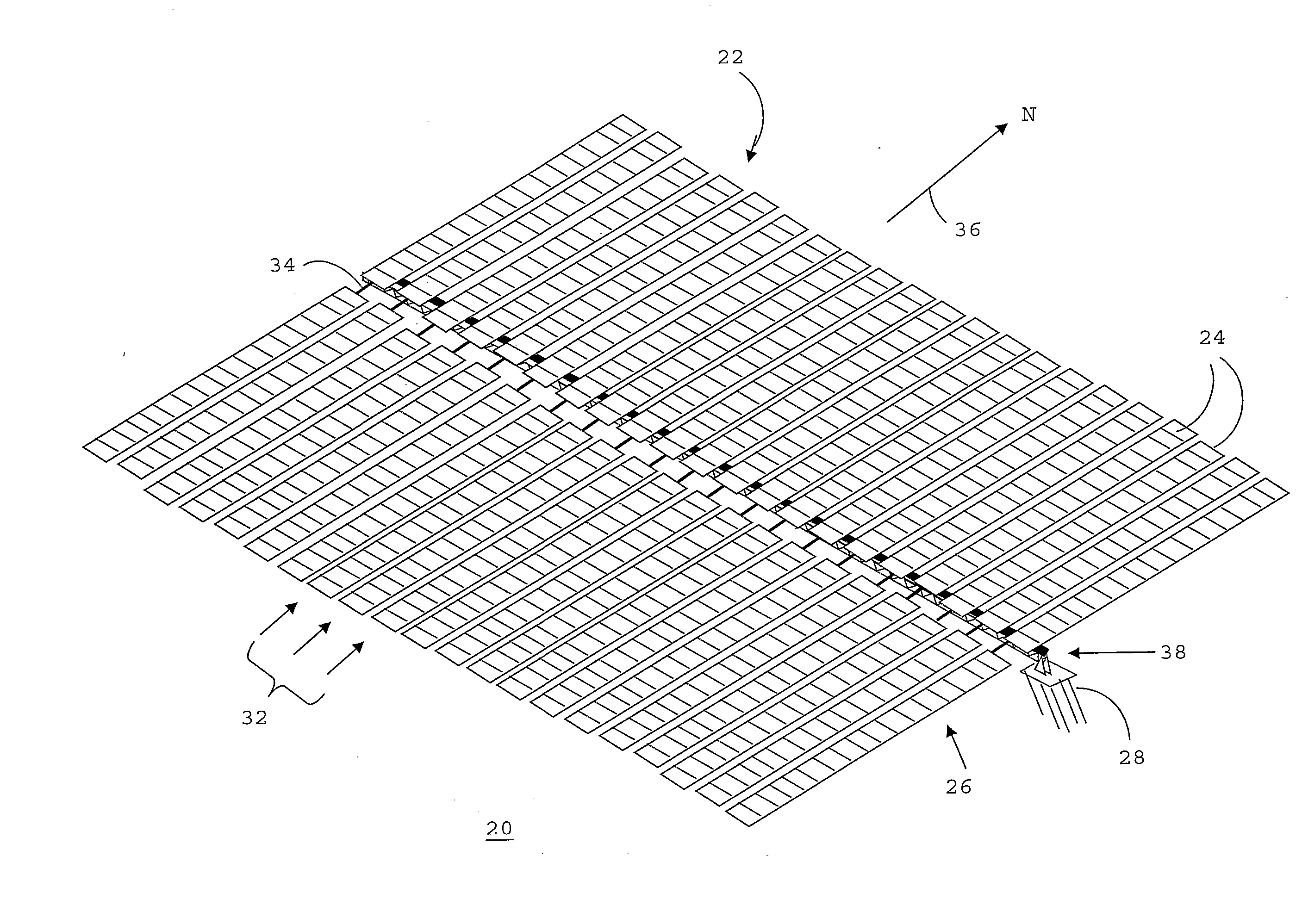

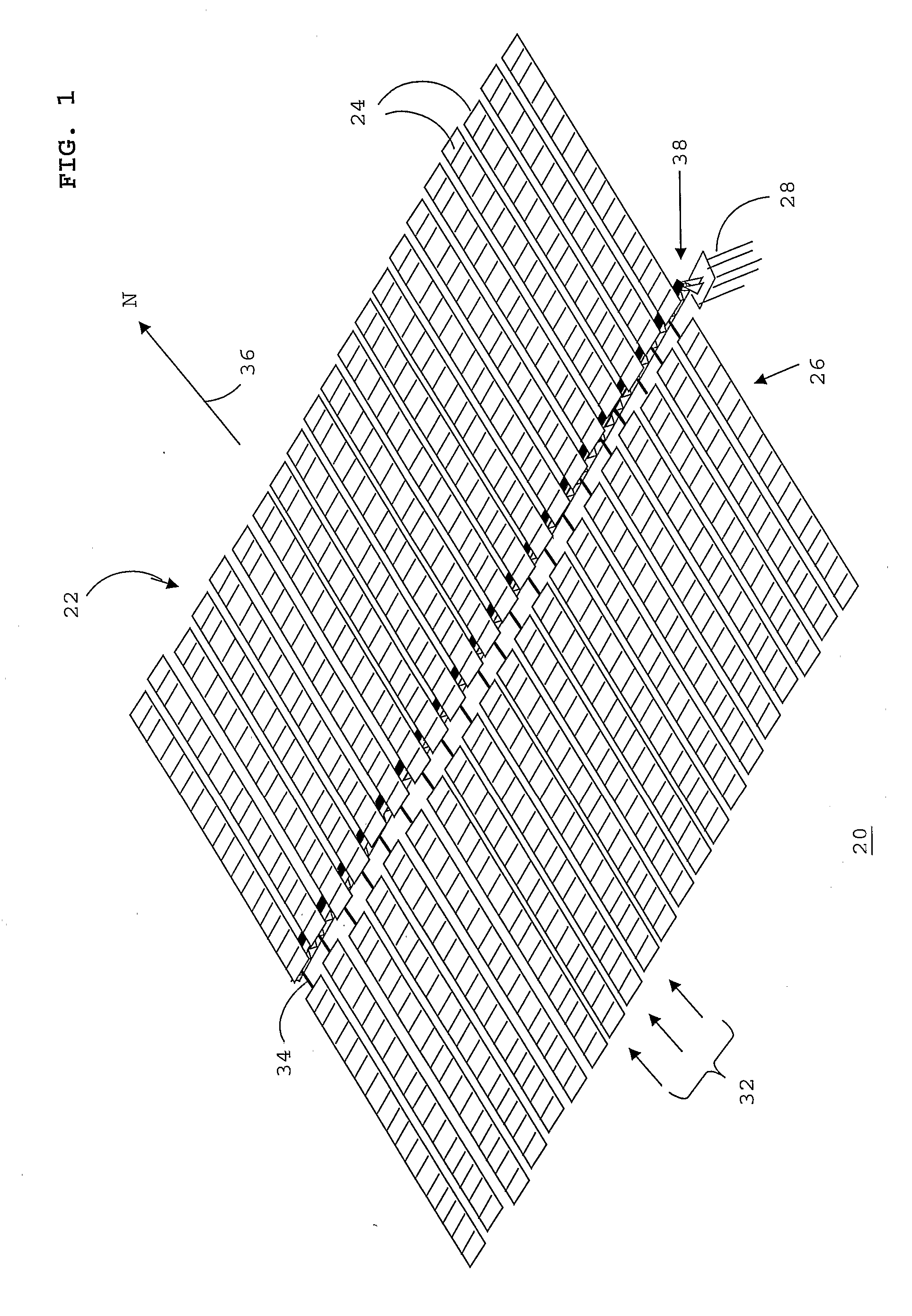

System for Supporting Energy Conversion Modules

InactiveUS20070215145A1Reduce in quantityWind evenlyPhotovoltaic supportsSolar heating energyCollection systemSolar energy harvesting

A structure (26) for supporting an array (22) of solar panels (24) in a solar energy collection system (20) includes a support assembly (140) formed from a ganged pier (44). The ganged pier (44) includes a truss (68), a post (46) downwardly extending from the truss (68) for attachment to a footing (48), and posts (50) upwardly extending from the truss (68). The structure (26) further includes torsion tubes (34), each of which is pivotally retained by one of the posts (50) to form parallel rows (32) of torsion tubes (34). Multiple ganged piers (44) can be interconnected to increase the number of rows (32) of the system (20). The solar panels (24) are attached to the torsion tubes (34) to form the array (22).

Owner:ARIZONA PUBLIC SERVICE

Structure for supporting energy conversion modules and solar energy collection system

InactiveUS20070012312A1Reduce in quantityWind evenlyPhotovoltaic supportsSolar heating energyCollection systemActuator

A structure (26) for supporting an array (22) of solar panels (24) in a solar energy collection system (20) includes a support assembly (42) formed from a rigid subassembly (44). The subassembly (44) includes an elongated truss (68), a base (46) coupled to the truss (68) for attachment to a footing (48), and posts (50) extending from a top edge of the truss (68). The structure (26) further includes torsion tubes (34), each of which is pivotally retained by one of the posts (50) to form parallel rows (32) of torsion tubes (34). A number of rigid subassemblies (44) can be interconnected to further increase the number of rows (32) of the system (20). The solar panels (24) are attached to the torsion tubes (34) to form the array (22), and a drive mechanism (38) pivots the torsion tubes (34) via a single elongated actuator and multiple torque arms (90).

