Cable tension self-adjustment winch and control method thereof

A self-adjusting, cable technology, applied in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problem of interfering with the coordinated movement of cable winches and flying mobile robots, low tensile strength of thin cables, The influence of cable retraction and unwinding motion, etc., can overcome the problem of low strength, improve the accuracy of motion control, and accurately measure the tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

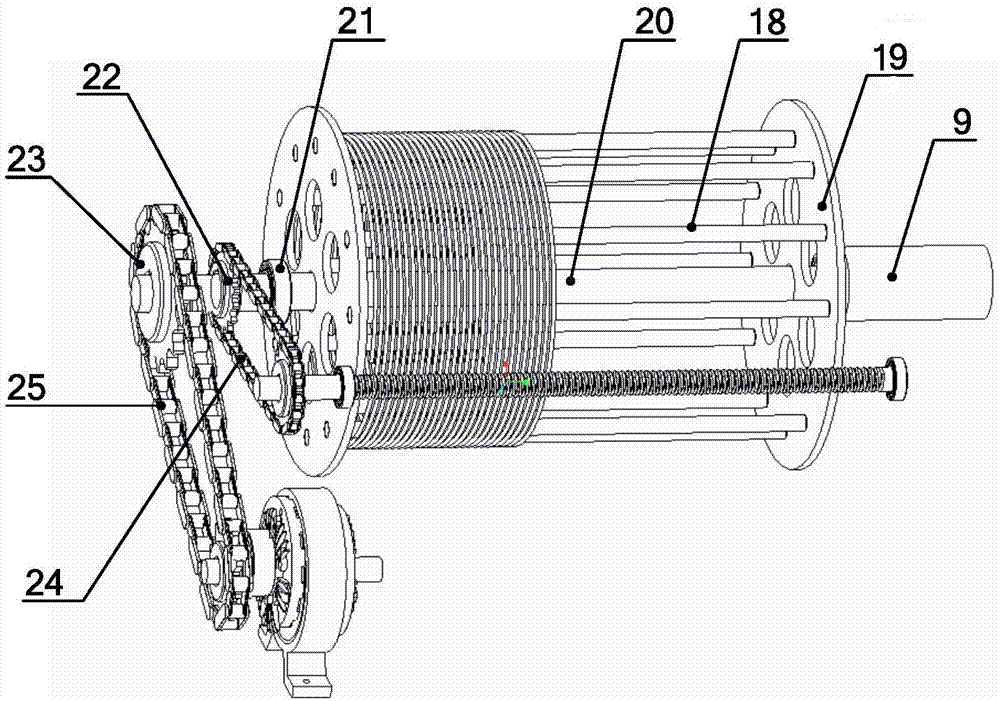

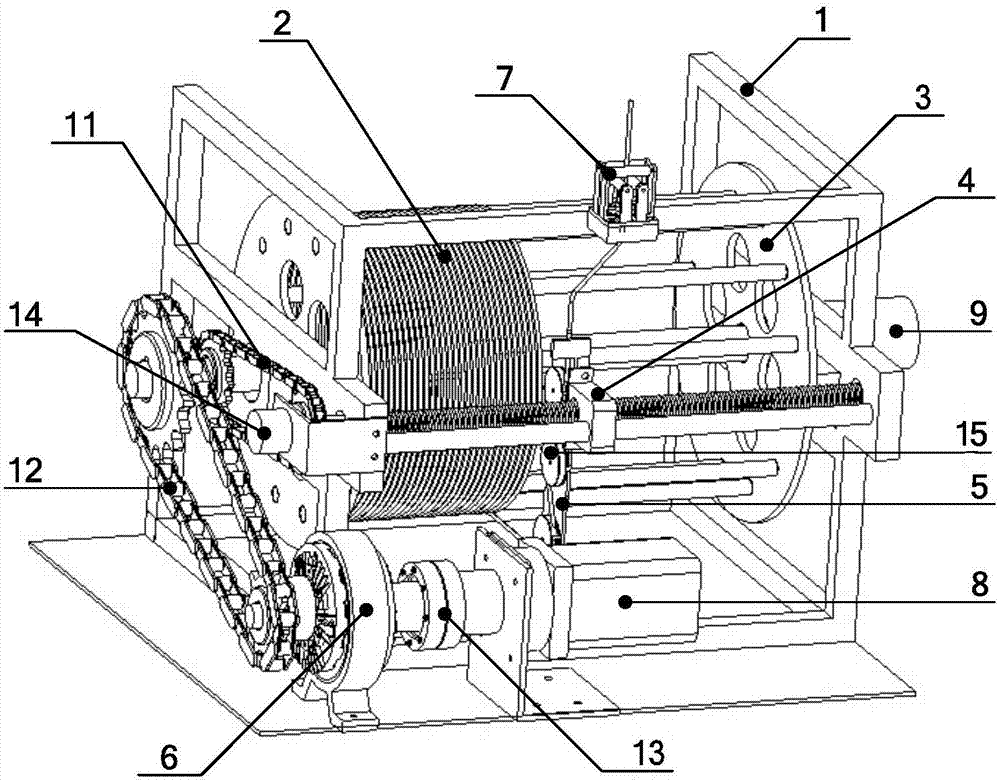

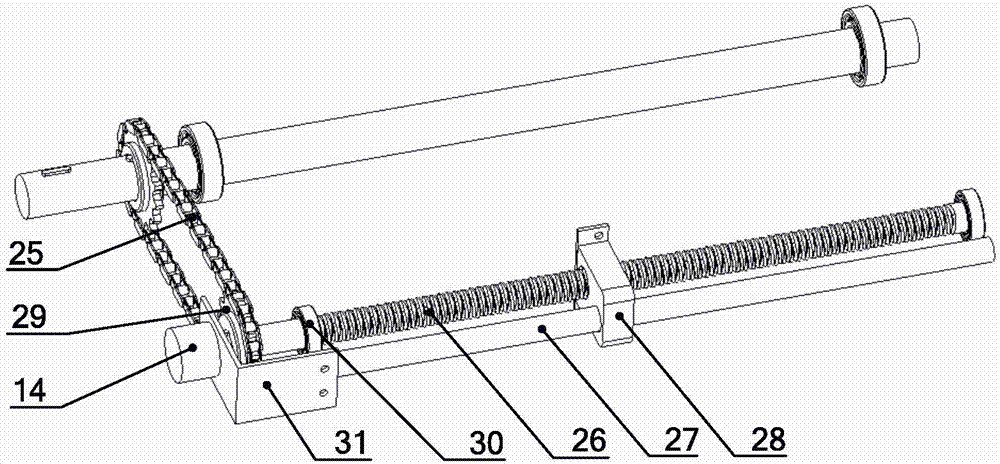

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below by taking the flying mobile robot as an example and in conjunction with the accompanying drawings, and the contents mentioned in the embodiments are not limitations of the present invention.

[0037] For high-speed moving objects, especially flying mobile robots, due to the strict restrictions on their own weight, it is difficult to use fuel or batteries to provide flight power to meet the requirements of long endurance. However, providing energy for flying mobile robots through wired cables can properly solve the problem of long endurance. question. In practical applications, in order to reduce the load of the flying mobile robot, the insulating layer and protective sheath of the multi-core cable used are designed with a lightweight structure. However, this also brings about the problem of low strength of the protective layer of the cable structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com