Owner:UNIRAC INC

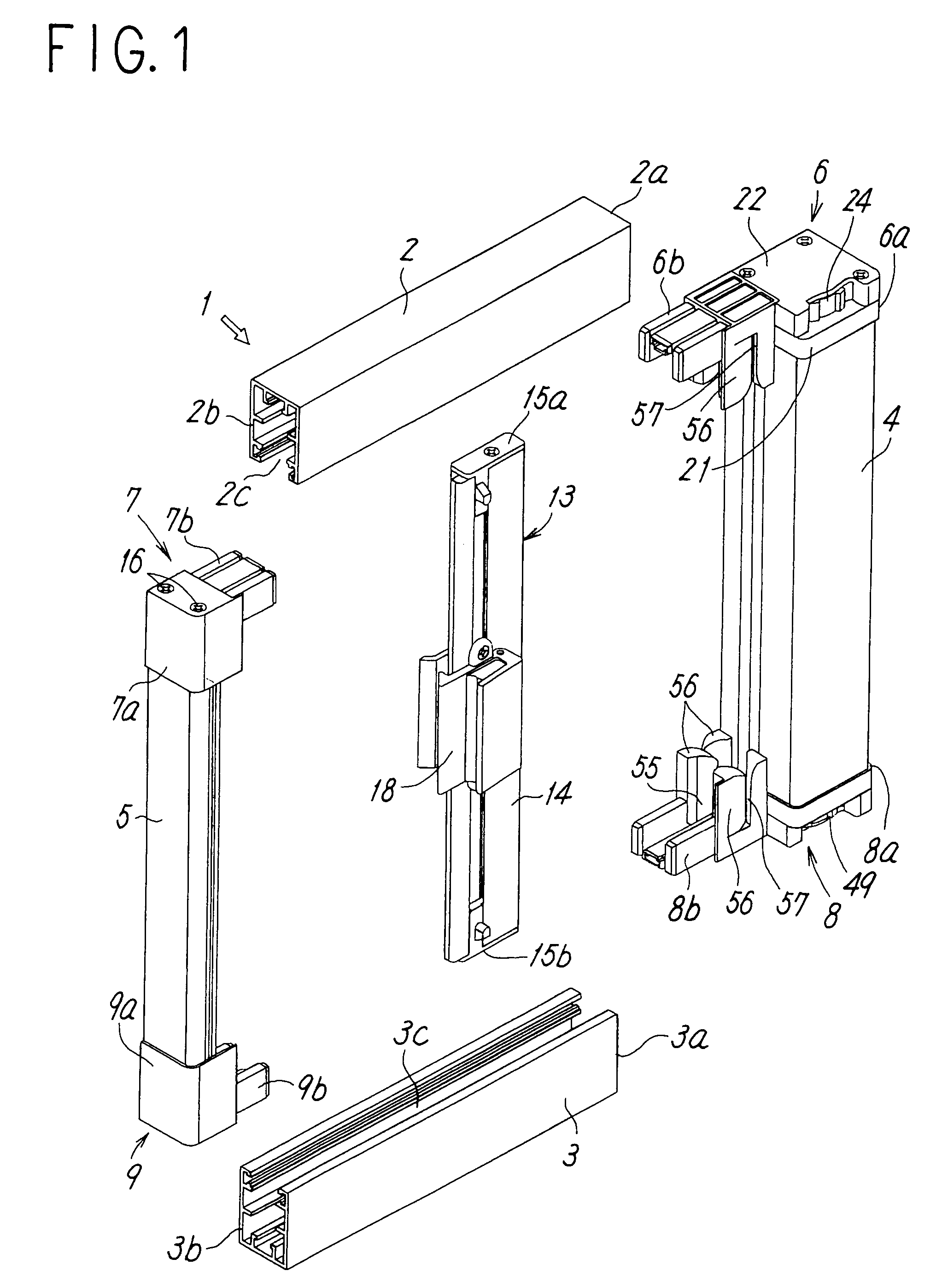

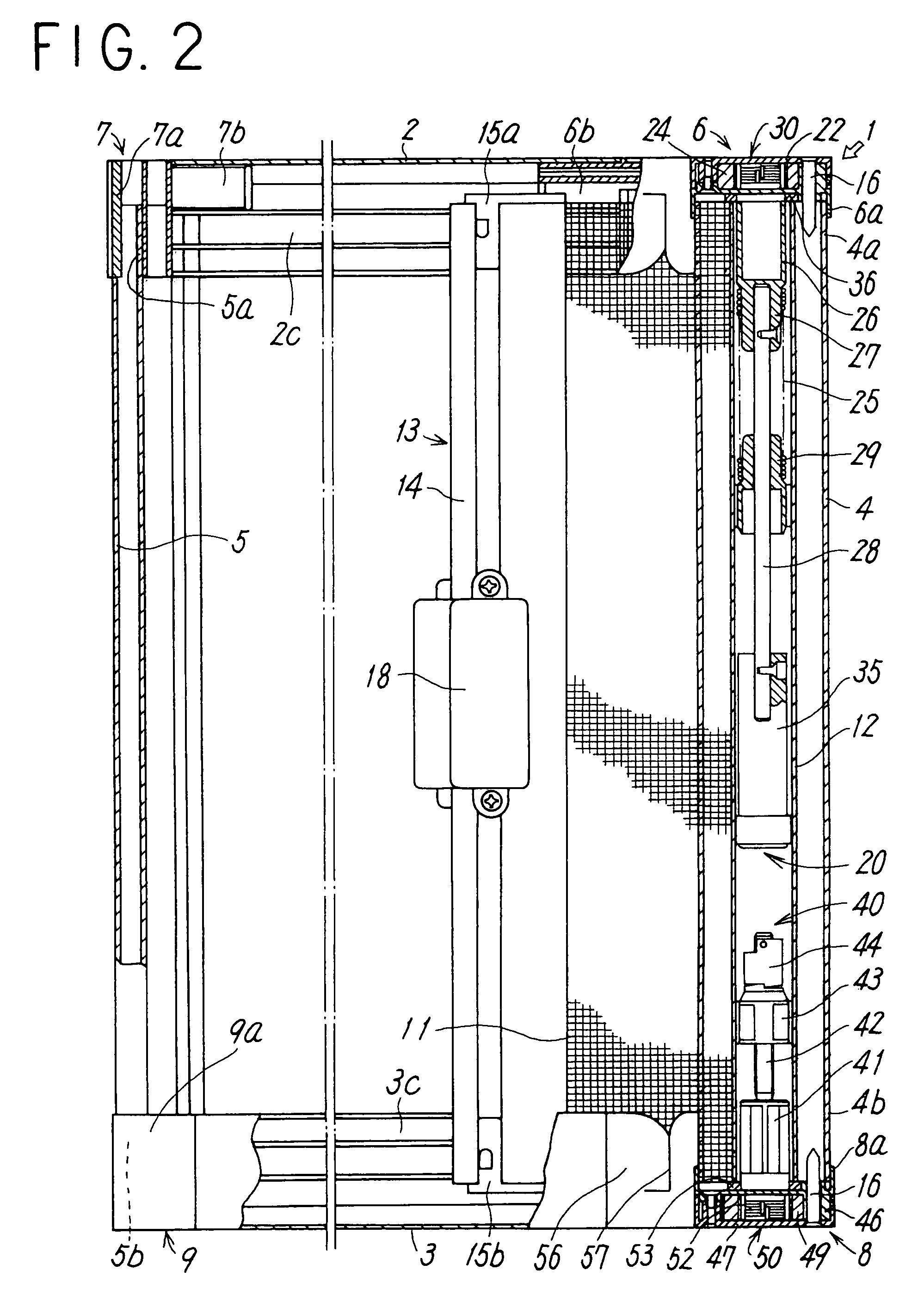

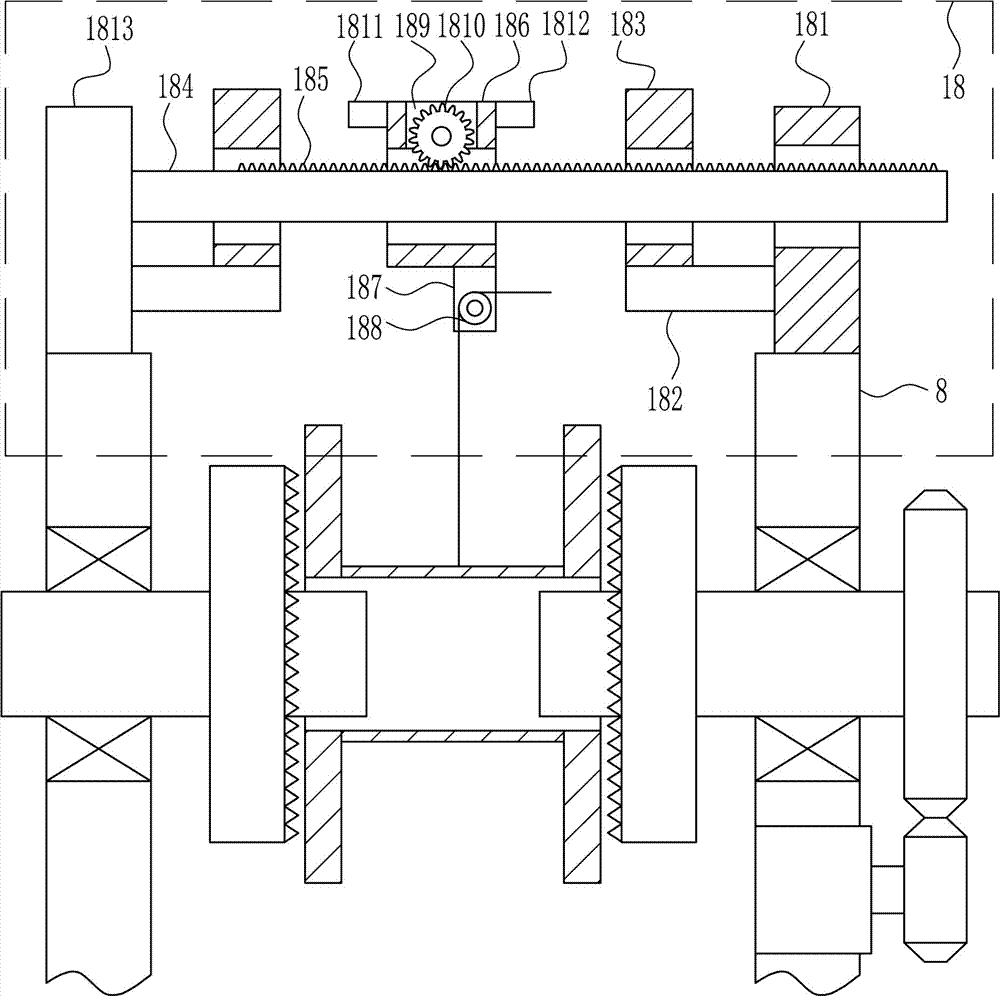

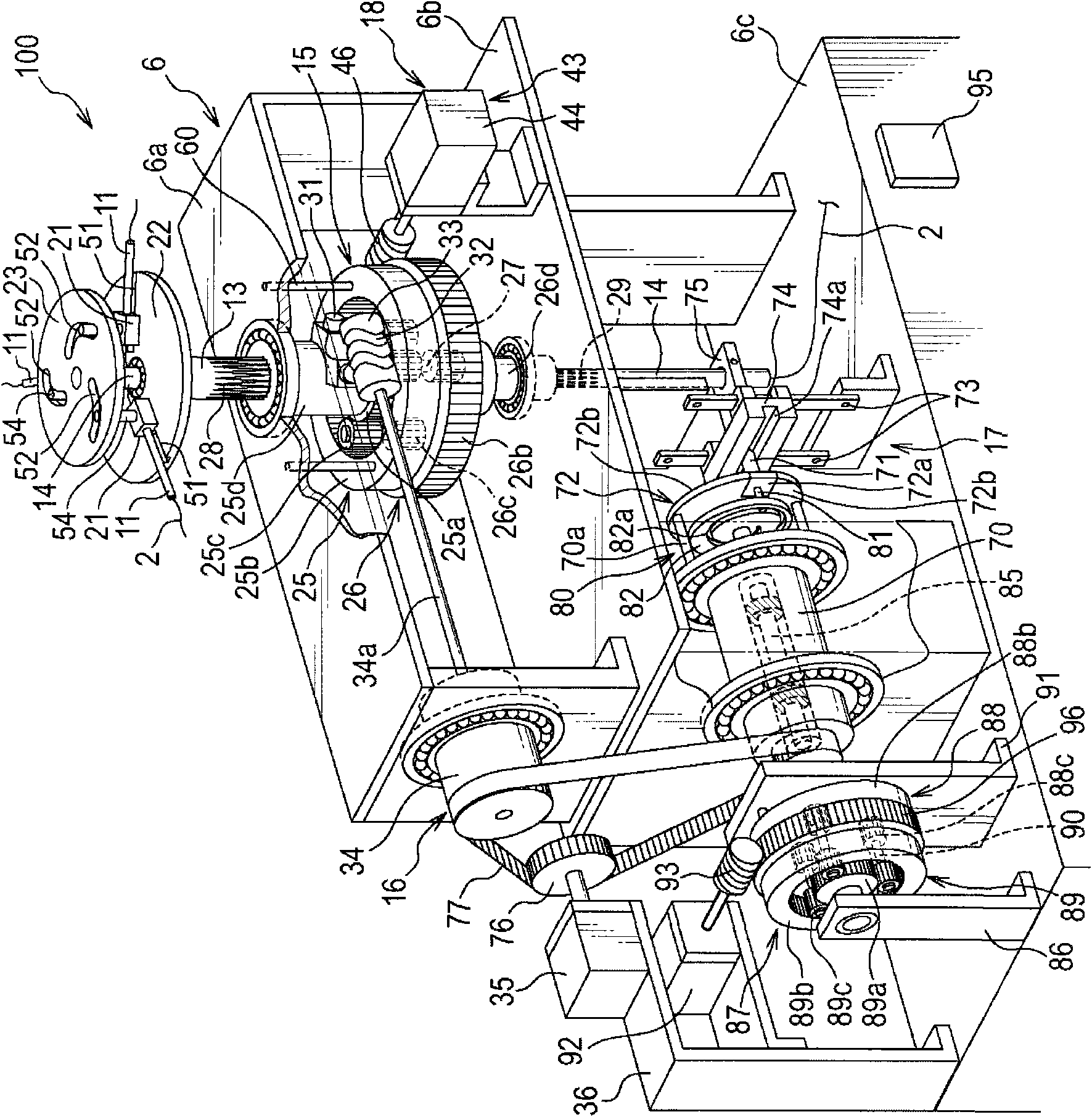

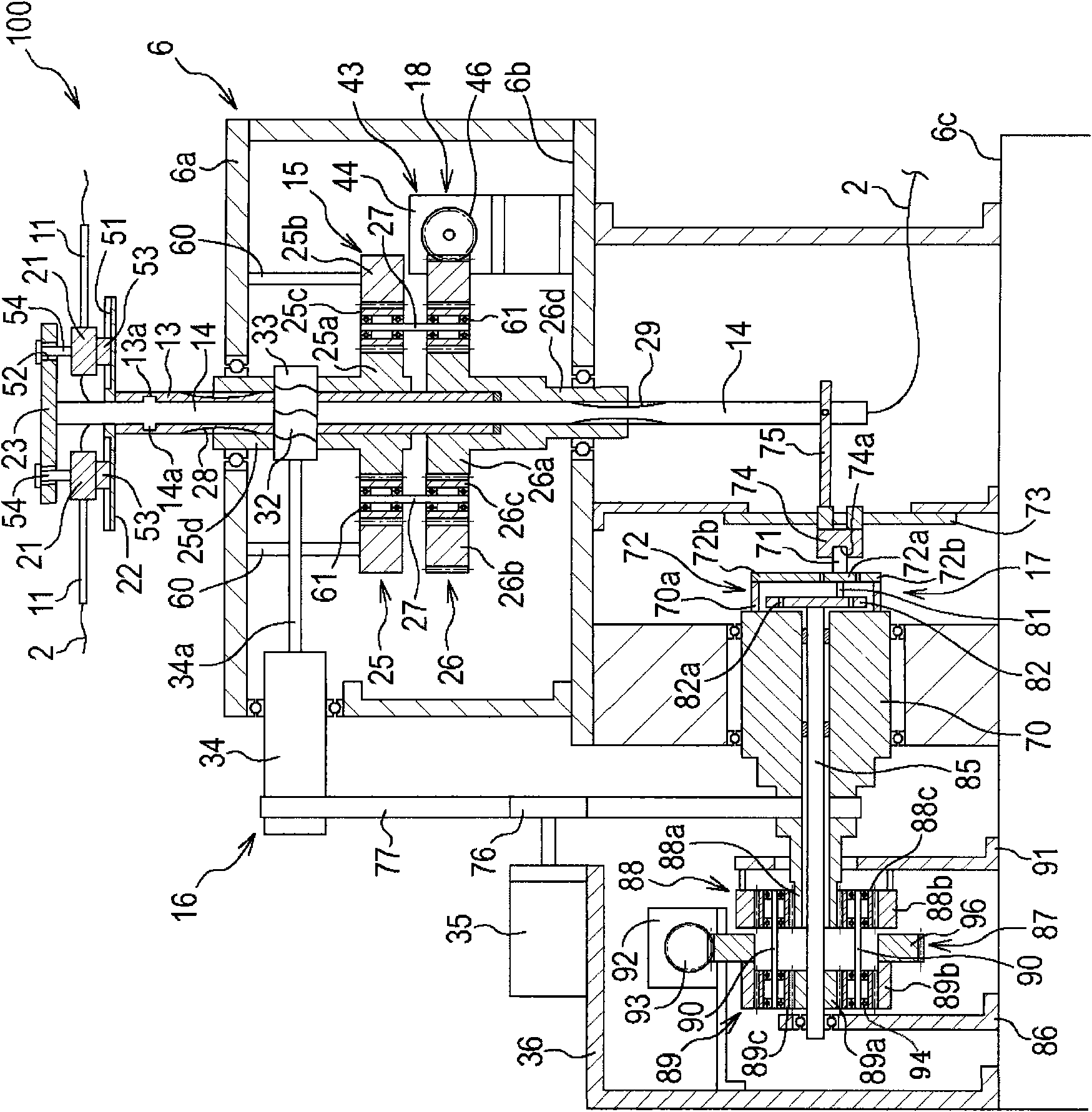

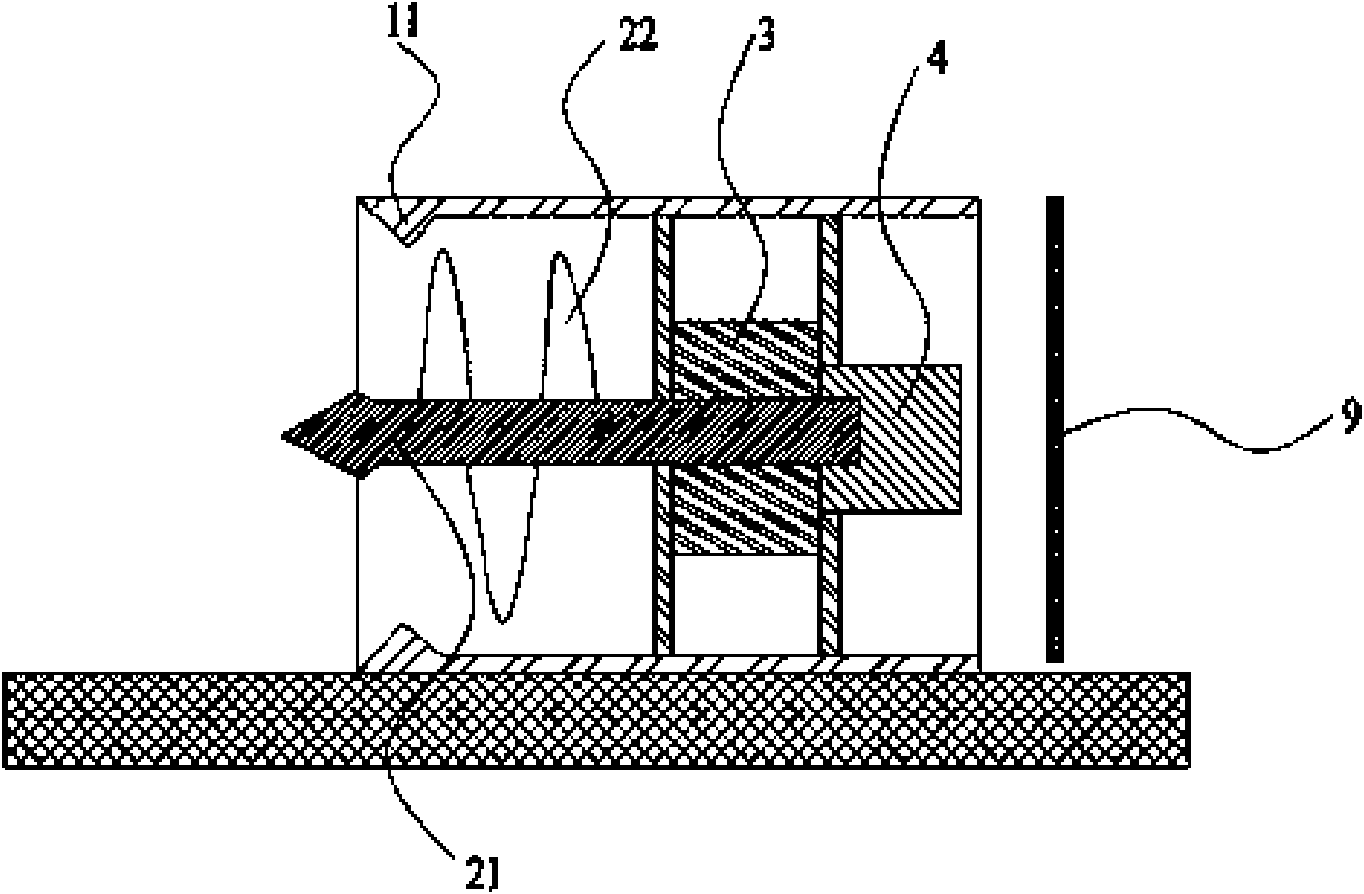

Winding device and winding method

ActiveCN101588115AWind evenlyManufacturing dynamo-electric machinesCoils manufactureMagnetic polesEngineering

The invention provides a winding device and a winding method. The winding device for winding wires on a magnetic pole comprises a head, a head supporting shaft, a traverse shaft, a shaft connecting mechanism, a head rotating mechanism, a nozzle moving mechanism and a head moving mechanism, wherein the head is used for supporting a nozzle; the head supporting shaft is used for supporting the head; the rotation of the traverse shaft around a shaft center is relatively independent from the head supporting shaft, and the traverse shaft is connected with the head supporting shaft along an axial direction; the shaft connecting mechanism is connected with the head supporting shaft and the traverse shaft to enable the rotation to be transferred to the traverse shaft by enabling the head supporting shaft to rotate around the shaft center, and the rotation can not be transferred to the head supporting shaft even the traverse shaft rotates around the shaft center; the head rotating mechanism enables the traverse shaft and the head supporting shaft to synchronously rotate and enables the head to rotate around the shaft center by enabling the head supporting shaft to rotate; the nozzle moving mechanism enables the traverse shaft to rotate relative to the head supporting shaft and enables the nozzle to move along the axial direction by enabling the traverse shaft to rotate; and the head moving mechanism enables the head to move along the axial direction by enabling the head supporting shaft and the traverse shaft to move along the axial direction.

Owner:NITTOKU ENG CO LTD

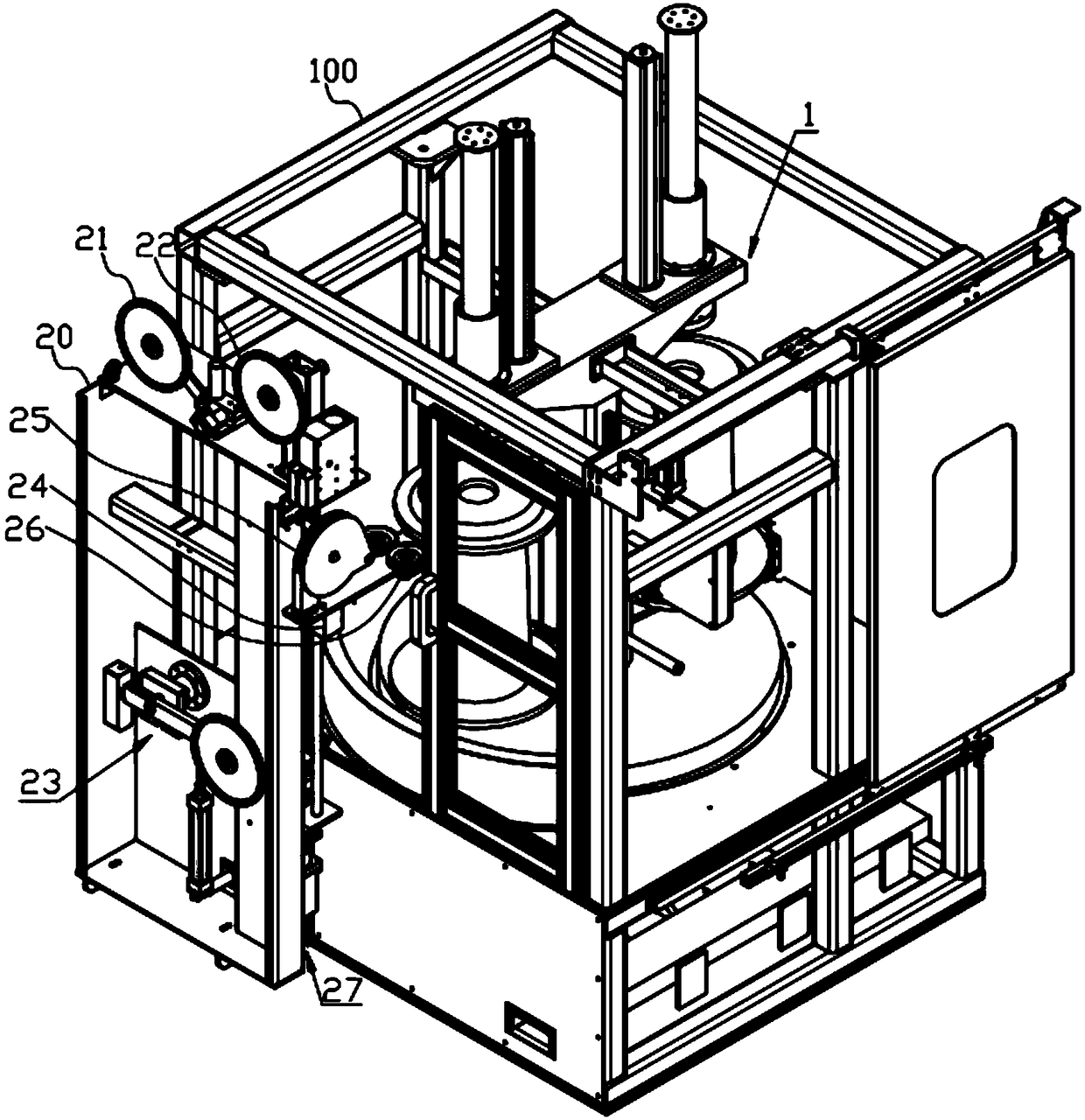

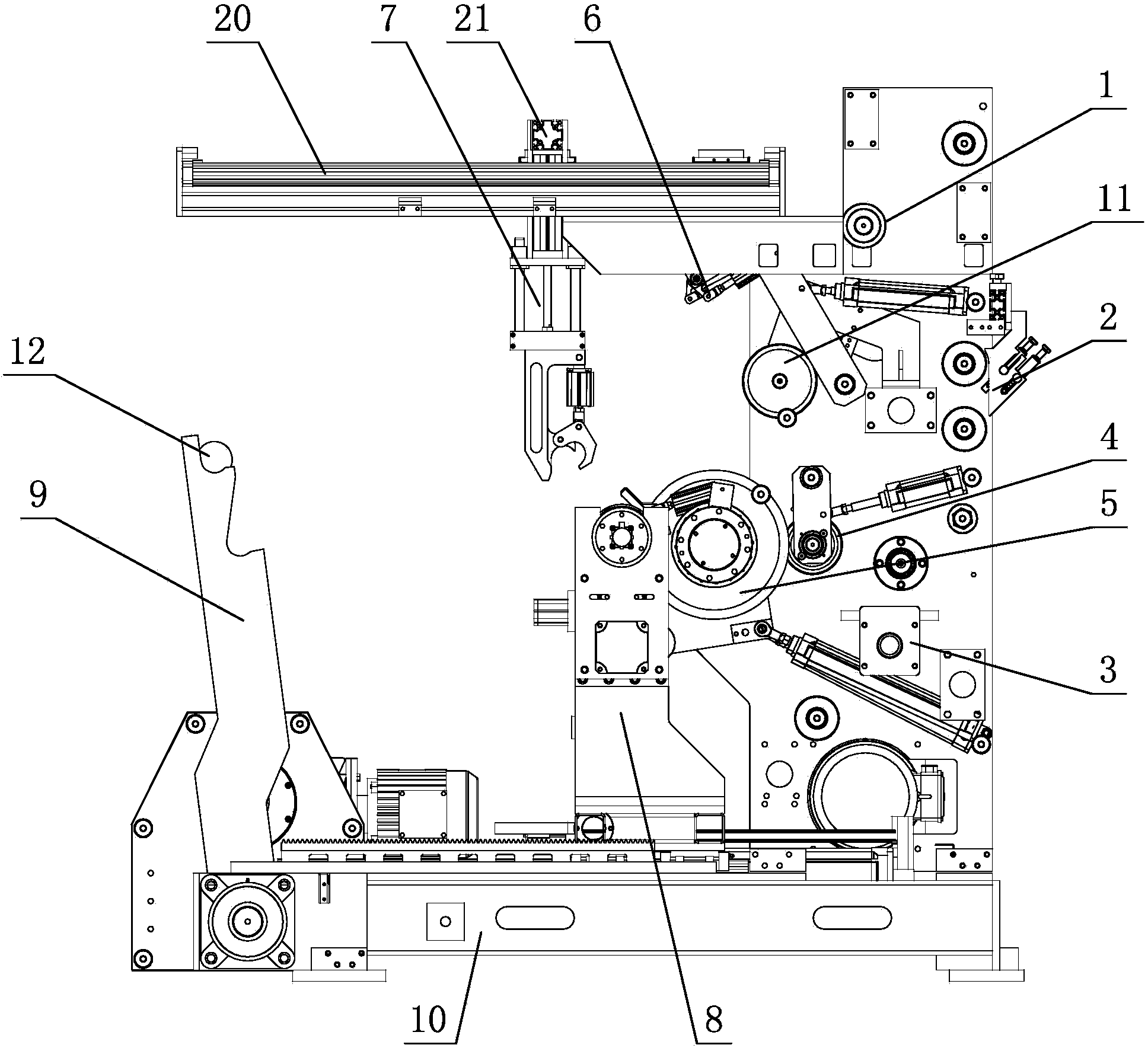

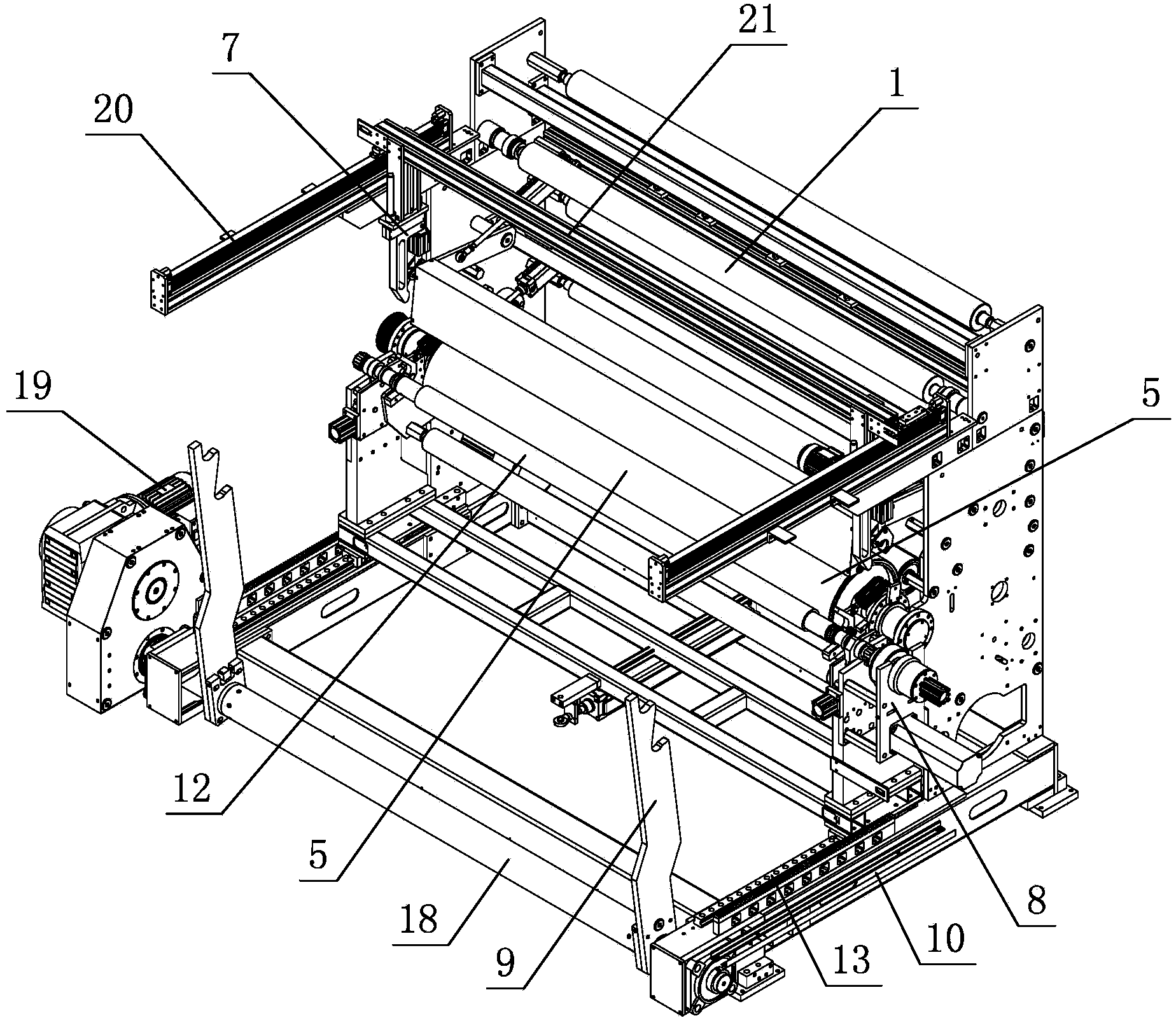

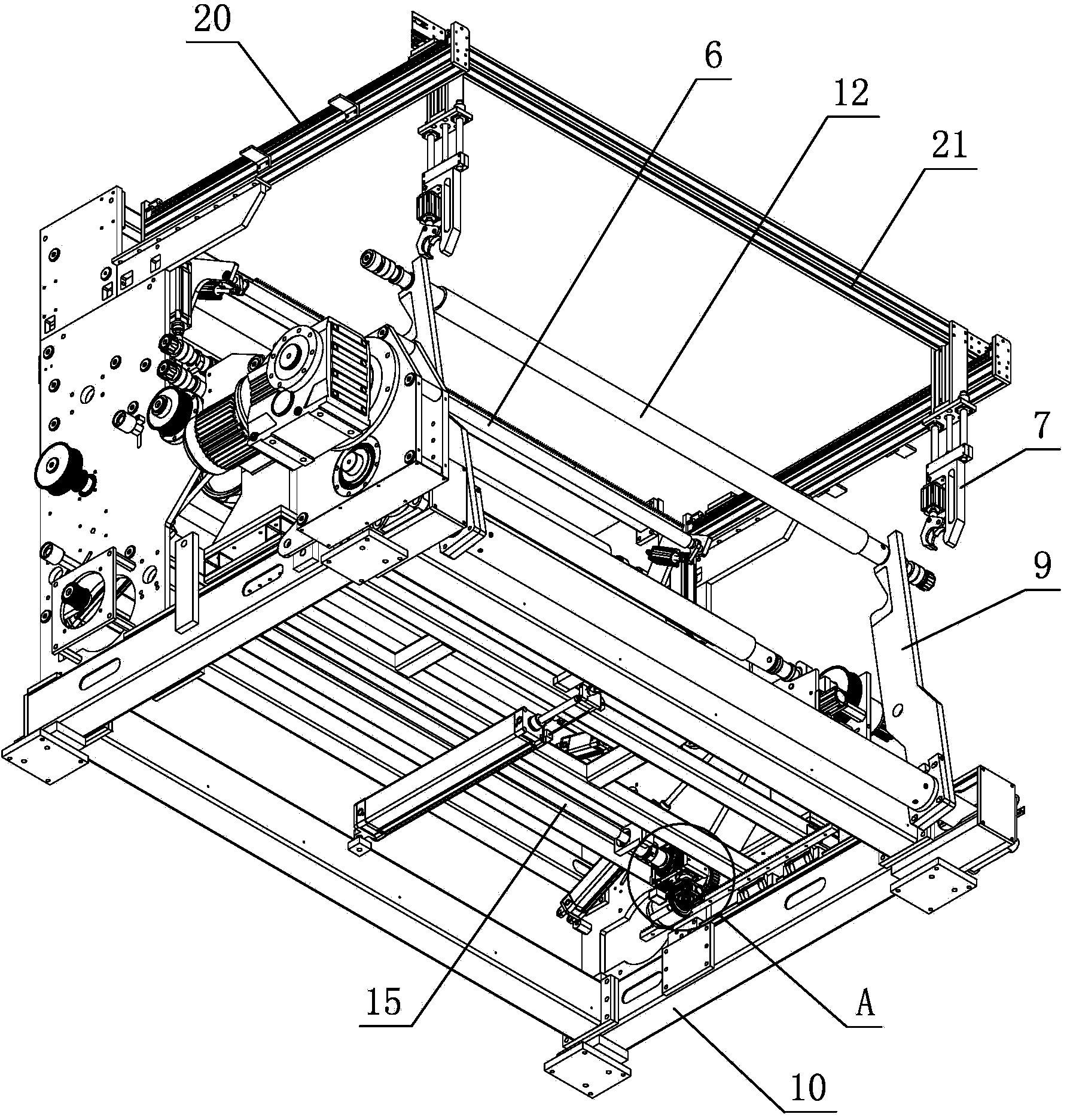

Thin film center and surface winding machine

The invention discloses a thin film center and surface winding machine which comprises a machine frame. An inflatable shaft, a tension roller, a cutter device, a flattening arc roller, a clamping roller, a large slotting rubber roller, a thin film cutting-off device, an inflatable shaft conveying device, a winding trolley device, a coil discharging device and an inflatable shaft accelerating device. A moving guide assembly is arranged between the machine frame and the winding trolley device, the winding trolley device moves on the machine frame in a linear mode through the moving guide assembly, and therefore the winding tension of the winding machine is controlled. Two parallel linear guide rails are arranged on the left side and the right side of the machine frame, and the winding trolley device moves on the machine frame in the linear mode through the two linear guide rails. The winding trolley device can achieve moving and horizontal adjusting functions, and the inflatable shaft placed on the winding trolley device can achieve the center winding and surface winding functions. The problem that the quality of wound finished products is poor due to the fact that a traditional thin film center and surface winding machine is integrated to a wall board is effectively solved, and flatness, smoothness and quality of the wound finished products are ensured.

Owner:广东恒立电气自动化有限公司

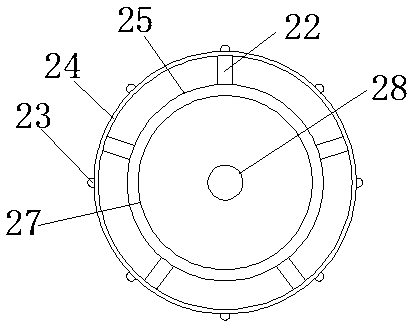

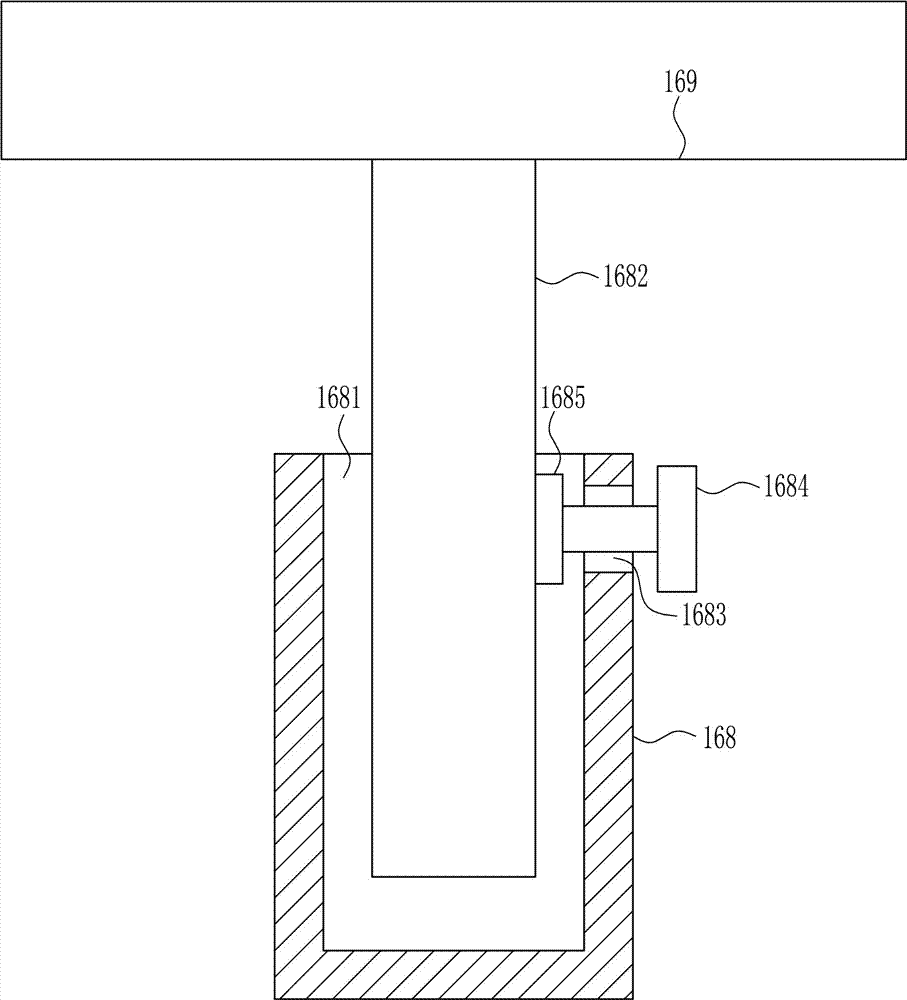

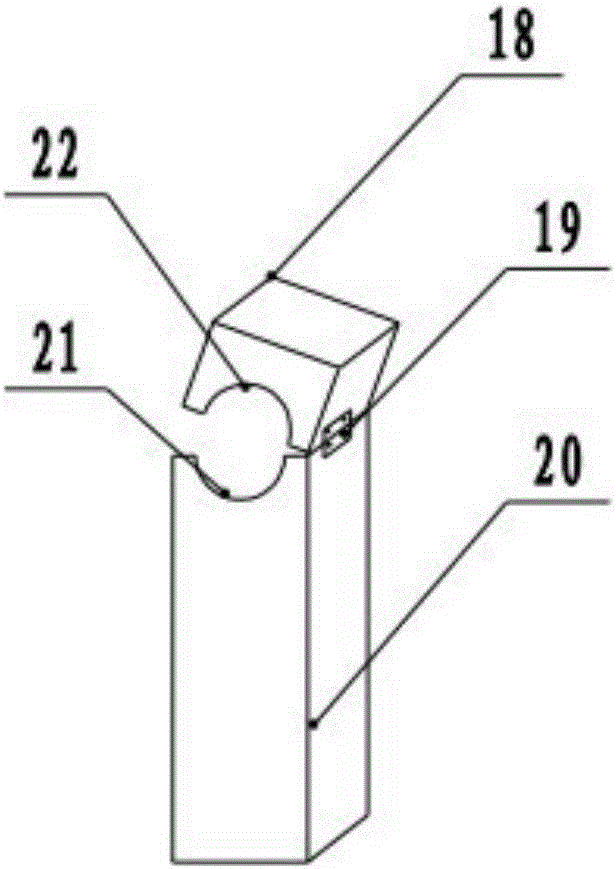

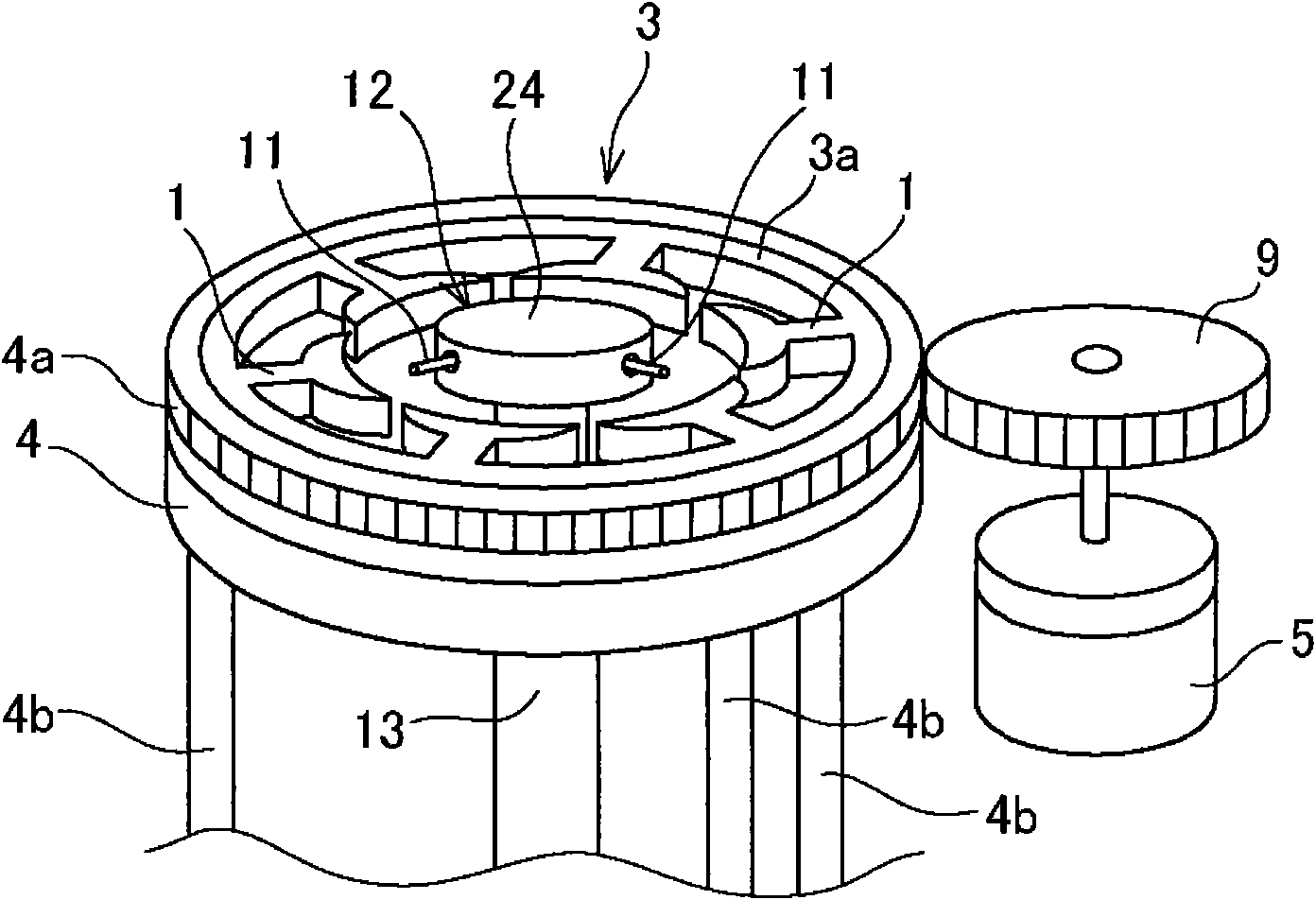

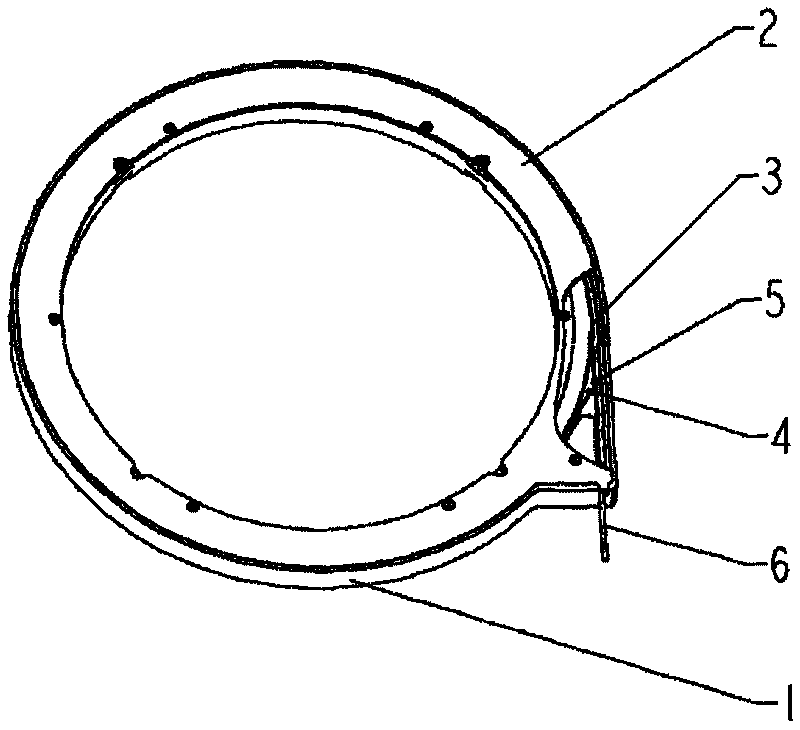

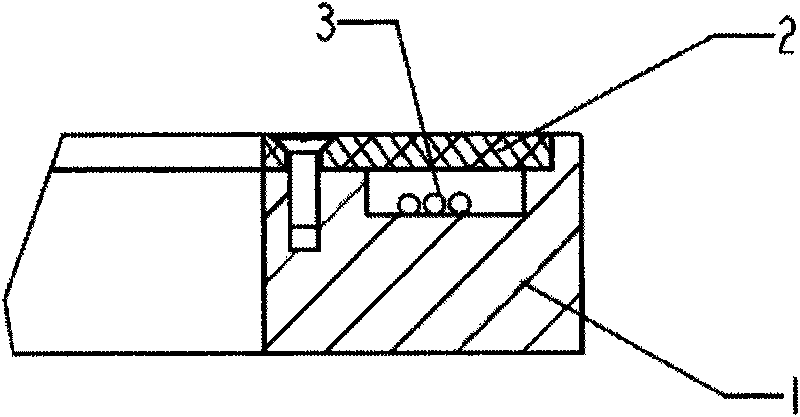

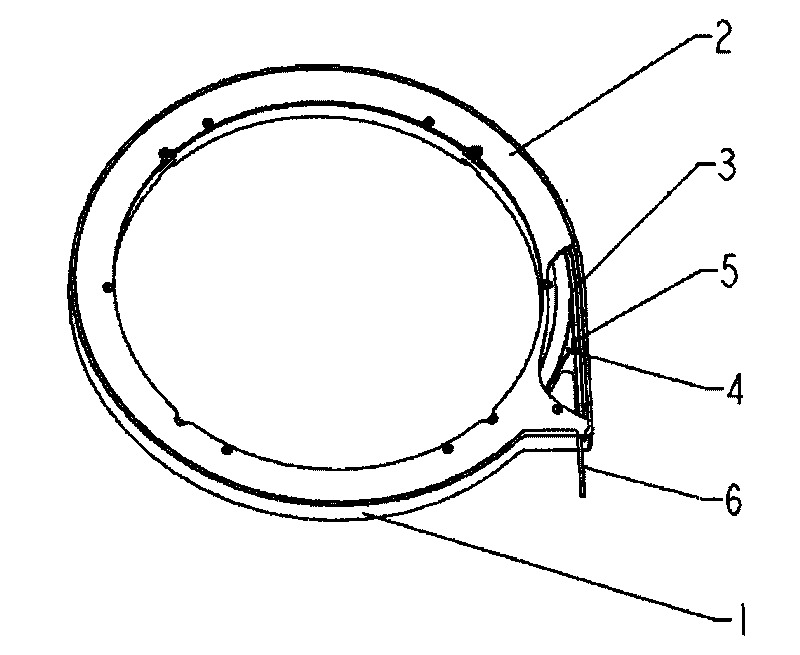

Sensing ring of all-fiber electronic current transformer

The invention discloses a sensing ring of an all-fiber electronic current transformer, which consists of a sensing ring body, a sensing ring upper cover, a sensing optical fiber, a reflector, a 1 / 4 wave plate and a polarization-preserving fiber, wherein both the sensing ring body and the sensing ring upper cover have an annular structure, a U-shaped groove is preserved on the upper surface of the sensing ring body and the sensing optical fiber is wound at the bottom surface of the U-shaped groove uniformly; the sensing ring upper cover is fixed on the upper part of the sensing ring body and closes the U-shaped groove; and the reflector and the 1 / 4 wave plate are positioned on two ends of the sensing optical fiber respectively and fixed in the U-shaped groove, the reflector and the 1 / 4 wave plate are parallel in the direction of the tangents of the annular structures and arranged in a way of clinging together along the direction of the normal of the annular structures, and the tail end, fixedly provided with the 1 / 4 wave plate, of the sensing optical fiber is connected with the polarization-preserving fiber which serves as the leading-out end of the sensing ring. The sensing ring has the characteristics of flexible application mode, small volume, light weight, high safety, convenient installation and maintenance and the like and provides a necessary guarantee for the development and application of the all-fiber electronic current transformer.

Owner:NAE BEIJING ELECTRIC CONTROL TECH

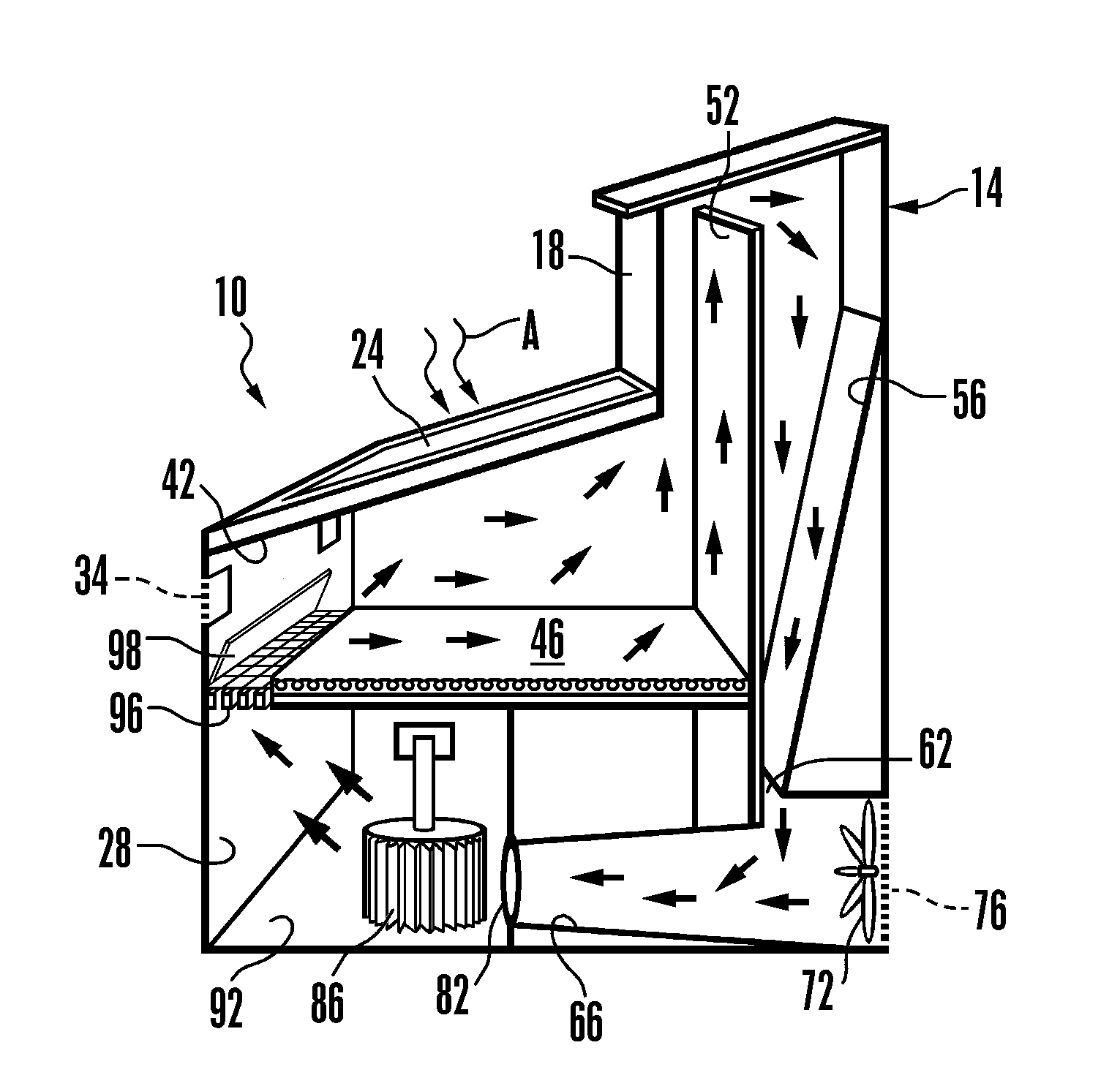

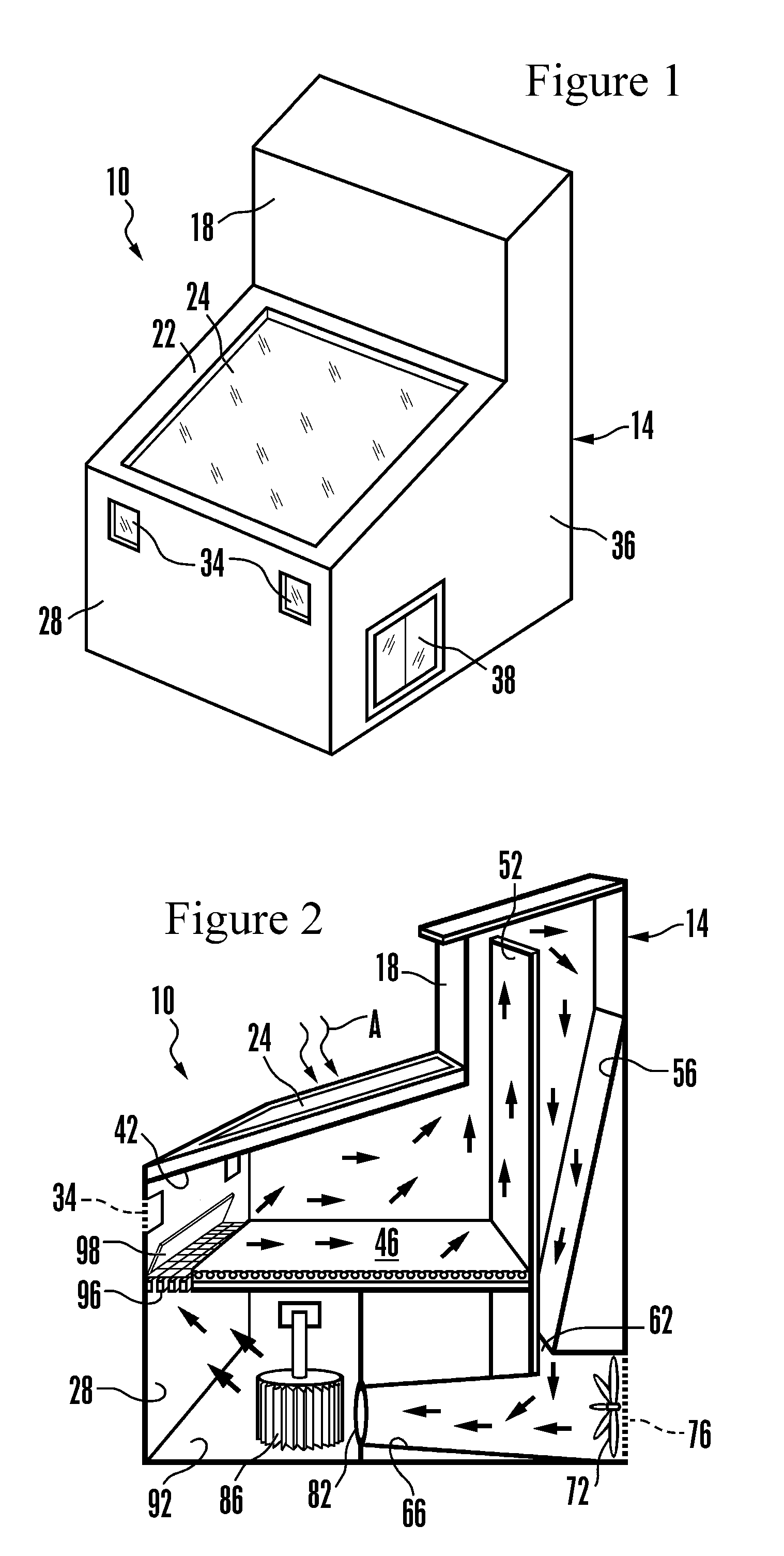

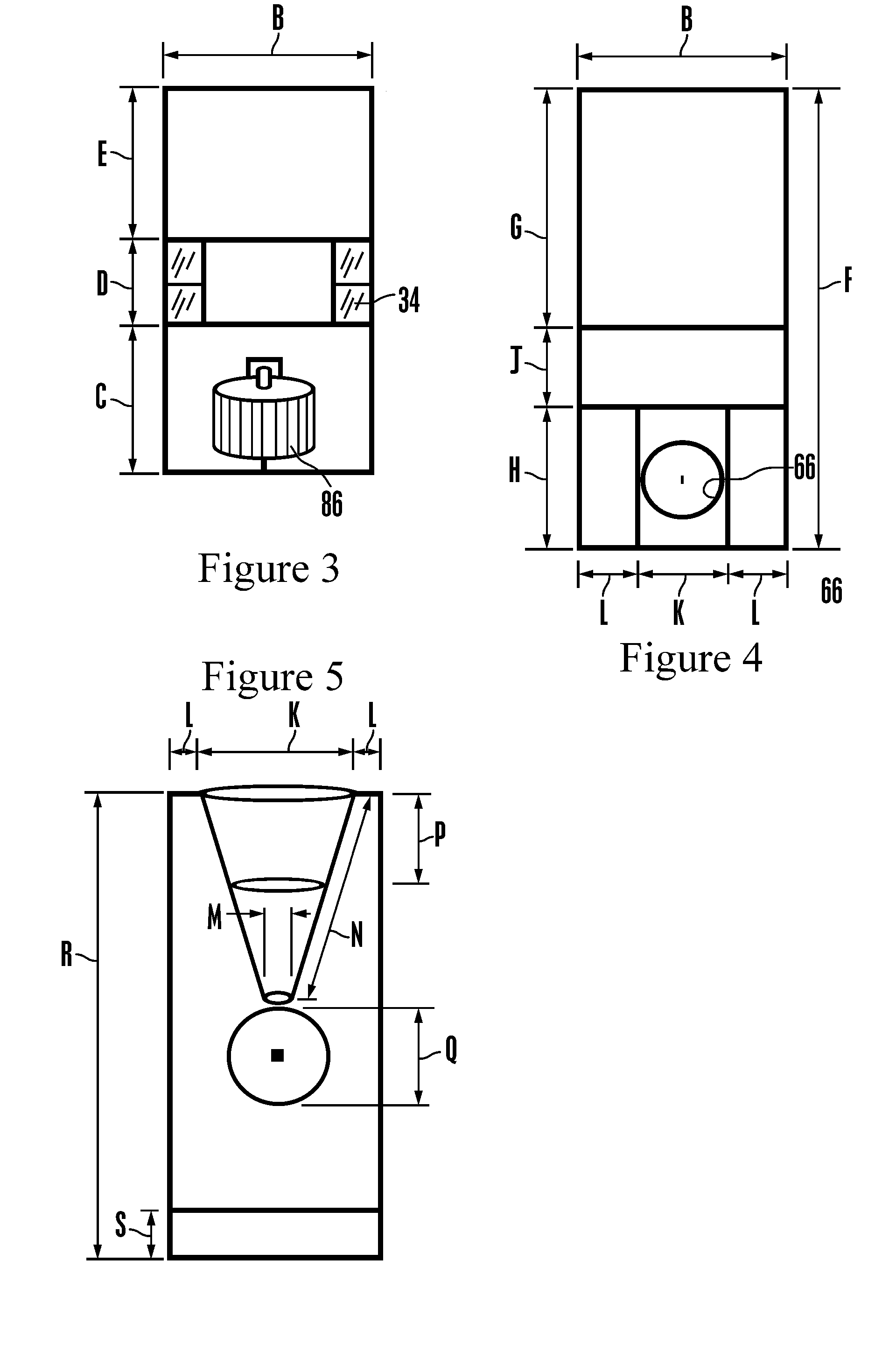

Enhanced multi-mode power generation system

ActiveUS20110181049A1Maximize useMaximize conversionWind motor with solar radiationPV power plantsElectricityTurbine

An enhanced multi-mode power generation system harnesses solar energy, wind, and heat within a designed building or within a large enclosed area, providing an indoor system to generate electricity. Air within an enclosure is heated, either by solar energy or by use of an electrified exothermic heating material, to enhance the airflow velocity within the enclosure. A system of narrowed passageways within the enclosure further increases the airflow velocity, which enhancement may also include or be supplemented by a blower. The enhanced velocity air is passed through one or multiple-staged wind turbines to generate electrical power.

Owner:HO ANDY +1

Cable rolling device for electric power engineering construction

The invention relates to a cable rolling device, in particular to a cable rolling device for electric power engineering construction so as to achieve the technical effects that the labor and time are saved, the rolling speed is high, and the labor intensity is small. The cable rolling device for electric power engineering construction comprises a bottom plate and the like, the top of the bottom plate is sequentially provided with a driving device, a left support and a sliding rail from left to right, and the left support and the sliding rail are connected with the top of the bottom plate in a bolted mode; the left support is vertically arranged, and the sliding rail is horizontally arranged; and a sliding block is slidably arranged on the sliding rail. According to the cable rolling device for electric power engineering construction, a first motor is adopted as driving, and a cable can be rapidly rolled and is rolled through a contacting wheel, work is stable, safety is higher, and the effects that the labor and time can be saved, the rolling speed is high, and the labor intensity is small are achieved.

Owner:喻杨凯

Fluidic kinetic energy generating set

InactiveCN102003216ACompact structureReduce manufacturing costsHydro energy generationWind motor combinationsAutomatic controlEngineering

The invention relates to a fluidic kinetic energy generating set. The fluidic kinetic energy generating set comprises a horn-shaped pressure control collector cover, a shutter and a side baffle plate, wherein the bottom of the collector cover is fixedly connected with the inlet end of an enclosure; the shutter comprises a framework and a plurality of mutually linked blades, each blade is rotationally connected on the framework through a blade rotating shaft, and the framework is fixedly connected on the inner wall of the pressure control collector cover; and the side baffle plate is used for sensing the flow rate and the direction of the fluid and linked with the blades of the shutter, and the side baffle plate is vertical when the shutter is opened and horizontal when the shutter is closed. After sensing the changes of the flow rate and the direction of the fluid (wind or water), the side baffle plate can rotate for a certain angle together with the direction of the fluid; and because the side baffle plate is linked with the blades of the shutter, the direction of the blades of the shutter is changed when the direction of the side baffle plate is changed, and the purpose of automatically controlling the opening and closing of the protective net shutter is fulfilled.

Owner:吴中平 +1

Trimming recycling device of splitting machine

InactiveCN103482410AWinding firmlyThere will be no material breakageFilament handlingEngineeringAlternating current

The invention discloses a trimming recycling device of a splitting machine. The trimming recycling device comprises a base provided with a vertical support and a crossbeam. A tension swing roller mechanism and a guide wheel are installed on the vertical support, and a discharging wheel and a guide rod are mounted on the crossbeam. A linear guide rail and a single-phase alternating-current stepless variable speed motor are arranged on the base, a movable base is arranged on the linear guide rail and provided with a rack meshed with a gear on the single-phase alternating-current stepless variable speed motor. A variable frequency motor and a wallboard are arranged on the movable base. A winding shaft is arranged on the wallboard, and a rolling mechanism is arranged below the winding shaft. For trimmings ranging from 5mm to 20mm in thickness, the trimming recycling device of the splitting machine can be started and stopped at any time, is synchronous with a main engine, stable to wind and free of trimming breakage and looseness at the speed of 400 meters per minute. Besides, the trimming recycling device is high in efficiency, noiseless, dustless and wide in application.

Owner:SHAANXI BEIREN PRINTING MACHINERY

Adhesive tape winding machine

ActiveCN103332319AWind evenlyReduce energy consumptionBinding material applicationBundling machine detailsWinding machineAdhesive belt

The invention relates to an adhesive tape winding machine. The winding machine comprises a rack, a drive motor, a line bundle drawing mechanism, an adhesive tape winding mechanism and a line bundle guide mechanism, wherein the line bundle drawing mechanism, the adhesive tape winding mechanism and the line bundle guide mechanism are sequentially arranged on the rack; the line bundle drawing mechanism comprises a transmission case, a drawing drive roll and a drawing driven roll, wherein the drive motor and the input shaft of the transmission case are connected in a mechanical transmission way, and the output shaft of the transmission case and the drawing drive roll are connected in a mechanical transmission way; the adhesive tape winding mechanism comprises an annular runner on which an adhesive tape mounting device is arranged, and the annular runner and the drive motor are connected in a mechanical transmission way; and the line bundle guide mechanism comprises a line bundle guide wheel and a support frame, wherein the line bundle guide wheel and the support frame are rotationally connected. According to the adhesive tape winding machine provided by the invention, the adhesive tape winding mechanism and the line bundle moving mechanism are driven by a same motor, so that the movement velocity ratio is constant, adhesive tapes are uniformly wound, the energy consumption is low, and the equipment cost is low.

Owner:HANGZHOU GOLDCOSMOS ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com